Patents

Literature

93 results about "Ferrite grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

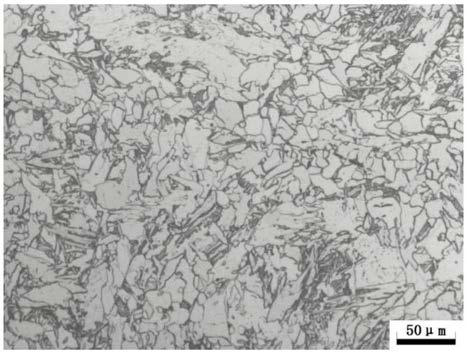

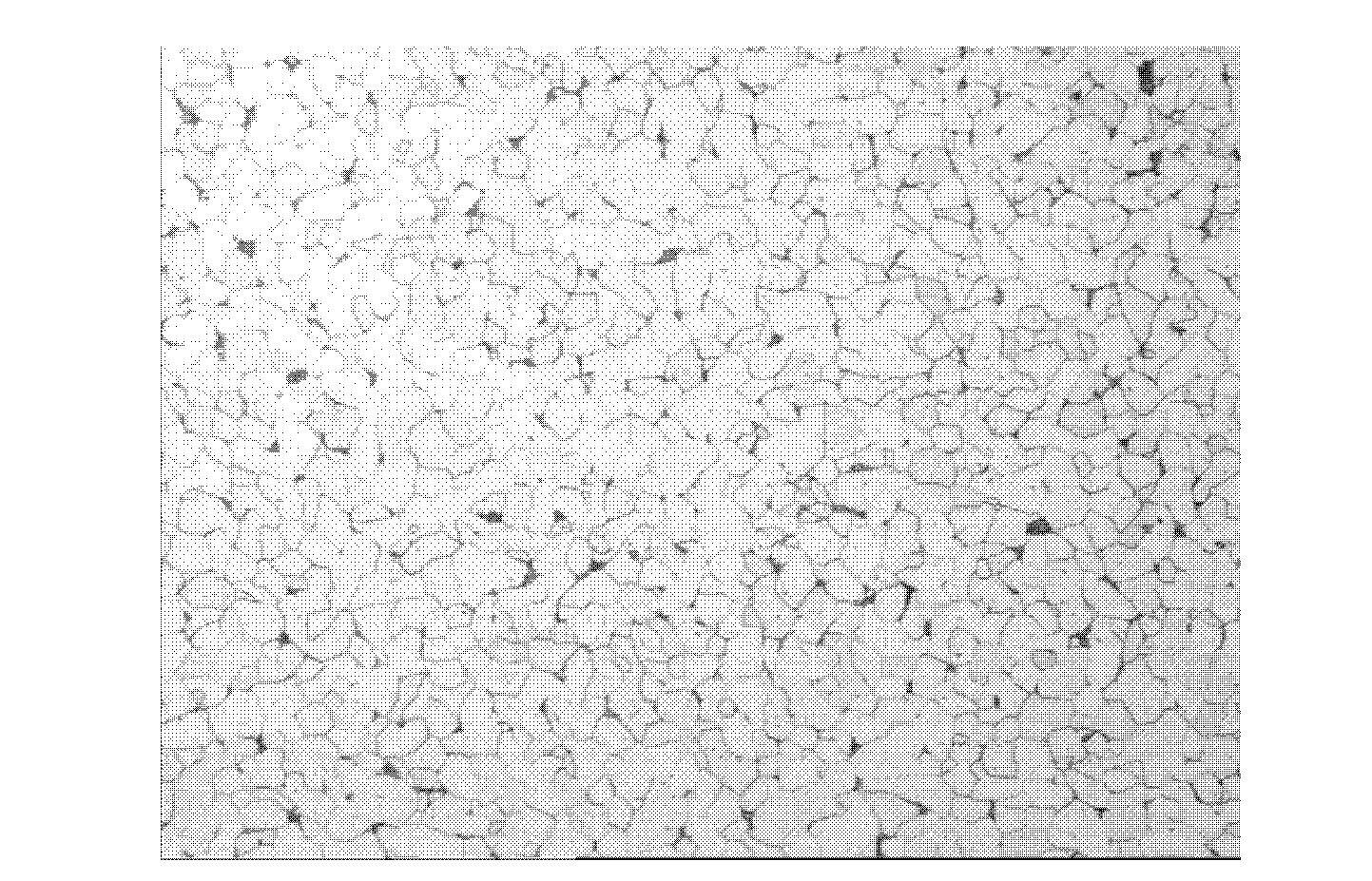

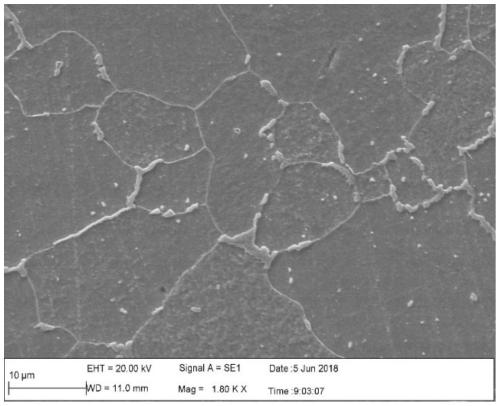

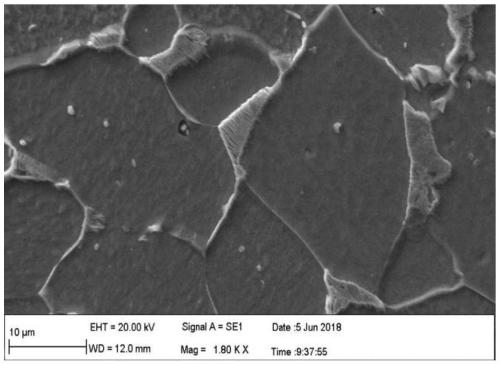

In homogeneous anneal condition (Anneal 1100), the ferrite grain size is quite large (40 µm) due to prolong holding at a higher temperature of 1100 °C and subsequent controlled furnace cooling. On execution of Anneal 950 treatment, the average grain size reduces nominally to 32 µm.

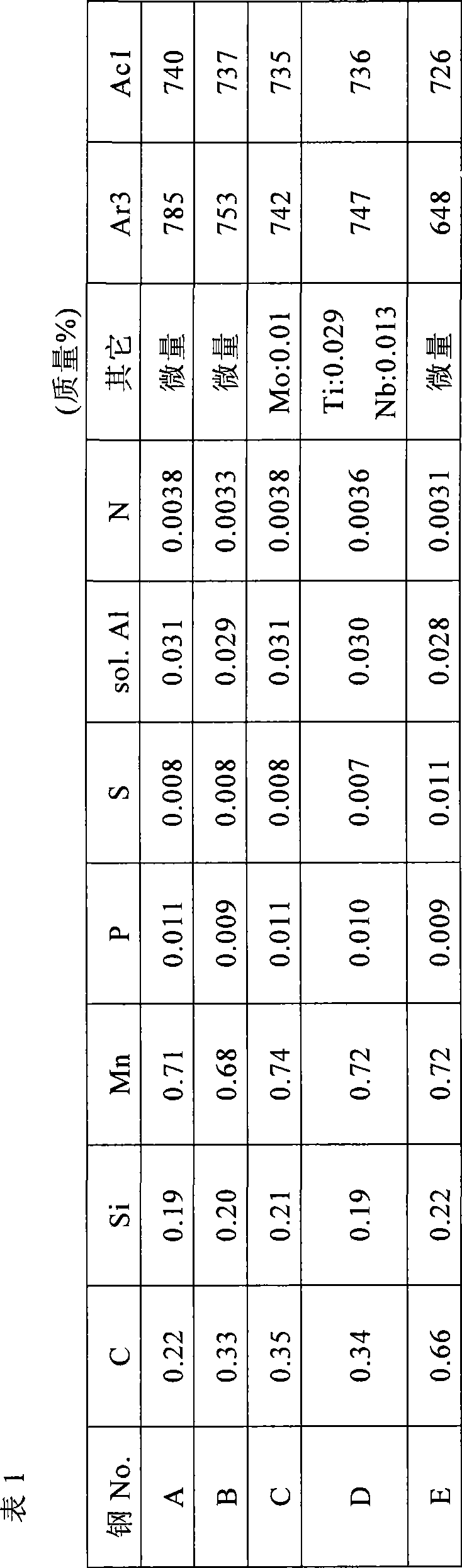

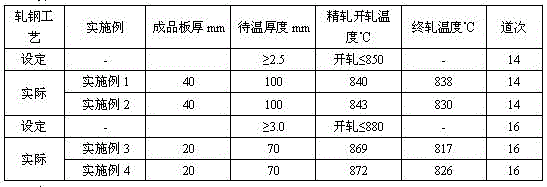

Medium carbon steel sheet, quenched member, and method for manufacturing medium carbon steel sheet and quenched member

ActiveCN103764862AEasy to processImprove stabilityFurnace typesHeat treatment furnacesCarbideCarbon steel

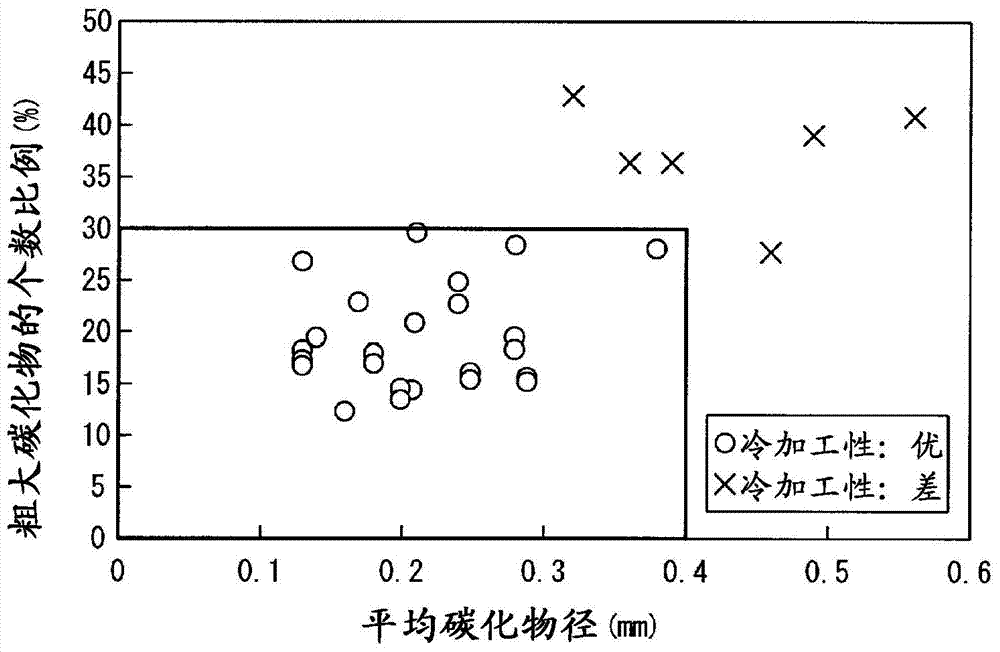

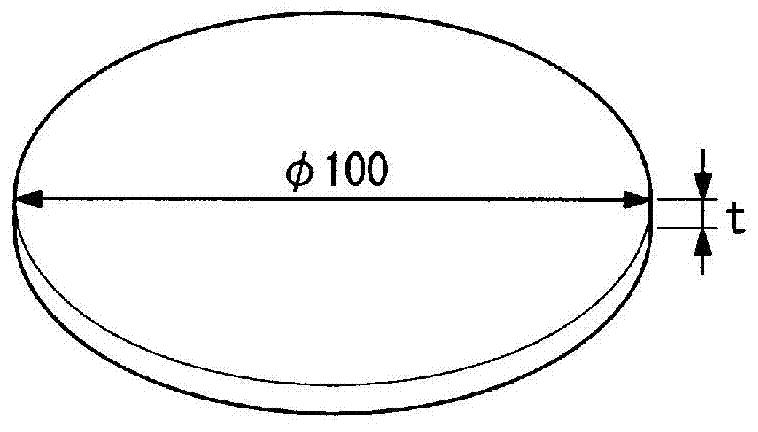

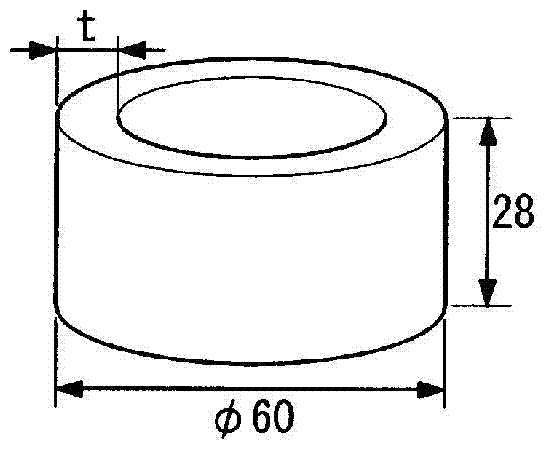

This medium carbon steel sheet contains 0.10-0.80% of C, 0.01-0.3% of Si, 0.3-2.0% of Mn, 0.001-0.03% of P, 0.0001-0.01% of S, 0.001-0.10% of Al, and 0.001-0.01% of N (percentages given with respect to weight); the average carbide diameter is 0.4 mum or less; the ratio of the number of carbides that are 1.5 times or greater than the size of the average carbide diameter is 30% or less of the total number of carbides; the carbide spheroidizing rate is 90% or greater; the average ferrite grain size is 10 mum or greater; and the tensile strength (TS) is 550 MPa or less.

Owner:NIPPON STEEL CORP

Method for online test of steel plate mechanic property during rolling process

InactiveCN1664550ASufficient reliabilityHigh precisionInvestigating material ductilityInvestigating material hardnessOnline testModel parameters

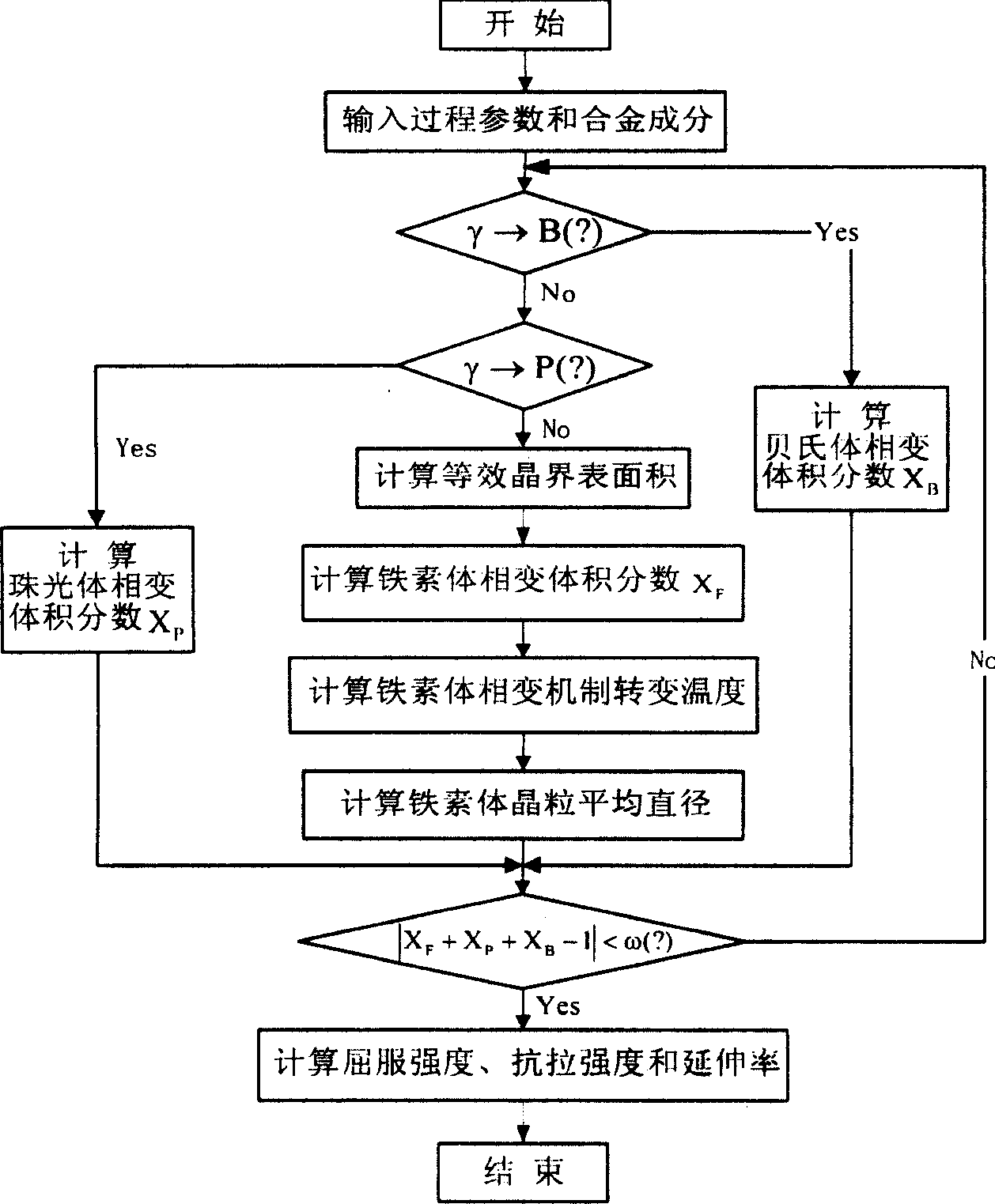

The invention relates to a method for testing the mechanical of the steel plate on line when rolling, providing a comprehensiveness on-line predicting method based on the physico-metallurgy model and combined with the database, information technology through setting up a corresponding model of microscopic structure, finished size, art component to the mechanical. The method including the following steps: (a) selecting and confirming the parameter of the model; (b) setting up the real-time traffic to the processing machine, calling the art parameter and alloying component dynamic data from the processing database; (c) predicting the ferrite grain size and temperature (d) predicting mechanical of the finished plate. The invention is used specially for low-carbon steel and mini alloyed steel, the adaptive process is heavy and medium plate mill or big mill and finisher in rolling process.

