Patents

Literature

33results about How to "Optimizing Section Shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

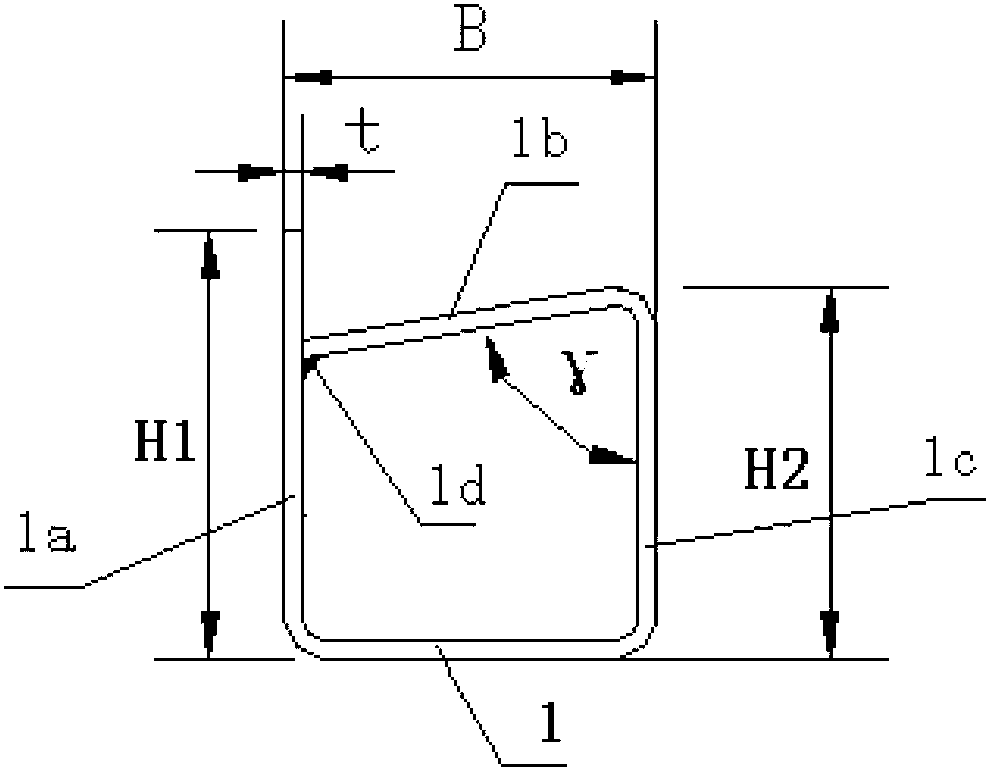

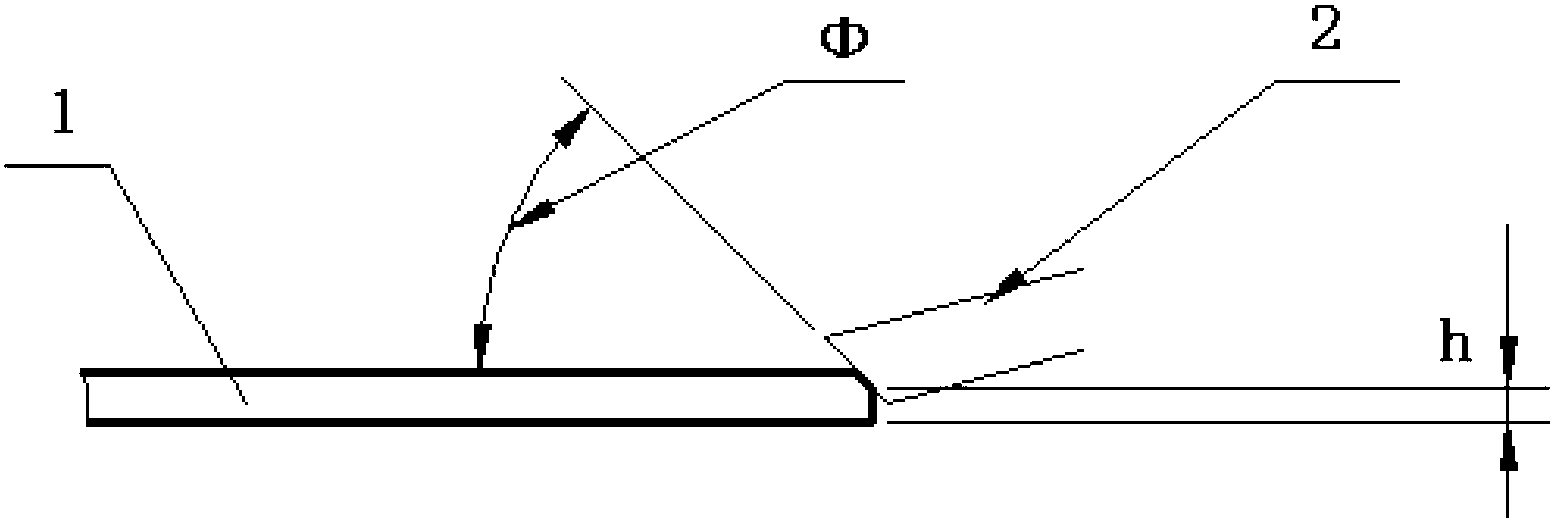

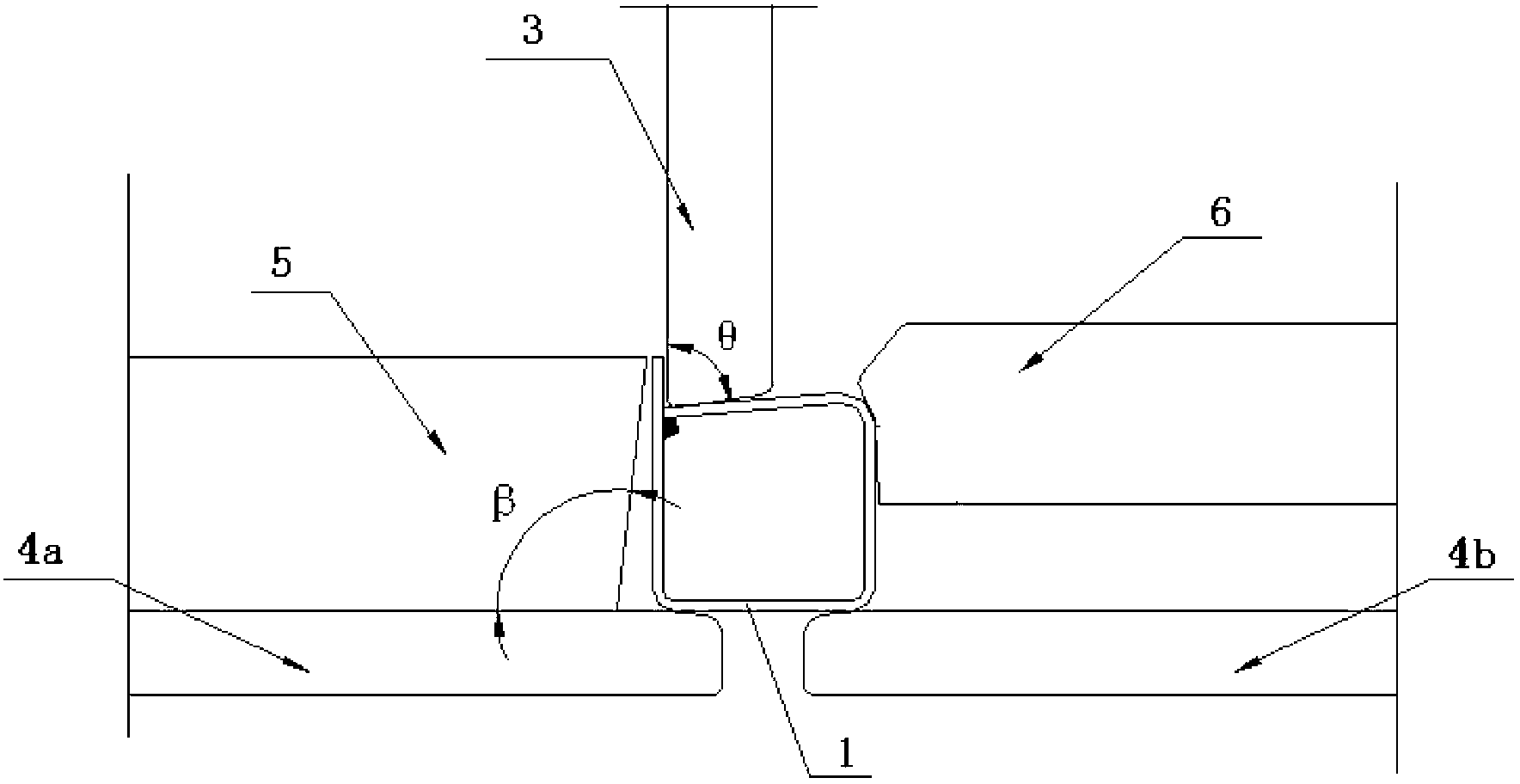

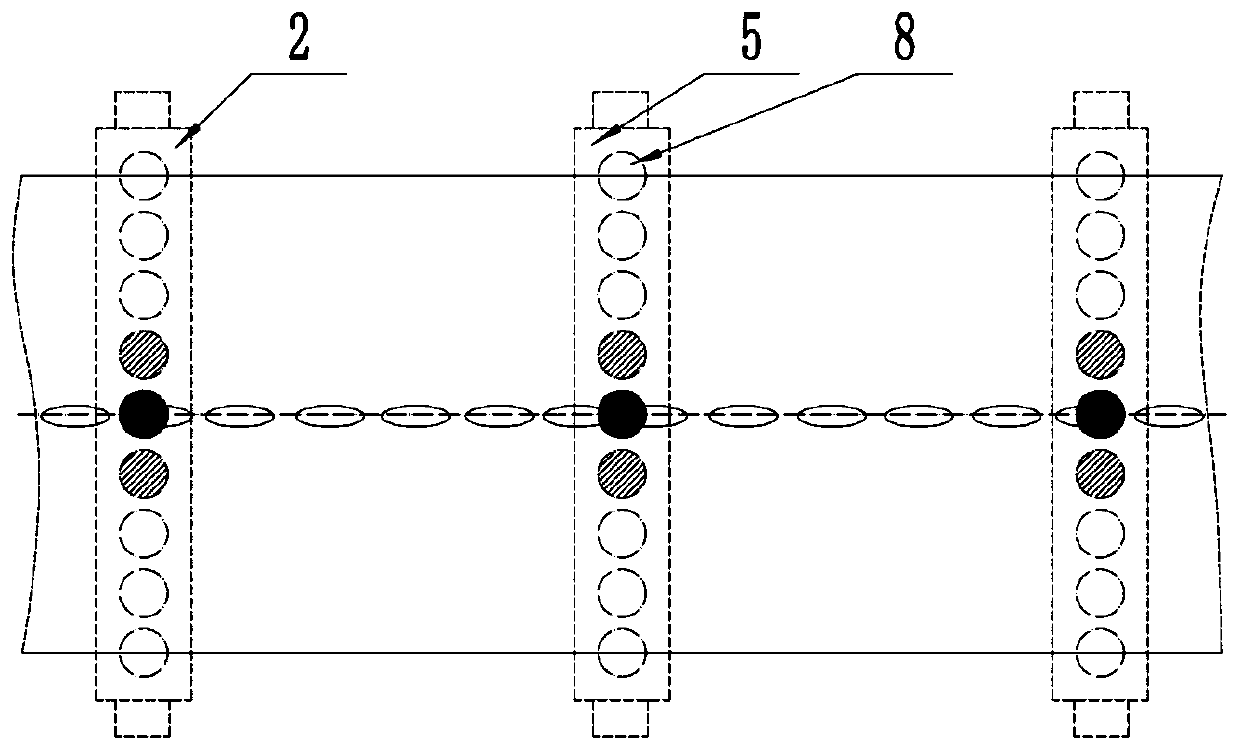

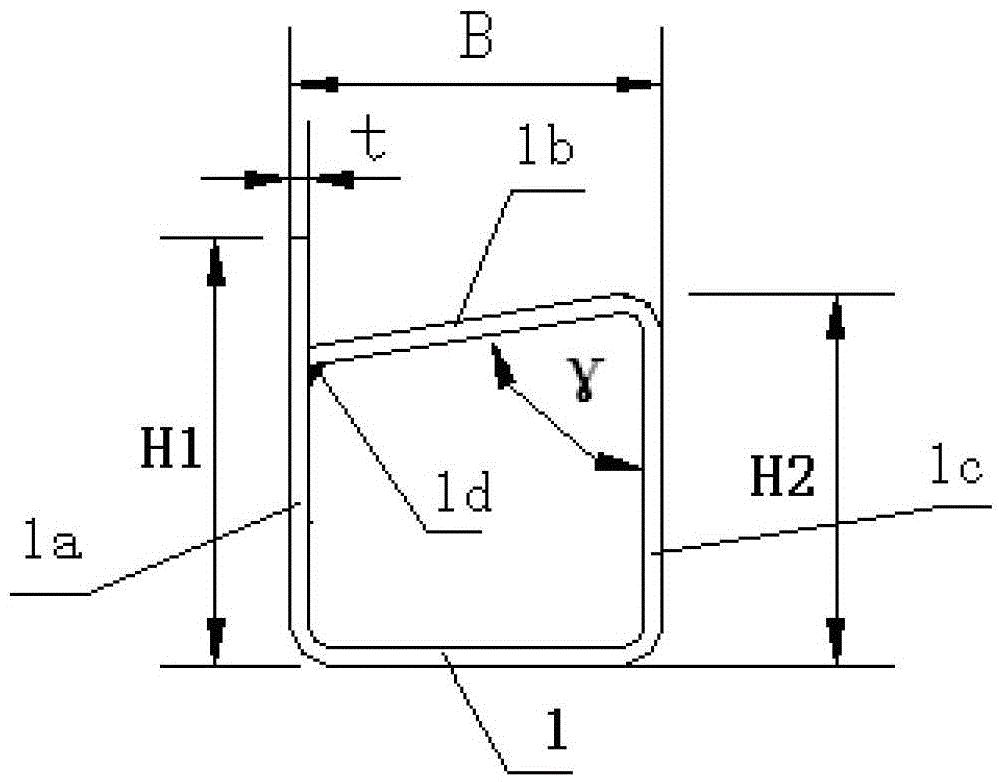

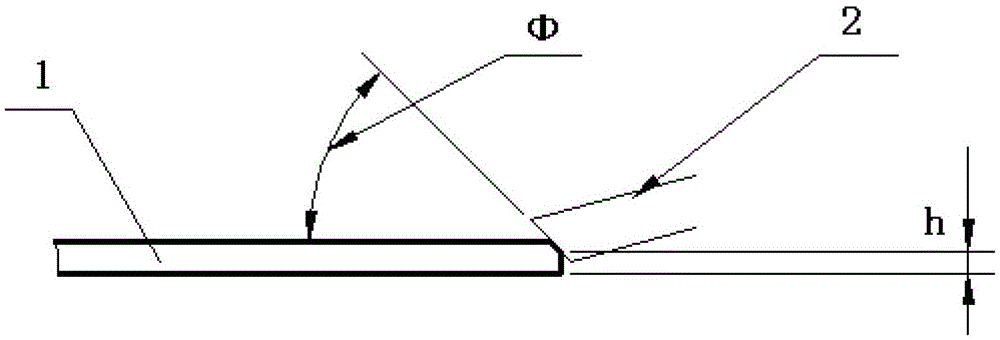

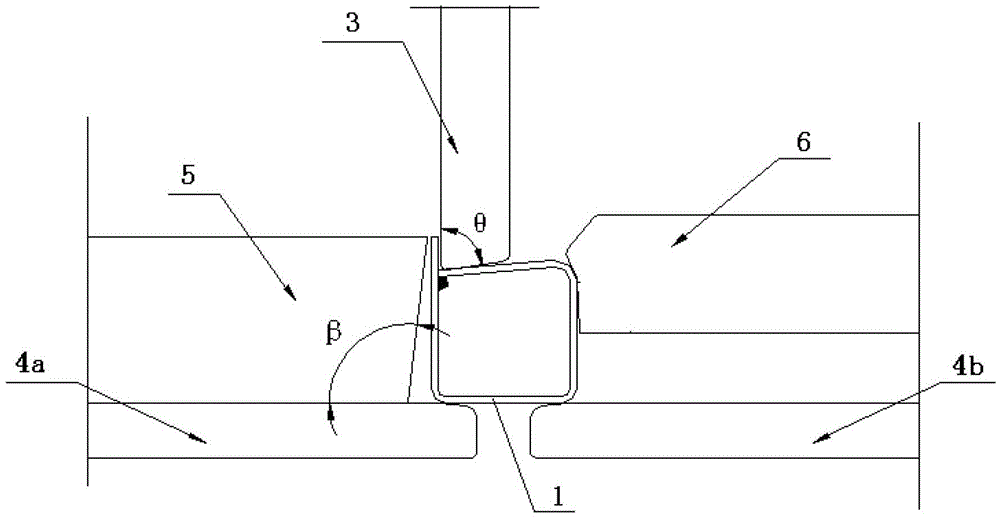

Method for manufacturing finned square rectangular steel tube

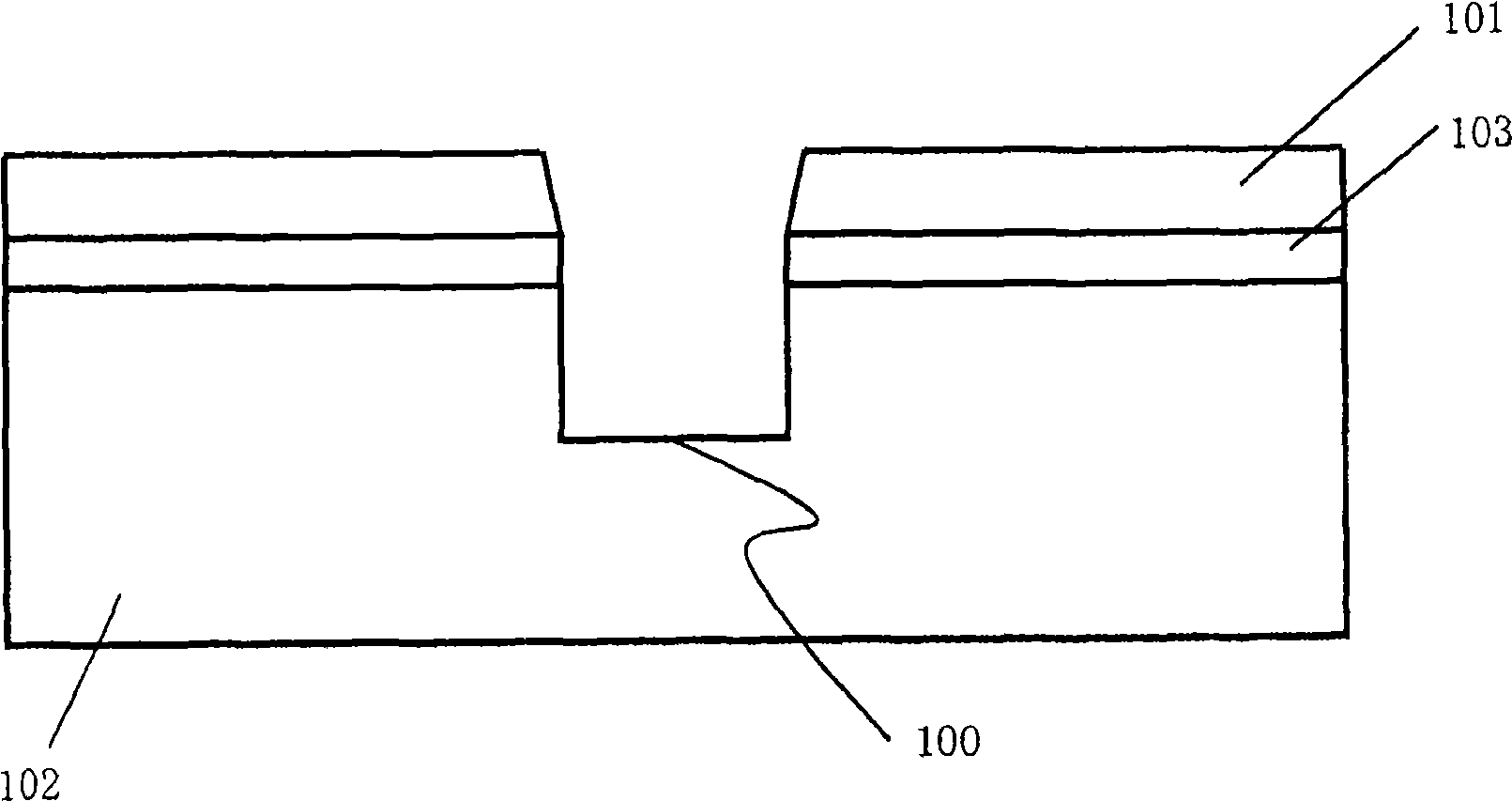

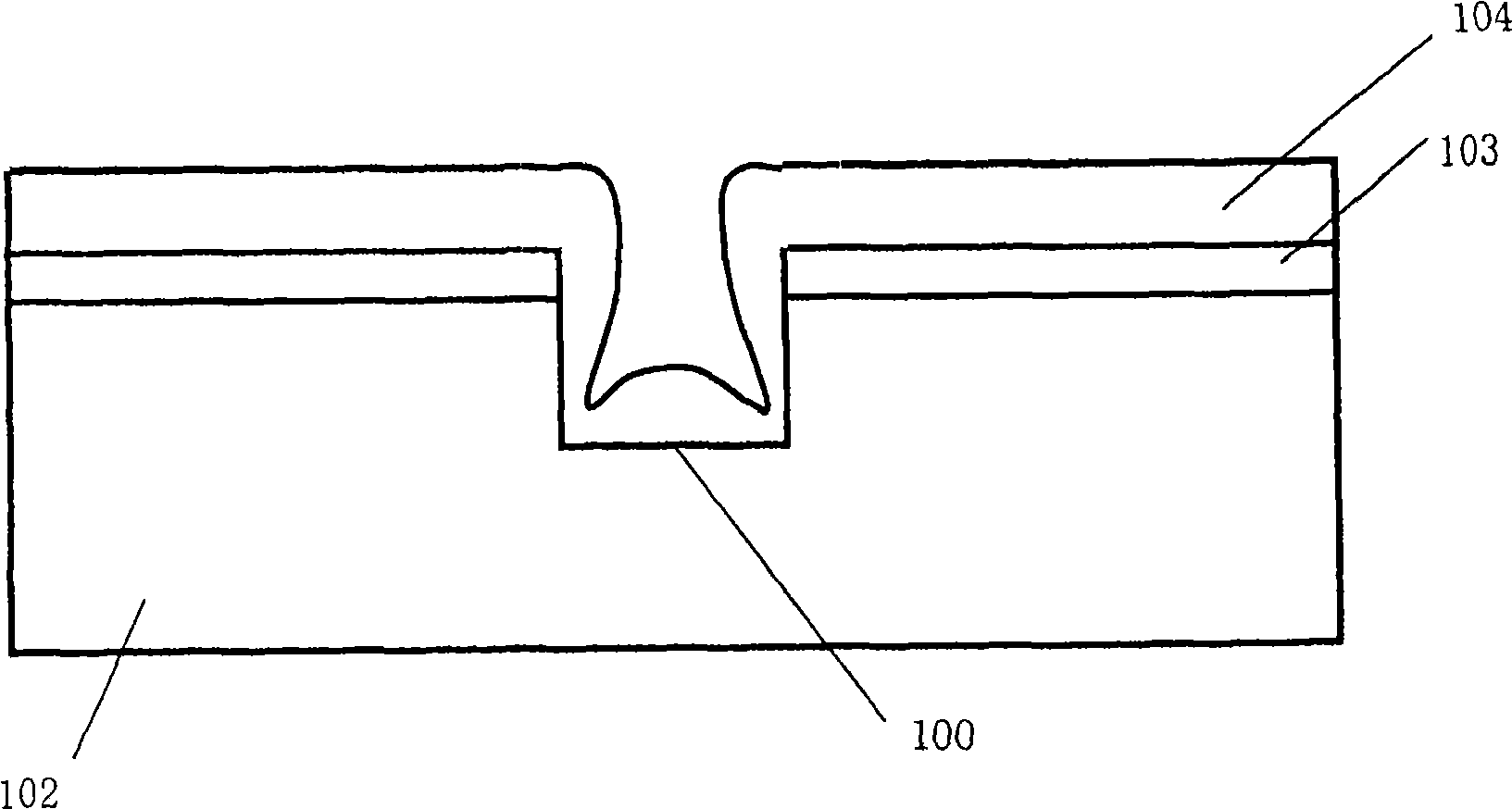

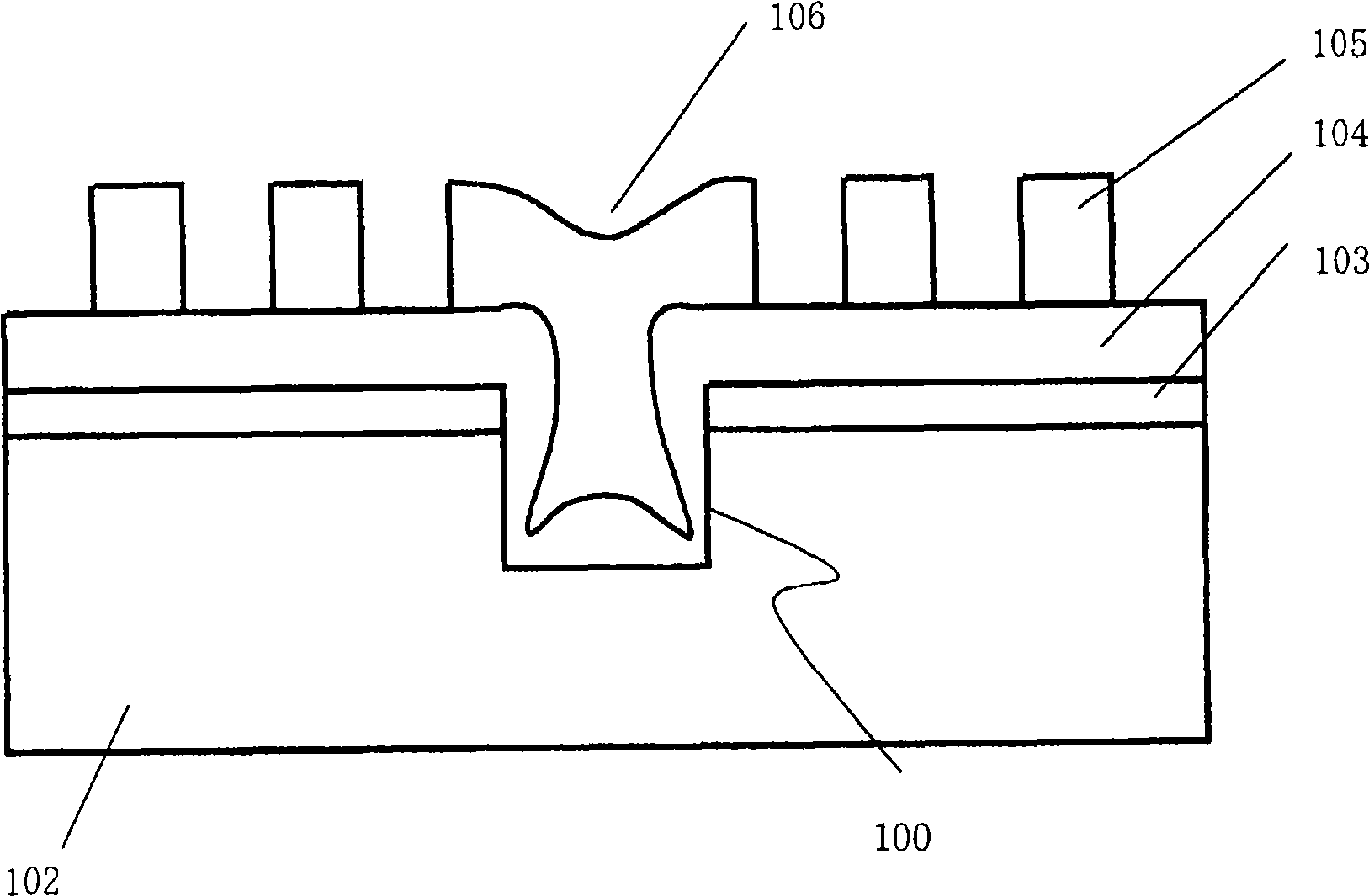

The invention provides a method for manufacturing a finned square rectangular steel tube. The method comprises the following steps: (1) carrying out trimming on the inner angle of the end face of a welding edge, wherein the trimming angle phi is 45+ / -2 degrees, and the trimming left root h meets the equation: h=1 / 2 thickness of a plate+ / -0.5mm; (2) carrying out pre-profiling of cold bending on strip steel through a die, and forming the shape and corresponding size of a product preliminarily; (3) carrying out extruding welding through four rollers: using an upper extrusion roller, a lower extrusion roller, a left extrusion roller and a right extrusion roller for extrusion, and bending a side extrusion roller of a finned edge by 3-6 degrees for carrying out high-frequency welding on the end face of the welding edge and the surface of the inner side of the finned edge; (4) planning welding burrs: