Patents

Literature

468results about How to "Achieve dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

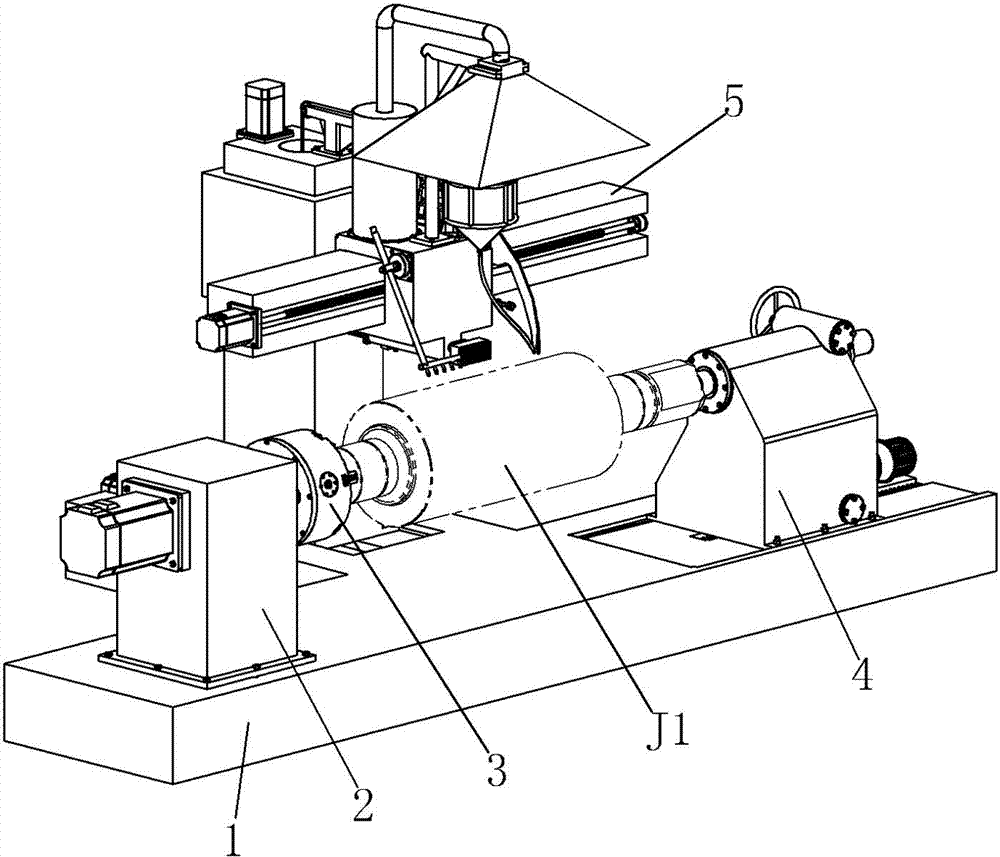

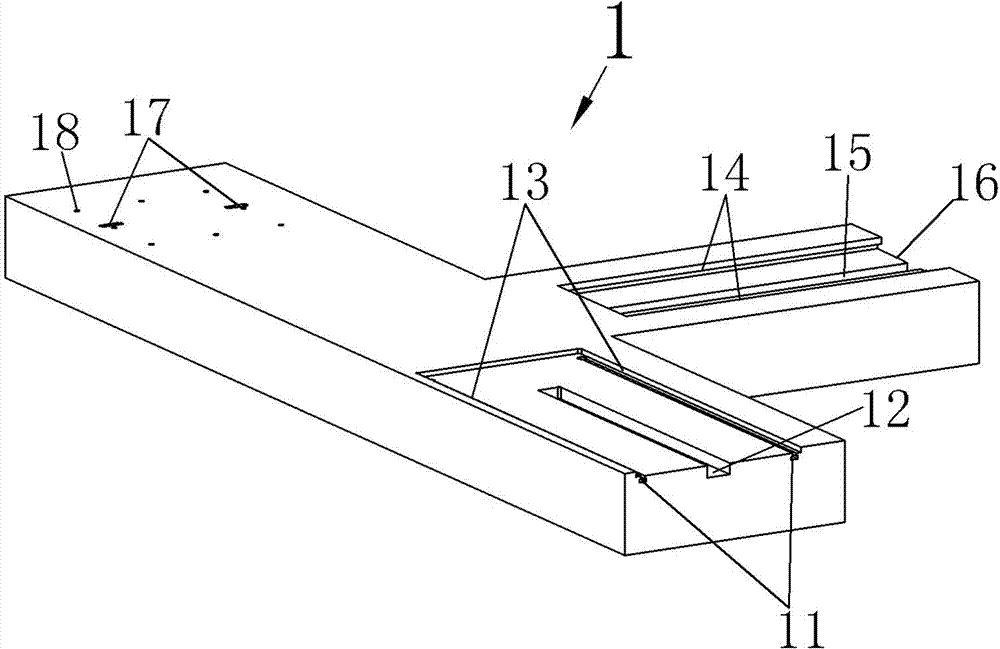

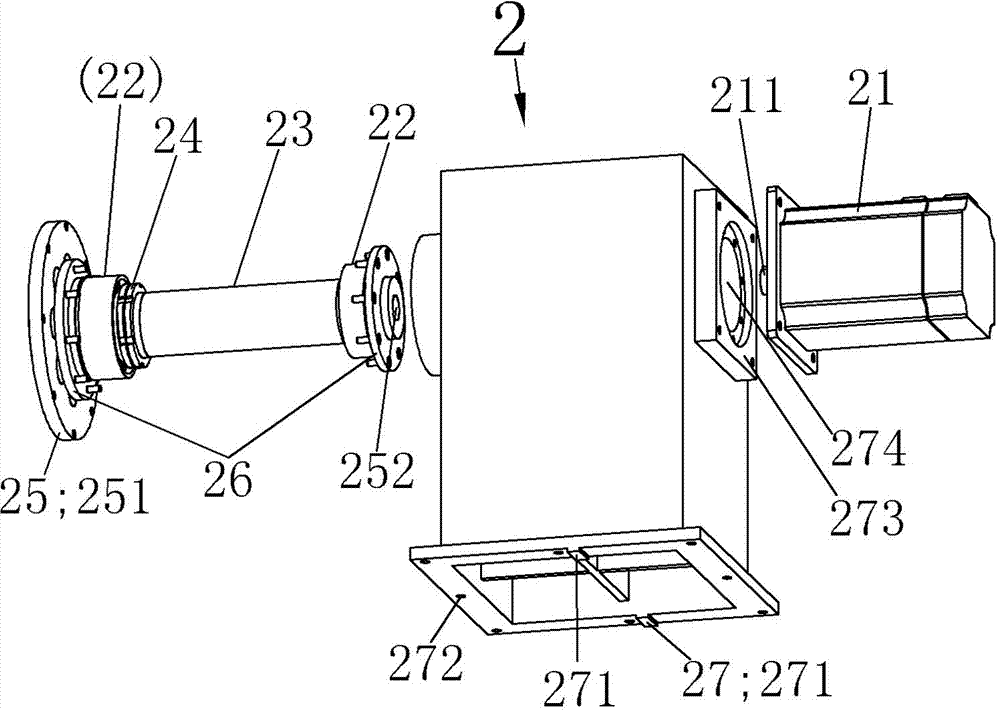

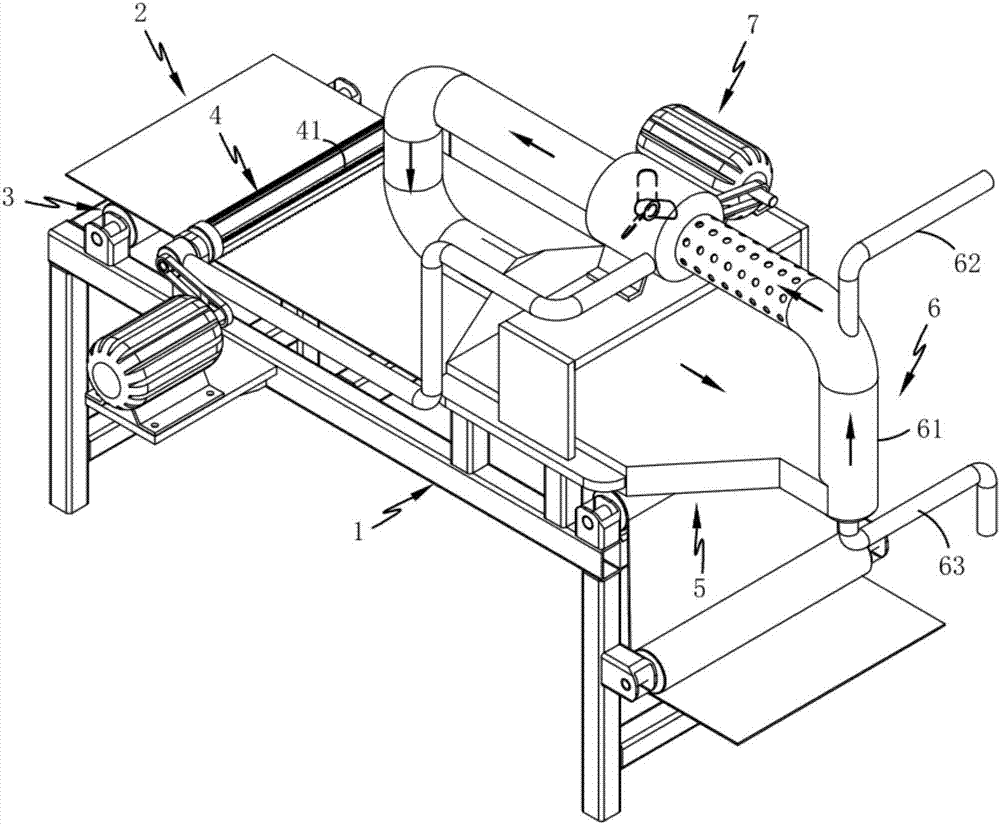

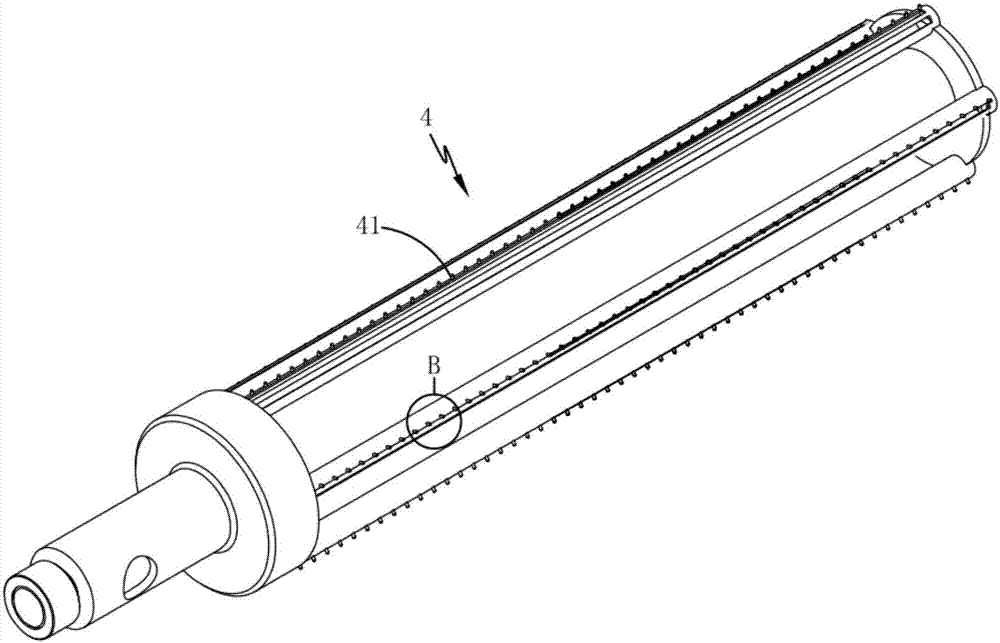

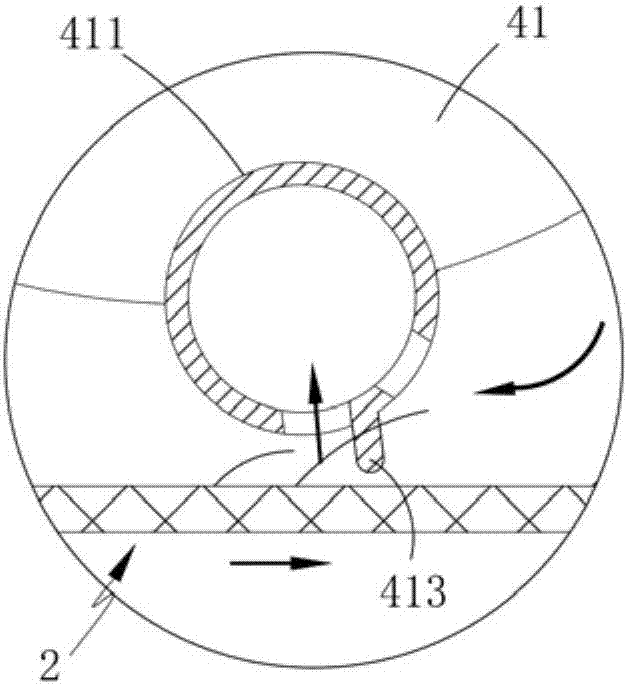

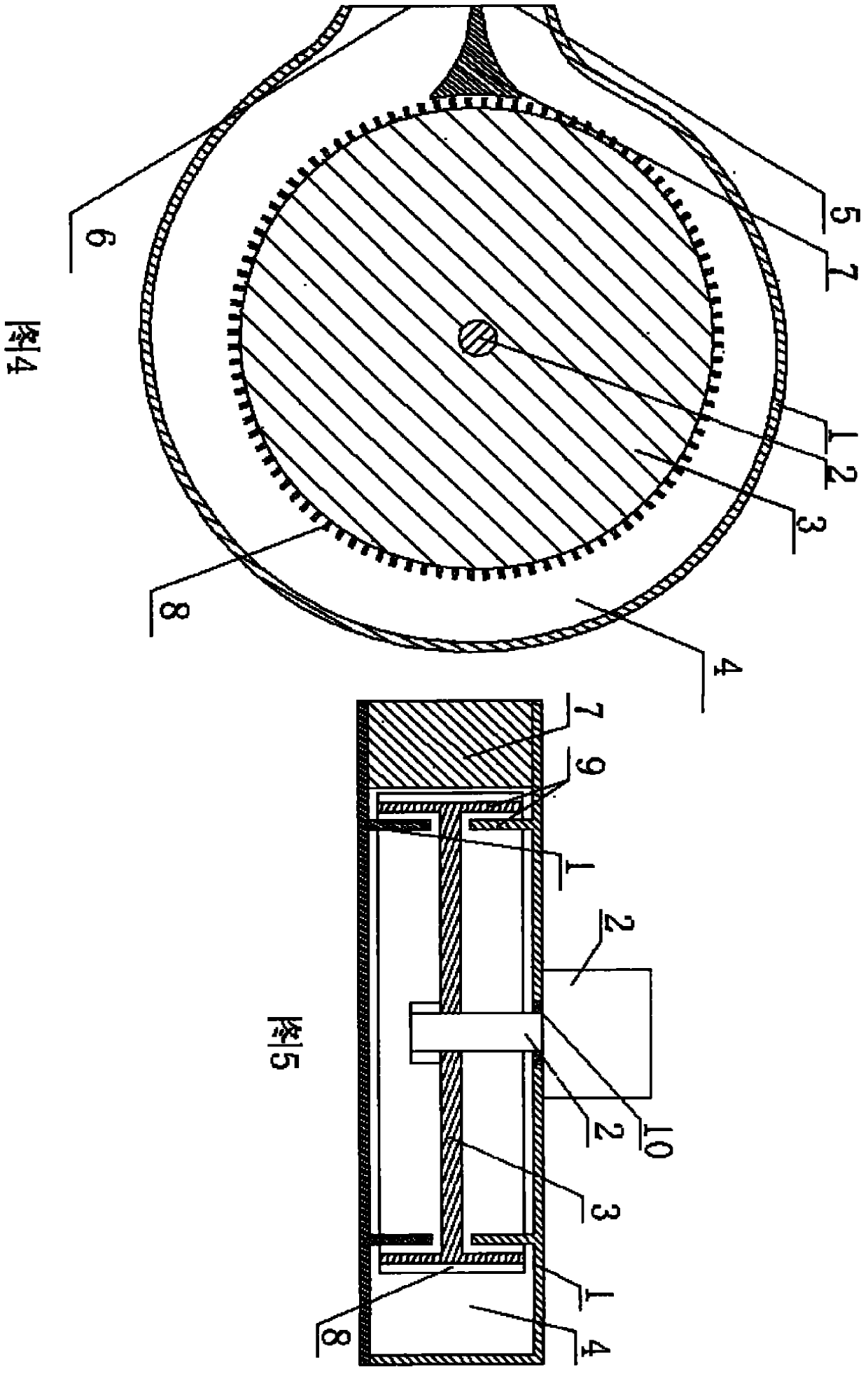

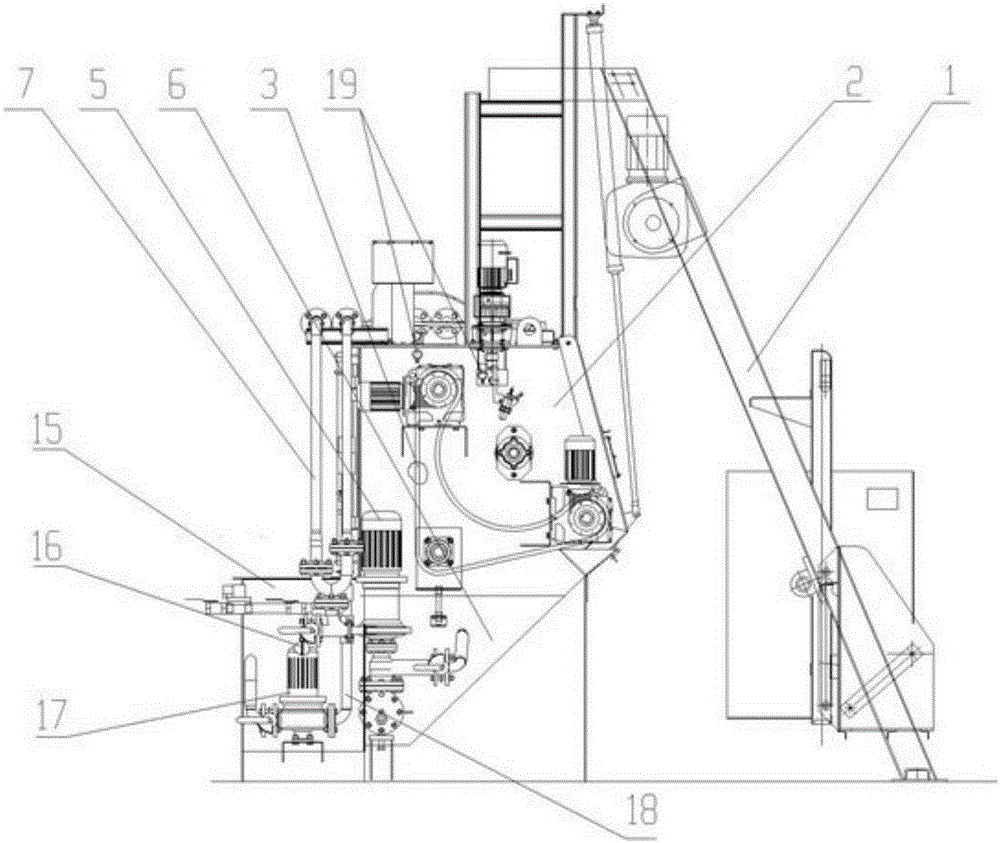

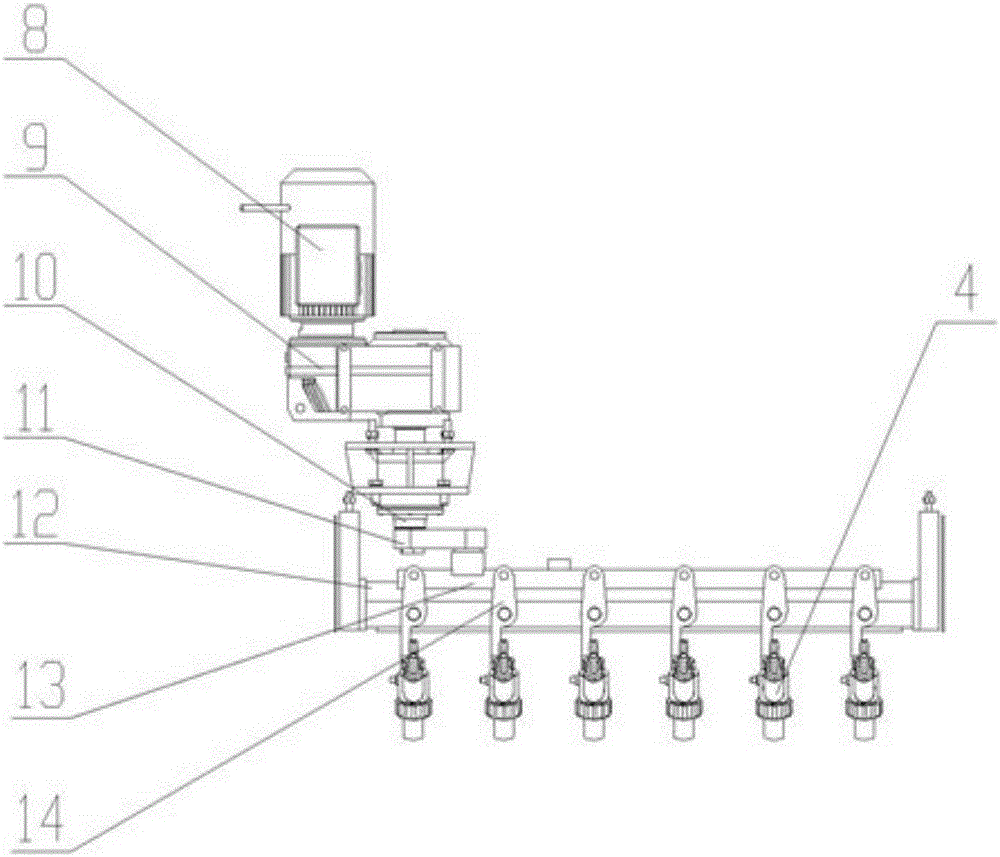

