Patents

Literature

39results about How to "Good temperature resistance and shear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-molecular-weight polymer fracturing liquid

ActiveCN102634329AFully consider the rheologyFully consider compatibilityDrilling compositionAcetic acidPhysical chemistry

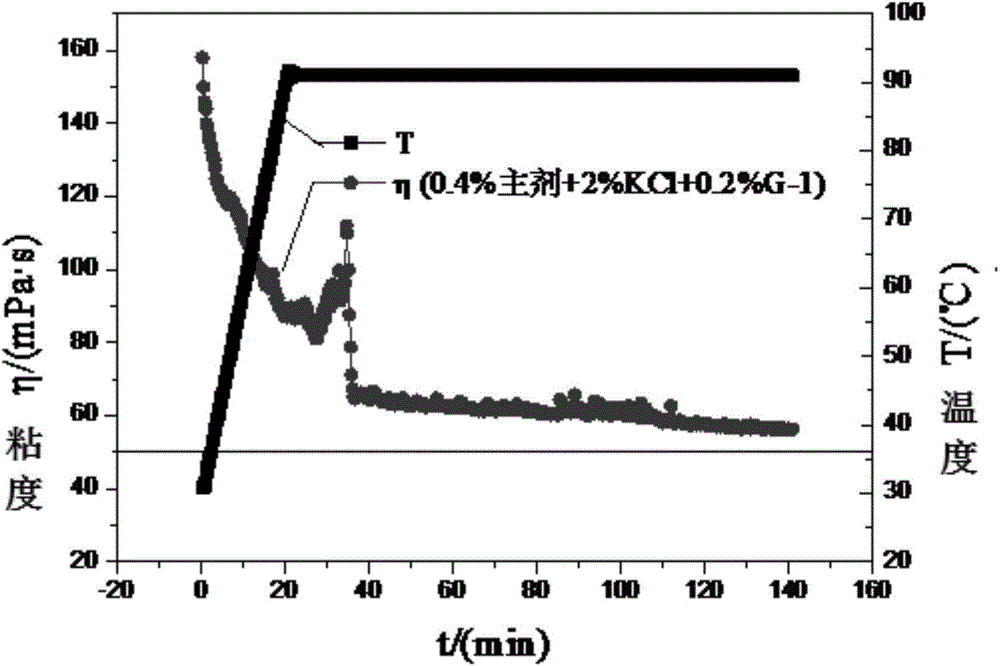

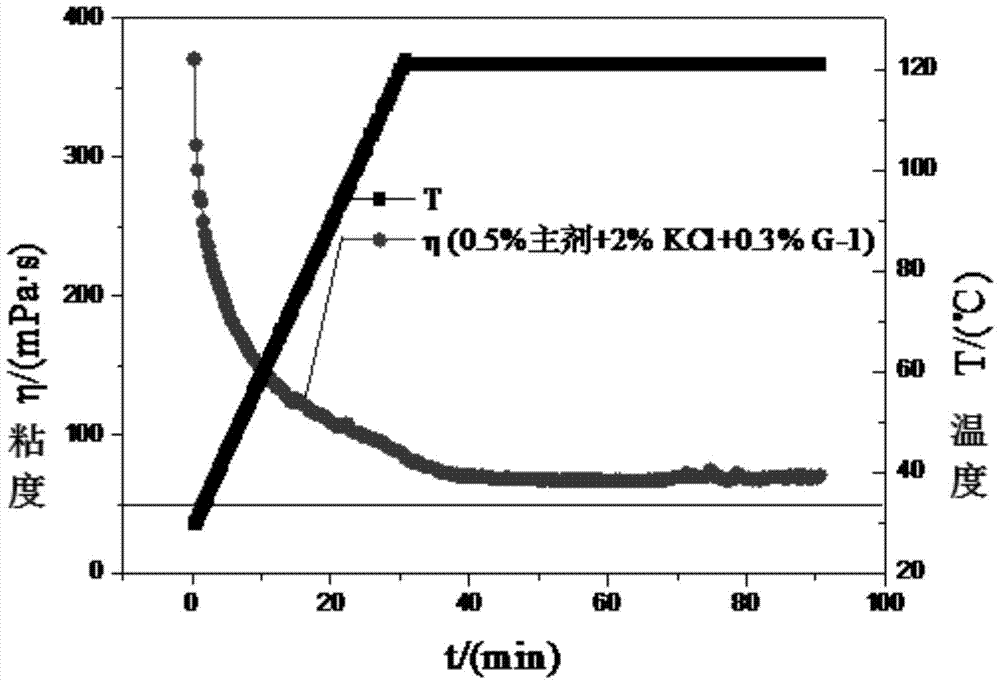

Low-molecular-weight polymer fracturing liquid is mainly applied to fracturing modification of low-infiltration alkali-sensitive reservoirs and water injection wells and consists of, in weight percentage, 0.25-0.6% of XT-3 low-molecular-weight polymer densifier, 0.2-0.6% of crosslinking agent, 0.5-2% of potassium chloride, 0.02-0.08% of crosslinking modifier, 0.2-0.5% of cleanup additive, 0.0001-0.15% of ammonium persulfate and the balance of water. The low-molecular-weight polymer fracturing liquid is prepared by adding clean water into a liquid preparation tank firstly, adding acetic acid during stirring, then adding the XT-3 low-molecular-weight polymer densifier, the potassium chloride and the cleanup additive after uniformly stirring, stirring more than 10 minutes after materials are added until density or viscosity of upper liquid and lower liquid in the liquid preparation tank are uniform, and finally, adding the crosslinking agent and adhesive breaker according to requirements during fracturing. The low-molecular-weight polymer fracturing liquid has the advantages that residues of the fracturing liquid and alkali-sensitive damages of the reservoirs are solved, the fracturing liquid is prepared and used conveniently, temperature resistance and shearing resistance are fine, and the requirements of fracturing modification of low infiltration and alkali-sensitive reservoirs can be met.

Owner:PETROCHINA CO LTD

Fracturing fluid capable of resisting high salinity water quality

ActiveCN102757778AWide range of crosslinkingReduce dosageDrilling compositionCross-linkWater quality

The invention relates to a fracturing fluid capable of resisting high salinity water quality. The fracturing fluid is characterized by being composed of a base fluid and a cross-linking fluid which are fully mixed in proportion. The base fluid contains a chelate cosolvent and a chelate stabilizer, wherein the chelate cosolvent can restrain high salinity of water quality and promote swelling of guanidine gum. The base fluid comprises 98.2-98.65 parts of high salinity surface water, 0.1-0.15 part of the chelate cosolvent,0.3-0.4 part of thickener, 0.1-0.15 part of bactericide, 0.3-0.5 part of clay stabilizer, 0.5 part of demulsifying cleanup agent and 0.05-0.1 part of the chelate stabilizer; the cross-linking fluid comprises 50 parts of water, 50 parts of organic cross-linking agents and 0.35 part of gel breaker; and the fracturing fluid comprises 99.2-99.5 parts of the base fluid and 0.5-0.8 part of the cross-linking fluid. By aid of the fracturing fluid, water resources can be saved effectively, and the success rate for fracturing construction can be improved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

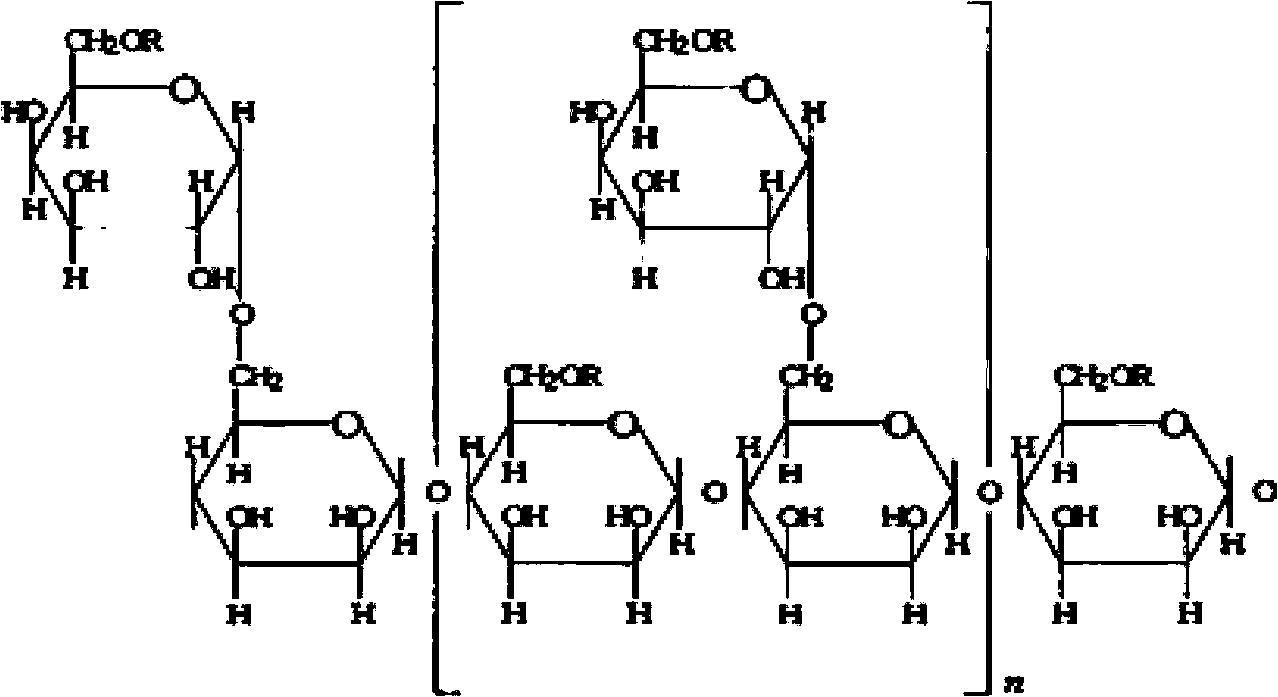

Carboxymethyl hydroxypropyl guanidine gum fracturing fluid

ActiveCN102634328AFully consider the rheologyFully consider compatibilityDrilling compositionCross-linkPreservative

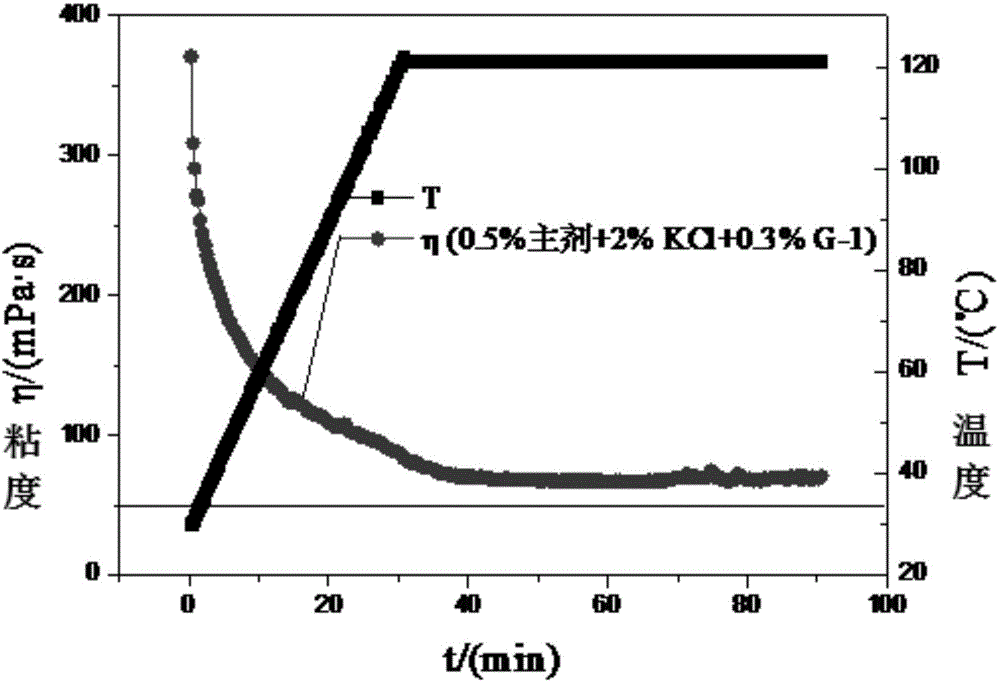

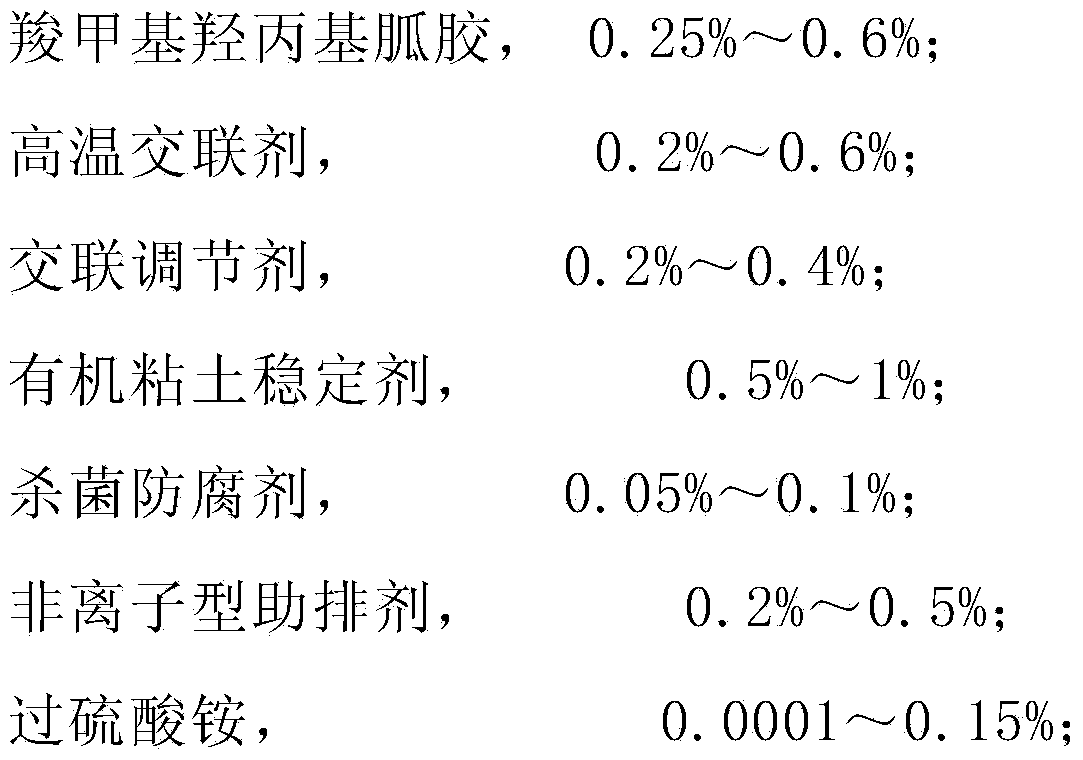

The invention relates to a carboxymethyl hydroxypropyl guanidine gum fracturing fluid which is used for fracturing reformation of a high-temperature and low-permeability reservoir. The carboxymethyl hydroxypropyl guanidine gum fracturing fluid comprises the components by weight percent: 0.25-0.6% of carboxymethyl hydroxypropyl guanidine gum, 0.2-0.6% of cross-linking agent, 0.2-0.4% of cross-linking regulator, 0.5-1% of clay stabilizer, 0.05-0.1% of bactericidal preservative, 0.2-0.5% of discharge aiding agent, 0.0001-0.15% of ammonium persulfate and the balance of water. A preparation method of the fracturing fluid comprises the steps of: adding clear water into a large tank, adding the carboxymethyl hydroxypropyl guanidine gum into the large tank under the stirring condition, and then sequentially adding the clay stabilizer, the discharge aiding agent, the cross-linking regulator and the bactericidal preservative into the large tank; and stirring for 10 minutes until the concentration or the viscosity of liquid at the upper part and the lower part of the large tank is uniform and consistent. During fracturing construction, the cross-linking agent and gel breaker are added into the large tank according to the requirement. The carboxymethyl hydroxypropyl guanidine gum fracturing fluid has the effects of being suitable for the reservoir temperature of 80-200DEG C, reducing the residue of the fracturing fluid and the construction friction, and meeting the demand of fracturing reformation of the high-temperature and low-permeability reservoir.

