Patents

Literature

3612 results about "Powder talc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-emanation automobile inner fitting special-purpose material and preparation thereof

The invention relates to a kind of low emission type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, organic expellent of low molecule 1.0-3.0 parts, antioxidant 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and organic expellent of low molecule, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 3) three-stage vacuum extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

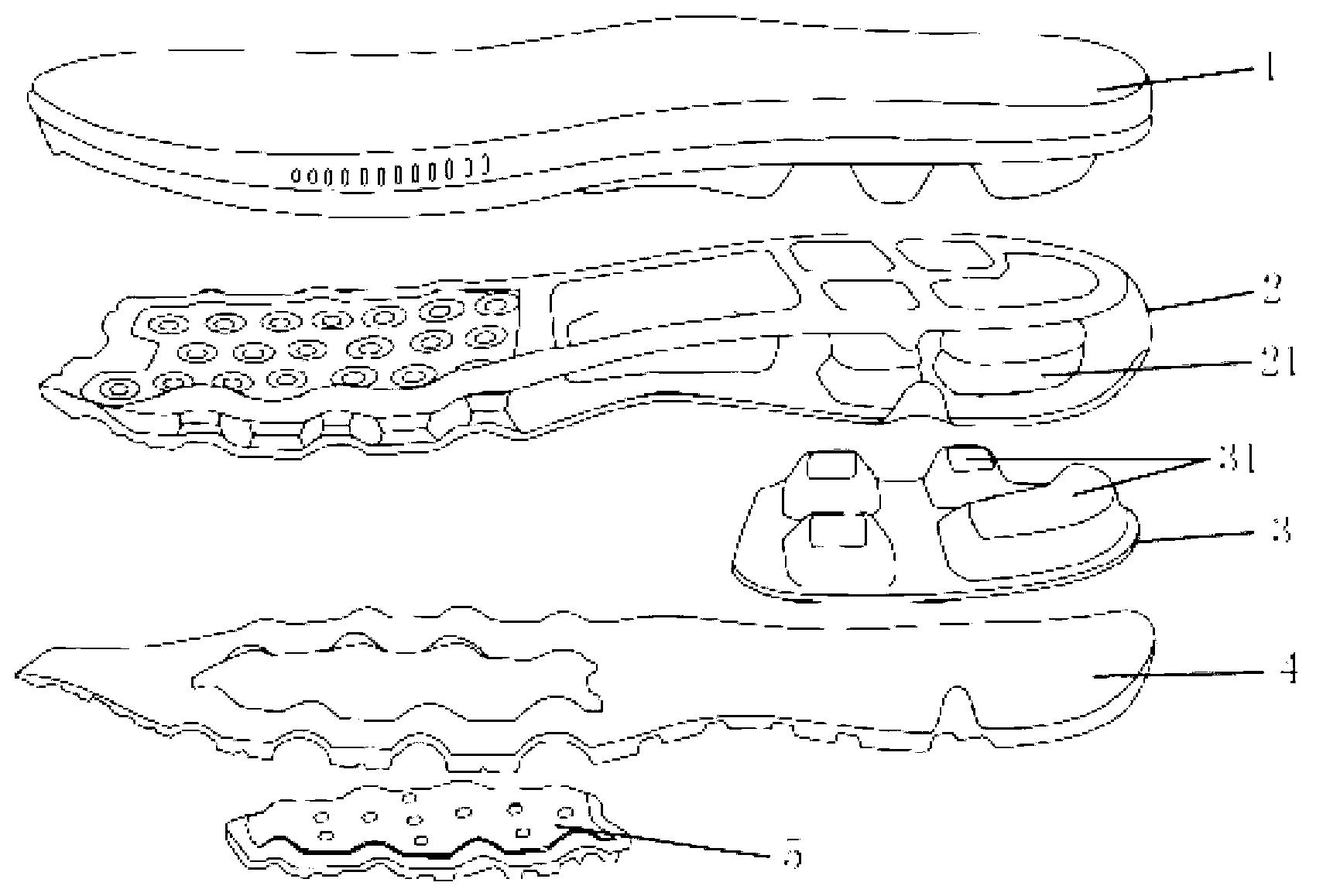

High-elasticity sneaker air cushion sole and production method thereof

The invention provides a high-elasticity sneaker air cushion sole and a production method thereof and researches a sneaker sole with high elasticity, high wear resistance and low hardness. The high-elasticity sneaker air cushion sole comprises a phylon (MD) midsole, an air cushion and a large sole which are sequentially and fixedly connected with one another from top to bottom, wherein an ethylene-vinyl acetate copolymer (EVA) cushion piece is assembled on a heel part of the air cushion; and the material formula of the MD midsole comprises the following components in parts by weight: 40-60 parts of EVA, 0-20 parts of ethylene propylene ternary gel, 0-30 parts of polyolefin elastomer (POE), 0-10 parts of talcum powder, 2.0-4.0 parts of a foaming agent, 0.6-1.0 part of a bridging agent, 1.0-2.0 part of a zinc oxide desulfurizing agent, 0.6-1.2 parts of stearic acid, 0.5-1.0 part of zinc stearate, 0.8-1.5 parts of a flow promotor and 0.3-0.8 part of a bridging addition agent.

Owner:新侨伟(福建)鞋服有限公司

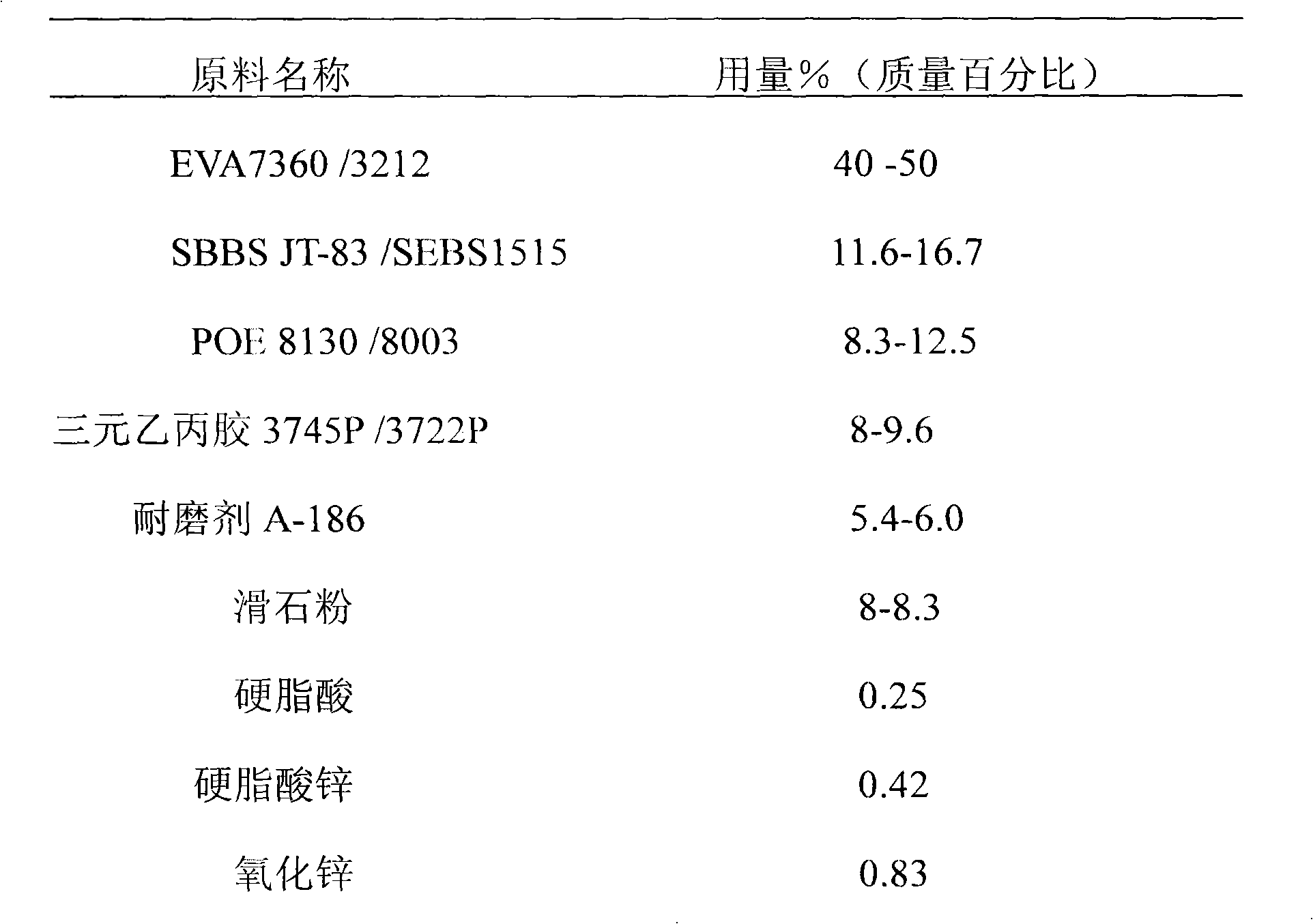

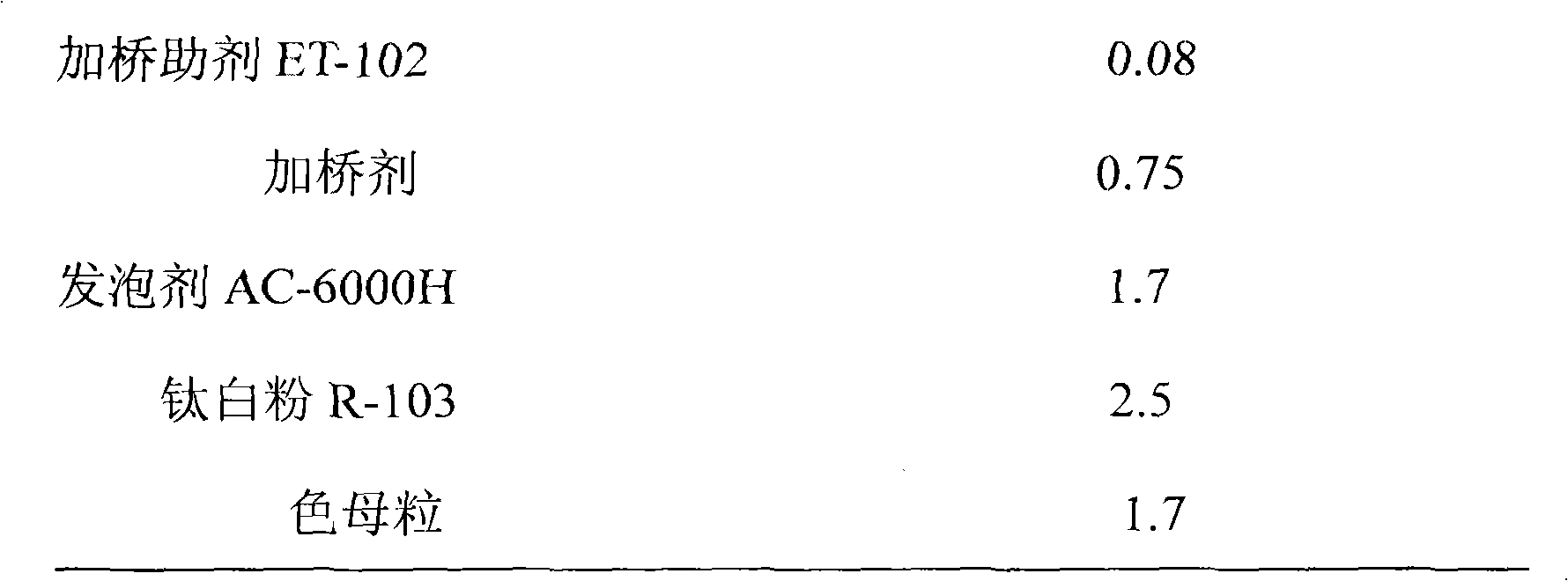

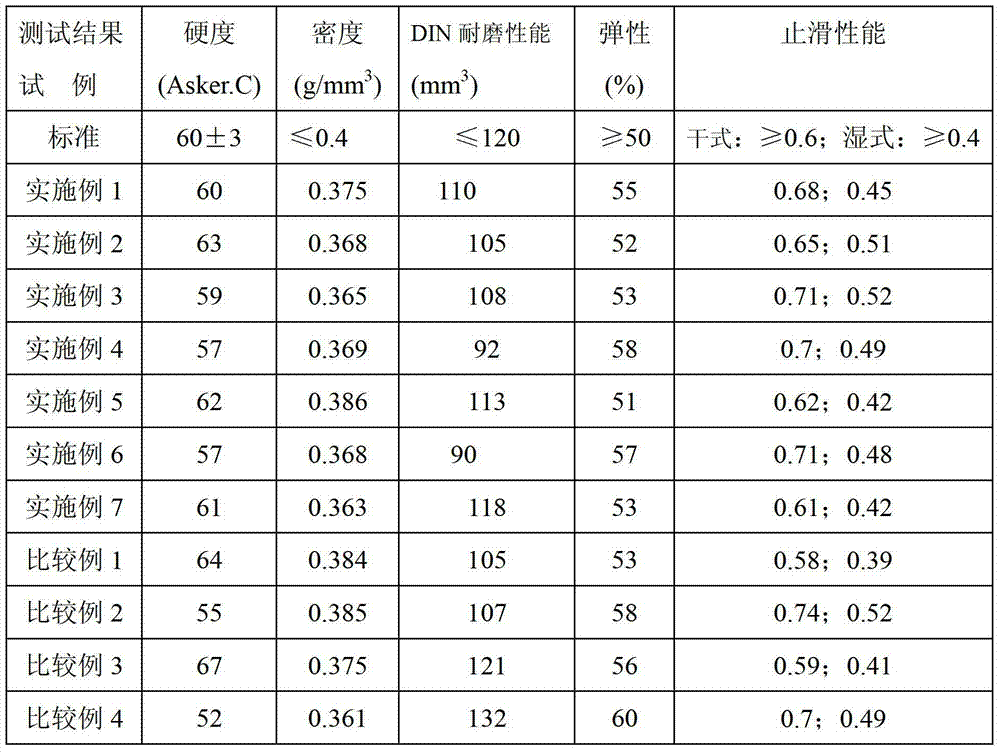

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Anti-refiring ultrafine ammonium phosphate dry chemical fire-extinguishing agent and its preparation method

InactiveCN1597024AUltrafine particle sizeLarge specific surface areaFire extinguisherSilicone oilTalc

A superfine ammonium phosphate dry chemical fire-extinguishing agent for preventing refiring is prepared from ammonium phosphate, ammonium sulfate, talc powder, mica powder, white carbon black and calcium carbonate through airflow pulverizing, proportional mixing, coating silicon oil, and coating F-C surfactant.

