Patents

Literature

1032 results about "Butyronitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

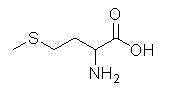

Butyronitrile or butanenitrile or propyl cyanide, is a nitrile with the formula C₃H₇CN. This colorless liquid is miscible with most polar organic solvents.

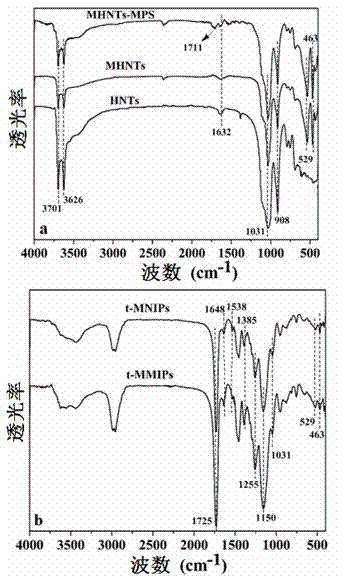

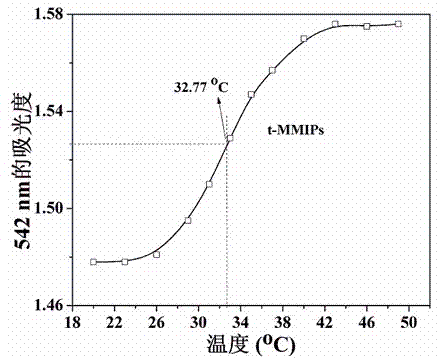

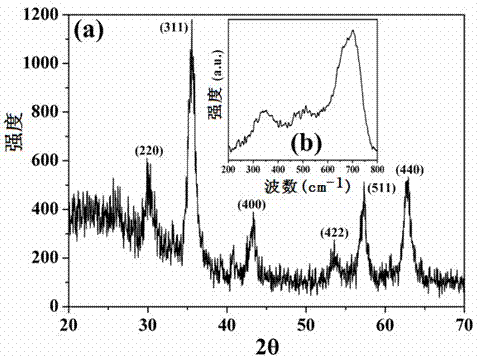

Magnetic composite material surface imprinting thermosensitive adsorbent, and preparation method and application thereof

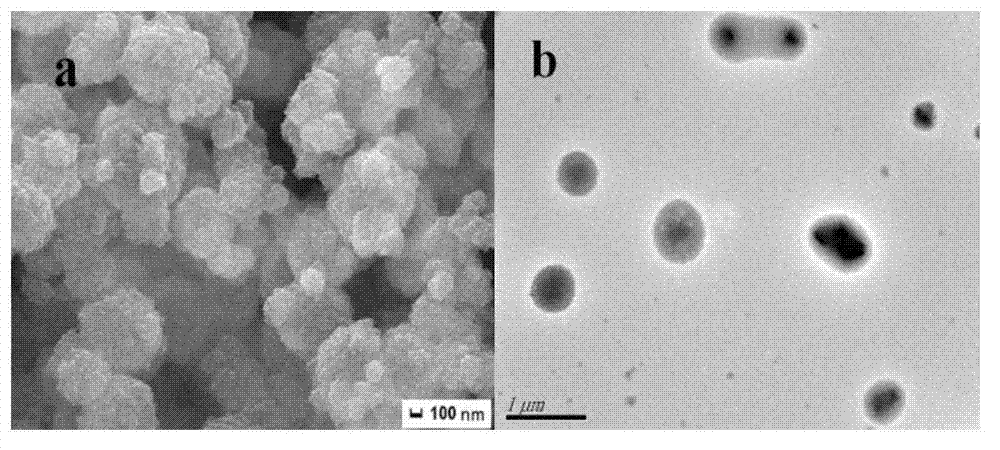

InactiveCN102527349AHigh mechanical strengthImprove adsorption capacityOther chemical processesSolid sorbent liquid separationMethacrylateMagnetic stability

The invention relates to the technical field of preparation of environment functional materials, in particular to a magnetic composite material surface imprinting thermosensitive adsorbent, and a preparation method and the application thereof. The method comprises the following steps that: firstly, a ferroferric oxide / nerchinskite nanotube magnetic composite material is prepared by a solvent thermal synthesis method; secondly, the magnetic composite material is modified on ethenyl by using 3-(methacrylo) propyltrimethoxyl silane; and finally, the nerchinskite nanotube magnetic composite material is prepared by using the ethenyl-modified magnetic composite material as a substrate material, 2, 4, 5-trichlorophenol as a template molecule, methacrylate as a functional monomer, N-isopropylacrylamide as a thermosensitive functional monomer, ethylene glycol dimethacrylate as a cross-linking agent, and 2,2'-azodiisobutyronitrile as an initiator. The prepared thermosensitive imprinting adsorbent is obvious in thermal stability and magnetic stability, sensitive in magnetic effect and thermosensitive effect, relatively high in adsorption capacity, obvious in reversible absorption / release function along with temperature and obvious in tertiary calcium phosphate (TCP) molecule recognition performance.

Owner:JIANGSU UNIV

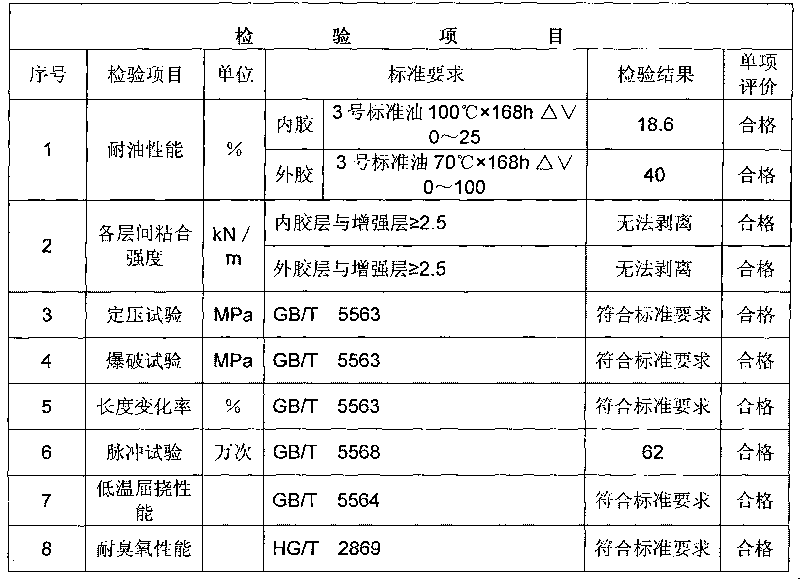

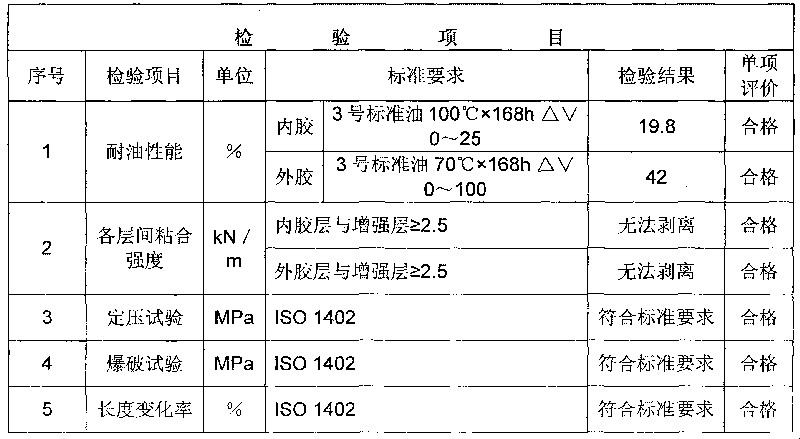

Lignin reinforcing filled butadiene-acrylonitrile rubber hose

The invention discloses a lignin reinforcing filled butadiene-acrylonitrile rubber hose which mainly comprises a lignin reinforcing filled butadiene-acrylonitrile rubber blended elastomer, sulfur, zinc oxide, stearic acid, a accelerant, an anti-aging agent and the like. The lignin reinforcing filled butadiene-acrylonitrile rubber hose has the advantages of high mechanical strength, favorable oil resistance, high adhesion strength with framework materials, such as steel wires and the like; and the finished product has the characteristics of light weight, high pulse resisting capacity and long service life, and can reduce the material cost and the environmental pollution.

Owner:张仲伦

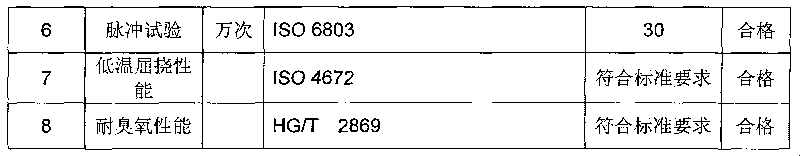

Environment-friendly rubber plastic heat-insulating material and its preparation method

The invention relates to an environment-friendly rubber plastic heat-insulating material and its preparation method, and the rubber plastic heat-insulating material is prepared from butyronitrile rubber (NBR), antimonous oxide (Sb2O3), zinc oxide, sulfur, dioctyl-phthalate (DOP), epoxidized soybean oil (ADDA), mercaptobenzothiazole (M), anti-aging agent (4020), antioxidant (AST-500), protective wax (HGB-3), ethylene-vinyl acetate copolymer (EVA), dicumyl peroxide (DCP crosslinking agent), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, foaming agent-dinitrosopentamethylene tetraamine (H), diphenylguanidine (D), pigment, anti-aging agent (RD), anti scorching agent (PVI), and the like. By limited use of raw materials containing chlorine ion components and cooperation of a new vulcanization foaming technology, environment-friendly and heat-insulating performances of the product can be stabilized, the prepared environment-friendly rubber plastic heat-insulating material has no corrosion performance in use, the material life is prolonged, metal pipes in refrigeration equipment can be effectively protected, and maximized performance of the product can be performed.

Owner:周良文

Production of soft thin butyronitrile gloves

A process for preparing the thin and flexible butanenitrile gloves includes such steps as preparing butanenitrile latex from butanenitrile emulsoid, sulfur, zinc oxide and promoter, dipping a mould in coagulant, baking, dipping it in said butannitrile emulsoid, dripdrying, rolling edge, baking, chlorinating, and demoulding.

Owner:镇江华扬乳胶制品有限公司

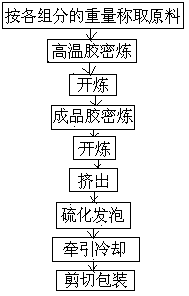

Butyronitrile-PVC (polyvinyl chloride) compound elastomer insulation material for wires and cables and preparation method of butyronitrile-PVC compound elastomer insulation material

InactiveCN103205034ALower surface energyGood dispersionRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxElastomer

The invention discloses a butyronitrile-PVC (polyvinyl chloride) compound elastomer insulation material for wires and cables and a preparation method of the butyronitrile-PVC compound elastomer insulation material. The butyronitrile-PVC compound elastomer insulation material comprises, by weight, 100-120 parts of butyronitrile rubber, 30-40 parts of PVC resin, 2-3 parts of accelerant TMTD, 1-2 parts of accelerant DM, 1-2 parts of antiager, 2-3 parts of antiager MB, 6-8 parts of paraffin, 8-12 parts of zinc oxides, 1-1.5 parts of stearic acid, 10-15 parts of DOP (dioctyl-phthalate), 2-4 parts of gas-mixed carbon black, 30-40 parts of precipitated white carbon black and 50-60 parts of modified nano calcium carbonate. The insulation material produced has the advantages of good mechanical and physical performance, insulation performance, good high and low temperature resistance, oil resistance, solvent resistance, wear resistance, ozone resistance, ageing resistance and the like, is long-lasting, durable, environment-friendly, pollution-free and capable of meeting the requirements of modern wires and cables completely.

Owner:ANHUI HUAJIN CABLE GROUP

Cable sheath material for coal mine

ActiveCN101538380AImprove stabilityEasy to useInsulated cablesInsulated conductorsPolymer sciencePolyvinyl chloride

The invention discloses a cable sheath material for a coal mine, which is characterized by comprising the following raw materials for preparing effective constituents according to the parts by weight: 70-100 of butyronitrile-polyvinyl chloride compound, 10-30 of neoprene, 30-60 of white carbon black, 2-8 of magnesium oxide, 20-60 of aluminum hydroxide, 30-60 of chlorcosane, 2-6 of accelerant CZ, 3-8 of zinc oxide, 1-5 of stearic acid, 3-8 of age inhibitor, 4-15 of diantimony trioxide, 2-7 of titanium pigment and 3-9 of vulcanizing agent. The cable sheath material for the coal mine has better performance of stink resistance, cold resistance, flame resistance, oil resistance, ageing resistance, and the like and has good elasticity, high tensile strength, good tear resistance, good extrusion performance and low cost.

