Heat treatment method for improving medium-carbon non-quenched and tempered steel connecting rod cracking performance

A heat treatment method and technology for non-quenched and tempered steel, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as the inability of microalloying elements to play an effective role, achieve significant technical effects, reduce decarburization layers, and improve connecting rod expansion. The effect of breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

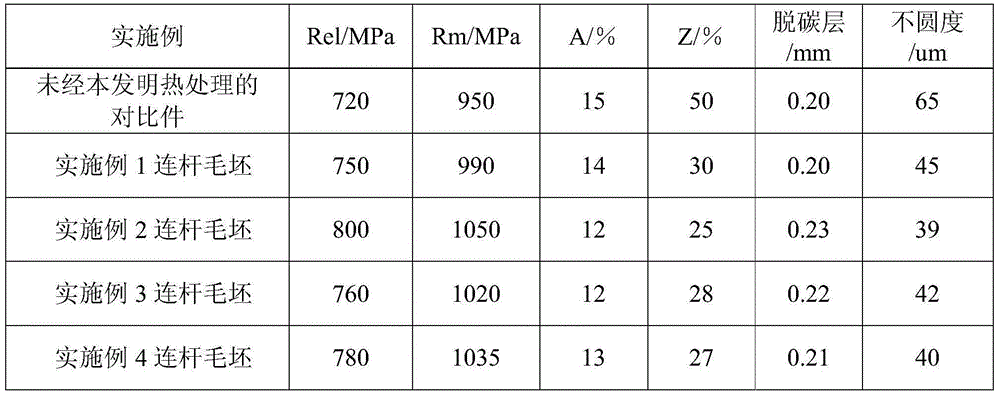

Examples

Embodiment 1

[0018] In terms of mass percentage, the composition is C: 0.34%, Si: 0.55%, Mn: 1.25%, V: 0.25%, N: 0.0140%, and the balance is iron and unavoidable inclusions of medium-carbon non-quenched and tempered steel. The rod blank is placed in a vacuum induction heating furnace for vacuum heat treatment, and the vacuum degree of the vacuum induction heat treatment furnace is controlled to be 0.1 Pa; the heating temperature is controlled at 1150 ° C, and the holding time is 20 minutes; then the cooling step is controlled: the vacuum induction furnace The connecting rod blank is placed on a chain cooling device for air cooling, and the cooling rate is controlled at 8°C / s; after cooling to 300°C, the connecting rod blank is collected in a box cooling device and slowly cooled to room temperature.

Embodiment 2

[0020] In terms of mass percentage, the composition is C: 0.38%, Si: 0.65%, Mn: 1.35%, V: 0.35%, N: 0.0180%, and the balance is iron and unavoidable inclusions of medium carbon non-quenched and tempered steel. The rod blank is placed in a vacuum induction heating furnace for vacuum heat treatment, and the vacuum degree of the vacuum induction heat treatment furnace is controlled to be 0.1 Pa; the heating temperature is controlled at 1200°C, and the holding time is 40min; then the cooling step is controlled: The connecting rod blank is placed on a chain cooling device for air cooling, and the cooling rate is controlled at 9°C / s; after cooling to 320°C, the connecting rod blank is collected in a box cooling device and slowly cooled to room temperature.

Embodiment 3

[0022]In terms of mass percentage, the composition is C: 0.36%, Si: 0.60%, Mn: 1.30%, V: 0.30%, N: 0.0160%, and the balance is iron and unavoidable inclusions of medium-carbon non-quenched and tempered steel. The rod blank is placed in a vacuum induction heating furnace for vacuum heat treatment, and the vacuum degree of the vacuum induction heat treatment furnace is controlled to 0.5 Pa; the heating temperature is controlled at 1180 ° C, and the holding time is 30 minutes; then the cooling step is controlled: the vacuum induction furnace The connecting rod blank is placed on a chain cooling device for air cooling, and the cooling rate is controlled at 10°C / s; after cooling to 350°C, the connecting rod blank is collected in a box cooling device and slowly cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com