Owner:PETROCHINA CO LTD

High-concentration water-in-oil emulsion-state associating polymer fracturing fluid and preparation method thereof

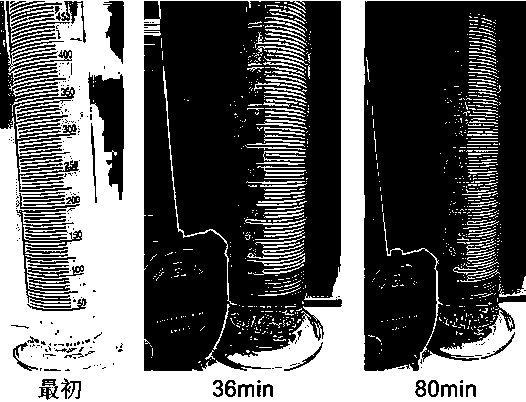

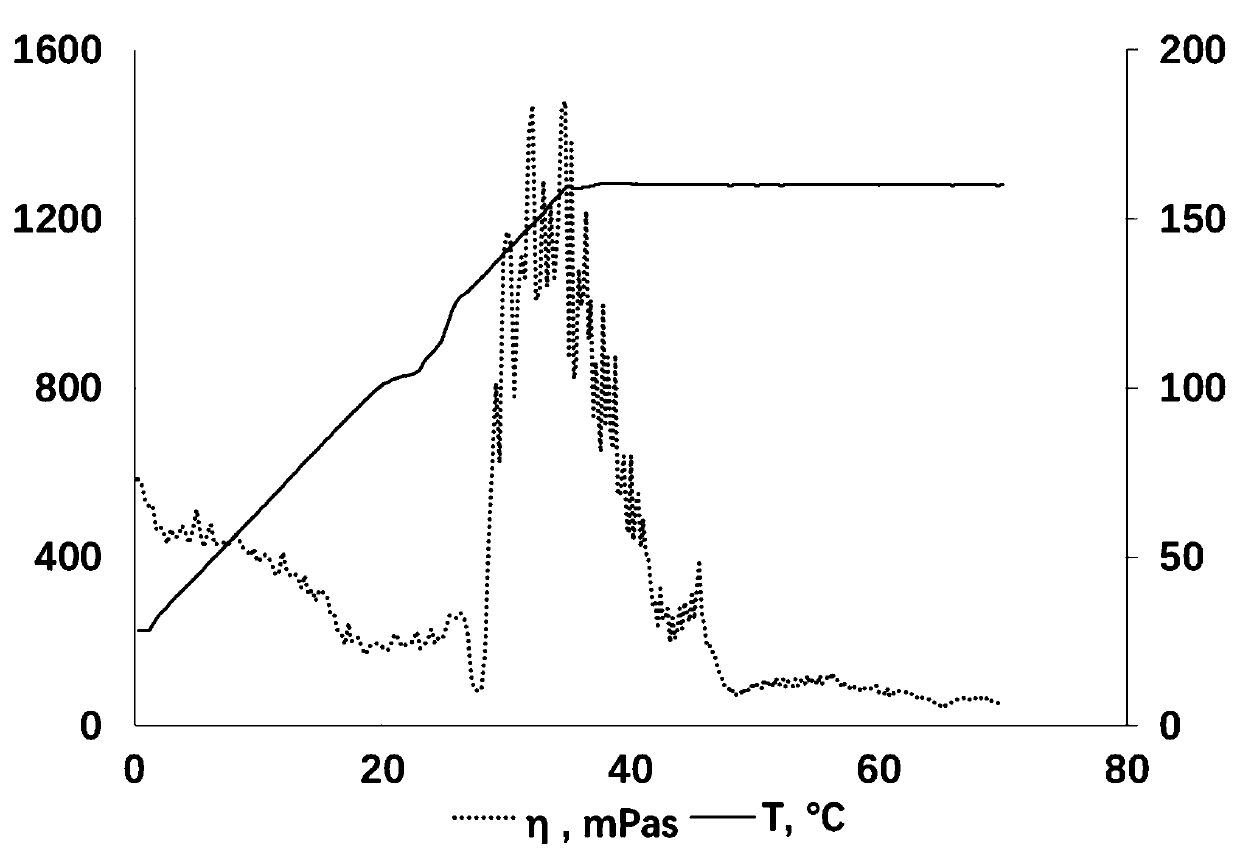

ActiveCN104449649AImprove rheologyEnhanced pumpabilityDrilling compositionHigh concentrationPolymer science

The invention relates to a high-concentration water-in-oil emulsion-state associating polymer fracturing fluid and a preparation method thereof. The fracturing fluid comprises the following components in mass fraction: 38.7-45.18% of water, 25.30-28.67% of diesel oil, 25-30% of a fracturing fluid thickening agent and 2.53-2.88% of an emulsifier. The high-concentration water-in-oil emulsion-state associating polymer fracturing fluid disclosed by the invention has a stable time greater than 15 days at 0 DEG C-40 DEG C and has the characteristics that the fracturing fluid is easy to prepare, dissolve and disperse and the like, and rapid mixing, construction and fracturing on the spot can be achieved.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

High-temperature-resistant ground cross-linked acid liquor and preparation method thereof

InactiveCN104073237AGood temperature resistance and shear resistanceLow toxicityDrilling compositionCross-linkAcid fracturing

The invention provides high-temperature-resistant ground cross-linked acid liquor. The acid liquor comprises the following components in percentage by mass: 15-28 weight percent of acid, 0.4-1.0 weight percent of polyacrylamide polymer, 0.1-0.5 weight percent of aldehyde cross-linking agent, 0.05-0.25 weight percent of phenol cross-linking agent, 0.05-0.02 weight percent of crosslinking promoter, 0.5-2.0 weight percent of corrosion inhibitor, 0.5-2.0 weight percent of ferric ion stabilizer, 0.01-0.1 weight percent of ammonium persulfate and the balance of water, wherein the acid is calculated based on pure substances. The invention also provides a method for preparing the high-temperature-resistant ground cross-linked acid liquor. Industrial raw materials which are low in toxicity and low in price are taken as cross-linking agents and cross-linking promoter, the toxicity of the cross-linking agents can be reduced, the process for preparing the high-temperature-resistant ground cross-linked acid liquor is simple, further synthesis is not needed, the field operability is high, the cost is effectively reduced, and application of acid fracturing is further widened.

Owner:PETROCHINA CO LTD

Super guanidine gum fracturing fluid

ActiveCN102676146AFully consider compatibilityReduce frictionDrilling compositionFracturing fluidPotassium

The invention discloses super a guanidine gum fracturing fluid, which is used for the fracturing modification of a high-temperature and low-permeability water-sensitive storage layer. The super guanidine gum fracturing fluid comprises the following components in percentage by weight: 0.25-0.6% of super guanidine gum, 0.5-2% of potassium chloride, 0.5-1.0% of organic clay stabilizing agent, 0.05-0.1% of JA-1 sterilizing preservative, 0.2-0.5% of non-ionic discharge aiding agent, 0.1-0.2% of crosslinking regulator, 0.0001-0.15% of ammonium persulfate, 0.2-0.6% of organic boron and zirconium compound crosslinking agent and the balance of water. The super guanidine gum is added into clear water ,followed by circulating for 15 minutes at a big displacement; and then, the potassium chloride, the organic clay stabilizing agent, the discharge aiding agent, sodium thiosulfate, triethanolamine, the crosslinking regulator and sterilizing preservative are successively added to cause the concentration or the viscosity of liquid to be consistent. During the fracturing construction, the crosslinking agent and the ammonium persulfate are added. The super guanidine gum fracturing fluid has the effects that a super guanidine gum fracturing fluid series formula suitable for the temperature of the reservoir stratum is formed, the residues of the fracturing fluid are reduced, and the modification requirement on the high-temperature and low-permeability water-sensitive storage layer can be satisfied.

Owner:PETROCHINA CO LTD

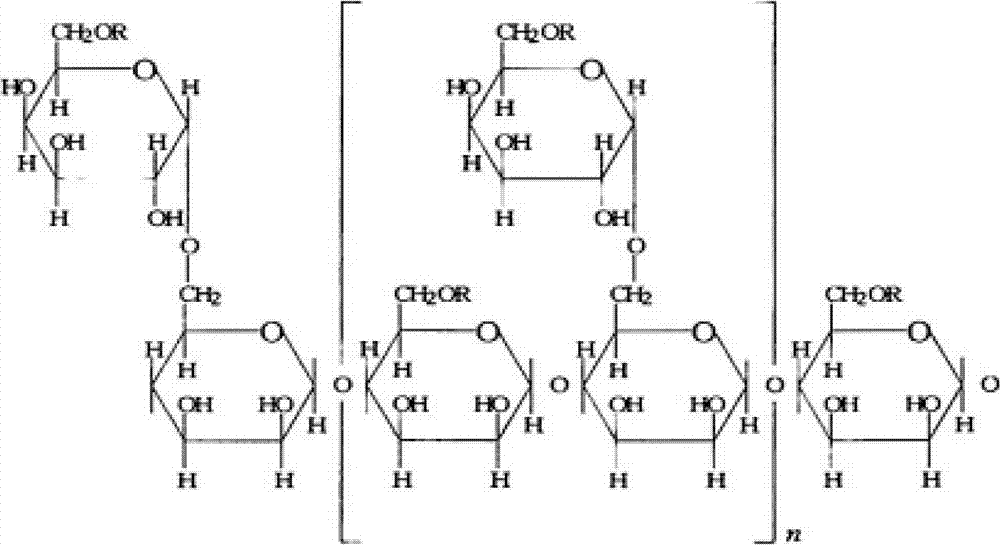

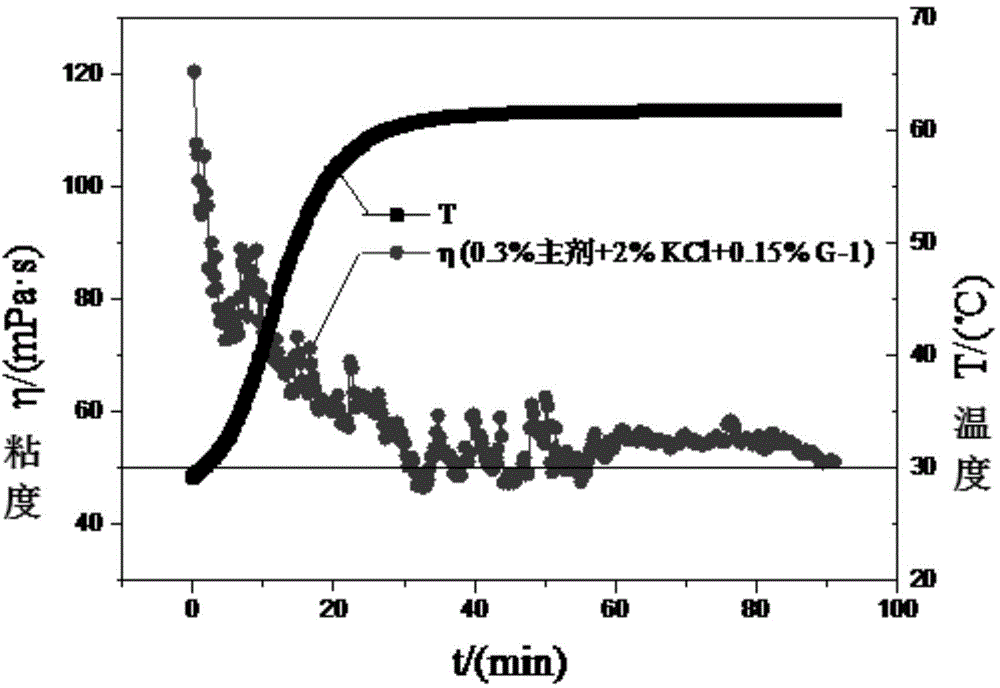

Synthesis of thickening agent for methanol-based fracturing fluid

InactiveCN102492414AFast dissolutionGood temperature resistance and shear resistanceDrilling compositionSolubilityWater based

At present, more than 90 percent of fracturing fluids used in the fracturing improvement of oil and gas fields are water-based fracturing fluids with water as dispersion medium, and as a result, for gas reservoirs with low formation pressure, low permeability and strong water-locking characteristic, particularly highly water-sensitive gas reservoirs, the difficulty of fluid flowback can be easily caused because the formation pressure coefficient is greatly smaller than the pressure coefficient of water in a shaft; and formation pores can be easily blocked due to the water-locking effect of formations to cause the failure of fracturing improvement. Because low-molecular weight alcohol, particularly methanol, has a lot of excellent physical and chemical properties, the low-molecular weight alcohol can be used in the improvement of low-pressure, water-sensitive formations for stimulation, and compared with conventional water-based fracturing fluids, methanol-based fracturing fluid has the characteristics of low surface tension, good water-solubility, low freezing point, high steam, high compatibility with formation rocks and the like. The invention relates to a thickening agent for methanol-based fracturing fluid, which is used in the fracturing stimulation process of natural gas wells or oil wells; because methanol and water can be formed into any proportions of mixtures, the methanol-based fracturing fluid can absorb the water constrained by water-locking formations to the maximum limit after entering the formations, and moreover, as the fracturing fluid is drained out of the ground, the water locking of the formations is released, which is favorable for the flowback of the fluid.