Owner:NORTHEASTERN UNIV

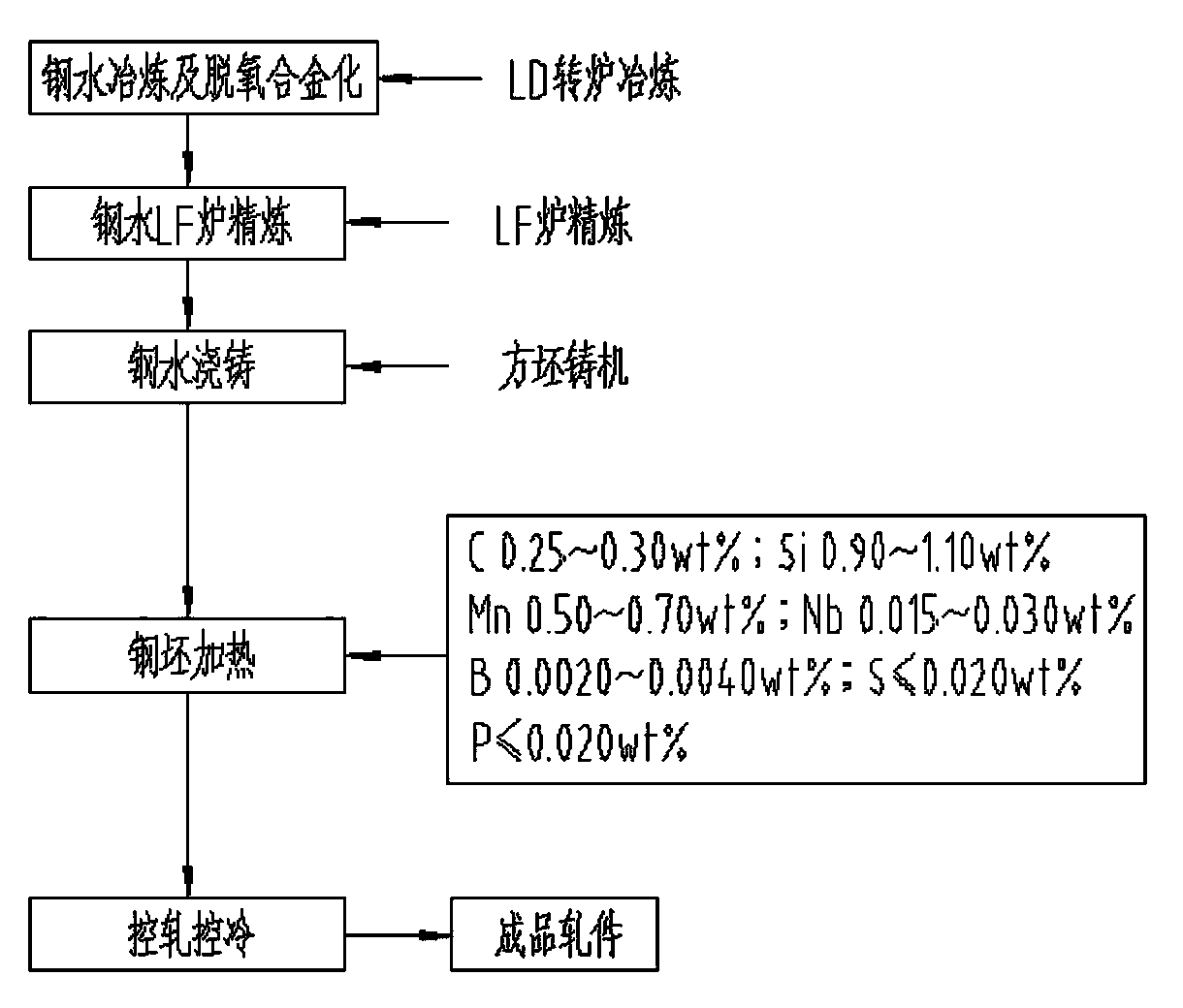

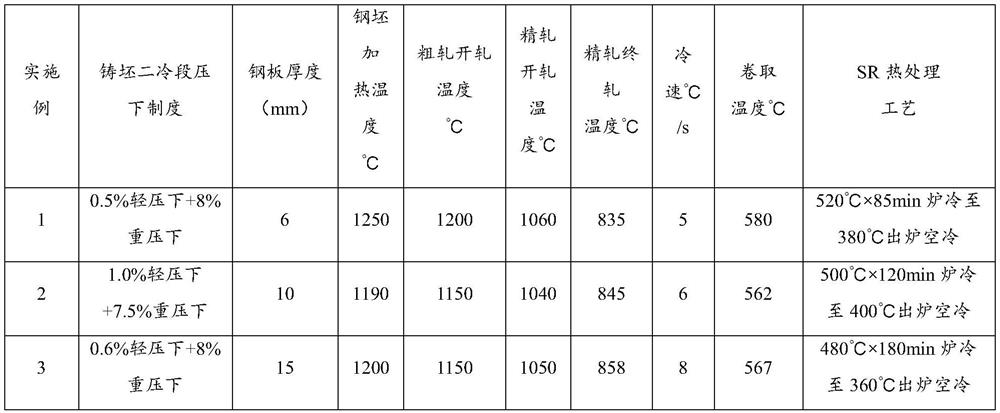

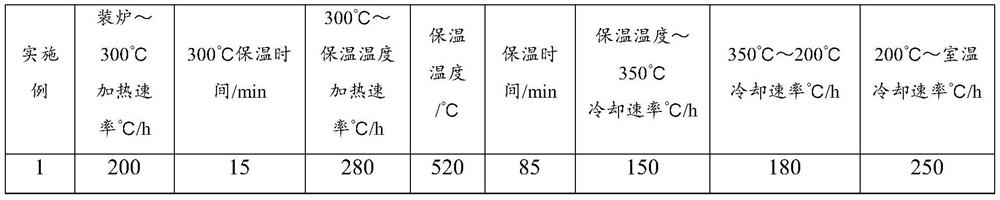

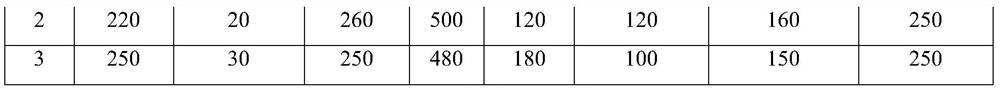

Optical round wire rod reinforcement bar for producing prestressed concrete steel rod and processing method

The invention discloses an optical round wire rod reinforcement bar for producing a prestressed concrete steel rod and a processing method. A steel blank comprises in percentage by weight: 0.25-0.30% of C, 0.90-1.10% of Si, 0.50-0.70% of Mn, 0.015-0.030% of Nb, 0.0020-0.0040% of B, no more than 0.020% of S, no more than 0.020% of P and the balance of Fe and inevitable impurities; the optical round wire rod reinforcement bar with the nominal diameter of 8.0-14.0mm is produced by heating and performing controlled rolling and controlled cooling to the steel blank, and has the following characteristics that the tensile strength (Rm) is 630-660MPa, the percentage reduction of area is more than or equal to 65%, and the ferrite grain size is 10.0-11.5 level. Through integration and creation of converter melting, LF melting, steel blank heading and multiple technology of standard and delay type controlled rolling and controlling cooling and the like, the invention provides a production method of the optical round wire rod reinforcement bar for producing the prestressed concrete steel rod, and the product is high in hardenability, and uniform in microscopic structure. The method has the advantages of excellent quality, low production cost, good processability, strong popularization and the like.

Owner:WUKUN STEEL

Hot rolled dual-phase steel sheets with high stretch-flangeability and manufacturing method thereof

Owner:SHANDONG IRON & STEEL CO LTD

Hot galvanizing steel plate with yield strength more than or equal to 550MPa, and manufacturing method thereof

ActiveCN102796949AHigh yield strengthHigh strengthHot-dipping/immersion processesReduction rateSheet steel

The invention discloses a hot galvanizing steel plate with yield strength more than or equal to 550MPa, and a manufacturing method of the hot galvanizing steel plate; the hot galvanizing steel plate with the yield strength more than or equal to 550MPa comprises the following components by mass percent: 0.05-0.12% of C, less than or equal to 0.08% of Si, 0.3-0.9% of Mn, 0.020-0.060% of Als, less than or equal to 0.03% of P, less than or equal to 0.03% of S and the balance of Fe and unavoidable impurities; the manufacturing method of the hot galvanizing steel plate with the yield strength more than or equal to 550MPa comprises the steps of cast steel plate (CSP) continuous casting and rolling, steel plate pickling cold rolling and steel plate continuous zinc coating; according to the invention, the chemical components of the hot galvanizing steel plate are designed in an optimal way, alloying elements with high price are not added into the hot galvanizing steel plate, the strength of products can be improved by structure strengthening and solution strengthening of C and Mn, and the production cost is greatly reduced; the grain size is reduced, and the product strength is improved by reducing the CSP rolling temperature; the product strength is improved by controlling the acid rolling reduction rate; and the yield strength of the products can be guaranteed by controlling the galvanized annealing temperature and speed as well as the hydrogen content.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

High-strength steel product excelling in fatigue strength and process for producing the same

A high-strength and high-fatigue-strength steel having a base metal strength of 1000 MPa or more and a rotating bending fatigue strength of 550 MPa or more is provided. The steel contains 0.3-0.8 percent by mass of C, 0.01-0.9 percent by mass of Si, 0.01-2.0 percent by mass of Mn, and Fe and unavoidable impurities as the remainder. The steel has a ferrite-cementite structure having a grain size of 7 mum or less or a ferrite-cementite-pearlite structure having a grain size of 7 mum or less. A surface metal of the steel after high-frequency induction quenching has a martensite structure having a prior austenite grain size of 12 mum or less. Alternatively, a surface metal of the steel after nitriding has a fine structure having a ferrite grain size of 10 mum or less.

Owner:JFE STEEL CORP

High Strength Multiphase Steel, Production Method and Use

ActiveUS20170137906A1High strengthHot-dipping/immersion processesFurnace typesHigh intensityImpurity

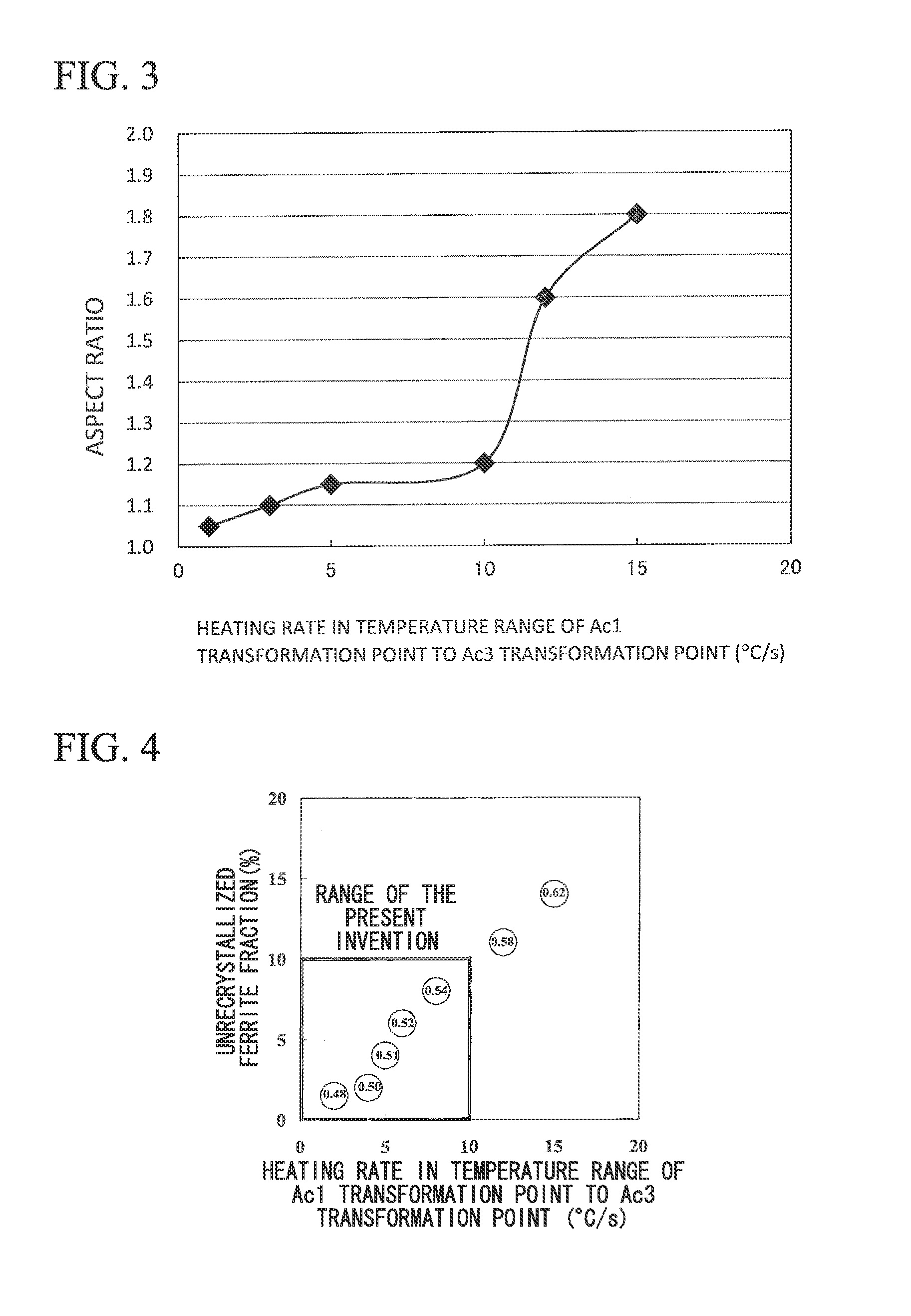

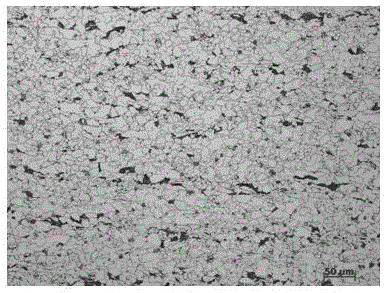

The invention deals with a cold rolled and hot dip steel sheet, with a tensile strength of at least 980 MPa, with yield strength above or equal to 500 MPa, with total elongation above or equal to 8%, the composition consisting by weight percent: 0.05<C<0.15%, 2<Mn≦3%, Al<0.1%, 0.3<Si<1.5%, 0.01%<Nb<0.05%, N<0.02%, 0.1<Cr+Mo<1%, 0.0001<B<0.0025, Ti<0.5%, V<0.01%, S<0.01%, P<0.05% the remainder of the composition being iron and unavoidable impurities resulting from the smelting and the microstructure contains, in surface fraction: between 50 and 95% of martensite and between 5 and 50% of the sum of ferrite and bainite, wherein the ferrite grain size is below 10μιτι, and wherein the aspect ratio of the ferrite grain size is between 1 and 3. The steel according to the invention is oxidized and subsequently reduced during heating, soaking and cooling steps of the annealing.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

