High-performance architectural reflective thermal insulation coating, and preparation method and applications thereof

A reflective heat-insulating coating, high-performance technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of unstable performance, single color, large limitations, etc., and achieve the best heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

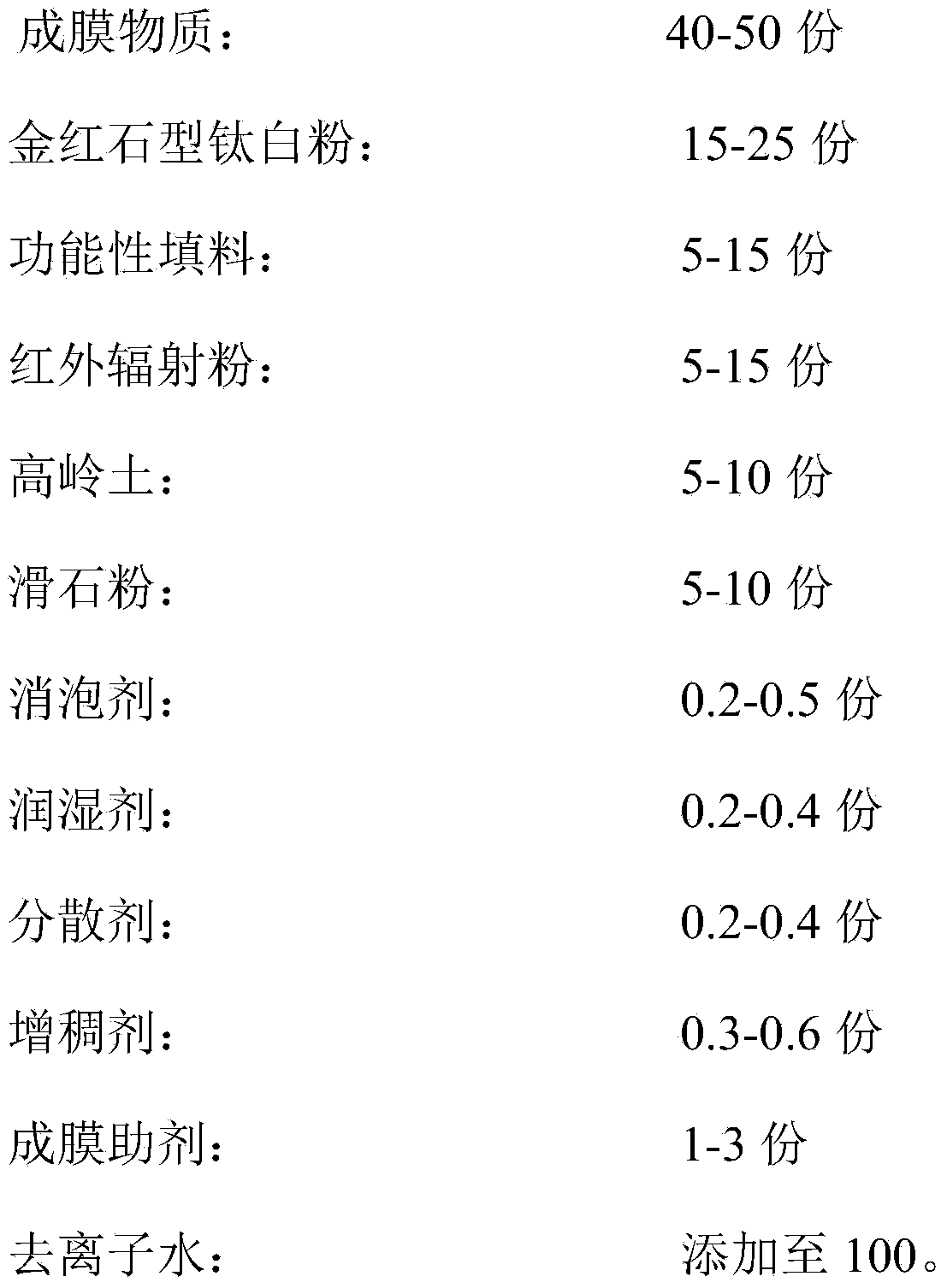

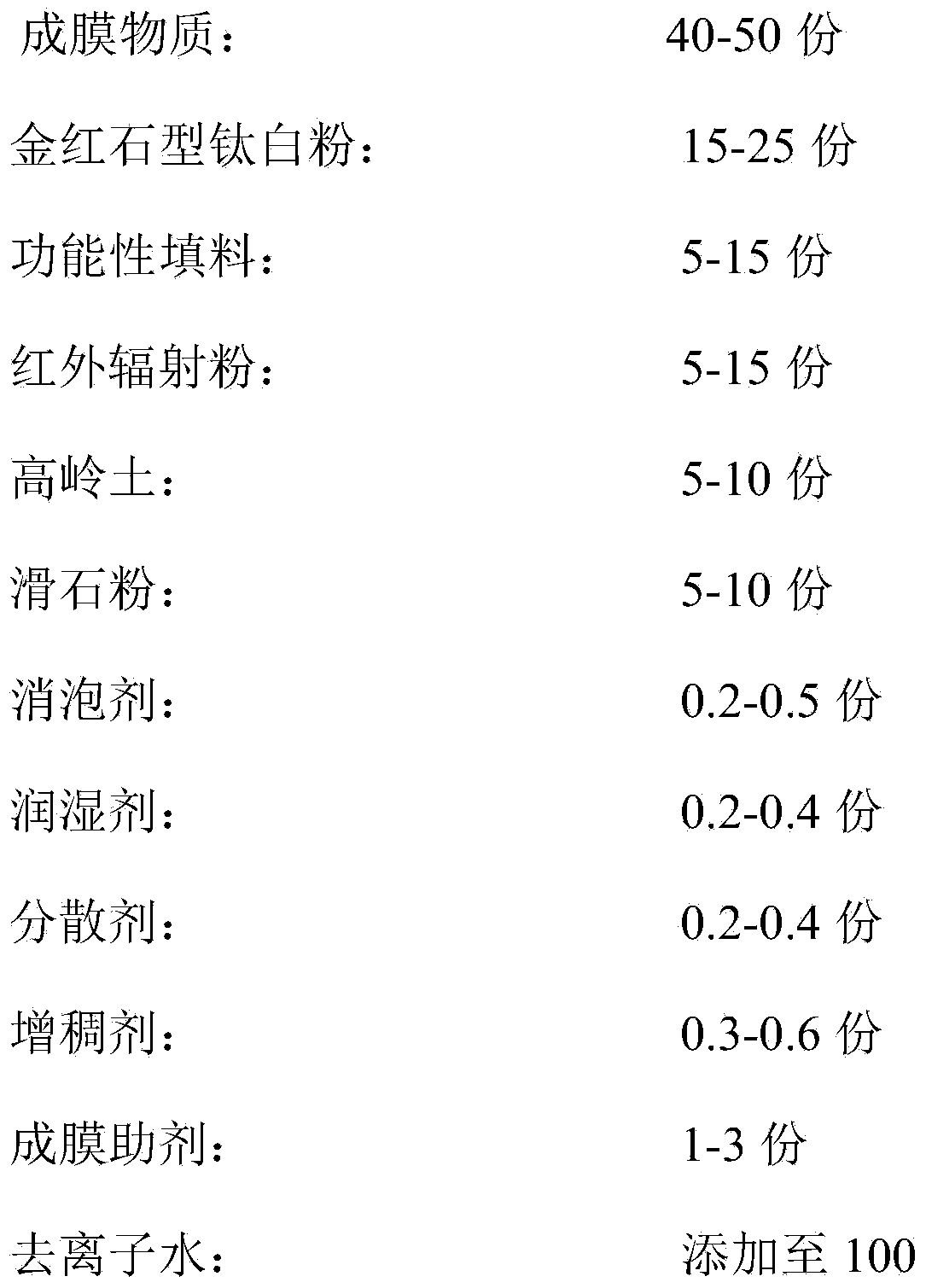

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of infrared radiation powder: in the matrix Al 2 O 3 Add 15% MnO to the powder 2 And 10% mass fraction of TiO 2 The powder is thoroughly mixed and then sieved. The powder is put into a high-alumina ceramic crucible and kept at 1150°C for 2 hours. The synthesized product is crushed and ground to obtain an infrared radiation type powder.

[0022] (2) Preparation of reflective insulation coating: a. Add 0.3 parts of dispersant, 0.2 part of wetting agent, 0.3 part of defoamer and other additives into 16 parts of deionized water according to the formula amount, at a speed of 300~500r / min Stir for 5 min to obtain a thorough mixing; b. Add 16 parts of rutile titanium dioxide, 5 parts of infrared radiation powder, 6 parts of talc and 6 parts of kaolin to the mixture obtained in step a, and disperse for 45 min at a rotation speed of 1000-2000r / min A mixed system with a fineness of 60 μm is obtained; c. At a speed of 300 to 600 r / min, add 40 parts of film-forming mate...

Embodiment 2

[0024] (1) Preparation of infrared radiation powder: in the matrix Al 2 O 3 Add 20% MnO to the powder 2 And 10% mass fraction of TiO 2 The powder is thoroughly mixed and then sieved. The powder is put into a high-alumina ceramic crucible and kept at 1250°C for 2 hours. The synthesized product is crushed and ground to obtain an infrared radiation type powder.