Owner:SICHUAN UNIV

Transparent super-hydrophobicity wood coating and preparation method thereof

InactiveCN103756541AParticle size controllableHydrophobic hasPolyurea/polyurethane coatingsPolyester coatingsOctadecyltrichlorosilanePolymer science

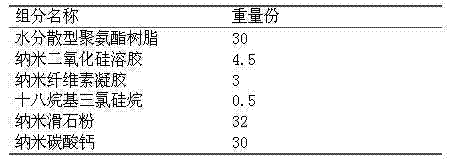

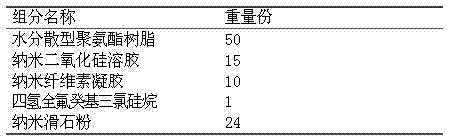

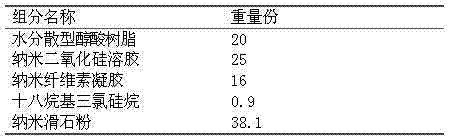

The invention discloses a transparent super-hydrophobicity wood coating which comprises the following components in parts by weight: 20-50 parts of water dispersive polyurethane resin or water dispersive alkyd resin, 4.5-25 parts of nano silica sol, 3-16 parts of nano cellulose gel, 0.1-1 part of octadecyl trichlorosilane or tetrahydroperfluorodecyltrichlorosilane or stearic acid and 0-45 parts of nano talc powder or nano calcium carbonate. A preparation method of the transparent super-hydrophobicity wood coating comprises the following steps: adding matrix resin and filler into a stirring kettle, and stirring uniformly to obtain slurry; grinding the slurry with a sand mill; adding a low-surface energy substance and supported nano silica sol; performing ultrasonic sufficient mixing for 30 minutes to obtain the transparent super-hydrophobicity coating. The transparent super-hydrophobicity wood coating disclosed by the invention has the advantages of low cost, controllable process, adjustable size and good applicability and is suitable for a preparation method of large-area preparation of transparent super-hydrophobicity surface; the prepared super-hydrophobicity film has good self-cleaning property, antifouling property, hydrophobic property, oleophobic property and the like.

Owner:GUANGDONG YIHUA TIMBER IND +1

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

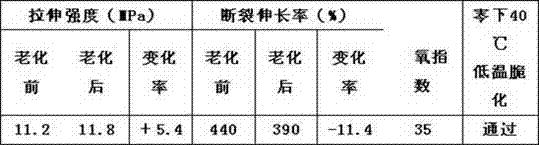

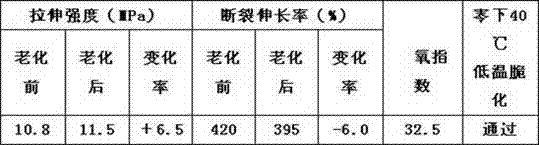

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

Environment-protection flame-proof electrostatic resistance polypropylene material and method for producing the same

The invention relates to an environmental-friendly polypropylene material with flame resistance and antistatic capacities, which comprises parts by weight of components that: 100pbw of pp resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers and 10-30 portions of antistatic agent. The PP resin is high fluidity homopolymerization PP; the flame retardant is deca-diphenylethane; the flame-retardant synergist is antimony trioxide; the filler is 2000 meshes talcum powder; the antistatic agent is conductive carbon black; lubrication dispersing agent is aethylenum double fatty acid amide TAS-2A. The preparation method of the material is that: according to the part by weight, 100 portions of PP resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers, 10-30 portions of antistatic agent and 1-10 portions of lubrication dispersant are weighted and mixed in a high-speed mixer for 3 to 5 minutes, and after mixing, the mixed raw materials are molten, squeezed and made into particles in a parallel twin-screw extruder. The polypropylene material of the invention has the advantages of good mechanical intensity, antistatic effect, flame resistance and being environment-friendly.

Owner:ANHUI KEJU NEW MATERIALS

Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

The invention relates to a pair of soles and particularly relates to a pair of soles of ejection foamed rubber-plastic sports shoes and a manufacturing method of the soles. The pair of soles of the ejection foamed rubber-plastic sports shoes consists of the following raw materials: an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a hydrogenated styrene-butadiene-styrene block copolymer, an ethylene propylene diene monomer, polysiloxane resin, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and masterbatch. The manufacturing method comprises the steps of: mixing the dicumyl peroxide and an azo foaming agent for later use, mixing other raw materials and then pouring into an internal mixer for first-stage internal mixing, then adding a mixture of the dicumyl peroxide and the azo foaming agent for second-stage internal mixing to obtain an internally mixed mixture, thinning the mixture on a roller machine, conveying the material which is evenly mixed by the roller machine into a granulator for granulation, proportioning aggregates after granulation according to set ratios, injecting the aggregates into a shoe mould by using an injection molding machine for molding, and sizing the molded soles into foamed profile products by using an incubator.

Owner:泉州泰亚鞋业有限公司

Modified talcpowder and preparation method thereof

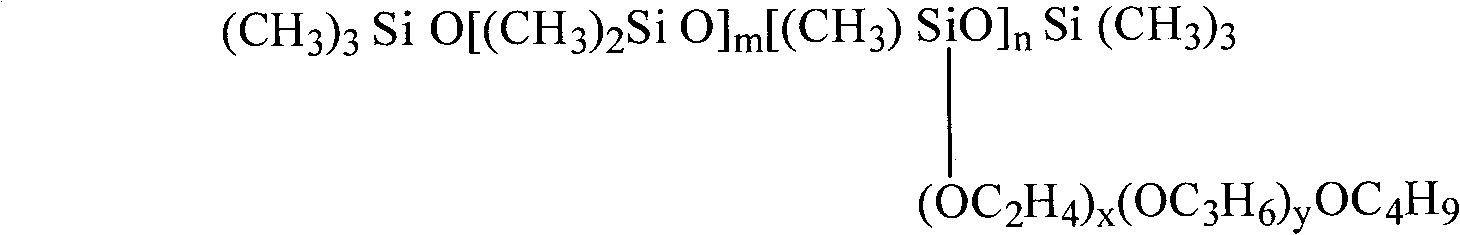

ActiveCN102311669AImprove bindingGood dispersionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsAlcoholEther

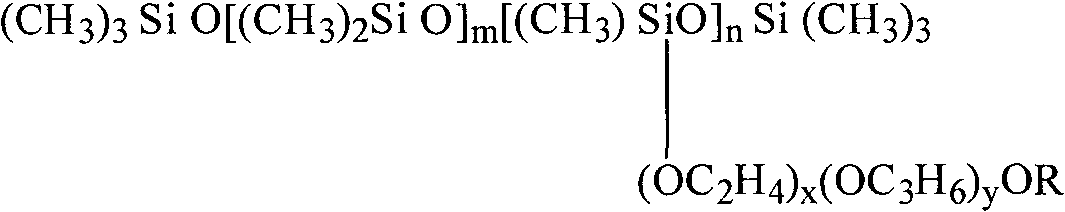

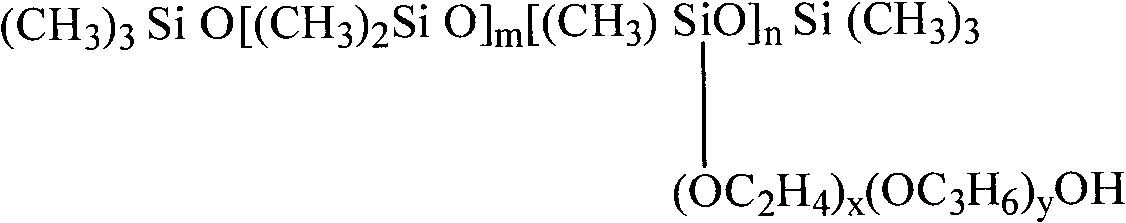

The invention relates to modified talcpowder and a preparation method thereof. The modified talcpowder comprises 100 mass parts of talcpowder and 0.5 to 2.5 mass parts of modifier, wherein the modifier is a mixture of polyatomic alcohol laurate and organic silicon / polyether copolymer; and the organic silicon / polyether copolymer is alpha,omega-di(trimethylsiloxyl)polydimethyl polymethyl (R-polyoxyethylene polyoxypropylene ether) siloxane, and R is H, alkyl or hydroxyl-containing alkyl. A preparation method for the modified talcpowder comprises the following steps of: loading dried talcpowder materials into a temperature controllable high mixer; weighing the modifier in a mass ratio of the talcpowder to the modifier of 100:(0.5-2.5); mixing the materials, adding the weighed modifier into the high mixer filled with the talcpowder uniformly, and stirring at the temperature of between 80 and 120 DEG C for 12 to 25 minutes; and taking out to obtain the modified talcpowder.

Owner:PETROCHINA CO LTD

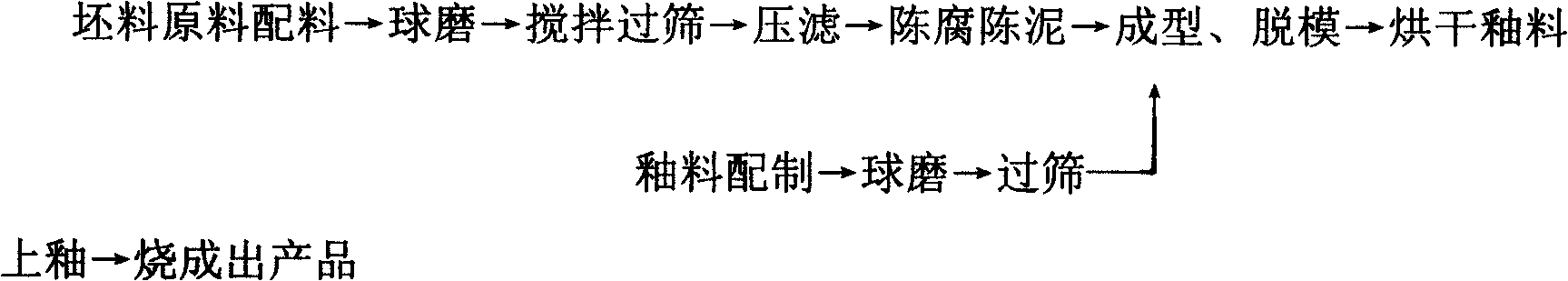

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

Clay molding sand for cast steel and preparation method thereof

The invention discloses clay molding sand for cast steel and a preparation method thereof. The clay molding sand is prepared from the following raw materials in parts by weight: 60-80 parts of quartz sand, 20-30 parts of forsterite sand, 8-12 parts of bentonite, 5-8 parts of composite powder, 4-6 parts of talcum powder, 2-3 parts of nanometer aluminum oxide, 3-5 parts of pine sawdust, 2-4 parts of alpha-starch, 1-2 parts of dextrin, 3-6 parts of calcium phosphate, 1.5-2.5 parts of sulfite lye and 4-8 parts of water. The molding sand is high-temperature resistant, high in strength and high in impact resistance, can be used for overcoming the defects on hot spot parts and avoiding sand adhesion, and a phenomenon that the sand mold is broken due to impact force of liquid steel casting is avoided. Moreover, the clay molding sand is low in air release amount, good in air permeability effect and high in liquidity, the defects of air holes, cold shut and shrinkage porosity in the casting can be effectively overcome, and the yield of the casting is improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

