Patents

Literature

81results about How to "Maintain physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

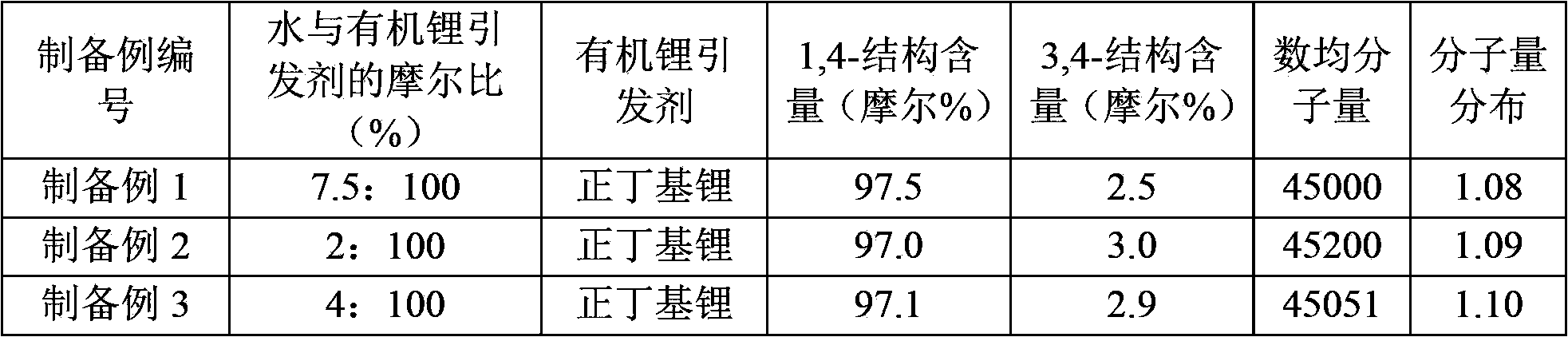

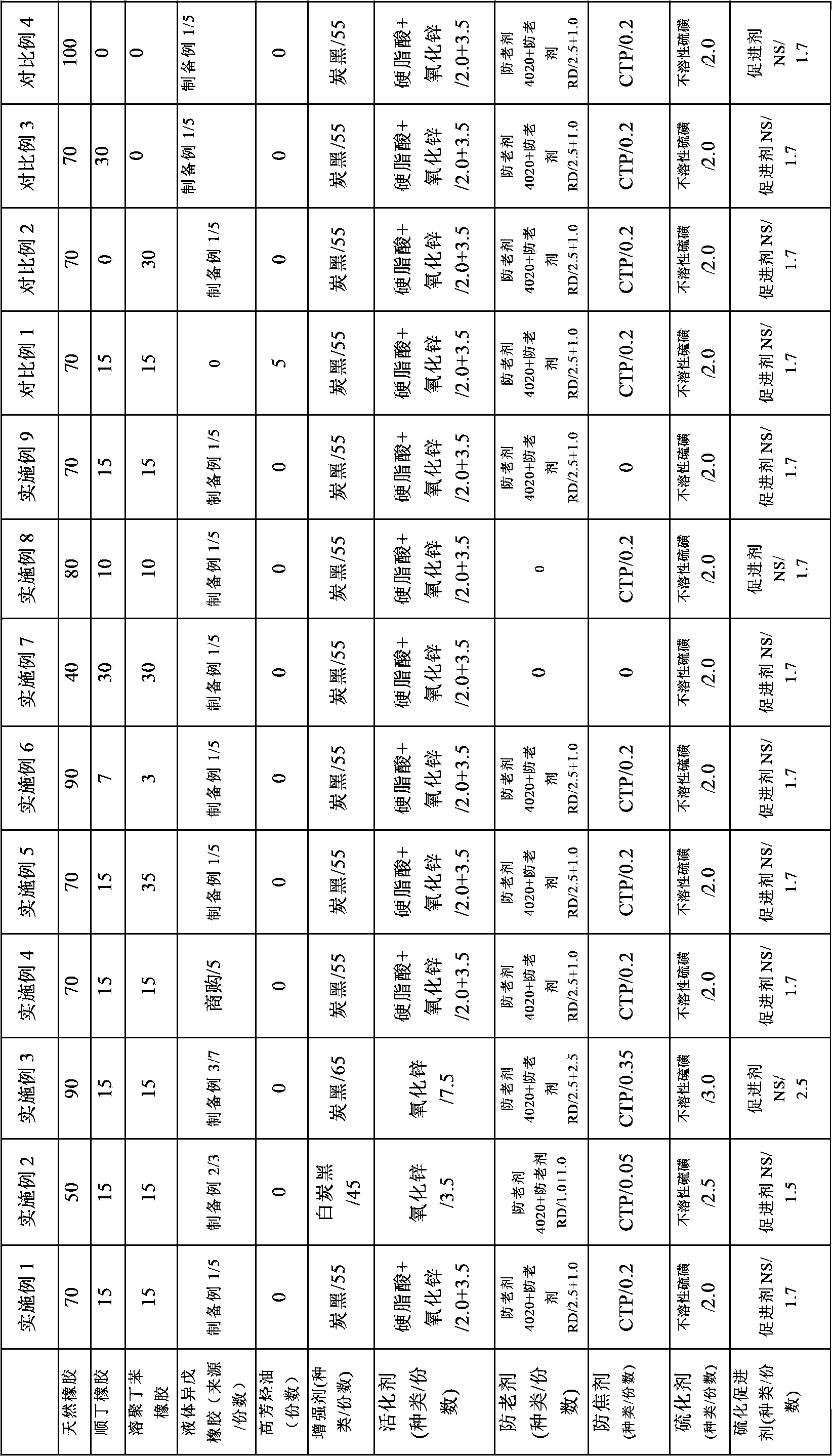

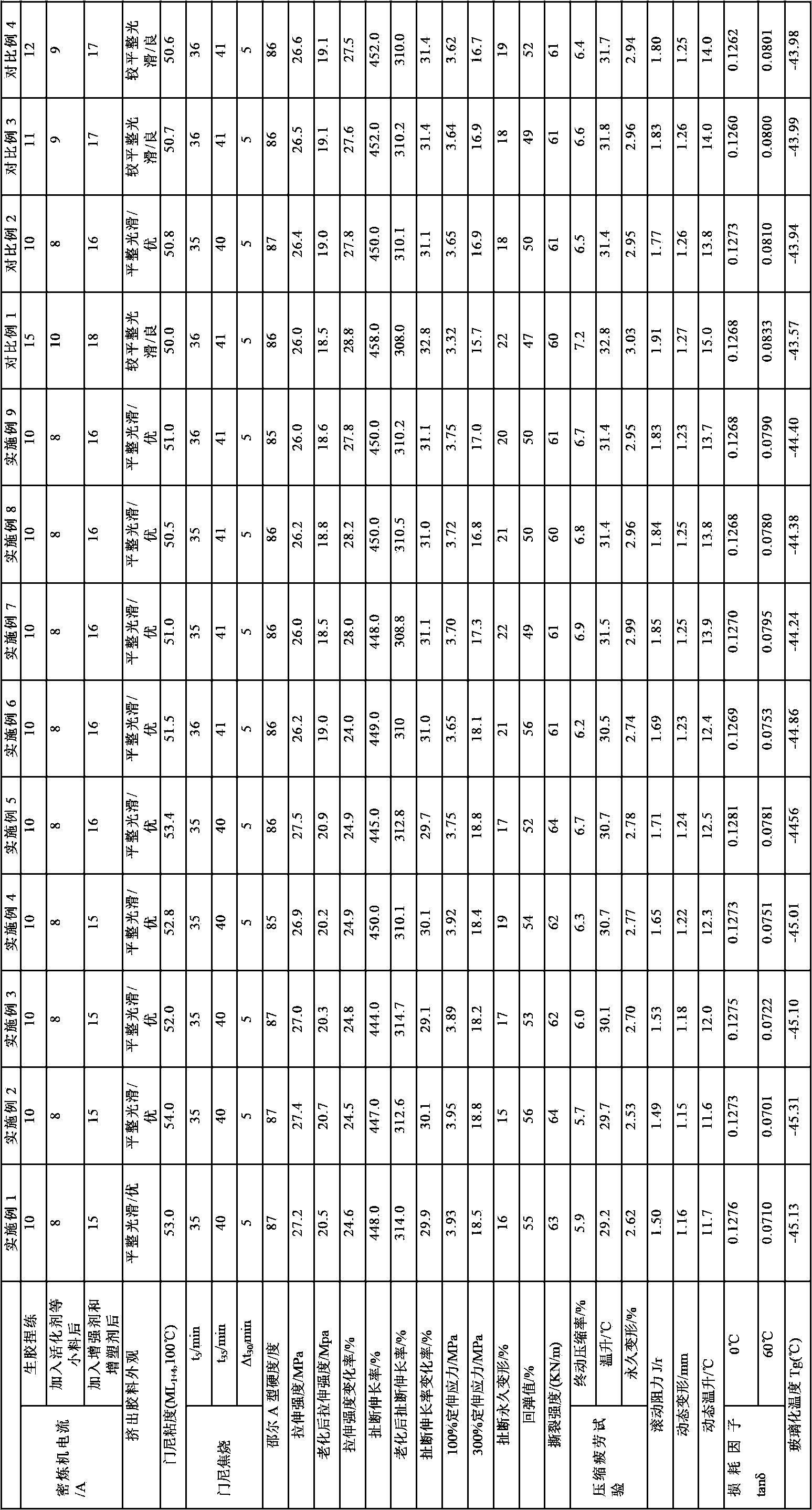

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

Filling masterbatch used in biodegradable plastic, and preparation method thereof

InactiveCN102516723AGuaranteed DispersionAvoid reunionArtifical filament manufactureMasterbatchPolymer science

The invention discloses a filling masterbatch used in biodegradable plastic. The masterbatch is composed of components of, by mass: (A) 20.0-80.0% of biodegradable polyester, (B) 1.0-80.0% of a filling material, (C) 0.1-10.0% of a lubricating agent, (D) 0.1-5.0% of a high-temperature-resistant agent, and (E) 0.1-5.0% of a hydrolysis-resisting agent. The masterbatch is advantaged in that: (1) compatibility of the carrier is consistent with that of the biodegradable plastic, such that the filling masterbatch has excellent dispersity in the biodegradable plastic; (2) the obtained filling masterbatch satisfies an application requirement of biodegradable plastic En13432; when the filling masterbatch is mixed with biodegradable plastic, the biodegradation performance of the original material is completely maintained; (3) high temperature and hydrolysis resistances of the filling masterbatch are good, and the filling masterbatch has high physical mechanical properties; (4) with the filling masterbatch, while the cost of biodegradable plastic is reduced, physical chemical properties especially the biodegradation performance of the filled material are maintained.

