Patents

Literature

149results about How to "Efficient winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

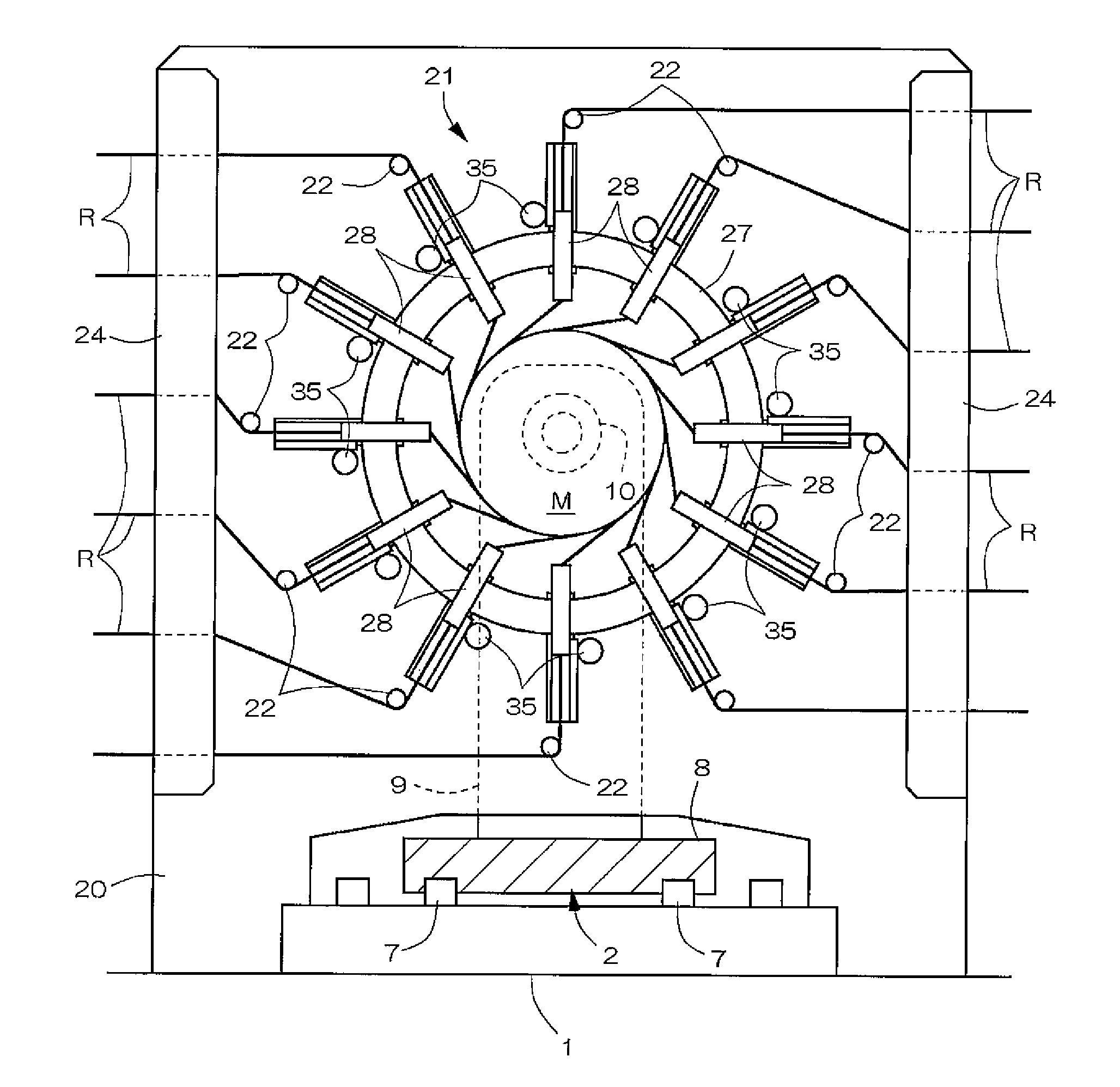

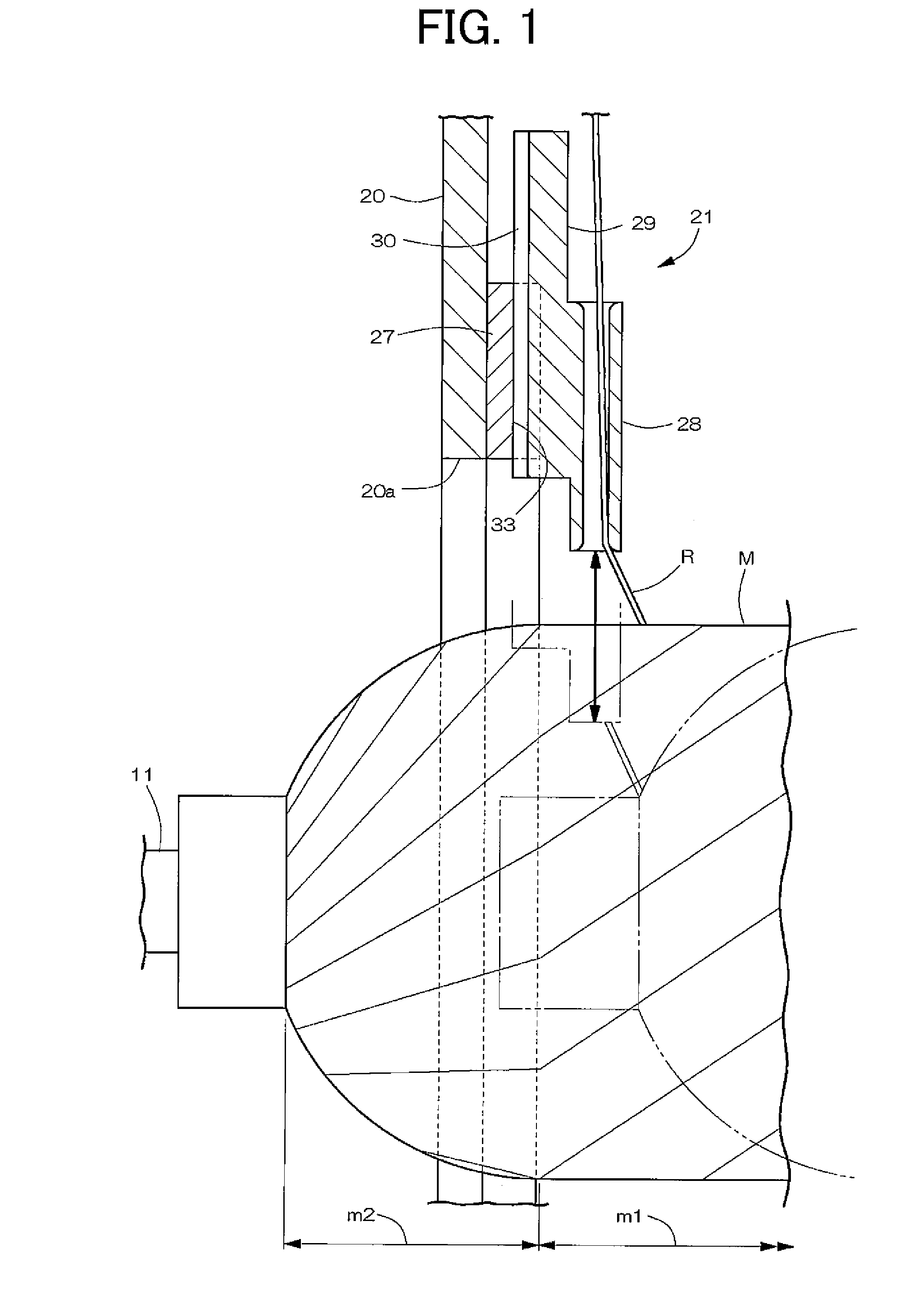

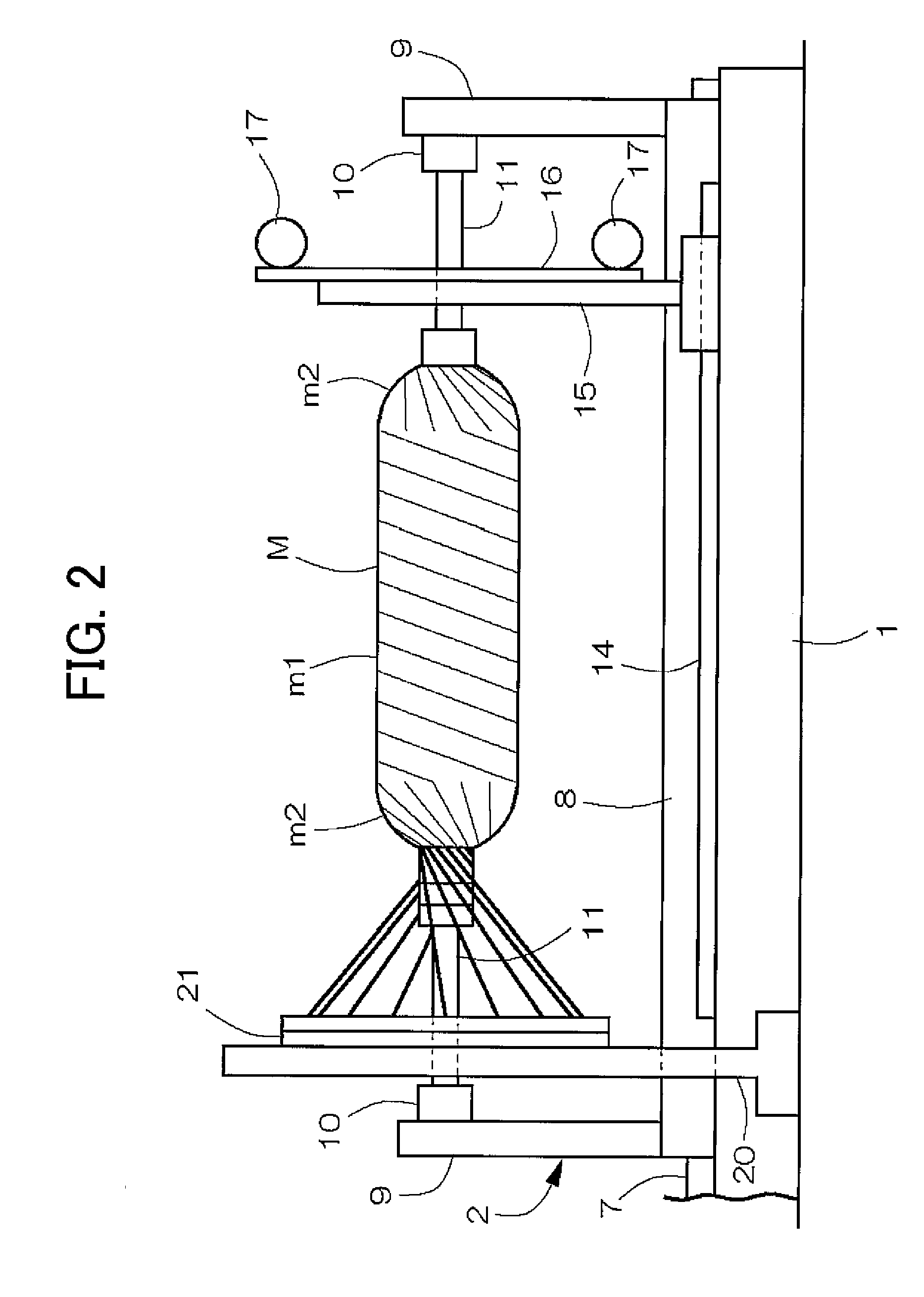

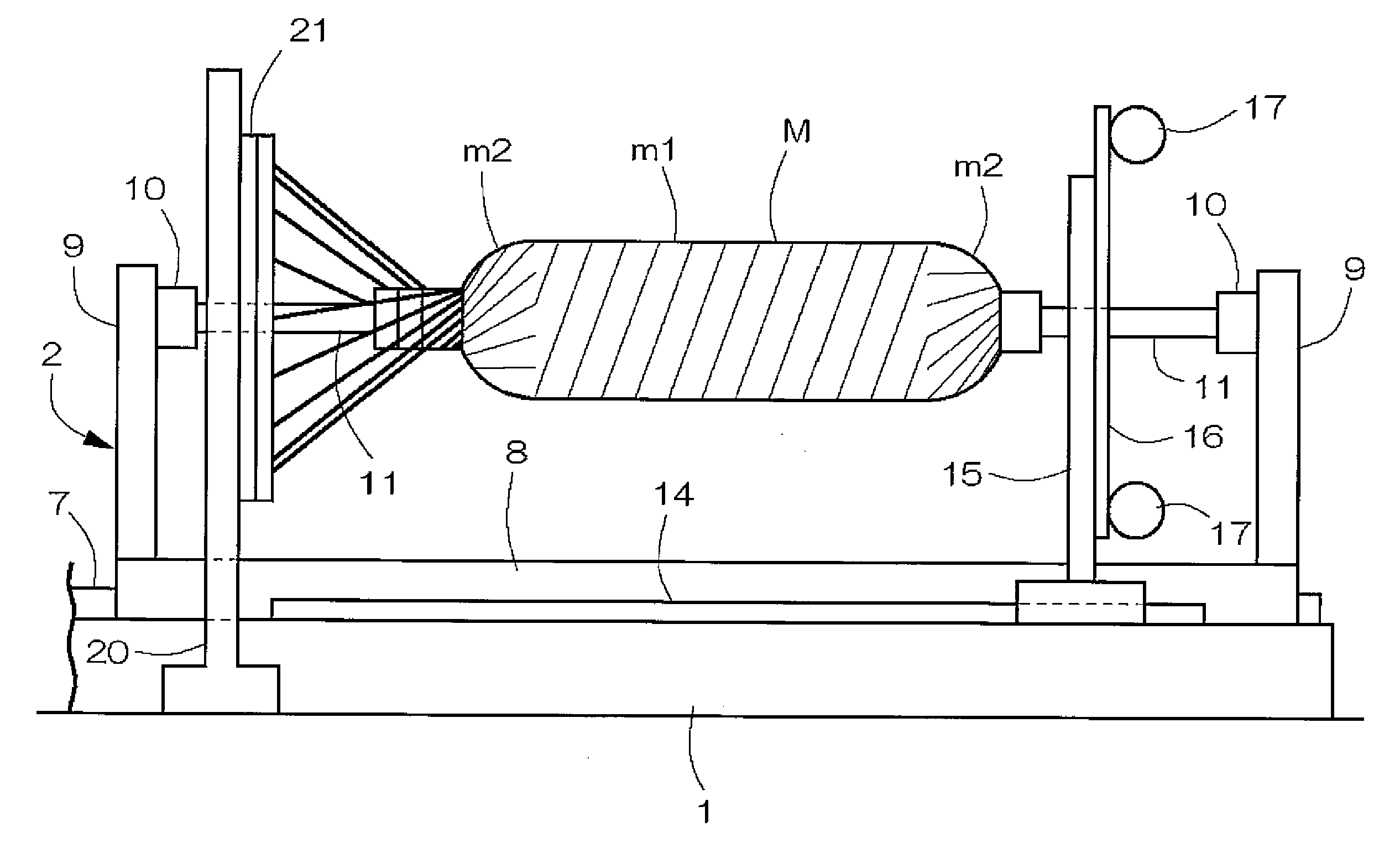

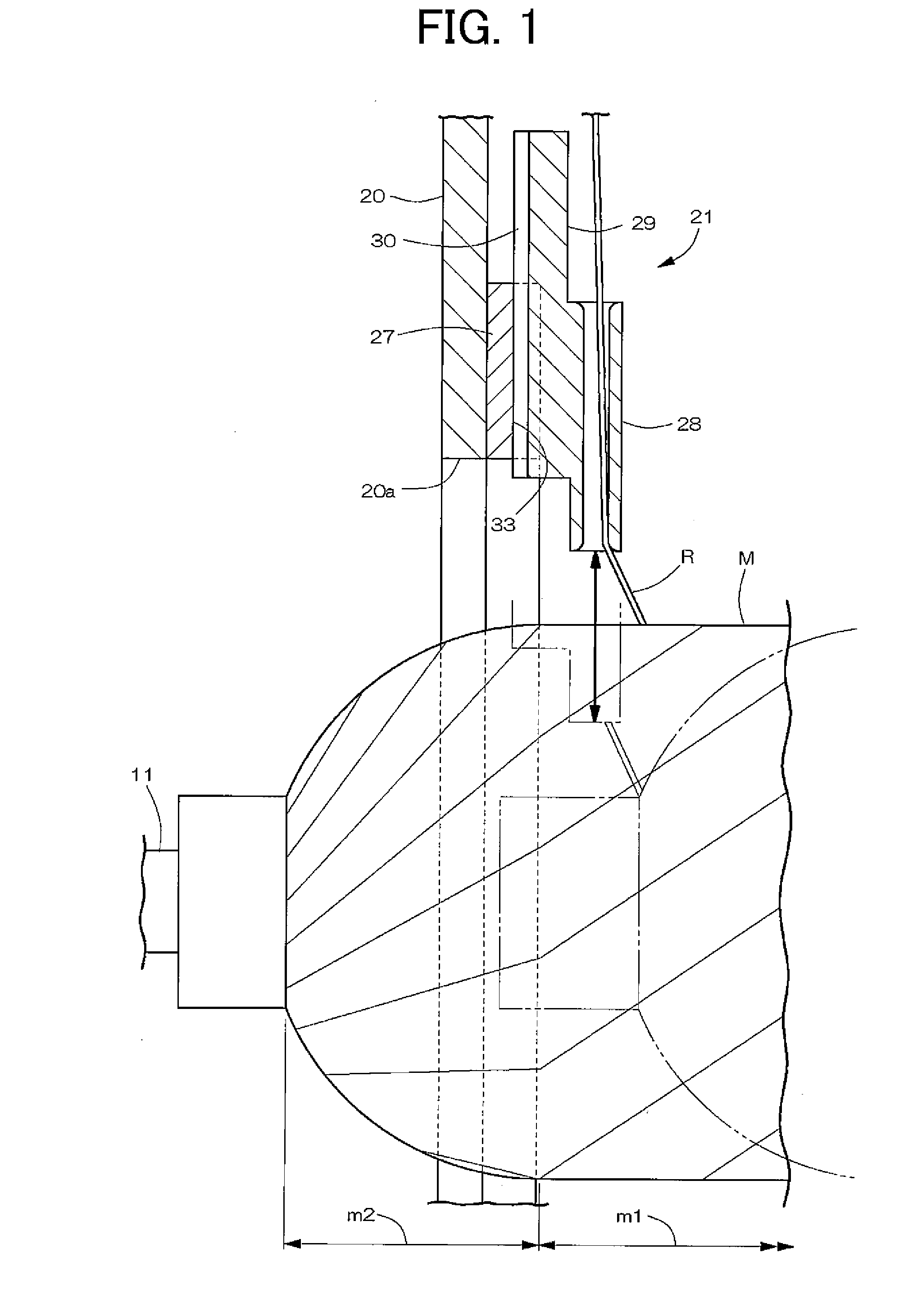

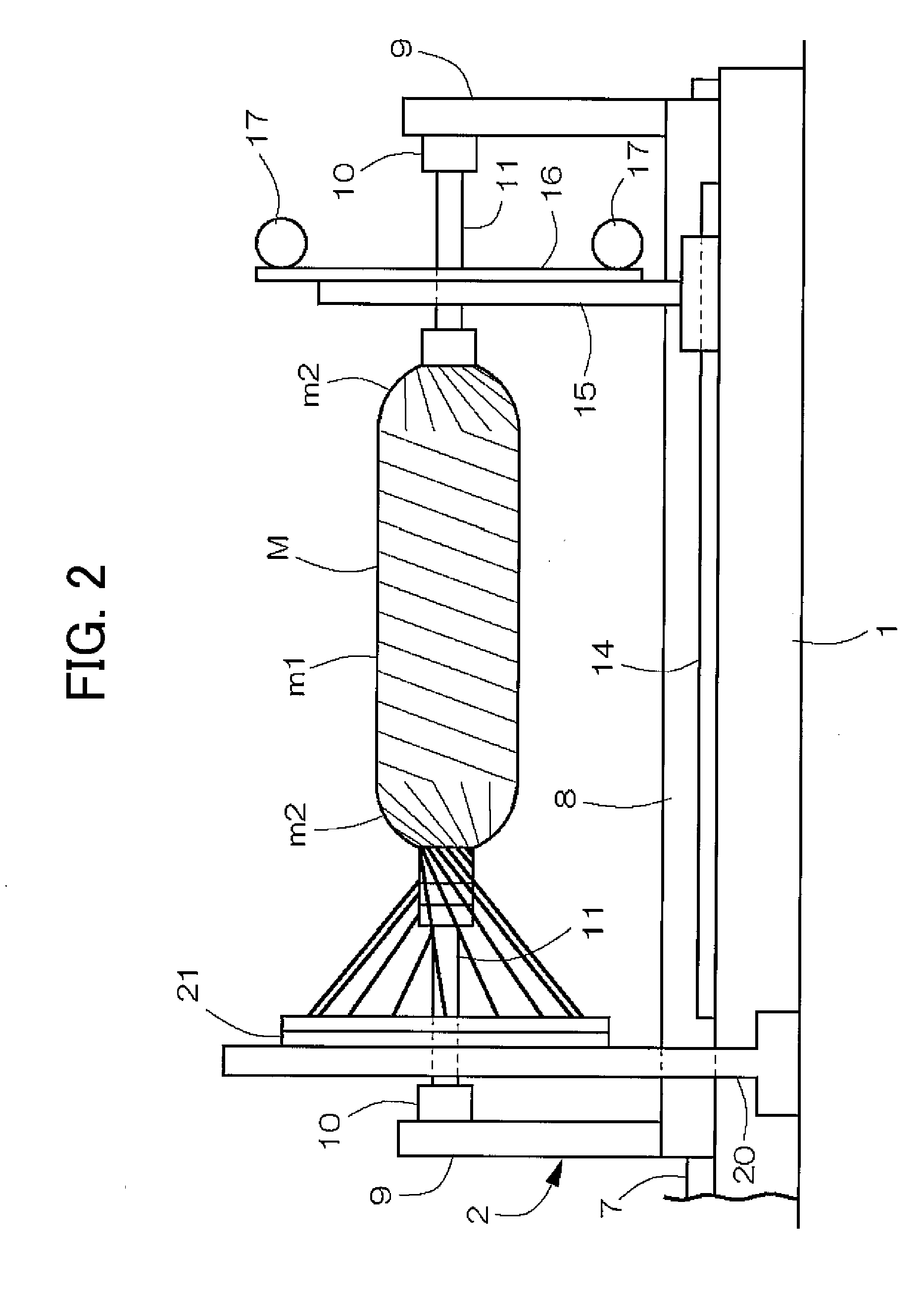

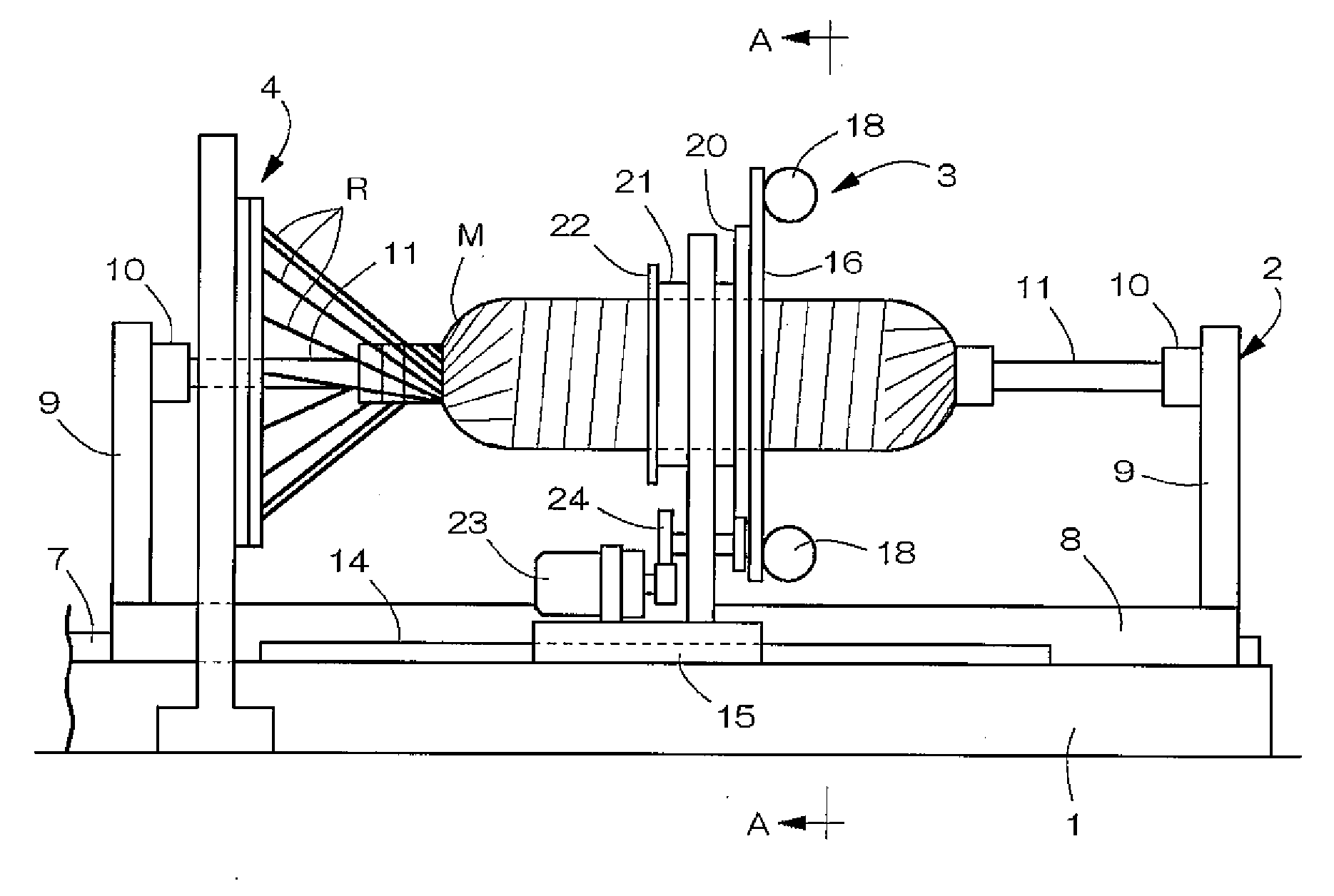

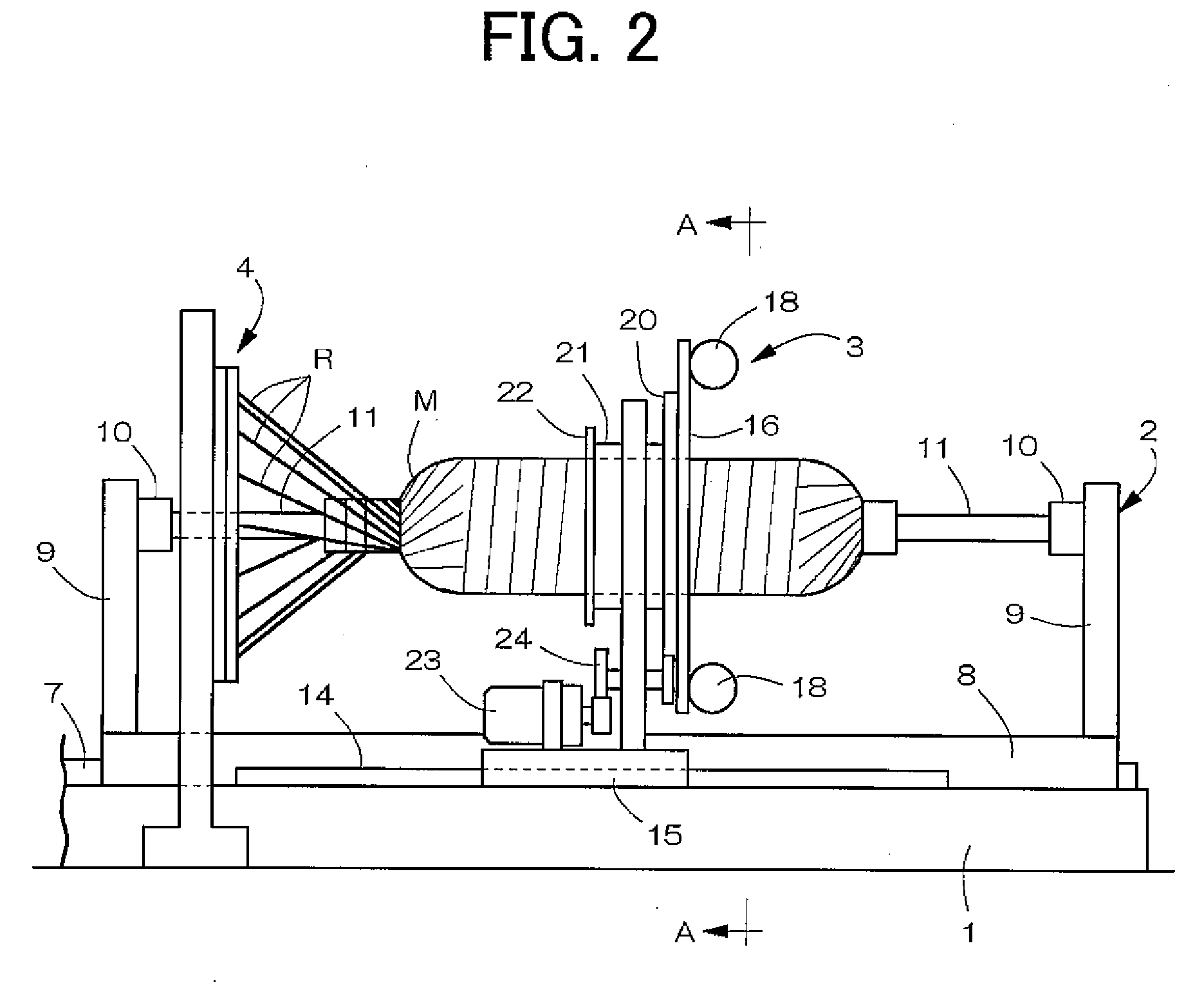

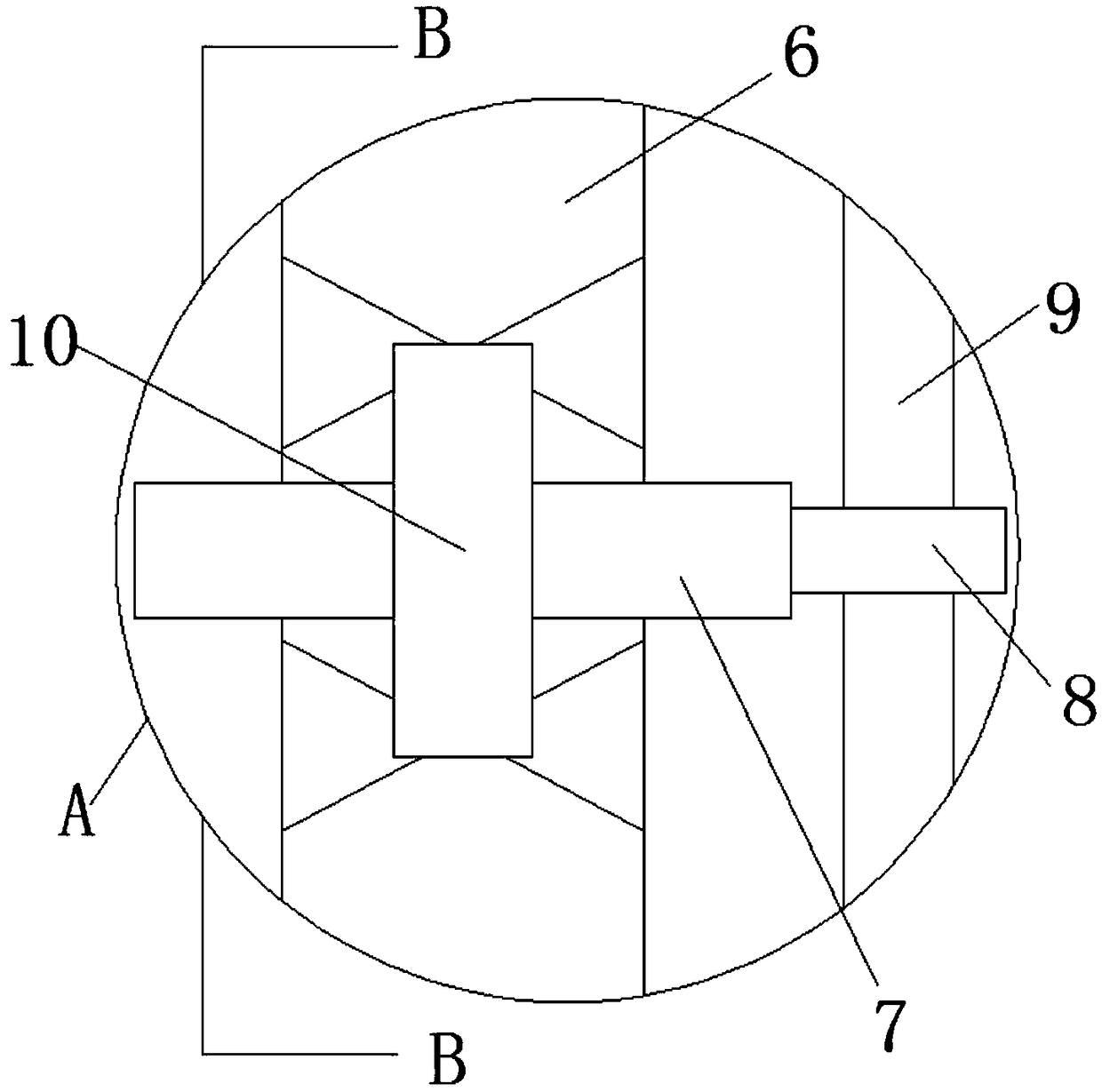

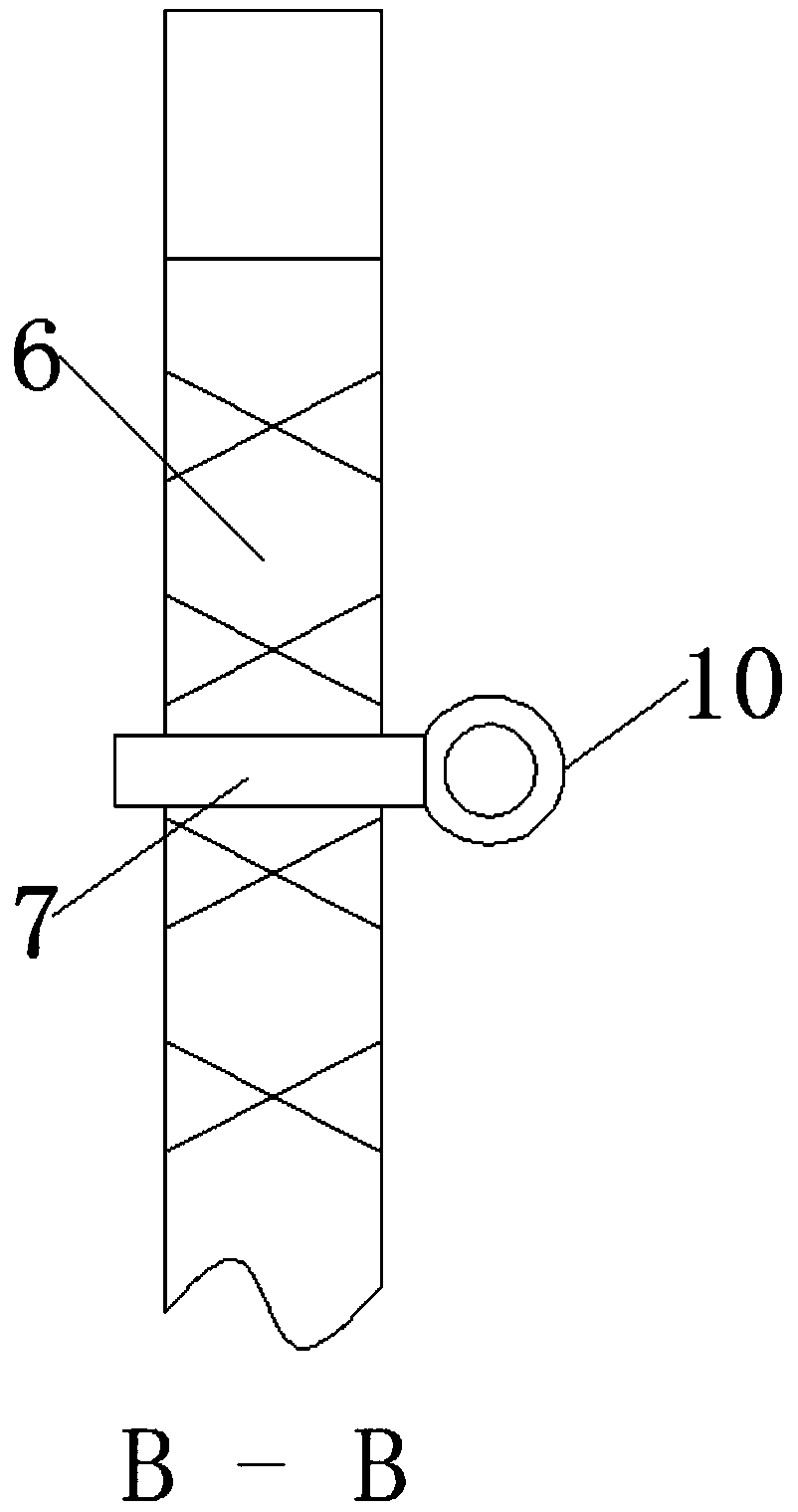

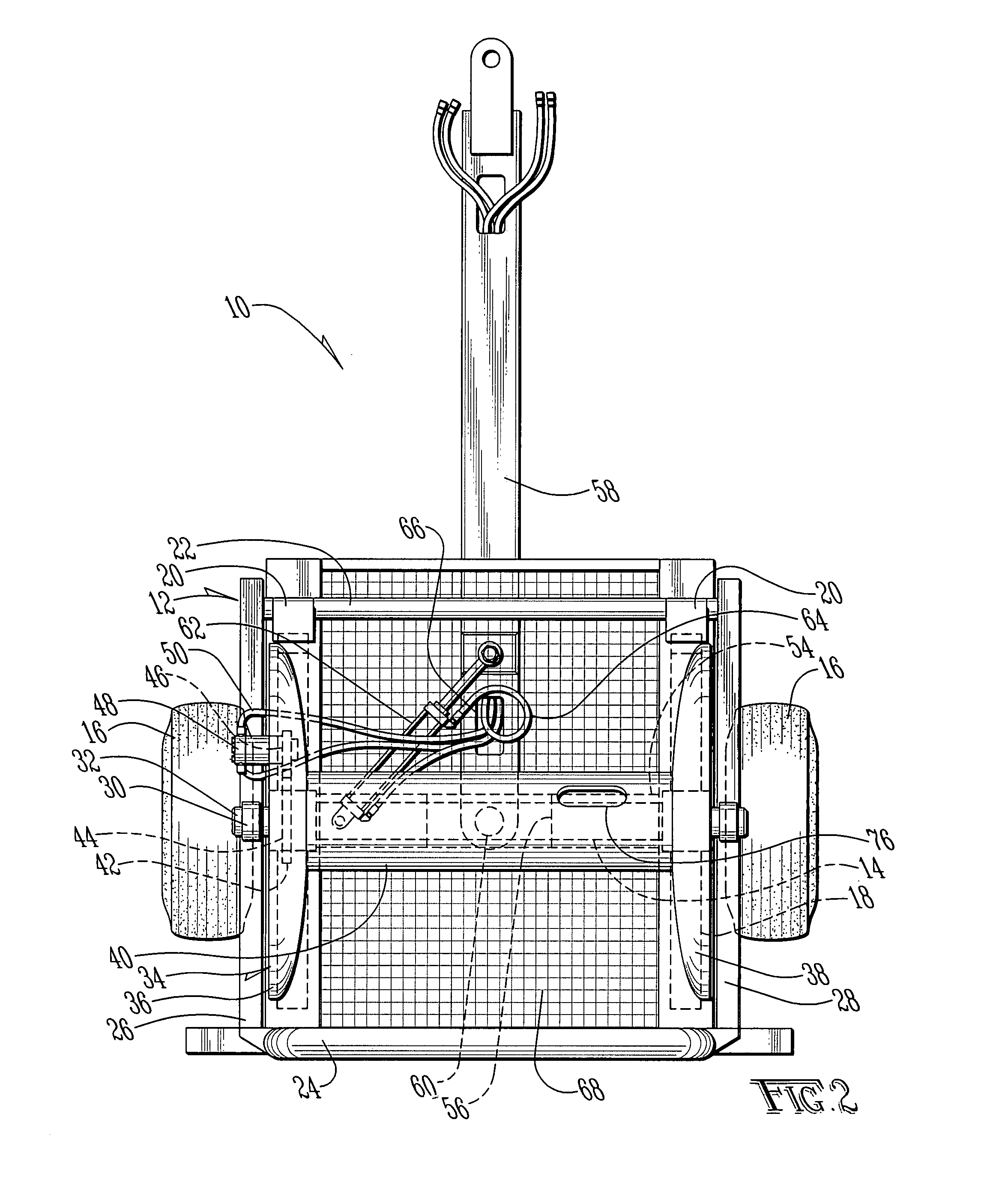

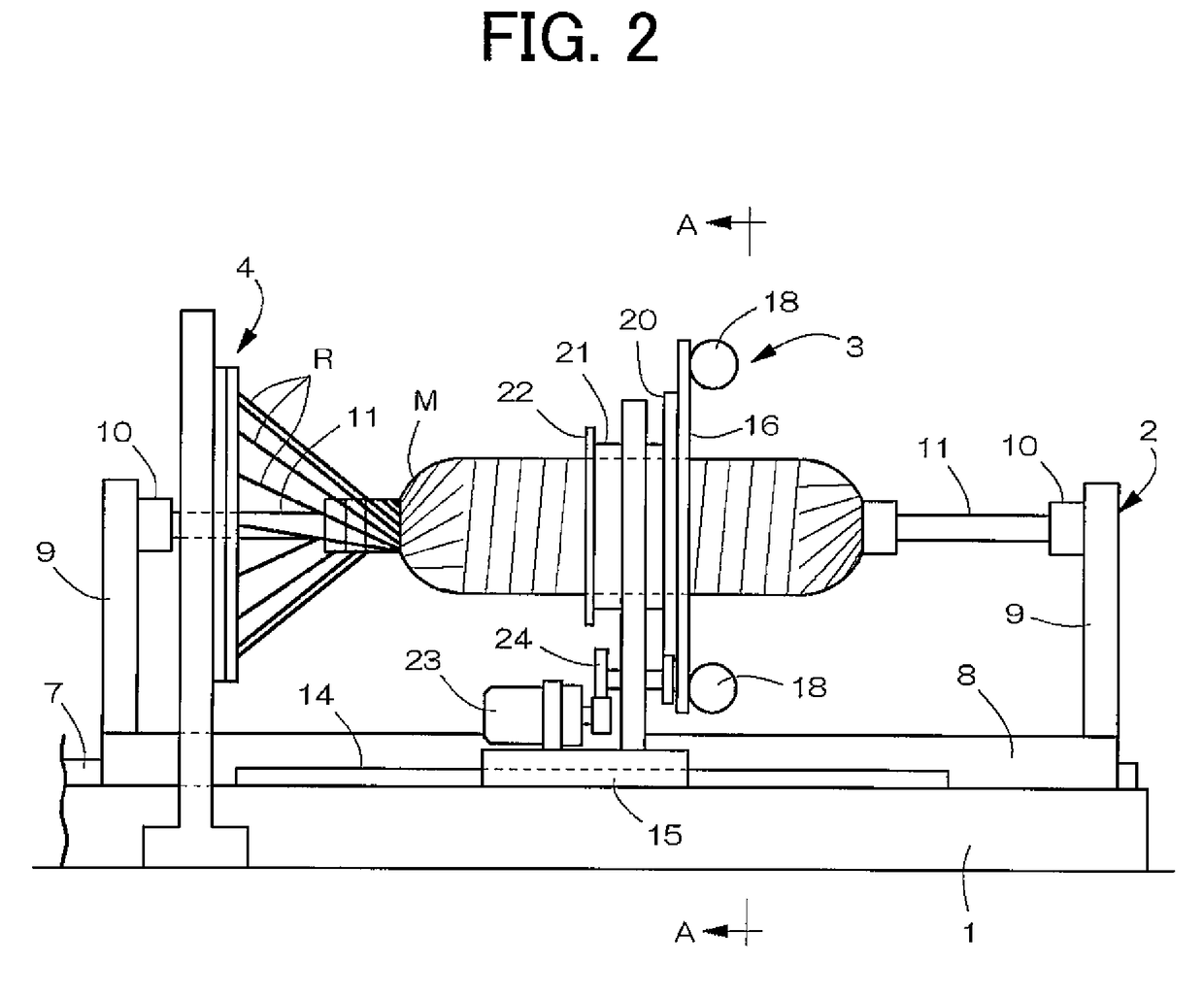

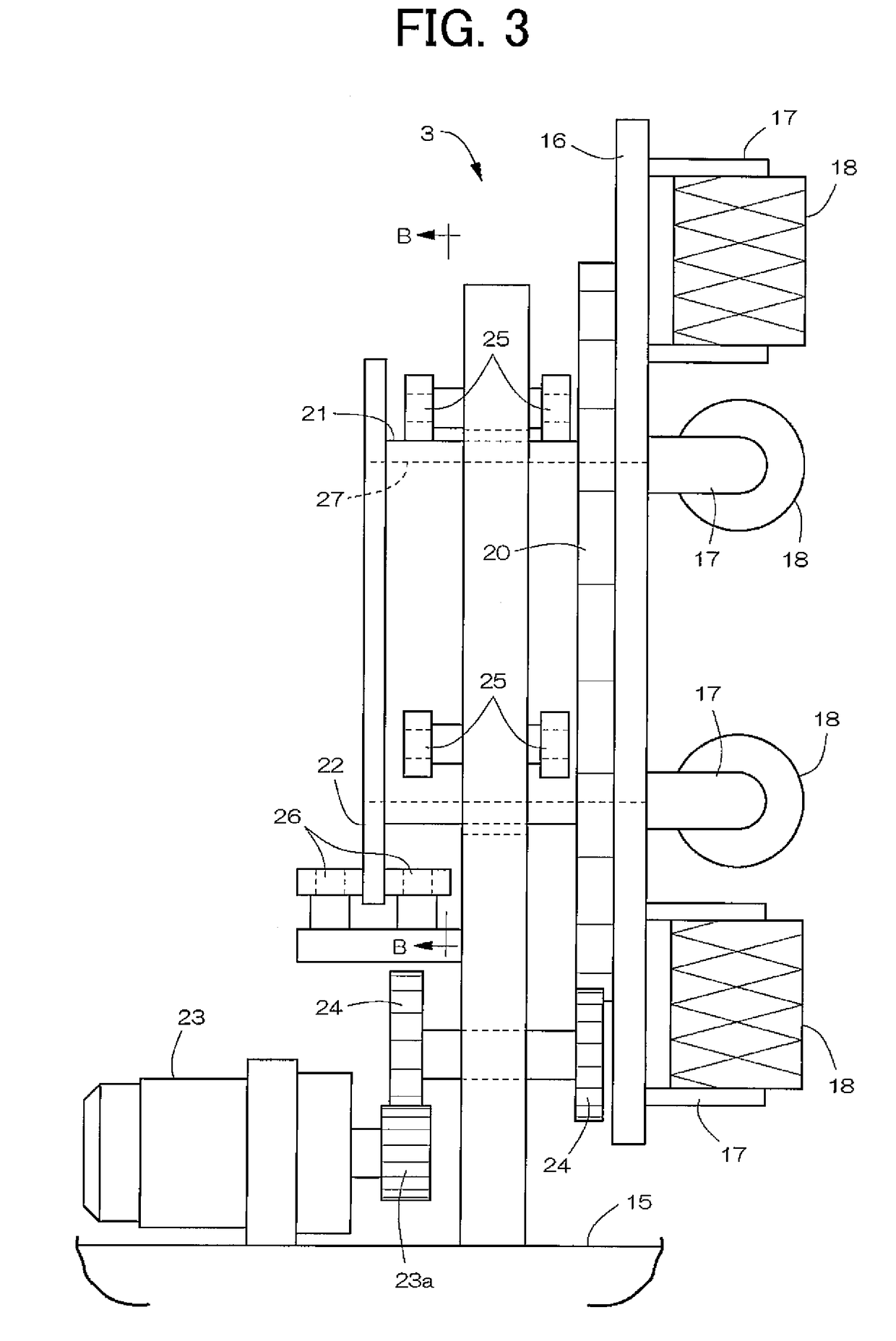

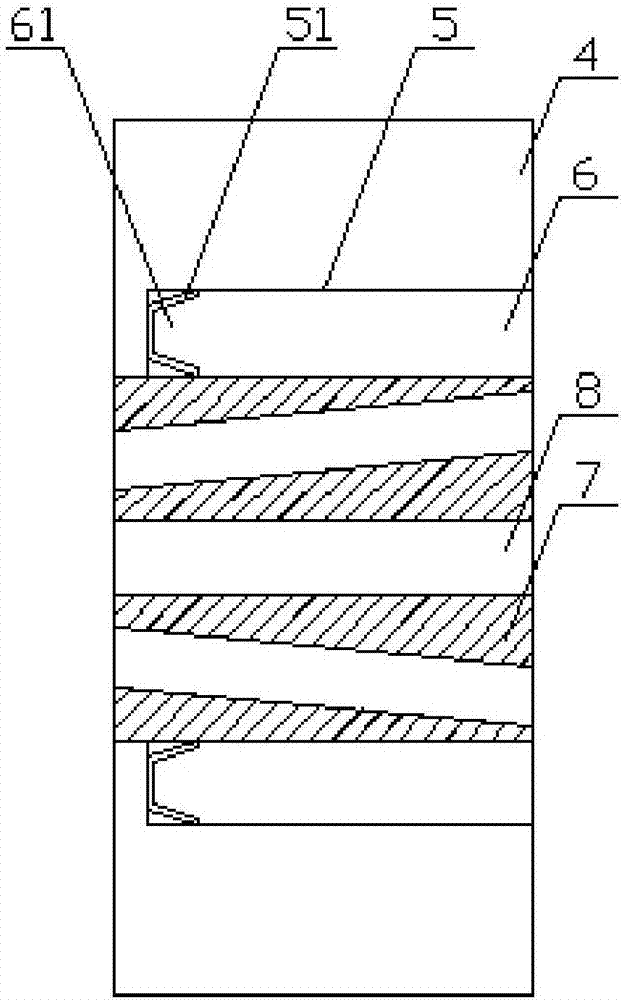

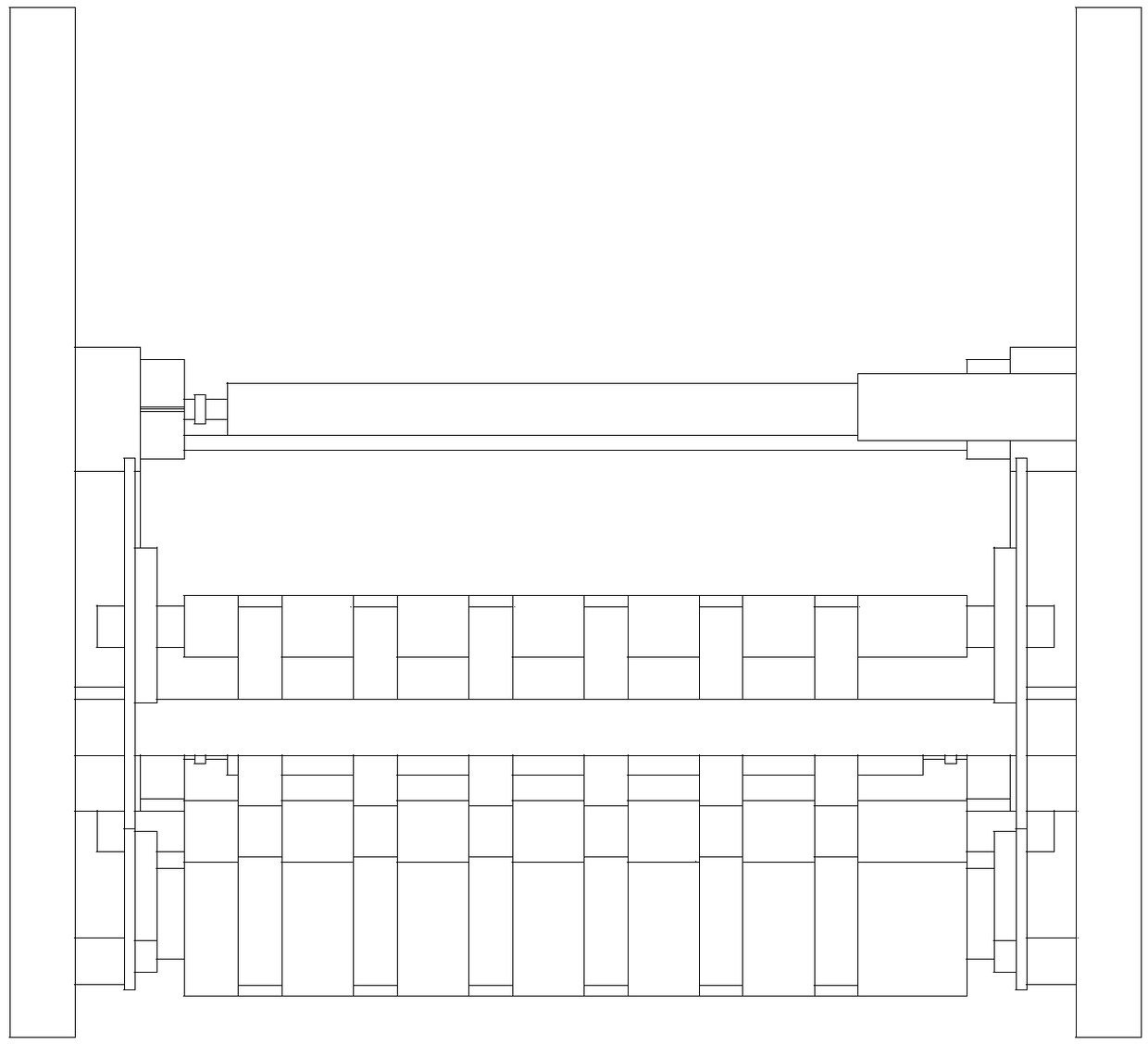

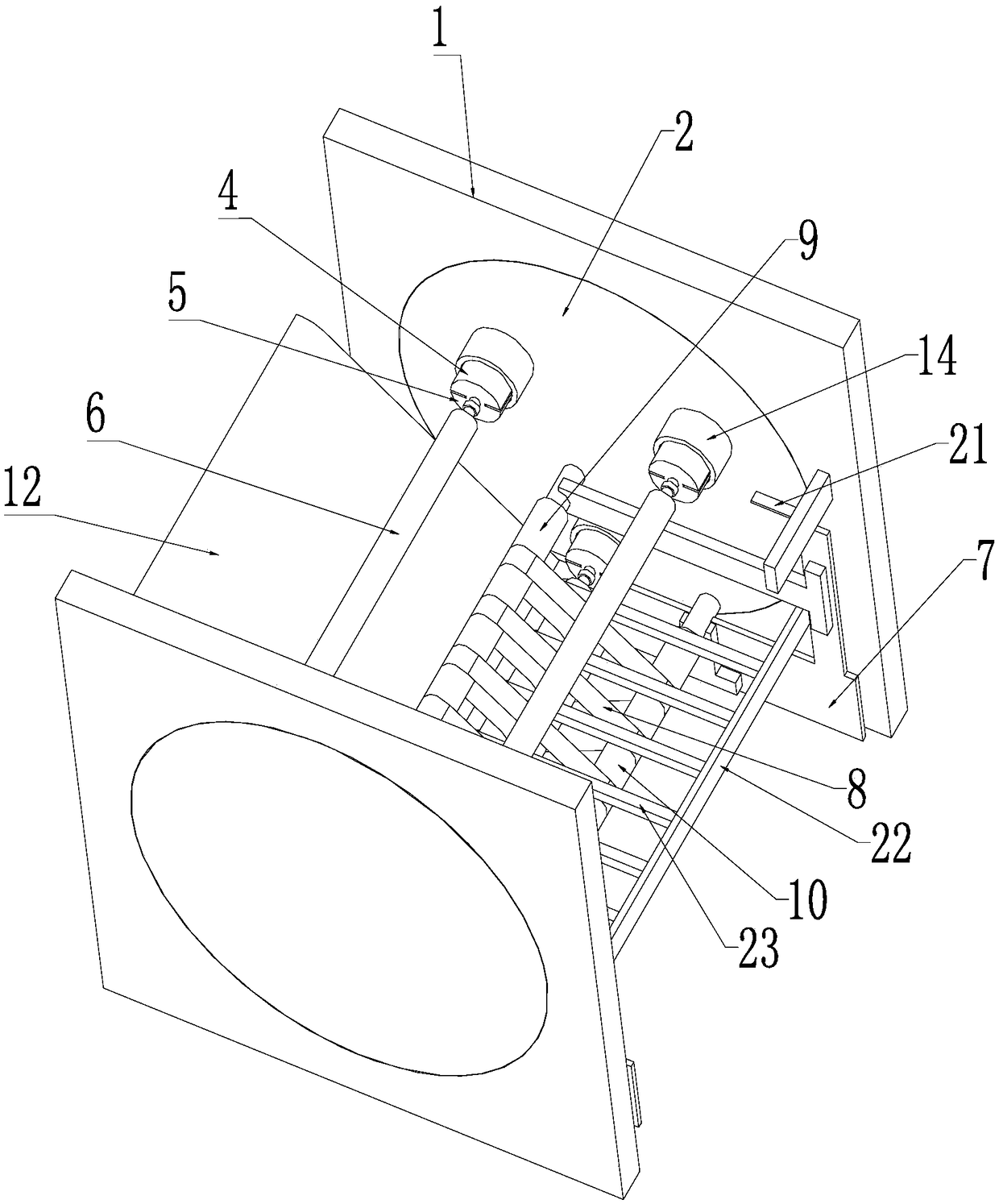

Filament winding apparatus

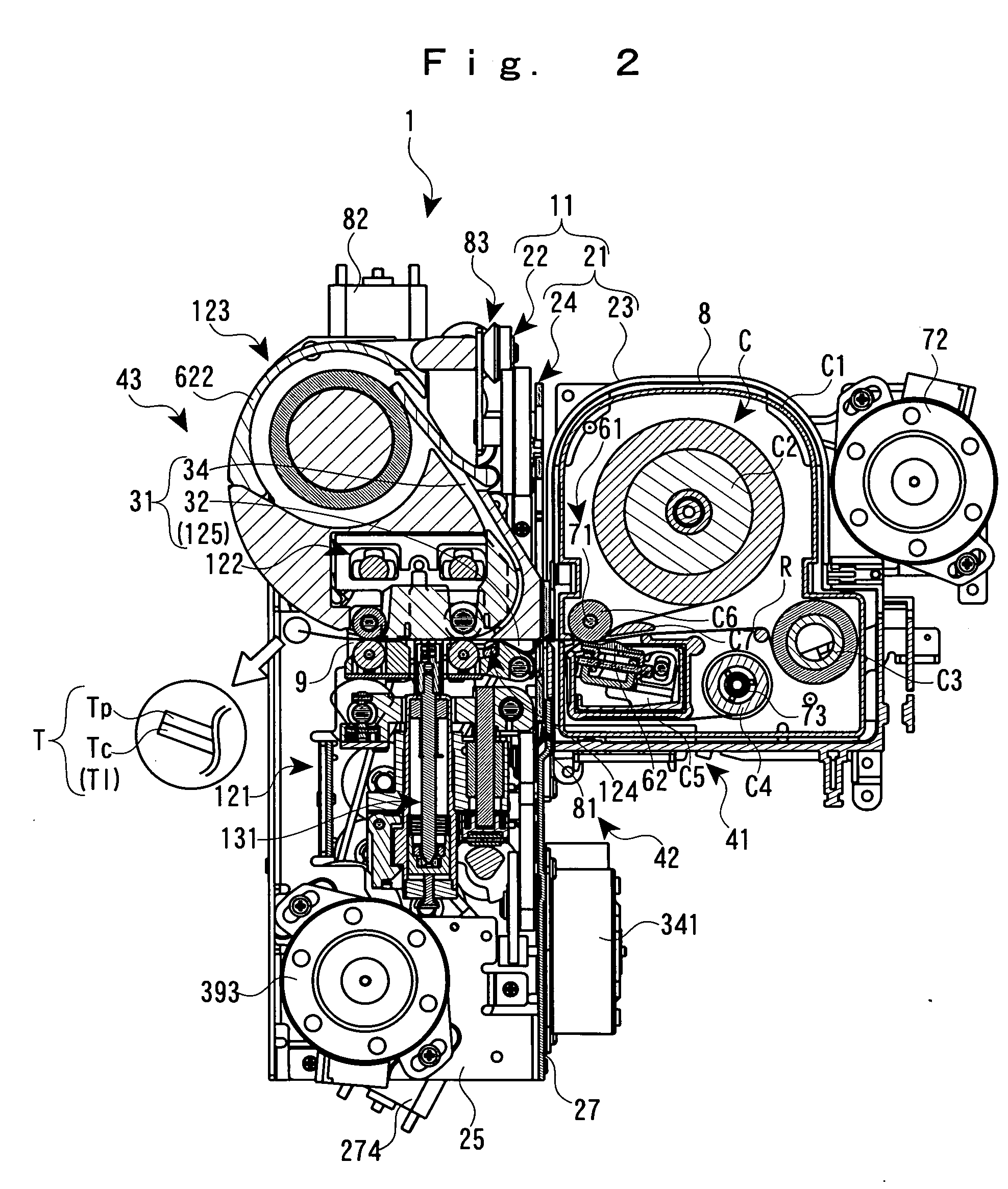

ActiveUS7815141B2Efficient executionWinding orderlyFilament handlingCoils manufactureFiber bundleReciprocating motion

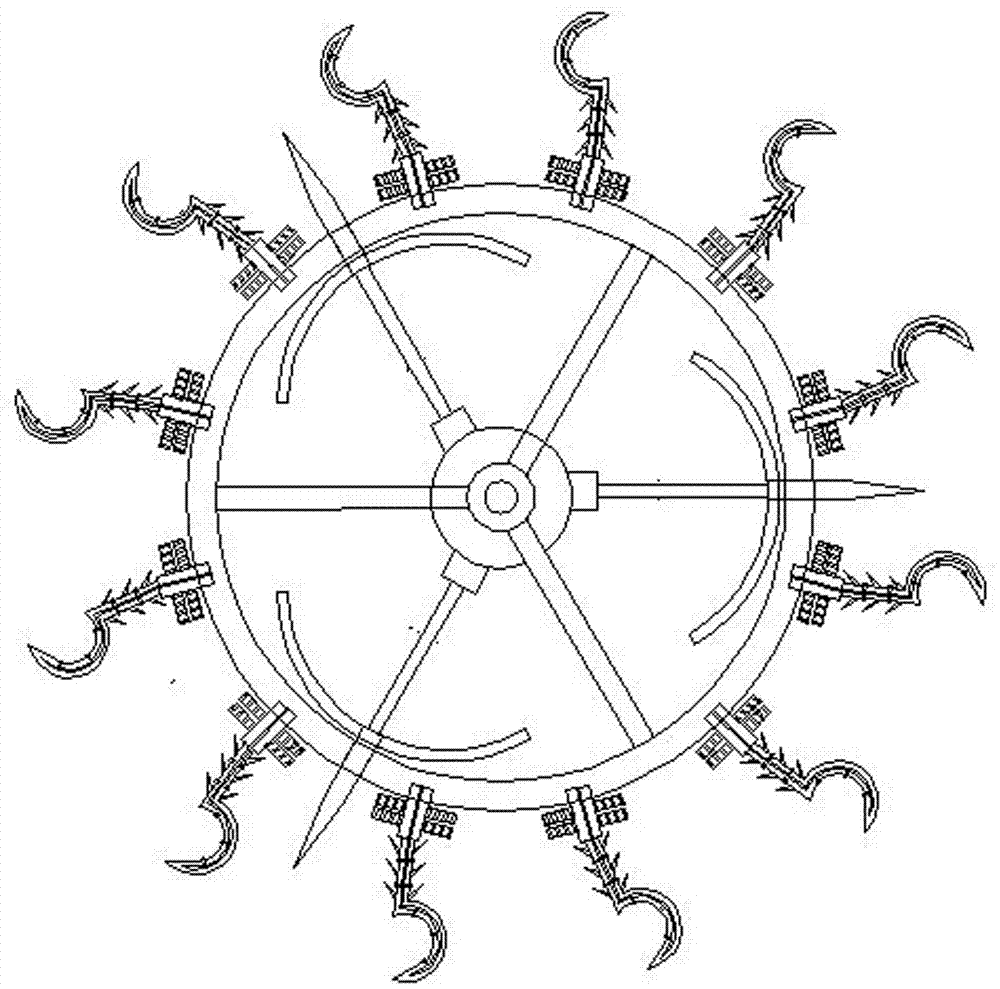

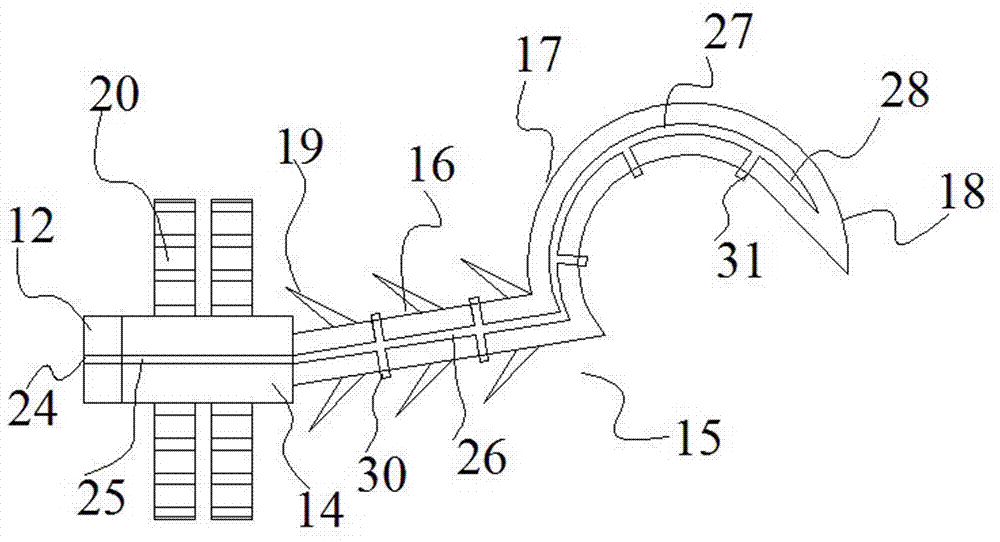

A filament winding apparatus that efficiently and orderly winds a fiber bundle with respect to a mandrel in a short period of time. A supporting board supports the mandrel, and a helical winding head supplies and guides the fiber bundle towards the mandrel. The helical winding head includes a group of guide tubes radially arranged on a circumferential surface of a guide ring, and a tube operation mechanism that reciprocates the guide tube along a tube axis center direction. The guide tube is moved closer to a circumferential surface of the dome part when the guide tube is facing a dome part of the mandrel such that the distance between the winding position of the fiber bundle and the guide tube at the dome part can be reduced, and the fiber bundle is orderly wound according to an appropriate winding trajectory.

Owner:MURATA MASCH LTD

Filament Winding Apparatus

ActiveUS20090127373A1Quality improvementReduce distanceFilament handlingCoils manufactureFiber bundleReciprocating motion

A filament winding apparatus that efficiently and orderly winds a fiber bundle with respect to a mandrel in a short period of time. A supporting board supports the mandrel, and a helical winding head supplies and guides the fiber bundle towards the mandrel. The helical winding head includes a group of guide tubes radially arranged on a circumferential surface of a guide ring, and a tube operation mechanism that reciprocates the guide tube along a tube axis center direction. The guide tube is moved closer to a circumferential surface of the dome part when the guide tube is facing a dome part of the mandrel such that the distance between the winding position of the fiber bundle and the guide tube at the dome part can be reduced, and the fiber bundle is orderly wound according to an appropriate winding trajectory.

