Photo sensitive resin compositon, optical spacer, protective film, coloring pattern, display device and substrate thereof

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve problems such as difficulty in obtaining spacer shape and film thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0285] Hereinafter, although an Example demonstrates this invention more concretely, unless the summary is exceeded, this invention is not limited to a following Example. In addition, "part" is based on mass unless otherwise indicated.

[0286] In addition, the weight average molecular weight is measured using gel permeation chromatography (GPC). For GPC, HLC-8020GPC (manufactured by TOSOH Co., Ltd.) was used. Three TSKgel and Super Multipore HZ-H (manufactured by TOSOH Co., Ltd., 4.6 mmID×15 cm) were used as columns, and THF (tetrahydrofuran) was used as an eluent. In addition, as conditions, the sample concentration was set to 4.5% by mass, the flow rate was set to 0.35 ml / min, the sample injection volume was set to 10 μl, and the measurement temperature was set to 40° C., and the measurement was performed using an IR detector. In addition, the calibration curve is "Standard sample TSK standard, polystyrene" manufactured by TOSOH Corporation: "F-40", "F-20", "F-4", "F-1", "...

Synthetic example 1

[0290] (Synthesis of Exemplary Compound PD-52)

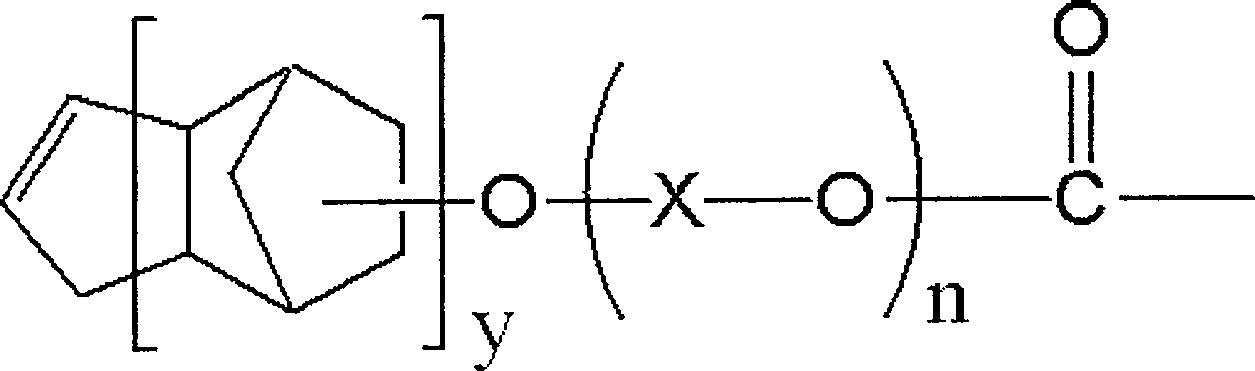

[0291] 7.48 parts of 1-methoxy-2-propanol (manufactured by MFG, Nippon Emulsifier Co., Ltd.) was previously added to the reaction vessel, the temperature was raised to 90°C, and the reaction vessel was added dropwise to the reaction vessel at 90°C over 2 hours under a nitrogen atmosphere. 3.1 parts of styrene (St), 4.28 parts of tricyclopentenyl methacrylate (TCPD-M manufactured by Hitachi Chemical Industry Co., Ltd.; x), 11.7 parts of methacrylic acid (MAA; y), and an azo polymerization initiator (Wako Pure Chemical Industries, Ltd., V-601) 2.08 parts and 55.2 parts of 1-methoxy-2-propanol. After dripping, it was made to react for 4 hours, and the acrylic resin solution was obtained.

[0292] Next, 0.15 parts of hydroquinone monomethyl ether and 0.34 parts of tetraethylammonium bromide were added to the above-mentioned acrylic resin solution, and then 26.4 parts of glycidyl methacrylate (GLM, manufactured by Tokyo Chemical Ind...

Synthetic example 2

[0297] (Synthesis of Exemplary Compound PU-52)

[0298] 7.48 parts of 1-methoxy-2-propanol (manufactured by MFG, Nippon Emulsifier Co., Ltd.) was previously added to the reaction vessel, the temperature was raised to 90°C, and the reaction vessel was added dropwise to the reaction vessel at 90°C over 2 hours under a nitrogen atmosphere. 3.1 parts of styrene (St), 4.28 parts of tricyclopentenyl methacrylate (TCPD-M manufactured by Hitachi Chemical Industry Co., Ltd.; x), 11.7 parts of methacrylic acid (MAA; y), and an azo polymerization initiator (Wako Pure Chemical Industries, Ltd., V-601) 2.08 parts and 55.2 parts of 1-methoxy-2-propanol. After dripping, it was made to react for 4 hours, and the acrylic resin solution was obtained.

[0299] Next, 0.15 parts of hydroquinone monomethyl ether and 0.34 parts of tetraethylammonium bromide were added to the above-mentioned acrylic resin solution, and then 26.4 parts of glycidyl methacrylate (GLM, manufactured by Tokyo Chemical Ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com