Owner:北京希涛技术开发有限公司

Low-damage nitrogen foam fracturing liquid for weak water-bearing coal-bed gas well

ActiveCN108130067AGood temperature resistance and shear resistanceStrong ability to suspend sandDrilling compositionGas phaseDesorption

The invention provides a low-damage nitrogen foam fracturing liquid for a weak water-bearing coal-bed gas well and a preparation method thereof. The gas phase of the foam fracturing liquid is nitrogen, the liquid phase of the foam fracturing liquid is an additive solution, and the foam mass is 60 to 80 percent. The foam fracturing liquid is prepared from the following components in percentage by mass: 0.5 to 1.5 percent of a foaming agent, 0.3 to 0.7 percent of a foam stabilizing agent, 0.2 to 0.6 percent of a clay stabilizing agent, 0.1 to 1.0 percent of an auxiliary desorption agent and 96.2to 98.9 percent of water. The foaming agent is mainly an anionic surfactant; the foam stabilizing agent is mainly an amphoteric surfactant; the clay stabilizing agent is mainly an organic solvent; the auxiliary desorption agent is mainly a fluorocarbon surfactant. The foam fracturing liquid does not contain a macromolecular additive, has good temperature resistance and shearing resistance, high sand suspending capacity, good coal powder dispersing performance and negative damage to a coal rock core, and has a great significance to efficient development of weak water-bearing coal-bed gas and reservoir protection.

Owner:SOUTHWEST PETROLEUM UNIV

Anhydrous fracturing fluid suitable for shale gas and preparation method of anhydrous fracturing fluid

The invention belongs to the technical field of petrochemical engineering, and particularly relates to an anhydrous fracturing fluid suitable for shale gas and a preparation method of the anhydrous fracturing fluid. The anhydrous fracturing fluid suitable for shale gas is prepared from the following raw materials in percentage by mass: 0.5-2% of a crosslinking agent, 2-6% of a complex iron activator and the balance of a low carbon hydrocarbon; in a pressure vessel with a pressure of 0.8-3.0 MPa, the crosslinking agent is added into the low carbon hydrocarbon to be uniformly mixed, the complex iron activator is added to be stirred for 2-5 min, so that the anhydrous fracturing fluid suitable for shale gas is obtained; and the low carbon hydrocarbon is one or a mixture of more of propane, butane, n-hexane, n-heptane and kerosene. The anhydrous fracturing fluid suitable for shale gas easily flows back, has a good sand-carrying property, does not harm reservoirs, and can satisfy the needs of fracturing reconstruction of shale oil and gas and strong water-sensitive compact oil and gas reservoirs. A synthetic method is simple, and the content of an effective component dialkyl phosphate in a product is high, thereby facilitating the industrialization production of the anhydrous fracturing fluid.

Owner:SOUTHWEST PETROLEUM UNIV

High density fracturing fluid and preparation method thereof

InactiveCN103232840AReduce frictionReduced shear resistanceDrilling compositionPolymer scienceHigh density

The invention discloses a high density fracturing fluid and further provides a method for preparing the fracturing fluid. To solve the technical problem, the following technical scheme is adopted, wherein a formula of the high density fracturing fluid comprises, by weight, 0.4-0.5% of a thickening agent, 25-47% of a weighting agent, 0.2-0.4% of a multi-effect additive, 0.4-0.6% of a cleanup additive, 0.4-0.6% of a cross-linking agent, 0.001-0.1% of a gel breaker, and the balance of water.

Owner:HEBEI HUABEI PETROLEUM TIANCHENG IND GRP CO LTD

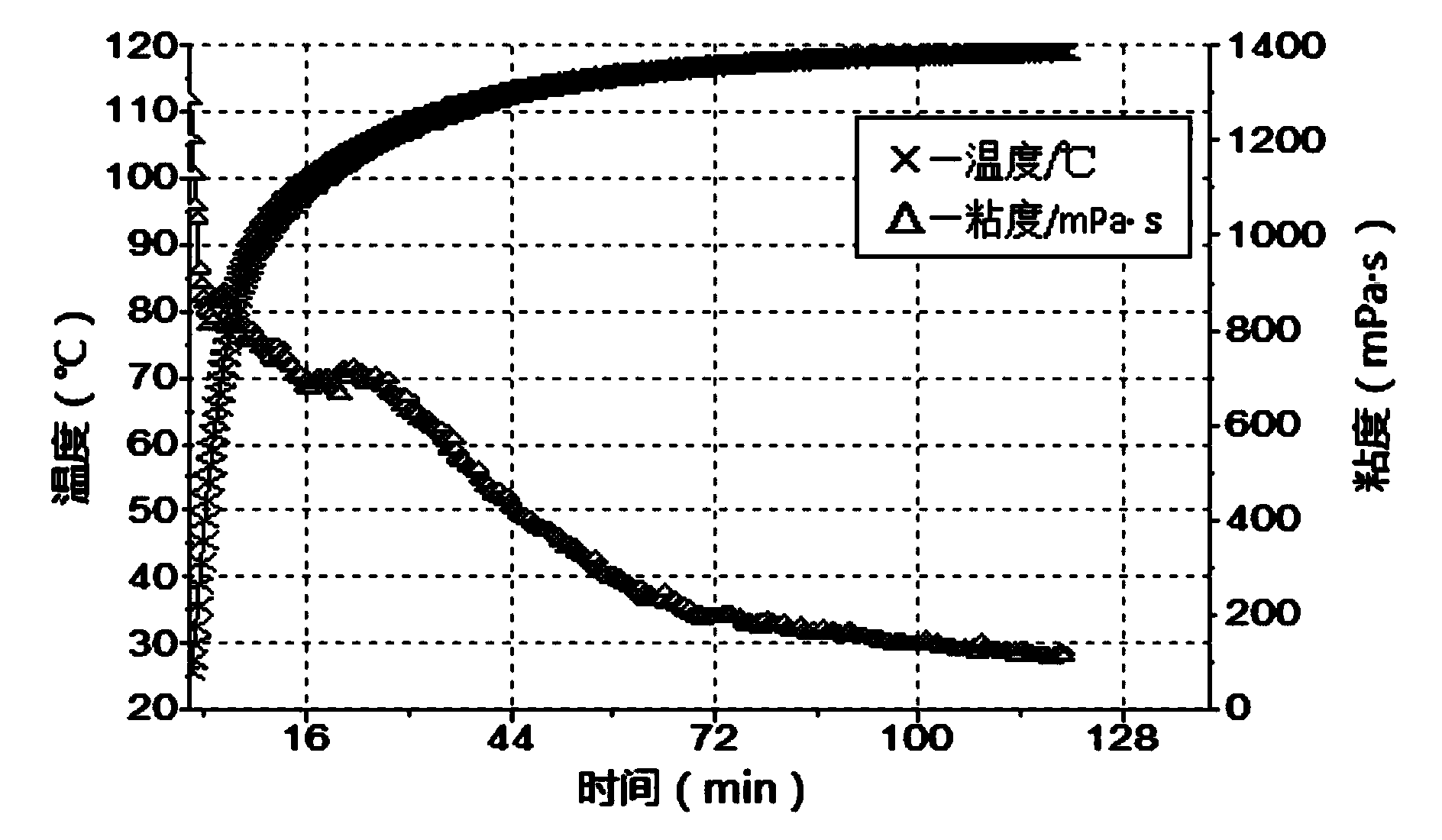

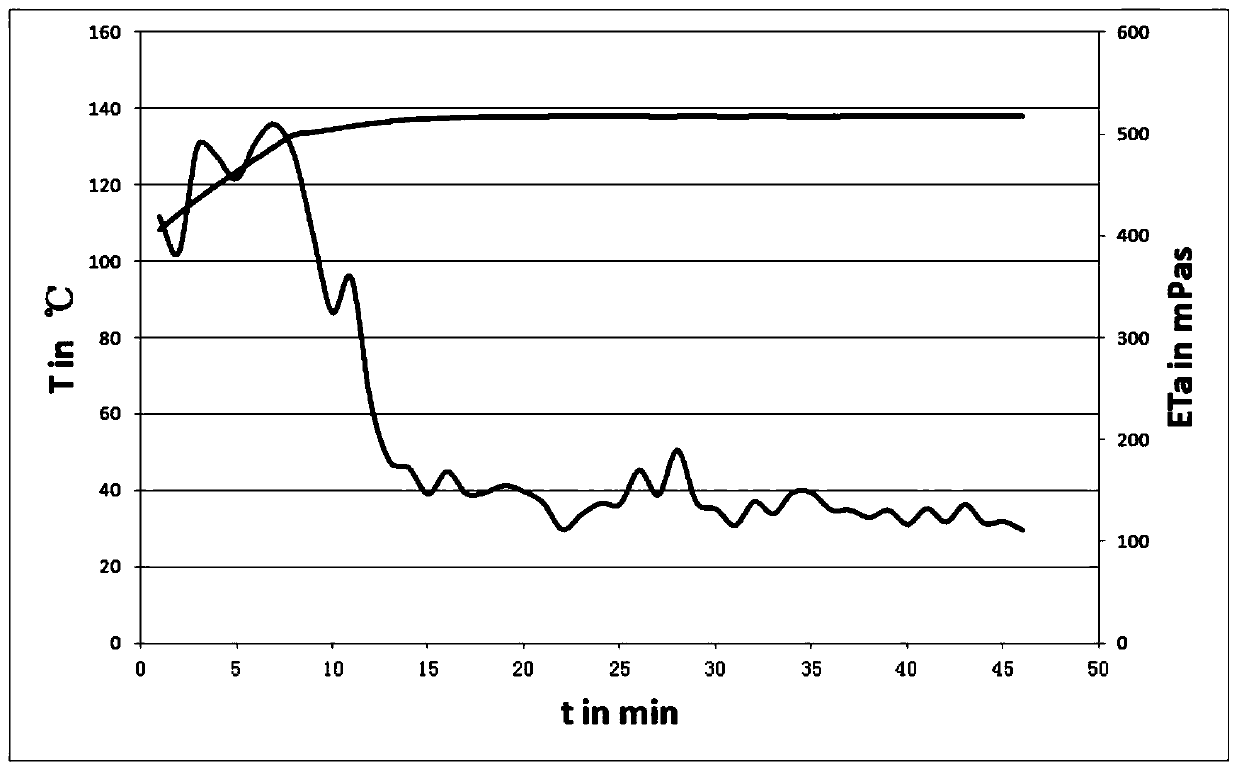

High-temperature guanidine gum cross-linking agent and preparation method thereof

InactiveCN106590615AGood temperature resistance and shear resistanceFacilitate cross-linkingDrilling compositionCross-linkPhysical chemistry

