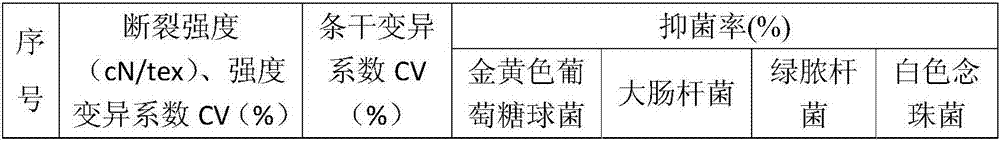

Patents

Literature

40results about How to "Low cost of spinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

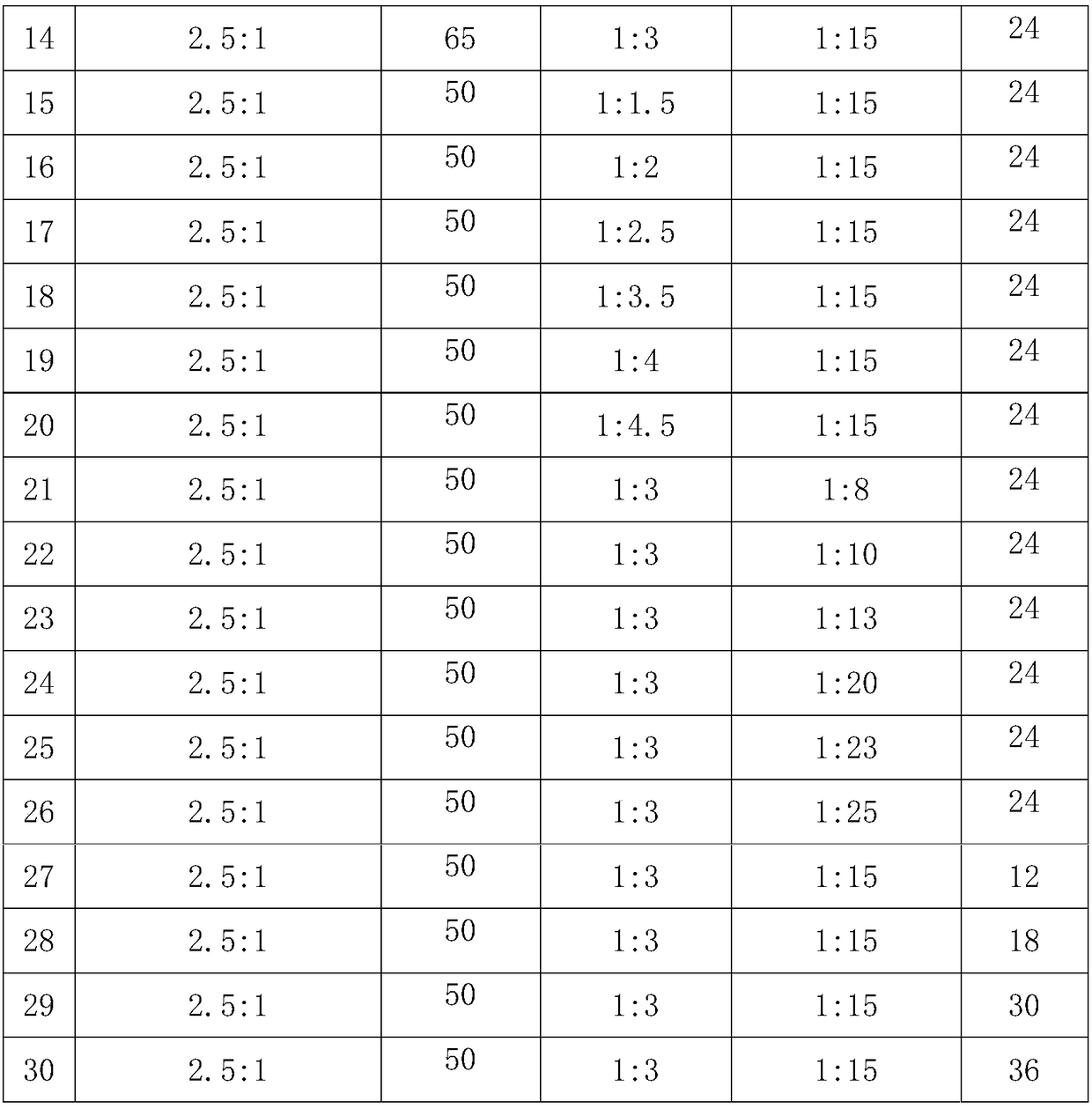

Inventor

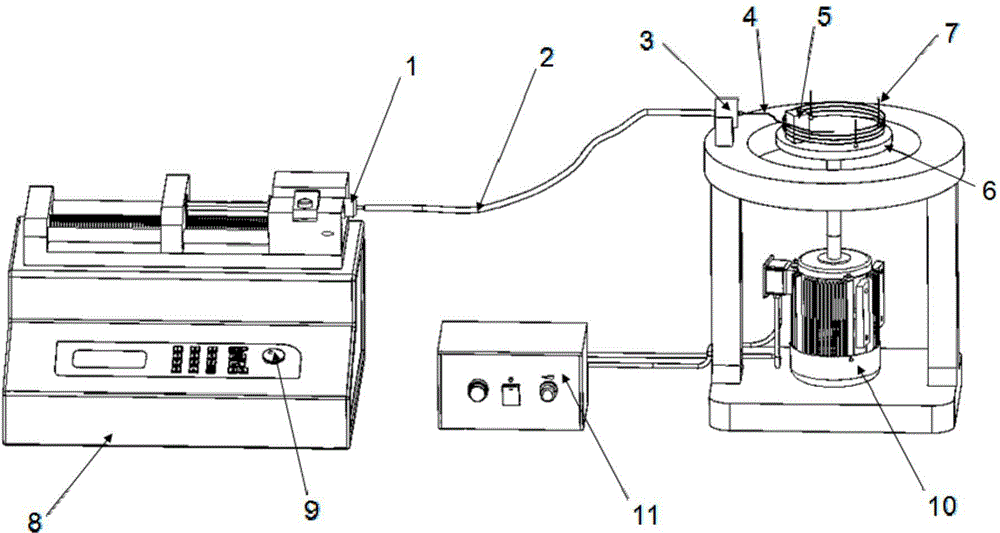

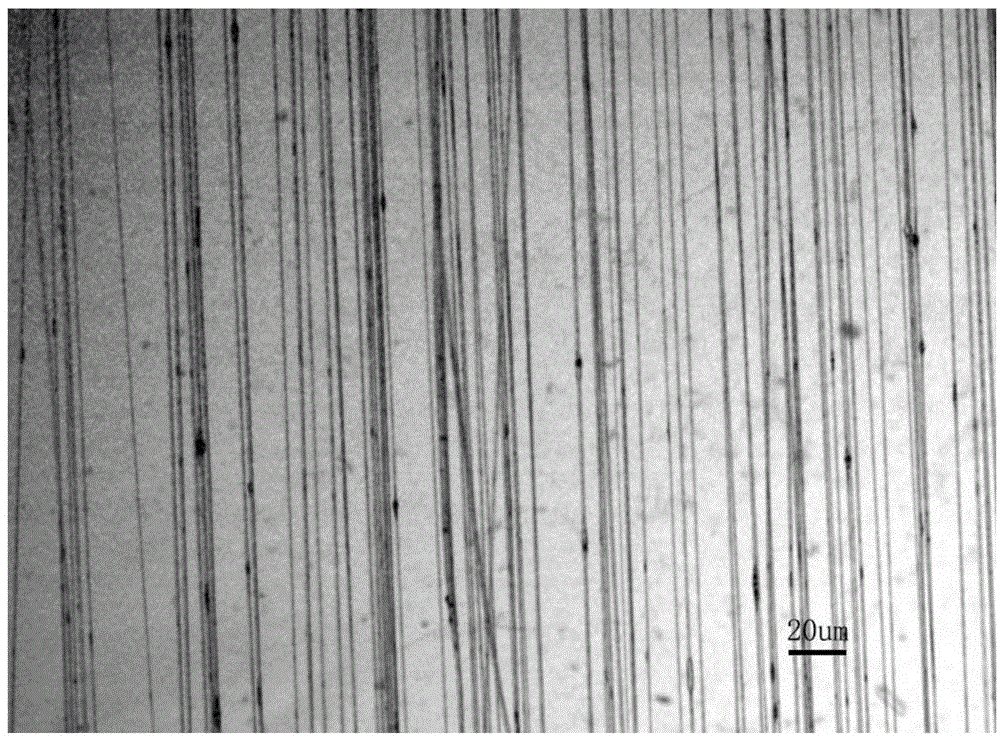

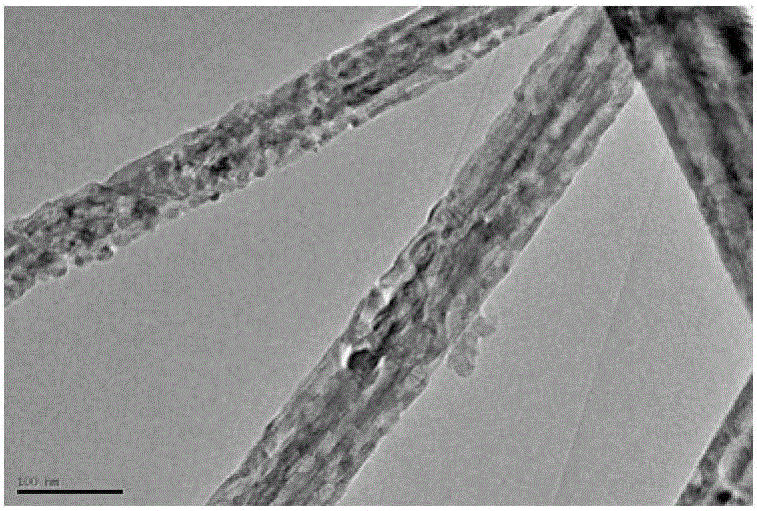

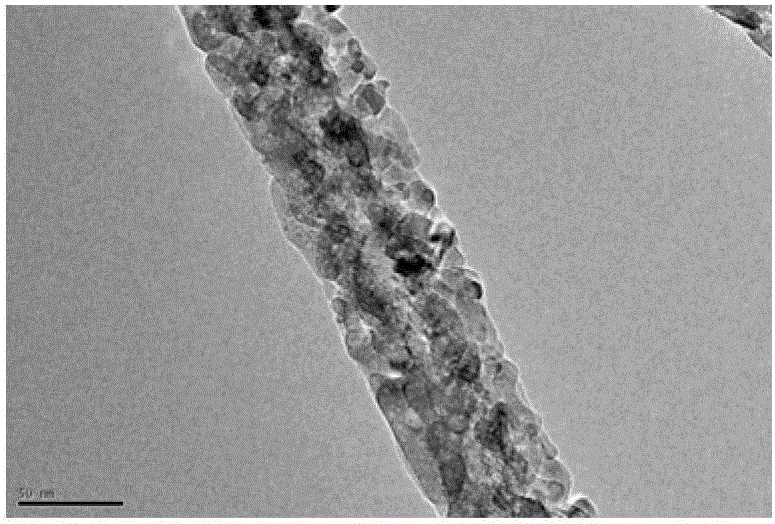

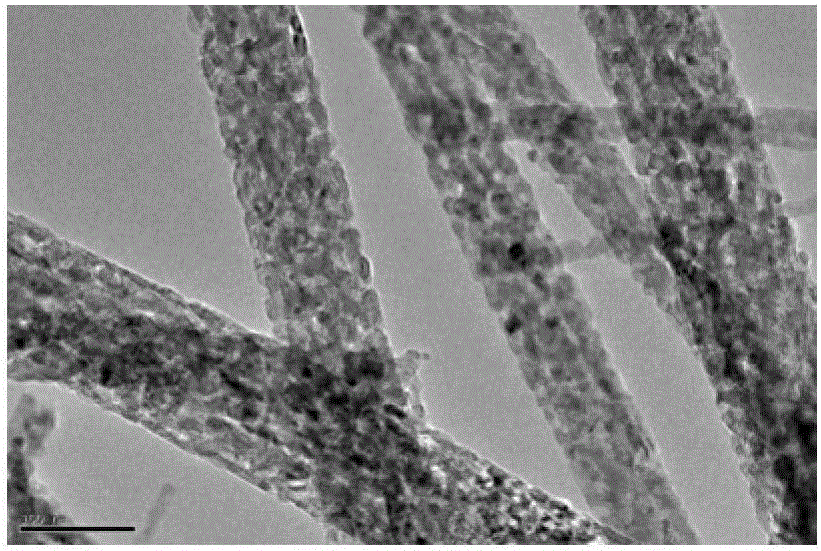

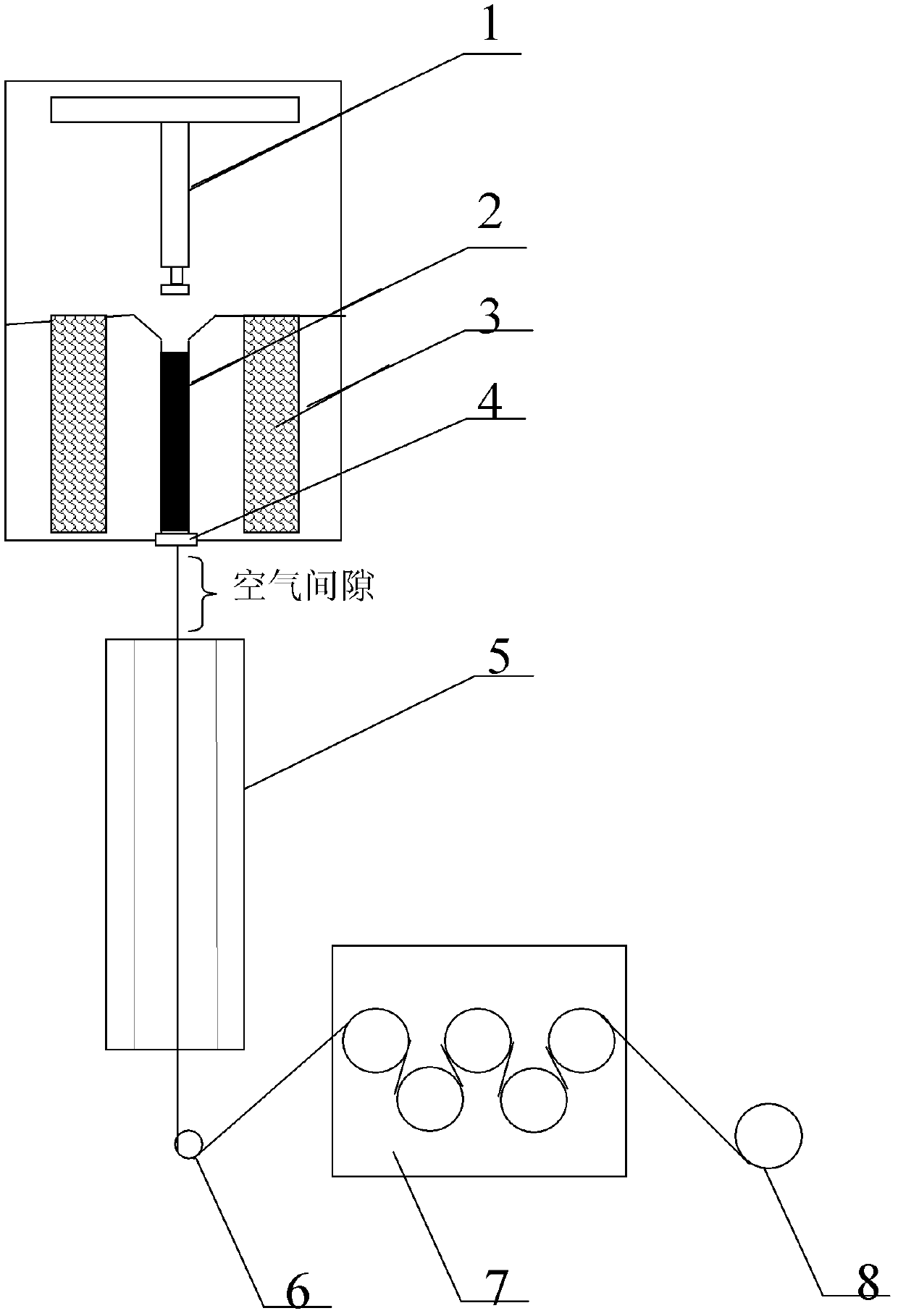

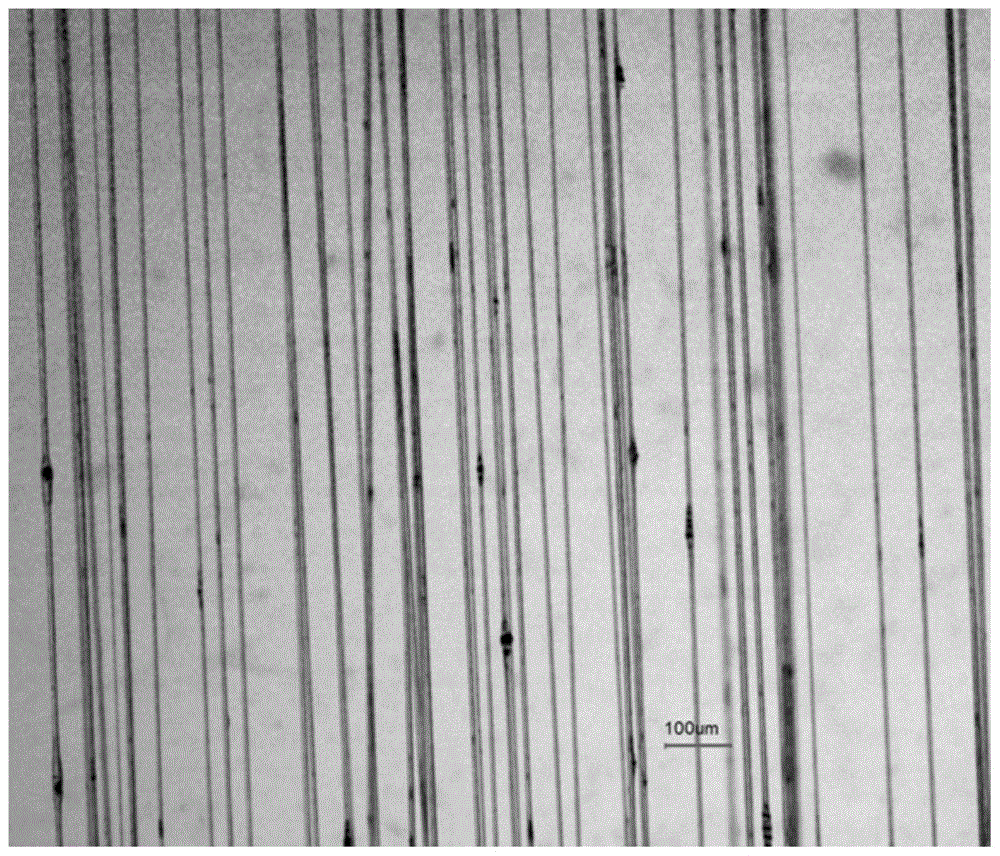

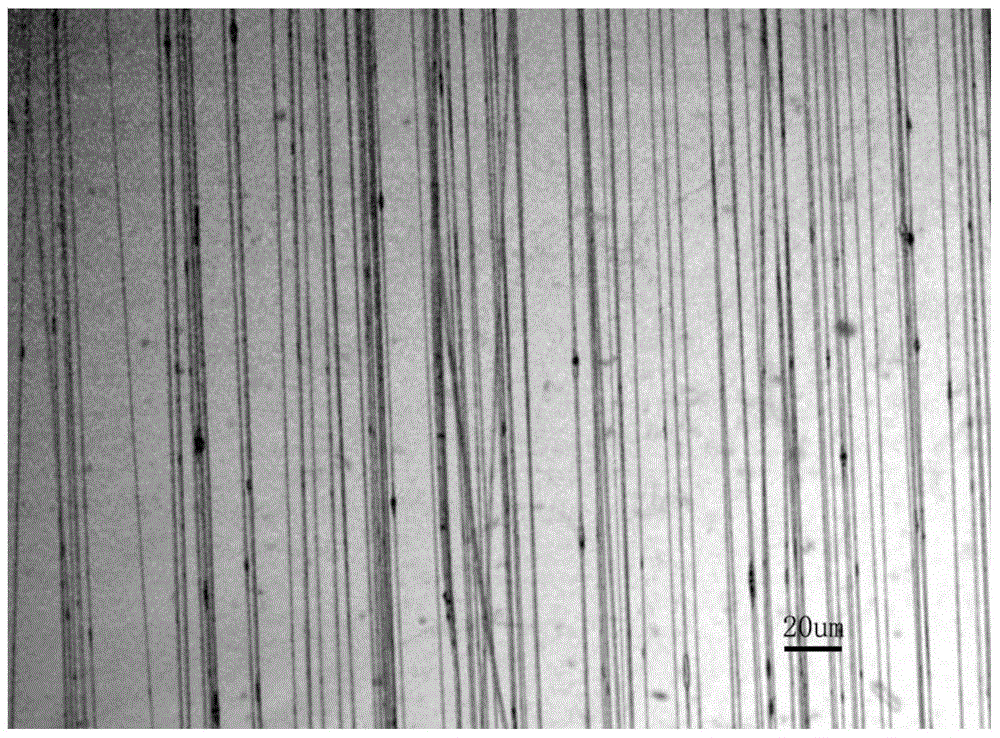

Preparation device and preparation method of cellulose-based fiber membrane with nanostructure

InactiveCN102277689ASmall fiber sizeHigh porosityFilament/thread formingNon-woven fabricsPorosityCellulose

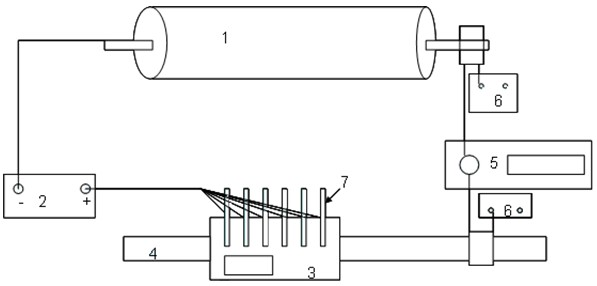

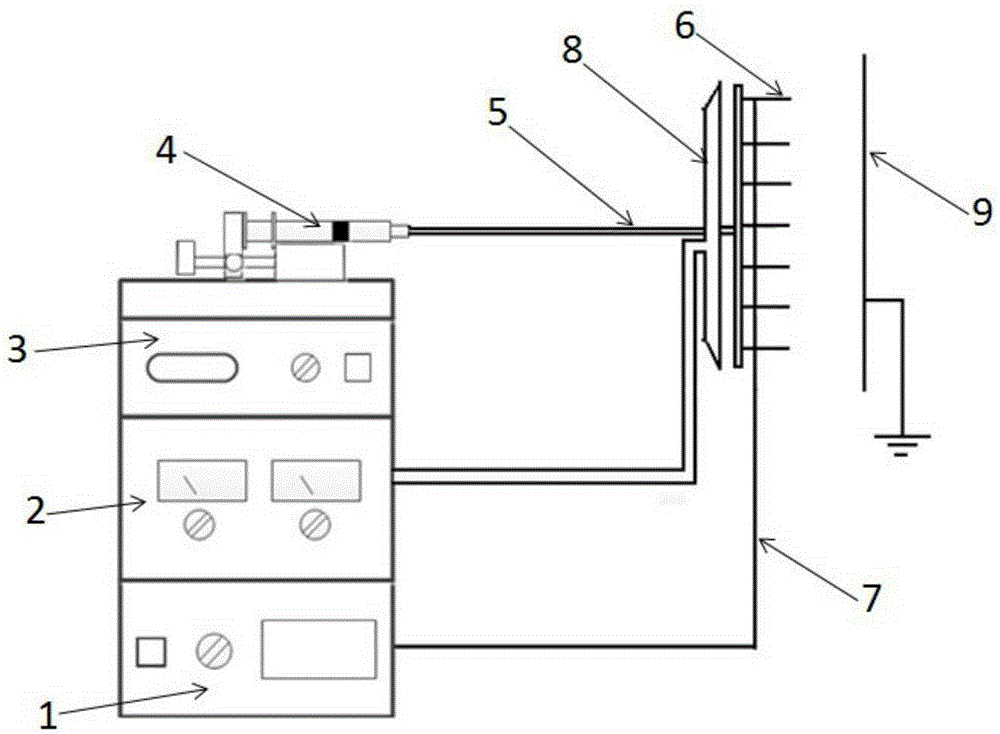

The invention relates to a preparation device and method of a cellulose fiber film with a nanometer structure. The device includes a rotatable slide table, and the liquid supply injection pump is arranged on the slide table. When the slide table rotates, the liquid supply injection pump moves along the slide table. The liquid supply injection pump is fixedly connected to at least one spinneret, and the spinneret There is a rotary receiving device in front of the head, the spinneret and the rotary receiving device are connected to a high-voltage power supply, and the rotating shafts of the slide table and the rotary receiving device are connected to a motor and a speed controller. The method is as follows: dissolving the cellulose polymer with a solvent to obtain a polymer solution with uniform properties; inputting the polymer solution to a spinneret at a constant flow rate for electrospinning to obtain cellulose with a nanostructure fibrous membrane. The cellulose fiber membrane with nanometer structure prepared by the invention has the advantages of small fiber size, high porosity, large specific surface area, good fiber uniformity and the like.

Owner:DONGHUA UNIV

Spinning process of bamboo-like flat filaments produced by semi-continuous high-speed spinning machine

ActiveCN103290495AEasy maintenanceLow cost of spinningArtificial thread manufacturing machinesArtificial filaments from viscoseFrequency changerPolymer science

The invention relates to a spinning process of bamboo-like flat filaments produced by a semi-continuous high-speed spinning machine and belongs to the technical field of spinning of semi-continuous spinning machines. The spinning process comprises glue supply, filament strip forming, spinning and winding. The spinning process is characterized in that the glue supply is achieved through a glue supply device which comprises a metering pump, a glue supply tube and a filter; the metering pump is connected with a frequency converter which is used for controlling the amount of the glue supply of the metering pump; the frequency converter controls the metering pump to perform intermittent glue supply; the spinning is achieved through a spinning device which comprises at least one spinning roller which is horizontally arranged relative to an operating surface of a spinning surface; and filament strips surround the spinning roller to achieve drafting, solidification and deacidification in the spinning processes under the rotation of the spinning roller. The spinning process of the bamboo-like flat filaments produced by the semi-continuous high-speed spinning machine has the advantages of solving the problems that the filament strips of the semi-continuous spinning machines are inadequate in response, so that the spinning speed cannot be improved and the production efficiency and product quality cannot be integrated, enabling the arrangement direction of the spinning roller to be changed to enable the spinning speed of the spinning machine to be improved and enabling the high quality bamboo-like flat filaments to be spun out.

