High-energy electric pulse strip shape regulation and control method for high-hardness and high-brittleness cold-rolled strip

A cold-rolled strip, electric pulse technology, applied in metal rolling, profile control, metal rolling, etc., to achieve the effect of facilitating thickness accuracy control, reducing deflection and flattening, and reducing rolling pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

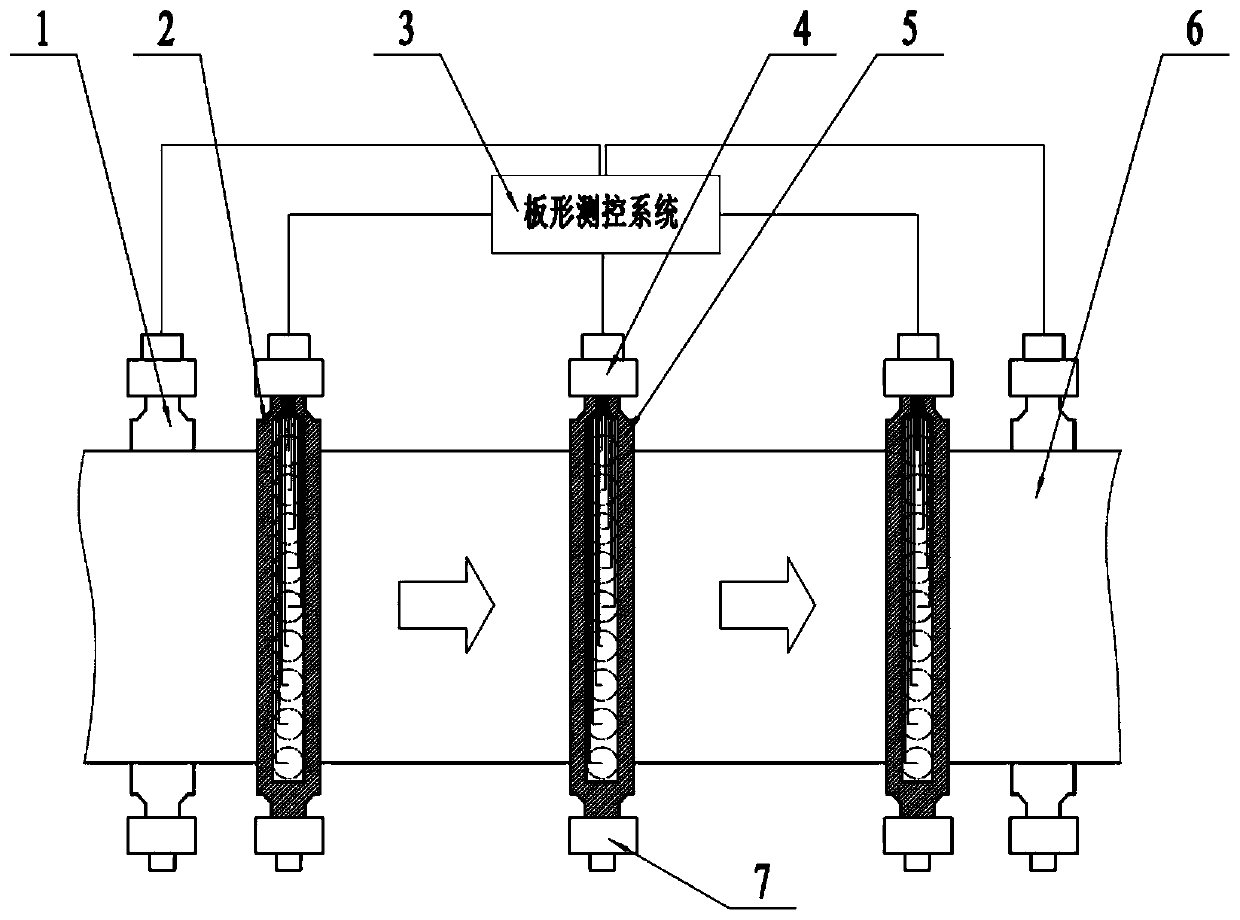

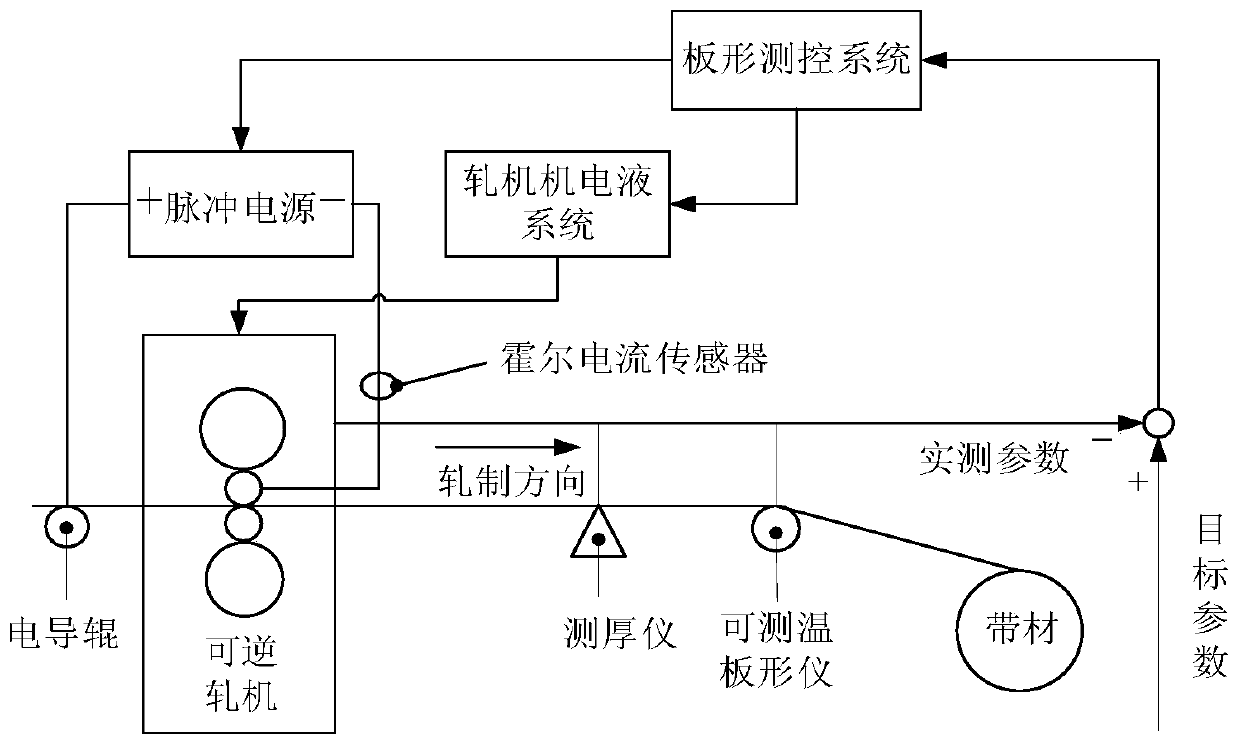

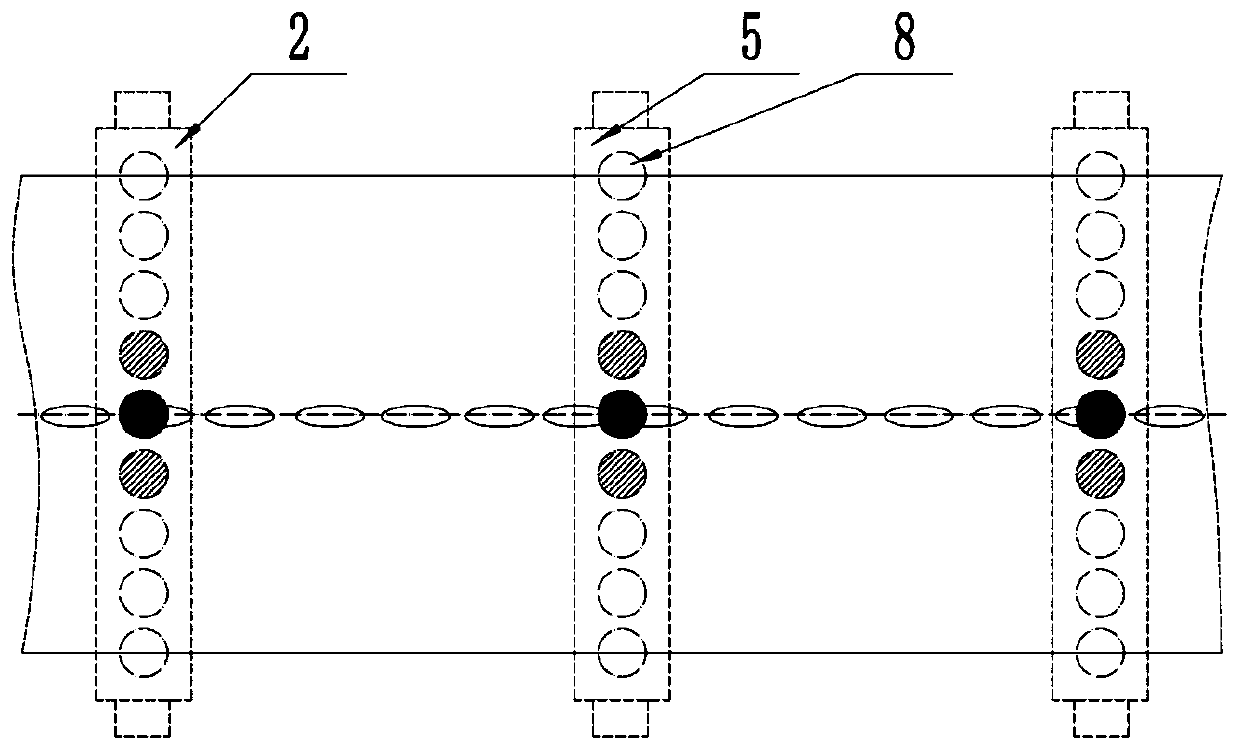

[0058] The rolling object of the embodiment of the present invention is a high-brittle AZ31 magnesium alloy strip, such as figure 1 As shown, the rolling device used in the embodiment of the present invention includes a temperature-measurable flatness detection roll 1 , a conductive roll 2 , a flatness measurement and control system 3 and an electric roll 5 .

[0059] figure 1 It is the schematic diagram of the high-energy electric pulse shape control principle diagram of the embodiment of the present invention. The measurement and control method of the present invention controls the current value of the corresponding loop between the electric roll 5 and the conductive roll 2, and uses the high-energy pulse current to control the temperature of the strip in sections to realize A new on-line shape control, the operation process of this method is as follows Figure 5 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com