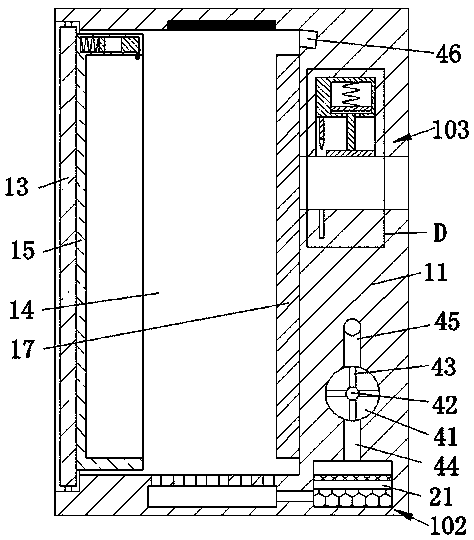

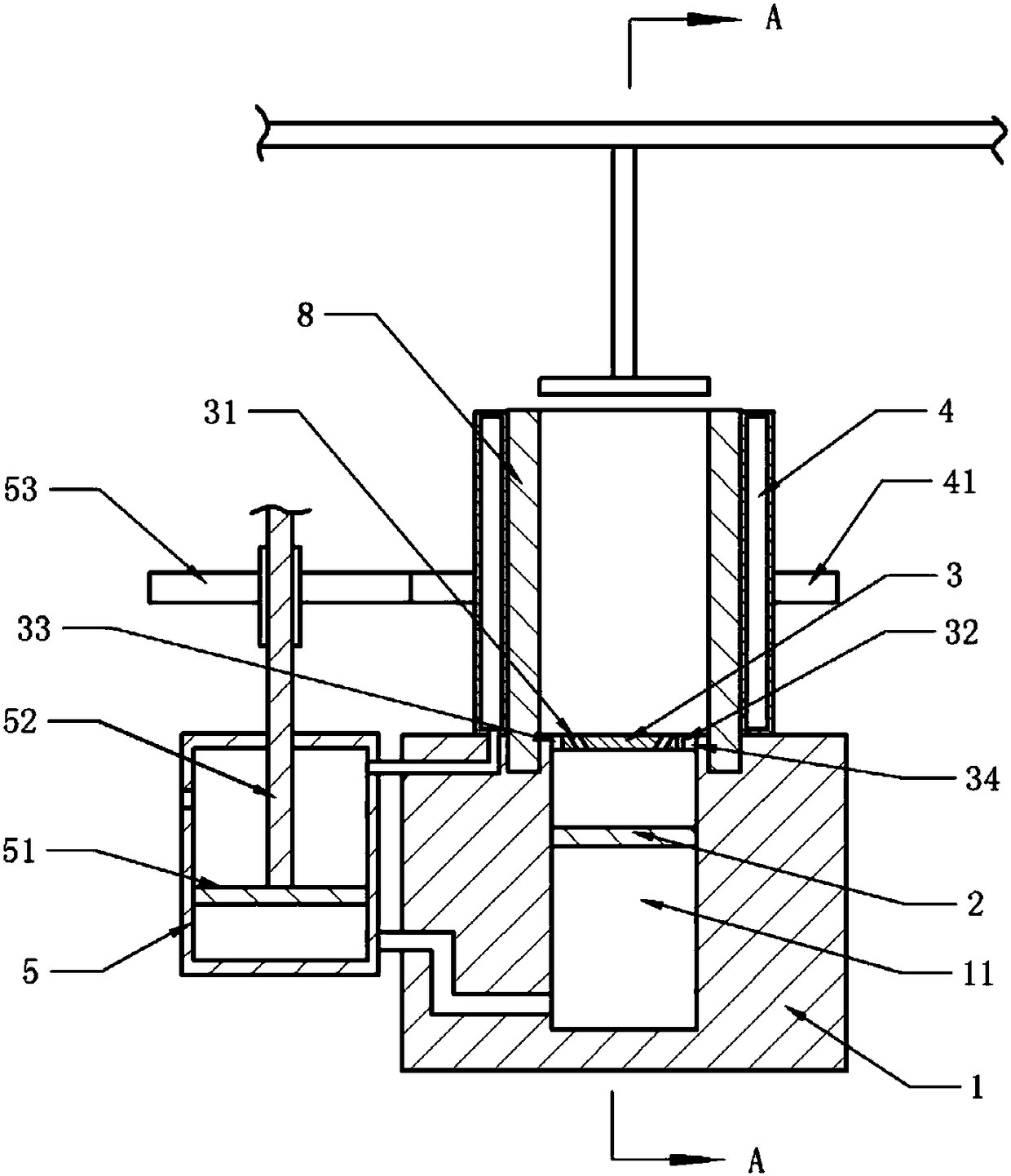

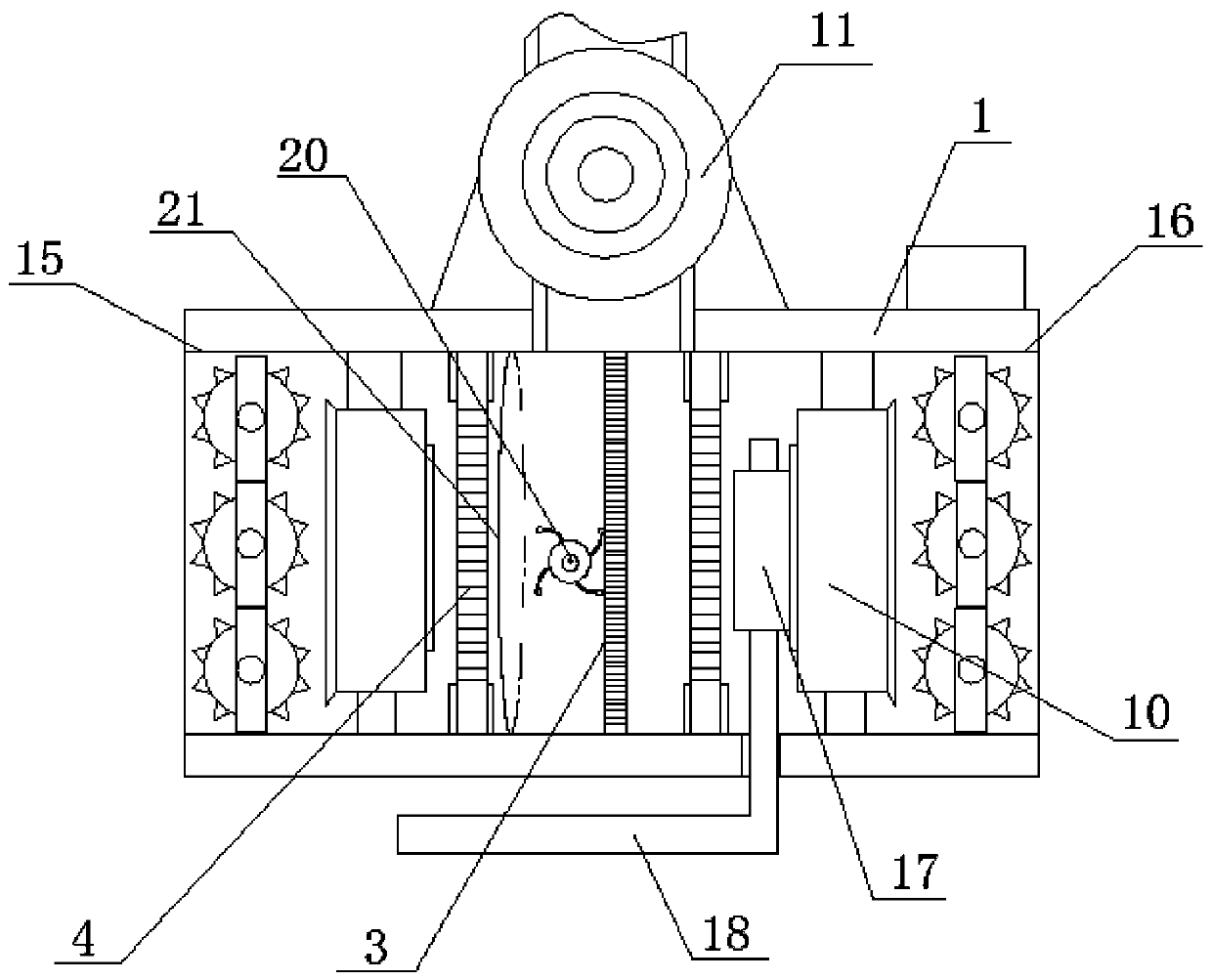

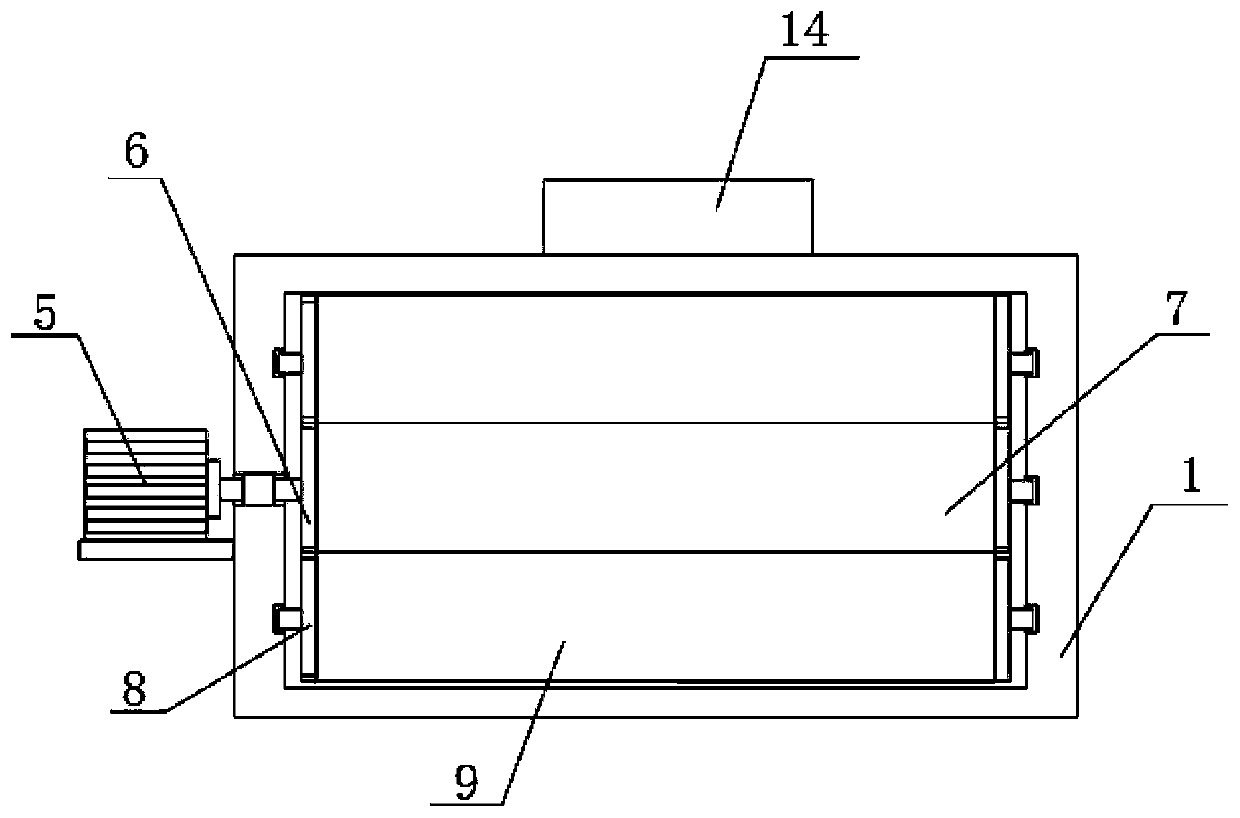

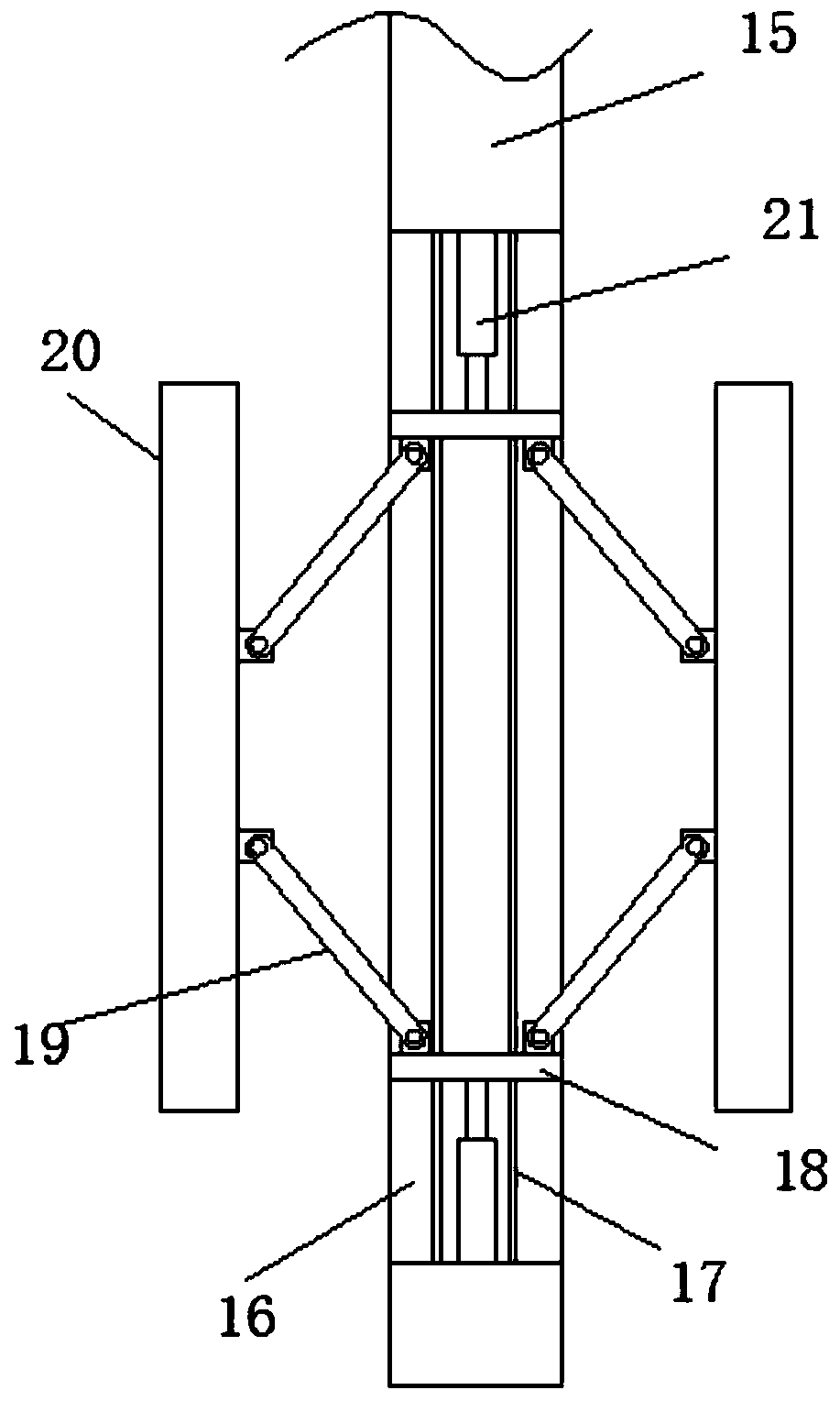

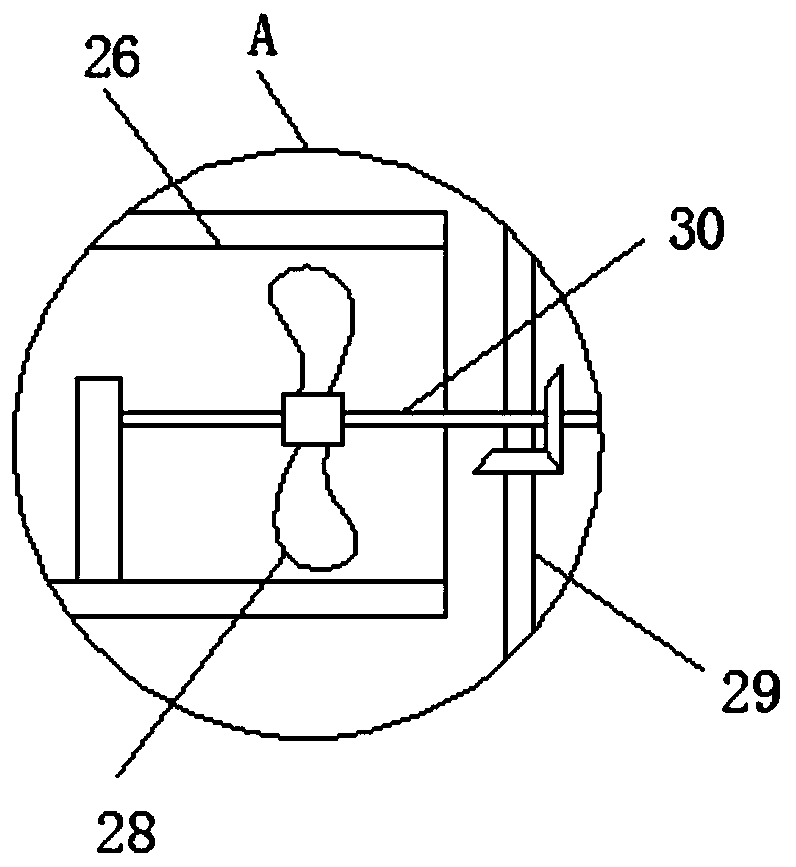

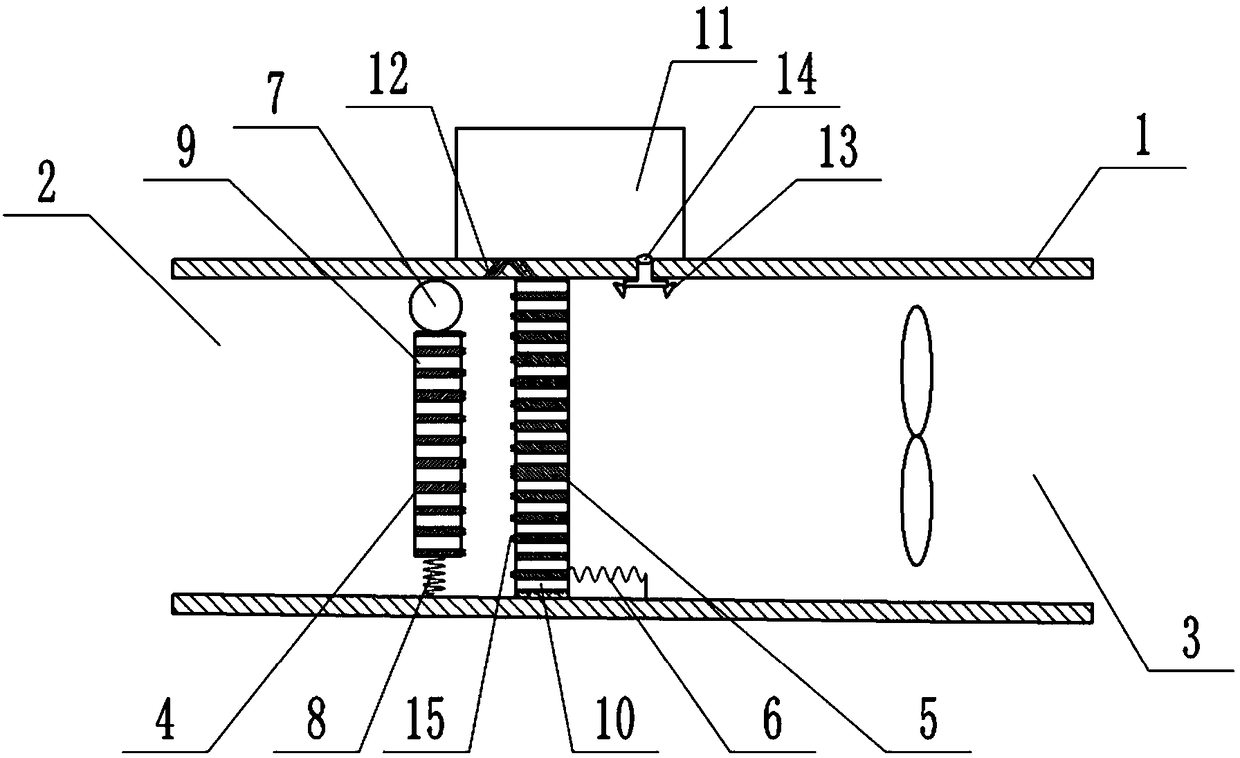

Roller repairing surfacing machine

InactiveCN107088696AReliable clamping functionReduce distortionWelding/cutting auxillary devicesAuxillary welding devicesSurface cleaningTailstock

