Patents

Literature

126 results about "Proof construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

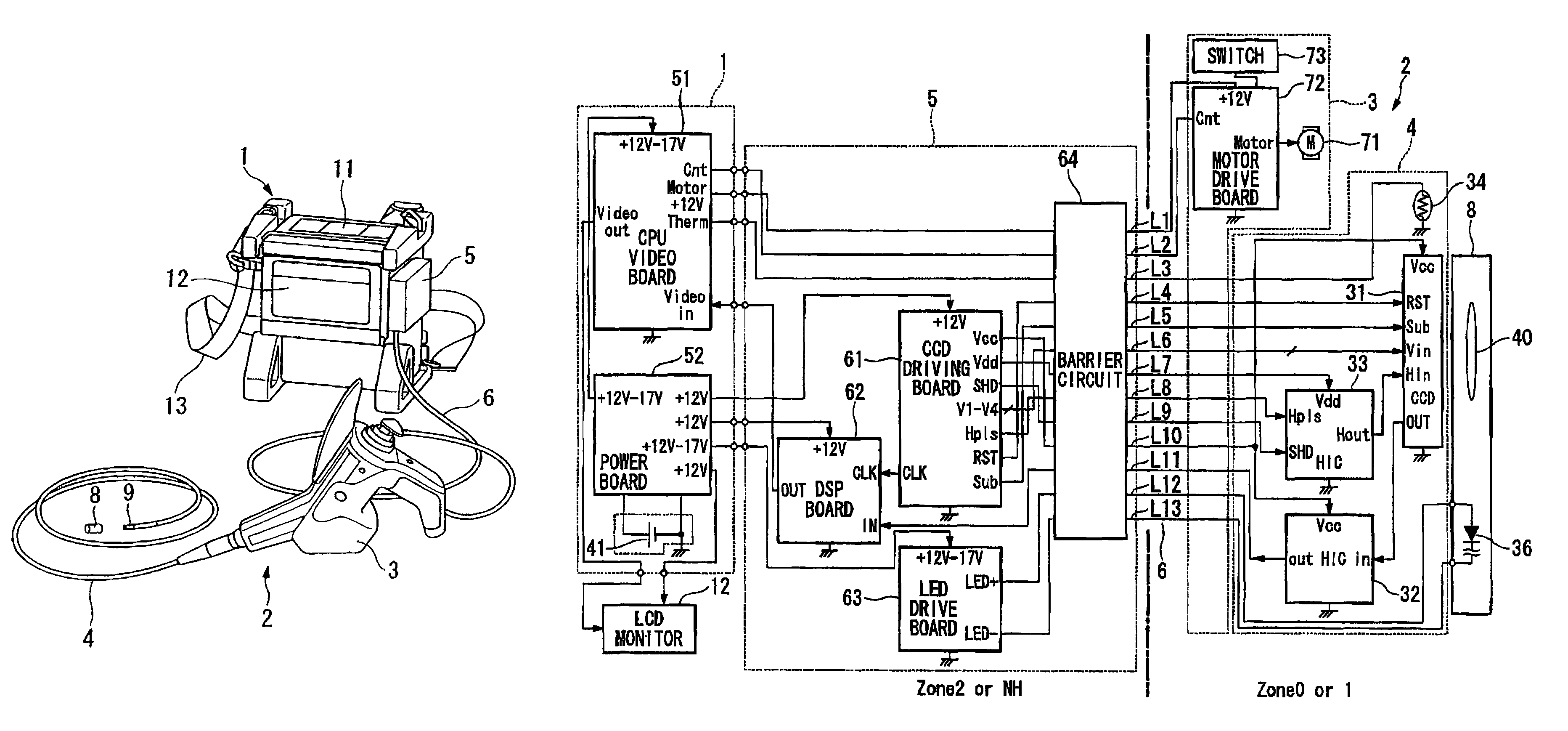

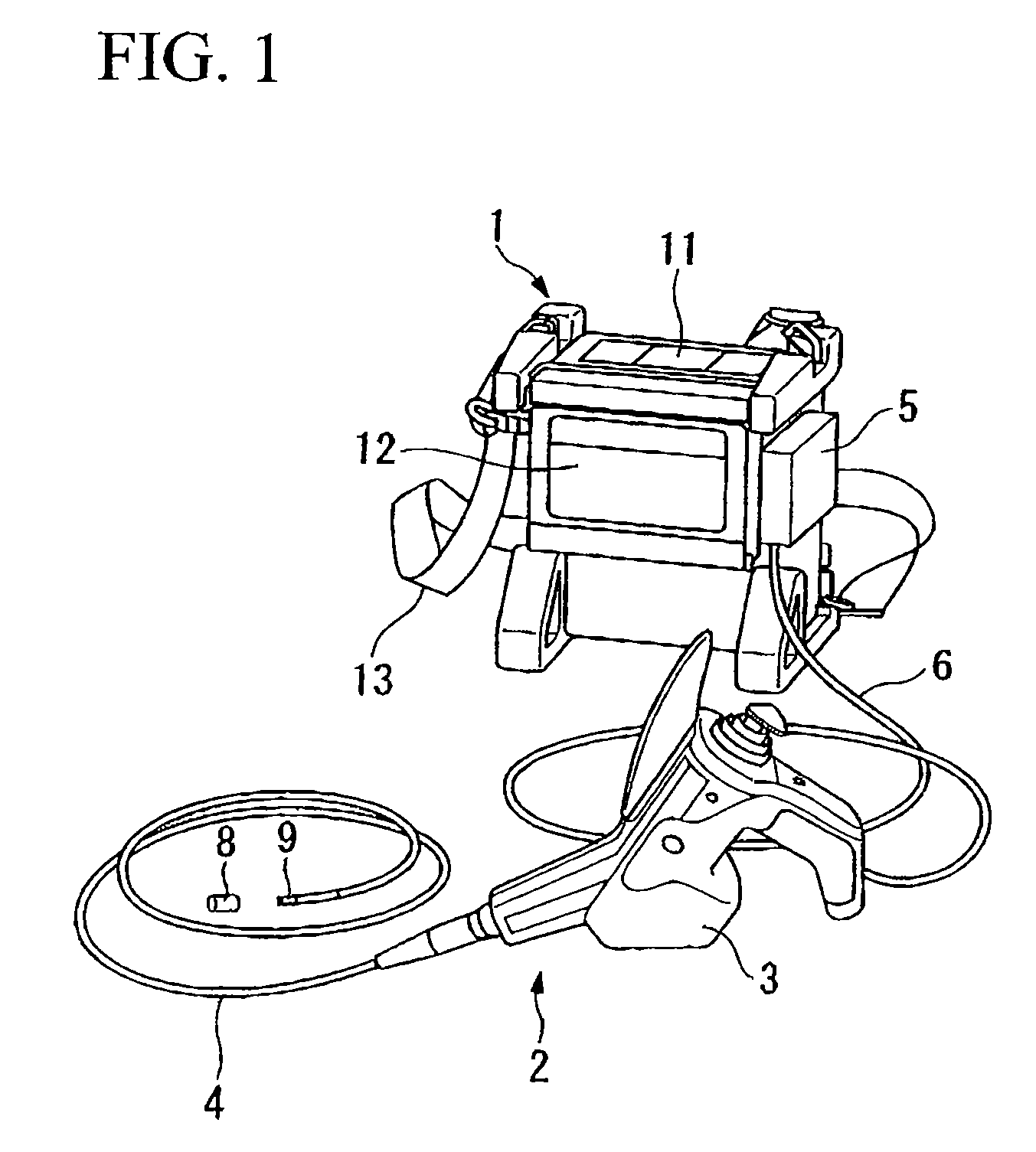

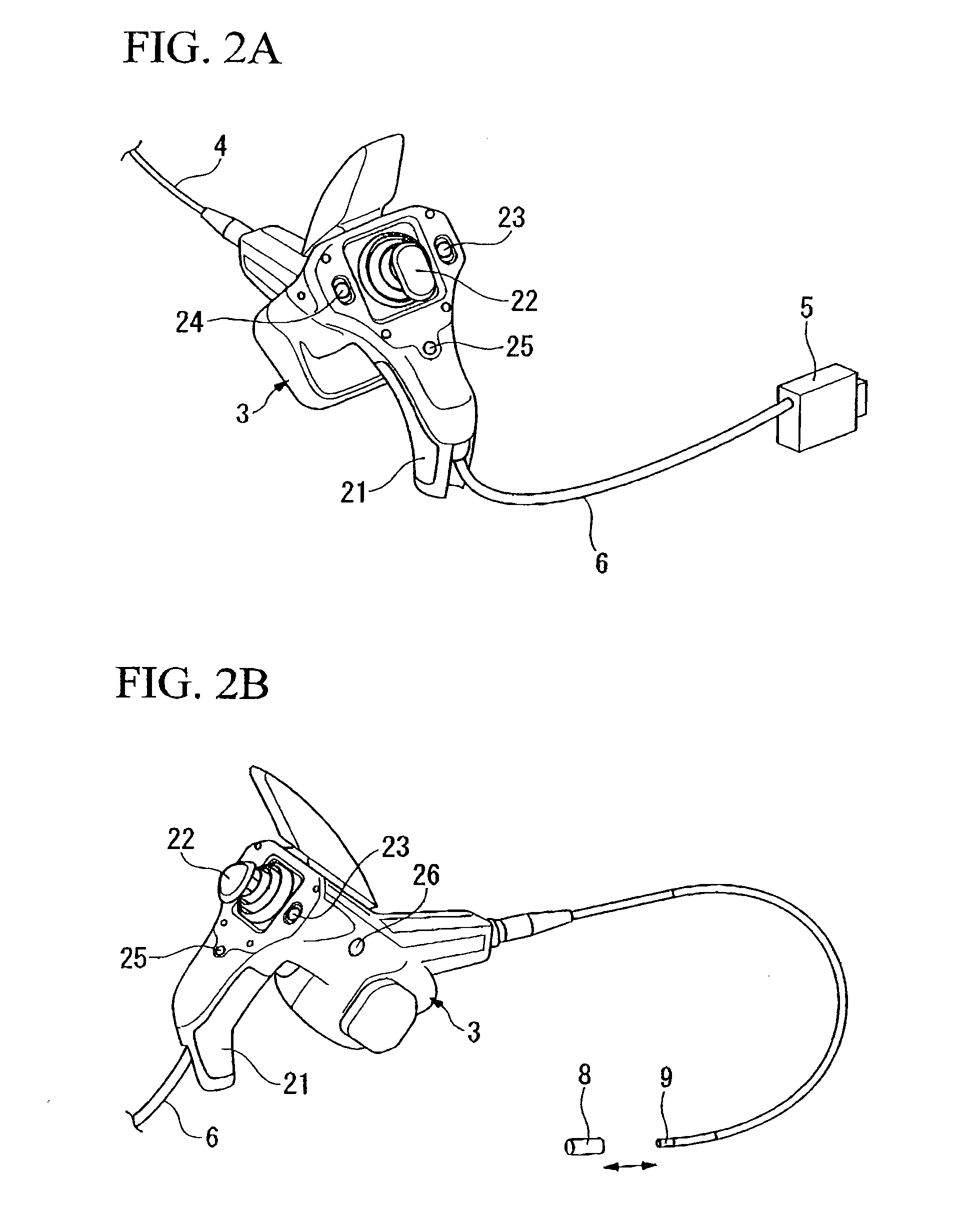

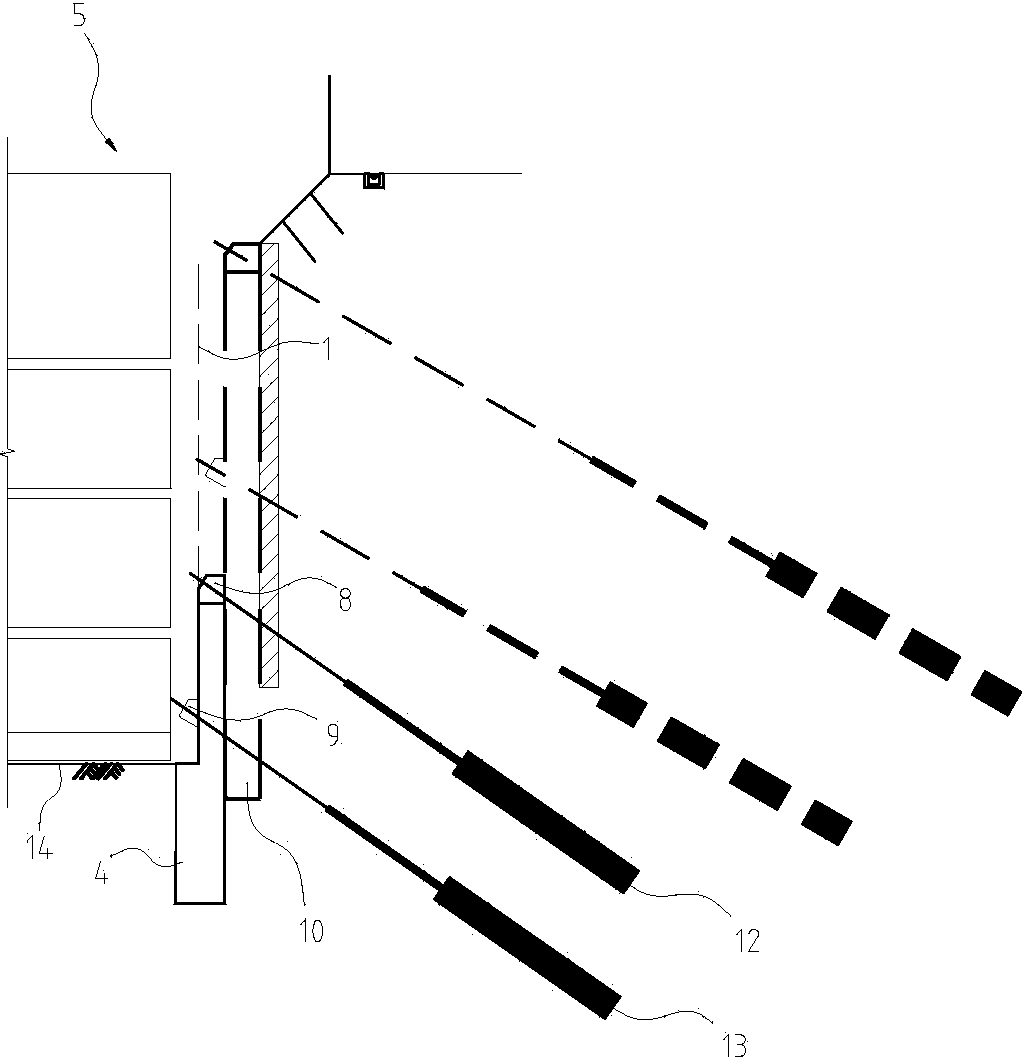

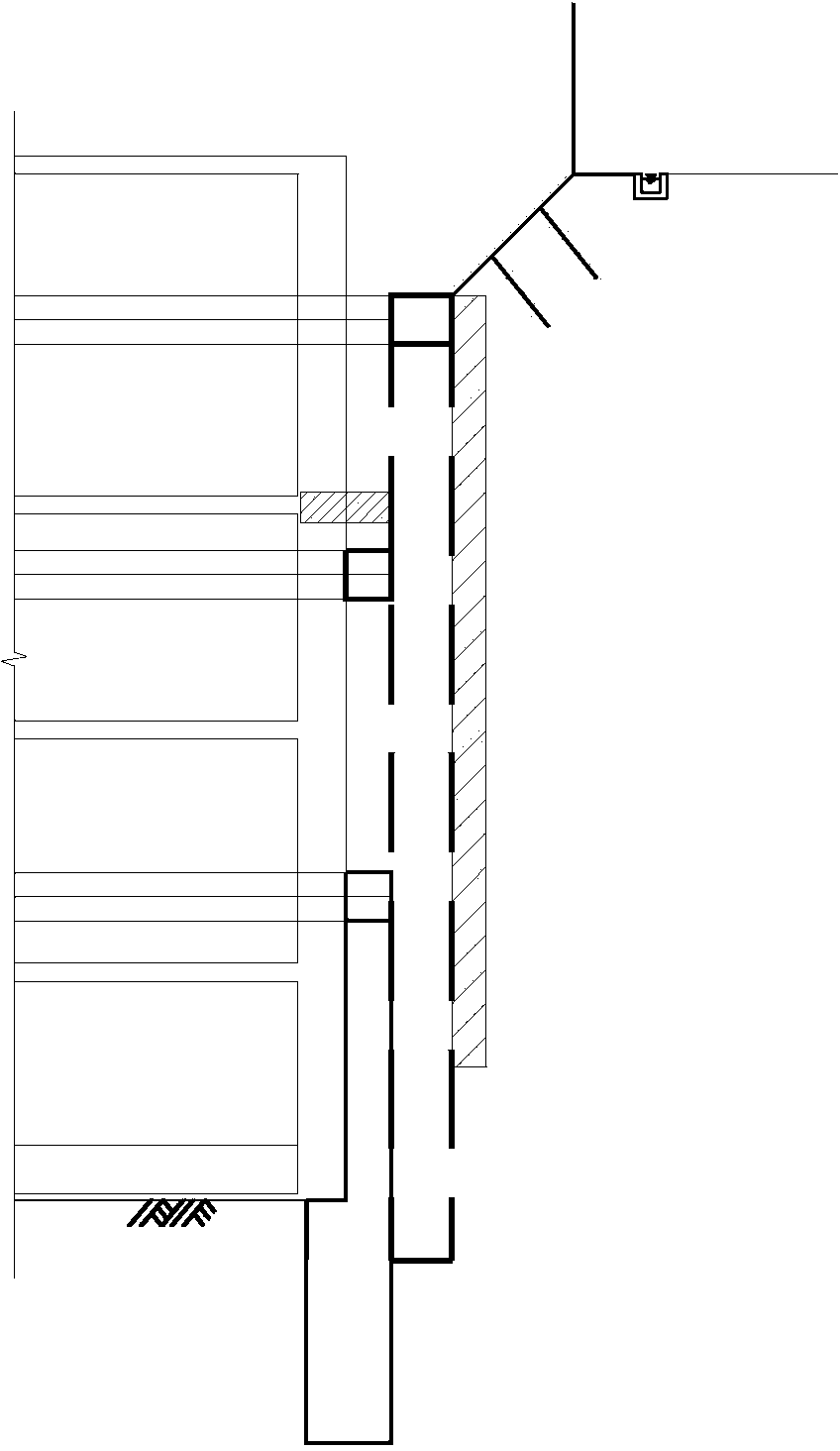

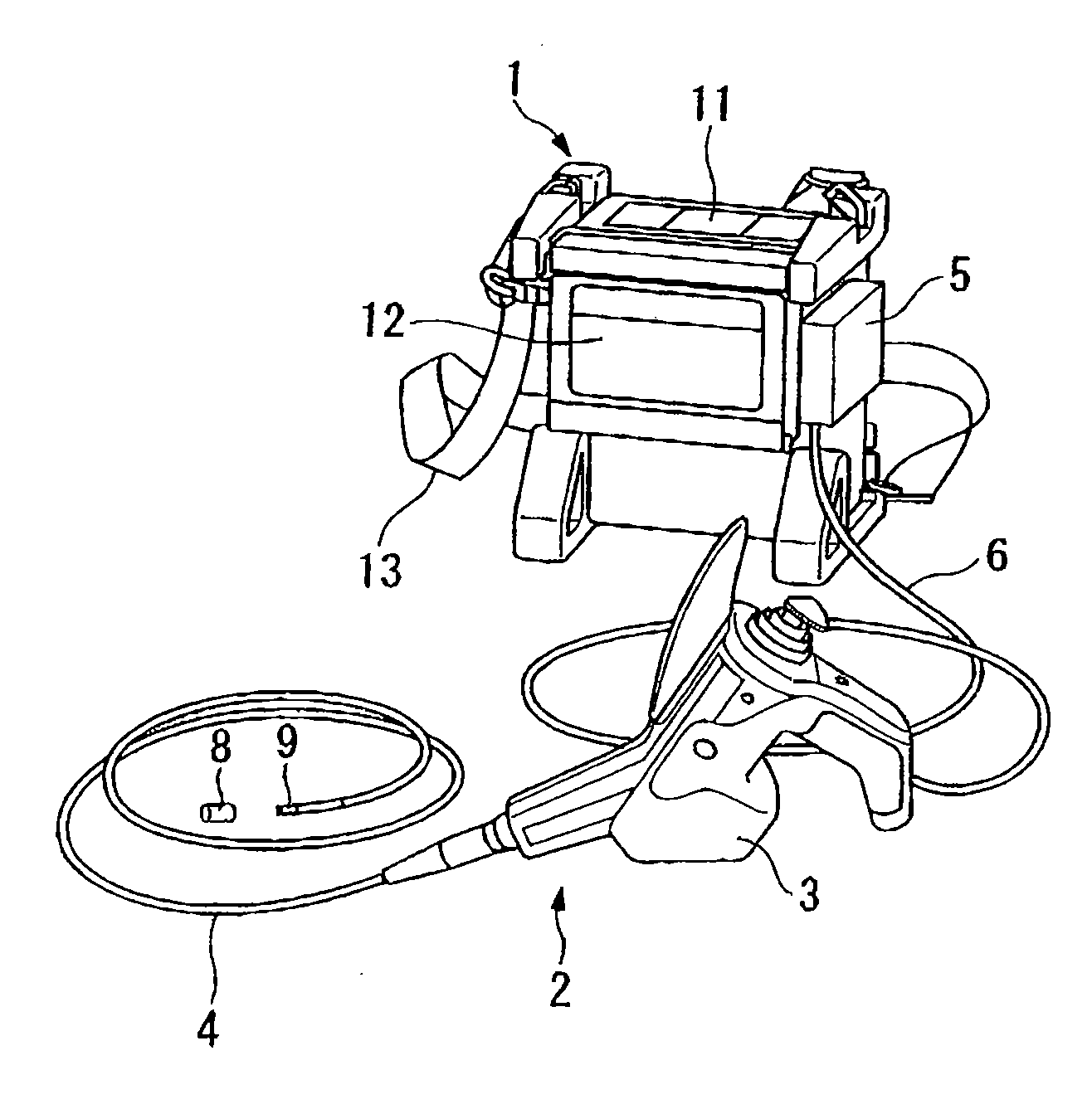

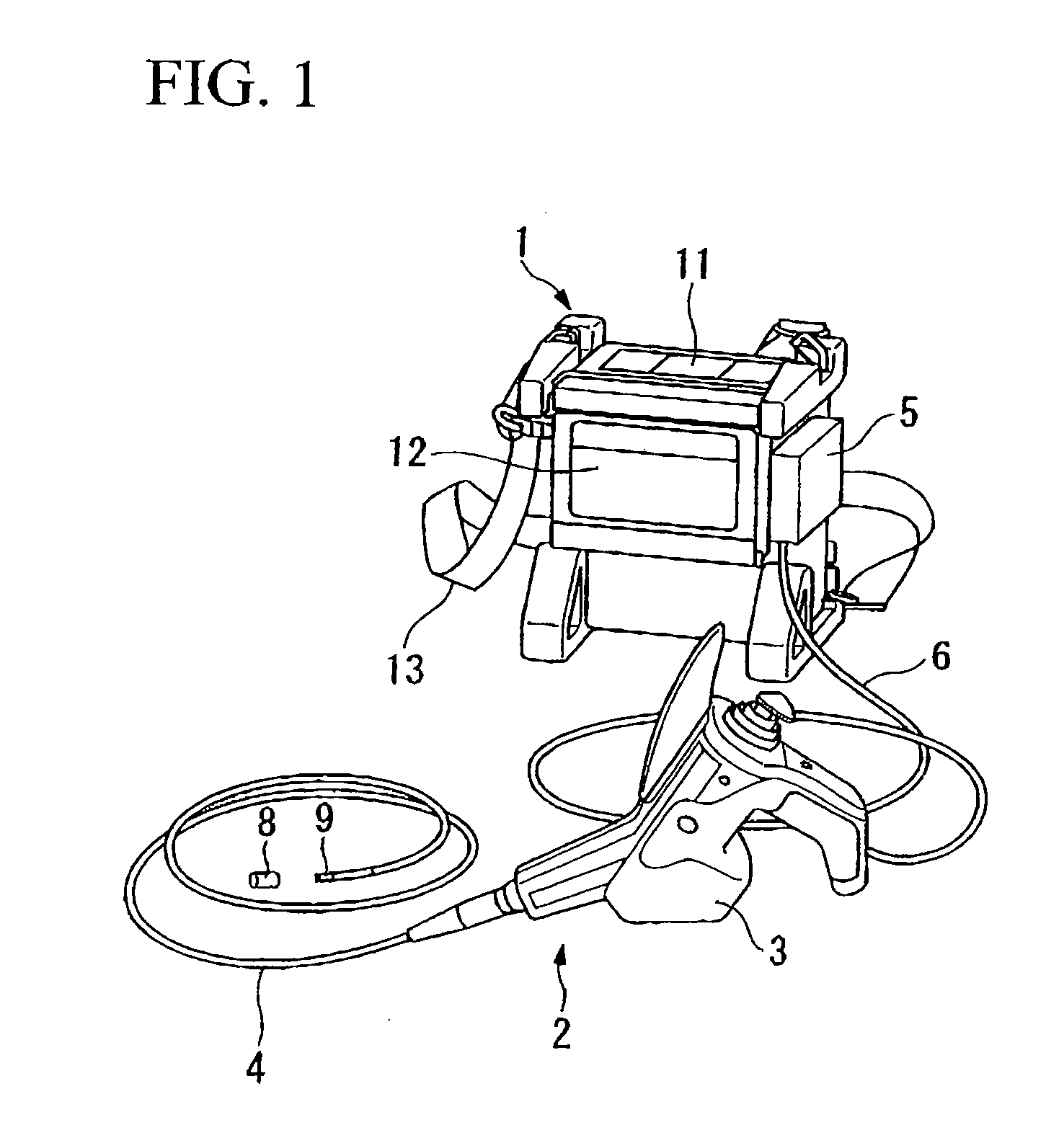

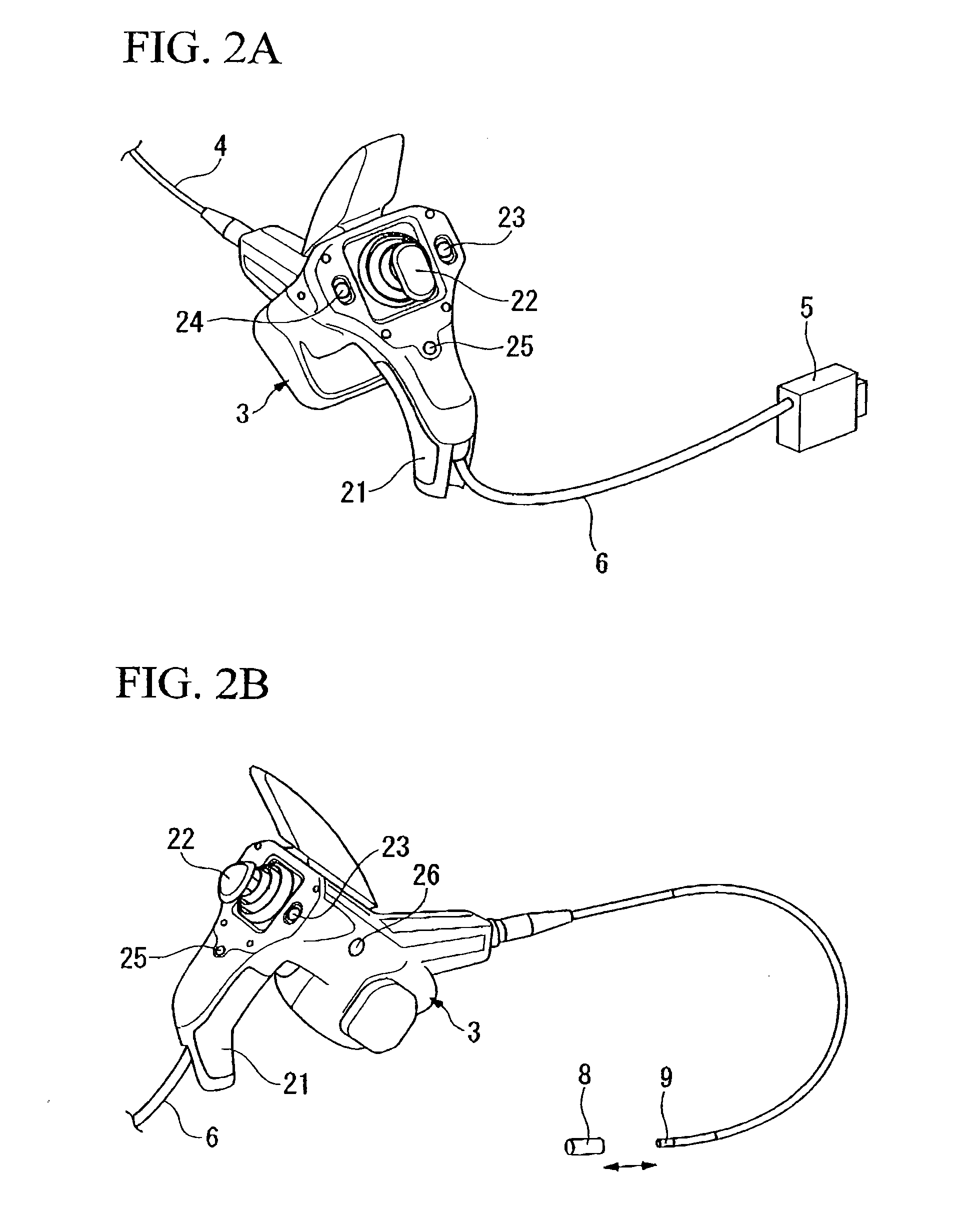

Endoscope apparatus

A scope unit 2 including a control unit 3 and an insertion portion 4 is attached to a main unit 1 via a scope connector 5. An optical adaptor 8 is attached to a tip of the insertion portion 4. The CCD 31, HICs 32, 33, and the thermistor34 are attached to the tip of the insertion portion 4. A liquid crystal module 36 is attached to the optical adaptor 8. A barrier circuit 64 limits energy supplied to these components in a circuit disposed in the scope unit 2. By disposing the barrier circuit 64 in the scope connector 5, the portion extending from the barrier circuit 64 to, i.e., the control unit 3, the insertion portion 4, and the optical adaptor 8 are of the explosion-proof construction. Thus, these can be used in a hazardous explosive location. Thus, an endoscope apparatus that can be used in combustible gas or dust can be provided.

Owner:EVIDENT CORP

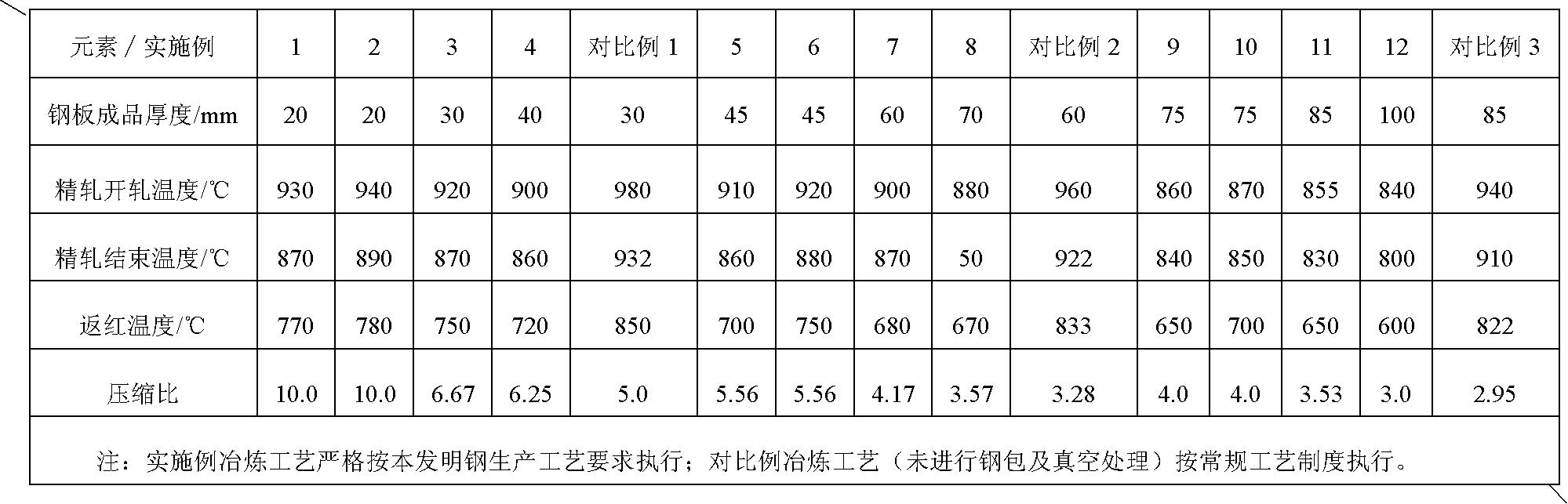

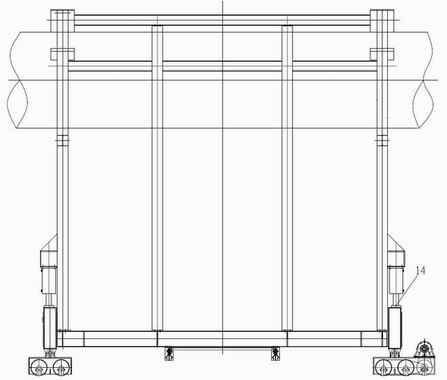

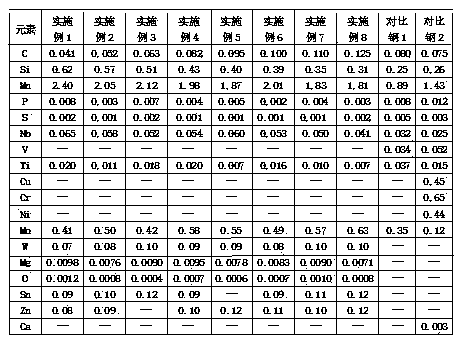

Quake-proof construction steel with lamellar tearing resistance and excellent performance and production method thereof

InactiveCN101994058AGood welding performanceSimplify welding production processProof constructionSheet steel

The invention relates to quake-proof construction steel with lamellar tearing resistance and excellent performance and a production method thereof. The steel is suitable for steel plates of which the thicknesses are between 20 and 100 millimeters and comprises the following chemical components: less than or equal to 0.015 percent of C, less than or equal to 0.015 percent of Si, less than or equal to 0.015 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.02 to 0.04 percent of Nb, 0.005 to 0.020 percent of Ti, 0.010 to 0.060 percent of Als and the balance of Fe. The method comprises the following steps of: performing the pretreatment of molten iron; performing desulfuration treatment; controlling target components of a smelting terminal point, wherein the target components comprise 0.05 to 0.07 percent of [C] and less than or equal to 0.015 percent of [P]; refining through a ladle furnace, and feeding aluminum wires and blasting argon; performing relative humidity (RH) vacuum treatment, and introducing the argon before the treatment; adding SiCa wires; casting continuously and performing the pouring of full-process protection; heating casting blanks; performing rough rolling; performing precision rolling; and cooling. The steel of the invention has the excellent quake-proof performance (ReH / Rm is less than or equal to 0.77); and the contractibility rate of a cross section in the full-thickness direction is between 40 and 70 percent, so the steel meets the requirements of key stressed points of major constructions such as steel structure work and the like fully.

Owner:武钢集团有限公司

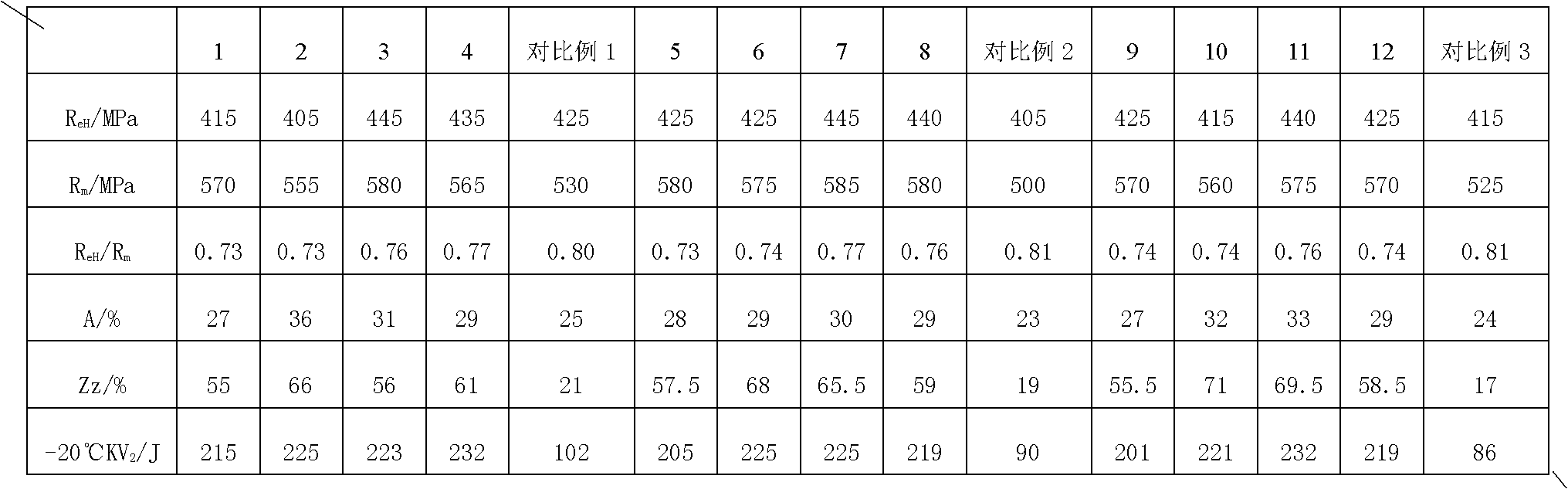

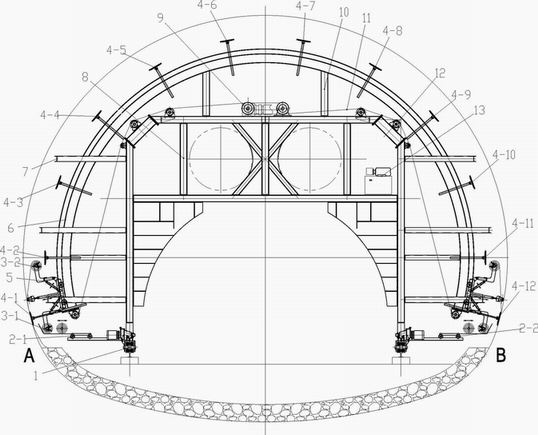

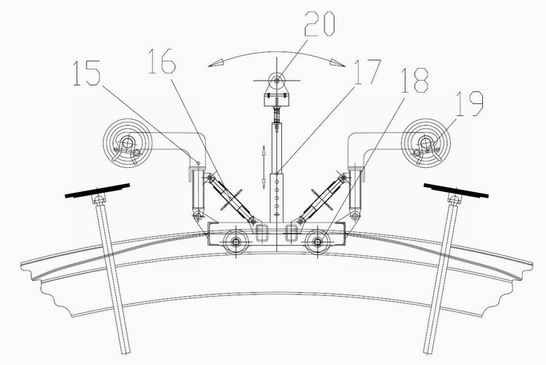

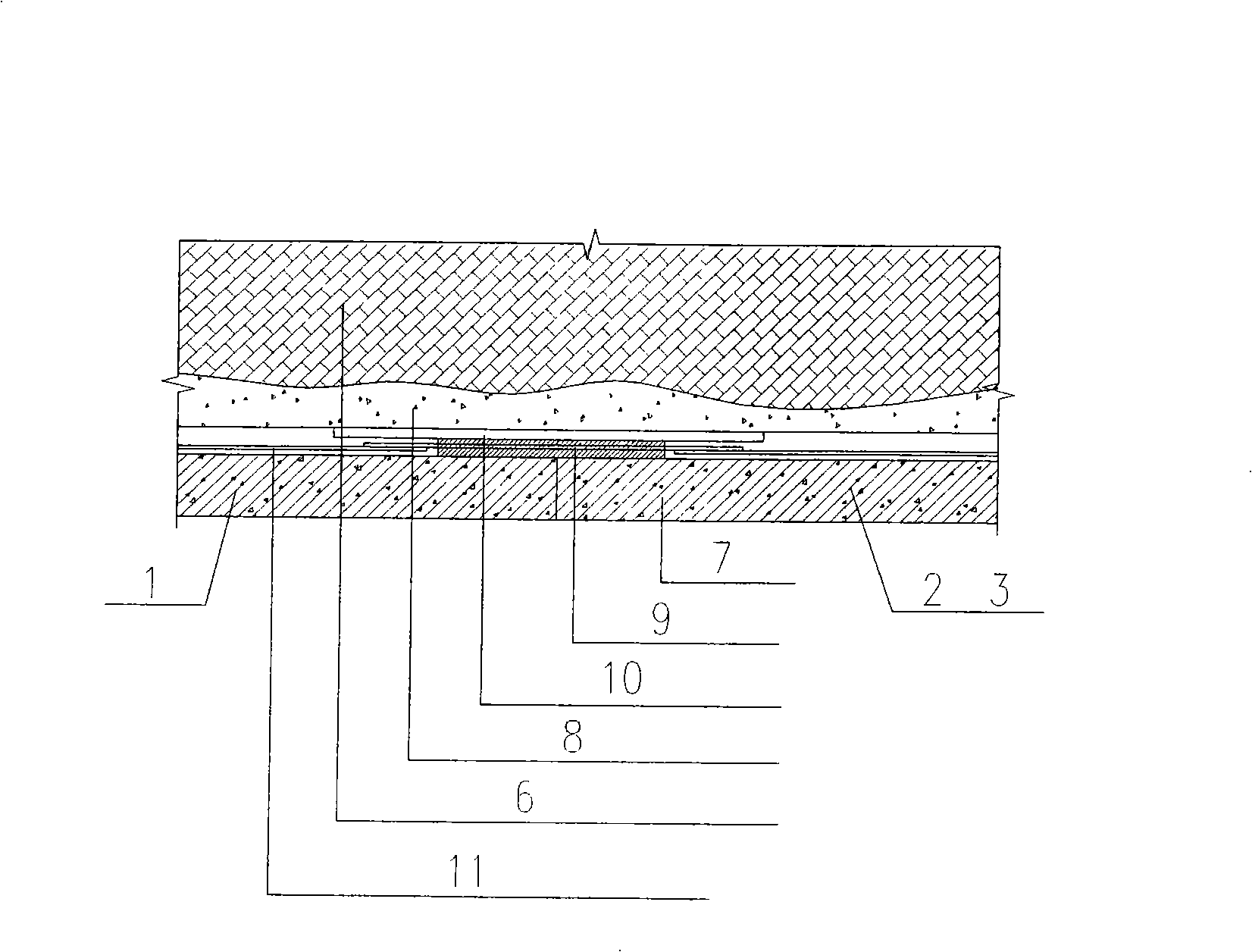

Tunnel waterproof material laying equipment and method

ActiveCN102061927AEasy to assemble and disassembleReduce labor intensityUnderground chambersTunnel liningProof constructionElectricity

The invention discloses novel tunnel waterproof material laying equipment and method, used for replacing waterproof material manual laying and supporting operation in tunnel water proofing constructions. The laying equipment comprises a trolley travelling mechanism, a waterproof material installing device, a laying device, a supporting device, a laying track and a laying trolley. The tunnel waterproof material laying equipment is convenient to disassemble and assemble, can reduce labor intensity and labor cost and improve laying efficiency and quality when used for laying tunnel waterproof materials with large breadth. The tunnel waterproof material laying equipment is mainly used for mechanically laying waterproof materials, such as geotextile and waterproof boards used in tunnel water proofing constructions of national defense / civil air defense constructions, railway / submarine tunnels, urban subway / water, electricity and road transportation and the like.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

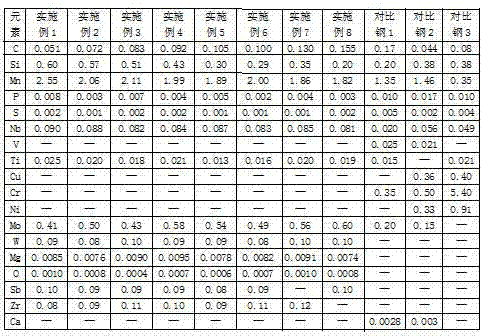

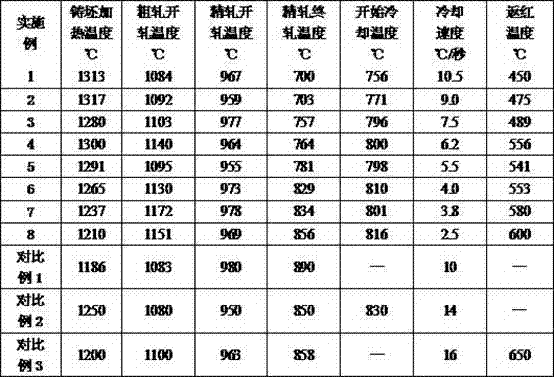

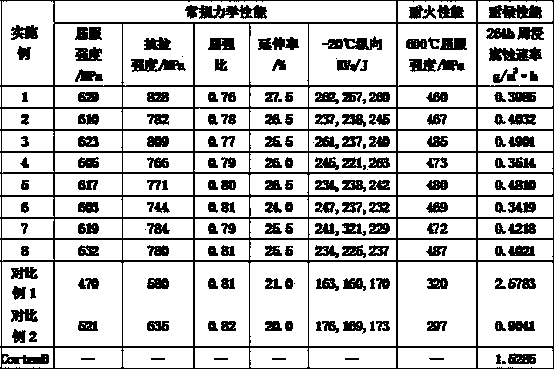

690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695773AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

The invention relates to a 690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.051-0.155% of C, 0.20-0.60% of Si, 1.82-2.55% of Mn, at most 0.008% of P, at most 0.002% of S, 0.081-0.090% of Nb, 0.010-0.025% of Ti, 0.41-0.60% of Mo, 0.08-0.10% of W, 0.0071-0.0095% of Mg and at most 0.0010% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 690-850MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

550MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695772AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

The invention relates to a 550MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.041-0.125% of C, 0.31-0.62% of Si, 1.81-2.40% of Mn, at most 0.008% of P, at most 0.002% of S, 0.041-0.065% of Nb, 0.007-0.020% of Ti, 0.41-0.63% of Mo, 0.07-0.10% of W, 0.0071-0.0098% of Mg and at most 0.0012% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 550-700MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

Manual hole digging non-uniform pile support construction technology

