Patents

Literature

46results about How to "Excellent physical performance index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High flame retardancy type soft foam plastic insulation product and preparation method thereof

ActiveCN103102533AHigh oxygen indexImprove flame retardant performancePolyvinyl chloridePolyethylene glycol

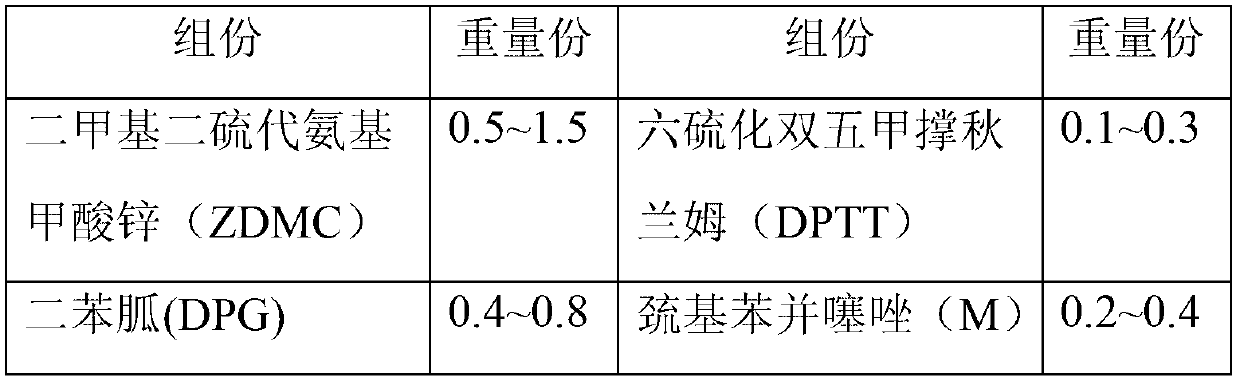

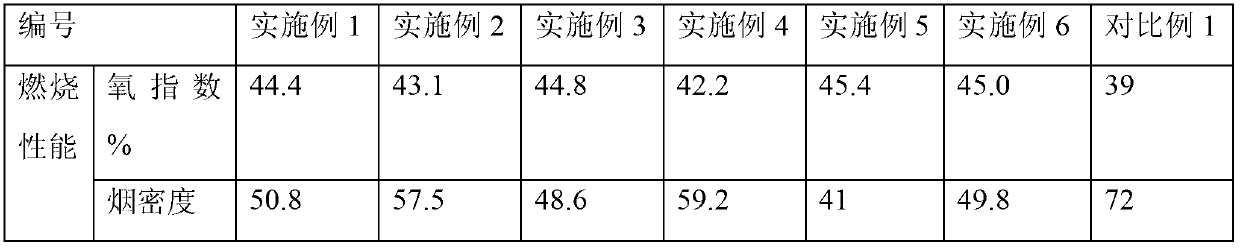

The invention provides a high flame retardancy type soft foam plastic insulation product and a preparation method thereof. The product comprises the following components in parts by weight: 12 to 15 parts of nitrile rubber, 8 to 10 parts of talcum powder, 0.5 to 0.8 parts of polyethylene glycol, 0.2 to 0.4 parts of antiager 4020, 15 to 20 parts of chlorinated paraffin, 0.6 to 0.9 parts of paraffin, 1 to 2 parts of epoxidized soybean oil, 0.1 to 0.3 parts of antiager RD, 0.4 to 0.7 parts of carbon black, 7 to 10 parts of polrvinyl chloride, 26 to 36 parts of fire retardant based on the total amount, 2 to 5 parts of dioctyl ester, 8 to 12 parts of azodicarbonamide, 0.2 to 0.5 parts of stearic acid, 0.4 to 0.7 parts of zinc oxide, 0.4 to 0.7 parts of sulphur, and 1.3 to 1.8 parts of accelerant based on the total amount. By adopting the high flame retardancy type soft foam plastic insulation product, the technical problem that the oxygen index and the smoke density are mutually conflicted in the technological manufacture is solved, and the bottleneck due to mutual limitation is broken through.

Owner:HEBEI HUAMEI CHEM & BUILDING MATERIALS GRP

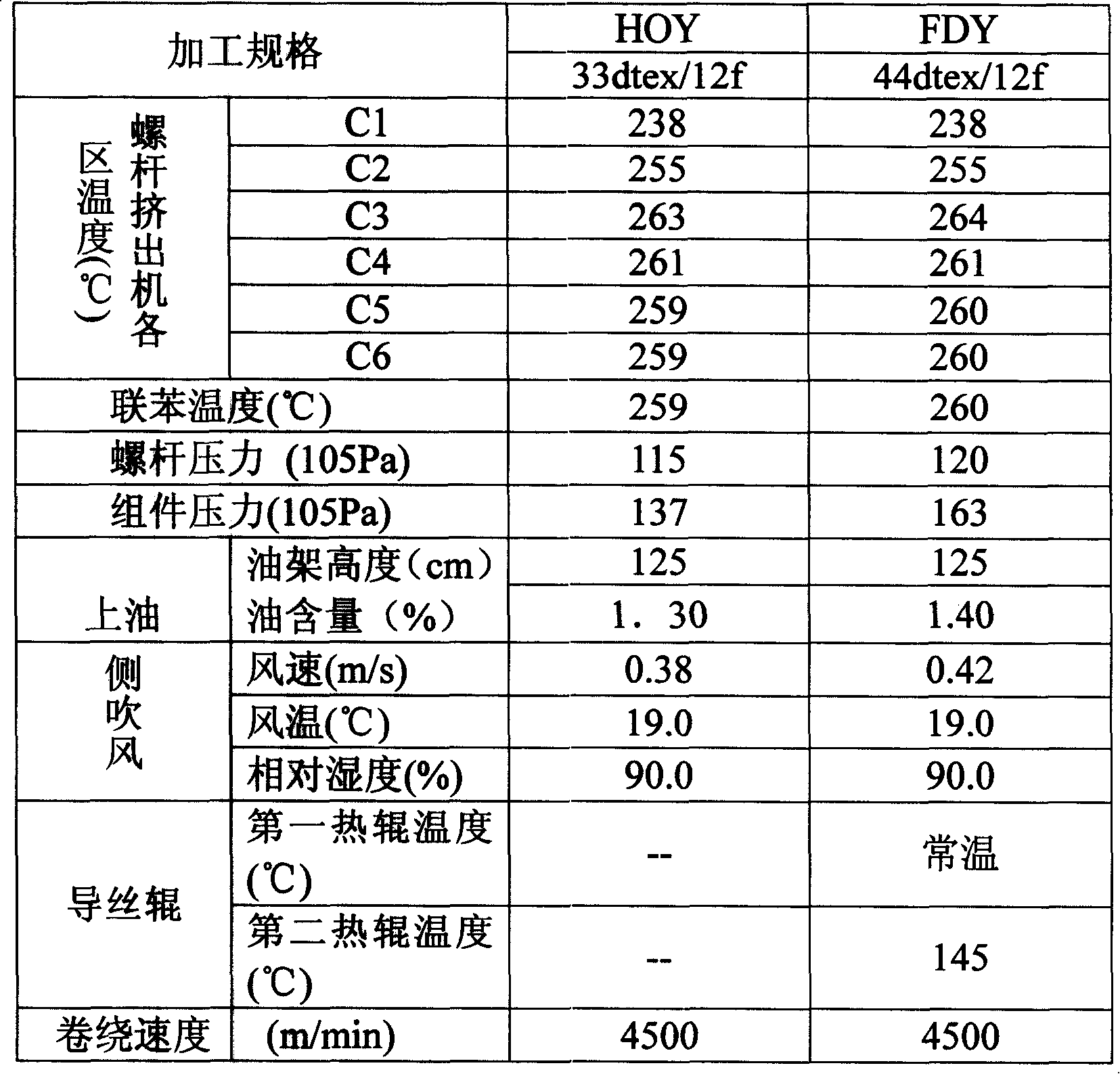

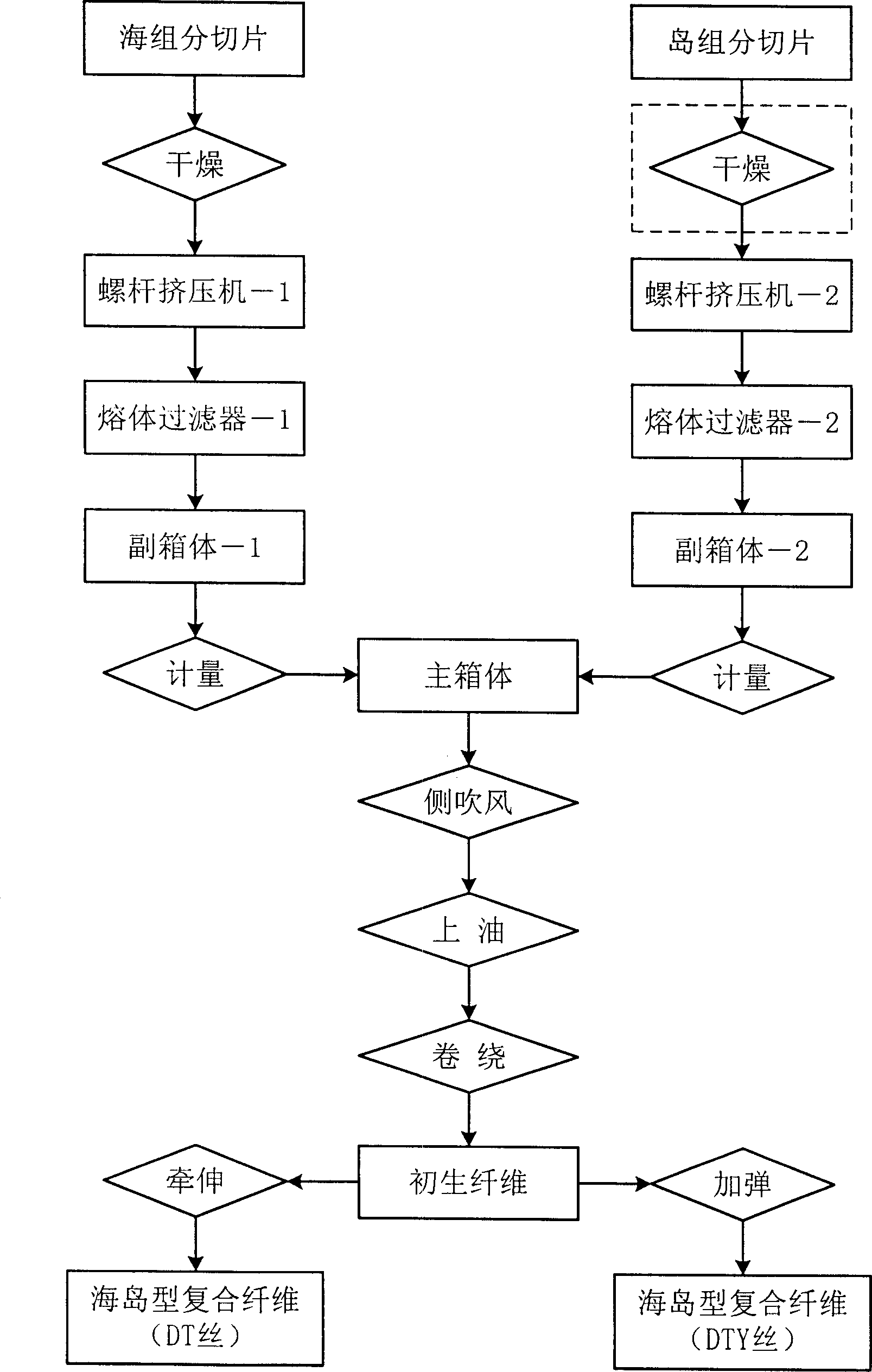

Moisture absorption polyamide 6 fibre and production method thereof

ActiveCN101195934AHigh single fiber gapReduce size and weightFilament/thread formingMonocomponent polyamides artificial filamentPolyamideManufacturing engineering

