Polyoxymethylene fibers in concrete

A technology of concrete and polyoxymethylene copolymer, applied in the direction of fiber chemical characteristics, one-component polyether artificial filament, one-component polyurethane artificial filament, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] POM fibers are formed from the following monomer reactants:

[0093] 1) Use BF 3 Initiators and formal chain transfer agents make three Alkanes are polymerized with 1,3-dioxolane - called POM.

[0094] 2) Use BF 3 Initiators and glycol chain transfer agents make three Alkanes are polymerized with 1,3-dioxolane - called POM-OH.

[0095] 3) Use BF 3 Initiators and glycol chain transfer agents make three Polymerization of alkanes with glycerol formals - known as pendant OH-POM.

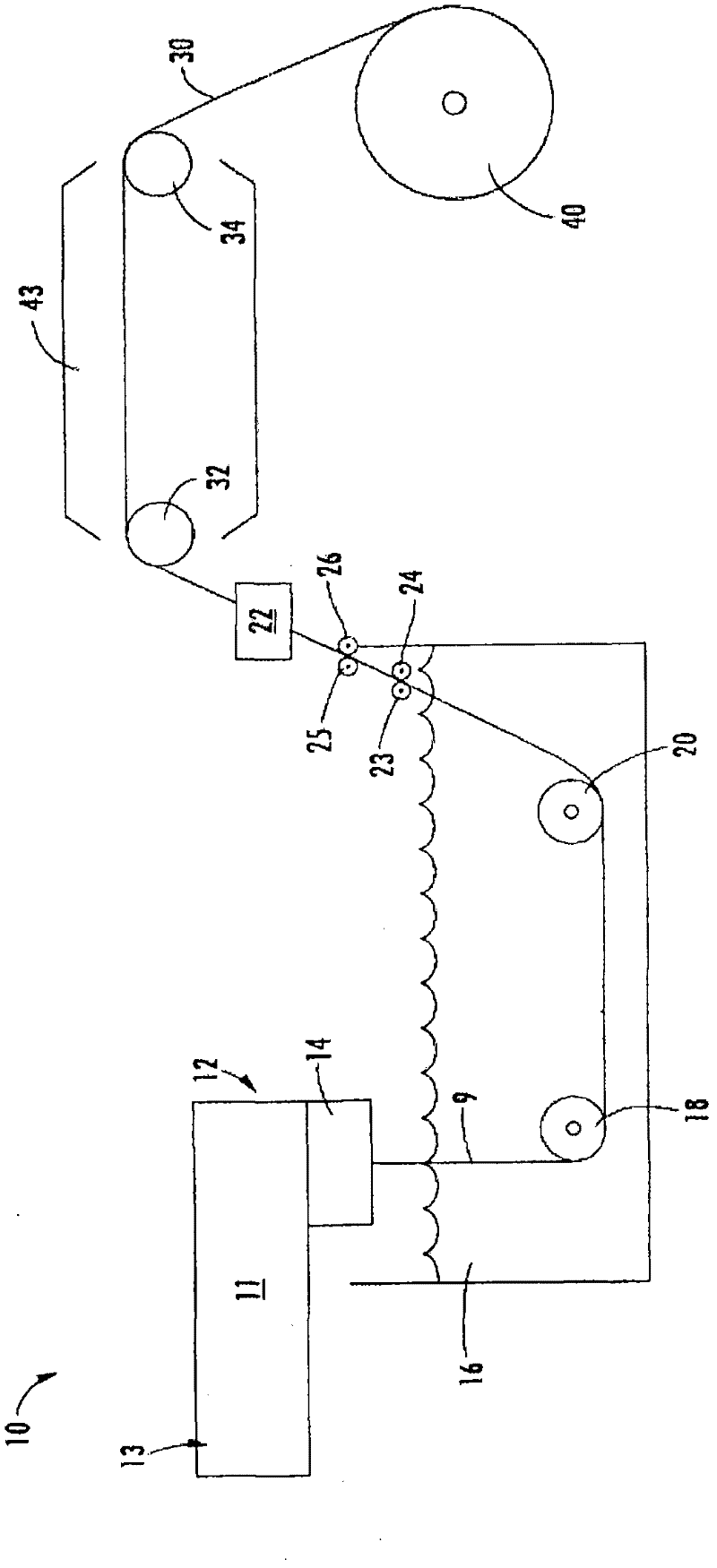

[0096] POM fibers are formed using a twin screw reactor with mixing, grinding and conveying sections. The L / D of the reactor was 15:1. The feed rate was 10000 to 20000 lb / hr. Dioxolane concentration is 3.4 (to 6.2)% (w / w), methylal concentration is about 600ppm, BF 3 is 10 to 20 ppm. The screw speed was about 30 rpm. The temperature in the reactor was 90°C-95°C. The base polymer was quenched with triethylamine in a methanol / water solvent as it exited the reactor, followed by soluti...