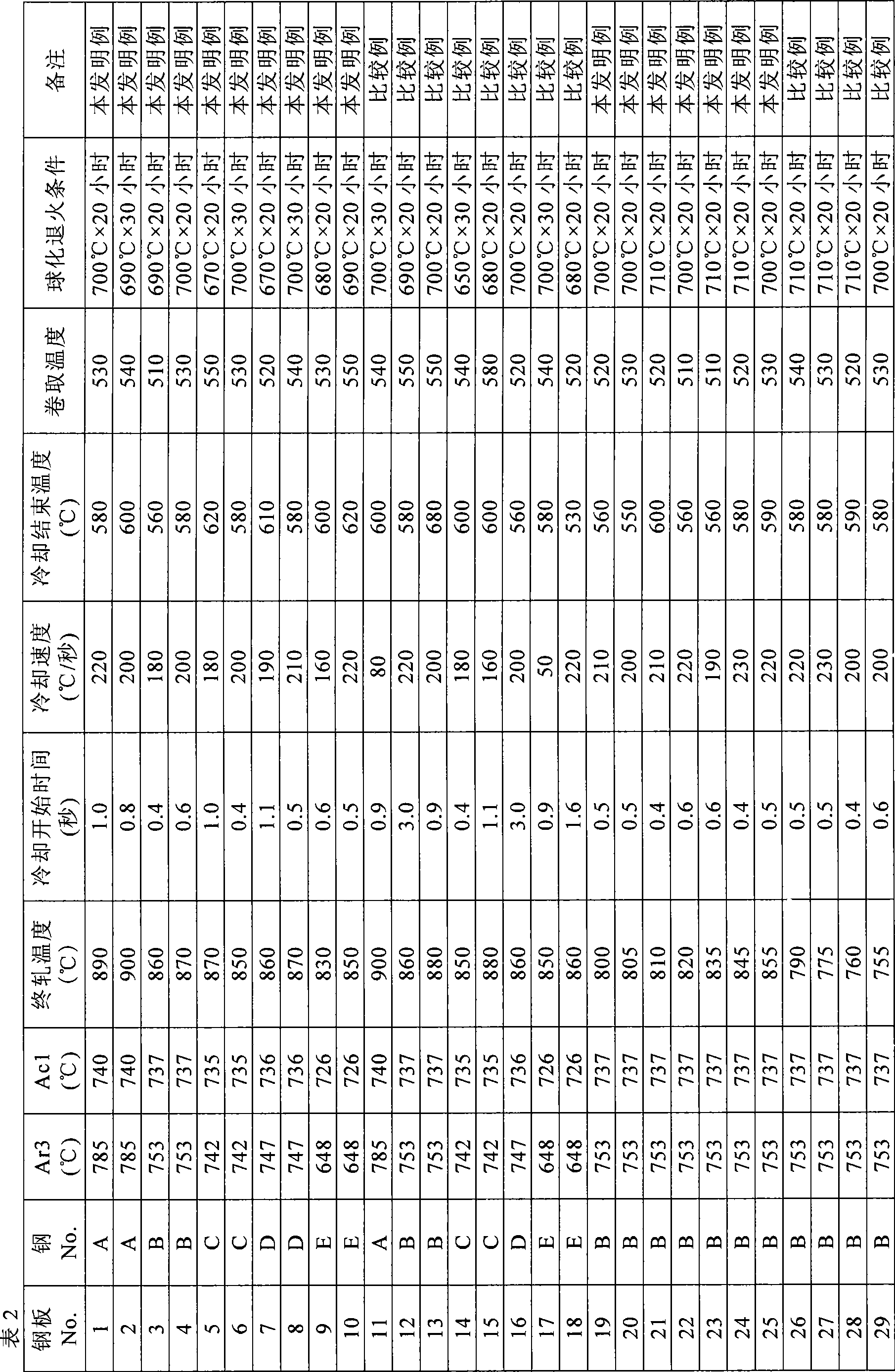

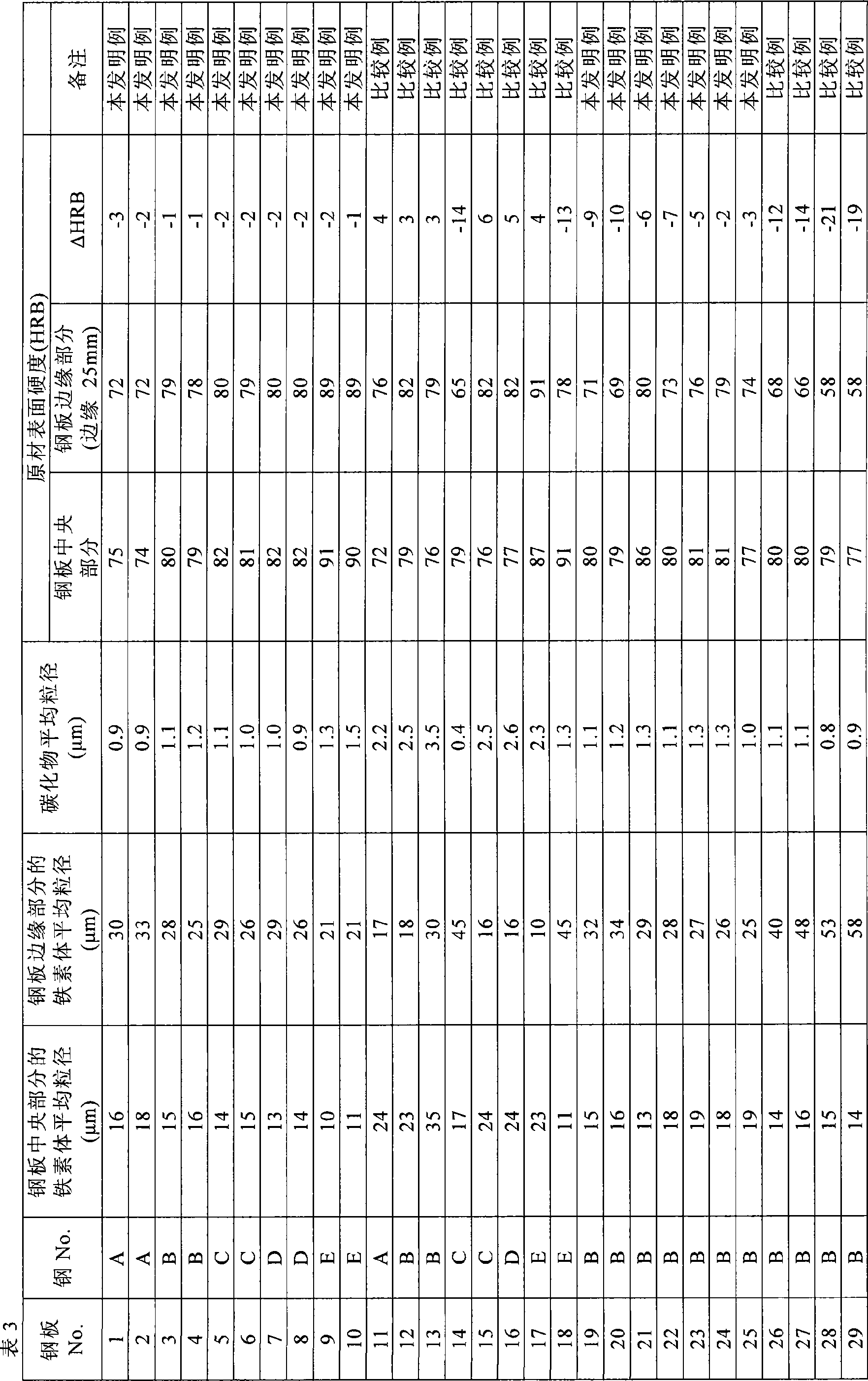

Hot-rolled high-carbon steel sheets and process for production of the same

ActiveCN101490296AImprove homogeneityImprove hardenabilityFurnace typesMetal rolling arrangementsSheet steelHigh carbon

The invention provides a hot-rolled high-carbon steel sheet excellent in the homogeneity in the width direction. The steel sheet contains C: 0.2 to 0.7%, Si: 0.01 to 1.0%, Mn: 0.1 to 1.0%, P: 0.03% or below, S: 0.035% or below, Al: 0.08% or below and N: 0.01% or below with the balance consisting of Fe and unavoidable impurities. The texture of the sheet is characterized by a mean ferrite grain size in the sheet edge of less than 35[mu]m, a mean ferrite grain size in the central area of less than 20[mu]m, and a mean carbide grain size of 0.10mum to less than 2.0mum. The steel sheet of the invention is manufactured by rough rolling, finish rolling at a finishing temperature of (Ar3+40 DEG C) or above, cooling initiated within two seconds after the finish rolling at a cooling rate exceeding 120 DEG C / s until a cooling stop temperature exceeding 550 DEG C and below 650 DEG C, coiling at a temperature of 550 DEG C or below, pickling, and then spheroidizing at a temperature of 670 DEG C to Ac1 transformation point.