Owner:KINGFA SCI & TECH CO LTD +2

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

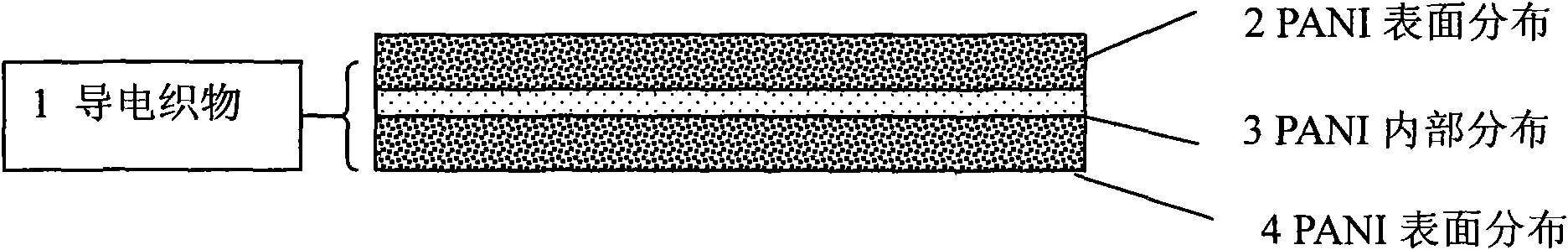

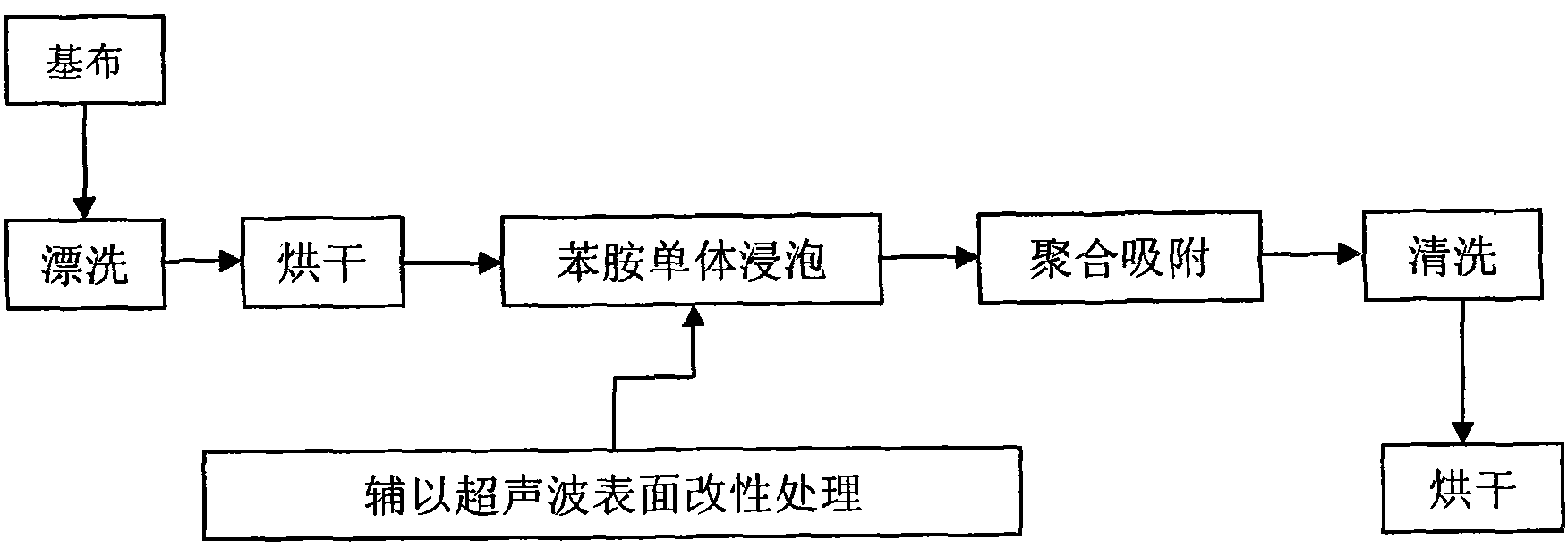

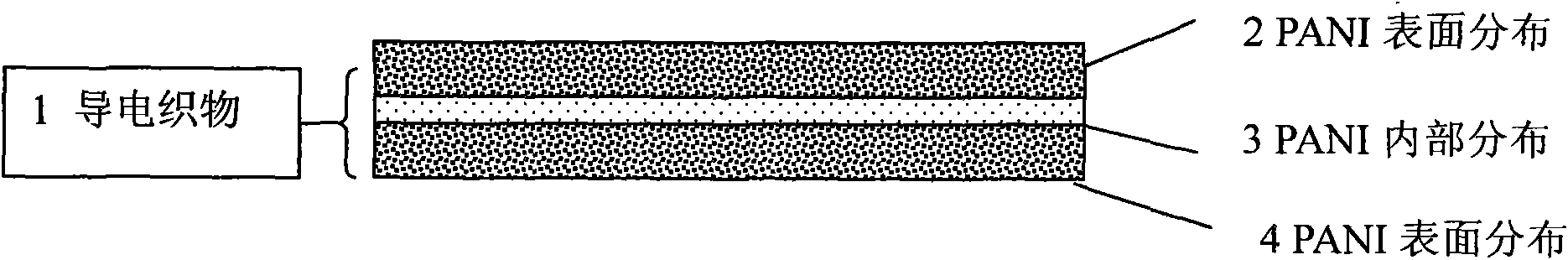

Novel method for preparing polyaniline composite conductive fabric

InactiveCN102337679AAutomatic elimination of influenceAccurate measurementPhysical treatmentFiberConductive polymer

The invention relates to a novel method for preparing a polyaniline composite conductive fabric. The novel method for preparing a polyaniline composite conductive fabric is characterized in that a conductive fabric with good conductive properties is prepared from a chemical fiber fabric as a matrix material and polyaniline as a conductive material through an in-situ polymerization method (also known as an in-situ adsorption polymerization method). The novel method for preparing a polyaniline composite conductive fabric adopts an ultrasonic dipping treatment process as an auxiliary process of a base fabric dipping process adopting aniline. Therefore, the novel method for preparing a polyaniline composite conductive fabric has good surface modification effects on a base fabric, is beneficial for depositing a conductive material on fiber surfaces of the base fabric in polymerization and enabling the conductive material to permeate into fibers of the base fabric, and improves conductivity and conductive stability. A conductive fabric prepared by the novel method has high conductivity and good environmental stability, is easy for synthesis, and keeps physical and mechanical properties belonging to fabrics on the basis of acquirement of conductive properties, wherein surface resistance R of the conductive fabric is reduced to a value of 1 to 5 kilo-ohm.

Owner:WUYI UNIV

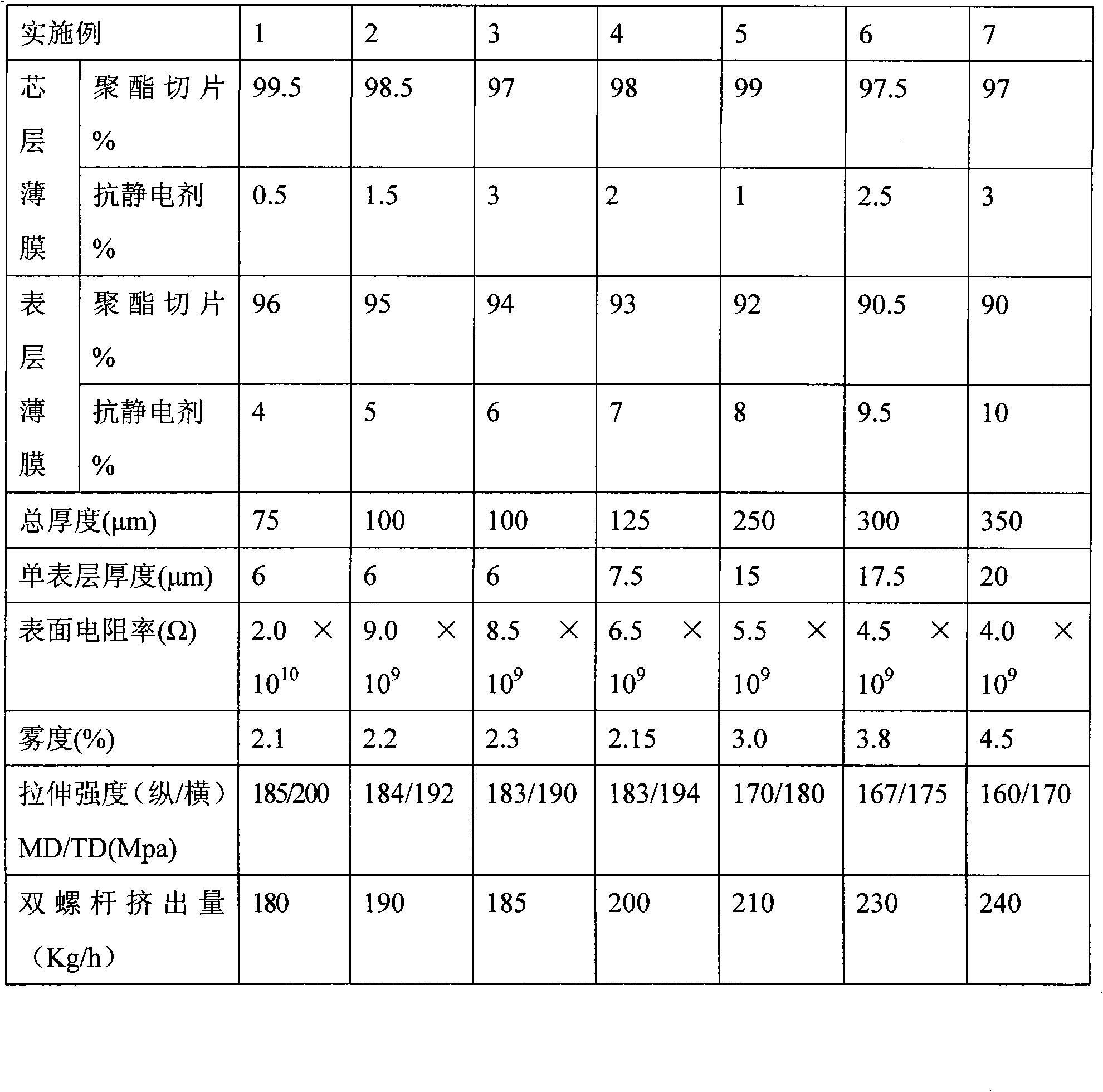

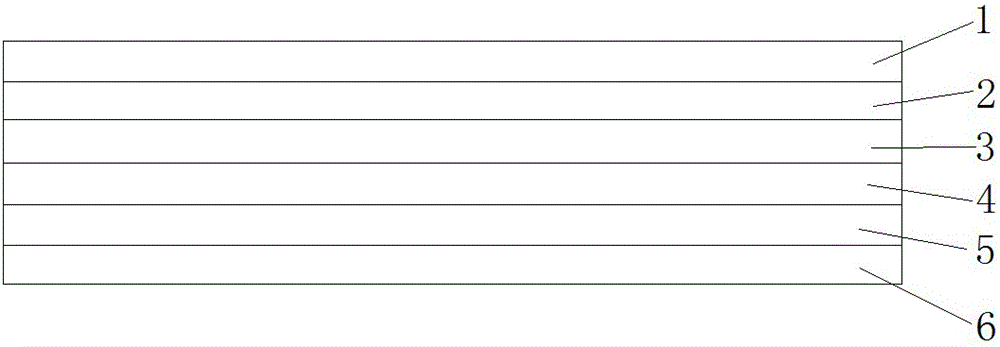

Electrostatic resistant heavy duty polyester film and method of preparing the same

ActiveCN101318393ALong-term antistatic protectionImprove antistatic performanceSynthetic resin layered productsPolyesterHigh concentration

The invention relates to an anti-static thick type polyester film which includes three layers of coextruded films. Calculated by the weight percentage, the film of a core layer is provided with 97 to 99.5 percent of polyester chips and 0.5 to 3 percent of an antistatic agent; the film of a surface layer is provided with 90 to 96 percent of the polyester chips and 4 to 10 percent of the antistatic agent; the thickness of the film of the core layer is between 0.075 to 0.31mm; the thicknesses of the films of the two surface layers are equal; besides, the thickness of the film of the surface layer is between 0.006 to 0.02mm. The invention adopts the anti-static polyester film of ABA three-layer structure to modify the conductive performance of a polyester substrate; especially, the film of the surface layer has high concentration of the antistatic agent and the antistatic agent added in the polyester substrate is capable of partially moving to the surface of the film; the anti-static thick type polyester film has the advantages of scrub resistance and solvent resistance, thus leading the polyester film to have the anti-static function for a long period.

