Patents

Literature

407results about How to "Easy to make and use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

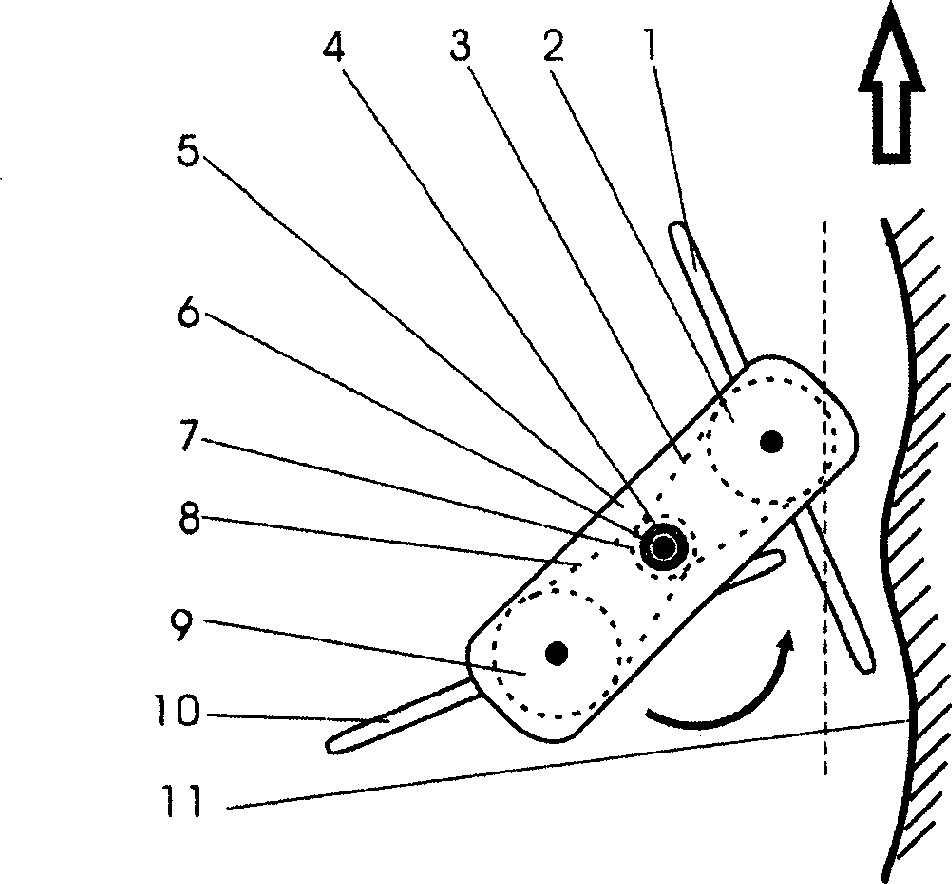

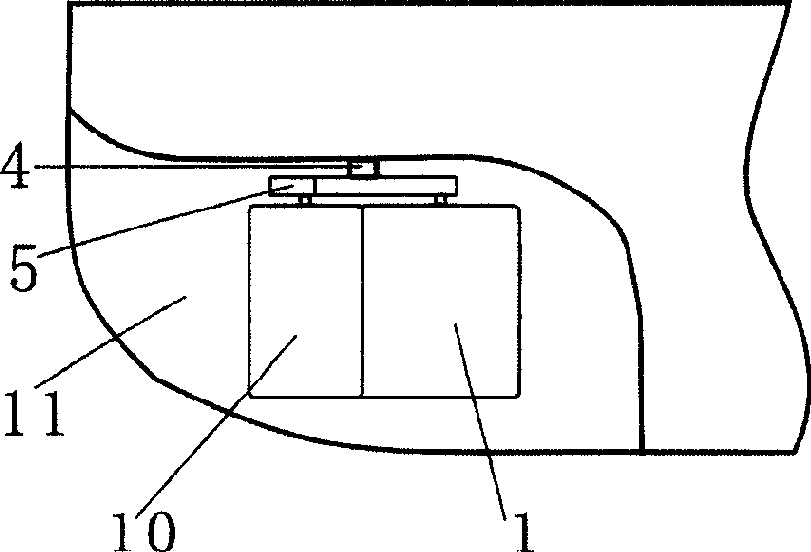

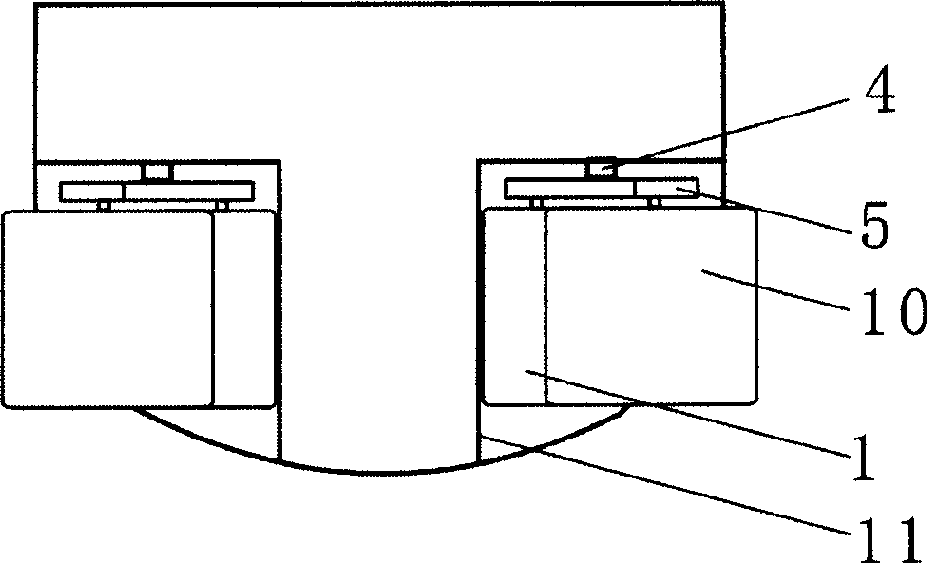

Biotic plate propoller ship for

InactiveCN1537778AManeuverable and flexibleEasy to manufacturePropulsive elements of non-rotary typeMarine engineering

A bionic flat propulsion mechanism ship is composed of two units which are left-right symmetrical relative to the longitudinal axis of ship and respectively installed at left and right of hull bottom at ship tail. Each unit consists of fixed wall, rotary arm and its axle, and two paddles. When the paddles are rotating, a bionic Weist-Fogh effect is generated between paddle and wall for increasing its propulsion efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Promoter for generation of gas hydrate, and preparation method and application thereof

InactiveCN102784604APromote generationAchieve a high degree of dispersionPressurized chemical processGaseous fuelsGeneration rateSesquioxide

The invention discloses a promoter for generation of gas hydrates, and a preparation method and application thereof. The promoter for generation of gas hydrates is a dry powdery solution formed after high speed shearing and dispersion of a surfactant solution and strong hydrophobic solid particles in a high intensity stirrer, wherein the surfactant solution is an aqueous solution of one or more anionic surfactants, cationic surfactants or nonionic surfactants, and the strong hydrophobic solid particles are one or more selected from the hydrophobically modified particles consisting of silica, titanium dioxide, titanium sesquioxide, alumina, zinc oxide, calcium carbonate, montmorillonite, diatomite, fly ash, zeolite, talcum and mica particles, etc. The promoter provided by the invention is highly dispersed solution microdroplets and has a great gas-liquid contact area, the dispersed microdroplets contain surfactants, which enables gas-liquid contact during growth process of hydrates to be further reinforced, and therefore, a generation rate of gas hydrates and gas storage amount in a static system are substantially improved; meanwhile, the promoter has the advantages of low cost, no pollution and convenient preparation and usage.

Owner:SOUTH CHINA UNIV OF TECH

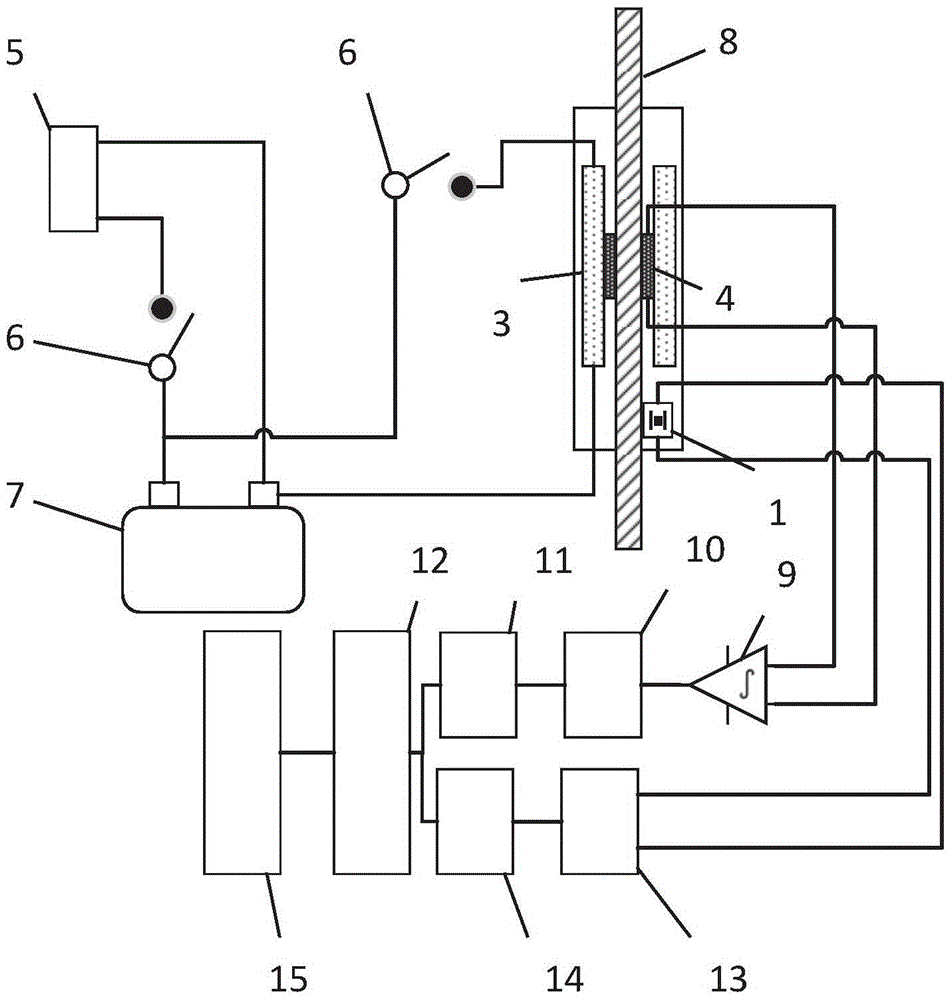

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Acid pickling promotor for iron and steel

The acid pickling promoter for iron and steel consists of inorganic salt as reducing agent 10-80 wt%, organic metal ion chelating chelating agent 1-20 wt%, synergist 1-20 wt% and water 10-50 wt%. The acid pickling promoter is suitable for being added into acid pickling liquid to promote the elimination of dense oxide scale on the surface of steel, shapes and other iron and steel product. It can raise the surface quality of silicon steel plate after being acid pickled, shorten acid pickling period, reduce acid consumption and improve acid pickling environment.