planning outer burrs through an arc blade and avoiding the finned edge, and regulating the angle of a planer tool until the included angle alpha 1 between the planer tool and the vertical direction of the finned edge is 6 degrees, wherein the angle alpha 2 of the bottom of a planer tool is 18 degrees; (5) carrying out sizing shaping: when the four rollers are sized and shaped in an extrusion mode, bending the side extrusion roller of the finned edge by 2-3 degrees, and enabling the angle of the finned edge to meet the standard requests. The product produced through the method is good in shape of the cross section, good in surface quality, free of scratch, good in planeness, and stable and qualified in welding.

Owner:HANKOU STEEL ROLLING MILL WUHAN IRON & STEEL CORP

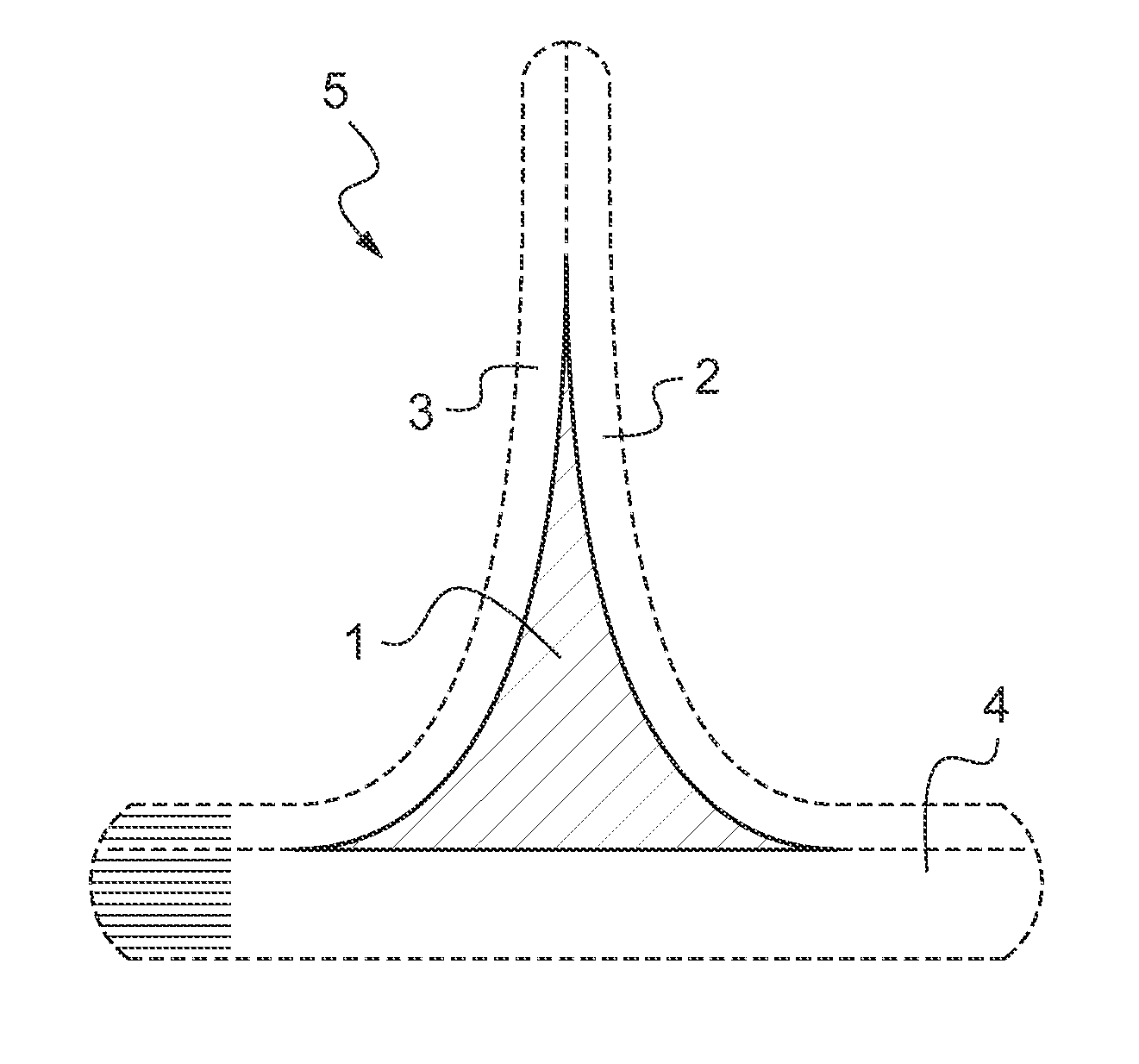

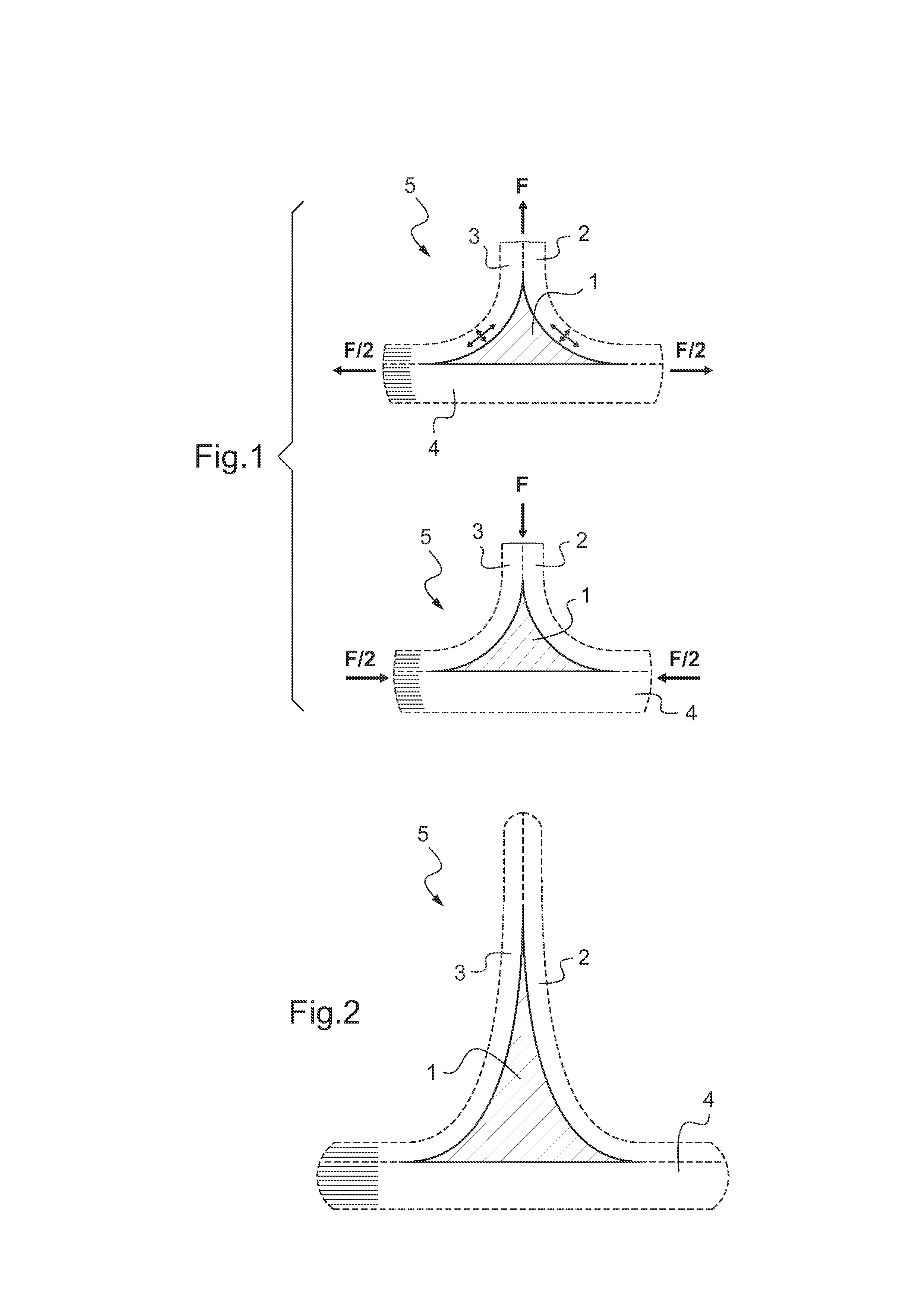

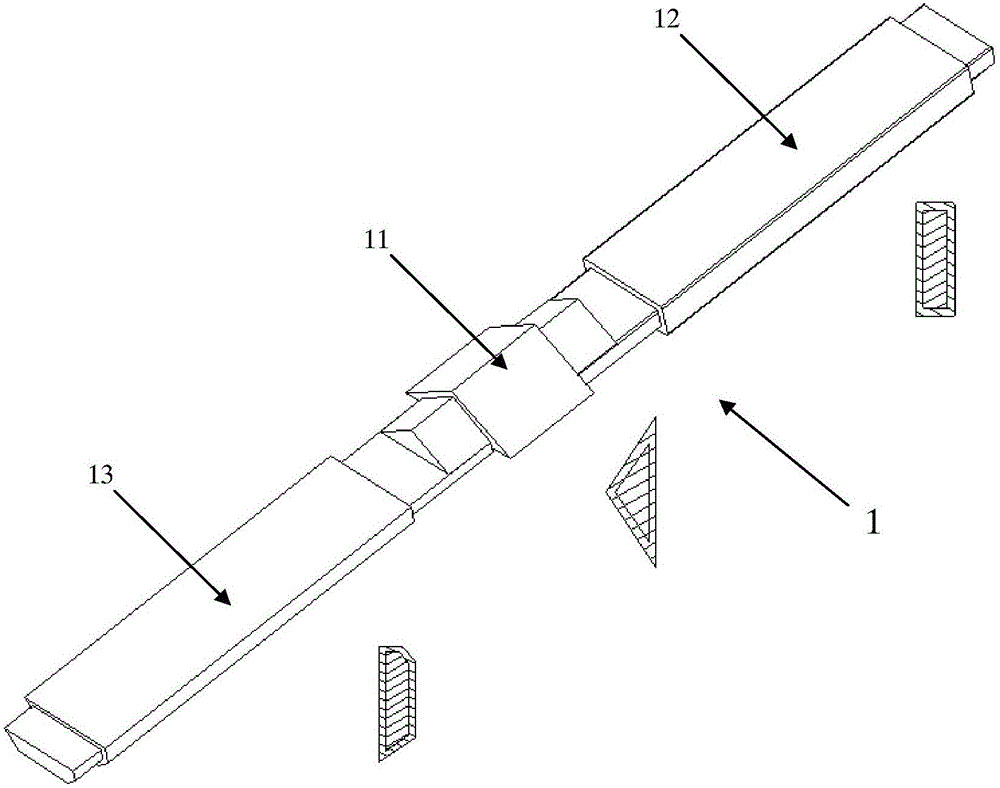

Composite gusset filler and method of manufacture of said composite gusset filler

InactiveUS20130171895A1High strengthImproves Structural IntegrityLayered productsWarp knittingYarnFiber

A composite gusset filler (1) of cut-off material from fiber fabrics (2, 3) trimmed into fragments of 2 min-10 mm length, separated into single yarn or roving elements mixed to quasi-homogeneous raw material for a semi-finished gusset filler (1). The present invention relates as well to specific shapes and a method of manufacture of said composite gusset filler (1) and to applications of said composite gusset filler (1).

