Electrostatic spinning nano-fibre yarn system and preparation of nano-fiber yarn

A nanofiber and electrospinning technology, applied in spinning machines, fiber treatment, fiber chemical characteristics, etc., can solve the problems that the fibers cannot be well oriented and cannot obtain stable and continuous nanofiber yarns, and achieve the goal of optimizing the process method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

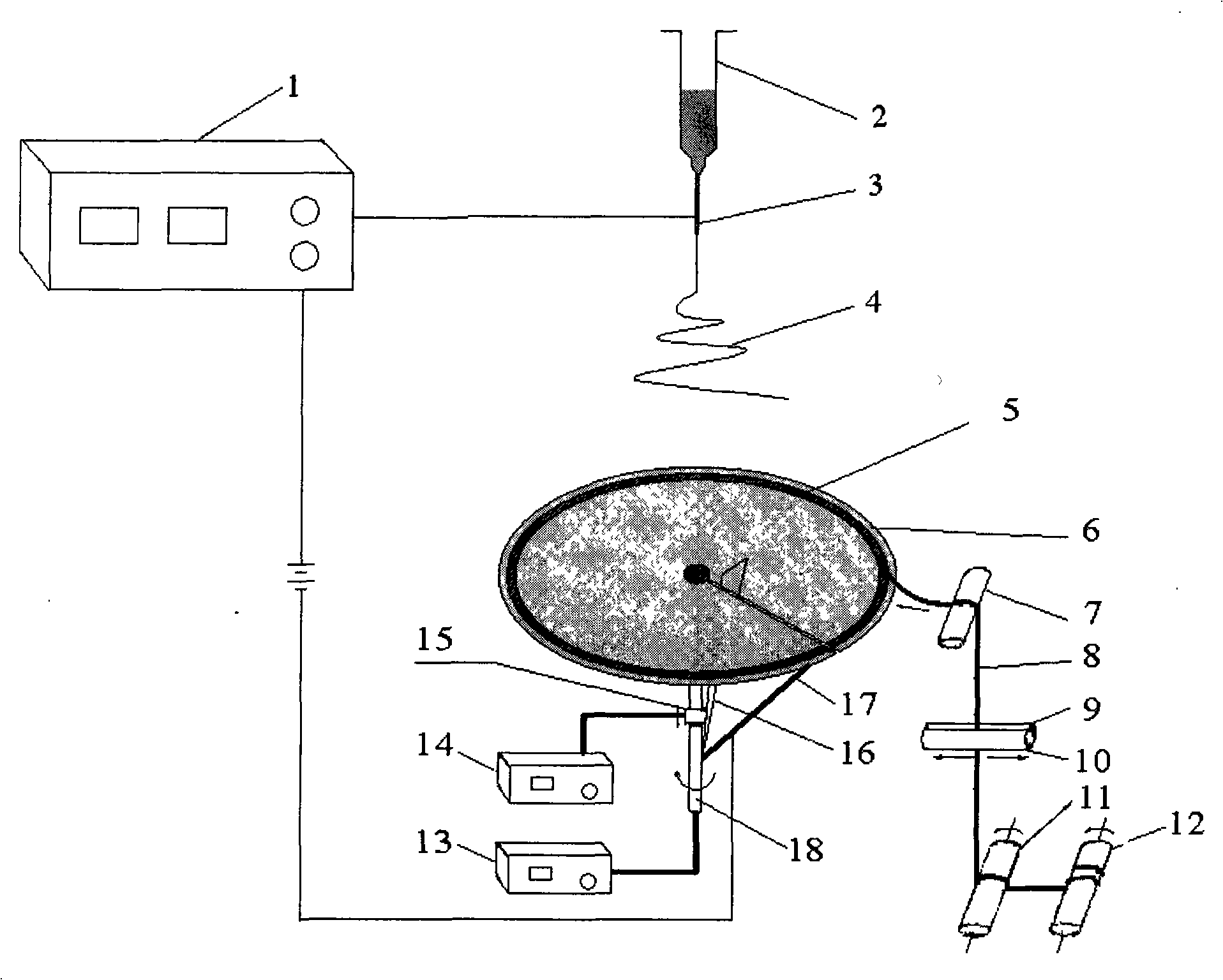

[0053] Polyacrylonitrile (PAN) (Mw=70,000 g / mol) was dissolved in solvent N,N-dimethylformamide (DMF) to prepare a spinning solution with a concentration of 13 wt%. Inject the spinning solution into the injector 2 of the electrospinning nanofiber yarn system, and in an environment with room temperature and a relative humidity of 40%, turn on the DC high voltage generator 1 of the above system, control the voltage at 20kV, and the electrospinning jet flows in a spiral Shaped motion tracks are deposited on the surface of the copper film 5 in an orderly manner. The receiving distance between the injector 2 and the copper film 5 is 70 mm. After the fibers are deposited for a period of time, the obtained ring-shaped nanofiber bundles are cut off by a cutter 16, and the copper film is rotated at the same time. The film 5, take-up roll 11 and lead wire recovery roll 12 pass through a wire that is pre-placed on the copper film 5, bypasses the godet roll 7, passes through the twisting d...

Embodiment 2

[0055] Dissolve polyvinyl alcohol (PVA) 1788 powder in distilled water at 70° C. to prepare a spinning solution with a concentration of 16 wt%. Inject the spinning solution into the syringe 2 of the electrospinning nanofiber yarn system. In an environment with room temperature and a relative humidity of 55%, turn on the DC high-voltage generator 1 of the above system, and control the voltage to 30kV. The electrospinning jet flows in a spiral Shaped motion tracks are deposited on the surface of the copper film 5 in an orderly manner. The receiving distance between the injector 2 and the copper film 5 is 110 mm. After the fibers are deposited for a period of time, the obtained ring-shaped nanofiber bundles are cut off with a cutter 16, and the copper film is rotated at the same time. The film 5, take-up roll 11 and lead wire recovery roll 12 pass through a wire that is pre-placed on the copper film 5, bypasses the godet roll 7, passes through the twisting device, the take-up roll...

Embodiment 3

[0057] Polyethylene oxide (PEO) (Mw=3×105 g / mol) was dissolved in 70° C. distilled water to prepare a spinning solution with a concentration of 10 wt%. Inject the spinning solution into the syringe 2 of the electrospinning nanofiber yarn system, and in an environment with room temperature and a relative humidity of 70%, turn on the DC high-voltage generator 1 of the above system, control the voltage at 40kV, and the electrospinning jet flows in a spiral Shaped motion tracks are deposited on the surface of copper film 5 in an orderly manner. The receiving distance between injector 2 and copper film 5 is 150 mm. After the fibers are deposited for a period of time, the obtained ring-shaped nanofiber bundles are cut off by cutter 16, and the copper film is rotated at the same time. The film 5, take-up roll 11 and lead wire recovery roll 12 pass through a wire that is pre-placed on the copper film 5, bypasses the godet roll 7, passes through the twisting device, the take-up roll 11,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com