Owner:HUAZHONG UNIV OF SCI & TECH +2

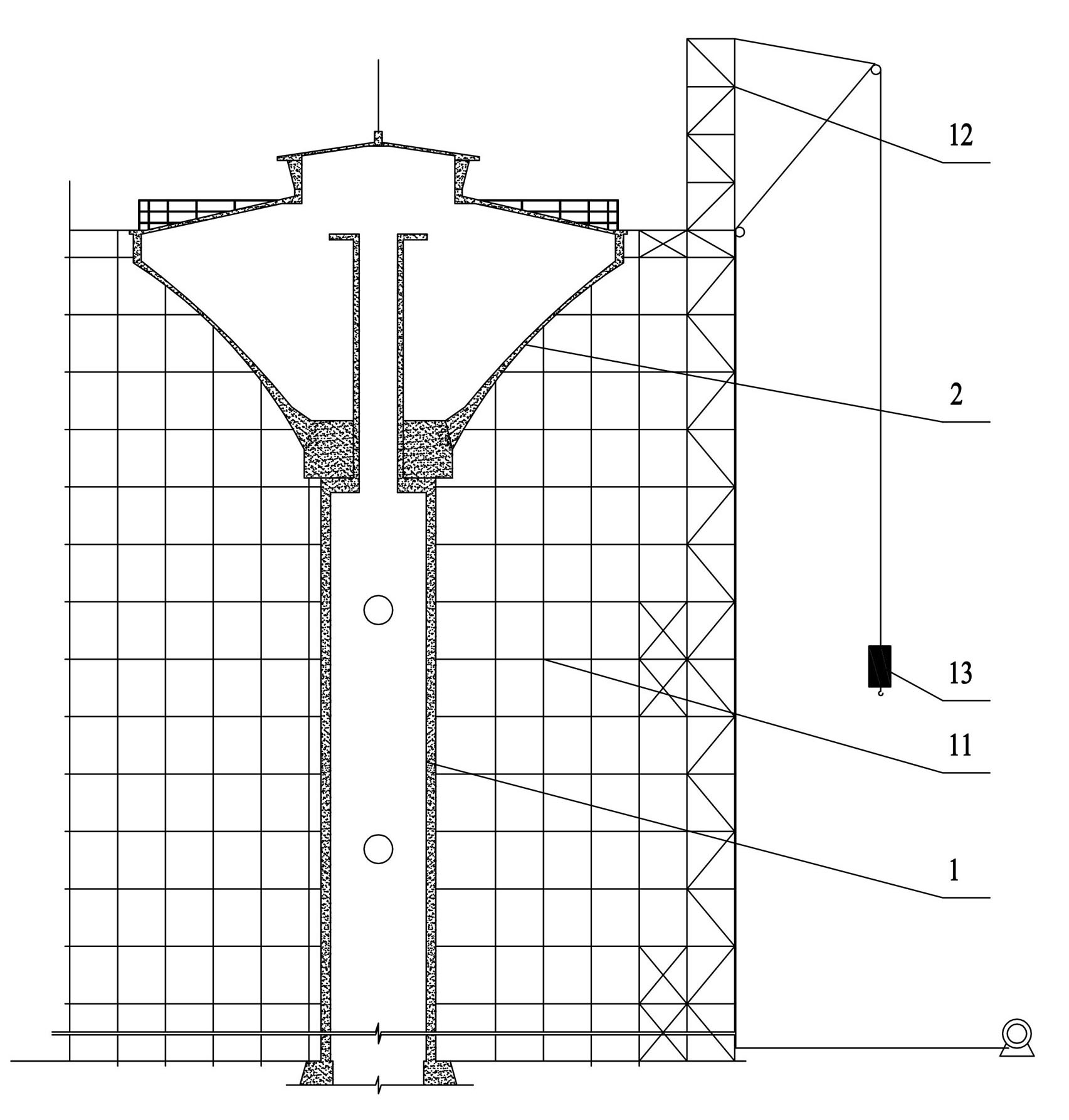

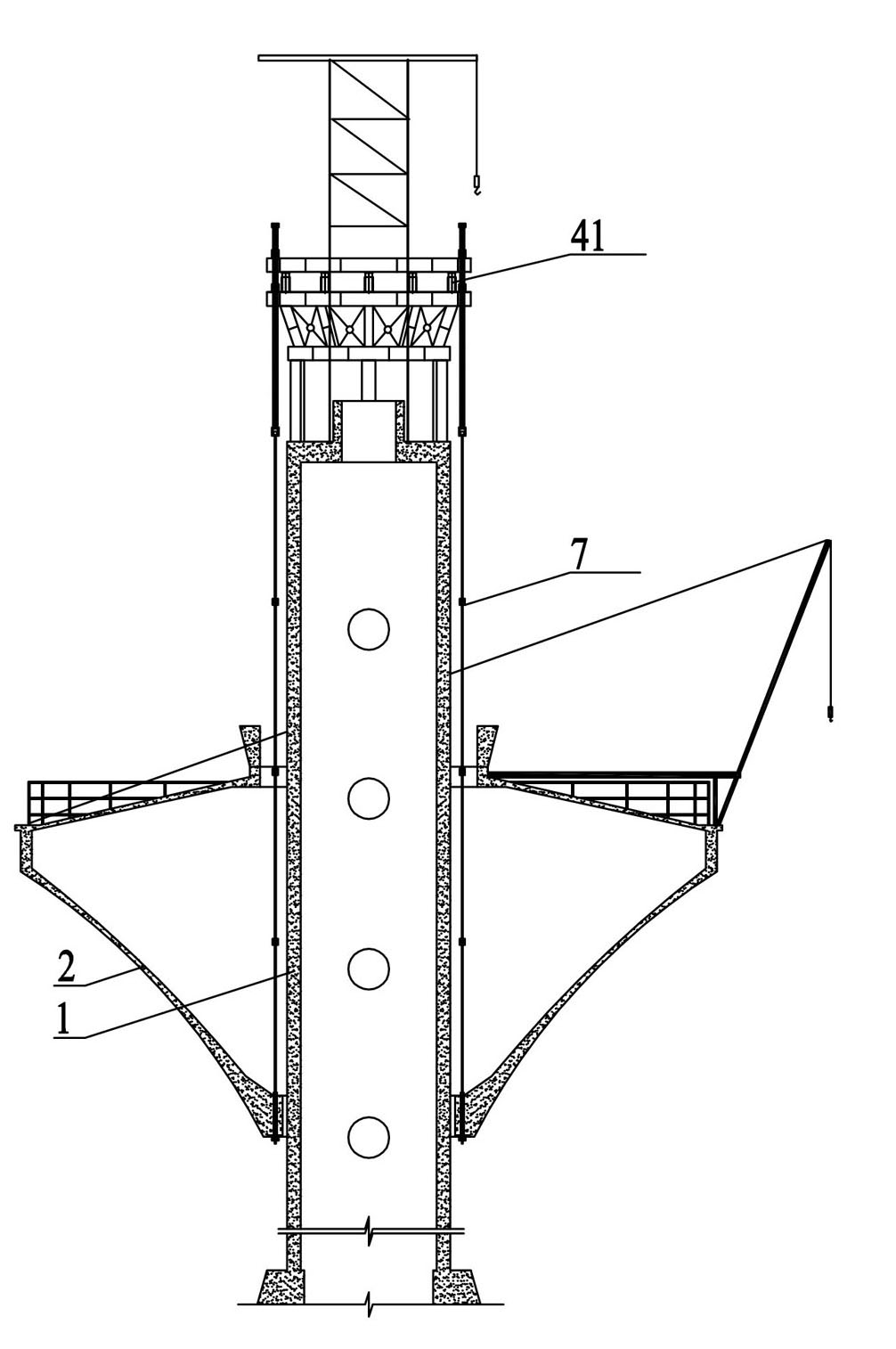

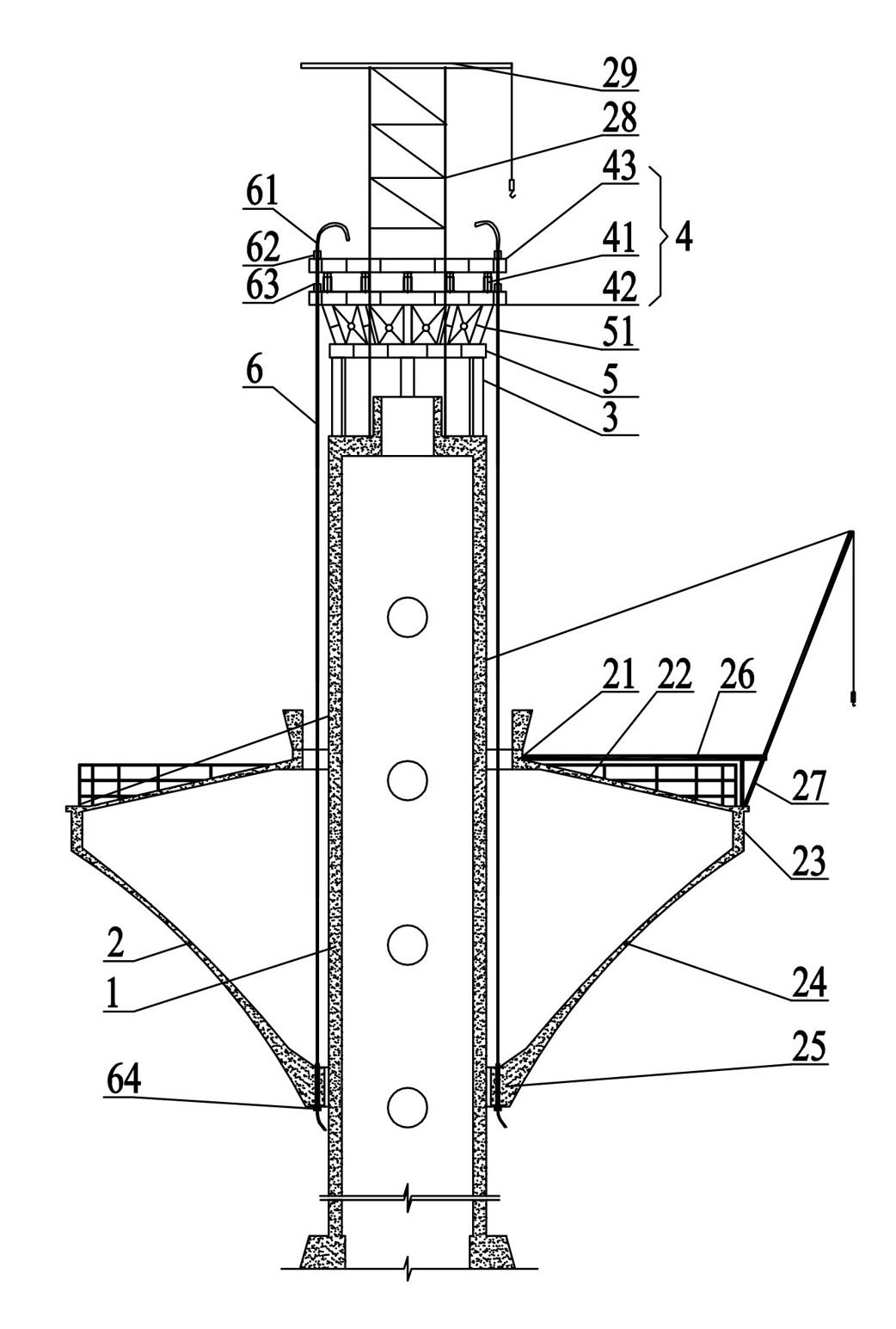

Hoisting method of hyperbolic water-tower water tank and hoisting device

The invention discloses a hoisting method of a hyperbolic water-tower water tank and a hoisting device. The hoisting method comprises the following steps of: firstly, prefabricating a water tank, installing lifting equipment, and starting to lift after a real-load pressure test is qualified; during lifting, firstly, jacking steel beams and driving a steel strand to lift; after a stroke is completed, utilizing a locking anchorage device to clamp the steel strand at a static steel beam, returning oil, then utilizing the locking anchorage device to clamp the steel strand onto a moving steel beam after falling back, thereby completing a hoisting cycle for one time; and repeatly lifting until the water tank is lifted to the position and then fixing. The hoisting device comprises a lifting part, a supporting part and a sling assembly, wherein the lifting part comprises a moving steel beam, a static steel beam and a hydraulic lifting device arranged between the moving steel beam and the static steel beam; and the sling assembly comprises a steel stand. The top of the steel stand penetrates through the moving steel beam and the static steel beam and is clamped on the steel beams through the locking anchorage device, and the bottom of the steel stand is connected with the water tank. The construction method and the device are simple in operation and have the advantages of low cost, low labor strength, low energy consumption, strong safety and reliability and good quality of construction.

Owner:五矿二十三冶建设集团有限公司

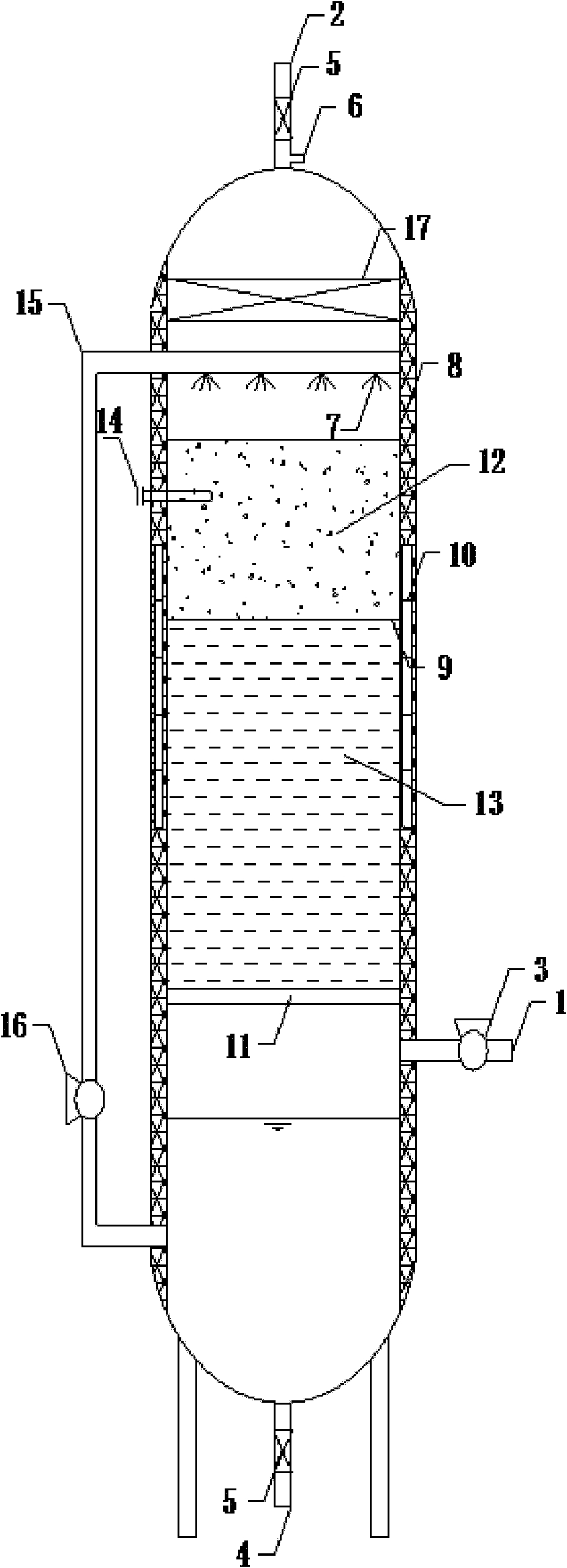

Efficient rainwater filter

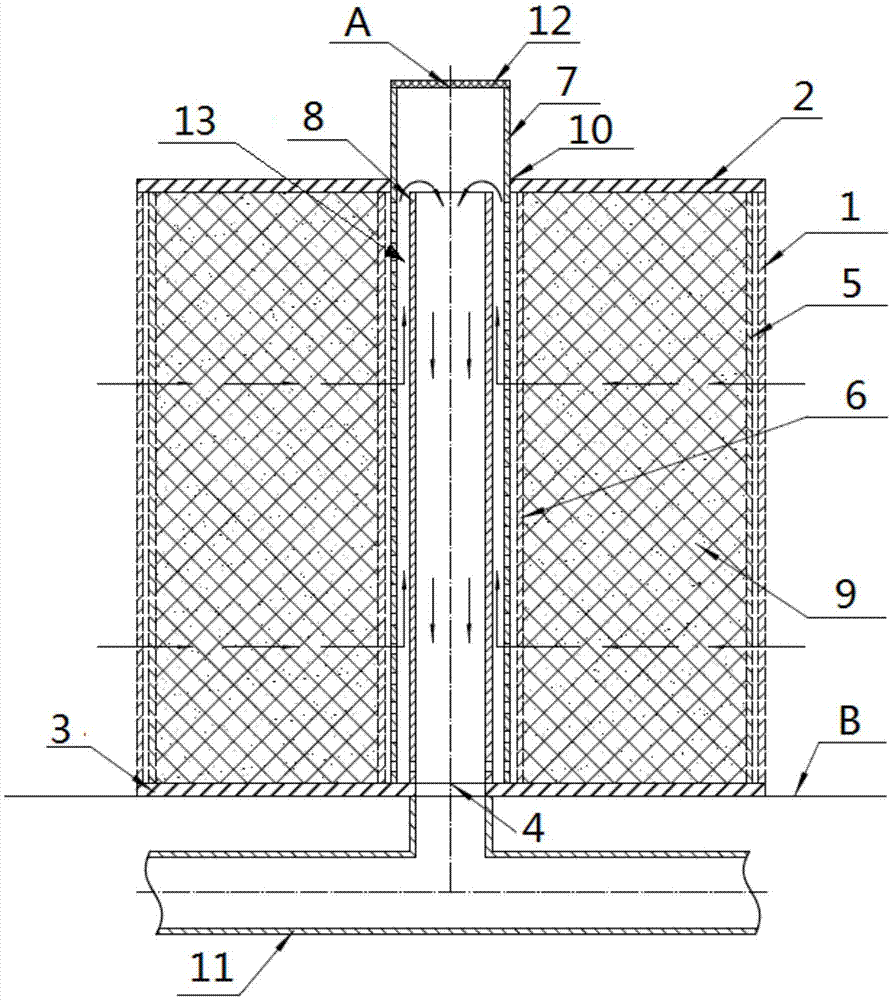

ActiveCN105435495AGuaranteed utilizationGuaranteed processing efficiencyMembrane filtersLoose filtering material filtersFilter mediaEngineering

The invention discloses an efficient rainwater filter and belongs to the technical field of rainwater treatment devices. The efficient rainwater filter comprises a filter communicated with a drain pipe, a collecting pipe with a water hole is coaxially arranged in the filter, and a central cylinder is coaxially arranged in the collecting pipe. The central cylinder is provided with an overflow hole, the bottom end of the central cylinder is communicated with the drain pipe, and a rainwater retention channel is formed between the collecting pipe and the central cylinder. Rainwater accumulated in the rainwater retention channel is discharged through the overflow hole in the central cylinder. The efficient rainwater filter is simple in structure and convenient to manufacture and use; in the whole filtering process, not only is full contact between the rainwater and a filtering medium guaranteed, but also pollutants in the rainwater can be effectively removed, and the filtering medium utilization rate and the treatment efficiency of the filter are also guaranteed.

Owner:WUHAN MEIHUA YUSHUI ENVIRONMENT CO LTD

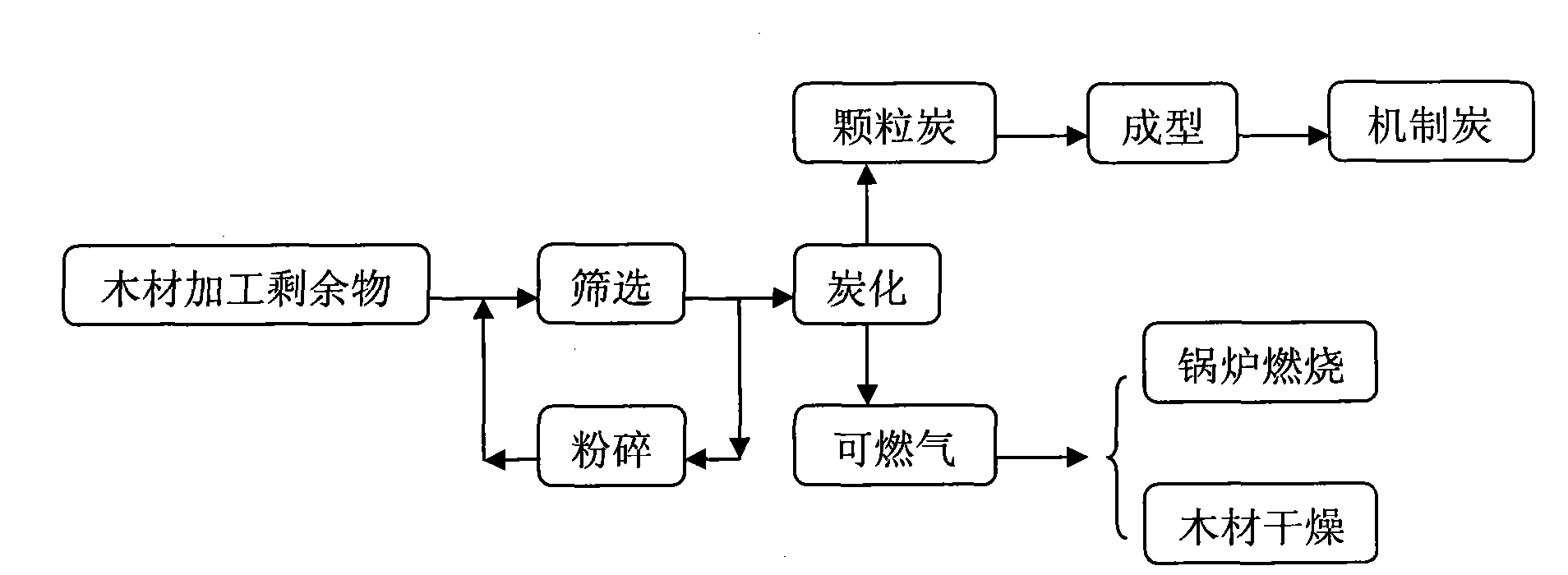

Treatment method of wood processing residues and charcoal prepared thereby

ActiveCN101629083AEasy to prepare and useImprove combustion efficiencyBiofuelsSolid fuelsCompression moldingCarbonization

The invention relates to a treatment method of wood processing residues, a method for preparing machine-made charcoal by utilizing the wood processing residues and the machine-made charcoal prepared by the method. The treatment method of the wood processing residues comprises the steps of carrying out carbonization treatment and obtaining the charcoal and combustible gas, wherein, the carbonization temperature for carbonization treatment is 400-900 DEG C, the time of carbonization treatment is 0.5-4 hours, and air of less than 4m<3> is introduced into each 1kg of the wood processing residues during the process of carbonization treatment. The treatment method can improve the energy utilization rate of the wood processing residues and reduce environmental pollution; the treatment method adopts the way of firstly carrying out the carbonization and then carrying out molding for preparing the charcoal, thereby greatly reducing energy consumption of wood wastes during direct compression molding and carrying out the thorough carbonization; the treatment method does not produce black smoke during ignition, and the performance indicators of the machine-made charcoal are in line with the requirements of standard of first-grade charcoal of national standard GB / T17664-1999.