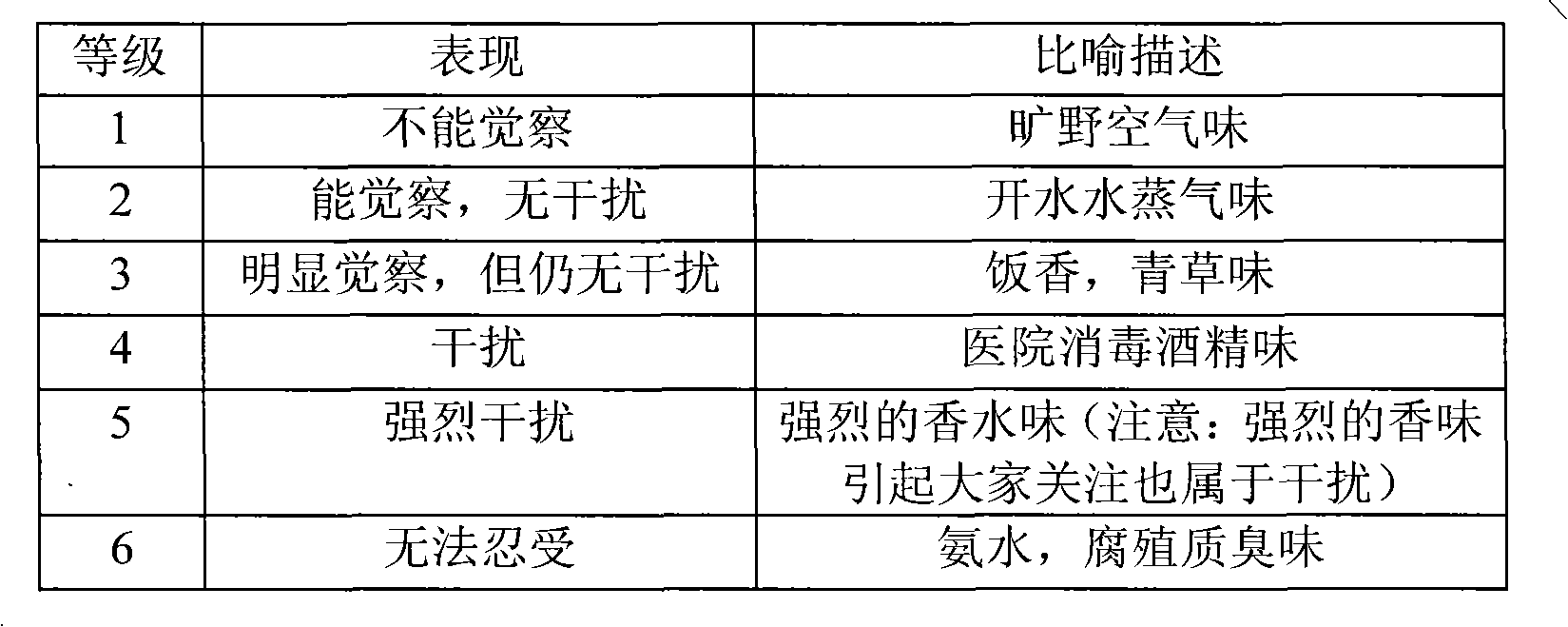

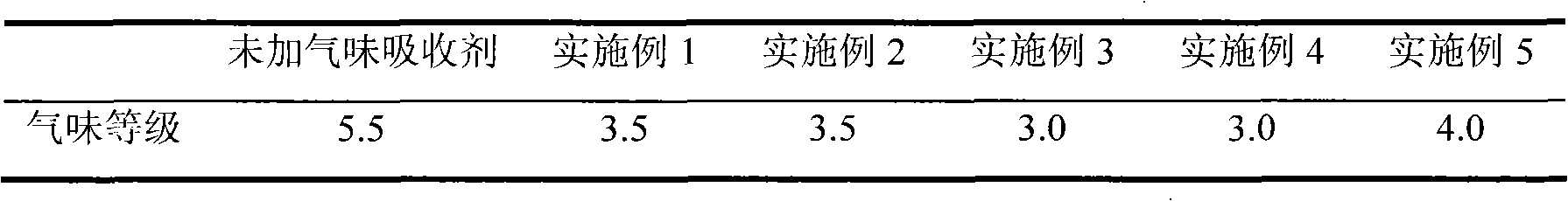

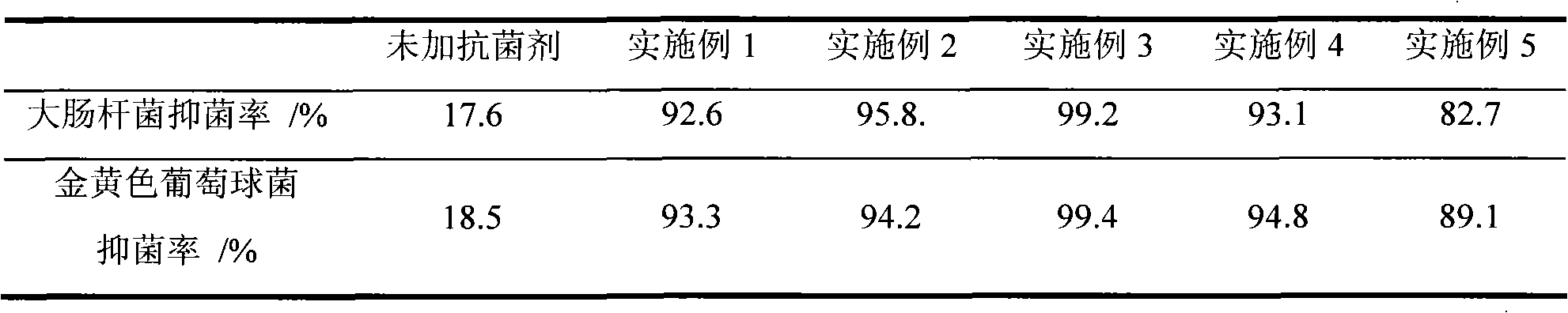

Antibacterial and low-odor decorative polypropylene material used in saloon car and preparation method thereof

The invention discloses an antibacterial and low-odor decorative polypropylene material used in a saloon car and a preparation method thereof, wherein the material comprises the following components in percentage by weight: 60 to 80 percent of polypropylene, 1 to 20 percent of elastic body, 10 to 30 percent of talcum powder, 1 to 5 percent of photocatalytic micro-powder, 0.5 to 2.0 percent of antibacterial agent, and 0.3 to 1.0 percent of odor absorbent. The polypropylene material can keep low odor enduringly, has antibacterial and mould-proof functions, and has the advantages of strong bactericidal power, quick disinfectant effect, good durability, good stability, no secondary pollution and the like. According to the invention, odorous small molecules such as paraffin, olefins, arenes, amine, phenol, thiol, peroxide, aldehydes, ketones and the like can be effectively removed.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

Method for preparing roll-coating type diatom ooze environment-friendly inner-wall coating

InactiveCN102584147AHas zero VOCWith temperature resistance and fire preventionFiberMaterials science

The invention relates to a method for preparing a roll-coating type diatom ooze environment-friendly inner-wall coating, which includes steps of: firstly choosing 30 parts of kieselguhr of 300 meshes to 350 meshes, 10 parts of rubber powder, 0.3 part of methyl fiber, 10 parts of talcum powder of 700 meshes to 900 meshes, 14.3 parts of heavy calcium carbonate powder of 400 meshes to 600 meshes, 5 parts of white cement of 300 meshes to 350 meshes, 5 parts of kaolin of 700 meshes to 900 meshes, 5 parts of concave-convex rod powder of 500 meshes to 700 meshes, 5 parts of titanium dioxide, 15 parts of calcium carbonate of 1250 meshes and 0.4 part of wood fiber. The materials are added accurately according to proportion and then placed in a horizontal high-speed disperser for evenly dispersing. The method mainly aims at solving the problems in the background technology, is easy to construct and cannot affect functions of diatom ooze.

Owner:湖南金煌硅藻泥新材料有限公司

Dry powder paint for construction as well as preparation method and use method thereof

The invention relates to dry powder paint for construction, which is prepared from polymer latex powder, titanium pigment, calcium carbonate, calcined kaolin, talcum powder, cellulose ether, a solid defoaming agent, a solid dispersing agent, a solid thixotropic agent and coloring pigment. The preparation method of the dry powder paint comprises the following steps: putting the components of the dry powder paint into a dry powder mixer for mixing for 20-40min, and then, removing bigger particles by using a vibratory screen with 120 meshes. The use method of the dry powder paint comprises the following steps: carrying out surface pretreatment on a wall body; pouring the dry powder paint into clear water and stirring and mixing evenly, standing, and then stirring again; and applying the obtained liquid paint by adopting a roller painting, spray painting or brush painting mode. The formed paint film has the characteristics of good water resistance, alkali resistance, weather resistance, washing resistance, dirt resistance and the like, has the performances of the traditional latex paint and does not contain components of VOC (zero VOC), heavy metals and the like harmful to the environment and the human health.

Owner:SOUTH CHINA UNIV OF TECH

Dry powder latex paint for inner wall and preparation thereof

The invention relates to an environment-friendly inner wall dry powder latex coating and a preparation method thereof. The compositions according to weight percentages are as follows: 10-40% of re-dispersible polymer latex powder, 10-40% of titanium dioxide, 10-40% of ground calcium carbonate, 5-20% of calcined kaolin, 5-10% of talcum powder, 0.1-0.5% of cellulose ether, 0.2-0.6% of solid defoamer, 0.2-1.0% of multifunctional auxiliary agent, and 0.01-10% of tinting pigment. The inner wall dry powder latex coating formed in the invention can have scumble construction after thinning by being added with two to three times of water, and the thickness of dry film is 20 microns to 200 microns; the color is tunable; the storage is stable, and the transportation is convenient; the VOC thereof cannot be detected (real zero VOC), and the coating film performances meet the technical requirements of national standard of inner wall latex coating; and the combination properties of products can reach international most advanced level of similar products.

Owner:SOUTH CHINA UNIV OF TECH

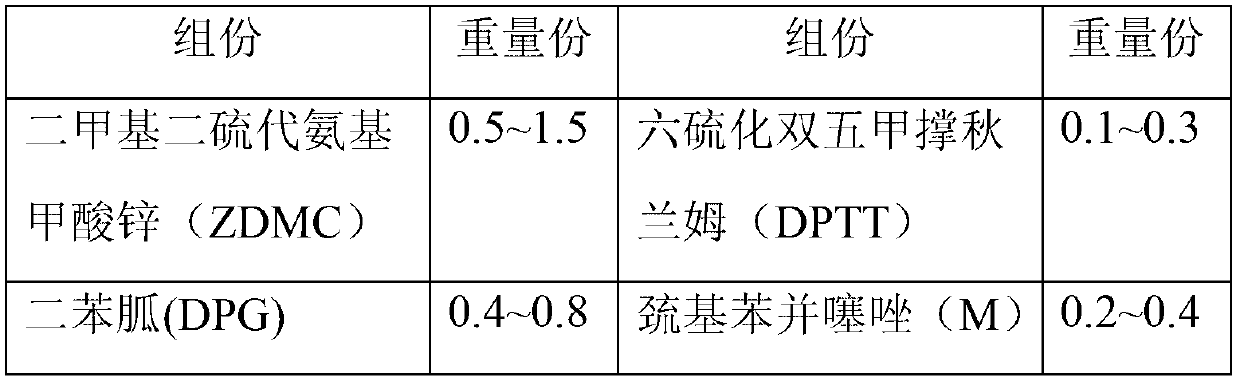

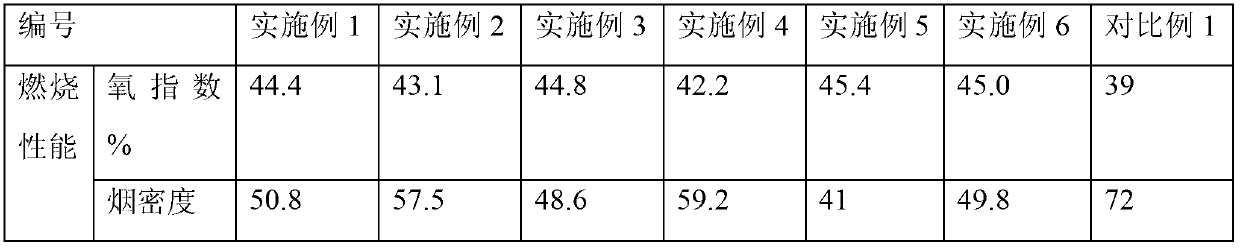

High flame retardancy type soft foam plastic insulation product and preparation method thereof

ActiveCN103102533AHigh oxygen indexImprove flame retardant performancePolyvinyl chloridePolyethylene glycol

The invention provides a high flame retardancy type soft foam plastic insulation product and a preparation method thereof. The product comprises the following components in parts by weight: 12 to 15 parts of nitrile rubber, 8 to 10 parts of talcum powder, 0.5 to 0.8 parts of polyethylene glycol, 0.2 to 0.4 parts of antiager 4020, 15 to 20 parts of chlorinated paraffin, 0.6 to 0.9 parts of paraffin, 1 to 2 parts of epoxidized soybean oil, 0.1 to 0.3 parts of antiager RD, 0.4 to 0.7 parts of carbon black, 7 to 10 parts of polrvinyl chloride, 26 to 36 parts of fire retardant based on the total amount, 2 to 5 parts of dioctyl ester, 8 to 12 parts of azodicarbonamide, 0.2 to 0.5 parts of stearic acid, 0.4 to 0.7 parts of zinc oxide, 0.4 to 0.7 parts of sulphur, and 1.3 to 1.8 parts of accelerant based on the total amount. By adopting the high flame retardancy type soft foam plastic insulation product, the technical problem that the oxygen index and the smoke density are mutually conflicted in the technological manufacture is solved, and the bottleneck due to mutual limitation is broken through.

