Patents

Literature

135results about "Monocomponent polyethers artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of Applying Skin Wellness Agents to a Nonwoven Web Through Electrospinning Nanofibers

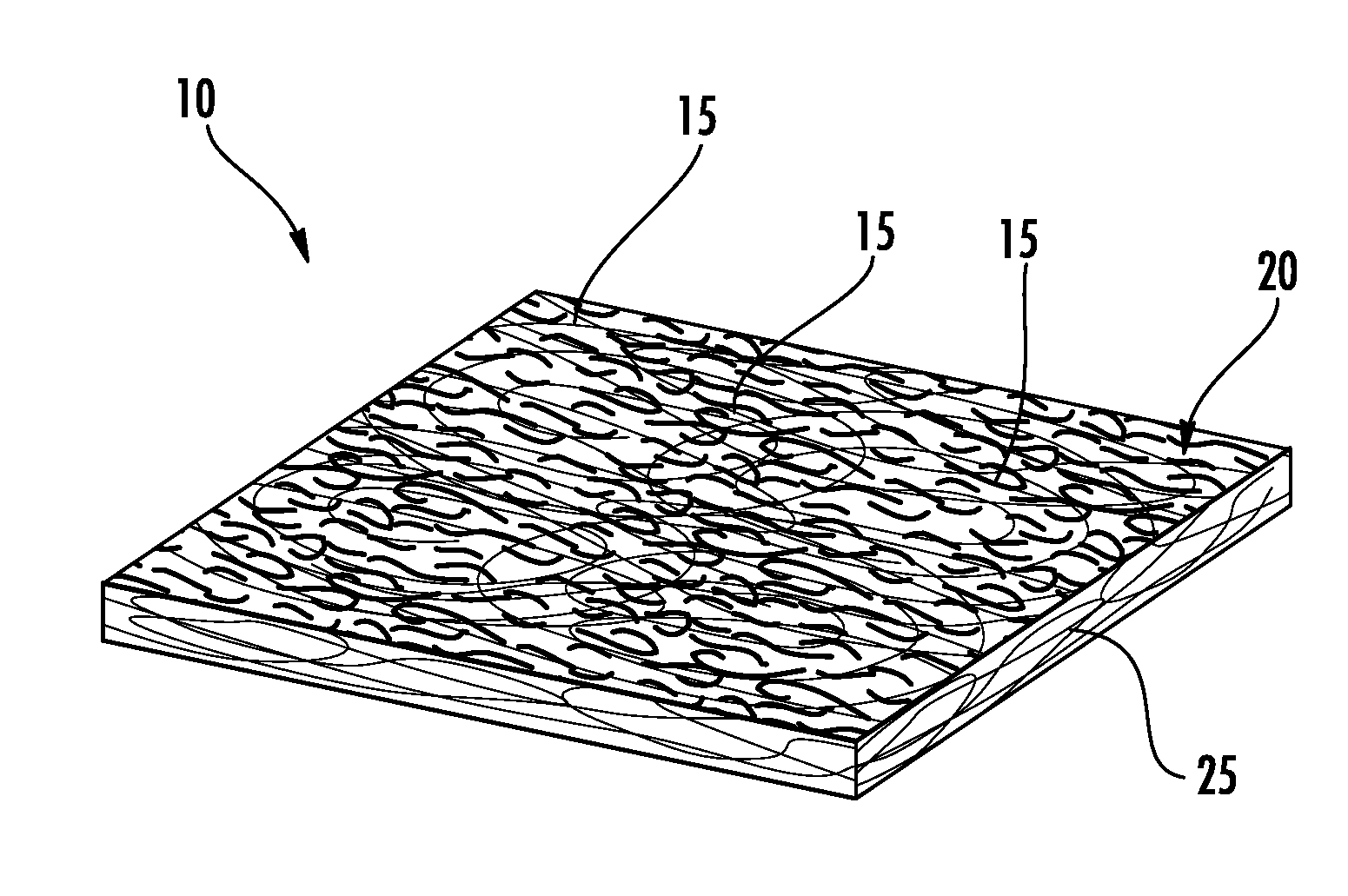

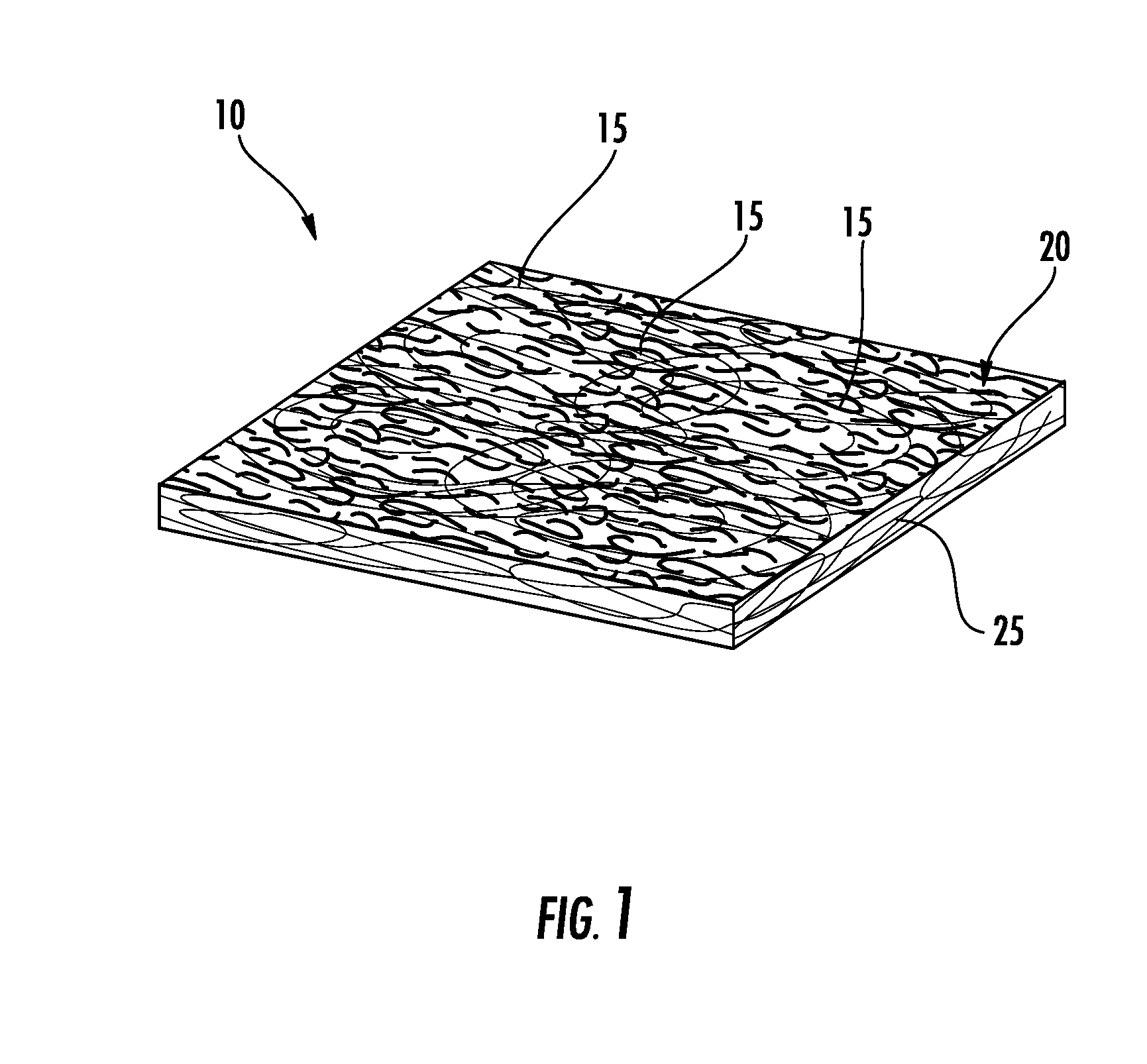

Generally, the present invention is directed to, in one embodiment, a method for forming a composite nonwoven web configured to deliver skin wellness agents to the skin of a user. According to the method, an aqueous system of a hydrophilic polymer and a skin wellness agent is formed. The aqueous system is then electrospun onto a surface of a nonwoven web containing synthetic fibers. The resulting nanofibers have an average diameter of from about 50 nanometers to about 5000 nanometers, such as from about 200 nanometers to about 700 nanometers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