Owner:MURATA MASCH LTD

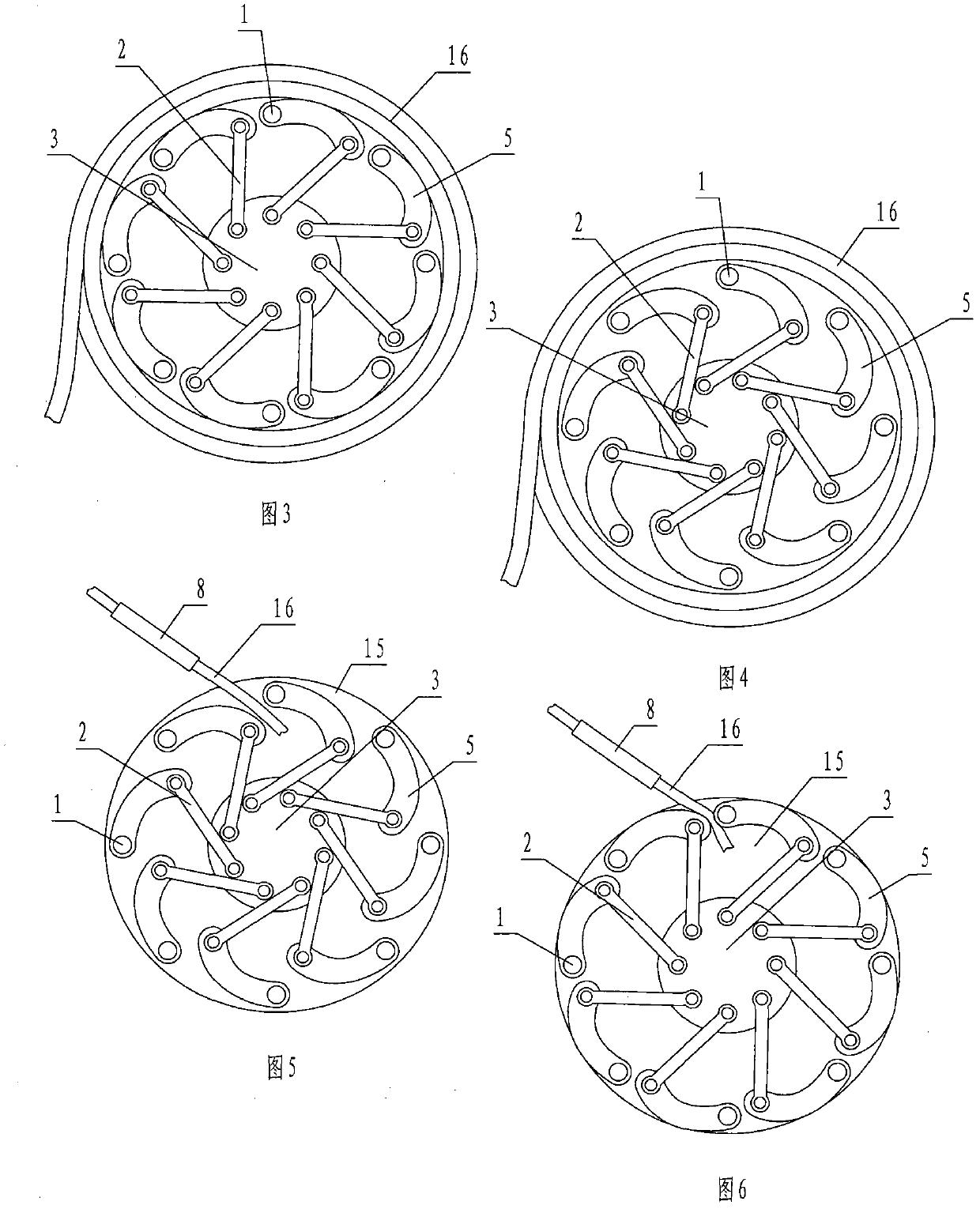

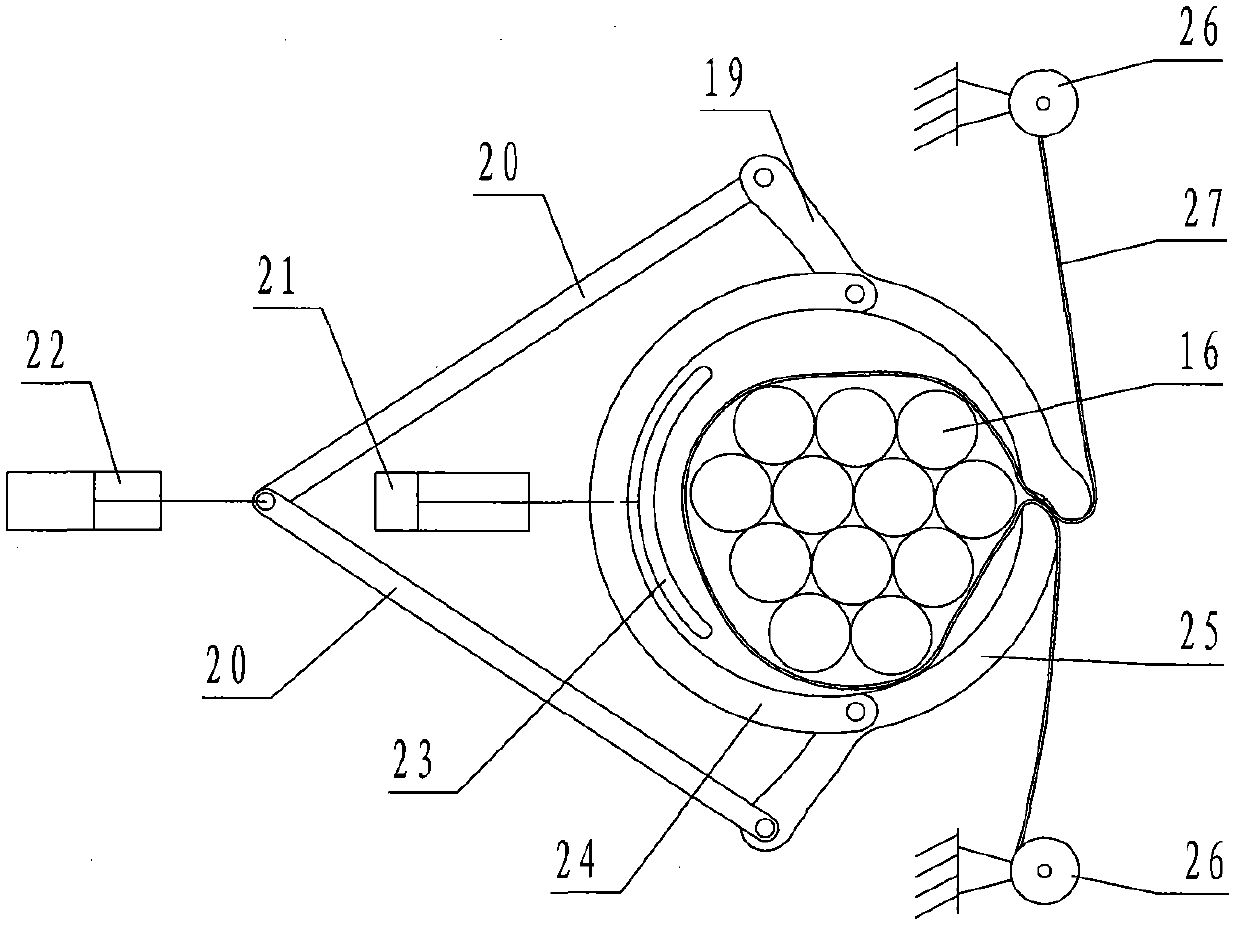

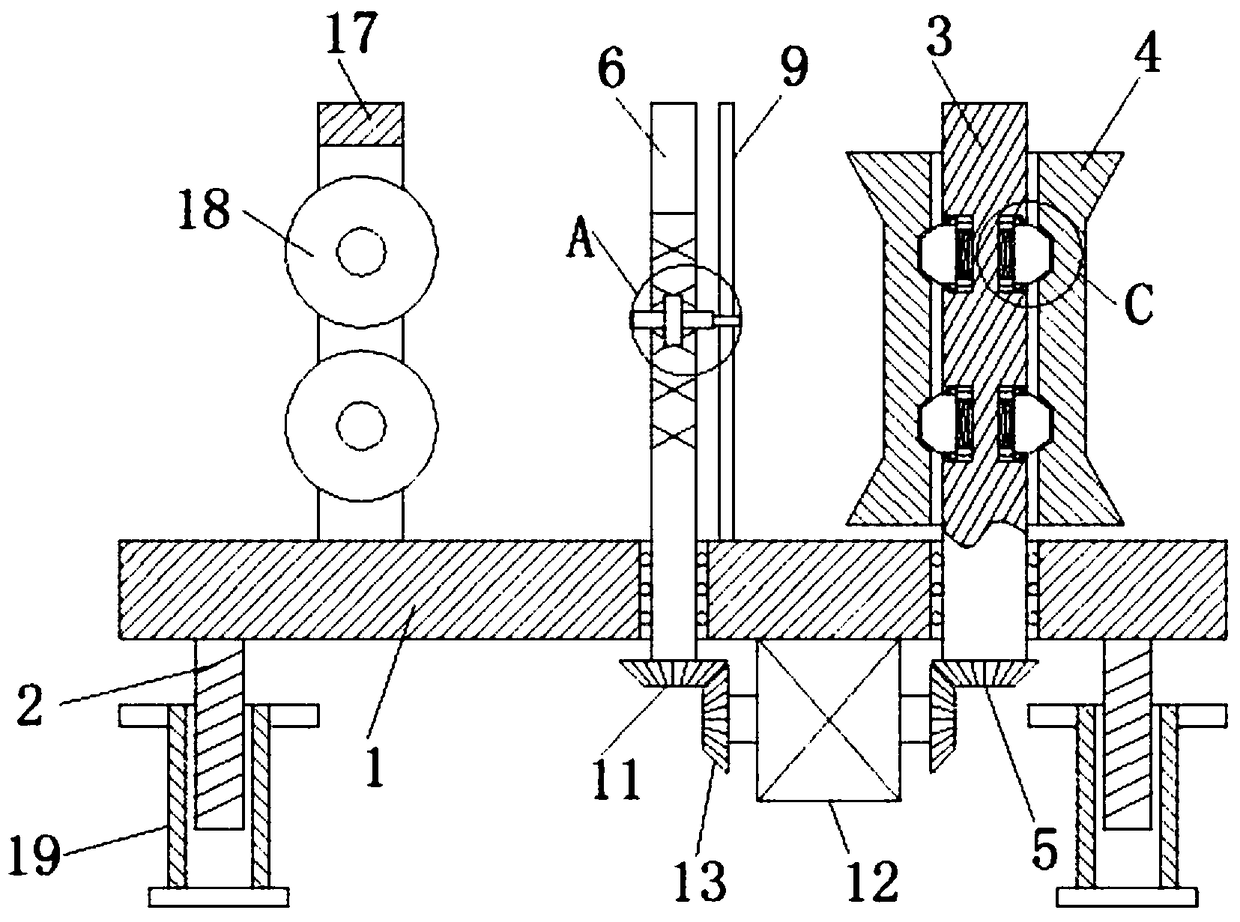

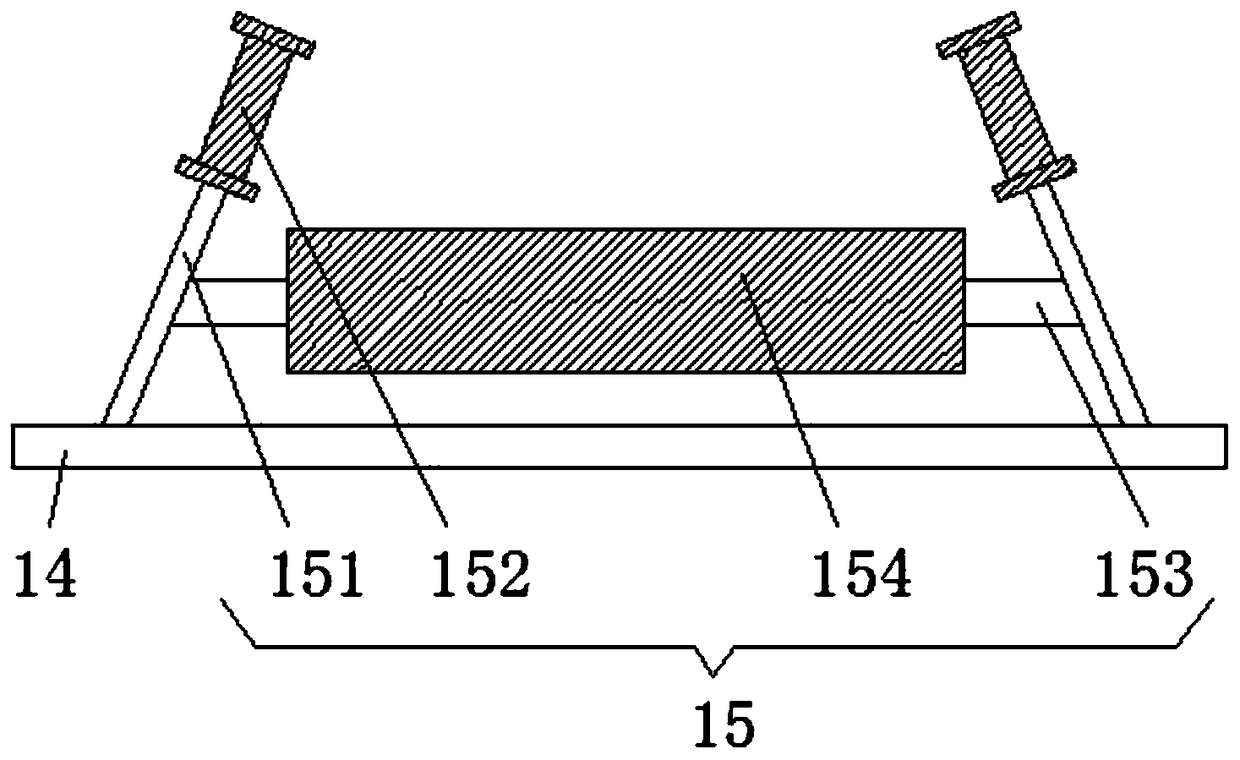

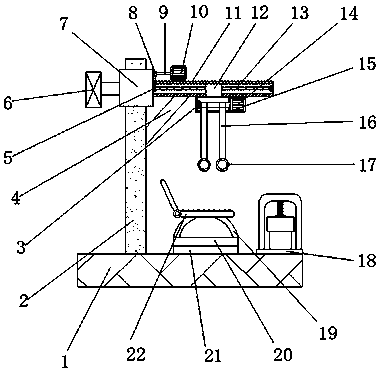

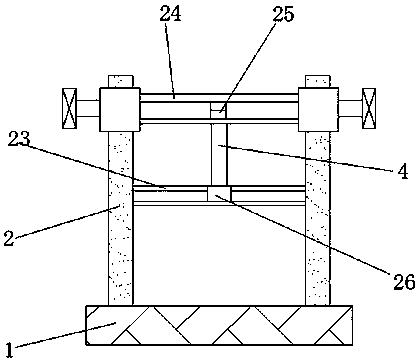

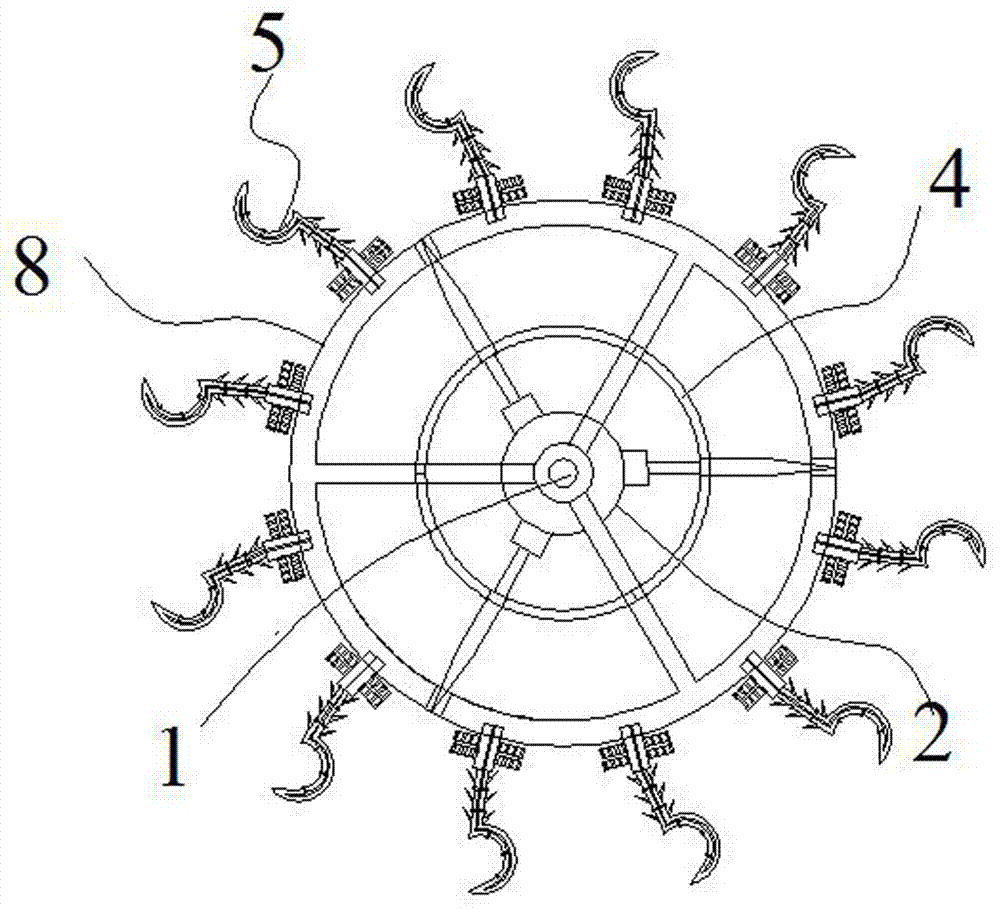

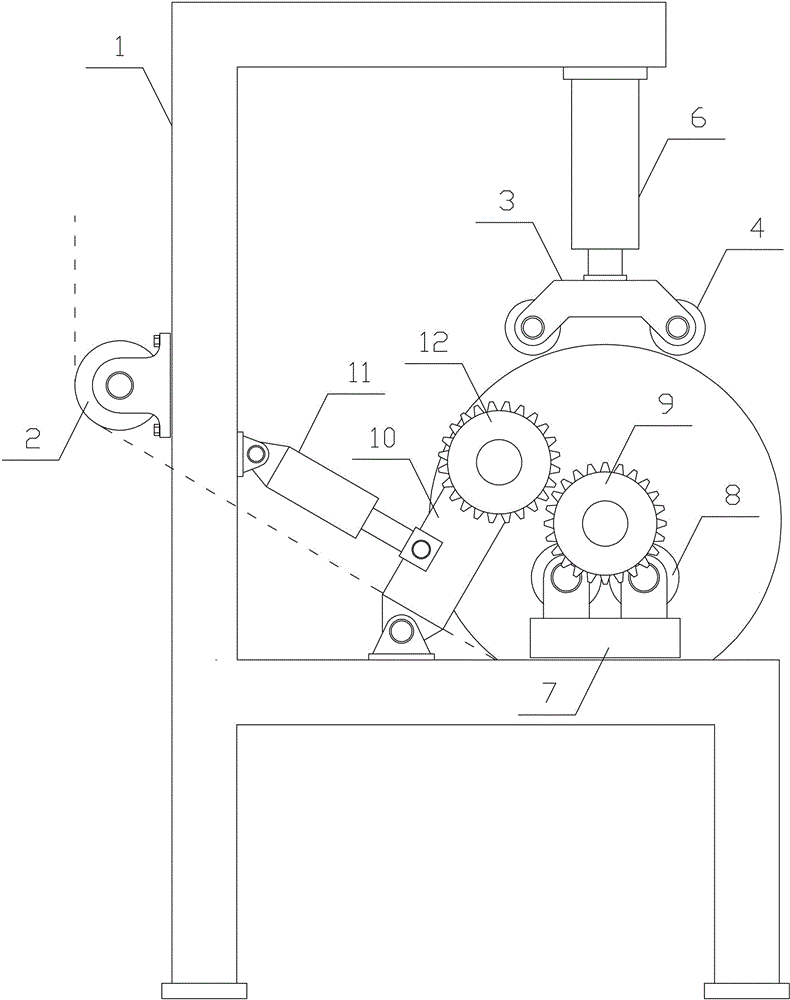

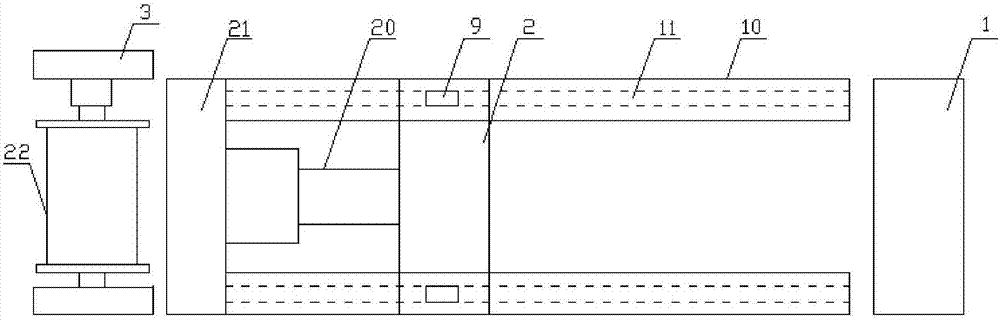

Full-automatic plastic detonating tube winding and bundling device

InactiveCN101948016AEasy to removePrecise deliveryFilament handlingBundling machine detailsDrive motorEngineering

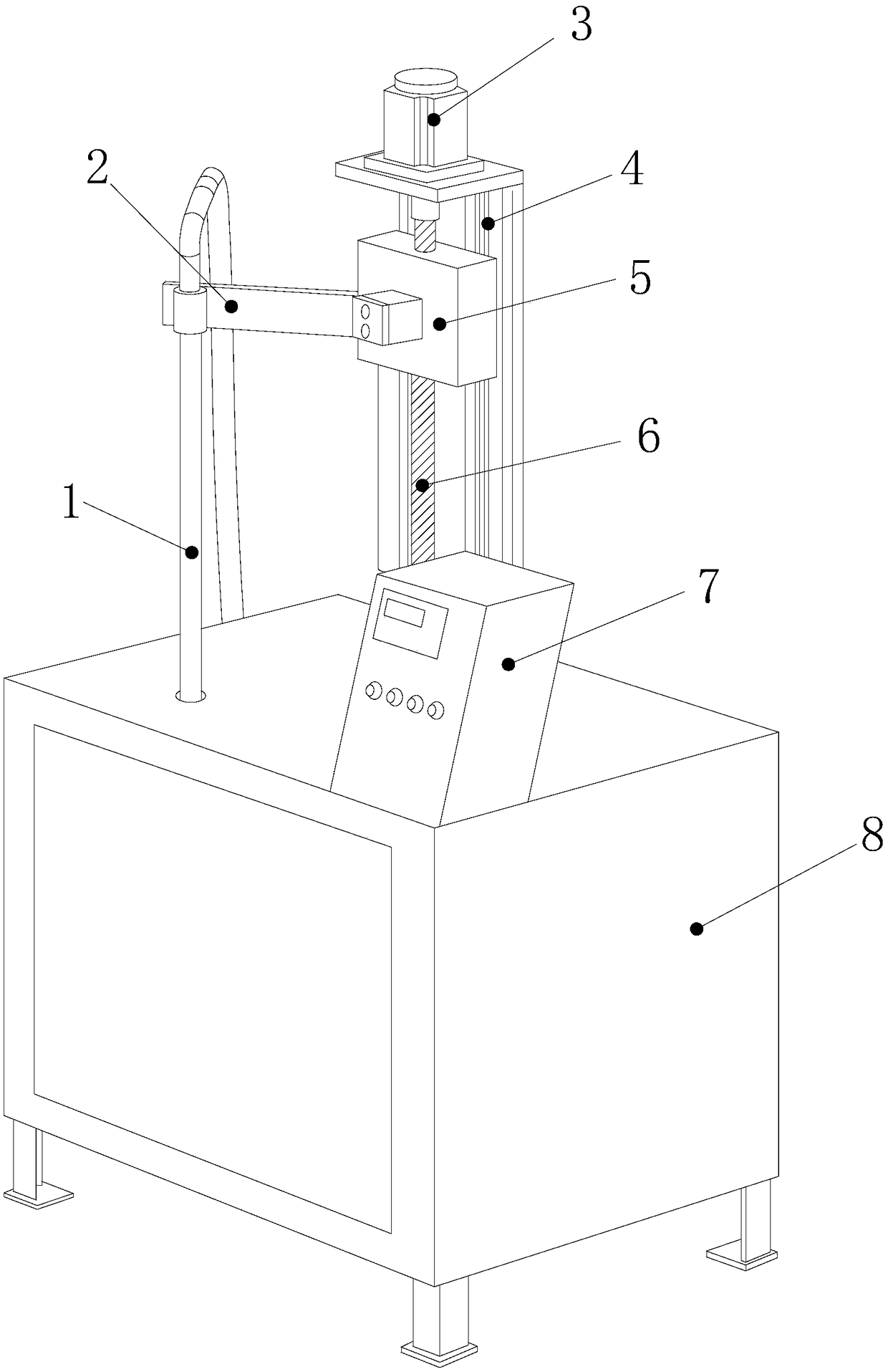

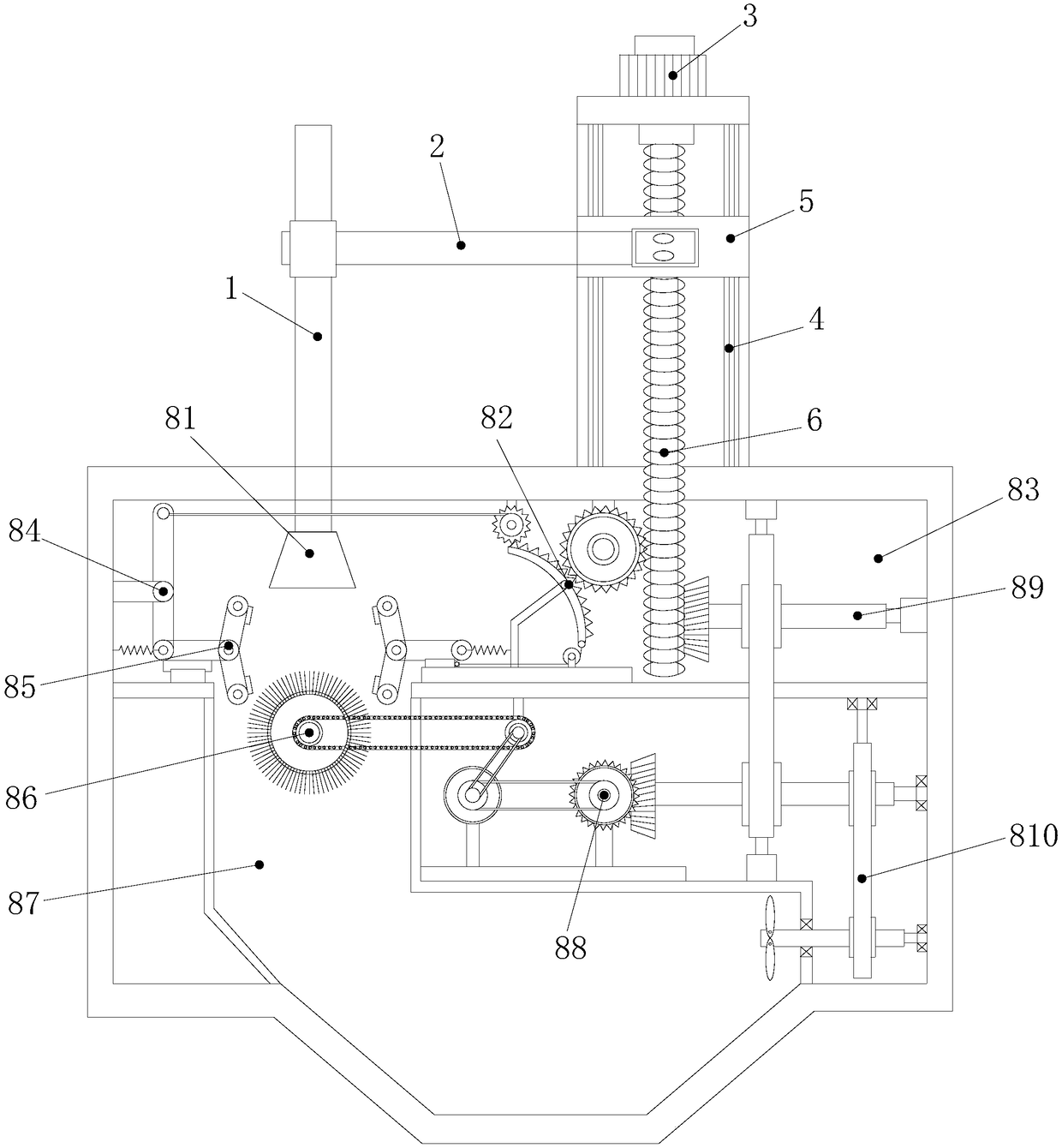

The invention discloses a full-automatic plastic detonating tube winding and bundling device. The device comprise a frame, a horizontal revolving shaft, a turnplate, a driving disc, a driving rod, arc-shaped supporting plates, a supporting plate adjusting rod and a drive motor; the horizontal revolving shaft is rotatably supported on the centre holes of the frame and the turnplate by bearing; one end of the horizontal revolving shaft is connected with the drive motor and the other end of the horizontal revolving shaft is fixed with the driving disc which is concentric with the horizontal revolving shaft; a plurality of arc-shaped supporting plates are uniformly distributed along the circumference of one side of the turnplate; each arc-shaped supporting plate is rotatably supported on each positioning shaft; each positioning shaft is fixed on the turnplate and is parallel to the horizontal revolving shaft; the free end of the arc-shaped supporting plate is hinged with the outer edge of the driving disc through the supporting plate adjusting rod; and the driving disc is in transmission connection with the turnplate through the driving rod. The device can automatically and efficiently wind the plastic detonating tubes into coils, greatly reduces the labor intensity of an operator, and improves the production efficiency of the detonating tubes.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