Owner:阳谷新太平洋电缆有限公司

Friction material of disc brake pad, disc brake pad and preparation technology of disc brake pad

ActiveCN102965078AOvercoming performance deficienciesImprove performanceOther chemical processesFriction liningFiberPotassium

The invention discloses a friction material of a disc brake pad. The friction material comprises the following raw materials in parts by weight: 13-18% of cashew nut shell oil-modified phenolic resin, 9-16% of butyronitrile rubber powder, 3-7% of steel wool fiber, 6-11% of calcium sulfate whisker, 2-5% of potassium feldspar powder, 3-6% of graphite, 2-6% of brown fused alumina, 3-5% of antimony sulfide, 11-16% of baryta powder, 5-9% of chromite powder, 6-11% of heavy calcium carbonate, 2-4% of zircon sand and 3-6% of brass powder. Visibly, in the preparation raw materials, the cashew nut shell oil-modified phenolic resin is adopted for replacing ordinary phenolic resin as an organic carrier of a brake pad material, so that the shortcomings of poor resistance to thermal ablation, high abrasiveness, low anti-impact strength and the like of the ordinary phenolic resin are eliminated, the performance defects of the friction material of the disc brake pad caused by the ordinary phenolic resin can be avoided, and the overall performance of the friction material of the disc brake pad can be further improved.

Owner:SHANDONG GOLD PHOENIX

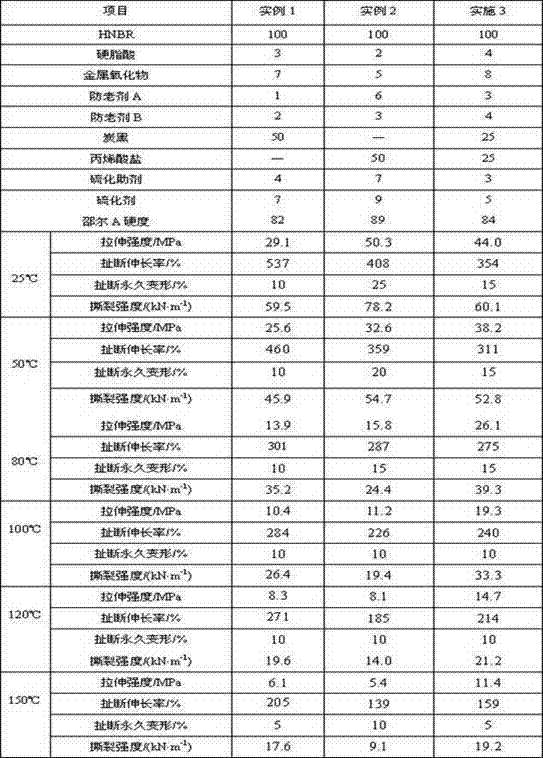

Preparation method of reinforced hydrogenated butyronitrile composite material

InactiveCN103589027ARaise room temperatureImprove mechanical propertiesDrilling compositionNitrile rubberVulcanization

The invention discloses a preparation method of a reinforced hydrogenated butyronitrile composite material. The preparation method comprises the steps: firstly, placing hydrogenated butyronitrile rubber in a mixing mill for plasticating, after a roller is coated with the hydrogenated butyronitrile rubber, successively adding stearic acid, a metal oxide and an anti-aging agent into the mixing mill to mix for 5 min, then adding a reinforcing agent, mixing evenly, followed by adding a vulcanizing agent and a vulcanizing auxiliary agent, mixing evenly, and then carrying out mill run and batching-off to obtain mixed rubber; under conditions of the temperature of 170 DEG C, the vulcanization time of 20 min and the vulcanization pressure of 15 MPa, vulcanizing the mixed rubber after mixing to form the hydrogenated butyronitrile vulcanized rubber by a flat-plate vulcanizing machine. With adopting of acrylate, carbon black or a mixture thereof as the reinforcing agent, the rubber composite material with excellent performance is prepared; and a rubber canister processed form the material has good sealing effect under the temperature of 170 DEG C and the pressure difference of 30-60 MPa, and the prepared rubber has high mechanical properties and aging resistance at the room temperature or the high temperature, and can work in an oil medium under the temperature of 170 DEG C and the pressure of 30-60 MPa for a long time.

Owner:QINGDAO UNIV OF SCI & TECH

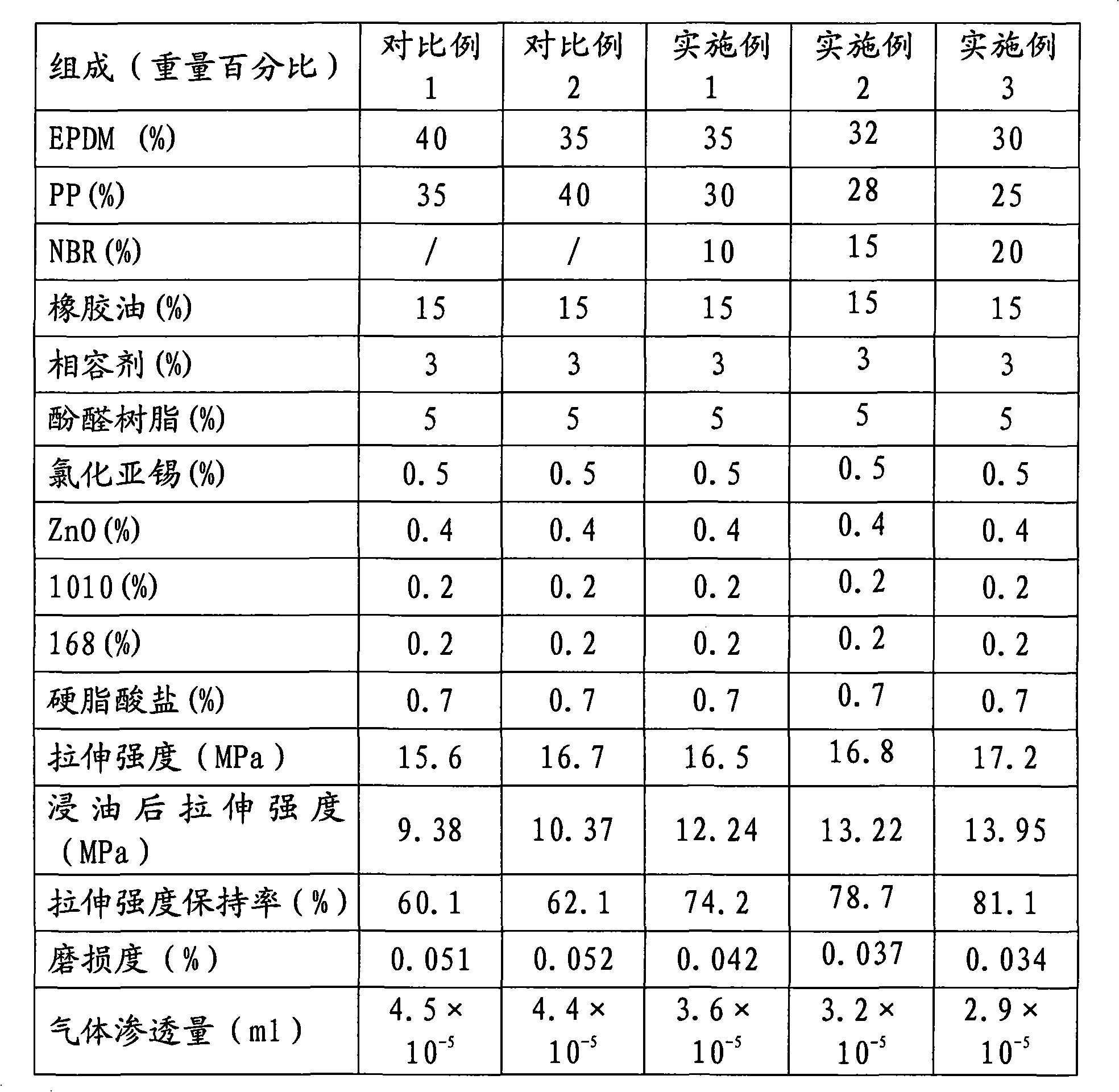

High-performance EPDM (Ethylene-Propylene-Diene Monomer)/PP(Polypropylene)/NBR(Nitrile -Butadiene Rubber) ternary

The invention discloses a high-performance EPDM (Ethylene-Propylene-Diene Monomer) / PP(Polypropylene) / NBR(Nitrile-Butadiene Rubber) ternary blending dynamic vulcanized thermoplastic elastomer and a preparation method thereof. The high-performance EPDM / PP / NBR ternary blending dynamic vulcanized thermoplastic elastomer comprises the following components in percentage by weight: 20-50 percent of ethylene-propylene-diene monomer, 20-50 percent of polypropylene, 10-20 percent of nitrile-butadiene rubber, 2-30 percent of rubber oil, 2-5 percent of compatilizer, 3-6 percent of phenolic resin, 0.4-0.6percent of stannous chloride, 0.2-0.6 percent of weather-resistant agent, 0.2-0.6 percent of heat stabilizer and 0.5-1 percent of lubricating agent. The prepared high-performance EPDM / PP / NBR ternary blending dynamic vulcanized thermoplastic elastomer not only has the characteristics of oxidation resistance, ozone resistance, high mechanical property, easy forming and the like of the traditional TPV (Thermoplastic Vulcanizate), but also has favorable oil resistance, wear resistance and airtightness.

Owner:徐东

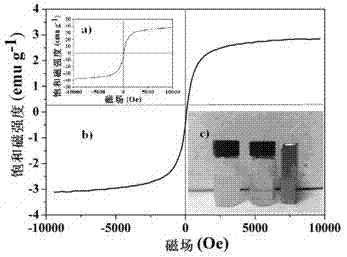

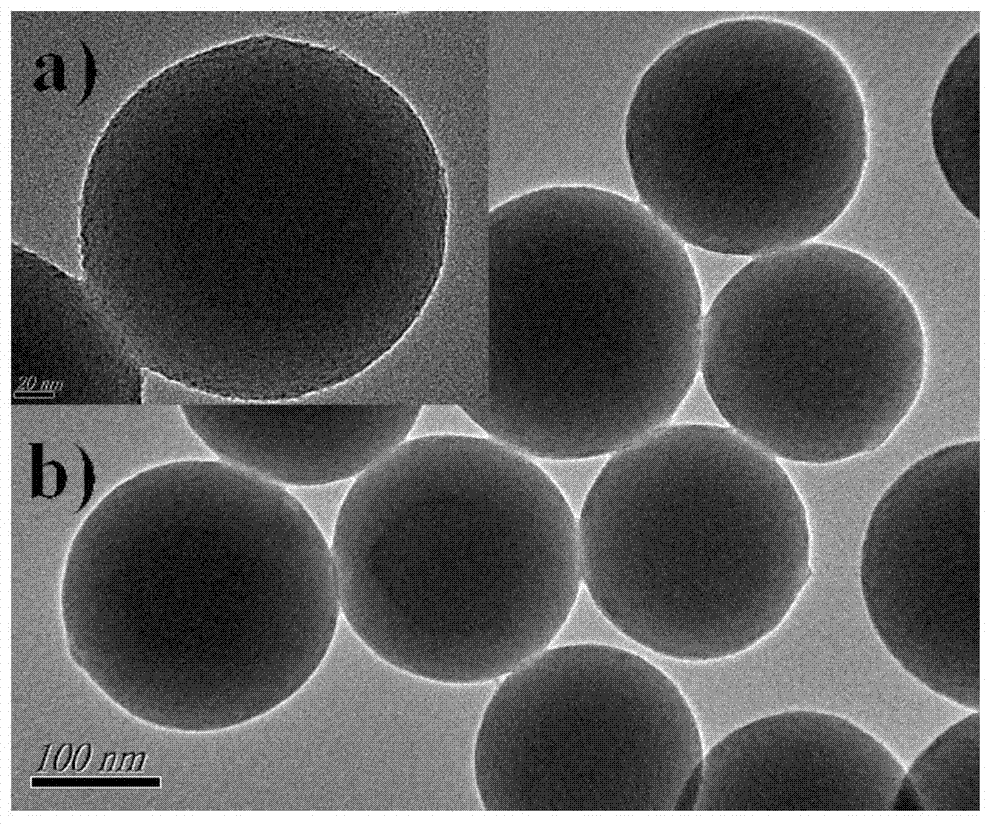

Temperature-sensitive magnetic sulfadimidine molecular imprinted adsorbent as well as preparation method and application thereof

InactiveCN102784626AHigh mechanical strengthImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceFunctional monomer

The invention discloses a temperature-sensitive magnetic sulfadimidine molecular imprinted adsorbent as well as a preparation method and application thereof, belonging to the technical field of preparation of environment functional materials. A gamma-Fe2O3 / SiO2 magnetic composite material is prepared by using a sol-gel method and is subjected to vinyl modification by using 3-(methylacryloyloxy) trimethoxypropylsilane; with a vinyl-modified magnetic composite material (MPS (Modified Polystyrene)-gamma-Fe2O3 / SiO2) as a substrate material, sulfadimidine as a template molecule, acrylamide as a functional monomer, N-isopropylacrylamide as a temperature-sensitive monomer, ethylene glycol-bis(methylacrylic acid) ester as a cross-linking agent and 2,2'-azobisisobutyronitrile as an initiator, a temperature-sensitive magnetic molecular imprinted polymer is prepared by using a free group polymerization process and is applied to selective recognition and separation of the sulfadimidine in an aqueous solution; and the obtained polymer has the advantages of remarkable heat and magnet stability, sensitive magnet and heat inducting effect, higher adsorption capacity, reversible adsorption / release function along with the temperature and remarkable recognition performance of a sulfadimidine molecule.

