Patents

Literature

75results about How to "Reliable winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

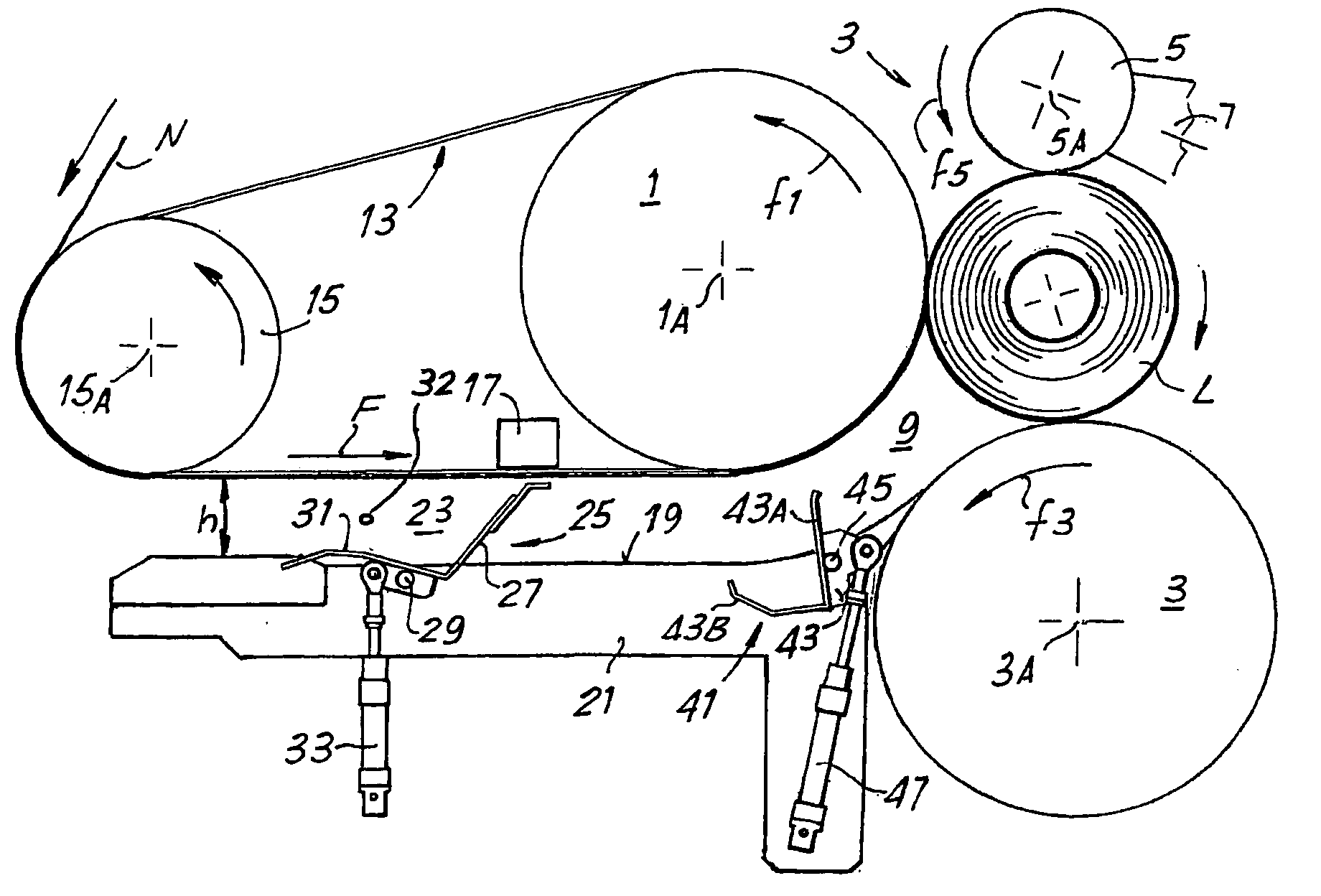

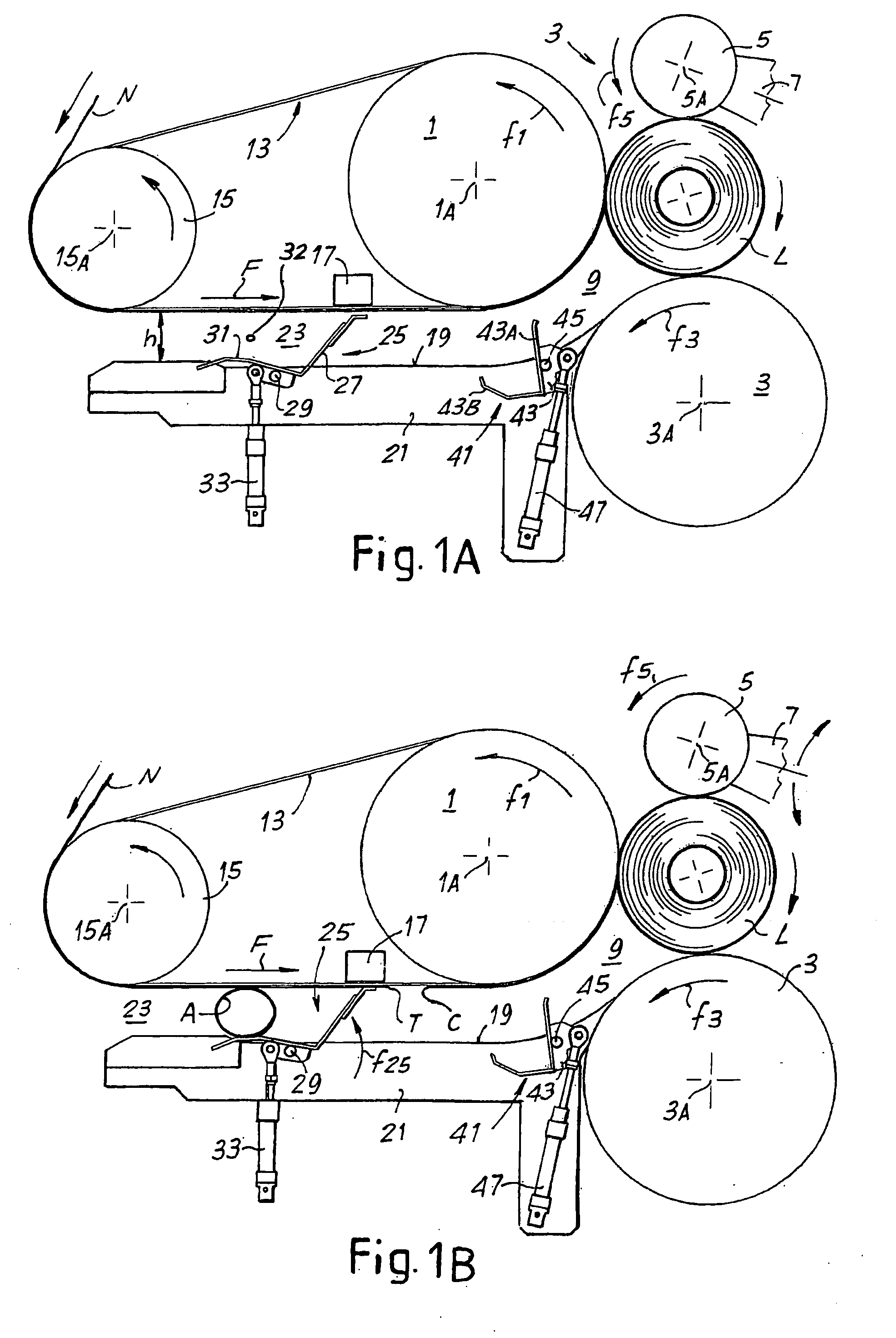

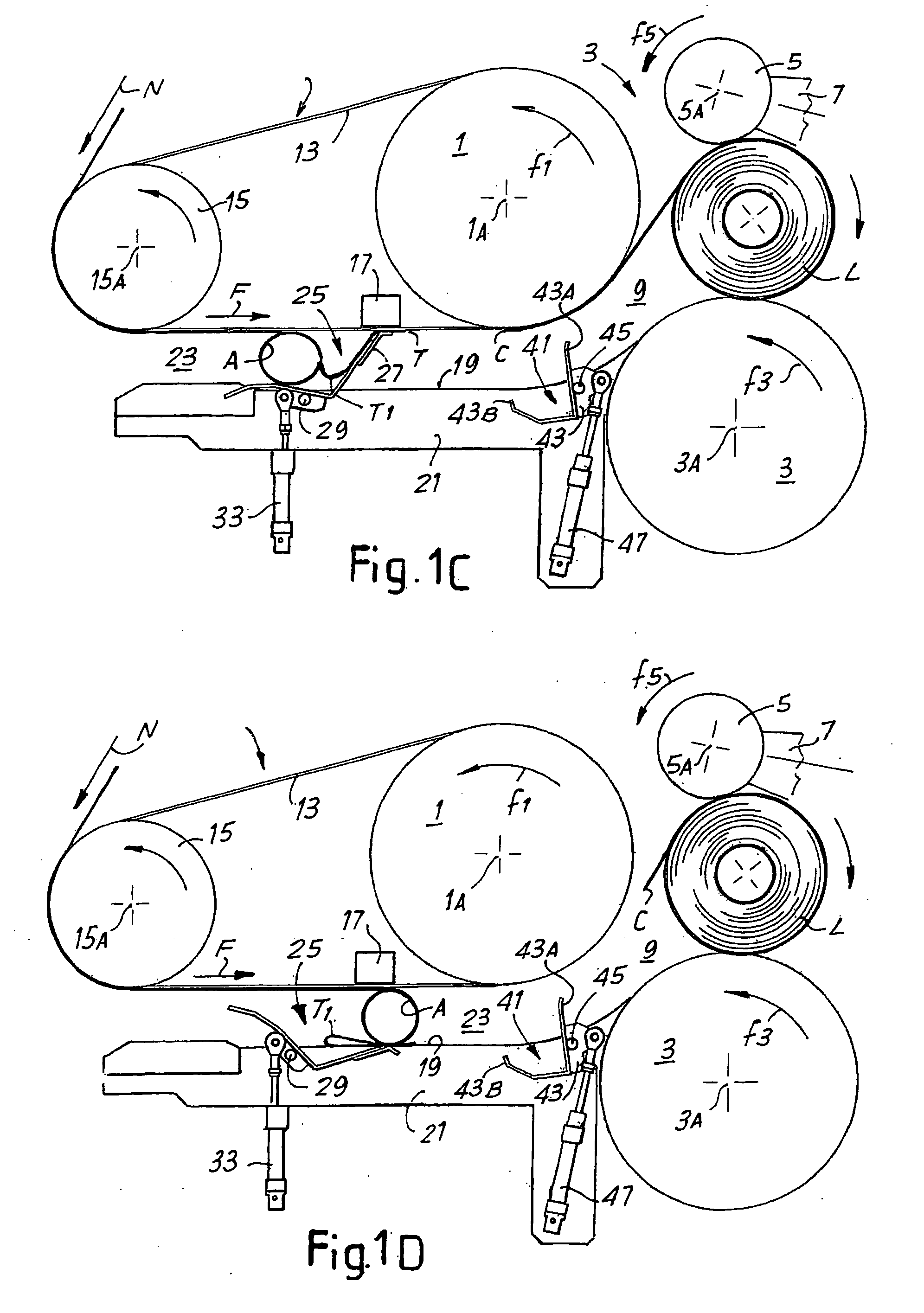

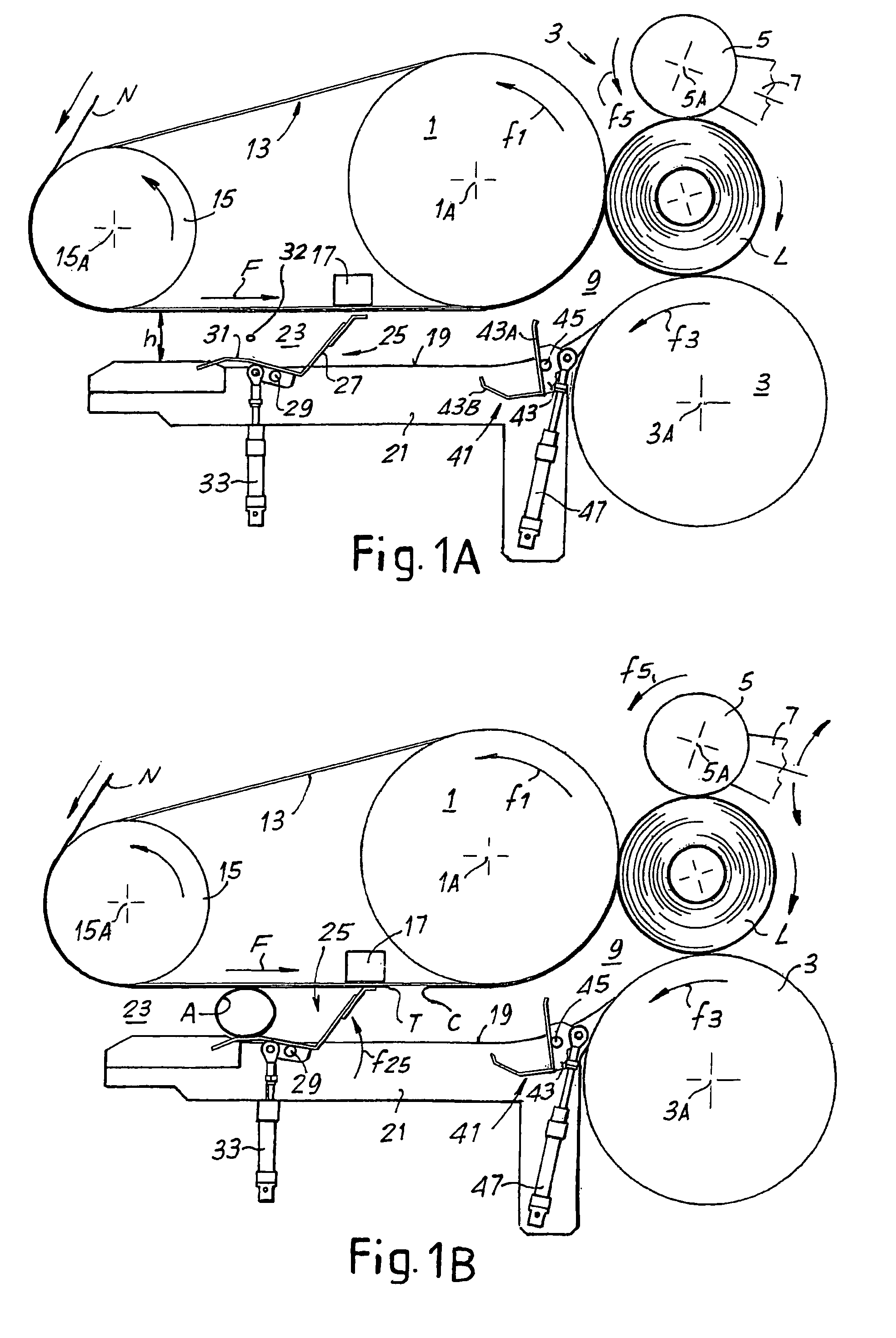

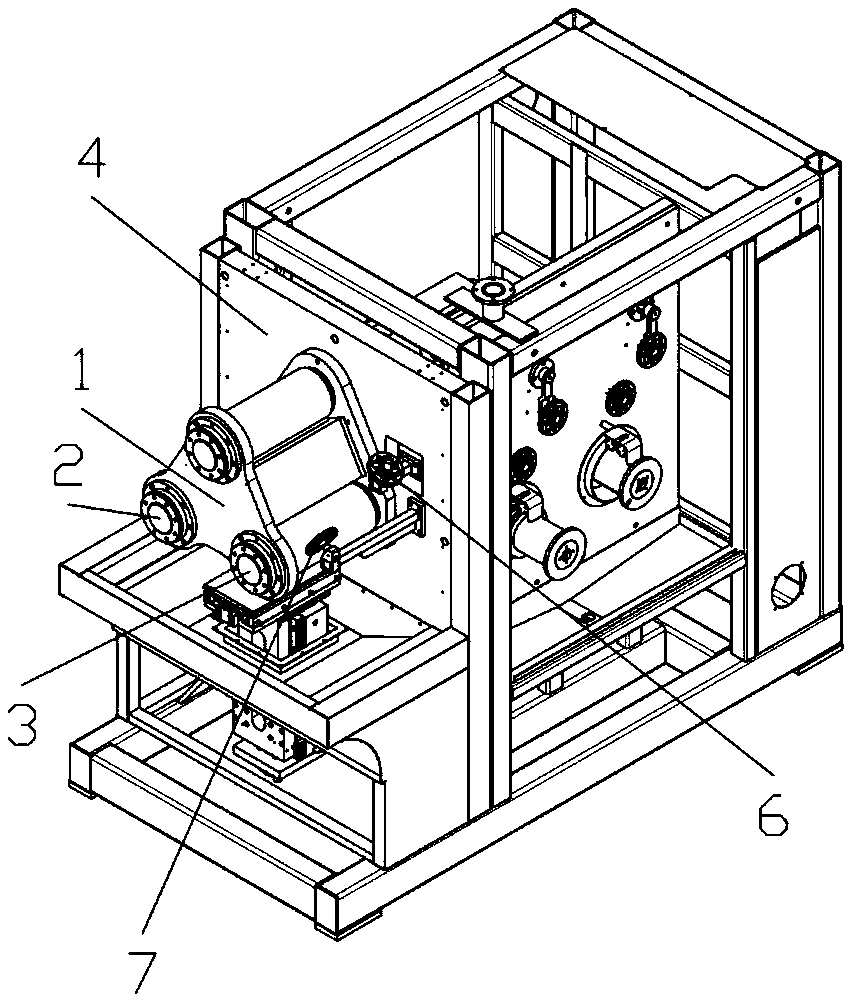

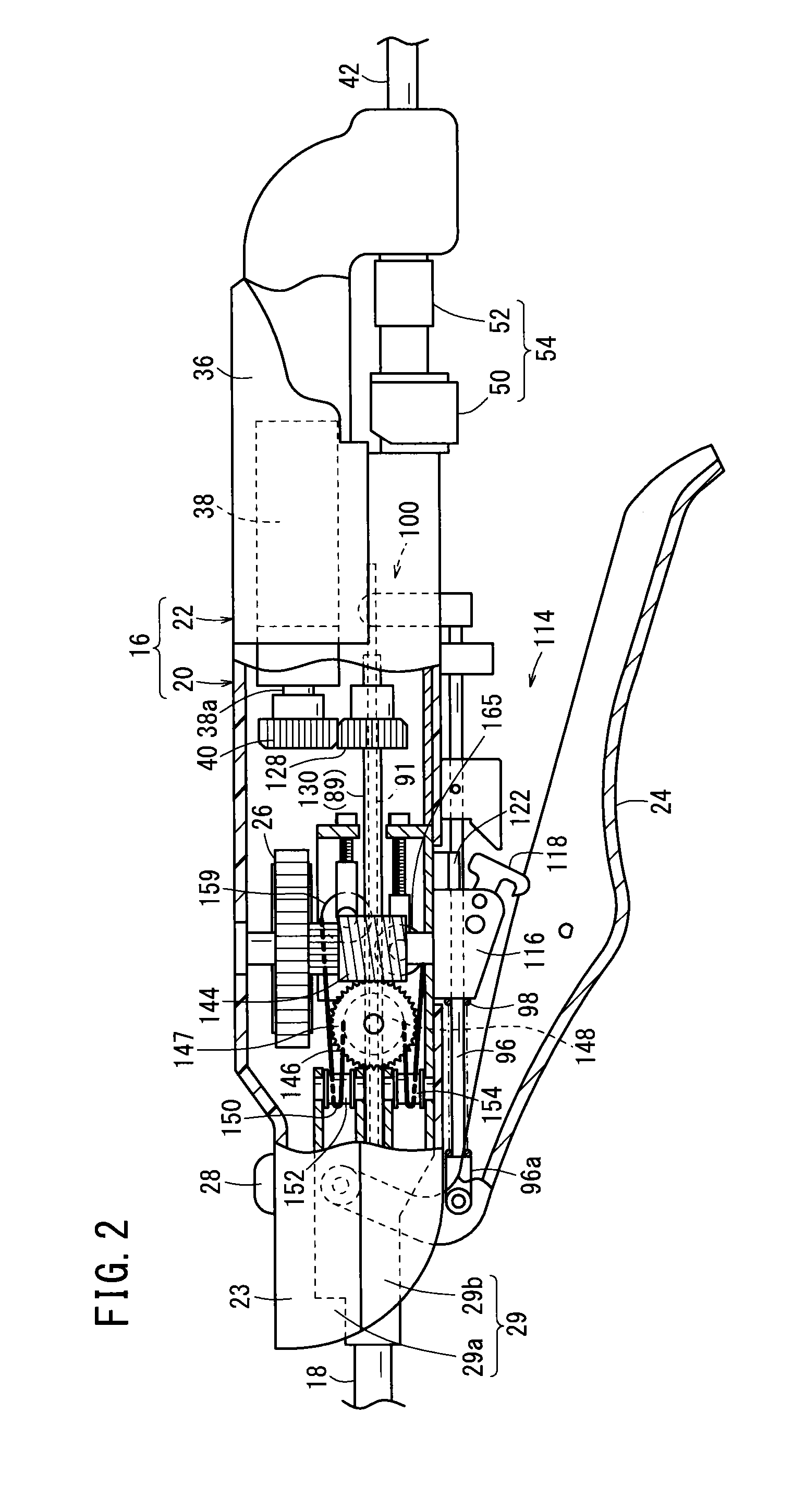

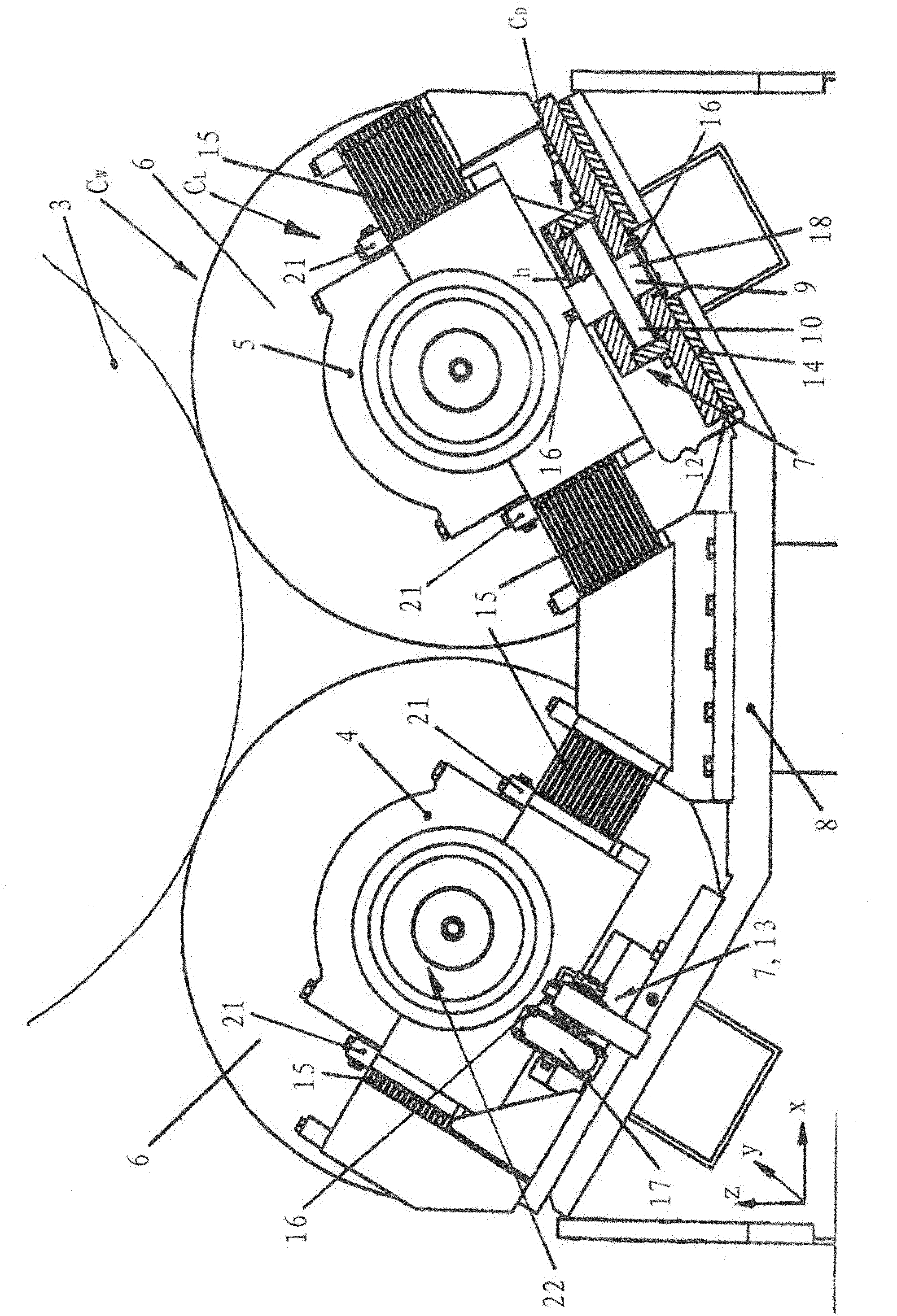

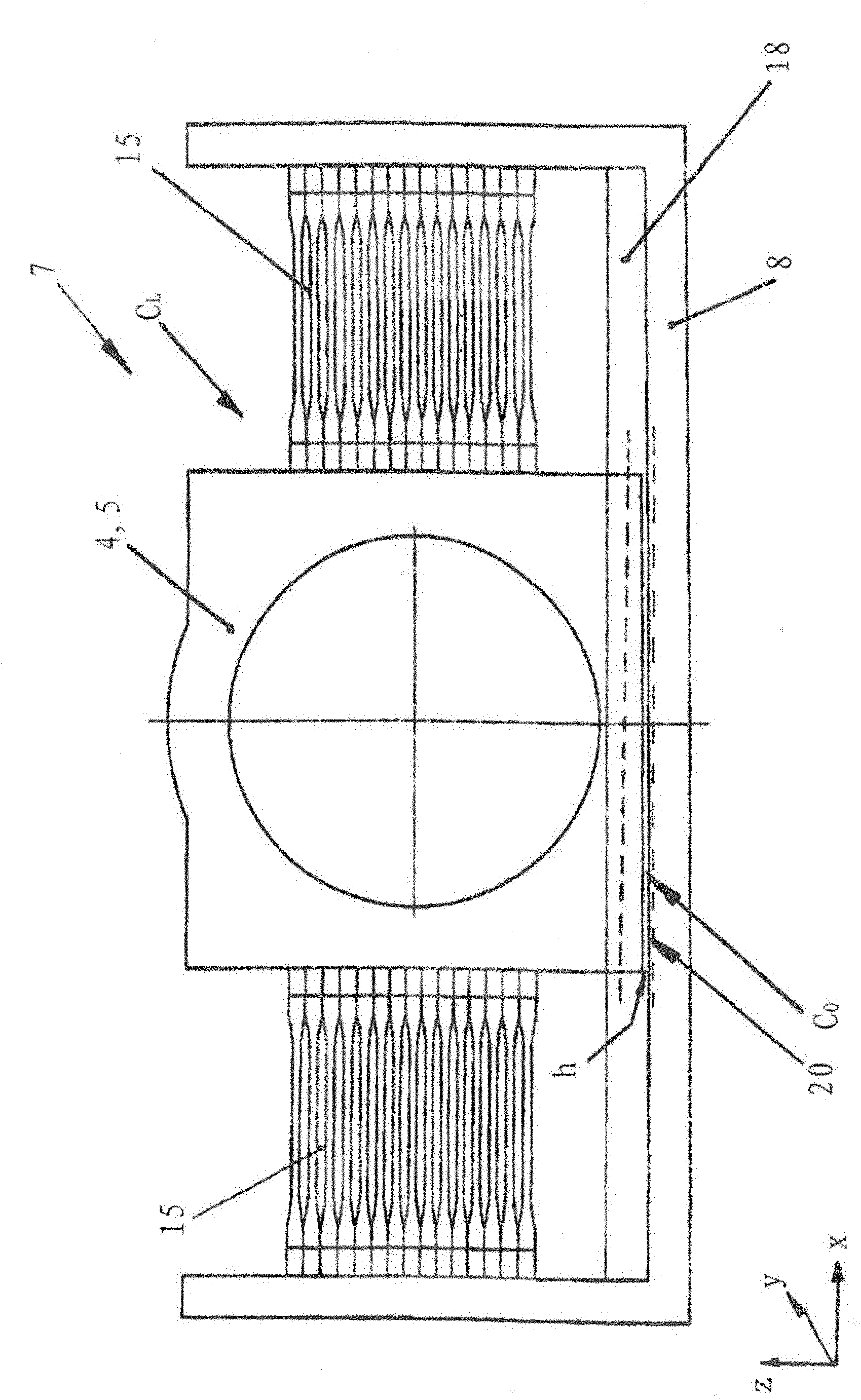

Method and Machine for Forming Logs of Web Material, with a Mechanical Device for Forming the Initial Turn of the Logs

ActiveUS20090272835A1Overcomes drawbackReliable windingFilament handlingArticle deliveryEngineeringMechanical engineering

The rewinding machine includes a winding unit; a feed path of a web material; a separator device to sever the web material upon completion of winding each log; an insertion path of the winding cores towards the winding unit; a movable mechanical member to facilitate forming a first turn of web material around each winding core inserted in the insertion path.

