Recovered fracturing fluid used in natural gas well

A fracturing fluid and natural gas technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as difficulty in meeting construction scale, rapid gel breaking and flowback, formation pore throat and micro-fracture damage, and inability to flow back fluid. Reuse and other issues to achieve a good effect of increasing production, saving the cost of pollution prevention and control, and increasing the production of wellhead testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

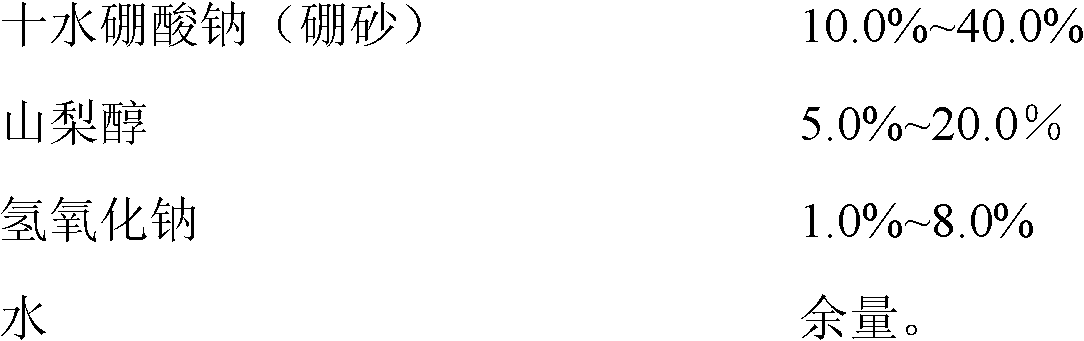

Method used

Image

Examples

Embodiment 1

[0021] Take 490ml of water and place it in a mixer with a volume of 1000ml, add 0.01g of fungicide D580 and 15g of potassium chloride in sequence, stir for 2 minutes to dissolve, then slowly add 2.1g of low-viscosity hydroxypropyl guar gum, stir until the liquid becomes thicker, and then Add 5.0g of drainage aid, stir evenly, and let it stand for 1-2 hours to make base liquid for later use. Take 100ml of base fluid, add 0.5g of cross-linking fluid, and record the time from adding the cross-linking fluid to forming a jelly as the cross-linking time of the fracturing fluid. The pH value of the base fluid was measured by a pH meter to be 7.8, the pH value of the crosslinked fracturing fluid was 10.2, and the crosslinking time was 67s. Using an M5500 rotational viscometer at a shear rate of 170s-1, the viscosity of the base fluid was measured to be 13.5mPa·s, and the viscosity of the cross-linked jelly reached 369mPa·s. Add 0.15 g of citric acid gel breaker to the prepared jelly,...

Embodiment 2

[0024] Take 490ml of water and place it in a mixer with a volume of 1000ml, add 0.01g of fungicide D580 and 15g of potassium chloride in sequence, stir for 2 minutes to dissolve, then slowly add 2.1g of low-viscosity hydroxypropyl guar gum, stir until the liquid becomes thicker, and then Add 5.0g of drainage aid, stir evenly, and let it stand for 1-2 hours to make base liquid for later use. Take 100ml of base fluid, add 0.45g of cross-linking fluid, and record the time from adding the cross-linking fluid to forming a jelly as the cross-linking time of the fracturing fluid. The pH value of the base fluid was measured by a pH meter to be 7.8, the pH value of the crosslinked fracturing fluid was 10.1, and the crosslinking time was 67s. Using a M5500 rotational viscometer at a shear rate of 170s-1, the viscosity of the base fluid was measured to be 13.5mPa·s, and the viscosity of the cross-linked jelly reached 389mPa·s. Add 0.1 g of hydrochloric acid breaker to the prepared jelly...

Embodiment 3

[0027] Take 490ml of water and place it in a mixer with a volume of 1000ml, add 0.01g of fungicide D580 and 12.5g of potassium chloride in sequence, stir for 2 minutes to dissolve, then slowly add 1.8g of low-viscosity hydroxypropyl guar gum, and stir until the liquid becomes thicker. Then add 5.0g of drainage aid, stir evenly, and let it stand for 1-2 hours to make base liquid for later use. Take 100ml of base fluid, add 0.4g of cross-linking fluid, and record the time from adding the cross-linking fluid to forming a jelly as the cross-linking time of the fracturing fluid. The pH value of the base fluid was measured by a pH meter to be 7.6, the pH value of the crosslinked fracturing fluid was 9.7, and the crosslinking time was 49s. Using a M5500 rotational viscometer at a shear rate of 170s-1, the viscosity of the base fluid was measured to be 10.5mPa·s, and the viscosity of the cross-linked jelly reached 246mPa·s. Add 0.12 g of citric acid gel breaker to the prepared jelly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com