Deformation control method for heat treatment of airplane upper edge strip component

A technology of parts and flanges, which is applied in the field of aircraft manufacturing, can solve the problems of thermal deformation, thermal expansion and contraction, etc., and achieve the effects of improving efficiency, reasonable fixture structure, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

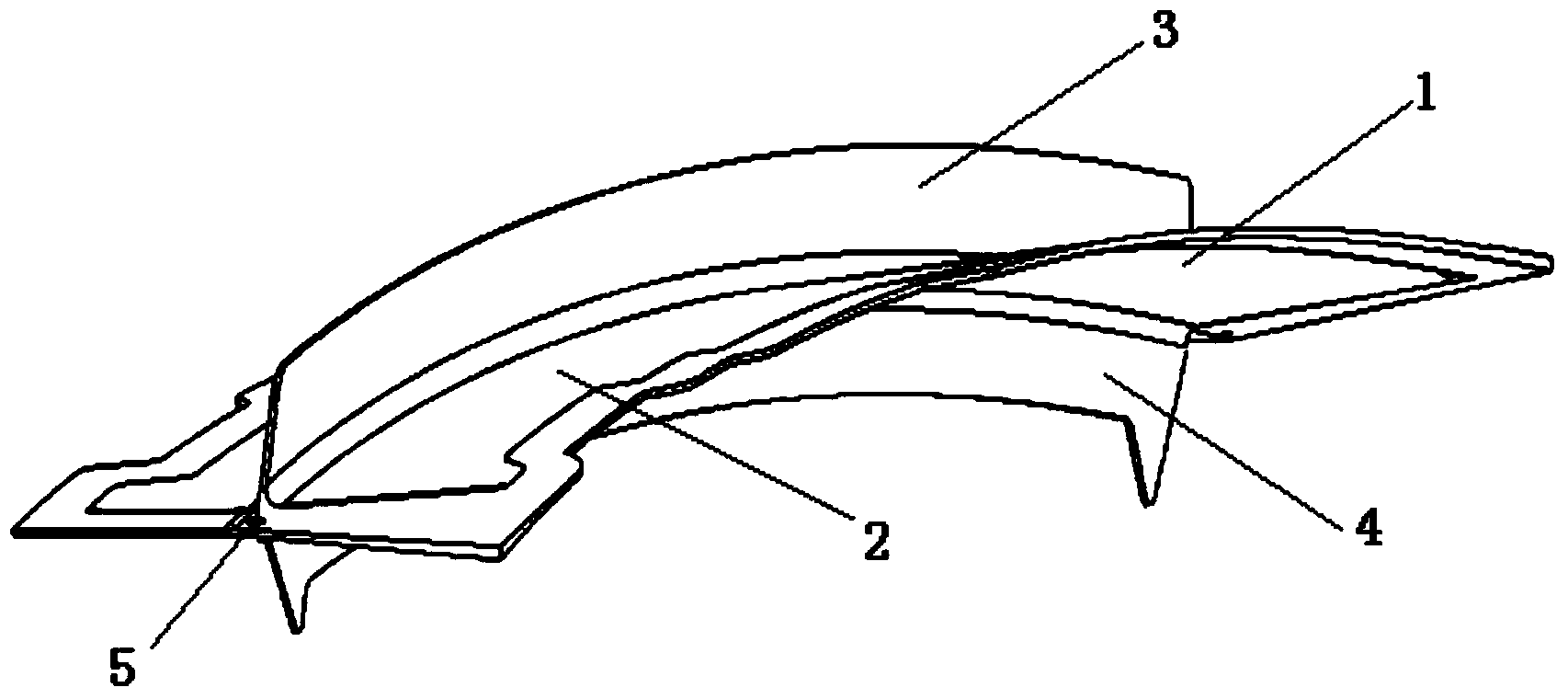

[0019] Referring to the accompanying drawings, part 1 in the embodiment is a middle and upper edge part of a certain type of aircraft, and the material of this part is a Ti-6Al-4V forging, such as figure 1 As shown, the part is about 3 meters long, the wall thickness and rib thickness are less than 4mm, the upper surface and the lower surface of the part wing plate 2 are precision surfaces, that is, the surface that must control deformation, and there are upper vertical ribs 3 on the upper surface, There are lower vertical ribs 4 on the lower surface, and the two ends of the part are provided with process lugs 5 and positioning holes on the process lugs. The design theoretical shape data of the part is known.