[0025] (2) Preparation of reflective insulation coating: a. Add 0.3 parts of dispersant, 0.2 part of wetting agent, 0.3 part of defoamer and other additives into 16 parts of deionized water according to the formula amount, at a speed of 300~500r / min Stir for 5min to get a thorough mixing; b. Add 18 parts of rutile titanium dioxide, 6 parts of infrared radiation powder, 5 parts of talc and 5 parts of kaolin to the mixture obtained in step a, and disperse for 45min at a rotation speed of 1000~2000r / min A mixed system with a fineness of 60 μm is obtained; c. At a rotation speed of 300 to 600 r / min, add 40 parts of film-forming ...

Embodiment 3

[0027] (1) Preparation of infrared radiation powder: in the matrix Al 2 O 3 Add 20% MnO to the powder 2 And 10% mass fraction of TiO 2 The powder is thoroughly mixed and then sieved. The powder is put into a high-alumina ceramic crucible and kept at 1150°C for 3 hours. The synthesized product is crushed and ground to obtain an infrared radiation type powder.

[0028] (2) Preparation of reflective insulation coating: a. Add 0.3 parts of dispersant, 0.2 part of wetting agent, 0.3 part of defoamer and other additives into 15 parts of deionized water according to the formula amount, at a speed of 300~500r / min Stir for 5 minutes to get a thorough mixing; b. Add 18 parts of rutile titanium dioxide, 5 parts of infrared radiation powder, 5 parts of talc and 5 parts of kaolin to the mixture obtained in step a, and disperse for 45 minutes at a speed of 1000-2000r / min A mixed system with a fineness of 60 μm is obtained; c. At a rotation speed of 300 to 600 r / min, sequentially add 45 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Water resistance | aaaaa | aaaaa |

| Alkali resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com