Production method of four-segment high-strength aseismic reinforcement

A technology of anti-seismic steel bars and production methods, which is applied in the direction of workpiece surface treatment equipment, heat treatment process control, metal rolling, etc., can solve problems such as difficulty in realizing industrial production, limited equipment conditions, reduction of toughness, plasticity and weldability, etc., and achieve economical Significant benefits, comprehensive cost reduction, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The chemical composition of billet used in Φ12mm HRB400E four-wire slitting is C: 0.22wt%, Mn: 1.40wt%, Si: 0.53wt%, P: 0.032wt%, S: 0.021wt%, Ceq: 0.46wt%.

[0031] 1. Water cooling before pre-cutting: In order to reduce the microalloying elements of high-strength steel bars, low-temperature finish rolling and low-temperature cutting can significantly increase the dislocation density, increase the proportion of pearlite, and induce the precipitation of intragranular ferrite to improve the material quality. Intensity, for this reason, three sets of coolers are arranged at the entrance of the finishing mill, each set has two coolers, and the coolers are forward and reverse turbulent coolers;

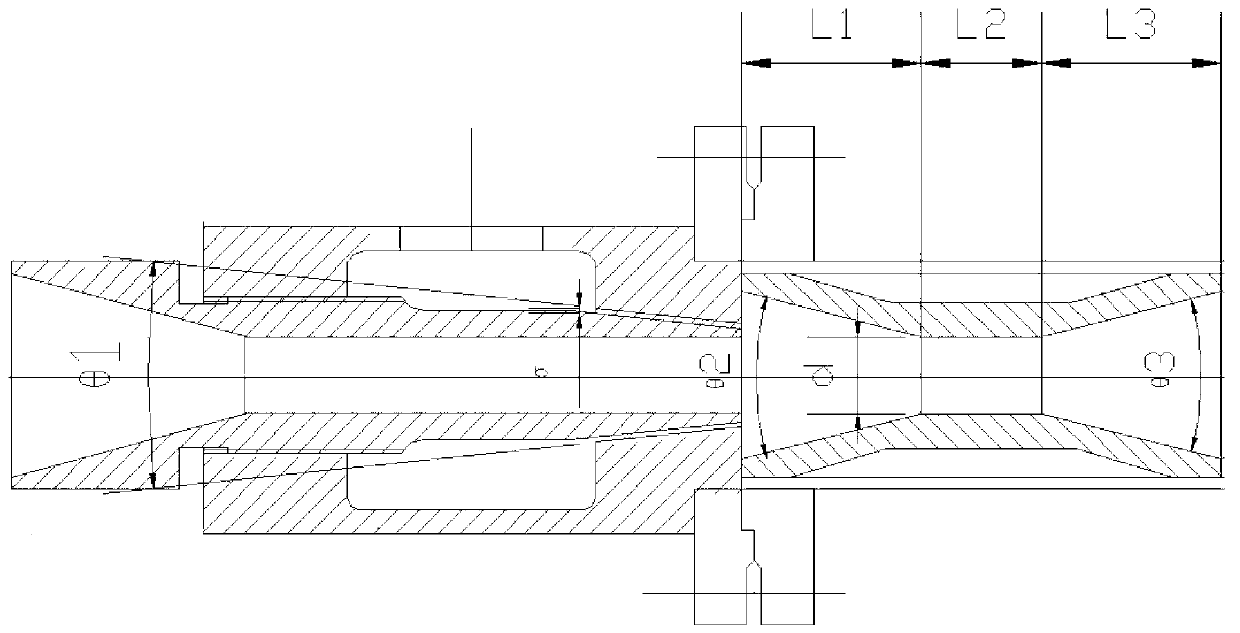

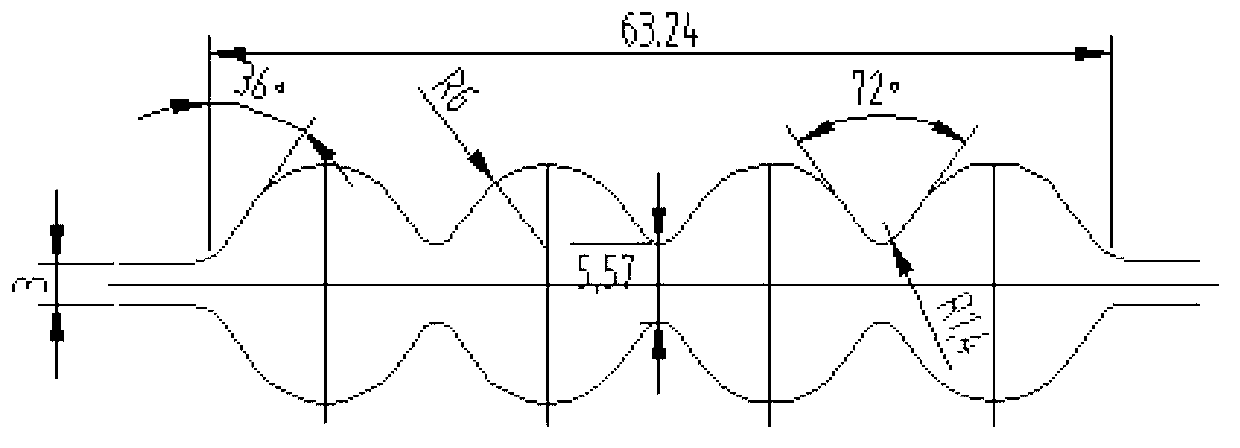

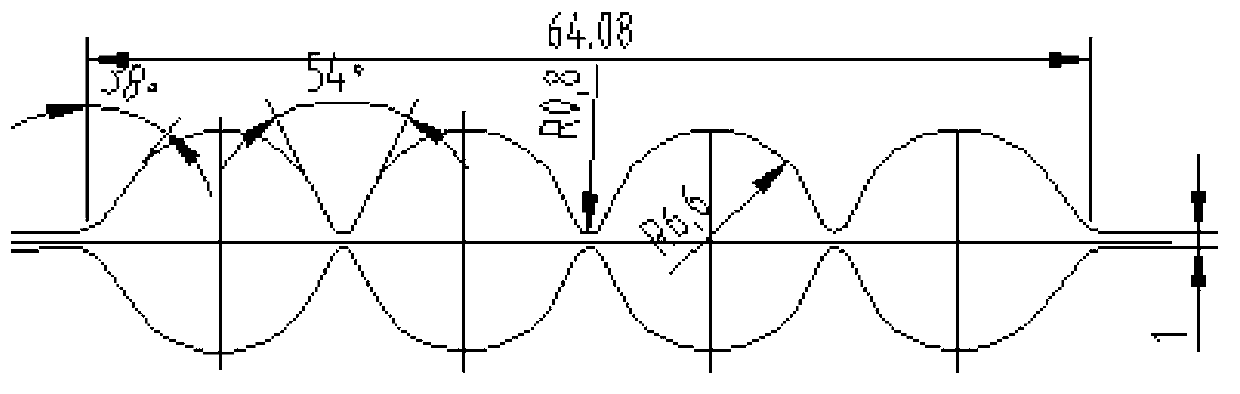

