Patents

Literature

5075 results about "Core (optical fiber)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

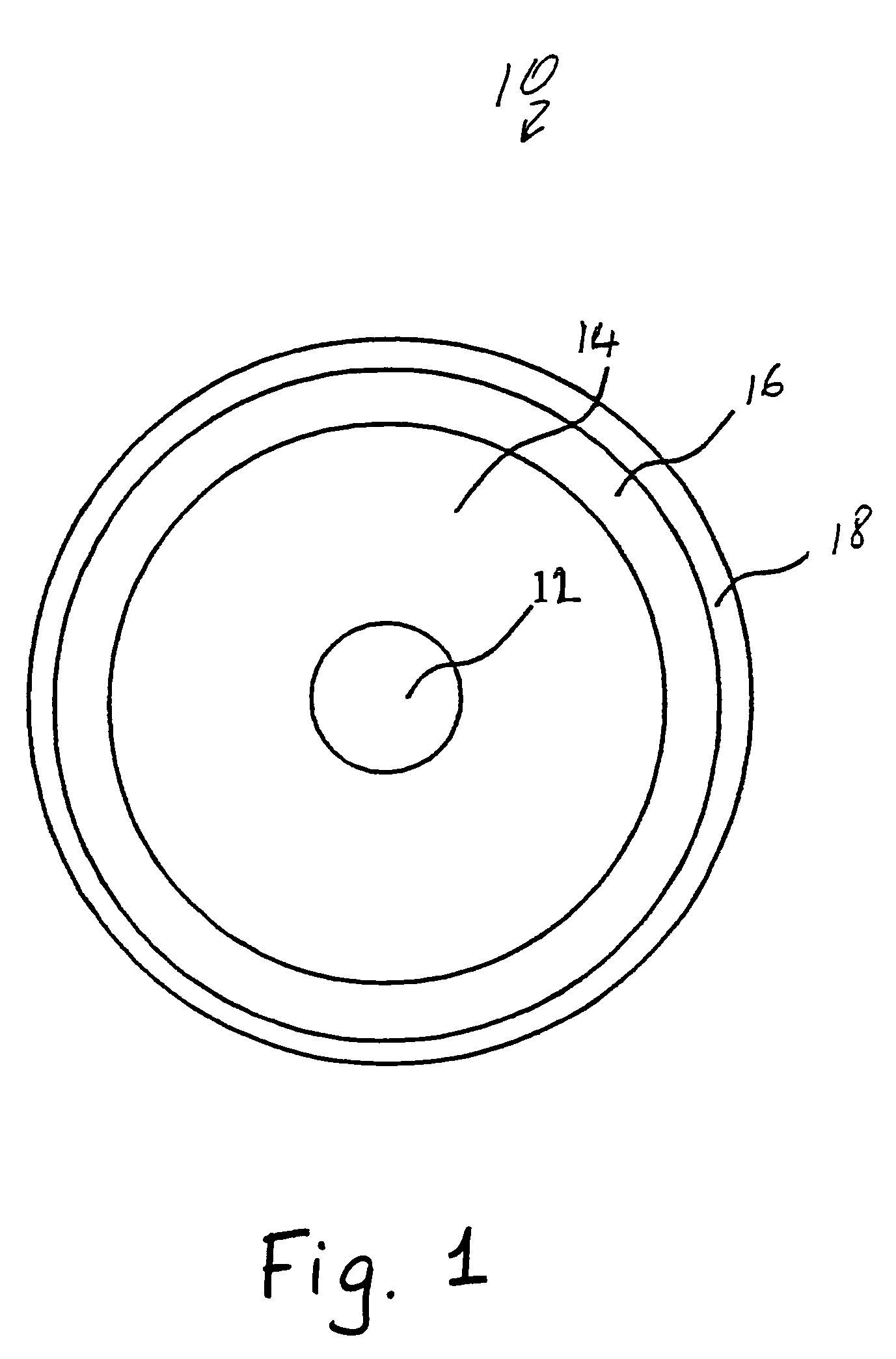

The core of a conventional optical fiber is a cylinder of glass or plastic that runs along the fiber's length. The core is surrounded by a medium with a lower index of refraction, typically a cladding of a different glass, or plastic. Light travelling in the core reflects from the core-cladding boundary due to total internal reflection, as long as the angle between the light and the boundary is greater than the critical angle. As a result, the fiber transmits all rays that enter the fiber with a sufficiently small angle to the fiber's axis. The limiting angle is called the acceptance angle, and the rays that are confined by the core/cladding boundary are called guided rays.

Optical fiber

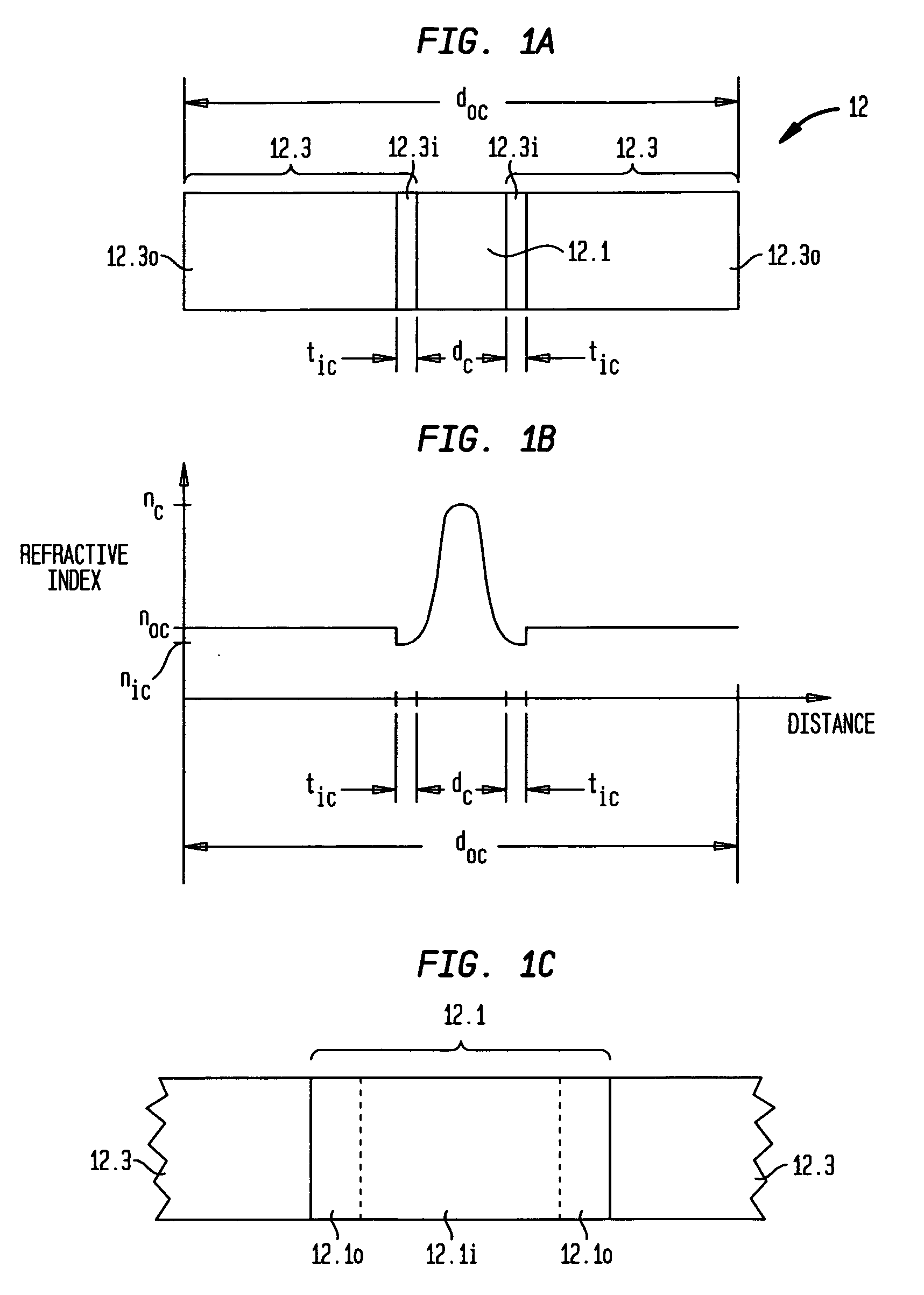

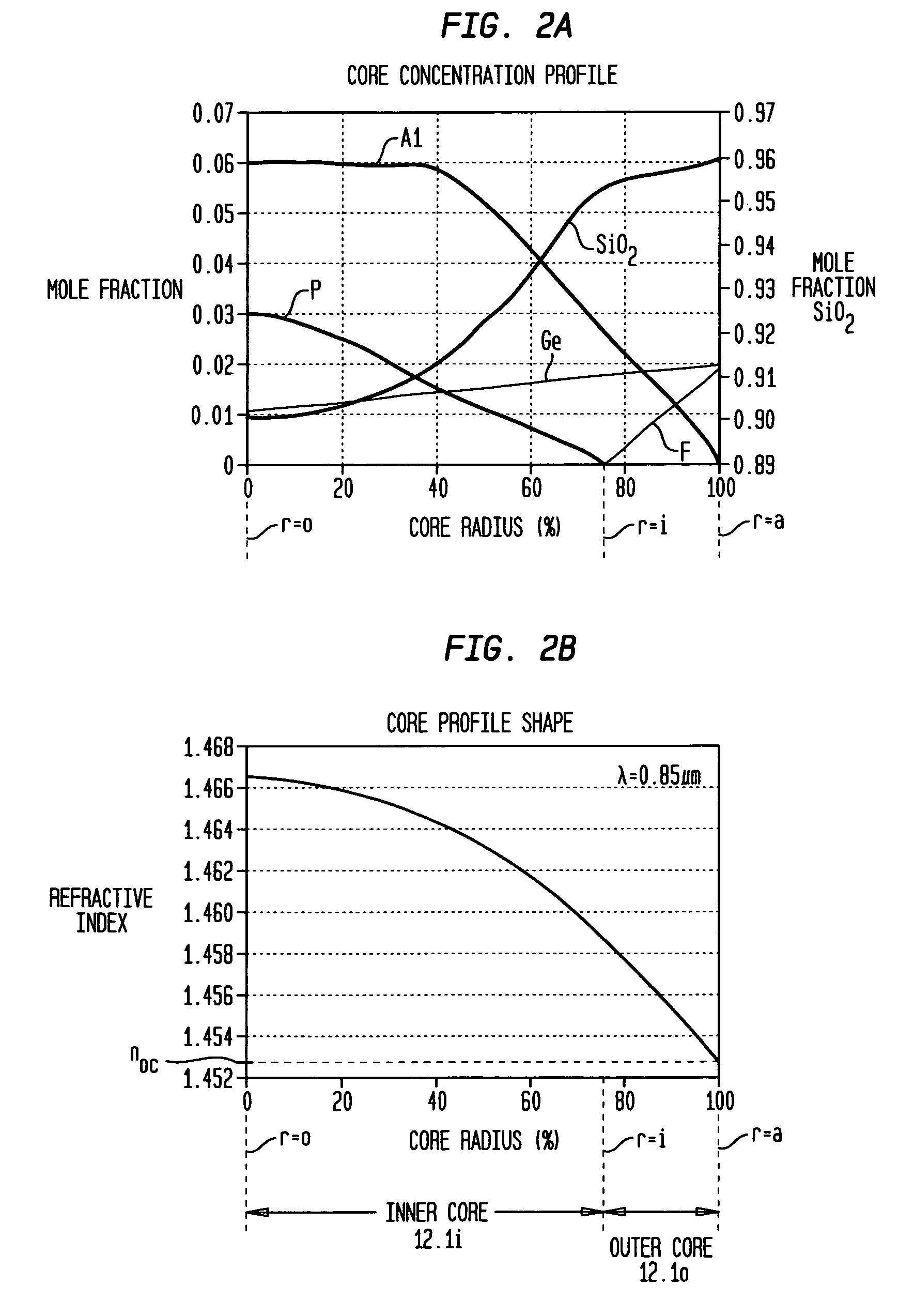

ActiveUS7555186B2Optical fibre with multilayer core/claddingCoupling light guidesRefractive indexMaterials science

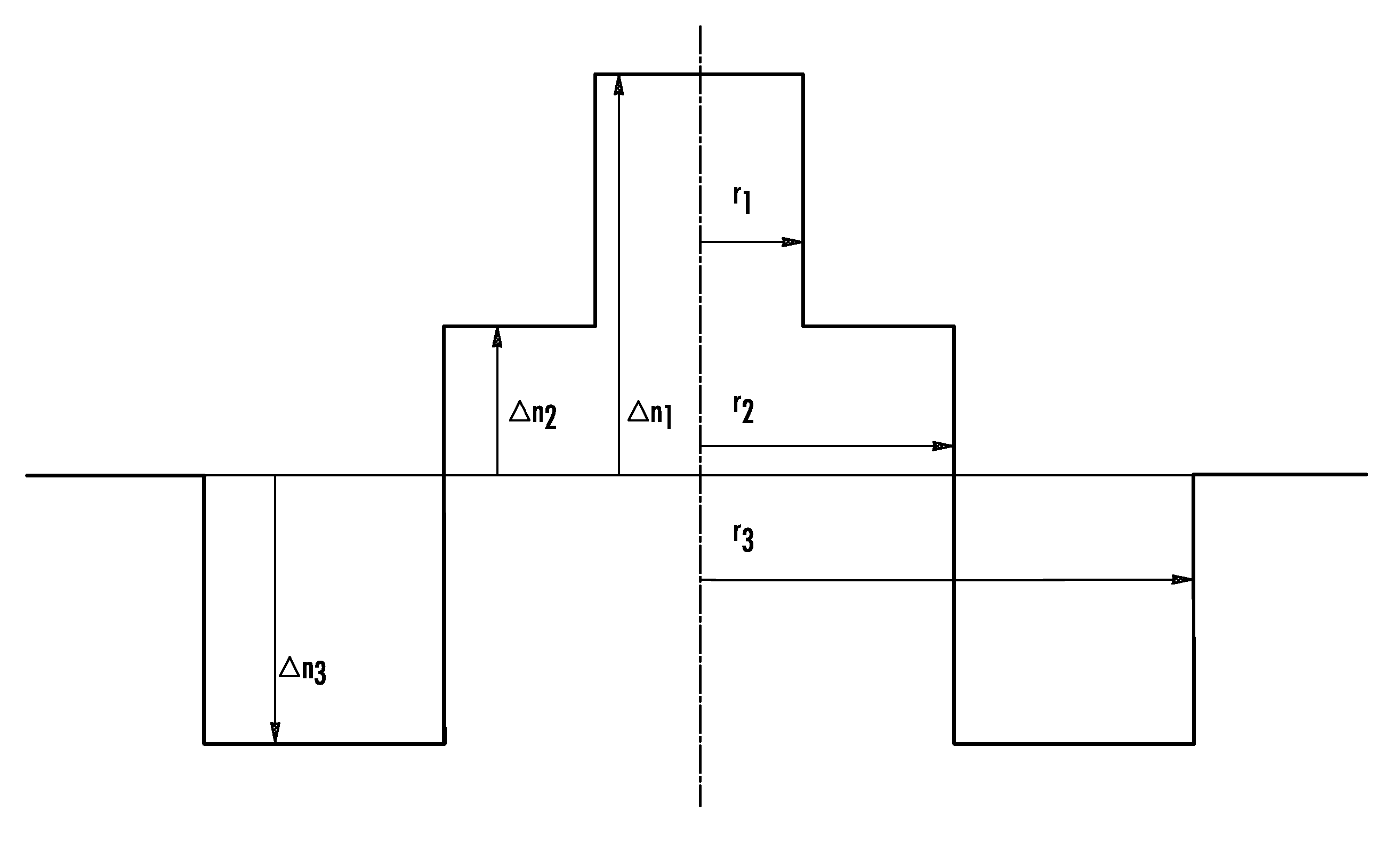

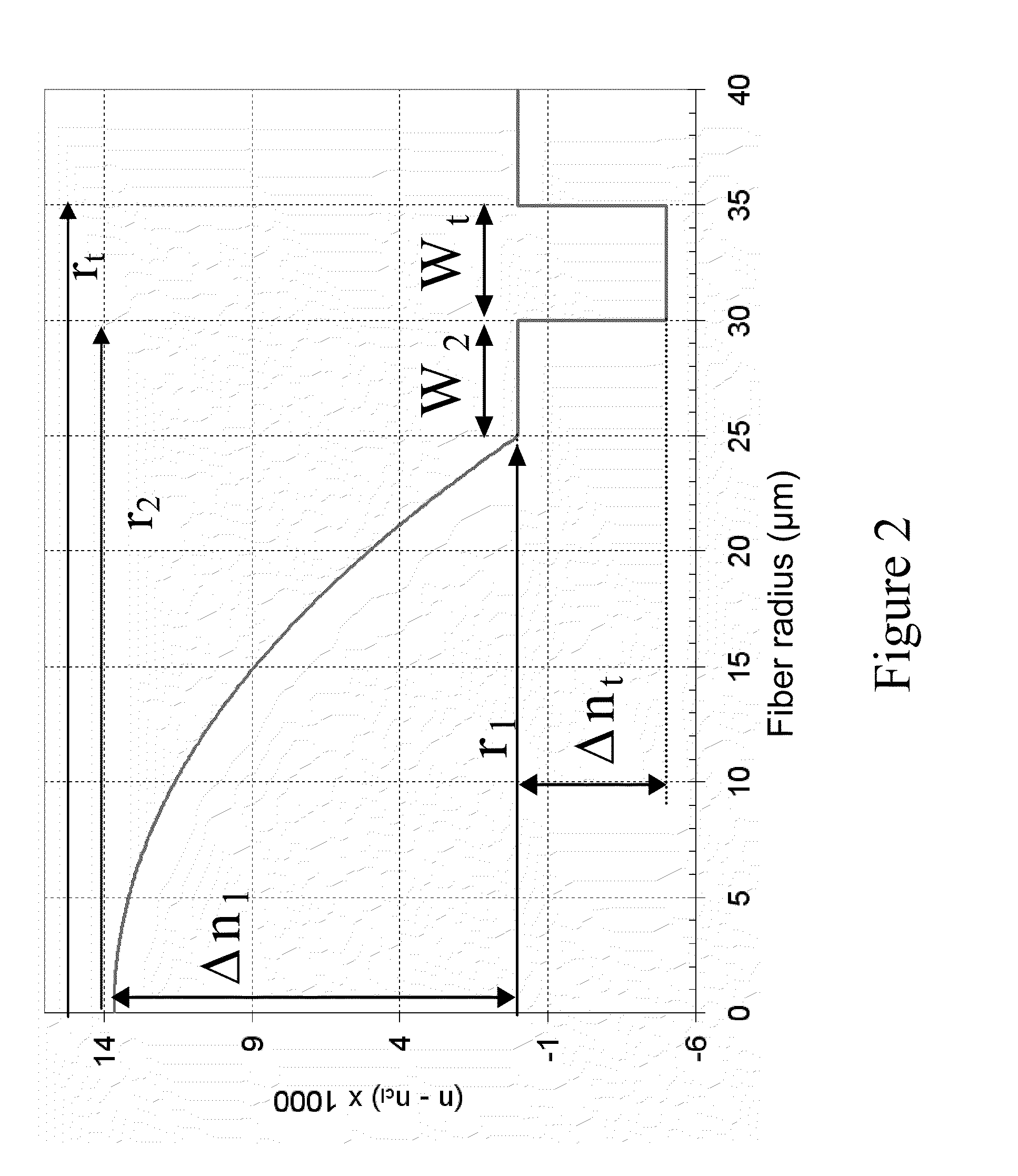

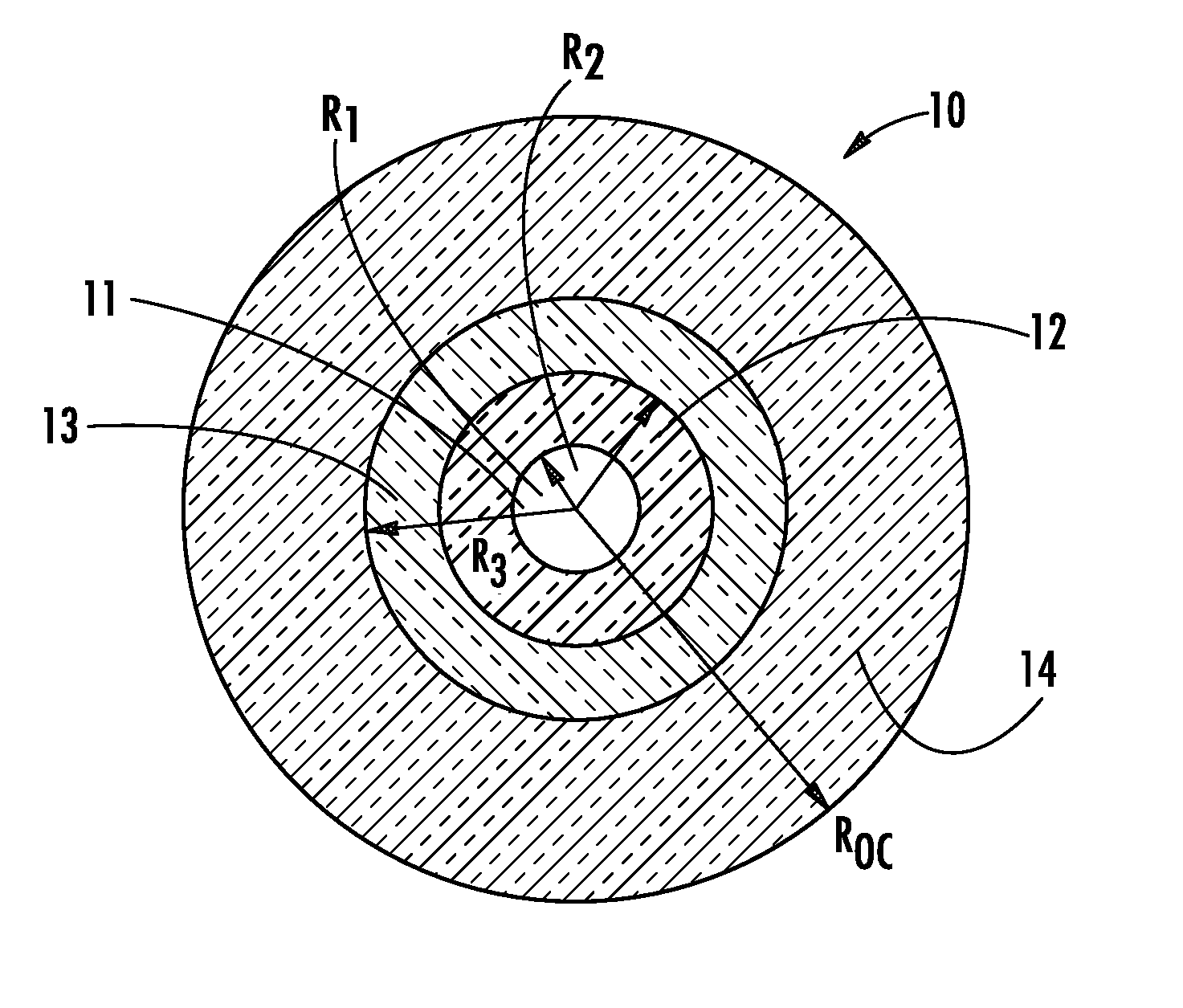

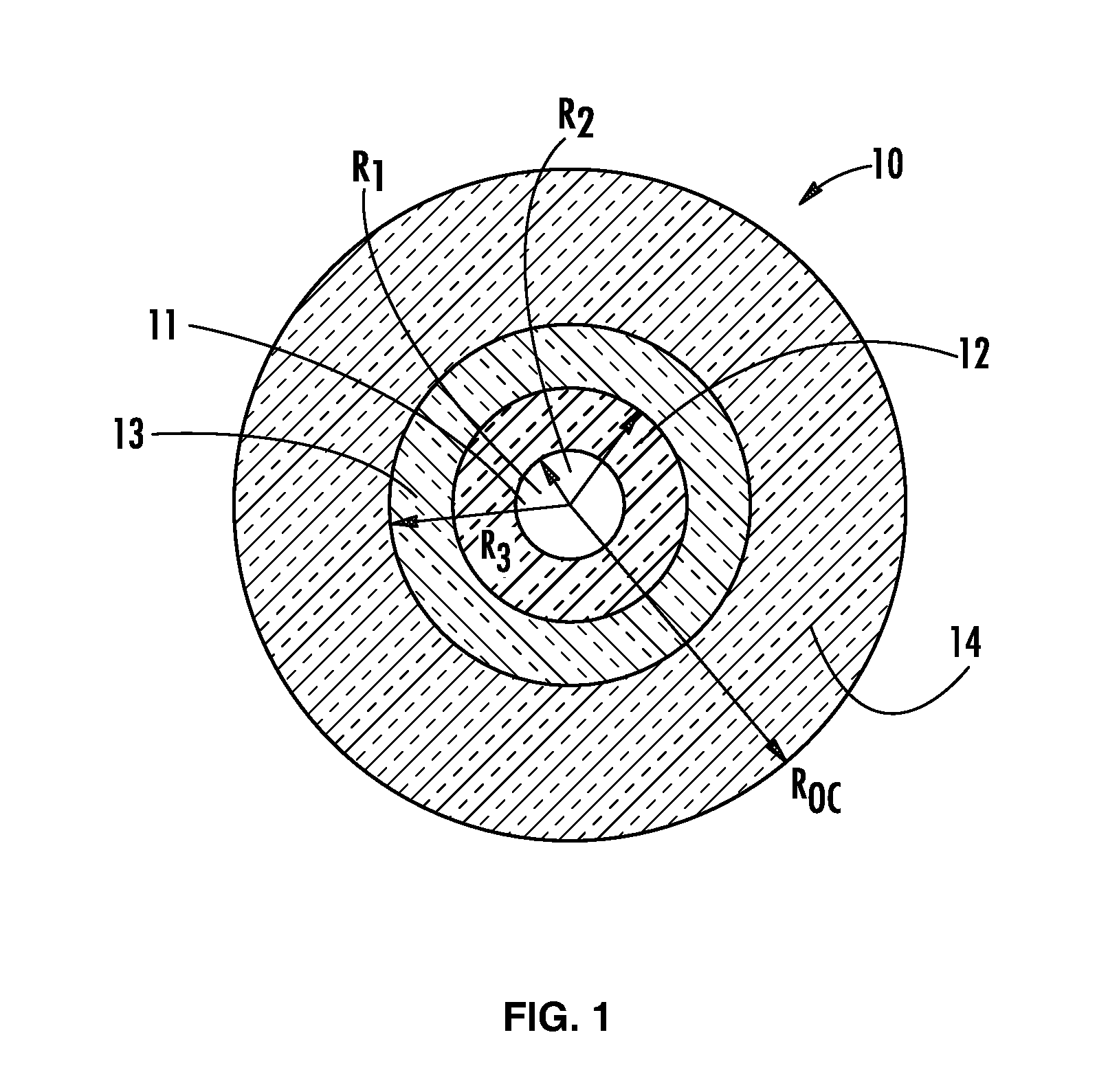

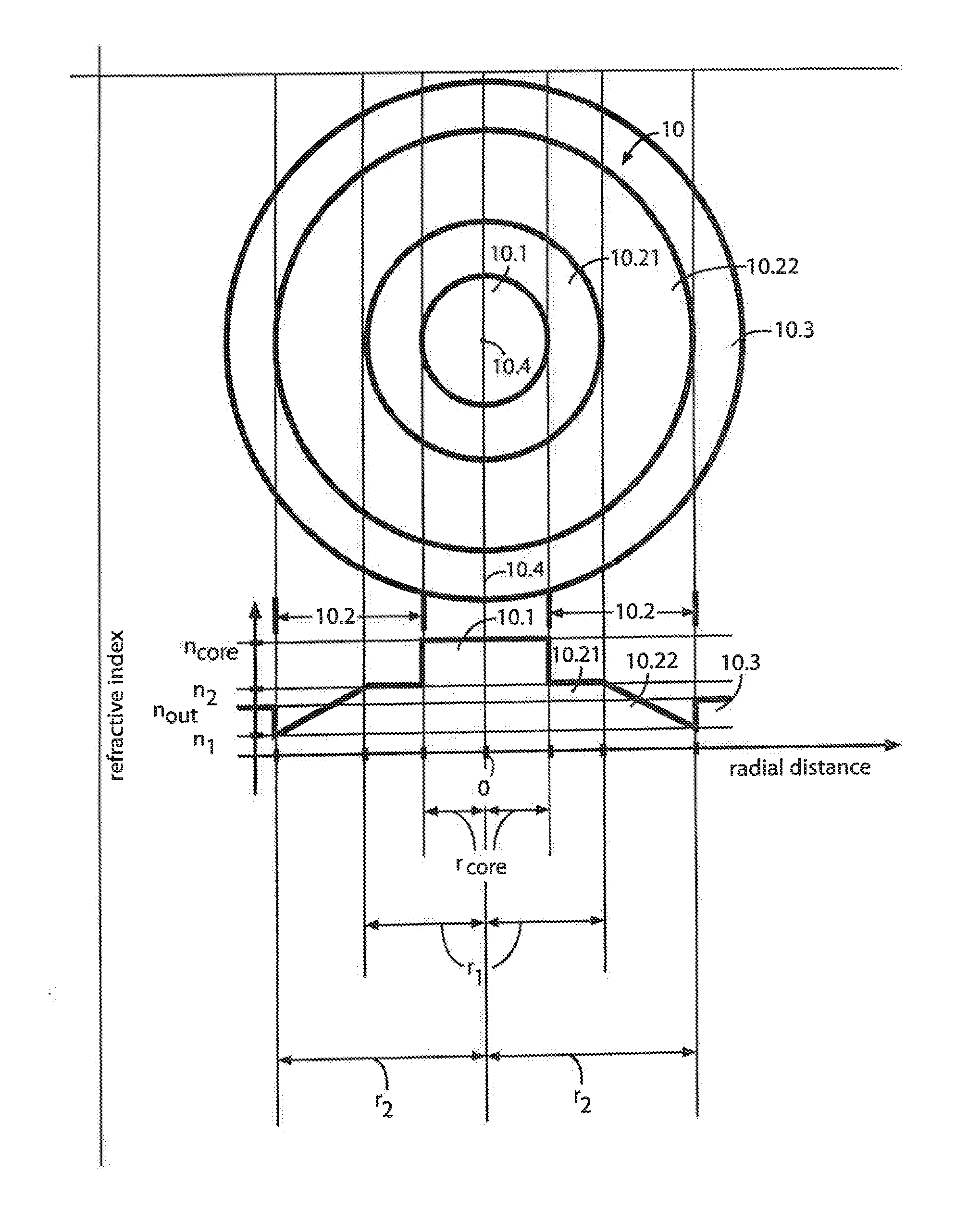

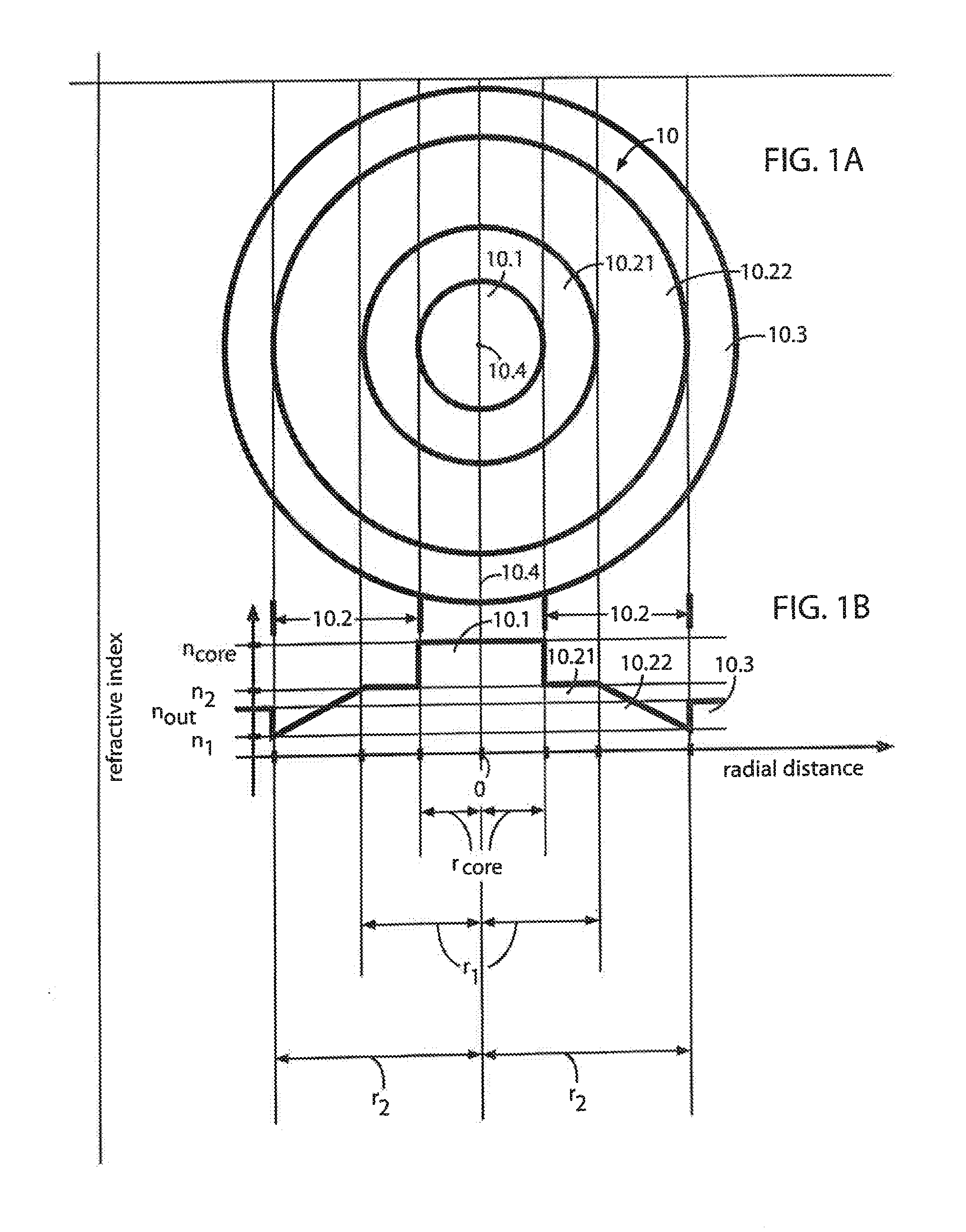

An improved optical fiber achieves both reduced bending and microbending losses, as well as a much higher Brillouin threshold, as compared to standard transmission fibers. The optical fiber comprises a core including at least two dopants and having a refractive index difference Δn1 with an outer optical cladding, a first inner cladding having a refractive index difference Δn2 with the outer cladding, and a depressed, second inner cladding having a refractive index difference Δn3 with the outer cladding of less than −3×10−3. The radial concentration of at least one of the core dopants varies continuously over the entire core region of the optical fiber.