Owner:JIANGSU UNIV

Ceramic brake pad of high-performing automobile

InactiveCN101555920AExtended service lifeImprove the lubrication effectFriction liningBoron nitrideCopper

A ceramic brake pad of high-performing automobile comprises the following components according to weight percentages: 7%-11% of ceramic fibre, 7-9% of glued aluminium silicate fibre, 5-8% of polyacrylonitrile fibre, 2-3% of aramid fibre 7-9% of red copper fibre, 7-10% of acicular aedelforsite fibre, 7-12% of barite, 7-9% of chromite, 1-2% of butyronitrile rubber, 7-11% of graphite particle, 0.2-0.5% of zinc oxide, 5-8.5% of calcined petroleum coke, 1-3% of expansion graphite, 6-10% of boron containing phenolic resin, 3-5% of magnetite, 1-1.5% of heavy-burned magnesia, 0.3-0.5% of modified whiten bead of resin acceptor, 3-5% of boron nitride and 0.3-0.5% of alumina; the invention can form excellent friction layer and transmission film in using process, thereby having good lubricating effect without damaging the couple plate; therefore, the service life of the friction material is greatly prolonged.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

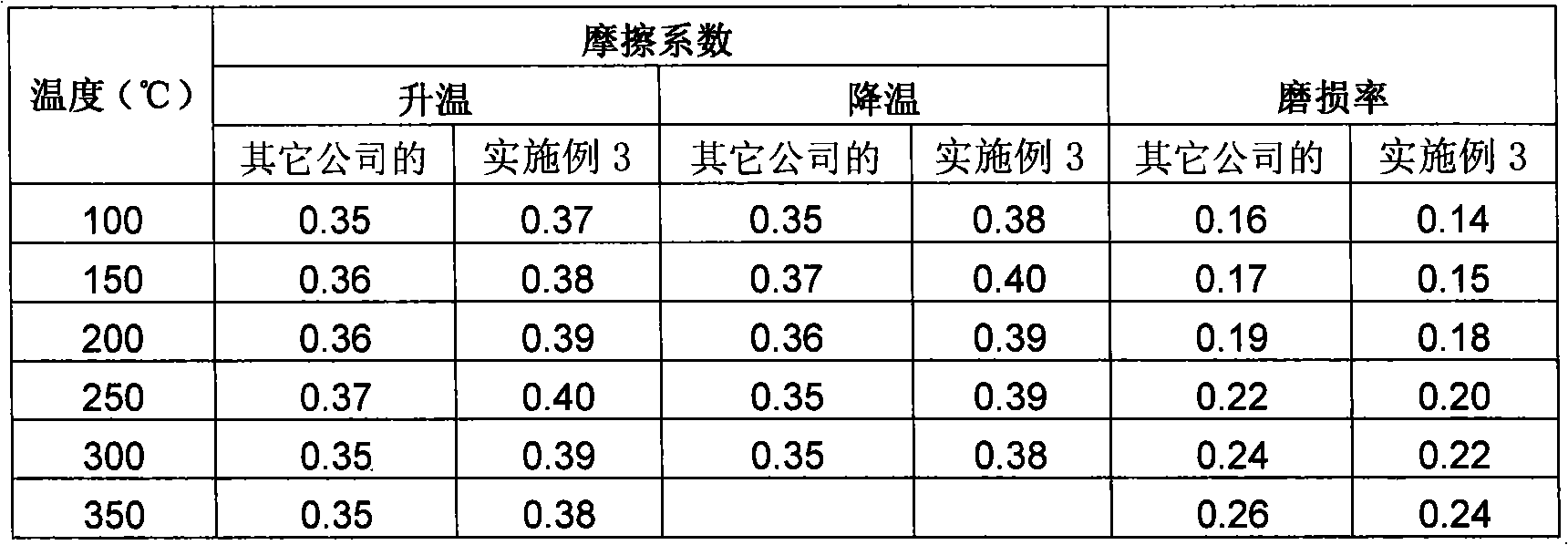

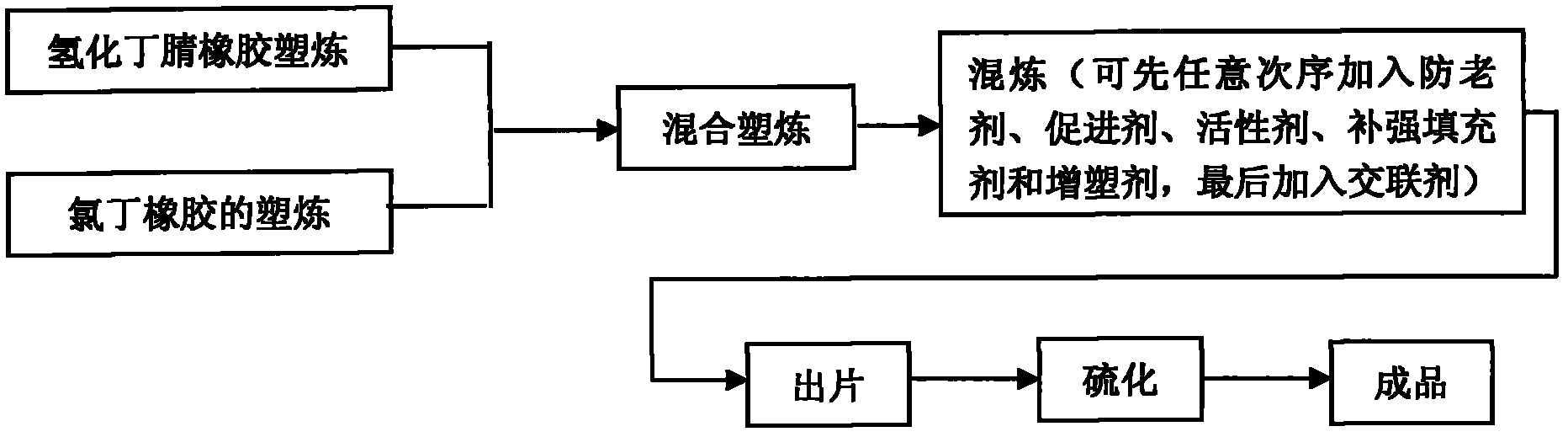

Method for preparing hydrogenated nitrile rubber and chloroprene rubber blended vulcanized rubber

InactiveCN102108143AImprove high temperature resistanceImprove high pressure resistancePolymer scienceNitrile rubber

The invention discloses a method for preparing a hydrogenated nitrile rubber and chloroprene rubber blended vulcanized rubber. The blended vulcanized rubber is prepared by blending and vulcanizing a hydrogenated nitrile rubber and a chloroprene rubber. The defect that the mechanical property of the hydrogenated nitrile rubber is relatively poor is obviously overcome after the chloroprene rubber and the hydrogenated nitrile rubber are blended; the material processability of the hydrogenated nitrile rubber is also obviously improved; the vulcanizing speed is obviously increased; the vulcanizing efficiency is improved; and the market price of the chloroprene rubber is much lower than that of the hydrogenated nitrile rubber, so that the cost of the product can be also greatly reduced after the chloroprene rubber is added into the hydrogenated nitrile rubber. The blended vulcanized rubber has the advantages of the hydrogenated nitrile rubber and the chloroprene rubber, makes up for the deficiencies of the hydrogenated nitrile rubber and the chloroprene rubber, can be widely applied at occasions having relatively high requirements on oil resistance, coldness resistance, heat resistance, fire retardance and the like, and also can be widely applied in fields, such as transmission belts, conveyer belts, sealing rings, rubber pipes, rubber belts and the like.