ActiveCN104264688AEasy constructionDoes not affect the constructionProtective foundationExcavationsBasementProof construction

The discloses a manual hole digging non-uniform pile support construction technology for construction along the inner side of the former support structure, the construction steps are as follows: (1) digging the first order, the second order and the third order hole digging piles according to the process of every three for one; (2) forming crown beam at the top of pile for enhancing support structure integral rigidity, having layering construction for horizontal support or anchor cable according to the design calculation requirement, after getting the design strength requirement, excavating the foundation trench earthwork to the bottom in the foundation trench; (3) making level for the manual hole digging non-uniform pile, having the water proof construction, making the basement bottom plate, casting the bottom plate concrete with the former support pile; (4) removing the second strengthening anchor cable or removing the support, finishing the basement structure; (5) extending the rebar in the hollow part of the manual hole digging pile into the basement bottom plate as basement structure pile and anti-floating pile. The manual hole digging non-uniform pile support construction technology solves the problem that the big diameter strengthening support pile construction machinery cannot be contained for the inner support at upper part or convex waist beam while the remain construction space between the support pile and the basement outer side line is small.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

Endoscope apparatus

A scope unit 2 including a control unit 3 and an insertion portion 4 is attached to a main unit 1 via a scope connector 5. An optical adaptor 8 is attached to a tip of the insertion portion 4. The CCD 31, HICs 32, 33, and the thermistor 34 are attached to the tip of the insertion portion 4. A liquid crystal module 36 is attached to the optical adaptor 8. A barrier circuit 64 limits energy supplied to these components in a circuit disposed in the scope unit 2. By disposing the barrier circuit 64 in the scope connector 5, the portion extending from the barrier circuit 64 to, i.e., the control unit 3, the insertion portion 4, and the optical adaptor 8 are of the explosion-proof construction. Thus, these can be used in a hazardous explosive location. Thus, an endoscope apparatus that can be used in combustible gas or dust can be provided.

Owner:EVIDENT CORP

Leakage-proof construction process method of toilet and kitchen

InactiveCN109356295AOvercoming the quality problems of water seepage and leakageImprove waterproof performanceBuilding insulationsFlavorProof construction

The invention provides a leakage-proof construction process method of a toilet and a kitchen. The quality problem that the weak positions such as floor drains, wall footings, pipe roots and wall surface holes leak water is solved, the waterproof property of the toilet and the kitchen is improved, peeling and cement blooming of wall surface emulsion paint and wallpaper are avoided, and the servicelife of decorative materials and decoration projects is prolonged; through slope finding and floor drain reforming, the problem that water is accumulated on ground mortar layers of the toilet and thekitchen is effectively avoided, and thus the foreign flavor is avoided; and a construction method is simple, the construction cost is low, and the healthy and sanitary living environment is created for people.

Owner:陕西中林建筑装饰工程有限公司

Mass concrete cracking proof construction technology

ActiveCN104264678AAvoid crackingReduce water consumptionFoundation engineeringProof constructionTemperature difference

The invention discloses a mass concrete cracking proof construction technology which can prevent the concrete from cracking and improve the concrete pouring quality. The mass concrete cracking proof construction technology comprises the following steps of firstly building a steel reinforcement framework and a template, then selecting the type and the ratio of the concrete, pouring the concrete, regulating the internal and external temperature difference and the maximum temperature of the concrete after concrete pouring is achieved; cooling the concrete by water-passing cooling, when the internal and external temperature difference of the concrete cannot be smaller than 25 DEG C by the water-passing cooling, reducing the internal and external temperature difference of the concrete by rising the temperature of the exterior of the concrete and maintaining naturally concrete temperature reducing when the internal and external temperature difference is smaller than 25 DEG C and the internal maximum temperature is smaller than 50 DEG C; removing the template when the concrete temperature is not changed to achieve construction of the concrete. According to the mass concrete cracking proof construction technology, cracking during a solidification process of the concrete is effectively avoided and the concrete quality is improved.

Owner:SEPCO ELECTRIC POWER CONSTR CORP

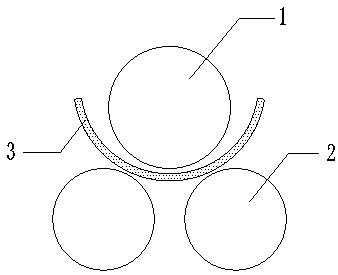

Manufacturing method of thick wall steel pipe with small radius-thickness ratio used for building structure

The invention relates to a manufacturing method of steel pipes, in particular to a manufacturing method of a thick wall steel pipe with a small radius-thickness ratio used for a building structure. The manufacturing method comprises the following steps of: with a Q345GJ-B-level steel pipe as a mother blank, blanking, heating, rolling into a circle, welding, correcting distortion, carrying out heat treatment and the like to obtain the thick wall steel pipe with the small radius-thickness ratio. The steel pipe is suitable for requirement of earthquake proof construction of the building structure and has lower manufacturing cost.