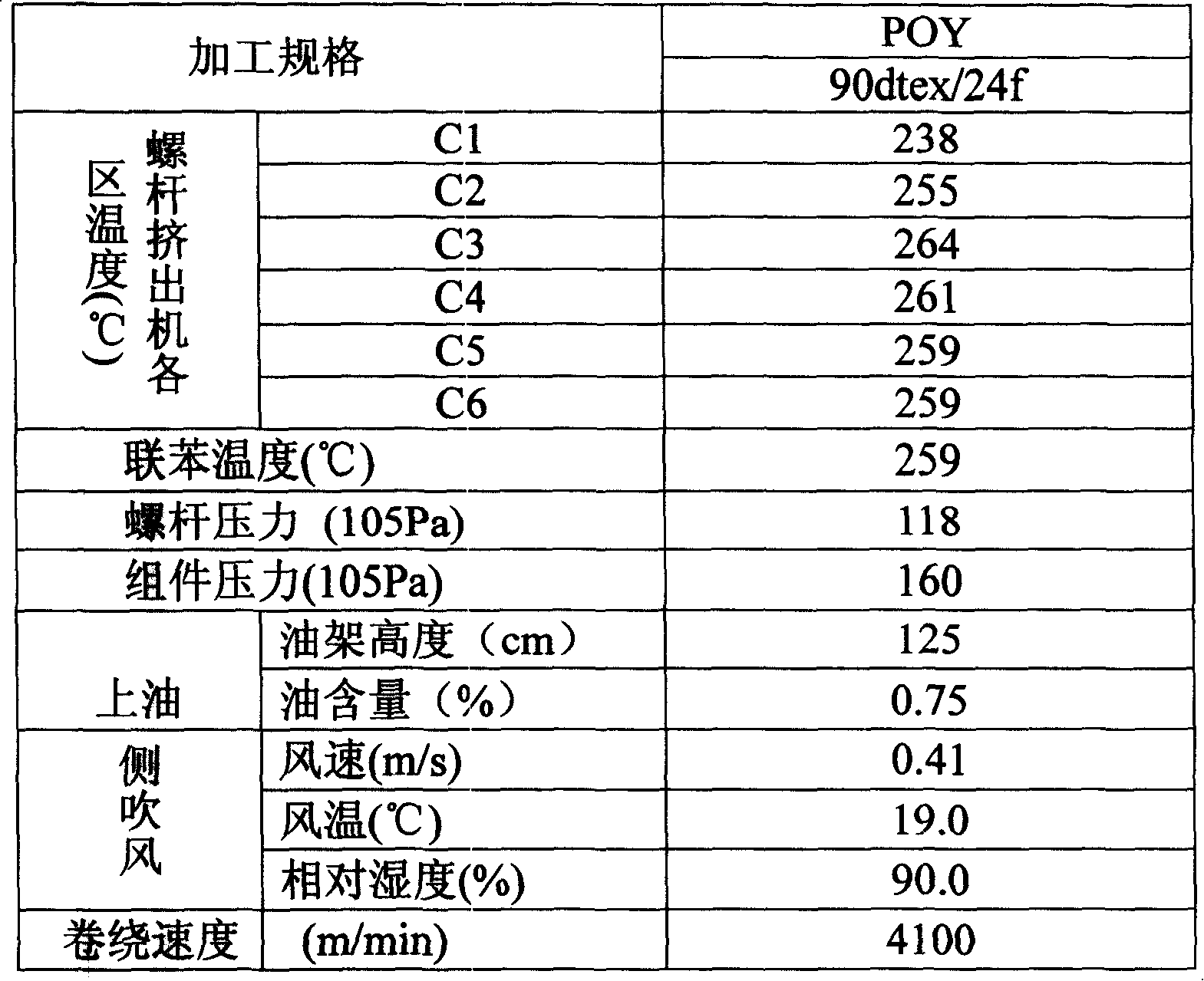

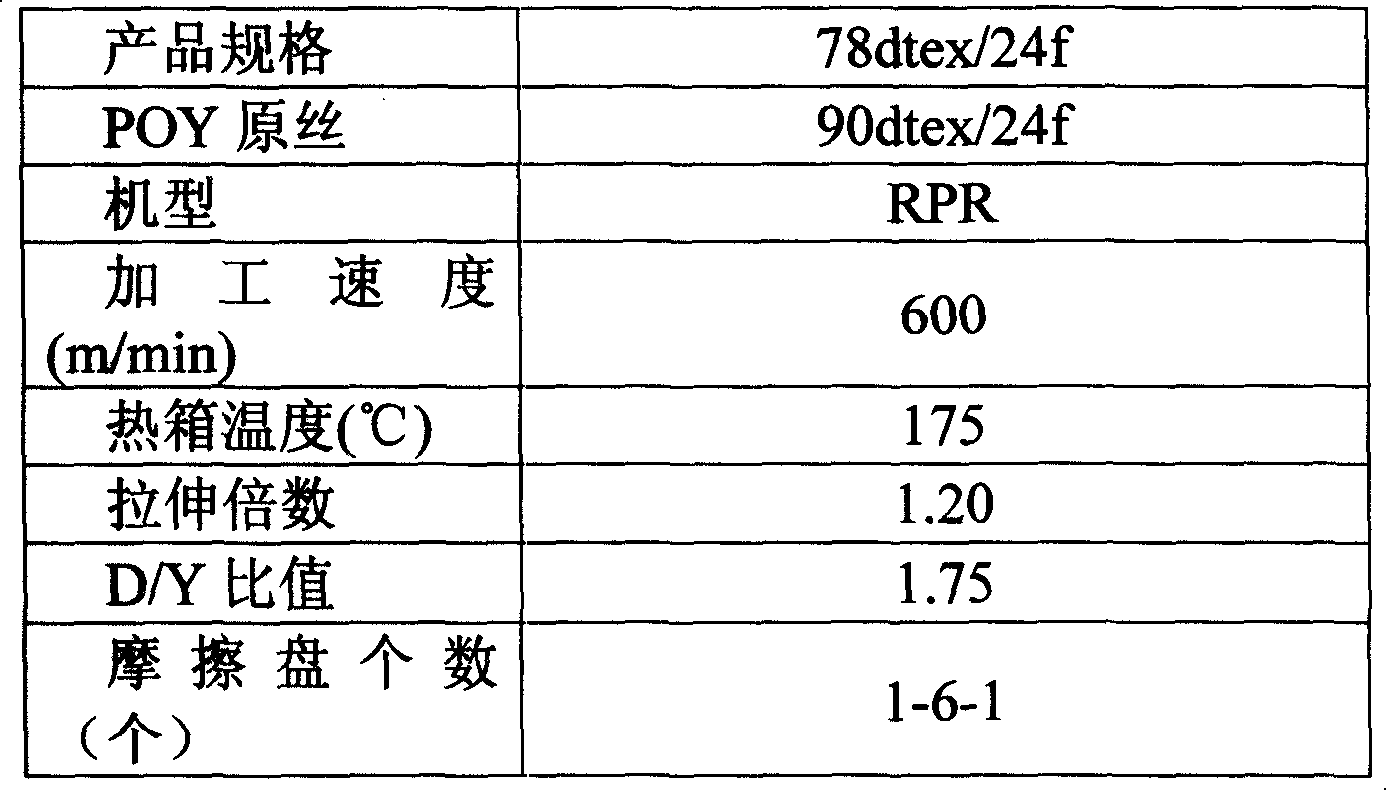

The invention relates to moisture-absorption polyamide-6 fiber and the manufacturing method. The invention utilizes a special-shaped spinning plate to produce the polyamide-6 fiber with a cross type cross section, the fiber of the invention has good moisture-absorption function, simultaneously, the invention also overcomes the default of the prior art for producing polyamide-6 fiber, and provides a manufacturing technology of high product qualification ratio.