[0032] 2. Four-wire pre-slitting: The four-wire slitting of low-temperature finish rolling reduces the rheological velocity of the metal. Φ12mm HRB400E (400MPa anti-seismic steel bar) adopts low-temperature starting rolling, and the starting rolling temperature is 970°C; the design ...

Embodiment 2

[0038] The chemical composition of billets used in Φ14mm HRB500E four-wire cutting is C: 0.22wt%, Mn: 1.40wt%, Si: 0.53wt%, P: 0.032wt%, S: 0.021wt%, V: 0.052wt%, N: 0.011wt%, Ceq: 0.46wt%.

[0039] 1. Water cooling before pre-cutting: In order to reduce the microalloying elements of high-strength steel bars, low-temperature finish rolling and low-temperature cutting can significantly increase the dislocation density, increase the proportion of pearlite, and induce the precipitation of intragranular ferrite to improve the material quality. Intensity, for this reason, three sets of coolers are arranged at the entrance of the finishing mill, each set has two coolers, and the coolers are forward and reverse turbulent coolers;

[0040] 2. Four-wire pre-slitting: The four-wire slitting of low-temperature finish rolling reduces the rheological velocity of the metal. Φ14mm HRB500E (500MPa anti-seismic steel bar) considers the full solid solution of V, and adopts a lower temperature f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com