Owner:HEBEI HUAMEI CHEM & BUILDING MATERIALS GRP

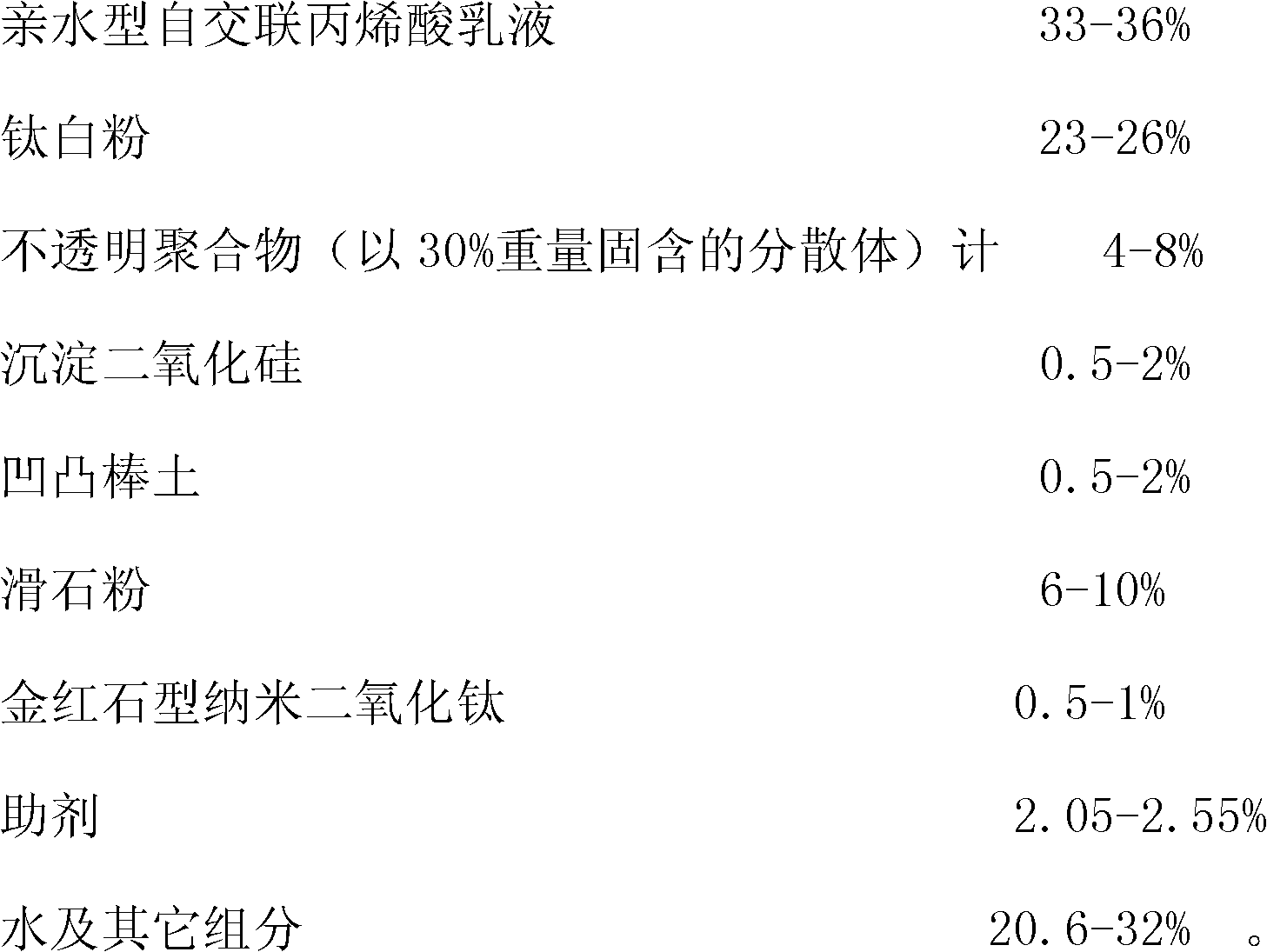

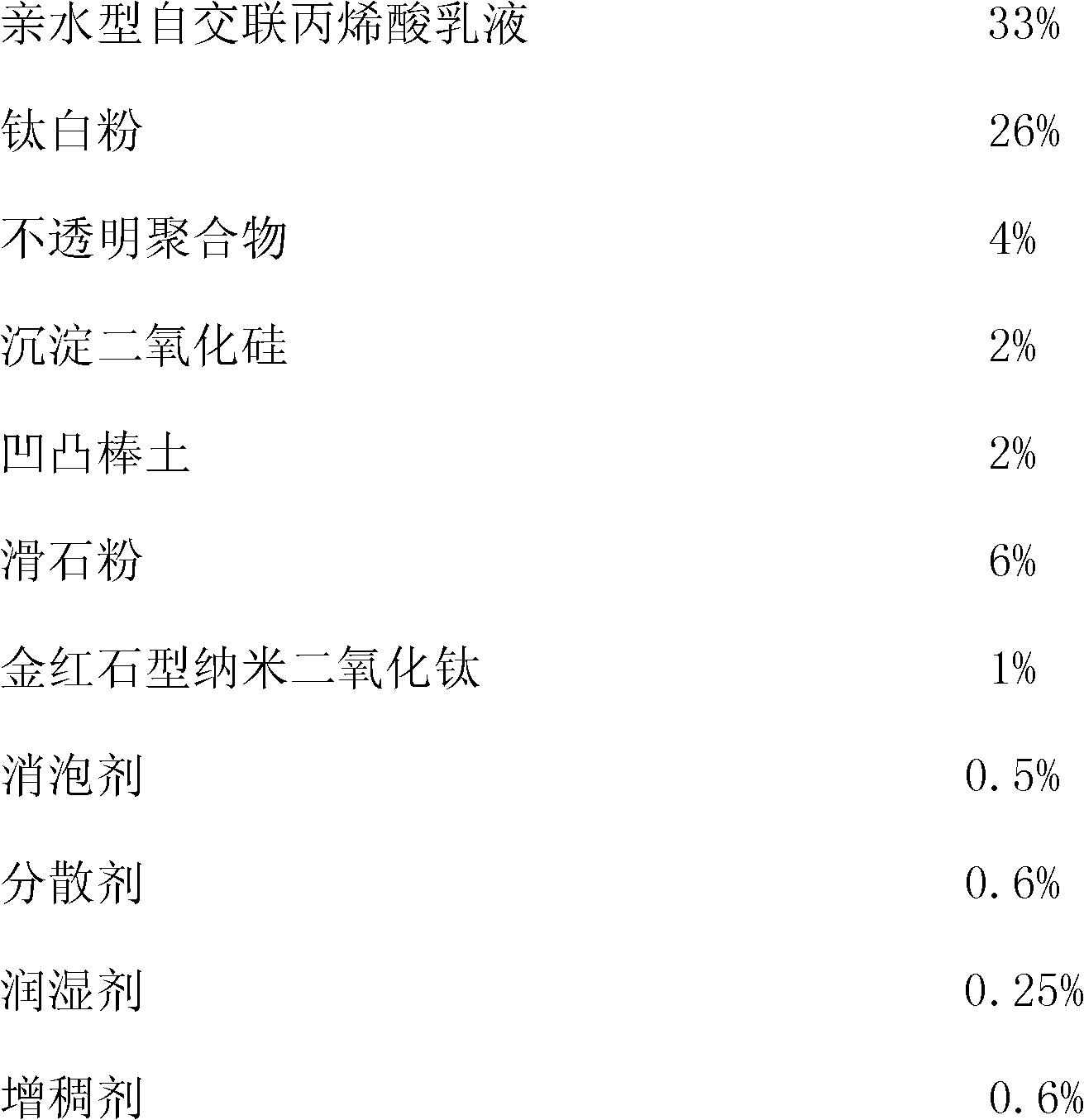

High-pollution-resistant high weatherproof water-based external wall emulsion paint and preparation method thereof

ActiveCN102604498AIdeal volume concentrationGood weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention discloses high-pollution-resistant high weatherproof water-based external wall emulsion paint and a preparation method thereof. The external wall emulsion paint comprises hydrophilic self-crosslinking acrylic emulsion, titanium dioxide, non-transparent polymer, precipitated silica, attapulgite, talcum powder, rutile type nano titanium dioxide, auxiliaries, water and other components. The invention aims at overcoming the defects in the prior art and providing external wall paint with high weather resistance and stain resistance and relatively low production cost; and the invention also aims at providing a method for preparing the external wall paint.

Owner:深圳清宇海洋环保新材科技有限公司

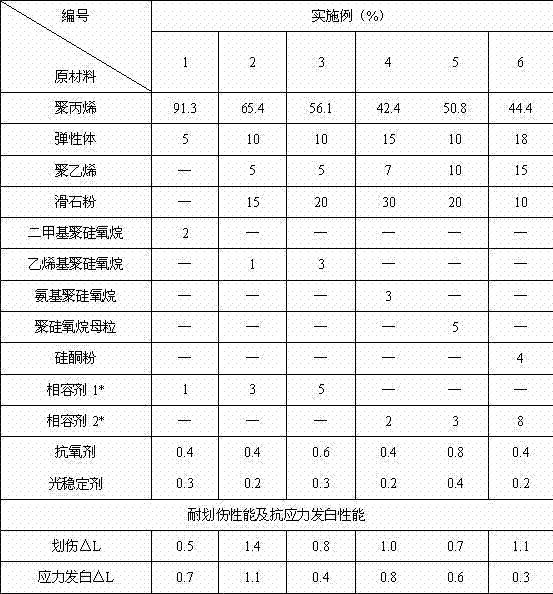

Scratching-resistant and stress-whitening prevention polypropylene compound and preparation method

The invention discloses a scratching-resistant and stress-whitening prevention polypropylene compound, which comprises, by weight, 40% to 95% of polypropylene, 2% to 20% of elastomers, 0% to 15% of polyethylene, 0% to 30% of talcum powder, 1% to 5% of scratching-resistant agent, 0.5% to 8% of compatilizer, 0.1 % to 1% of oxidation inhibitor and 0.1% to 0.5% of light stabilizer, wherein the compatilizer is polyolefin organosilicon copolymer or alkyl modified polysiloxane. The preparation method of the scratching-resistant and stress-whitening prevention polypropylene compound includes steps offirstly, taking all components by weighing according to the percentage, mixing the polypropylene, the elastomers, the polyethylene, the scratching-resistant agent and the compatilizer in a high-mixing machine for one to three minutes, then adding the talcum powder, the oxidation inhibitor and the light stabilizer to be mixed together for one to three minutes, and obtaining pre-mixed materials; and secondly, melting and extruding the pre-mixed materials by a double-screw extruder, and pelleting in a vacuum state so as to obtain the scratching-resistant and stress-whitening prevention polypropylene, wherein the temperature of each area of screws ranges from 190 DEG C to 230 DEG C. The scratching-resistant and stress-whitening prevention polypropylene compound has the advantages that scratching resistance is improved by the aid of polysiloxane scratching-resistant agent, the problem of serious stress whitening of workpieces during injection molding, mounting and using due to introductionof the scratching-resistant agent is solved, and pass rate of products is high.

Owner:WUHAN JINFA TECH CO LTD

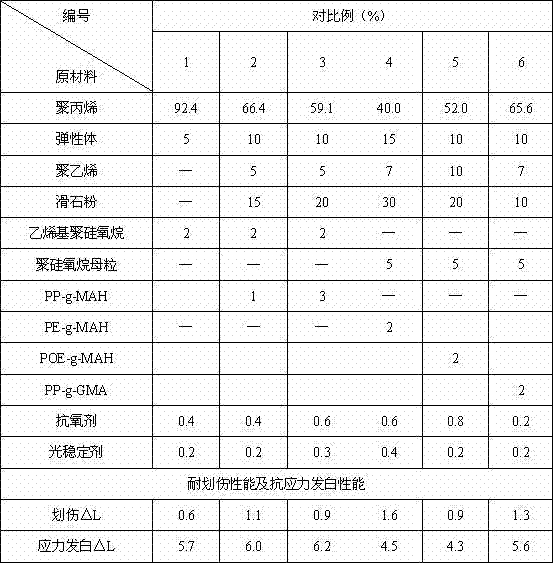

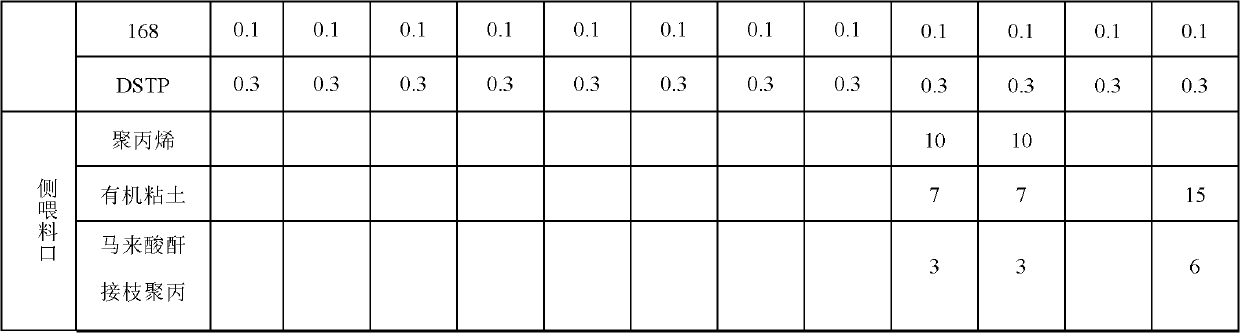

High-performance polypropylene nano composite material and preparation method thereof

The invention discloses a high-performance polypropylene nano composite material and a preparation method thereof, and belongs to the field of polymer modification and processing. The high-performance polypropylene nano composite material comprises the components in percent by weight: 39 to 98% of polypropylene, 1 to 15% organic clay, 0 to 30% of inorganic filling material, 0.1 to 6% of compatilizer, 0 to 20% of flexibilizer, 0.2 to 2% of stabilizer, and 0 to 4% of other additive. Through the cooperative modification of nanoscale organic clay and micron-sized talcum powder to polypropylene, a nano composite material with higher rigidity, higher tenacity and other performance is obtained at a lower material density.