Owner:YIWU HUADING NYLON

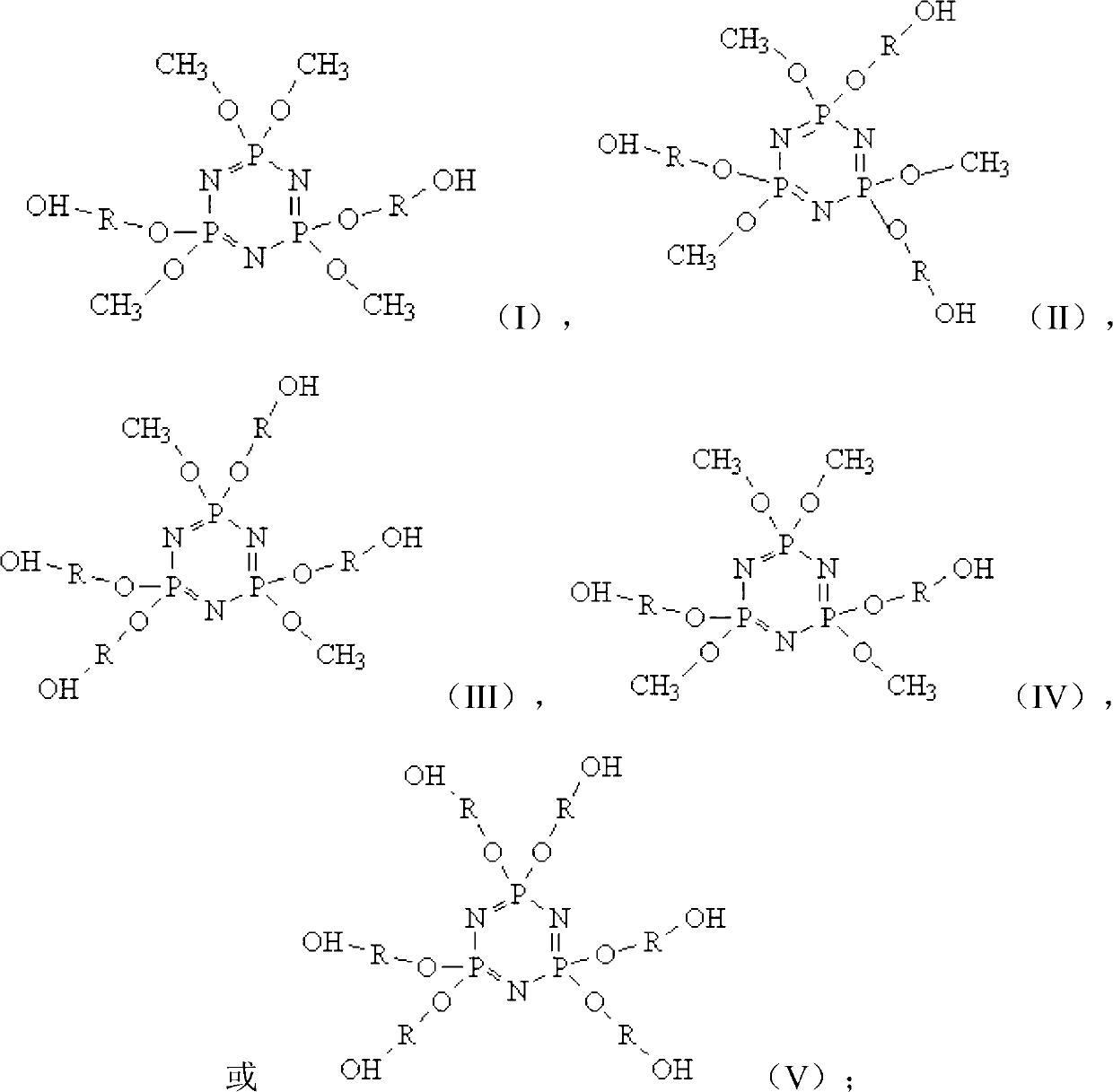

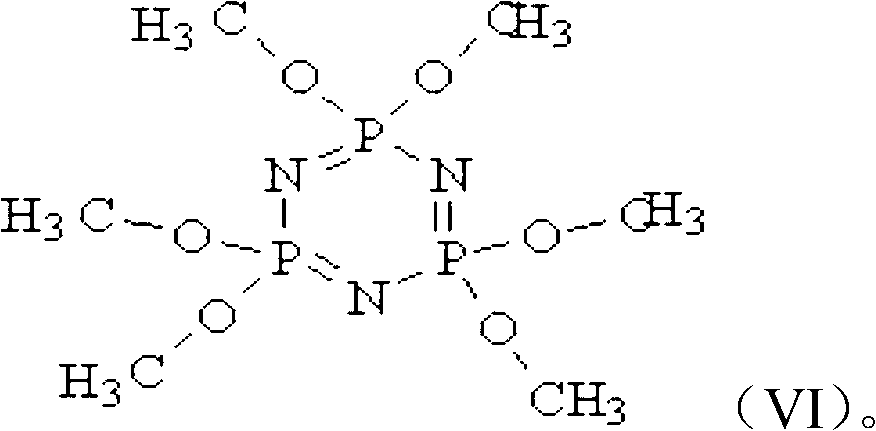

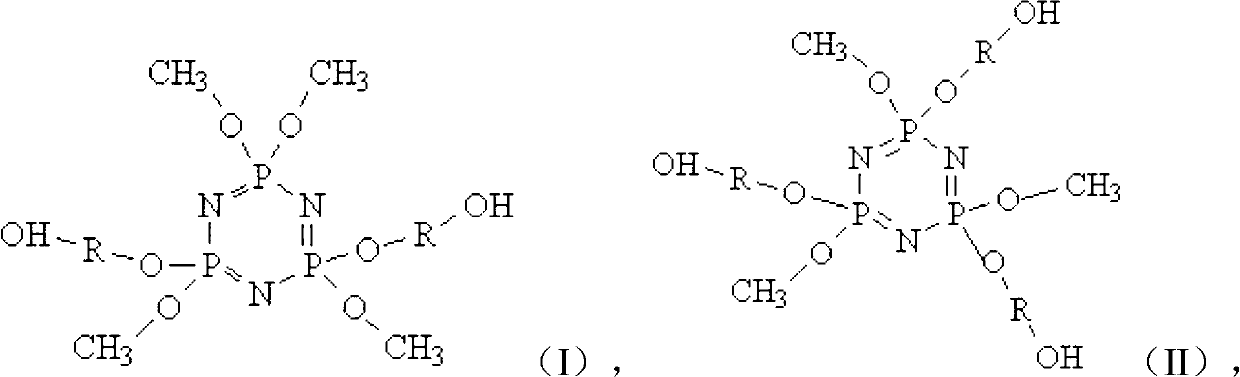

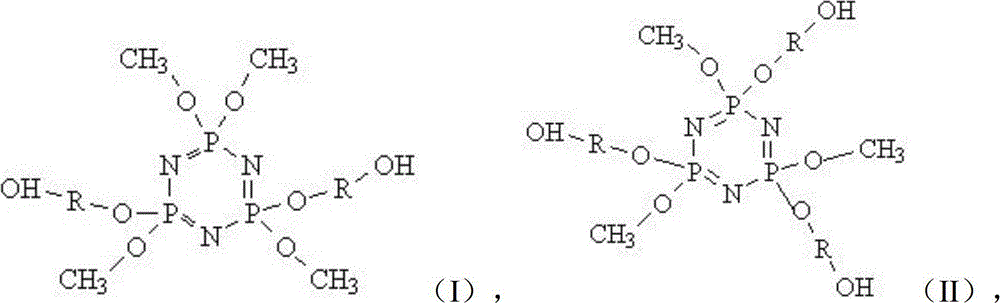

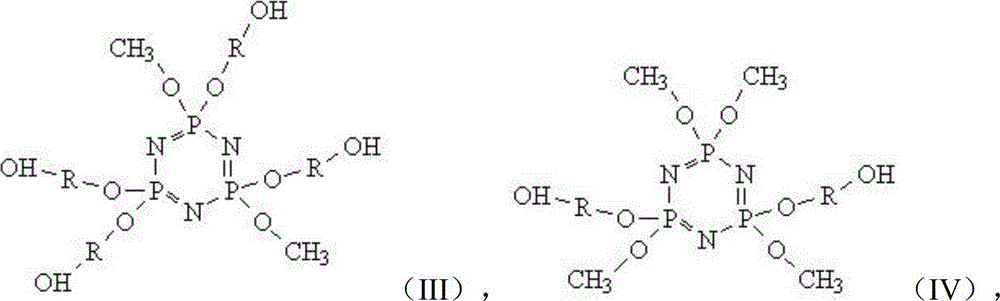

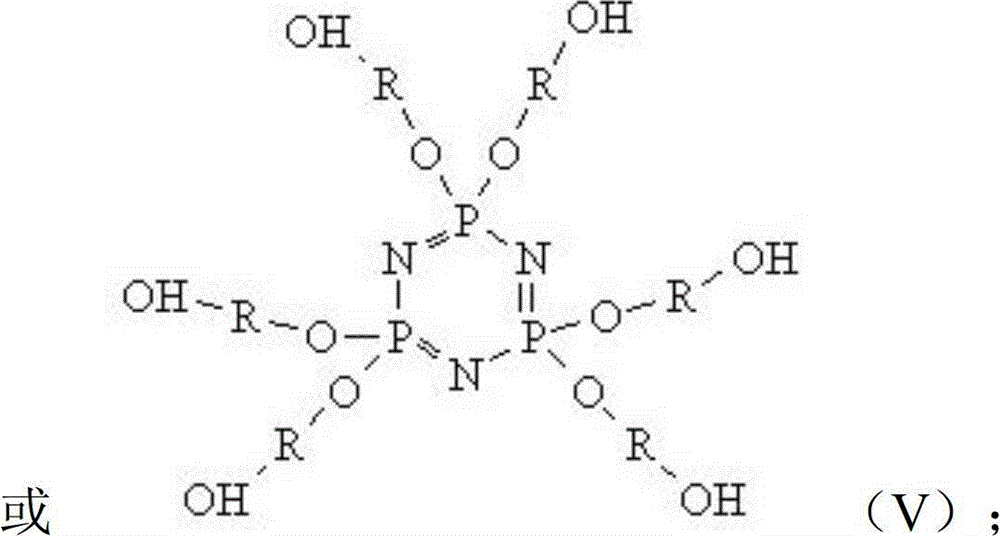

HPCP resin with polyhydroxy structure and preparation method thereof

ActiveCN102816186AExcellent physical performance indexGroup 5/15 element organic compoundsPolymer scienceCombustion

The invention discloses a HPCP resin with a polyhydroxy structure which has the representative structural formula as follows, wherein R=-(CH2)n-or -(CH2)mO(CH2)m-; and n is larger than 2 or equal to 6, and m is larger than 2 or equal to 6. A preparation method the HPCP resin with the polyhydroxy structure comprises the following steps of: having a trans-etherification reaction between HMPN HPCP resin and dihydric alcohol under the catalysis of solid acid catalyst, and carrying out aftertreatment, so that the HPCP resin with the polyhydroxy structure can be obtained. According to the technical scheme disclosed by the invention, the methyl on the HMPN HPCP resin can be exchanged into the HPCP resin with 2-6 hydroxy structures through the trans-etherification technology, and can be further reacted with the isocyanate, so that the phosphorus fine polyurethane foamed plastics can be generated, wherein the foamed plastics is novel polyurethane material: the oxygen combustion index of the phosphorus fine polyurethane foamed plastic can reach to be more than 40-50, the inflaming retarding grade can reach B1 grade of GB / T8624-2012 standard, and each physical performance index of the phosphorus fine polyurethane foamed plastics is better than that of the other polyurethane foamed plastics.

Owner:杨彦威 +1

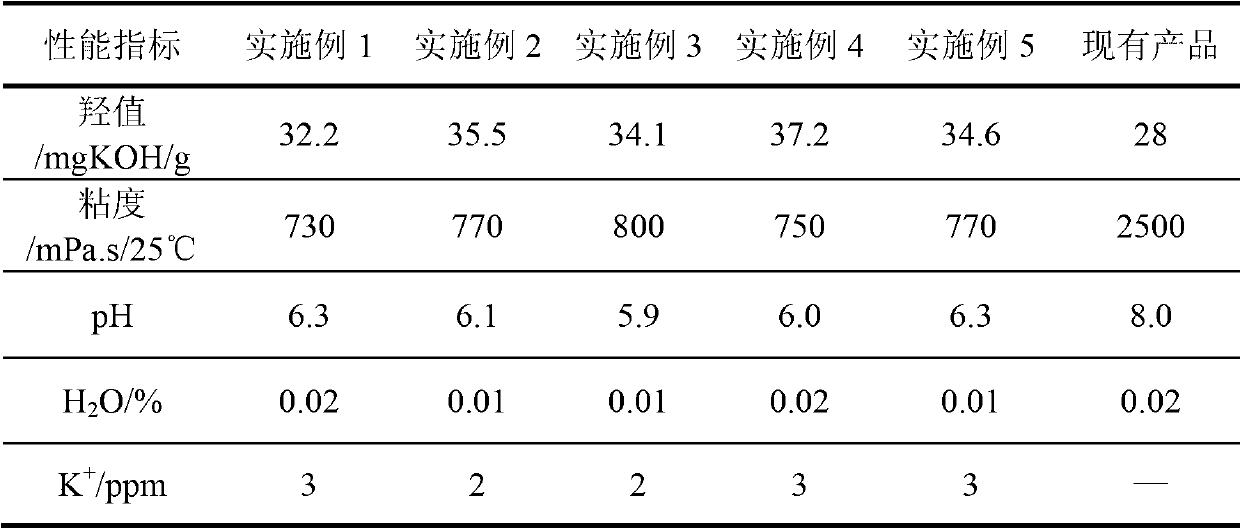

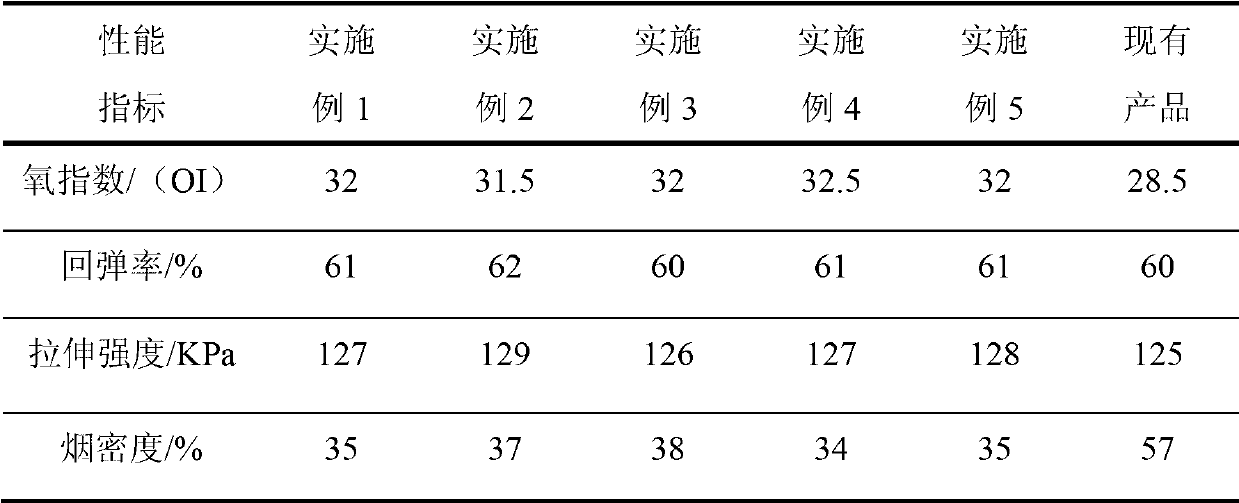

Flame retardant soft foam polyether polyol and synthesis method thereof

ActiveCN102875791AGood durability of flame retardant performanceExcellent physical performance indexHigh oxygenBase metal

The invention relates to a flame retardant soft foam polyether polyol and a synthesis method thereof. The technical scheme is to provide the flame retardant soft foam polyether polyol which is good in flame retardant property, safe and non-toxic, simple in preparation process and low in cost and the synthesis method of the flame retardant soft foam polyether polyol. The synthesis method disclosed by the invention comprises the following steps of enabling melamine-formaldehyde condensation compound to react with amine compounds, polymerizing the reaction product with an acid compound to obtain a polyether initiator, further polymerizing the polyether initiator with oxyalkylene with the action of a base metal catalyst so as to obtain the flame retardant polyether polyol. The flame retardant polyether polyol synthesized by the method has the advantages of light colour, low viscosity and good material flowability, and can be widely used for preparing the flame retardant polyether soft foam. The flame retardant soft polyether foam plastic products foamed and prepared by the flame retardant polyether polyol disclosed by the invention have the characteristics of good flame retardant effect, high oxygen index, good foam uniformity, good size stability and high mechanical strength.

