Optical fiber tape core wire able to be branched and branching

A fabric and double-weave technology, applied in the direction of fabrics, woven fabrics, multi-strand fabrics, etc., can solve the problems of increased blending ratio of conductive filaments, increased manufacturing costs, etc., and achieve excellent surface conductivity and high conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

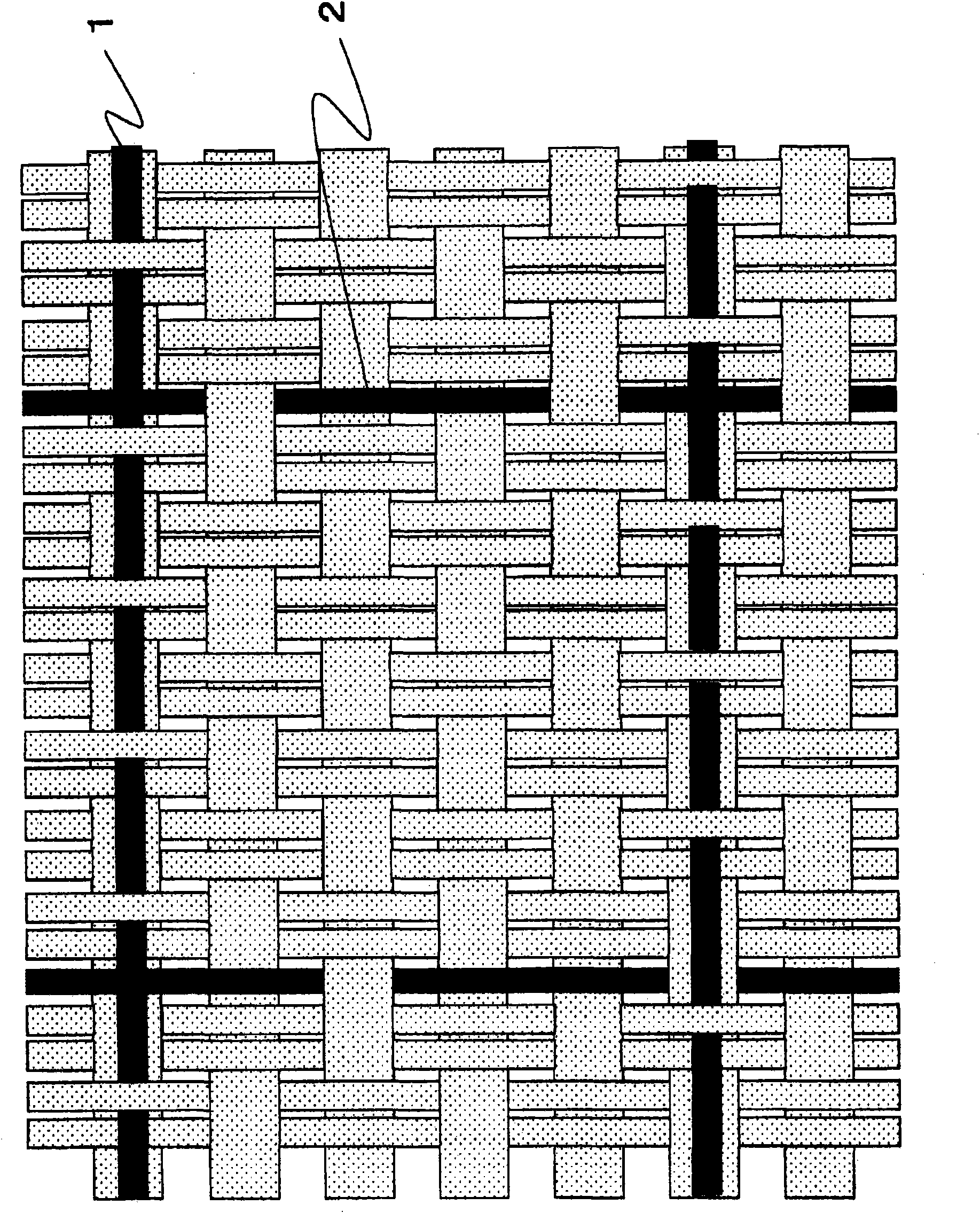

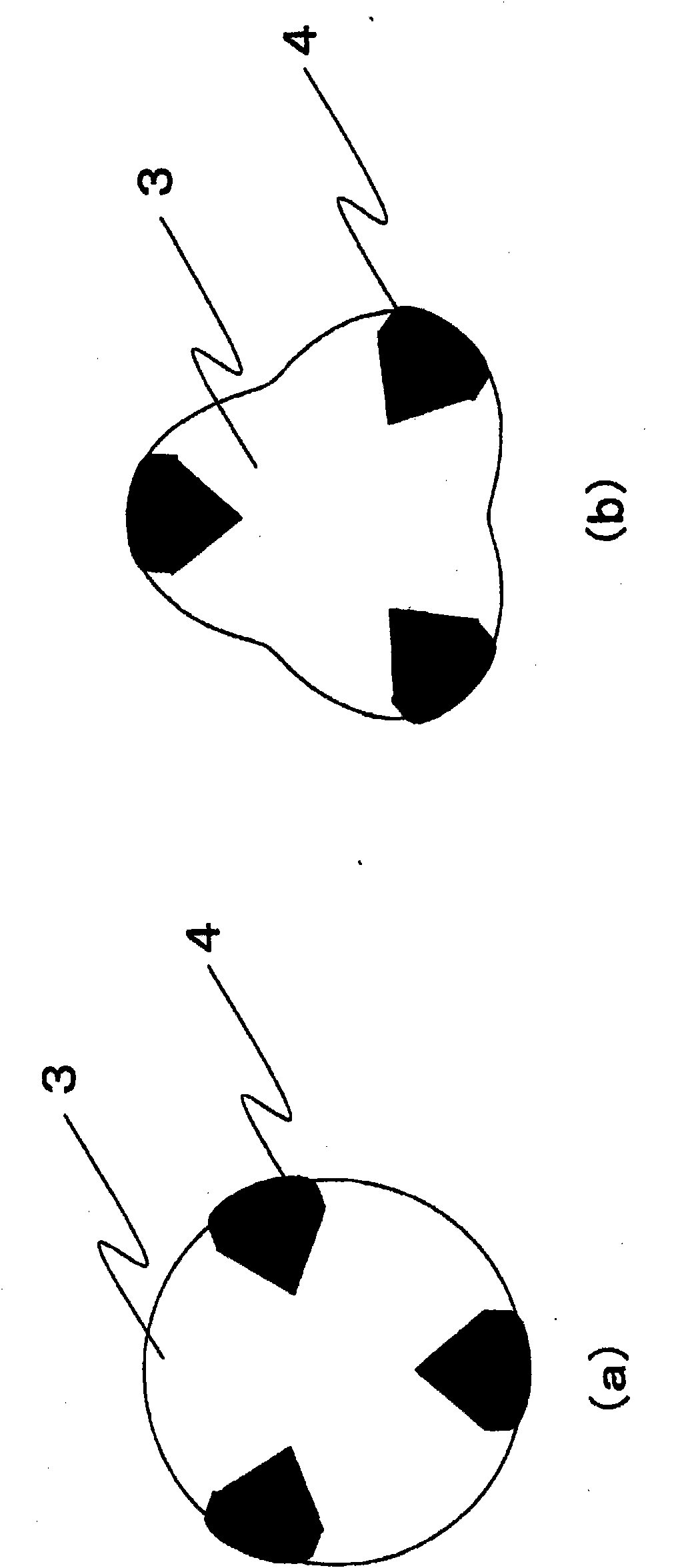

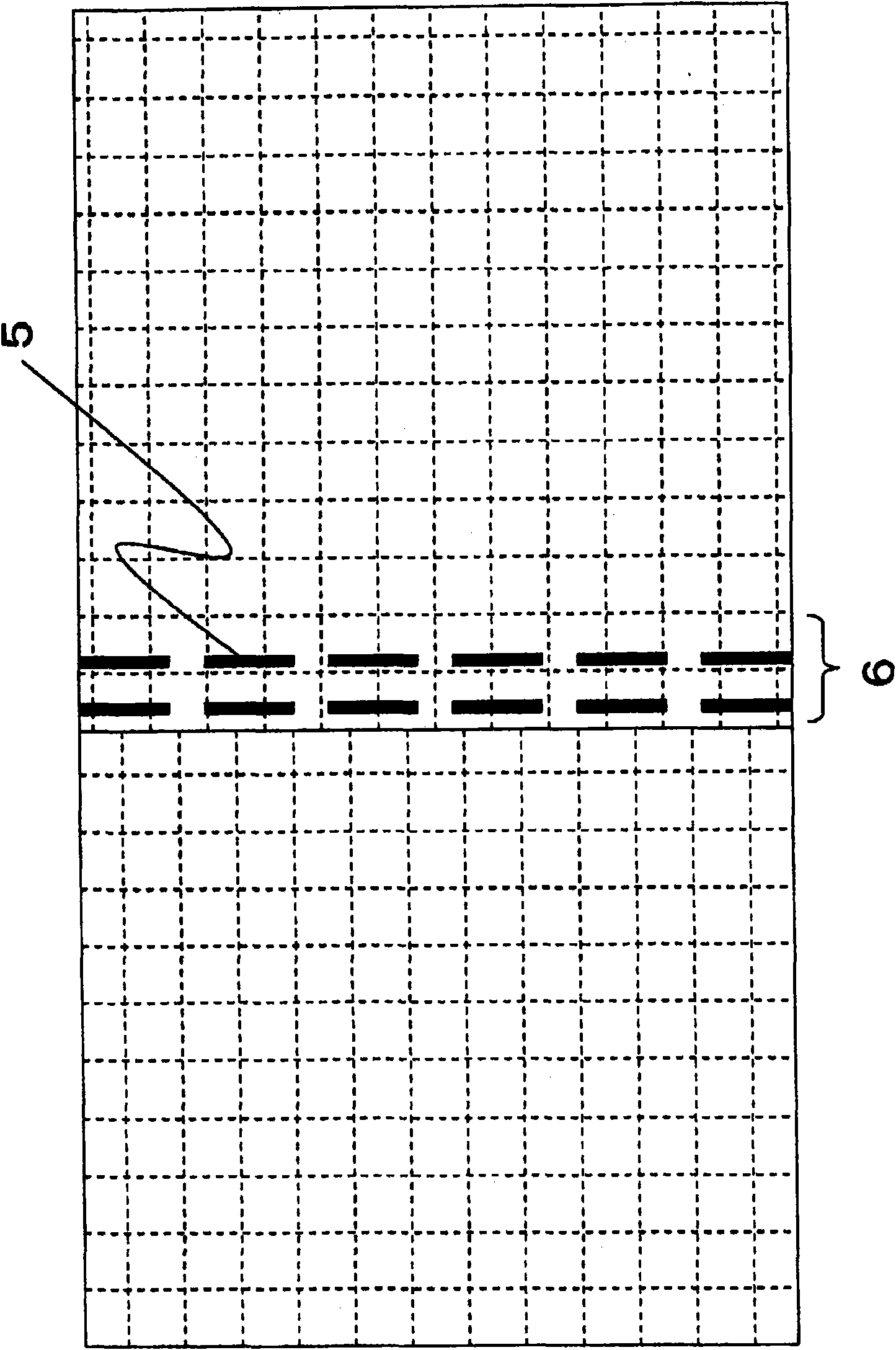

[0072] Two double-ply yarns of polyester fusion yarn (84 decitex-36 filaments) are used as the warp yarn forming the ground structure, and polyester false-twisted processed yarn (334 decitex-96 filaments) is used as the warp yarn Conductive thread and weft conductive thread use contains figure 2 Conductive filaments of surface-exposed fibers (84 decitex-9 filaments). Use the ground weave as plain weave (single dense pattern), weave through the dobby so that the warp conductive yarns are