Owner:SHENZHEN GENERAL INST OF ARCHITECTURAL DESIGN & RES

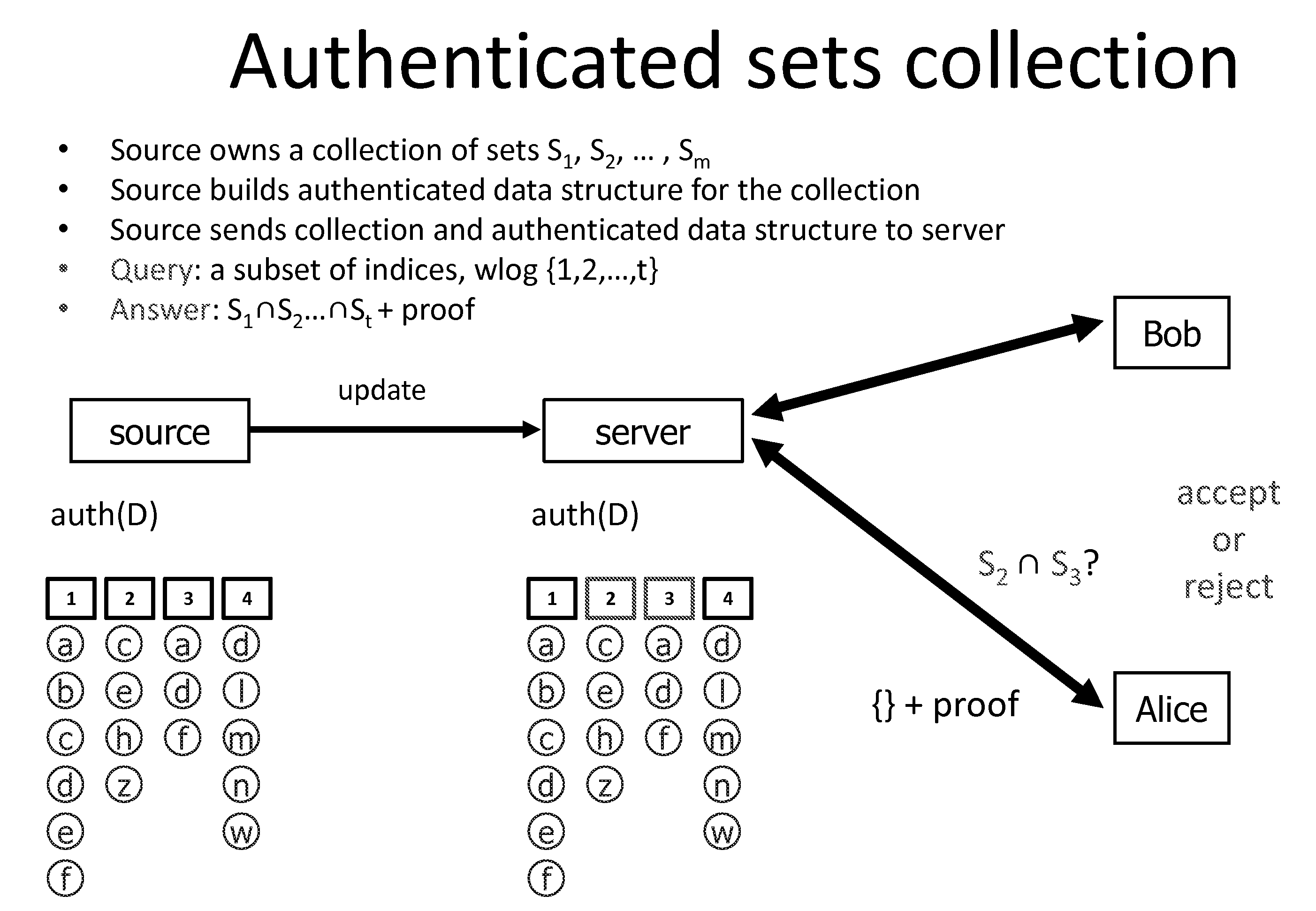

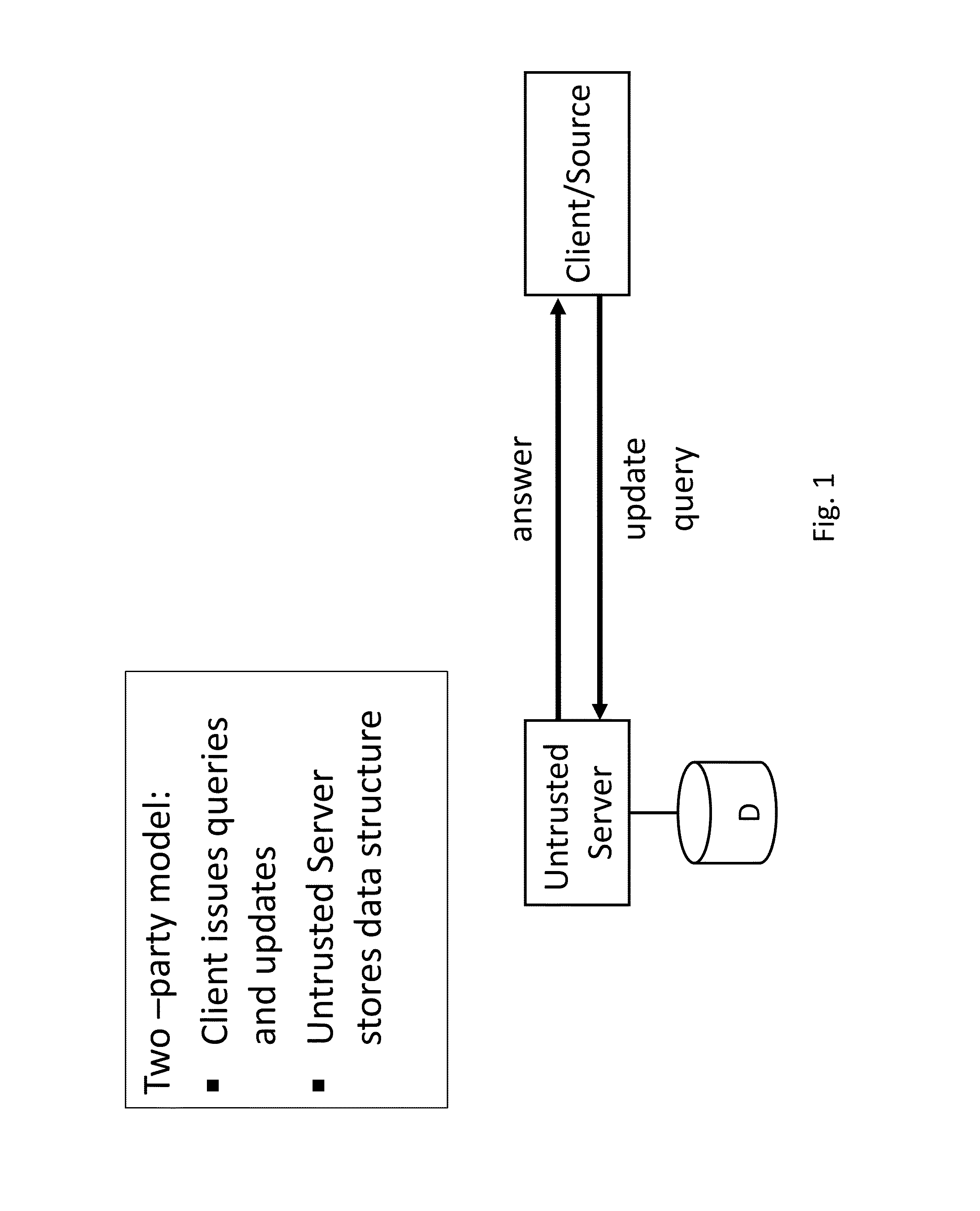

System and method for optimal verification of operations on dynamic sets

Owner:BROWN UNIVERSITY

System and method for optimal verification of operations on dynamic sets

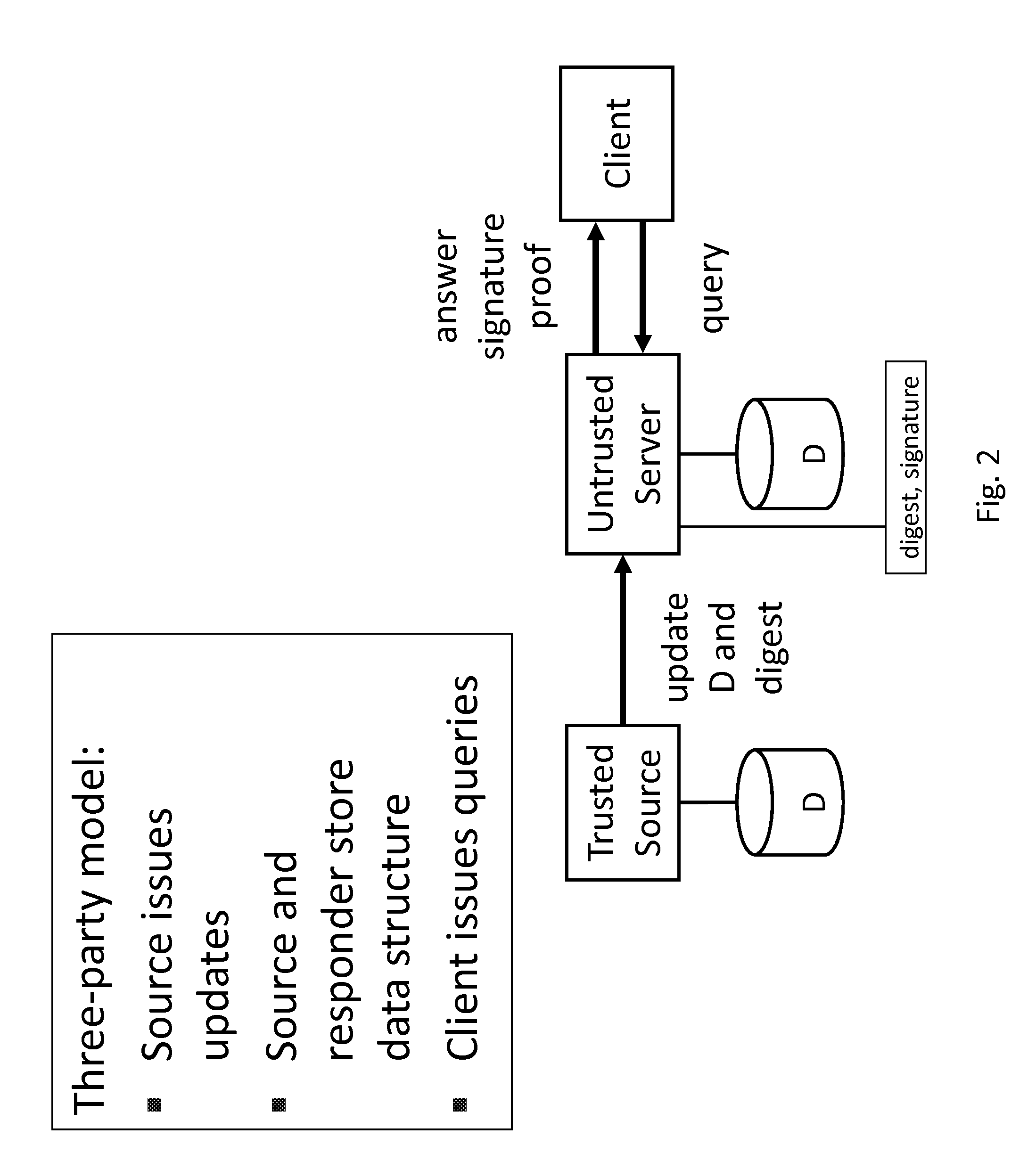

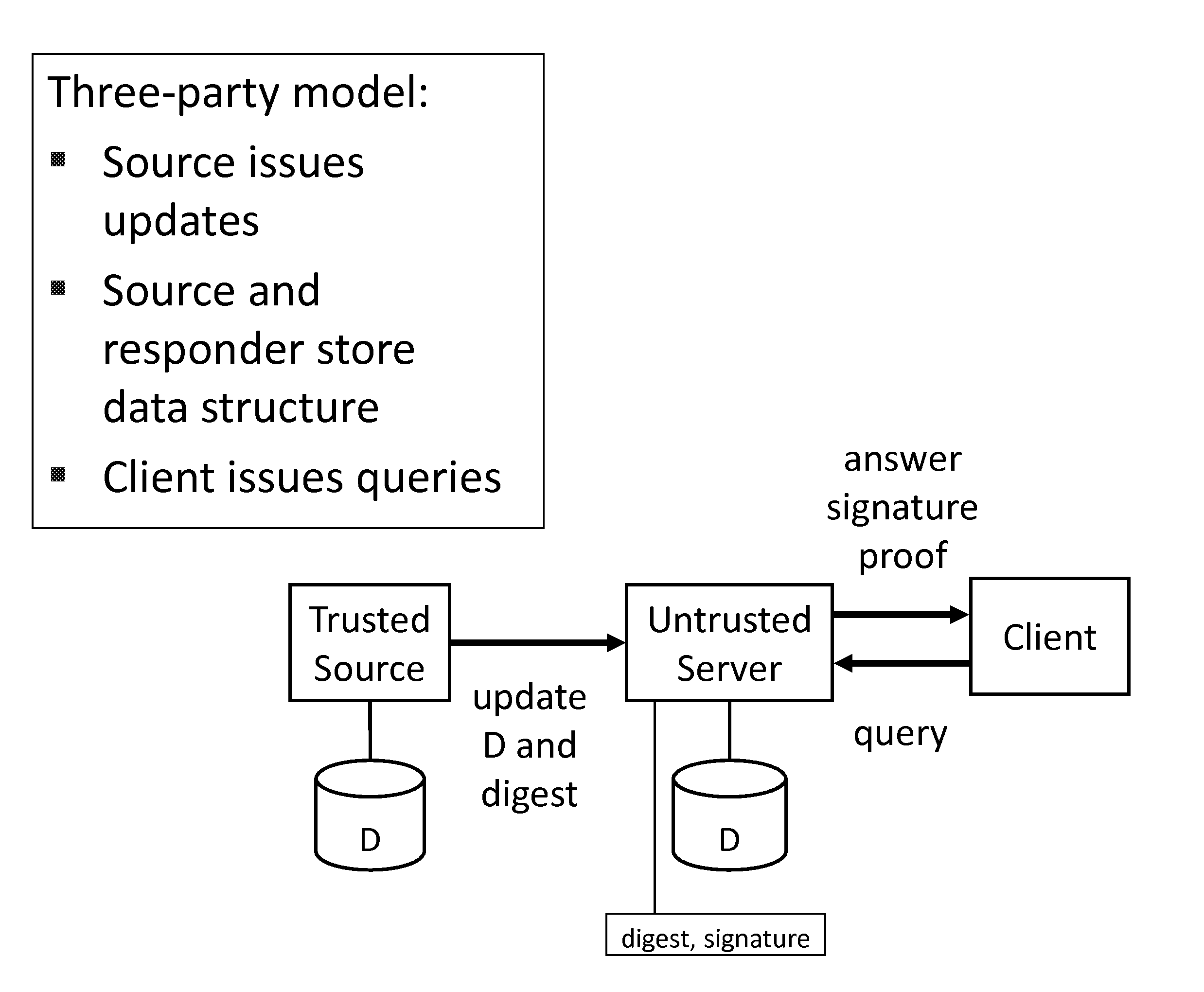

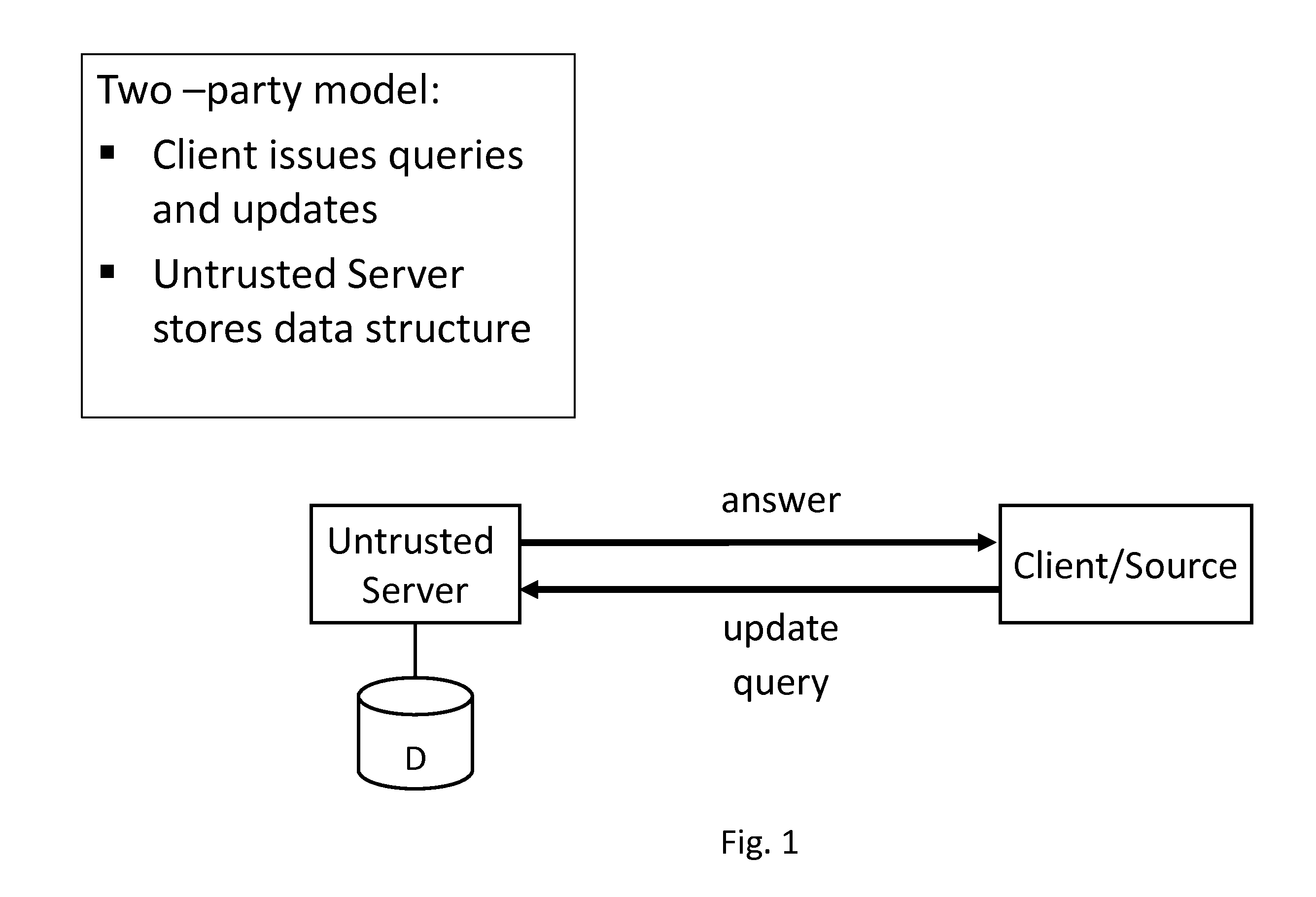

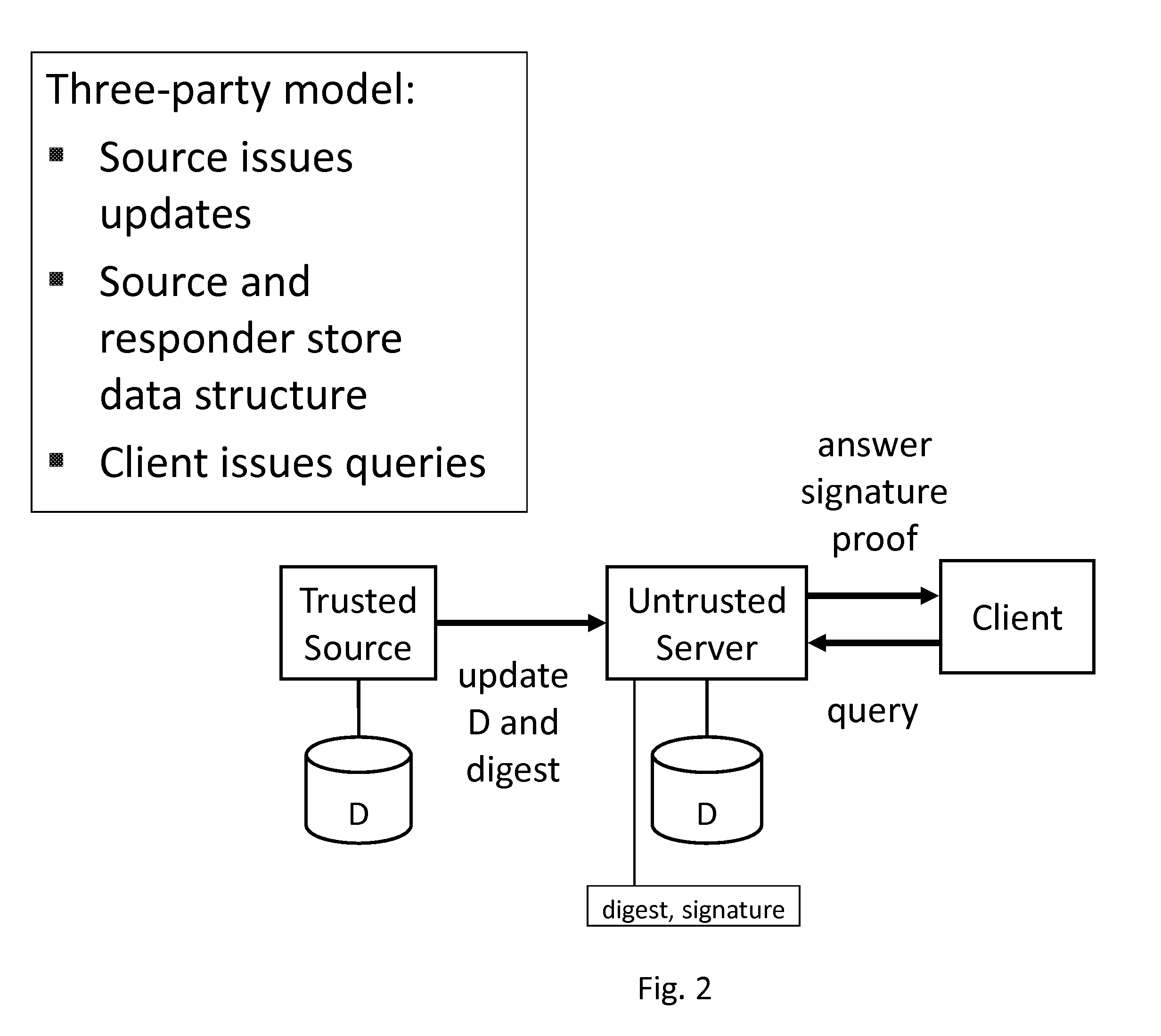

ActiveUS20120030468A1Improve validityReduce decreaseUser identity/authority verificationProof constructionRound complexity

A system and method for cryptographically checking the correctness of outsourced set operations performed by an untrusted server over a dynamic collection of sets that are owned (and updated) by a trusted source is disclosed. The system and method provides new authentication mechanisms that allow any entity to publicly verify a proof attesting the correctness of primitive set operations such as intersection, union, subset and set difference. Based on a novel extension of the security properties of bilinear-map accumulators as well as on a primitive called accumulation tree, the system and method achieves optimal verification and proof complexity, as well as optimal update complexity, while incurring no extra asymptotic space overhead. The method provides an efficient proof construction, adding a logarithmic overhead to the computation of the answer of a set-operation query. Applications of interest include efficient verification of keyword search and database queries.

Owner:BROWN UNIVERSITY

Leakage-proof construction method for building roofs

InactiveCN101555722AExtended service lifeStop water leakRoof covering using slabs/sheetsRoof covering using sealantsProof constructionPolyvinyl alcohol

The invention discloses a leakage-proof construction method for building roofs. For the cracks at the building roof of prefabricated plate or cast-in-place structure, the method comprises the following steps of: cleaning the cracks by water; pouring an absorbent resin in the cracks by a high-pressure pump or mixing a sodium methane-siliconic alkoxide and a polyethylene by the weight ratio of 8:1 uniformly and filling the mixture in the cracks; coating a polyisobutene on the upper surface of the absorbent resin till the thickness being of 2-3mm; and covering the upper surface by a fiberglass cloth. For the leakage at the top of the building due to missing edge or corner and unevenness on the roof surface, the method comprises the following steps of cleaning up the roof surface, using a polyvinyl alcohol cement mortar, mixing the sodium methane-siliconic alkoxide as well as a water (8 weight parts) uniformly and spraying the mixed solution on the roof surface; mixing the sodium methane-siliconic alkoxide and water by the weight ratio of 1:8 uniformly and mixing the mixed solution with the cement mortar material by the weight ratio of 1:2 uniformly, and smearing the mixture on the roof surface till the thickness being of 8-12mm. The method has the advantages that the roof with the leakage supplemented has long service life ranging from 15 years to 25 years generally.

Owner:杨进林

Quake-proof construction steel with yield strength of 160MPa and production method thereof

InactiveCN101775541AImprove purityHigh strengthTemperature control deviceFurnace typesProof constructionChemical composition

The invention discloses quake-proof construction steel with the yield strength of 160MPa and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.002 to 0.005 percent of C, less than or equal to 0.03 percent of Si, 0.10 to 0.50 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.002 to 0.007 percent of Mg, 0.020 to 0.070 percent of Ti, 0.010 to 0.030 percent of Nb, 0.001 to 0.003 percent of N, less than or equal to 0.050 percent of Al, and the balance of Fe and inevitable impurities. The production method thereof comprises the steps of desulfuration of molten iron, converter blowing, vacuum treatment, continuous casting, hot rolling, cooling and the like. When the yield strength of steel products exceeds 180Mpa, an annealing treatment step is added after the cooling step. Experiments prove that the quake-proof construction steel with the yield strength of 160MPa has the characteristics of low yield strength, high elongation and excellent impact toughness; and the production method of the steel has the advantages of simple process flow and low production cost.

