Flame-retardant polyolefin composition and preparation method thereof

A composition and polyolefin technology, applied in the field of olefin resins, can solve problems such as poor flame retardancy, toxic gas release, and poor low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

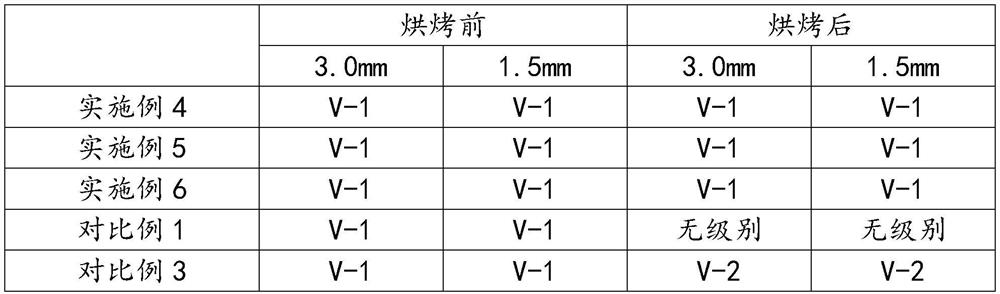

Examples

Embodiment 1

[0027] Preparation of flame retardant:

[0028] Step A11, mix pentaerythritol and dioxane, add phosphorus oxychloride at a temperature of 95°C, stir and react for 6 hours, filter after the reaction, and wash the filter cake with dioxane and n-hexane in sequence, and the washing is completed Finally, dry to constant weight at 70°C under vacuum conditions to obtain intermediate 1; wherein, the amount ratio of pentaerythritol, phosphorus oxychloride and dioxane is 3g: 1mL: 35mL; the mass fraction of phosphorus oxychloride is 50%;

[0029] Step A12. Mix intermediate 1, triethylamine and dichloromethane, then add acryloyl chloride, stir and react at 35°C for 16 hours, after the reaction is completed, cool to room temperature, filter, and concentrate the obtained filtrate under reduced pressure to remove Solvent to obtain intermediate 2; wherein, the ratio of intermediate 1, acryloyl chloride, triethylamine and dichloromethane is 2g: 1g: 1.1g: 20mL;

[0030] Step A13. Mix intermed...

Embodiment 2

[0032] Prepare the filler:

[0033] Step S11, mix talc powder and sodium hydroxide solution, stir at 90°C for 6h, then cool to room temperature, filter, wash with deionized water, after washing, dry at 80°C to constant weight to obtain hydroxyl To talcum powder, mix hydroxylated talc powder, ethanol and deionized water, adjust the pH value to 4 with acetic acid, disperse ultrasonically for 30 minutes, then add 3-aminopropyltrimethoxysilane, and react for 6 hours at 85°C. After the reaction, cooling, centrifugal washing, and drying were performed to obtain aminoated talcum powder; wherein, the mass fraction of sodium hydroxide solution was 30%, and the ratio of talcum powder and sodium hydroxide solution was 10g:150mL; hydroxylated talc powder, The dosage ratio of 3-aminopropyltrimethoxysilane, ethanol and deionized water is 10g: 2g: 75mL: 10mL;

[0034] Step S12, mix p-hydroxybenzaldehyde and absolute ethanol, then add aminoated talc powder, heat and reflux for 4 hours, after...

Embodiment 3

[0037] Prepare the filler:

[0038] Step S11, mix talc powder and sodium hydroxide solution, stir at 90°C for 6h, then cool to room temperature, filter, wash with deionized water, after washing, dry at 80°C to constant weight to obtain hydroxyl To talcum powder, mix hydroxylated talc powder, ethanol and deionized water, adjust the pH value to 4 with acetic acid, disperse ultrasonically for 30 minutes, then add 3-aminopropyltrimethoxysilane, and react for 6 hours at 85°C. After the reaction, cooling, centrifugal washing, and drying were performed to obtain aminoated talcum powder; wherein, the mass fraction of sodium hydroxide solution was 30%, and the ratio of talcum powder and sodium hydroxide solution was 10g:150mL; hydroxylated talc powder, The dosage ratio of 3-aminopropyltrimethoxysilane, ethanol and deionized water is 10g: 2g: 75mL: 10mL;

[0039] Step S12, mix p-hydroxybenzaldehyde and absolute ethanol, then add aminoated talc powder, heat and reflux for 4 hours, after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com