Embodiment 2

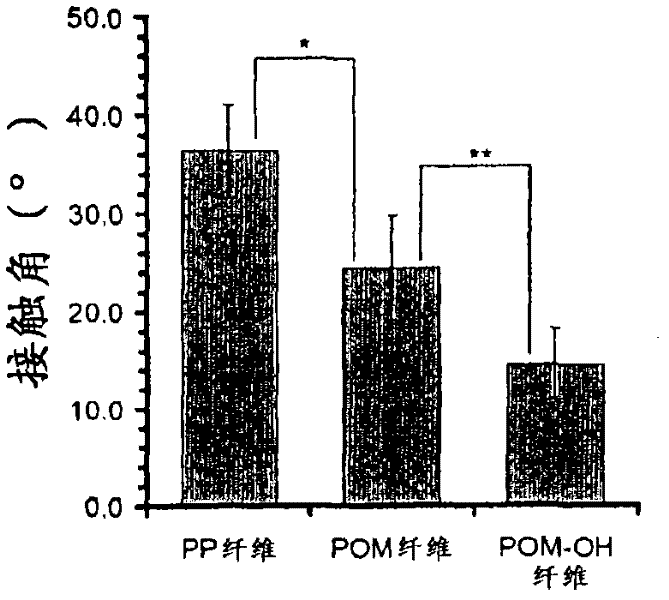

[0102] POM, POM-OH and PP fibers formed as described in Example 1 were mixed with wet concrete and used in experimental sidewalk casts. The portion using only polypropylene fibers showed a significant concentration of fibers on the surface. This result was used to test the prediction that the combination of increased hydrophilicity and higher density of POM fibers would generally lead to greater miscibility of POM fibers relative to polypropylene fibers in the wet concrete matrix.

Embodiment 3

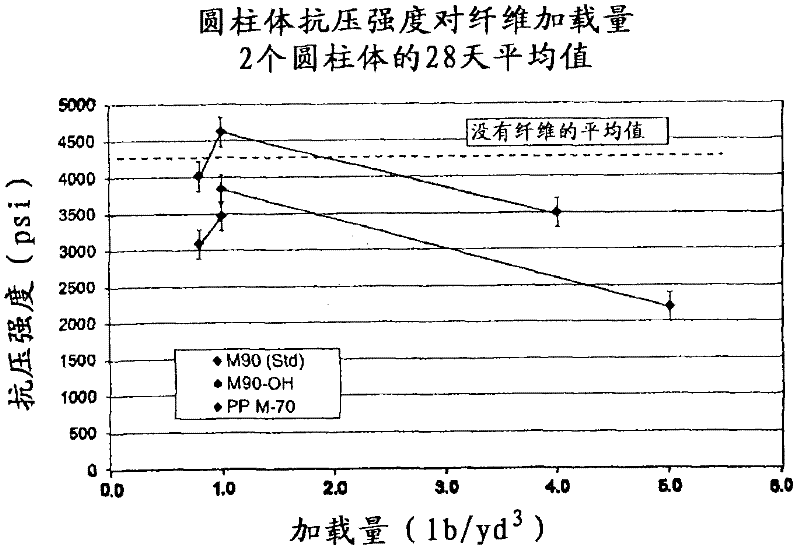

[0104] During the walkway casting of Example 2, concrete cylinders were also cast using different concretes incorporating different fibers as additives. The compressive strength values of the concrete cylinders were measured. The result is as figure 2 shown. It can be seen that the observed trends are consistent with the improved secondary reinforcement of concrete provided by POM fibers, which exhibit improved toughness and adhesion compared to polypropylene fibers.

[0105] figure 2 It is shown that there is little difference between polypropylene and POM fibers, indicating that the increase in the polarity of the POM fibers has little effect on the increase in the strength of the concrete, although it brings about an increase in miscibility. This is probably due to the fact that in the standard POM -C 2 Low content of OH end groups. On the other hand, the compressive strength of the samples comprising POM-OH was significantly higher than that observed for the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com