Owner:YIBIN HIEST FIBER +2

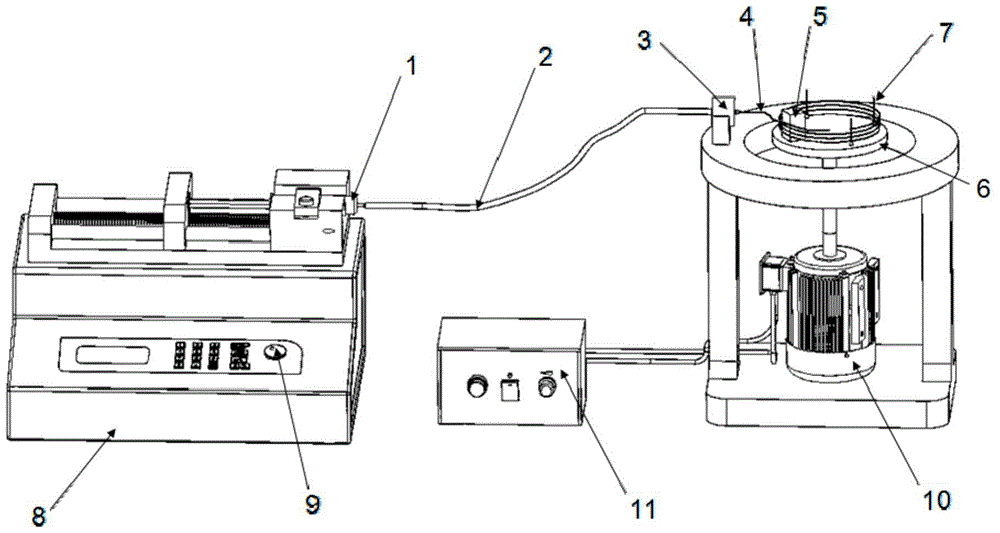

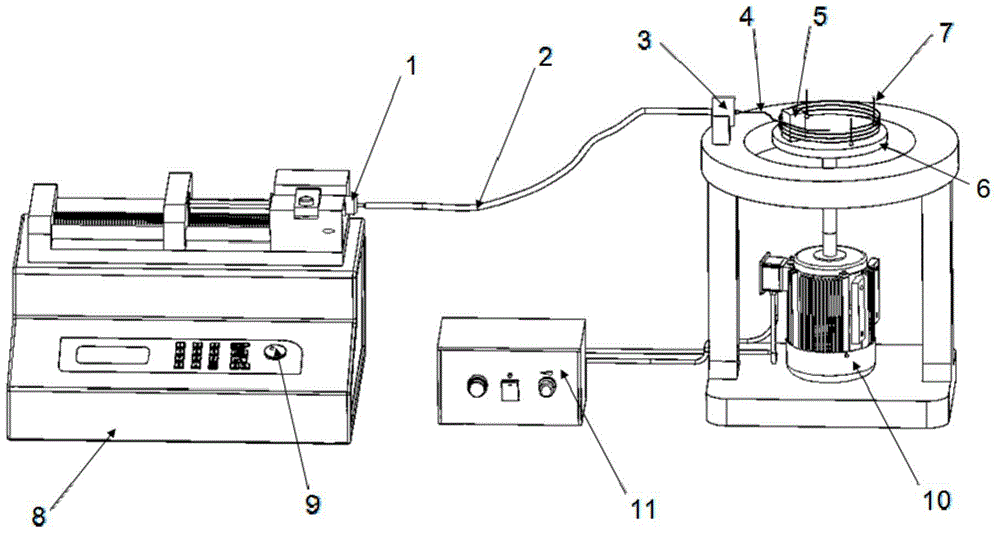

Method for preparing conducting polymer micro-nanofibers in magnetic spinning mode

ActiveCN104911719AArranged in an orderly mannerIncrease productionElectroconductive/antistatic filament manufactureFilament/thread formingMicro nanoFiber

The invention discloses a method for preparing conducting polymer micro-nanofibers in a magnetic spinning mode. The method comprises the steps that 1, a magnetic spinning device is built, wherein the magnetic spinning device comprises a rotary collection disc with a permanent magnet; 2, a spinning precursor solution is prepared, wherein magnetic nano particles, high-molecular polymer and conducting polymer are mixed and dissolved in an organic solvent solution; 3, the magnetic spinning device is utilized for preparing conducting polymer micro-nano complex fibers, wherein the spinning precursor solution is injected into a feeding device, the feeding device is started, liquid drops on an opening of a spinning nozzle forms a jet flow under the effect of magnetic field force to be connected with the permanent magnet to be a bridge, a brushless direct-current motor is started to drive the collection disc to rotate, the ferrofluid jet flow is continuously pulled out under the effect of magnetic field force, and conducting polymer micro-nanofibers are wound and formed among vertical supporting columns of the collection disc. The method does not need the high voltage effect, reduces the production cost and potential safety hazards, is suitable for large-scale production and has the good application prospect, and the fibers are distributed in order.

Owner:QINGDAO UNIV

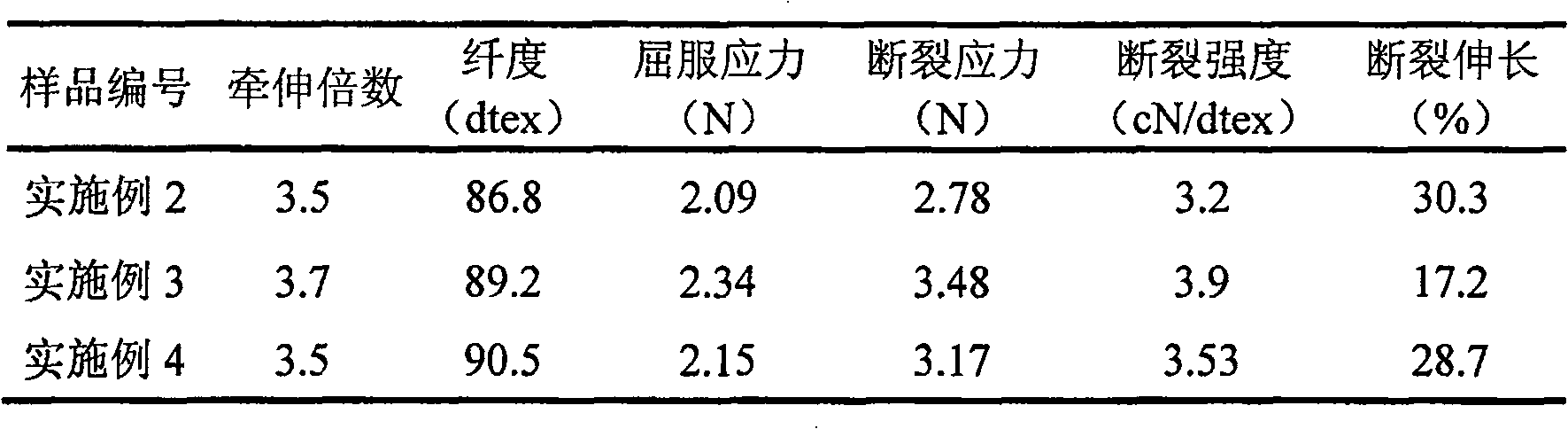

Modified polyphenylene sulfide fiber and method for making same

InactiveCN101187088AHigh glossImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentMelt spinning methodsUltimate tensile strengthSilicon dioxide

The invention provides a modified polyphenylene sulfide fiber and process for preparing, whose components and parts by weight comprise 100 parts of polyphenylene sulfide and 0.2-2 parts of nano-silica whose surface is treated, the particle size of the silica is 20-60 nanometer, and the denier of the fiber is 85-91 dtax. The invention prepares the polyphenylene sulfide fiber through modifying polyphenylene sulfide resins and using special spinning process, the fiber strength and tension toughness are all improved, simultaneously, the glossiness of the fiber is further improved, the spinning is capable of being done by a common spinning device, the cost of spinning is reduced, the fluidity of substrate is changed better during spinning, the temperature of spinning is reduced by 5-10 DGE C, the draft multiple of as-spun fiber is improved, and the mechanical properties of the fiber are capable of being improved.

