Intumescent flame retardant for polyurethane, flame-retardant polyurethane and preparation of flame-retardant polyurethane

An intumescent flame retardant, polyurethane technology, applied in the field of flame retardants, can solve the problems of poor compatibility and dispersion of polyurethane matrix, damage to the physical and mechanical properties of the substrate, and deterioration of the physical and mechanical properties of the substrate, so as to maintain the physical and mechanical properties of the substrate. Effects of mechanical properties, suppression of smoke release, and improvement of limiting oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] First, sodium tartrate and linseed gum were added to a ball mill in a mass ratio of 2:1, and after ball milling for 1 hour, the flame retardant composition was taken out and dried in a blast drying oven at 80°C for 4 hours to obtain an intumescent flame retardant. The residual carbon content of the flame retardant in the thermogravimetric test in the air atmosphere is 56%, and the expansion into carbon under the heating condition of 300 ° C is 22 times the original volume.

[0066] Then, 80 parts by weight of polyether polyol (hydroxyl value 30mgKOH / g), 20 parts by weight of grafted polyether polyol (hydroxyl value 20mgKOH / g), 1 part by weight of water, 1 part by weight of triethanolamine, 0.5 parts by weight of pore-opening agent, 1.0 parts by weight of silicone oil, 0.1 part by weight of foaming tertiary amine catalyst, 0.4 part by weight of gel-type tertiary amine catalyst, and 15 parts by weight of intumescent flame retardant are added to the same container, and mixe...