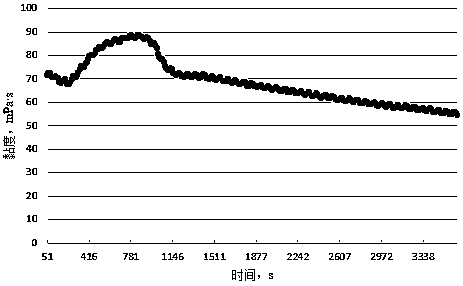

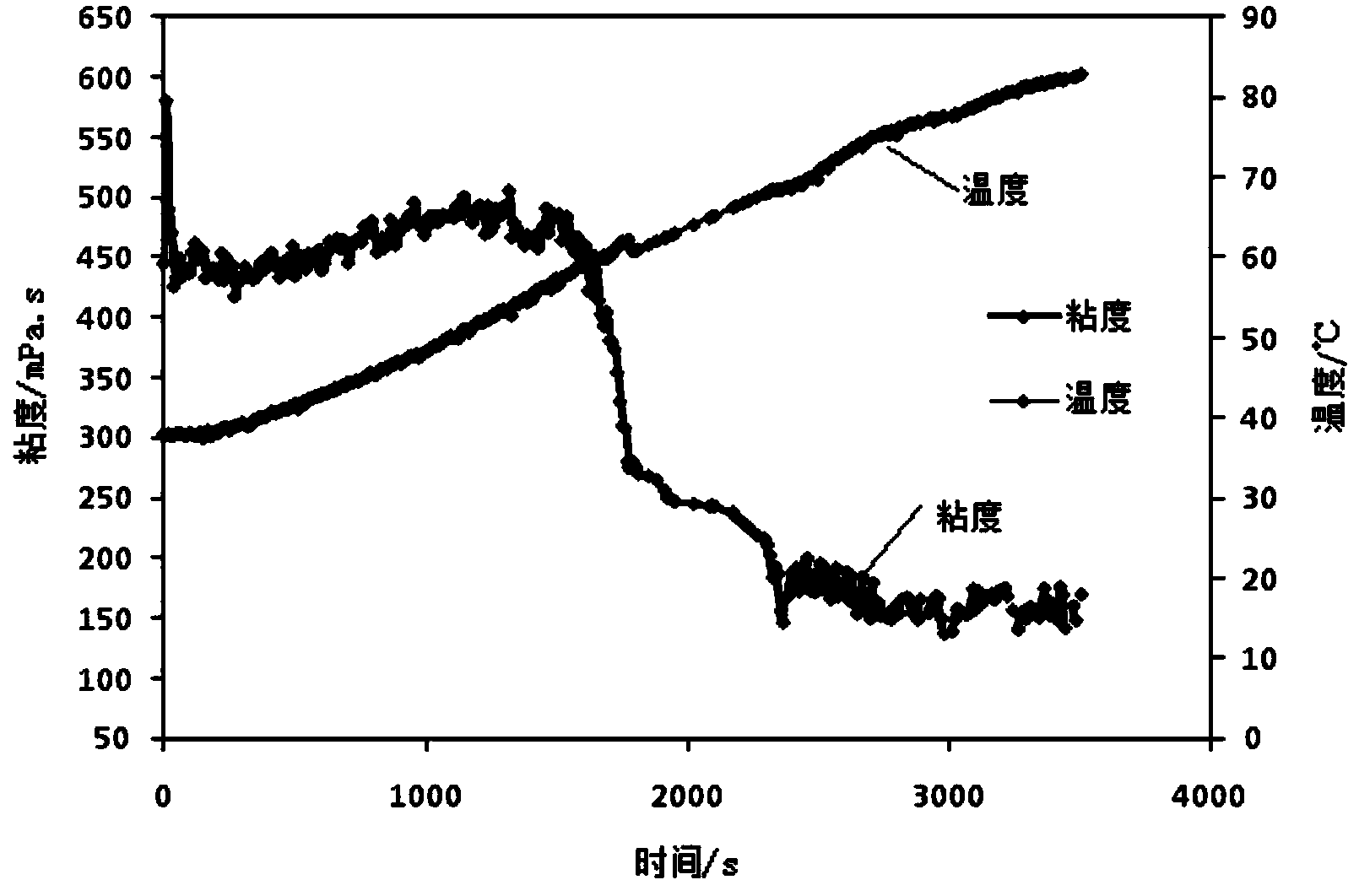

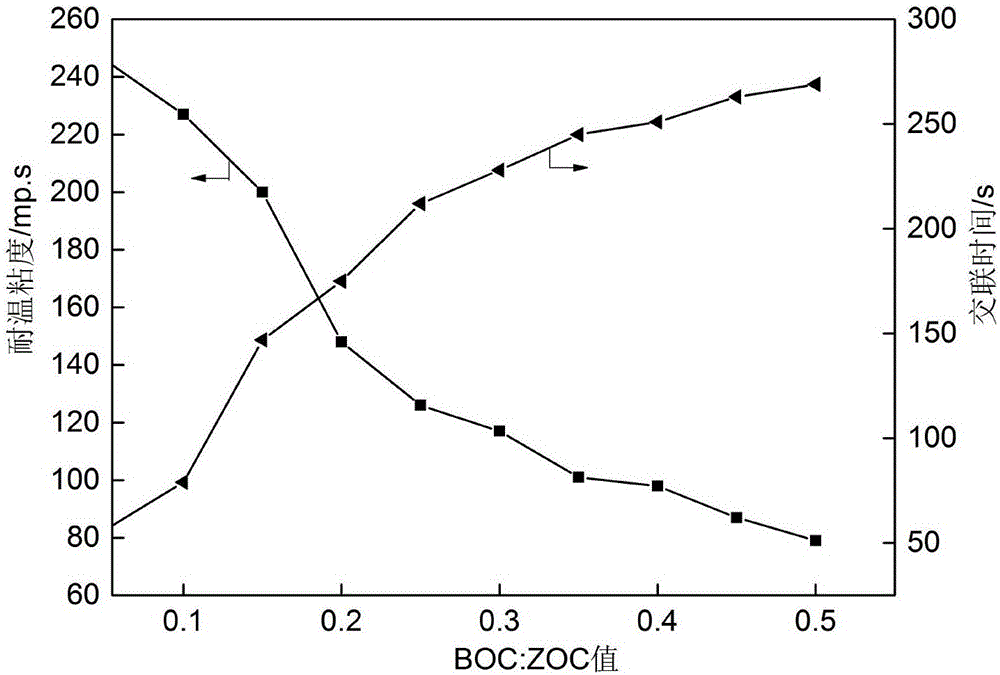

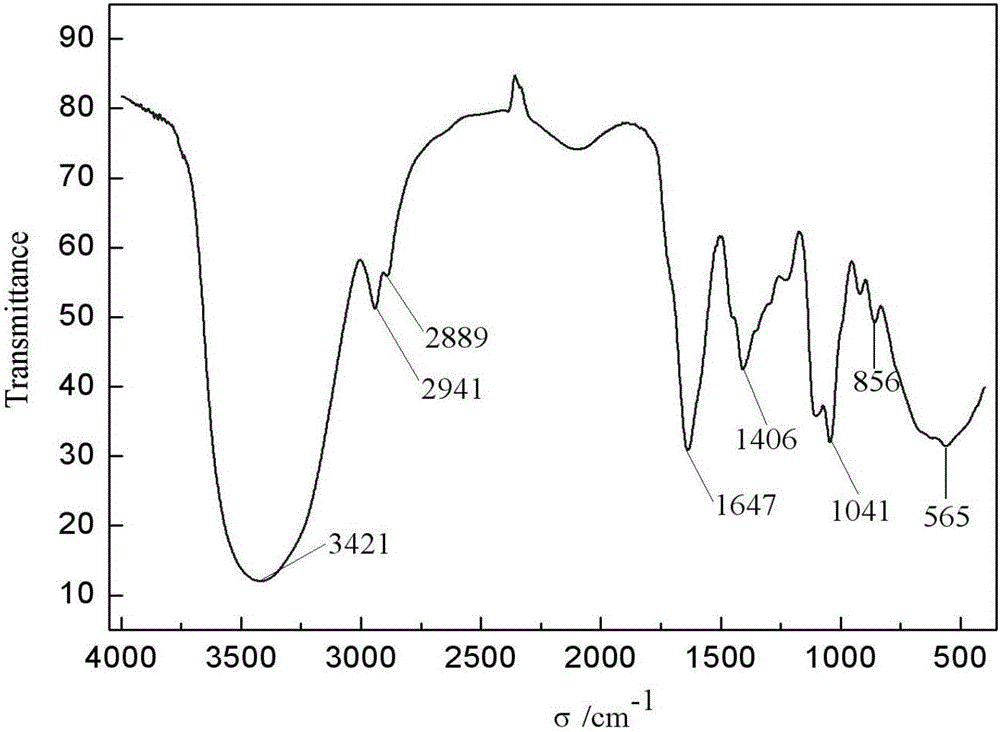

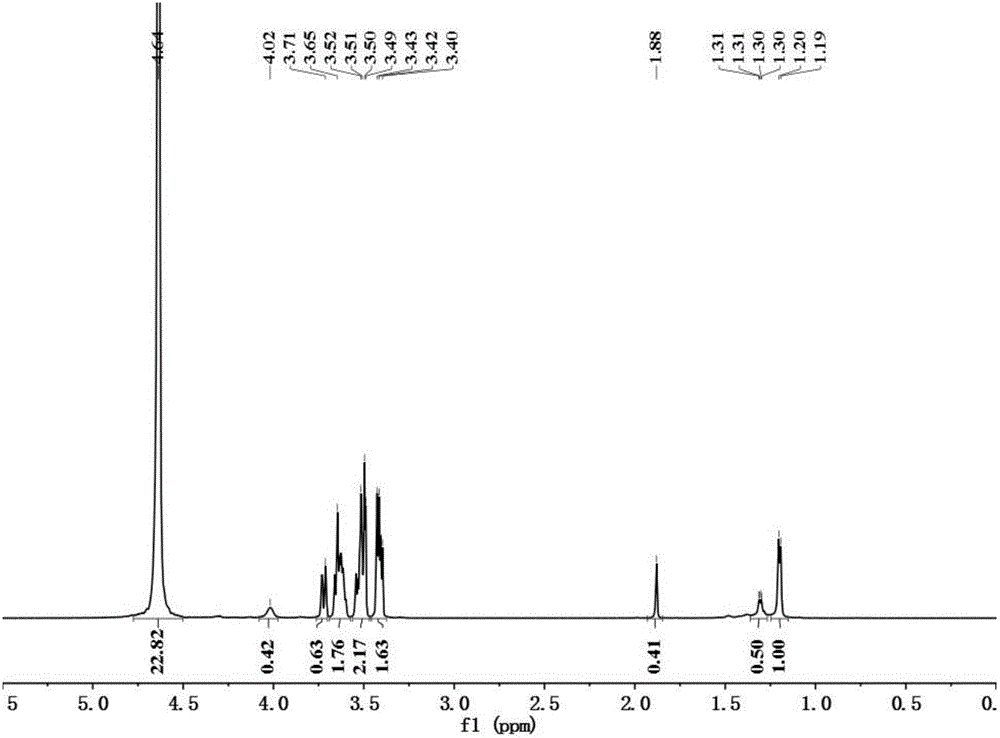

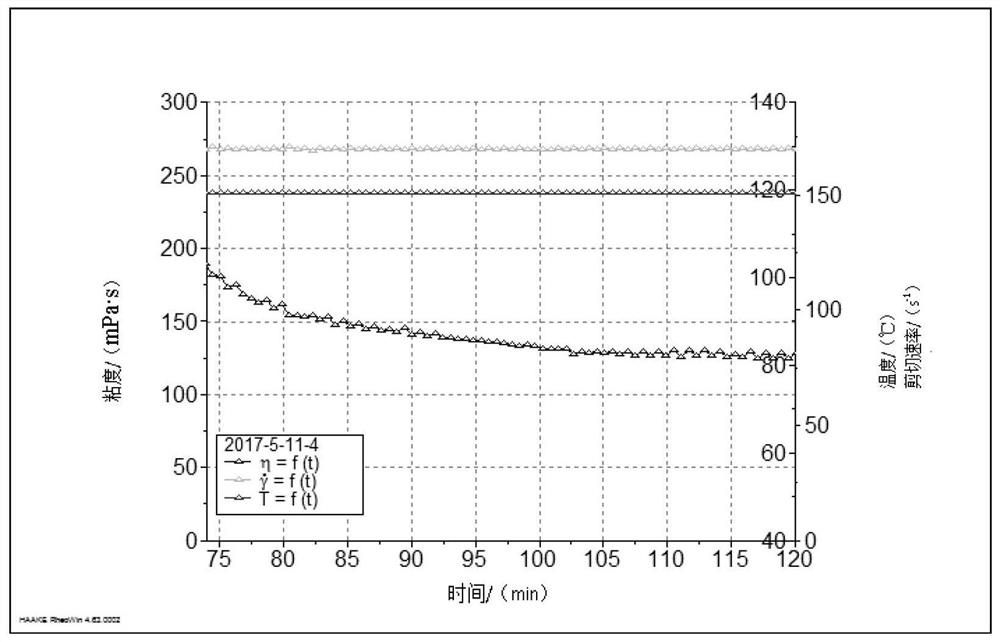

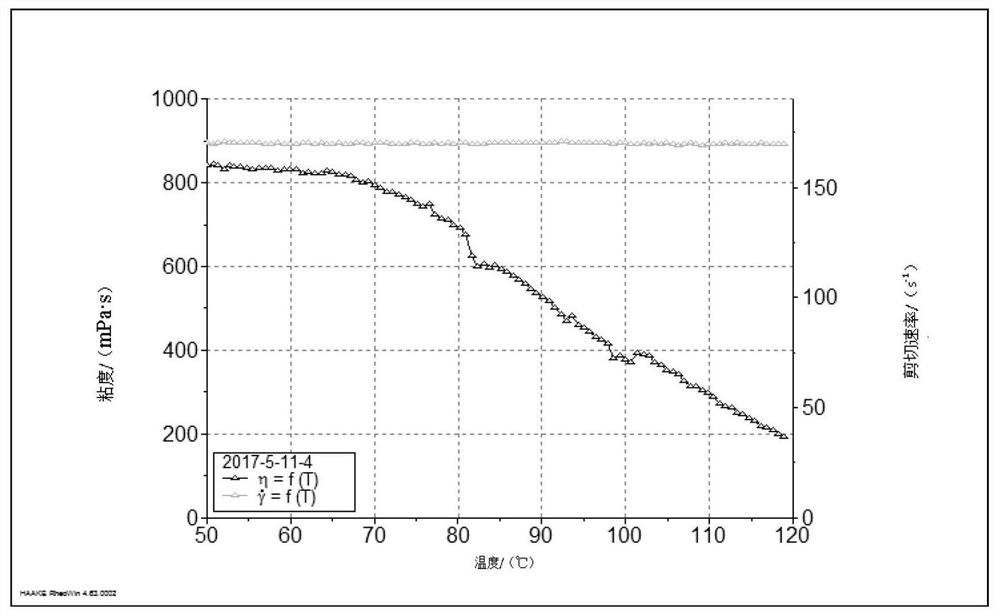

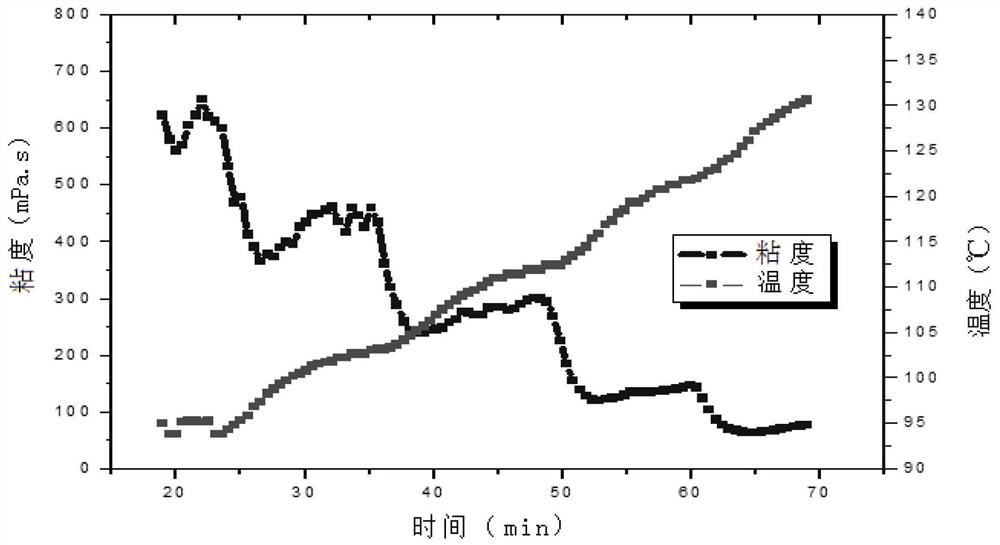

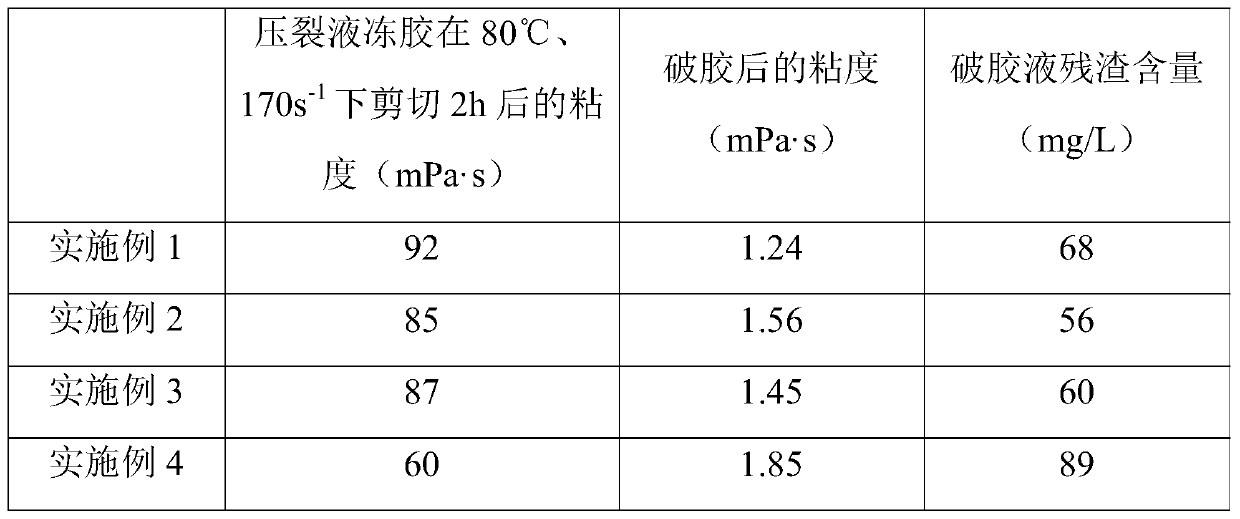

The invention discloses a high-temperature guanidine gum cross-linking agent and a preparation method thereof. A preparation process of the guanidine gum cross-linking agent includes steps: preparing an organic boron cross-linking agent and an organic zirconium cross-linking agent, and well mixing according to a volume ratio of 0.15-0.2:1 to obtain an organic boron-zirconium cross-linking agent. The guanidine gum cross-linking agent is excellent in temperature resistance and shear resistance, gum viscosity measured by a HAAKE rheometer is still kept to be 100mPa.s or above after shearing of a cross-linking system for 2h at 180 DEG C and 170s<-1>, and ultrahigh-temperature-resistant guanidine gum cross-linking agent BZC and GHPG cross-linked gel is excellent in temperature resistance and shear resistance; the researched organic boron-zirconium cross-linking agent is capable of retarding cross linking for 1-4min; the cross-linking agent is excellent in gel breaking performance, short in gel breaking time and low in gel breaking liquid residue quantity and surface tension.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Oil-gas field fracturing fluid, oil-gas field well cementing agent and oil-gas field fracturing temporary plugging agent containing PVA (Polyvinyl alcohol) fiber

