Method and apparatus for a dual mode burner yielding low NOx emission

A technology of burners and combustion chambers, applied in the direction of combustion methods, burners, gas fuel burners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

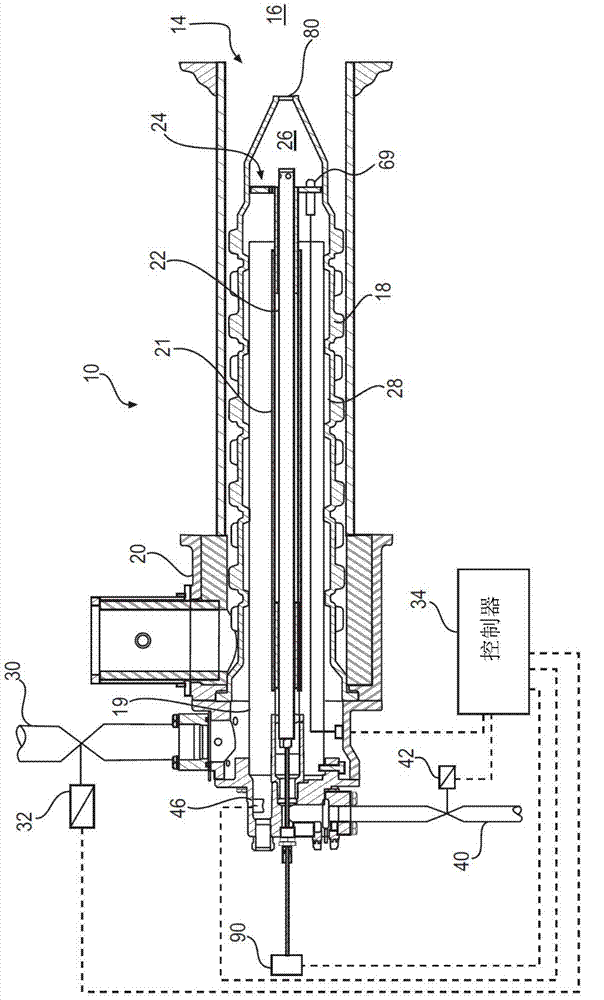

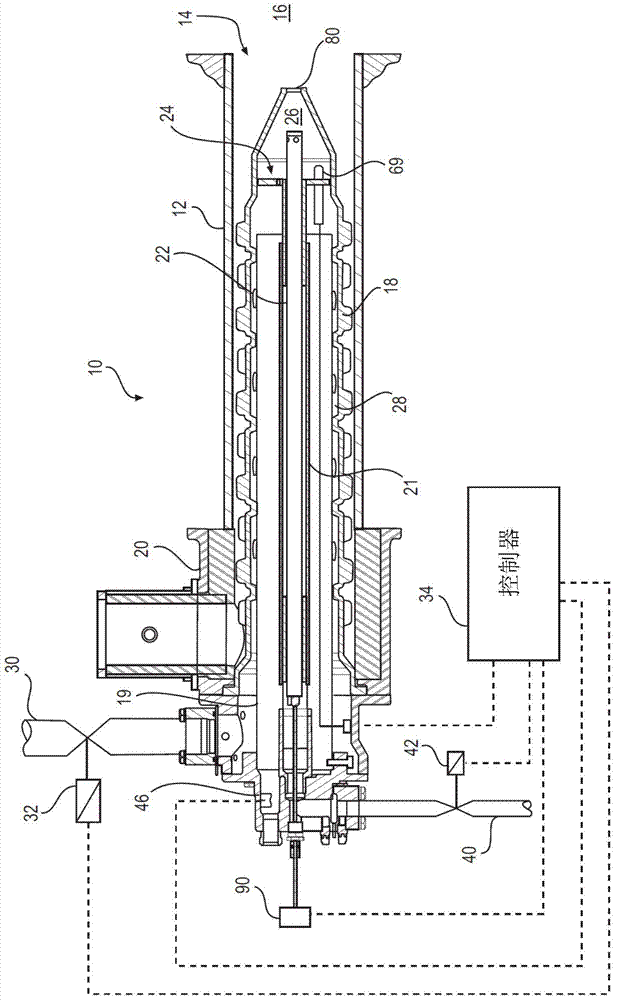

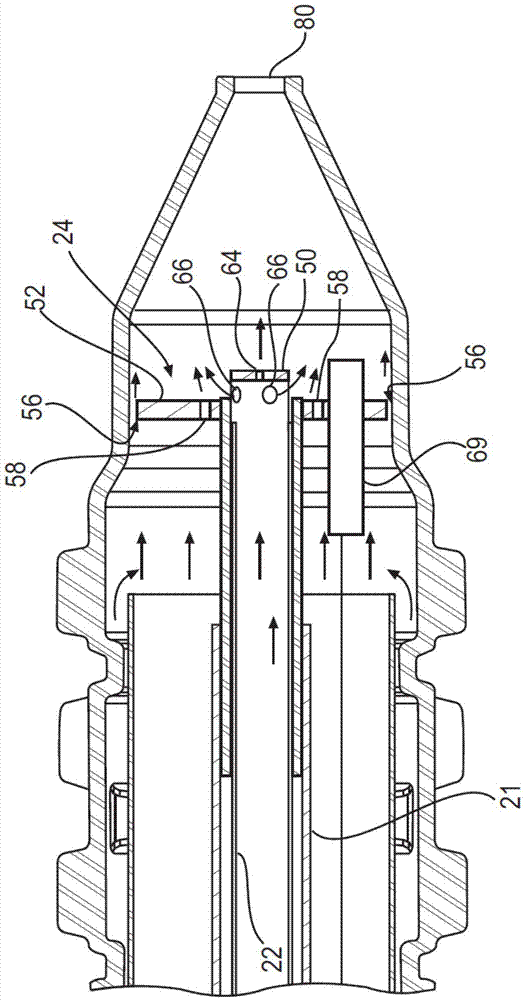

[0018] Reference will now be made to the drawings in which like elements are denoted by like reference numerals in the different drawings. figure 1 A burner 10 is shown comprising a generally hollow tubular cover tube 12 having an open end 14 which projects into a furnace / radiant tube 16 or other environment to be heated. By way of example only, the burners 10 may extend into closed radiant heating tubes or the like well known to those skilled in the art for indirect heating of the fire while avoiding substantial introduction of combustion products into the fire. As another example, the burner 10 may extend into the fire to provide direct heat to the fire while simultaneously introducing a bulk of the products of combustion into the fire. In the illustrated embodiment, the cover tube 12 is disposed around a hollow heat exchanger 18 made of ceramic or the like, having a surface of revolution extending outwardly from the shell 20 . The heat exchanger 18 may surround an air shro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com