Owner:JIANGSU YUXING FILM TECH

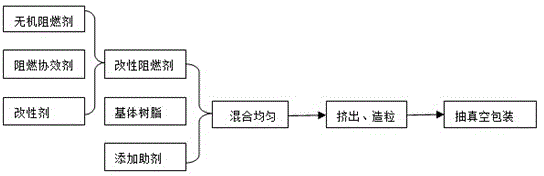

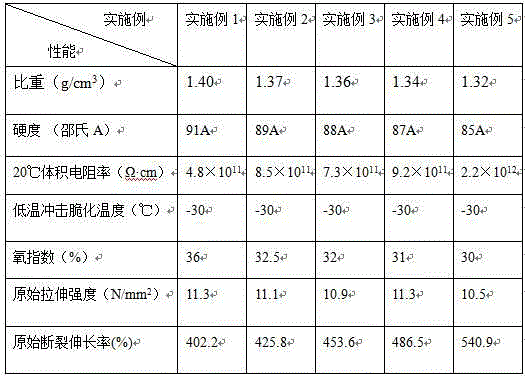

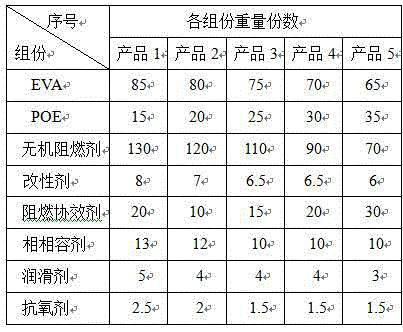

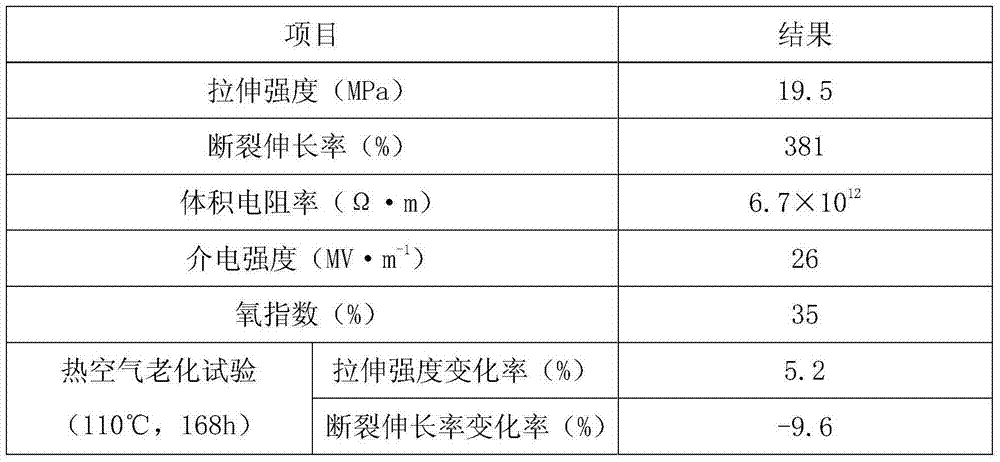

Flexible environment-friendly polyolefin cable material and preparation method of flexible environment-friendly polyolefin cable material

ActiveCN102942734AReduce hardnessImprove flexibilityInsulated cablesInsulated conductorsPolyolefinWeak current

The invention discloses a flexible environment-friendly polyolefin cable material and a preparation method of the flexible environment-friendly polyolefin cable material. The flexible environment-friendly polyolefin cable material is prepared from the following components in following parts by weight: 65 to 85 parts of EVA (ethylene vinyl acetate), 15 to 35 parts of POE (polyolefin elastomer), 70 to 130 parts of inorganic flame retardant agent, 10 to 30 parts of flame retardant adjuvant, 5 to 8 parts of modifier, 8 to 13 parts of compatilizer, 1.5 to 2.5 parts of antioxidant, and 3 to 5 parts of lubricant. A flexible thermoplastic elastomer is used as a matrix resin, and a certain proportion of flame retardant adjuvant is added, so on the premise of not affecting the flame retardant property of the cable material, the adding quantity of the inorganic flame retardant agent is greatly reduced, and then the flexible environment-friendly polyolefin cable material is prepared. The flexible environment-friendly polyolefin cable material has the advantages that the flexibility is high, the mechanical property is high, and the flexible environment-friendly polyolefin cable material is suitable for the industries with higher requirements on the flexibility of cables, such as communication cables and weak current cables.

Owner:YANGZHOU HAONIANHUA POLYMER MATERIALS CO LTD

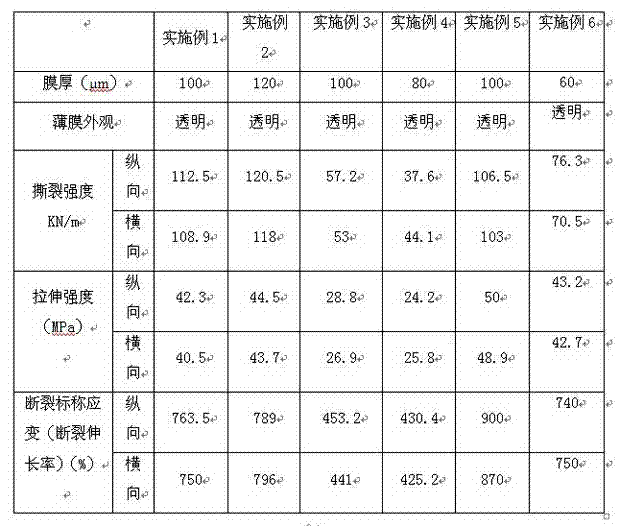

Multilayer coextrusion medical blister composite packaging film and preparation method thereof

InactiveCN102225646AHigh elongationGood compatibilitySynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a multilayer coextrusion medical blister composite packaging film which comprises an inner film, a middle film and an outer film; each layer from outside comprises the following components in parts by mass: 20-30 parts of outer layer made from copolymer of low-density polyethylene and linear low-density polyethylene, 20-40 parts of middle layer made from polymer of the liner low-density polyethylene and low-density metallocene polyethylene, and 30-50 parts of inner layer made from polypropylene. The product is obtained by extruding, film-blowing, air-cooling, water-cooling shaping, surface processing and winding. The multilayer coextrusion medical blister composite packaging film is safe, sanitary, transparent and airtight, has good elongation and varieties respectively suitable for three sterilizing forms, the blister forming is realized in the packaging process. The layers of the product have good compatibility, and cannot be separated from each other when performing the blister forming; and therefore, the physical mechanical property is maintained.