Owner:AIRBUS HELICOPTERS DEUT GMBH

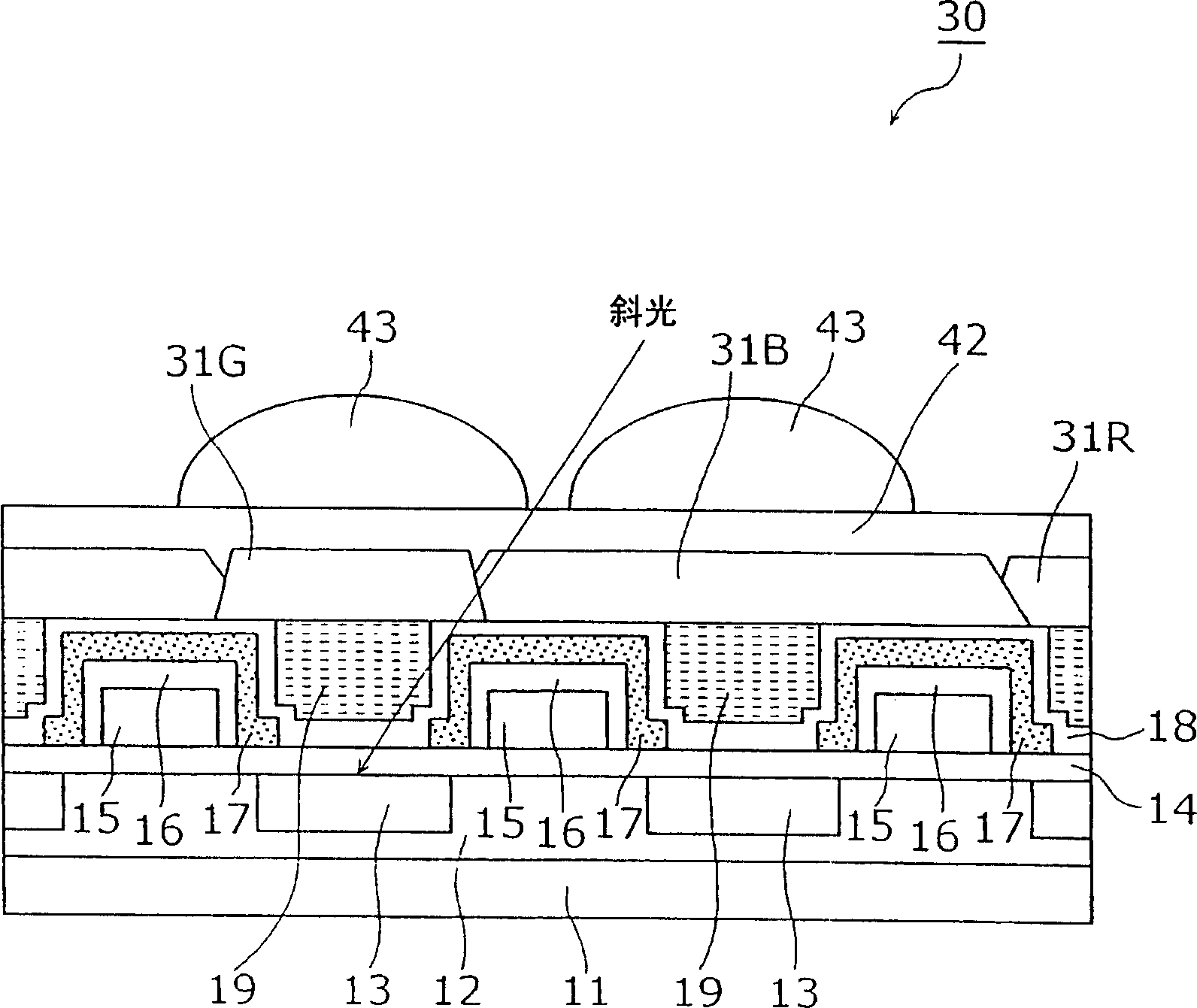

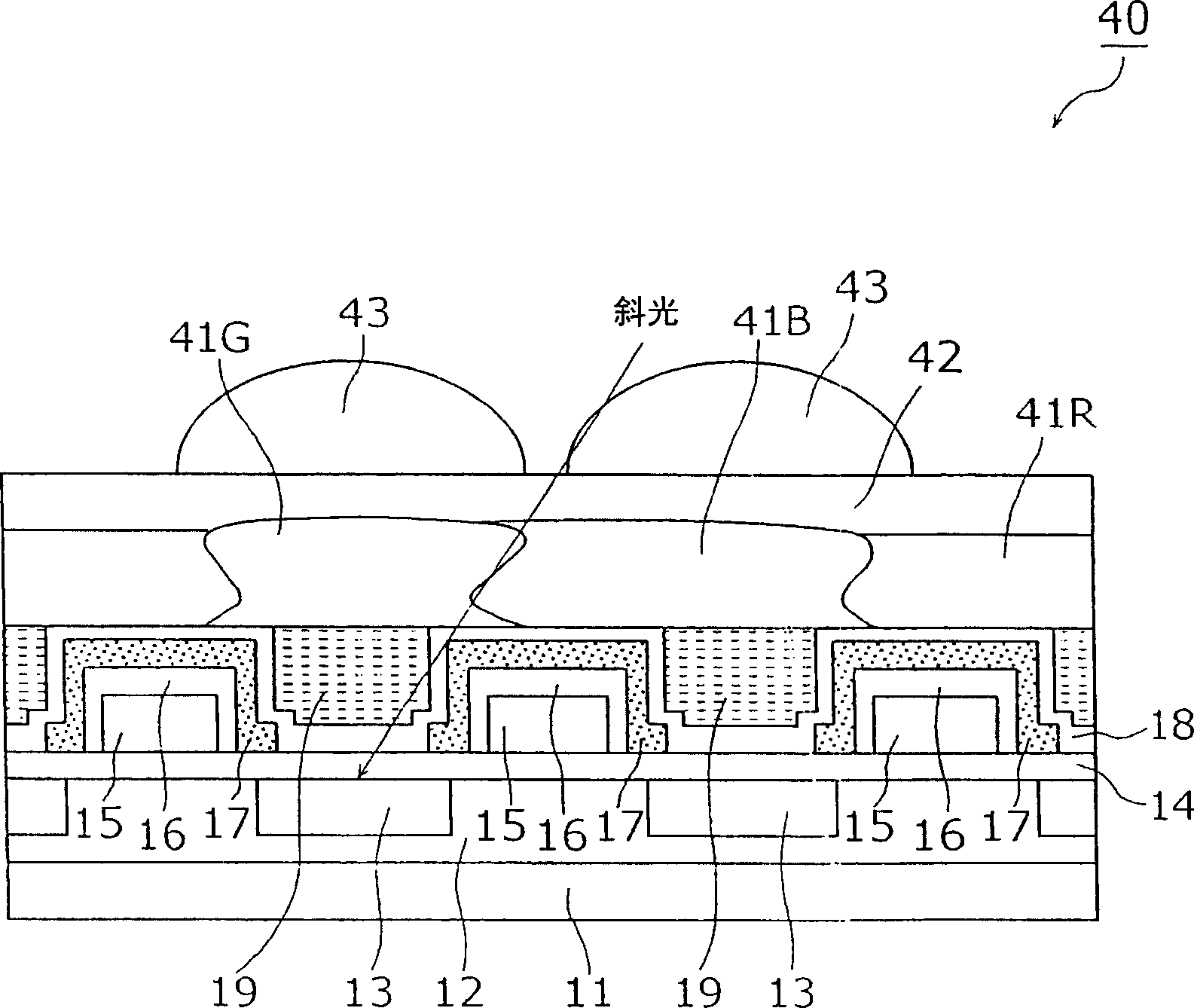

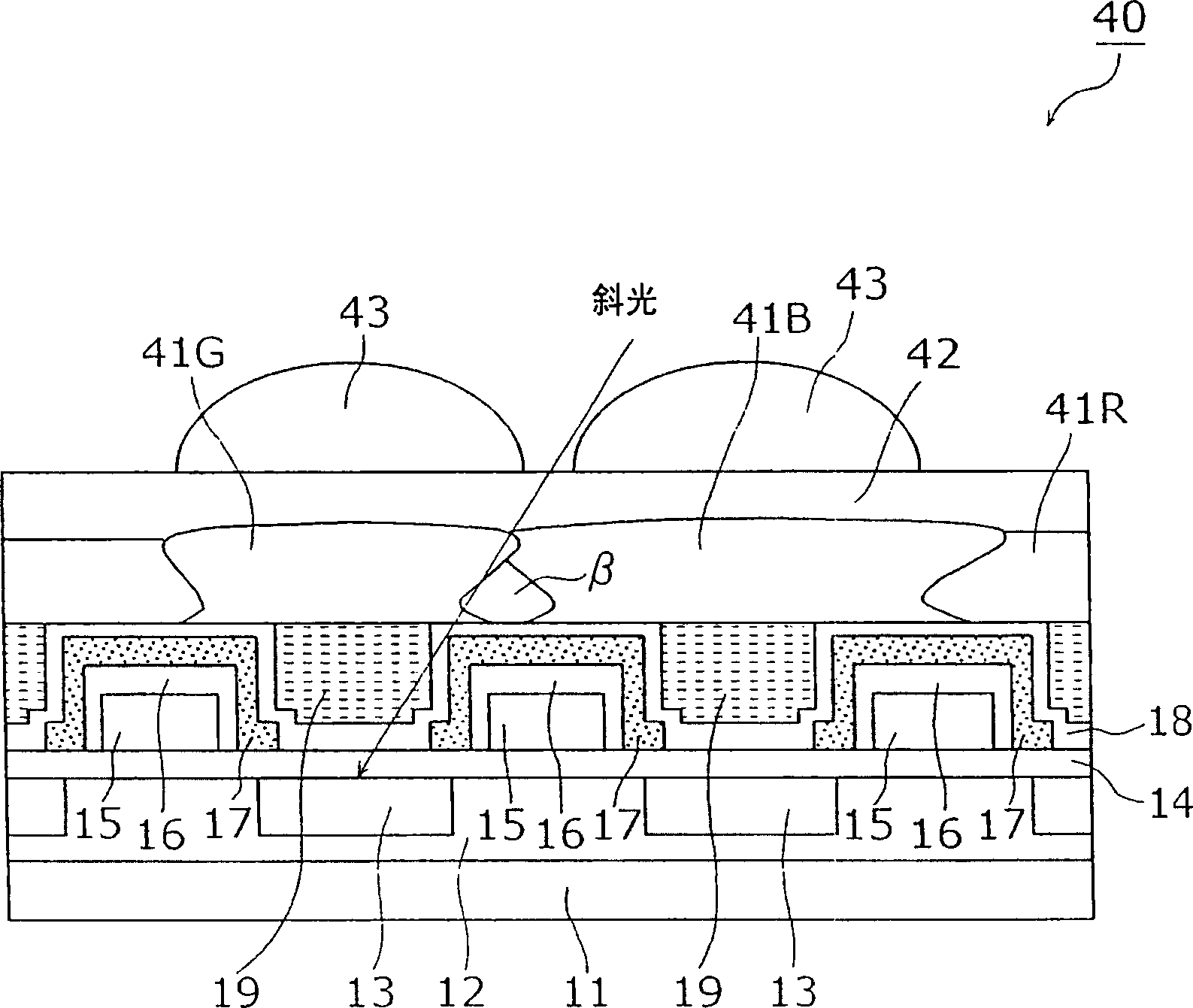

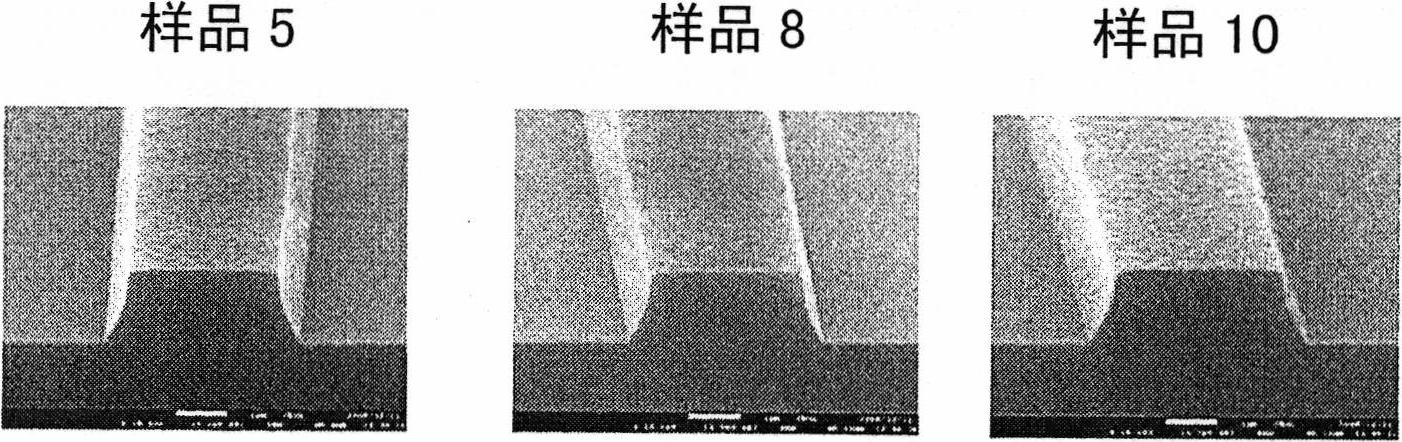

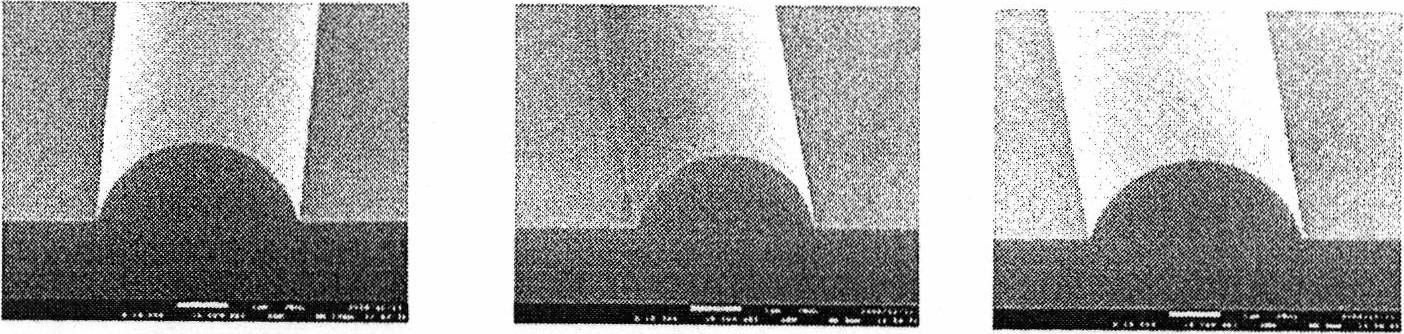

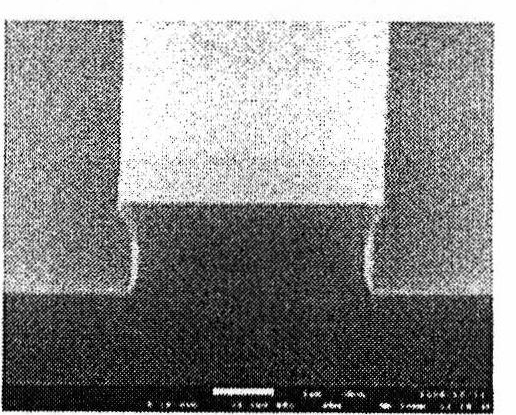

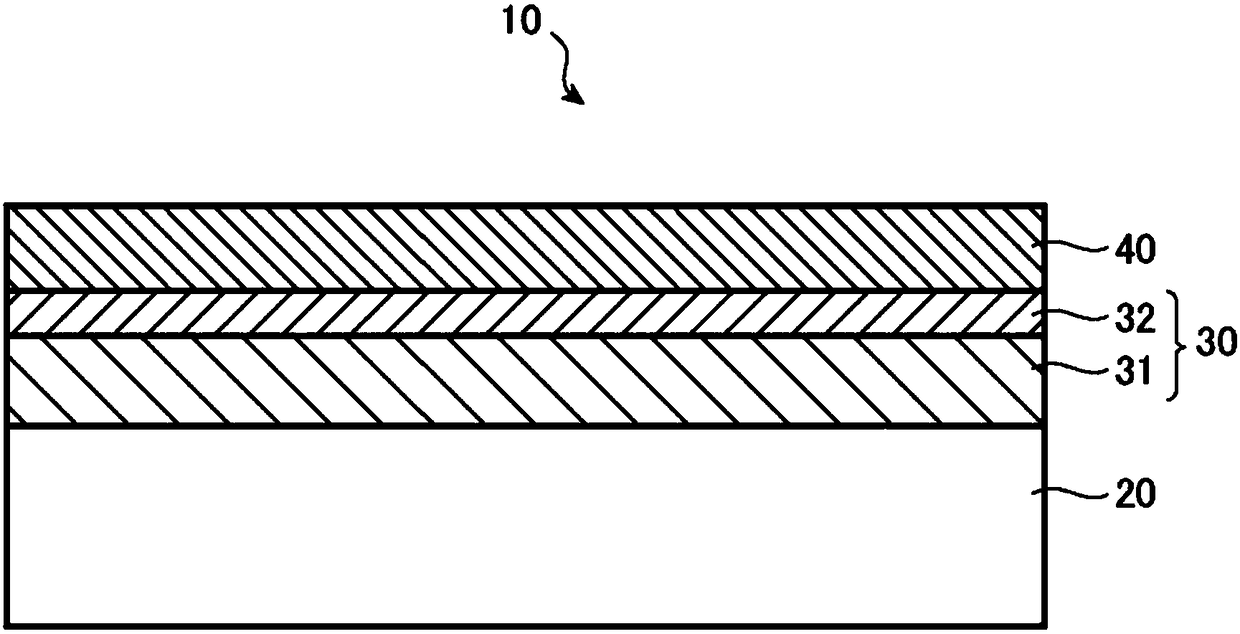

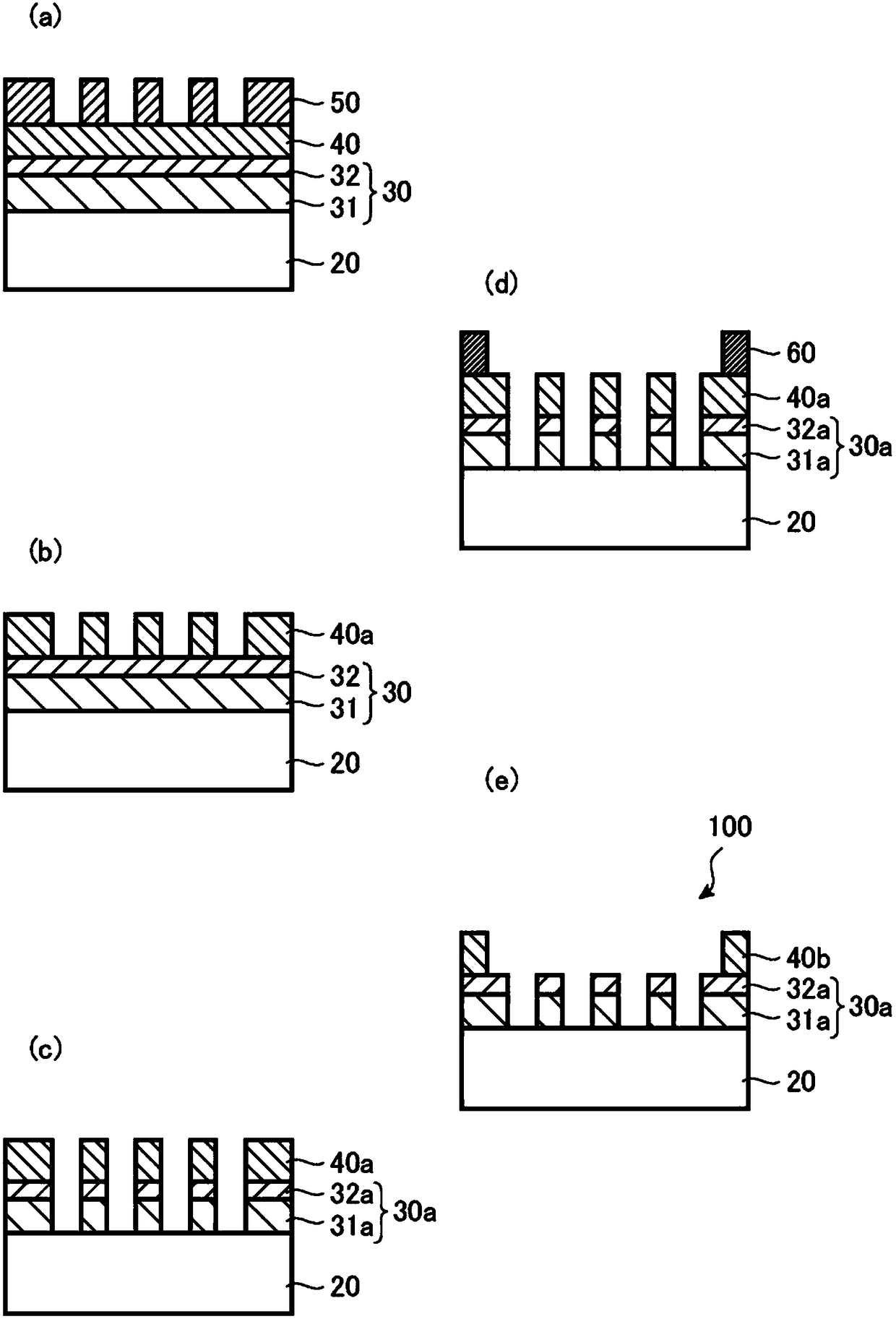

Solid-state imaging device and solid-state imaging device manufacturing method

InactiveCN1763963AImprove shadingImprove vertical accuracyOptical filtersSolid-state devicesSolid massEngineering

To provide a solid-state imaging device capable of improving color mixing, line shading, and sensitivity errors from adjacent color filter layers. It is a solid-state imaging device (1) in which a plurality of pixels having a photoelectric conversion element (13) and a color filter layer (21) formed on the photoelectric conversion element (13) are arranged in a matrix on a semiconductor substrate (11). ), in addition, on the boundary area with the adjacent photoelectric conversion element (13), there is a resin portion (20) formed protruding from the formation surface, and each color filter layer (21) is formed on the adjacent resin portion (20) ), the film thickness of each color filter layer (21) in the peripheral portion corresponding to the top portion is formed thinner than that in the central portion.

