Patents

Literature

95results about How to "Good surface conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

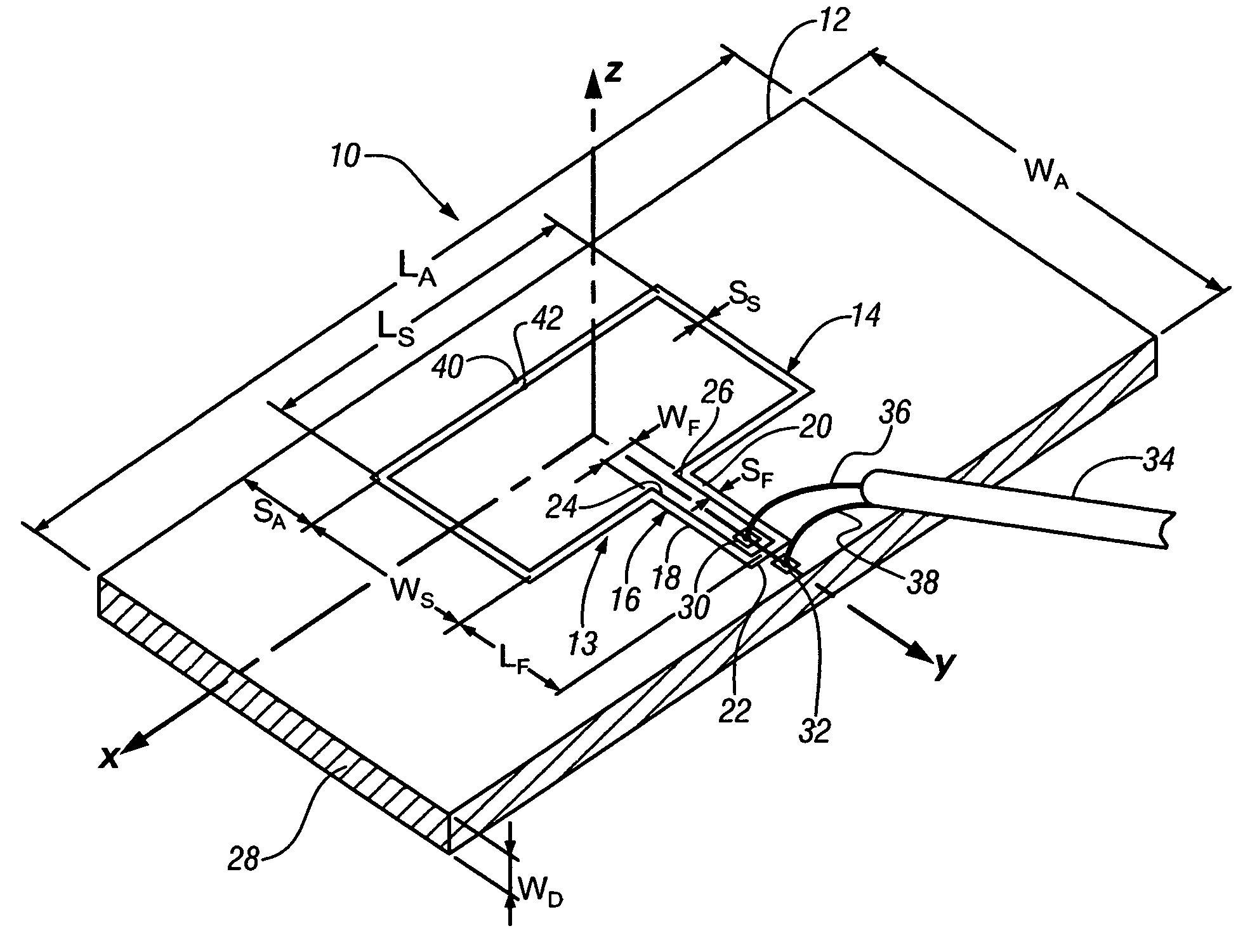

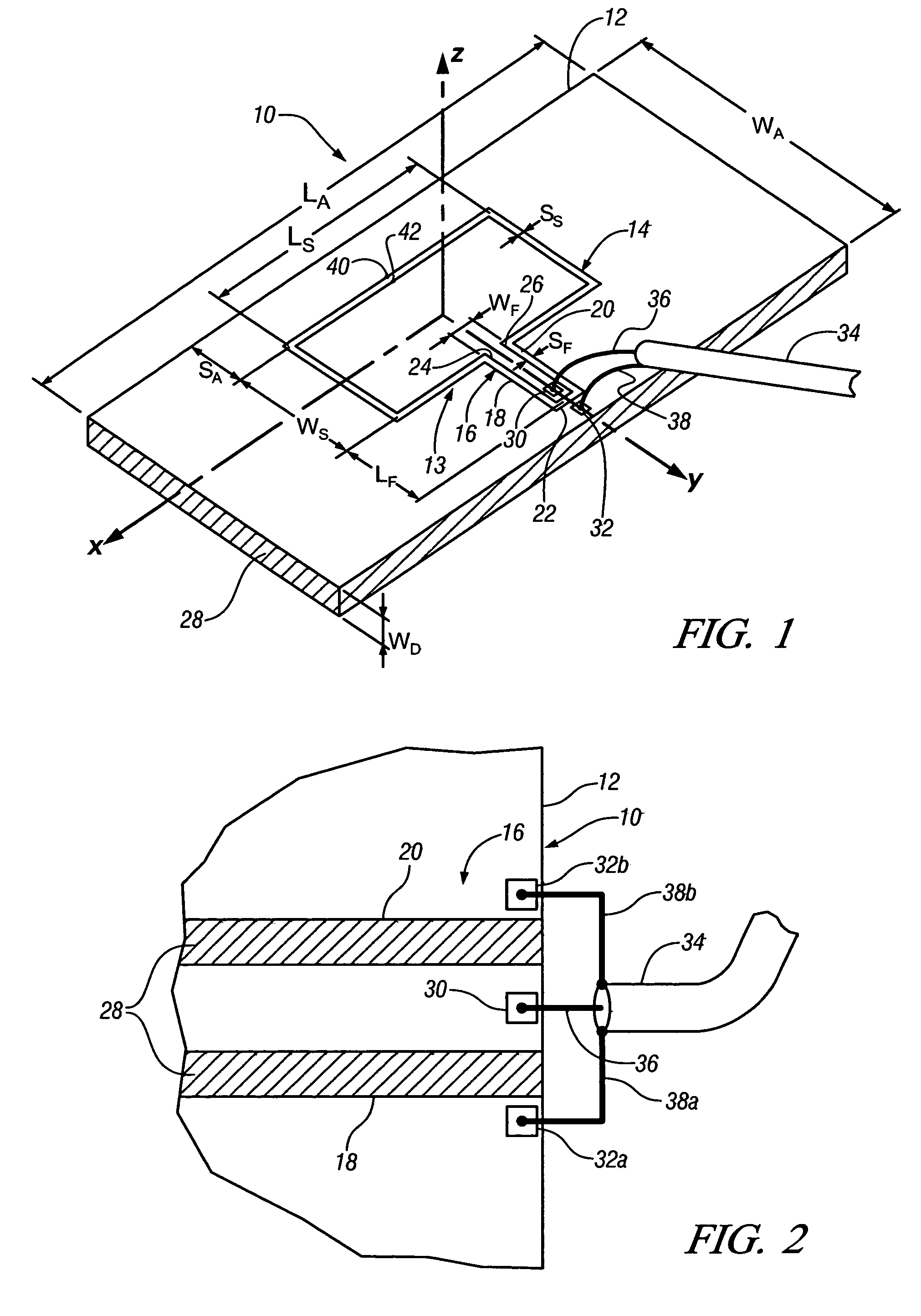

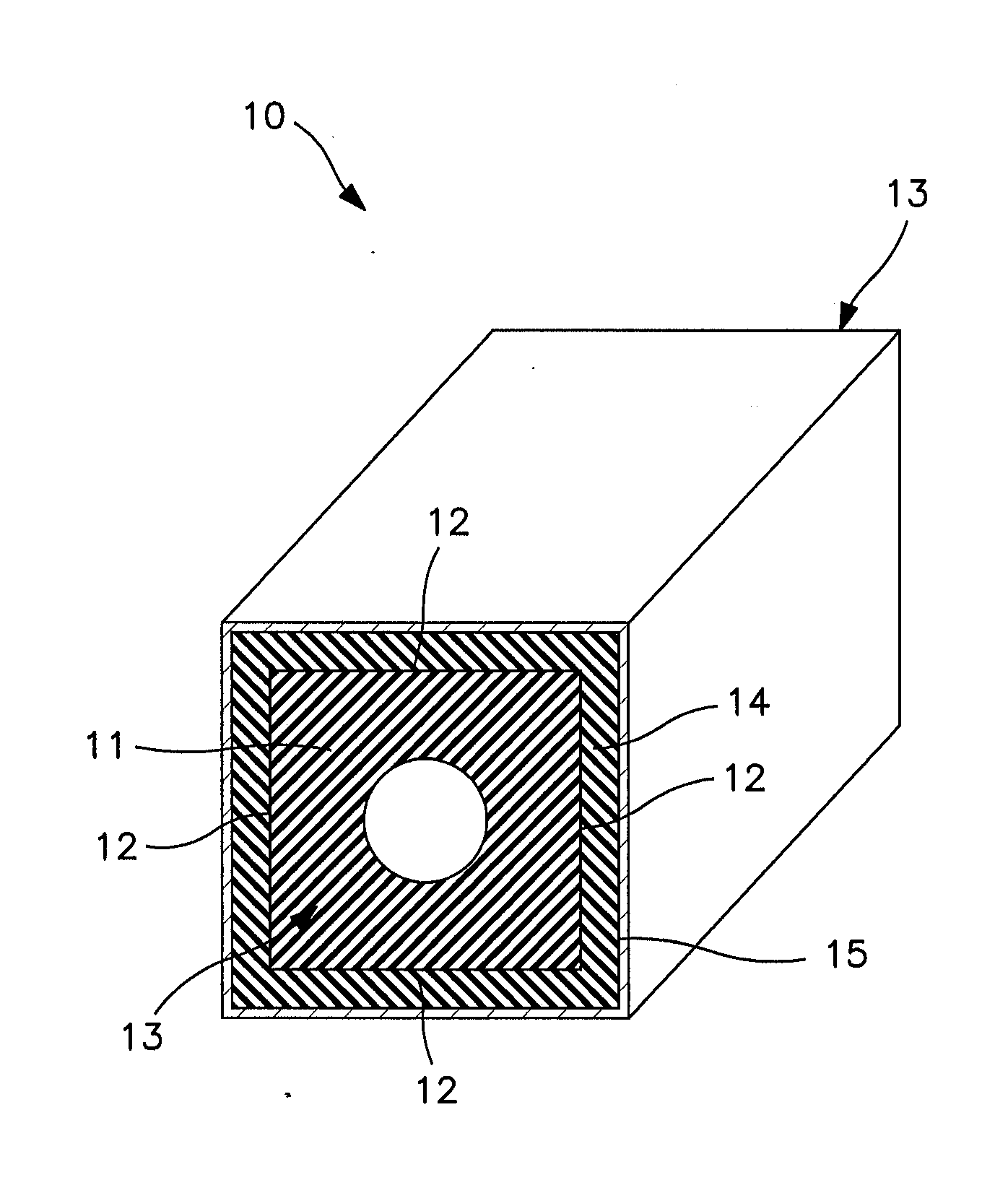

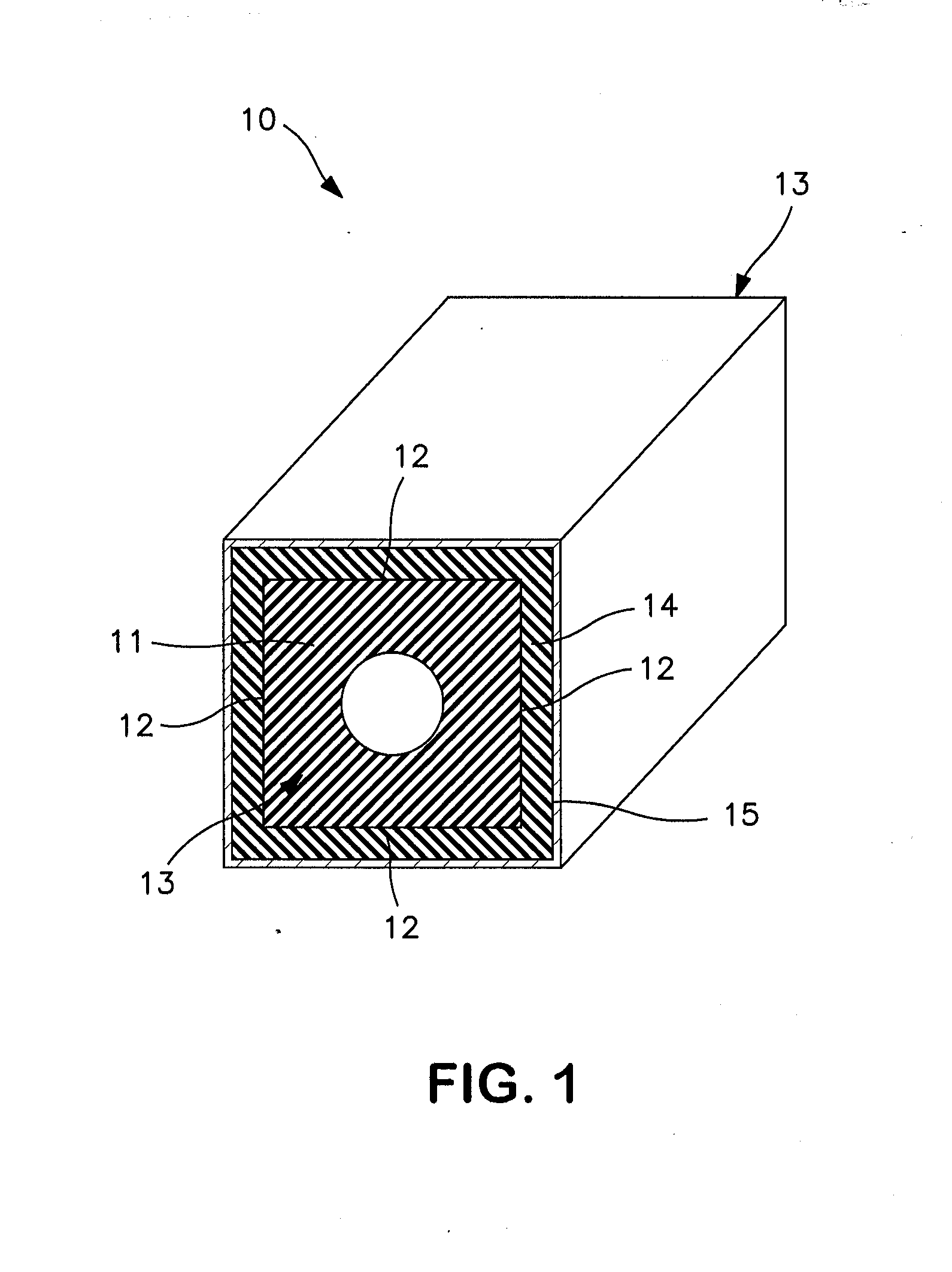

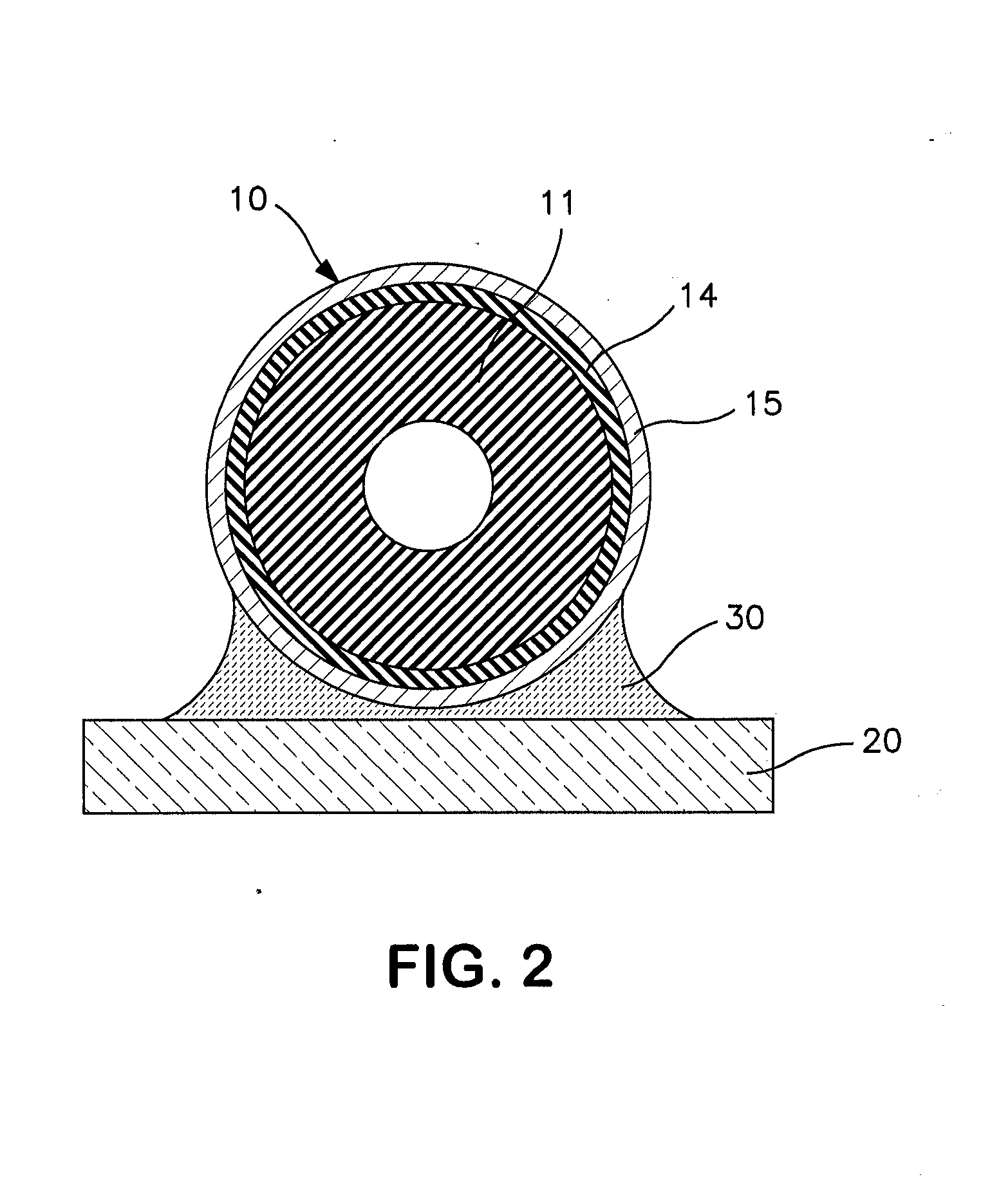

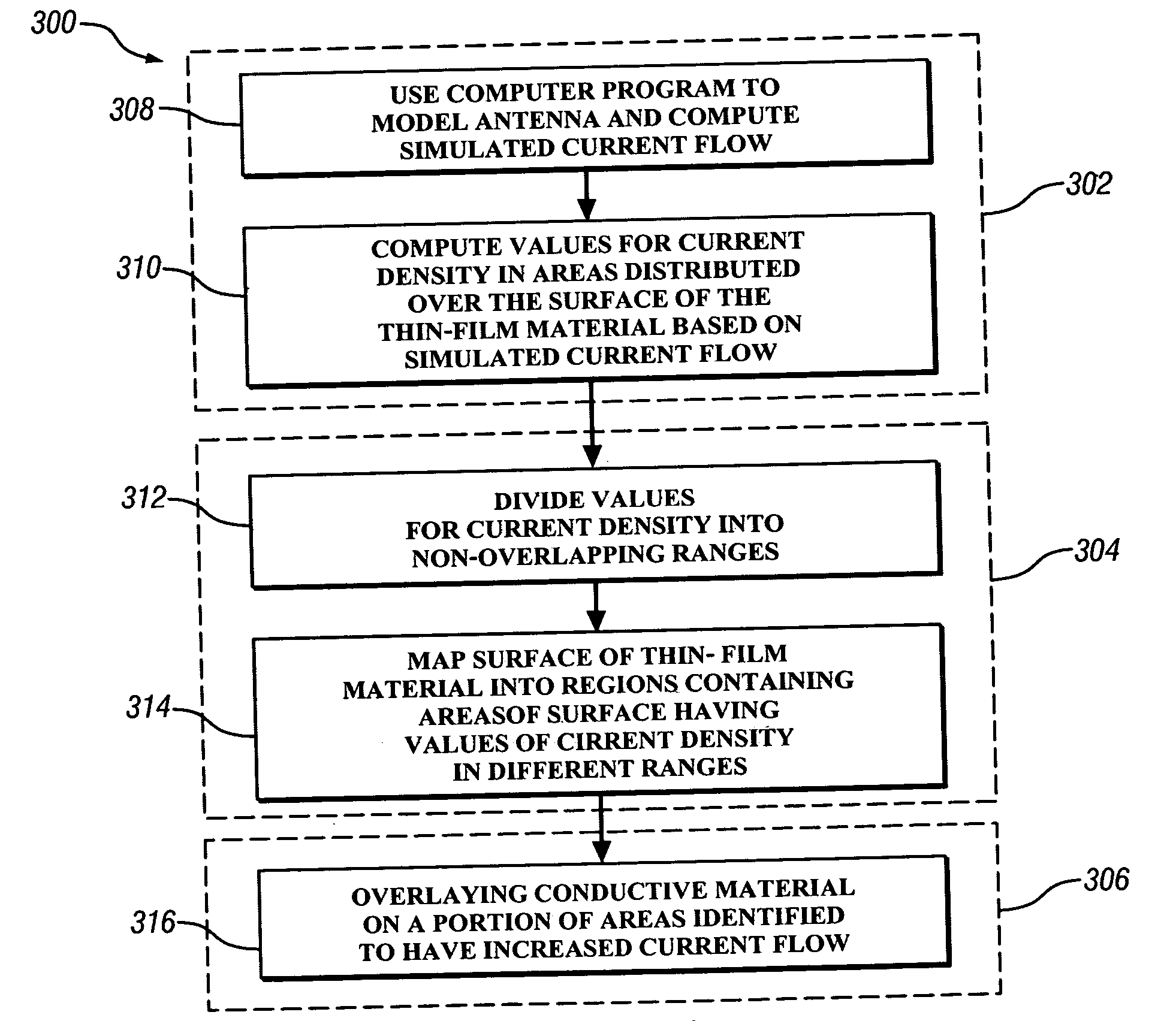

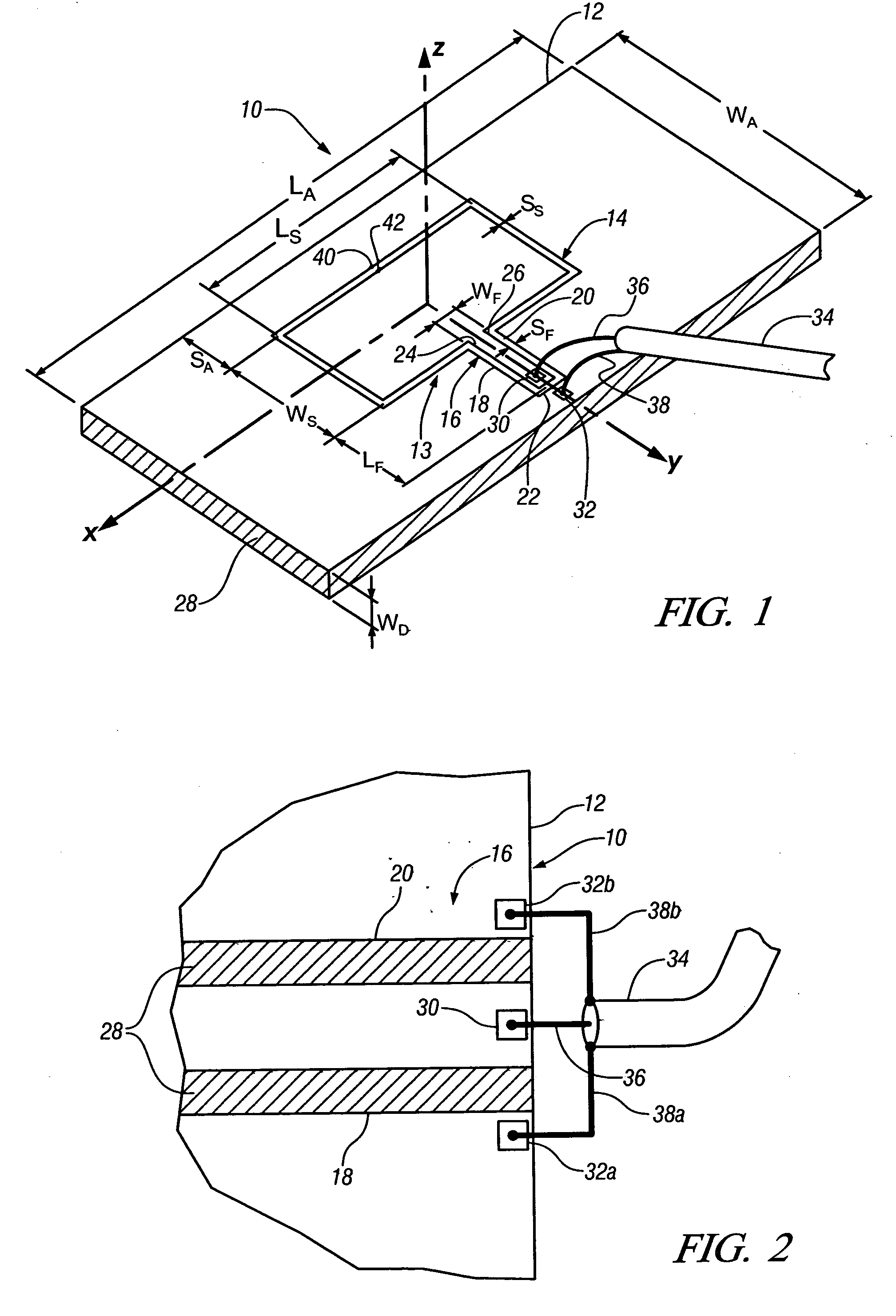

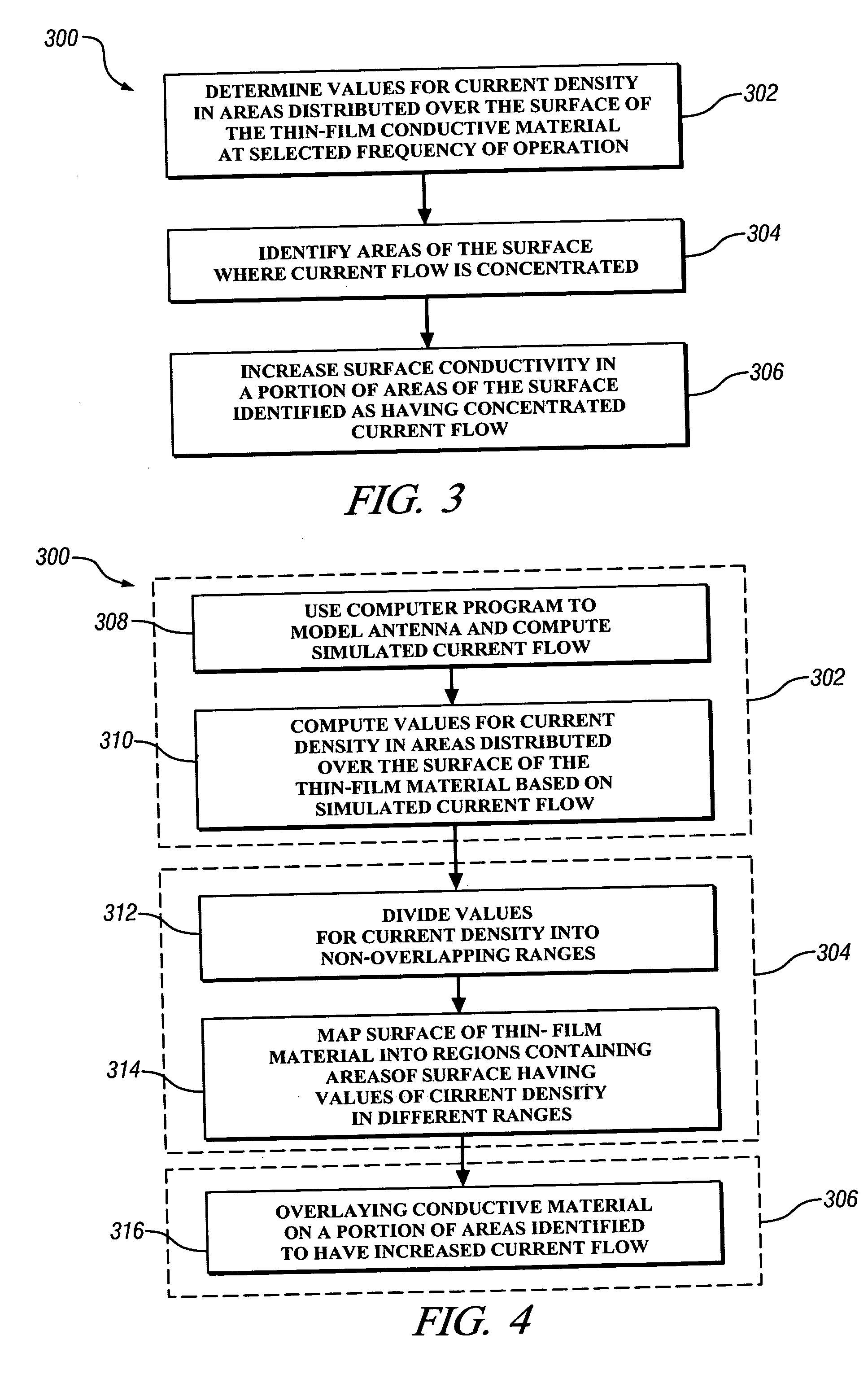

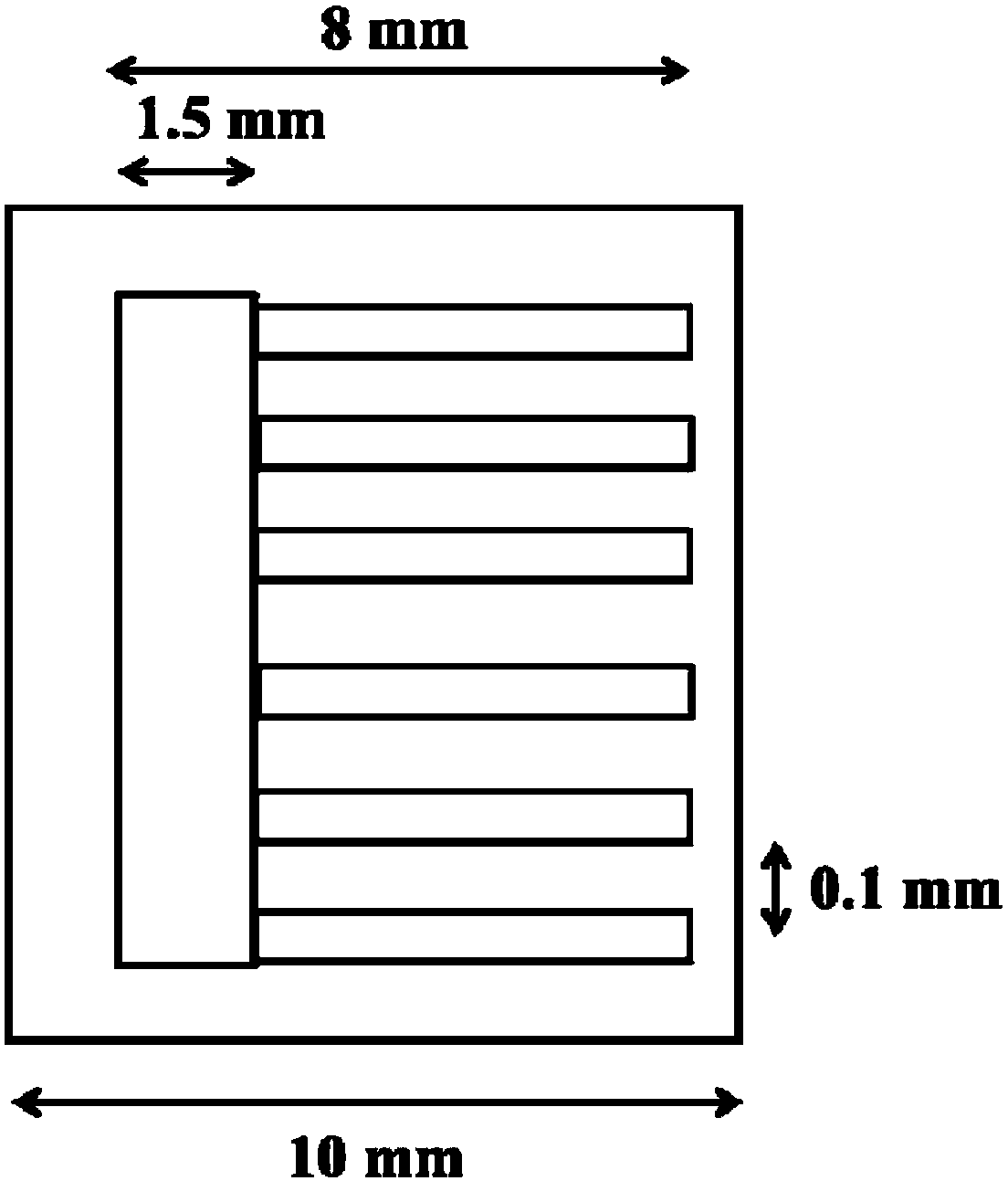

Transparent thin film antenna

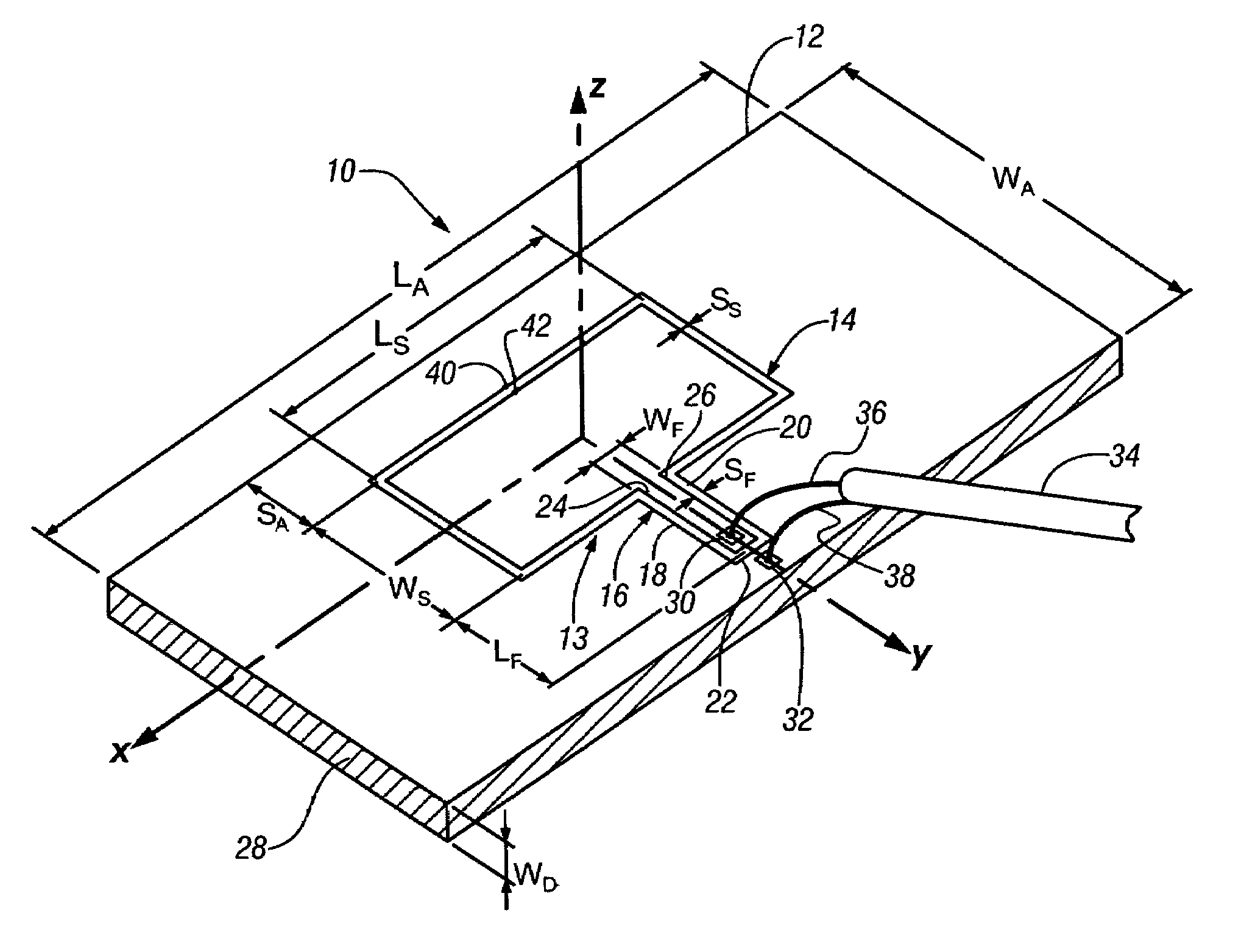

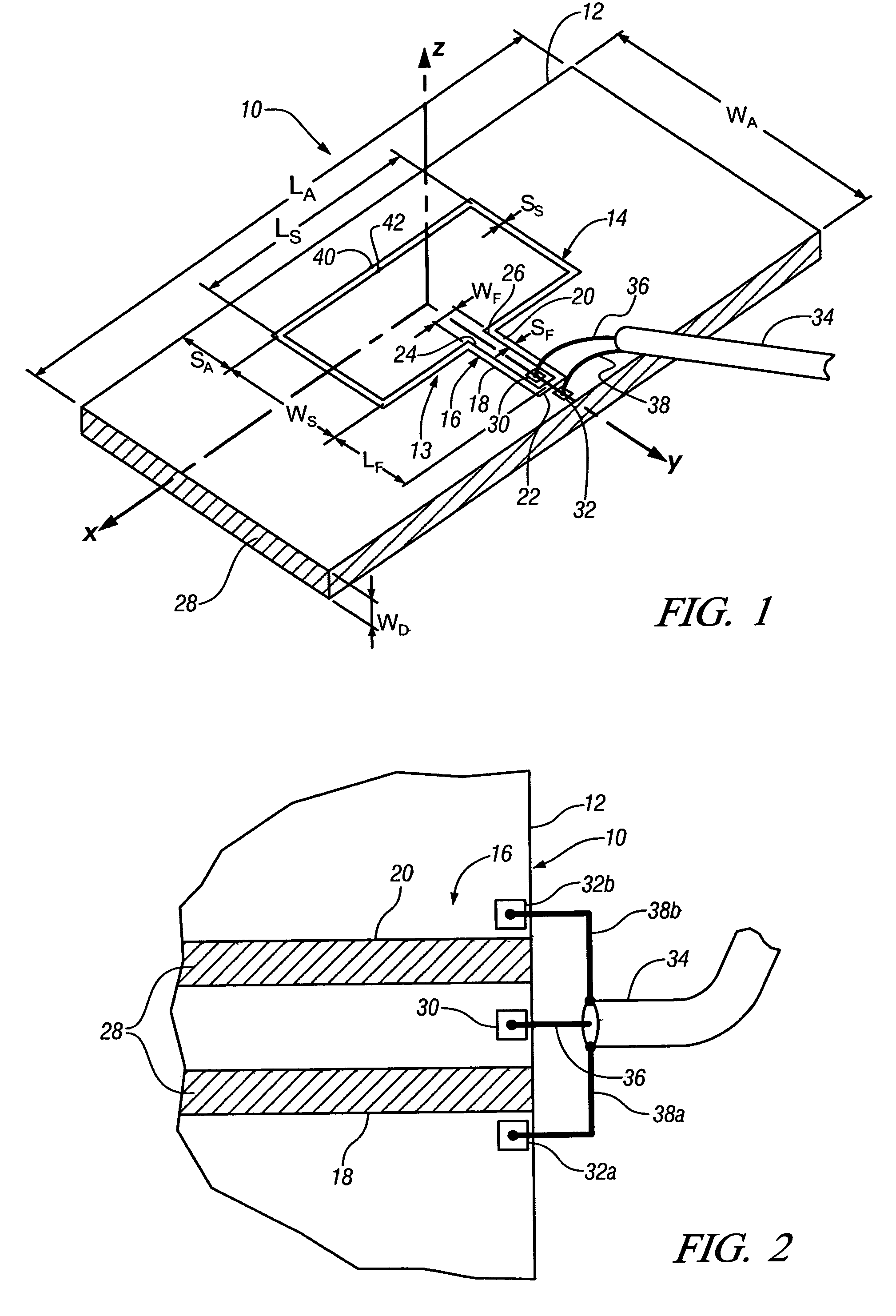

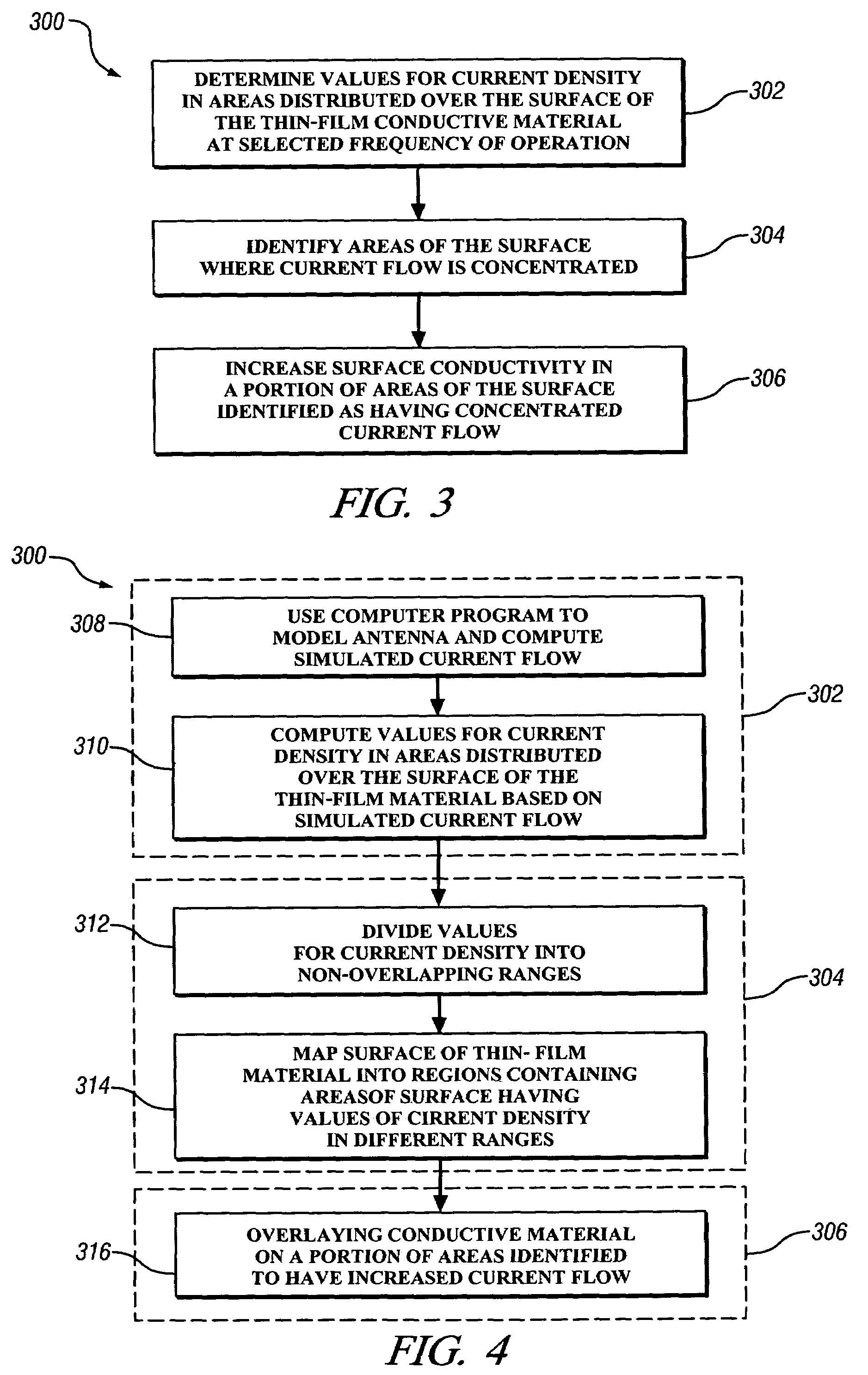

ActiveUS7233296B2Improve antenna efficiencyGood surface conductivityAntenna adaptation in movable bodiesSlot antennasEngineeringElectric current

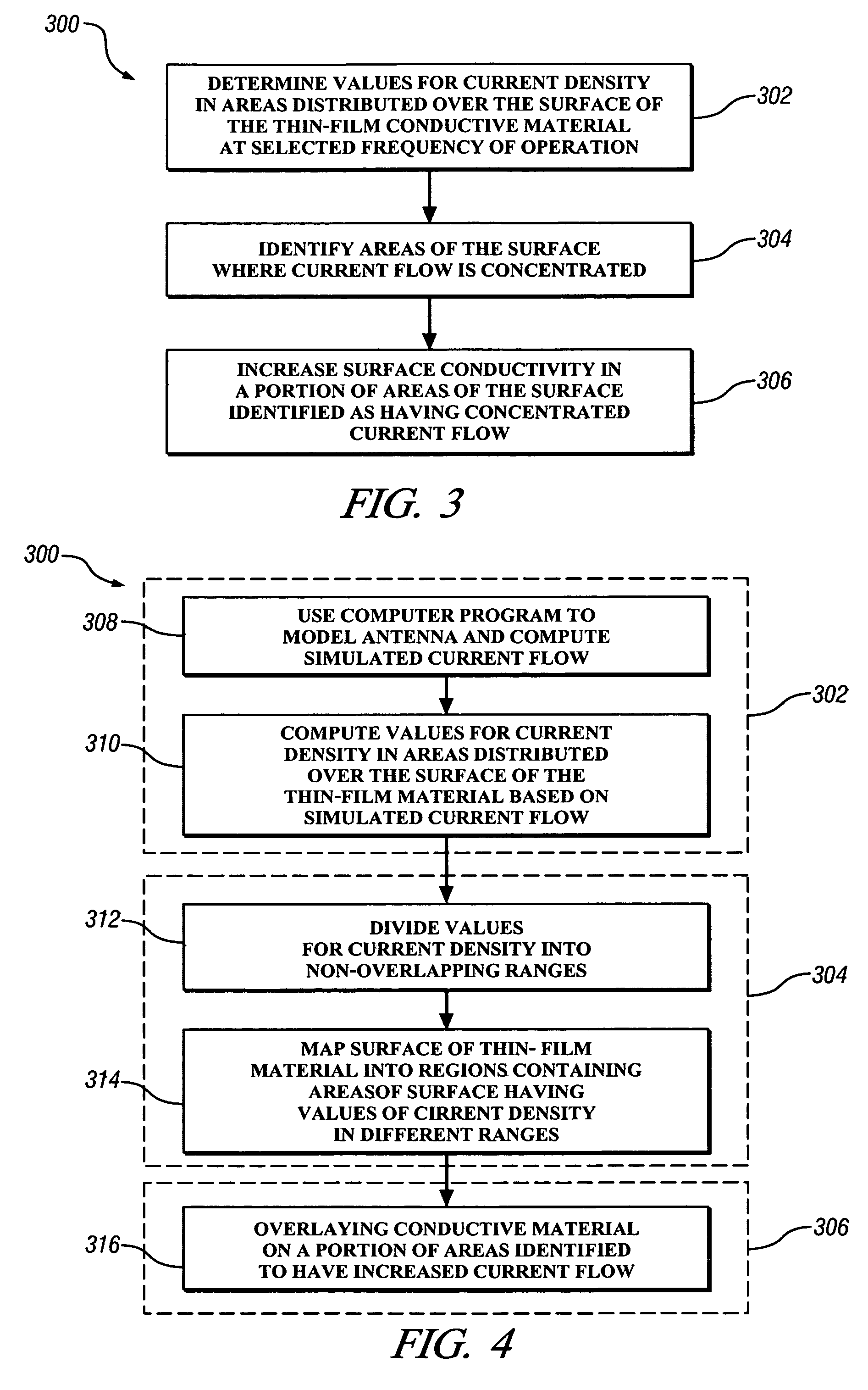

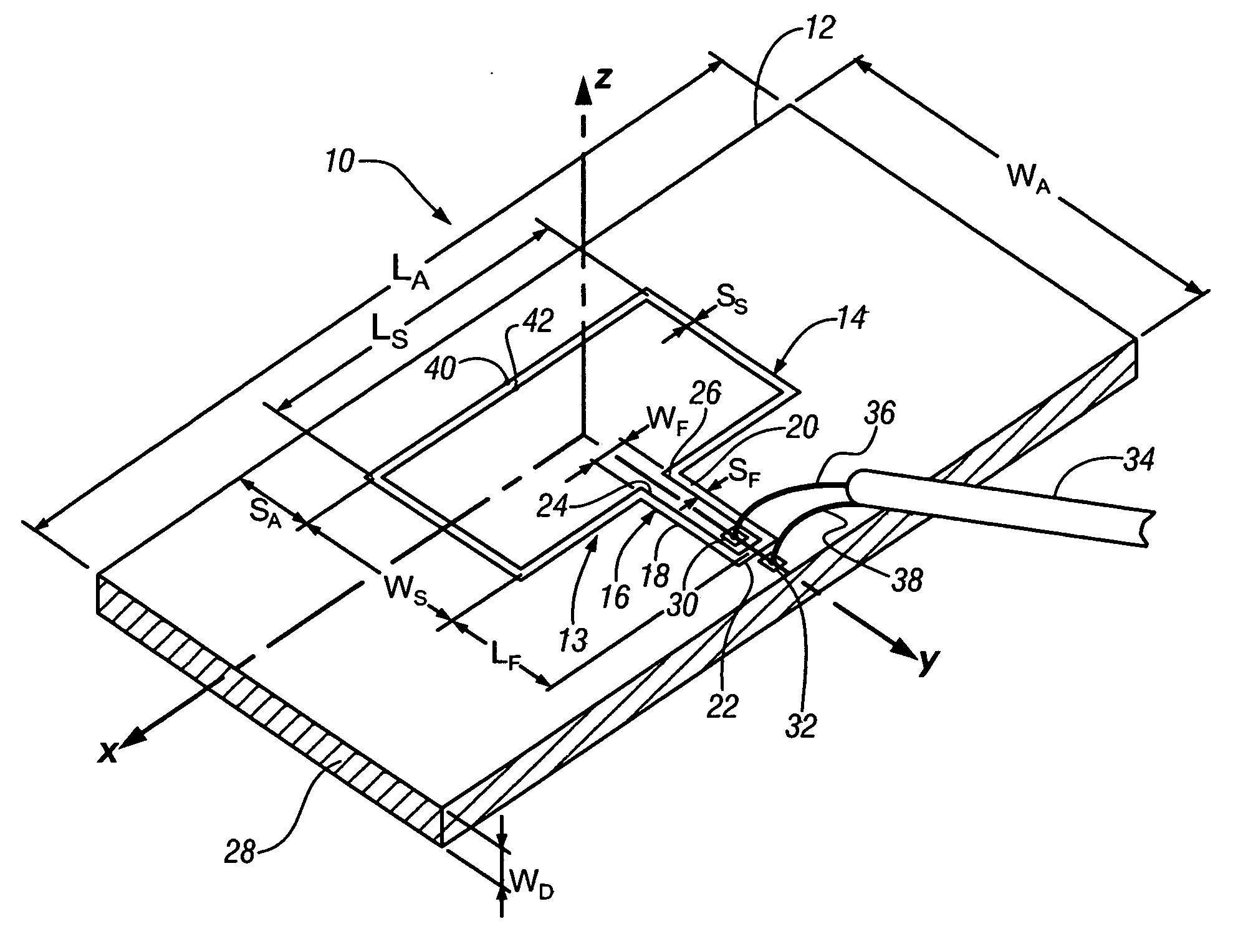