Owner:BEIJING FORESTRY UNIVERSITY

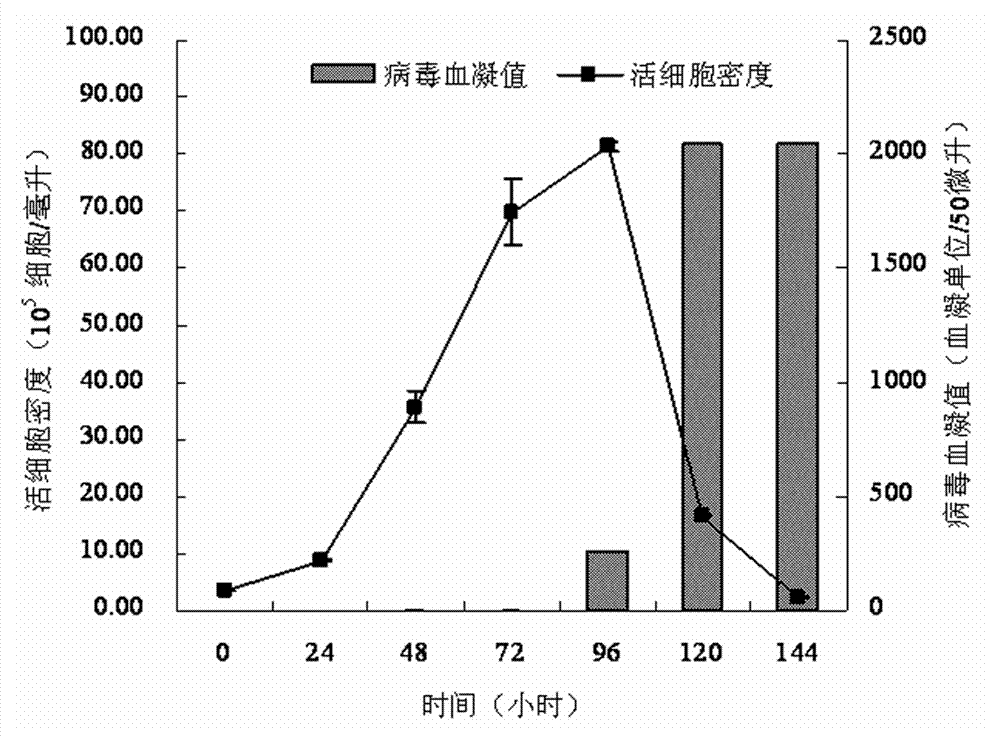

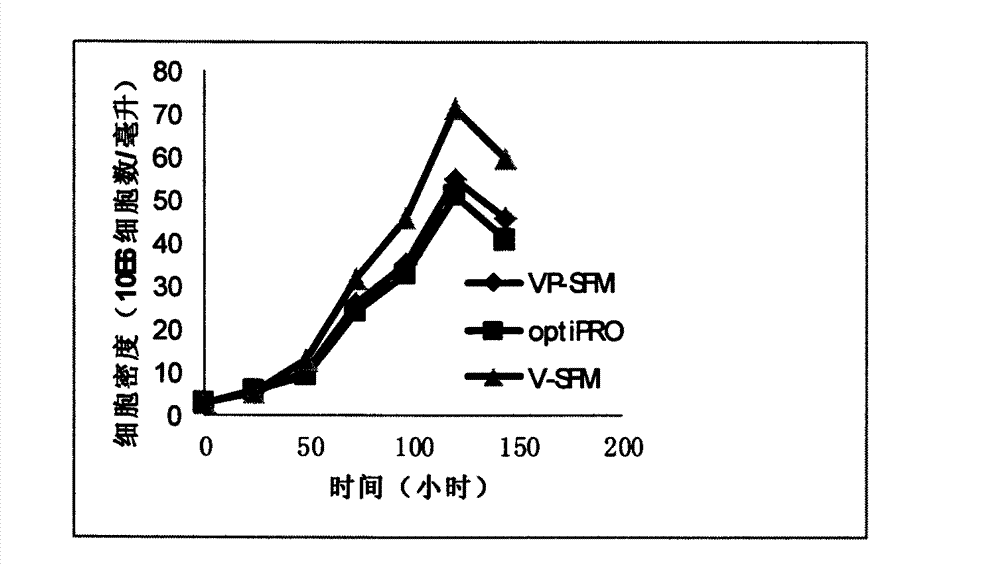

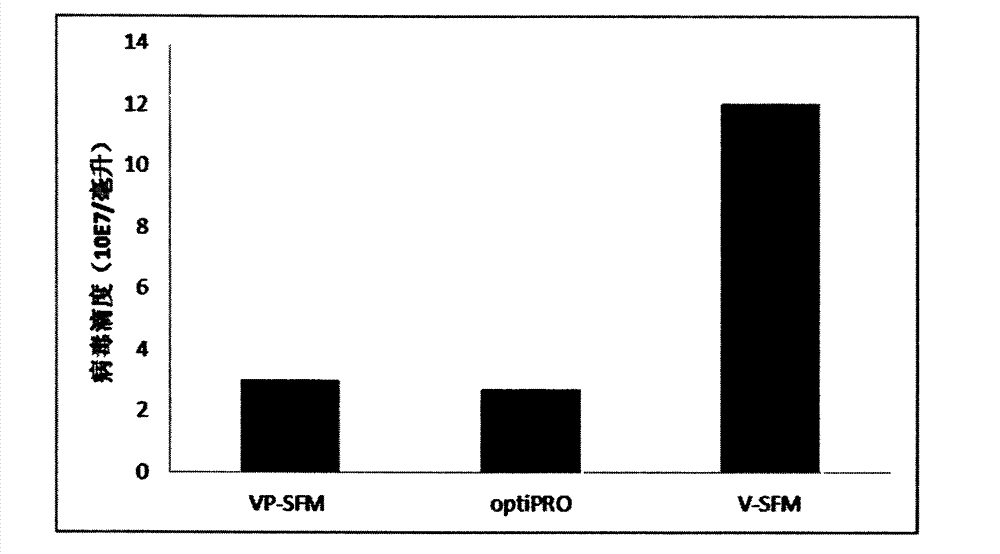

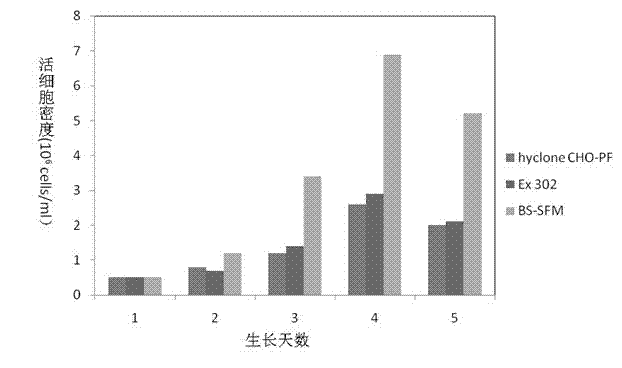

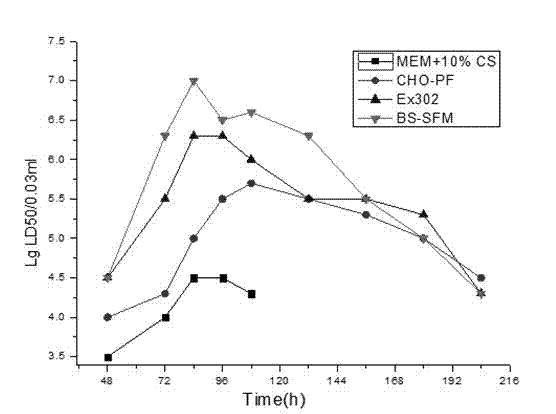

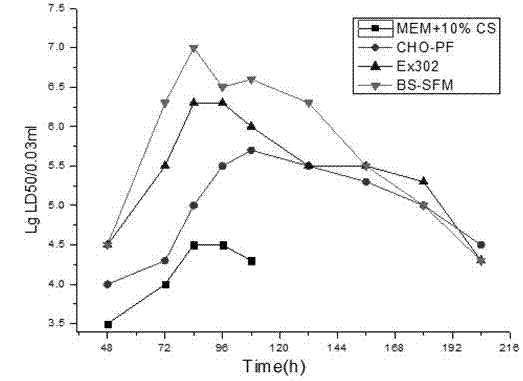

Serum-free medium suitable for large-scale production of influenza vaccines

ActiveCN103045533AEasy to separateEasy to purifyArtificial cell constructsVertebrate cellsBiotechnologyNutrition

The invention relates to the technical field of culture medium development and research of biotechnology and discloses a serum-free medium suitable for large-scale production of influenza vaccines. The serum-free medium comprises 23 basic metabolism nutrients, two nucleic acid compounds, 6 vitamins, 9 inorganic salt compounds, a shear force protective agent, two acidity and alkalinity buffer agents, an acidity and alkalinity indicator, 10 virus reproduction promoters and three additives. The conventional preparation method of the serum-free medium comprises the following steps of: dissolving the components in ultrapure water without a heat source so as to prepare the serum-free medium. The using method is a conventional method. The serum-free medium has the beneficial effects that the serum is not contained, the total protein content is lower than 10mg per liter, separation and purification of the product are promoted, and the serum-free medium is suitable for production of influenza vaccines, supports the normal growth and long-term continuous cell culture of animal cells and can be used without adaption; and moreover, because the components are clear, the serum-free medium is convenient to prepare, controllable in cost and suitable for large-scale production of the influenza vaccines.

Owner:EAST CHINA UNIV OF SCI & TECH

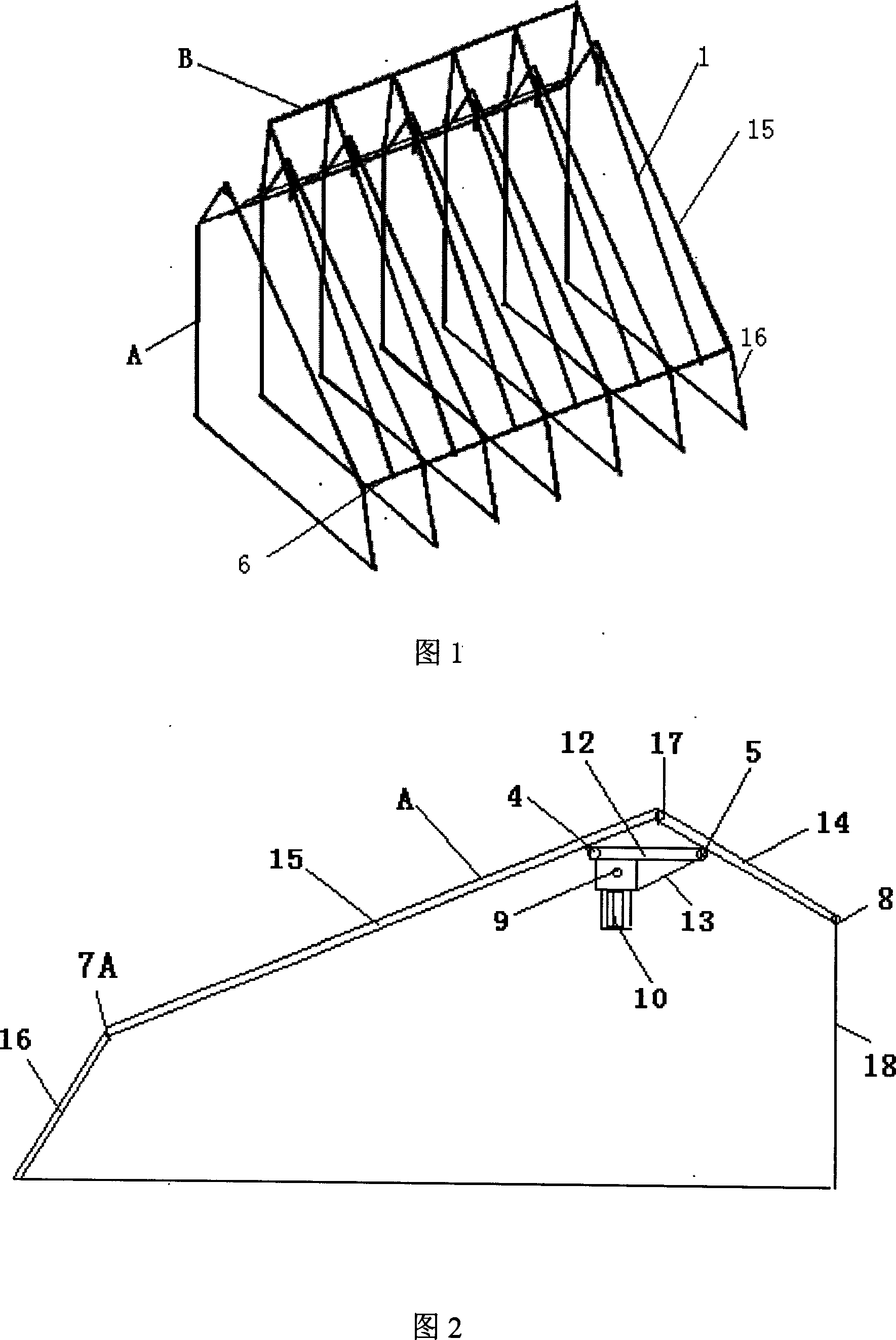

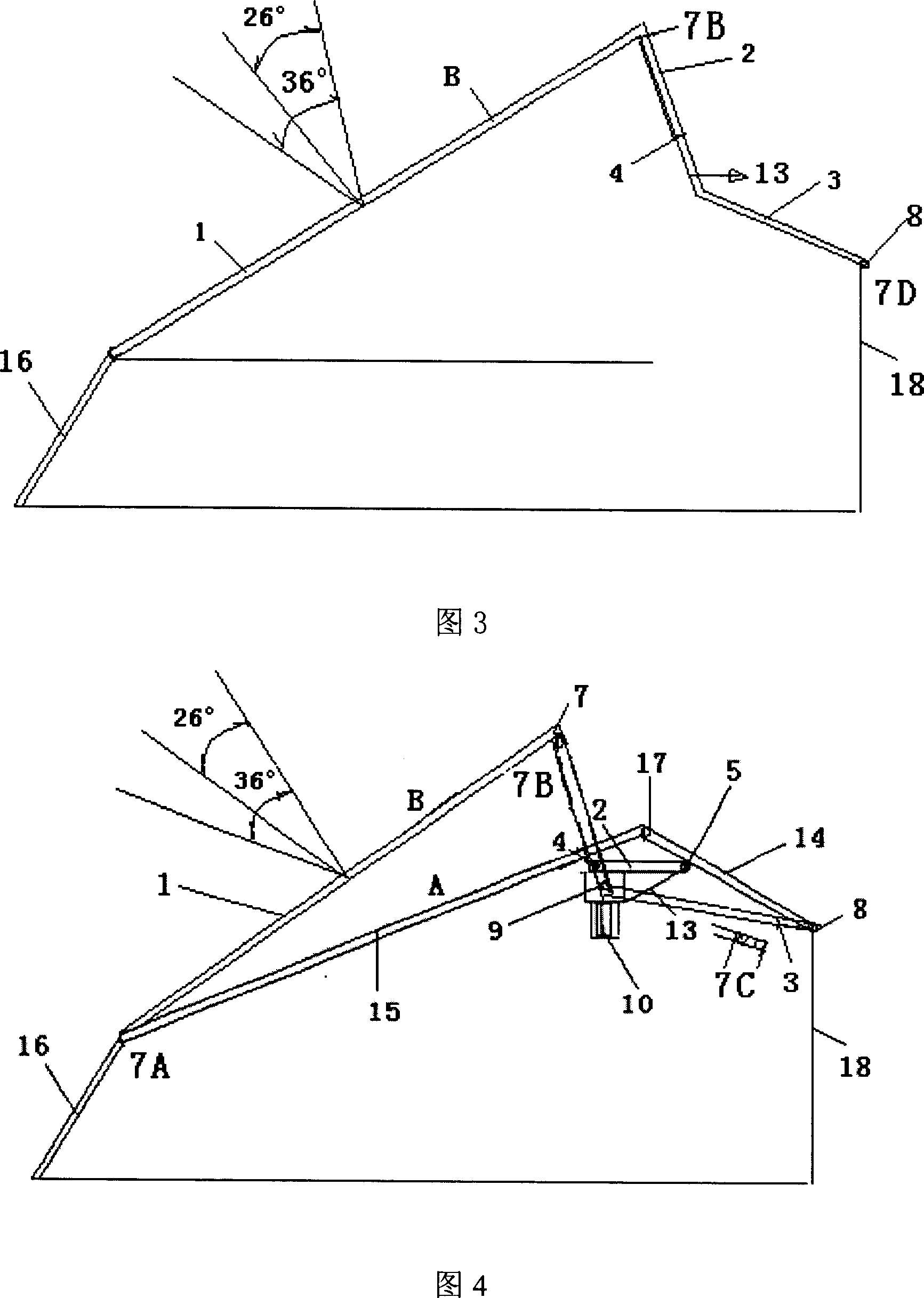

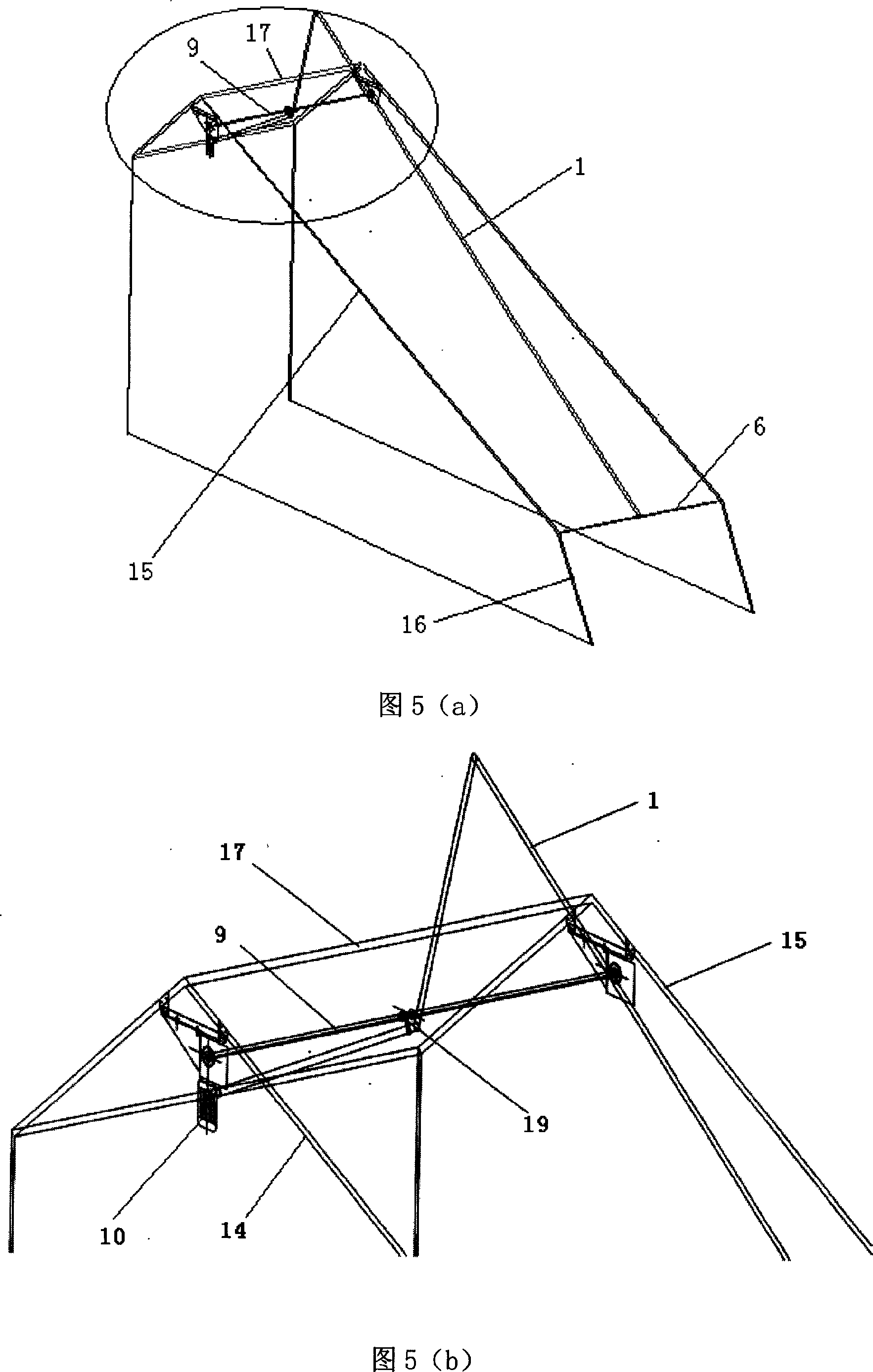

Day-light greenhouse with the lighting surface incidence changeable

InactiveCN101116408AReasonable structureIncrease the level of automationAgricultural buildingsClimate change adaptationFixed frameDrive shaft

