Patents

Literature

34results about How to "Reduce temperature peaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

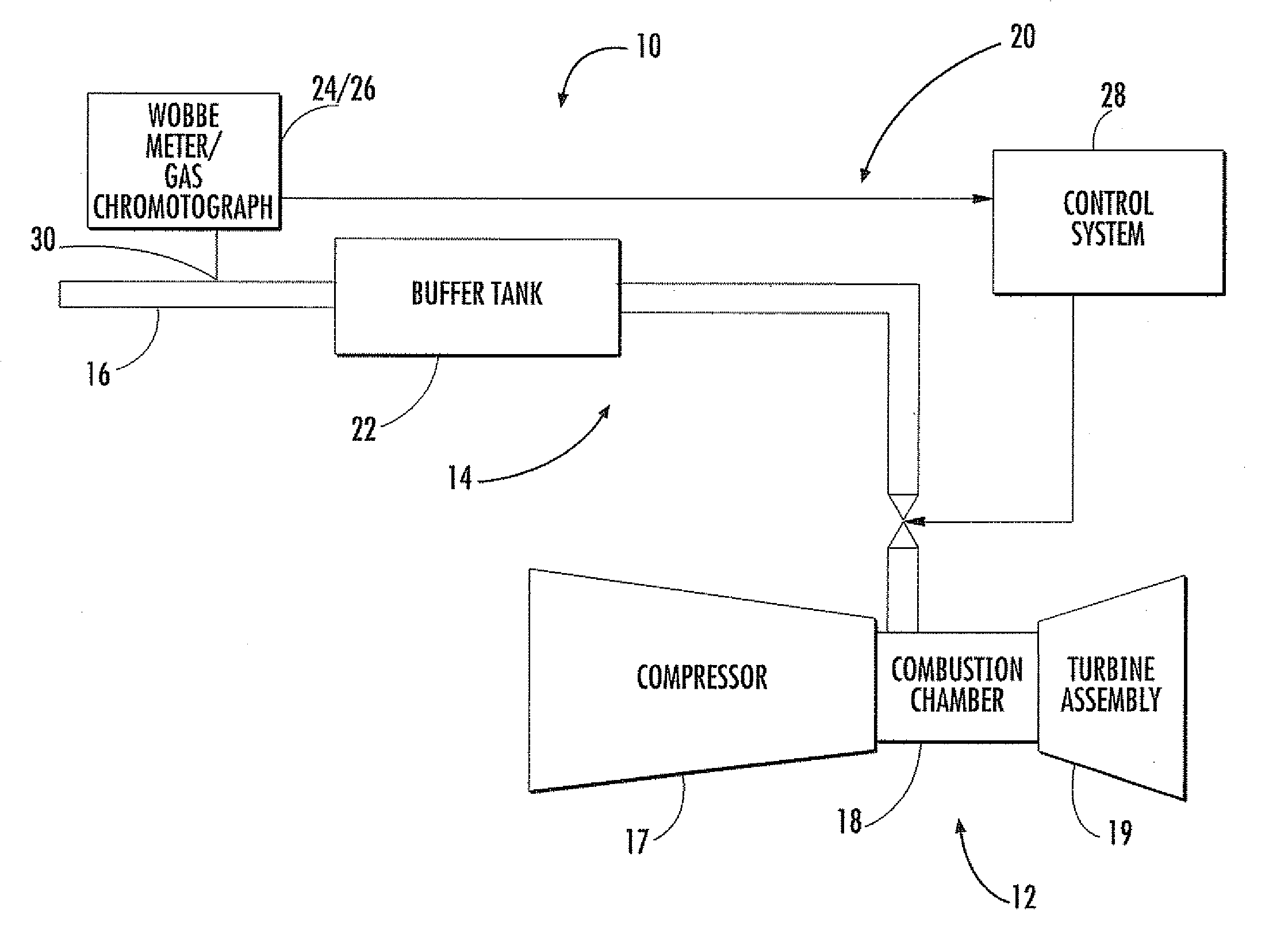

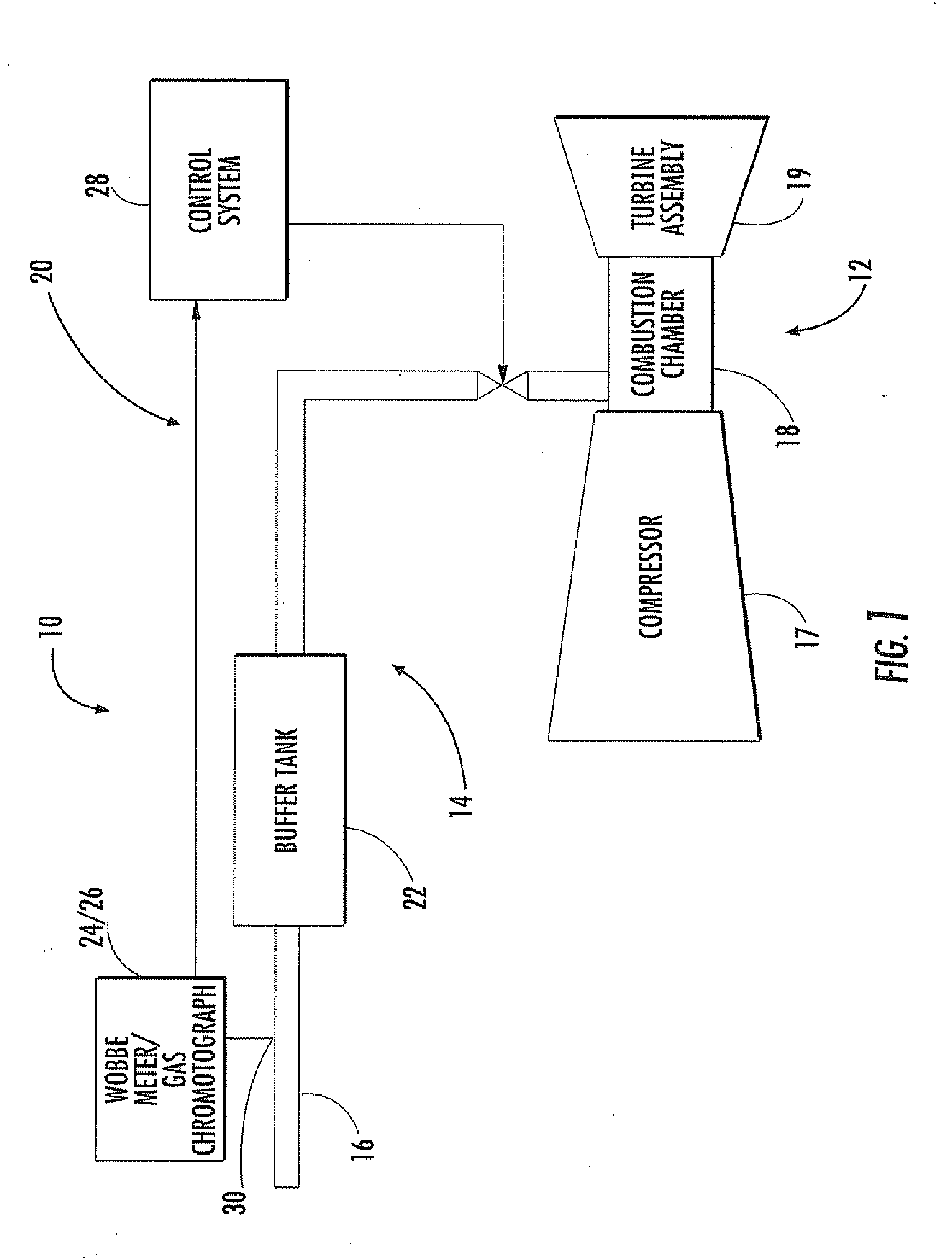

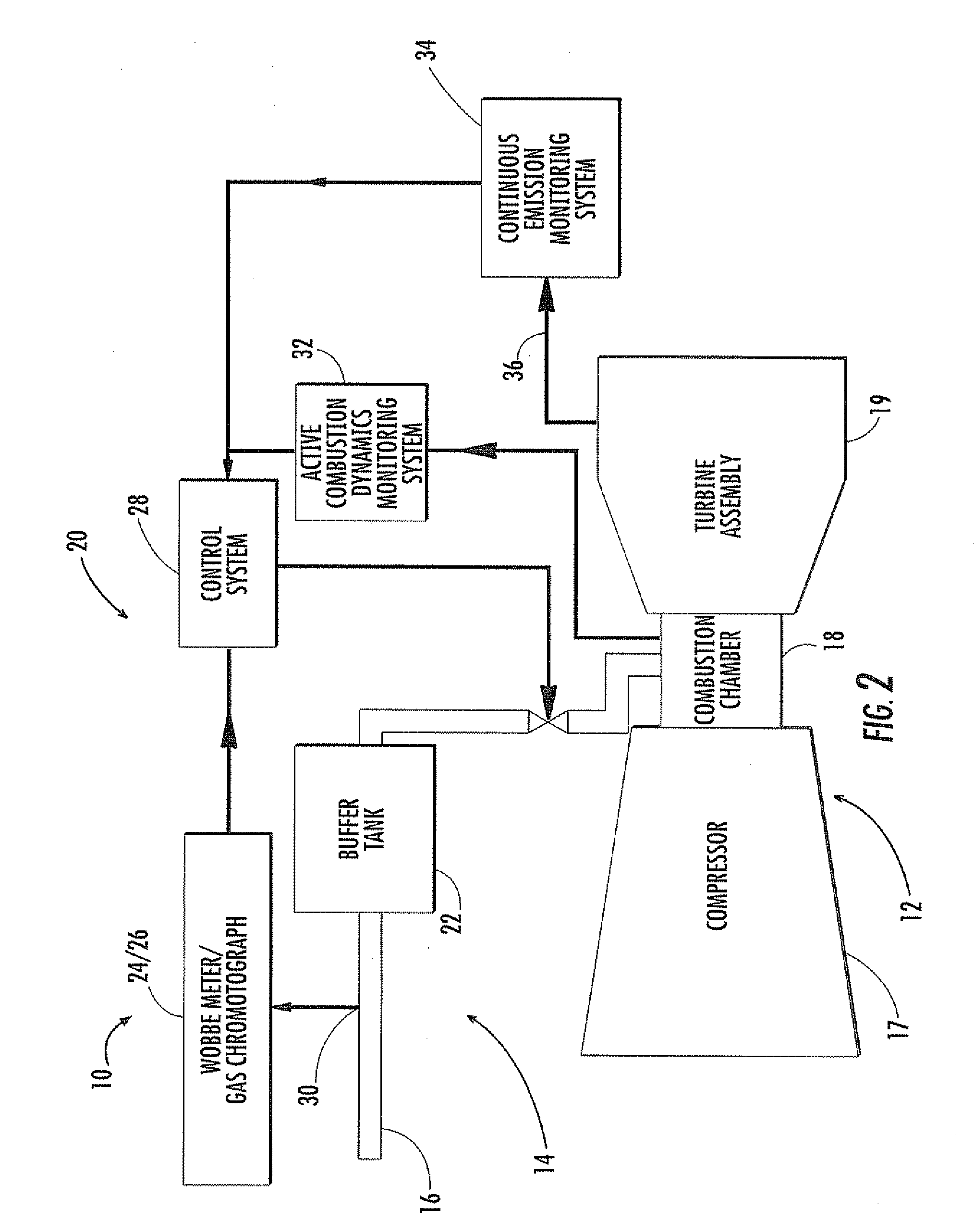

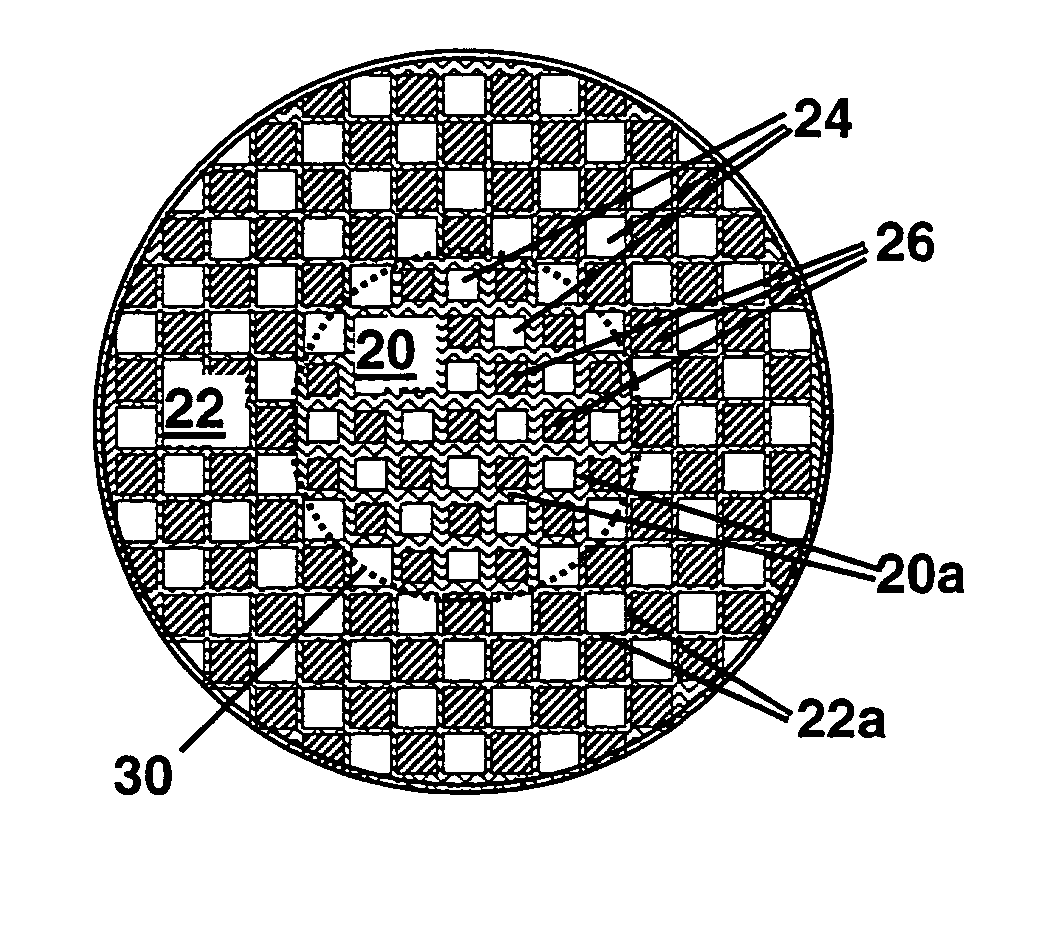

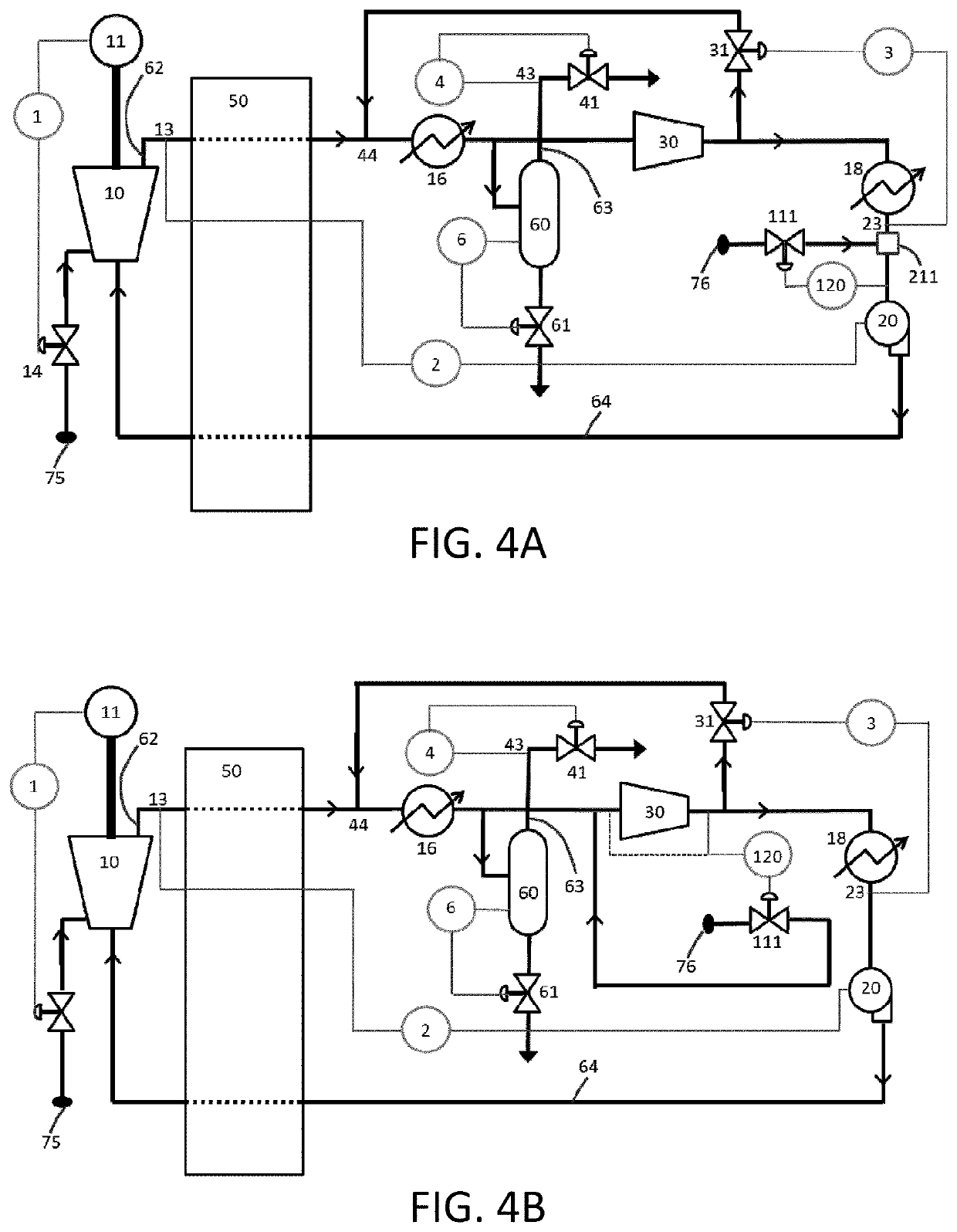

Integrated Fuel Gas Characterization System

InactiveUS20080115482A1Reduce temperature peaksAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlBuffer tankEngineering

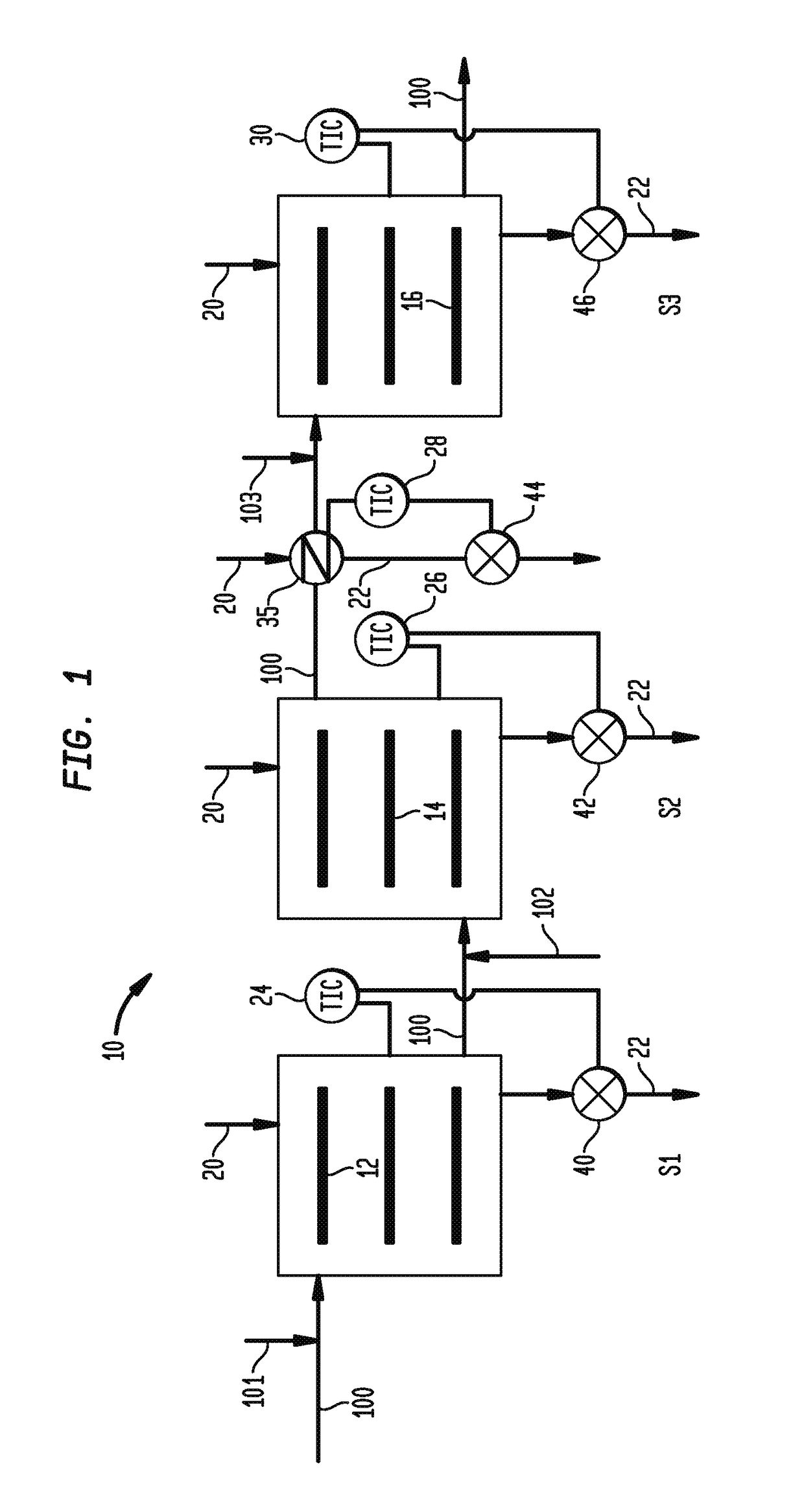

A gas turbine engine that includes a compressor, a combustion stage, a turbine assembly, a fuel gas feed system for supplying fuel gas to a combustion stage of the gas turbine, and an integrated fuel gas characterization system. The integrated fuel gas feed system can include a buffer tank. The integrated fuel gas characterization system for determining the amount of energy provided by the fuel prior to combustion of the fuel in the combustion stage. The integrated fuel gas characterization system minimizes megawatt swings by adjusting the operating parameters of the gas turbine engine based on the rate of change in fuel gas energy content. The integrated fuel gas characterization system also provides improved turbine engine start-up reliability by tuning the turbine engine operating parameters using fuel gas energy content measurements obtained prior to actual start-up.

