Automatic cleaning finish for exterior walls, and preparation method thereof

A finish paint and self-cleaning technology, which is applied to biocide-containing paints, anti-fouling/underwater paints, conductive paints, etc., can solve the problem of poor light transmission performance, poor brush resistance and self-cleaning performance of finish paints Poor problems, to achieve the effect of enhancing surface conductivity, prolonging service life, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

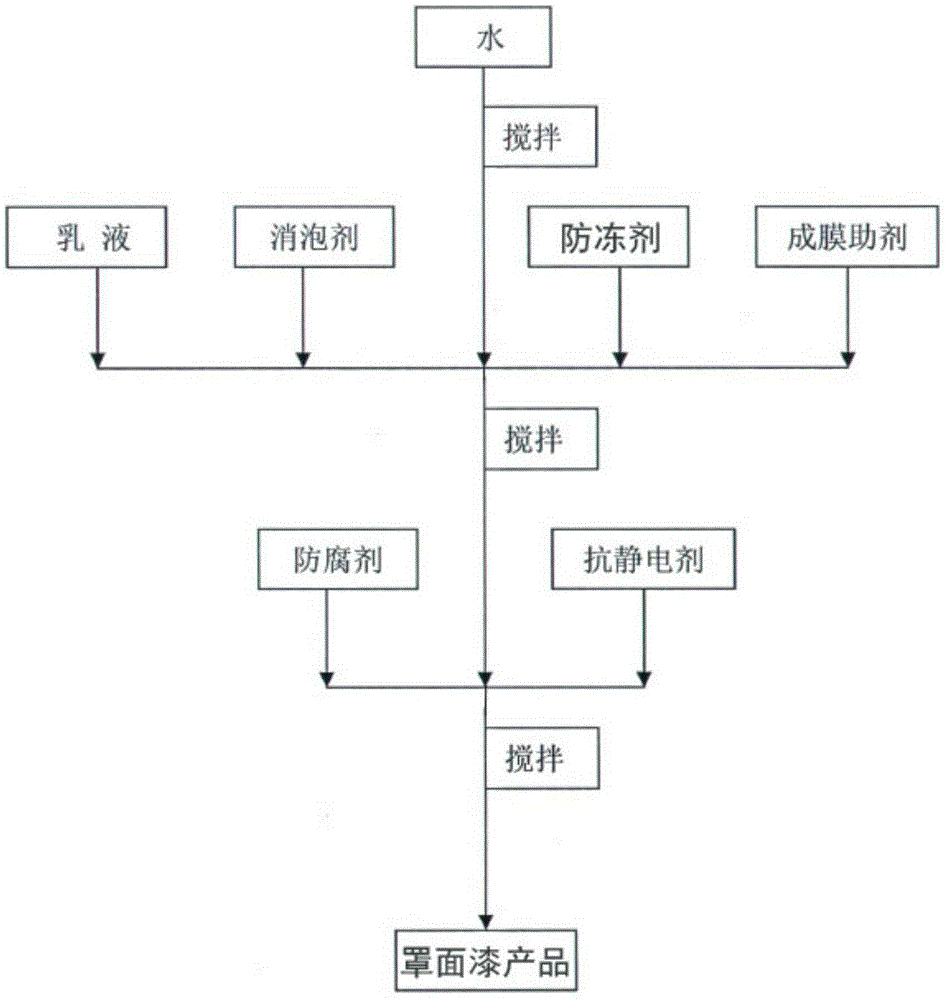

[0029] Such as figure 1 As shown, the self-cleaning finish paint for exterior wall of the present embodiment and preparation method thereof comprise the steps:

[0030] a, take the finish paint component by weight ratio;

[0031] b. First put 58 parts of water into the paint making kettle;

[0032] c. Add 40 parts of Richu TD-661 emulsion, 0.2 part of silicone modified mineral oil defoamer AM1512, 0.5 part of antifreeze ethylene glycol, and 1 part of Runtai Chemical under stirring at a speed of 600 rpm. C-12 film-forming aid;

[0033] d. After stirring evenly, add 0.2 part of Sol MV preservative and 0.1 part of internal mixed non-polymer antistatic agent;

[0034] e. Finally, stir evenly to obtain the finished finish paint.

Embodiment 2

[0036] Such as figure 1 As shown, the self-cleaning finish paint for exterior wall of the present embodiment and preparation method thereof comprise the steps:

[0037] a, take the finish paint component by weight ratio;

[0038] b. First put 52.7 parts of water into the paint making kettle;

[0039] c. Add 45 parts of Baolijia BLJ-9301 emulsion, 0.2 parts of silicone modified mineral oil defoamer NXZ, 0.6 parts of antifreeze ethylene glycol, and 1.2 parts of Runtai Chemical under stirring at a speed of 600 rpm. C-12 film-forming aid;

[0040] d. After stirring evenly, add 0.2 part of Sol MV preservative and 0.1 part of internal mixed non-polymer antistatic agent;

[0041] e. Finally, stir evenly to obtain the finished finish paint.