InactiveCN107286922AEasy to plug inIncrease formation pressureProductsReagentsFiberPolyvinyl alcohol

The invention discloses an oil-gas field fracturing fluid, a temporary plugging agent and a well cementing agent containing a PVA (Polyvinyl alcohol) fiber. The PVA fiber is prepared by spinning PVA being 1000 to 3500 in polymerization degree, and 80 to 99.9 mole percent in alcoholysis degree. The oil-gas field fracturing fluid has the advantages of higher temperature resistance and shearing resistance, small environmental damage, low cost, environmental friendliness, very good sand carrying function and facilitation of fracturing fluid flowback; the oil-gas field well cementing agent can enhance the strength and the toughness of a well cementing material, can play a role in preventing leakage, is degradable and has low environmental damage; the oil-gas field fracturing temporary plugging agent has a good filtration reduction effect, forms a shielding layer at a position to be plugged temporarily to realize successful steering of the fracturing fluid, and is degradable; components left underground do not cause environmental pollution.

Owner:CHINA PETROCHEMICAL CORP +1

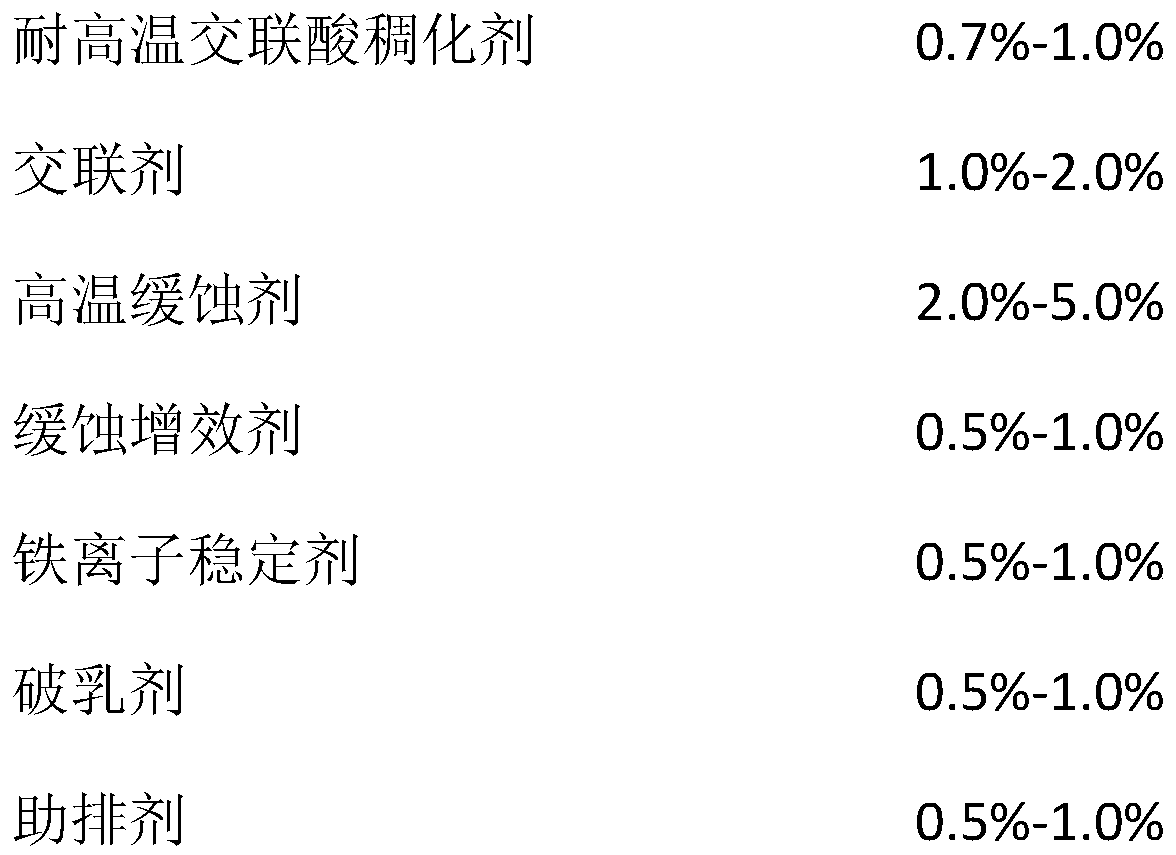

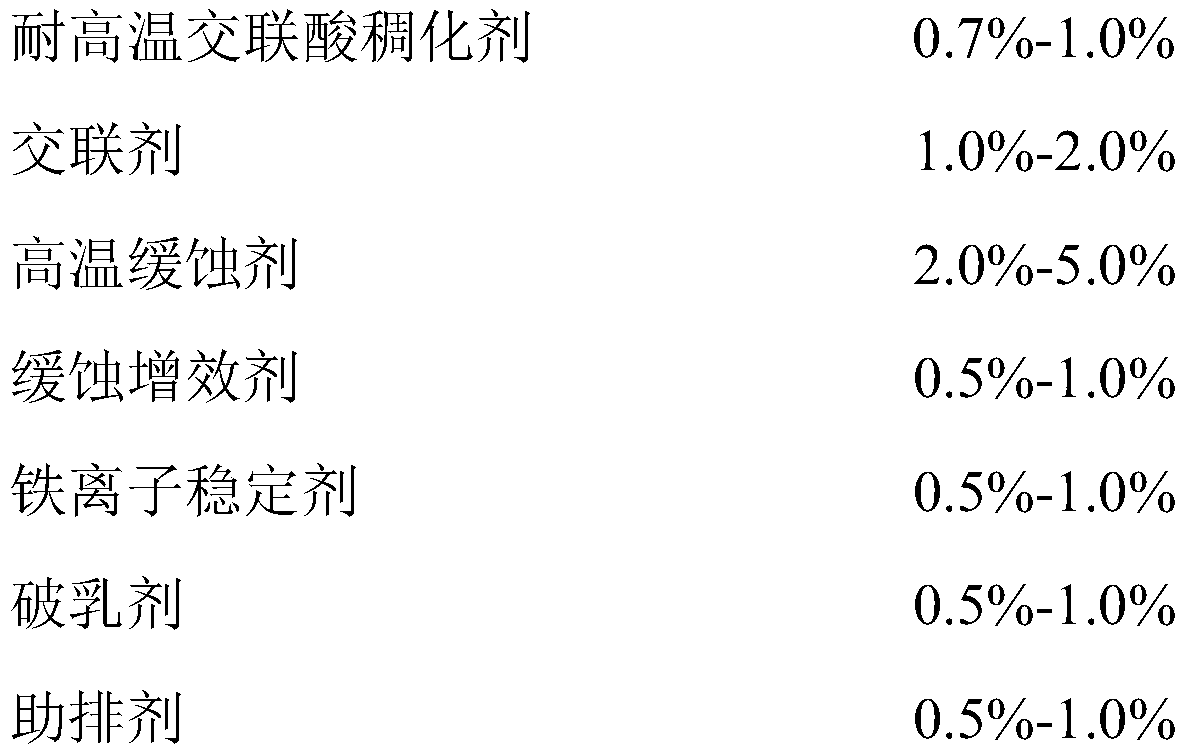

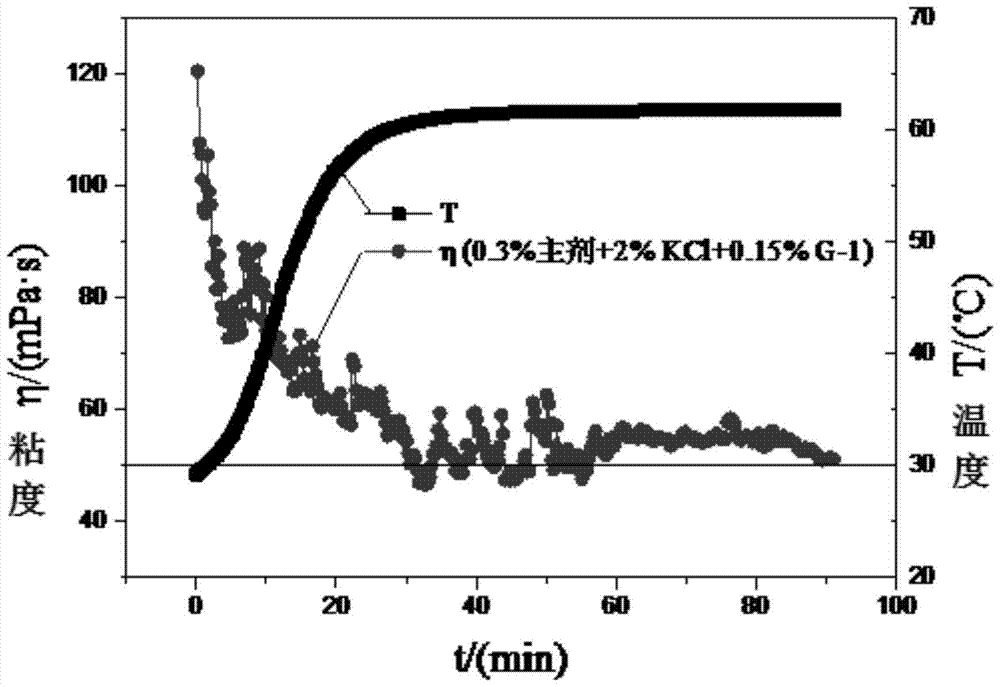

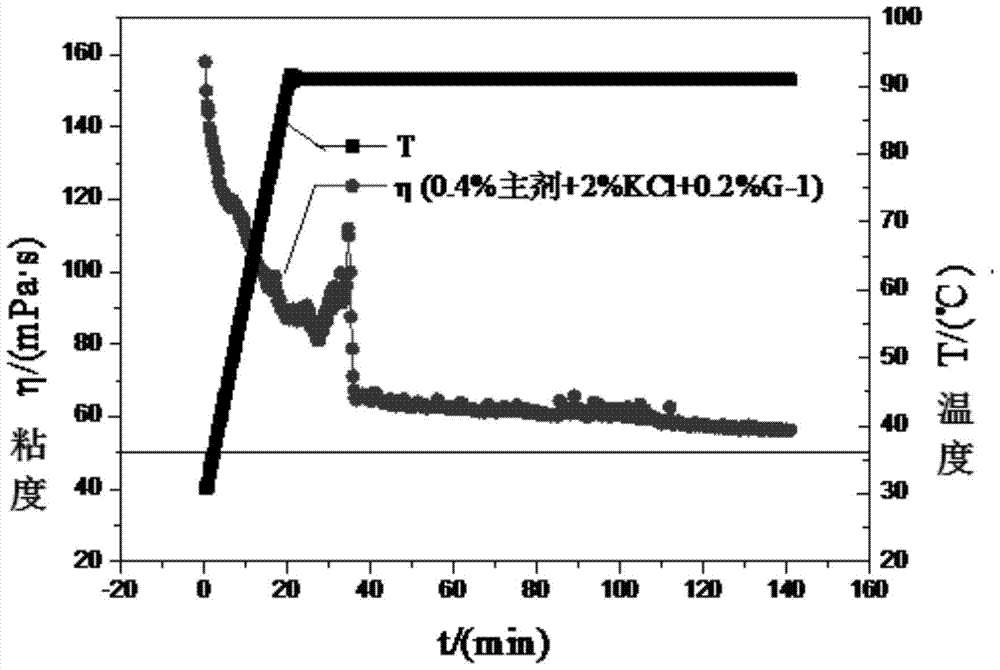

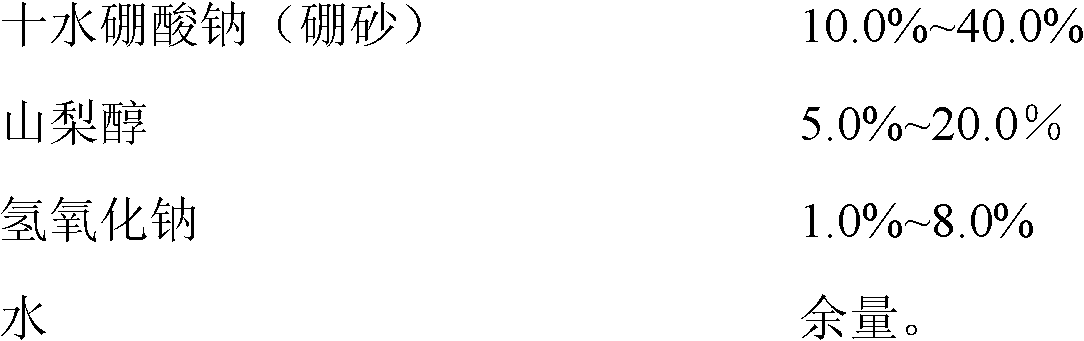

High temperature resistant crosslinked acid system for acid fracturing and preparation method thereof

PendingCN110628410AFast dissolutionImprove performanceDrilling compositionAcid fracturingTemperature resistance

The invention belongs to the field of oil field production, and specifically relates to a high temperature resistant crosslinked acid system for acid fracturing and a preparation method thereof. An improved high temperature resistant crosslinked acid thickener is adopted, the temperature resistance and stability of an acid solution are improved, a corresponding additive with good compatibility andthe crosslinked system with controllable delay, temperature resistance and shear resistance are adopted, and good rheological performance and corrosion inhibition performance at the temperature of 160 DEG C are realized. Compared with the prior art, the high temperature resistant crosslinked acid thickener adopted in the invention has the advantages of high dissolving speed, complete dissolutionin hydrochloric acid with the mass fraction of 15-31% for 20 min and stable performance in the acid solution within 10 days; through the added concentrations of a high-temperature corrosion inhibitorand a corrosion inhibition synergist, the corrosion inhibition performance at different temperatures is adjusted; and by adjusting the concentration of the crosslinked agent, different delay, temperature resistance and shear resistance performances can be realized, so that deep acid fracturing transformation of an oil-gas reservoir is realized.