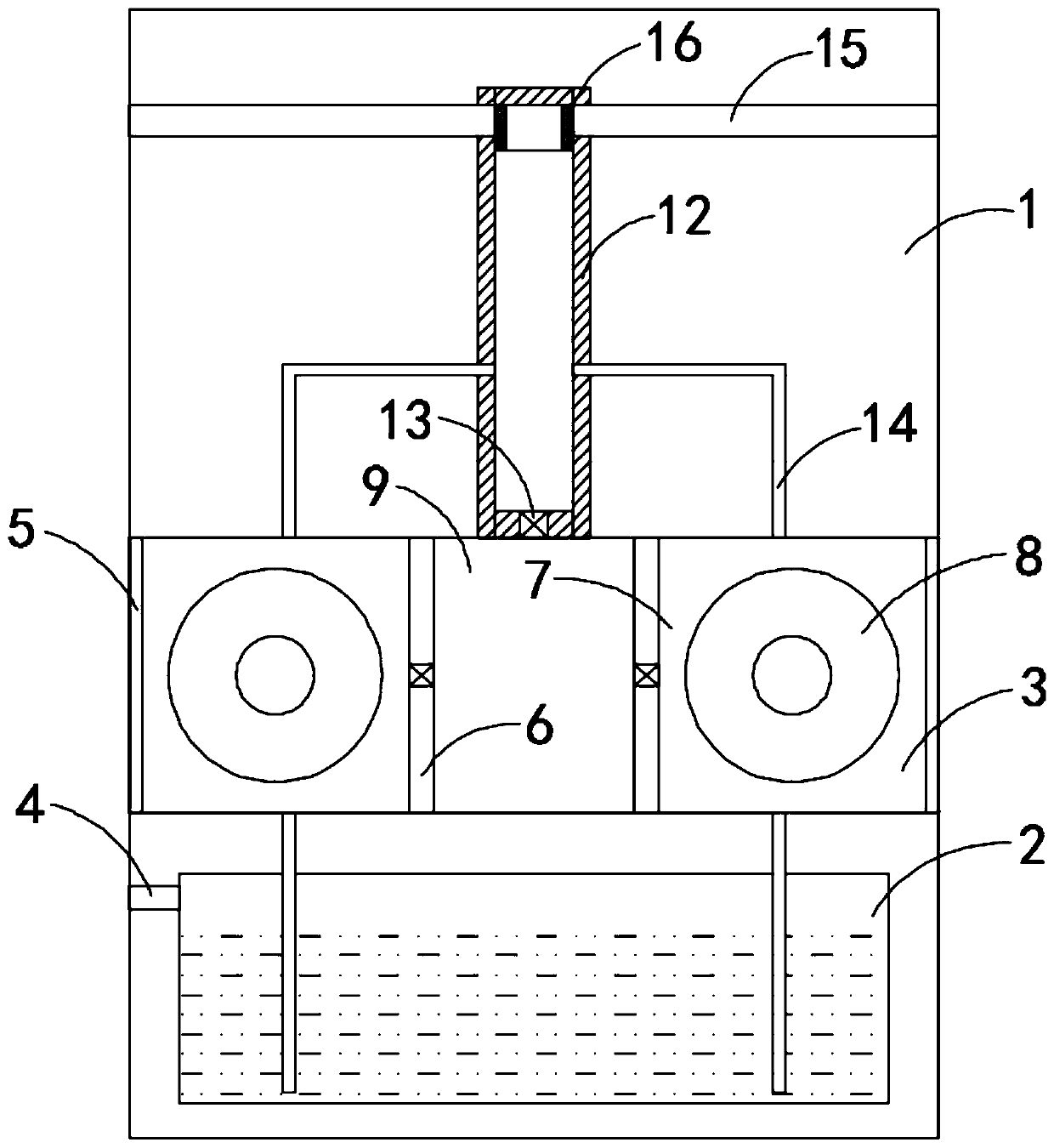

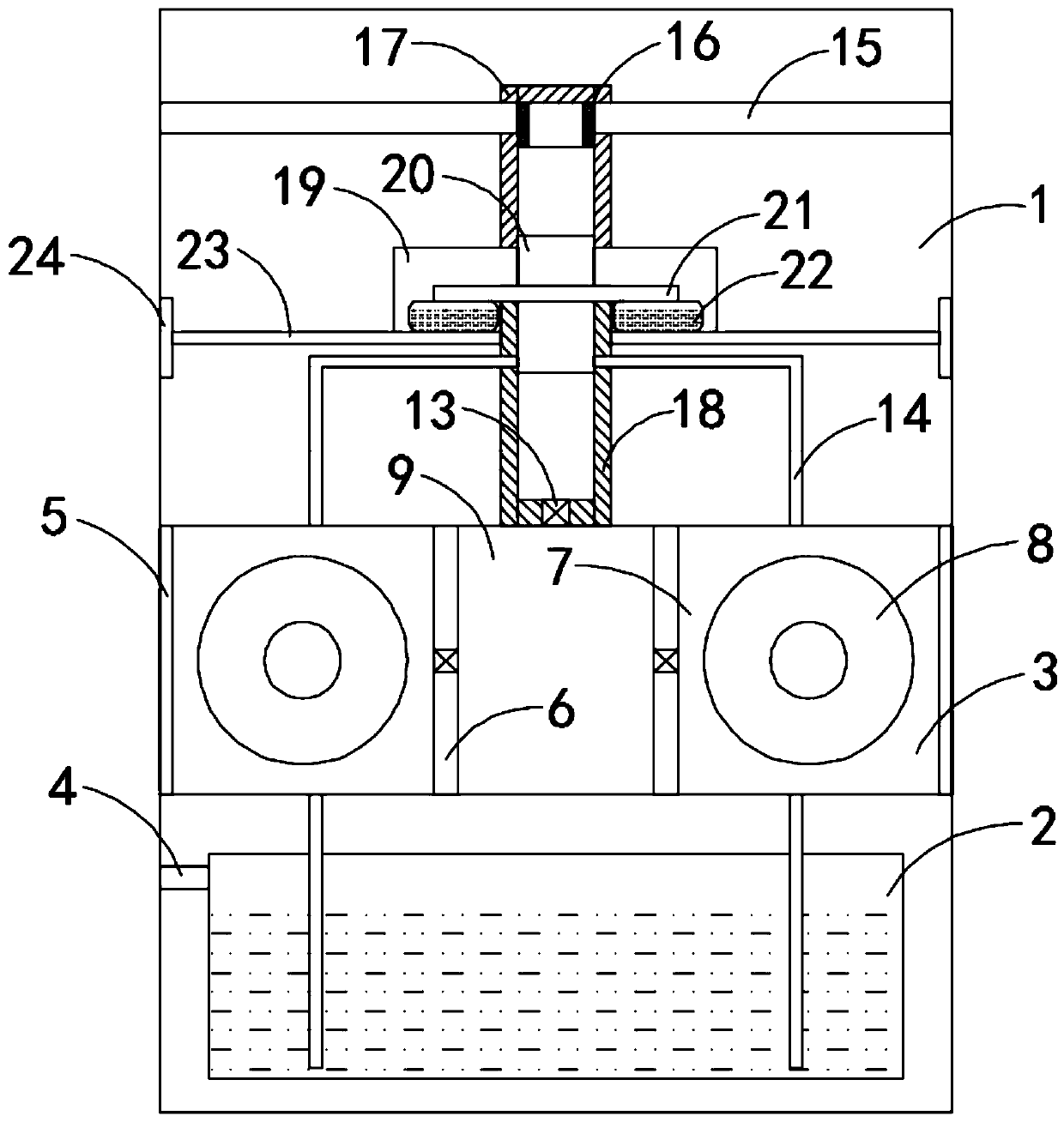

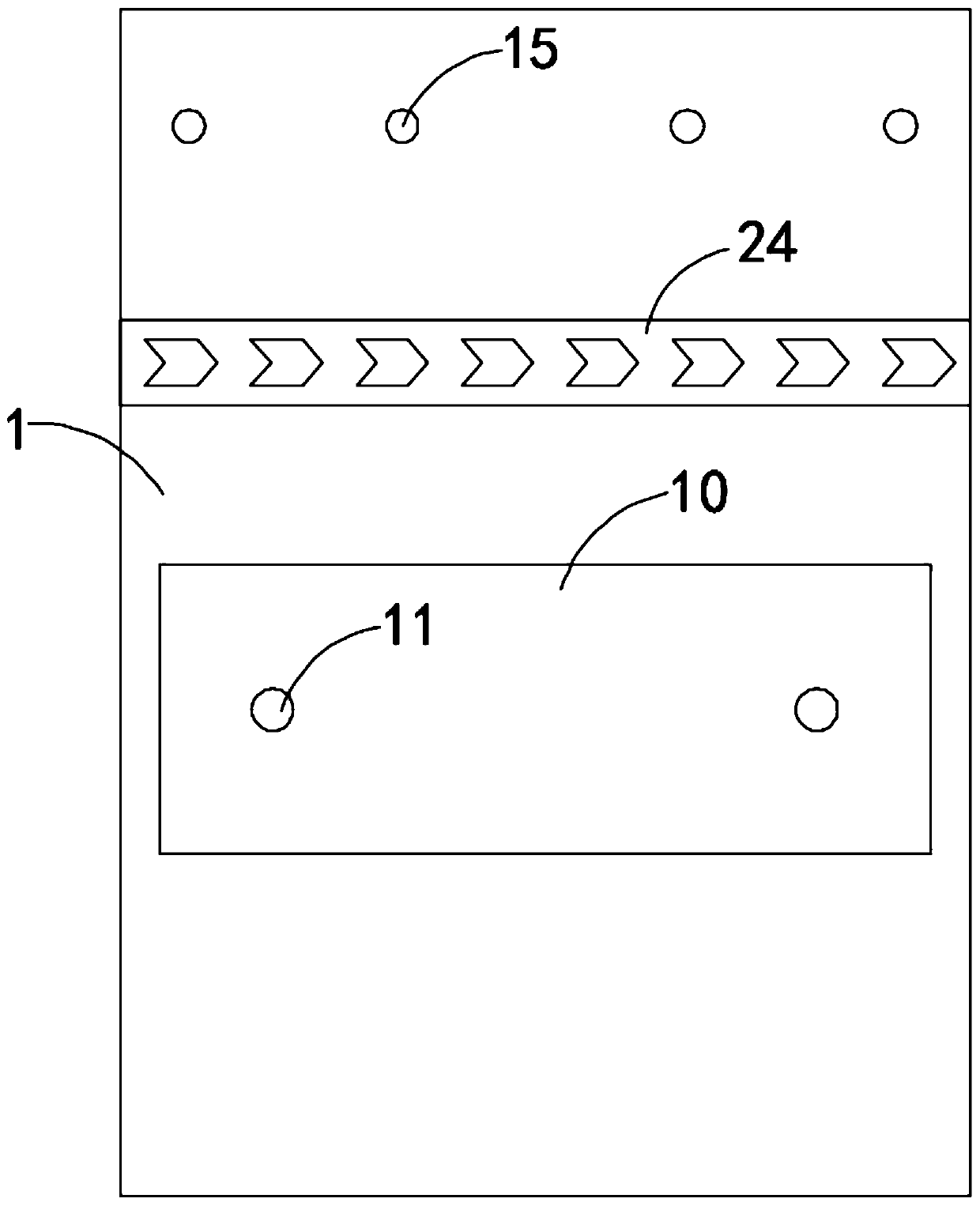

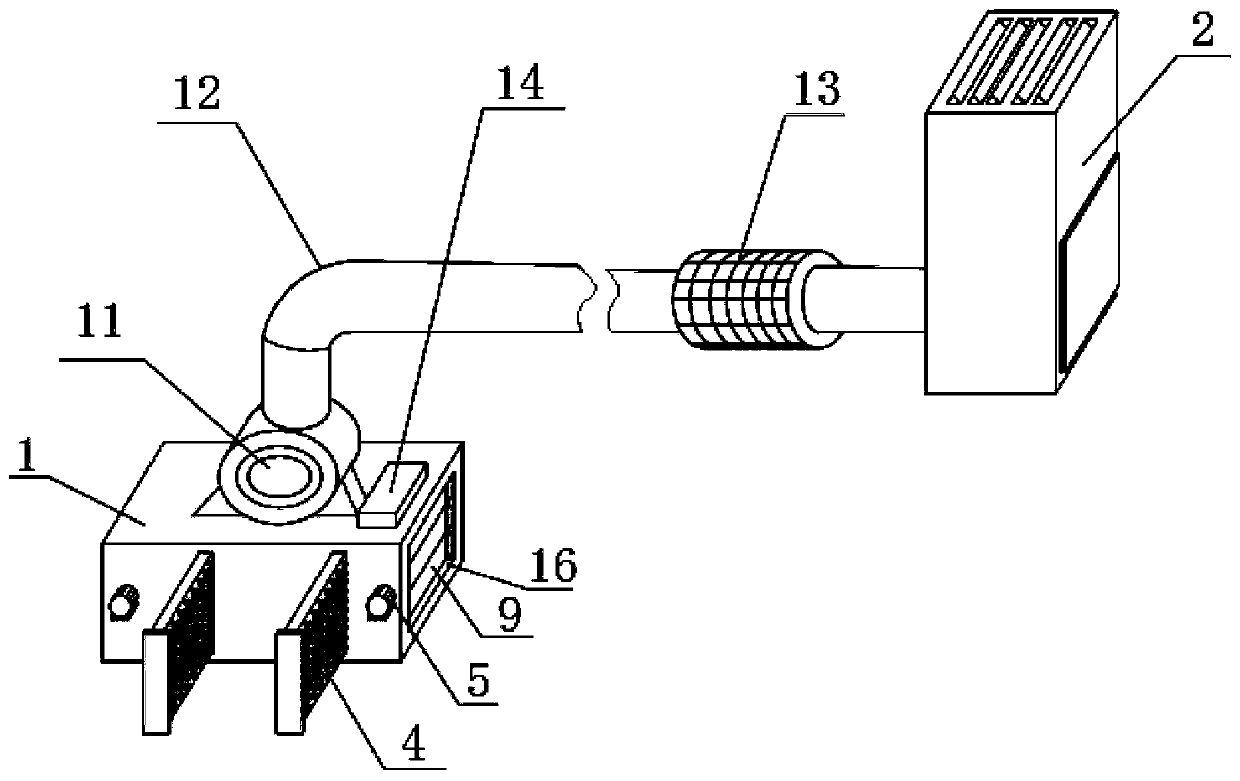

The invention discloses a roller repairing surfacing machine and belongs to the field of metal welding. The roller repairing surfacing machine has a pre-welding preheating function, an automatic surfacing function, a welding fume removing function and a welding surface cleaning function, and also has the characteristics that a surfacing station can be adjusted rapidly, and the dimension expansion capacity of a surfacing workpiece is high. The roller repairing surfacing machine is provided with a foundation base, a headstock, a six-jaw chuck, a tailstock centre device and a working device. According to the technical scheme, a single stand column cross beam structure is adopted by the working device, surfacing, preheating, welding fume removing and welding surface cleaning are integrated onto one working head, thus, the structure is compact, and energy saving and environmental friendliness are achieved; a repairing roller is clamped through the six-jaw chuck and the tailstock center device, and clamping is fast and reliable; and the roller repairing surfacing machine is simple in structure, easy to manufacture and convenient to maintain.

Owner:KUNMING UNIV

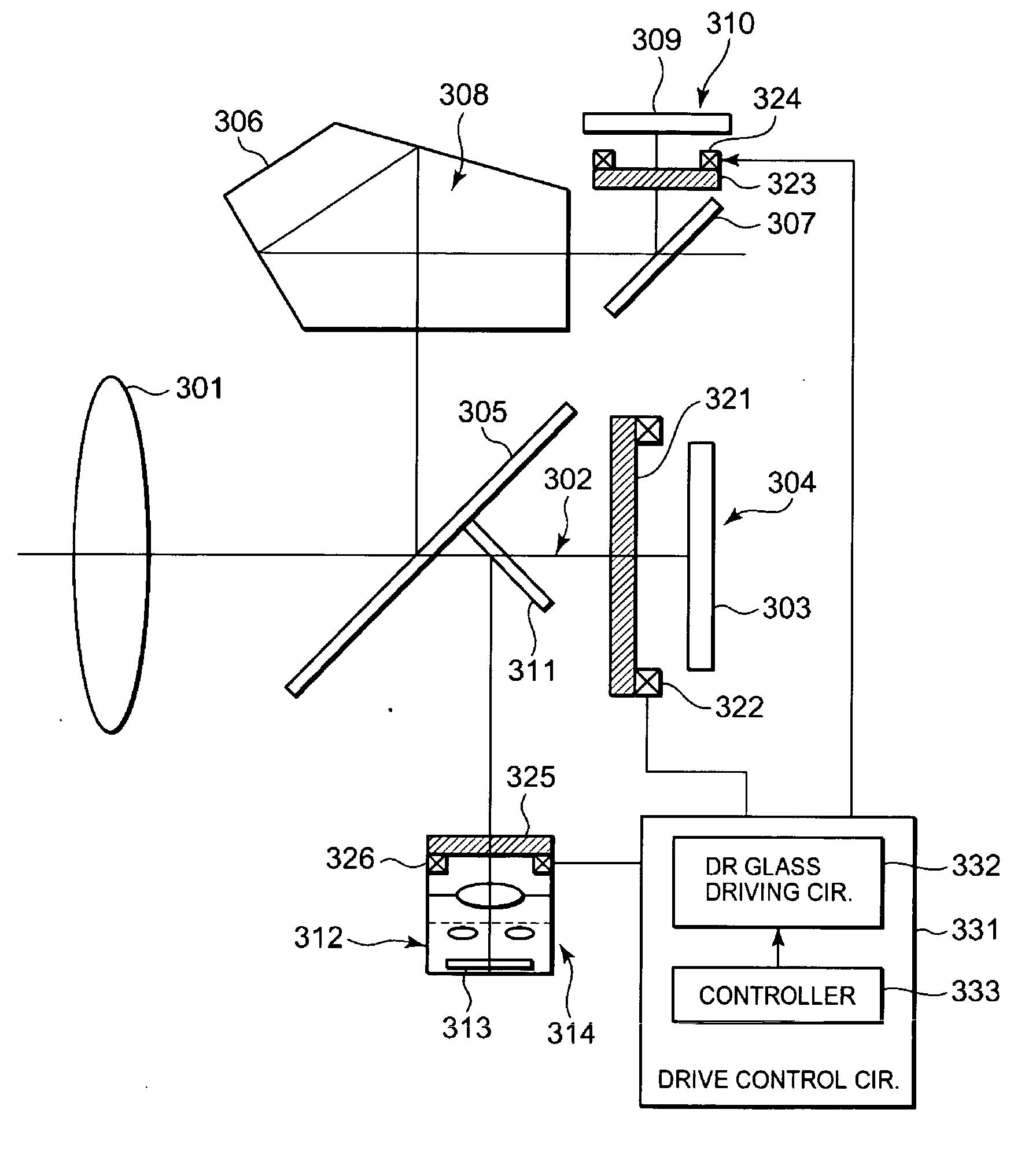

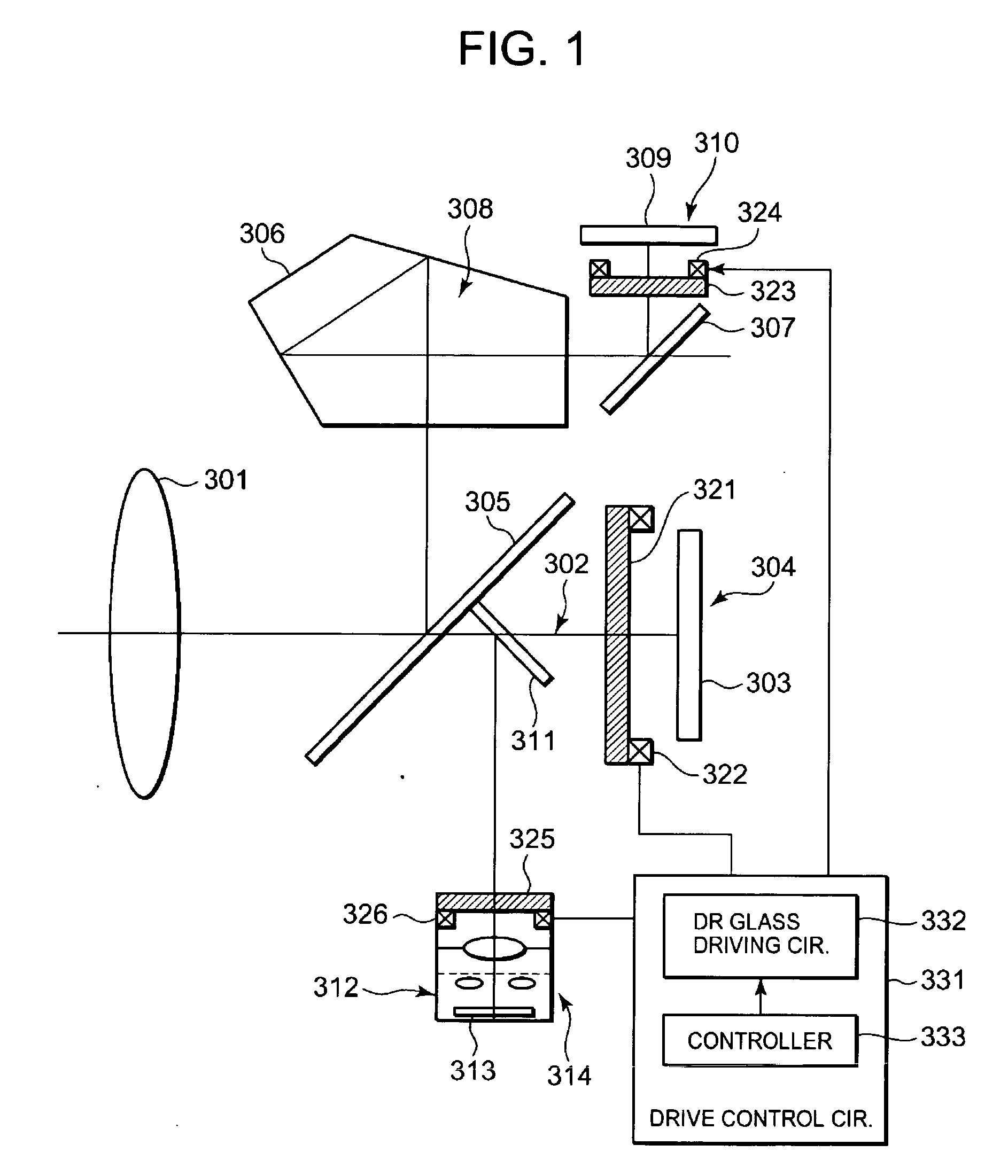

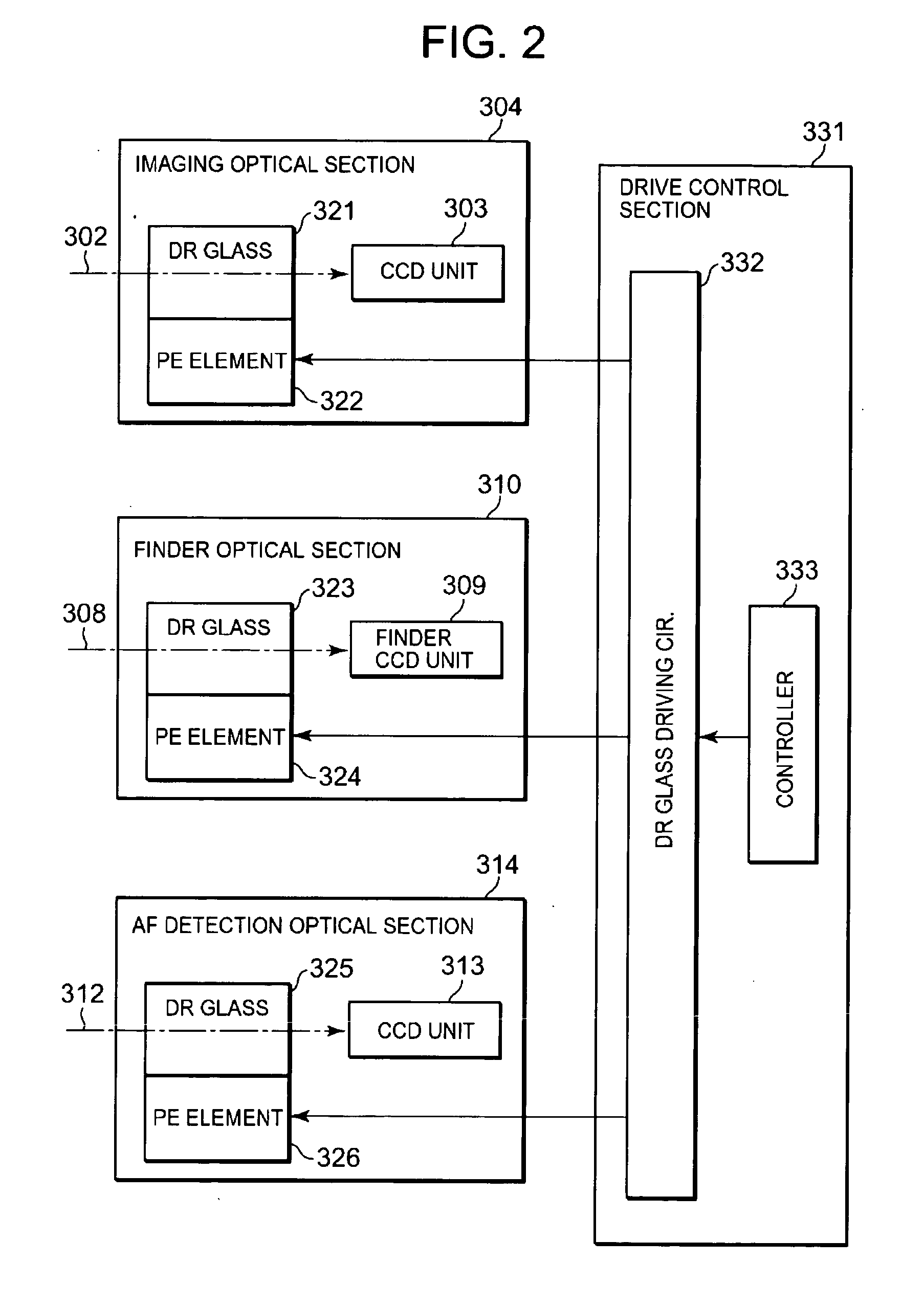

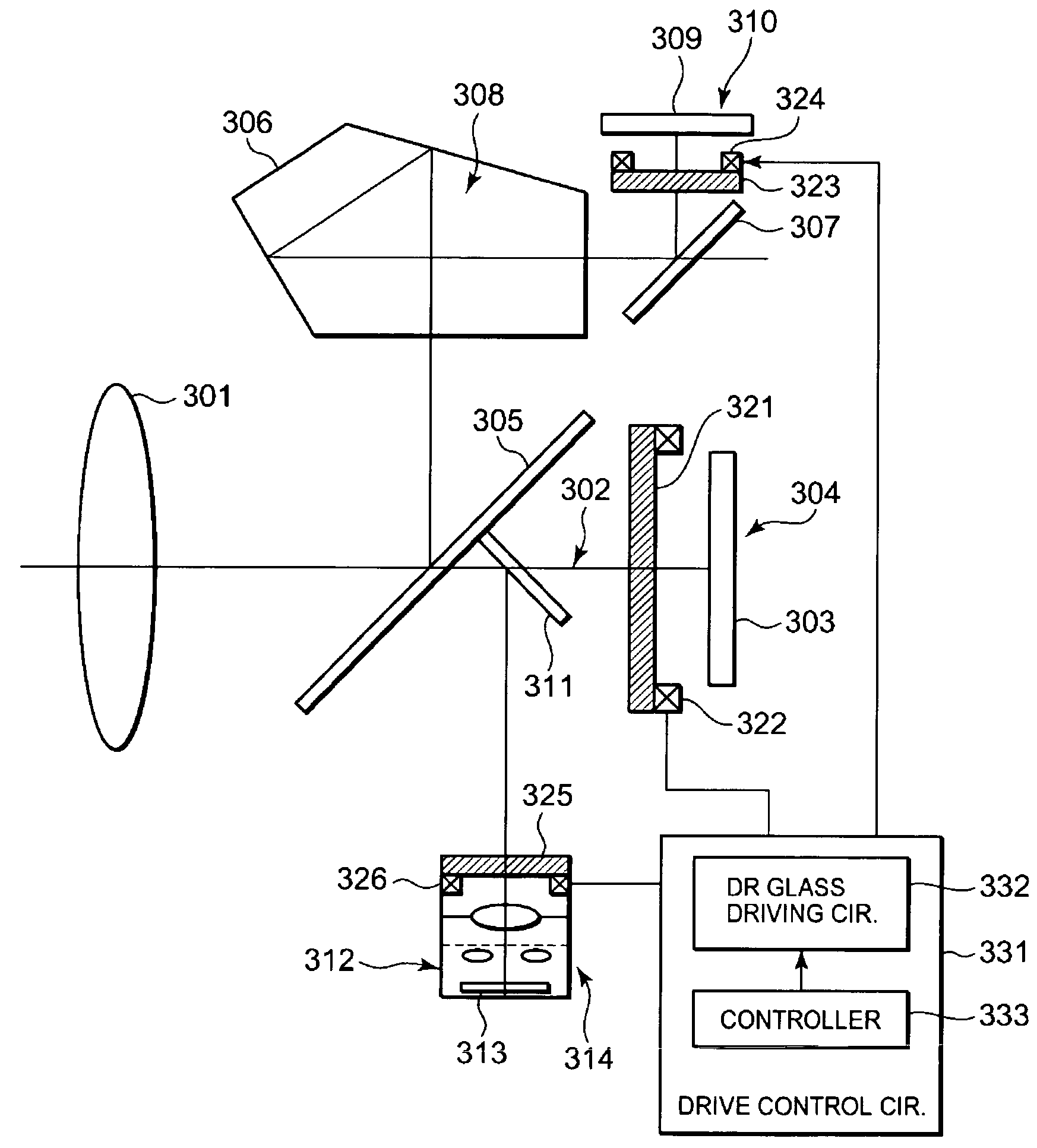

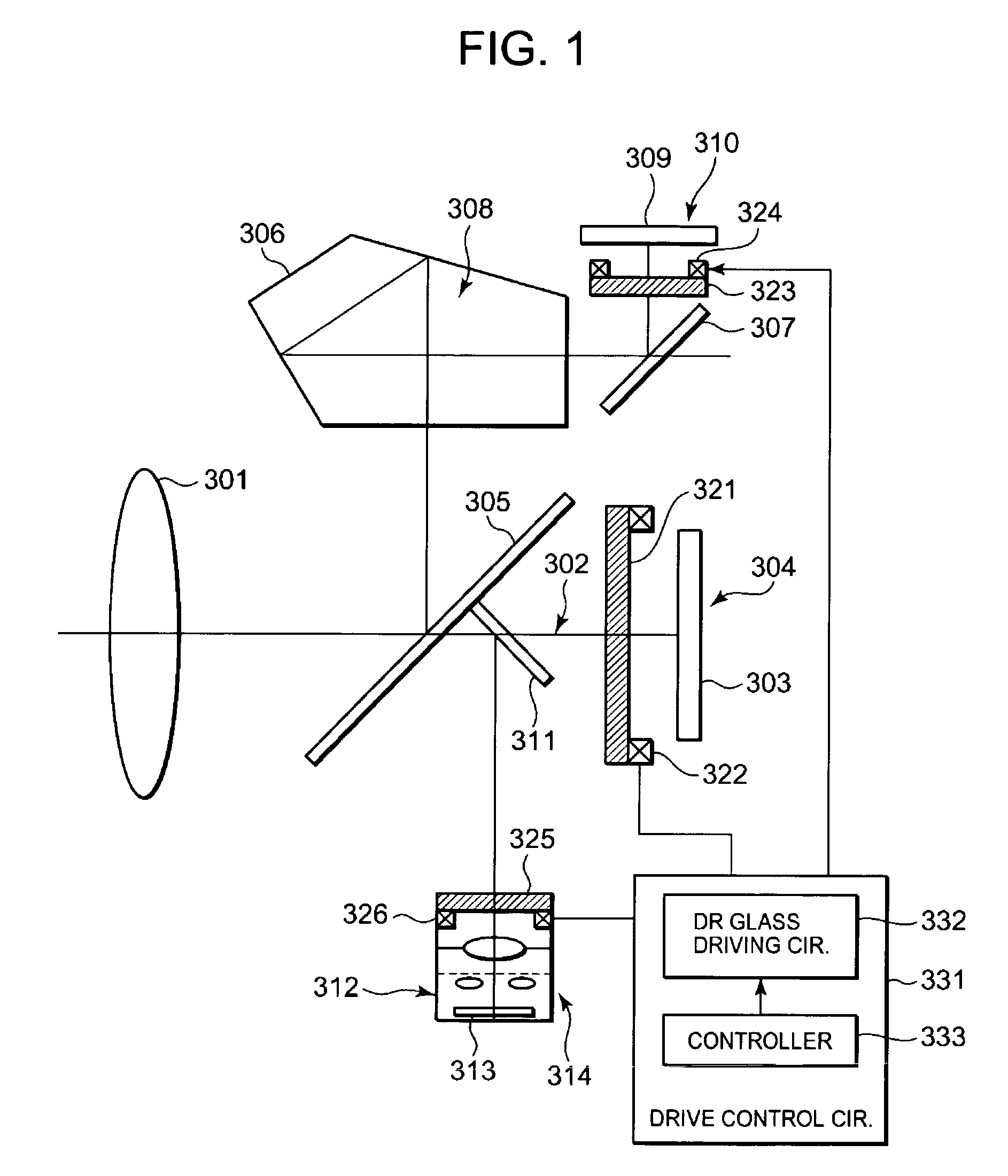

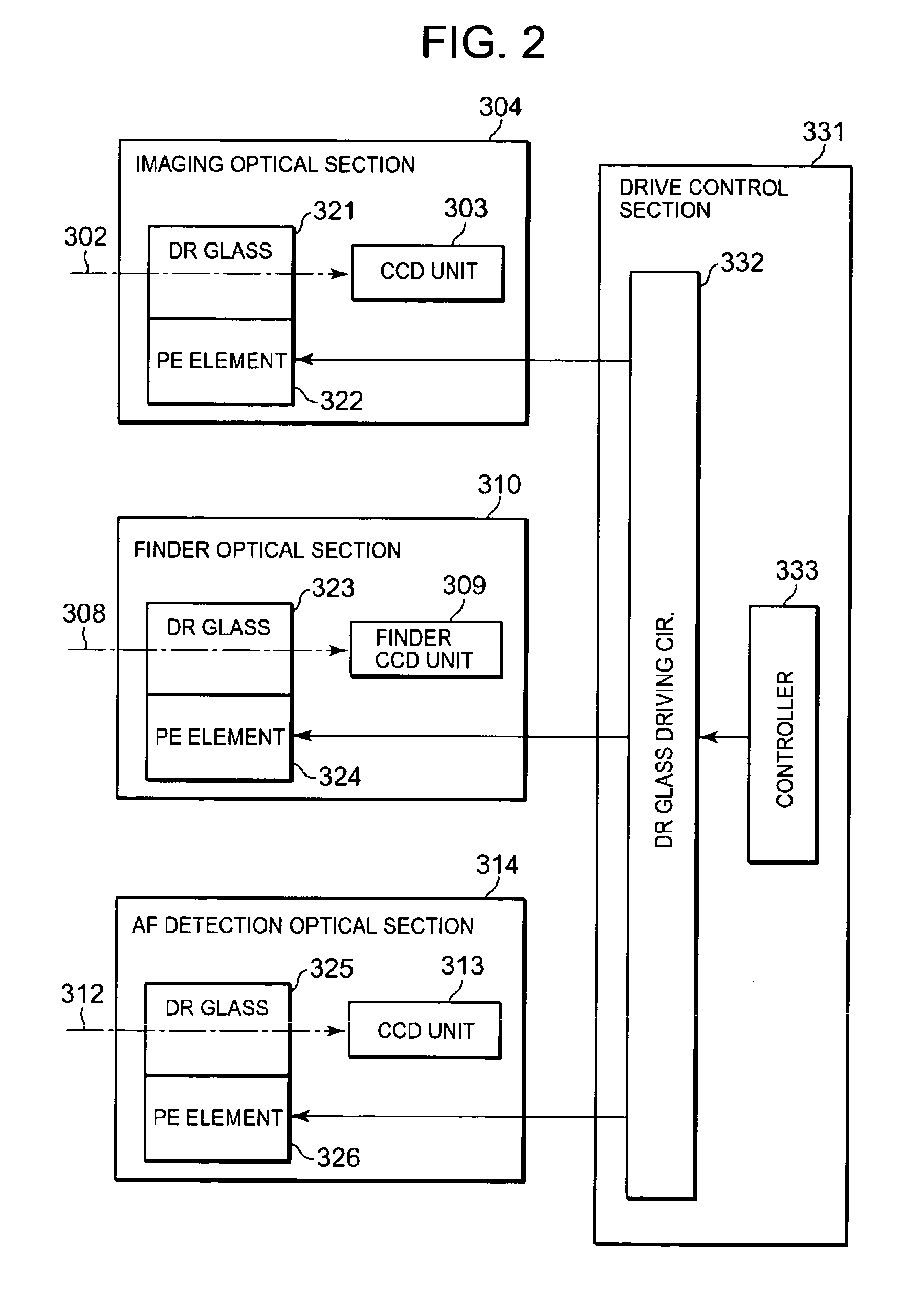

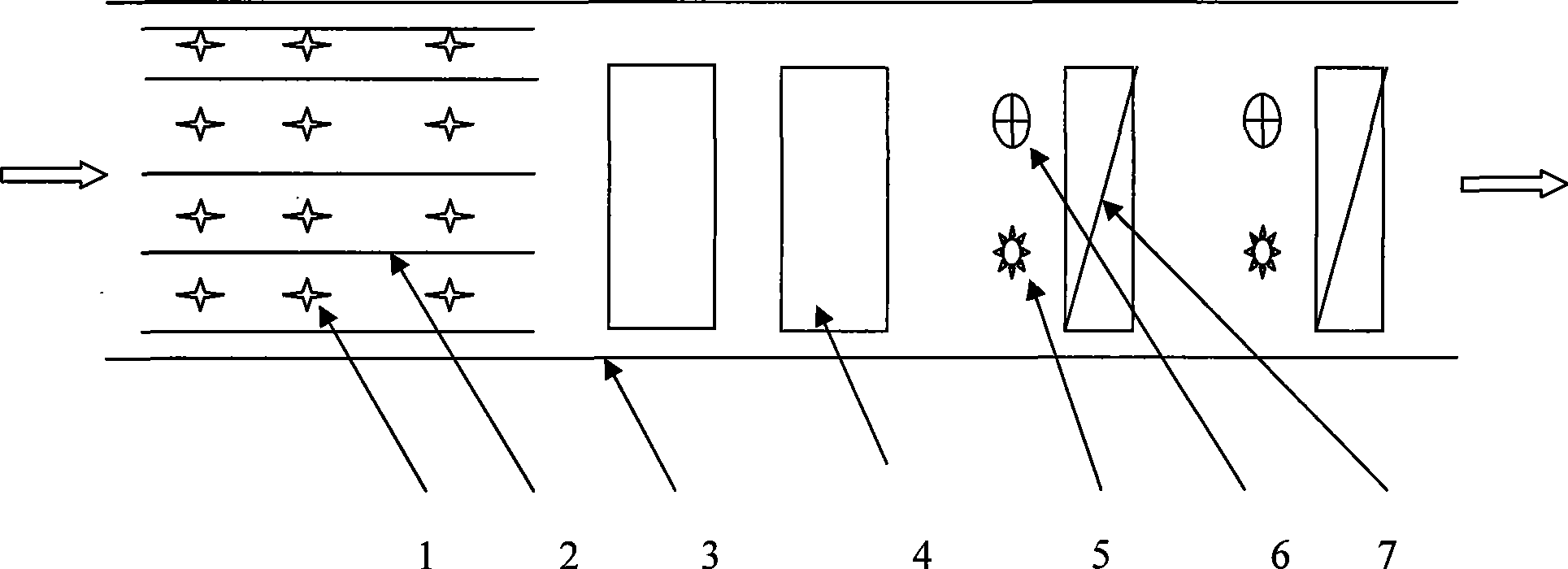

Optical apparatus with dust reduction capability

InactiveUS20060207290A1Low costSave energy consumptionTelevision system detailsCharging furnaceResonanceVoltage

The present invention realizes efficient dust removal in an optical apparatus in such a manner that a single circuit drives a plurality of dust reduction optical elements to vibrate. When the optical elements have different resonance frequencies, it can be configured such that the vibration exciting frequency can be changed in a range including the resonance frequencies of all the optical elements. In this case, the optical element driven can also be switched according to the change in frequency so that only the optical element having a resonance frequency close to the driving frequency will be driven. Alternatively, it can be configured such that the driving time or applied voltage can be changed according to the characteristics of the optical element driven.