Owner:FUZHOU GREEN SAIL PACKAGE MATERIAL

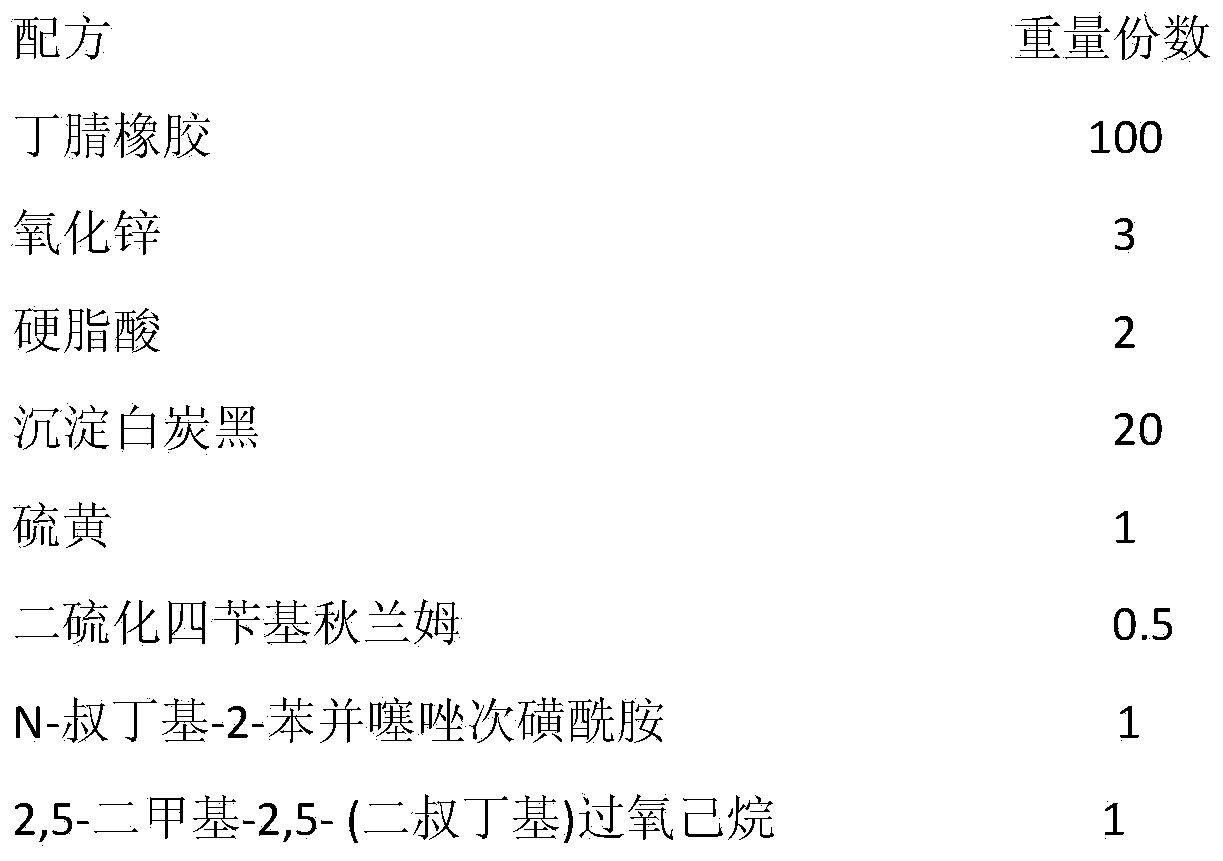

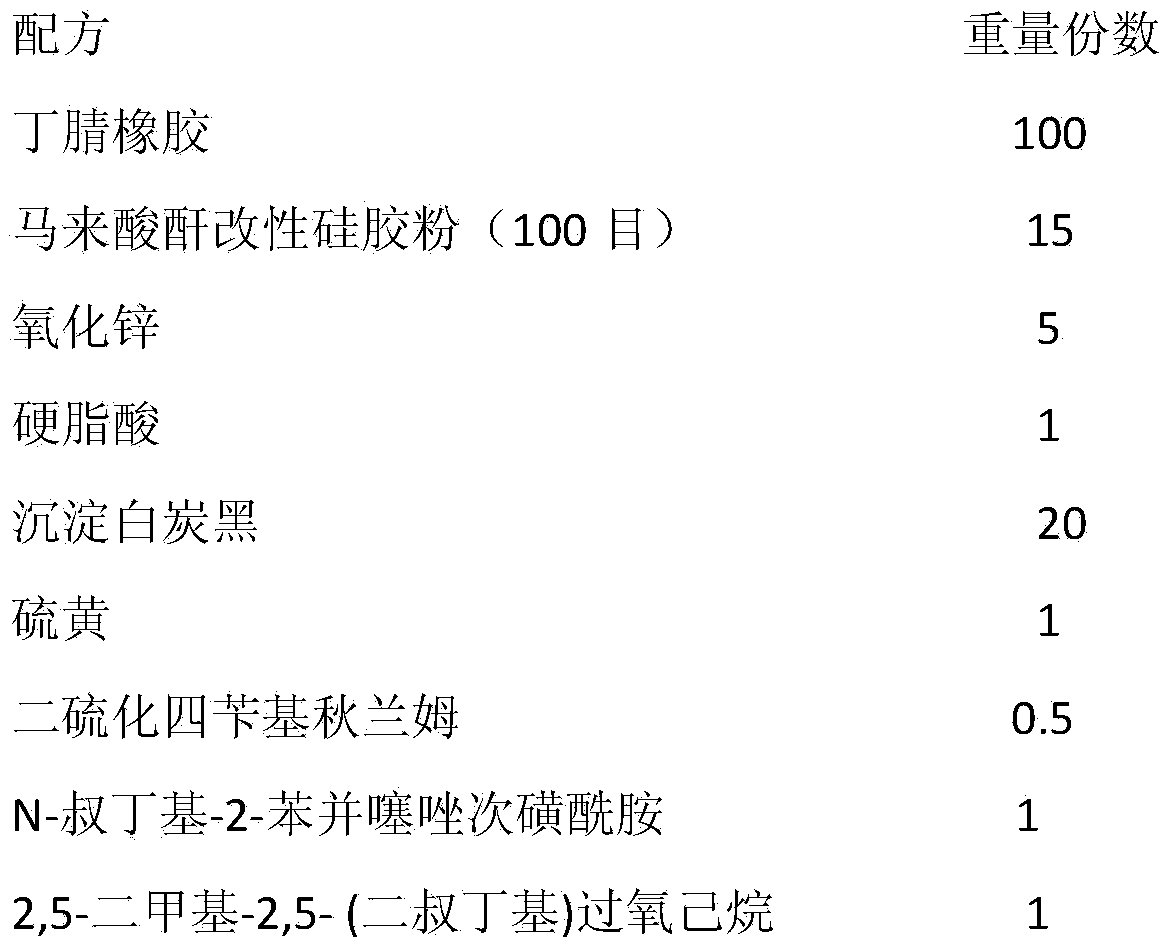

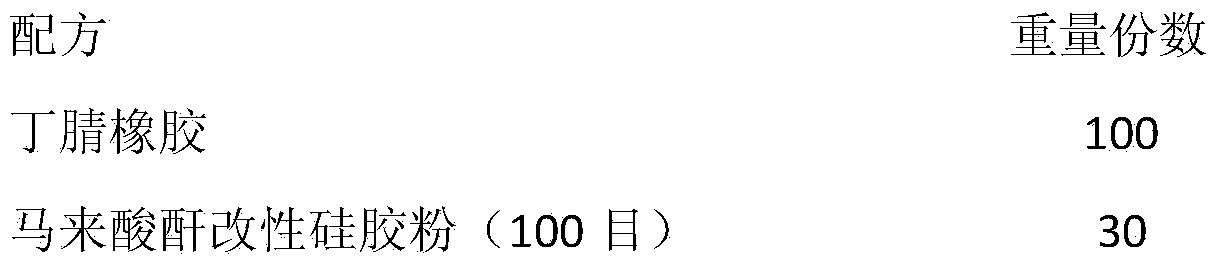

Nitrile rubber/modified silica-gel powder blend and preparation method thereof

The invention provides a nitrile rubber / modified silica-gel powder blend and preparation method thereof. The method comprises the following steps: adding nitrile rubble in an open mill or internal mixer; plasticating for 3-5 minutes; adding zinc oxide, eleaostearic acid, deposited white carbon black, modified silica-gel powder, sulfur, promoter and peroxide; carrying out mixing and milling at 40-60 DEG C, and obtaining the nitrile rubber / modified silica-gel powder blend; the promoter is tetrabenzylthiuramdisulfide and N-t butyl-2-benzothiazolesulfenamide; compression molding of the blend is carried out in a flat vulcanizer, and the vulcanizing temperature is 150-200 DEG C, and the vulcanizing time is 10-30 minutes, and the nitrile rubber / modified silica-gel powder blended vulcanized rubber is prepared. The blended vulcanizied rubber has the advantages of good low temperature resistance, high temperature resistance and higher fracture elongation rate. The invention can improve regeneration utilization rate of wasted silicone rubber, extend application range of silica-gel powder, and the invention has the advantages of simple processing technology, low production cost and good economic benefit.

Owner:SOUTH CHINA UNIV OF TECH +1

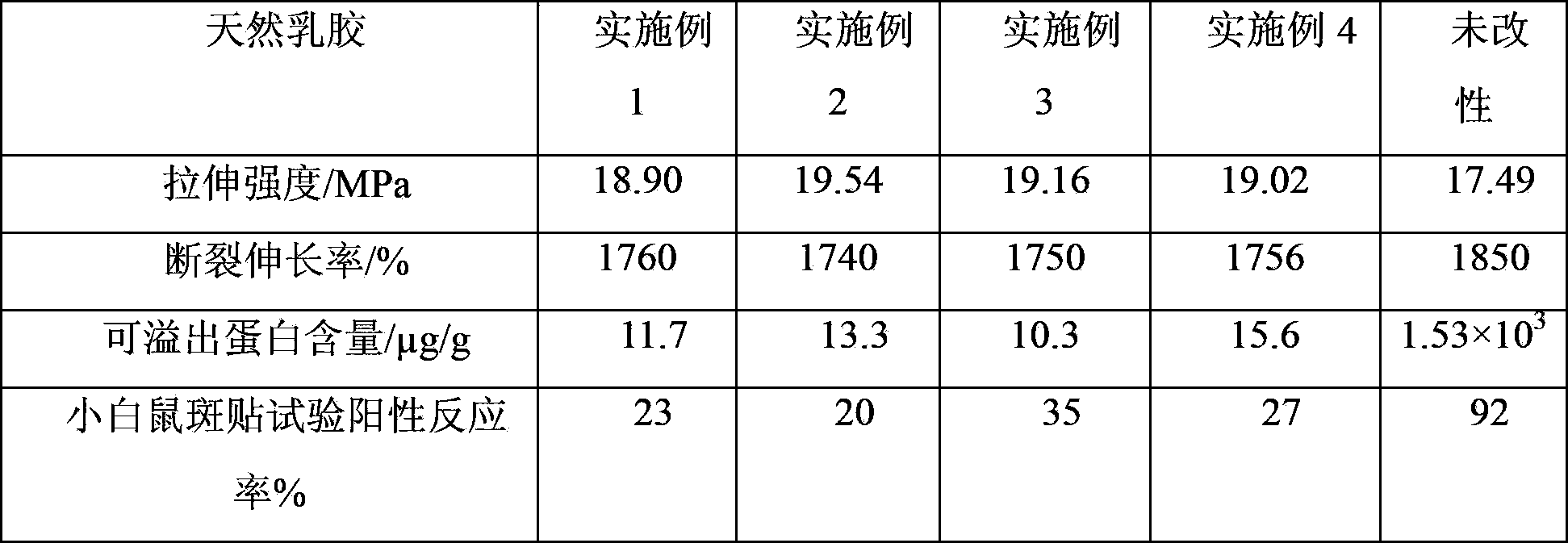

Modified nature latex, preparation method and use thereof

The invention belongs to the technical field of rubber chemical modification, and relates to a preparation method and a use of a modified nature latex. The modified nature latex is prepared from the following components by weight: 100 parts of nature latex, and 10-30 parts of sericin grafted aqueous polyurethane emulsion. According to the present invention, the modified rubber has advantages of surface functionalization, good biocompatibility and the like; the mechanical property and the allergy of the nature latex gloves are improved; and the traditional method that the protein removing method is adopted to solve the allergy of the latex product is changed, the allergy problem is solved without reduction of the protein content, and the physical and mechanical properties of the latex product are ensured.

Owner:HEFEI GENIUS NEW MATERIALS

Method for preparing anticoagulant composite coating

InactiveCN107456611AExcellent anticoagulant propertiesIncreased anticoagulationSurgeryPharmaceutical delivery mechanismBiocompatibility TestingPre treatment

The invention discloses a method for preparing an anticoagulant composite coating. The method for preparing the anticoagulant composite coating comprises the steps of first using a coupling agent to process the surface of a pre-processed biomedical base material to obtain a hydrophilic surface, using a specific anticoagulant composite coating to modify the biomedical base material, and obtaining a biomedical material having good anticoagulation property after drying. Studies have shown that the biomedical material modified by the anticoagulant composite coating is greatly improved in hydrophilicity and shows excellent biocompatibility. The modified material can not only maintain its original physical and mechanical properties, but also greatly extend activated partial thromboplastin time (APTT) in the coagulation test to show excellent anticoagulant properties.

Owner:BEIJING UNIV OF CHEM TECH

Polyisoprene preparation method and prepared polyisoprene

ActiveCN103254332AReduce contentMaintain physical and mechanical propertiesAlkaline earth metalPolymer solution

The invention relates to a polyisoprene preparation method and polyisoprene prepared with the method. According to the method, under the condition of solution polymerization, isoprene monomers in a mixture comprising isoprene monomers, a catalyst and an organic solvent are polymerized, such that a polyisoprene solution is obtained, wherein the catalyst comprises titanium halide and an organic aluminum compound. The method also comprises the steps that the obtained polyisoprene solution contacts oleic acid; a water solution of alkali metal hydroxide and / or a water solution of alkaline earth metal hydroxide is mixed with the solution obtained by the contact of the polyisoprene solution and oleic acid; and oil-water separation is carried out. With the method provided by the invention, the obtained polymer solution is stable; metal titanium content in separated polymer polyisoprene can be effectively reduced, such that polymer physical and mechanical performances can be ensured; and the method is simple and is easy to operate. Also, oleic acid is used for replacing a catalyst deactivator such as methanol, such that environment pollution can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