Embodiment 2

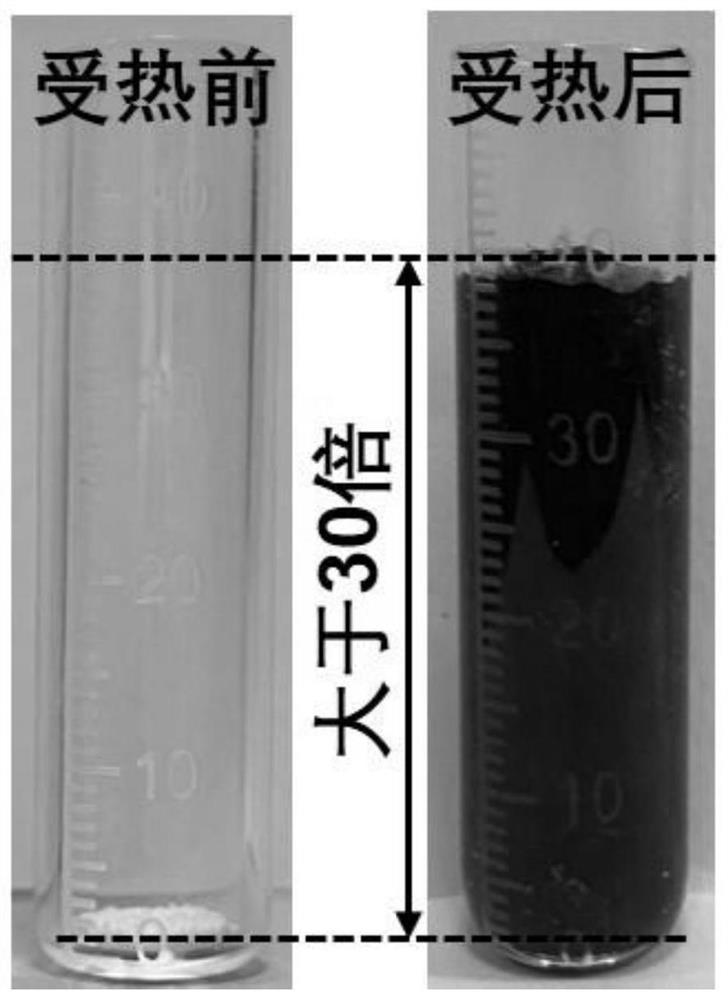

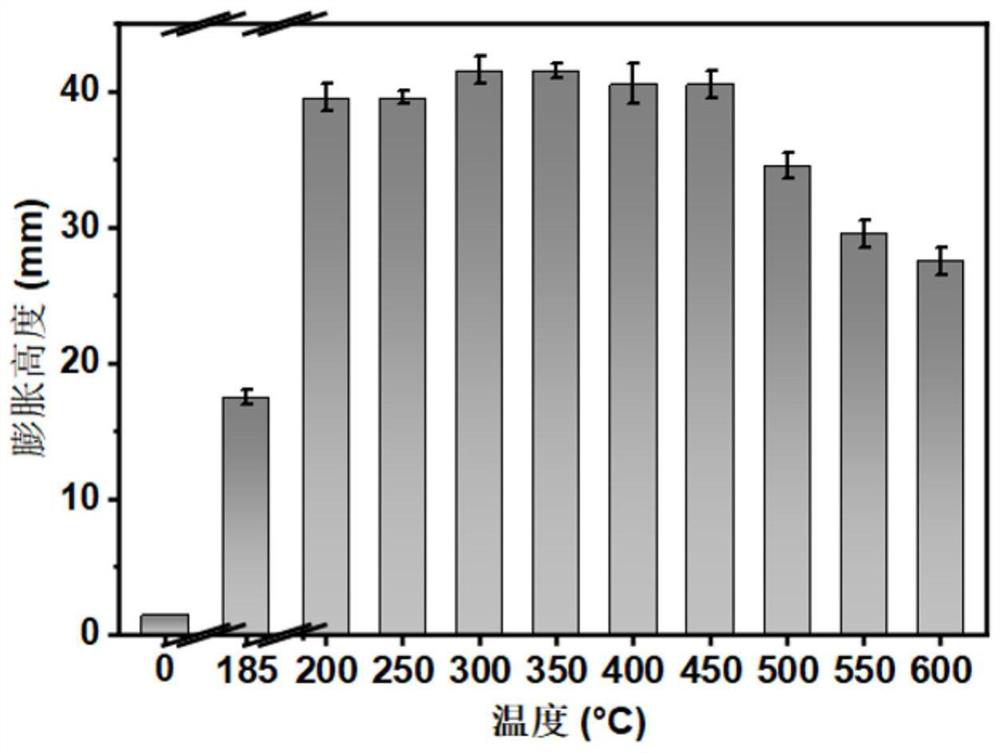

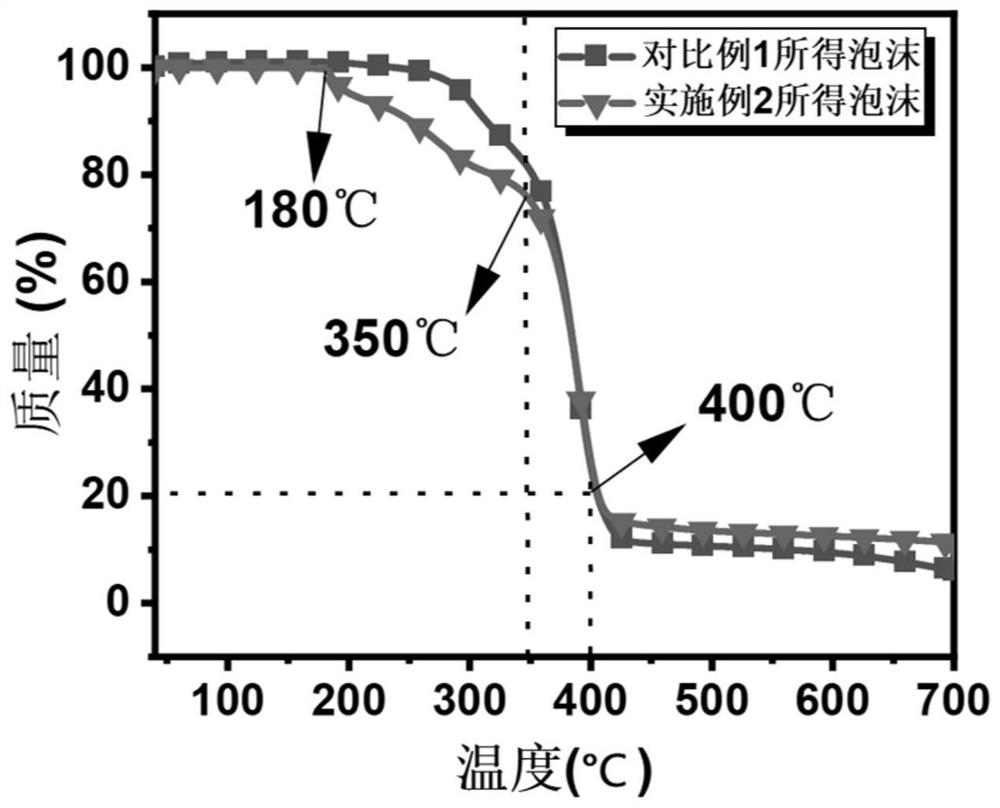

[0068] First, lignosulfonic acid and magnesium carbonate (the molar ratio of sulfonate to magnesium ion is 1:2) are reacted in water at 60 degrees Celsius until the pH is stable, and then continue to react for 0.5 h, then the solvent is removed, and the preparation is made after drying. Obtain magnesium lignosulfonate; then add magnesium lignosulfonate and magnesium gluconate into a ball mill at a mass ratio of 2:3, and after ball milling for 1.5 hours, take out the flame retardant compound and place it in a blast drying oven at 80 °C for drying After 4 hours, an intumescent flame retardant was obtained. The residual carbon content of the flame retardant in the thermogravimetric test in an air atmosphere is 65%, and the expansion into carbon under heating conditions at 300 ° C is 47 times the original volume.

[0069]Then, 80 parts by weight of polyether polyol (hydroxyl value 30mgKOH / g), 20 parts by weight of grafted polyether polyol (hydroxyl value 20mgKOH / g), 1 part by weig...

Embodiment 3

[0071] First, react malic acid and cesium hydroxide (the molar ratio of carboxylate to cesium ion is 1:1) in ethanol at room temperature until the pH is stable, and then continue the reaction for 2 h, then remove the solvent and dry to obtain apples Cesium acid. 80 parts by weight of polyether polyol (hydroxyl value 30mgKOH / g), 20 parts by weight of grafted polyether polyol (hydroxyl value 20mgKOH / g), 1 part by weight of water, 1 part by weight of triethanolamine, 0.5 part by weight parts of pore-opening agent, 1.0 parts by weight of silicone oil, 0.1 part by weight of foaming tertiary amine catalyst, 0.4 part by weight of gel-type tertiary amine catalyst, and 20 parts by weight of cesium malate were added to the same container, stirred and mixed at high speed, and then It is blended with 35 parts by weight of modified isocyanate MDI (NCO content: 26%), quickly poured into a mold, and heated and cured at 80°C to obtain a flame-retardant flexible polyurethane foam; after testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com