Owner:OLYMPUS CORP

Optical apparatus with dust reduction capability

InactiveUS7580628B2Save energy consumptionAchieve dust removalCharging furnaceTelevision system detailsResonanceEngineering

The present invention realizes efficient dust removal in an optical apparatus in such a manner that a single circuit drives a plurality of dust reduction optical elements to vibrate. When the optical elements have different resonance frequencies, it can be configured such that the vibration exciting frequency can be changed in a range including the resonance frequencies of all the optical elements. In this case, the optical element driven can also be switched according to the change in frequency so that only the optical element having a resonance frequency close to the driving frequency will be driven. Alternatively, it can be configured such that the driving time or applied voltage can be changed according to the characteristics of the optical element driven.

Owner:OLYMPUS CORP

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

Cloth negative pressure finishing singeing device

InactiveCN107217436AAvoid cloggingSingeing orderlyMechanical cleaningPressure cleaningFiberEngineering

The invention relates to a cloth negative pressure finishing singeing device, which comprises a frame, a cloth guide roller, a carding assembly and a negative pressure hair removal assembly. During the rotation, the fibers attached to the surface of the cloth are erected, adsorbed and pulled; there is a fluff shaping space between the negative pressure hair removal component and the cloth. And the adsorption holes and the deflectors and heating wires respectively arranged on both sides of the removal pores, the airflow flows along the hair removal chamber and is guided by the deflectors to form an airflow acceleration zone, and a negative pressure zone is formed between the deflectors and the adsorption holes; The carding component erects the fiber and shapes it, and then pulls the fiber with the adsorption force to contact the heating wire to realize singeing. At the same time, the broken fiber is collected by the airflow conduction separation component, which solves the problems existing in the prior art. Poor singeing effect and inconvenient dust removal technical problems.

Owner:长兴天赫纺织科技有限公司

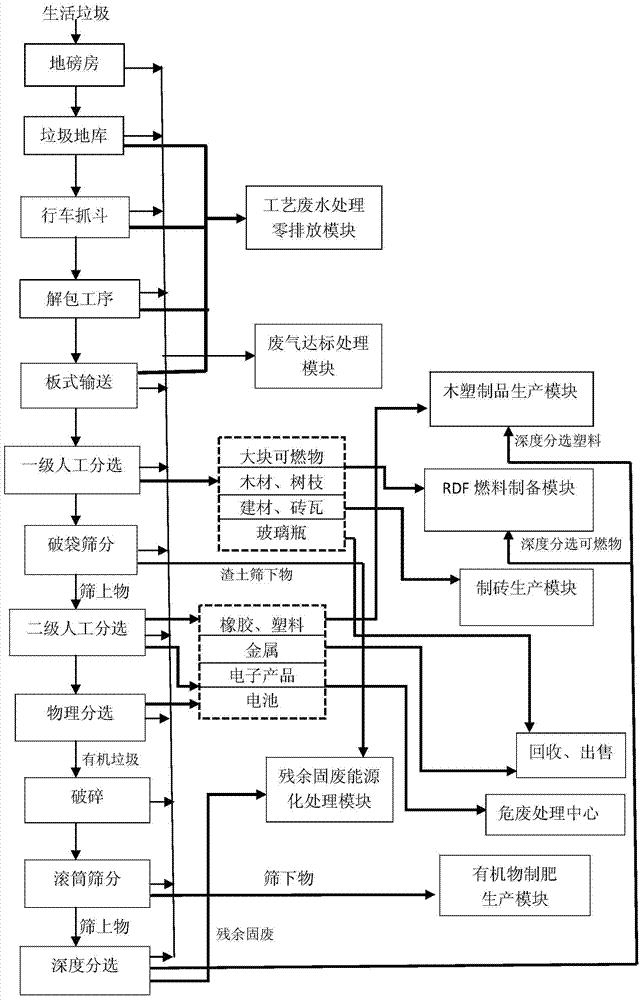

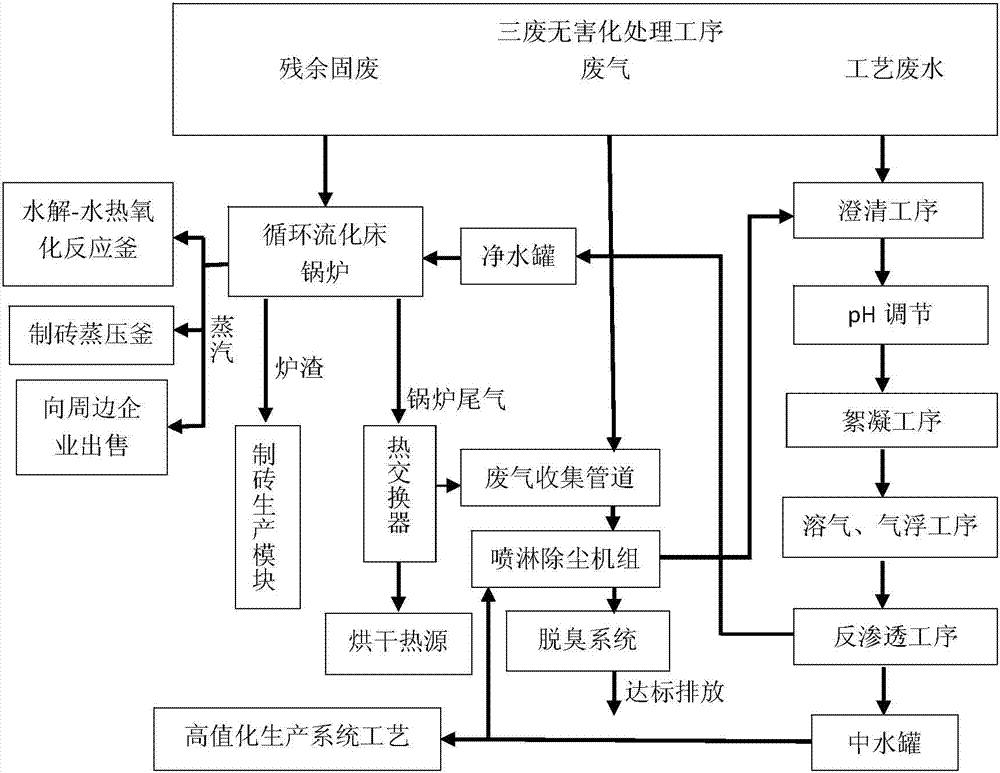

Household garbage complete recycling harmless comprehensive processing method

ActiveCN103934253AMeet application requirementsAchieving zero emissionsSolid waste disposalFurniture waste recoveryBrickWastewater

The invention discloses a household garbage complete recycling harmless comprehensive processing method. During the household garbage processing process, the technology is divided into three technology processes, namely a fine sorting process, a high value regenerating and utilizing process, and a three wastes harmless disposal process; the first step is a multi-grade fine sorting process: the household garbage is divided into five recyclable categories: inorganic substance, waste metal and glass, kitchen garbage, plastics, and combustible garbage; the second step is a high value regenerating and utilizing process: established are four regeneration production modules namely a brick manufacturing module, a module for converting organic substances into fertilizer, a wood and plastic product production module, and a garbage derivated fuel RDF production module, the household garbage is completely converted into a series of technical products such as novel fertilizer, energy, materials, and the like; the third step is a three wastes harmless disposal process: a module for converting residual solid wastes into energy, a module for processing technology wastewater without discharging, and a module that can make the waste gas reach the discharge standard, are established to achieve the goal that household garbage is completely converted into resources and harmlessly disposed. The method can harmlessly reduce the garbage weight and convert the garbage into resources.