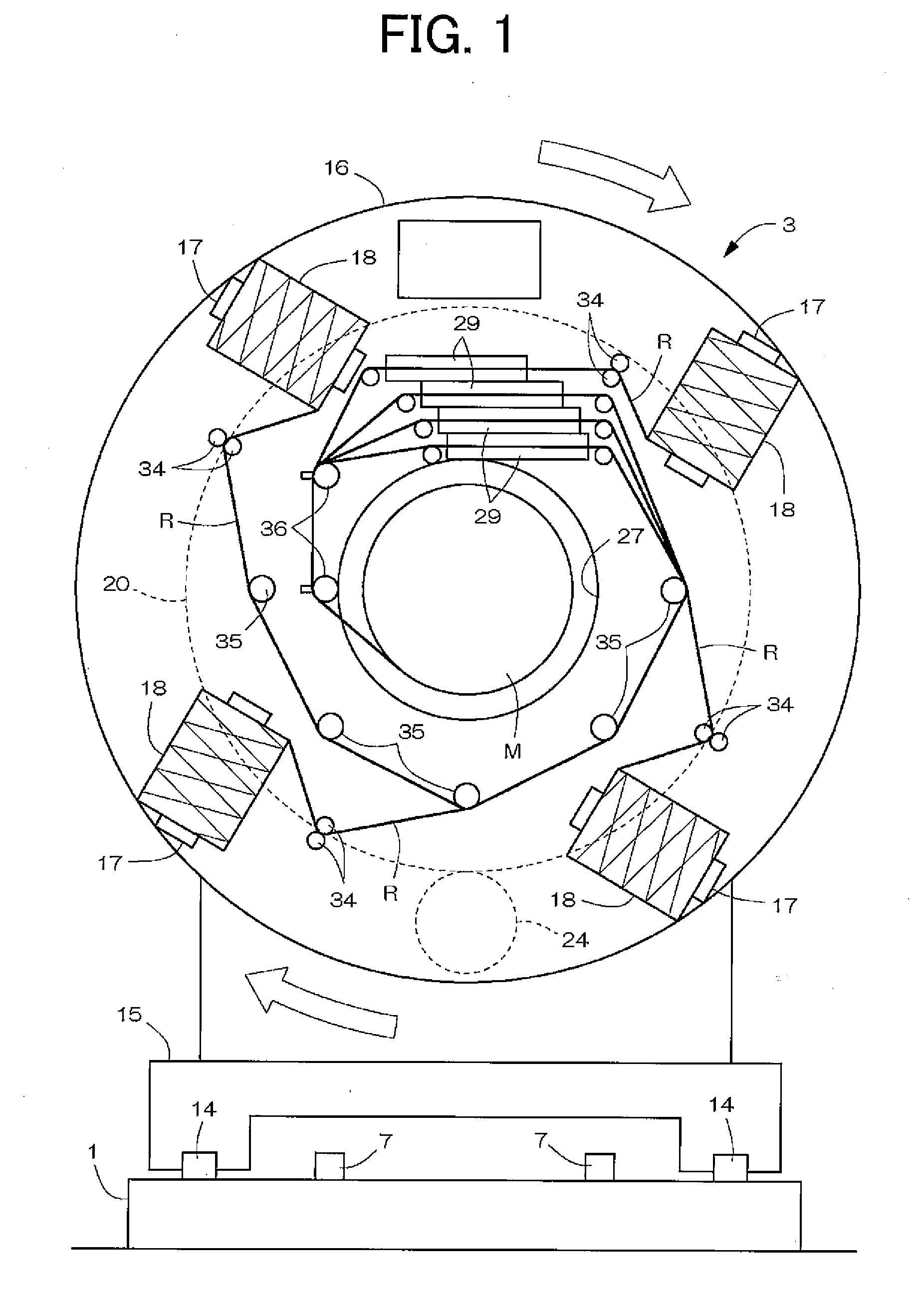

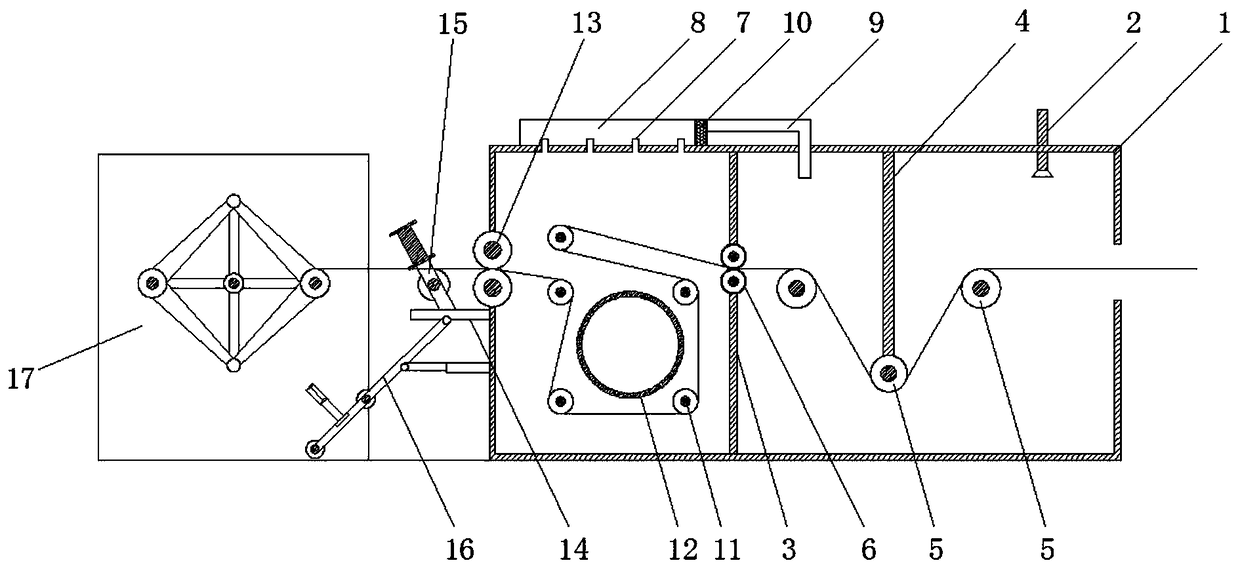

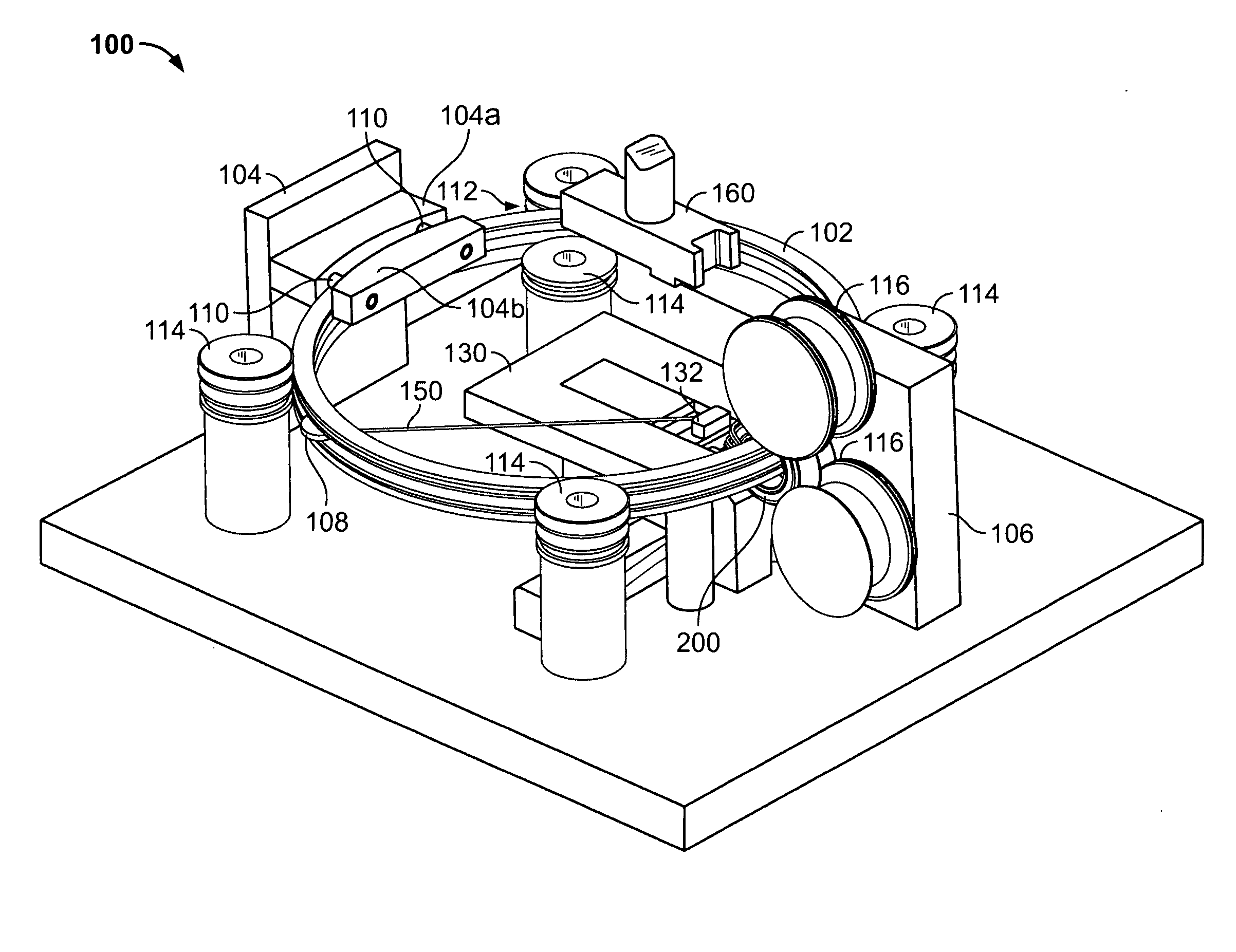

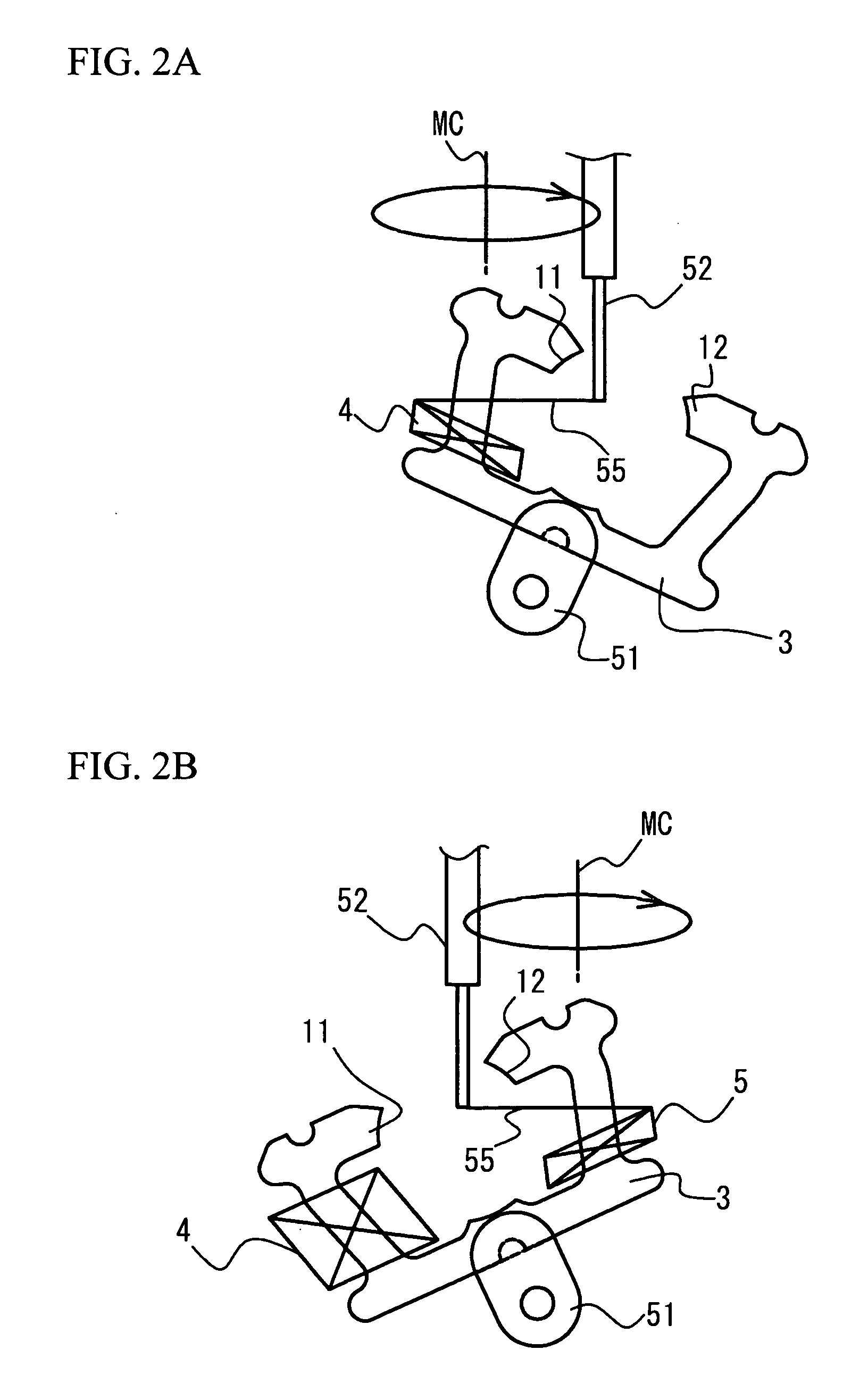

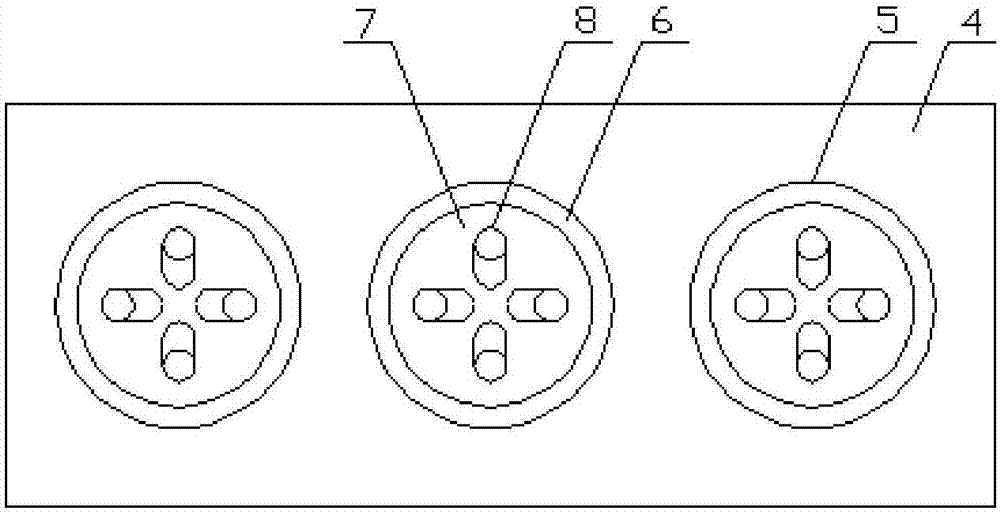

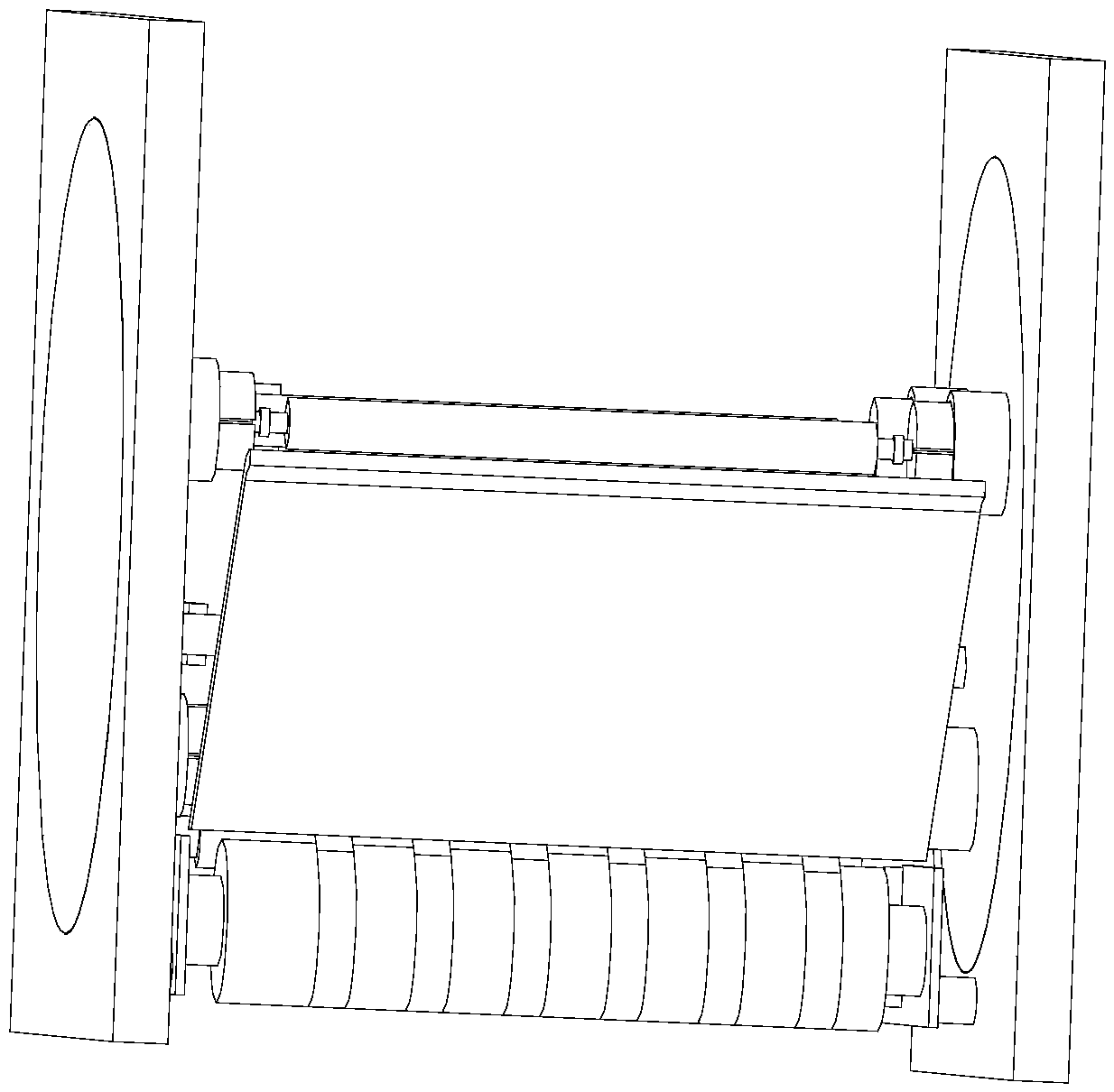

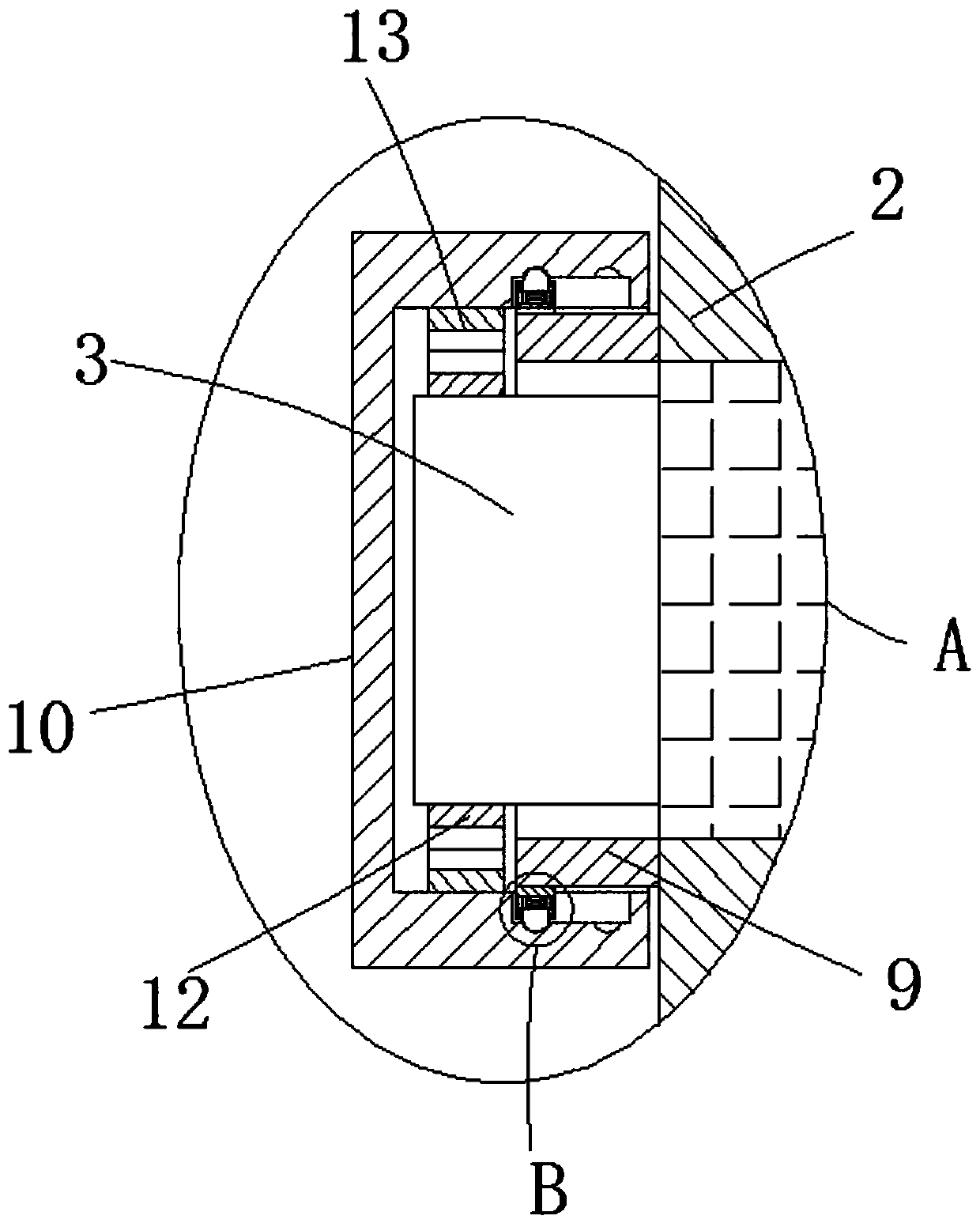

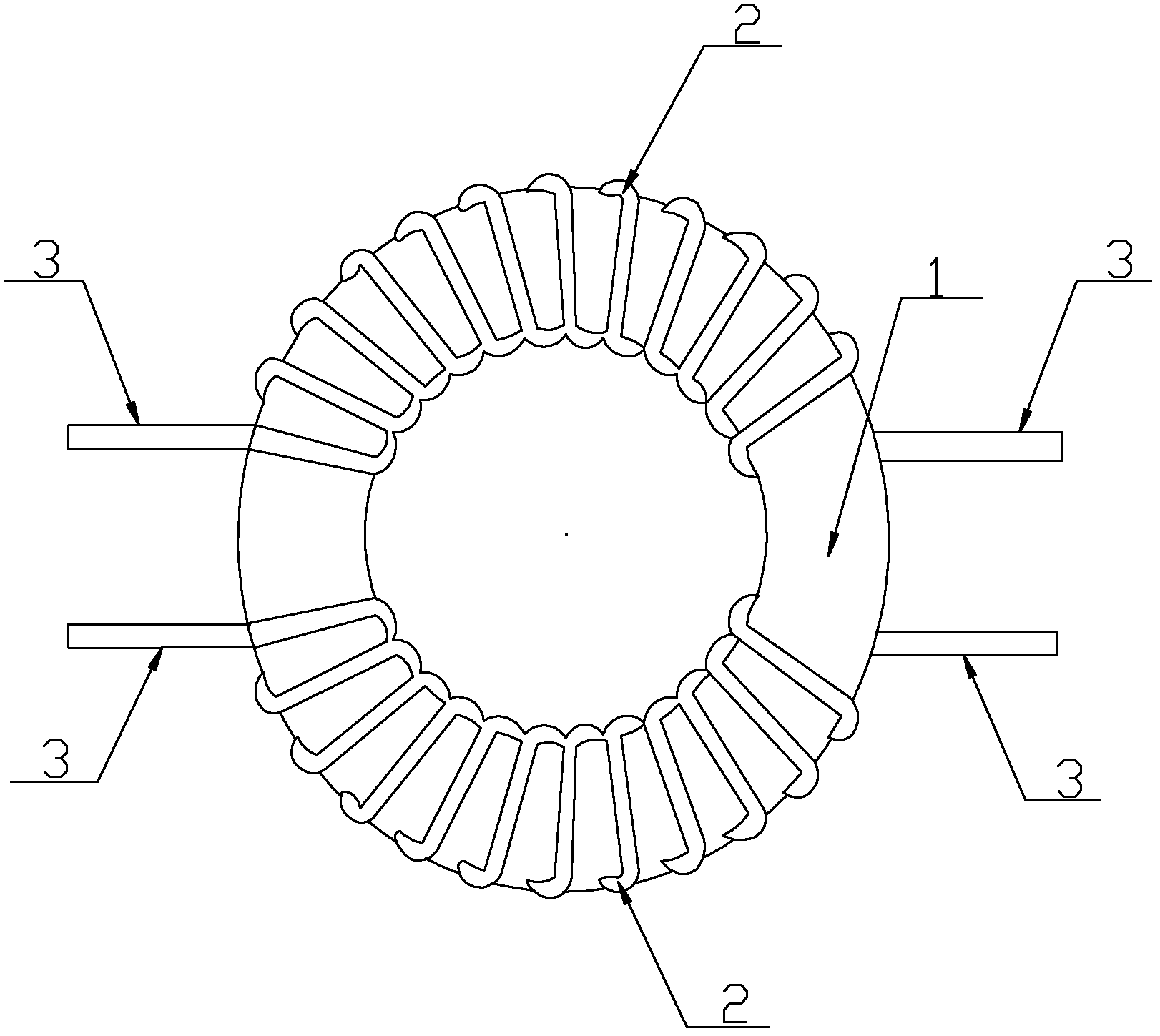

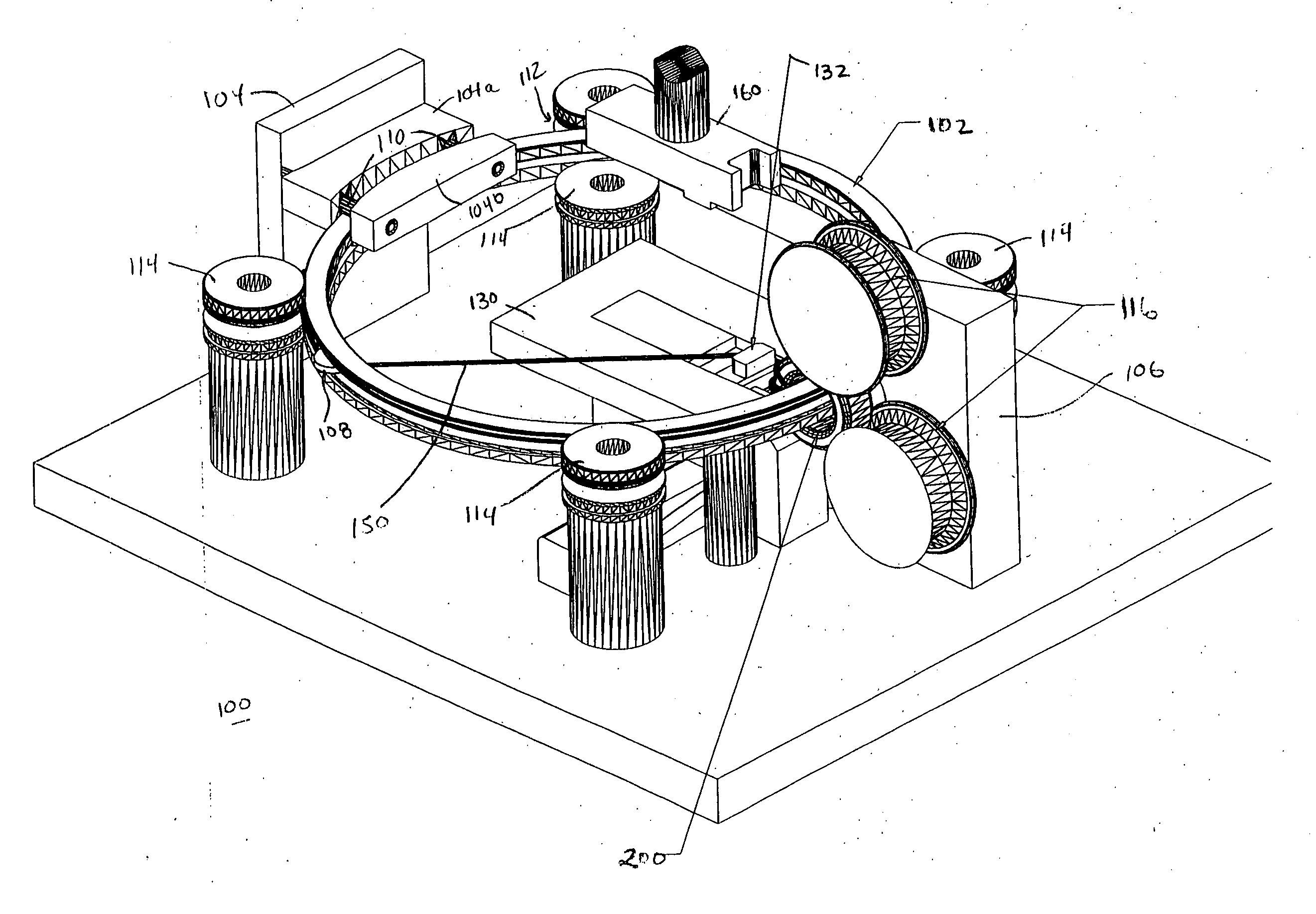

Filament Winding Apparatus

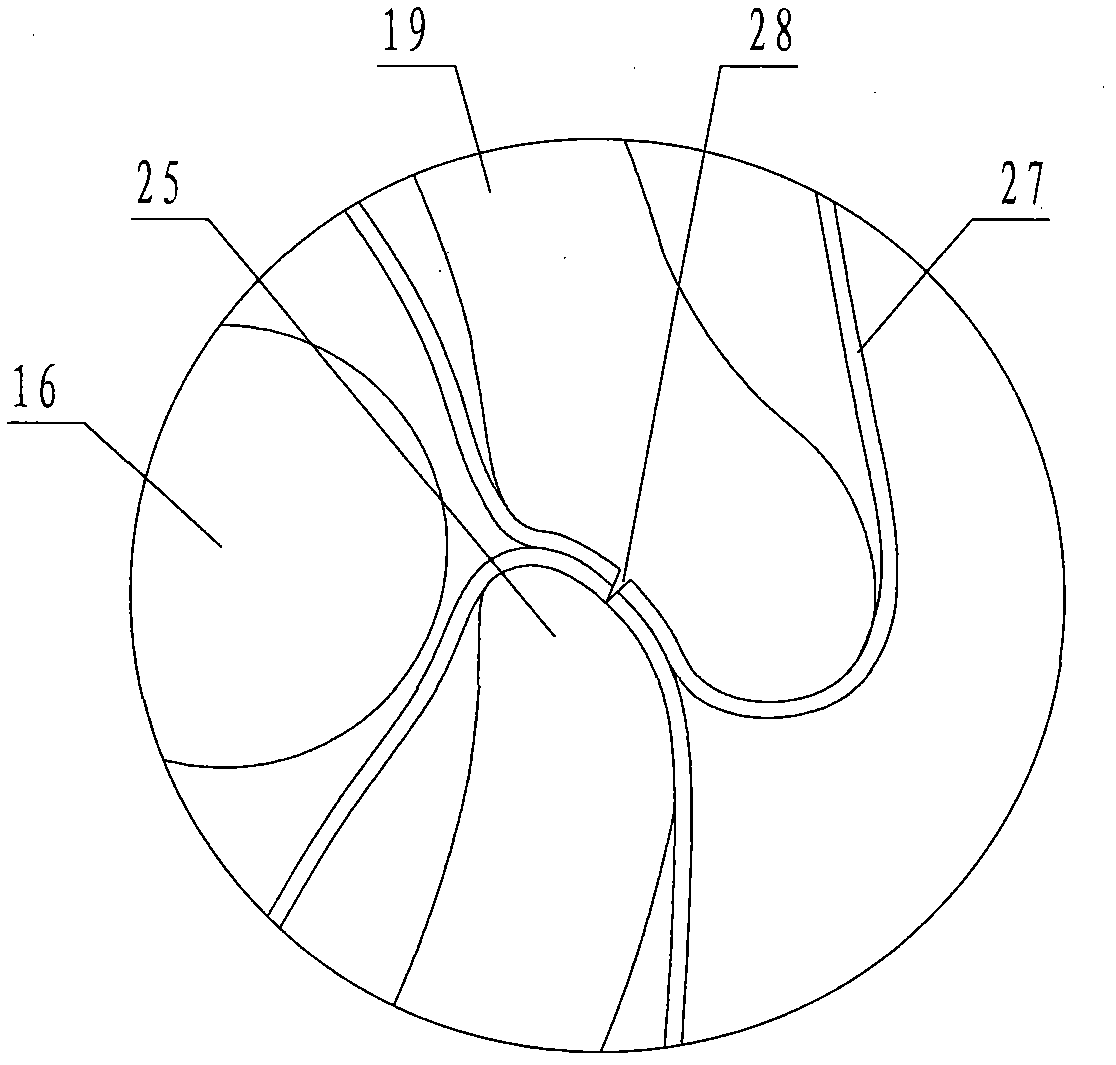

ActiveUS20090065622A1Improve productivityReduce manufacturing costFilament handlingCoils manufactureFree rotationFiber bundle

A filament winding apparatus includes a hoop winding device and a helical winding device. The hoop winding device includes a disc-shaped wrapping table, a drive mechanism that rotatably drives the wrapping table, four bobbins supported along a peripheral edge of the wrapping table, and a guide member that moves and guides a fiber bundle fed from the bobbin to a mandrel arranged in an insertion hole of the wrapping table. The bobbin is axially supported in a freely rotatable manner with a chuck of a holder fixed to the wrapping table. A ratchet mechanism, which prevents over-rotation in a fiber bundle feeding direction of the bobbin, is arranged between the holder and the chuck.

Owner:MURATA MASCH LTD

Textile yarn winding device

The invention discloses a textile yarn winding device which comprises a base. Four corners of the lower end of the base are fixedly connected with adjusting mechanisms, the left side of the upper endof the base is rotatably connected with a rotating rod through a first rolling bearing, a reel sleeves the wall of the rotating rod in a fastened manner by a fixing mechanism, the lower end of the rotating rod penetrates the base and extends to the lower portion of the base, the lower end of the rotating rod is fixedly connected with a first bevel gear, the center of the upper end of the base is rotatably connected with a reciprocating lead screw through a second rolling bear, a slider matched with the reciprocating lead screw movably sleeves the wall of the reciprocating lead screw, one sidewall, close to the reel, of the slider is fixedly connected with a connecting block, a through hole is formed in the upper end of the connecting block, a sliding rod is movably arranged in the throughhole, the lower end of the sliding rod is fixedly connected with the base, and the side wall of the front of the slider is fixedly connected with a thread guide. Textile yarns can be effectively wound neatly and uniformly, winding effects are good, and the textile yarns are conveniently used by people during spinning.