Owner:DRAKA COMTEQ BV

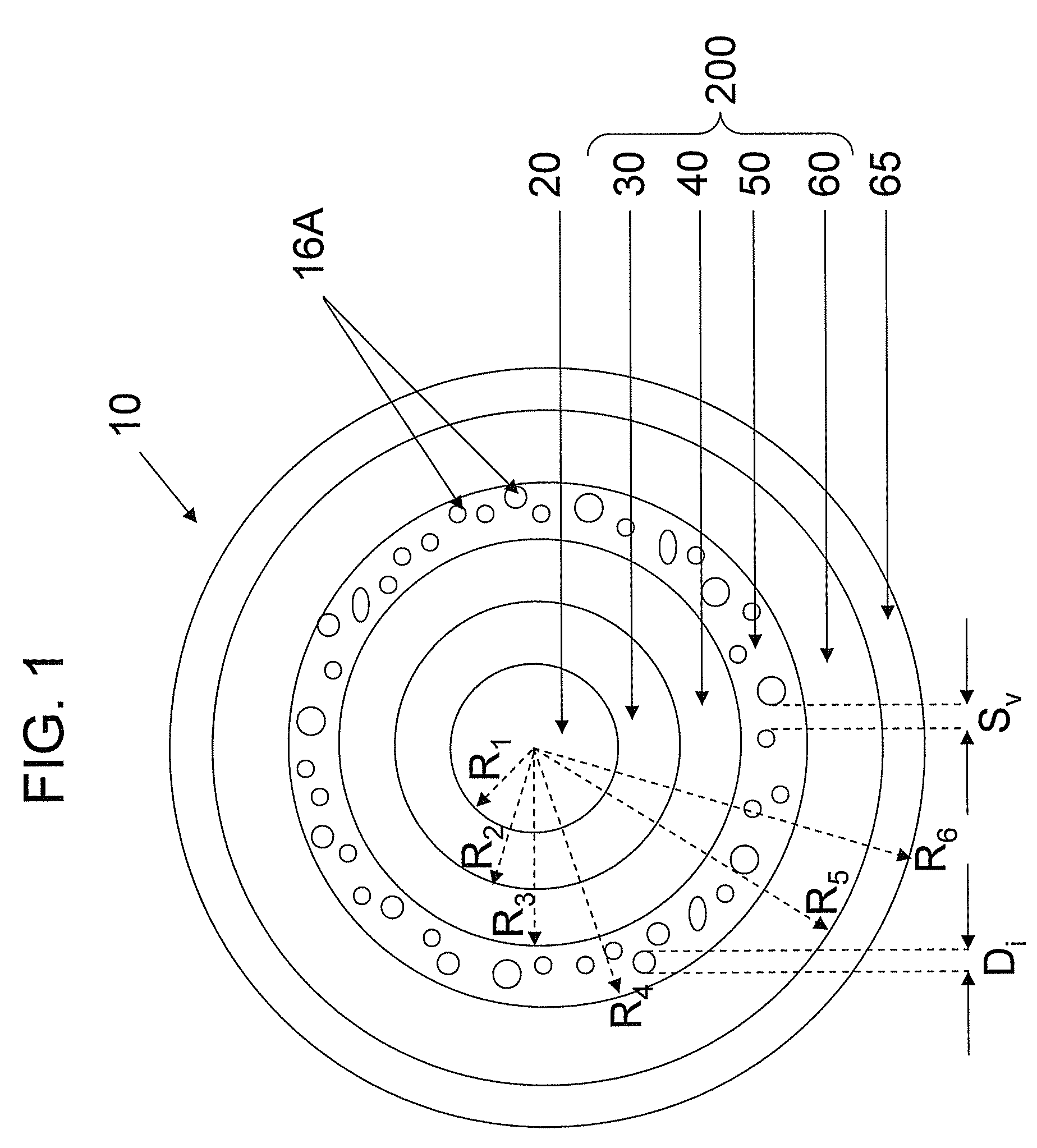

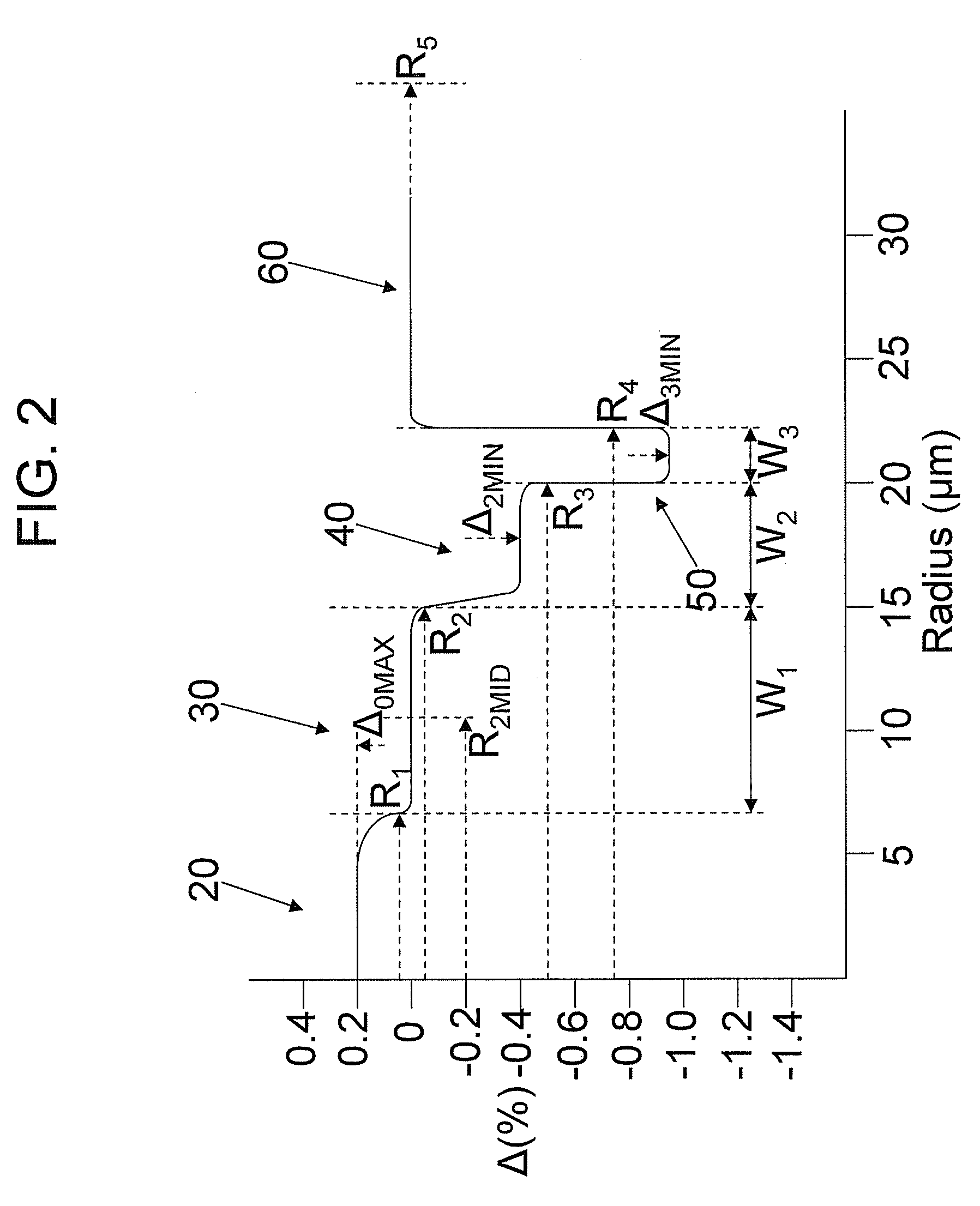

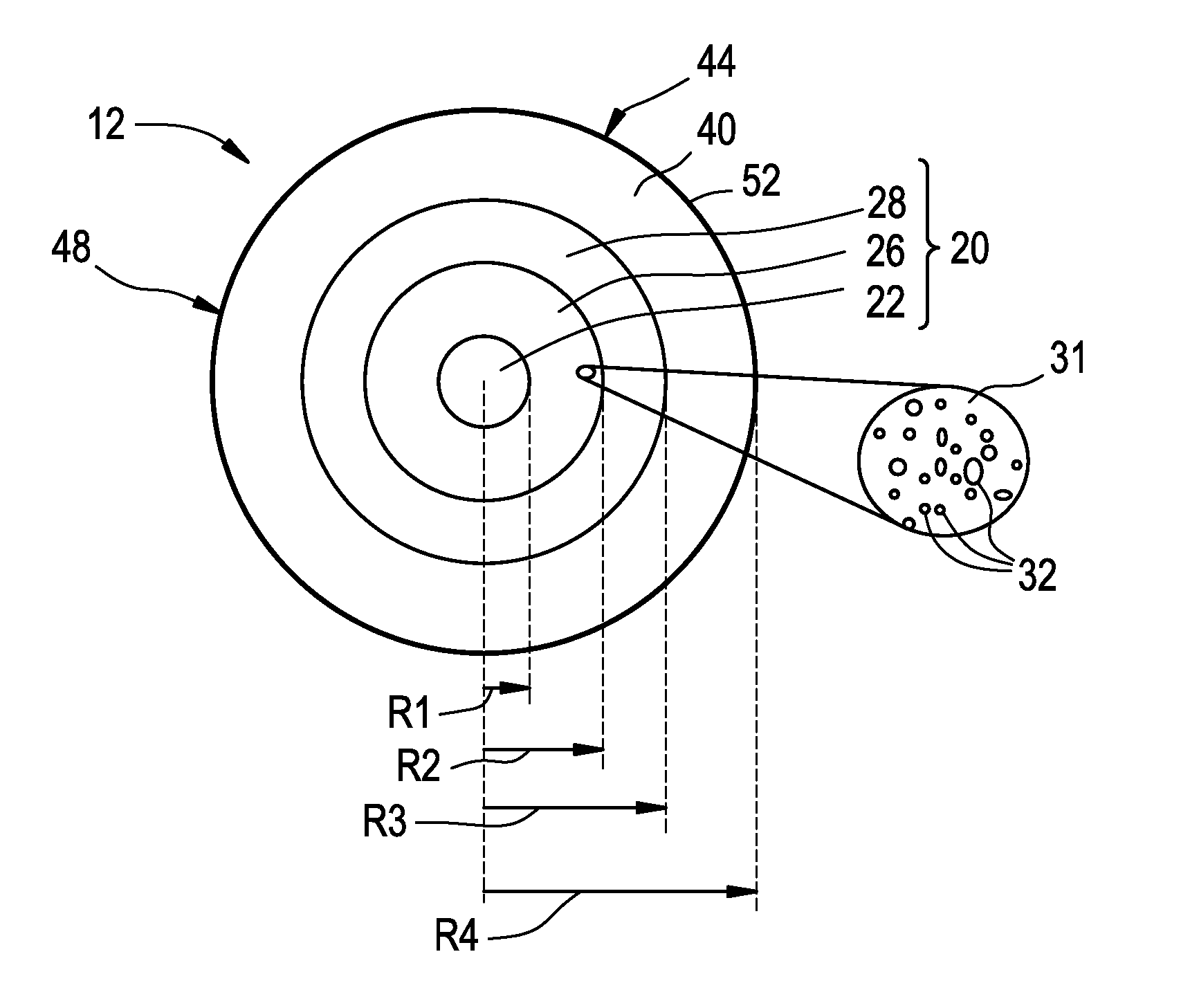

Large effective area fiber

ActiveUS7555187B2Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRelative refractive indexEngineering

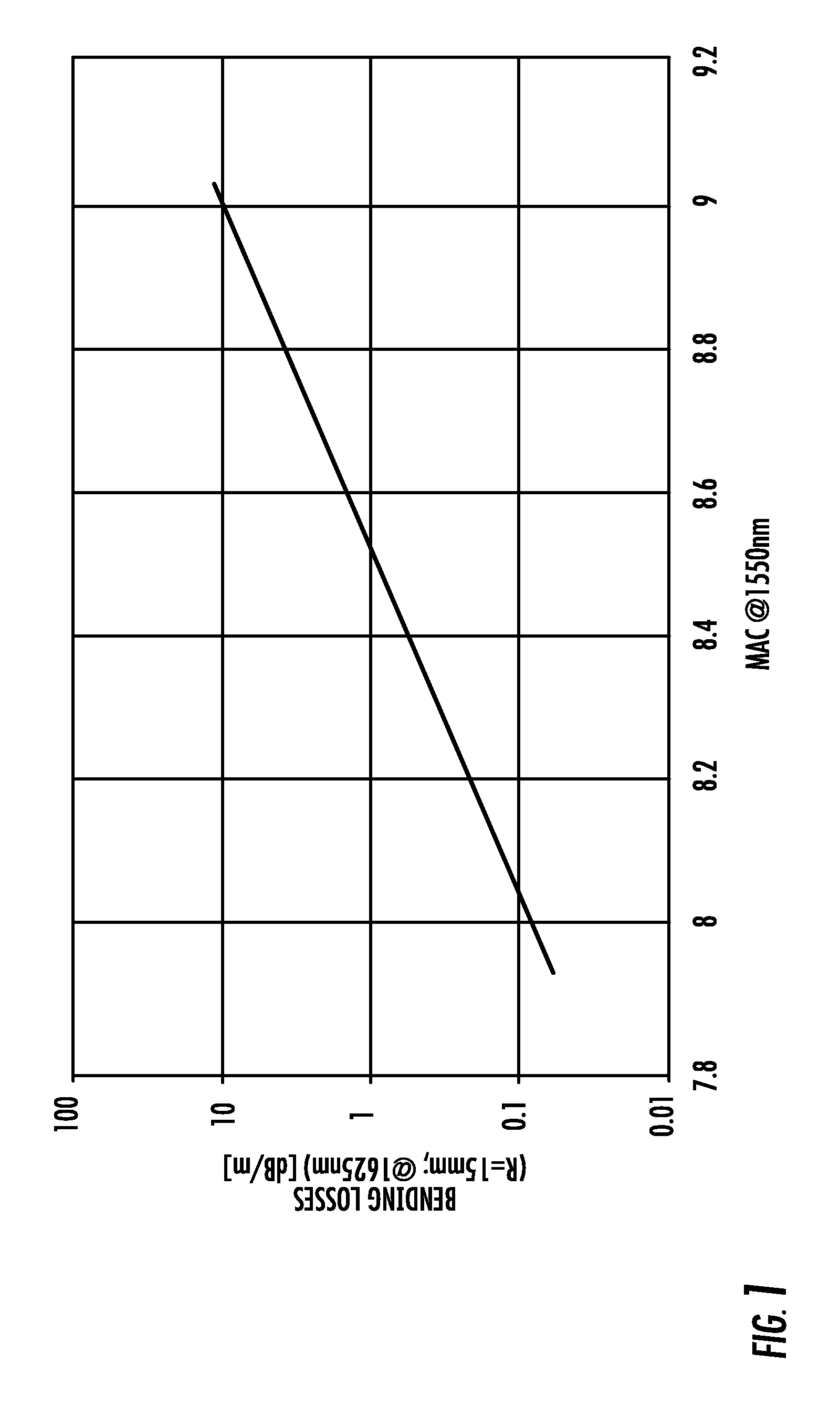

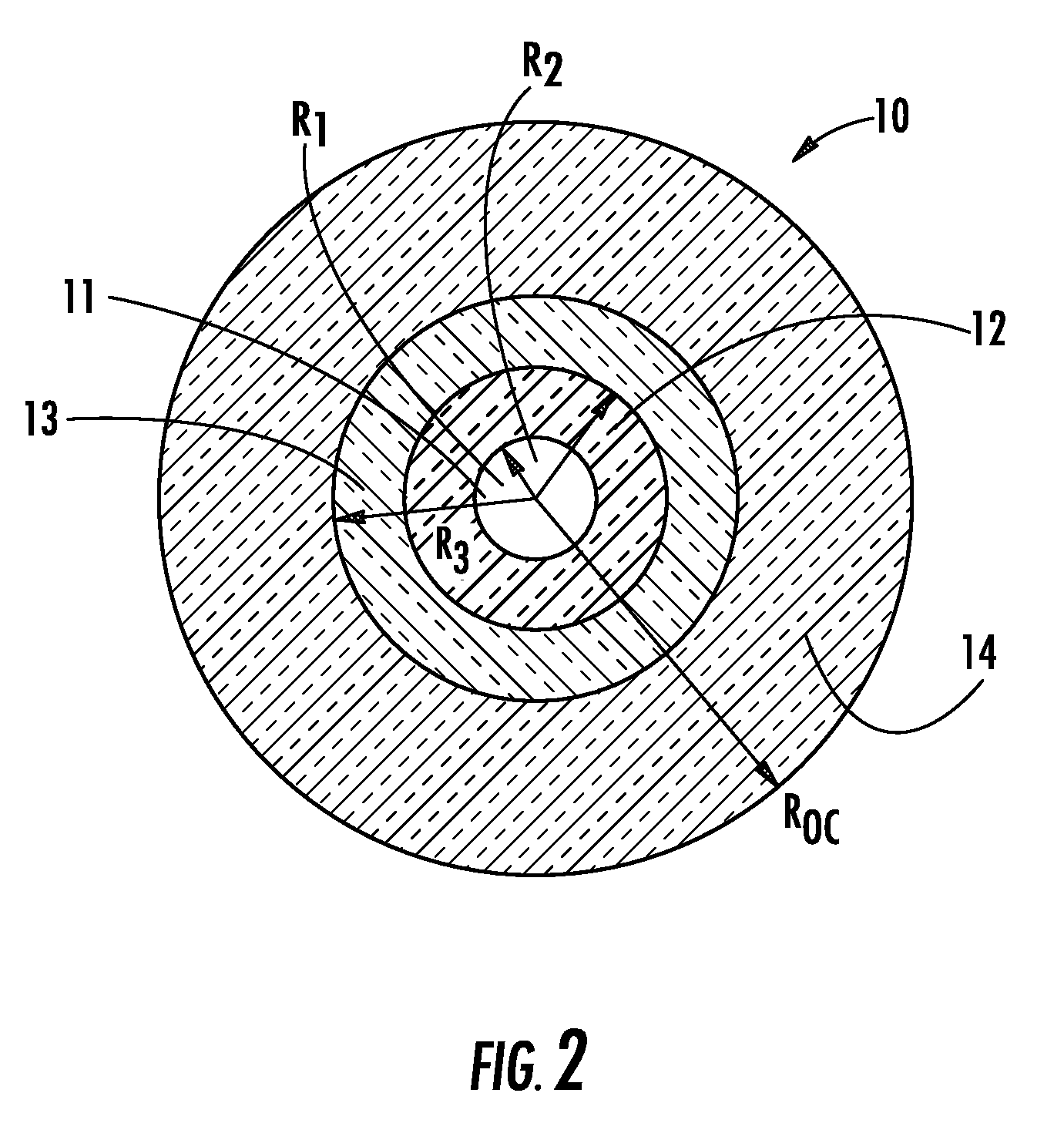

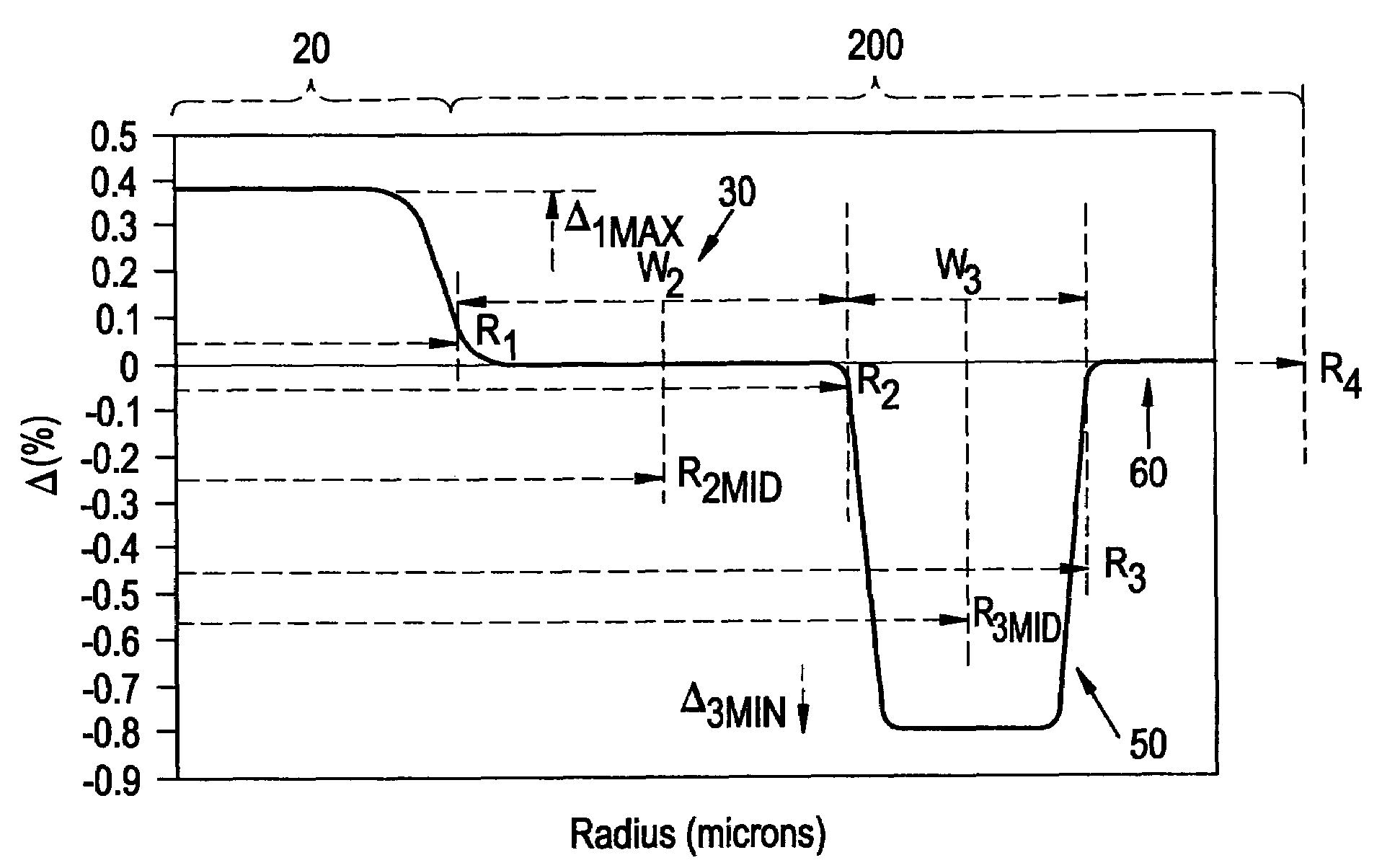

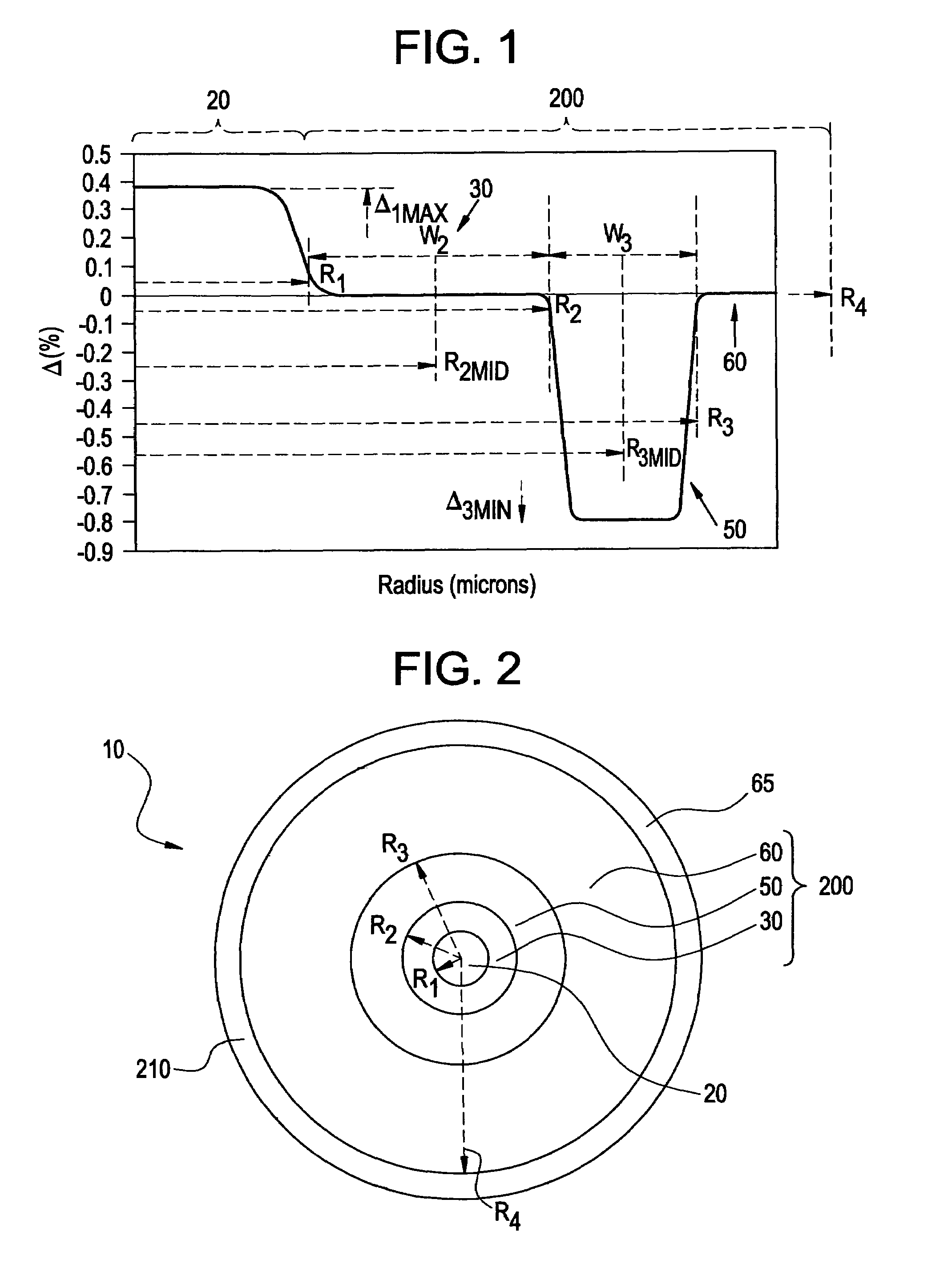

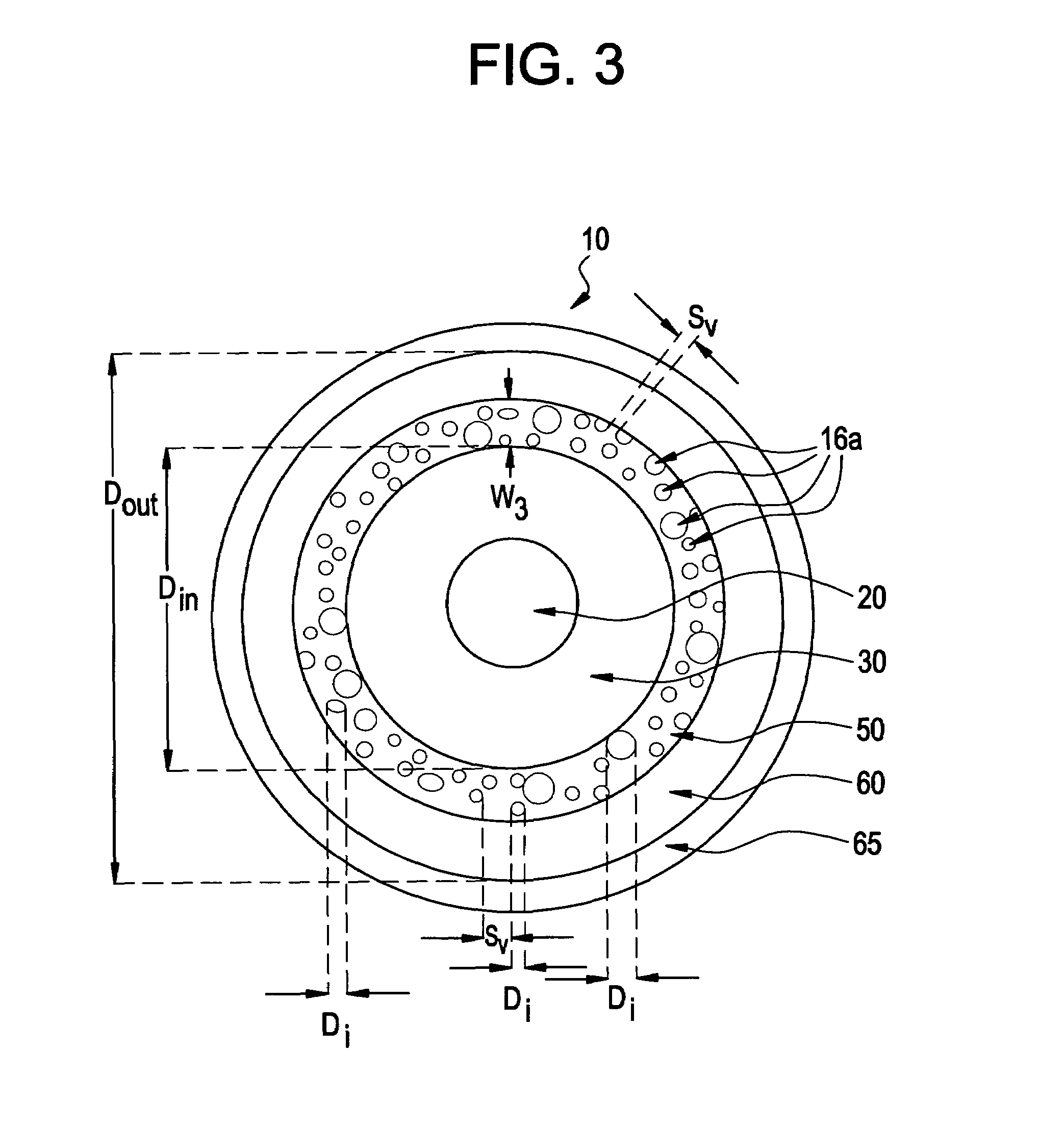

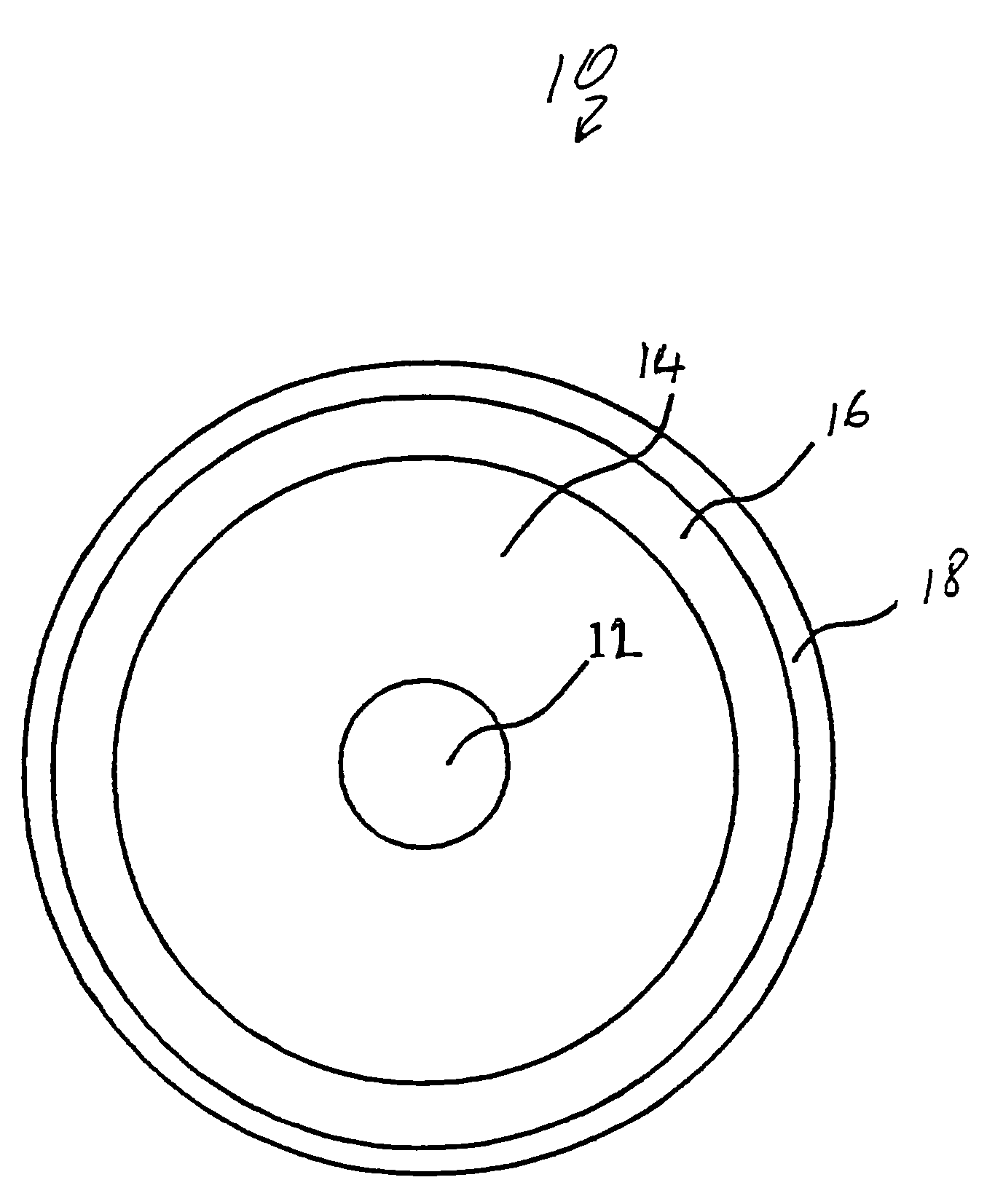

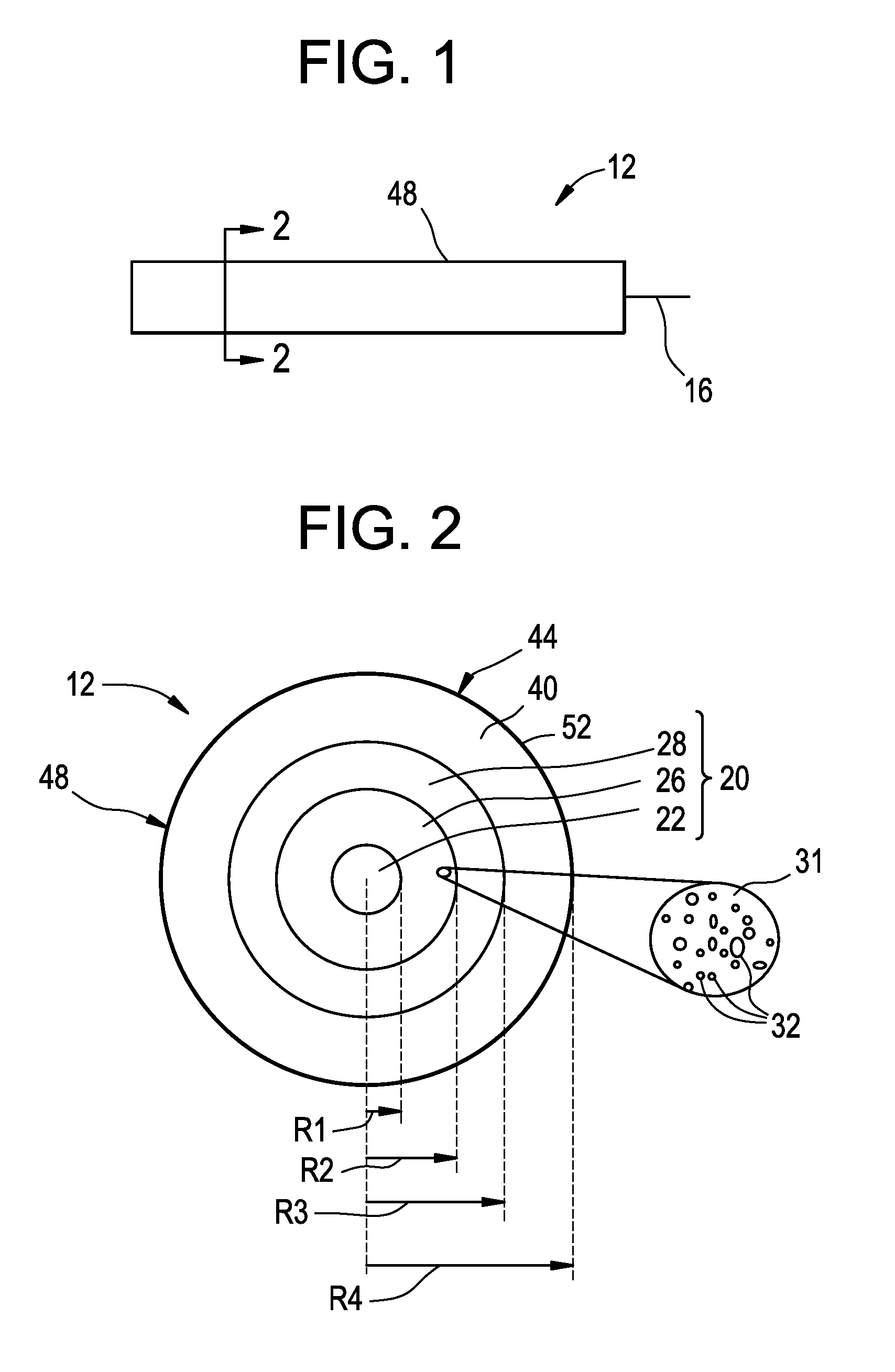

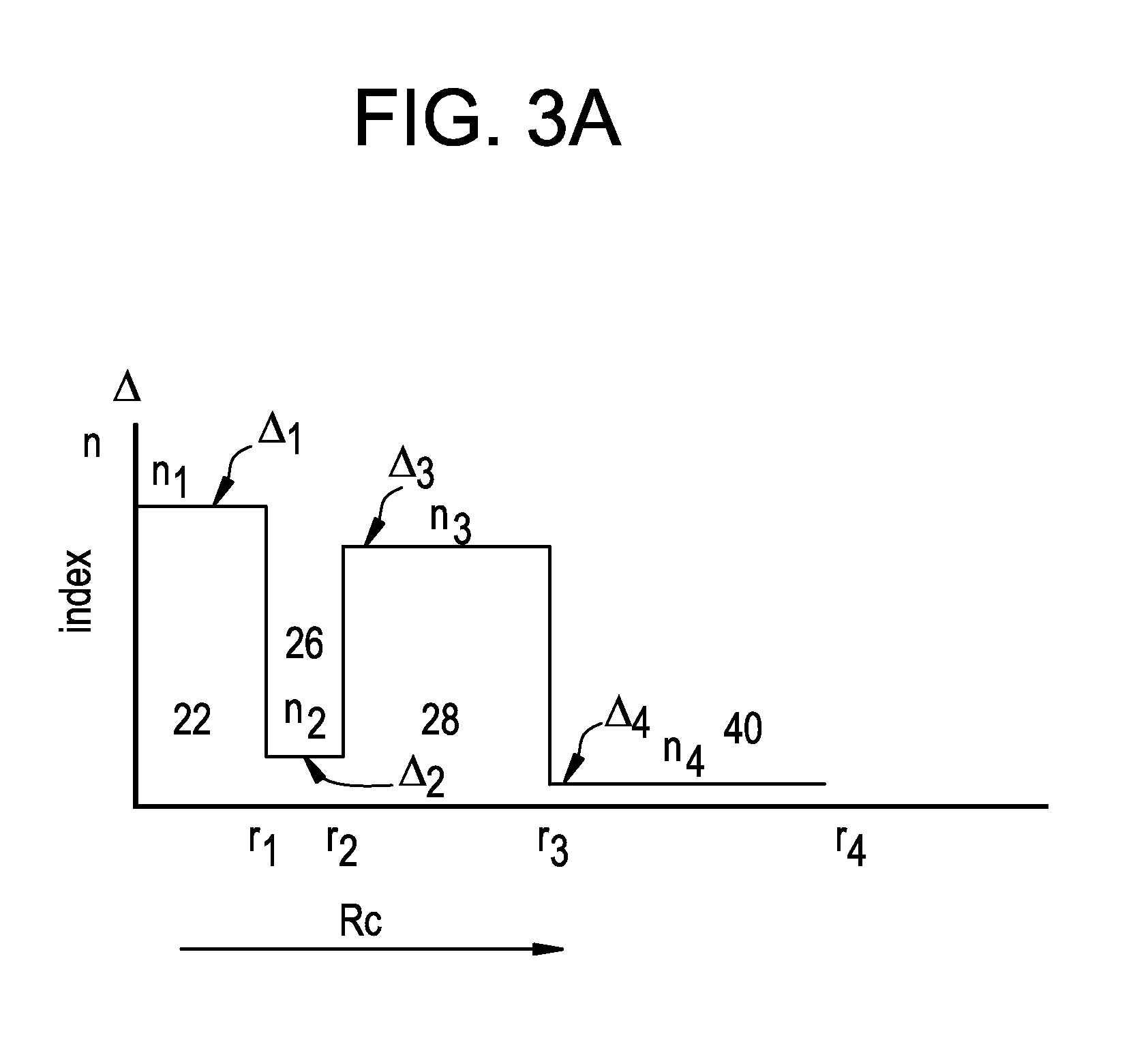

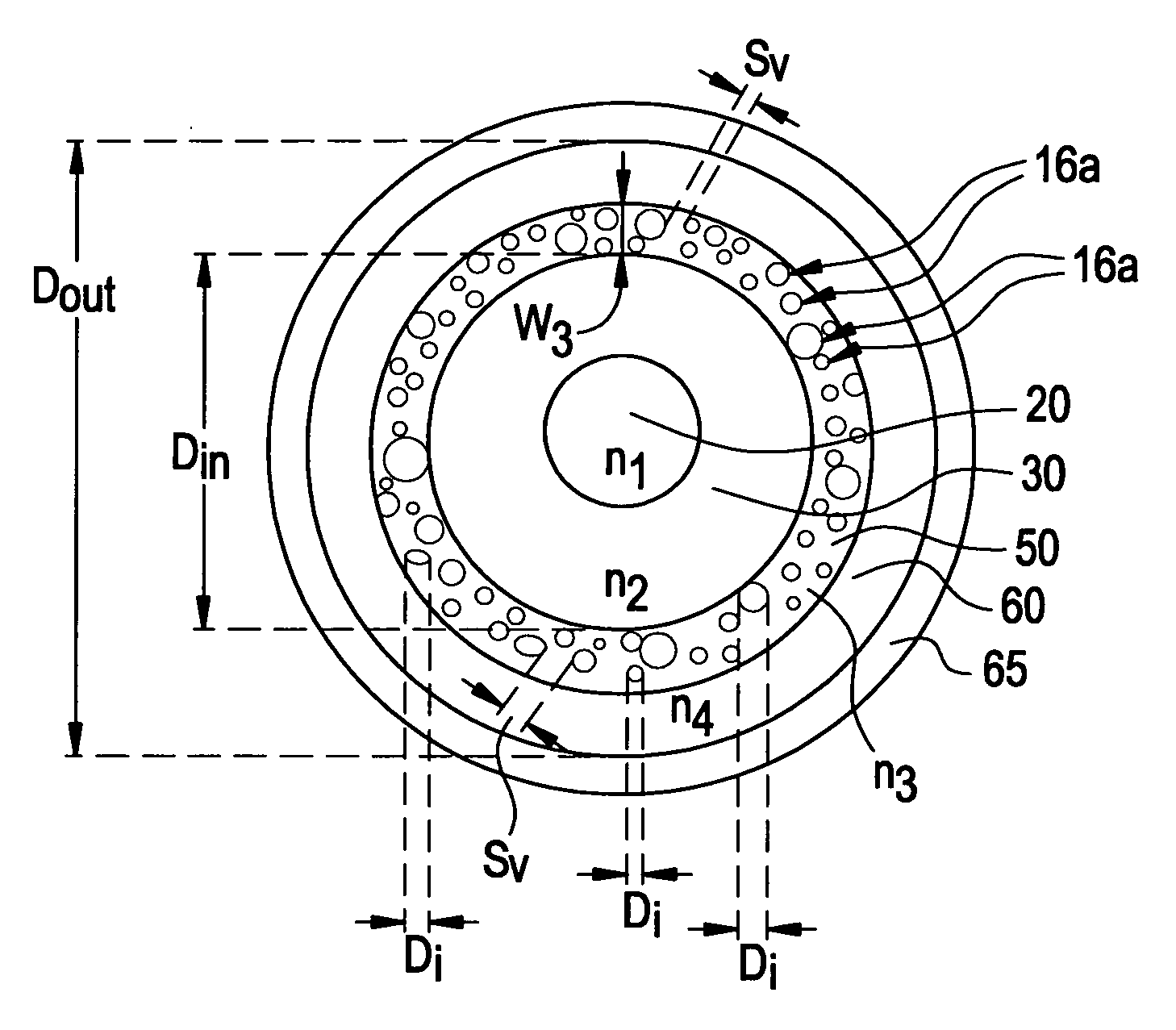

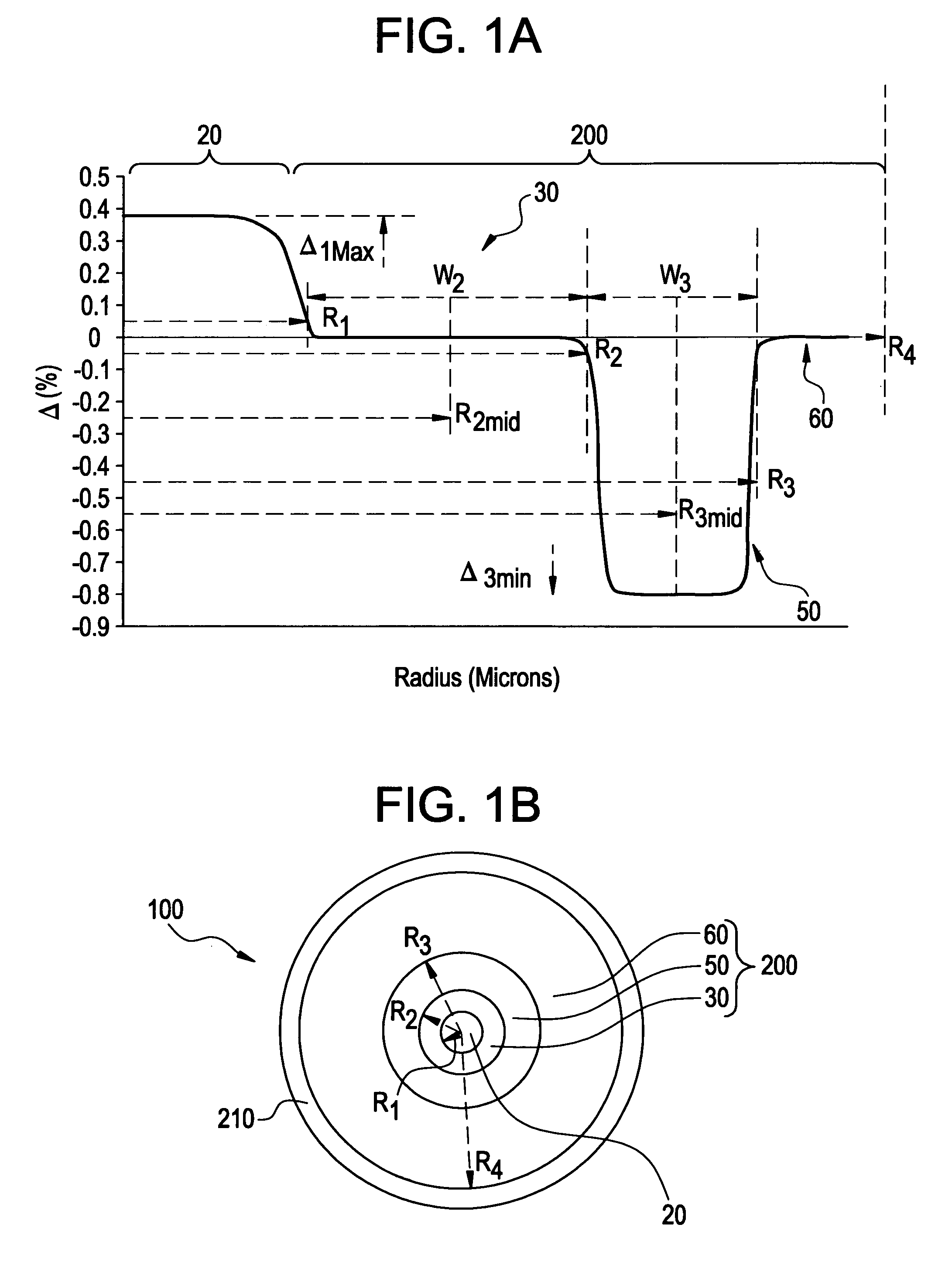

An optical fiber according to an embodiment of the present invention comprises: a glass core extending from a centerline to a radius R1 wherein R1 is greater than about 5 μm; a glass cladding surrounding and in contact with the core, the cladding comprising: (i) a first annular region extending from the radius R1 to a radius R2, the first annular region comprising a radial width, W2=R2−R1, (ii) a second annular region extending from the radius R2 to a radius R3, and comprising a radial width, W3=R3−R2, and (iii) a third annular region surrounding the second annular region and extending from the radius R3 to an outermost glass radius R4; wherein the core comprises a maximum relative refractive index, Δ1MAX, relative to the third annular region, and wherein Δ1MAX is greater than about 0.1% and less than about 0.3%; the first annular region has a refractive index delta Δ2(r) is less than about 0.025%; wherein the second annular region comprises a minimum relative refractive index, Δ3MIN, relative to the third annular region;wherein Δ1MAX>Δ2MAX>Δ3MIN, and Δ2MIN>Δ3MIN<0; andwherein the core and the cladding provide a fiber with cable cutoff less than 1500 nm, and an effective area at 1550 nm greater than 95 μm2 and bend loss of ≦0.5 dB / turn on a 20 mm diameter mandrel.