arranged according to the ratio of 1 of the 24 ground warp yarns (with a distance of 5 mm), skipping 2 outer warps and skipping 1 inner warp yarn. like figure 1 organization. In addition, the weft yarn conductive thread is inserted in the ratio of 1 out of 11 ground weft yarns (5mm spacing) in the weft double weave and arranged on the ground weft yarn (that is, it becomes a floating yarn), skipping 3 on the outside and skipping 1 on the inside. roots form as figure 1 organization. In this...

Embodiment 2

[0074] It carried out under the same conditions as Example 1, only changing the conductive thread. That is, as the conductive yarn, a parallel-twisted yarn (89 decitex-18 filament) of a polyester false-twisted processed yarn (33 decitex-12 filaments) and a surface-exposed conductive yarn (56 decitex-6 filaments) was used . The resulting fabric was sewn with a sewing machine, and the surface resistance value of the seamed portion was measured. Various data are described in Table 1.

Embodiment 3

[0076] Two double-ply yarns of polyester false-twisted processed yarn (84 decitex-36 filaments) are used for the warp yarn forming the ground structure, and polyester false-twisted processed yarn (334 decitex-96 filaments) is used for the weft yarn, A surface-exposed conductive yarn (84 dtex-9 filament) was used for the warp conductive yarn and the weft conductive yarn. The ground weave is used as plain weave (single dense pattern), and the warp conductive yarns are arranged according to the ratio of 1 out of 32 ground warp yarns (with a distance of 5 mm) through dobby weaving, forming 3 skipped outer threads and 1 skipped inner thread organization. In addition, the weft yarn conductive thread is inserted on the ground weft yarn in a ratio of 1 out of 15 ground weft yarns (5mm pitch) in a weft double weave, forming a weave that skips 6 outer and 2 inner weaves. In this way, the warp density is 202 / 2.54cm, and the weft density is 74 / 2.54cm. Refining, dyeing, and processing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com