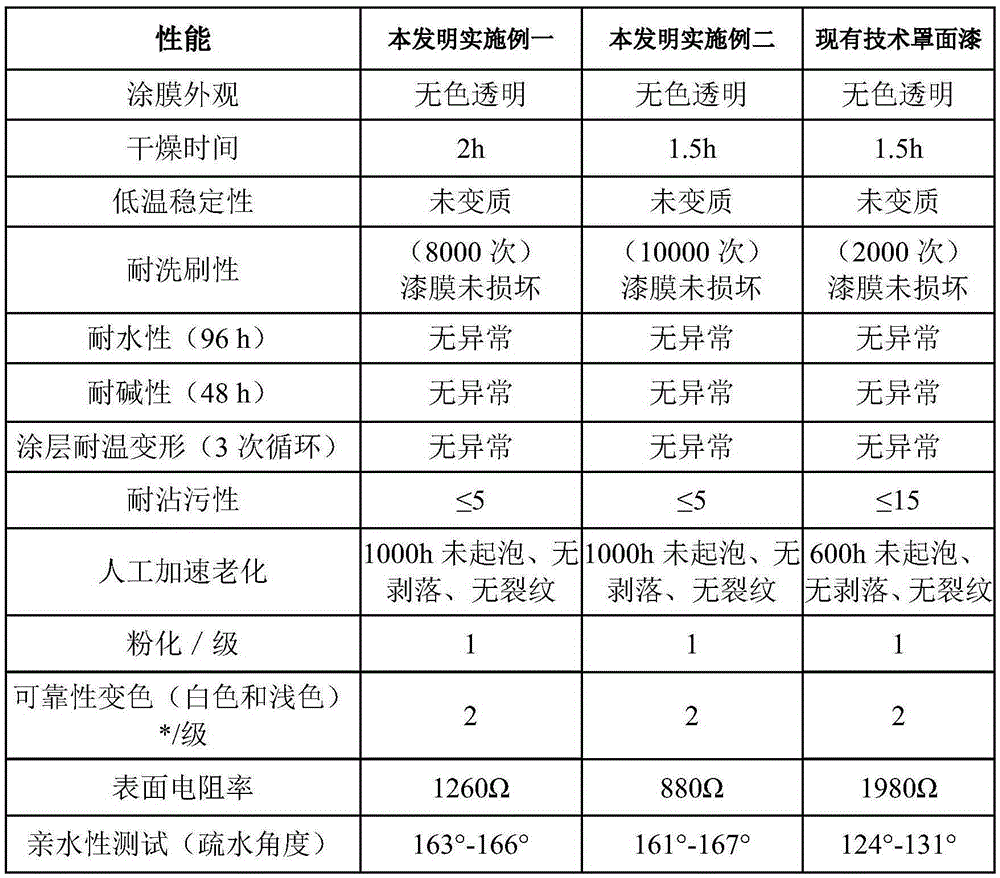

[0042] The performance of above-mentioned embodiment one, embodiment two and prior art finish paint (in enterprise production at present) is compared, and result is as shown in the table below:

[0043]

[0044] As can be seen from the ab...

Embodiment 3

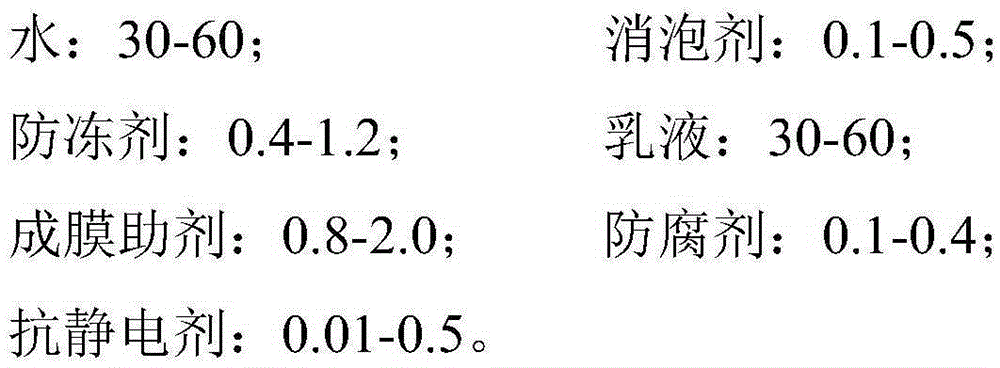

[0046] A kind of self-cleaning finish paint for exterior wall of the present embodiment, the component weight proportion of described finish paint is:

[0047]

[0048] The defoamer is silicone modified mineral oil defoamer AM1512. The antifreeze is ethanol. The emulsion is Bardford RS-9765, with a silicone content of 3%, a hydrophilic auxiliary agent content of 3.0%, and an emulsifier content of 1.0%. The film-forming aid is Runtai Chemical C-12. The preservative is Thor MV; the antistatic agent is an internally mixed non-polymer antistatic agent.

[0049] Such as figure 1 As shown, the preparation method of the self-cleaning finish paint for the exterior wall of the present embodiment, the preparation method comprises the following steps:

[0050] a, take the finish paint component by weight ratio;

[0051] b. First put water into the paint kettle;

[0052] c. Put in emulsion, defoamer, antifreeze and film-forming aid in turn under stirring;

[0053] d. Add preserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com