Owner:SIEMENS ENERGY INC

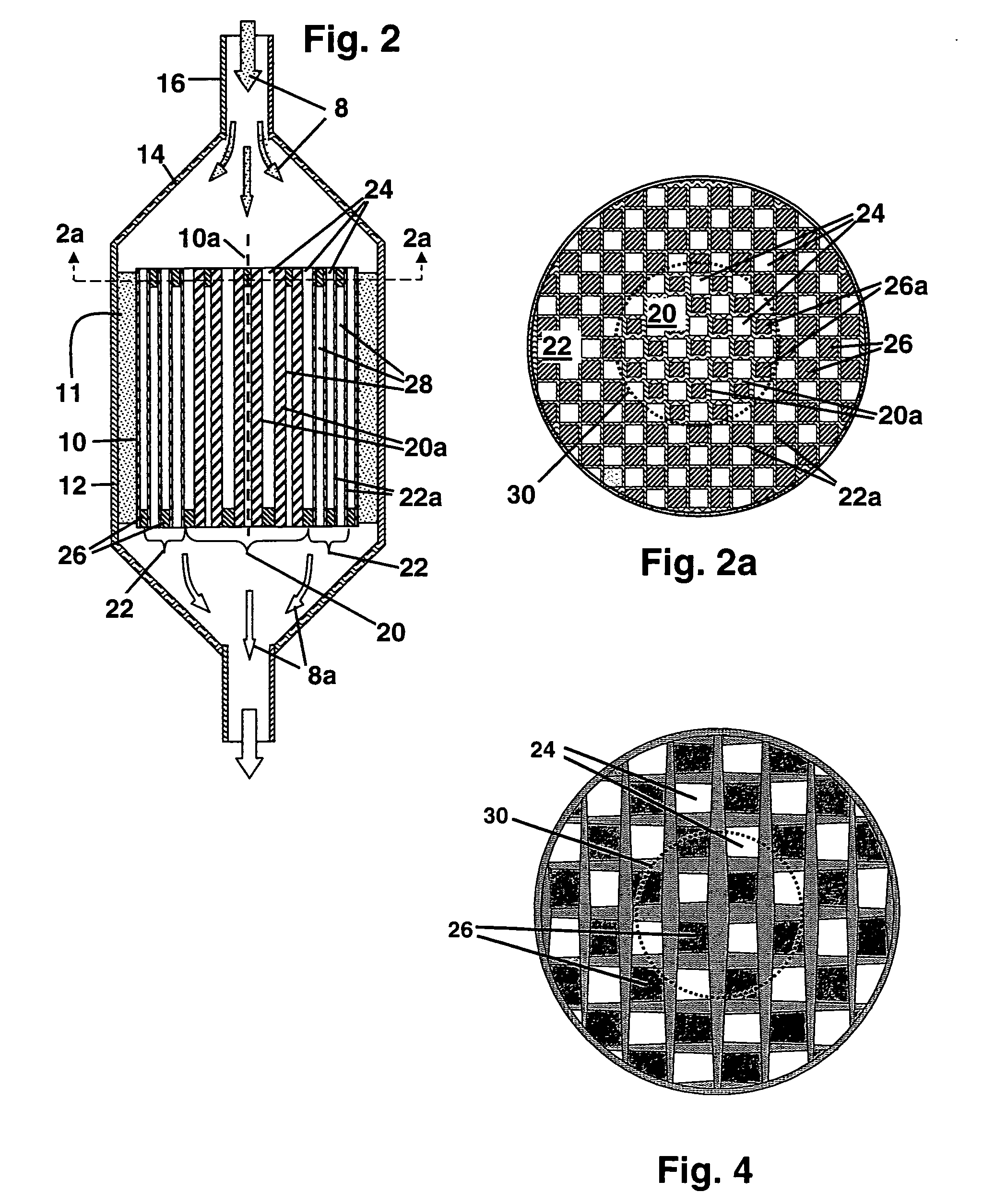

Diesel engine exhaust filters

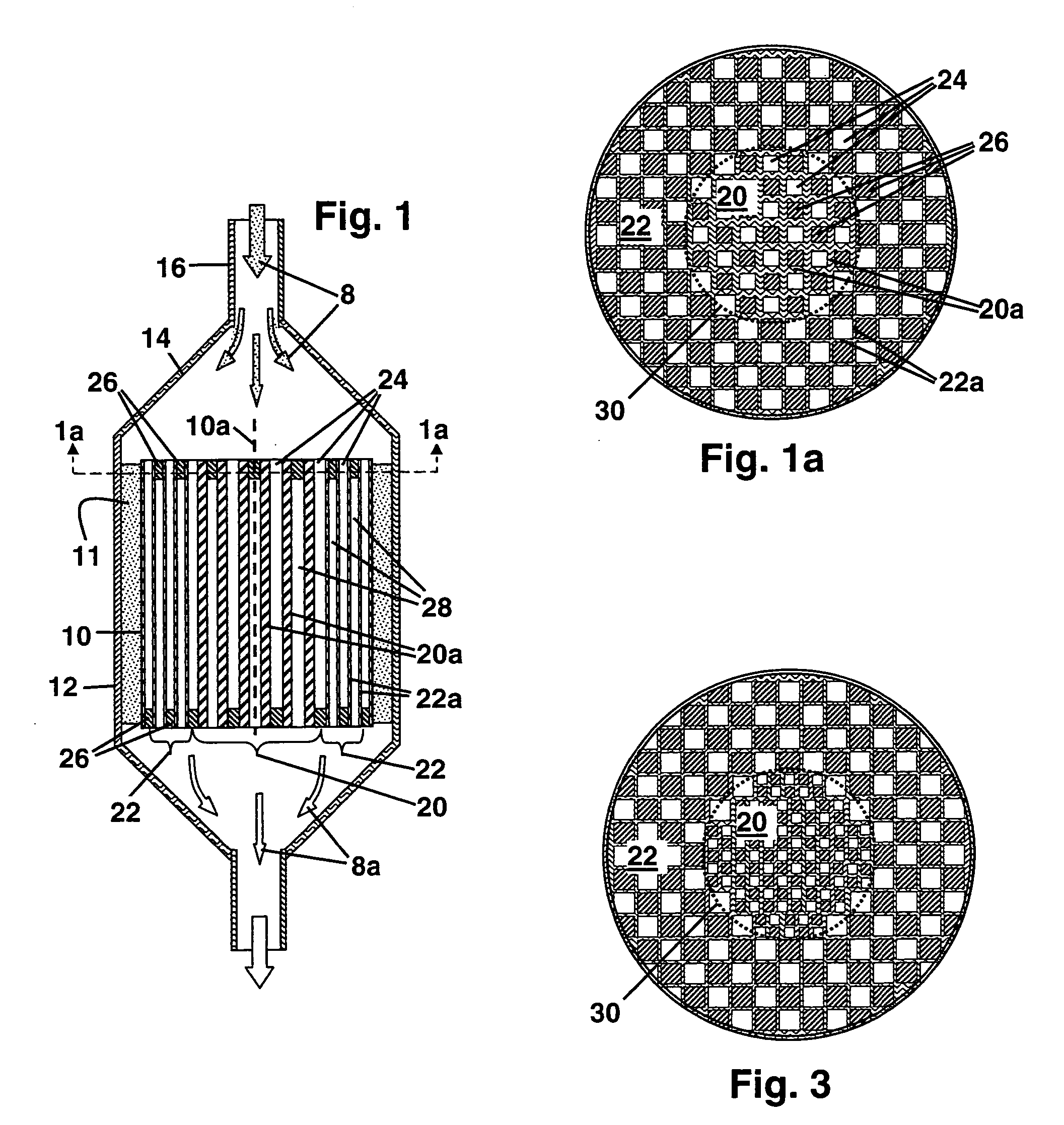

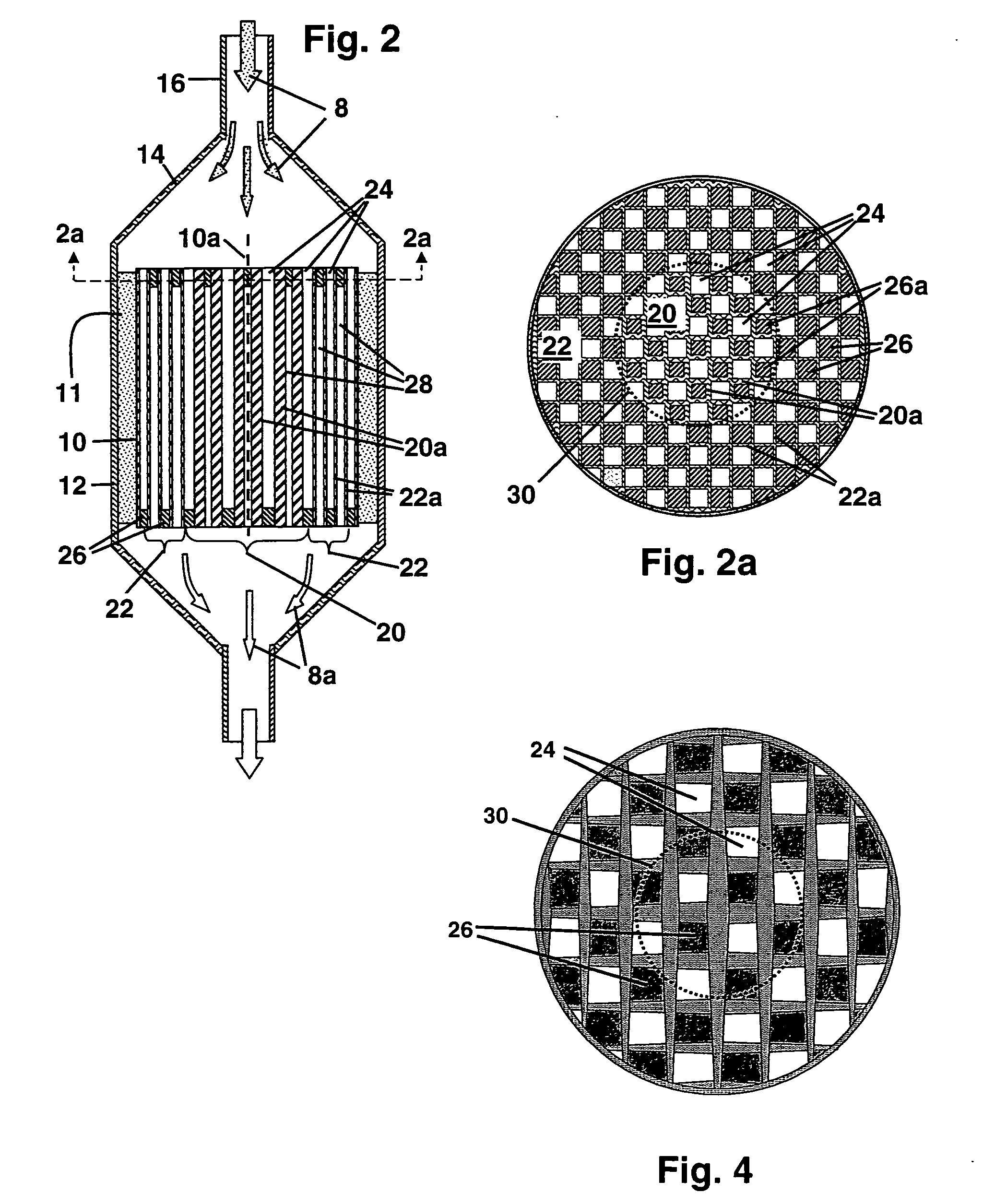

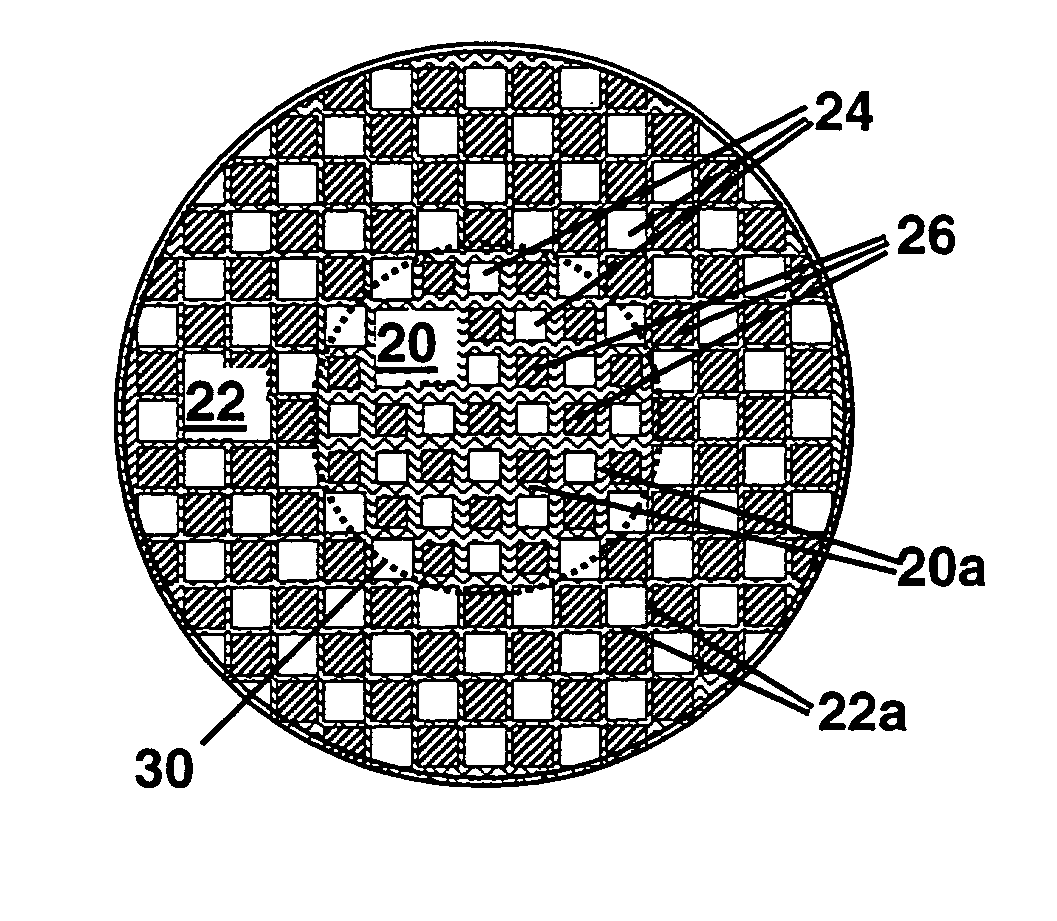

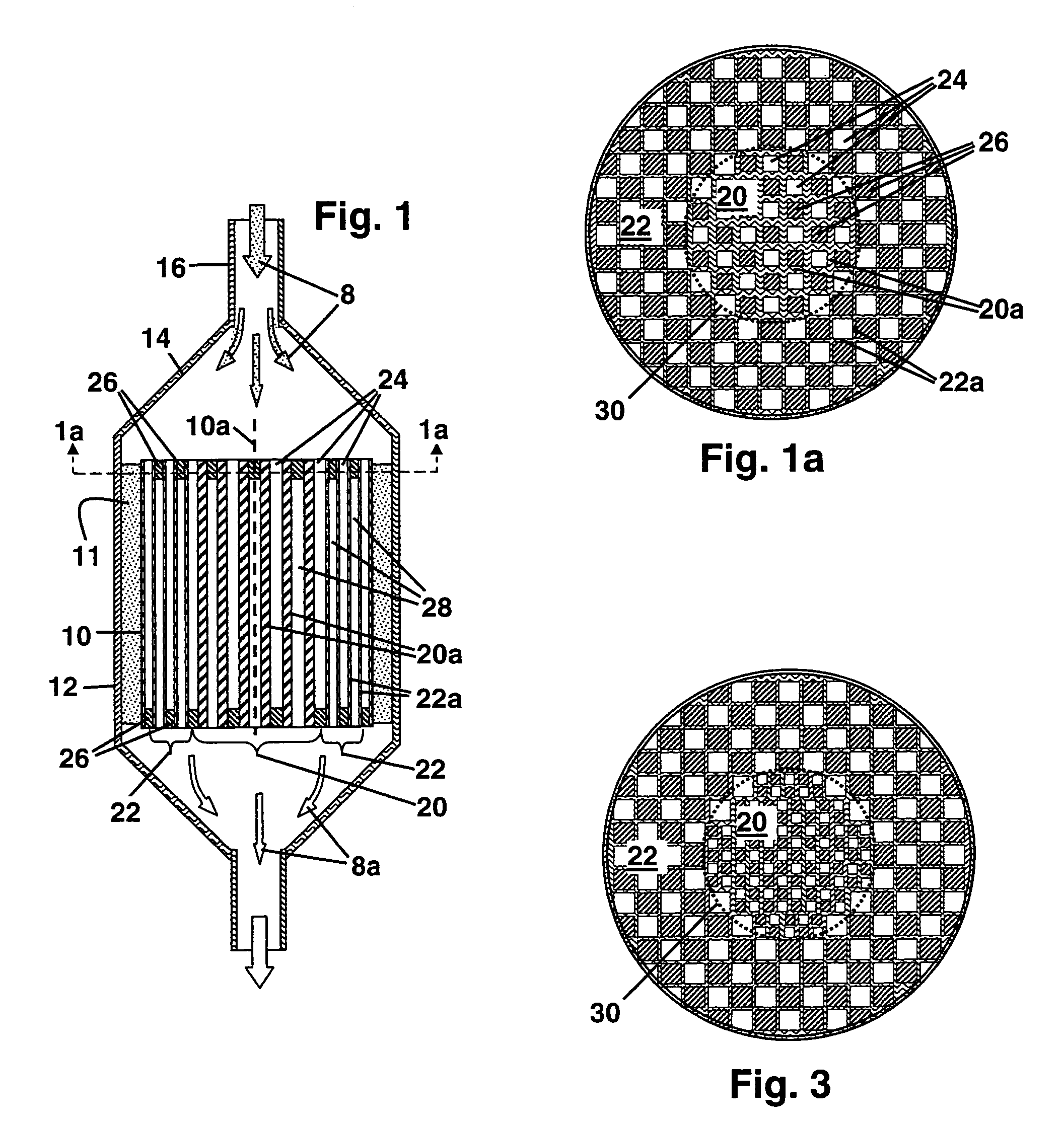

ActiveUS20050235622A1Speed up the processResist damageCombination devicesGas treatmentFiltrationEngineering

Diesel engine exhaust filtration systems, and ceramic honeycomb wall flow exhaust filters for such systems, wherein the filters comprise axially centralized filter sections having a higher heat capacity and / or a higher gas flow resistance than peripheral filter sections disposed radially outwardly thereof, the filters thereby exhibiting increased resistance to thermal damage from filter regeneration over-heating.

Owner:CORNING INC

Diesel engine exhaust filters

ActiveUS7238217B2Resist damageSpeed up the processCombination devicesGas treatmentDieselingMechanical engineering

Diesel engine exhaust filtration systems, and ceramic honeycomb wall flow exhaust filters for such systems, wherein the filters comprise axially centralized filter sections having a higher heat capacity and / or a higher gas flow resistance than peripheral filter sections disposed radially outwardly thereof, the filters thereby exhibiting increased resistance to thermal damage from filter regeneration over-heating.

Owner:CORNING INC

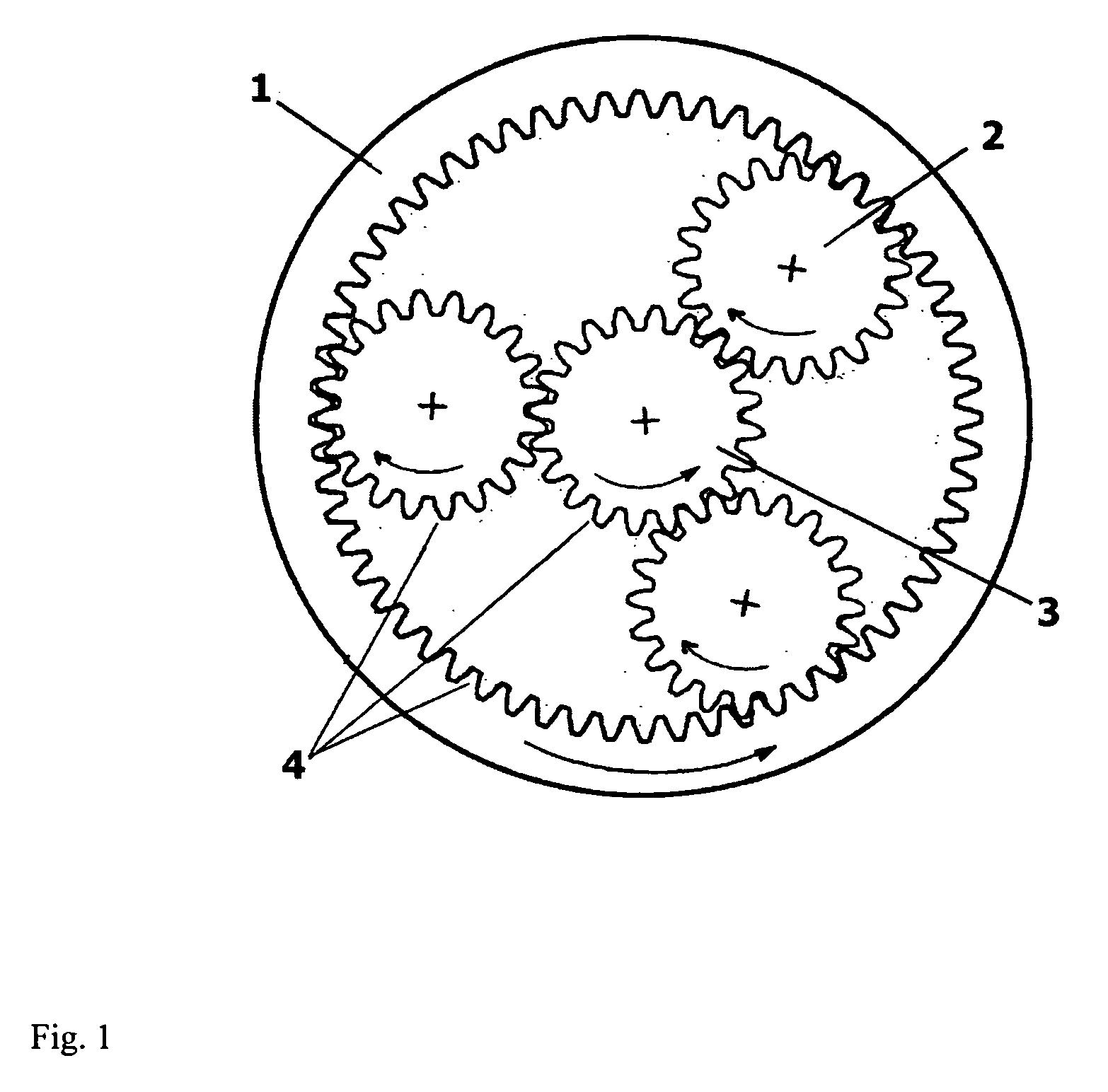

Superfinishing large planetary gear systems

ActiveUS20050014597A1Reduces and eliminates lubricant debrisAvoid damageEdge grinding machinesPolishing machinesGear wheelEngineering

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:OSRO GMBH +1

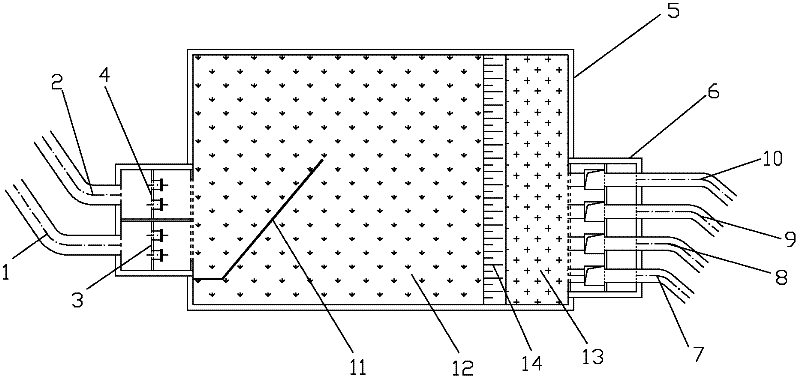

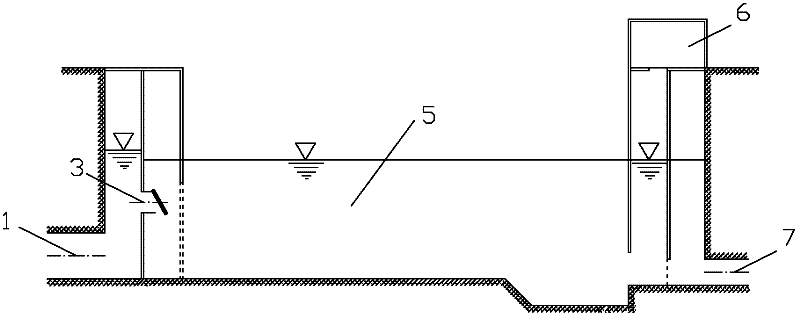

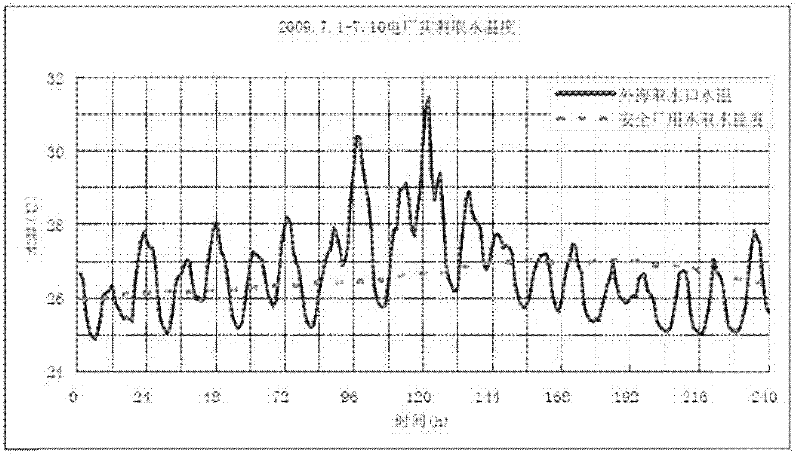

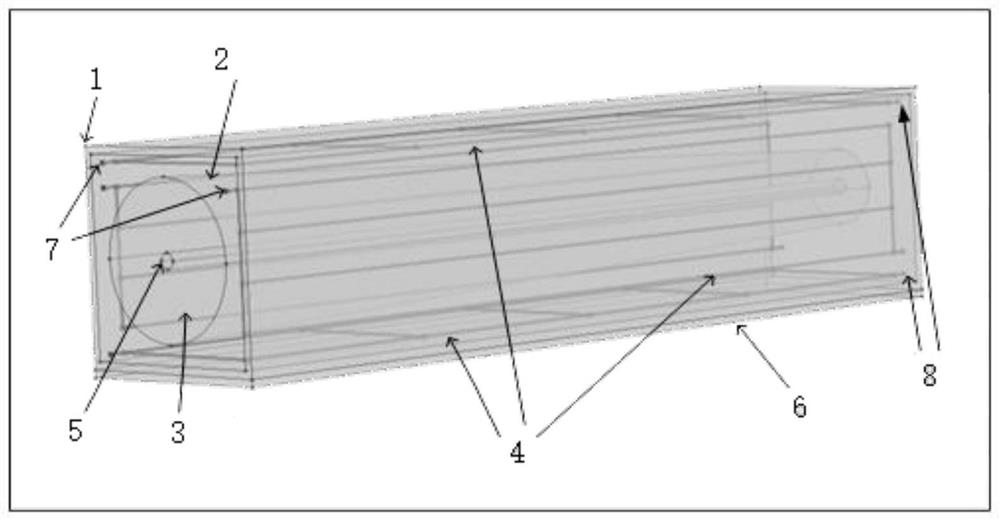

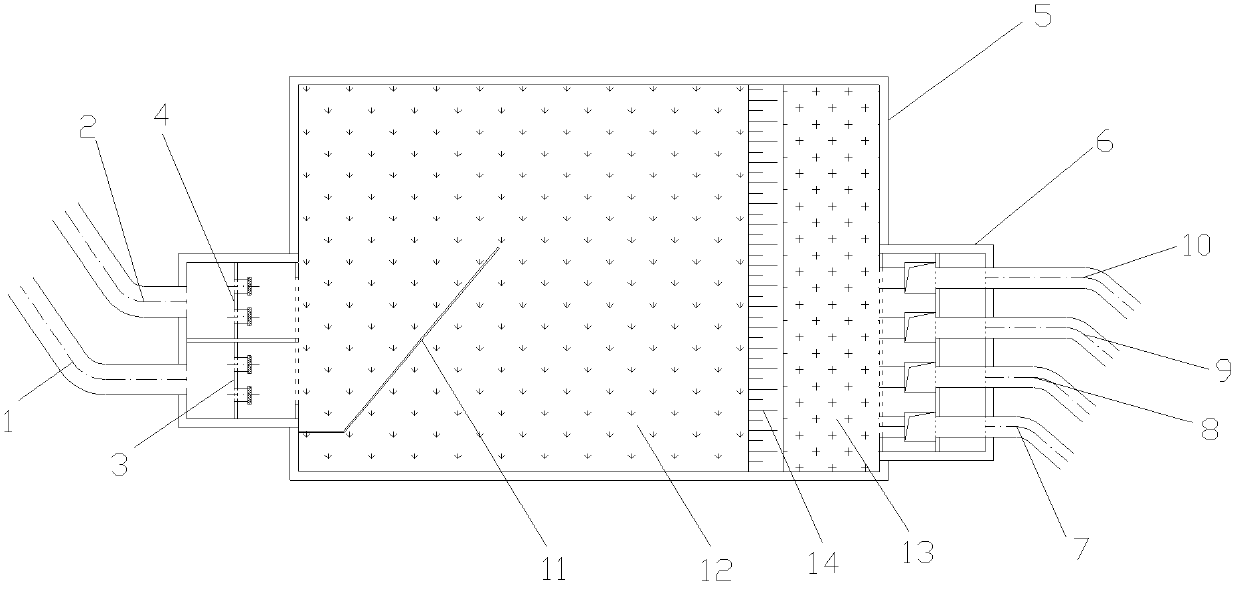

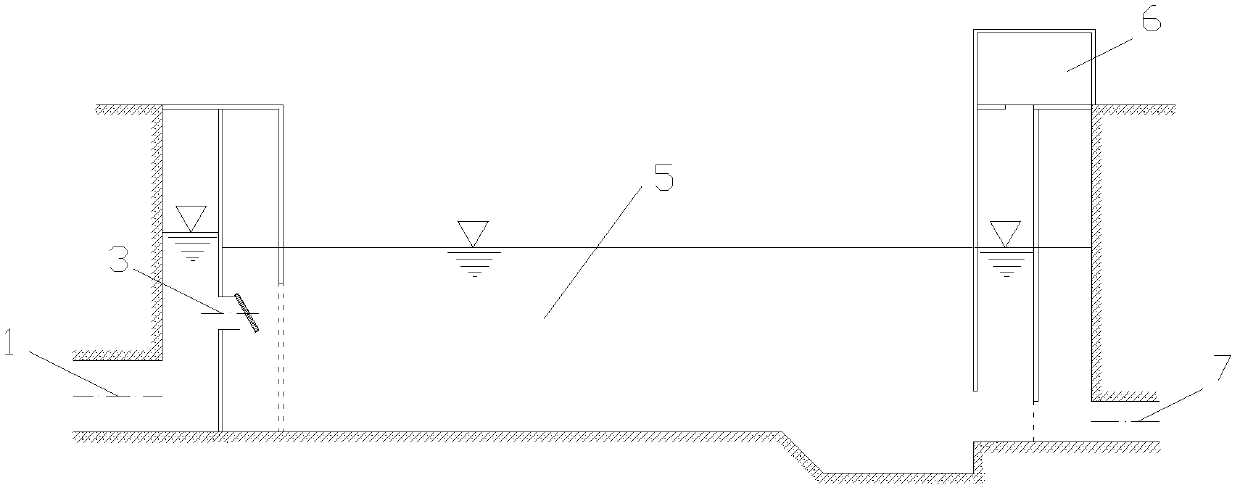

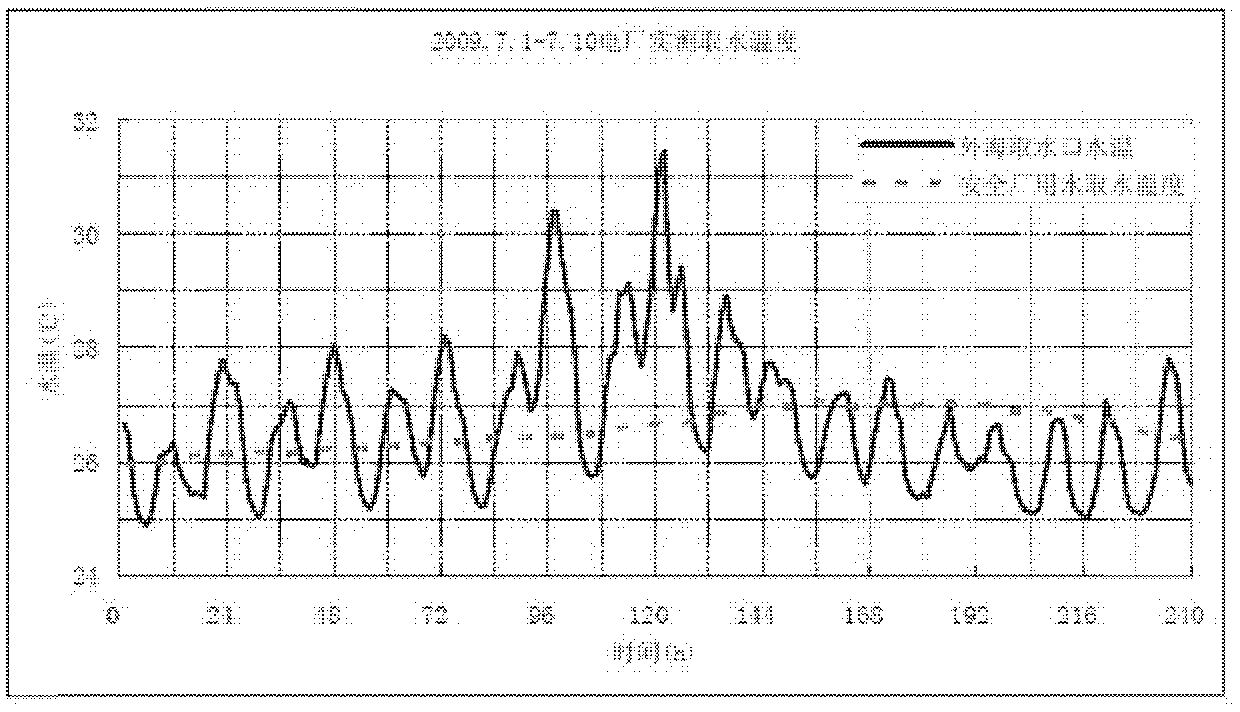

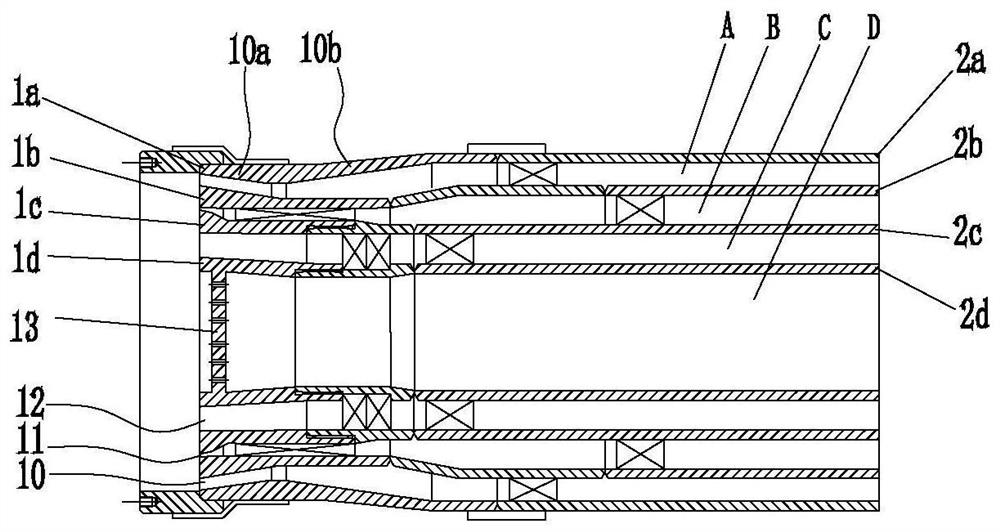

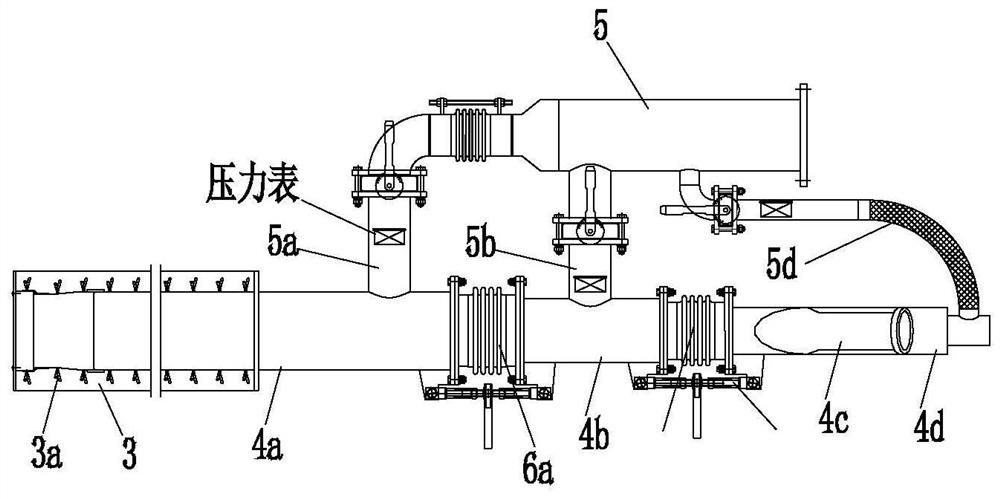

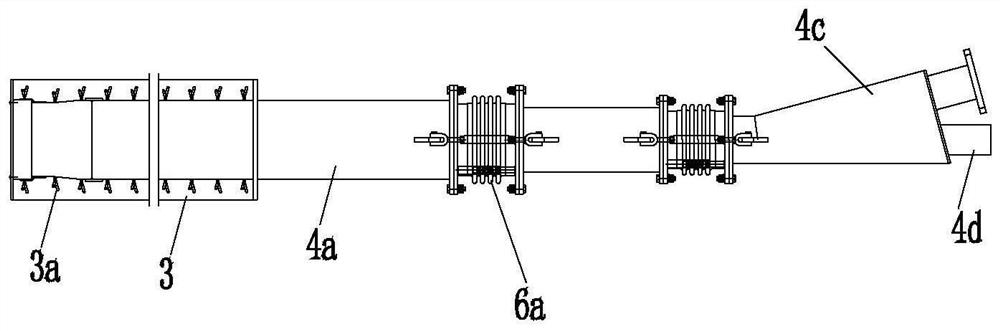

Selective inlet water temperature stabilizing device and water temperature value simulating and forecasting method

InactiveCN102359146ASmooth out water temperature peaksSmall water flowWater supply tanksHydraulic modelsSeawaterPeak value

The invention discloses a selective inlet water temperature stabilizing device. The selective inlet water temperature stabilizing device comprises a water reservoir, a clapper door inflow device and a water taking building, wherein the clapper door inflow device and the water taking building are respectively arranged on the two sides of the water reservoir; and the bottom of the water taking building is connected with a water taking culvert pipe. The invention also discloses a water temperature value simulating and forecasting method. According to the invention, external seawater used as a power plant safety plant water source flows in through the device while higher water level and lower temperature of the external seawater are obtained; and the external seawater is conveyed into a safety plant cooling water taking pump house after cold water and hot water are sufficiently mixed and the surface is cooled; therefore, the temperature of the water taken from the safety plant water is obviously reduced while being compared with the variation gradient and the peak value of the water temperature at the external seawater taking opening so that the high peak value of the water taking temperature can be stabilized, the reduction amplitude of the safety plant water temperature can be also forecasted after using the system and the device, and design parameters are provided for building the selective water temperature stabilizing device.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +2