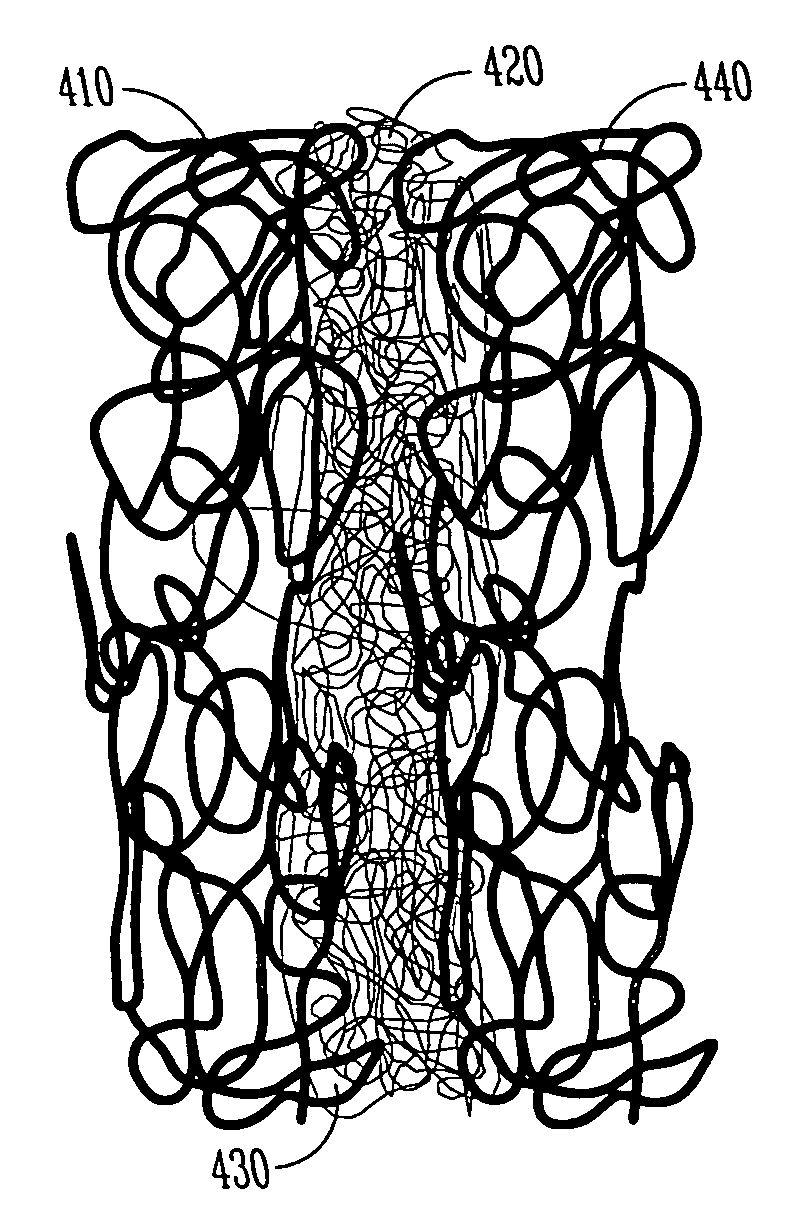

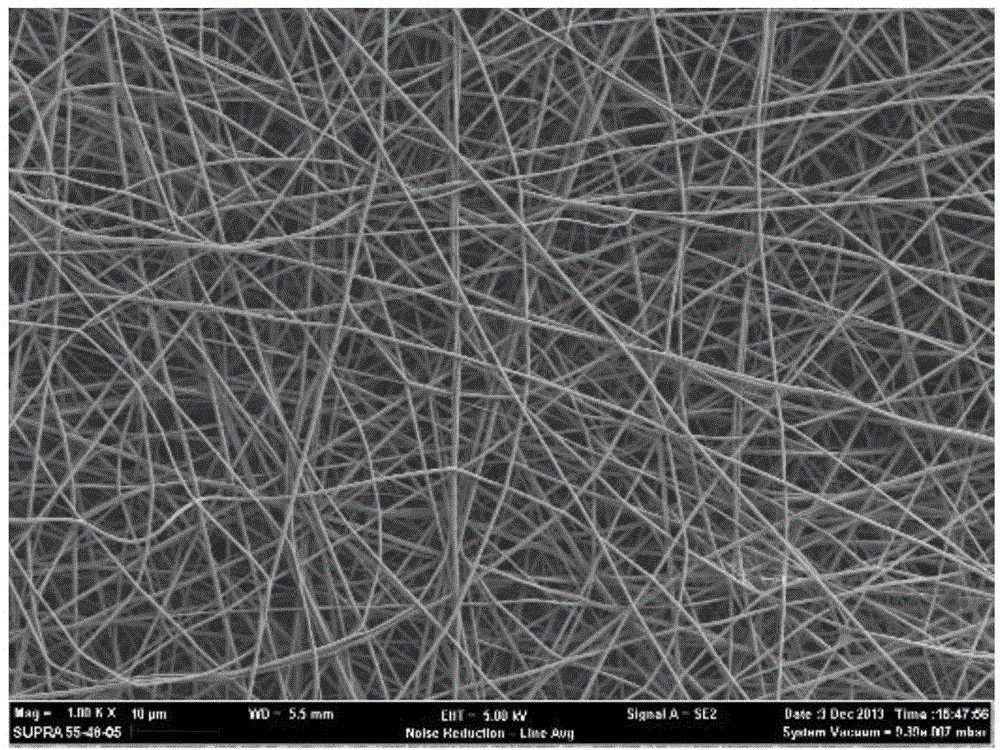

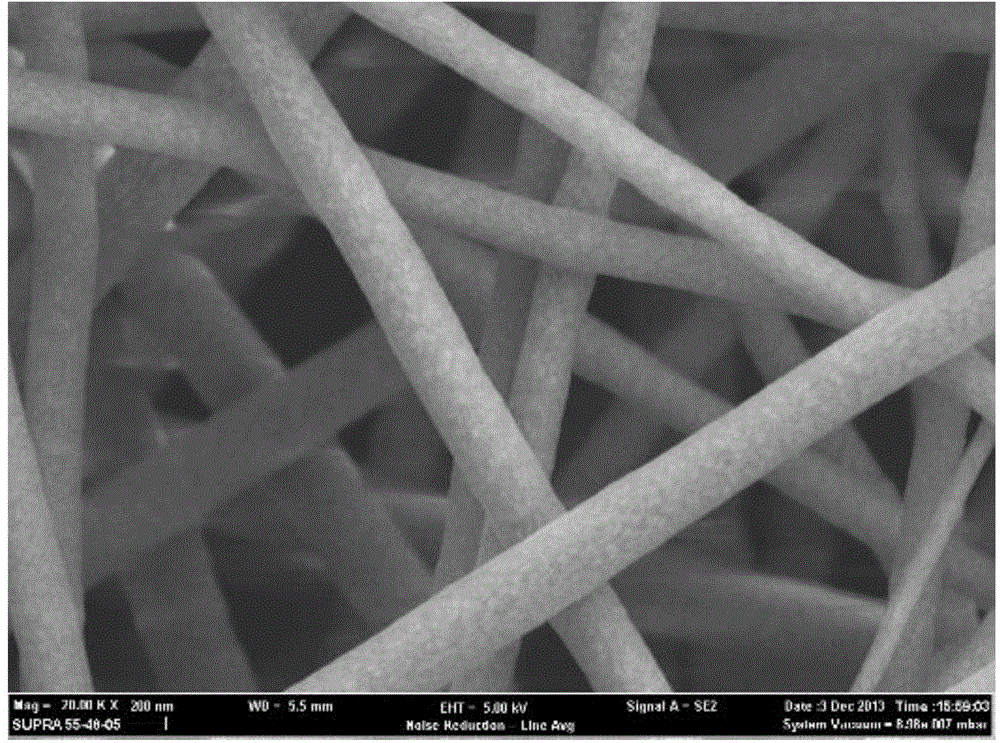

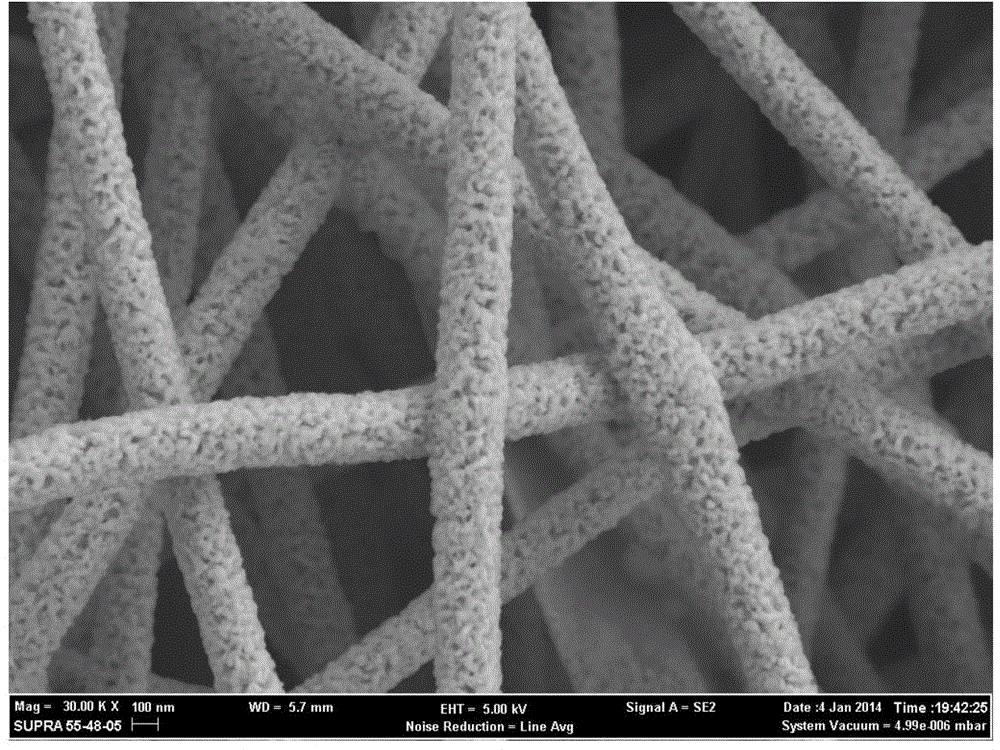

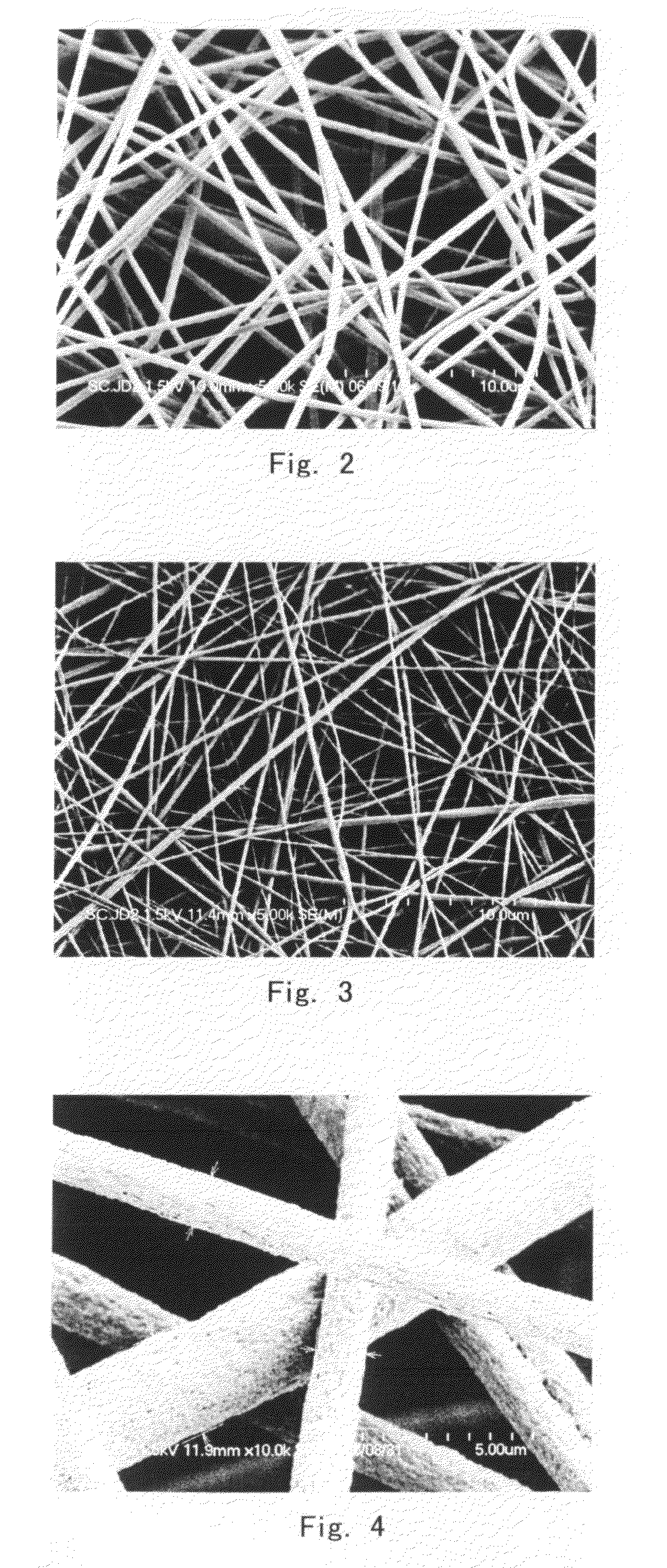

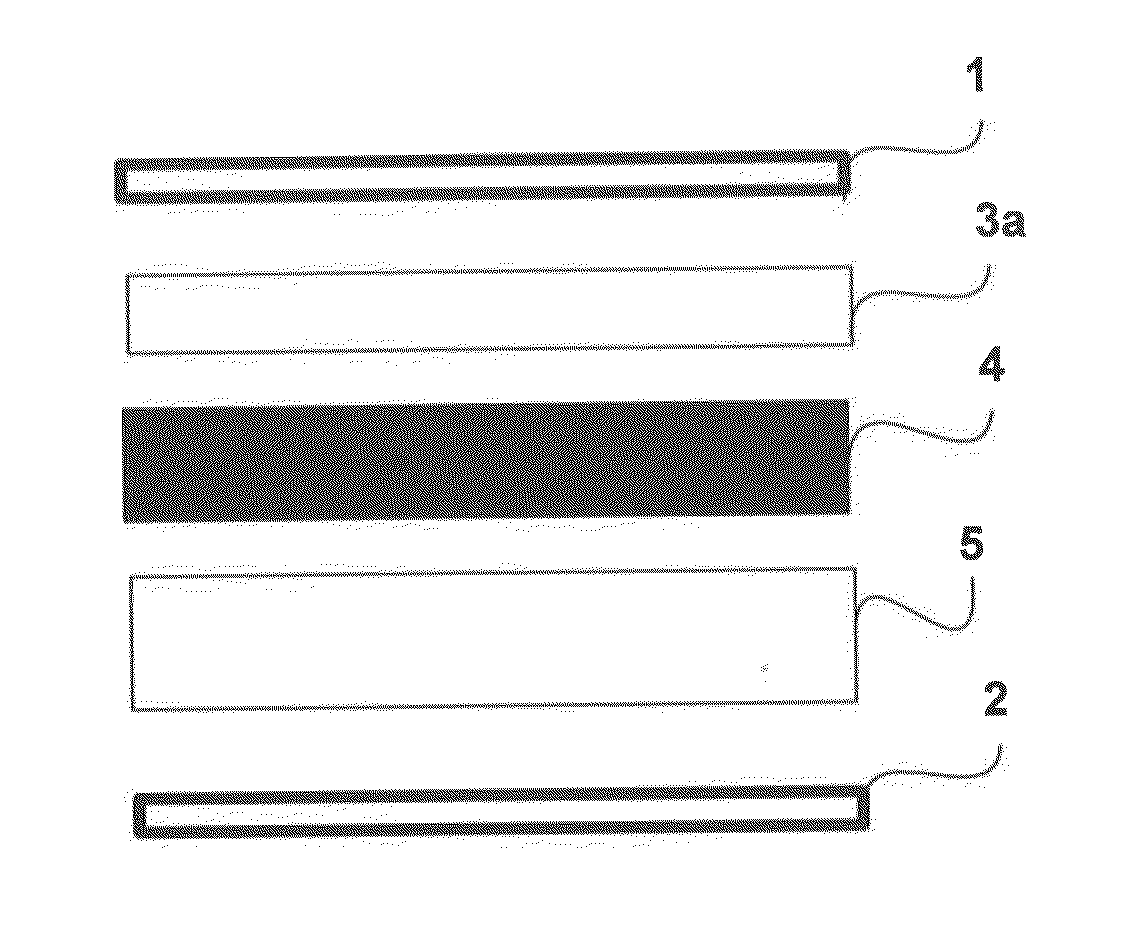

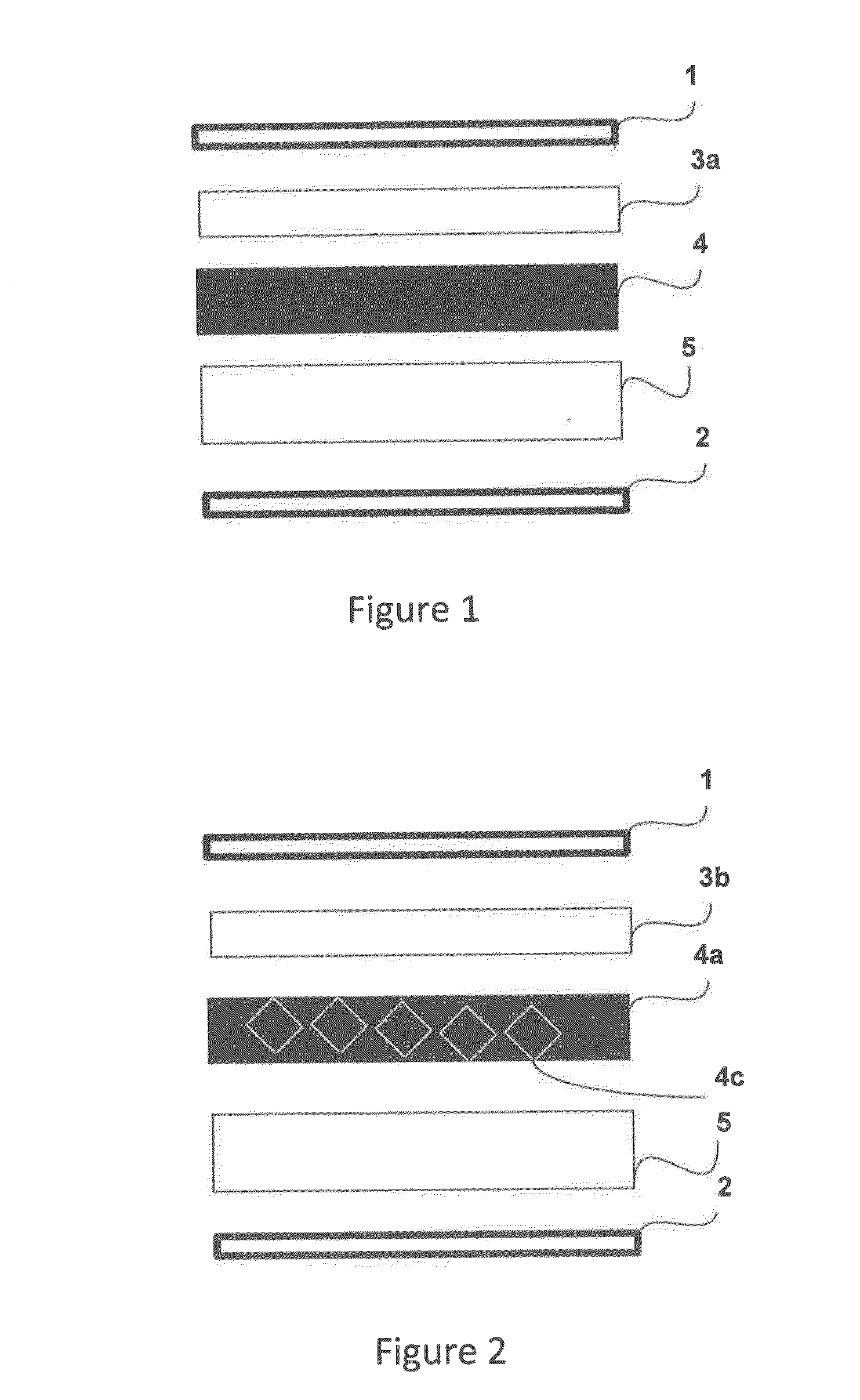

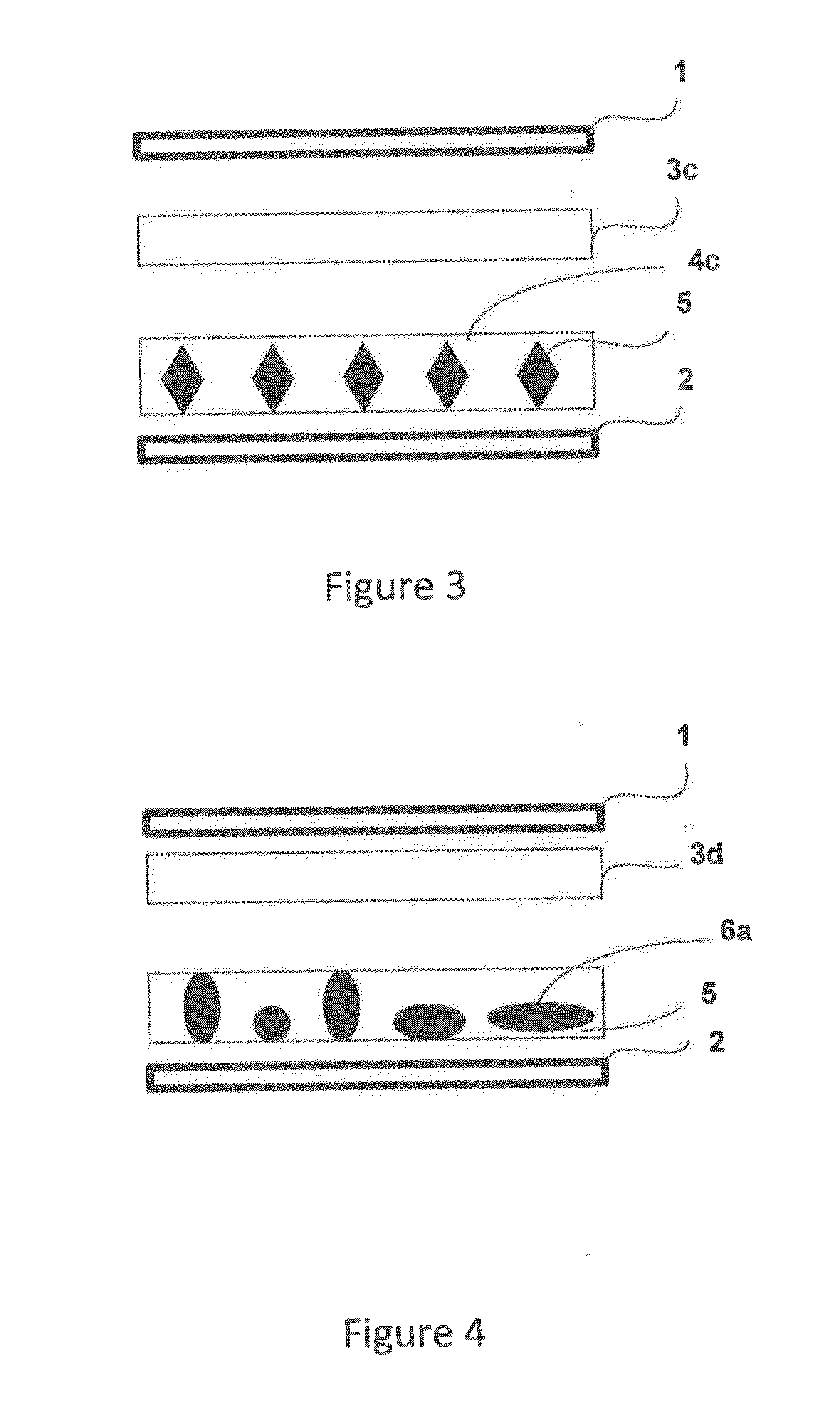

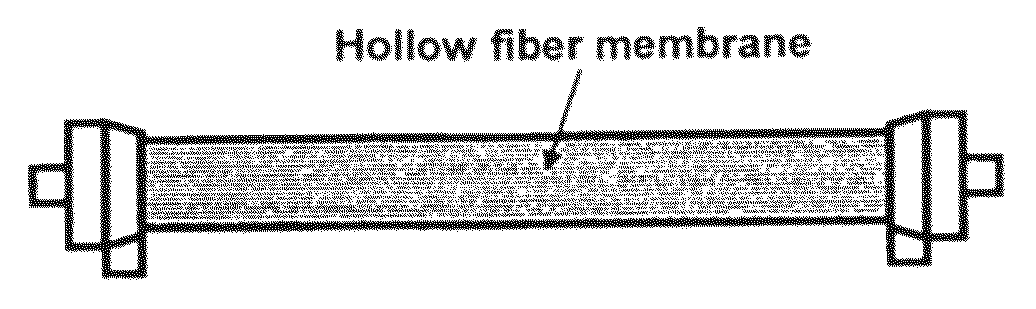

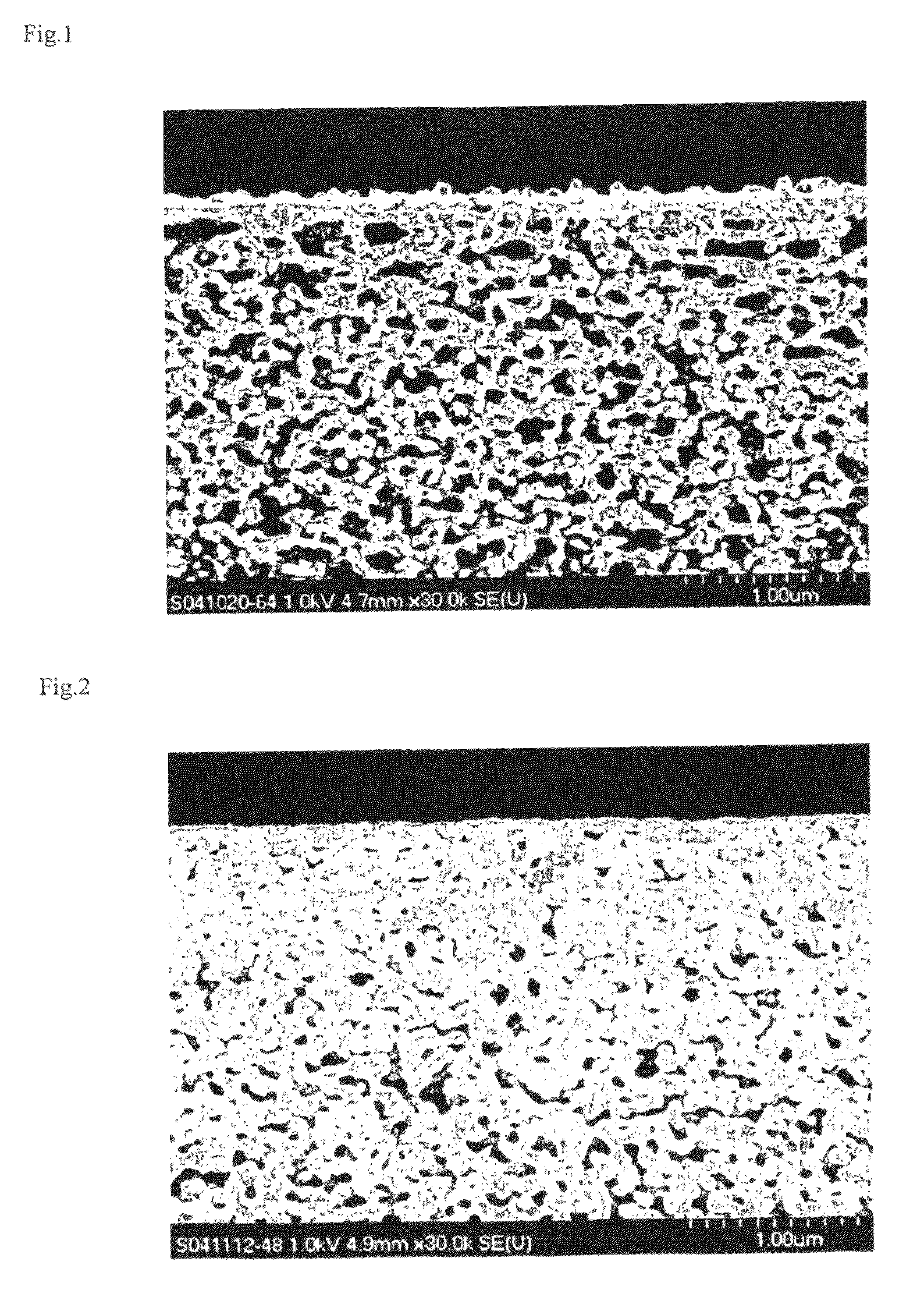

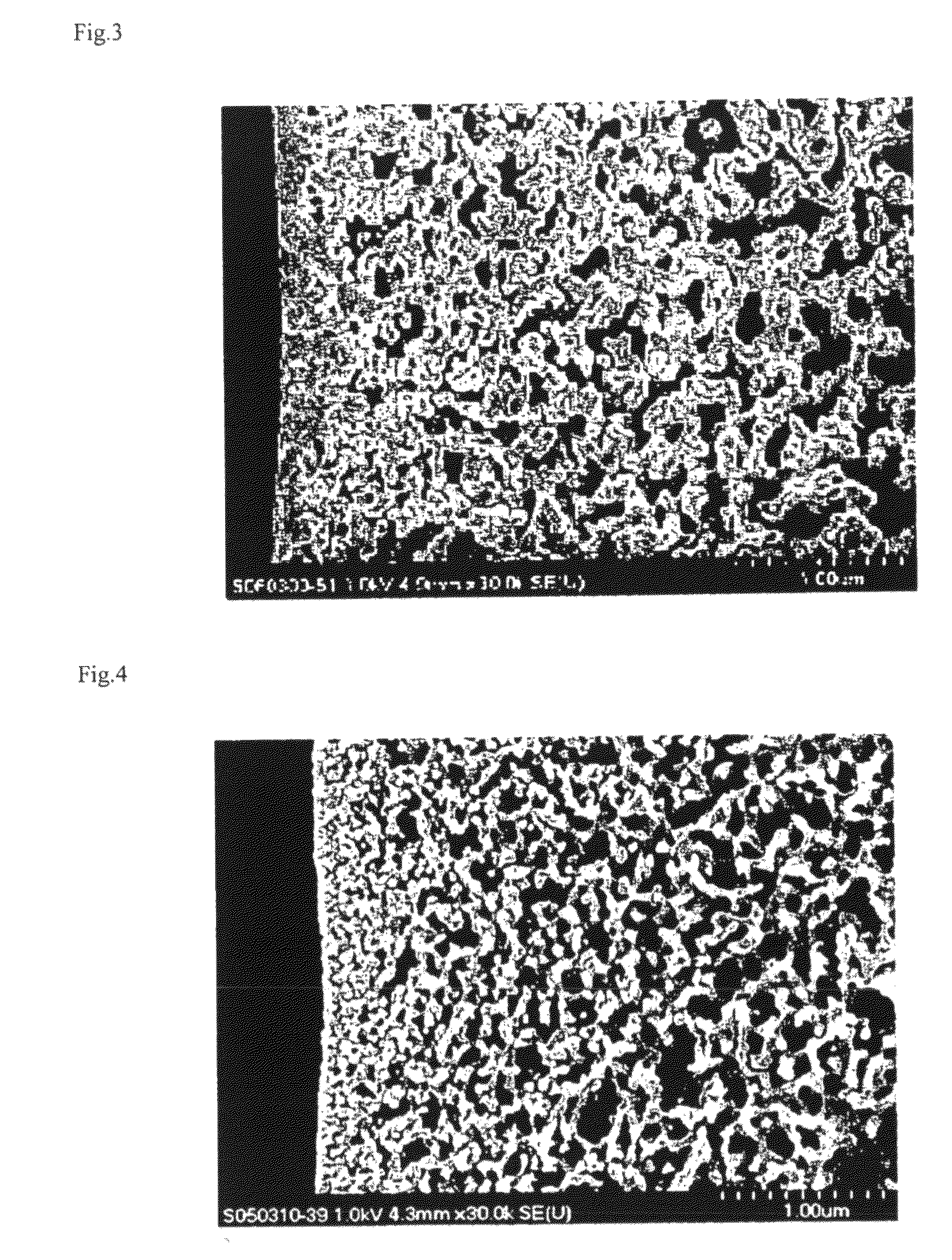

Microfiber supported nanofiber membrane

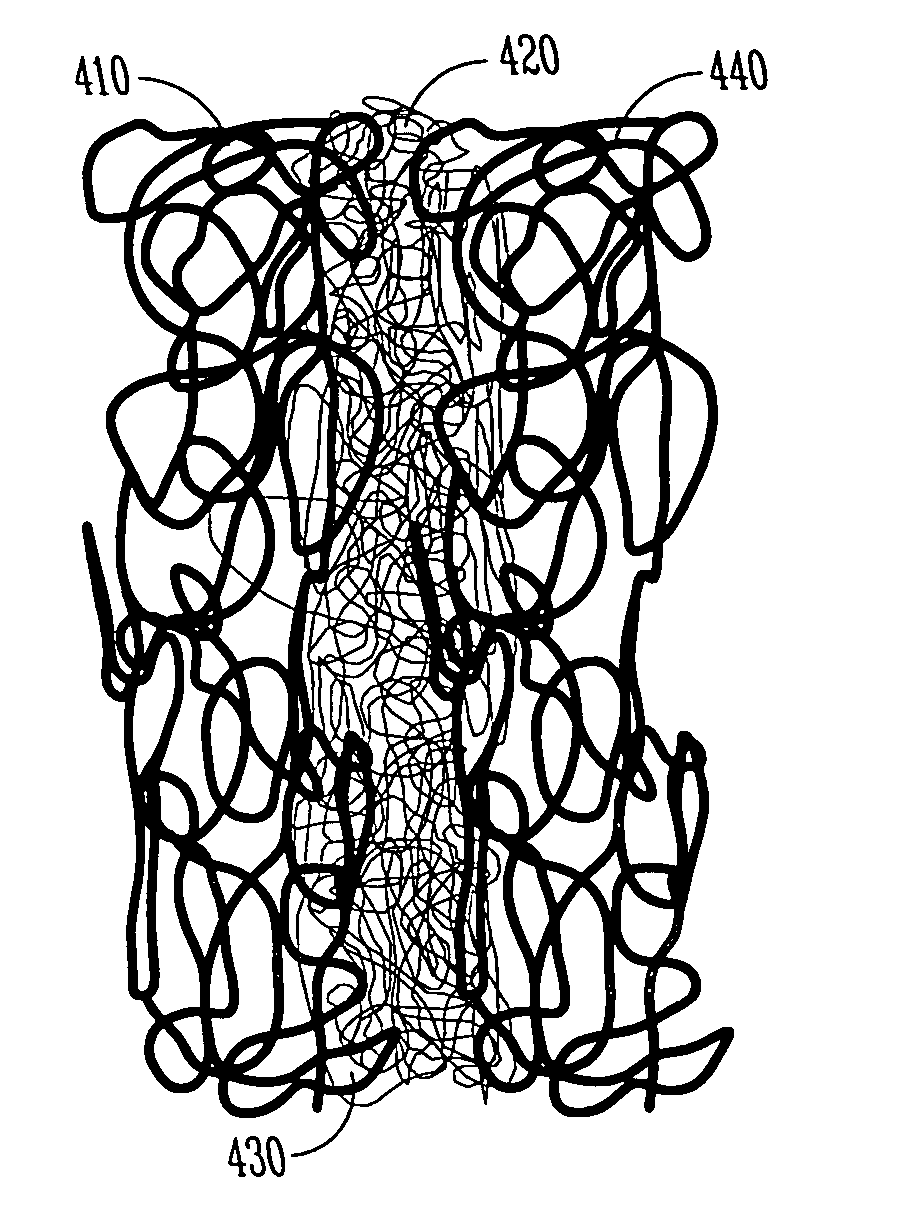

A nanofiber membrane is formed on a microfiber membrane. The nanofiber membrane may be electro sprayed directly onto the microfiber membrane and becomes integrated with the microfiber membrane to form a filter. The microfiber membrane provides structural integrity to for the nanofiber membrane, and an additional microfiber membrane may be added to sandwich the nanofiber membrane.

Owner:CORNELL RES FOUNDATION INC

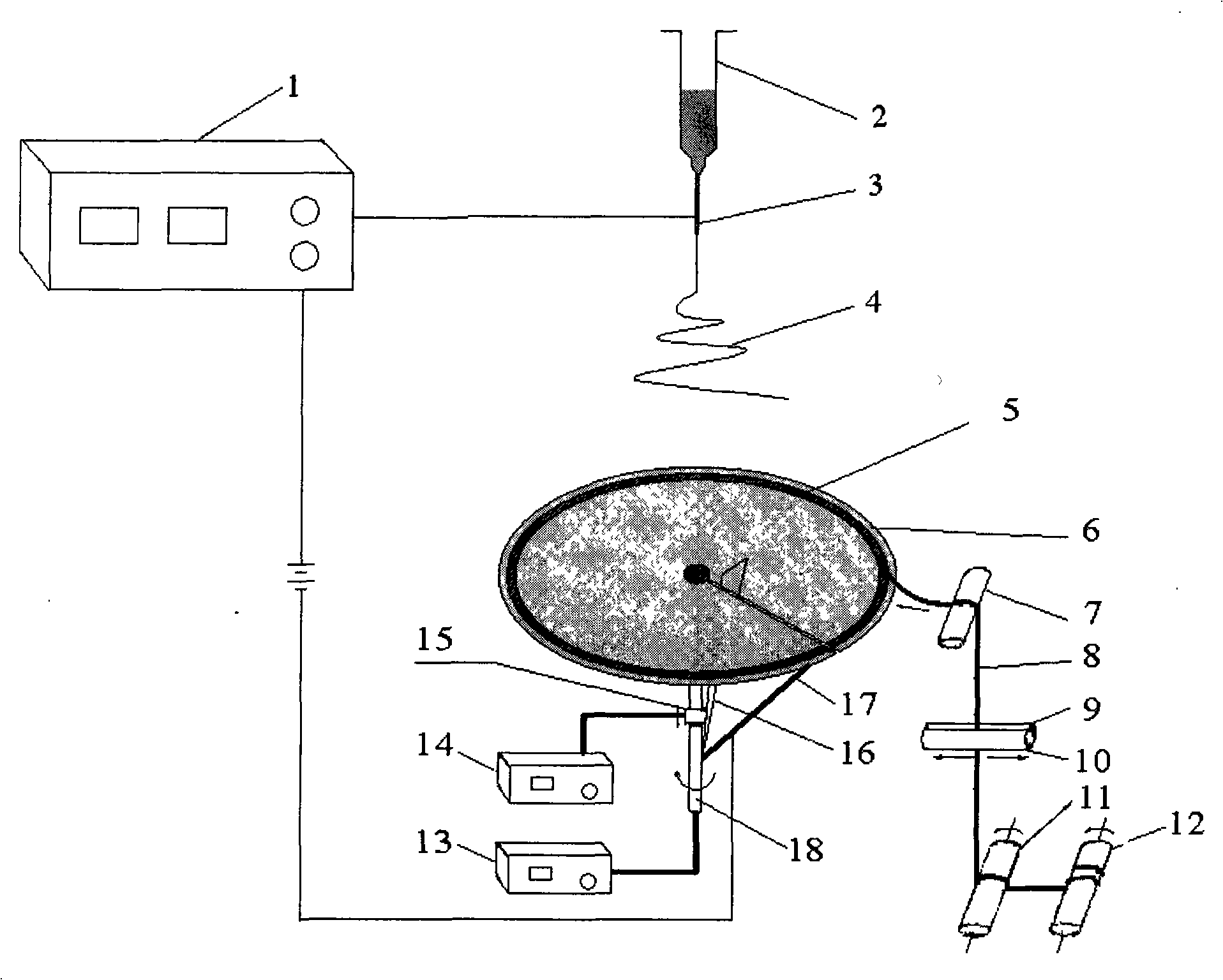

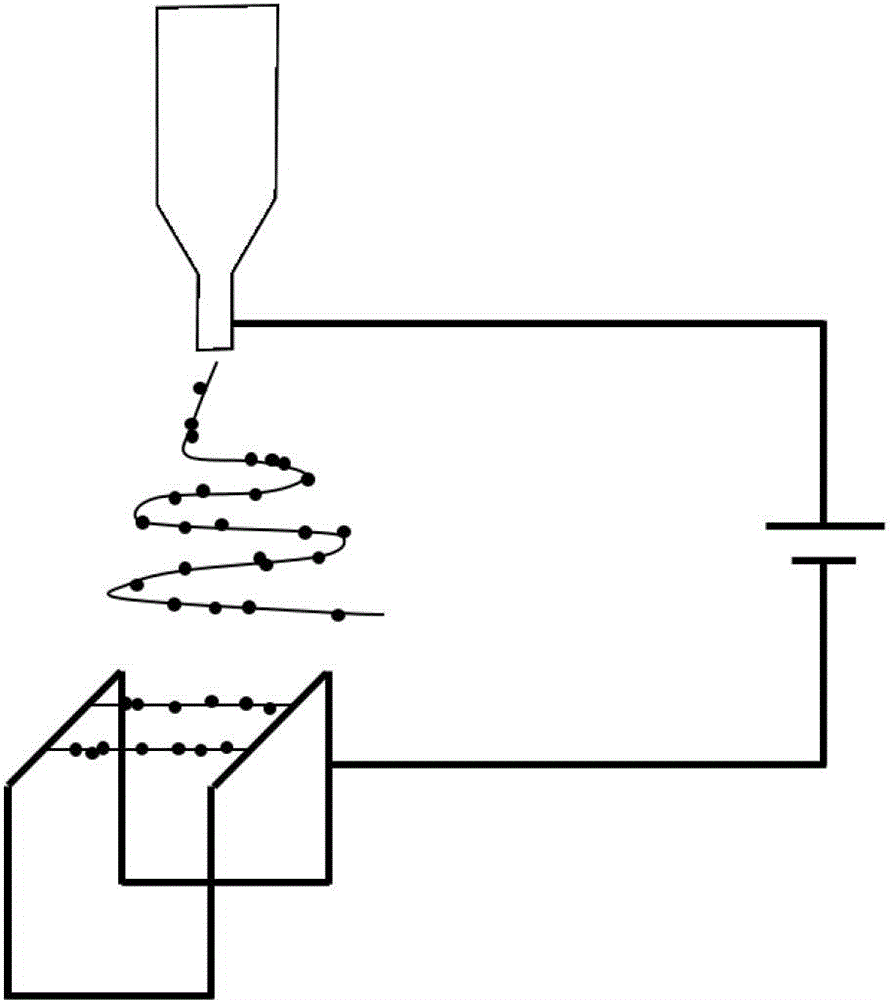

Electrostatic spinning nano-fibre yarn system and preparation of nano-fiber yarn

InactiveCN101302673ASimple processing methodMonocomponent polyethers artificial filamentFilament/thread formingCircular discFiber

The invention discloses a static spinning nano-fiber yarn system and a preparation method for the nano-fiber yarn. The invention comprises a rotation axis which is provided with a disc grooved along the radius, a sliding block and a cutter groove, wherein, the upper surface of the disc is provided with an annular copper film which has a radial notch corresponding to the groove of the disc; the upper part of the disc is provided with a syringe, the outlet of which is provided with a metal syringe needle connected with the positive pole of a direct-current high voltage generator. One end of the cutter groove goes through the disc groove to contact with both sides of the radial notch of the copper film and be connected with the negative pole of the direct-current high voltage generator; a cutter with one free end is arranged in the cutter groove, wherein, the free end extends above the disc through the disc groove and moves along the groove. The sliding block slides axially along the rotation axis. Furthermore, the outer side of the disc is provided with a silk guide roller, a twister, a winding roller and a lead recovery roller. The spinning solution is made into nano-fiber yarn by the system. The yarn prepared by the invention has relatively higher strength, thus being prospective to provide the static spinning fiber products with a wider application field.

Owner:XI'AN POLYTECHNIC UNIVERSITY

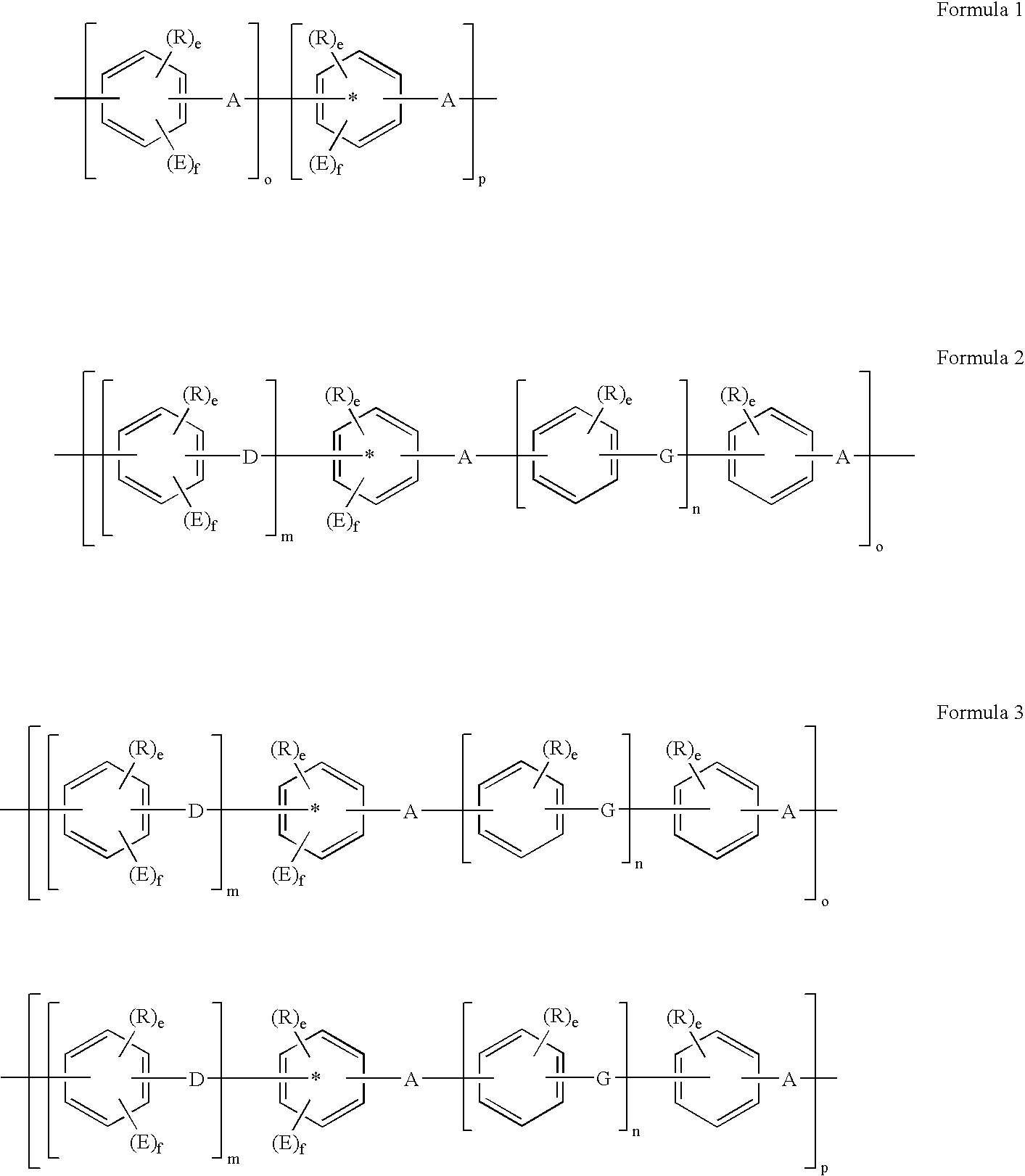

Thermoplastic polymers with thermally reversible and non-reversible linkages, and articles using same

InactiveUS20050037194A1Color stableHigh strengthMonocomponent polyurethanes artificial filamentMonocomponent polyethers artificial filamentPolymer chemistryChemistry

The invention provides a polymer adapted for use in melt processes, the polymer having thermally reversible and non-thermally reversible bonds which polymer is adapted to evanesce at an elevated temperature and revert to a thermally reversible bond upon cooling to ambient temperature so that the polymer is adapted, upon being heated to the elevated temperature, to dissociate into melt processable polymeric fragments and, upon being cooled to ambient temperature, to re-associate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