Owner:SHENZHEN XUJING LIBO ENVIRONMENTAL PROTECTION TECH

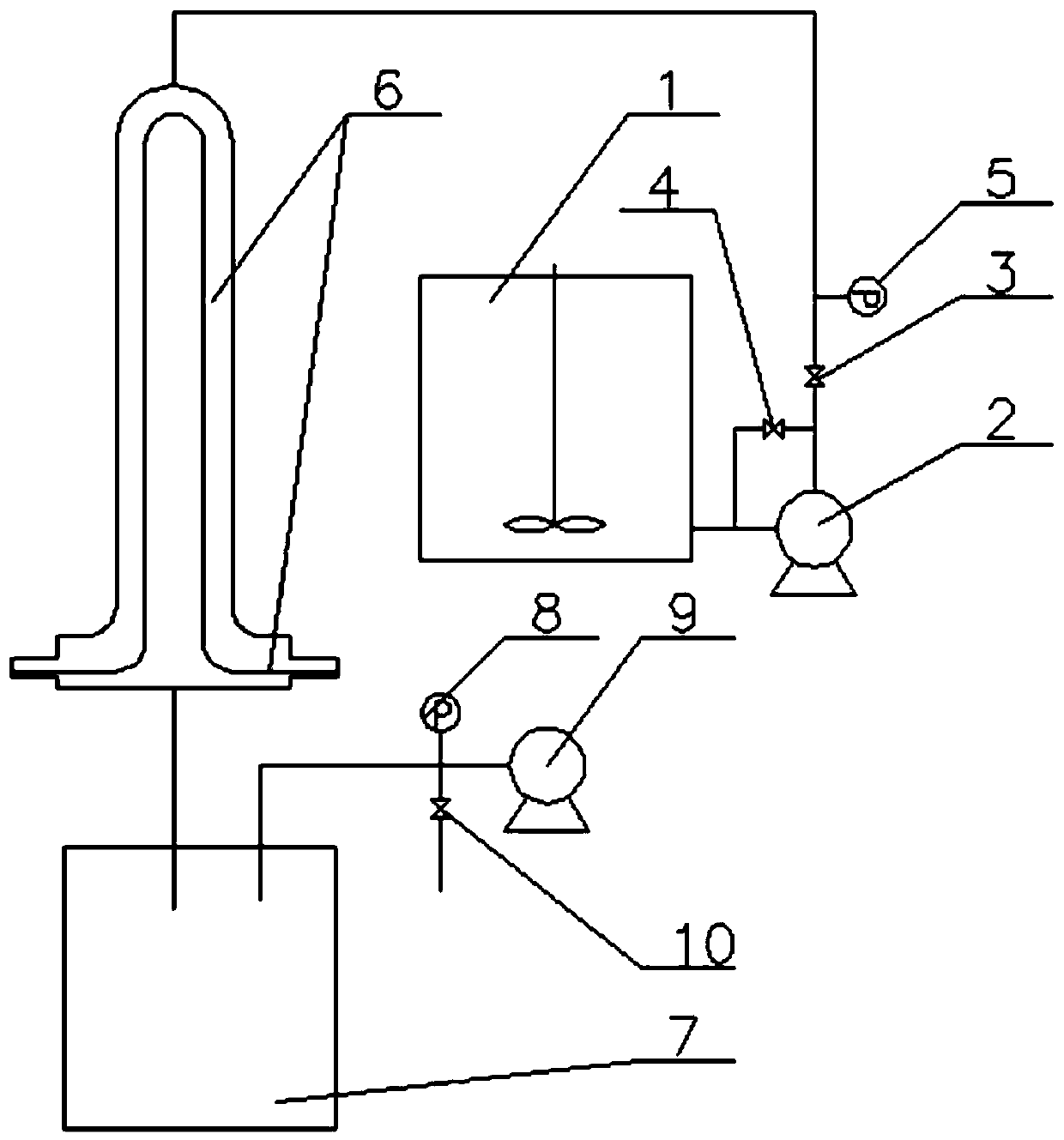

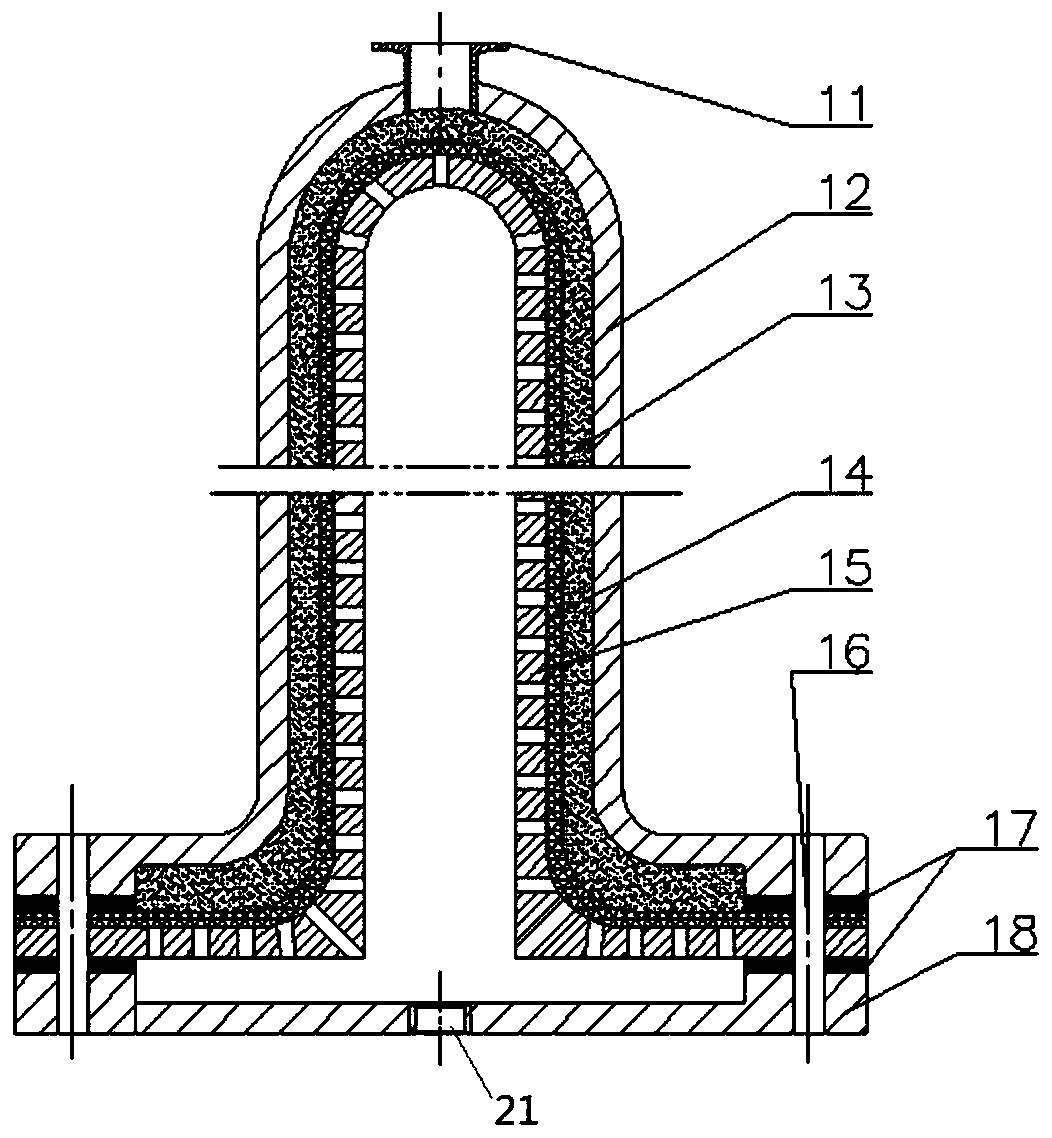

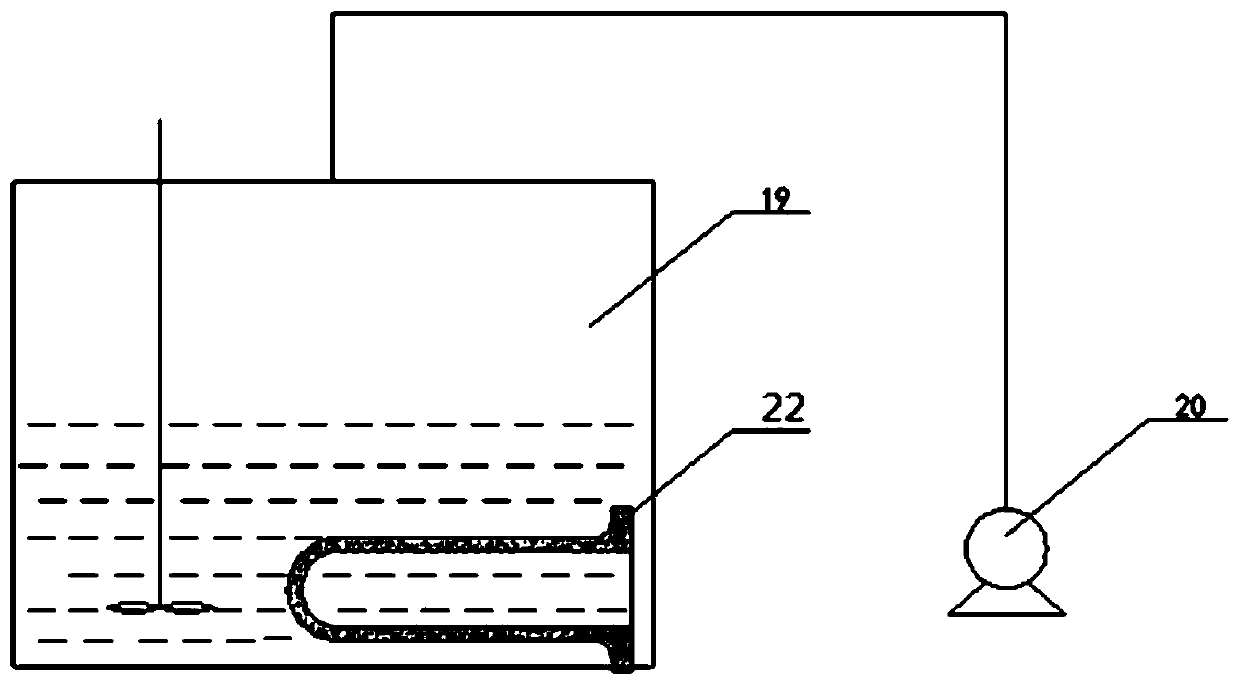

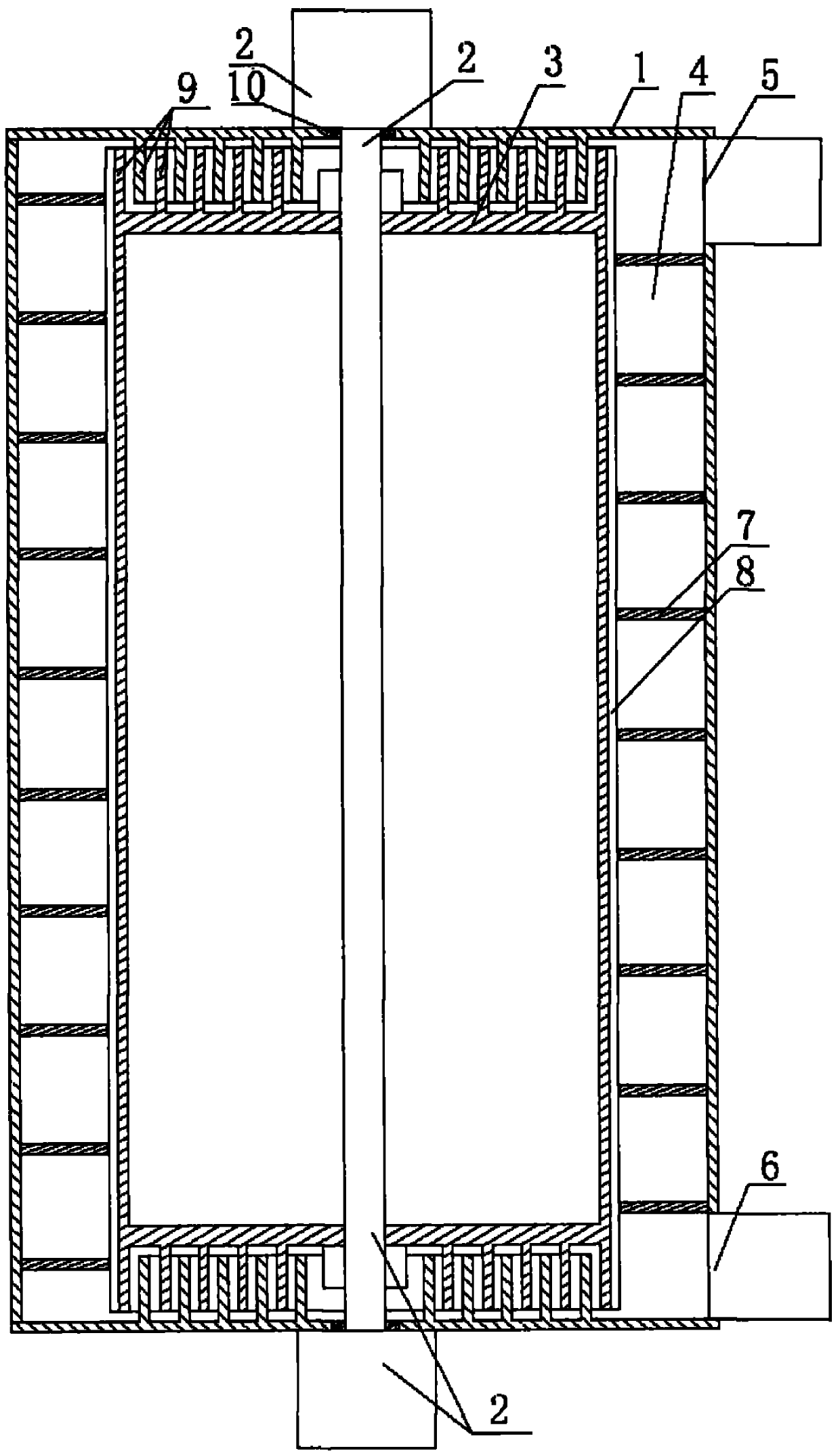

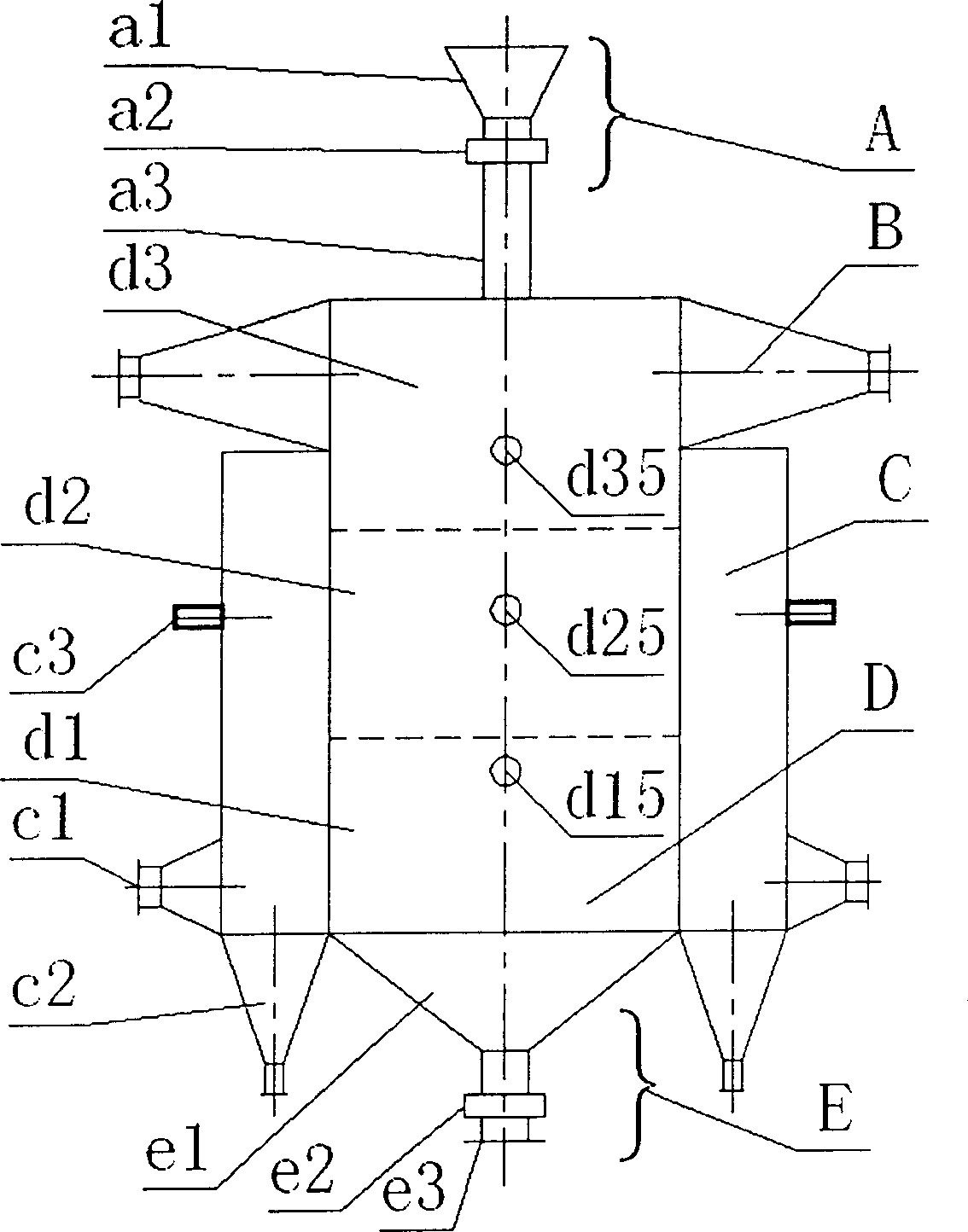

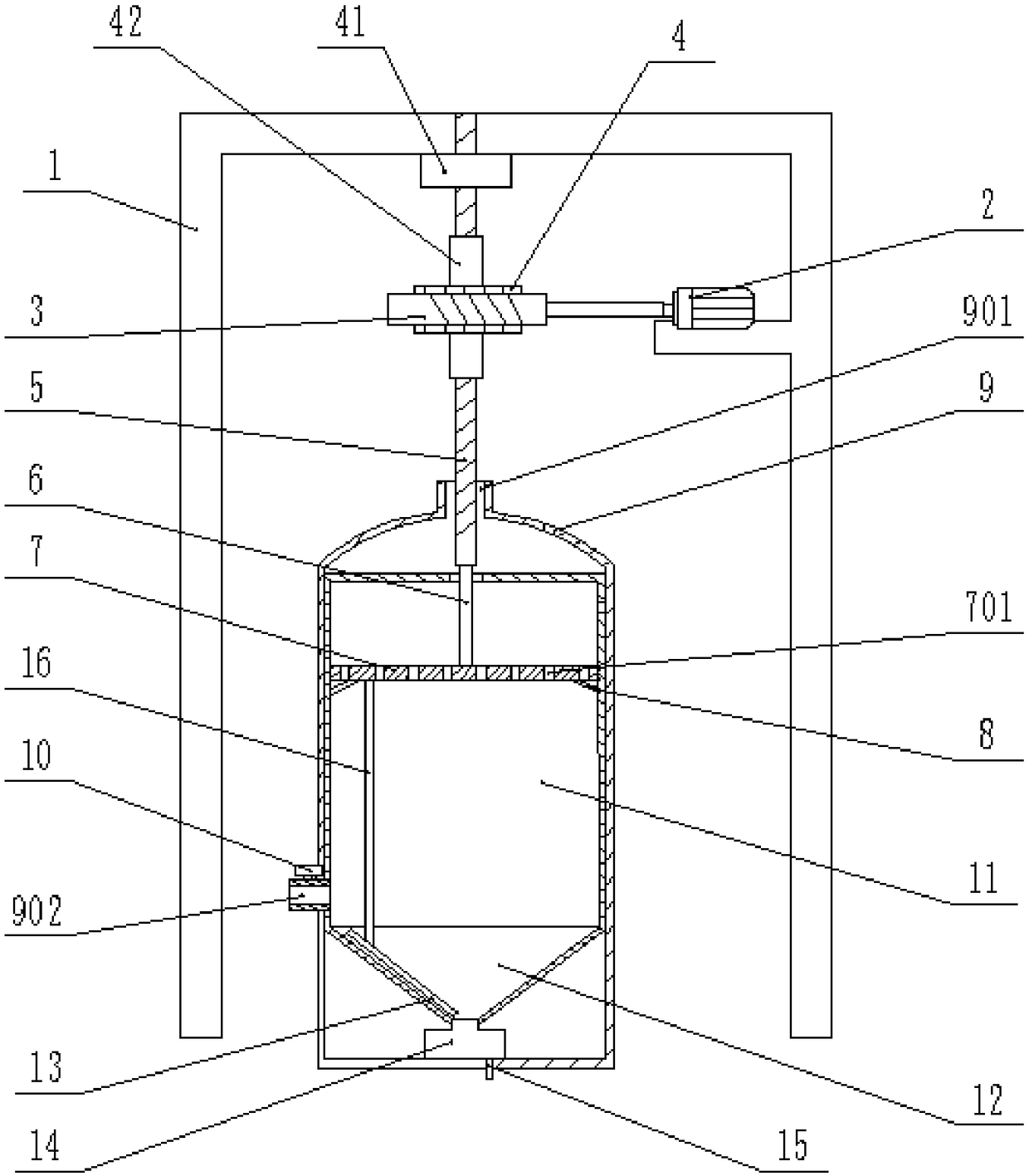

Ceramic fiber filtering tube, preparation method and pressurization and suction forming device

ActiveCN110038368AHigh strengthUniform densityDispersed particle filtrationMembrane filtersFiberVacuum pressure

The invention discloses a ceramic fiber filtering tube, a preparation method and a pressurization and suction forming device. The pressurization and suction forming device comprises a forming mold, apressurization pump, a dosage bunker, a vacuum pump and a vacuum filtrate tank, wherein the forming mold comprises an inner template, an upper template, a lower template, filter cloth and a blank tubecavity; the filter cloth and the blank tube cavity are arranged between the inner template and the upper template respectively; the filter cloth is arranged on the inner template; the lower templateis connected with the upper template; the upper and lower flange faces of the inner template are provided with sealing gaskets respectively; the top of the upper template is provided with a quick coupler for charging water or slurry; the quick coupler is connected with the pressurization pump; the pressurization pump is connected with the dosage bunker; the middle part of the lower template is provided with a water outlet for discharging water or slurry; the water outlet is connected with the vacuum filtrate tank; the vacuum filtrate tank is connected with the vacuum pump; a vacuum pressure gauge and a blow-off valve are arranged between the vacuum filtrate tank and the vacuum pump. The pressurization and suction forming device adopts a pressurization forming and suction sizing demolding form, is simple in structure, is convenient for forming, and is convenient to operate.

Owner:HEFEI HEYI ENVIRONMENTAL PROTECTION TECH ENG

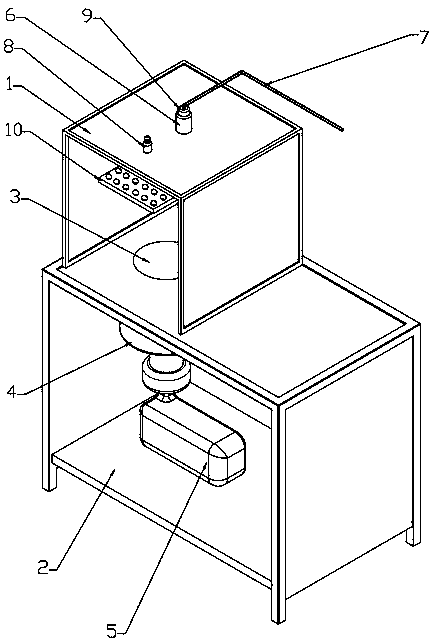

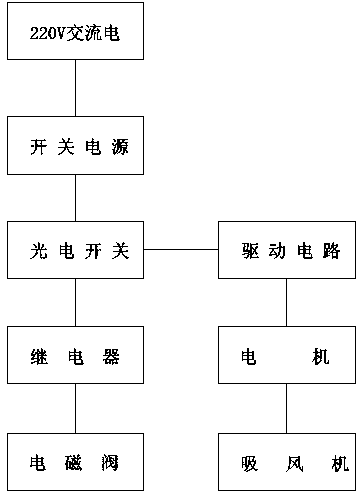

Dedusting device for intelligent electric meter

InactiveCN103551338AExquisite structureEasy to useDirt cleaningCleaning using gasesElectric machineryEngineering

A dedusting device for an intelligent electric meter comprises an upper box body and a lower box body, wherein the side of the upper box body and the side of the lower box body are provided with box covers. The bottom surface of the upper box body and the upper surface of the lower box body are fixed to be a whole and provided with a through opening. The lower box body is internally provided with a motor, a suction fan and a recycling bag, the upper end of the suction fan is communicated with the opening, the lower end of the suction fan is connected with the recycling bag, and the motor is connected with the suction fan through a wire. The upper box body is internally provided with a baffle, the baffle is parallel to the upper surface of the upper box body and is provided with a plurality of through holes, a dedusting air gun is arranged on the upper surface of the upper box body, a gun opening of the dedusting air gun penetrates through the upper surface of the upper box body to extend to be above the baffle, and an air inlet of the dedusting air gun is connected with an air inlet pipe. The dedusting device is ingenious in structure and convenient to use, not only guarantees dedusting effect, but also greatly improves dedusting efficiency, and is suitable for a dedusting process of electric meters of various models.

Owner:中电装备山东电子有限公司

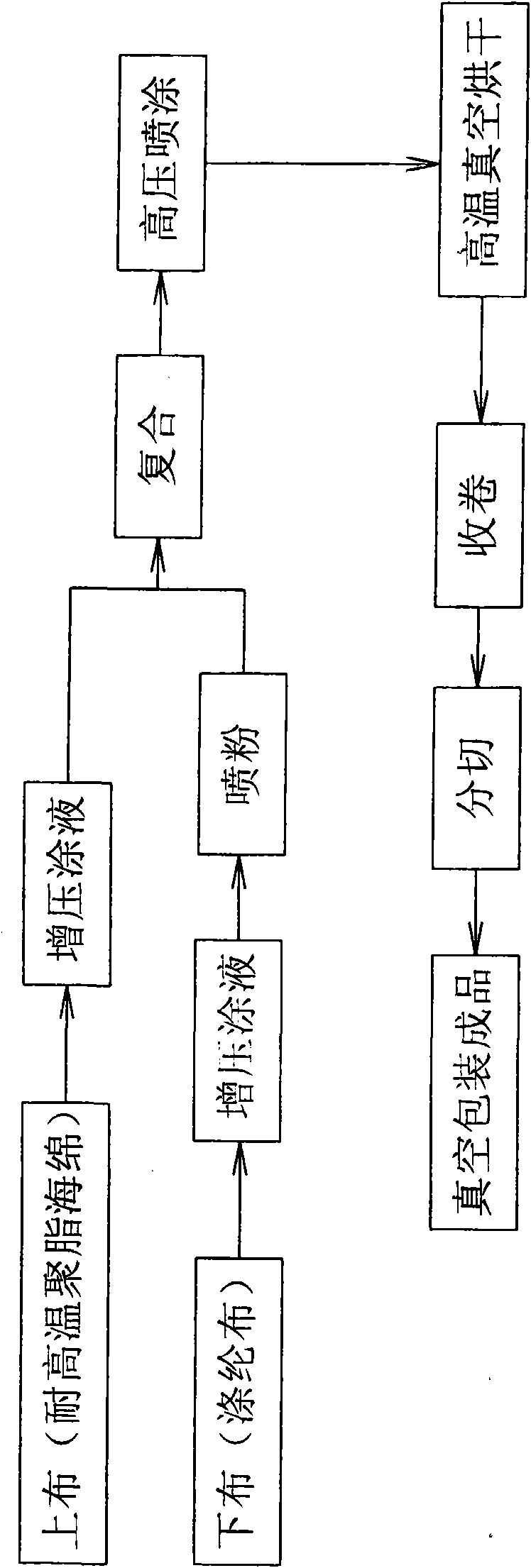

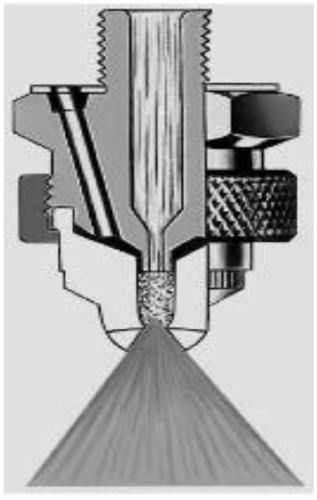

Production method of semi-conductive buffer water-blocking band

ActiveCN101567236AGood surface conductivityReduce surface resistanceFibre treatmentClimate change adaptationPolyesterVacuum pack

The invention relates to a production method of a water-blocking band, in particular to a production method of a semi-conductive buffer water-blocking band. The production method comprises the following steps: firstly, supercharging and soaking a high-temperature resistant polyester sponge and terylene cloth in conductive liquid, spraying high water-absorbent resin on the terylene cloth and compounding the high-temperature resistant polyester sponge and the terylene cloth; then, spraying the conductive liquid with a high-pressure spray gun and drying the high-temperature resistant polyester sponge and the terylene cloth which are compounded in vacuum at a high temperature; and finally, coiling, cutting and packaging the high-temperature resistant polyester sponge and the terylene cloth which are compounded in vacuum to be a finished semi-conductive buffer water-blocking band . Proved by detection, the semi-conductive buffer water-blocking band has the advantages of high intensity, thinness, rapid swelling in water, high water absorption, good water-blocking effect, high-temperature environment influence resistance, small surface resistance, low volume electric resistivity, European Union environmental protection accordance, and the like, can satisfy the water blocking and the electric field shielding among parts of power cables, and the like, maintains the safe use of the cables, can generate the semi-conductive shielding action so as to buffer an electric field, can be lined at the inner side of a metal protective sleeve to buffer the friction between the inner protective sleeve and the metal protective sleeve and can satisfy the normal working temperature of the cables.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

Circulator

InactiveCN103216450AWonder Material PropertiesAchieve separationCircumferential flow pumpsPump componentsDust controlEngineering

The invention relates to a circulator. The circulator comprises a shell body and a transmission device, wherein the transmission device is mounted on the shell body, a rotary wheel is mounted on the transmission device, a plurality of vanes are arranged on the periphery of the rotary wheel, the rotary wheel is arranged in the shell body, a circulation cavity is formed in the inner wall of the shell body at the periphery of the rotary wheel, a circulation cavity port A is formed in one end of the circulation cavity, a circulation cavity port B is formed in the other end of the circulation cavity, and an isolating body is arranged on the inner wall of the shell body between the circulation cavity port A and the circulation cavity port B. According to the circulator provided by the invention, circular motion and fluid motion are used sufficiently; torsion is better converted into pressure through fluid; pressure is better converted into torsion through the fluid; and the fluid separation is realized by using vortex. The circulator provided by the invention can serve as a water pump, a slurry pump, a sewage pump, a blower, a compressor, spray equipment, a reactor, a steam turbine, vacuum equipment or a separator and be applied to wastewater treatment, seawater desalination, marine chemical engineering, mineral processing, waste disposal, hydrogen production, carbon dioxide decomposition, harmful gas decomposition, air purification, dedusting, dust absorption, refrigeration, oxygen production, oil refining and the like; and the blue sky and water can be completely realized, and foamed materials can be produced so as to bring a material revolution.

Owner:陈久斌

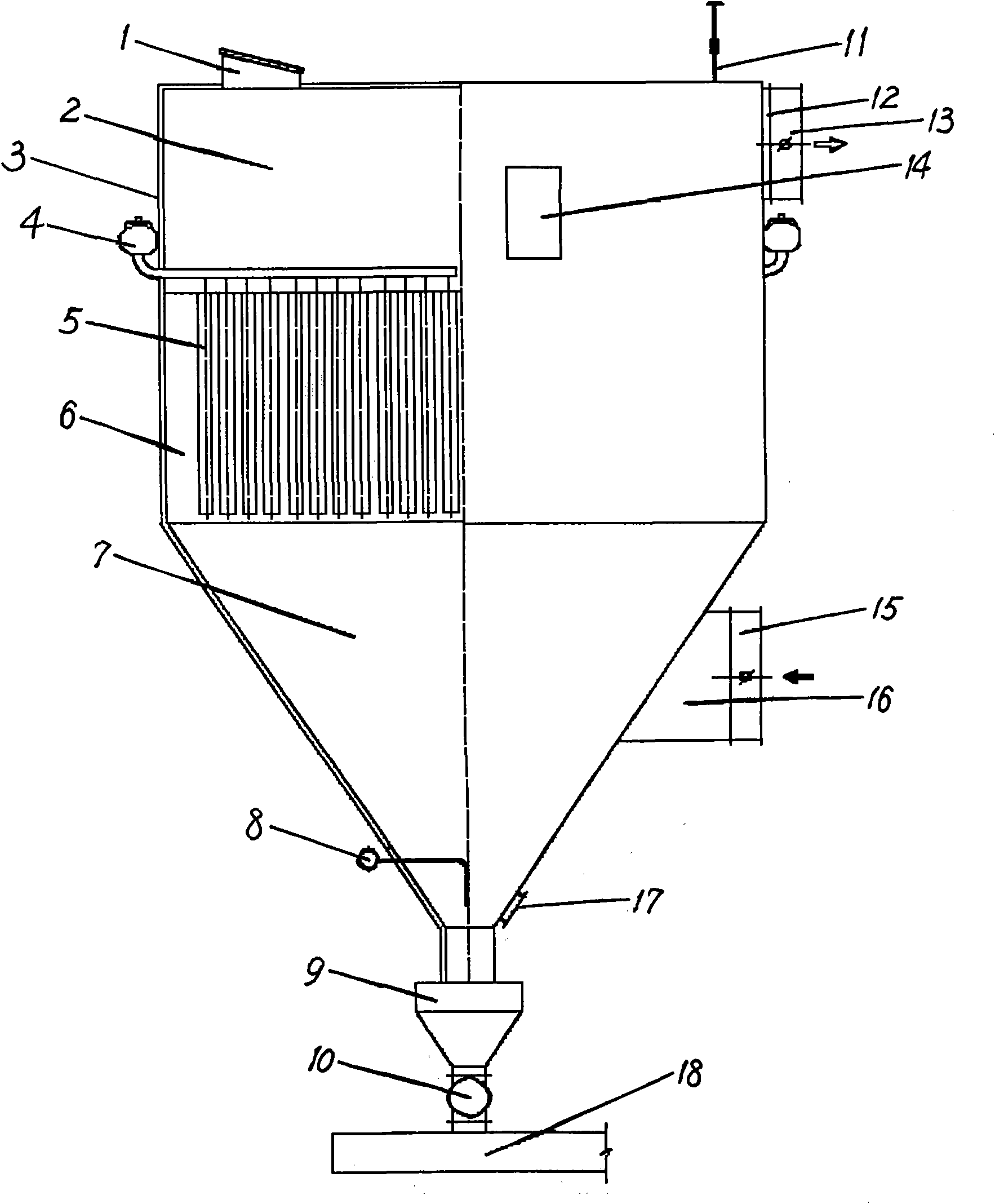

High temperature resistant dust collector

InactiveCN101559307AImprove dust removal efficiencyReduce energy consumptionHuman health protectionDispersed particle filtrationMetal fibersEngineering

The invention relates to a high temperature resistant dust collector, which comprises a heat insulation shell, a dust hopper, a pulse blowing device, a metal filter cartridge, a filter chamber, a purified gas outlet, a dust containing gas inlet and a dust conveying device. The dust hopper is connected to the bottom of a tank body of the filter chamber; one side of the dust hopper is provided with the dust containing gas inlet which is communicated with the filter chamber; one side of the top of the heat insulation shell is provided with the purified gas outlet which is communicated with a clean chamber; the metal filter cartridge is arranged in the filter chamber, and is made of a high temperature resistant metal material; a nozzle of a blowing pipe in the pulse blowing device aligns to the metal filter cartridge; and the dust conveying device is connected to the lower part of the dust hopper. The filter material of the high temperature resistant dust collector is special metal fiber, and can be applied to a flue-gas at 300 to 1,000 DEG C to replace multiple cooling devices such as a water-cooling flue, an air cooler and the like in a dust removing system; and the high temperature resistant dust collector has high collection efficiency, low energy consumption, and safe and stable operation of the system, and realizes the dust removing of high temperature flue gas of equipment such as electric stoves, oxygen argon decarbonization converters and the like.

Owner:BAOSTEEL ENG & TECH GRP

Feedstock scattering device for coir mattress

The invention belongs to the technical field of pretreatment of fiber materials and discloses a feedstock scattering device for a coir mattress. The feedstock scattering device comprises a scattering box and a power case, wherein a hollow scattering ball is arranged in the scattering box, a plurality of scattering holes are uniformly distributed in the sidewall of the scattering ball, the scattering ball communicates with a ventilating pipe, and the ventilating pipe penetrates through the scattering box and communicates with the power case; the power case contains water, a water surface is located below a communicating position of the ventilating pipe and the power case, a piston is arranged in the power case, and a piston rod is arranged at the upper end of the piston; a control device is arranged at the upper end of the piston rod and can drive the piston rod to slide up and down, and the piston rod can stay static during the switching of upward sliding and downward sliding. According to the feedstock scattering device for the coir mattress, the technical problem in the prior art that the feedstock scattering effect is poor during the manufacturing of the coir mattress is solved.

Owner:重庆市永川区植成家俱厂

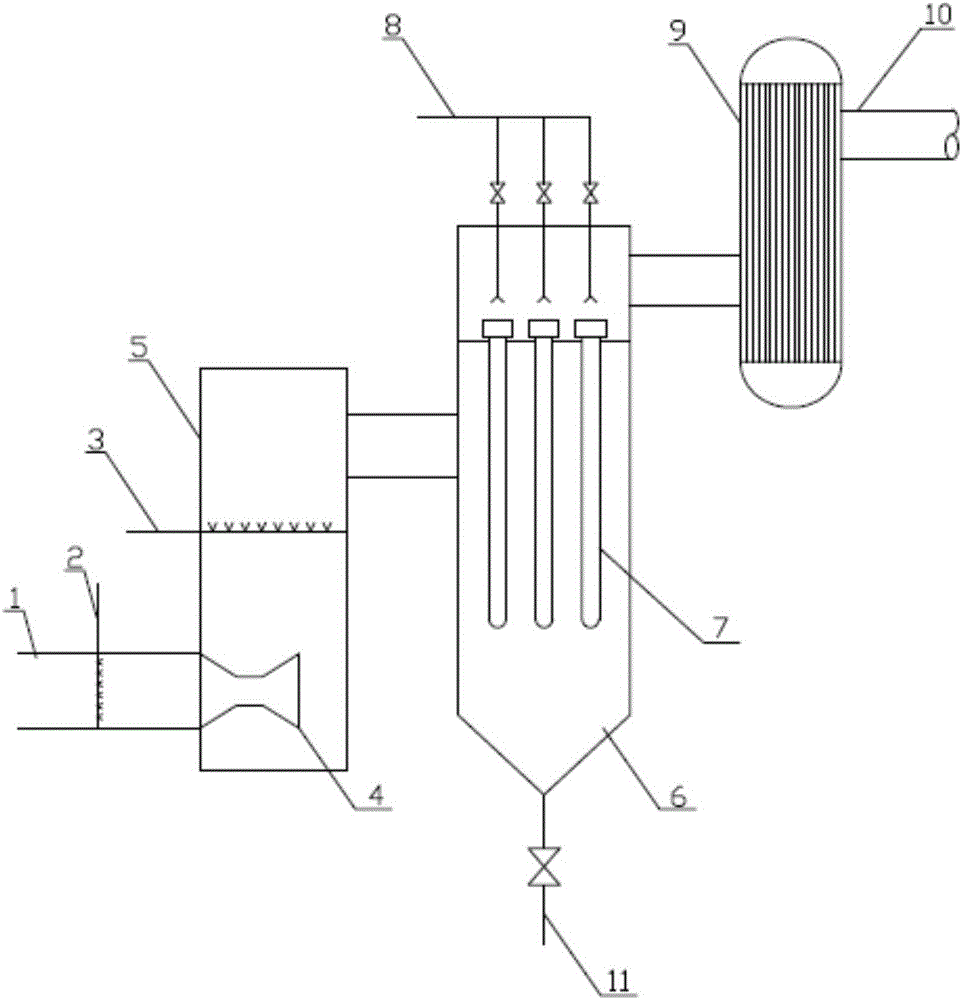

Desulphurization, denitration and dust removal integrated treatment process of exhaust gas

InactiveCN105664717AAchieve desulfurizationAchieve dust removalGas treatmentDispersed particle filtrationOperational costsFlue gas

The invention relates to a desulphurization, denitration and dust removal integrated treatment process of exhaust gas. The treatment process comprises the following steps: introducing the flue gas into an integrated catalytic agent ceramic filter drum device at an appropriate temperature section, wherein the integrated catalytic agent ceramic filter drum device is provided with a back flushing ash removal device; injecting a desulphurization agent and a denitration agent before the exhaust gas enters the integrated catalytic agent ceramic filter drum device; arranging a flue gas mixing device in front of the integrated catalytic agent ceramic filter drum device; and introducing the treated flue gas reaching the standard into an energy recycling system to recycle the heat by virtue of a pressurizing fan, and finally discharging the flue gas into a chimney, wherein the appropriate temperature section is 280 to 420 DEG C. The process has the advantages of stable and reliable system, small maintenance workload, long product service life, low device operation cost and small device occupation area; and the flue gas flowing into a waste heat boiler is clean gas, so that the heat exchanging efficiency of the energy recycling device is greatly improved, the service life of the energy recycling device is greatly prolonged, and the economic benefit is vast.