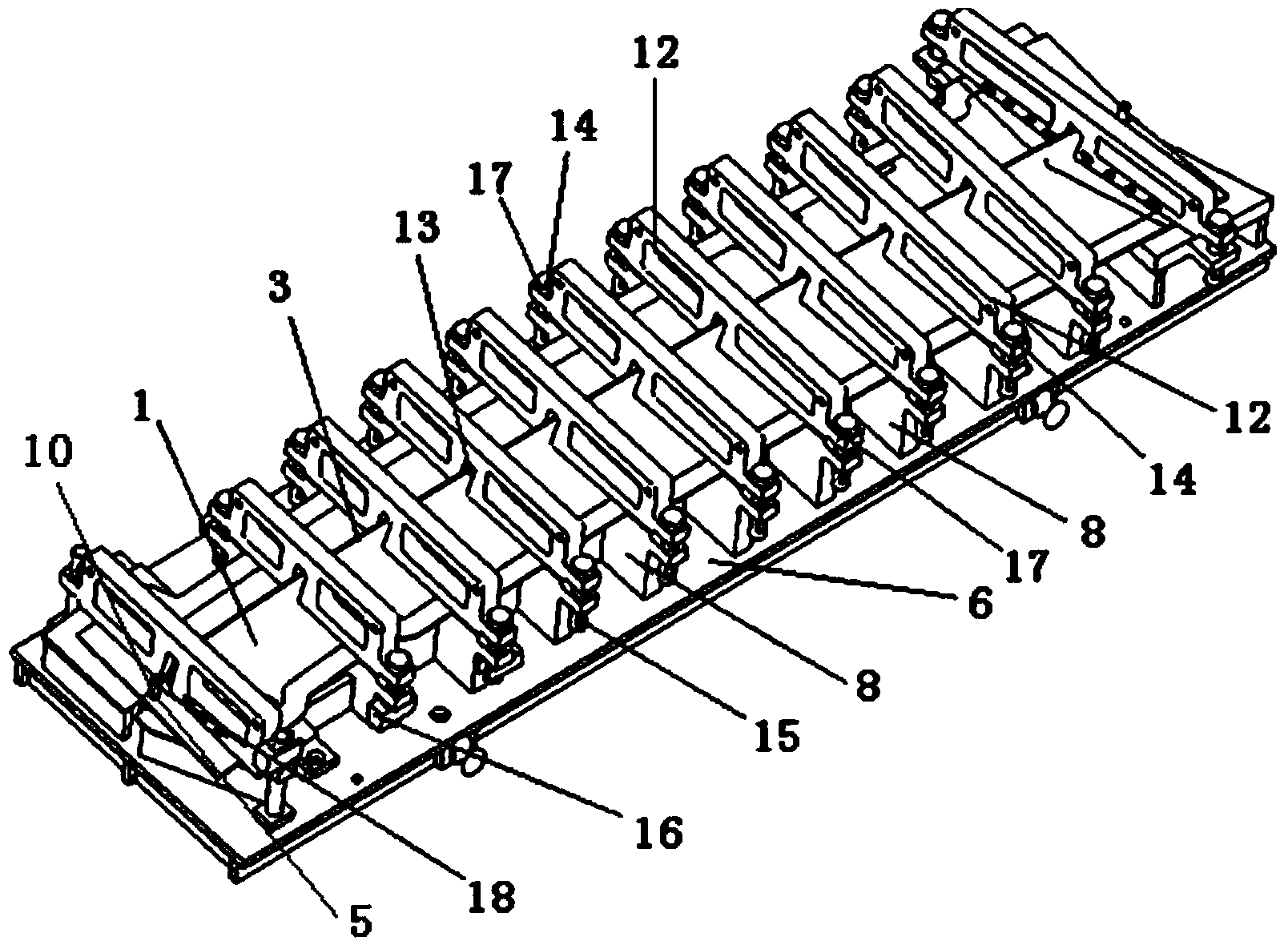

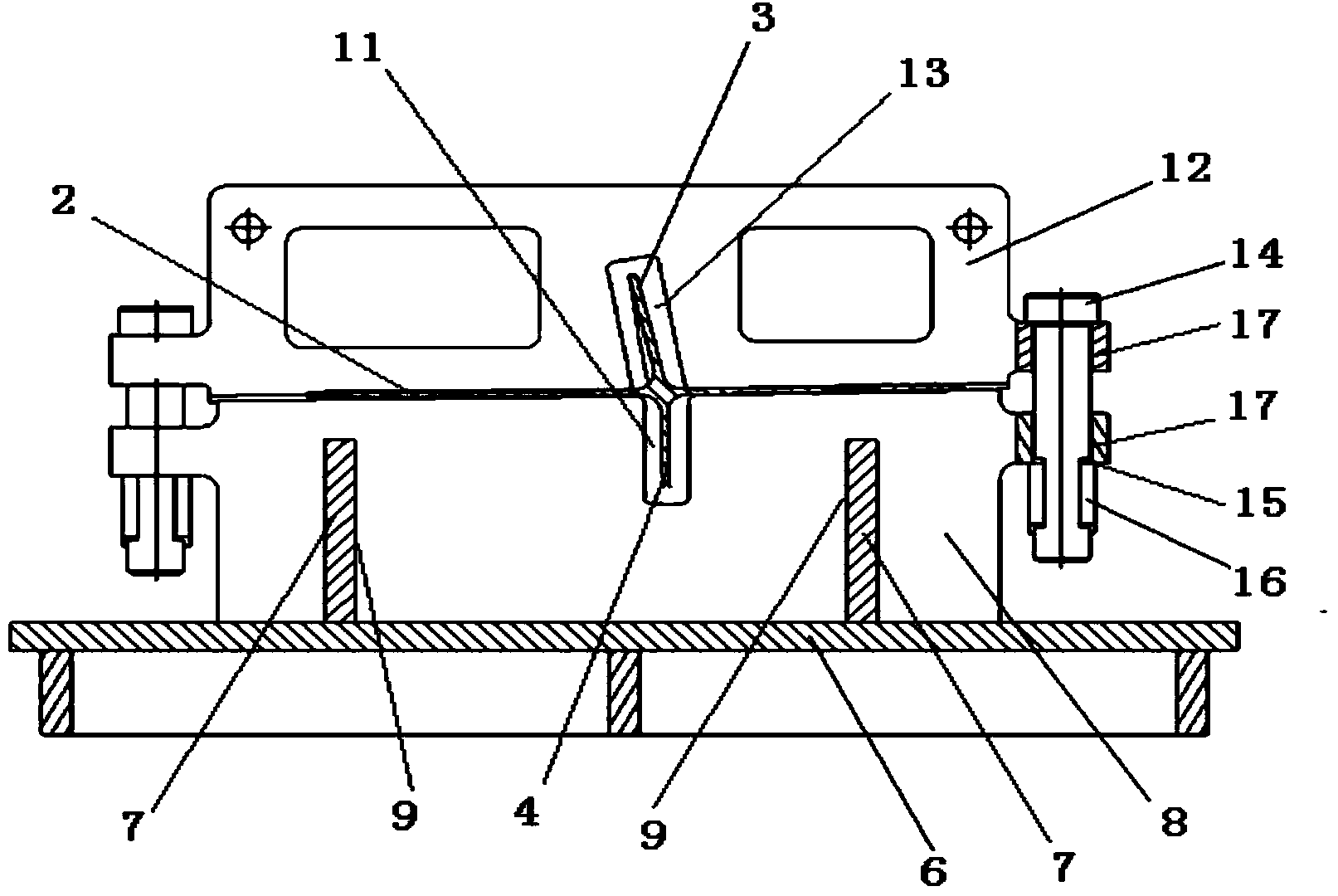

[0020] In order to control the deformation of the part during heat treatment, the present invention discloses such as figure 2 In the shown control method, a deformation control fixture must first be provided, which contains a fixture body 6, a plurality of positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com