Owner:SHANGHAI PRET COMPOSITES

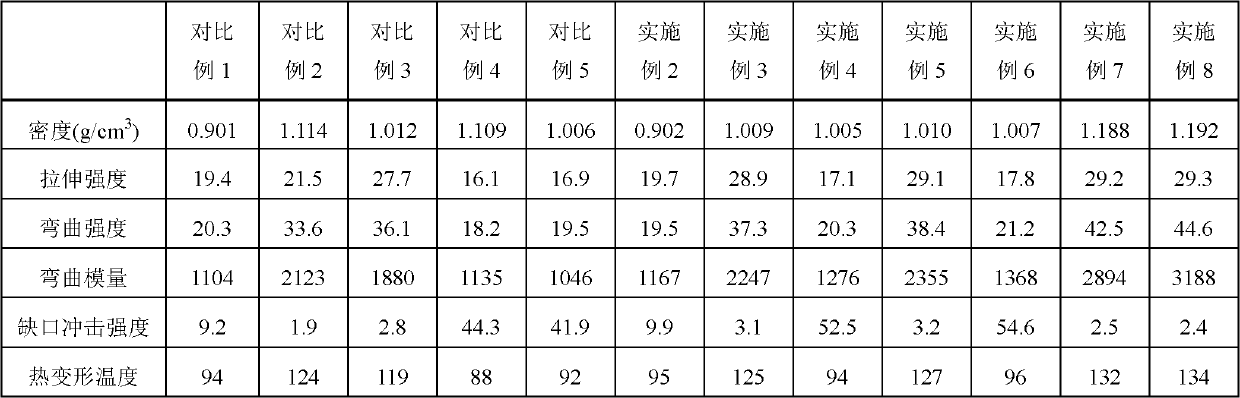

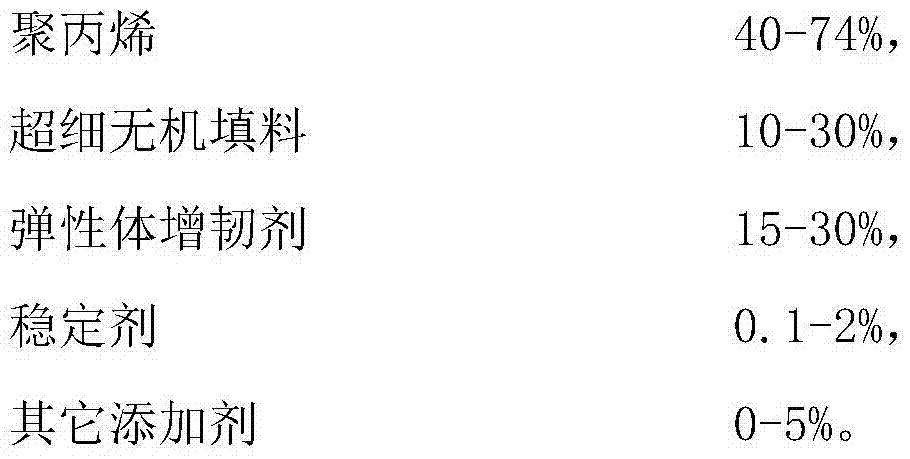

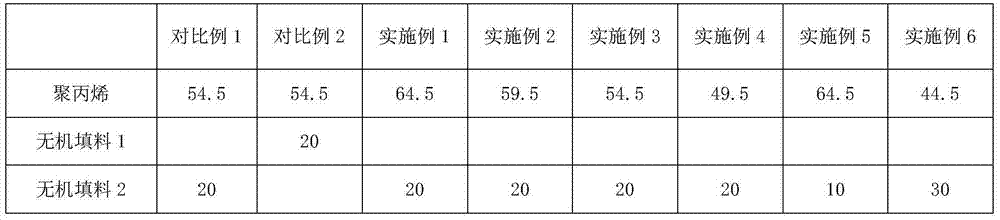

High-modulus and ultrahigh-impact polypropylene composite material and its preparation method

ActiveCN103923381AImprove low temperature toughnessImprove rigidityElastomerPolypropylene composites

The invention discloses a high-modulus and ultrahigh-impact polypropylene composite material and its preparation method. The composite material comprises 40-74wt% of polypropylene, 10-30wt% of an ultrafine inorganic filler, 15-30wt% of an elastomer flexibilizer, 0.1-2wt% of a stabilizer, and 0-5wt% of other additives. The preparation method comprises the following steps: carrying out dry mixing on raw materials in a high speed mixer for 3-15min, adding the mixed raw materials into a double screw extruder, carrying out melt extrusion, and carrying out cooling granulation. The preparation method has the following advantages:1, a ethylene-butylene copolymer is used as the elastomer flexibilizer, so the polypropylene composite material has better low temperature toughness than traditional toughening modified polypropylene; 2, ultrafine talcum powder is used as the inorganic filler, so the toughness loss can be reduced as much as possible, and the rigidness of the material is greatly improved; and 3, the synergistic effect of the ultrafine talcum powder and the elastomer flexibilizer is utilized, so the polypropylene composite material has more ideal rigidness-toughness balance than the traditional toughening modified polypropylene.

Owner:SHANGHAI PRET COMPOSITES +2

Scraping-resistant automobile inner fitting special-purpose material and preparation thereof

ActiveCN101255253AExcellent surface scratch resistanceLow costUltimate tensile strengthPolypropylene

The invention relates to a kind of scraping tolerance type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, lubricant 0.5-3.0 parts, antioxidant1010 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and lubricant, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes; 3) stirring and mixing at rotate speed of 1500-2000 rpm for 10-15 minutes; 4) stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 5) extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:南京金杉合成材料有限公司

White master batch applied for polyolefin film and preparation method thereof

The invention discloses a white master batch applied to a polyolefine film and a preparation method thereof. The white master batch consists of 20 to 75 percent of a white pigment and 25 to 80 percent of a polyethylene resin, wherein, the white pigment is one or a plurality of titanium pigment, zinc oxide, rubberlith, limestone powder and talcum powder. The white pigment and the polyethylene resin are mixed in a banbury mixer, the mixing temperature is between 115 and 190 DEG C, the pressure is between 0.5 and 1.0MPa and the white master batch is produced after the pelleting process. The white master batch does not have any organic dispersing auxiliary, and the coloured master batch product with high concentration, high dispersing property, small dosage and even coloration is produced by selecting appropriate mixing temperature according to different mixing system compositions.

Owner:MALION NEW MATERIALS CO LTD

Nano modified paint used for inner and outer wall

The main structure of said invented internal and external wall coating material respectively includes film-forming substance, dispersion medium, pigment filler and adjuvant, and its raw material formula is formed from (wt%) 35-55% of acrylic resin emulsion, 0.1-0.3% of dispersion moistening agent, 4-8% of titanium white powder, 4-8% of lithopone, 2-6% of talcum powder, 1.5-4.5% of nano SiO2, 1.5-4.5% of nano Tio2, 0.1-0.3% of pH regulating agent and 20-30% of water. The above-mentioned materials are stirred, ground and filtered so as to obtain the invented coating material with improved water-proofing property, contamination resistance, ageing resistance, UV ray resistance and bacteria-resisting property. Said coating material can be washed for above 11000 times, and its service life can be up to above 10 years.

