Hot-continuous-rolled steel strip for 500 MPa-grade earthquake-proof construction structure and production method thereof

A technology for building structures and production methods, which is applied in the field of 500MPa grade vanadium-titanium micro-alloyed hot continuous-rolled steel strips for seismic building structures, can solve the problems of high alloy cost, poor equipment and process adaptability, undisclosed equipment conditions, etc. Low cost, narrow intensity fluctuation range, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

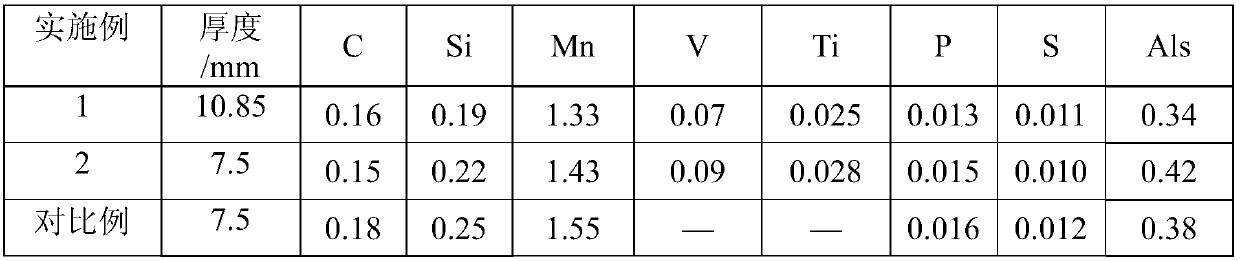

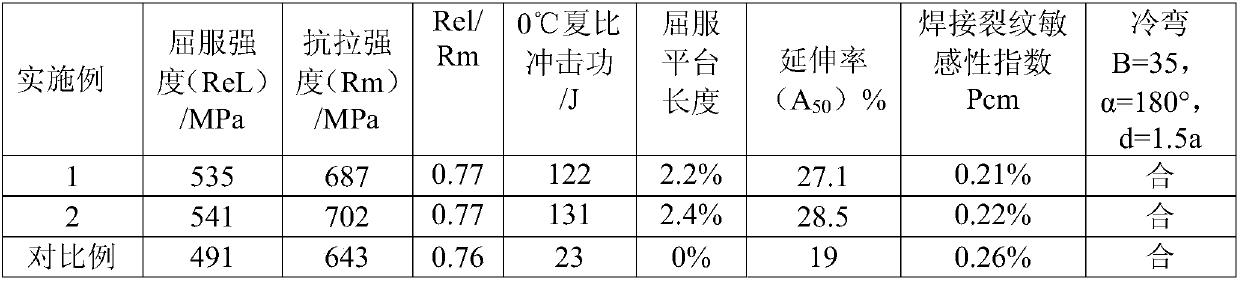

[0031] The steel for 500MPa-level earthquake-resistant building structures adopts the composition route of vanadium-titanium microalloying, and is produced by a 2050 hot rolling line in a steel plant; while the comparative example adopts the composition route of C-Mn steel, and the layer cooling adopts the front-stage cooling method, and the steel ( plate) with layer cooling and then air cooling directly. Table 1 is the chemical composition of the embodiment of the present invention, Table 2 is the control value of the hot rolling process, and Table 3 is the mechanical properties of the steel coil. Use GB / T 228-2010, GB / T 232-2010 for testing.

[0032] The chemical composition of table 1 embodiment

[0033]

[0034] The hot rolling process control value of table 2 embodiment

[0035]

[0036] The mechanical property of the steel coil of table 3 embodiment

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com