Owner:FABIO PERINI SPA

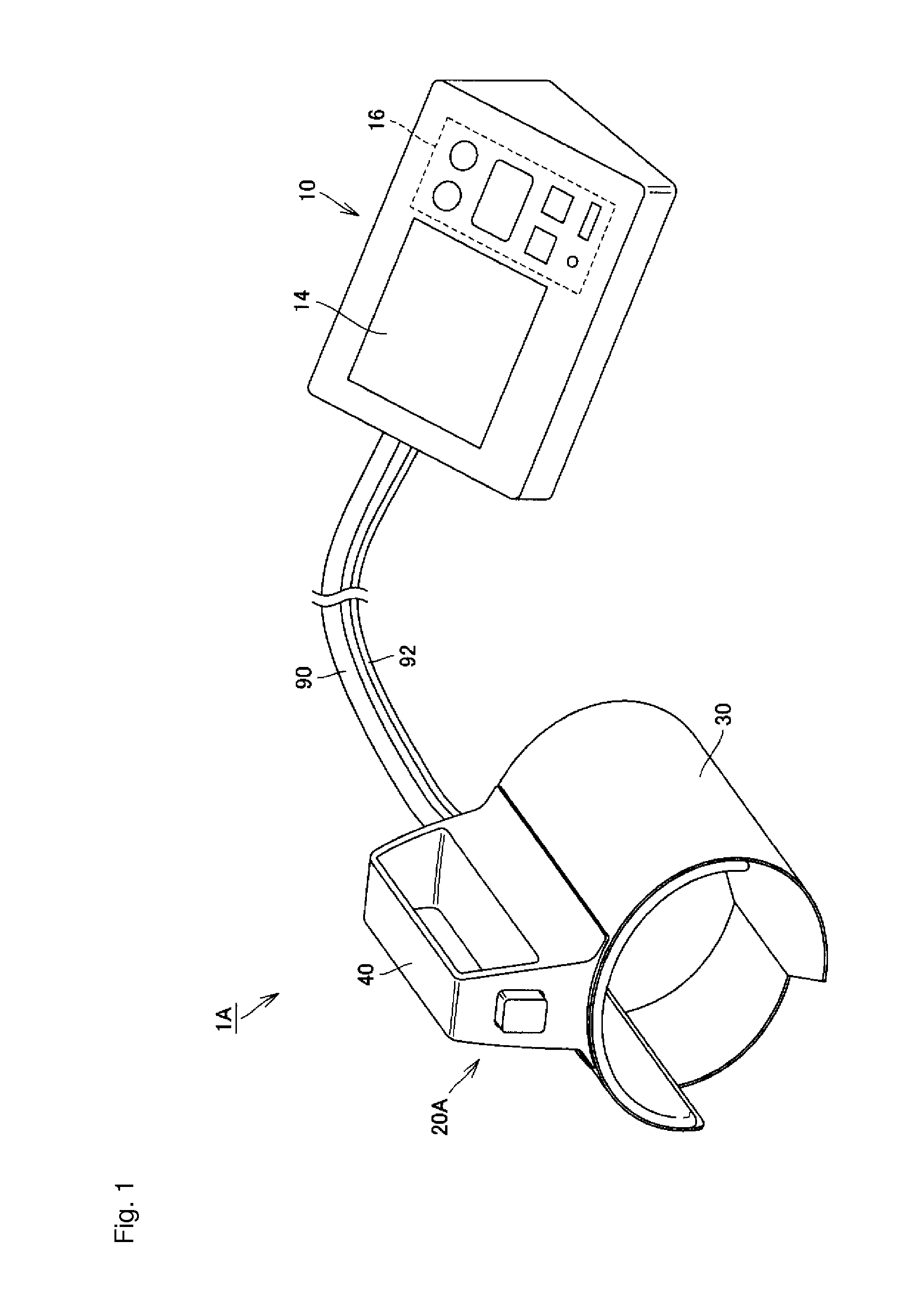

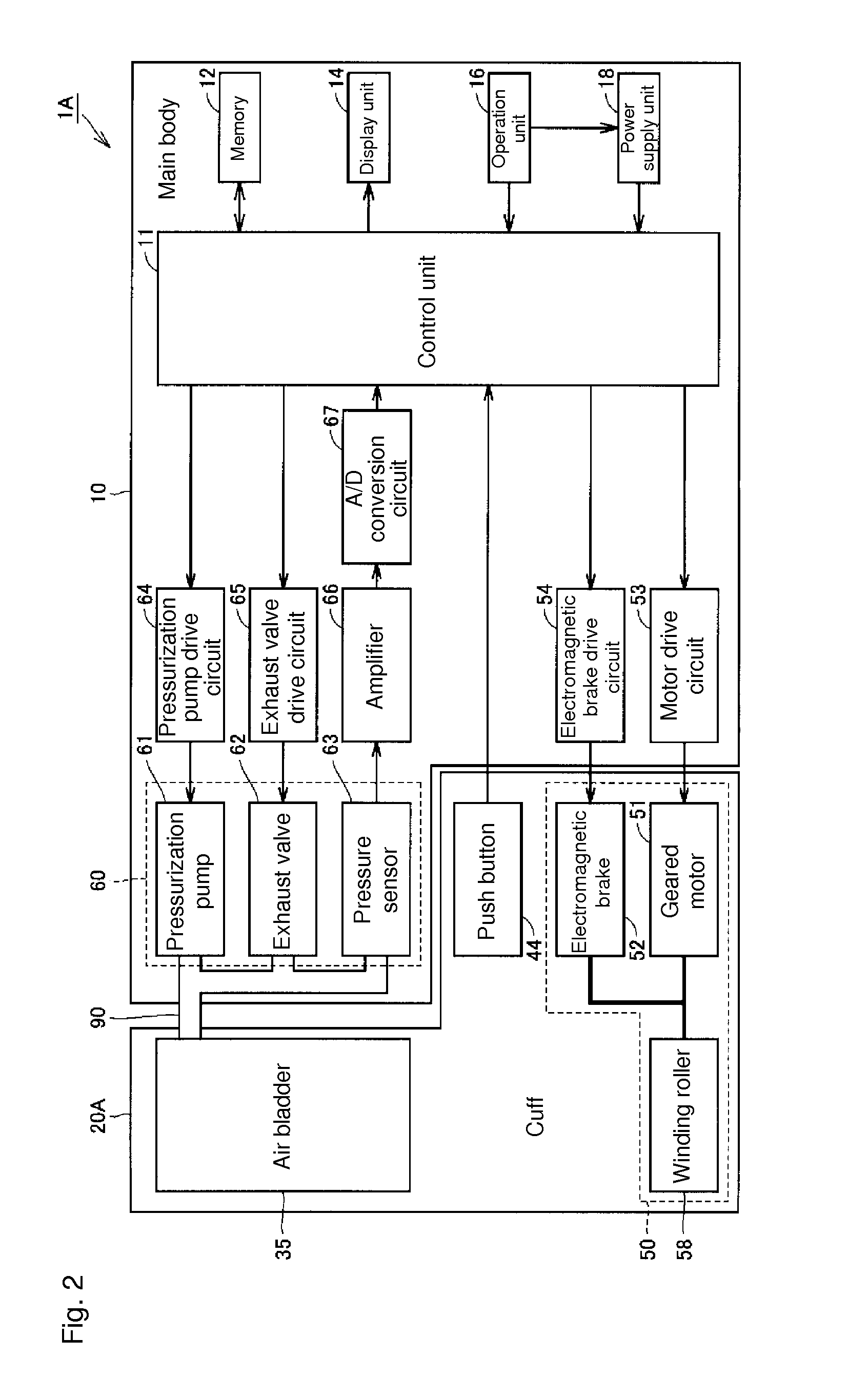

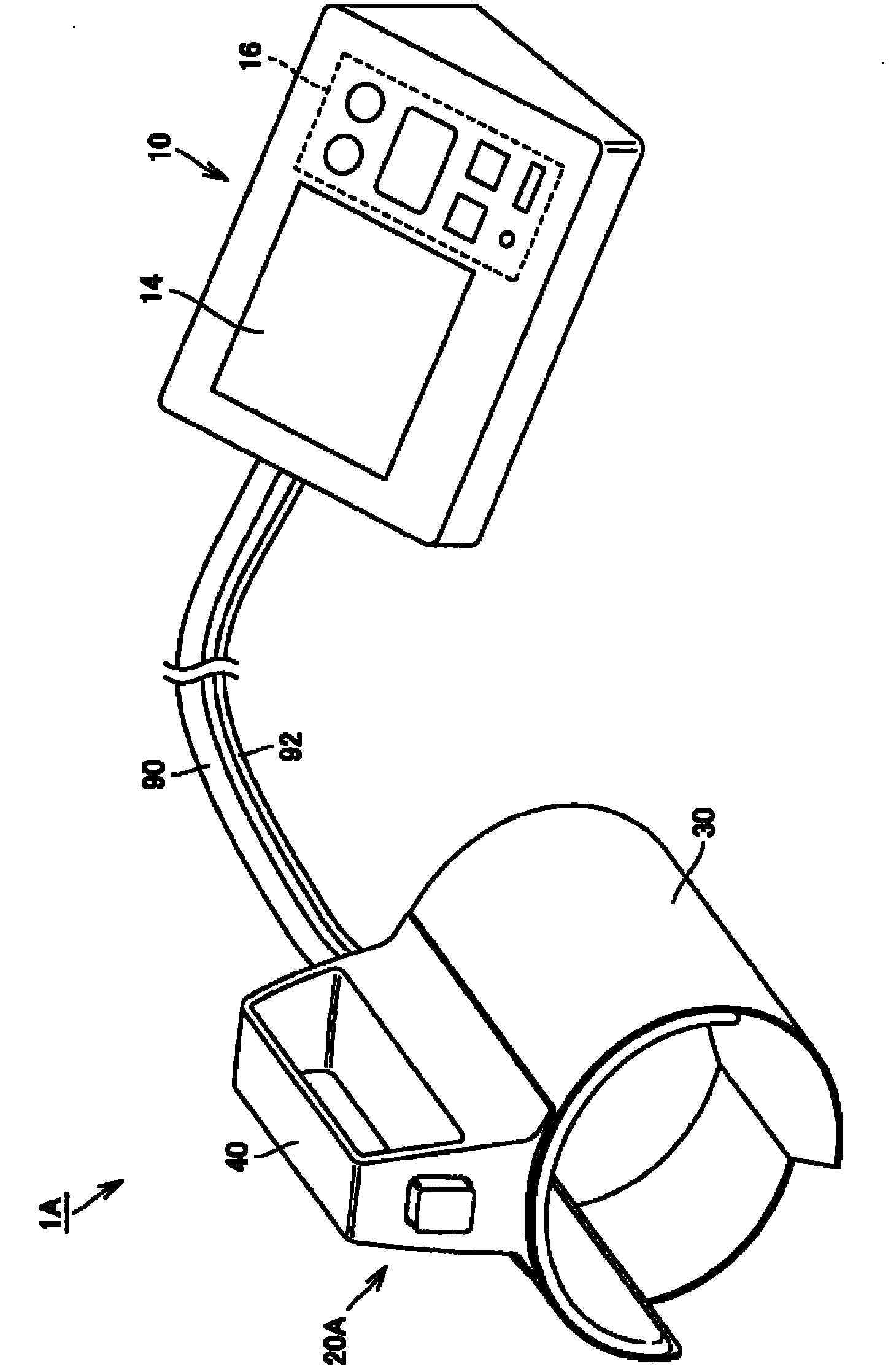

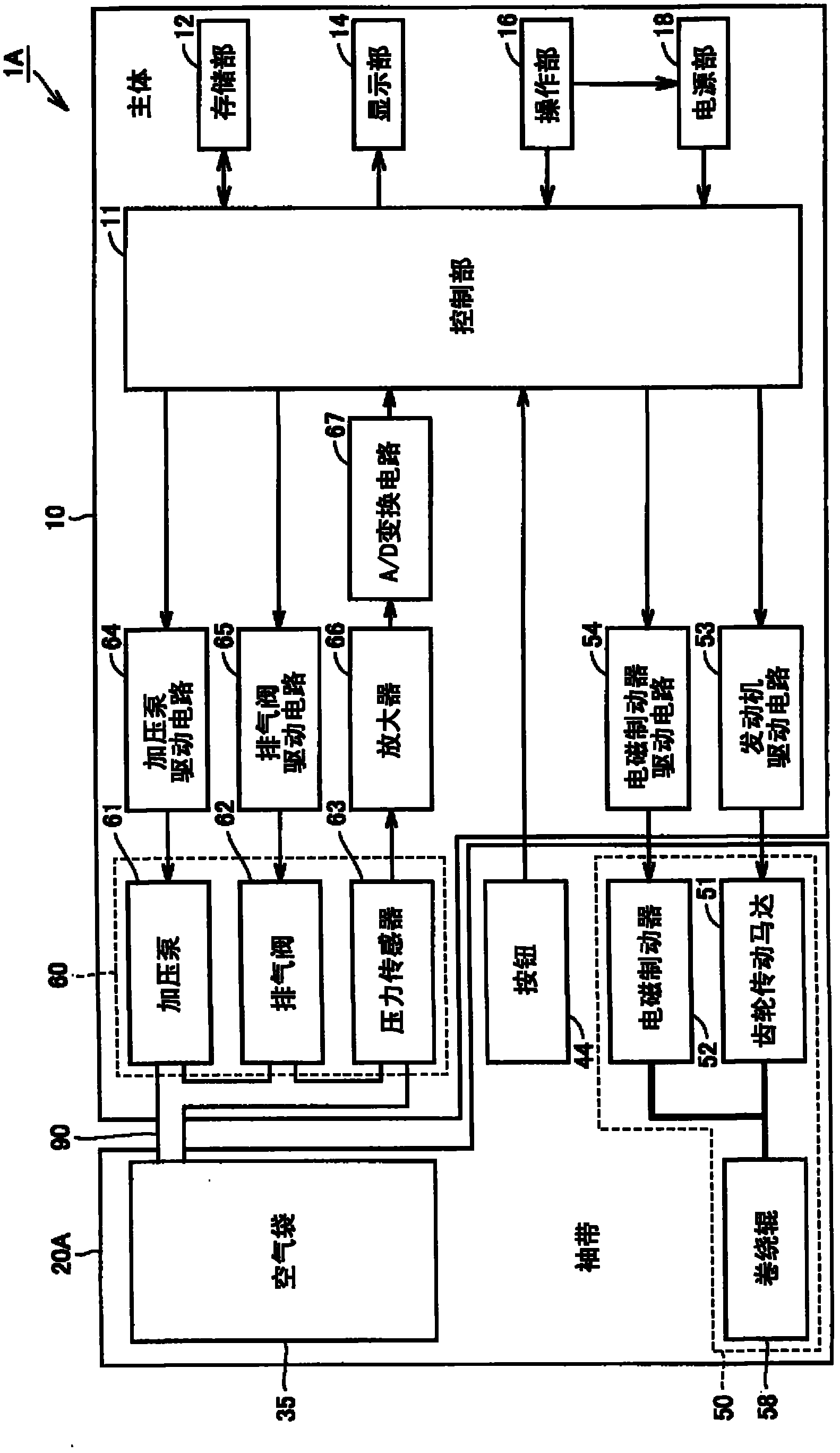

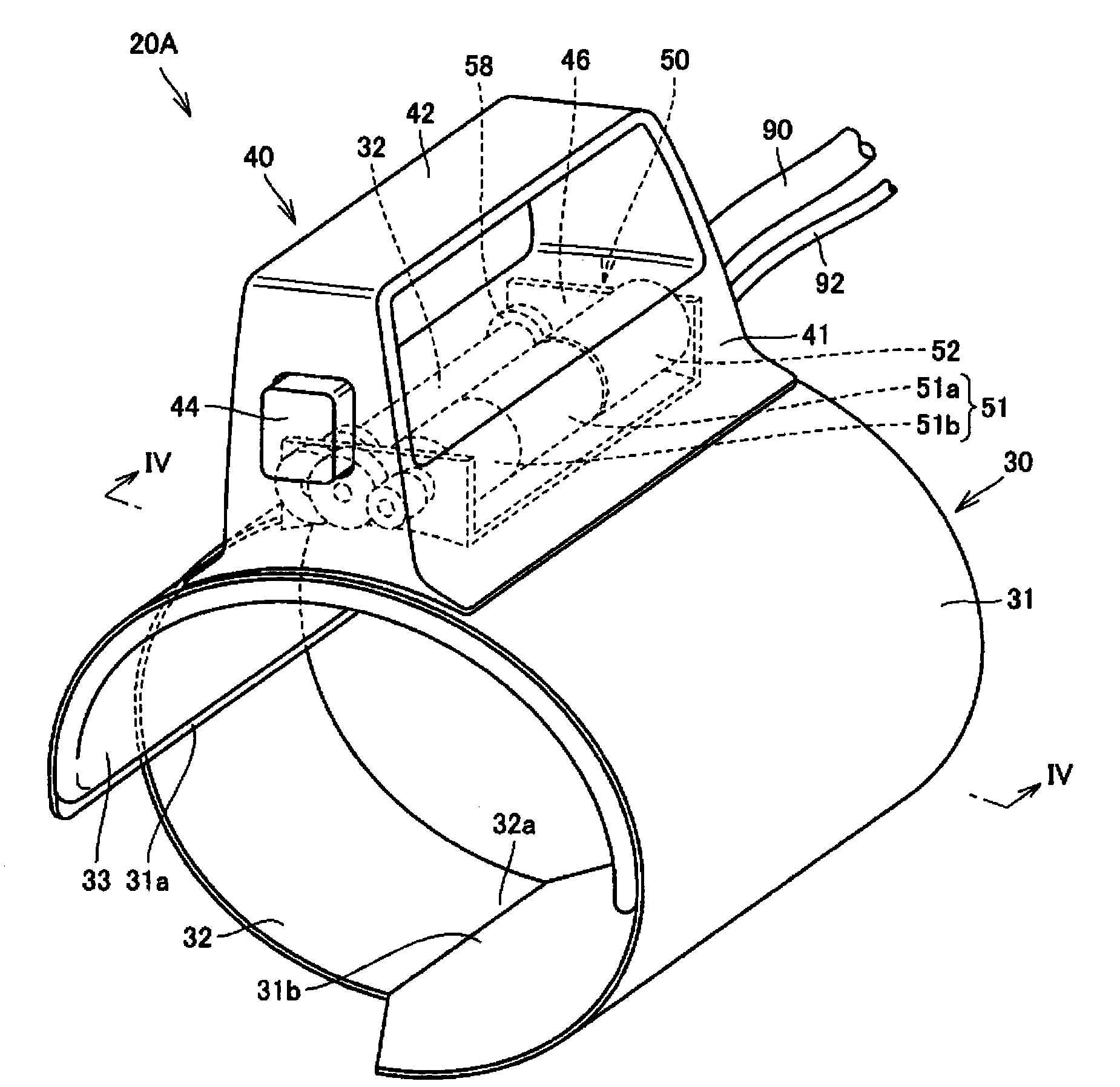

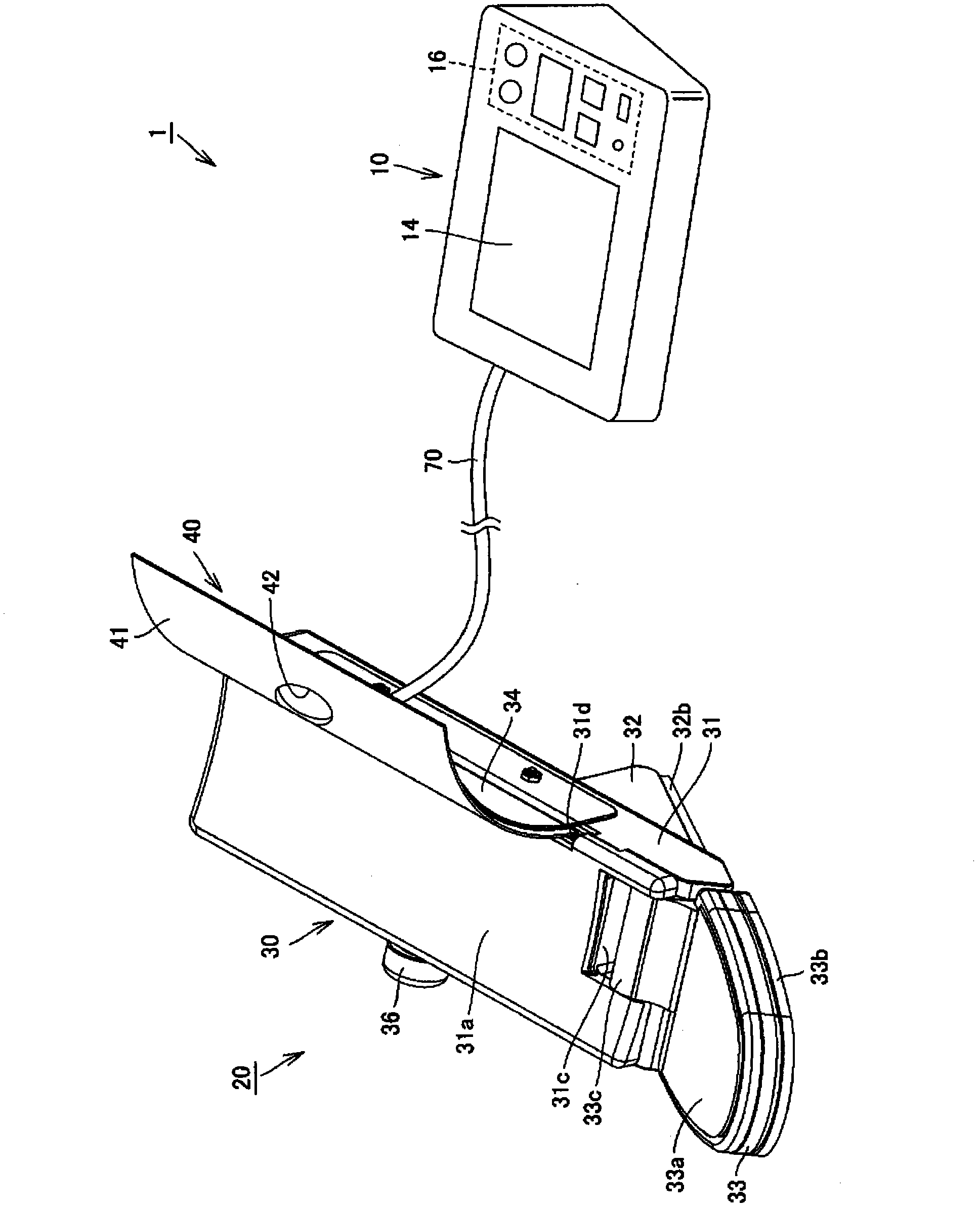

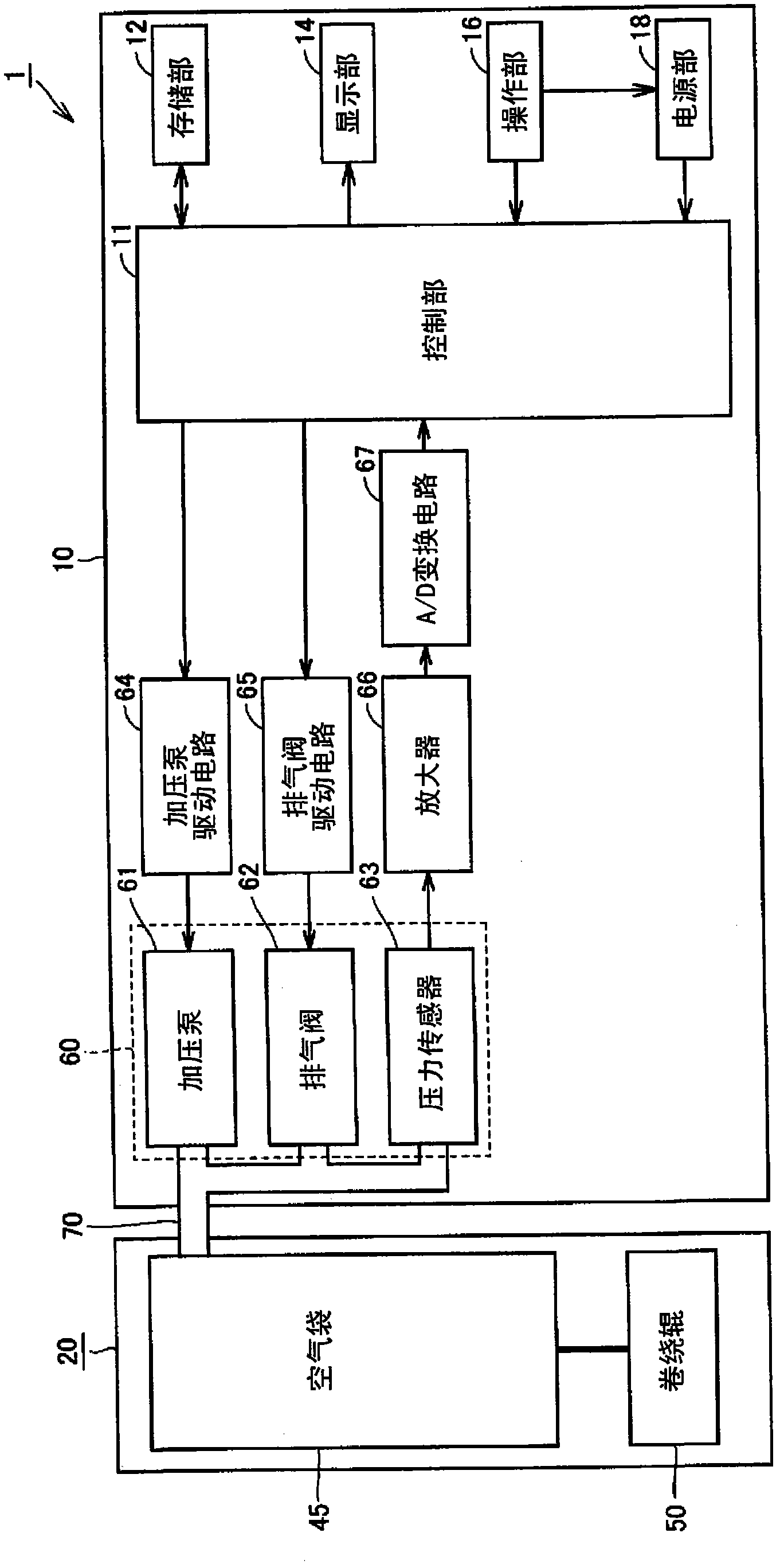

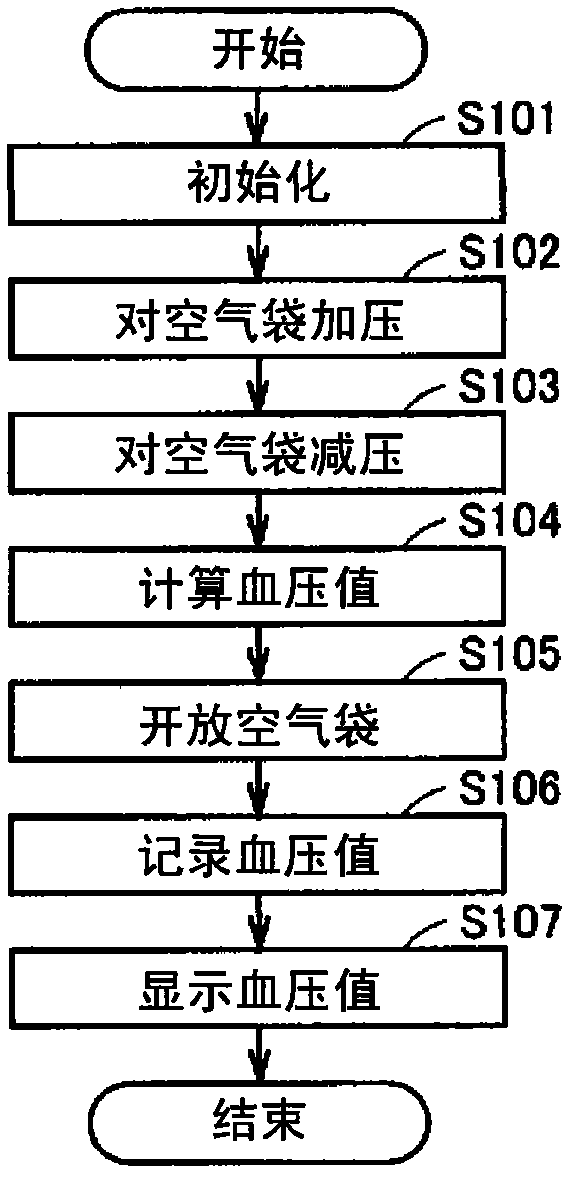

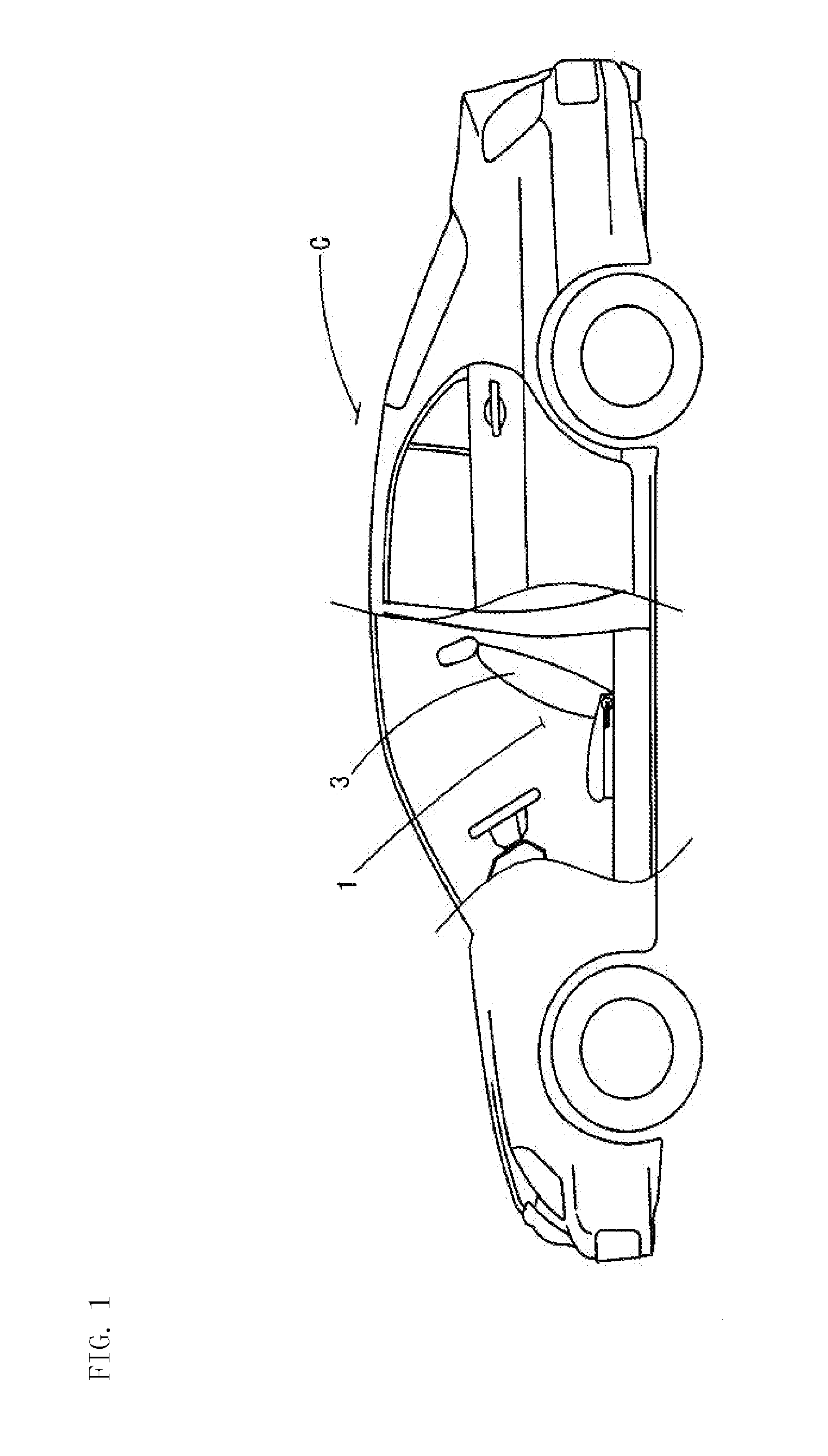

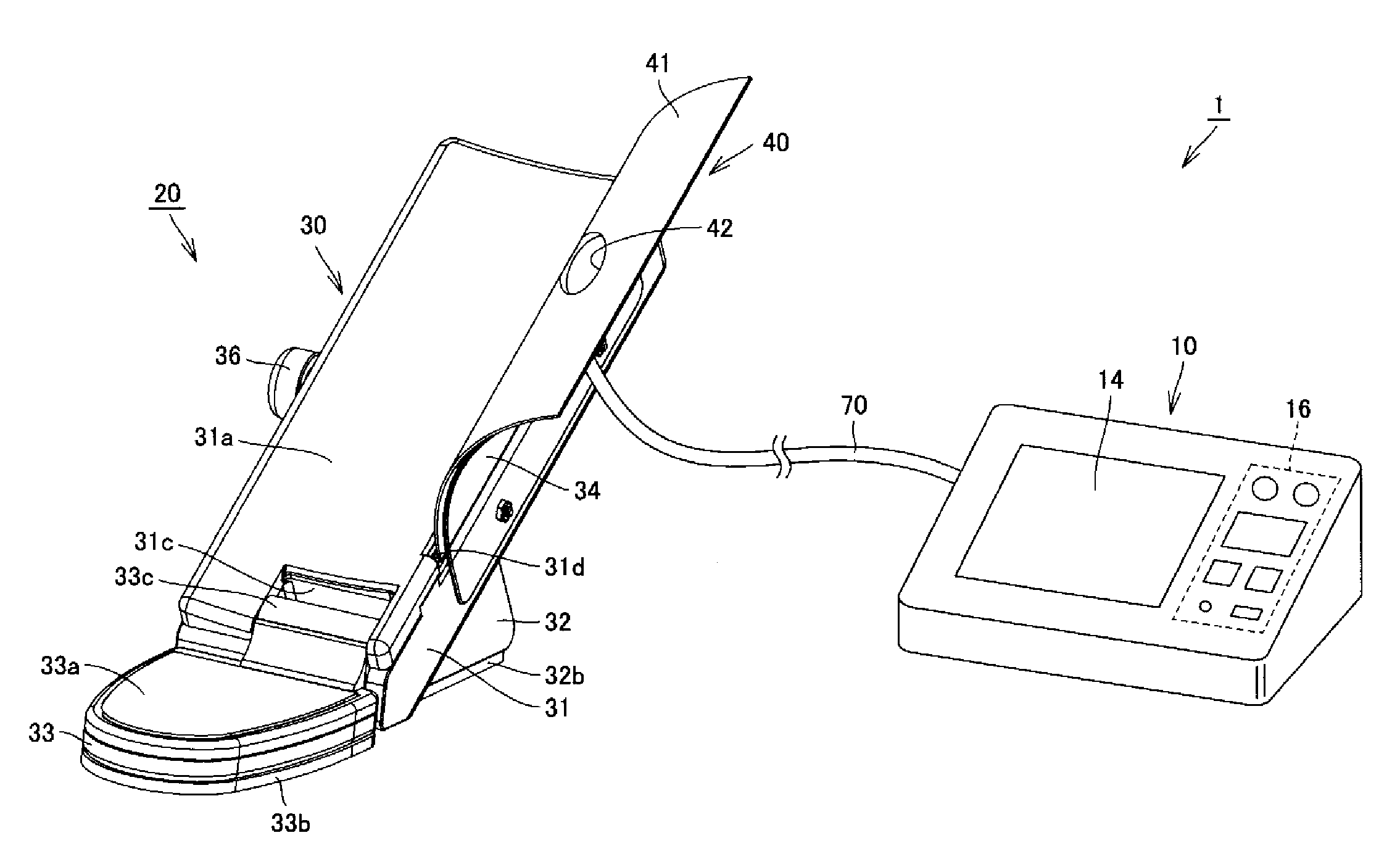

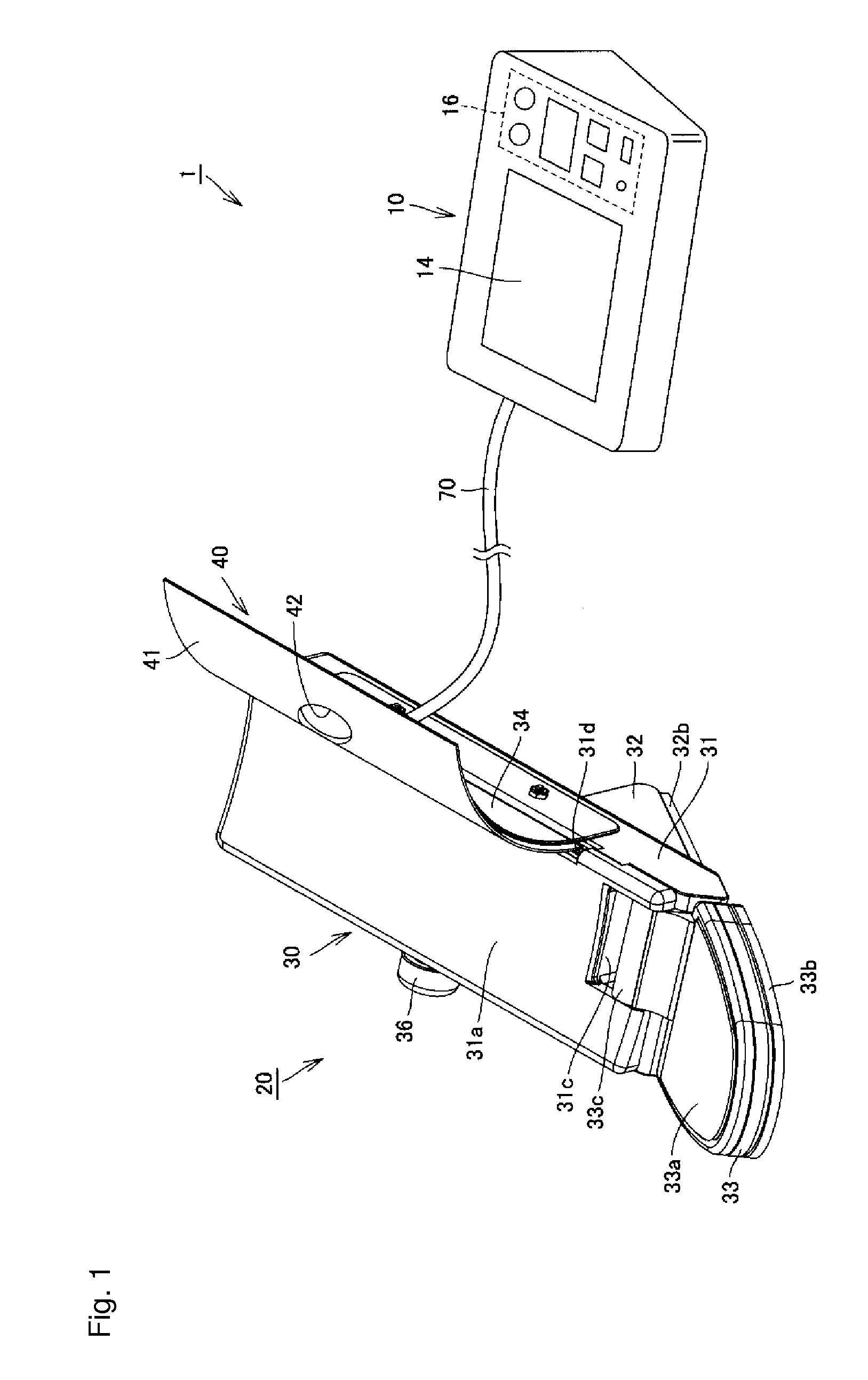

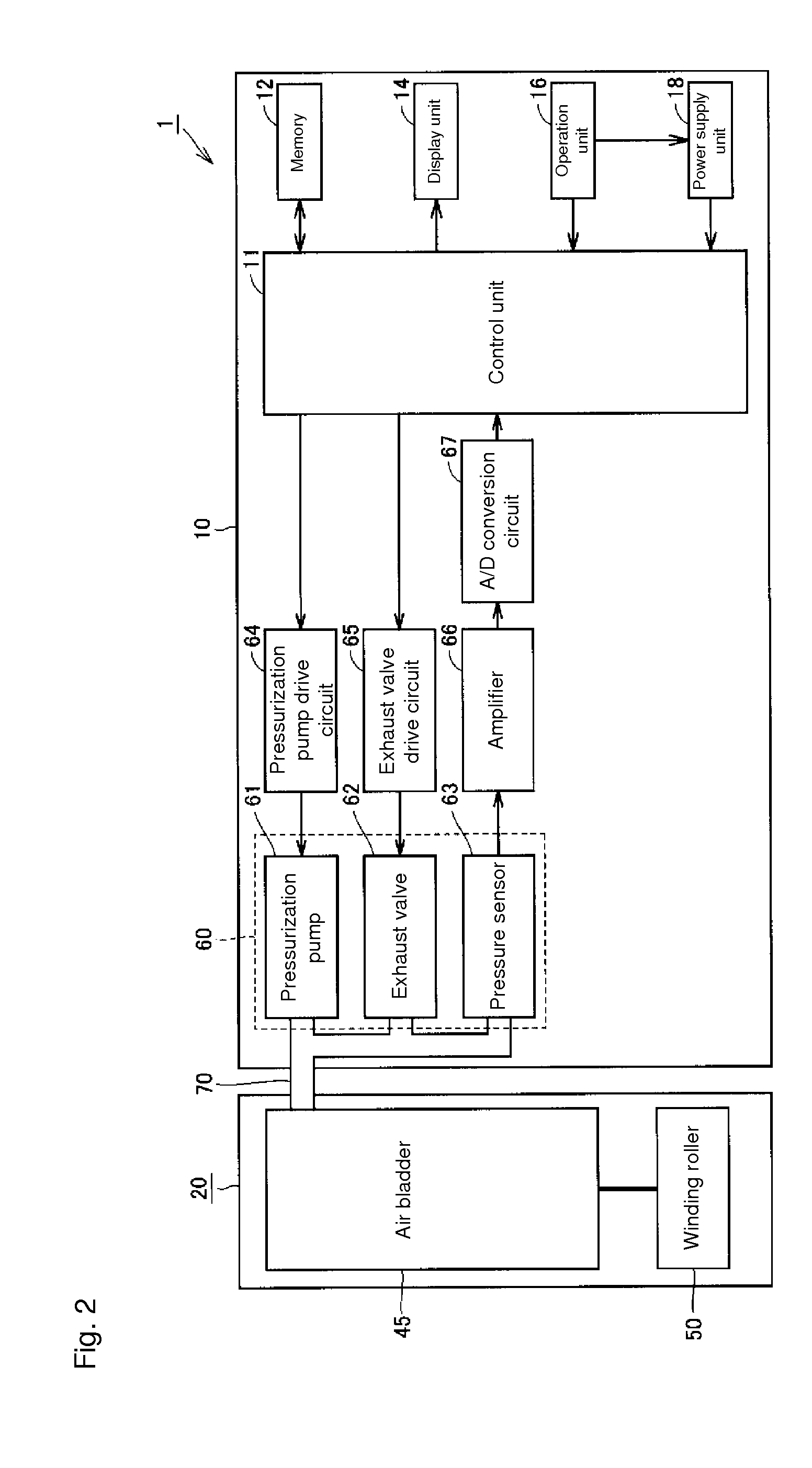

Blood pressure information measurement device

InactiveUS20110009757A1Good adhesionReliable windingEvaluation of blood vesselsCatheterSphygmomanometerEngineering

A sphygmomanometer separately includes a cuff accommodating an air bladder and a main body provided with an expanding / contracting mechanism arranged to expand and contract the air bladder, and the cuff includes a tubular cuff main body portion into which an upper arm is insertable and a gripping portion provided on an outer peripheral surface of the cuff main body portion. The cuff main body portion has a tightening belt wrapped around the outer side of the air bladder and a tightening length adjustment mechanism arranged to variably adjust a tightening length of the tightening belt over the upper arm. The tightening length adjustment mechanism includes a winding roller arranged to wind and feed the tightening belt, a geared motor arranged to drive and rotate the winding roller, and an electromagnetic brake arranged to apply a braking force to the winding roller. With such a configuration, in the sphygmomanometer in which the cuff and the main body are separated from each other, the cuff can be easily attached to a measurement site, and reliable winding of the cuff around the measurement site can be repeated in every measurement.