Owner:DONGHUA UNIV

Spinning technology of two-spinning-roller semicontinuous high-speed spinning machine

InactiveCN103409824AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesWet spinning methodsSpinningMachine

The invention relates to a spinning technology of a two-spinning-roller semicontinuous high-speed spinning machine, and belongs to the technical field of semicontinuous spinning machines. The spinning technology comprises the steps of glue supplying, thread-line forming, spinning and winding, wherein the spinning is carried out through a spinning device. The spinning device comprises two spinning rollers which are transversely arranged relative to an operating surface of a spun surface, thread lines surround the spinning rollers, and drafting, solidifying and deacidification in the spinning steps are achieved when the spinning rollers rotate. The spinning technology solves the problems that thread lines of a semicontinuous spinning machine in the prior art are insufficient in reaction, the spinning process cannot be accelerated, and production efficiency and the product quality cannot be taken into consideration. The arrangement direction of the spinning rollers is changed so that the thread lines can walk for a longer distance while the spinning process of the spinning machine is accelerated and the structures of other components of original equipment are not changed, the thread lines can be reacted with acid bath more fully, and both production efficiency and product quality are taken into consideration.

Owner:YIBIN HIEST FIBER +2

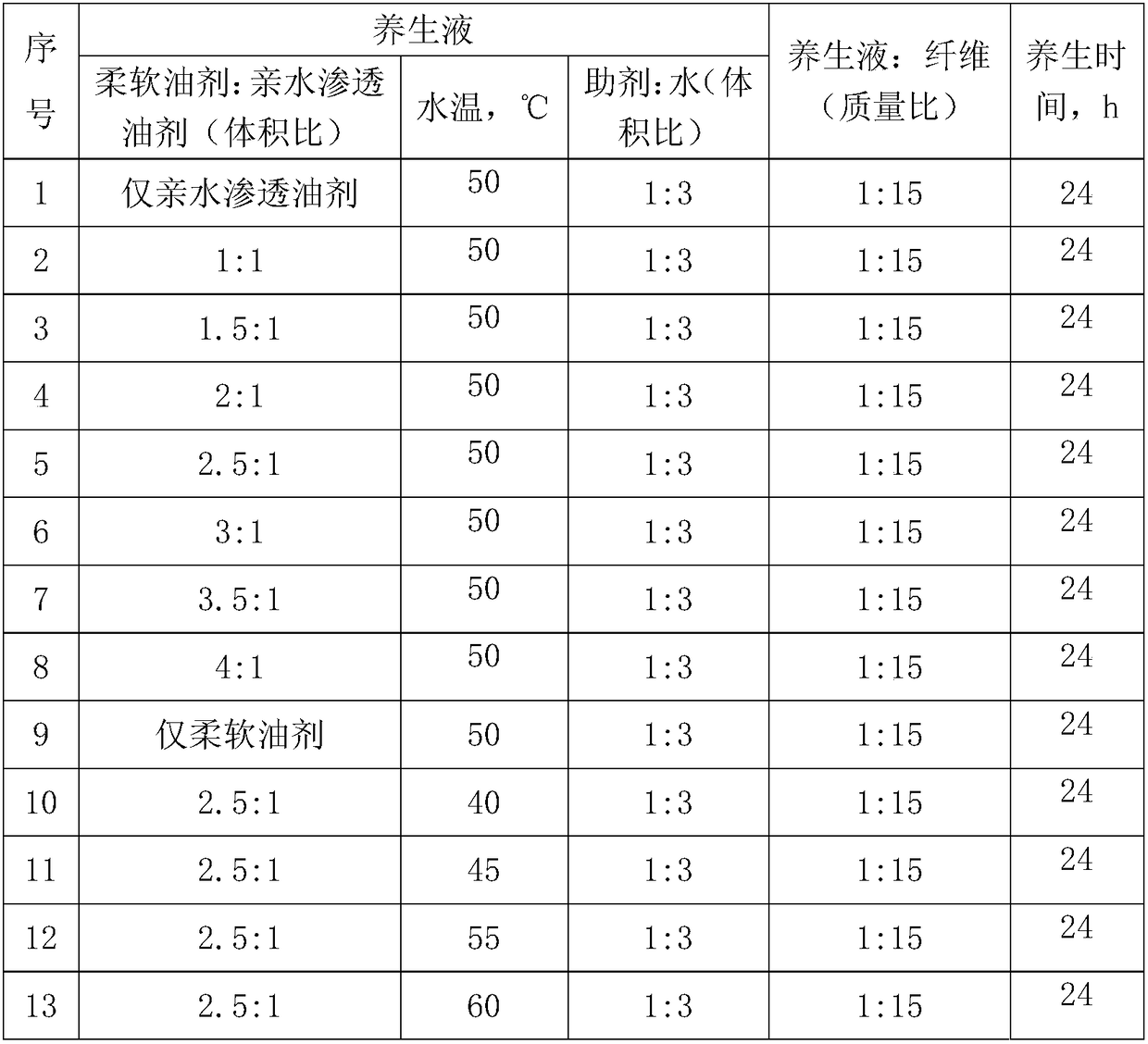

Yarn for hemp/cotton blended high-grade underwear fabric and processing method of yarn

InactiveCN105803608AImprove flexibility and spinnabilityWell spreadGrip property fibresYarnHemp fiberYarn

The invention provides a processing method of yarn for hemp / cotton blended high-grade underwear fabric. The processing method is characterized by comprising the steps that hemp fibers and cotton fibers are pretreated respectively, the pretreated hemp fibers and the pretreated cotton fibers are blended, and then the blended fibers are subjected to cotton opening and scutching, cotton carding, combing, drawing, roving and spinning in sequence. The processing method solves the problem that high-count hemp blended yarn is difficult to produce, the count of the hemp / cotton blended yarn is increased to 70 S-120 S, and the requirement for producing the hemp / cotton blended high-grade underwear fabric is met.

Owner:DONGHUA UNIV +1

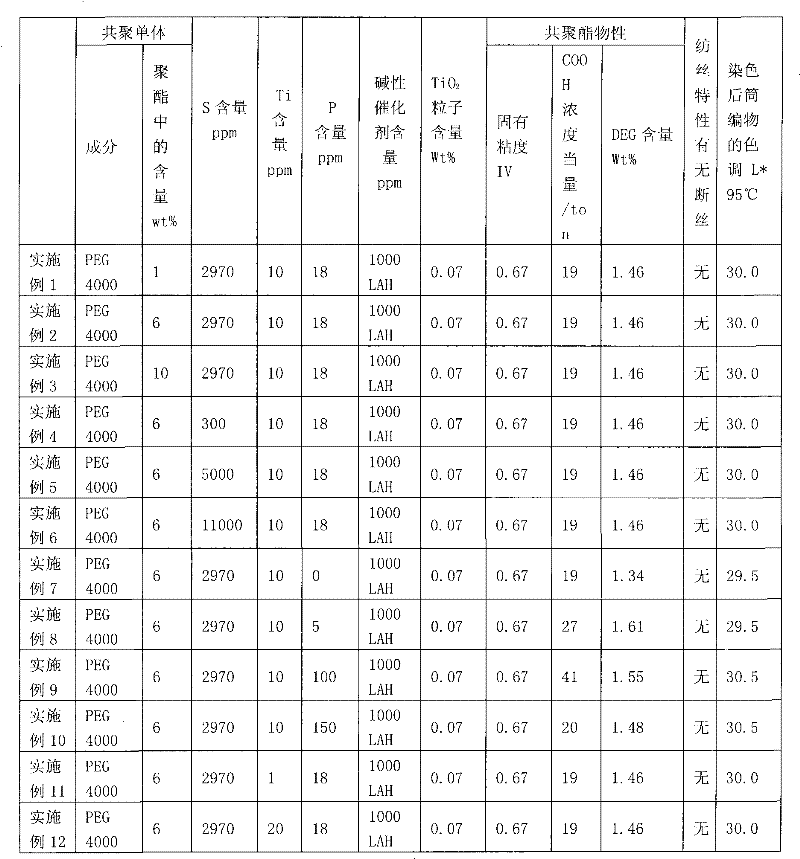

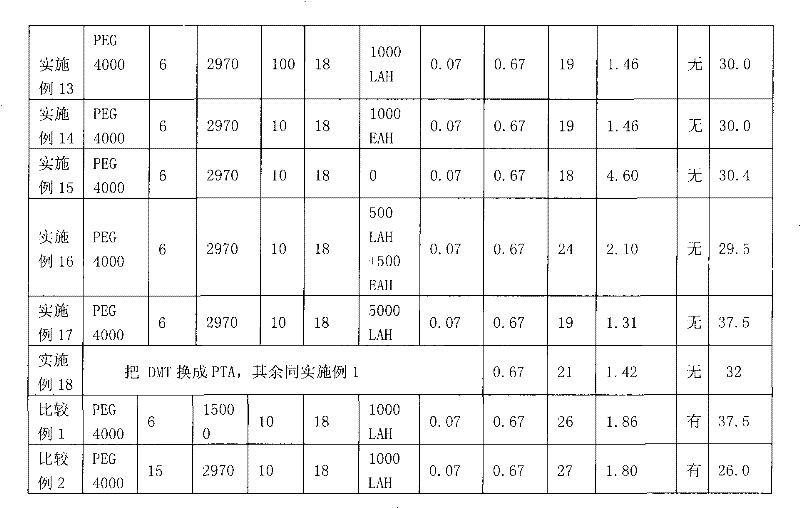

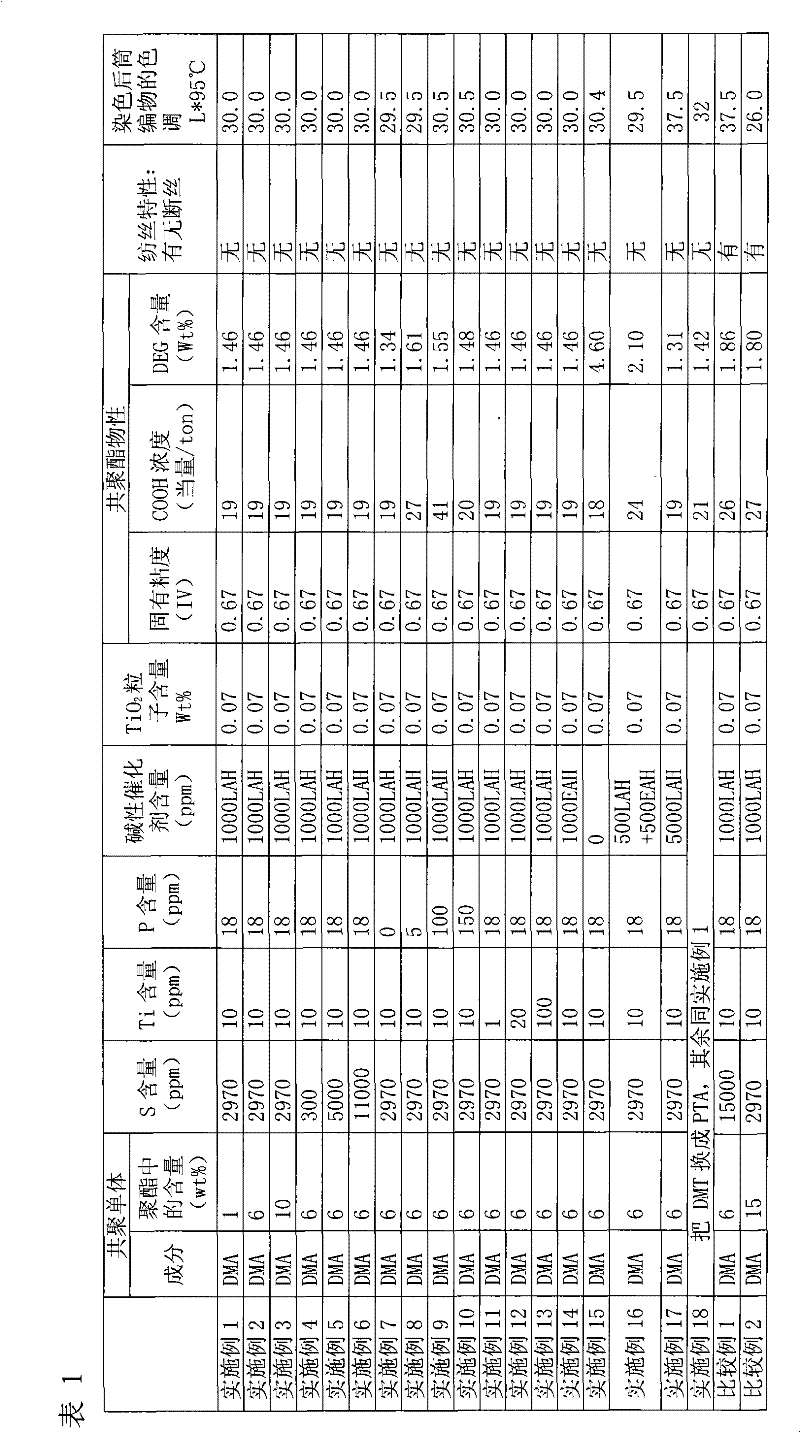

Atmospheric pressure cationic dyeable polyester and its production method and use

InactiveCN102260373AImprove heat resistanceHigh melting pointMonocomponent copolyesters artificial filamentFiberPolyester

The invention discloses a normal-pressure cationic dye-dyeable polyester and its production method and application. The polyester is composed of dimethyl terephthalate, ethylene glycol, polyalkylene glycol and metal sulfonate groups. The group of dimethyl isophthalate is copolymerized under the catalysis of soluble titanium compounds; relative to the weight of polyester, the content of sulfur in polyester is 300-11000ppm, and the content of alkylene glycol groups is 0.1-10wt%, the content of soluble titanium element is 1-1000ppm, and the content of antimony element is less than 3ppm. The present invention uses a non-toxic and environment-friendly titanium compound as a catalyst, and the obtained polyester has the characteristics of high melting point, high thermal stability, and good spinnability, and the fiber fabric produced by it has good dyeability, and has Atmospheric dyeability.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

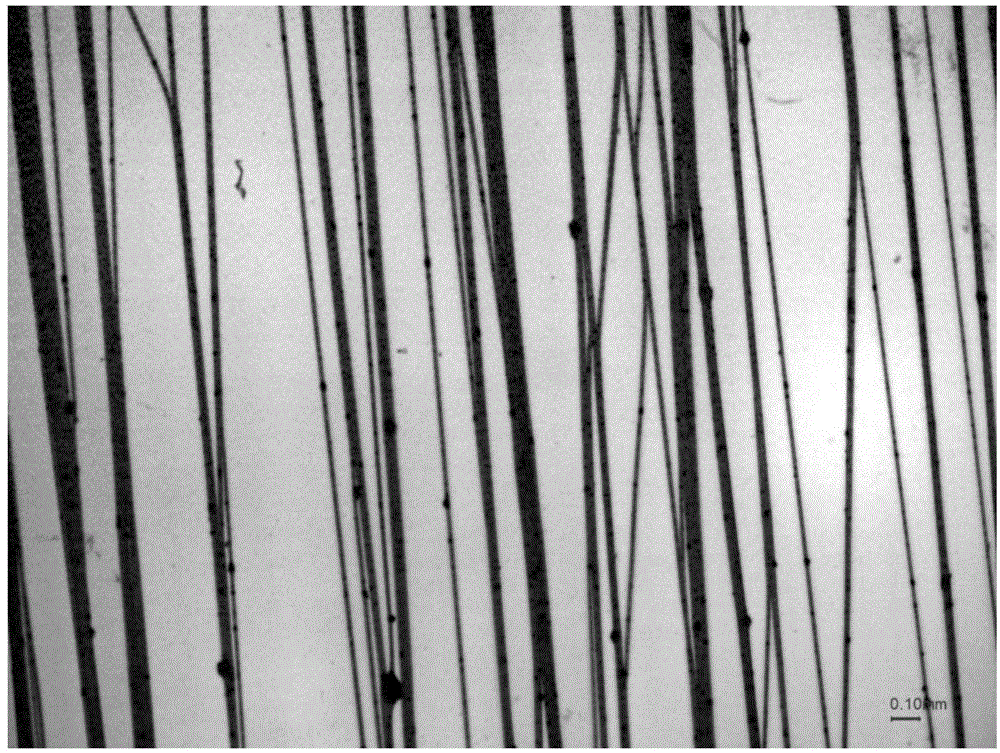

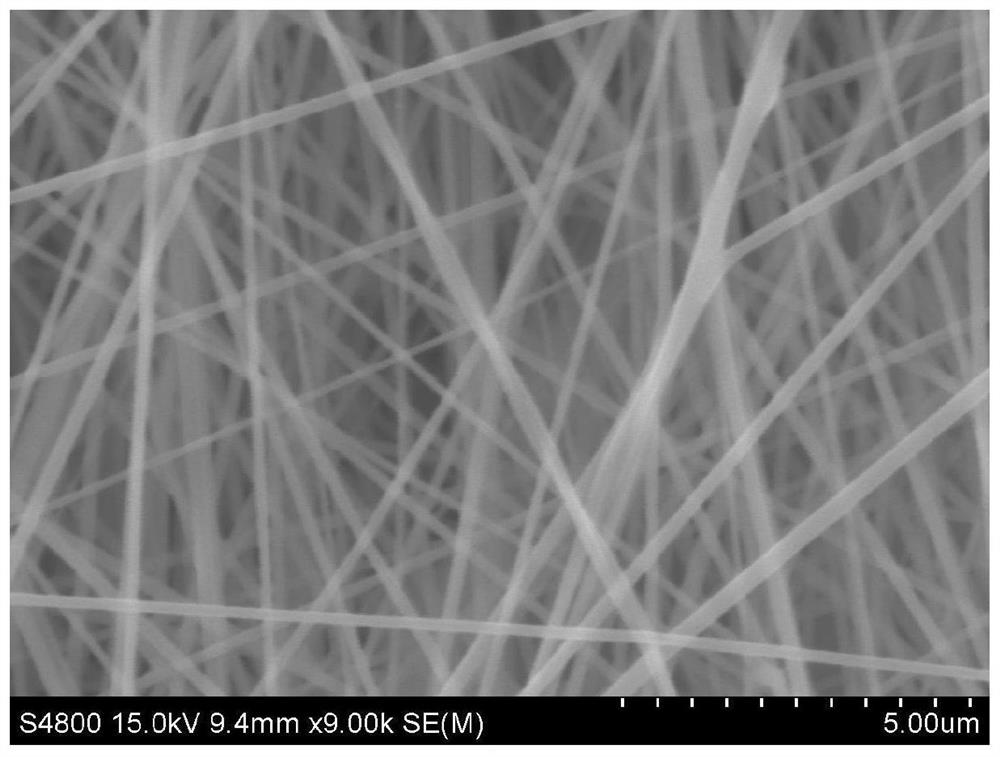

Sodium alginate nanofiber as well as large-scale electrospinning preparation method and application thereof