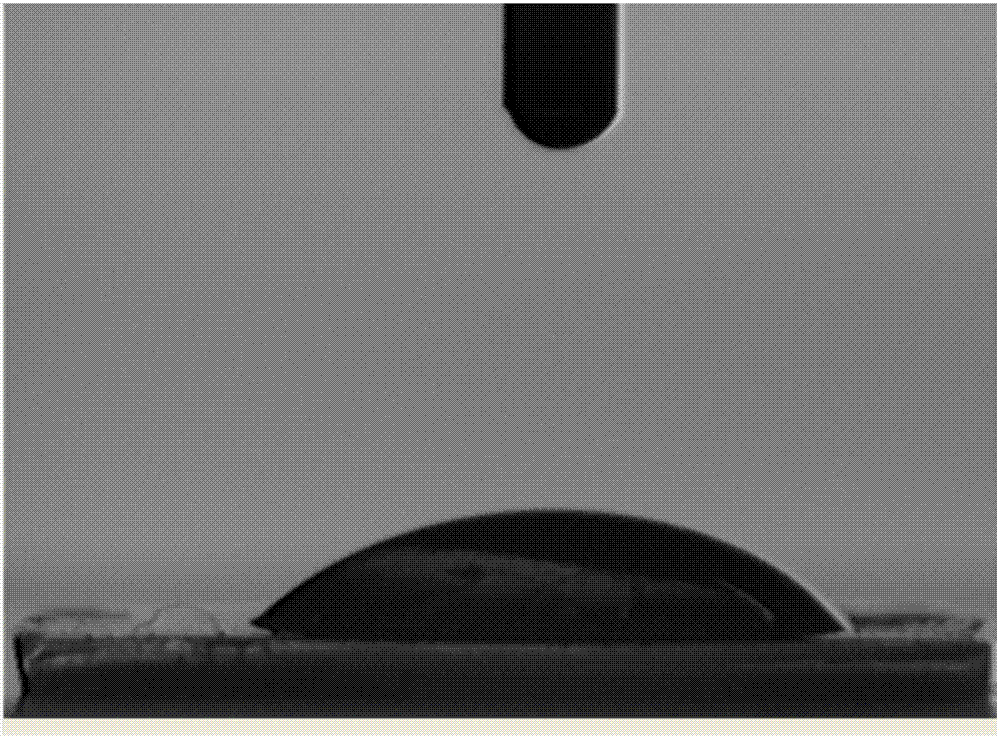

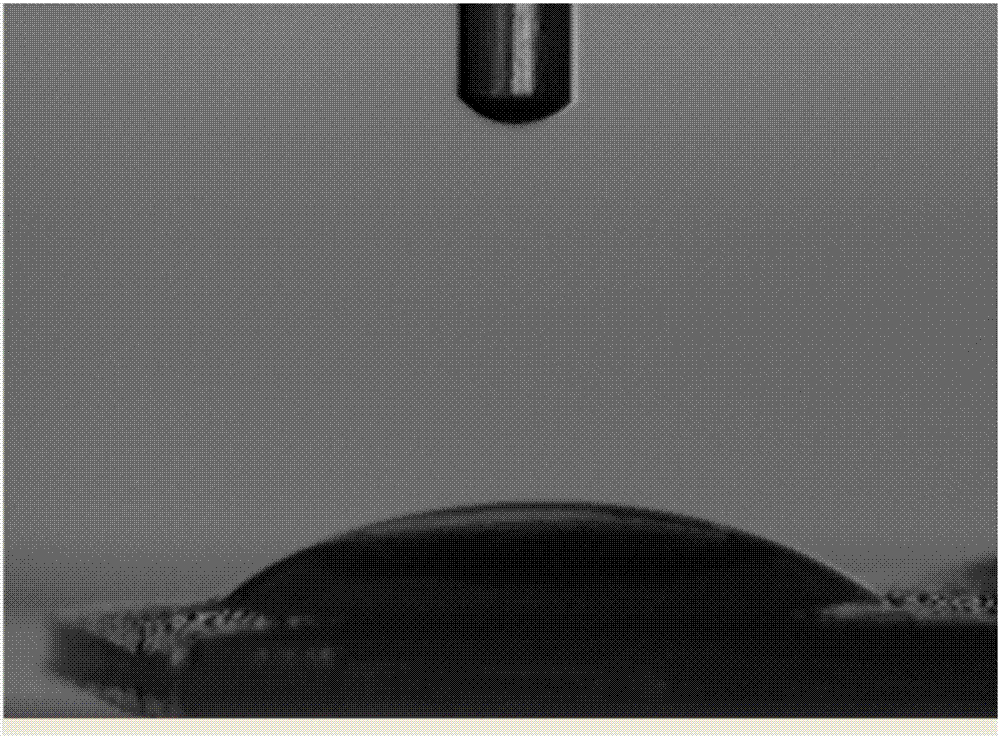

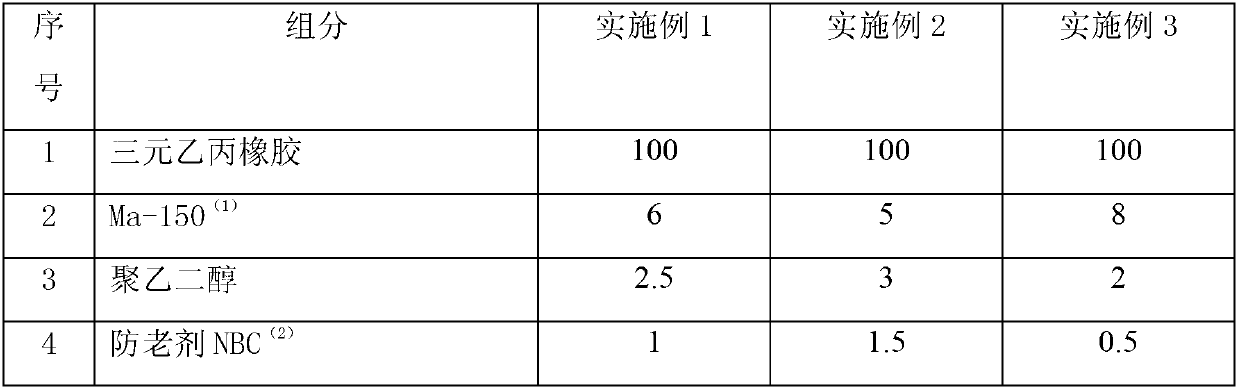

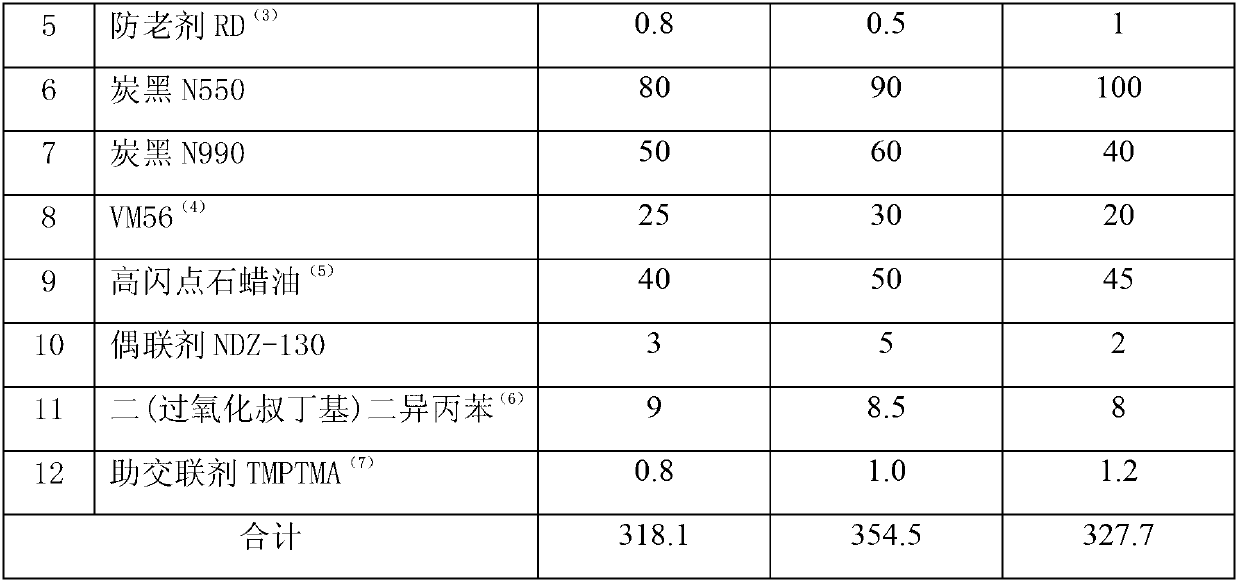

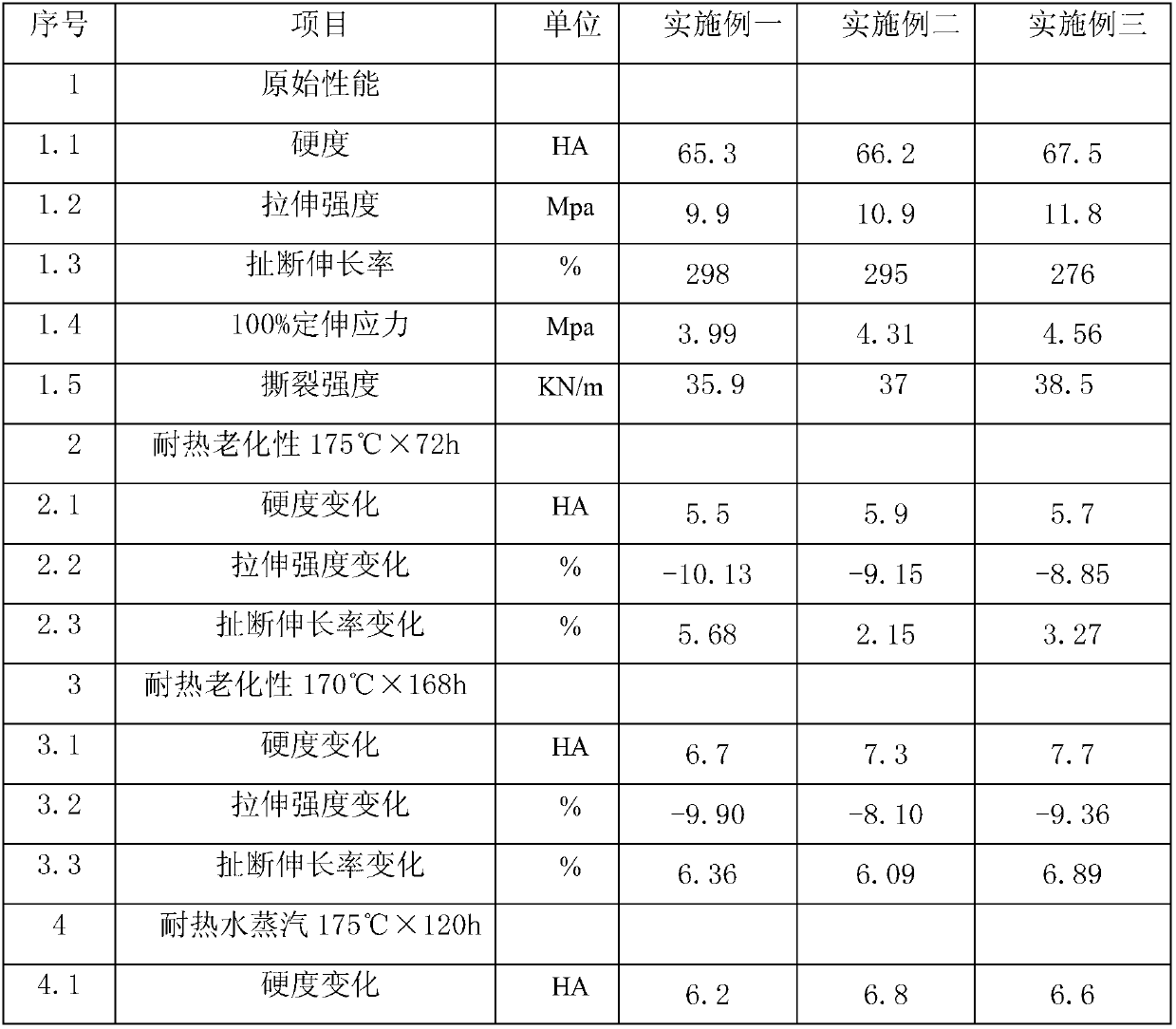

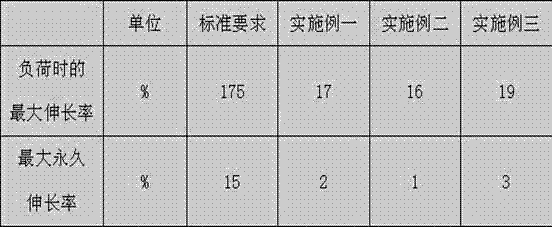

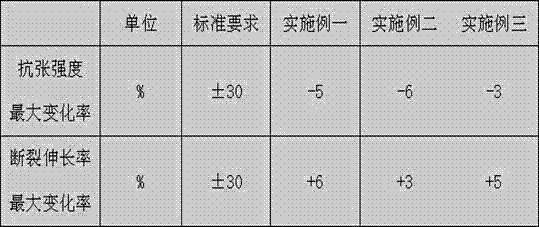

Ethylene-propylene-diene monomer composition with limiting temperature of 175 DEG C for vehicle rubber pipe

InactiveCN102875906AImprove resistance to oxidative degradationLow resistance to oxidative degradationFlexible pipesPolymer sciencePolyethylene glycol

The invention relates to an ethylene-propylene-diene monomer composition with a limiting temperature of 175 DEG C for a vehicle rubber pipe. The ethylene-propylene-diene monomer composition comprises ethylene-propylene-diene monomer rubber, methyl acrylate (Ma)-150, polyethylene glycol, anti-aging agents, carbon black, VM56, high flash point paraffin oil, coupling agent NDZ-130, di(tert-butylperoxy) diisopropyl benzene and assistant crosslinker trimethylopropane trimethacrylate (TMPTMA). According to the formula of the composition, the high temperature resistance is excellent, the performance is slightly reduced after 72 hours under the high temperature of 175 DEG C, the variation in hardness is maintained within 10, the compression set after high temperature resistance is low, simultaneously the performance retention rate after oil resistance is good, the volume change is maintained within 100%, the low temperature resistance is good, the ethylene-propylene-diene monomer composition can be used at the low temperature of 45 DEG C below zero, the ozone resistance is excellent, and the formula can meet requirements of heating system and air intake and exhaust system rubber pipes and intercooler air outlet and radiator flexible pipes which are used at short time under the limiting condition of high temperature of 175 DEG C.

Owner:TIANJIN PENGYI GRP CO LTD

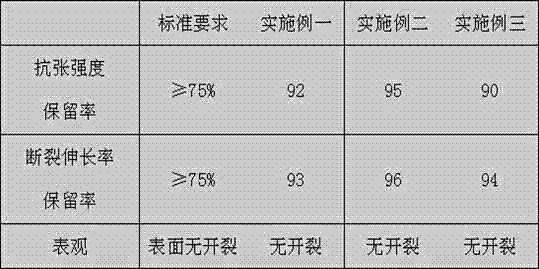

Moldproof polyethylene sheath material for cables and preparation method thereof

ActiveCN103571029AMaintain physical and mechanical propertiesExtended service lifeInsulated cablesInsulatorsPhosphateTurpentine

The invention discloses a moldproof polyethylene sheath material for cables and a preparation method thereof. The moldproof polyethylene sheath material for cables is prepared from the following raw materials in parts by weight: 80-90 parts of linear low density polyethylene, 15-20 parts of chlorosulfonated polyethylene, 10-15 parts of poly(4-methyl-1-pentene), 20-30 parts of carbon black N660, 4-8 parts of turpentine, 5-10 parts of dioctyl terephthalate, 1-2 parts of anilinomethyl triethoxy silane, 3-5 parts of methyl p-hydroxybenzoate, 8-12 parts of decabromodiphenyl oxide, 5-10 parts of zinc borate, 10-15 parts of aluminum hydroxide, 4-8 parts of brucite powder, 5-10 parts of tri(2-chloropropyl)phosphate, 2-4 parts of light magnesium oxide, 1-2 parts of tributyltin chloride, 2-3 parts of barium stearate, 3-6 parts of calcium hydroxide, 3-4 parts of oxidized polyethylene wax, 5-8 parts of quartz powder, 3-5 parts of nano silver and 4-6 parts of composite filler. On the premise that the excellent moldproof function of the sheath material is ensured, the sheath material can effectively inhibit Aspergillus niger, Aspergillus terreus and other molds from growth and reproduction, so that the cable is free from mold invasion, and the service life of the sheath is prolonged.