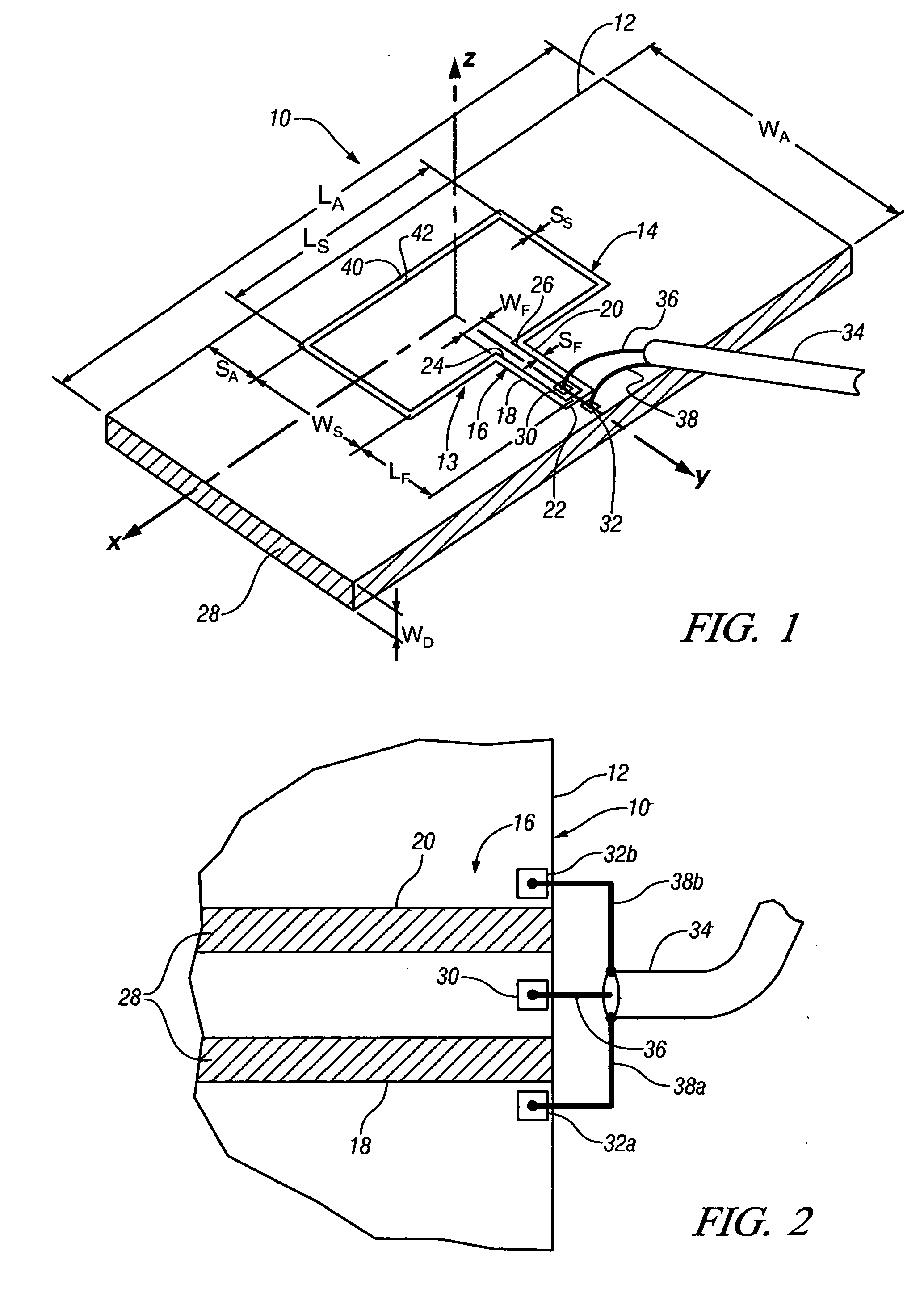

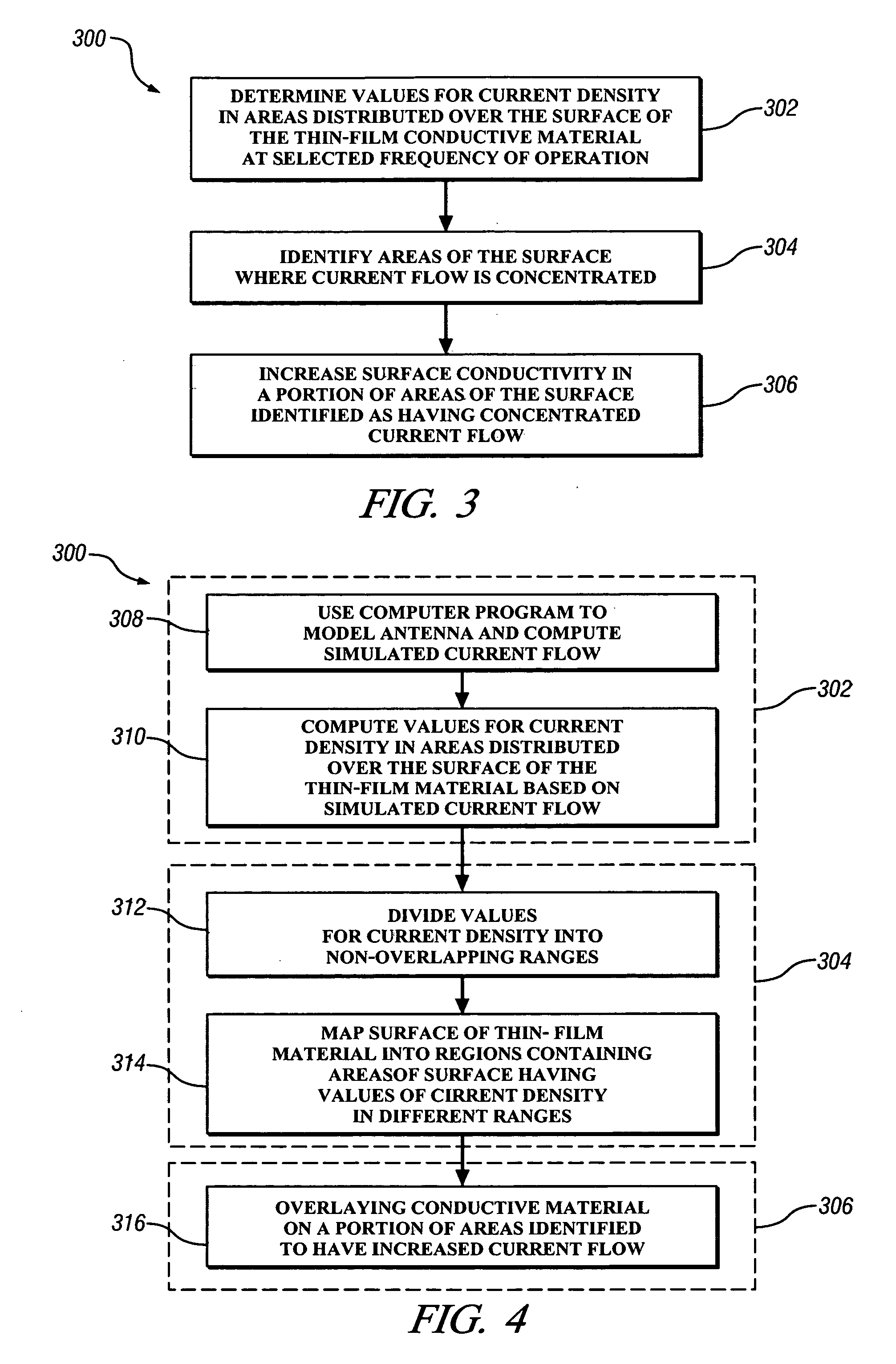

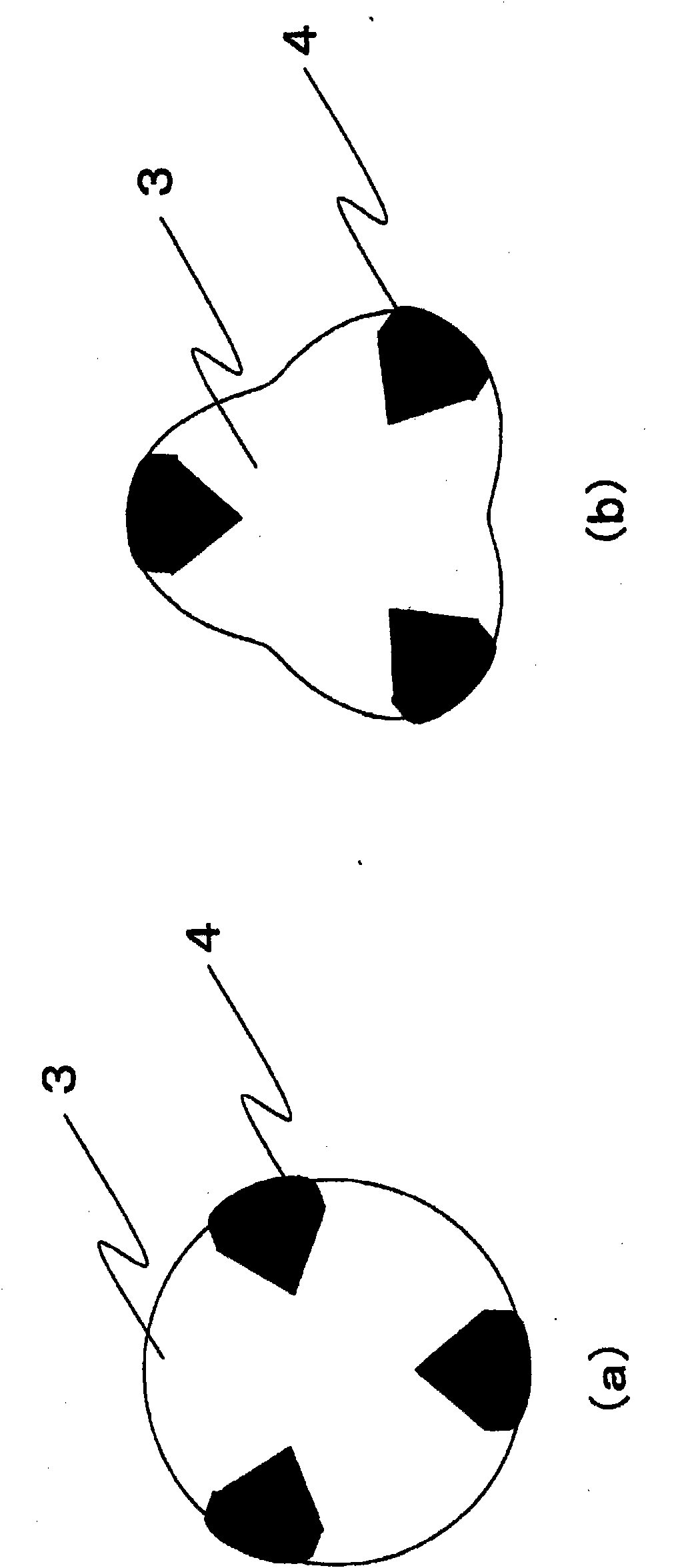

A method for improving the efficiency of antennas having transparent thin-film conductive surfaces, and antennas improved by the method are disclosed. For a selected frequency of antenna operation, values for surface current density in areas distributed over the surface of the thin-film are determined. Regions of the surface containing areas having concentrated current flow are identified based upon the determined values of current density. Antenna efficiency is improved by increasing conductivity in areas of the thin-film surface found to have concentrated current flow. The method enables the improvement of the efficiency of antennas having transparent thin-film conducting surfaces, without unnecessarily obstructing the optical view through the thin-film surfaces of the antennas.