Owner:OMRON HEALTHCARE CO LTD

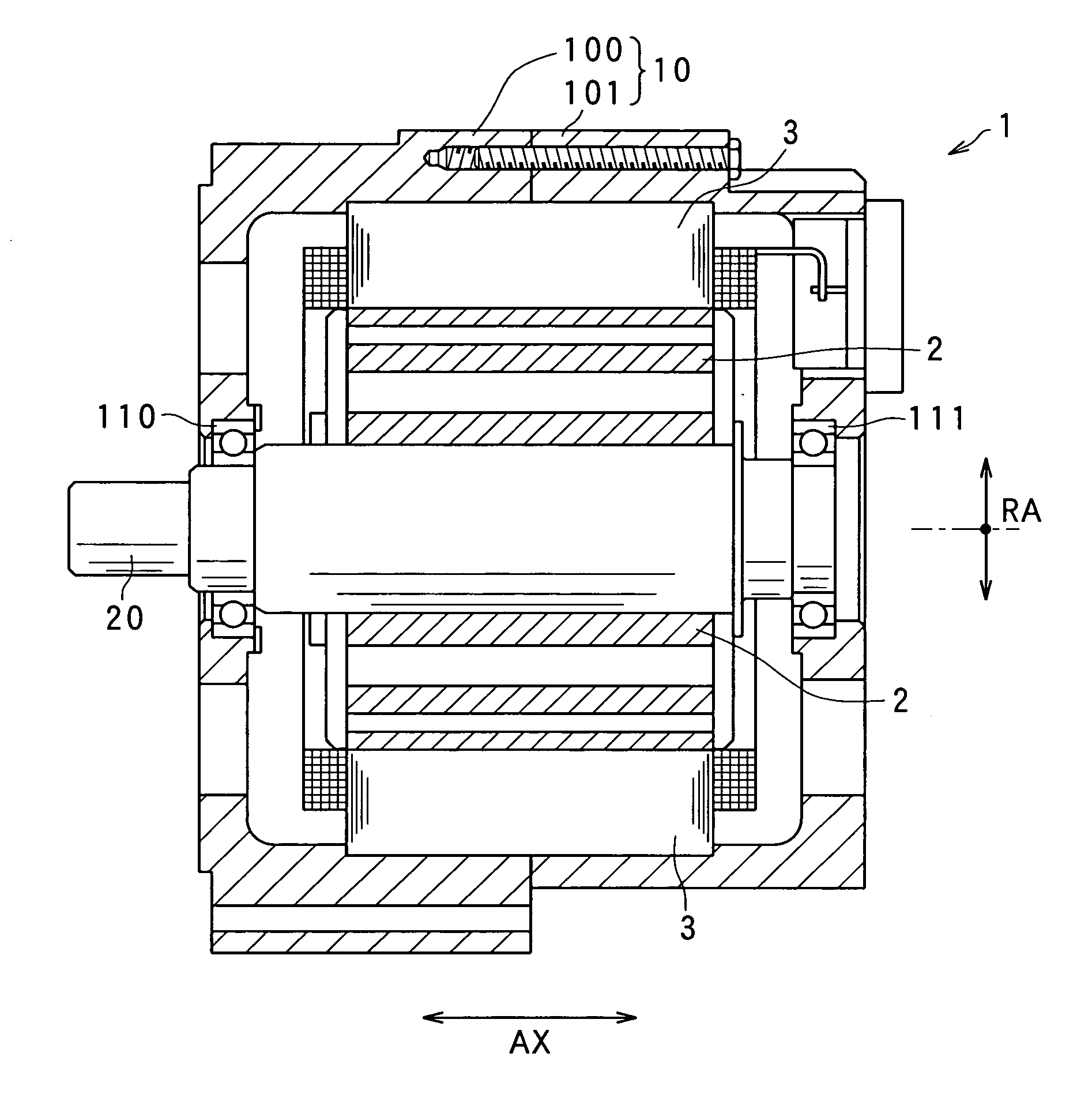

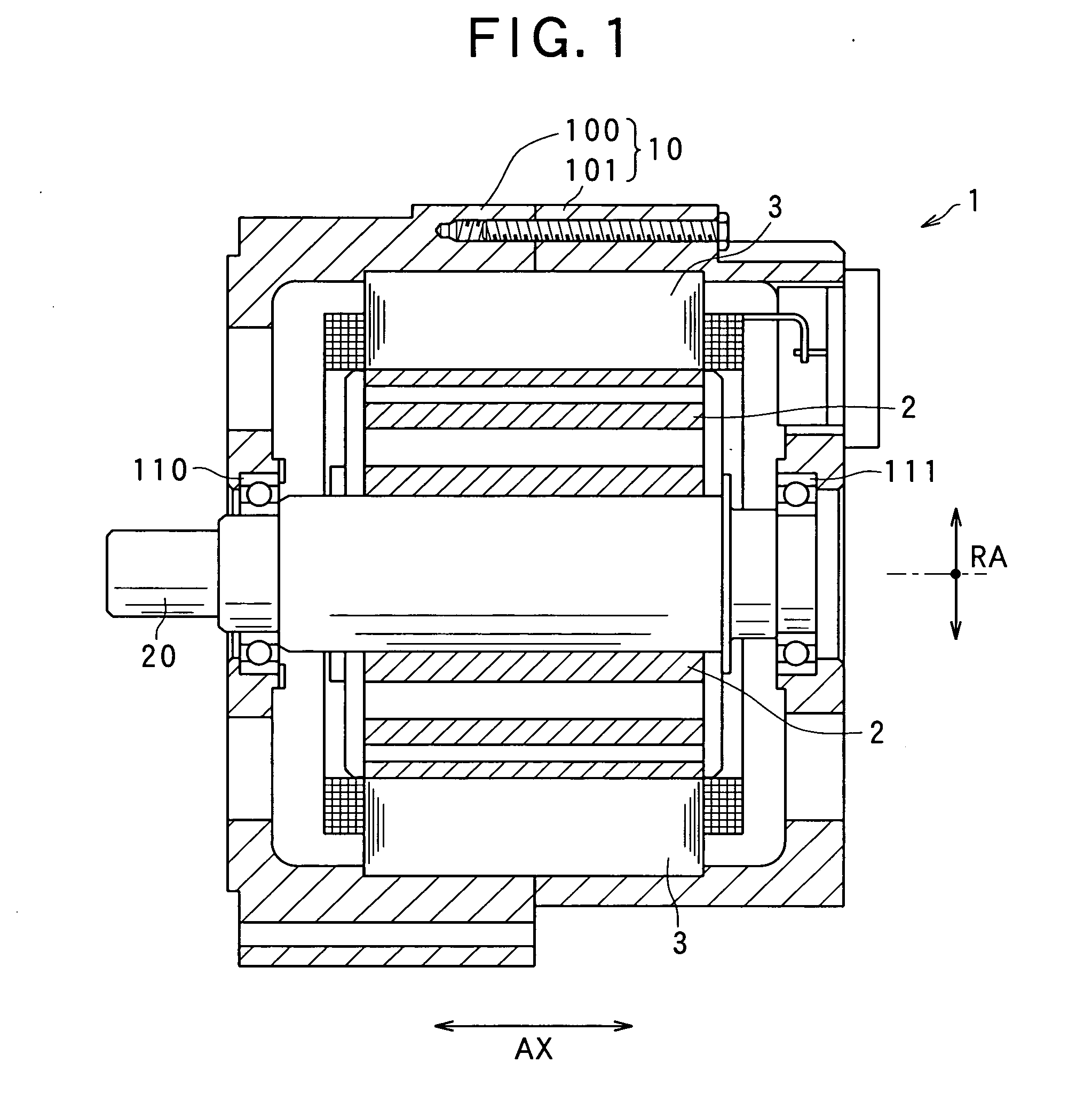

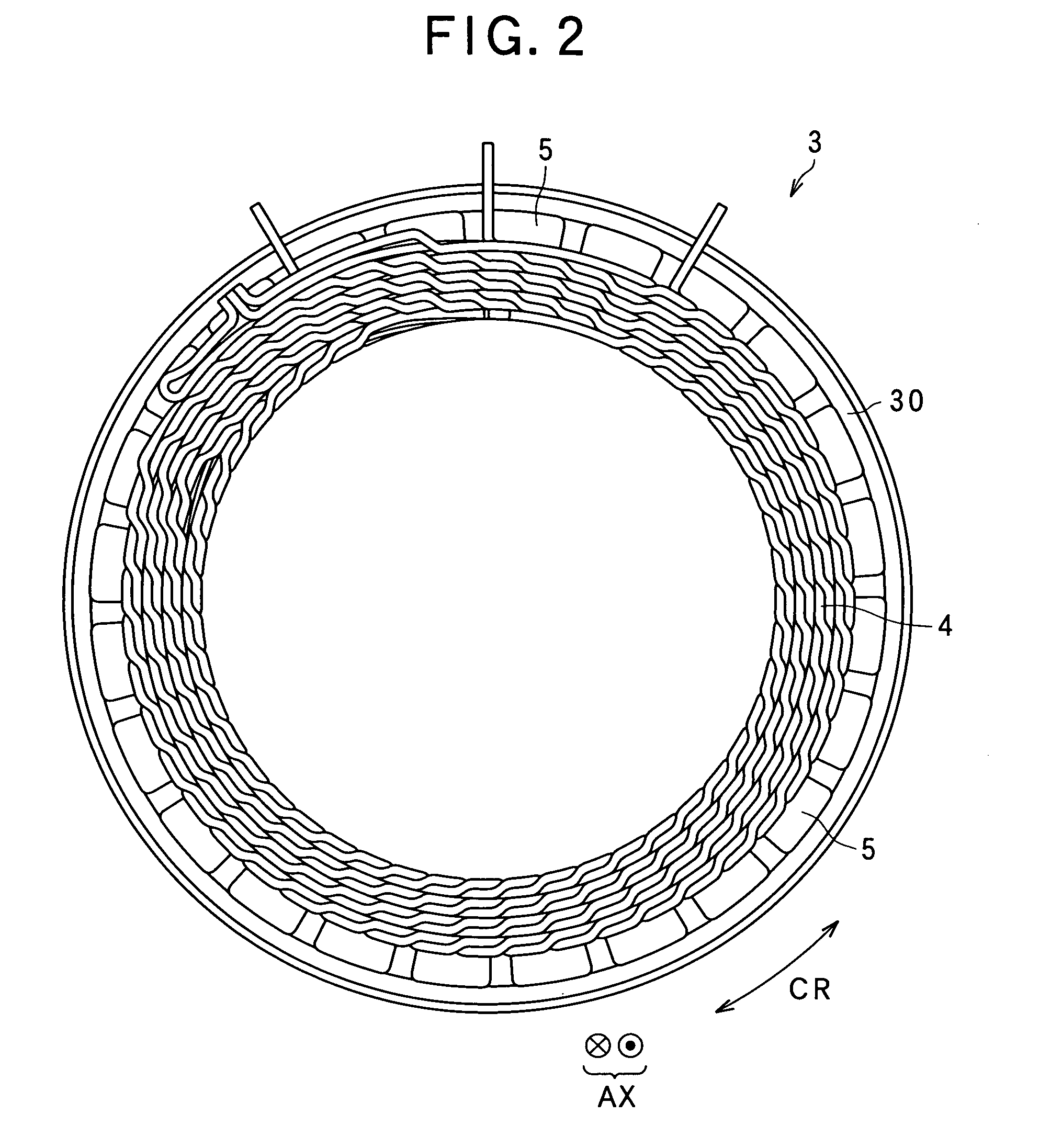

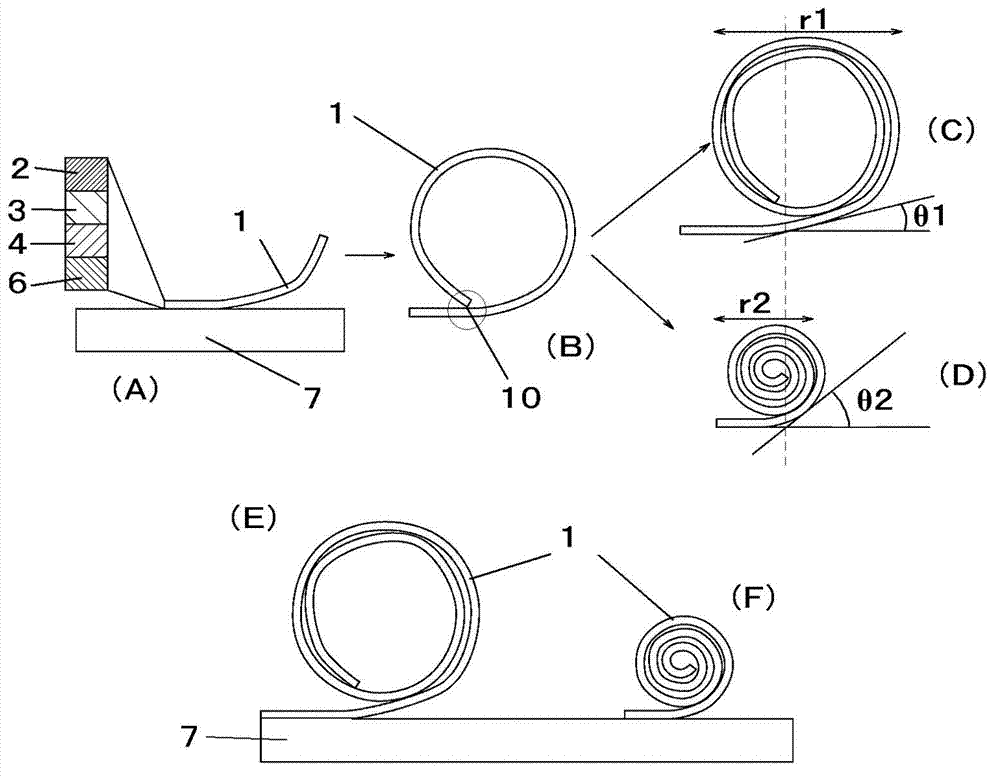

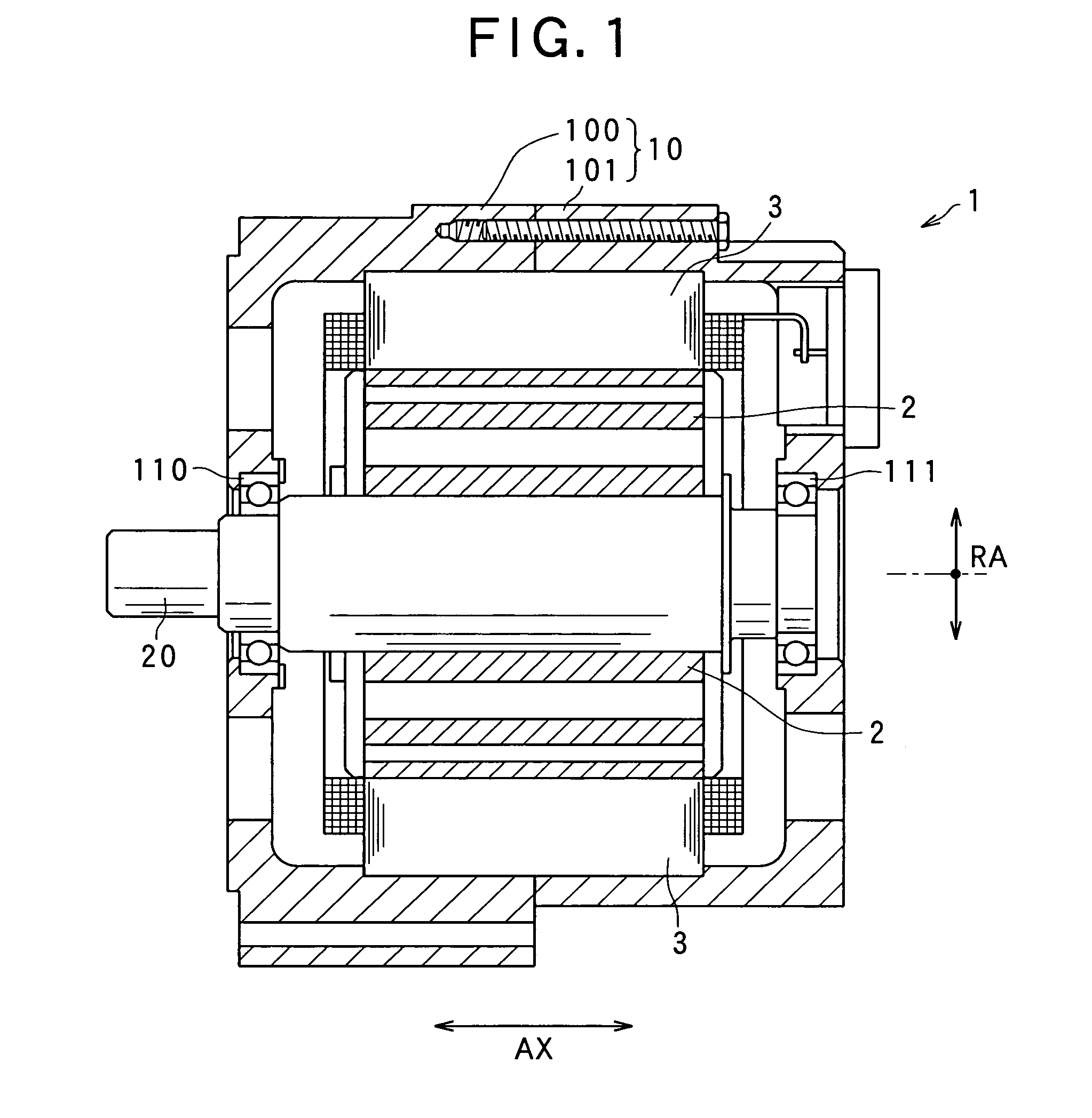

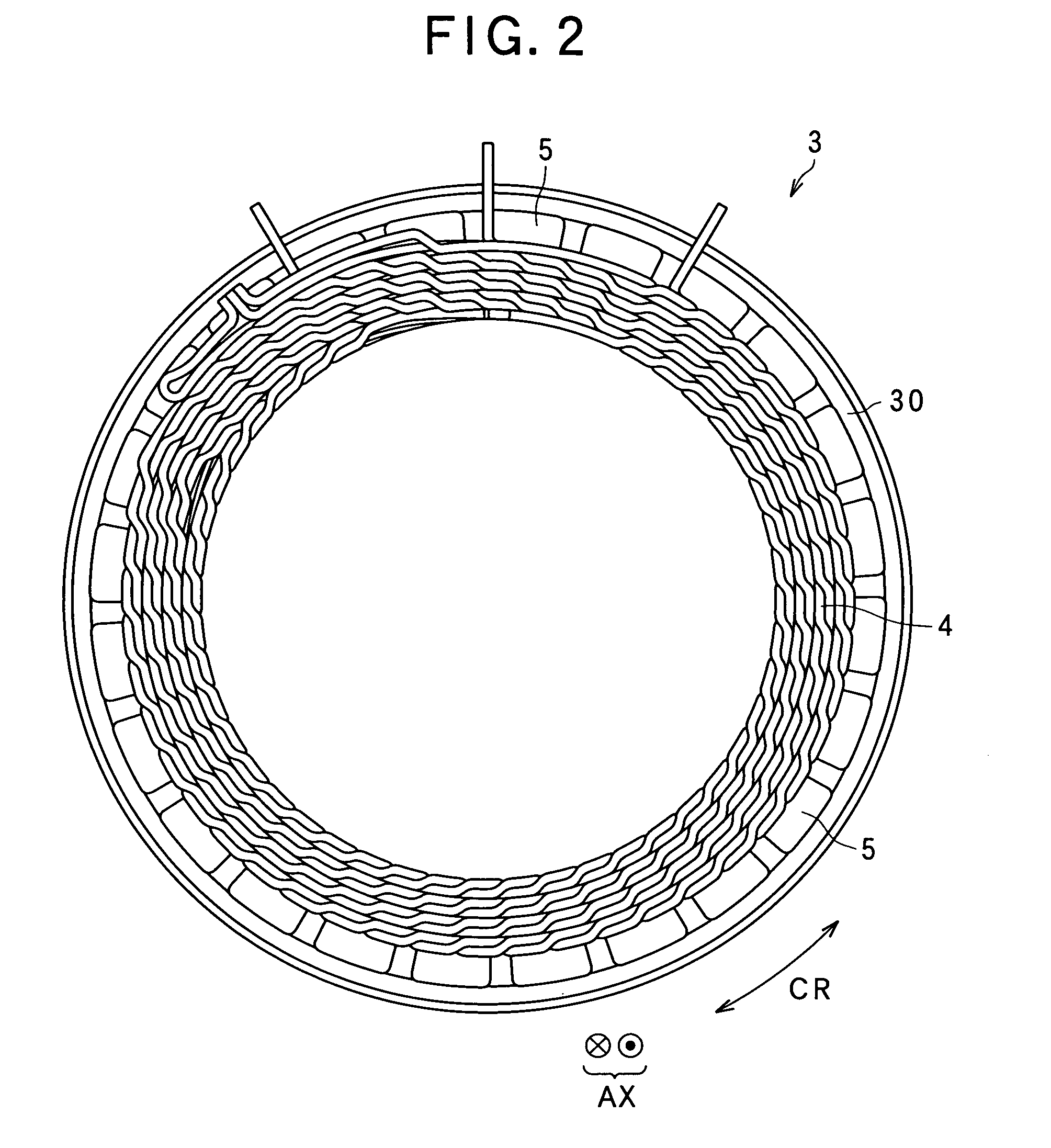

Method of manufacturing coil for stator incorporated in rotary electric machine

ActiveUS20090260219A1Improve accuracyReliable windingSynchronous generatorsWindingsElectric machineCurve shape

A method is provided for manufacturing a stator coil for a rotary electric machine, which is formed by winding up a plurality of phase wires. The method includes a shaping step for shaping a plurality of shaped wire members from electrically conductive wires, an integrating step for integrating the plurality of shaped wire members with each other to form an integrated body, and a winding-up step for winding the integrated body about a core member to form a wound body. At the winding-up step, curve forming is performed by plastically deforming turn portions of the integrated body into a curved shape, during conveyance of feeding the integrated body to the core member.

Owner:DENSO CORP

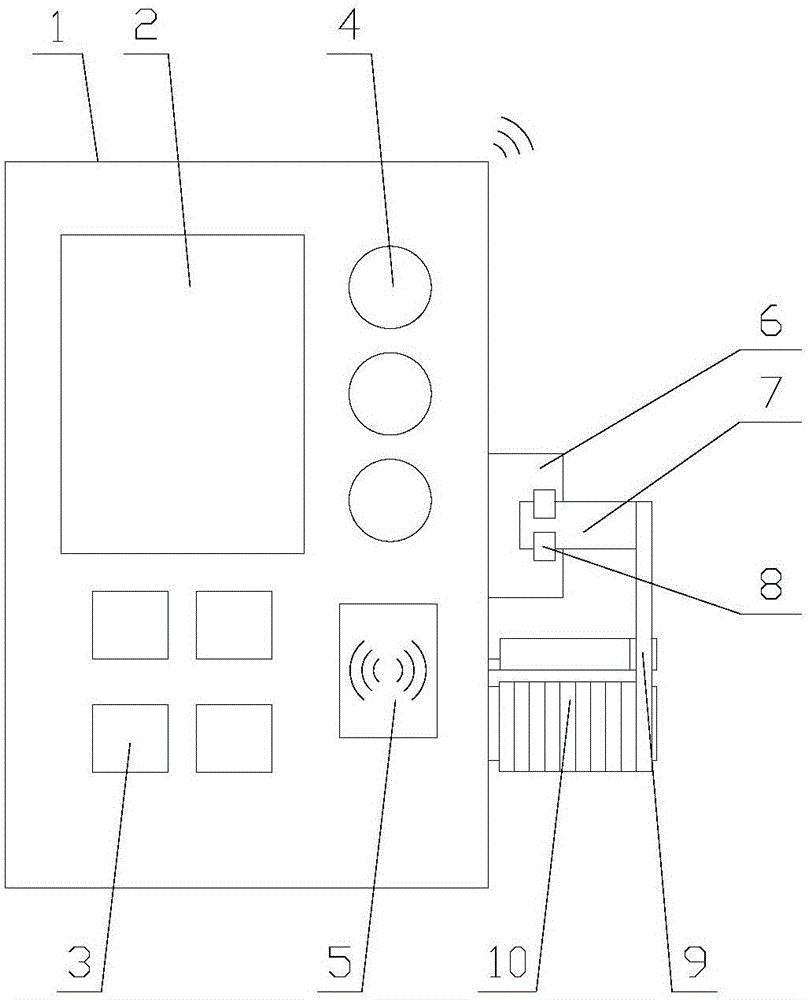

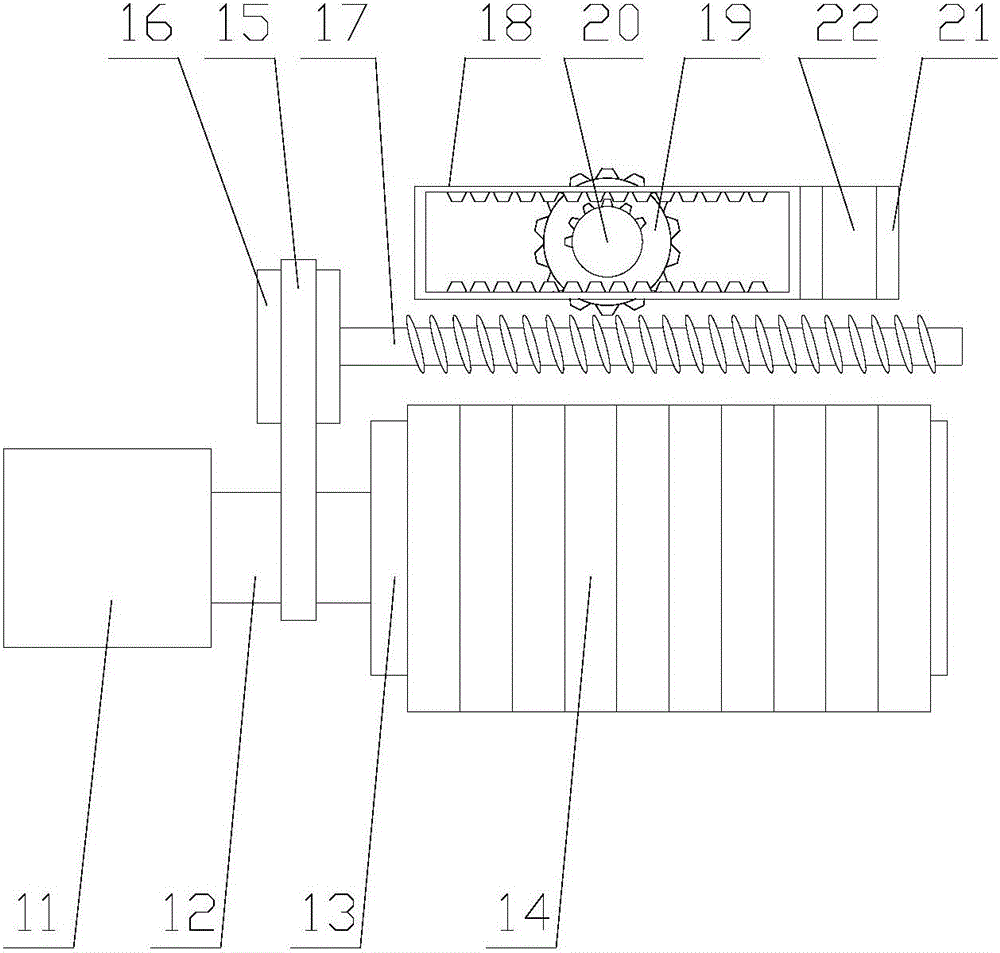

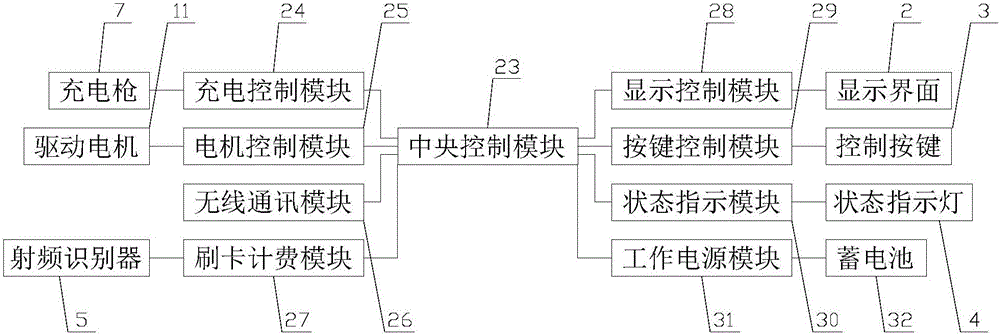

Charging pile for charging of new energy automobiles

InactiveCN106740237AImprove practicalityReliable windingCharging stationsElectric vehicle charging technologyDrive shaftNew energy

The invention relates to a charging pile for charging of new energy automobiles. The charging pile comprises a body, a center control mechanism and a charging mechanism. The charging mechanism comprises a fixed socket, a charging gun, a wire and a wire winding mechanism. The wire winding mechanism comprises a driving assembly, a transmission assembly and a wire winding assembly. The transmission assembly comprises a belt wheel, a driven shaft, a transmission gear, a driving gear and a transmission frame. The wire winding assembly comprises a wire frame and a wire winding wheel. A working power module comprises a working power circuit. According to the charging pile for charging of the new energy automobiles, the wire at the position of the charging gun after charging is completed is reliably wound through a limiting mechanism, and therefore the practicality of the charging pile is improved. Thus, in the working power circuit, an integrated circuit acquires and detects input and output voltage in real time, therefore, a triode is controlled to be switched on and off, and the reliability of the charging pile is improved.