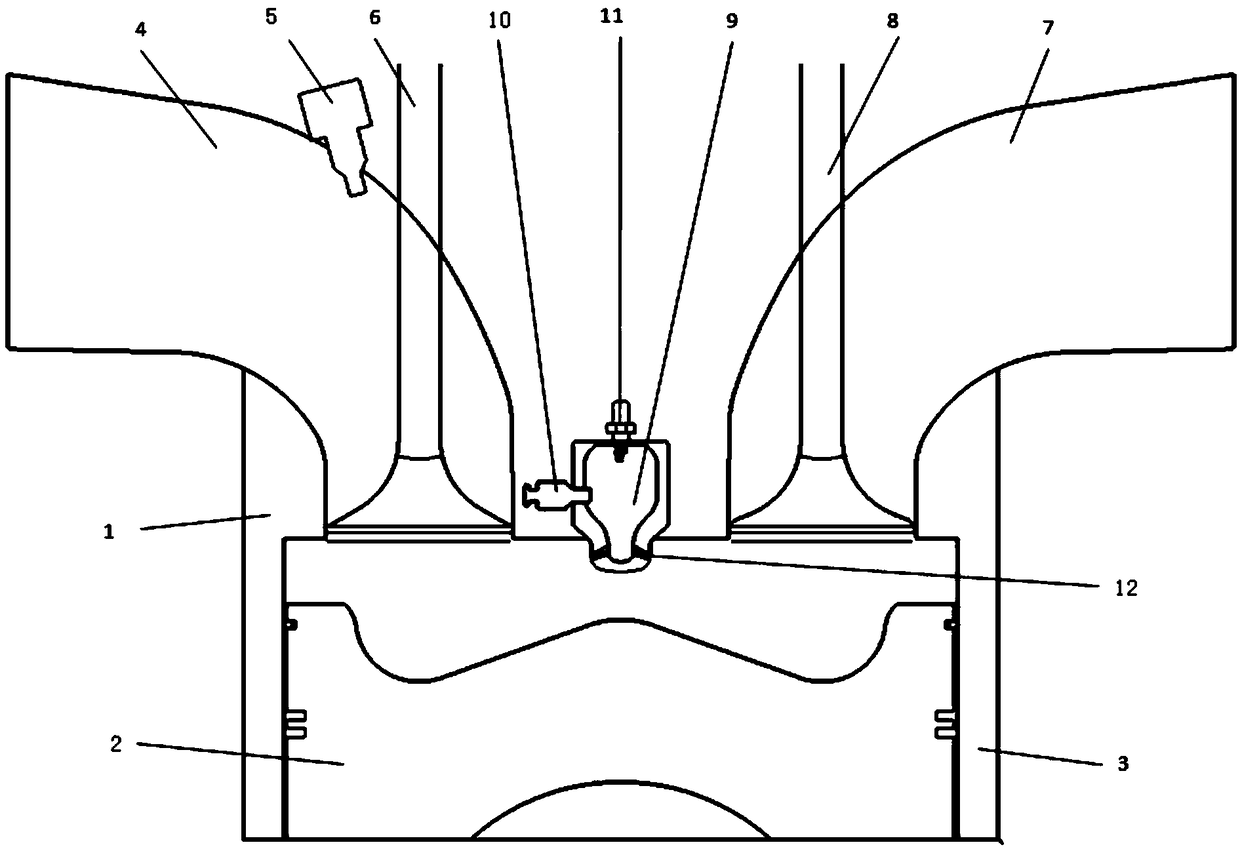

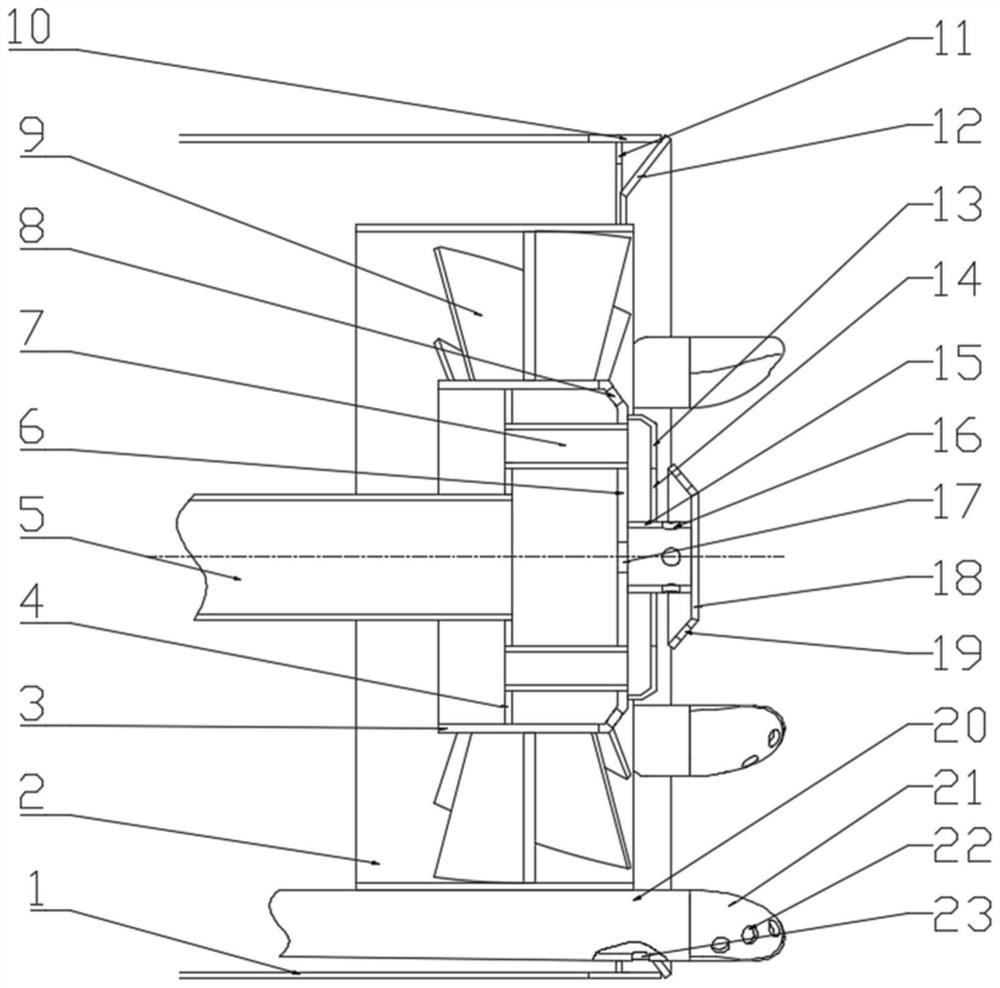

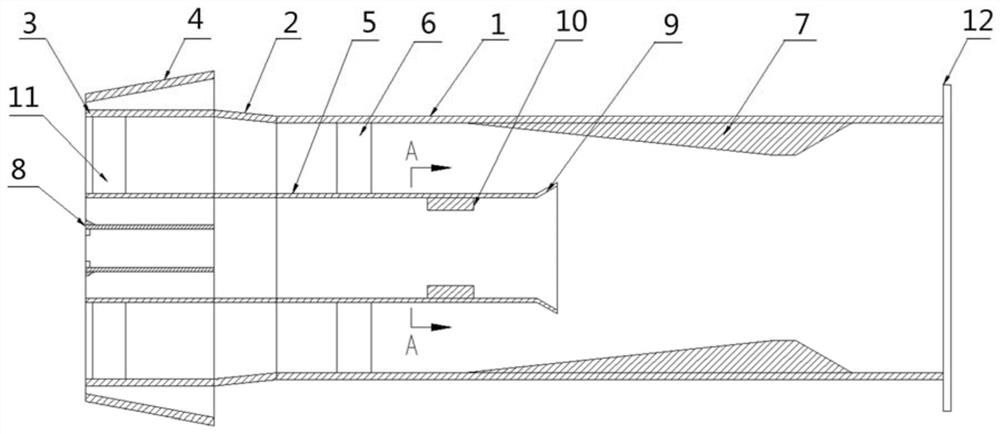

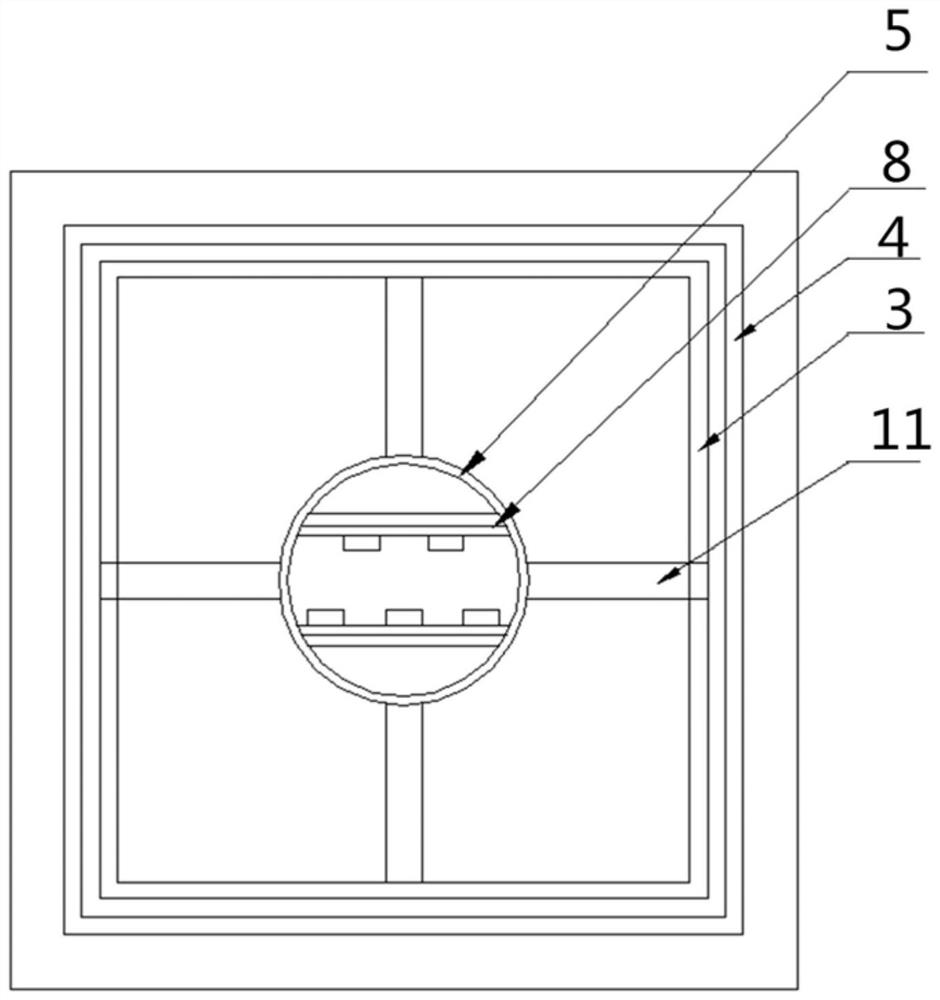

Marine large-bore natural gas engine precombustion chamber porous jet flow ignition type efficient combustion system

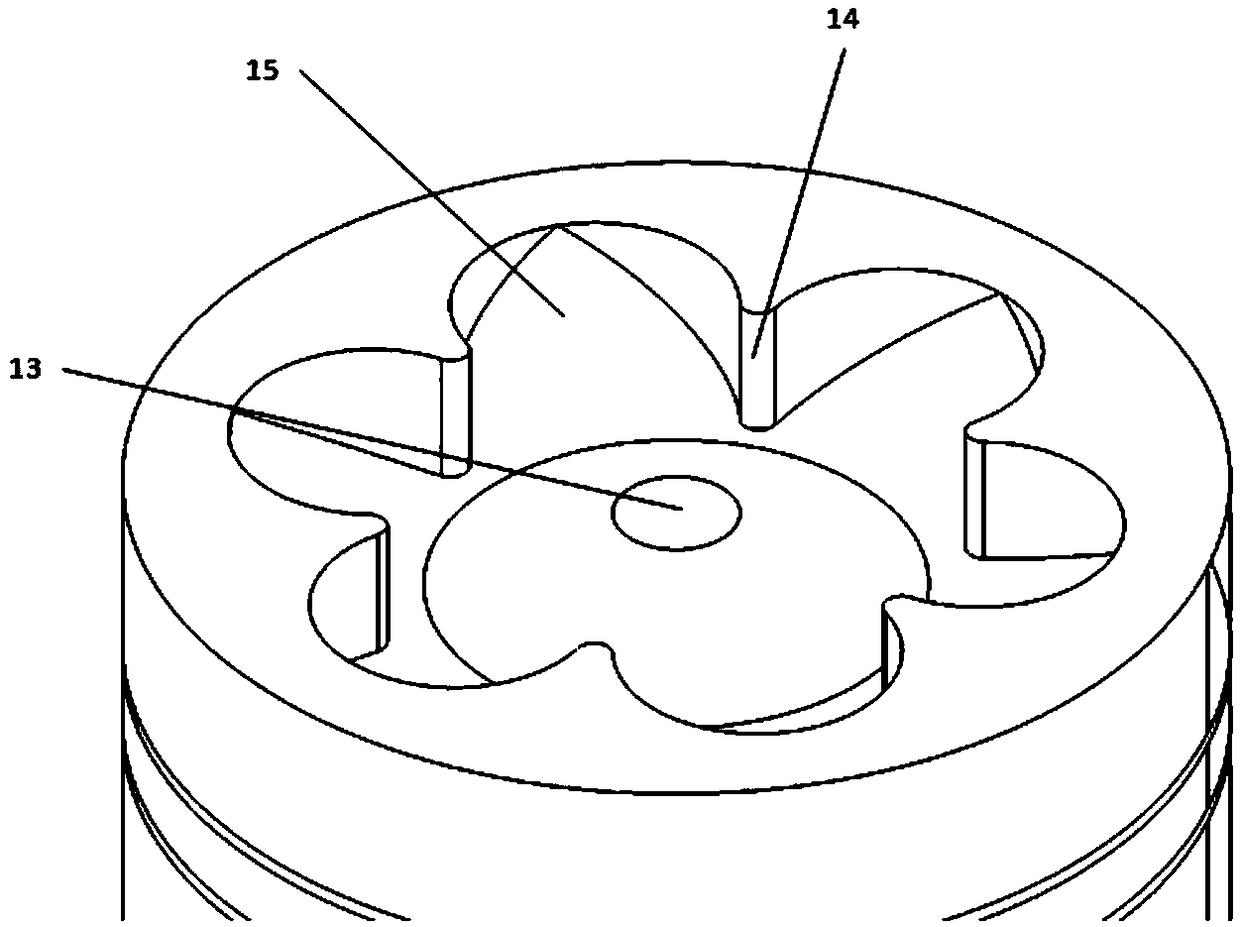

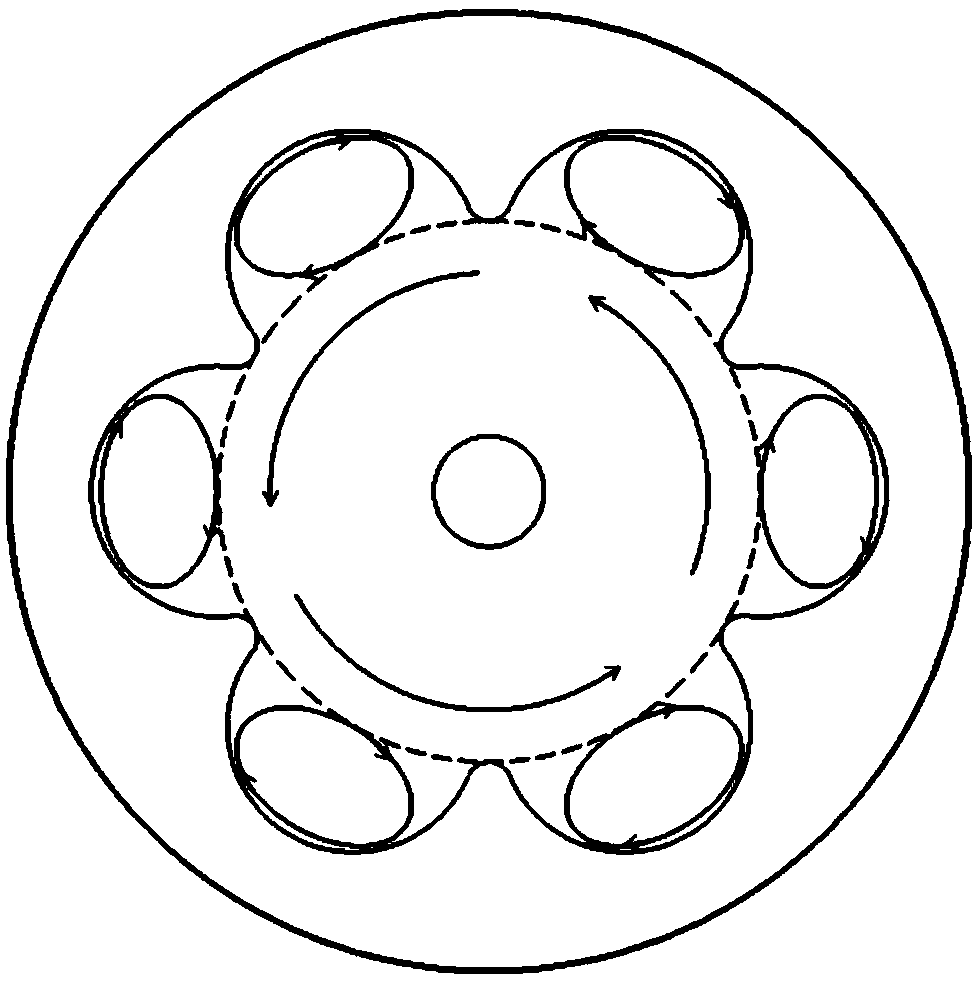

PendingCN109184898AImprove combustion efficiencyShorten the flame propagation distanceInternal combustion piston enginesFuel supply apparatusCombustion chamberInlet valve

The invention provides a marine large-bore natural gas engine precombustion chamber porous jet flow ignition type efficient combustion system which comprises a cylinder cover, an air cylinder sleeve,a piston, an air inlet passage and an air discharging passage, wherein the piston is positioned in the air cylinder sleeve; a combustion chamber is formed between the top of the piston and the cylinder cover; an air inlet valve is arranged in the air inlet passage; an air discharging valve is arranged in the air discharging passage; a natural gas supply device is arranged in the air inlet passageand is positioned in front of the air inlet valve; a precombustion chamber is formed in the cylinder cover; a sparking plug and a precombustion chamber natural gas jetting device are arranged in the precombustion chamber; and a jet orifice is formed in the part, stretching into the combustion chamber, of the precombustion chamber. The system utilizes high-temperature and high-pressure flue gas jetted by a porous passage to form a plurality of ignition sources and the compact structure of a main combustion chamber, so that the spreading distance of the natural gas flame is shortened, and multi-area ignition combustion of rate mixed gas in the cylinder is realized; and in addition, the high-temperature and high-pressure flue gas jet flow damages the large-scale eddy current in the cylinder,so that the turbulence intensity in the cylinder is improved and the combustion efficiency is remarkably improved.

Owner:HARBIN ENG UNIV

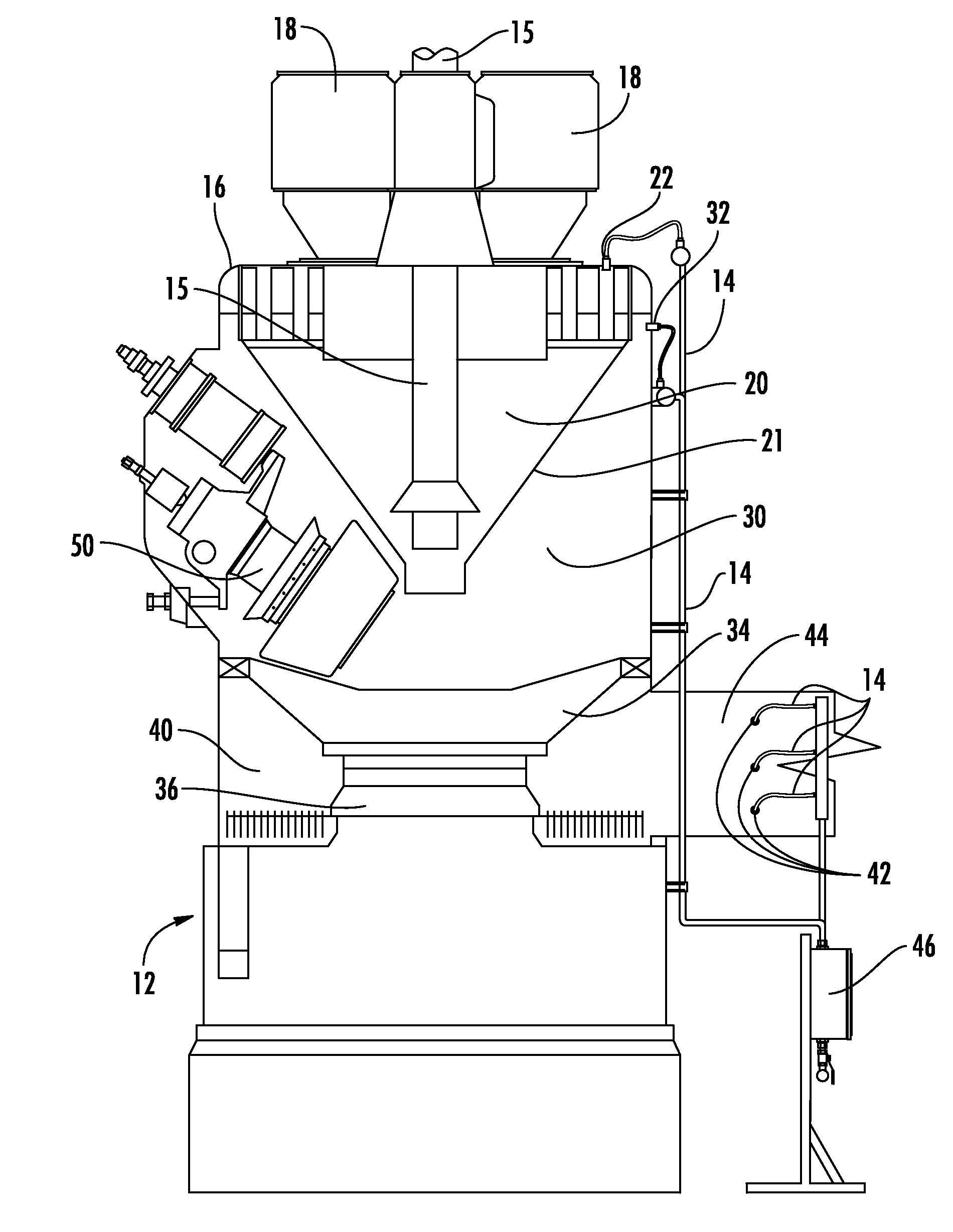

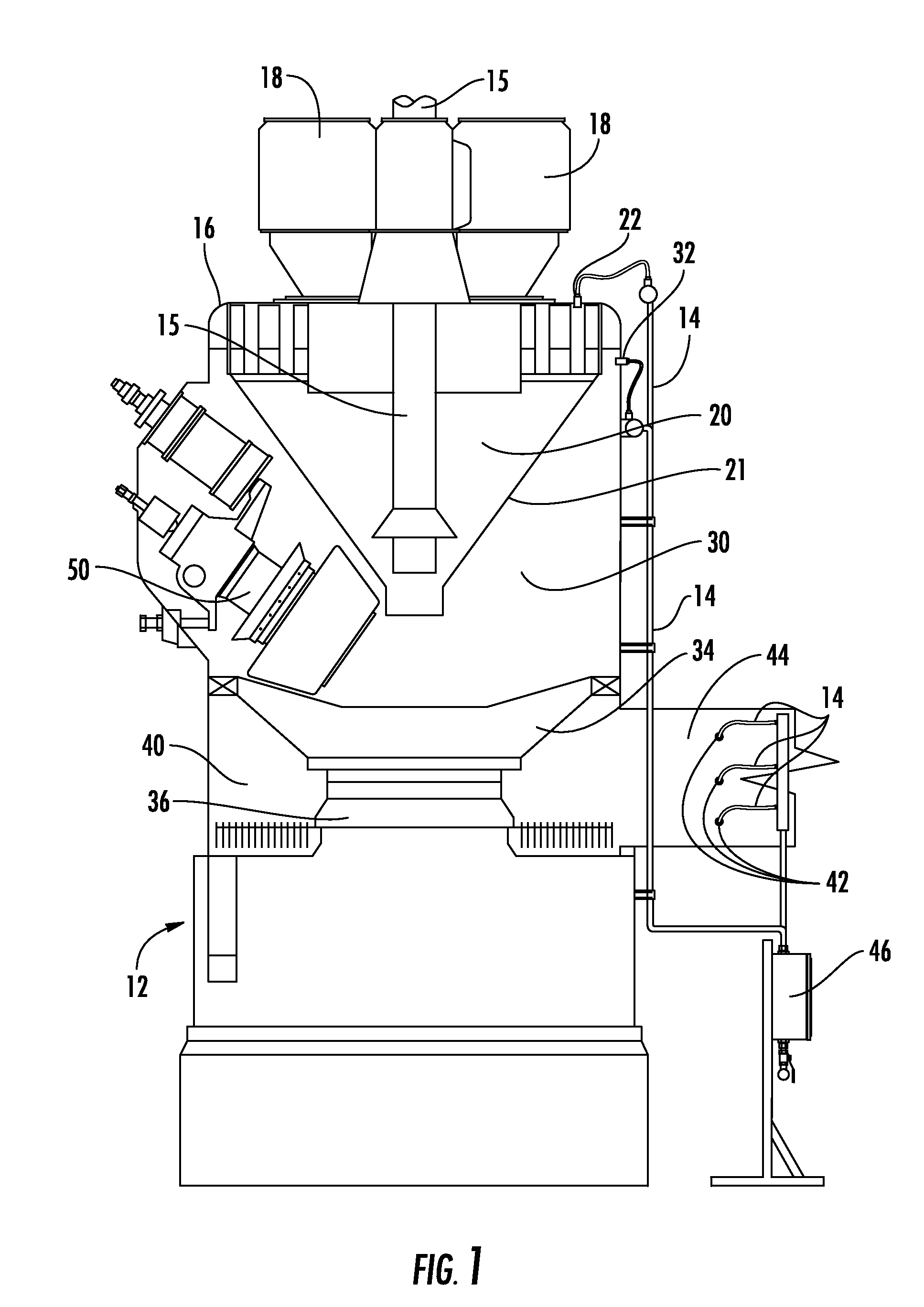

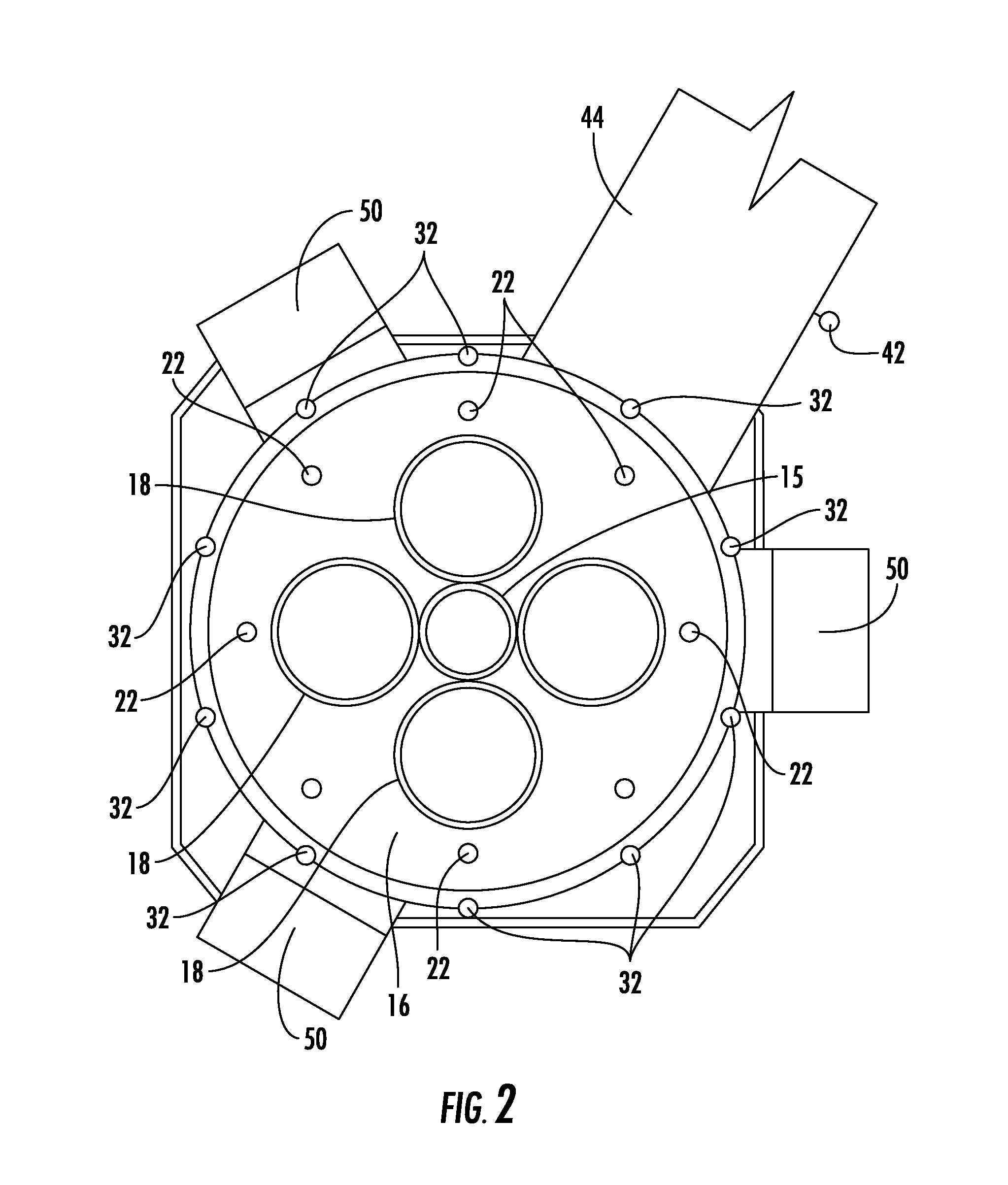

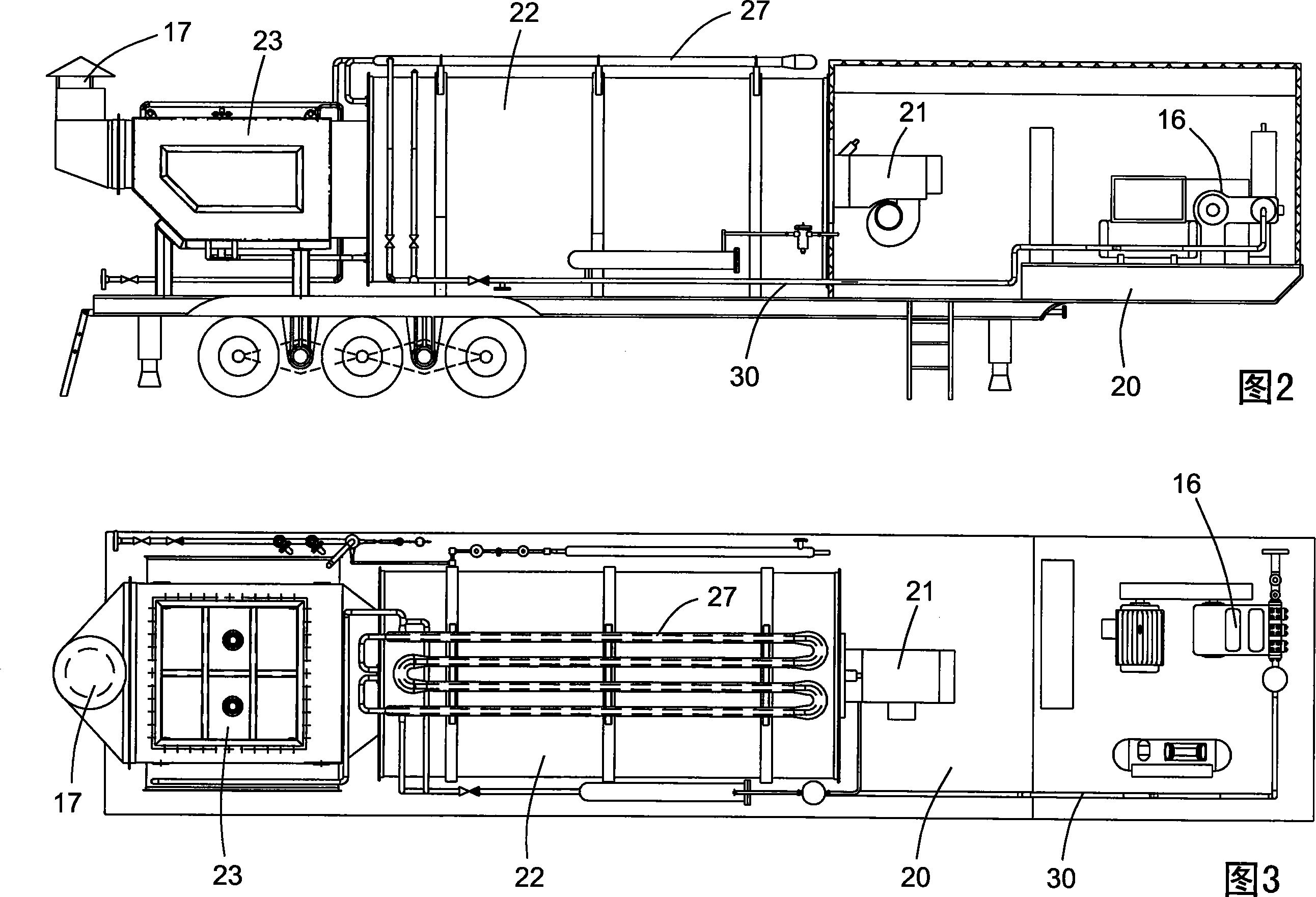

Pulverizer mill protection system

ActiveUS20150053799A1High riskProvide protectionFire rescueGrain treatmentsDistribution systemSpray nozzle

A system for suppressing and inhibiting fires in coal pulverizer mills can include a fire suppression solution storage tank, a flow control cabinet, an equipment control / pumping enclosure, an air distribution system, and injection piping and nozzles installed at various positions in one or more pulverizer mills. A first set of nozzle assemblies in communication with the fire suppression solution are positioned in the mill to disperse the suppression solution within the classifier zone of the mill. A second set of nozzle assemblies in communication with the suppression solution are positioned within the mill to disperse the suppression solution within the grinding zone. A third set of nozzle assemblies are positioned within the primary air duct of the mill.