Owner:刘尚文 +1

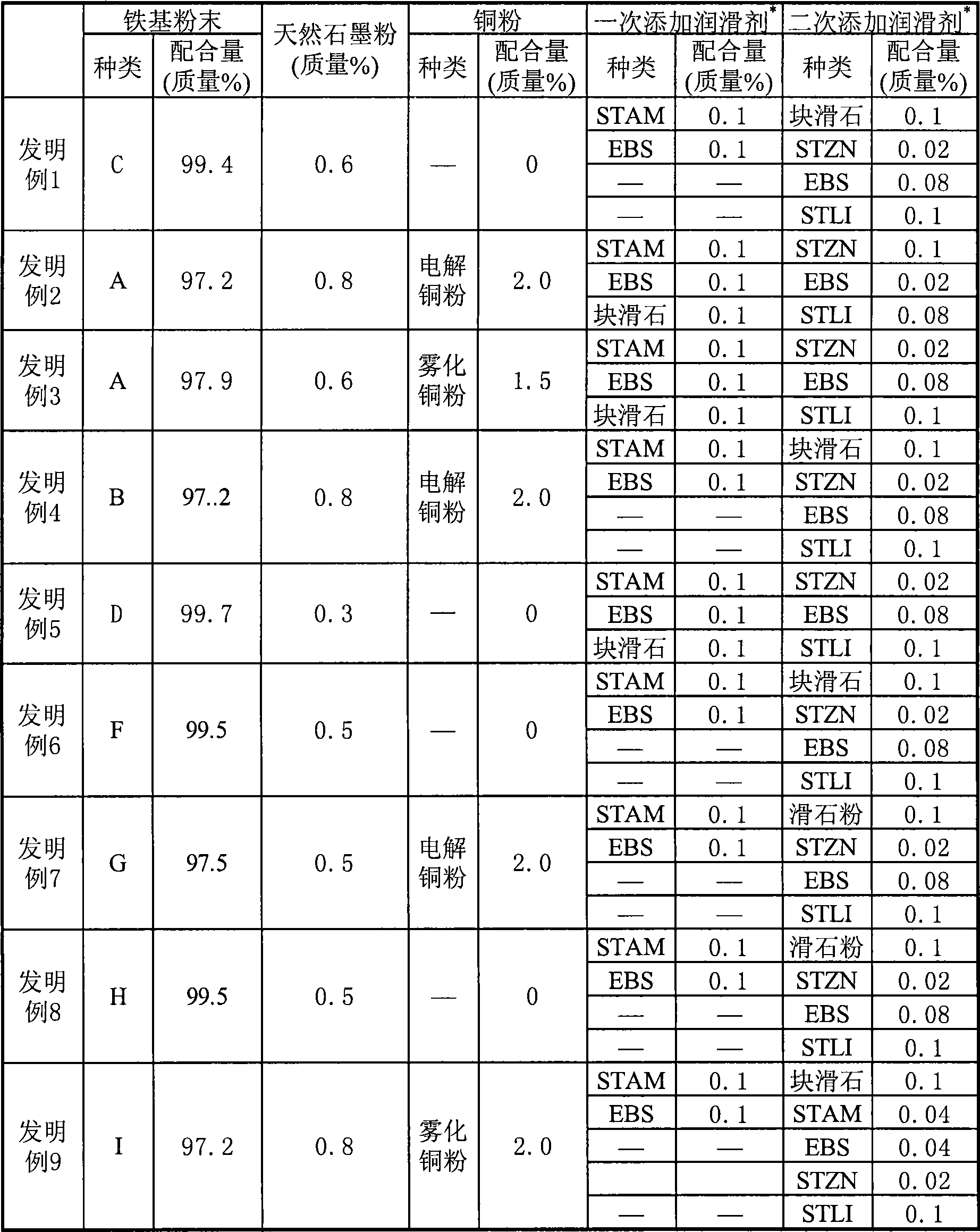

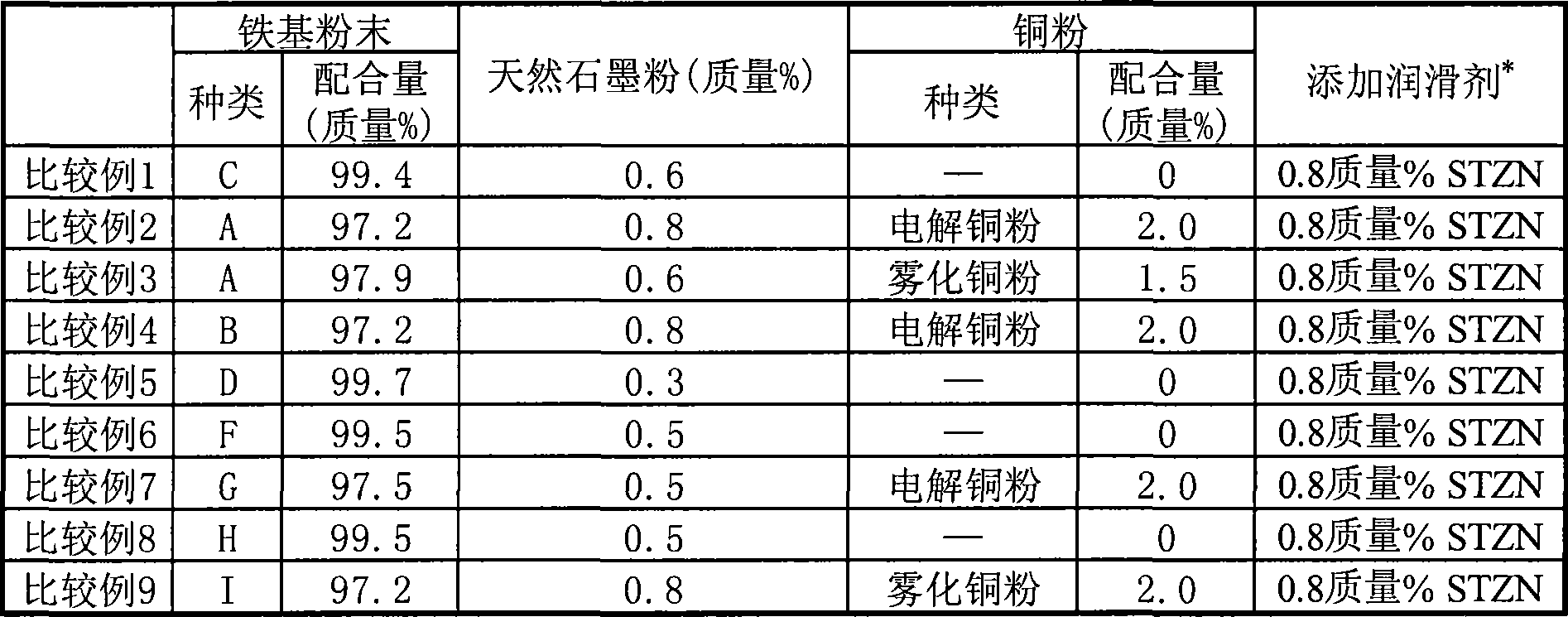

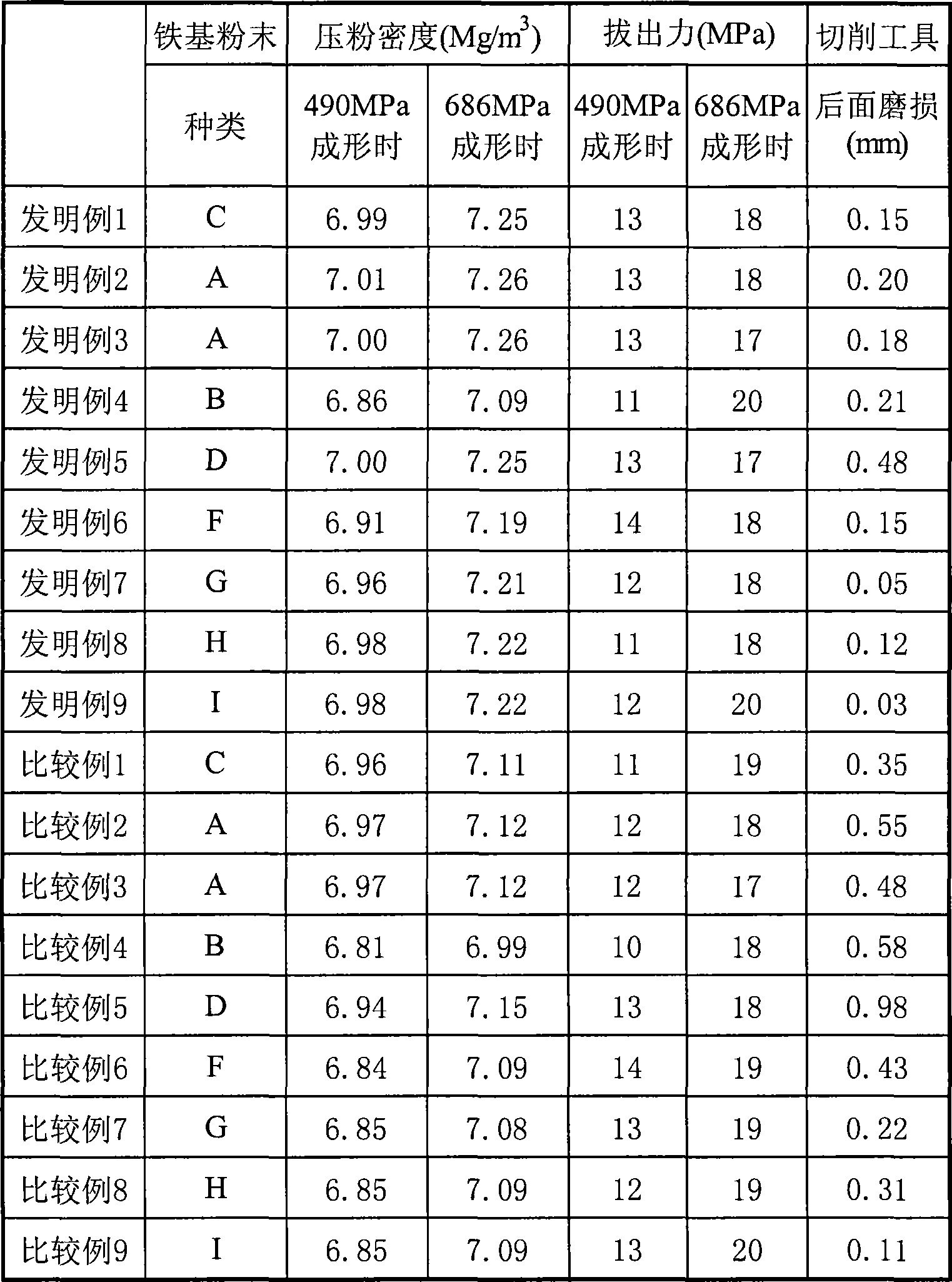

Iron-based powder mixture, and method of manufacturing iron-based compacted body and iron-based sintered body

ActiveCN101384387AGood formabilityHigh densityTransportation and packagingMetal-working apparatusPowder mixtureTalc

An iron-base mixed powder for powder metallurgy which comprises an iron-base powder and at least one member selected from between talc and steatite and preferably further contains a metal soap.This mixed powder does not produce adverse effect on furnace atmosphere in sintering a compact of the powder and exhibits excellent compactibility even in a low-temperature region of below 100 DEG C and the sintered compact made from the powder is favorably excellent in machinability.

Owner:JFE STEEL CORP

Putty powder used for walls in house

InactiveCN101705027AExcellent scratch coating construction performanceGuaranteed crack resistanceFilling pastesCalcium hydroxideSodium Bentonite

The invention provides putty powder used for walls in a house. The putty powder comprises the following ingredients: ground calcium carbonate, sodium-base bentonite, 1788 powder of polyving akohol, hydroxypropyl methyl cellulose and talcum powder, besides, white cement or / and calcium hydroxide powder is / are added therein as a reinforcing material, and also, sodium hexametaphosphate powder and / or tourmaline powder are / is added in the product. The putty powder has excellent scraping construction performance, long-acting mould-proof performance and excellent dense degree of the putty coating as well as the function of releasing negative ions for a long time, can effectively adsorb various harmful substances in the air and purify the air, and has excellent environment-friendly performance.

Owner:毕家新

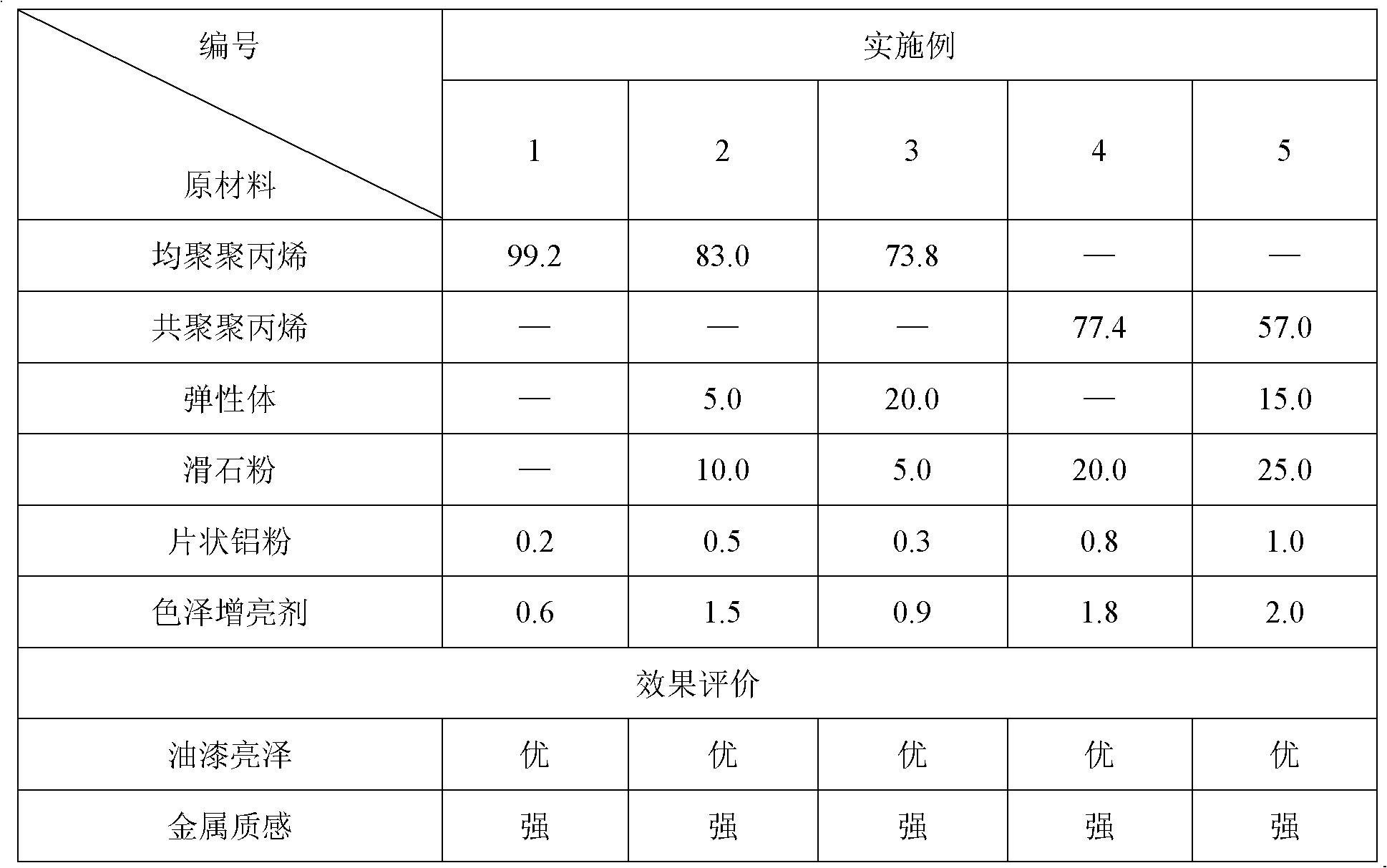

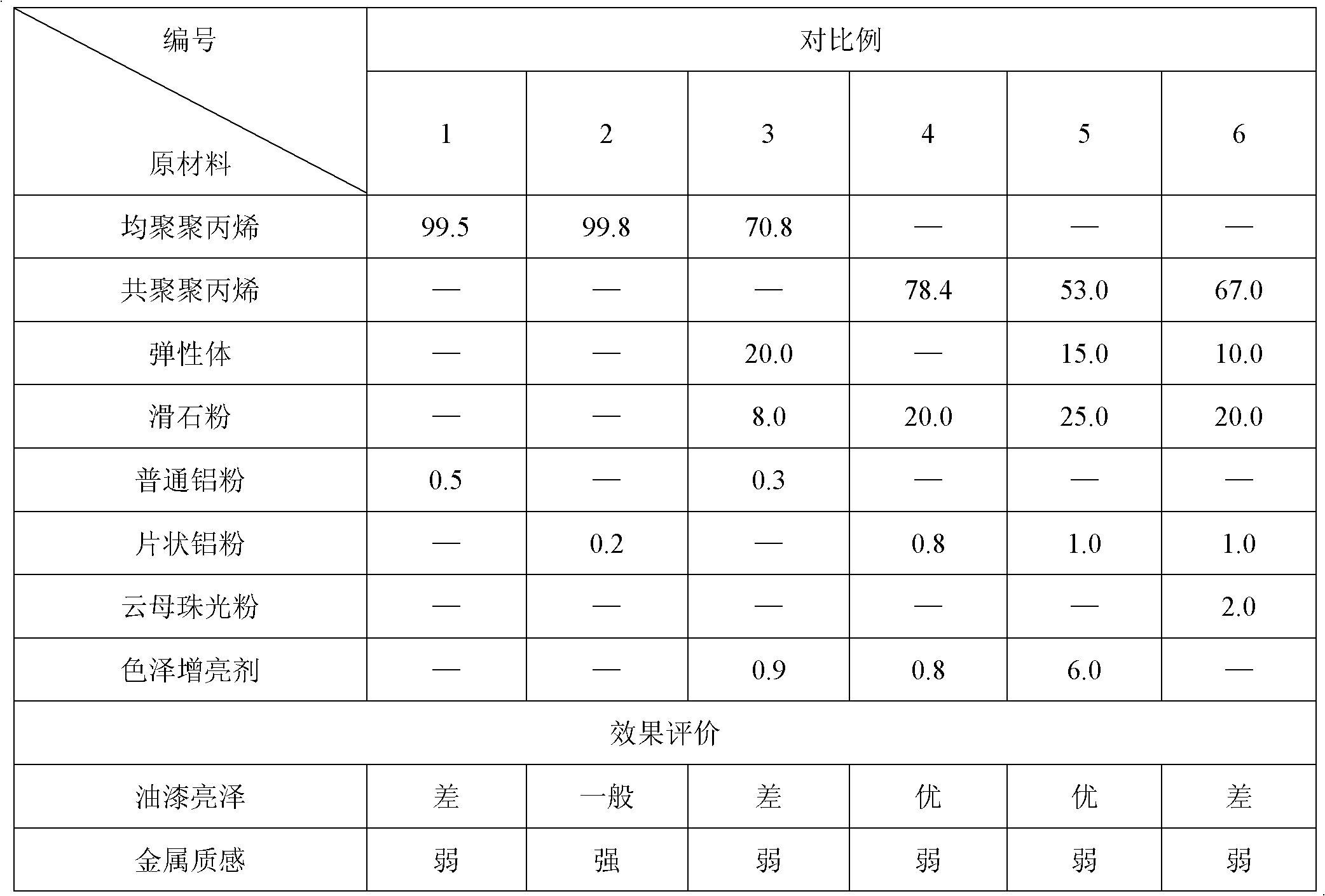

Coating-free polypropylene composition with paint brightness and metal texture and preparation method thereof

The invention discloses a coating-free polypropylene composition with paint brightness and metal texture, which is prepared from the following components in percentage by mass: 50-99.8% of polypropylene, 0-20% of elastomer, 0-30% of talc powder, 0.1-2% of sheet-shaped aluminum powder and 0.1-2% of color brighter, wherein the mass ratio of the sheet-shaped aluminum powder to the color brighter is 1:(2-5). The coating-free polypropylene composition with paint brightness and metal texture can be directly made into a component through injection molding, wherein the component has excellent paint brightness and metal texture, and the appearance effect of the component is close to a paint coating effect. The preparation method of the coating-free polypropylene composition with paint brightness and metal texture has the advantages of avoiding complex operation of the traditional paint coating technique, greatly simplifying operation steps, being simple in preparation process, having low device requirement and high product yield, saving energy, protecting environment and reducing cost.