Owner:SHANGHAI SAFEGREEN TECH

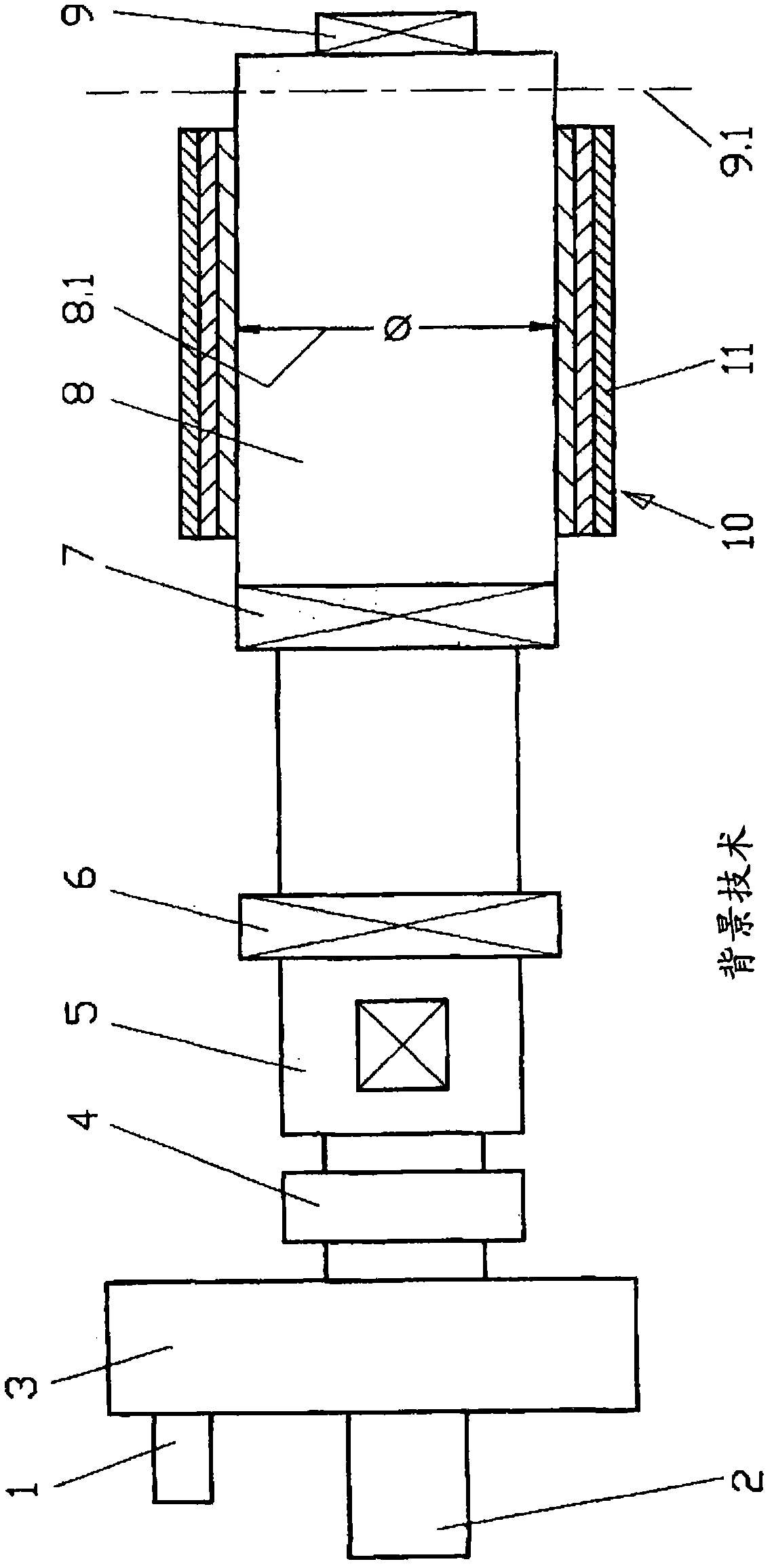

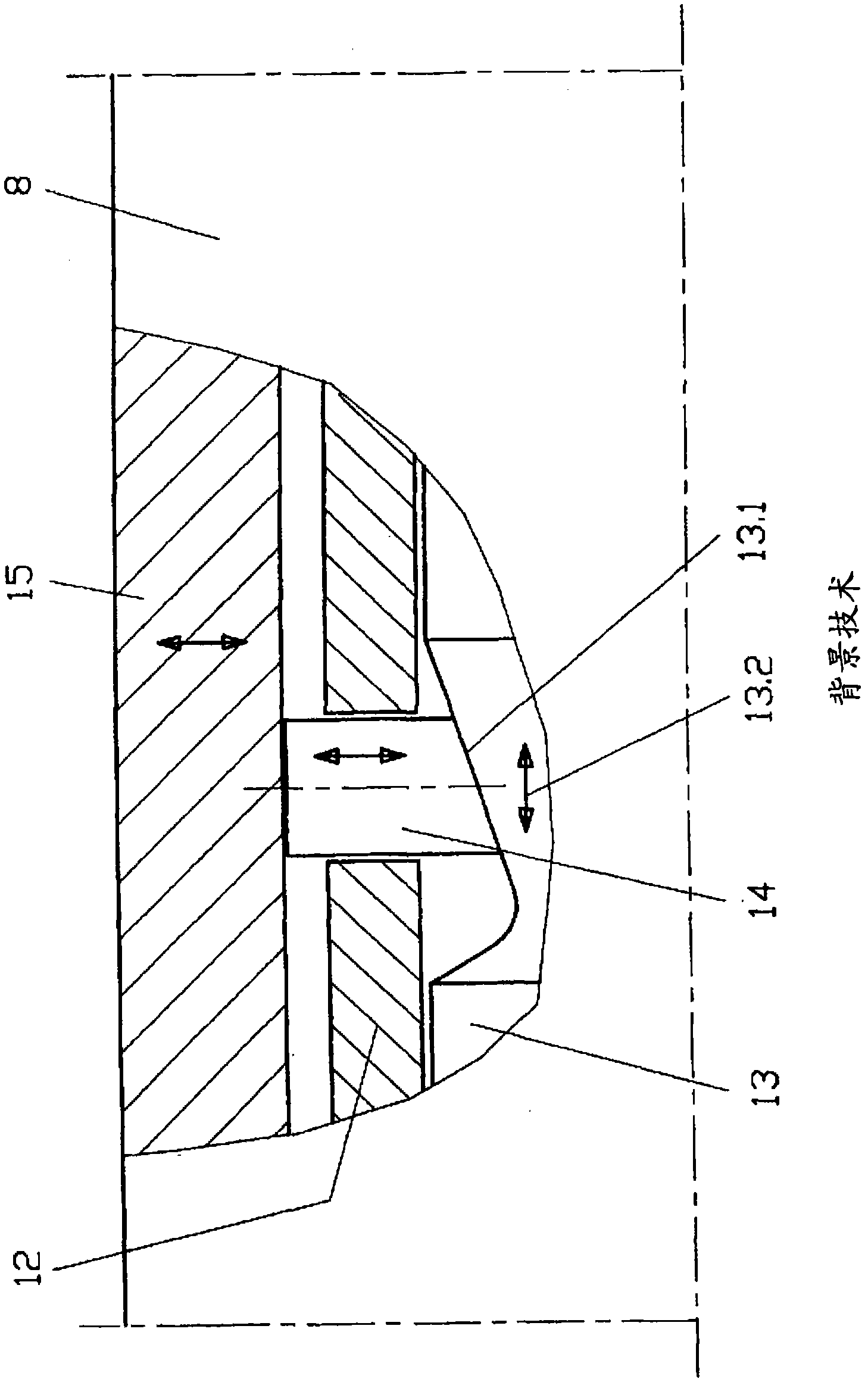

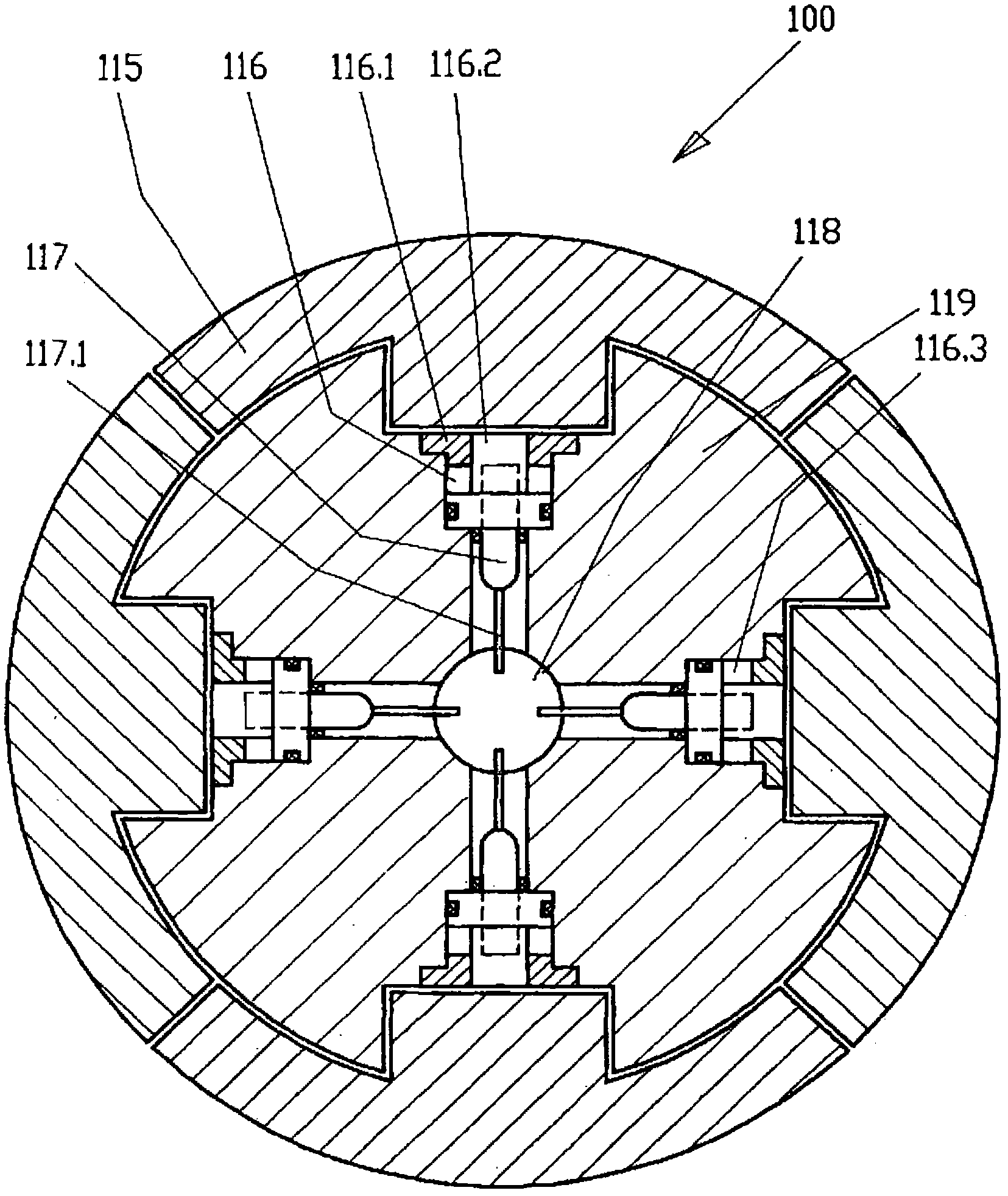

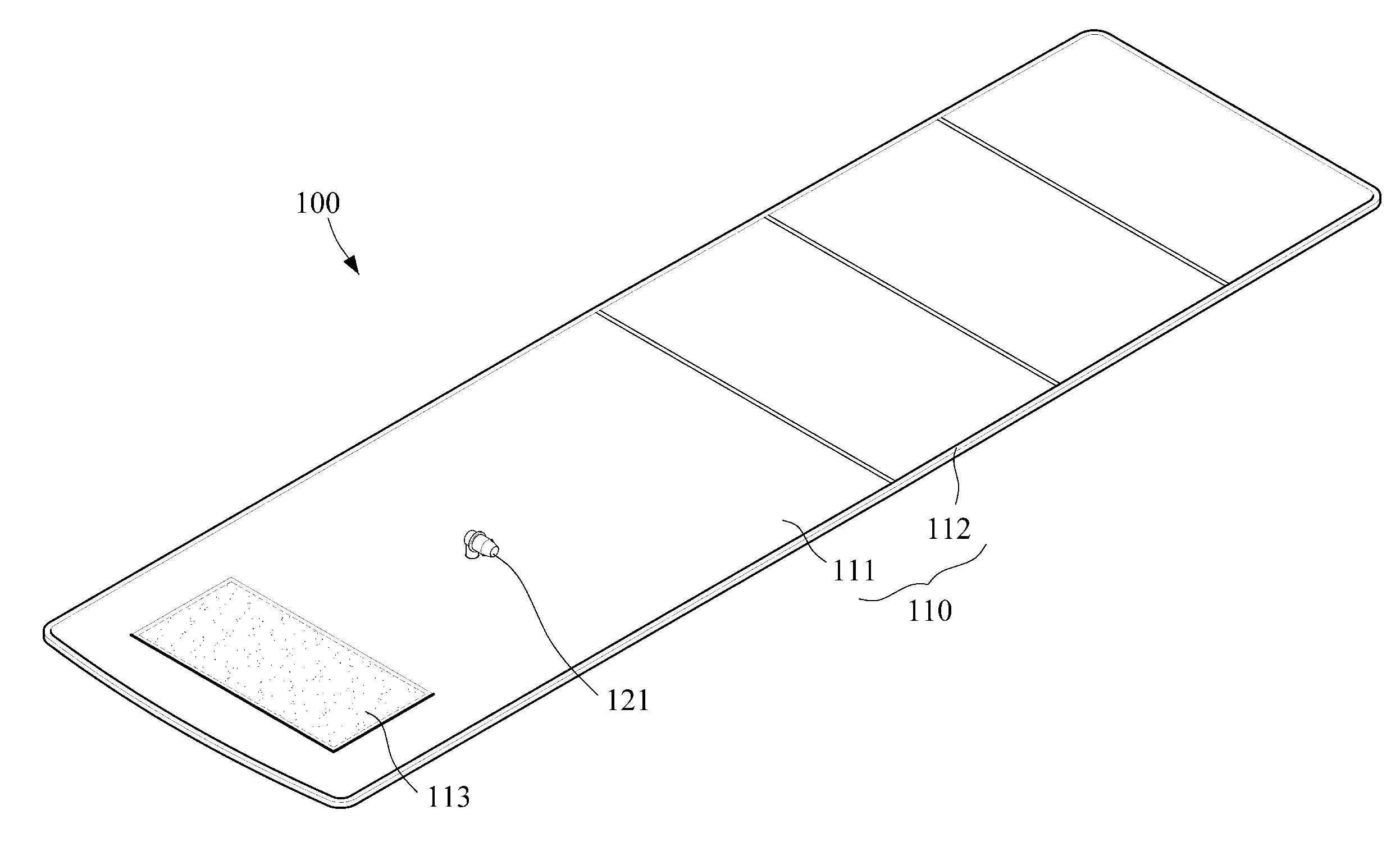

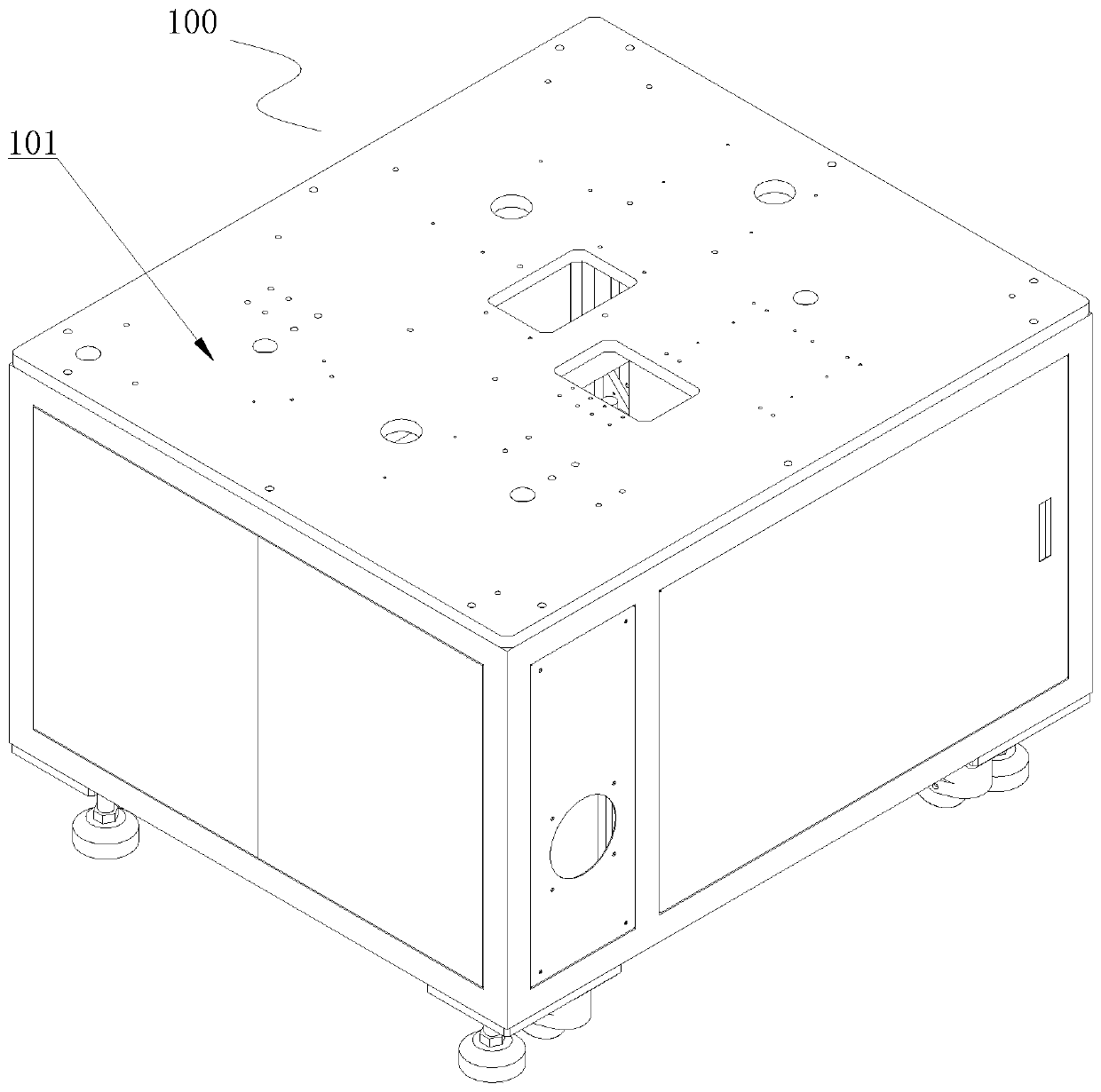

Method and device for winding metal strip material

InactiveCN102076587AAvoid damageExtend your lifeSleeve/socket jointsWebs handlingHydraulic cylinderMetal strips

The invention relates to a method and a decoiler mandrel for winding metal strip material (110), wherein the decoiler mandrel (100) comprises a mandrel body (120), a plurality of radially spreadable segments (115) being disposed about the mandrel body (120), and a plurality of hydraulic cylinders (116) through which the segments (115) are moved radially. In order to also be able to wind the metal strip material utilizing a circular coil eye when the friction is different in the individual cylinders, the invention provides that each cylinder (116) of the plurality is controlled individually.

Owner:SMS DEMAG AG

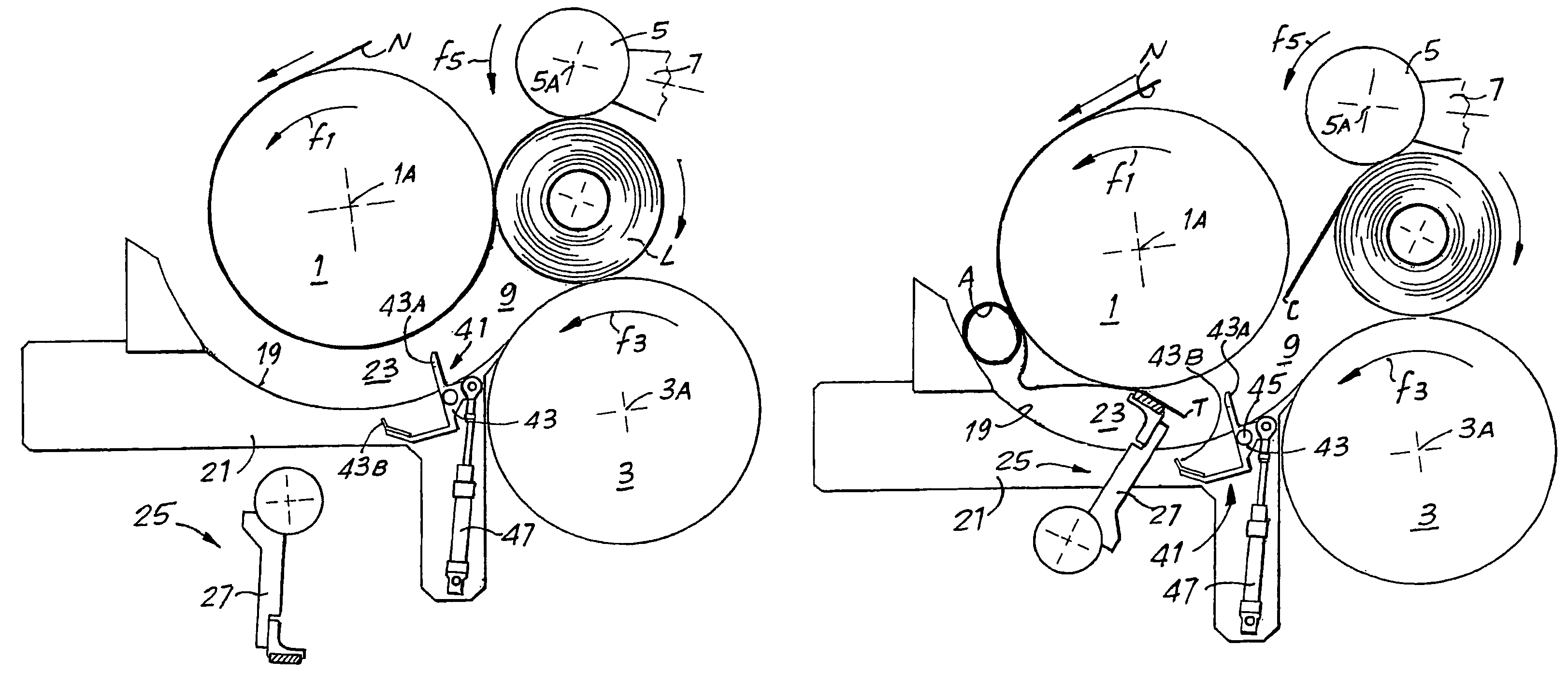

Method and machine for forming logs of web material, with a mechanical device for forming the initial turn of the logs

ActiveUS7931226B2Reliable windingSimple structureFilament handlingArticle deliveryEngineeringMechanical engineering

The rewinding machine includes a winding unit; a feed path of a web material; a separator device to sever the web material upon completion of winding each log; an insertion path of the winding cores towards the winding unit; a movable mechanical member to facilitate forming a first turn of web material around each winding core inserted in the insertion path.

Owner:FABIO PERINI SPA

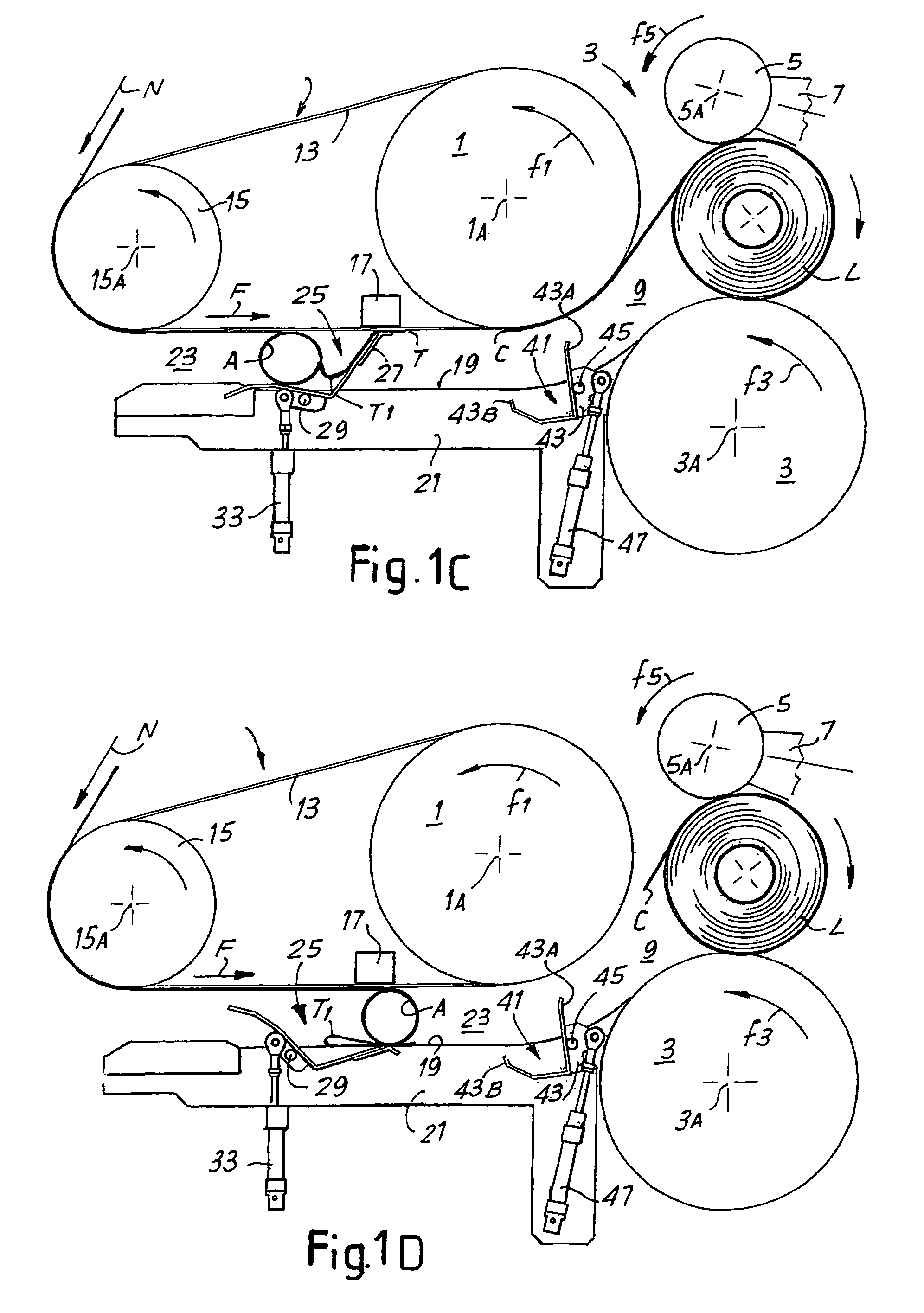

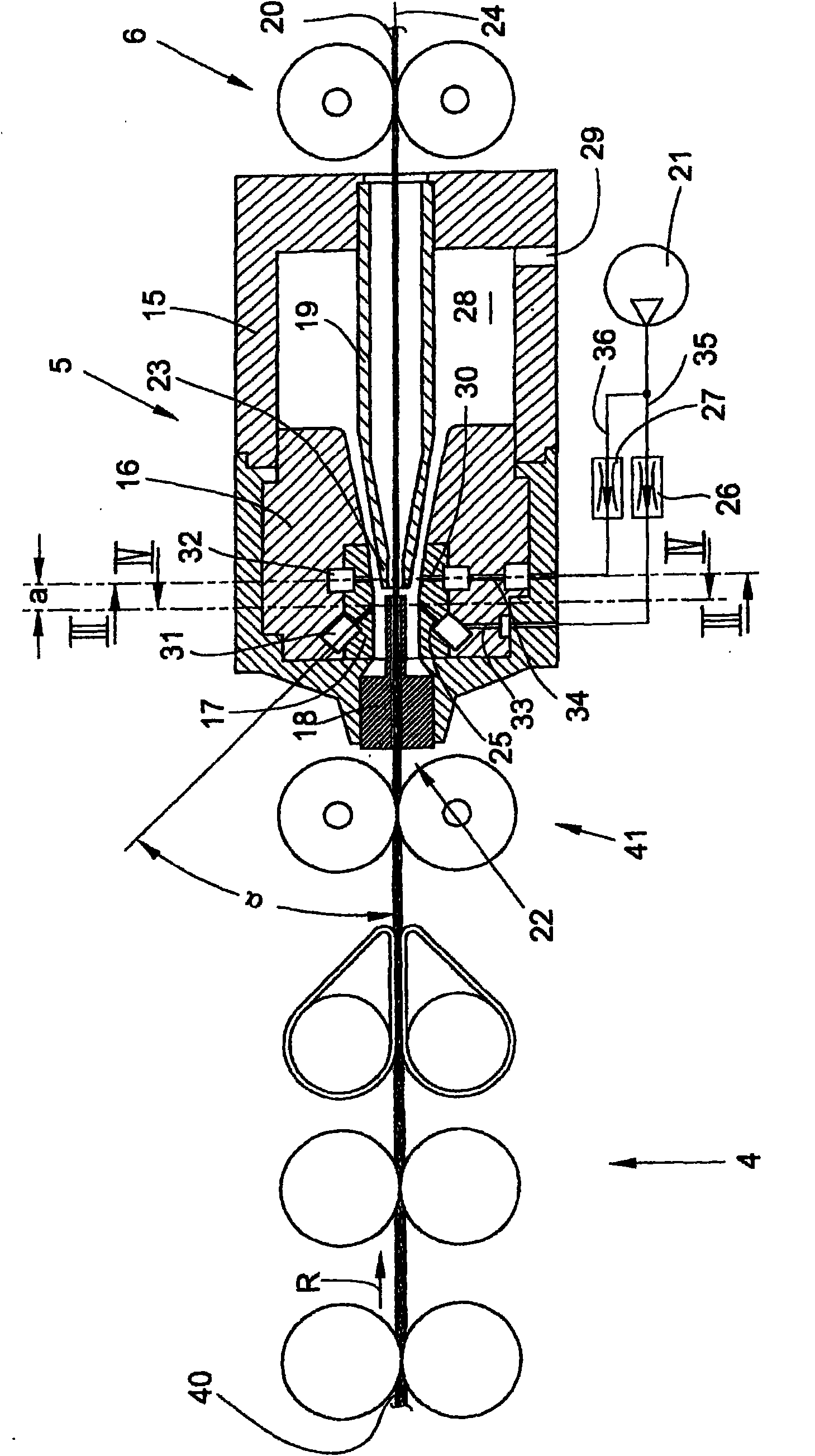

Jet spinning apparatus

ActiveCN101600826AEffective assistanceSoft treatmentContinuous wound-up machinesOpen-end spinning machinesYarnUltimate tensile strength

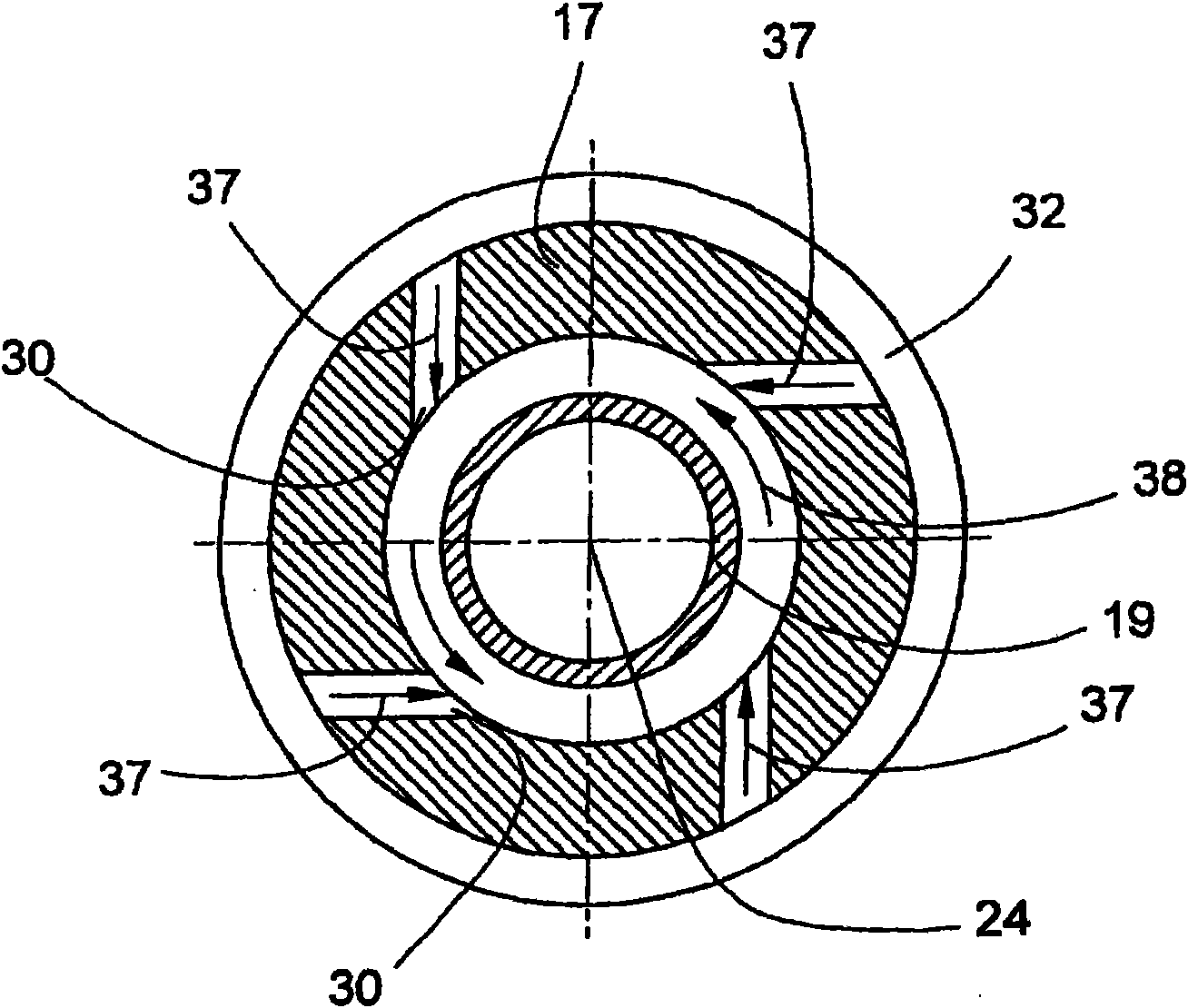

The invention relates to a jet spinning apparatus (5) for producing a thread (20) by means of a circulating airflow, having a hollow spinning cone (19) which is arranged in a spinning housing (15), and having two separate groups of blown air nozzles (25, 30) which can be loaded with compressed air independently of one another, wherein the strength of a vacuum flow which acts on a sliver inlet opening (22) during the spinning process can be set via the arrangement of a first group of blown air nozzles (25) and the strength of an airflow which circulates in the region of the spinning cone (19) can be predefined via the arrangement of a second group of blown air nozzles (30). There is provision according to the invention for the blown air nozzles (25) of the first group to be arranged offset at a spacing (b) with regard to the longitudinal centre axis (24) of the jet spinning apparatus (5), with the result that an airflow can be introduced into the jet spinning apparatus (5) via the blown air nozzles (25) during the spinning process, which airflow has a tangential blown air component in order to assist the airflow which circulates in the region of the spinning cone (19).