Owner:武钢集团有限公司

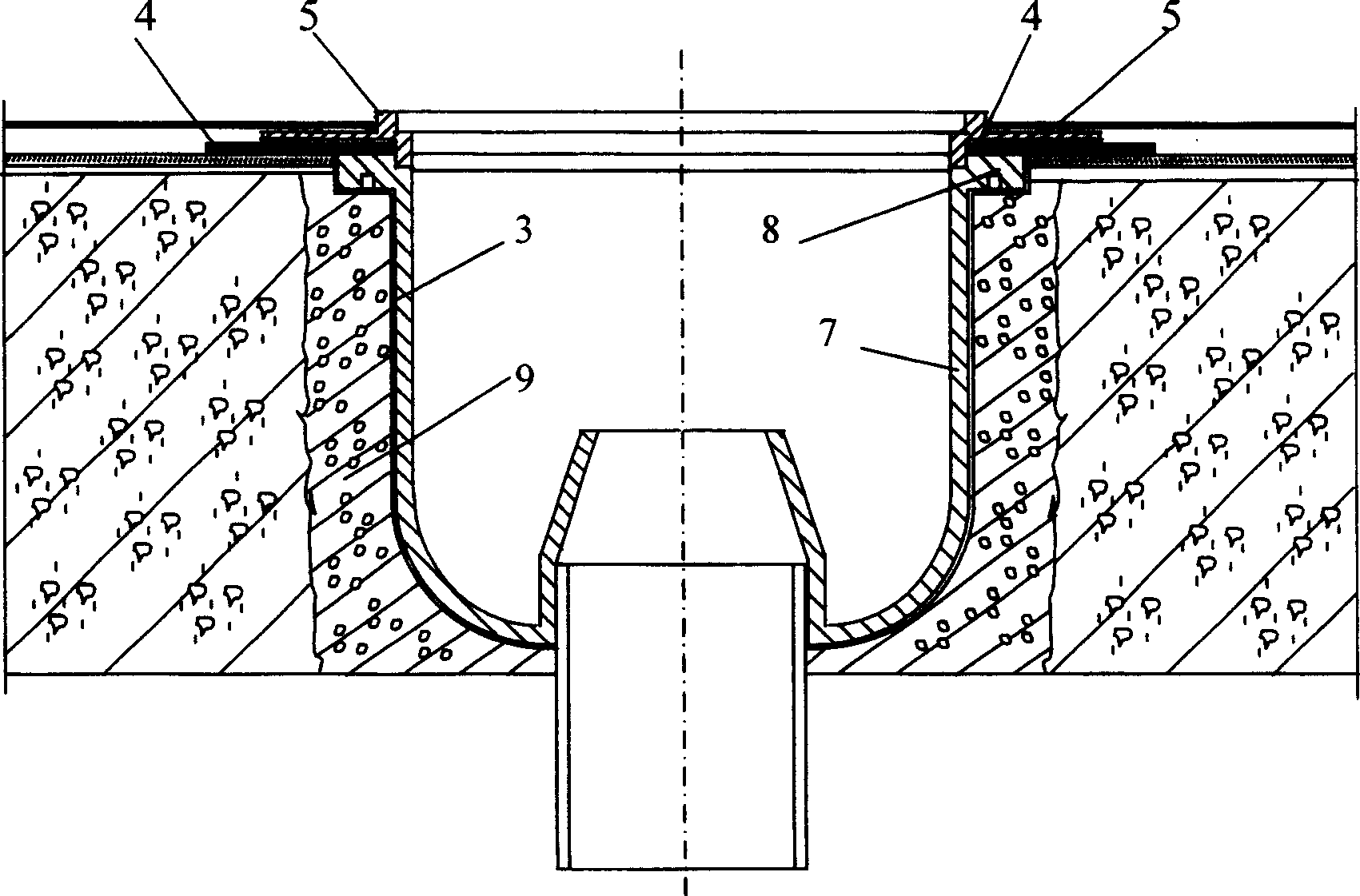

Pipeline and floor joint position water proof construction method

InactiveCN1851185AImprove uptimeSimple and fast constructionBuilding insulationsProof constructionFloor slab

The invention belongs to a water-proofing constructing method for junctions between pipelines and floors of buildings, smearing adhesive watertight material on the junction between outer surface of pipeline or floor drain and floor seam, compacting the watertight material with shaping disc, and after the watertight material is solidified, obtaining a watertight component compounded of watertight material and shaping disc. And the standard shape of the shaping disc becomes a standard shape of the watertight component. And it has advantages of: raising yield of watertight finished products, raising construction efficiency, etc.