Owner:SHANDONG BLUSR DONGDA CHEM

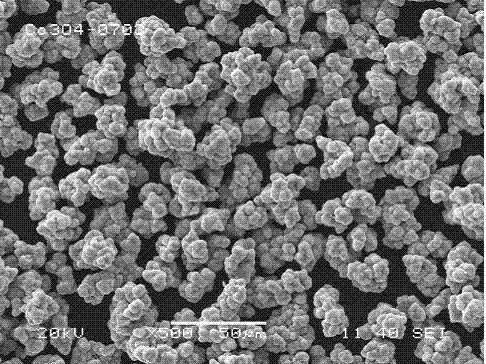

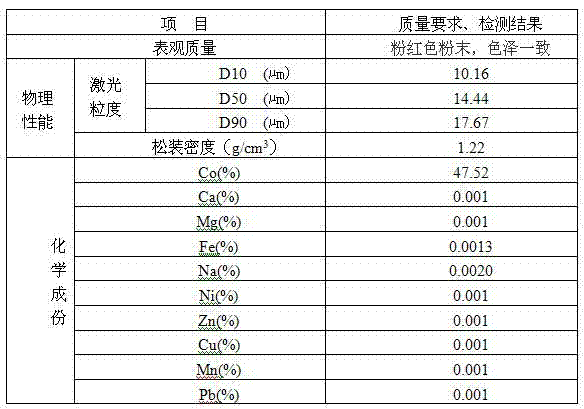

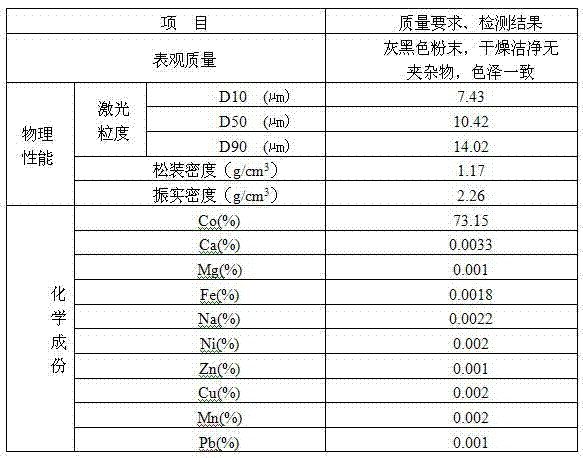

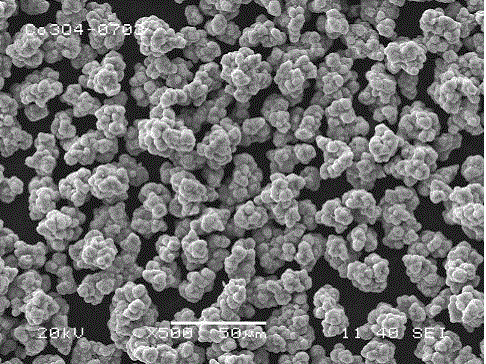

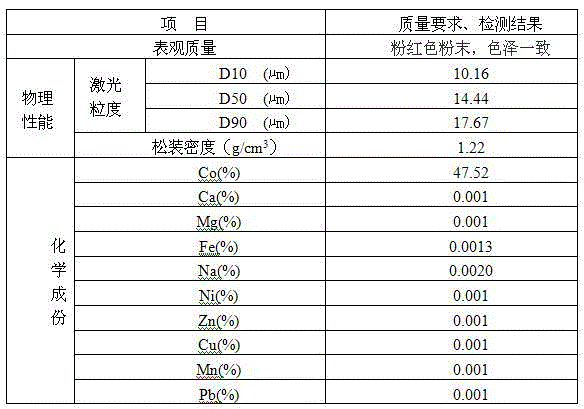

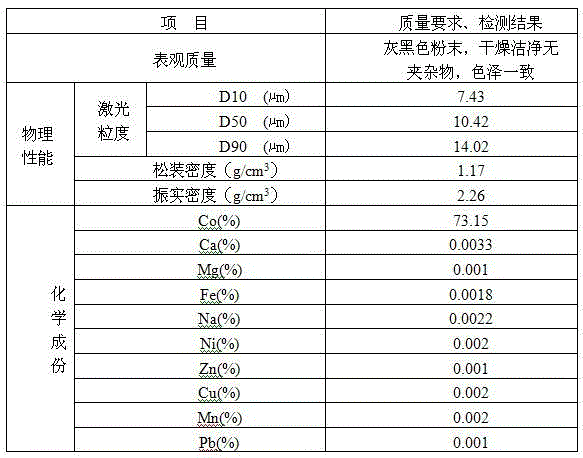

Preparation process of cobaltosic oxide for continuous production of batteries

ActiveCN102820468AGood lookingFine granularityCell electrodesCobalt compoundsAfter treatmentLithium carbonate

A preparation process of cobaltosic oxide for continuous production of batteries is a process for preparing the cobaltosic oxide by using a cobalt contained material to continuously synthesize cobalt carbonate and continuously roasting and resolving in an oxidizing atmosphere. Continuous production of the cobaltosic oxide can be completed through several steps of preparation of cobalt solution, preparation of precipitator, lithium carbonate synthesizing, ageing, filtering and washing, burning and after treatment. The preparation process continuously synthesizes the cobalt carbonate, and continuously roasts and resolves the cobaltosic oxide, is apt to control technical indexes in a production procedure, can achieve automatic production, is favorable for reduction of labor intensity, improves efficiency of labor and lowers cost. Produced products are high in purity, excellent in physical performance indexes and good in stability and consistency.

Owner:GANZHOU TENGYUAN COBALT INDAL

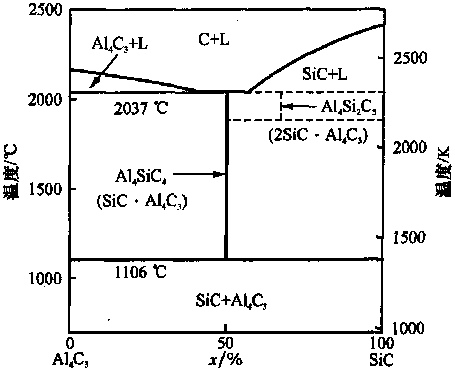

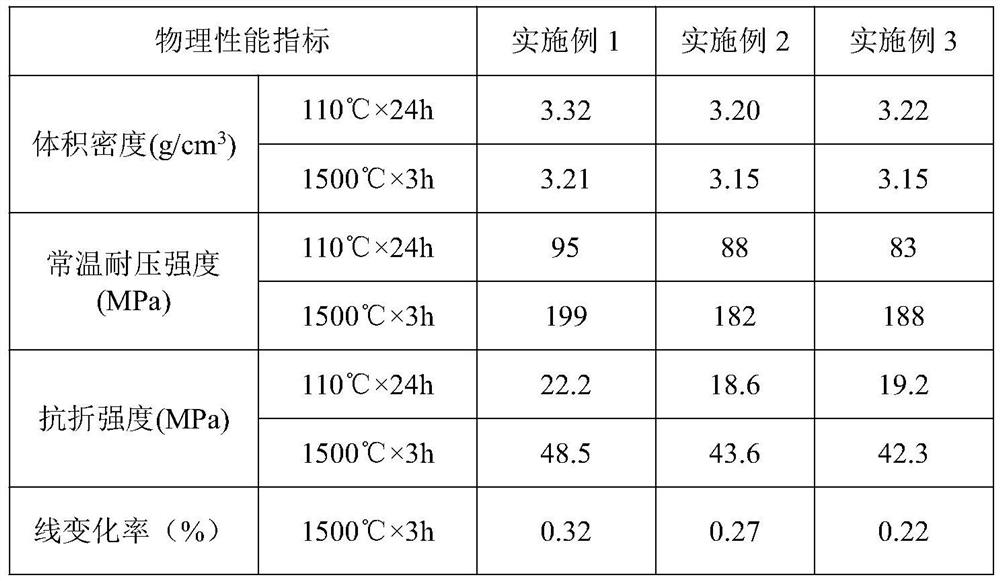

Preparation method of Al4SiC4-Al2O3-SiC composite material

ActiveCN108218408AHigh strengthIn situ generation of high strength during high temperature firingThermal expansionChemical stability

The invention relates to a preparation method of an Al4SiC4-Al2O3-SiC composite material, and belongs to the field of refractory materials. The composite material is prepared from the following raw materials in percentage by weight: 45 to 86 percent of high bauxite, 10 to 25 percent of silicon carbide, 5 to 15 percent of active alumina, 1 to 15 percent of metal aluminum, 0 to 5 percent of carbon black or graphite and phenolic resin binder in an amount of 2 to 6 percent based on the total amount of the abovementioned materials. The preparation method comprises the following steps: during production, weighing the raw materials according to a proportion; mixing uniformly to obtain mud; performing press molding; drying at the temperature of 120 to 250 DEG C for 10 to 25 hours; then sintering in a carbon-buried atmosphere of 1,300 to 1,700 DEG C for 5 to 12 hours. Al4SiC4 sintered in situ in a high-temperature sintering process of the product is a binder phase. The composite material has the advantages of high melting point, high strength, high wear resistance, high chemical stability, low thermal expansion coefficient, excellent oxidation resistance and excellent hydration resistance,and is a high-temperature structural material as well as a high-performance refractory material.

Owner:江苏诺明高温材料股份有限公司

Little-chlorine and little-pollution bleaching process for paper pulp biomimetic pretreatment

The invention relates to a little-chlorine and little-pollution bleaching process for paper pulp biomimetic pretreatment, in particular to a little-chlorine element chlorine-free bleaching (ECF) process for the paper pulp biomimetic pretreatment. The process is a novel little-pollution bleaching technology in the paper pulp biomimetic pretreatment and belongs to the technical field of paper making. The process mainly comprises the following steps of: (1) carrying out metal salen biomimetic pretreatment to paper pulp bleaching, wherein metal salen, pyridine, H2O2 and O2 are used for carrying out bleaching pretreatment to oxygen-removal kraft pulp in alkaline condition; and (2) carrying out subsequent little-chlorine and little-pollution bleaching, wherein paper pulp after the biomimetic pretreatment undergoes three-section bleaching treatment, i.e., a chlorine dioxide bleaching section, a chelation treating section and a hydrogen peroxide bleaching section. The process is simple and easy to implement, has remarkable effect and can improve the whiteness and the property of the paper pulp. Compared with the conventional little-chlorine bleaching procedures, the bleaching process uses less chlorine. Compared with the conventional CEH bleaching, the bleaching process can reduce the time for pulping.

Owner:KUNMING UNIV OF SCI & TECH

Al23O27N5-combined corundum composite slide plate and preparation method thereof

InactiveCN103214256AImprove thermal shock resistanceImprove performanceSlide plateActivated Aluminum Oxide

The invention discloses an Al23O27N5-combined corundum composite slide plate and a preparation method thereof, belonging to the field of a refractory material. The slide plate consists of the following raw materials in percentage by weight: 55-85% of corundum, 5-30% of activated aluminum oxide, 1-15% of metal Al and 0-3% of carbon black and graphite; and phenolic resin accounting for 2-6% of the total weight of the raw materials is added as a bonding agent. The preparation method comprises the following steps of: weighing the raw materials according to the proportions, and mixing uniformly; mixing to obtain pug; performing compression moulding; drying at 120-600 DEG C for 5-25 hours; and then sintering in a nitriding atmosphere at 1,200-1,600 DEG C for 5-25 hours. The apparent porosity of the product disclosed by the invention is 4-13%, the volume density is 3.0-3.4g / cm<3>, the cold crushing strength is 150-280MPa, and the high temperature bending strength is 20-55MPa. The Al23O27N5-combined corundum composite slide plate has good erosion resistance and thermal shock resistance and low cost; the main components of the raw materials have high chemical stability and low oxygen potential; and secondary pollution caused by C, O, H and other impurities is avoided in clean steel continuous casting.