Owner:GM GLOBAL TECH OPERATIONS LLC

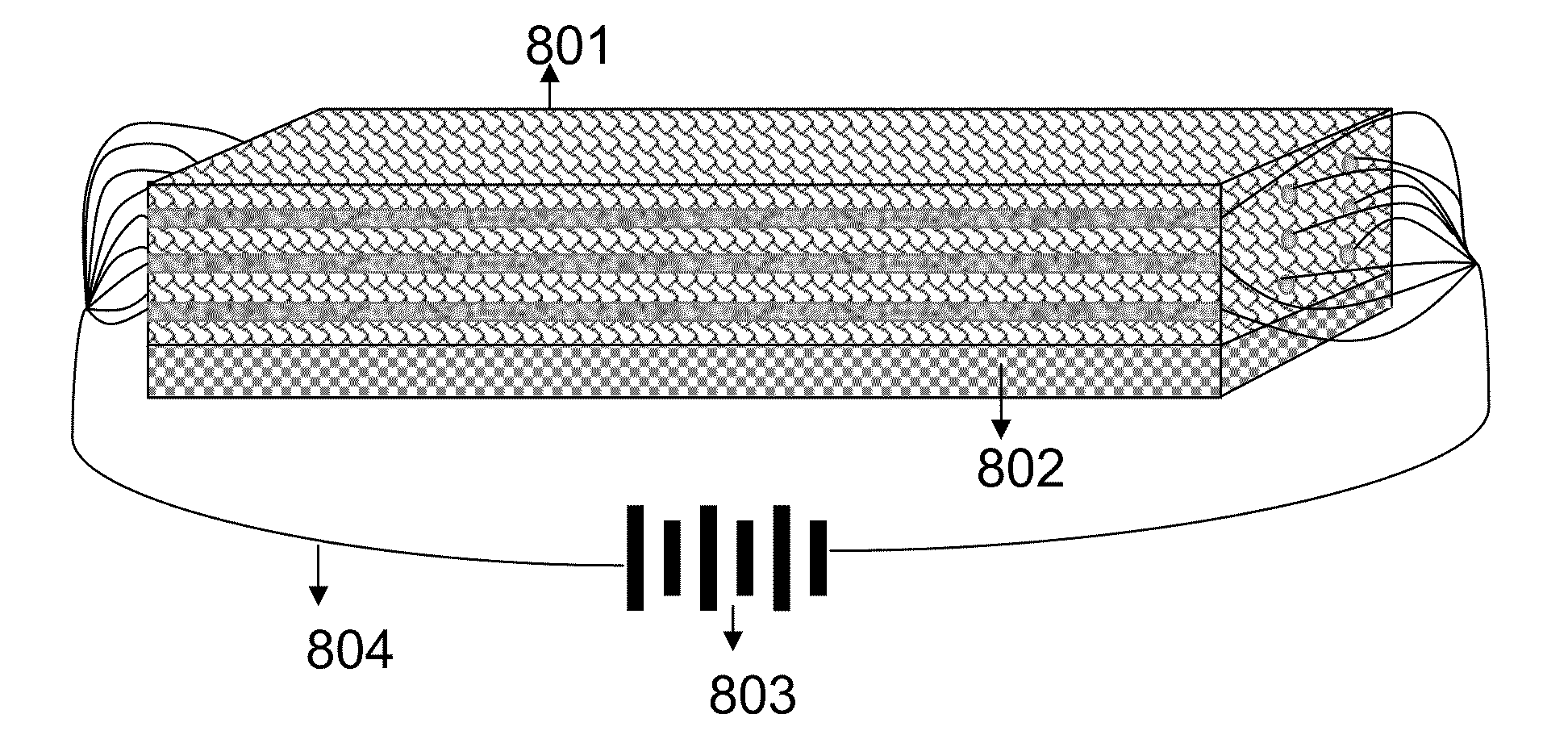

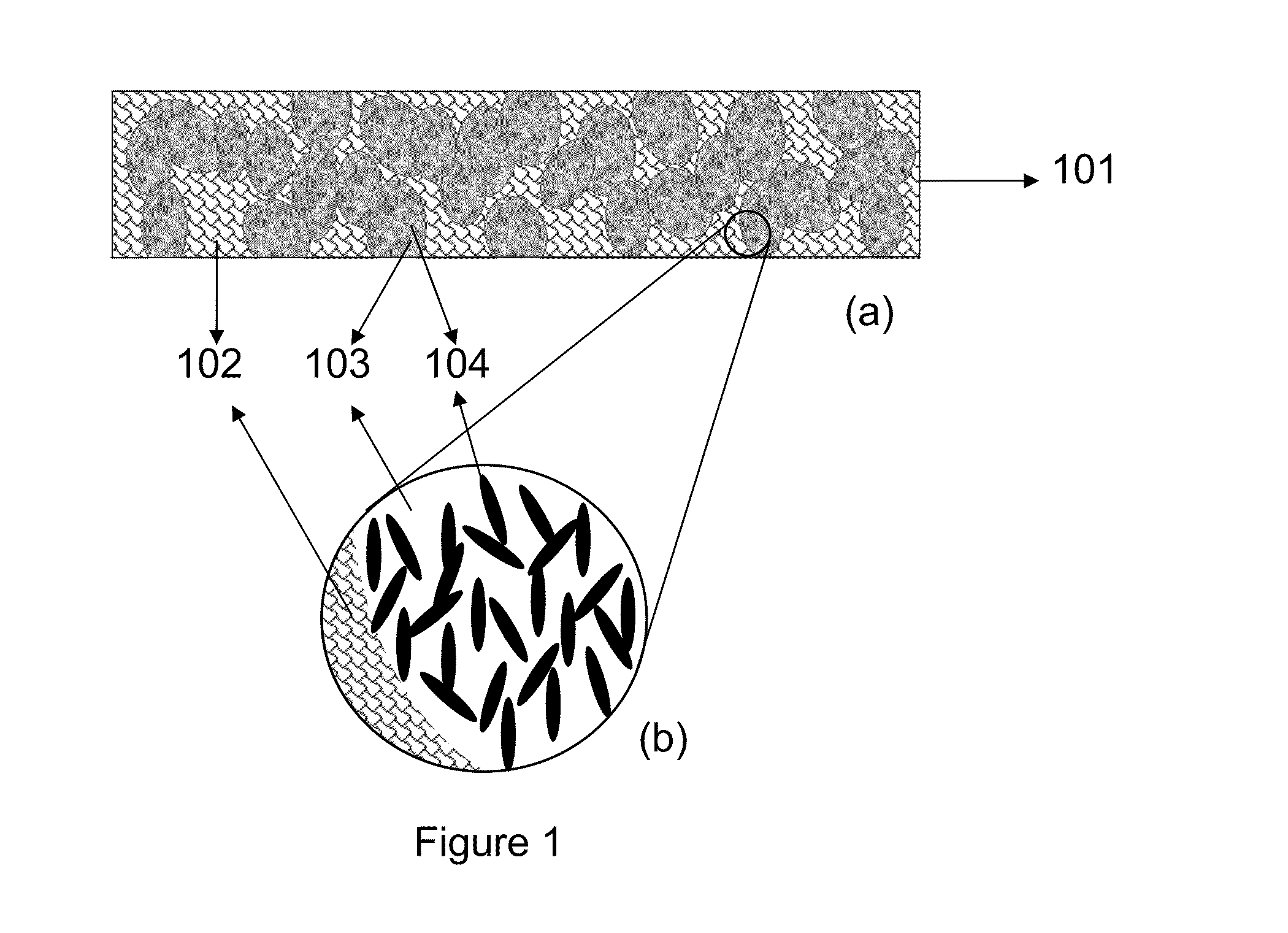

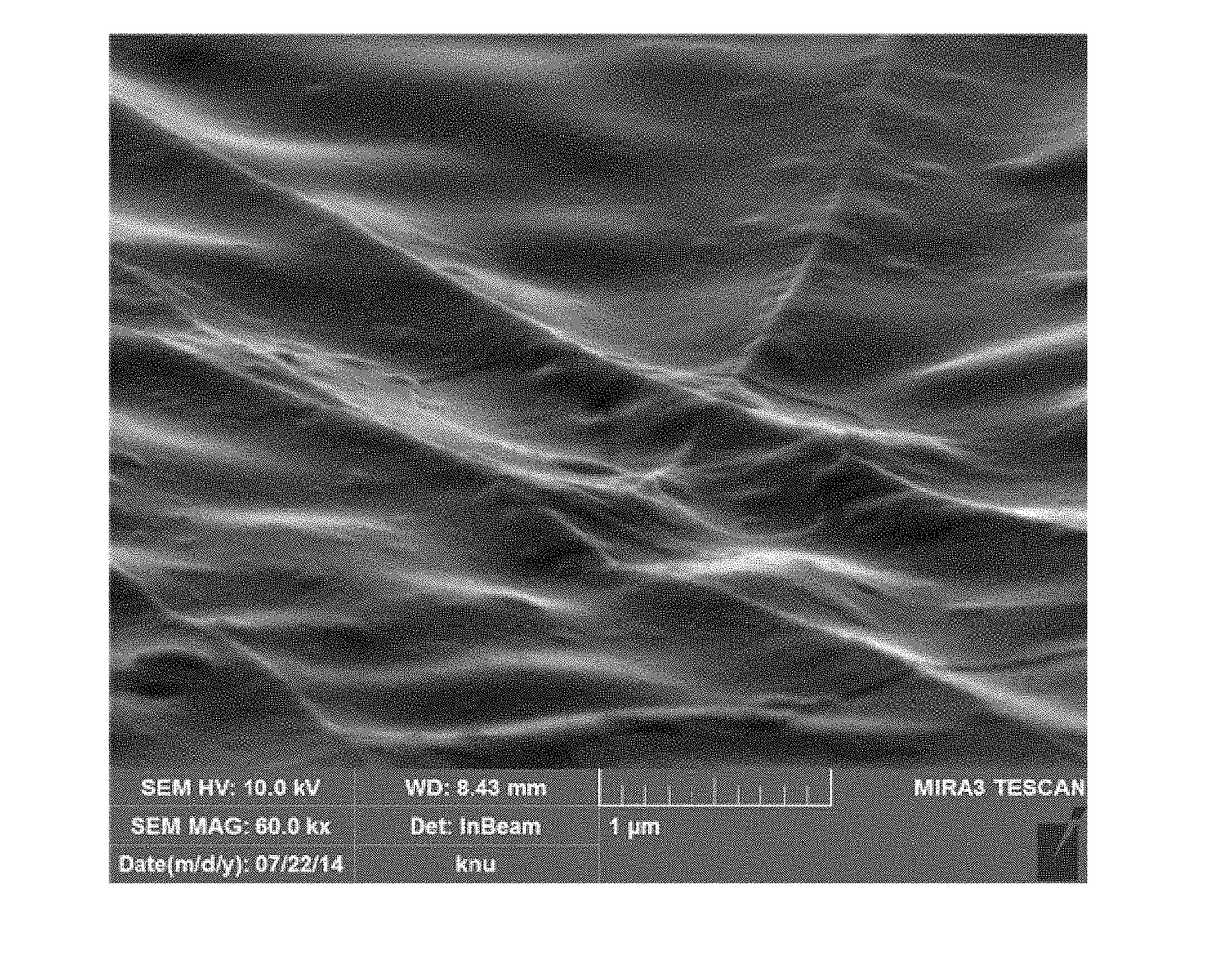

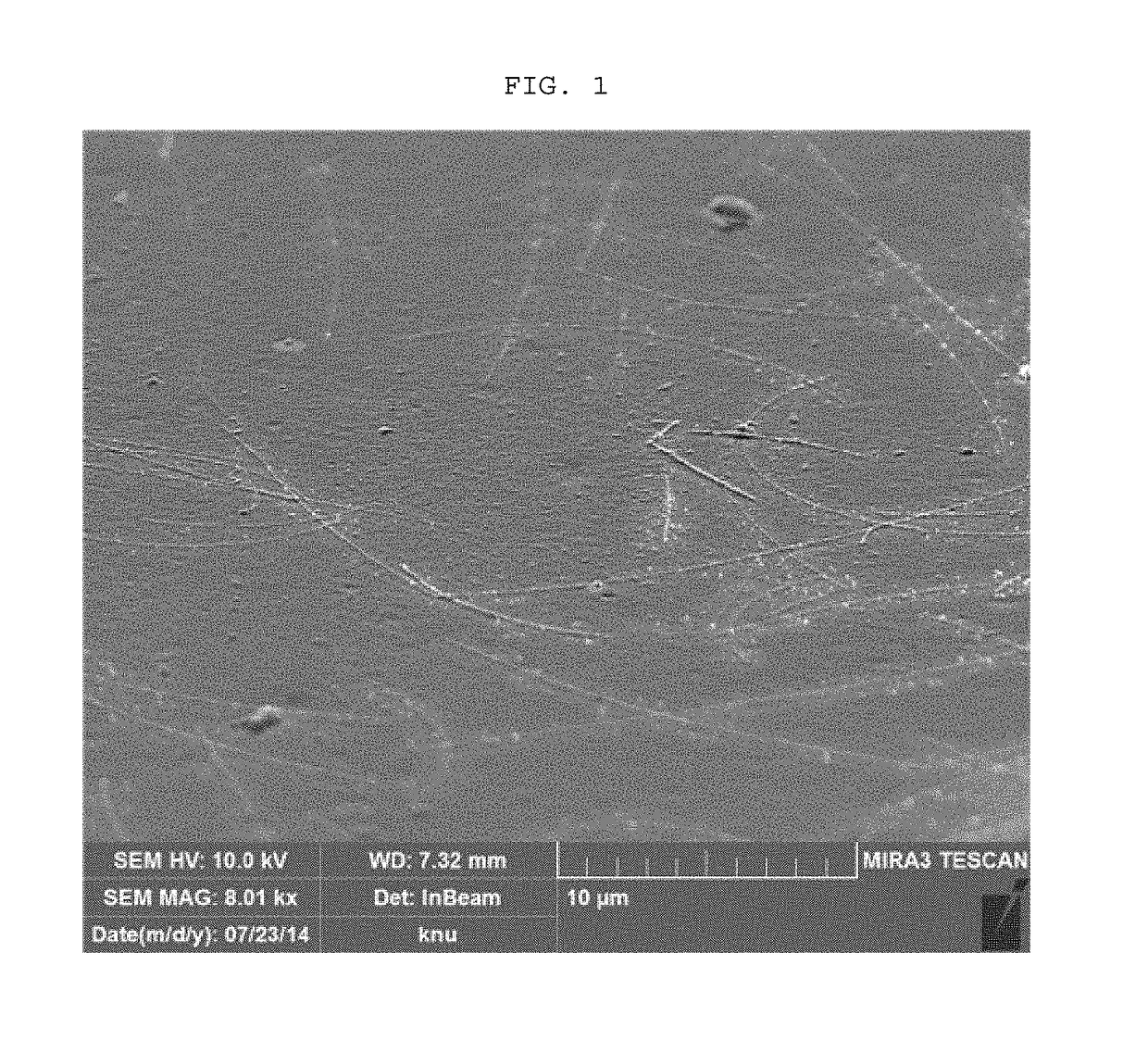

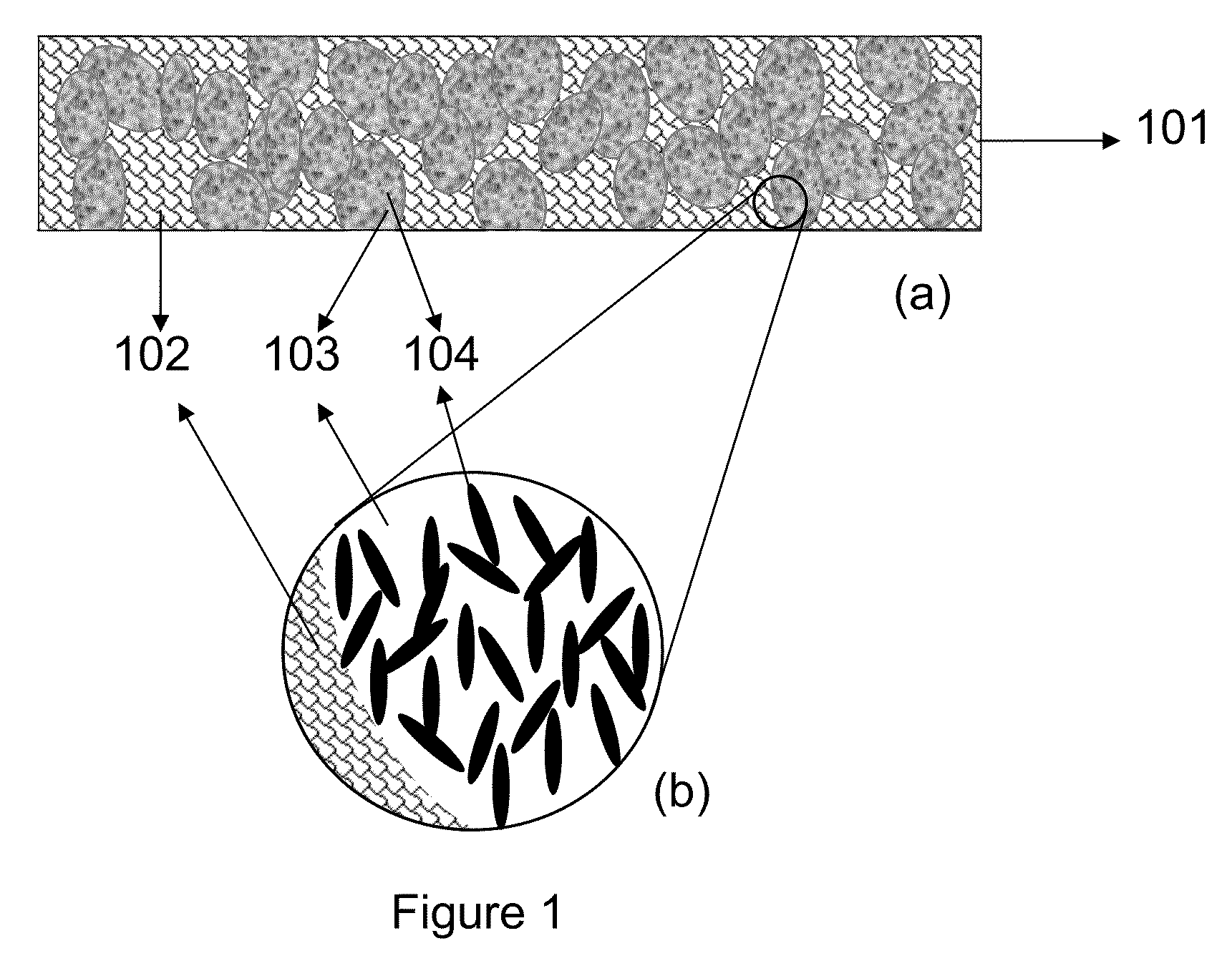

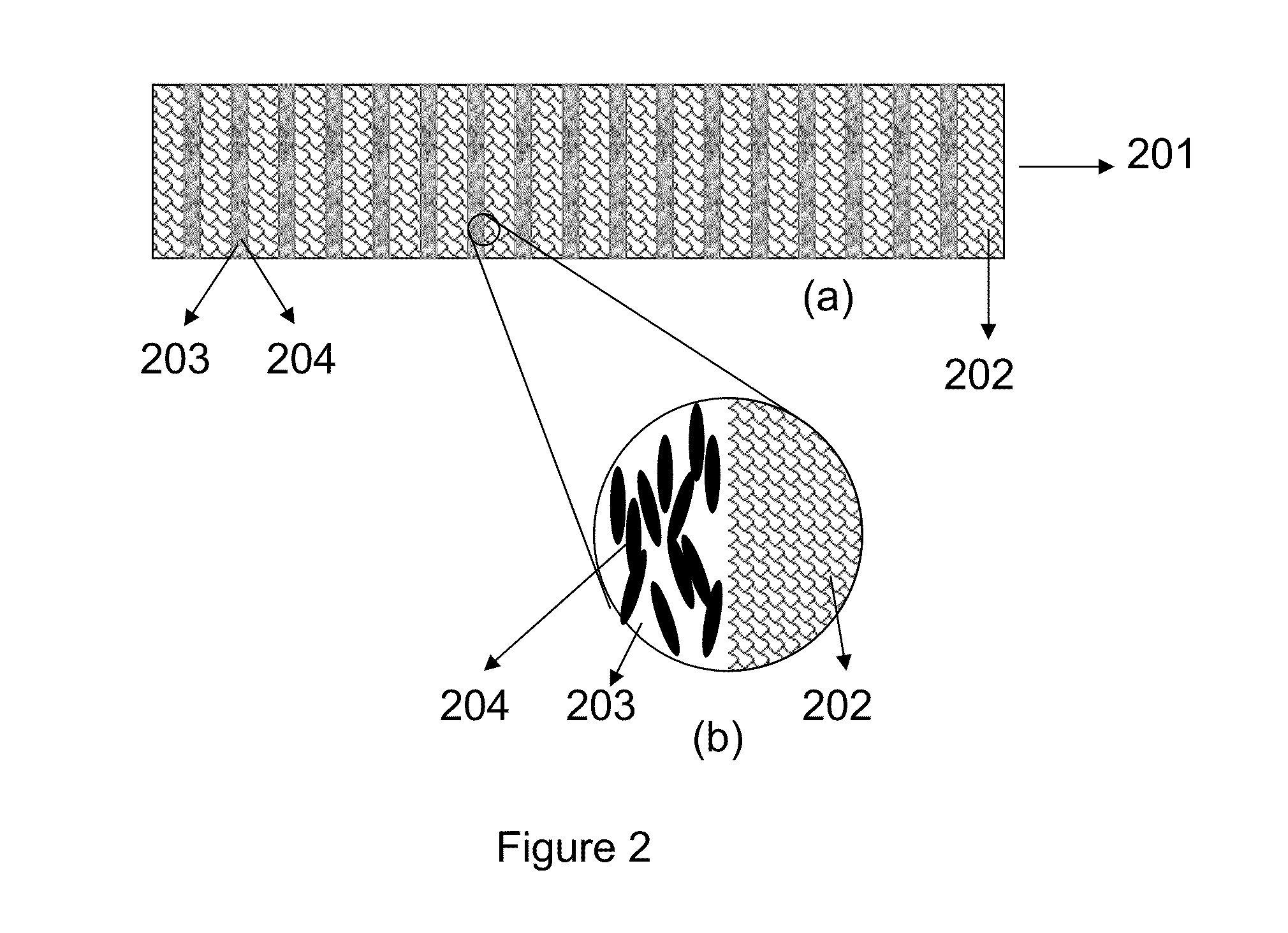

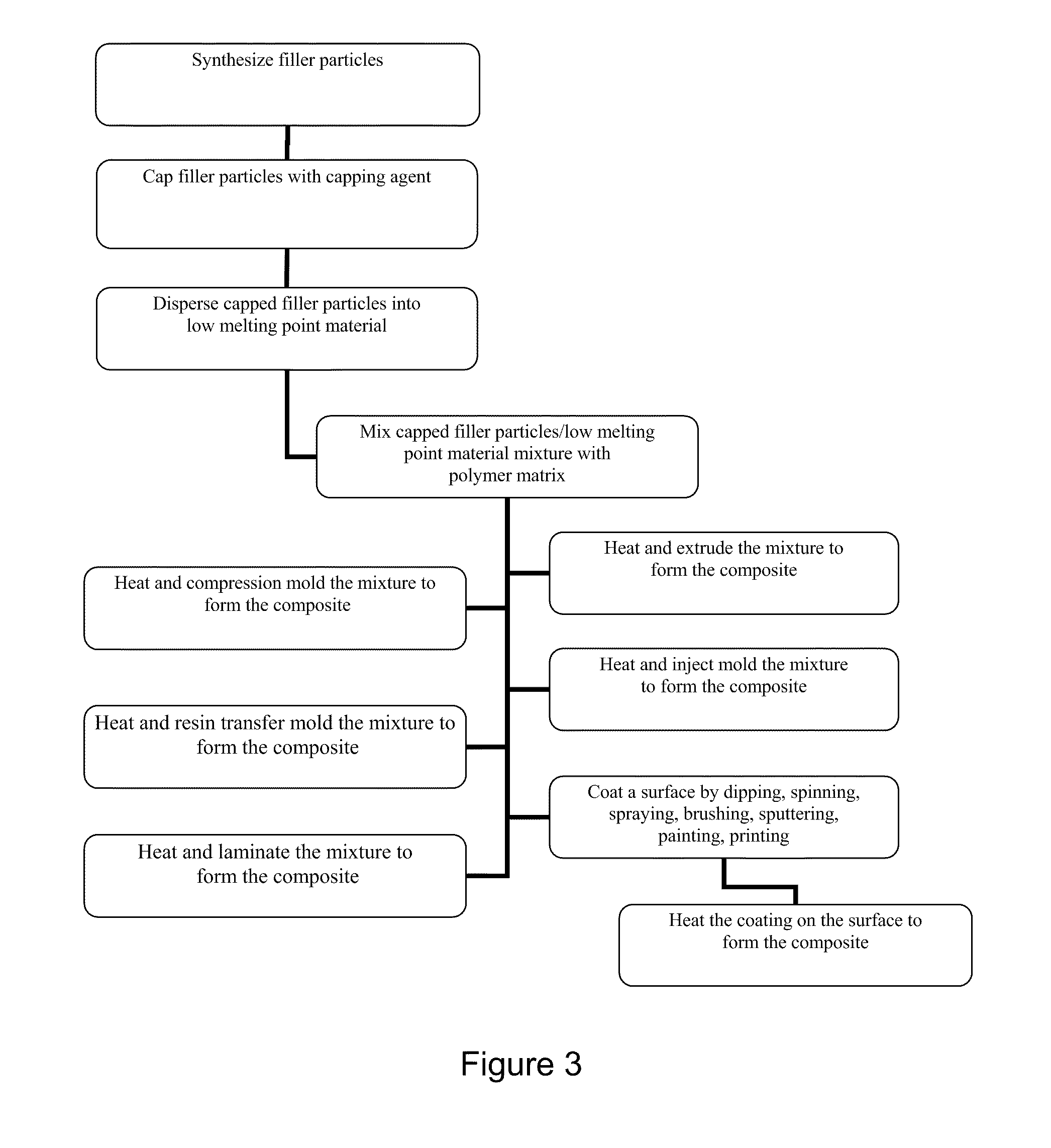

Highly conductive composites

InactiveUS20110214284A1Decreased percolation thresholdLow percolation thresholdConductive materialPretreated surfacesConductive polymerConducting pathway

Domain segregation of polymer blends or block copolymers in the presence of thermal conducting high aspect ratio nanocrystals leads to preferential placement of conductive filler either inside one domain, which promote the self-assembly of a thermal and / or electrical conducting pathway composed of high aspect ratio filler. The self-assembly of such thermal and / or electrical conducting pathway effectively enhances the thermal and / or electrical conductivity of the composite with significantly less amount of filler.

Owner:PIXELLIGENT TECH LLC

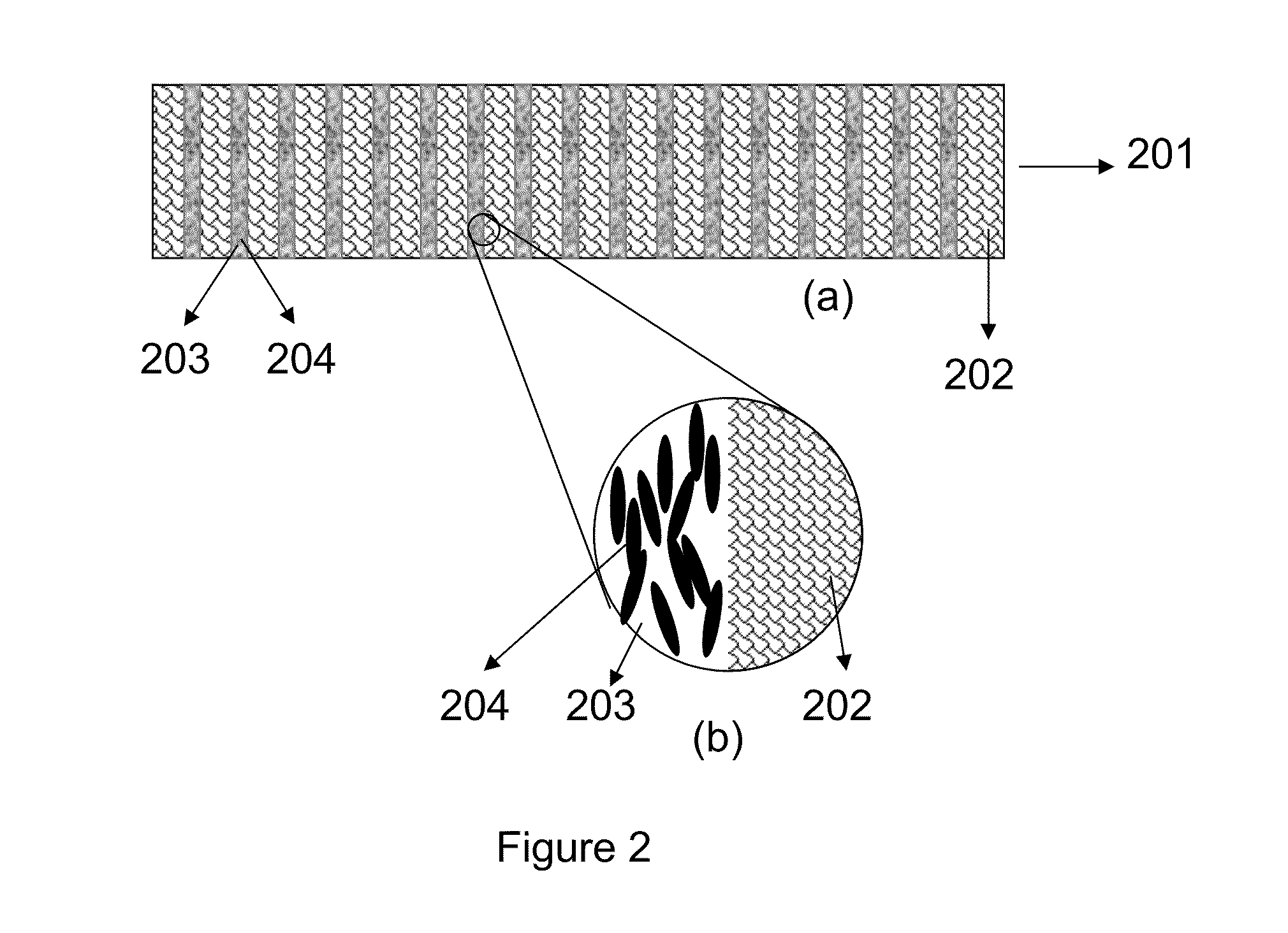

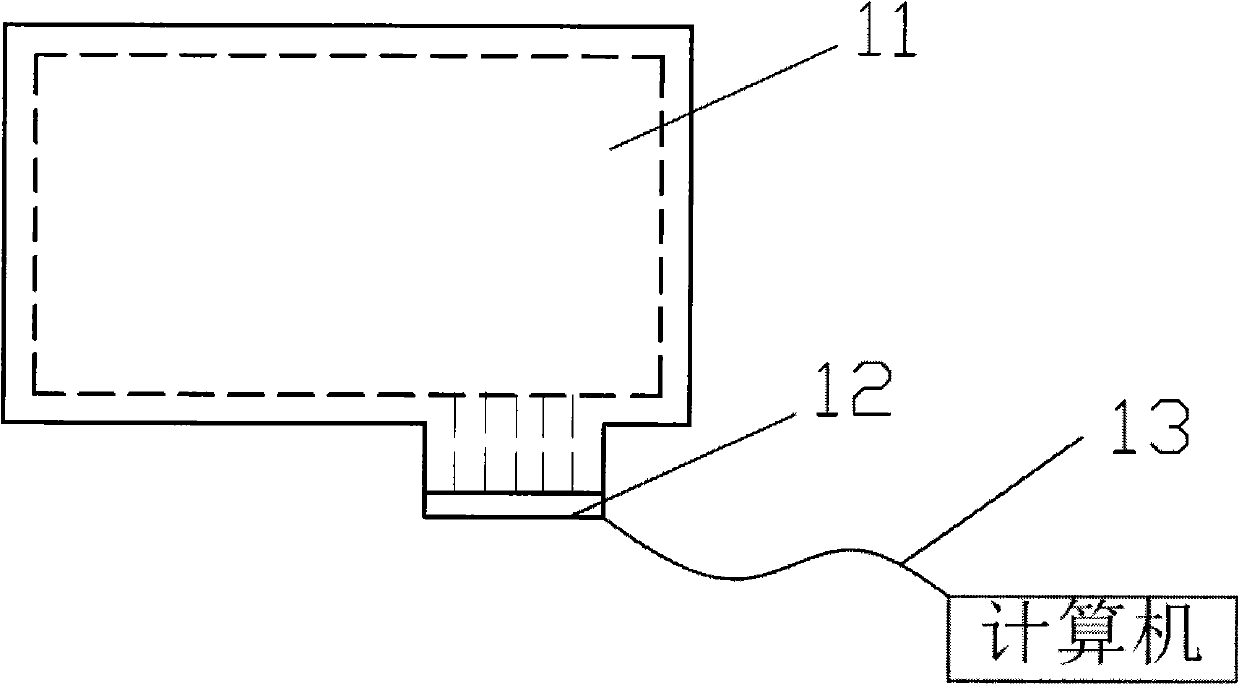

Curve screen based on nanometer touch-control membrane technique and manufacturing method thereof

ActiveCN102169388AImprove mechanical propertiesMalleableInput/output processes for data processingSystem integrationCarbon product

The invention discloses a curve screen based on nanometer touch-control membrane technique and a manufacturing method thereof. The curve screen comprises a curve substrate, wherein the curve substrate is an arc-shaped imaging device; the radian of the curve substrate is 0-180 degrees; the curve substrate is adhered to a nanometer touch-control membrane having flexibility; a sensing signal acquisition control integrated circuit is arranged on the nanometer touch-control membrane and is connected to a computer control unit through an interface; and the computer control unit is connected to the curve substrate in a wired or wireless communication manner. In the invention, the touch control technique is realized on the curved surface. The curve screen provided by the invention is suitable fordisplay devices in different sizes. The unit cost is low, the system integration is simple, and the operation is easy, thereby ensuring that the curve screen provided by the invention is a low energy-consumption and low-carbon product.