Owner:CORNING INC

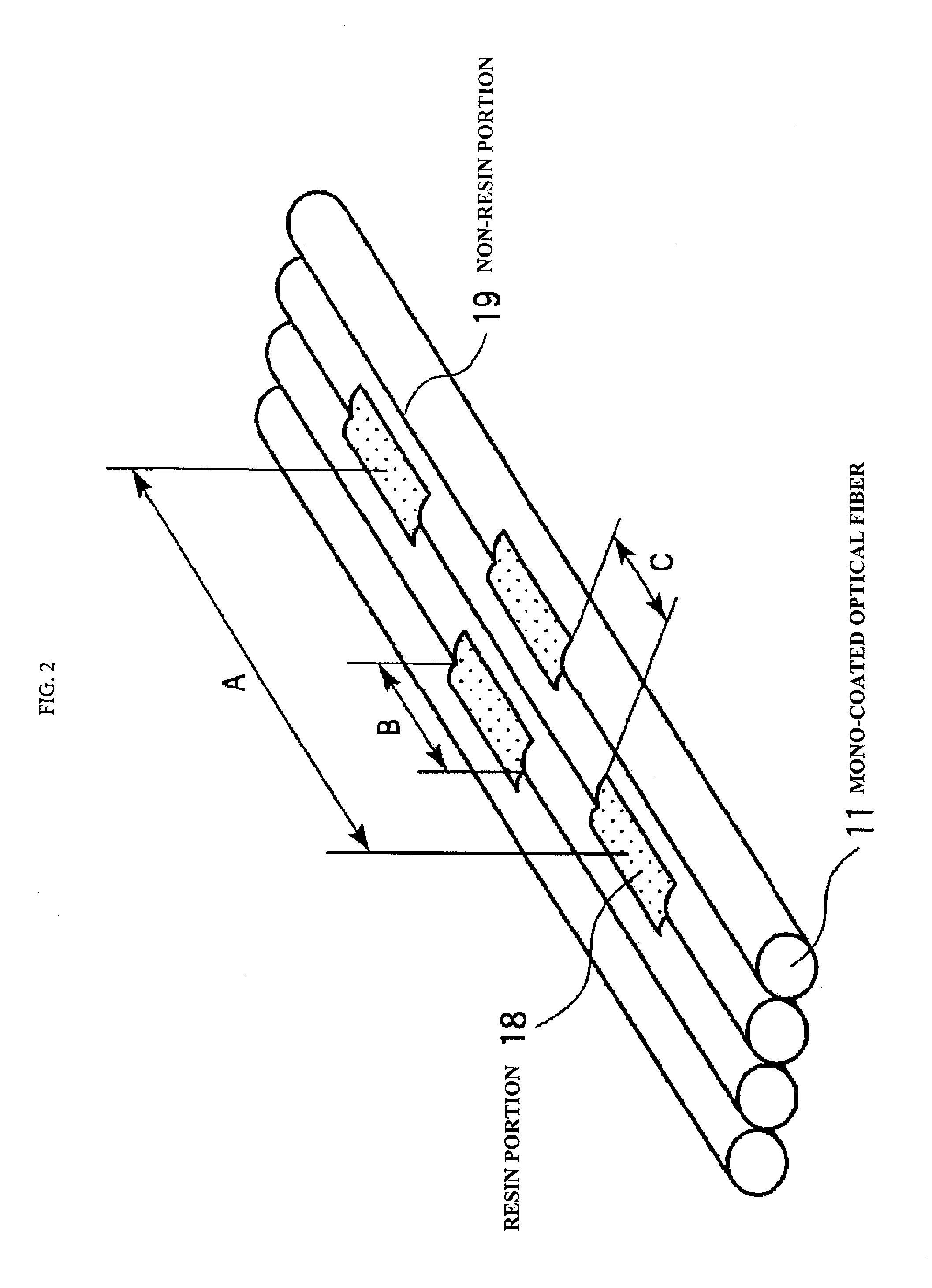

Optical fiber cable and optical fiber ribbon

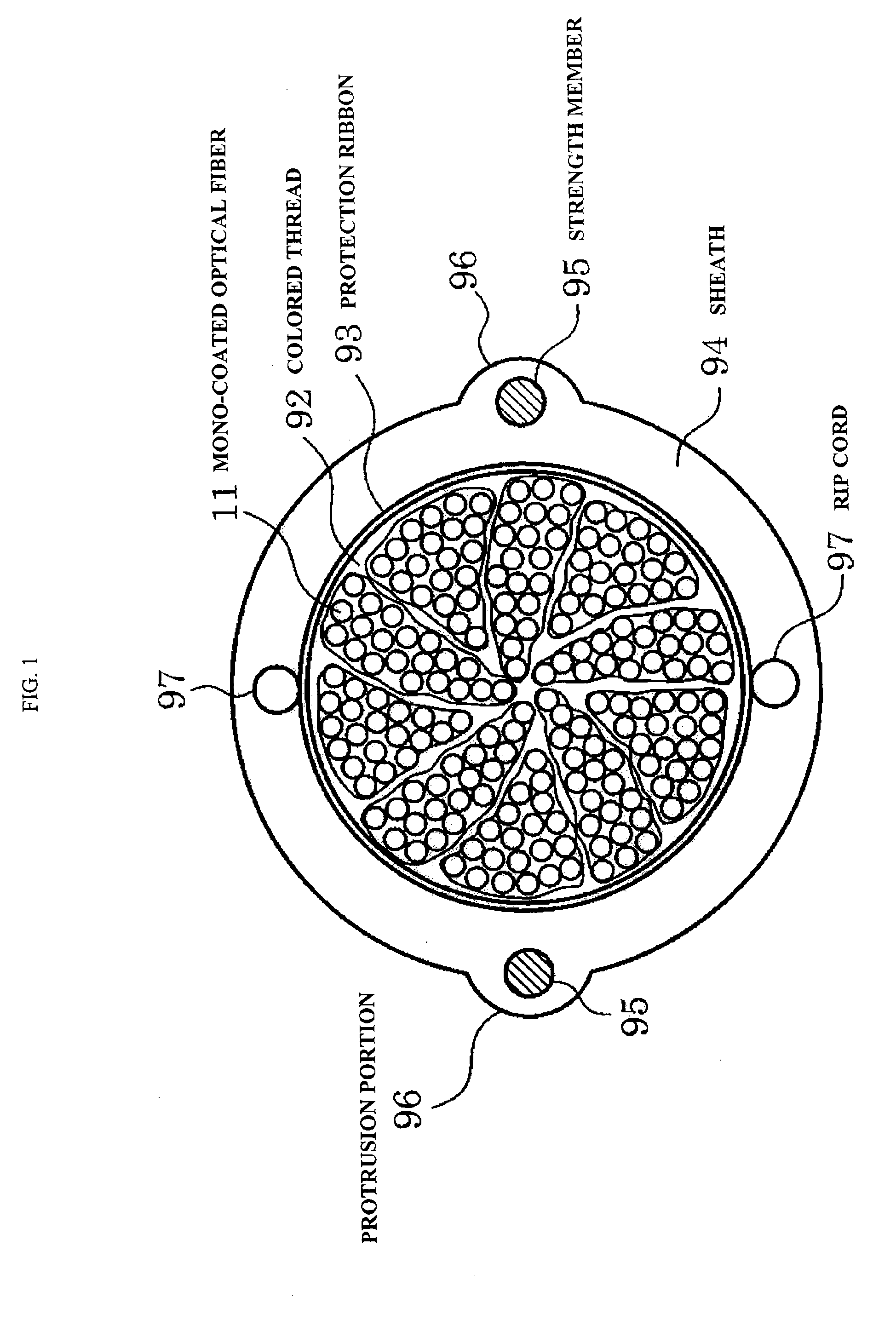

ActiveUS8548294B2Stable optical loss characteristicReduce warpageFibre mechanical structuresEngineeringBend radius

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Large effective area low attenuation optical fiber

InactiveUS8218929B2Optical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationBend loss

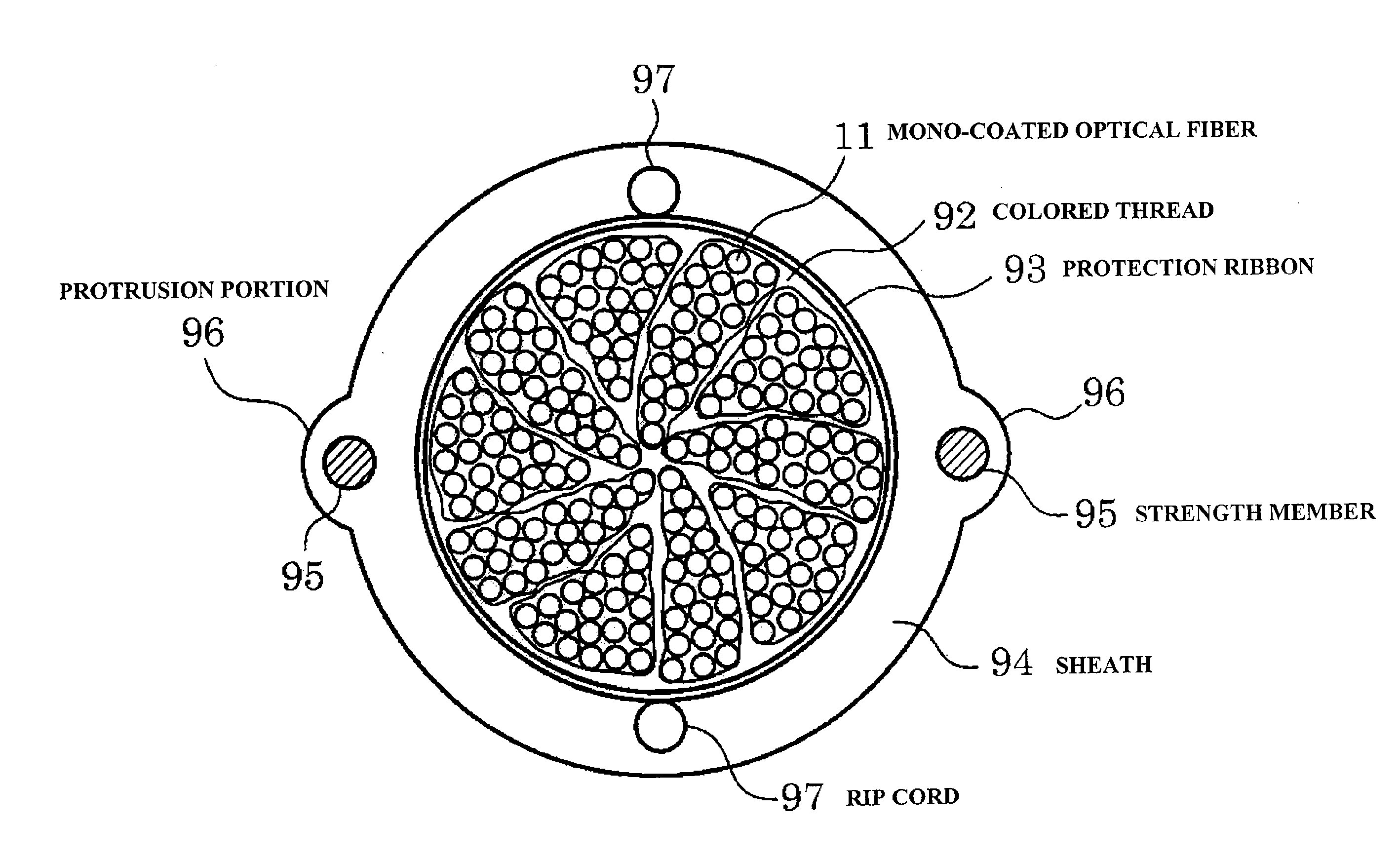

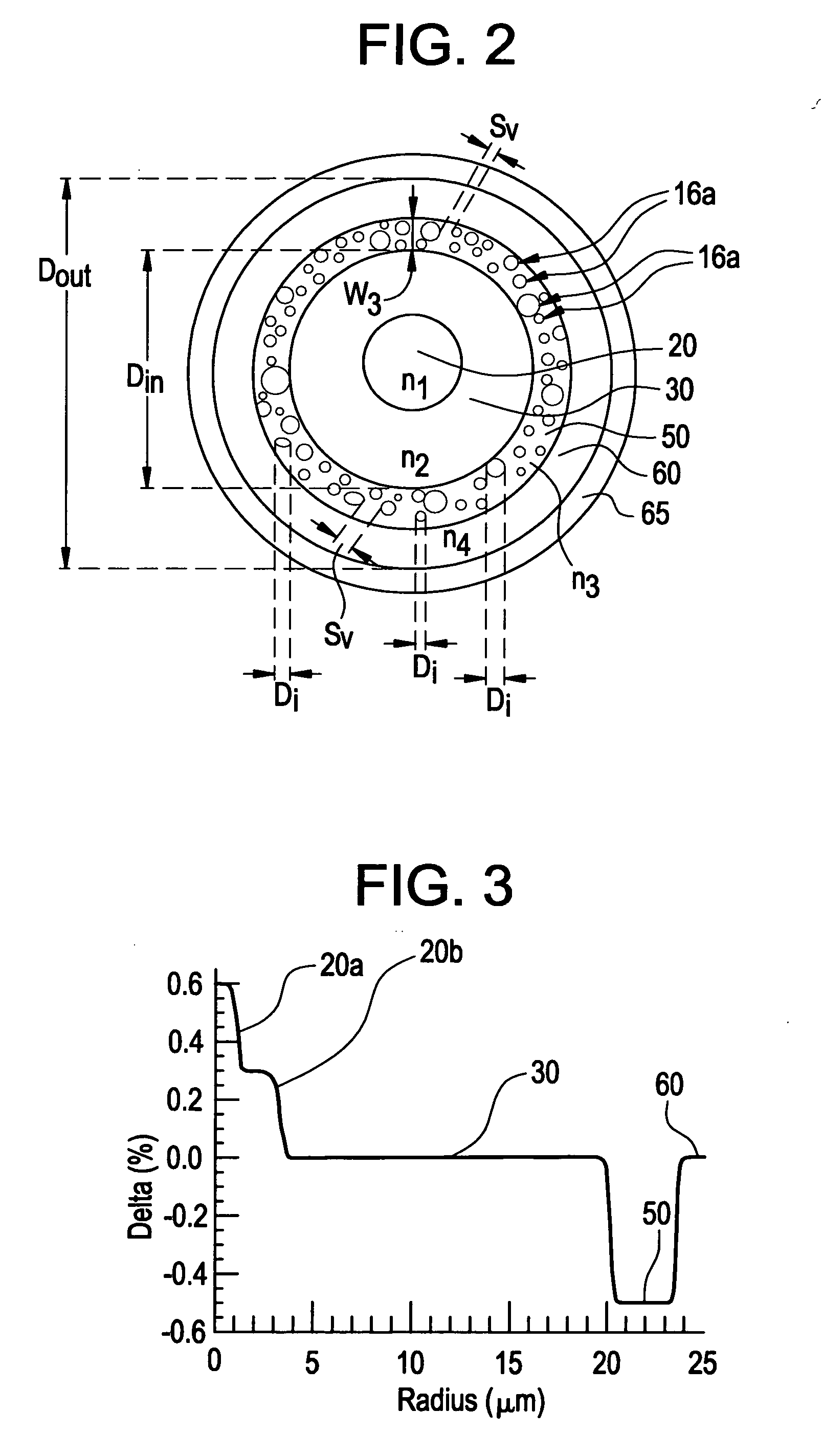

Optical waveguide fiber that has large effective area and low loss characteristics, such as low attenuation and low bend loss. The optical waveguide fiber includes a dual trench design wherein an annular region closer to the core is preferably doped with at least one downdopant such as fluorine, which annular region is surrounded by another annular region that preferably includes closed, randomly dispersed voids.

Owner:CORNING INC

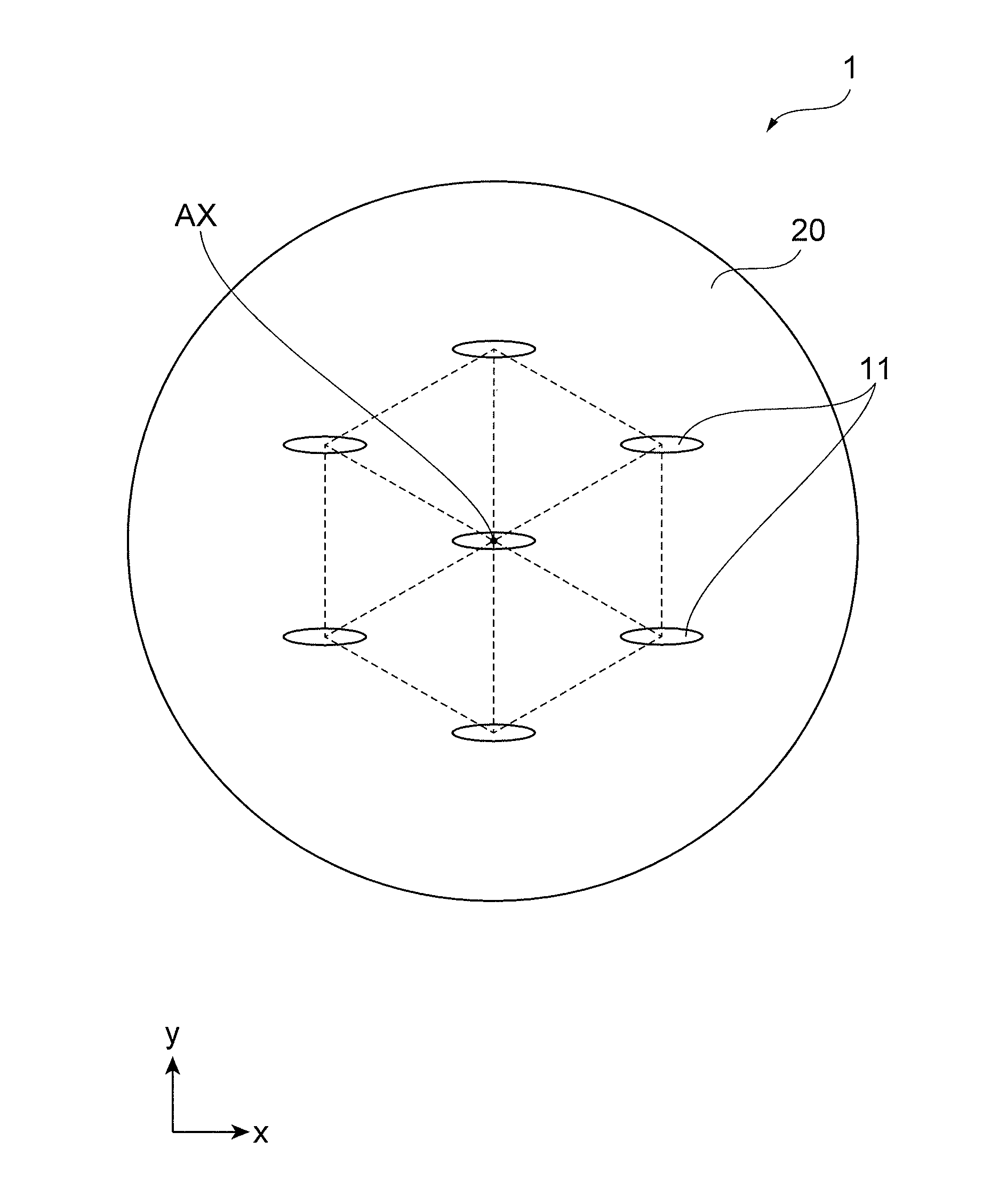

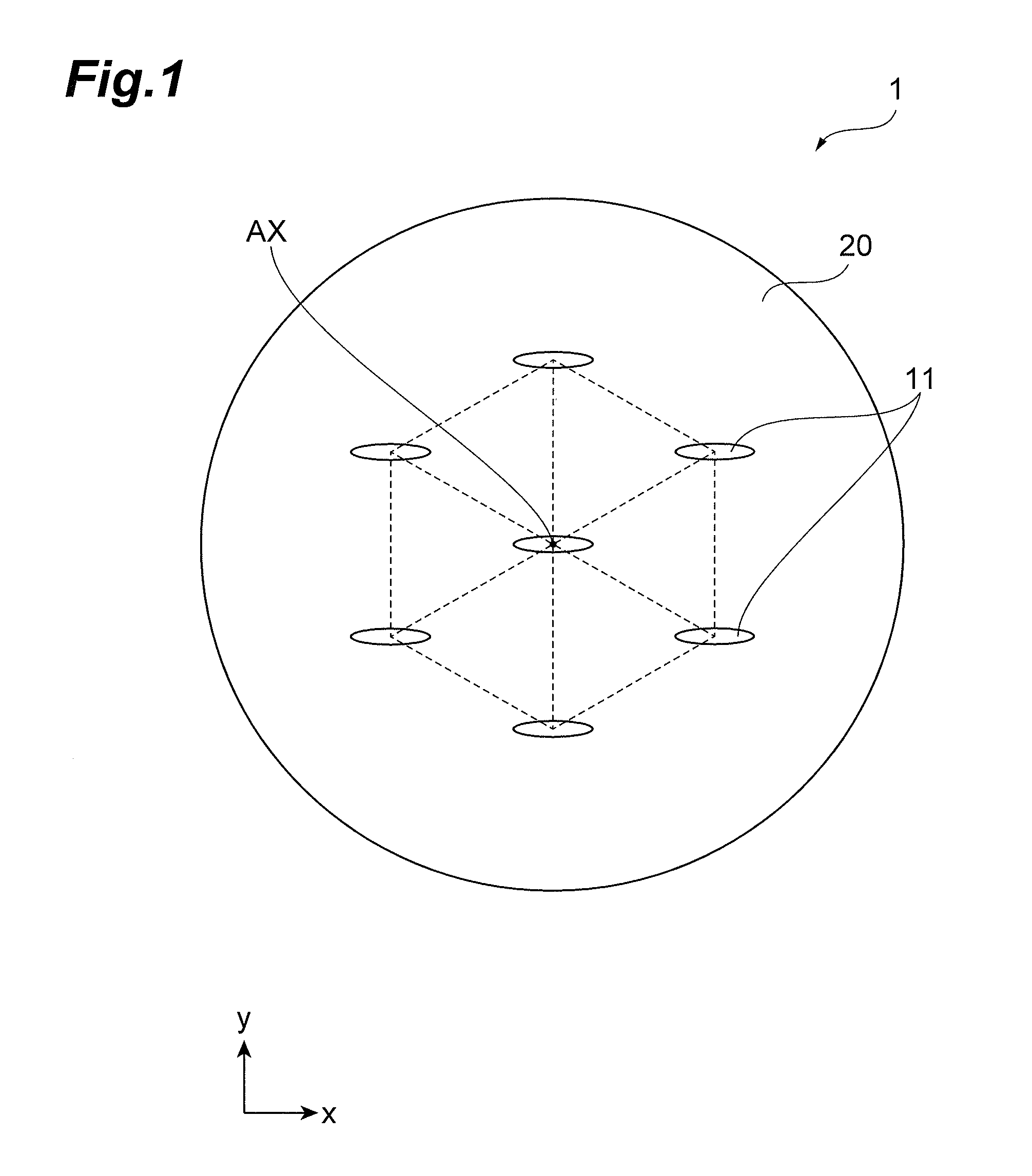

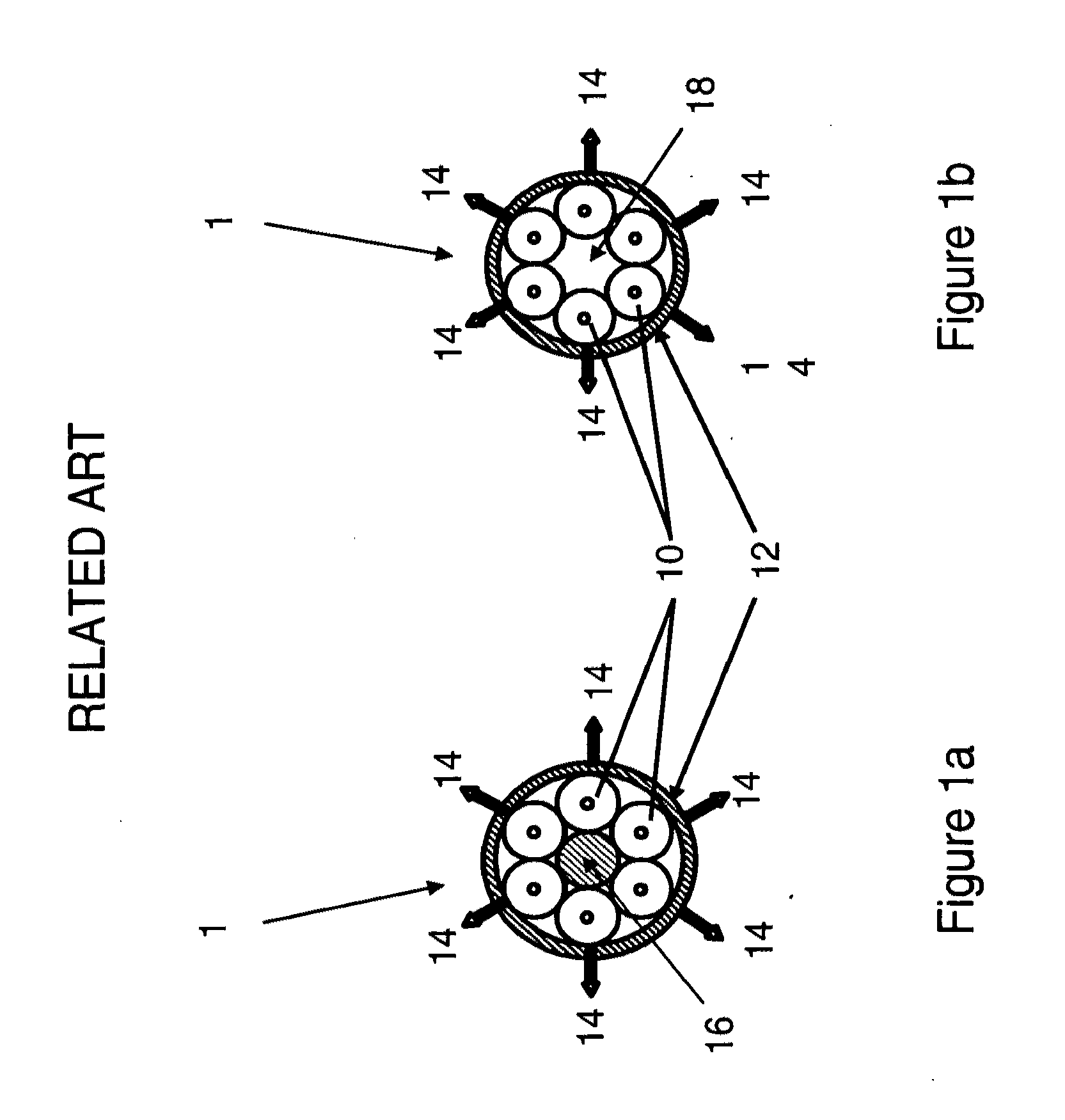

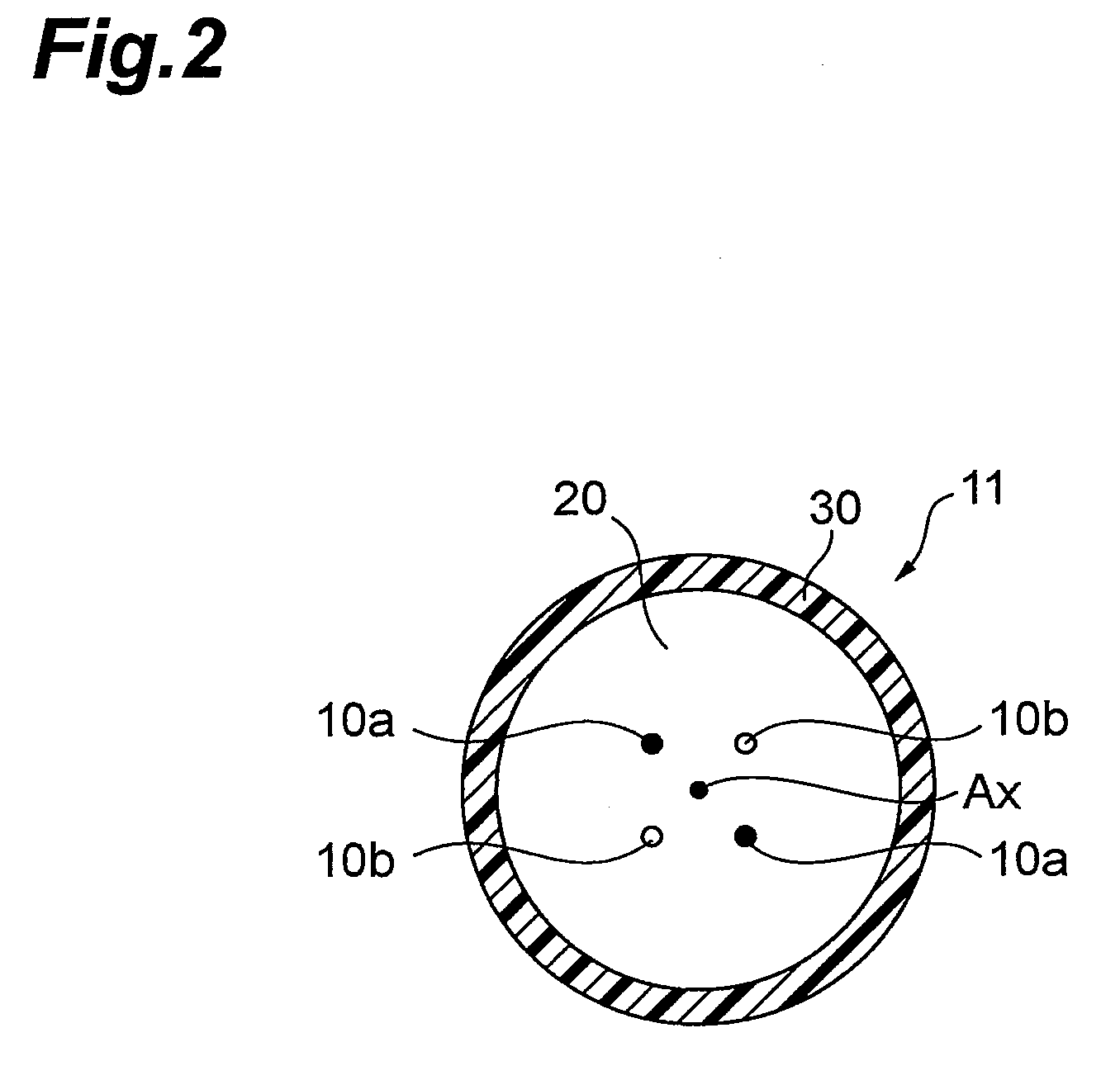

Polarization maintaining multi-core optical fiber

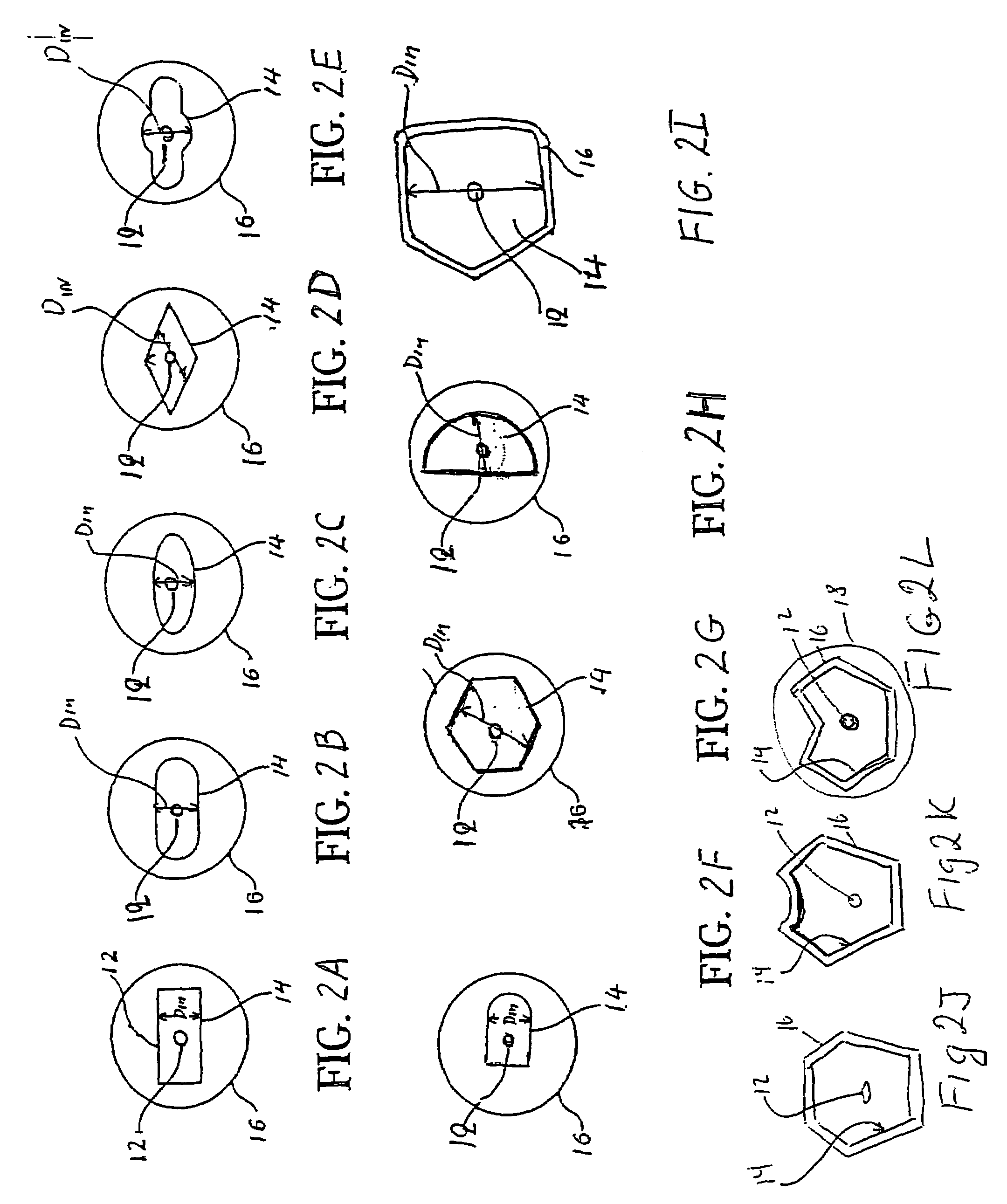

InactiveUS20130108206A1High densityField distribution is reducedOptical fibre with polarisationMulticore optical fibreLong axisOptical polarization

In a polarization maintaining multi-core optical fiber according to the present invention, structural birefringence is generated since an elliptic core is applied. In addition, each core is arranged so that a direction of a line connecting between centers of the nearest cores and a long axis direction of a field distribution in each core may be different from each other, and thereby, overlap of field distributions between the nearest cores is reduced. As a result, a crosstalk among cores is reduced.

Owner:SUMITOMO ELECTRIC IND LTD

Optical fiber and method for making such fiber

ActiveUS7313312B2Coupling efficiency is highIncrease optical powerOptical fibre with polarisationOptical fibre with multilayer core/claddingFiberRare earth

According to one example of the invention an optical fiber comprises: (i) silica based, rare earth doped core having a first index of refraction n1; (ii) at least one silica based cladding surrounding the core and having a second index of refraction n2, such that n1>n2; wherein at least one of the core or cladding is doped with Al2O3, such that the ratio of max wt % to min wt % of Al2O3 concentration is less than 2:1.