Owner:SAURER GERMANY GMBH & CO KG

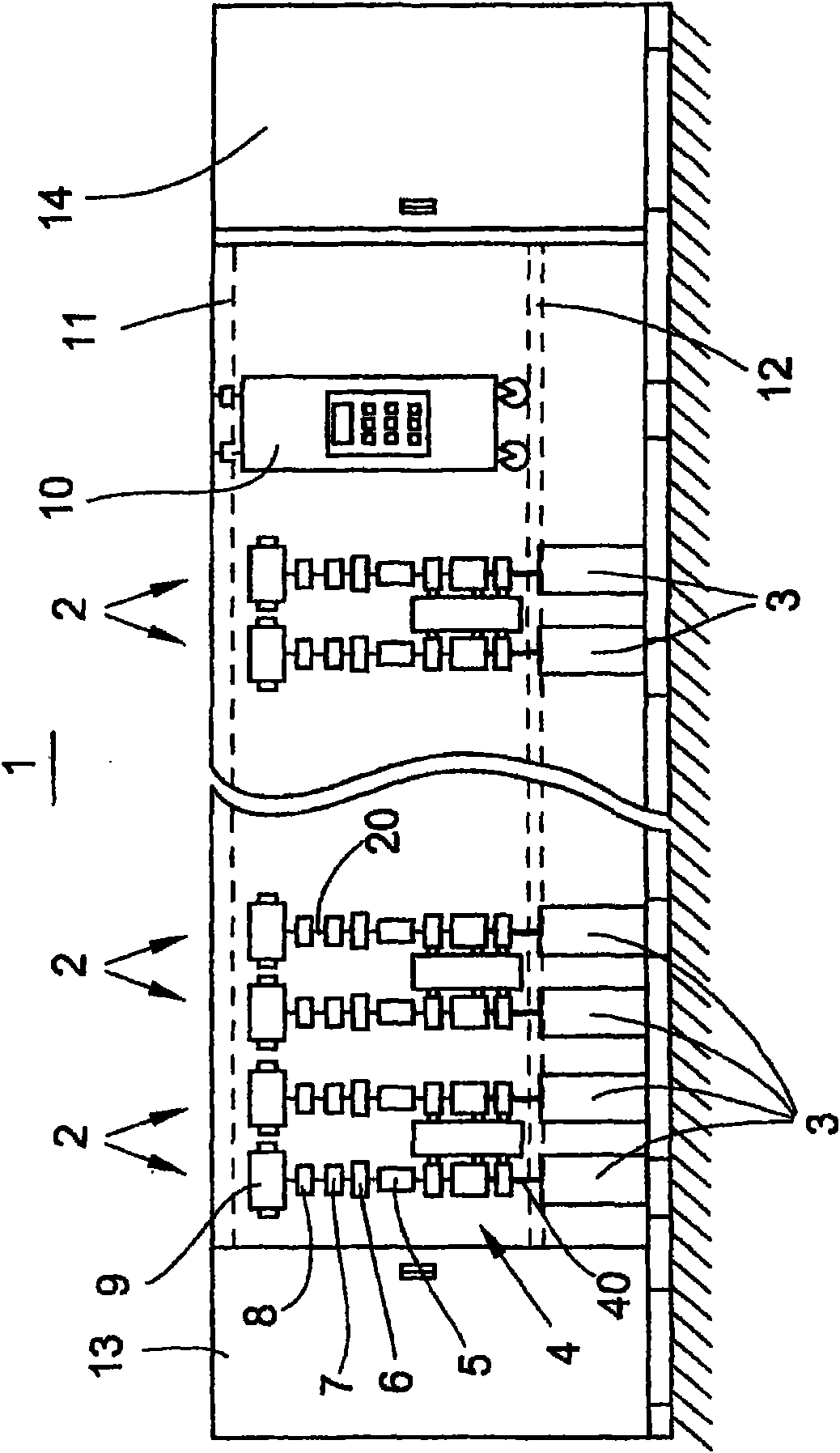

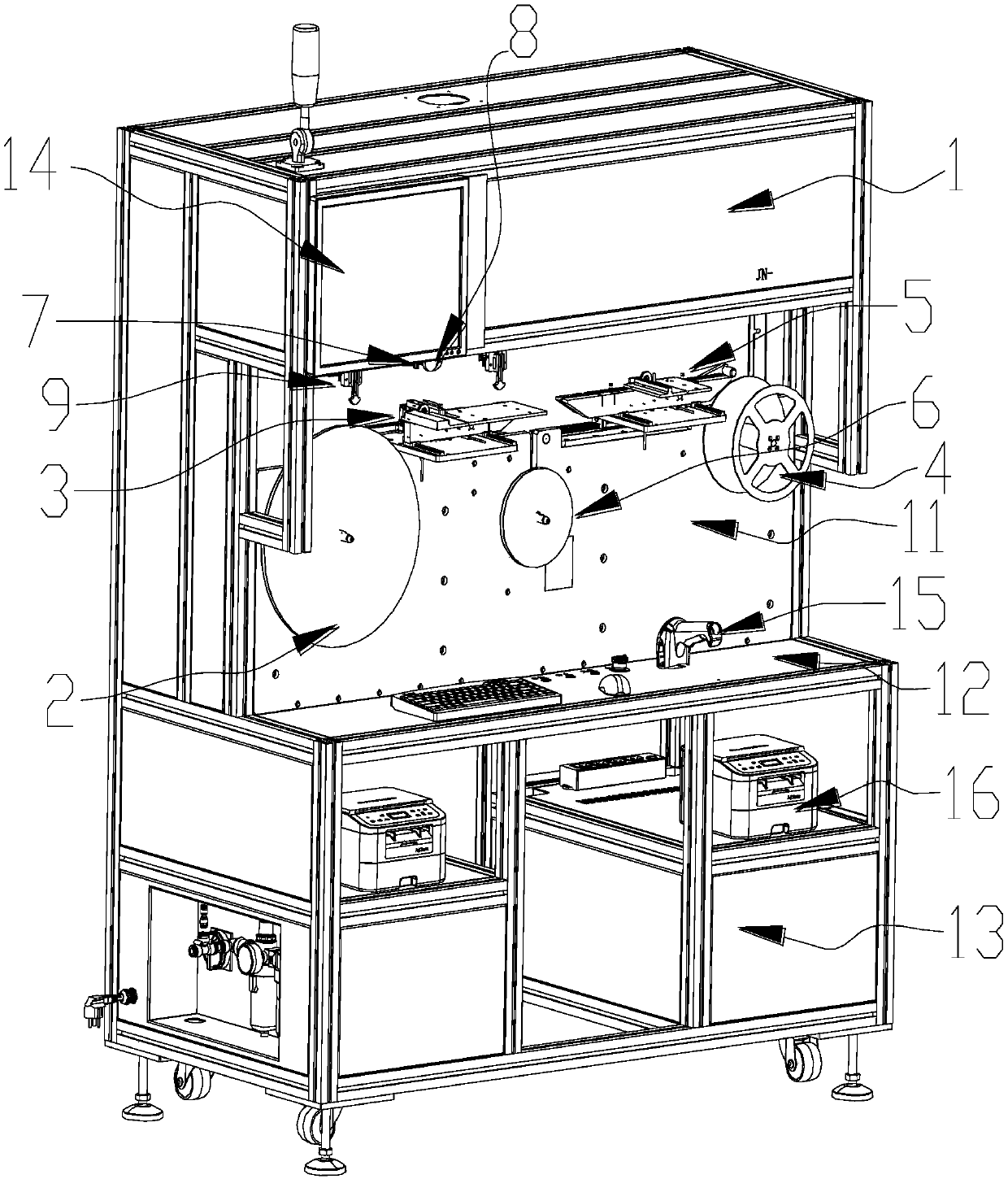

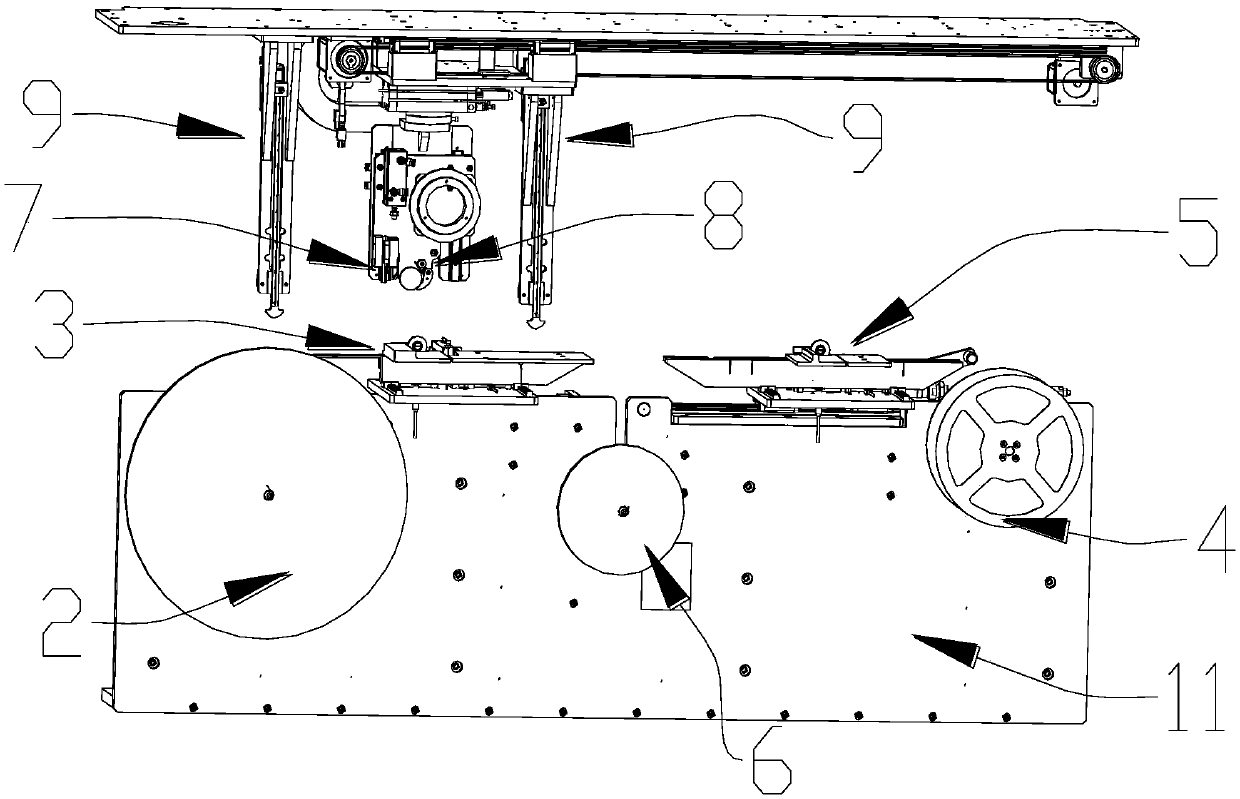

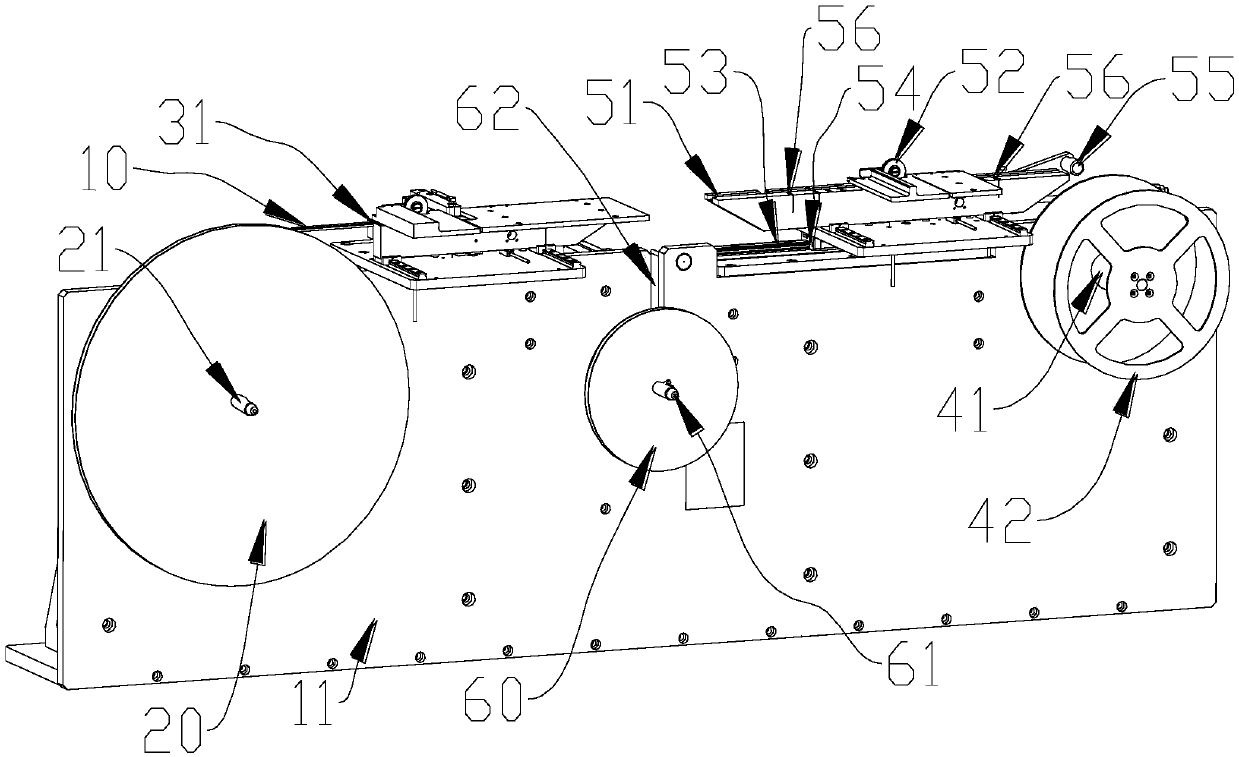

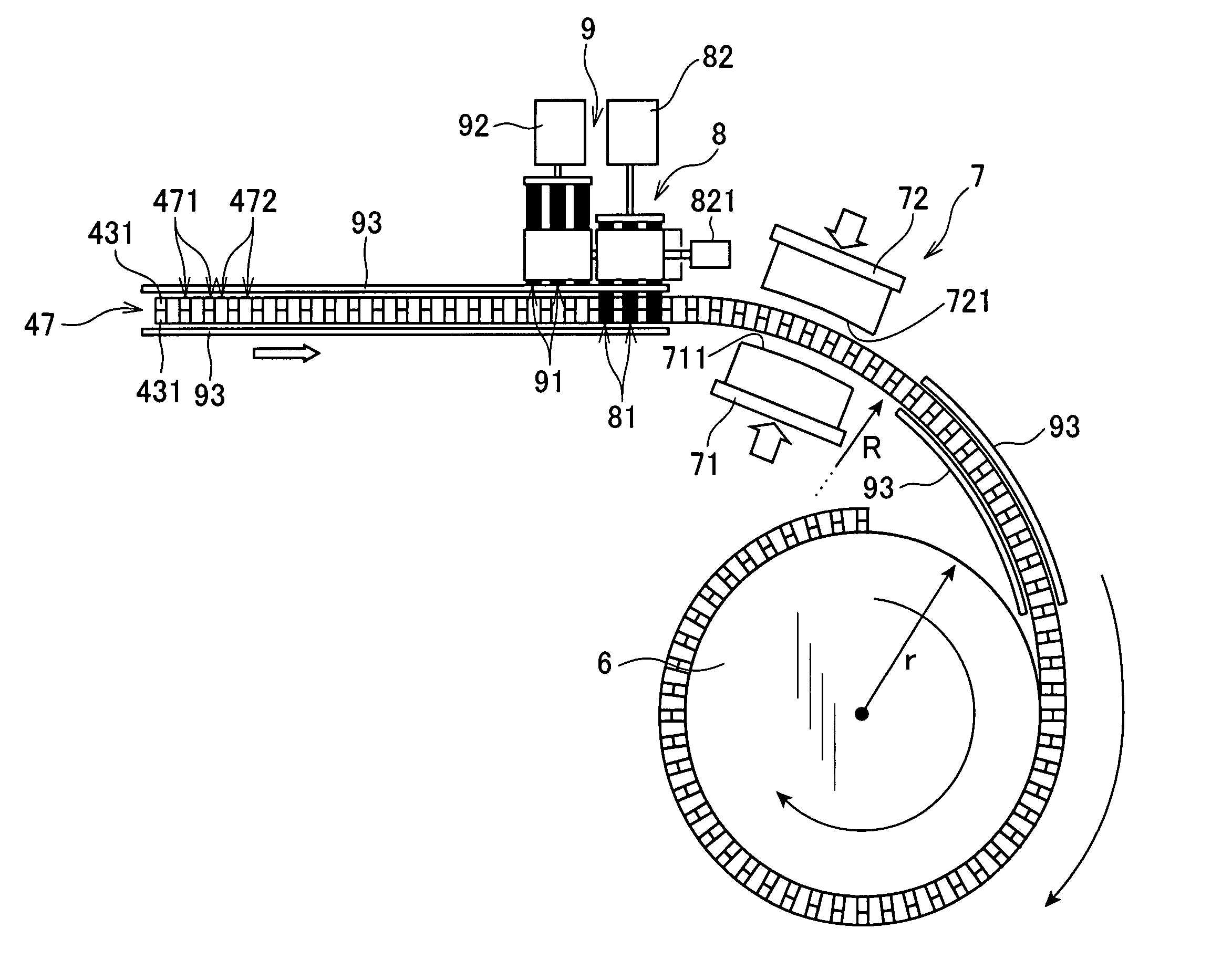

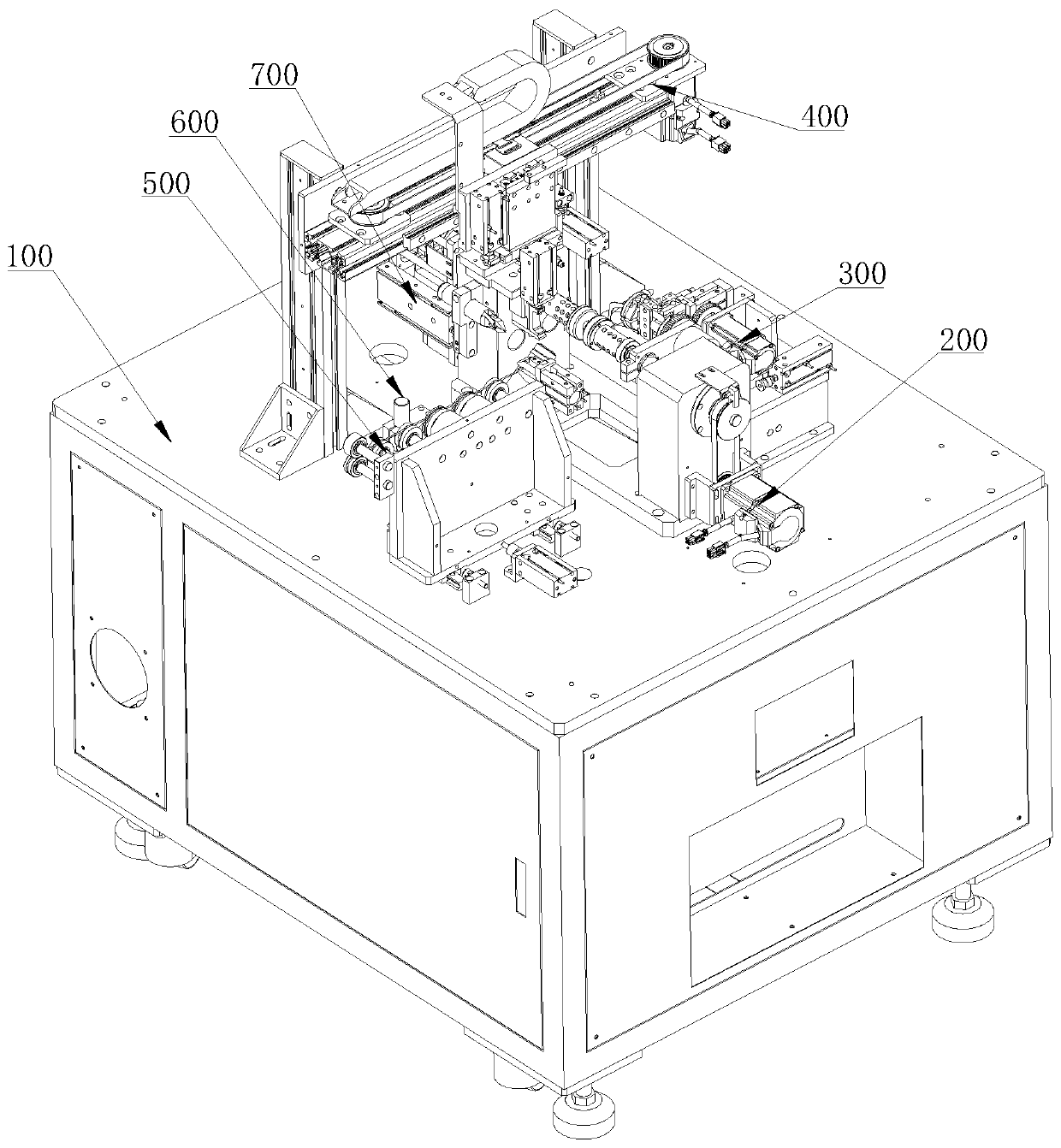

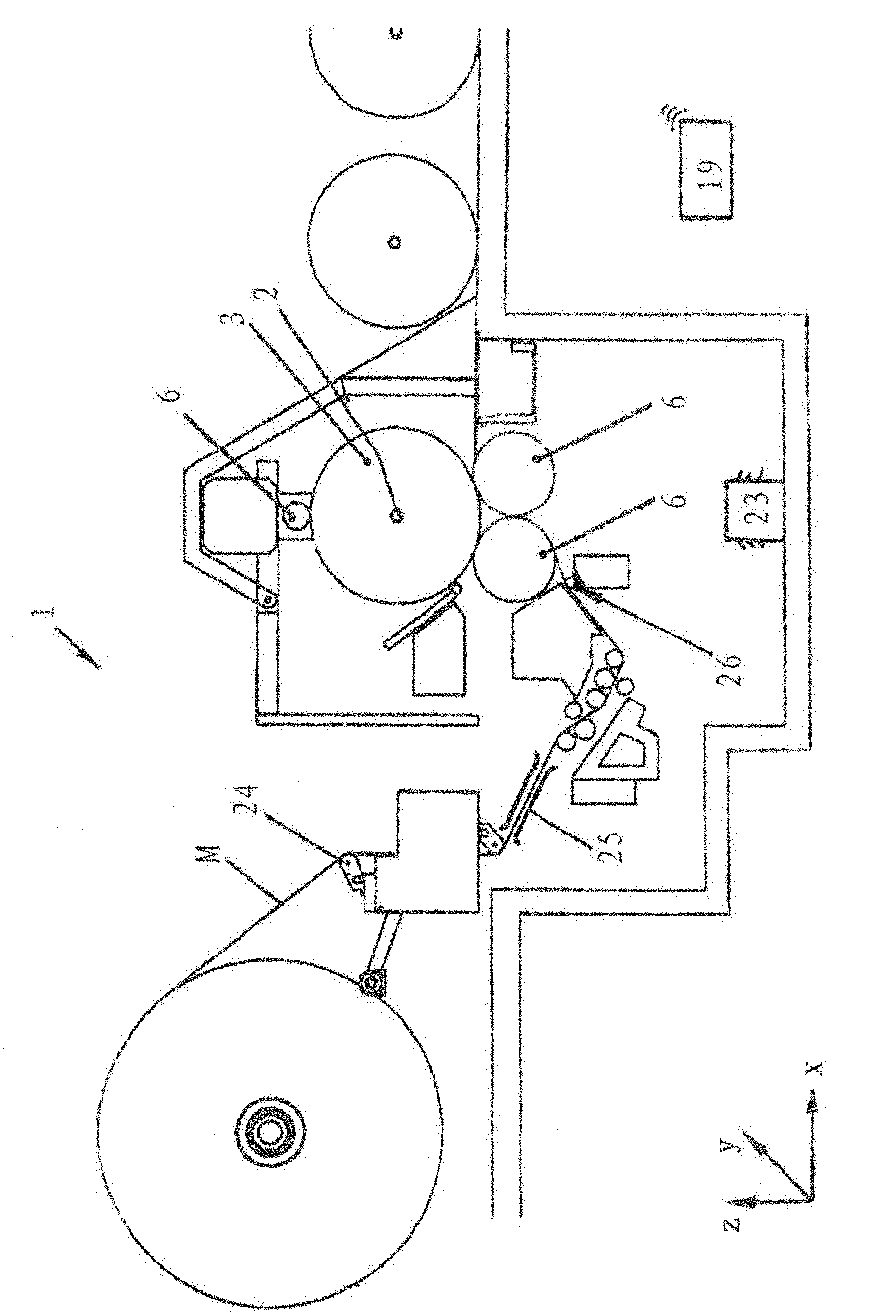

Material belt subpackaging machine, material belt subpackaging machine system and material belt subpackaging method

PendingCN109607290ASave administrative timeStable and efficient transmissionElectrical componentsArticle deliveryEngineeringMachining system

The invention discloses a material belt subpackaging machine, a material belt subpackaging machine system and a material belt subpackaging method. The subpackaging machine comprises a feeding device,a guiding device, a moving platform, a material belt transition device, a separating receiving device, a slitting device, an adhesive tape pasting device, a pressing device, a machine frame and a control module. Due to the fact that the subpackaging machine is reasonable in structural design, small in occupied space, high in automation and integration level, and high in subpackaging speed, the design thought that formerly, the integer quantity of packaging material discs do not subpackaged, and the tail disc material allowance is counted by improving the intelligence of the automatic system isbroken through, the steps that the integer quantity of packaging material discs is divided according to the actual production requirements, thus, the integer quantity of packaging material discs be subpackaged into two or more subpackaging material discs, accordingly, tail disc material allowance counting is thoroughly given up are designed, material effective management is substantially improved, the material management time is saved, and remarkable effects on material control and cost reduction in the production technology are achieved.

Owner:深圳市迦南伟业科技有限公司

Blood pressure information measurement device

ActiveCN101977547AEasy to wearReliable windingEvaluation of blood vesselsAngiographySphygmomanometerMeasurement device

Owner:OMRON HEALTHCARE CO LTD

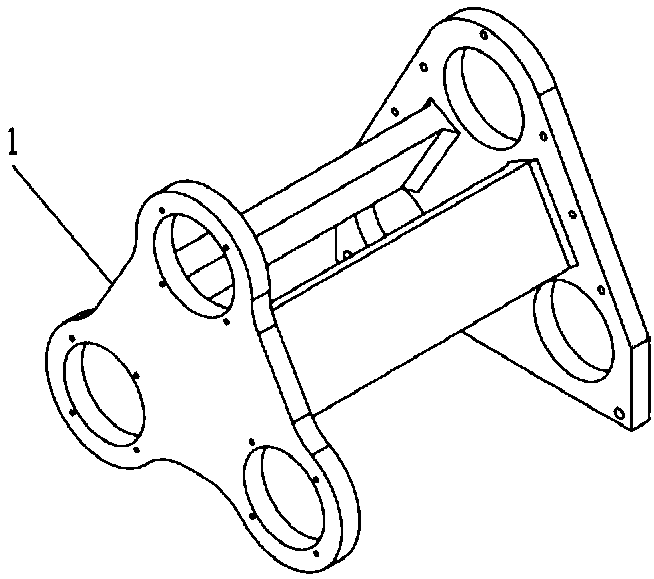

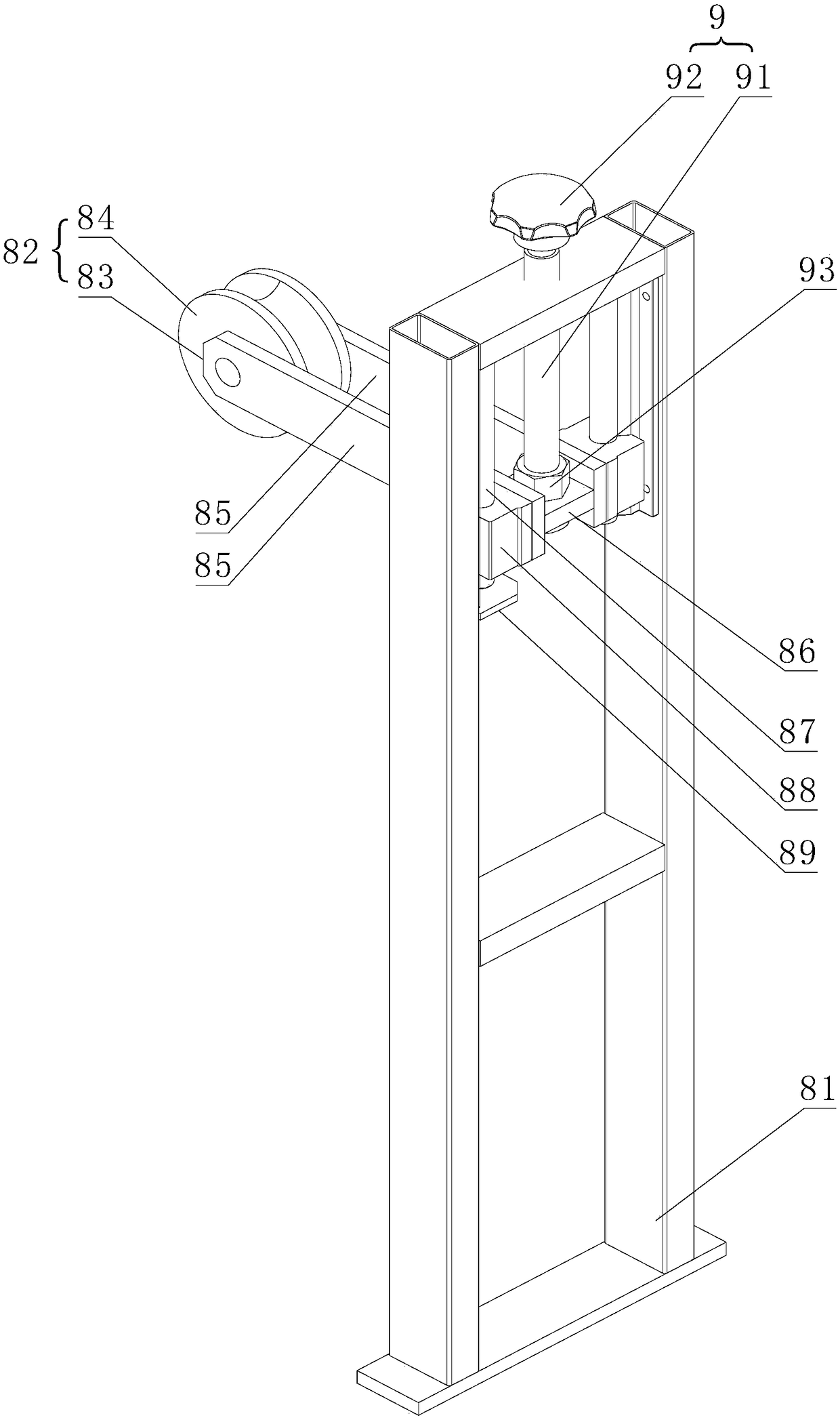

Knife rest for multi-wire cutting machine and multi-wire cutting machine with same

PendingCN109648723AReliable windingExtended service lifeWorking accessoriesFine working devicesWire cuttingLower body

The invention discloses a knife rest for a multi-wire cutting machine and the multi-wire cutting machine with the same. The knife rest is divided into a knife rest lower body and a knife rest upper body, the knife rest lower body and the knife rest upper body are rotationally connected through a shaft assembly, the shaft body assembly includes a shaft body and a shaft seat assembly, the shaft bodyis rotationally connected with the shaft seat assembly, the shaft body sequentially comprises a lower shaft body, an upper shaft body, a top fixing disc and a pulling head which are coaxial from bottom to top, and the shaft seat assembly comprises a bearing seat, a bearing, an oil seal cover, an oil seal and an end cover. The multi-wire cutting machine includes the above knife rest. According tothe requirement for slicing sheets with different thicknesses, in particular to the requirement for slicing sheets with large thicknesses, the spacing between steel wires is adjusted, the adjusted steel wires are reliably wound in wire troughs, scraping with wire trough walls is not prone to happening, moving to other wire troughs is not prone to happening, accurate cutting is achieved, the cutting precision and efficiency are greatly improved, and the service life of an upper winding main shaft, a lower winding main shaft and the steel wires is prolonged.

