Moldproof polyethylene sheath material for cables and preparation method thereof

A polyethylene sheath, anti-mold technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems that the anti-mold function is not obvious, the flame-retardant polyethylene sheath material does not have the function of anti-mold agent, and cannot satisfy users, etc. , to achieve the effect of improving the anti-mold function, prolonging the service life and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

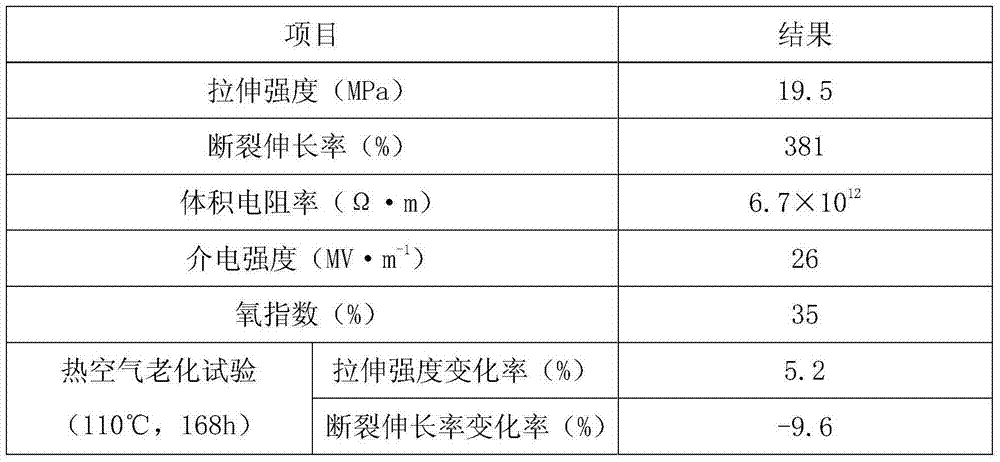

Examples

Embodiment Construction

[0010] A anti-mold polyethylene sheath material for cables, made of the following raw materials in weight (kg): linear low-density polyethylene 80, chlorosulfonated polyethylene 20, poly-4-methyl-1-pentene 10, Carbon black N66025, turpentine 6, dioctyl terephthalate 8, anilinomethyltriethoxysilane 1.5, methyl p-hydroxybenzoate 4, decabromodiphenyl ether 10, zinc borate 8, aluminum hydroxide 12, Brucite powder 6, tris(2-chloropropyl) phosphate 8, light magnesium oxide 3, tributyl tin chloride 1.5, barium hardate 2, calcium hydroxide 4, oxidized polyethylene wax 3, quartz powder 6. Nano silver 4, composite filler 5;

[0011] The preparation method of the composite filler is as follows: a. Take bentonite, barite, and monazite in a weight ratio of 5:4:3, then add 2% coal powder and 1% activated carbon by weight of bentonite, and mix them uniformly at 560 ° C. Calcined for 3 hours, cooled to room temperature, crushed to a particle size below 15 μm, then added water to beat to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com