Owner:PANASONIC CORP

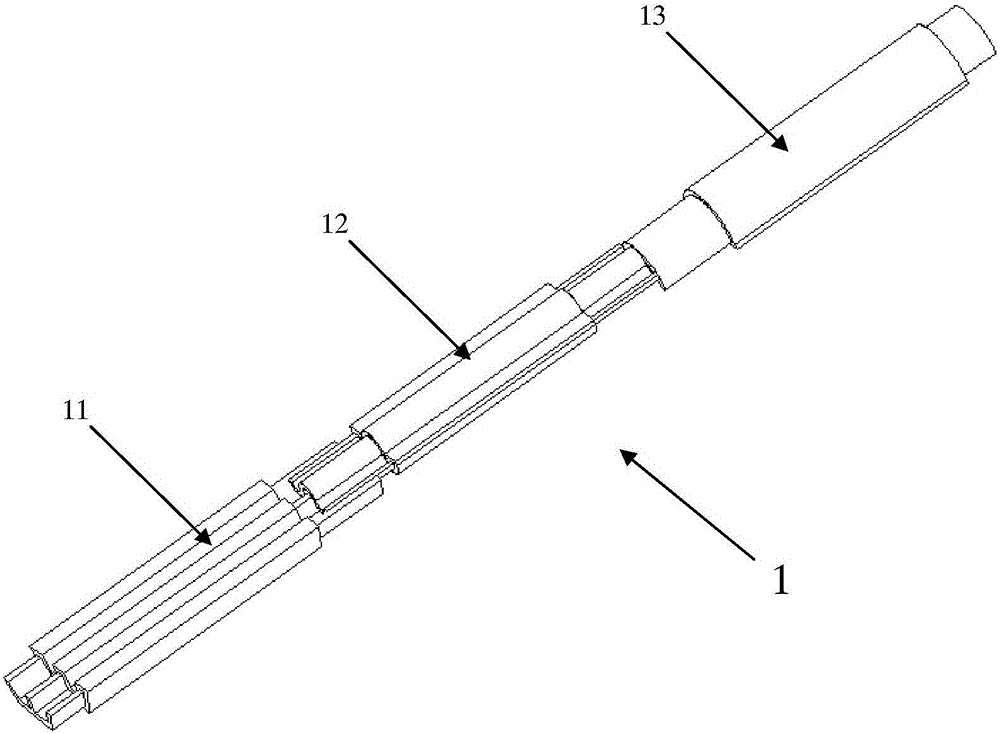

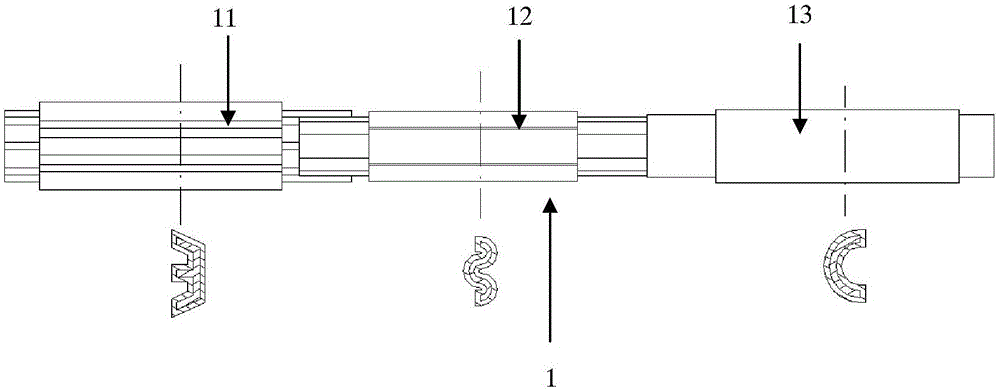

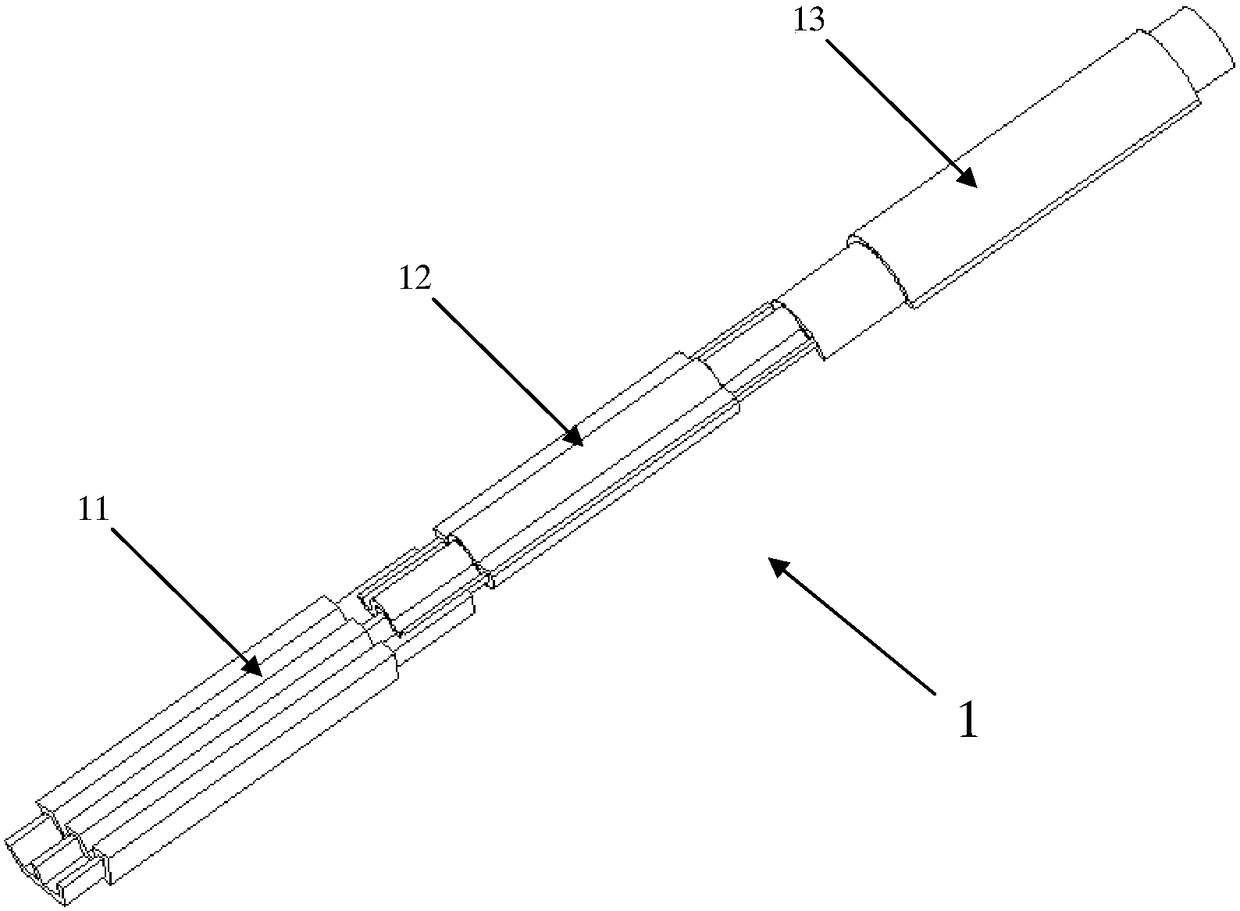

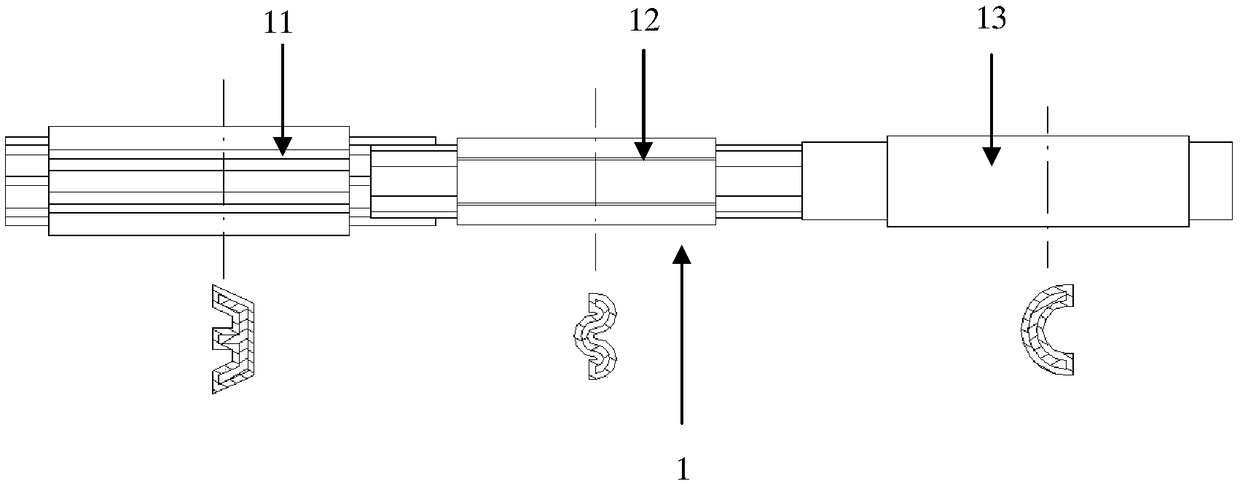

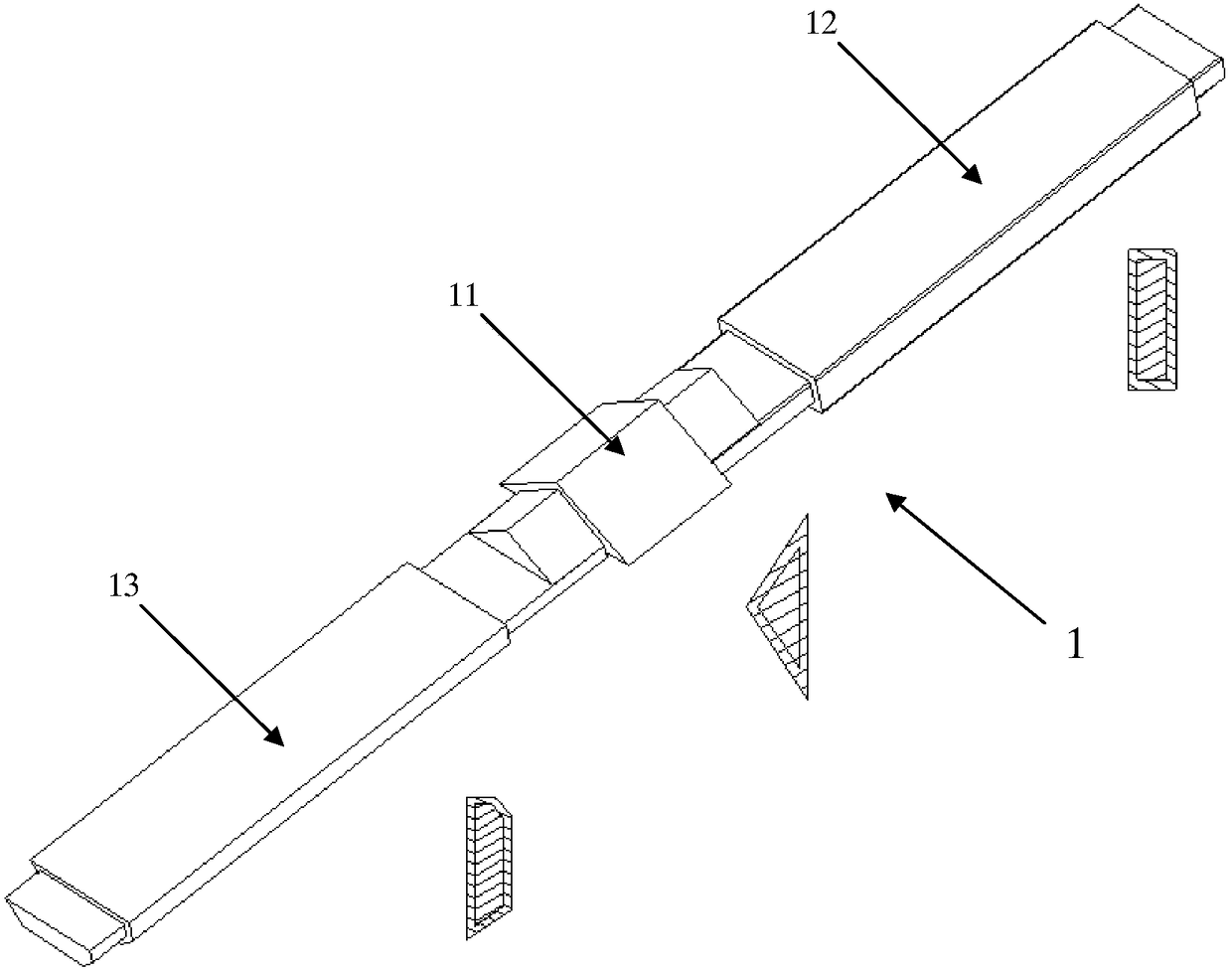

Special-shaped cable and preparation method thereof

ActiveCN106653163ADoes not affect operationReduced eddy current effectDetails of conductive coresManufacturing wire harnessesAbnormal shapedConsumables

The invention discloses a special-shaped cable and a preparation method thereof. The conductive core of the special-shaped cable is composed of at least two conductive core segments in an end-to-end way, wherein the cross sections of the conductive core segments are different in shape. The conductive core segments are externally wrapped by an insulating layer. The contour of the insulating layer is fit with the conductive core segments. The cable has great bending performance and can also be greatly fit with a vehicle body so that consumables can be saved and the safety performance can be greatly enhanced. The cable is made of the aluminum or aluminum alloy conductive cores so that the vehicle body is enabled to be light-weighted, and the production cost of the motor vehicle can be reduced. The preparation method of the special-shaped cable comprises the steps of manufacturing the conductive core segments, connection of the conductive core segments and manufacturing of the insulating layer so that the production efficiency and the productivity can be effectively enhanced according to different production requirements and the production cost can be reduced.

Owner:长春捷翼汽车科技股份有限公司

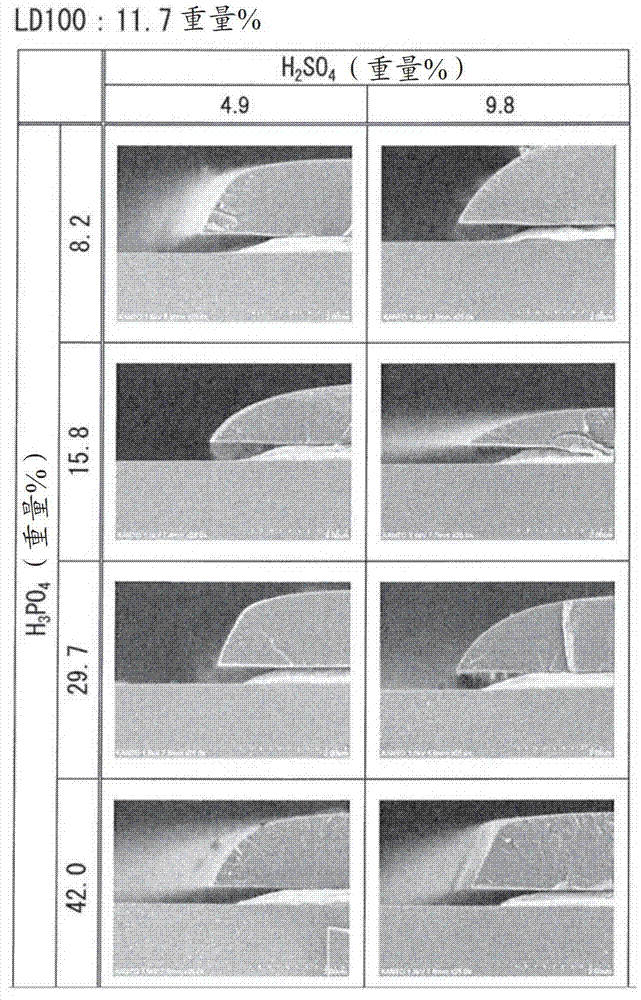

Etching solution composition and etching method for copper and copper alloy

InactiveCN102995021AHigh in-plane uniformity of suppressionControl etch rateSemiconductor/solid-state device manufacturingPhosphoric acidCopper oxide

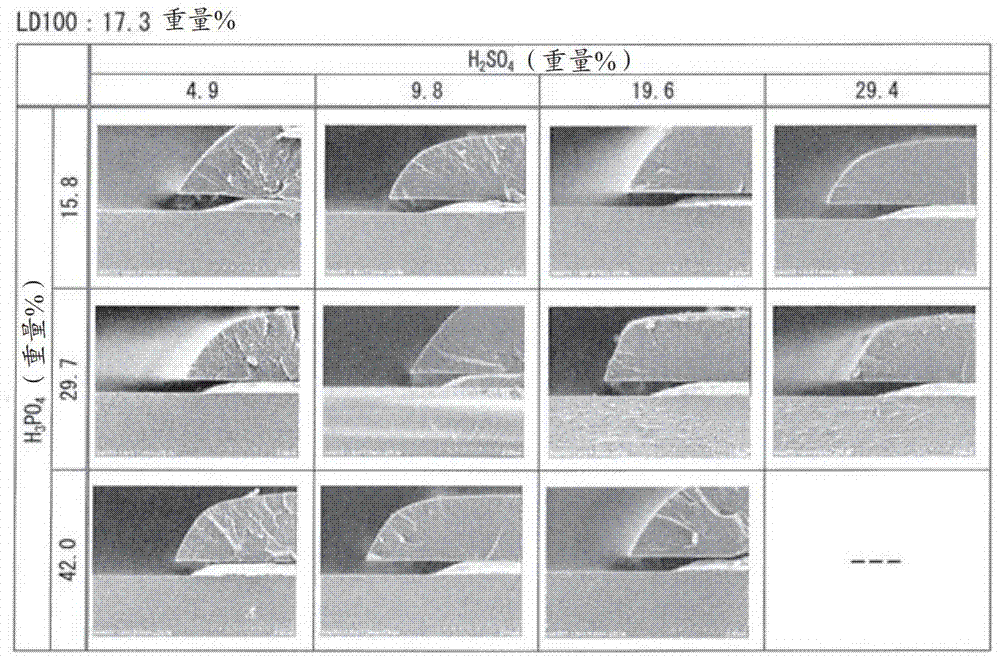

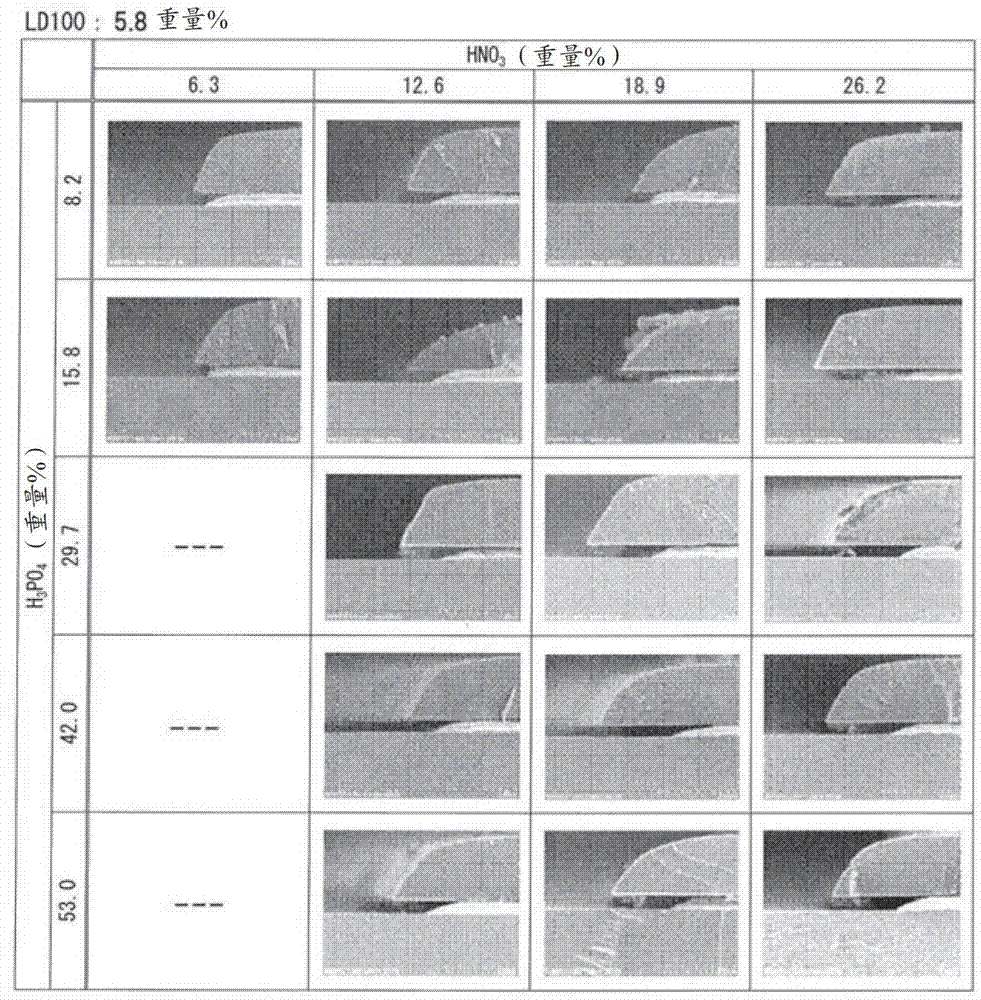

The invention aims to provide an etching solution composition and an etching method for copper and copper alloy. A metal laminated film containing a copper layer and a copper oxide layer and / or a copper alloy layer is etched by the etching solution composition with good precision, thereby forming an excellent sectional shape, realizing excellent practicability and stability and achieving long service lifetime. The etching solution composition is used to etch the metal laminated film containing the copper layer and the copper oxide layer and / or the copper alloy layer. In addition, the etching solution composition contains 0.1-80 wt% of persulfate solution and / or persulfuric acid solution, 0.1-80 wt% of phosphoric acid and 0.1-50 wt% of nitric acid and / or sulfuric acid and is further added with chloride ions and ammonium ions, thereby making it easy to control the etching rate and the sectional shape.

Owner:KANTO CHEM CO INC

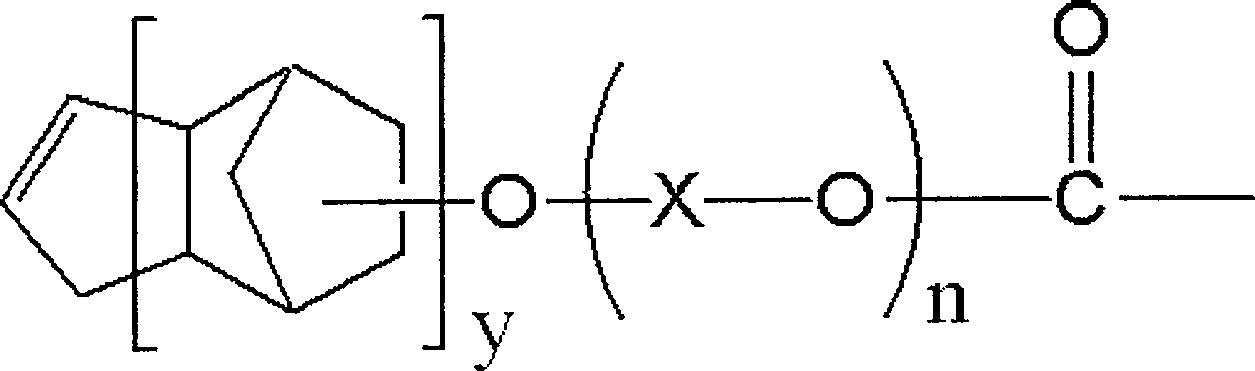

Photo sensitive resin compositon, optical spacer, protective film, coloring pattern, display device and substrate thereof

ActiveCN101470350AHigh sensitivityExcellent mechanical propertiesPhotomechanical apparatusLiquid stateSide chain

The present invention relates to a photosensitive resin compound, an optical spacer, a protective film, a coloring pattern, a display device and a substrate thereof. The photosensitive resin compound provided by the invention comprises the following components: (A) a resin which is provided with branched structure and / or alicyclic ring structure on the side chain, acidic group and substituted alkyl that is provided with two ethylenic linkage type unsaturated bonds, (B) a polymeric compound which is provided with ethylenic linkage type unsaturated bond, and (C) a photopolymerization initiatingagent. The photosensitive resin compound can form a pattern structure or protective film which has the advantages of high sensitivity, excellent storability in liquid state, excellent ageing stability and mechanical characteristic of photosensitive film after film forming.

Owner:FUJIFILM CORP

A photosensitive resin composition and a method forming a pattern using the same

ActiveCN101794073AOptimizing Section ShapeReduce processSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusSolventQuinone

Provided is a photosensitive resin composition, which has short drying time, no coating unevenness and uniform coating film thickness when the pressure reduction drying or vacuum drying method are not adopted to perform natural drying after narrow slit coating, and has good against corrosion pattern shape after exposure and developing. The photosensitive resin composition adopting a photosensitive resin composition containing alkali soluble phenolic resin, photosensitizer containing quinone diazido, and a mixed solvent of propylene glycol monomethyl ether acetate (A) and a solvent (B) whose boiling point is below 145 DEG C and n-butyl acetate evaporation velocity is more than 50, is coated on the substrate through a narrow slit coating method, dried without adopting a pressure reduction drying or vacuum drying method, and then exposure and developing are performed to form anticorrosion patterns.

Owner:MERCK PATENT GMBH

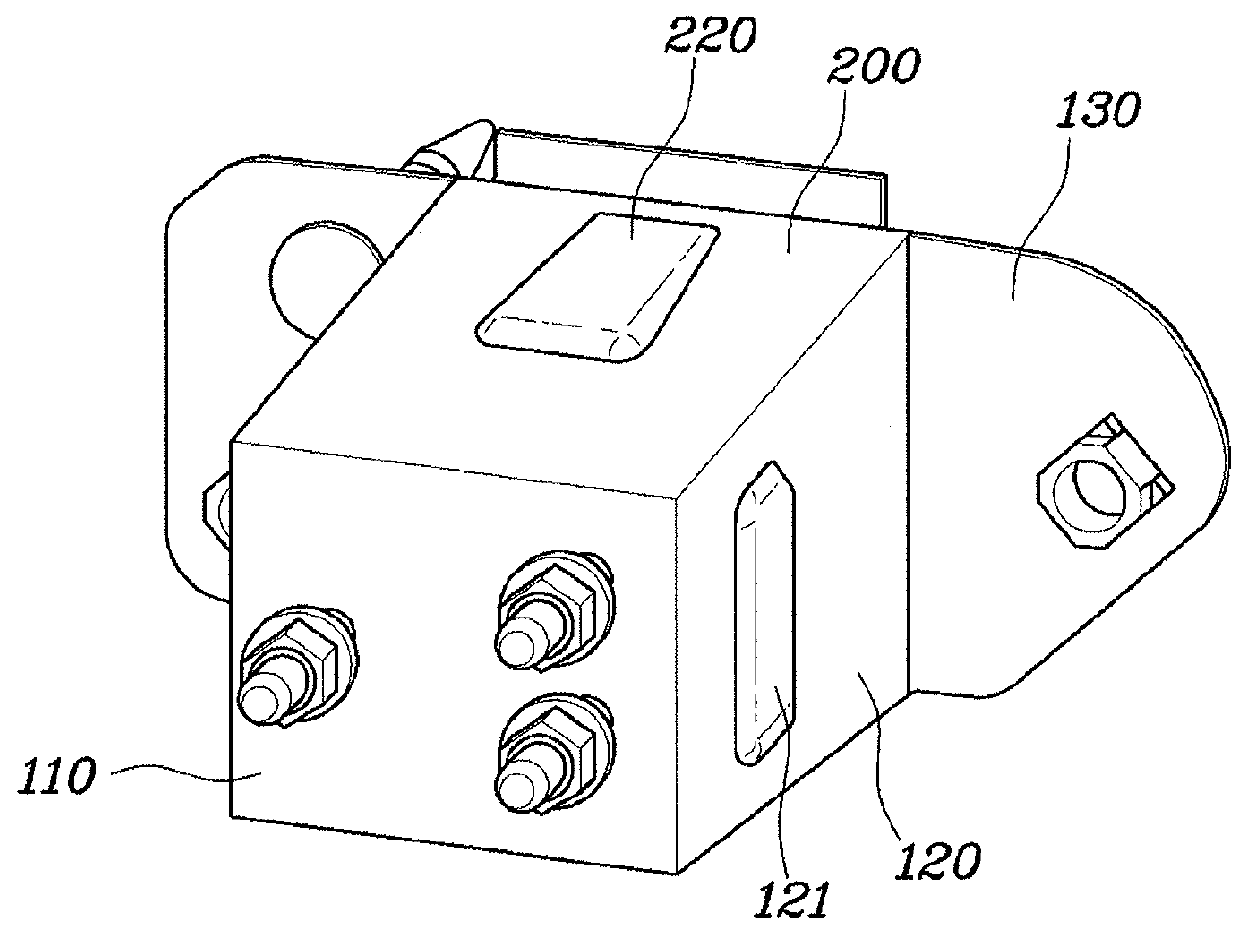

Crash box for vehicle

ActiveUS20180093626A1Reduce weightOptimizing Section ShapePedestrian/occupant safety arrangementElastic dampersEngineeringCrash box

A crash box for a vehicle, which mediates a back beam and a side member disposed in a width direction of the vehicle and absorbs crash energy when a crash occurs, may include a connecting body including a front coupling portion coupled to the back beam, a pair of side connecting portions bent from the front coupling portion to face each other, and a rear coupling portion extending from an end portion of each of the side connecting portions by being bent to be coupled to the side member; and a pair of connecting plates coupled to open upper and lower end portions of the connecting body, respectively.