Owner:玉田县昌通电子有限公司

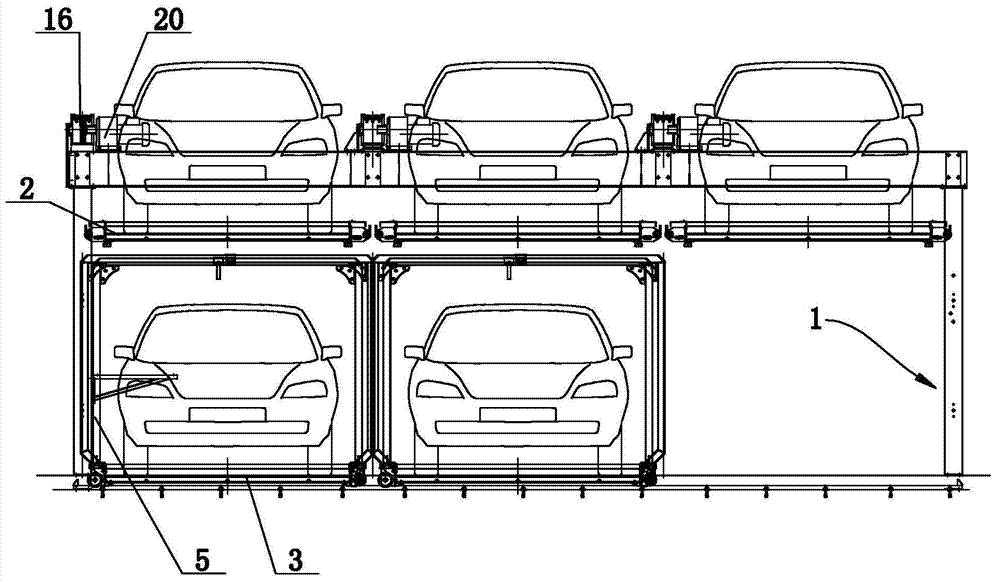

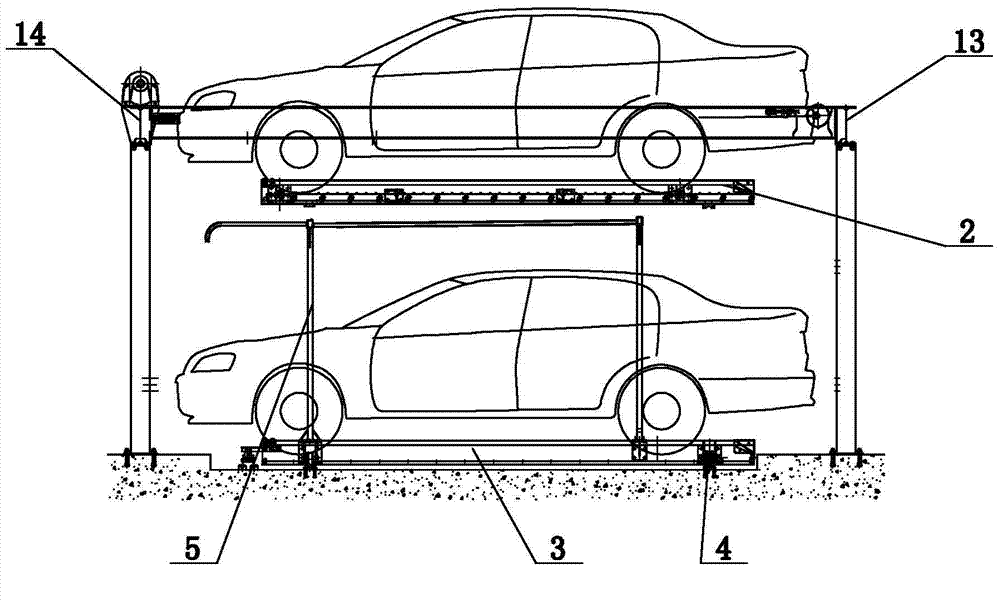

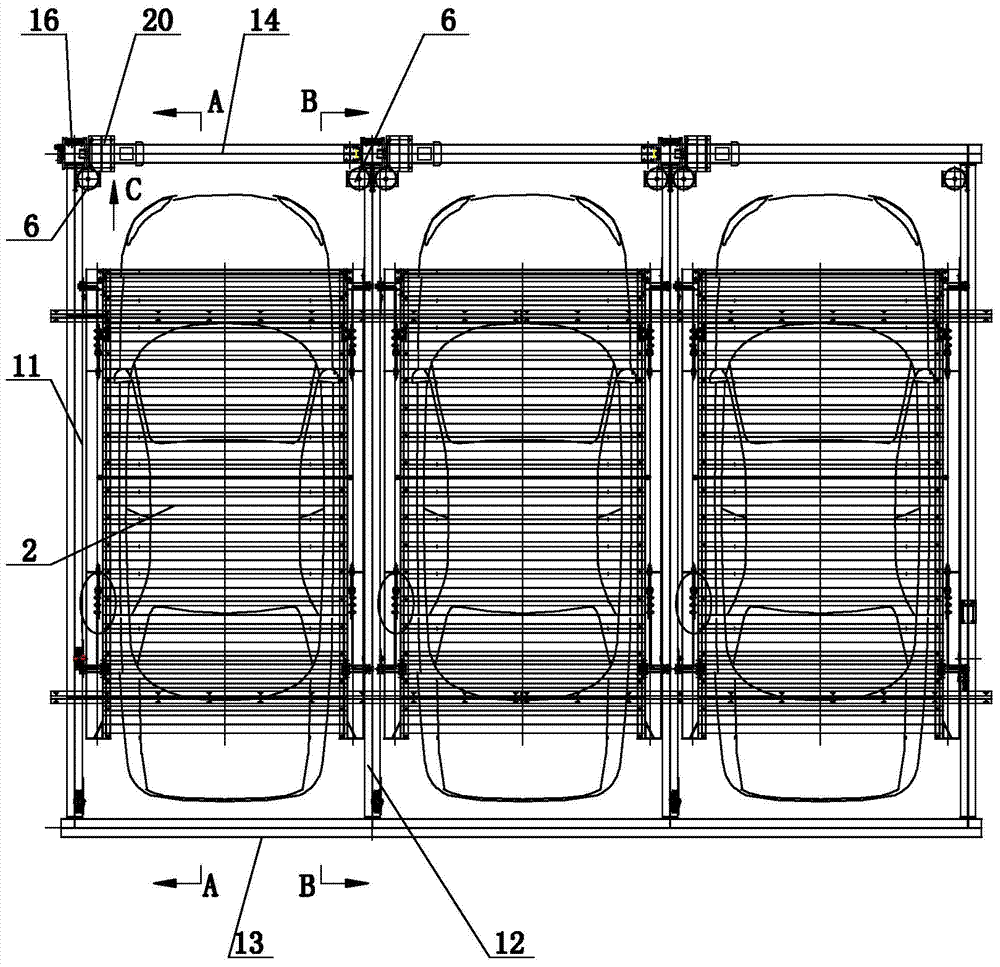

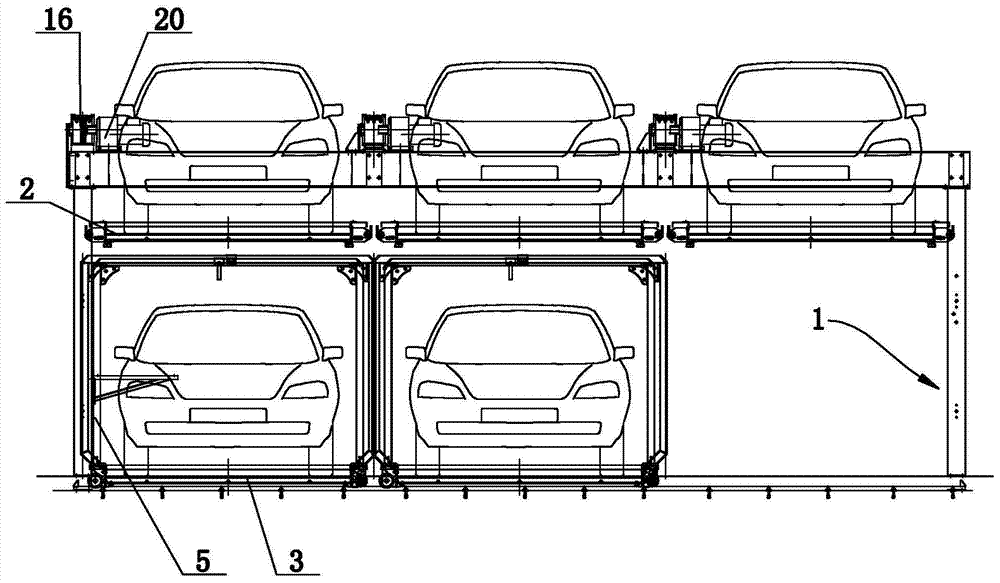

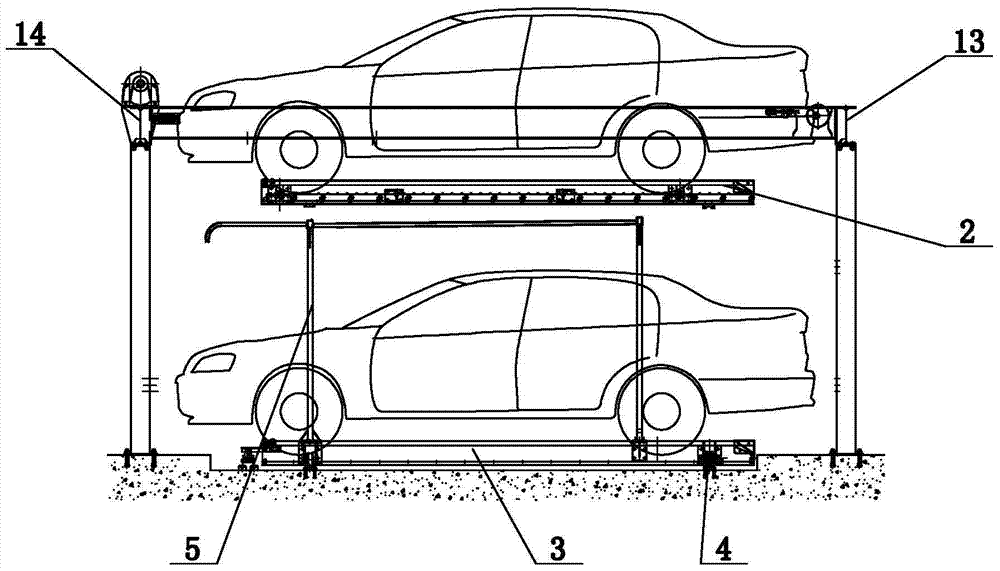

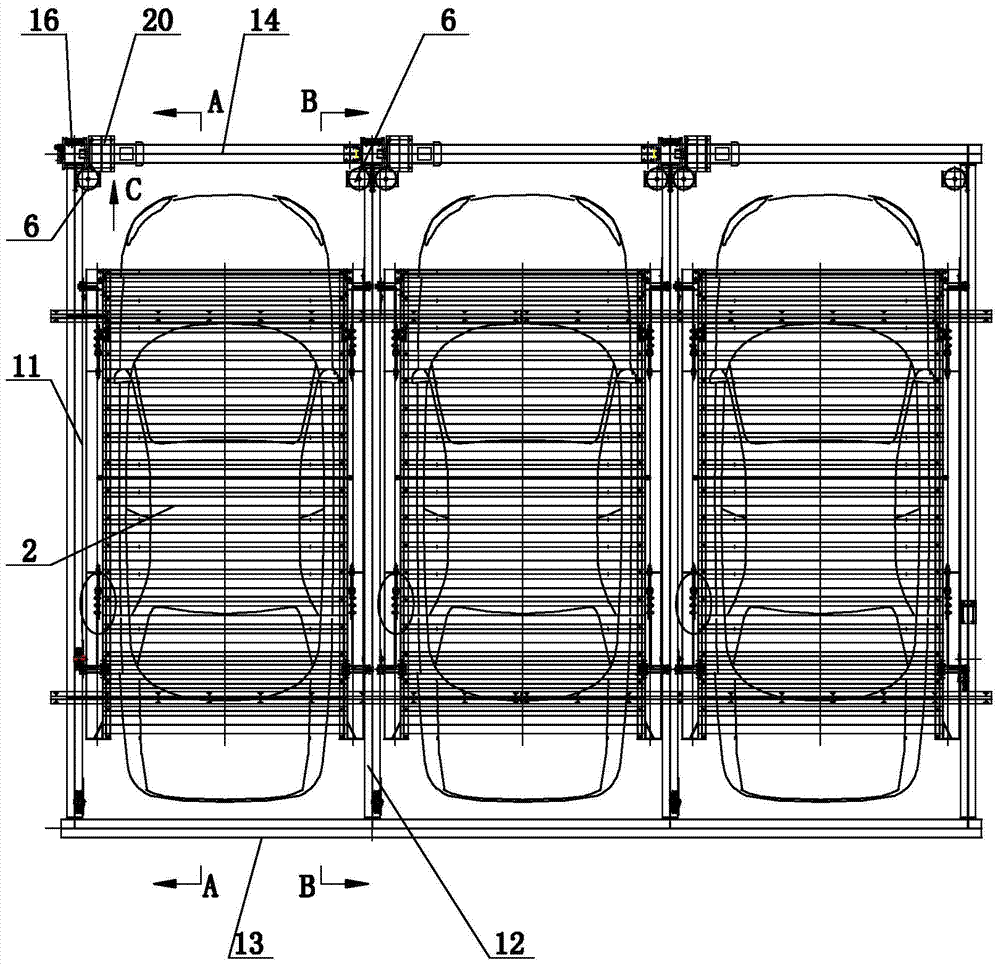

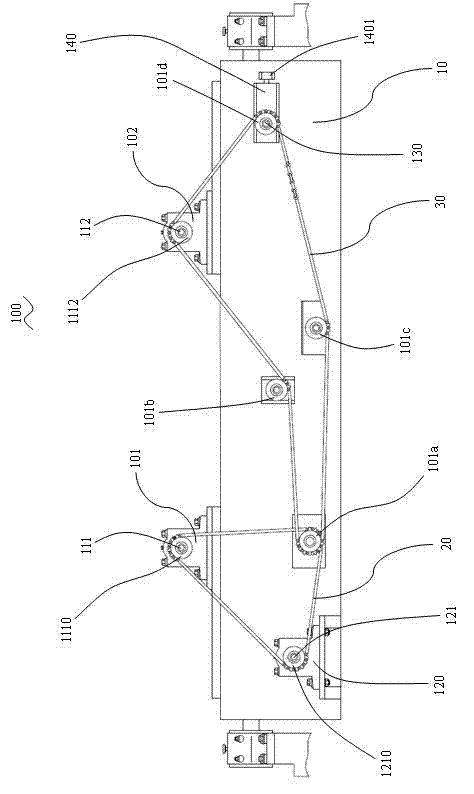

Lifting horizontal-moving type parking equipment

The invention discloses lifting horizontal-moving type parking equipment and belongs to the technical field of stereo garages. The equipment comprises m rows of steel structure frames, m lifting car carrying plates, m-1 horizontal-moving car carrying plates, an anti-falling mechanism, a duplex horizontal steering fixed pulley block, a first vertical steering fixed pulley, a first duplex vertical steering fixed pulley block, a moving pulley, a third vertical steering fixed pulley, two second vertical steering fixed pulleys and a coiling block driven by a power mechanism. A transmission steel wire rope arranged on the coiling block is wound around the first vertical steering fixed pulley and the moving pulley and then is fixed at the end, close to a first horizontal beam, of a first longitudinal beam. A second rope winding device for pulling the lifting car carrying plate is arranged on the moving pulley. The lifting horizontal-moving type parking equipment is simple in structure, low in manufacturing cost, attractive in appearance and high in reliability.

Owner:DAYANG PARKING CO LTD

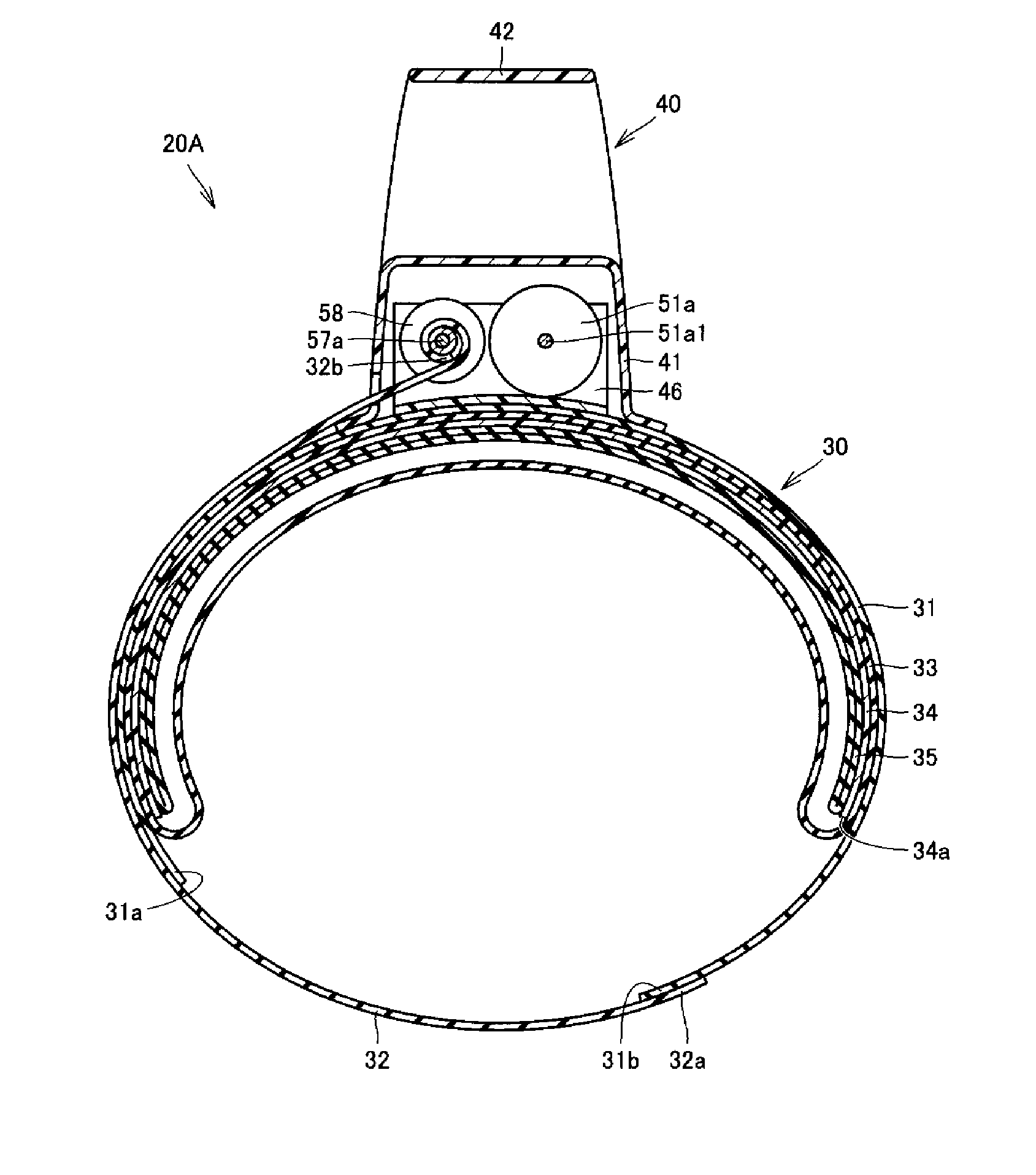

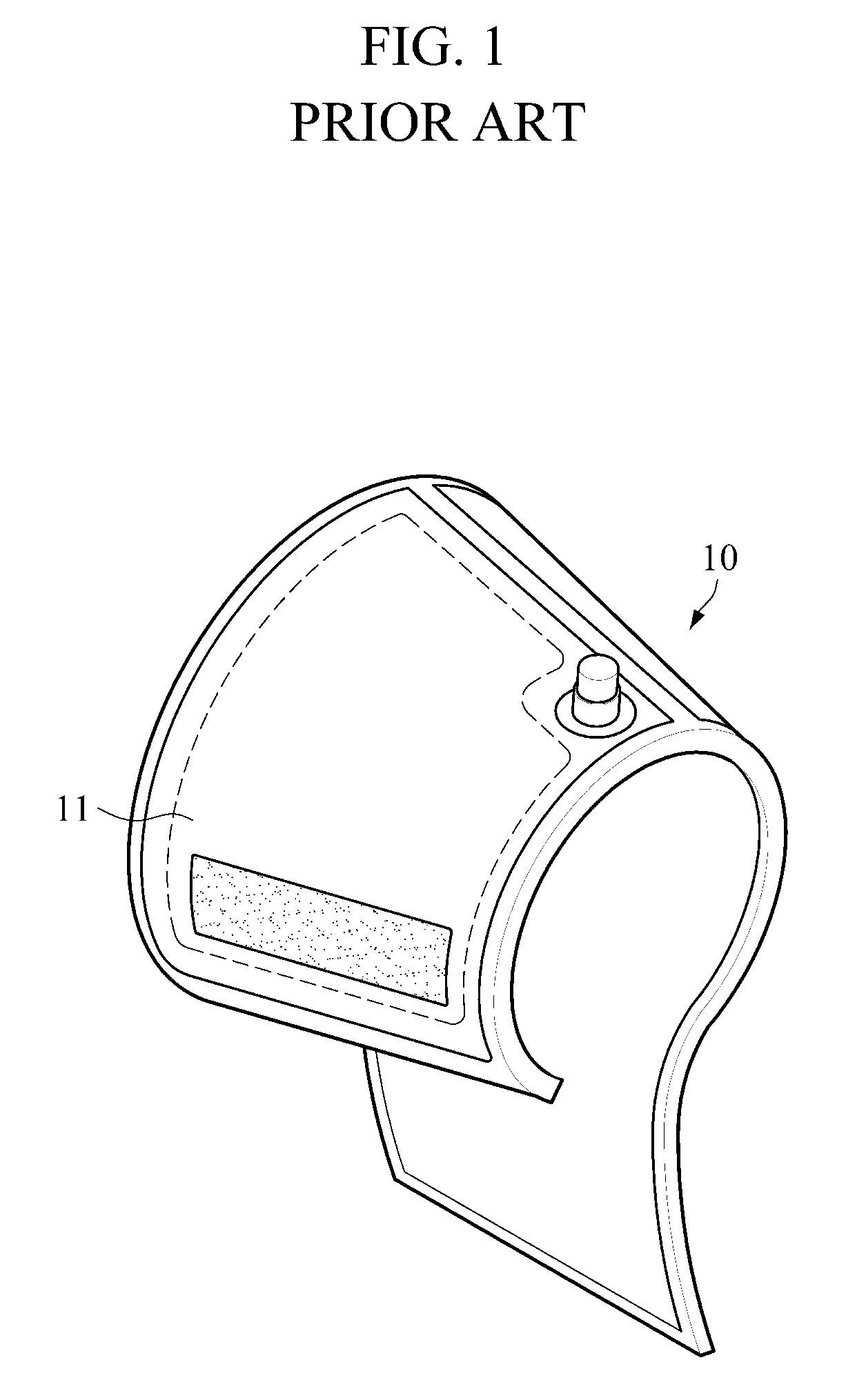

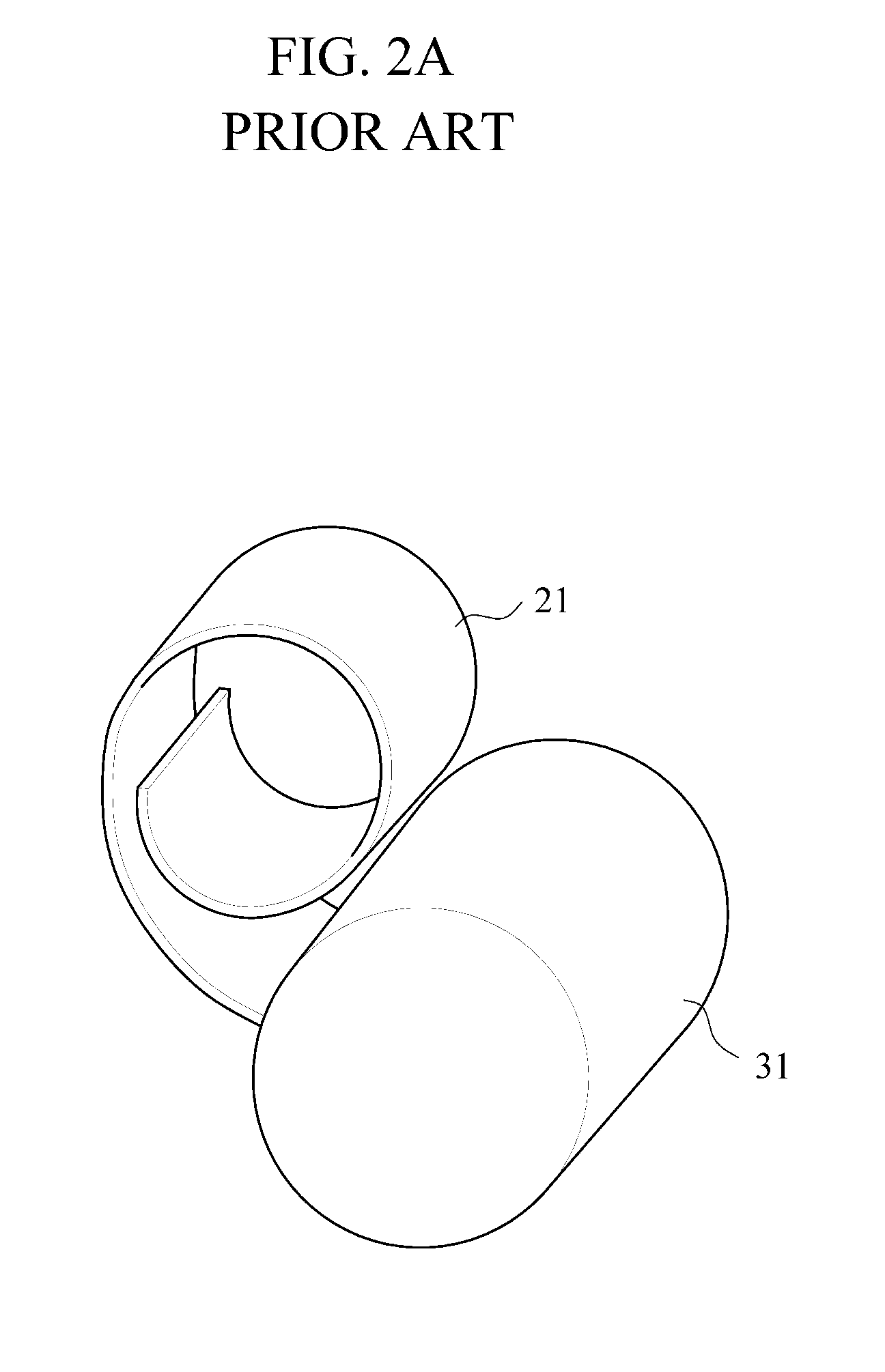

Cuff for hemadynamometer

InactiveUS20110071410A1Reliable windingEasily reliably precisely windEvaluation of blood vesselsCatheterBlood pressureCuff

Disclosed is a cuff for a hemadynamometer, which is used for measuring blood pressure of a testee. The cuff includes a fluid bag for applying pressure to a body of the testee, at least one flexible member disposed at an outer portion of the fluid bag and a cover member accommodating the fluid bag and the flexible member therein. The flexible member is maintained in a stretched state and is deformed into an annular state when a force is applied to the flexible member in a winding direction of the cuff such that the cuff is wound around the testee. The cuff can be wound around the testee, so that blood pressure is measured. A testee is able to wind the cuff around his or her own arm without the need for assistance.

Owner:BIOSPACE

Automatic winding machine for producing magnetic core

The invention relates to an automatic winding machine for producing a magnetic core. A through sliding groove is formed in a support in the length direction, a winding framework is arranged on the support and extends downwards to form a sliding rail matched with the sliding groove, and a first driving device can drive the winding framework to slide in the sliding groove. A winding device is arranged on the winding framework and comprises a first winding body and a second winding body, the first winding body and the second winding body are opposite in position and form bearing space used for containing the magnetic core, and a second driving device can drive the winding device to rotate. An unwinding frame is arranged on the support, an unwinding wheel is rotationally connected with the unwinding frame, and a metal wire on the unwinding frame is output through the unwinding wheel and connected to the winding device. A wire breaking device is arranged on the support, and a third driving device can drive the wire breaking device to cut the metal wire between the unwinding wheel and the winding device. By means of the automatic winding machine for producing the magnetic core, the device is simple, winding is reliable, and work efficiency is high.