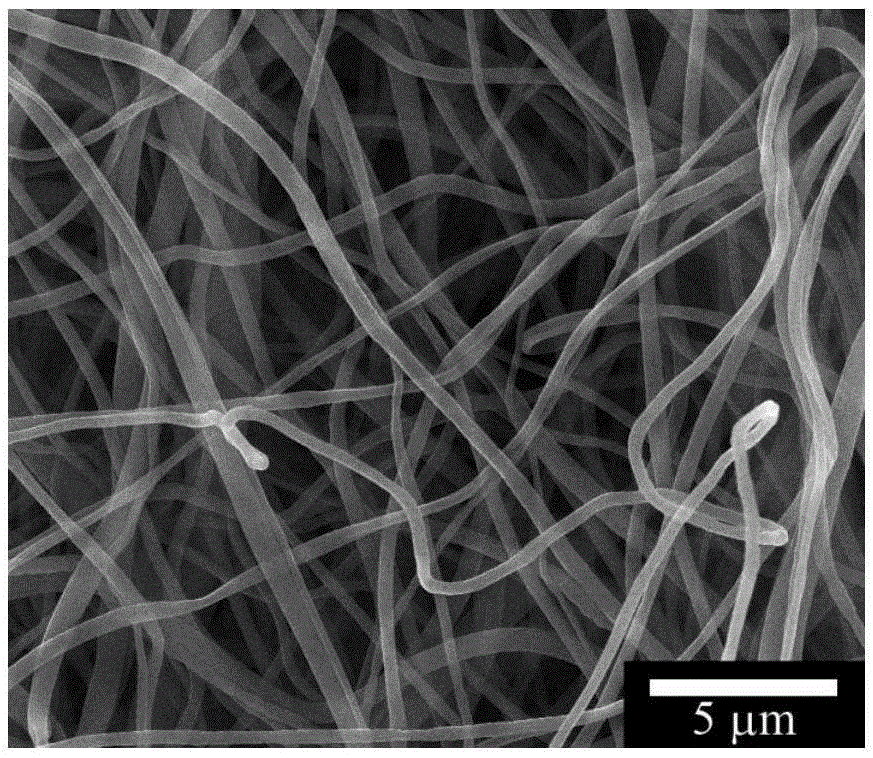

InactiveCN106480517ALarge specific surface areaPromote healingFilament/thread formingAlginate artificial filamentsCross-linkElectrospinning

The invention discloses a sodium alginate nanofiber as well as a large-scale electrospinning preparation method and application thereof. A sodium alginate micro-nanofiber is prepared by an airflow-assisted electrospinning method, wherein the content of sodium alginate in the micro-nanofiber is 75% or higher; the fiber diameter is 50-900 nm; the sodium alginate nanofiber is prepared according to the air-assisted electrospinning method; airflow same as a spinning jet direction is provided by a gas producing mechanism in the spinning process, so as to accelerate the evaporation of a solvent and promote the formation of spun silk; the sodium alginate nanofiber is simple in preparation method, low in requirement on spinning conditions, high in yield, and suitable for large-scale production; spinning precursor liquid is simple in formula, without adding a cross-linking agent and an irritant or toxic solvent; the content of sodium alginate in the obtained nanofiber is high, so that the sodium alginate nanofiber has significant advantage in application in fields of biological tissue engineering materials, wound repair materials or beauty and cosmetics.

Owner:QINGDAO XINZHIYUAN HEALTH TECH

Cationic dye dyeable polyester and preparation method thereof

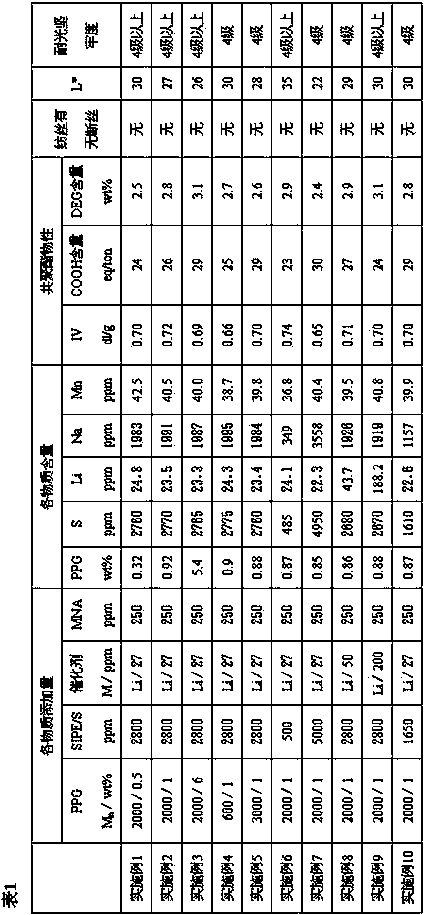

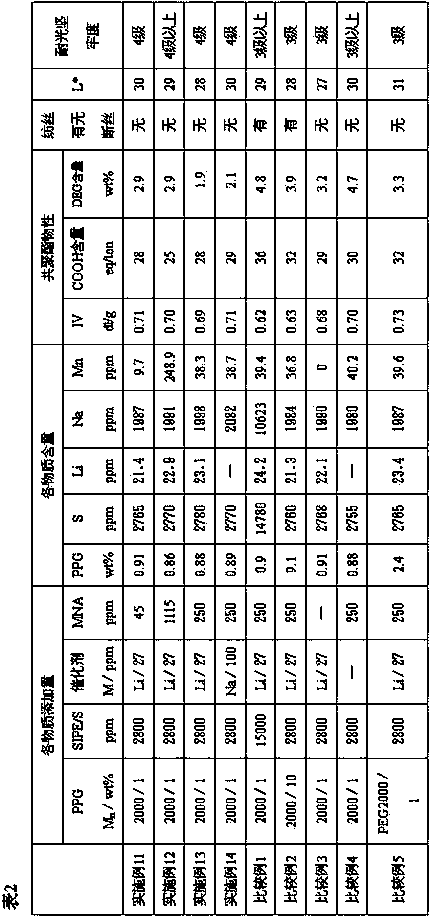

InactiveCN103509175AImprove heat resistanceImprove spinnabilityMonocomponent polyesters artificial filamentManganeseAlkali metal

The invention discloses a cationic dye dyeable polyester and a preparation method thereof. The polyester is obtained by copolymerizing p-phthalic acid, glycol, poly[oxy(methyl-1,2-ethanediyl)] and ethyleneglycol m-phthalate having a metal sulfonic group under the action of an alkali metal element-containing catalyst, and the polyester also contains a manganese element and an alkali metal element. The preparation method of the polyester comprises the following steps: carrying out an esterification reaction of terephthalic acid and glycol to obtain an oligomer, and carrying out condensation polymerization of the oligomer to prepare the polyester, wherein poly[oxy(methyl-1,2-ethanediyl)] is added in the esterification and / or condensation polymerization phase, and the ethyleneglycol m-phthalate having a metal sulfonic group, a manganese compound and the catalyst containing an alkali metal element are mainly added in the condensation polymerization phase.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