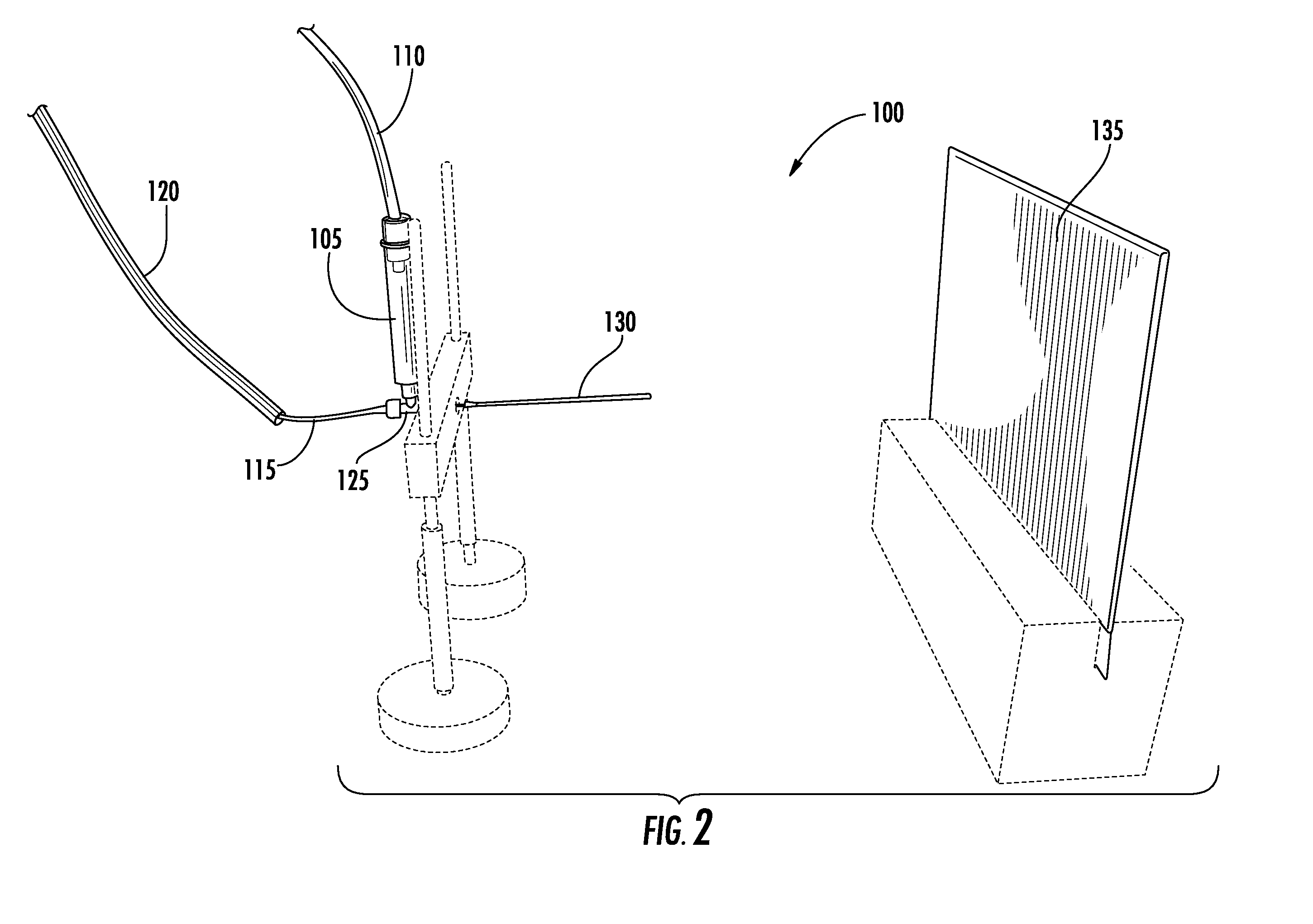

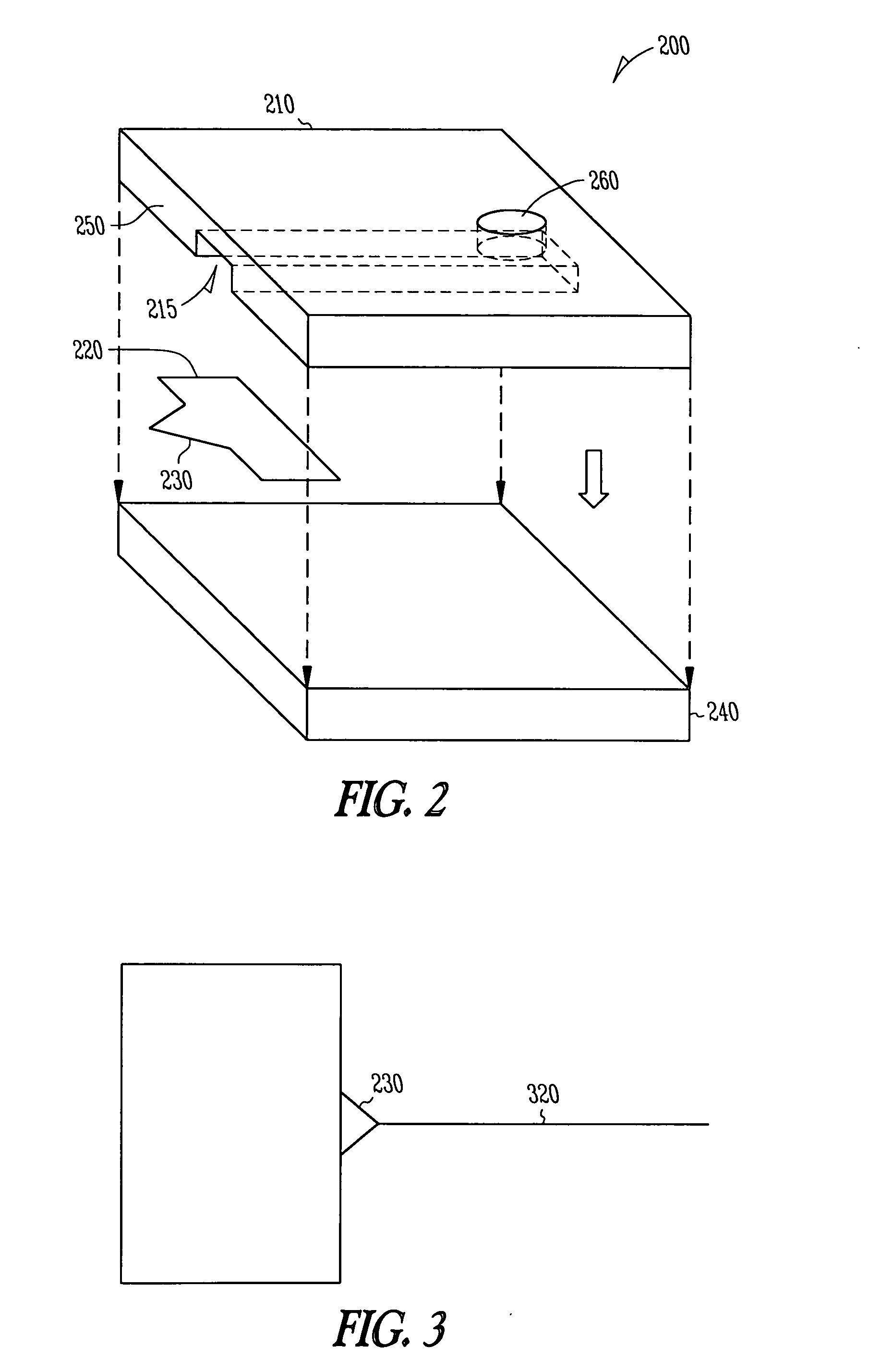

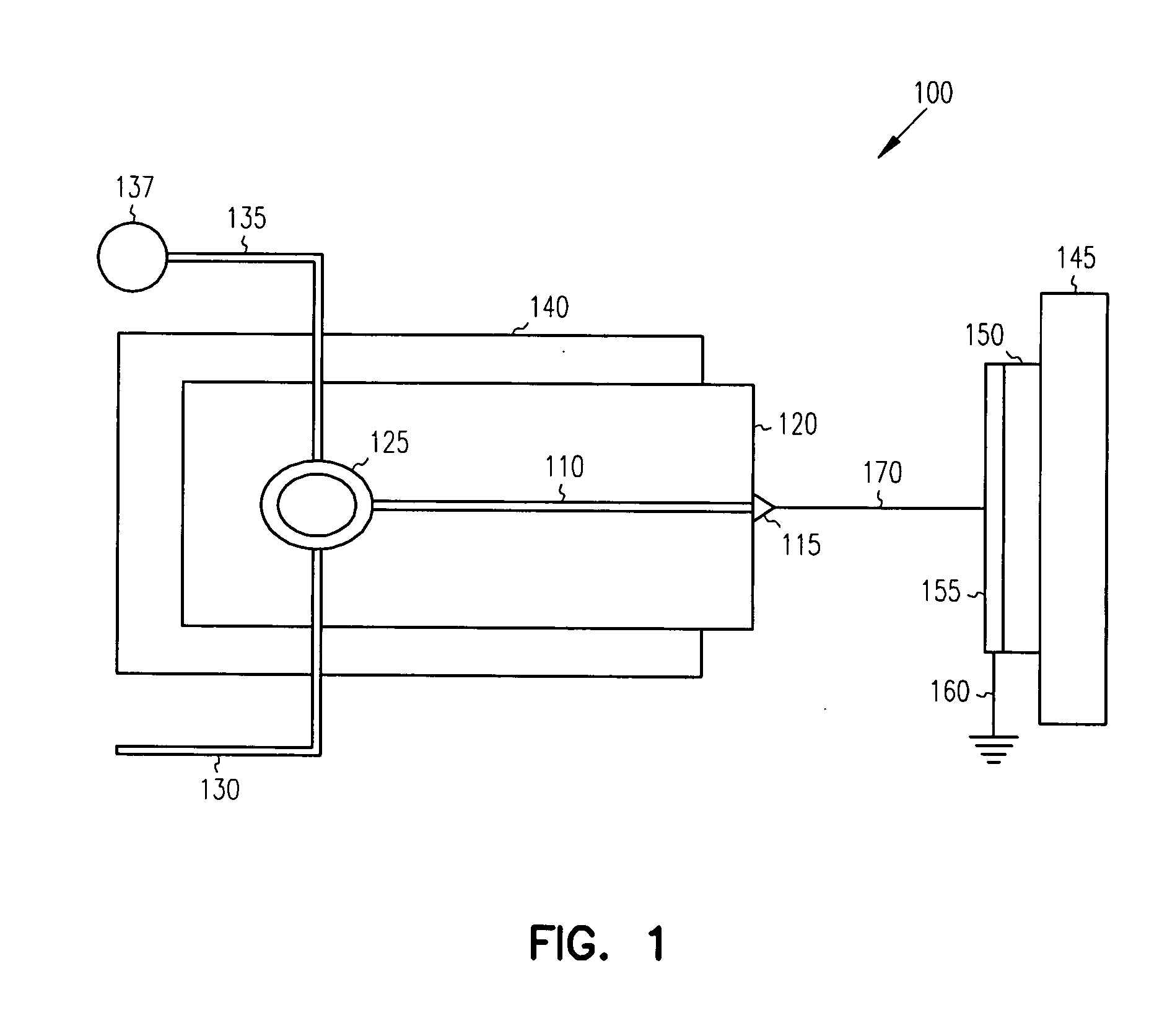

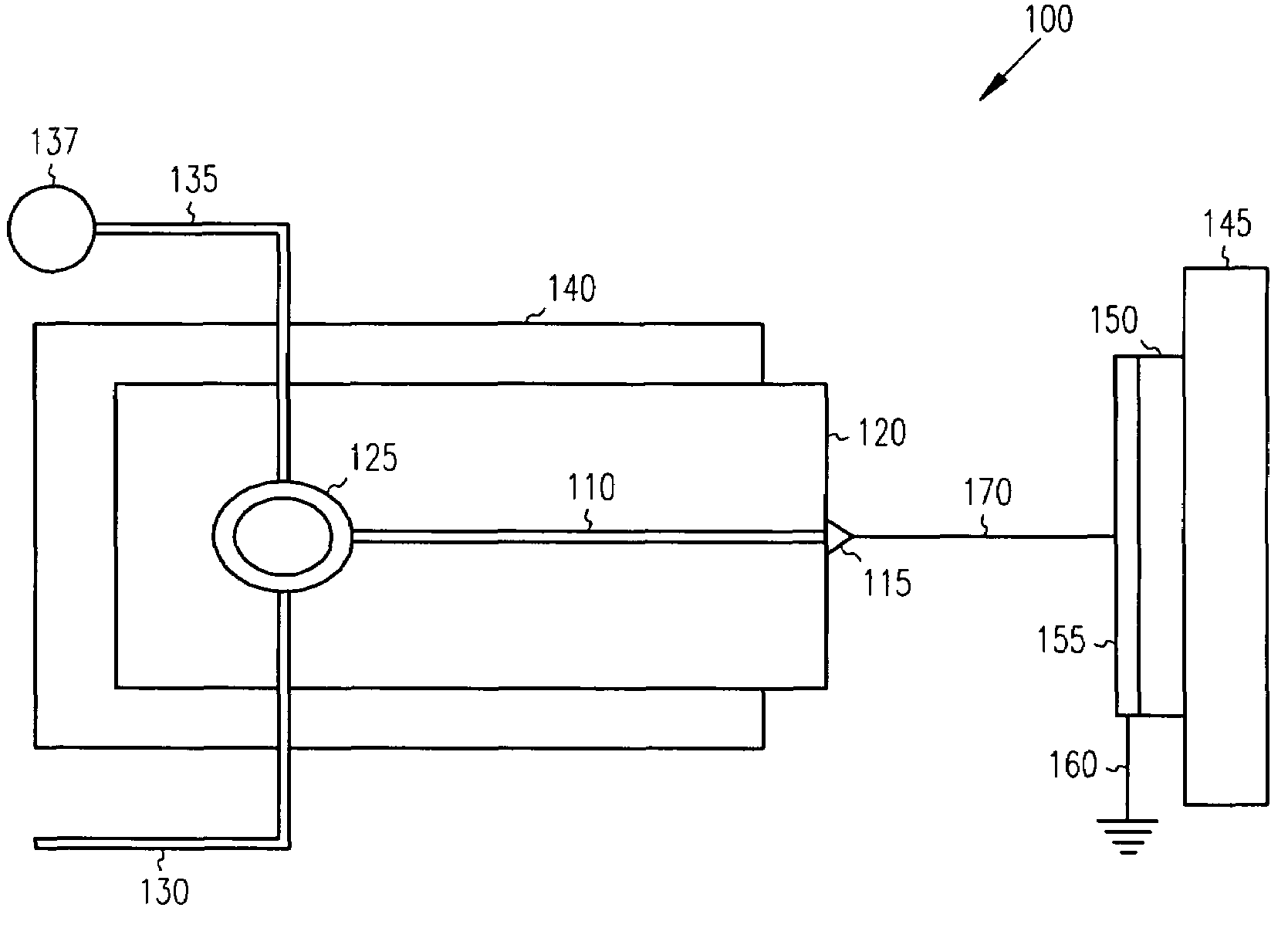

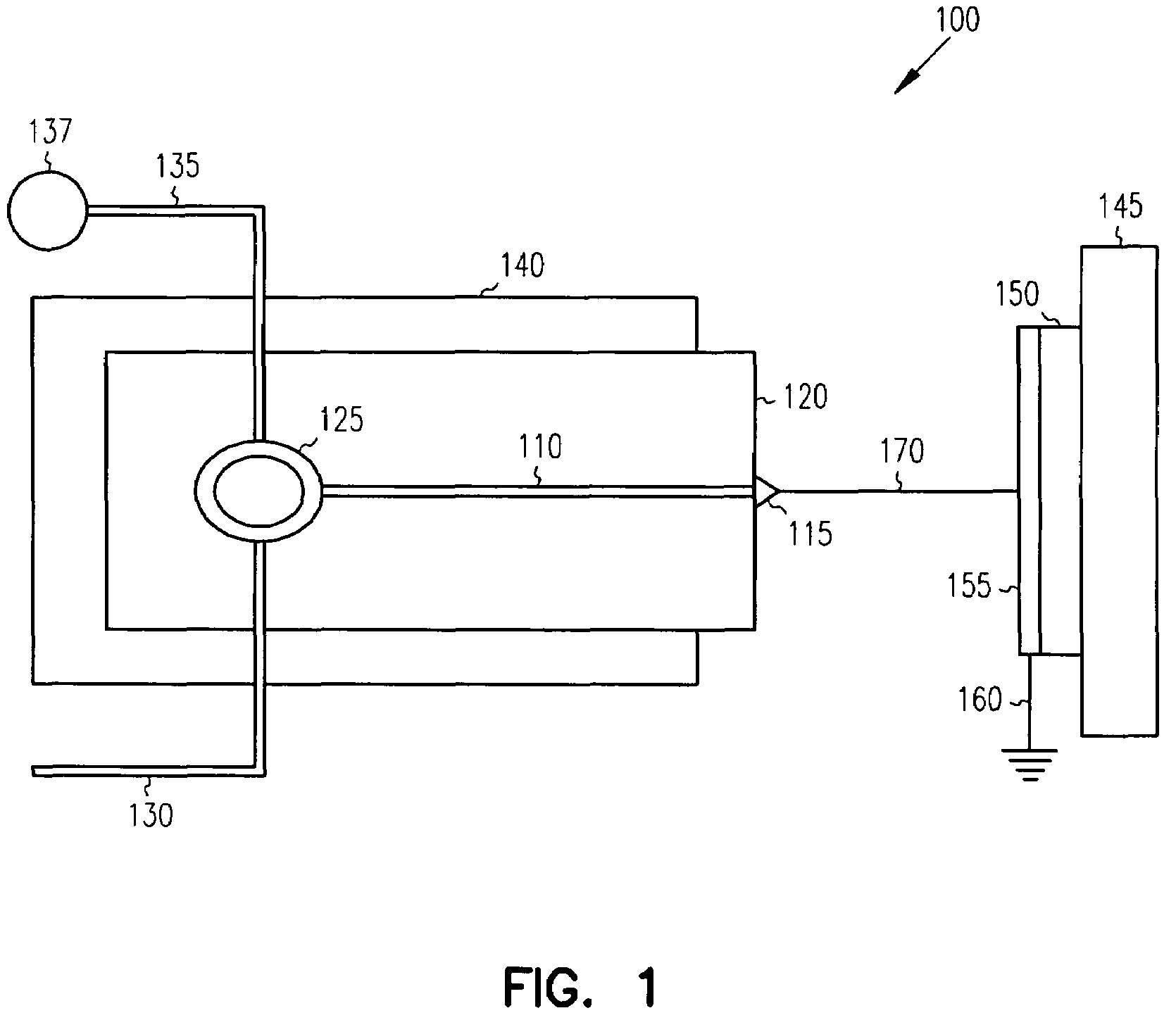

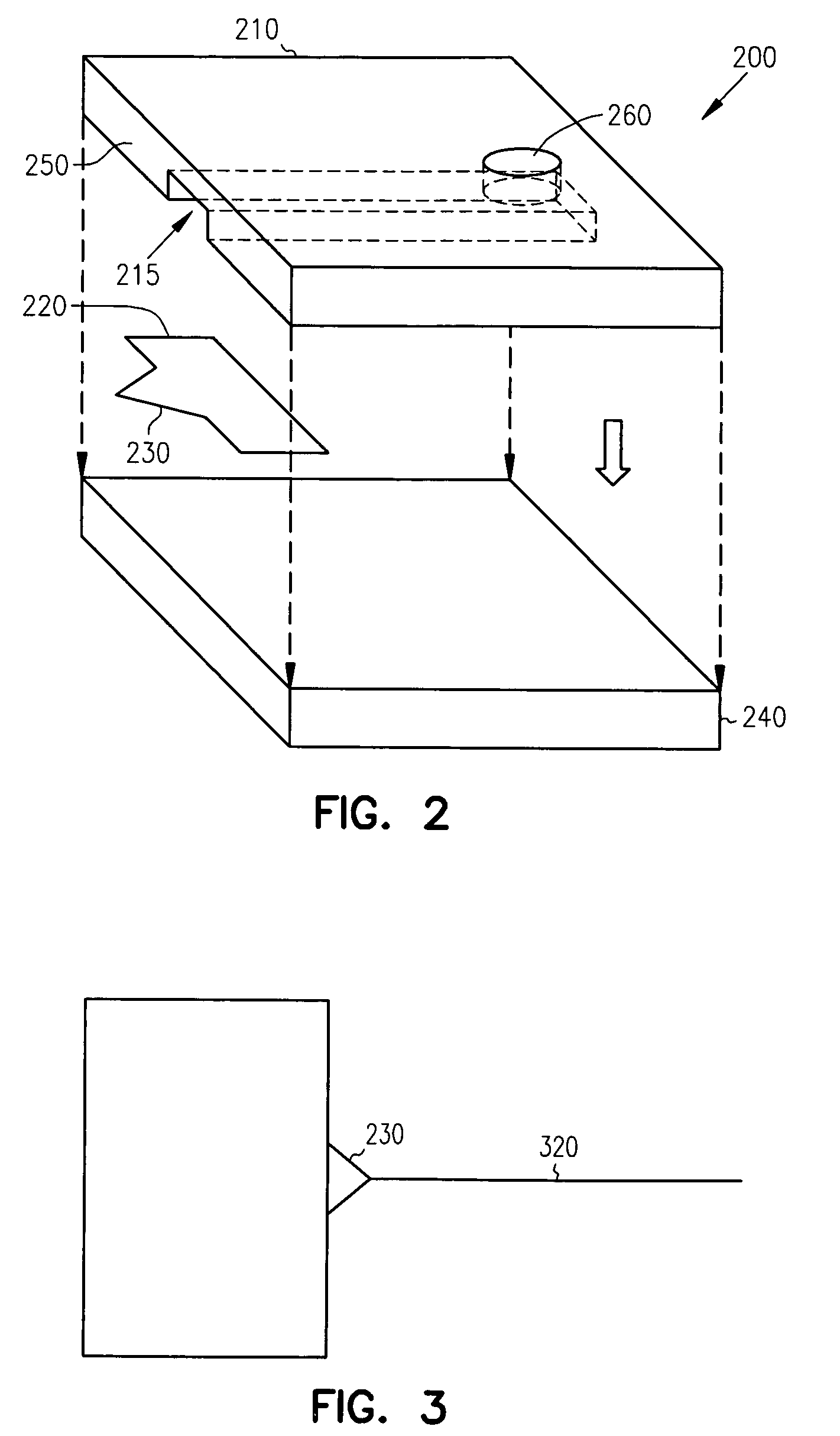

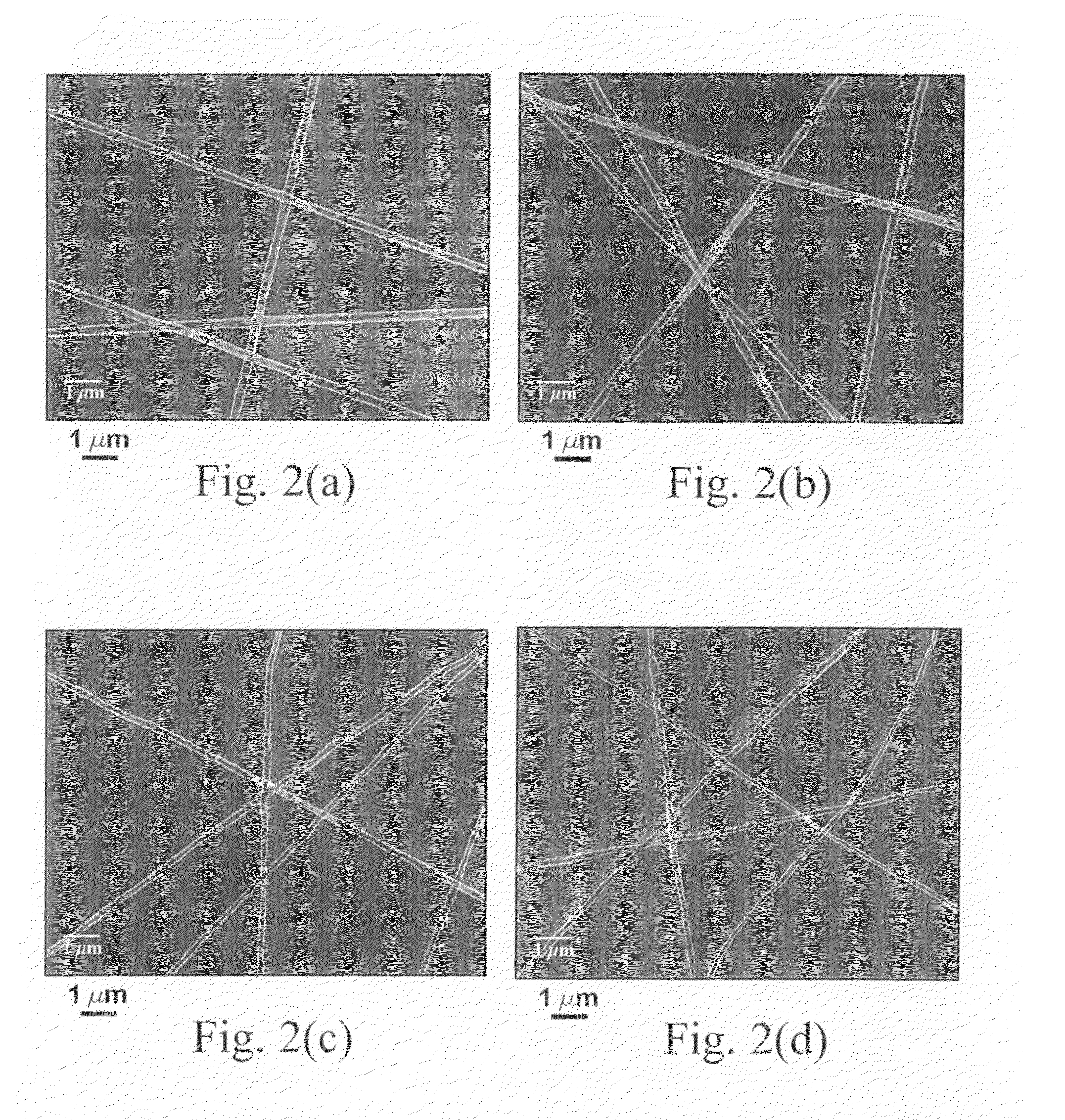

Scanned source oriented nanofiber formation

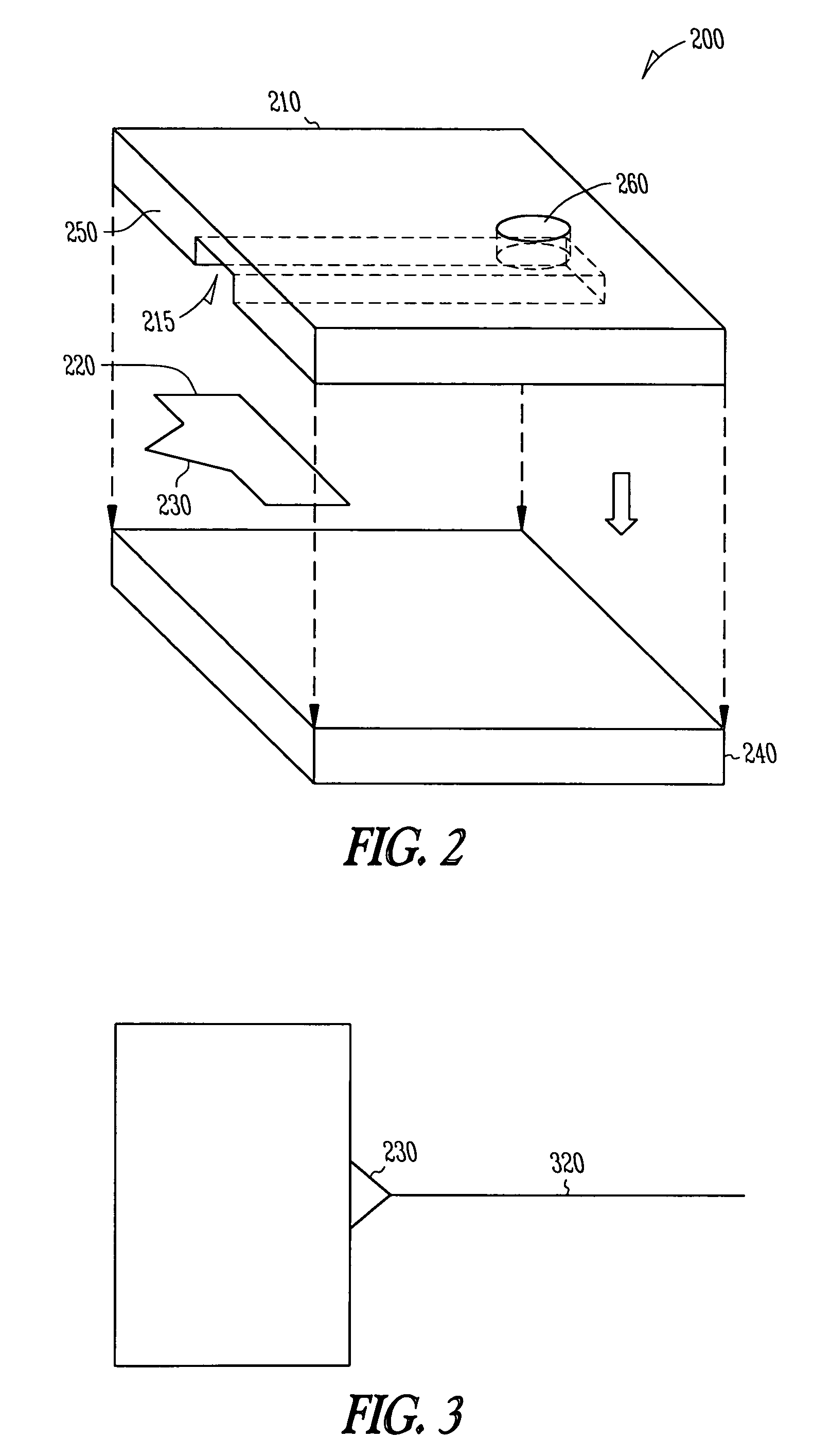

Nanofibers are formed using electrospray deposition from microfluidic source. The source is brought close to a surface, and scanned in one embodiment to form oriented or patterned fibers. In one embodiment, the surface has features, such as trenches on a silicon wafer. In further embodiments, the surface is rotated to form patterned nanofibers, such as polymer nanofibers. The nanofibers may be used as a mask to create features, and as a sacrificial layer to create nanochannels.