Owner:ZIBO KUAKE MEDICINE TECH

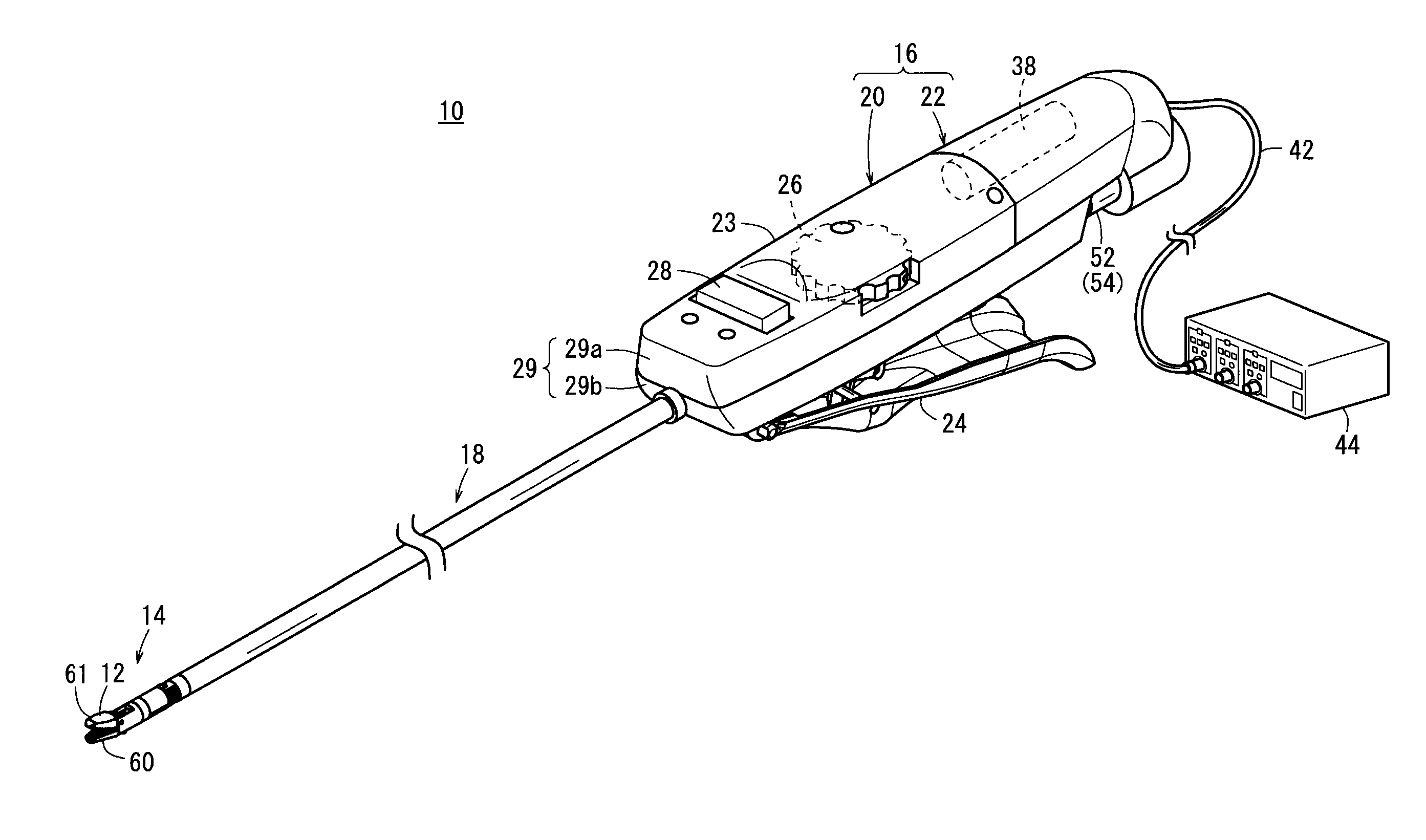

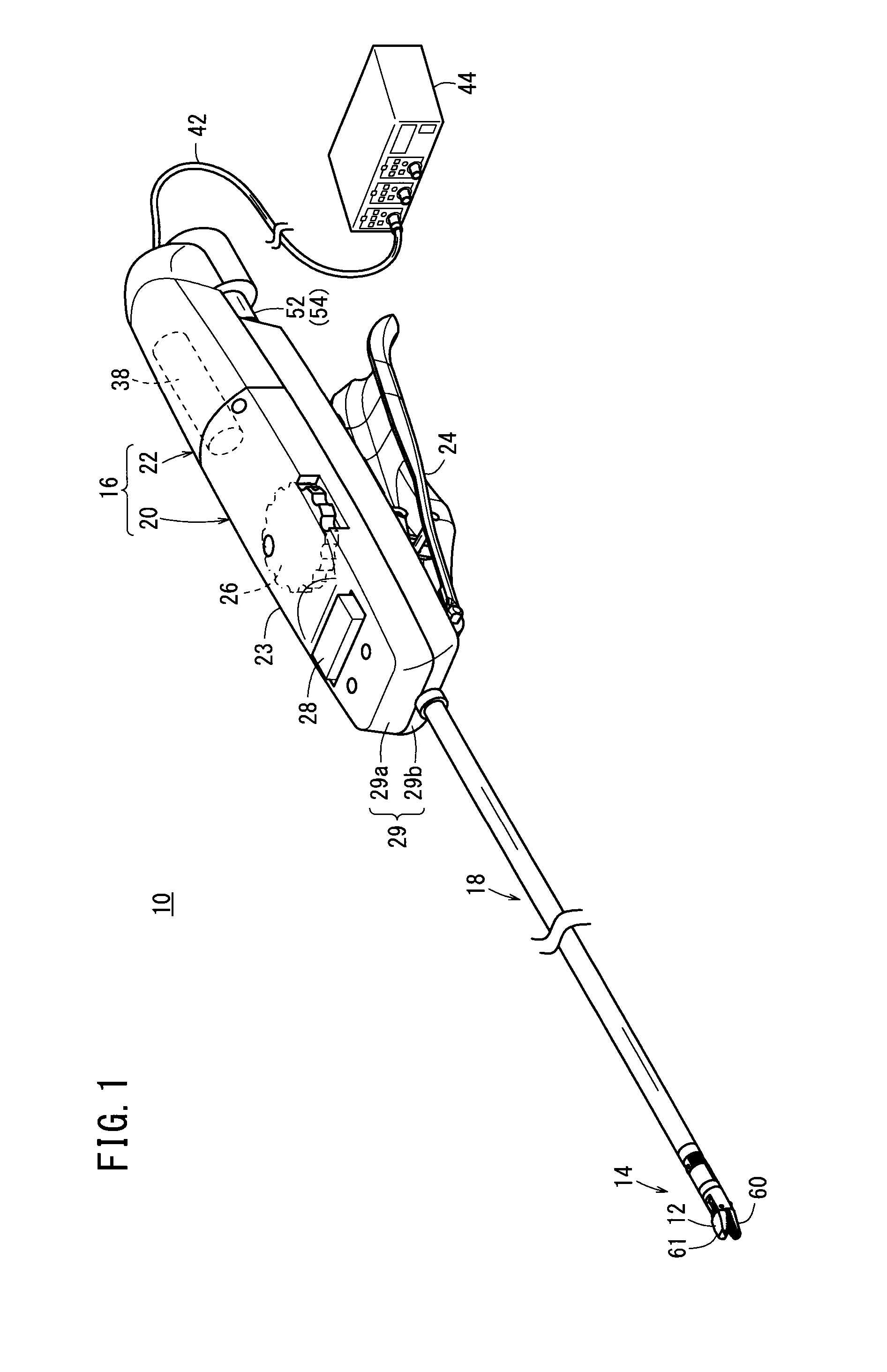

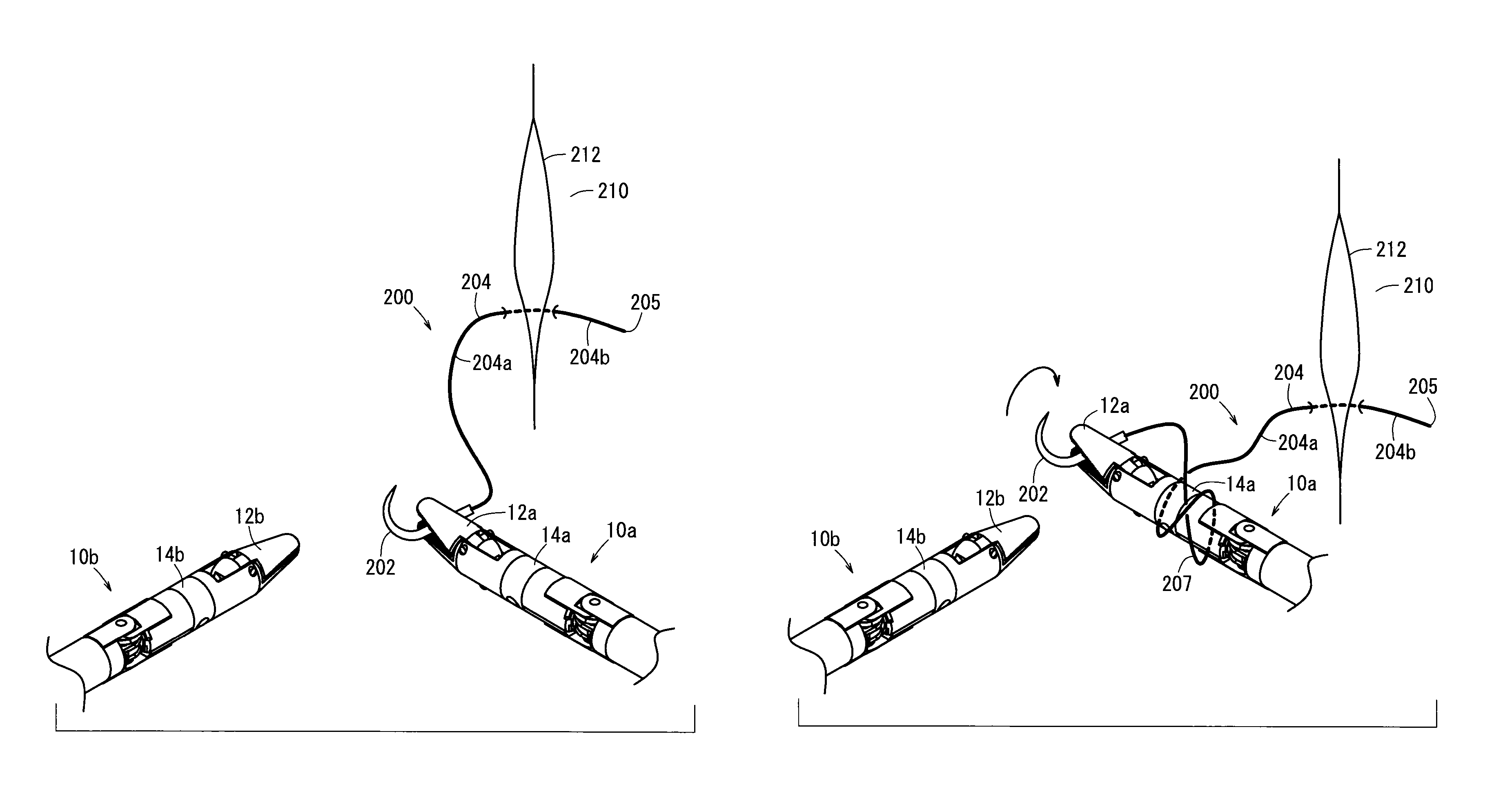

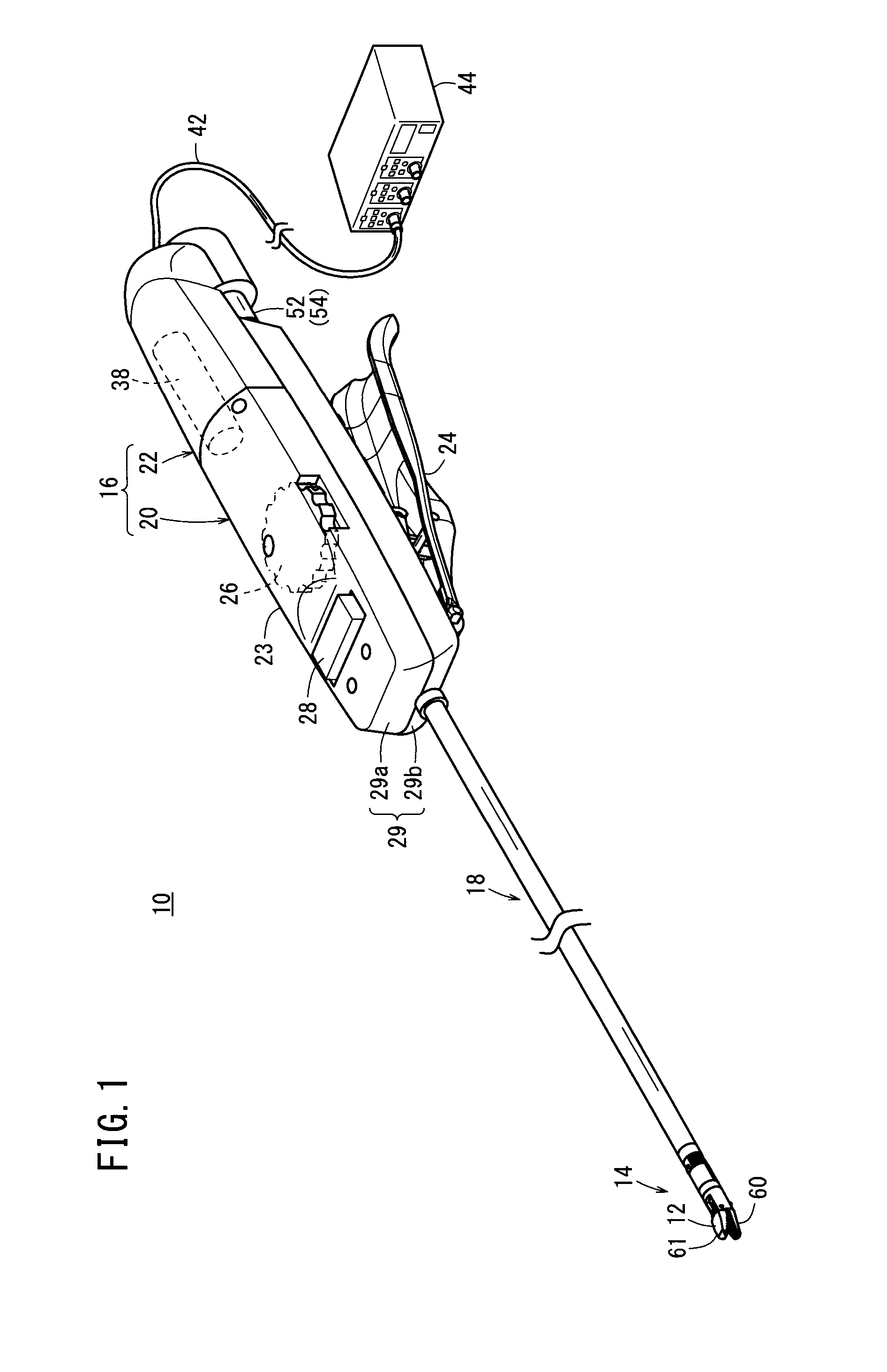

Suturing and ligating method

ActiveUS20140121680A1Easy to sutureConvenient ligationSuture equipmentsSurgical needlesSuturing needleEngineering

A suturing and ligating method includes a needle piercing step of inserting a needle of a suture-needle assembly through a tissue in a body cavity, a needle gripping step of gripping the needle with a first gripper, a winding step of winding a suture strand of the suture-needle assembly in at least one turn around a first distal-end working unit by rolling the first distal-end working unit in at least one revolution, a transferring step of transferring the suture-needle assembly from the first gripper to a second gripper, a suture strand gripping step of gripping a portion of the suture strand that has not passed through the tissue, with the first gripper, a pulling step of pulling the first distal-end working unit out of a loop of the suture strand, and a tightening step of forming a knot of the suture strand.

Owner:KARL STORZ GMBH & CO KG

Cuff for blood pressure gauge, and blood pressure gauge having the cuff

ActiveCN101977548AEasy to wearReliable windingEvaluation of blood vesselsAngiographySize differenceBlood pressure

Provided is a blood pressure gauge cuff (20) comprising an upper arm supporting bed (30) which can support an upper arm, and an arm band (40) which can be wound on the upper arm. The upper arm supporting bed (30) includes an upper arm supporting face (31a) for supporting the upper arm applied thereto, a take-up mechanism which is enabled, by pulling one end portion of the arm band (40) in the take-up direction, to take up a portion near the one end portion of the arm band (40), and a hook (36) capable of retaining the portion near the other end portion of the arm band (40) extracted from the take-up mechanism against the tension of the take-up mechanism. The upper arm, which is supported on the upper arm supporting bed (30), is fastened, while the portion near the other end portion of thearm band (40) is being retained by the hook (36), by the upper arm supporting face (31a) and the arm band (40) of the portion extracted from the take-up mechanism. The blood pressure gauge cuff thus constituted can be easily mounted on the upper arm as a measurement region having a size difference, and its reliable winding on the upper arm can be repeated at each time of measurement.

Owner:OMRON HEALTHCARE CO LTD

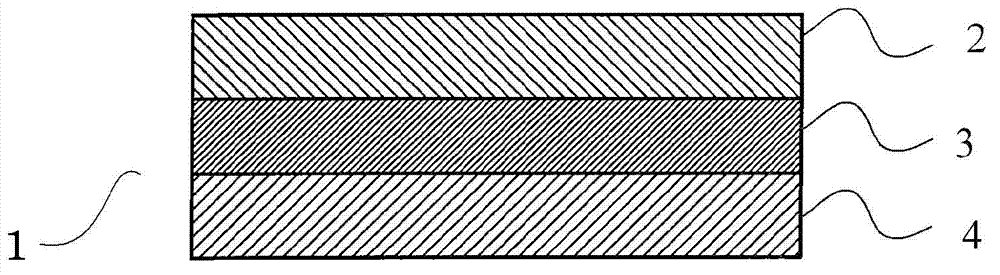

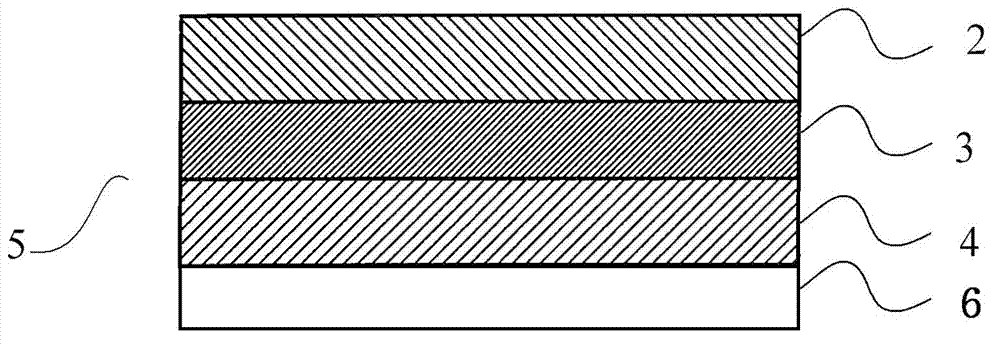

Self-rolling adhesive film

InactiveCN103289585AReliable windingHigh yieldAdhesive processesLayered productsStress concentrationShear stress

The invention provides a self-rolling adhesive film. In detachment by self-rolling, if the leading end of the rolling adhesive layer comes into contact with the rear surface thereof, which is not an adhesive layer side of an easily detachable adhesive sheet, the diameter of the circular cross section of a roll cannot be reduced. If so, the detachment angle is lowered. Because of this, it becomes difficult to minimize detachment stress and the amount of remaining glue increases. Furthermore, if rolling into a cylindrical roll is stopped in the middle, for example, the shape of a roll becomes unstable. Consequently, it is difficult to smoothly deform into a cylindrical roll and subsequently collect an easy detachable adhesive sheet. Besides these, since stress is concentrated to a local point, there is a high possibility of breaking a workpiece. A self-rolling adhesive film formed by laminating a substrate film formed of a laminate having at least one thermal contraction film and an adhesive layer on a surface of the substrate film, not formed of a thermal contraction film, in which shear stress between the surface of the thermal contraction film of the substrate film and the adhesive layer thereof is 240 g / mm 2 or less.

Owner:NITTO DENKO CORP

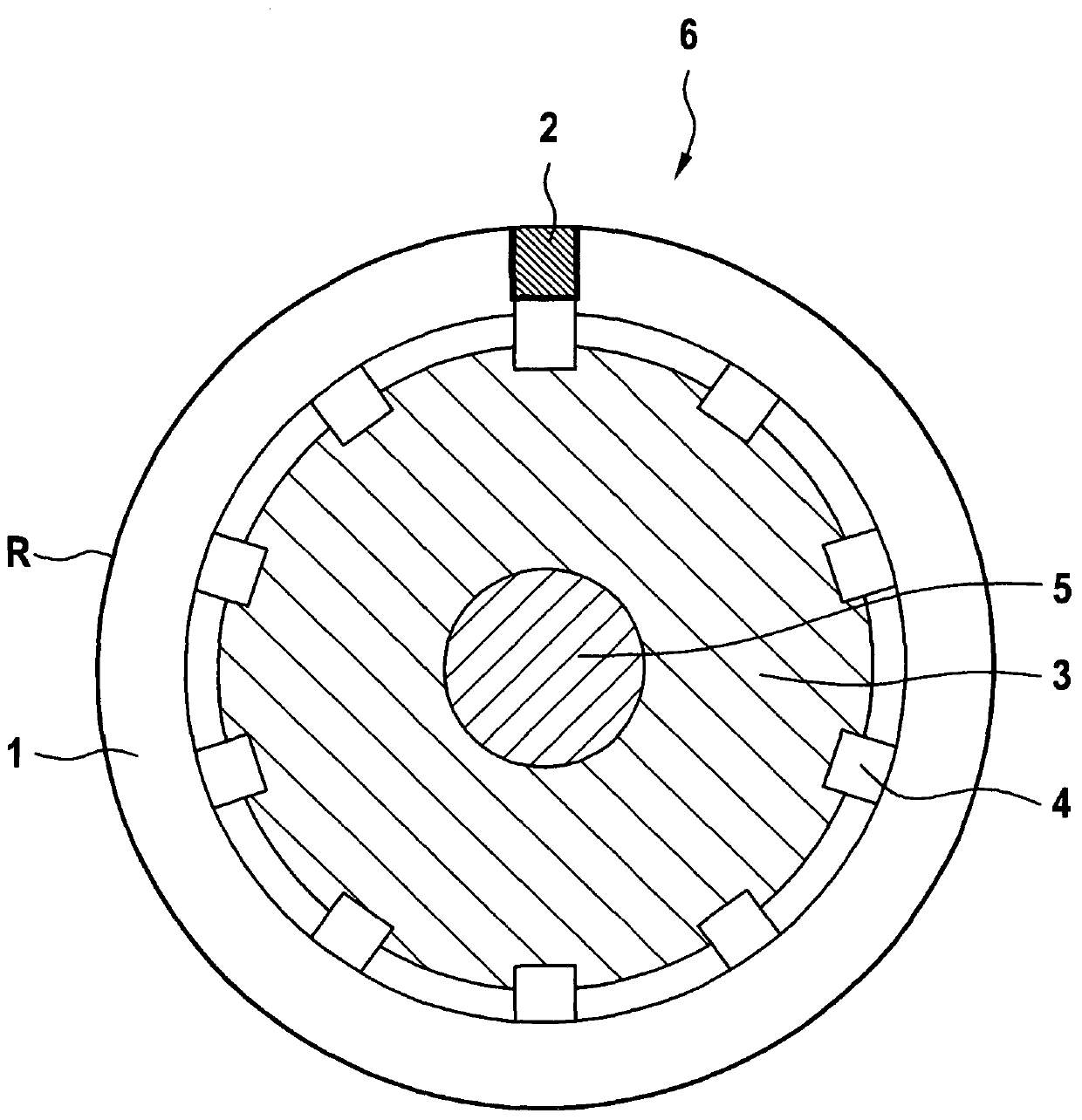

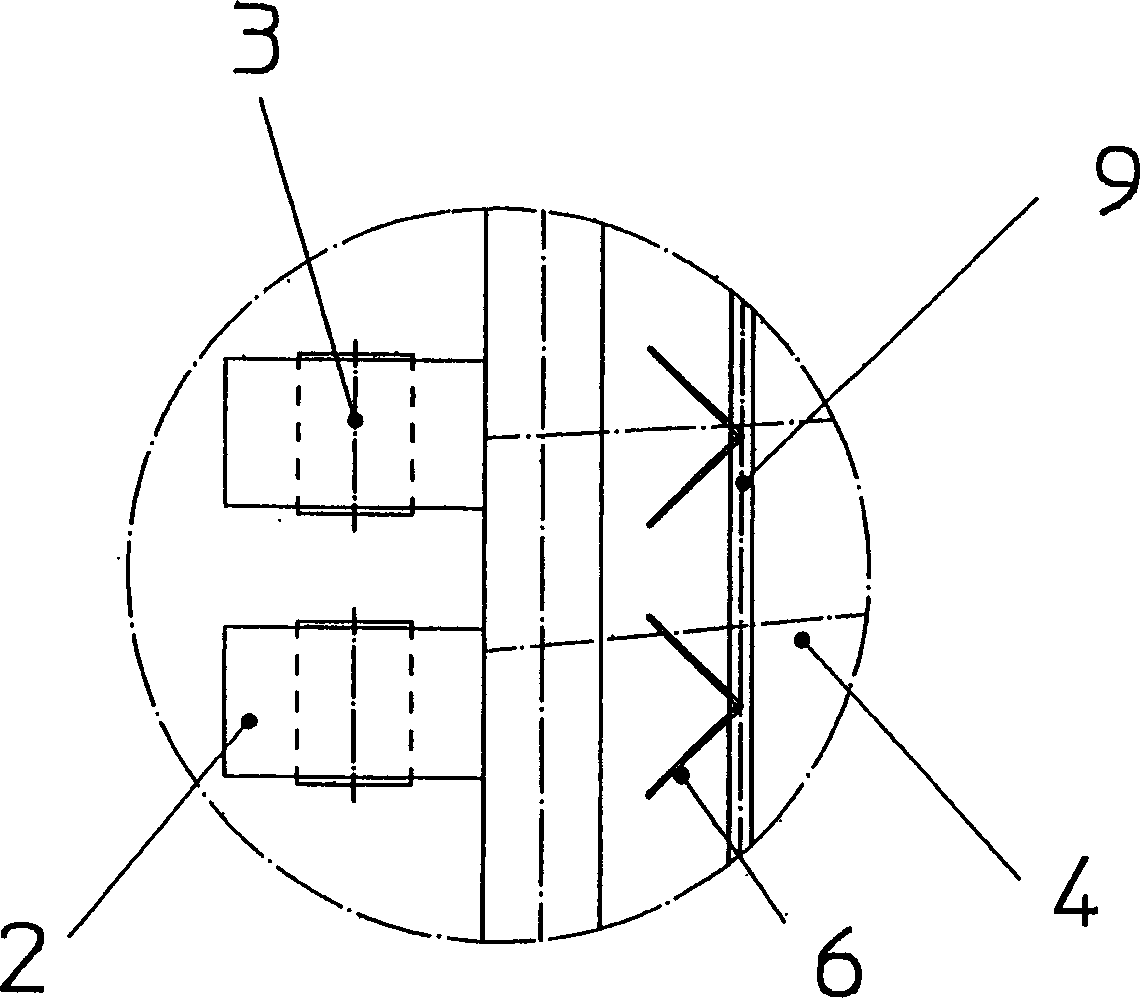

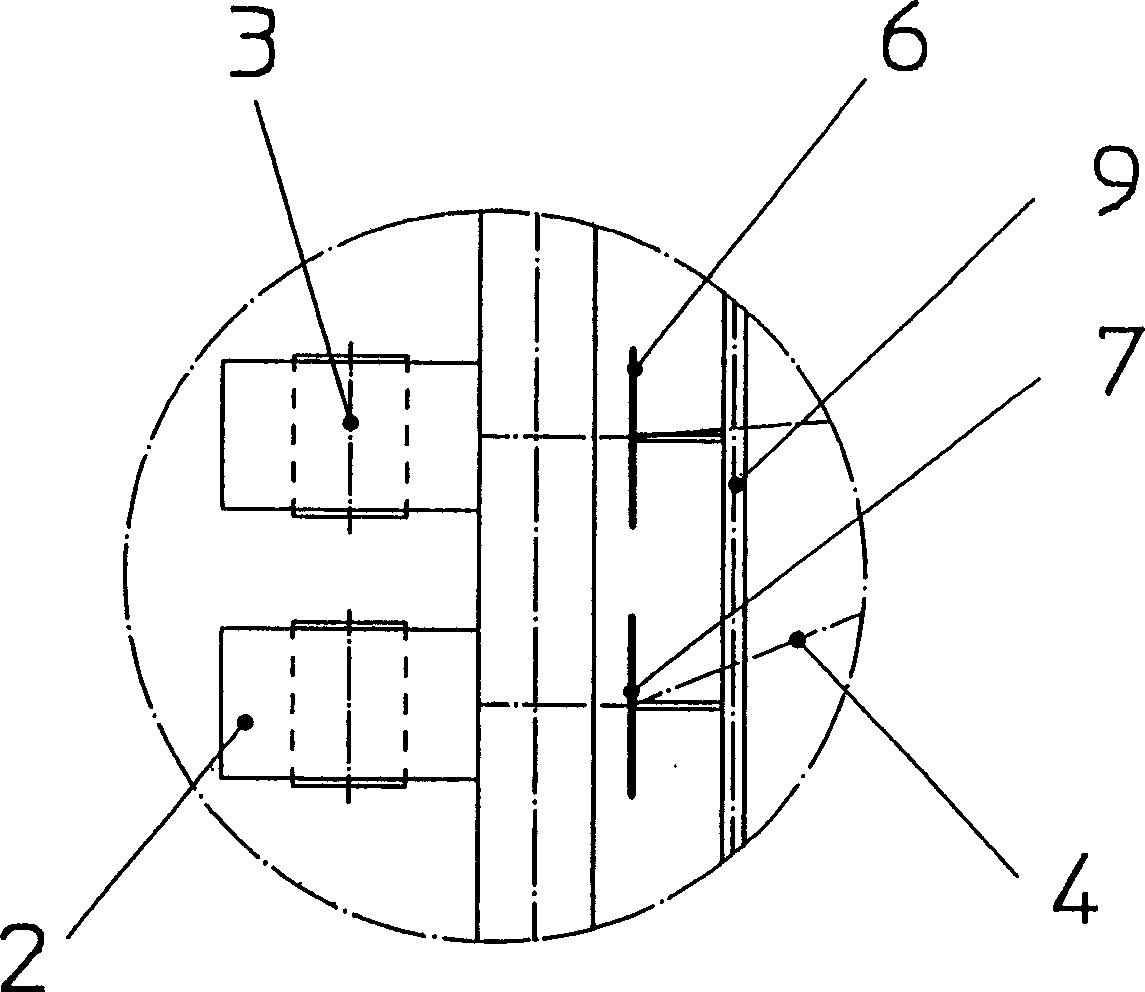

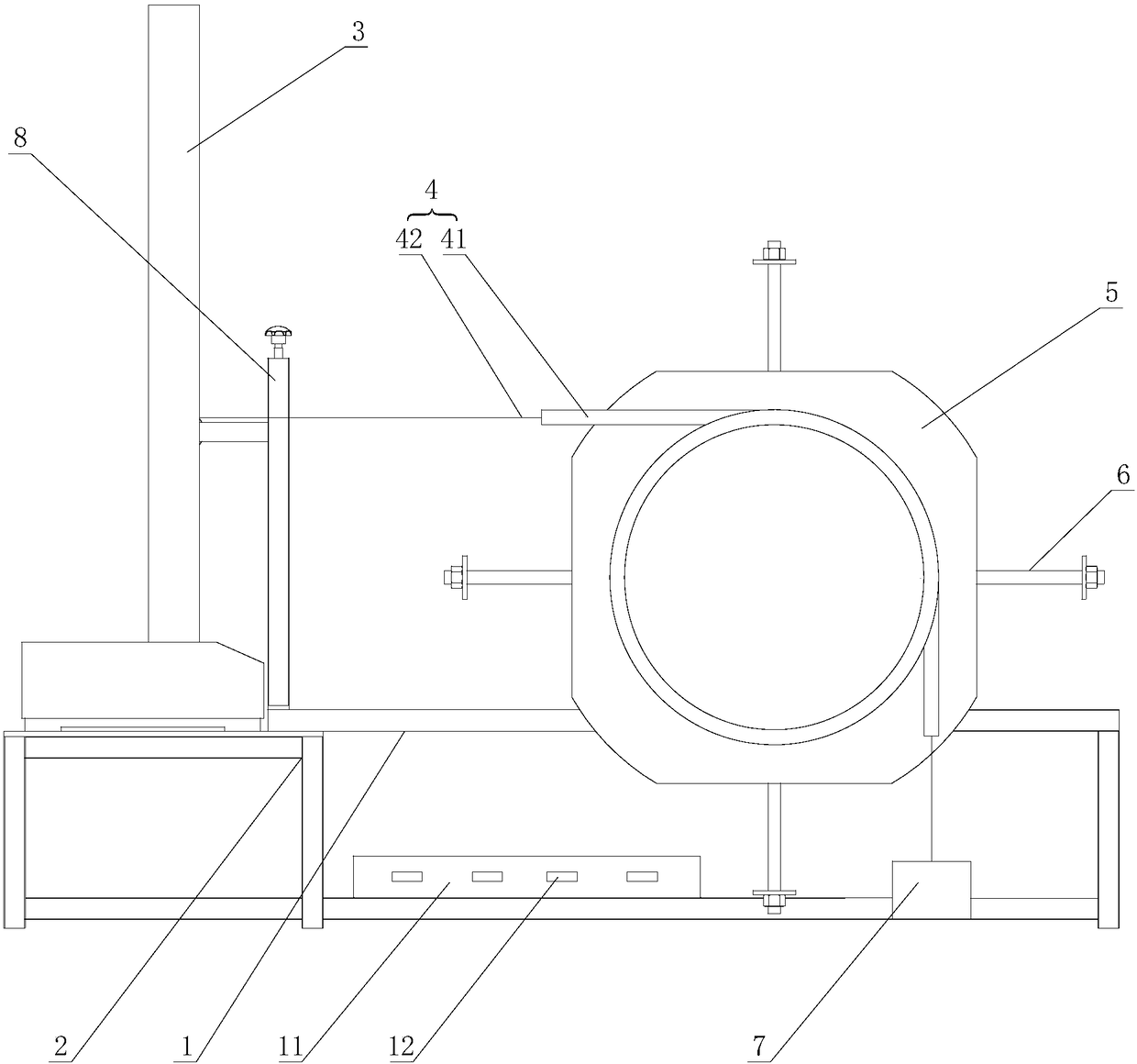

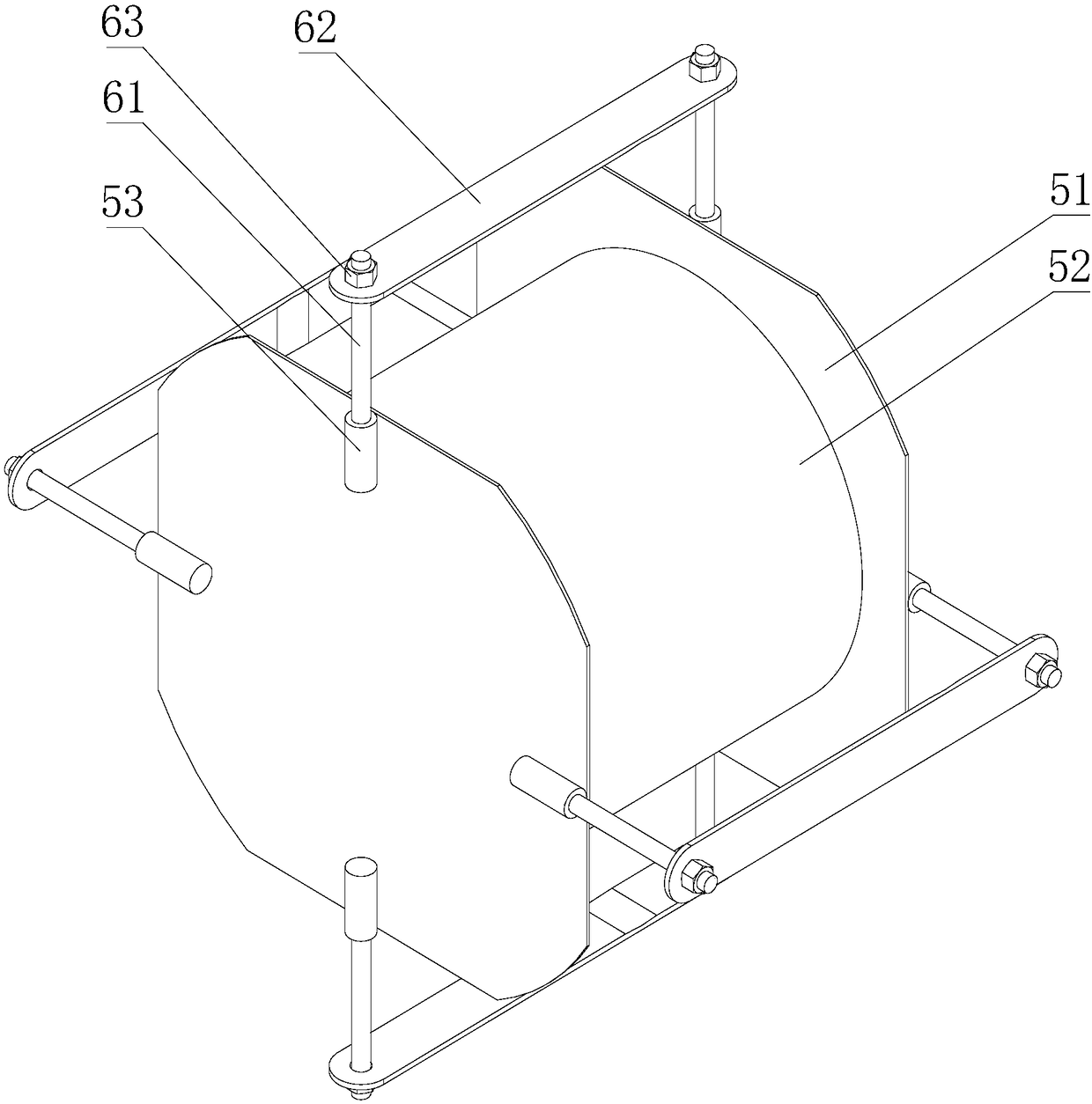

Arrangement for winding a web of material

The invention relates to an arrangement for winding a web of material, in particular a web of tire cord fabric, comprising a sleeve-like winding body (1), which can be set into rotation by a shaft coupled thereto, onto which the web of material is wound, and a holding mechanism that is based on a clamping force in order to hold an edge of the web of material to be wound to the winding body at thebeginning of the winding process. The winding body (1) is operable for the adjustment of the clamping force caused by means of the shaft coupling.

Owner:TEXTILCORD STEINFORT

Method of manufacturing coil for stator incorporated in rotary electric machine

ActiveUS8136221B2Improve accuracyReliable windingSynchronous generatorsWindingsElectric machineCurve shape

A method is provided for manufacturing a stator coil for a rotary electric machine, which is formed by winding up a plurality of phase wires. The method includes a shaping step for shaping a plurality of shaped wire members from electrically conductive wires, an integrating step for integrating the plurality of shaped wire members with each other to form an integrated body, and a winding-up step for winding the integrated body about a core member to form a wound body. At the winding-up step, curve forming is performed by plastically deforming turn portions of the integrated body into a curved shape, during conveyance of feeding the integrated body to the core member.

Owner:DENSO CORP

Suturing and ligating method

ActiveUS9107657B2Easy to sutureConvenient ligationSuture equipmentsSurgical needlesSuturing needleEngineering

A suturing and ligating method includes a needle piercing step of inserting a needle of a suture-needle assembly through a tissue in a body cavity, a needle gripping step of gripping the needle with a first gripper, a winding step of winding a suture strand of the suture-needle assembly in at least one turn around a first distal-end working unit by rolling the first distal-end working unit in at least one revolution, a transferring step of transferring the suture-needle assembly from the first gripper to a second gripper, a suture strand gripping step of gripping a portion of the suture strand that has not passed through the tissue, with the first gripper, a pulling step of pulling the first distal-end working unit out of a loop of the suture strand, and a tightening step of forming a knot of the suture strand.