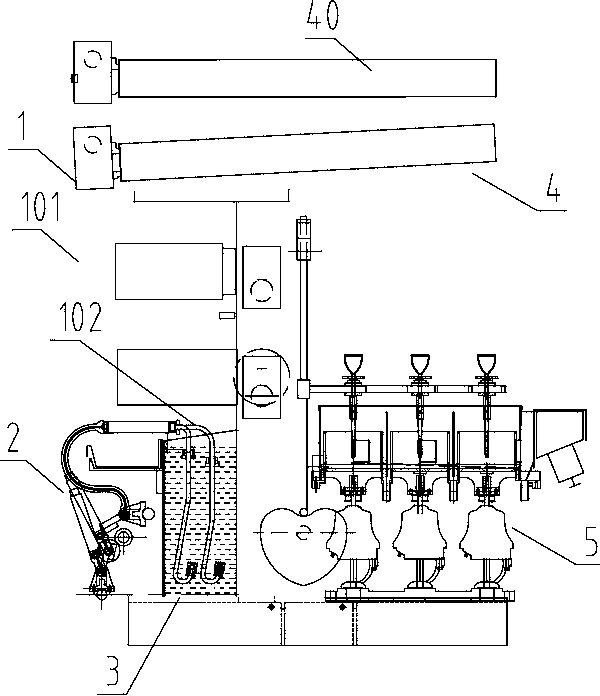

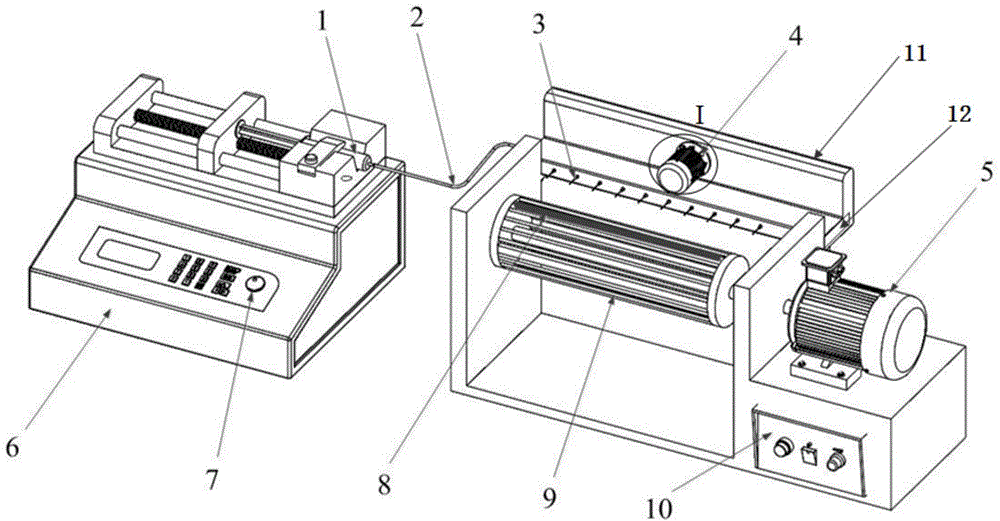

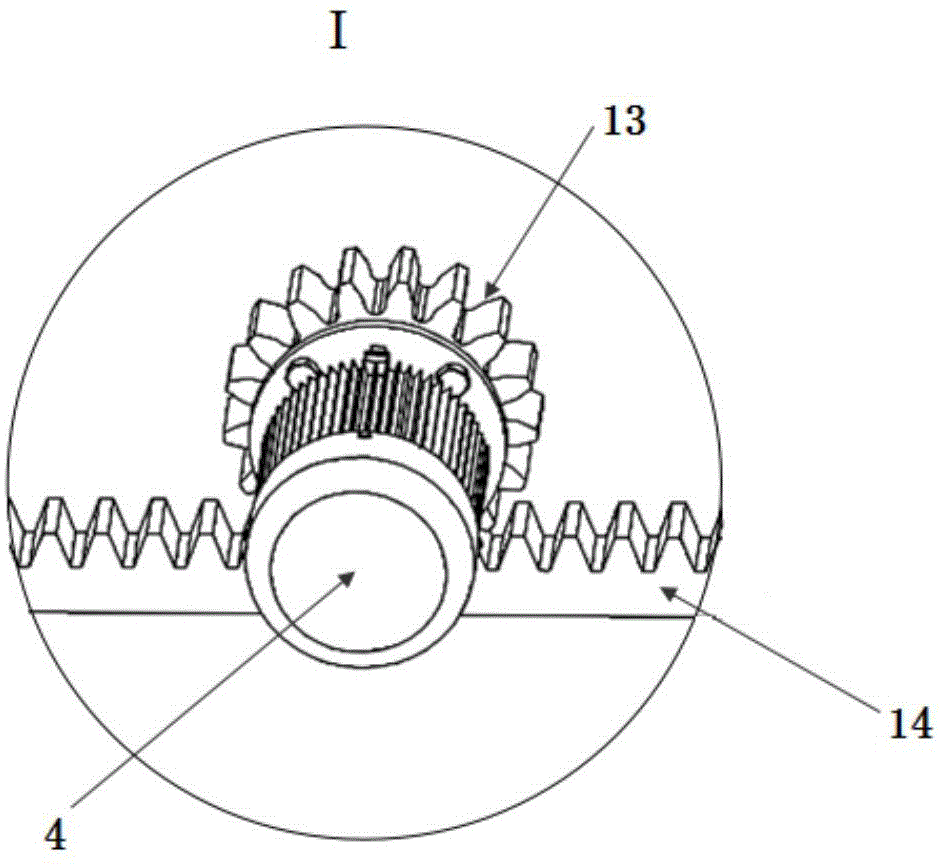

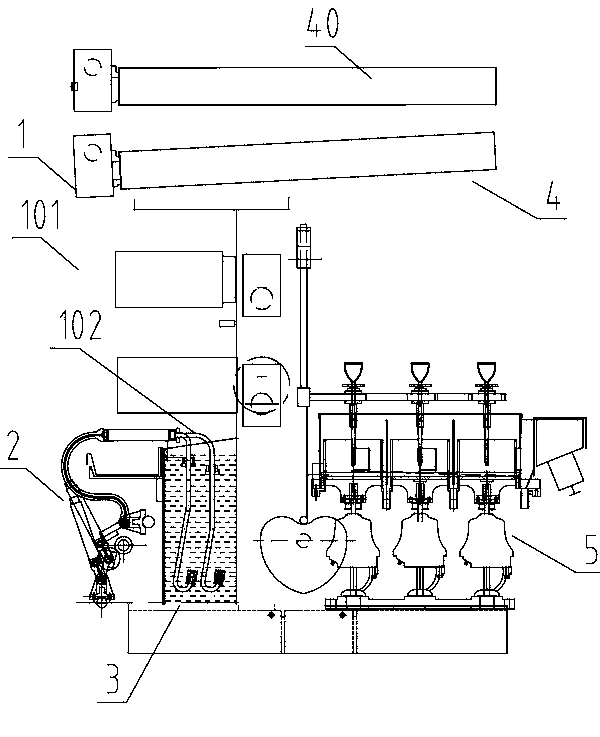

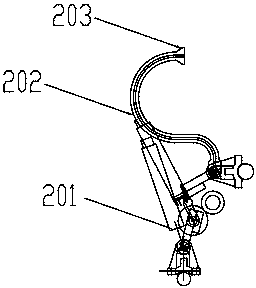

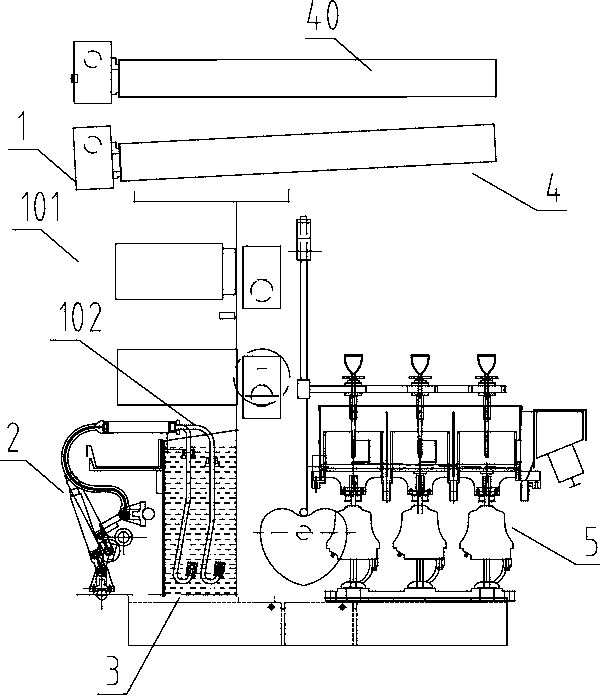

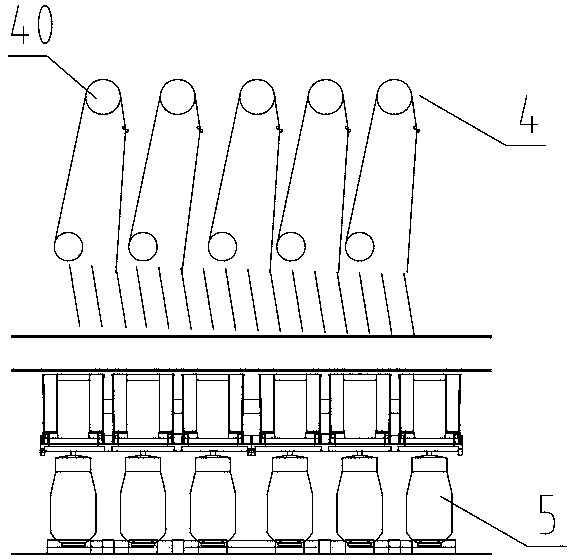

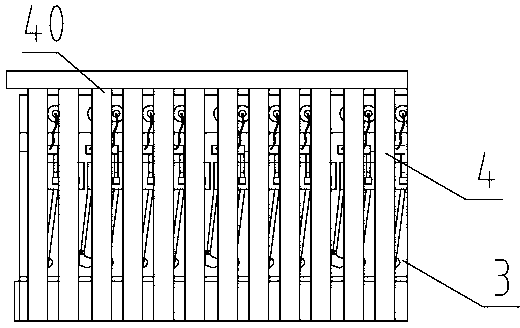

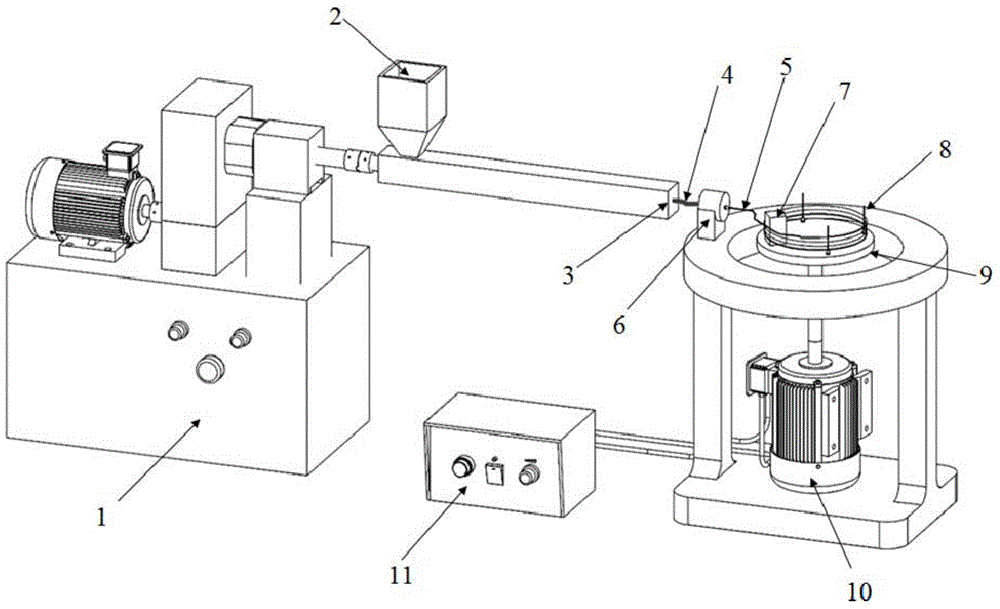

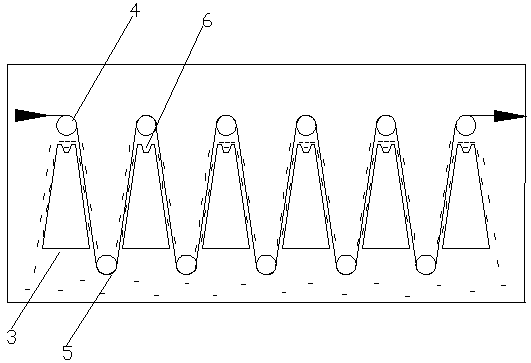

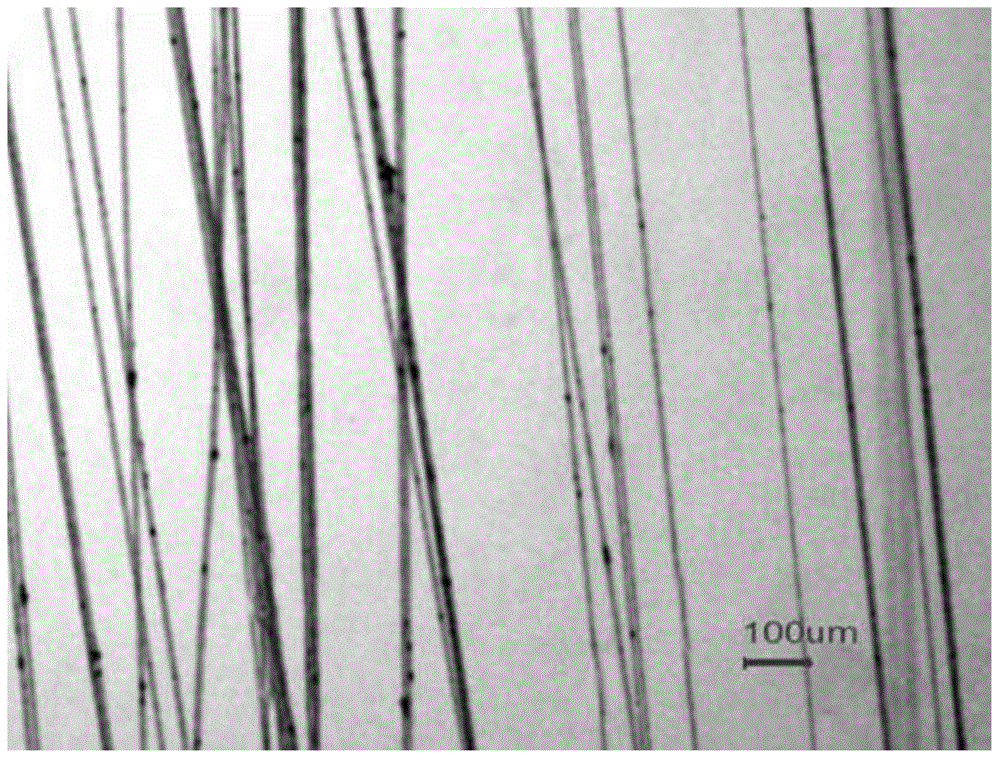

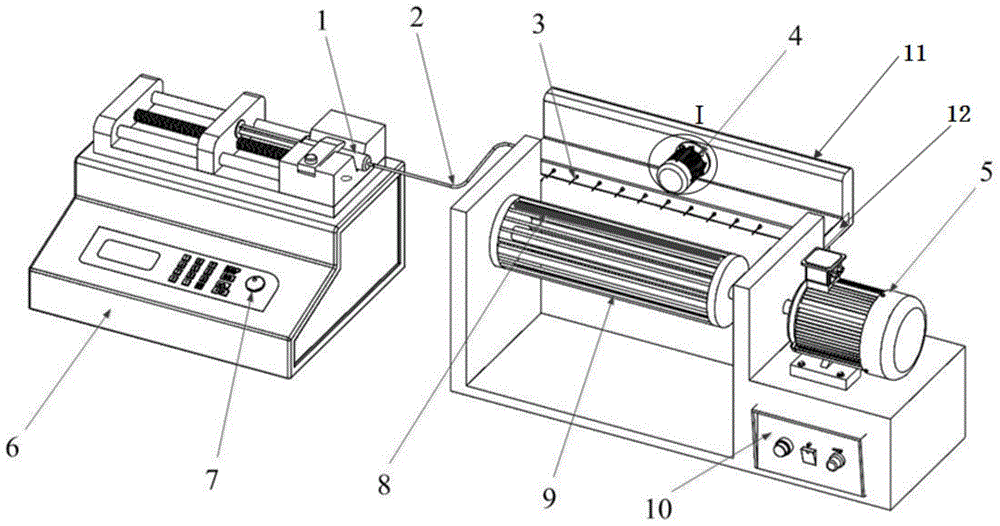

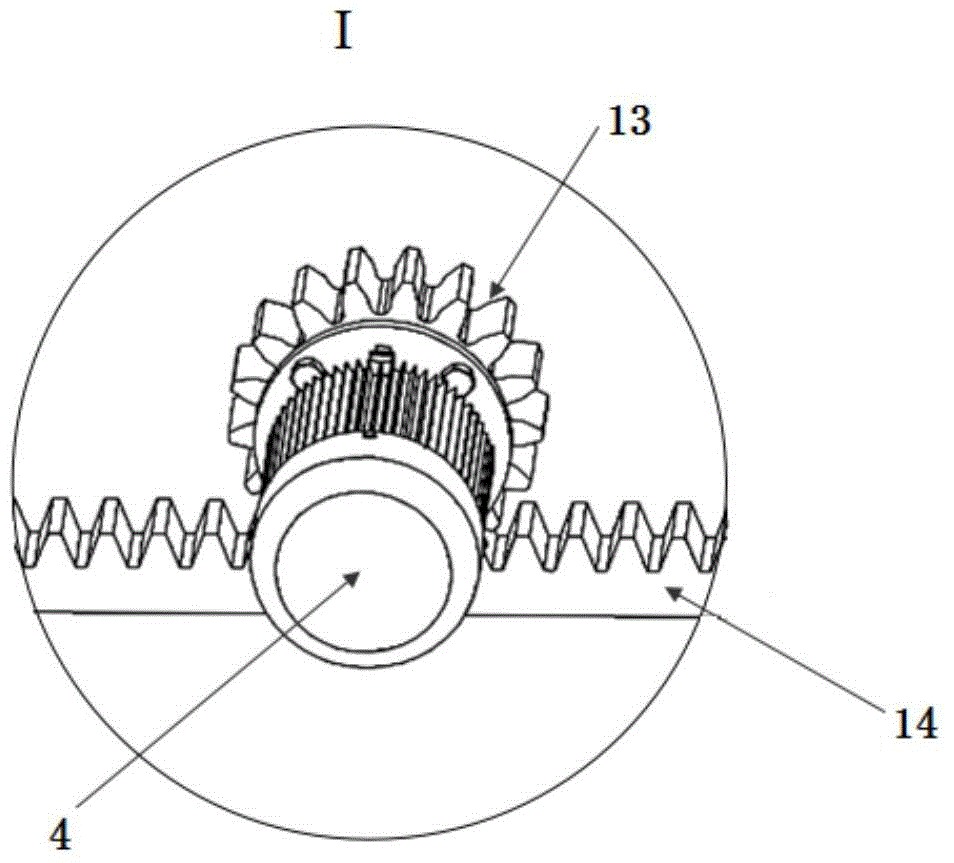

Large-scale magnetic spinning equipment and method using equipment for manufacturing micro-nano-meter fibers

ActiveCN104878461AArranged in an orderly mannerIncrease productionArtificial thread manufacturing machinesFilament/thread formingMicro nanoFiber

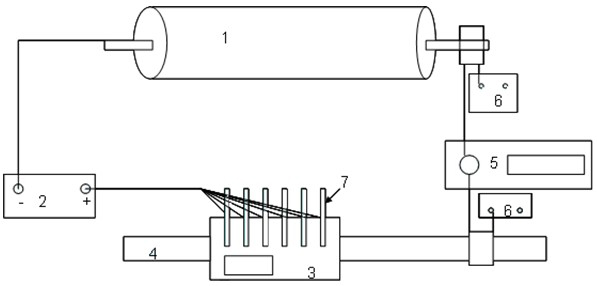

The invention discloses large-scale magnetic spinning equipment and a method using the equipment for manufacturing micro-nano-meter fibers. The equipment comprises a support, a feeding device, a spinning spraying device and a roller type collecting device horizontally arranged. Bar-shaped permanent magnets for providing a magnetic field are fixed to the surface of a collecting roller of the roller type collecting device. The spinning spraying device is provided with a plurality of spinning spraying heads which are uniformly arranged in a column. Injection orifices of the spinning spraying heads point to the bar-shaped permanents of the surface of the collecting roller. The spinning spraying device further comprises a spraying head drive mechanism which can drive the spinning spraying heads to do reciprocating motion in the center axis direction of the collecting roller. According to the equipment, magnetic field force replaces electric field force, under the effect of the alternating magnetic field, ferrofluid is stretched to manufacture the magnetic micro-nano-meter fibers, the high-voltage effect is not needed in the whole process, the production cost and the potential safety hazards are reduced effectively, the micro-nano-meter fibers can be produced continuously in batches, the manufactured fibers are arranged orderly, the yield is high, and the magnetic spinning equipment is suitable for mass production.

Owner:QINGDAO UNIV

Ag-TiO2 nano fiber as well as preparation and application thereof

InactiveCN105964249ASimple installationLow cost of spinningHydrocarbon from carbon oxidesCatalystsElectrospinningChemistry

The invention discloses Ag-TiO2 nano fiber as well as preparation and application thereof. The preparation method of the Ag-TiO2 nano fiber is characterized by comprising the following steps: 1) performing a sol-gel method, namely, dissolving titanate, PVP and acetic acid in absolute ethyl alcohol so as to prepare a solution A; dissolving silver nitrate in deionized water so as to prepare a solution B; adding the solution B into a solution A so as to obtain a mixed solution; (2) performing electrostatic spinning method, namely, adding the mixed solution obtained in step (1) into an injector of an electrostatic spinning instrument, and spinning so as to obtain the Ag-TiO2 nano fiber; (3) calcining the Ag-TiO2 nano fiber obtained in the step (2) at 400-500 DEG C, thereby obtaining the Ag-TiO2 nano fiber. The preparation method of the Ag-TiO2 nano fiber disclosed by the invention is simple in device, low in spinning cost, rich in spinnable substance morphology, controllable in process and the like.

Owner:武汉汉缘和环保科技有限公司

Heavy-denier-yarn spinning technology of semi-continuous and high-speed spinning machine

ActiveCN103409821AReduce in quantityLow manufacturing costWet spinning methodsYarnManufacturing engineering

The invention relates to a heavy-denier-yarn spinning technology of a semi-continuous and high-speed spinning machine, and belongs to the technical field of spinning of the semi-continuous and high-speed spinning machine. The technology comprises the steps of glue supplying, thread-line forming, spinning and winding. The spinning is finished through the spinning device, the spinning device comprises three spinning rollers which are transversely arranged relative to an operation face of a spinning surface, the three spinning rollers are respectively a drafting roller, a solidifying roller and a disacidifying roller, thread-lines sequentially surround the drafting roller, the solidifying roller and the disacidifying roller, and the drafting, the solidifying and the disacidifying in the spinning steps are finished under the rotation of the spinning rollers. The heavy-denier-yarn spinning technology of the semi-continuous and high-speed spinning machine solves the problems that due to the fact that response of thread-lines of a semi-continuous spinning machine in the prior art is insufficient, the spinning speed can not be accelerated, and the production efficiency and the product quality can not be improved at the same time; by changing the arrangement direction of the spinning rollers, the thread-lines can walk a longer distance while the spinning speed of the spinning machine is accelerated and structures of other parts of original equipment are not changed, the thread-lines and acid bath react more fully, and the production efficiency and the product efficiency can be improved at the same time.

Owner:YIBIN HIEST FIBER +2

Spinning process of three-spinning-roller semicontinuous high-speed spinning machine

InactiveCN103409823AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesArtificial filament washing/dryingPolymer scienceSpinning

The invention relates to a spinning process of a three-spinning-roller semicontinuous high-speed spinning machine, and belongs to the technical field of spinning of semicontinuous spinning machines. The spinning process comprises the steps of glue supplying, silk strip forming, spinning and winding. The spinning is completed through a spinning device, the spinning device comprises three spinning rollers transversely arranged relative to an operating surface of a spinning face, silk strips surround the spinning rollers, and drafting, solidification and deacidification in spinning steps are completed under rotation of the spinning rollers. The spinning process solves the problem that due to the fact that the silk strips of a semicontinuous spinning machine in the prior art reacts insufficiently, the spinning speed cannot be improved, and consideration cannot be given to production efficiency and product quality at the same time; the distribution direction of the spinning rollers is changed, so the spinning speed of the spinning machine is improved, structures of other parts of original equipment are not changed, meanwhile the silk strips can be moved for longer distances and react with acid bath more sufficiently, and the consideration is given to the production efficiency and the product quality at the same time.