Owner:北京弘毅恩泽能源技术有限公司

A high-concentration water-in-oil emulsion state association polymer fracturing fluid and its preparation method

ActiveCN104449649BDissolve fastDoes not produce "fish eye" powder particles and other phenomenaDrilling compositionHigh concentrationPolymer science

The invention relates to a high-concentration water-in-oil emulsion-state associating polymer fracturing fluid and a preparation method thereof. The fracturing fluid comprises the following components in mass fraction: 38.7-45.18% of water, 25.30-28.67% of diesel oil, 25-30% of a fracturing fluid thickening agent and 2.53-2.88% of an emulsifier. The high-concentration water-in-oil emulsion-state associating polymer fracturing fluid disclosed by the invention has a stable time greater than 15 days at 0 DEG C-40 DEG C and has the characteristics that the fracturing fluid is easy to prepare, dissolve and disperse and the like, and rapid mixing, construction and fracturing on the spot can be achieved.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

Recovered fracturing fluid used in natural gas well

The invention relates to recovered fracturing fluid used in a natural gas well. The fracturing fluid comprises components of, by weight: 0.25% to 0.45% of a natural plant gum thickener, 2.0% to 3.0% of potassium chloride, 0.01% to 0.02% of a bactericide, 0.40% to 1.20% of a cleanup additive, 0.3% to 0.7% of cross-linking liquid, 0.01% to 0.025% of a pH value regulator, 0.08% to 0.2% of a gel breaker, and balance of water. During on-site construction, the fracturing fluid is adopted in fracturing construction; the liquid discharged back from the stratum is settled, and filtered; silt and mechanical impurities are removed, and the liquid is stored in a tank. When fracturing construction is carried out again, the pH value regulator is added to the liquid, such that a gel is formed again, andthe gel can be used. With the recovered fracturing fluid provided by the invention, waste liquid discharging and processing can be reduced, a large amount of water can be saved, liquid blending time can be saved, and construction period can be shortened.

Owner:PETROCHINA CO LTD

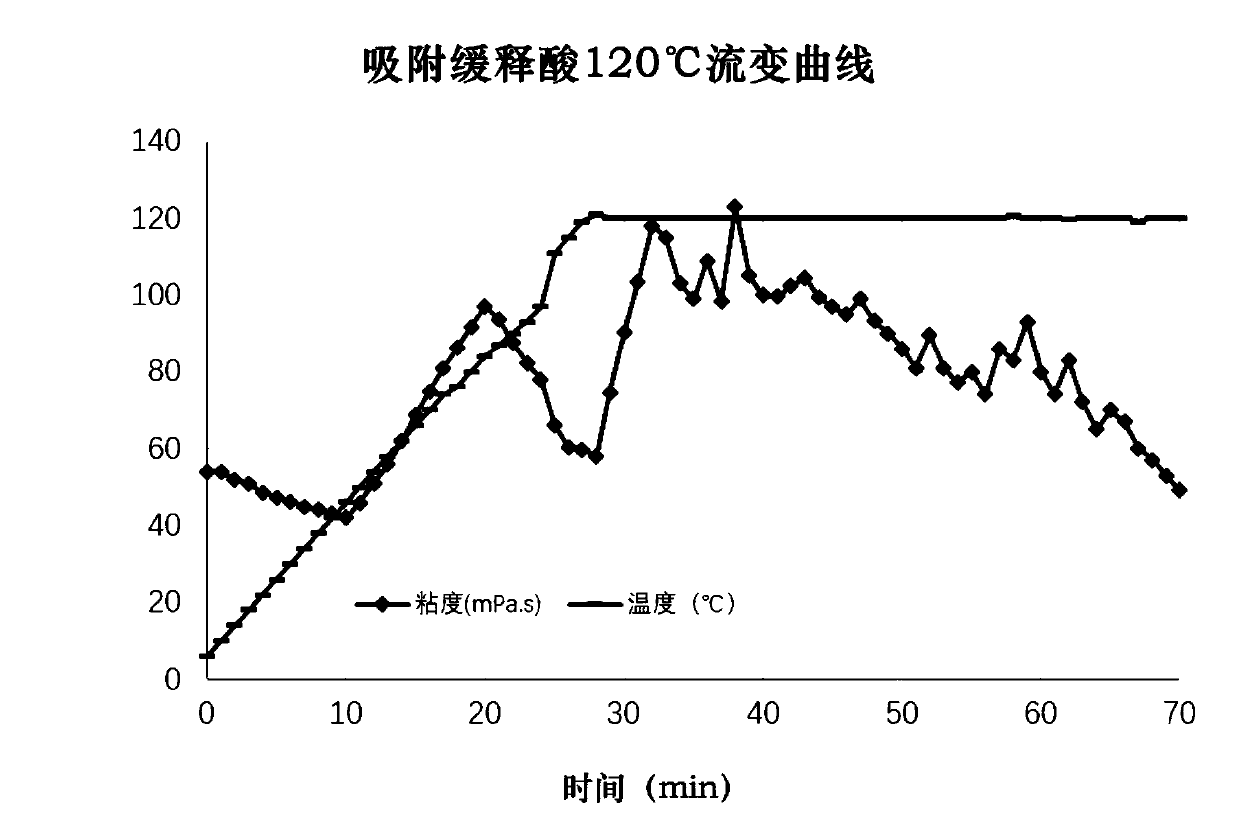

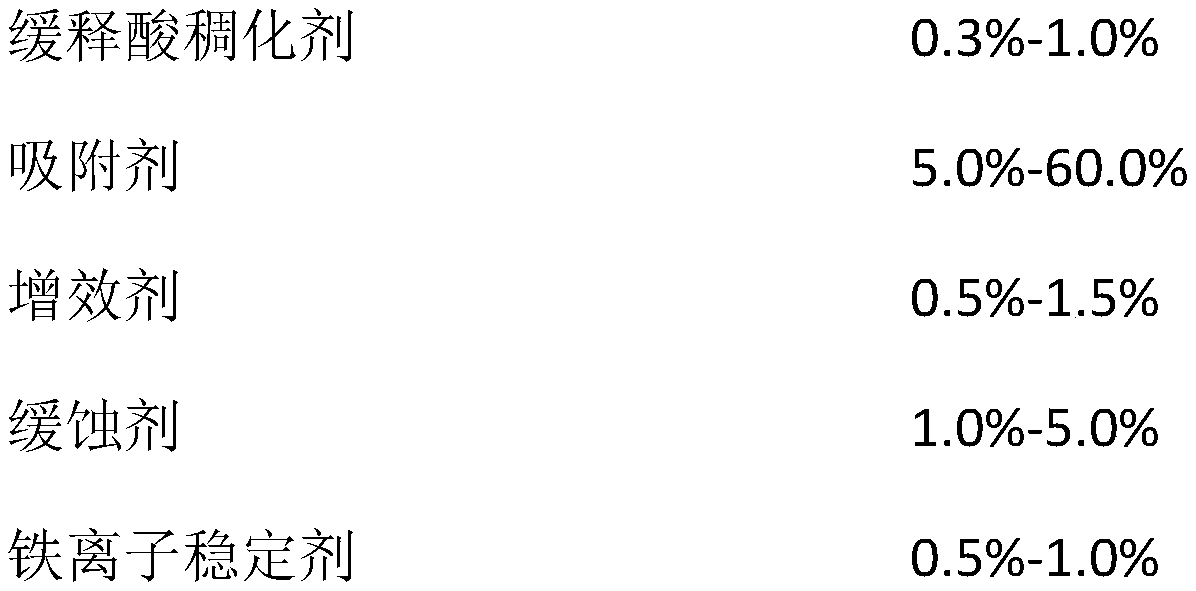

Adsorption slow-release acid system for acid fracturing and preparation method thereof

ActiveCN110643345AImprove rheologyAct as a temporary blockDrilling compositionAcid fracturingSorbent

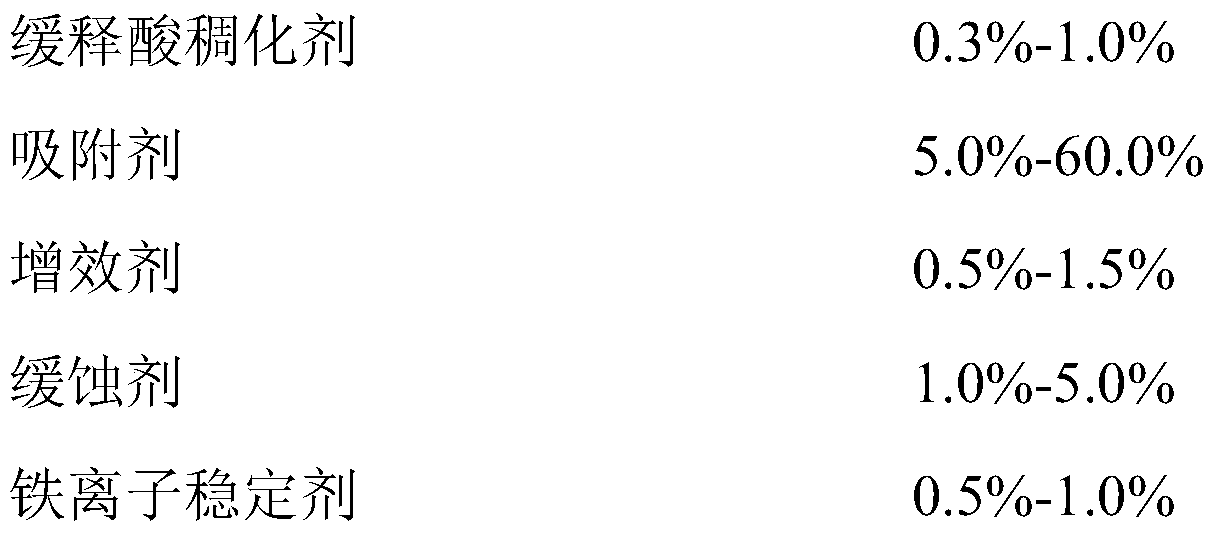

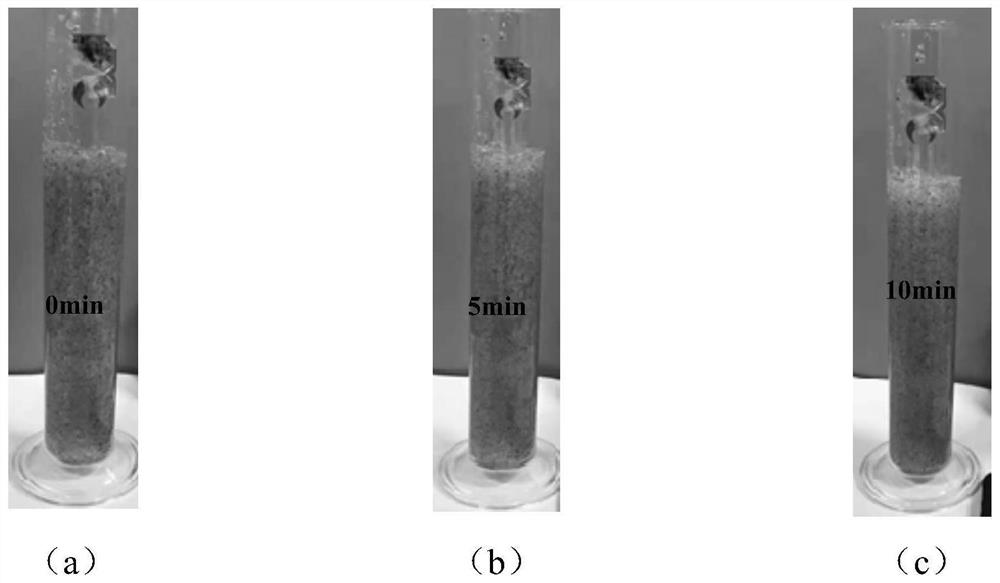

The invention belongs to the field of oil field production enhancement, and particularly relates to an adsorption slow-release acid system for acid fracturing. The adsorption slow-release acid systemfor acid fracturing comprises the following raw material composition in percent by mass: 0.3%-1.0% of a slow-release acid thickener, 5.0%-60.0% of an adsorbent, 0.5%-1.5% of a synergist, 1.0%-5.0% ofa corrosion inhibitor, 0.5%-1.0% of an iron ion stabilizer, and the balance hydrochloric acid of 15-28%. A multi-component copolymerized polymer is used as the thickener of a slow-release acid, and the thickener and the synergist can produce viscoelastic effects, so that the slow-release acid has relatively good rheological properties at a high temperature. According to reservoir geological characteristics, construction displacement and the like, a sand addition ratio of the adsorbent is adjusted, and adjustment of a total amount of the slow-release acid is realized while sand blockage is effectively prevented. The system not only makes full use of performance advantages of an existing acid solution system, but also originally uses the solid adsorbent to transport a high-concentration acidsolution to the front of an acid-fracturing fracture, and at the same time, the adsorbent can also play multiple functions such as temporary blocking and direction changing.

Owner:北京弘毅恩泽能源技术有限公司

Single-component full-function fracturing fluid additive and preparation process thereof

InactiveCN112961665AGood dispersionUniform and stable dispersionDrilling compositionOctanolGlycol synthesis

The invention discloses a single-component full-function fracturing fluid additive and a preparation process thereof. The process comprises the following steps: mixing ethylene glycol, isopropanol, 1-butanol, 1-hexanol and 1-octanol, and conducting heating to uniformly disperse the mixture to obtain a water-based dispersant; adding a high-molecular polymer thickening agent and an auxiliary agent into a water-based dispersing agent, wherein the auxiliary agent is one or more of a clay stabilizer, a discharge aiding agent, a drag reducer, an anti-emulsifying agent, a filtrate reducer, a corrosion inhibitor and a sterilizing agent; conducting stirring at a high speed to obtain suspension; and slowly stirring the suspension at a low speed, conducting cooling, and collecting a suspension sample when the temperature of the suspension is reduced to room temperature. The additive has the characteristics of good temperature resistance, shearing resistance, salt resistance, sand suspension and the like. The problems that an existing fracturing fluid system is serious in stratum pollution, difficult to dissolve, single in function, poor in performance and the like are solved, and the additive has the advantages of being good in use performance, environmentally friendly, capable of saving energy and reducing consumption and can be used as a clean and environment-friendly single-component type full-function fracturing fluid additive.