Owner:滁州三界外信息科技有限公司

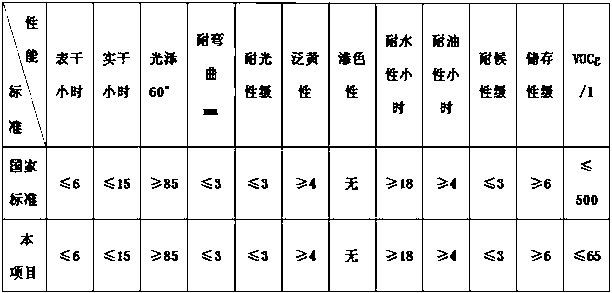

Water-diluted alkyd paint and preparation method thereof

InactiveCN103224748AReduce usageMaintain physical and mechanical propertiesPolyester coatingsPolymer scienceActive agent

The invention discloses water-diluted alkyd paint which comprises the following components in percentage by weight: 30-50% of alkyd resin, 5-30% of tinting pigment, 0.1-20% of filler pigment, 0.5-2% of assistant and 10-40% of dilution water, wherein the dilution water is tap water with a certain amount of specific surfactant; the surfactant refers to sodium sulfonate or nonylphenol polyoxyethylene ether and derivative thereof (bigger than 10 alkyls); and the dilution water comprises the following components in percentage by weight: 0.1-5% of surfactant, 95-99.5% of tap water and 0.5-2% of defoaming agent. According to the invention, the dilution water is used instead of organic solvent to greatly reduce the use of organic solvent, and the inherent physical and mechanical properties of the alkyd paint are ensured; and alkoxy groups in the dilution water and carbon groups in the alkyd resin are connected through hydrogen bonds (i.e. subjected to hydrogen bonding reaction), and the both are combined to compose a high-molecular-weight polymer grid structure so as to enhance the affinity of the alkyd resin, so that the formed emulsion is very stable, and the prepared paint is very stable in storage performance.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Cable sheathing material containing modified dickite powder and preparation method thereof

InactiveCN106633227AImprove crack resistance and frost resistanceGood low temperature resistanceRubber insulatorsCarbon blackEpoxidized soybean oil

The invention discloses a cable sheathing material containing modified dickite powder and a preparation method thereof. The cable sheathing material is prepared from the following raw materials in parts by weight: 50 to 60 parts of natural rubber, 20 to 30 parts of butadiene rubber, 10 to 15 parts of polybutylene terephthalate, 15 to 20 parts of stearic acid, 4 to 6 parts of chlorosulfonated polyethylene, 8 to 10 parts of p-tert-butyl-phenolic resin, 4 to 6 parts of microcrystalline wax, 3 to 6 parts of epoxidized soybean oil, 8 to 10 parts of anilmomethyl triethoxy silane, 5 to 7 parts of decabromodiphenyl ether, 1 to 3 parts of nanometer alumina, 3 to 5 parts of zinc borate, 3 to 5 parts of fumed white carbon black, 8 to 10 parts of bentonite, 8 to 12 parts of modified dickite powder, 4 to 7 parts of brucite powder and 3 to 6 parts of tree ash. The cable sheathing material provided by the invention has excellent low-temperature resistance with the lowest temperature reaching minus 65 DEG C on the basis of guaranteeing physical and mechanical performances and flame retardance of the sheathing material.

Owner:ANHUI TIANYUAN CABLE

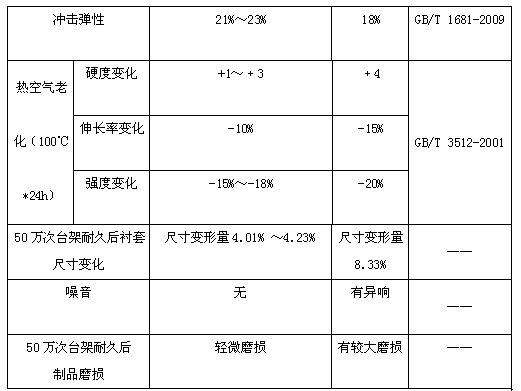

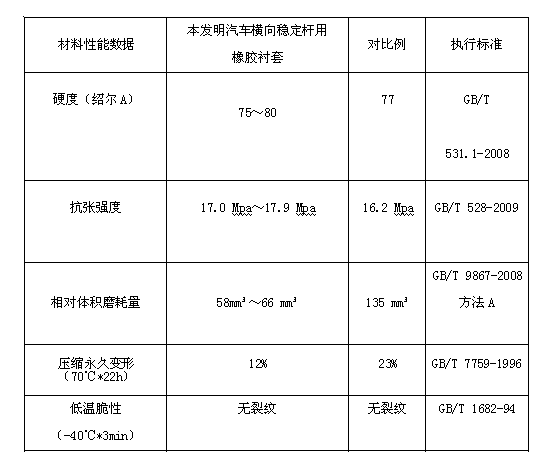

High-hardness low-compression-deformation self-lubricating rubber bush used in vehicle transverse stabilizing bar

ActiveCN103131064AMaintain physical and mechanical propertiesRapid precipitationStearic acidMechanical property

The invention relates to a high-hardness low-compression-deformation self-lubricating rubber bush used in a vehicle transverse stabilizing bar. The rubber bush is prepared from the raw materials of, by mass, 50-70 parts of butadiene rubber, 40-65 parts of styrene-butadiene rubber, 5-8 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of a silane coupling agent Si-69, 3-9 parts of an antioxidant, 2-5 parts of a flow aid Disperaid4A, 1-5 parts of paraffin FLY-3, 10-20 parts of oleamide CP, 65-105 parts of carbon black, 3-10 parts of aromatic oil 790, 1-2 parts of sulfur, 1-1.5 parts of an accelerator CBS, 0.3-0.8 parts of an accelerator TT, and 0.1-0.3 parts of an anti-scorching agent CTP. According to the invention, raw material ratio is optimized, such that various physical and mechanical properties of the rubber bush are ensured, and the defect of the influence on entire-vehicle NVH due to noise caused by poor material resilience due to large compression permanent deformation caused by the addition of amide slippery agents is substantially ameliorated.

Owner:GREAT WALL MOTOR CO LTD

Sericin graft-modified natural latex, preparation method and applications thereof

InactiveCN103626940AReduce contentReduce the possibility of inducing an allergic reactionNitrogen atmosphereWater soluble

The invention belongs to the technical field of rubber chemical modification, and discloses a sericin graft-modified natural latex, a preparation method and applications thereof. The natural latex comprises following ingredients, by weight, 50 to 100 parts of natural latex, 25.3 to 69.6 parts of a sericin water solution, 0.2 to 1.0 part of a first initiator, and 0.2 to 1.0 part of a second initiator. The preparation method comprises following step: in nitrogen atmosphere, 50 to 100 parts of natural latex and 25.3 to 69.6 parts of the sericin water solution are stirred with a uniform speed; 0.2 to 1 part of the first initiator is added dropwise; and 0.2 to 1.0 of the second initiator is added dropwise at a uniform speed; and an obtained mixture is subjected to polymerization, and is allowed to stand so as to obtain the sericin graft-modified natural latex. The preparation method is based on surface energy difference of sericin and natural latex, and sericin is gathered at the surface of natural latex so as to isolate allergic proteins. At the same time, hydrogen-bond interaction between amino acids in sericin and allergic water soluble proteins in natural laxe is induced, and the allergic water soluble proteins are denatured, so that occurrence possibility of induced allergic reaction is reduced greatly without influencing rubber physical and mechanical properties.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Anti-seepage coated fabric manufacturing method

ActiveCN106120359AStrong tensile breaking strengthHigh tear strengthWoven fabricsCoatingsPolyesterGram

The invention relates to an anti-seepage coated fabric manufacturing method which includes the steps of base fabric weaving, coating agent preparation, primary coating, secondary coating, plasticizing or plasticizing and surface treatment. High-strength polyester fibers with the fineness of 1000-1500D are used as raw materials and woven into a polyester base fabric by a Panama weaving method, the gram weight of each inch (14-20)*(14-20) is 244-540g / m<2>, the coated amount of front coating is 480-700g / m<2>, and the coated amount of back coating is 220-380g / m<2>. The thickness of a manufactured product is far larger than that of a conventional product, various physical and mechanical performances can still be ensured, surfaces are compact and even, defects are fewer, and the product has the advantages of seepage resistance, mildew prevention, bacterial inhibition, environmental protection, aging resistance, stripping resistance and the like. The grade of the product is higher than that of a common waterproof fabric for an awning, and the product can be applied to waterproof engineering of drinking water containers, small swimming pools, tunnels, dams, roofs and the like, and accordingly has high market and vitality.

Owner:HAININ JINDA COATING

Medicinal synthetic spacing piece and preparation method thereof

ActiveCN102516676AMaintain physical and mechanical propertiesGuaranteed stabilityElastomerStearic acid

The invention relates to a medicinal packaging material, in particular to a medicinal synthetic spacing piece and a preparation method thereof. The medicinal synthetic spacing piece is characterized by being prepared from the following raw materials: chlorinated butyl rubber, calcined kaolin, tertiary octyl phenol formaldehyde resin, stearic acid, zinc oxide, modified polyethylene, titanium pigment, semi-reinforced furnace treated black and magnesia. The medicinal synthetic spacing piece has the advantages that: (1) a medicinal elastomer is taken as a major raw material, so that production cost is reduced greatly while the physical and mechanical properties required by the spacing piece are ensured; (2) various raw materials used in a formula are free from toxic or side effect, are completely consistent with the standard of medicinal raw materials, are completely environmentally-friendly, and are free from environmental pollution; (3) a production process is simple, energy consumptionis lowered greatly, and production efficiency is increased; (4) procedures are reduced, so that manual error factors are reduced greatly, and the stability of quality is ensured; and (5) product performance is high, and an ecdysis phenomenon is avoided.