Owner:HYUNDAI MOTOR CO LTD +3

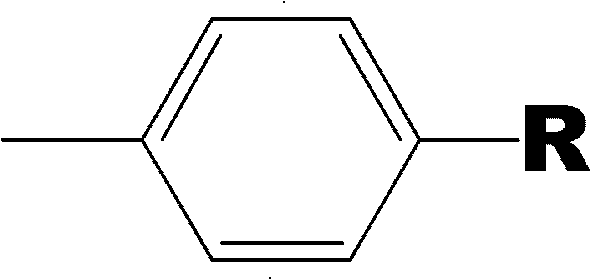

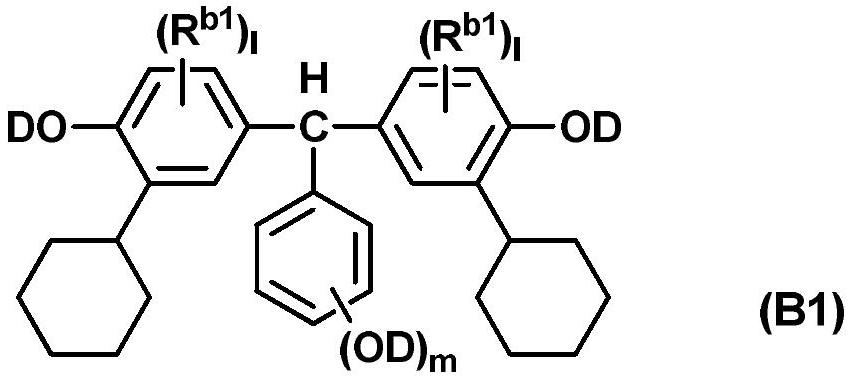

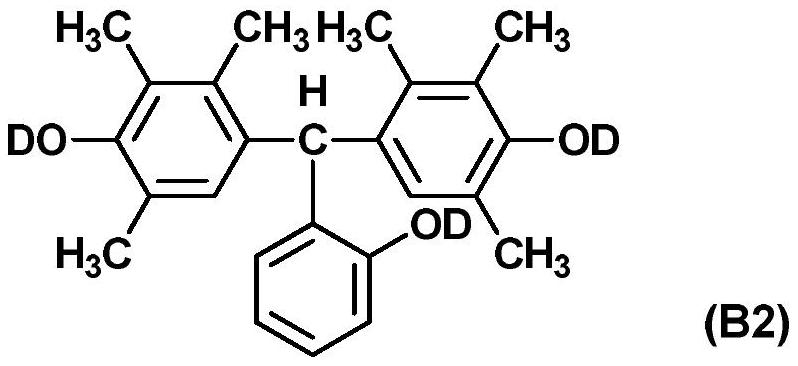

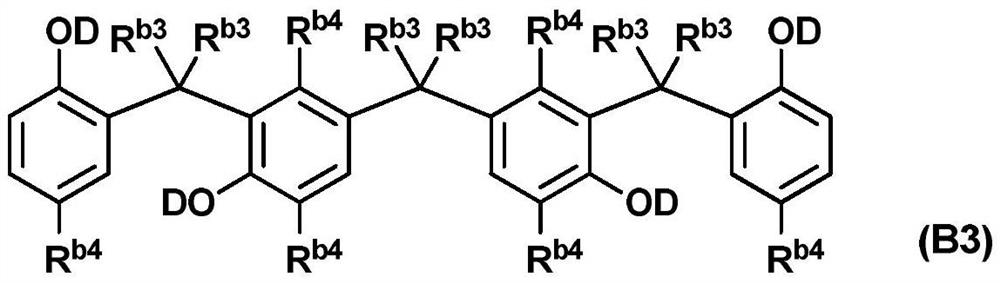

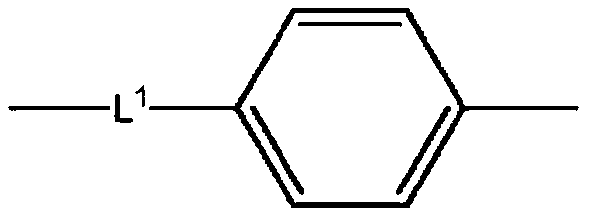

Photosensitive coloring composition and color filter

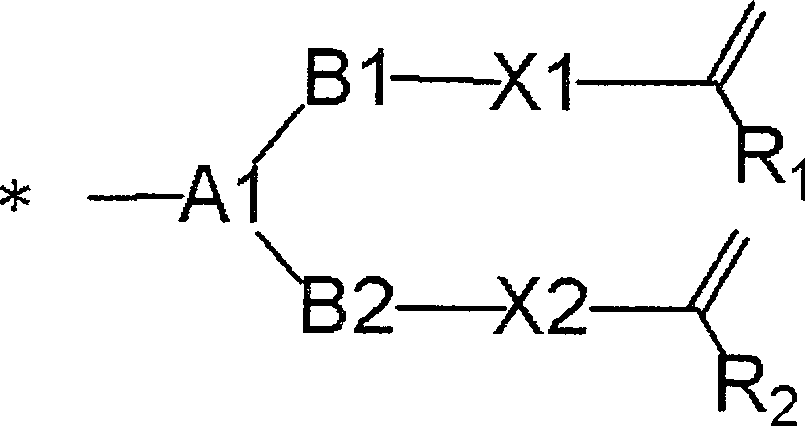

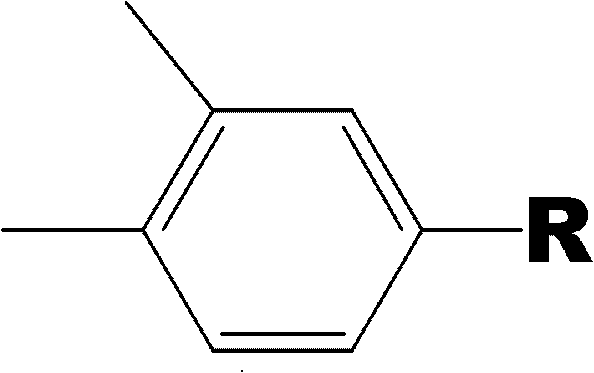

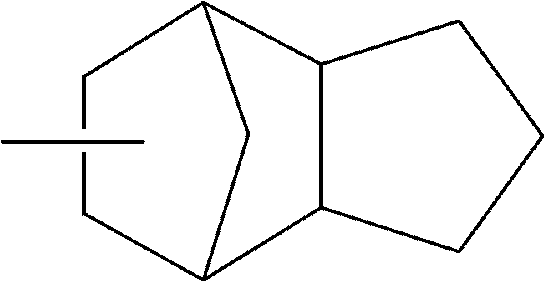

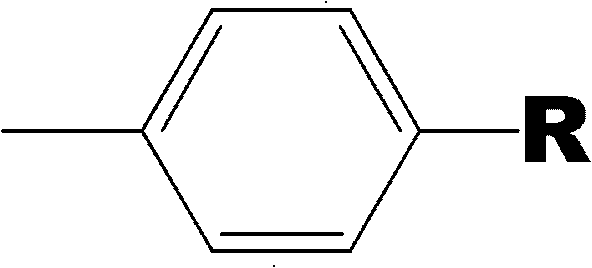

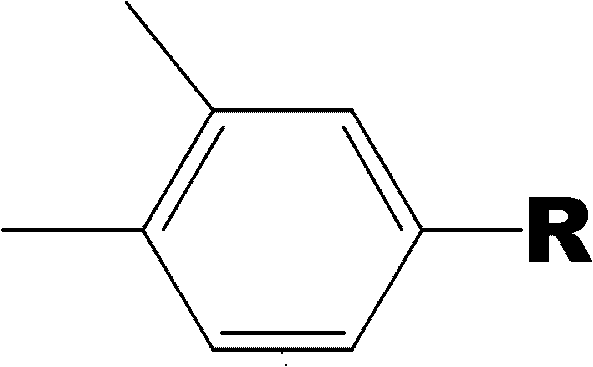

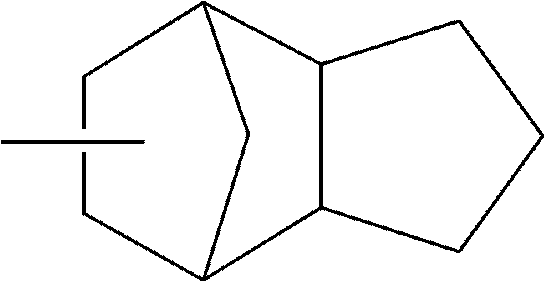

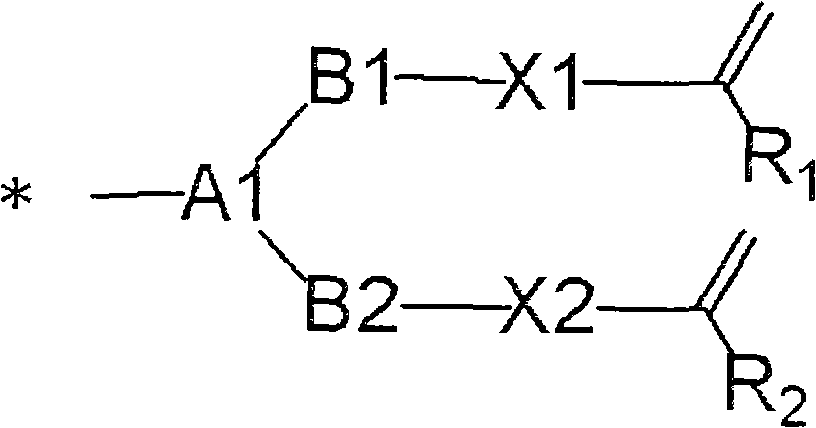

ActiveCN102365586AFull shape retentionImprove thermoplasticityOptical filtersChemical recyclingDispersion stabilityHydrogen atom

Disclosed is a photosensitive coloring composition which has excellent dispersion stability of a pigment and good reworkability, and is capable of forming a colored layer that has a good cross-sectional shape. The photosensitive coloring composition contains a resin (A), a pigment (B), an active energy ray polymerization initiator (C), an active energy ray-curable monomer (D) and a solvent (E). The resin (A) contains a vinyl resin (F) in an amount of not less than 50% by weight, and the vinyl resin (F) contains a constituent unit (a) having a carboxyl group in an amount of 2-50% by weight, a constituent unit (b) having one or more cyclic structures, which are selected from the group consisting of aromatic rings represented by general formula (1), aromatic rings represented by general formula (2), aliphatic rings represented by general formula (3) and aliphatic rings represented by general formula (4), in an amount of 2-50% by weight, and other constituent units (c) in an amount of 10-80% by weight. (In general formulae (1) and (2), R represents a hydrogen atom or an alkyl group having 1-20 carbon atoms, which may have a benzene ring.)

Owner:TOYO INK SC HOLD CO LTD +1

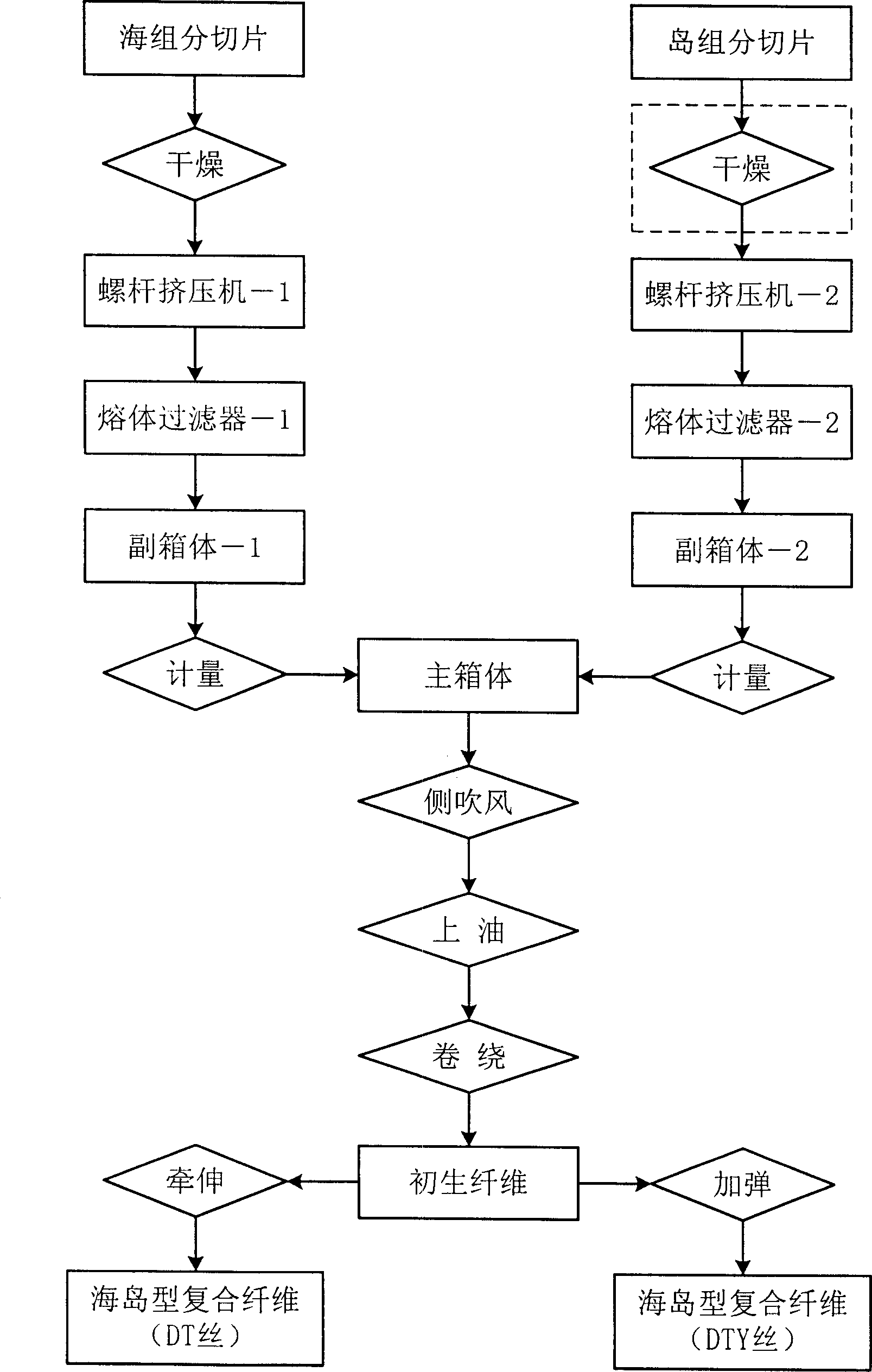

Sea island type composite fiber and its manufacturing method and application

ActiveCN1284890CSectional shape is regularOptimizing Section ShapeFilament/thread formingConjugated synthetic polymer artificial filamentsCopolymerPhysical property

The invention provides a sea-island type composite fiber and its production method and application. It uses thermoplastic resins such as PP and PA6 as island components, biodegradable polylactic acid PLA or its copolymers as sea components, and adopts composite spinning method to obtain sea-island composite fibers with regular cross-sectional shape and excellent physical properties. The indicators are excellent. This sea component is biodegradable and can be dissolved by alkali under relatively mild conditions. The composite fiber or its fabric can be treated with alkaline water to produce superfine fiber or fabric. The alkaline treatment process is simple and easy to control, and the product dissolved by alkaline solution is easy to be post-treated, basically pollution-free and environmentally friendly. The technical scheme of the invention can be used to make clothing, high-grade synthetic leather, artificial suede and the like.

Owner:SINOPEC YIZHENG CHEM FIBER

Composition for reflection reducing coating

InactiveCN1169884CDimensionally stableOptimizing Section ShapeSemiconductor/solid-state device manufacturingCoatingsWater soluble polymersStanding wave

A composition for a reflection reducing coating which comprises (A) a perfluoroalkylsulfonic acid represented by the general formula: CnF2n+1SO3H, wherein n denotes an integer of 4 to 8, (B) an organic amine, (C) a water-soluble polymer, (D) a perfluoroalkylsulfonamide represented by the general formula: CnF2n+1SO2NH2, wherein n denotes an integer of 1 to 8, and (E) water, and has a pH of 1.3 to 3.3. A resist pattern is obtained by coating the composition on a photoresist film formed on a substrate to form a reflection reducing coating, and then subjecting it to exposure and development. This composition for a reflection reducing coating can be coated uniformly on a photoresist film irrespective of the type of resist and the shape of the surface of a substrate, and can be used for providing a resist pattern which is free from the occurrence of standing wave effect, multireflection effect, and a T-shape pattern form and a dimensional change caused through the elapse of time after exposure.

Owner:MERCK PERFORMANCE MATERIALS GK +1

Manufacturing method of semiconductor device

InactiveCN101504931AEnsuring anisotropic etchingOptimizing Section ShapeSemiconductor/solid-state device detailsSolid-state devicesResistInterconnection

A method of forming a metal interconnection that has a favorable cross-sectional shape is provided without the fear of side etching, even in a sparse arrangement of metal interconnections. The method, the following structure is employed. A region for placing a dummy metal interconnection is provided close to a region in which a metal interconnection is formed. A trench is formed in the dummy metal interconnection region and a resist pattern for the metal interconnection is then formed, giving the resist above the trench a large surface area per unit area. The metal interconnection is subsequently formed by dry etching in which an organic component from the resist above the trench forms a solid sidewall protection film, permitting anisotropic etching. The metal interconnection can thus have a favorable cross-sectional shape.

Owner:SII SEMICONDUCTOR CORP

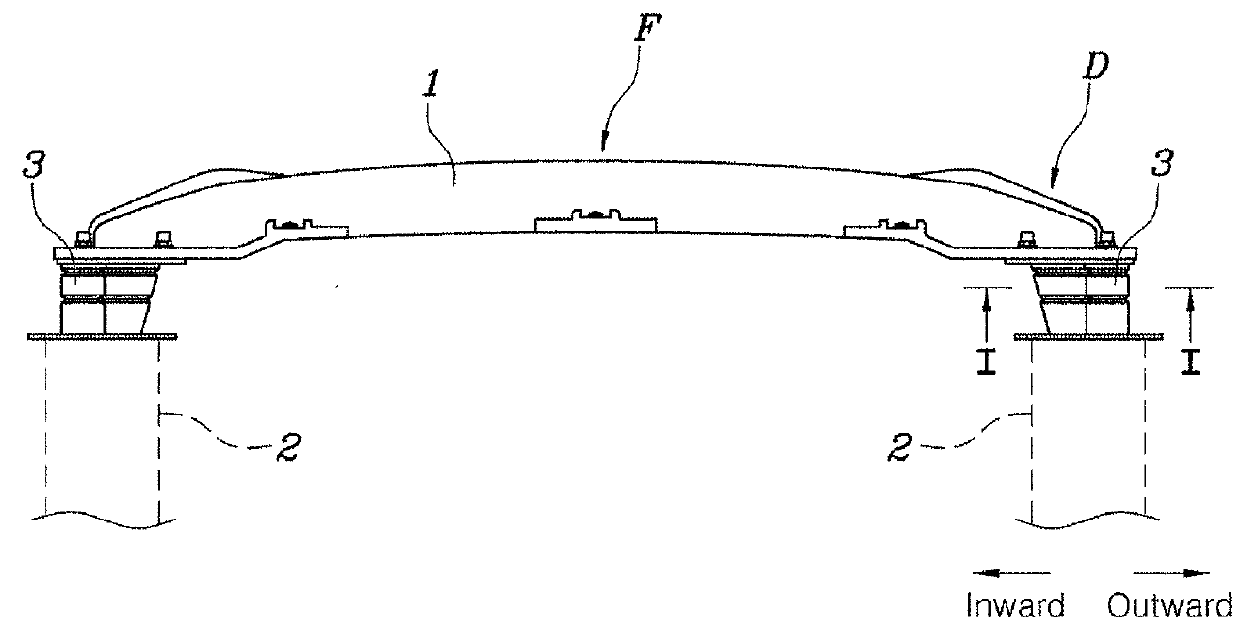

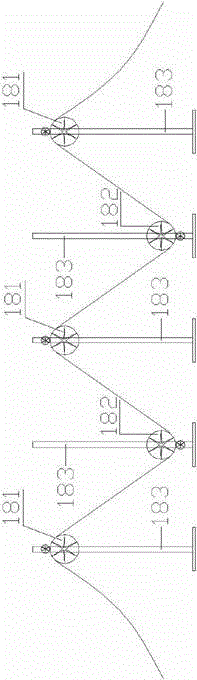

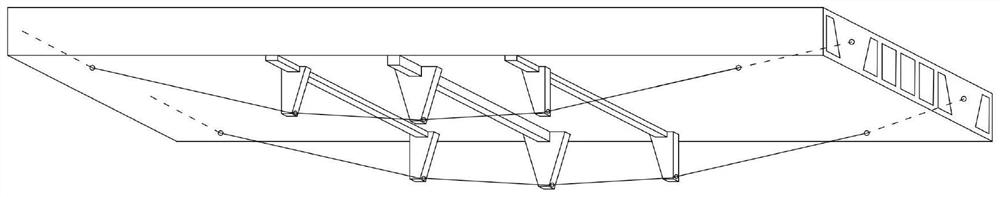

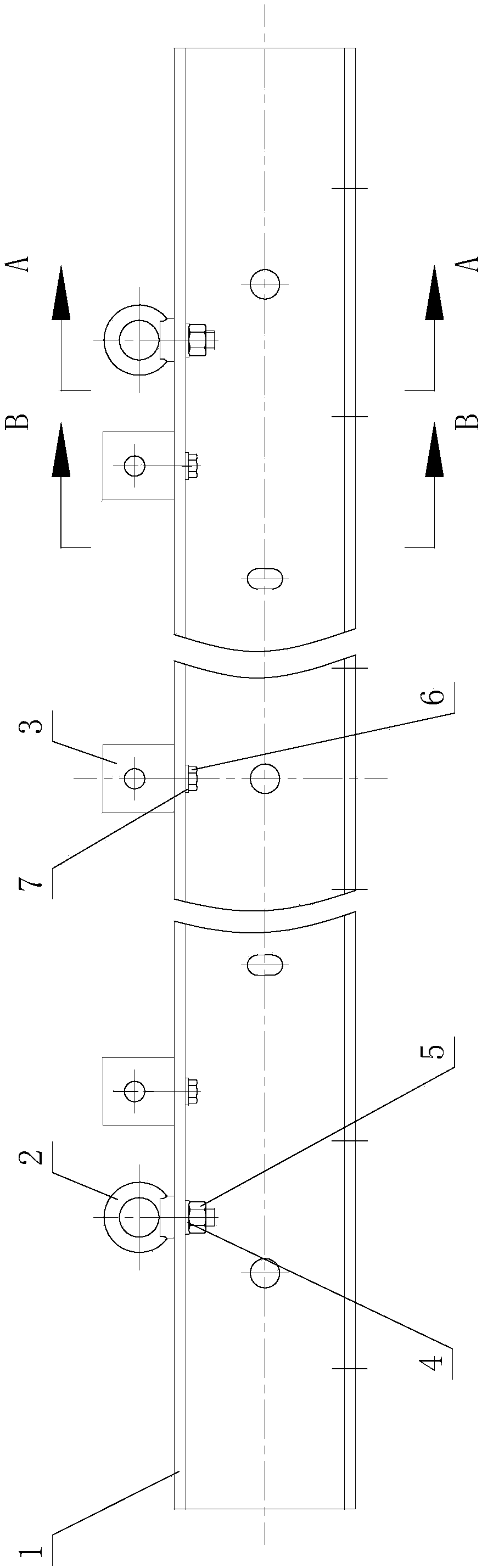

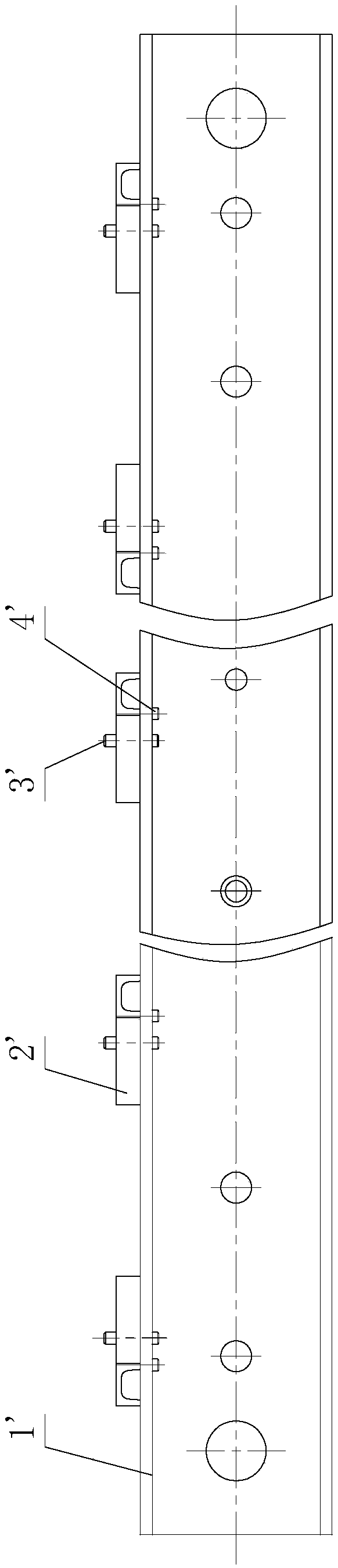

Direct cable weaving and hanging method for cable strand of suspension bridge

ActiveCN102121231BOptimizing Section ShapeHigh precisionBridge structural detailsBridge erection/assemblyEngineering

The invention relates to the field of cable suspension of bridges, in particular to a direct cable weaving and hanging method for a cable strand of a suspension bridge. A field direct cable weaving and hanging method for the cable strand of the suspension bridge comprises the following steps of: weaving a unit strand; arranging weaving equipment; drawing the unit strand; thermally casting an anchor; cooling an anchor device; arranging a strand anchor device; and linearly adjusting. The method is characterized in that the unit strand is directly drawn after being woven to erect the suspension bridge. The unit strand is woven after the weaving equipment is arranged and before drawing. The method has high working efficiency, and a large quantity of costs is saved.

