Supported catalyst for synthesis of dimethyl carbonate, preparation method and using method thereof

A supported catalyst, dimethyl carbonate technology, applied in catalyst activation/preparation, chemical instruments and methods, carbon dioxide or inorganic carbonate preparation, etc., can solve the problem of uneven catalytic effect, unstable catalytic activity, volatile It can achieve the effect of high activity and stability, convenient repeated regeneration and activation, and easy separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Accurately weigh 3gSiO 2 , add 40ml absolute ethanol, ultrasonically disperse for 1 hour; accurately weigh 0.1820gCu(NO 3 ) 2 ·3H 2 O, 0.1521gFe(NO 3 ) 3 9H 2 O and 0.2849g citric acid, dissolved in 20ml deionized water. Pour the citric acid solution of metal ions into the ultrasonically dispersed carrier, stir at room temperature for 24 h, and ultrasonically disperse for 1 h. Afterwards, the above mixed solution was evaporated to dryness at 60° C. and dried in an oven at 80° C. overnight. After calcining at 450° C. for 3 hours, and then reducing and activating with hydrogen at 500° C. for 3 hours, the catalyst was obtained.

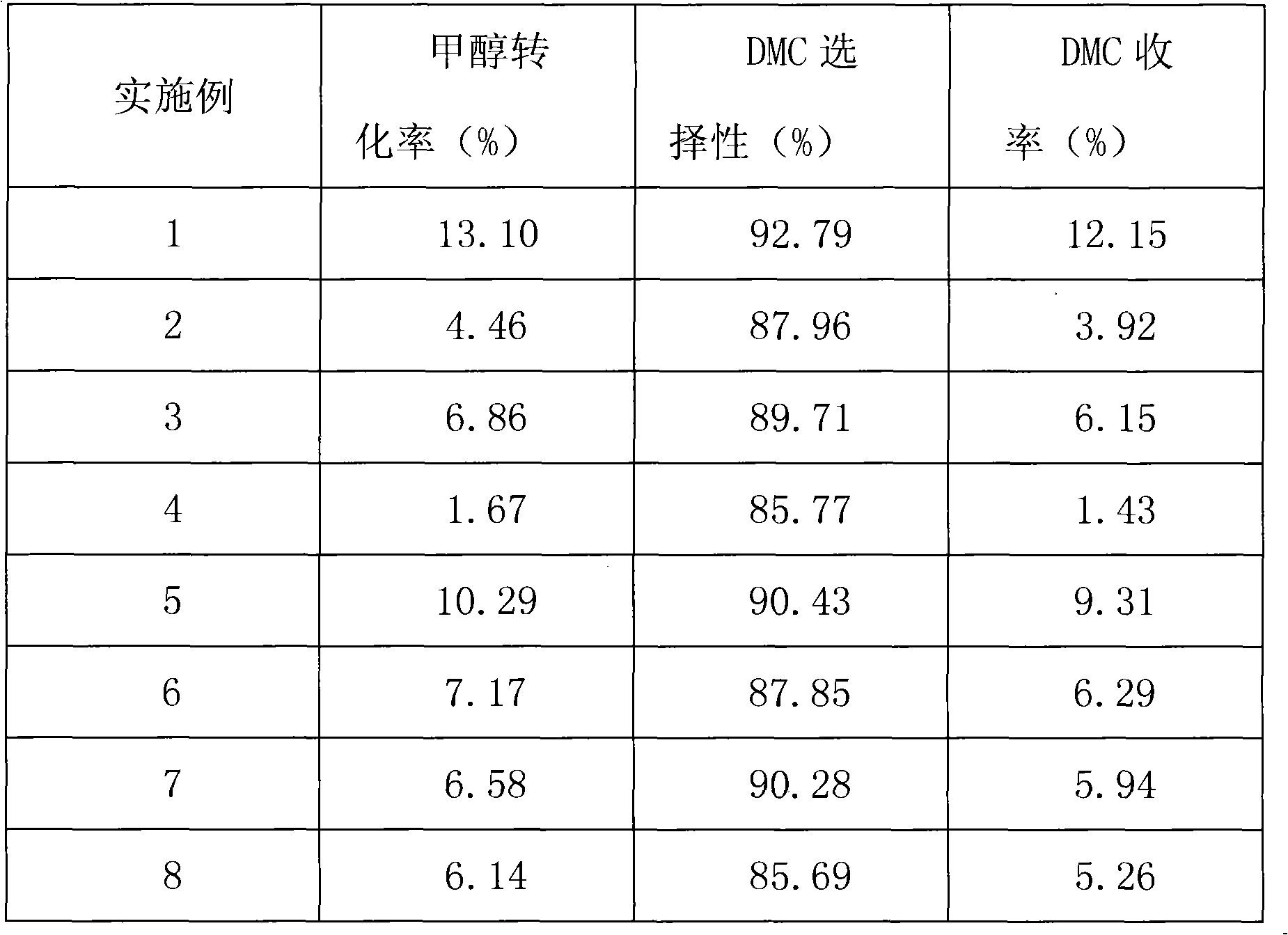

[0022] Weigh 1g of the above-mentioned catalyst, add it to the catalytic bed of the fixed-bed catalytic micro-reactor device for reaction performance evaluation, adjust the ratio of carbon dioxide and methanol to 1:2, the reaction pressure is 1.2MPa, the temperature of the catalyst bed is 130°C, and a 7890F gas chromatograph is used The pr...

Embodiment 2

[0024] Preparation method as embodiment 1, carrier SiO 2 , and transition metal nitrate Cu(NO 3 )2·3H 2 O, Fe(NO 3 ) 3 9H 2 The amounts of O and complex citric acid are respectively: 3g, 0.8190g, 0.9130g and 1.4245g. The catalytic reaction test conditions are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0026] Preparation method is the same as embodiment 1, carrier SiO 2 , and transition metal nitrate Cu(NO 3 )2·3H 2 O, Fe(NO 3 ) 3 9H 2 The amounts of O and complex citric acid are respectively: 3g, 0.4553g, 3.8070g and 2.8515g, the catalytic reaction test conditions are as in Example 1, and the results are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com