Owner:GUIZHOU WANGFENGLIN TEXTILE TECH CO LTD

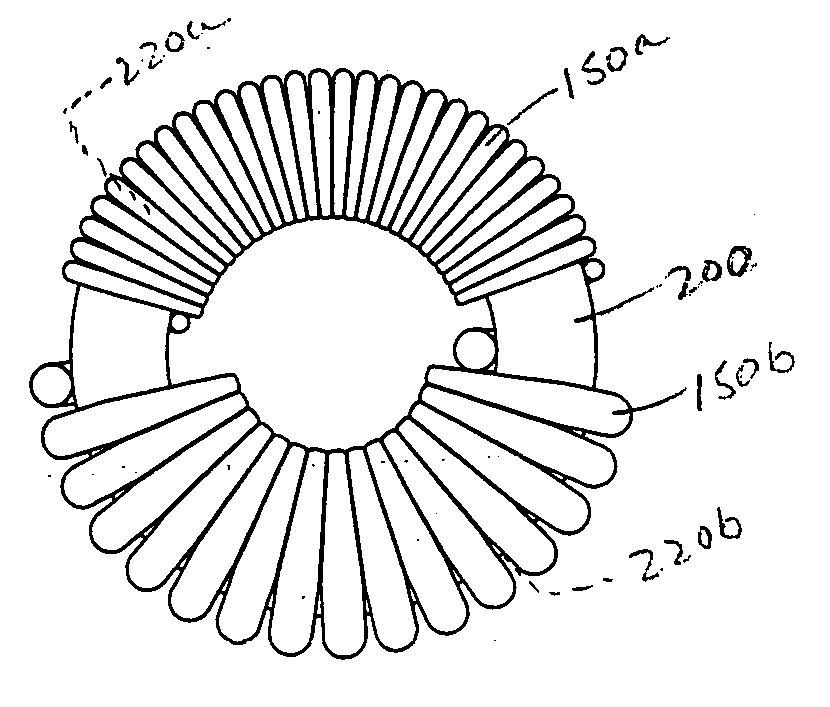

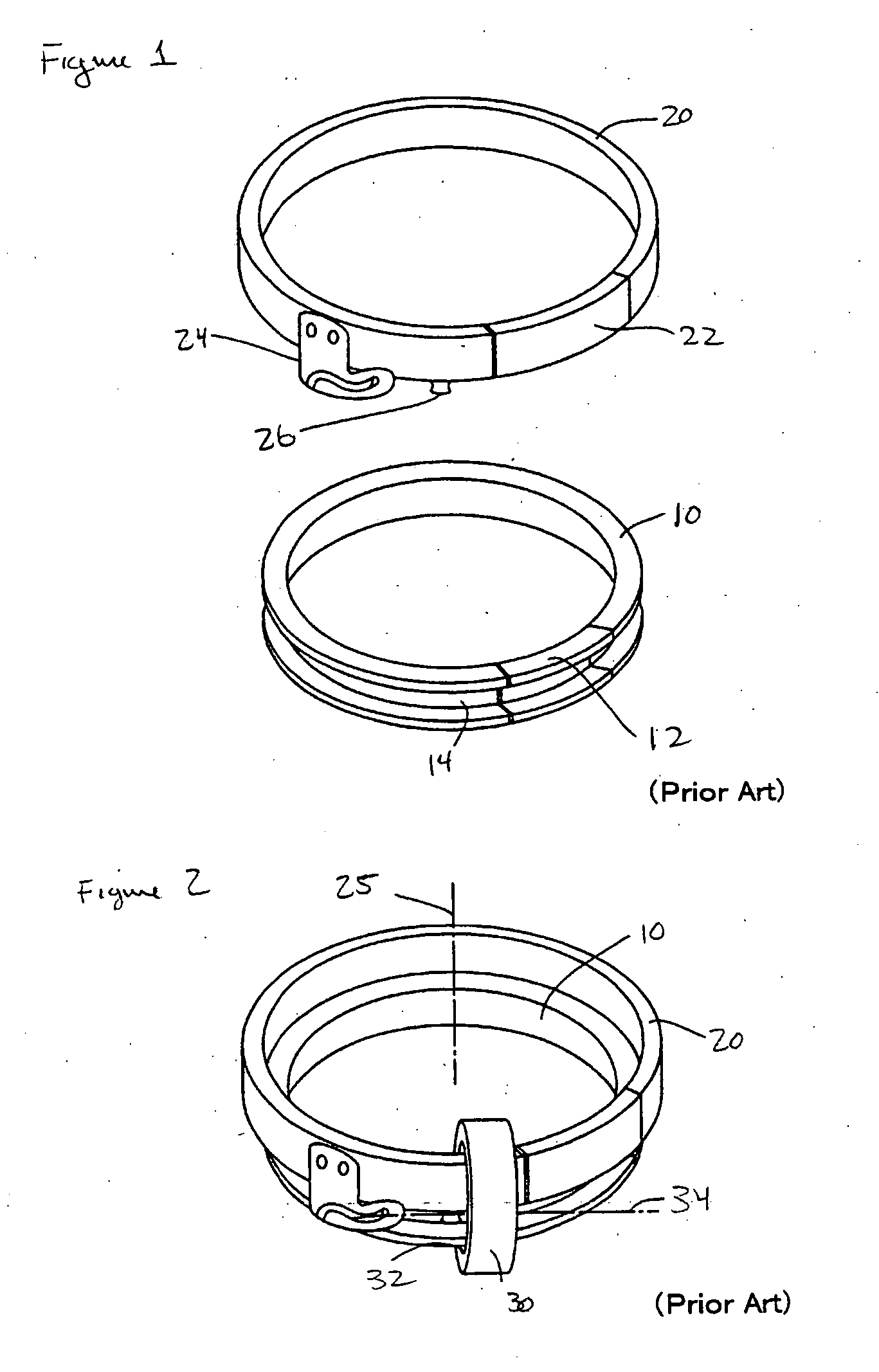

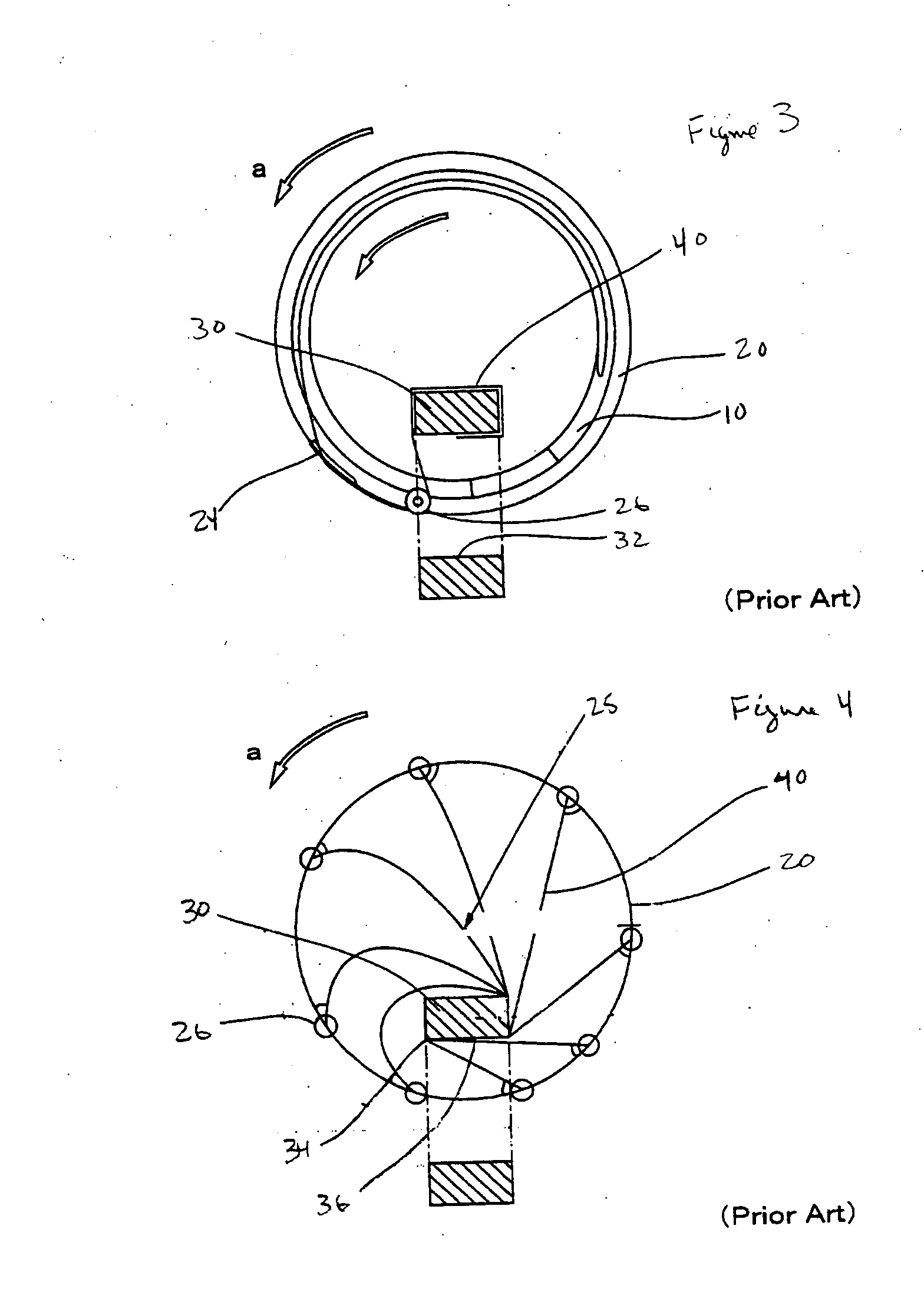

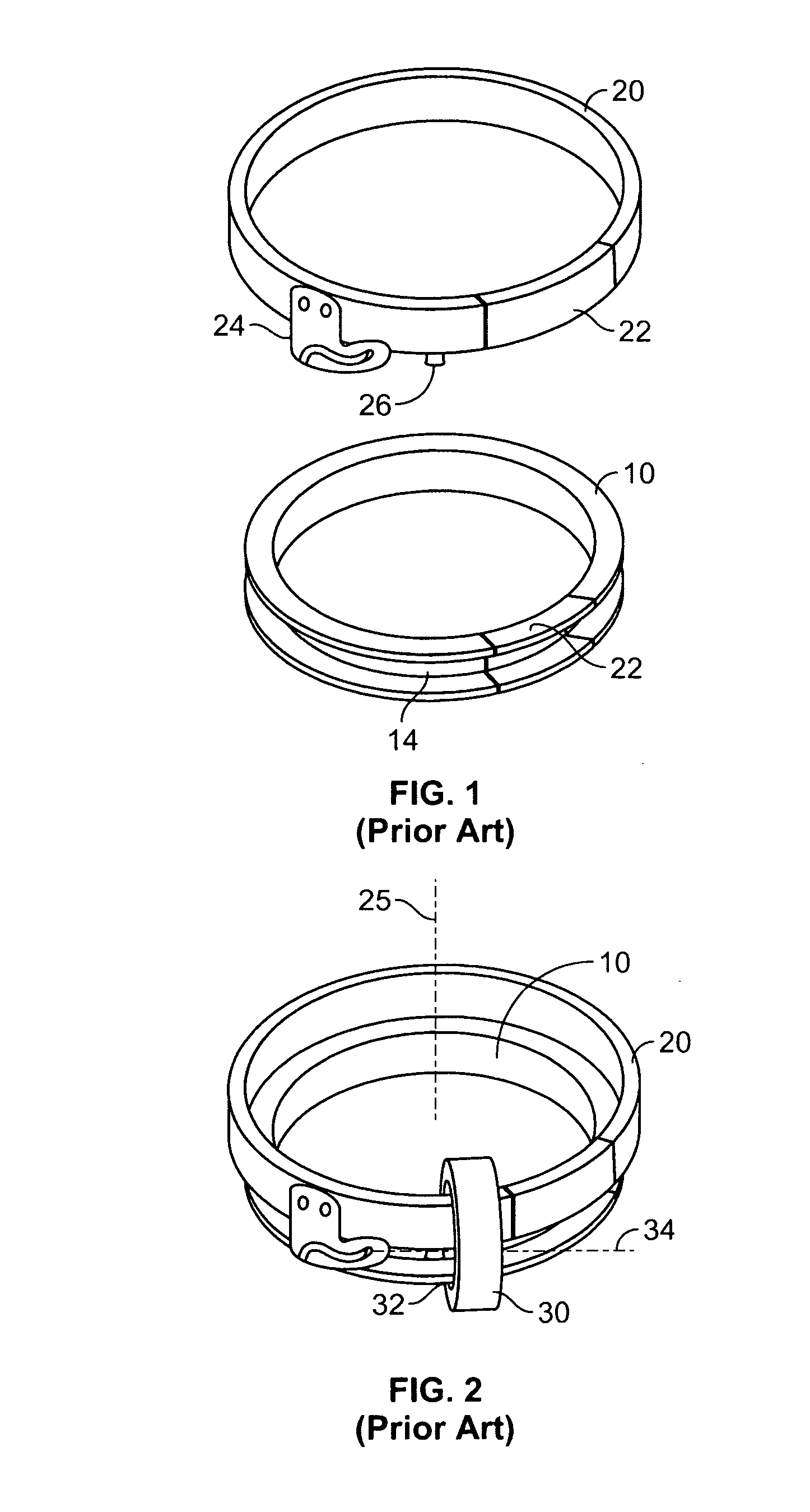

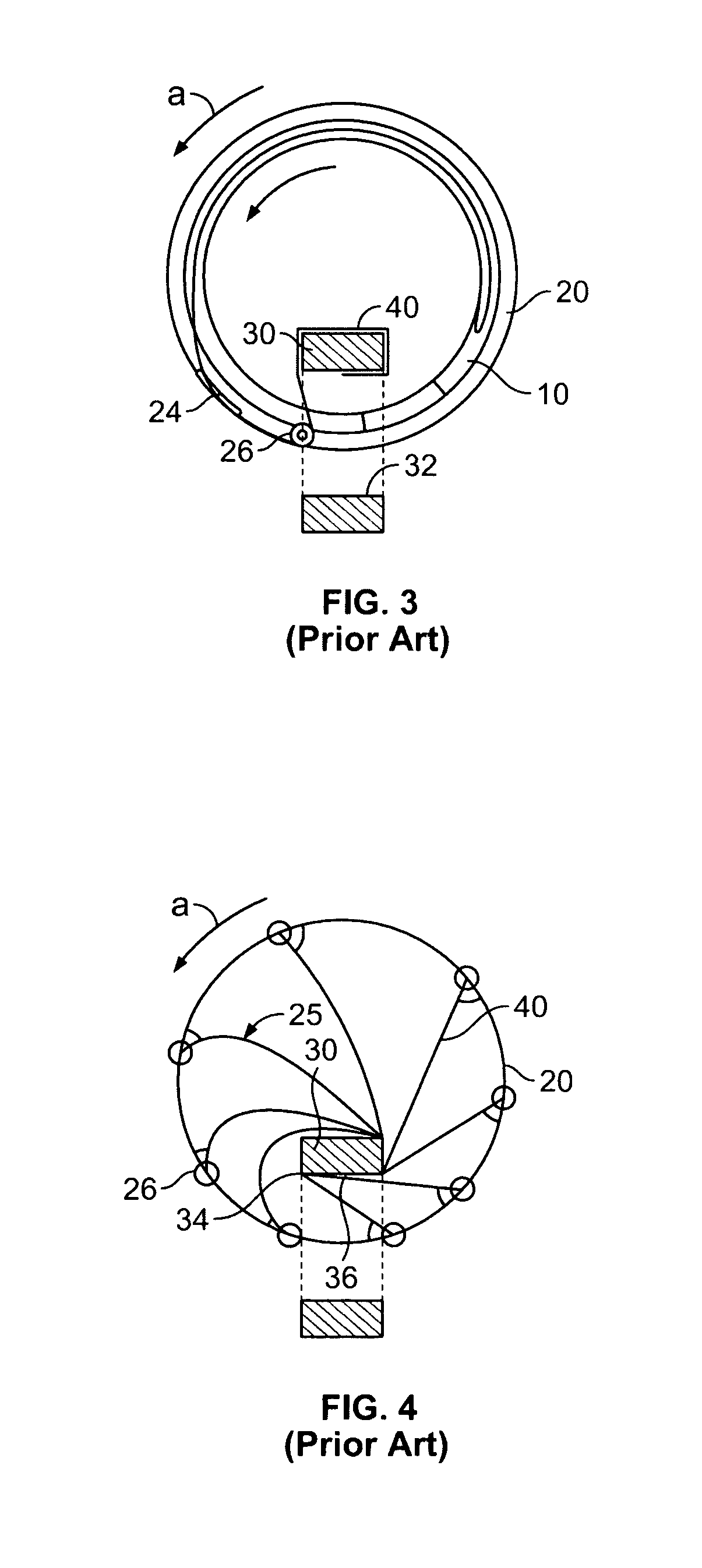

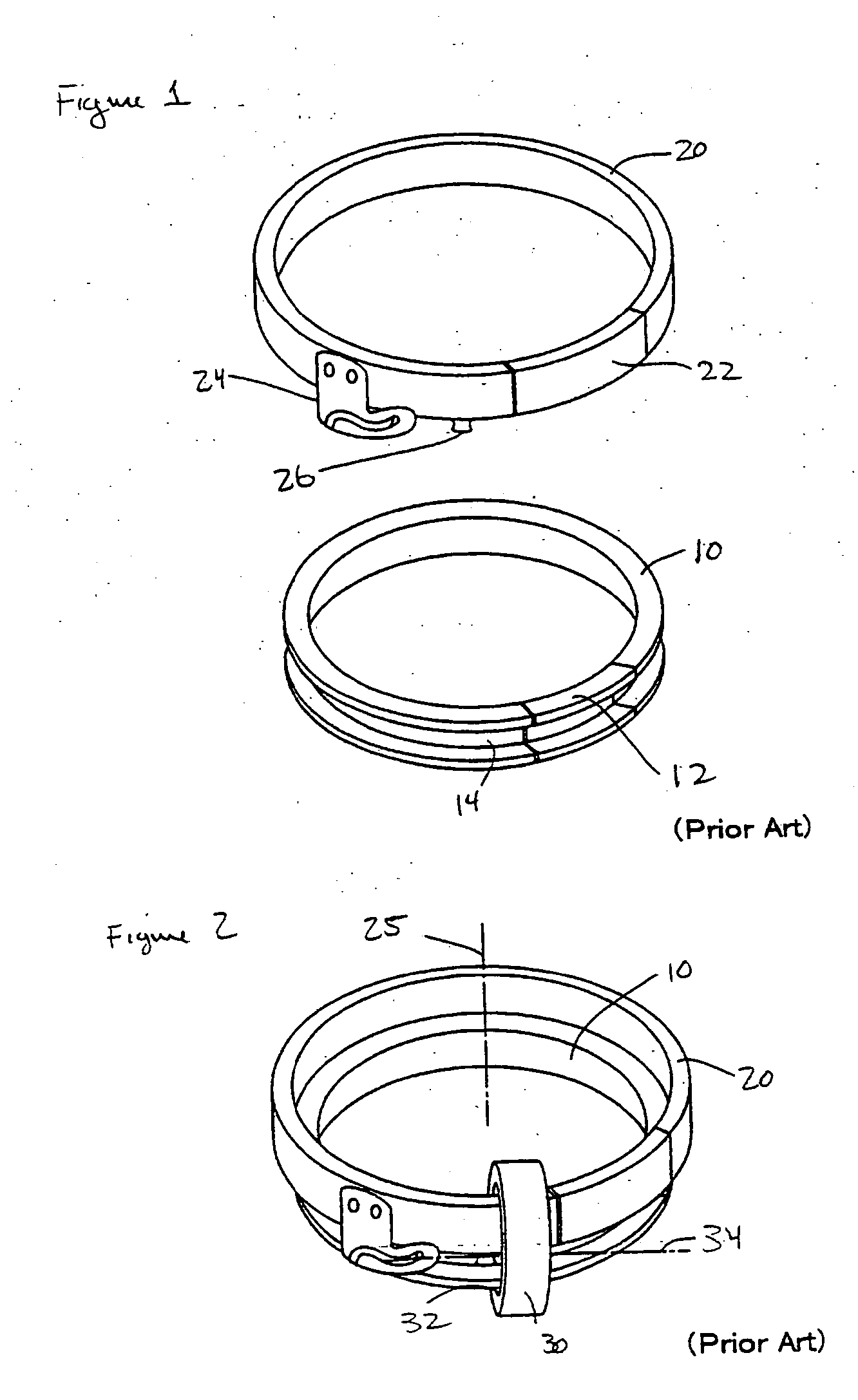

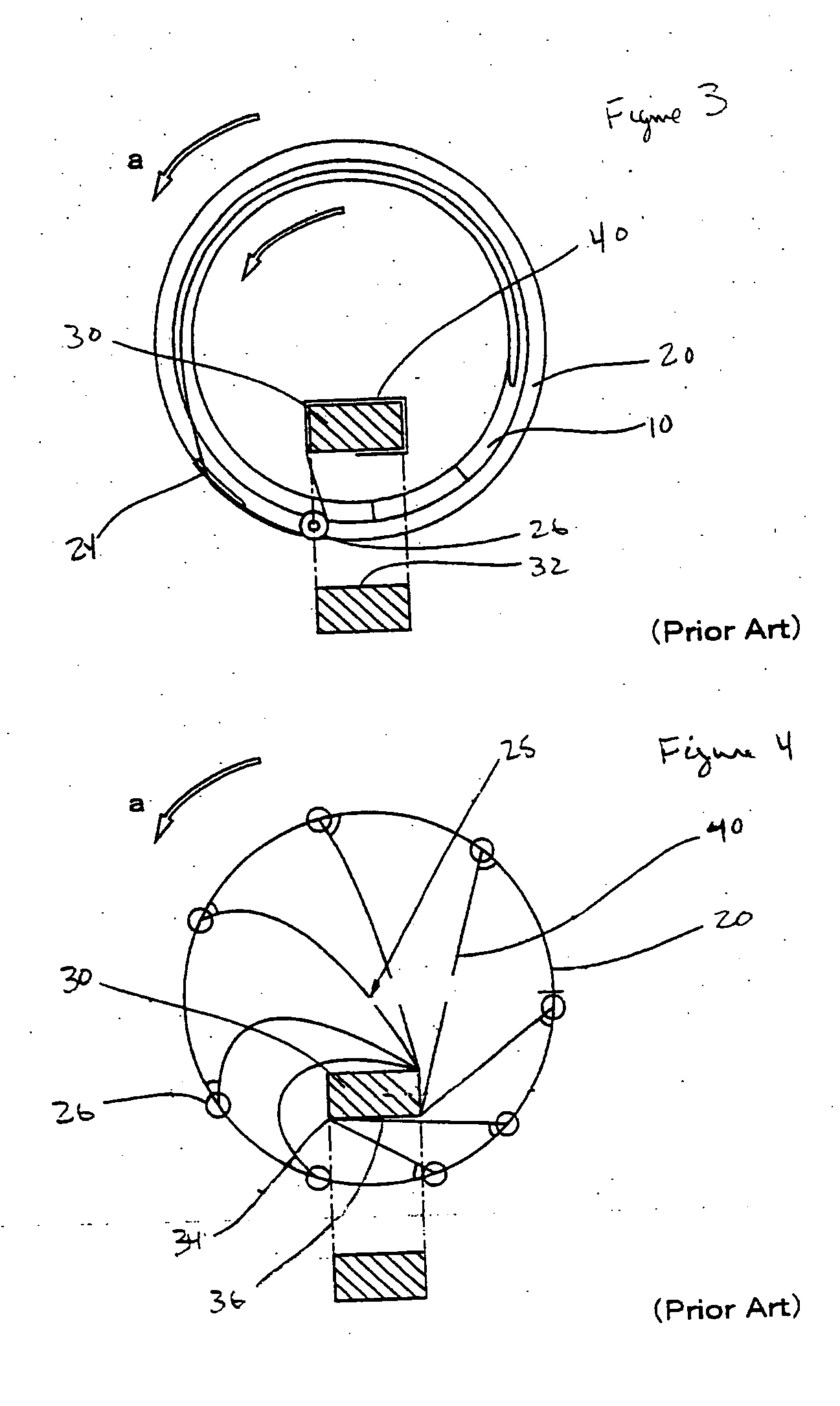

Magnetic core winding method, apparatus, and product produced therefrom

The invention relates to winding wire around a magnetic core. The invention includes forming corners on the wire that align with inside corners of the magnetic core such that the wire is more tightly wound around the magnetic core. The invention also includes pinching a portion of wire that is positioned on the internal diameter of a magnetic core when the wire is wound around the core to provide more turns of the wire around the magnetic core. A magnetic inductor made in accordance with the present invention can have increased inductance, lower temperature rise, smaller size, and exhibit less EMI noise than the prior art.

Owner:HUBBELL INC

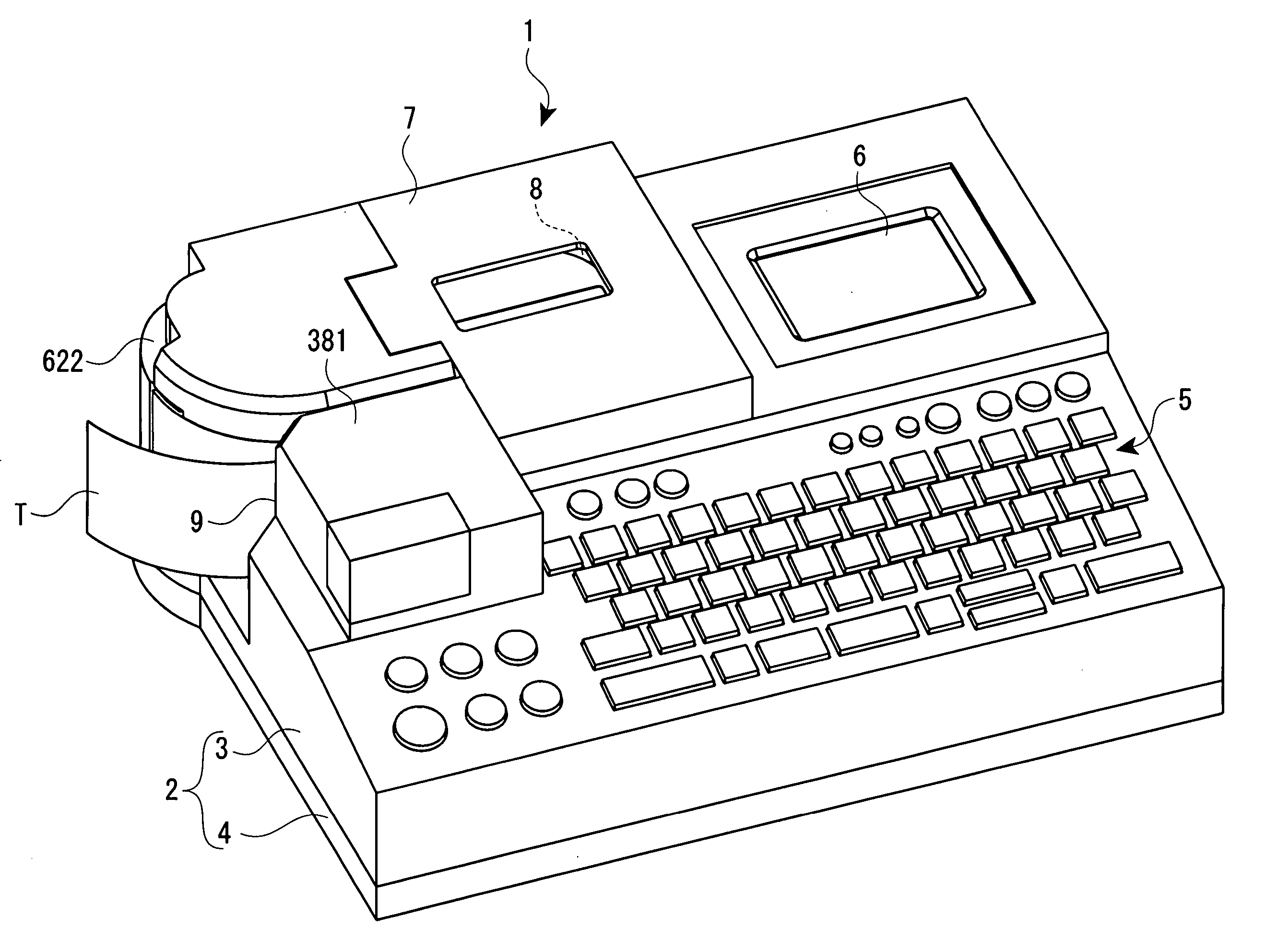

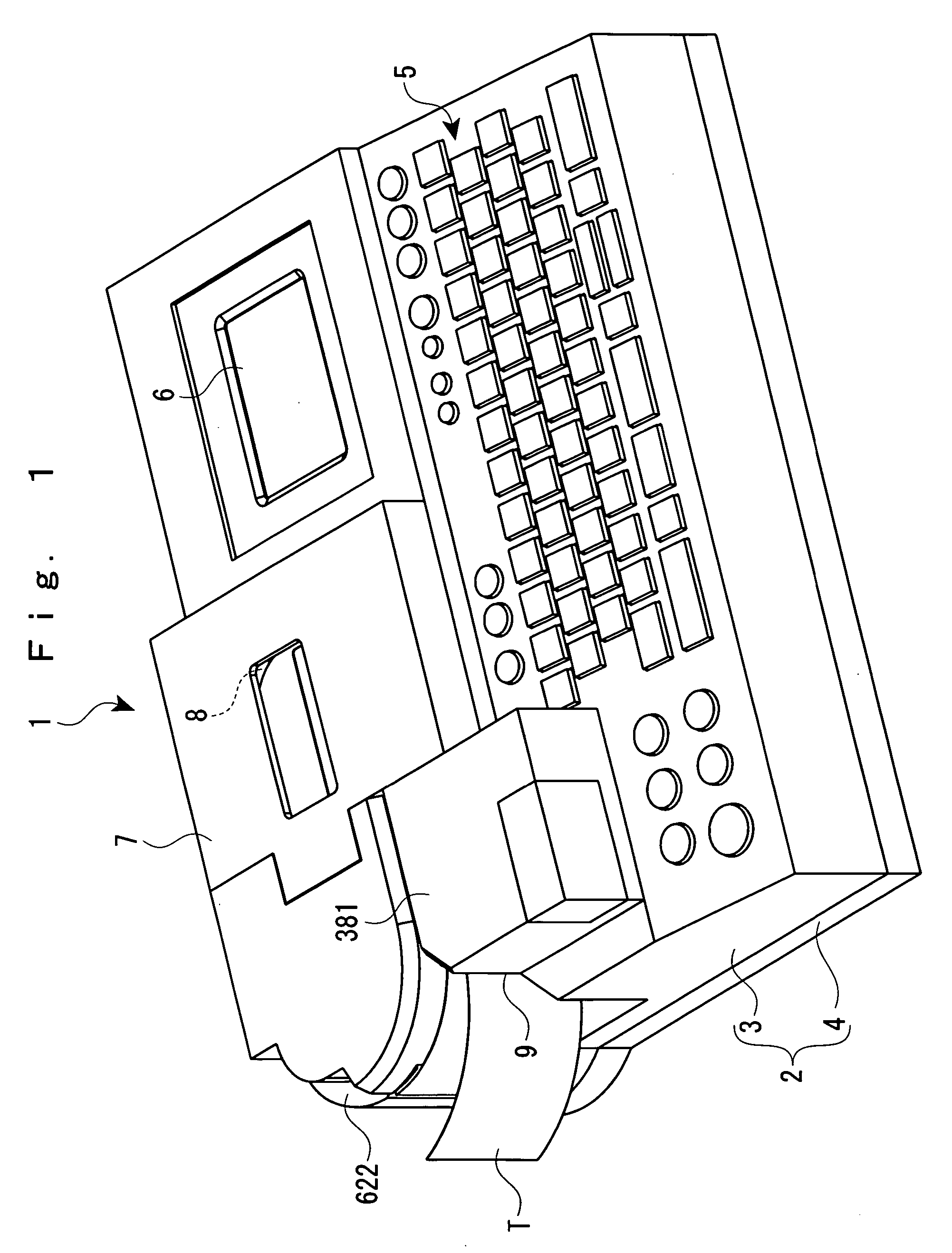

Cutting device and sheet processing apparatus

InactiveUS20060269346A1Efficient windingEfficiently accommodatingTypewritersOther printing apparatusPaper sheetEngineering

A cutting device performs cutting processing on a sheet for separated characters by reciprocating a cutting tool forward and backward in a direction which is orthogonal to a feed direction of the sheet for separated characters while the sheet for separated characters is fed forward and backward along a sheet feed path by a sheet feed section. The cutting device includes a sheet accommodating section which accommodates the sheet for separated characters which is fed forward and backward so that the sheet can be loaded into and unloaded from the sheet accommodating section. The sheet accommodating section has a take-up drum which winds up the fed sheet for separated characters into a roll shape and a power supply section which supplies the power for rotating the take-up drum for take-up.