Owner:SHANGHAI PUJIANG CABLE

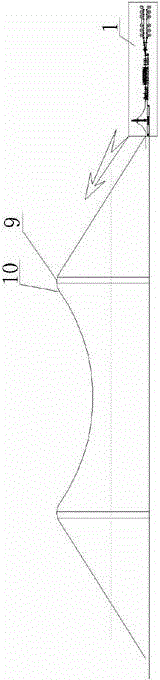

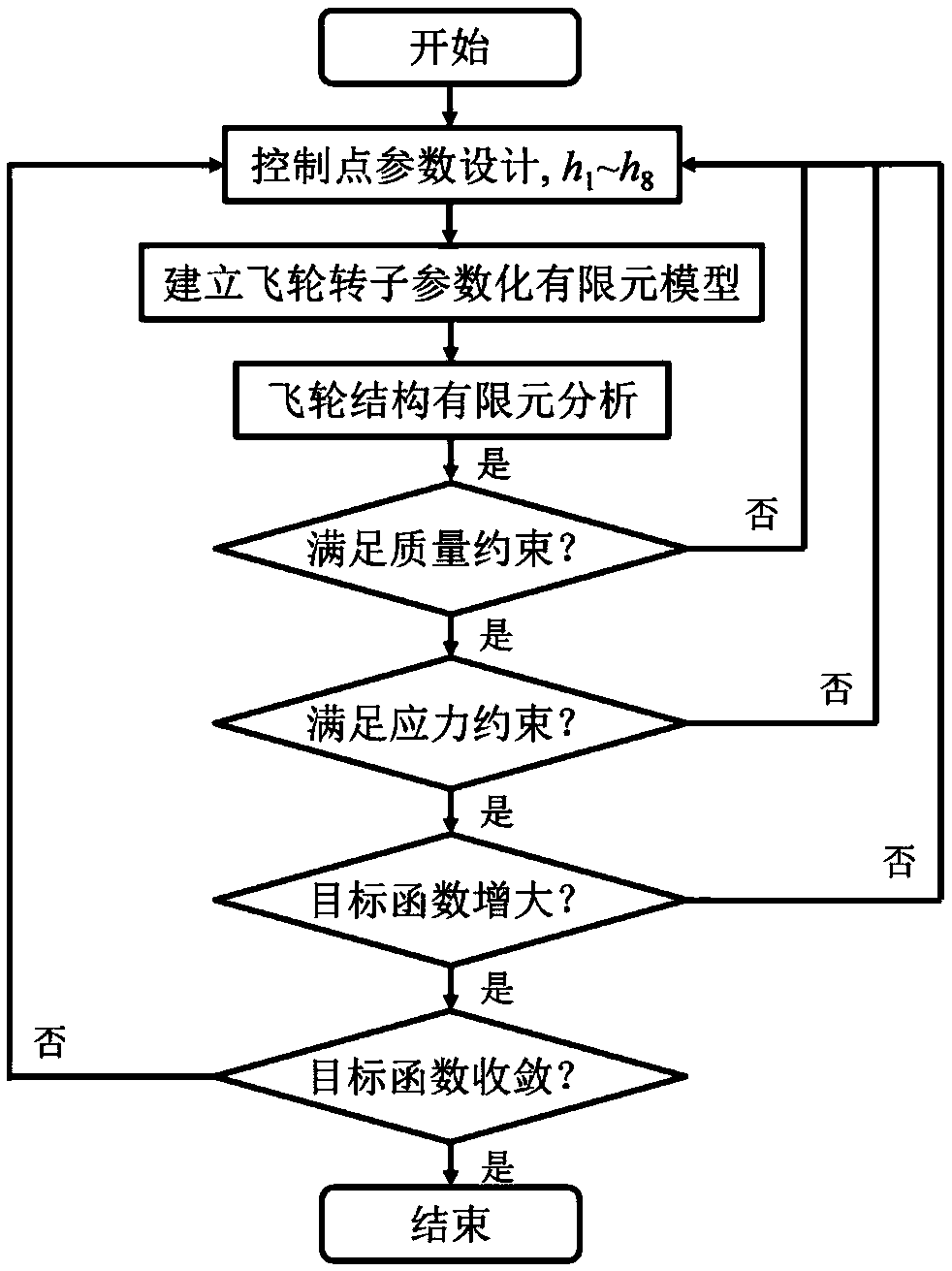

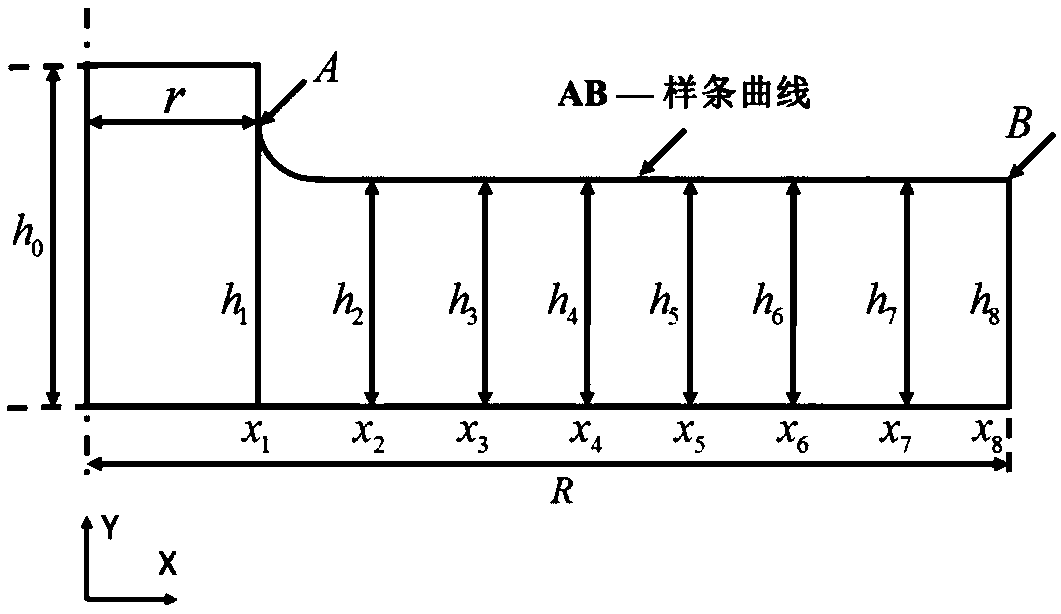

A structural design method and device for increasing the energy storage density of a flywheel rotor

ActiveCN107092726BOptimizing Section ShapeHigh energy storage densityGeometric CADDesign optimisation/simulationNew energyElement analysis

The invention belongs to the field of new energy, and provides a structural design method and device for improving the energy storage density of a flywheel rotor. Control points are arranged along the radius direction of the rotor, a spline curve fitting method is used for describing the thickness distribution of the rotor, a flywheel structure parameter optimization model is established, a mathematical method of finite element analysis and structure optimization is adopted to carry out optimal design on the section shape of the flywheel rotor, and a design goal for improving the energy storage density of the flywheel rotor is realized. The method has the effects and the benefits that the thickness distribution of the flywheel rotor is designed to effectively improve energy storage density when quality and structure stress conditions are met. In addition, an end plate is reinforced on the outer layer of the flywheel rotor to effectively lower resistance generated by surrounding fluid during high-speed rotation. The structural design method and device can be widely suitable for designing flywheel structures in various engineering fields.

Owner:DALIAN UNIV OF TECH

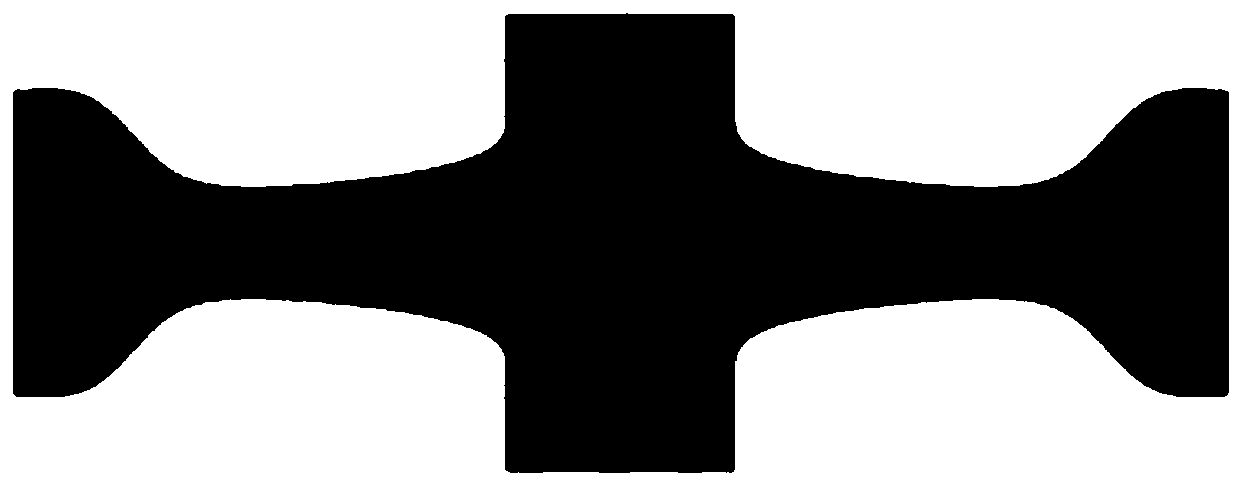

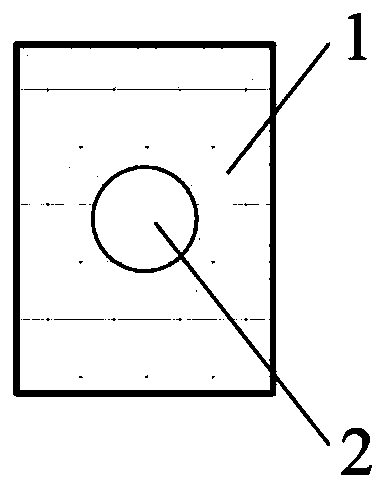

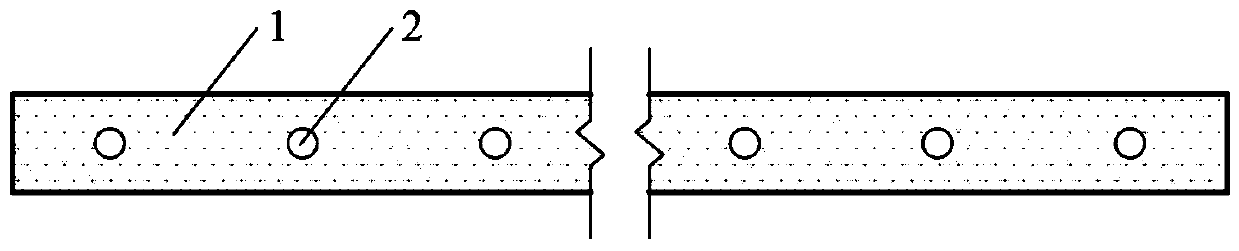

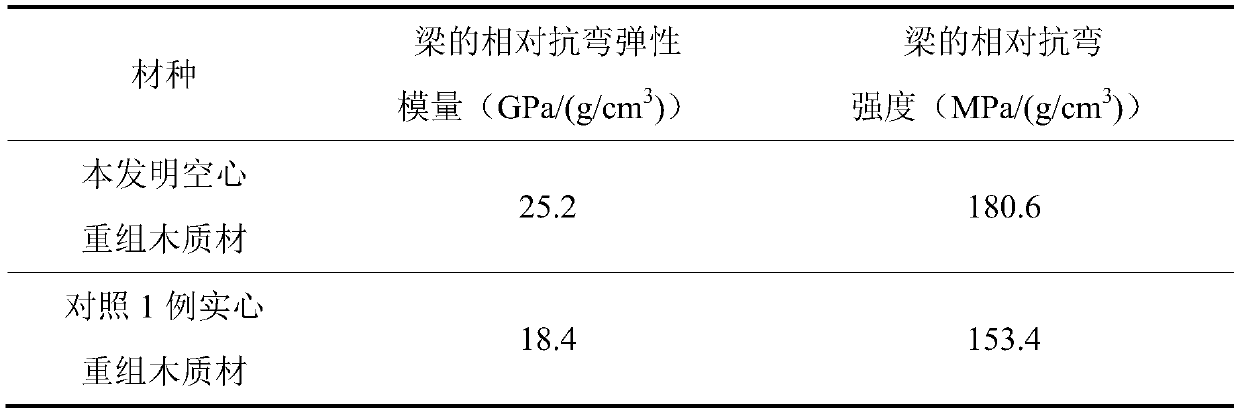

Manufacturing method of hollow reconstituted wood material for structure

InactiveCN109808022AEasy to manufactureReduce manufacturing costDomestic articlesFlat articlesWood veneerAdhesive

The invention relates to a manufacturing method of a hollow reconstituted wood material for a structure, and belongs to the technical field of green building materials. According to the method, raw bamboo, wood veneers and adhesives are used as raw materials for manufacturing the hollow reconstituted wood material for the structure through steps of defibering, drying, impregnation, laying, pressing shaping and the like. In the process of manufacturing the reconstituted wood material by a conventional process, a solid steel sectional material laying and demolding process is added so as to optimize the cross section shape of the reconstituted wood material; the reconstituted wood material with the hollow cross section is manufactured; the manufacturing cost is low; and the manufacturing process is simple and convenient. When the reconstituted wood material is used as structure components such as beams and plates, the relative mechanical properties of the whole components can be obviouslyimproved by using the optimized hollow cross section. The hollow reconstituted wood material for the structure can be simply, conveniently and fast manufactured by the method; and the manufactured reconstituted wood material for the structure has the characteristics of low cost and high mechanical properties, and has wide application prospects in building structures.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

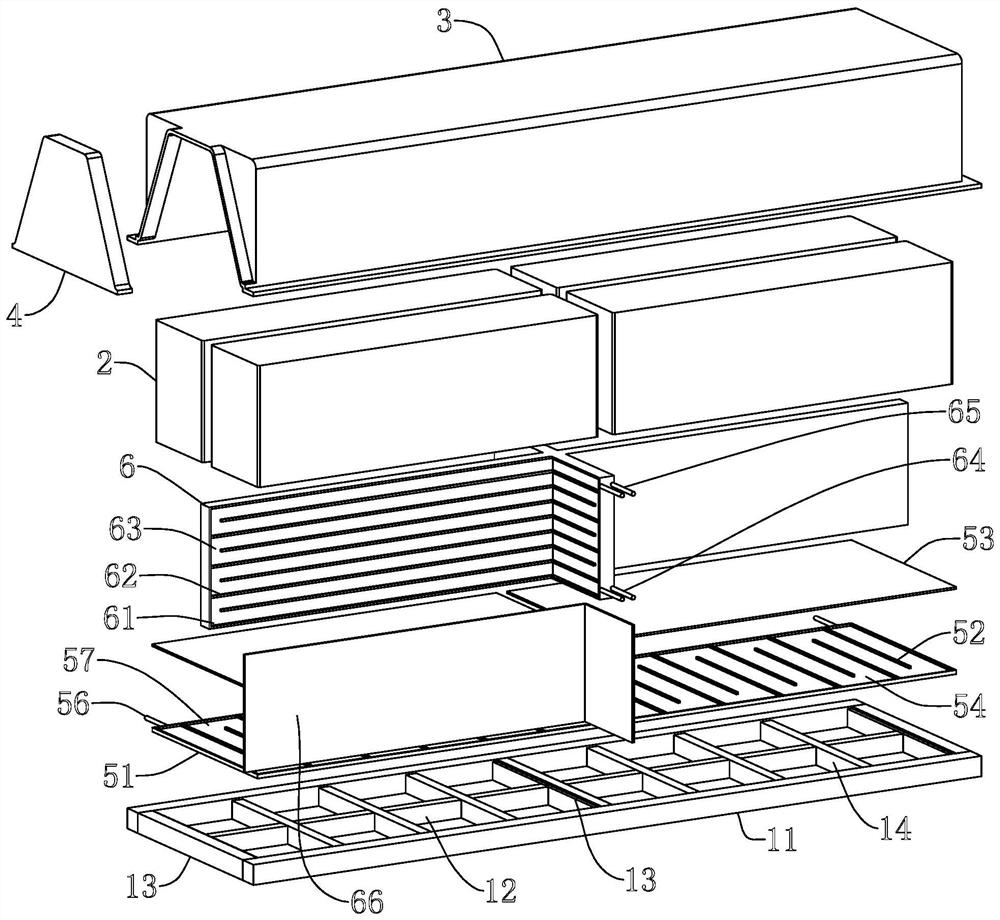

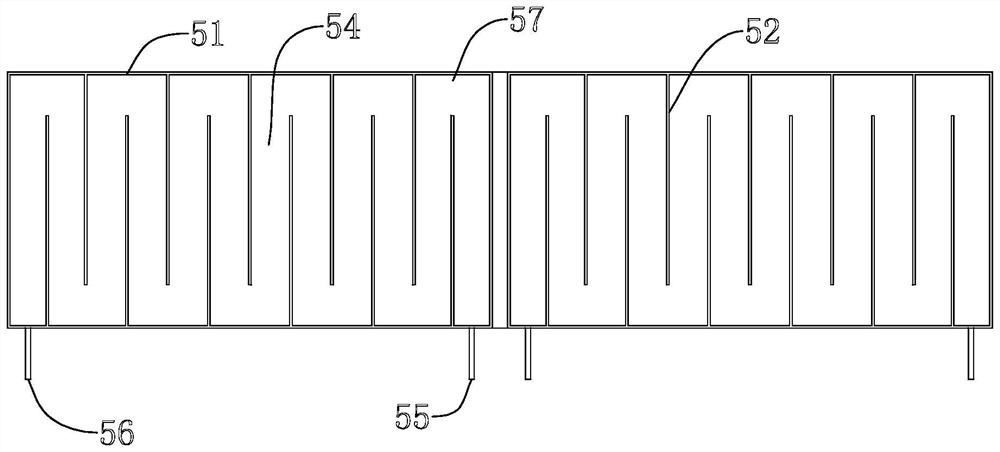

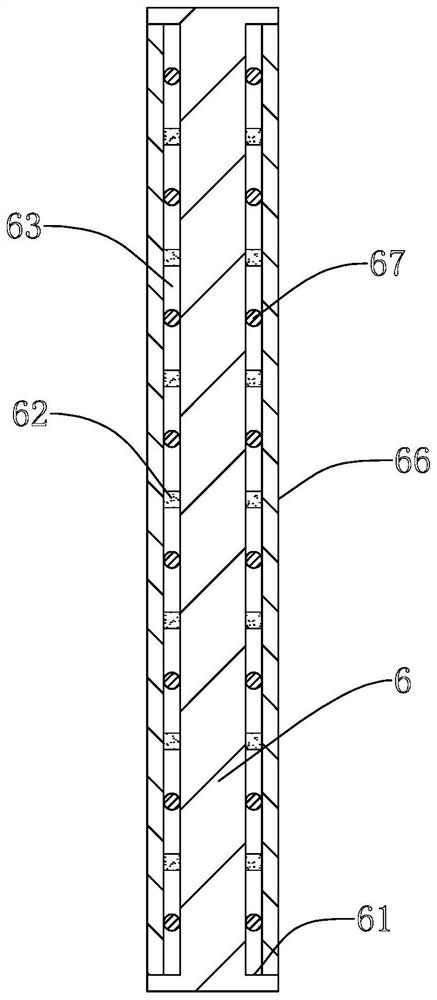

Multi-material fused light high-strength battery pack structure and design method thereof

ActiveCN114284598AGuaranteed StrengthGuaranteed tightnessSecondary cellsCell lids/coversStructural engineeringBattery cell

The invention discloses a multi-material fused light high-strength battery pack structure and a design method thereof.The multi-material fused light high-strength battery pack structure comprises a bearing frame, battery modules, an upper cover and a plug board, a cooling plate is arranged at the upper end of the bearing frame, the battery modules are arranged on the upper surface of the cooling plate, partition plates are arranged between every two adjacent battery modules, and first grooves are formed in the partition plates; a first partition strip is arranged in the first groove, the first partition strip divides the first groove into a continuous S-shaped first flow channel, the first flow channel is communicated with a first water inlet pipe and a first water outlet pipe, a first heat conduction metal plate is sealed in the first groove, the upper cover covers the battery module, and the plug board is matched with the upper cover for use. And the upper cover, the cooling plate and the plug board form a closed cavity. According to the bearing frame, the strength needed by the battery pack is guaranteed while the battery pack is lightened through the frame type structure, the battery module is wrapped by the upper cover, the plug board and the cooling plate, the sealing performance of the battery module is guaranteed, and the bearing frame has the effects of being simple in structure and low in cost.