Owner:UC NANO TECH CO LTD

Transparent thin film antenna

ActiveUS20070040756A1Good surface conductivityReducing ohmic lossAntenna adaptation in movable bodiesSlot antennasVolumetric Mass DensityElectrical resistivity and conductivity

A method for improving the efficiency of antennas having transparent thin-film conductive surfaces, and antennas improved by the method are disclosed. For a selected frequency of antenna operation, values for surface current density in areas distributed over the surface of the thin-film are determined. Regions of the surface containing areas having concentrated current flow are identified based upon the determined values of current density. Antenna efficiency is improved by increasing conductivity in areas of the thin-film surface found to have concentrated current flow. The method enables the improvement of the efficiency of antennas having transparent thin-film conducting surfaces, without unnecessarily obstructing the optical view through the thin-film surfaces of the antennas.

Owner:GM GLOBAL TECH OPERATIONS LLC

Permanent antistatic paint and its prepn

InactiveCN1441012AThe preparation method is simple and easyEasy constructionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterEpoxy

The antistatic paint is prepared with resin varnish 100(in weight portions, the same below), high structure carbon black 5-40 and preferably 20-25, solvent 15-50, and coupling agent 0.1-0.3. The resin varnish is acrylate, epoxy resin, polyester or polyurethane. The production process includes stoving carbon black at 60-100 deg.c, spraying carbon black with coupling agent, adding carbon blac, resin and solvent successively into container while stirring, and ball milling. The paint of the present invention has the same antistatic effect as antistatic plastic but much less consumption and thus much lower cost, and has no influence on the other performance, such as mechanical performance, of the painted body.

Owner:NANJING PANDA ELECTRONICS

Solderable EMI Gasket and Grounding Pad

InactiveUS20090008431A1Avoid less flexibilityGood surface conductivityEngine sealsScreening gaskets/sealsElastomerEngineering

Apparatus, which is useful as both a conductive gasket and a grounding pad, which has a compressible elastomeric substrate having at least one side surface and two ends, a conductive elastomeric layer adjacent to all of the side surfaces of the compressible substrate, and a metal layer adjacent to the conductive layer.

Owner:WL GORE & ASSOC INC

Method for improving the efficiency of transparent thin film antennas and antennas made by such method

ActiveUS20070040746A1Increase surface conductivityReduce ohmic lossSimultaneous aerial operationsAntenna adaptation in movable bodiesEngineeringElectrical resistivity and conductivity

A method for improving the efficiency of antennas having transparent thin-film conductive surfaces, and antennas improved by the method are disclosed. For a selected frequency of antenna operation, values for surface current density in areas distributed over the surface of the thin-film are determined. Regions of the surface containing areas having concentrated current flow are identified based upon the determined values of current density. Antenna efficiency is improved by increasing conductivity in areas of the thin-film surface found to have concentrated current flow. The method enables the improvement of the efficiency of antennas having transparent thin-film conducting surfaces, without unnecessarily obstructing the optical view through the thin-film surfaces of the antennas.

Owner:GM GLOBAL TECH OPERATIONS LLC

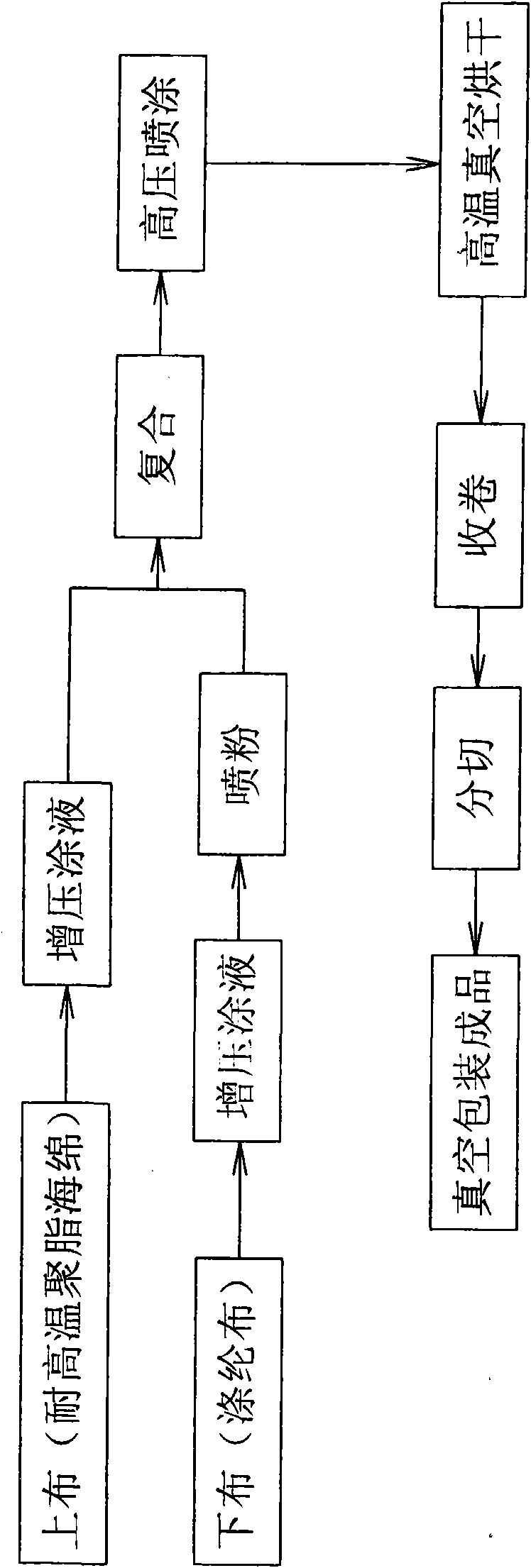

Production method of semi-conductive buffer water-blocking band

ActiveCN101567236AGood surface conductivityReduce surface resistanceFibre treatmentClimate change adaptationPolyesterVacuum pack

The invention relates to a production method of a water-blocking band, in particular to a production method of a semi-conductive buffer water-blocking band. The production method comprises the following steps: firstly, supercharging and soaking a high-temperature resistant polyester sponge and terylene cloth in conductive liquid, spraying high water-absorbent resin on the terylene cloth and compounding the high-temperature resistant polyester sponge and the terylene cloth; then, spraying the conductive liquid with a high-pressure spray gun and drying the high-temperature resistant polyester sponge and the terylene cloth which are compounded in vacuum at a high temperature; and finally, coiling, cutting and packaging the high-temperature resistant polyester sponge and the terylene cloth which are compounded in vacuum to be a finished semi-conductive buffer water-blocking band . Proved by detection, the semi-conductive buffer water-blocking band has the advantages of high intensity, thinness, rapid swelling in water, high water absorption, good water-blocking effect, high-temperature environment influence resistance, small surface resistance, low volume electric resistivity, European Union environmental protection accordance, and the like, can satisfy the water blocking and the electric field shielding among parts of power cables, and the like, maintains the safe use of the cables, can generate the semi-conductive shielding action so as to buffer an electric field, can be lined at the inner side of a metal protective sleeve to buffer the friction between the inner protective sleeve and the metal protective sleeve and can satisfy the normal working temperature of the cables.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

Preparation method of composite antistatic agent for fiber fabric

The invention discloses a preparation method of a composite antistatic agent for a fiber fabric. The composite antistatic agent for the fiber fabric in the preparation method comprises the following components: a butanol phosphate ester antistatic agent, a terminal hydroxyl hyperbranched antistatic agent, a terminal carboxyl hyperbranched antistatic agent and a terminal quaternary ammonium salt hyperbranched antistatic agent; and the preparation method comprises the following steps: firstly, respectively preparing the butanol phosphate ester antistatic agent, the terminal hydroxyl hyperbranched antistatic agent, the terminal carboxyl hyperbranched antistatic agent and the terminal quaternary ammonium salt hyperbranched antistatic agent; and mixing the four antistatic agents to prepare the composite antistatic agent for the fiber fabric. The preparation method is simple and feasible; and the prepared antistatic agent has a good antistatic effect, good heat resistance and good acid and alkali resistance.

Owner:SUZHOU CHENHENG WEAVING

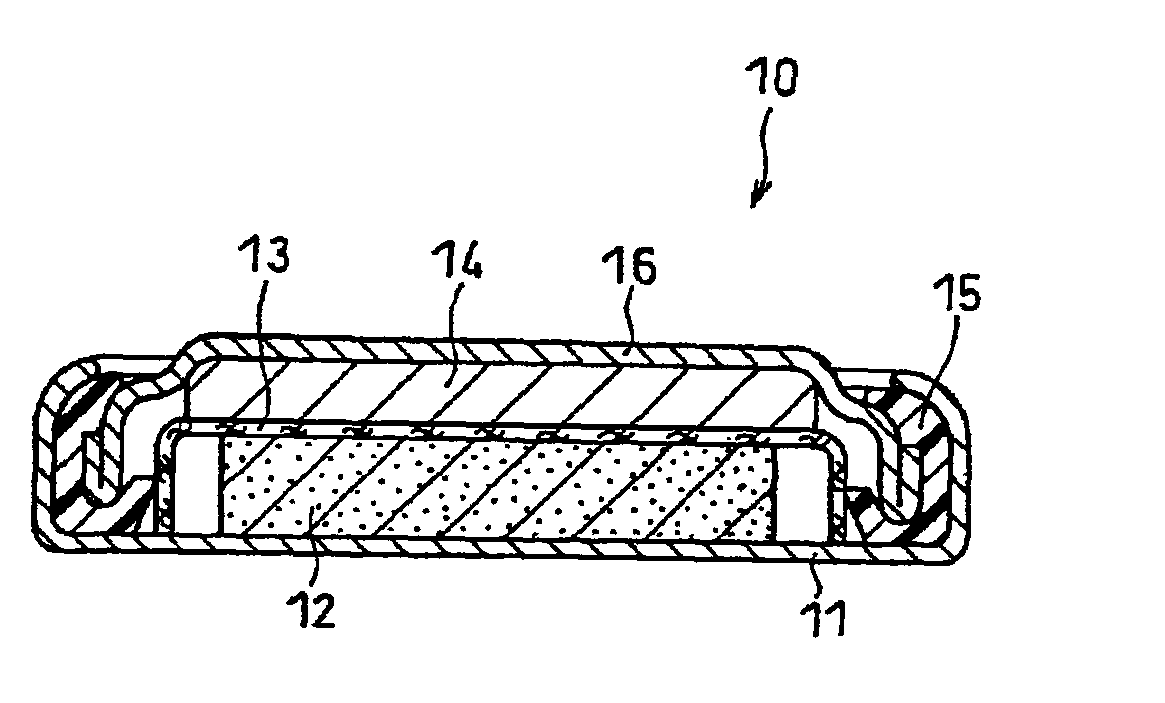

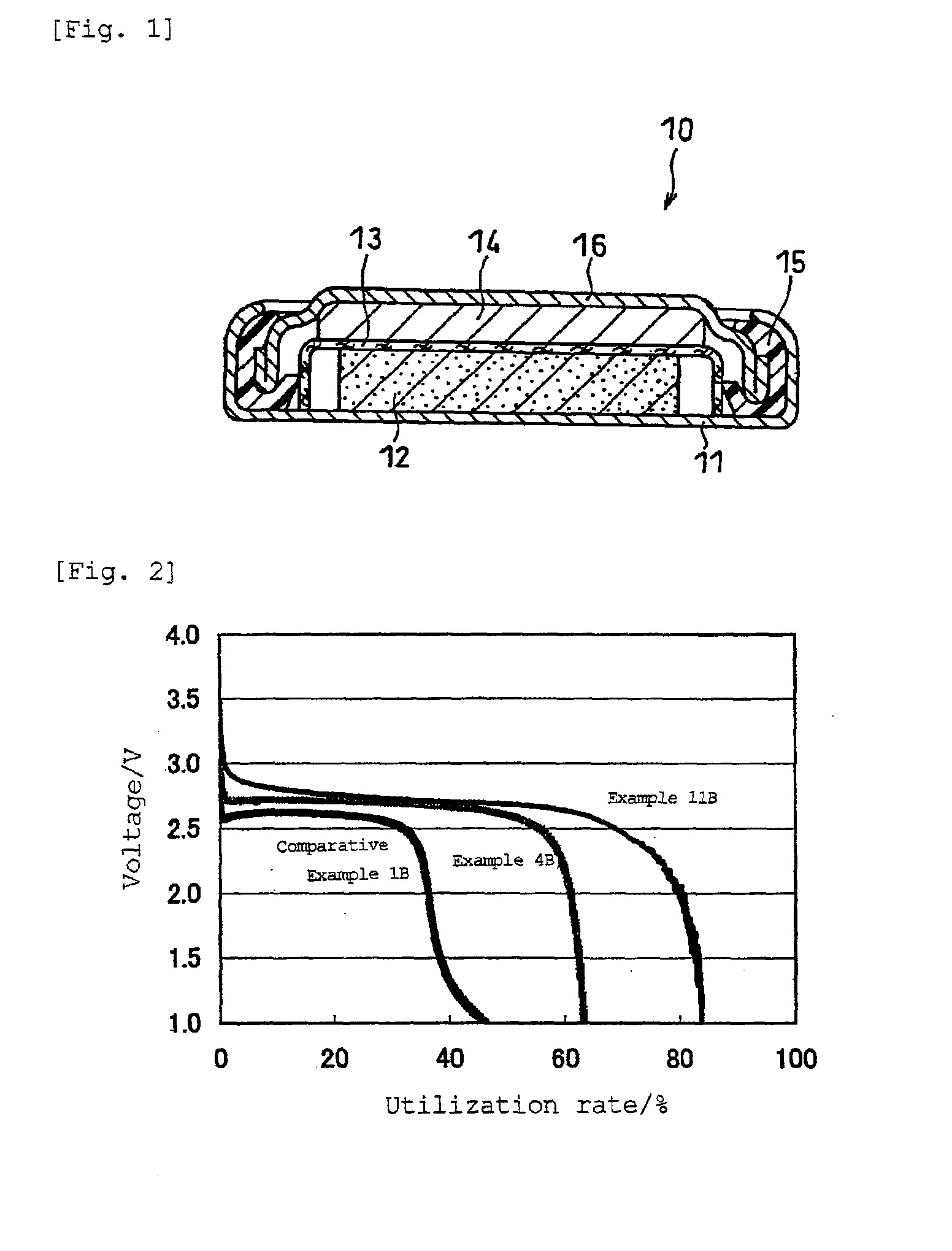

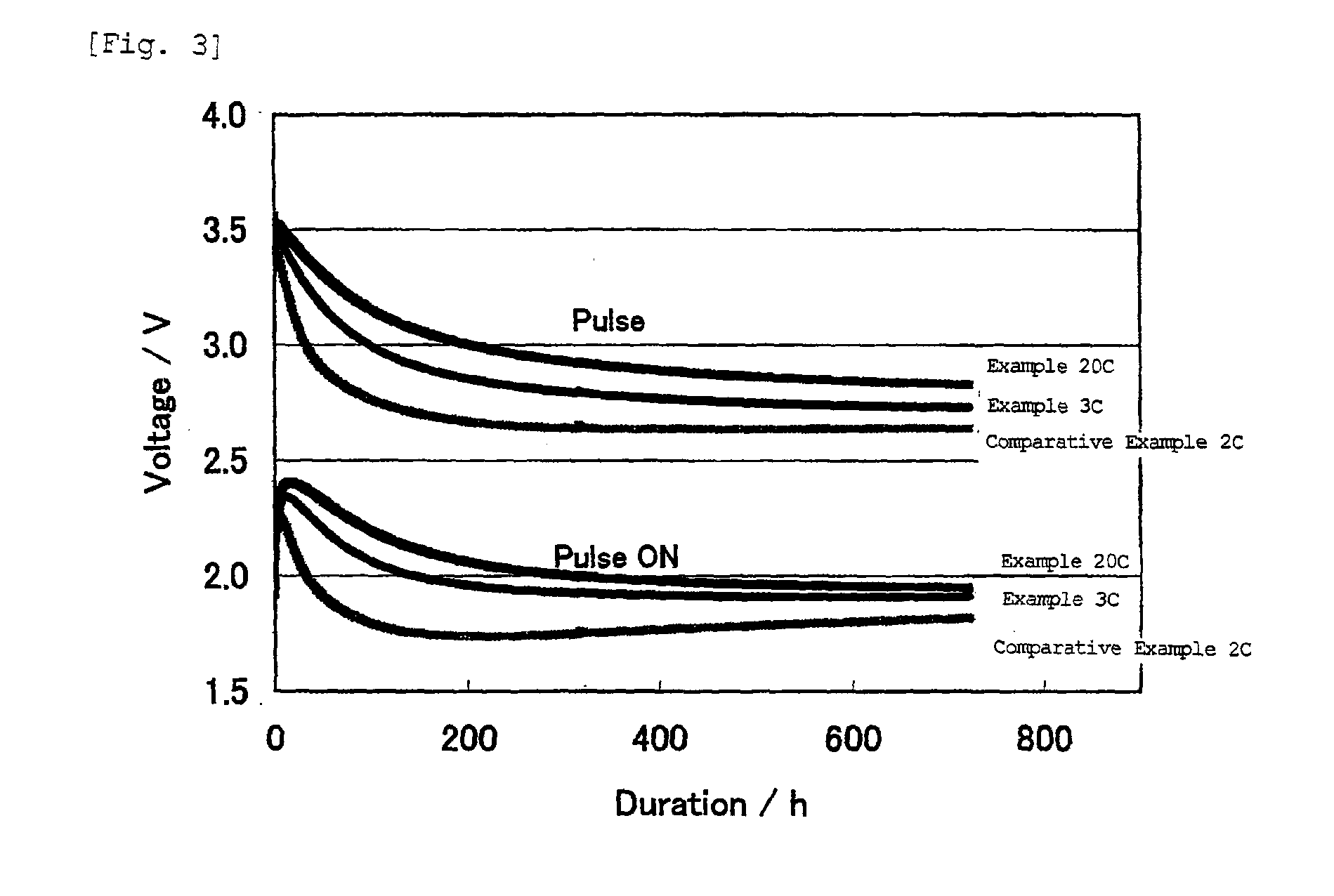

Non-aqueous electrolyte battery

InactiveUS20100203390A1Excellent in large-current discharge characteristicGood surface conductivityGraphiteOrganic electrolyte cellsGraphiteAlloy

A non-aqueous electrolyte battery including a negative electrode including metal lithium or a lithium alloy as a negative electrode active material, a positive electrode including a fluorinated graphite as a positive electrode active material, a separator provided between the positive electrode and the negative electrode, and a non-aqueous electrolyte. The concentration ratio [F] / [C] of fluorine atoms to carbon atoms on the surface of the fluorinated graphite is 1.0 or more and less than 1.8. This improves the large-current discharge characteristics particularly in a low temperature environment.

Owner:PANASONIC CORP

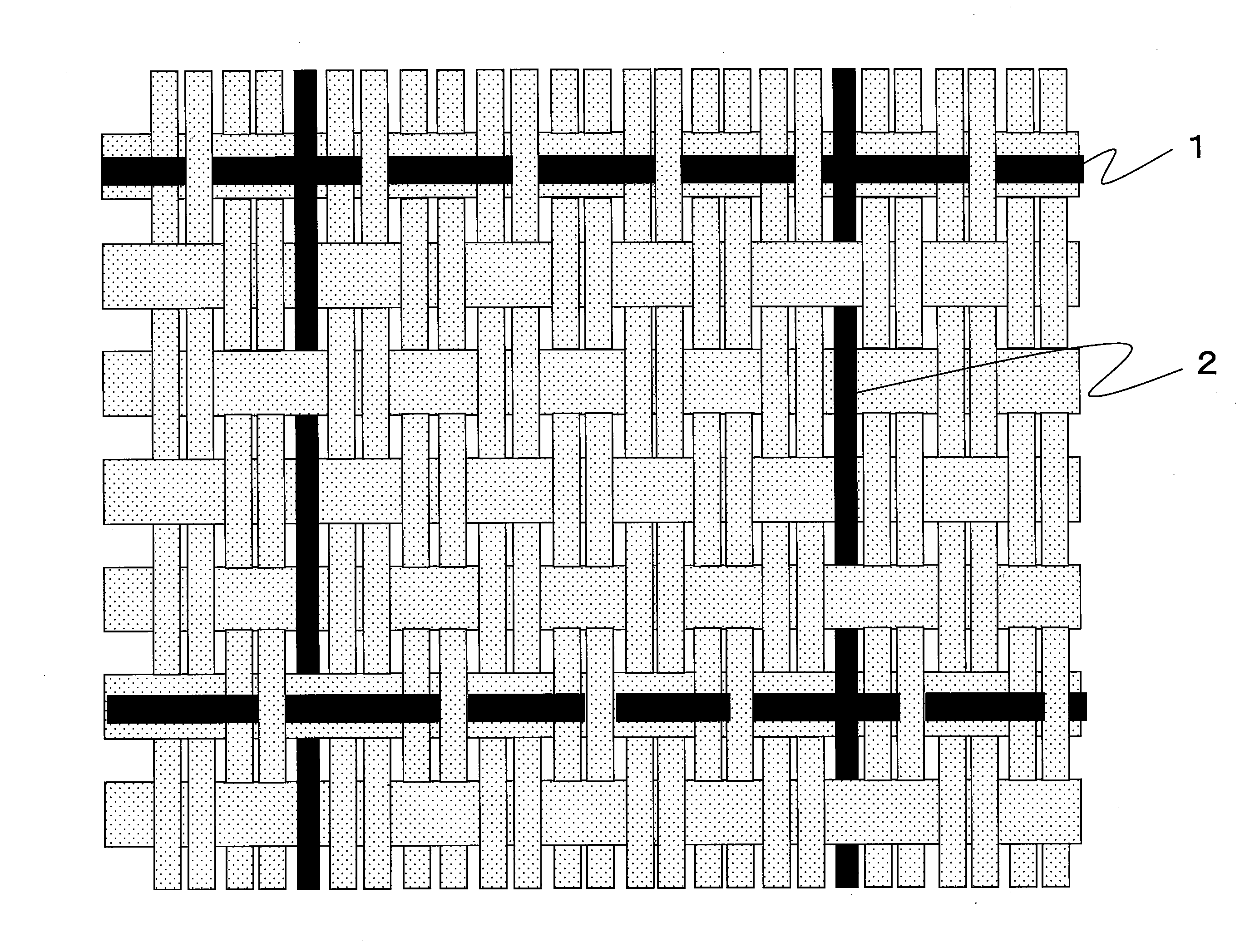

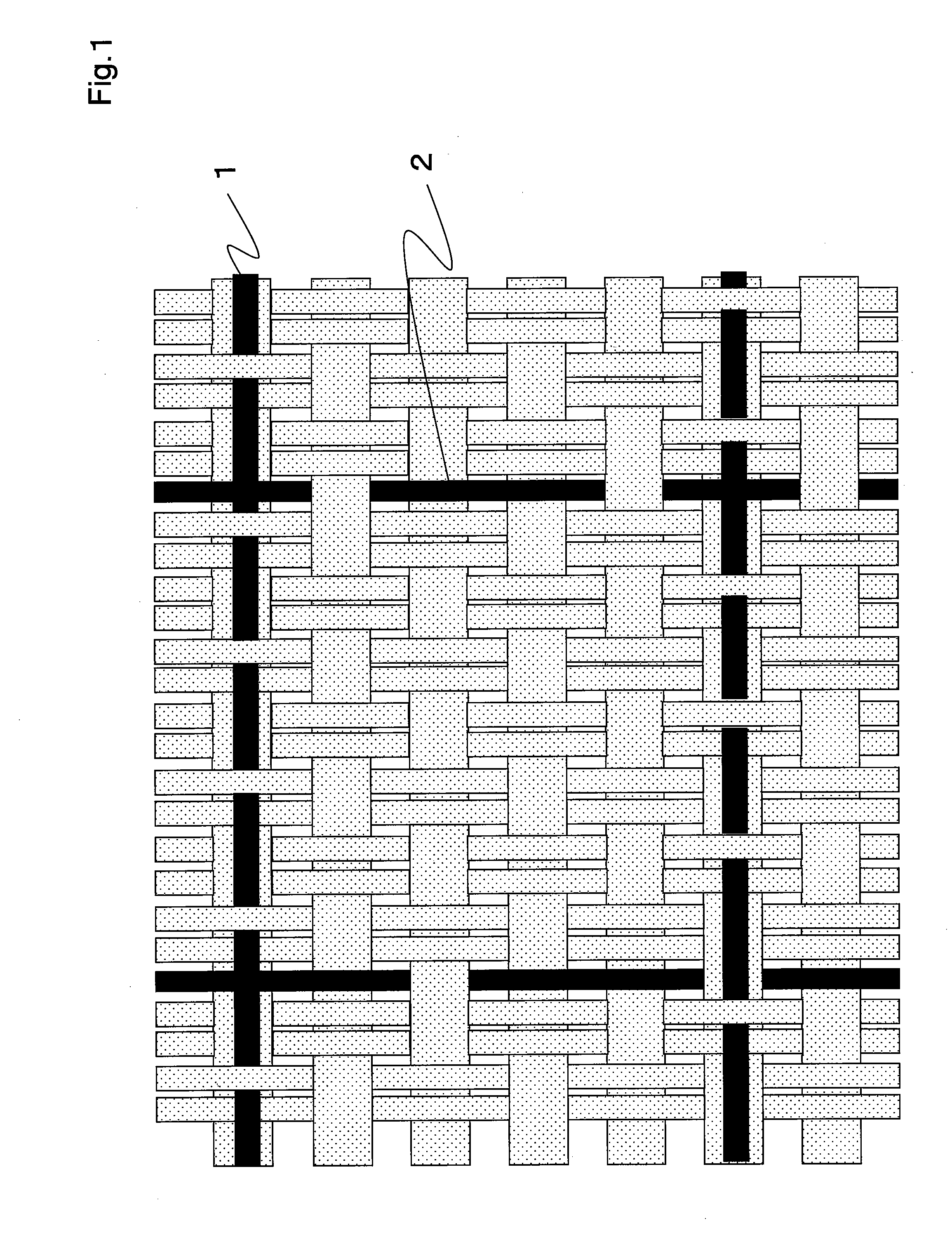

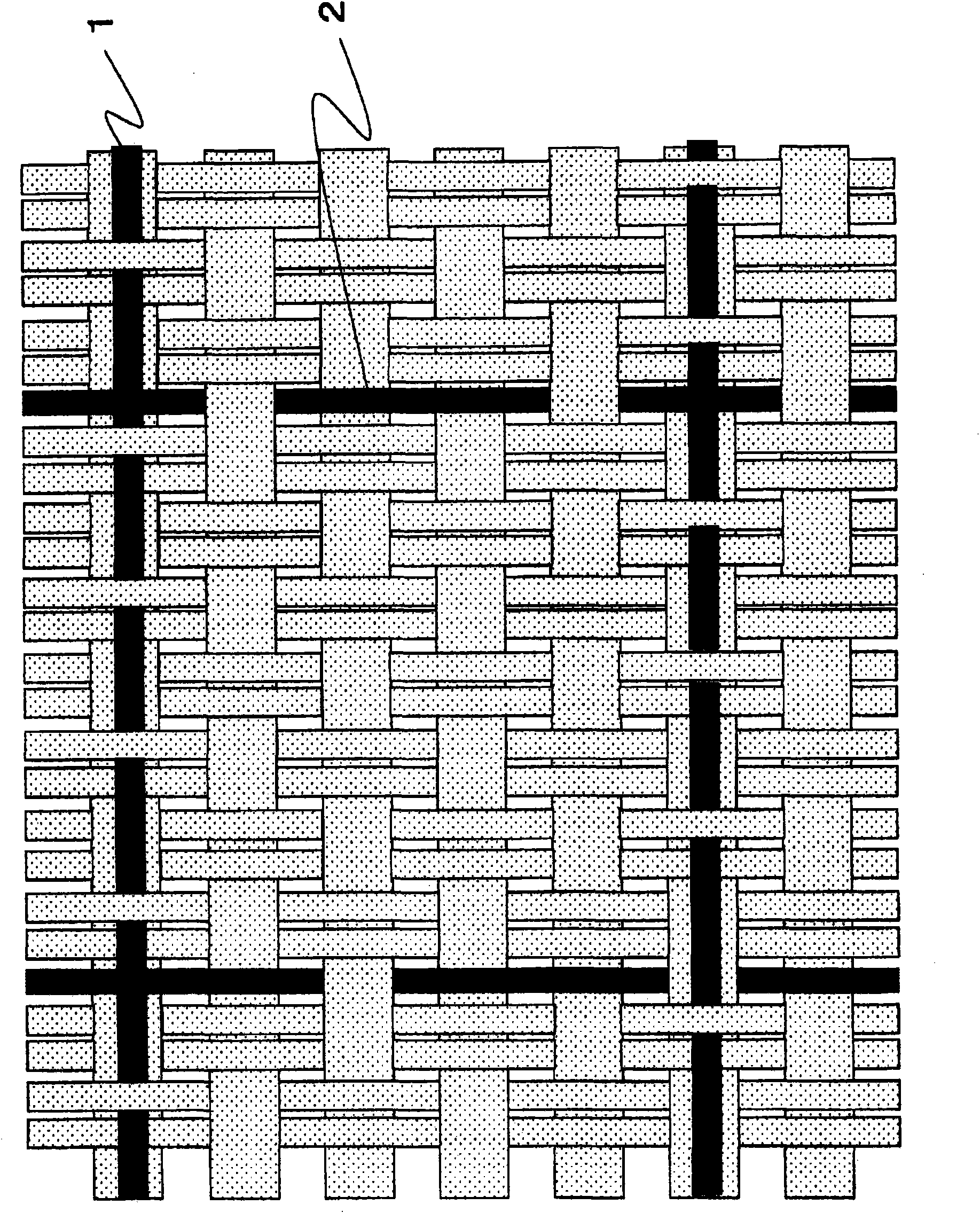

Fabric and clothes using the same

InactiveUS20100279572A1Good surface conductivityDiffusion fastOther chemical processesProtective fabricsEngineeringConductive yarn

A fabric comprises conductive yarns inserted each in a warp direction and a weft direction and disposed in a lattice at intervals, wherein at least either one of the conductive yarns in the warp direction or the weft direction is inserted as a double weave to be a float yarn on the surface that the conductive yarn becomes a float yarn in the double weave, wherein a ratio of the conductive yarn inserted as the double weave not covered by an orthogonal nonconductive yarn but exposed is not less than 50% in arithmetic average, and a ratio of the conductive yarns in the warp direction and the weft direction intersect and contact each other is not less than 40% in arithmetic average. Clothes comprise the fabric, wherein the conductive yarn is inserted as the double weave in an obverse side of the clothes.