Owner:张晶

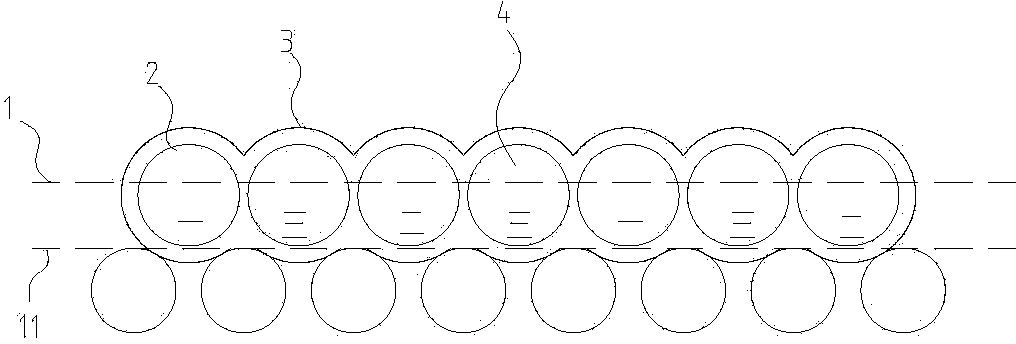

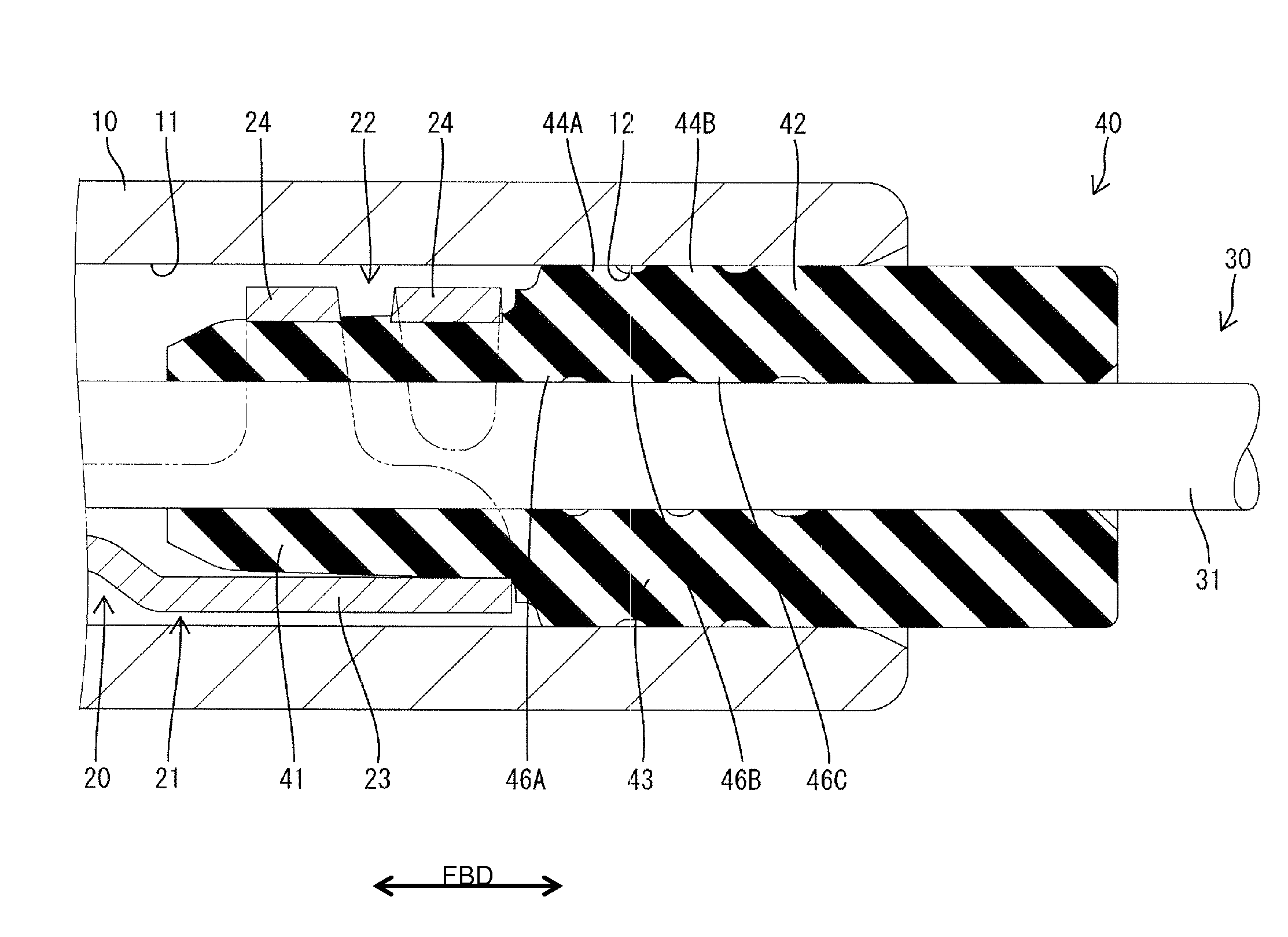

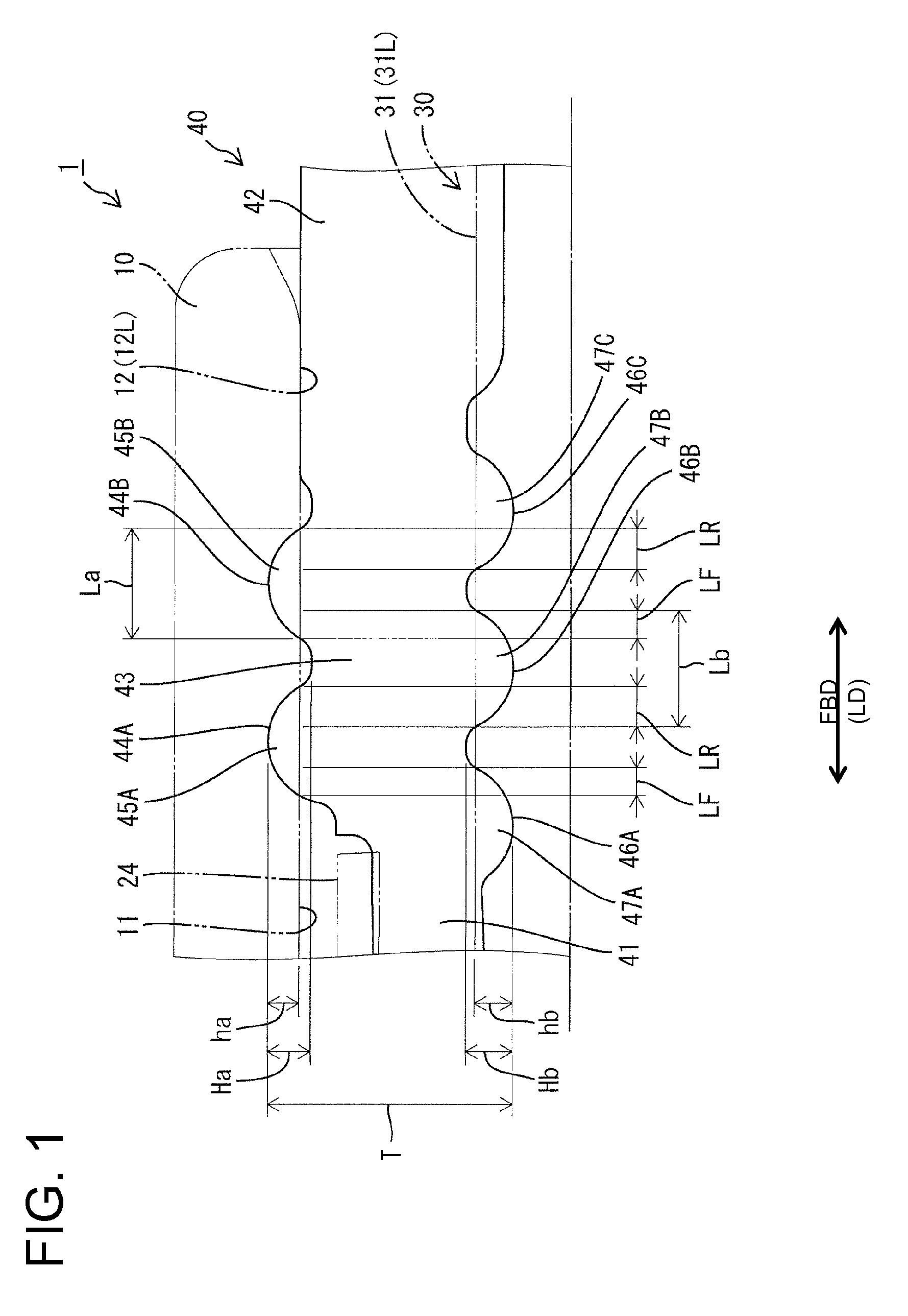

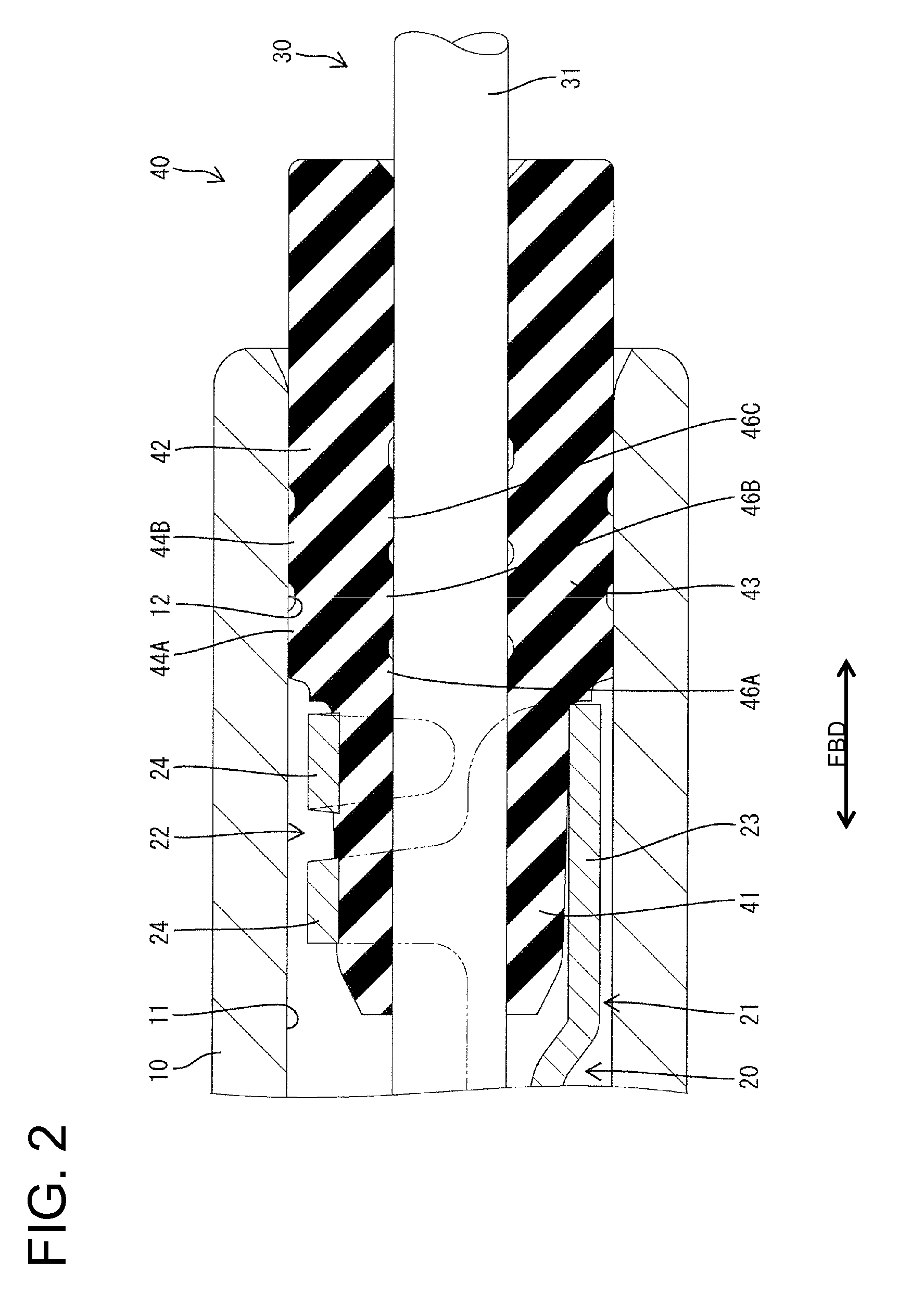

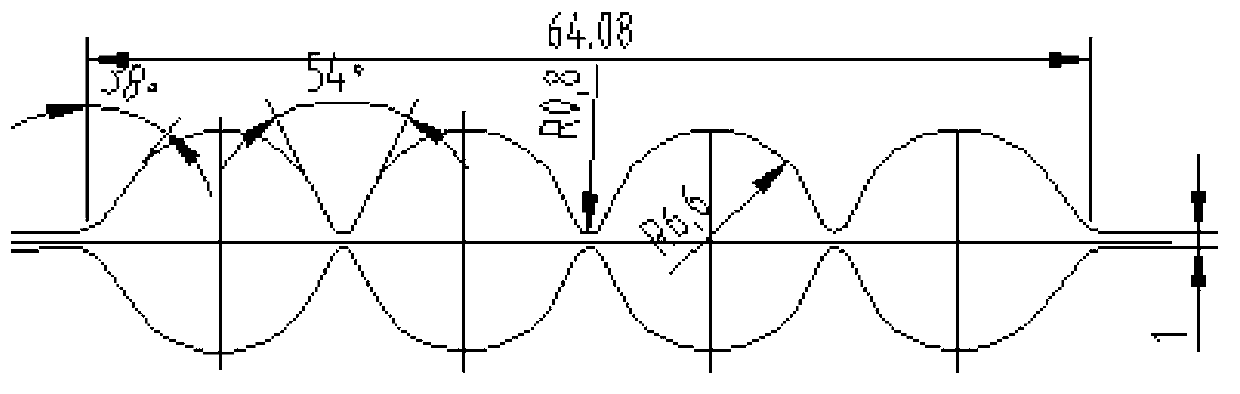

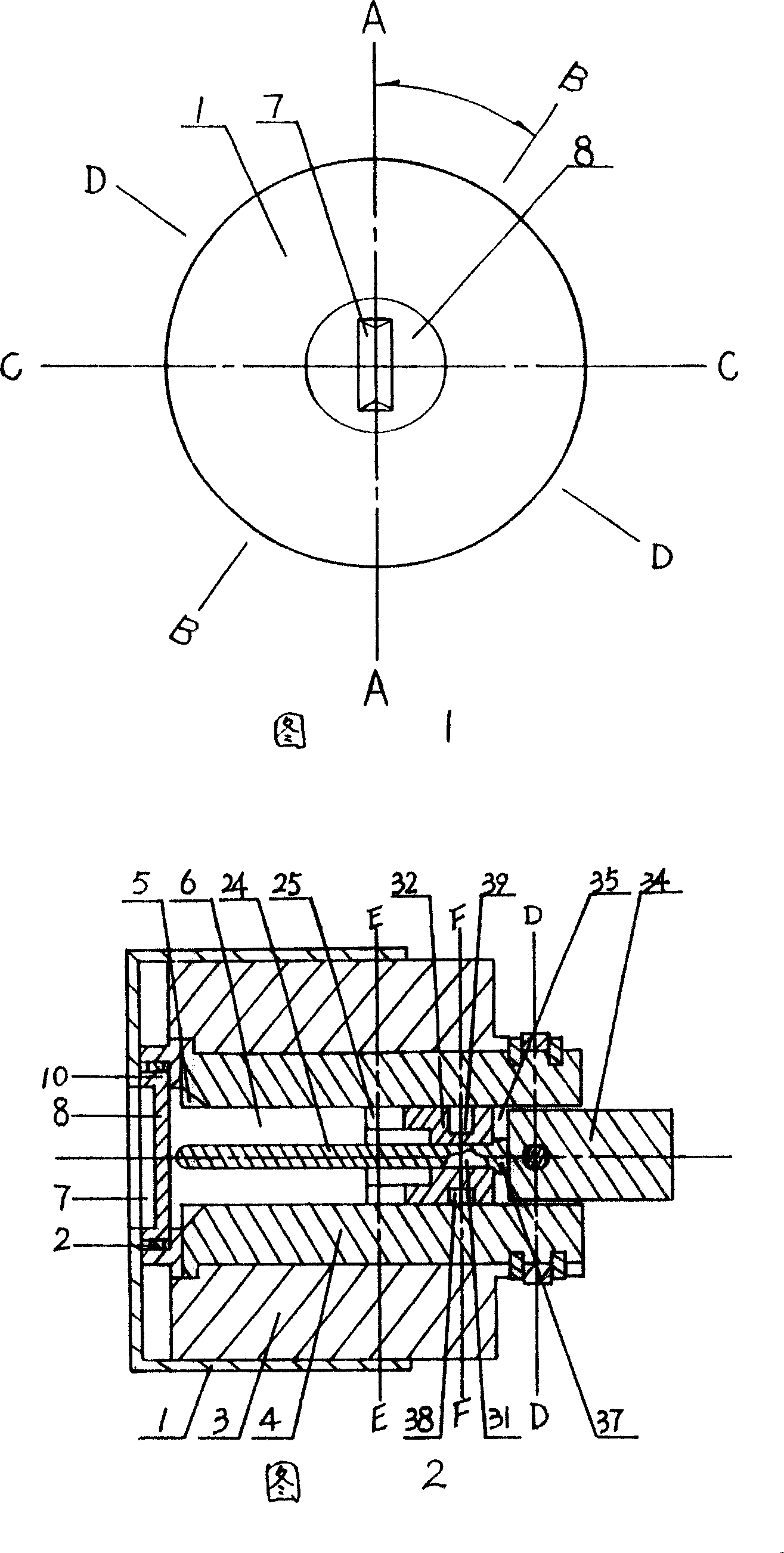

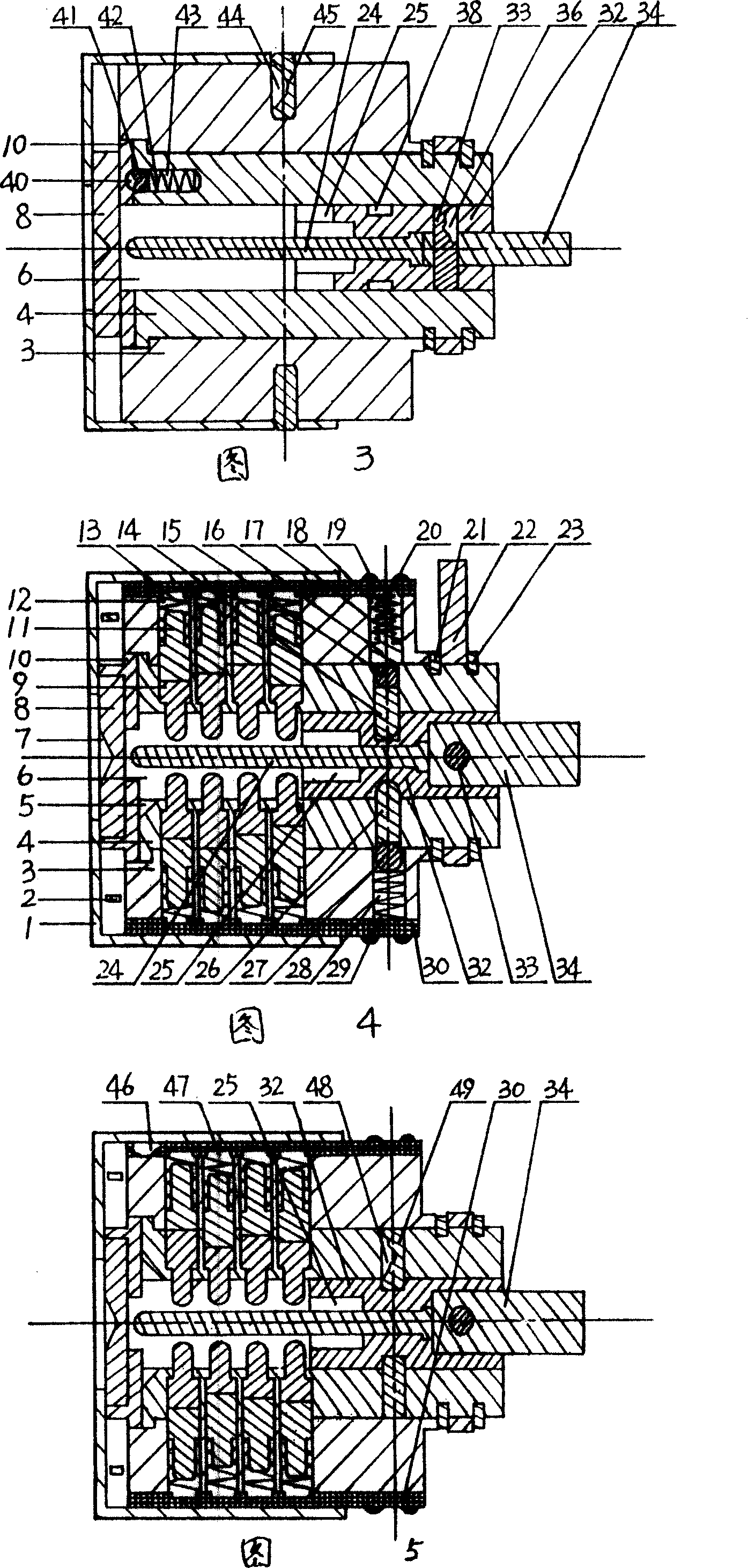

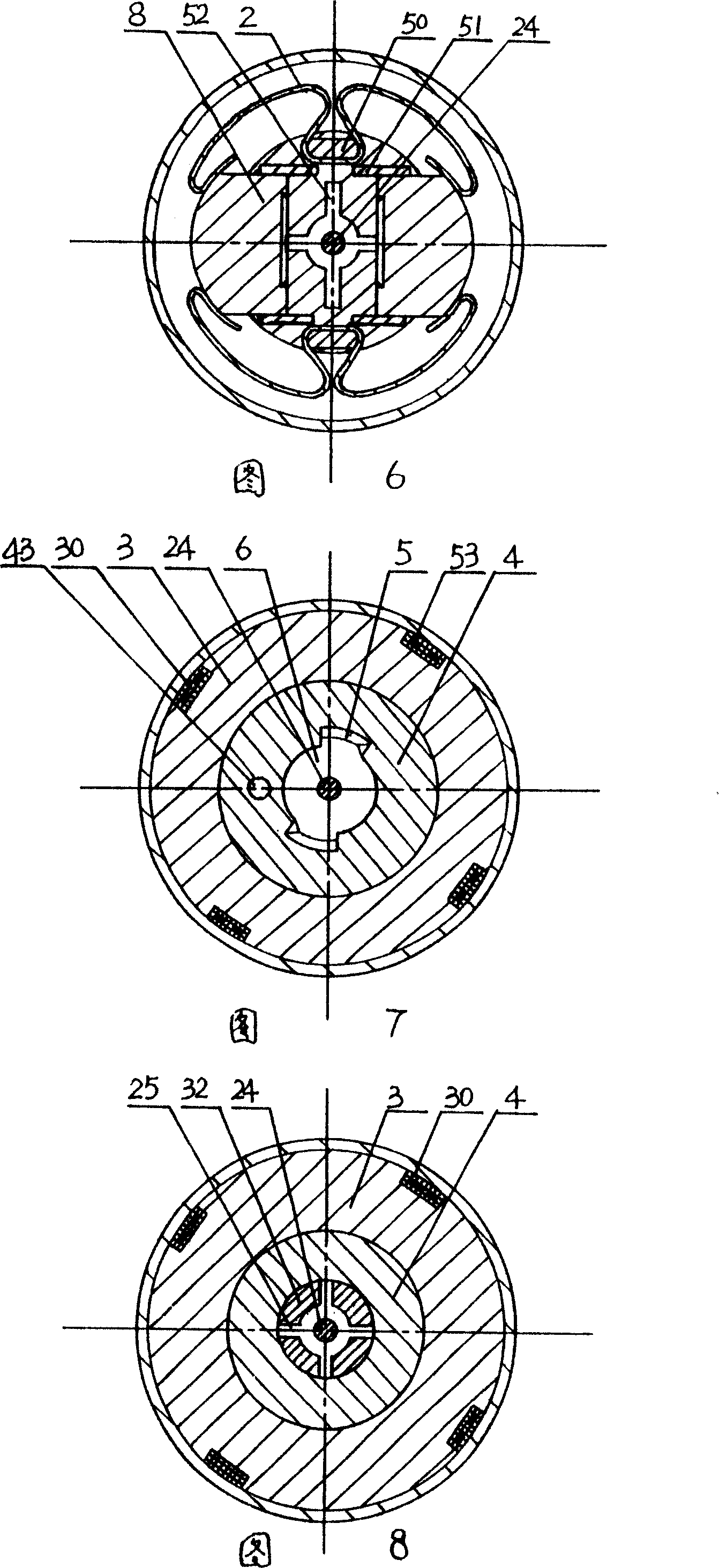

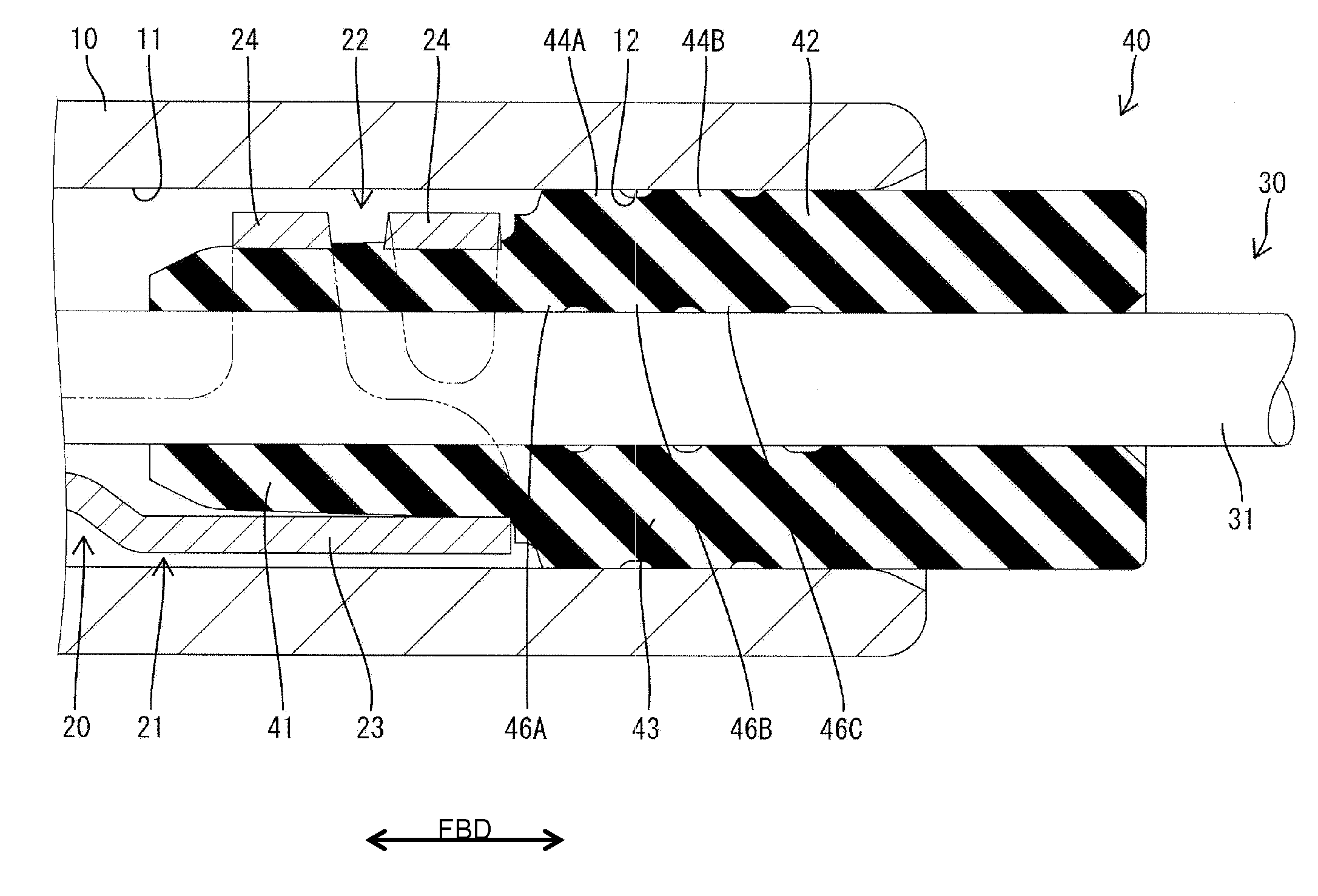

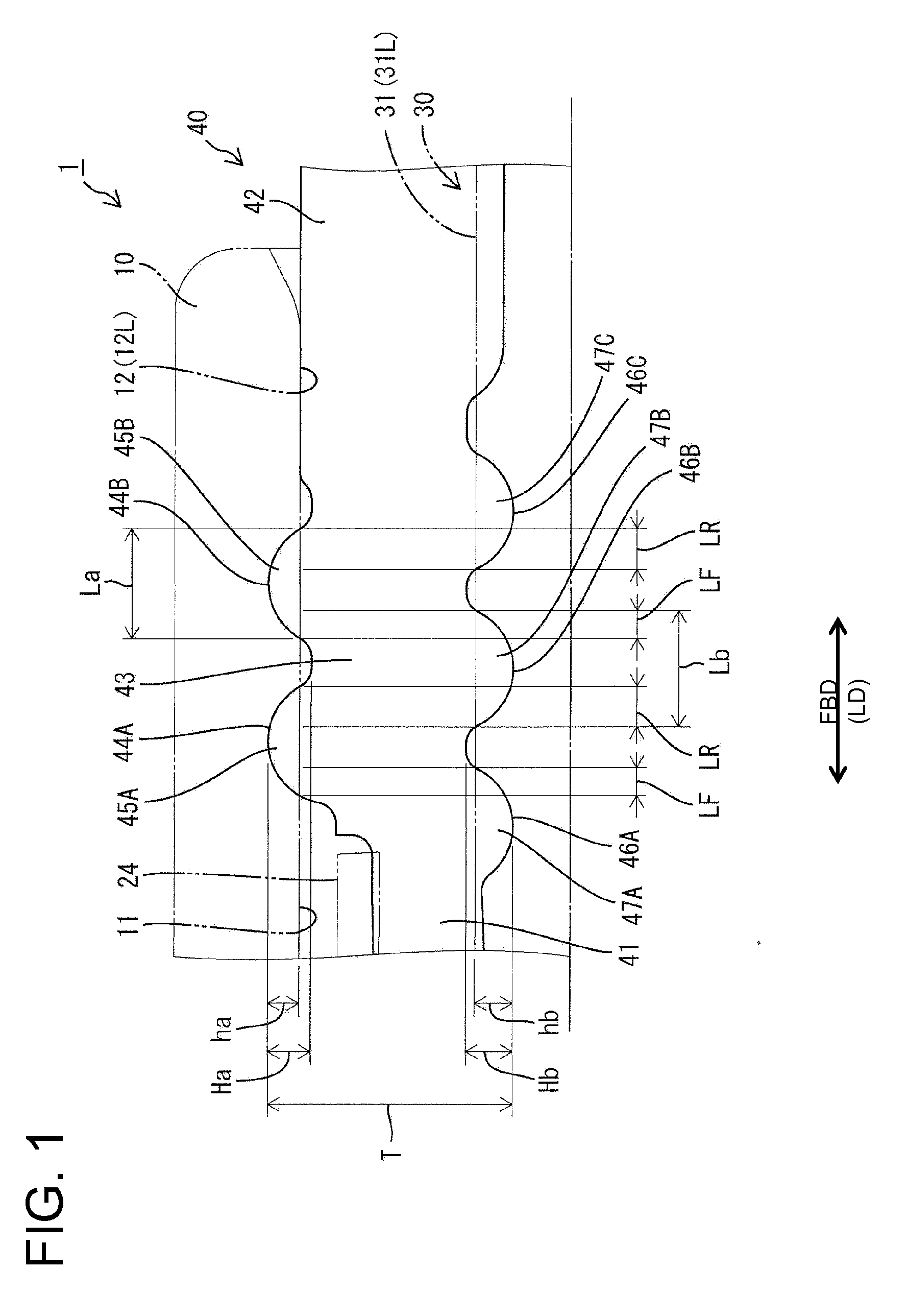

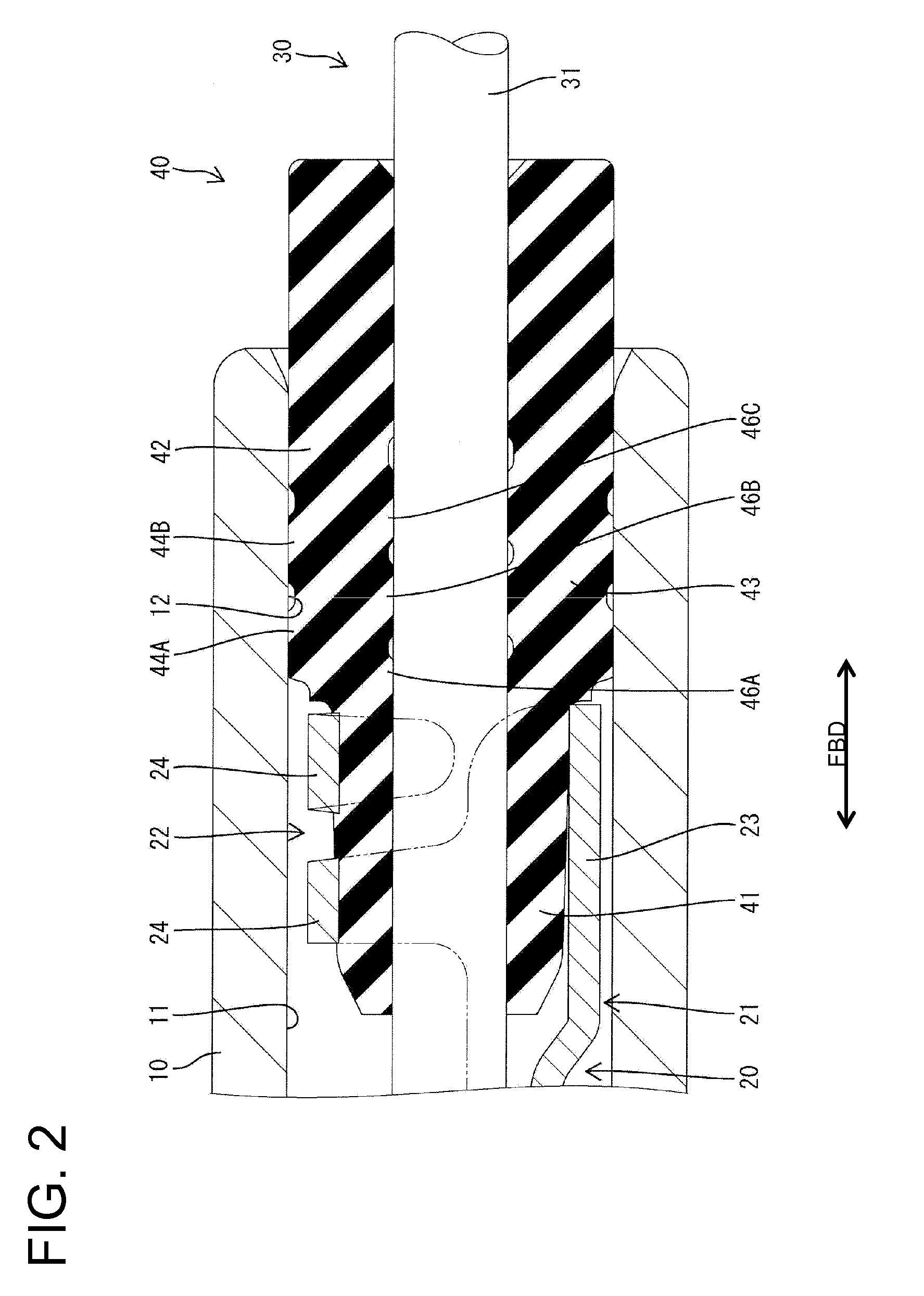

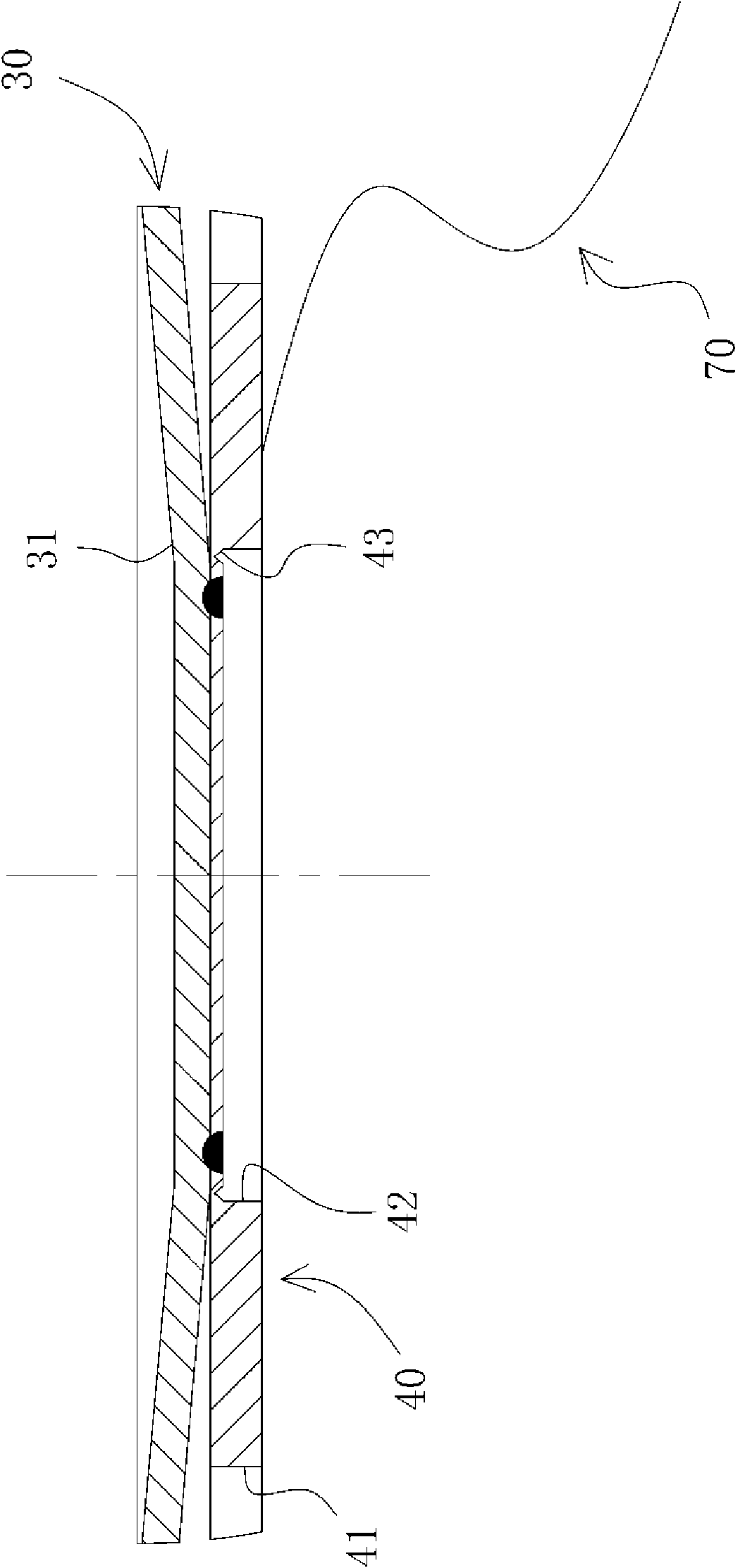

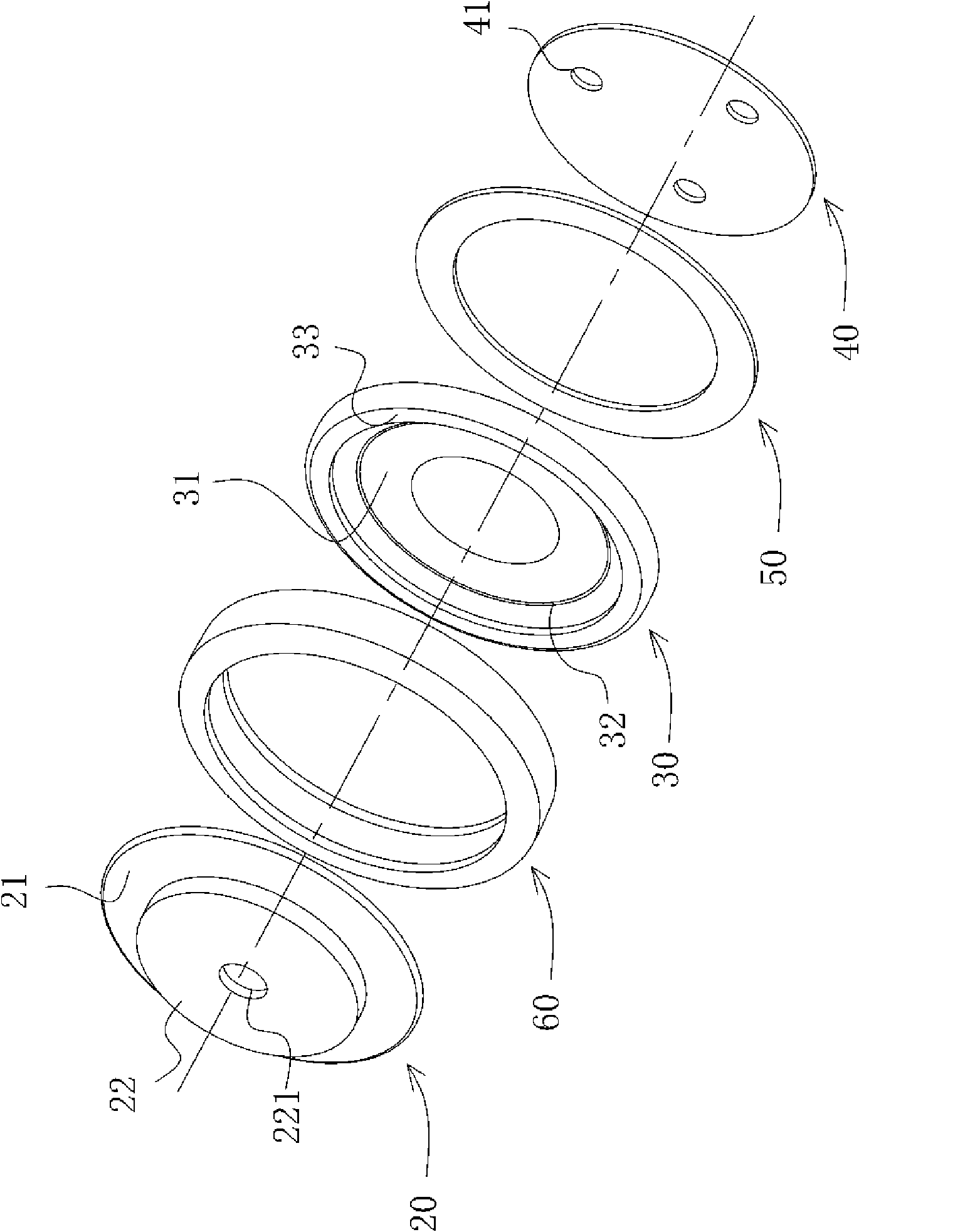

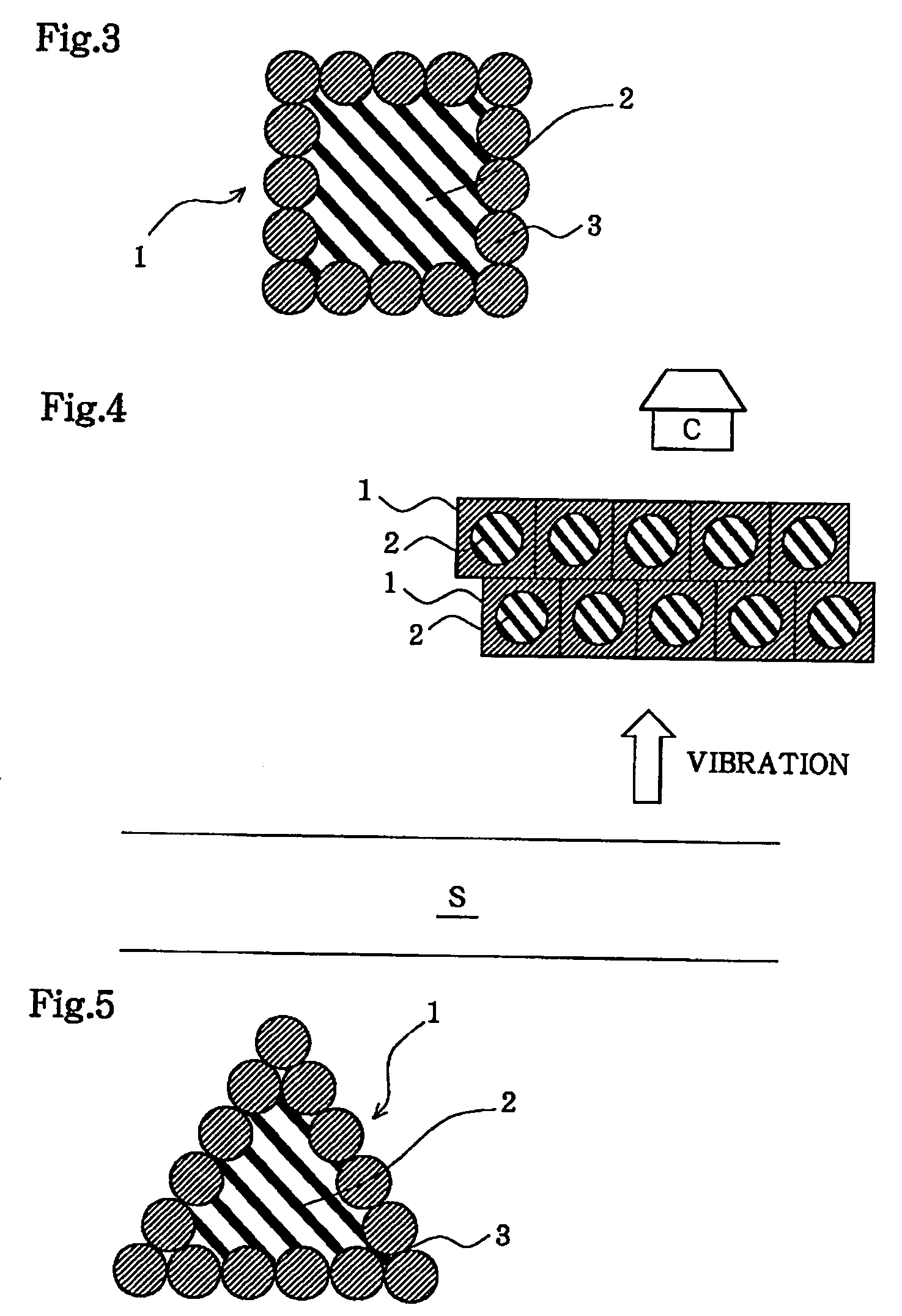

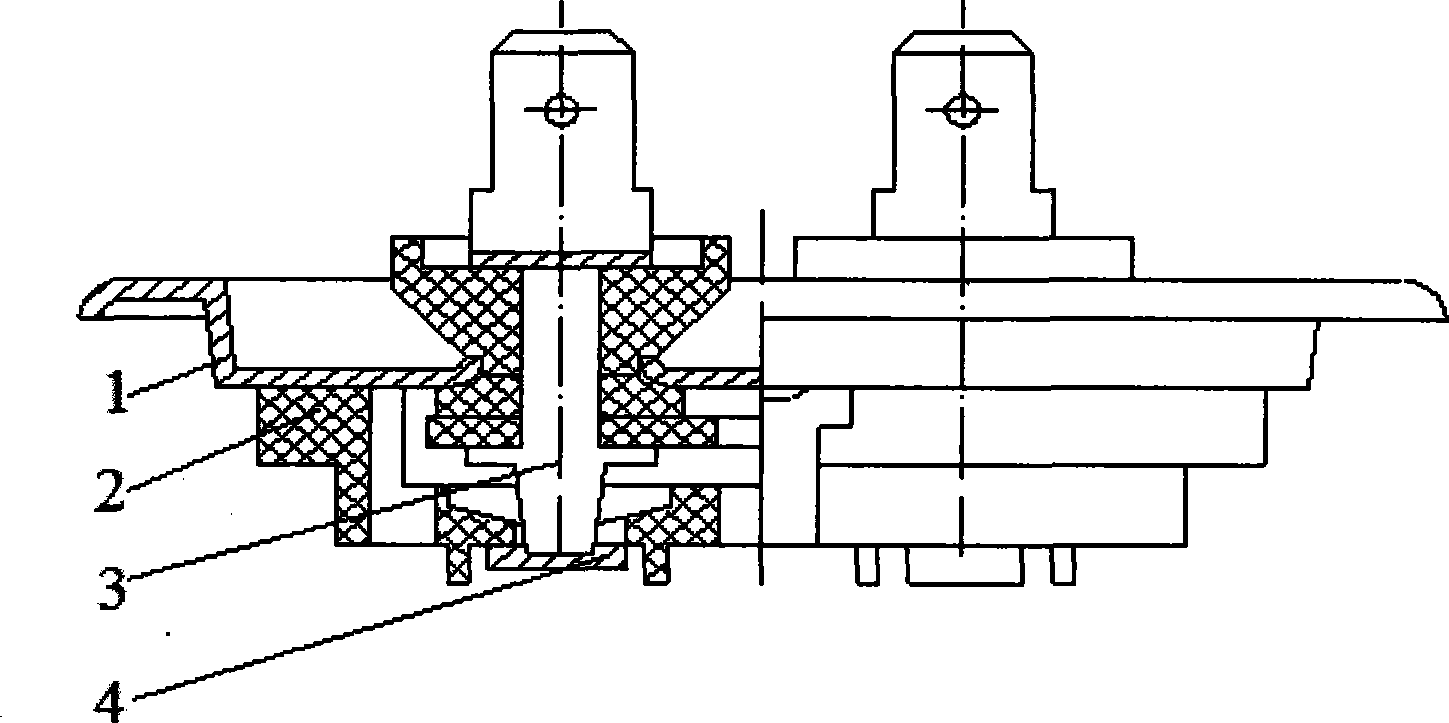

Resilient plug, fluid proof construction and connector

ActiveUS7997916B2Improve sealingReduce frictional resistancePipesCouplings bases/casesProof constructionEngineering

A rubber plug (40) is provided with a stable sealing property while reducing frictional resistance when the rubber plug (40) is inserted into a cavity. In a cross section including axis lines of the rubber plug (40), a cavity (11) and a wire (30), areas of outer lips (44A, 44B) not resiliently deformed radially outward of a virtual line (12L) corresponding to the inner circumferential surface of the cavity (11) are specified as outer virtual deforming portions (45A, 45B), areas of inner lips (46A, 46B and 46C) not resiliently deformed radially inward of a virtual line (31L) corresponding to the outer circumferential surface of the wire (30) are specified as inner virtual deforming portions (47A, 47B, and 47C) and at least parts of the inner virtual deforming portions (47A, 47B and 47C) correspond to only parts of the outer virtual deforming portions (45A, 45B).

Owner:SUMITOMO WIRING SYST LTD

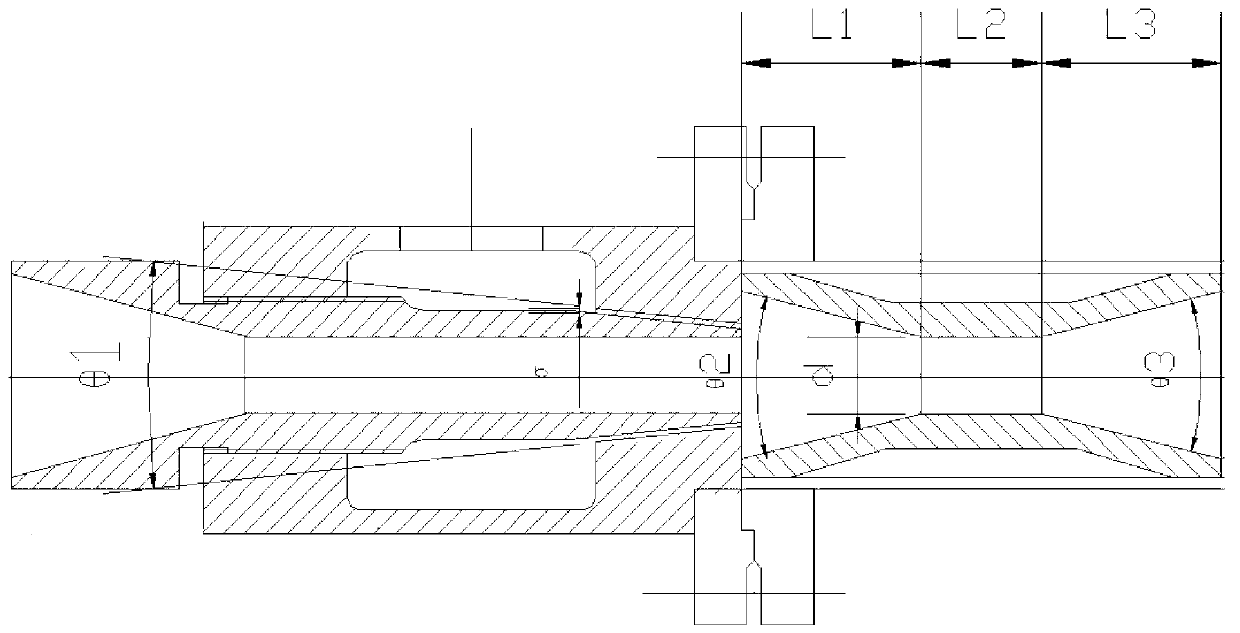

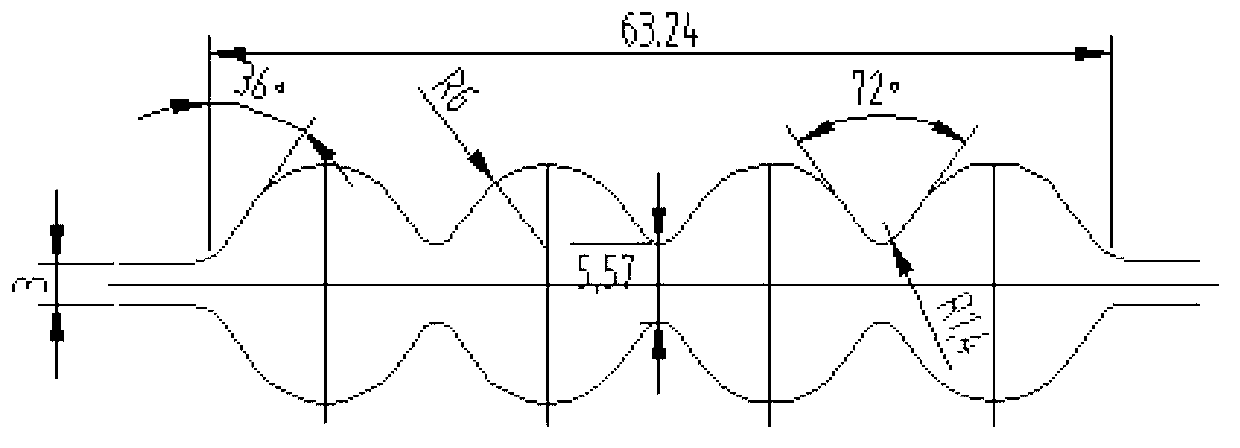

Production method of four-segment high-strength aseismic reinforcement

ActiveCN102989763AImprove stabilityAvoid bendingTemperature control deviceWork treatment devicesProof constructionRebar

The invention discloses a production method of four-segment high-strength aseismic reinforcement, and belongs to the technical field of steel for earthquake proof construction. Controlled rolling and controlled cooling processes are low-temperature initial rolling of a heating furnace, water cooling before pre-segmentation, four-line pre-segmentation, four-line segmentation, finally rolling, and two-stage control cooling after rolling. The production method has the advantages that minimization of micro-alloy elements of four-line segmentation of phi12mm and phi14mm under the condition that the edge organization of a basic circle is P+F is achieved; and the problems of low-temperature phase change organization, four-line line difference, poor mechanical property and the like caused by bending and water cooling in the four-line low temperature segmentation and water cooling processes are avoided.

Owner:SHOUGANG CORPORATION +1

Screened twin-core separately controlled pick-proof alarm lock head and key