The invention discloses a sunlight greenhouse with a daylighting area with a changeable dip angle, comprising a surface fixed framework A and a surface movable framework B, wherein the surface fixed framework A is connected with the surface movable framework B though a connecting gear comprising a motor bracket arranged between a slope of roof component 14 behind a fixed frame of roof of the surface fixed framework A and a main frame of surface fixing element, and a gear motor is arranged on the motor bracket and is connected with a transmission shaft connected with a tightwire. Under the drive of the tightwire, the daylighting surface can adjust the own dip angle with different outside light conditions, thereby improving the lighting effect. Because of the particularity of the projection of lighting materials the change range of the dip angle fortunately makes the lighting surface angle shift from unfavorable conditions to the angle range of high projection rate, thereby greatly improving the lighting performance of the greenhouse. The sunlight greenhouse with a daylighting area with a changeable dip angle of the invention has the advantages of a reasonable structure, simple manufacture and manipulation and long service life.

Owner:NORTHWEST A & F UNIV

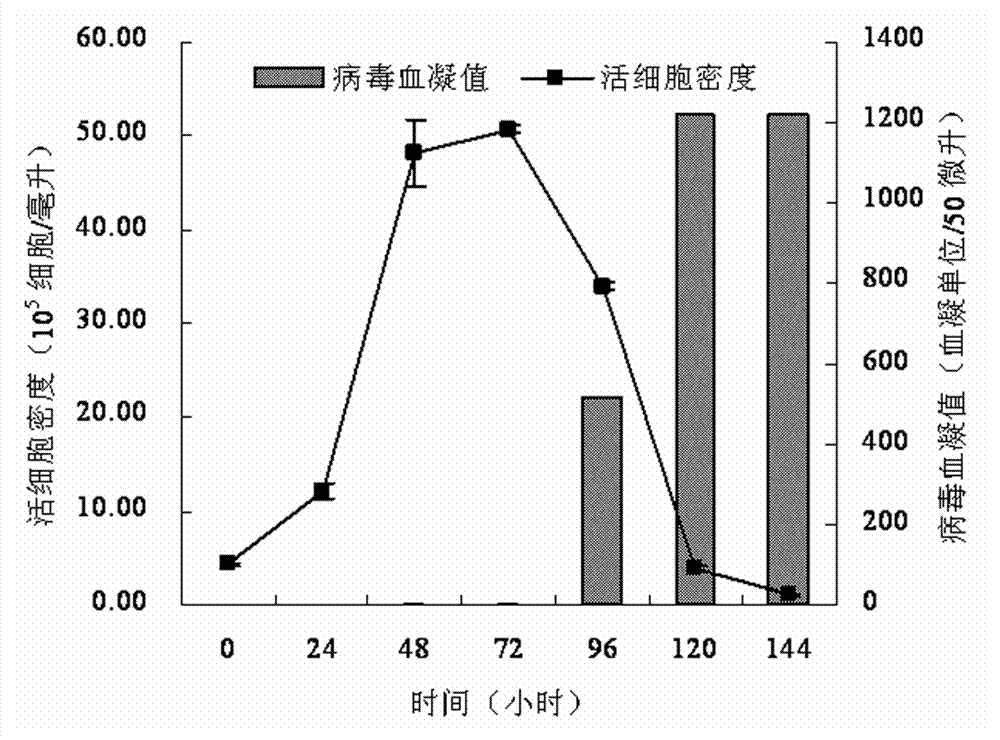

Culture medium applicable to suspension and magnification cultivation of Vero cell microcarriers and method for suspension magnification cultivation of Vero cell microcarriers

ActiveCN102827804AIncrease productivityEasy to separate and purifyArtificial cell constructsVertebrate cellsBottleCulture mediums

The invention discloses a culture medium applicable to suspension and magnification cultivation of Vero cell microcarriers. The culture medium comprises amino acid, inorganic salt, vitamins, protein hydrolysate, lipid, buffer components and additives. The culture medium not only is applicable to static cultivation in a Vero square bottle and cultivation in a roller bottle, but also is supportive for suspension cultivation of the microcarriers and magnification cultivation of the microcarriers in a reactor, and can be used as a serum-free virus maintenance medium to realize serum-free virus production.

