High flame retardancy type soft foam plastic insulation product and preparation method thereof

A high flame-retardant, rubber-plastic technology, applied in the field of thermal insulation materials, can solve problems such as poor combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

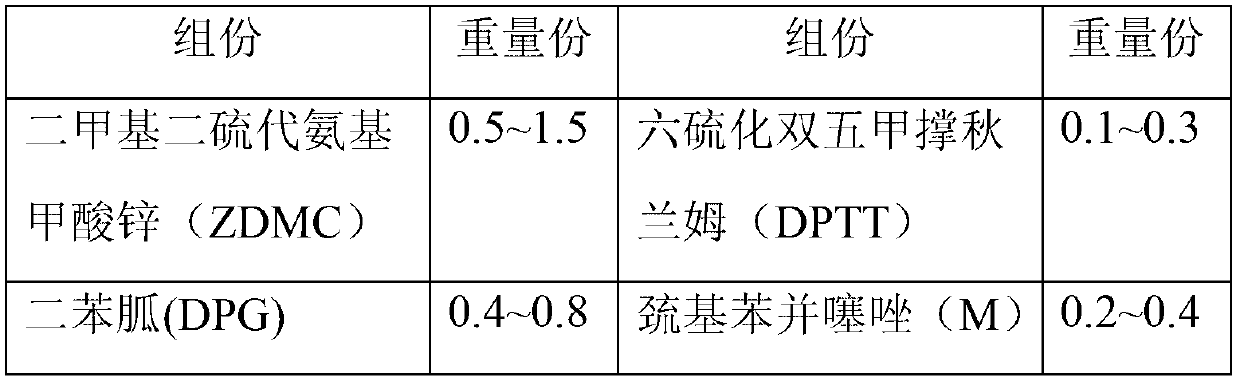

Method used

Image

Examples

Embodiment 1

[0066] 1. Ingredients: Accurately weigh the required raw materials according to the formula requirements of the above-mentioned flexible foam rubber and plastic insulation products.

[0067] 2. Internal mixing and open refining: the raw materials are separately internally mixed and opened, and rolled into raw material films for later use.

[0068] (1) Weigh NBR: 8.4kg, talcum powder: 6.4kg and PEG: 0.5kg, 4020: 0.2kg, CLP: 20kg, paraffin: 0.9kg, ADDA: 1kg, RD: 0.1kg, C: 0.4kg, PVC : 9kg, zinc borate: 4kg, Sb 2 o 3 : 2kg, Al(OH) 3 : 16kg, CPVC: 10kg, put it into the internal mixing room of the internal mixer and discharge the material after internal mixing. After mixing and slicing through the open mill, it is the No. 1 material. The temperature in the internal mixing room of the internal mixer is 140°C and the material is discharged. The thickness of the film is 10mm, the width is 600mm, and the length is 800mm, and it is stacked after cooling.

[0069] (2) Weigh DOP: 1....

Embodiment 2

[0078] The method of Example 1 was used to prepare flexible foam rubber and plastic thermal insulation products, the difference being that:

[0079] (1) In step 1, weigh the raw materials according to the formula in Table 3, in step 2, banburying and refining 2 o 3 : 2kg, Al(OH) 3 : 15.5kg, CPVC: 9kg.

[0080] (2) Step 2: Mixing and refining (3) The step is: ZnO: 0.5kg, S: 0.7kg, DPG: 0.6kg, ZDMC: 0.9kg and DOP: 1kg, NBR: 2.25kg 1. Talc powder: 0.9 kg is made into a vulcanization accelerator film through banburying and rolling, which is the No. 3 material for subsequent use.

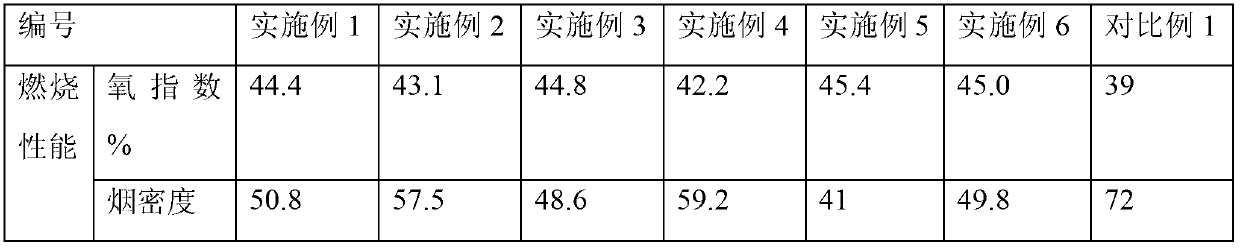

[0081] The obtained product is a flexible foam rubber and plastic insulation product, and the test data of the product are listed in Table 4.

Embodiment 3

[0083] The method of Example 1 was used to prepare flexible foam rubber and plastic thermal insulation products, the difference being that:

[0084] (1) In step 1, weigh the raw materials according to the formula in Table 3, in step 2 banburying and refining, the proportion of flame retardant in step 1 is: zinc borate: 3kg, 2 o 3 : 3kg, Al(OH) 3 : 17kg, CPVC: 8kg.

[0085] (2) Step 2: Mixing and refining (3) The step is: ZnO: 0.6kg, S: 0.6kg, DPTT: 0.3kg, ZDMC: 1.4kg and DOP: 1.5kg, NBR: 2.1 kg, talcum powder: 0.9 kg is made into a vulcanization accelerator film by banburying and rolling, which is used as the No. 3 material for later use.

[0086] The obtained product is a flexible foam rubber and plastic insulation product, and the test data of the product are listed in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com