The invention discloses a covered pick-proof alarm lock with double-control cores and a cylindrical cross-shaped key for unlocking the lock. An inner plate of the lock can cover a lock hole completely, and a drawn pole and a drawn sheet are installed on front-and-rear lock cores for using one key to unlock two locks. A needle column installed in the lock hole can limit or stop picklocks in the lock and pick the lock core strongly, while a pick-proof construction consists of a marble group and a circuit chip for connecting the circuit and making an external alarm which is connected with the construction to alarm as being illegal unlocked or picked, therefore the lock still can not be unlock and can not stop the alarm as one of the lock core picked.

Owner:黄小能

Resilient plug, fluid proof construction and connector

ActiveUS20100255703A1Improve sealingReduce frictional resistanceEngine sealsPipesProof constructionEngineering

A rubber plug (40) is provided with a stable sealing property while reducing frictional resistance when the rubber plug (40) is inserted into a cavity. In a cross section including axis lines of the rubber plug (40), a cavity (11) and a wire (30), areas of outer lips (44A, 44B) not resiliently deformed radially outward of a virtual line (12L) corresponding to the inner circumferential surface of the cavity (11) are specified as outer virtual deforming portions (45A, 45B), areas of inner lips (46A, 46B and 46C) not resiliently deformed radially inward of a virtual line (31L) corresponding to the outer circumferential surface of the wire (30) are specified as inner virtual deforming portions (47A, 47B, and 47C) and at least parts of the inner virtual deforming portions (47A, 47B and 47C) correspond to only parts of the outer virtual deforming portions (45A, 45B).

Owner:SUMITOMO WIRING SYST LTD

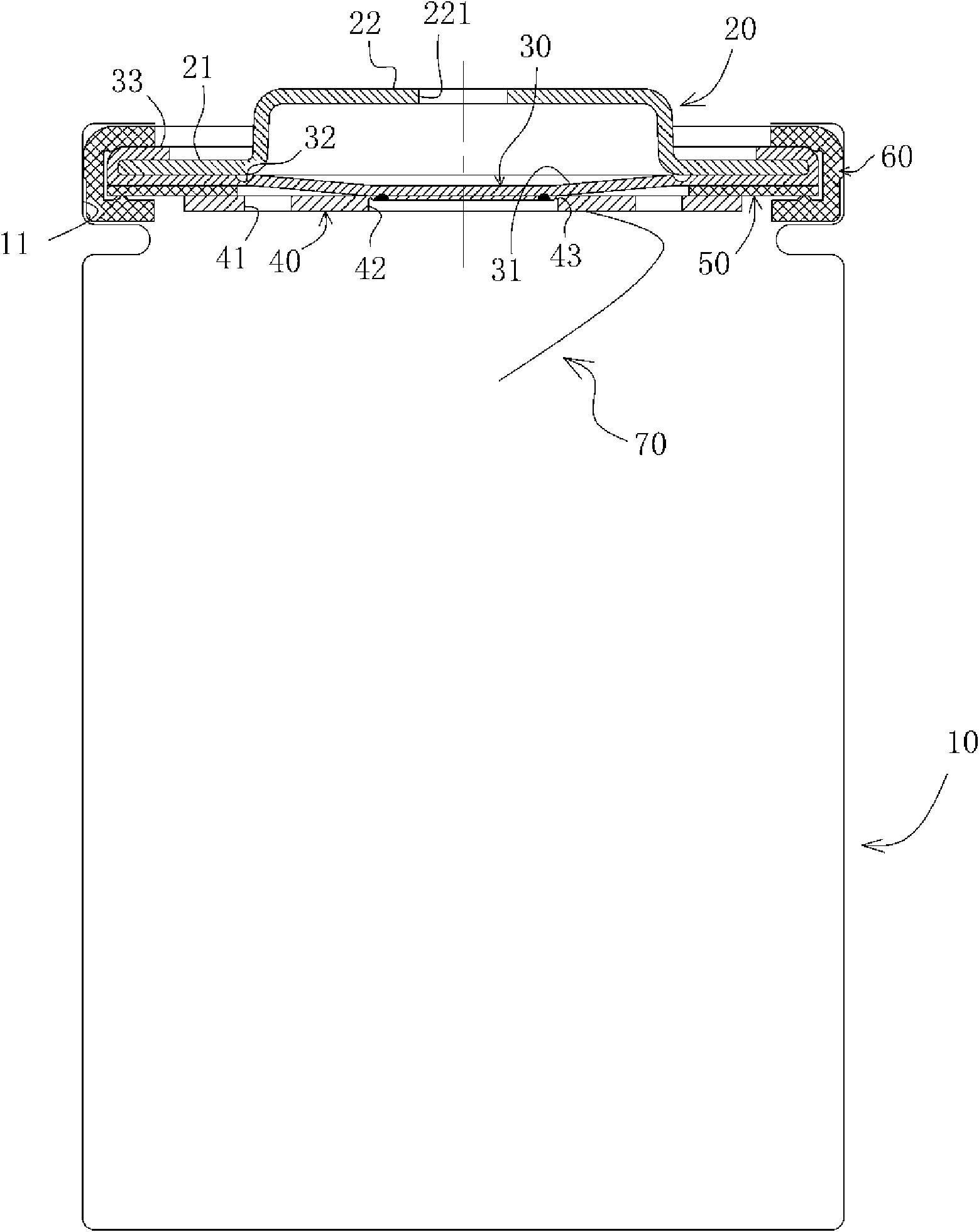

Lithium battery electric core explosion prevention and power-off protection device and producing method

ActiveCN101567432ANo explosionExplosion safetyFinal product manufactureSecondary cellsProof constructionInternal pressure

A lithium battery electric core explosion prevention and power-off protection device and a producing method. The device comprises an electric core casing, a metal top cover, a metal rupture disc, a metal vent hole plate, an annular insulation spacer, an annular sealed ring and an electric core tab. The explosion-proof construction are arranged on the rupture disc and the vent hole plate and comprises a V-shaped ring groove on the vent hole plate and a ring groove on the rupture disc. The rupture disc and the vent hole are connected through multi-point connection mode. The method comprises: stamping molding of top cover, rupture disc, vent hole plate and insulation spacer, injection moulding of sealing ring at high temperature, edging of rupture disc and laser welding of rupture disc and vent hole plate and sealing connection of parts and with the electric core. When the inner pressure of the electric core is higher than the preset value, an upward pressure through the vent hole lifts the recess of the rupture disc and cuts off the V-shaped ring groove of the vent hole plate and switches out the circuit by separating from the rupture disc. If the inner pressure enhances continuously, the ring groove of the rupture disc is cut off for pressure relief.

Owner:SHENZHEN KEDALI IND CO LTD

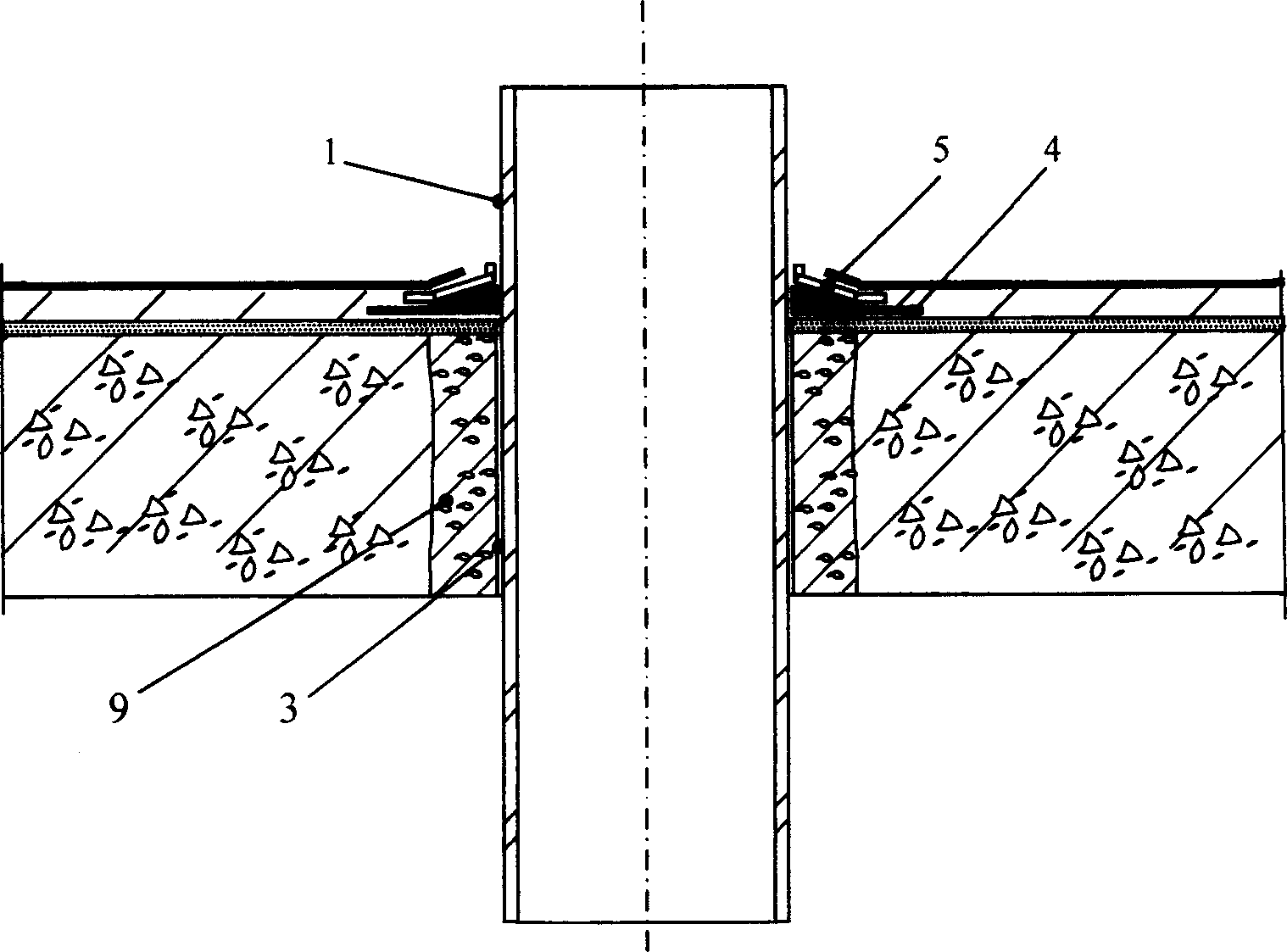

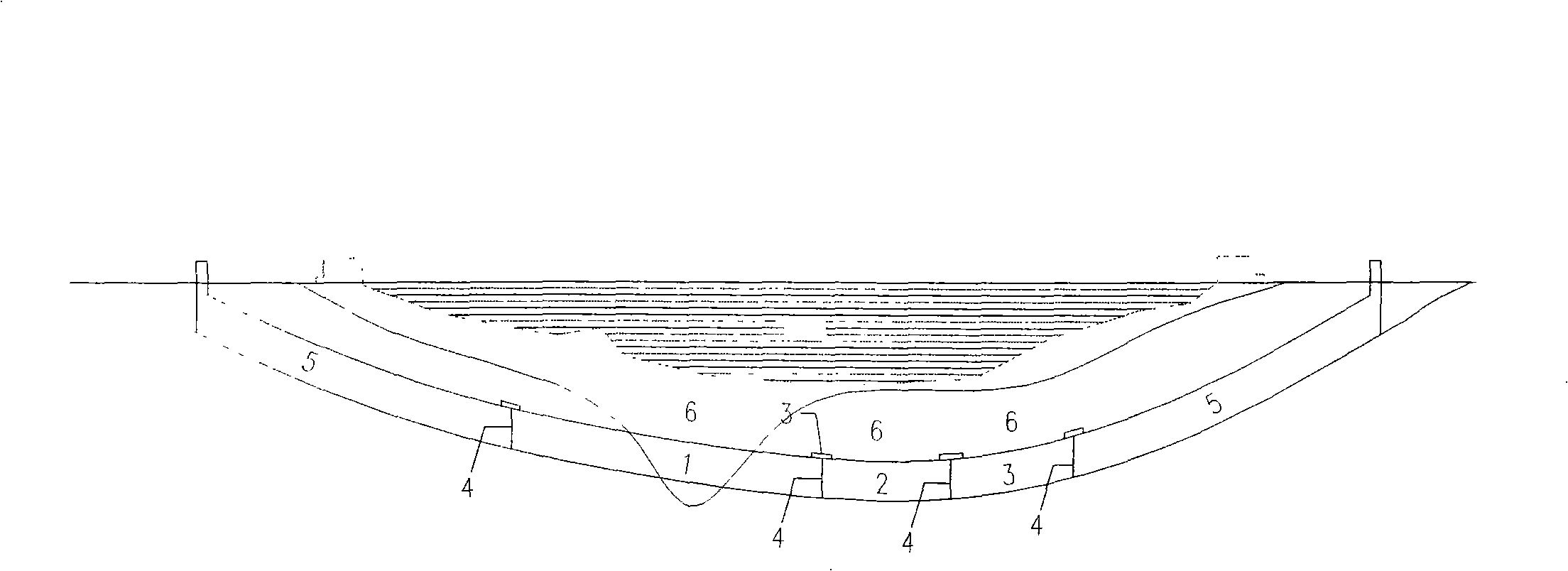

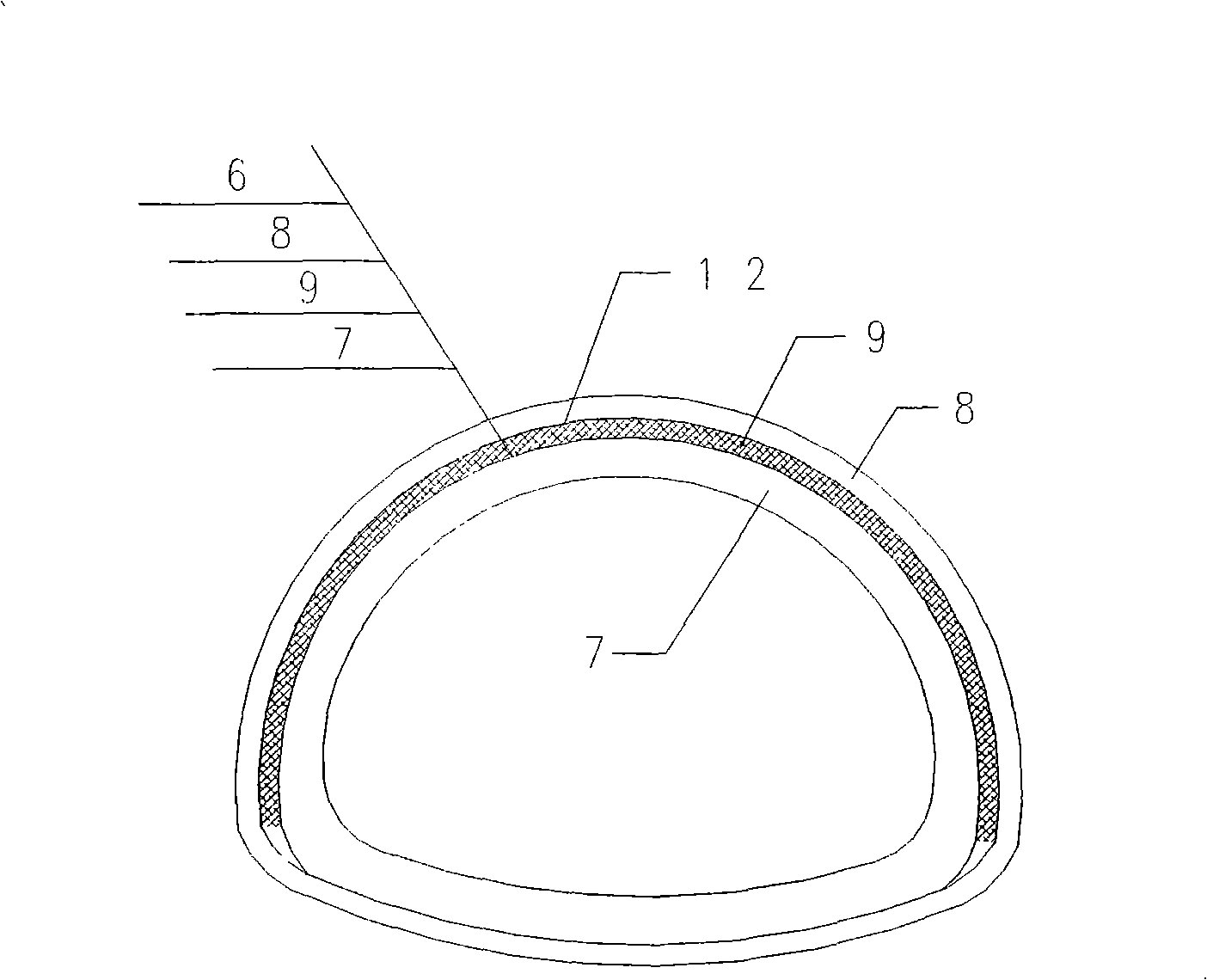

Submarine tunnel composite lining interlaminar water seepage longitudinal cross flow-proof construction method