Owner:NANJING CEEP TECH

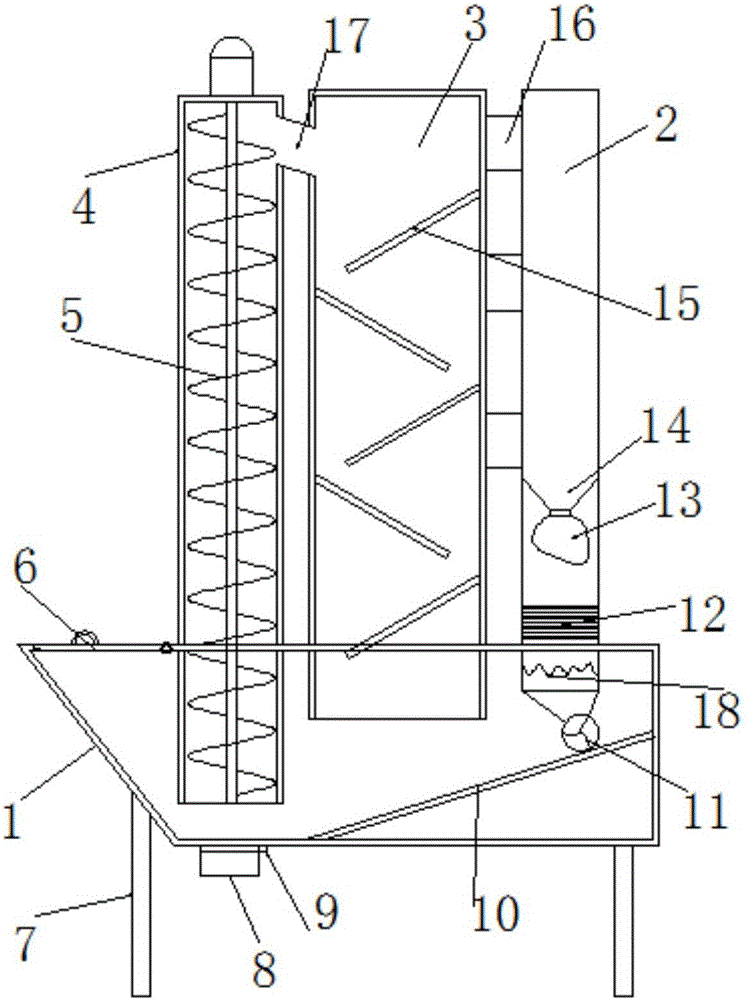

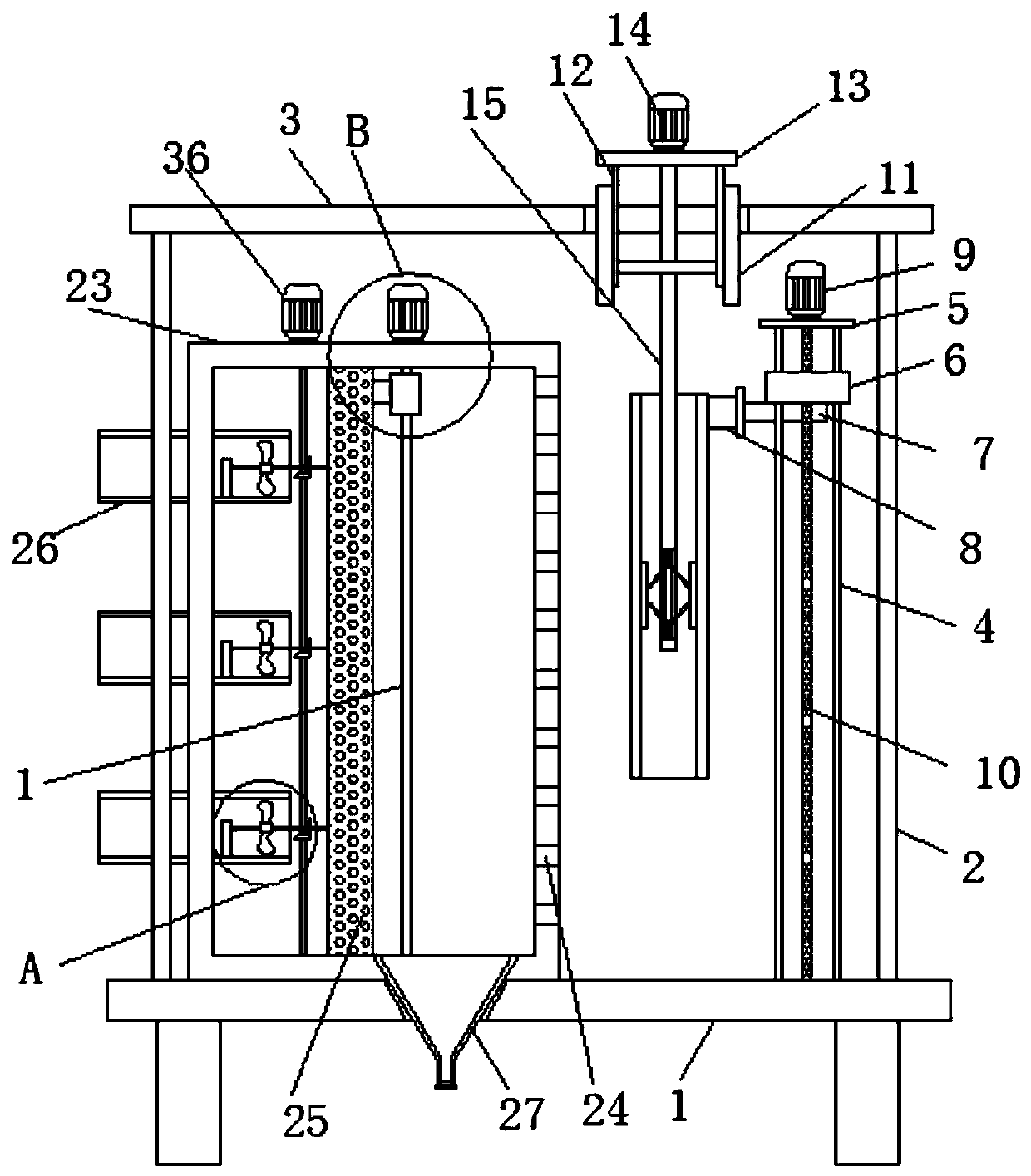

Environment-friendly and energy-saving type cereal drying, cooling and dust removing device

ActiveCN106403566AAchieve dryingAchieve dust removalFood processingDrying gas arrangementsEngineering

The invention discloses an environment-friendly and energy-saving type cereal drying, cooling and dust removing device. The environment-friendly and energy-saving type cereal drying, cooling and dust removing device comprises a box, a purifying barrel and a raise dust barrel. Landing legs are arranged on the two sides of the lower end of the box. A feeding barrel is arranged at the upper left end of the box and internally provided with a feeding packing auger. The lower end of the feeding barrel stretches into the box. The left end face of the box is an oblique face. An oblique material guiding plate with the low left part and the high right part is arranged in the part, on the right side of the feeding barrel, of the box. Through the arrangement of the oblique face and the oblique material guiding plate, materials are conveniently gathered to the position below the feeding barrel. A charging port and a charging cover plate located at the position of the charging port are arranged on the upper end face of the part, on the left side of the feeding barrel, of the box. The raise dust barrel is arranged at the upper end of the part, on the right side of the feeding barrel, of the box. The lower end of the raise dust barrel communicates with the box. A material guiding pipe is arranged between the upper end of the raise dust barrel and the feeding barrel. The left end of the material guiding pipe is higher than the right end of the material guiding pipe. A plurality of oblique raise dust plates are arranged in the raise dust barrel in a crossed manner. The environment-friendly and energy-saving type cereal drying, cooling and dust removing device is simple and reasonable in structure, energy saving and emission reduction are achieved, people can conduct drying and dust removal on cereal conveniently, and practicability is high.

Owner:绍兴上虞国风风机制造有限公司

Wet type sand-blasting machine

ActiveCN106272090AImprove blast cleaning resultsImprove injection efficiencyBlast gunsAbrasive machine appurtenancesSand blastingEnergy conservation

The invention discloses a wet type sand-blasting machine. The wet type sand-blasting machine comprises a feeding device and a sand-blasting machine body, wherein a cleaning chamber is arranged in the sand-blasting machine body; a carrier for a workpiece to be cleaned and a plurality of sand-blasting spray guns for cleaning the workpiece to be cleaned are arranged in the cleaning chamber; a grinding fluid pump conveys grinding fluid in a grinding fluid storage tank to the sand-blasting spray guns through a grinding fluid conveying pipe; and the plurality of sand-blasting spray guns are arranged on a spray gun oscillating mechanism. The wet type sand-blasting machine also comprises a water cleaning device, wherein the water cleaning device comprises a sedimentation water tank; the sedimentation water tank and the grinding fluid storage tank are separated by one, two or more filter screens, so that the grinding fluid can be filtered to obtain clean washing water and the clean washing water is stored in the sedimentation water tank; and a washer pump conveys the washing water to a washing spray gun through a washing water conveying pipe to wash the workpiece and the cleaning chamber. The wet type sand-blasting machine has the characteristics that the production cost is low; the surface of the workpiece is processed perfectly; the dust-removing effect is good; and energy conservation and emission reduction are realized.

Owner:永红保定铸造机械有限公司

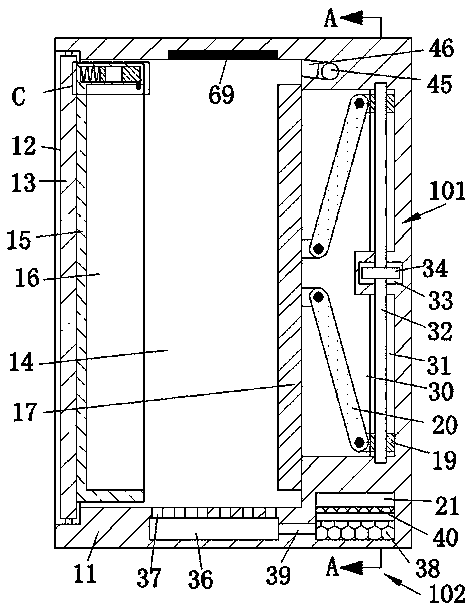

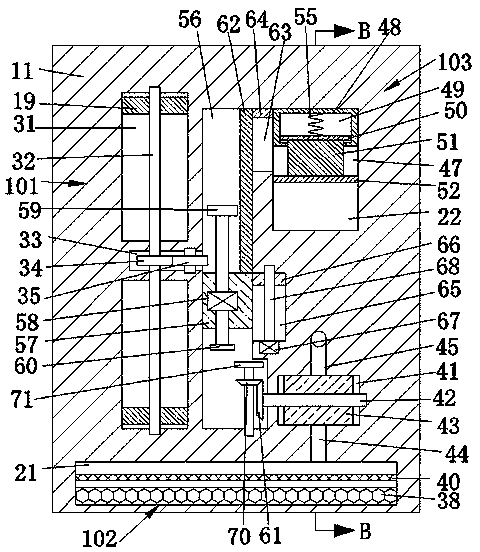

Fireproof and moistureproof distribution box

InactiveCN110970819AAvoid harm and lossReduce lossesProtective switch detailsSubstation/switching arrangement cooling/ventilationEngineeringDust control

The invention discloses a fireproof and moistureproof distribution box. The box comprises a box body, and an opening and closing cavity is formed in the left end surface of the box body; a turnover door is arranged in the opening and closing cavity in a turnover manner; the right wall of the opening and closing cavity is communicated with a power distribution cavity; a sealing plate located in thepower distribution cavity is fixedly arranged on the right end face of the turnover door; a fire extinguishing cavity with a rightward opening is formed in the sealing plate; the right side in the power distribution cavity is provided with a power distribution board used for installing an electric appliance and a line; the size of the distribution board is matched with that of the fire extinguishing cavity. According to the invention, the air circulation is carried out in the power distribution cavity, so the internal moisture prevention and dust removal are realized; meanwhile, when a fire occurs, a line can be cut off rapidly, and an electric appliance can be moved into the fire extinguishing cavity rapidly to be sealed, so the fire extinguishing is achieved due to rapid consumption ofoxygen in the fire extinguishing cavity; meanwhile, dry powder is scattered on the electric appliance to extinguish fire. The line can be cut off at the first time, so more serious harm and loss are avoided, and the electric appliance can be extinguished rapidly, and loss is reduced.

Owner:宁波奉化平西配电科技有限公司

Device and method for producing high-purity ultrafine spherical silicon micro-powder by means of gas heating

The invention discloses a device for producing high-purity ultrafine spherical silicon micro-powder by means of gas heating. The device comprises a micro-powder stock bin, an atomization device, a high-temperature melting furnace, a gathering cooling bin, a finished product bin and a dust removing system, wherein the atomization device comprises an atomizer and a compressed air channel; a discharge hole of the micro-powder stock bin is connected with the atomizer by means of a conduit, and the conduit is connected with the compressed air channel; the upper end of the high-temperature melting furnace is provided with the atomizer, and the lower end of the high-temperature melting furnace is connected with the gathering cooling bin; the lower end of the gathering cooling bin is connected with the finished product bin, and the side face of the lower end of the gathering cooling bin is connected with the dust removing system. The device provided by the invention has the beneficial effectsthat the high-temperature melting furnace is used for melting or gasifying fine particles, the molten or gasified particles are then pelletized by means of gathering cooling, and the power is screenedand collected according to the particle sizes, so that the pelletizing, grading and dust-removing of the silicon micro-powder are realized; the gathering cooling bin adopts the design of a sphericalcrown type upper cover, so that the molten micro-powder is naturally cooled so as to shrink into spheres and is easy to collect; real-time adjustment of the particle size is achieved by controlling the air volume of an induced draft fan, the gas flow rate of compressed air, the particle size of the raw material and the feeding amount.

Owner:HUANGGANG NORMAL UNIV

Automobile part machining device

ActiveCN108515461AAchieve grindingAchieve rotationRevolution surface grinding machinesGrinding drivesEngineeringSlide plate

The invention belongs to the technical field of equipment used for grinding or polishing and discloses an automobile part machining device. The device comprises a rack and a mounting base. A grindingsupport and an air cylinder are arranged on the rack. A grinding head is arranged on the grinding support. A cavity is formed in the mounting base and internally provided with a sliding plate. A stripe-shaped hole is formed in the mounting base, and a corrugated plate is arranged in the stripe-shaped hole. A grinding barrel is arranged on the mounting base, a grinding brush is arranged on the inner wall of the grinding barrel, and an outer gear ring is arranged on the outer wall of the grinding barrel. A piston barrel is arranged on one side of the mounting base. A piston is connected into thepiston barrel in a sliding mode. A piston rod is arranged on the piston, and the piston rod and the piston barrel form a threaded pair. A drive gear is arranged on the rack. An air outlet is formed in the upper portion of the piston barrel. The upper portion of the piston barrel communicates with a dedusting hole. The lower portion of the piston barrel communicates with the lower portion of the cavity. By means of the automobile part machining device, the problems that the inner wall and the outer wall of a steel pipe in the prior art need to be ground through two devices, the outer wall canbe ground only after the inner wall is ground, and consequentially, the grinding efficiency is low are solved.

Owner:宁波高新区新柯保汽车科技有限公司

Glass fiber coated filter material with catalytic function and preparation method thereof

InactiveCN109603306AAvoid deactivationTo achieve the purpose of comprehensive prevention and controlDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsGlass fiberReactive site

The invention discloses a glass fiber coated filter material with a catalytic function and a preparation method thereof. The glass fiber coated filter material consists of a glass fiber filter material base material, a glass fiber protective film, a catalyst nano-particle layer and an expanded microporous polytetrafluoroethylene filter film. During application in filtering, dust is firstly blockedby the expanded microporous polytetrafluoroethylene filter film of the glass fiber coated filter material with the catalytic function, so that the active sites on catalyst nano-particles are prevented from being covered with the dust and thus losing activity, the catalytic function of the catalyst is efficient and can last for a long time, and residual harmful gas is decomposed by the catalyst nano-particle layer to achieve the purpose of comprehensive prevention and control of the dust and harmful gas. The integration of dust removal, desulfurization, denitration, dioxin removal, mercury removal and the like is achieved, and the filter material is particularly suitable for industrial production.

Owner:太湖金锦鸿过滤材料有限公司

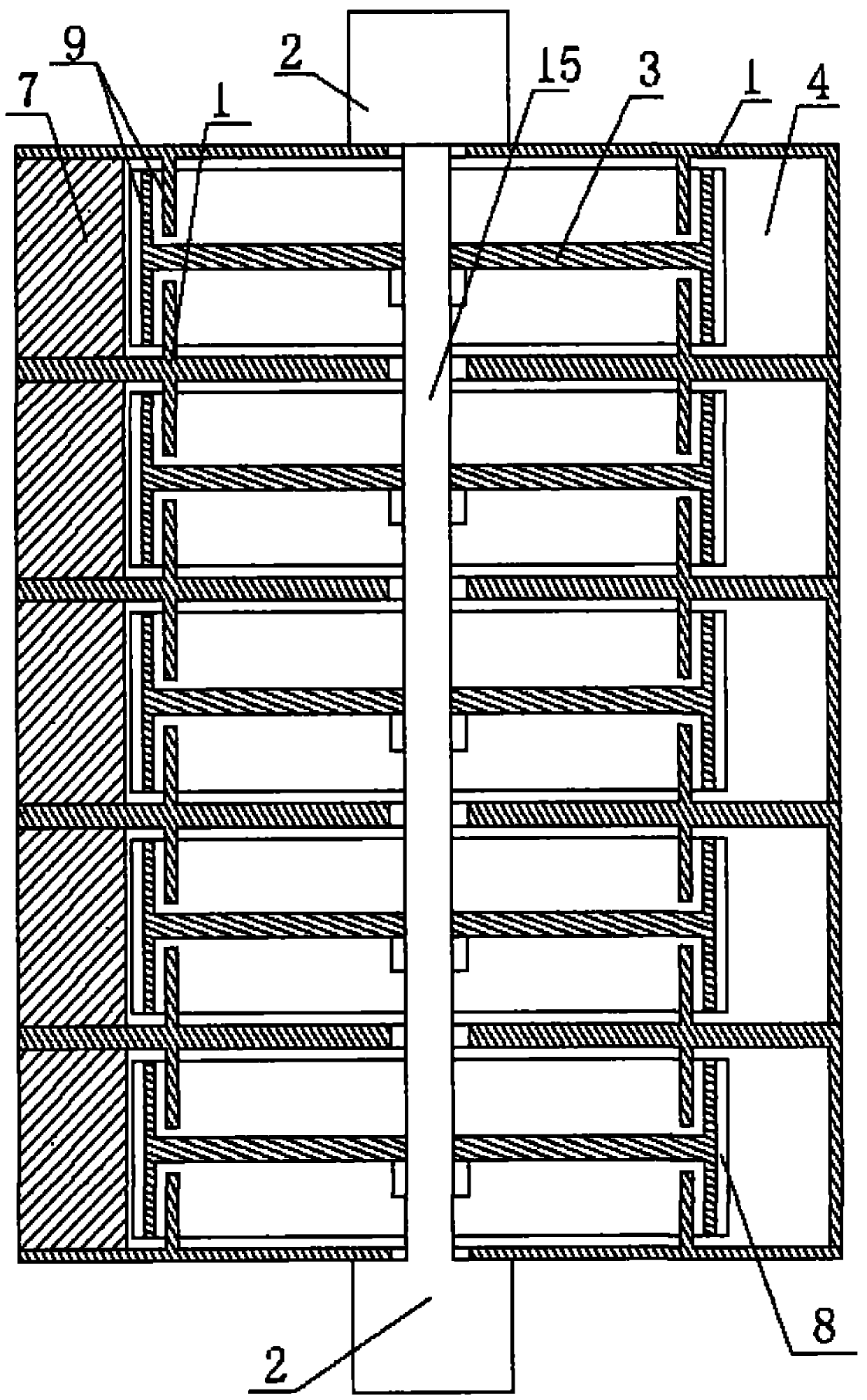

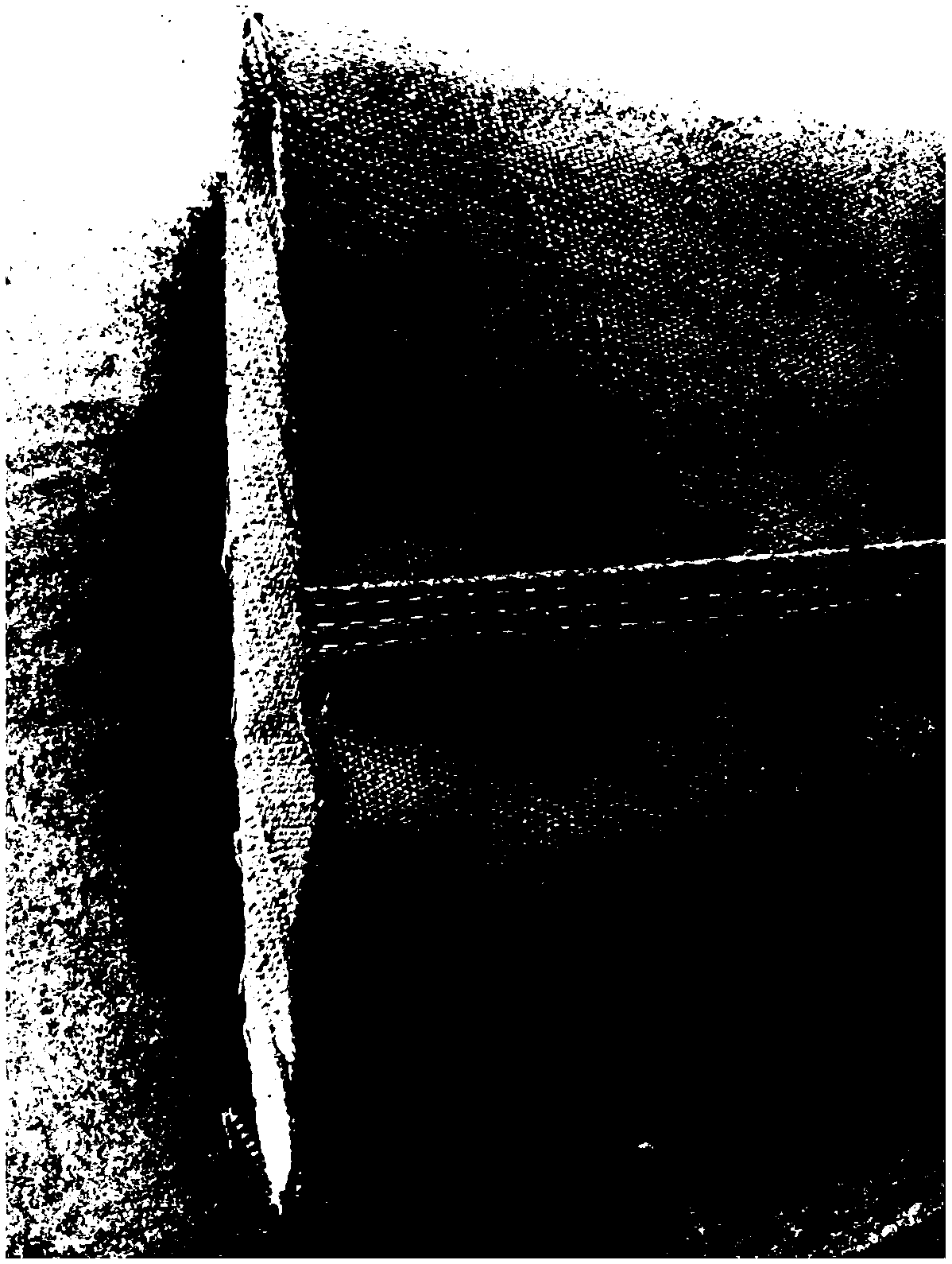

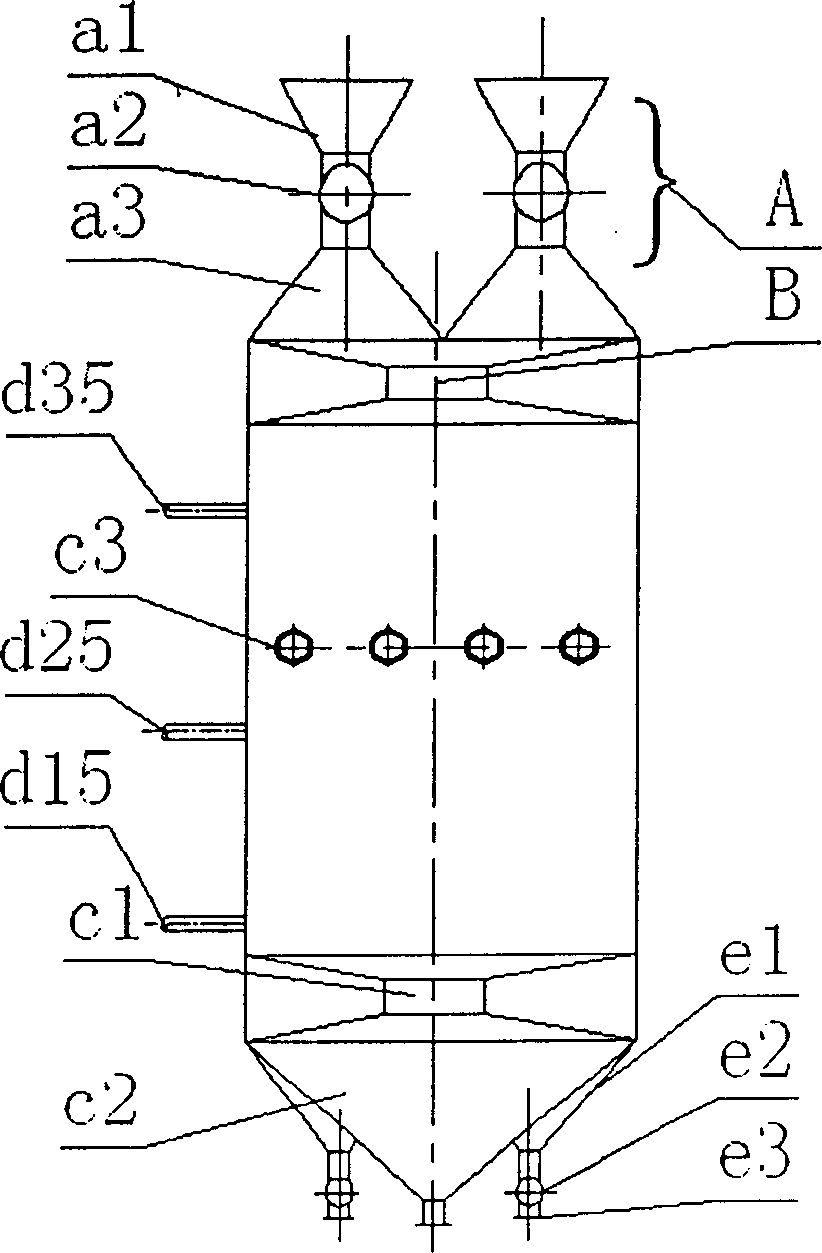

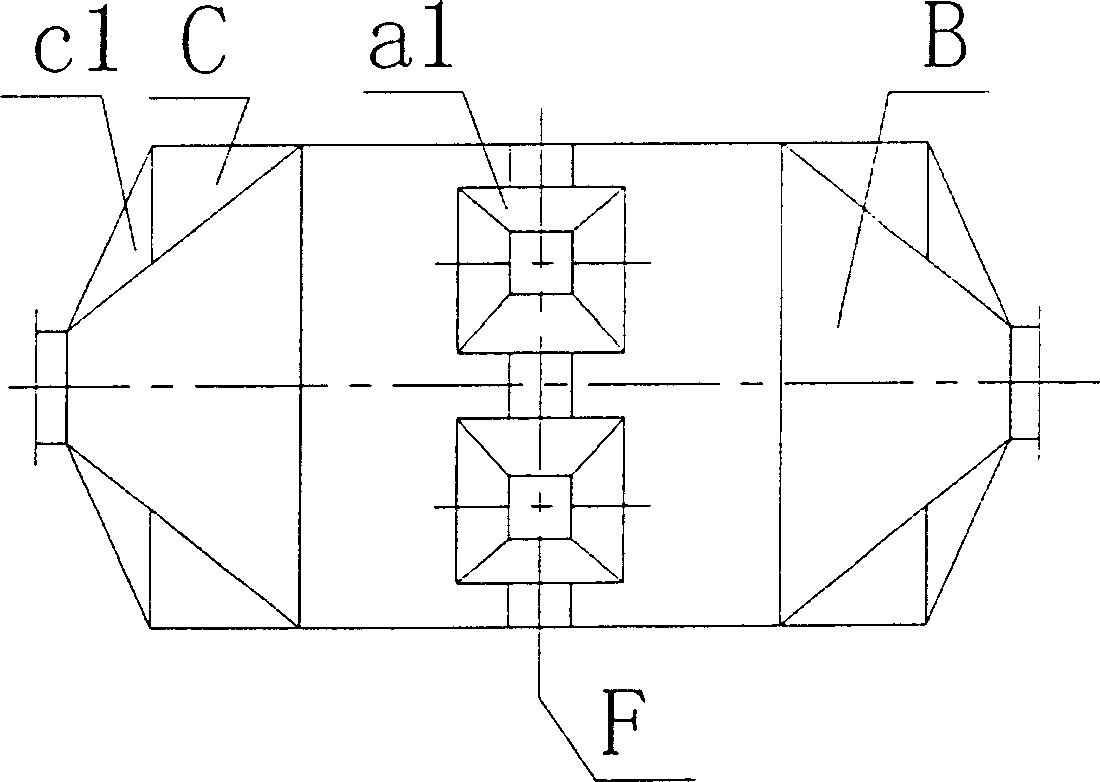

Coupling multistage device with active carbon purifying waste gas

InactiveCN1820819ATake advantage ofCompact structureDispersed particle separationActivated carbonMaterial distribution

The present invention provides coupling multistage apparatus with active carbon to purify waste gas, and the apparatus is used in desulfurizing, denitrating, dedusting, eliminating heavy metal and eliminating organic compound of waste gas. It consists of pre-purifying room, movable adsorption bed, purified gas outlet, material feeding mechanism, and discharging mechanism. Each of the material feeding mechanism and the discharging mechanism consists of material bin, material guide pipe and gas trap valve. The movable adsorption bed consists of one or several adsorption sections superposed sequentially, the material feeding mechanism is set on the top, the discharging mechanism is set in the bottom, and the pre-purifying room and the purified gas outlet are set in the side. The apparatus has compact structure, simple material distribution, complete functions, less resistance, high purifying effect, fully use of active carbon, long service life and low running cost.