Owner:SHAANXI UNIV OF SCI & TECH

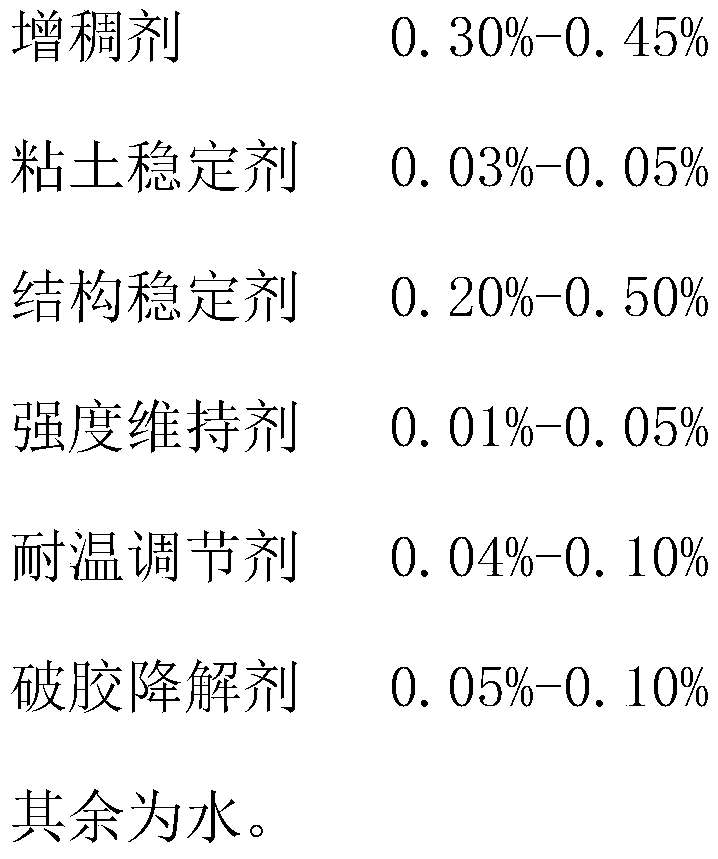

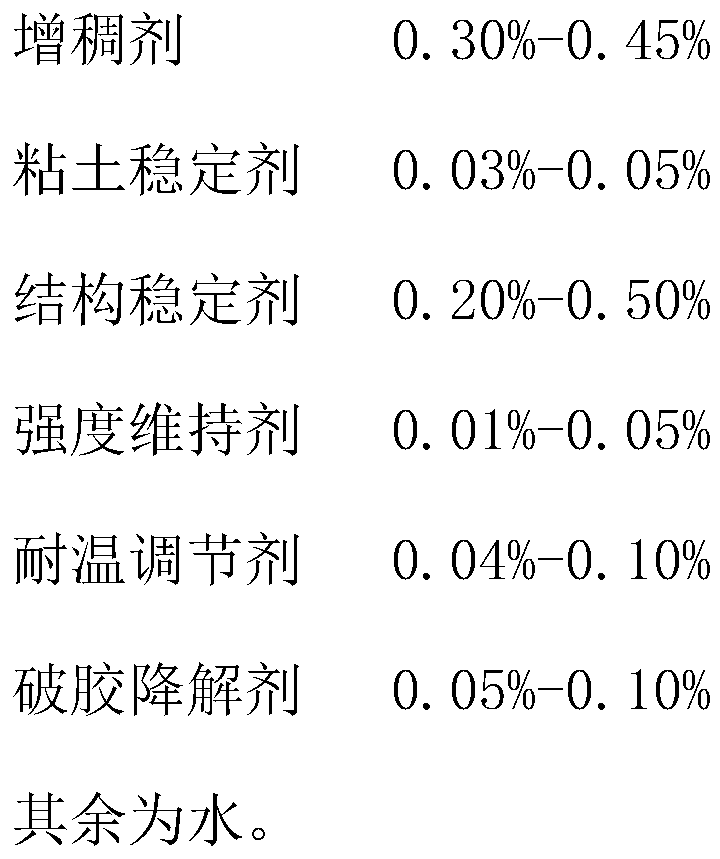

Slick water fracturing fluid for medium-high temperature compact reservoir and preparation method thereof

InactiveCN110295036AEasy to stretchPromote swellingDrilling compositionReduction rateFracturing fluid

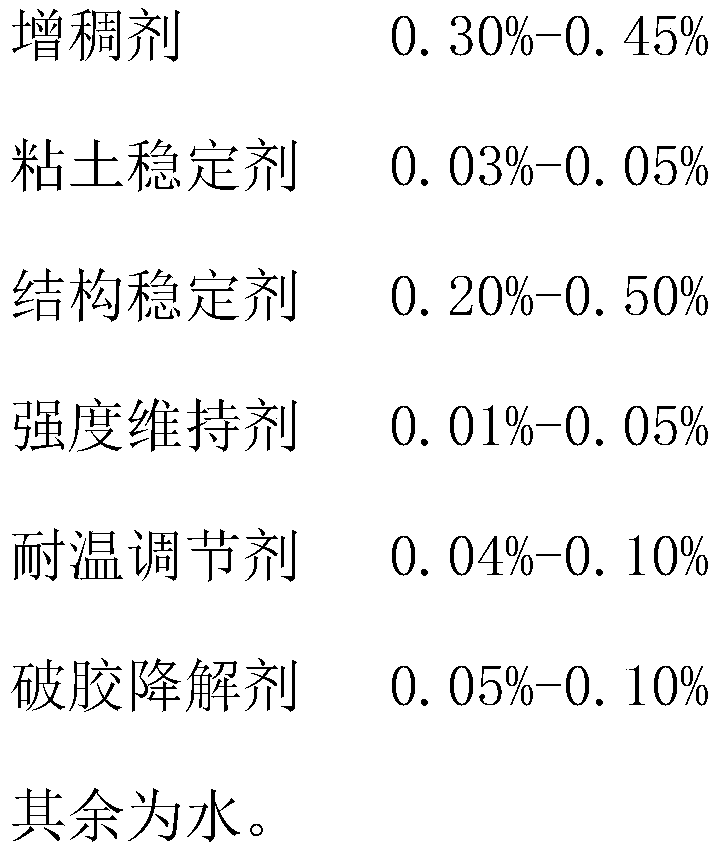

The invention belongs to the technical field of oil field stimulation, and particularly relates to a slick water fracturing fluid for medium-high temperature compact reservoirs and a preparation method thereof. The slick water fracturing fluid comprises the following components in percentage by weight: 0.30 to 0.45 percent of a thickening agent, 0.03 to 0.05 percent of a clay stabilizer, 0.20 to 0.50 percent of a structural stabilizer, 0.01 to 0.05 percent of a strength maintaining agent, 0.04 to 0.10 percent of a temperature resistant regulator, 0.05 to 0.10 percent of a gel breaker degradingagent and the balance of water. The slick water fracturing fluid has fast dissolution. In 30 seconds, 80% of the final viscosity increase can be achieved, the drag reduction rate can reach more than80%, the core damage rate is less than 10%, well temperature resistance and shear resistance can be satisfied under the medium and high temperature conditions of 90 deg c to 180 deg c, the sand carrying concentration can meet the construction requirements of more than 750 kg / m<3>, the gel breaking is complete, the drainage rate can reach more than 40%, and after simple sand settling treatment, theslick water fracturing fluid can be reused for more than 20 times to maintain more than 90% of the original performance.

Owner:PETROCHINA CO LTD

Fracturing fluid capable of resisting high salinity water quality

ActiveCN102757778BWide range of crosslinkingReduce dosageDrilling compositionFracturing fluidWater resources

The invention relates to a fracturing fluid capable of resisting high salinity water quality. The fracturing fluid is characterized by being composed of a base fluid and a cross-linking fluid which are fully mixed in proportion. The base fluid contains a chelate cosolvent and a chelate stabilizer, wherein the chelate cosolvent can restrain high salinity of water quality and promote swelling of guanidine gum. The base fluid comprises 98.2-98.65 parts of high salinity surface water, 0.1-0.15 part of the chelate cosolvent,0.3-0.4 part of thickener, 0.1-0.15 part of bactericide, 0.3-0.5 part of clay stabilizer, 0.5 part of demulsifying cleanup agent and 0.05-0.1 part of the chelate stabilizer; the cross-linking fluid comprises 50 parts of water, 50 parts of organic cross-linking agents and 0.35 part of gel breaker; and the fracturing fluid comprises 99.2-99.5 parts of the base fluid and 0.5-0.8 part of the cross-linking fluid. By aid of the fracturing fluid, water resources can be saved effectively, and the success rate for fracturing construction can be improved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Low-molecular-weight polymer fracturing liquid

ActiveCN102634329BFully consider the rheologyFully consider compatibilityDrilling compositionAcetic acidPolymer science

Low-molecular-weight polymer fracturing liquid is mainly applied to fracturing modification of low-infiltration alkali-sensitive reservoirs and water injection wells and consists of, in weight percentage, 0.25-0.6% of XT-3 low-molecular-weight polymer densifier, 0.2-0.6% of crosslinking agent, 0.5-2% of potassium chloride, 0.02-0.08% of crosslinking modifier, 0.2-0.5% of cleanup additive, 0.0001-0.15% of ammonium persulfate and the balance of water. The low-molecular-weight polymer fracturing liquid is prepared by adding clean water into a liquid preparation tank firstly, adding acetic acid during stirring, then adding the XT-3 low-molecular-weight polymer densifier, the potassium chloride and the cleanup additive after uniformly stirring, stirring more than 10 minutes after materials are added until density or viscosity of upper liquid and lower liquid in the liquid preparation tank are uniform, and finally, adding the crosslinking agent and adhesive breaker according to requirements during fracturing. The low-molecular-weight polymer fracturing liquid has the advantages that residues of the fracturing liquid and alkali-sensitive damages of the reservoirs are solved, the fracturing liquid is prepared and used conveniently, temperature resistance and shearing resistance are fine, and the requirements of fracturing modification of low infiltration and alkali-sensitive reservoirs can be met.

Owner:PETROCHINA CO LTD

Polymer acidic cross-linking agent and preparation method thereof

The invention provides a polymer acidic cross-linking agent, which is prepared from the following raw materials in percentage by weight: 20-30% of a complexing agent, 0.1-5% of nanoparticles with core-shell structure, 5-10% of a zirconium compound, 1-3% of a stabilizer, 3-5% of a corrosion inhibitor and the balance of deionized water, wherein the nanoparticles with the core-shell structure take sulfide-loaded amorphous alumina as a core and oligomeric chitosan as a shell material, and the particle size of the nanoparticles is 50-500 nm. According to the cross-linking agent, the problem of more residues after gel breaking of a zirconium cross-linking agent is remarkably improved, the flowback rate is remarkably increased, and the damage to a reservoir is remarkably reduced.

Owner:陕西天成旭化工科技有限公司

Clear fracturing fluid

ActiveCN102643637BEasy to make and useGood anti-expansion effectDrilling compositionSalicylic acidFracturing fluid

The invention relates to clear fracturing fluid, which is used for fracturing treatment of a hypotonic and water-sensitive reservoir, and comprises the following components in percentage by weight: 0.5-5 percent of dimethyl octadecyl ethoxy quaternary ammonium nitrate; 0.2-2 percent of sulfosalicylic acid triethanolamine ester; 0.5-2 percent of potassium chloride; and the balance of water, wherein the weight percentage of the components is a hundred percent. A preparation method comprises the following steps of: adding clear water into a mixing liquid tank, adding the potassium chloride and the sulfosalicylic acid triethanolamine ester under a stirring condition, uniformly stirring, adding the dimethyl octadecyl ethoxy quaternary ammonium nitrate, and stirring for 15 minutes after adding the materials, so that the concentration or the viscosity of liquid in the upper part and the lower part of the tank is uniform. The clear fracturing fluid has the effects that: the clear fracturing fluid is suitable for fracturing the reservoir at the temperature of 10 DEG C-110 DEG C, the damage caused by residues of the fracturing liquid and reservoir water sensitivity can be reduced, and the crude output is improved.

Owner:PETROCHINA CO LTD

Crosslinking agent capable of crosslinking organic acid, and preparation method and application thereof

ActiveCN109852368AHigh viscosityImprove temperature resistanceDrilling compositionAcid etchingOrganic acid

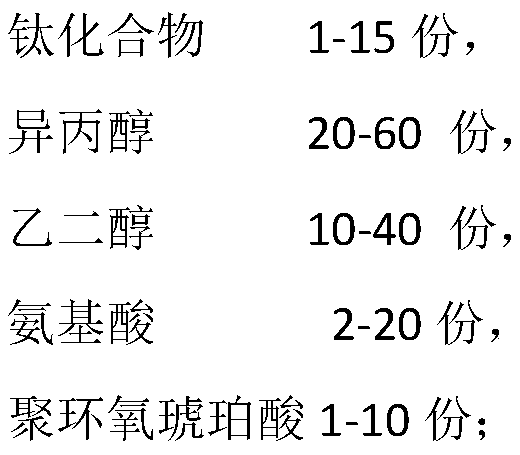

The invention relates to a crosslinking agent capable of crosslinking organic acid, and a preparation method and application thereof. The organic acid crosslinking agent is prepared from a titanium compound, isopropyl alcohol, ethylene glycol, amino acid and polyepoxysuccinic acid. The organic acid crosslinking agent is used for crosslinking of the organic acid in acidification and acid fracturingof an oil field, so the viscosity of an organic acid liquid system is increased; the temperature resistance of the acid liquid system is improved; the effective action distance of acid etching is longer; and the needs of deep-burial and high-temperature reservoirs are met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Carboxymethyl hydroxypropyl guanidine gum fracturing fluid

ActiveCN102634328BFully consider the rheologyFully consider compatibilityDrilling compositionCross-linkPreservative

Owner:PETROCHINA CO LTD

A kind of cross-linking accelerator for carbon hydrocarbon anhydrous fracturing fluid and carbon hydrocarbon anhydrous fracturing fluid

ActiveCN108690596BHigh viscosityImprove gel performanceDrilling compositionIron sulfateFracturing fluid

The invention discloses a crosslinking accelerant for anhydrous hydrocarbon fracturing fluid. Each 100 mL of the crosslinking accelerant contains 3-10 g of alkali metal hydroxides, and 0.6-1.5 g of iron sulfate, 50-90 mL of organic alcohols. The organic alcohols refer to one or any of ethyl alcohol, ethylene glycol and propylene glycol. In addition, the invention also provides anhydrous hydrocarbon fracturing fluid prepared with the crosslinking accelerant; the anhydrous hydrocarbon fracturing fluid comprises a base liquid, a gelling agent and the crosslinking accelerant; the anhydrous hydrocarbon fracturing fluid is subjected to gel breaking after gelling, a gelling accelerant and a gelling agent are added to form a fracturing fluid for secondary use. The crosslinking accelerant herein can effectively improve viscosity and gelling performance of fracturing fluids, and temperature resistance, shear resistance and gel breaking capacity are improved for fracturing fluids; after the fracturing fluids are subjected to gel breaking, the fracturing fluids are suitable for secondary use; the fracturing fluids have good temperature resistance and are good for the development and application of unconventional reservoirs.