Owner:KARL STORZ GMBH & CO KG

Unclosed type device for winding ropes on trees on saline and alkaline land

ActiveCN105493982AImprove work efficiencyEasy to carryPlant protective coveringsElectricityStructure of the Earth

The invention discloses an unclosed type device for winding ropes on trees on saline and alkaline land. The device comprises a base, a metal flexible body is arranged on the base, a metal flexible sliding rail is arranged on the metal flexible body and is as long as the metal flexible body, a sliding base is arranged on the metal flexible sliding rail, a walking motor and a rope guide tube are arranged on the sliding base, a plurality of friction structures are arranged on the inner wall of the rope guide tube, a plurality of positioning pieces are arranged on the metal flexible body, and each positioning piece is a C-shaped elastic piece. The device also comprises a start key electrically connected with the walking motor and a power supply. When the device is in use, the base is placed near a tree, the metal flexible body is bent spirally upwards around the tree, and the metal flexible sliding rail on the metal flexible body is also bent along with the bending of the metal flexible body; to be noted, the metal flexible sliding rail is oriented to the tree. When the device is started, the sliding base moves on the metal flexible sliding rail, and then the rope is wound on the tree through the rope guide tube. Therefore, when the device is applied to the saline and alkaline land, the work efficiency is improved.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

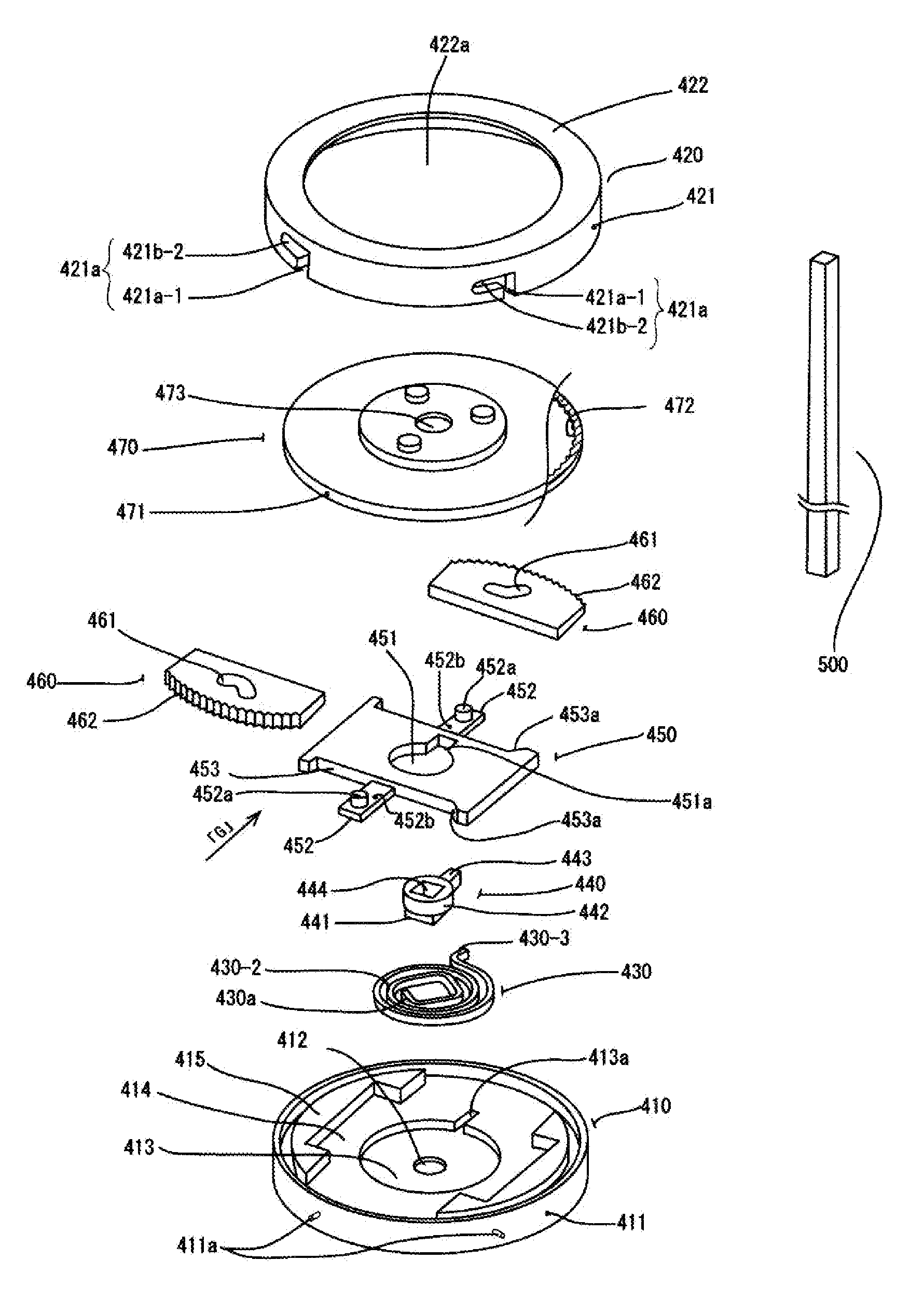

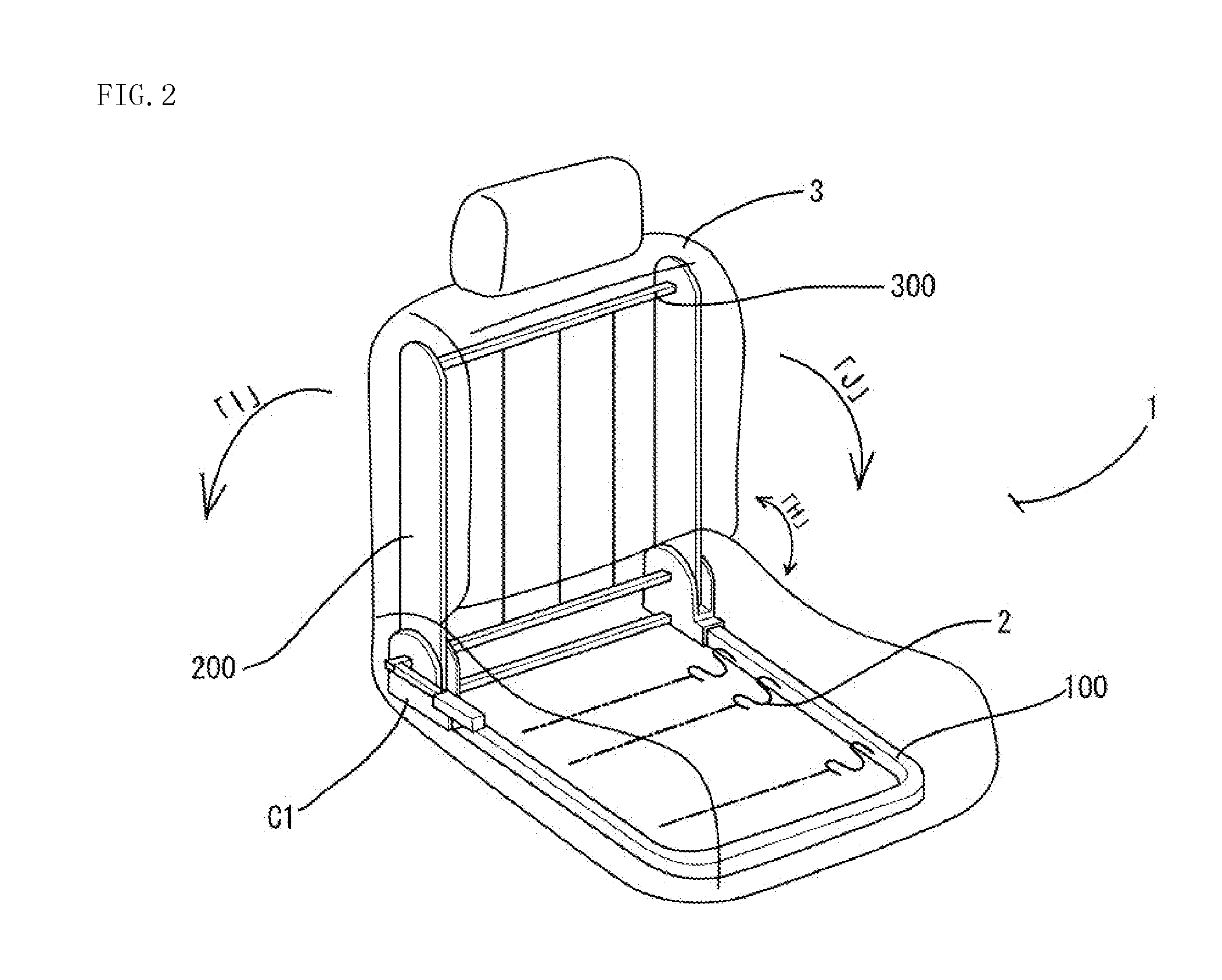

Spiral spring

A spiral spring for a reclining adjustment mechanism for a vehicle seat in which ridges are formed on both ends in a direction perpendicular to a coiling direction of a surface of a spring plate member formed by a band-like steel plate having high hardness so that the ridges project from the surface, projected surfaces of the ridges are curved, and the spring plate member is spirally formed into a coil. The spring plate member has a pitch coiled structure in which a gap between an intermediate spring plate member and an inner spring plate member is formed to be smaller than a gap between an outer spring plate member and the intermediate spring plate member. An engagement piece bent in the radial direction is formed at the end of the outer spring plate member, and an engagement coiled core section is formed in the inner spring plate member.

Owner:NIPPON TECH CO LTD

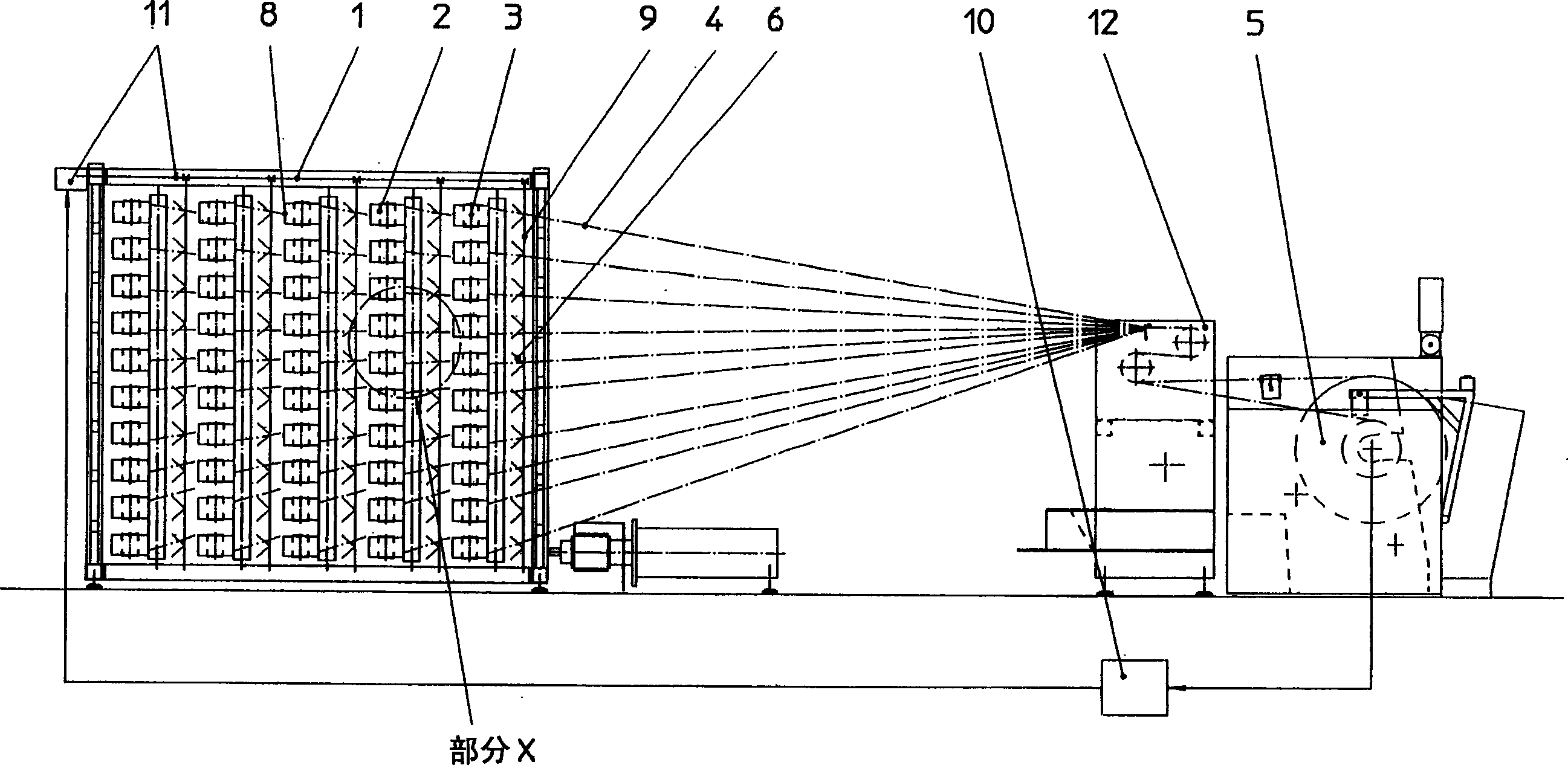

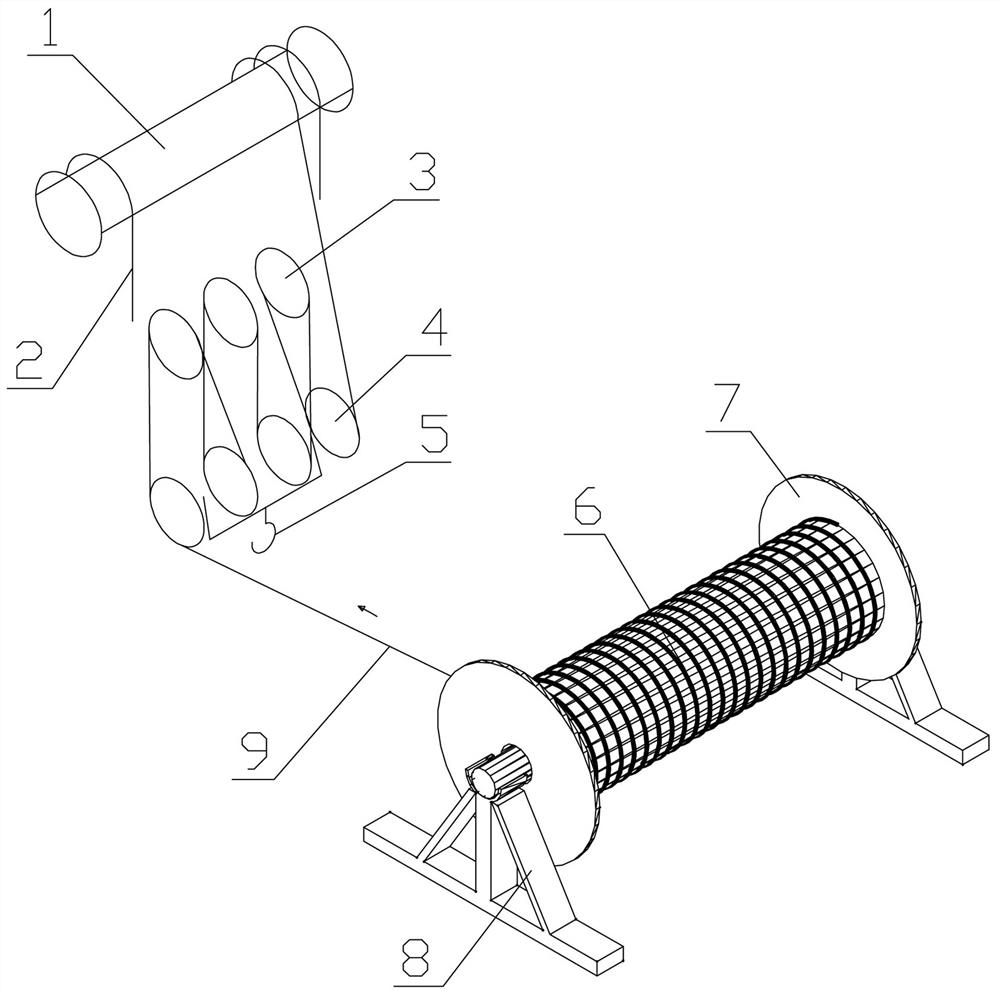

Warping machine

The present invention relates to a warping machine having a driven bobbing bracket (1) which is equipped with a plurality of bobbing (2) thereon. The yarns (4) from the bobbing (2) wind at the cane roller (5) (positive direction operation) and unwind from the cane roller (5) to the bobbing (2) especially when yarns break, meaning that the yarns wind at the bobbing (2) (inverted running) again. Each bobbing (2) is equipped with a yarn guide (6) which engage with the yarns (4) during the inverted running. The yarn guide (6) is set with the scope of the reel for yarn of the bobbing (2) when being at the bonding station, then the yarns (4) wind at the direct scope of the reel for yarn of the bobbing (2) again during the inverted running, wherein each member is started-up to maintain the preset pre-unbent yarn velocity of the elastomeric yarns within the length scope of the yarns when a production interrupt occurs.

Owner:LIBA MASCHFAB

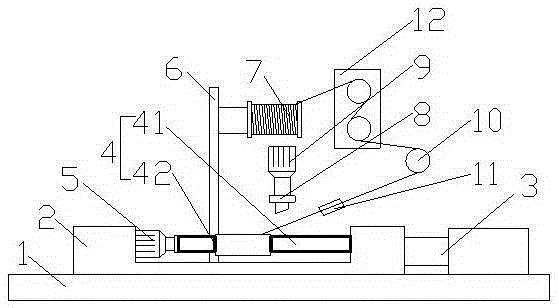

Device for testing dynamic friction coefficient

PendingCN108120669AReduce work intensityGood reliabilityUsing mechanical meansMaterial analysisDynamical frictionFixed frame

The invention relates to a device for testing a dynamic friction coefficient. The device comprises a fixed frame, a worktable, a tensile testing machine and a sample, wherein the sample comprises a fixed part and a movable part, a round drum mechanism for being wound with the fixed part is arranged on the fixed frame, a compression assembly is arranged on the round drum mechanism, a weight connected with one end of the movable part is arranged on the fixed frame, and the other end of the movable part is connected with the tensile testing machine. The device has the advantages that the round drum mechanism is wound with the fixed part in the sample, the movable part is pulled to move in the fixed part through the tensile testing machine, and the dynamic friction coefficient between the movable part and the fixed part is calculated according to an average tensile load measured in a tensile testing process, the gravity of the weight connected to one end of the movable part and the windingangle of the fixed part on the round drum mechanism, and the dynamic friction coefficient among samples can be accurately calculated; and the working intensity is low, the reliability of a sample testing result is good, and the sample testing efficiency can be increased.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +2

Sphygmomanometer cuff and sphygmomanometer provided with the same

InactiveUS20110224560A1Good adhesionReliable windingCatheterDiagnostic recording/measuringSphygmomanometerEngineering

A sphygmomanometer cuff is provided with an upper arm support stand arranged to support an upper arm, and an arm band arranged to be wound around the upper arm. The upper arm support stand includes an upper arm support surface arranged to support the upper arm while the upper arm is placed thereon, a winding mechanism arranged to pull one end of the arm band in the winding direction so as to wind a portion of the arm band close to the one end, and a hook arranged to engage a portion of the arm band close to another end pulled out from the winding mechanism against a pulling force applied by the winding mechanism. The upper arm supported on the upper arm support stand is tightened by the upper arm support surface and the portion of the arm band pulled out from the winding mechanism in a state where the portion of the arm band close to the other end is engaged with the hook. With such a configuration, the sphygmomanometer cuff is capable of being easily attached to the upper arm serving as a measurement site having a difference in size as well as repeating reliable winding around the upper arm in every measurement.

Owner:OMRON HEALTHCARE CO LTD

Lifting and moving parking equipment

The invention discloses lifting horizontal-moving type parking equipment and belongs to the technical field of stereo garages. The equipment comprises m rows of steel structure frames, m lifting car carrying plates, m-1 horizontal-moving car carrying plates, an anti-falling mechanism, a duplex horizontal steering fixed pulley block, a first vertical steering fixed pulley, a first duplex vertical steering fixed pulley block, a moving pulley, a third vertical steering fixed pulley, two second vertical steering fixed pulleys and a coiling block driven by a power mechanism. A transmission steel wire rope arranged on the coiling block is wound around the first vertical steering fixed pulley and the moving pulley and then is fixed at the end, close to a first horizontal beam, of a first longitudinal beam. A second rope winding device for pulling the lifting car carrying plate is arranged on the moving pulley. The lifting horizontal-moving type parking equipment is simple in structure, low in manufacturing cost, attractive in appearance and high in reliability.

Owner:DAYANG PARKING CO LTD

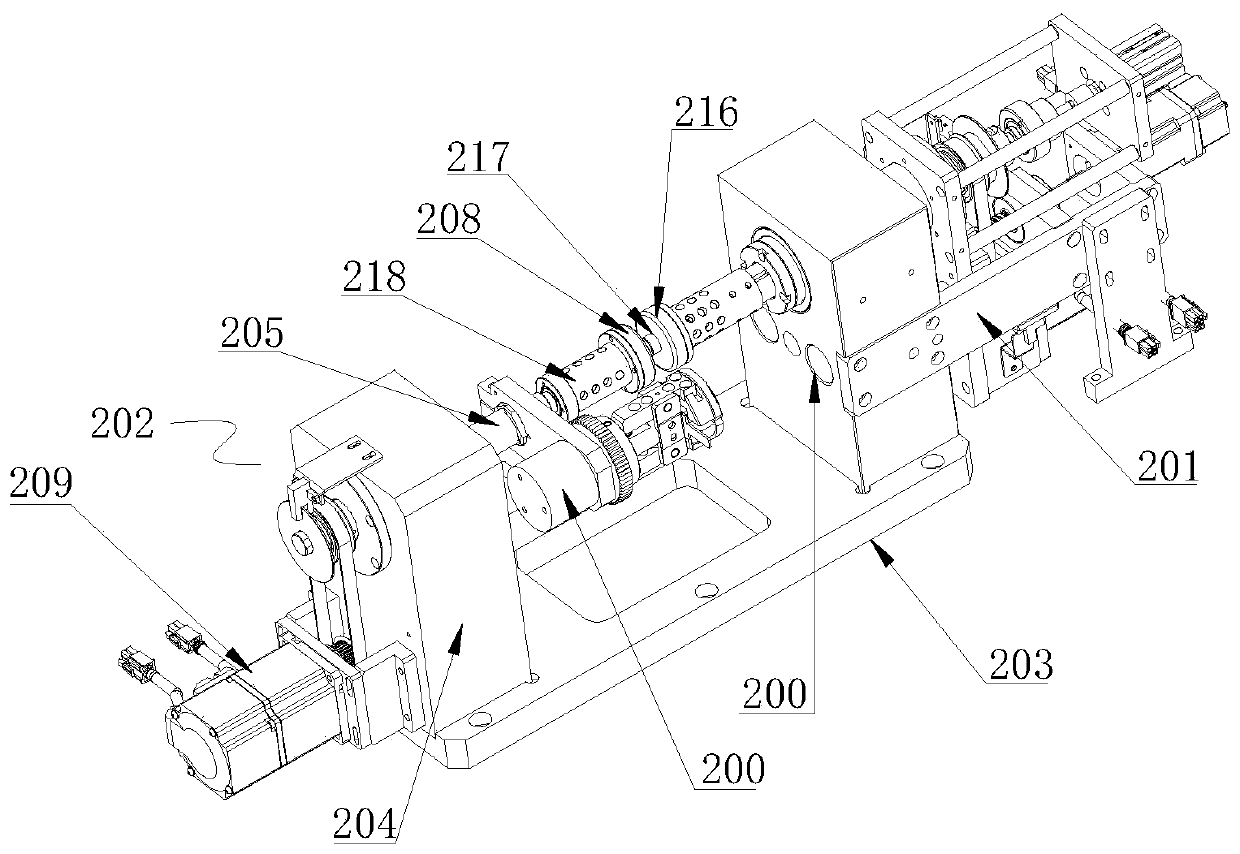

Transmission mechanism of rotational moulding machine

The invention provides a transmission mechanism of a rotational moulding machine. The transmission mechanism comprises a base, two first bearing blocks, four tensioning wheels, a second bearing block, a first transmission part and a second transmission part. The two first bearing blocks are arranged above the base. Driven shafts are contained in the first bearing blocks, and driven wheels are arranged at the tail ends of the driven shafts. The four tensioning wheels are arranged on the side of the base. A drive shaft is contained in the second bearing block, and a drive wheel is arranged at the tail end of the drive shaft. The first transmission part is wound on the drive wheel, the driven wheel and one tensioning wheel. The second transmission part and the first transmission part share the tensioning wheel and are wound on the other three tensioning wheels and the driven wheels. The transmission parts are designed as two independent structures and are abutted to the four tensioning wheels mutually, so that deformation of the transmission parts is prevented, and noise is lowered. The transmission parts in fine deformation can be adjusted in terms of position by an adjusting bolt arranged on a boss, and accordingly the transmission parts can be reliably wound on the drive wheel, the driven wheels and the tensioning wheels, and stability of the transmission mechanism of the rotational moulding machine is increased.

Owner:华瑞传动科技南通有限公司

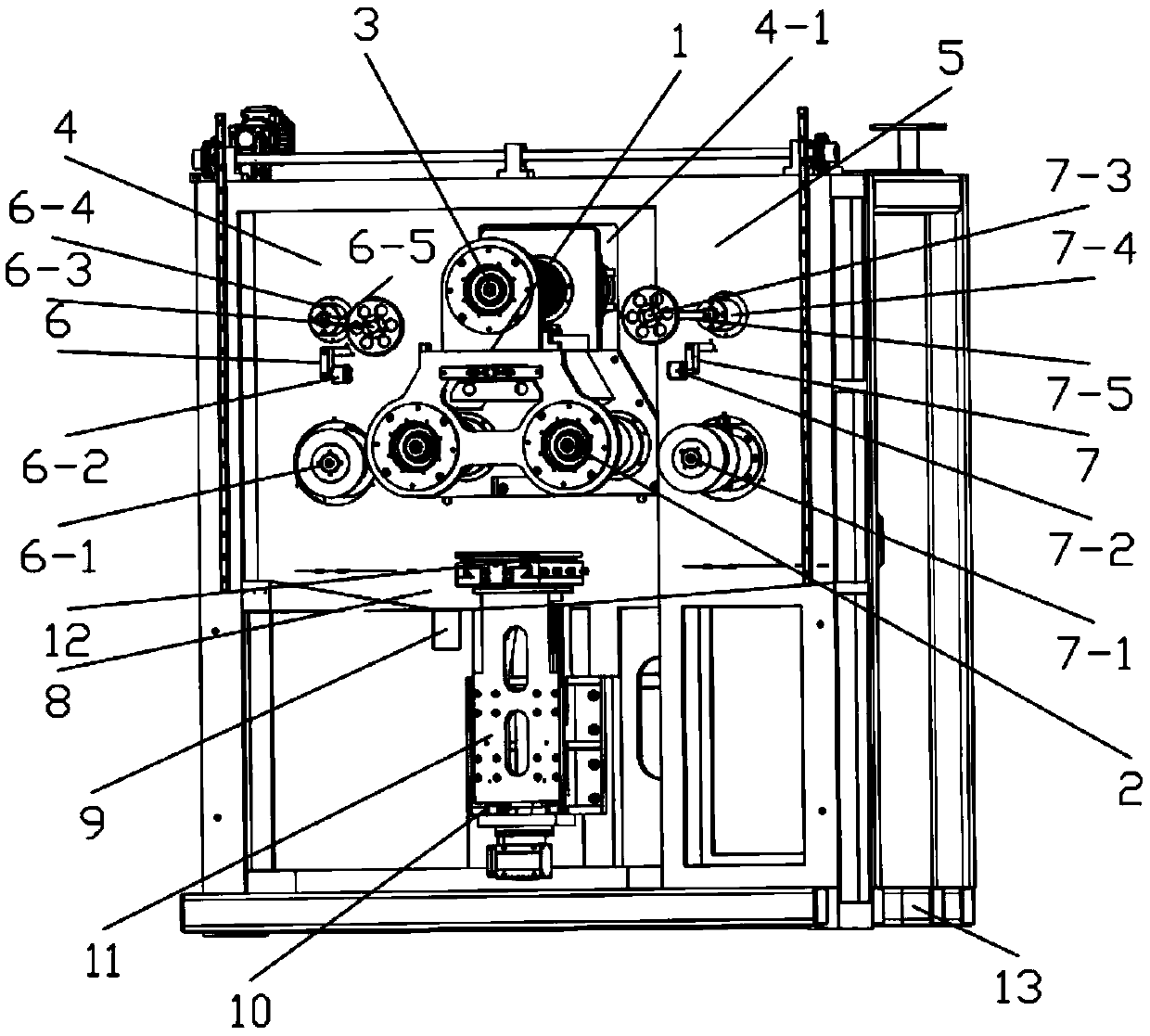

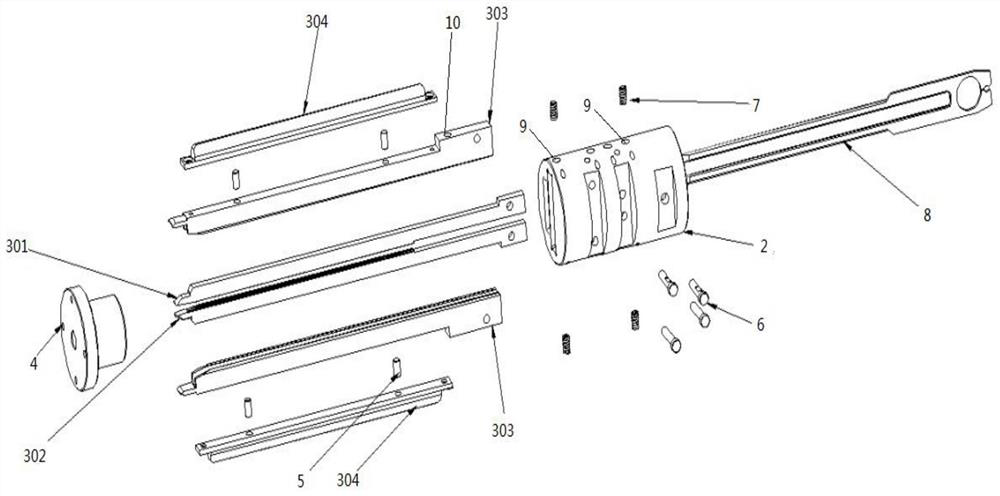

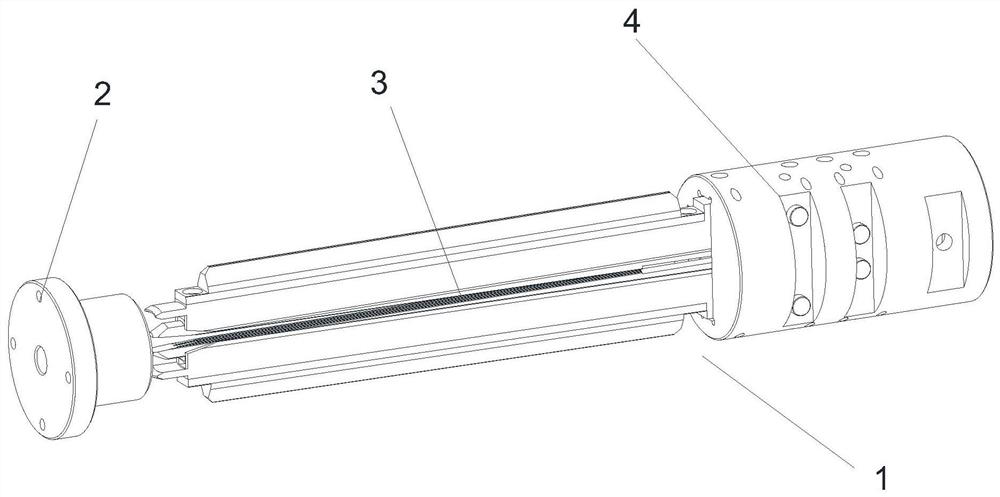

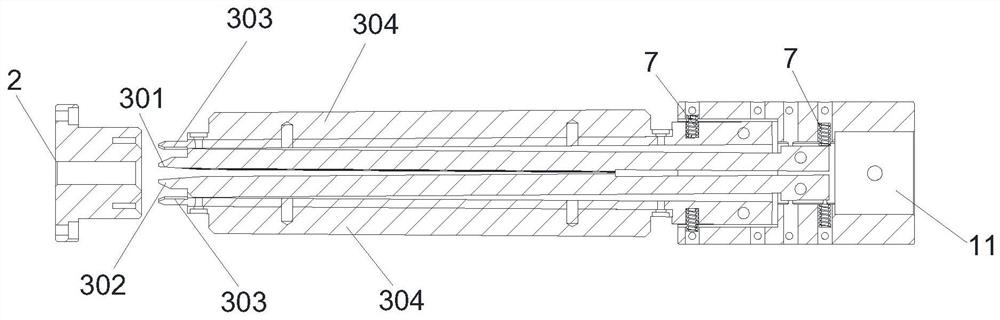

Novel winding needle mechanism

PendingCN112117500AEfficient windingReliable windingAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention discloses a novel winding needle mechanism which comprises a structure body, the structure body is composed of a winding needle connector, a winding needle assembly and a needle nozzle,the needle nozzle is arranged at the head end of the winding needle assembly, the winding needle connector is arranged at the tail end of the winding needle assembly, and the winding needle assembly comprises a first inner needle, a second inner needle, winding needle main pieces and auxiliary pieces. The first inner needle and the second inner needle are vertically overlapped, the first inner needle and the second inner needle are sleeved with the winding needle main pieces respectively, the auxiliary pieces are installed on the two sets of winding needle main pieces through pins, a winding needle connector pin and a winding needle compression spring are arranged in the winding needle connector, and an inserting piece is further arranged in the winding needle connector. The winding needlemechanism is simple in structure, reliable in mounting and positioning and high in diaphragm clamping stability; meanwhile, the winding needle further has an inserting piece function, an inserting piece is pushed out after a battery cell is wound around several circles, then winding is continued, deformation of the battery cell in the follow-up procedure is reduced, and the quality of the batterycell is guaranteed.

Owner:DONGGUAN HEMING MACHINERY

Automatic winding machine for flat wires

PendingCN111243855AHigh degree of automationImprove winding efficiencyInductances/transformers/magnets manufactureWinding machineWire rod

The invention discloses an automatic winding machine for flat wires. The automatic winding machine comprises a mounting platform, a main shaft device, a flying fork driving device, a wire pulling device, a tension device, a heating device and a wire shearing device; the main shaft device is connected to the mounting platform; the main shaft device comprises a driving shaft and a driven shaft; thewire drawing device is positioned above the main shaft device; the flying fork driving device is positioned on one side of the driven shaft; the tension device is mounted on the mounting platform on one side of the main shaft device; the heating device is positioned above the tension device; the thread trimming device is connected to the main shaft device; the wire pulling device clamps and pullsout the wire from the tension device; the wire is clamped after passing through main shaft device, stay wire device is reset, the flywheel driving device drives winding, then the flying fork driving device is reset, the main shaft device conducts die assembly, the driving shaft and the driven shaft rotate in the same direction at different rotating speeds, the wire is wound on the die, the heatingdevice is started to heat the wire to the set temperature, then the wire is cooled, and the wire shearing device shears off the wire, the main shaft device is reset, and the coil is disengaged.

Owner:东莞市鑫华翼自动化科技有限公司

Method for replacing steel wire rope of bridge crane

InactiveCN113387272AReliable windingSolve the phenomenon of self-reversingWinding mechanismsLoad-engaging elementsWire ropePulley

The invention relates to a method for replacing a steel wire rope of a bridge crane, which is characterized by comprising the following steps of: S1, manufacturing a steel frame capable of transversely supporting the whole roll of steel wire rope and rotating, and putting the whole roll of new steel wire rope with the diameter of 22mm on the steel frame; S2, temporarily closing ascending and descending limits in a hoisting mechanism of the bridge crane, and preparing electric welding and a cutting knife in place for cutting and welding a steel wire rope; S3, descending a lifting hook set in the hoisting mechanism to the ground, detaching steel wire rope pressing plates on the two sides of a winding drum, setting the position, two meters away from a movable pulley of the lifting hook set, of the winding drum to cut off, and then connecting the movable pulley with the end of the new steel wire rope in a welded mode; S4, starting the controller to enable the hoisting mechanism to be in an upshift; and S5, starting the hoisting mechanism, integrally winding the new steel wire rope on the winding drum, and lifting the lifting hook set. The method for replacing the steel wire rope is designed for replacing the lifting steel wire rope of the bridge crane hook, is few in working procedures and simple in process.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Material roll winding device

InactiveCN102107791APromote resultsReliable windingRolling contact bearingsSpringsCardboardEngineering

The invention relates to a material roll winding device, and the material roll winding device is used to wind a material web, and especially a paper web or a cardboard web on at least one winding core or one preferable reel to form at least one material roll; during winding, at least one roller supported on a rolling bearing with a bearing rigidity is pressed against the material roll, wherein the rolling bearing can be connected to the supporting part in a movable way through a buffering device with a seal rigidity. In order to improve the material roll structure and especially to stabilize the behaviors in the winding area, the invention defines that the ratio of the seal rigidity and the bearing rigidity is less than or equal to 0.55, is preferably less than or equal to 0.3, and is especially preferably close to zero.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com