Owner:宁波裕江特种胶带有限公司

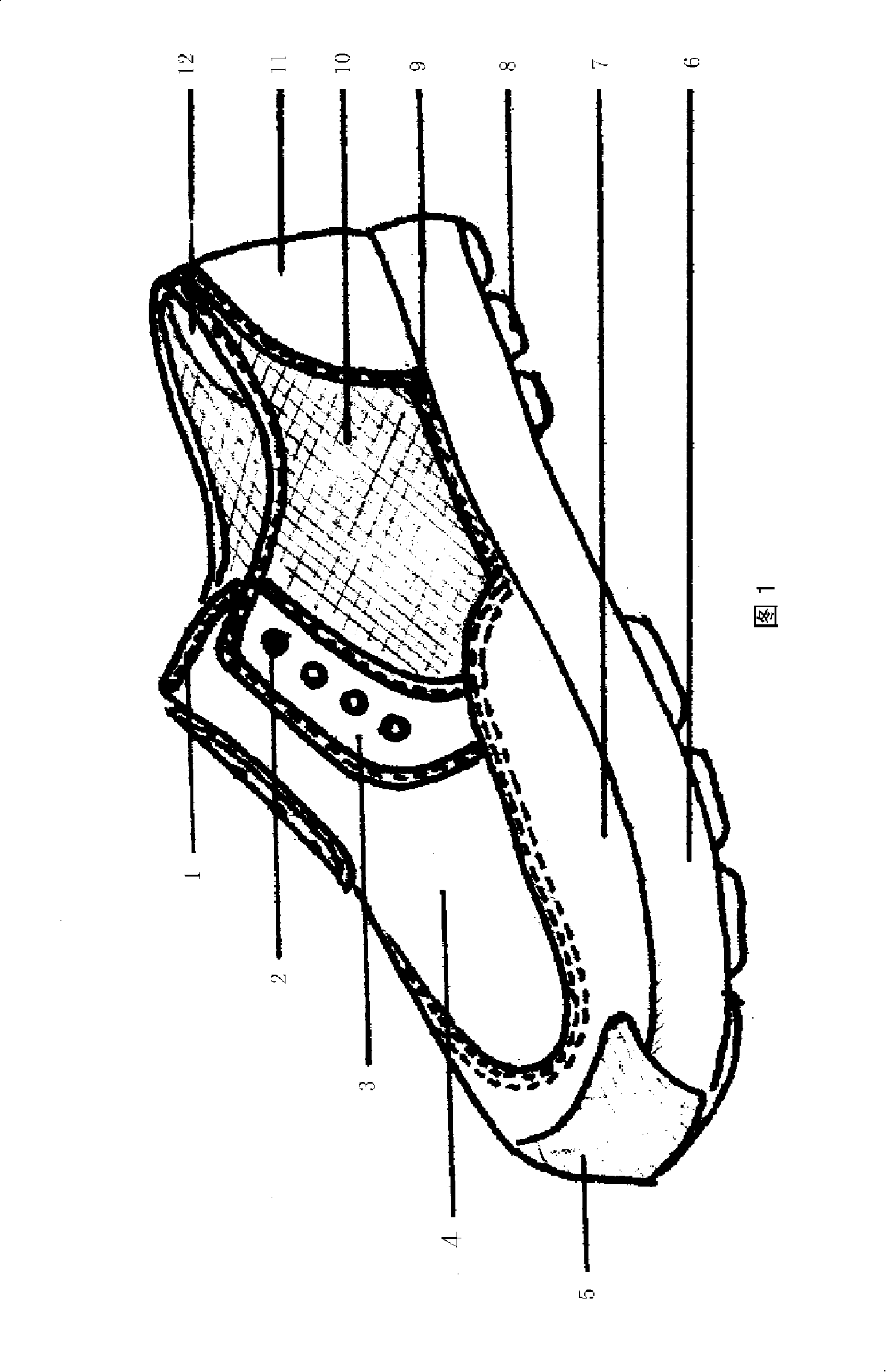

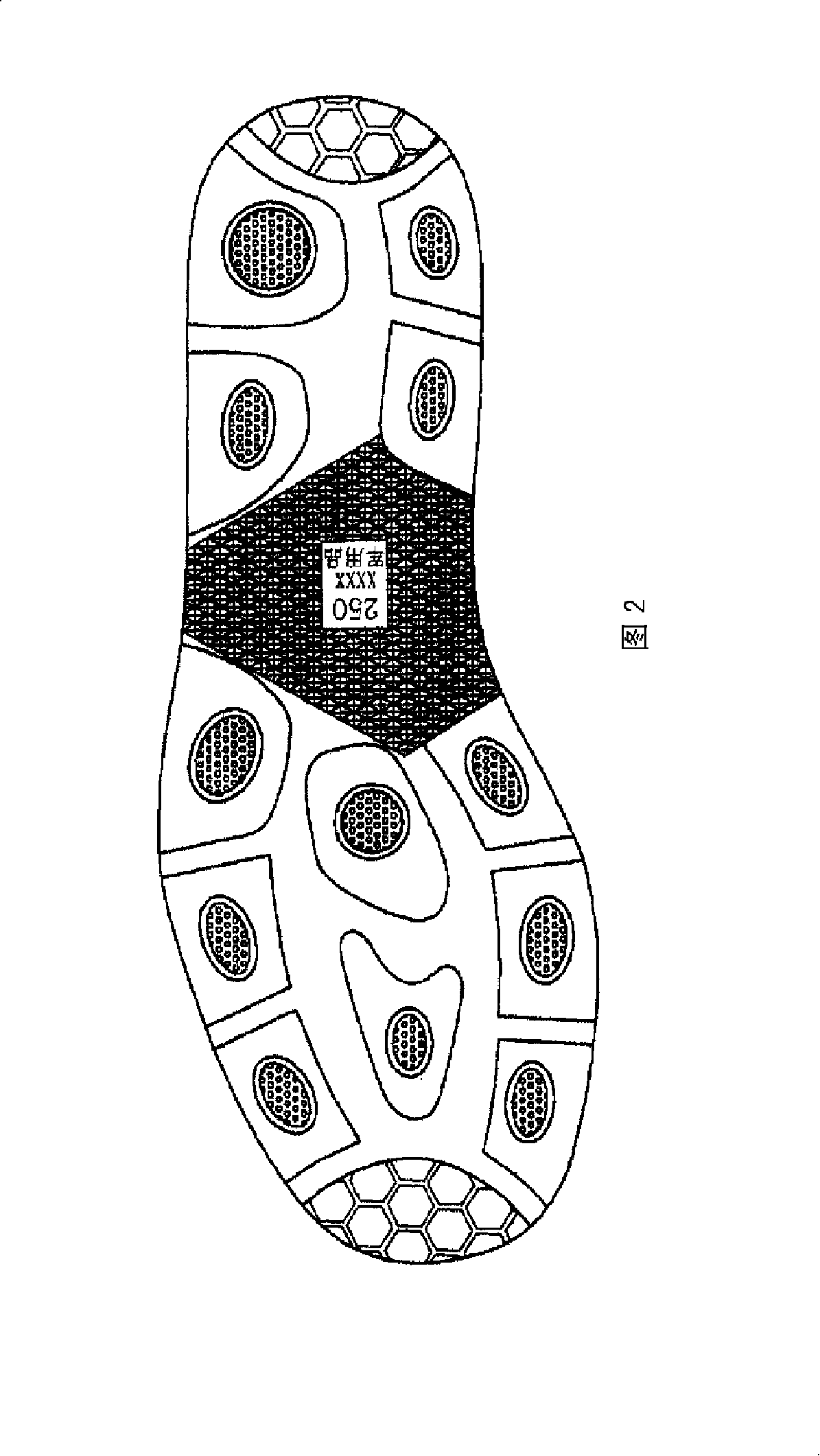

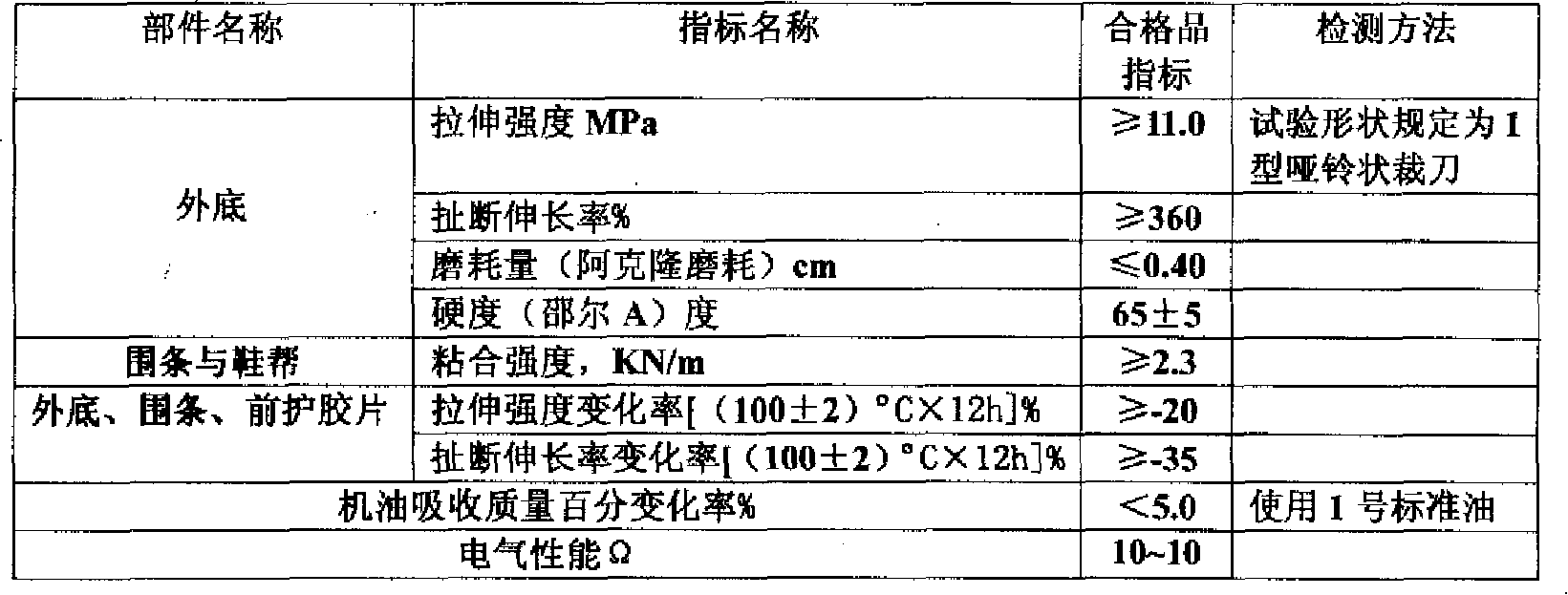

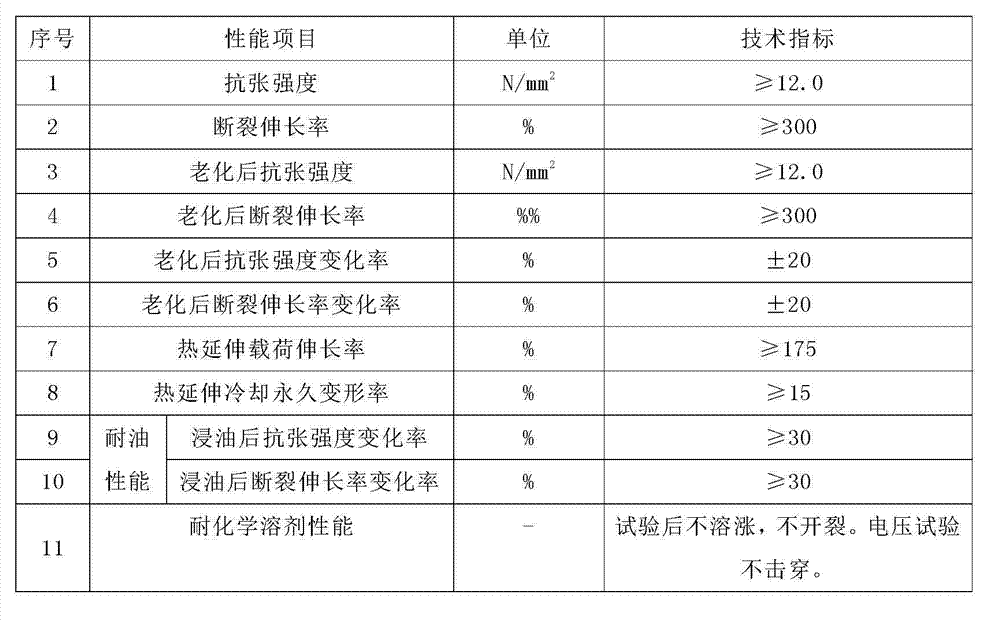

Special type protection work shoes with antistatic oil-resistant function

The invention relates to a shoes, especially a special protective footware with electrostatic resistant property and proof-oil property. The sole rubber is formed by material with electrostatic resistant property and proof-oil property and the insole sponge is formed by material with electrostatic resistant property, wherein the sole rubber comprises (mass ratio): 50-60 of natural glue, 10-20 of butyronitrile, 20-30 of cis-butadiene rubber, 2-3 of sulphur, 1.5-3 of accelerator, 1-2 of anti-aging agent, 2-3 of stearic acid, 4-6 of zinc oxide, 5-15 of conduct agent, 40-50 of strengthening agent, 25-35 of softener and the insole sponge comprises (mass ratio): 100 of natural glue, 2-3 of stearic acid, 1.5-3 of accelerator, 1-2 of anti-aging agent, 6-10 of stearic acid, 7-10 of zinc oxide, 3-6 of foaming agent, 50-60 of softener, 10-20 of conduct agent, 70-90 of clay. The insulation material is changed into electroconductive material by adding conducting material to conducting fibre in shoe insole lining, middle sole and outsole in foam sponge, so as to effectively release and export the static electricity on human by contacting the shoes with the ground.

Owner:JIHUA 3517 RUBBER PROD

Butyronitrile-PVC (polyvinyl chloride) compound elastomer flame-retardant sheath material for wires and cables and manufacturing method of butyronitrile-PVC compound elastomer flame-retardant sheath

InactiveCN103205033AImprove air tightnessDelay agingInsulated cablesInsulated conductorsElastomerPolyvinyl chloride

The invention discloses a butyronitrile-PVC (polyvinyl chloride) compound elastomer flame-retardant sheath material for wires and cables and a manufacturing method of the butyronitrile-PVC compound elastomer flame-retardant sheath material. The butyronitrile-PVC (polyvinyl chloride) compound elastomer flame-retardant sheath material is composed of, by weight, 100-120 parts of butyronitrile rubber, 40-45 parts of PVC resin, 1-2 parts of sulfur, 0.1-0.2 part of accelerant TMTD, 1-1.5 parts of accelerant CZ, 2-3 parts of antiager, 15-20 parts of antimonous oxide, 5-7 parts of zinc oxides, 1-2 parts of stearic acid, 12-14 parts of DOP (dioctyl-phthalate), 6-8 parts of DOS (dioctyl sebacate), 15-18 parts of TCP (tertiary calcium phosphate), 0.5-0.8 part of zinc stearate, 1-1.5 parts of barium stearate, 0.1-0.2 part of bisphenol A, 2-2.5 parts of butyl ester, 2.5-3 parts of carbon black master batch, 15-20 parts of modified diopside and 25-30 parts of semi-reinforced carbon black. The flame-retardant sheath material has the advantages of good mechanical and physical performance, good high and low temperature resistance, oil resistance, solvent resistance, wear resistance, ozone resistance, ageing resistance, flame retardancy, low smoke and the like and is long-lasting, durable, environment-friendly and pollution-free.