Owner:INNOVATIVE COMBUSTION TECH

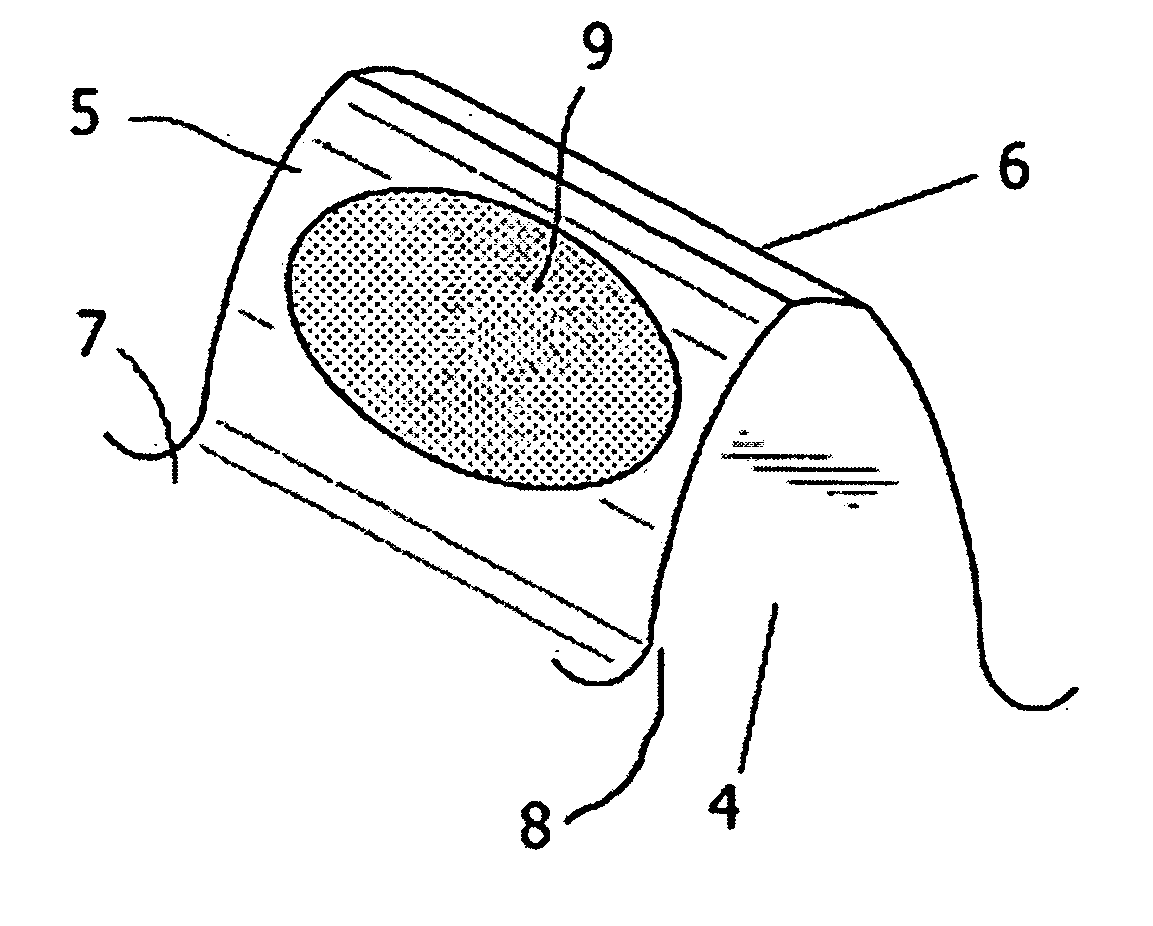

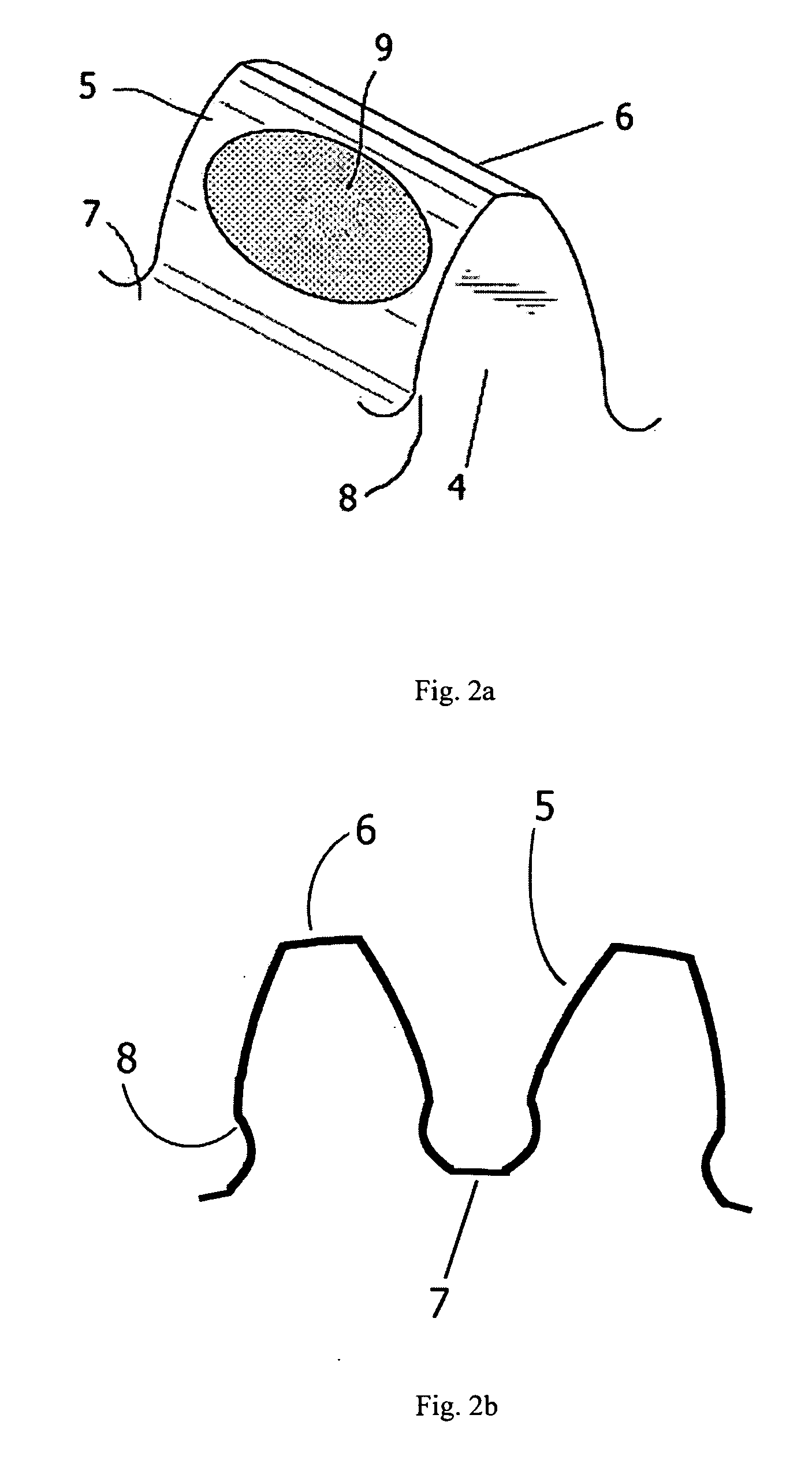

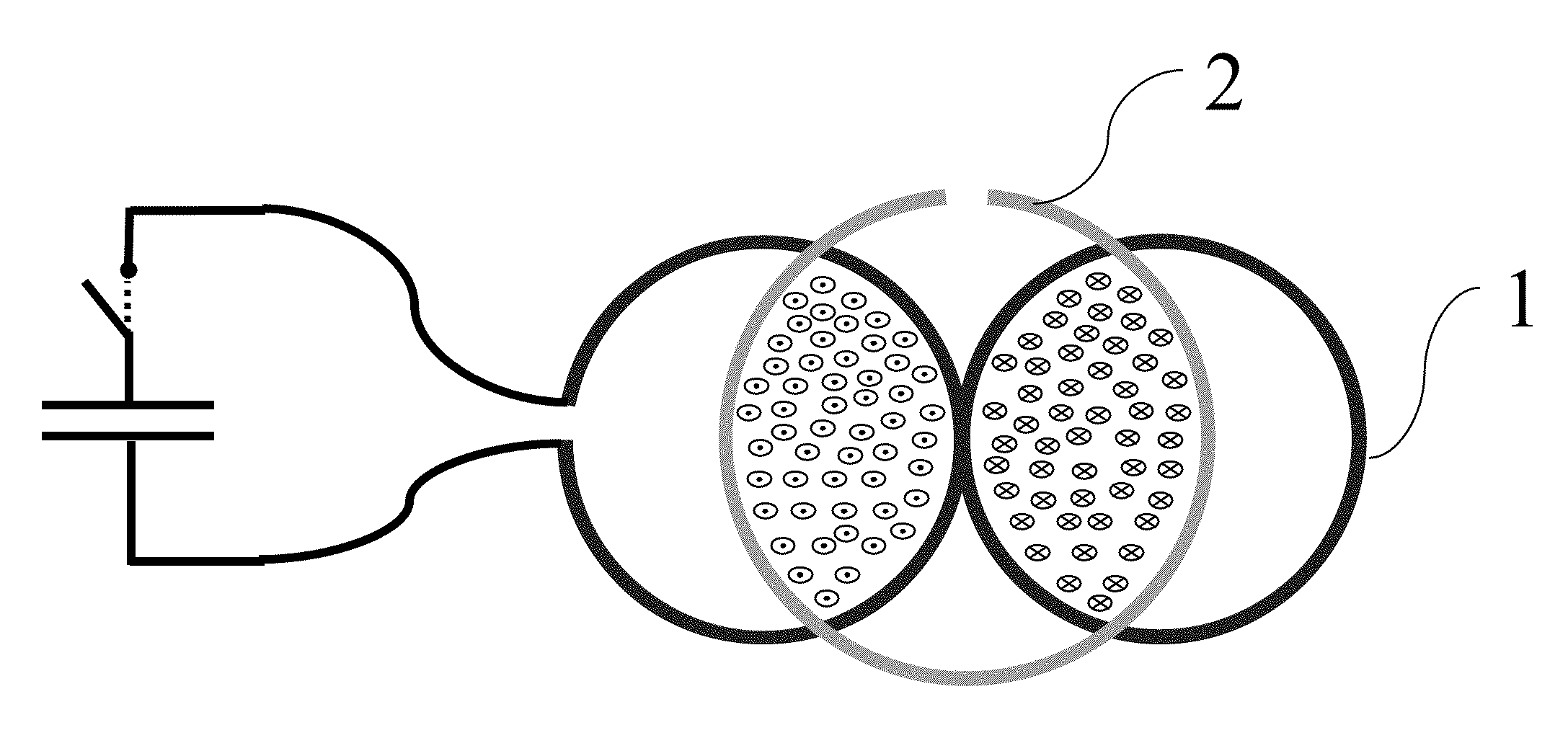

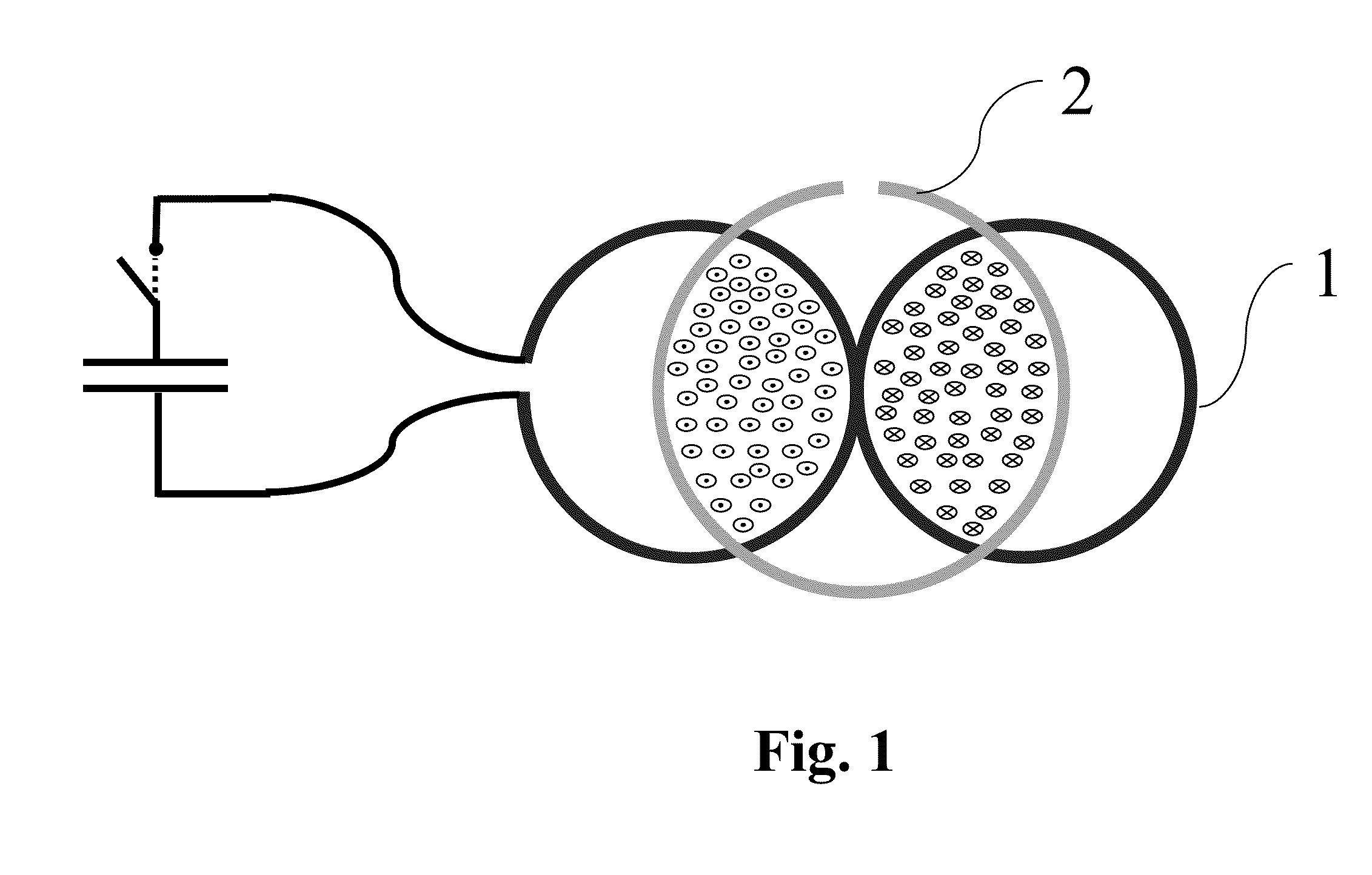

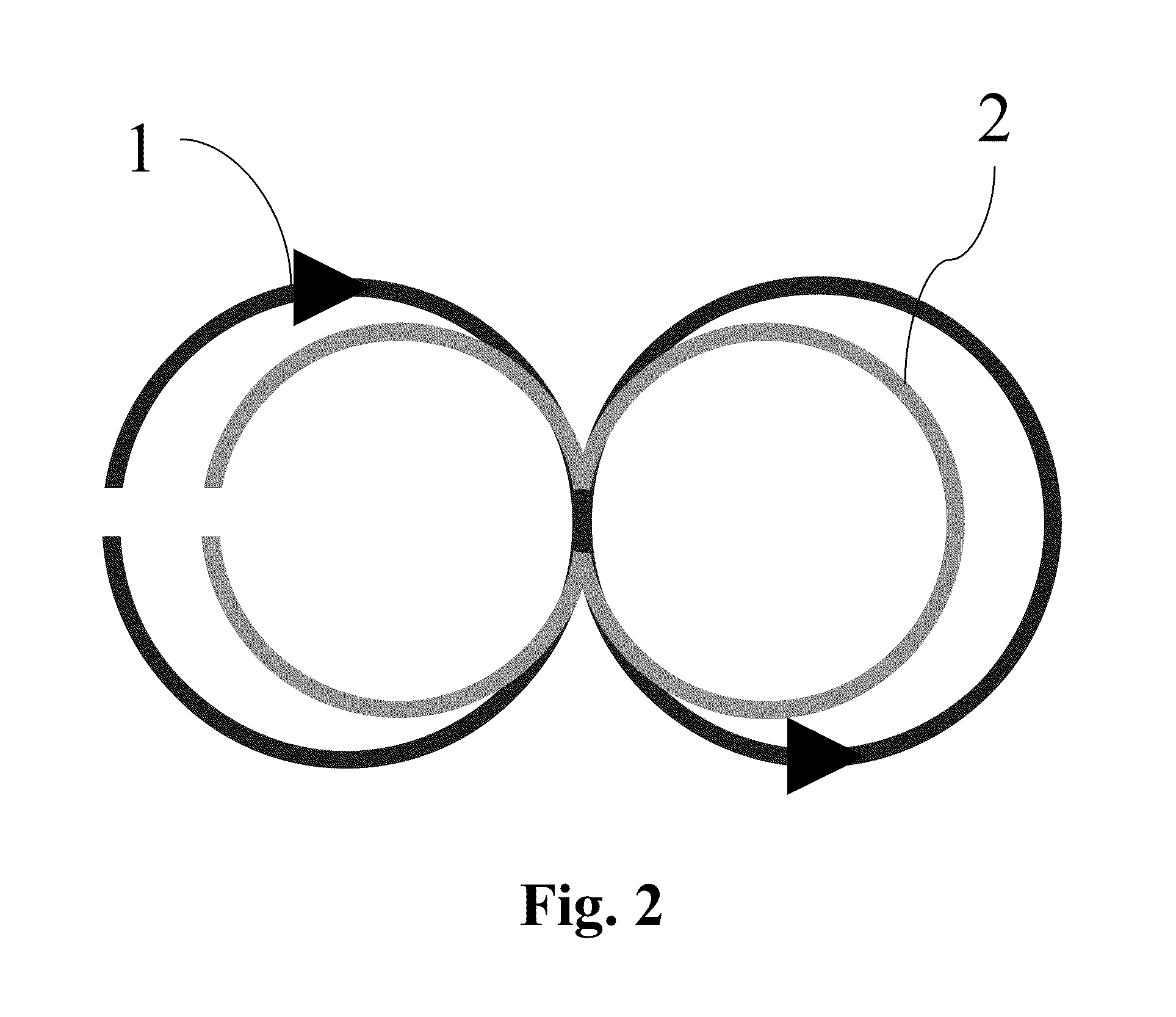

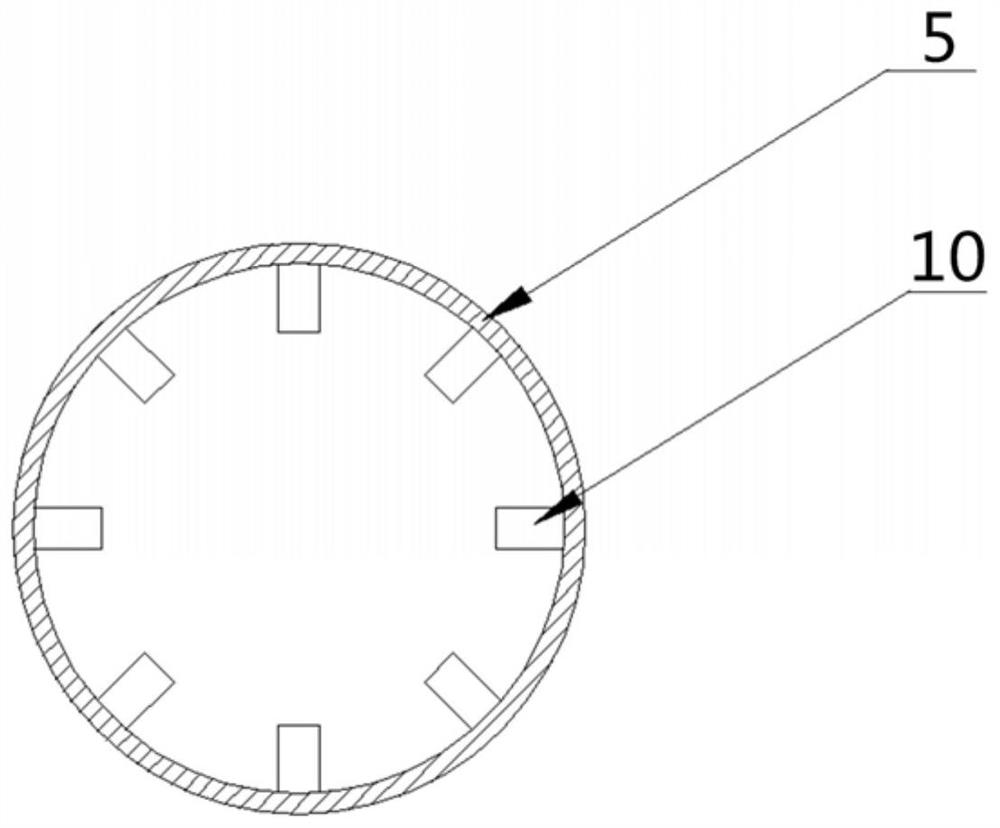

Magnetic Stimulation coils with electrically conducting structures

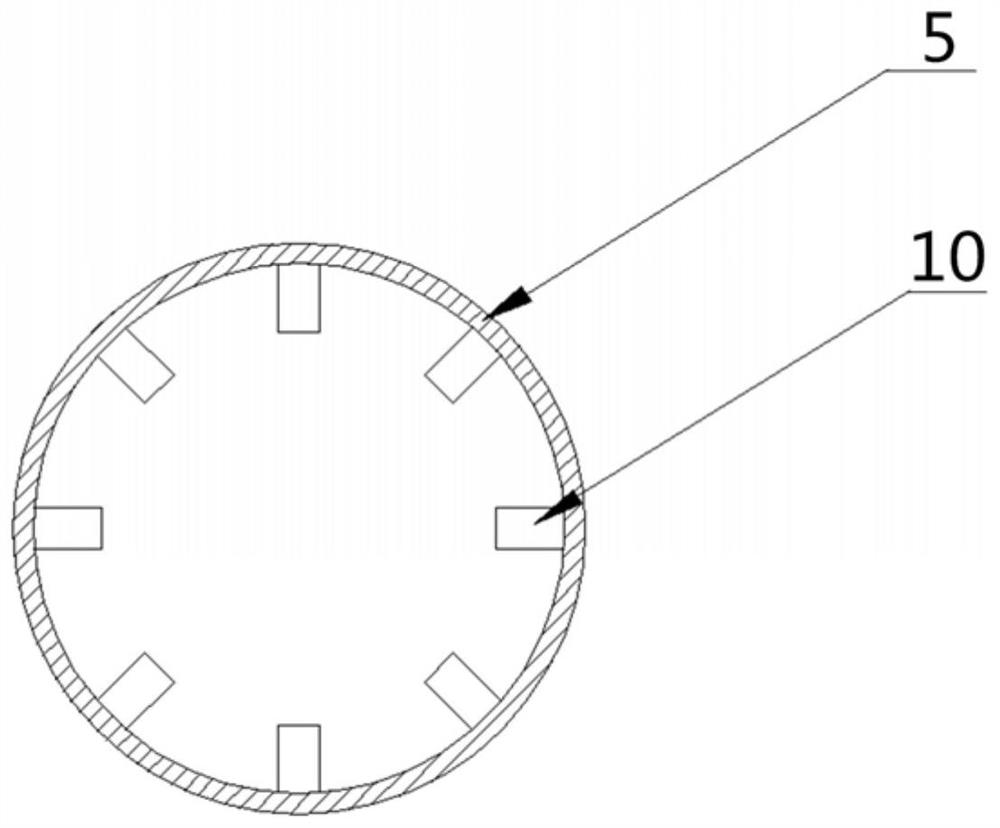

InactiveUS20110218381A1Improve rigidityTransfer of heatElectrotherapyMagnetotherapy using coils/electromagnetsNon magneticConductor Coil

The present invention introduces a novel apparatus (5) for providing magnetic stimuli to the human brain, the apparatus (5) comprising a casing (4) and at least one coil winding (1) adapted to carry electrical current and enclosed within the casing (4) as well as cooling means (2) situated in thermal connection with the coil (1) and comprising a body made of electrically conductive and non-magnetic material so that the mutual inductance between the coil (1) and the cooling means (2) is essentially zero.

Owner:NEXSTIM

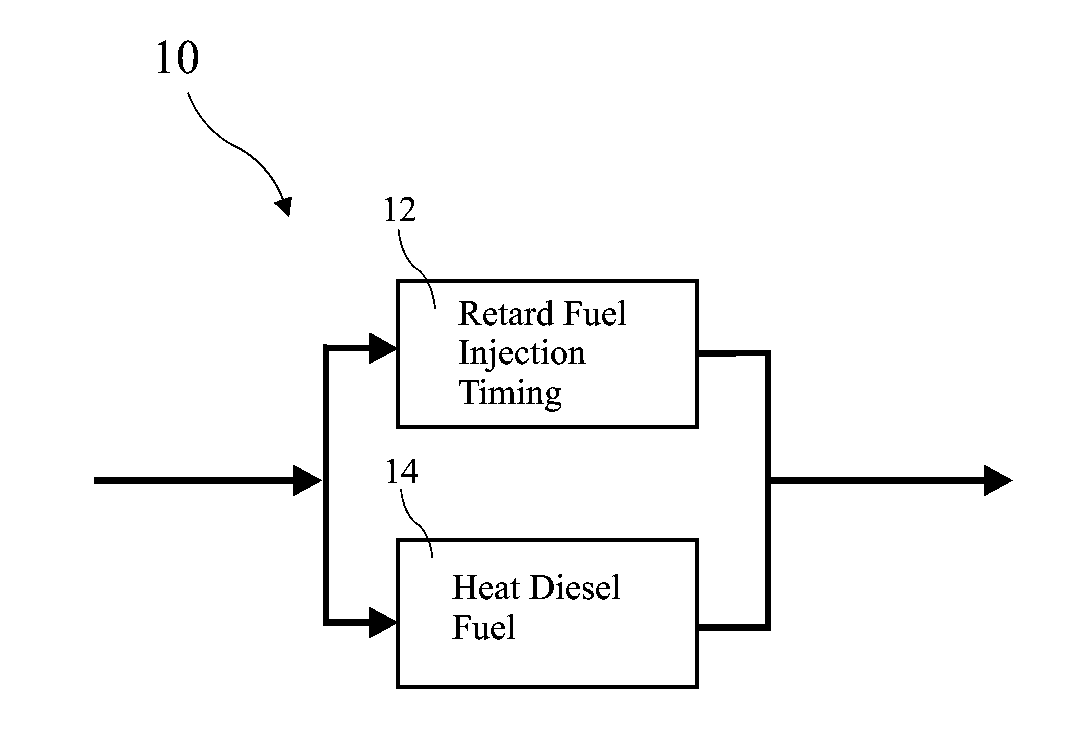

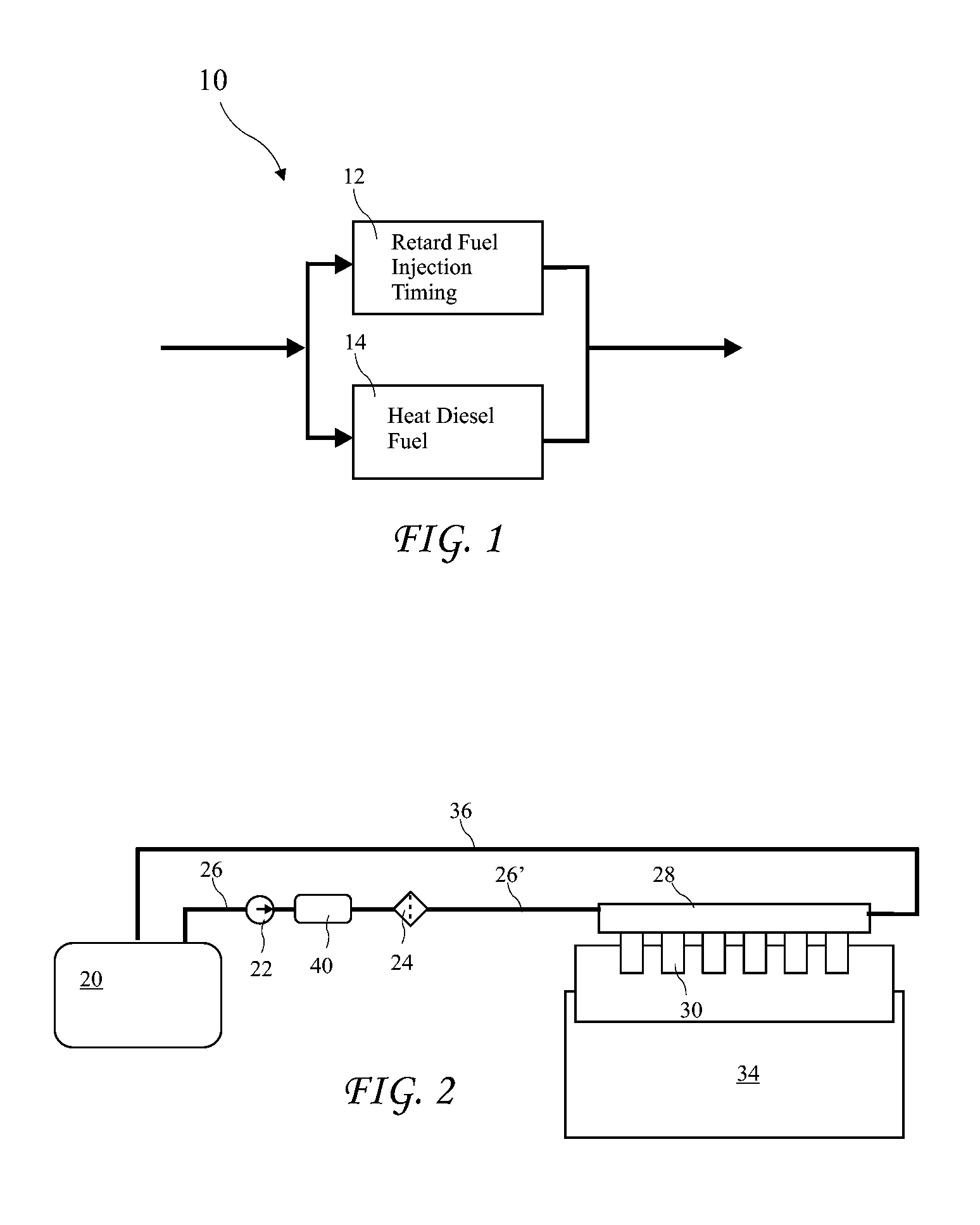

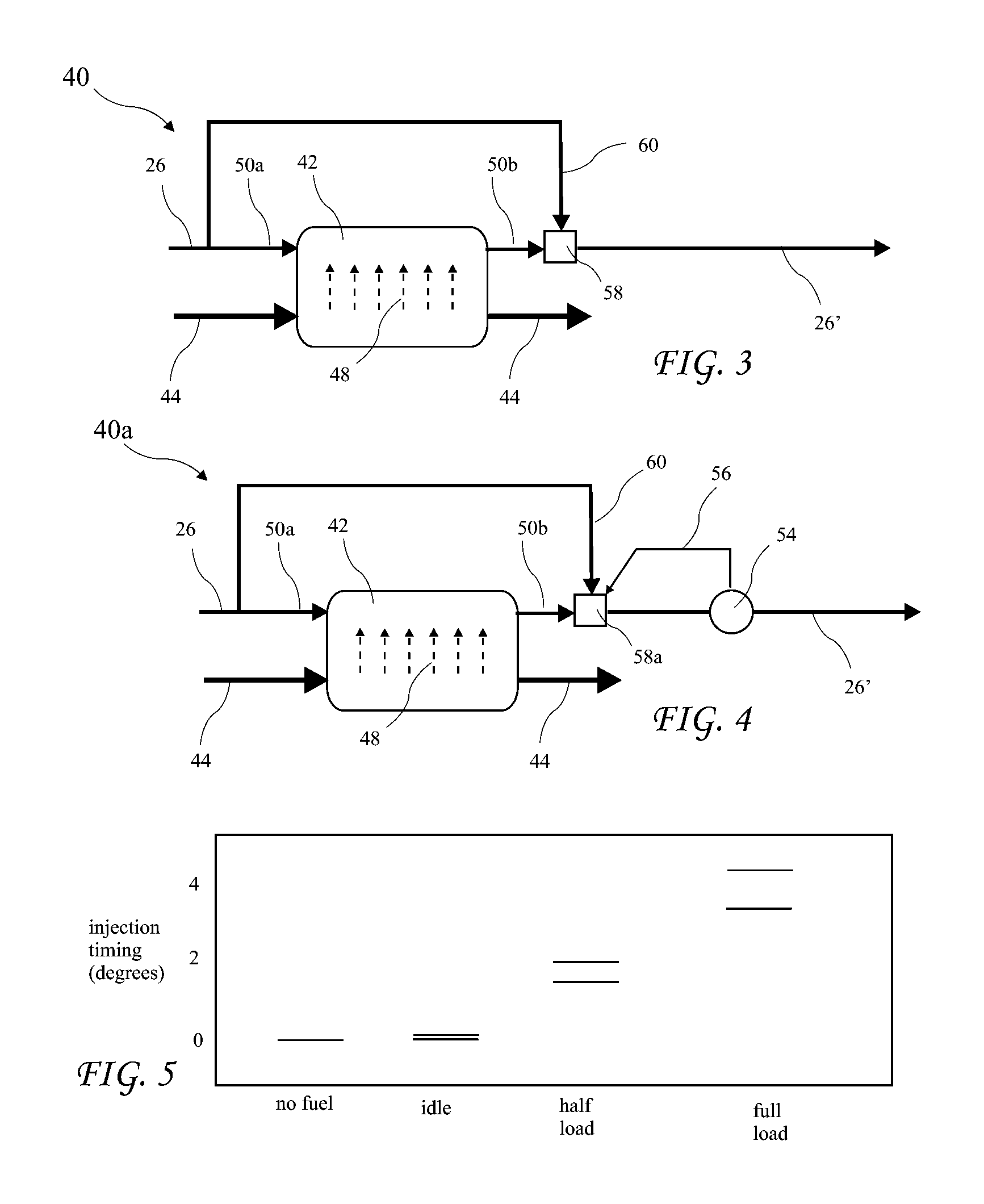

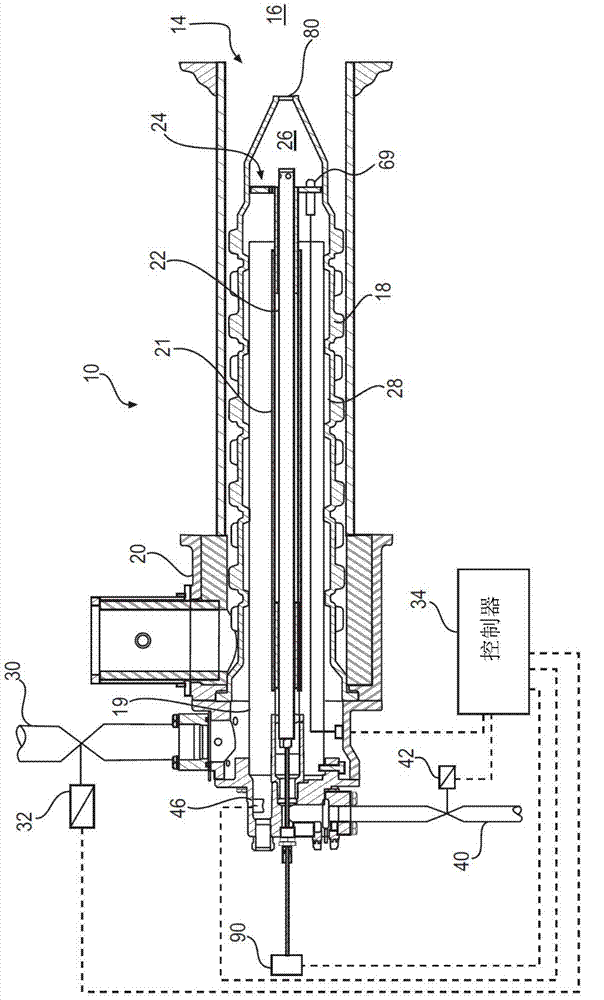

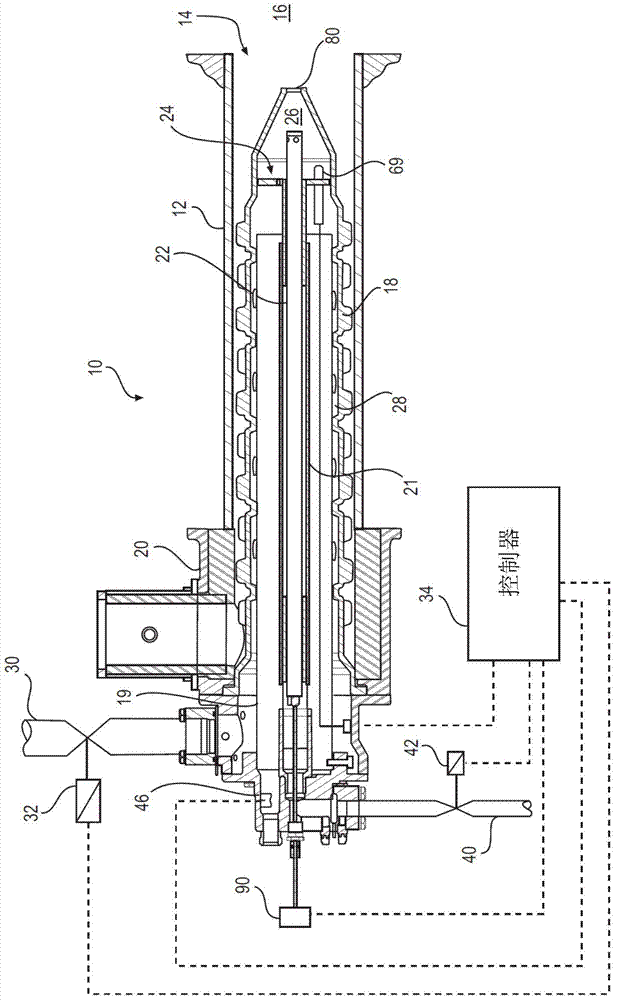

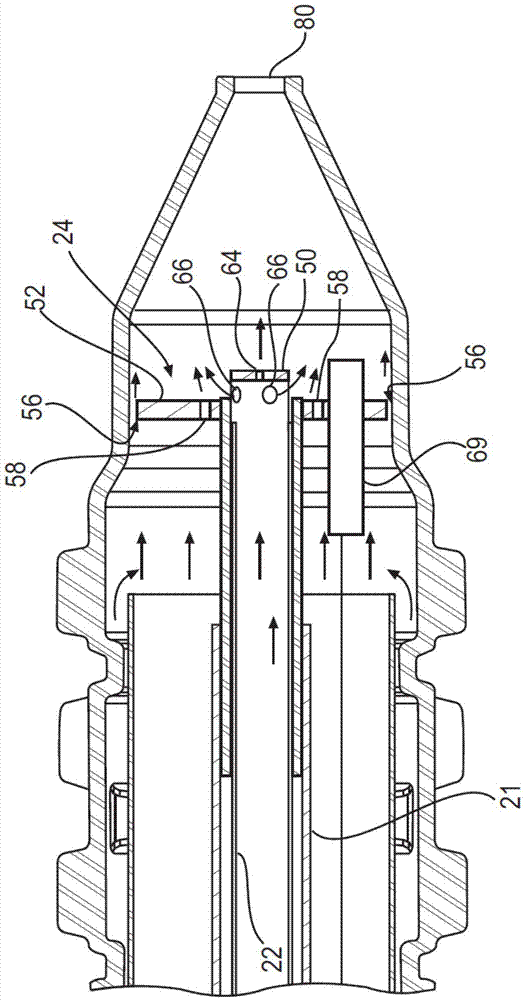

Tug Boat Engine Emissions Control Suite

InactiveUS20110253103A1Reduce temperature peaksIncreased particulate emissionElectrical controlInternal combustion piston enginesParticulatesNitrogen oxides

A tug boat diesel engine emissions control suite includes modified fuel injectors including a fuel injection timing retard feature, and diesel fuel heating. Tug boats are now required to comply with USEPA emission standards under 40 CFR Part 94 regulations. Retarding the fuel injection timing reduces peak temperatures during combustion which in turn reduces production of Nitrogen Oxides (NOx) but also increases emissions of particulate matter (PM), Carbon Monoxide (CO), and Hydrocarbons (HC) in the exhaust. Heating the diesel fuel provides a reduction in increased PM, CO, and HC to acceptable levels. Experiments showed that a novel modification to a plunger in the fuel injectors providing up to six degrees of fuel injection timing retarding, and fuel heated to 120 to 140 degrees Fahrenheit, resulted in meeting the 40 CFR Part 94 regulations.