Owner:WUHAN JINFA TECH CO LTD

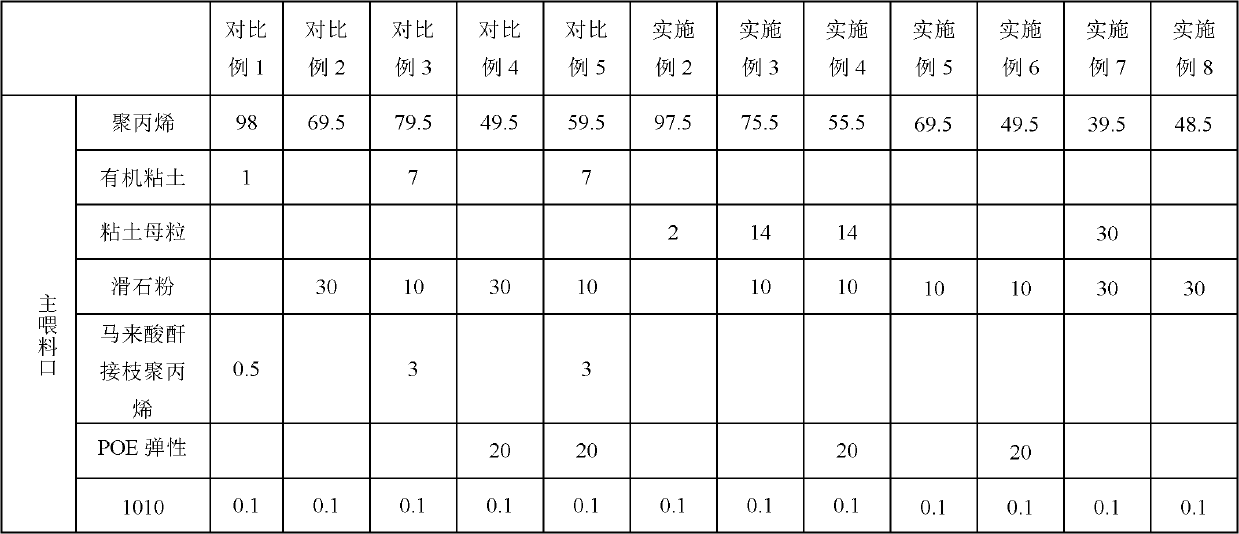

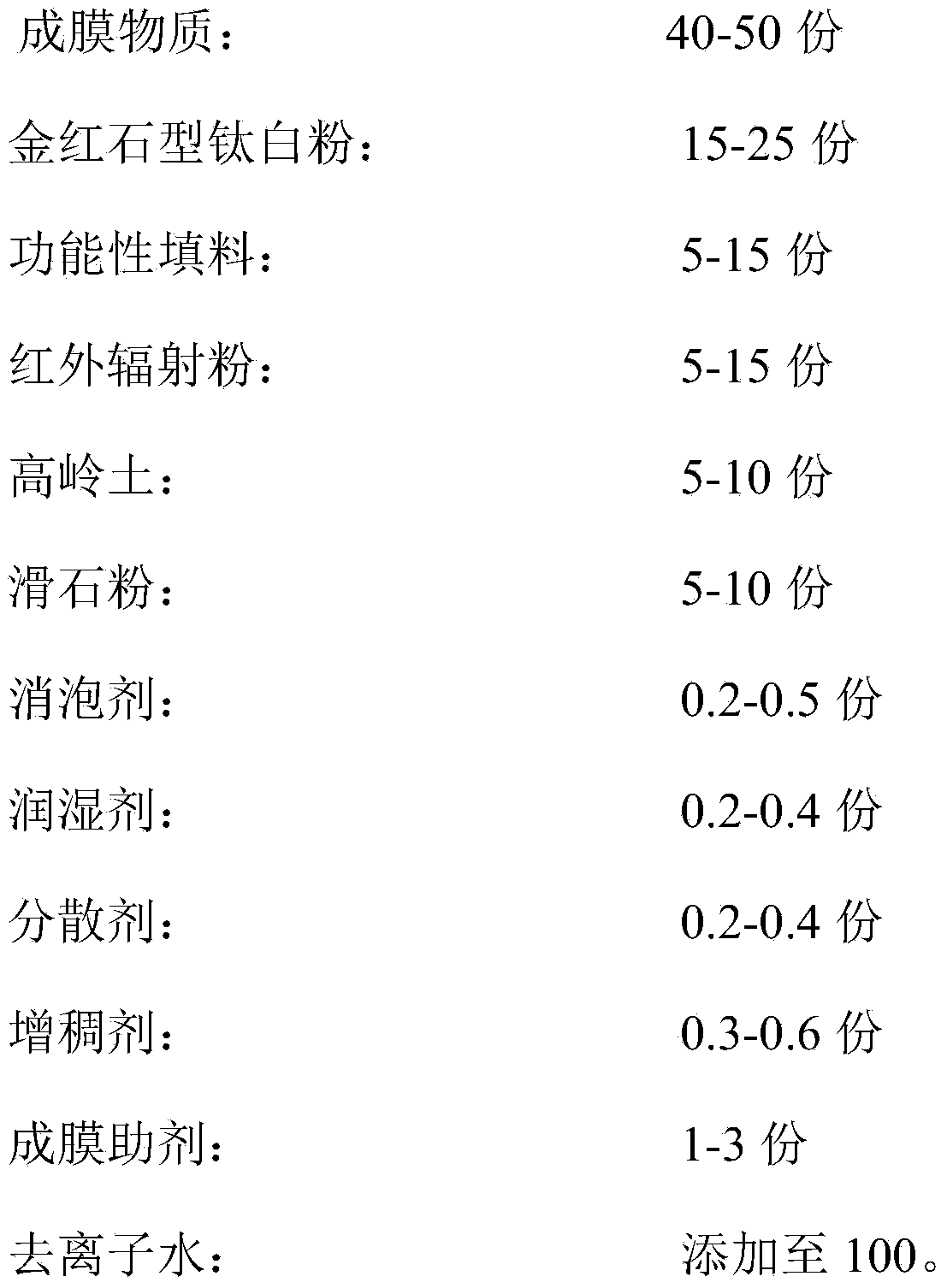

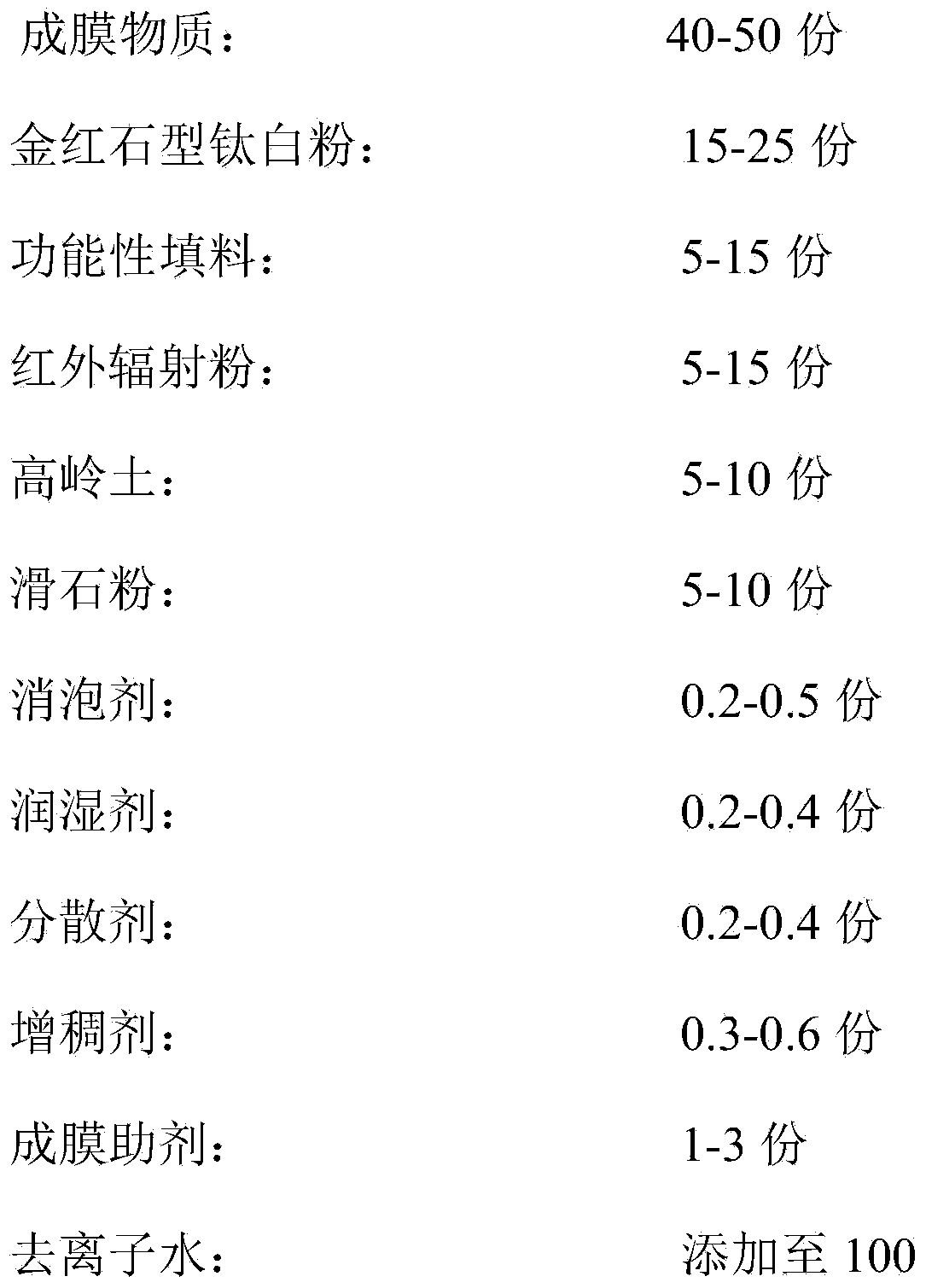

High-performance architectural reflective thermal insulation coating, and preparation method and applications thereof

The invention discloses a high-performance architectural reflective thermal insulation coating. 100 parts of the high-performance architectural reflective thermal insulation coating comprise following raw materials, by weight, 40 to 50 parts of a film forming agent, 15 to 25 parts of rutile titanium dioxide, 5 to 15 parts of a functional filling material, 5 to 15 parts of an infrared radiation powder, 5 to 10 parts of kaolin, 5 to 10 parts of talc, 0.2 to 0.5 part of an antifoaming agent, 0.2 to 0.4 part of a wetting agent, 0.2 to 0.4 part of a dispersant, 0.3 to 0.6 part of a thickening agent, 1 to 3 parts of a film forming auxiliary agent, and the balance deionized water. The infrared radiation powder is an ultrafine powder with high radiancy, and is prepared via high-temperature sintering of a plurality of metal oxides. The novel water-based thermal insulation coating is prepared via combination of traditional thermal insulation effects of hollow microspheres, and is suitable for applications in the field of thermal insulation of new building outer walls and improvement of existing buildings; and high radiancy and high radiation play a major role, and traditional thermal insulation effect plays a minor role in thermal insulation.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