Owner:ANHUI HUAJIN CABLE GROUP

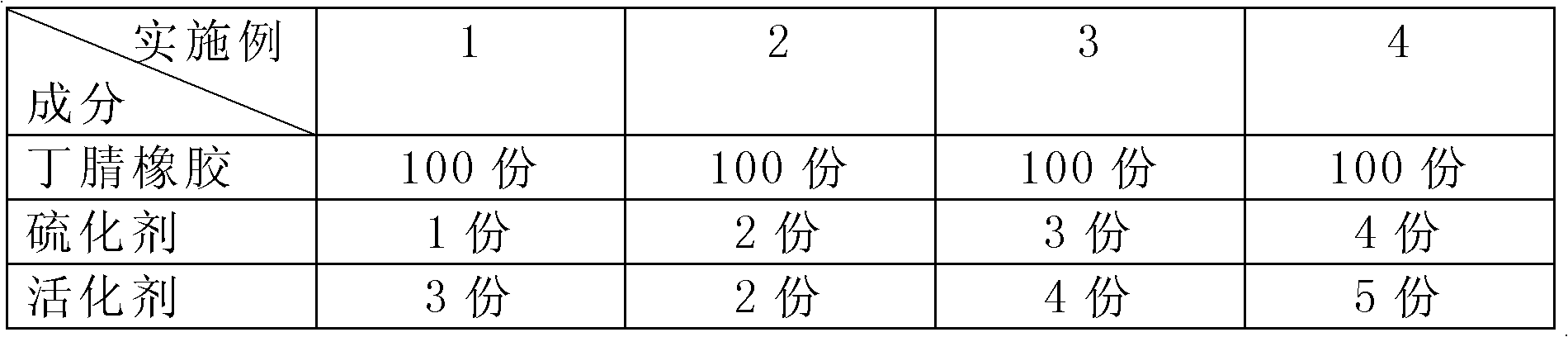

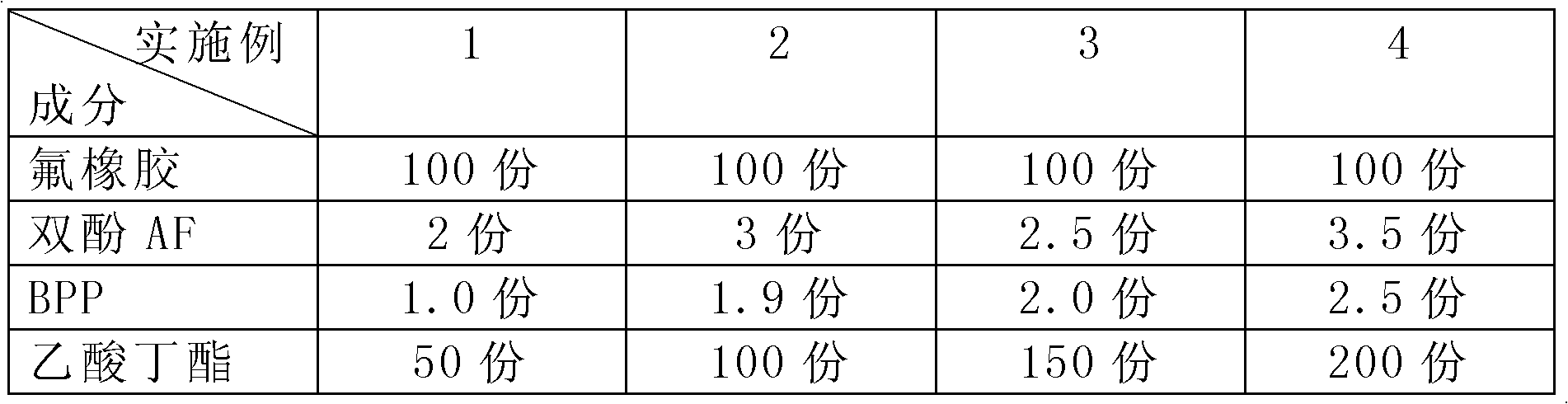

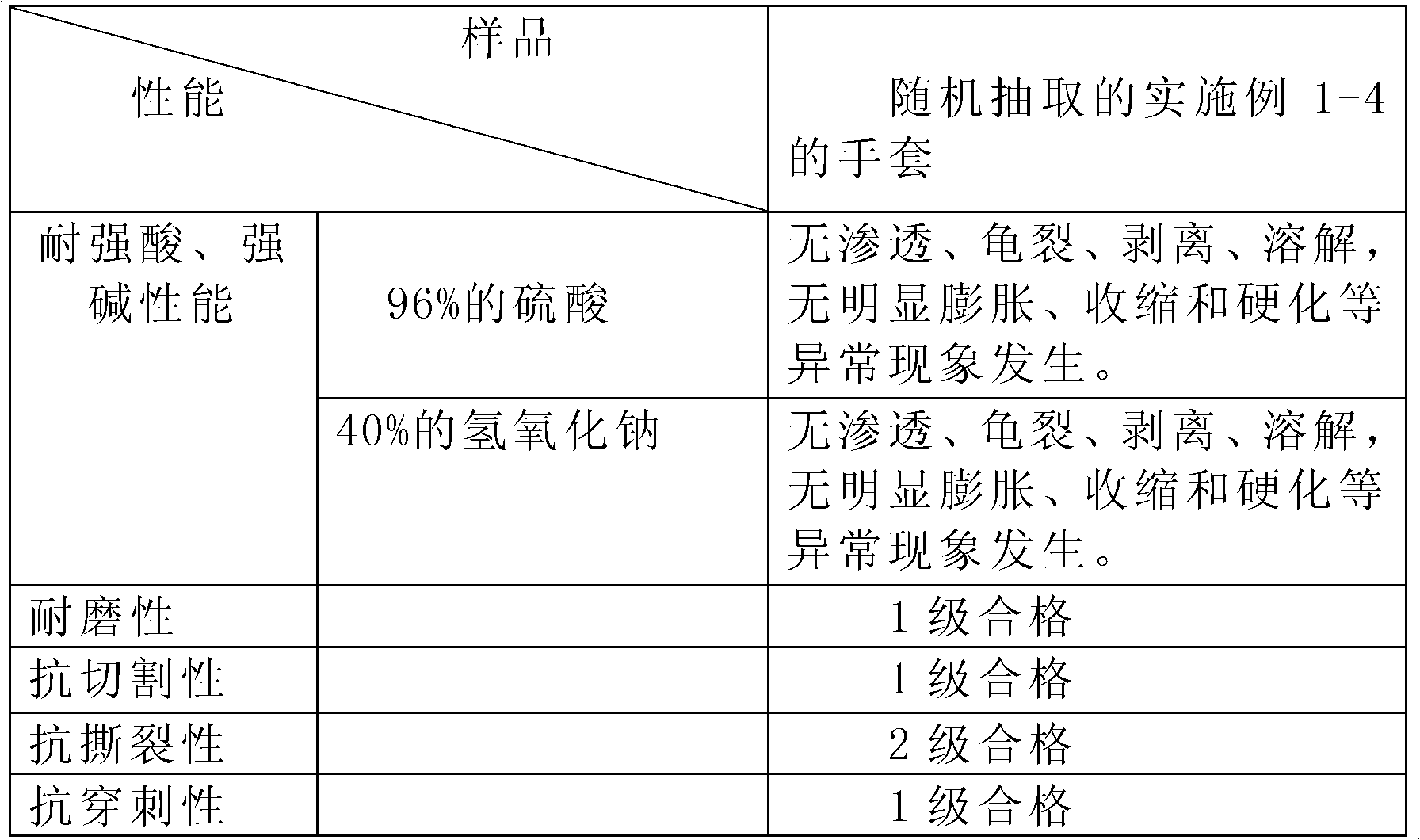

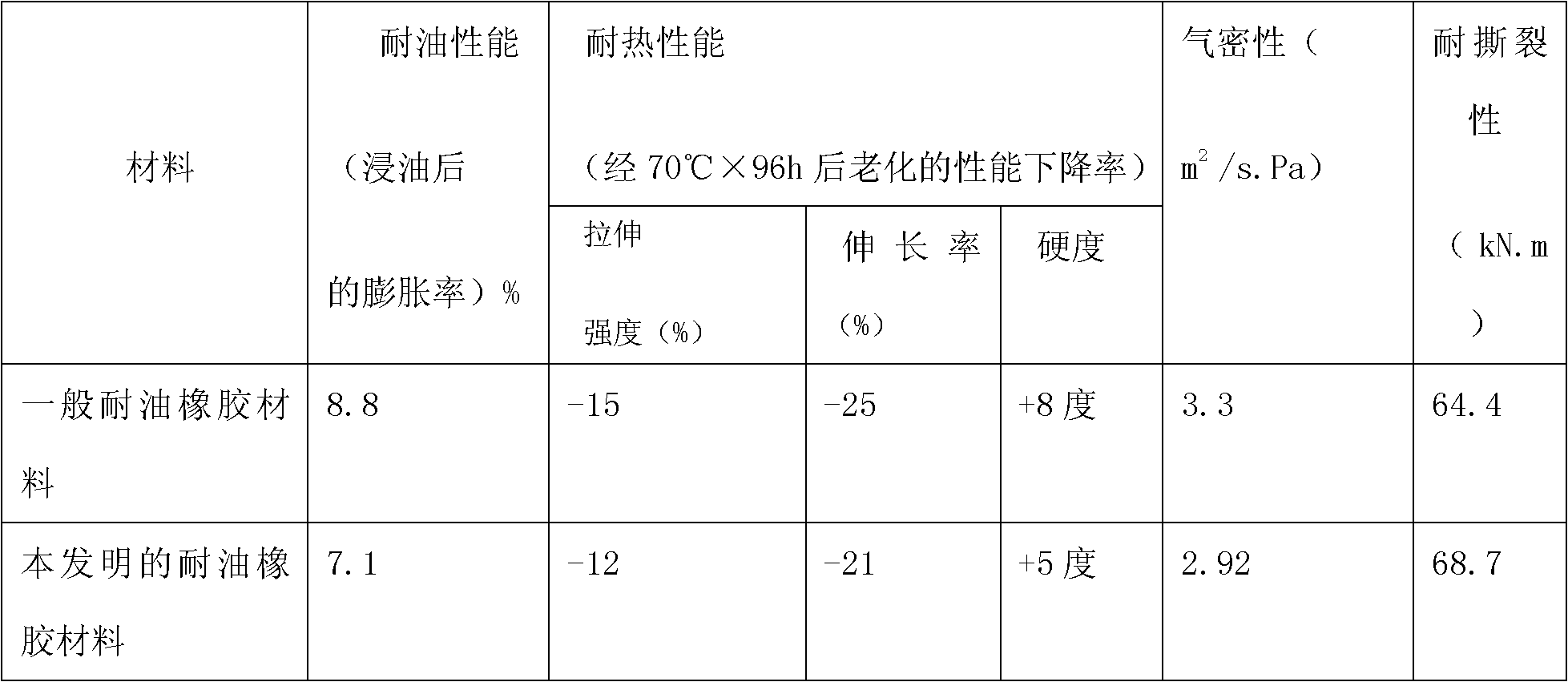

Fluorine/butadiene rubber composite glove and manufacturing method thereof

The invention relates to a fluorine / butadiene rubber composite glove and a manufacturing method thereof, belonging to the technical field of labour protection appliances. The glove comprises a fiber glove lining, the surface of the fiber glove lining is coated with a butyronitrile emulsion layer, the surface of the butyronitrile emulsion layer is coated with a fluorine rubber layer, and fluorine rubber particles are sprayed on the surface of the fluorine rubber layer, wherein the butyronitrile emulsion layer comprises the components such as butyronitrile rubber, a vulcanizer and an activator,and the fluorine rubber cement comprises the components of the fluorine rubber, the vulcanizer, a vulcanization accelerator and an ester solvent. The method for manufacturing the glove comprises three steps burdening, soaking cement and pouring cement. The glove and the manufacturing method in the invention have the following advantages: the performances of resistances to chemicals, strong acid, strong alkali and corrosion are achieved, and the cost is lower; and meanwhile, the method for manufacturing the glove adopts a flow line production manner during the production process, the product process is simple, the cost is lowers, and the glove is applicable to large-scale industrialized production.

Owner:台州达顿安防科技有限公司

Oil resistant sealing member rubber material and preparation method thereof

The invention discloses an oil resistant sealing member rubber material prepared from equal-proportioned and mixed components of an A rubber material and a B rubber material. The A rubber material comprises components of, by weight: 85 to 95 parts of butyronitrile rubber N41, 0.3 to 0.5 parts of sulfur, 4 to 6 parts of zinc oxide, 3 to 4 parts of stearic acid, 1 to 2 parts of an anti-aging agent RD, 1 to 2 parts of an anti-aging agent 4010NA, 3 to 4 parts of micro-crystalline wax, 22 to 25 parts of fast extruding furnace carbon black N660, 62 to 65 parts of high abrasion furnace black N330, 18 to 22 parts of DOP, 25 to 35 parts of calcium sulfate, 3 to 4 parts of a promoter DM, 1 to 2 parts of a promoter TMTD, and 1 to 2 parts of a promoter TETD. The B rubber material comprises components of, by weight: 82 to 87 parts of unitary homo-polymerized chlorohydrin rubber, 12 to 18 parts of copolymerized chlorohydrin rubber, 1 to 2 parts of zinc stearate, 1 to 3 parts of an anti-aging agent RD, 0.4 to 0.6 parts of Gum Easy T-78, 1 to 2 parts of clariant wax, 45 to 55 parts of fast extruding furnace carbon black, 10 to 14 parts of diatomite, 5 to 8 parts of DOP, 4 to 6 parts of dilead tetraoxide 0.4 to 0.6 parts of sulfur, and 1 to 2 parts of a promoter Na-22. Oil resistant sealing members (oil cylinder sealing members) produced from the rubber material provided by the invention has good oil resistance, heat resistance, air-tightness, flame retardance, tearing resistance, and low cost.

Owner:芜湖禾田汽车工业有限公司

Preparation method of high-content 2-hydroxy-4-(methylthio) butyl calcium

The invention relates to a preparation method of high-content 2-hydroxy-4-(methylthio) butyl calcium. The content of 2-hydroxy-4-(methylthio) butyl calcium prepared by the traditional synthesis method is lower. The preparation method provided by the invention comprises the following steps of: adding 2-hydroxy-4-methionine nitrile with content higher than 99.0% used as a raw material in concentrated HCl (hydrochloric acid) for carrying out hydrolysis reaction; after the reaction is finished, regulating pH with alkali till pH is between 7.8-8.0, cooling, crystallizing and filtering to obtain a 2-hydroxy-4-(methylthio) butyric amide crude product; recrystallizing with water to obtain high-content 2-hydroxy-4-(methylthio) butyric amide; and dissolving the high-content 2-hydroxy-4-(methylthio) butyric amide in water, adding excess Ca(OH)2 and directly hydrolyzing at 80-100 DEG C to generate 2-hydroxy-4-(methylthio) butyl calcium. The yield of the preparation method is very high, and the content of the prepared 2-hydroxy-4-(methylthio) butyl calcium is higher than 99.0%.