Owner:HELM ENVIRONMENTAL SOLUTIONS

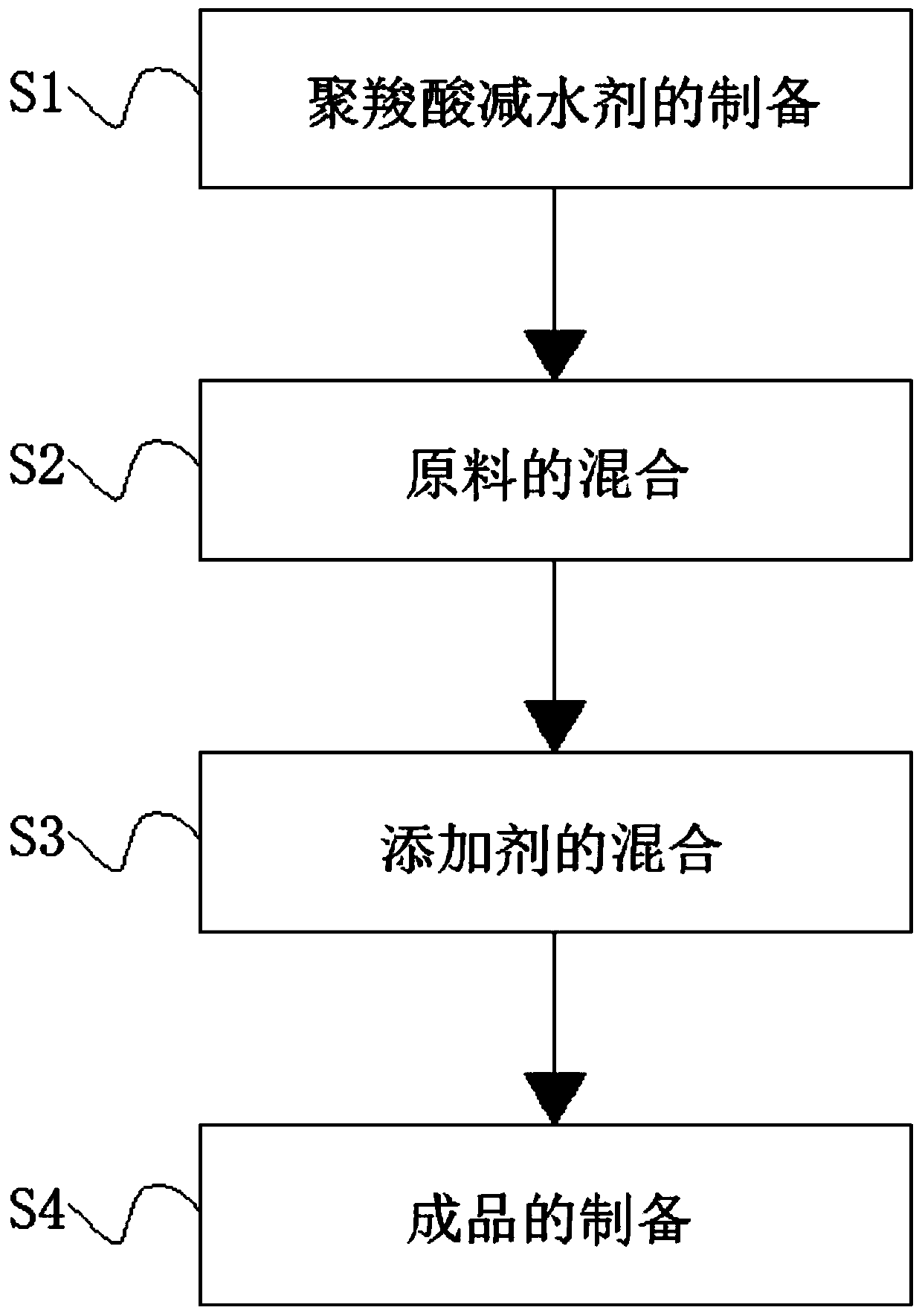

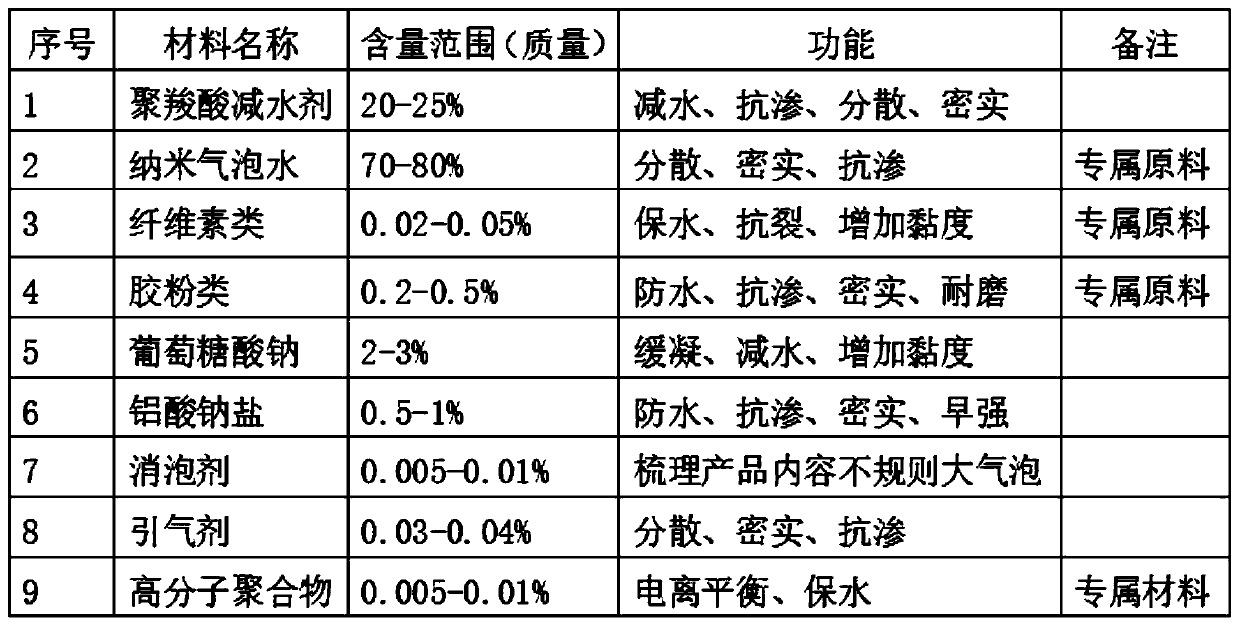

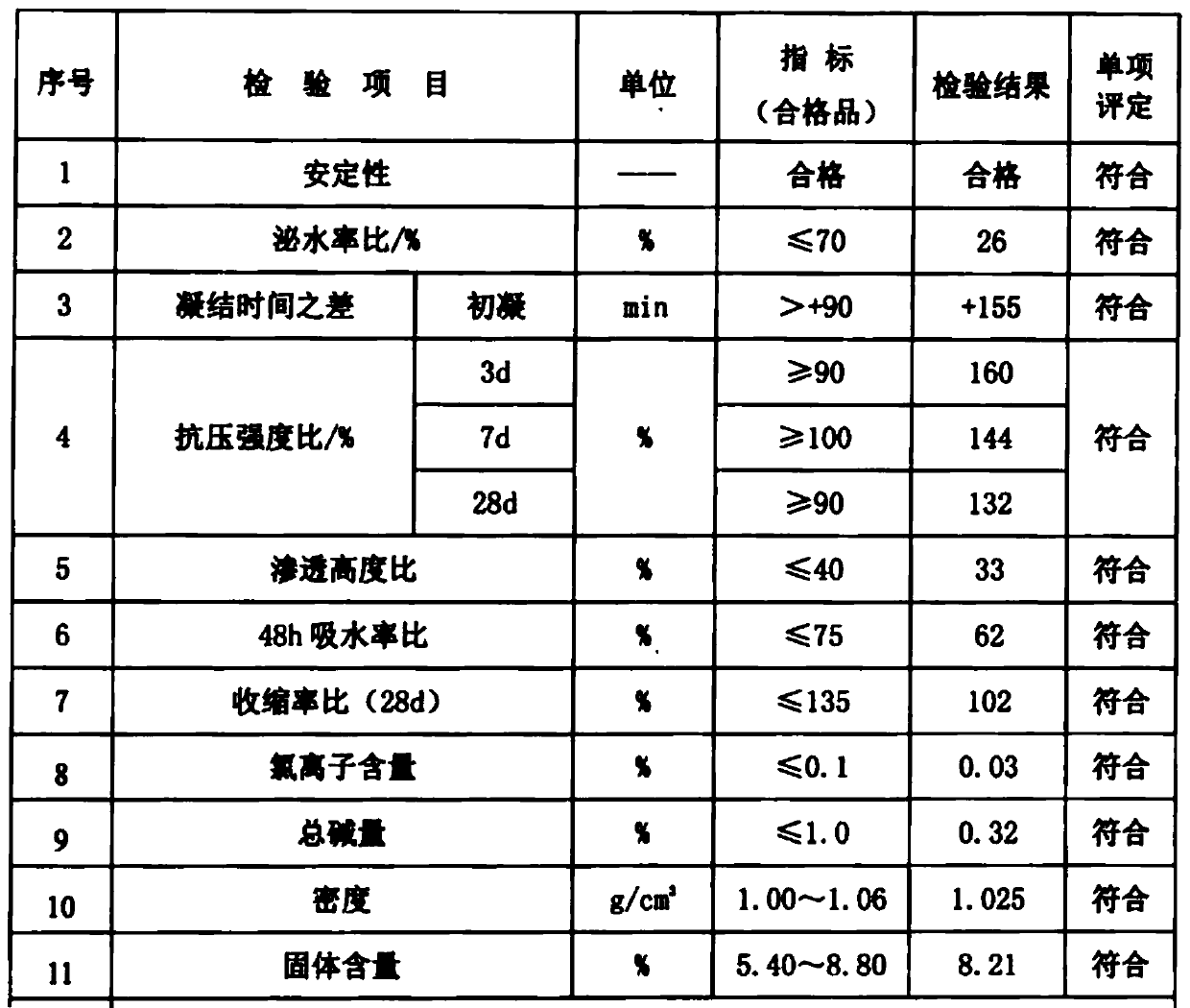

Preparation method of micro-nano porous impermeable crack-resistance concrete additive

The invention discloses a preparation method of a micro-nano porous impermeable crack-resistance concrete additive, and belongs to the technical field of building water resistance. The preparation method comprises following steps: 1, preparation of a polycarboxylic acid water reducer; 2, raw material mixing; 3, additive mixing; and 4, finished product preparation. According to the preparation method, combined water resistance is replaced by concrete structure type water resistance, water-proof material cost is reduced greatly, multi-layer water-proof construction process is avoided, so that construction time is shortened, construction working efficiency is increased greatly, artificial construction steps are reduced greatly, artificial cost is reduced, and artificial construction imbalancehidden trouble is avoided; a concrete self water-proof system is adopted, so that water resistance lasting period is as long as building service life, in the prior art, maintenance cost is extremelyhigh because of leakage caused by various factors in water proof construction, while almost no daily maintenance is needed in the invented technology.

Owner:广西北海市圣峰建材科技有限公司

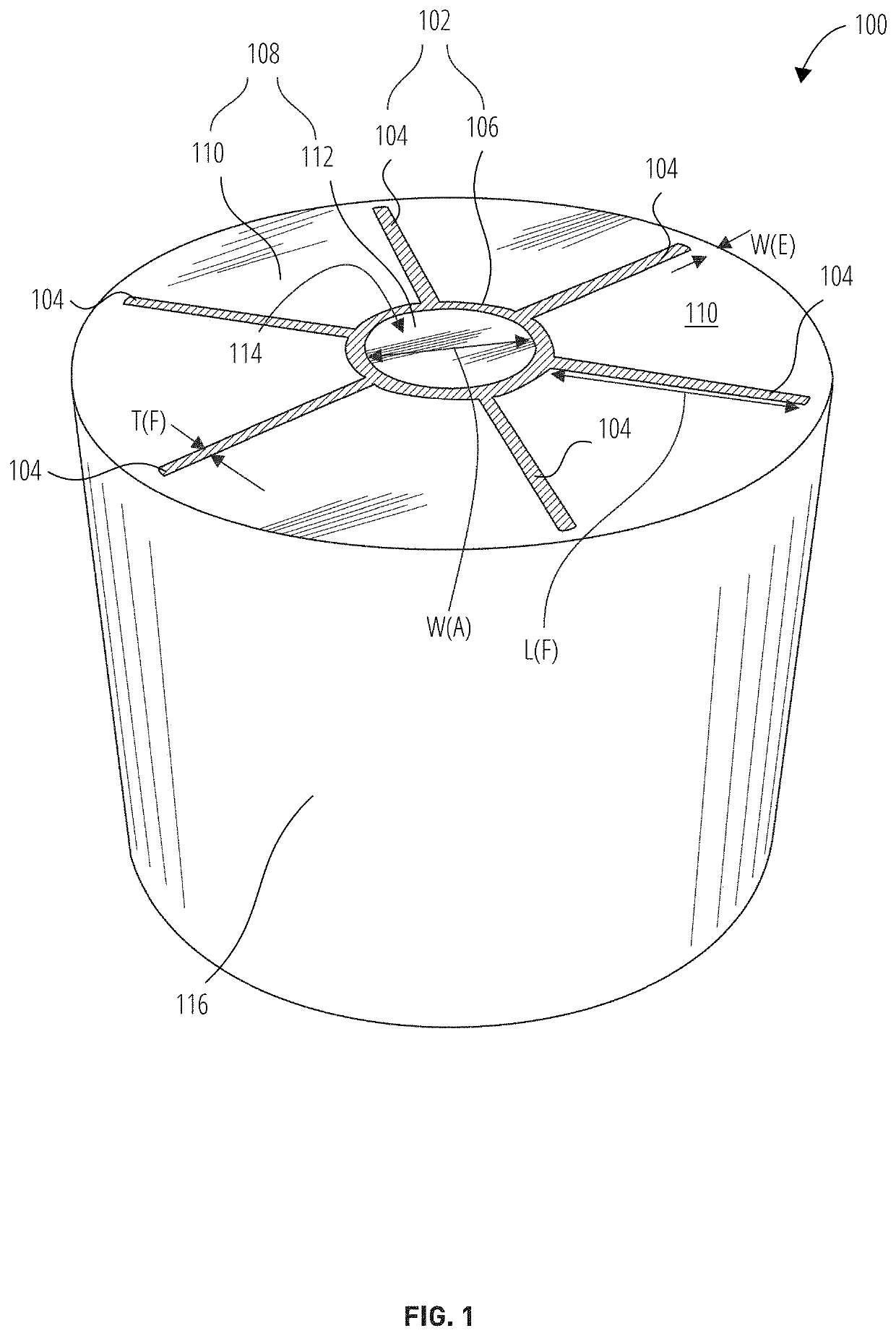

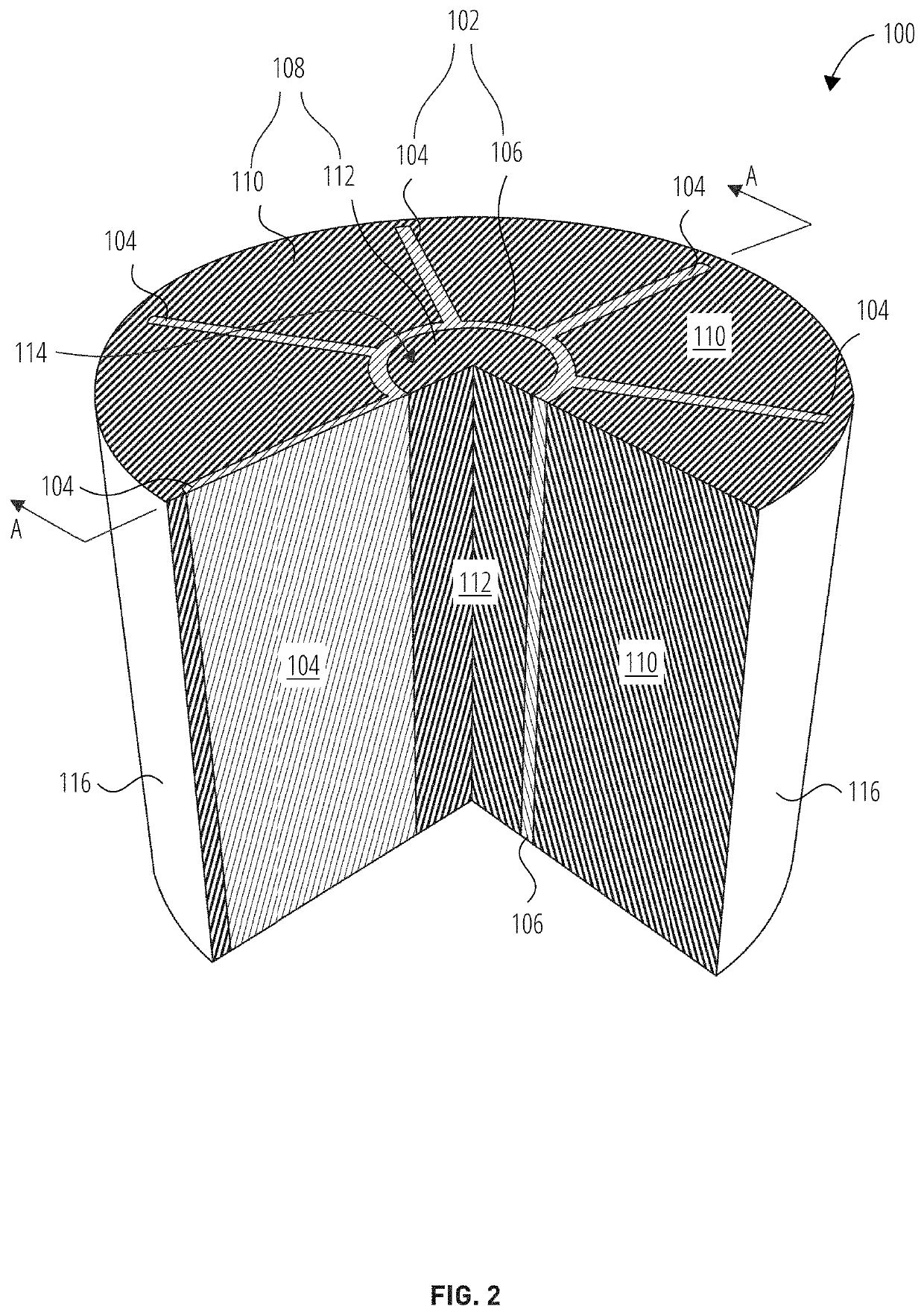

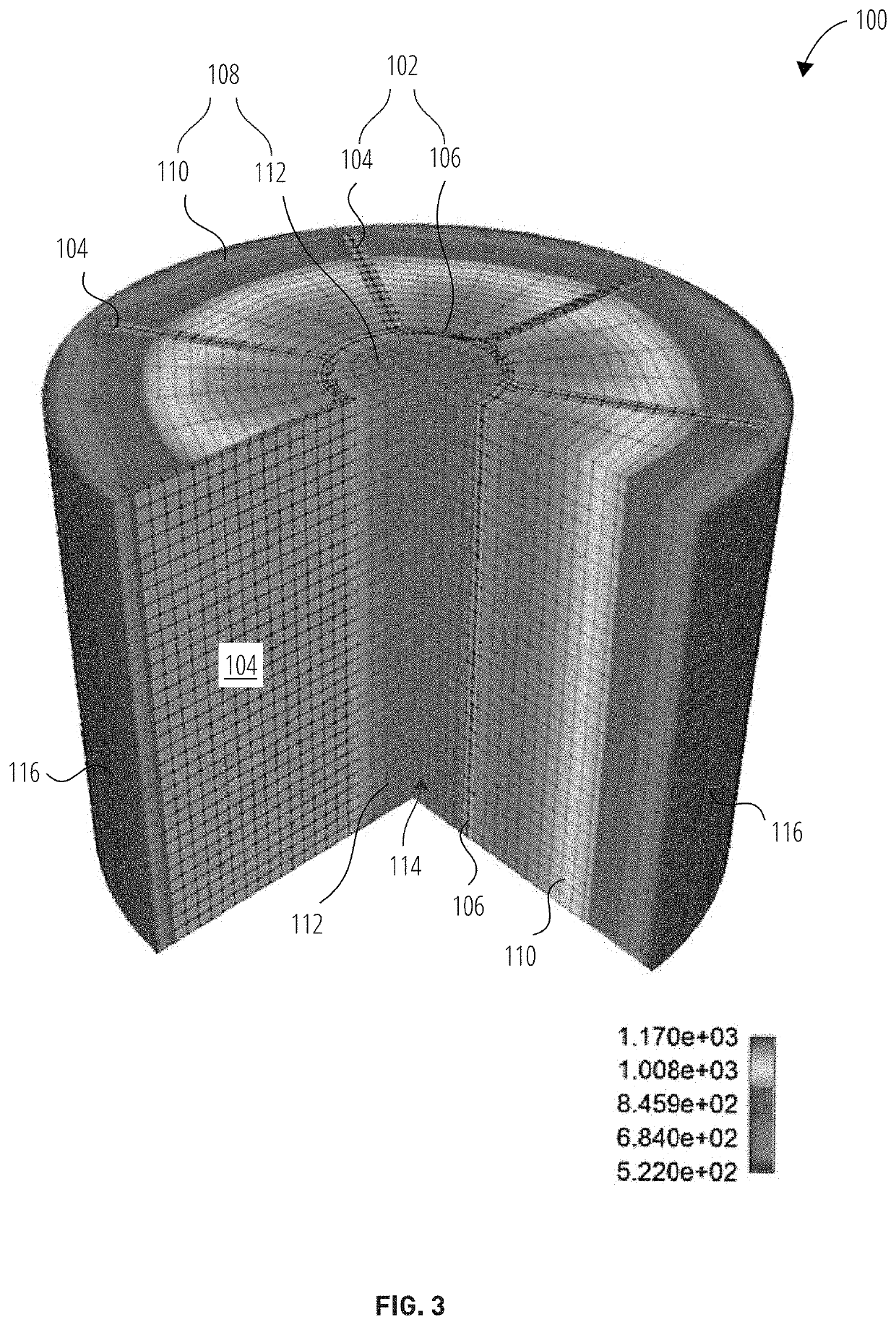

Reactor fuel pellets with thermally-conductive inserts, and related reactor fuel pellet arrangements

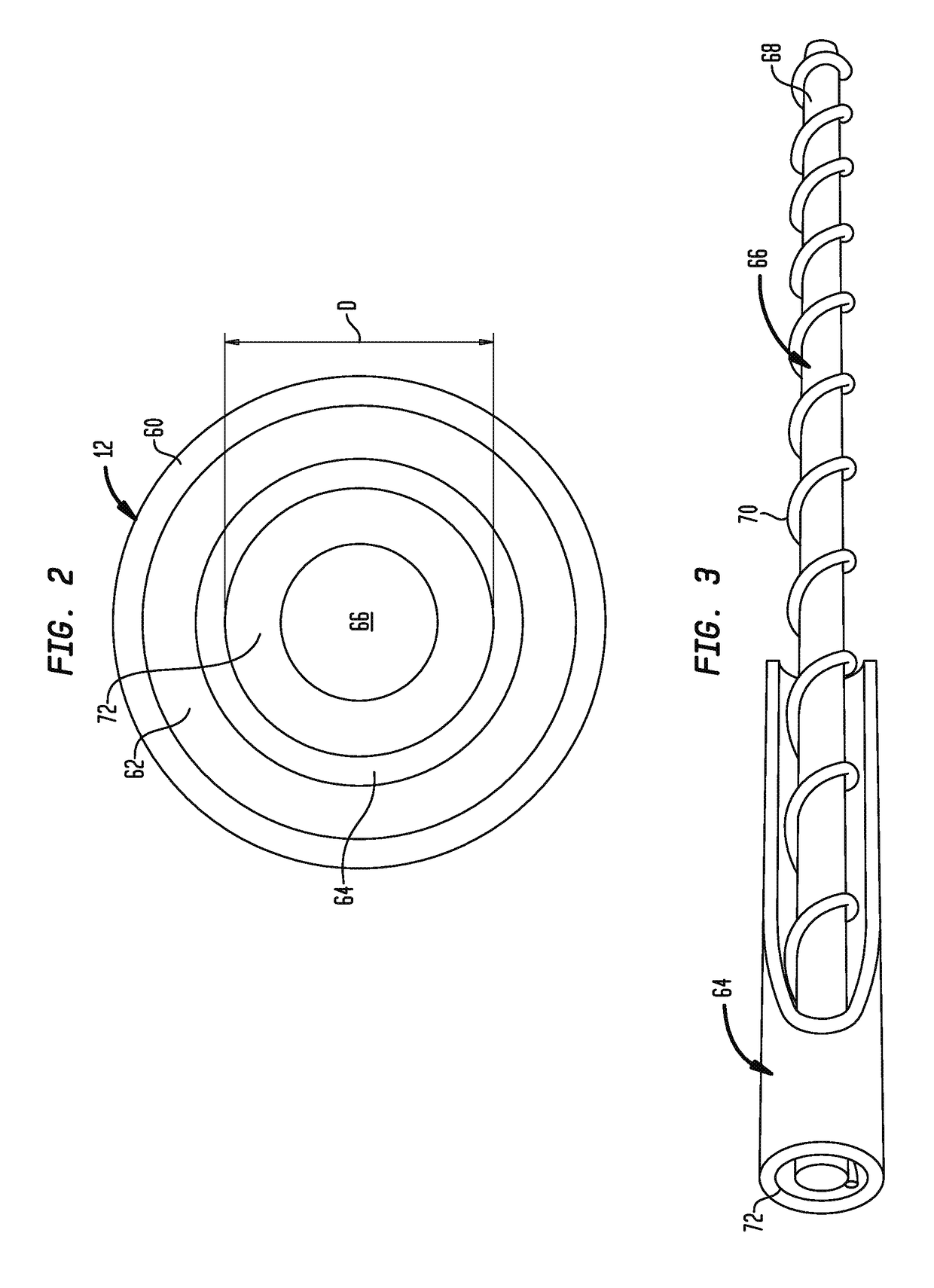

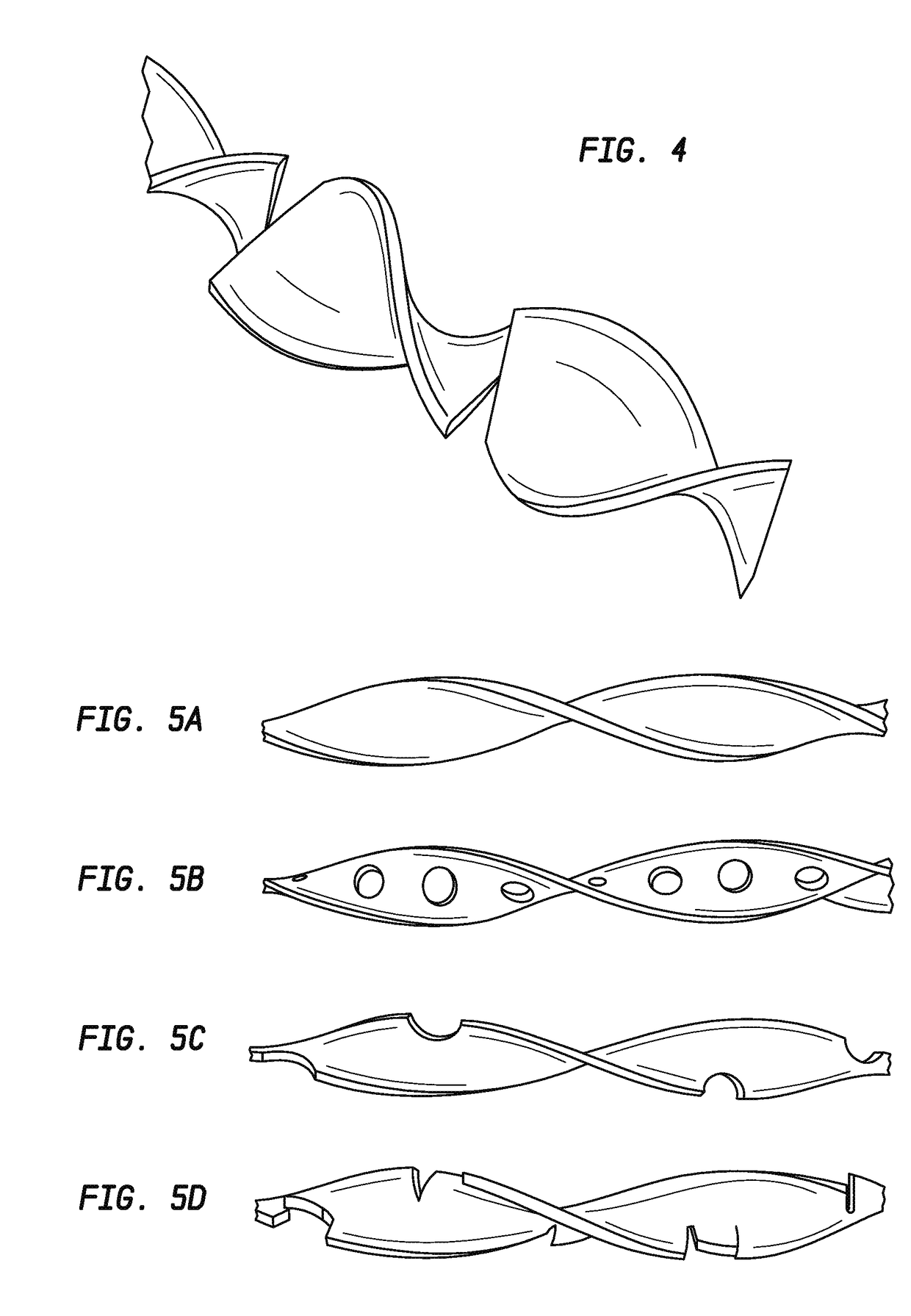

ActiveUS20210125735A1Small volumeReduce temperature peaksOptical rangefindersFuel elementsNuclear physicsNuclear engineering

Fuel pellets and fuel pellet arrangements include thermally-conductive inserts within a fuel. The inserts have at least one portion of a thermally-conductive material, such as radially-extending fins. The inserts are configured to dissipate heat during use of the fuel pellets, while minimizing the amount of the total volume of the fuel pellet that is occupied by non-fissile material. The inclusion of heat-dissipating inserts enables the fuel pellets to exhibit improved thermal performance over the lifetime of the fuel, including a relatively low peak temperature and relatively low integrated average temperatures, while the minimal volume of the inserts avoids significantly decreasing the percent of enrichment achievable.