Owner:史鱼海

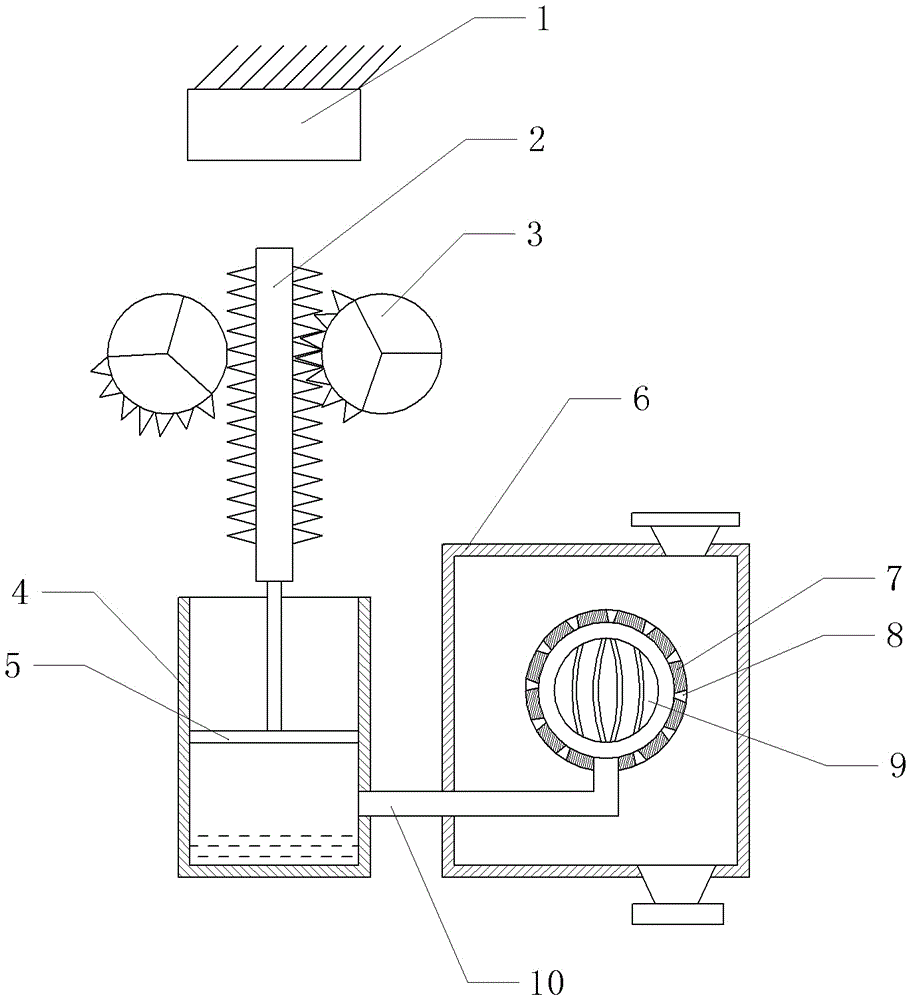

Dust collector for textile machine

ActiveCN108096976AAchieve dust removalMove fastCombination devicesHollow article cleaningEngineeringTextile

The invention relates to a dust removal device, in particular to a dust collector for a textile machine. The dust collector comprises a stander, a power mechanism and a dust removal shell, wherein thepower mechanism comprises a motor, a worm gear, a worm, a nut and a lead screw, the motor is fixed with the worm, the worm is engaged with the worm gear, the nut is fixed on the stander, the lead screw sleeves on the nut, and the lead screw is connected with the worm gear by virtue of a spline; the dust removal shell is provided with an air outlet and an air inlet pipe, a dust removal barrel anda dust collection box are also arranged in the dust removal shell, the inner wall of the dust removal barrel is provided with inner threads, a pressure plate is arranged in the dust removal barrel, apushing rod is fixed between the pressure plate and the lead screw, the pressure plate is also provided with an air outlet hole and a filtering net, the side wall of the pressure plate is provided with outer threads, and the lower surface of the pressure plate is provided with a scraper strip; the bottom wall of the dust removal barrel is provided with a dust scraper plate, a stretchable shaft isarranged between the dust scraper plate and the pressure plate, one end of the stretchable shaft is fixed on the pressure plate, and the other end of the stretchable shaft is fixed on the dust scraperplate; and the dust collection box is communicated with the dust removal barrel. By adopting the dust collector, the problems in the prior art that dust cannot be discharged timely and the accumulation of the dust influences the dust removal effect can be solved.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

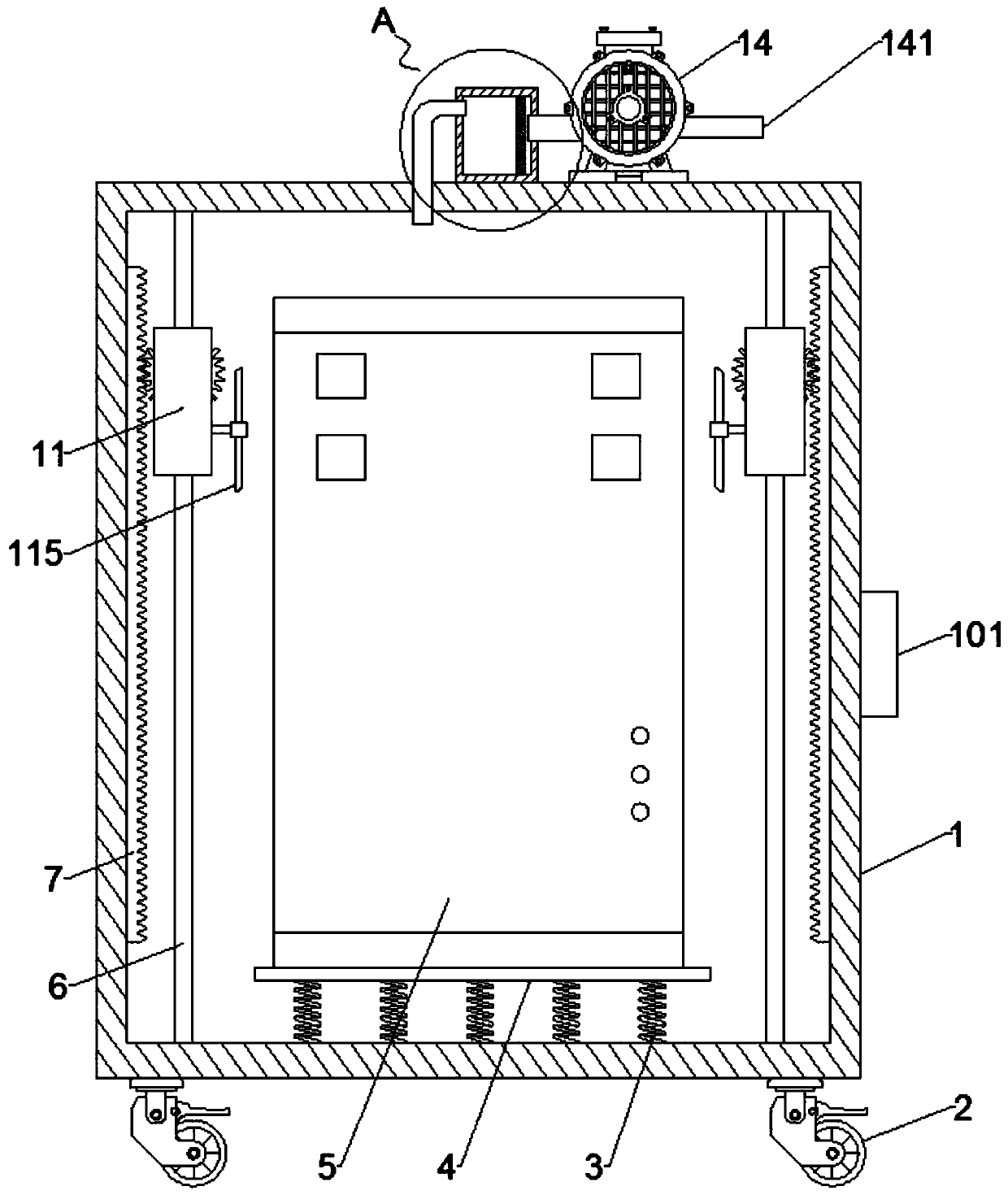

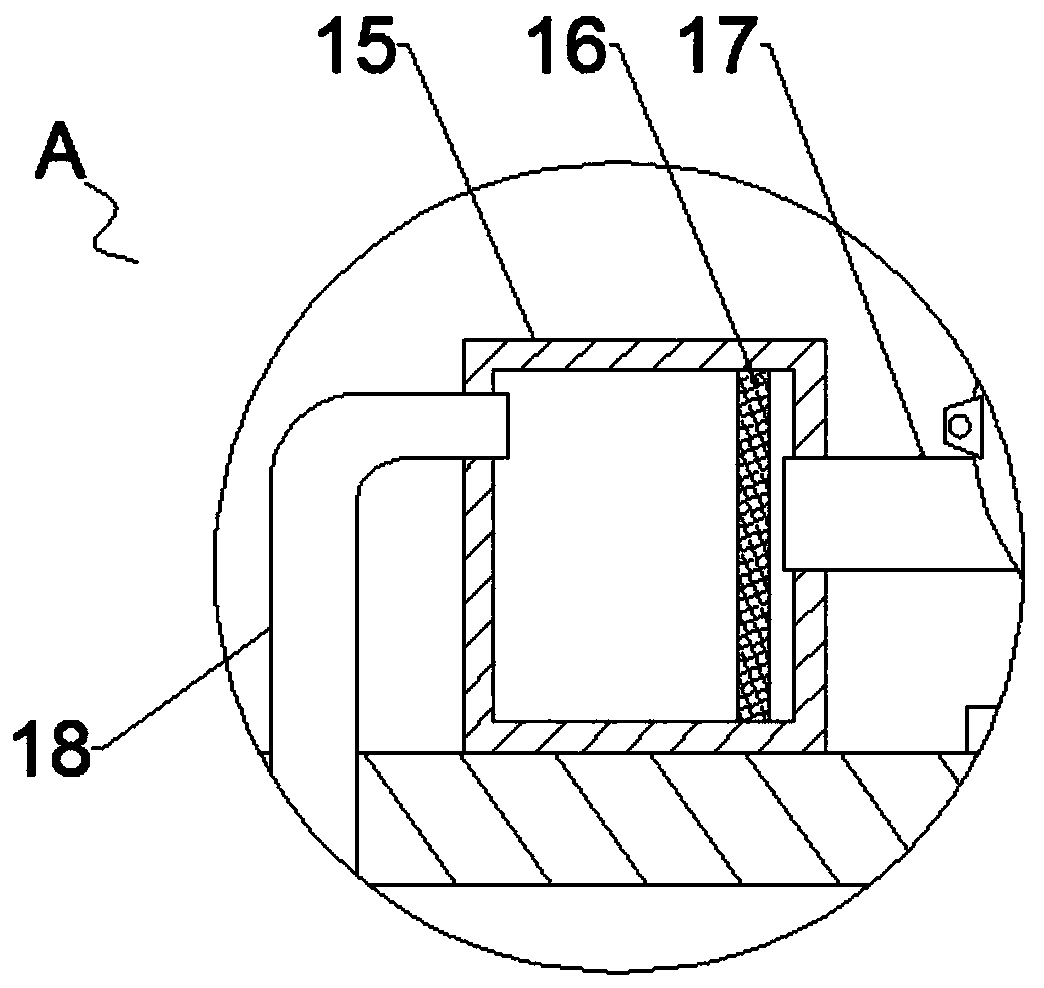

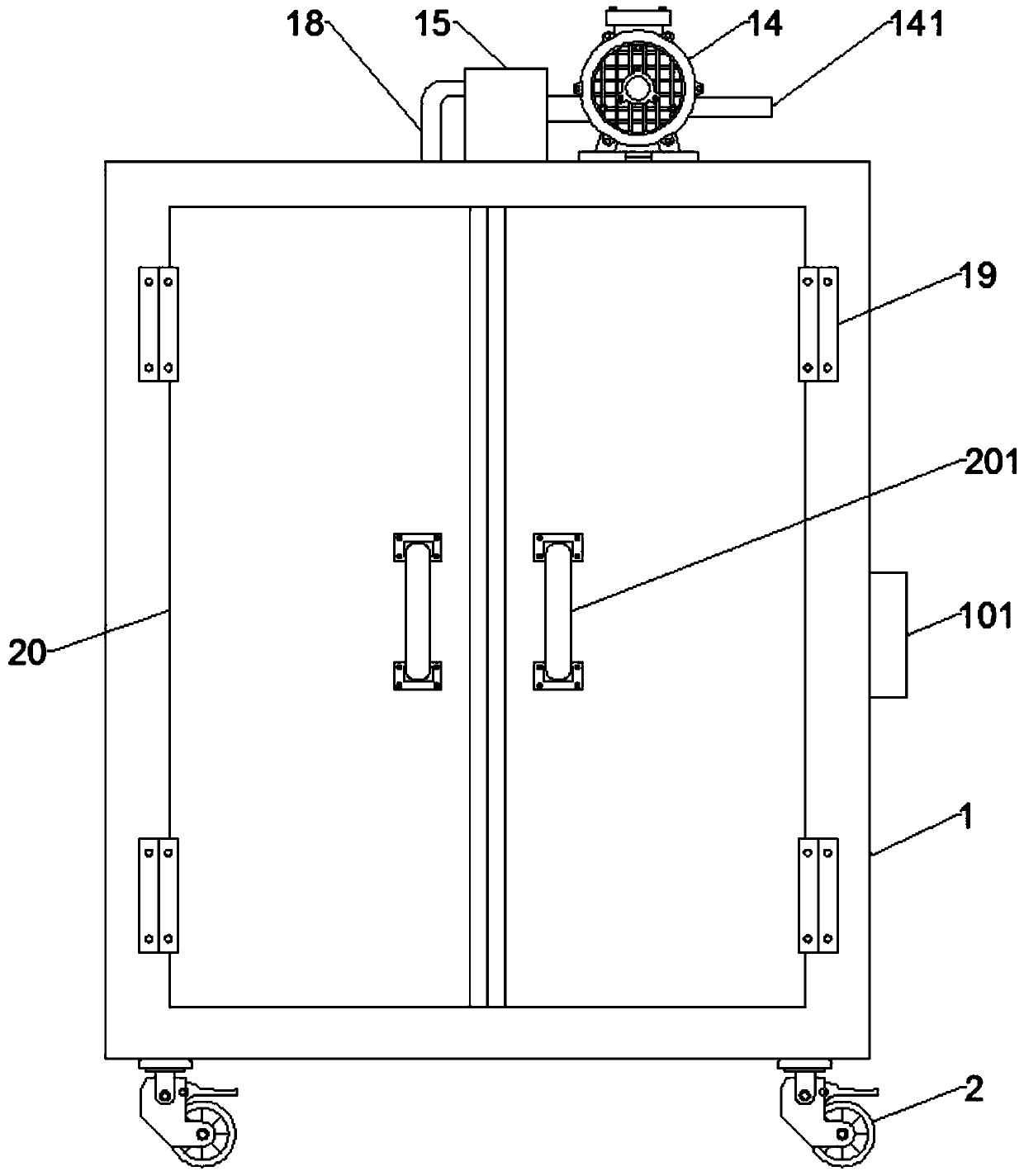

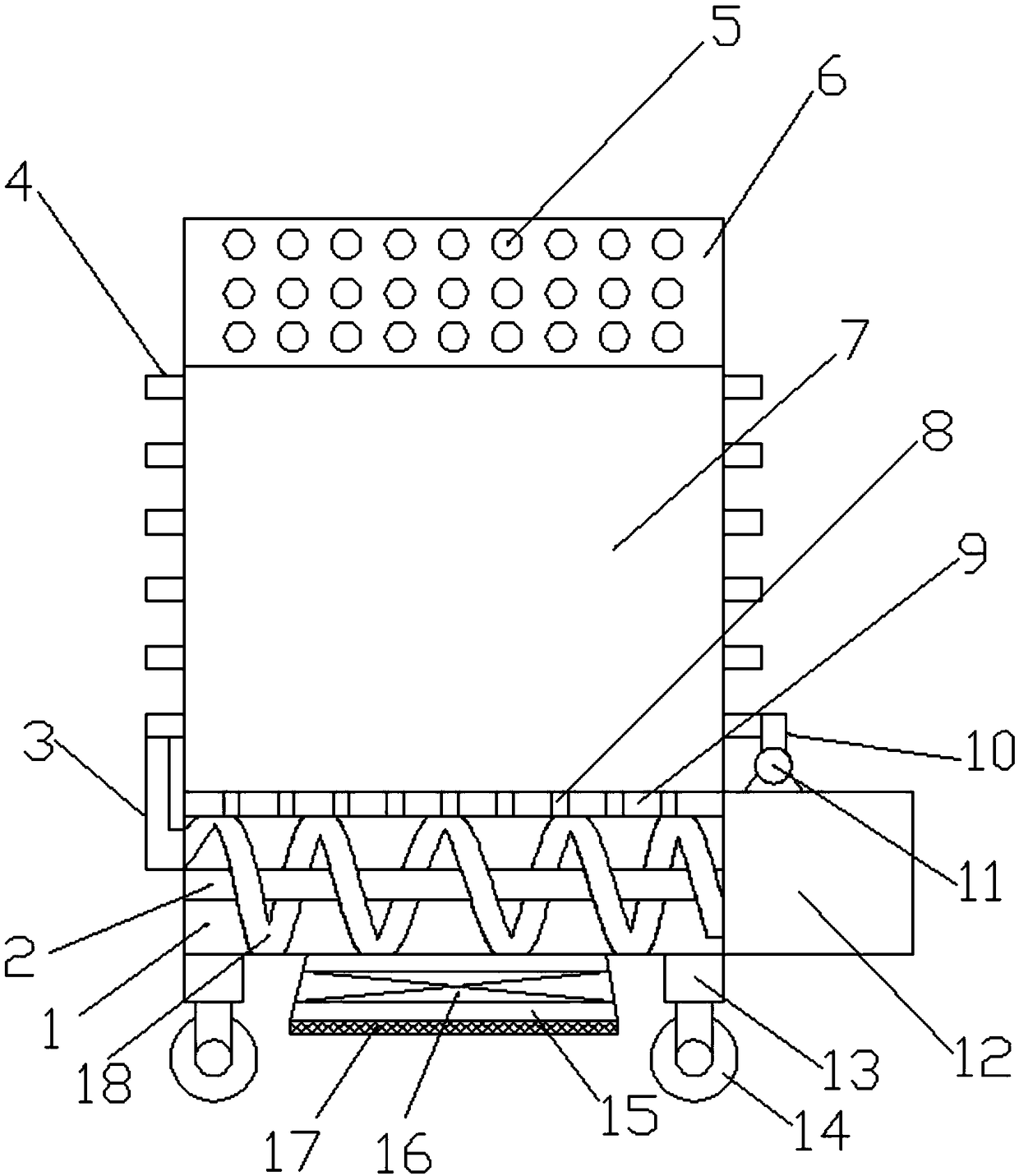

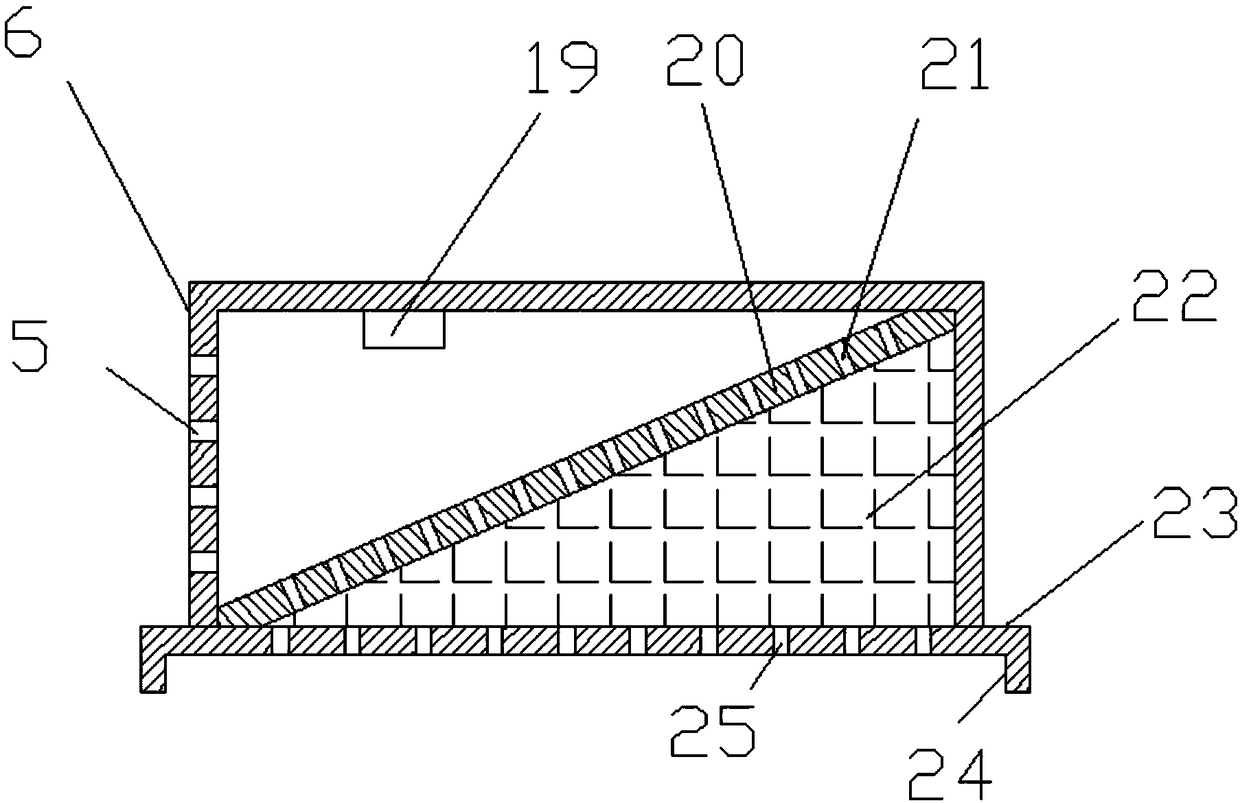

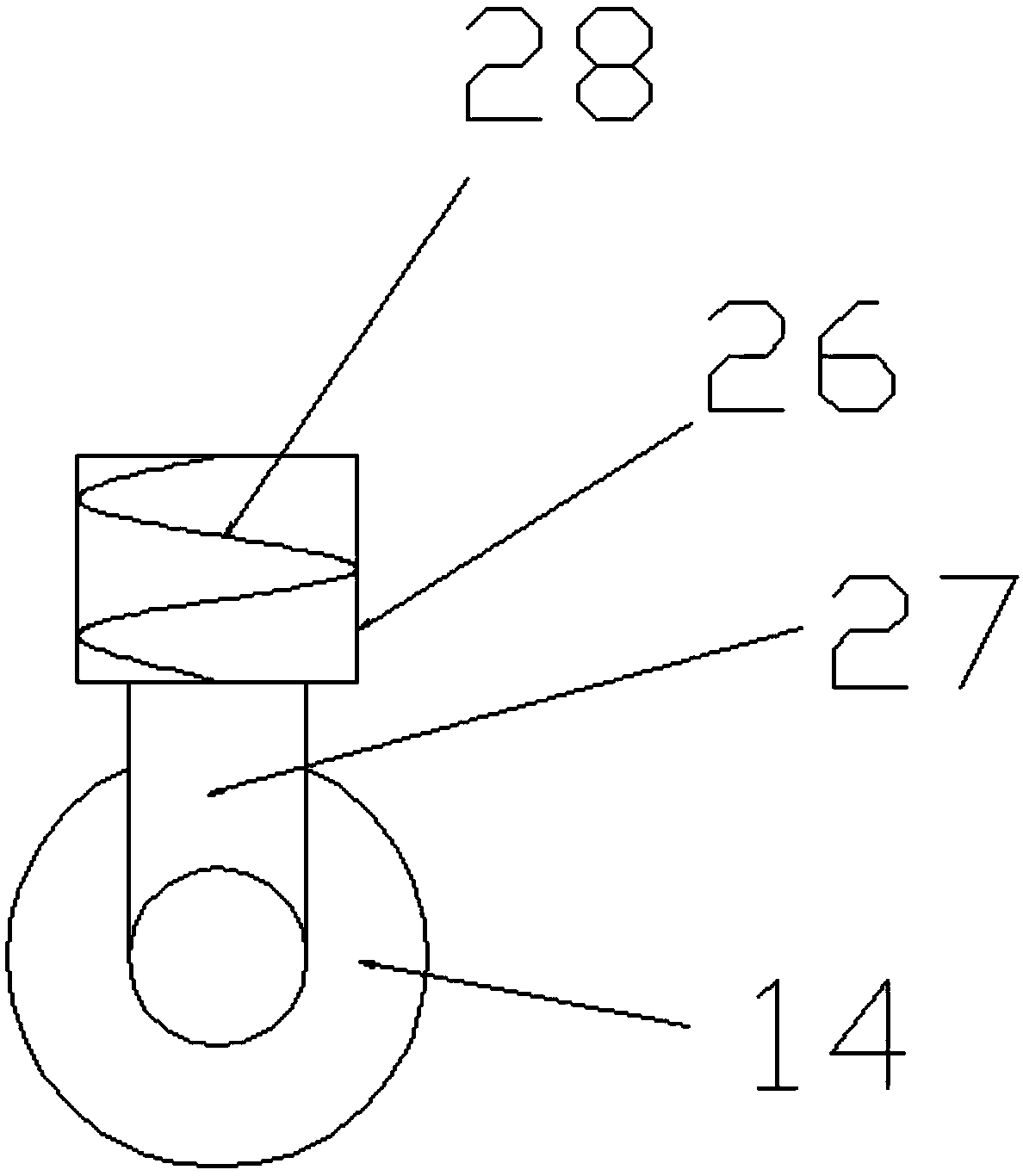

Heat dissipation and dust removal device of information communication cabinet

InactiveCN110586577AContinuous heat dissipationAchieve dust removalDispersed particle filtrationNon-rotating vibration suppressionGrey boxEngineering

The invention relates to the technical field of communication equipment, in particular to a heat dissipation and dust removal device of an information communication cabinet. The heat dissipation and dust removal device includes a shell, four sets of rollers are symmetrically and fixedly mounted on the front corner, the rear corner, the left corner and the right corner at the bottom of the shell, aplurality of sets of springs are fixedly mounted on the bottom side of the interior of the shell, supporting plates are fixedly mounted at the tops of the springs, the communication cabinet is placedon the supporting plates, and two sets of sliding rails are fixedly mounted at the left end and the right end of the rear side of the interior of the shell. The invention provides the heat dissipation and dust removal device for the information communication cabinet. A motor is used for driving a traveling gear to rotate through a connecting shaft, and so that a heat dissipation box and the motormounted on a connecting frame enables the heat dissipation box to up-down reciprocate in the arrangement direction of racks through forward and reverse drive of the motor through coordinated slidingof sliding blocks on the sliding rails, heat dissipation of the communication cabinet is continuous, and by using an exhaust fan, dust flying in the shell is inhaled into an ash collecting box throughan air suction pipe to achieve dust removal of the communication cabinet.