Owner:苏州沃美生物有限公司

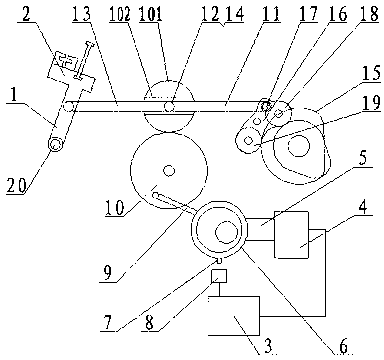

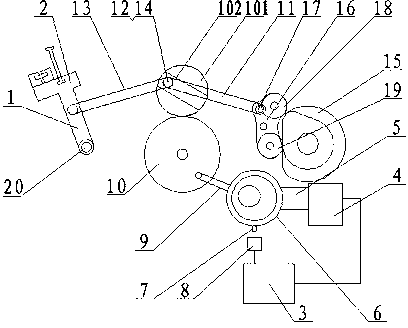

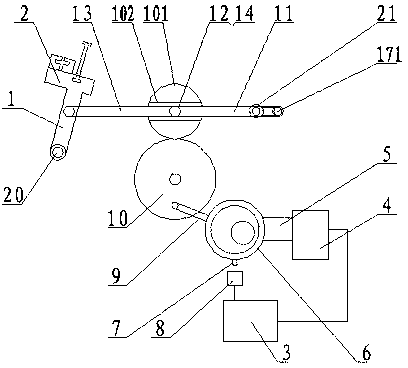

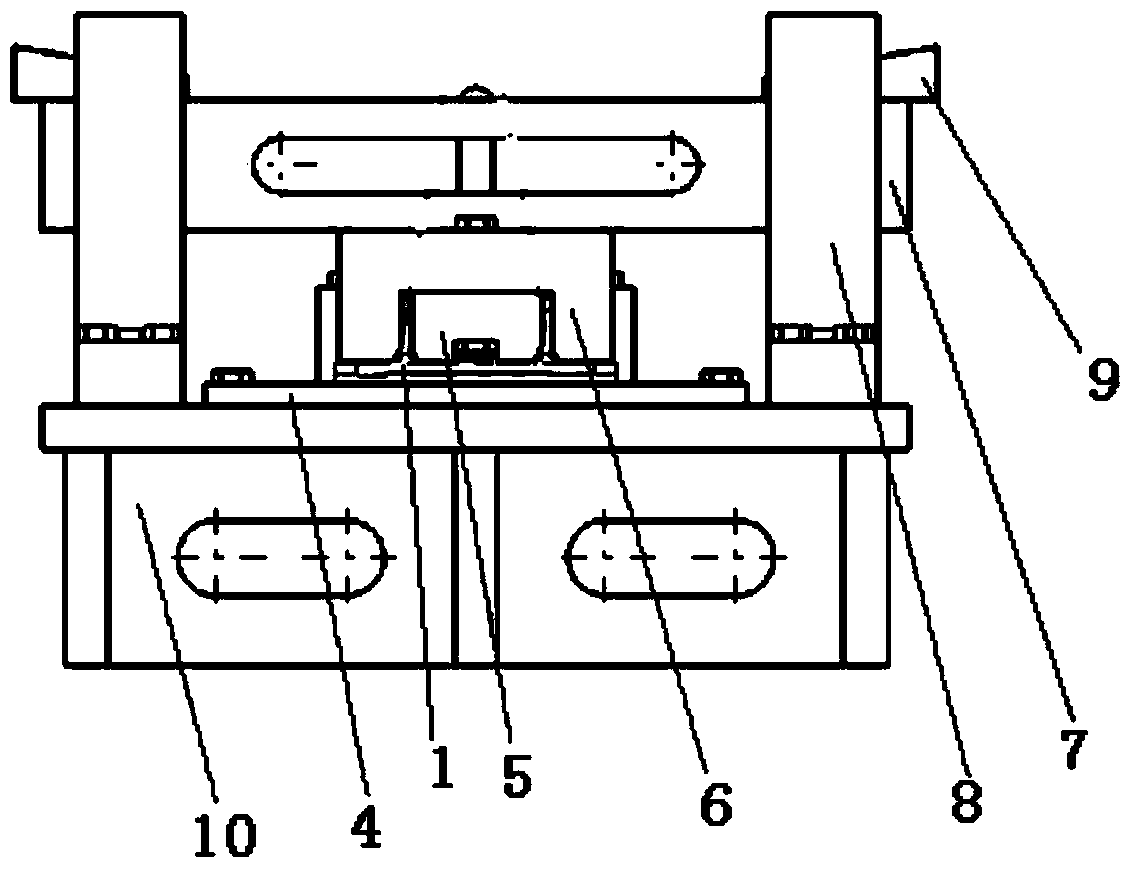

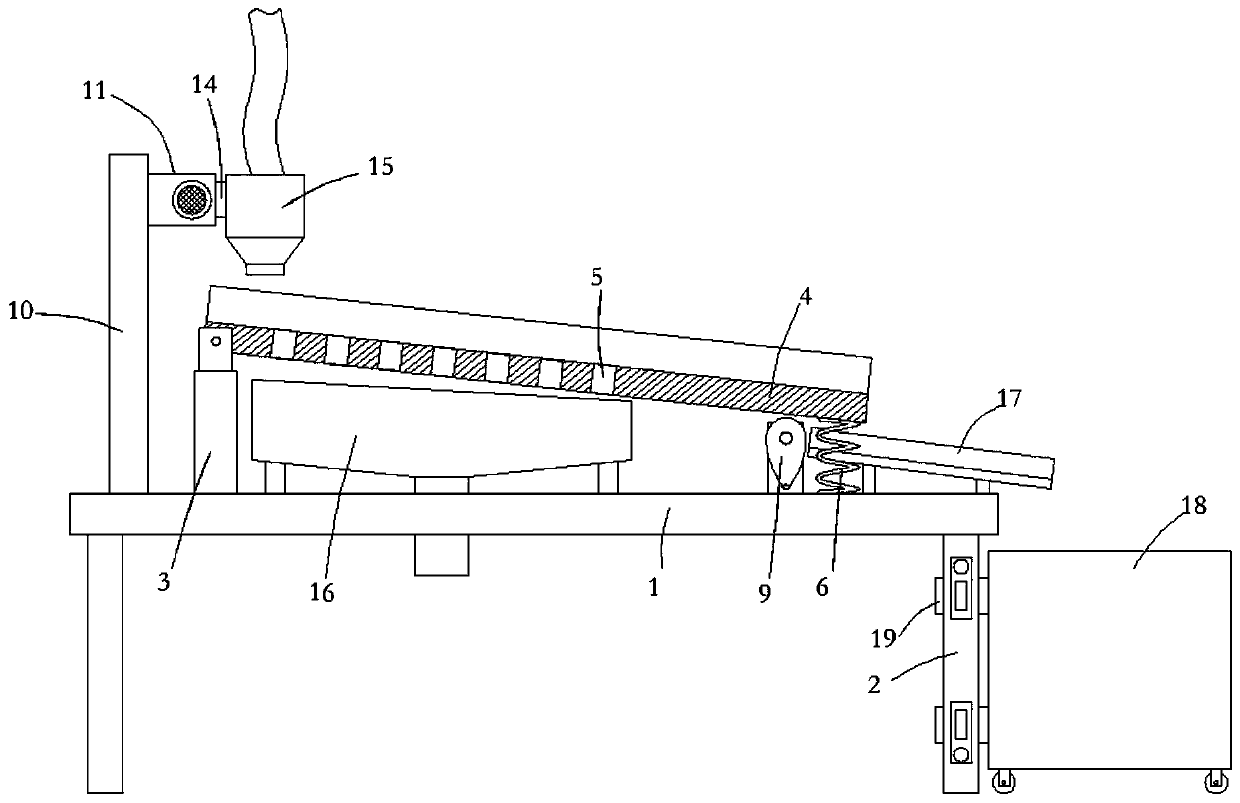

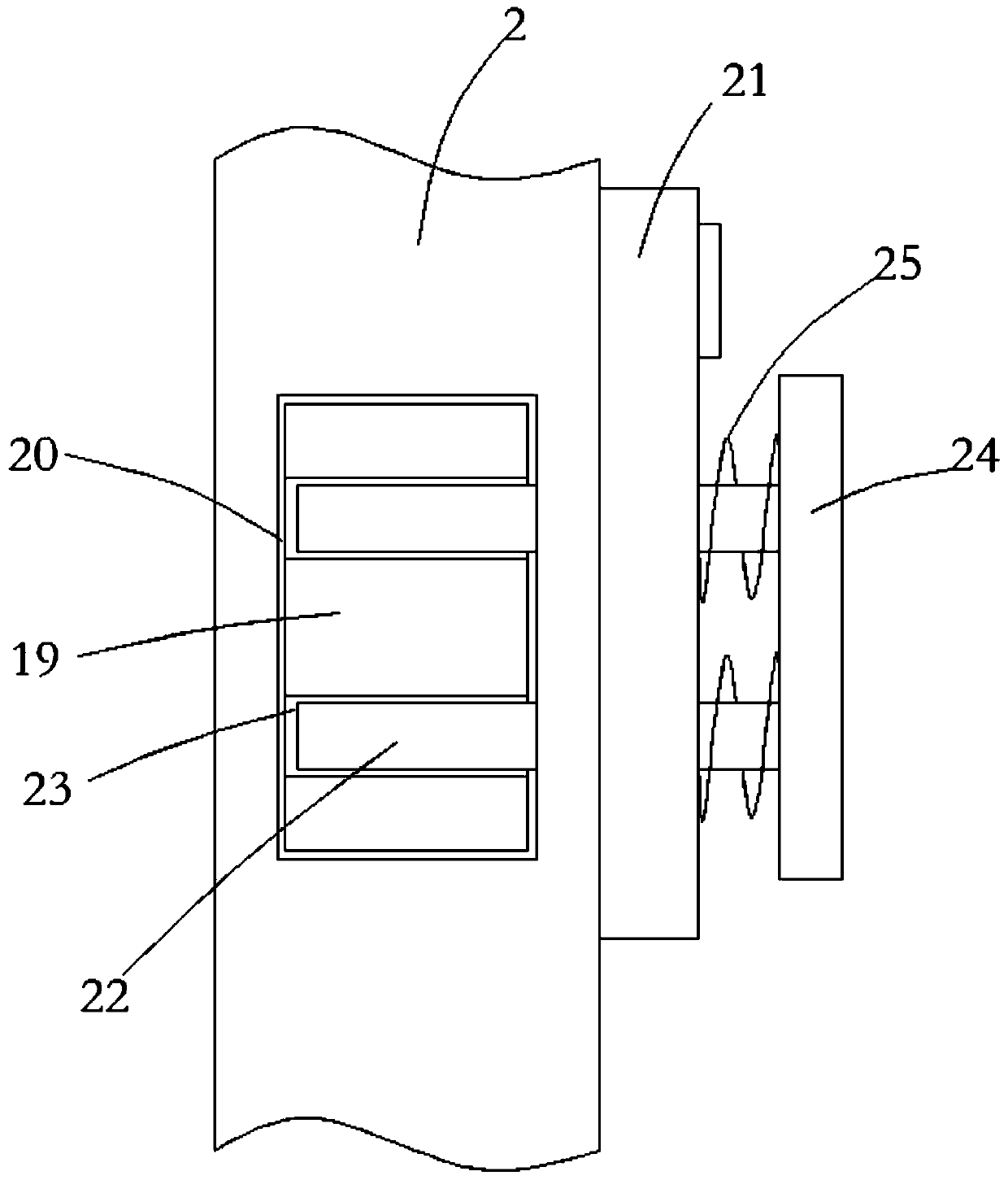

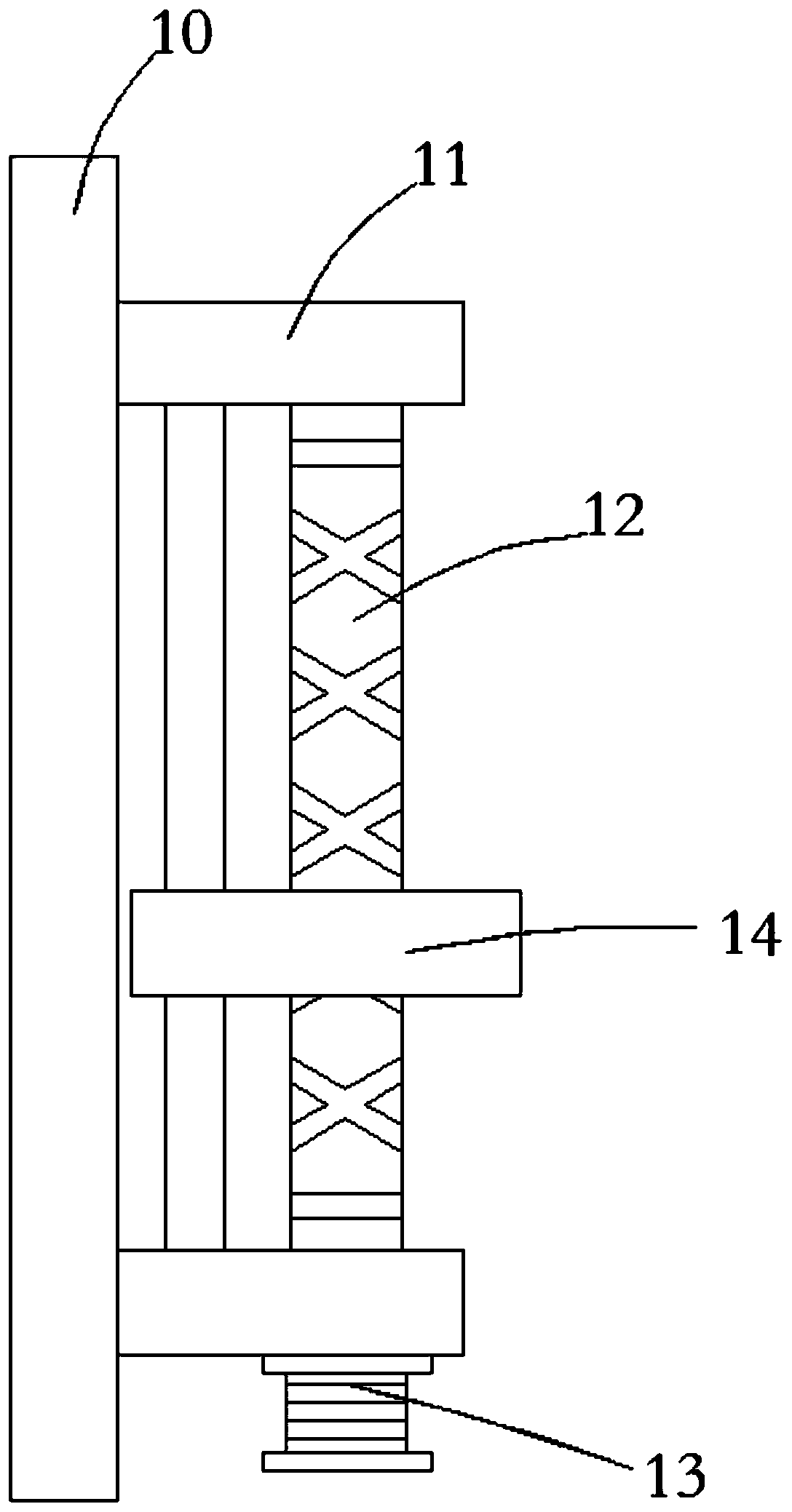

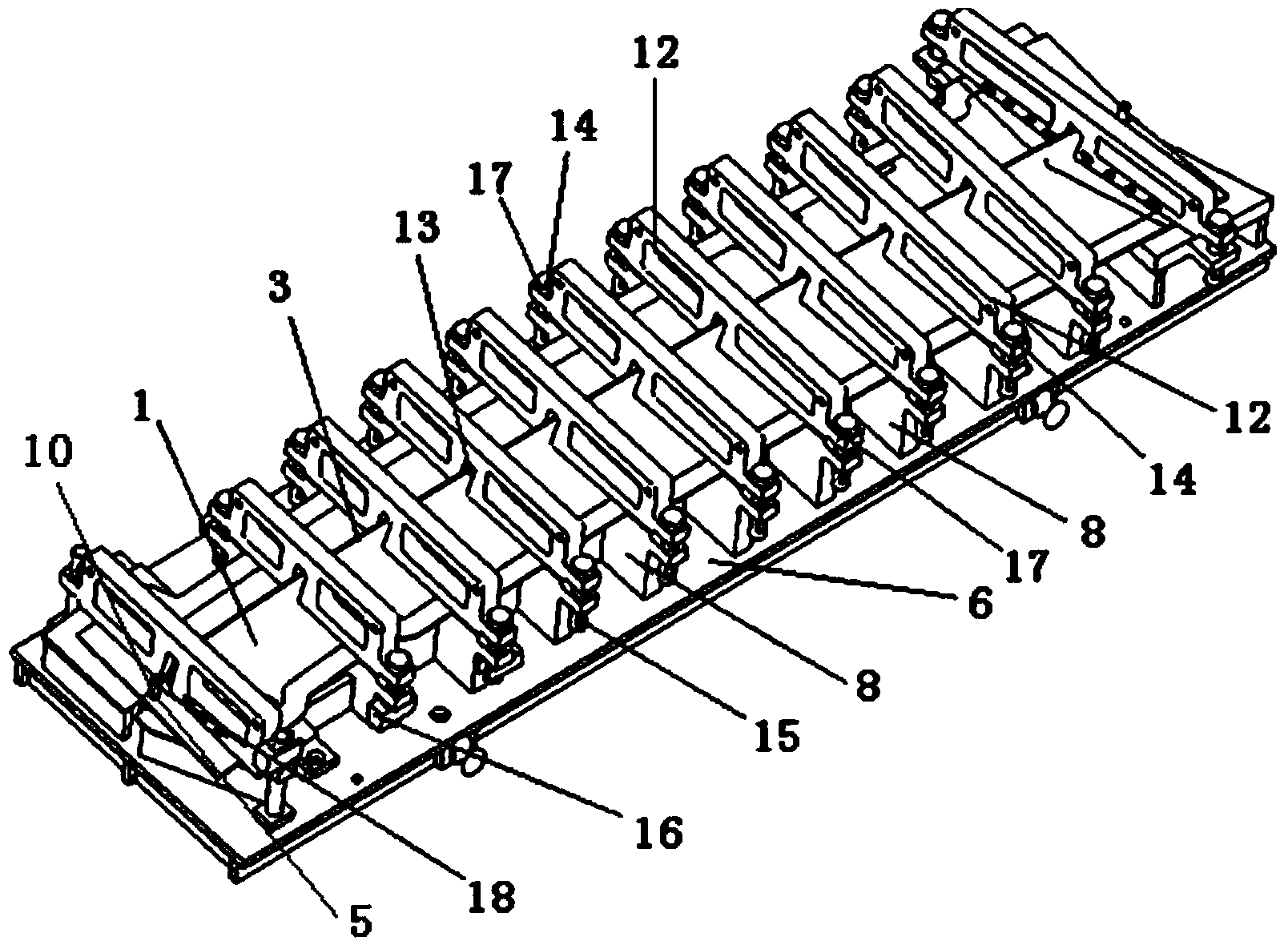

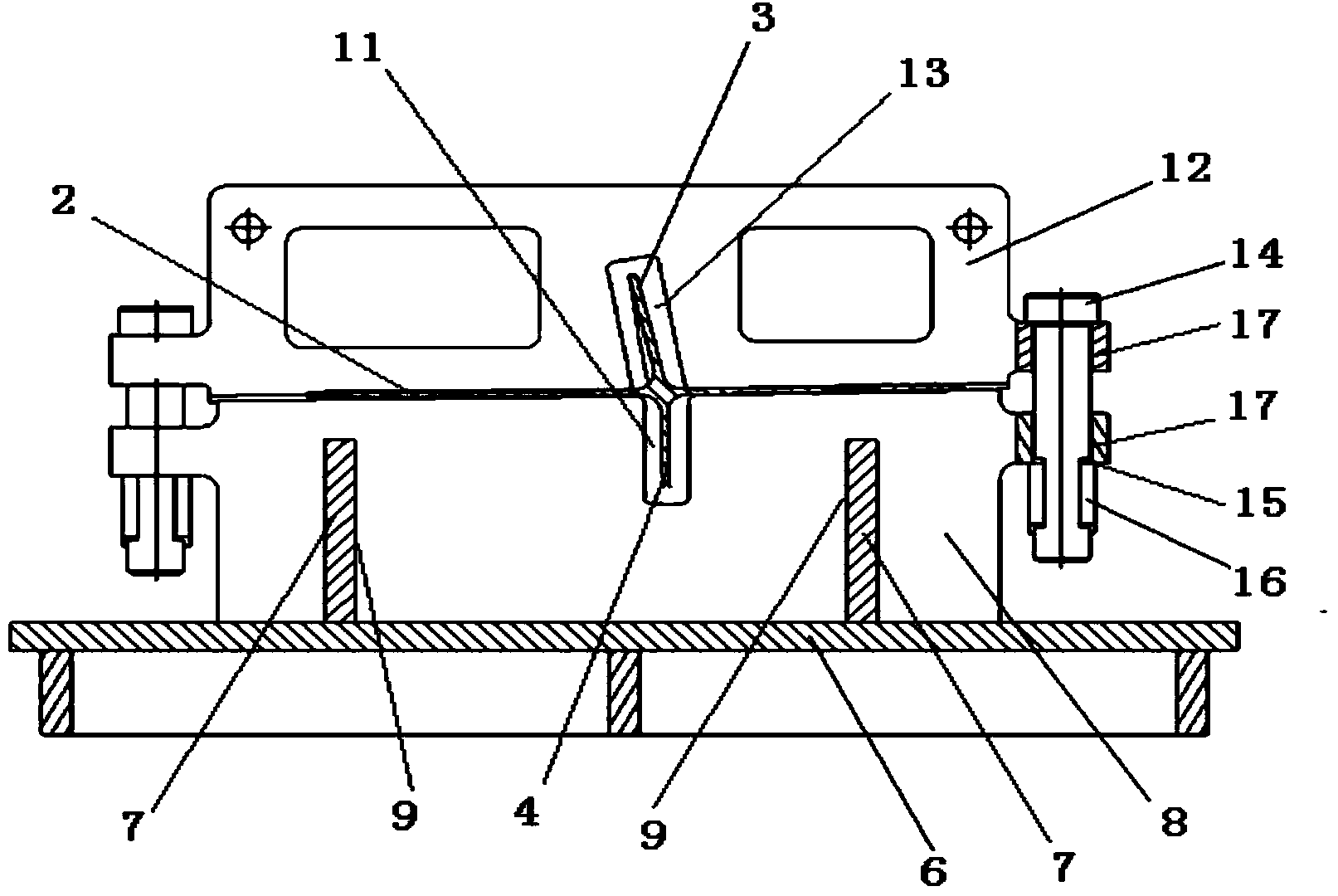

Numerical control rotating cam control fulcrum chute fuzzing mechanism

The invention relates to a numerical control rotating cam and control fulcrum chute fuzzing mechanism. The mechanism consists of a numerical control fuzzing drive mechanism, a fixed stroke reciprocating mechanism and a beating-up slay sword part which is under limiting control through a beating-up drive link and a numerical control fuzzing drive mechanism, wherein an electric box of the numerical control fuzzing drive mechanism drives an eccentric rotating cam through a numerical control motor and a reducing mechanism sequentially, and the eccentric rotating cam carries out drive control on a chute seat with a chute through a push-pull drive mechanism; and one end of the beating-up drive link is hinged with the fixed stroke reciprocating mechanism, the other end of the beating-up drive link is movably hinged to a slay sword, and the beating-up drive link is provided with a sliding block or a rotor which is limited in the chute and slides or rolls along the direction of the chute. A conjugate cam group or a crank changes a linear stroke of the beating-up drive link when the beating-up drive link moves towards the slay sword to a limiting point, so that the slay sword is stabilized, and beating up can be adjusted to beat weft yarns at different positions of a fell; and the mechanism is simple in structure, is convenient to manufacture and use and can be adjusted to meet different fuzz height requirements at any time.

Owner:JIANGSU YOUCHENG CNC TECH CO LTD

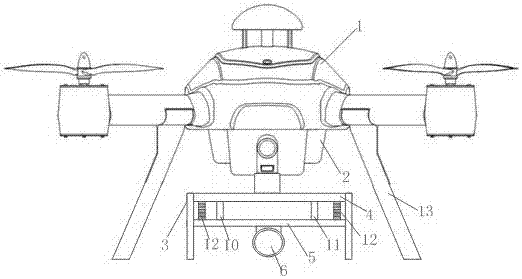

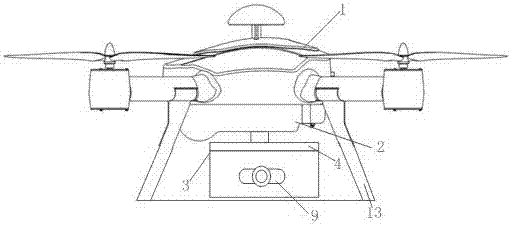

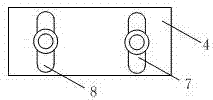

Fire protection unmanned aerial vehicle

InactiveCN106945836ABuffer rear thrustHigh precisionAircraft componentsFire rescueFire protectionFixed frame

The invention relates to a fire-fighting unmanned aerial vehicle, which includes a fuselage and a steering gear arranged at the bottom of the fuselage, an inverted U-shaped fixing frame arranged under the steering gear, a support rod arranged on the top plate of the fixing frame, and a The buffer rod at the lower end of the support rod and the fire extinguishing bomb launch tube fixedly connected with the buffer rod; two installation waist-shaped holes are arranged on the top plate, and a buffer waist-shaped hole is respectively provided on the two side plates of the fixing frame; the support rod is connected with the The connection of the waist hole is installed; the buffer rod is parallel to the top plate and penetrates in the two buffer waist holes. The present invention can buffer the back thrust generated by the fire extinguishing bomb launching tube when the fire extinguishing bomb is launched by sliding the buffer rod within a certain range in the buffer waist hole, so as to prevent the steering gear and the parts of the UAV from being damaged by the back thrust and prolong the The service life of the UAV and its components. The buffer structure of the invention is simple and convenient to manufacture and use.

Owner:西安旋飞电子科技有限公司

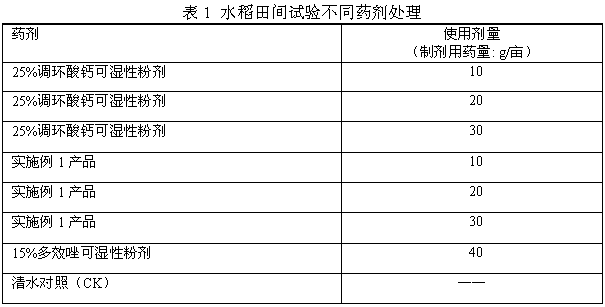

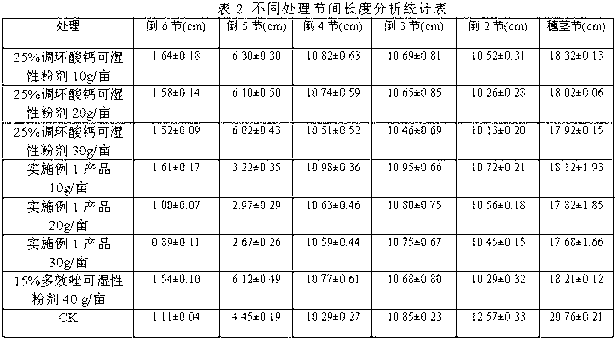

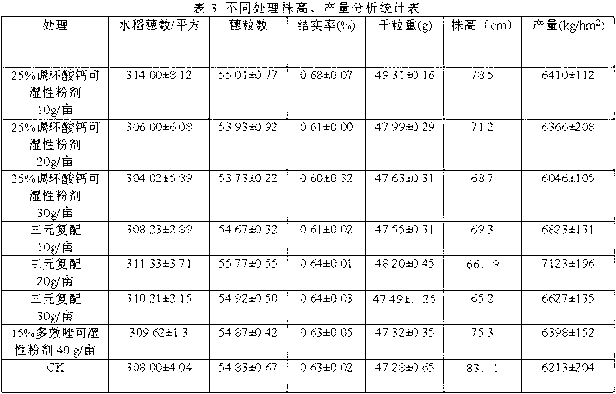

Regulator composition for controlling vigorous growth, resisting lodging and increasing yield of rice

ActiveCN102701858AControl prosperityLow costBiocidePlant growth regulatorsBULK ACTIVE INGREDIENTOrganic chemistry

The invention belongs to the field of plant growth regulation and control, and discloses a regulator composition for controlling vigorous growth, resisting lodging and increasing yield of rice. The composition comprises the following active ingredients in part by weight: 10 to 35 parts of prohexadione calcium, 0.1 to 5 parts of diethyl aminoethyl hexanoate (DA-6) and 3 to 10 parts of zinc element. The composition can be prepared into wettable powder and is low in cost and convenient to prepare and use; and the ternary compound regulator can effectively control the vigorous growth of the rice and inhibit lodging, and has an obvious effect of increasing the yield of the rice.