Owner:JFE STEEL CORP

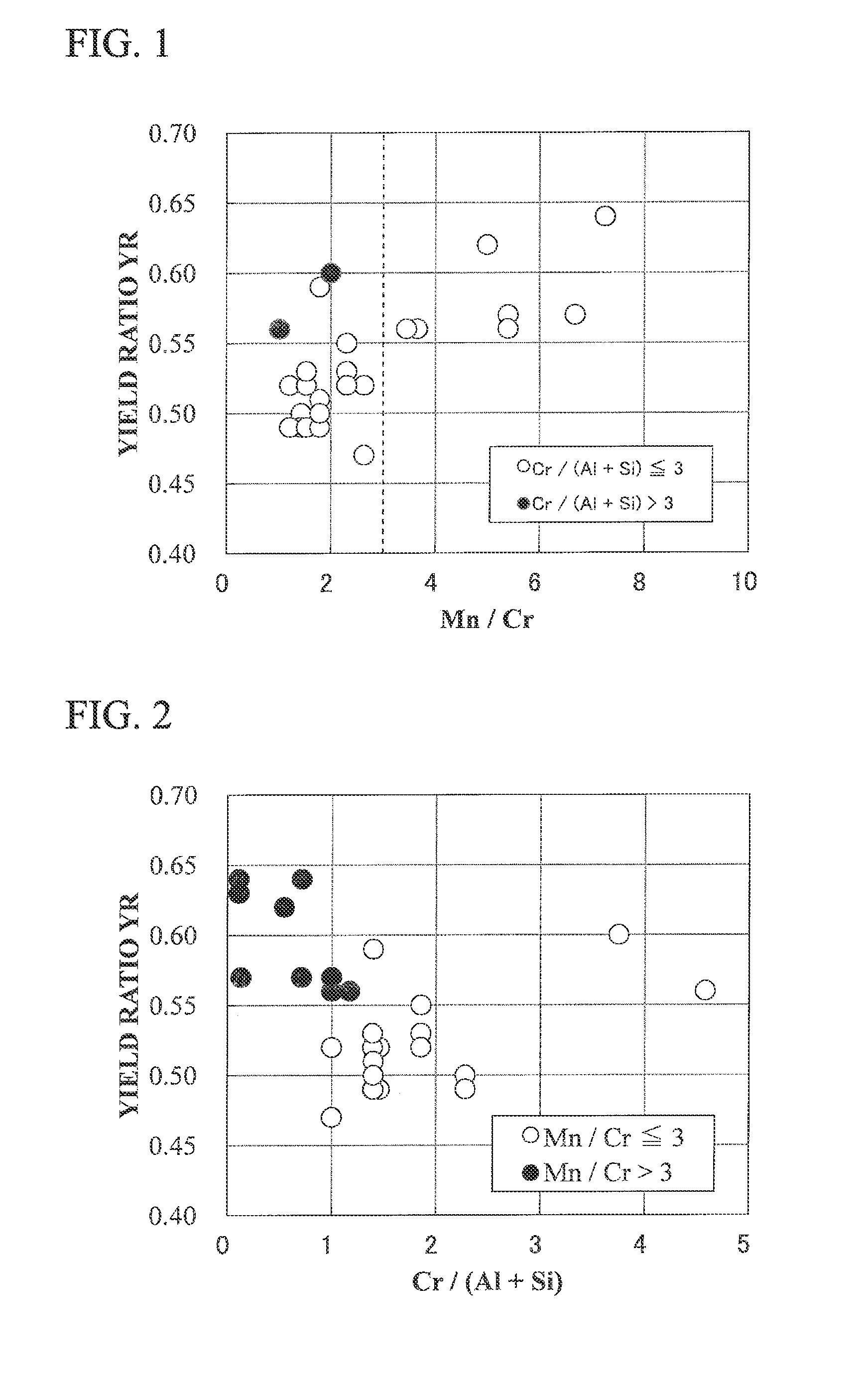

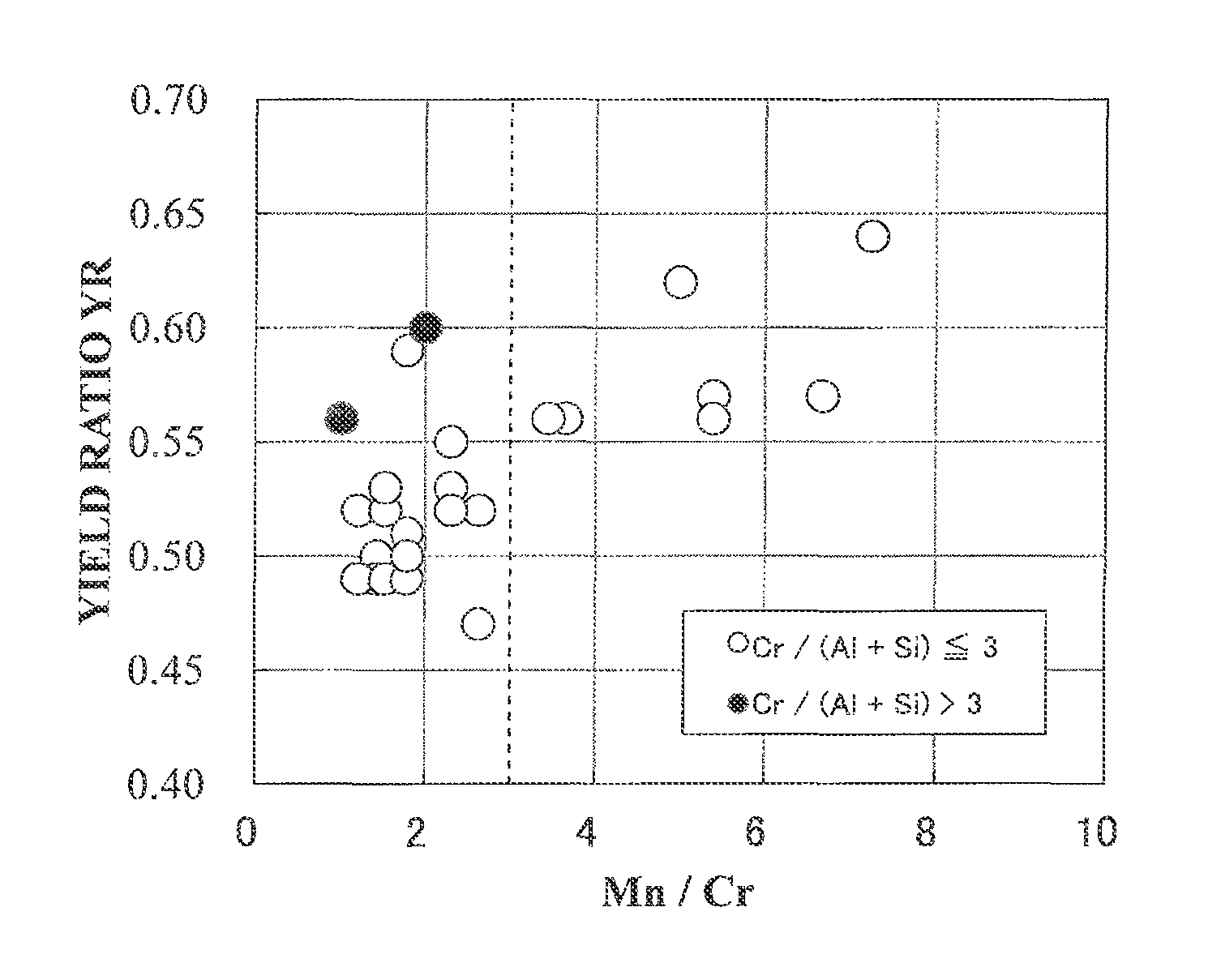

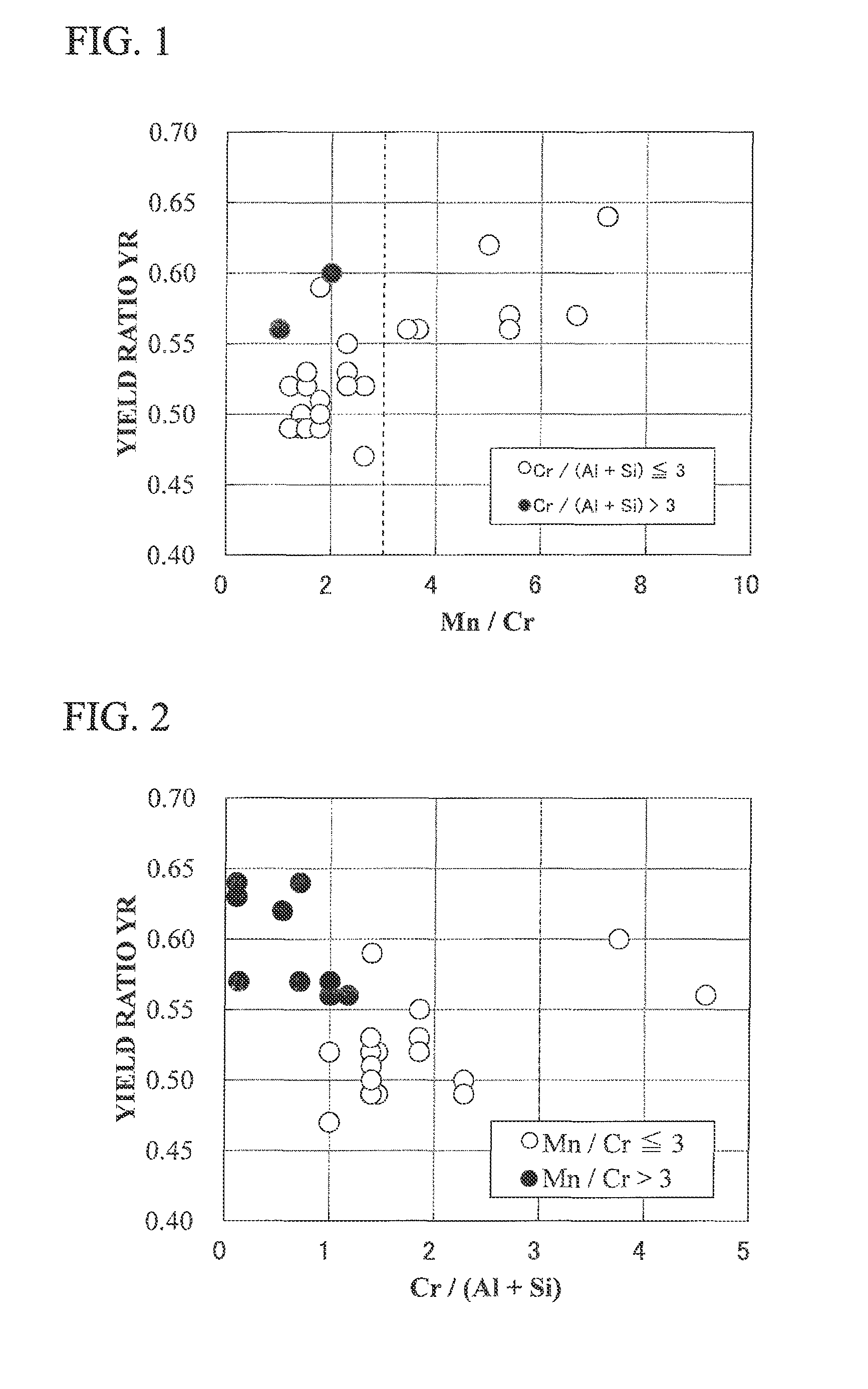

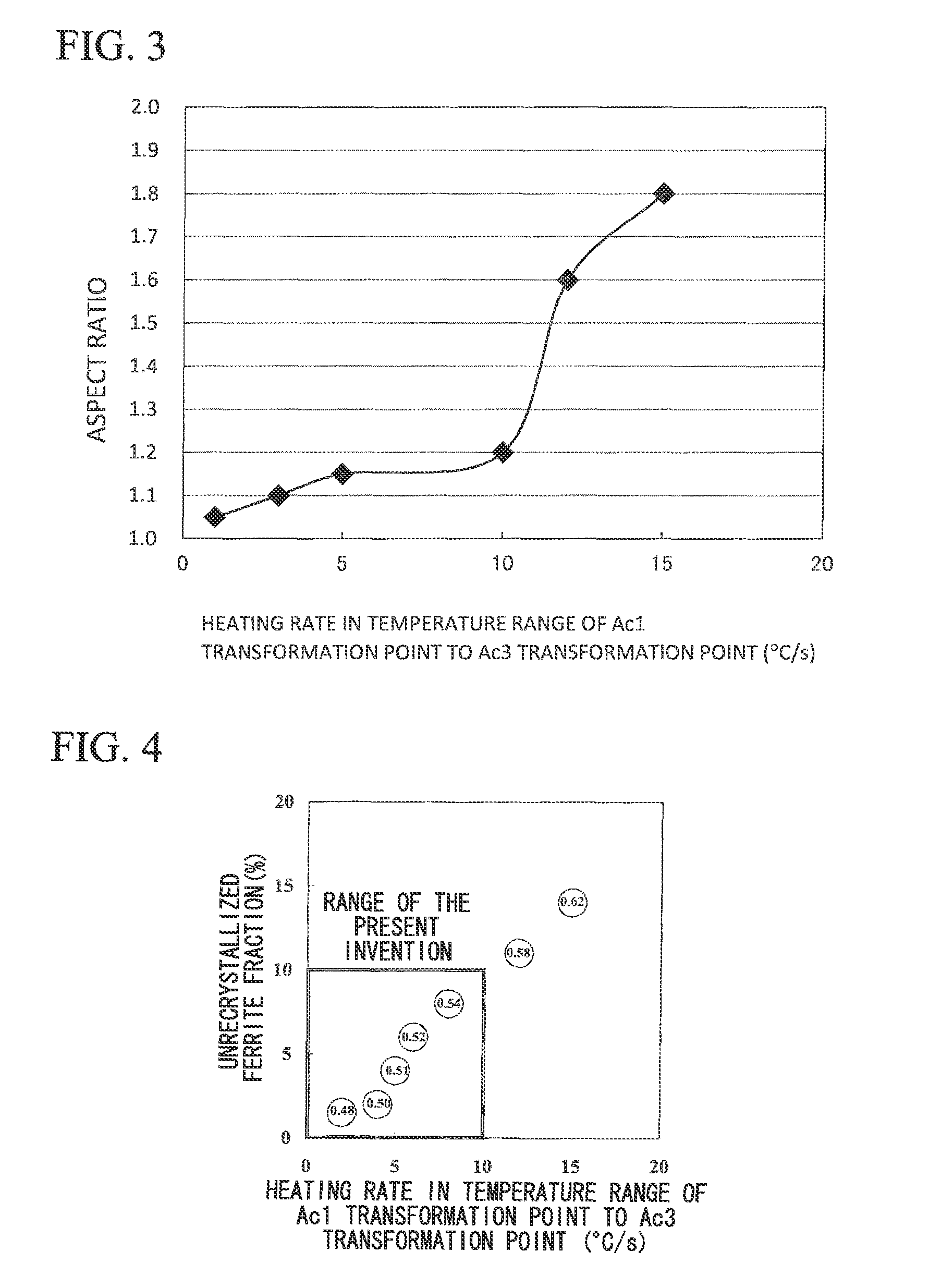

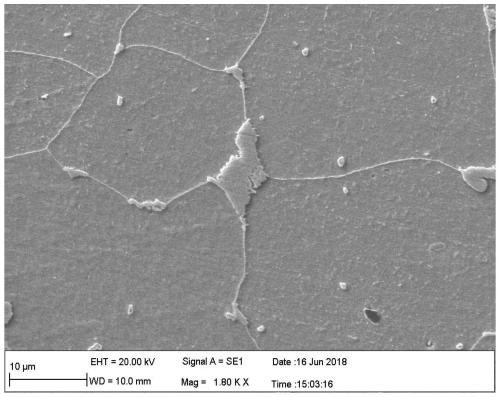

High-strength steel sheet having excellent processability and paint bake hardenability, and method for producing of high-strength steel sheet

InactiveUS20120282487A1Lower ratioLow strengthHot-dipping/immersion processesFurnace typesManganeseMaterials science

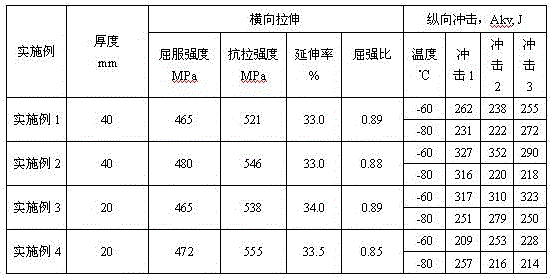

The high-strength steel sheet includes, by mass %: C: 0.01% to 0.10%; Si: 0.15% or less; Mn: 0.80% to 1.80%; P: 0.10% or less; S: 0.015% or less; Al: 0.10% to 0.80%; Cr: 0.01% to 1.50%; N: 0.0100% or less; and a balance consisting of iron and inevitable impurities, in which a metallic structure is composed of ferrite and a hard second phase, the area fraction of the ferrite is 80% or more, the area fraction of the hard second phase is 1% to 20%, the fraction of unrecrystallized ferrite in the ferrite is less than 10%, the ferrite grain sizes are 5 μm to 20 μm, and the fraction of the ferrite crystal grains having an aspect ratio of 1.2 or less in the entire ferrite crystal grains is 60% or more.

Owner:NIPPON STEEL CORP

Polar region ship steel plate capable of high heat input welding and making method for same

The invention relates to a polar region ship steel plate capable of high heat input welding. The steel plate comprises the following chemical components in percentage by mass: 0.03-0.07% of C, 0.15-0.30% of Si, 1.10-1.50% of Mn, less than or equal to 0.070% of P, less than or equal to 0.0030% of S, 0.008-0.020% of Ti, 0.0030-0.0060% of N, 0.10-0.30% of Cu, 0.10-0.40% of Ni, 0.010-0.040% of Nb, 0.020-0.050% of Al and the balance of Fe; the matrix structure of the steel plate is ferrite and pearlite; the pearlite is dispersedly distributed among the ferrite crystalline grains; and the size of the ferrite crystalline grains is 4-8 mu m. The steel plate has excellent 60-80 DEG C low-temperature impact toughness and low-temperature strain ageing resistance; and the welding performance is excellent through high-efficient welding of highest heat input of 200 KJ / cm.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Process for producing V-N micro alloy high strength steel band using thin plate blank continuously casting and continuously rolling technology

InactiveCN1748883ASpeed up coolingInhibit growthMetal rolling arrangementsMaterials scienceSteel plates

The continuous thin plate blank casting and rolling process for producing high strength V-N micro alloy steel belt includes smelting and refining in electric furnace or converter, continuous casting, heating after solidification inside bottom heating furnace, hot rolling, laminated flow cooling and winding. The continuous thin plate blank casting and rolling process has the technological parameters of: furnace entering temperature of cast blank 900-1050 deg c, homogeneous heating temperature 1050-1250 deg c, initially rolling temperature 1000-1170 deg c, finally rolling temperature 840-950 deg c and winding temperature 530-670 deg c. The molten steel contains: C 0.03-0.08 wt%, Si 0.01-0.8 wt%, Mn 0.1-2.0 wt%, V 0.01-0.20 wt%, Al 0.01-0.06 wt% and N 0.002-0.03 wt%. The produced high strength and fine grain steel belt and plate has ferrite grain size smaller than 6.0 micron, yield strength of 420-700 MPa, and excellent toughness, welding performance and forming performance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Wide and thick superfine-grain hot-rolled plate and method for producing same

InactiveCN1952197AIncrease temperatureIncrease spray coolingRoll mill control devicesMetal rolling arrangementsUltra fineCooling capacity

The invention discloses a generous specification ultra-fine grain hot rolling plate and its production methods. Its chemical composition (by weight percentage) is: C:0.12-0.18%,Si:0.12-0.25%,Mn: 0.70-1.30%,P:<=0.02%,S:<=0.015%, and Fe as the rest and inevitable impurities, plate thickness 8~14mm. In the invention through raising appropriately the mill inlet temperature, increasing the cooling capacity of the finishing mill , allocating the deflection of each finishing mill pass, to make it process in the non-recrystallization area of the austenite; rapid cooling after rolling and reeling at a low temperature, to obtain ultra-fined ferrite and multiphase of bainite, ferrite grain size3-6 mum, the mechanical properties of yield strength up to 400Mpa, over 520Mpa tensile strength, specific elongation over 28%. The invention can save alloy sources and bring great economic and social benefits for enterprises as there are no special steel alloy elements in the steel to substitute micro-alloyed steel with the same grade.