Owner:HAYES SOLOWAY PC +1

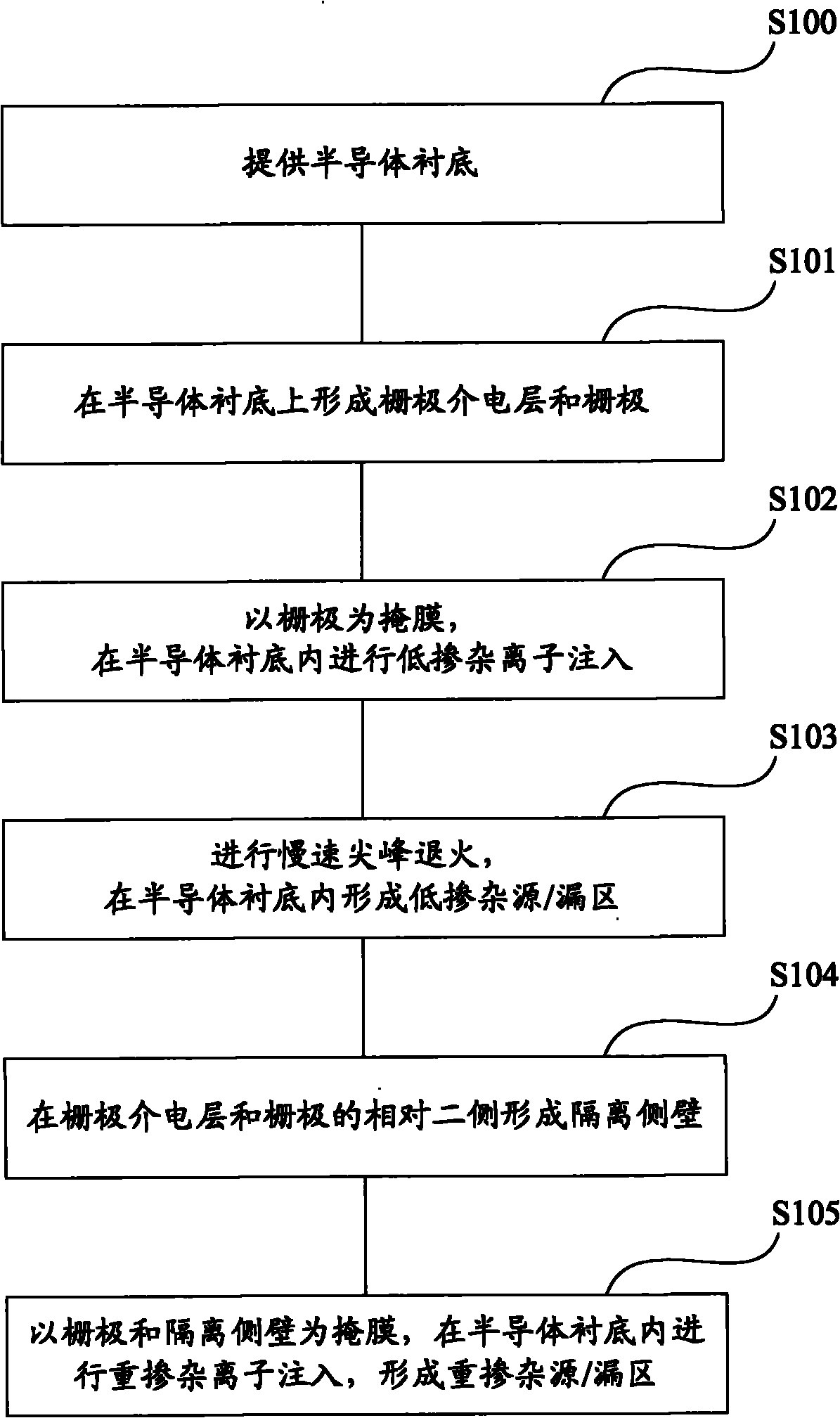

Method for manufacturing semiconductor device

InactiveCN101840861AReduce temperature peaksReduce the temperatureSemiconductor/solid-state device manufacturingSemiconductorState of art

The invention relates to a method for manufacturing a semiconductor device. The method comprises the following steps of: providing a semiconductor substrate, and forming a grid dielectric layer on the semiconductor substrate and a grid on the grid dielectric layer; taking the grid as a mask, and carrying out light-doping ion injection in the semiconductor substrate; carrying out slow spike-anneal, and forming a light-doping source / drain area in the semiconductor substrate; forming isolation side walls on two opposite sides of the grid dielectric layer and the grid; taking the grid and the isolation side walls as the masks, and carrying out heavy-doping ion injection in the semiconductor substrate to form a heavy-doping source / drain area. Compared with the prior art, the invention not only has the effects of activating doped elements and inhibiting the diffusion of the doped ions, but also can decrease the temperature fluctuation of the wafer, decrease the heat budge and enhance the sensitivity of the device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method and apparatus for a dual mode burner yielding low NOx emission

InactiveCN104508373AReduce temperature peaksAvoid generatingIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

A method and apparatus for a burner adapted to heat a furnace or other environment of use. In particular, a burner for providing a fuel gas in combination with an oxidant to effect controlled reaction of the fuel gas in a manner to reduce NOx emissions is described. Combustion of the fuel gas is shifted from the burner combustor to a location outside the burner once the temperature within the furnace / radiant tube has reached a sufficient level to complete combustion of the fuel gas.

Owner:ECLIPSE

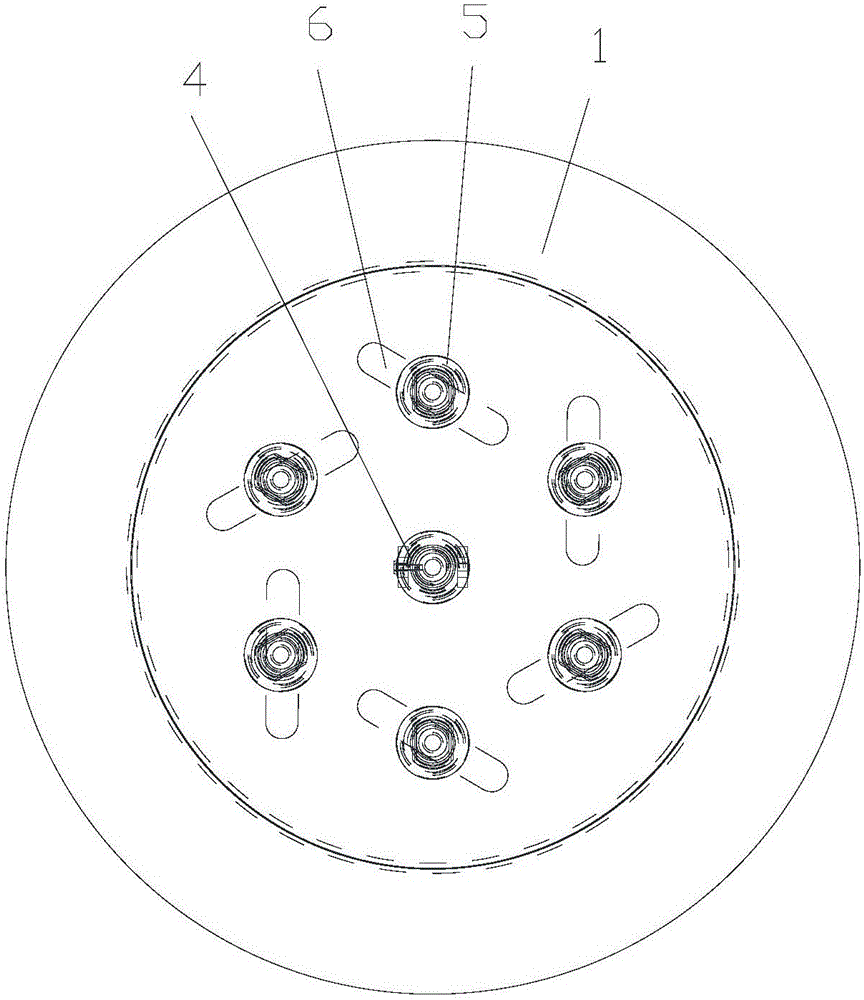

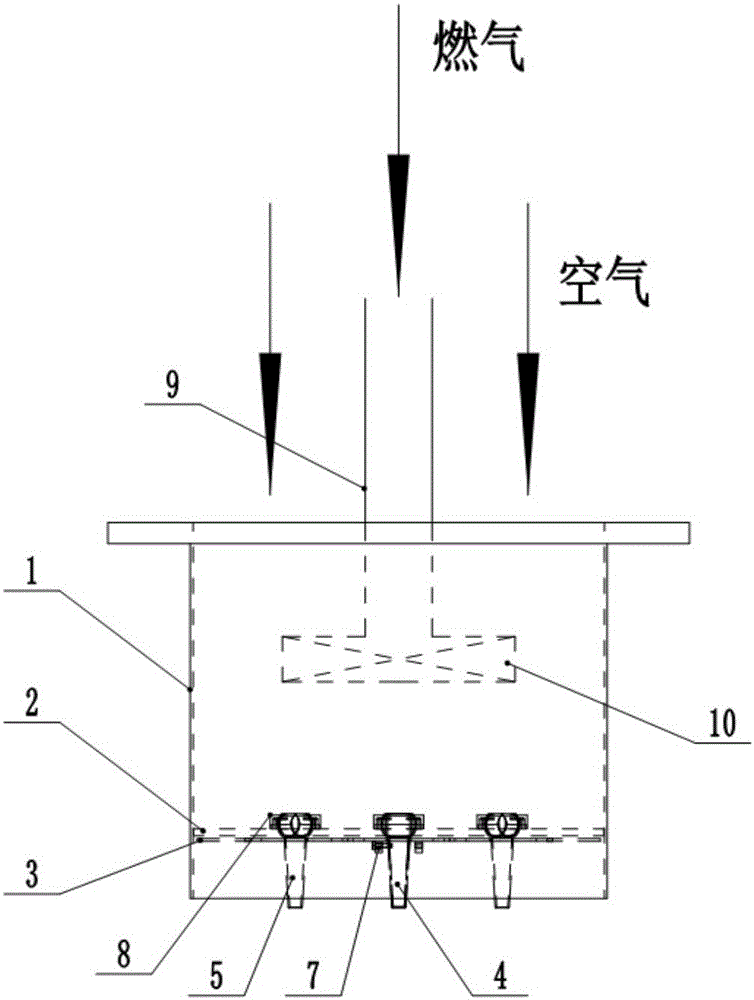

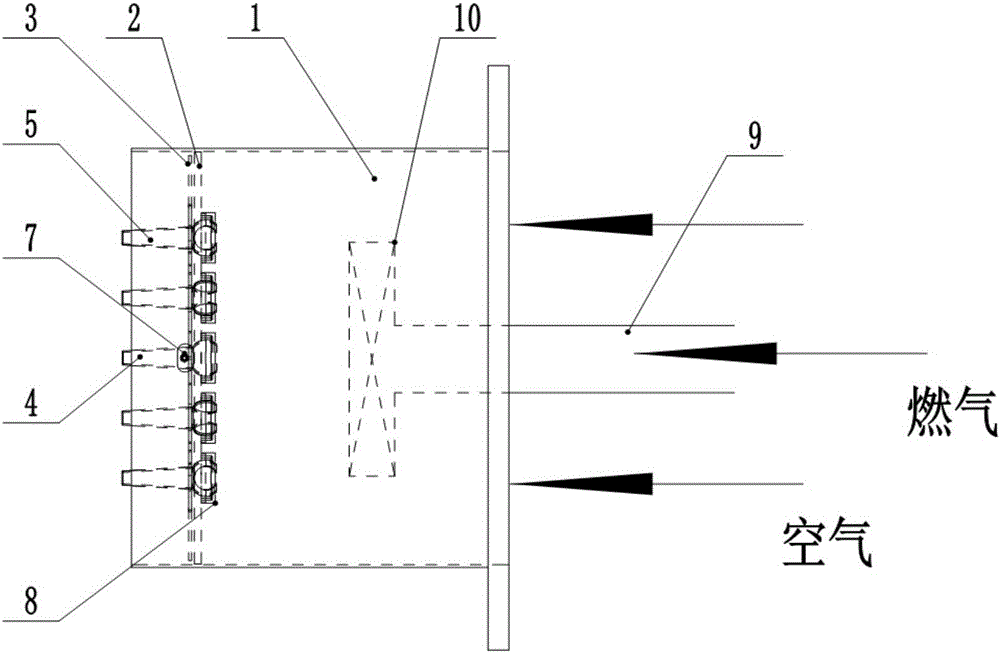

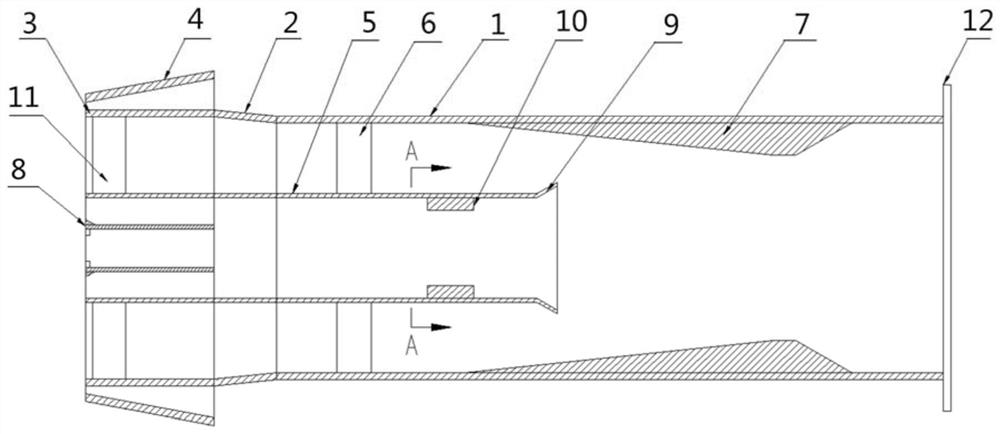

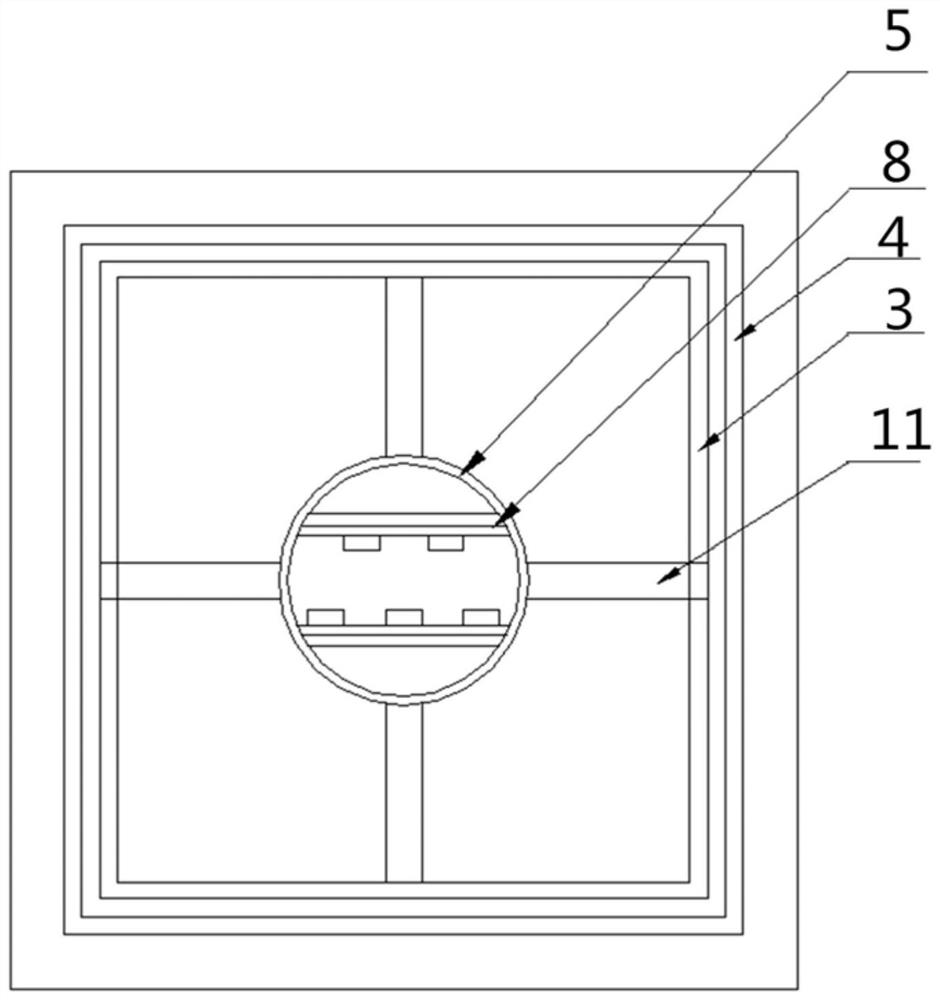

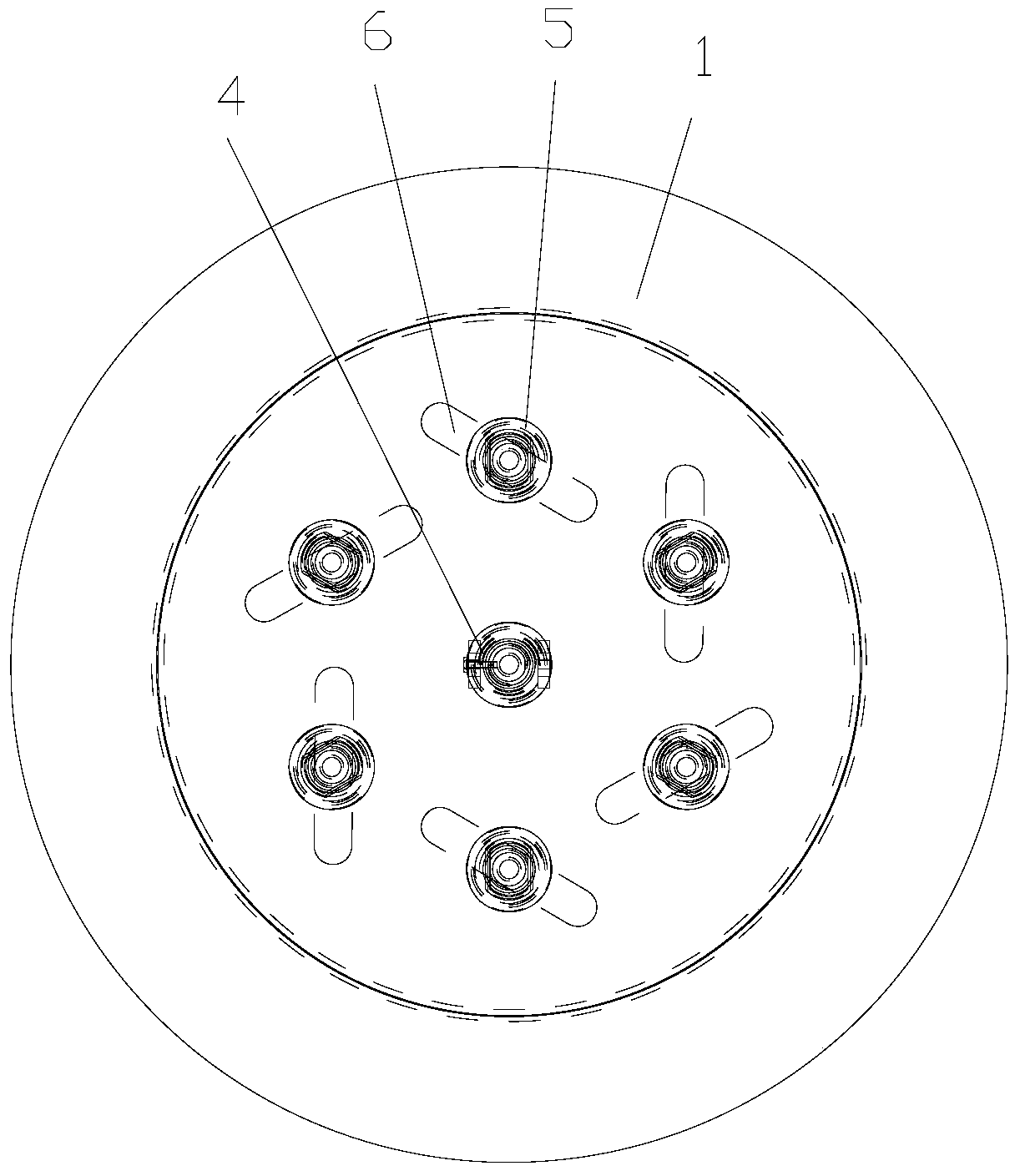

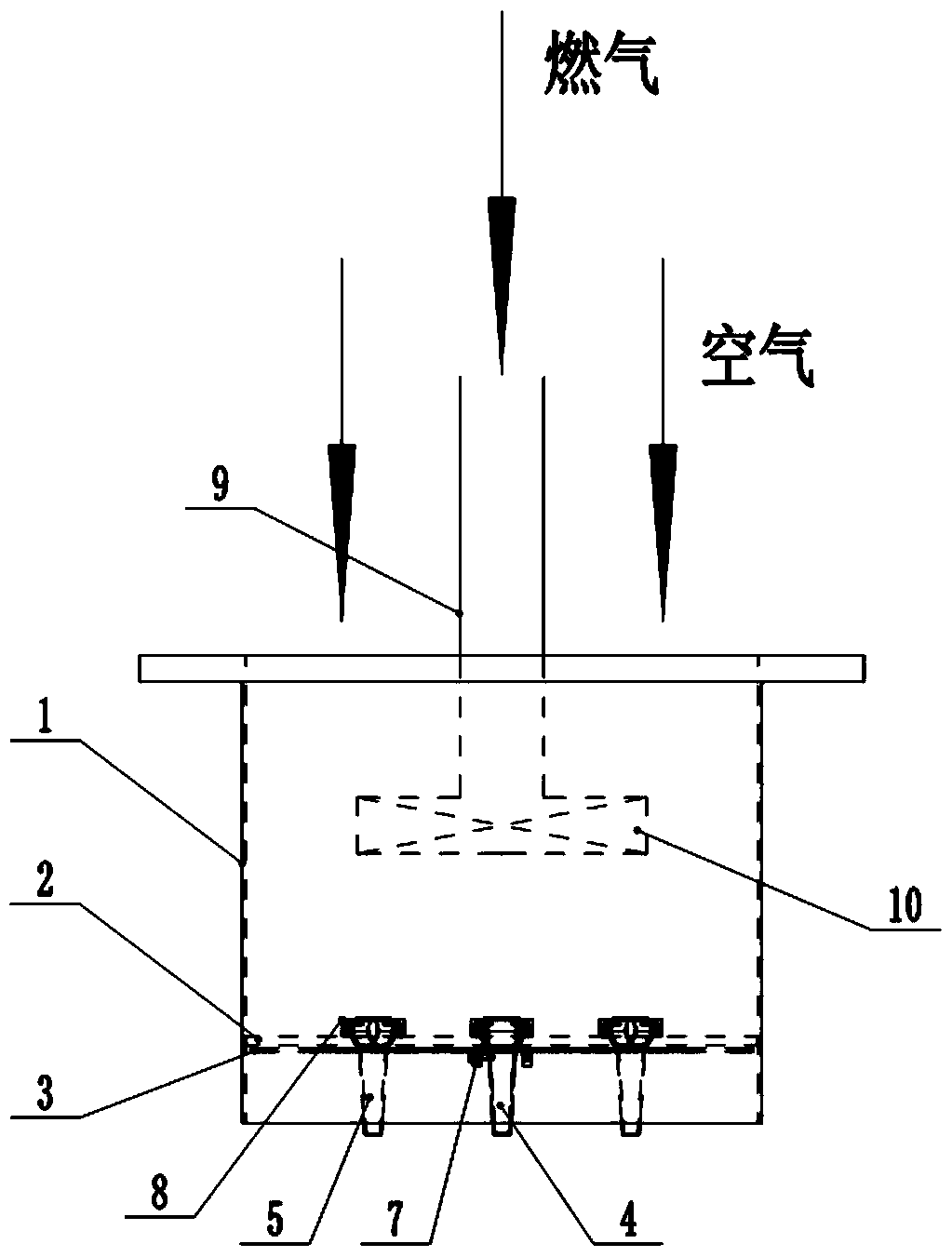

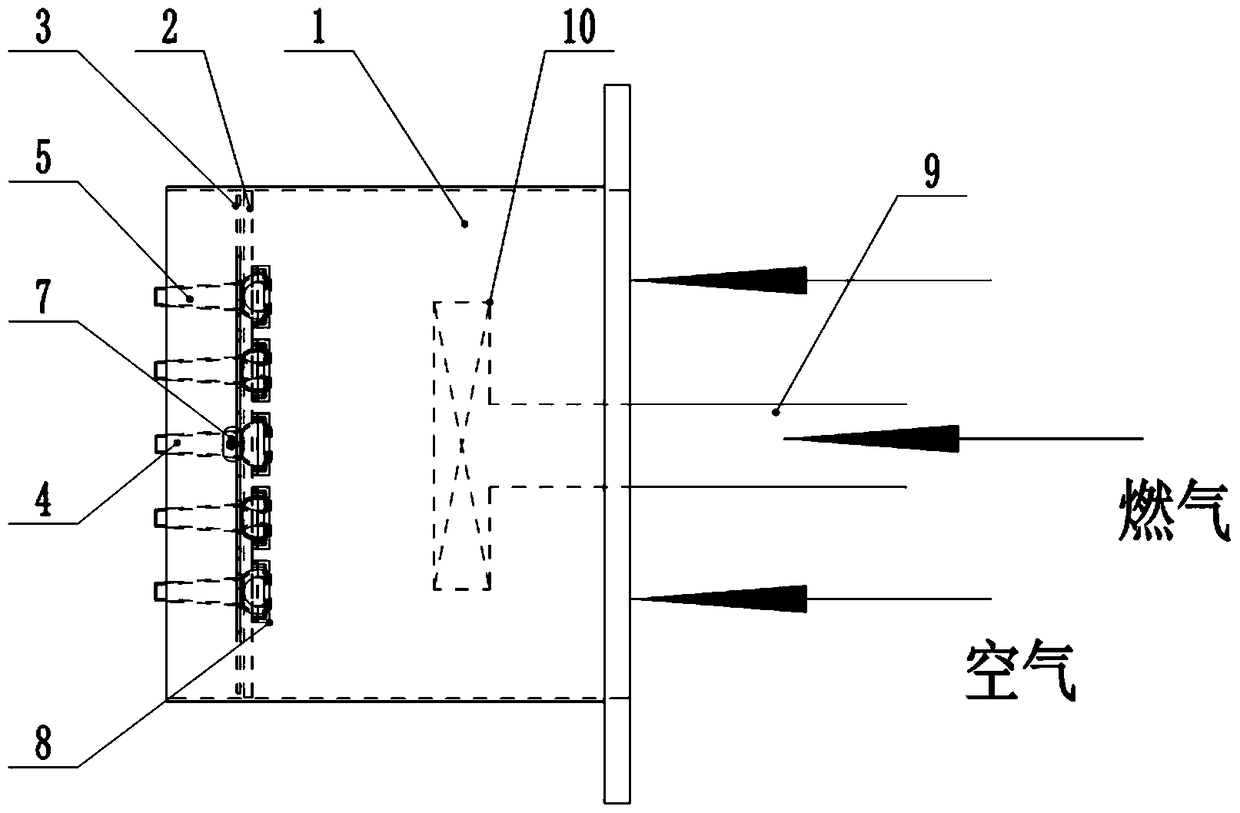

Premixed burner

ActiveCN105066126AFlame dispersionFlame temperature peak reductionGaseous fuel burnerNozzleCombustor

The utility model of the invention discloses a premixed burner. The premixed burner comprises a shell (1), a sealing plate (2) which is arranged in the shell (1) and multiple nozzles arranged on the sealing plate (2), wherein an adjusting part (3) is arranged between the sealing plate (2) and the outlet of the shell (1); and the adjusting part (3) is arranged to be matched with the multiple nozzles, and is used for adjusting the angles of the multiple nozzles. According to the premixed burner disclosed by the invention, the problem in the prior art that the discharge pollution is severe as the flame temperature of the burner is overhigh can be solved.

Owner:罗诺克兹(北京)能源设备技术有限公司

Low-load combustor capable of combusting stably

ActiveCN112325284AReduce temperature peaksReduce generationPulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to a combustor capable of combusting stably, and belongs to the technical field of combustion equipment. In order to solve the problems that an existing direct-current combustoris narrow in load adjusting range and weak in concentration capacity, the invention provides a low-load combustor capable of combusting stably. The low-load combustor capable of combusting stably comprises a pulverized coal nozzle body, a light-phase pulverized coal nozzle, a peripheral air nozzle, a concentrated-phase pulverized coal pipeline, a supporting plate, a Venturi concentrator, a flame stabilizer and a light-phase flow disturbing device, wherein the pulverized coal nozzle body is connected with the light-phase pulverized coal nozzle, the peripheral air nozzle, the light-phase pulverized coal nozzle, the concentrated-phase pulverized coal pipeline and the flame stabilizer are sequentially nested from outside to inside, the Venturi concentrator is arranged on the inner wall of thepulverized coal nozzle body, and the light-phase flow disturbing device is annularly arranged between the concentrated-phase pulverized coal pipeline and the light-phase pulverized coal nozzle. According to the low-load combustor capable of combusting stably, pulverized coal airflow entering the combustor is concentrated through the Venturi concentrator, so that concentrated and light pulverized coal airflow with a concentrated center and a light periphery is formed, and the effects of ignition and stable combustion are achieved.