Owner:HUNAN UNIV

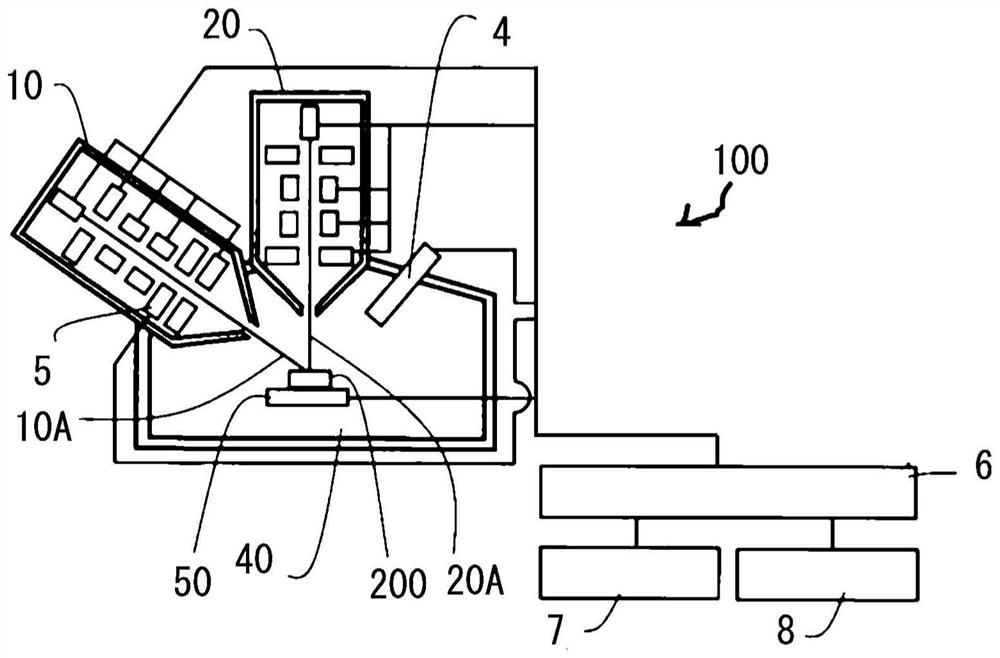

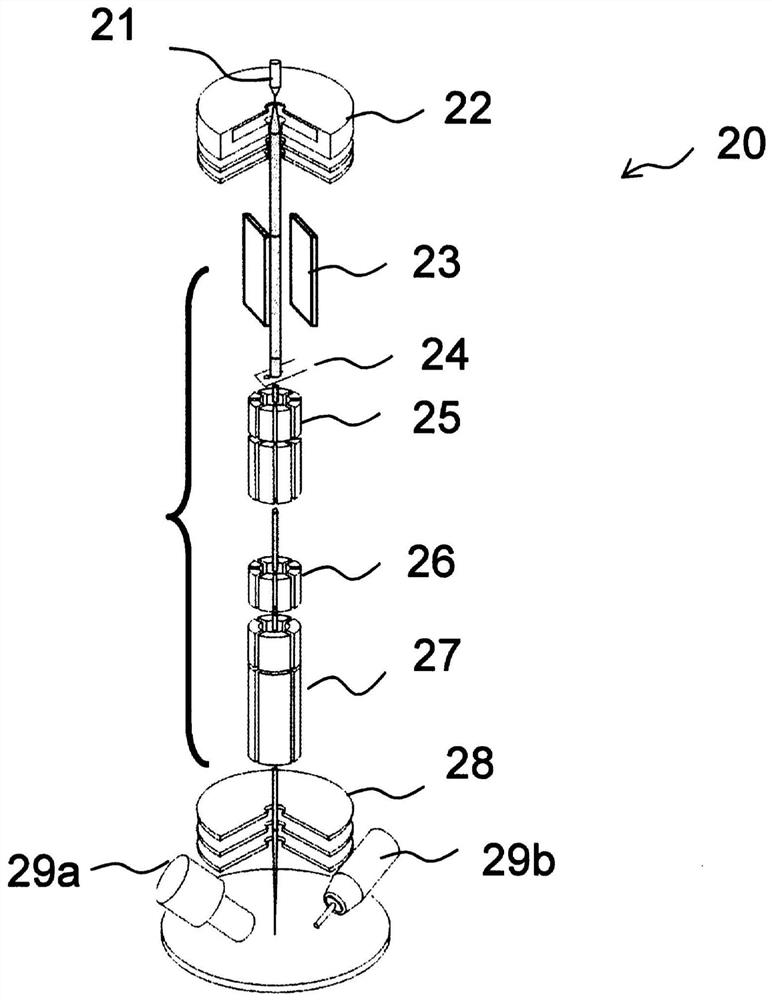

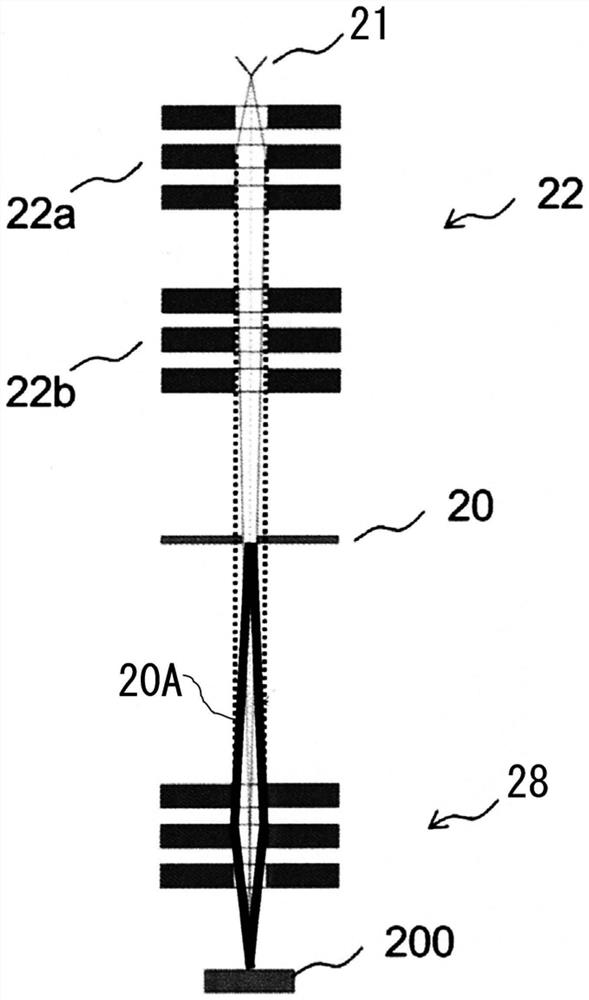

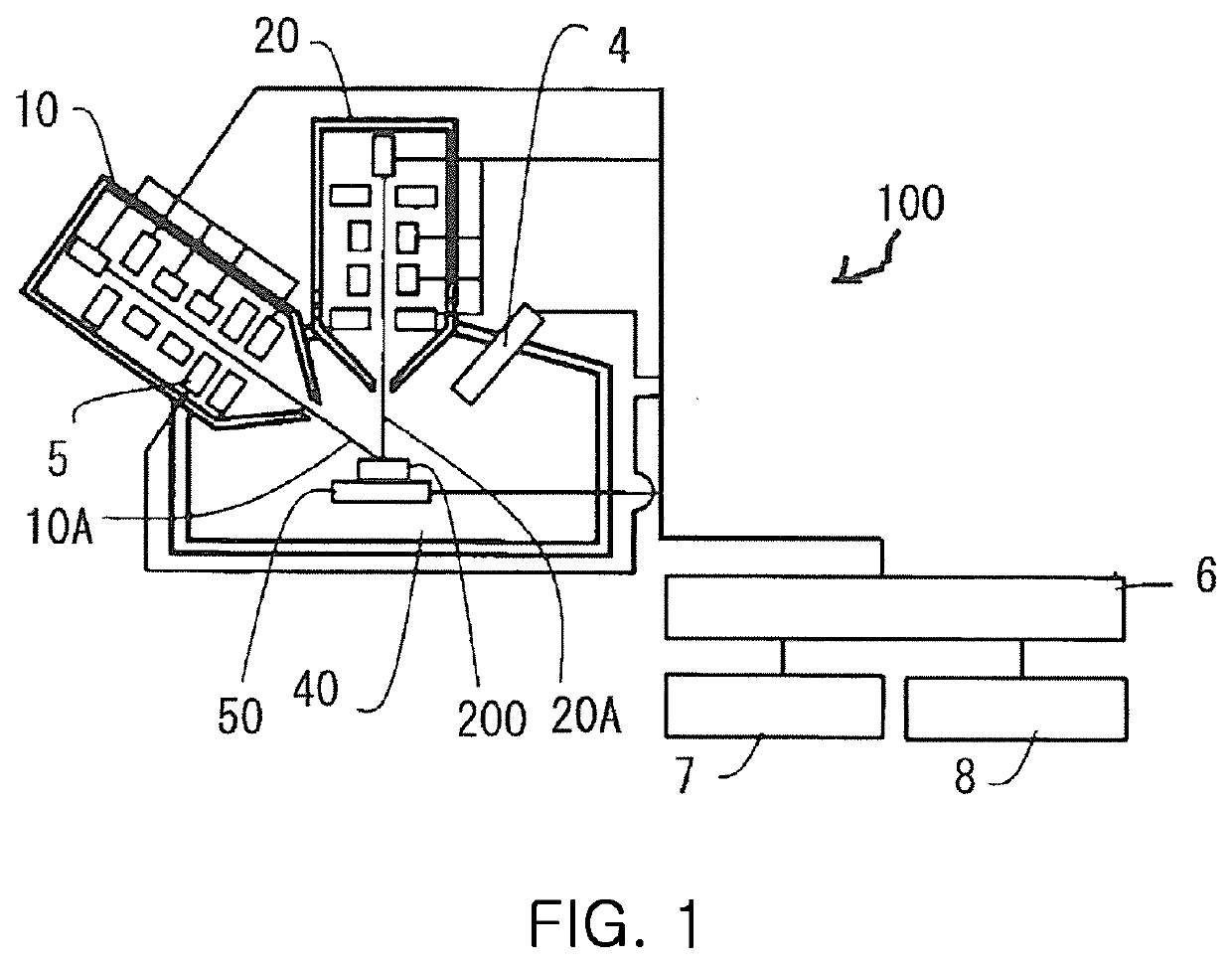

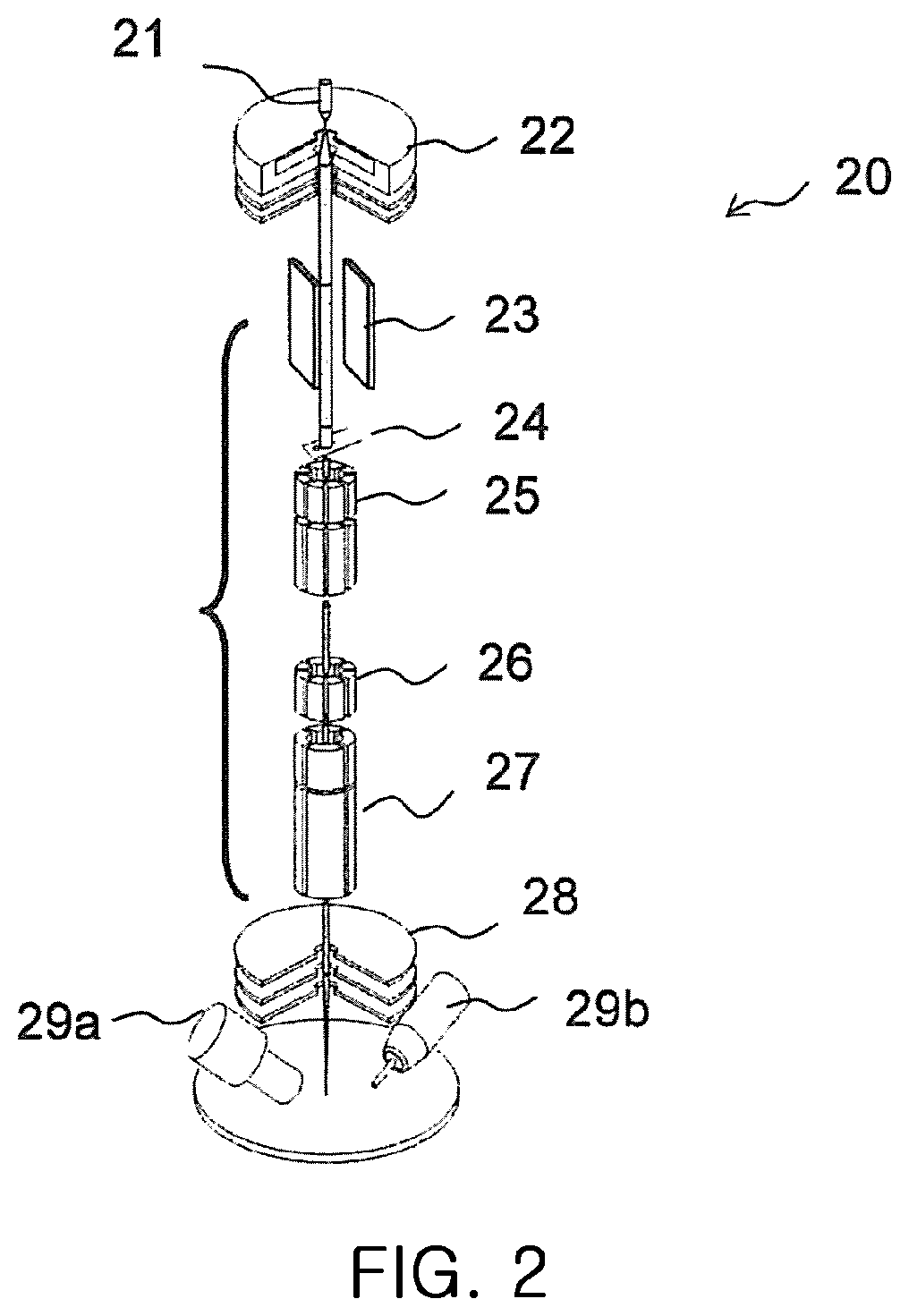

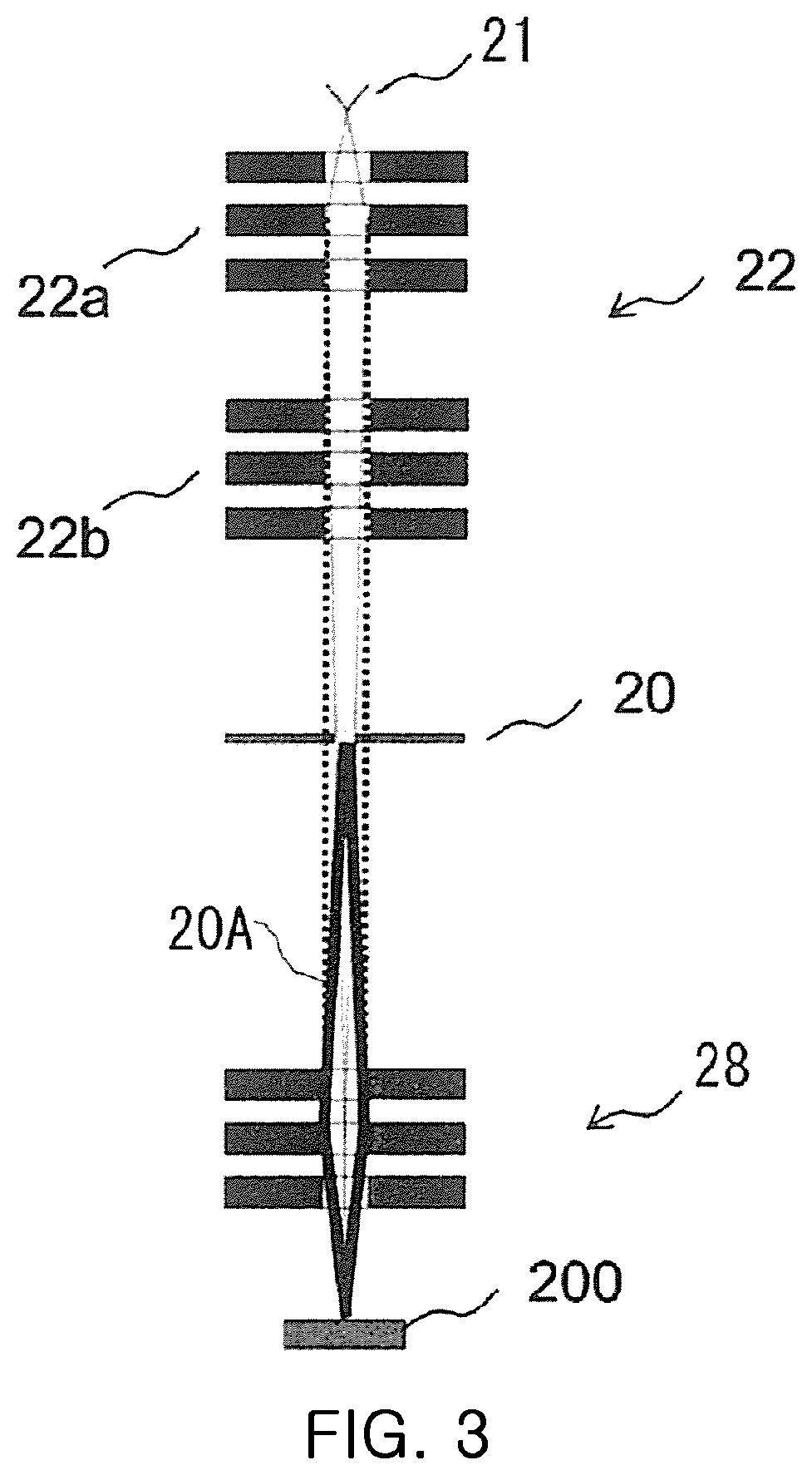

Focused ion beam processing apparatus

PendingCN113436952AOptimizing Section ShapeImprove work efficiencyElectric discharge tubesIon beam processingEngineering

The present disclosure is directed to providing a focused ion beam processing apparatus capable of improving a shape of a cross-section when cross-section processing is performed using a focused ion beam, and improving operation efficiency. The focused ion beam processing apparatus (100) includes: an ion source (21); a sample stage (50) holding a sample; a condenser lens (22); an aperture (24) having having a slit (24) with at least one side in a straight line shape; a projection lens (28) placed in a beam path between the aperture and the sample stage; the sample is machined with a section; in a transfer mode, by Kohler illumination, with an applied voltage of the condenser lens when the focused ion beam (20A) is focused on a main surface of the projection lens scaled to be 100, the applied voltage is set to be less than 100 and greater than or equal to 80; a position of the aperture is set such that the focused ion beam is masked by the aperture with the one side of the aperture at a distance greater than 0 [,u]m and equal to or less than 500 [mu]m from a center of the focused ion beam, so that the shape of the slit is transferred onto the sample.

Owner:HITACHI HIGH TECH SCI CORP

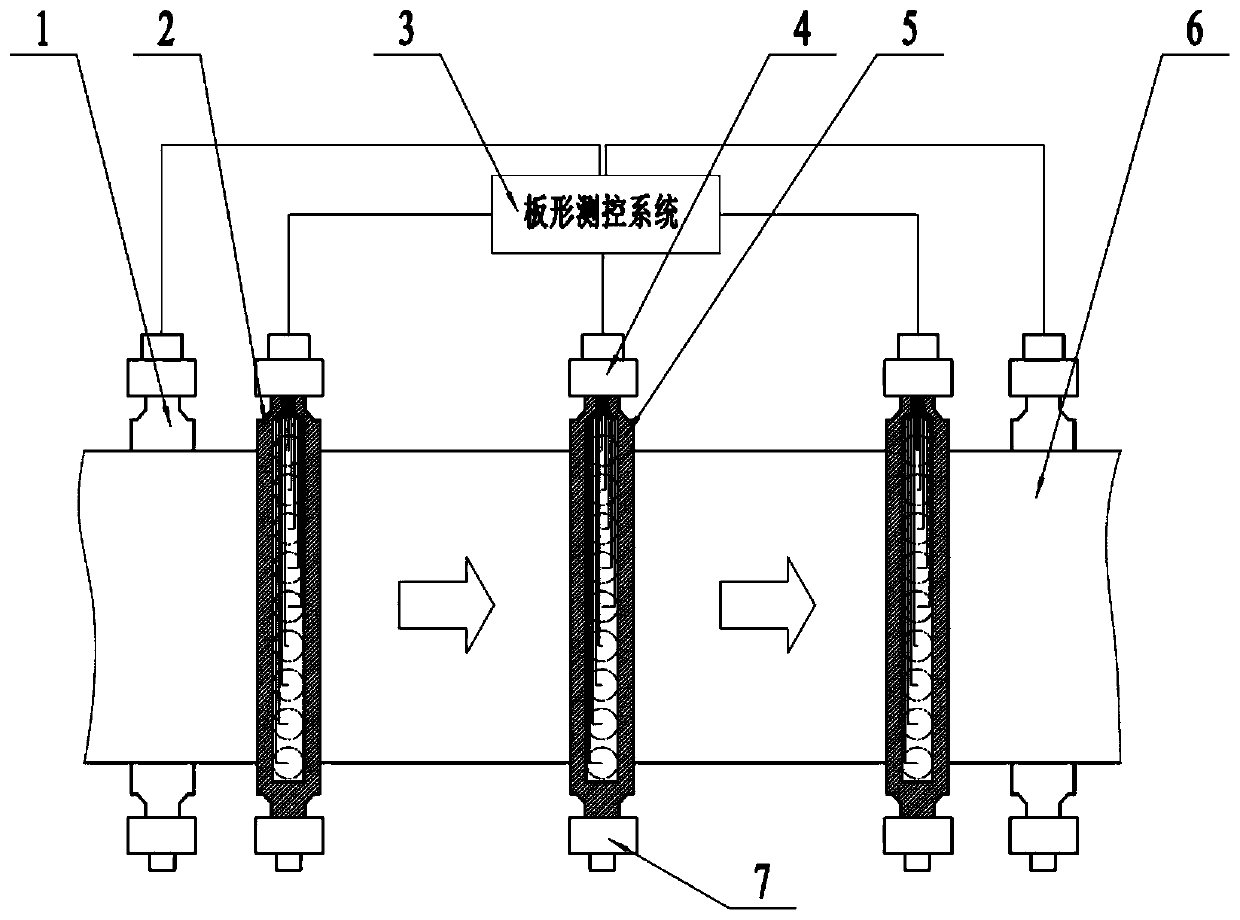

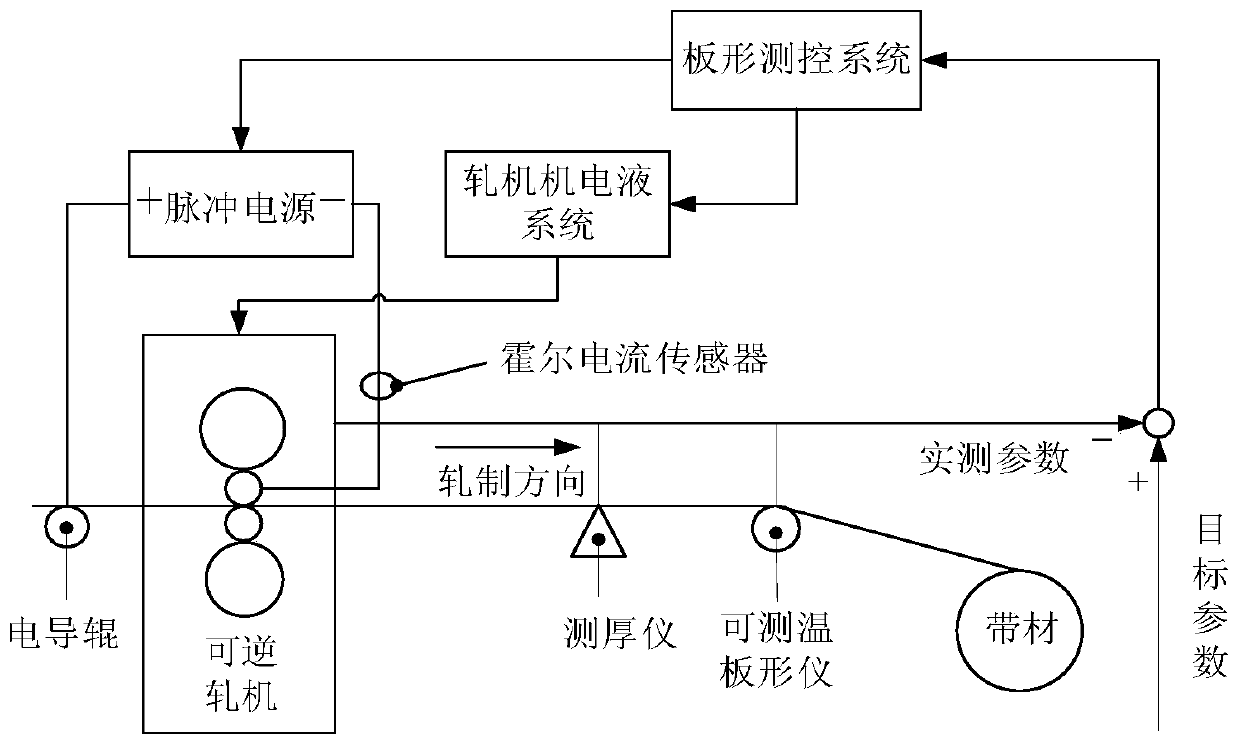

High-energy electric pulse strip shape regulation and control method for high-hardness and high-brittleness cold-rolled strip

InactiveCN111266413AImprove plasticityHigh elongationMeasuring devicesMetal rolling arrangementsFrictional coefficientEngineering

The invention provides a high-energy electric pulse strip shape regulation and control method for a high-hardness and high-brittleness cold-rolled strip. The method comprises the following steps of (1), rapidly improving the plasticity, elongation or tensile stress transverse distribution state of the cold-rolled strip difficult to deform by utilizing the electric plastic effect of high-energy electric pulses, finely regulating the electric field state in the cold-rolled strip, reducing the rolling pressure, improving the transverse shape of a roll gap, and finely adjusting the internal residual stress and local deformation; and (2), based on a high-energy electric pulse strip shape control relation, adjusting the strip shape of the cold-rolled strip by utilizing the high-energy electric pulse plasticizing mechanism, meanwhile, adjusting the strip thickness and the surface quality, controlling the thermal convexity of an electric roller in a segmented mode so as to enable the roller gap to meet the fixed proportional convexity relation, reducing the rolling force, keeping good pocket lubricating conditions, and obtaining a good friction peak or friction coefficient meeting the surface quality requirement.