Owner:ANGANG STEEL CO LTD

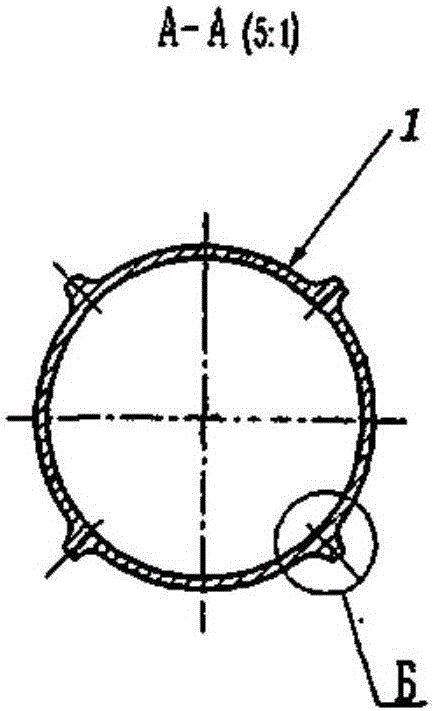

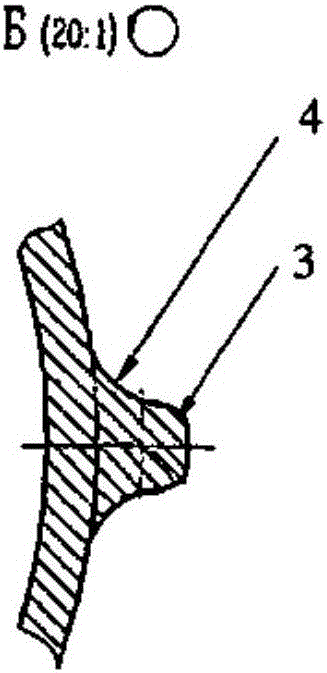

Fuel rod cladding, fuel rod and fuel assembly

ActiveCN105723465AImprove performanceAvoid corrosion damageFuel elementsNuclear energy generationNuclear engineeringLong term durability

The invention relates to the field of nuclear engineering and can be used in the manufacture of fuel rods and fuel assemblies for heavy liquid metal cooled reactors, and also in the manufacture of fuel rod simulators for use in irradiation devices designed to test the operability of real fuel assemblies. The present cladding of a fuel rod for a heavy liquid metal cooled reactor is in the form of a weldless tubular element with helically-coiled fins disposed on the outer surface of said element, which is made from a ferritic-martensitic chromium-silicon steel with a minimum ferrite grain size of 7 on the GOST 5639 scale, wherein each fin has an opening angle of from 22 to 40 DEG C (preferably from 30 to 40 DEG C) and the cross-section of the fin is in the shape of a trapezoid with rounded corners at the top of the trapezoid and smooth corners at the base of the trapezoid. Also disclosed are a fuel rod comprising the above cladding, and a fuel assembly. The technical result of the invention is an improvement in the performance characteristics of fuel rods and assemblies as a result of the long-term resistance of the cladding in the environment of a heavy liquid metal coolant such as lead or a eutectic of lead and bismuth.

Owner:JOINT CO AKME ENG

Method for controlling process for cooling hot-rolled ultra low carbon steel wire rod after rolling

ActiveCN102189122AImprove processing efficiencyHigh yieldTemperature control deviceWire rodBrittle fracture

The invention discloses a method for controlling a process for cooling a hot-rolled ultra low carbon steel wire rod after rolling and belongs to the technical field of steel rolling. Spinning temperature is controlled to be 900 to 950 DEG C; the speed of a roller bed of a cooling section is reasonably adjusted, and distance between rings and the cooling speed are controlled by controlling the speed of the roller beds of all sections; and fans are all switched off, heat insulation covers are all opened, the grain size of ultra-low carbon steel wire rod ferrite is controlled to be 20 to 40 mu m, tertiary cementite content is less than or equal to 2 percent, tensile strength is less than or equal to 330 MPa, area reduction is more than or equal to 80 percent, and the performance difference of the same ring is less than or equal to 20 MPa. Processing and using efficiency of a user is greatly improved, the possibility of drawing brittle fracture is reduced, and yield and production efficiency are improved.

Owner:SHOUGANG CORPORATION

Steel sheet for double wound pipe and method of producing the pipe

InactiveUS6110299AImprove metal performanceGood molding effectFurnace typesHeat treatment furnacesReduction rateSheet steel

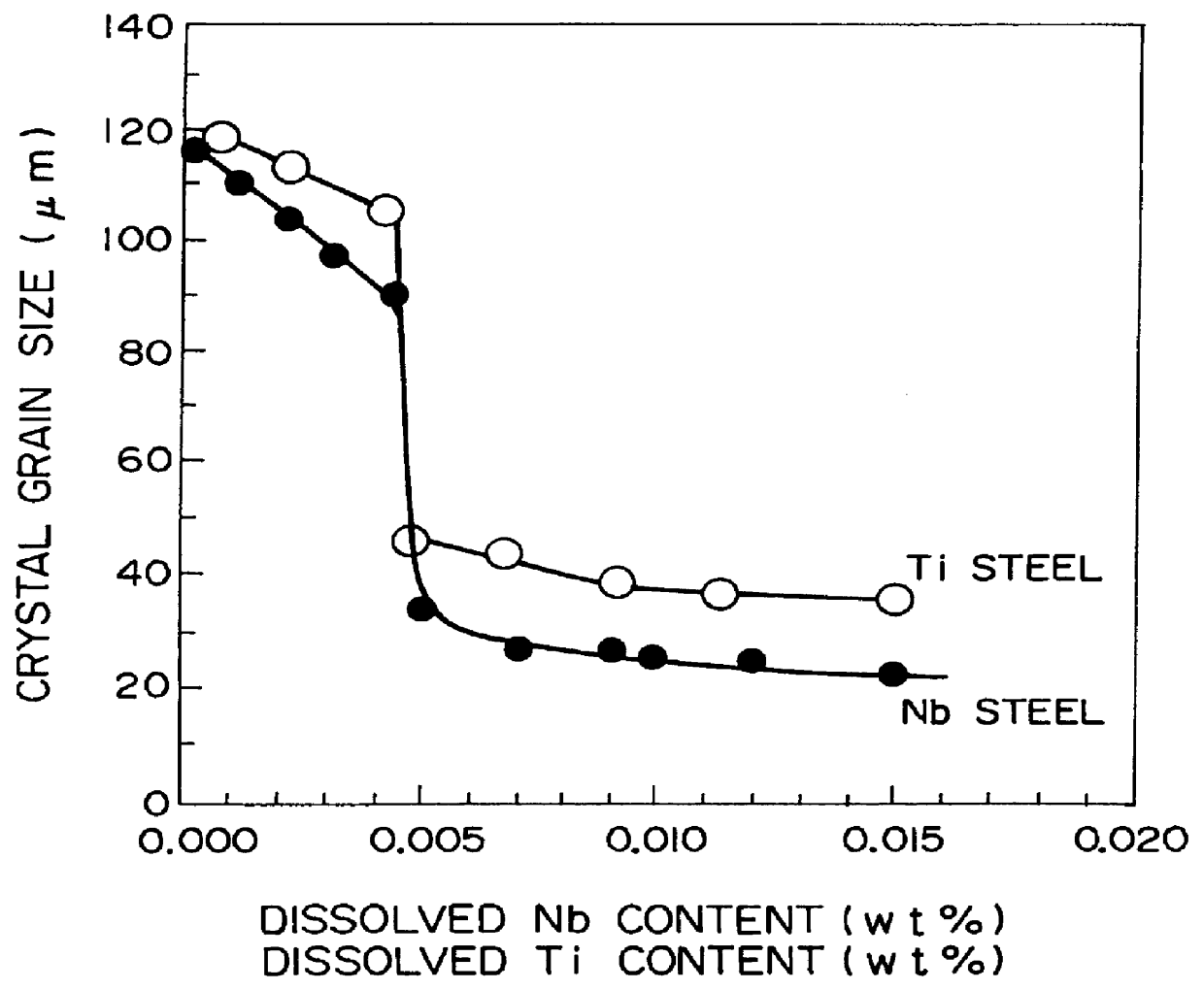

PCT No. PCT / JP97 / 04289 Sec. 371 Date Jun. 24, 1998 Sec. 102(e) Date Jun. 24, 1998 PCT Filed Nov. 25, 1997 PCT Pub. No. WO98 / 24942 PCT Pub. Date Jun. 11, 1998A steel sheet for double-rolled tubes has excellent formability, and excellent strength and toughness after forming and heat treatment of a tube because of suppressed coarsening of the ferrite grain size and a method for making the same comprises: hot finish-rolling of a steel material containing C: 0.0005-0.020 wt %, and one or two of Nb: 0.003-0.040 wt %, and Ti: 0.005-0.060 wt % at a final temperature of 1,000-850 DEG C., coiling at 750 DEG C. or less, cold rolling, continuous annealing at 650 DEG C.-850 DEG C. for 20 seconds or less, and second cold-rolling at a rolling reduction rate of 20% or less, so that at least one of Nb and Ti is present in a solid solution state in an amount of 0.005 wt % or more, and the crystal grain size in the ferrite structure is in the range of 5 to 10 mu m.

Owner:KAWASAKI STEEL CORP

High-strength and high-plasticity 1000 Mpa grade hot rolled steel plate and preparation method thereof

The invention discloses a high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate and a preparation method thereof. The high-strength and high-plasticity 1000 Mpa grade hot rolled steel plate is prepared from the following components by weight: 0.05%-0.40% of C, 1.00%-5.00% of Mn, 0.70%-1.60% of Si, 0.1%-1.00% of Al, 0.01%-0.10% of Nb, 0.01%-0.10% of V, 0.002%-0.005% of N and the balance Fe and inevitable impurities. The steel plate has high strength and high plasticity, and Nb and V microalloy elements are added to be combined with C and N to form nanoscale cluster precipitates, so that matrix structures are strengthened. Through chemical composition design, and combined with medium temperature coiling, the nanoscale cluster precipitates with small size, uniform distribution and high density can be obtained, the strength of ferrite is obviously strengthened, the strength difference between the two matrix structures (ferrite and martensite) is reduced, the ferrite grainsize is refined at the same time, and high reaming performance is obtained.

Owner:武汉钢铁有限公司

Soft magnetic low-carbon steel excellent in machinability and magnetic characteristic, method of manufacturing the same and method of manufacturing soft magnetic low-carbon part

ActiveUS20050139289A1Excellent magnetic characteristicImprove machinabilityMagnetic materialsChemical compositionGranularity

