Cement-based shrinkage-free wall hole-penetrating blocking material and preparation method and construction method

A technology of sealing materials and construction methods, applied in the direction of building insulation materials, building materials processing, building components, etc., can solve the problems of external wall leakage, hidden quality problems, low efficiency, etc., to ensure the sealing of the wall, Good effect of preventing moisture infiltration and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

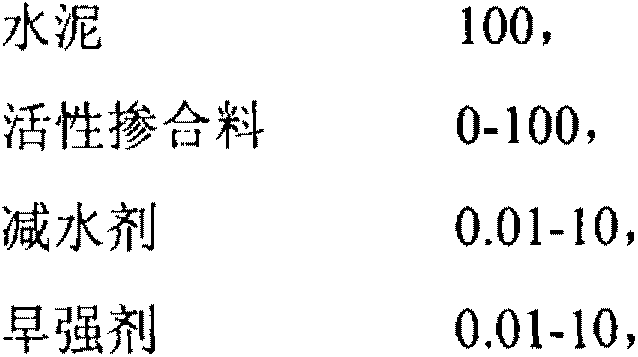

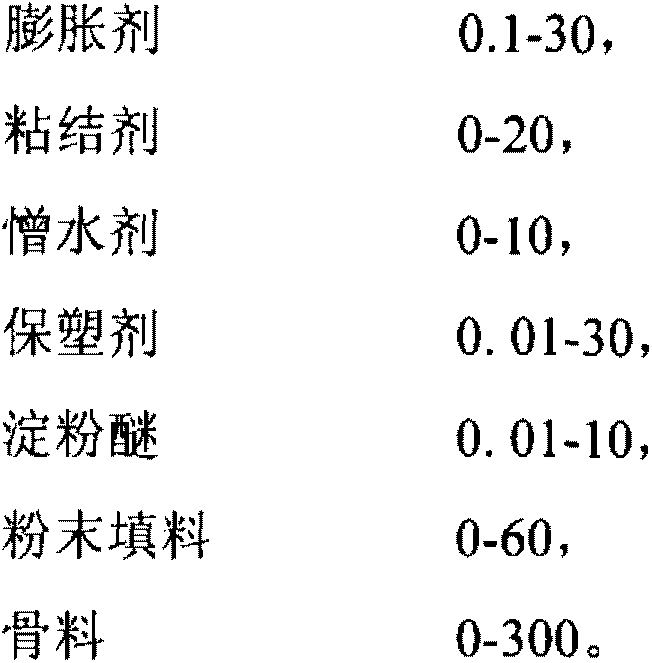

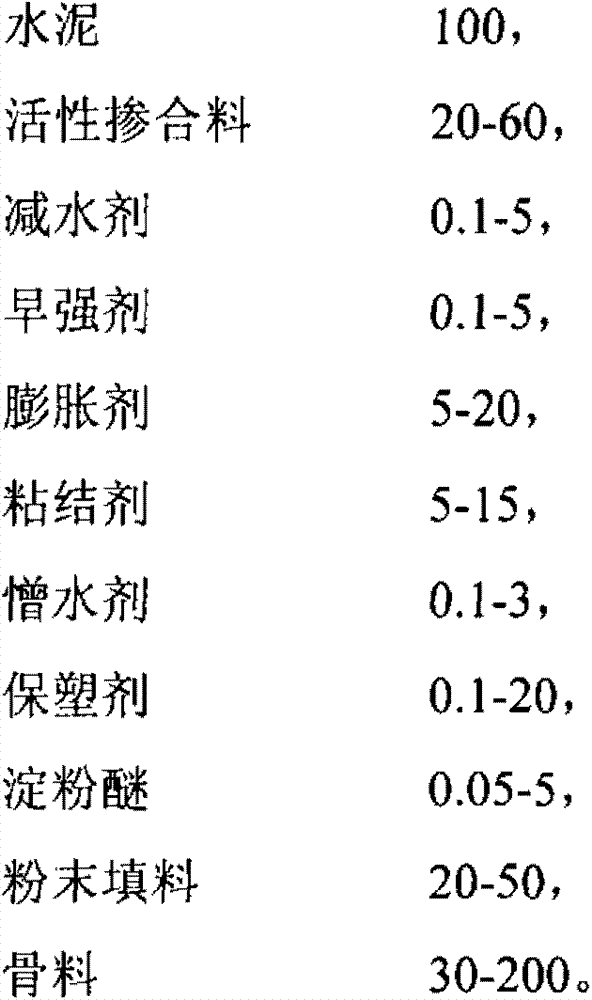

Embodiment 1

[0039]

[0040]

[0041] Preparation method: Weigh various raw materials according to the formula, add aggregate (graded quartz sand), powder filler (calcium carbonate powder), cement (P.O42.5 ordinary Portland cement), active blending Material (slag fine powder), water reducer (naphthalene series high-efficiency water reducer), early strength agent (anhydrous sodium sulfate), expansion agent (UEA expansion agent), binder (ethylene / vinyl acetate latex powder), hydrophobic Water agent (silicone powder), plasticizer (methyl cellulose) starch ether, fully stirred evenly, and packaged to form a product.

[0042] The construction method is as follows:

[0043] ①Clean and moisten the hole through the wall before the sealing construction, and blow off the floating water with compressed air.

[0044] ② Add water to the cement-based sealing material according to the ratio requirements, the amount of water added is 17% of the dry powder weight of the sealing mortar, and use a han...

Embodiment 2

[0052]

[0053]

[0054] Preparation method: Weigh various raw materials according to the formula, add aggregate (graded quartz sand, expanded perlite), cement (sulfoaluminate cement 42.5 grade), active admixture (silica fume), Water reducer (melamine high-efficiency water reducer), early strength agent (sodium silicate), expansion agent (calcium oxide), water repellent (organic silicon powder), plastic retainer (bentonite, hydroxyethyl cellulose ether), Modified starch ether, fully stirred evenly, packaged to form a dry powder product. The binding agent is weighed by comparison, and packaged to form a liquid product.

[0055] The construction method is as follows:

[0056] ①Clean and moisten the hole through the wall before the sealing construction, and blow off the floating water with compressed air.

[0057]②According to the ratio requirements, weigh the sealing material dry powder and liquid product in proportion, take water according to 20% of the weight of the dr...

Embodiment 3

[0065]

[0066]

[0067] Preparation method: Weigh various raw materials according to the formula, add aggregate (graded quartz sand), cement (P.O42.5 ordinary Portland cement), active admixture (fly ash), reducing Water agent (naphthalene-based high-efficiency water reducer), early strength agent (calcium formate), expansion agent (UEA expansion agent), binder (copolymer latex powder of vinyl acetate and higher fatty acid vinyl ester), water repellent (organic silicon powder), plastic retaining agent (diatomaceous earth, lignocellulose), starch ether, fully stirred evenly, and packaged to form a product.

[0068] The construction method is as follows:

[0069] ①Clean and moisten the hole through the wall before the sealing construction, and blow off the floating water with compressed air.

[0070] ② Add water to the cement-based sealing material according to the ratio requirements, the amount of water added is 25% of the dry powder weight of the sealing mortar, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com