Owner:CORNING INC

Multi-core fiber

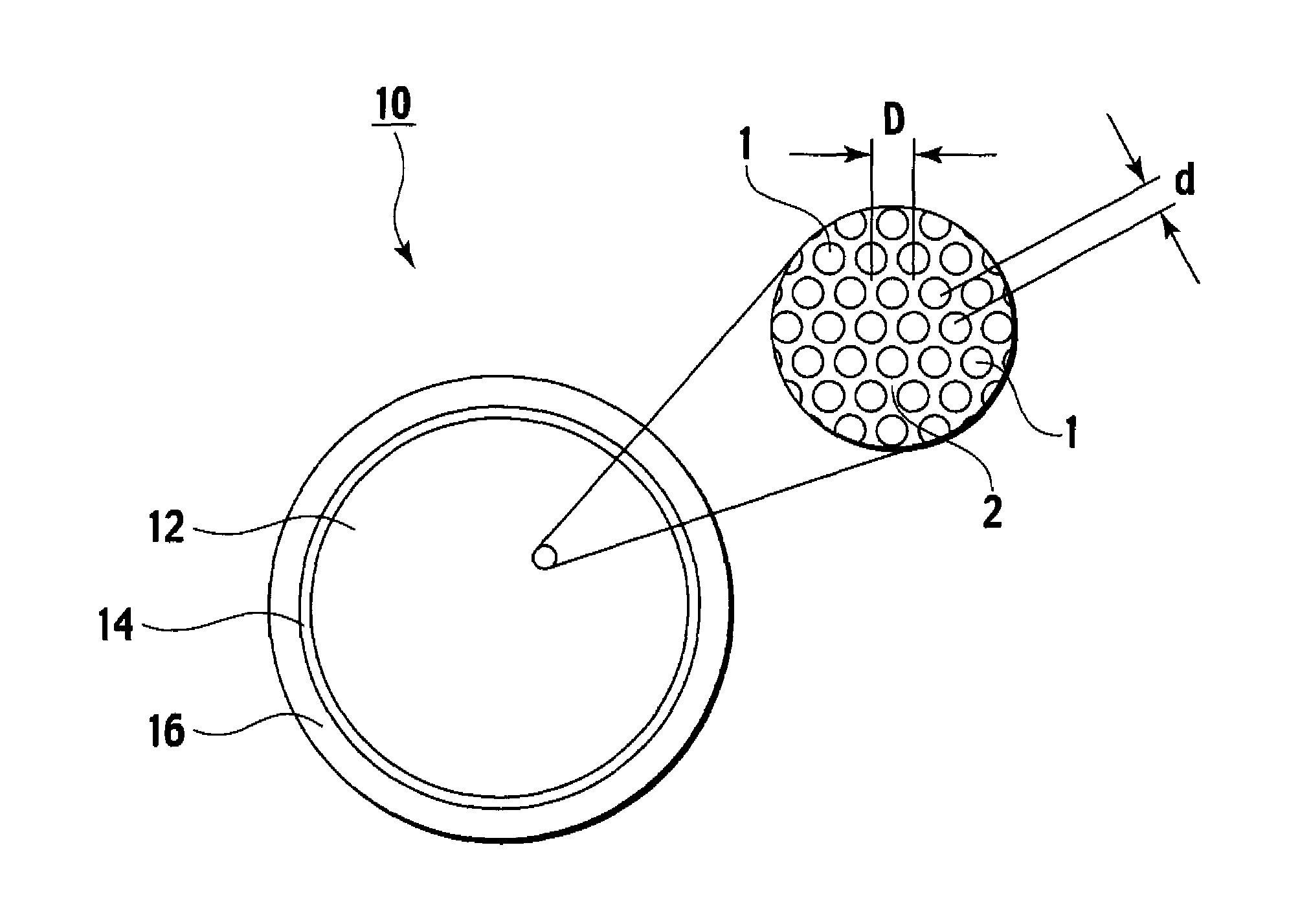

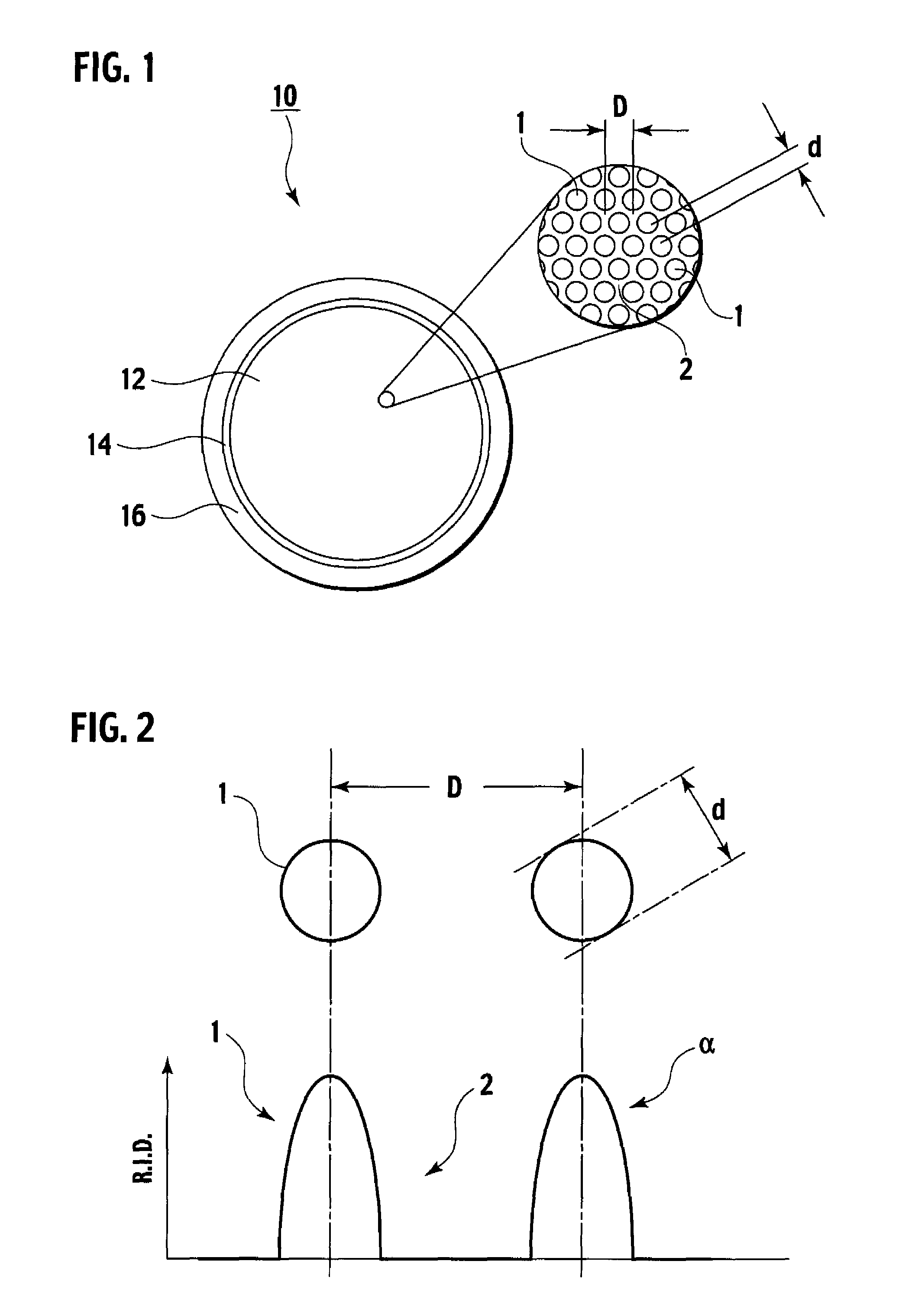

ActiveUS7418178B2Optical fibre with multilayer core/claddingBundled fibre light guideQuartzNumerical aperture

A multi-core optical fiber apparatus is disclosed. The multi-core optical fiber apparatus includes a cladding comprising quartz and a plurality of cores embedded in the cladding. Each of the cores has a diameter (D) ranging from 1.3 μm to 2.0 μm, a numerical aperture (NA) from 0.35 to 0.45 and a refractive index profile factor (α) from 2.0 to 4.0. A center of each of the cores has a germanium content of 20 wt % to 30 wt %. An interval between adjacent cores is 3.0 μm or more.

Owner:THE FUJIKURA CABLE WORKS LTD

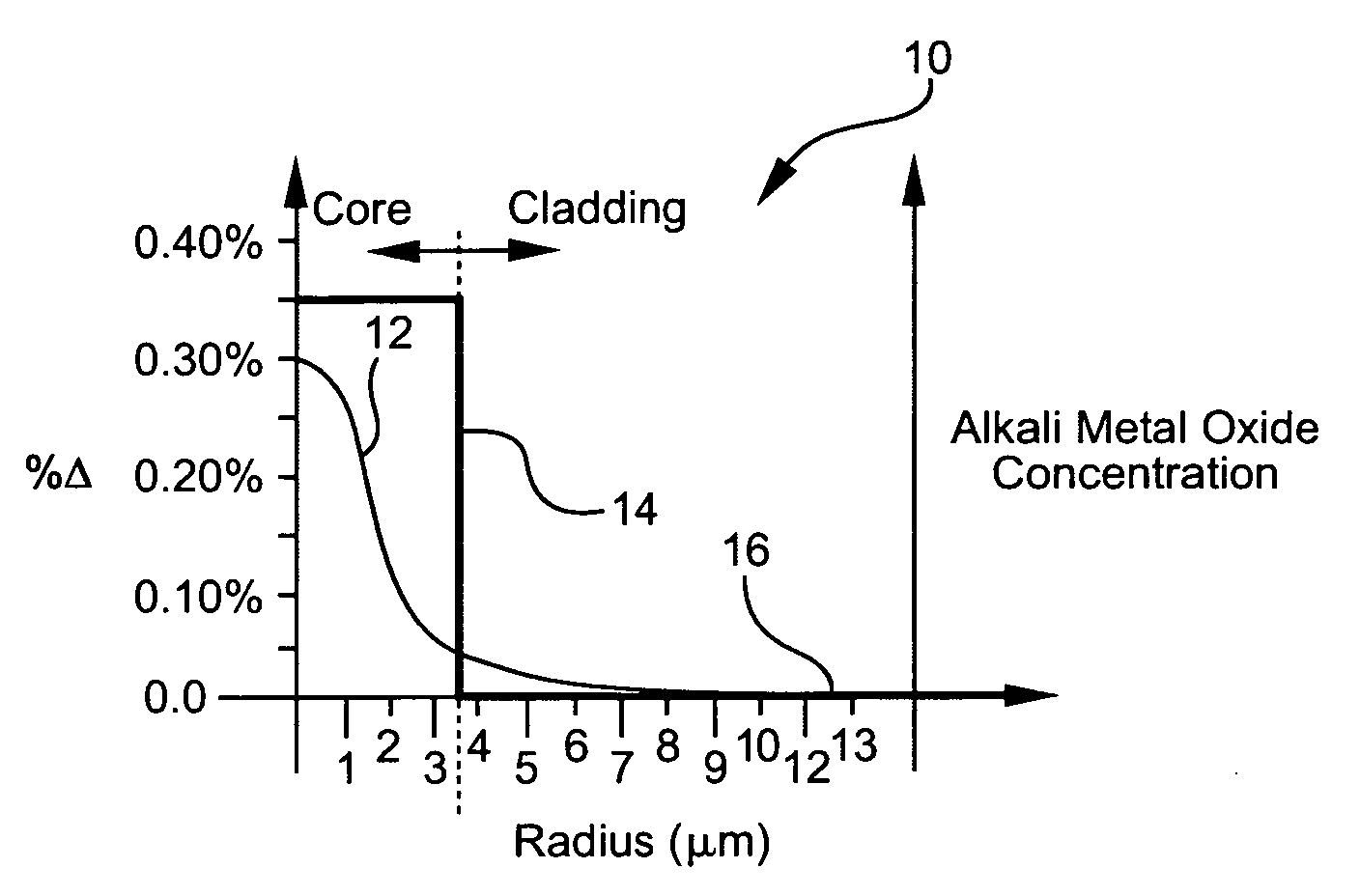

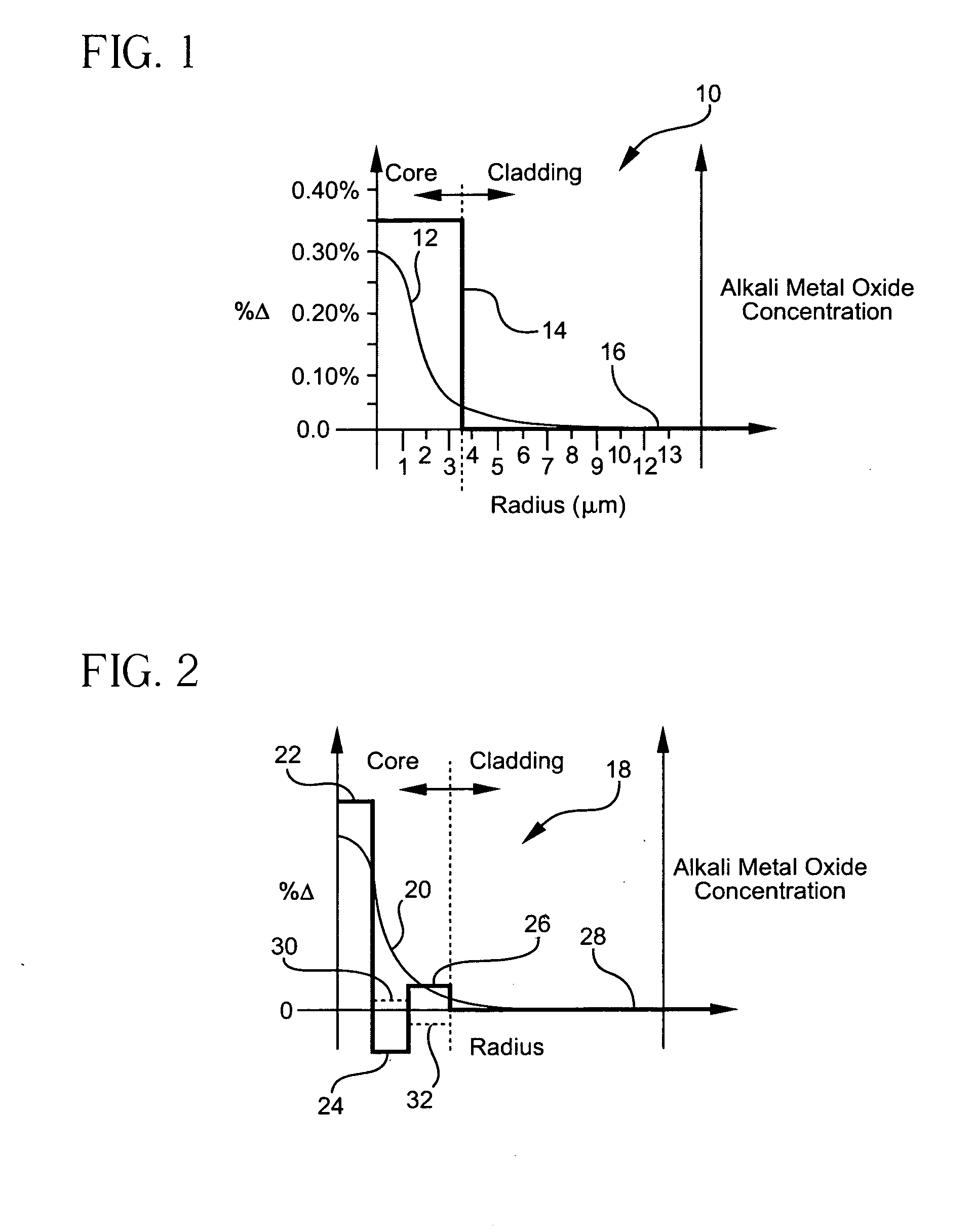

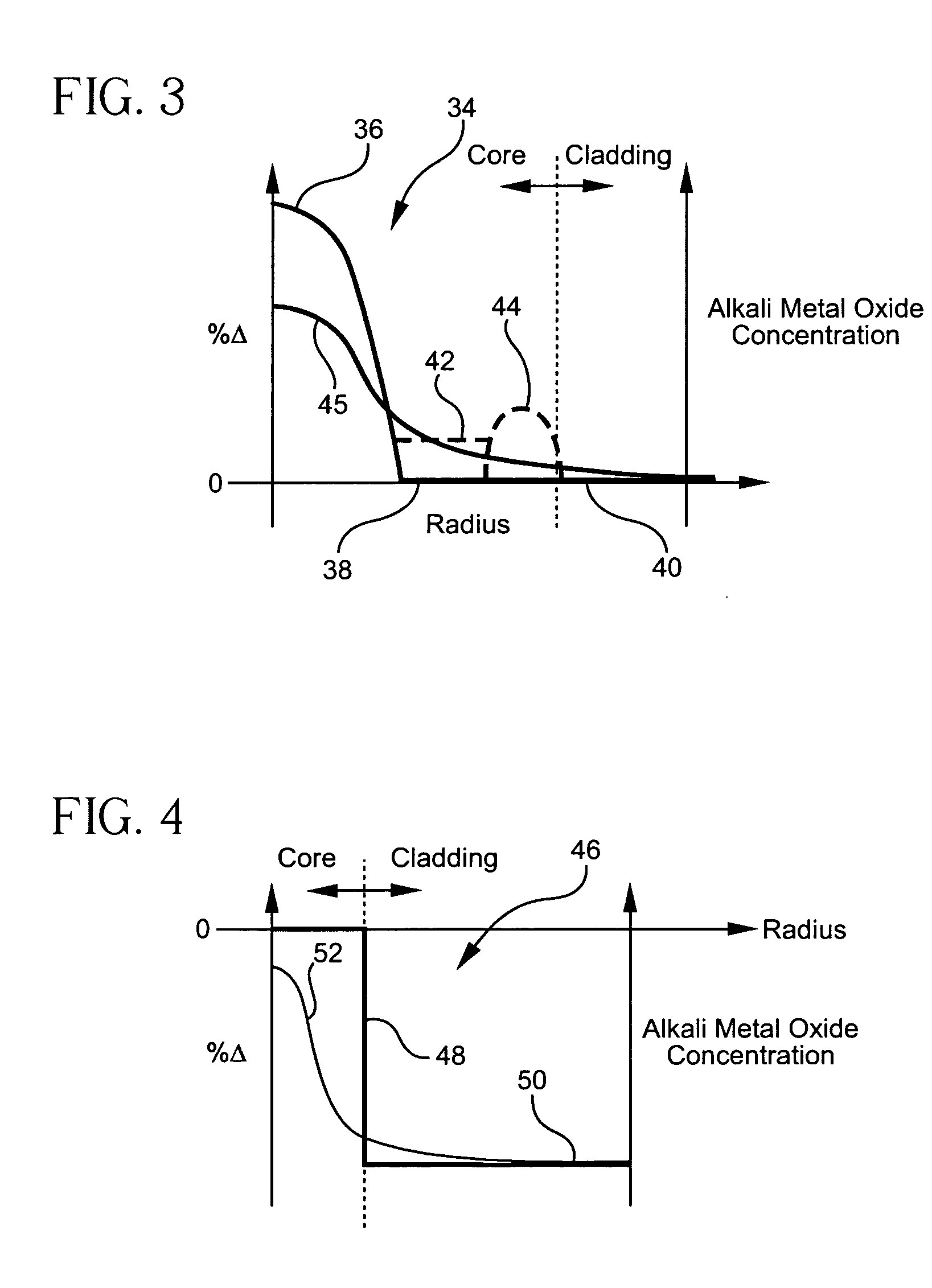

Optical fiber containing an alkali metal oxide and methods and apparatus for manufacturing same

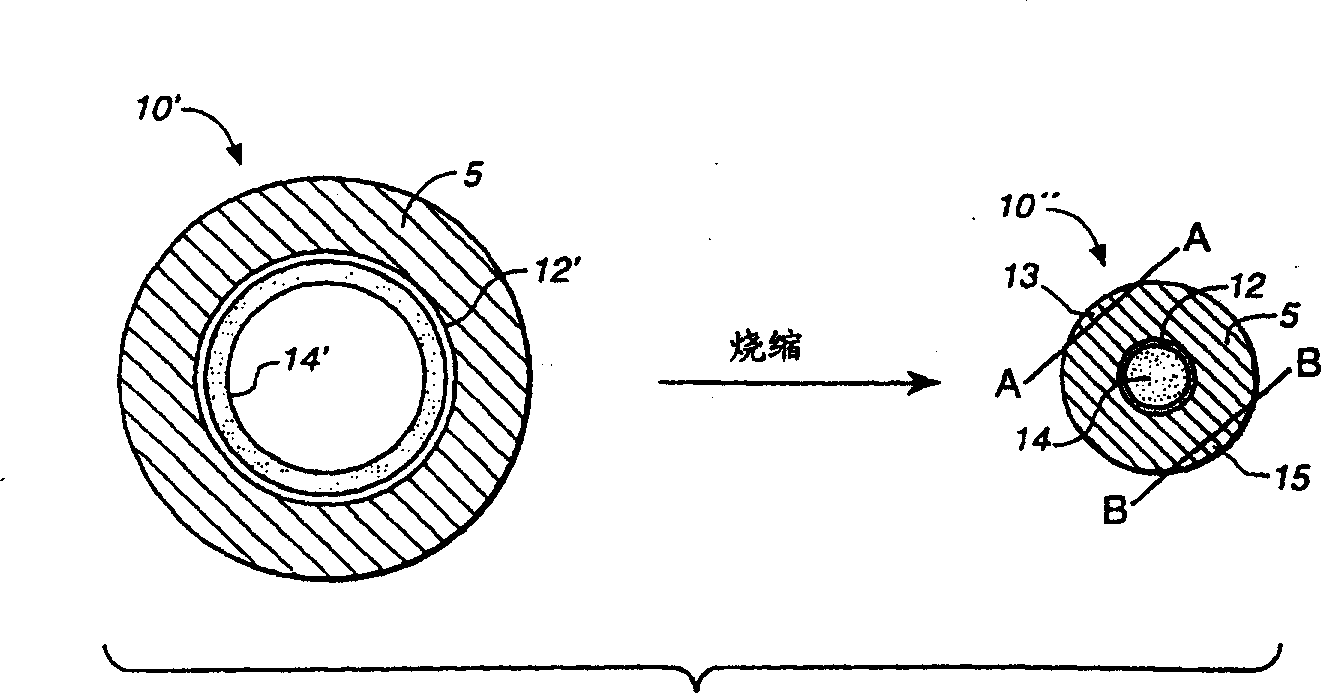

ActiveUS20050063663A1Increase radiusReduce doping concentrationOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingDopantAlkali metal oxide

Disclosed is an optical fiber having a core with an alkali metal oxide dopant in an peak amount greater than about 0.002 wt. % and less than about 0.1 wt. %. The alkali metal oxide concentration varies with a radius of the optical fiber. By appropriately selecting the concentration of alkali metal oxide dopant in the core and the cladding, a low loss optical fiber may be obtained. Also disclosed are several methods of making the optical fiber including the steps of forming an alkali metal oxide-doped rod, and adding additional glass to form a draw perform. Preferably, the draw preform has a final outer dimension (d2), wherein an outer dimension (d1) of the rod is less than or equal to 0.06 times the final outer dimension (d2). In a preferred embodiment, the alkali metal oxide-doped rod is inserted into the centerline hole of a preform to form an assembly.

Owner:CORNING INC

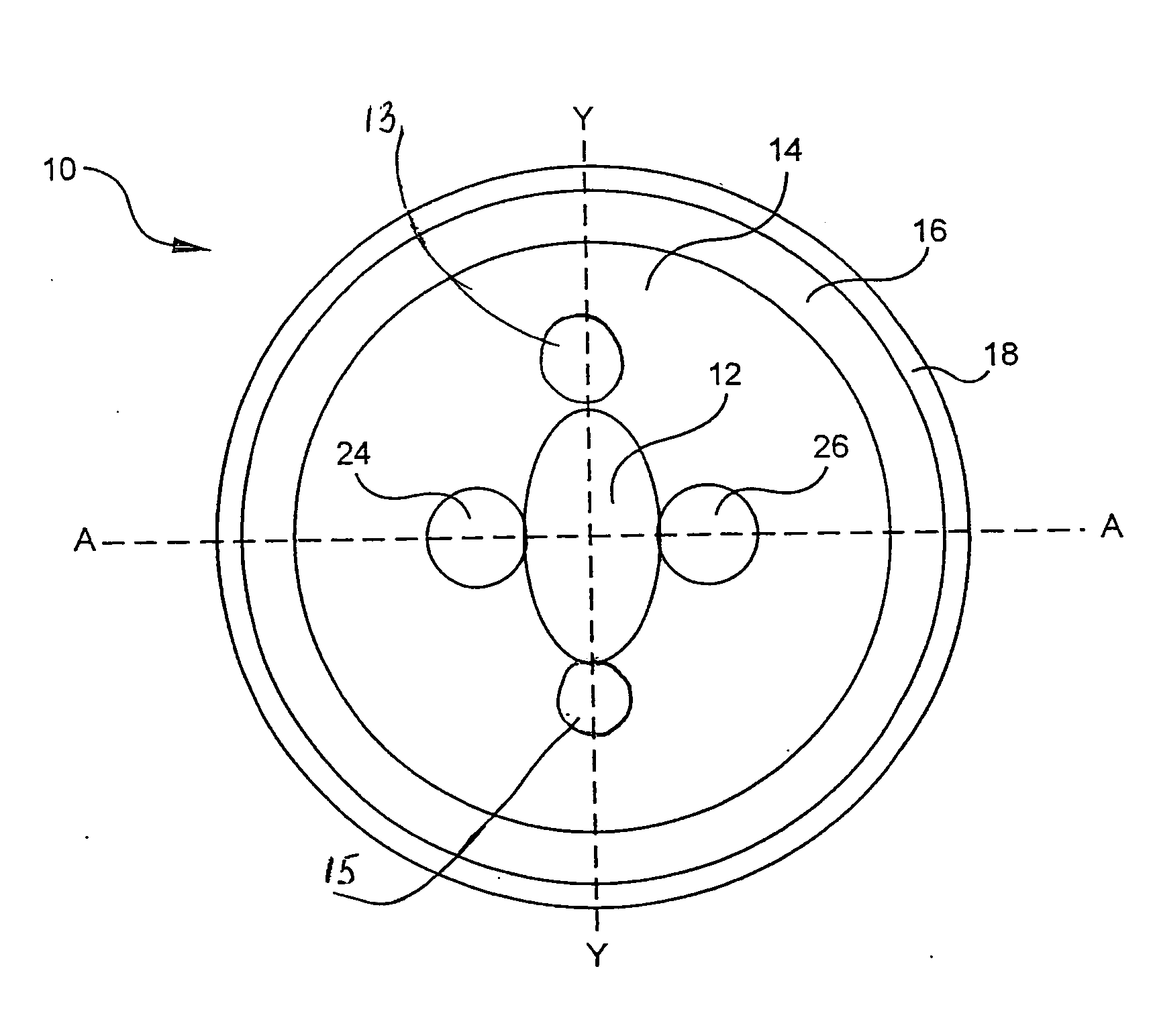

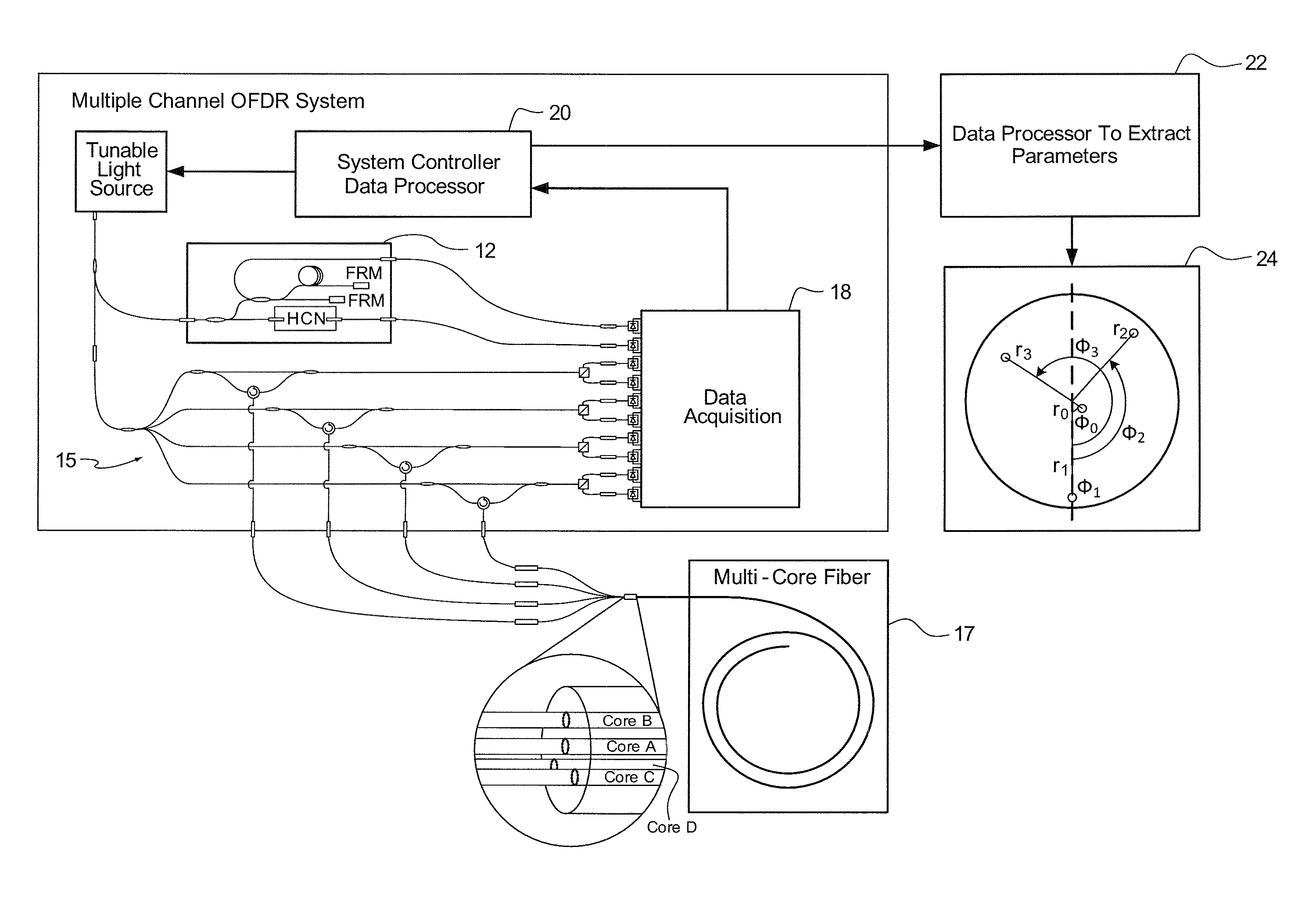

Multi-core optical fiber and method of making and using same

The apparatus includes a fiber comprising an axial center, a central single-mode waveguiding core and a plurality of peripheral single-mode waveguiding cores. The central core is located at a first distance from the axial center. The plurality of peripheral cores is located at respective second distances from the axial center. Each of the respective second distances is greater than the first distance, and each peripheral core of the plurality of peripheral cores follows a respective first helix about the axial center. The central core and the plurality of peripheral cores include an optical strain sensor rosette.

Owner:NAVY USA AS REPRESENTED BY THE SEC THE

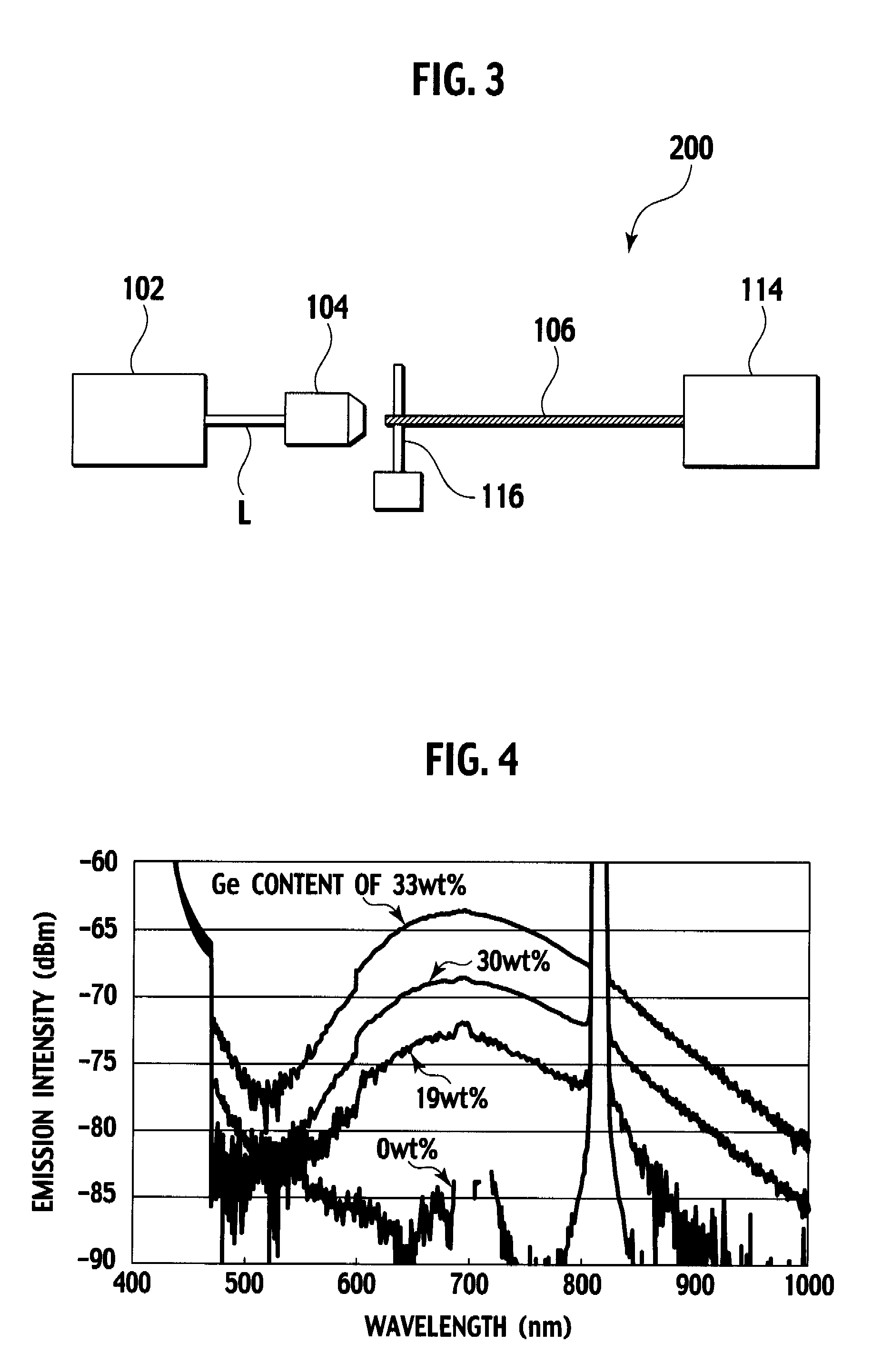

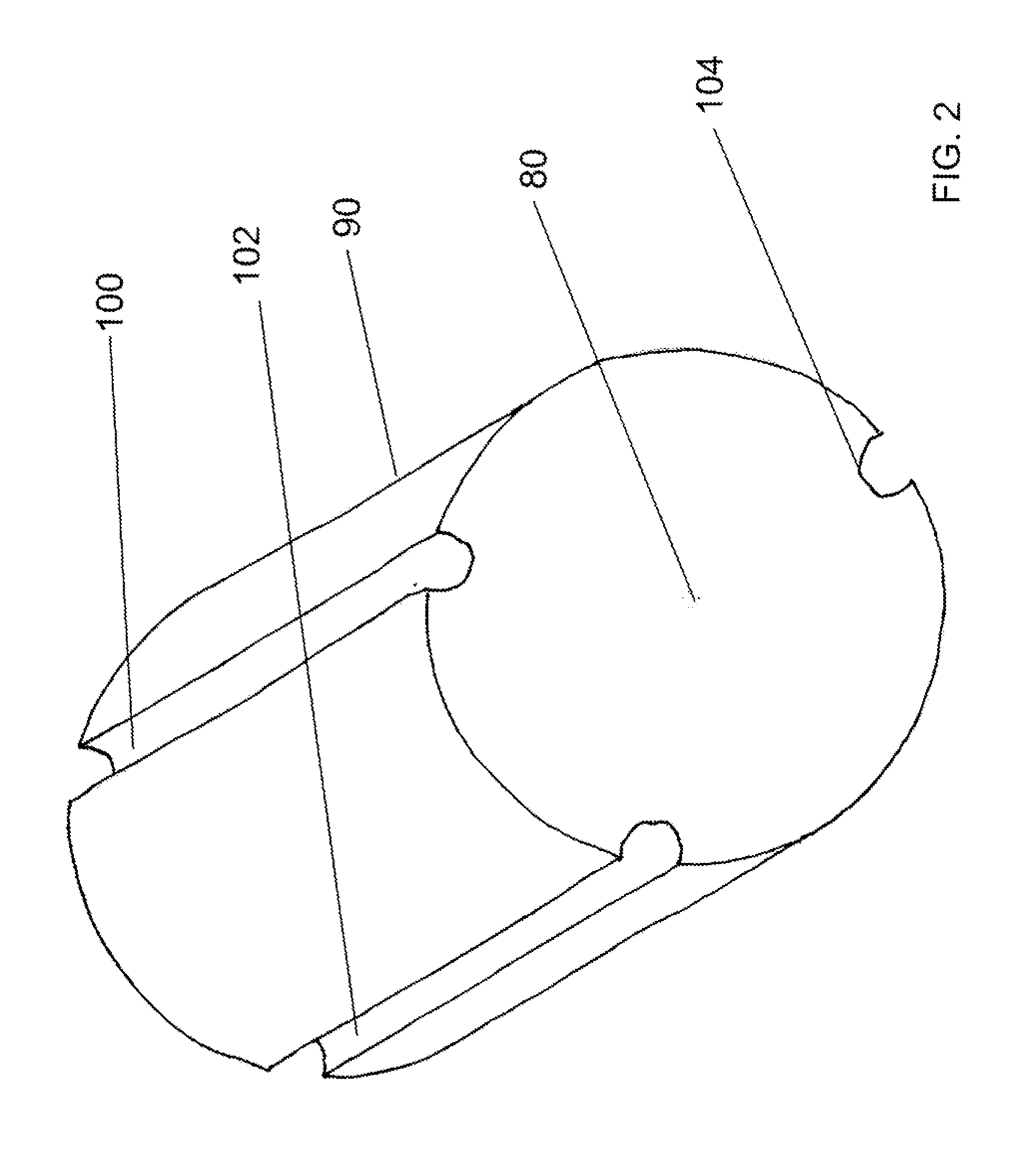

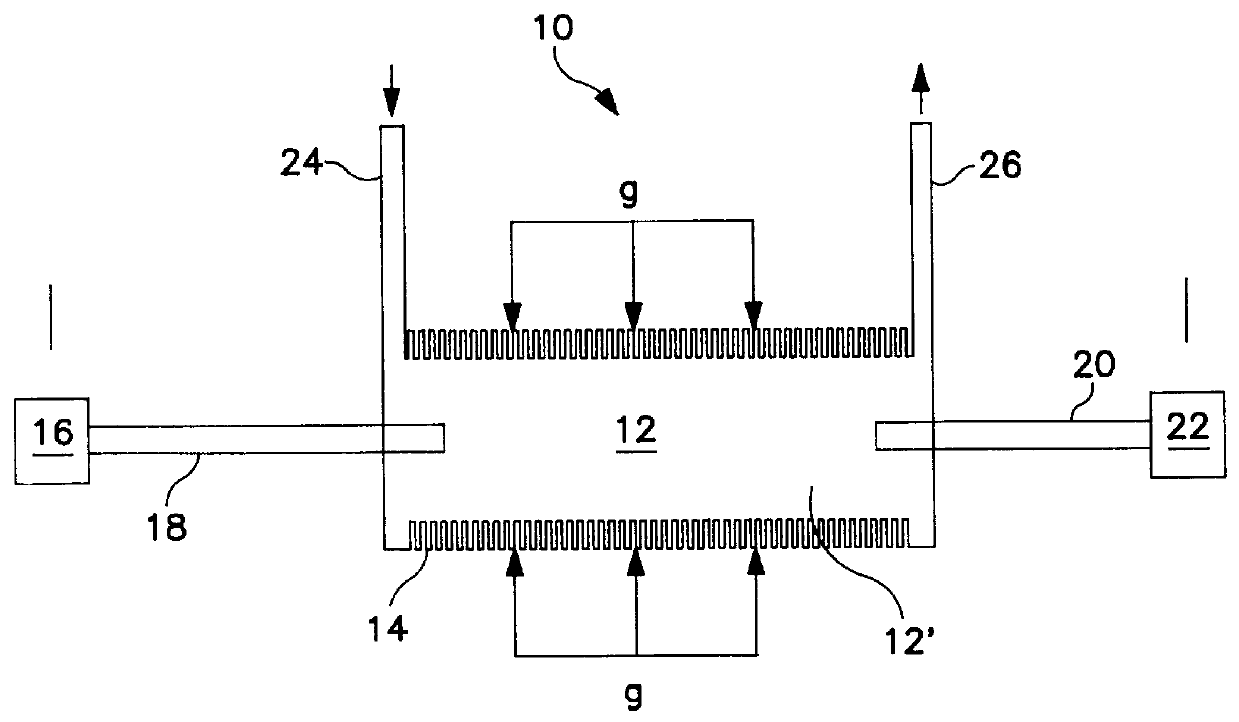

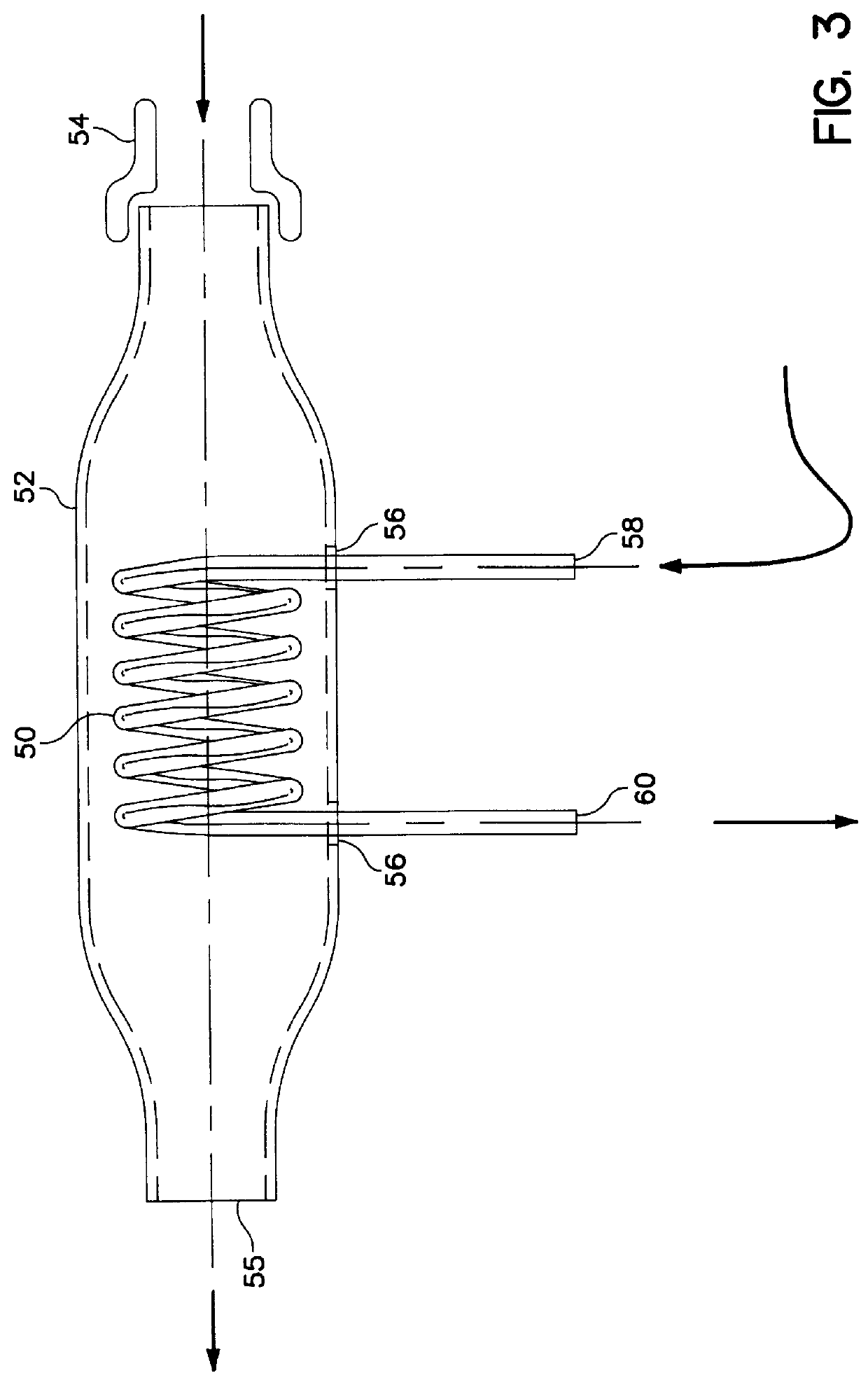

Method and apparatus for manufacturing a rare-earth metal doped optical fiber preform

InactiveCN1307544AHigh pump power absorptionSmall numerical apertureGlass deposition burnersOptical light guidesHigh concentrationGlass forming

A method and apparatus is disclosed for the manufacture of an optical fiber preform having incorporated therein a comparatively high concentration of rare earth metal dopant material, and which thus can be drawn and processed into an optical fiber having low numerical aperture, low core attenuation, and high pumping power absorption. The high concentrations of rare earth metal dopant material are accomplished through a ''hybrid vapor processing'' (HVP) method or a ''hybrid liquid processing'' (HLP) method, either being practiced in combination or independently of one another. The HVP method involves the vaporization of a rare earth metal halide by the exposure thereof to a sufficiently elevated temperature, independently, or contemporaneously with the transport of the resultant rare earth metal halide laden vapor, into a glass-forming oxidation reaction zone on a flowing stream of essentially an unreactive inert gas, such as helium. According to the HLP method, a first amount of rare earth metal dopant is provided according to the HVP method and / or other vapor source of rare earth metal dopant which is mixed with glass-forming vapors to form a deposited soot layer on the internal surface of a glass tube. The soot-deposited tube is then impregnated with a dopant solution comprising, a second amount of rare earth metal dopant. The tube is then thermally collapsed resulting in an optical preform with an enhanced amount of rare earth metal dopant incorporated at a comparatively high concentration. The apparatus comprises means, such as tubes, for introducing the rare earth metal dopant as a vapor, formed from a solid state form of the dopant, into the main glass deposition tube separately from glass-forming material vapors and oxygen for the reaction within the main tube.