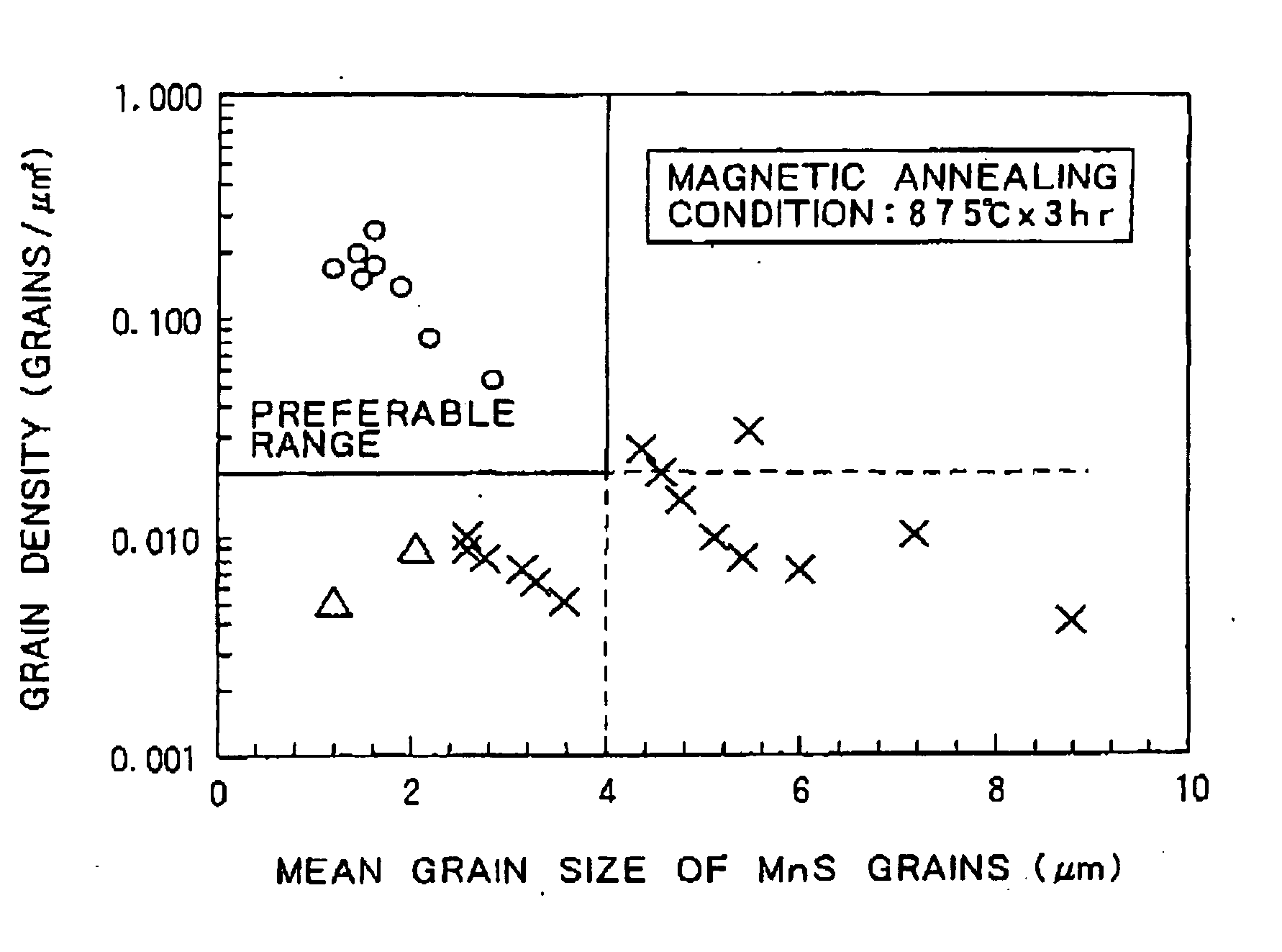

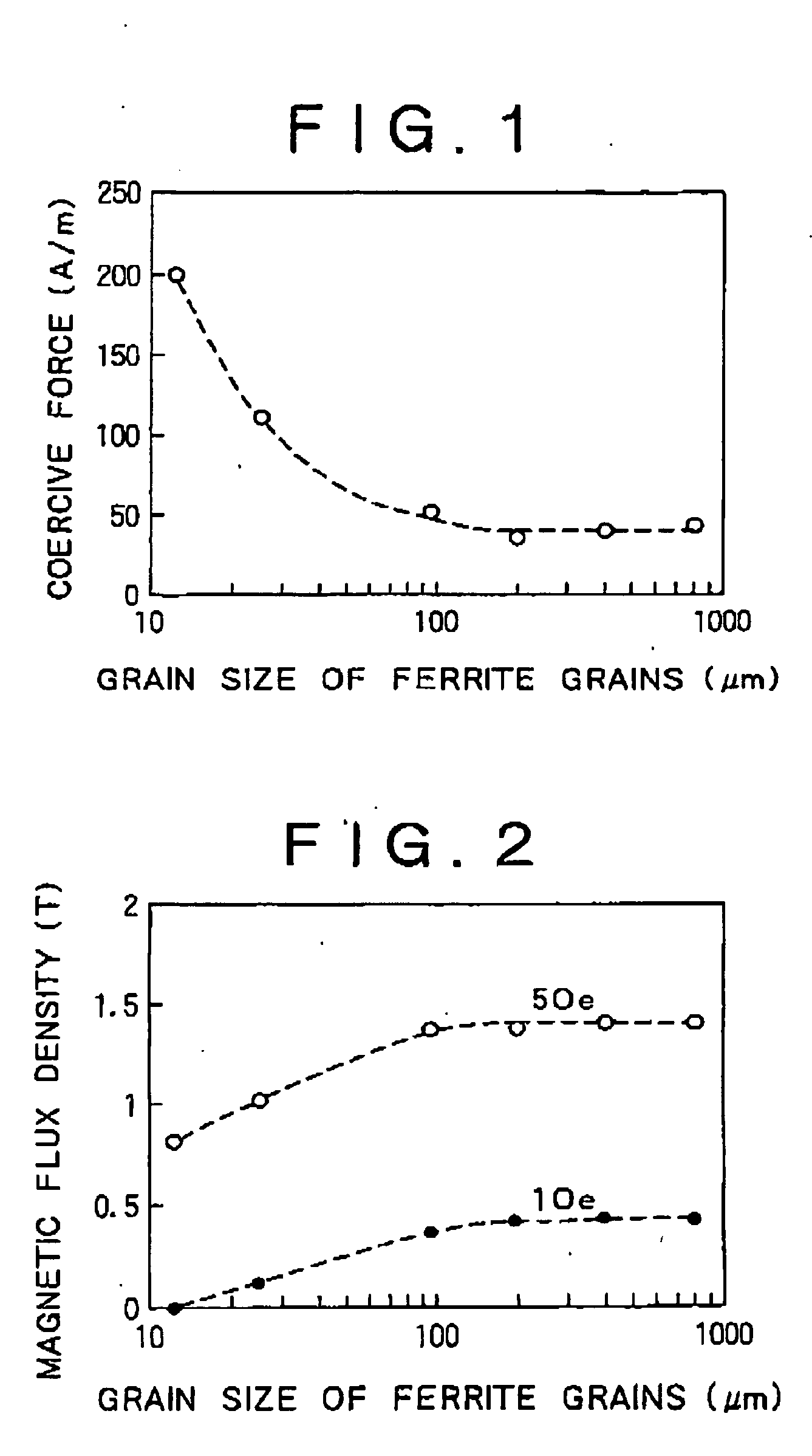

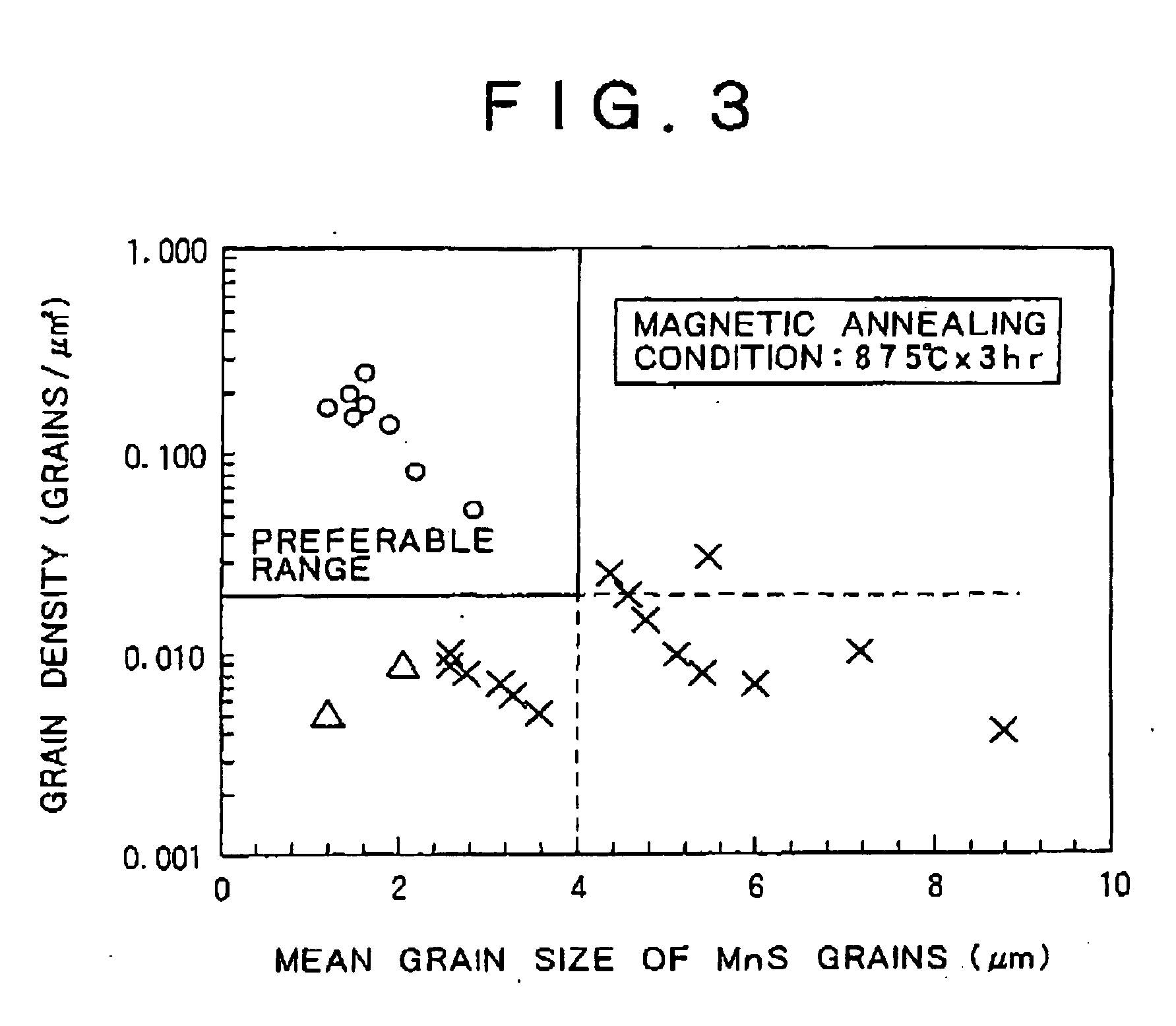

A soft magnetic low-carbon steel has a chemical composition having a C content of 0.05% by mass or below, Si content of 0.1% or below, a Mn content in the range of 0.10 to 0.50% by mass, a P content of 0.030% by mass or below, a S content in the range of 0.010 to 0.15% by mass, an Al content of 0.01% by mass or below, a N content of 0.005% by mass or below, and an 0 content of 0.02% by mass or below. In the soft magnetic low-carbon steel, Mn / S mass ratio is 3.0 or above, ferrite grain size is 100 μm or above, ferrite grains contain precipitated MnS grains of grain sizes of 0.2 μm or above in a density in the density range of 0.02 to 0.5 grains / μ2m and the precipitated MnS grains have a mean grain size in the range of 0.05 to 4 μm. The soft magnetic low-carbon steel is excellent in cold-rollability and machinability. Steel parts of the soft magnetic low-carbon steel having complicated shapes can be produced at a high yield.

Owner:KOBE STEEL LTD

Method for making ultrafine grained steel

InactiveCN102011045AGrain stabilizationInhibition of inverse phase transitionRoll mill control devicesMetal rolling arrangementsMass storageManganese

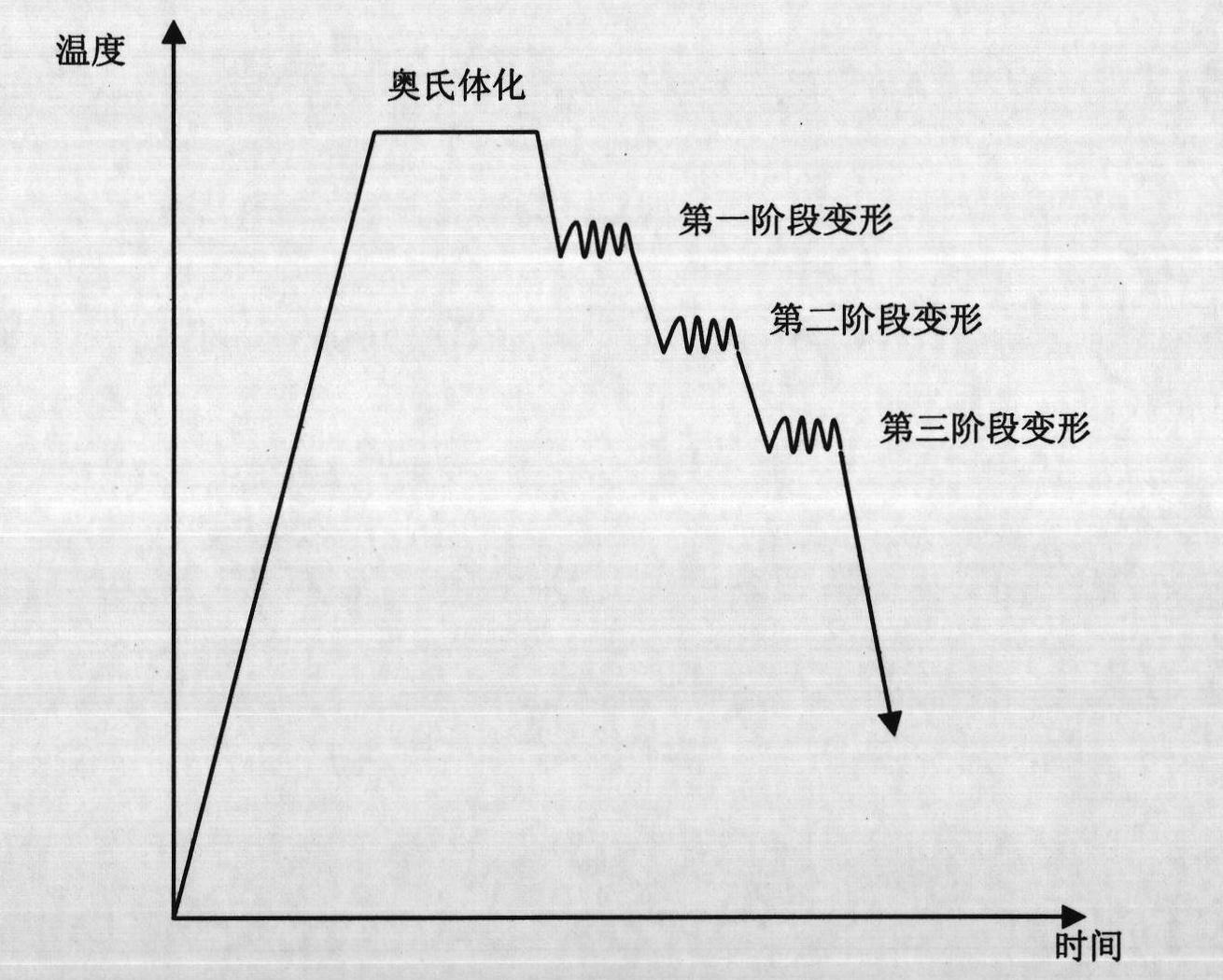

The invention discloses a method for making ultrafine grained steel, comprising the steps of: heating carbon steel to a temperature of 1200-1240DEG C to carry out austenization, wherein the carbon steel contains 0.02-0.20% of carbon and 0.40-1.60% of manganese by mass fraction; controlling to roll by using an austenite recrystallization area and an austenite non-recrystallization area; performing another deformation near an Ar3 temperature by combining the deformation induced ferrite transformation technology so as to restrain the reverse transformation from the ferrite to the austenite after twice transformation, accumulate mass storage energy of the second transformation, increase the nucleation points of the ferrite, and promote the increase of the volume fraction of the ferrite; and finally cooling to a temperature of 600-650DEG C at a cooling speed of 1-10DEG C / micron for air cooling. The ferrite grain dimension of the prepared ultrafine grained ferrite steel is less than 3.0 microns. The manufacturing method of the ultrafine grained steel does not need large deformation and ultrafast cooling process, and has small mill load and simple process; and the obtained room-temperature ultrafine ferrite grains are stable.

Owner:NANJING IRON & STEEL CO LTD

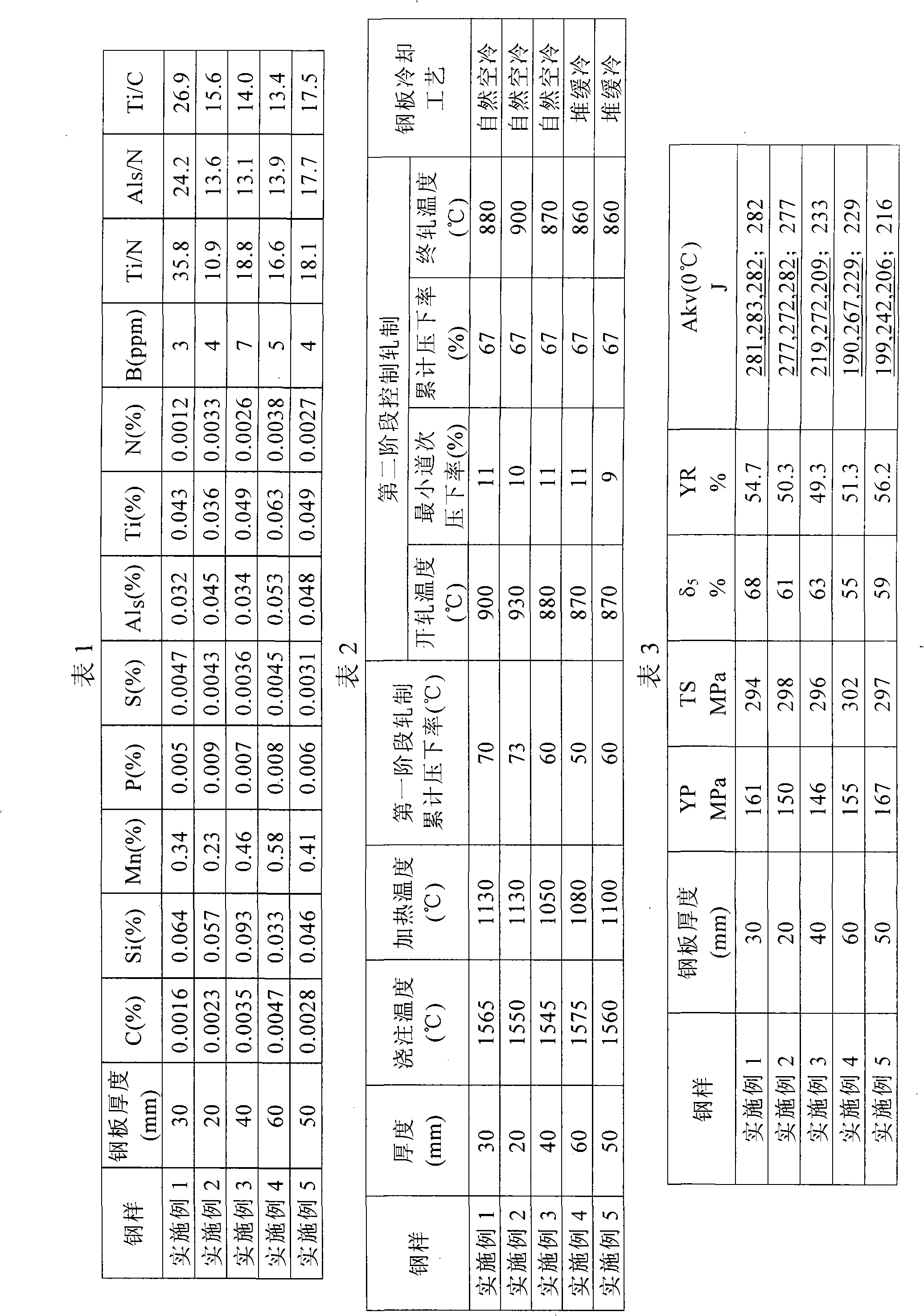

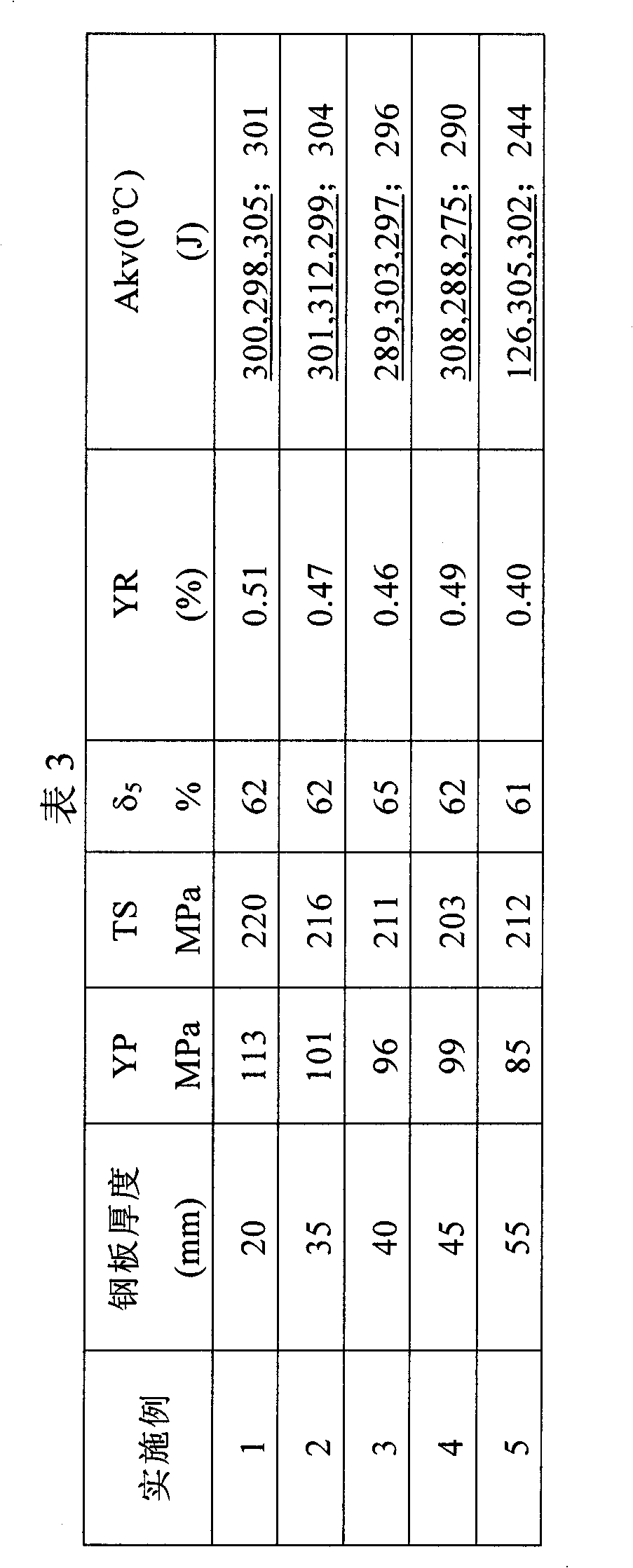

Steel plate with very low yield point and manufacturing method thereof

ActiveCN101845589AIncrease contentUniform grain sizeRoll force/gap control deviceTemperature control deviceLow-cycle fatigueDesign technology