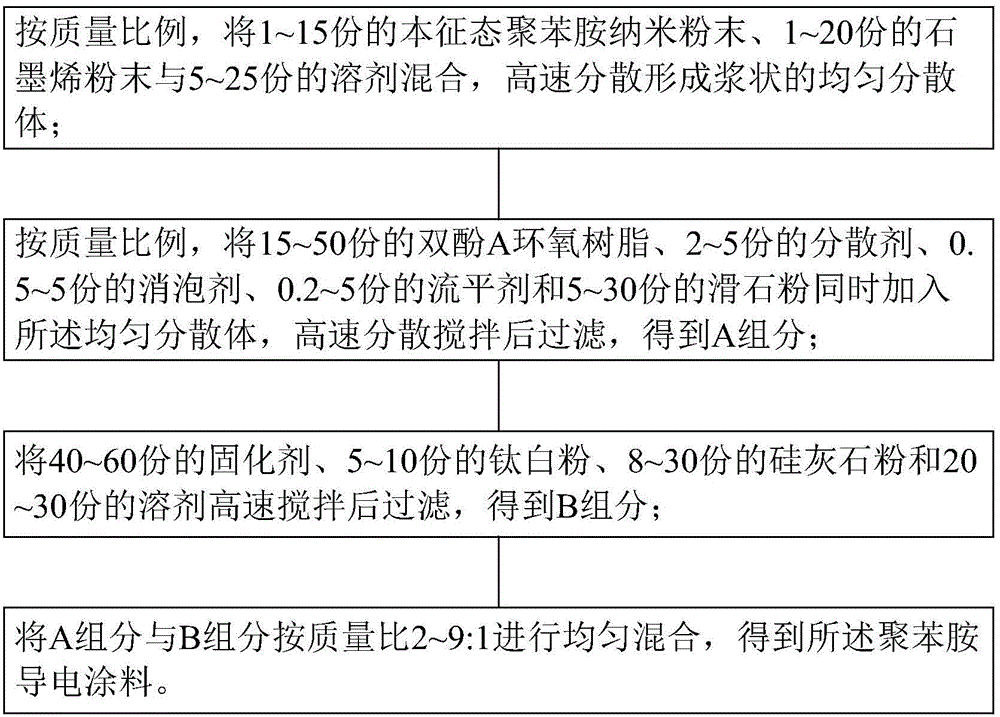

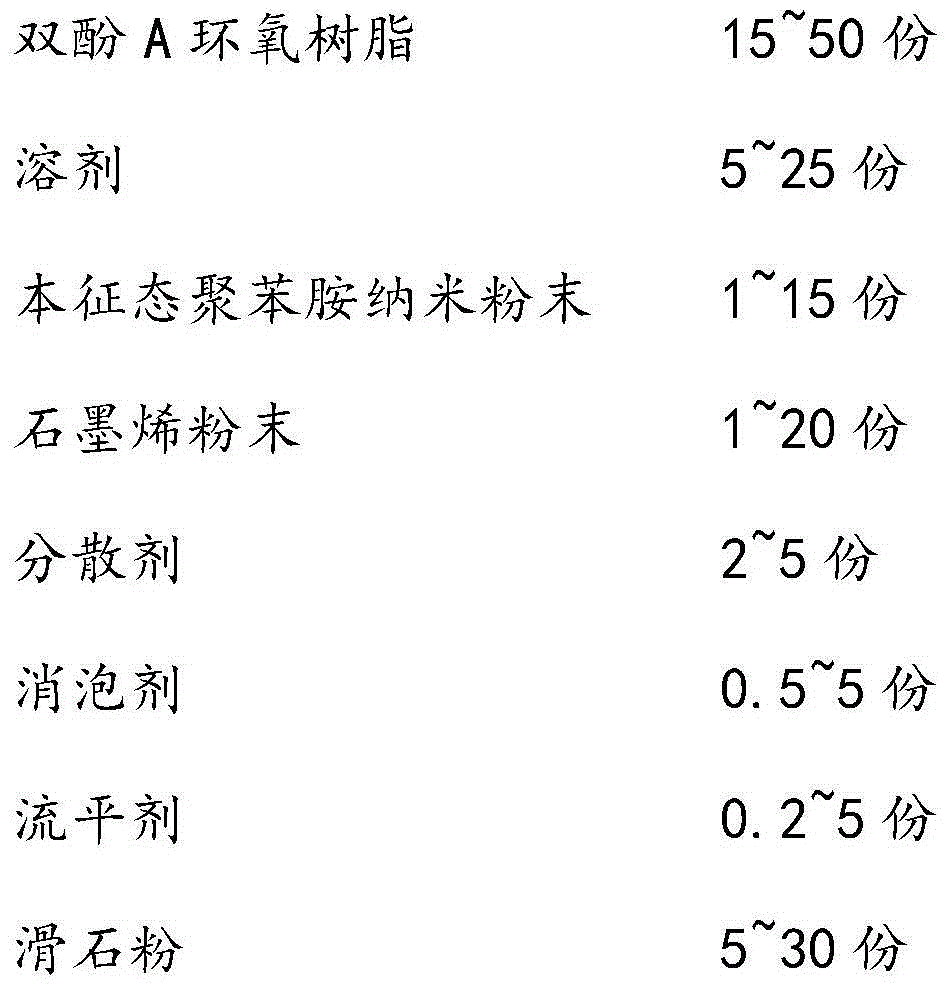

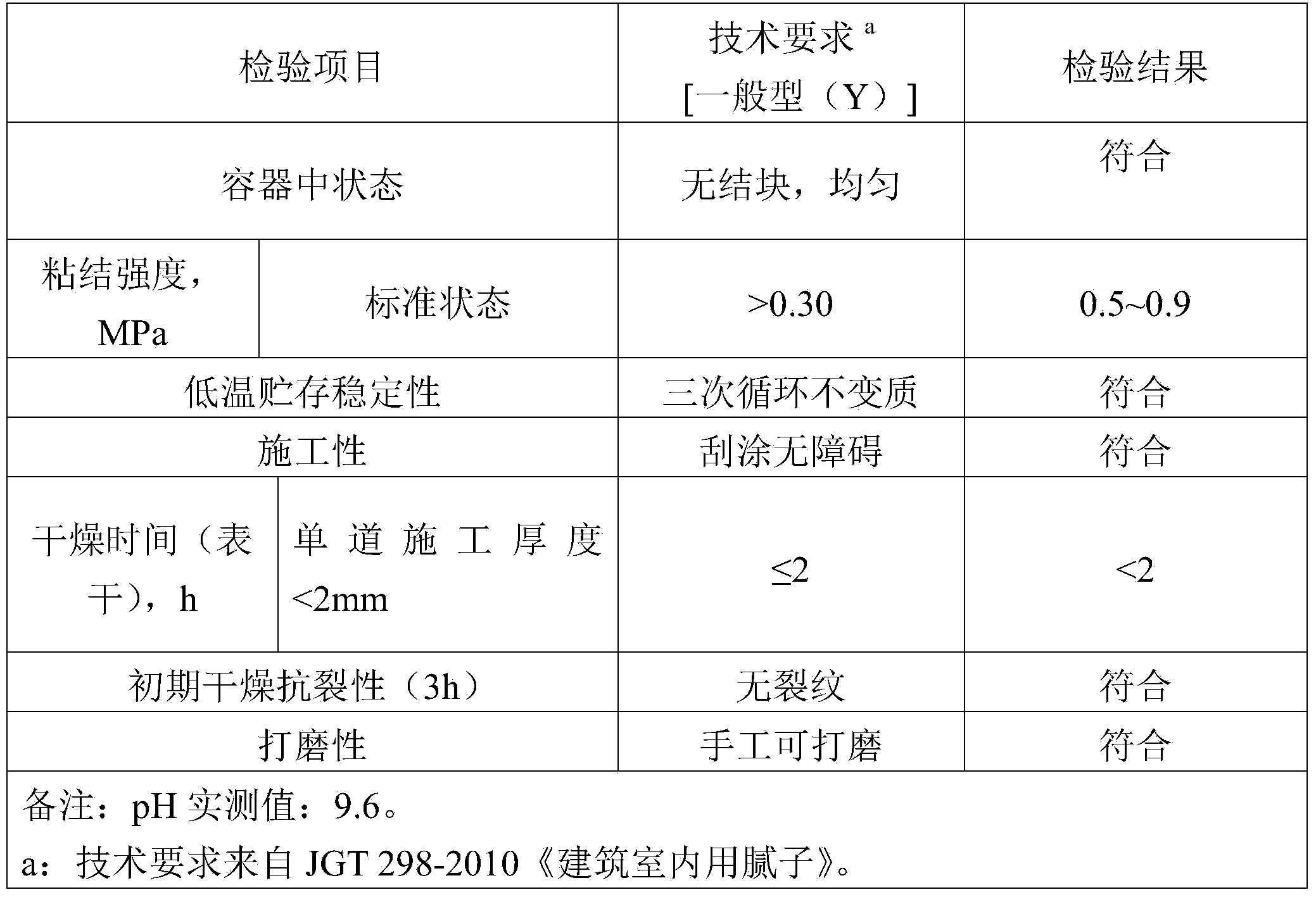

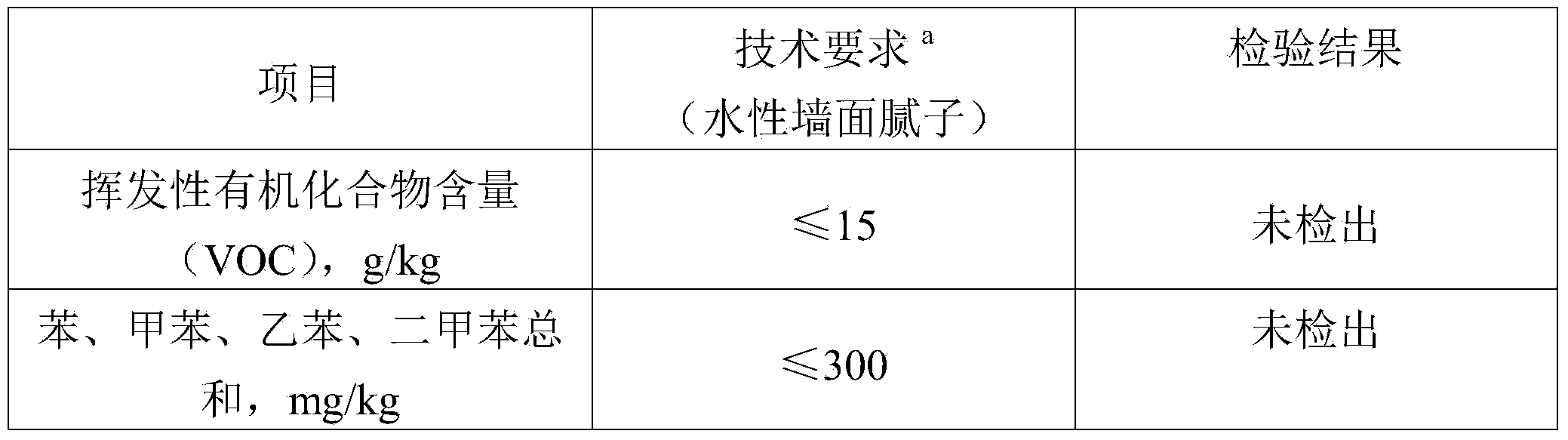

Graphene modified polyaniline conductive coating and preparation method thereof

InactiveCN104592857AImprove electrical conductivity and mechanical propertiesImprove binding performanceEpoxy resin coatingsElectrically-conductive paintsSolventConductive coating

The invention provides a graphene modified polyaniline conductive coating and a preparation method thereof. The polyaniline conductive coating comprises the following components in parts by mass: component A comprising 15-50 parts of bisphenol A epoxy resin, 5-25 parts of a solvent, 1-15 parts of eigenstate polyaniline nanometer powder, 1-20 parts of graphene powder, 2-5 parts of a dispersing agent, 0.5-5 parts of an antifoaming agent, 0.2-5 parts of a flatting agent and 5-30 parts of talcum powder; and component B comprising 40-60 parts of a curing agent, 5-10 parts of titanium dioxide, 8-30 parts of wollastonite in powder and 20-30 parts of a solvent. With the adoption of the scheme, polyaniline with high dissolution rate is adopted, and a proper amount of graphene is added, so that the conductivity and mechanical property of the coating are improved, the bonding property of the coating with the matrix is enhanced, the service life of the coating is prolonged, and the coating has high application value.

Owner:ANKE SMART CITY TECH PRC

Environmentally-friendly interior wall putty powder, putty paste, and preparation methods of putty powder and putty paste

InactiveCN103525151AReduce the content of heavy metal elementsImprove impact resistanceFilling pastesCrack resistanceHydroxyethyl cellulose

The invention discloses an environmentally-friendly interior wall putty powder, a putty paste, and preparation methods of the putty powder and the putty paste. The putty powder comprises, by weight, 45-72 parts of talcum powder, 18-30 parts of heavy calcium carbonate, 5-10 parts of calcium bentonite, 0.6-1.5 parts of carboxymethylcellulose sodium, 1-5 parts of polyacrylamide, 0.3-1.7 parts of hydroxyethyl cellulose, 0-20 parts of building gypsum powder, 0-0.8 parts of carboxymethyl cellulose, 0-8 parts of alpha-pregelatinized starch, 0-3 parts of hydroxypropyl methyl cellulose and 0-0.5 parts of sodium dodecyl benzene sulfonate. The preparation method of the putty powder comprises the following steps: uniformly mixing the above components, stirring for 10-15min, and discharging the above obtained mixture. The putty paste is obtained by adding water having a weight 0.3-0.5 times the weight of the putty powder and uniformly stirring. The putty powder / putty paste contains no or a tiny amount of formaldehyde and an extremely low content of heavy metal elements, is an environmentally-friendly product, and has the advantages of excellent impact resistance, excellent hydrophobicity and waterproofness, high elasticity, good crack resistance, stable storage and easy construction.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

High-temperature-resistant anticorrosive paint and preparation method thereof

InactiveCN102719191AImprove bindingGood color retentionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyester

The invention discloses high-temperature-resistant anticorrosive paint and a preparation method thereof. The paint comprises finishing paint and a primer which are matched, wherein calculated by mass percentage, the raw-material formula of the finishing paint comprises the following components: 20-30 percent of polyester modified organic silicon resin, 20-40 percent of filler, 30-50 percent of thinner and 0.5-1 percent of auxiliary agent; the filler is the mixture of glass powder, talcum powder, mica powder and carbon black; the raw-material formula of the primer comprises the following components: 10-20 percent of organic-silicon modified epoxy resin, 10-20 percent of phenolic resin, 20-40 percent of primer filler, 30-50 percent of thinner and 0.5-1 percent of auxiliary agent; and the primer filler is the mixture of iron red, mica powder, talcum powder and glass powder. The fillers adopted by the invention have the performances of acid resistance, alkali resistance, heat resistance, fire resistance, insulation and the like, and the obtained paint has the advantages of good weather resistance, high-temperature resistance, small color difference, good anticorrosive performance, good bonding force and low preparation cost.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com