Heat dissipation conductive shielding buffer foam and application

A cushioning foam and conductive shielding technology, which is applied in the field of foam materials, can solve the problems of reducing the life of electronic devices, large material loss, and high cost of shielding covers, and achieve the effects of improving thermal conductivity, reducing contact thermal resistance, and high shielding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

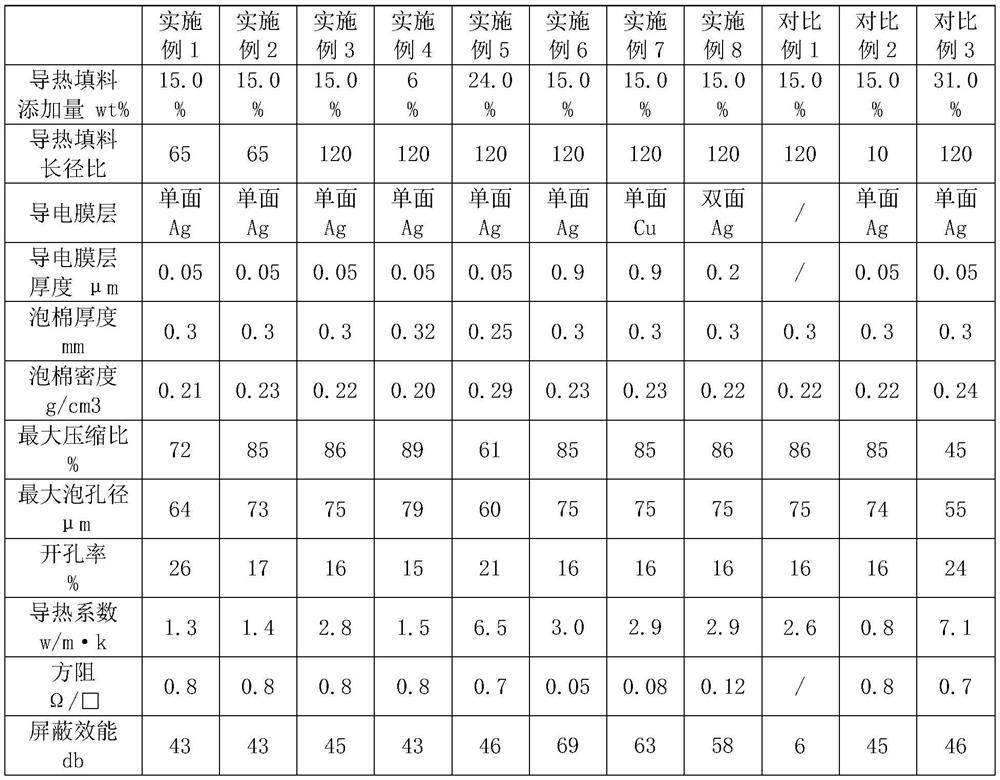

[0045] For the thermal conductive shielding buffer foam of this embodiment, 50 parts by weight of low-density polyethylene (LDPE) resin is selected as the basic resin, 30 parts by weight of ethylene-vinyl acetate copolymer (EVA) is used as the resin modifier, and azodicarbonamide is used as the resin modifier. 3 parts by weight are used as foaming agent (particle size < 10 μm), 15 parts by weight of carbon nanotubes (length-diameter ratio 65) are used as thermal conductive fillers, and 2 parts by weight of maleic anhydride are used as compatibilizers. Extruded and stretched into a sheet; cross-linked by irradiation, the irradiation dose is 25Mrad; foamed at 240 ° C, azodicarbonamide foamed to generate gas, and the sheet was foamed into cells with multiple cell structures Cotton, the thickness of the foam is 0.3mm; a 0.05μm thick metal Ag layer is deposited on the foam side by a magnetron sputtering process.

[0046] The prepared heat dissipation conductive shielding buffer foa...

Embodiment 2

[0048] The difference from Example 1 is that, in order to obtain a softer and thinner foam, ethylene-propylene-diene rubber (EPR) was added as a resin modifier, and 40 parts by weight of low-density polyethylene (LDPE) resin was selected as the basic material. Resin, 25 parts by weight of ethylene-vinyl acetate copolymer (EVA) and 15 parts by weight of ethylene propylene rubber (EPR) are used as resin modifiers, and 3 parts by weight of azodicarbonamide are used as foaming agents (particle size<10μm) , 15 parts by weight of carbon nanotubes (length-diameter ratio 65) are used as thermally conductive fillers, 2 parts by weight of maleic anhydride are used as compatibilizers, and other steps are the same as in Example 1.

[0049] The prepared heat dissipation conductive shielding buffer foam was sampled for the above test, and the test results are shown in Table (1).

Embodiment 3

[0051] The difference from Example 2 is that, in order to obtain a foam with more heat dissipation, the thermally conductive filler is changed to 15 parts by weight of carbon nanofibers (aspect ratio 120).

[0052] The prepared heat dissipation conductive shielding buffer foam was sampled for the above test, and the test results are shown in Table (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com