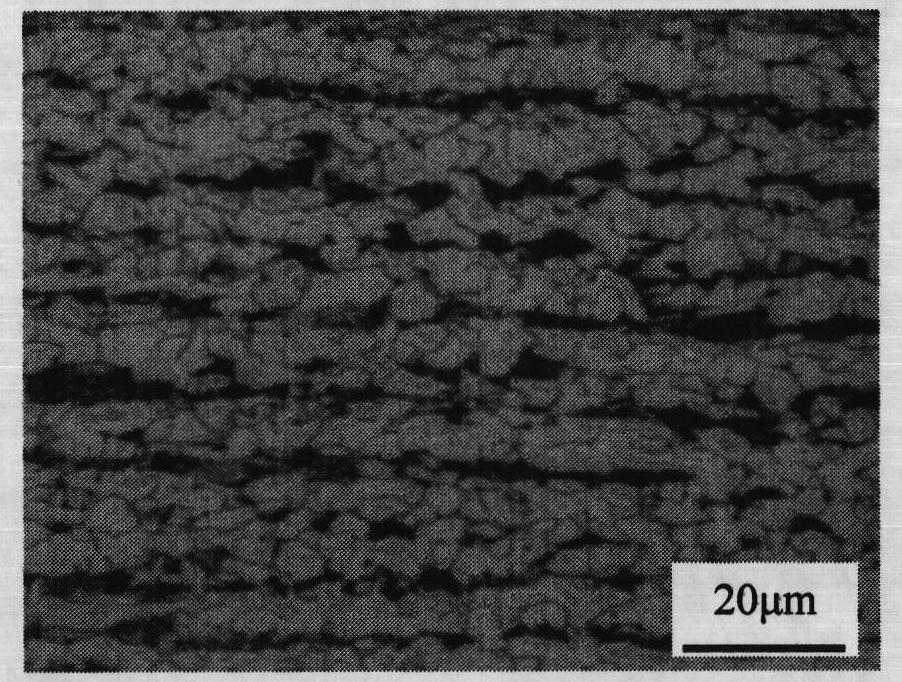

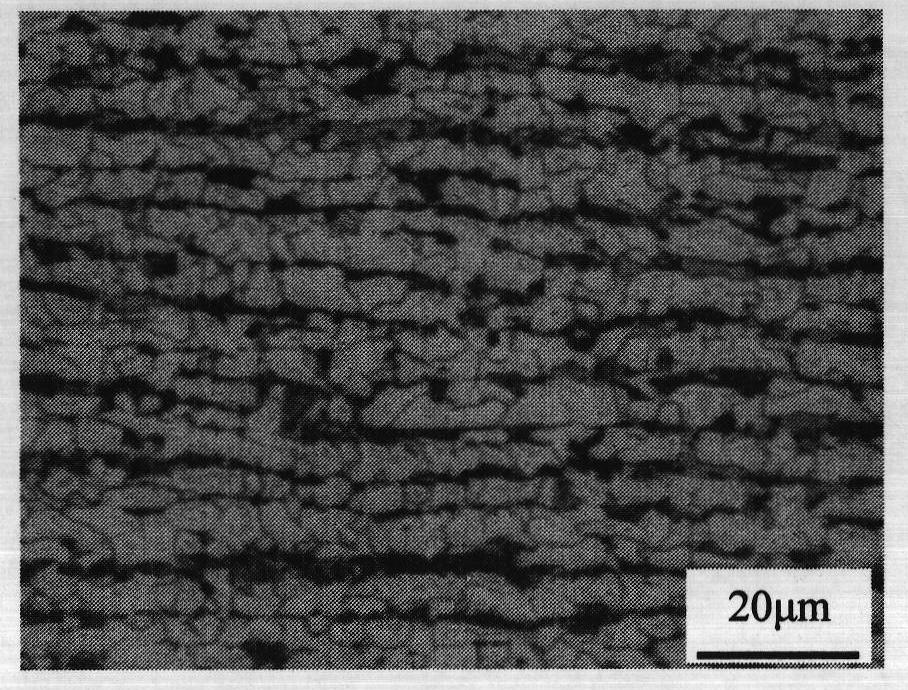

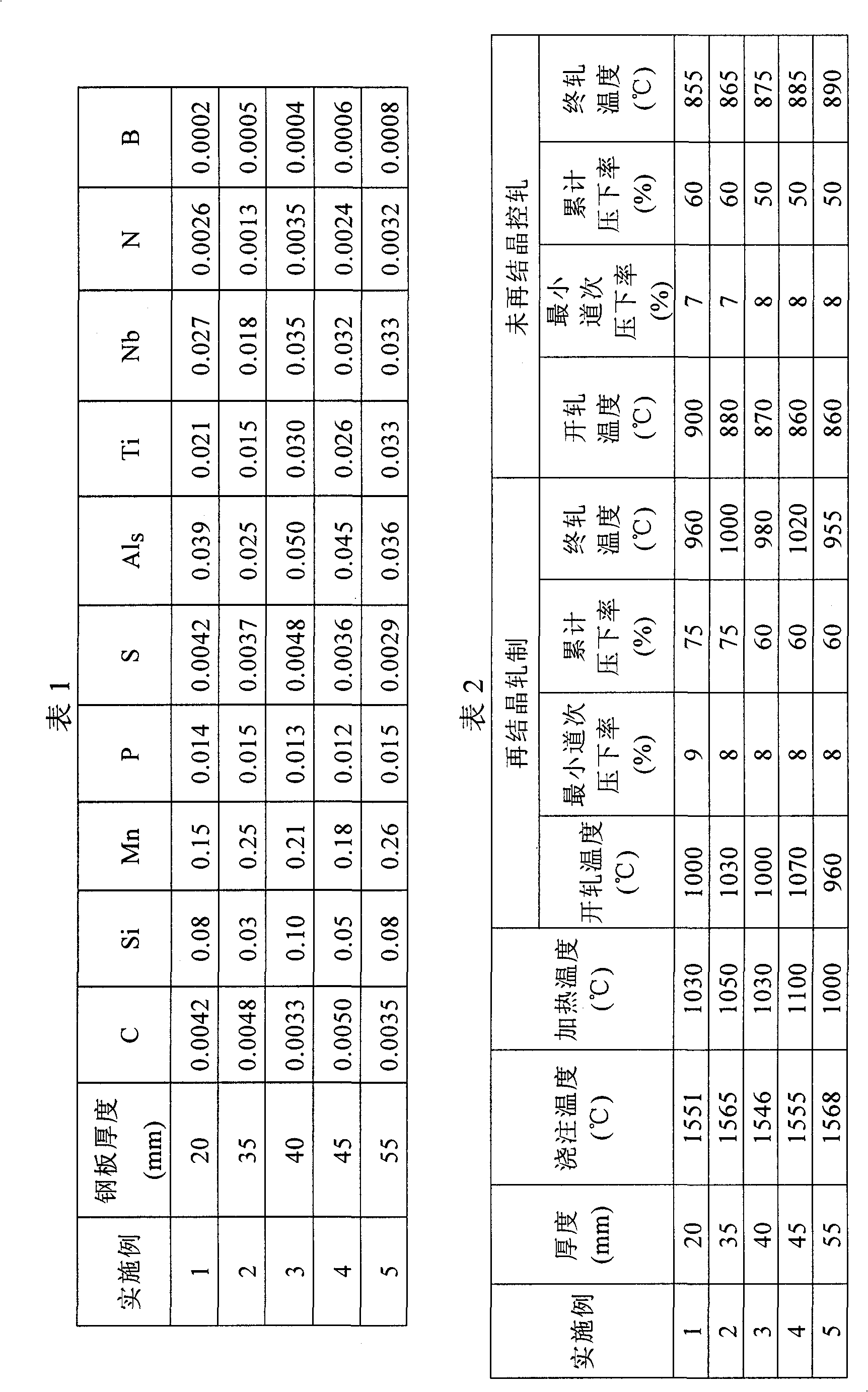

The invention relates to a steel plate with very low yield point and a manufacturing method thereof. The component design technology means of adopting a component system processed by very low C, super low Si, low Mn, high Als, low N, Ti microalloying and trace B, enhancing the content of acidly soluble Als and the Ti microalloying properly, controlling Ti / N to be not less than 10.0, Als / N to be not less than 12.0 and Ti / C to be not less than 13.0 and the like are adopted to optimize a rolling control process; the microscopic structure of a finished product of the steel plate is single-phase ferrite, the size of the crystal grains of the ferrite is uniform, and the average size of the crystal grains is between 50mum and 100mum; C and N interstitial atoms which are solidly soluble in steel are eliminated, and AlN and Ti (C and N) grains are bulky and are evenly distributed; and the invention obtains very low yield strength (YP=140 to 180MPa), superior room-temperature plastic deformation capability (the uniform elongation rate reaches more than 50 percent), superior impact toughness, superior low-cycle fatigue resistance performance and low rate of work hardening and is especially suitable for manufacturing a shock-resistant damper with a large-sized steel structure.

Owner:BAOSHAN IRON & STEEL CO LTD

Control method of cooling process of hot-rolled low-carbon boron-containing steel wire rod after rolling

InactiveCN102632089AImprove processing efficiencyHigh yieldTemperature control deviceTemperature controlBoron containing

The invention discloses a control method of a cooling process of a hot-rolled low-carbon boron-containing steel wire rod after rolling and belongs to the technical field of rolling steel. The control method comprises the following process steps: controlling cooling with a standard Stelmor cooling line, wherein in the cooling process, a parameter is controlled as follows: the spinning temperature is controlled to 900-950 DEG C; controlling the ring space and cooling speed through controlling and regulating the roller way speeds of various radiating and cooling sections; and completely closing fans, and completely opening heat preservation covers so as to evenly cool wire rods, thus the grain size of low-carbon boron-containing steel wire rod ferrite is controlled to 10-25 mu m, the tensile strength is controlled to 300-360Mpa, the reduction of area is 70-90%, and the performance difference of the same ring is 10-25Mpa. The control method has the advantages that the control method can be adopted when the low-carbon boron-containing steel wire rod is produced in a high-speed wire rod plant, can be used for processing and producing high-end products such as an explosion line; and by using the control method, the processing and using efficiency of a user is improved, the portability of drawing and brittle failure is reduced, and the yield and production efficiency are improved.

Owner:SHOUGANG CORPORATION

High-strength steel product excelling in fatigue strength and process for producing the same

InactiveUS20060057419A1Small grain sizeImprove fatigue strengthPig casting plantsIngot casting plantsQuenchingImpurity

A high-strength and high-fatigue-strength steel having a base metal strength of 1000 MPa or more and a rotating bending fatigue strength of 550 MPa or more is provided. The steel contains 0.3-0.8 percent by mass of C, 0.01-0.9 percent by mass of Si, 0.01-2.0 percent by mass of Mn, and Fe and unavoidable impurities as the remainder. The steel has a ferrite-cementite structure having a grain size of 7 μm or less or a ferrite-cementite-pearlite structure having a grain size of 7 μm or less. A surface metal of the steel after high-frequency induction quenching has a martensite structure having a prior austenite grain size of 12 μm or less. Alternatively, a surface metal of the steel after nitriding has a fine structure having a ferrite grain size of 10 μm or less.

Owner:JFE STEEL CORP

Low-internal-stress steel for bridge structure and production method of low-internal-stress steel

ActiveCN112501511ASimple welding processGood resistance to welding coldUltimate tensile strengthInternal stress

The invention discloses low-internal-stress steel for a bridge structure and a production method of the low-internal-stress steel. A steel plate comprises the following chemical components in percentage by weight: 0.10-0.15% of C, 0.25-0.50% of Si, 1.00-1.50% of Mn, less than than or equal to 0.002% of P, less than than or equal to 0.0010% of S, less than than or equal to 0.025% of Al, 0.010-0.070% of V, 0.040-0.060% of Nb, 0.01-0.05% of Ti, less than than or equal to 0.0065% and the balance of Fe and inevitable impurities, and meanwhile, V+Nb+Ti< / = 0.18, C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+ 5B < / = 0.35, and C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15 < / = 0.50. The steel plate is the low-internal-stress steel for the bridge structure, the yield strength is larger than or equal to 400 MPa, the tensile strength is 600-700 MPa, the ductility is larger than or equal to 25%, the structure is ferrite and pearlite, ferrite and pearlite are evenly distributed, the ferrite grain size reaches the 11-14 level, the internal stress of the steel plate is low after the steel plate is flattened, and the average stress of the steel plate is smaller than 40 MPa.

Owner:武汉钢铁有限公司

High-strength steel sheet having excellent processability and paint bake hardenability, and method for producing of high-strength steel sheet

InactiveUS8911567B2Lower ratioLow strengthHot-dipping/immersion processesFurnace typesImpurityArea fraction

The high-strength steel sheet includes, by mass %: C: 0.01% to 0.10%; Si: 0.15% or less; Mn: 0.80% to 1.80%; P: 0.10% or less; S: 0.015% or less; Al: 0.10% to 0.80%; Cr: 0.01% to 1.50%; N: 0.0100% or less; and a balance consisting of iron and inevitable impurities, in which a metallic structure is composed of ferrite and a hard second phase, the area fraction of the ferrite is 80% or more, the area fraction of the hard second phase is 1% to 20%, the fraction of unrecrystallized ferrite in the ferrite is less than 10%, the ferrite grain sizes are 5 μm to 20 μm, and the fraction of the ferrite crystal grains having an aspect ratio of 1.2 or less in the entire ferrite crystal grains is 60% or more.