Owner:郑州郑氏化工产品有限公司

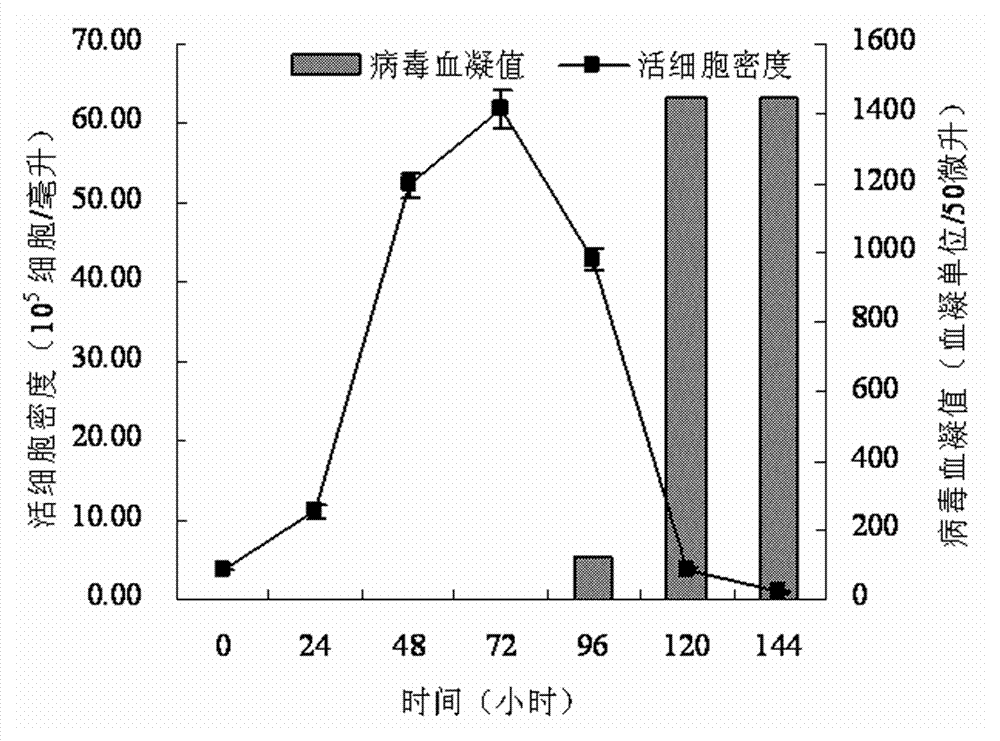

Serum-free medium suitable for large-scale single-cell suspension culture of young hamster kidney cells

InactiveCN102268403AIncrease productivityEasy to separate and purifyArtificial cell constructsVertebrate cellsCulture mediumsAmino acid

The invention discloses a serum-free medium suitable for large-scale single-cell suspension culture of young hamster kidney cells (BHK cells), including 21 kinds of amino acids, 11 kinds of inorganic salts, 12 kinds of vitamins, 1 kind of protein hydrolyzate, 2 kinds of Lipids, 2 buffer components and 6 additives. The BHK cell serum-free medium of the present invention produces biological products by single-cell suspension culture, which can not only avoid various disadvantages of serum culture, but also eliminate the problem of difficult scale-up of roller bottle adherent culture, thereby improving the production efficiency of BHK cell culture And reduce production costs, while ensuring product quality, has good application value and huge market prospects.

Owner:上海米迪生物技术有限公司

Carbon dioxide hydrate extinguishant and application thereof

The invention discloses a carbon dioxide hydrate extinguishant and application thereof. Carbon dioxide gas reacts with water or dry water under the pressure of 0.5-5MPa and at the temperature of -10-15 DEG C to generate carbon dioxide hydrate, and the carbon dioxide hydrate is grinded and screened into carbon dioxide hydrate powder with the grain size smaller than 1.0mm at the temperature below -10 DEG C, so that the extinguishant is prepared. When the hydrate extinguishant is used for extinguishing fire, the hydrate powder covers the surface of combustible, contact of the combustible and air can be decreased, the temperature of a combustion area can be reduced by means of decomposition and heat absorption, ambient air can be combusted when released carbon dioxide is diluted, the combustible can be cooled and covered by released water, and accordingly, the fire is extinguished. The carbon dioxide hydrate extinguishant is an efficient extinguishant, and has the advantages of low cost, cleanness, environmental protection and rapidness in fire extinguishing.

Owner:SOUTH CHINA UNIV OF TECH

Installation and construction method for large suspension glass curtain walls

InactiveCN104818787ASave entry feeSave rental feeWallsBuilding material handlingFalseworkSocial benefits

The invention discloses an installation and construction method for large suspension glass curtain walls. The installation and construction method comprises the steps of construction preparation, embedded part prefabrication, scaffold building, glass bracket designing and manufacturing, glass transportation, measurement and paying-off location, embedded part checking, rear-arranged embedded part installation, upper bearing structure installation, suspension clamp installation, lower and side frame installation, full glass panel installation, glass panel checking, glass rib installation, joint glue injection, cleaning and acceptance check. According to the invention, the slotting fee and rental fee of large suspension machines can be saved, manual labor use can be reduced and the labor cost can be lowered; manufacturing and use are convenient, the construction efficiency is high, the construction speed is high, the construction period can be shortened by more than 20%, and the comprehensive economic benefits are remarkable; construction noise is lowered, high-noise construction equipment is not adopted, and therefore the noise influence to the surroundings is lowered to the maximum degree; the whole installation process is completed on the ground and in scaffolds, and therefore the personal safety of constructors is guaranteed, and the social benefits are high.

Owner:CHANGZHOU HUISEN ELECTRONICS

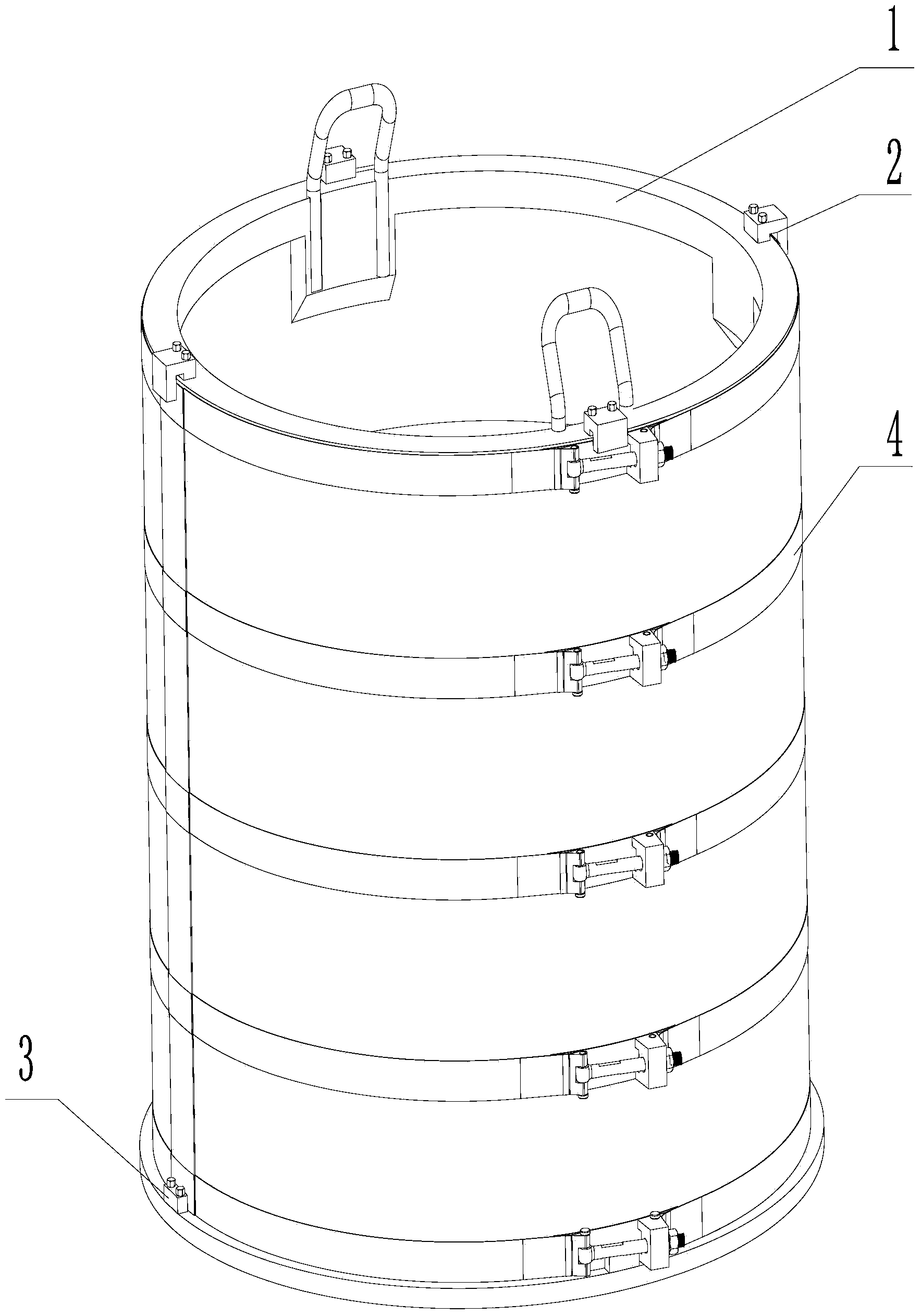

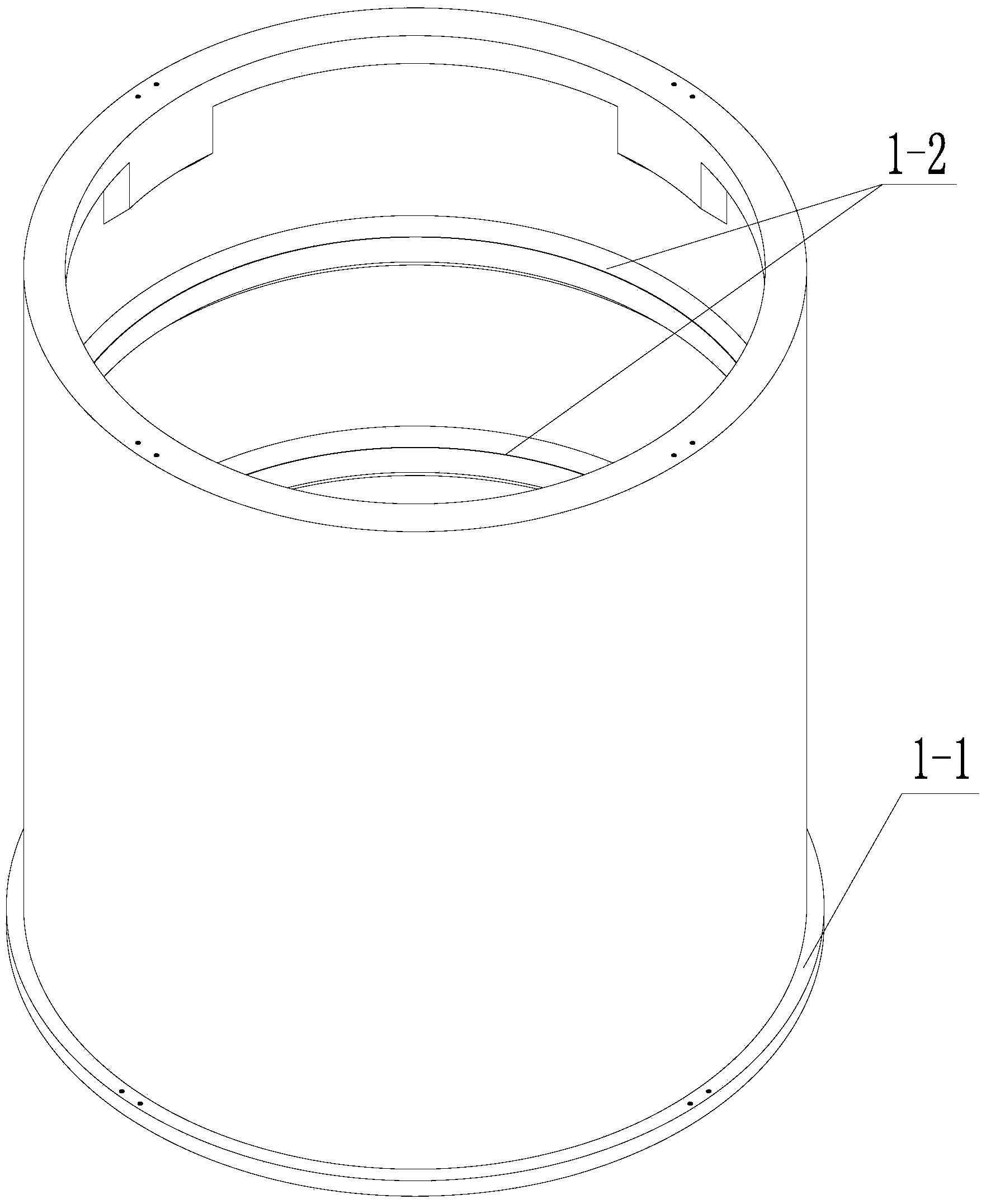

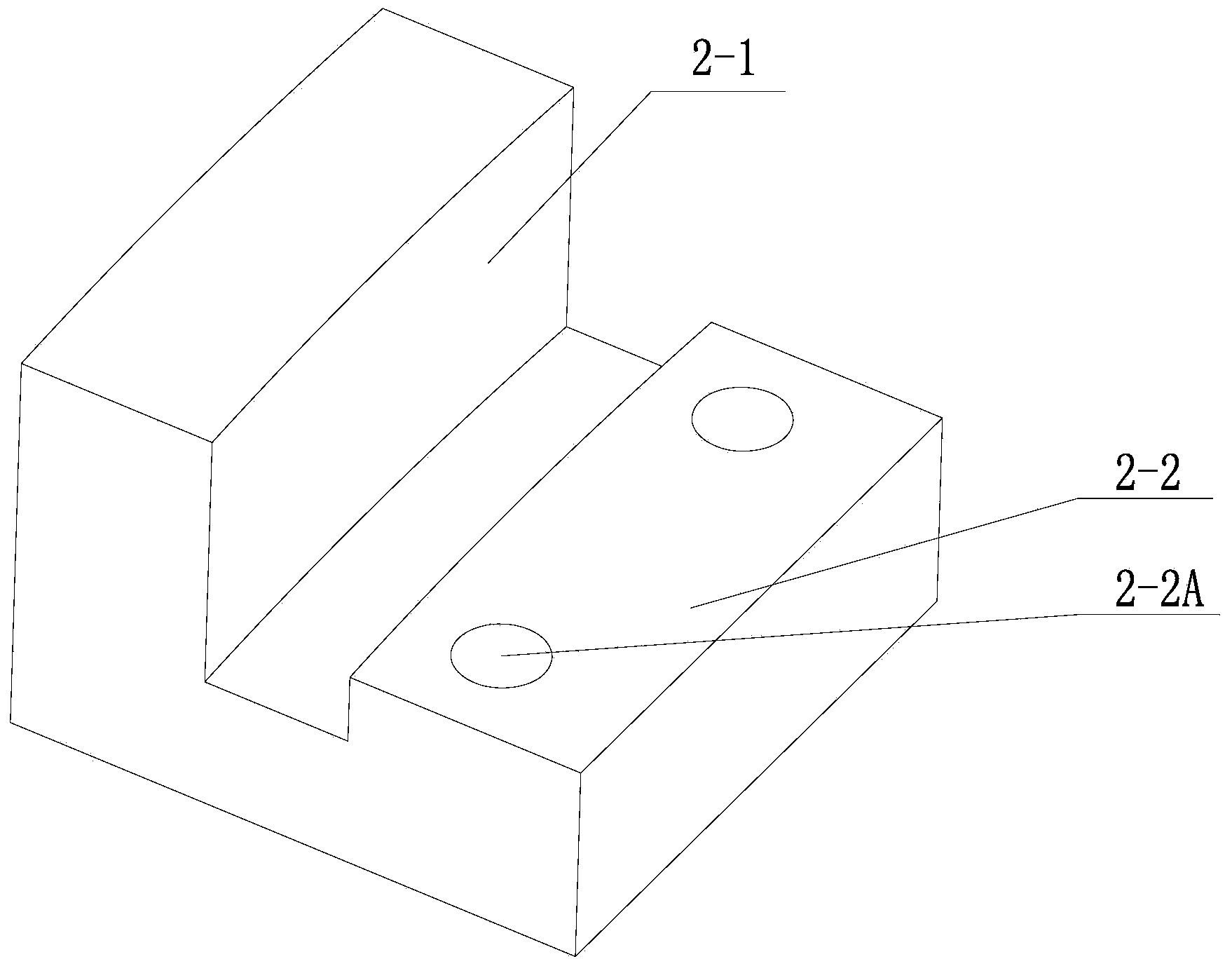

Arc-shaped titanium alloy thin-walled part forming tooling and method

The invention relates to an arc-shaped titanium alloy thin-walled part forming tooling and an arc-shaped titanium alloy thin-walled part forming method, belongs to a metal material forming mold and a use method thereof, and solves the problems of long processing period and high production cost of existing titanium alloy thin-walled parts. The arc-shaped titanium alloy thin-walled part forming tooling comprises a cylinder, four limit blocks, four positioning blocks and a plurality of wrapping tape components. When the forming tooling is used for forming, two arc-shaped thin-walled parts to be formed cover the outer surface of a cylinder, and are limited in the vertical direction by the four limit blocks and the four positioning blocks, then are tightly hooped by the plurality of wrapping tap components uniformly distributed along the vertical direction of the cylinder and are butted to form a complete cylinder. The forming method comprises cutting, pre-forming, assembling, fastening, heat setting and disassembling steps. The forming tooling provided by the invention is simple in structure and convenient to manufacture and use; the method provided by the invention can meet the forming demands of large-diameter titanium alloy thin-walled parts, avoids the traditional and complex long-cycle working procedures of welding, thermal expansion, cutting and the like, so that the production cycle is greatly shortened, and the production efficiency is greatly improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Bordeaux mixture as nutrient protecting agent