Owner:CORNELL RES FOUNDATION INC

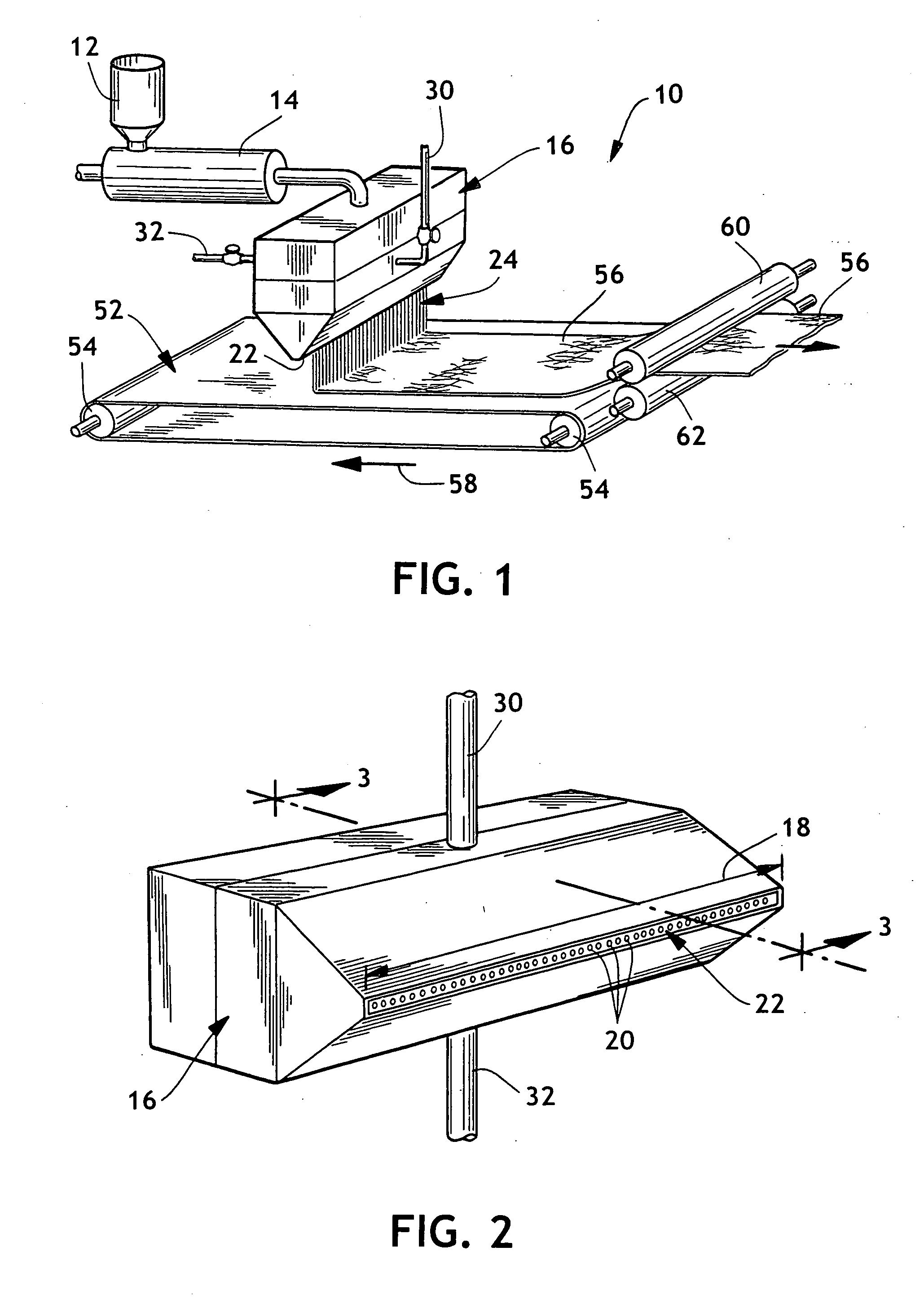

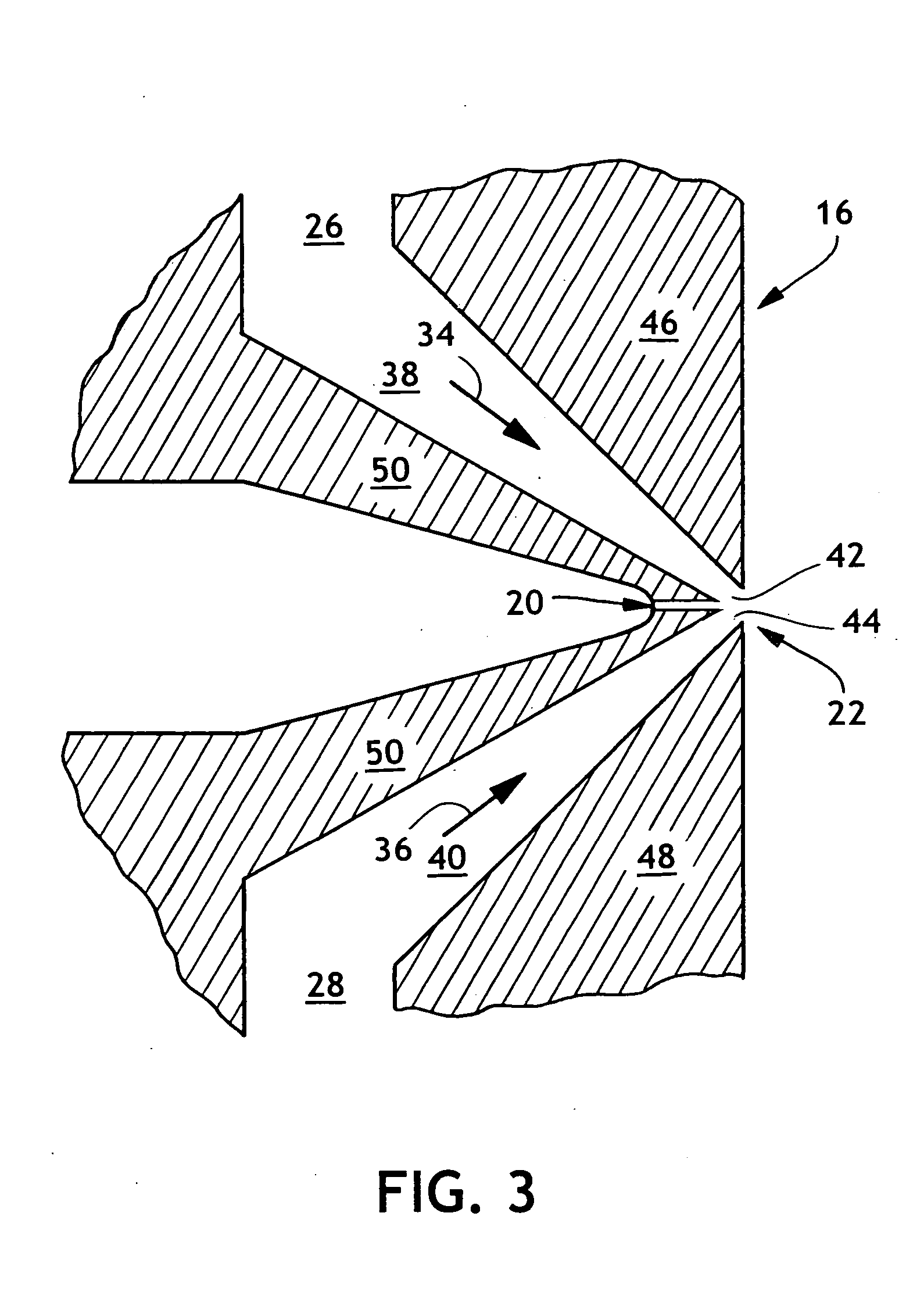

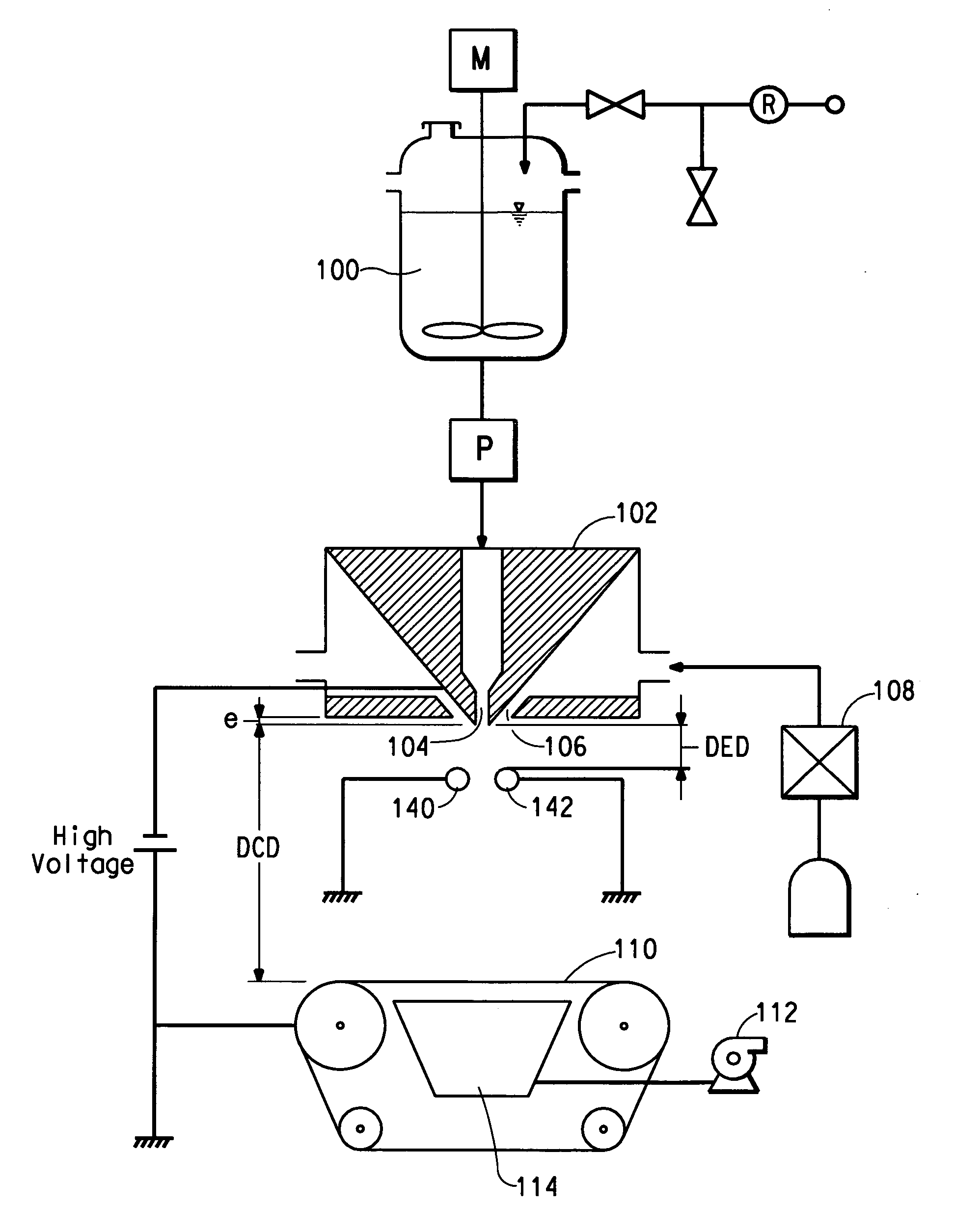

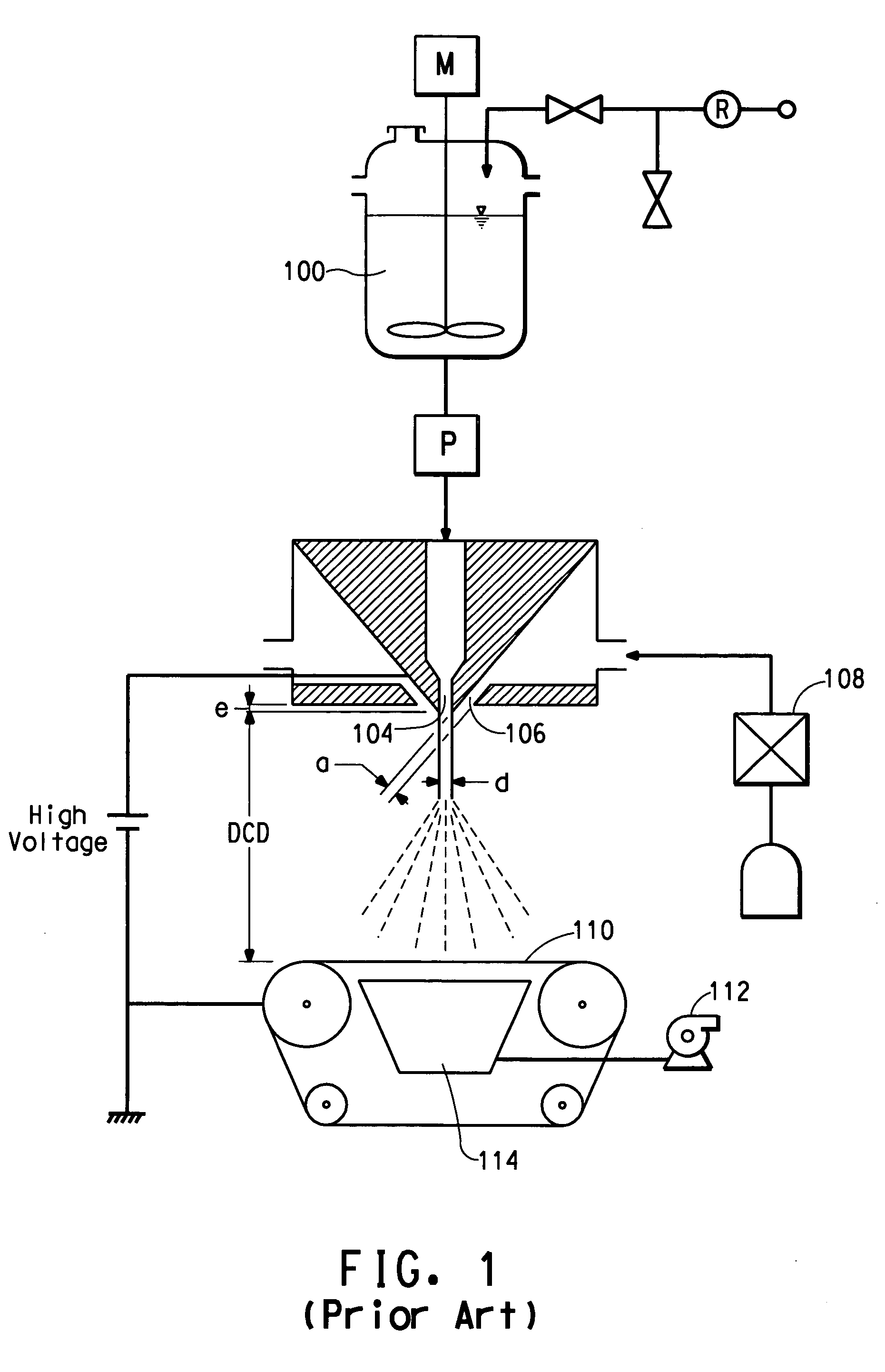

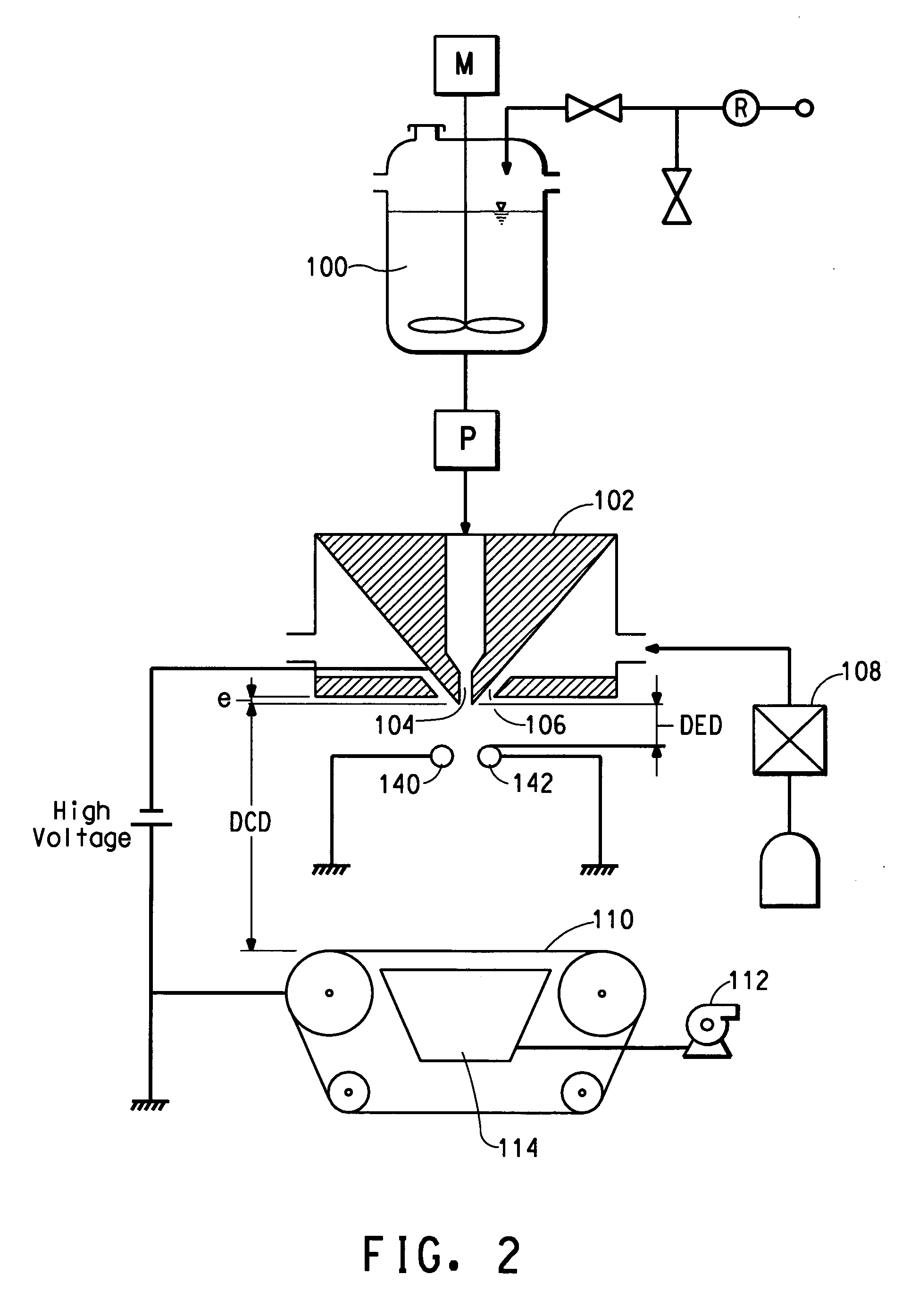

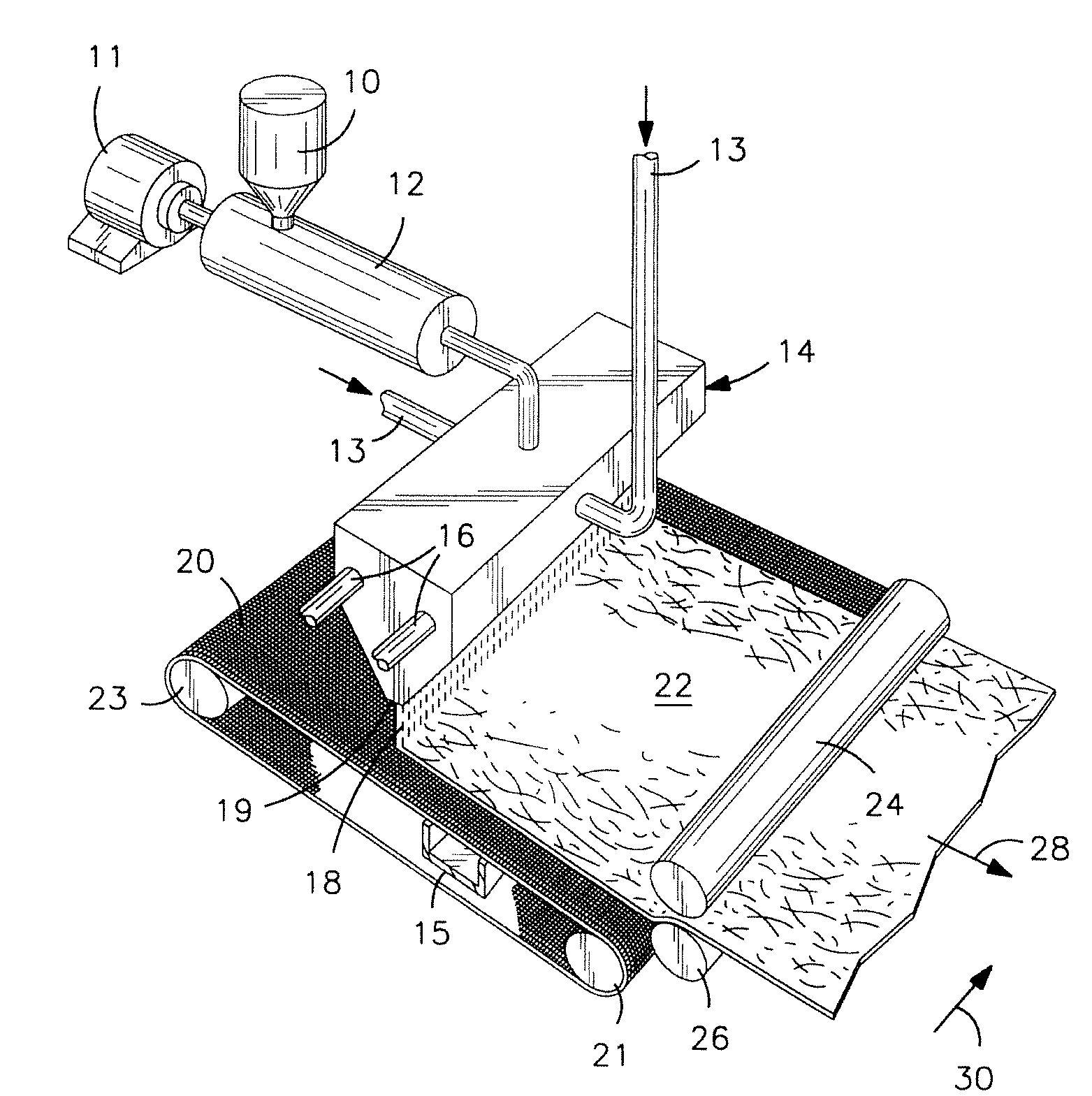

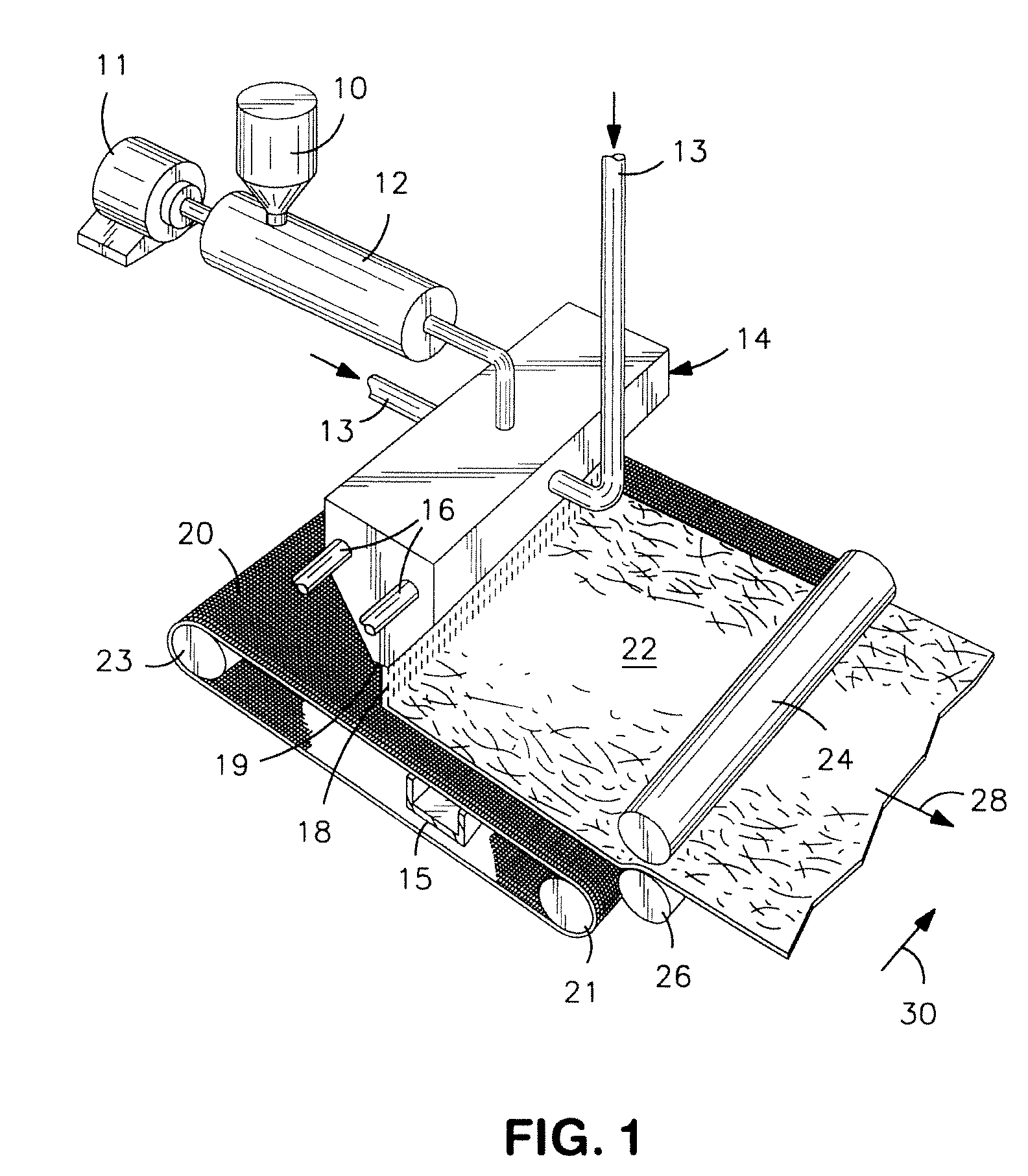

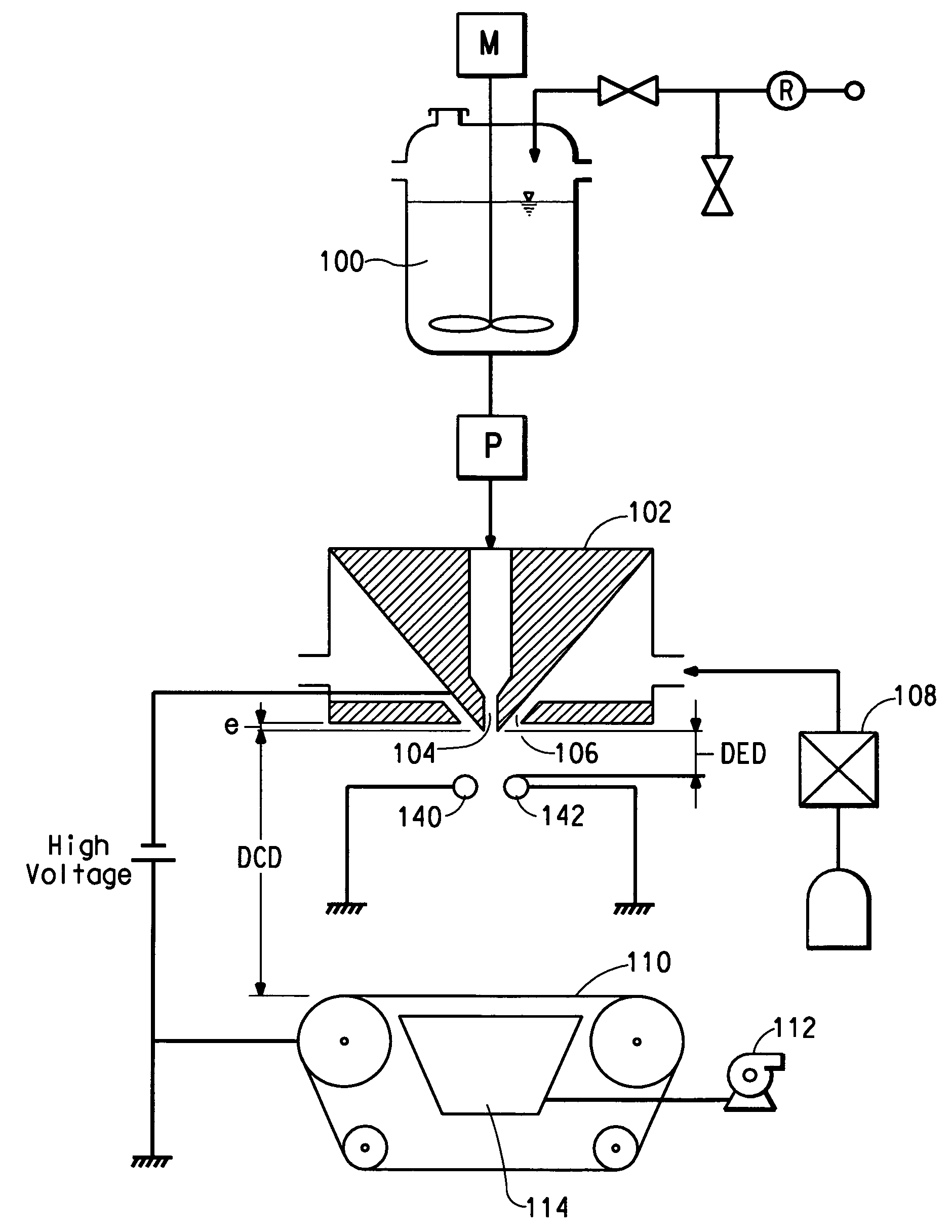

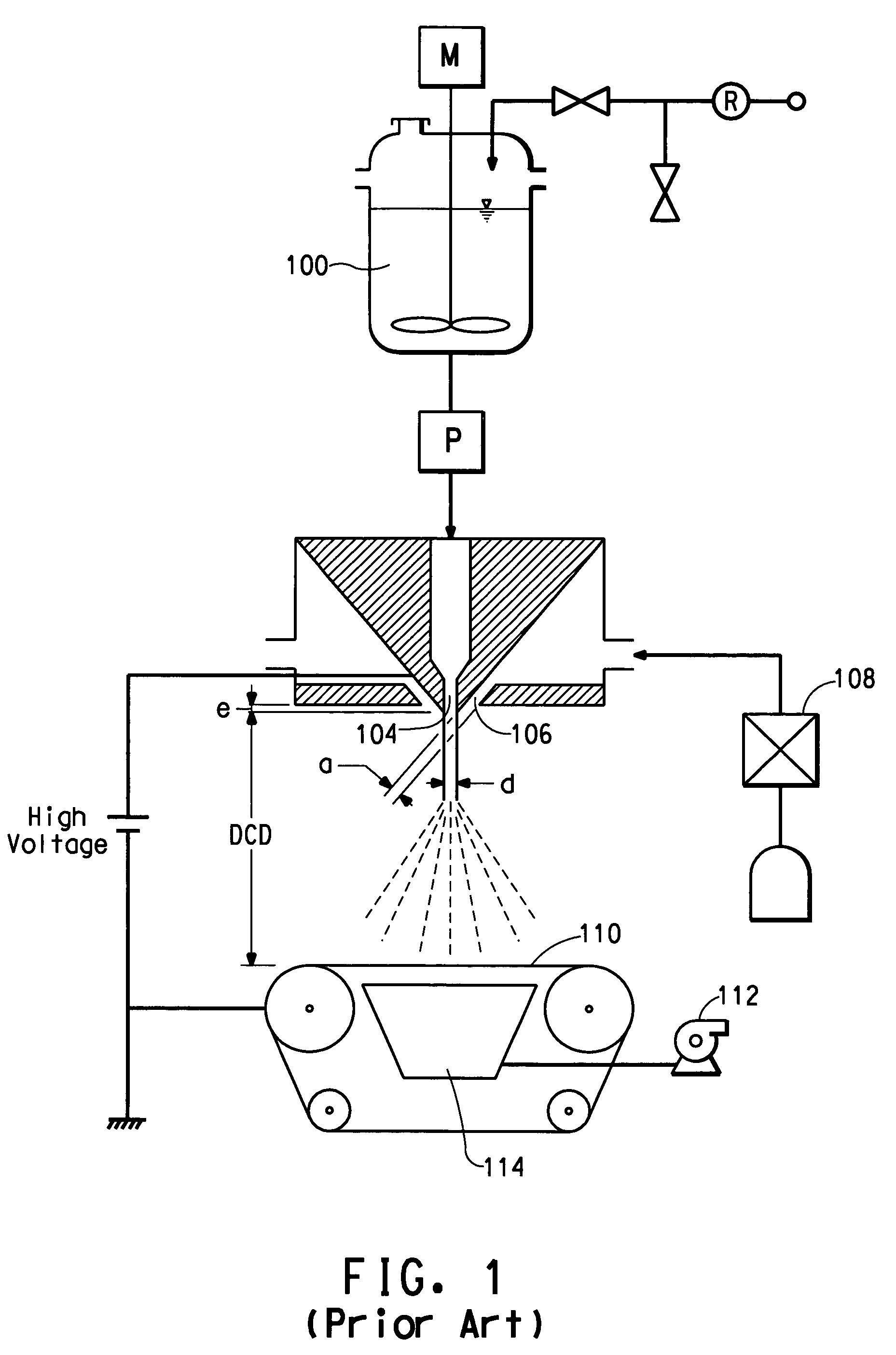

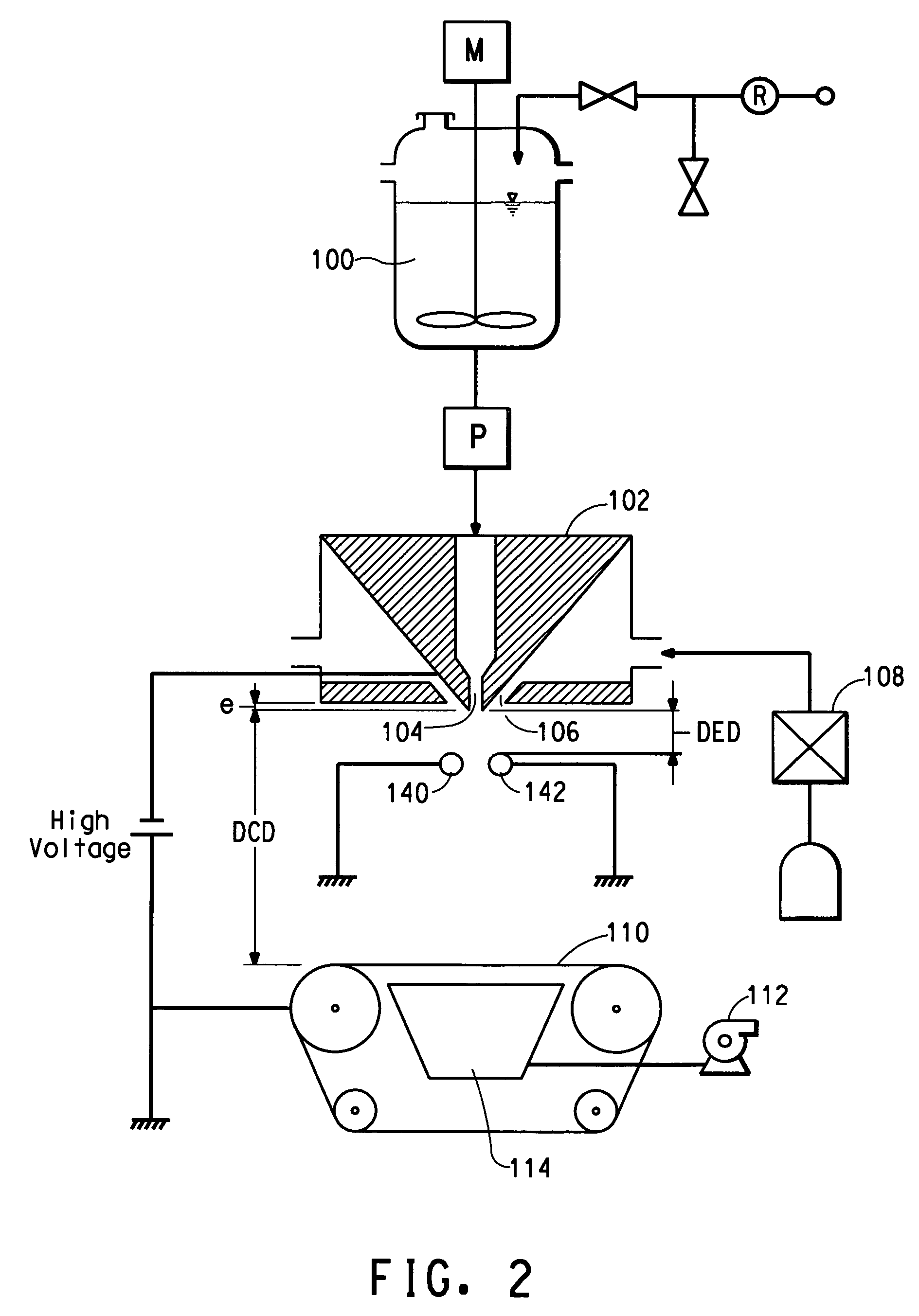

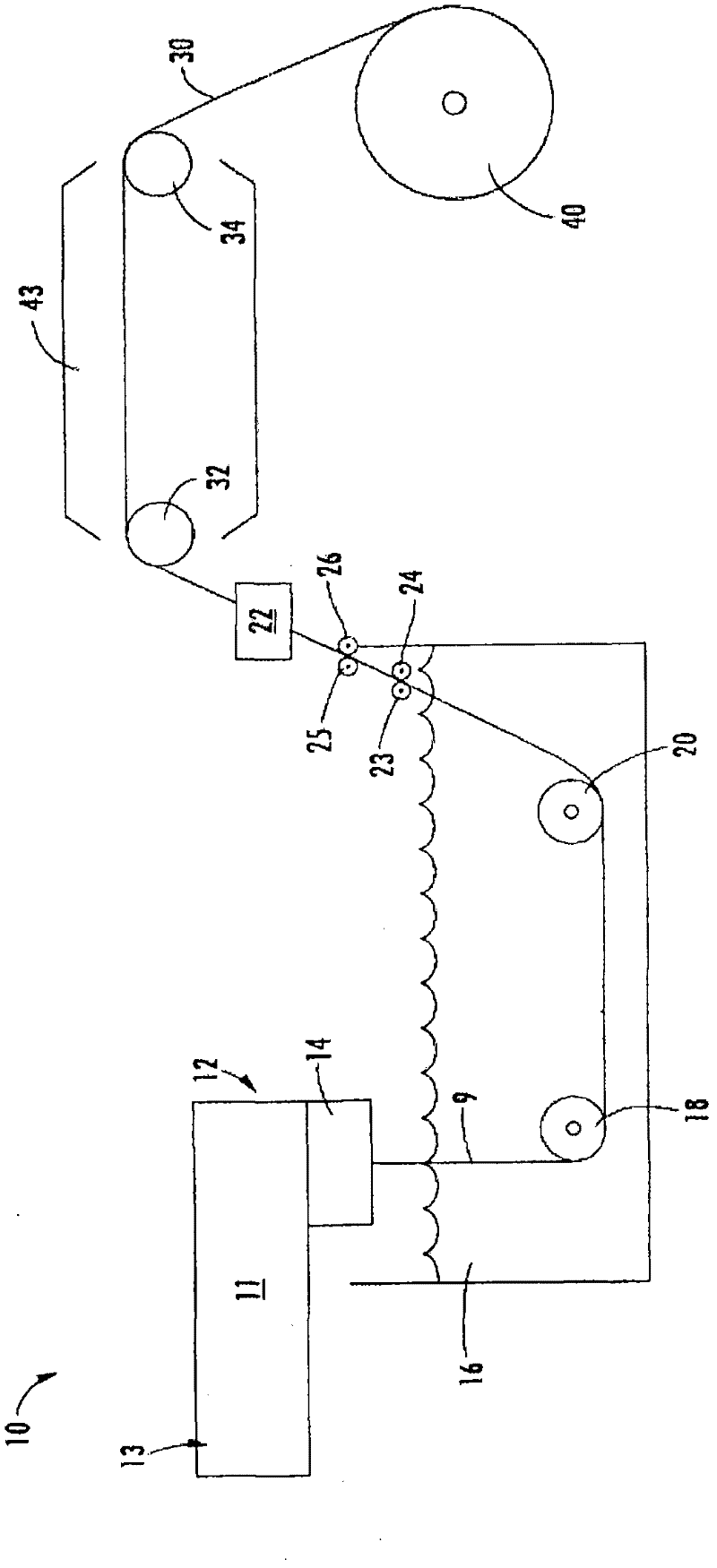

Electroblowing web formation process

ActiveUS20060138711A1High strengthElectric discharge heatingMonocomponent polyethers artificial filamentNanofiberEngineering

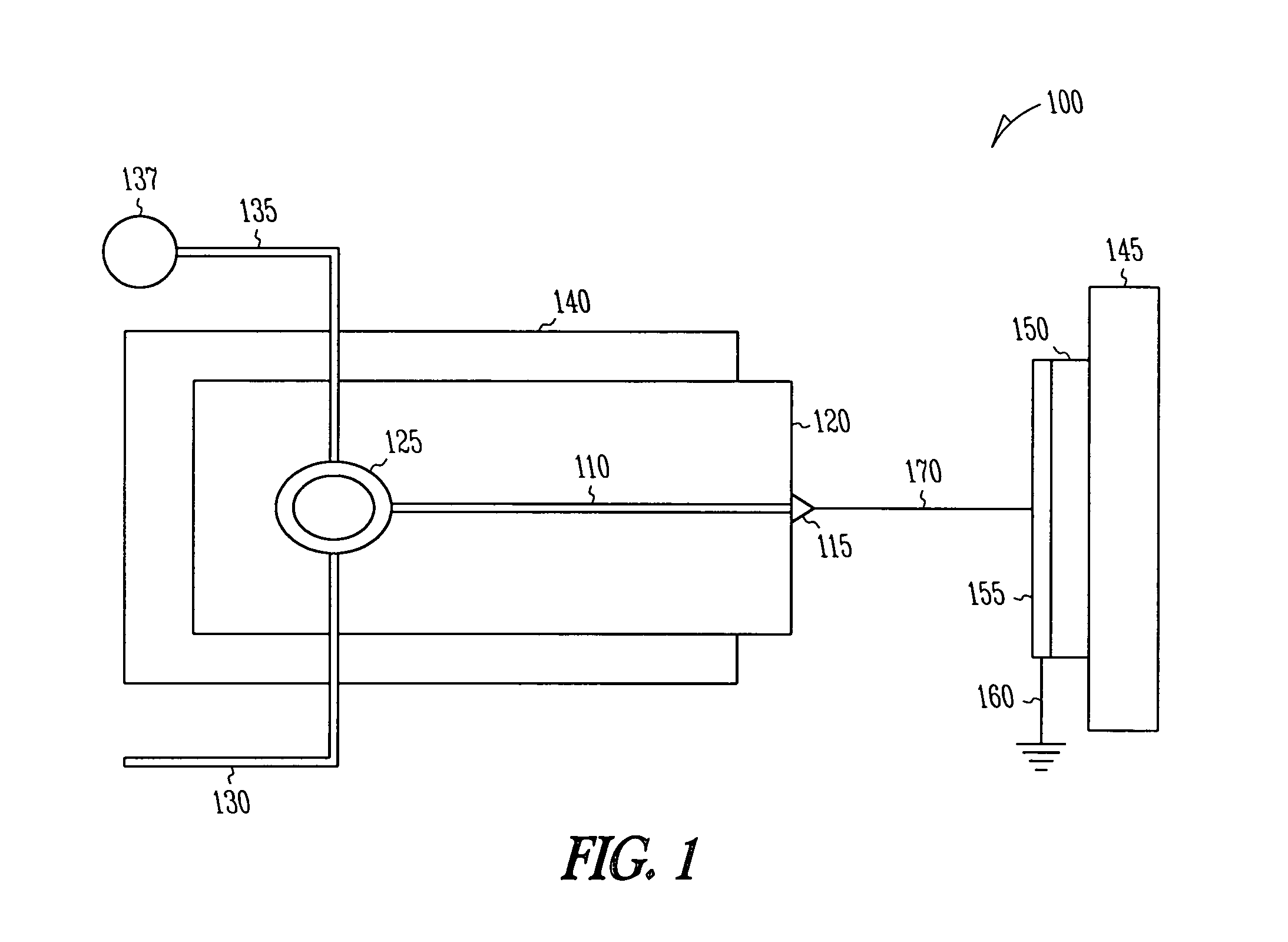

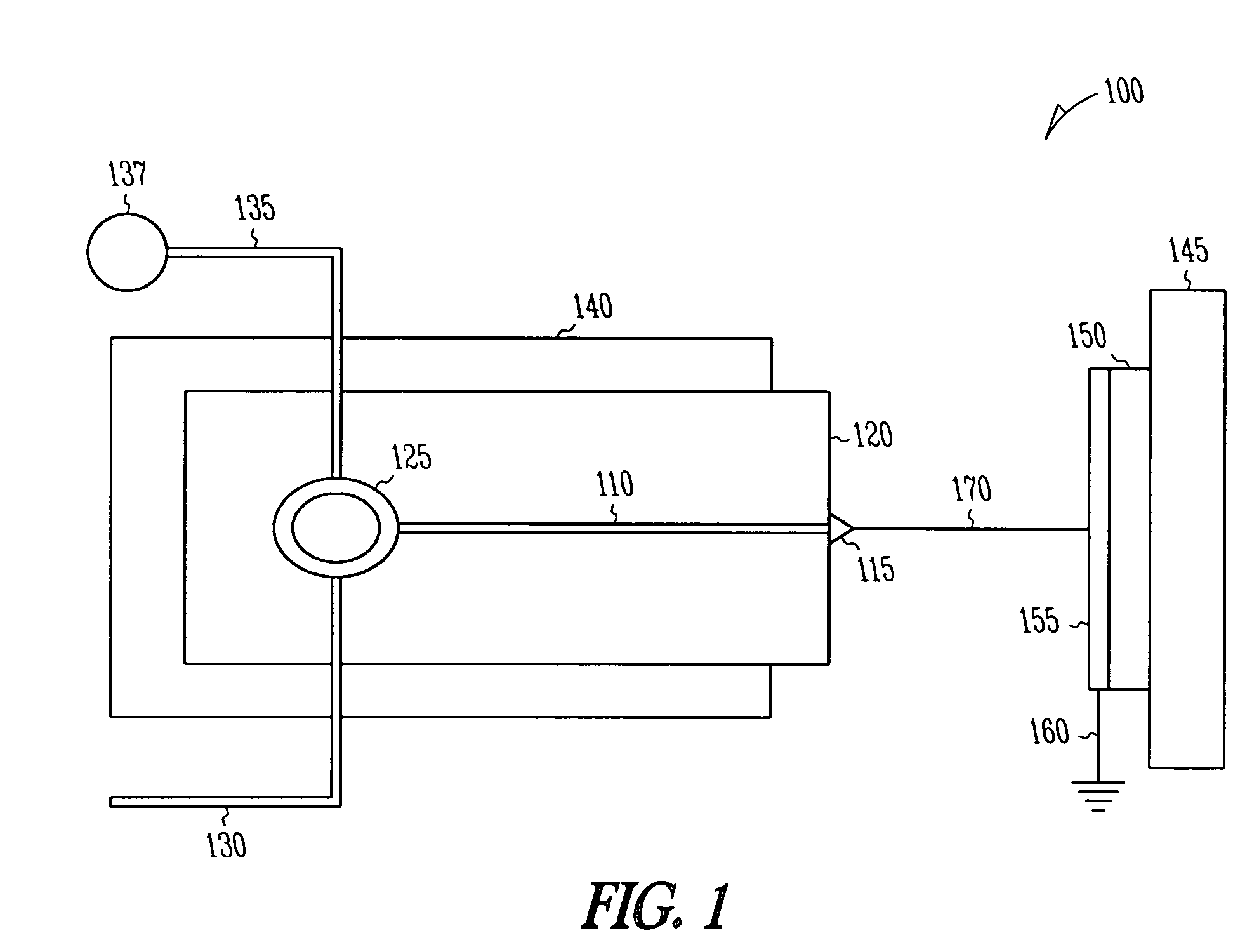

An improved electroblowing process is provided for forming a fibrous web of nanofibers wherein polymer stream is issued from a spinning nozzle in a spinneret with the aid of a forwarding gas stream, passes an electrode and a resulting nanofiber web is collected on a collector. The process includes applying a high voltage to the spinneret and grounding the electrode such that an electric field is generated between the spinneret and the electrode of sufficient strength to impart an electrical charge on the polymer as it issues from the spinning nozzle.

Owner:DUPONT SAFETY & CONSTR INC

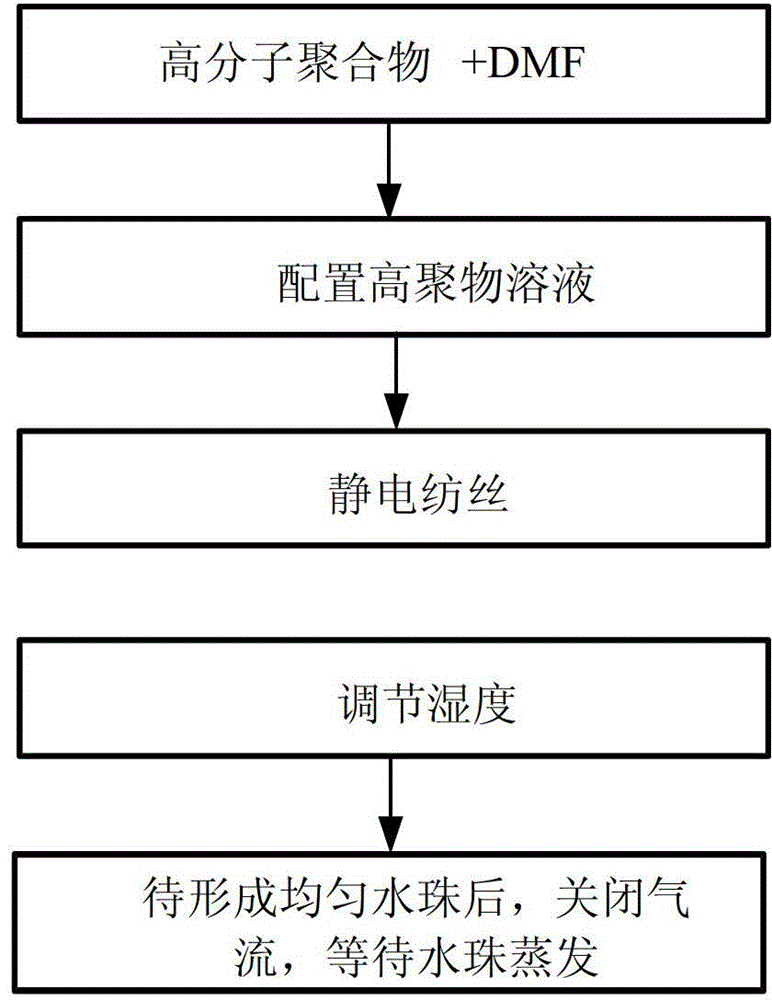

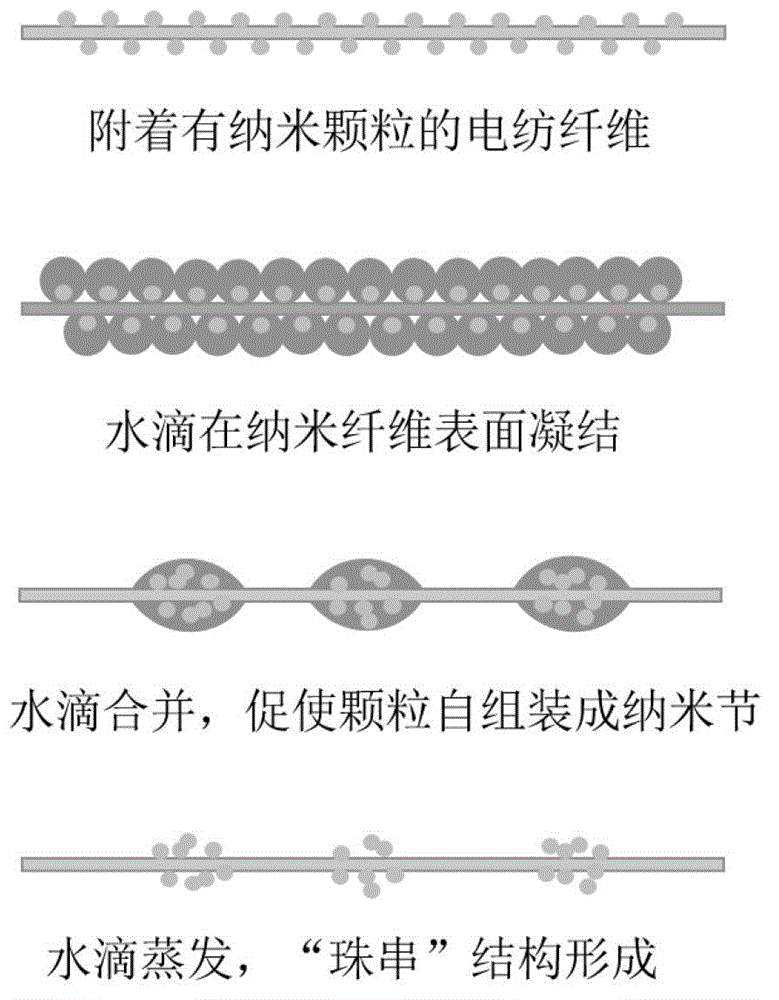

Preparation method for self-assembly of electrospinning rosary-like fibers

ActiveCN103334244AEasy to operateEasy to makeMonocomponent polyethers artificial filamentFilament/thread formingFiberOperability