Owner:SHANDONG PHARMA GLASS

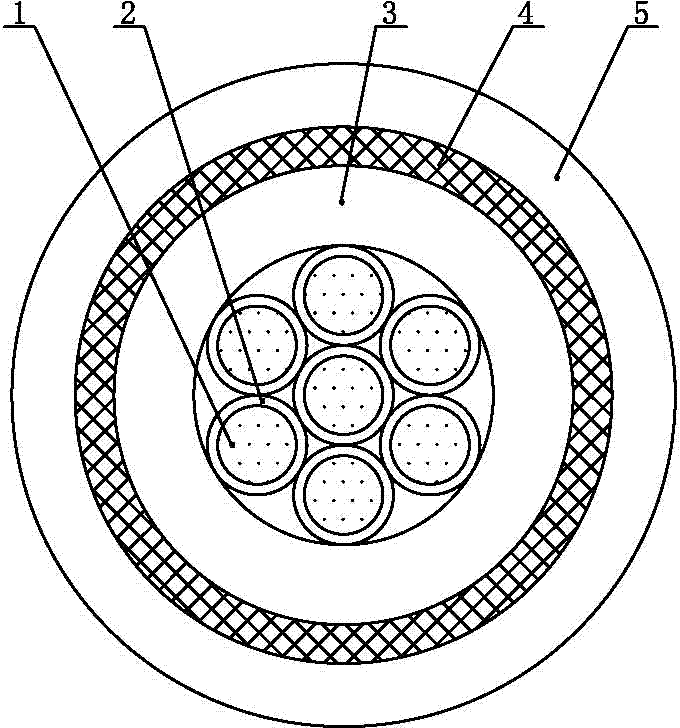

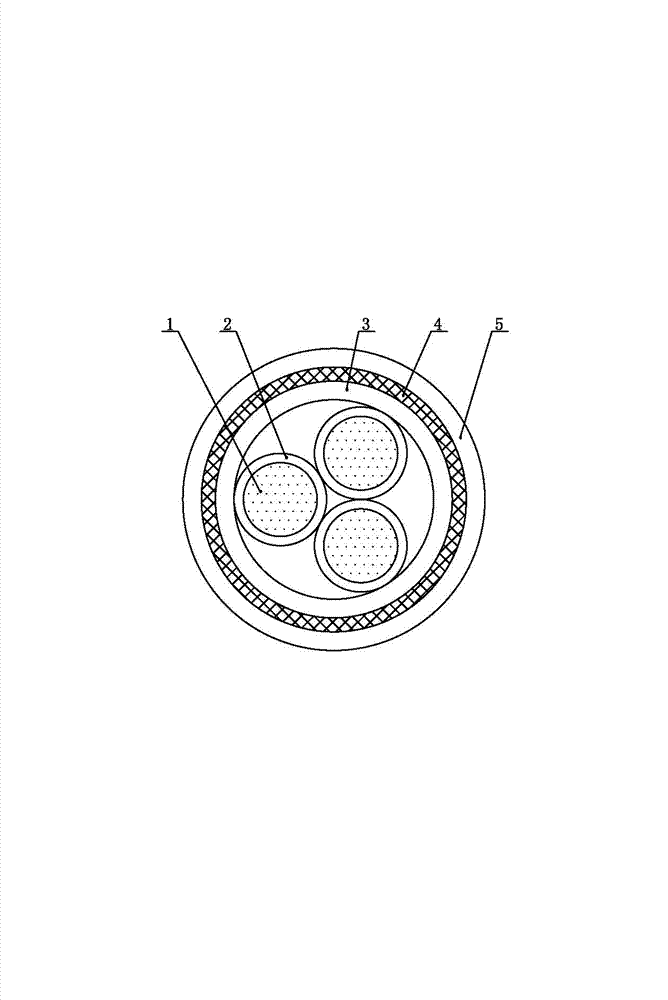

Whitening ultraviolet-proof ethylene-propylene rubber insulation control cable for ships and manufacturing method thereof

InactiveCN102969057AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesCopper conductorInsulation layer

The invention relates to a whitening ultraviolet-proof ethylene-propylene rubber insulation control cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a 0.35-2.5mm<2> tin-plated annealed stranded copper conductor to form an insulation wire core; a plurality of insulation wire cores are stranded to the right to form a cable core; and then an inner lining layer is extruded, a copper alloy wire weaving armor layer is coated, and an outer sheath is extruded successively. The insulation layer is prepared from the following raw material components: 12 parts of Keltan5508, 8 parts of Keltan21, 0.4-0.6 part of TAIC, 0.5-0.8 part of DCP (Dicumyl Peroxide), 0.3 -0.6 part of Ager MB, 0.1-0.2 parts of anti-aging agent 2246, 0.8-1.2 parts of oxidation zinc, 0.1-0.3 parts of stearic acid, 1-1.5 parts of rutile-type titanium dioxide, 10-12 parts of lightweight calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of 38# cylinder oil, 2-3 parts of vapor-phase-method hydrated silica, 0.05-0.1 parts of an ultraviolet absorbent UV-326, and 0.1-0.3 parts of coupling agent A-174. The insulation layer of the cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Preparation method of polyvinyl chloride disentanglement mother material with high polymerization degree and ultrahigh polymerization degree

The preparation method of high polymerization degree and ultrahigh polymerization degree polyvinyl chloride disentanglement mother material includes the following steps: dissolving the high polymerization degree of ultrahigh polymerization degree polyvinyl chloride in the mesomolecular solvent di-2-ethylhexyl phthalate (DOP), heating, stirring, dissolving to transparent, naturally cooling to roomtemp., the solution can be directly used in various formulae or washing solution with ethyl alcohol (or methyl alcohol), filtering and drying so as to obtain the disentangled high polymerization degree or ultrahigh polymerization degree polyvinyl chloride mother material.

Owner:NANJING UNIV

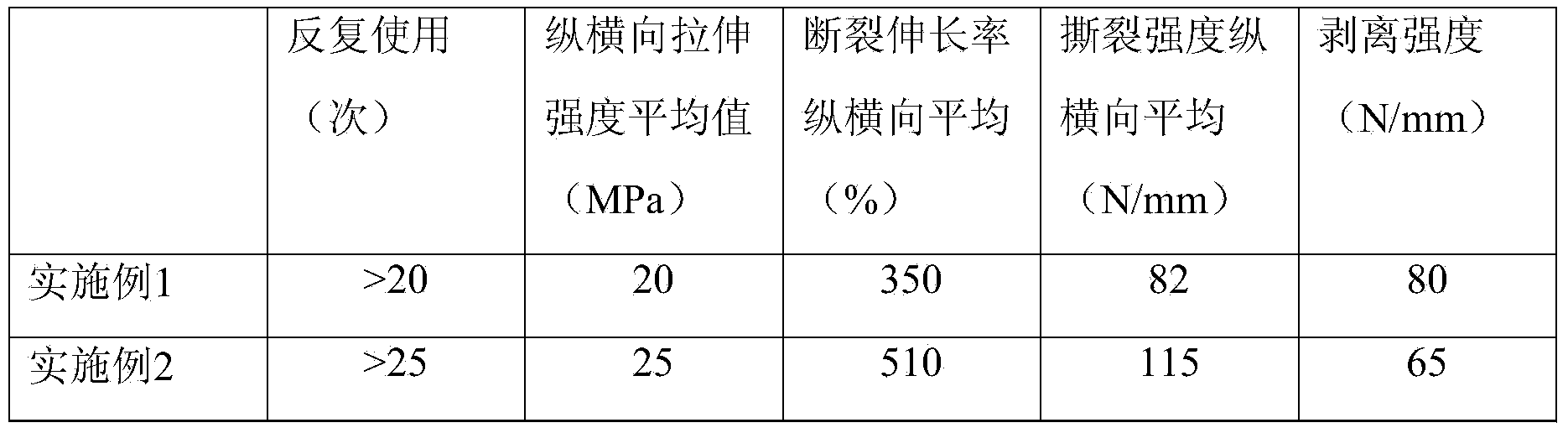

Polyethylene isolating film reusable in tire production and preparation method of polyethylene isolating film

ActiveCN103862768AImprove mechanical propertiesGood oxygen barrier effectSynthetic resin layered productsLaminationEngineeringOxygen

The invention relates to a polyethylene isolating film reusable in tire production and a preparation method of the polyethylene isolating film, in particular relates to an isolating film reusable in the production process of radial tires, and belongs to the technical field of production of the radial tires. The polyethylene isolating film comprises an outer film, an intermediate film and an inner film, wherein the thickness ratio of the three films is (3-4):(2-4):(3-4); the total thickness of the outer film, the intermediate film and the inner film is 30-150 microns; the polyethylene isolating film is prepared by batching, fusion, extrusion, film blowing, air-cooling sizing, surface treatment and winding. Oxygen can be isolated by the three-layer composite polyethylene isolating film prepared through the method, all layers of the polyethylene isolating film are well compatible, disengaging and separation of the layers can be avoided, and the physical and mechanical properties can be kept under the condition that the film is reused.

Owner:HAOCHEN WUXI PLASTIC IND CO LTD

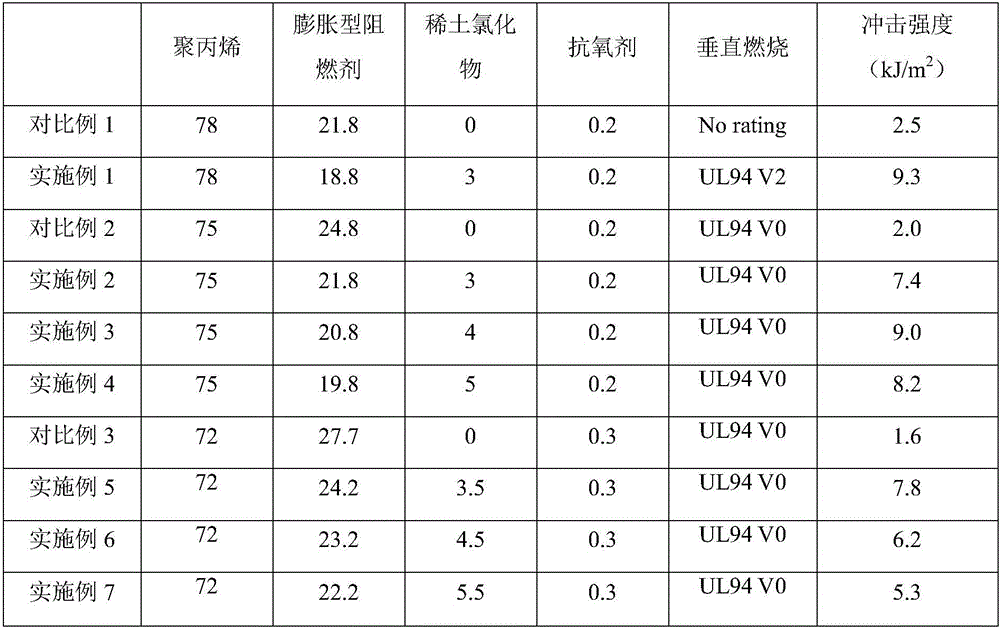

Rare-earth chloride and intumescent flame retardant synergic flame retardance polypropylene composite and preparation method thereof

ActiveCN106750936AHarm reductionLow heat generation and smoke generationPolypropylene compositesPolymer science

The invention discloses a rare-earth chloride and intumescent flame retardant synergic flame retardance polypropylene composite and a preparation method thereof. The composite is prepared from rare-earth chloride, an intumescent flame retardant and polypropylene. Rare-earth chloride is introduced into an intumescent flame retardant flame-resistant polypropylene material, rare-earth chloride and the intumescent flame retardant can achieve a synergic flame retardance effect, and the physical and mechanical performance of the intumescent flame retardant flame-resistant polypropylene material is effectively improved while the use amount of the intumescent flame retardant is reduced.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Rapid prototyping plastic

The invention relates to an organic polymer composite material, in particular to rapid prototyping plastic. The plastic comprises the following components in percentage by weight: 56-95.5 percent of nylon 66, 2.5-15 percent of molybdenum bisulfide, 0.3-3.5 percent of antioxidant, 0.1-4.2 percent of heat stabilizer, 0.1-2.9 percent of coupling agent, 0.1-3.0 percent of silicon oil with high molecular weight, 0.5-5.5 percent of activated carbon and 0.3-5.5 percent of emulsifying agent. According to the plastic disclosed by the invention, several agents with a certain proportion are added, so that the prototyping period of the plastic is shortened while certain physical performance of the plastic is ensured and the production efficiency can be improved to a great degree.

Owner:SUZHOU IND PARK XINFENGLIN PLASTIC TECH

Whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and manufacturing method thereof

InactiveCN102969064AExcellent light aging performanceGood physical and mechanical propertiesPower cablesCable/conductor manufactureCopper conductorInsulation layer

The invention relates to a whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; a plurality of insulation wire cores are stranded to the right to form a cable core; and then an inner lining layer is extruded, a copper alloy wire weaving armor layer is coated, and an outer sheath is extruded successively. The insulation layer is prepared from the following raw material components: 12 parts of Keltan5508, 8 parts of Keltan21, 0.4-0.6 parts of TAIC, 0.5-0.8 parts of DCP (Dicumyl Peroxide), 0.3 -0.6 part of Ager MB, 0.1-0.2 parts of anti-aging agent 2246, 0.8-1.2 parts of oxidation zinc, 0.1-0.3 parts of stearic acid; 1-1.5 parts of a rutile-type titanium dioxide, 10-12 parts of lightweight calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of 38# cylinder oil, 2-3 parts of vapor-phase-method hydrated silica, 0.05-0.1 parts of ultraviolet absorbent UV-326, and 0.1-0.3 parts of coupling agent A-174. The insulation layer of the cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Rubber gasket

The invention discloses a rubber gasket. The rubber gasket comprises, by weight, 10-20 parts of polysulfide rubber, 50-65 parts of fluororubber, 10-20 parts of polyamide, 2-6 parts of chlorosulfonated polyethylene, 1-2 parts of zinc sulfate, 0.5-2 parts of glass powder, 1-5 parts of terpene resin, 1-1.5 parts of anti-aging agent, 0.5-1.5 parts of vulcanizing agent, 10-20 parts of ethyl acetate and 10-15 parts of cyclohexanone. The rubber gasket is soft in texture, good in elasticity and high in chemical corrosion resistance.