InactiveCN101285389ASolve the problem of vertical channeling of water seepageSimple methodUnderground chambersTunnel liningProof constructionControl line

The invention discloses a constructional method for preventing water seepage longitudinal cross flow between composite lining layers in an underwater tunnel. The steps of the constructional method are as follows: A cleaning dust and impurities on the surface of a primary support; B. spraying water to wet the dry surface of the primary support; C. mechanically and uniformly stirring cement and water into grout for further use; D. bouncing out coiled materials from a base layer of the primary support to pave and paste control lines and Bondsure BAC double-faced self-adhere type water resistant coiled materials, paving and pasting the grout on the base layer, and rolling and paving the coiled materials forward along a datum line; E. welding the Bondsure BAC double-faced self-adhere type water resistant coiled materials with a composite water resistant layer after the grout begins to have strength; F. adopting a steel moulding plate trolley pump to cast a secondary lining after the construction of the composite water resistant layer is finished. The method is simple, convenient in construction, and solves the problem of the water seepage longitudinal cross flow between the primary support and the composite water resistant layer in the underwater tunnel. The method effectively prevents the water seepage at the back of a water pressure resistant lining from crosswise flowing to a water pressure nonresistant lining, and has good application value for underwater tunnels built by a drilling and blasting method.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

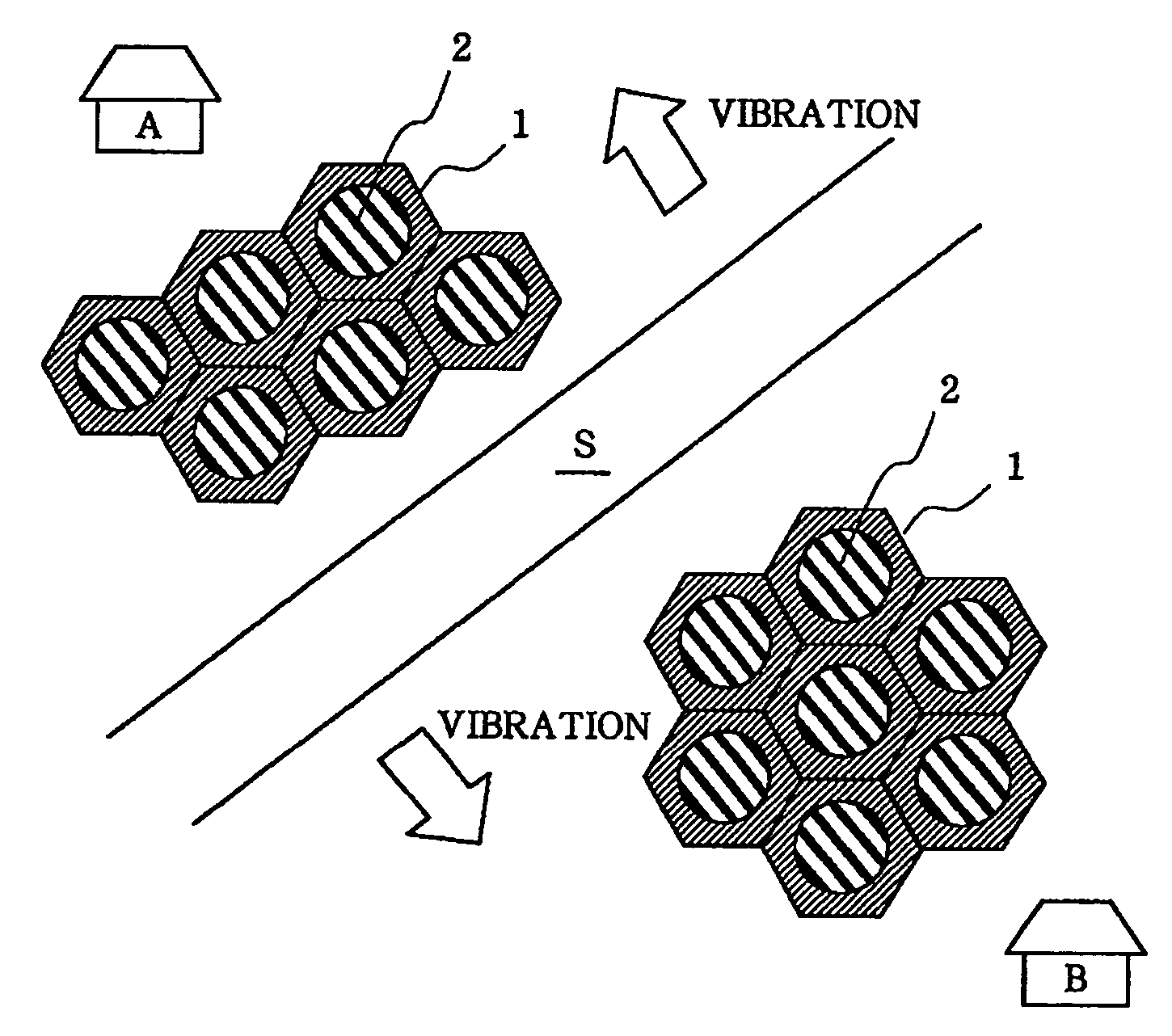

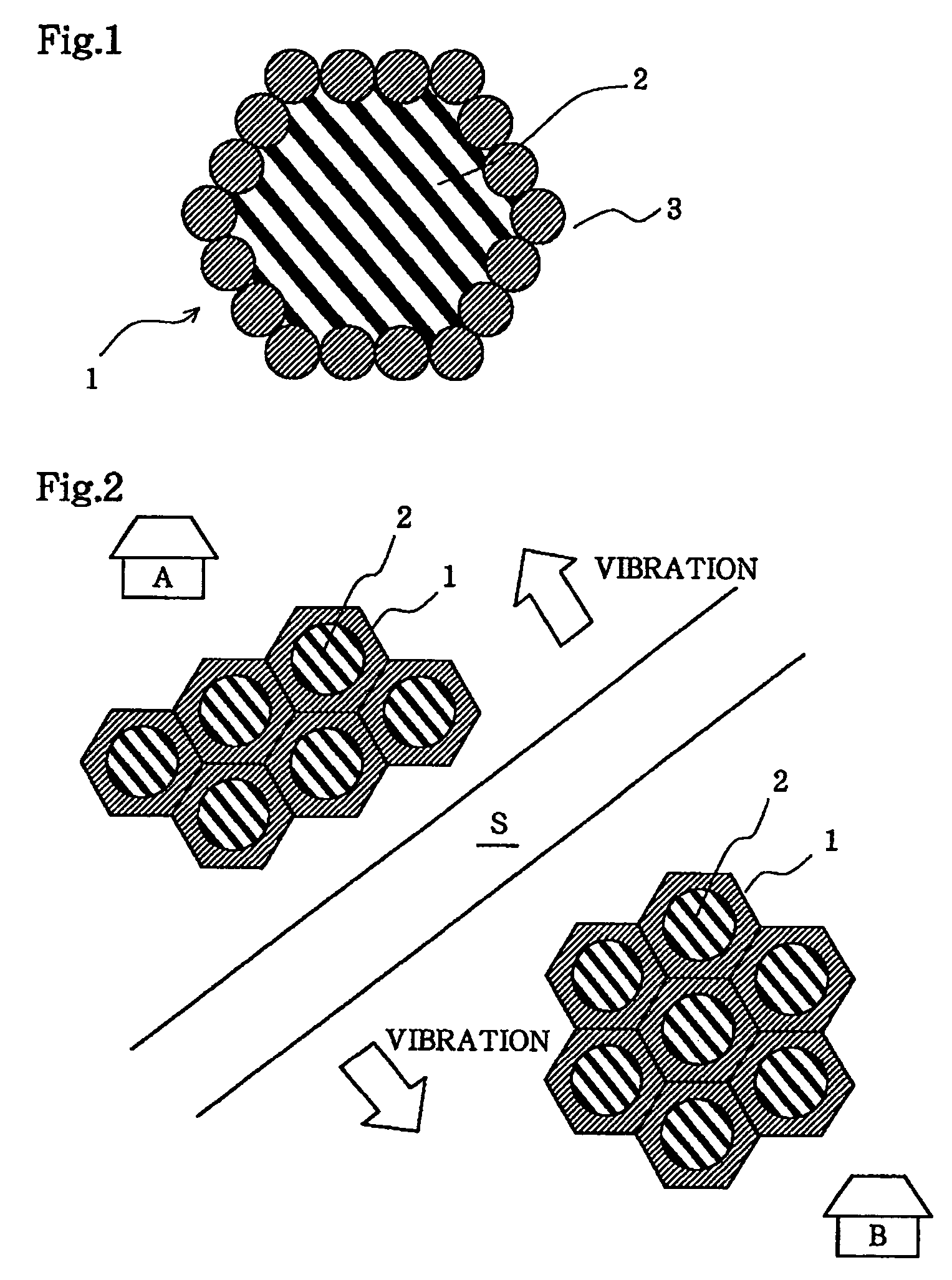

Vibration-proof construction method

InactiveUS7048473B2EffectReduce construction costsIn situ pavingsProtective foundationProof constructionHigh stiffness

A vibration-proof construction method for preventing and reducing vibration around a structure which generates vibration or receives vibration includes construction work wherein a hard member having higher stiffness than the surrounding ground and a rubber elastic member are adjacently laid underground, around or directly underneath the building structure, thereby forming a hard layer and an elastic layer. The hard member is preferably concrete, hardening-treated soil, or iron material, and the rubber elastic member is preferably scrap tires or pulverized scrap tire material. Thus, a practical and excellent vibration-proof construction method is provided, whereby even better vibration-proof effects can be obtained, and which contributes to reduction in construction costs.

Owner:HIROKAZU TAKEMIYA +2

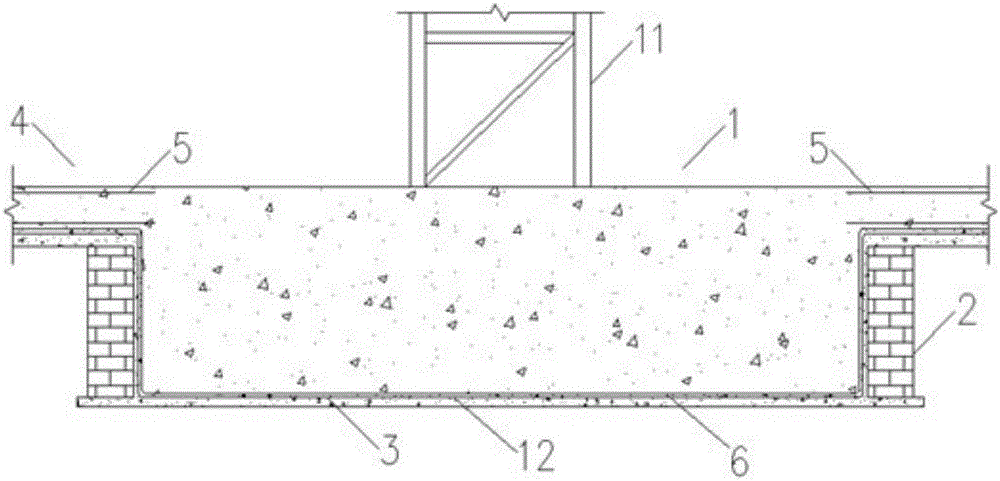

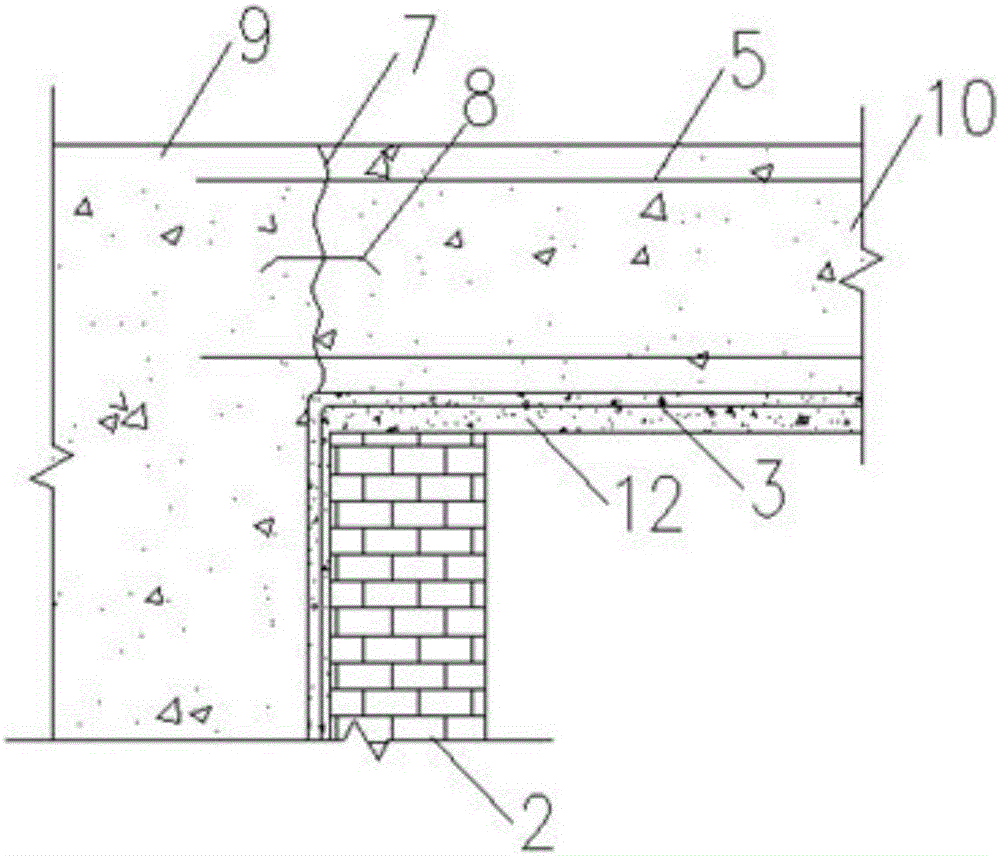

Leakage-proof construction method combining tower crane foundation and basement floor

InactiveCN106120872AEliminate potential safety hazards such as rustAvoid prolonged water accumulationProtective foundationProof constructionBrick

The invention discloses a leakage-proof construction method combining a tower crane foundation and a basement floor. The method comprises the following steps: excavating an earthwork groove and building a brick membrane along an inner wall of the earthwork groove, laying a waterproof material, distributing a foundation reinforcement cage, mounting supporting feet of a tower crane, mounting a grounding device, pouring concrete, mounting standard sections of the tower crane and the like. The leakage-proof construction method has the advantages that problems in a utilization process of the tower crane that the standard sections of a tower body are immersed in water for a long period to cause potential safety hazards including rusting and the like and the water is deposited in an installation position of the tower crane for a long period are effectively avoided, a dismounting procedure of the tower crane is simplified and the stability of connection between the earthwork groove and the basement floor is increased after the concrete is poured into the earthwork groove; and the leakage-proof construction method has very good leakage-proof effect and is suitable for being applied to a tower crane construction process of various types of mid-rise buildings and high-rise buildings.

Owner:TIANJIN 20 CONSTR

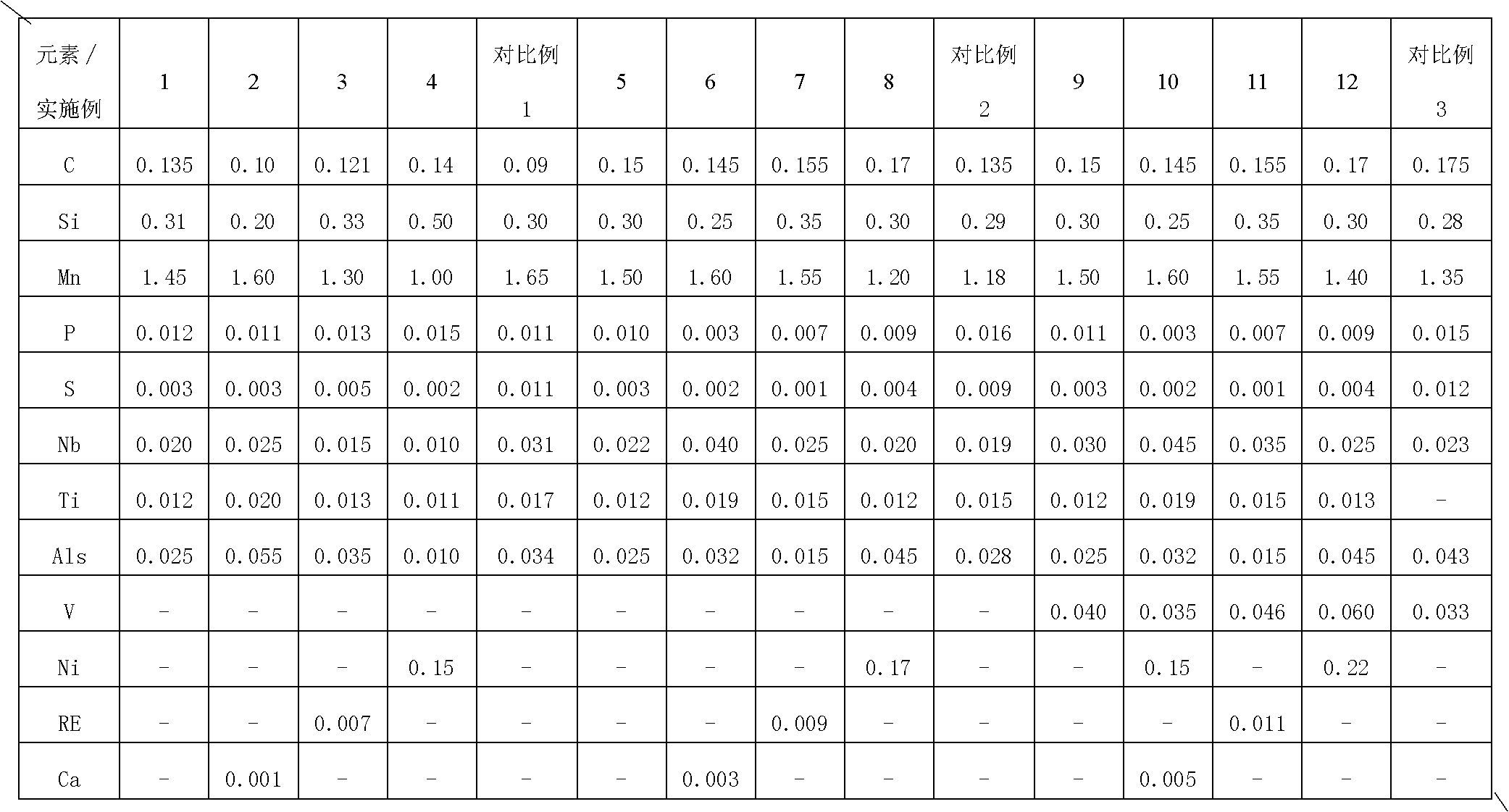

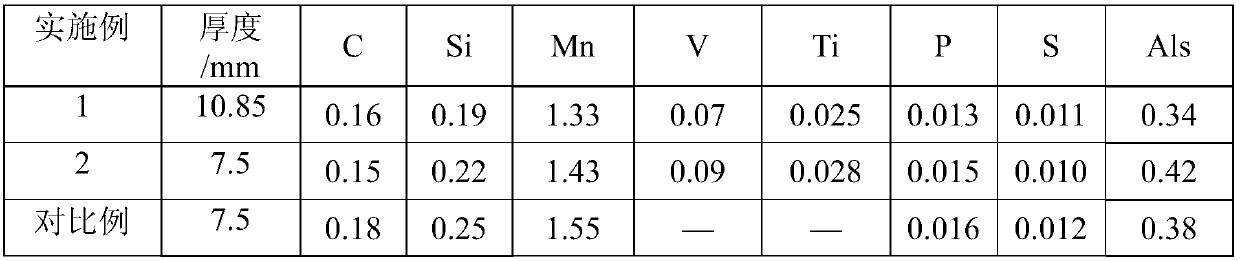

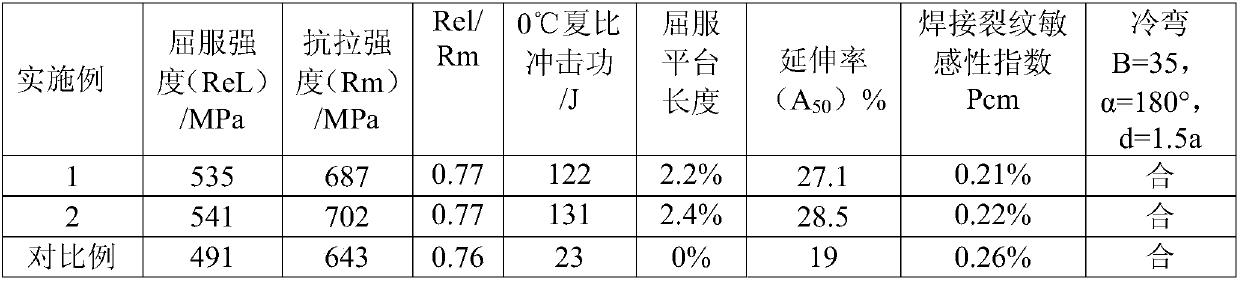

Hot-continuous-rolled steel strip for 500 MPa-grade earthquake-proof construction structure and production method thereof

The invention belongs to the field of metal plate strip production, and in particular, relates to a hot-continuous-rolled steel strip for a 500 MPa-grade earthquake-proof construction structure and aproduction method thereof. The hot-continuous-rolled steel strip for the 500 MPa-grade earthquake-proof construction structure comprises the following chemical components in percentage by weight: 0.12-0.20% of C, 0.15-0.30% of Si, 1.20-1.60% of Mn, 0.05-0.10% of V, 0.010-0.035% of Ti, P not more than 0.020%, S not more than 0.015%, 0.020-0.060% of Als, and the balance of Fe and inevitable impurities. In the hot-continuous-rolled steel strip for the 500 MPa-grade earthquake-proof construction structure, the yield strength is 500-630 MPa, the tensile strength is 610-770 MPa, the yield ratio is not more than 0.81, the ductility is not less than 24%, the 0-DEG C impact power is not less than 54 J, the yield platform length is not less than 2.2%, the carbon equivalent Ceq is not more than 0.45%, and the welding crack sensitivity index Pcm is not more than 0.28%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Quake-proof construction steel with yield strength of 100MPa and production method thereof

InactiveCN101775542ASimple processRefine the grain sizeTemperature control deviceMetal rolling arrangementsProof constructionChemical composition

The invention discloses quake-proof construction steel with the yield strength of 100MPa and a production method thereof. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.002 percent of C, less than or equal to 0.01 percent of Si, less than or equal to 0.10 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.002 to 0.007 percent of Mg, 0.020 to 0.070 percent of Ti, 0.010 to 0.020 percent of Nb, 0.001 to 0.003 percent of N, less than or equal to 0.050 percent of Al, and the balance of Fe and inevitable impurities. The production method thereof comprises the steps of desulfuration of molten iron, converter blowing, vacuum treatment, continuous casting, hot rolling, cooling and the like. When the yield strength of steel products exceeds 120Mpa, an annealing treatment step is added after the cooling step. Experiments prove that the quake-proof construction steel with the yield strength of 100MPa has the characteristics of low yield strength, high elongation and excellent impact toughness; and the production method of the steel has the advantages of simple process flow and low production cost.

