Positive photosensitive resin composition, method for forming patterned resist film, and patterned resist film

A technology of photosensitive resin and composition, which is applied in the field of resist film, can solve problems such as insufficient resolution and resist pattern peeling, and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0122]

[0123] The positive-type photosensitive resin composition can be prepared by mixing and stirring each of the above-mentioned components in a predetermined ratio, followed by mixing and stirring by a normal method. In addition, filtration may be further performed using a mesh, a membrane filter, or the like as necessary.

[0124] "Formation Method of Patterned Resist Film"

[0125] The patterned resist film can be formed by a method including the following steps:

[0126] A step of coating the aforementioned positive photosensitive resin composition on a substrate to form a coating film;

[0127] A step of exposing the coating film in a regioselective manner; and,

[0128] A process of developing the exposed coating film with a developing solution.

[0129] Coating of the positive photosensitive resin composition to the substrate is performed using a spin coater, roll coater, spray coater, slit coater, or the like. The coating device is not limited to these. Usu...

Embodiment 1~10、 and comparative example 1~6

[0138] In Examples and Comparative Examples, as the Novolac resin (A) ((A) component), a cresol Novolac resin (weight average molecular weight 6000) having a mass of m-cresol / p-cresol of 36 / 64 was used.

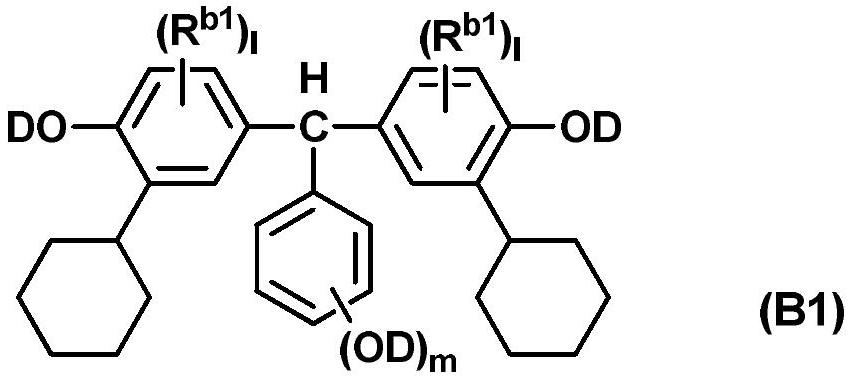

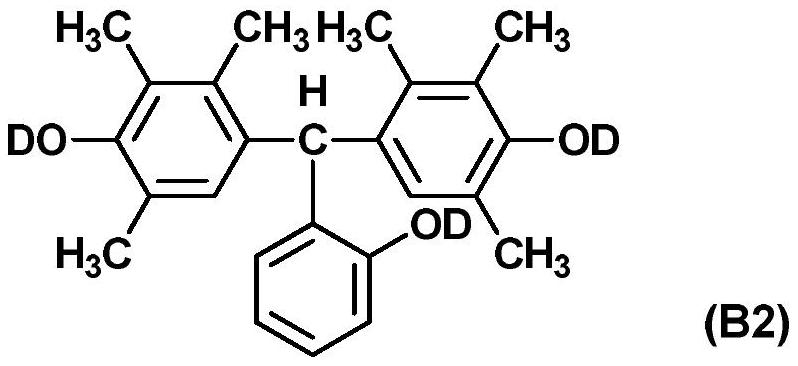

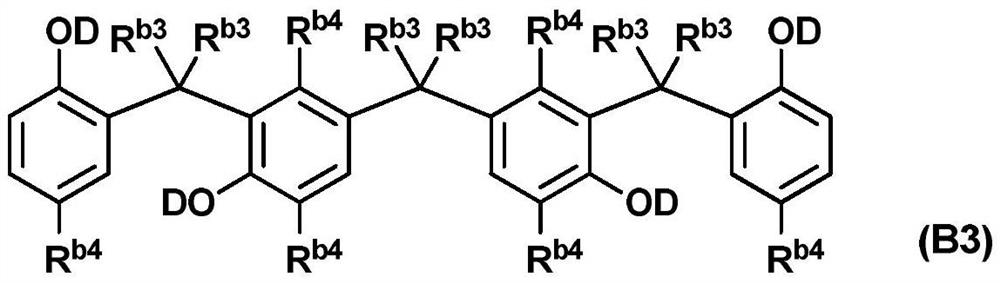

[0139] In Examples and Comparative Examples, the following B-I, B-II, and B-III were used as the quinonediazide group-containing compound (B) ((B) component). B-I belongs to the compound represented by the aforementioned formula (B1). B-II belongs to the compound represented by the aforementioned formula (B2). B-III belongs to the compound represented by the aforementioned formula (B3). It should be noted that, with regard to the average introduction rate of the quinonediazide group of each compound (referring to the average, how many moles of the substituent OD are substituted by the quinonediazide group), B-I is 2.1 moles, and B-II 1.7 moles for B-III and 2.5 moles for B-III.

[0140] [chemical formula 6]

[0141]

[0142] In Examples and Comparative Examples, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com