Owner:TORAY IND INC

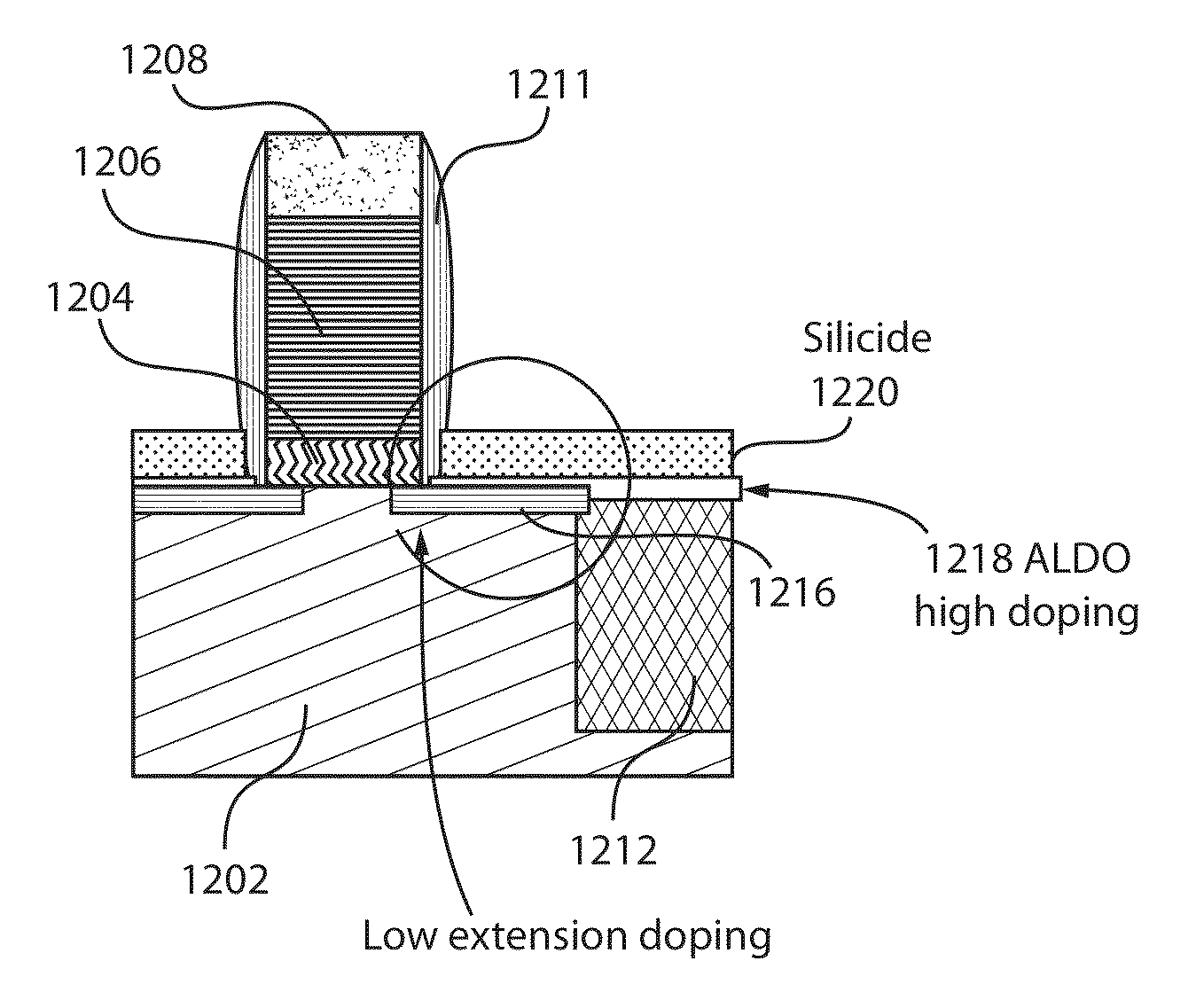

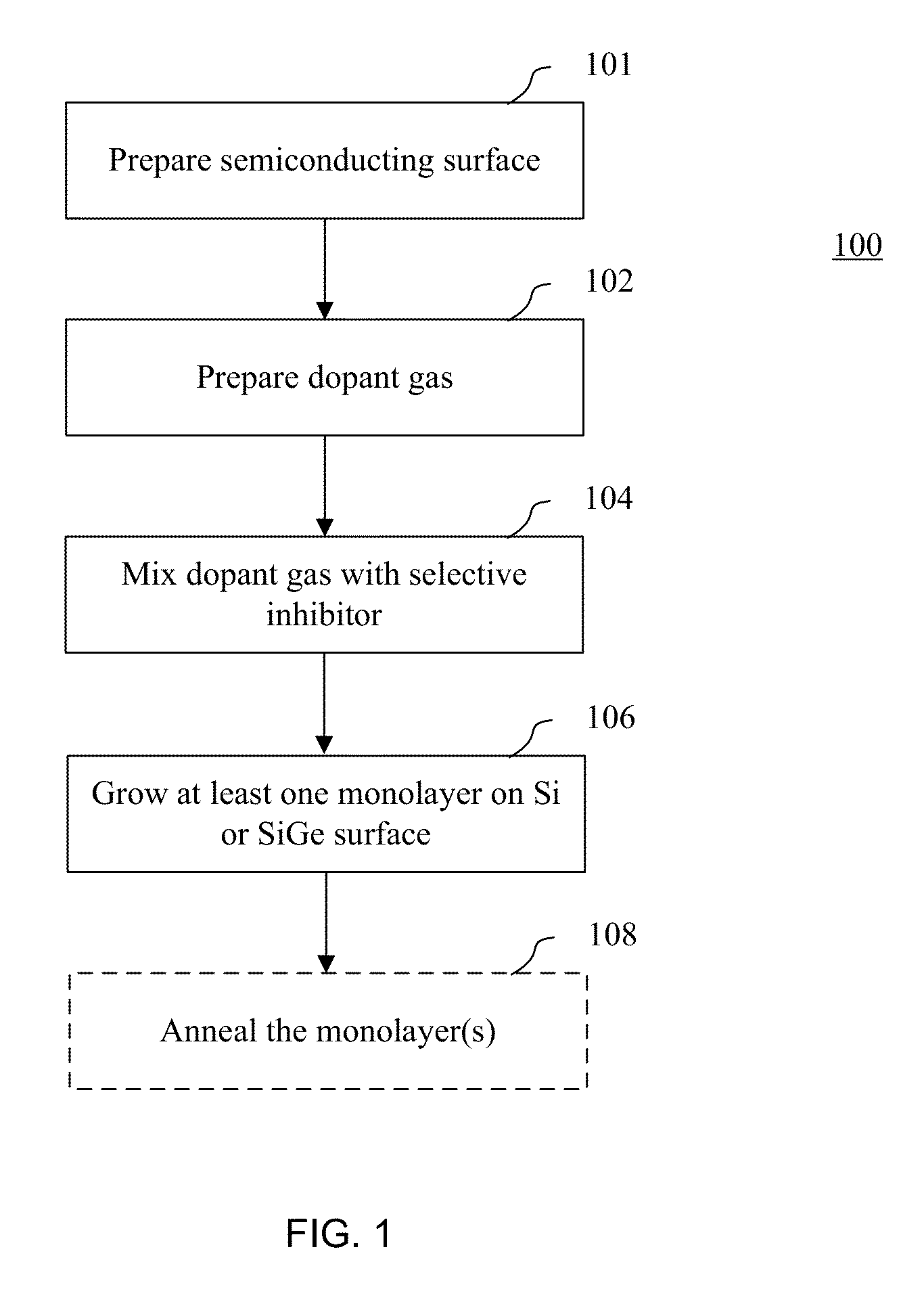

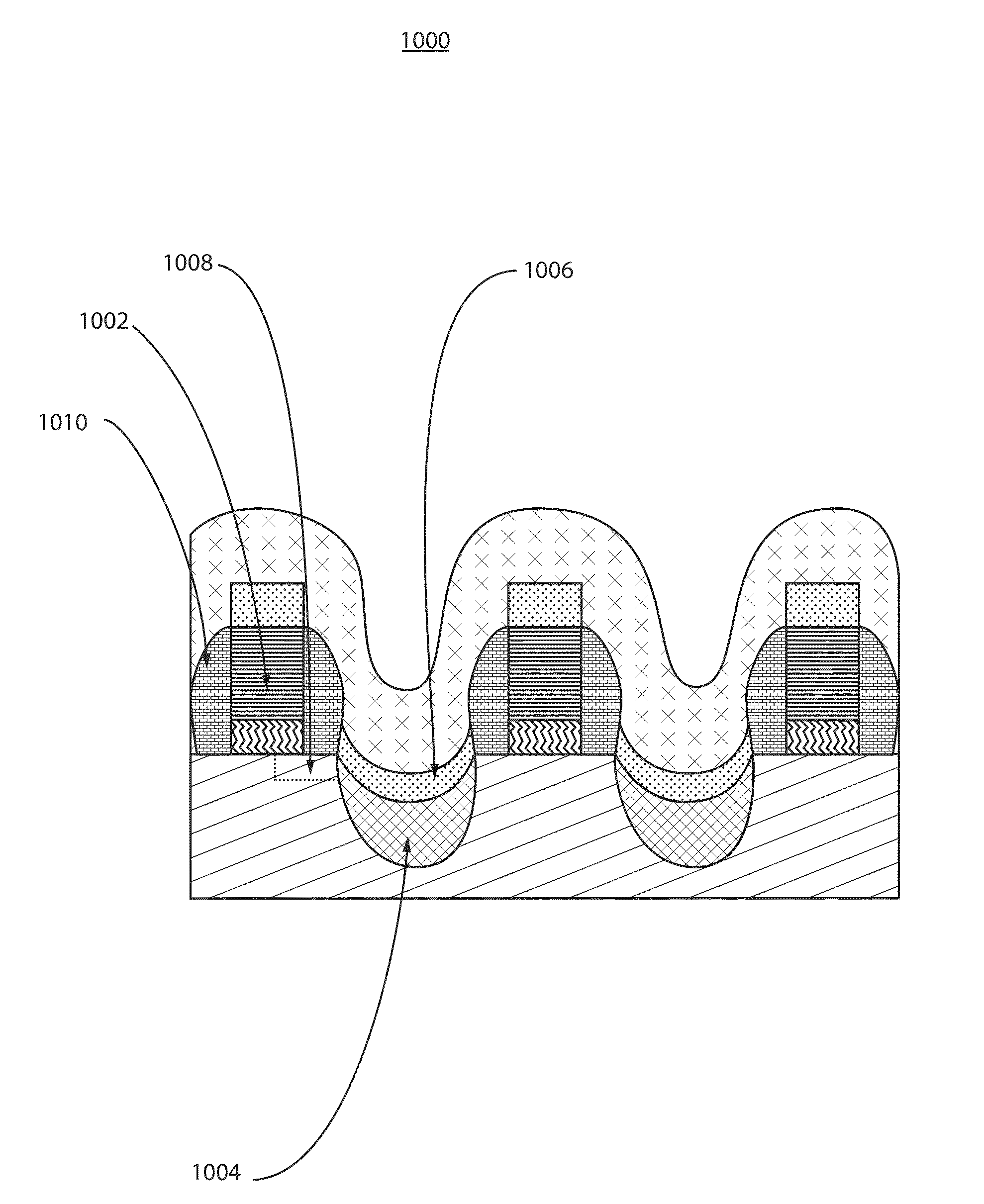

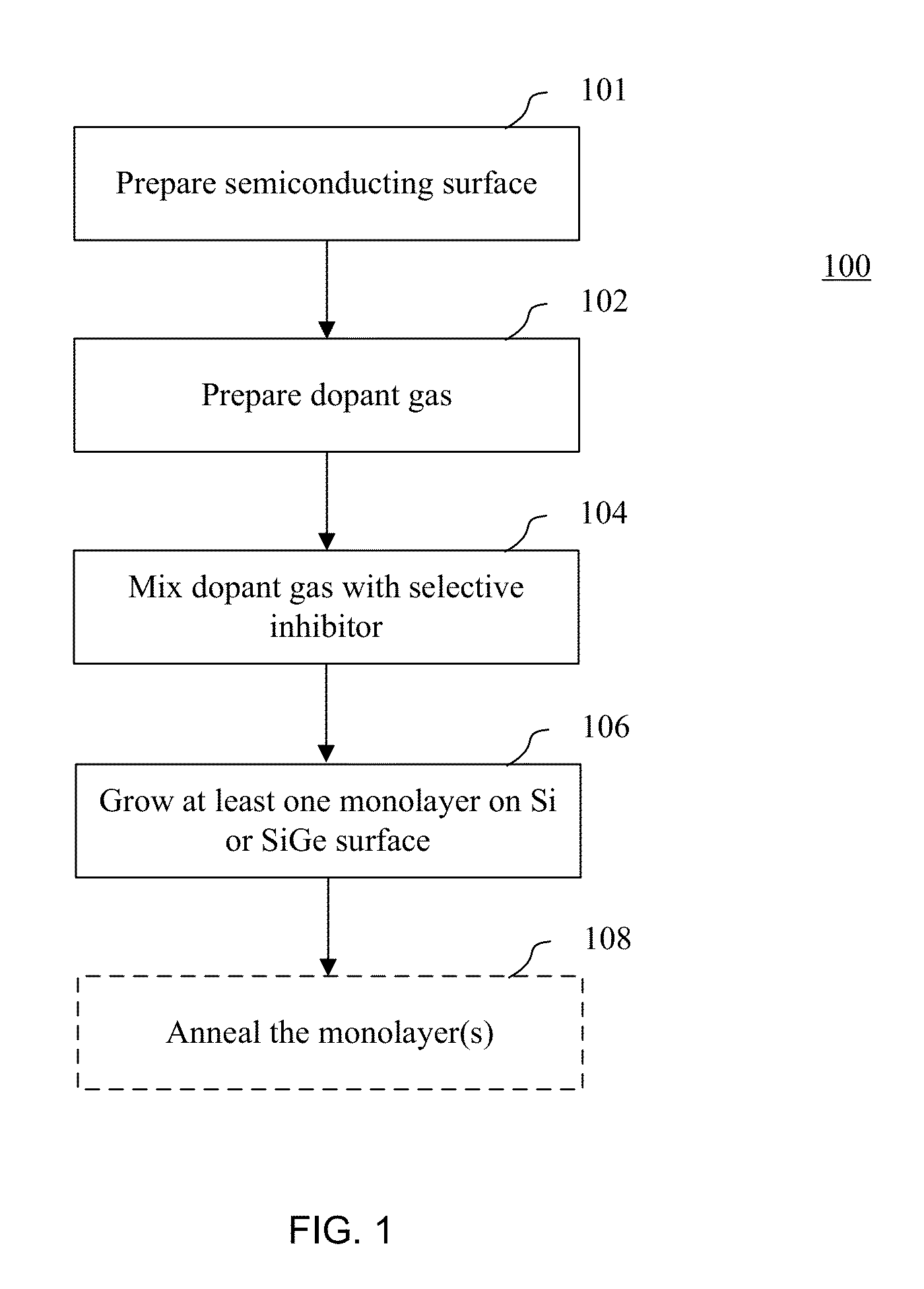

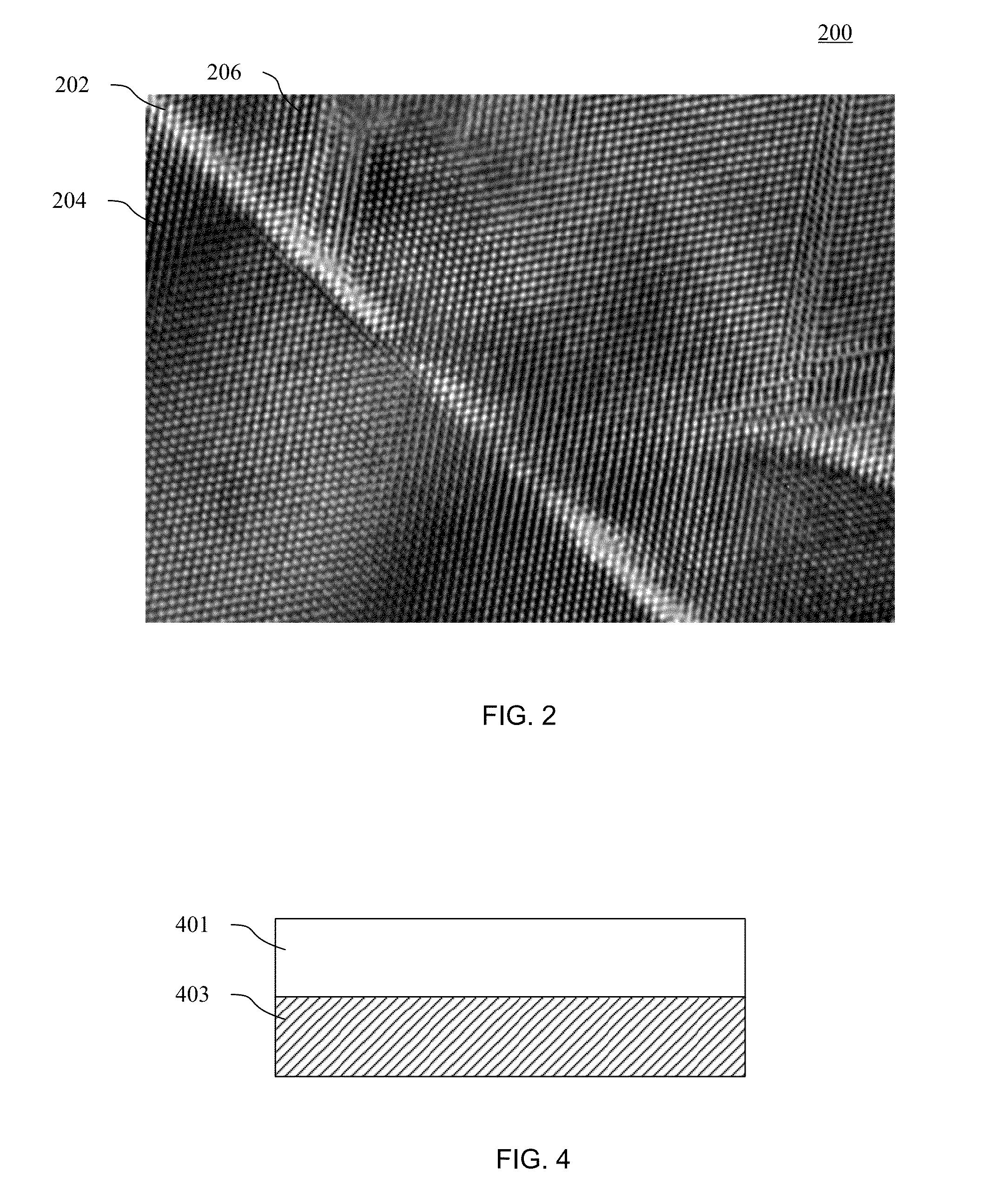

Fabrication of field-effect transistors with atomic layer doping

InactiveUS20130032883A1Improve conductivityGood surface conductivityTransistorSemiconductor/solid-state device manufacturingDopantField-effect transistor

Field effect transistors fabricated using atomic layer doping processes are disclosed. In accordance with an embodiment of an atomic layer doping method, a semiconducting surface and a dopant gas mixture are prepared. Further, a dopant layer is grown on the semiconducting surface by applying the dopant gas mixture to the semiconducting surface under a pressure that is less than 500 Torr and a temperature that is between 300° C. and 750° C. The dopant layer includes at least 4×1020 active dopant atoms per cm3 that react with atoms on the semiconducting surface such that the reacted atoms increase the conductivity of the semiconducting surface.

Owner:ALSEPHINA INNOVATIONS INC

Method for improving the efficiency of transparent thin film antennas and antennas made by such method

ActiveUS7289073B2Improve antenna efficiencyGood surface conductivityAntenna adaptation in movable bodiesElongated active element feedEngineeringElectric current

Owner:GM GLOBAL TECH OPERATIONS LLC

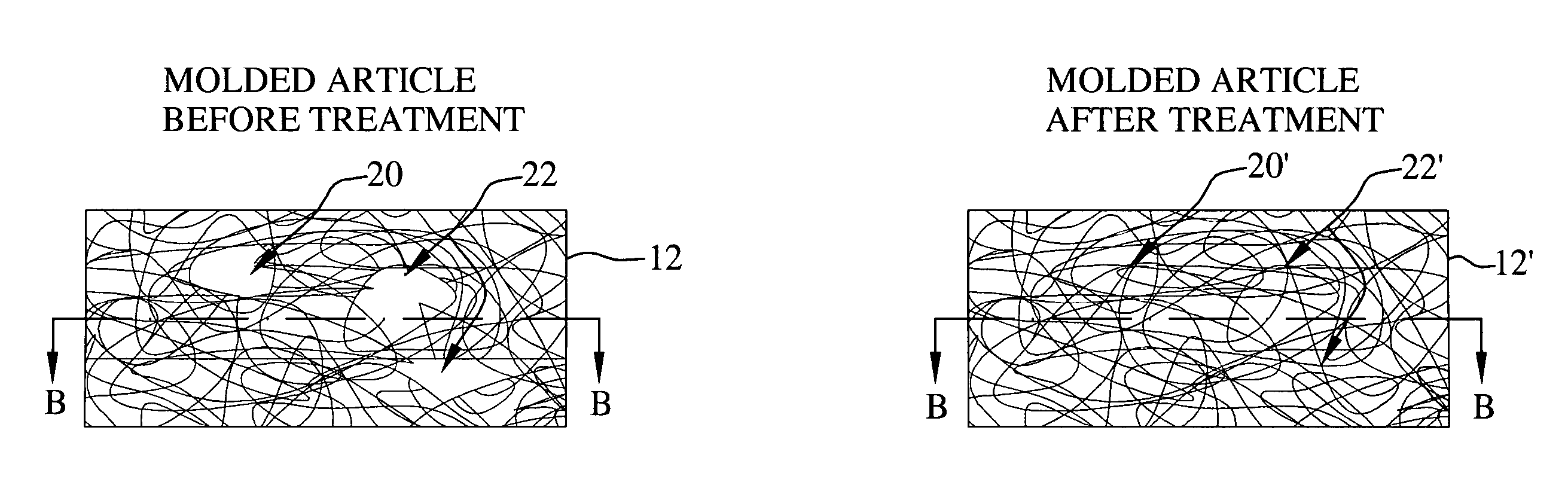

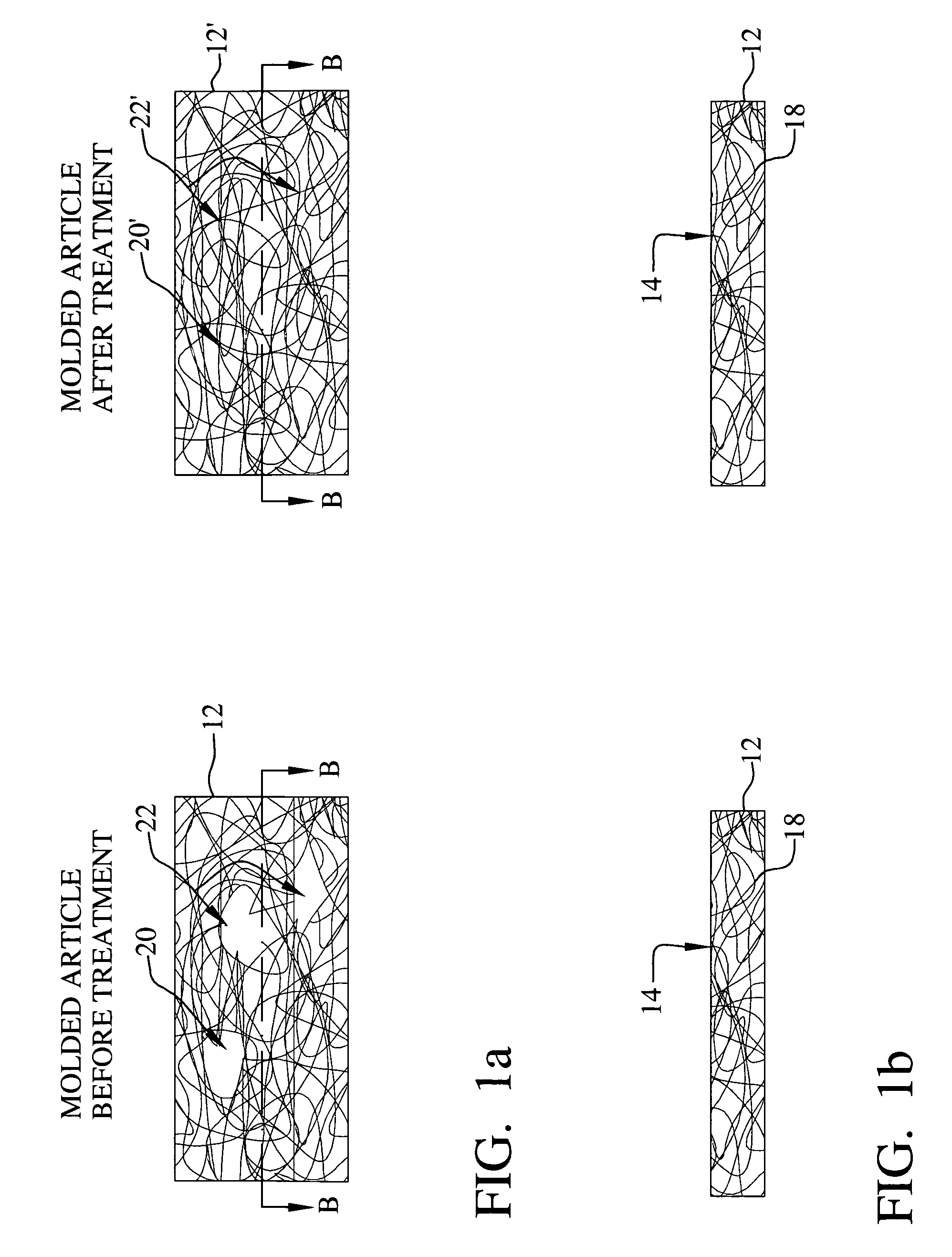

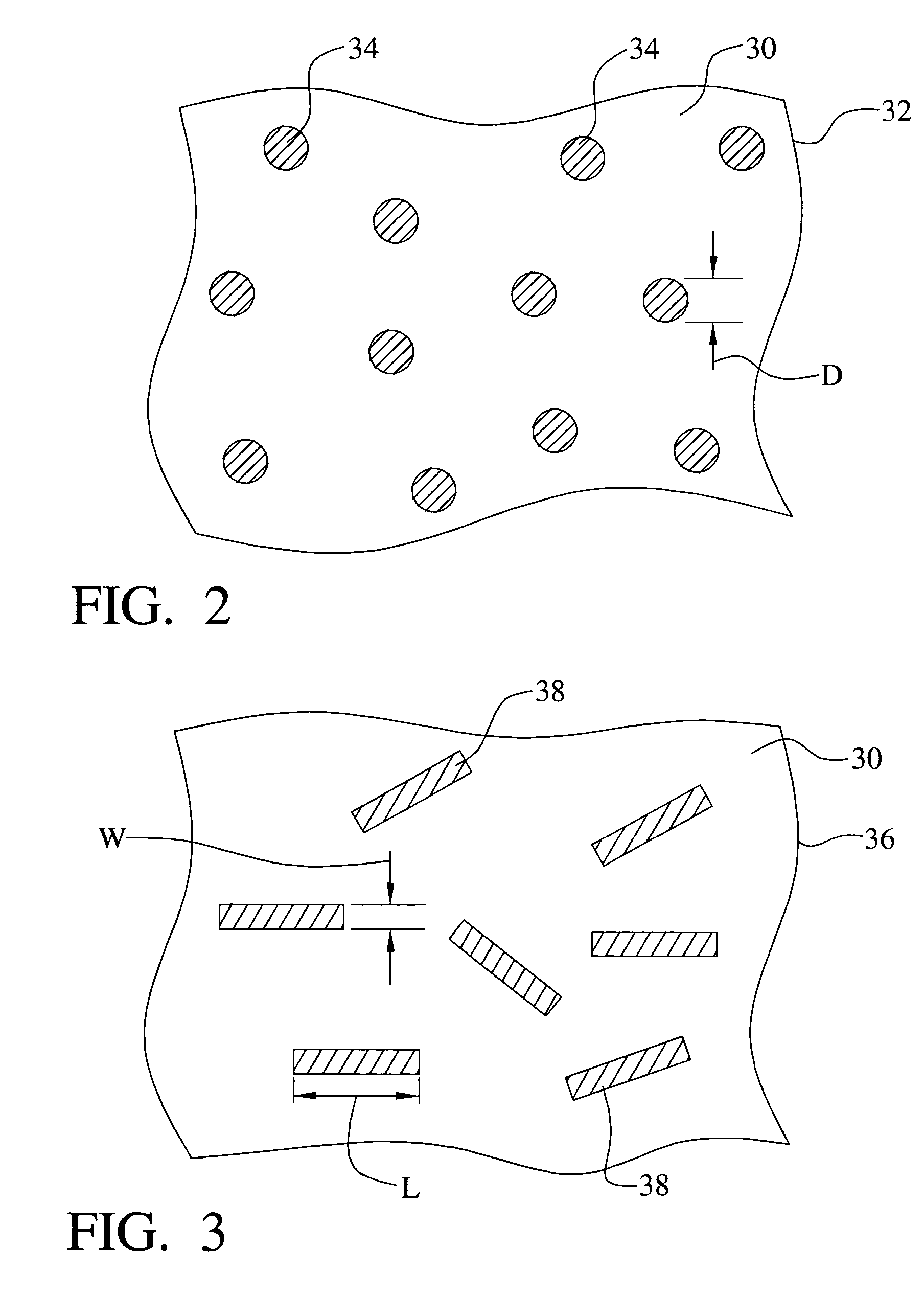

Surface preparation method for articles manufactured from conductive loaded resin-based materials

InactiveUS20050139811A1Good surface conductivityAntenna arraysAntenna supports/mountingsCarbon fibersSurface resistivity

A molded conductive loaded resin-based product is processed to reduce surface resistivity. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

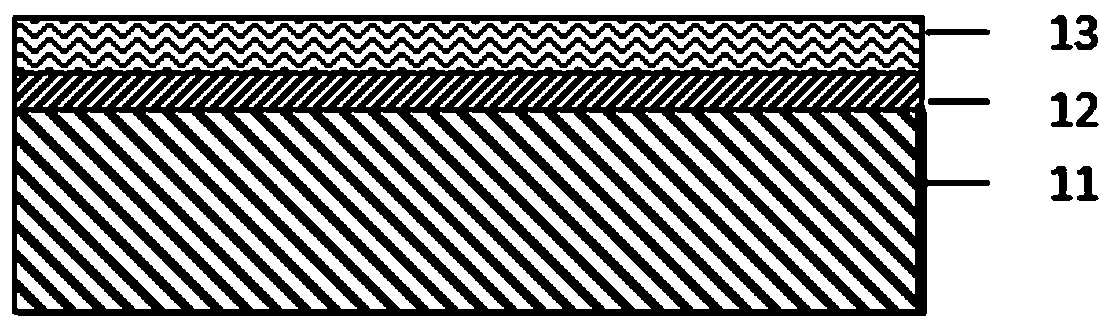

Transparent conductor and preparation method for same

ActiveUS20170345965A1Excellent binding forceExcellent surface conductivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersElectrical conductorPolymer

A preparation method for a transparent conductor, according to the present invention, comprises the steps of: a) preparing a laminate which has a transparent polymer layer and a conductive network sequentially laminated on a base material; and b) sinking the conductive network into the transparent polymer layer by applying energy to the laminate.

