Material roll winding device

A technology of winding device and material roll, which is applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems that the winding speed cannot improve the degree of reliable transfer, and the structure of the material roll is not satisfactory. The effect of less self-excited vibration and high production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

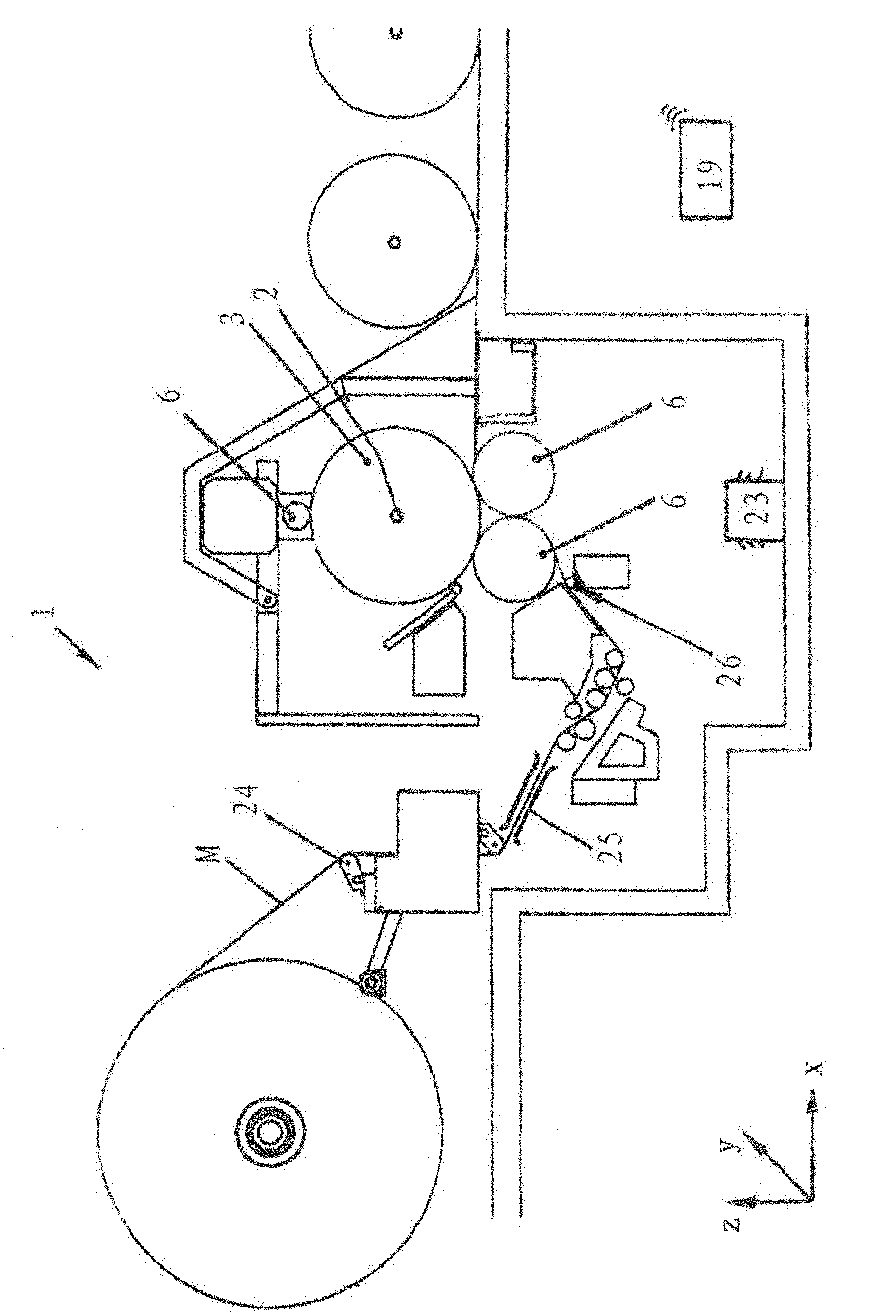

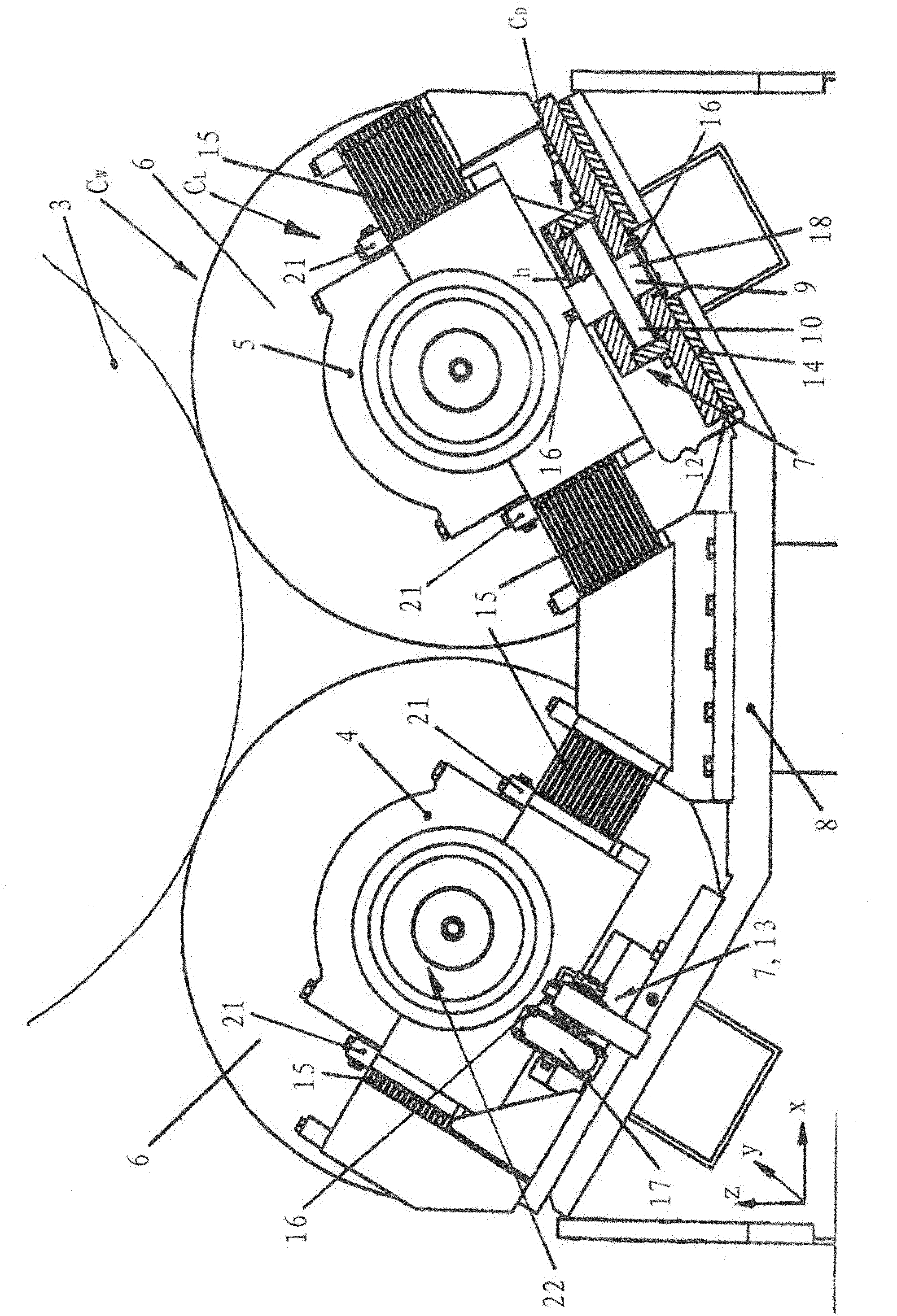

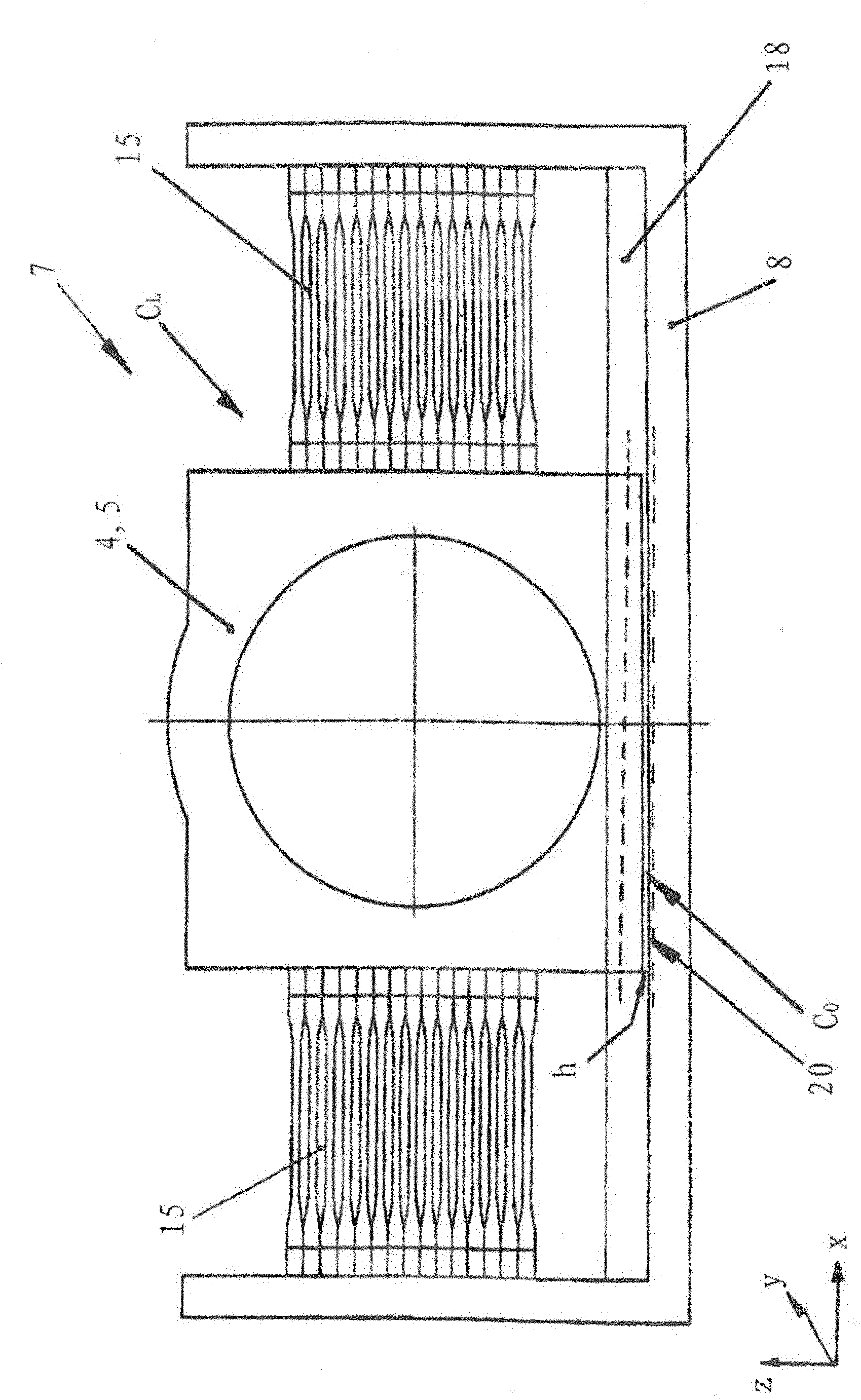

[0084] According to the material roll winding device 1 of the present invention in figure 1 and figure 2 The preferred embodiment shown in is realized in conjunction with an idler roll winding device which has a roller arrangement in its winding area. The roller arrangement has two rollers 6 configured as carrier rollers with a roller stiffness C w , the roller stiffness in the example shown should be the variable bearing stiffness C L double to triple.

[0085] At least one roller 6 can be driven by means of a drive 22 . In a preferred embodiment, the very torsionally rigid drive is formed by a direct drive integrated in the roller. Both rollers 6 are preferably drivable and connected to a common control / regulation unit 19 . In this case, it has proven to be suitable to adjust the rotational speed of the first roller 6 and to adjust the torque of the second roller 6 when the material web M, in particular the paper web, is in the running direction, ie in the x-direction....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com