Owner:SEIKO EPSON CORP

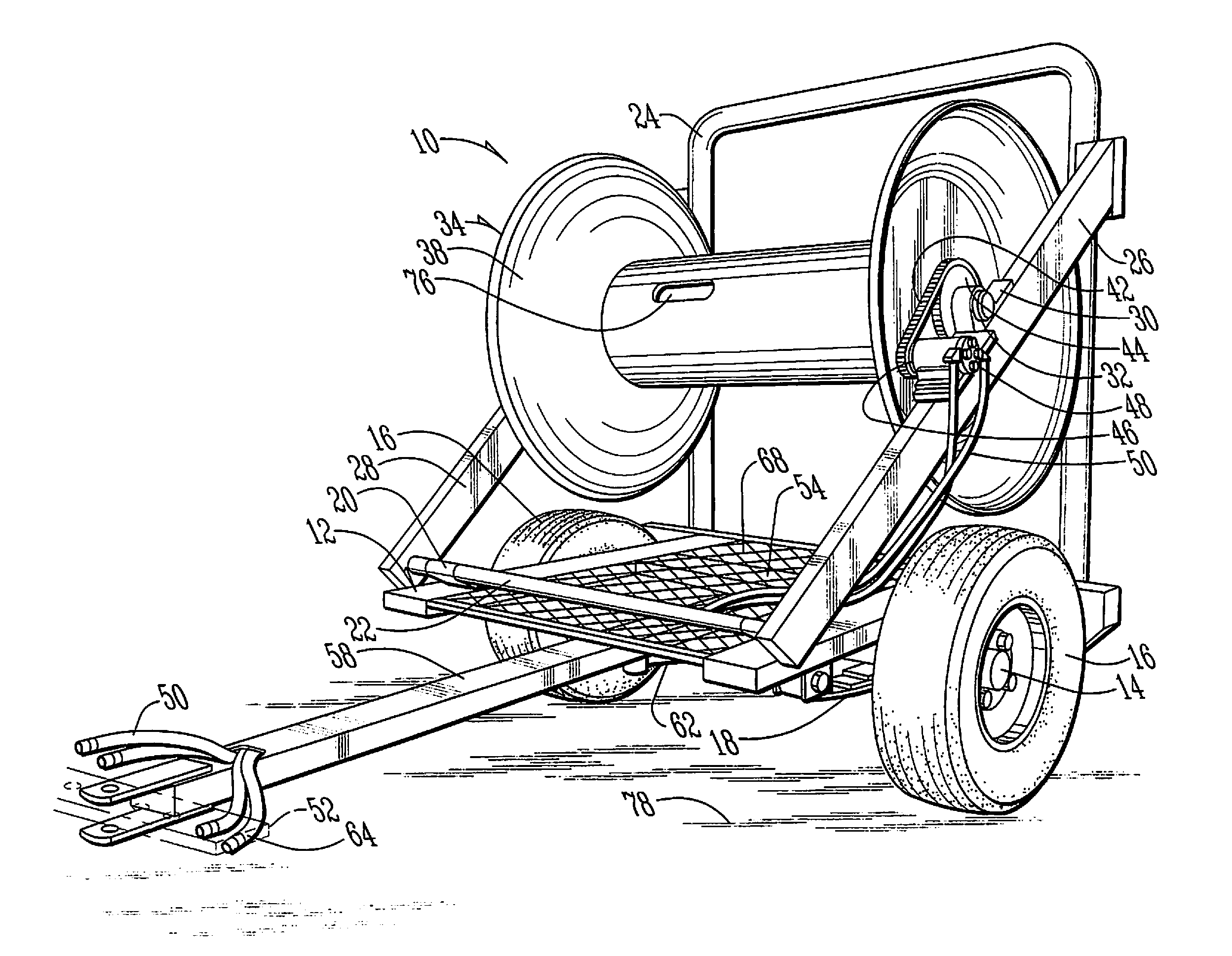

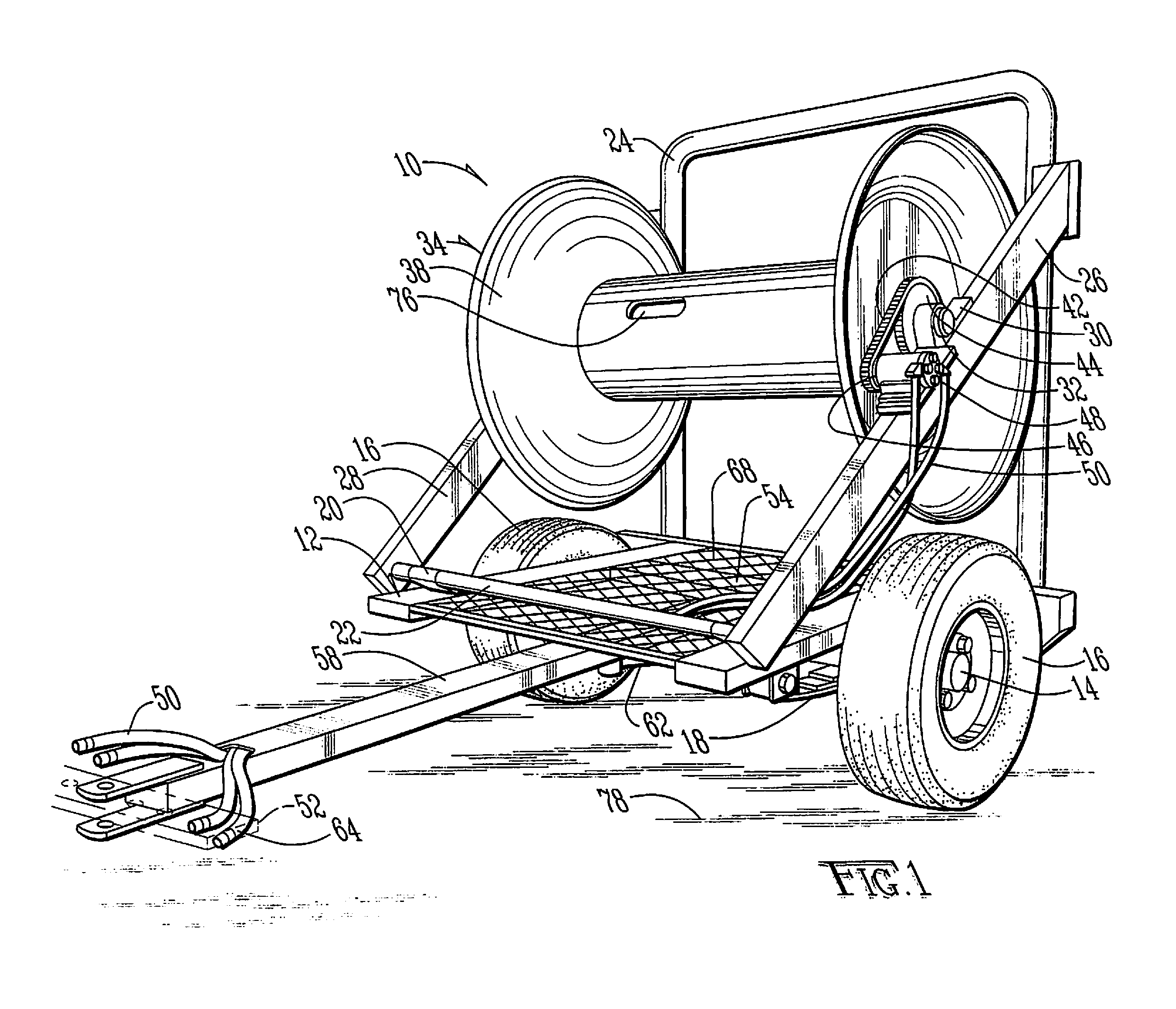

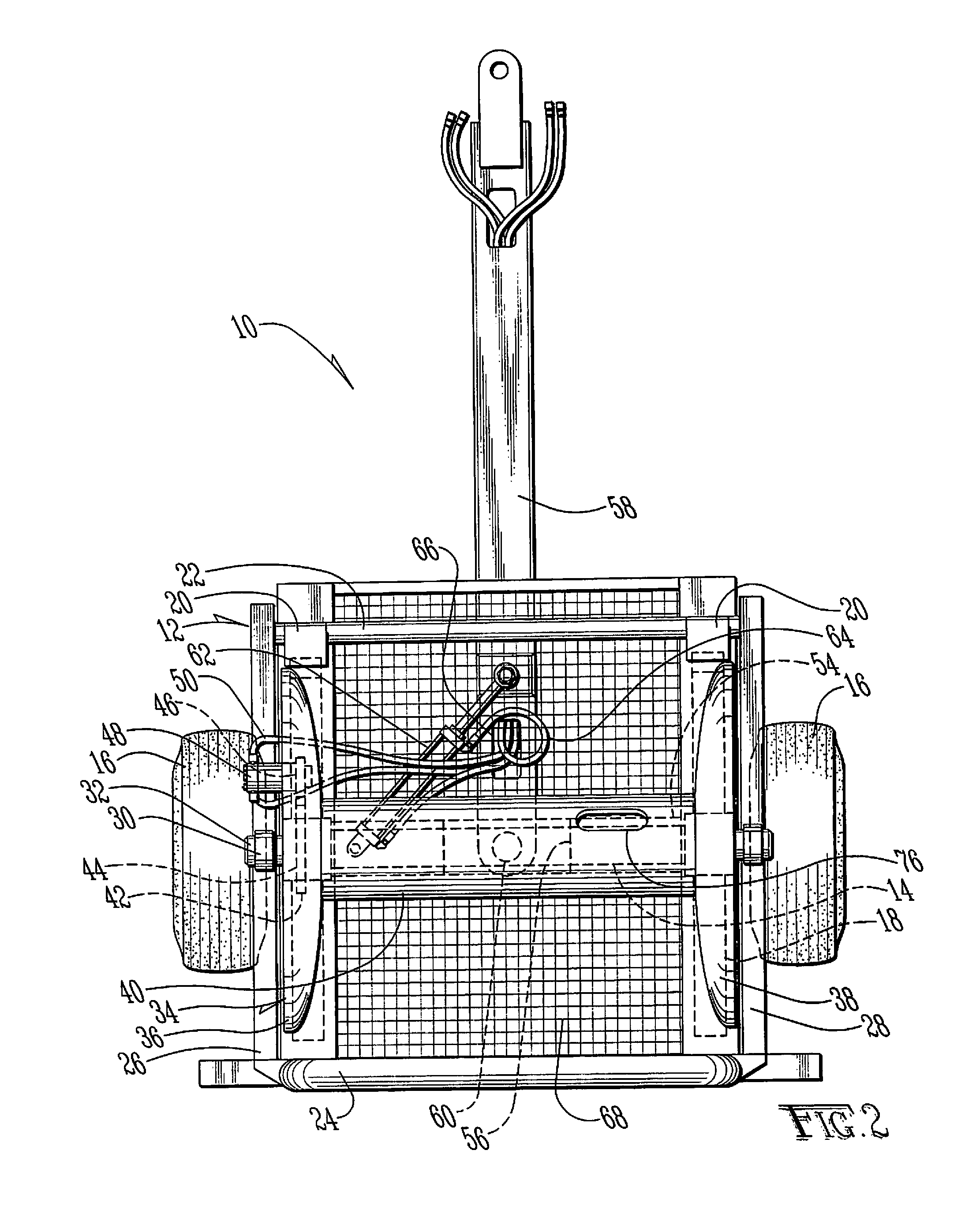

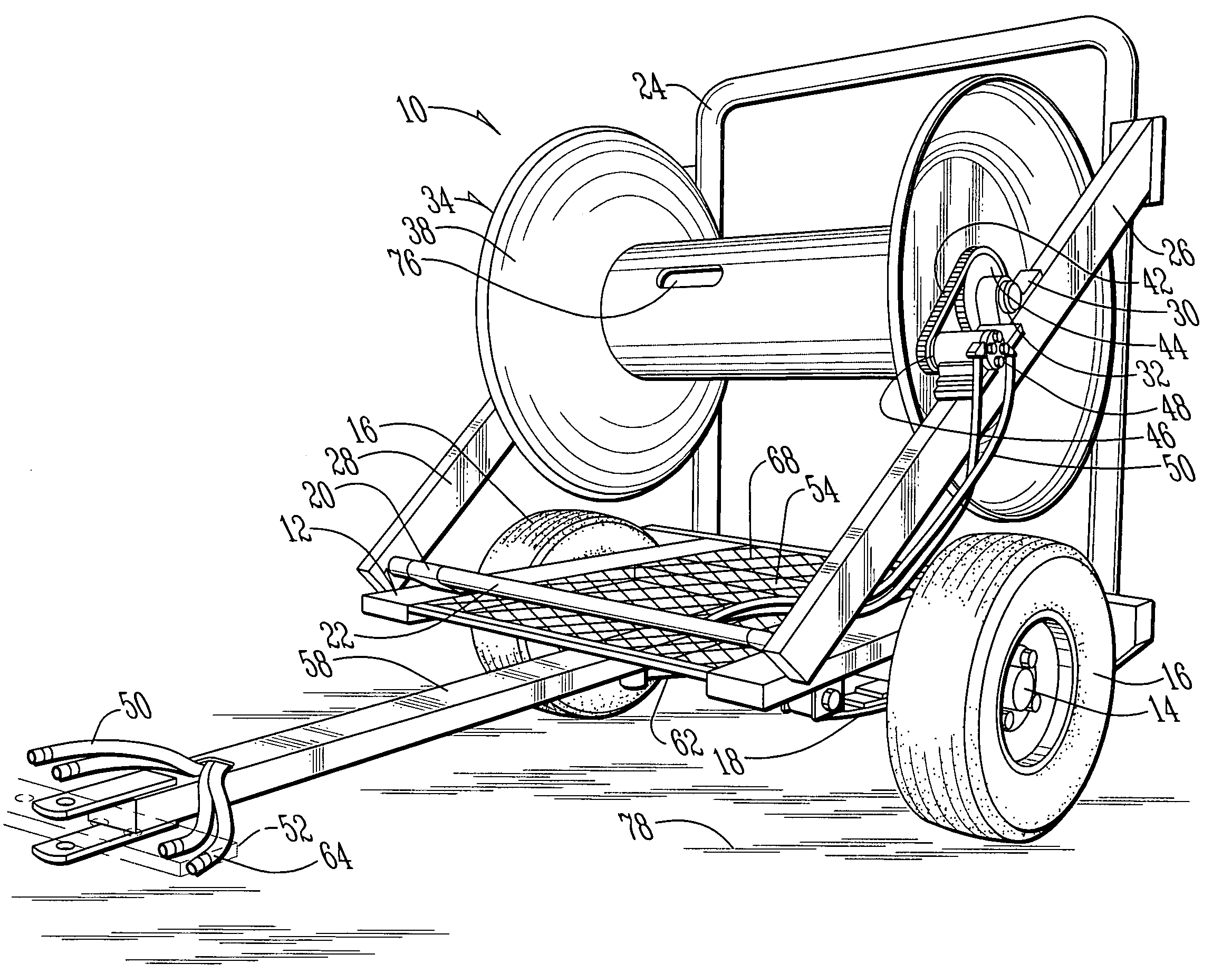

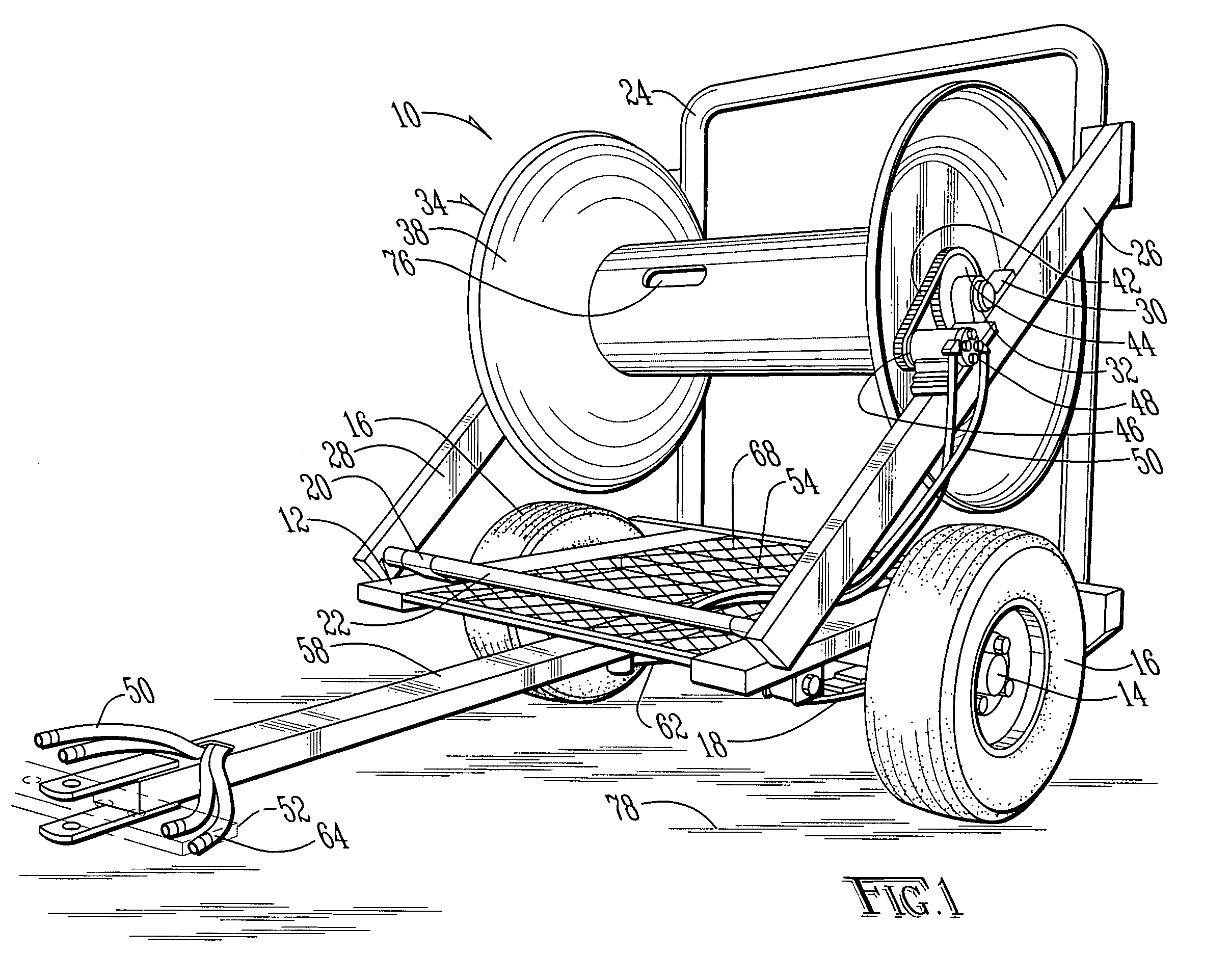

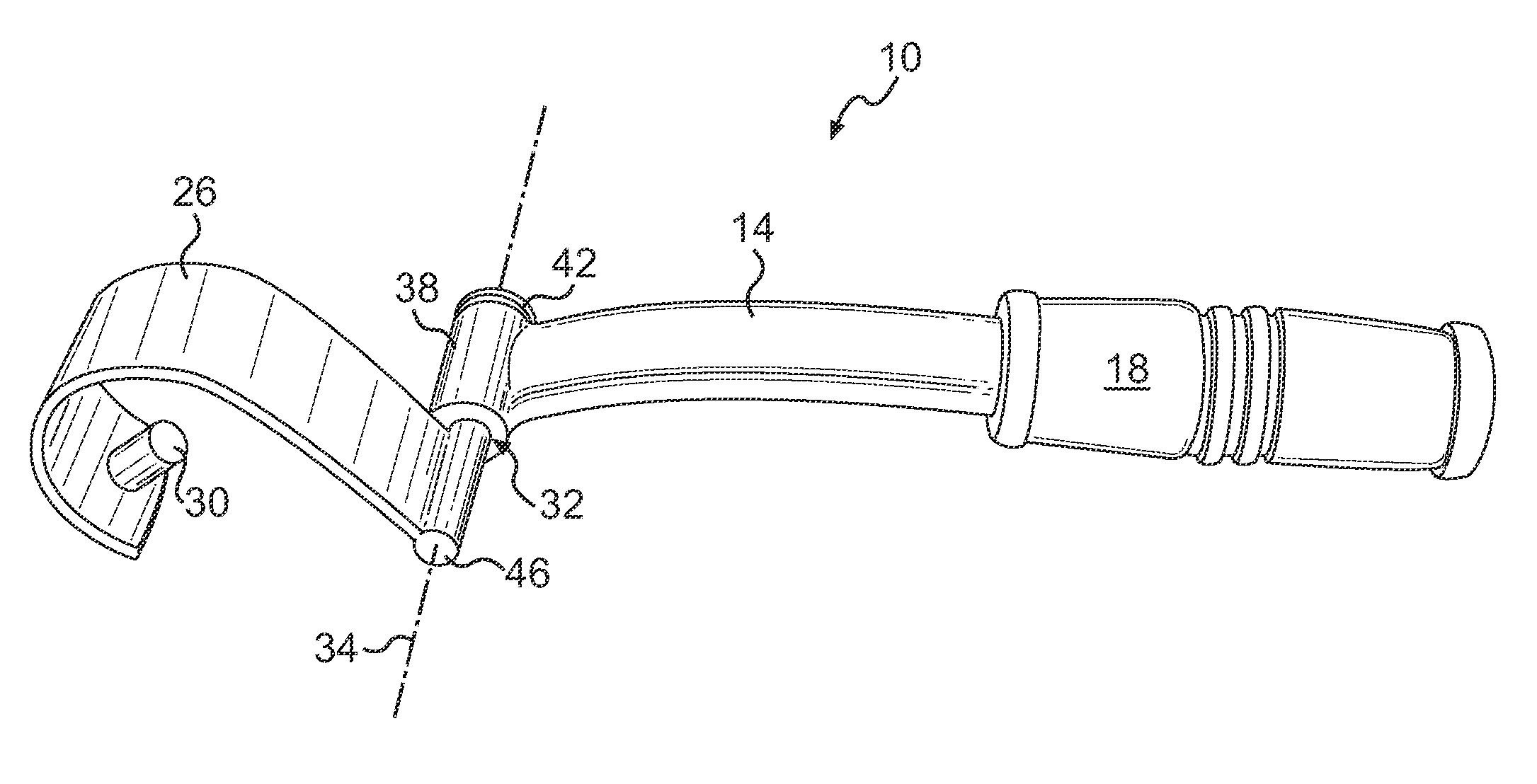

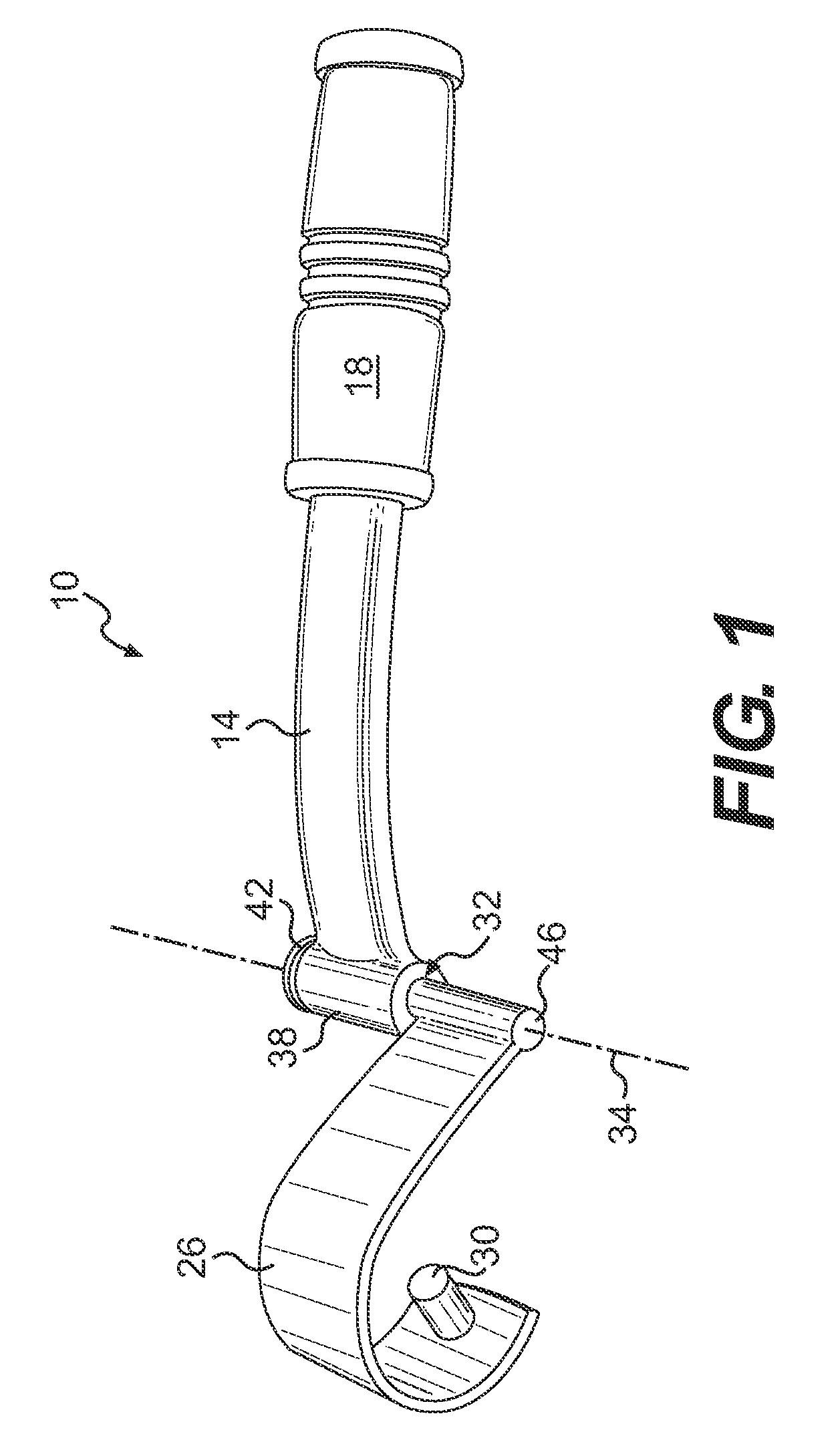

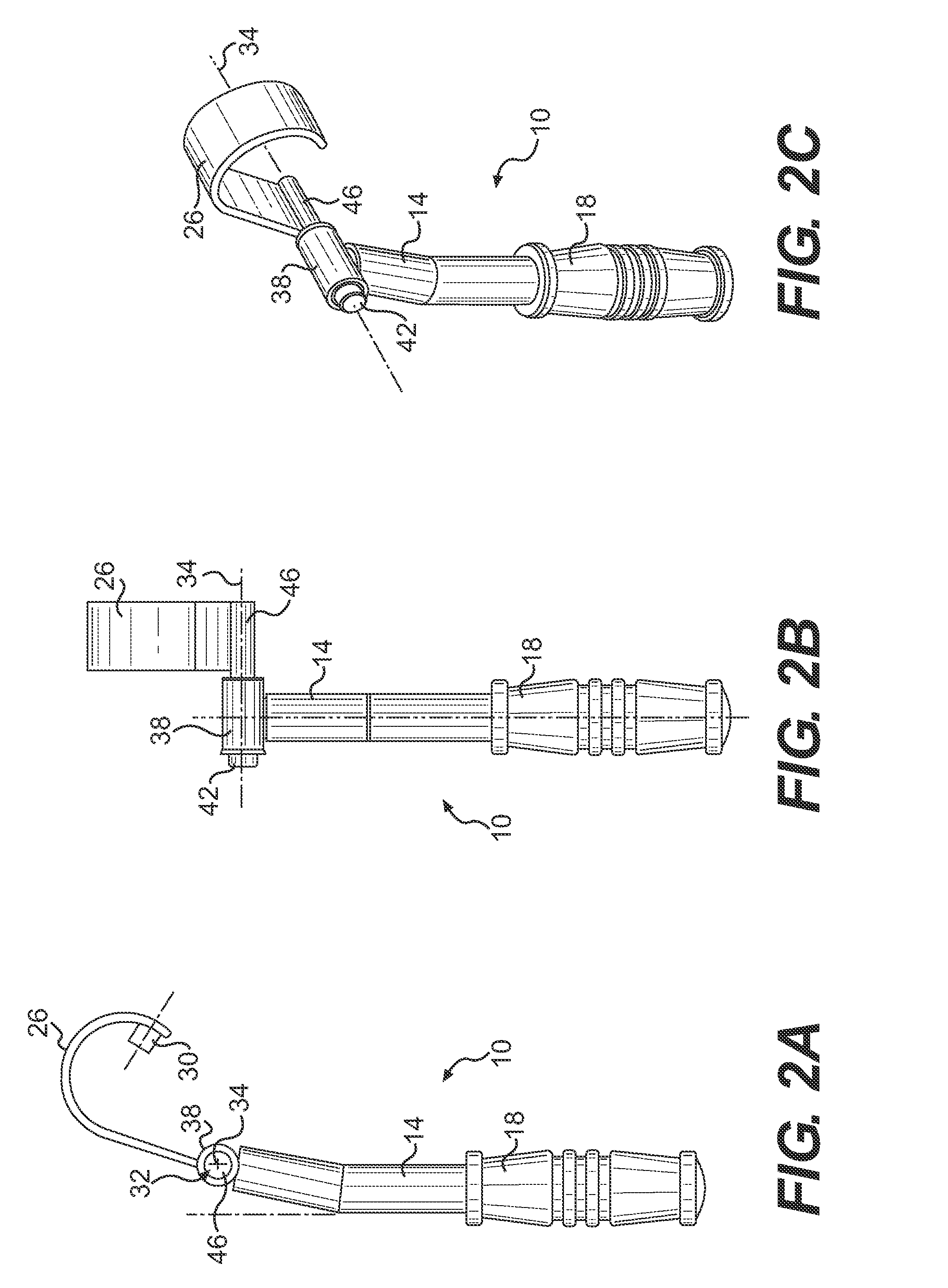

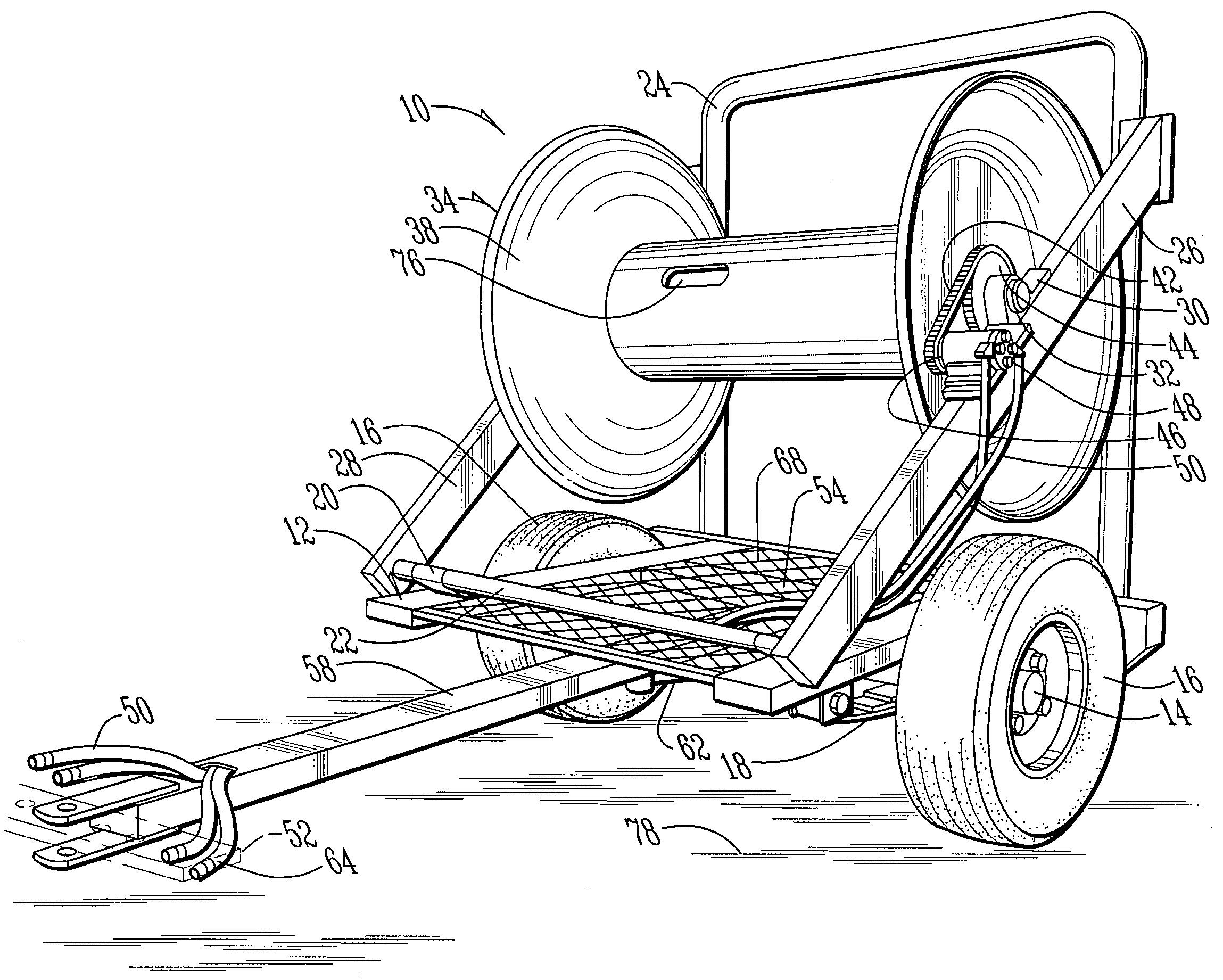

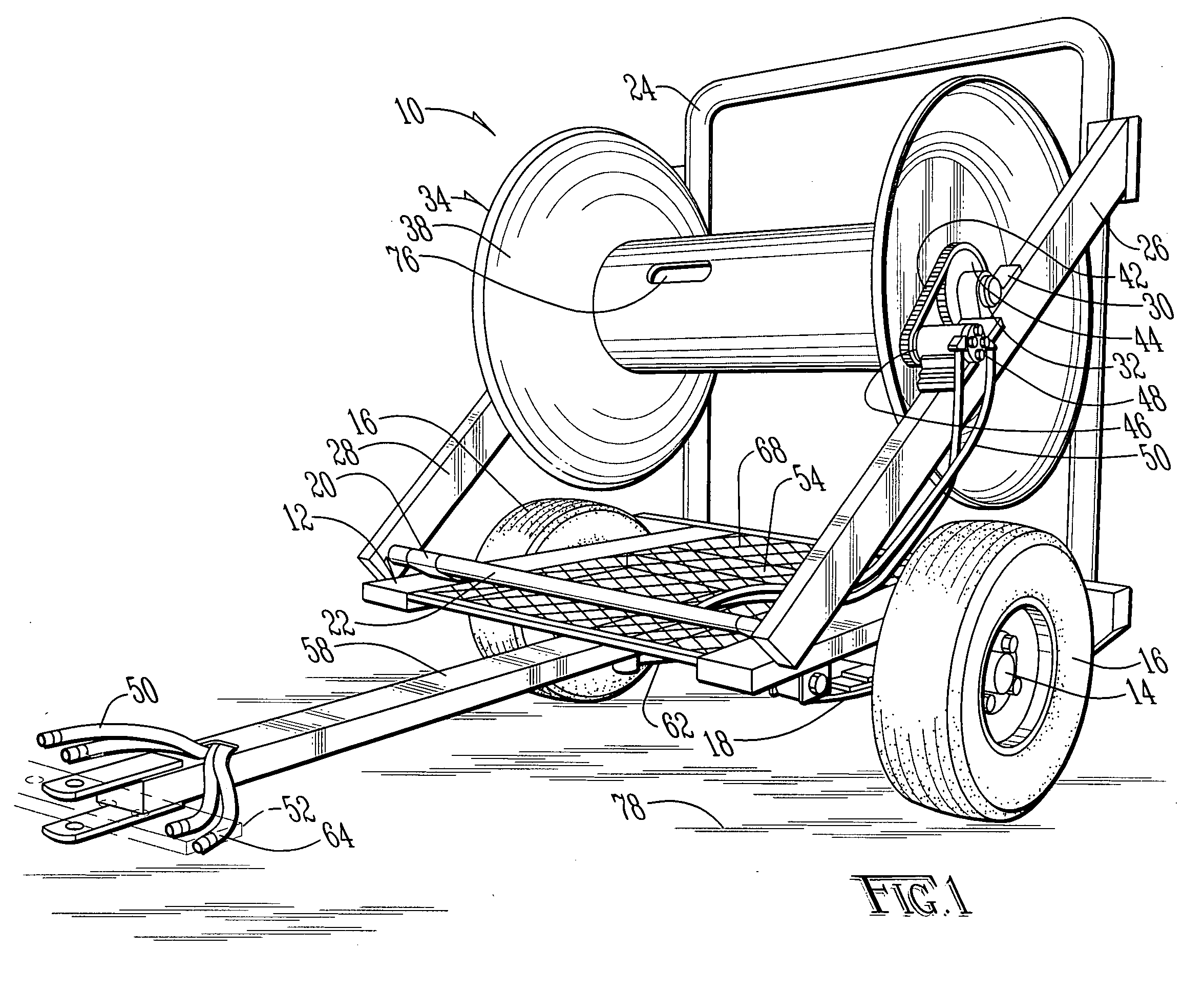

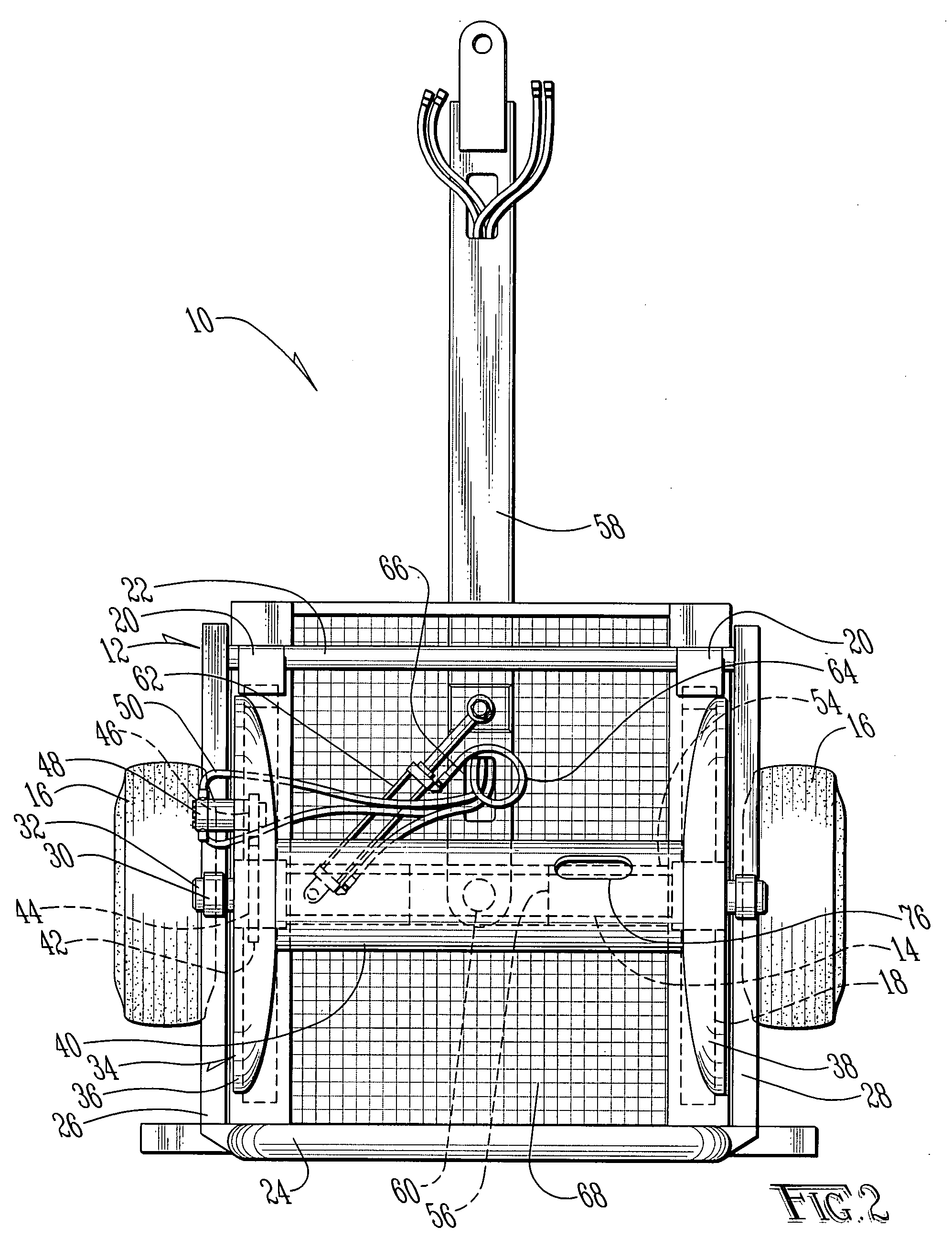

Hose reel system

A hose reel system for winding a liquid manure hose. The hose reel includes a spool pivoted in alignment with the wheels and axles of the system to allow for even winding of the hose on a spool. The spool is provided with curved domes on either, end and a protective bar to prevent the hose from winding beyond the ends of the spool. Pivoting the spool in alignment with the axle allows for a more even winding and unwinding of the hose, thereby reducing torsion, kinks and other damage to the hose during the rolling and unrolling processes.

Owner:PUCK BENNY D

Hose reel system

ActiveUS7530521B2Efficient windingLow costLiquid fertiliser distributionTowing devicesLiquid manureEngineering

A hose reel system for winding a liquid manure hose. The hose reel includes a spool pivoted in alignment with the wheels and axles of the system to allow for even winding of the hose on a spool. The spool is provided with curved domes on either, end and a protective bar to prevent the hose from winding beyond the ends of the spool. Pivoting the spool in alignment with the axle allows for a more even winding and unwinding of the hose, thereby reducing torsion, kinks and other damage to the hose during the rolling and unrolling processes.

Owner:PUCK CUSTOM ENTERPRISES

Filament winding apparatus

A filament winding apparatus includes a hoop winding device and a helical winding device. The hoop winding device includes a disc-shaped wrapping table, a drive mechanism that rotatably drives the wrapping table, four bobbins supported along a peripheral edge of the wrapping table, and a guide member that moves and guides a fiber bundle fed from the bobbin to a mandrel arranged in an insertion hole of the wrapping table. The bobbin is axially supported in a freely rotatable manner with a chuck of a holder fixed to the wrapping table. A ratchet mechanism, which prevents over-rotation in a fiber bundle feeding direction of the bobbin, is arranged between the holder and the chuck.

Owner:MURATA MASCH LTD

Non-woven fabric winding device with static electricity removal and drying functions

The invention provides a non-woven fabric winding device with static electricity removal and drying functions and relates to the technical field of non-woven fabric winding bundles. The non-woven fabric winding device with the static electricity removal and drying functions comprises a machine box. A partition and a fixing rod are fixedly arranged in the machine box. First pressure rollers are fixedly arranged on the partition. A water mist spray nozzle, exhaust ports and an air cover are fixedly arranged on the top of the machine box. Second conveying rollers and a wind-heat device are arranged on the left side of the partition. Second pressure rollers are arranged on a box body of the machine box. A support table is fixedly arranged on the outer wall on the left side of the machine box.A limiting device is fixedly arranged on the top of the support table. A cutting device is arranged on the bottom of the support table. A winding device is arranged on the left side of the machine box. The non-woven fabric winding device with the static electricity removal and drying functions is easy and convenient to use and high in automation degree and can realize the functions of static electricity removal, material compaction, material heating, material cutting and winding and the like.

Owner:江西美宝利实业有限公司

Winch tool

A mechanism for improving the use of winches adapted for securing cargo load on flat bed trailers pulled by road tractors provides the additional capability to continuously wind a belt thereon and to remove the wound belt from the mechanism for storage. The mechanism can be part of the winch or simply temporarily fasten to the winch and is activated with the winch. The mechanism further includes a device for rapidly and continuously rotating the winch.

Owner:NORCAN ALUMINUM

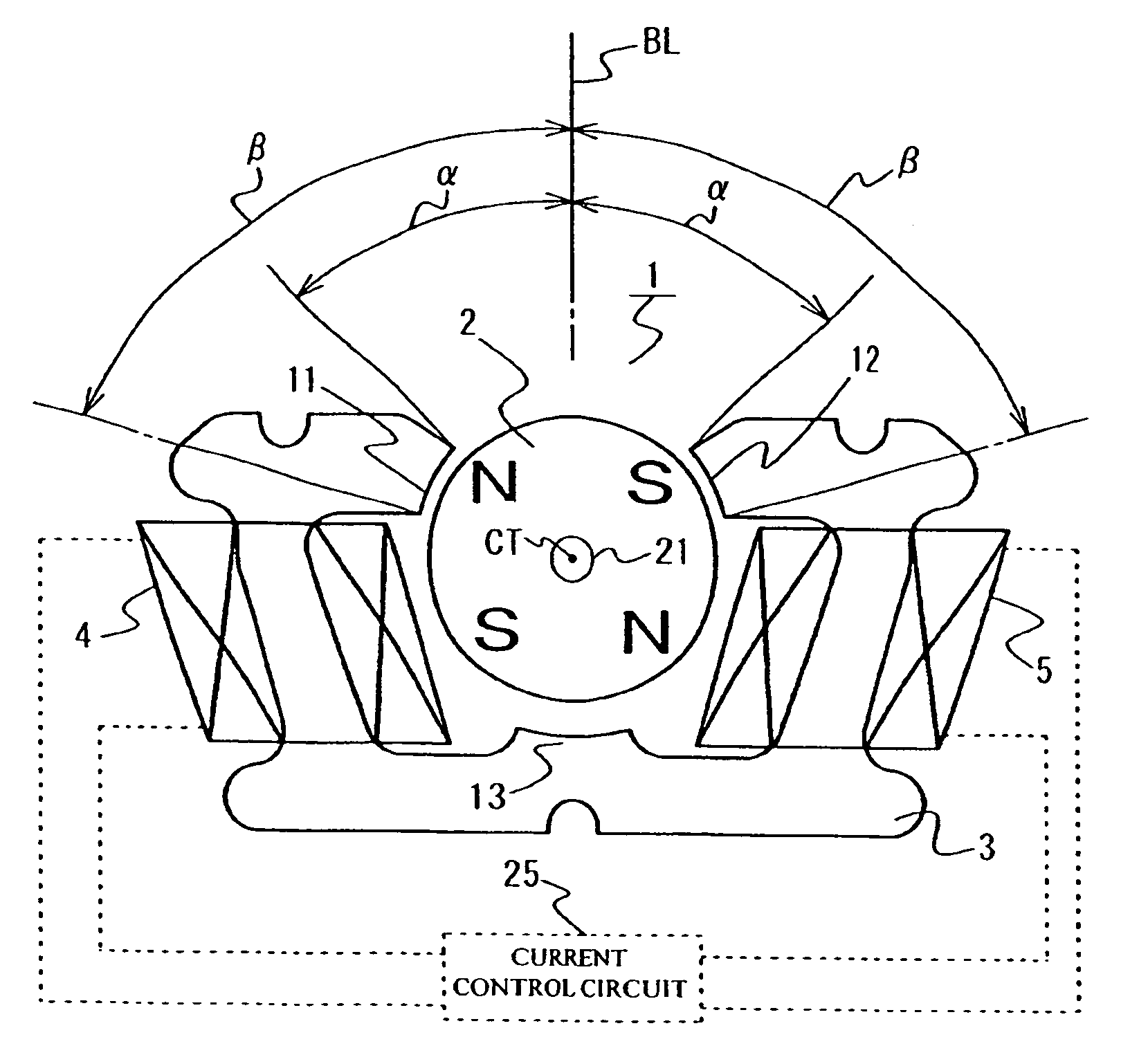

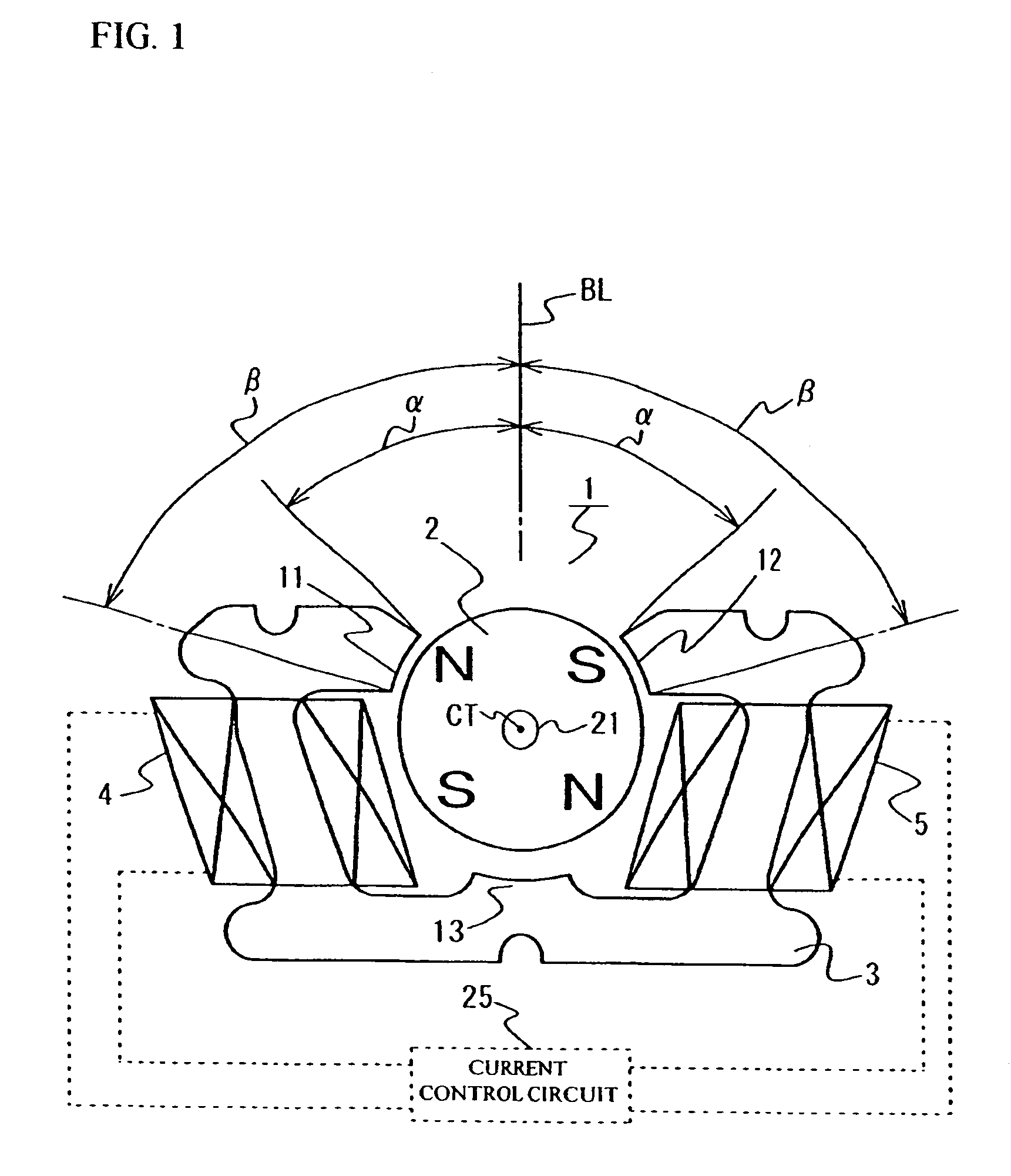

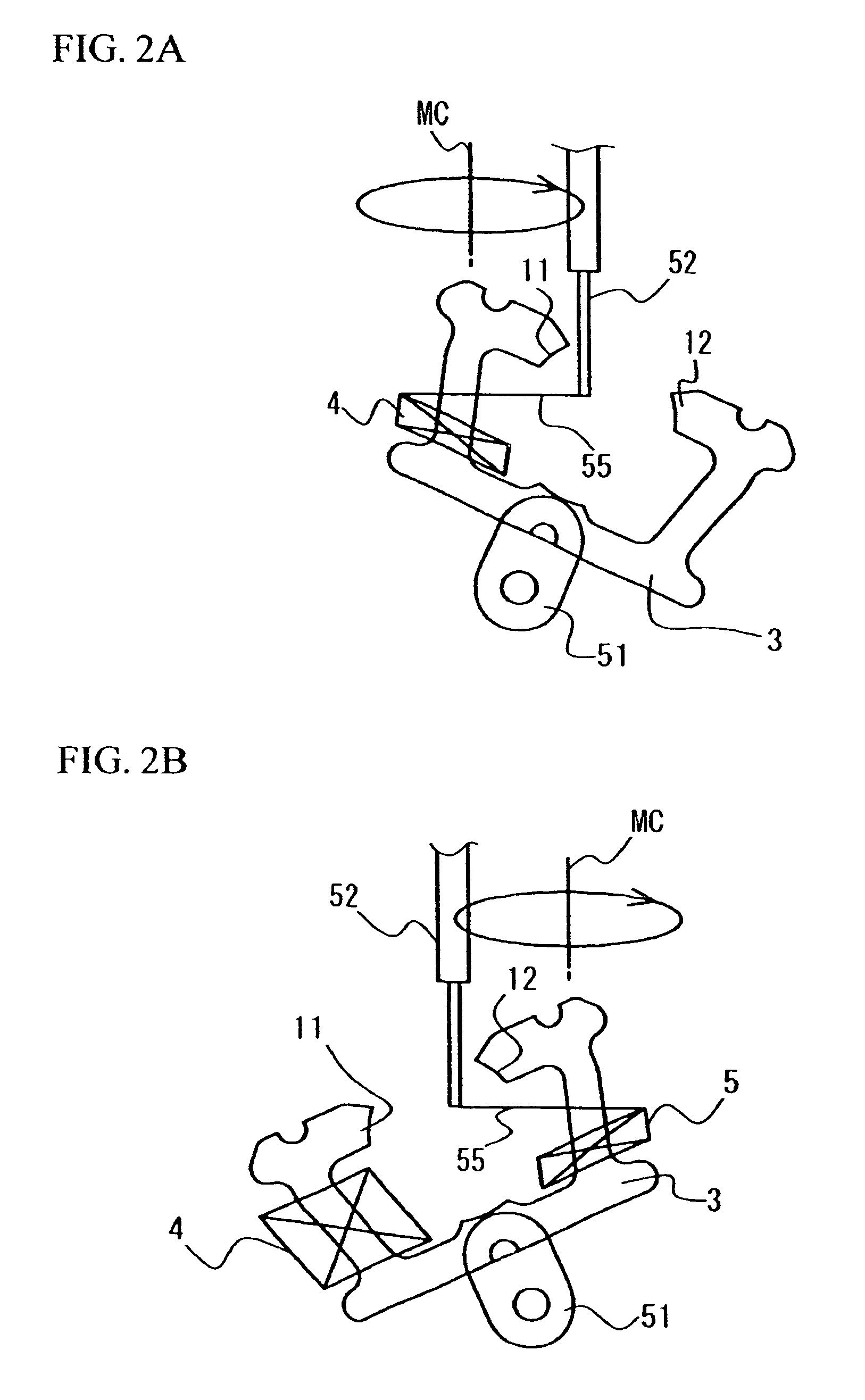

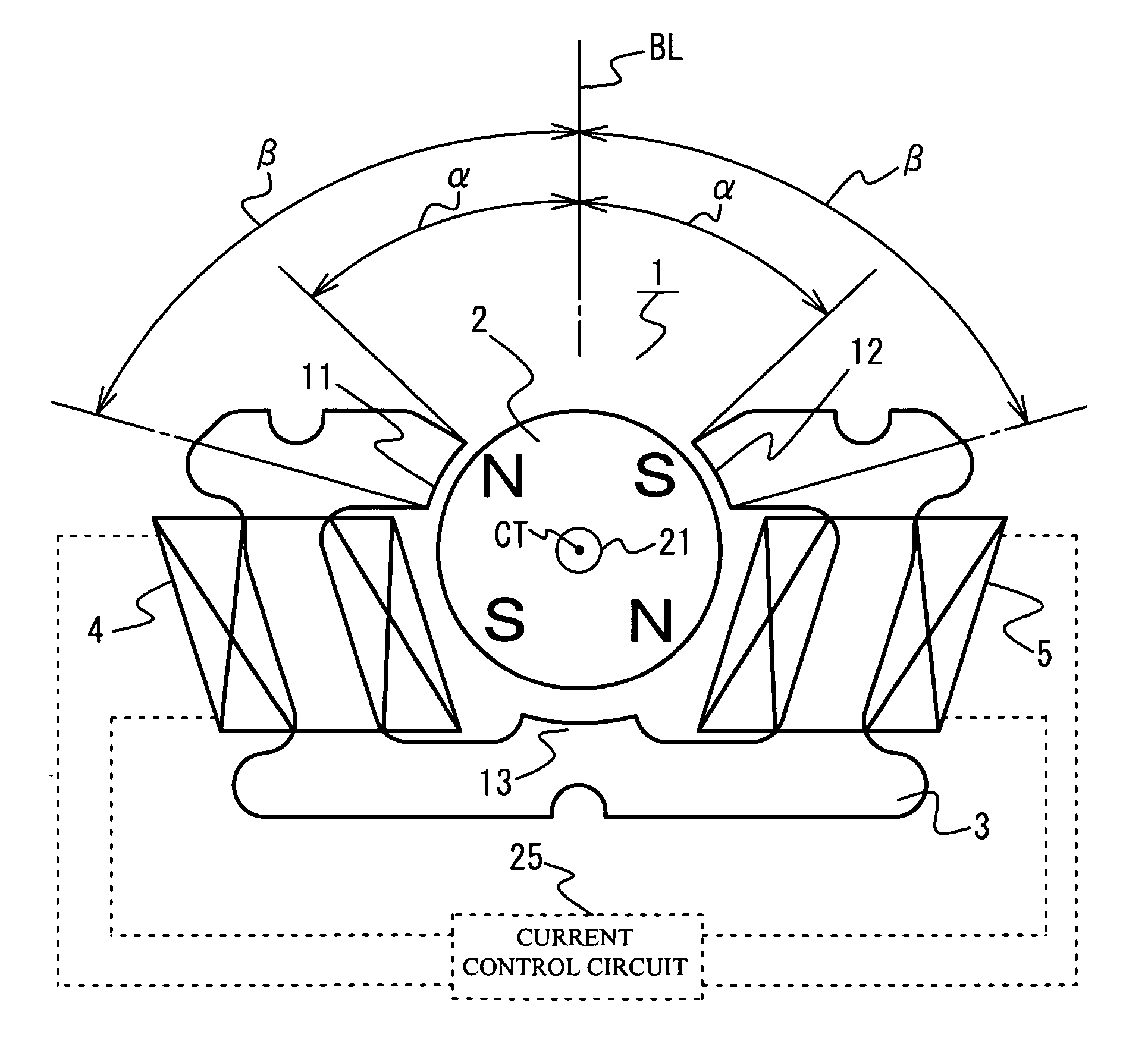

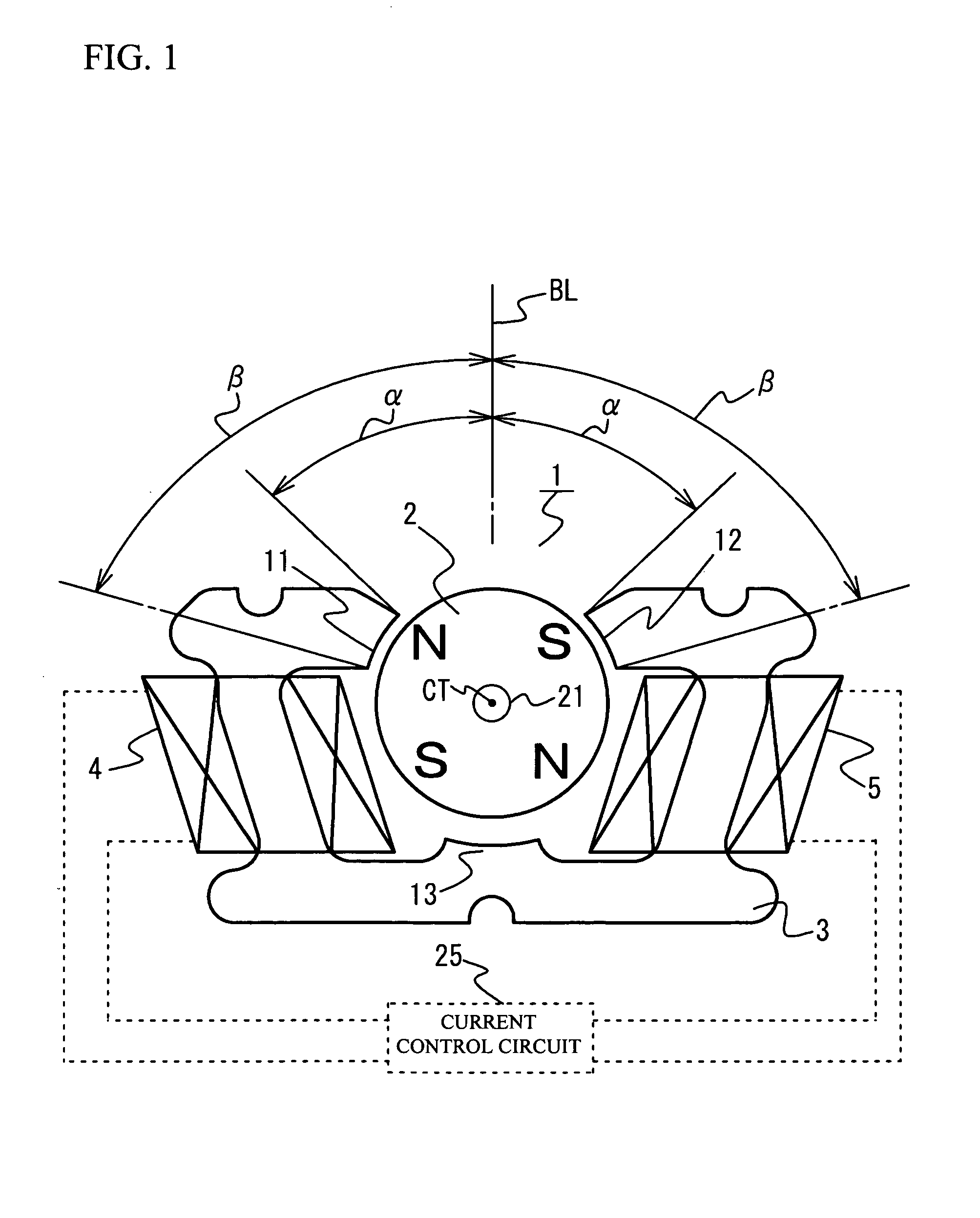

Electromagnetic actuator

ActiveUS7511391B2Improve efficiencyMaintain capacityMagnetic circuit stationary partsMaster clocksEngineeringMechanical engineering

An electromagnetic actuator has a rotor and a stator around which coils are wound to face portions of an outer surface of the rotor. The stator is C-shaped, the rotor is arranged so that a rotation axis thereof is existent in a space surrounded by the stator, and both ends of the stator are respectively formed within a range from 15 to 90 degrees from a virtual base line with respect to the rotation axis serving as a center, when the virtual base line is set to run a center of the rotation axis and separate the stator into left and right.

