Pellet low-nitrogen central burner and gas supply structure thereof

A central burner and pellet technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of environmental pollution, poor adaptability of coal quality, high nitrogen oxide content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be described in detail below in conjunction with specific embodiments.

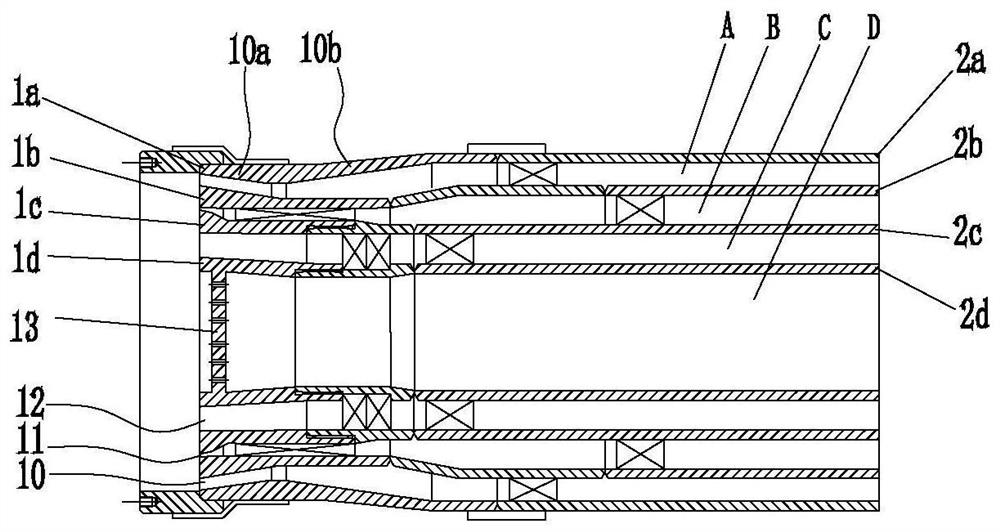

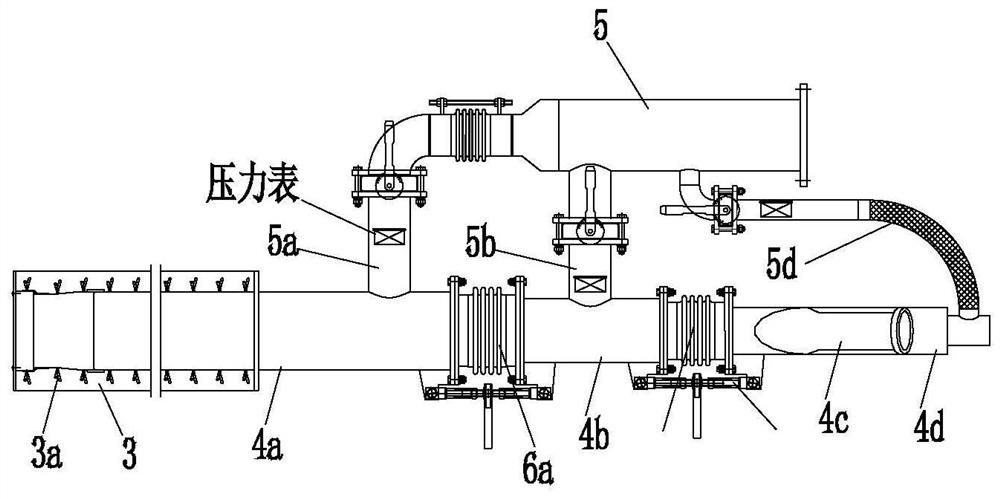

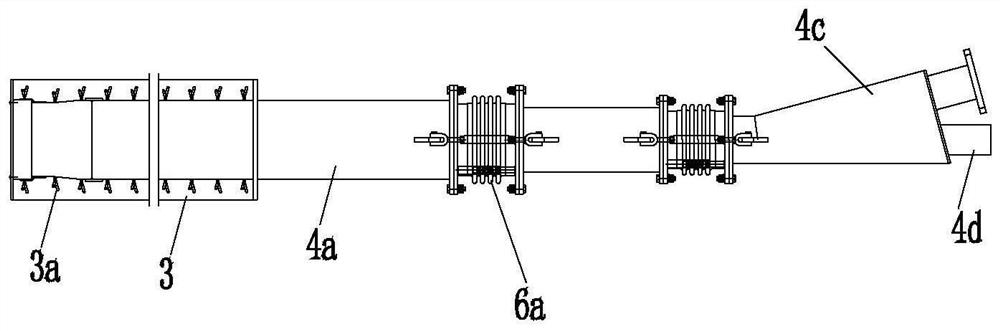

[0028] A pellet low-nitrogen central burner of the present invention includes a burner and an air guide pipe group connected to the burner; wherein the burner is mainly used to form a swirling flow of the combustion gas speed difference, and ensure the central air through the burner structure to achieve stable The flame effect improves the shape of the combustion flame, making it more complete and stable without fluctuations, and avoiding the phenomenon of sweeping the kiln lining. The air guide assembly is used to connect the gas supply system and the burner, and at the same time realize the adjustment of the gas flow and characteristics in the burner, so as to quickly adjust the strength and shape of the combustion flame, improve the performance of the burner, and ensure the burner at high temperature. Stability of structure and performance.

[0029] Such as figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com