Owner:ZHEJIANG NHU CO LTD +1

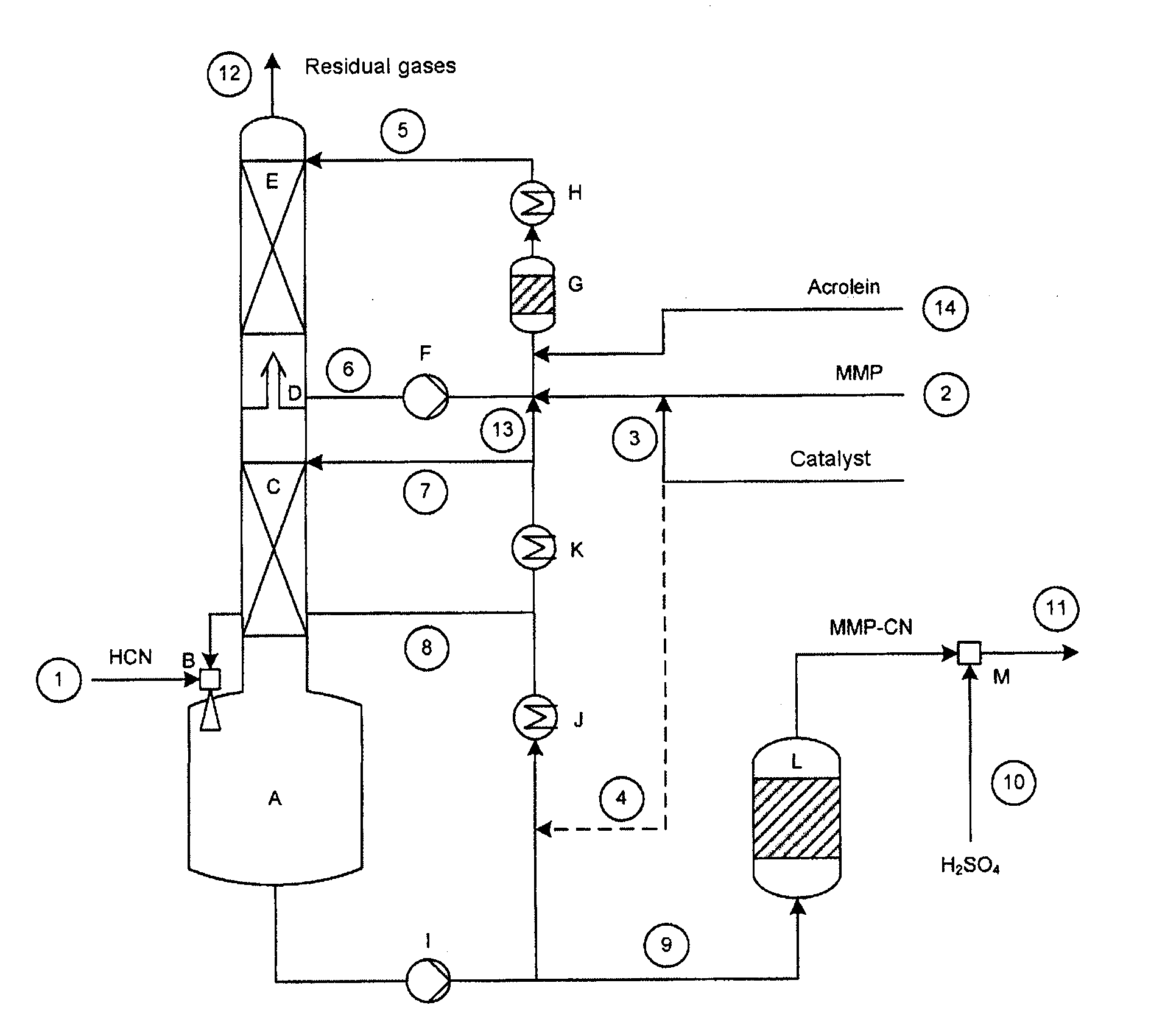

Method for the production of 2-hydroxy-4-(methylthio)butyronitrile from 3-(methylthio)propanal and hydrogen cyanide

ActiveUS20120215022A1Increase response rateLow byproduct formationOrganic compound preparationOrganic chemistry methodsCyanidePropynal

A method for the production of 2-hydroxy-4-(methylthio)butyronitrile having good storage stability in a multi-zone reactor, is provided. 3-methylmercaptopropionaldehyde is reacted with hydrogen cyanide in the presence of a base as catalyst in a main reaction zone of the multizone reactor to form a reaction mixture comprising the 2-hydroxy-4-(methylthio)butyronitrile, unreacted 3-methylmercaptopropionaldehyde, the catalyst and residual amounts of gaseous hydrogen cyanide. The residual gaseous hydrogen cyanide is removed from the main reaction zone to an absorption and post-reaction zone of the reactor which comprises a mixture of 3-methylmercaptopropionaldehyde and the catalyst; and the gaseous hydrogen cyanide is further reacted with the 3-methylmercaptopropionaldehyde in the absorption and post reaction zone. A molar ratio of hydrogen cyanide to 3-(methylthio)propanal in the main reaction zone is from 0.98 to 1.03.

Owner:EVONIK OPERATIONS GMBH

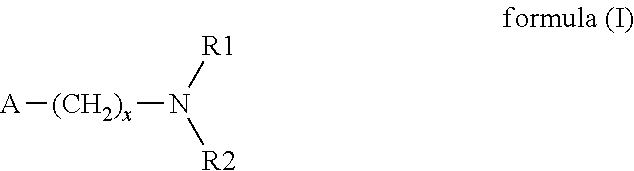

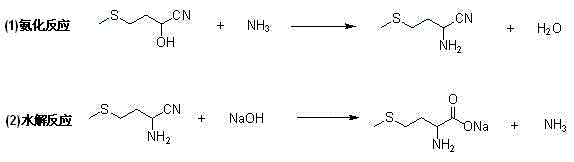

Environment-friendly clean production method of D,L-methionine

InactiveCN104130169AReduce processing costsNo three wastes pollutionOrganic compound preparationSulfide preparationAlkaline hydrolysisHydrolysis

The invention discloses an environment-friendly clean production method of D,L-methionine. The method comprises the following steps: (1) D,L-methionine salt water is adopted as a raw material, and is subjected to a bipolar membrane electrodialysis treatment in a bipolar membrane electrodialysis system, wherein the pH value in a salt chamber is controlled at 5.5-6.0, such that a D,L-methionine solution is obtained, and an alkali solution is obtained in an alkali chamber; and (2) D,L-methionine separated from the D,L-methionine solution obtained in the step (1). According to the invention, acid for neutralization is not needed, such that a by-product sulfate or hydrochloride is completely eliminated. The method causes no three-waste (waste gas, waste water, and solid waste) pollution, and helps reducing salt-containing waste water treatment cost. With the method, product quality is good, and yield is high. Also, according to the invention, the D,L-methionine salt is prepared with 2-hydroxy-4-methylthiobutyronitrile direct ammoniation, alkaline hydrolysis, and ammonia removing, such that carbonate is not produced. In the subsequent bipolar membrane electrodialysis treatment, energy consumption can be saved, and production cost can be reduced.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Acrylic ester rubber and preparation method thereof

InactiveCN101633768AImprove the defect of sticky rollerReasonable ratioSodium stearatePolymer science

The invention provides acrylic ester rubber and a preparation method thereof. The acrylic ester rubber is characterized by comprising the following components by weight: 70-90 portions of tri-acrylate rubber AR840, 10-30 portions of butyronitrile rubber NBR, 55-75 portions of fast extruding carbon black N550, 1-2 portions of anti-aging agent RD, 1-2 portions of anti-aging agent MB, 0.5-1 portion of anti-scorching agent CTP, 3-5 portions of dioctyl phthalate DOP, 1-2 portions of dispersant rhine powder-42, 0.3-0.5 portion of common sulphur, 0.2-0.4 portion of tetramethyl thiuram disulfide TMTD, 3.5-4.0 portions of sodium stearate and 0.3-0.5 portion of potassium stearate. The sticking phenomenon is reduced and the elasticity, extensile intensity and low temperature resistance of the acrylic ester rubber are improved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