Owner:UNIV OF SCI & TECH BEIJING

Recycling method of glass ceramic material

InactiveCN106430982ARealize comprehensive utilizationReduce pollutionGlass-ceramicEnergy consumption

The invention relates to a recycling method of a glass ceramic material. Waste generated in glass ceramic production is used as a main raw material, and recycling treatment is performed through the processes including smashing, screening, grading, binding agent adding, mixing and grinding, press-forming, drying, hot air hardening and the like to obtain a recycled glass ceramic product. Due to the fact that the waste produced in glass ceramic production is used as the main raw material, the energy consumption is reduced, stored waste glass ceramic materials can also be decreased, and environmental pollution is reduced. The production process is simple, the energy consumption is low, the production cost can be effectively reduced, different batches of products are good in reproducibility, and the recycling method is suitable for large-scale industrial production.

Owner:内蒙古科韵环保材料股份公司

Ti(C,N) solid solution-corundum combined refractory material and preparation method thereof

The invention particularly relates to a Ti(C,N) solid solution-corundum combined refractory material and a preparation method thereof, belonging to the field of refractory materials. The preparation method is characterized by comprising the following preparation steps: batching, mixing, mechanical pressing and forming, drying, and firing. The raw materials of the refractory material are composed of, by weight, 0-30% of brown fused alumina with a size of 3-5 mm, 30-50% of brown fused alumina with a size of 1-3 mm, 10-30% of brown fused alumina with a size of 0.1-1 mm, 20-50% of brown fused alumina with a size of no more than 200 meshes, 0-10% of metallic aluminum with a size of no more than 200 meshes, and phenolic resin accounting for 2-6% of the total amount of the above raw materials andused as a binding agent. A firing schedule is that drying is performed at 120-600 DEG C for 5-25 hours at first, and then sintering is performed at 1200-1600 DEG C in a nitriding atmosphere for 5-25hours. The Ti(C,N) solid solution-corundum combined refractory material prepared by using the method disclosed by the invention does not need an extra titanium source, and the method has the characteristics of simple process and low production cost. Meanwhile, the produced Ti(C,N) solid solution-corundum combined refractory material has very high normal-temperature and high-temperature strength and superior oxidation resistance, thermal shock resistance and erosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

Unfired ferro silicon nitride-alumina composite carbon-free sliding plate and preparation method thereof

InactiveCN103304245AMeet production requirementsReduce manufacturing costOxide compositeAlumina composite

The invention relates to an unfired ferro silicon nitride-alumina composite carbon-free sliding plate and a preparation method thereof, belonging to the field of refractory materials. The sliding plate is composed of the following raw materials in percentage by weight: 55-90% of corundum, 0-20% of activated alumina, 0-30% of ferro silicon nitride and phenolic resin accounting for 2-6% of total dosage of the raw materials to serve as a binding agent. The preparation method comprises the steps of: weighing the raw materials according to the proportions, uniformly mixing the raw materials, smelting the raw materials to obtain pug, pressing forming the pug, and the drying the pug at 120-600 DEG C for 5-25hours. The product is of an oxide-non oxide composite structure and has the following excellent physical performance indexes: the apparent porosity is 3-11%, the bulk density is 3.0-3.35g / cm<3>, the normal temperature compressive strength is 100-260MPa and the high temperature flexural strength is10-50Mpa. The product provided by the invention needs no high temperature firing and oil immersion procedures, so that the production cost is greatly reduced.

Owner:UNIV OF SCI & TECH BEIJING

Sialon bonded andalusite/sillimanite/SiC refractory material and preparation method

The invention discloses a sialon bonded andalusite / sillimanite / SiC refractory material and a preparation method, and belongs to the field of a refractory material. The refractory material comprises the following raw materials: andalusite, sillimanite, alpha-Al2O3 powder, polycrystalline silicon waste and aluminum powder, and dextrin and phenolic resin are taken as binding agents. The refractory material is produced by the following steps: weighing raw materials and mixing to obtain mud, compressing and moulding, and sintering in a nitrogen atmosphere at 1200-1600 DEG C. According to the product disclosed by the invention, characteristics of andalusite and sillimanite are developed and a sialon bonded phase is generated through the polycrystalline silicon waste; the refractory material has the following excellent physical performance indexes: apparent porosity is 9-18%, volume density is 2.5-3.0g / cm<3>, cold crushing strength is 100-300MPa and high temperature bending strength is 20-70MPa, thermal shock resistance, creep resistance, CO resistance and alkaline steam erosion resistance are excellent. The product disclosed by the invention is high in cost performance, and is applicable to the middle upper part of furnace body of a blast furnace. The refractory material is not only favorable for prolonging service life of the blast furnace but also realizes recycling of the polycrystalline silicon waste.

Owner:UNIV OF SCI & TECH BEIJING +1

SiC-AlN solid solution and Al2O3-C combined composite sliding plate and preparation method thereof

InactiveCN110436901AImprove performanceMeet production requirementsMelt-holding vesselsCeramicwarePorosityMetallic aluminum

The invention relates to a SiC-AlN solid solution and Al2O3-C combined composite sliding plate and a preparation method thereof, and belongs to the field of refractories. The SiC-AlN solid solution and Al2O3-C combined composite sliding plate is prepared from the following raw materials in percentage by weight: 60-90% of corundum, 1-20% of alpha-Al2O3 micro powder, 1-15% of metallic aluminum, 1-15% of silicon, and 0-5% of powdered carbon, and 2-7% of phenolic resin is added as a binder. During production, the raw materials are mixed evenly according to the proportion, a mud material is obtained through mixing, pressing forming is conducted, drying is conducted for 5-30 h at 120-400 DEG C, then heat preservation is conducted for 1-10 h under the nitrogen atmosphere at 400-660 DEG C, and finally firing is conducted under the nitrogen atmosphere at 1450-1700 DEG C. According to the SiC-AlN solid solution and Al2O3-C combined composite sliding plate, reaction of Al, Si, C and N2 is utilized to synthesize a SiC-AlN solid solution reinforced phase in situ in an Al2O3 matrix, and the excellent properties are realized as follows: the apparent porosity is 5-20%, the volume density is 3.00-3.40 g / cm<3>, and the normal-temperature compressive strength 100-400 MPa. During firing of the SiC-AlN solid solution and Al2O3-C combined composite sliding plate, the ultra-high temperature and highpressure are not needed, the cost of applying a SiC-AlN solid solution to a refractory is greatly lowered, and the SiC-AlN solid solution and Al2O3-C combined composite sliding plate is suitable for industrial production. The SiC-AlN solid solution and Al2O3-C combined composite sliding plate integrates the advantages of metal, non-oxides and oxides, and has good thermal shock resistance, erosionresistance and high-temperature stability

Owner:UNIV OF SCI & TECH BEIJING

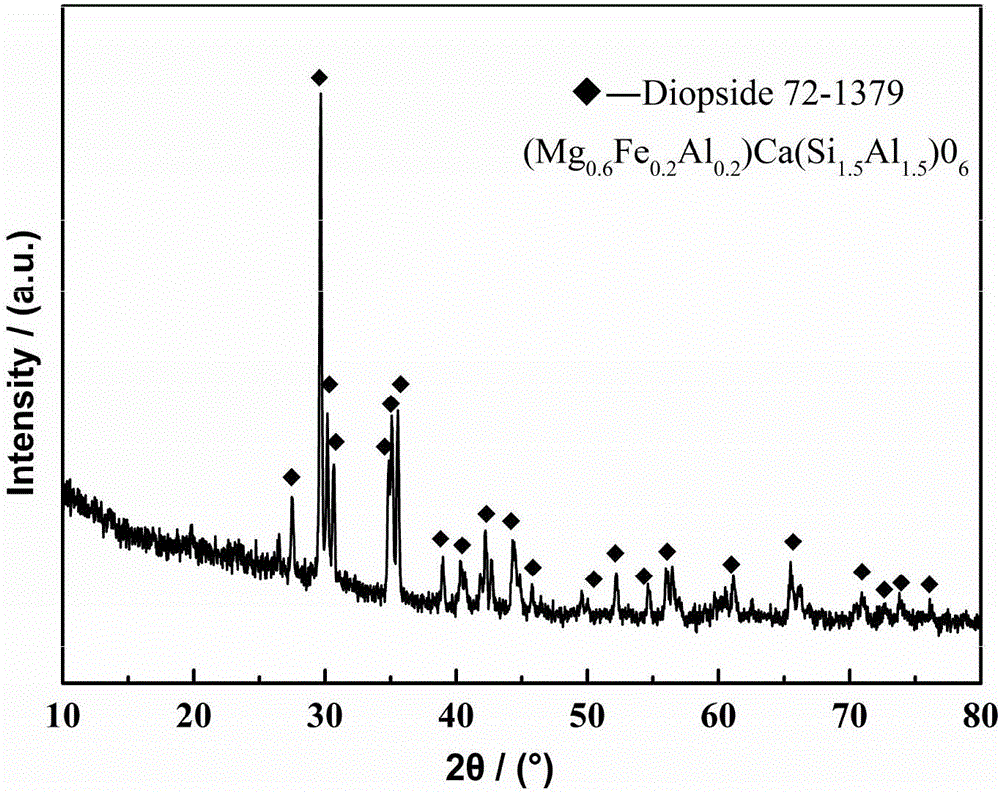

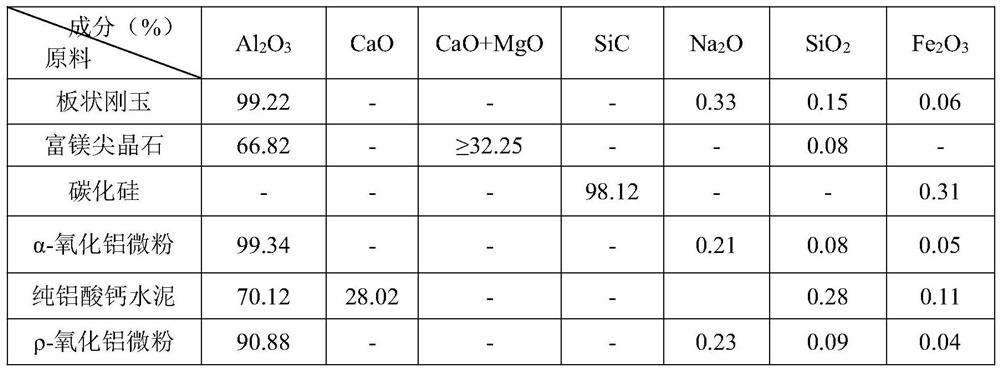

Cast-molded sliding plate brick for slag stopping of converter tapping hole and production method

The invention provides a cast-molded sliding plate brick for slag stopping of a converter tapping hole. The cast-molded sliding plate brick is prepared from the following raw materials: 65-78% of tabular corundum, 8-12% of magnesium-rich spinel, 3-7% of silicon carbide, 6-10% of alpha-aluminum oxide micro powder, 1-2% of pure calcium aluminate cement, 3-6% of rho-aluminum oxide micro powder and 0.05-0.2% of a water reducing agent. During production, the raw materials and the water reducing agent are weighed, stirring is conducted by a stirrer to obtain pug, pouring and vibration molding are carried out, after 24h of curing, demoulding is conducted, drying treatment is performed at 300+ / -10DEG C, and then grinding and coating are conducted to obtain the product. The sliding plate brick is excellent in integrity, good in erosion resistance, stripping resistance and thermal shock resistance, high in strength and good in use performance.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Sea island type composite fiber and its manufacturing method and application

ActiveCN1284890CSectional shape is regularOptimizing Section ShapeFilament/thread formingConjugated synthetic polymer artificial filamentsCopolymerPhysical property

The invention provides a sea-island type composite fiber and its production method and application. It uses thermoplastic resins such as PP and PA6 as island components, biodegradable polylactic acid PLA or its copolymers as sea components, and adopts composite spinning method to obtain sea-island composite fibers with regular cross-sectional shape and excellent physical properties. The indicators are excellent. This sea component is biodegradable and can be dissolved by alkali under relatively mild conditions. The composite fiber or its fabric can be treated with alkaline water to produce superfine fiber or fabric. The alkaline treatment process is simple and easy to control, and the product dissolved by alkaline solution is easy to be post-treated, basically pollution-free and environmentally friendly. The technical scheme of the invention can be used to make clothing, high-grade synthetic leather, artificial suede and the like.