Owner:JDS单相公司

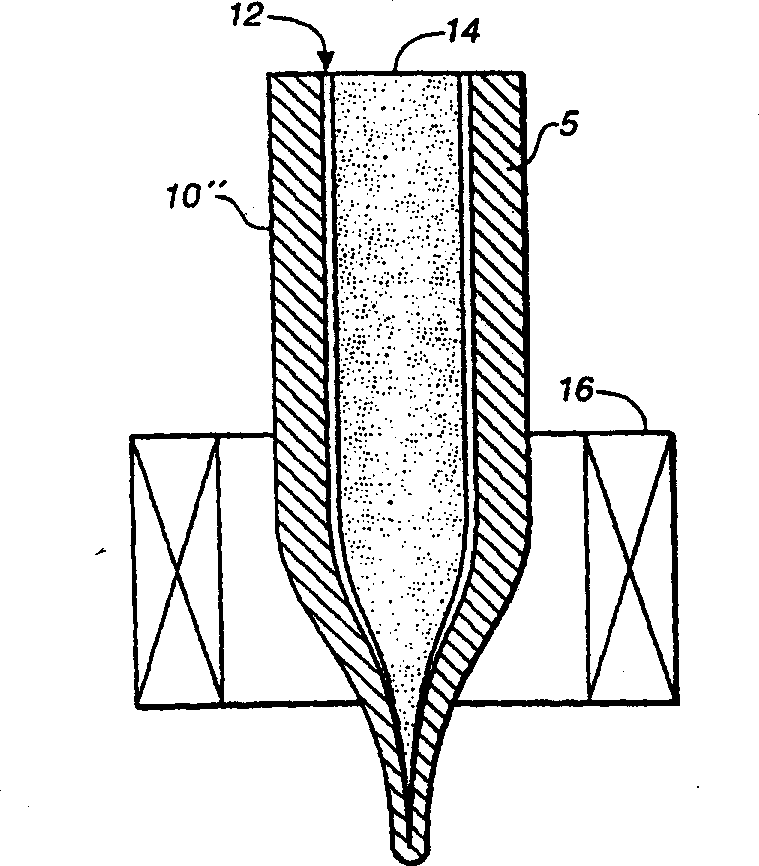

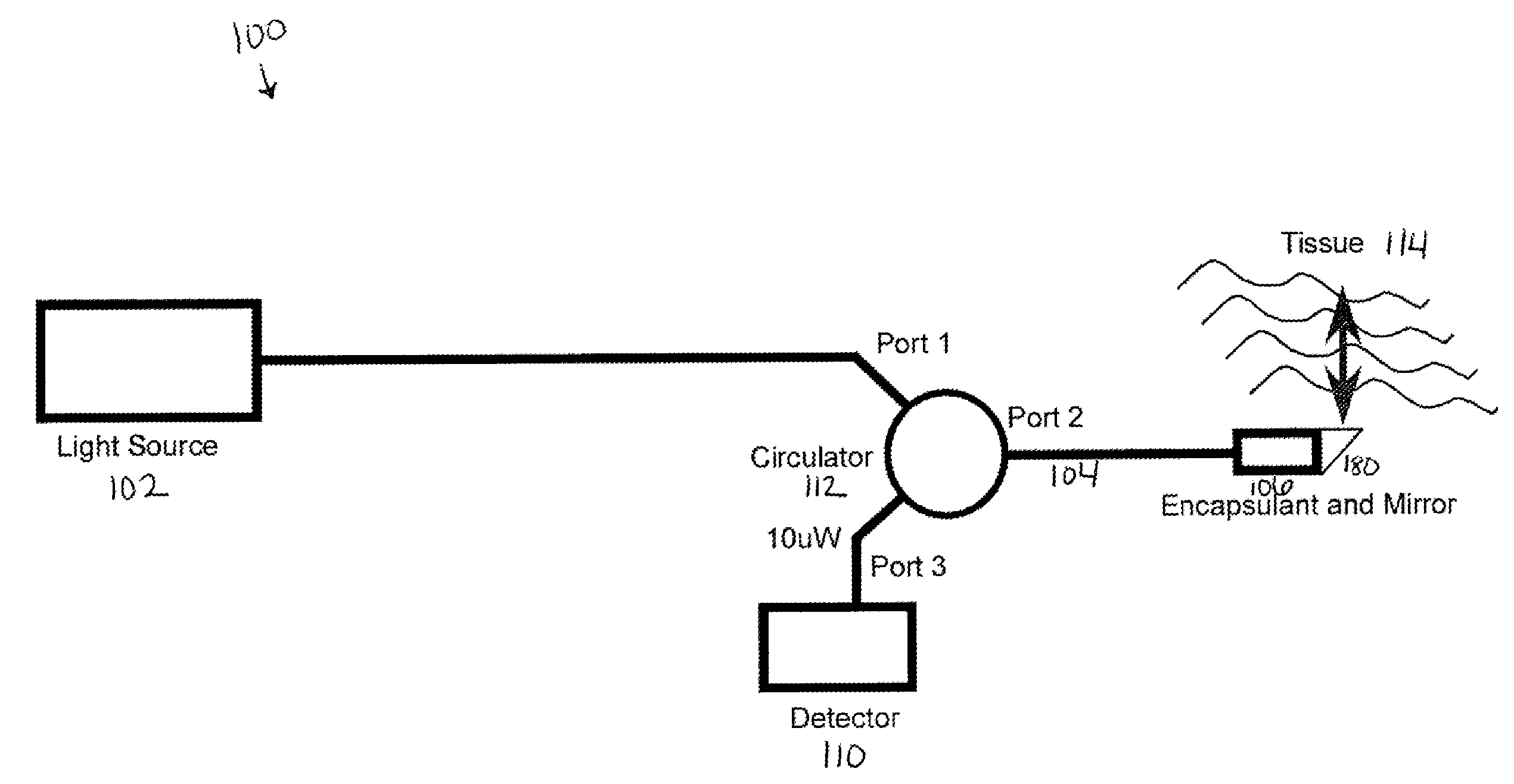

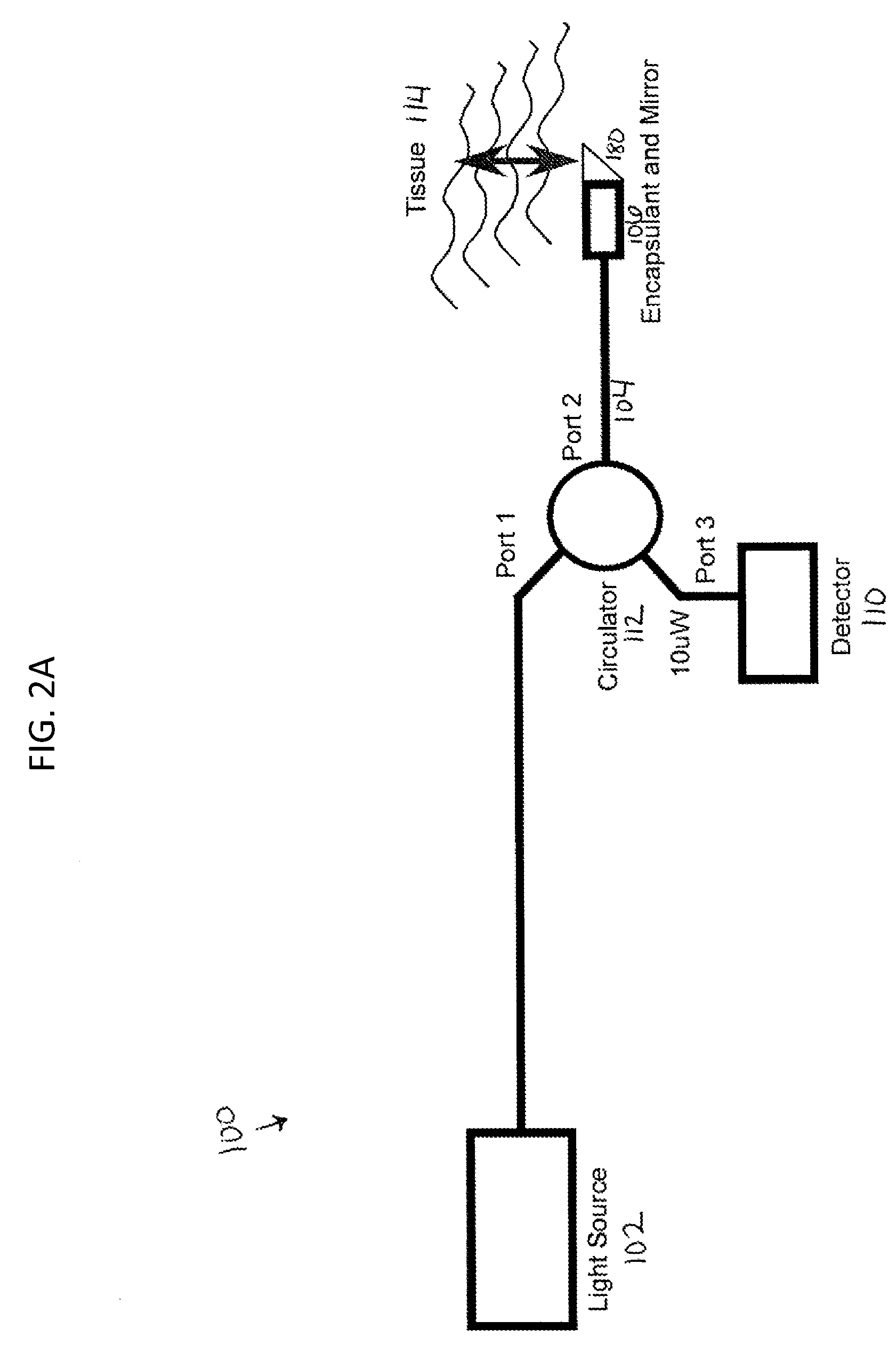

Optical coherence tomography for biological imaging

ActiveUS20100305452A1Shorten operation timeImprovement longCatheterDiagnostic recording/measuringOptical radiationRefractive index

Described herein are catheters for use with Optical Coherence Tomography (OCT) that include an optical fiber core having a first refractive index and an interface medium having a second refractive index, where the first and second refractive indexes are mismatched such that receiving electronics configured to receive optical radiation reflected from the reference interface and the target operate in a total noise range that is within 5 dB of the shot noise limit. These OCT catheters may include a silicon die mirror having a reflective coating that is embedded in the interface medium. The optical fiber can be fixed at just the distal end of the catheter, and may be managed within a handle that is attached to the proximal end of the catheter body, and is configured to allow rotation of the both catheter body and the optical fiber relative to the handle.

Owner:AVINGER

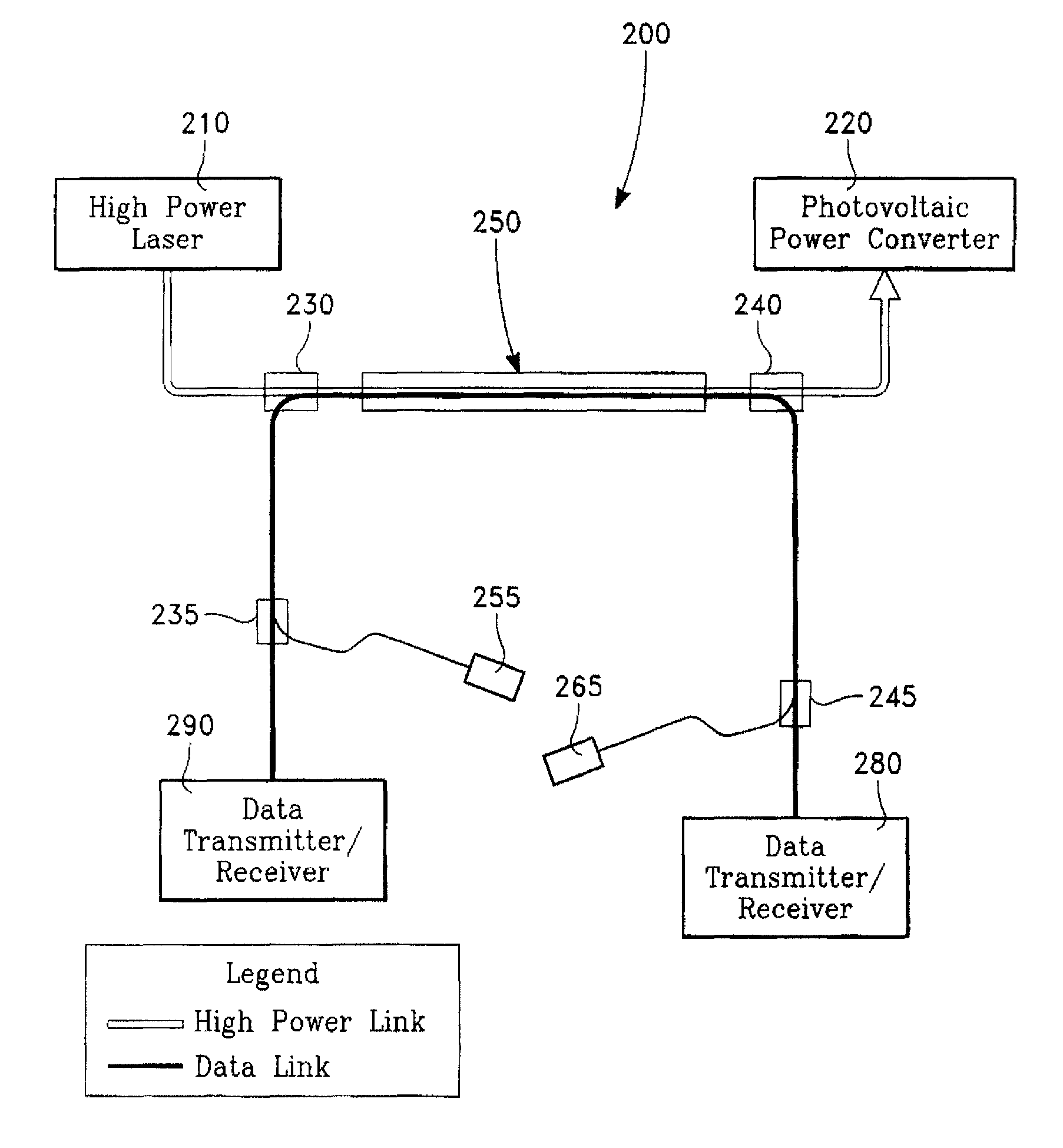

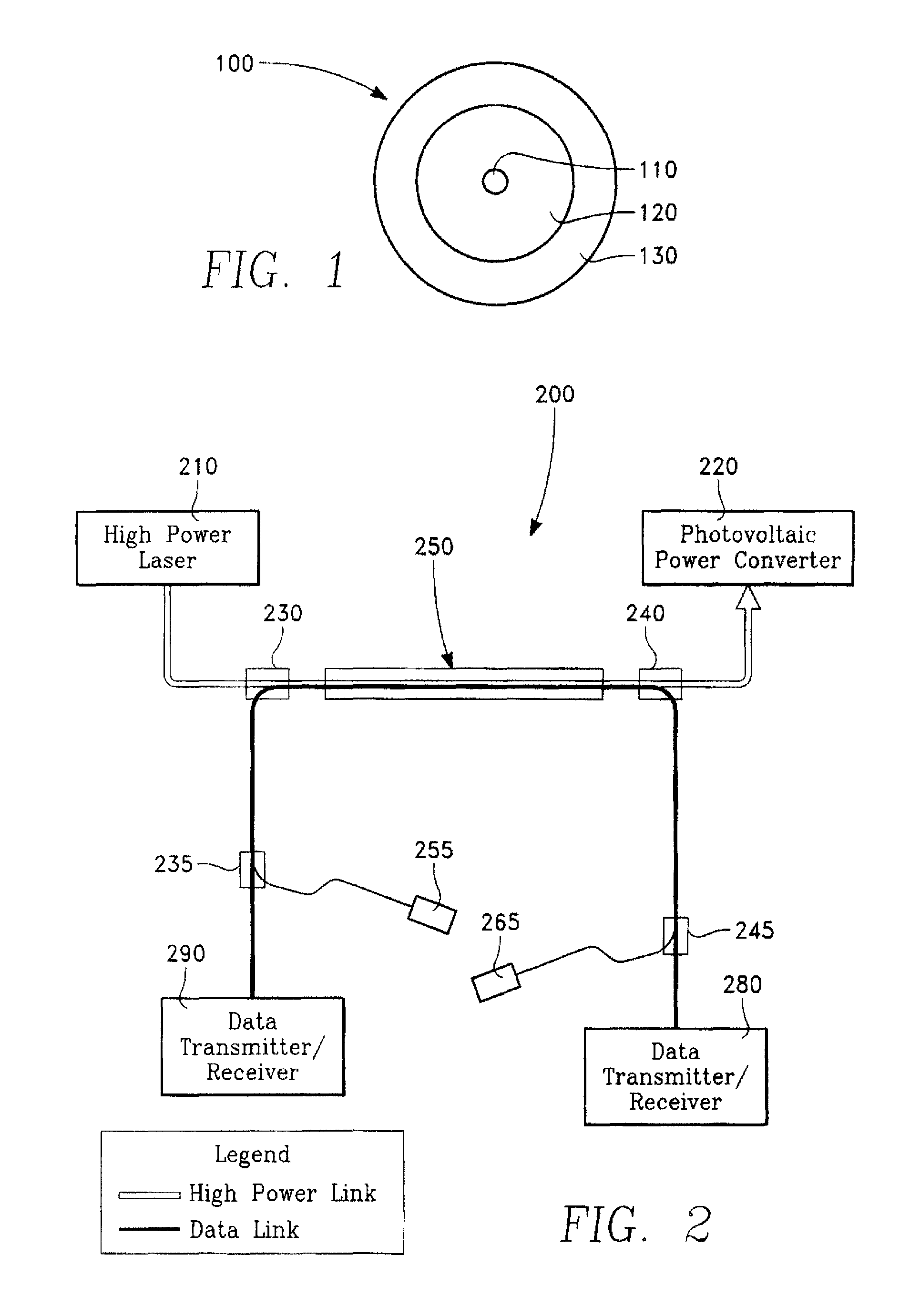

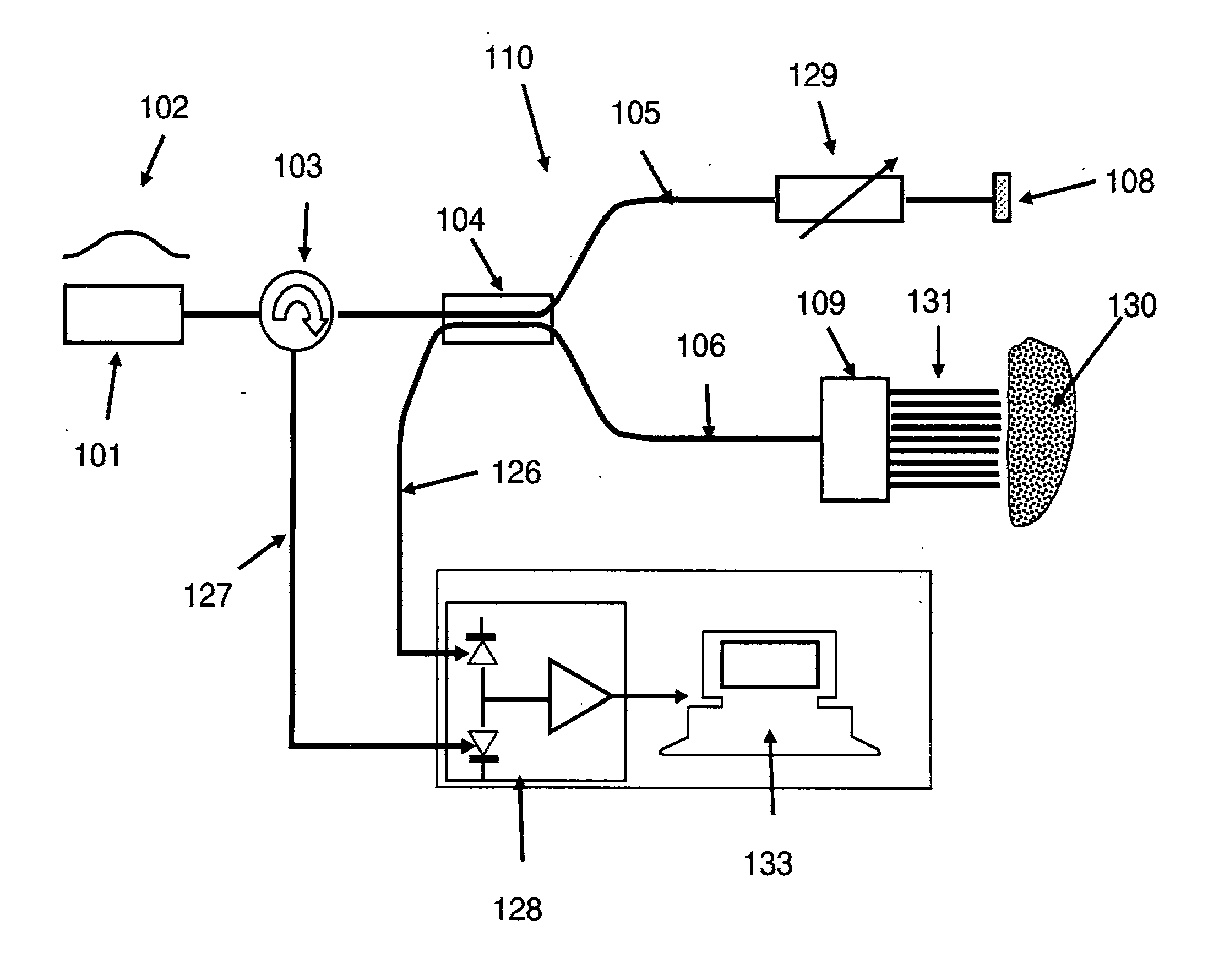

Single fiber optical links for simultaneous data and power transmission

ActiveUS7941022B1Optical fibre with multilayer core/claddingElectromagnetic transmissionWavelength selectivityOptical power

Owner:HRL LAB

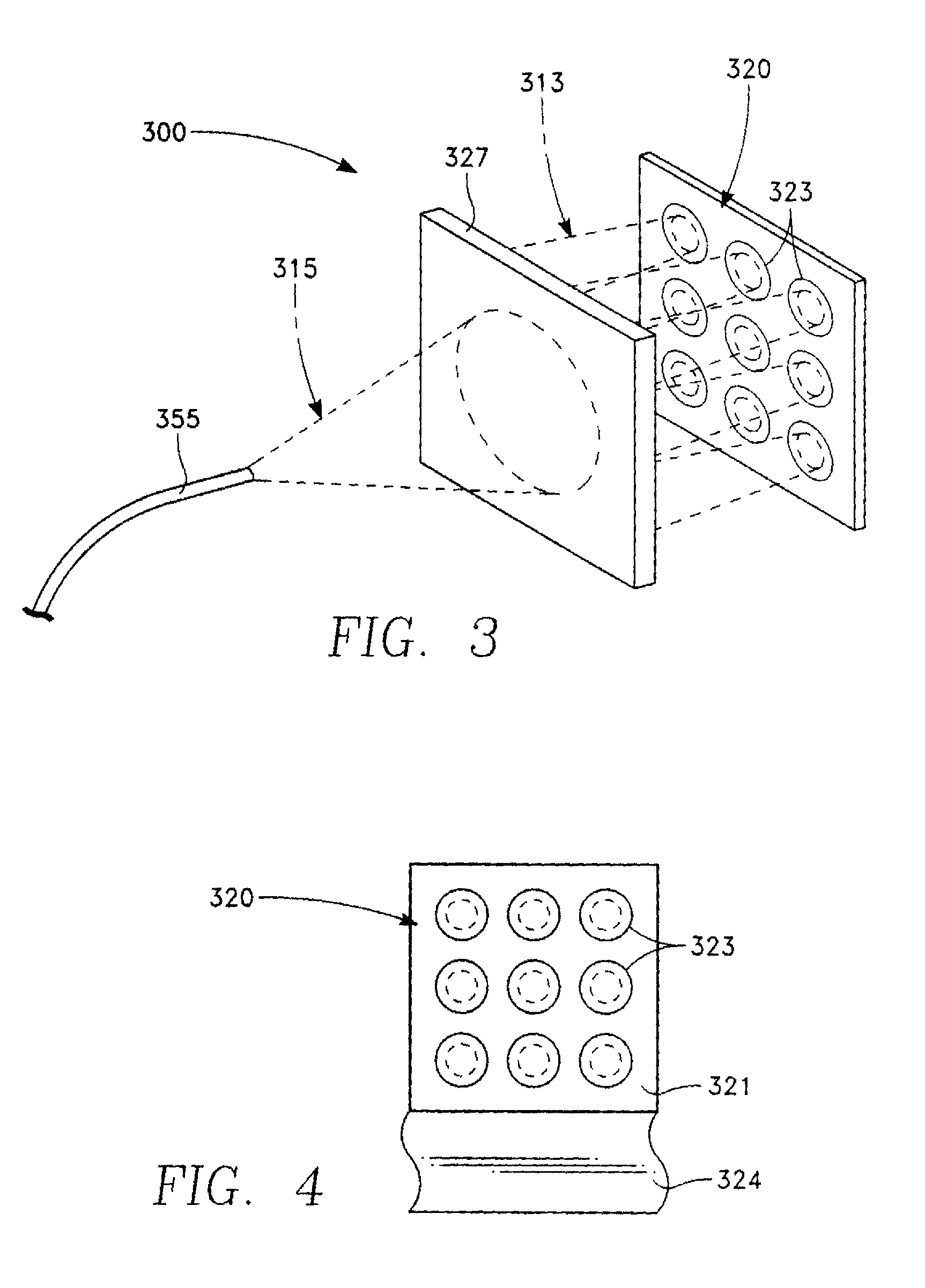

Multi-core low reflection lateral output fiber probe

InactiveUS20120099112A1Added fabricationEndoscopesUsing optical meansLight propagationCore (optical fiber)

Multi-core optical fiber probe includes a multi-core optical fiber (and method of manufacturing the probe) including a plurality of cores adjacent a cladding material, and a plurality of angled reflectors disposed at a distal end of the cores. An angled reflector of the plurality of angled reflectors deflects light propagating in the core at a deflection angle that is different from an axis of light propagation in the core. Light propagating toward a distal end of the core of the multi-core probe is emitted, after reflection by the corresponding reflector, out of the multi-core optical fiber probe.

Owner:ALPHONSE GERARD ARGANT +1

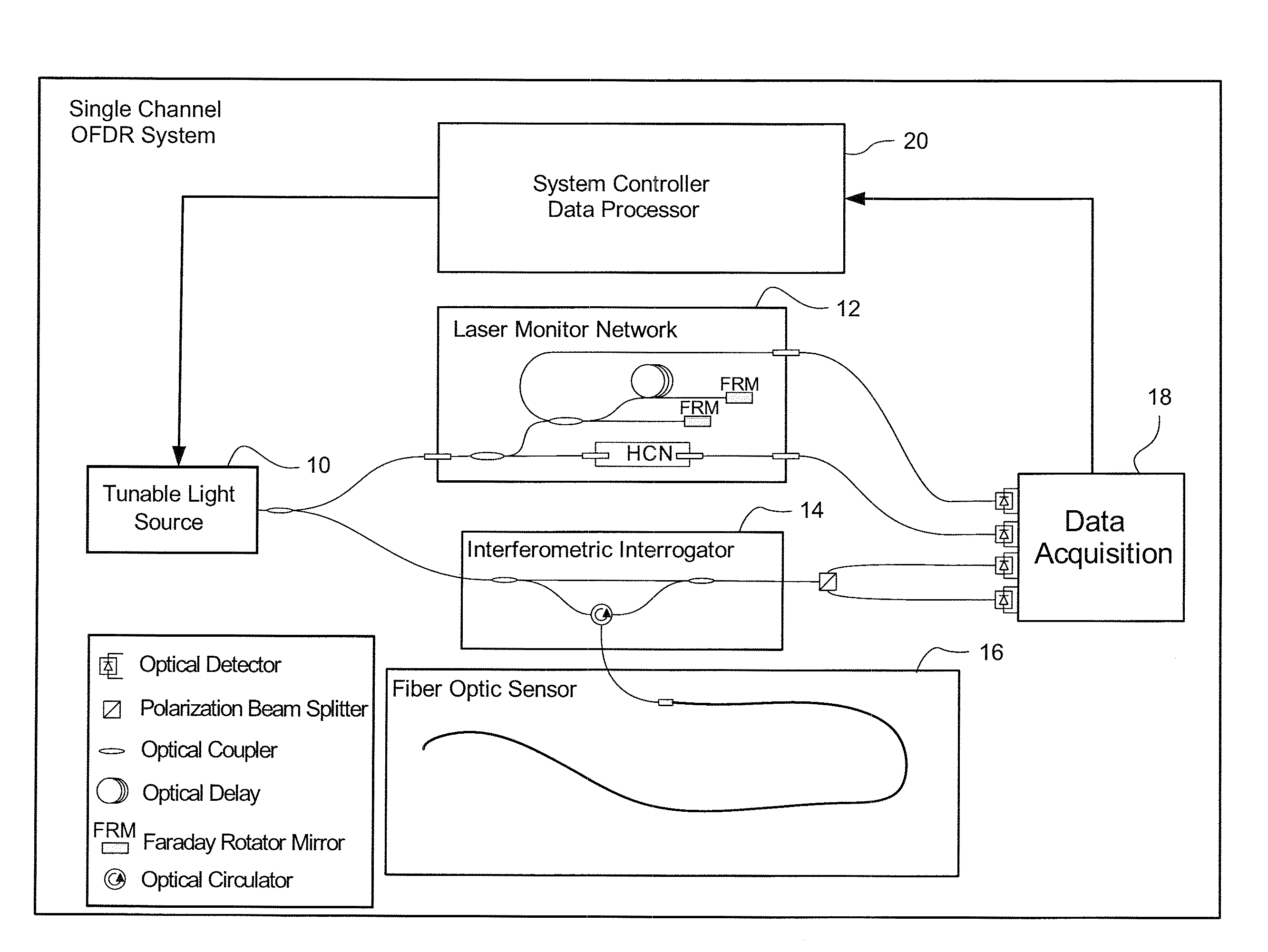

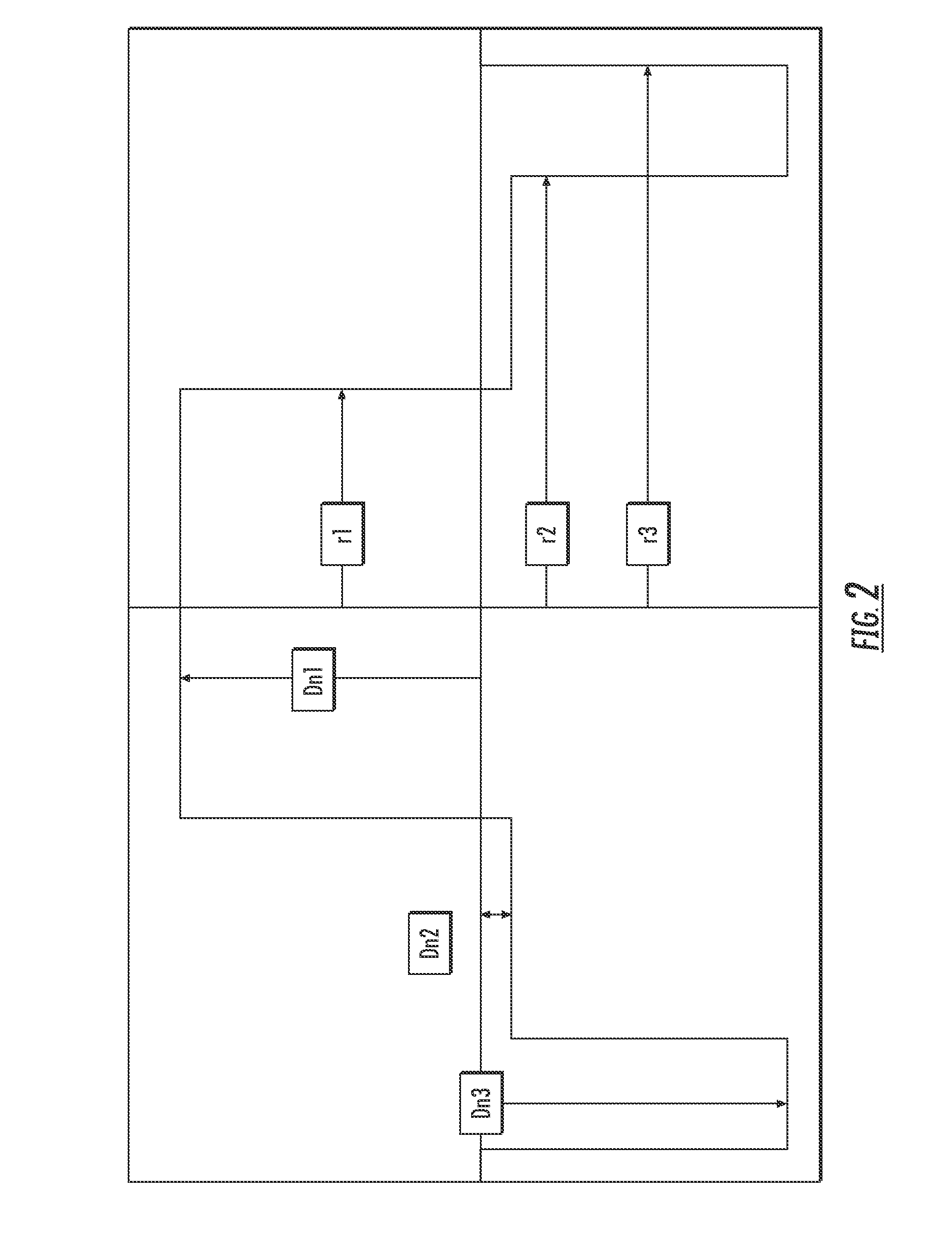

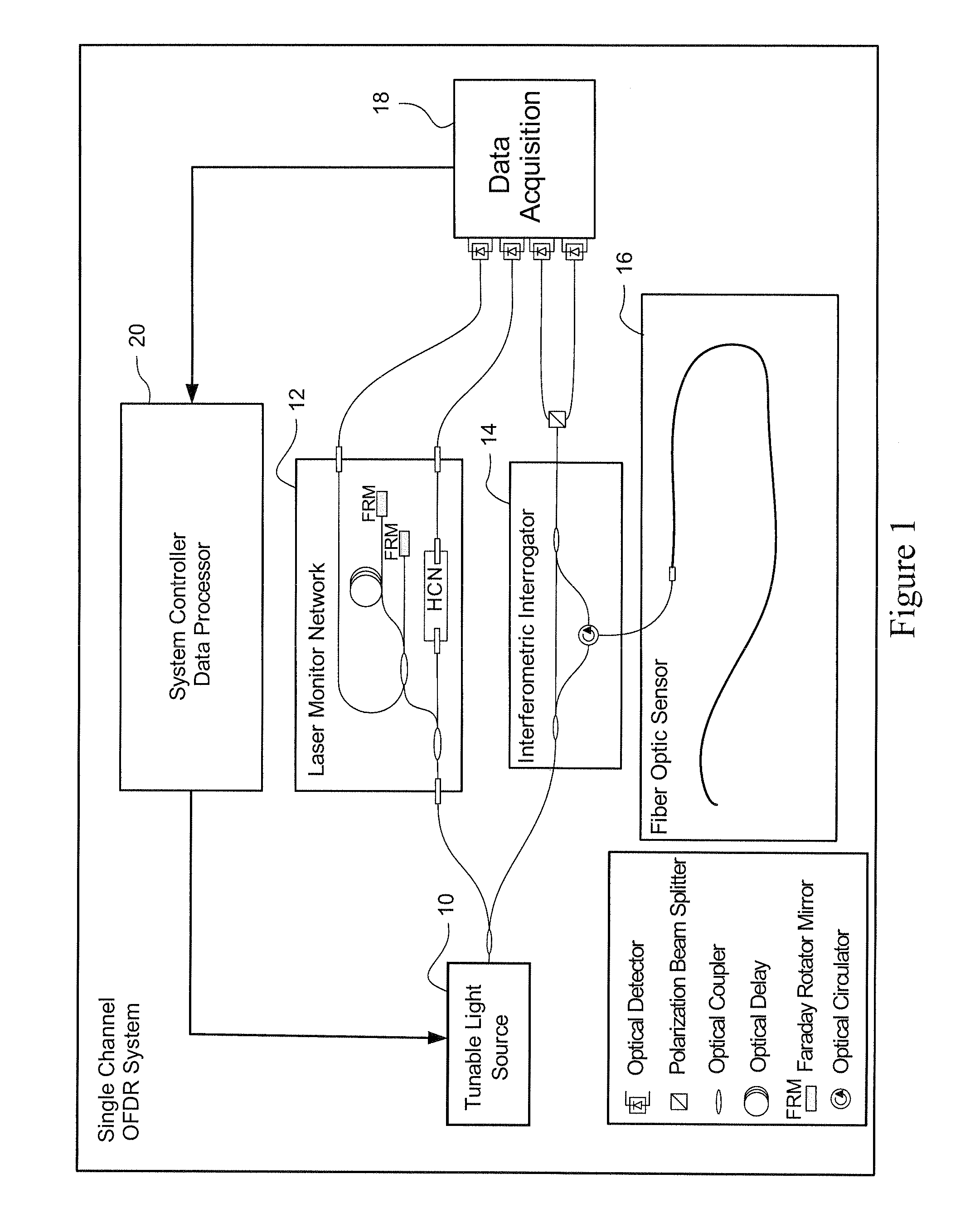

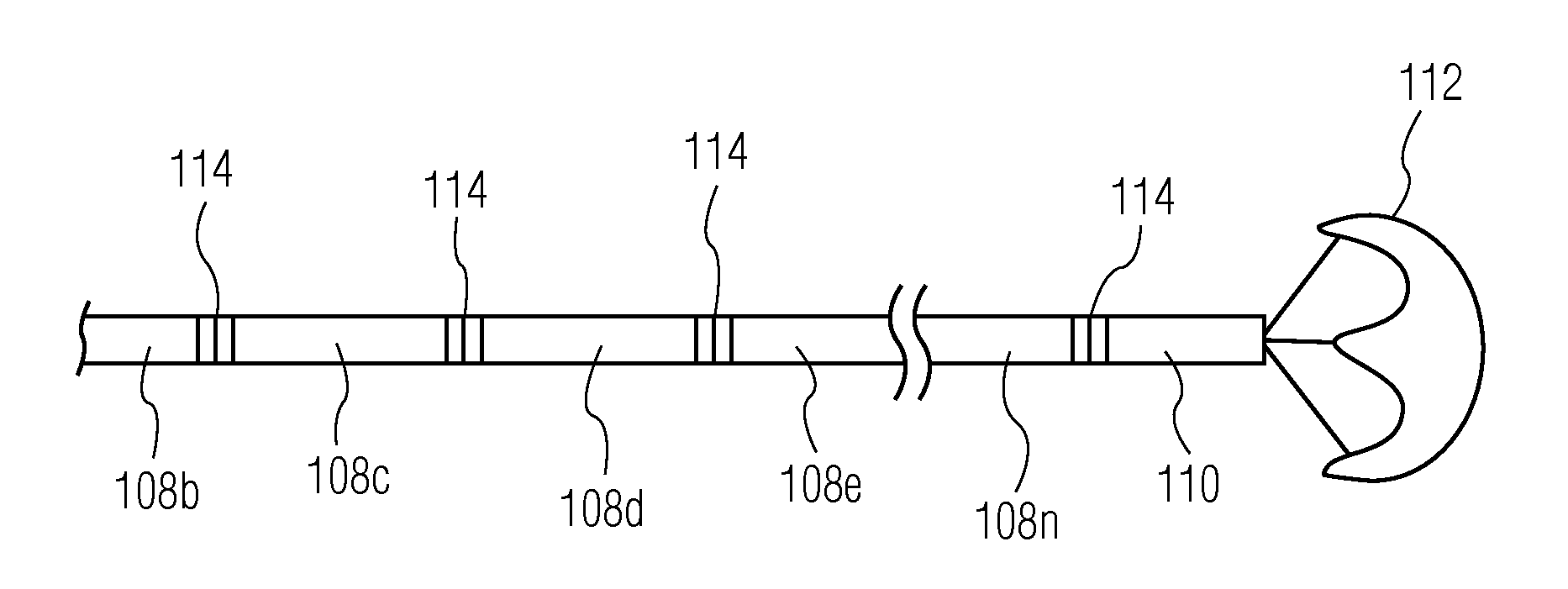

Compensating for non-ideal multi-core optical fiber structure

ActiveUS20120069347A1Accurately determineWithout loss in positional accuracyForce measurementMaterial analysis by optical meansEngineeringMechanical engineering

An interferometric measurement system includes a spun optical fiber including multiple optical waveguides configured in the fiber. Interferometric detection circuitry detects measurement interferometric pattern data associated with each of the multiple optical waveguides when the optical fiber is placed into a bend. Data processing circuitry determines compensation parameters that compensate for variations between an optimal configuration of the multiple optical waveguides in the fiber and an actual configuration of multiple optical waveguides in the fiber. The compensation parameters are stored in memory for compensating subsequently-obtained measurement interferometric pattern data for the fiber. The compensation parameters are applied to the subsequently-obtained measurement interferometric pattern data in order to distinguish between axial strain, bend strain, and twist strain on the fiber and to accurately determine one or more strain values for the fiber corresponding to one or more of the axial strain, bend strain, or twist strain on the fiber.