Owner:HARBIN BOILER

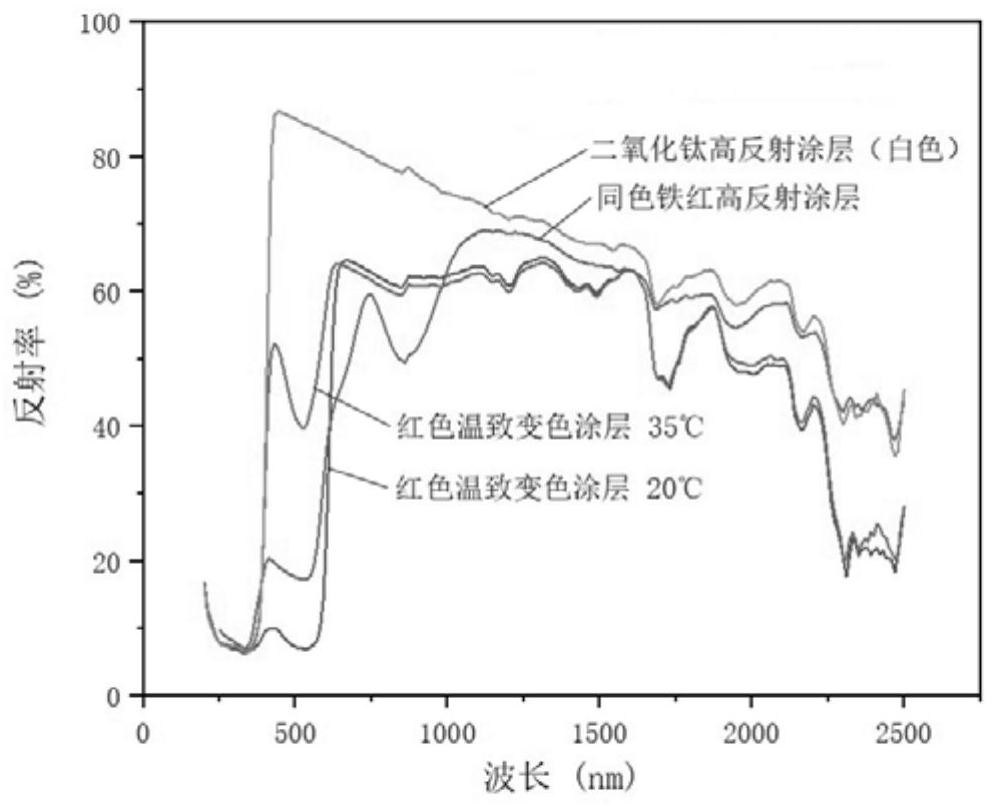

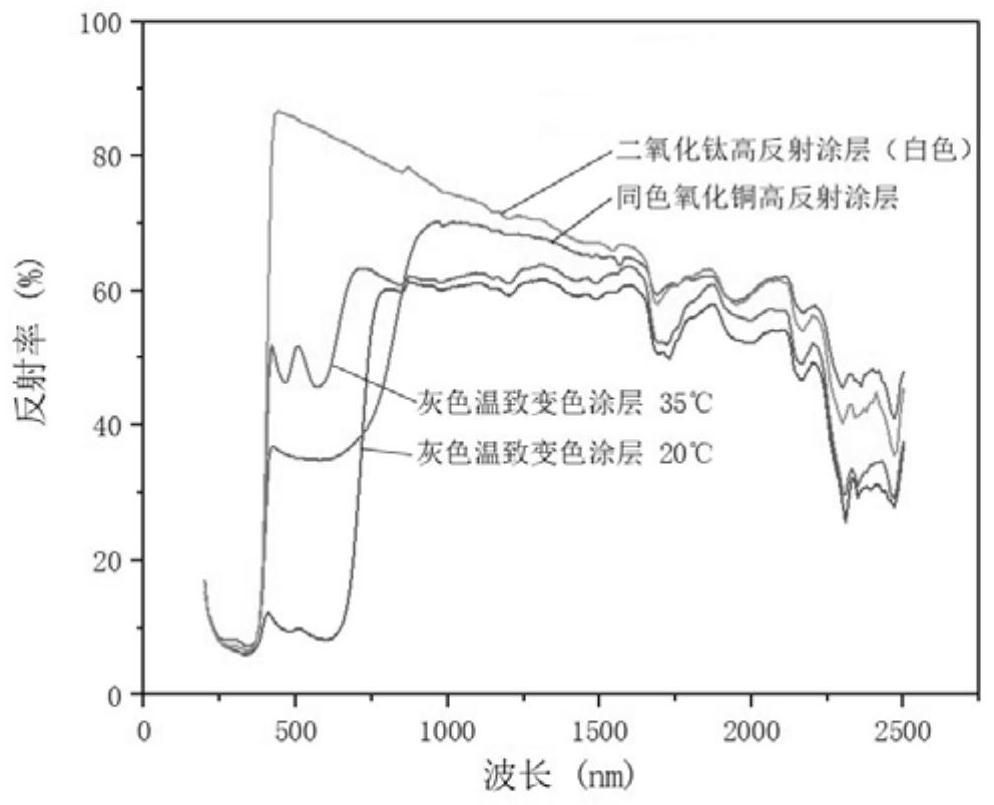

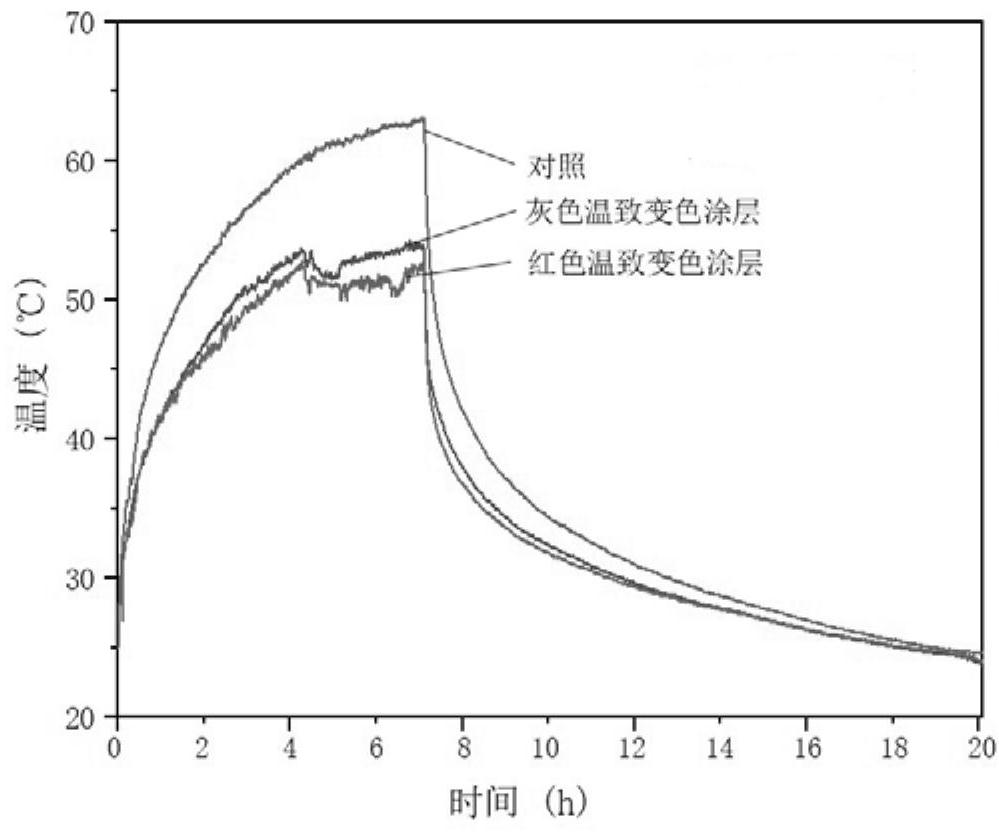

Thermochromic pavement coating with automatic temperature regulation function and preparation method thereof

ActiveCN113072847AImprove reflectivityIncrease brightnessClimate change adaptationRadiation-absorbing paintsLight pollutionRoad surface

The invention discloses a thermochromic pavement coating with an automatic temperature regulation function. The thermochromic pavement coating is prepared from the following raw materials in parts by mass: 18-30 parts of pigment and filler, 50-60 parts of a water-based silicone acrylic emulsion, 5-10 parts of various additives, 5-10 parts of a coalescing agent and 20-30 parts of deionized water, wherein the pigment and filler comprises the following components in parts by weight: 2-5 parts of titanium dioxide and 16-25 parts of thermochromic powder, wherein a mass ratio of the titanium dioxide to the thermochromic powder is 1: (4-10); the titanium dioxide is rutile type titanium dioxide; and the average particle size of the titanium dioxide is 0.2 [mu]m. The pavement coating disclosed by the invention can reflect more solar radiation under a high-temperature environment condition in summer, so pavement surface temperature can be effectively reduced; a pavement can absorb more solar radiation under a low-temperature environment condition in winter, so the situation that the pavement surface temperature is continuously reduced by a high-reflection coating under the low-temperature condition is avoided, and it is guaranteed that the pavement is at a proper temperature; and meanwhile, brightness before and after the color change of the coating is controlled in a medium-low brightness range, so the problems of glare, urban light pollution and the like caused by a light-color high-reflection coating can be effectively relieved.

Owner:TONGJI UNIV

Fuel gas decoupling combustor and using method thereof

The invention relates to a fuel gas decoupling combustor and a using method thereof. The fuel gas decoupling combustor adopts a partition staged combustion mode of central and peripheral oxygen deficit and central area lean combustion, diffusion type oxygen-deficient combustion with high combustion stabilizing capacity and low heat intensity is adopted in the central combustion area, reliable ignition and low-load stable combustion of the oxygen-deficient combustion area are ensured, the peripheral oxygen-deficient combustion area controls temperature distribution of a combustion chamber by accurately controlling partition mixing of fuel gas and air, the radiation heat transfer capacity is improved, and mixed burnout of the peripheral fuel gas and the main combustion area is promoted. In aword, the problem that the combustion temperature of a diffusion combustion mode is too high in the central stage is effectively solved by the fuel gas decoupling combustor and the using method thereof, the combustion chamber is more uniform in heat intensity, high in flame fullness, high in heat transfer capacity and long in smoke retention time, the combustion efficiency is guaranteed under thecondition of low fan power consumption, meanwhile, generation of thermal NOX is reduced, and decoupling combustion of the fuel gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

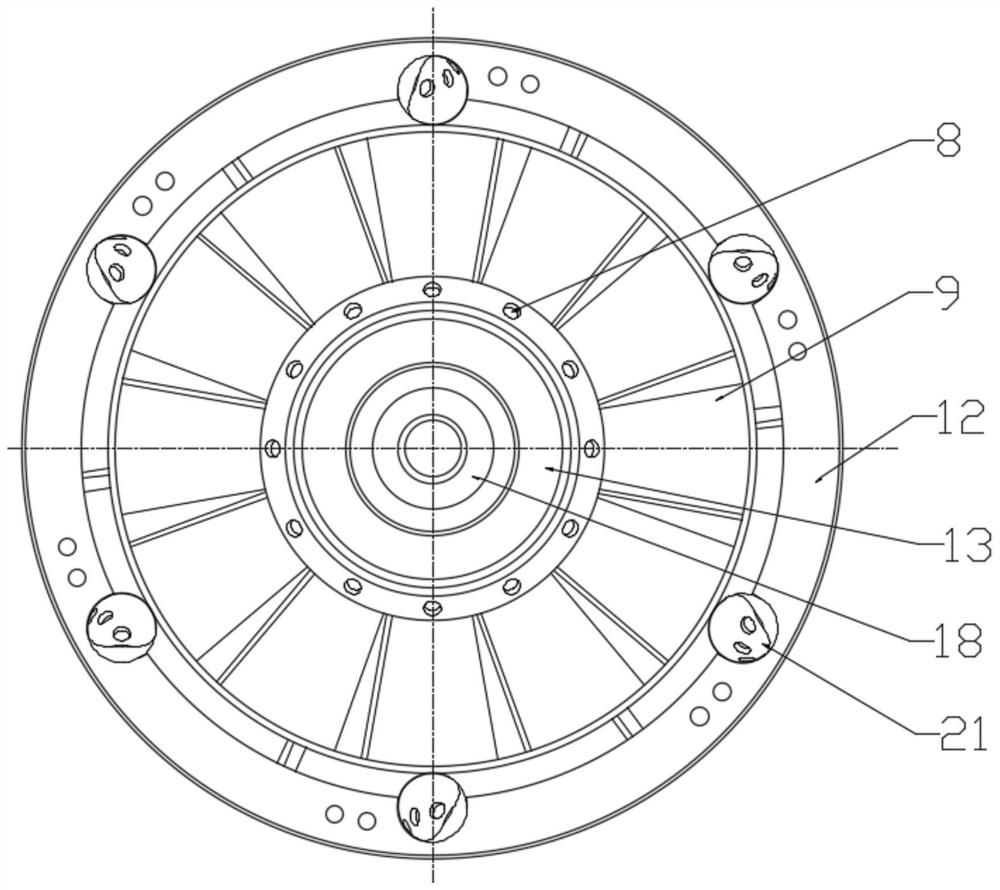

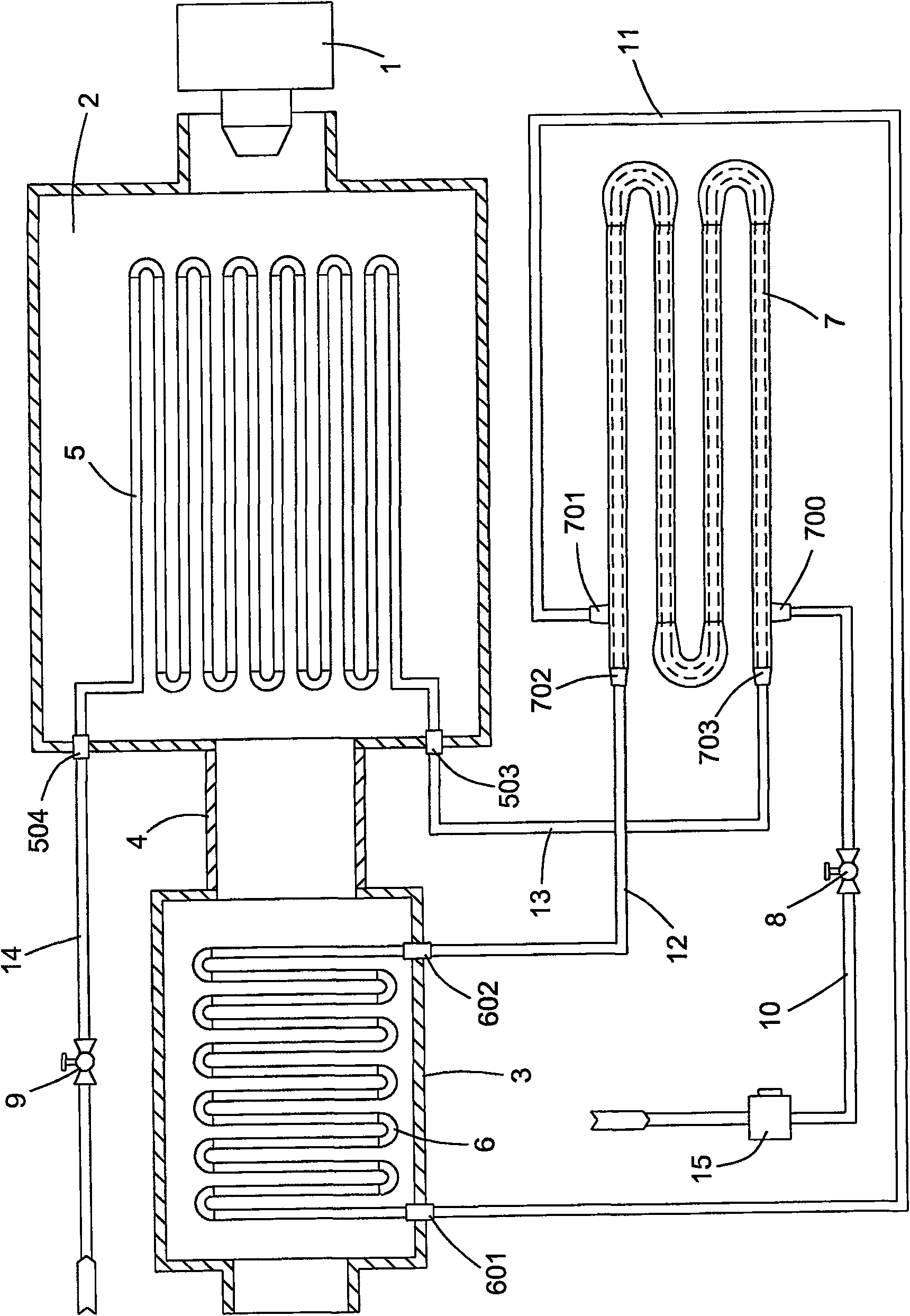

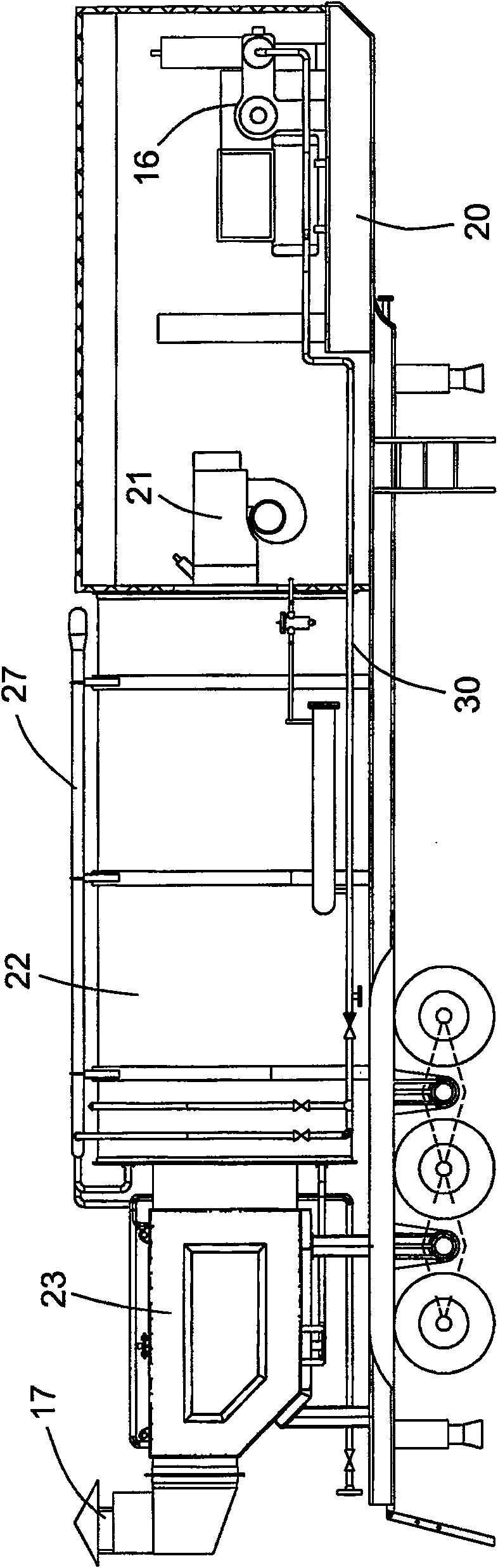

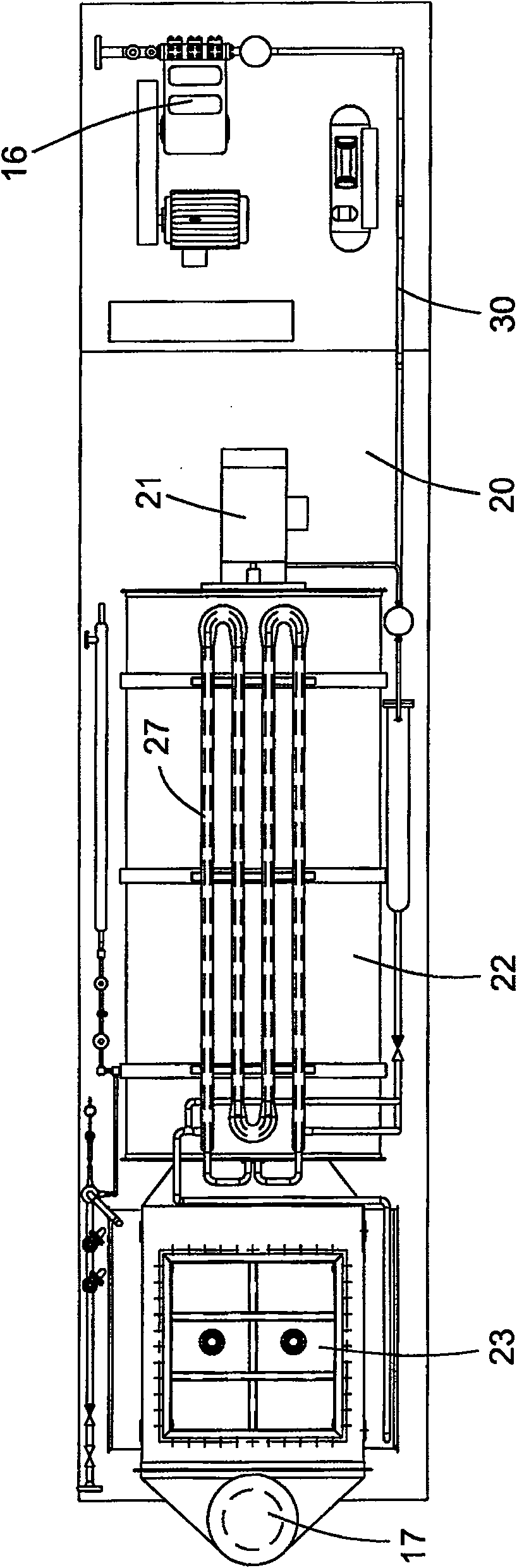

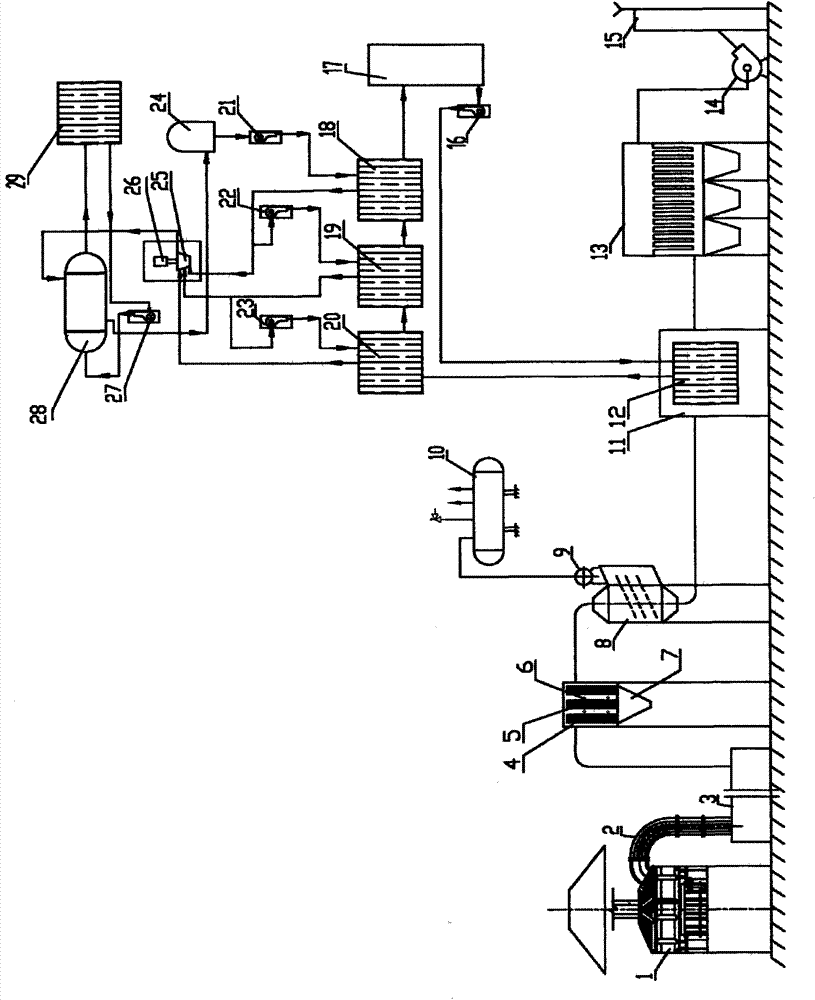

Supercritical pressure steam pouring furnace

This invention relates to a supercritical pressure steam injection boiler including the burner, the hearth, the flue and the water supply pipe. The first and second radiant tube bundles are positioned inside the hearth, the first and second convection tube bundles are positioned inside the flue, the water supply pipe is connected to the shell side input of the heat exchanger, the shell side output of the heat exchanger is connected to the input of the first convection tube bundle via the first pipeline, the output of the first convection tube bundle is connected to the input of the first radiant tube bundle via the second pipeline, the third pipeline connects the output of the first radiant tube bundle and the tube side input of the heat exchanger, the forth pipeline connects the tube side output and the input of the second radiant tube bundle, the fifth pipeline connects the output of the second convection tube bundle, and the output of the second convection is connected to the steam discharge pipe. This invention moves the steam terminal heating tube bundle from the radiant section to the convection section, which avoids heat transfer deterioration, increases the steam pressure to 26MPa and solves the exploitation problem in high pressure deep block and super heavy oil block.

Owner:THE EIGHTH CONSTR COMPANY OF CNPC

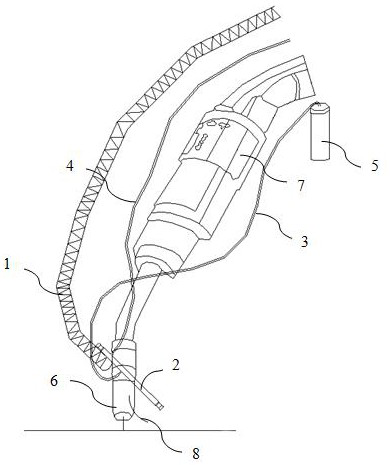

Aluminum alloy fusion welding device

PendingCN111618403AMaterial deformation coordinationThe peak value of longitudinal residual tensile stress is reducedWelding/cutting auxillary devicesElectrode supporting devicesWeld seamFusion welding

The invention discloses an aluminum alloy fusion welding device. The aluminum alloy fusion welding device comprises welding equipment, a fixing device and cooling equipment, wherein the welding equipment comprises a welding gun; the upper end of the fixing device is fixedly connected with the welding equipment; the cooling equipment is connected with the lower end of the fixing device; and the included angle between the cooling equipment and the welding gun is 45 + / -5 degrees. A nozzle of the welding gun is 20 + / -5 mm away from a welding seam; and the distance between a cold source and a molten pool is 45 + / -10 mm. According to the aluminum alloy fusion welding device, the fixing device is adopted to accurately control the angle between the cooling equipment and the welding equipment, thetemperature peak value of materials behind a heat source can be effectively reduced, deformation of the welding seam and the materials in the surrounding area of the welding seam is more coordinated,and the longitudinal residual tensile stress peak value of a welding seam area is obviously reduced; a heat affected zone can be reduced, and grains are refined; the tensile strength and the fatigue strength of a welding joint are obviously improved; the area of a fatigue fracture crack propagation area is large, and the area of an instantaneous fracture area and the distance between fatigue striations are reduced; and the mechanical property of the aluminum alloy fusion welding joint can be effectively improved.

Owner:CRRC SIFANG CO LTD

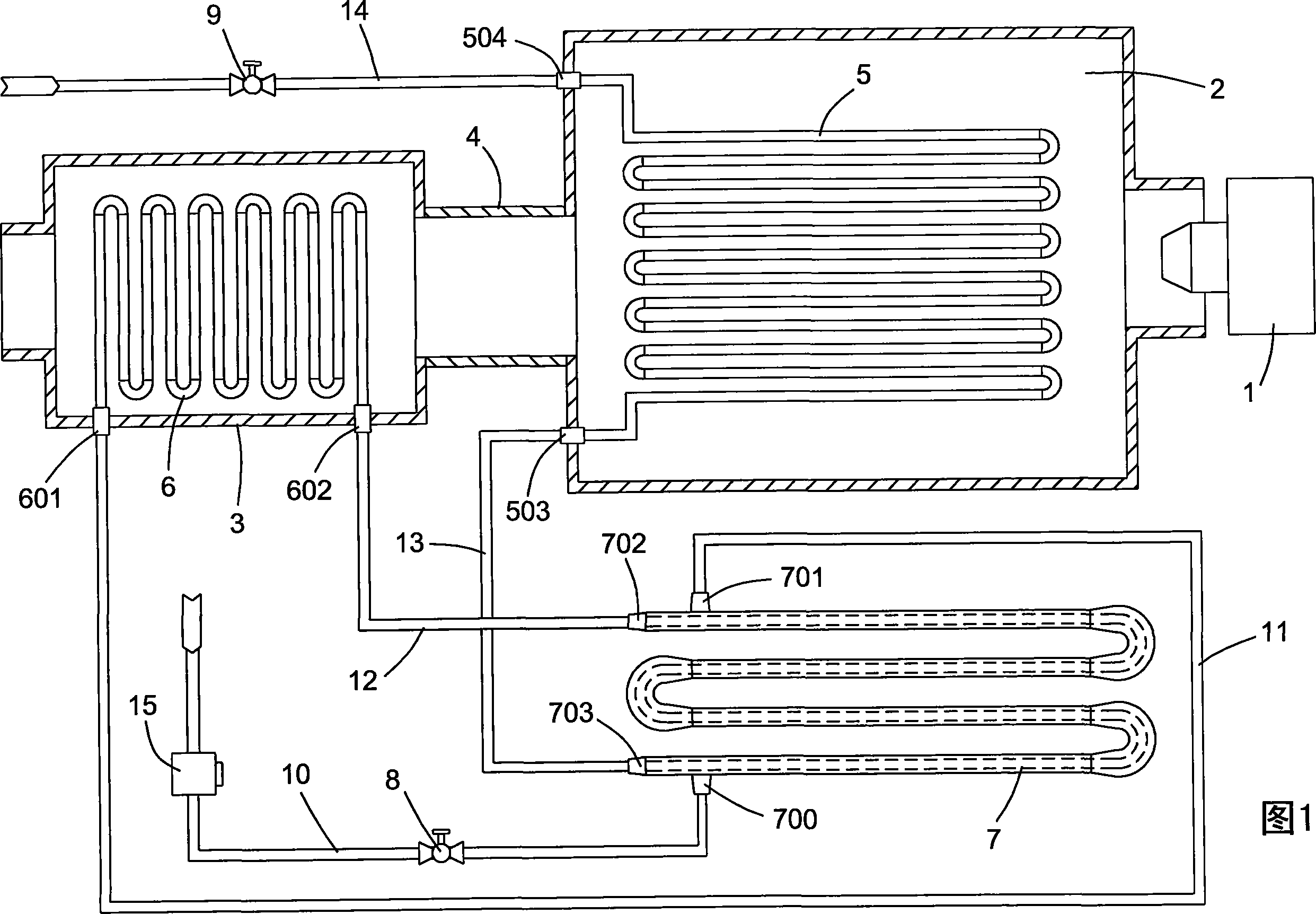

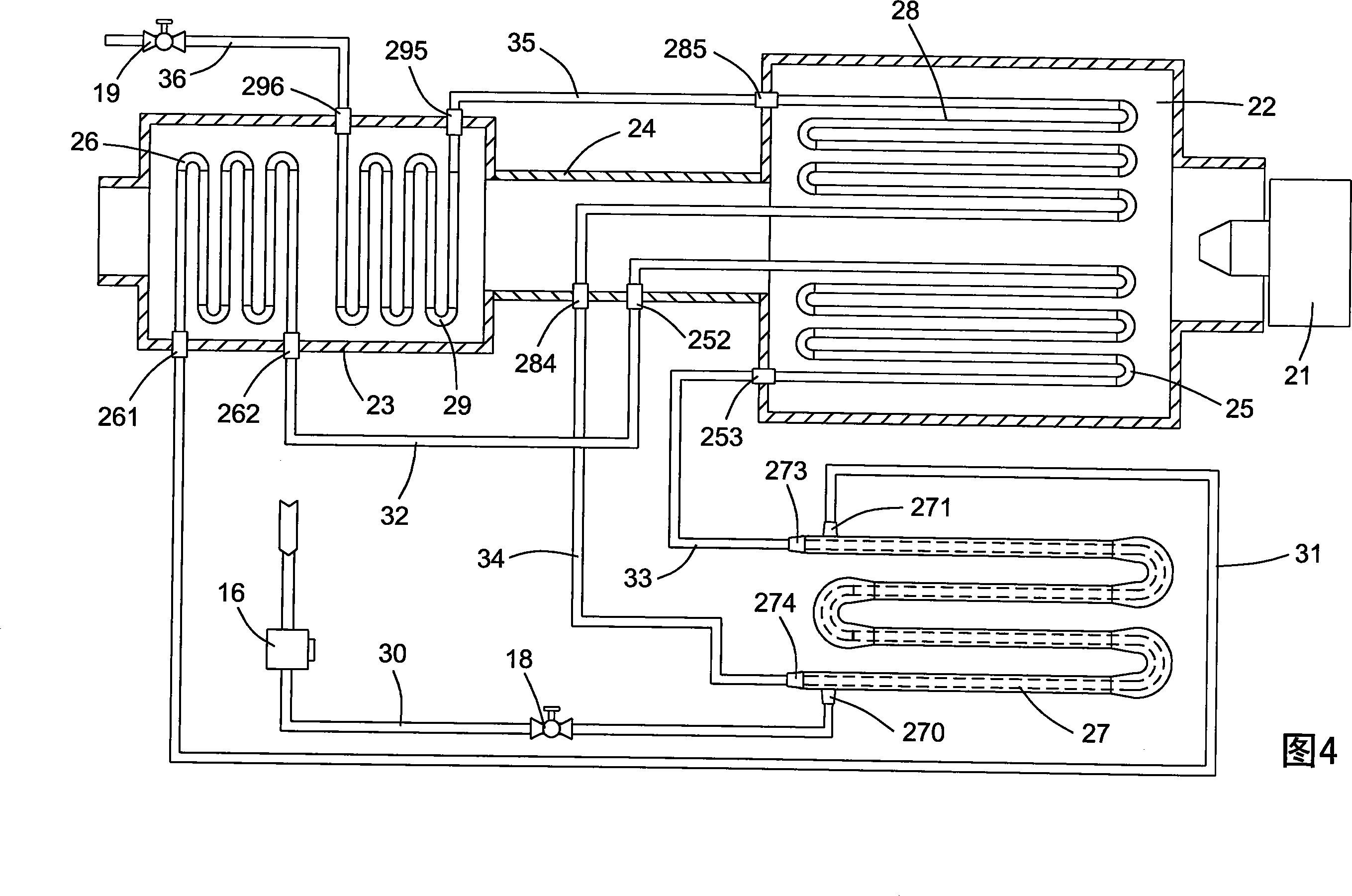

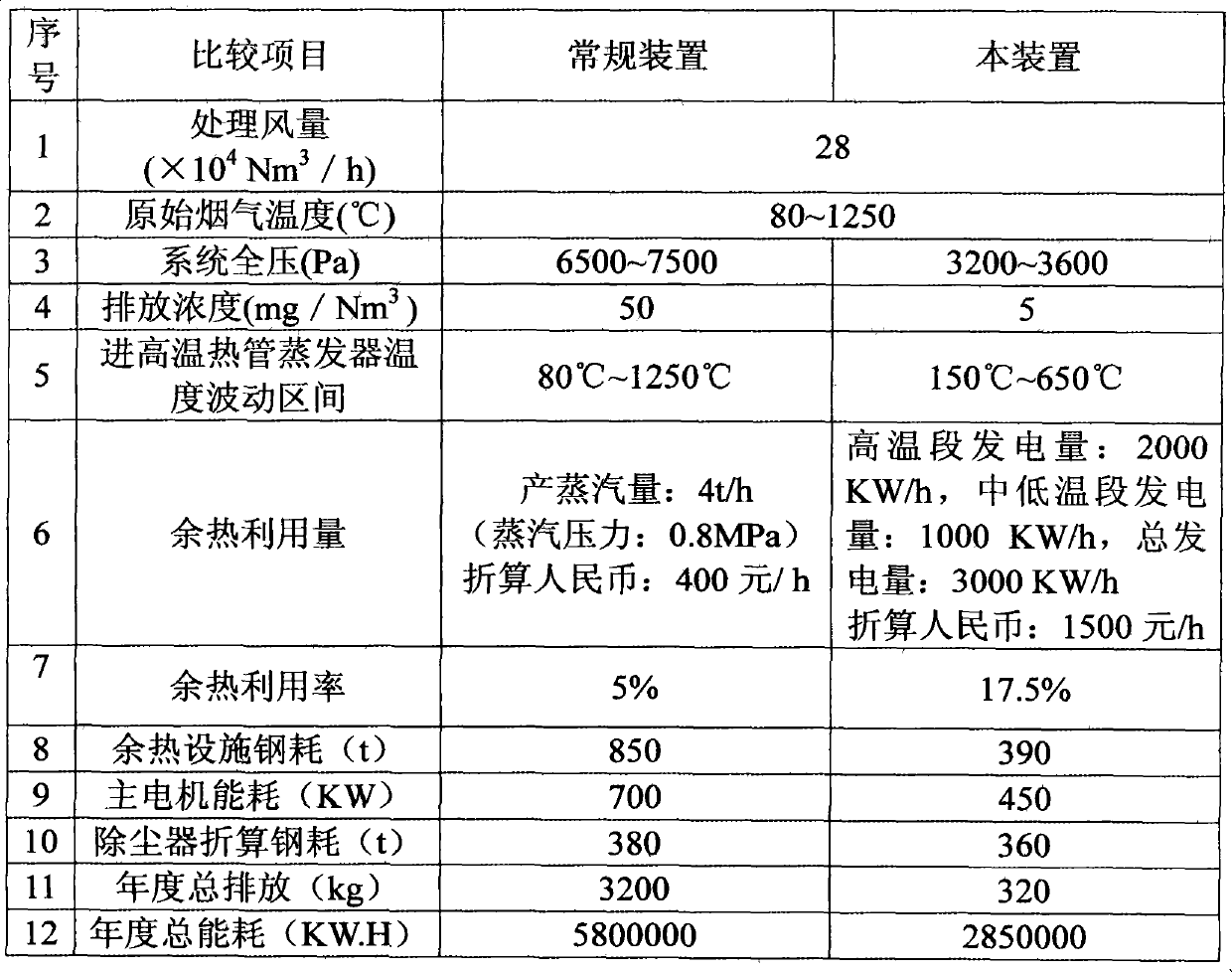

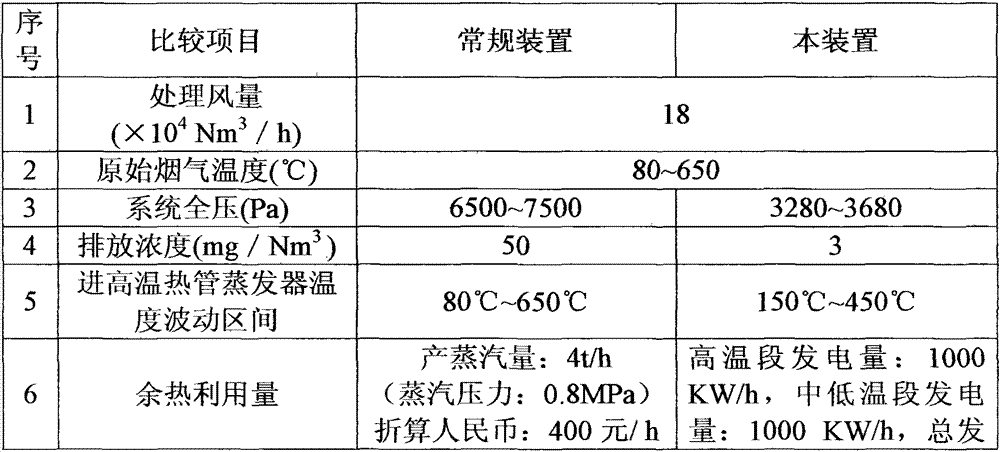

Electric furnace high-temperature alternating flue gas waste heat power-generation energy-conservation and dust-removal method

InactiveCN103836992AReduce temperature peaksReduce peakEnergy industryIncreasing energy efficiencyThermal energyAtmospheric air

Provided is an electric furnace high-temperature alternating flue gas waste heat power-generation energy-conservation and dust-removal method. The method is characterized in that electric furnace flue gas is exhausted from a fourth hole, cold air is mixed into the electric furnace flue gas through a water-cooled sliding sleeve, after carbon monoxide gas is combusted, the mixture of the electric furnace flue gas and the cold air enters a settling chamber, then enters a thermal storage temperature evening device for temperature evening and enters a heat pipe evaporator, steam is generated and then enters a bag-type dust remover, after dust removal is carried out, the steam enters a medium and low temperature flow equalizing thermal storage chamber, and the flue gas emits heat and is pressed into an exhaust funnel through a main air blower to be exhausted to atmosphere; meanwhile, circulating water absorbs the heat of the flue gas from a heat exchanger, so that a steam-water mixture is formed and enters the evaporator, heat is given off, low boiling point organic working media absorb the heat of the steam-water mixture in the evaporator through a working medium pump to become saturated steam, and working medium steam does work in a low boiling point working medium steam turbine in an expansion mode and drives a three-phase generator to generate electricity; R245fa is adopted to serve as the circulating organic working media. According to the method, heat in the flue gas can be recycled to be converted into high-grade electric energy to the maximum degree, the dust removal capacity can be improved, and a good environment protection effect is achieved.