Owner:SINOPEC YIZHENG CHEM FIBER

Railway turnout oil-resistant rubber base plate and preparation process thereof

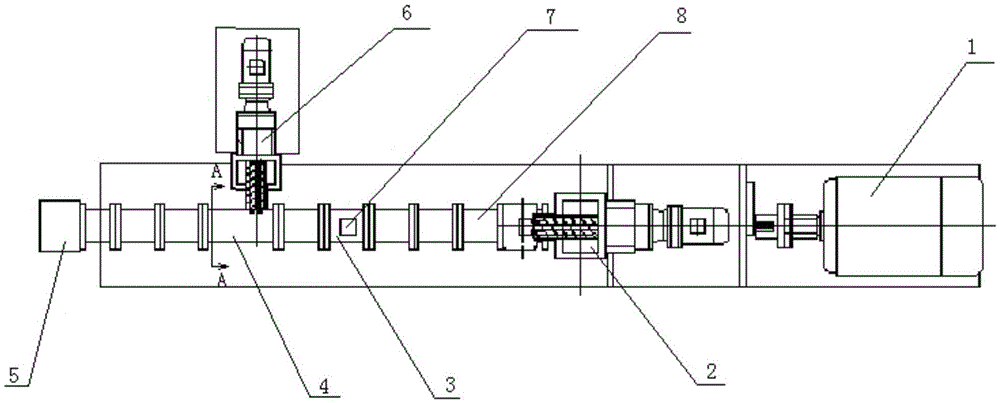

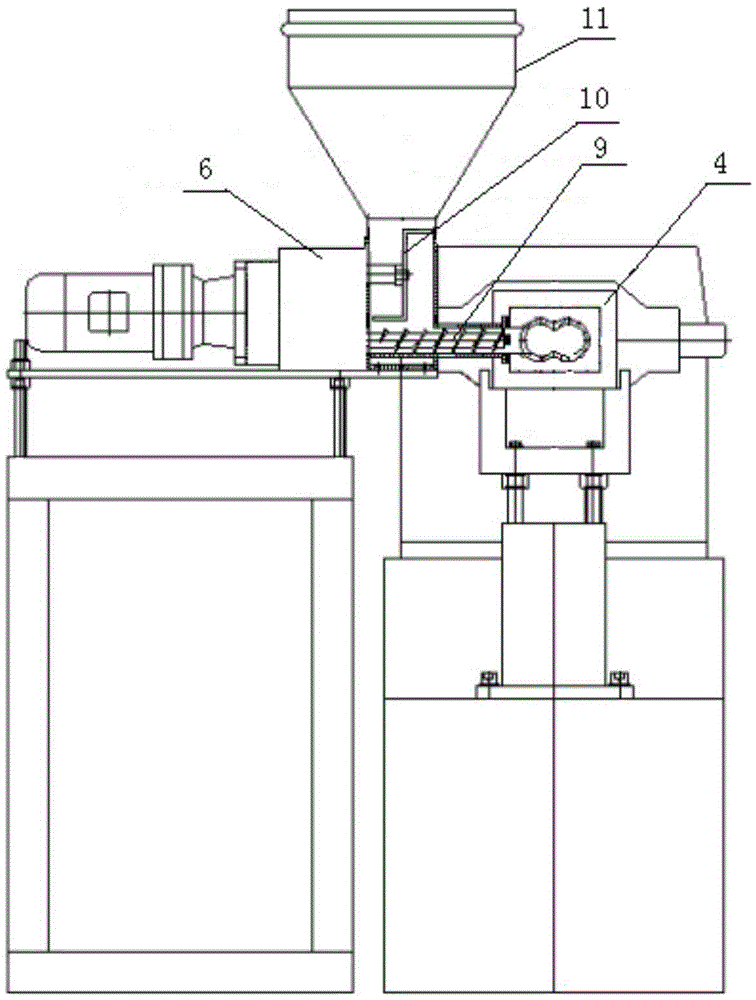

The invention discloses a railway turnout oil-resistant rubber base plate and a preparation process thereof, and belongs to the field of railway accessories. The railway turnout oil-resistant rubber base plate comprises the following raw materials in parts by weight: 70-85 parts of polyurethane, 20-35 parts of PBT, 15-25 parts of nylon, 20-30 parts of carbon black, 10-15 parts of mica powder, 3-6parts of paraffin oil, 5-8 parts of zinc oxide, 1-2 parts of stearic acid, 2-8 parts of an anti-aging agent, 1-2 parts of an accelerant and 2-5 parts of a surface modifier. The preparation process comprises the following steps: preparing the mixed rubber, drying the rubber, carrying out injection molding, trimming, warehousing and the like. The turnout rubber base plate has good oil resistance, the application influence problem of the lubricating oil on the turnout rubber base plate is solved, the service life of the lubricating oil is prolonged, the maintenance amount of the railway engineering department can be reduced, and the operation safety of the train can be guaranteed; the injection molding machine is adopted for injection molding to prepare the rubber base plate, and the production efficiency is greatly improved.

Owner:毛利

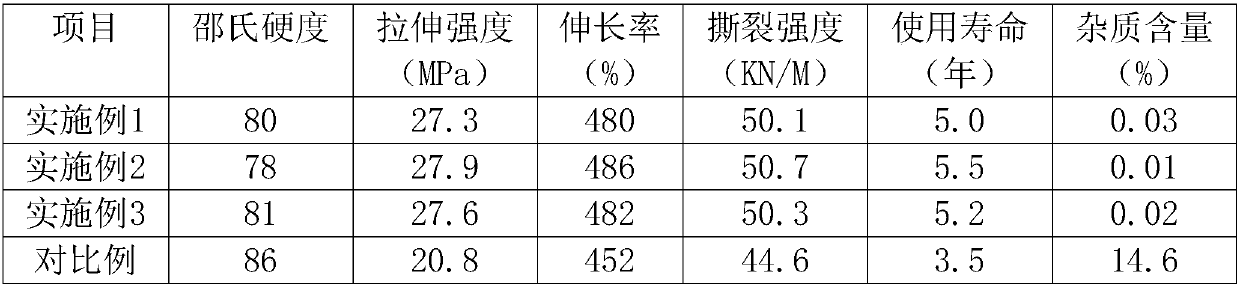

Recycling method of waste mining machinery tire

InactiveCN109679179AReduce the content of impurity componentsIncrease the plasticity of Wei stylePlastic recyclingEngineeringHardness

The invention discloses a recycling method of a waste mining machinery tire and belongs to the technical field of recover of waste tires. The recycling of the waste mining machinery tire is realized by the six steps of crushing, strong magnetic separation, modification, low-temperature grinding, extrusion and mold forming. The recycling method of the waste mining machinery tire, disclosed by the invention, has the beneficial effects that the waste mining machinery tire is recycled, is excellent in all physical performance indexes and has a shore hardness of 78-81, a tensile strength of 27.3-27.9 MPa, a tensile rate of 480-486 percent, a tear strength of 50.1-50.7 KN / M, a service life of five-five and a half years and an impurity constituent of less than 0.03 percent; through test, the mainperformance is excellent. The recycling method disclosed by the invention can bring along outstanding economic and social beneficial effects, thereby having a wide market application prospect.

Owner:甘肃兰煤机械制造有限公司

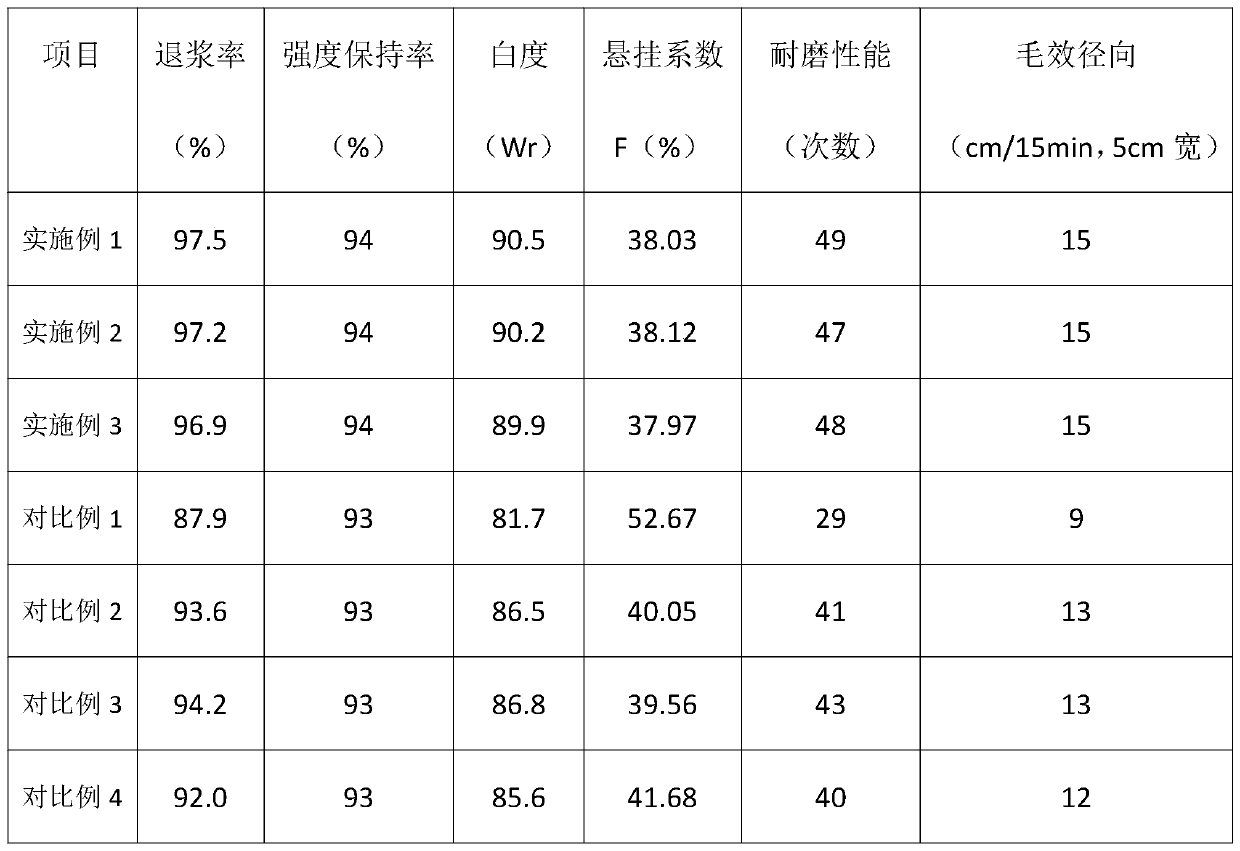

Biological-enzyme pretreatment method for regenerated cellulose fibers

PendingCN109706723AActivateTo achieve the craft effectDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentTextile technologyPectinase

The invention provides a biological-enzyme pretreatment method for regenerated cellulose fibers, and belongs to the technical field of spinning. The biological-enzyme pretreatment method for the regenerated cellulose fibers comprises the steps of pretreatment, biological treatment, bleaching treatment, washing treatment, drying and the like, wherein biological treatment is carried out in an ultrasonic-wave environment through enzyme liquid of alkaline pectinase and amylase. By means of the method, it can be guaranteed that various physicochemical performance indexes such as the desizing rate,whiteness, wear resistance and capillary-effect radial direction of the regenerated cellulose fibers can reach or even exceed those of traditional technologies; meanwhile, the treatment method has a mild acting condition, has no damage to fabric, lowers the energy consumption, is environmentally friendly, and has a good market prospect.