The invention discloses a preparation method for the self-assembly of electrospinning rosary-like fibers, and belongs to the technical field of chemistry and material. By inspired by the situation that a cobweb can be assembled to a spindle structure in the wet environment respectively, a static electricity spinning device is utilized to prepare man-made fibers, and an aluminum bracket is used for receiving, so as to form the man-made fibers with the structure that nano-particles are adhered to surfaces; the man-made fibers are allowed to be assembled to the micron-sized ' rosary' structure respectively in the wet environment. According to the preparation method provided by the invention, the manufacturing process is simpler, the cost is lower, the operability is strong, and the method is suitable for mass productions; the respectively assembled fibers have stable quality and long practicability; the method can be used for collecting fresh water, reducing fog, solving the problem of serious water shortage in deserts and wastelands, and dispersing the steam around airports, street lamps, and signal lamps.

Owner:BEIHANG UNIV

Polyoxymethylene fiber and method for production thereof

InactiveCN1555430AIncrease productivityHigh strengthMonocomponent polyethers artificial filamentFilament/thread formingMolten stateFiber

A polyoxymethylene fiber which comprises a polyoxymethylene copolymer which exhibits a half crystallization time of 30 sec or more when it is cooled from the molten state at 200 DEG C to 150 DEG C at a cooling rate of 80 DEG C / min and then is held at 150 DEG C constantly. The polyoxymethylene fiber has a high strength and a high modulus of elasticity.