Owner:SG GLOBAL +1

Non-charging resin composite and method for manufacturing the same

InactiveUS20030003307A1Increasing low conductivityAvoid chargingOther chemical processesSynthetic resin layered productsIon exchangeMetal

The present invention offers a non-charging resin composite material and method for manufacturing said resin composite material. In particular, a non-charging resin composite material can be manufactured by using liquid containing metal ions to treat the surface of a resin base treated with ion-exchange group introduction agent, thereby introducing metal ions. By then converting said metal ions, a component containing metal element is introduced at the surface of the resin base in such a small amount that charging of the resin base can be prevented, without increasing the low conductivity intrinsic to the resin base to above a certain level, which has been difficult in the past. With said non-charging resin composite material, damage due to the adhesion of dirt or dust on the base is prevented, as is damage to the base caused by static electricity resulting from charging.

Owner:SHIPLEY CO LLC

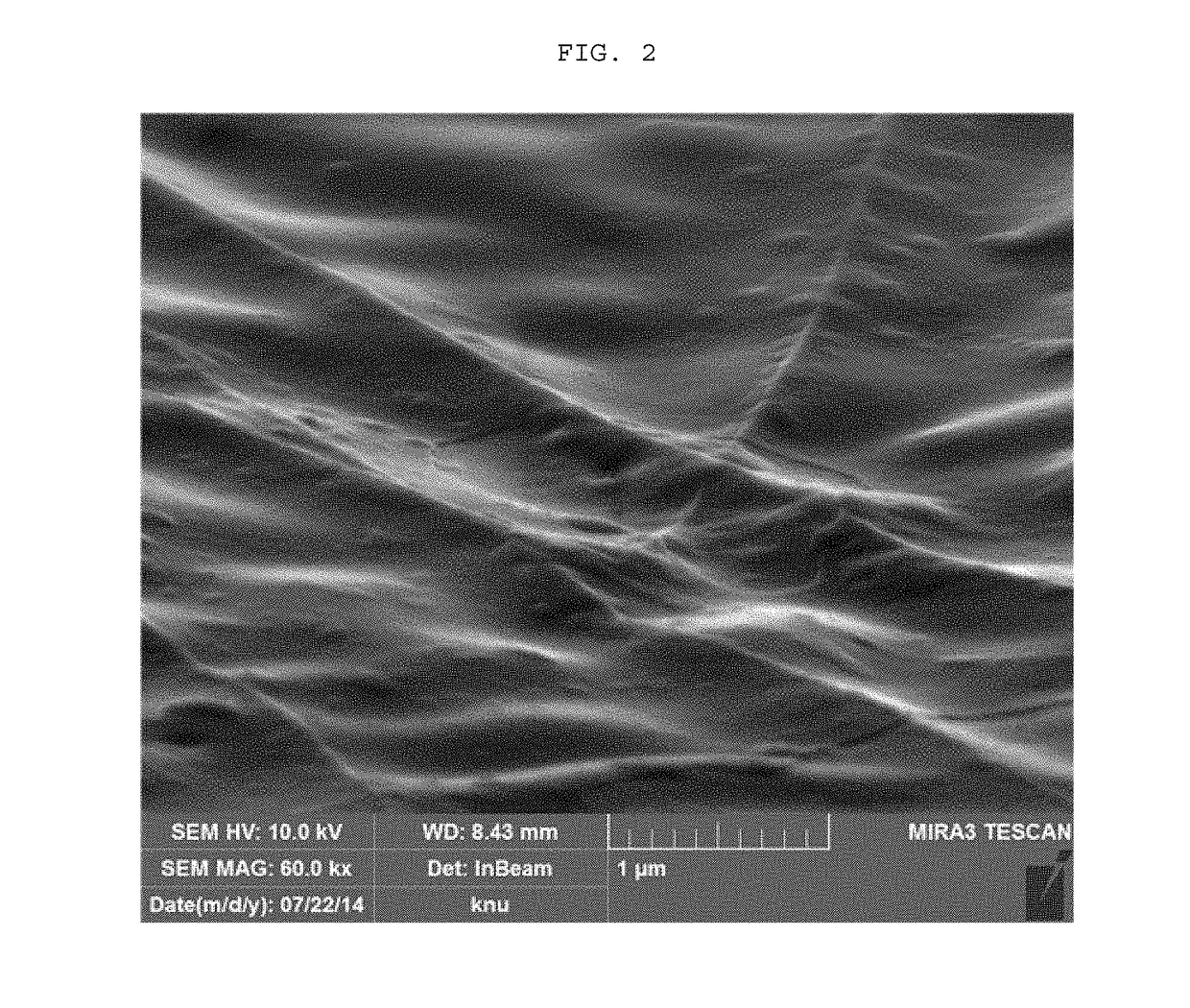

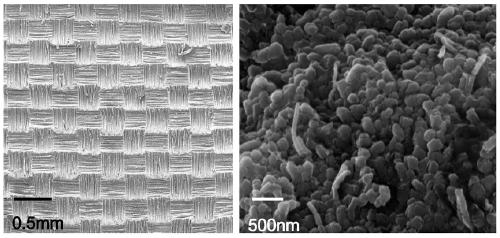

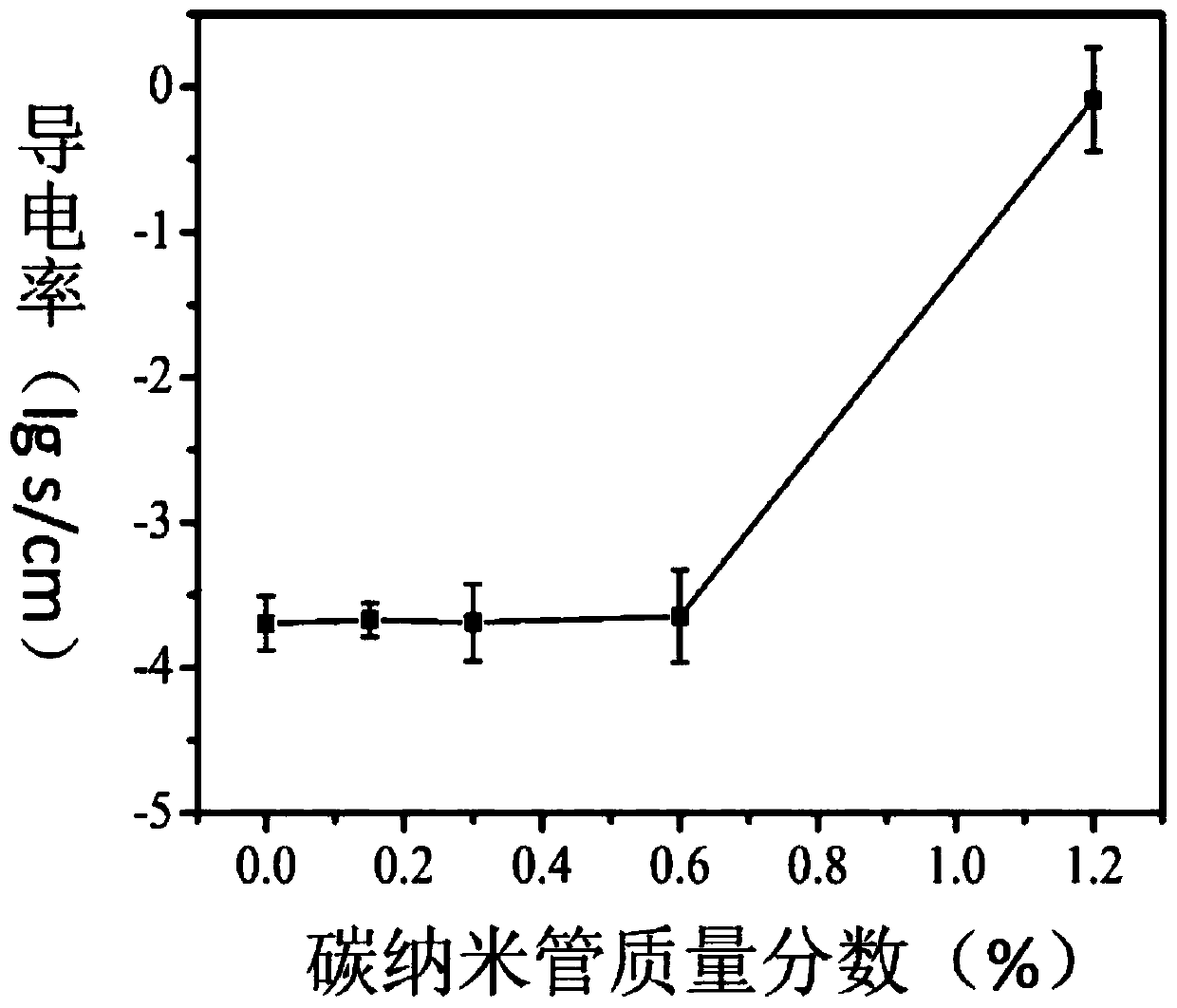

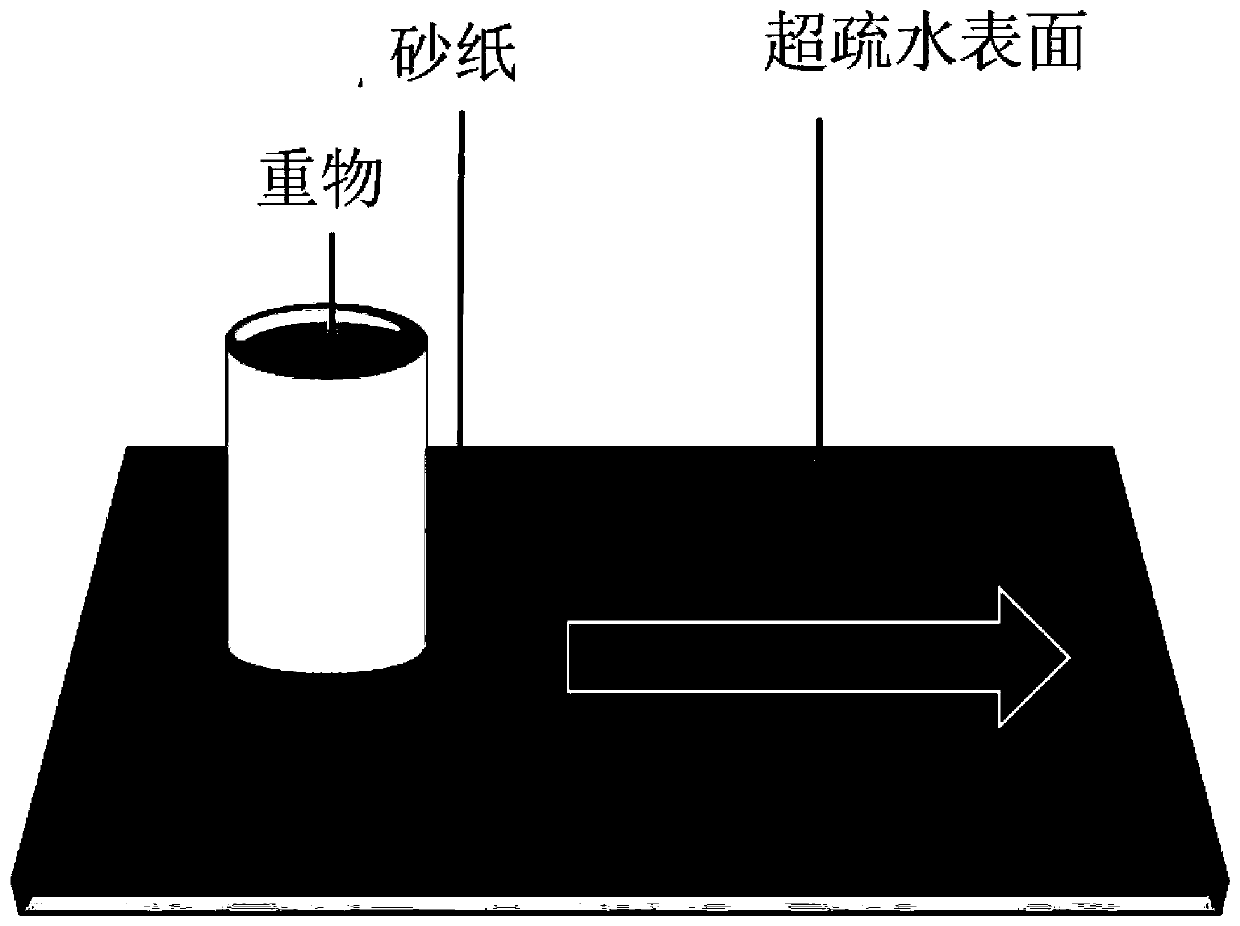

Epoxy-based super-hydrophobic fiber reinforced composite material and preparing method thereof

ActiveCN109777012AImprove corrosion resistanceExcellent superhydrophobic propertiesEpoxyTetrafluoroethylene

The invention discloses an epoxy-based super-hydrophobic fiber reinforced composite material and a preparing method thereof. The composite material includes a fiber fabric, and a resin and filler part, wherein the resin and filler part includes 100 g of epoxy resin, 220-400 g of polytetrafluoroethylene particles, 242-610 g of an organic solvent, 25-40 g of a curing agent and 3-6 g of carbon nanotubes. The method includes preparing the resin and filter part, preparing a prepreg material and curing the prepreg material to obtain the composite material. The composite material has good super-hydrophobic performance, good wear resistance, good corrosion resistance, good resistance to water flow shock, good adhesive force, high electrical conductivity, and the like, and has high application value and a good application prospect. The method is simple in process and convenient to operate, is suitable for large-scale preparation and facilitates industrial application.

Owner:NAT UNIV OF DEFENSE TECH

Fabrication of field-effect transistors with atomic layer doping

InactiveUS20130032865A1Improve conductivityGood surface conductivityTransistorSemiconductor/solid-state device manufacturingDopantField-effect transistor

Field effect transistors fabricated using atomic layer doping processes are disclosed. In accordance with an embodiment of an atomic layer doping method, a semiconducting surface and a dopant gas mixture are prepared. Further, a dopant layer is grown on the semiconducting surface by applying the dopant gas mixture to the semiconducting surface under a pressure that is less than 500 Torr and a temperature that is between 300° C. and 750° C. The dopant layer includes at least 4×1020 active dopant atoms per cm3 that react with atoms on the semiconducting surface such that the reacted atoms increase the conductivity of the semiconducting surface.

Owner:ALSEPHINA INNOVATIONS INC

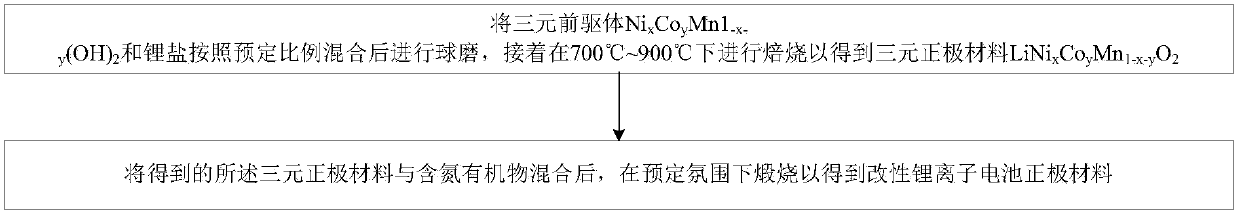

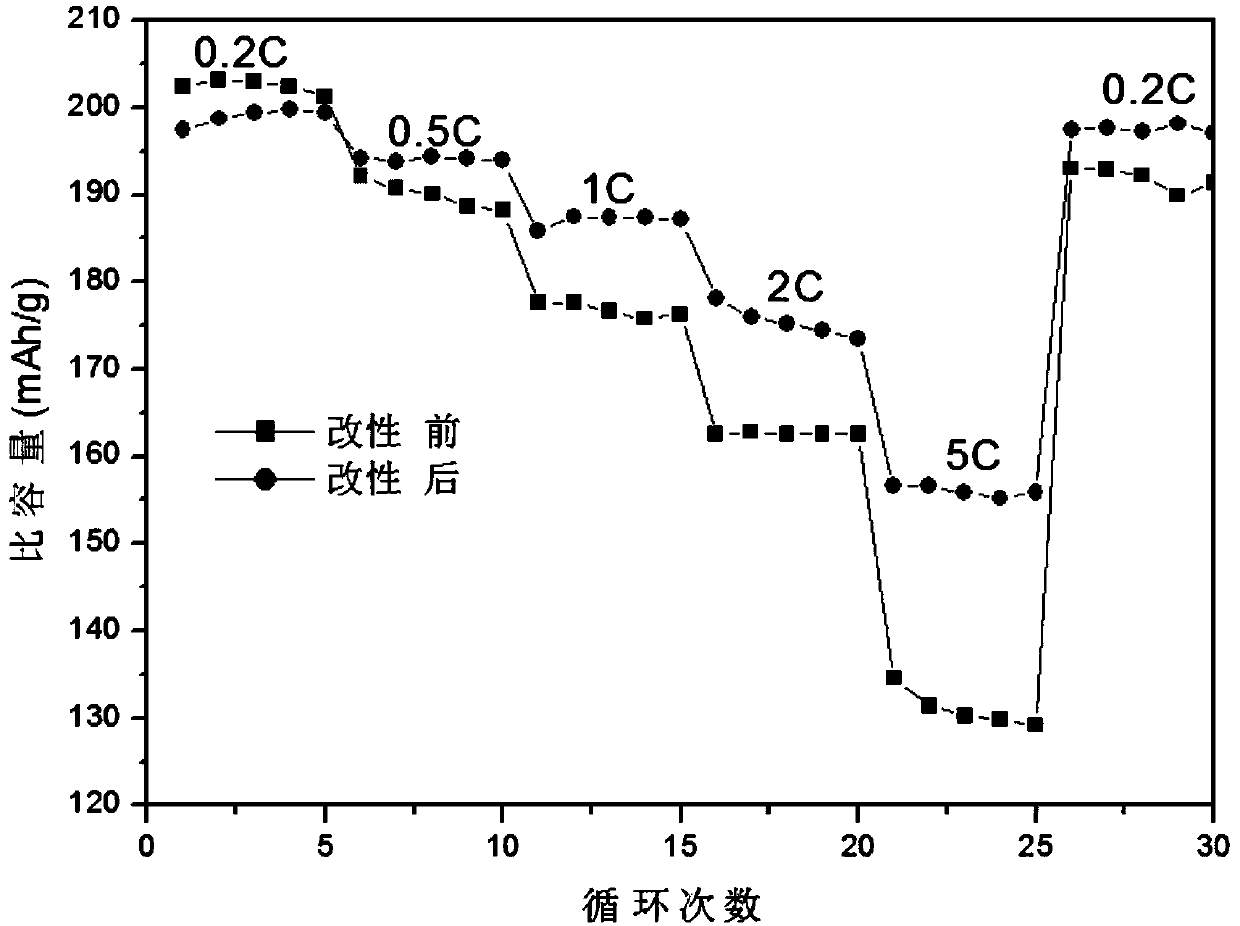

Lithium ion battery, modified lithium ion battery anode material and preparation method of anode material

InactiveCN107785555AWide range of materialsSimple processElectrode thermal treatmentSecondary cellsAluminium-ion batterySodium-ion battery

The invention belongs to the related technical field of anode materials and discloses a preparation method of the modified lithium ion battery anode material. The method comprises the following steps:(1) mixing a ternary precursor NixCoyMn(1-x-y)(OH)2 with lithium salt in a preset proportion to be ball-milled, and then roasting the mixture at 850 DEG C to obtain a ternary anode material LiNixCoyMn(1-x-y)O2; and (2) mixing the obtained ternary anode material with a nitrogen-containing organic matter and calcining the mixture in a preset atmosphere to obtain the modified lithium ion battery anode material. The invention also relates to the modified lithium ion battery anode material and a lithium ion battery. According to the invention, the rate performance and the cyclic stability of the lithium ion battery are improved, and the process is simple and easy to implement.

Owner:HUAZHONG UNIV OF SCI & TECH

Polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate and manufacturing method thereof

InactiveCN102364738ALow critical cooling rateStrong ability to inhibit crystallizationCell electrodesElectric arcCorrosion

The invention discloses a polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate and a manufacturing method thereof. Materials are prepared according to a required atomic moore proportion of a composition formula, namely Zr60-xNbxCu20Al10Ni10 (x is equal to a value ranging from 0 to 20). A mother alloy ingot is smelted by electric arc under the protection of argon; and the mother alloy ingot is re-smelted for at least three times, so that the chemical uniformity can be guaranteed. Current of a vacuum electric arc furnace is 150 to 250 amperes; and a zirconium-base bulk metallic glass plate with a thickness of between 0.1 and 3 millimeters is cast and formed by a Cu die. The purity of elements, namely Zr, Nb, Cu, Ni and Al is more than or equal to 99.95 weight percent; the zirconium-base bulk metallic glass at least contains 95 vol percent of amorphous phase; a corrosion speed is lower than 16 mu A per square centimeters; and the conductivity is more than 5,000 S per centimeters. The polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate has higher conductivity and high corrosion resistance, and the cost can be reduced greatly; and the polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate can be applied to the field of manufacturing of fuel cells.

Owner:DALIAN JIAOTONG UNIVERSITY

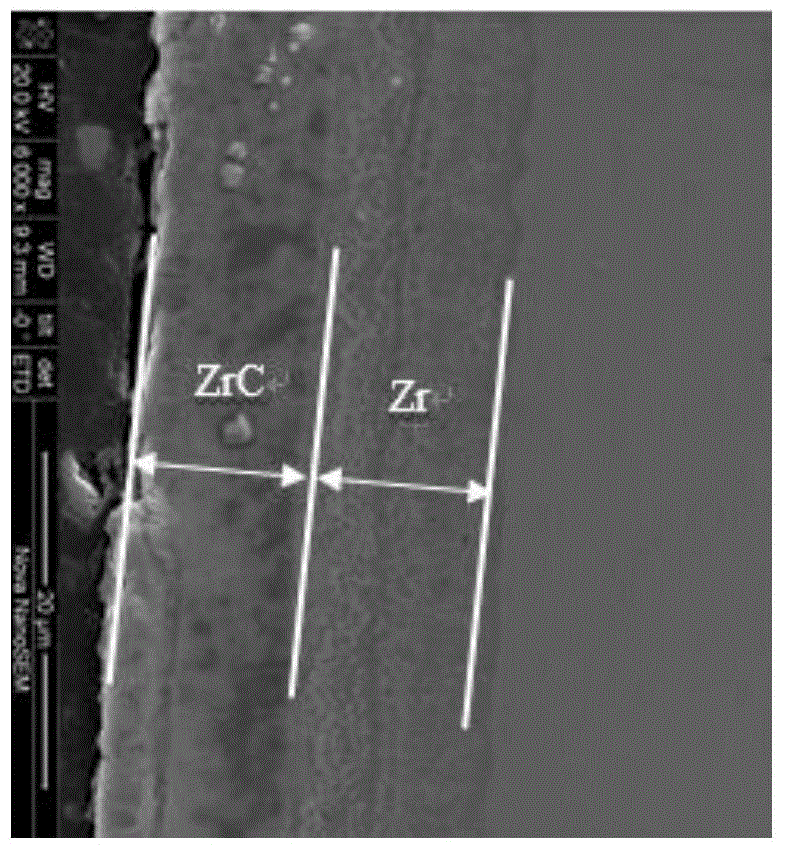

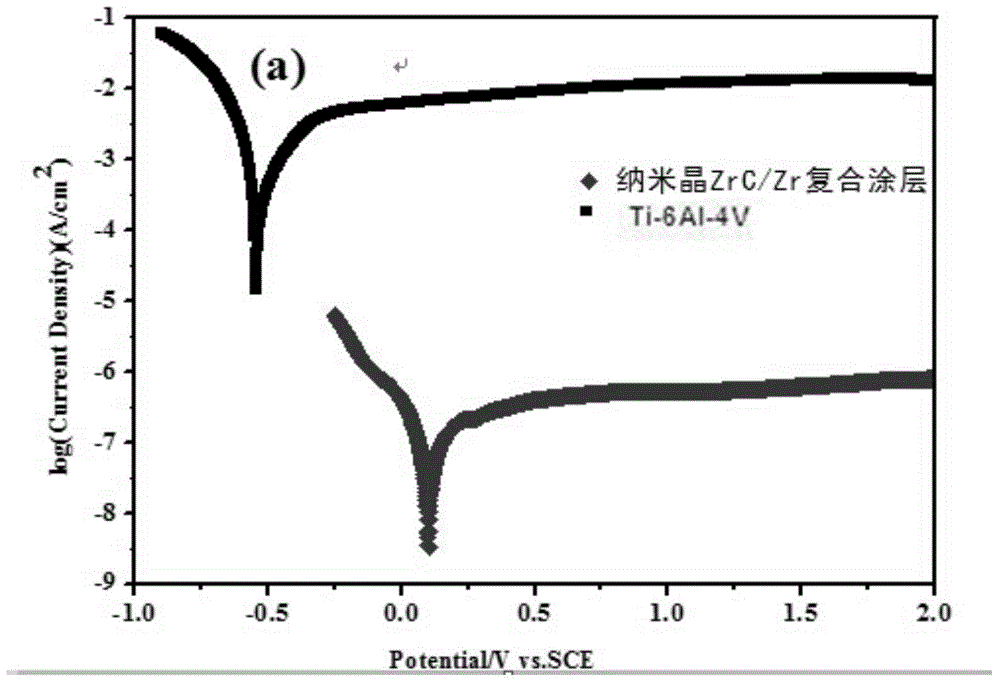

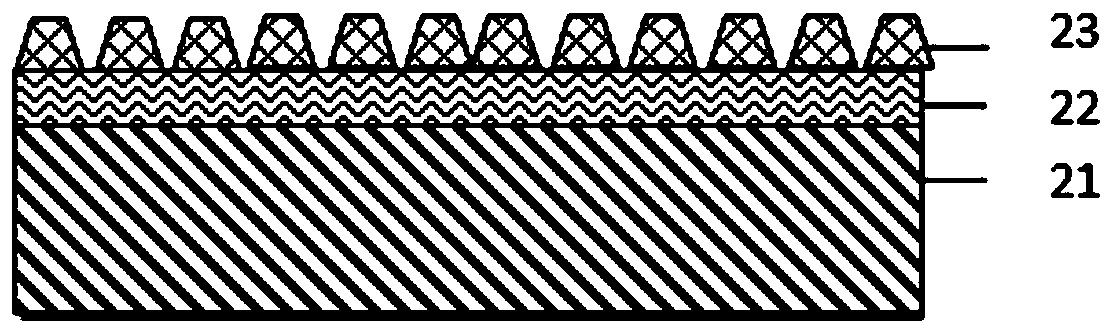

Nanocrystalline ZrC/Zr composite coating of metal bipolar plate of proton exchange membrane fuel cell and preparation method thereof

InactiveCN104611679AGood surface conductivityReduce contact resistanceVacuum evaporation coatingSputtering coatingAlloy substrateTitanium alloy

The invention belongs to the field of proton exchange membrane fuel cells, and relates to a nanocrystalline ZrC / Zr composite coating of a metal bipolar plate of a proton exchange membrane fuel cell and a preparation method thereof. Bicathode plasma sputtering deposition equipment is employed for sputtering the nanocrystalline ZrC / Zr composite coating on the surface of a titanium alloy bipolar plate used for the proton exchange membrane fuel cell. The coating is composed of an outer layer ZrC deposition layer and inner layers Zr deposition layer and diffusion layer; and the ZrC deposition layer is composed of equiaxial nanocrystalline ZrC with the average dimension of about 15-20 nm, the diffusion layer is formed by mutual diffusion of alloy elements of the Zr deposition layer and the titanium alloy bipolar plate, and the alloy elements in the diffusion layer show gradient distribution. The nanocrystalline ZrC / Zr composite coating possesses high density, has strong combination force with a titanium alloy substrate, has high corrosion resistance and low contact resistance when being in a proton exchange membrane fuel cell work environment, and is capable of satisfying usage requirements of a fuel cell bipolar plate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