Owner:YANSHAN UNIV

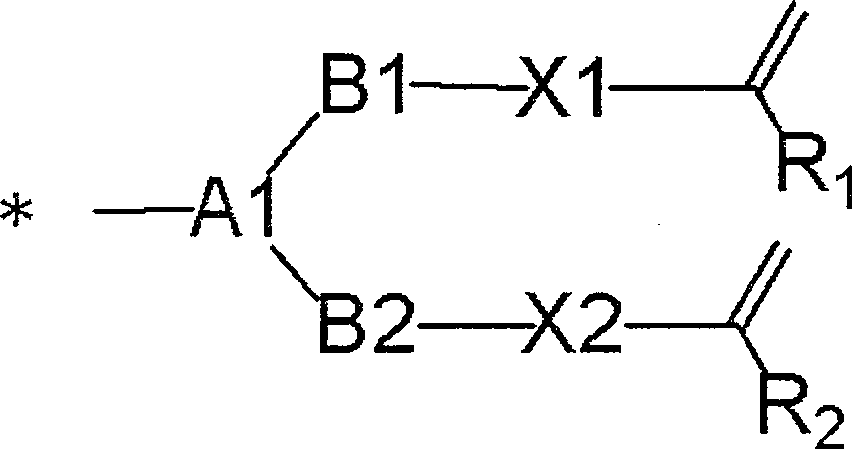

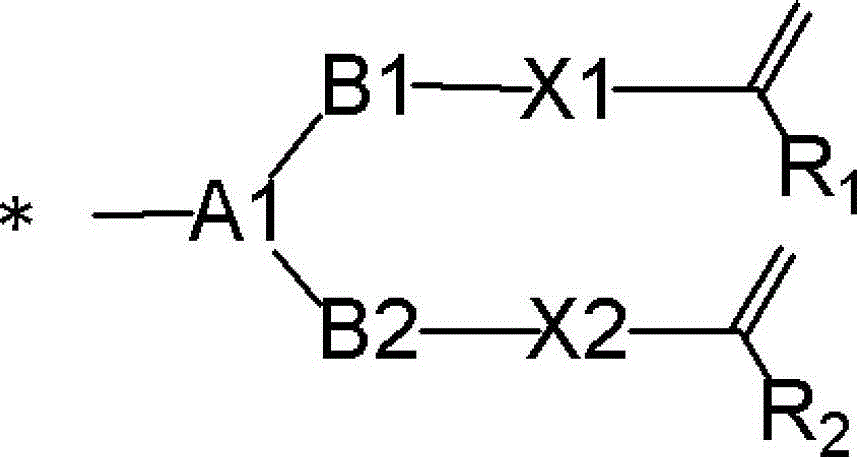

Photosensitive coloring composition and color filter

ActiveCN102365586BFull shape retentionImprove thermoplasticityOptical filtersChemical recyclingDispersion stabilityHydrogen atom

Disclosed is a photosensitive coloring composition which has excellent dispersion stability of a pigment and good reworkability, and is capable of forming a colored layer that has a good cross-sectional shape. The photosensitive coloring composition contains a resin (A), a pigment (B), an active energy ray polymerization initiator (C), an active energy ray-curable monomer (D) and a solvent (E). The resin (A) contains a vinyl resin (F) in an amount of not less than 50% by weight, and the vinyl resin (F) contains a constituent unit (a) having a carboxyl group in an amount of 2-50% by weight, a constituent unit (b) having one or more cyclic structures, which are selected from the group consisting of aromatic rings represented by general formula (1), aromatic rings represented by general formula (2), aliphatic rings represented by general formula (3) and aliphatic rings represented by general formula (4), in an amount of 2-50% by weight, and other constituent units (c) in an amount of 10-80% by weight. (In general formulae (1) and (2), R represents a hydrogen atom or an alkyl group having 1-20 carbon atoms, which may have a benzene ring.)

Owner:TOYO INK SC HOLD CO LTD +1

A method of manufacturing square rectangular steel pipe with fins

The invention provides a method for manufacturing a finned square rectangular steel tube. The method comprises the following steps: (1) carrying out trimming on the inner angle of the end face of a welding edge, wherein the trimming angle phi is 45+ / -2 degrees, and the trimming left root h meets the equation: h=1 / 2 thickness of a plate+ / -0.5mm; (2) carrying out pre-profiling of cold bending on strip steel through a die, and forming the shape and corresponding size of a product preliminarily; (3) carrying out extruding welding through four rollers: using an upper extrusion roller, a lower extrusion roller, a left extrusion roller and a right extrusion roller for extrusion, and bending a side extrusion roller of a finned edge by 3-6 degrees for carrying out high-frequency welding on the end face of the welding edge and the surface of the inner side of the finned edge; (4) planning welding burrs: planning outer burrs through an arc blade and avoiding the finned edge, and regulating the angle of a planer tool until the included angle alpha 1 between the planer tool and the vertical direction of the finned edge is 6 degrees, wherein the angle alpha 2 of the bottom of a planer tool is 18 degrees; (5) carrying out sizing shaping: when the four rollers are sized and shaped in an extrusion mode, bending the side extrusion roller of the finned edge by 2-3 degrees, and enabling the angle of the finned edge to meet the standard requests. The product produced through the method is good in shape of the cross section, good in surface quality, free of scratch, good in planeness, and stable and qualified in welding.

Owner:HANKOU STEEL ROLLING MILL WUHAN IRON & STEEL CORP

A special-shaped cable and its preparation method

ActiveCN106653163BDistribute stressAvoid force breakingDetails of conductive coresManufacturing wire harnessesEngineeringAbnormal shaped

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

Positive photosensitive resin composition, method for forming patterned resist film, and patterned resist film

PendingCN112346302AOptimizing Section ShapeIncreased sensitivityPhotomechanical coating apparatusPhotomechanical exposure apparatusQuinonePolymer science

The invention relates to a positive photosensitive resin composition, a method for forming a patterned resist film, and a patterned resist film. The present invention addresses the problem of providing: a positive-type photosensitive resin composition which is capable of forming a patterned resist film having a good cross-sectional shape and has high sensitivity, a method for forming a patterned resist film using the positive-type photosensitive resin composition, and a patterned resist film formed from the positive photosensitive resin composition. A positive photosensitive resin compositioncomprising: a Novolac resin (A); a quinone diazido group-containing compound (B); a sensitizer (C) that is a compound having a phenolic hydroxyl group and having a molecular weight of 1000 or less; and a phenolic hydroxyl group-containing resin (D) in an amount within a predetermined range, the phenolic hydroxyl group-containing resin (D) being a resin having a weight average molecular weight of more than 1000 other than Novolac resin A.

Owner:TOKYO OHKA KOGYO CO LTD

Phase shift mask blank and method for manufacturing phase shift mask using the same and pattern transfer method

PendingCN108663896AEasy transferReduce absorptionPhotomechanical apparatusOriginals for photomechanical treatmentOptical propertyPhase difference

The present invention provides a phase shift mask blank capable of producing a phase shift mask which is capable of accurately transferring a high-definition phase shift film pattern. The phase shiftfilm of the present invention has at least a lower layer and an upper layer, the lower layer has a function of adjusting a reflectance for light incident from a side of the transparent substrate, theupper layer is disposed on an upper side of the lower layer and has a function of adjusting the transmittance and the phase difference of the exposure light, the phase shift film has a given optical characteristic for the transmittance and phase difference of the exposure light, and the phase shift film has a reflectance of more than 20% for light of a wavelength range of 365 nm to 436 nm incidentfrom the side of the transparent substrate, and the fluctuation range of the reflectance of light in the wavelength range of 365 nm to 436 nm incident from the transparent substrate side is 10% or less.

Owner:HOYA CORP

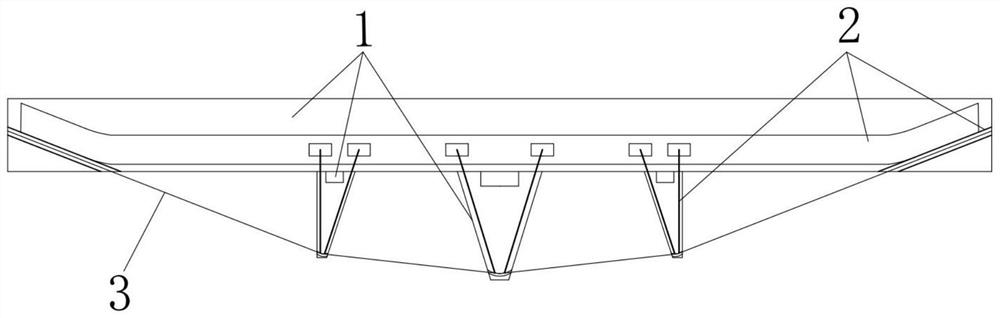

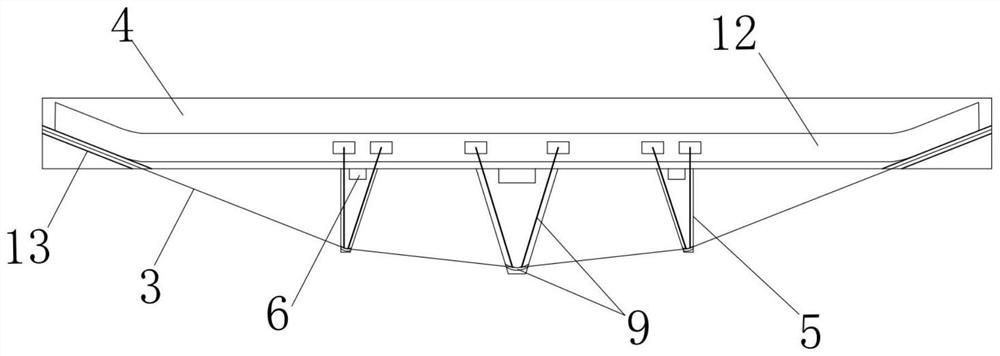

Large-span light subway evacuation platform plate and manufacturing process thereof

PendingCN114658477AImprove carrying capacityImprove deformation resistanceCeramic shaping mandrelsCeramic shaping coresCrack resistancePre stress

The invention discloses a large-span light subway evacuation platform plate and a manufacturing process thereof, and belongs to the technical field of assembly. In order to solve the problems that the construction speed is affected due to the fact that an existing subway evacuation platform plate is large in weight, difficult to assemble and small in span, and fire resistance, cracking resistance, corrosion resistance and the like cannot be considered at the same time, a novel light-weight high-strength concrete material is developed, and the platform plate takes the novel material as a base body, takes a hollow ribbed structure as a plate type and takes basalt fiber woven ribs as prestressed ribs; rib feet are arranged, a steel pipe system is embedded, and prestress is applied to the lower portion of the plate, so that the hollow plate, the steel pipe system and prestressed tendons form a balance system, and the bottom face of the main plate is pressed but not pulled. The limitation that prestress cannot be applied in an existing platform plate due to plate thickness limitation is broken through. The advantages of materials, prestress and a combined structure are fully exerted, and the manufactured platform plate has the characteristics of light weight, large span, fire resistance, cracking resistance, erosion resistance and the like, and has remarkable economic benefits and wide engineering applicability.

Owner:HARBIN INST OF TECH

Photo sensitive resin compositon, optical spacer, protective film, coloring pattern, display device and substrate thereof

ActiveCN101470350BHigh sensitivityExcellent mechanical propertiesPhotomechanical apparatusLiquid stateSide chain

The present invention relates to a photosensitive resin compound, an optical spacer, a protective film, a coloring pattern, a display device and a substrate thereof. The photosensitive resin compound provided by the invention comprises the following components: (A) a resin which is provided with branched structure and / or alicyclic ring structure on the side chain, acidic group and substituted alkyl that is provided with two ethylenic linkage type unsaturated bonds, (B) a polymeric compound which is provided with ethylenic linkage type unsaturated bond, and (C) a photopolymerization initiatingagent. The photosensitive resin compound can form a pattern structure or protective film which has the advantages of high sensitivity, excellent storability in liquid state, excellent ageing stability and mechanical characteristic of photosensitive film after film forming.

Owner:FUJIFILM CORP

Focused ion beam processing apparatus

ActiveUS20210296080A1Easy to operateOptimizing Section ShapeElectric discharge tubesIon beam processingOphthalmology

Provided is a focused ion beam processing apparatus including: an ion source; a sample stage a condenser lens; an aperture having a slit in a straight line shape; a projection lens and the sample stage, wherein, in a transfer mode, by Köhler illumination, with an applied voltage of the condenser lens when a focused ion beam is focused on a main surface of the projection lens scaled to be 100, the applied voltage is set to be less than 100 and greater than or equal to 80; a position of the aperture is set such that the focused ion beam is masked by the aperture with the one side of the aperture at a distance greater than 0 μm and equal to or less than 500 μm from a center of the focused ion beam; and the shape of the slit is transferred onto the sample.

Owner:HITACHI HIGH TECH SCI CORP

A photosensitive resin composition and a method forming a pattern using the same

ActiveCN101794073BOptimizing Section ShapeReduce processSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusQuinonePolymer science

Provided is a photosensitive resin composition, which has short drying time, no coating unevenness and uniform coating film thickness when the pressure reduction drying or vacuum drying method are not adopted to perform natural drying after narrow slit coating, and has good against corrosion pattern shape after exposure and developing. The photosensitive resin composition adopting a photosensitive resin composition containing alkali soluble phenolic resin, photosensitizer containing quinone diazido, and a mixed solvent of propylene glycol monomethyl ether acetate (A) and a solvent (B) whose boiling point is below 145 DEG C and n-butyl acetate evaporation velocity is more than 50, is coated on the substrate through a narrow slit coating method, dried without adopting a pressure reduction drying or vacuum drying method, and then exposure and developing are performed to form anticorrosion patterns.

Owner:MERCK PATENT GMBH

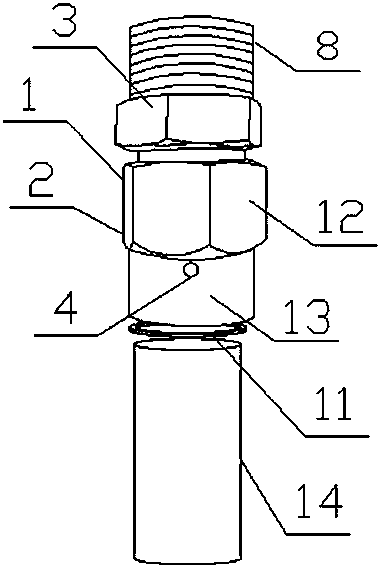

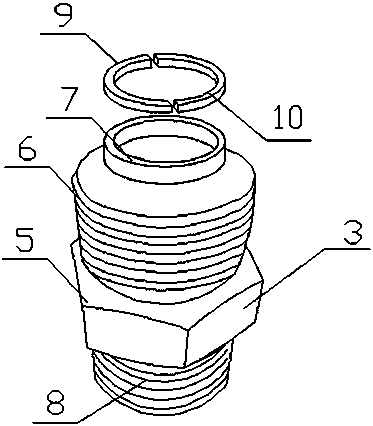

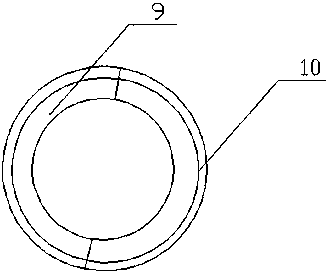

Hard seal corrugated pipe rapid connector with detection function

The invention discloses a hard seal corrugated pipe rapid connector with a detection function. The connector comprises a rapid connector body, a thread head, a seal ring, a first clamping ring and a second clamping ring, wherein the rapid connector body and the thread head are mutually matched. The rapid connector body comprises a thread sleeve and a bottom sleeve connected to one end of the thread sleeve. A detection hole is formed in the outer circumference of the bottom sleeve, and an internal thread is arranged on the inner circumferential wall of the thread sleeve. The thread head comprises a thread head hexagonal prism, a first thread rod and a second thread rod, the end of the first thread rod is provided with an arc face, the top of the arc face is provided with a positioning ring,the first thread rod is matched with the internal thread on the inner circumferential wall of the thread sleeve, the positioning ring is used for being inserted into a corrugated pipe to be connectedto achieve positioning, the first clamping ring and the second clamping ring are located on the two sides of the positioning ring correspondingly and used for clamping the corrugated pipe to be connected to the outer circumferential wall of the positioning ring, the inner diameter of the bottom sleeve is smaller than that of the thread sleeve, a step portion is formed at the combined portion between the thread sleeve and the bottom sleeve, and the step portion is provided with the seal ring.

Owner:王睿

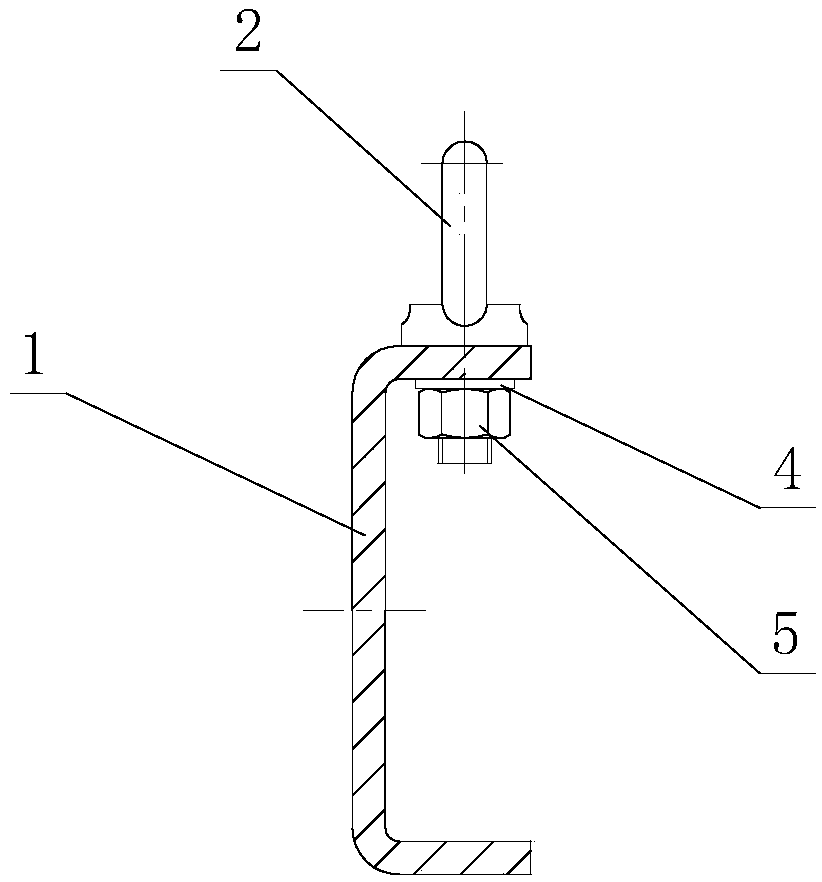

Dry type transformer aluminum alloy clamp

PendingCN108777221AIncreased contact corrosionReduce contact corrosionTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerThermal expansion

A dry type transformer aluminum alloy clamp includes an upper clamp part and a lower clamp part which are made by 6061-T6 aluminum alloy to replace steel-structure clamps commonly used nowadays. The surface of 6061-T6 aluminum alloy is subjected to anodic oxidation treatment, the thickness of an anodic oxide film is 8-10 micrometers, and the corrosion resistance of the surfaces of the upper clamppart and the lower clamp part can be largely improved. Finite element modeling is used for calculating the strength of the upper clamp part and the lower clamp part, the lifting, hoisting and swinging, transportation and turnover conditions of a dry type transformer clamped by the upper clamp part and the lower clamp part are calculated, the cross-sectional shapes of the upper and lower clamp parts are optimized, and the cost of the upper and lower clamp parts is reduced. By omitting the use of welding of the upper and lower clamp parts, the strength of the upper and lower clamp parts is increased; elastic washers are added at the positions of iron core clamping, coil pressing and steel structure bolt connection parts so as to compensate for clamping-force reduction caused by thermal expansion and cold contraction, zinc plating or zinc-nickel plating anticorrosive treatment is adopted for the surfaces of steel-structure parts and steel fasteners making contact with aluminum alloy clamps, the thickness of a plating layer is 8-12 micrometers, and the bimetallic contact corrosion degree of aluminum alloy is reduced.

Owner:顺特电气设备有限公司

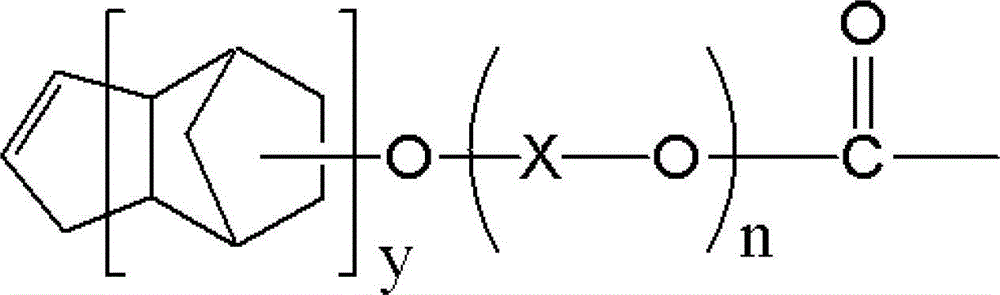

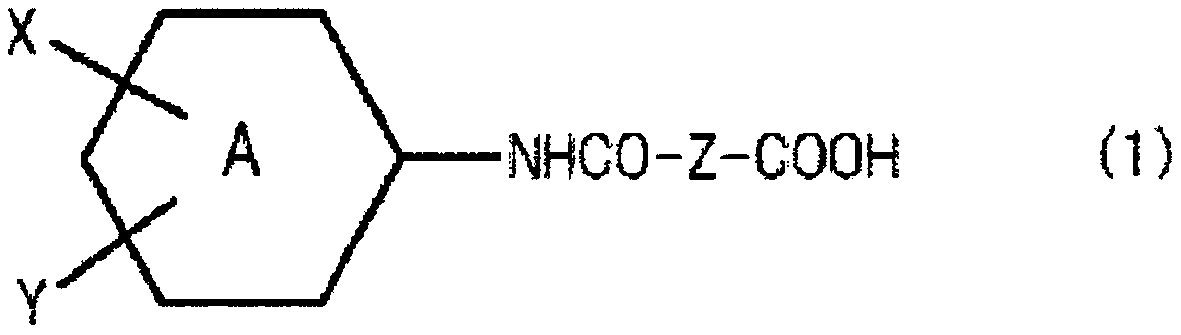

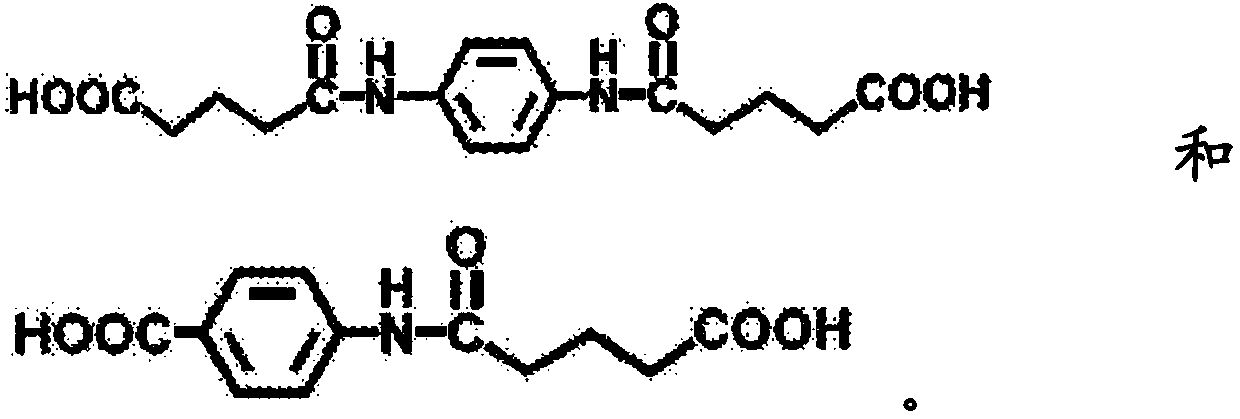

Resist underlayer film-forming composition comprising amide group-containing polyester

InactiveCN109843852AFull anti-reflection functionGood solvent resistanceOrganic chemistryPhotomechanical exposure apparatusPolyesterResist

Provided is a resist underlayer film-forming composition which is capable of providing a resist underlayer film, said resist underlayer film exerting a sufficient anti-reflection function particularlyin a KrF process, a high solvent resistance and a high dry etching speed, and enables the formation of a photoresist pattern having a good cross-sectional shape. The resist underlayer film-forming composition comprises a copolymer which contains: structural unit (A) derived from a diepoxy compound; and structural unit (B) derived from a compound represented by formula (1) [wherein: A represents abenzene ring or a cyclohexane ring; X represents a hydrogen atom, an alkyl or alkoxy group having 1 to 10 carbon atoms and optionally substituted by a halogen atom, or an alkoxycarbonyl group having2 to 11 carbon atoms; and Y represents -COOH or -L-NHCO-Z-COOH (wherein: Z represents an alkylene group having 3 to 10 carbon atoms and optionally substituted by an oxygen atom, a sulfur atom or a nitrogen atom; and L represents a single bond or a spacer)].

Owner:NISSAN CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com