Owner:NIPPON STEEL CORP

Steel wire rod for aluminum-containing steel fibers and used for deep drawing, and rolling method thereof

InactiveCN111485175AImprove flowUniform tissueHeat treatment process controlWire rodSmelting process

The invention belongs to the field of metal materials, and specifically discloses a steel wire rod for aluminum-containing steel fibers and used for deep drawing, and a rolling method thereof. A continuous casting billet comprising specific components is obtained according to an aluminum-containing pure steel smelting process, reasonable heating temperature and heating time of the continuous casting billet are controlled in a heating furnace, and the process parameters of the wire rod in a rolling process and the cooling process parameters of the wire rod on a Stelmor cooling line are optimized, so that the produced wire rod for the steel fibers is high in universality, uniform in structure, small in crystal grain, excellent in mechanical property, and good in plasticity index, and an ironoxide sheet has a thickness of 10-20[mu]m, and is suitable for mechanical shelling and low in wire fracture; and the wire rod produced by the method has tensile strength Rm of 350-390MPa, percentageelongation A of not less than 40% after fracture, area reduction Z of not less than 80%, and ferrite grain size of 7-8, the wire fracture in a drawing process of a user can be controlled to be less than 0.25 times per ton, and the technical requirement of a wire rod for high-grade steel fibers is completely met.

Owner:ZENITH STEEL GROUP CORP +1

Hot-dip galvanized steel sheet with yield strength of 550MPa and production method thereof

ActiveCN111647821AHigh strengthHigh extensionHot-dipping/immersion processesMetallic materialsUltimate tensile strength

The invention discloses a hot-dip galvanized steel sheet with yield strength of 550MPa and a production method thereof, and belongs to the technical field of metal materials. The hot-dip galvanized steel sheet comprises the following chemical components in percentage by weight: 0.006% to 0.010% of C; less than or equal to 0.01% of Si; 0.10 to 0.30% of Mn; less than or equal to 0.015% of P; less than or equal to 0.040% of S; 0.005% to 0.070% of Als; 0.001% to 0.080% of Ti; 0.001% to 0.060% of Nb; less than or equal to 0.0030% of N; less than or equal to 0.0020% of O; 0.030 to 0.060% of Cu; 0.010 to 0.040% of Cr; and the reset is iron and other impurities. By controlling the content of C element in the steel sheet, adding Mn, Cr, Al, Cu and other elements, and controlling the contents of theadded elements, the strength of steel is improved. Ti and Nb are also added to the steel and the contents of the two elements satisfy the equation that Ti+Nb is greater than or equal to 0.050% but less than or equal to 0.120%. The two elements can not only increase the strength, but also make the toughness better, which is the most economical and most effective method to improve the performance of the steel. Through the compounding of the two elements, the ferrite grain size can be further refined, and the strength and toughness of the steel sheet can be improved at the same time, so that thestrength and toughness of the steel can be well matched, and the requirements of yield strength and elongation are satisfied at the same time.

Owner:MAANSHAN IRON & STEEL CO LTD

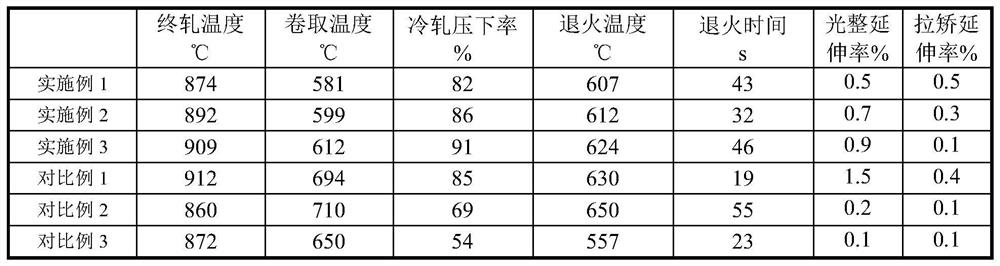

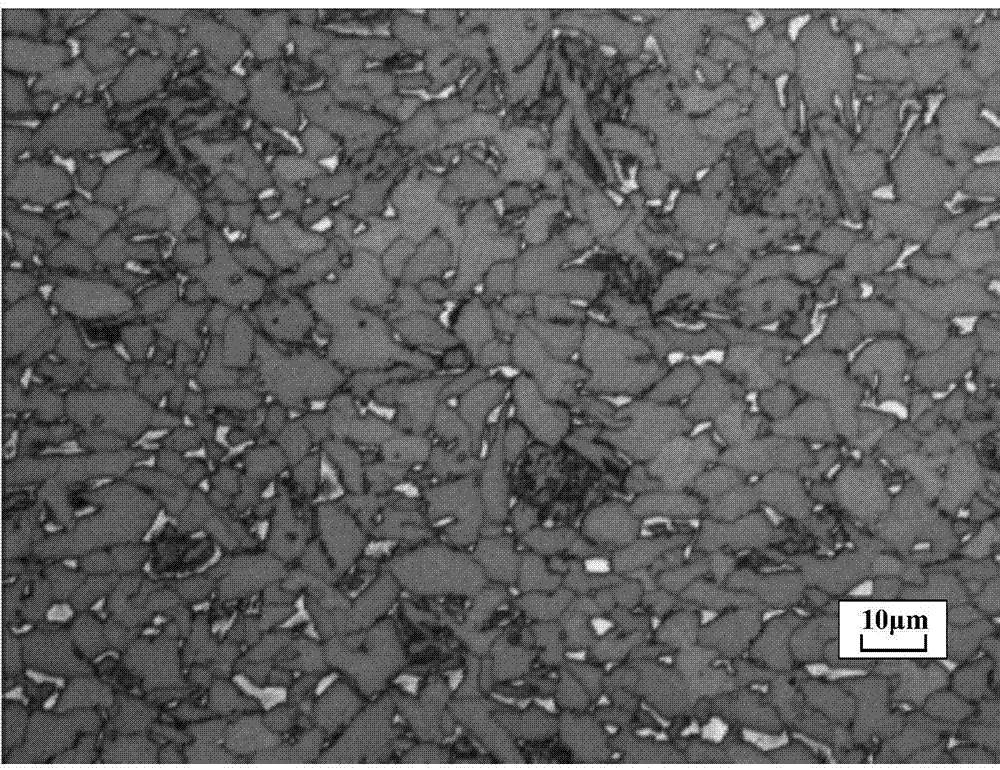

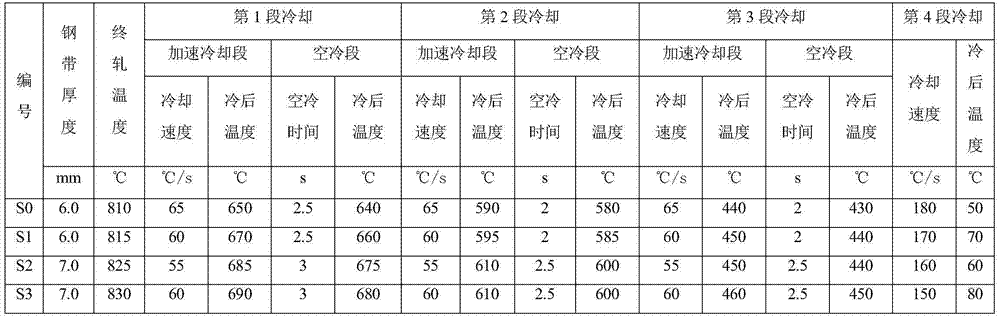

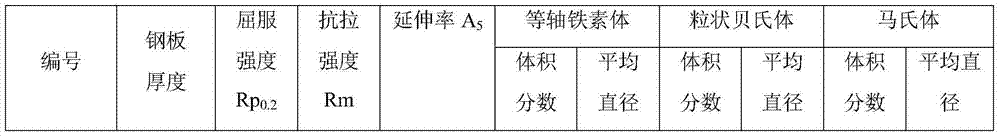

Hot rolled steel for rims, with tensile strength of 560-590MPa and preparation method thereof

The invention discloses hot rolled steel for rims, with tensile strength of 560-590MPa and a preparation method thereof, belonging to the technical field of rolled steel. The hot rolled steel and the preparation method have the technical effects that a process of subsection cooling after hot rolling is adopted, the sizes and volume fractions of ferrite, bainite and martensite in the structure are accurately controlled, the tensile strength of the steel is improved via bainite and martensite phases in the structure and the residual stress of a steel strip is reduced and the elongation of the steel is improved by controlling the sizes and volume fractions of ferrite grains and adopting multistage air cooling; the hot rolled steel for rims has tensile strength of 560-590MPa, elongation (A5) of 34-36% and thickness specification of 6.0-7.0mm and is suitable for manufacturing rims of heavy duty automobiles.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Steel sheet for can having excellent surface roughening resistance and manufacturing method thereof

ActiveUS20120255656A1Excellent deep drawing performanceExcellent ironing workabilityFurnace typesHeat treatment furnacesReduction rateSurface layer

Provided is a steel sheet having excellent surface roughening resistance and a manufacturing method thereof. The steel sheet for cans contains 0.0040 to 0.01% C and 0.02 to 0.12% Nb. An average ferrite grain size in a cross section in the rolling direction in a region ranging from a surface layer of the steel sheet to a position ¼ of a sheet thickness away from the surface layer of the steel sheet is set to 7 μm or more and 10 μm or less, and the average ferrite grain size in a cross section in the rolling direction in a region ranging from the position ¼ of a sheet thickness away from the surface layer of the steel sheet to a sheet thickness center portion of the steel sheet is set to 15 μm or less. The average ferrite grain size in the cross section in the rolling direction in the region ranging from the surface layer of the steel sheet to the position ¼ of a sheet thickness away from the surface layer of the steel sheet is set smaller than the average ferrite grain size in the cross section in the rolling direction in a region ranging from the position ¼ sheet thickness away from the surface layer of the steel sheet to the sheet thickness center portion of the steel sheet. The steel sheet for cans is obtained by cooling a steel sheet at 50 to 100° C. / s within 1 second after final finish rolling, is wound at 500° C. to 600° C., is subsequently subjected to pickling treatment, is subjected to cold rolling at a reduction rate of 90% or more, and is subjected to continuous annealing at a temperature of equal to more than a recrystallization temperature to 800° C. or below.

Owner:JFE STEEL CORP

YP100MPa steel plate and manufacture method thereof

ActiveCN102168225AImprove performanceSolve the embrittlement problemTemperature control deviceMetal rolling arrangementsNiobiumLow-cycle fatigue

The invention relates to a YP100MPa steel plate and a manufacture method thereof. According to the method, a rolling process is optimized by adopting the metallurgy technical approaches of using an extreme low C-extreme low Si-extreme low Mn-high Als-low N-(Nb+Ti) microalloying-B treatment component system, properly improving the content of acid insoluble Als, microalloying (Ti+Nb), controlling Ti / Nb to be of between 0.50 and 1.00, controlling Ti / N to be larger than or equal to 8.0, Als / N to be larger than or equal to 10, (0.13Nb+0.25Ti) to be larger than or equal to 1.05C and (P+S) / B to be less than or equal to 95, and the like; the microscopic structure of the finished steel plate is single-phase ferrite, the grain size of the ferrite is uniform, and the average grain size is between 50microns and 100 microns; solid soluble C and N interstitial atoms in steel are eliminated, titanium / niobium carbonitride particles and AlN particles are thick and are uniformly distributed, and the ferrite grain boundary is strengthened by microB treatment; and by means of the manufacture method, the YP100MPA obtains extreme low yield strength (YP:80-120MPa), favorable room temperature plastic deformation capability (uniform elongation reaches more than 55 percent), low cycle fatigue resistance and low processing hardening rate and is particularly suitable for being used as a quake-proof damper of a large steel structure.

Owner:BAOSHAN IRON & STEEL CO LTD

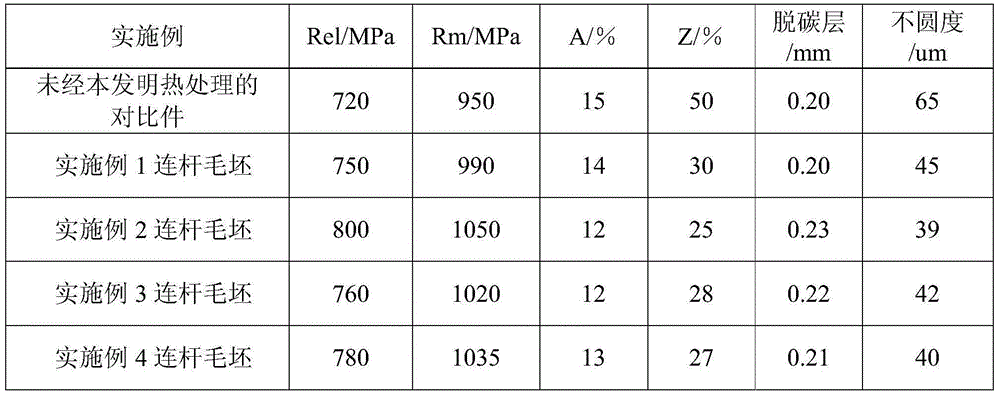

Heat treatment method for improving medium-carbon non-quenched and tempered steel connecting rod cracking performance

InactiveCN104988295AImprove breaking performanceHigh tensile strengthFurnace typesHeat treatment furnacesComing outSlow cooling

The invention provides a heat treatment method for improving medium-carbon non-quenched and tempered steel connecting rod cracking performance, and belongs to the field of heat treatment of metals. The method is the heat treatment method of a medium-carbon non-quenched and tempered steel connecting rod of which the components are set, a medium-carbon non-quenched and tempered steel connecting rod blank of which the components are set is placed in a vacuum induction heating furnace, the vacuum degree of the heating furnace ranges from 0.1 Pa to 1.0 Pa, the heating temperature in the furnace ranges from 1150 DEG C to 1200 DEG C, the heat preservation time ranges from 20 min to 40 min, microalloy elements in the steel are fully dissolved in austenite, and it is guaranteed that a low oxidizing or non-oxidizing decarburizing reaction occurs on the surface of the connecting rod; the cooling speed of the medium-carbon non-quenched and tempered steel connecting rod blank come out of the furnace is controlled to be 8-12 DGE C / second through a wind-cooling device, after the medium-carbon non-quenched and tempered steel connecting rod blank is cooled to be at 300-400 DEG C, the medium-carbon non-quenched and tempered steel connecting rod blank is naturally cooled to be at the room temperature in a slow cooling device, the microalloy elements dissolved in the austenite are separated out in a dispersion mode, and meanwhile the ferrite grain size and the content of the pearlite are increased; therefore, tensile strength and cracking performance of the medium-carbon non-quenched and tempered steel connecting rod are improved, and standard requirements of an automobile engine cracking connecting rod are met.

Owner:武钢集团有限公司

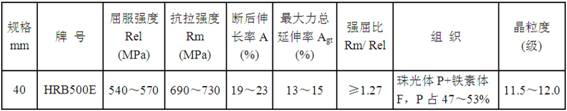

Production method of HRB500E fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar

InactiveCN112779460ACorrosion resistantImprove corrosion resistanceMetal rolling arrangementsAlloyShock resistance

The invention discloses a production method of an HRB500E fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar. The method comprises the following steps of converter smelting, deoxidizing alloying, LF refining, square billet continuous casting, steel billet heating, rolling and cooling in sequence to produce the fine-grain high-strength anti-seismic anti-corrosion reinforcing steel bar which is stable in quality, excellent in plasticity and toughness, greater than 1.27 in yield ratio and 11.5-12.0 in ferrite grain size. The Cr, V and Ni composite microalloying process is adopted, converter smelting and LF external refining are matched, the rolling technology for controlling the inner diameter and negative deviation of the reinforcing steel bar at low temperature is adopted, finishing is combined, formation and precipitation of a fine and dispersed microalloy carbon (nitrogen) compound second phase are promoted, the steel strength is improved, meanwhile, the plasticity and toughness are remarkably improved, mechanical connection is further facilitated, reasonable matching of high strength, obdurability, low strain timeliness, shock resistance and corrosion resistance of the reinforcing steel bar is achieved, and the method can be applied to the fields of main stream hydropower station flood discharge tunnel engineering, expressway road and bridge engineering and the like.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com