Owner:YIBIN HIEST FIBER +2

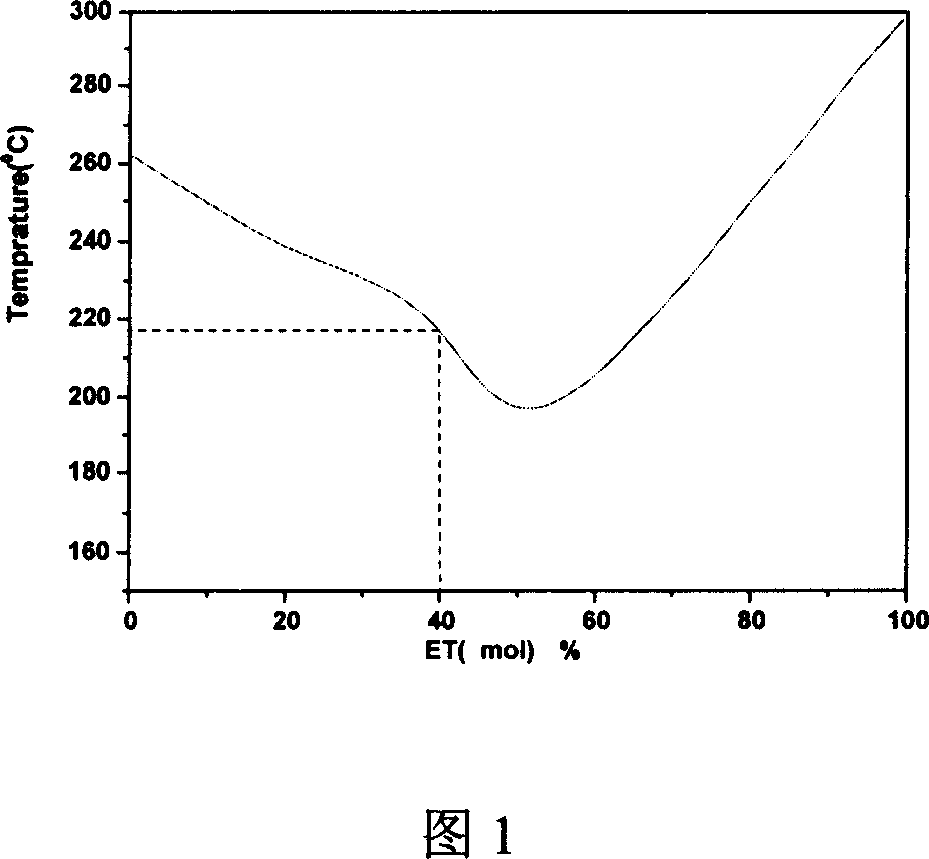

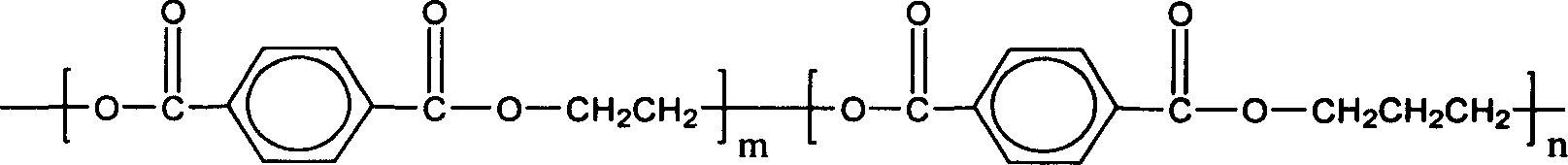

PET/PTT copolyester fiber and its production process

InactiveCN1932093AReduce manufacturing costEasy to processMonocomponent copolyesters artificial filamentMelt spinning methodsFiberChain structure

The present invention discloses one kind of PET / PTT copolyester fiber and its production process. The PET / PTT copolyester fiber has chain structure with ET units accounting for 0.05-0.95 of the total chain units and limiting viscosity value of 0.6-0.9 dL / g. The PET / PTT copolyester fiber is superior to Dacron in softness, dyeability, elasticity, etc. and has high strength similar to that of Dacron. The production process optimizes the performance of the fiber and lowers the production cost.

Owner:DONGHUA UNIV

Processing method of cotton and copper alginate blended yarn

The invention relates to a processing method of cotton and copper alginate blended yarn and belongs to the technical field of yarn manufacturing processes. Copper alginate fiber and cotton are pretreated respectively, and after the copper alginate fiber and the cotton are mixed evenly, mixed fiber is sequentially subjected to opening picking, carding, combing, drawing, roving and spinning, wherein the opening picking process comprises the steps that the mixed fiber sequentially passes through a bale plucker, a mixing opener, a roller card wire opener, a vibration cotton feeding box and a single beater scutcher to be treated, the roller card wire opener and all beater screens of the single beater scutcher are sealed; a half holding and beating gauge is adopted, and in the carding process, controllable half-hold licker-in opening is adopted; needle teeth small in working angle and low in density are adopted in carding machine card clothing. When applied to processing of the copper alginate fiber and cotton mixed yarn, the method has the advantages that the mixed yarn is less in hairiness, high in strength, less in nep, good in yarn levelness and the like.

Owner:浙江吉麻良丝新材料股份有限公司 +2

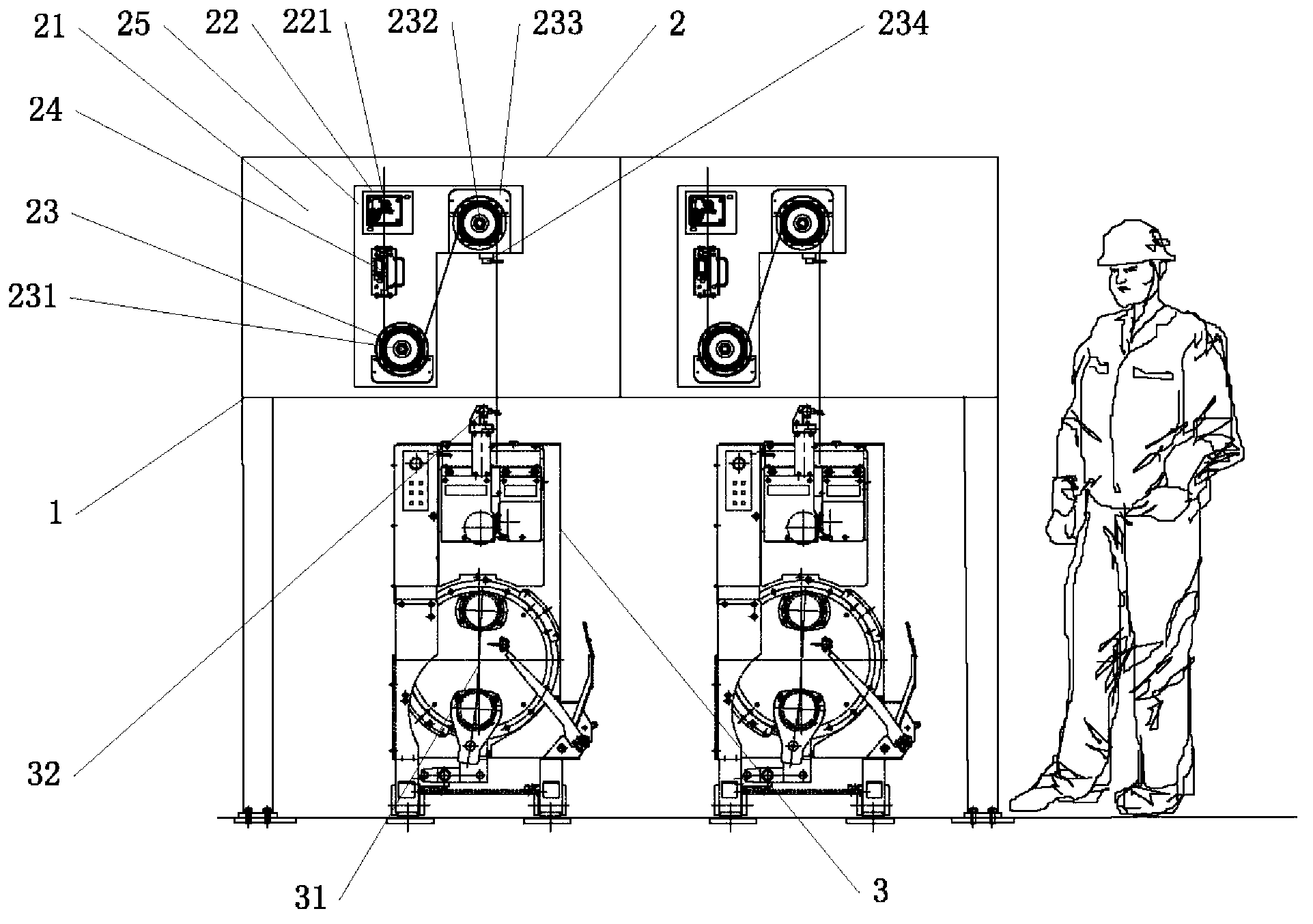

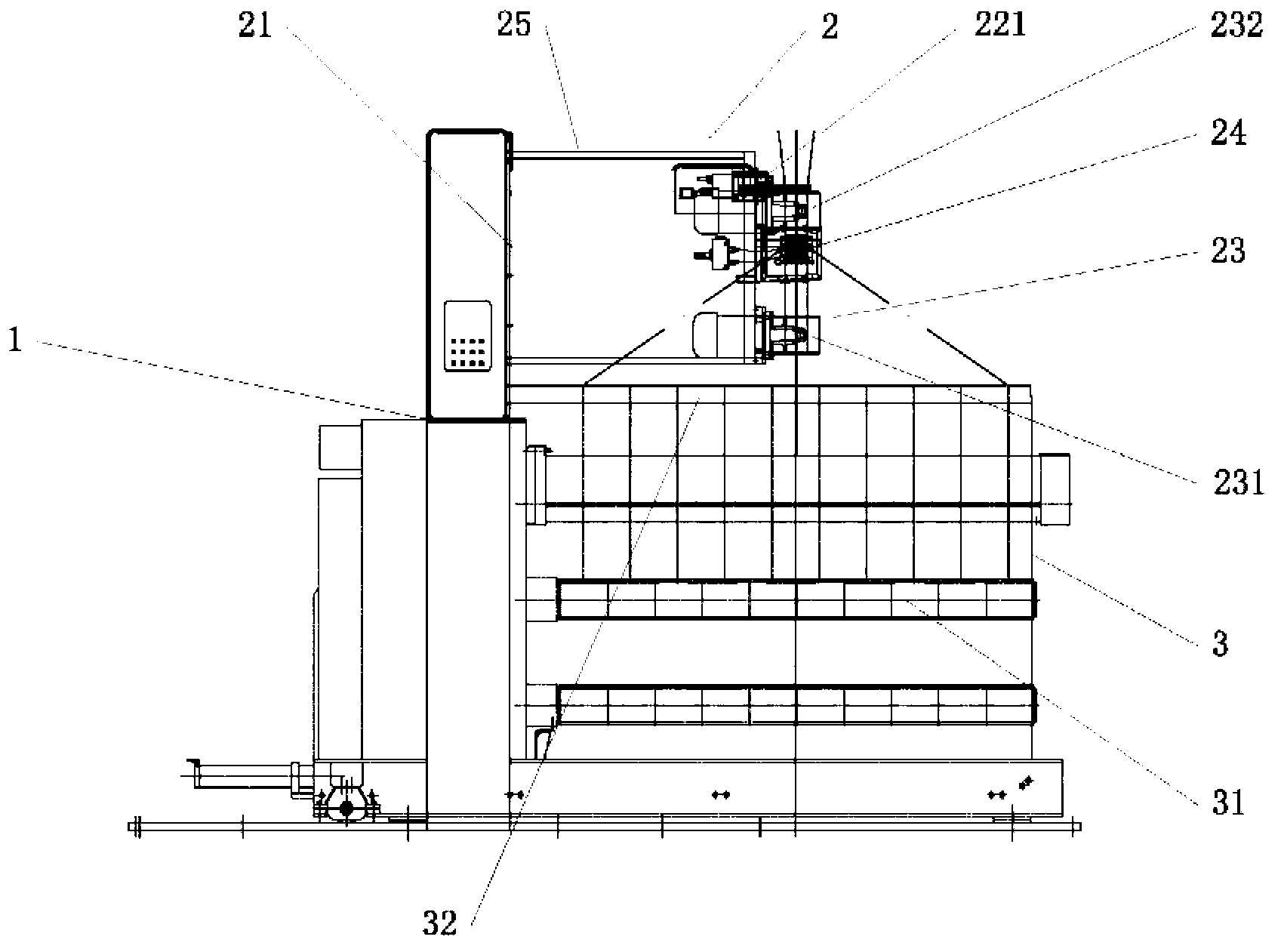

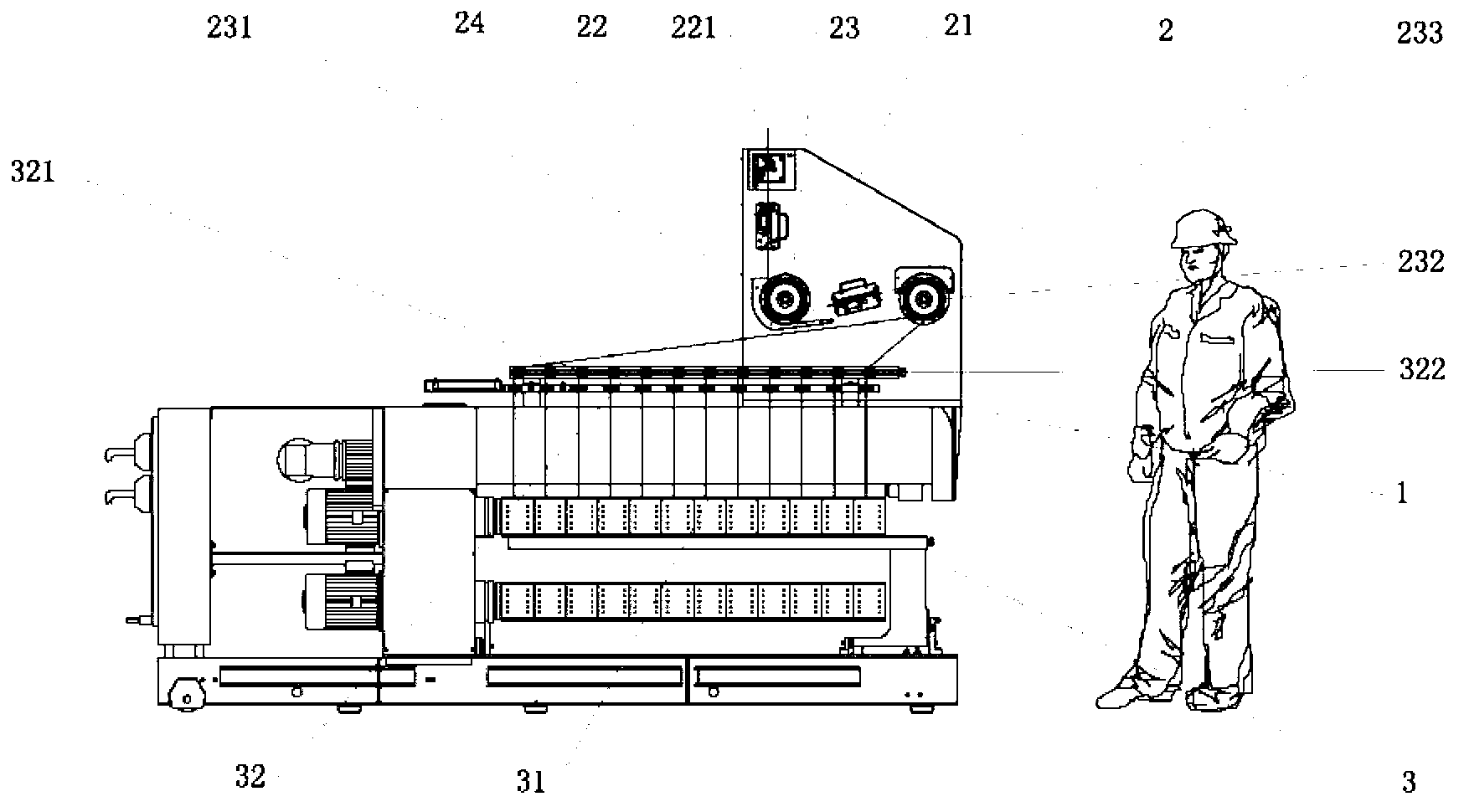

Filament drawing and winding device

ActiveCN102839436ALower the altitudeReduce infrastructure costsNew-spun product collectionArtificial thread manufacturing machinesEconomic benefitsEngineering

The invention discloses a filament drawing and winding device, falling into the technical field of chemical fiber mechanical manufacturing. The device comprises a frame, a drawing apparatus located at the upper part of the frame, and a winding apparatus located at the lower part of the frame. The drawing apparatus includes a mounting panel vertically arranged at the upper part of the frame; a preprocessing part and a drawing part are sequentially distributed along the filament tow circulating direction on the mounting panel; the length directions of a filament inlet and a filament outlet of the preprocessing part are parallel to the axial direction of the drawing part; and at least one network part is arranged on the circulating path of the filament tow between the preprocessing part and the winding apparatus. The inventive device improves the filament quality, saves the labor cost for spinning, eliminates potential safety hazards, shortens the stringup time, improves the spinning production capacity, reduces stringup waste filaments, shortens the equipment mounting period, saves mounting costs, can obtain economic benefits in advance, and saves the manufacturing cost of equipment and the capital construction cost of factory building.

Owner:BEIJING CHONGLEE MACHINERY ENG

Atmospheric pressure cationic dyeable polyester and its production method and use

InactiveCN102276814AImprove heat resistanceHigh melting pointMonocomponent copolyesters artificial filamentPolyesterFiber

The invention discloses a normal-pressure cationic dye-dyeable polyester and its production method and application. The polyester is composed of dimethyl terephthalate, ethylene glycol, aliphatic dibasic acid or its derivatives and Dimethyl isophthalate with salt group is copolymerized under the catalysis of soluble titanium compounds; relative to the weight of polyester, the content of sulfur in polyester is 300-11000ppm, and the aliphatic dibasic acid group The content of the soluble titanium element is 0.1-10wt%, the content of the soluble titanium element is 1-1000ppm, and the content of the antimony element is less than 3ppm; the content of the basic compound in the polyester is 10-5000ppm; the present invention uses a non-toxic and environment-friendly titanium compound As a catalyst, the obtained polyester has the characteristics of high melting point, high thermal stability, and good spinnability, and the fiber fabric made from it has good dyeability and dyeability under normal pressure.