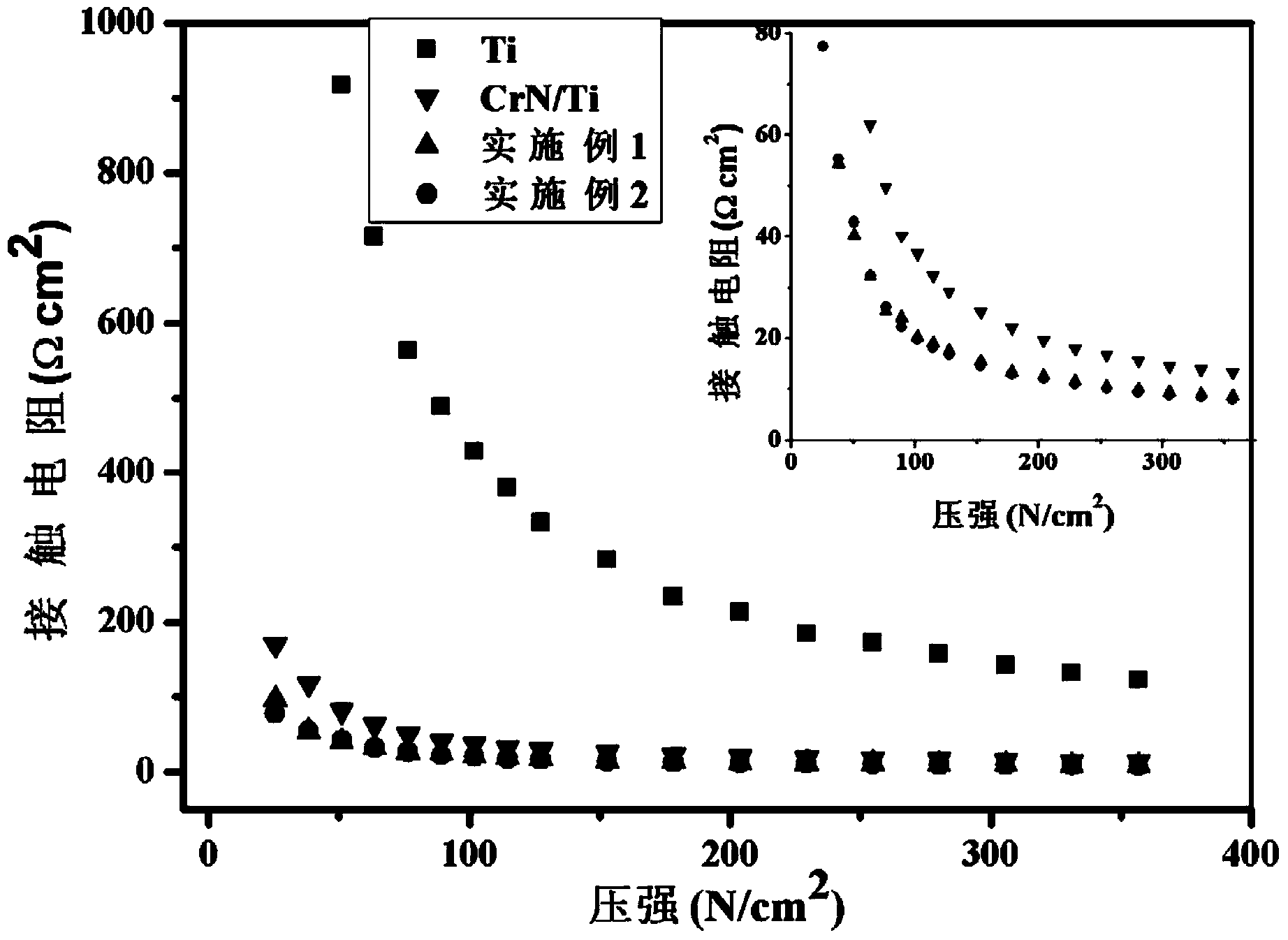

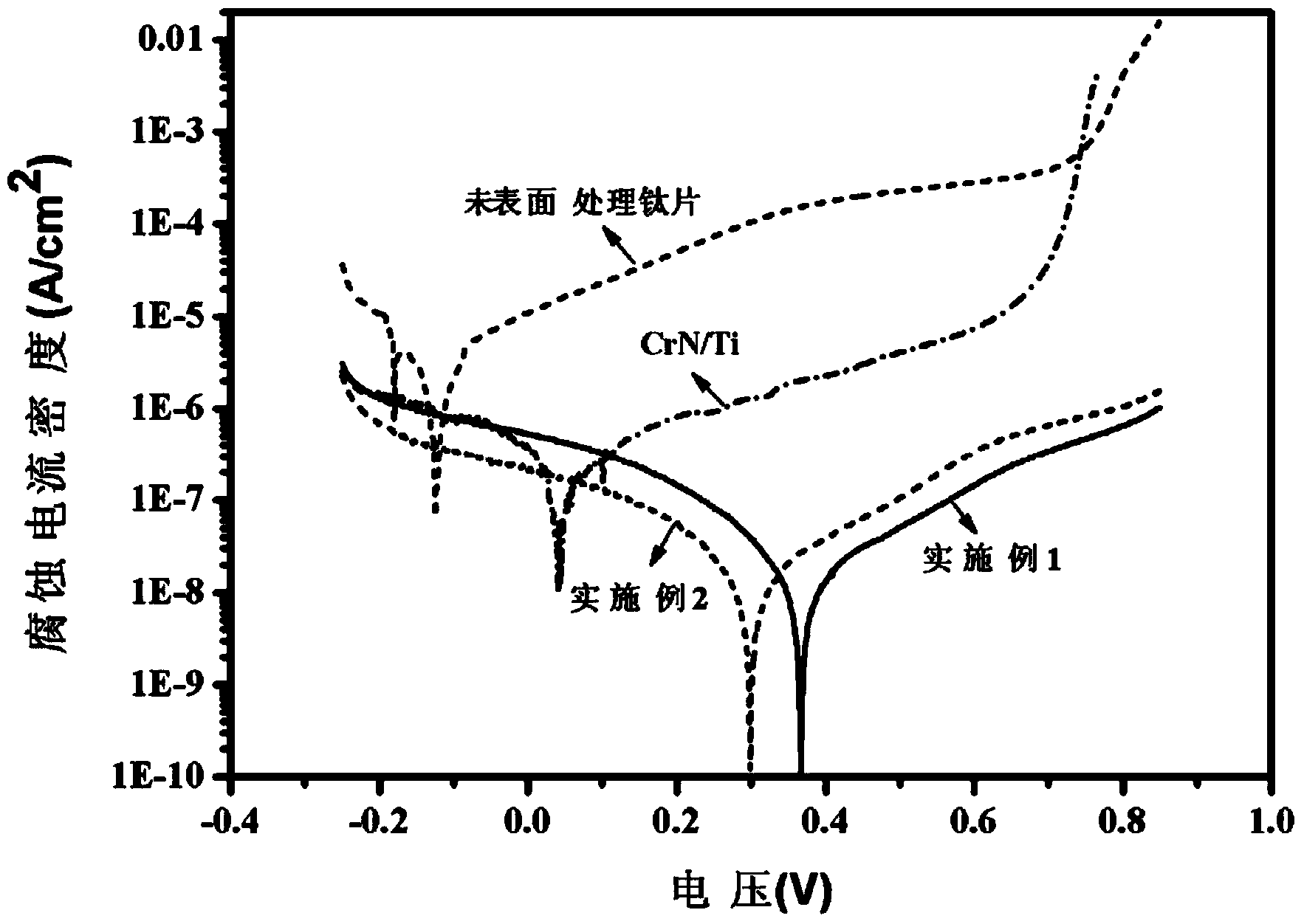

Metal bipolar plate and preparation method thereof

ActiveCN104051743AGood surface conductivityExtended service lifeCell electrodesSurface conductivityTitanium

The invention discloses a metal bipolar plate. The metal bipolar plate comprises a titanium substrate and a surface modified layer, wherein the surface modified layer is formed by a titanium modified layer close to the titanium substrate and a chromium modified layer close to the titanium modified layer. The metal bipolar plate adopts the titanium modified layer as a transition layer and is mainly used for increasing the binding force of the chromium modified layer and the titanium substrate, and also achieving corrosion resistance, so that the adhesive force for a film layer is improved, and a high-hardness Cr compound film is prevented from cracking and dropping off; the chromium modified layer has effects of resisting corrosion and reducing contact resistance, so that the surface conductivity of the metal bipolar plate is improved and the service life of the metal bipolar plate is prolonged.

Owner:BEIJING INST OF SPACE LAUNCH TECH

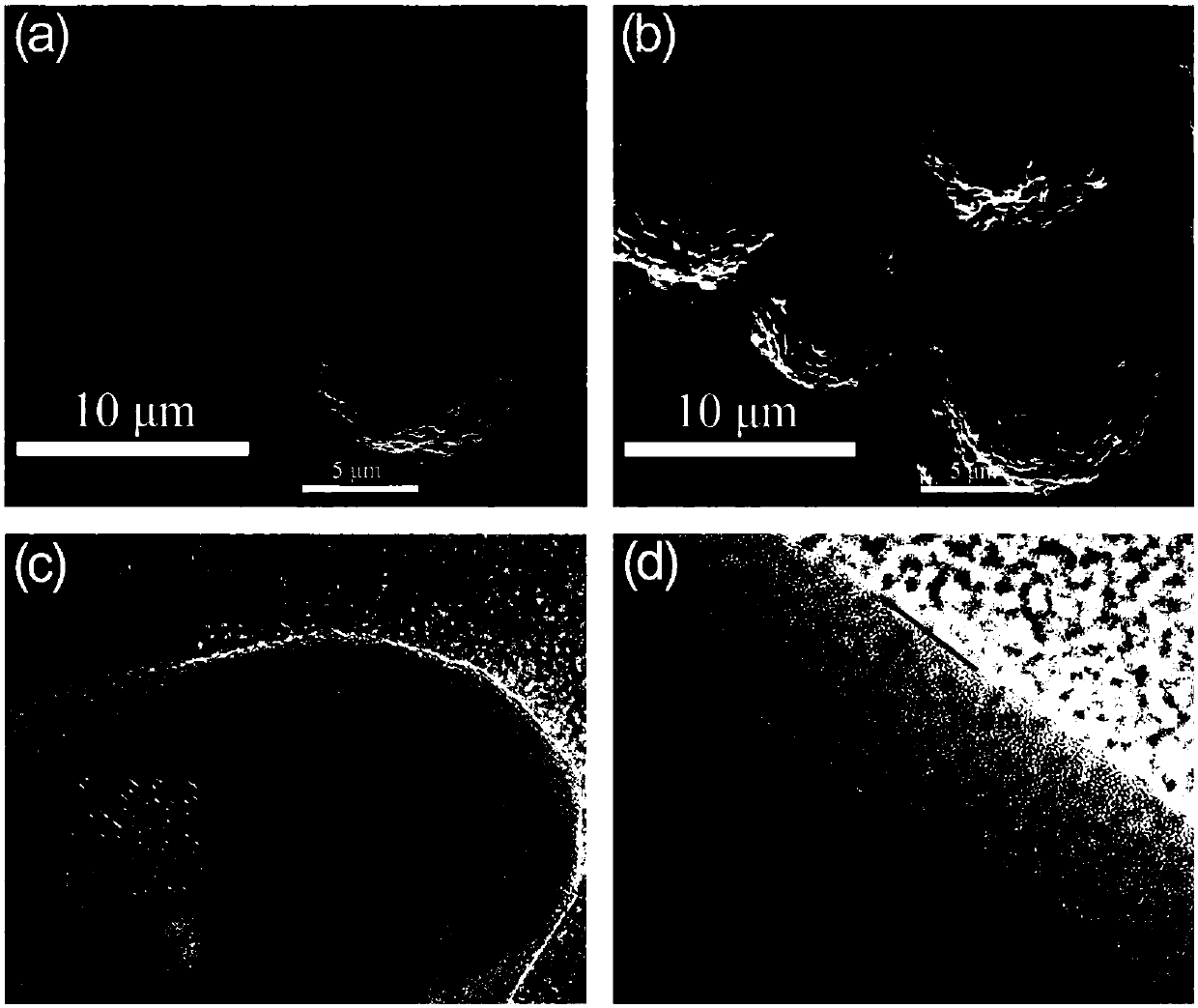

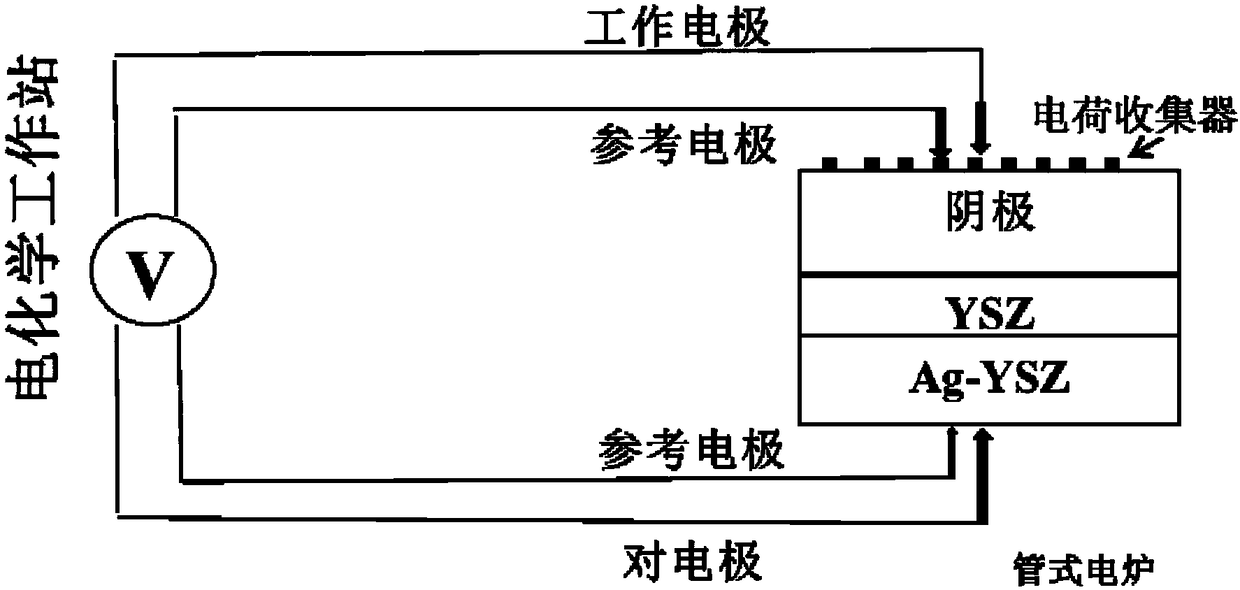

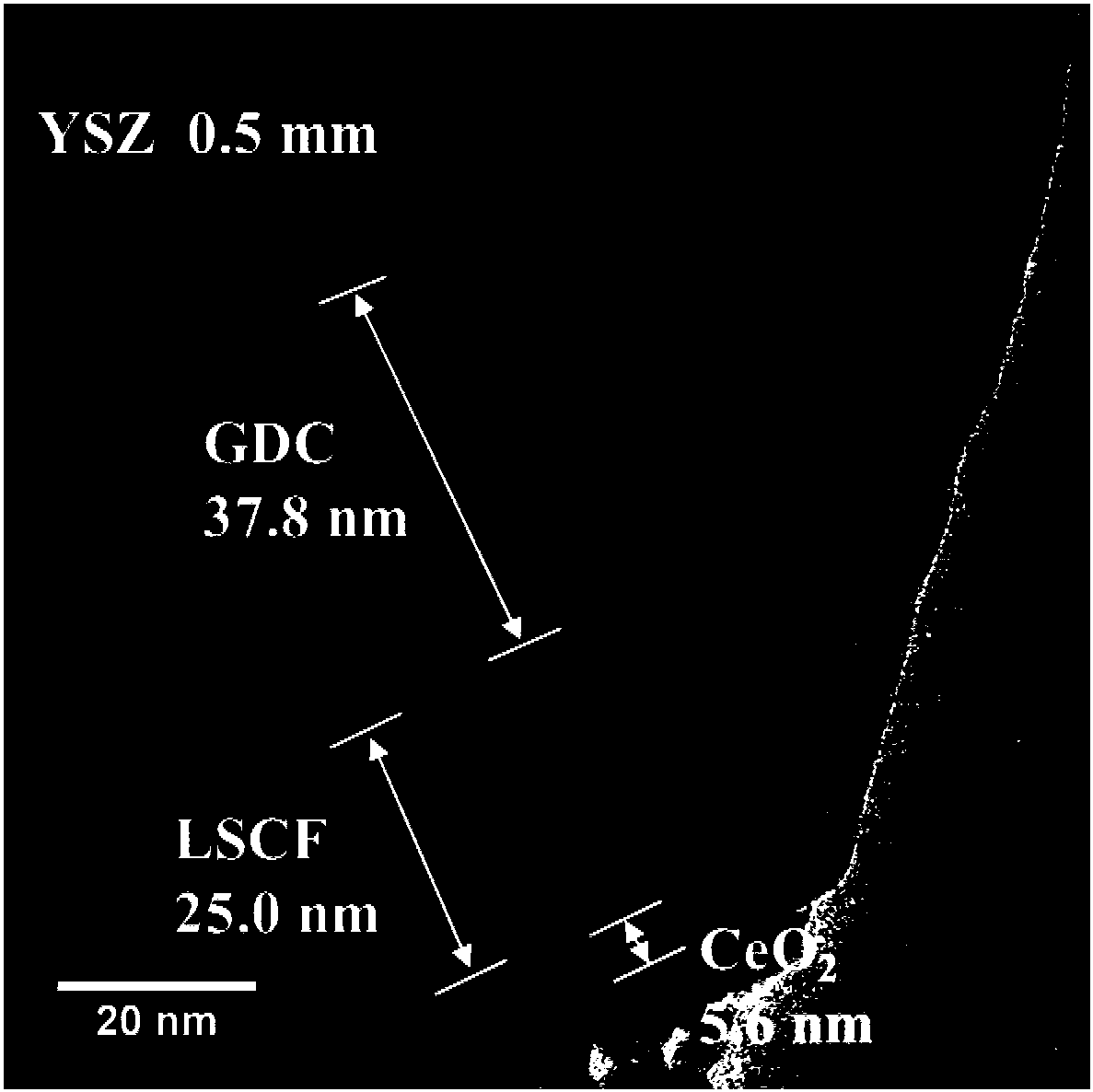

Negative electrode surface modification method of solid oxide fuel cell

ActiveCN108390071APrecise thickness controlInhibition of strontium segregationCell electrodesSingle crystalOxygen

The invention discloses a negative electrode surface modification method of a solid oxide fuel cell. The modification method specifically comprises the steps of synthesizing an LSCF target material, aGDC target material and a praseodymium cerium oxide target material of a pulse laser deposition instrument (PLD) through a combustion method and a high-temperature calcining method, wherein the praseodymium cerium oxide has the chemical formula of Pr<x>Ce<1-x>O<2>, and x is equal to 0-1; depositing SOFC negative electrode material lanthanum strontium cobalt ferrite on a monocrystal substrate electrolyte through the pulse laser deposition instrument, and depositing a nanoscale praseodymium cerium oxide on the surface to be used as a surface modification layer. An electrochemical impedance diagram is tested in a high-temperature air condition to prove that the negative electrode oxygen reduction activity and long-term stability of the lanthanum strontium cobalt ferrite can be obviously improved by virtue of the surface modification layer, thereby achieving significance to guidance of synthesis of the novel negative electrode material and popularization of commercialization of the solidoxide fuel cell.

Owner:SOUTH CHINA UNIV OF TECH

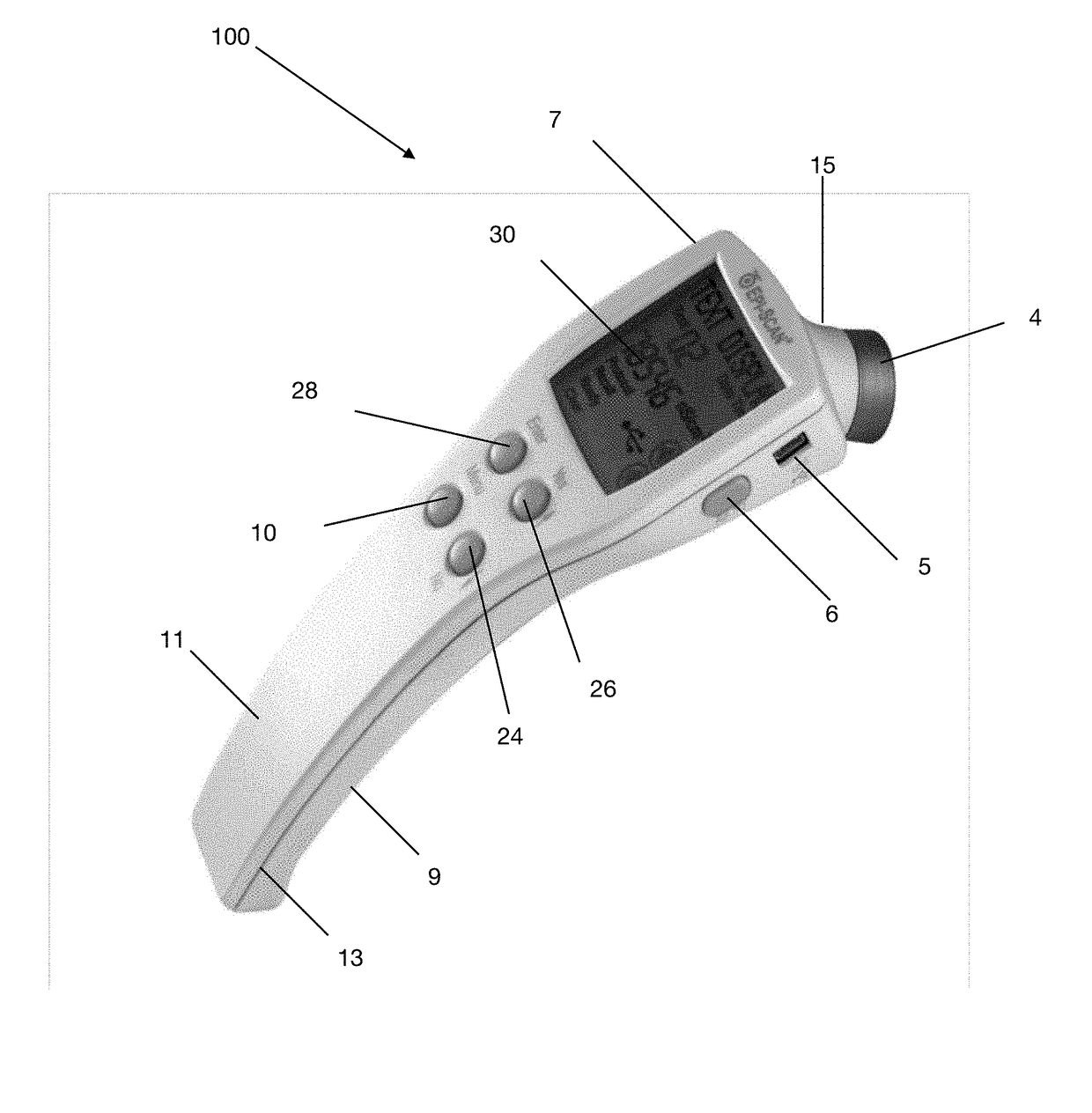

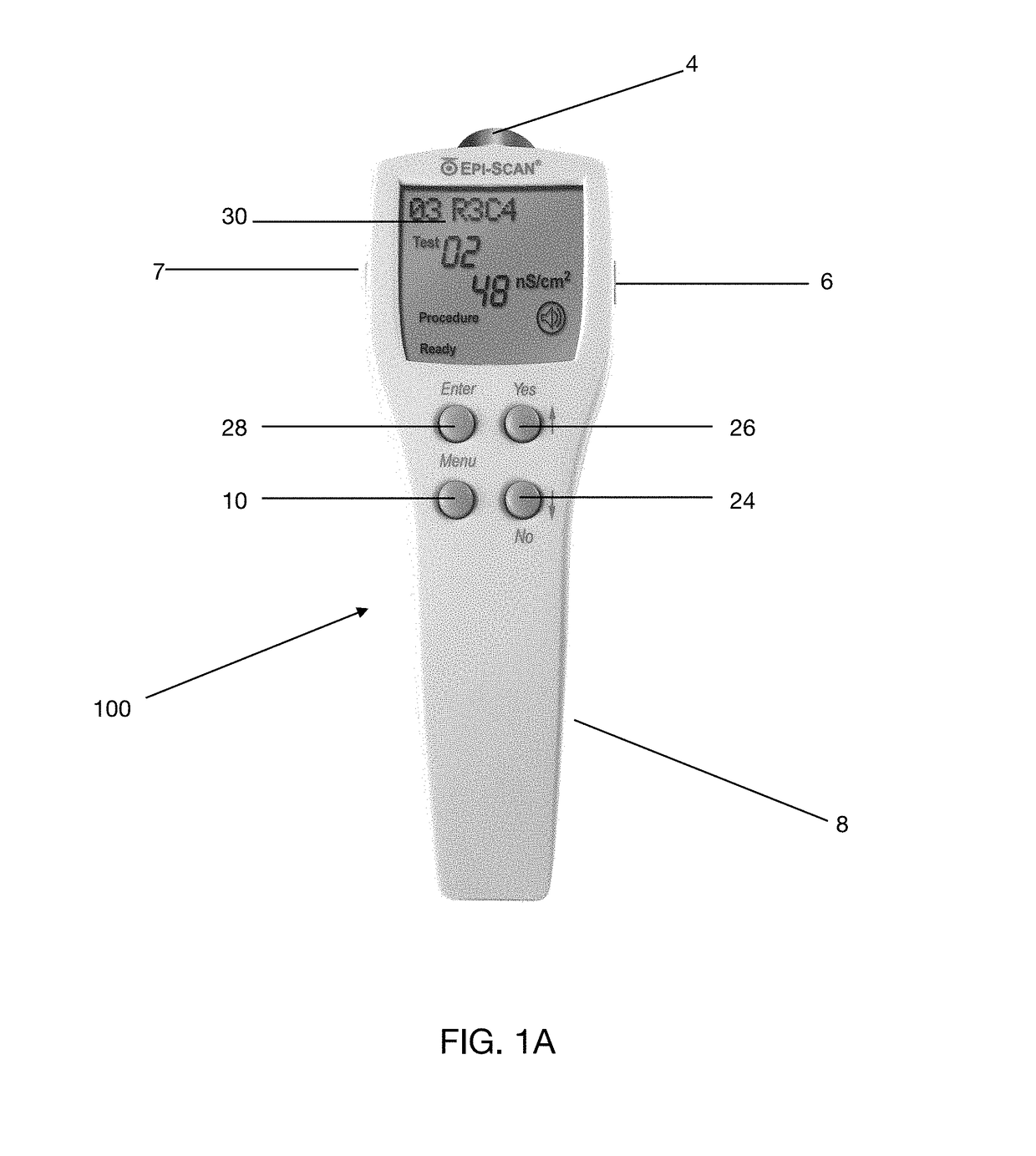

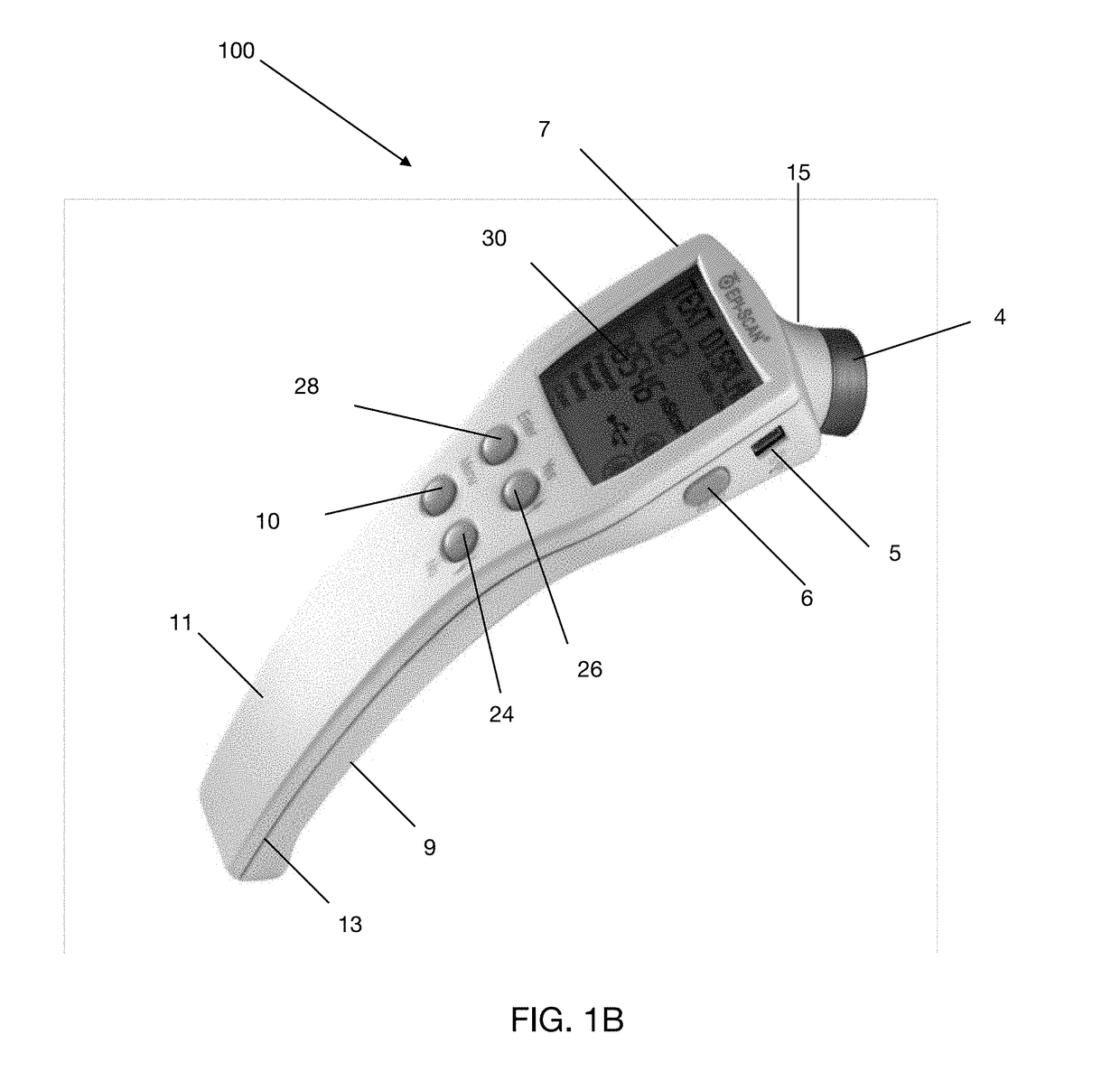

Apparatus, system, and method for the objective evaluation of corporeal pain

ActiveUS20180289317A1Low costGood surface conductivityPhysical therapies and activitiesMechanical/radiation/invasive therapiesNervous systemNon invasive

Various methods and machines have been used in the past to measure electrical characteristics of living tissue for purpose of locating an area of abnormal nervous system activity. However, whereas prior art methodologies merely allow for the detection of pain, the apparatus, system and method of the present invention allow for the objective assessment pain severity that finds utility not only the initial diagnosis but also the on-going treatment of any disease, disorder or injury associated therewith. To that end, the apparatus, system and method of the present invention allows medical practitioners to non-invasively and quantitatively distinguish organic pain from psychosomatic pain and legitimate pain patients from drug seekers and opiod addicts, as well as to directly and objectively compare the efficacy of different drug regimens and therapy protocols.