Owner:TAIHE SANBAO TONGDA TEXTILE

Silicon-corundum-high-titanium mullite composite refractory material for blast furnace and preparation method of silicon-corundum-high-titanium mullite composite refractory material

The invention discloses a silicon-corundum-high-titanium mullite composite refractory material for a blast furnace and a preparation method, and belongs to the field of refractory materials. Metal silicon powder, high-titanium fused mullite and tabular corundum are used as raw materials, and resin powder and ethylene glycol are used as binding agents. Wherein titanium in the electric smelting mullite raw material exists in the form of a Ti2O3 independent phase. During production, the raw materials are weighed according to the proportion and mixed to obtain pug, and the pug is subjected to compression molding and sintered for 6-12 h at the temperature of 1100-1450 DEG C in the N2 atmosphere in the presence of solid carbon. The apparent porosity of the obtained product is 10-20%, the volume density is 2.70-3.05 g / cm < 3 >, the normal-temperature compressive strength is 70-230 MPa, and the product has good thermal shock resistance and erosion resistance. According to the prepared silicon-corundum-high titanium mullite composite refractory material for the blast furnace, a transition plastic phase process is utilized, metal silicon powder is added into the refractory material, a non-oxide reinforced phase (SiC, O '-Sialon) with excellent performance is generated in situ, and Ti (C, N) with an obvious furnace protection effect can be generated in the composite material in situ without additionally adding a titanium source.

Owner:UNIV OF SCI & TECH BEIJING +1

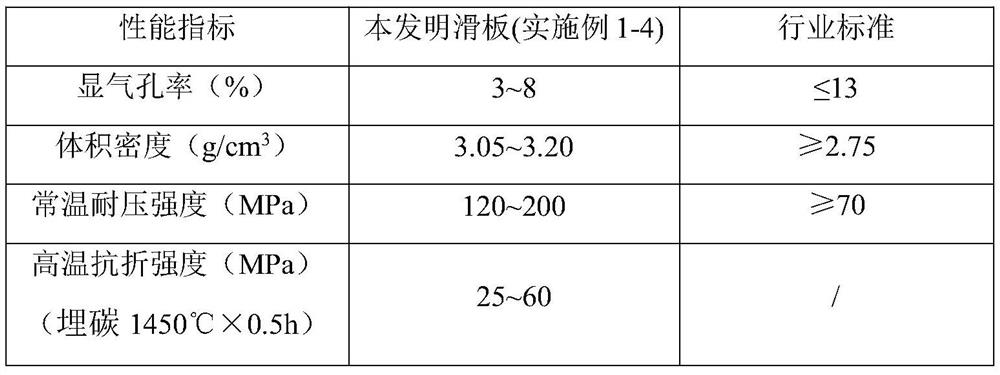

Titanium-magnesium aluminate spinel-brown fused alumina composite sliding plate and production method thereof

ActiveCN112647007AImprove performanceReduce manufacturing costMelt-holding vesselsMetallic aluminumAlumina composite

The invention particularly relates to a titanium-magnesium-aluminum spinel brown fused alumina composite sliding plate and a production method thereof. The titanium-magnesium-aluminum spinel brown fused alumina composite sliding plate comprises the following raw materials in percentage by weight: 35-65% of brown fused alumina, 4-8% of activated alumina micro-powder, 10-38% of magnesium-aluminum spinel, 5-15% of metallic titanium, 5-10% of metallic aluminum and 3-5% of phenolic resin as a binding agent; and the production method comprises the following steps: weighing various raw materials in proportion during production, uniformly mixing, mixing to obtain pug, carrying out mechanical pressing for forming, drying at 180-250 DEG C for 24-48 hours, hooping, grinding, and coating to obtain the product. According to the production method, high-temperature firing and asphalt dipping are not needed, energy conservation and environmental protection are achieved, the production cost is lower, the prepared product is good in oxidation resistance, thermal shock stability and erosion resistance, the apparent porosity is 3%-8%, the volume density is 3.05 g / cm < 3 >-3.20 g / cm < 3 >, the normal-temperature compressive strength is 120-200 MPa, and the high-temperature breaking strength (carbon burying 1450 DEG C * 0.5 h) is 25-60MPa.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Al23O27N5-combined corundum composite slide plate and preparation method thereof

InactiveCN103214256BImprove thermal shock resistanceImprove performanceSlide plateActivated Aluminum Oxide

The invention discloses an Al23O27N5-combined corundum composite slide plate and a preparation method thereof, belonging to the field of a refractory material. The slide plate consists of the following raw materials in percentage by weight: 55-85% of corundum, 5-30% of activated aluminum oxide, 1-15% of metal Al and 0-3% of carbon black and graphite; and phenolic resin accounting for 2-6% of the total weight of the raw materials is added as a bonding agent. The preparation method comprises the following steps of: weighing the raw materials according to the proportions, and mixing uniformly; mixing to obtain pug; performing compression moulding; drying at 120-600 DEG C for 5-25 hours; and then sintering in a nitriding atmosphere at 1,200-1,600 DEG C for 5-25 hours. The apparent porosity of the product disclosed by the invention is 4-13%, the volume density is 3.0-3.4g / cm<3>, the cold crushing strength is 150-280MPa, and the high temperature bending strength is 20-55MPa. The Al23O27N5-combined corundum composite slide plate has good erosion resistance and thermal shock resistance and low cost; the main components of the raw materials have high chemical stability and low oxygen potential; and secondary pollution caused by C, O, H and other impurities is avoided in clean steel continuous casting.

Owner:UNIV OF SCI & TECH BEIJING

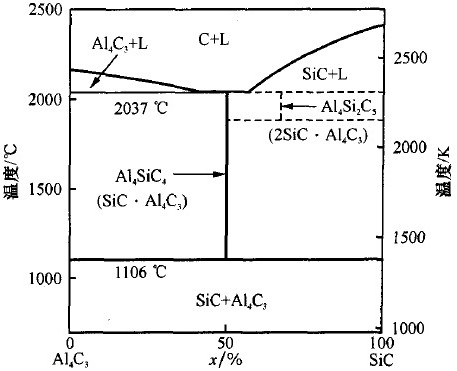

a kind of al 4 sic 4 combined al 2 o 3 - Preparation method of sic composite material

ActiveCN108218408BHigh strengthIn situ generation of high strength during high temperature firingThermal dilatationMetallic aluminum

The present invention relates to an Al 4 SiC 4 Combined with Al 2 o 3 The invention discloses a method for preparing a SiC composite material, which belongs to the field of refractory materials. The raw material composition of this composite material by weight percentage is: 45%-86% high alumina bauxite, 10-25% silicon carbide, 5-15% activated alumina, 1-15% metal aluminum, 0-25% 5% carbon black or graphite, plus a phenolic resin binder of 2‑6% of the total amount of the above materials. During production, various raw materials are weighed according to the proportion, mixed evenly, and mud is obtained through mixing, and then pressed into shape, firstly dried at 120-250°C for 10-25 hours, and then sintered at 1300-1700°C under a charcoal-buried atmosphere 5‑12 h. Al is synthesized in situ during the high temperature firing process of the product of the present invention 4 SiC 4 As a binding phase, it has high melting point, high strength, high wear resistance, high chemical stability, low thermal expansion coefficient, and excellent oxidation resistance and hydration resistance. It is a high-temperature structural material and high-performance refractory material.

Owner:江苏诺明高温材料股份有限公司

Unfired ferro silicon nitride-alumina composite carbon-free sliding plate and preparation method thereof

The invention relates to an unfired ferro silicon nitride-alumina composite carbon-free sliding plate and a preparation method thereof, belonging to the field of refractory materials. The sliding plate is composed of the following raw materials in percentage by weight: 55-90% of corundum, 0-20% of activated alumina, 0-30% of ferro silicon nitride and phenolic resin accounting for 2-6% of total dosage of the raw materials to serve as a binding agent. The preparation method comprises the steps of: weighing the raw materials according to the proportions, uniformly mixing the raw materials, smelting the raw materials to obtain pug, pressing forming the pug, and the drying the pug at 120-600 DEG C for 5-25hours. The product is of an oxide-non oxide composite structure and has the following excellent physical performance indexes: the apparent porosity is 3-11%, the bulk density is 3.0-3.35g / cm<3>, the normal temperature compressive strength is 100-260MPa and the high temperature flexural strength is10-50Mpa. The product provided by the invention needs no high temperature firing and oil immersion procedures, so that the production cost is greatly reduced.

Owner:UNIV OF SCI & TECH BEIJING

HPCP resin with polyhydroxy structure and preparation method thereof

ActiveCN102816186BExcellent physical performance indexGroup 5/15 element organic compoundsPolymer scienceCombustion

Owner:杨彦威 +1

Preparation process of cobaltosic oxide for continuous production of batteries

ActiveCN102820468BGood lookingFine granularityCell electrodesCobalt compoundsAfter treatmentLithium carbonate

A preparation process of cobaltosic oxide for continuous production of batteries is a process for preparing the cobaltosic oxide by using a cobalt contained material to continuously synthesize cobalt carbonate and continuously roasting and resolving in an oxidizing atmosphere. Continuous production of the cobaltosic oxide can be completed through several steps of preparation of cobalt solution, preparation of precipitator, lithium carbonate synthesizing, ageing, filtering and washing, burning and after treatment. The preparation process continuously synthesizes the cobalt carbonate, and continuously roasts and resolves the cobaltosic oxide, is apt to control technical indexes in a production procedure, can achieve automatic production, is favorable for reduction of labor intensity, improves efficiency of labor and lowers cost. Produced products are high in purity, excellent in physical performance indexes and good in stability and consistency.

Owner:GANZHOU TENGYUAN COBALT INDAL

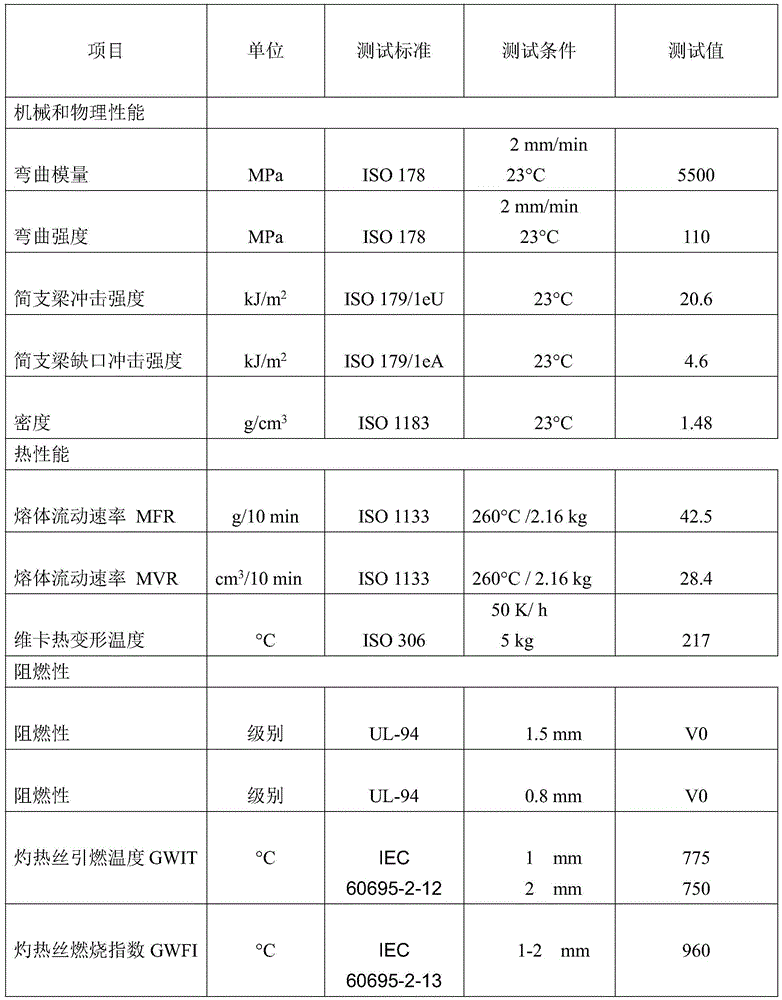

Preparation method of glass fiber-reinforced halogen-free environmentally friendly flame-retardant modified polyester material

The invention discloses a method for preparing a glass fiber reinforced halogen-free environment-friendly flame-retardant modified polyester material. The method comprises the following steps: 1) weighing raw materials: PBT, calcium hypophosphite, PETS, PTFE, an antioxidant 168, an antioxidant 1010 and short glass fibers; 2) reforming parallel twin-screw extruders in identical directions and connecting the seventh zone of a main cylinder with an auxiliary charging device through a flange; and 3) uniformly mixing PBT, PETS, PTFE and antioxidants, continuously adding the mixture from a main charging device, continuously adding the short glass fibers from the fifth zone of the main cylinder and continuously adding calcium hypophosphite from the auxiliary charging device. By the method, the difficult problems that the flame retardant in the prior art has poor thermal stability and is easily decomposed during the processing are solved. The process is simple and convenient and low in cost, the flame retardant can be smoothly added and uniformly distributed; the prepared glass fiber reinforced halogen-free environment-friendly flame-retardant modified polyester material reaches UL94-V0-level flame retardant effect and also has good physical property indexes.