Owner:TORAY IND INC

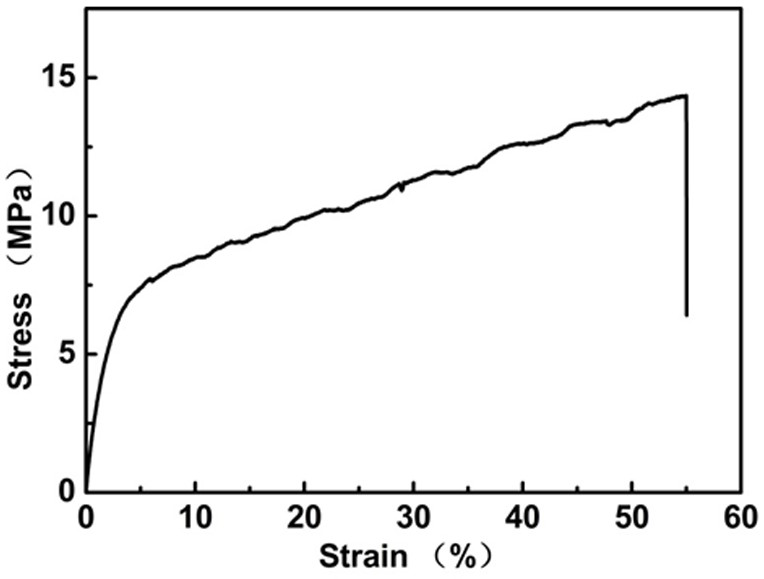

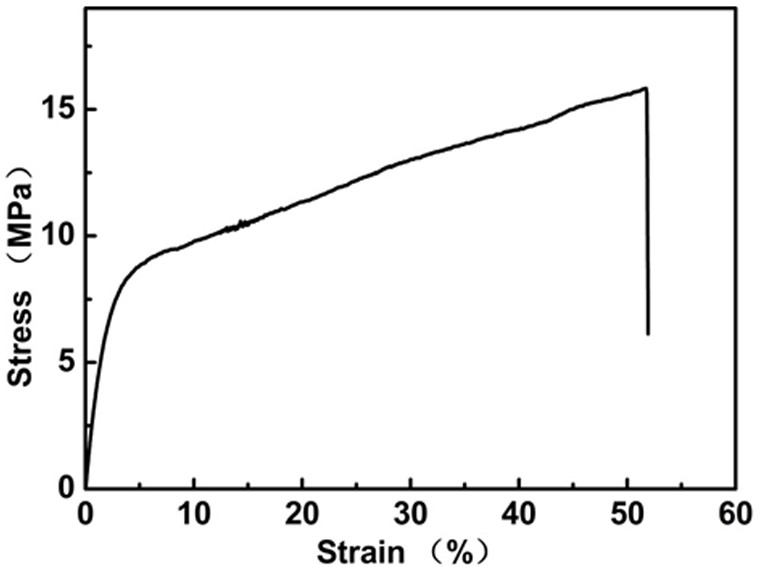

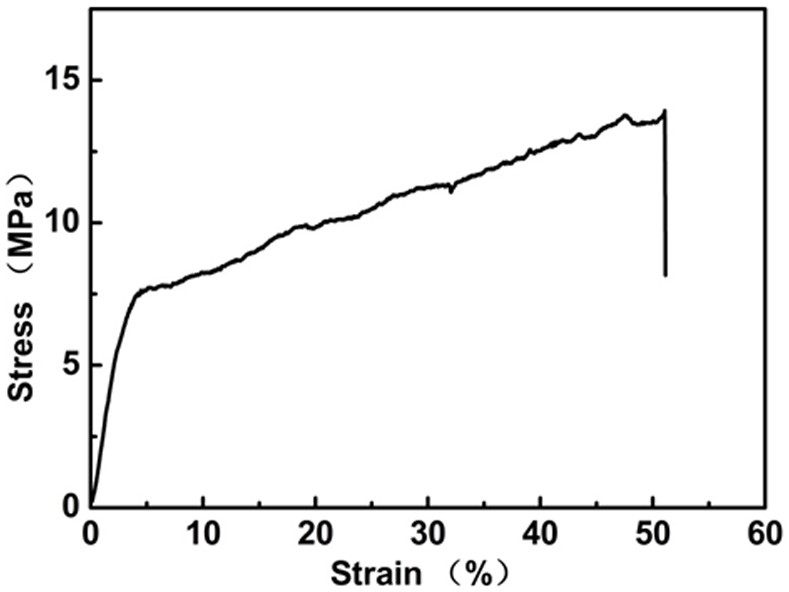

Spinning method of PEDOT:PSS conductive fiber high in elongation

ActiveCN111793853ASimple preparation processLow costElectroconductive/antistatic filament manufactureWet spinning methodsFiberSpinning

The invention relates to a wet spinning method of PEDOT:PSS conductive fiber high in elongation in an organic polymer conductive fiber preparation technology. The method includes the following steps that firstly, PEDOT:PSS spinning fluid is prepared; then, the spinning fluid enters an ethyl alcohol and water mixed coagulating bath through a wet spinning spinneret plate to be subjected to coagulation forming, wherein LiCl is added in the ethyl alcohol and water mixed coagulating bath, and the addition concentration is 0.1-0.5 mol / L; and fiber obtained after coagulation forming is dried and cooled after being subjected to drafting, and the PEDOT:PSS conductive fiber high in conductivity and elongation is prepared. According to the method, one-step method wet spinning is adopted, the water / ethyl alcohol system coagulating bath is adopted as the main body, lithium ions are added in the coagulating bath to assist in fiber solidification forming, the lithium ions are doped in the fiber, andtherefore the fiber tensile elongation and conductivity are obviously improved, the application range of the fiber in textile materials is widened, and processing adaptability of the fiber is improved.

Owner:YANGZHOU UNIV

Method of preventing corrosion by marine microorganisms by using artificial supper-smooth surfaces

InactiveCN104805532AImprove rigidityImprove toughnessFilament forming substance formingArtificial filament heat treatmentAntioxidantTorque motor

The invention discloses a method of preventing corrosion by marine microorganisms by using artificial supper-smooth surfaces. The method comprises the following steps: weighing and taking polycarbonate, acrylonitrile and styrene copolymer, a compatilizer, a flexibilizer, an antioxidant, a lubricating agent, a flame-retardant synergist, a brominated flame retardant, nanoscale dried titanium dioxide, a turpentine assistant for spinning, an acrylic acid type additive with perfluoroalkyl group, a heat-resistant agent and inorganic nanoparticles according to parts by weight; blending the raw materials, mixing and pelletizing the blended materials through a double-screw extruder to obtain mixed material aggregates; preparing the mixed material aggregates into nascent composite filaments through a single screw extruder; cooling the nascent composite filaments and carrying out hot stretching two times; degreasing the stretched composite filaments with high pressure draft and quickly cooling the degreased composite filaments, and using the filament-collecting machine of a torgue motor to collect and roll filament tows of composite filaments to obtain finished products. According to the invention, special proportion and special spinning technology are adopted, so as to improve the surface smoothness, capacity of microbiological corrosion resistance, breaking strength, knot strength, knot use ratio, durability and suitability of rope nets.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

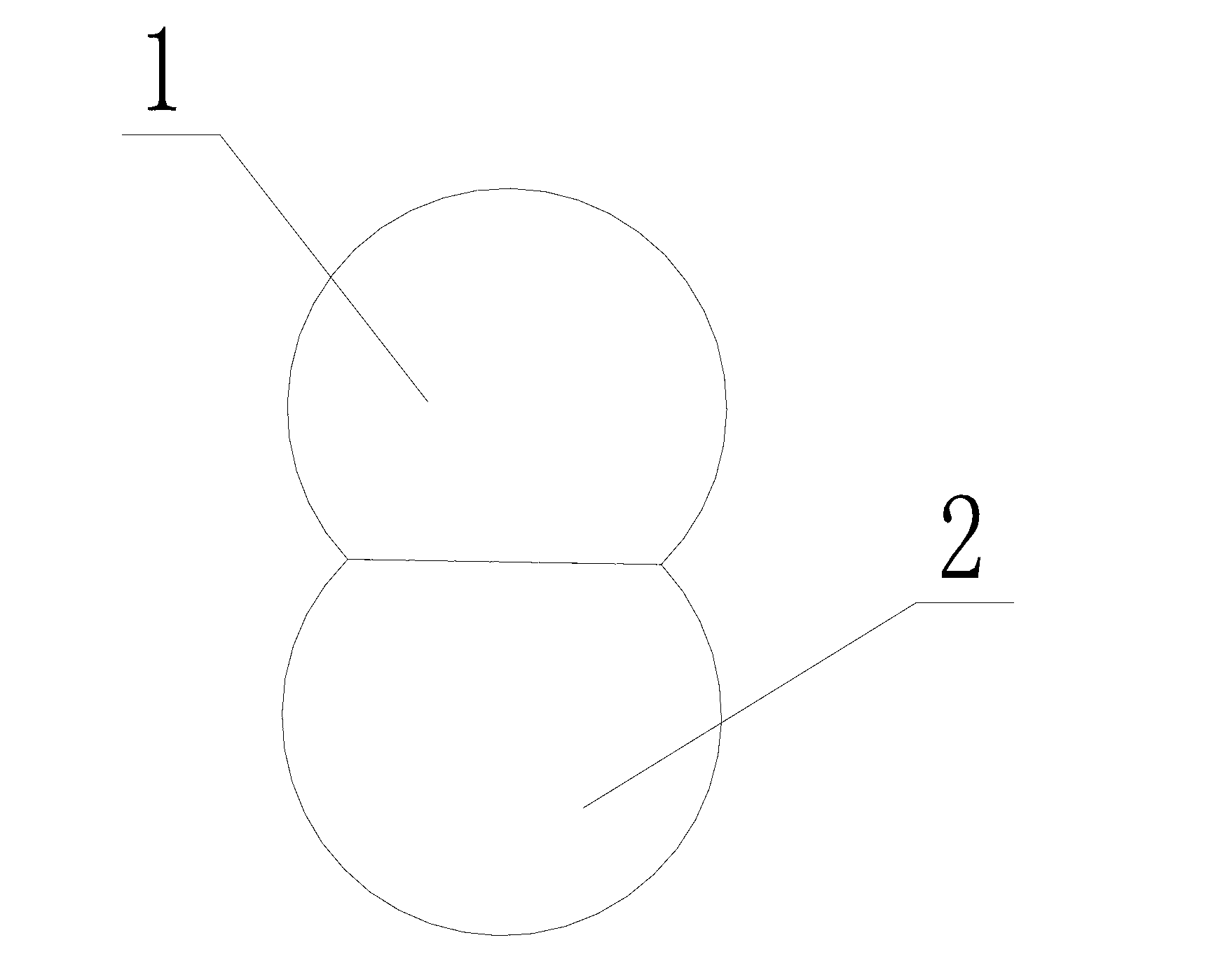

Composite combined filament yarn and method for producing combined filament yarn for spinning by utilizing composite filament yarn

InactiveCN102704033AEasy to produceIncrease productionMonocomponent polyesters artificial filamentPolytrimethylene terephthalatePolyamide

The invention discloses a method with steady production process for producing a composite combined filament yarn with steady quality. The method comprises the steps of: fusing dry slices of a PTT (Polytrimethylene Terephthalate) material accounting for 60%-90% of the total weight to form a spinning PTT material melt; fusing dry slices of a PA6 (polyamide 6) material accounting for10%-40% of the total weight to form a spinning PA6 material melt; extruding the PTT material melt and the PA6 material melt after passing through respective spinning melt channels by an eight-shaped spinning component; then cooling, oiling and forming the composite combined filament yarn after the melt passes through a spinning channel, a pre-networking device and a hot roller drawing device; then enabling the composite combined filament yarn to pass through an NaOH solution with a percentage by weight of 0.5-10% in a boiling water state; and thereby separating the composite combined filament yarn into the combined filament yarns for spinning. According to the composite combined filament yarn and the method for producing the combined filament yarn for spinning by utilizing the composite combined filament yarn, disclosed by the invention, the production process of the combined filament yarn is simplified, and output and quality of the combined filament yarn are improved greatly.

Owner:张家港保税区长江塑化有限公司

A melt magnetic spinning device and a method for preparing micro-nano fibers using the device

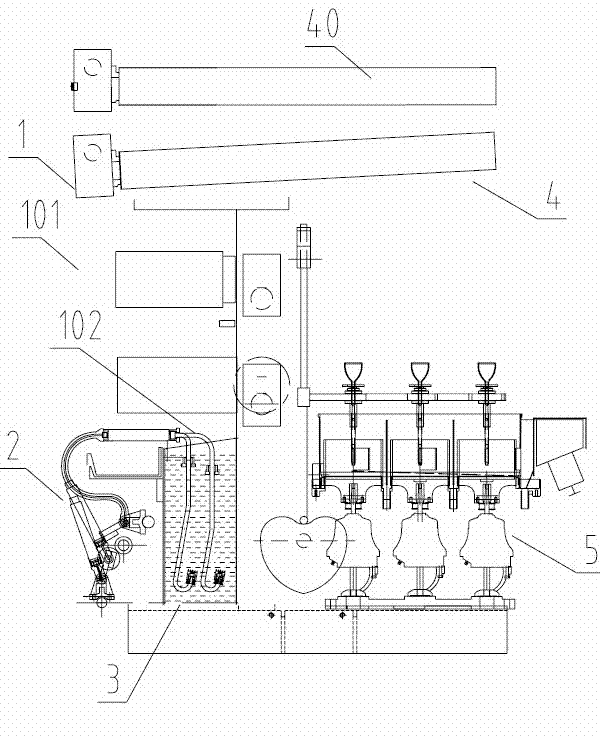

ActiveCN104878455BIncrease productionArranged in an orderly mannerArtificial thread manufacturing machinesFilament/thread formingEngineeringHigh pressure

The invention discloses a melt magnetic spinning device and a method for preparing micro-nano fibers by using the device. The device includes a heating feeding device with a controllable feeding rate, a spinning nozzle, a nozzle driving mechanism and a spinning receiving device , the spinning receiving device includes a horizontal collection disk, the center of the bottom of the collection disk is connected with the output shaft of the DC brushless motor for linkage, and the upper surface of the collection disk is symmetrically arranged with a plurality of vertical shafts with the central axis of the disk as the symmetrical axis. One of the vertical pillars is a permanent magnet, and the rest are metal needles. The spinning nozzle is arranged horizontally, and the injection port of the spinning nozzle points to the permanent magnet of the spinning receiving device. The connection of the spinning nozzle can drive its The nozzle drive mechanism that reciprocates in the vertical direction. The device does not need high-voltage action during use, effectively reduces production costs and potential safety hazards, and the prepared fibers are arranged in an orderly manner, with high output and suitable for large-scale production, and the obtained micro-nano fibers have good application prospects.

Owner:QINGDAO UNIV

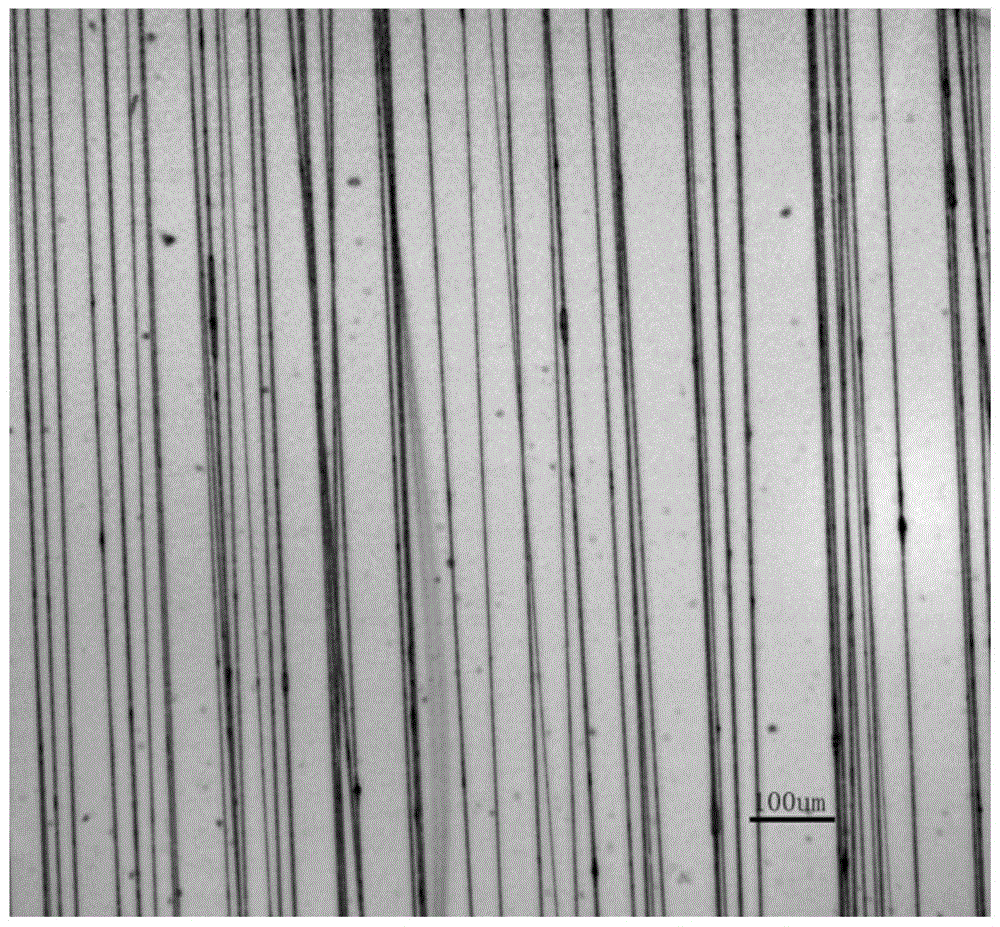

Modified polyphenylene sulfide fiber and method for making same

InactiveCN100567601CHigh glossImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceSilicon oxide

The invention provides a modified polyphenylene sulfide fiber and a preparation method thereof. The components and parts by weight include: 100 parts of polyphenylene sulfide (PPS); 0.2 to 2 parts of nano silicon dioxide after surface treatment, two The particle size of silicon oxide is 20-60 nanometers; the fineness of the fiber is 85-91dtax. The present invention modifies the polyphenylene sulfide resin and adopts a specific spinning process to prepare polyphenylene sulfide fiber, the fiber strength and tensile toughness are improved, and the glossiness of the fiber is also improved at the same time. The spinning equipment is used for spinning, which reduces the spinning cost, and the fluidity of the matrix becomes better during the spinning process, the spinning temperature is reduced by 5-10°C, the draft ratio of the primary fiber is improved, and the mechanical properties of the fiber Improved.