Owner:LIUZHOU YINGHANG AUTO PARTS

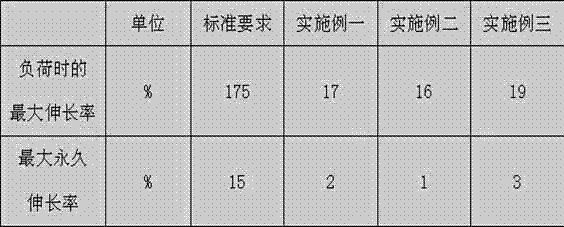

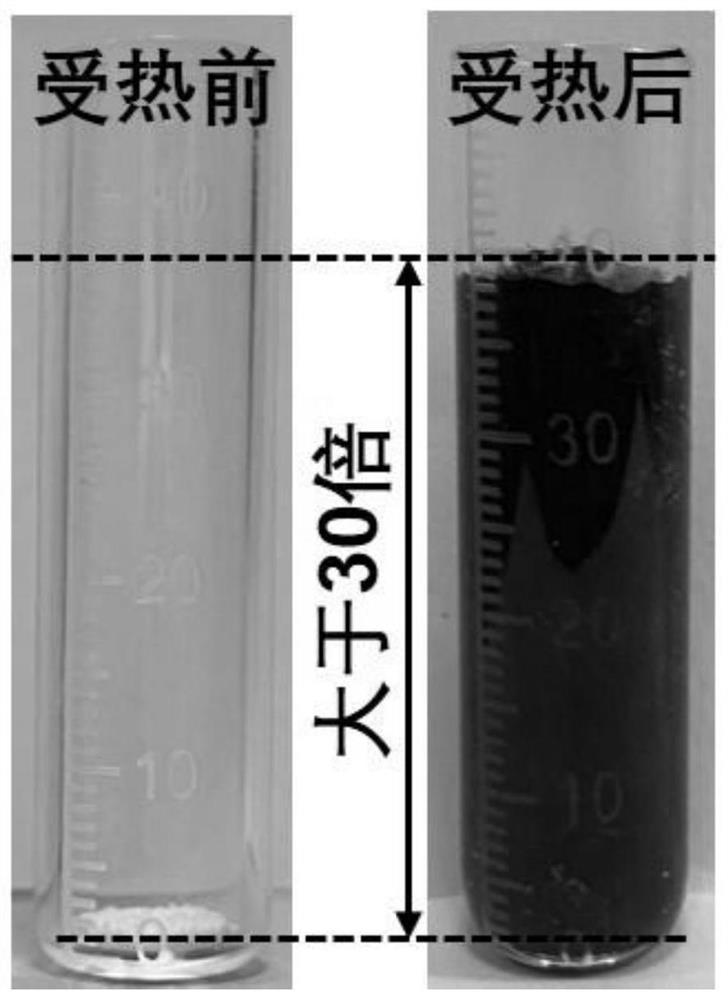

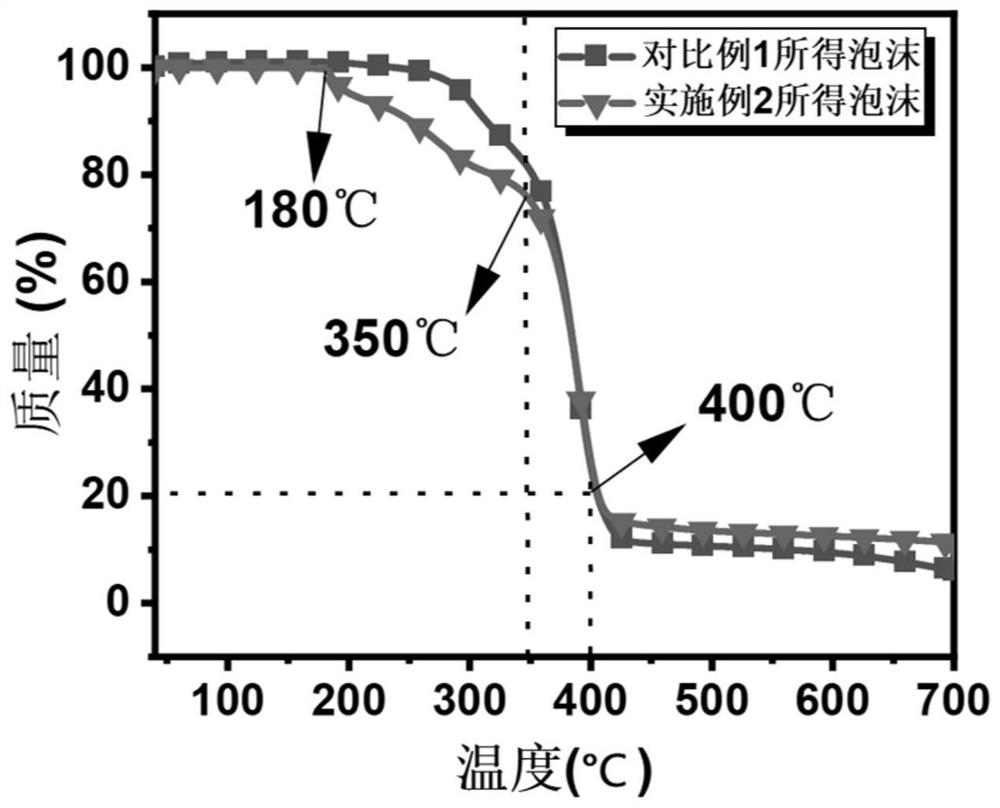

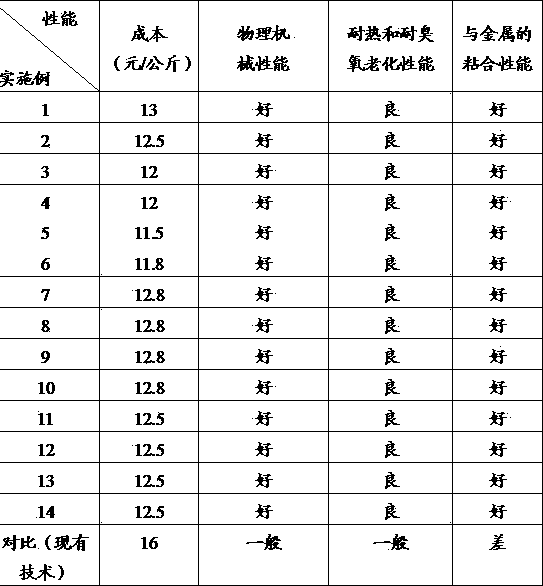

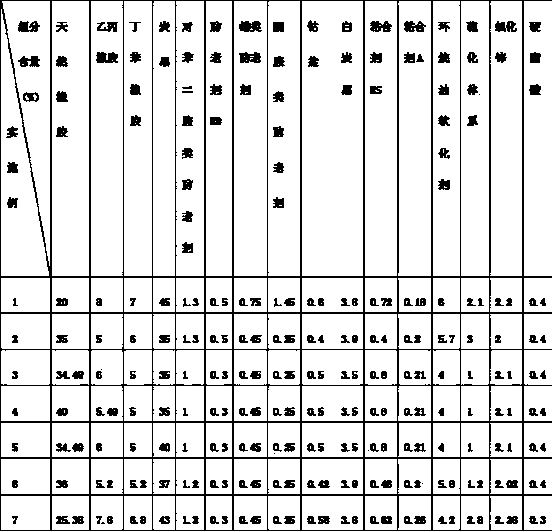

Intumescent flame retardant for polyurethane, flame-retardant polyurethane and preparation of flame-retardant polyurethane

PendingCN114672068AGood char formationGood dispersionFireproof paintsPolyurea/polyurethane coatingsPolymer scienceHalogen

The invention relates to an intumescent flame retardant for polyurethane and a preparation method of the intumescent flame retardant, which can endow the polyurethane with flame retardance and low smoke, and belongs to the field of flame retardants. The invention provides an intumescent flame retardant for polyurethane. The intumescent flame retardant is a compound or composition containing an alkaline organic metal component and a carbon source substance component at the same time. The invention provides a flame retardant for polyurethane. The obtained flame retardant is only composed of alkaline organic metal salt and a carbon source substance according to a proper proportion; the flame retardant does not contain phosphorus, halogen and other traditional flame retardant elements, and when the flame retardant is used for flame retardant polyurethane, the flame retardant can endow the polyurethane with flame retardancy and low smoke property.

Owner:SICHUAN UNIV

Rubber hose and preparation method thereof

InactiveCN105906880AStrong impact resistanceImprove corrosion resistanceFlexible pipesAluminium sulfateNitrile rubber

The invention discloses a rubber hose. The rubber hose is prepared from, by weight, 30-50 parts of butadiene styrene rubber, 25-50 parts of nitrile rubber, 8-15 parts of white carbon black, 3-10 parts of polyisobutene, 1-5 parts of aluminum sulfate, 2-6 parts of glass powder, 5-10 parts of alkyd resin, 0.5-2 parts of a sulfurizing agent, 20-30 parts of xylene and 0.5-1 part of a crosslinking agent. A preparation method of the rubber hose comprises the steps that the raw materials are weighed by weight of parts, and all the raw materials are arranged in an ultrasonoscope for mixing, then shifted into a mixing mill for extrusion molding and finally molded. The rubber hose is high in mixing efficiency and high in shock resistance and corrosion resistance, and a hose body is solid and durable in use.

Owner:LIUZHOU YINGHANG AUTO PARTS

Rubber matrix for inflating valve

ActiveCN103665449AReduce adhesive application processIncrease productivityVulcanizationHexamethylenetetramine

The invention discloses a rubber matrix for an inflating valve, which comprises the following components in percentage by weight: 20-40% of natural rubber, 5-8% of ethylene-propylene rubber, 5-7% of styrene-butadiene rubber, 35-45% of filler reinforcement system, 2-4% of antiaging system, 0.4-0.6% of cobalt salt, 4.5-4.7% of resorcinol-hexamethylenetetramine-white carbon black system, 4-6% of softening agent, 1-3% of vulcanization system and 2.4-2.6% of activator system. According to the invention, a part of rubber matrix in an inflating valve is replaced with natural rubber, thus greatly lowering the cost of the rubber matrix and providing better physical and mechanical properties for the rubber; the originally needless antiaging system is added and combined in the composition, and the antiaging system can overcome the decrease of static / dynamic ozone resistance and aging resistance of the rubber matrix for an inflating valve and can promote the bonding between the rubber matrix and a metal core at the same time; a small amount of cobalt salt and resorcinol-hexamethylenetetramine-white carbon black system are added in the composition, thereby increasing the bonding force of the rubber matrix; and a large amount of filler reinforcement agent is used in the composition, thereby ensuring the physical and mechanical properties of the rubber matrix, and further lowering the cost.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Conveyor roller high temperature resistant acid and alkali resistant rubber coated layer

InactiveCN104893302AMaintain physical and mechanical propertiesHigh temperature resistantDiaminePolypropylene

The invention discloses a conveyor roller high temperature resistant acid and alkali resistant rubber coated layer which consists of the following components by weight: 70-90 parts of methyl vinyl phenyl silicone rubber, 60-80 parts of nitrile rubber, 25-35 parts of rubber and plastic alloy, 8-12 parts of polypropylene resin, 10-13 parts of thermosetting epoxy resin, 2-3.5 parts of tetramethylthiuramdisufide, 1-1.4 parts of disulfide dibenzothiazole, 20-25 parts of high abrasion furnace black, 8-20 parts of dioctyl phthalate or dibutyl phthalate, 3-4 parts of N-isopropyl-N'-phenyl para-phenylene diamine and 10-20 parts of barium sulfate. Compared with the prior art, the rubber coated layer can keep original physical and mechanical properties for a long time under the action of acid and alkali bath, and has high temperature resistant characteristics.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com