Owner:SEIKO INSTR INC

Magnetic core winding method

ActiveUS20050247815A1Small sizeReduce temperature riseMagnetic circuitManufacturing dynamo-electric machinesInductorConductor Coil

The invention relates to winding wire around a magnetic core. The invention includes forming corners on the wire that align with inside corners of the magnetic core such that the wire is more tightly wound around the magnetic core. The invention also includes pinching a portion of wire that is positioned on the internal diameter of a magnetic core when the wire is wound around the core to provide more turns of the wire around the magnetic core. A magnetic inductor made in accordance with the present invention can have increased inductance, lower temperature rise, smaller size, and exhibit less EMI noise than the prior art.

Owner:HUBBELL INC

Medical exercise device used for recovery in orthopedics department

InactiveCN108325165AEffective movementEasy to moveSuction-kneading massageMuscle exercising devicesPurlinMedical equipment

The invention belongs to the technical field of medical equipment, particularly relates to a medical exercise device used for recovery in orthopedics department, and solves the problems of low adjustability, safety and adaptability and relatively single function. Through the proposed scheme, the device comprises a fixed plate, two supporting rods are fixed on the outer wall of the top of the fixedplate through bolts, and first connecting rods are fixedly arranged on the outer walls of the opposite sides of the two supporting rods through bolts; a first sliding groove is formed in the outer wall of one side of each first connecting rod, and each sliding groove is internally slidably connected with a first sliding block; the outer wall of the top of each sliding block is welded with enclosing purlins; the ends, away from the fixed plate, of the two supporting rods are connected with sliding sleeves in an inserted manner, and threaded holes are formed in the outer sides of one side of each of the two sliding sleeves respectively. According to the device, a third sliding block can move effectively, so that the third sliding block is smoother during moving, the device can be firmer according to the stability of a triangle when the device is used, and the stability and safety of the device are improved.

Owner:陈茂伟

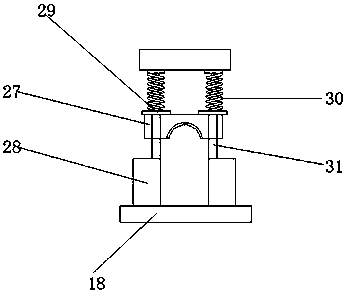

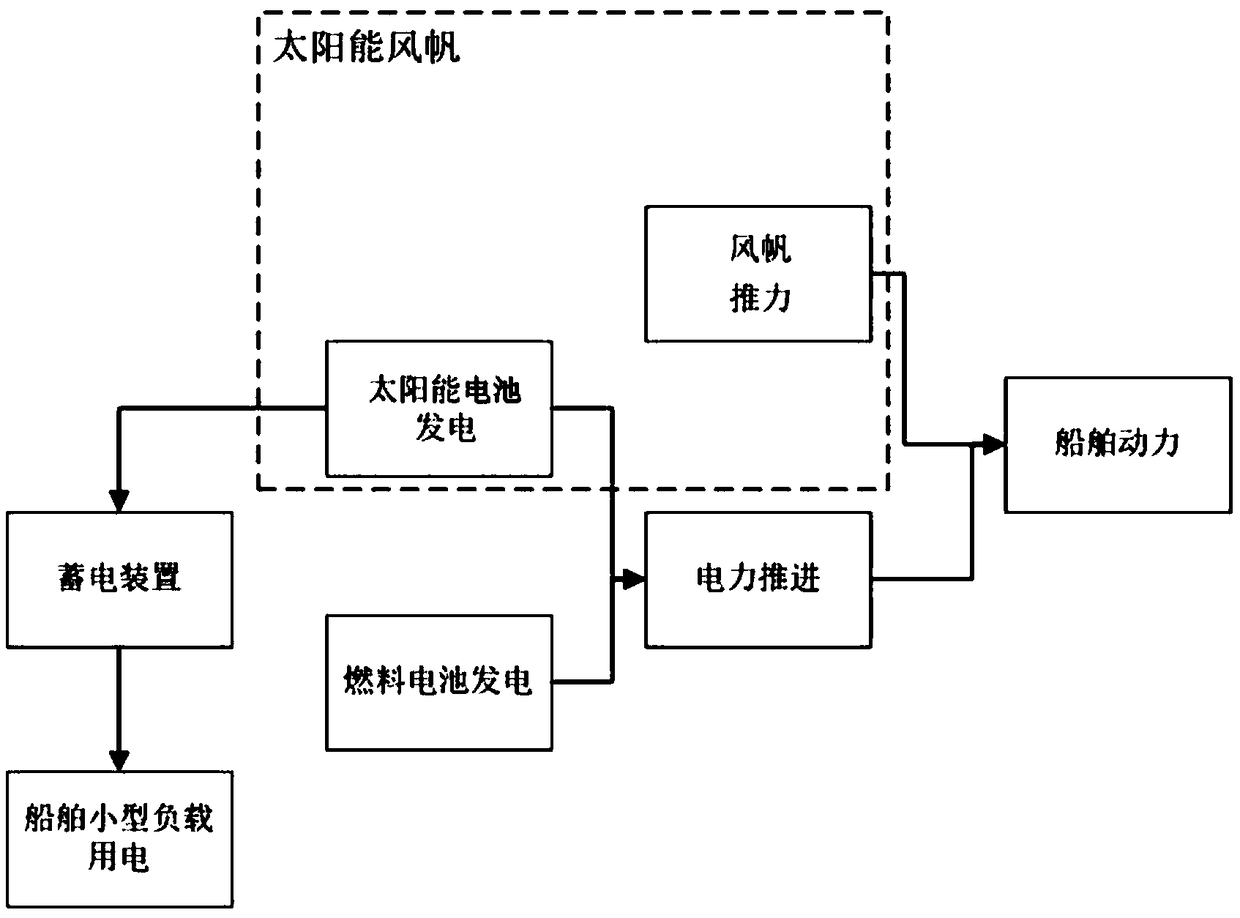

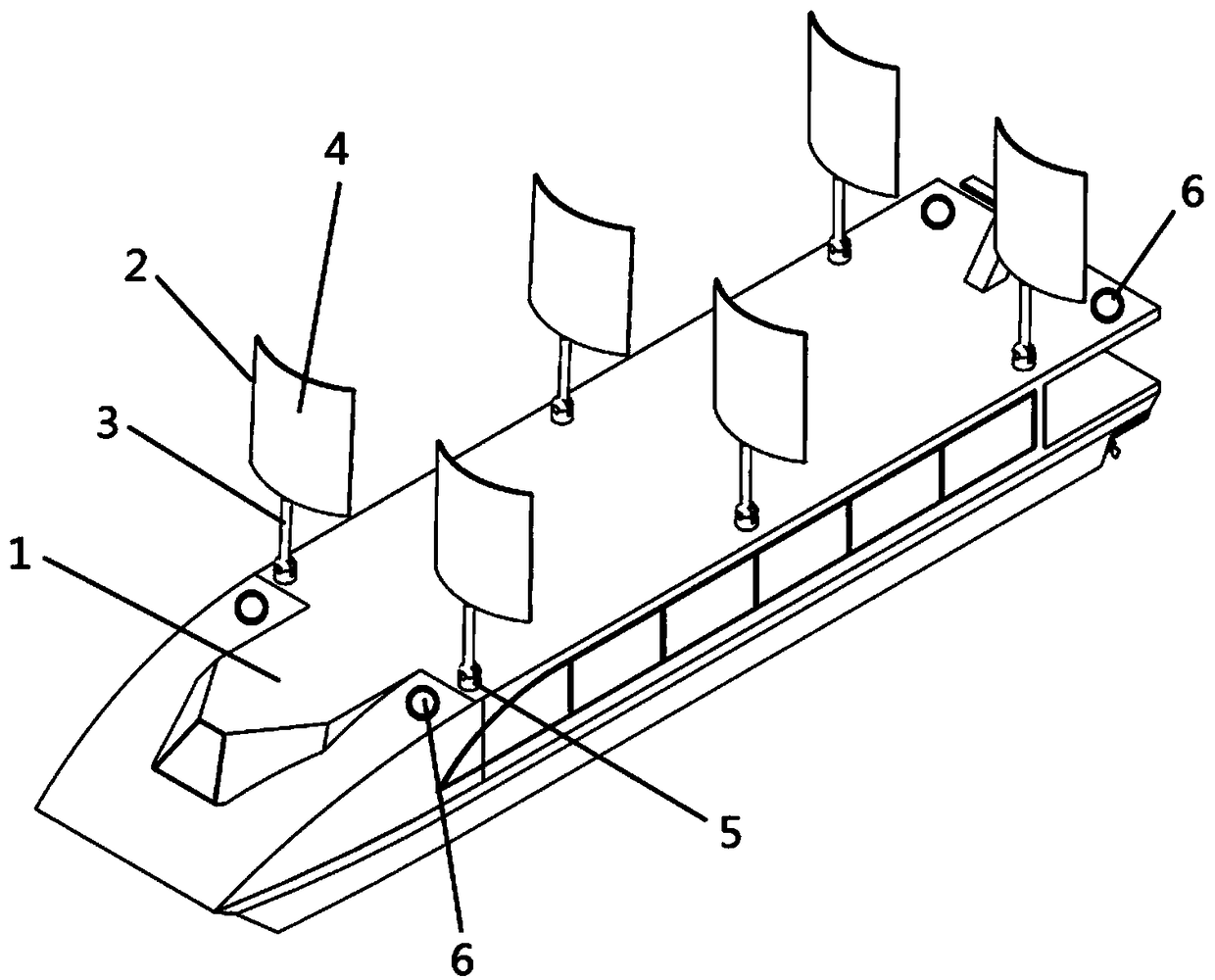

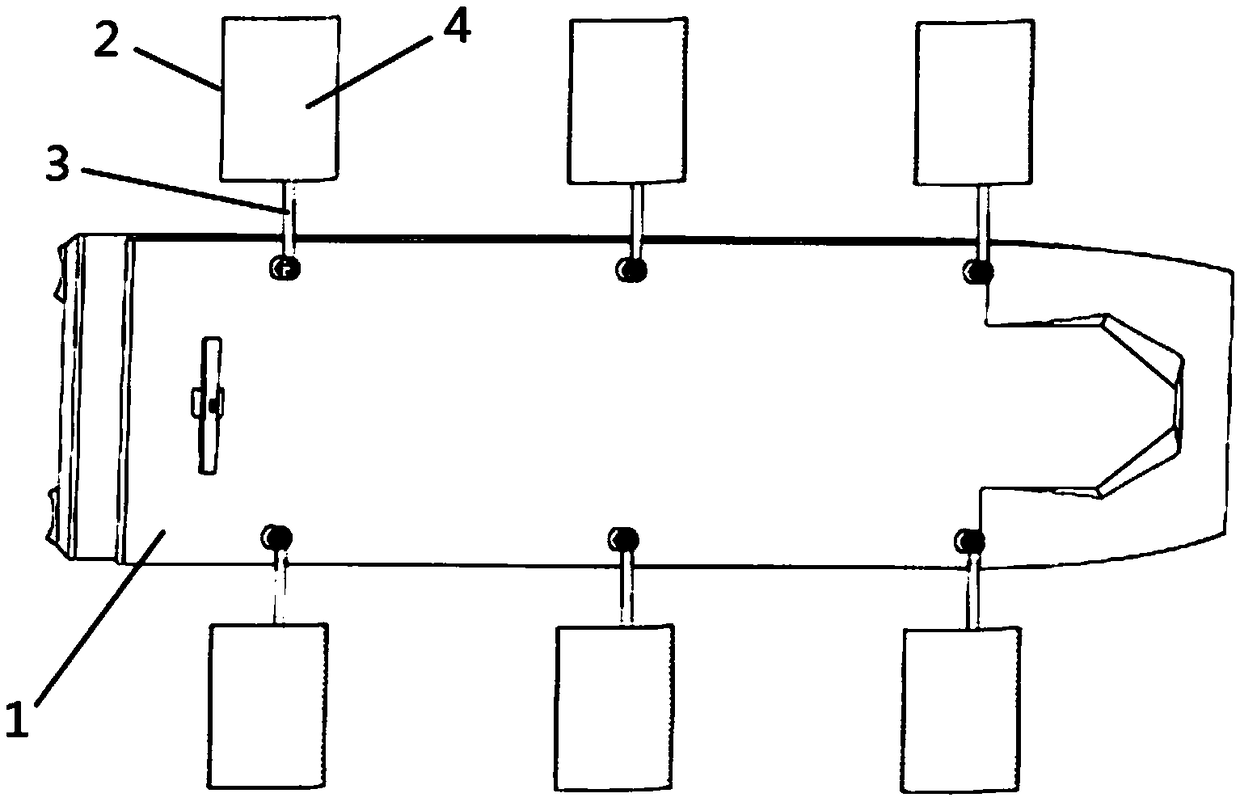

Wind-optical propelling sailing boat

InactiveCN108910001ARealize comprehensive utilizationEfficient and complementary advancementVessel superstructuresVessel mastsEngineeringSolar battery

The invention relates to a wind-optical propelling sailing boat. The sailing boat comprises a hull, a sail, a mast and a solar battery panel, wherein the sail is arranged on the mast, and the lower end of the mast is connected with the hull. The sailing boat further comprises an adjusting mechanism used for adjusting the inclination angle of the mast and a mast rotary angle adjusting mechanism, and the solar battery panel adheres to the sail surface. According to the sailing boat, a photovoltaic power generation-sail sailing assisting integrated designing scheme is adopted, the state of the sail is adjusted through a mast angle control device and a mast accommodating device, the efficient and stable utilization of solar energy and wind power is maintained for the sailing boat, and the efficient complementation propelling of two kinds of energies is achieved.

Owner:WUHAN UNIV OF TECH

Electromagnetic actuator

ActiveUS20060145798A1Wide angleEfficient preparationMagnetic circuit stationary partsMaster clocksEngineeringMechanical engineering

An electromagnetic actuator has a rotor and a stator around which coils are wound to face portions of an outer surface of the rotor. The stator is C-shaped, the rotor is arranged so that a rotation axis thereof is existent in a space surrounded by the stator, and both ends of the stator are respectively formed within a range from 15 to 90 degrees from a virtual base line with respect to the rotation axis serving as a center, when the virtual base line is set to run a center of the rotation axis and separate the stator into left and right.

Owner:SEIKO INSTR INC

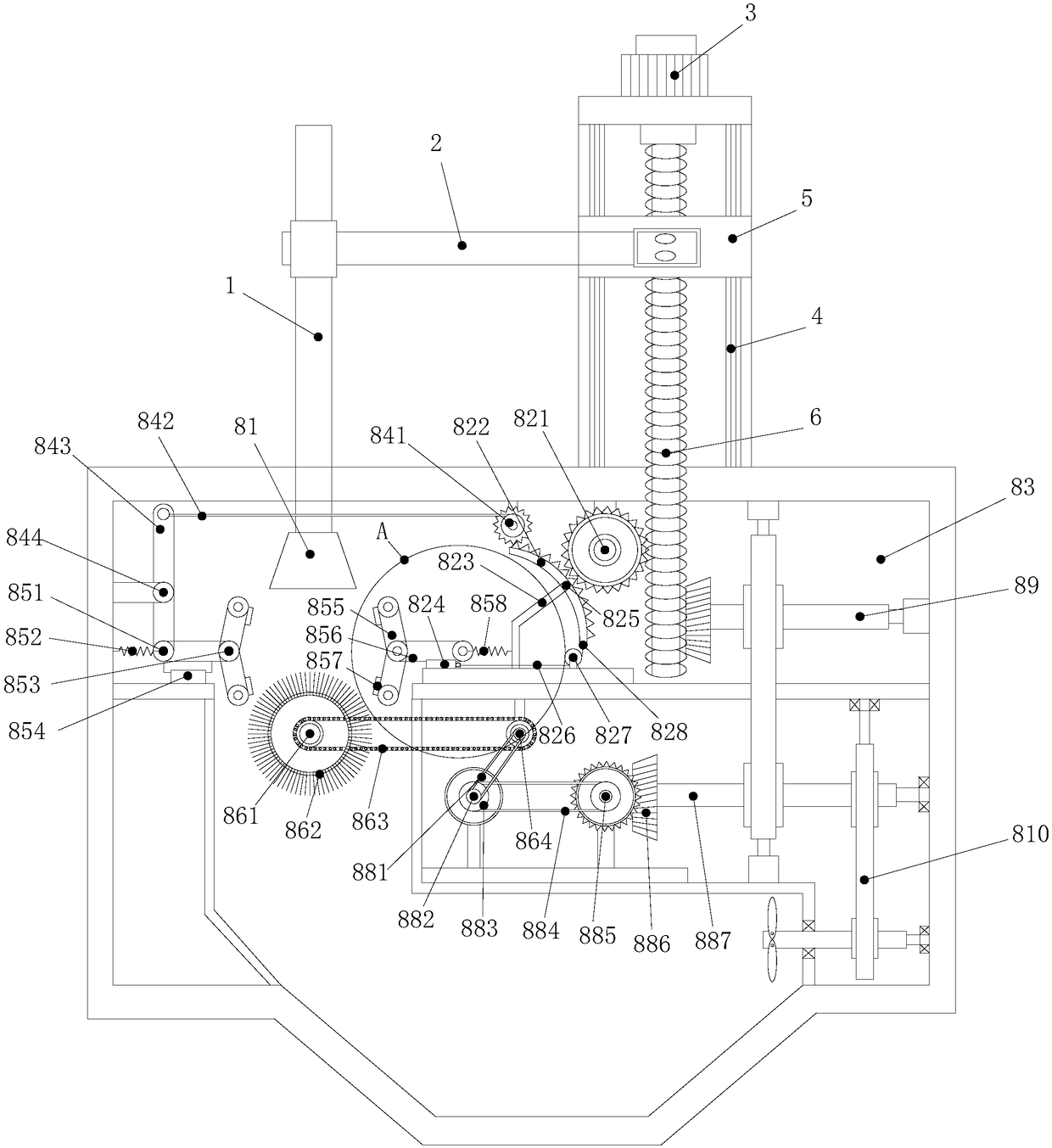

Grass-collecting grass-chopping mechanism for rotary cultivator

ActiveCN107278392ANovel structureHigh grass cutting efficiencySpadesPloughsEngineeringMechanical engineering

The invention discloses a grass-collecting grass-chopping mechanism for a rotary cultivator. The grass-collecting grass-chopping mechanism for the rotary cultivator comprises a rotation shaft and a hollow shaft. The hollow shaft is sheathed on the exterior of the rotation shaft. The hollow shaft is provided with at least one driving device. The exterior of the hollow shaft is provided with an arc plate. The driving device is connected with the arc plate by a push rod I. The arc plate is provided with an installing hole I. A grass cutter is installed in the installing hole I along the radial direction of the rotation shaft. The exterior of the hollow shaft is provided with a grass-pressing soil-pulverizing roller. Two ends of the grass-pressing soil-pulverizing roller are connected with two ends of the rotation shaft by a connecting rod I. The grass-pressing soil-pulverizing roller is provided with a grass-cutting passage by which the grass cutter is protruded from the grass-pressing soil-pulverizing roller and used for cutting the grass. The grass-pressing soil-pulverizing roller is further provided with an all-dimensional grass-collecting soil-pulverizing cutting unit. The grass-collecting grass-chopping mechanism for the rotary cultivator has the characteristics of novel structure and high grass-chopping efficiency, and is suitable for the large-scale production promotion and application.

Owner:CHANGSHA XINQIXIANG AUTOMATION TECH

Dust removing equipment for top-grade instrument boxes

InactiveCN108746068AEffectively fixedAchieve dust removalCleaning using toolsCleaning using gasesEngineeringPollution

The invention discloses dust removing equipment for top-grade instrument boxes. Traditional dust removing equipment is optimized; the instrument boxes are fixed by a clamping device aligned to an airspraying port; after the fixation is stable, the mode of dust removal by air spraying is combined with a cleaner; the air spraying port is mounted at the upper end of the clamping device; the cleaneris mounted at the bottom end of the clamping device; the upper end spraying mode is combined with the lower end cleaning mode to realize comprehensive dust removal of the instrument boxes to achieve optimal dust removal; the dust removal is performed in a set dust removing channel; and dust is effectively discharged along the dust removing channel under the effect of a suction fan arranged on thedust removing channel to prevent pollution of internal environment, so that the environmental protection is achieved when the multifunctional dust removing operation is realized.

Owner:刘培珠

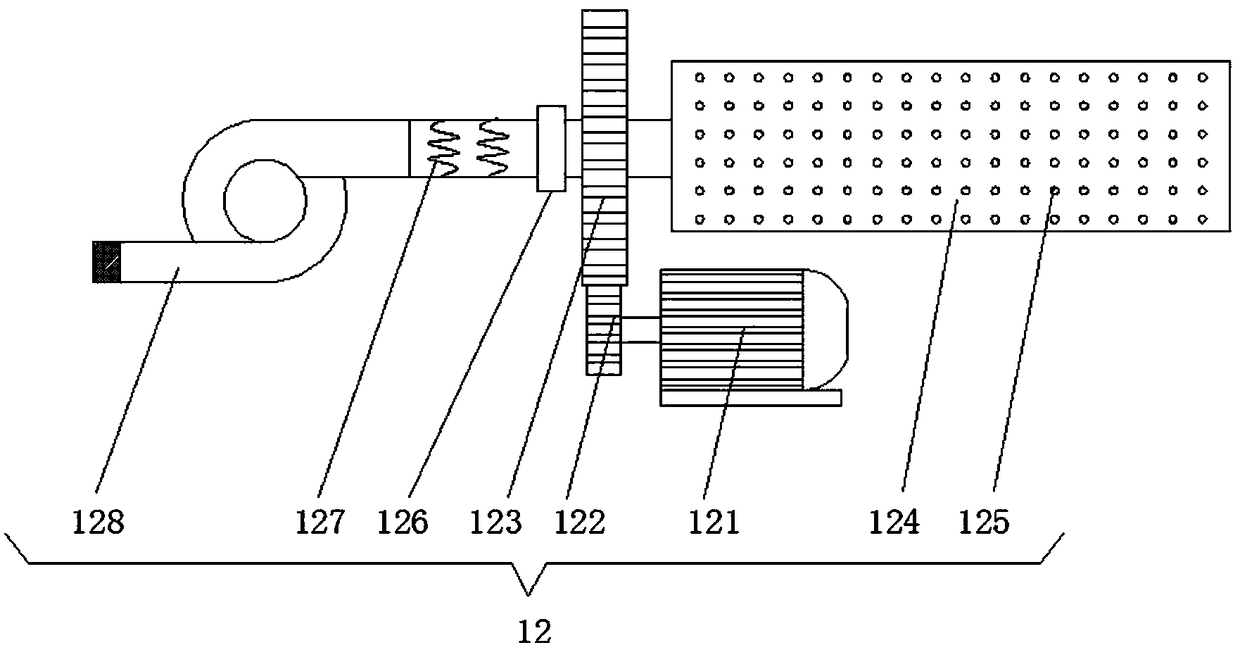

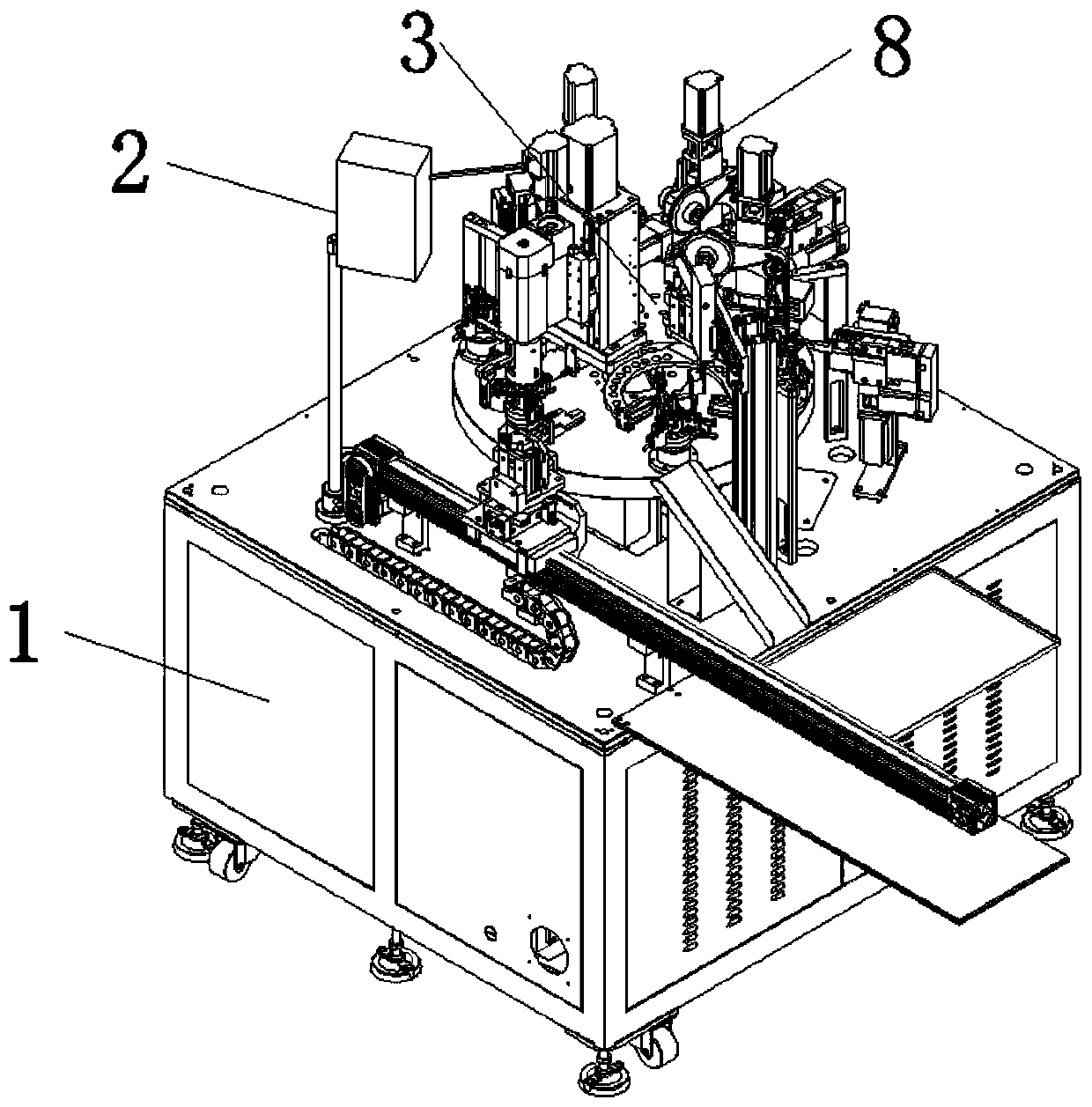

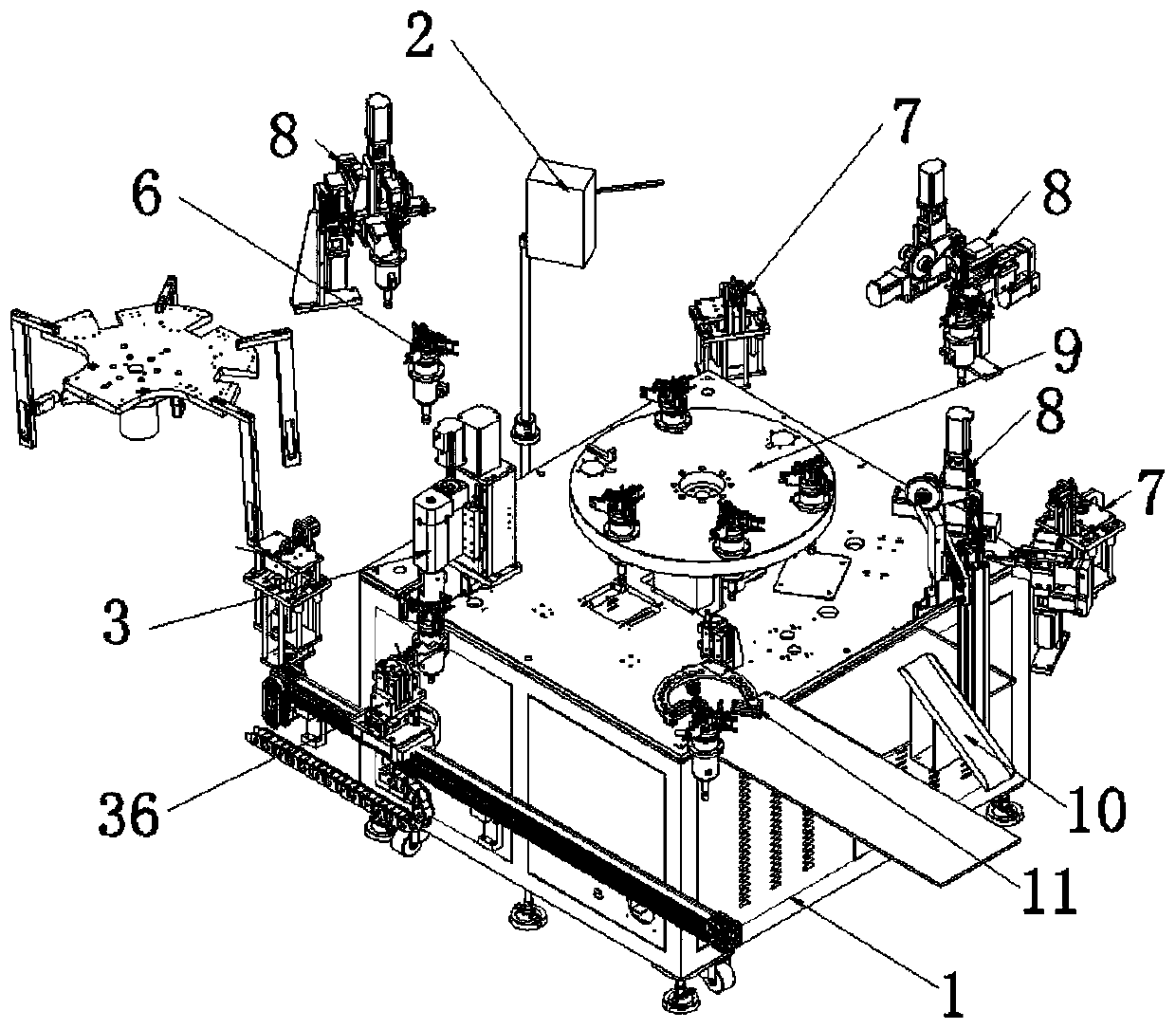

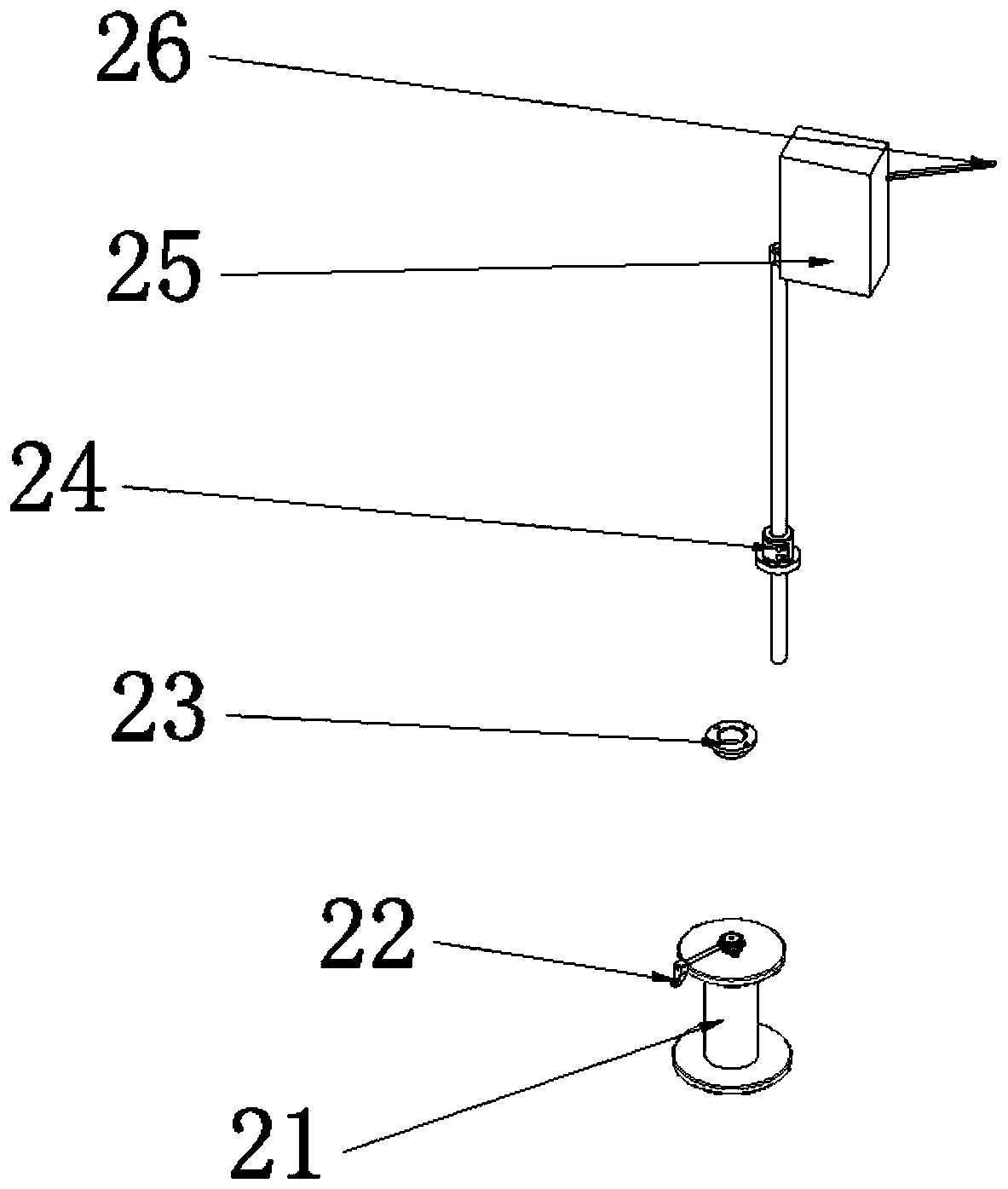

Automatic winding machine for single wire cake

PendingCN111403171AReduce defective rateSo as not to damageCoils manufactureWinding machineMechanical equipment

The invention discloses an automatic winding machine for a single wire cake. The machine comprises a machine base, a hexa-section index plate, a discharge port and a product loosening clamp. A tensionmechanism is installed on the machine base. The bottom end of a winding rotating main shaft is connected with a rotating clamp mechanism, and the lower part of the rotating clamp mechanism is connected with a rotating clamp power mechanism. At least three adhesive tape mechanisms are arranged on the machine base at equal angles, and a rotating clamp mechanism and a rotating clamp power mechanismare also arranged in each adhesive tape mechanism. The hexa-section index plate is arranged in the center of the upper end surface of the machine base, and the discharge port and the product looseningclamp are arranged on the machine base. According to the automatic winding machine for a single wire cake, the step of manual operation is completed through mechanical equipment, and the high efficiency and the low defect rate of wire cake machining are guaranteed through structural transmission and automatic operation in the mechanical equipment while it is guaranteed that the structure of a cable is not damaged.

Owner:东莞市捷信机电设备有限公司

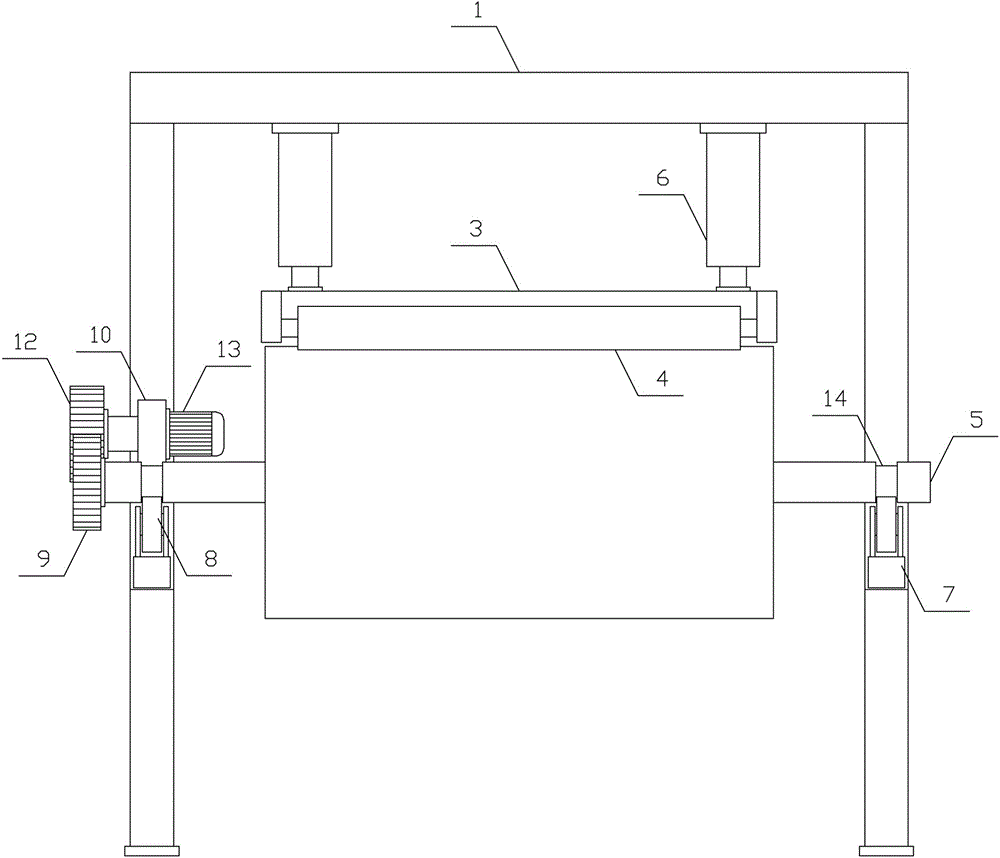

Cloth conveying and winding device

The invention discloses a cloth conveying and winding device, and belongs to the field of textile processing mechanical equipment. The cloth conveying and winding device comprises a conveying support, a cloth guide roll, a lifting support, cloth press rolls, a winding roll and a cloth winding driving mechanism. The cloth guide roll is horizontally rotationally connected to a side of the conveying support, cloth press hydraulic cylinders are respectively vertically downwardly arranged on two upper sides of the conveying support, the cloth press rolls are respectively horizontally rotationally connected with two sides of the lifting support, roll bearing wheels are respectively vertically rotationally connected with two sides of positions above each roll bearing plate, each end of the winding roll is horizontally arranged between the two corresponding roll bearing wheels, a rotary gear is vertically arranged at an end of the winding roll, the cloth winding driving mechanism is arranged on a side of the conveying support and comprises a rotary plate, a rotary hydraulic cylinder, a winding gear and a winding motor, and the winding gear is connected with the rotary gear in a meshing manner. The cloth conveying and winding device has the advantages that the cloth conveying and winding device is reasonable in structural design, cloth can be quickly, efficiently, stably and neatly wound by the aid of the cloth conveying and winding device, and accordingly production and service requirements can be met.