Owner:INTUITIVE SURGICAL OPERATIONS INC

High-Bandwidth Multimode Optical Fiber with Reduced Cladding Effect

ActiveUS20110123161A1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingHigh bandwidthHigh data rate

The present invention embraces an optical fiber that includes a central core having an alpha refractive index profile with respect to an outer cladding. The optical fiber also includes an inner cladding, a depressed trench, and an outer cladding. The optical fiber achieves reduced bending losses and a high bandwidth with a reduced cladding effect for high-data-rate applications.

Owner:DRAKA COMTEQ BV

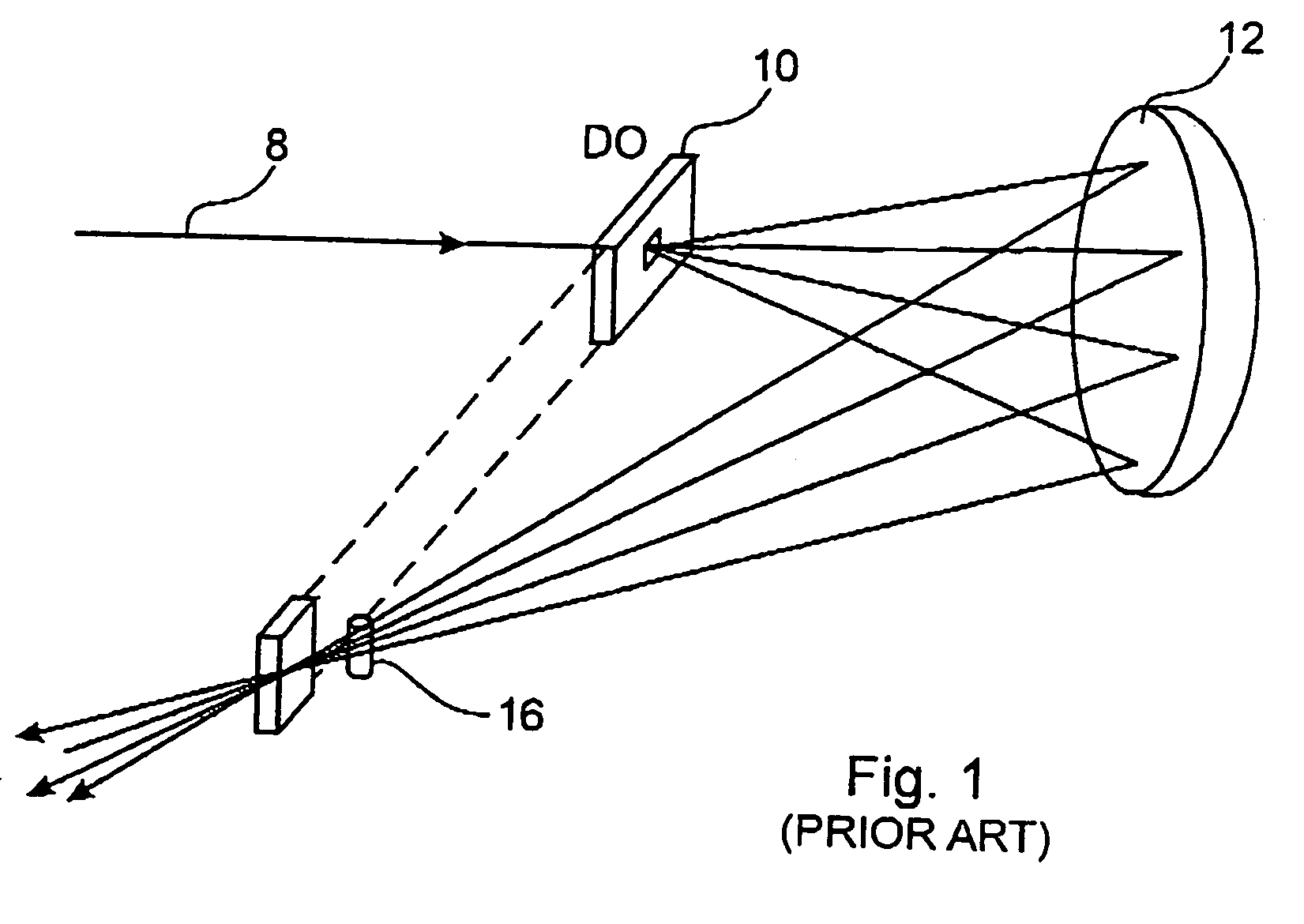

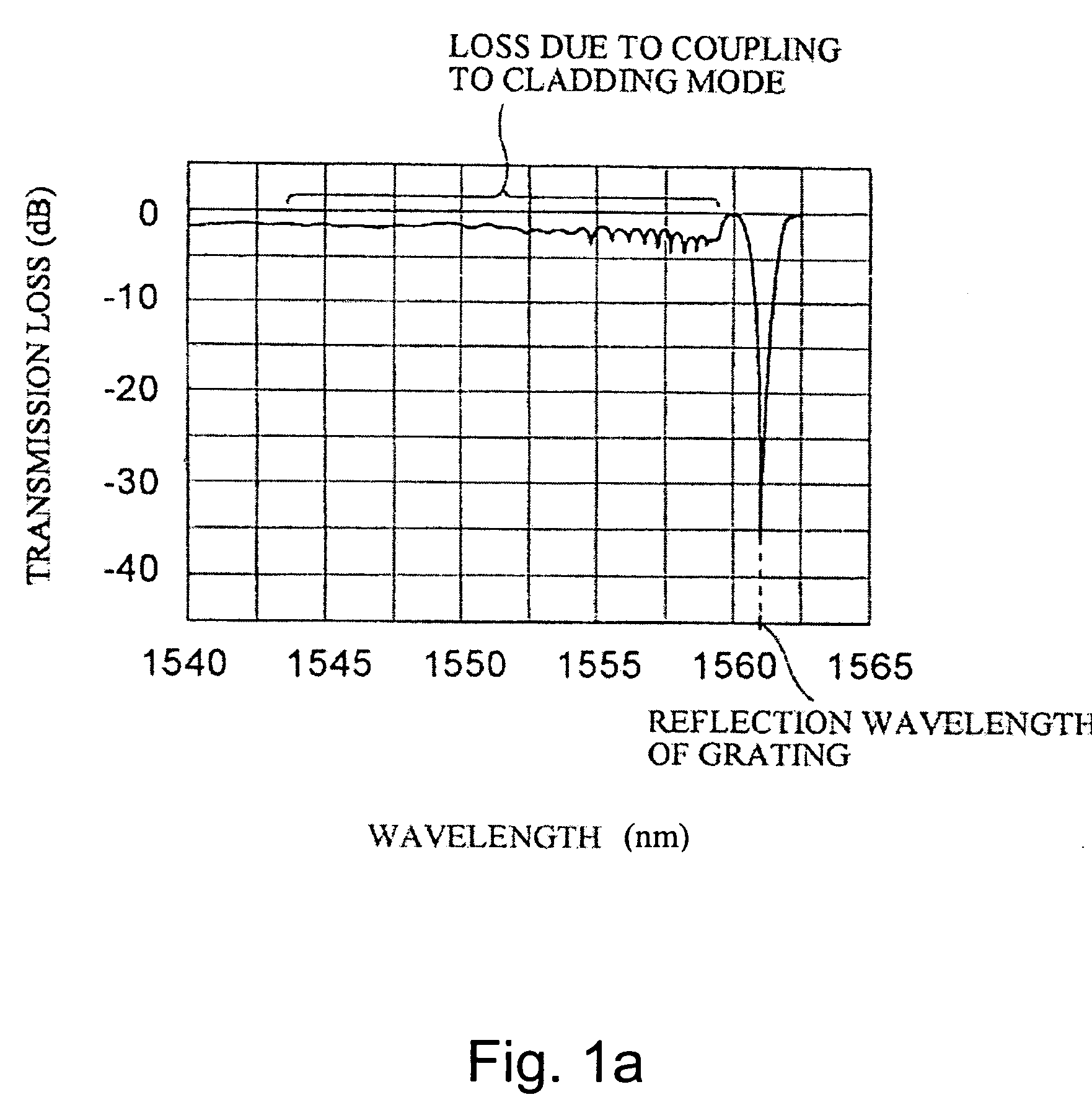

Bragg grating and method of producing a Bragg grating using an ultrafast laser

A novel Bragg grating filter in optical waveguiding fiber with suppressed cladding mode coupling and method of producing same is disclosed. The novel grating structure is induced in both the core and the cladding of the optical fiber irrespective of the photosensitivity of the core or cladding to actinic radiation. Such core and cladding of the optical fiber need not be chemically doped to support the grating. The method incorporates an ultra short duration pulse laser source. Electromagnetic radiation provided from the laser propagates to a diffractive element positioned a specific distance to the target material such that the diffracted electromagnetic radiation forms a 2-beam interference pattern, the peaks of which are sufficiently intense to cause a change in index of refraction.

Owner:NAT RES COUNCIL OF CANADA

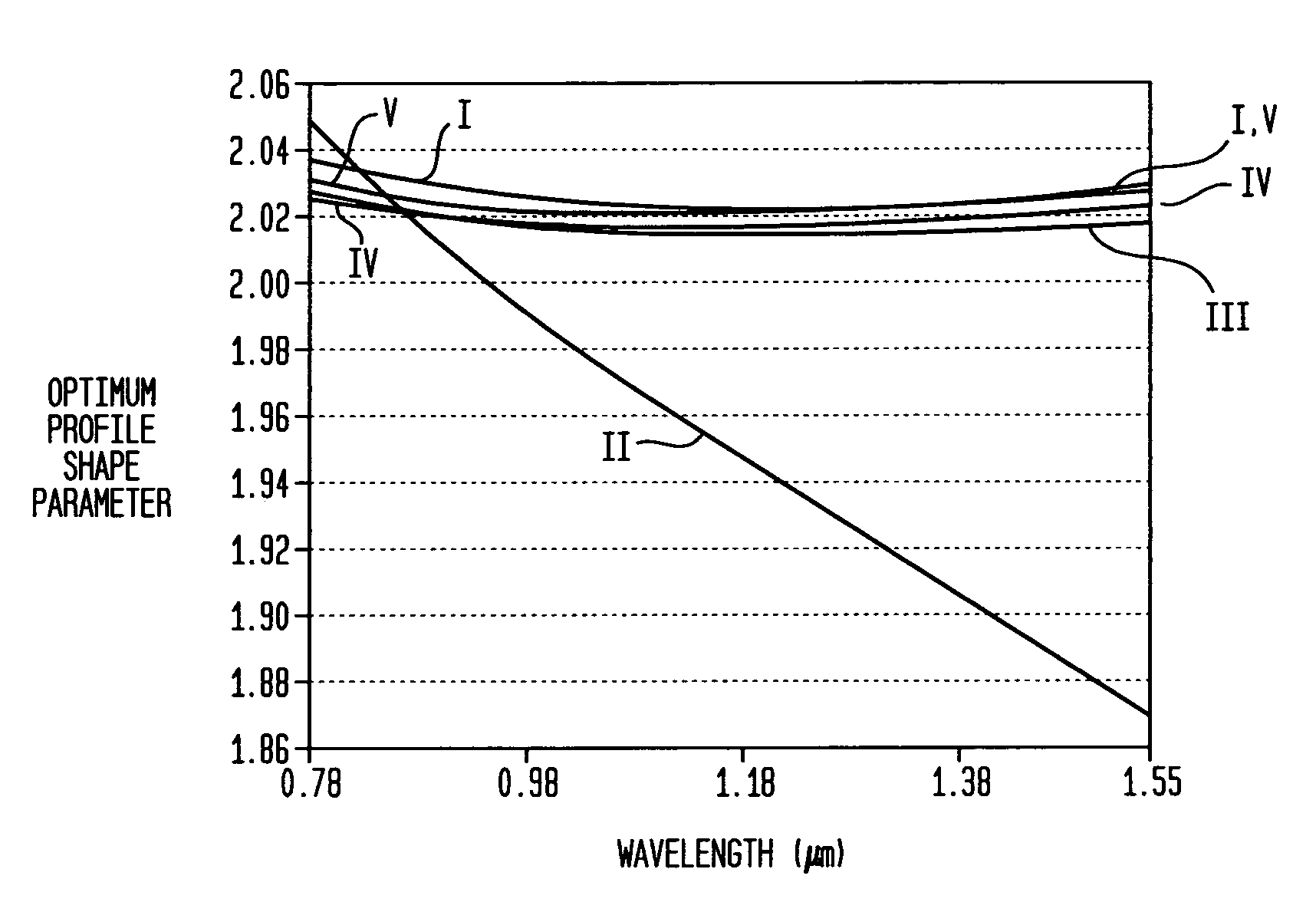

Multi-wavelength, multimode optical fibers

ActiveUS7421174B2Optical fibre with graded refractive index core/claddingOptical waveguide light guideFiberRefractive index

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Optical Fiber Illumination Systems and Methods

ActiveUS20110305035A1Efficient deliveryReduce dependenceGlass making apparatusElectric discharge tubesFiberUltrasound attenuation

An illumination system generating light having at least one wavelength within 200 nm a plurality of nano-sized structures (e.g., voids). The optical fiber coupled to the light source. The light diffusing optical fiber has a core and a cladding. The plurality of nano-sized structures is situated either within said core or at a core-cladding boundary. The optical fiber also includes an outer surface. The optical fiber is configured to scatter guided light via the nano-sized structures away from the core and through the outer surface, to form a light-source fiber portion having a length that emits substantially uniform radiation over its length, said fiber having a scattering-induced attenuation greater than 50 dB / km for the wavelength(s) within 200 nm to 2000 nm range.

Owner:CORNING INC

Chemical sensing techniques employing liquid-core optical fibers

A gas or vapor permeable optical fiber waveguide with a liquid core is employed as a probe for the detection or measurement of a chemical specie of interest by filling the waveguide core region with a reagent liquid which undergoes a change in an optical characteristic thereof when exposed to the chemical specie and then inserting the filled waveguide into an environment in which the chemical specie may be present. The chemical specie, if present, will permeate through the waveguide wall and react with or be absorbed in the core liquid. Sensitivity is enhanced by controlling the pressure differential across the waveguide wall and / or by shaping the waveguide to enlarge the surface area. When the reaction generates light, the devices which detect that light will be shaped and disposed to maximize the collection thereof.

Owner:WORLD PRECISION INSTR

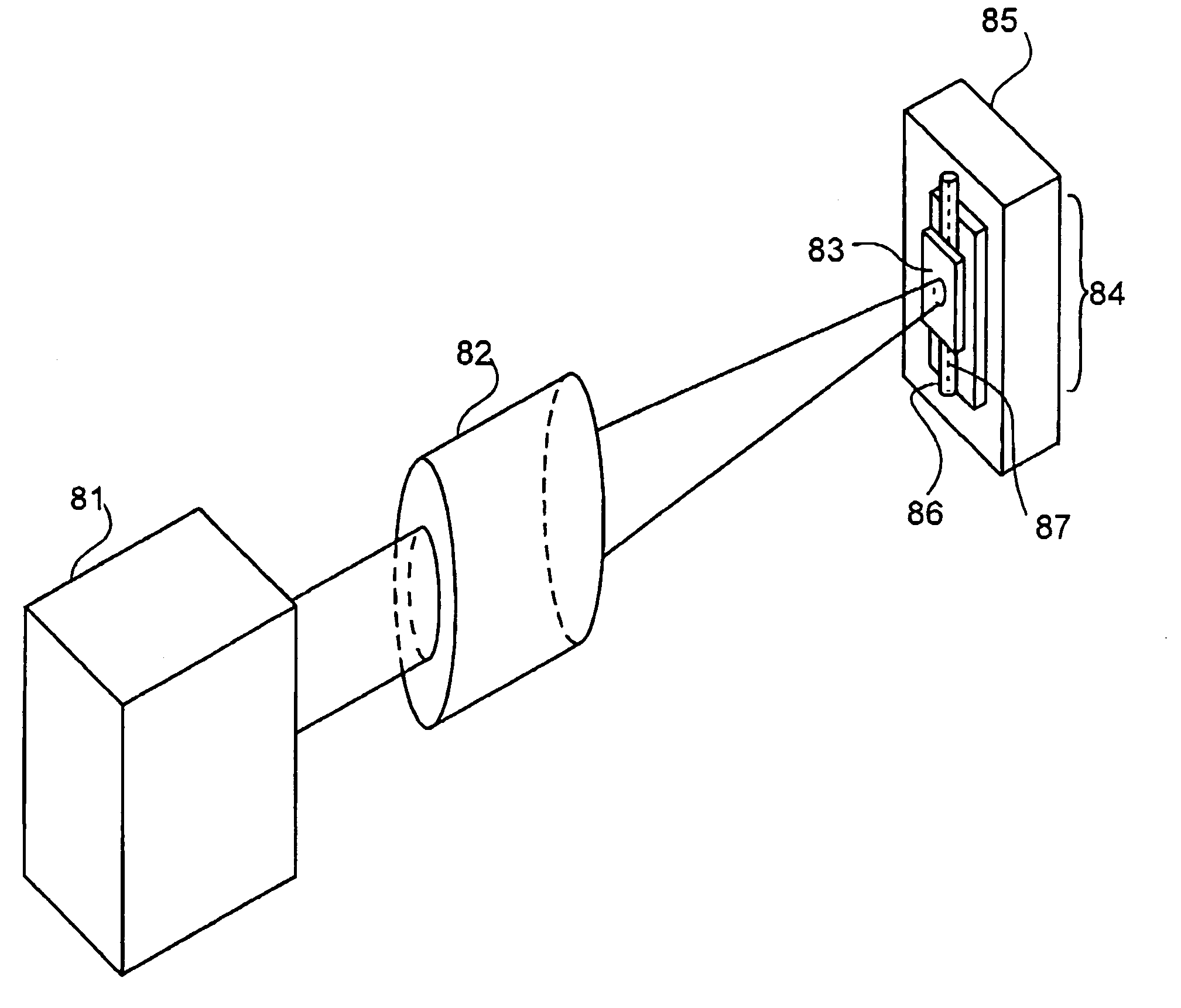

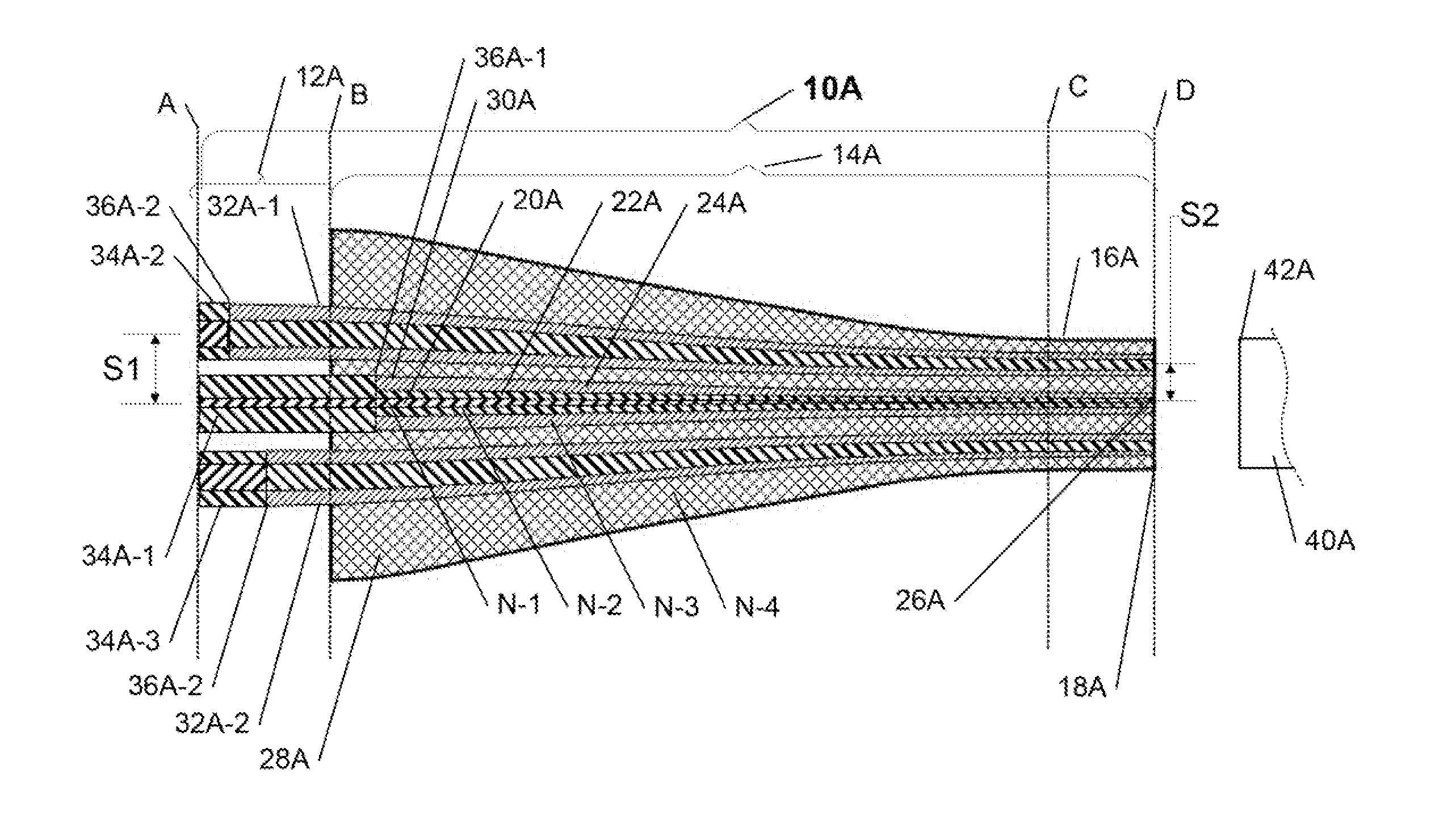

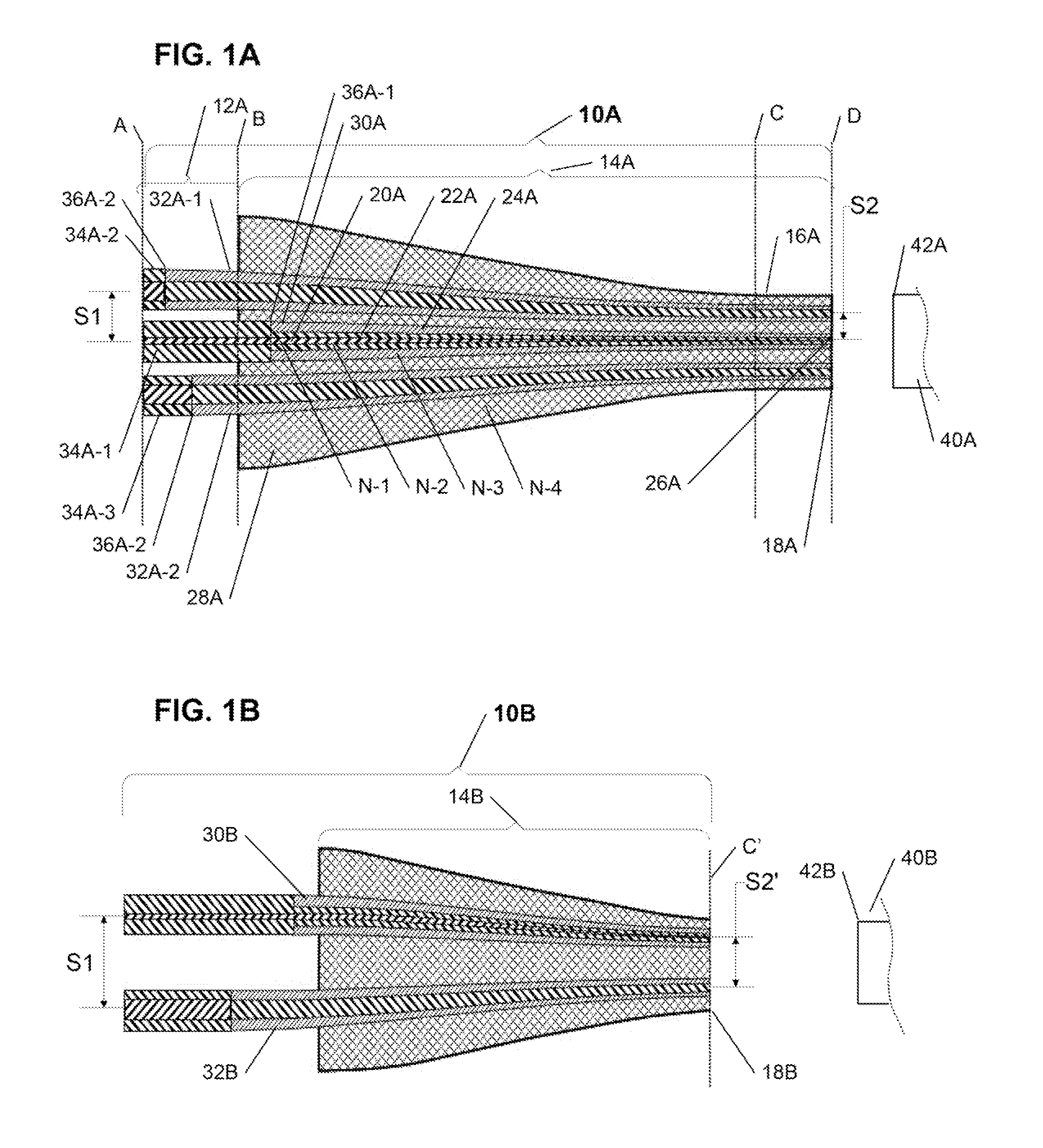

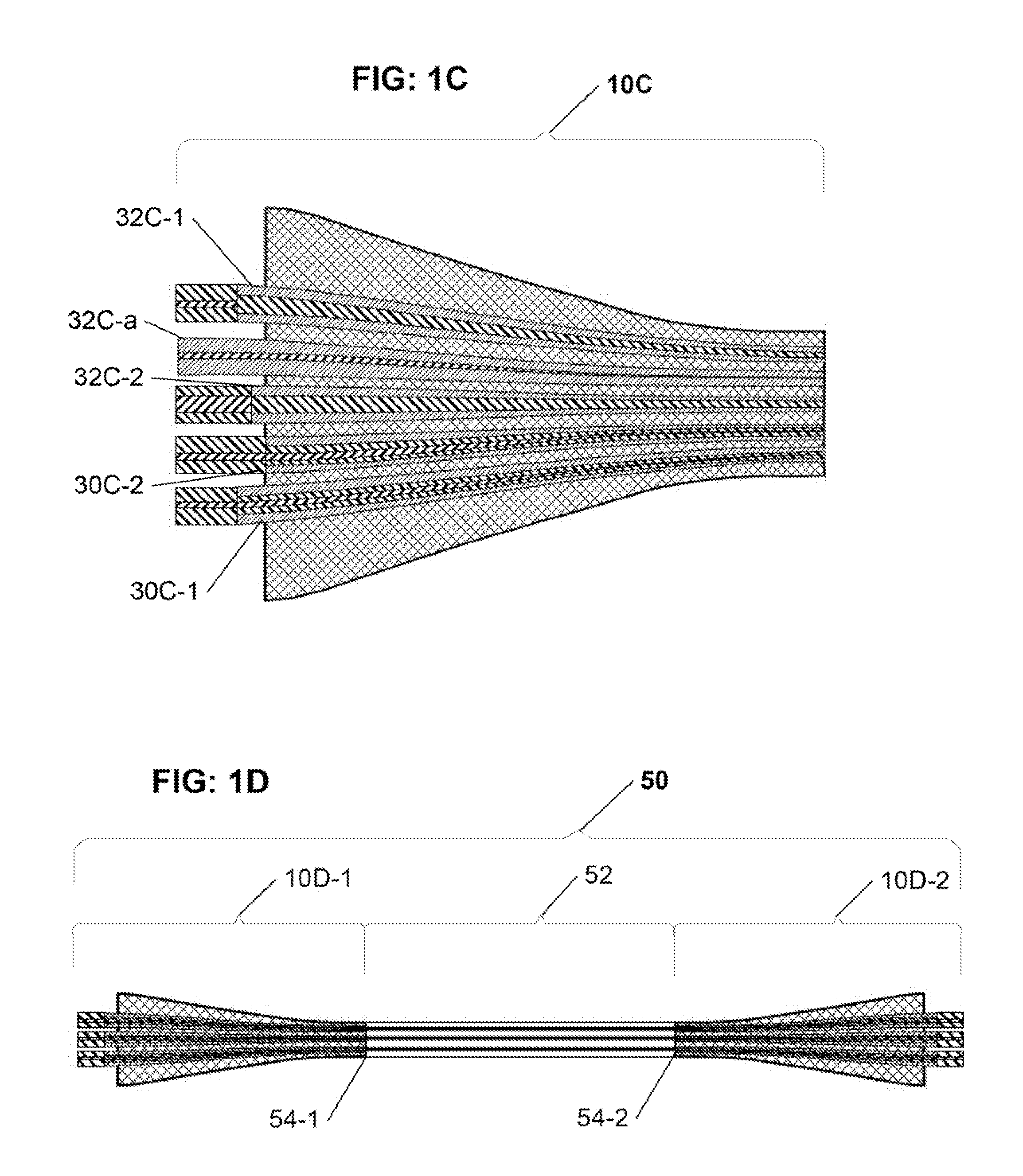

Configurable pitch reducing optical fiber array

InactiveUS20130216184A1Coupling light guidesBundled fibre light guideErbium lasersOptical fiber coupler

The inventive optical fiber coupler array is capable of providing a low loss, high-coupling coefficient interface with high accuracy and easy alignment between a plurality of optical fibers (or other optical devices) with a first channel-to-channel spacing, and an optical device having a plurality of closely-spaced waveguide interfaces with a second channel-to-channel spacing, where each end of the optical fiber coupler array is configurable to have different channel-to-channel spacing, each matched to a corresponding one of the first and second channel-to-channel spacing. The novel optical coupler array includes a plurality of waveguides (at least one of which may optionally be polarization maintaining), that comprises at least one gradually reduced vanishing core fiber, at least in part embedded within a common housing structure. Alternatively, the novel coupler array may be configured for utilization with at least one of an optical fiber amplifier and an optical fiber laser.