Owner:无锡市东优环保科技有限公司

Manufacture of methylolalkanes with augmented heat transfer and improved temperature control

ActiveUS9676689B2Improve heat transfer performanceReduce temperature peaksOrganic compound preparationFlow mixersAlkaneContinuous reactor

A multistage tubular reaction system and method for preparing methylol derivatives of an aldehyde includes a tubular reaction system with a plurality of successive reactor stages comprising a plurality of jacketed reaction tubes provided with a cooling system adapted to control flow of a cooling medium through said jacketed reaction tubes. The cooling medium flow is controlled independently in different stages in response to temperature measurements in the reaction system to regulate temperature. In order to further reduce temperature spikes and byproduct generation, aldehyde is stepwise added to the production stream at a plurality of feed ports proximate to reaction tubes equipped with tube inserts to enhance mixing and heat transfer.

Owner:OQ CHEM BISHOP LLC

Negative electrode material for lithium ion secondary batteries, method for manufacturing the same, paste for negative electrode, negative electrode sheet, and lithium ion secondary battery

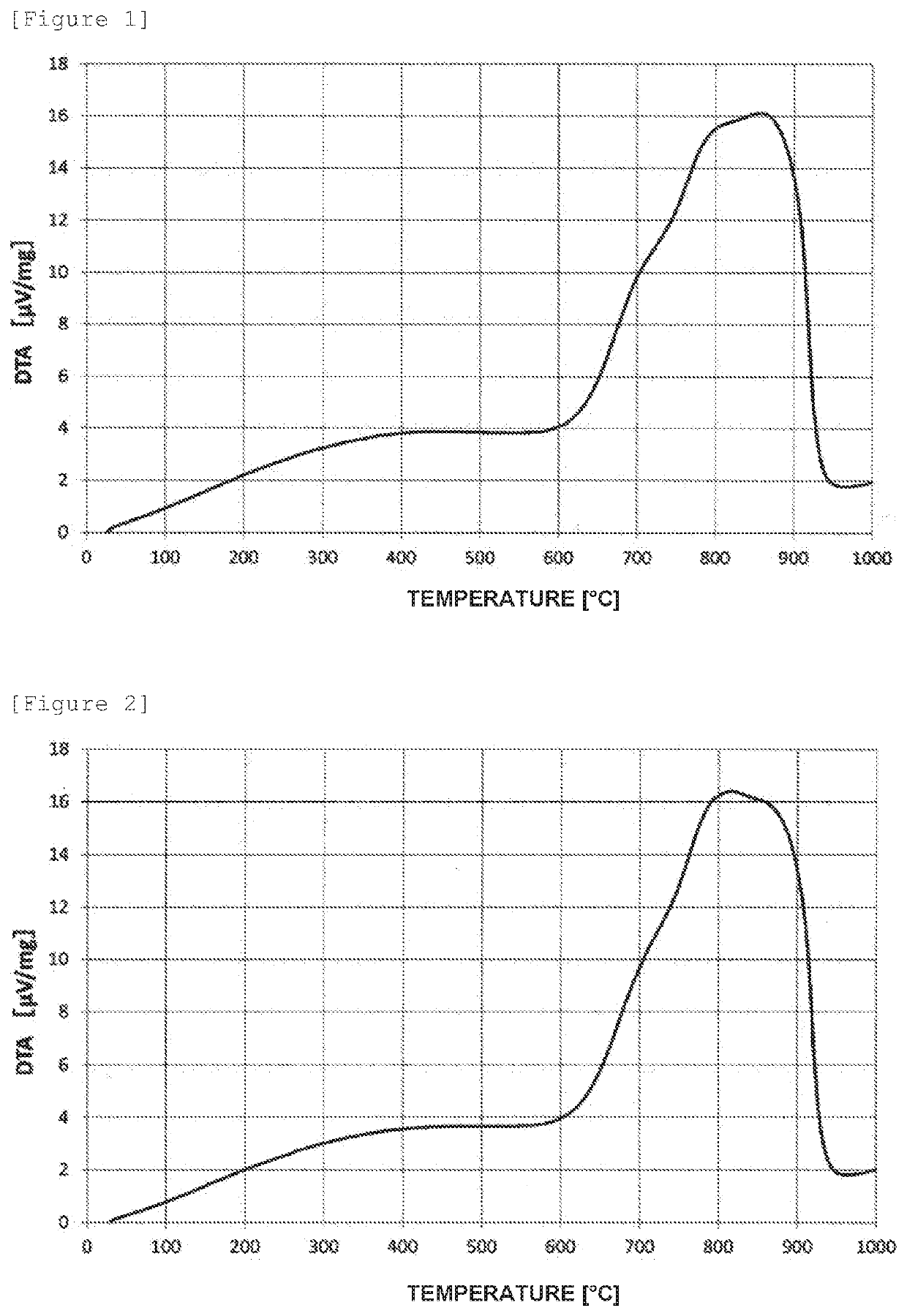

ActiveUS20200295359A1Excellent Si dispersibilityImprove featuresSiliconGraphiteNano siliconElectrical battery

A negative electrode material for lithium ion secondary batteries, including composite material particles containing nanosilicon particles having a 50% particle diameter (Dn50) of 5 to 100 nm in a number-based cumulative particle size distribution of primary particles, graphite particles and an amorphous carbon material; the composite material particles containing the nanosilicon particles at a content of 30 to 60 mass % or less, and the amorphous carbon material at a content of 30 to 60 mass % or less; the composite material particles having a 90% particle diameter (DV90) in the volume-based cumulative particle size distribution of 10.0 to 40.0 μm, a BET specific surface area of 1.0 to 5.0 m2 / g, and an exothermic peak temperature in DTA measurement of 830° C. to 950° C. Also disclosed is a paste for negative electrodes, a negative electrode sheet, a lithium ion secondary battery and a method for manufacturing the negative electrode material.

Owner:SHOWA DENKO KK +1

Supercritical pressure steam pouring furnace

ActiveCN100559074CSimple structureQuality assuranceFluid removalForced-flow steam boilerSteam pressureCombustor

A supercritical pressure steam injection boiler has a burner, a furnace, a flue, and a water supply pipe. First and second radiant tube bundles are arranged in the furnace, first and second convective tube bundles are arranged in the flue, and the water supply pipe and heat exchange The shell-side inlet of the heat exchanger is connected, the shell-side outlet of the heat exchanger is connected with the inlet of the first convection tube bank through the No. 1 pipe, the outlet of the first convection tube bank is connected with the inlet of the first radiant tube bank through the No. The outlet of the heat exchanger communicates with the tube-side inlet of the heat exchanger through No. 3 pipe, the tube-side outlet of the heat exchanger communicates with the inlet of the second radiant tube bundle through No. The inlet of the tube bundle is connected, and the outlet of the second convection tube bundle is connected with the steam discharge pipe; the invention moves the tube bundle heated by the final stage of steam from the radiation section to the convection section, avoiding the deterioration of heat transfer, and the steam pressure can reach 26MPa, solving the problem of high-pressure deep well The problem of difficulty in mining block and super-heavy oil block.

Owner:THE EIGHTH CONSTR COMPANY OF CNPC

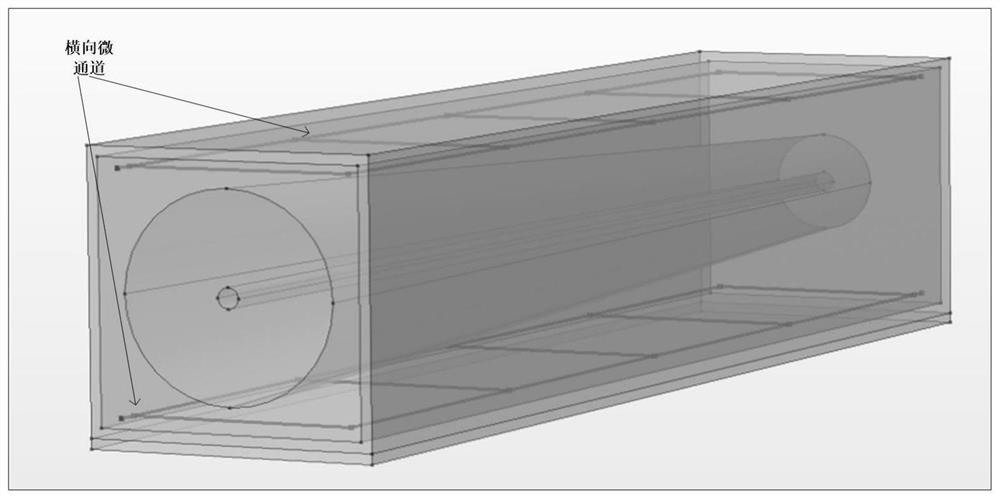

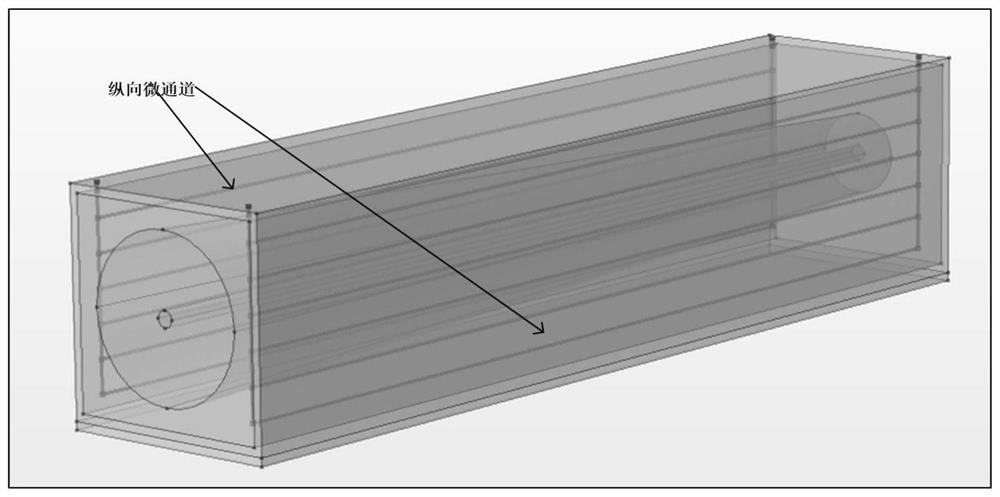

Cladding power stripper adopting graphite and white graphite materials and micro-channel water cooling

InactiveCN113224628AAccelerated dissipationEnsure mechanical hardnessActive medium shape and constructionLaser cooling arrangementsRefractive indexEngineering

The invention discloses a cladding power stripper adopting graphite and white graphite materials and micro-channel water cooling. The cladding power stripper comprises a heat sink protection shell, a heat sink, a high-refractive index glue cavity and an optical fiber; the optical fiber is arranged in the center of the interior of the high-refractive index glue cavity; the high-refractive index glue cavity is coated with the heat sink; the heat sink is made of the graphite material; a micro-channel is arranged on the surface, close to the high-refractive index glue cavity, in the heat sink; the heat sink protection shell wraps the heat sink; and cooling fins are arranged under the bottom of the heat sink protection shell and are made of the white graphite. According to the cladding power stripper, the graphite is used as the heat sink material, the white graphite is used as the material of the cooling fins at the bottom of the heat sink shell; and a micro-channel water cooling technology with reasonable micro-channel diameter and shape is applied to the cladding power stripper, so that the temperature of the stripper can be reduced, efficient heat dissipation is realized, and uniform internal heat distribution is ensured.

Owner:NANCHANG HANGKONG UNIVERSITY

Selective inlet water temperature stabilizing device and water temperature value simulating and forecasting method

InactiveCN102359146BSmooth out water temperature peaksReduce gradientWater supply tanksHydraulic modelsPlant safetyWater source

The invention discloses a selective inlet water temperature stabilizing device. The selective inlet water temperature stabilizing device comprises a water reservoir, a clapper door inflow device and a water taking building, wherein the clapper door inflow device and the water taking building are respectively arranged on the two sides of the water reservoir; and the bottom of the water taking building is connected with a water taking culvert pipe. The invention also discloses a water temperature value simulating and forecasting method. According to the invention, external seawater used as a power plant safety plant water source flows in through the device while higher water level and lower temperature of the external seawater are obtained; and the external seawater is conveyed into a safety plant cooling water taking pump house after cold water and hot water are sufficiently mixed and the surface is cooled; therefore, the temperature of the water taken from the safety plant water is obviously reduced while being compared with the variation gradient and the peak value of the water temperature at the external seawater taking opening so that the high peak value of the water taking temperature can be stabilized, the reduction amplitude of the safety plant water temperature can be also forecasted after using the system and the device, and design parameters are provided for building the selective water temperature stabilizing device.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +2

Pellet low-nitrogen central burner and gas supply structure thereof

PendingCN111795382AStable structureCompact structurePulverulent fuel combustion burnersRotary kilnMechanics

The invention belongs to the technical field of rotary kiln burners and accessories thereof, and particularly relates to a pellet low-nitrogen central burner and a gas supply structure thereof. The pellet low-nitrogen central burner comprises a burner and a guide duct group connected with the burner, wherein the burner consists of a plurality of barrel structures which are sleeved coaxially, including an axial flow wind barrel, a rotational flow wind barrel, a coal wind barrel and a central barrel in sequence; and a guide duct assembly consists of a plurality of circular pipes which are sleeved coaxially, including an axial flow wind pipe, a rotational flow wind pipe, a coal wind pipe and a central wind pipe. The gas supply structure comprises a protective structure arranged on the outer side of the pellet low-nitrogen central burner, a gas guide pipe group arranged on the back side of the pellet low-nitrogen central burner, and a gas supply pipe group. According to the pellet low-nitrogen central burner disclosed by the invention, the shape of burning flame is regular and complete by means of large speed difference, strong rotational flow and central wind flame stabilizing effect;the flame is stable without fluctuation; and the phenomenon of kiln lining sweeping is avoided.

Owner:襄阳中和机电技术有限公司

premix burner

ActiveCN105066126BEasy to adjust nozzle angleReduce temperature peaksGaseous fuel burnerCombustorBiochemical engineering

The utility model of the invention discloses a premixed burner. The premixed burner comprises a shell (1), a sealing plate (2) which is arranged in the shell (1) and multiple nozzles arranged on the sealing plate (2), wherein an adjusting part (3) is arranged between the sealing plate (2) and the outlet of the shell (1); and the adjusting part (3) is arranged to be matched with the multiple nozzles, and is used for adjusting the angles of the multiple nozzles. According to the premixed burner disclosed by the invention, the problem in the prior art that the discharge pollution is severe as the flame temperature of the burner is overhigh can be solved.

Owner:罗诺克兹(北京)能源设备技术有限公司

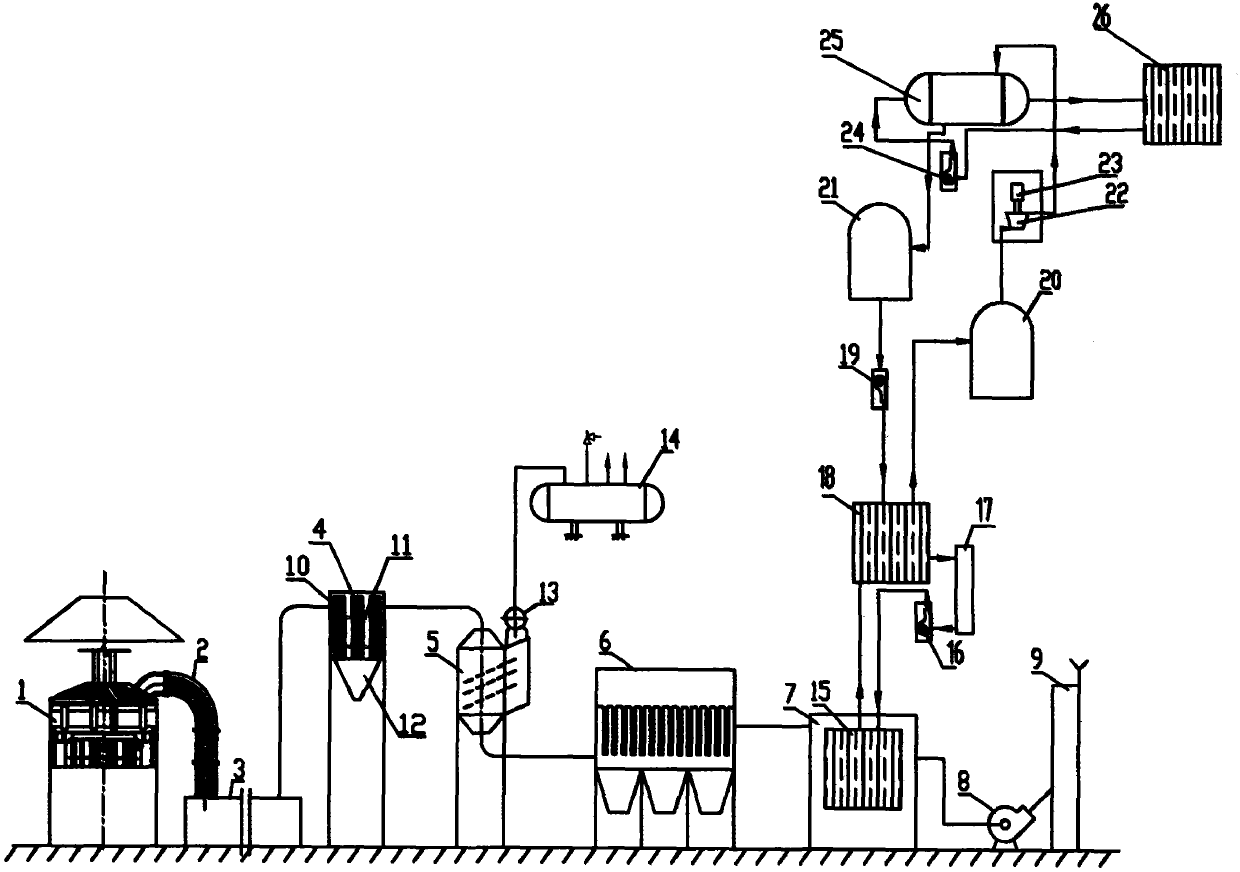

Cupola smoke temperature uniformizing type waste heat power generation, energy conservation and dust removal method

InactiveCN104748562AHigh temperature peakReduce temperature peaksIncreasing energy efficiencySteam engine plantsElectric generatorSedimentation

A cupola smoke temperature uniformizing type waste heat power generation, energy conservation and dust removal method is characterized in that cupola smoke is exhausted out of a cupola, cold air is mixed into the cupola smoke through a water-cooling flue, and after carbon oxide is combusted, the mixture enters a sedimentation chamber, enters a heat storage temperature uniformizing device, enters a high-temperature heat pipe evaporator, enters a flow uniformizing waste heat exchange chamber, sends out heat, enters a sinter-plate dust remover, is pressed into an exhaust cylinder through a main air blower after dust removal is conducted and is then discharged into the atmosphere; meanwhile, circulating water absorbs heat of smoke in the heat exchanger to form a smoke-water mixture to enter the evaporator and send out heat, an organic liquid working medium absorbs heat of smoke waste heat carriers in a low-pressure stage evaporator, an intermediate-pressure stage evaporator and a high-pressure stage evaporator to become working medium steam, and the working medium steam expands to act in an organic turbine with steam supplementing openings and drives an electric generator to generate electricity; an R141B is adopted as a circulating organic working medium. By means of the method, heat in recovered smoke can be converted into high-level electric energy to the maximum extent, the dust removal capacity can be improved, and the good environment protection effect is achieved.

Owner:无锡市东优环保科技有限公司

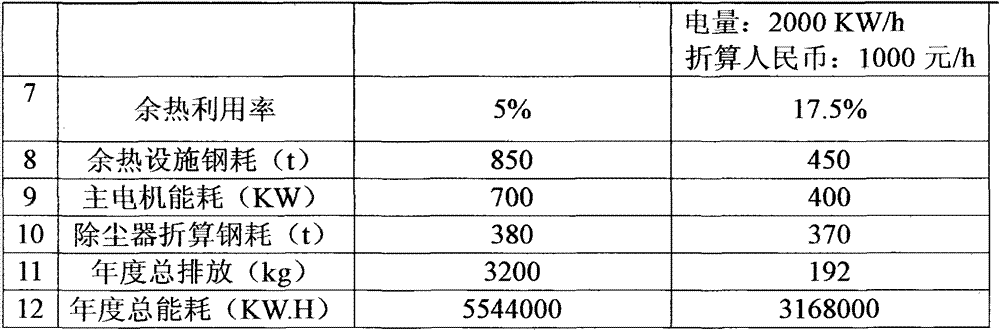

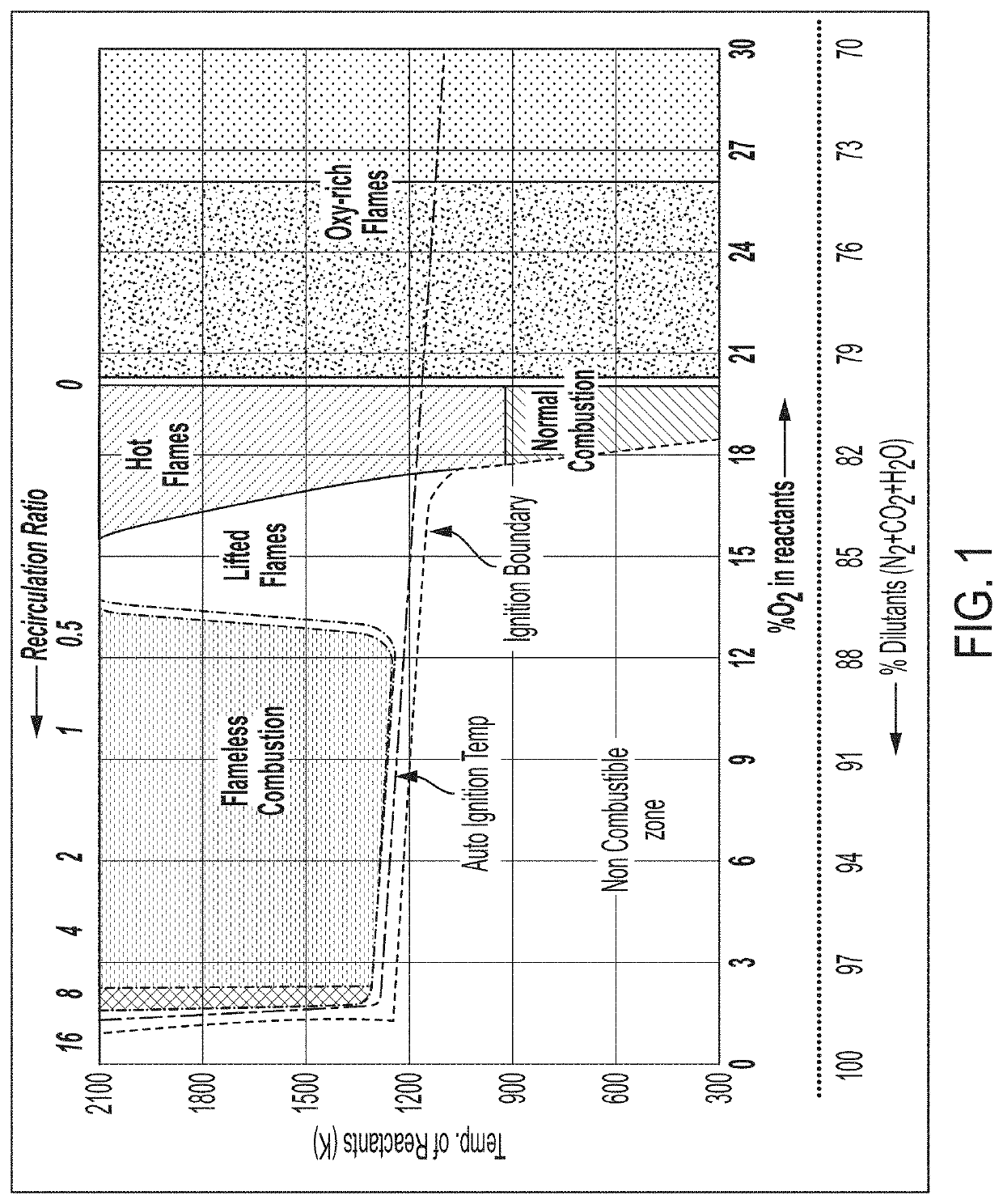

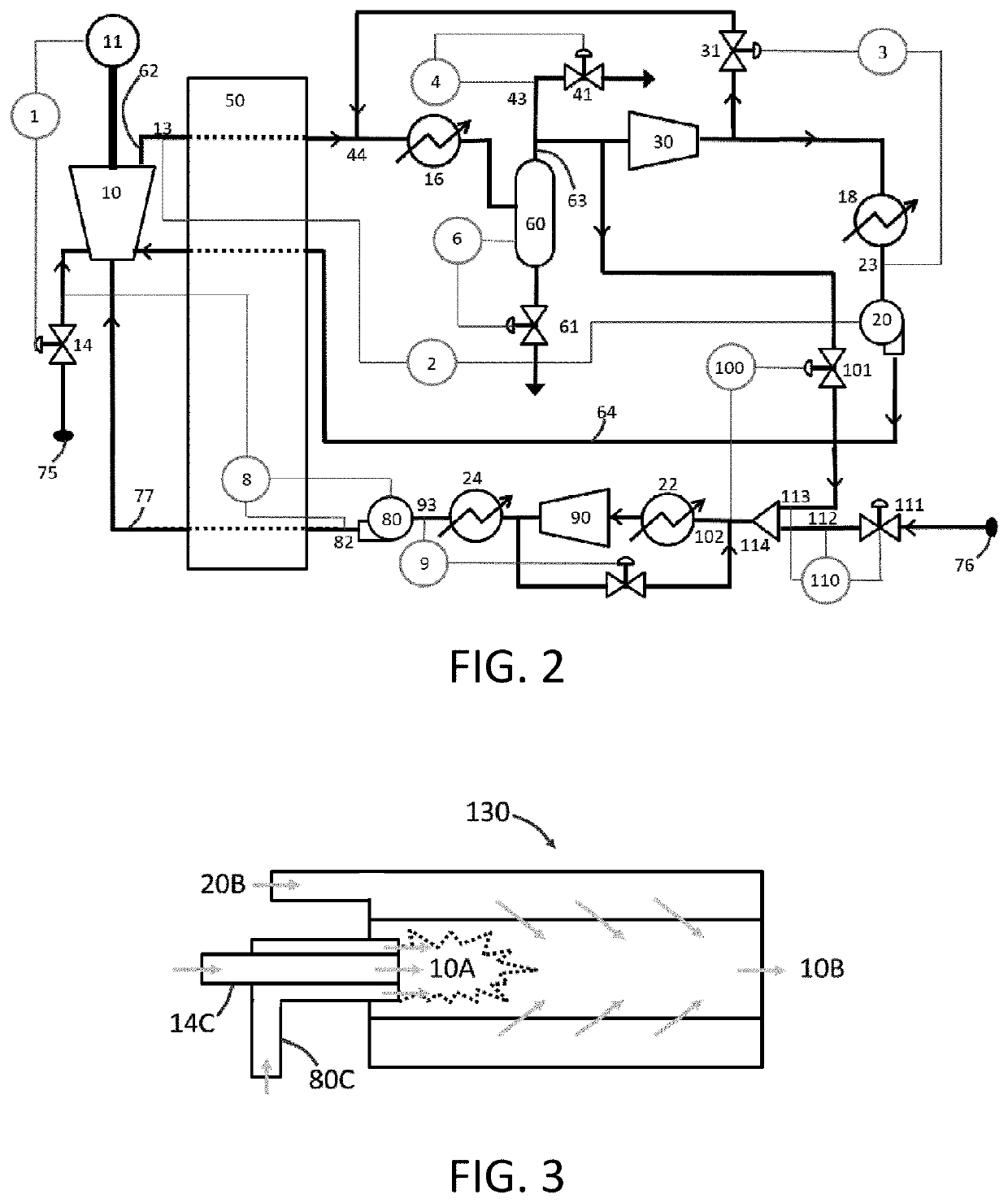

Systems and methods for power generation with flameless combustion

ActiveUS20200040817A1Improve controllabilityReduce temperature peaksEngine fuctionsGas turbine plantsCombustorProcess engineering

The present disclosure provides systems and methods wherein power production can be achieved with combustion of a fuel utilizing flameless combustion. A fuel may be combusted in a combustor / turbine in a substantially flameless operation to produce a combustion product stream that can be expanded for power generation. After expansion, the output stream can be treated to generate a recycle CO2 stream into which an oxidant can be input. The recycle CO2 stream including the oxidant can be injected into the combustor / turbine to effect combustion in a substantially flameless state. Various control schemes can be implemented to automatically control the concentration of oxygen present in the recycle CO2 stream that is injected into the combustor / turbine in order to achieve and / or maintain substantially flameless combustion.

Owner:8 RIVERS CAPTTAL LLC

A low-load stable combustion burner

ActiveCN112325284BReduce temperature peaksReduce generationPulverulent fuel combustion burnersThermodynamicsCombustor

Owner:HARBIN BOILER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com