Owner:POLYPLASTICS CO LTD

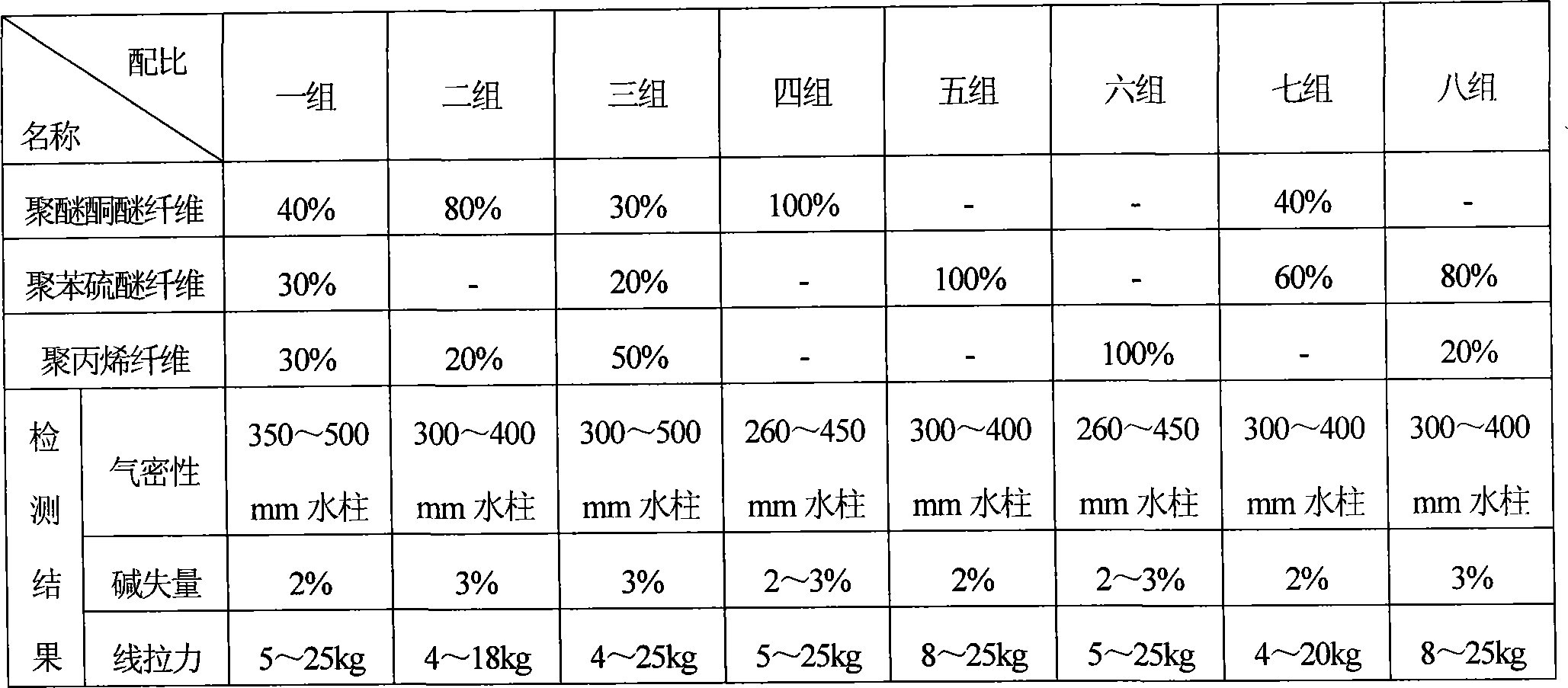

Non-zillerite environment protection energy-saving diaphragm cloth and weaving method thereof

ActiveCN101195944AImprove the level ofBreak down trade barriersMonocomponent polyethers artificial filamentMonocomponent polypropylene artificial filamentLongitudeKetone

The invention provides asbestos free environment protective and energy-saving type diaphragm cloth and the weaving method, which relates to diaphragm material and the weaving method. The diaphragm cloth of the invention adopts one, two or three component(s) from the polyether ketone ether fiber, the polyphenyl thioether fiber, and the polypropylene fiber, and meets the following requirements: unit weight: 0.5 to 1.5 kg / square meter; cloth thickness range: 0.5 to 1.5 mm; gauge of cloth: longitude 100 to 280 piece / 10 cm, latitude 56 to 150 piece / 10 cm; alkali loss: no larger than 2 percent; airtight protection performance: no air bubble produced in two minutes under the pressure of 300 mm water column, and the weaving can be performed according to the wool spinning technology and the cotton spinning technology. The invention breaks the trade barrier of the developed countries, the overall level of the hydrogen making and oxygen making equipment of our country is enhanced, and the pollution to the environment and the harm to the human body by the asbestos dust are reduced. Compared with the traditional asbestos diaphragm cloth, the thickness of the production can be reduced as low as 55 to 85 percent, and more than 10 percent of the energy can be conserved.

Owner:牡丹江市旺通新型隔膜材料有限责任公司

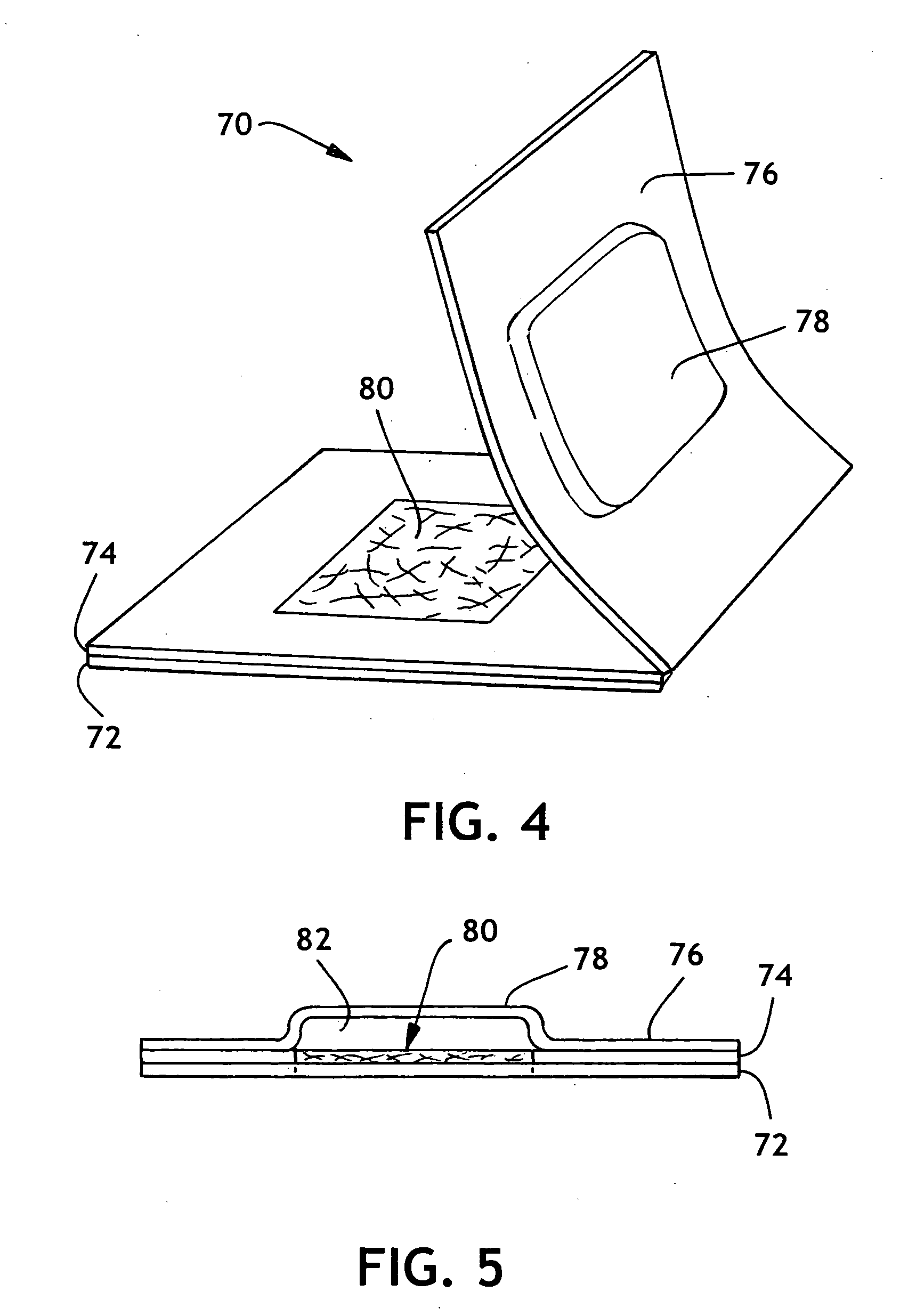

Microfiber supported nanofiber membrane

A nanofiber membrane is formed on a microfiber membrane. The nanofiber membrane may be electro sprayed directly onto the microfiber membrane and becomes integrated with the microfiber membrane to form a filter. The microfiber membrane provides structural integrity to for the nanofiber membrane, and an additional microfiber membrane may be added to sandwich the nanofiber membrane.

Owner:CORNELL RES FOUNDATION INC

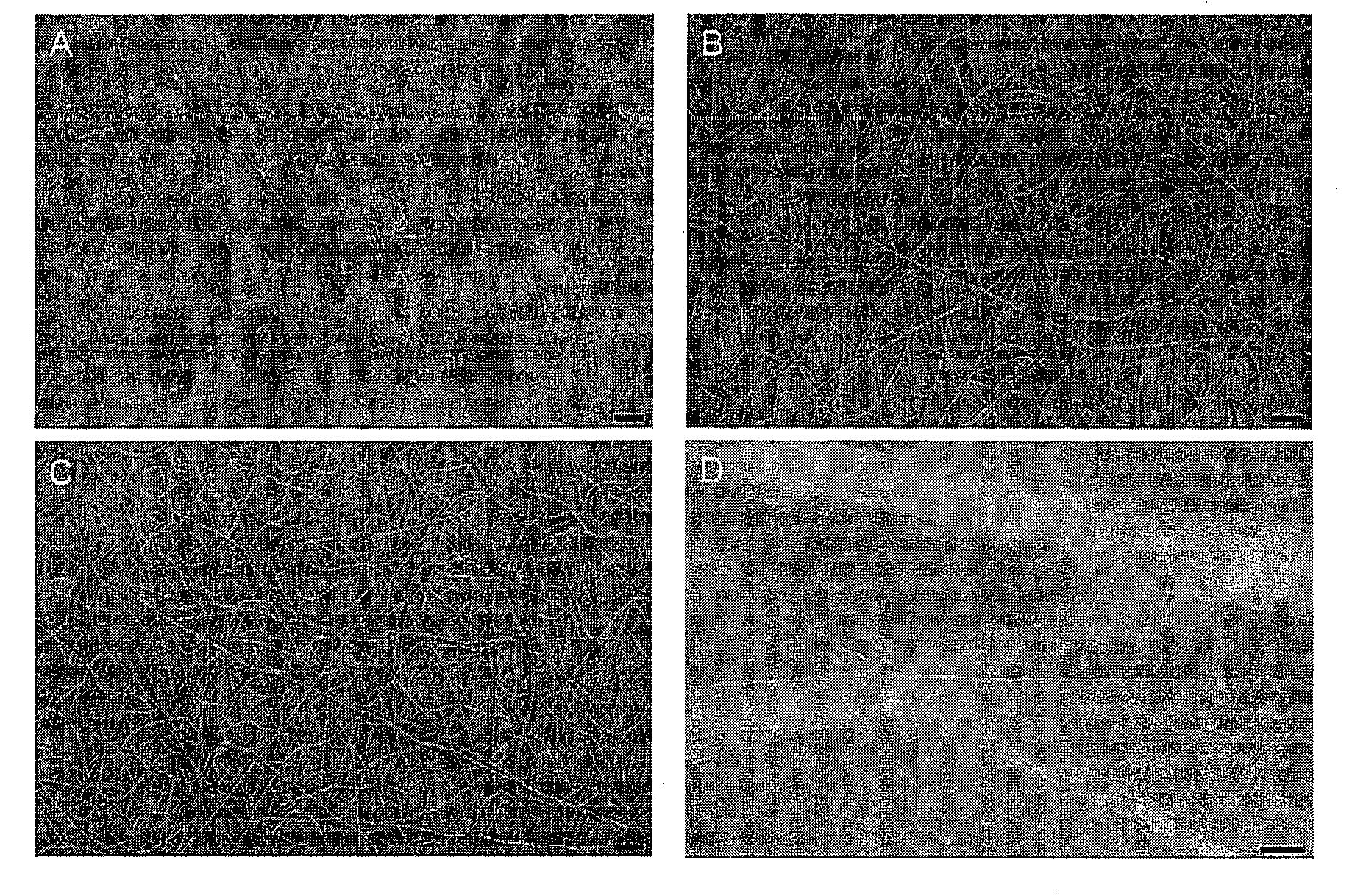

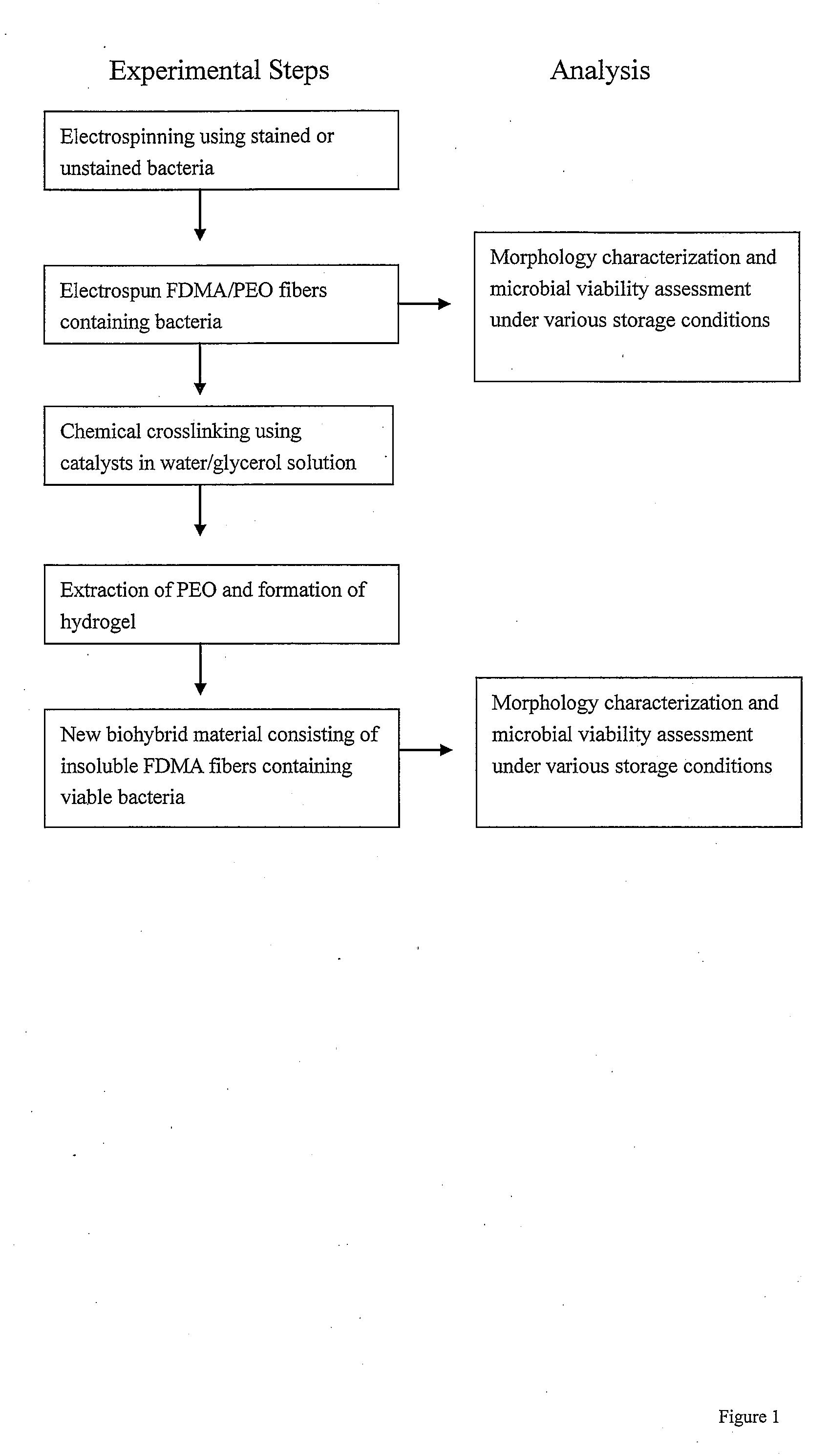

Microbes Encapsulated Within Crosslinkable Polymers

The invention relates to porous films comprising crosslinked electrospun hydrogel fibers. Viable microbes are encapsulated within the crosslinked electrospun hydrogel fibers. The crosslinked electrospun hydrogel fibers are water insoluble and permeable. The invention also relates to methods of making and using such porous films.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

Amorphous polyetherimide fiber and heat-resistant fabric

ActiveUS20120015184A1Improve mechanical propertiesSmall single fiber finenessMonocomponent polyethers artificial filamentMelt spinning methodsPolymer sciencePolyetherimide

Provided are an amorphous polyetherimide fiber having not only a small single fiber fineness suitable for producing fabrics, and a fabric comprising the amorphous polyetherimide fiber. The fiber comprises an amorphous polyetherimide polymer having a molecular weight distribution (Mw / Mn) of less than 2.5, and having a shrinkage percentage under dry heat at 200° C. of 5% or less, and a single fiber fineness of 3.0 dtex or less. The fiber may have a tenacity at room temperature of 2.0 cN / dtex or greater.

Owner:KURARAY CO LTD

Method for preparing porous molybdenum carbide nanofiber by adopting electrostatic spinning

InactiveCN104357937AEasy to operateFacilitate multiple recycling and reuseMonocomponent polyethers artificial filamentFilament/thread formingFiberPolymer science

The invention discloses a method for preparing a porous molybdenum carbide nanofiber by adopting electrostatic spinning, and belongs to the technical field of nano materials. The method comprises the following steps: with water-soluble molybdate as a molybdenum source, and a water-soluble high-molecular polymer as a carbon source, dissolving and evenly mixing the water-soluble molybdate and the water-soluble high-molecular polymer at room temperature; and preparing a molybdate nano fiber by adopting an electrostatic spinning method; burning in an inert atmosphere or a reducing atmosphere; and simultaneously achieving high-temperature thermal decomposition, reduction and carbonization, so as to obtain the porous molybdenum carbide nanofiber in one step. According to the method, cheap molybdate and water-soluble high-molecular polymer are taken as raw materials; the method is artfully combined with a relatively mature electrostatic spinning technology in industry; and the method is high in preparation efficiency and product quality, low in cost, simple and easy to control, friendly to environment, free of pollution, and suitable for industrial production, and has important application value and industrial prospect in a plurality of fields such as catalysts, electrode materials, super capacitors and sensors.

Owner:SHANGHAI JIAO TONG UNIV

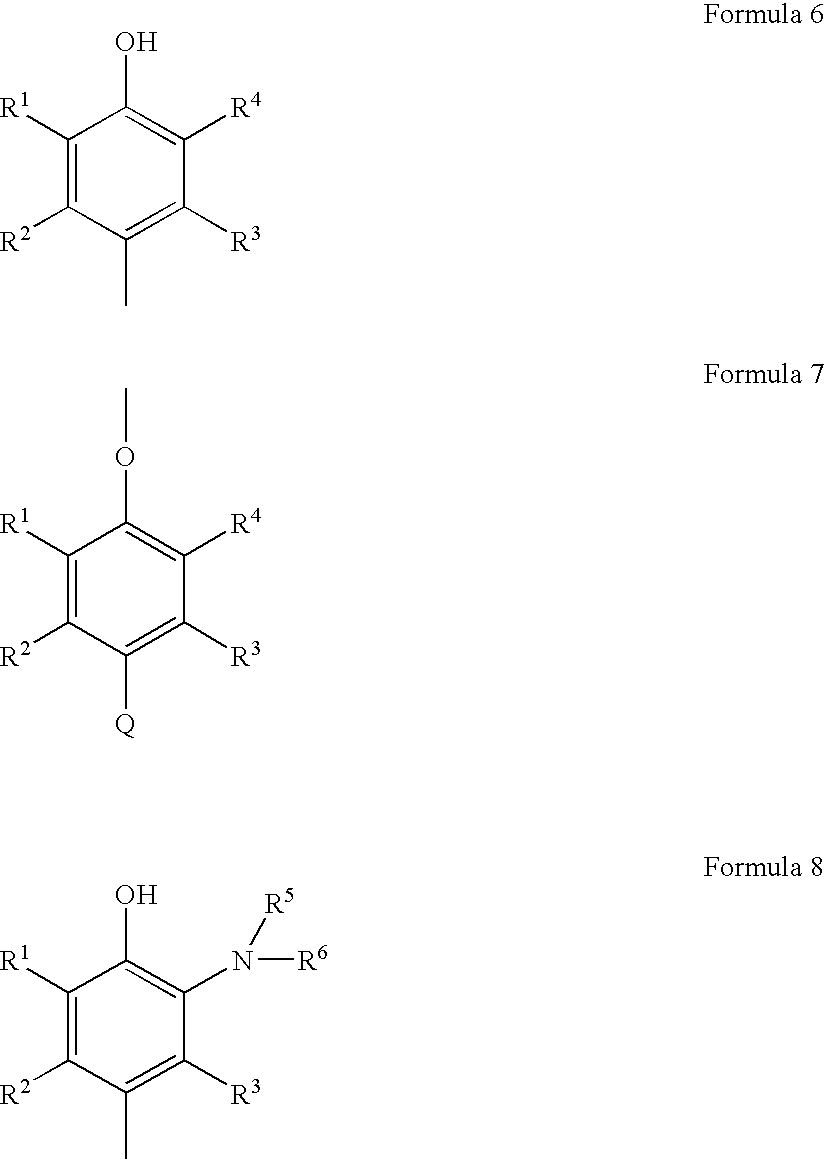

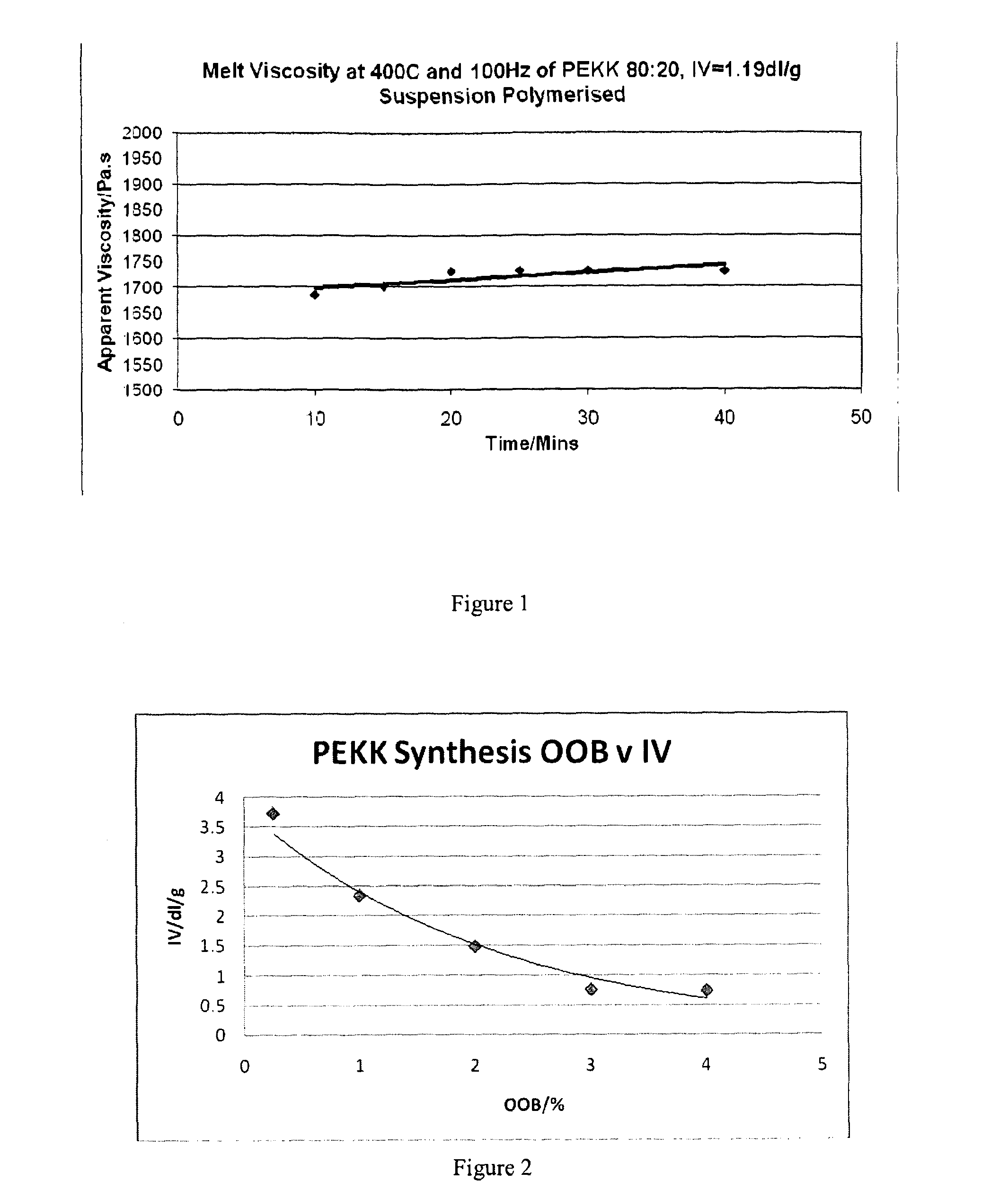

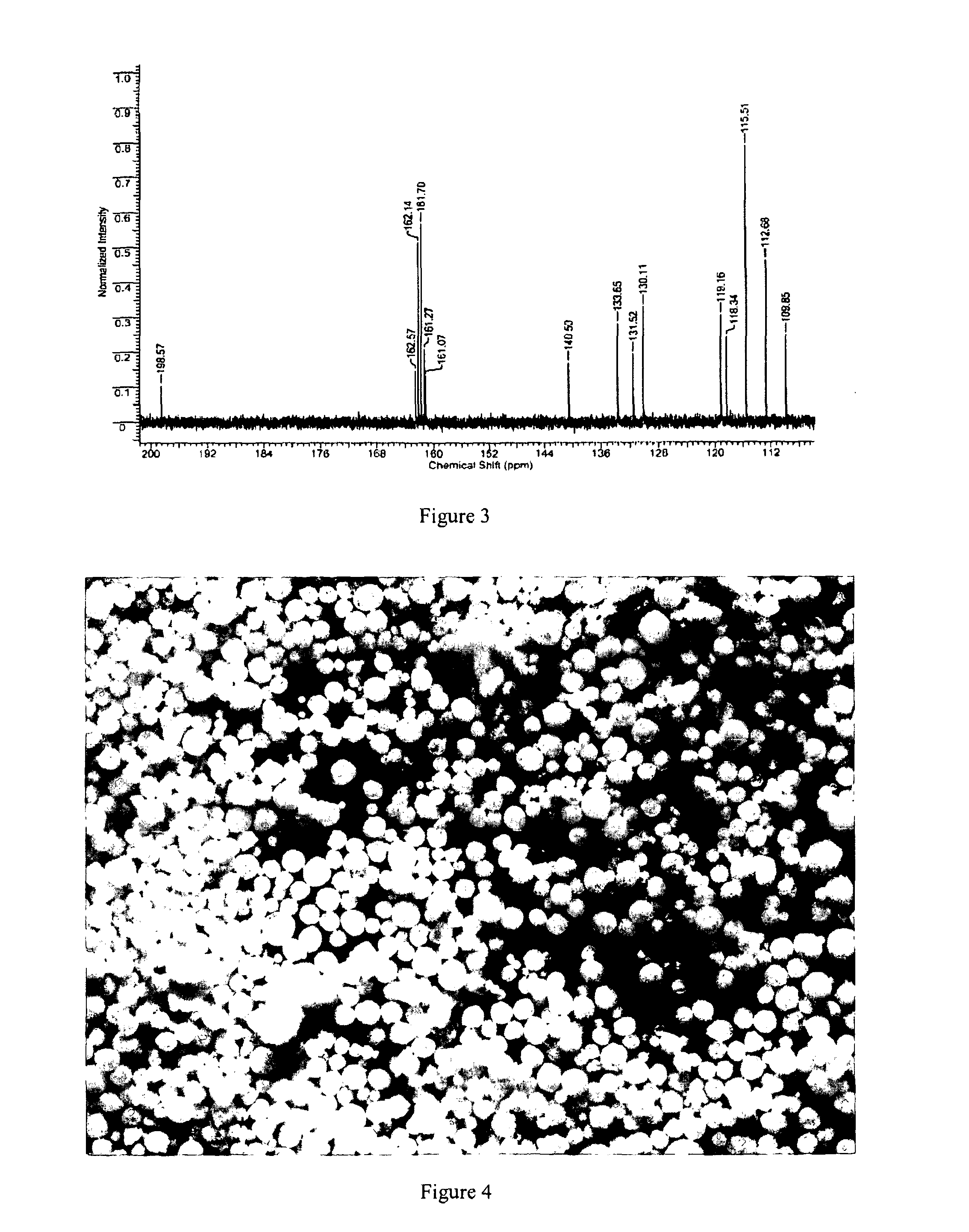

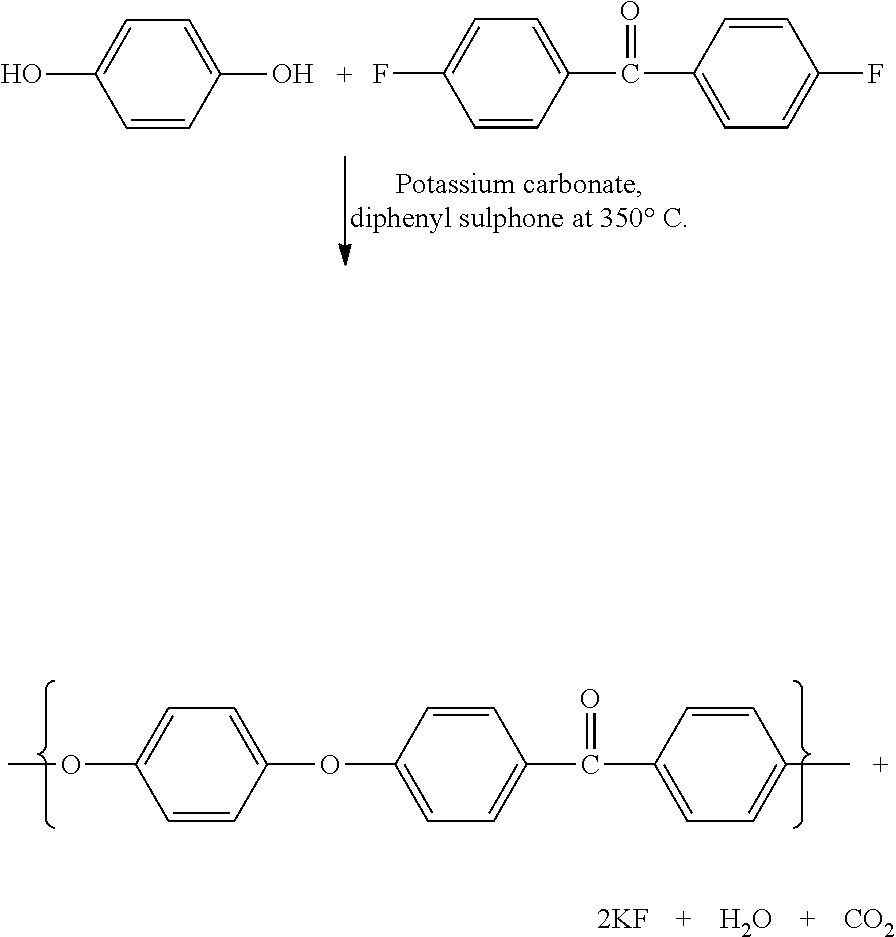

Method for preparing poly (ether ketone ketones)