Owner:EPISCAN GLOBAL LLC

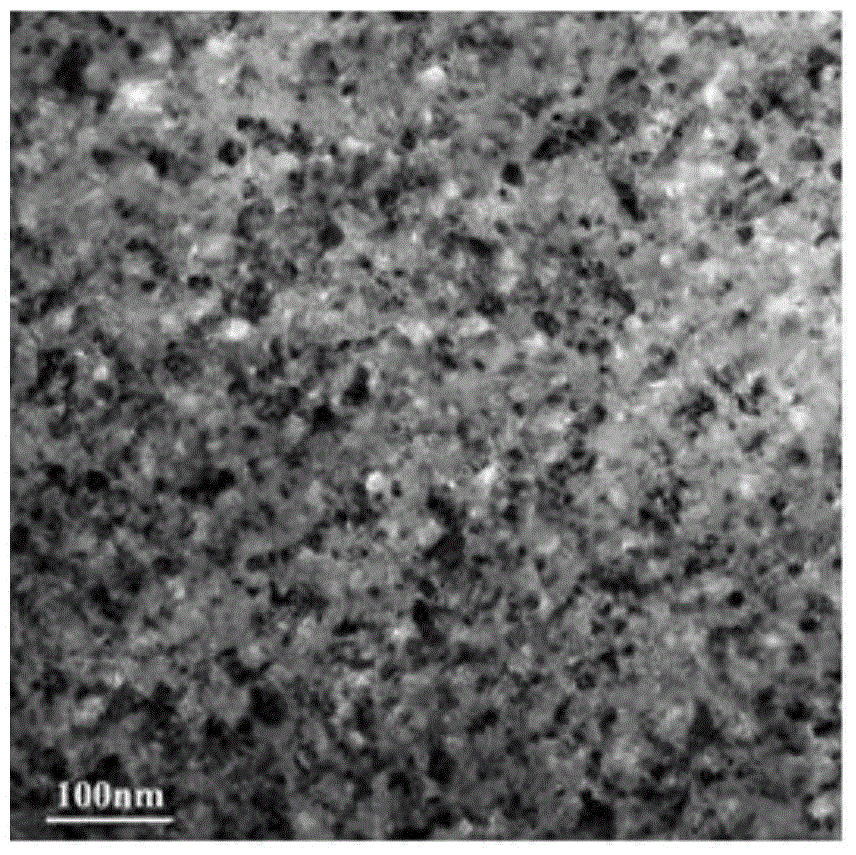

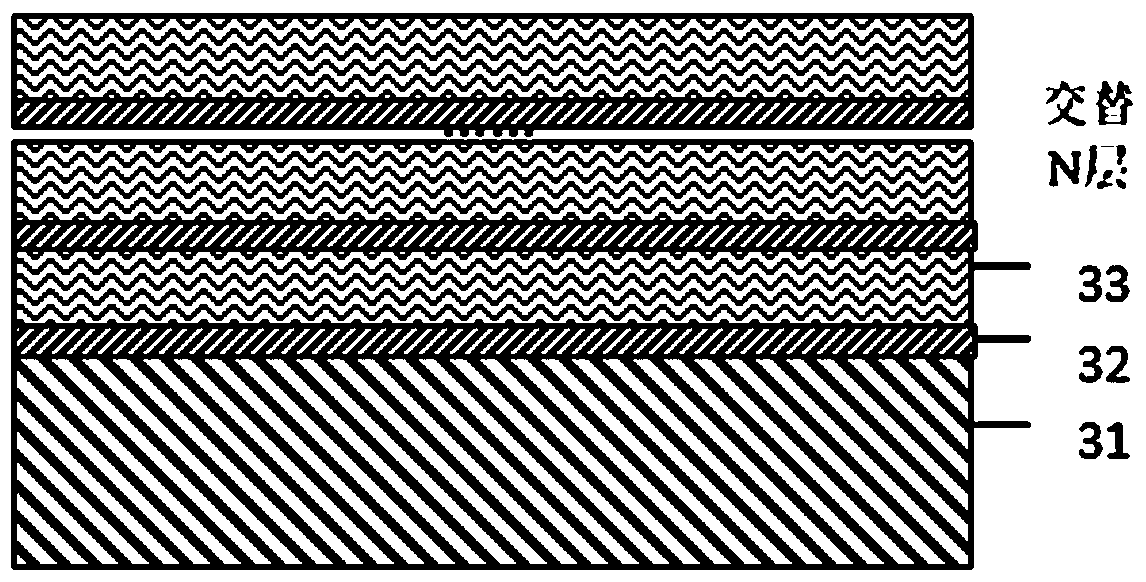

Nanometal layer for fuel cell metal pole plate and preparation method

PendingCN108598497AImprove conductivityImprove bindingMaterial nanotechnologyCell electrodesFuel cellsNon noble metal

The invention provides a nanometal coating for a fuel cell metal pole plate, the nanometal coating comprises a substrate layer composed of a metal pole plate, at least one non-noble metal layer is deposited on the substrate layer, a hybrid layer alternatively composed of a non-noble metal and a noble metal is deposited on the non-noble metal layer, the noble metal is located at the outermost sideof the nanometal coating, thickness of the non-noble metal is 1-500nm, and in the hybrid layer composed of the non-noble metal and the noble metal, mass ratio of the non-noble metal to the noble metalis 1-90:100, and the coating thickness of the hybrid layer is 1-100nm. The invention also provides a preparation method of the nanometal coating for the fuel cell metal pole plate. In comparison withthe existing coating, by coating provided by the invention, dosage of the noble metal can be reduced remarkably, surface conductive performance and anti-corrosion performance of the metal pole platecan be enhanced, and endurance quality of the fuel cell pole plate is improved.

Owner:SHANGHAI ZHIZHEN NEW ENERGY EQUIP CO LTD

Highly conductive composites

InactiveUS8344053B2Low percolation thresholdDecreased percolation thresholdLine/current collector detailsPretreated surfacesConductive polymerConducting pathway

Domain segregation of polymer blends or block copolymers in the presence of thermal conducting high aspect ratio nanocrystals leads to preferential placement of conductive filler either inside one domain, which promote the self-assembly of a thermal and / or electrical conducting pathway composed of high aspect ratio filler. The self-assembly of such thermal and / or electrical conducting pathway effectively enhances the thermal and / or electrical conductivity of the composite with significantly less amount of filler.

Owner:PIXELLIGENT TECH LLC

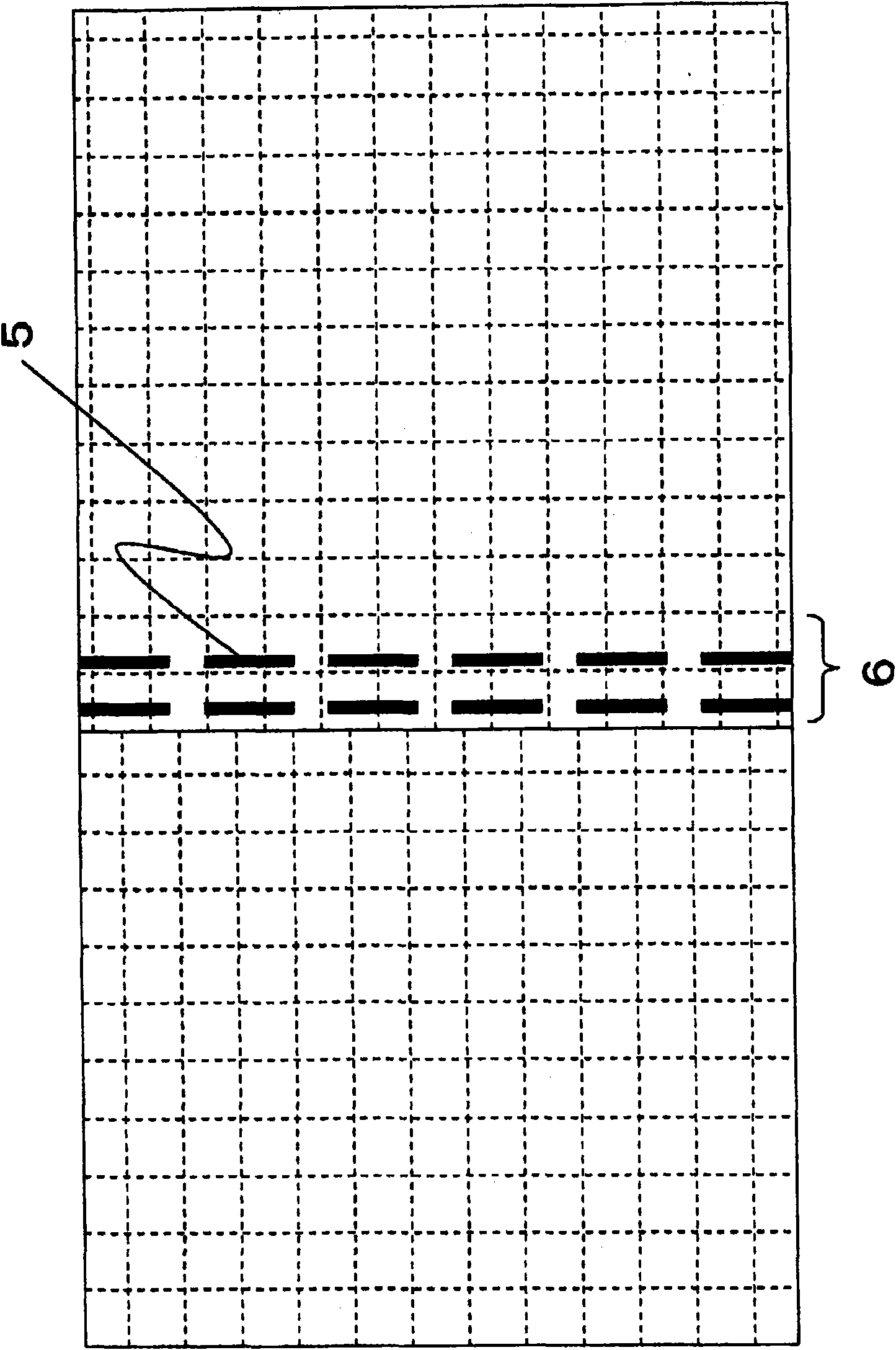

Optical fiber tape core wire able to be branched and branching

ActiveCN101910484AGood surface conductivityHigh surface conductivityOther chemical processesProtective fabricsEngineeringMechanical engineering

An optical fiber tape core wire can be branched using some tool. The optical fiber tape core wire comprises a plurality of optical fibers running in parallel, a collective coating which covers the plurality of optical fibers entirely, a recess formed in at least any one gap between the optical fibers and on the collective coating, and a plurality of slits arranged in series along each recess at a predetermined interval and permitting cleavage of the collective coating by inserting a tool through the collective coating and moving the tool along the recess. Length of the slit is set such that the bend of the optical fiber caused by spreading the slit with the tool does not exceed the allowable radius of curvature of the optical fiber.

Owner:TORAY IND INC

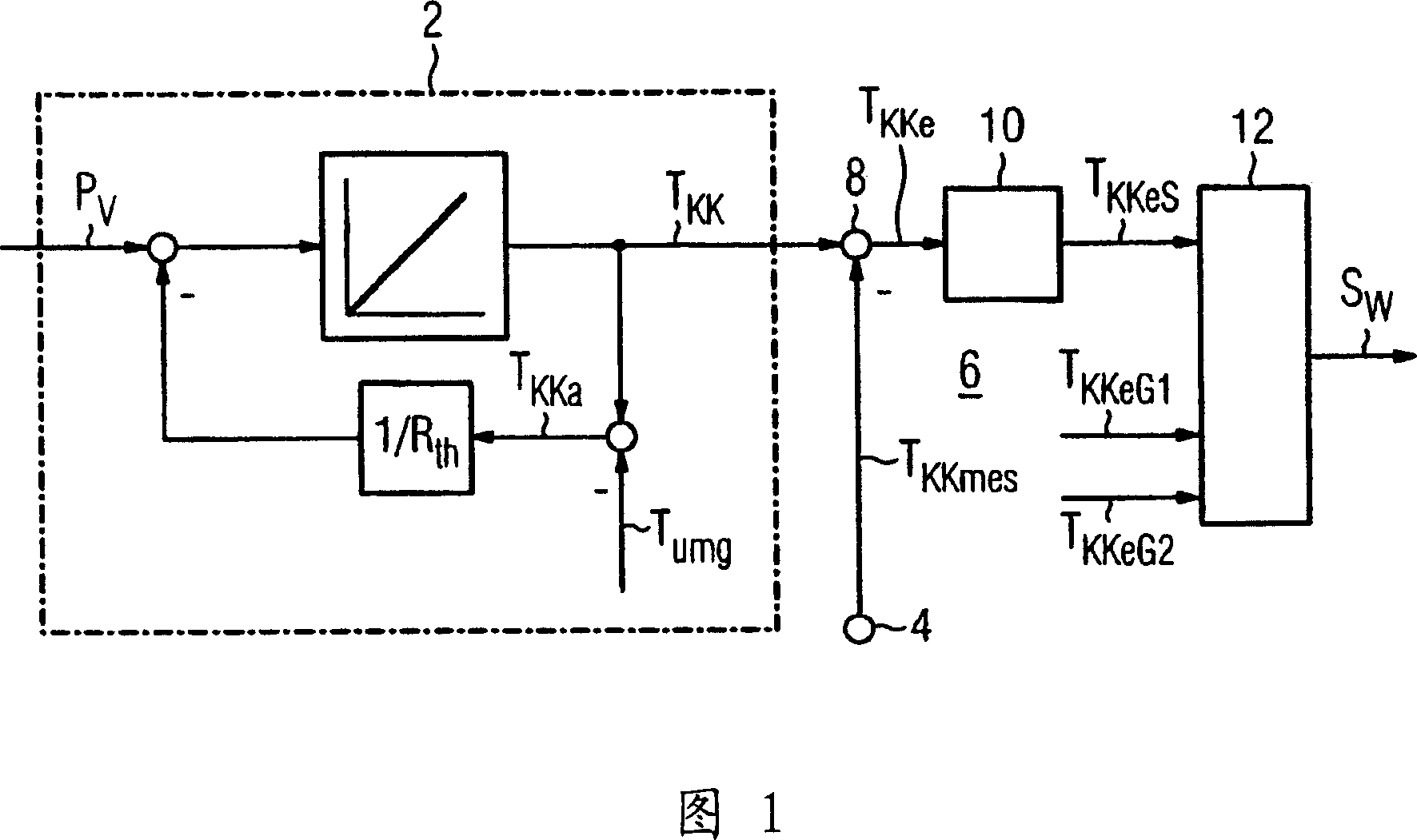

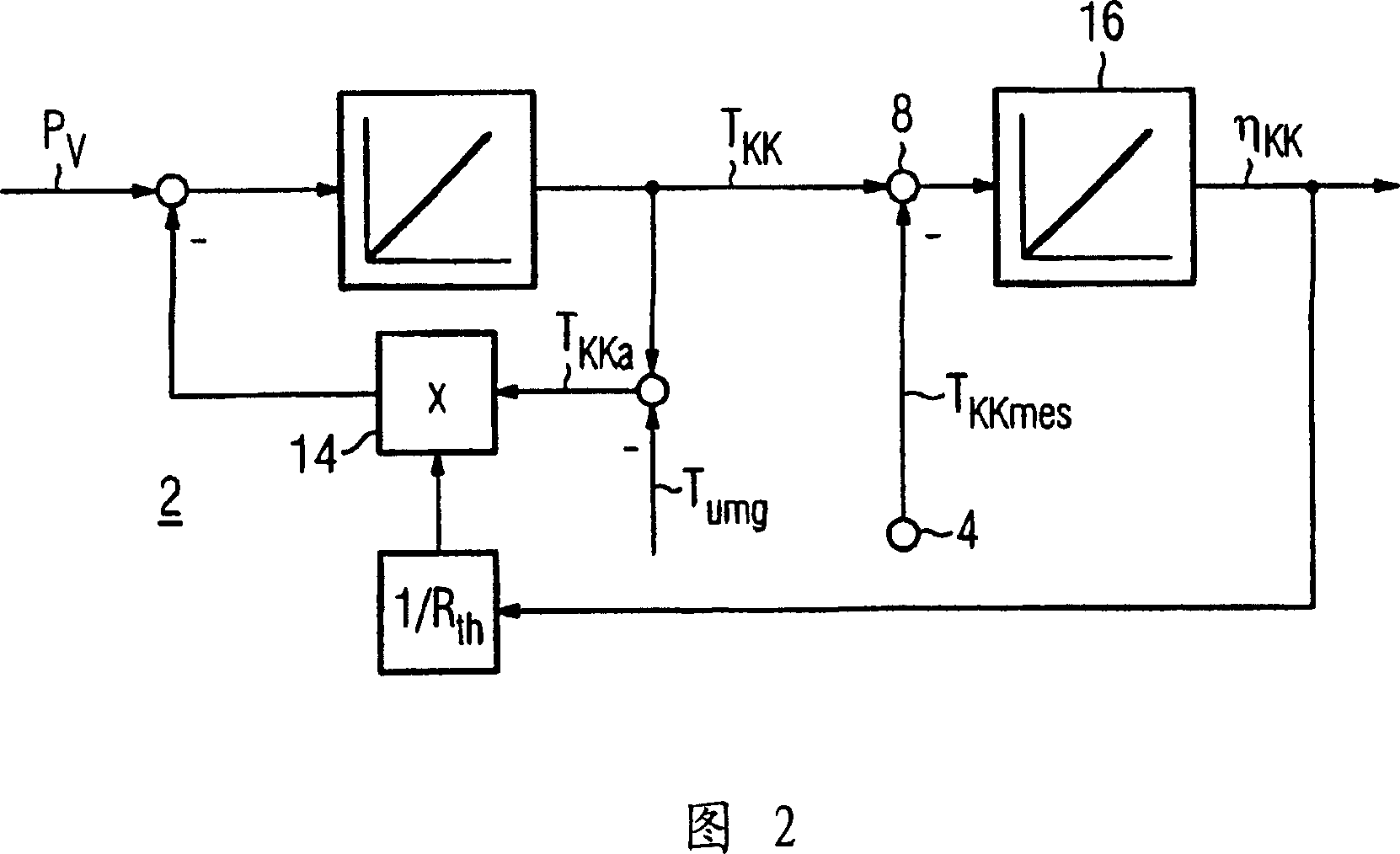

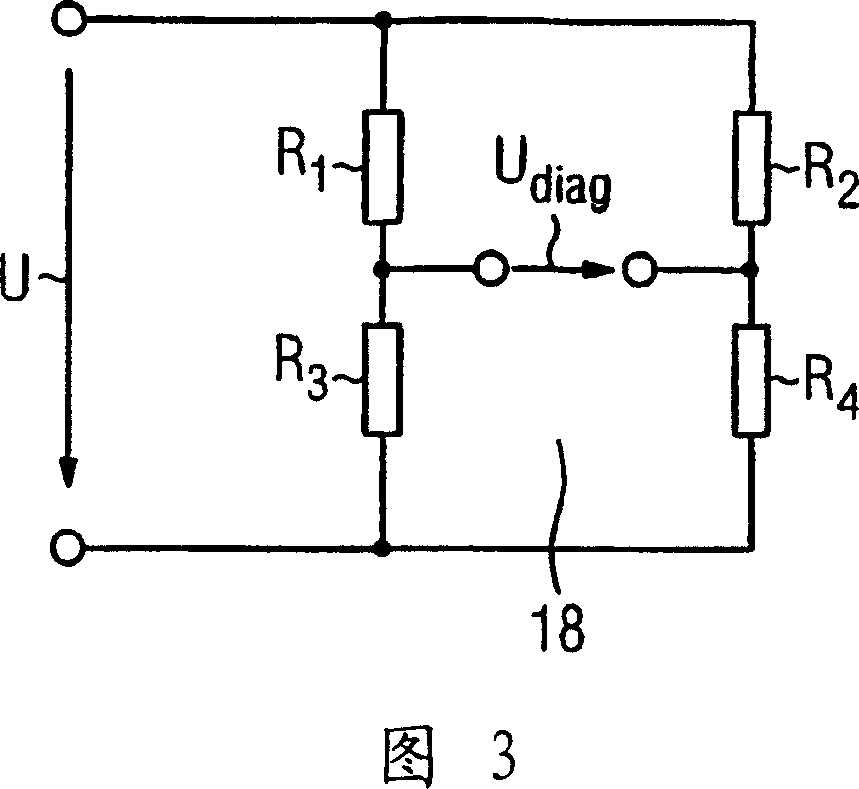

Method and device for detecting the degree of pollution in an operational converter

InactiveCN1942982AInferred pollution levelGood surface conductivityTransformers/inductances circuitsEmergency protective arrangements for automatic disconnectionAmbient airPollution

Owner:SIEMENS AG

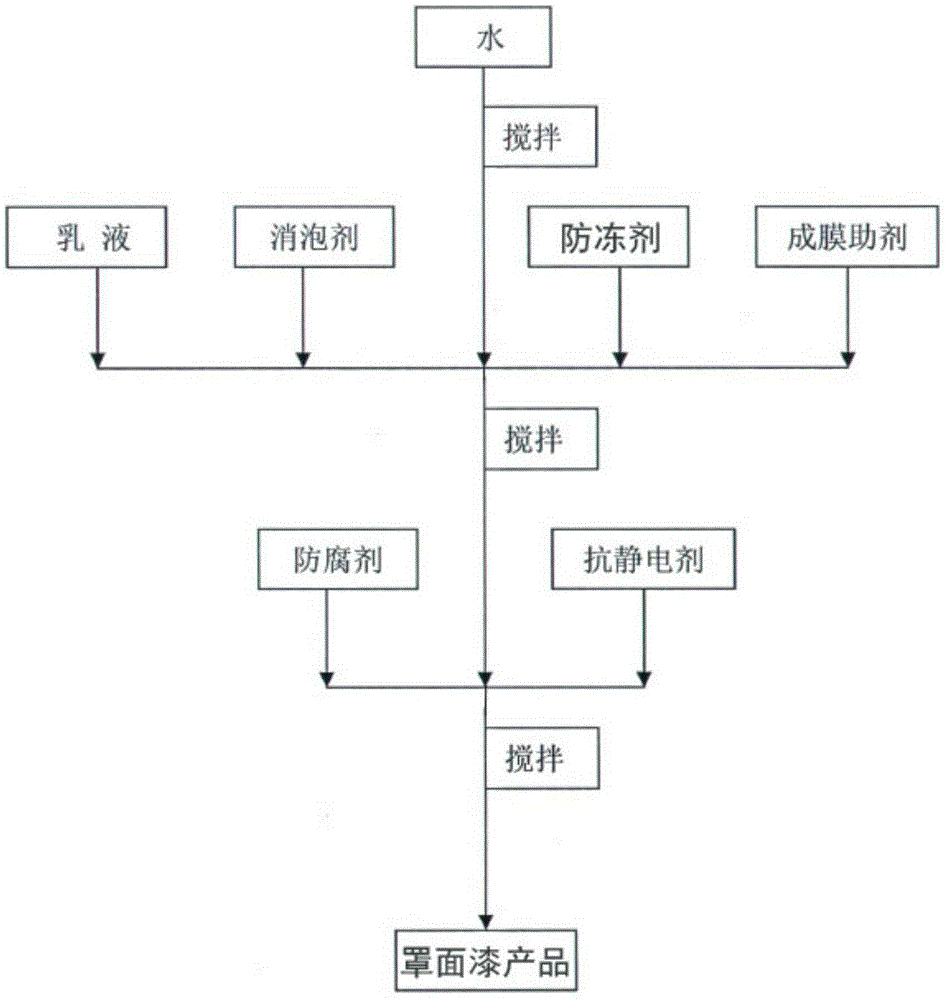

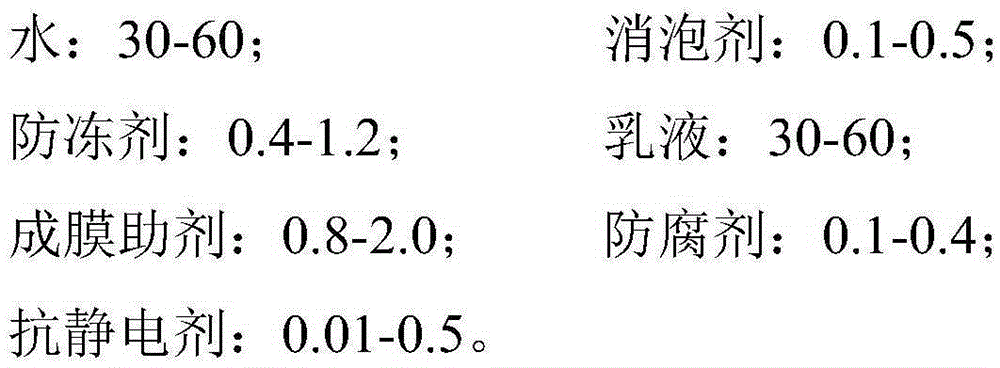

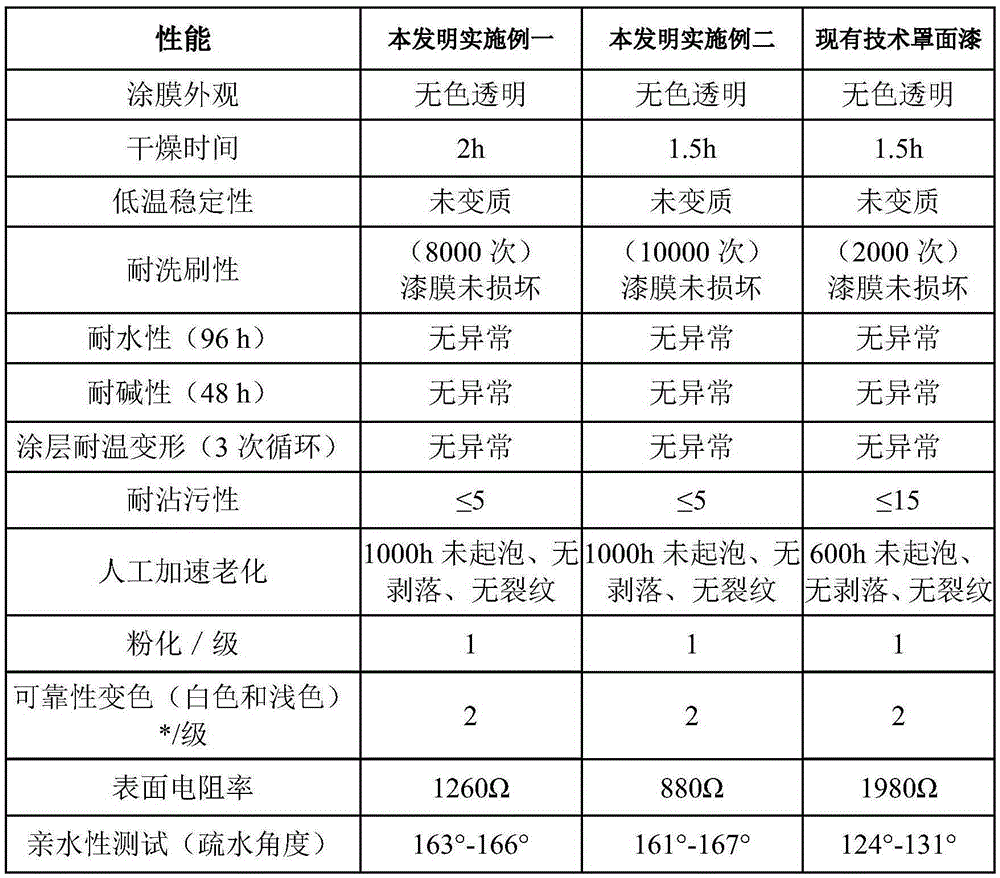

Automatic cleaning finish for exterior walls, and preparation method thereof

InactiveCN105419445ALower surface energyReduce hydrophobicityAntifouling/underwater paintsPaints with biocidesColor changesStain

The invention discloses an automatic cleaning finish for exterior walls, and a preparation method thereof. The finish comprises, by weight, 30-60 parts of water, 0.1-0.5 parts of an antifoaming agent, 0.4-1.2 parts of an antifreeze agent, 30-60 parts of an emulsion, 0.8-2.0 parts of a film forming assistant, 0.1-0.4 parts of an antiseptic and 0.01-0.5 parts of an antistatic agent. The preparation method comprises the following steps: weighing above finish components according to above weight proportions; adding water to a finish preparation kettle; sequentially adding the emulsion, the antifoaming agent, the antifreeze agent and the film forming assistant while stirring; uniformly stirring above added components, and adding the antiseptic and the antistatic agent; and stirring above obtained components until uniformity to obtain the finished finish. The finish has exterior wall protection and decoration effects, has the advantages of excellent stain resistance, weatherability, low surface energy, high antistatic property and high light transmittance, can realize automatic cleaning of building exterior walls by using wind and rainwater in natural environment, solves the problems of easy pollution, easy efflorescence, color change and spalling of surfaces of buildings, and prolongs the service life of building exterior wall coatings.

Owner:XINJIANG TUNHE PAINTING

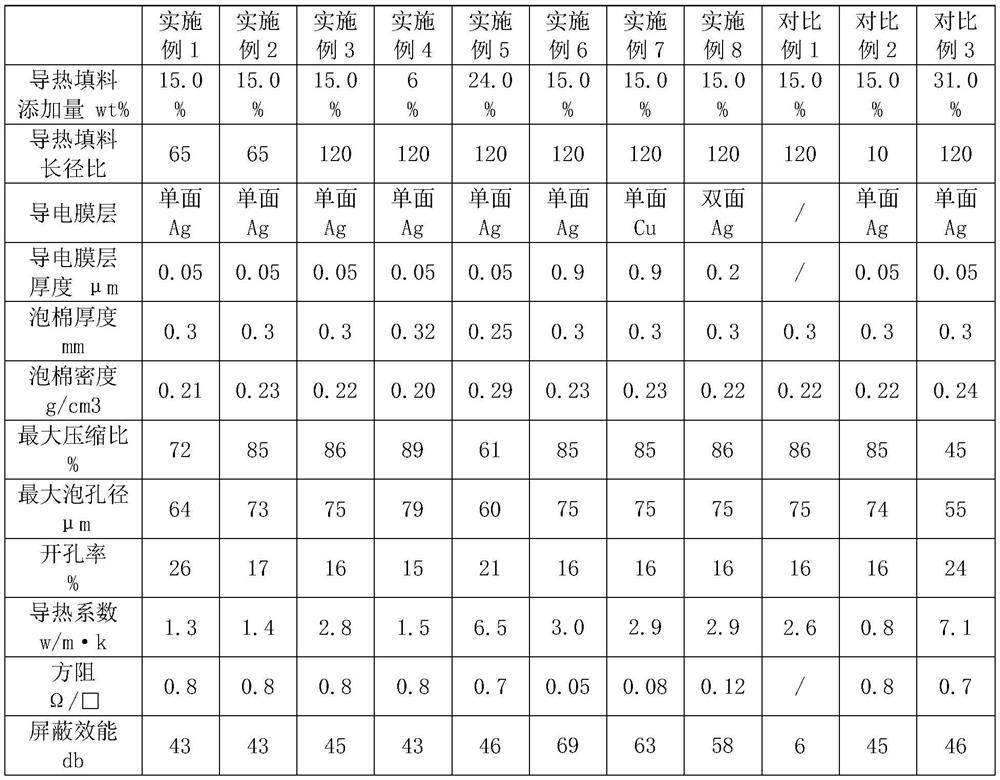

Heat dissipation conductive shielding buffer foam and application

PendingCN114650725AIncrease the compression ratioGood surface conductivityShielding materialsVacuum evaporation coatingSurface conductivityPhysical chemistry

The invention discloses heat dissipation conductive shielding buffer foam which comprises a buffer foam layer and a conductive film layer arranged on one side or two sides of the buffer foam layer, and the conductive film layer is attached to the surface of the buffer foam layer in a layer-by-layer sputtering mode. The thickness of the heat dissipation conductive shielding buffer foam ranges from 0.06 mm to 1 mm, the density ranges from 0.03 g / cm < 3 > to 0.8 g / cm < 3 >, the maximum compression ratio is larger than or equal to 60%, the maximum bubble hole diameter in each direction does not exceed 80 micrometers, and the foam aperture ratio is smaller than or equal to 30%. The buffer foam layer contains fibrous heat-conducting filler which is used for improving the heat-conducting property of the buffer foam layer, and the heat conductivity coefficient is within 1-10w / m.k. The heat dissipation conductive shielding buffer foam is soft, has a higher compression ratio, can better adapt to concave-convex gap scenes in electronic equipment, fills interface gaps, reduces contact thermal resistance, and improves the heat conduction effect by combining with the internally added heat conduction filler; and meanwhile, the conductive film layer has better surface conductivity, so that the material can be used as an electromagnetic wave shielding material.

Owner:湖北祥源高新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com