Ternary rubber composite with wide temperature range and high damping property and preparation method thereof

A rubber composition and high damping technology, which is applied in the wide temperature range high damping ternary rubber composition and its preparation field, can solve the problems of large amount of resin addition, difficult processing, poor mechanical properties, etc., and achieve improved processing and damping Performance, simple processing and molding methods, good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

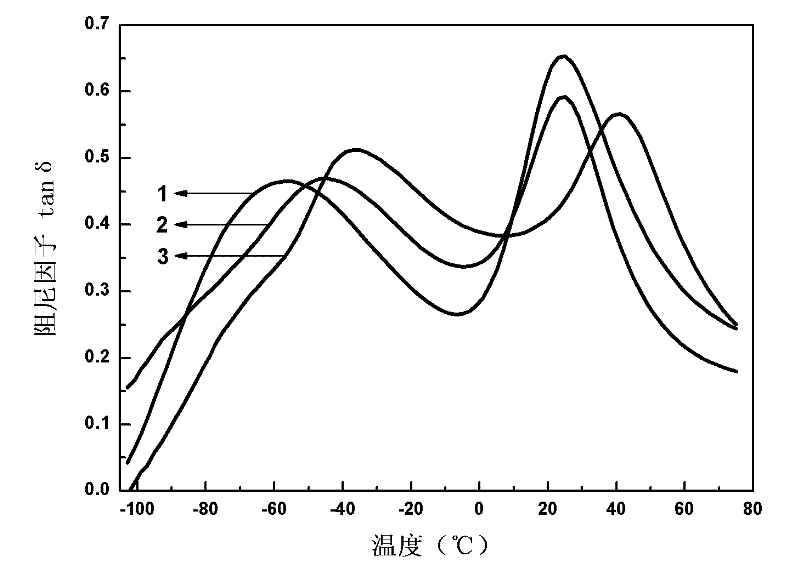

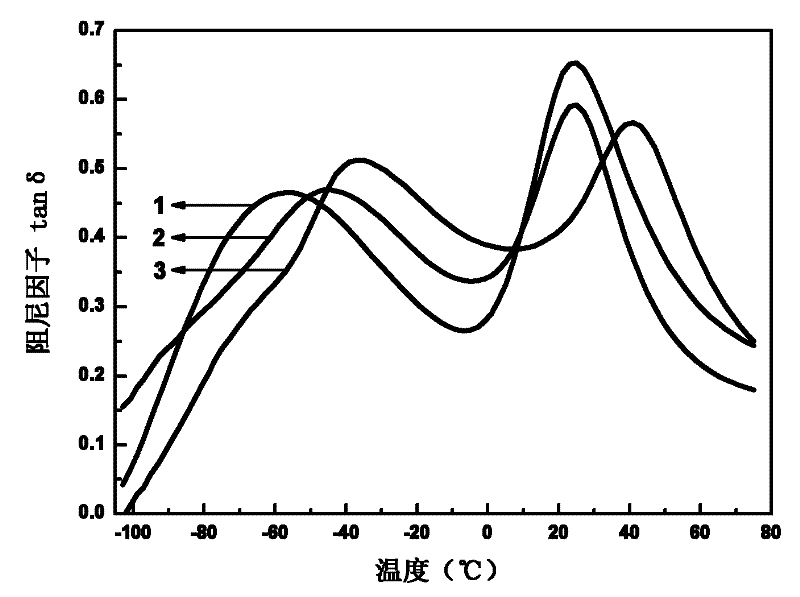

Image

Examples

Embodiment 1

[0033] At 40°C, 100 g of butyl rubber, 10 g of nitrile rubber, and 10 g of neoprene rubber were put into an open mill, masticated for 20 minutes, and then blended; then 5 g of stearic acid, 7 g of zinc oxide, and 2 g of sulfur were added. , 4 g of dibenzothiazole disulfide (DM), and 5 g of carbon black with a model of N330, prepared into a mixed rubber, the mixed rubber was parked for 10 hours, and then vulcanized on a flat vulcanizer at a temperature of 100 ° C and a pressure of 18 MPa In 60 minutes, the desired ternary rubber composition can be prepared.

[0034] The properties of the prepared butyl rubber / nitrile rubber / chloroprene rubber composition are shown in Table 1.

Embodiment 2

[0036] At 80°C, 100 g of butyl rubber, 10 g of nitrile rubber, and 40 g of neoprene rubber were put into an open mill, masticated for 10 minutes, and then blended; then 2 g of stearic acid, 8 g of zinc oxide, and 3 g of sulfur were added. , 4 g of dibenzothiazole disulfide (DM), and 15 g of carbon blacks of N330 and N550 models, respectively, to prepare a mixed rubber. The mixed rubber was parked for 10 hours, and then at a temperature of 150 ° C and a pressure of 18 MPa, on a flat plate Vulcanize on a vulcanizer for 30 minutes.

[0037] The properties of the prepared butyl rubber / nitrile rubber / chloroprene rubber composition are shown in Table 1.

Embodiment 3

[0039] At 100°C, put 100 g of butyl rubber, 10 g of nitrile rubber, and 60 g of neoprene rubber into an open mill, masticate for 1 minute, and then blend; then add 2 g of stearic acid, 10 g of zinc oxide, and 5 g of sulfur , 0.5 g of phenolic resin (1055 resin), 5 g of dibenzothiazole disulfide (DM), and 40 g of carbon black with a model of N330 to prepare a mixed rubber. Under the pressure of 18MPa, vulcanize on a flat vulcanizer for 1 minute.

[0040] The properties of the prepared butyl rubber / nitrile rubber / chloroprene rubber composition are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com