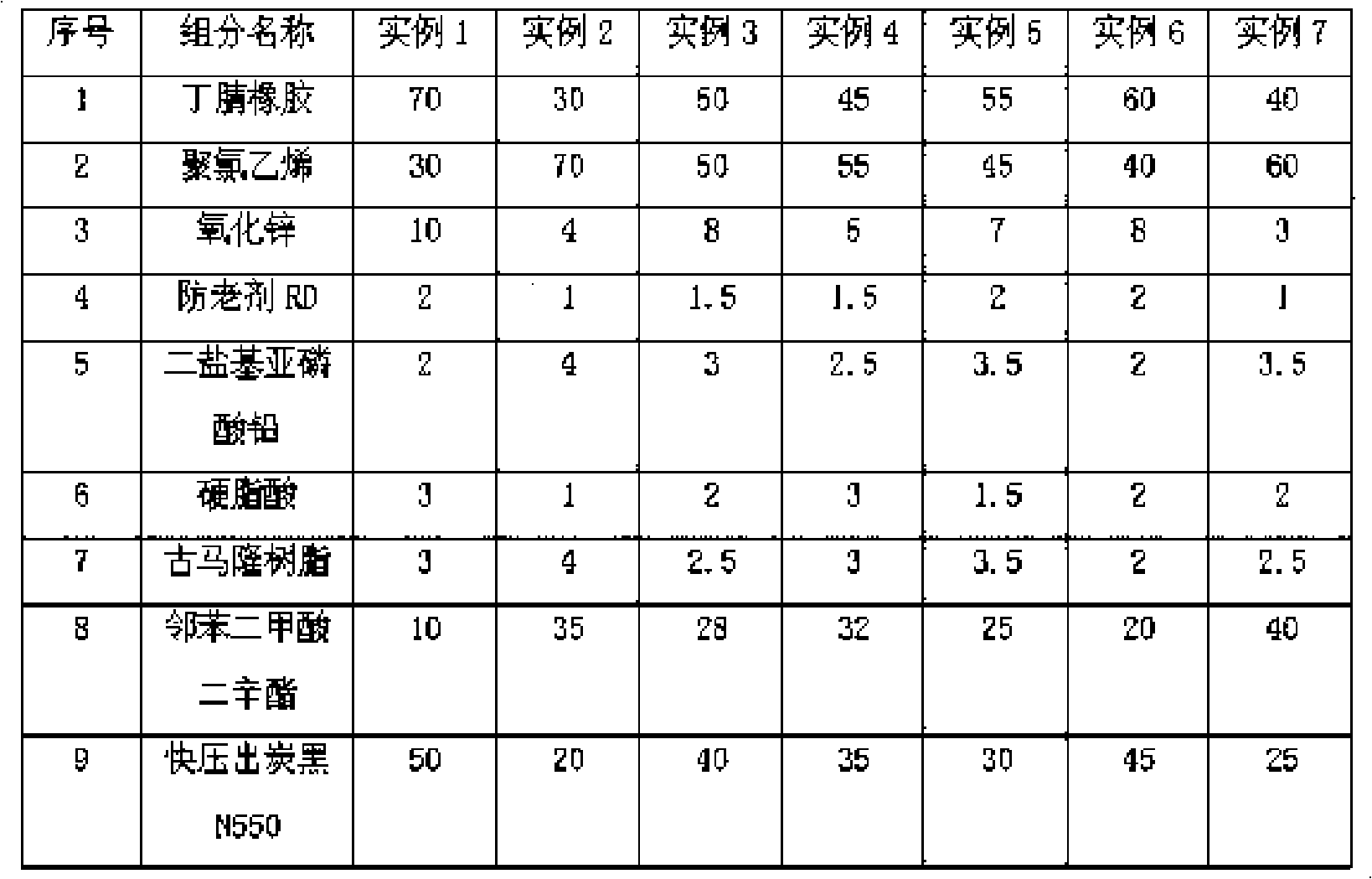

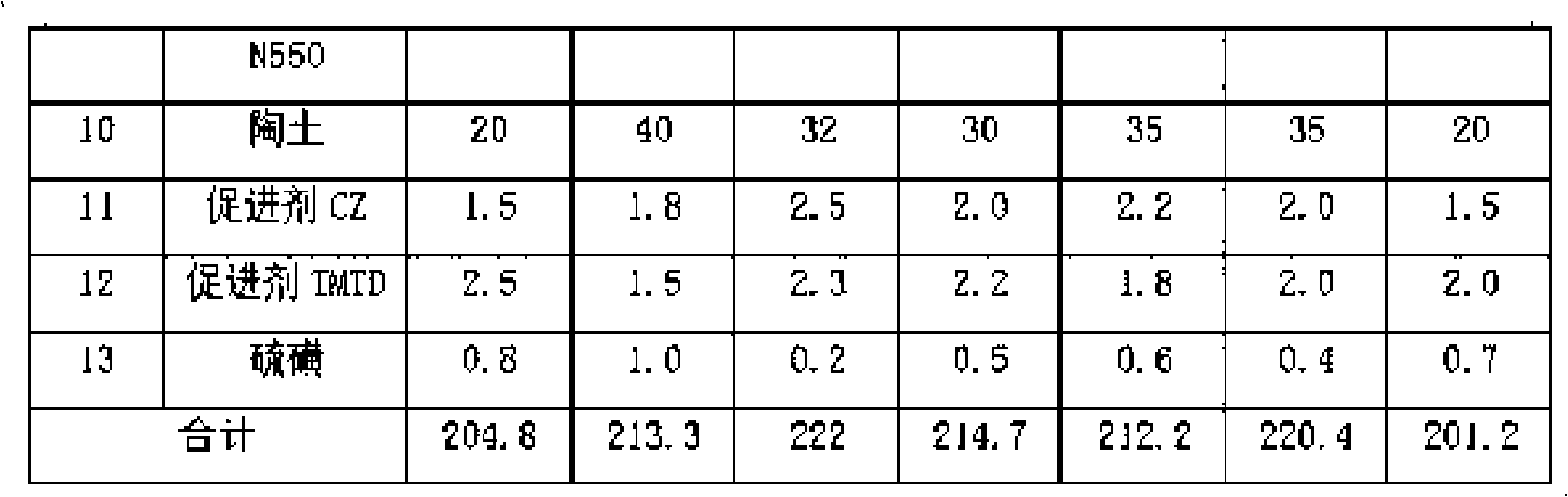

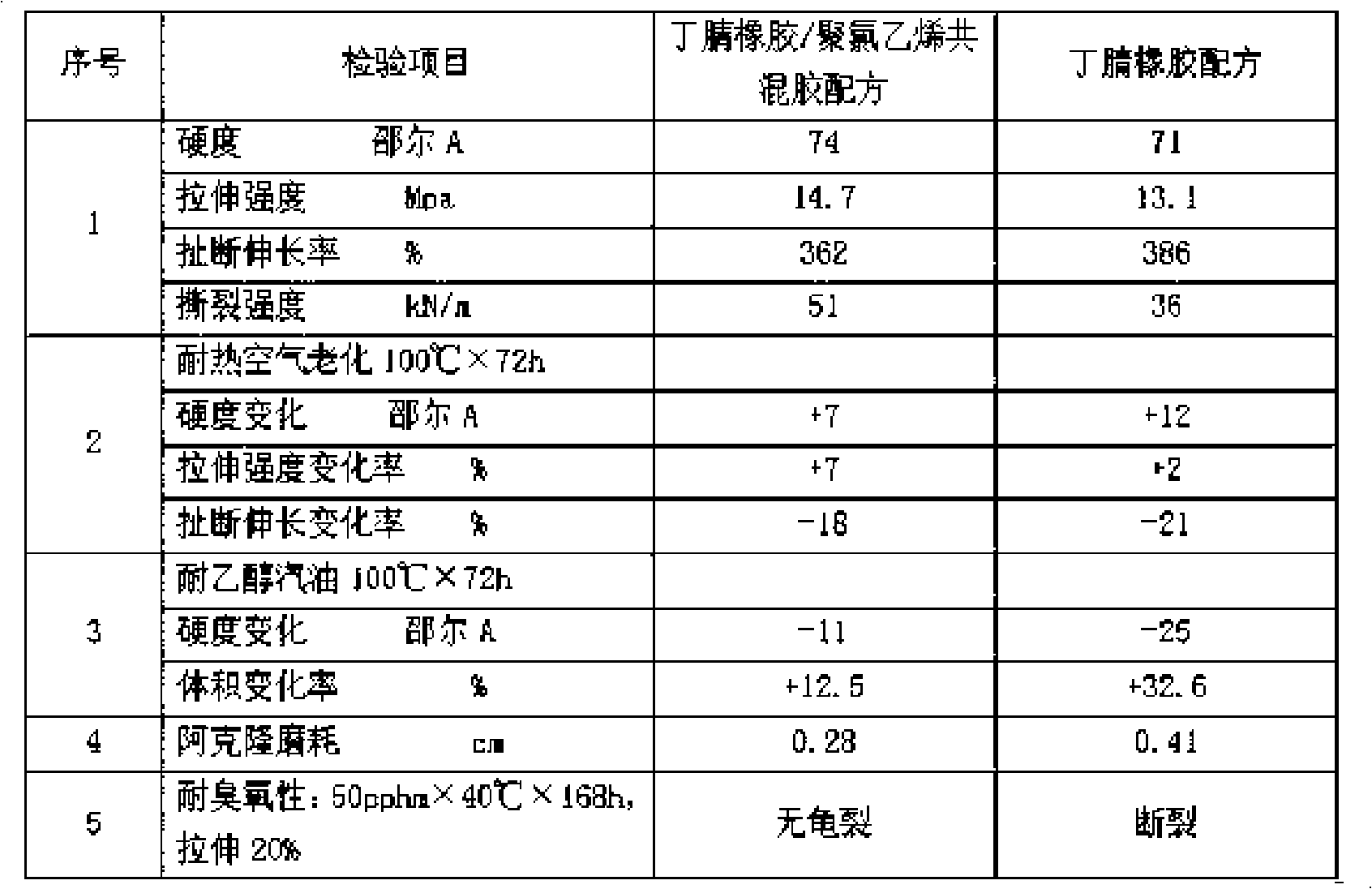

Formula of butyronitrile rubber/polyvinyl chloride co-mixed rubber ethanol resistance gasoline rubber pipe

ActiveCN101805467ASolve the shortcomings of poor resistance to ethanol gasolineMeet the use requirementsFlexible pipesPolymer scienceLead phosphate

The invention relates to a formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber ethanol resistant gasoline rubber pipe, comprising the following components in parts by weight: 30-70 parts of butyronitrile rubber, 70-30 parts of polyvinyl chloride, 3-10 parts of zinc oxide, 1-2 parts of anti-aging agent RD, 2-4 parts of dibasic lead phosphate, 1-3 parts of stearic acid, 2-4 parts of coumarone-indene resin, 10-40 parts of dioctyl phthalate, 20-50 parts of fast extruding furnace black (N550), 20-40 parts of figuline and 1.5-2.5 parts of an accelerating agent CZ. Through the performance contrastive analysis of the formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber and the formula of the butyronitrile rubber, the comprehensive performance of the formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber is better with low cost, which can satisfy the requirements of the traditional ethanol resistant gasoline.

Owner:TIANJIN PENGYI GRP CO LTD

Formulation of high-concentration ozone resistant rubber tube

InactiveCN101555327AImprove performanceMaintain physical and mechanical propertiesHigh concentrationPolymer science

The invention relates to a formulation of a high-concentration ozone resistant rubber tube, which comprises the following compositions by mass parts: 100 parts of butyronitrile PVC rubber, 20 to 40 parts of fast extruding furnace black (FEF), 20 to 40 parts of MT-N990, 5 to 15 parts of diphenyl octyl phosphate(DOP), 5 to 15 parts of light magnesium oxide, 4 to 10 parts of zinc oxide ( ZnO ), 1.5 to 3 parts of dibenzothiazyl disulfide, 1.5 to 3 parts of 1, 4-bis(tert-butyl peroxy diisopropyl) benzene, 1.5 to 2.5 parts of trially isocyanurate, 0.2 to 0.4 part of sulfur, 3 to 5 parts of coumarone, 1 to 3 parts of stearic acid, 1 to 2 parts of microcrystalline wax, 1 to 2 parts of N-isopropyl-N'-diphenyl-para-phenylene diamine, and 1 to 2 parts of 2, 2, 4-trimethyl-1, 2-dihyaroquinoline polymer. Compared with the traditional formulation, the formulation of the invention improves the function of high-concentration ozone resistance of butyronitrile PVC rubber and leads the butyronitrile PVC rubber to be suitable to the extrusion processing for producing the rubber tube of fuel tank filler, thereby improving the service life of the rubber tube of an automobile fuel tank filler and better satisfying the requirements of fuel resistance and ozone resistance of the rubber tube of the automobile fuel tank filler.

Owner:TIANJIN PENGYI GRP CO LTD

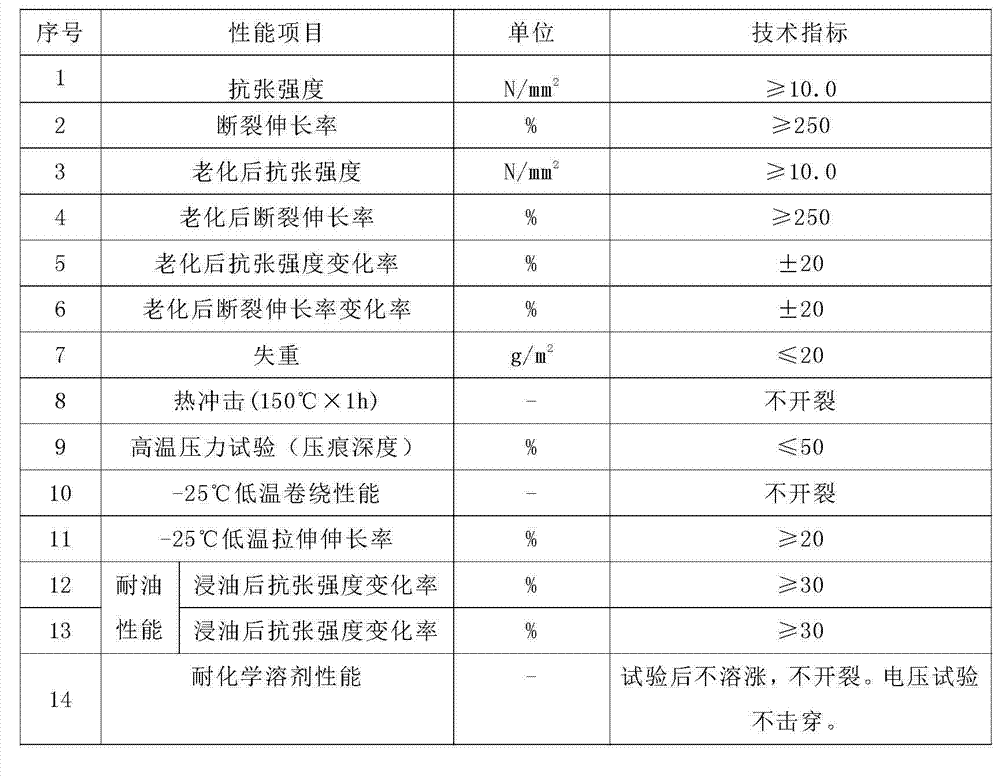

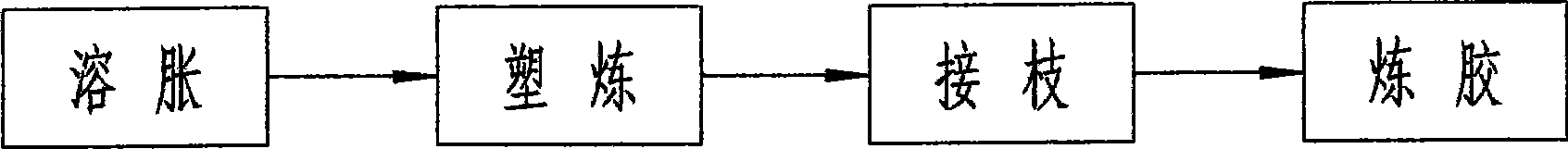

Preparing technology of environment protection type butyronitrile / polychloroethylene blended rubber

InactiveCN101463148AMeet the requirements of the ELV directiveAvoid poisonousEpoxyPolyvinyl chloride

The invention discloses a preparation technology of an environment-friendly butyronitrile / polyvinyl chloride blend rubber. The preparation technology comprises a formulation process flow and a preparation process flow. In the preparation technology, environment-friendly epoxy soybean oil is employed to replace a lead sulfate tribasic stabilizer in the prior art, and the preparation technology is provided with a corresponding formula and a technical scheme of the preparation process, thus avoiding problems of being toxic, harmful and not environment-friendly and not satisfying ELV directive requirements in the prior art. Oil resistant rubber products made of the environment-friendly butyronitrile / polyvinyl chloride blend rubber which is prepared by the preparation technology achieve the purposes of being nontoxic, nonharmful, environment-friendly and satisfying the ELV directive requirements while satisfying various mechanical strength indexes, physical and chemical indexes.