Owner:KOPP VICTOR ILICH +4

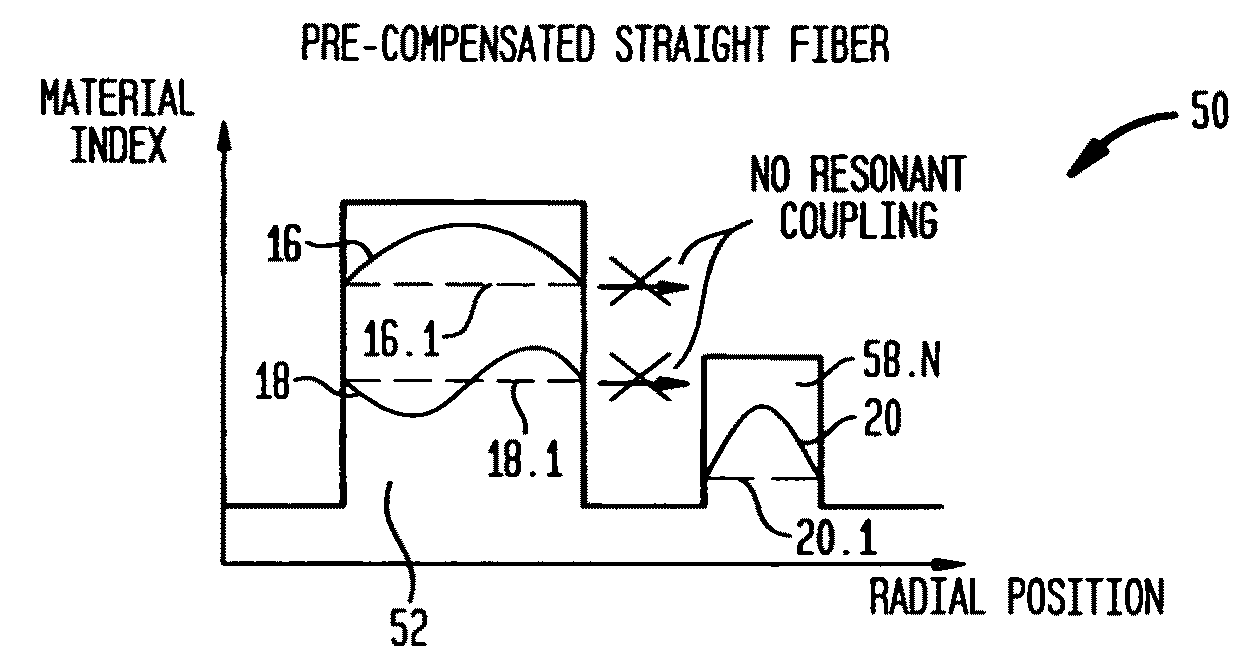

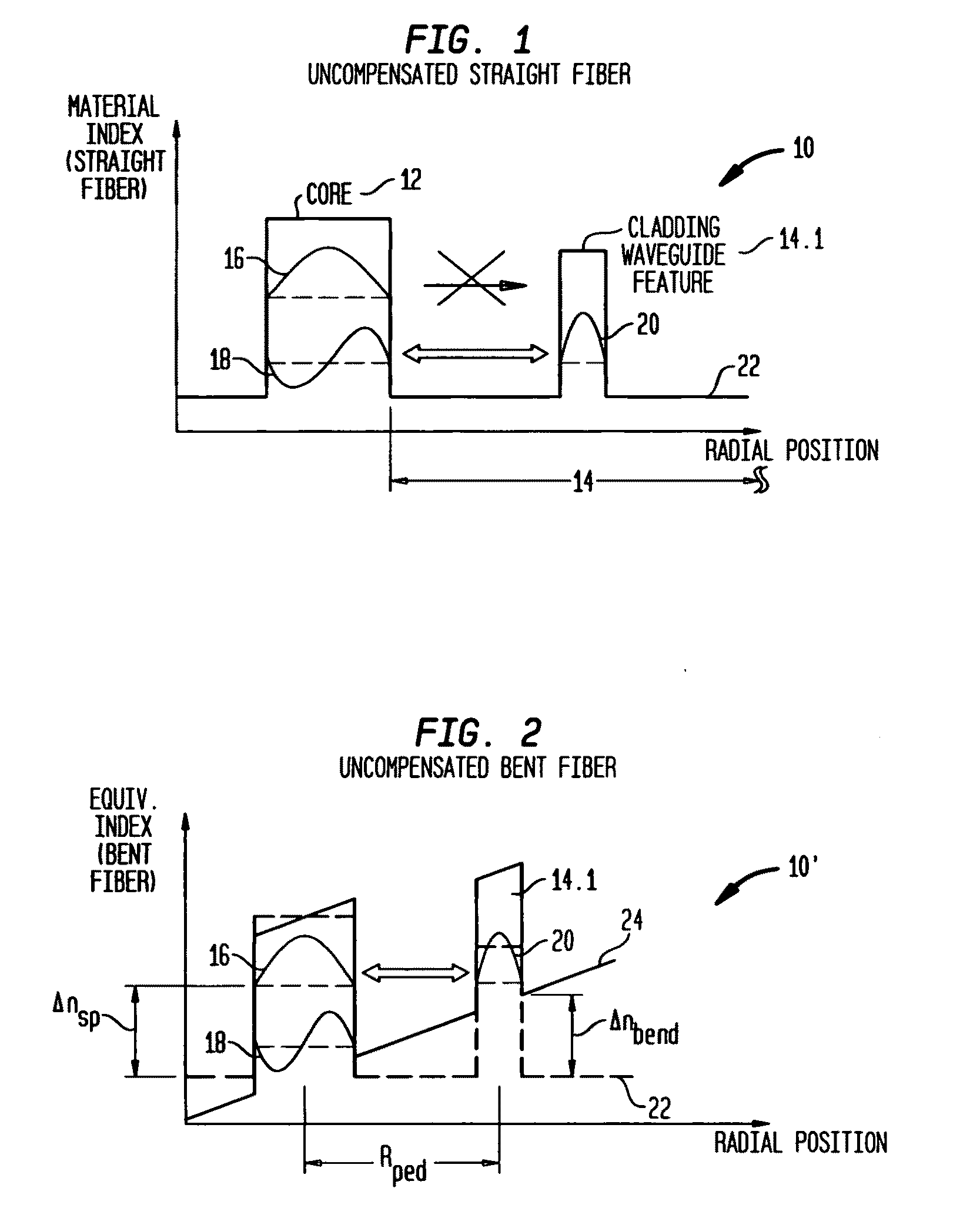

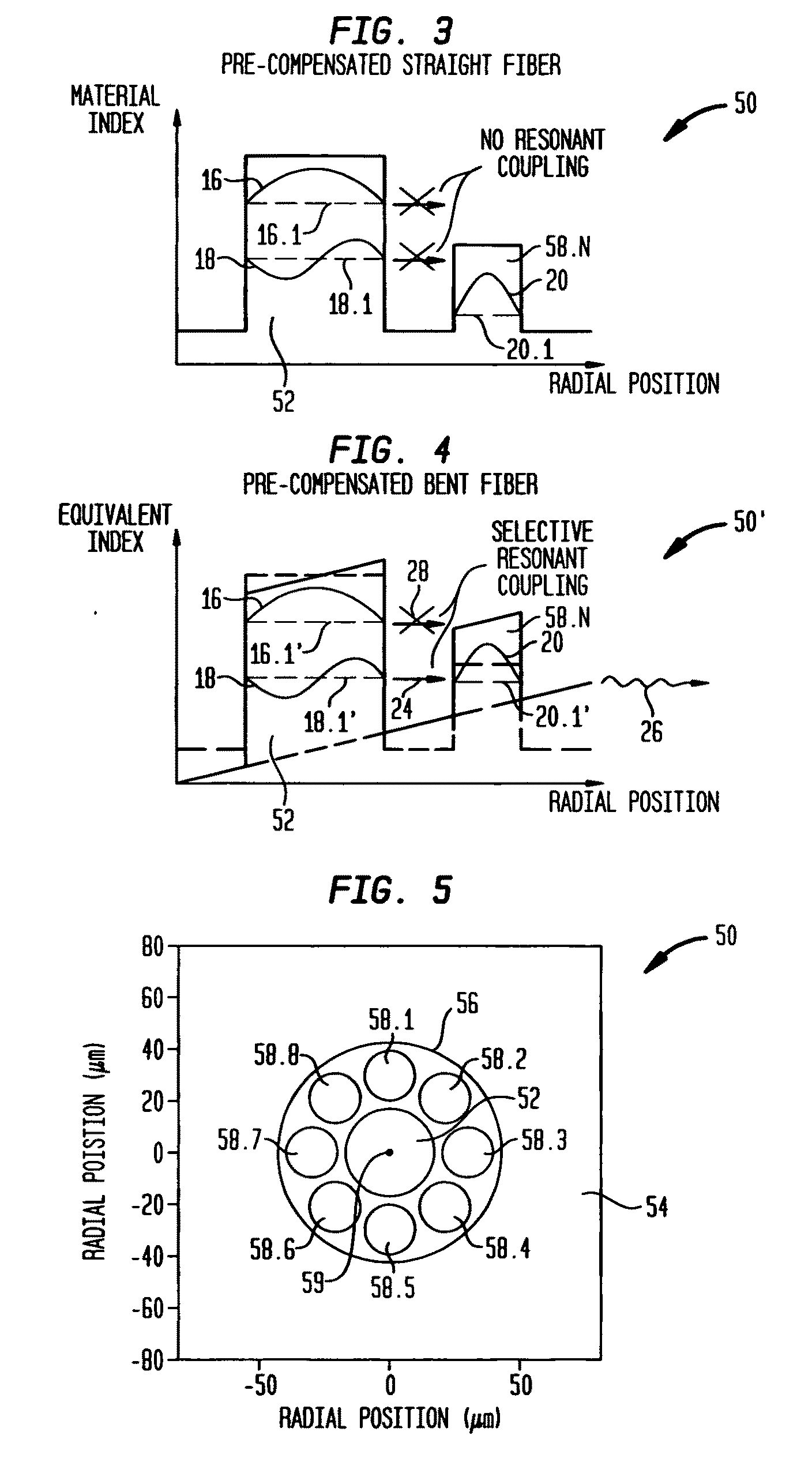

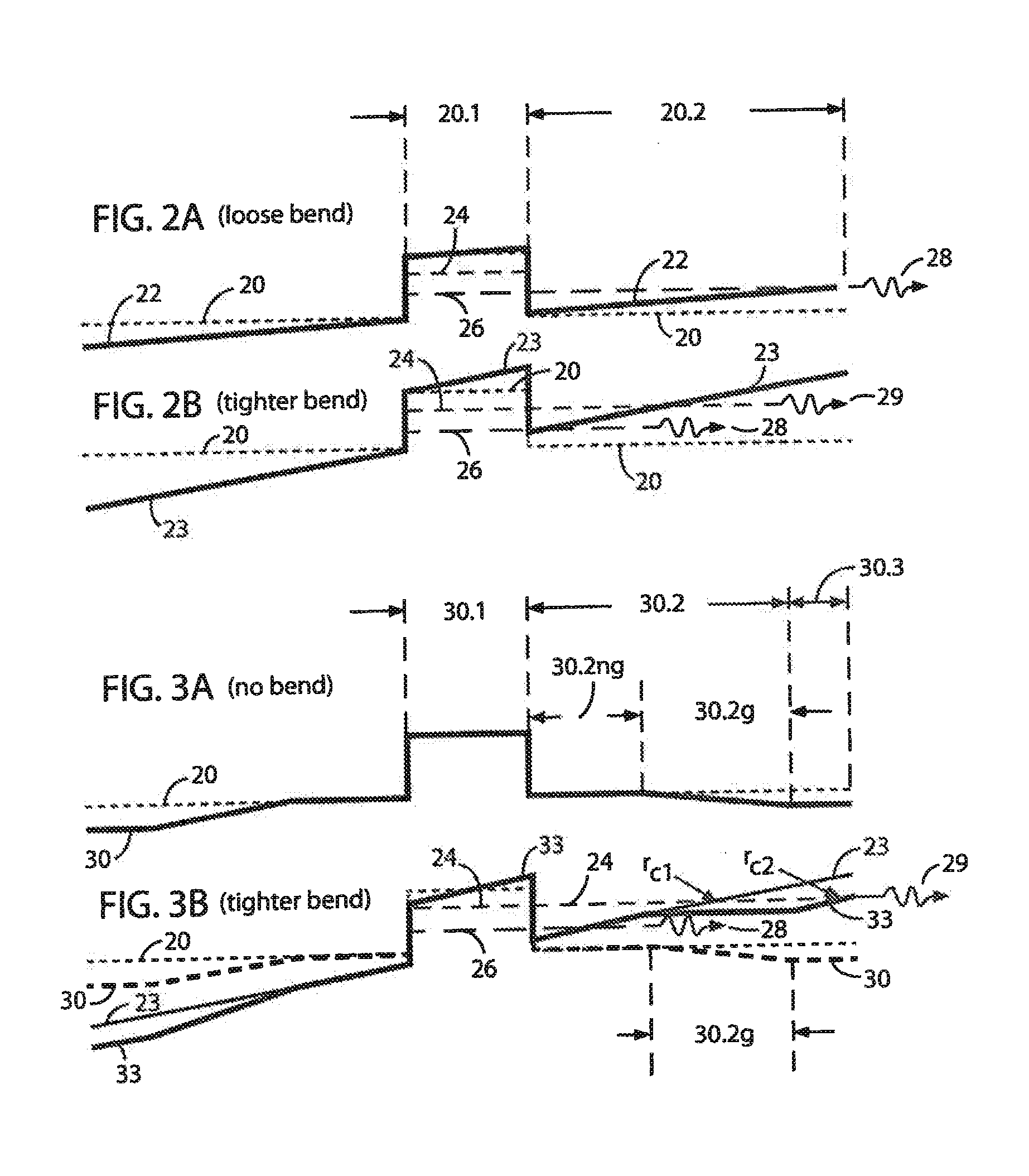

Suppression of higher-order modes by resonant coupling in bend-compensated optical fibers

ActiveUS20090034059A1High fundamental mode lossLaser detailsOptical fibre with multilayer core/claddingFiberCoupling

The effect of bending is anticipated in an optical fiber design, so that resonant coupling remains an effective strategy for suppressing HOMs. The index profile of the fiber and its bend radius are configured so that there is selective resonant coupling of at least one HOM, but not the fundamental mode, in the bent segment of the fiber. In an illustrative embodiment, the bend radius (or predetermined range of bend radii) of an optical fiber is known a priori. The core and cladding regions are configured to support (guide) the propagation of signal light in a fundamental transverse mode and at least one higher-order transverse mode in the core region. The cladding region includes an outer cladding region and an annular trench region. The trench region includes at least one axially extending, raised-index pedestal (waveguide) region having a refractive index higher than that of the outer cladding region. Within at least the bent segment the at least one pedestal region is configured (i) to support the propagation of at least one transverse mode and (ii) to resonantly couple at least one of the higher-order transverse modes (HOMs) of the core region to at least one transverse mode (e.g., the fundamental mode) of the pedestal region when the fiber is bent to a radius within the predetermined range of radii. In effect, the pedestal regions are configured so that the fiber is pre-compensated for the effect of bending; that is, an uncompensated bent fiber segment suffers high fundamental mode loss due to resonant coupling, whereas the pre-compensated bent fiber segment selectively couples any unwanted HOM from the core region into the pedestal region. In a preferred embodiment, the optical fiber is a LMA fiber incorporated in an optical fiber amplifier or laser package.

Owner:OFS FITEL LLC

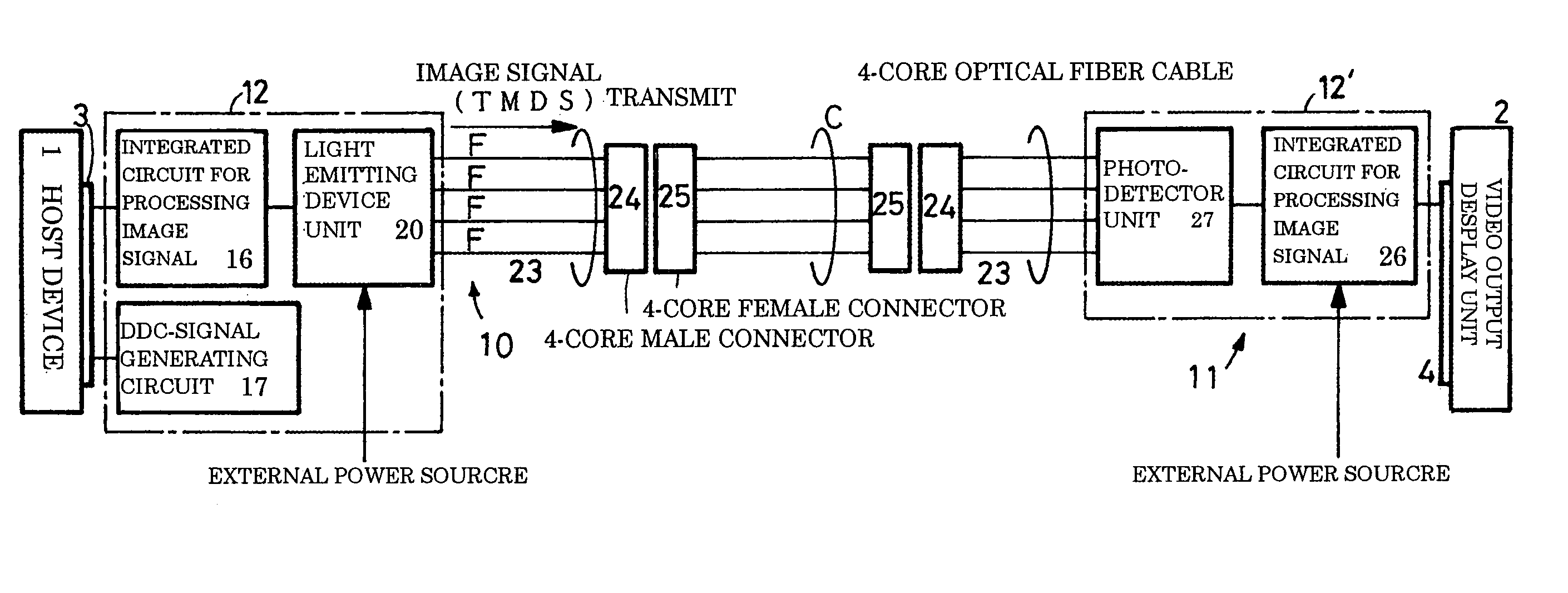

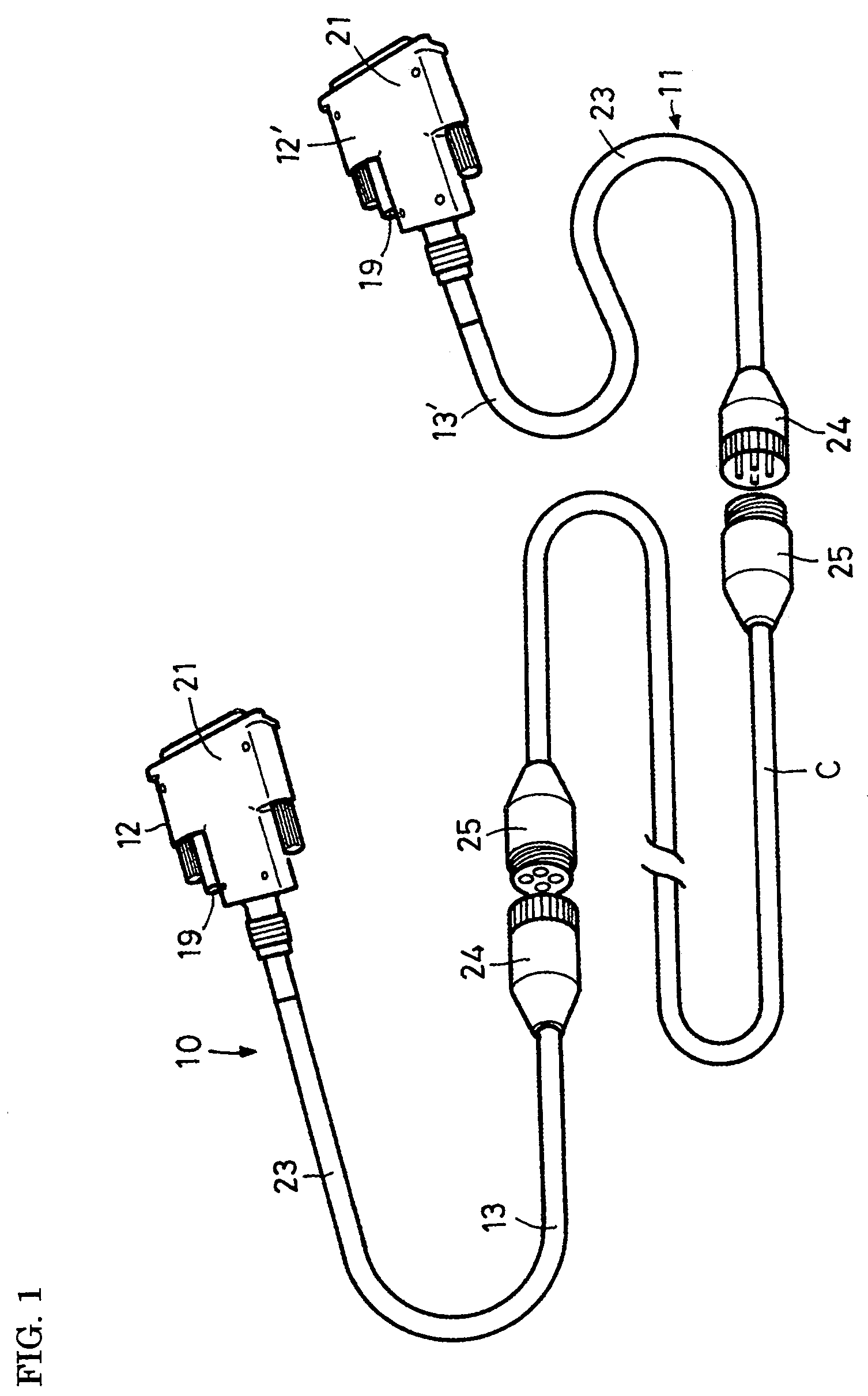

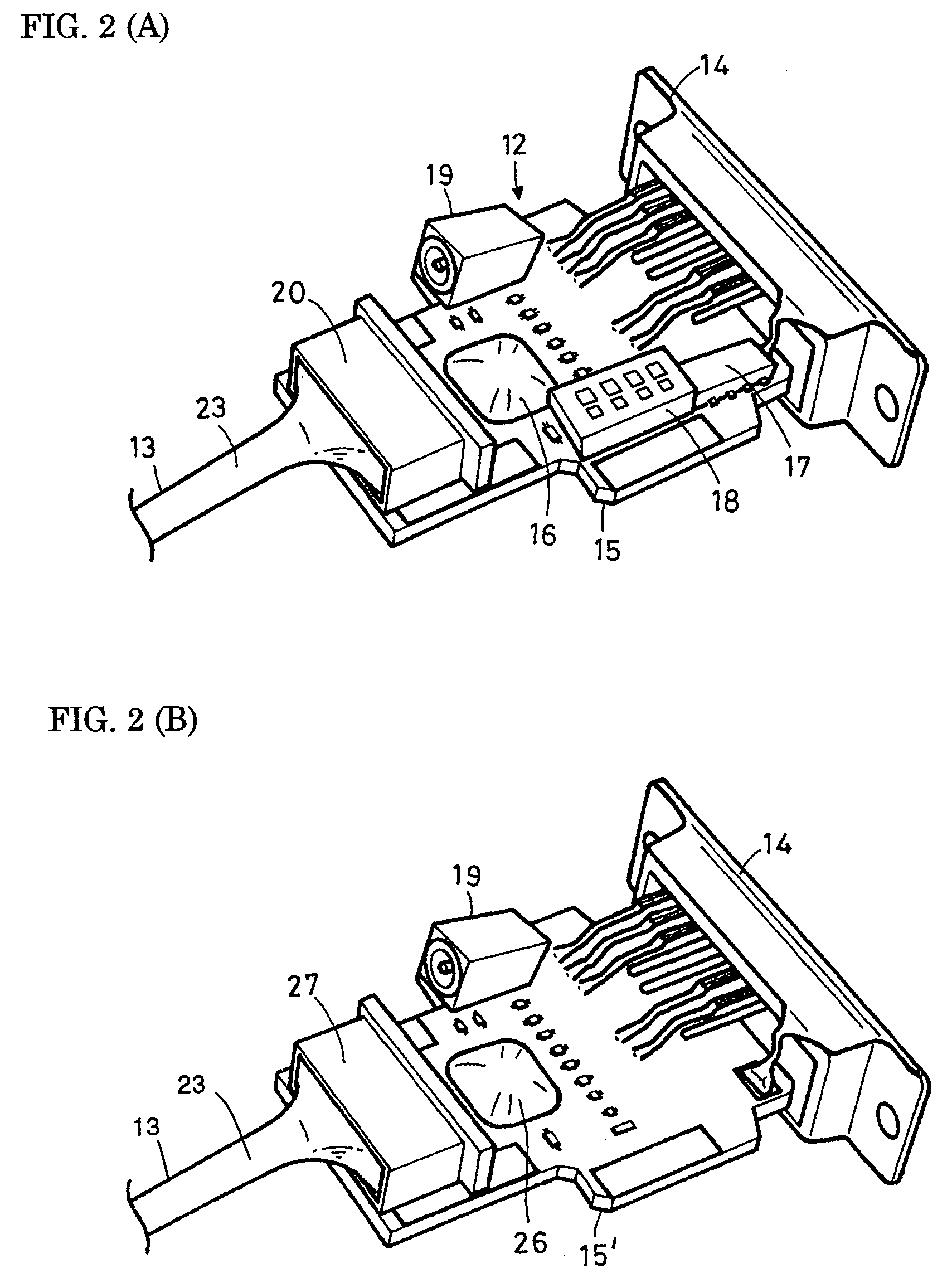

Interface module for transmitting digital video signal

InactiveUS7065604B2Long-distance transmissionReduce excess spaceDigital data processing detailsOptical transmission adaptationsDigital videoComputer module

An interface module for transmitting a digital video signal includes: a transmitting interface unit which is designed to be connected to a host device for outputting a video signal, and which has a cable connection consisting of a 4-core optical fiber cable and a 4-core male connector provided at one end thereof; a receiving interface unit having a cable connection designed to be connected to a video output display unit and consisting of a 4-core optical fiber cable and a 4-core male connector provided at one end thereof; and an optical cable unit for transmitting TMDS signals consisting of RGB signals and clock signals. The transmitting and receiving interface units are interconnected by the optical cable unit. The transmitting interface unit includes a second integrated circuit outputting identification information (DDC signal) associated with the video output display unit.

Owner:SUMITOMO ELECTRIC IND LTD

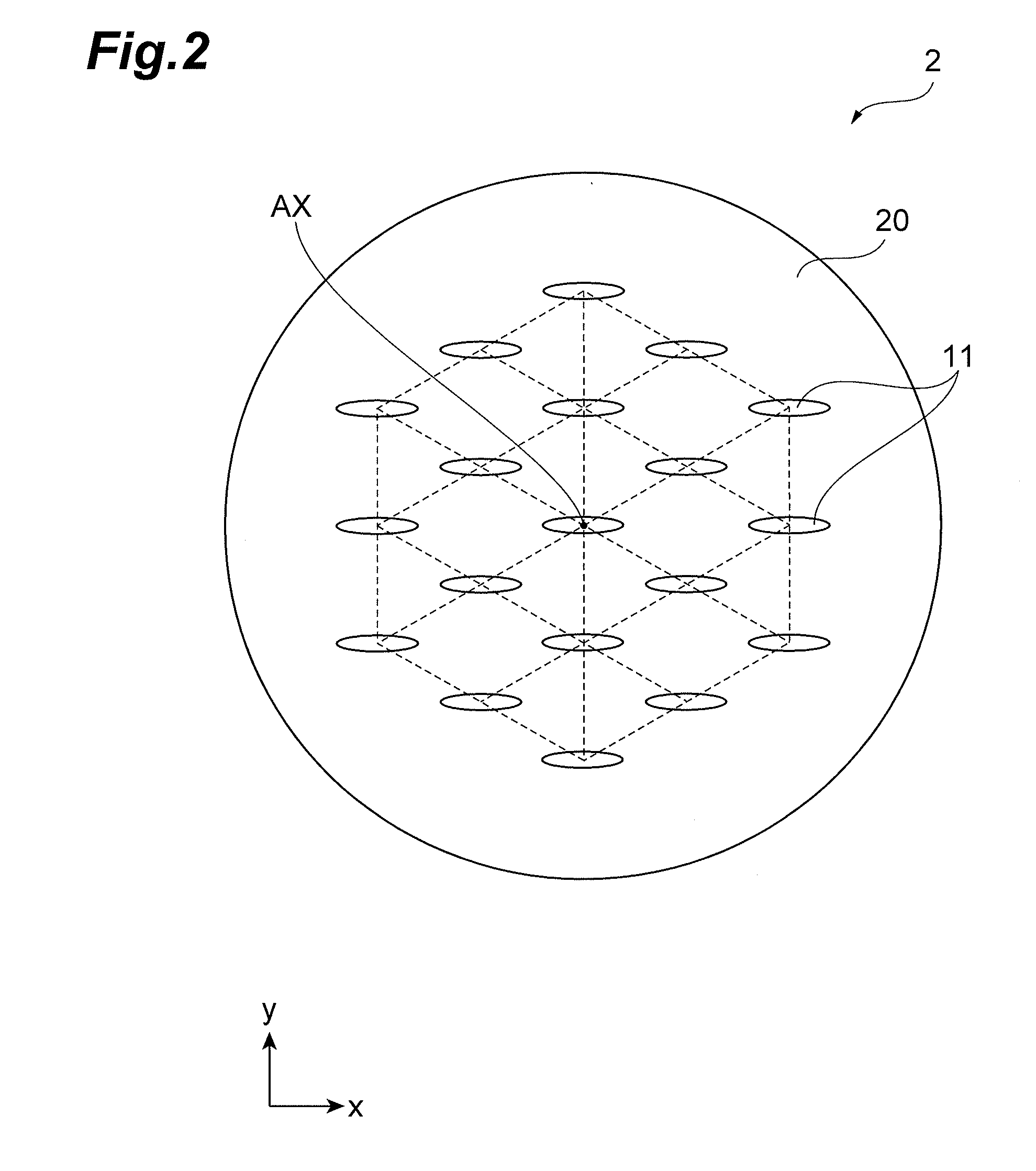

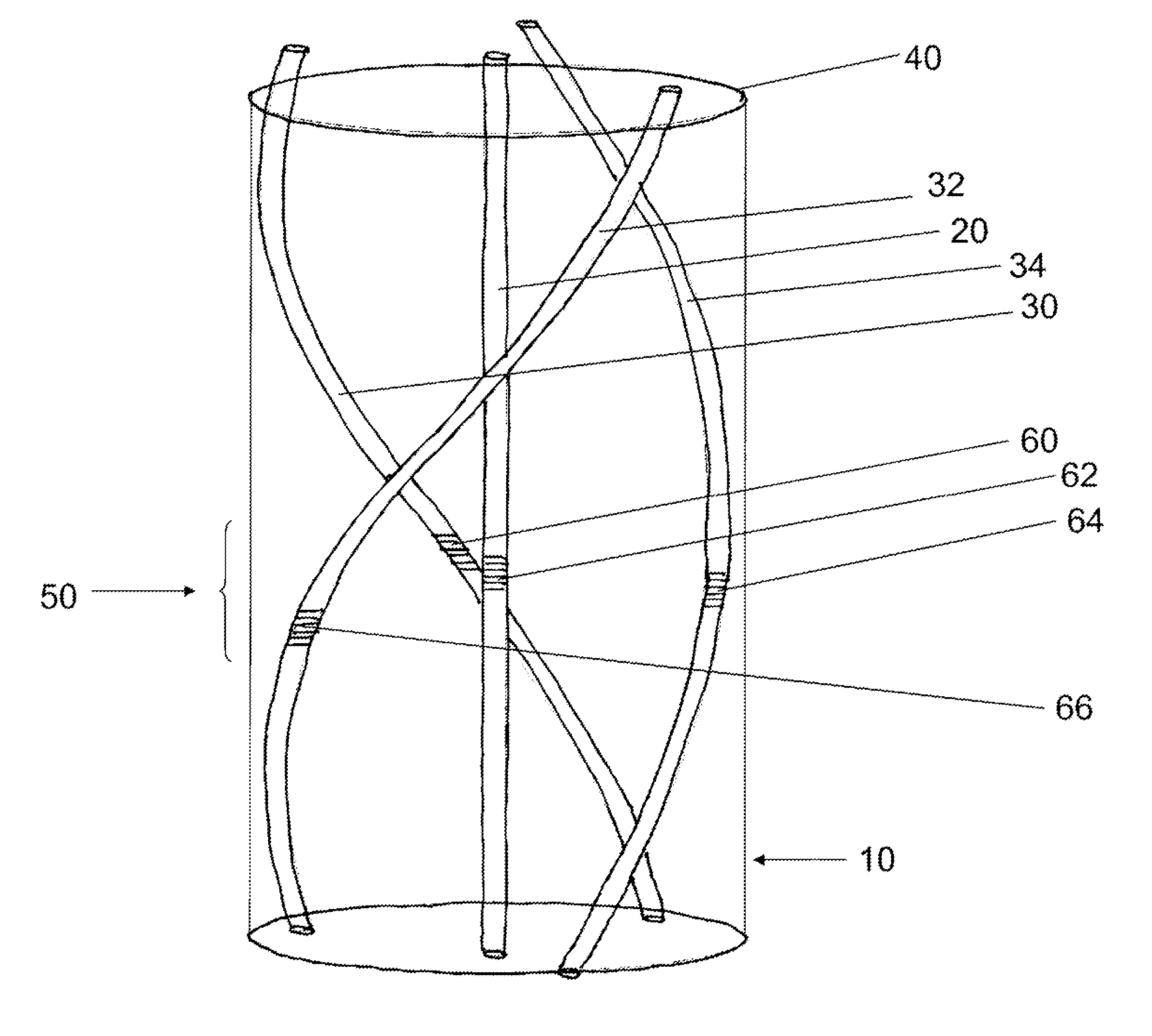

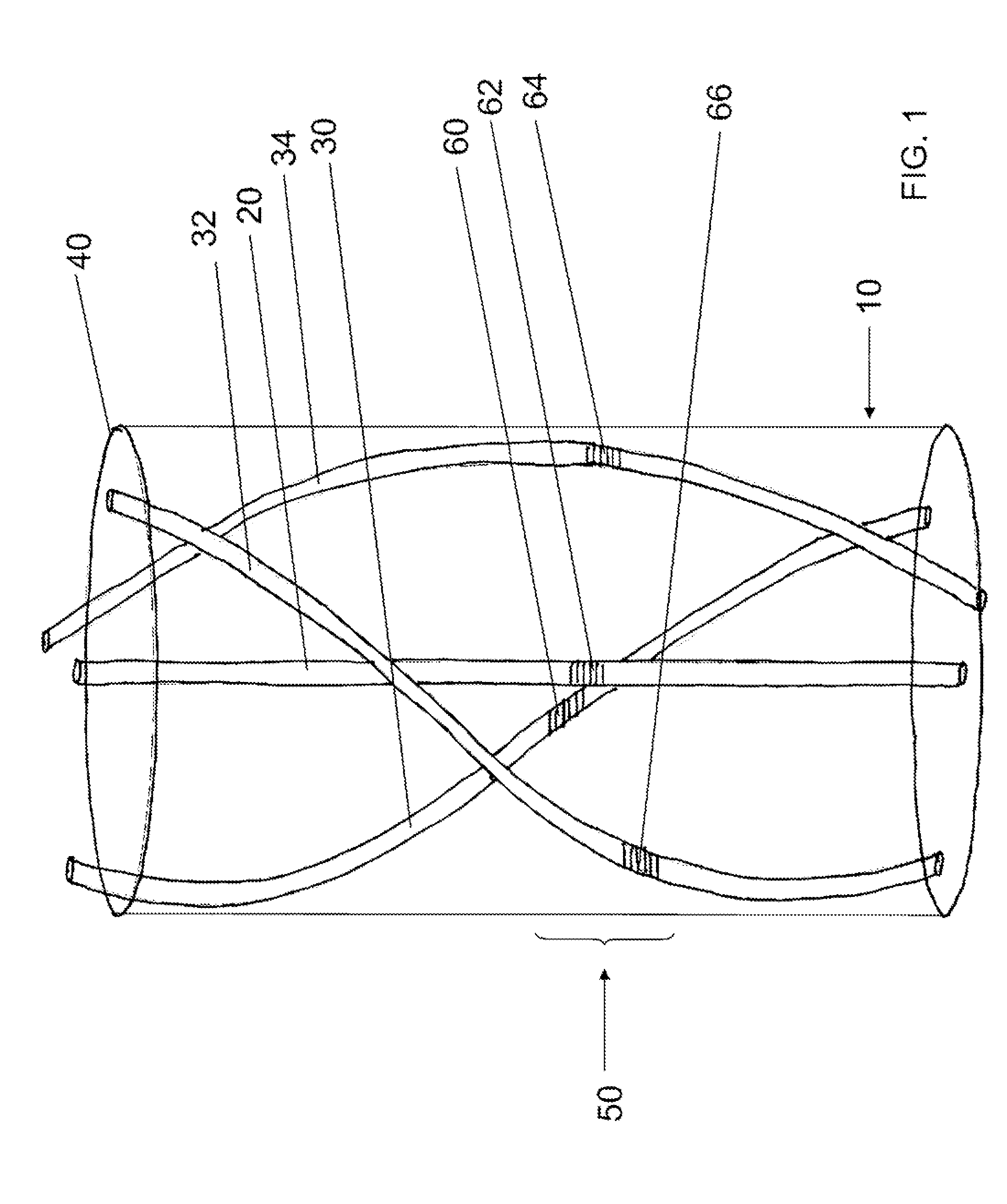

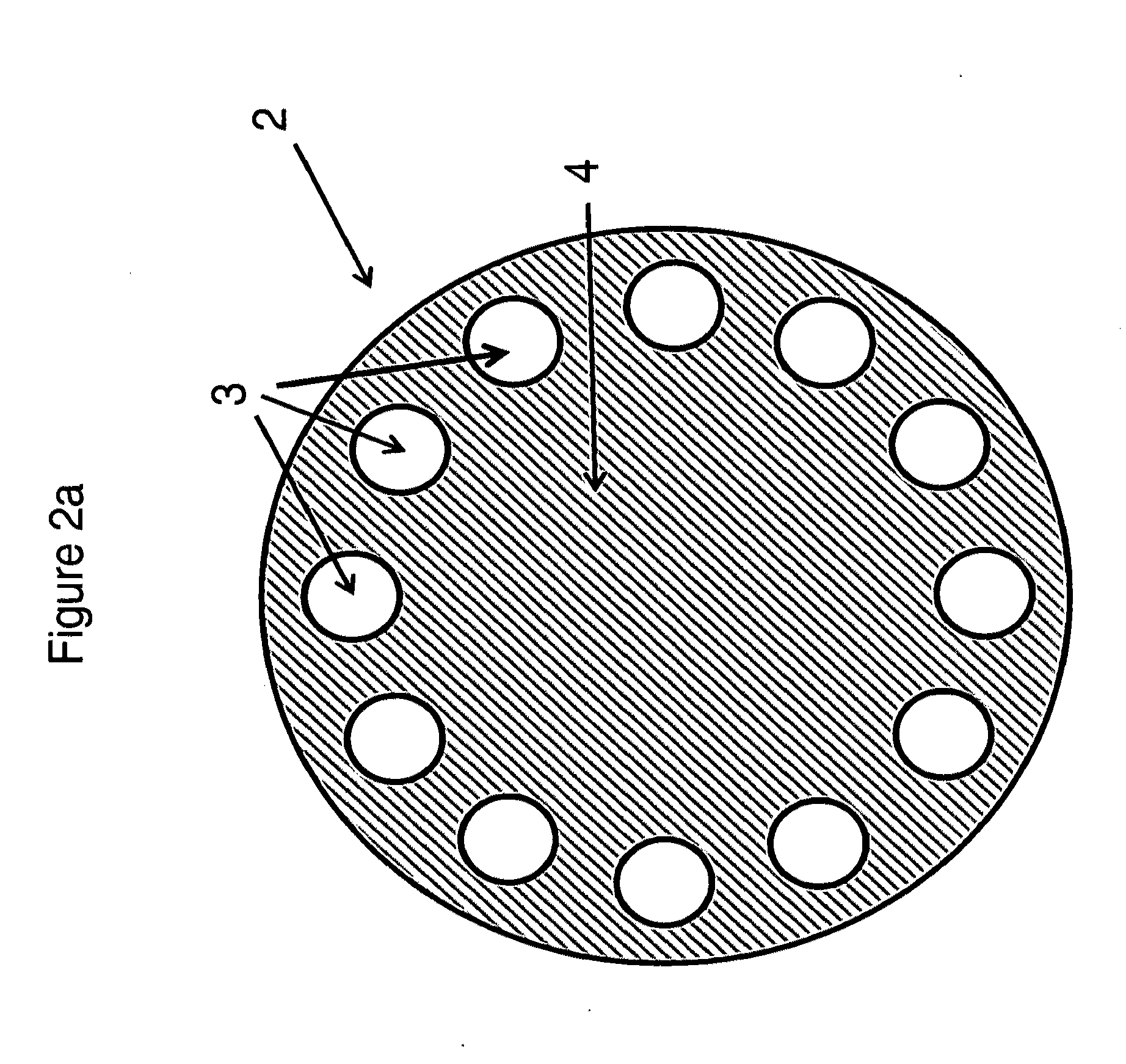

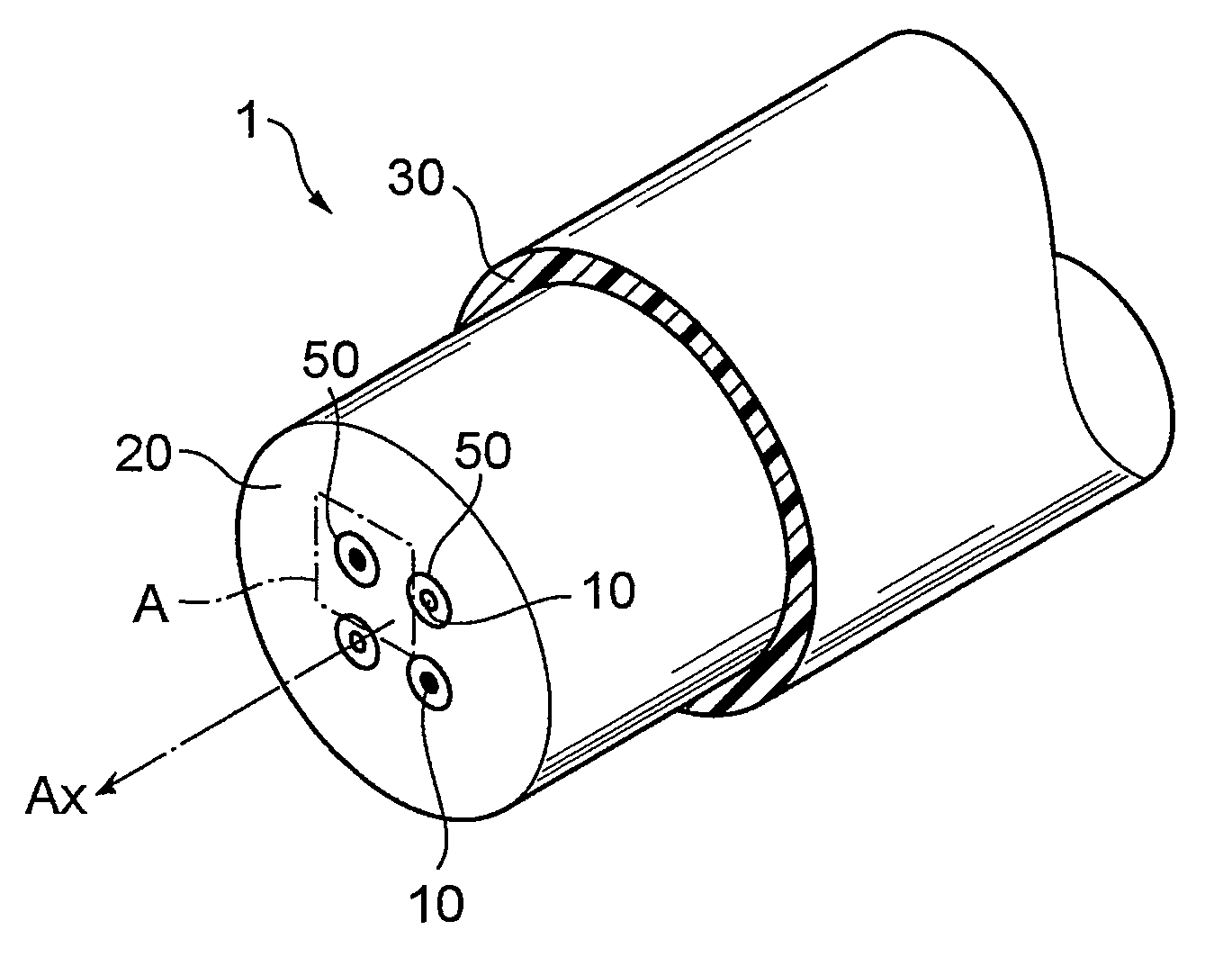

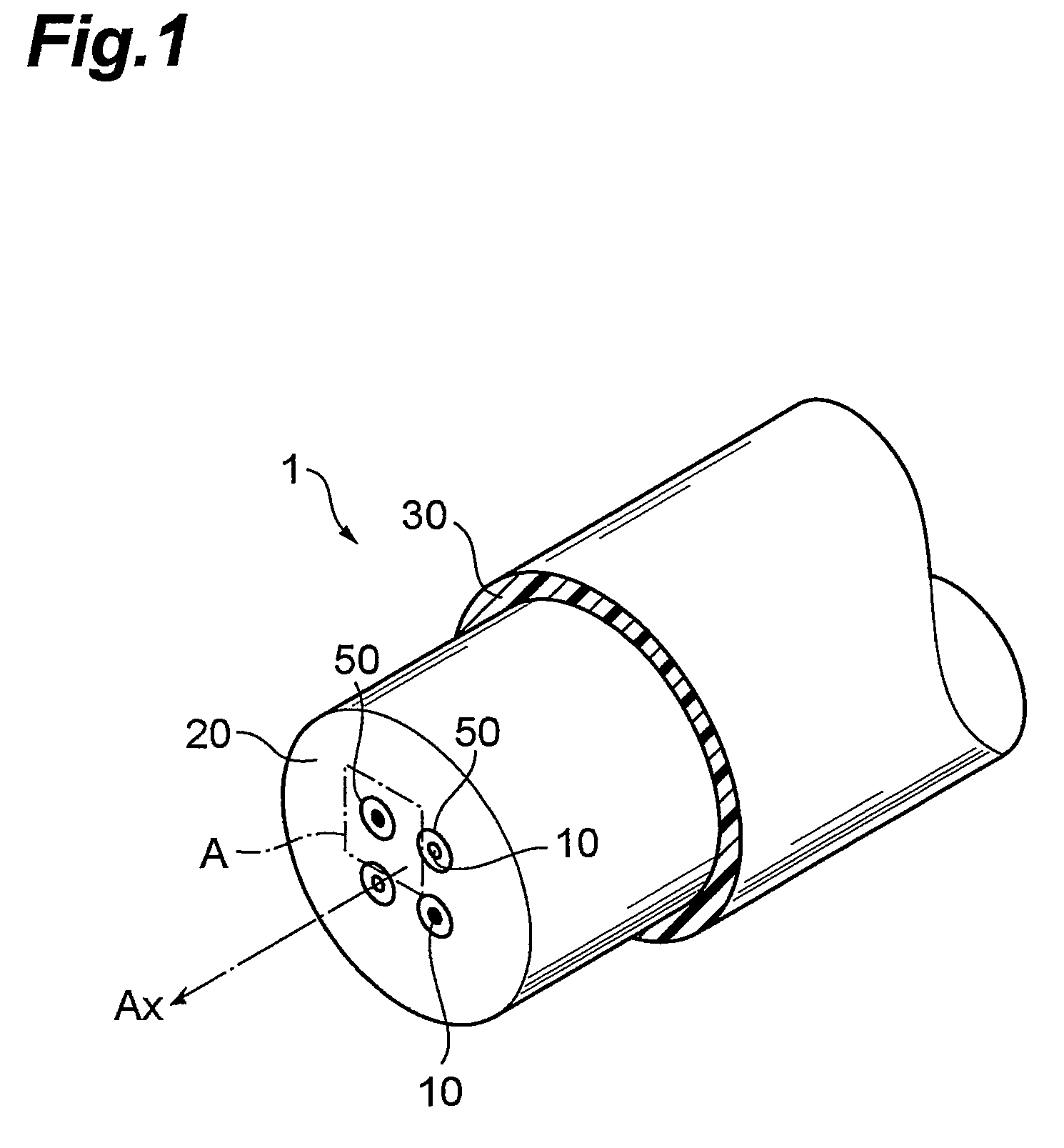

Multi-core optical fiber

ActiveUS20110052129A1Improve transmission lossReduce crosstalkOptical fibre with multilayer core/claddingMulticore optical fibreEngineeringCore (optical fiber)

The present invention relates to a multi-core optical fiber having a structure to effectively reduce crosstalk between adjacent core regions among a plurality of core regions. The multi-core optical fiber (1) has a leakage reduction portion (50), at least a portion of which is arranged at a position on a straight line connecting adjacent core regions together among a plurality of core regions (10). The leakage reduction portion (50) reduces leakage light in the multi-core optical fiber (1) from each of the core regions (10), thereby effectively reducing crosstalk between adjacent core regions.