ActiveUS9023468B2Reduce the amount of waterLower the volumeMonocomponent polyethers artificial filamentSynthetic resin layered productsAromatic moietyEther

A method of preparing a poly (ether ketone ketone) consisting essentially of the repeat unit:—Ar—O—Ar—C(═O)—Ar—C(═O)—wherein each Ar is independently an aromatic moiety is provided. The method may comprise the step of polymerising a monomer system in a reaction medium comprising: (a) a Lewis acid; and (b) a controlling agent comprising an aromatic carboxylic acid, an aromatic sulphonic acid, or a derivative thereof.

Owner:OXFORD PERFORMANCE MATERIALS

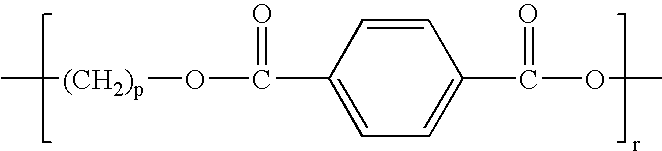

Fibers Formed from Aromatic Polyester and Polyether Copolymer

A method for forming a fiber is provided. The method comprises supplying at least one aromatic polyester to a melt processing device and modifying the aromatic polyester with at least one polyether copolymer within the device to form a thermoplastic composition having a melt flow rate that is greater than the melt flow rate of the aromatic polyester. The polyether copolymer contains a repeating unit (A) having the following formula:C2H4Ox (A)wherein,x is an integer from 1 to 250,the polyether copolymer further containing a repeating unit (B) having the following formula:CnH2nOy (B)wherein,n is an integer from 3 to 20; andy is an integer from 1 to 150.

Owner:KIMBERLY-CLARK WORLDWIDE INC

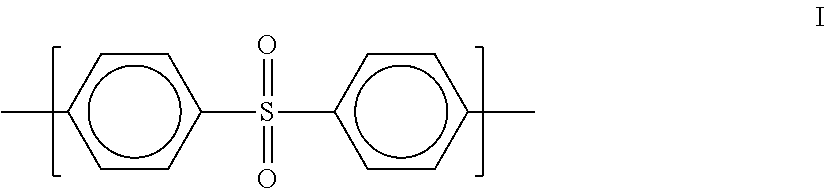

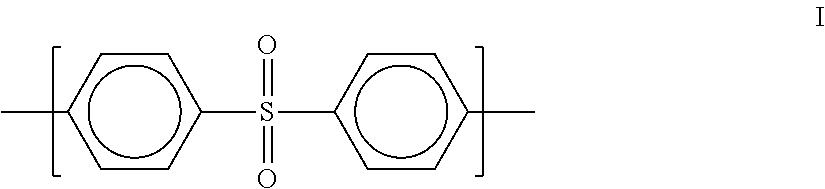

Performance Enhancing Additives For Fiber Formation And Polysulfone Fibers

ActiveUS20130338297A1Sharpen the sieving curveGood removal effectMembranesSemi-permeable membranesFiberPolymer science

Owner:FRESENIUS MEDICAL CARE HLDG INC

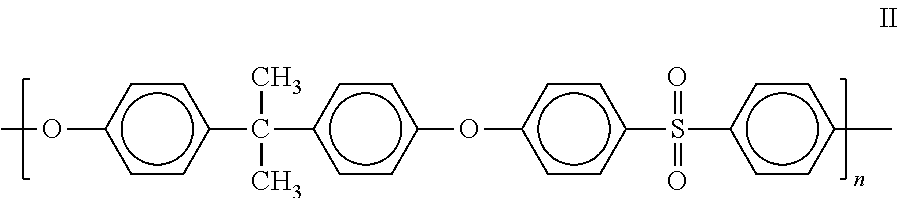

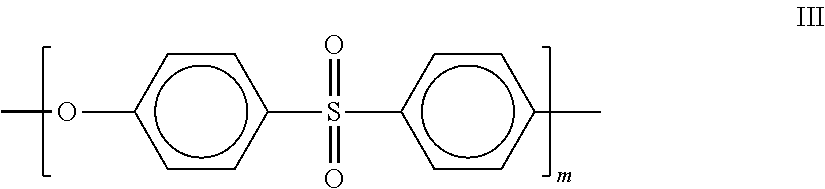

Method for producing polyethersulfone fiber

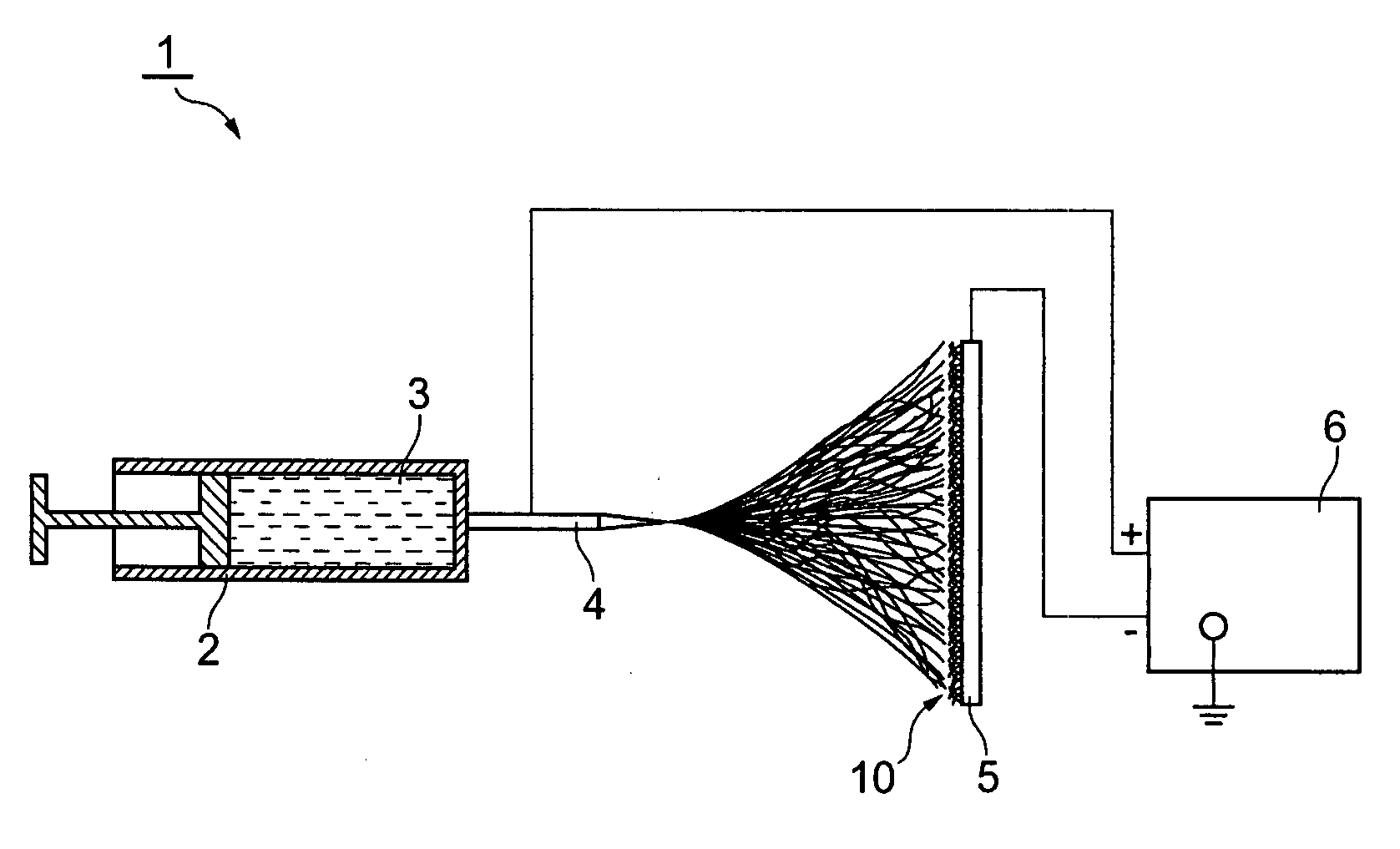

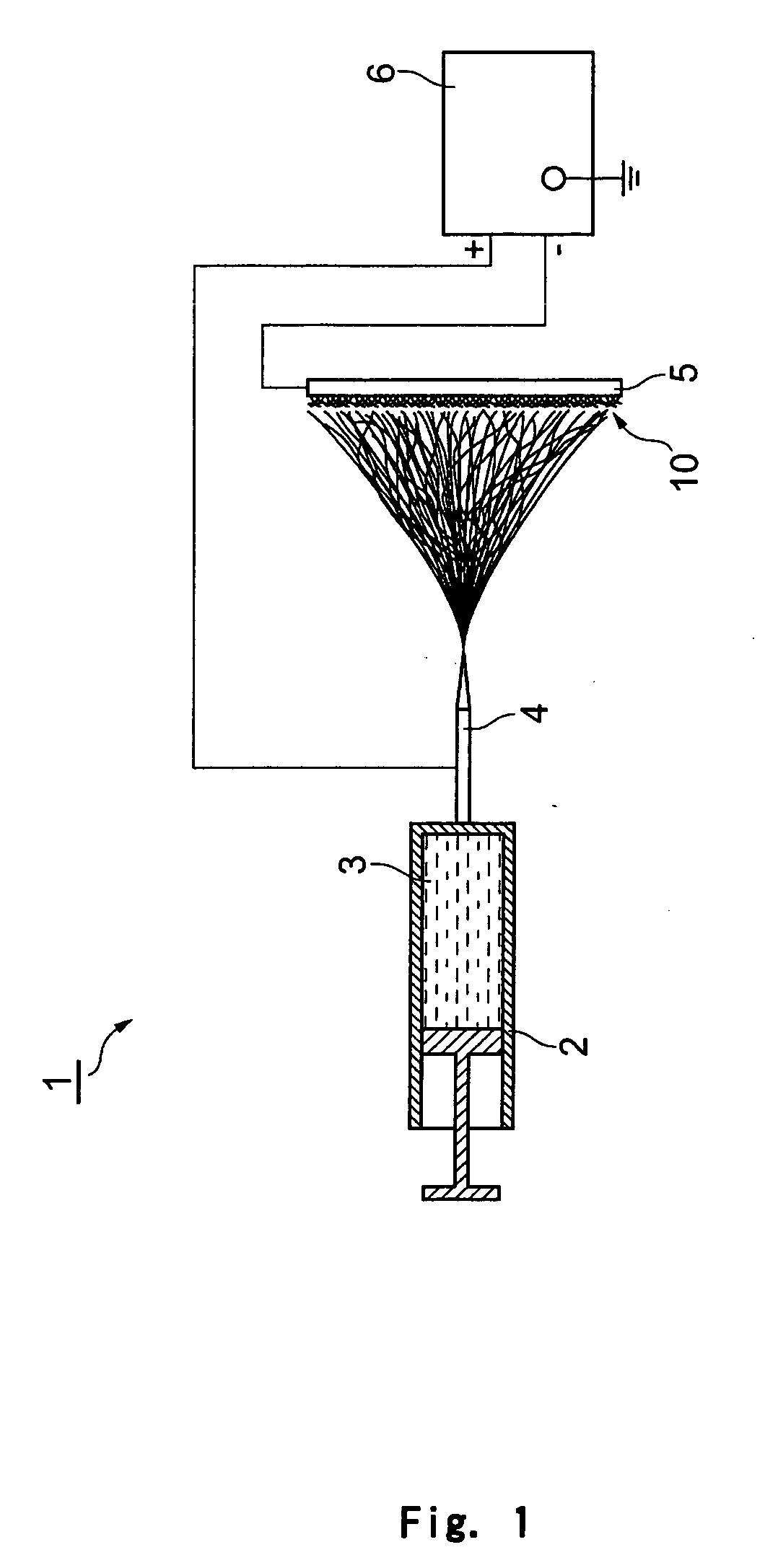

ActiveUS20090047515A1ThinnerThinner polyethersulfone fiberElectric discharge heatingMonocomponent polyethers artificial filamentSolventElectric field

The present invention provides a method for producing a polyethersulfone fiber, the method comprising the steps of discharging an electrically charged solution comprising a polyethersulfone and a solvent from a container; and drawing the charged solution by electrical attraction in an electrical field generated between the solution and an electrically charged collecting means having the opposite charge of the solution, while evaporating at least a portion of the solvent to form a polyethersulfone fiber. The fiber obtained in the present invention has a small average fiber diameter and can be made into a thin fiber cloth.

Owner:SUMITOMO CHEM CO LTD

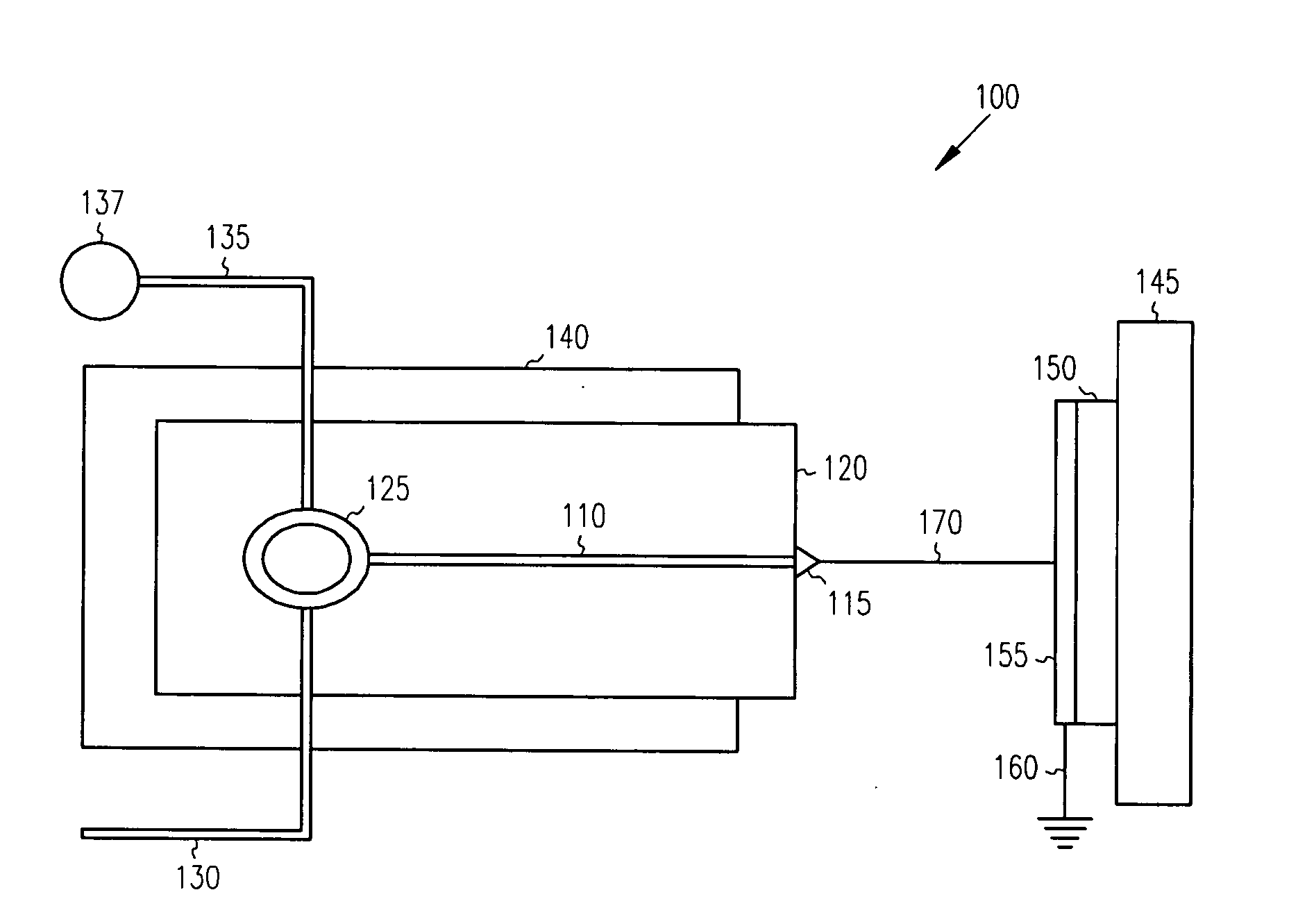

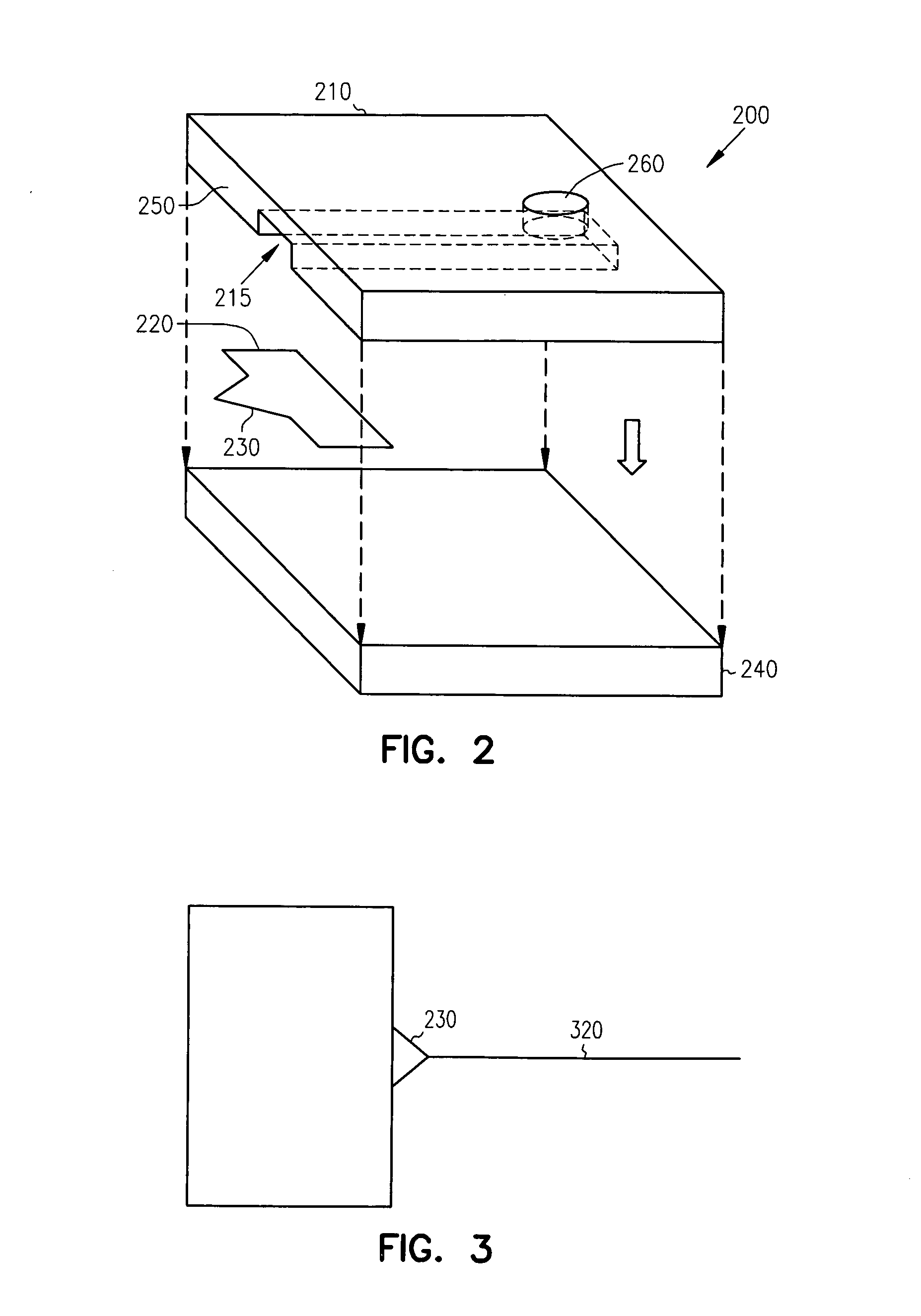

Electroblowing web formation process

ActiveUS7585451B2Electric discharge heatingMonocomponent polyethers artificial filamentNanofiberEngineering

An improved electroblowing process is provided for forming a fibrous web of nanofibers wherein polymer stream is issued from a spinning nozzle in a spinneret with the aid of a forwarding gas stream, passes an electrode and a resulting nanofiber web is collected on a collector. The process includes applying a high voltage to the spinneret and grounding the electrode such that an electric field is generated between the spinneret and the electrode of sufficient strength to impart an electrical charge on the polymer as it issues from the spinning nozzle.

Owner:DUPONT SAFETY & CONSTR INC

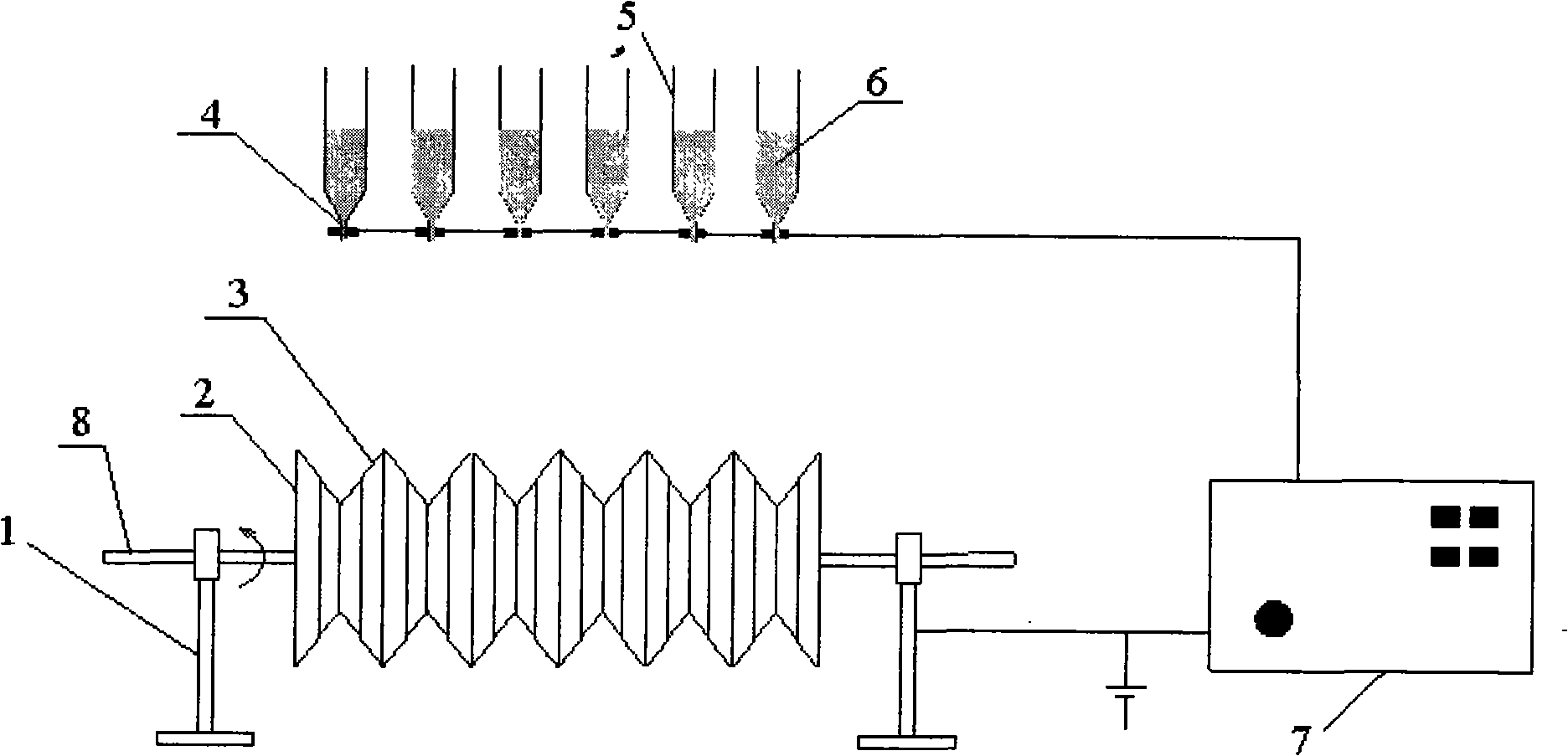

Multi-needle V-shaped groove drum electrostatic spinning system and preparation of nano-fiber tuft

InactiveCN101280468AIncrease productivityMonocomponent polyethers artificial filamentArtificial thread manufacturing machinesFiber bundleInsertion stent

The invention discloses a V-groove drum electro-spun nano-fiber bundle system, which comprises a drum that the external circumference surface is composed of a plurality V-grooves in sequent connection. The drum is fixed on the drum shaft, which can be driven to rotate through the drum shaft. The drum and the drum shaft are supported through a stent. The upper part of the drum is arranged side by side with a plurality of syringes. The exit of each syringe is corresponded with a V-groove bottom of the drum, and the exit part of each syringe is provided with a metal needle. All the metal needles are in series connection through a wire, which are also connected to the anode of a high-voltage direct current transmitter. The cathode of the high-voltage direct current transmitter is in grounding with the drum. With the use of the system that control voltage is 15 to 40KV, the winding speed is 200 to 500r / min and the deposition distance is 100 to 200mm, the nano-fiber bundle with a better-oriented alignment along the V-groove bottom is obtained. The fiber obtained from the invention is the electro-spun nano-fiber bundle with a better degree of oriented alignment, which provides a wider range of applications for the electro-spun fiber products.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Scanned source oriented nanofiber formation

Nanofibers are formed using electrospray deposition from microfluidic source. The source is brought close to a surface, and scanned in one embodiment to form oriented or patterned fibers. In one embodiment, the surface has features, such as trenches on a silicon wafer. In further embodiments, the surface is rotated to form patterned nanofibers, such as polymer nanofibers. The nanofibers may be used as a mask to create features, and as a sacrificial layer to create nanochannels.