Owner:DONGHUA UNIV

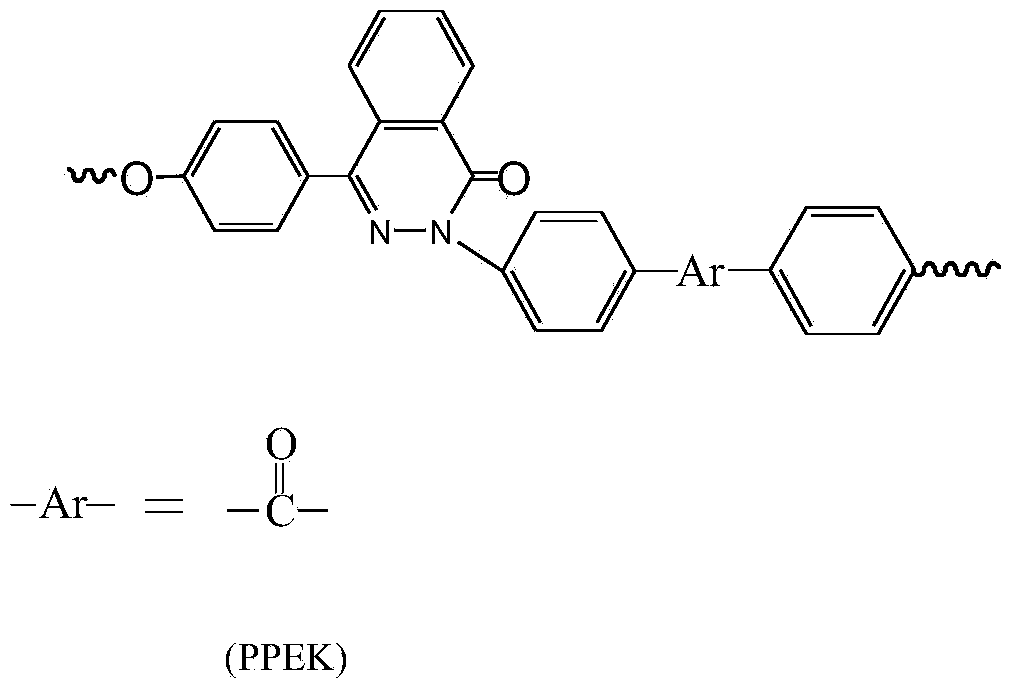

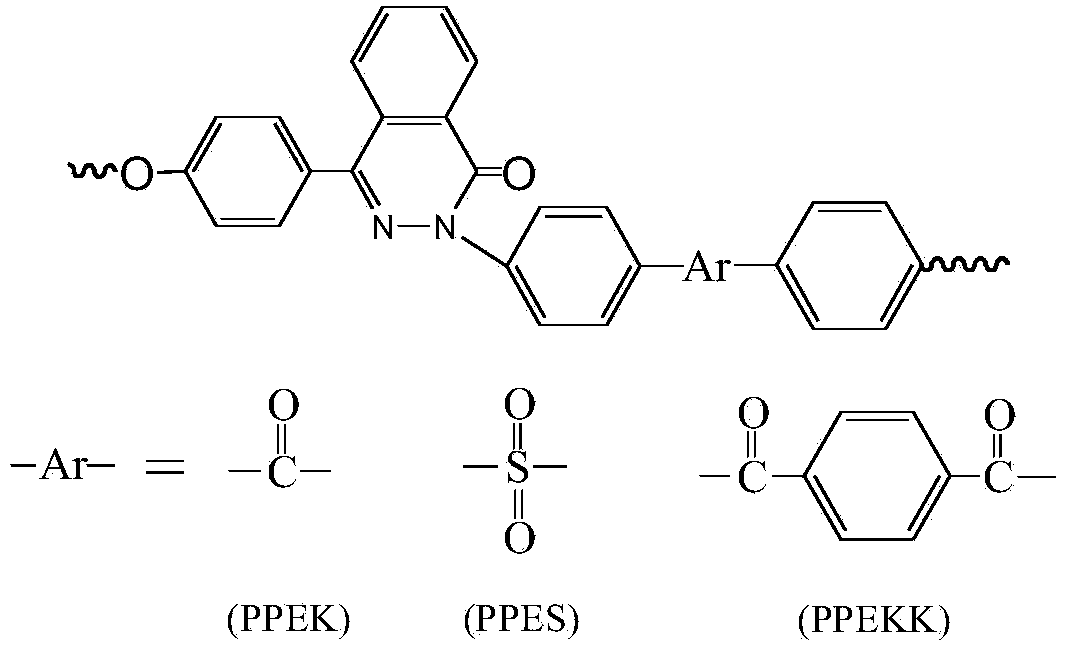

Dry spinning preparation method of polyarylether fibers with phthalazone structure

ActiveCN102505174BImprove heat resistanceHigh mechanical strengthMonocomponent polyethers artificial filamentArtificial filament heat treatmentFiberPolymer science

Owner:DALIAN UNIV OF TECH

A kind of processing method of cotton and copper alginate blended yarn

The invention relates to a processing method of cotton and copper alginate blended yarn and belongs to the technical field of yarn manufacturing processes. Copper alginate fiber and cotton are pretreated respectively, and after the copper alginate fiber and the cotton are mixed evenly, mixed fiber is sequentially subjected to opening picking, carding, combing, drawing, roving and spinning, wherein the opening picking process comprises the steps that the mixed fiber sequentially passes through a bale plucker, a mixing opener, a roller card wire opener, a vibration cotton feeding box and a single beater scutcher to be treated, the roller card wire opener and all beater screens of the single beater scutcher are sealed; a half holding and beating gauge is adopted, and in the carding process, controllable half-hold licker-in opening is adopted; needle teeth small in working angle and low in density are adopted in carding machine card clothing. When applied to processing of the copper alginate fiber and cotton mixed yarn, the method has the advantages that the mixed yarn is less in hairiness, high in strength, less in nep, good in yarn levelness and the like.

Owner:浙江吉麻良丝新材料股份有限公司 +2

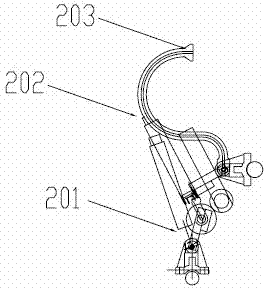

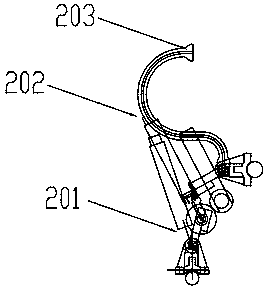

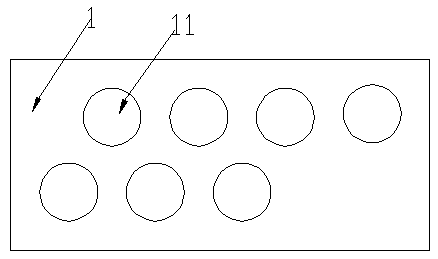

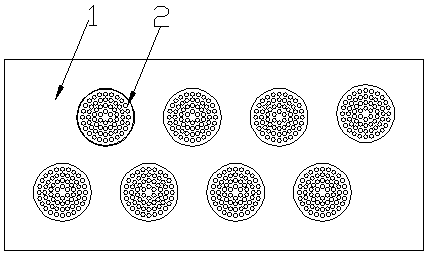

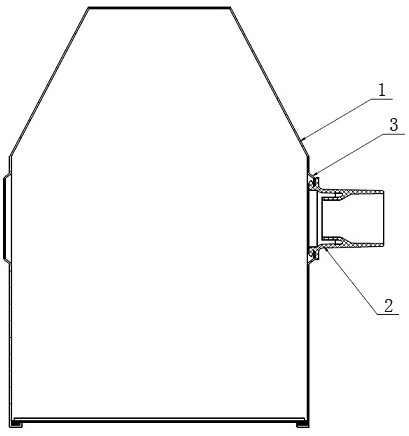

A kind of spinning method of aramid fiber

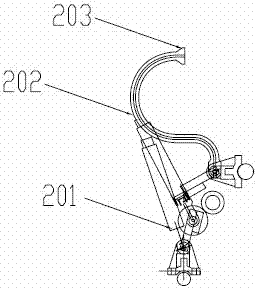

ActiveCN106757452BGuaranteed performanceLow cost of spinningSpinnerette packsArtificial thread manufacturing machinesYarnVolumetric Mass Density

The invention provides an aramid fiber III fiber spinning method. The method includes the first step of jetting, the second step of primary extraction and solidification to form gummy fibers, the third step of plastification and drawing, the fourth step of secondary extraction and solidification to form nascent fibers, the fifth step of washing and the sixth step of thermal treatment achieved through a thermal treatment path of an electromagnetic induction heating device to obtain aramid fiber III fibers. In the first step, a spinning jet comprises a rectangular plate surface and a plurality of round spinneret caps on the rectangular plate surface, the rectangular plate surface is provided with a plurality of through holes 11, and the round spinneret caps are embedded in the through holes 11. The method is capable of guaranteeing the property of the aramid fiber III fibers, the fiber spinning cost is reduced, and the problems that a single strand of yarn of aramid fiber III fibers manufactured through a current wet spinning technology is small in density, the production efficiency is low, energy consumption is high, the production cost is high, and high-performance aramid III cannot be used in the bulletproof field are solved.

Owner:中蓝晨光化工有限公司

A method for preparing graphene/polymer ordered micro-nano composite fibers by magnetic spinning

InactiveCN104862799BArranged in an orderly mannerIncrease productionArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentBrushless motorsCircular disc

The invention discloses a method for preparing graphene / polymer micro-nano fibers by magnetic spinning, which comprises the following steps: (1) building a magnetic spinning device: the magnetic spinning device includes a rotating collection disc with a permanent magnet; (2) ) Preparation of precursor spinning solution: magnetic nanoparticles, high molecular polymer and graphene dispersion are mixed and dissolved in an organic solvent to prepare a solution; (3) graphene / polymer micro-nano composite fiber is prepared by using a magnetic spinning device: the precursor The spinning solution is injected into the feeding device, and the feeding device is turned on. The liquid droplets at the nozzle of the spinning nozzle form a jet flow and bridge the permanent magnet under the action of the magnetic field force, and the DC brushless motor is turned on to drive the collecting disc to rotate. Under the action of the magnetic field force, the ferrofluid jet is continuously pulled out and entangled between the vertical pillars of the collecting disc to form micro-nano fibers. The method does not require high-voltage action, reduces production costs and safety hazards, has orderly fiber arrangement, is suitable for large-scale production, and has good application prospects.

Owner:QINGDAO UNIV

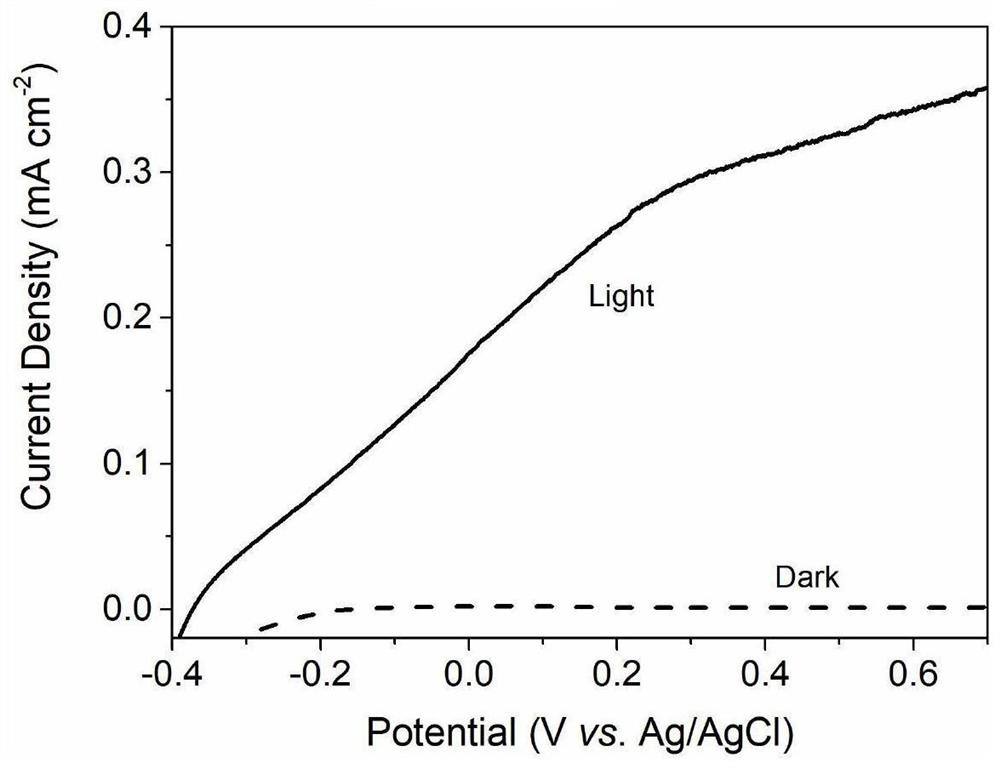

A method of preparation of a tungsten nano -nanofiber photogenic materials

ActiveCN113293391BReduce distanceImprove decomposition efficiencyMaterial nanotechnologyEnergy inputSpinningClean energy

The invention relates to the technical field of photoelectrode materials, in particular to a preparation method of a tin tungstate nanofiber photoanode material. The preparation method provided by the present invention includes the following steps: mixing an inorganic tin source, an inorganic tungsten source, an organic high molecular polymer and an organic solvent to obtain a spinning solution; adopting electrostatic spinning, using the spinning solution in FTO Three-dimensional nanofibers are prepared on the surface of conductive glass; the three-dimensional nanofibers are calcined to obtain the SnWO 4 Nanofiber photoanode material. The preparation method has the advantages of simple process route, convenient equipment and low spinning cost, and can realize SnWO 4 mass production and large area SnWO 4 Controllable fabrication of photoelectrodes. Prepared SnWO 4 The photoelectrode can generate relatively excellent photocurrent and lower onset potential under simulated sunlight irradiation, which increases the efficiency of photoelectric conversion of water splitting, and has strong application prospects in the field of clean energy production in the future.

Owner:TAIZHOU UNIV +1

A magnetic spinning device and a method for preparing micro-nano fibers using the device

ActiveCN104878456BIncrease productionHigh degree of orderFilament/thread formingSpinning solutions preparationMicro nanoFiber

Owner:QINGDAO UNIV

A large-scale magnetic spinning device and a method for preparing micro-nano fibers using the device

ActiveCN104878461BArranged in an orderly mannerIncrease productionArtificial thread manufacturing machinesFilament/thread formingMicro nanoFiber

The invention discloses a large-scale magnetic spinning equipment and a method for preparing micro-nano fibers using the equipment. The equipment includes a support, a feeding device, a spinning injection device and a horizontally arranged drum-type collecting device. The drum-type collecting device The surface of the collection drum is fixed with a bar-shaped permanent magnet that provides a magnetic field. The spinning injection device is provided with a plurality of spinning nozzles, and the plurality of spinning nozzles are evenly arranged in a row. The strip-shaped permanent magnet on the surface of the collecting drum, and the spinning jet device also includes a nozzle driving mechanism that can drive the used spinning nozzle to reciprocate along the central axis of the collecting drum. This equipment replaces electric field force with magnetic field force, and stretches ferrofluid under the action of alternating magnetic field force to prepare magnetic micro-nano fibers. The whole process does not require high-voltage electricity, which effectively reduces production costs and safety hazards, and can continuously produce micro-nano fibers in batches. fibers, and the prepared fibers are arranged in an orderly manner, and the yield is high and suitable for large-scale production.

Owner:QINGDAO UNIV

Novel connector device for air pipe of ring spinning frame

PendingCN113235196AIncrease suction negative pressureReduce spinning costsTextiles and paperStructural engineeringMaterials science

The invention discloses a novel connector device for an air pipe of a ring spinning frame. The device comprises the air pipe and a cotton suction flute pipe connector; the cotton suction flute pipe connector is arranged on a connector of the air pipe; the air pipe adopts an outwards-convex connector; the cotton suction flute pipe connector is arranged on the outwards-convex connector of the air pipe; and the tail of the cotton suction flute pipe connector and the inner wall of the air pipe are kept on the same plane. During working, flying cotton in the air pipe can be smoothly adsorbed to a fan filter screen, so that the phenomenon that the tail end of the cotton flute pipe connector in the air pipe is hung with the cotton is avoided, the cotton suction negative pressure in the air pipe is greatly improved, the situation that a leather roller and a leather ring are damaged as a broken end cannot be adsorbed and is wound on the leather roller is avoided, the spinning cost is reduced, and the spinning efficiency is improved.

Owner:JINGWEI INTELLIGENT TEXTILE MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com