InactiveCN1636459AExcellent adhesionReduce wasteBiocideAnimal repellantsEcological environmentSuspending Agents

Into Bordeaux mixture, effective nutritive components and other nutritive assistant are added to compound wettable powder of nutritive Bordeaux mixture. Suspension, thickener and other components are added to make the Bordeaux mixture dispersed in water fast to form stable suspension. Compared with traditional Bordeaux mixture, the present invention has homogeneous spraying and no blocking of the nozzle, and the atomized drop after drying can attach to leaf for long time to resistance rain flushing. The new type of germicide has less consumption and raised economic and environmental utility.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

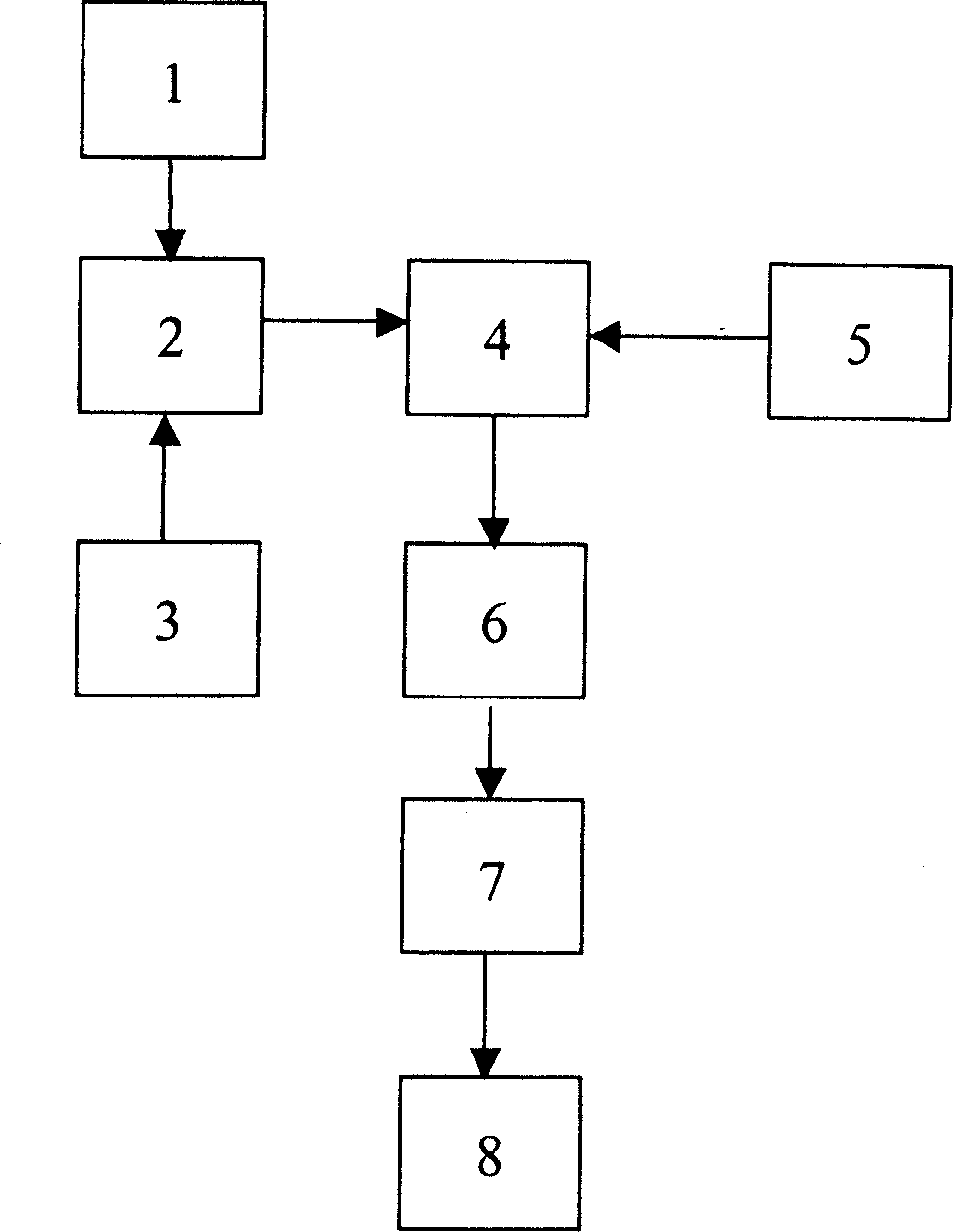

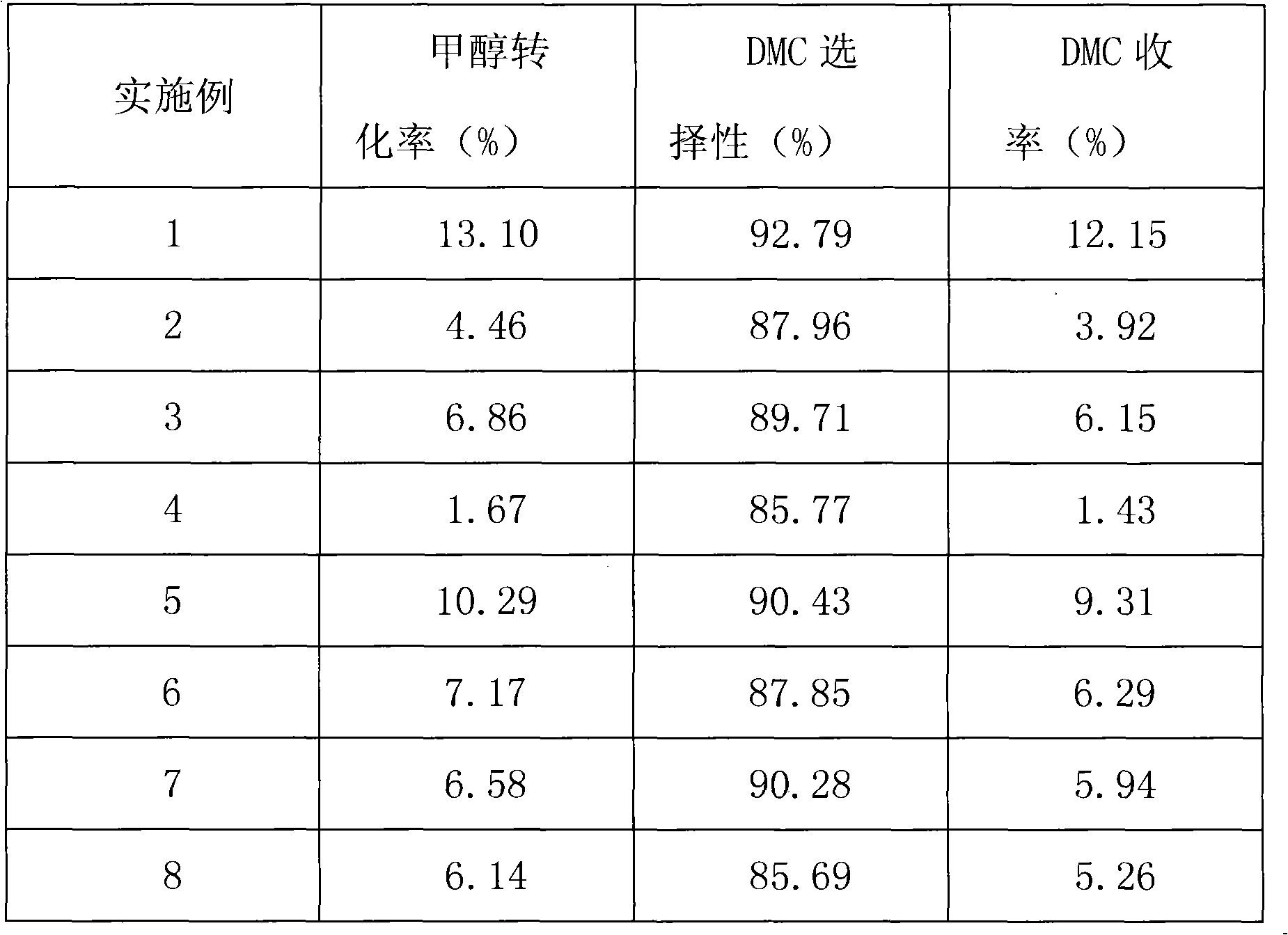

Supported catalyst for synthesis of dimethyl carbonate, preparation method and using method thereof

The invention discloses a supported catalyst for synthesis of dimethyl carbonate, a preparation method and a using method thereof. The supported catalyst comprises active metal components, an auxiliary agent and a carrier, wherein the active metal components mainly comprise a copper-iron metal or a copper-iron ion-containing compound and the like; and preferably, the molar ratio of a copper element to an iron element in the active metal components is from 1:5 to 5:1. The preparation method comprises the following steps of: dispersing the active metal components and the auxiliary agent in the catalyst to the carrier completely and uniformly; and drying, roasting and reducing to obtain the catalyst. The using method comprises the following steps of: placing the catalyst in a catalyst bed ofa reaction device; and adjusting the temperature of the catalyst bed to be between 90 and 140 DEG C and the reaction pressure to be 0.3 to 3.0 MPa. When the molar ratio of carbon dioxide to carbinol is 1:4 to 4:1, the effect is best, wherein the carbon dioxide and the carbinol are reactants passing through the catalyst bed. Compared with the prior art, the invention has the characteristics of high activity, high selectivity and high stability and has the advantages of low price, ready availability, simple preparation, use and recovery operation and the like.

Owner:SUN YAT SEN UNIV

Chemical cleaning method of heat exchanger

The invention provides a chemical cleaning method of a heat exchanger, which is short in cleaning time and low in corrosive property. The chemical cleaning method comprises the following steps: (1) configuring a pipe for the heat exchanger in the shutdown state of a cooling system, and connecting a liquid preparation tank and a cleaning pump to the outside of the configured pipe to form a closed system for pump circulation cleaning; (2) adding soaking liquid obtained by mixing a dispersion chelating agent with a stripping agent into the closed system in the step (1), and soaking the heat exchanger for 1 hour; (3) selecting corresponding acid and corrosion inhibitor according to the material of the heat exchanger, adding the acid and the corrosion inhibitor into the soaking liquid of the closed system in the step (1) to form cleaning liquid, performing pump circulation acid-washing for 2-3 hours, and properly prolonging or shortening the acid-washing time according to the scale formation thickness; and (4) adjusting the pH value of the cleaning liquid in the step (3) to be about 7 by using sodium hydroxide, discharging, and flushing to finish the cleaning process.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

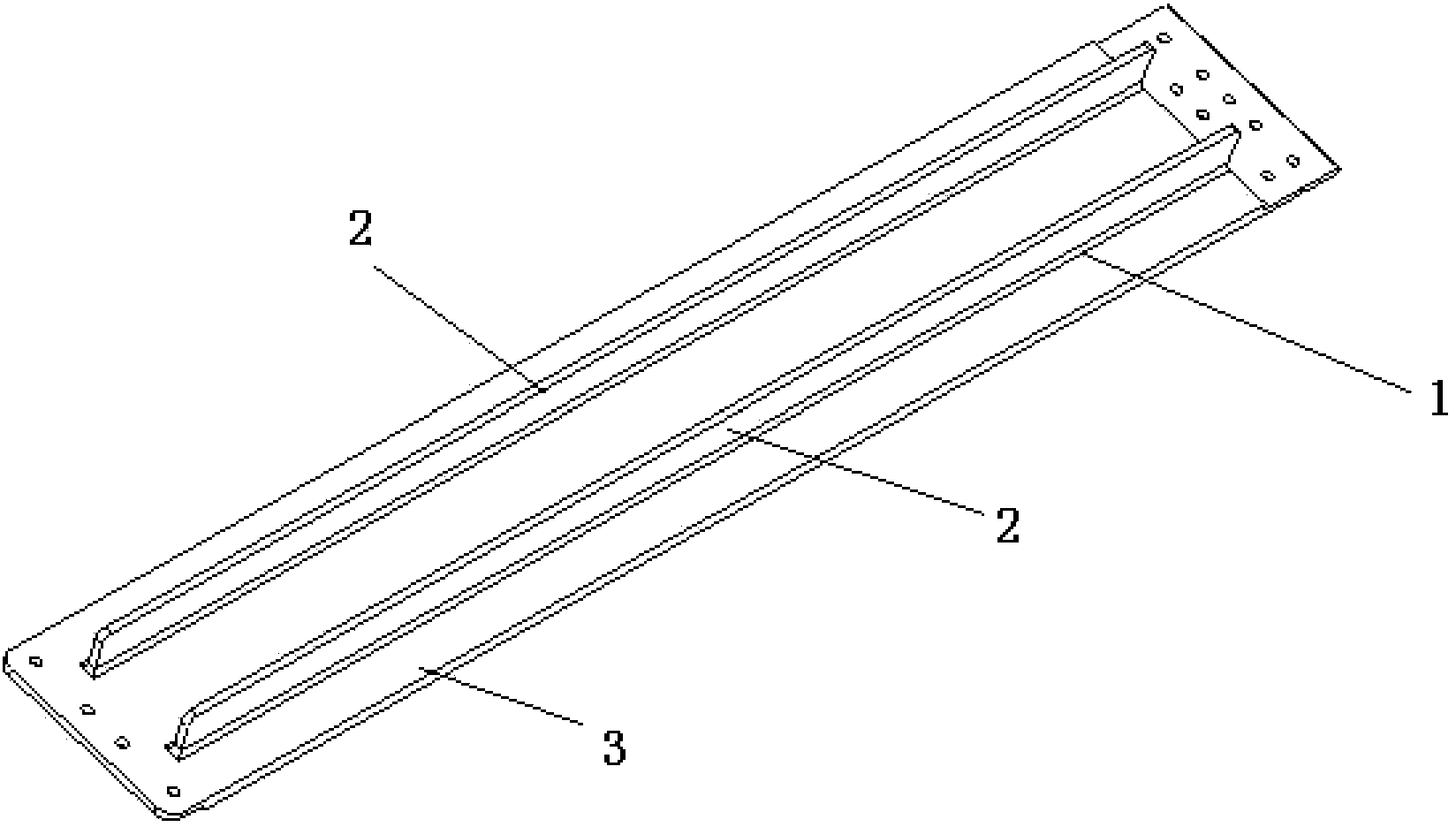

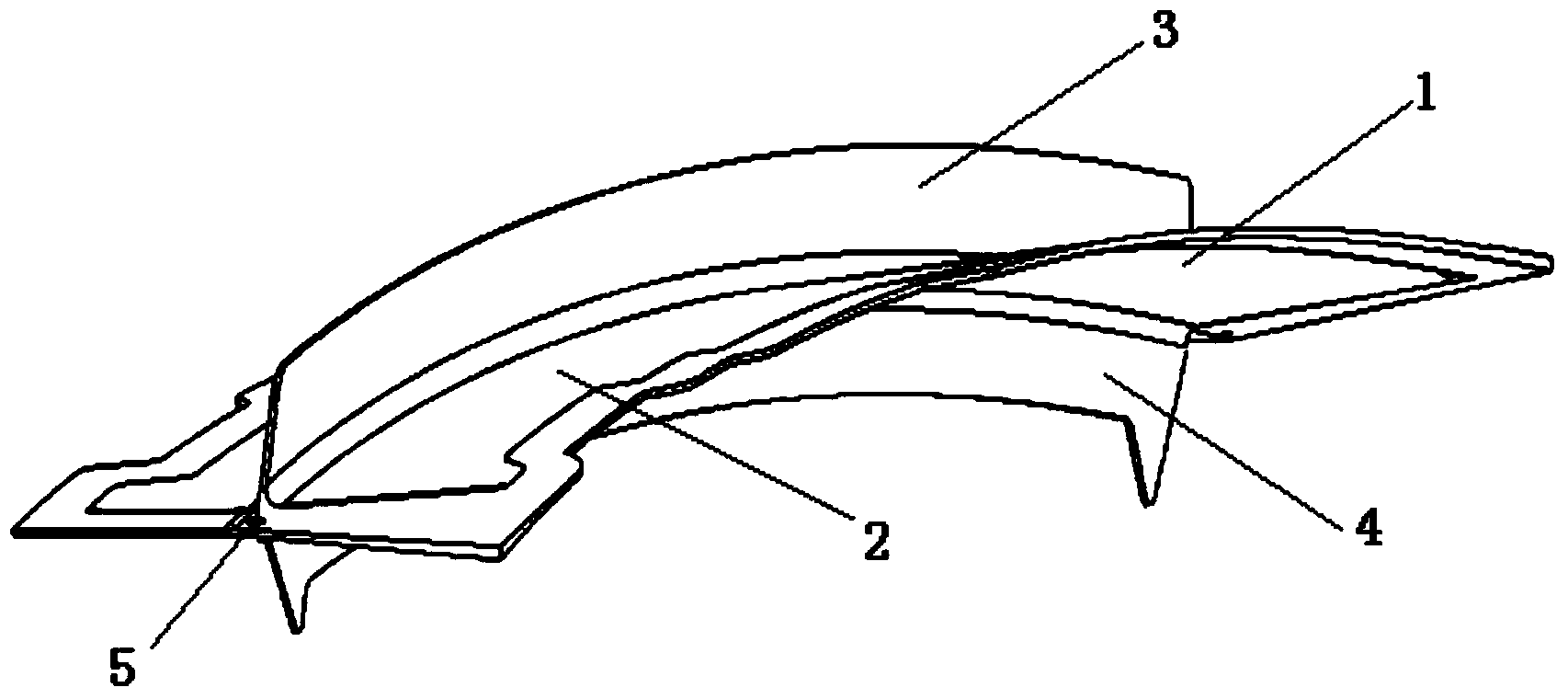

Deformation control method and control fixture for heat treatment of airplane sliding rail component

ActiveCN104109749AWith shape correction functionReasonable structureFurnace typesHeat treatment process controlJet aeroplaneEngineering

The invention relates to a deformation control method for heat treatment of an airplane sliding rail component, particularly of high sliding rail components such as vertical ribs with complex and irregular shape, large curvature change, large volume and thin wall. The invention also relates to a deformation control fixture. An upper surface of a positioning platform of the fixture has a theoretical shape identical to a lower surface of a component planar wing plate. A shape-keeping space of the vertical ribs of the component is formed between a positioning block and a positioning core. A wedge-shaped block is used to press a press bar tightly in cooperation of a connecting hole on a vertical column. The deformation control fixture and the component are subjected to the heat treatment together and then separated from each other.