Owner:武钢集团有限公司

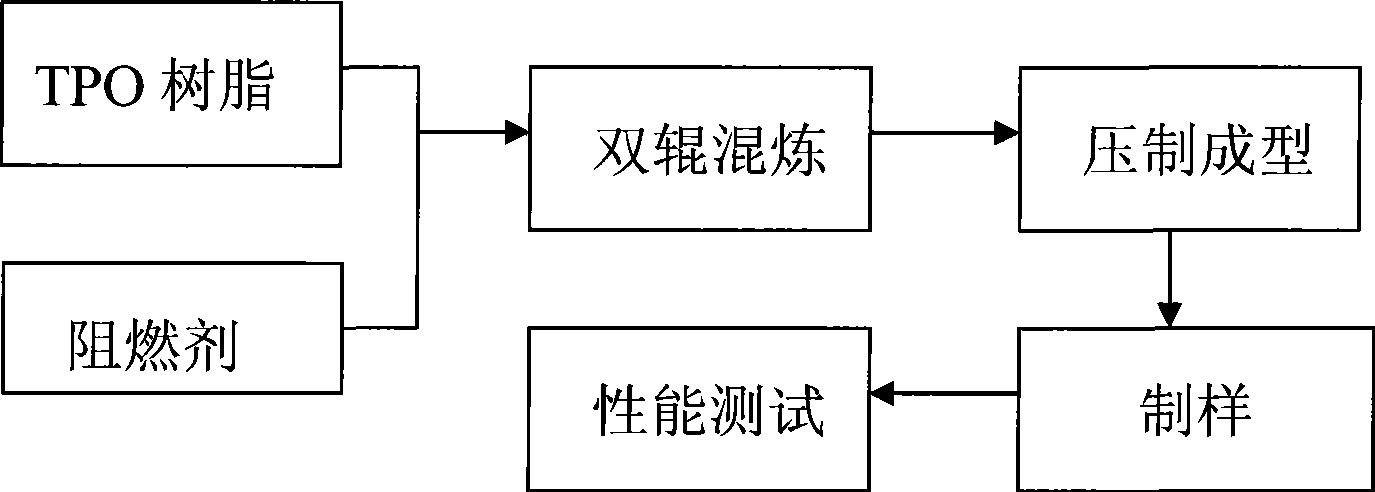

Halogen-free flame retardant weldable elastic water proof building sheet material

InactiveCN101362843AOvercome expensiveImprove flame retardant performanceBuilding insulationsFire proofingProof constructionElastomer

The invention relates to a halogen-free inflaming retarding water-proof construction sheet of a weldable elastomer; TPO is taken as a matrix resin; the matrix resin is mixed with flame retardants according to a proportion; the mixed material is plasticated by two rollers under the temperature of 130 to 150 DEG C and is shaped in a hot-press way by a flat vulcanizing machine under the temperature of 160 to 170 DEG C to obtain the sheet; wherein, the flame retardants are divided into an inorganic flame retardant and an expansion flame retardant; the inorganic flame retardant is modified magnesium hydrate; expansion flame retardant is mixed and compositely prepared by monoammonium phosphate, faecula and magnesium hydrate. The halogen-free inflaming retarding water-proof construction sheet of the weldable elastomer has the advantages of effective flame retardation and excellent comprehensive mechanical property as well as being capable of improving the durability and the weatherability.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Entire terminal cover explosion proof construction for capacitor

InactiveCN101477891AIncrease contact areaImprove conductivityCapacitorsProof constructionCopper foil

The invention discloses a whole end cover blast-resistance structure of a capacitor. A blast-resistance sheet (2) is arranged on the end cover (1); a rivet (3) is adopted as a wire connecting terminal of the capacitor; a blast-resistance copper foil (4) is arranged on the surface of the blast-resistance sheet (2); and an end part, which faces to the inside of the capacitor, of the rivet (3) is connected with the blast-resistance copper foil (4). The invention adopts the novel, safer and more reliable whole end cover structure without the requirement of assembly, and the structure can be used directly when in assembly, so that the time and the cost for manufacturing the product are saved at the same time. Moreover, the whole end cover doesn't need welding, thereby saving tin wires and material costs.

Owner:WUHU JINCHENG ELECTRONICS CO LTD

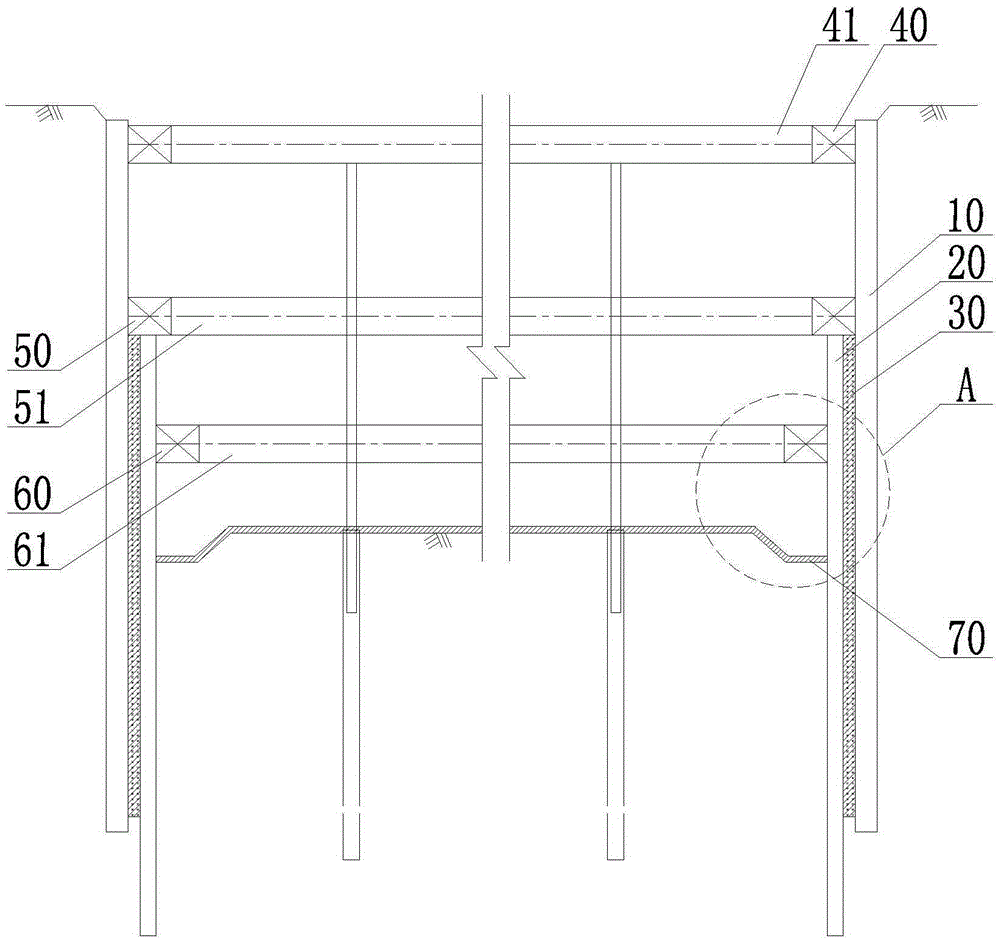

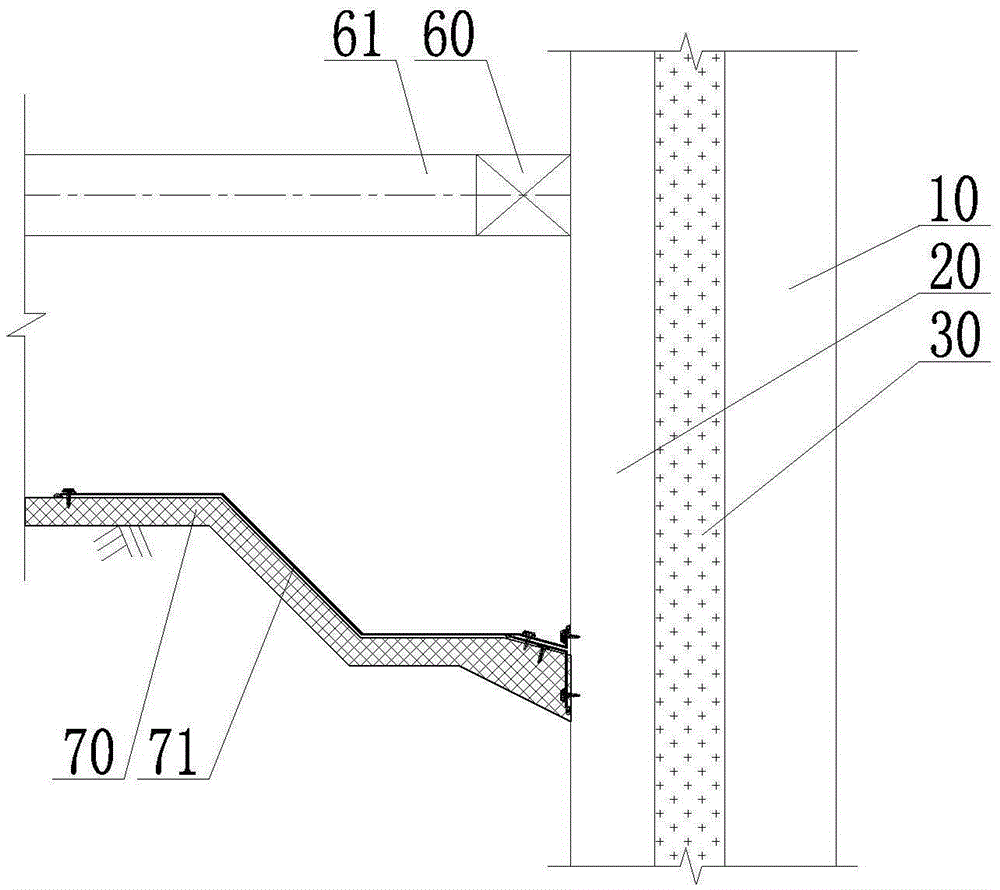

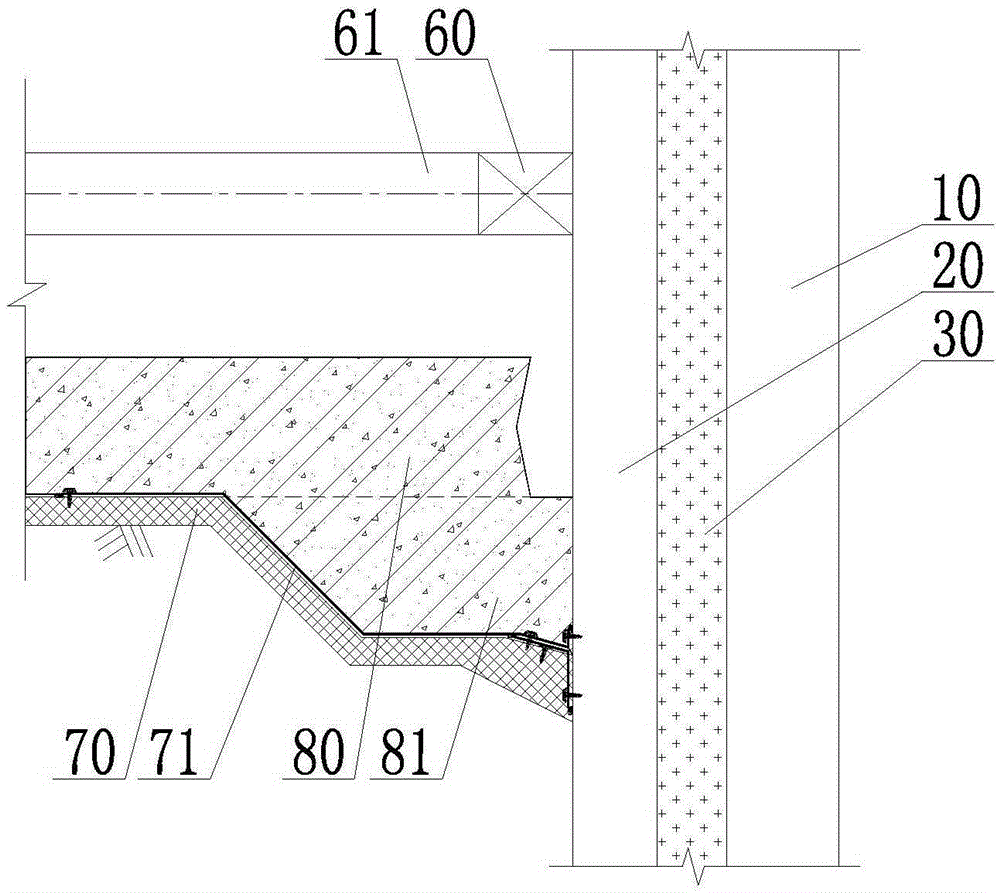

Water-proof construction method for connected nodes of foundation slab and ground wall in composite surround system

ActiveCN105421497AImprove self-waterproof performanceGuaranteed waterproof performanceProtective foundationProof constructionHigh pressure

The invention discloses a water-proof construction method for connected nodes of a foundation slab and a ground wall in a composite surround system, and relates to the technical field of underground engineering water-proof construction. The water-proof construction method aims at the problems that the interface of a new concrete structure and an old concrete structure and the chiseled portion of a bored cast-in-place pile are prone to forming underground water seepage path, and the construction quality of the foundation slab is influenced. The water-proof construction method comprises that 1, a sunken portion is dug on the edge of a foundation pit, a concrete base layer is constructed, a first geosynthetic clay liner is laid to the bored cast-in-place pile, and closing up is carried out; 2, the foundation slab to be poured and a reinforcing steel bar bracket to be turned downwards are erected and bond, and a space on the edge of the foundation slab to be poured is reserved; the foundation slab is poured, and the bracket is turned downwards; 3, the portions, over the bottom elevation of the foundation slab, of the bored cast-in-place pile and a high-pressure jet grouting pile are chiseled away, and a depth D is dug downwards along the bottom elevation of the foundation slab continuously; a base layer is poured on the chiseled portion and coated by a second geosynthetic clay liner, and closing up is carried out; and 4, after a pouring belt is poured, the pouring belt and the foundation slab are fixedly connected into a whole.

Owner:SHANGHAI NO 7 CONSTR

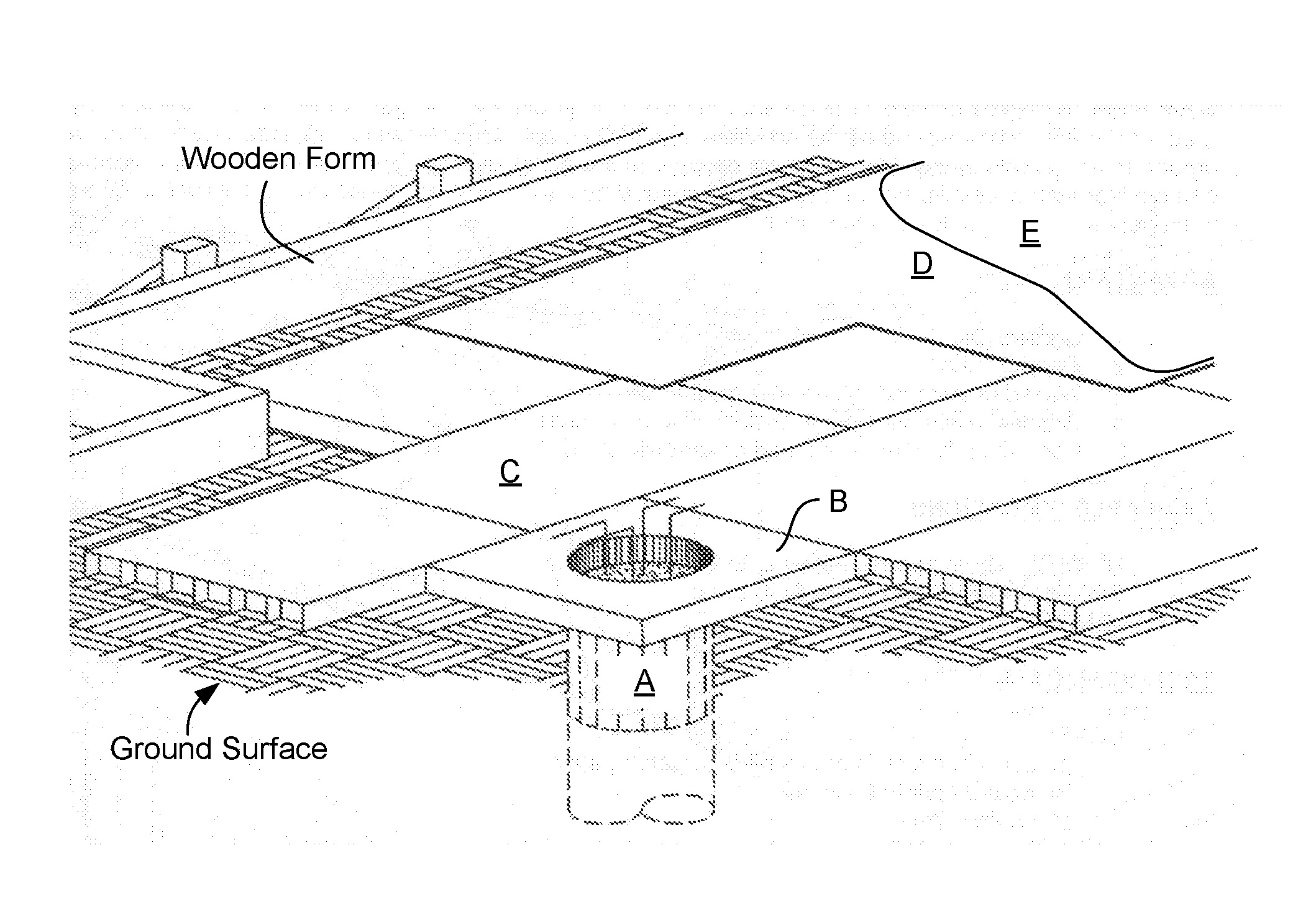

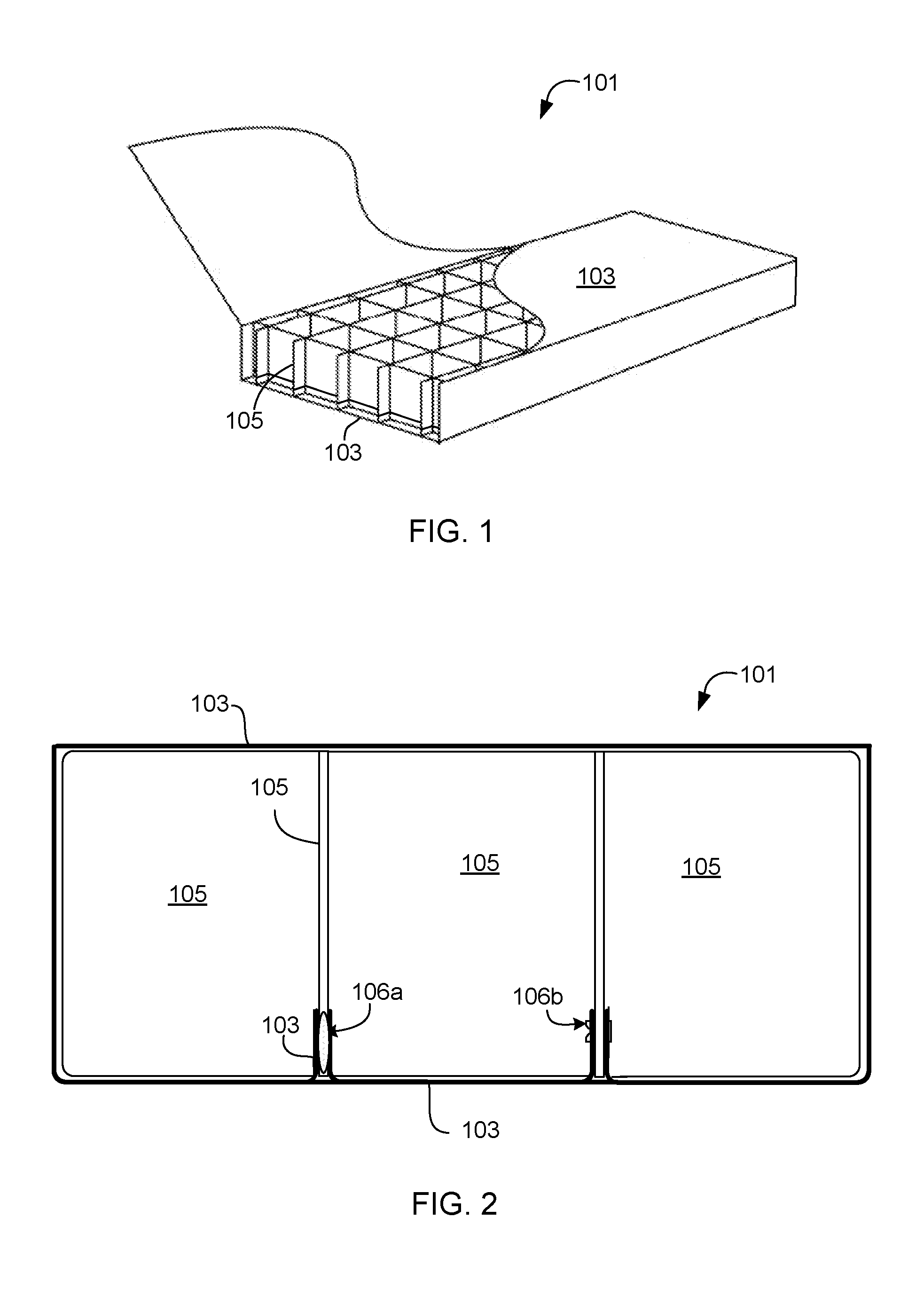

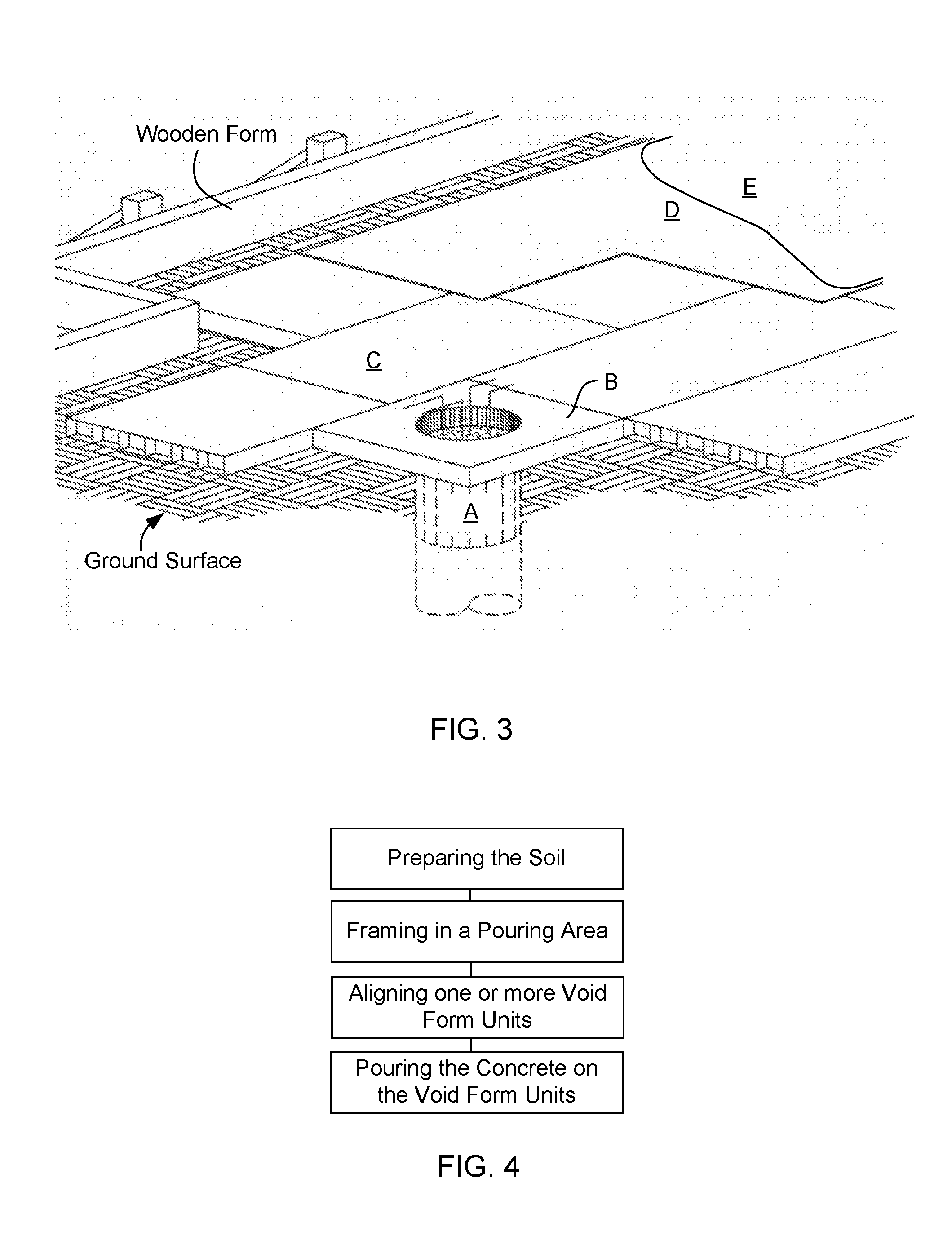

Water proof construction unit

The present application includes a void form unit for creating a void space between concrete structures and expansive soil. The unit includes a cellular structure surrounded by a paper based shell. The cellular structure is impervious to moisture. Together the cellular structure and the shell make a singular rigid member. The rigid member is configured to temporarily support concrete and gradually increase in flexure so as to flex with the movement of the expansive soil. The shell is configured to weaken over time from the regulated absorption of moisture. The flexure of the cellular structure configured to increase with the deterioration of the shell.

Owner:VOIDFORM PROD LLC

Heat proof, flexible break resistant, and water-repellent construction method for external wall of beam column in architecture of frame construction

InactiveCN1916309AReduce stressImprove crack resistance and waterproof abilityCovering/liningsWallsProof constructionLayer interface

The present invention discloses a beam-column exterior wall heat-insulating flexible anticracking water-proofing construction method for frame structure building. Its construction method includes the following steps: preparing heat-insulating layer, making heat-insulating layer interface treatment, preparing flexible anti-cracking layer, making internal water-proofing layer, sticking mesh fabric, preparing secondary water-proofing layer and making decorative layer. Said construction method can effectively resolve the quality problem of crack and leakage of exterior wall.

Owner:山东隆济时节能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com