Owner:天津然跃环保创新科技有限公司

β-sic/si2n2o composite sic kiln furniture and its preparation method

The invention discloses a beta-SiC / Si2N2O complex phase combined SiC kiln furniture and a preparation method, belonging to the field of fireproof materials. Raw materials comprise silicon carbonate, metallic Si, a polycrystalline silicon waste material as well as waste pulping liquor which is 2%-6% of the raw materials in total content and is used as a binding agent. During production, various raw materials are weighed in proportion and mixed to obtain a pug material, and the pug material is compression-molded, dried for 24-28 hours at the temperature of 110+ / -10 DEG C and then sintered at the temperature of 1200-1500 DEG C under a carbon-buried condition. The product has the following excellent physical performance indexes: apparent porosity being 9% to 22%, volume density being 2.3g / cm<3> to 2.9g / cm<3>, compression strength at normal temperature being 60MPa to 200MPa, rupture strength at normal temperature being 20MPa to 75MPa, good oxidation resistance and good thermal shock resistance. In the method disclosed by the invention, the polycrystalline silicon waste material is taken as the raw material, and a carbon-buried sintering mode is adopted to simplify the production process, so the production cost of the SiC kiln furniture is lowered, the recycle of the polycrystalline silicon waste material is realized as well, and the waste of resources and environmental pollution are reduced.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of unfired Al-Al2O3 carbon-free composite sliding plate

The invention relates to an unfired Al-Al2O3 carbon-free composite sliding plate and a preparation method thereof, belonging to the field of refractory materials. The sliding plate is prepared from 57-87% of corundum, 2-25% of active aluminum oxide and 1-20% of metal Al as well as binder phenolic resin accounting for 2-6% of the total amount of the raw materials. The preparation method comprises the following steps: proportionally weighing various raw materials, evenly mixing, compounding to obtain paste, carrying out pressure molding, and drying at 120-600 DEG C for 5-25 hours. The product has metal-nonmetal combined structure; and the apparent porosity is 3-10%, the volume density is 3.05-3.40 g / cm<3>, the ambient compressive strength is 100-250 MPa, and the high-temperature folding strength is 10-70 MPa. The product does not need high-temperature firing or oil impregnation, and has the advantage of low production cost; the used raw materials have high chemical stability and low oxygen potential, are free of carbon and easily hydrated Al4C3, and do not have secondary pollution of C, O, H and other impurities; and the product has excellent thermal shock resistance.

Owner:UNIV OF SCI & TECH BEIJING

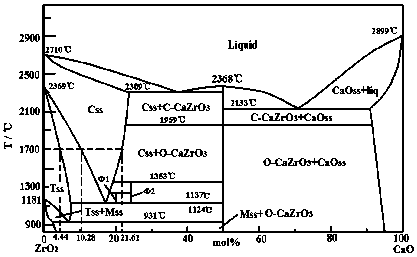

Preparation method for chromium-free ZrO2-CaO.ZrO2 composite material for coal-water slurry gasification furnace

InactiveCN108249916AExcellent performance indexLow costGranular/pulverulent flues gasificationCoal waterSlag

The invention relates to a preparation method for chromium-free ZrO2-CaO.ZrO2 composite material for a coal-water slurry gasification furnace, and belongs to the field of refractory materials. The preparation method comprises the following steps: (1) preserving the heat of a CaO source, a ZrO2 source and a bonding agent at 1500-1750 DEG C for a certain time, carrying out sintering to prepare a CaO.ZrO2 composite material with high density and perfect crystal grain development; and (2) crushing the synthesized CaO.ZrO2 composite material into different granular sizes, mixing the synthesized CaO.ZrO2 composite materials with ZrO2 in different granular sizes according to different proportions, adding a proper proportion of a binding agent, adding a proper ratio of a bonding agent, carrying out pressing formation, carrying out drying at 120-250 DEG C for 10-25 hours, and then carrying out high-temperature sintering at 1550-1800 DEG C for 5-12 hours. The product provided by the invention has high compactness, high strength, excellent thermal shock stability, hydration resistance, and coal ash slag erosion resistance and permeability resistance, can meet the use of the coal-water slurrygasification furnace, has high cost performance, does not cause environmental pollution in production and use, can be recycled, and is an environment-friendly material.

Owner:江苏诺明高温材料股份有限公司

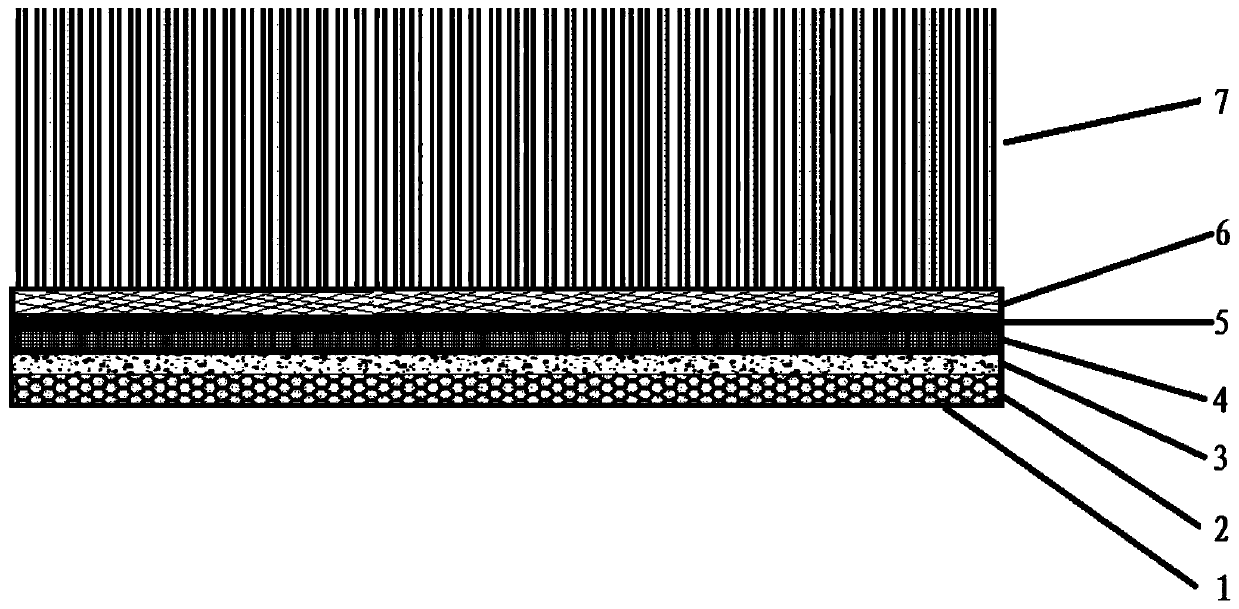

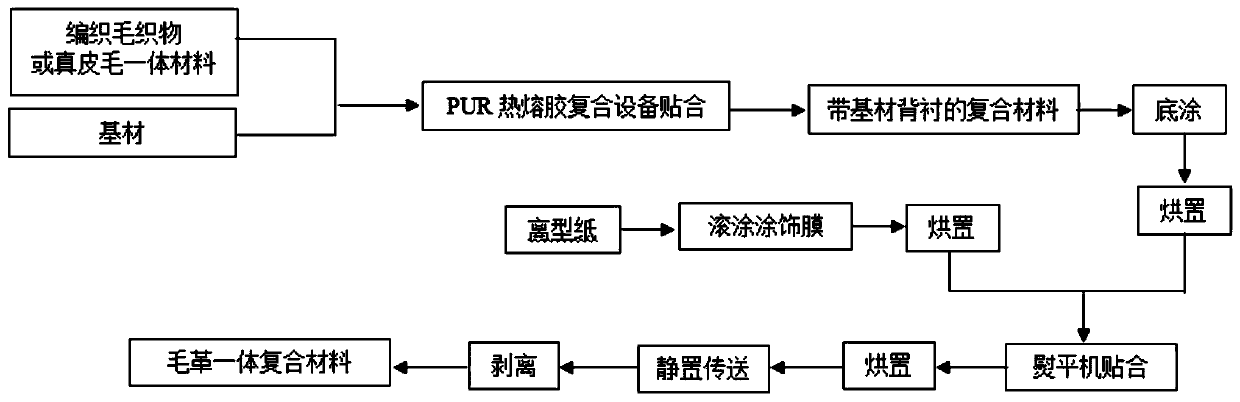

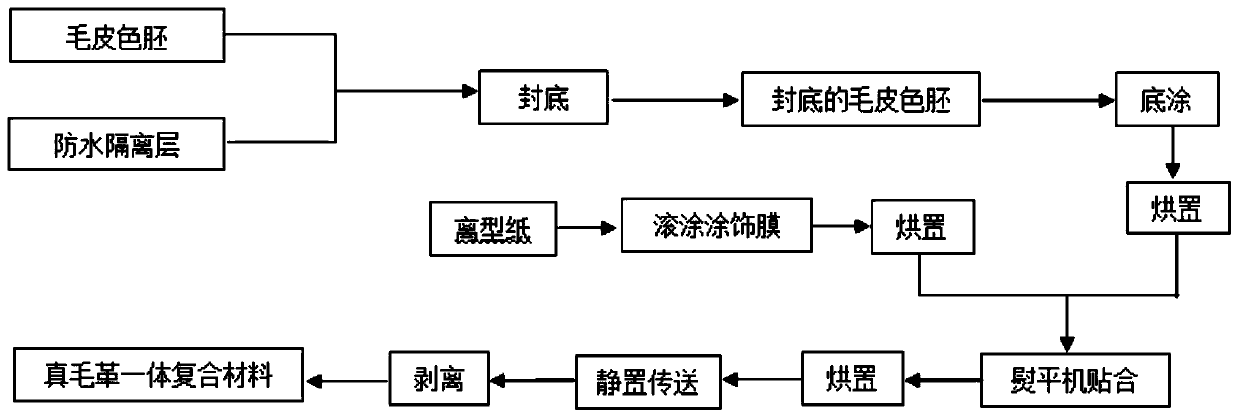

Fur and leather integrated composite material and preparation method thereof

PendingCN111519446ADoes not affect original softnessGood physical propertiesLamination ancillary operationsSynthetic resin layered productsMicron scaleBraid

The invention provides a fur and leather integrated composite material which comprises a coating film, a primer layer compounded on the coating film, a base material compounded on the primer layer, anadhesive layer compounded on the base material and a braided fabric layer with a fur layer compounded on the adhesive layer or a real fur integral layer compounded on the adhesive layer, wherein theadhesive layer is compounded on the braided fabric face of the braided fabric layer with the fur layer, and the adhesive layer is compounded on the skin layer of the real fur integral layer. Accordingto the fur and leather integrated composite material, the thickness of the coating can be controlled at the micron level, any grain or visual effect can be realized by the style of the board surface,meanwhile, the physical property index of the product is good, the quality stability and consistency are good, the production process is simple, the environmental protection efficiency is high, and the fur and leather integrated composite material is environmentally friendly and sustainable, and is suitable for large-scale production popularization and application.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com