Owner:尤建义

High-performance rubber seal gasket for car radiator and air conditioner, and its preparation process

InactiveCN1569930AImprove sealingImproved high temperature aging resistanceEngine sealsElastomerEngineering

The invention provides a high-performance rubber seal gasket for car radiator and air conditioner, and its preparation process, wherein the sealing gasket mainly comprises EP rubber and natural rubber, as well as added chloroprene rubber, butyronitrile rubber, butylbenzene rubber, epichlorohydrin rubber, methyl acrylate rubber, fluorine rubber, silicon rubber, sulphur, the gasket also contains reinforcing material, supplementary elastomer, anti-ageing agent and pigment known in the prior art.

Owner:SHANGHAI SIMING RUBBER & PLASTIC PRODS

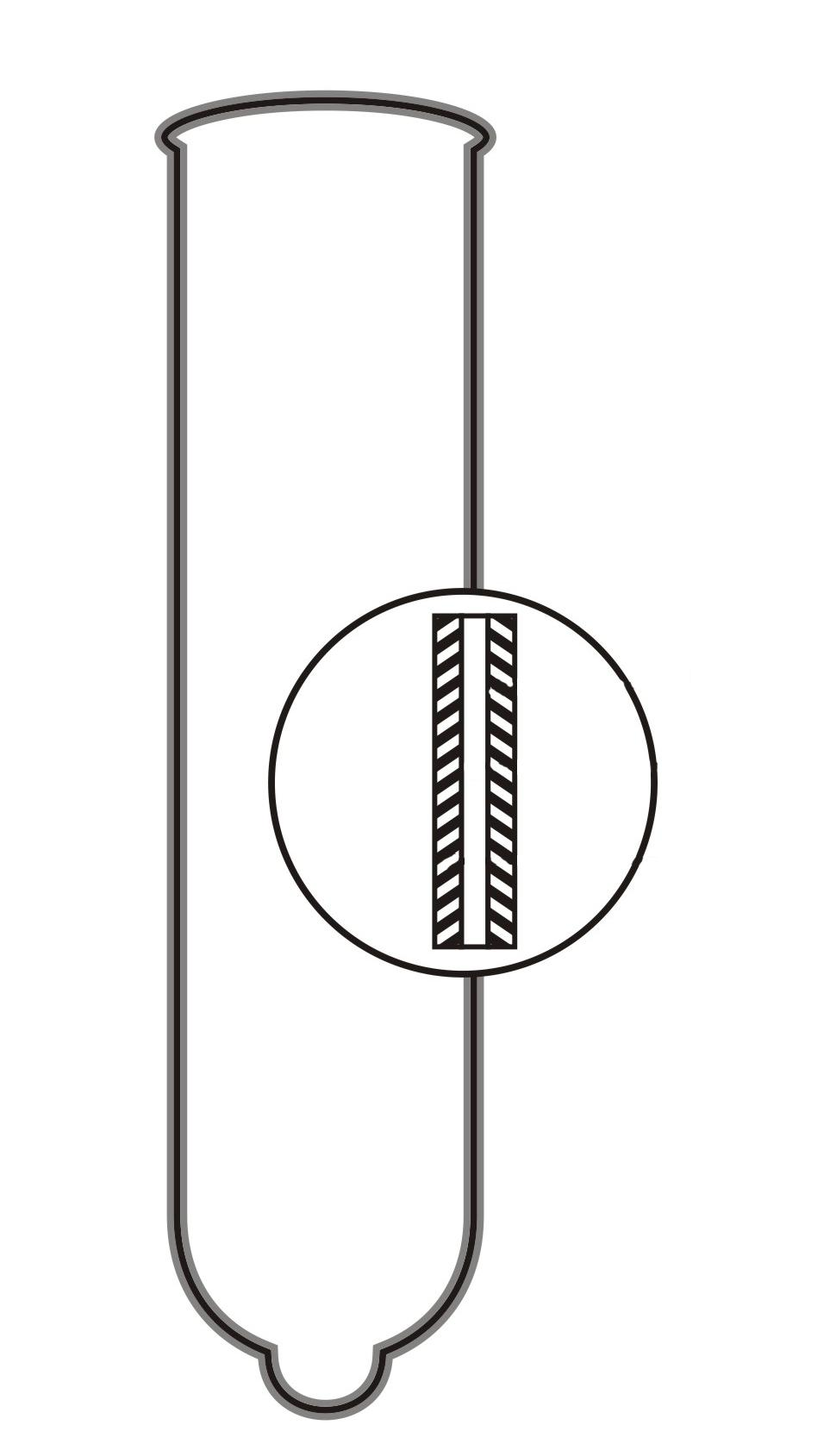

Double-layer sandwich or multi-layer sandwich multi-latex condom and preparation method thereof

ActiveCN101961279APermeation barrierImprove compactnessContraceptive devicesPolymer scienceStretch rate

The invention provides a double-layer sandwich or multi-layer sandwich multi-latex condom and a preparation method thereof. The preparation method of the condom comprises the following steps: vulcanizing natural latex; emulsifying and dispersing polymer materials such as polyurethane or polyisoprene or butyronitrile or other non-natural latex and making the polymer materials into synthetic latex; and dipping a condom die in the natural latex and the synthetic latex respectively and then drying to finally obtain the double-layer sandwich or multi-layer sandwich multi-latex condom the middle layer of which is made from the natural latex or the synthetic latex, wherein, the innermost layer and the outermost layer of the condom can be made from the same material or different materials. The double-layer sandwich or multi-layer sandwich multi-latex condom of the invention has stretch rate and comfortability of the natural latex as well as high compactness of the synthetic latex, thus being applicable to obstructing penetration of small molecules such as hepatitis, AIDS virus and the like.

Owner:桂林恒保健康防护有限公司

Antistatic butyronitrile gloves and preparation method thereof

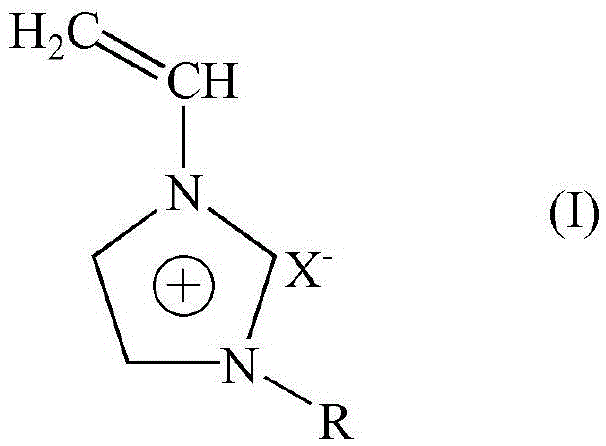

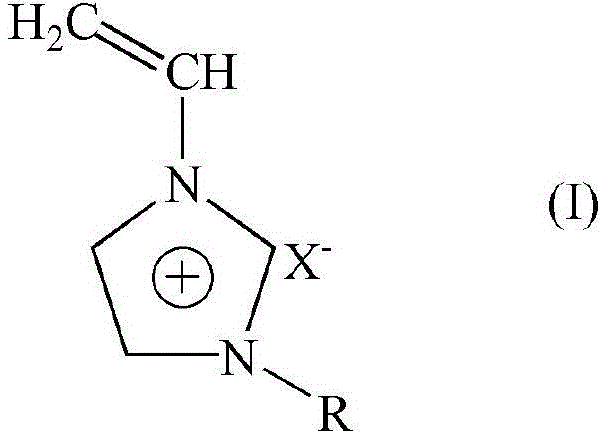

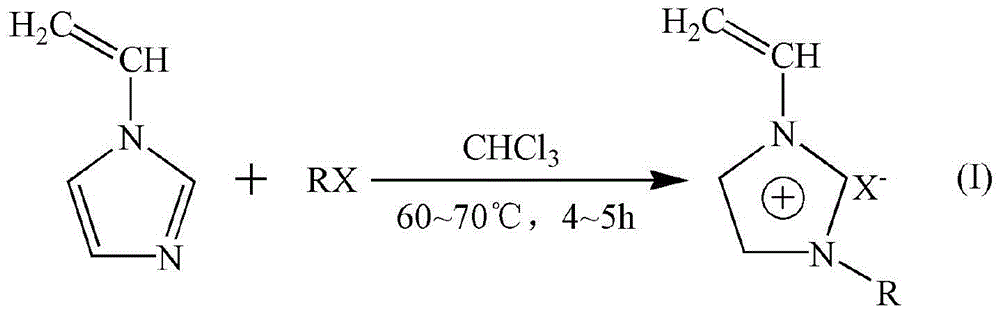

ActiveCN105462006APermanent antistatic effectImprove antistatic performanceGlovesProtective garmentHigh resistanceAntistatic agent

The invention discloses a pair of antistatic butyronitrile gloves. The pair of butyronitrile gloves is mainly prepared from raw materials including butyronitrile latex, deionized water, potassium hydroxide, an accelerator, a vulcanizing agent, a catalyst, imidazolium salt type ionic liquid antistatic agents and the like. The problems that the domestic butyronitrile gloves for clean rooms have higher resistance and don't have an antistatic effect are solved; in the forming process of the gloves, the antistatic agents and butyronitrile latex have a cross-linking reaction, and the prepared butyronitrile gloves have the advantages of good antistatic effect and high cleanness and have the characteristics that the washability is good and the resistance value can be still maintained in the range from 106 omega to 108 omega after repeated ultra-clean washing. The invention further discloses a preparation method of the antistatic butyronitrile gloves. The butyronitrile gloves can be used in the environment of the clean rooms and plays a role in preventing static electricity and protecting operators and the environment of the clean rooms.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Rubber packing leather material used for brake cylinder system and rubber packing leather prepared by utilizing same

The invention relates to a rubber packing leather material used for a brake cylinder system. The rubber packing leather material comprises the following ingredients in parts by weight: 70-80 parts of butyronitrile rubber (N250S), 20-30 parts of butyronitrile rubber (N240S), 4-6 parts of zinc oxide (with the purity of 99.8%), 1.5-2.0 parts of stearic acid (industrial grade), 4.0-5.0 parts of modified methyl acrylic acid magnesium (modified), 1.0-2.0 parts of nano SiO2, 1.0-2.0 parts of Molijie TM-80, 2.0-2.5 parts of anti-aging agent RD (industrial grade), 0.5-1.5 parts of anti-aging agent BLE (Diphenylamine Condensation Compound) (industrial grade), 1.5-2.0 parts of vulcanizing agent DCP (Dibasic Calcium Phosphate) (industrial grade), 100-120 parts of carbon black, 15 parts of plasticizer MBA and 10 pars of plasticizer MDA. The rubber packing leather material used for the brake cylinder system, provided by the invention, is resist in grease, resist in fatigue, strong in permanent deformation capability resistance and long in service life.

Owner:JIANGSU TIEKE NEW MATERIAL CO LTD

Nitrile copolymer latex composition and nitrile copolymer rubber composition

ActiveUS20100330319A1Small in gasoline permeabilityIncrease resistanceLiquid surface applicatorsSynthetic resin layered productsPolymer sciencePlasticizer

A nitrile copolymer latex composition containing a latex of a nitrile copolymer rubber (A) having α,β-ethylenically unsaturated nitrile monomer units in 10 to 75 wt %, conjugated diene monomer units in 5 to 89.9 wt %, and cationic monomer units and / or monomer units able to form cations in 0.1 to 20 wt %, an inorganic filler (B) having an aspect ratio of 30 to 2,000, and a plasticizer (C) having an SP value by the HOY method of 8 to 10.2 (cal / cm3)1 / 2, wherein a content of said plasticizer (C) is 0.1 to 200 parts by weight with respect to said nitrile copolymer rubber (A) as 100 parts by weight is provided.

Owner:ZEON CORP

Manufacturing method of lalex gloves or butyronitrile gloves possessing skin protective function

A latex (or butanenitrile) gloves for protection and nutritive health of skin is prepared through preportionally mixing conventional raw materials with nutritive liquid, mixing with natural latex or butanenitrile latex, heating while stirring for sulfurizing, shaping, spraying said nutritive liquid, turn-over, chlorinating, washing, spraying said nutritive liquid, and finishing.

Owner:ZHENJIANG SUHUI LATEX PROD

Micro porous friction material and its producing method

The present invention relates to one kind of microporous friction material and its production process. The friction material is produced with the raw materials including modified resin 10-35 wt%, butyronitrile powder 0-10 wt%, kaolin 20-40 wt%, precipitated barium sulfate 25-50 wt%, graphite 5-20 wt%, zinc oxide 1-10 wt%, corundum 0-1 wt%, chromite powder 0-5 wt%, iron oxide red 0-2 wt%, steel fiber 10-30 wt%, aramid fiber pulp 0.1-10 wt%, and carbon fiber 0- 10 wt%. The production process includes mixing the raw materials, reaction and forming at the temperature from room temperature to 140 deg.c and the pressure of 200-800 kg / sq cm for 20-800 sec, and final sintering in a sintering furnace at 150-200 deg.C for 2-16 hr. Compared with available technology, the present invention has the advantages of excellent friction performance, excellent physical and mechanical performance, no noise, etc.

Owner:SHANGHAI RENPHEN COMPOSITE MARERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com