Owner:SUMITOMO ELECTRIC IND LTD

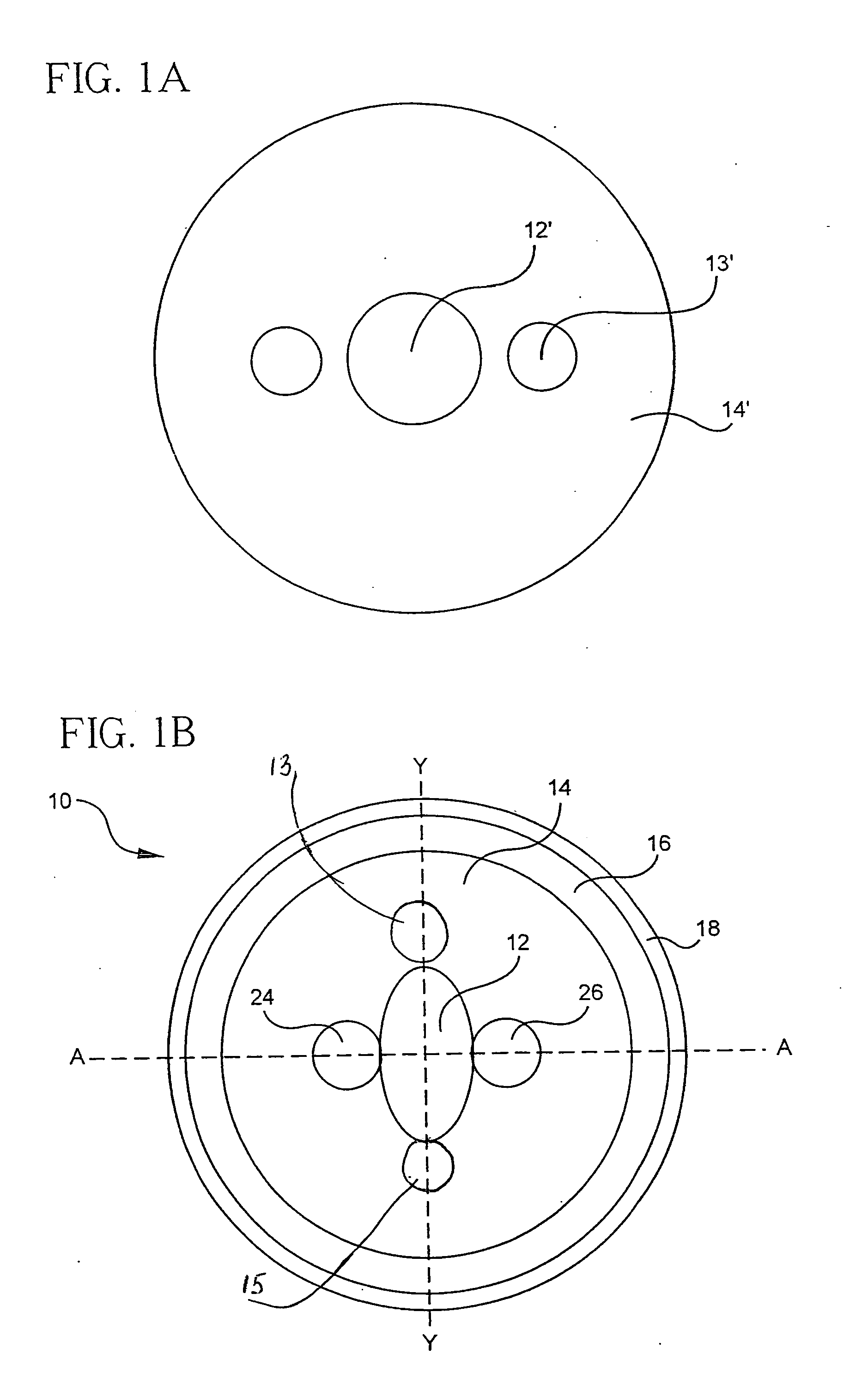

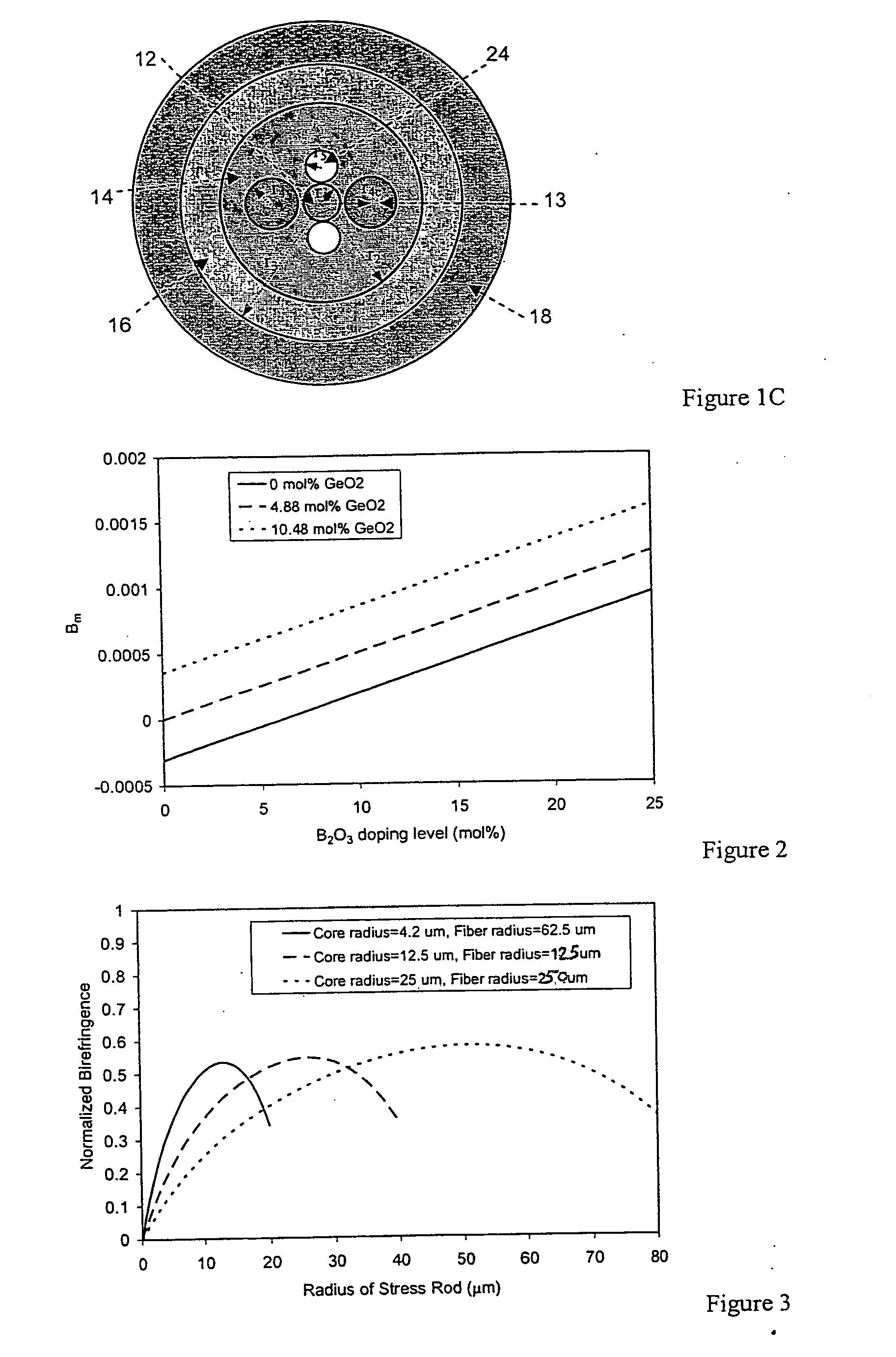

Rare earth doped double clad optical fiber with plurality of air holes and stress rods

ActiveUS20070177846A1Large mode areaProduced in advanceLaser detailsOptical fibre with polarisationSingle polarizationWavelength range

An optical fiber including: (i) a silica based, rare earth doped core having a first index of refraction n1; and (ii) at least one silica based cladding surrounding the core and having a second index of refraction n2, such that n1>n2, said cladding having a plurality of stress rods and a plurality of air holes extending longitudinally through the length of said optical fiber; wherein said optical fiber supports a single polarization mode or poses-polarization maintaining properties within the operating wavelength range.

Owner:CORNING INC

Transmission Optical Fiber Having Large Effective Area

ActiveUS20110044595A1Increase the effective areaRestrict propagationOptical fibre with graded refractive index core/claddingOptical waveguide light guideUltrasound attenuationLength wave

The present invention relates to a transmission optical fiber. The optical fiber includes, from its center to its periphery a central core, an intermediate cladding, and a depressed cladding. The optical fiber has an effective area (Seff) of at least about 120 μm2 at a wavelength of 1550 nm and an effective cutoff wavelength (λCeff) of less than 1600 nm. The optical fiber has an effective area of more than 120 μm2 with a cutoff wavelength limited to less than about 1600 nm without degradation of other optical parameters (e.g., attenuation losses and dispersion).

Owner:DRAKA COMTEQ BV

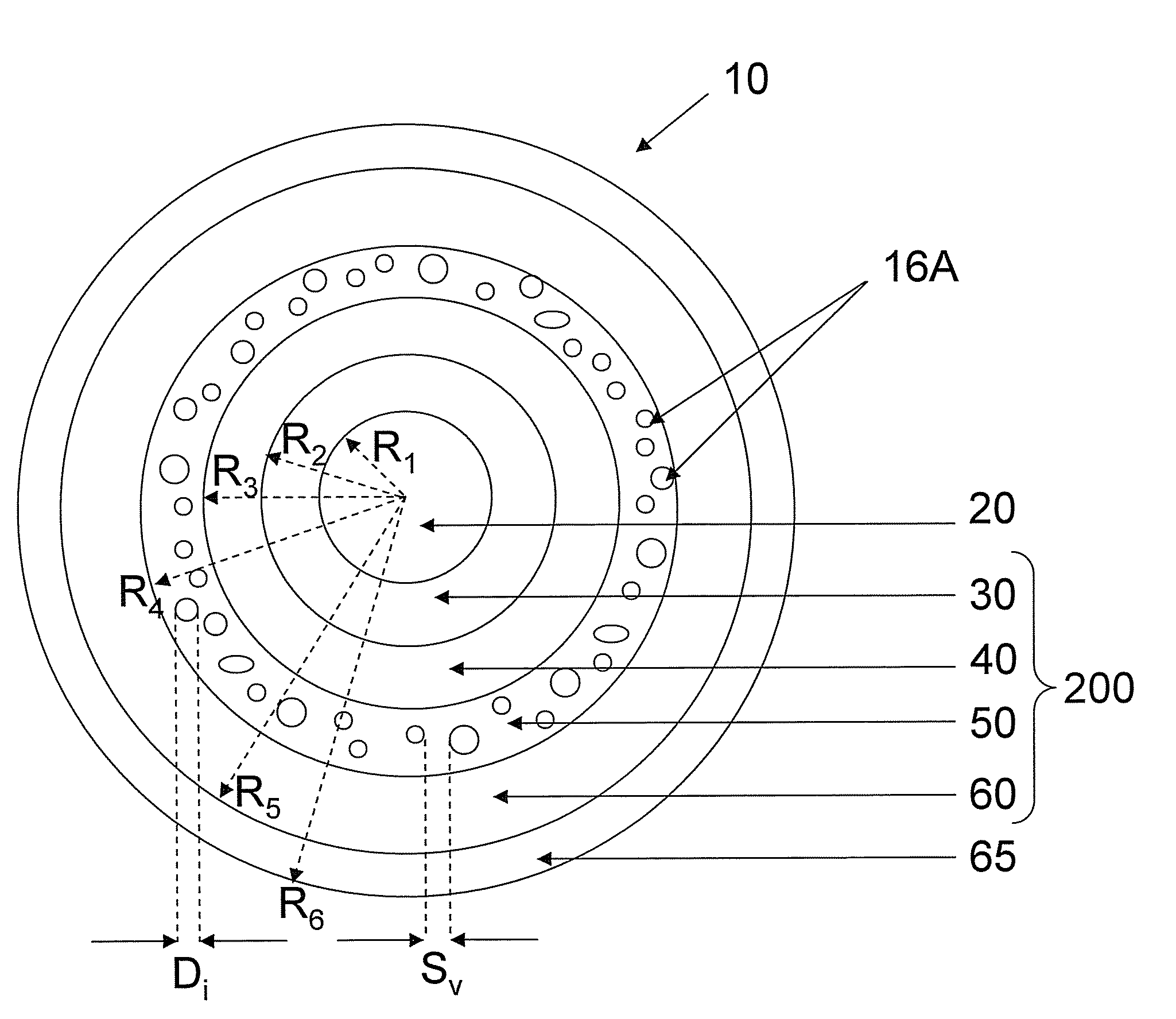

Optical fiber with large effective area

InactiveUS20080304800A1Optical fibre with multilayer core/claddingOptical waveguide light guideRelative refractive indexMaterials science

An optical fiber comprising: a glass core extending from a centerline to a radius R1; a glass cladding surrounding and in contact with the core, the cladding comprising:a first annular region extending from R1 to a radius R2, the first annular region comprising a radial width, W2=R2−R1, a second annular region extending from R2 to a radius R3, the second annular region comprising a radial width, W3=R3−R2, and a third annular region extending from R3 to an outermost glass radius R4; wherein (i) the core comprises a maximum relative refractive index, Δ1MAX, relative to the third annular region; (ii) wherein the first annular region comprises a radial width W2; and (iii) the second annular region comprises a minimum relative refractive index, Δ3MIN, relative to the third annular region wherein Δ1MAX>Δ2MAX>Δ3MIN, and Δ2MIN>Δ3MIN; and the core and the cladding provide a fiber with cable cutoff less than 1500 nm, dispersion at 1550 nm less than 12 ps / nm / km, effective area at 1550 nm greater than 60 μm2, and preferably greater than 70 μm2. The second annular cladding region may contain a plurality of randomly dispersed holes.

Owner:CORNING INC

Compensating for non-ideal multi-core optical fiber structure

ActiveUS8531655B2Without loss in positional accuracyAccurately determinedForce measurementMaterial analysis by optical meansFiberBending strain

Owner:INTUITIVE SURGICAL OPERATIONS INC

Large Mode Area Optical Fibers With Bend Compensation

ActiveUS20130251324A1Optical fibre with graded refractive index core/claddingOptical waveguide light guideEngineeringBend radius

A LMA, single-mode optical fiber comprises a core region, an inner cladding region surrounding the core region, and an outer cladding region surrounding the inner cladding region. The inner cladding region is configured to provide bend compensation. In one embodiment the index profile of the inner cladding region is graded with a slope of γncore / Rb, where ncore is the refractive index of the core region, Rb is the bend radius, and γ=0.6-1.2. In addition, the inner cladding is annular and the ratio of its outer radius to its inner radius is greater than 2. In a preferred embodiment this ratio is greater than 3. The overall index profile may be symmetric or asymmetric.

Owner:OFS FITEL LLC

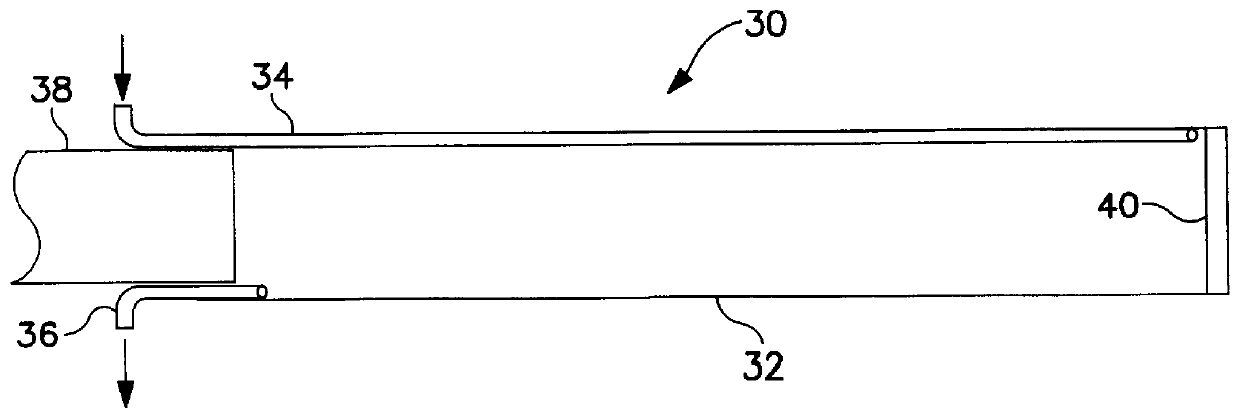

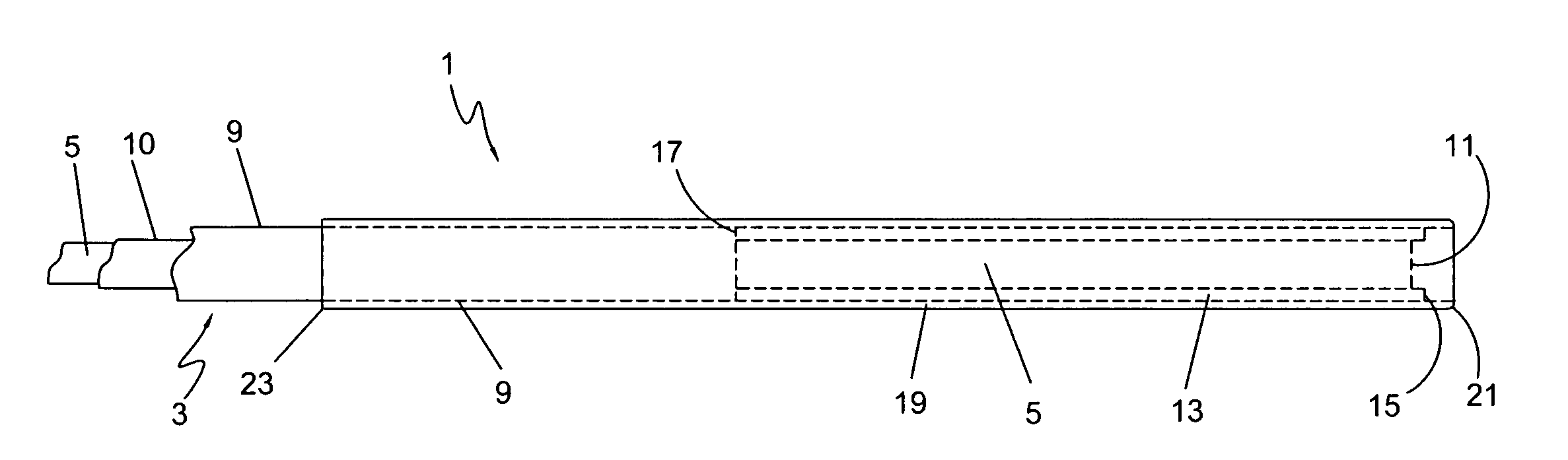

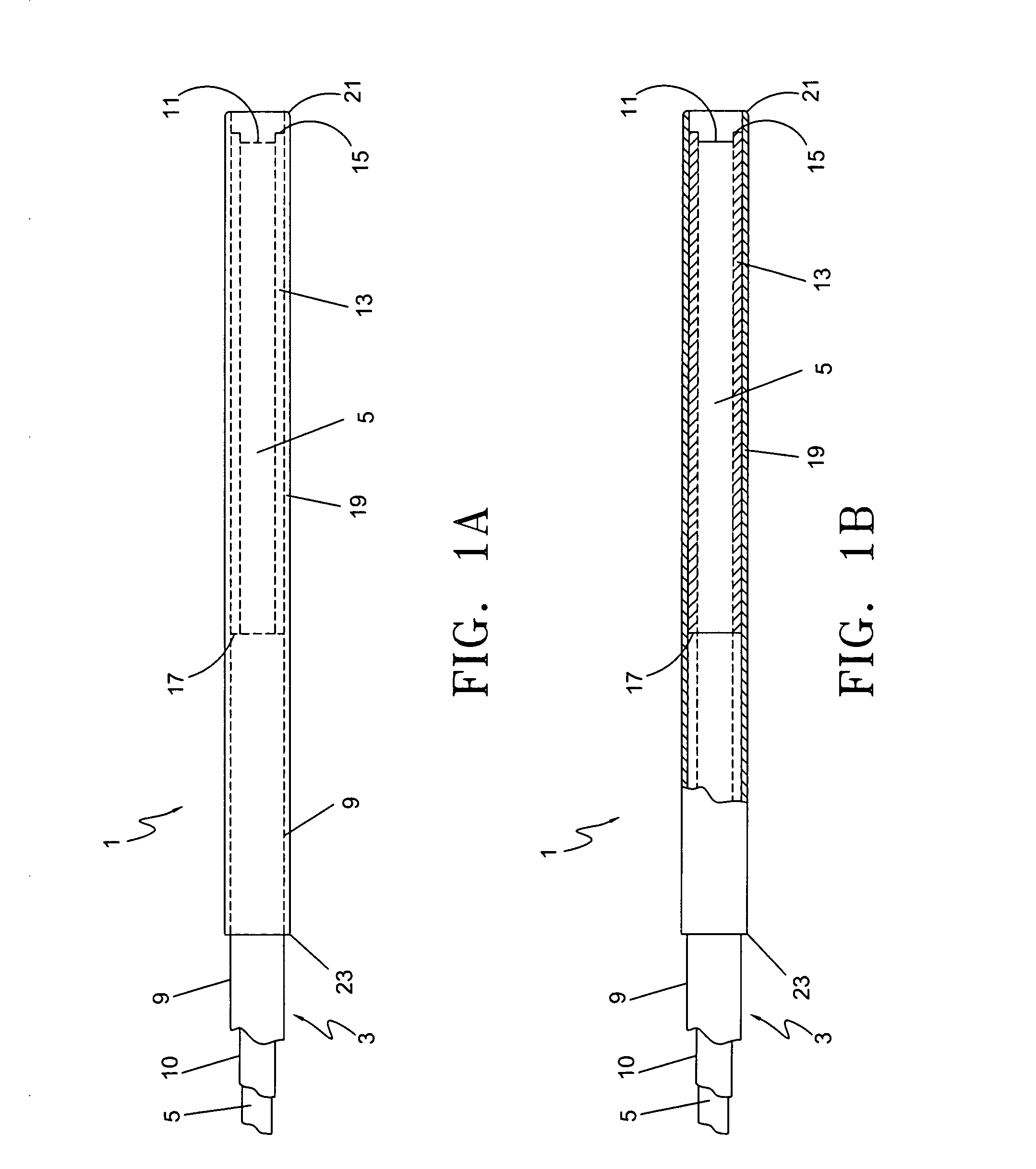

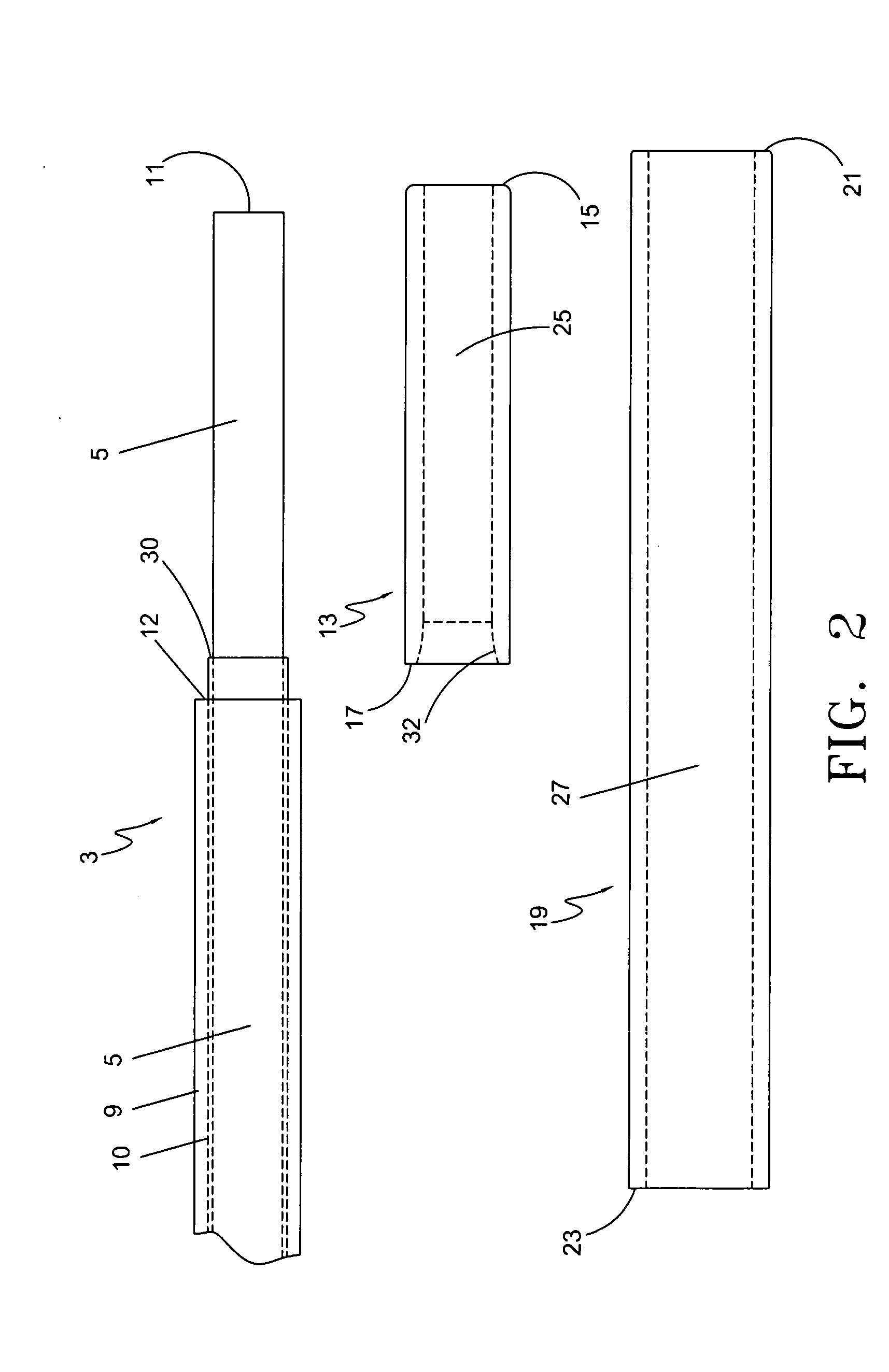

Device and method for endovascular treatment for causing closure of a blood vessel

ActiveUS20080188843A1Reduce power densityReduce temperature peaksCatheterSurgical instrument detailsEndovascular treatmentLaser light

An endovascular laser treatment device for causing closure of a blood vessel uses an optical fiber adapted to be inserted into a blood vessel. An inner sleeve is arranged around a distal portion of the optical fiber core such that both distal ends of the inner sleeve and the optical fiber core form an enlarged light emitting face. The enlarged emitting face provides substantially lower power density while providing the same amount of total energy during a treatment session. An outer sleeve arranged around the inner sleeve acts as a spacer to position the light emitting face away from an inner wall of the blood vessel. The enlarged light emitting face and the outer sleeve acting as a spacer reduces the possibility of thermal run-away and device damage, and reduce the possibility of vessel perforations, leading to less bruising, post-operative pain and other clinical complications. In yet another aspect of the present invention, a spacer comprises an inner sleeve and an outer sleeve both arranged around a distal portion of the core to prevent the laser light from traveling laterally and to position the light emitting face away from an inner wall of the vessel. The inner sleeve can be a heat resistive material such as ceramic and the outer sleeve can be, for example, a metallic sleeve to provide structural integrity and strength to the distal section of the treatment device.

Owner:ANGIODYNAMICS INC

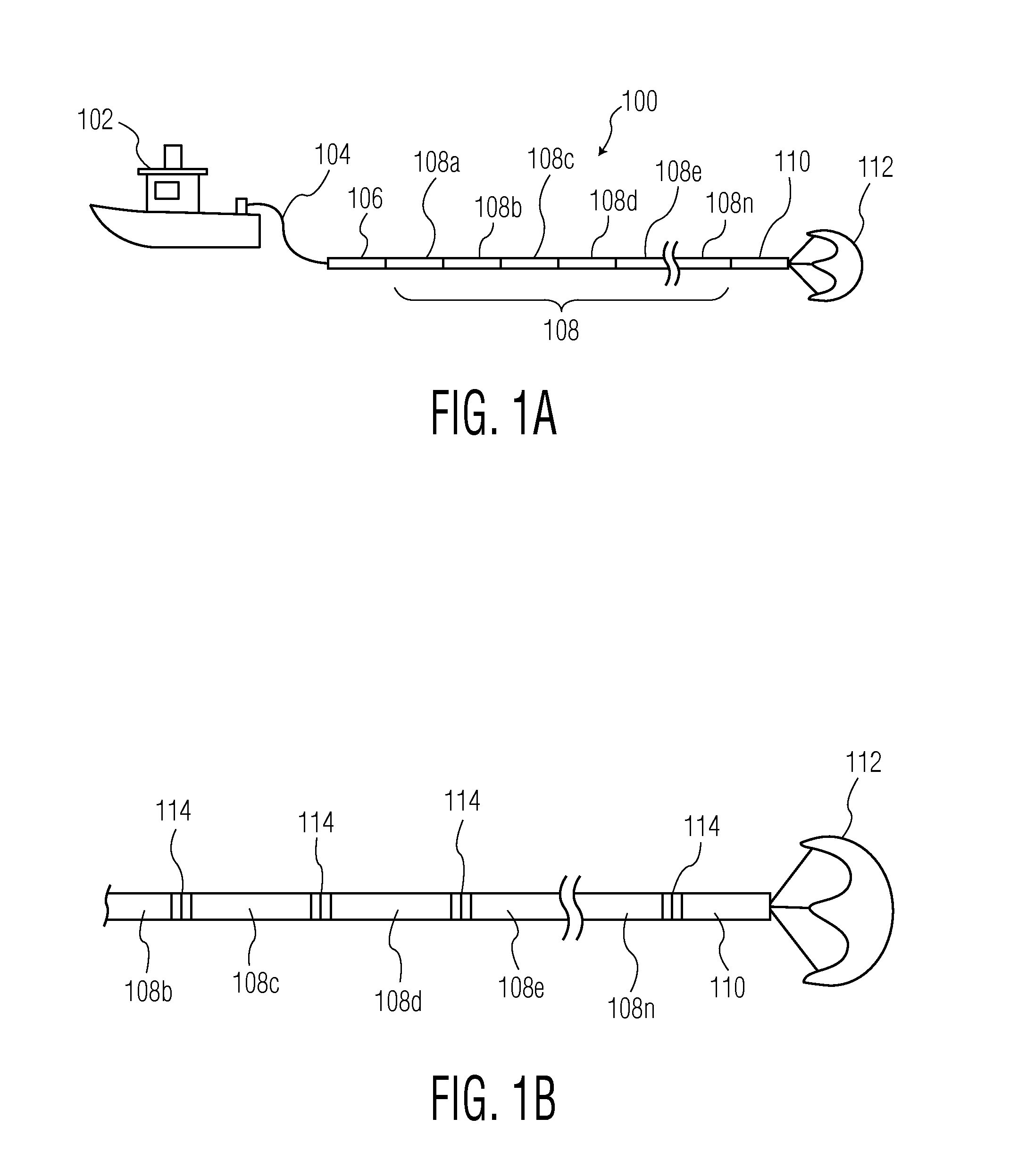

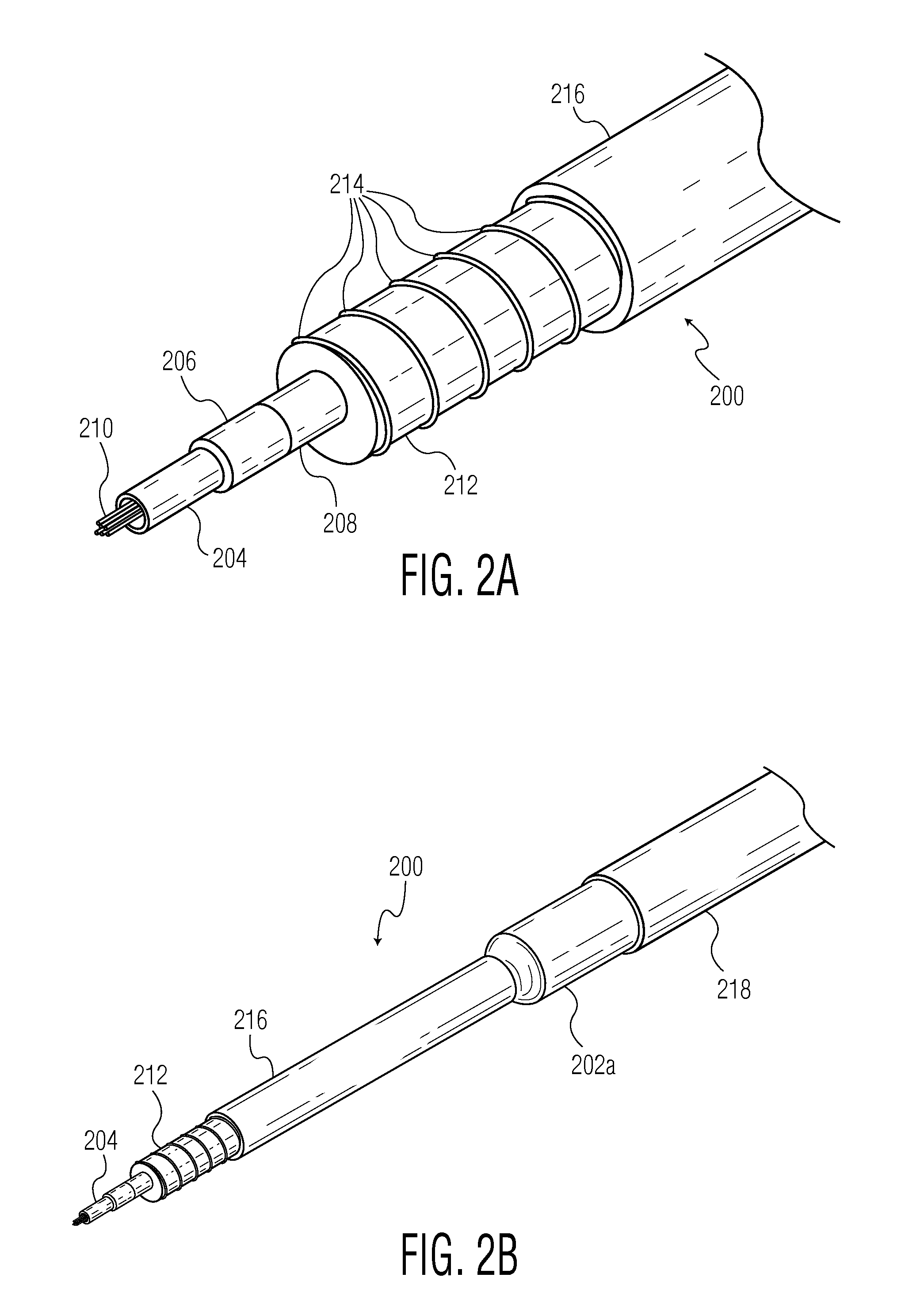

Fiber optic acoustic sensor arrays and systems, and methods of fabricating the same

ActiveUS20120227504A1Vibration measurement in solidsMaterial analysis by observing immersed bodiesFiberSensor array

A fiber optic acoustic sensor system. The fiber optic acoustic sensor system includes an optical source, and a fiber optic acoustic sensor array configured to receive an optical signal from the optical source. The fiber optic acoustic sensor array includes a core, a first polymer layer disposed on the core, an optical fiber wound around the first polymer layer, and a second polymer layer disposed on the first polymer layer such that the optical fiber is between the first polymer layer and the second polymer layer.

Owner:AVALON SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com