Owner:张帼威

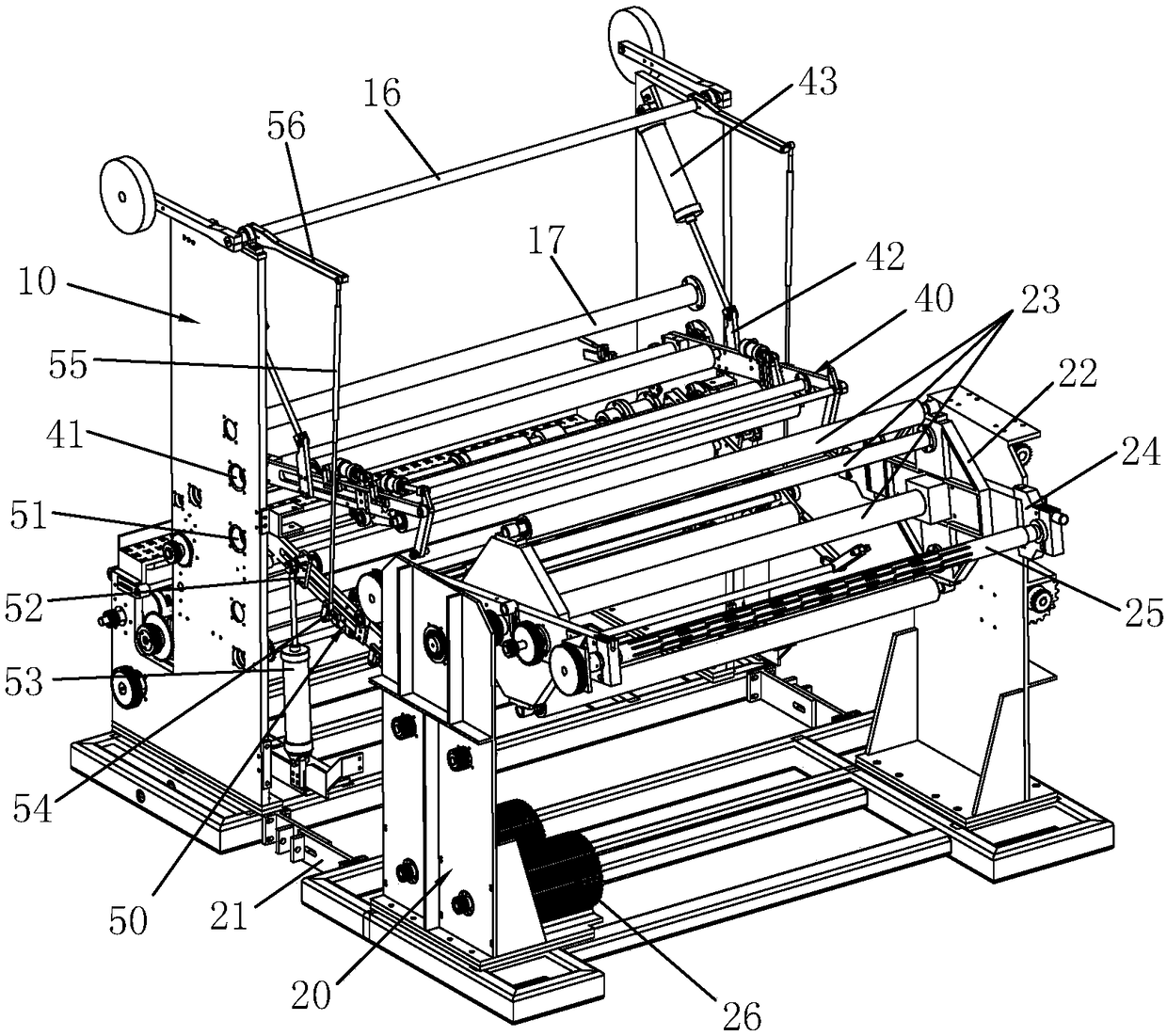

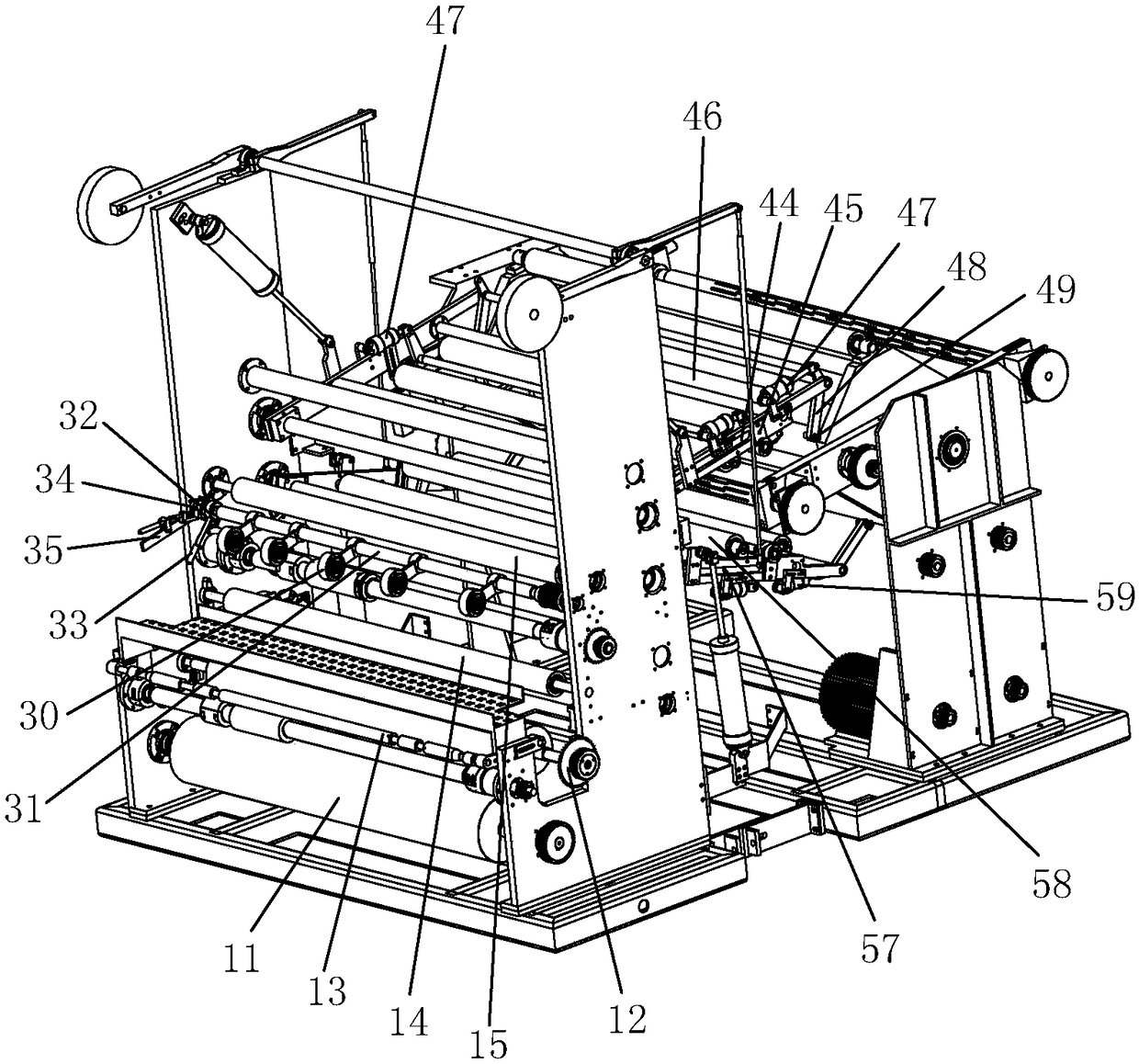

Non-woven fabric automatic slitting and winding machine

ActiveCN108163596AEfficient windingSolve the deformationSevering textilesWebs handlingWinding machineEngineering

Owner:安慕斯科技有限公司

Bunching device

InactiveCN108010640AEasy to replaceAffects winding qualityCable/conductor manufactureWire fixationMechanical engineering

The invention discloses a bunching device comprising a branching mechanism, a bunching mechanism and a winding mechanism. The bunching mechanism is arranged at one side of the branching mechanism; andthe winding mechanism is arranged one side of the bunching mechanism. The branching mechanism includes a branching shell with a mounting slot; a first bearing is arranged inside the mounting slot; awire arrangement block is arranged inside the first bearing; and through holes are formed in the wire arrangement block. According to the bunching device, because the groove is in a spiral shape, on the one hand, a composite wire fixation effect is realized by cooperation of the groove with the wound composite wire, so that a phenomenon that the winding is not compact because of sliding of multiple strands of single wires during rotation of the bunching hole and thus the cable winding quality is affected can be avoided; and on the one hand, the spiral groove and the composite wire cooperate with each other to drive conveying of the composite wire when the bunching hole is rotating and multiple groups of cables can be wound simultaneously under cooperation of a first gear, a second gear, and a third gear based on setting of a plurality of bunching holes and through holes, so that the bunching device is used conveniently with reduced energy consumption and lowered costs.

Owner:安徽电信实业集团有限公司器贸分公司

Glass fiber felt continuous production line

ActiveCN109051932AReduce human inputImprove work efficiencyPaper article packagingWork benchesGlass fiberYarn

The invention discloses a glass fiber felt continuous production line. The production line comprises a glass fiber yarn cluster cutting device, a settling chamber, a water spraying device, a powder scattering device, a drying device, a compaction and cutting device, a winding device and a packing device arranged in sequence. Glass fiber yarn clusters are treated by the cutting device, the settlingchamber, the water spraying device, the powder scattering device, the drying device, the compaction and cutting device, a detecting device and the winding device to form glass fiber felt rolls; and the glass fiber felt rolls are packed in cartons by the packing mechanism. Through the winding device, the electric control of an air expansion shaft is controlled to change among at least three stations, so that the labor investment is reduced, and the working efficiency is improved. Through the design of an auxiliary winding mechanism, the effective winding of the glass fiber felts on the air expansion shaft in a machining station is guaranteed, and the uneven winding is prevented. Through the design of a winding shaft placing platform, the operation efficiency of the production line is improved, and the labor cost is reduced.

Owner:嘉兴市宏宇新材料股份有限公司

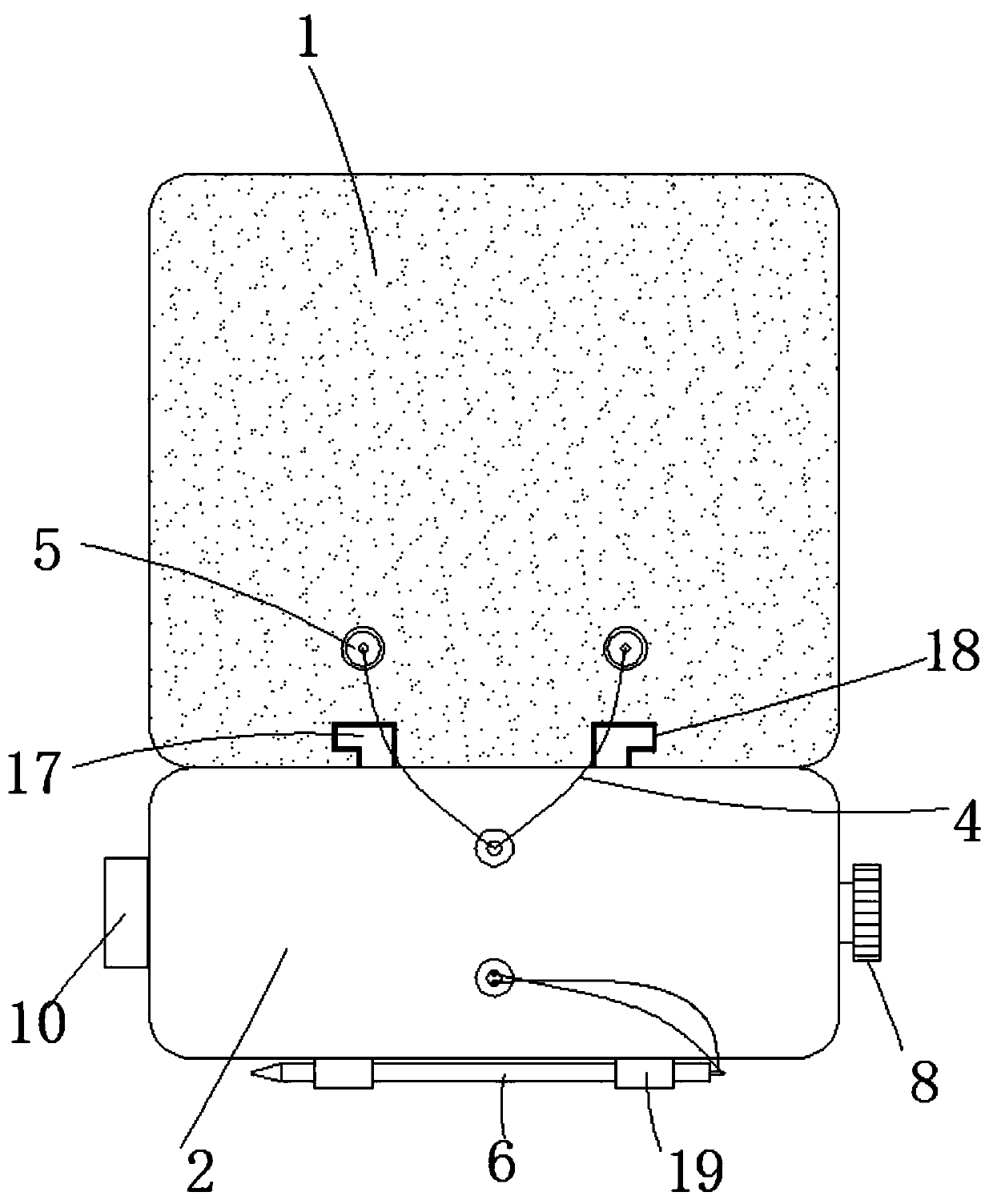

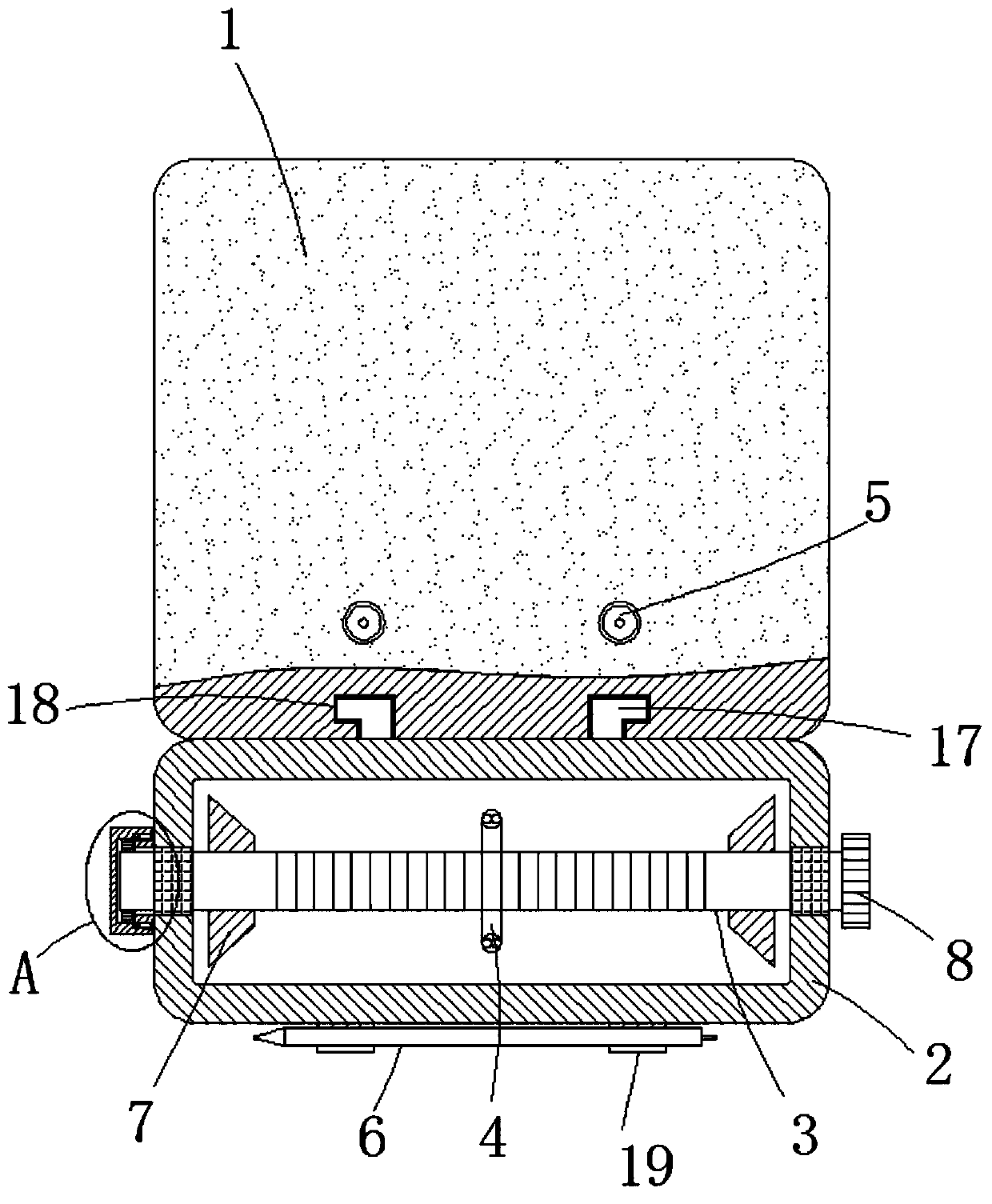

Measuring instrument with wire harness simple and convenient to store

InactiveCN110255298AEasy to storeAvoid damageCurrent/voltage measurementFault locationMeasuring instrumentEngineering

The invention relates to the technical field of measuring instruments and discloses a measuring instrument with a wire harness simple and convenient to store. The measuring instrument comprises a measuring instrument body and a wire storage box. A transversely arranged reel is arranged in the wire storage box. A detection wire is wound around the reel wall of the reel. The middle of the detection wire is fixedly connected with the reel, and the two ends of the detection wire and the reel are arranged in a same-direction wound mode. The front face of the wire storage box is provided with two wire penetrating holes. The two ends of the detection wire penetrate through the two wire penetrating holes correspondingly, and two wire inserting rods are fixedly connected to one end of the detection wire. The lower portion of the front face of the measuring instrument body is provided with two wire inserting holes matched with the wire inserting rods. A detection pen is fixedly connected to the other end of the detection wire. According to the measuring instrument, the detection wire can be wound effectively, damage caused by random placing of the detection wire is avoided, releasing is convenient, the reel can also be limited, looseness of the detection wire is avoided, and use is convenient for people.

Owner:MAANSHAN HETIAN ELECTRONICS INTELLIGENCE CONTROL SYST CO LTD

Common mode inductor

InactiveCN103035361ALow costIncrease inductanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductorConductor Coil

The invention relates to an inductance coil, in particular to a common mode inductor. The common mode inductor comprises a magnetic core, two coils and four terminals, wherein the two coils and the four terminals are wound on the magnetic core; the two coils are in the same size and have the same number of turns in opposite winding directions; the magnetic core is a ferrite annular magnetic core; and the coils are insulated conductors, and the coils are wound on the magnetic core in a single layer way. The common mode inductor has the advantages of low cost and convenience in installation and can be wound by a machine with high efficiency. An insulating layer is formed between the magnetic core and the coils, the winding process can be controlled better, and a higher inductance value can be achieved.

Owner:孔明

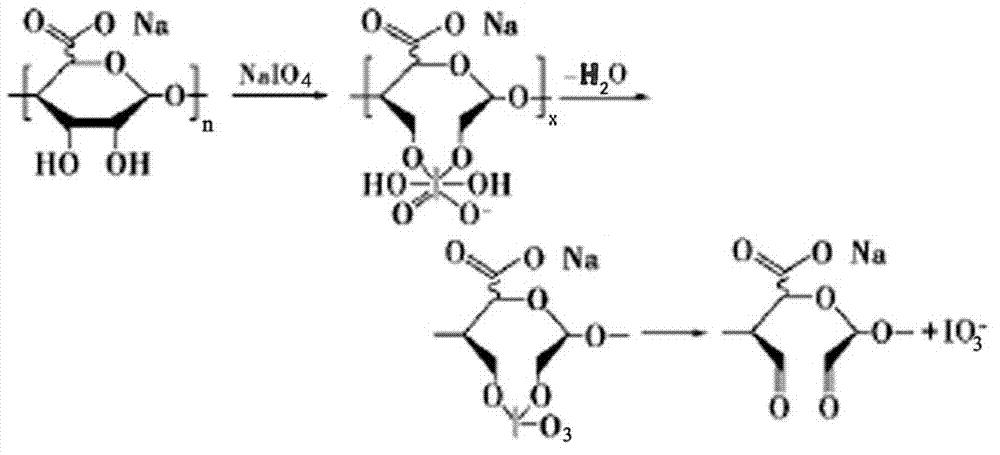

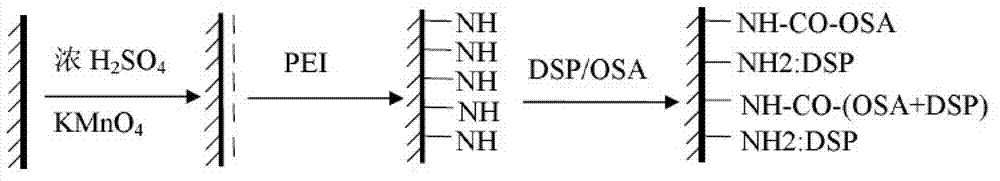

Preparation method and application of dexamethasone sodium phosphate-sodium alga acid composite slow-release coating

InactiveCN102861364AGood biocompatibilityGood bioadhesionSurgeryPharmaceutical containersExtracorporeal circulationWhole body

The invention discloses a preparation method and application of a dexamethasone sodium phosphate-sodium alga acid composite slow-release coating. A high polymer material is soaked in a sulfuric acid solution of potassium permanganate to conduct acidizing; then the high polymer material is placed in a polymine solution to obtain an amination embellished surface; and oxidation treatment is carried out on the sodium alga acid by using periodic acid or sodium periodate to enable aldehyde groups to be exposed at the tail end of an alginic acid segment to obtain multi-aldehyde group oxidation sodium alga acid, the dexamethasone sodium phosphate solution is soluble in deionized water, and finally materials of the amination embellished surface is placed in a reaction liquid to obtain the composite coating. The technical scheme is that the dexamethasone sodium phosphate and the sodium alga acid can be fixed on the surface of an extracorporeal circulation pipeline in a surface coating mode and has anti-freezing and anti-inflammatory double activity, external medicines are durable and stable in slow-release performance, the dexamethasone sodium phosphate-sodium alga acid composite slow-release coating can replace vein heparinization in a short period, systemic inflammatory response can be lightened through slow release, and short-period operation requirements in department of cardiac surgery can be met.

Owner:TIANJIN CITY THIRD CENT HOSPITAL

Hose reel system

InactiveUS20080302902A1Efficient windingLow costLiquid fertiliser distributionWheel and axleMechanical engineering

A hose reel system for winding a liquid manure hose. The hose reel includes a spool pivoted in alignment with the wheels and axles of the system to allow for even winding of the hose on a spool. The spool is provided with curved domes on either, end and a protective bar to prevent the hose from winding beyond the ends of the spool. Pivoting the spool in alignment with the axle allows for a more even winding and unwinding of the hose, thereby reducing torsion, kinks and other damage to the hose during the rolling and unrolling processes.

Owner:PUCK CUSTOM ENTERPRISES

Magnetic core winding apparatus

ActiveUS20050218257A1Small sizeReduce temperature riseMagnetic circuitManufacturing dynamo-electric machinesInductorInductance

The invention relates to winding wire around a magnetic core. The invention includes forming corners on the wire that align with inside corners of the magnetic core such that the wire is more tightly wound around the magnetic core. The invention also includes pinching a portion of wire that is positioned on the internal diameter of a magnetic core when the wire is wound around the core to provide more turns of the wire around the magnetic core. A magnetic inductor made in accordance with the present invention can have increased inductance, lower temperature rise, smaller size, and exhibit less EMI noise than the prior art.

Owner:HUBBELL INC

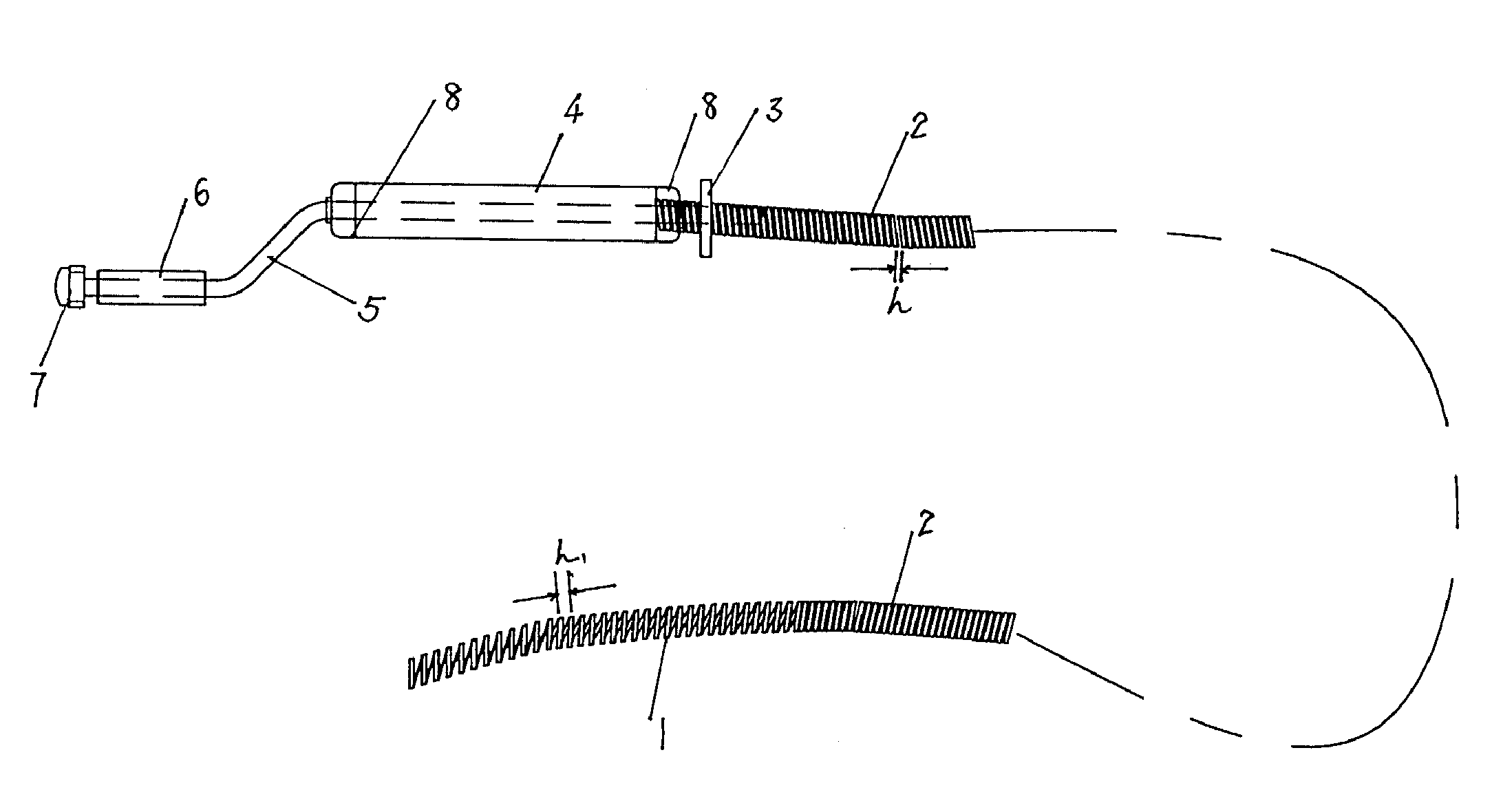

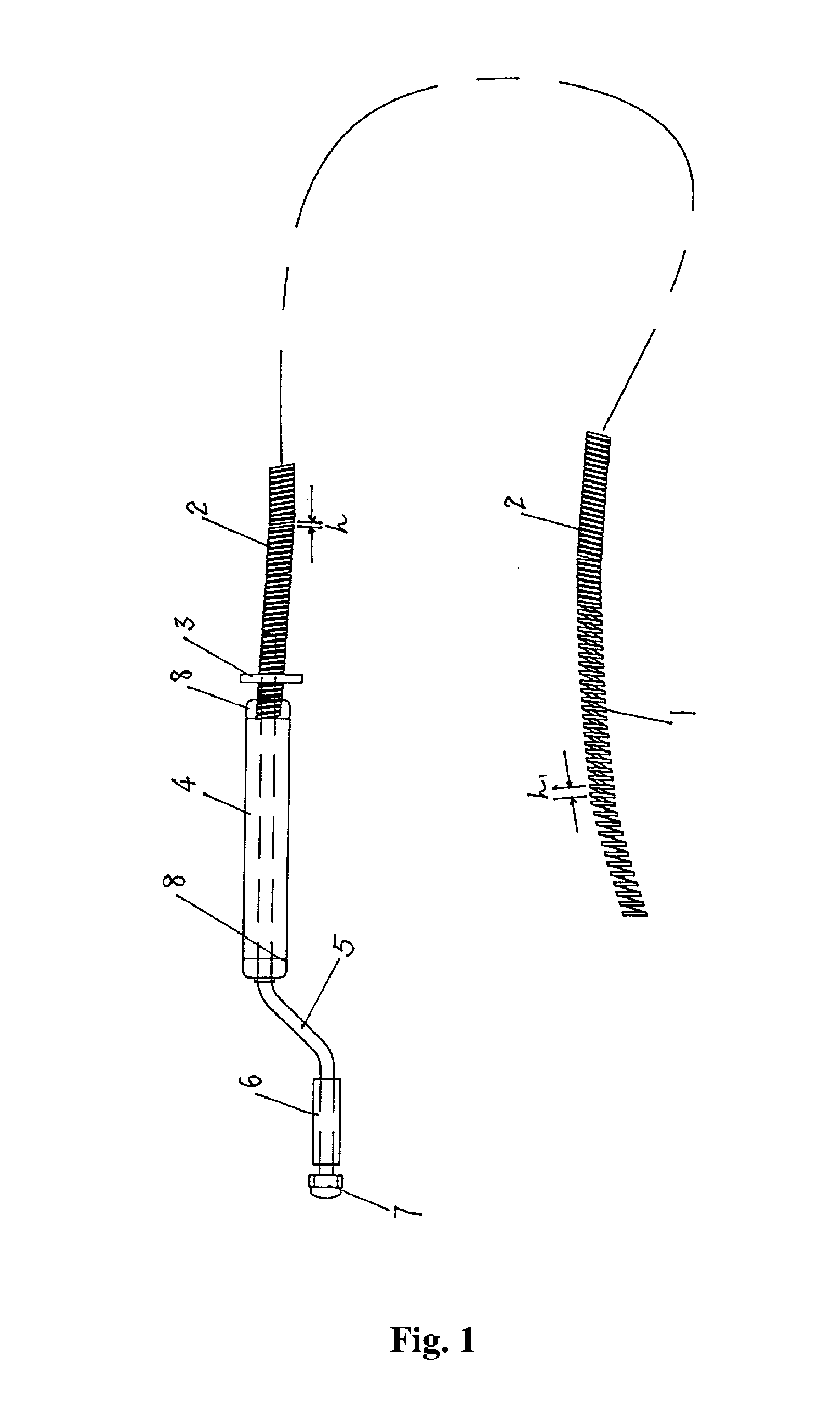

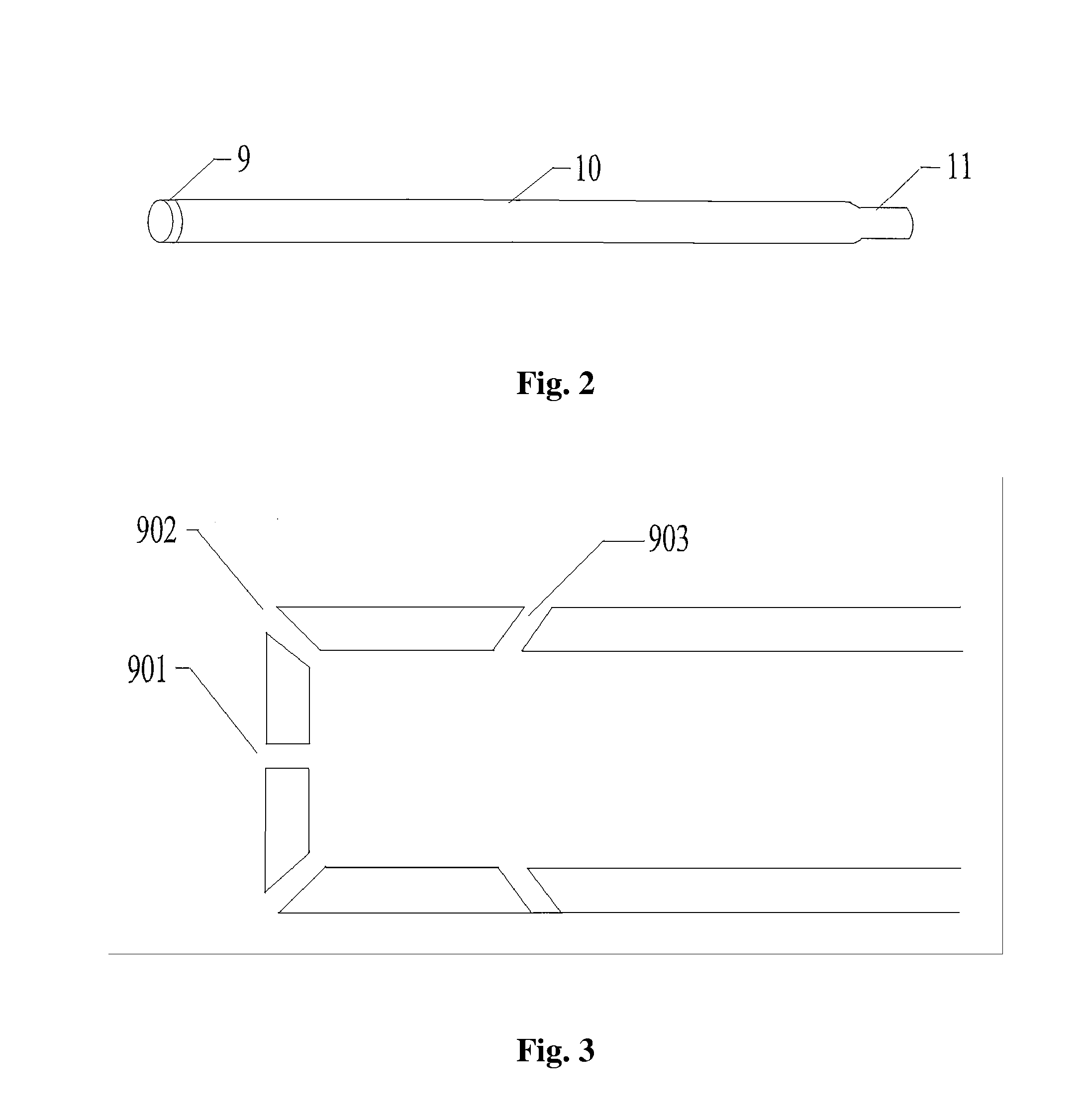

Manual system for dredging heavy turning pipeline

InactiveUS20080173332A1Efficient windingIncrease flushing powerSewer cleaningHollow article cleaningGear wheelEngineering

Provided is a manual system for dredging a heavy-turning pipeline, comprising a pipeline dredger and a water-pressure dredge pipe comprising a rocker and a spring-type dredge pipe connected thereto; wherein a spring-type dredge bit is disposed on an end of the spring-type dredge pipe; the water-pressure dredge pipe is a hollow hose having an back end that may be inserted into a pipeline to be dredged; and a cross section of the dredge bit has a cog or a sharp corner. In a process of dredging a pipeline, the cog or the sharp corner may easily winds blocking objects, so that it is possible to quickly dredge the pipeline and improve dredging efficiency. Furthermore, since an opening having a diameter less than the water-pressure dredge pipe is disposed at an end of the water-pressure dredge pipe, water column with higher pressure may be formed, and sprayed water column has enhanced scouring force. In addition, since openings with different spraying directions are used, the end of the water-pressure dredge pipe is capable of spraying at different angles, and thus dredging efficiency is improved.

Owner:ZHANG JIAYI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com