Owner:合肥泾渭信息通讯有限公司

Indoor air cleaning unit

InactiveCN101468208AGood dust removal effectReduce noiseDeodrantsRadiationAir cleaningActivated carbon

The present invention relates to an indoor air cleaning unit which mainly comprises a dust removing unit, an active carbon absorbing unit and an ultraviolet sterilizing unit. The dust removing unit adopts an electrostatic dust collecting structure and is provided with dust collecting plates parallel with each other and discharge electrodes distributed between the dust collecting boards. The active carbon absorbing unit is obtained by stacking a plurality of activated carbon fiber blocks. The ultraviolet sterilizing unit is provided with a plurality of photocatalytic modules which are arranged transversely and are composed of a plurality of layers of photocatalytic wire meshes. An ultraviolet lamp and an ultrasonic atomizer are installed between each photocatalytic module. The ultrasonic atomizer is provided with a water supplying device. The device has a simple structure, fully exerts the synthetic predominance of a plurality of purifying techniques and effectively settles the problem of indoor air pollution.

Owner:HAISIBOTE BEIJING SCIENE & TECH

Computer case with efficient cooling and dedusting functions

InactiveCN108710412ACleverly structuredReasonable arrangementStands/trestlesDigital processing power distributionSoftware engineeringEngineering

The invention discloses a computer case with efficient cooling and dedusting functions. The computer case comprises a base, wherein the base is a hollow structure; a cabin for mounting a computer hostis fixedly set on the base; a clapboard is set between the cabin and the base; vent holes are uniformly set on the clapboard; the cabin is communicated with the inner cavity of the base through the vent holes; a liquid storage bin is fixedly set at the right side of the base; the liquid storage bin is filled with cooling liquid; an upper cooling pipe is set on the side wall of the cabin; the upper cooling pipe is spirally wound on the outer side wall of the cabin; a lower cooling pipe is set in the base; the bottom end of the upper cooling pipe is communicated with the left end of the lower cooling pipe through a water inlet pipe; the right end of the lower cooling pipe is communicated with the bottom end of the liquid storage bin; and the top end of the upper cooling pipe is communicatedwith the top of the liquid storage bin through a water outlet pipe. The computer case with the efficient cooling and dedusting functions provided by the invention is ingenious in structure setting and reasonable in layout. According to the computer case, the efficient cooling and dedusting are realized.

Owner:苏州洋紫瑞信息科技有限公司

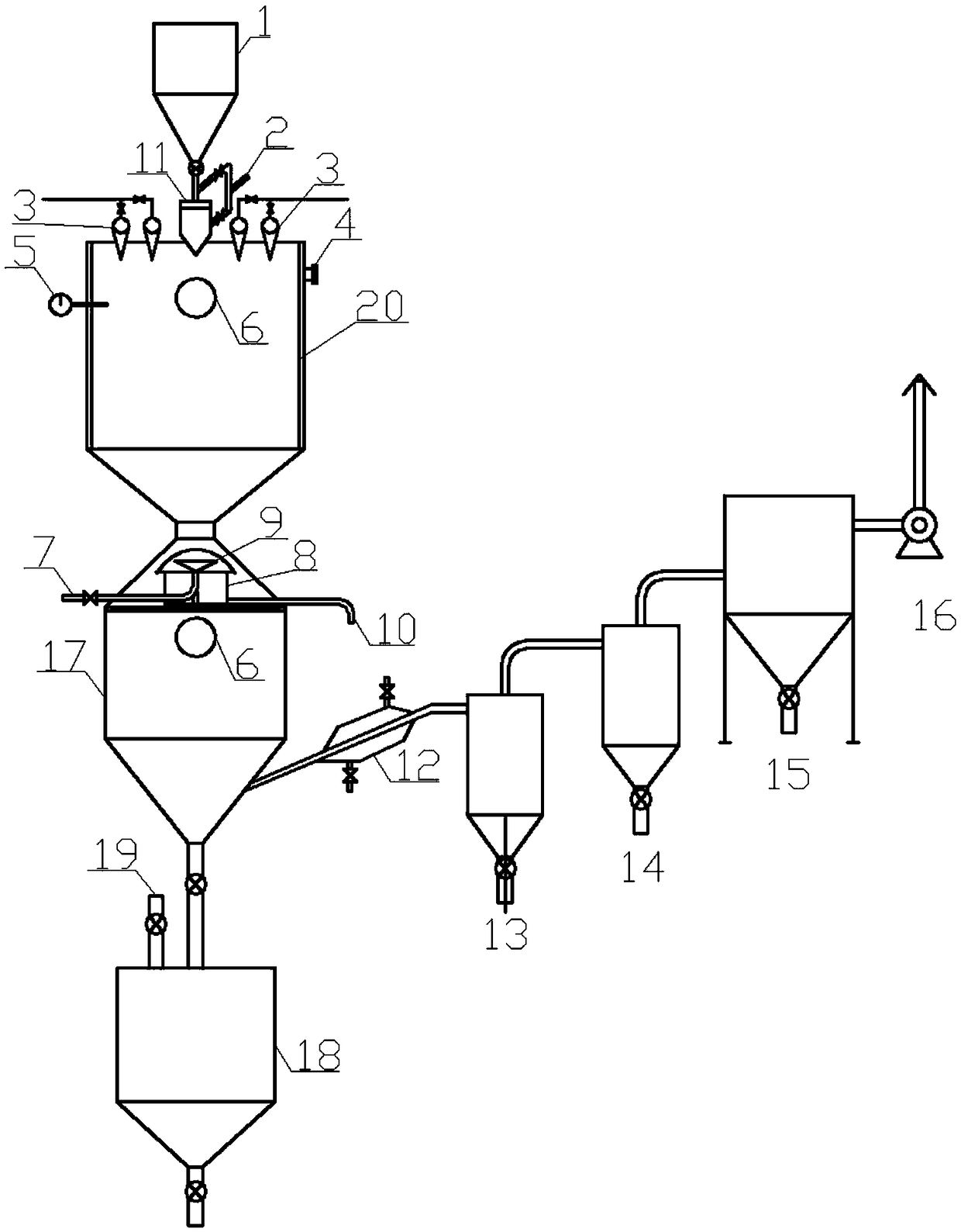

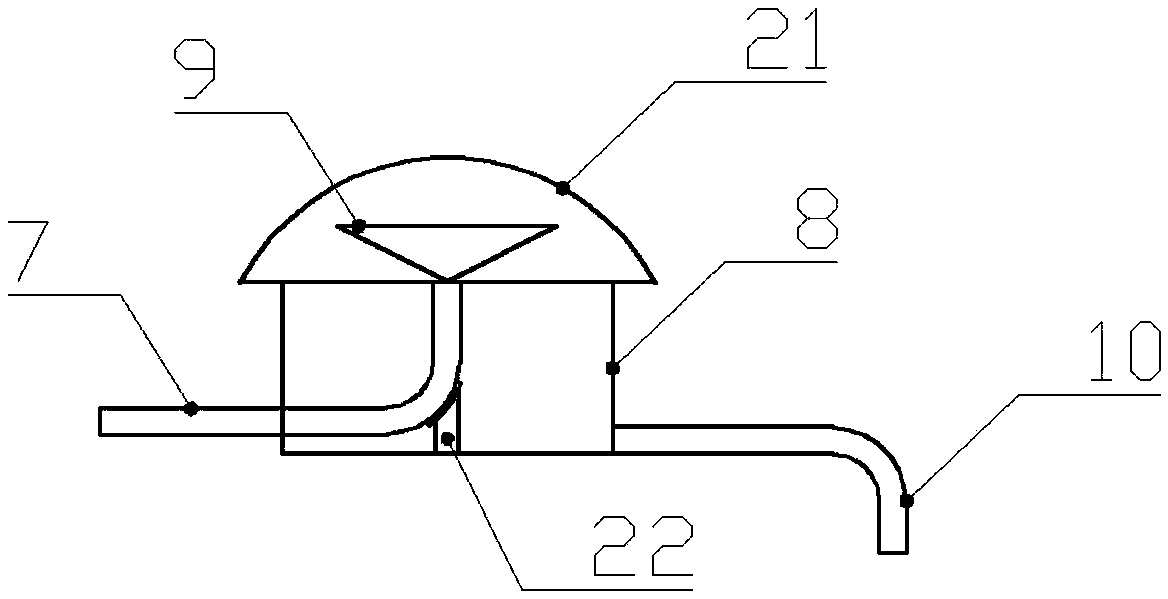

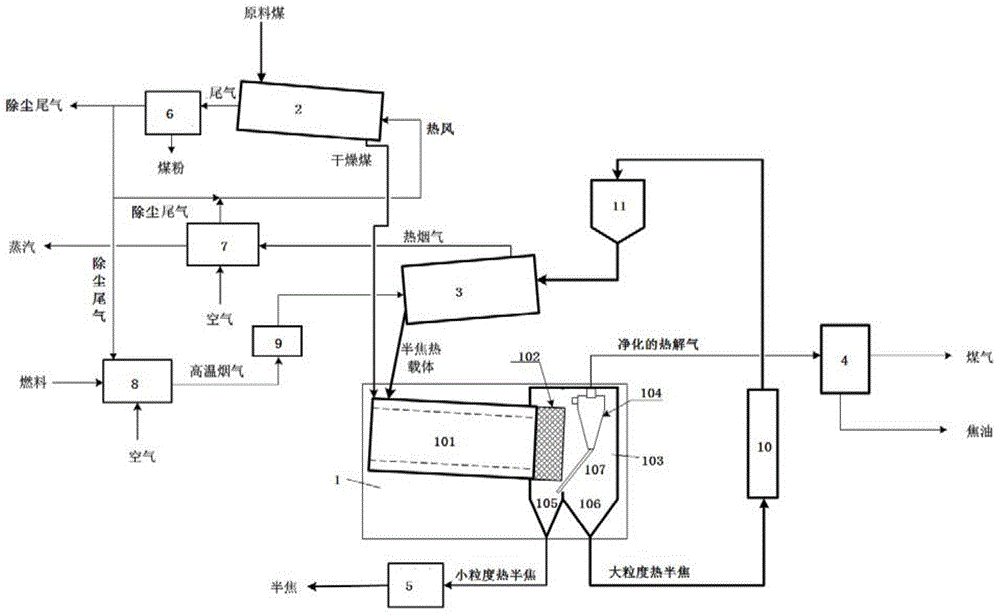

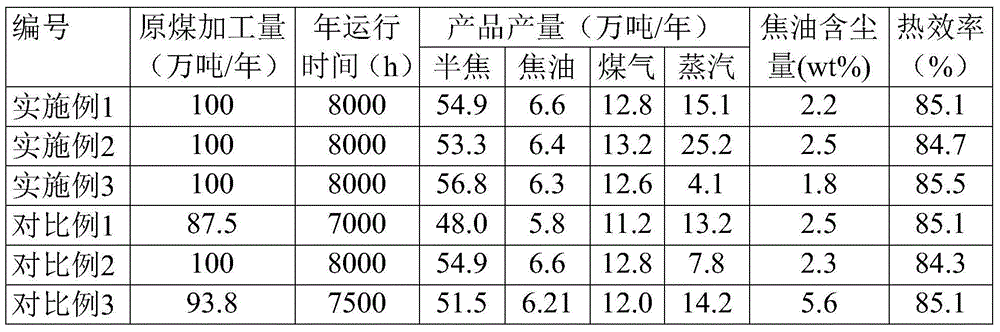

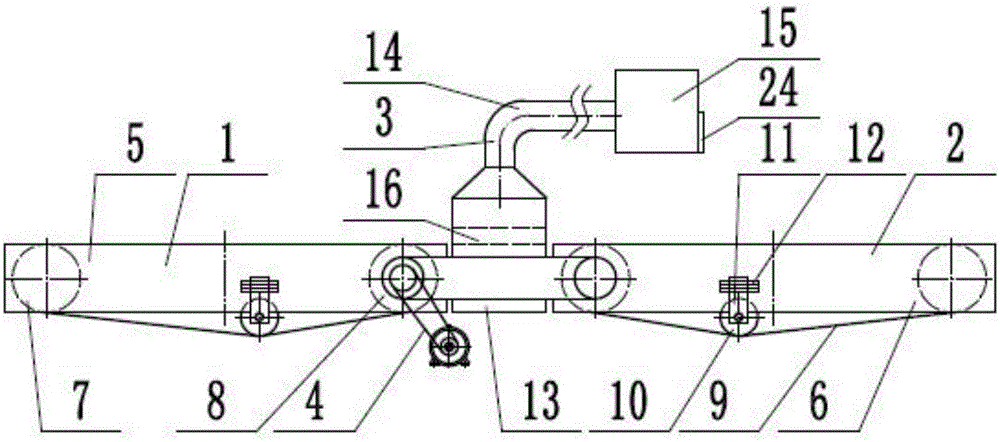

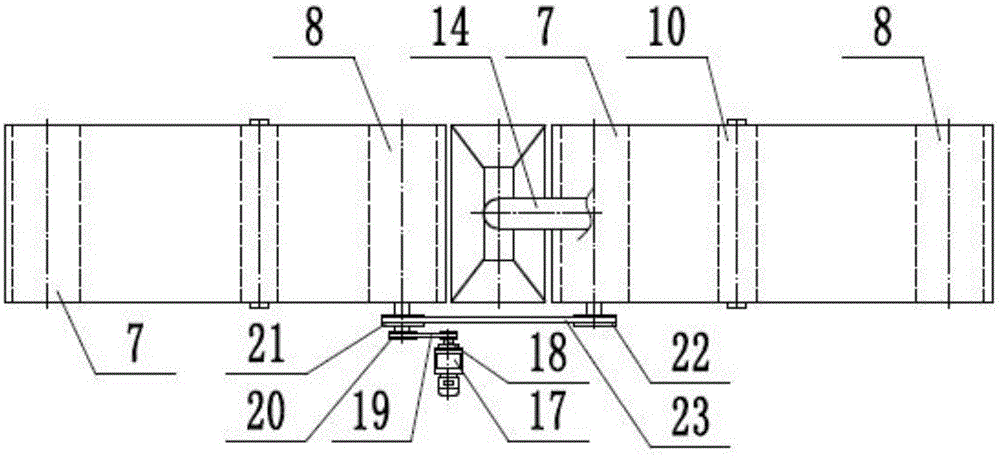

Pyrolysis system for pyrolysis of broken coal, and device and method for producing semicoke, tar and coal gas by pyrolysis of broken coal

ActiveCN104152162AAvoid condensationIncrease productionDirect heating destructive distillationSpecial form destructive distillationThermodynamicsSolid particle

The invention discloses a pyrolysis system for pyrolysis of broken coal, and a device and a method for producing semicoke, tar and coal gas by pyrolysis of broken coal. The pyrolysis system comprises a pyrolyzer, a particle size classifier, a distributing cabin, a cyclone separator, a small hopper, a large hopper and a discharge tube, wherein the pyrolyzer, the distributing cabin, the small hopper and the large hopper are tightly connected; the small hopper and the large hopper are connected below the distributing cabin; the particle size classifier is connected to the outlet of the pyrolyzer and is arranged inside the distributing cabin; the cyclone separator is arranged inside the distributing cabin, and used for separating pyrolysis gas discharged by the pyrolyzer to obtain solid particles and purified pyrolysis gas. The device comprises the pyrolysis system. The tar obtained by adopting the method is high in yield and high in quality, the coal gas is high in effective components and high in heating value, the yield of the semicoke is improved, the whole energy efficiency is high, and the device can run within a long period.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

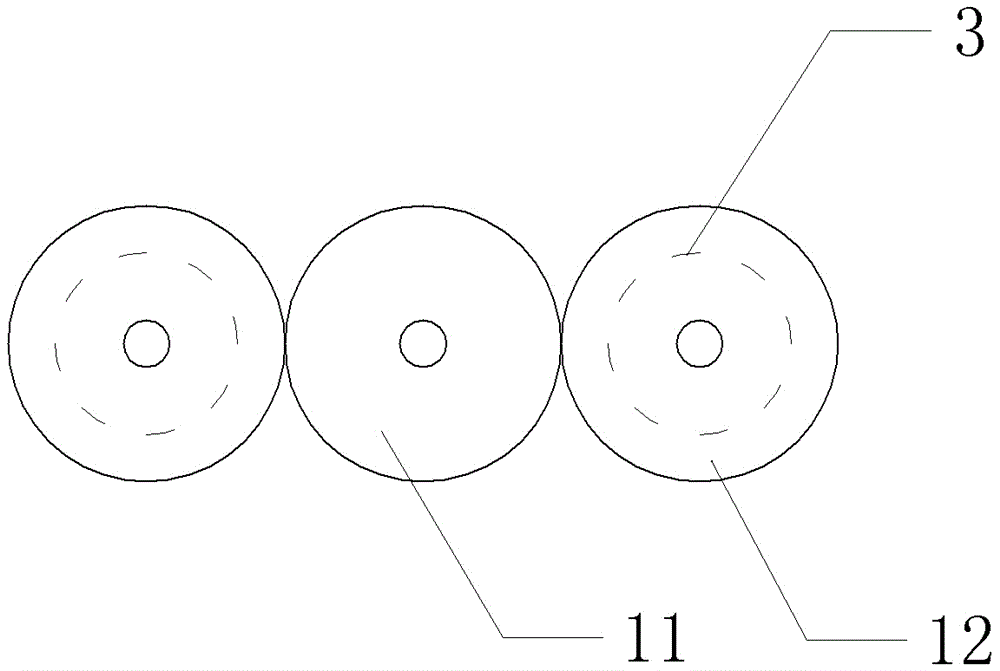

Plate dust removal device

InactiveCN105107793AAchieve dust removalEasy to remove dustCleaning using gasesDrive wheelElectric machinery

The invention provides a plate dust removal device and belongs to the technical field of machining. The plate dust removal device comprises a conveying mechanism, a dust removal mechanism and a drive mechanism. Both a front conveying assembly and a rear conveying assembly of the conveying mechanism comprise tension rollers and tension roller supports. The upper ends of the tension roller supports are arranged on clamping grooves. The tension rollers are arranged at the lower ends of the tension roller supports in a rotating mode. A conveying belt is arranged on first conveying rollers, second conveying rollers and the tension rollers in a surrounding mode. A dust removal box of the dust removal mechanism is arranged between the front conveying assembly and the rear conveying assembly. One end of a dust suction pipe is connected to the upper end of the dust removal box, and the other end of the dust suction pipe is connected with a dust remover. A first drive wheel and a second drive wheel of the drive mechanism are connected through a second belt, a first belt wheel is connected with a second belt wheel through a first belt, and the first belt wheel is coaxially connected with a drive motor. According to the plate dust removal device, plates pass through the dust removal mechanism on the dependence of the conveying mechanism step by step, comprehensive dust removal of the plates is achieved effectively, and the dust removal effect is good.

Owner:TIANJIN CHAOMAI TECH DEV CO LTD

Environment-friendly air purification hard shoulder

ActiveCN109958076AEasy dischargeReduce dust contentHuman health protectionDispersed particle filtrationWork periodWater storage

The invention belongs to the field of road administration facilities and particularly relates to an environment-friendly air purification hard shoulder. The environment-friendly air purification hardshoulder comprises a hard shoulder body, wherein the hard shoulder body is internally provided with a water storage cavity and an air suction channel; a water supplementing inlet communicated with theoutside is formed in the side wall of the water storage cavity; elastic membranes are fixedly connected to openings at two ends of the air suction channel; two isolation panels arranged in parallel are fixedly connected in the air suction channel; the isolation panels, the elastic membranes and the air suction channel jointly form air suction cavities; a purification filter element is fixedly connected in each air suction cavity; the two isolation panels and the air suction channel jointly form a pressurizing chamber; one-way valves for allowing gas to flow into the pressurizing chamber fromthe air suction cavities are fixedly connected to the isolation panels; a sealing door is in sealed connection with the side wall of the air suction channel. According to the environment-friendly airpurification hard shoulder disclosed by the invention, purification, dust removal and cooling of air are realized by taking wind energy produced in the running process of an automobile as power, so that energy consumption is lower; in addition, work period can be automatically changed according to traffic flow, and energy saving and environmental protection are realized.

Owner:赣州金振环保设备有限公司

Indoor ventilation and air purifying circulating system

ActiveCN109990406AImprove air qualityAvoid enteringDucting arrangementsMechanical apparatusIndoor air qualityAir purifiers

The invention discloses an indoor ventilation and air purifying circulating system. The system is characterized in that an air purifier and an air cylinder are controlled by a controller to externallydischarge air flow for a certain period of time every time when the system is started to conveniently blow dust in the air purifier and air cylinder outdoors, dust in the equipment is prevented fromentering indoors, indoor air quality is improved, and the problem that dust enters indoors is relieved. When air is discharged outwards, blades can be driven to rotate by the air flow, dust shaking balls at the ends of the blades can be touched to allow internal filter nets to shake and deform to achieve the dust removing on inner layer filter nets, dust on the inner layer filter nets can be effectively removed to improve the dust removing effect of the equipment and prevent dust from attaching to the filter nets, when the air flow is controlled to internally discharged by the controller, rotation preventing elastic nets can be prevented from bending in the direction towards the blades by the air flow, the shielding of the blades is achieved, the rotation of the blades is prevented, the dust on the filter nets can be prevented from being shaken indoors when the air flow is circulated indoors, and therefore the ventilation purifying effect is ensured.

Owner:CENT SOUTH UNIV

Dust removal device for paper core tube production and processing

PendingCN111589751AAchieve fixationEasy to fixDispersed particle filtrationTransportation and packagingDust controlProcess engineering

The invention discloses a dust removal device for paper core tube production and processing, and belongs to the technical field of paper core tube production. The device comprises a workbench, a support column is arranged at the top of the workbench, a top plate is installed at the top of the support column, a lifting plate is arranged above the workbench, and an adjustment mechanism for adjustingthe height of the lifting plate is installed at the top of the workbench; a transverse plate is slidably installed on the lifting plate, a dust removal brush is installed at one end of the transverseplate, and a horizontal plate is arranged above the top plate; a driving mechanism for adjusting the height of the horizontal plate is arranged on the top plate, a positioning rod is rotatably installed at the bottom of the horizontal plate, a servo motor is installed at the top of the horizontal plate, and an output shaft of the servo motor is connected with the positioning rod in a transmissionmode. According to the device, the fixation of a paper core tube is realized, the dust removal is convenient to carry out, the fixation is convenient, omni-directional dust removal of the paper coretube is realized, the operation is motorized, the labor is saved, dust removal efficiency is improved, dust collection is achieved, the pollution is avoided, the operation is convenient, and the cleaning is convenient.

Owner:响水明恒包装有限公司

Intelligent dust-removal and ventilating system

InactiveCN108692418APromote exchangeAchieve coolingLighting and heating apparatusSpace heating and ventilation detailsEngineeringAirbag

The invention discloses an intelligent dust-removal and ventilating system and relates to the field of air purification devices. The intelligent dust-removal and ventilating system comprises a channel. A first filtering plate and a second filtering plate which can be attached are arranged in the channel, and the first filtering plate is slidably connected with the inner wall of the channel in thevertical direction. The second filtering plate is slidably connected with the inner wall of the channel in the horizontal direction. An airbag is fixedly connected to the top of the first filtering plate, and the other side of the airbag is fixedly connected with the top wall of the channel. An elastic piece is arranged between the bottom of the first filtering plate and the bottom wall of the channel, and a through hole is formed in the first filtering plate. A slim hole is formed in the second filtering plate, and the communicating area of the through hole and the slim hole is increased gradually in the process of downward moving of the first filtering plate. A water tank is arranged on the upper portion of the channel, a plurality of spray holes communicating with the water tank are formed in the top wall of the channel, and when the second filtering plate and the first filtering plate are attached, the spray holes can be shielded. The problems that an existing ventilating device isprone to being blocked and cannot automatically adjust the ventilation quantity according to the environment temperature are solved, and the intelligent dust-removal and ventilating system is mainlyused for ventilating and dust removal of a factory.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com