Owner:XI'AN PETROLEUM UNIVERSITY

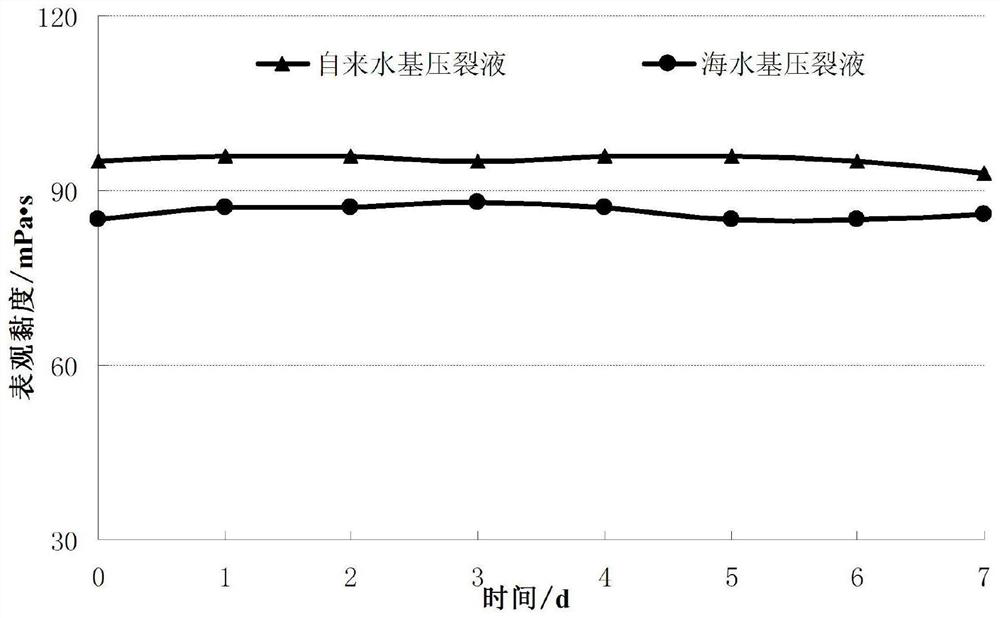

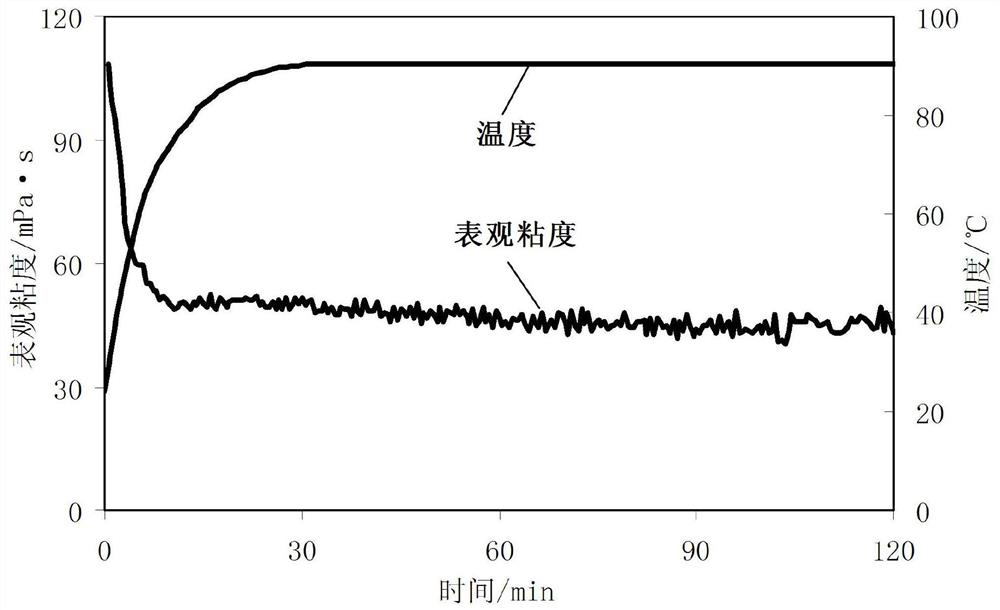

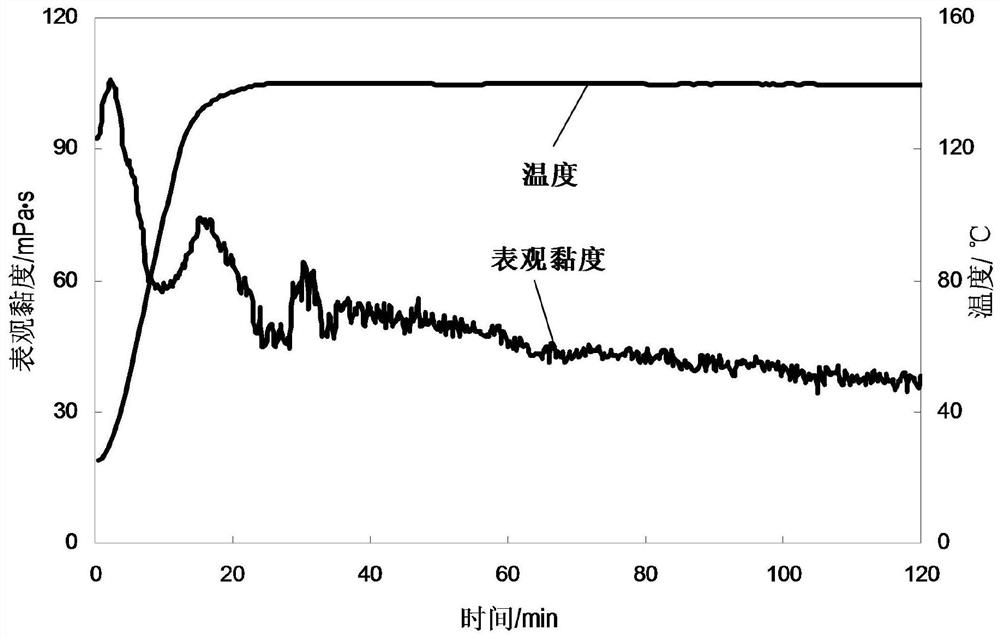

High temperature resistant seawater-based polymer fracturing fluid capable of continuous mixing and preparation method thereof

ActiveCN107474816BAlleviate needsReduce construction costsDrilling compositionApparent viscosityFracturing fluid

A high-temperature resistant seawater-based polymer fracturing fluid capable of continuous blending and a preparing method thereof are disclosed. The fracturing fluid includes 0.4-0.8 wt% of a thickening agent, 0.3-0.6 wt% of an auxiliary synergist, 0.2-0.4 wt% of an activating agent, 0.2-0.4 wt% of a metal ion stabilizer, and 0.3-0.4 wt% of a temperature stabilizer, with the balance being seawater. Beneficial effects of the fracturing fluid are that: a water-soluble multi-component copolymer is adopted as the thickening agent of the fracturing fluid system so that the fracturing fluid can rapidly swell in seawater having a high degree of mineralization; a low-viscosity high-elasticity fluid having a high space structure is formed through synergistic effects (non-crosslinking functions) with the auxiliary synergist; a sand-carrying property is good when the apparent viscosity is greater than 20 mPa.s; the prepared fracturing fluid is not eroded by bacteria, has characteristics of salt resistance, good temperature resistance and shearing resistance, low harm, no residue after cleaning, and the like, and can be prepared in batch or mixed continuously by adopting sea water; and the fracturing fluid can significantly reduce offshore fracturing construction costs and can increase fracturing construction efficiencies and reservoir yield-increasing effects.

Owner:SOUTHWEST PETROLEUM UNIV +1

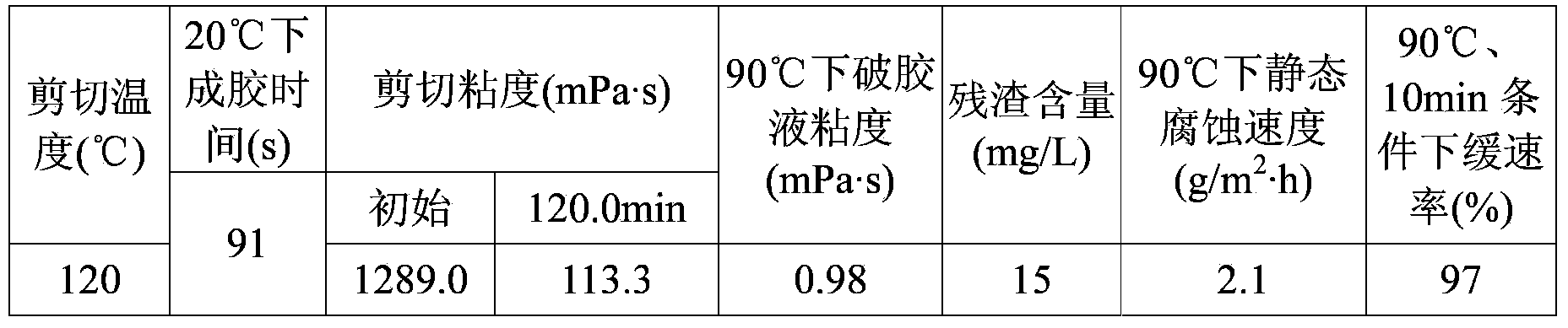

A kind of fracturing fluid and preparation method thereof

The invention relates to a fracturing fluid, which includes a densifier I, a densifier II, a clay stabilizer, a bactericide, a pH conditioning agent, a cross-linking agent, a gel breaker and water, wherein the densifier I is nonionic polyacrylamide, and the densifier II is hydroxyethyl carboxymethyl cellulose. The invention further relates to a preparation method of the fracturing fluid. The preparation method includes: (1) during stirring, adding the densifier I and the densifier II to water, then adding the clay stabilizer, the bactericide, and the pH conditioning agent, performing uniform stirring to obtain an original glue solution, and performing standing for 3-5 h; and (2) adding the gel breaker, and then adding the cross-linking agent to obtain the fracturing fluid. The densifier I is nonionic polyacrylamide, and the densifier II is hydroxyethyl carboxymethyl cellulose. Since the fracturing fluid includes two densifiers of nonionic polyacrylamide and hydroxyethyl carboxymethyl cellulose, the fracturing fluid is small in densifier consumption, good in temperature-resistant shearing resistance, complete in gel breaking, low in residue content, cheap and available in raw materials, and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis of thickening agent for methanol-based fracturing fluid

InactiveCN102492414BFast dissolutionGood temperature resistance and shear resistanceDrilling compositionSolubilityWater based

At present, more than 90 percent of fracturing fluids used in the fracturing improvement of oil and gas fields are water-based fracturing fluids with water as dispersion medium, and as a result, for gas reservoirs with low formation pressure, low permeability and strong water-locking characteristic, particularly highly water-sensitive gas reservoirs, the difficulty of fluid flowback can be easily caused because the formation pressure coefficient is greatly smaller than the pressure coefficient of water in a shaft; and formation pores can be easily blocked due to the water-locking effect of formations to cause the failure of fracturing improvement. Because low-molecular weight alcohol, particularly methanol, has a lot of excellent physical and chemical properties, the low-molecular weight alcohol can be used in the improvement of low-pressure, water-sensitive formations for stimulation, and compared with conventional water-based fracturing fluids, methanol-based fracturing fluid has the characteristics of low surface tension, good water-solubility, low freezing point, high steam, high compatibility with formation rocks and the like. The invention relates to a thickening agent for methanol-based fracturing fluid, which is used in the fracturing stimulation process of natural gas wells or oil wells; because methanol and water can be formed into any proportions of mixtures, the methanol-based fracturing fluid can absorb the water constrained by water-locking formations to the maximum limit after entering the formations, and moreover, as the fracturing fluid is drained out of the ground, the water locking of the formations is released, which is favorable for the flowback of the fluid.

Owner:北京希涛技术开发有限公司

A multi-lithologic fracturing fracture test method

ActiveCN113218770BMeet the requirements of continuous sand fracturingGood temperature resistance and shear resistancePreparing sample for investigationMaterial strength using tensile/compressive forcesHorizontal wellsEngineering

Owner:SOUTHWEST PETROLEUM UNIV

A low-damage nitrogen foam fracturing fluid for weakly water-bearing coalbed methane wells

ActiveCN108130067BGood temperature resistance and shear resistanceStrong ability to suspend sandDrilling compositionActive agentFracturing fluid

The invention provides a low-damage nitrogen foam fracturing liquid for a weak water-bearing coal-bed gas well and a preparation method thereof. The gas phase of the foam fracturing liquid is nitrogen, the liquid phase of the foam fracturing liquid is an additive solution, and the foam mass is 60 to 80 percent. The foam fracturing liquid is prepared from the following components in percentage by mass: 0.5 to 1.5 percent of a foaming agent, 0.3 to 0.7 percent of a foam stabilizing agent, 0.2 to 0.6 percent of a clay stabilizing agent, 0.1 to 1.0 percent of an auxiliary desorption agent and 96.2to 98.9 percent of water. The foaming agent is mainly an anionic surfactant; the foam stabilizing agent is mainly an amphoteric surfactant; the clay stabilizing agent is mainly an organic solvent; the auxiliary desorption agent is mainly a fluorocarbon surfactant. The foam fracturing liquid does not contain a macromolecular additive, has good temperature resistance and shearing resistance, high sand suspending capacity, good coal powder dispersing performance and negative damage to a coal rock core, and has a great significance to efficient development of weak water-bearing coal-bed gas and reservoir protection.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com