Owner:CORNELL RES FOUNDATION INC

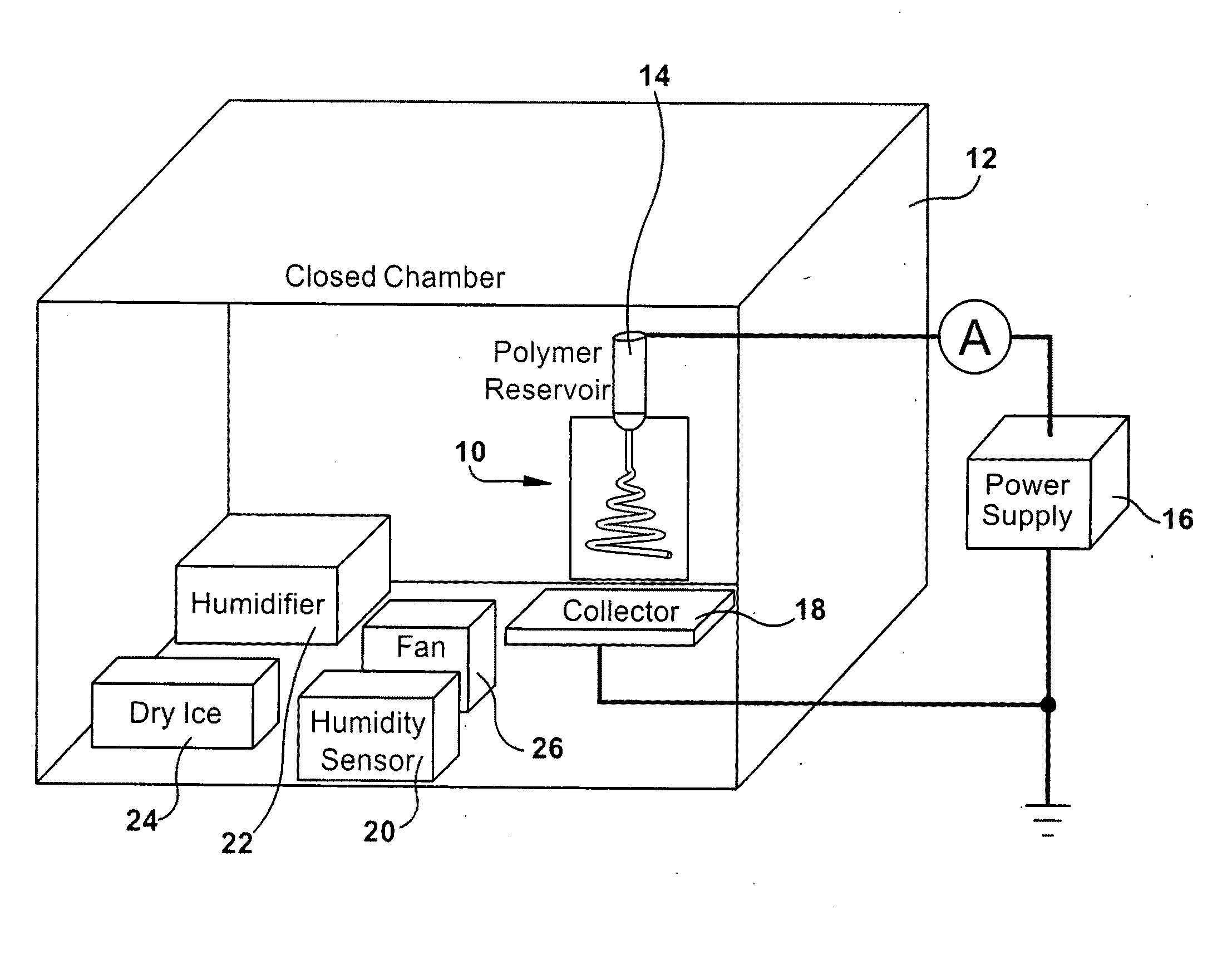

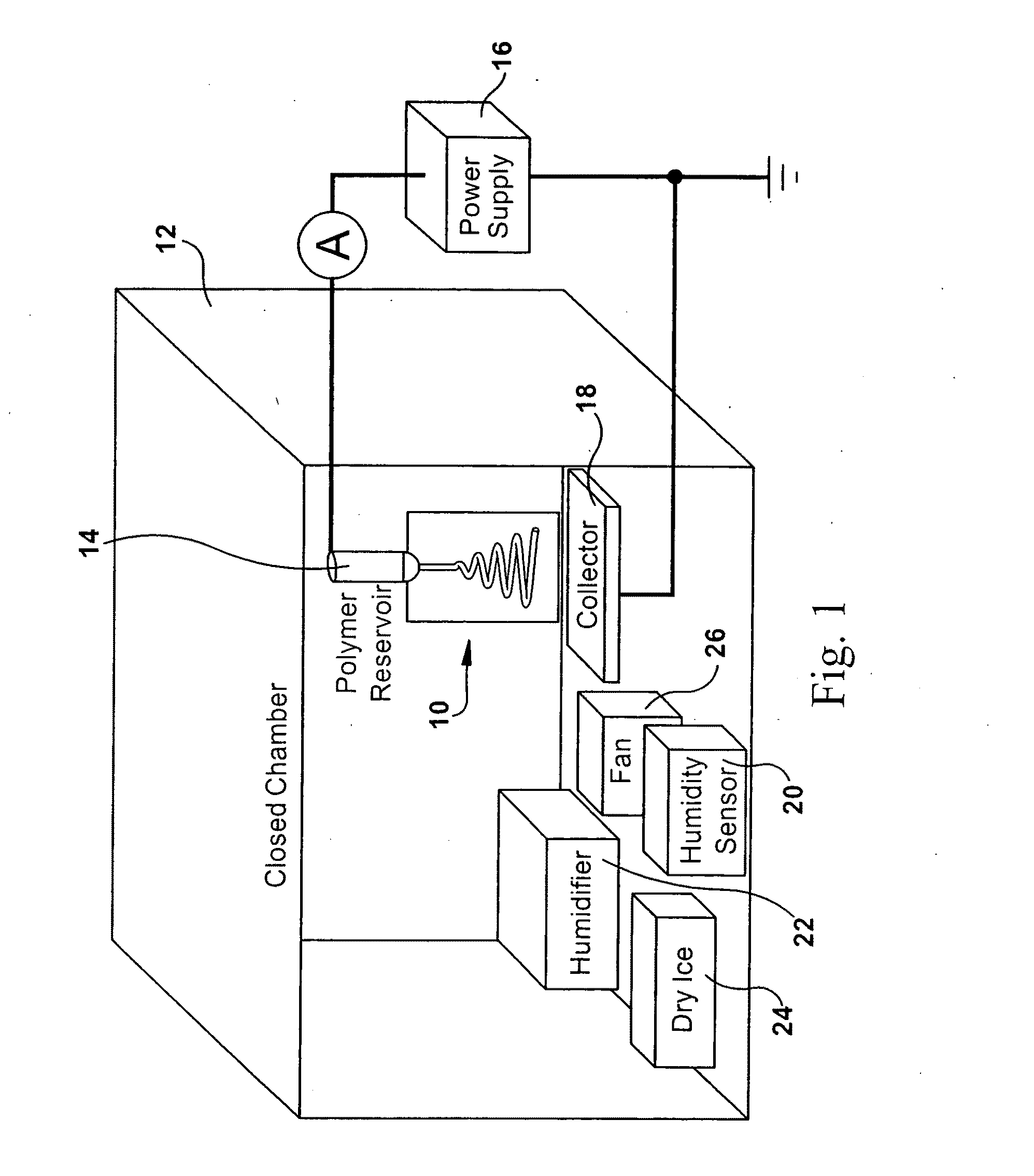

Process for controlling the manufacture of electrospun fiber morphology

InactiveUS20090321997A1Small diameterElectric discharge heatingMonocomponent polyethers artificial filamentFiberPolymer science

A apparatus and process of forming electrospun fibers including the steps of supplying a substantially homogeneous mixture of a solvent and a polymer which can be formed into an electrospun fiber; electrospinning the polymer into a fiber in an enclosed chamber; monitoring the humidity in said chamber; and changing the partial pressure of solvent evaporation to thereby modify the morphology of the thus formed fibers.

Owner:THE UNIVERSITY OF AKRON

Odour control material, method for preparation of an odour control material and an absorbent product comprising the odour control material

ActiveUS20150290052A1Easy to operateImprove adsorption capacityOther chemical processesMonocomponent polyethers artificial filamentParticulatesWater insoluble

The present invention relates to an odour control material consisting of a water-insoluble particulate odour control agent and a thermoplastic water-soluble carrier matrix encapsulating the odour control agent. The carrier matrix dissolves when in contact with an aqueous solution, such as urine and the odour control material is obtained by means of thermoforming. The invention relates also to a method for the preparation of the odour control material and the use of the odour control material in absorbent products. The present odour control material minimizes dusting problems caused by particulate odour control agents in production processes.

Owner:ESSITY HYGIENE & HEALTH AB

Composite fiber and its preparation method

InactiveCN1948564ALow costMonocomponent polyethers artificial filamentFilament/thread formingPolyesterPolyamide

The invention relates to a kind of composite fiber and its preparation method. Composite fiber is long fiber or short fiber spinning by taking PPS as cortex and taking PET, PA6 or PA66 as skin-core structure of sandwich layer. The preparation method contains (1) Vacuum drying. (2) Spinning wind. (3) After-stretch hot established. The composite fiber has low cost and good quality, which is fiber filter material using extensively in environmental protection.

Owner:DONGHUA UNIV +1

Performance enhancing additives for fiber formation and polysulfone fibers

ActiveUS9617421B2Sharpen the sieving curveGood removal effectMembranesSemi-permeable membranesFiberPolymer science

Owner:FRESENIUS MEDICAL CARE HLDG INC

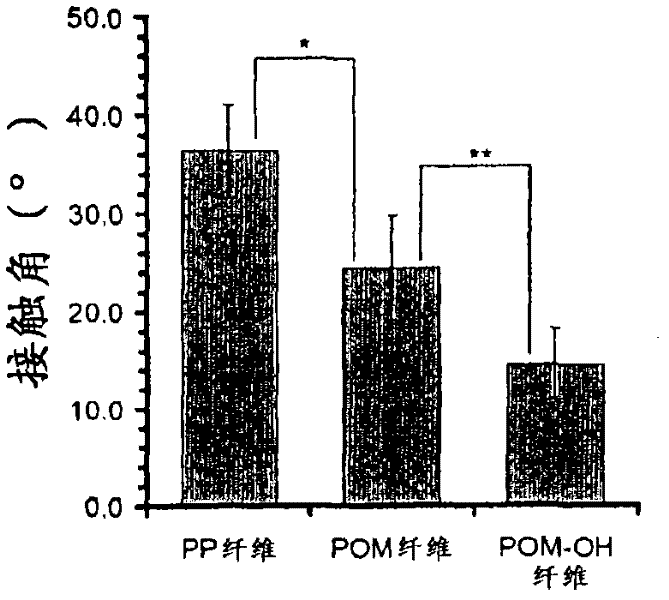

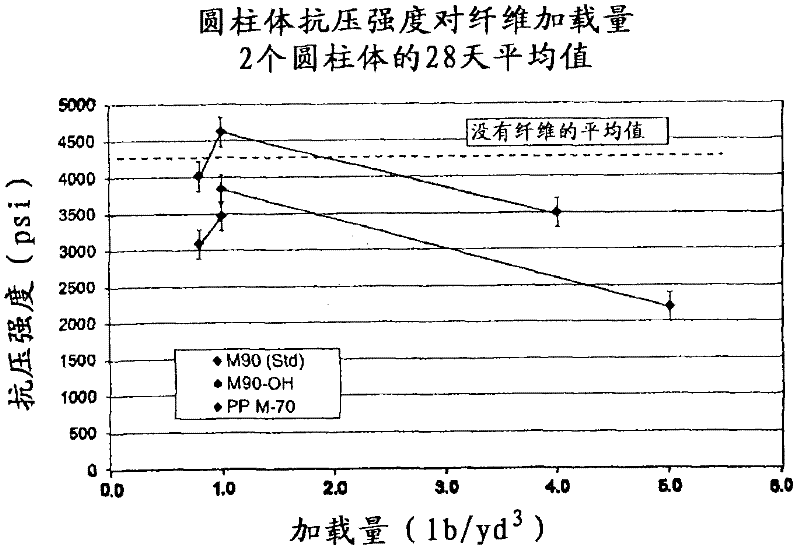

Polyoxymethylene fibers in concrete

InactiveCN102603232AMonocomponent polyurethanes artificial filamentMonocomponent polyethers artificial filamentFiberPolyoxymethylene

Disclosed are polymeric additives for concrete formed of a polyoxymethylene (POM) copolymer. POM copolymers can be utilized to form fibrous additives for concrete, i.e., microfibers and / or macrofibers. The POM copolymers can include one or more chemical groups, e.g., end groups and / or pendant groups that can increase the polarity of the POM and increase the hydrophilicity of the formed fibers, which can improve miscibility of the fibers in wet concrete. Chemical groups of the POM copolymers can bond with components of the concrete or can hydrolyze to form groups that can bond with components of the concrete, e.g., form covalent or noncovalent (e.g., electrostatic or ionic) bonds with one or more components of the concrete binder.

Owner:TICONA LLC

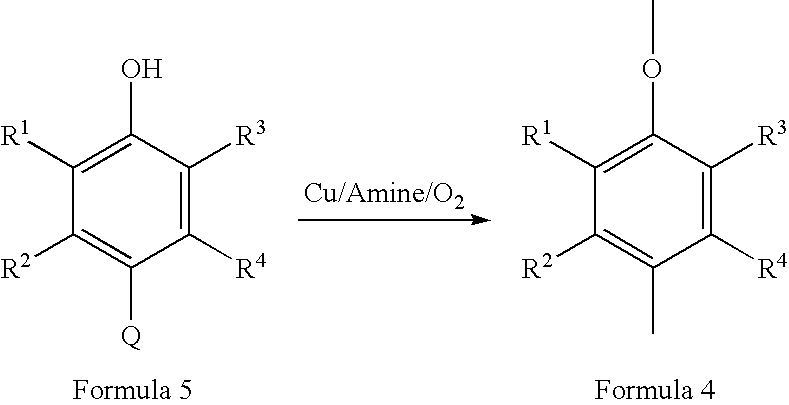

Preparation of high intrinsic viscosity poly(arylene ether) resins

A poly(aryl ether) resin having an intrinsic viscosity greater than about 0.8 dL / g obtained by reacting phenol with oxygen in the presence of an organic solvent and a metal complex catalyst. The concentration of phenol is about 5-15% by weight of the total amount of phenol and solvent, and the molar ratio of metal to phenol in the metal complex catalyst is about 1:100 to 1:200.

Owner:SHPP GLOBAL TECH BV

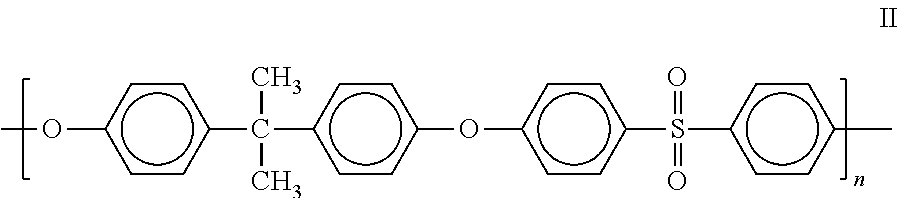

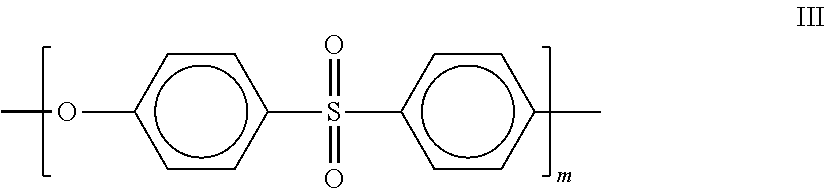

Separation membrane for use in treatment of liquid comprising aromatic ether polymer hydrophilized with hydrophilizing agent

InactiveUS8602221B2Less deteriorationSmall sizeSemi-permeable membranesMembranesHydrophilizationHigh energy

Owner:ASAHI KASEI KK

Ultra-hydrophobic conductive macromolecular nano fiber and method for preparing same and use thereof

InactiveCN100360725CLong-term stabilityShape is easy to controlElectroconductive/antistatic filament manufactureMonocomponent polyethers artificial filamentPolymer scienceSpinning

The invention discloses an ultra-hydrophobic conductive macromolecular nanometer fiber, which is characterized by the following: the fiber possesses coaxial nanometer fiber of core case structure; the core is 80-300 nanometer diameter polymerization fiber, whose coaxial case is 80-200 nanometer conductive macromolecular layer of 20-40 nanometer conductive macromolecular grain; the polymerization is polyacrylonitile, ethane polyepoxide, polythene pyrrolidone, polymethyl methacrylate, polyvinyl alcohol, cellulose acetate, polycarbonate; the conductive macromolecular is polyaniline, polythiofuran or polypyrrole. The invention utilizes electrostatic spinning and original position chemical oxidized polymeric method, which possesses reversible conversion property of ultra-hydrophobic and ultra-hydrophilic pH value respond in the intelligent microfluid switch, controllable separating technology, electromagnetic screen and sensor.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Electret nano fiber filter material for HVAC (heating, ventilating, and air conditioning) and preparation method thereof

PendingCN109569092AEnhanced surface electrostatic potentialEnhanced electret lifetimeMonocomponent polyurethanes artificial filamentMonocomponent polyethers artificial filamentFiberUltrasound attenuation

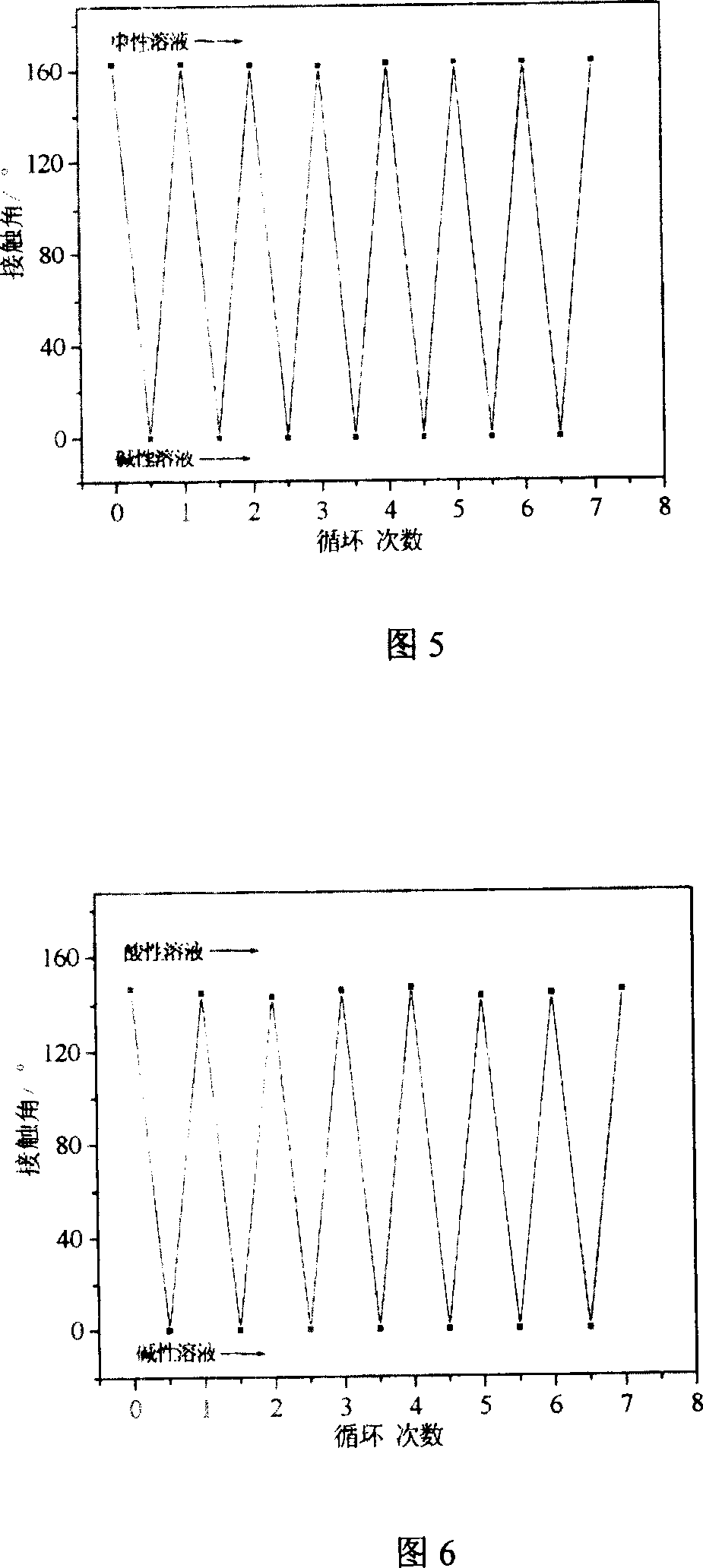

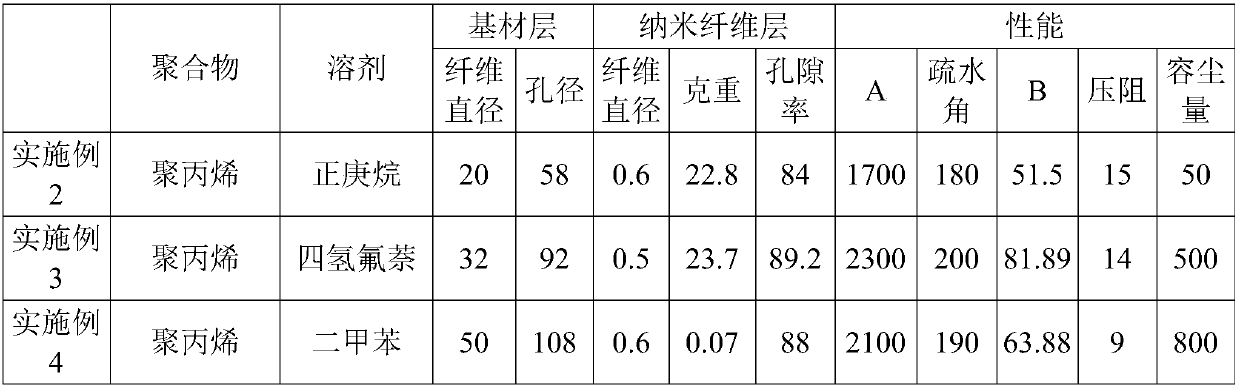

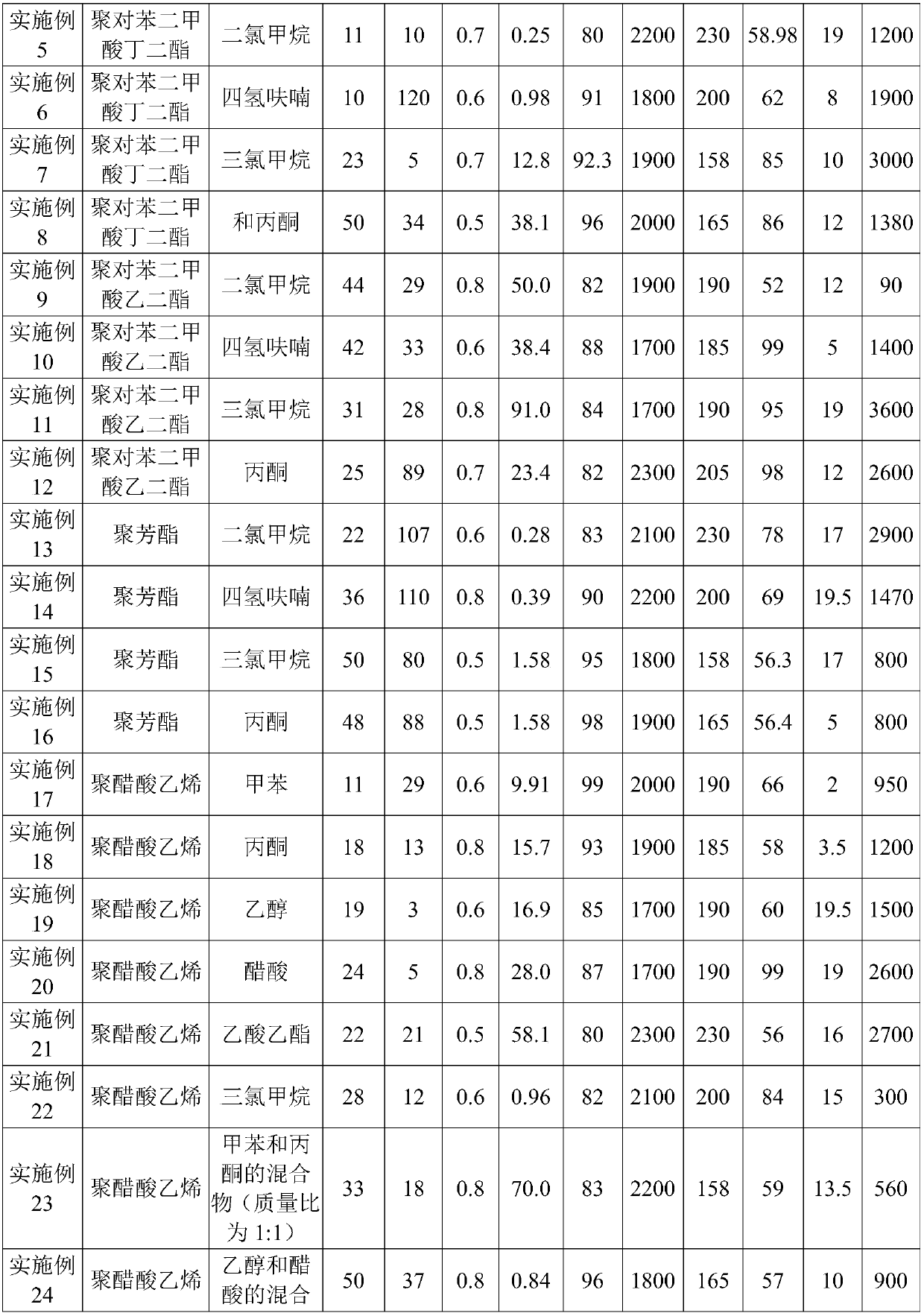

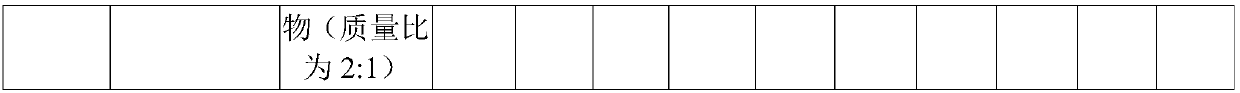

The invention relates to an electret nano fiber filter material for HVAC (heating, ventilating, and air conditioning) and a preparation method thereof. The preparation method includes: subjecting a liquid mixture with a polymer to electrostatic spinning to obtain an electret nano fiber filter material for HVAC; subjecting the liquid mixture with the polymer at a spinneret outlet during electrostatic spinning to quick cooling curing, wherein quick cooling curing refers to cooling the liquid mixture with the polymer 3-5 cm away from a spinneret outlet to -40 DEG C to -20 DEG C within 0.1-0.9 ms.The finished product has surface electrostatic potential of 1700-2300 V, drain angle of >150 DEG, and piezo-resistance of less than 20 Pa; charge attenuation never occurs even after one month of storage. The preparation method is simple and low in cost and has low equipment requirement; a produced HVAC system with the electret nano fiber filter material has good electret effect, excellent filtering performance and excellent application prospect.

Owner:嘉兴富瑞邦新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com