Owner:XI'AN AIRCRAFT INTERNATIONAL

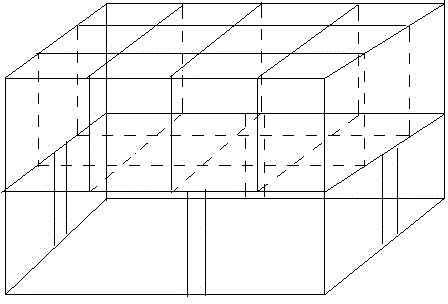

Bottled liquid leakage detecting device

InactiveCN104807599AAvoid pollutionEasy to make and useDetection of fluid at leakage pointBottleTest strips

The invention discloses a bottled liquid leakage detecting device. The bottled liquid leakage detecting device comprises a cuboid box, the box is divided into an upper layer and a lower layer which are partitioned by a partition board, a rectangular grid for partitioning a liquid containing bottle is arranged above the partition board, a sponge is arranged below the partition board, and test paper is arranged around the sponge. The bottled liquid leakage detecting device has the advantage that since the test paper is arranged on the lower side of the bottled liquid leakage detecting device, when liquid leaks, the test paper can change in color to warn a user of liquid leakage.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

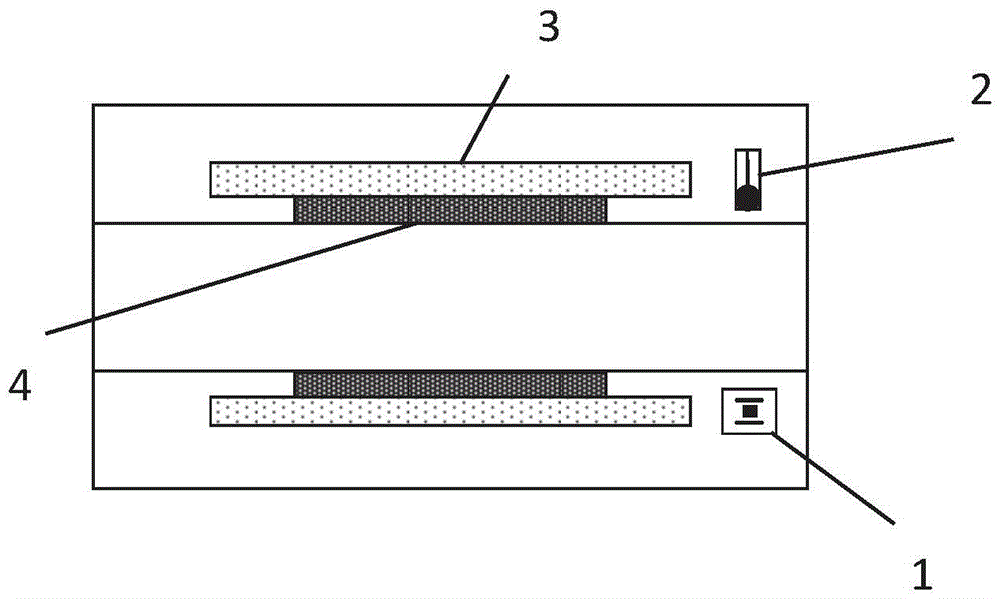

Magnetic flux cable force detecting device based on MEMS (Micro Electro Mechanical System) acceleration sensor correction

ActiveCN105527047ASolve the time drift problemImprove effectivenessTension measurementData displayMicrocontroller

The invention relates to a magnetic flux cable force detecting device based on MEMS (Micro Electro Mechanical System) acceleration sensor correction. The device comprises an MEMS acceleration sensor, an excitation coil, an induction coil, an anti-alias filter, a microcontroller, a data display module and the like. After the anti-alias filter filters aliasing signal from vibration signals generated by external excitation borne by a bridge cable, an analog-digital converter converts the vibration signals into digital signals, the microcontroller performs FFT (Fast Fourier Transform) operation, and the MEMS acceleration sensor finally obtains a feature frequency value of bridge cable vibration. Aiming at the problems that field calibration is needed due to data drift caused by ageing of internal electronic components, the use cost is high and the data processing difficulty is high in the present bridge cable force detecting device based on magnetic flux detection, the aim of the invention is to provide a magnetic flux cable force detecting device with the characteristics of simple structure and convenience in manufacturing and use. The magnetic flux cable force detecting device can solve the maximum problem of time drift of the present magnetic flux cable force detecting device by arranging one MEMS acceleration sensor inside the magnetic flux sensor, reduce the monitoring cost and improve the validity and the reliability of the monitored data.

Owner:CCCC ROAD & BRIDGE CONSULTANTS +1

Marsh gas biological desulphurization energy-saving method

The invention provides a marsh gas biological desulphurization energy-saving method, which relates to a marsh gas desulphurization method. The invention solves the problems that the biological desulphurization process in the prior art is not easy to control, the conditions and requirements are harsh, and sulfureted hydrogen can be easily and directly converted into sulfur oxides by germs, so the sulfur oxide can not be easily discharged from a system. The method comprises the following steps of: 1. adding thiobacillus denitrificans and nitrobacteria into nutrient fluid, then spraying the nutrient fluid onto filling materials and culturing the filling materials until biomembranes are formed; and 2. completing the process after the marsh gas is in contact and reacts with the biomembranes. The biological desulphurization energy-saving method in the invention is easy to control, has slack condition requirements and solves the problem that the sulfureted hydrogen can be easily and directly converted into the sulfur oxides by the germs to be released to the marsh gas again, the desulphurization efficiency can achieve higher than 95 percent when the sulfureted hydrogen content in the marsh gas is between 1000 and 4000mg / L, in addition, elemental sulfur can be recovered, the thiobacillus denitrificans and the nitrobacteria are symbiotic systems, the self-sufficiency effect is realized basically through the marsh gas, and the energy-saving effect is realized.

Owner:HARBIN INST OF TECH

Crop straw organic fertilizer and preparation method thereof

InactiveCN105906461AIncrease profitImprove recycling ratesBio-organic fraction processingMagnesium fertilisersBiotechnologyInsect pest

The invention discloses a crop straw organic fertilizer and a preparation method thereof. The crop straw organic fertilizer includes, by weight, 30-50 parts of crop straw, 20-30 parts of excrement of poultry and livestock, 1-2 parts of micro-bacterial spore powder, 10-20 parts of urea, 5-10 parts of mushroom residue, 5-10 parts of humic acid, 3-5 parts of enzyme bacteria, 2-3 parts of magnesium sulfate and 2-3 parts of cobalt sulfate. The micro-bacterial spore powder is composed of bacillus laterosporus and bacillus subtilis according to the weight ratio of 1:1-3. The crop straw organic fertilizer achieves effective utilization of wastes, is free of environment pollution, is simple in preparation method, is low in cost, can achieve stable and high production of crops and also effectively prevent plant diseases and insect pests, and has great economic significance of agricultural development.

Owner:BEICHUAN QIANG AUTONOMOUS COUNTY JIANCHENG FORESTRY PROD DEV CO LTD

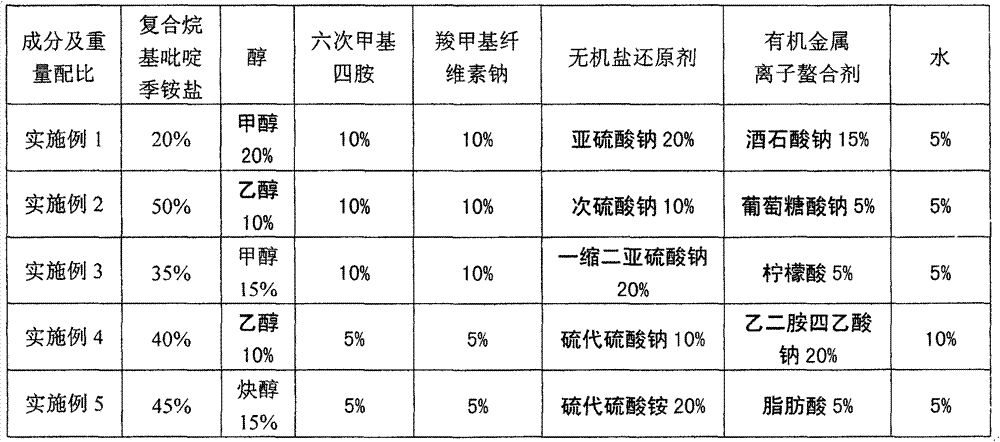

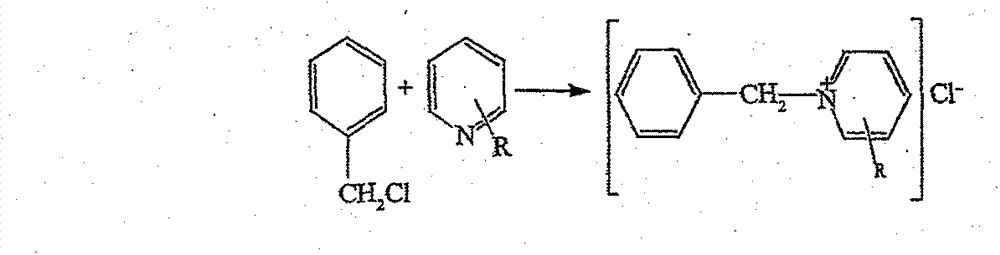

Corrosion-inhibiting mist-suppressing promoter for steel pickling

The invention discloses a corrosion-inhibiting mist-suppressing promoter for steel pickling, belonging to metal surface treatment chemicals. The promoter comprises, by weight, 20 to 50% of composite alkyl pyridine quaternary ammonium salt, 10 to 20% of alcohol, 5 to 10% of hexamethylene tetramine, 5 to 10% of sodium carboxymethylcellulose, 10 to 20% of an inorganic salt reducing agent, 5 to 20% of an organic metal ion chelating agent and 5 to 10% of water, wherein the inorganic salt reducing agent is one or two selected from the group consisting of sodium sulfite, sodium hydrosulfite, sodium metabisufite, sodium thiosulfate and ammonium thiosulfate, the organic metal ion chelating agent is one selected from the group consisting of aliphatic acid and a salt thereof, gluconic acid and a salt thereof, tartaric acid and a salt thereof and disodium EDTA, and the alcohol is methanol, ethanol or alkynol. The corrosion-inhibiting mist-suppressing promoter provided by the invention can substantially improve surface quality of a pickled steel plate.

Owner:官军

Separation equipment for iron trioxide pigment preparation

PendingCN111389714AEasy to separateEasy to prepare and useSievingScreeningPhysical chemistryPhotopigment

The invention relates to the technical field of pigment preparation, and discloses separation equipment for iron trioxide pigment preparation. The separation equipment for iron trioxide pigment preparation comprises a workbench, wherein support legs are fixedly connected to the four corners of the bottom of the workbench separately; a support block is fixedly connected to the left side of the upper end of the workbench; a separation frame is rotationally connected to the upper end of the support block; a plurality of sieving holes are uniformly formed in the surface of the separation frame; aplurality of return springs are fixedly connected between the lower end of the right side of the separation frame and the upper end of the workbench; a double-axis motor is further fixedly connected to the right side of the upper end of the workbench; a rotary rod is fixedly connected to output shafts at the two ends of the double-axis motor separately; and a cam is fixedly connected to one end away from the double-axis motor, of the rotary rod. The separation equipment for iron trioxide pigment preparation has the advantages of being capable of realizing rapid material separation, and convenient to prepare and use.

Owner:TONGLING RELY TECH

Compound gel of goldenlarch bark preparation method

InactiveCN1695642ALow in ethanolPromote transdermal absorptionAntimycoticsPharmaceutical delivery mechanism

A compound golden larch bark gel is prepared from golden larch bark tincture, benzoic acid salicylic acid, carbomer, ethanol, propanediol, glycerine and polyethanediol 400 through sequential mixing and sterilizing.

Owner:童玉新

Clothes mildew preventive

The invention relates to a clothes mildew preventive. The clothes mildew preventive is composed of the following components in parts by mass: 2-10 parts of benzoic acid, 10-25 parts of p-nitrophenol, 1-6 parts of fatty alcohol-polyoxyethylene ether, 2-10 parts of carnauba wax, 2-10 parts of castor oil, 5-12 parts of dimethyl silicone oil, 7-18 parts of glacial acetic acid, 20-40 parts of glycol, 2-8 parts of vinyl acetate, 1-5 parts of sodium sulfate, 10-20 parts of a boric acid solution, 2-10 parts of silicone emulsion, 3-8 parts of dibutyl phthalate and 100-200 parts of deionized water. The preparation method of the clothes mildew preventive is simple, and the prepared mildew preventive has a good using effect as being put in clothes, and also is excellent in mildew preventing effect and resistant to water wash, and does not cause the damage to the surfaces of the clothes; adopted chemical substances are easy to get, low in cost and convenient to use and prepare.

Owner:艾和美

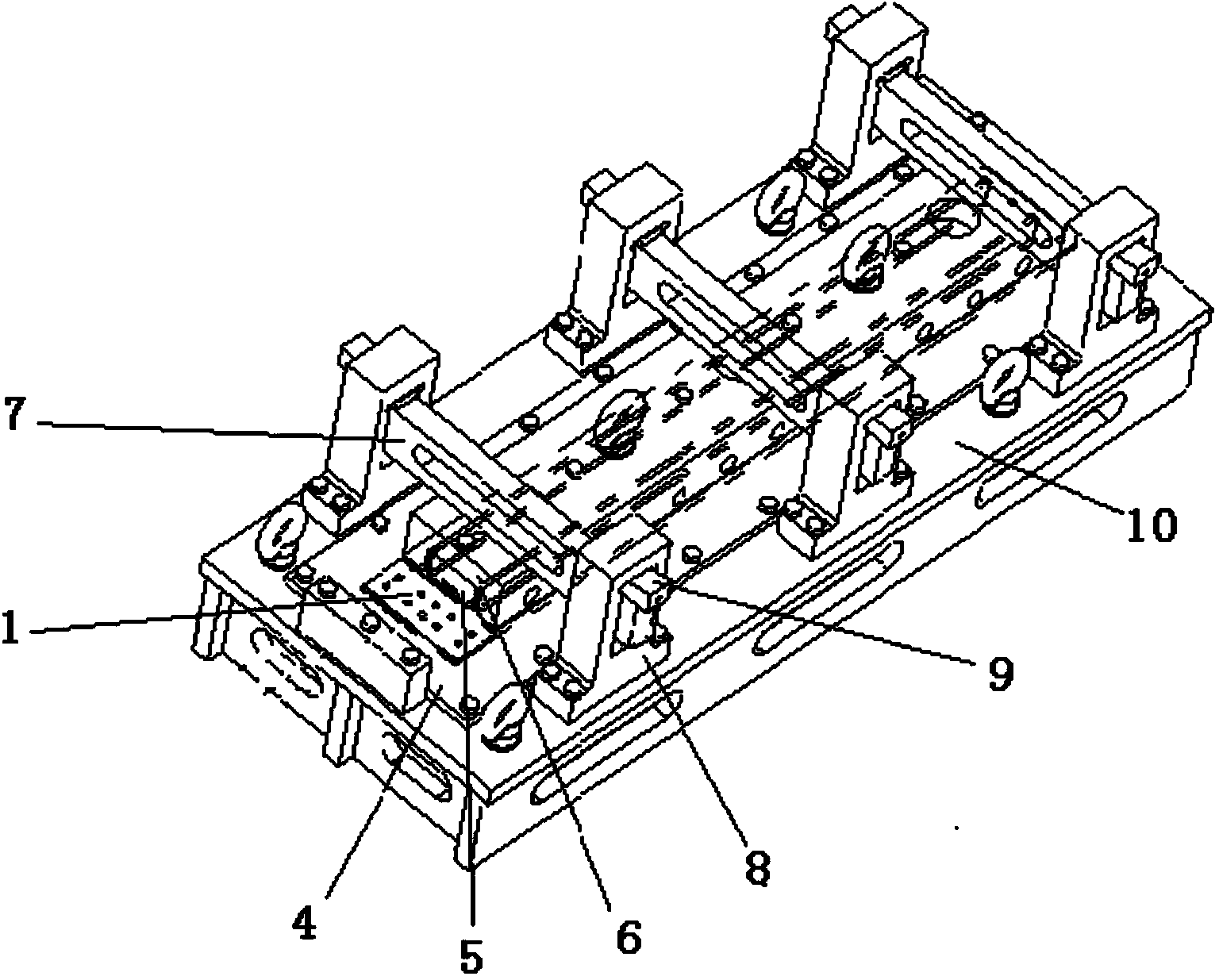

Deformation control method for heat treatment of airplane upper edge strip component

ActiveCN104109748ALow costImprove efficiencyFurnace typesHeat treatment process controlDeformation controlHeat treated

The invention relates to a deformation control method for heat treatment of airplane upper edge strip components. A component is composed of a thin wall-shaped curved wing plate and an upper vertical rib and a lower vertical rib which are disposed at a center of the wing plate, and has a known component shape. The invention also relates to a deformation control fixture. The fixture comprises a fixture body, a plurality of positioning blocks, a plurality of compression blocks and a connecting pin. The middle of an upper surface of each positioning block is provided with a an avoiding slot of a lower vertical rib at a corresponding portion of the component; and the middle of a lower surface of each compression block is provided with an avoiding slot of an upper vertical rib at a corresponding portion of the component. The deformation control fixture and the component are subjected to the heat treatment together and then separated from each other.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com