Patents

Literature

252results about "Preparation from carbon dioxide or inorganic carbonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic Composition for the Insertion of Carbon Dioxide Into Organic Compounds

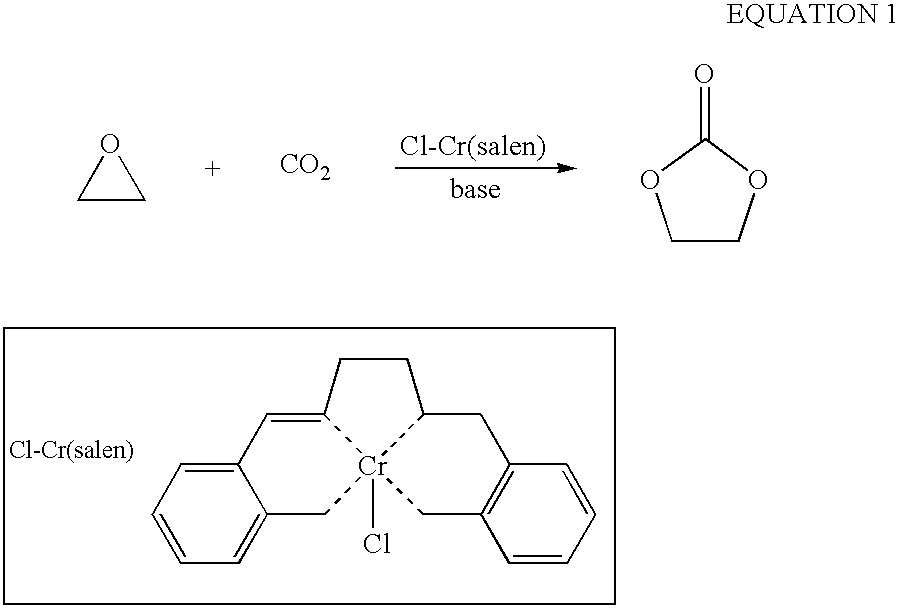

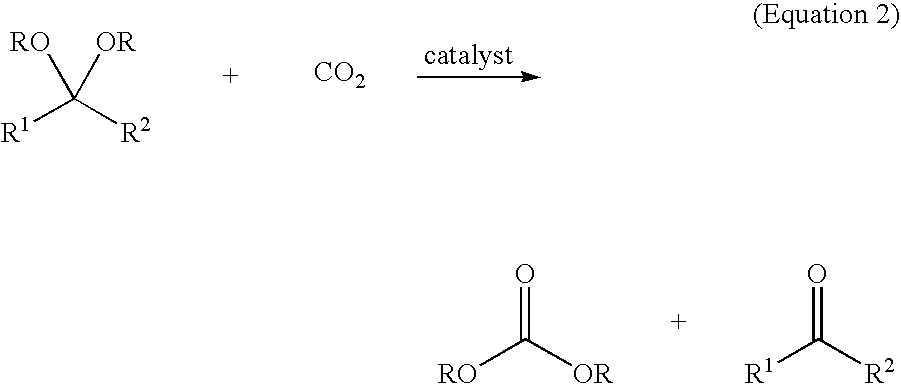

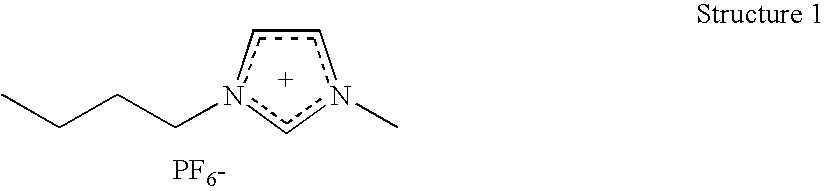

The invention relates to a catalytic composition comprising: a first component which is at least a component with one or more metals from groups 3A, 4A, 5A, 6A, 7A, 8, 1B, 2B, 3B, 4B; and a second component selected from (1) at least one ionic liquid which consists of a compound formed by cations and anions and which is a liquid at ambient temperature, (ii) a matrix to which the first component is bound or on which it is supported, and (iii) a combination of the two. The invention relates to the use of said catalytic composition in a method for the insertion of carbon dioxide into an organic compound and, preferably, a compound selected from epoxides, acetals and orthoesters. The invention also relates to catalytic compositions comprising said metallic compounds.

Owner:RODRIGUEZ MERCEDES ALVARO +3

Synthesis of dimethyl carbonate from carbon dioxide and methanol

InactiveUS20110196167A1Molecular sieve catalystsChemical industryAtmospheric pressureHomogeneous catalysis

A method for producing dimethyl carbonate from methanol and carbon dioxide using a heterogeneous catalyst is described. The heterogeneous catalyst provides both acidic sites and basic sites. The reaction can be carried out at atmospheric pressure and relatively low temperatures.

Owner:KING ABDULAZIZ CITY FOR SCIENCE AND TECHNOLOGY

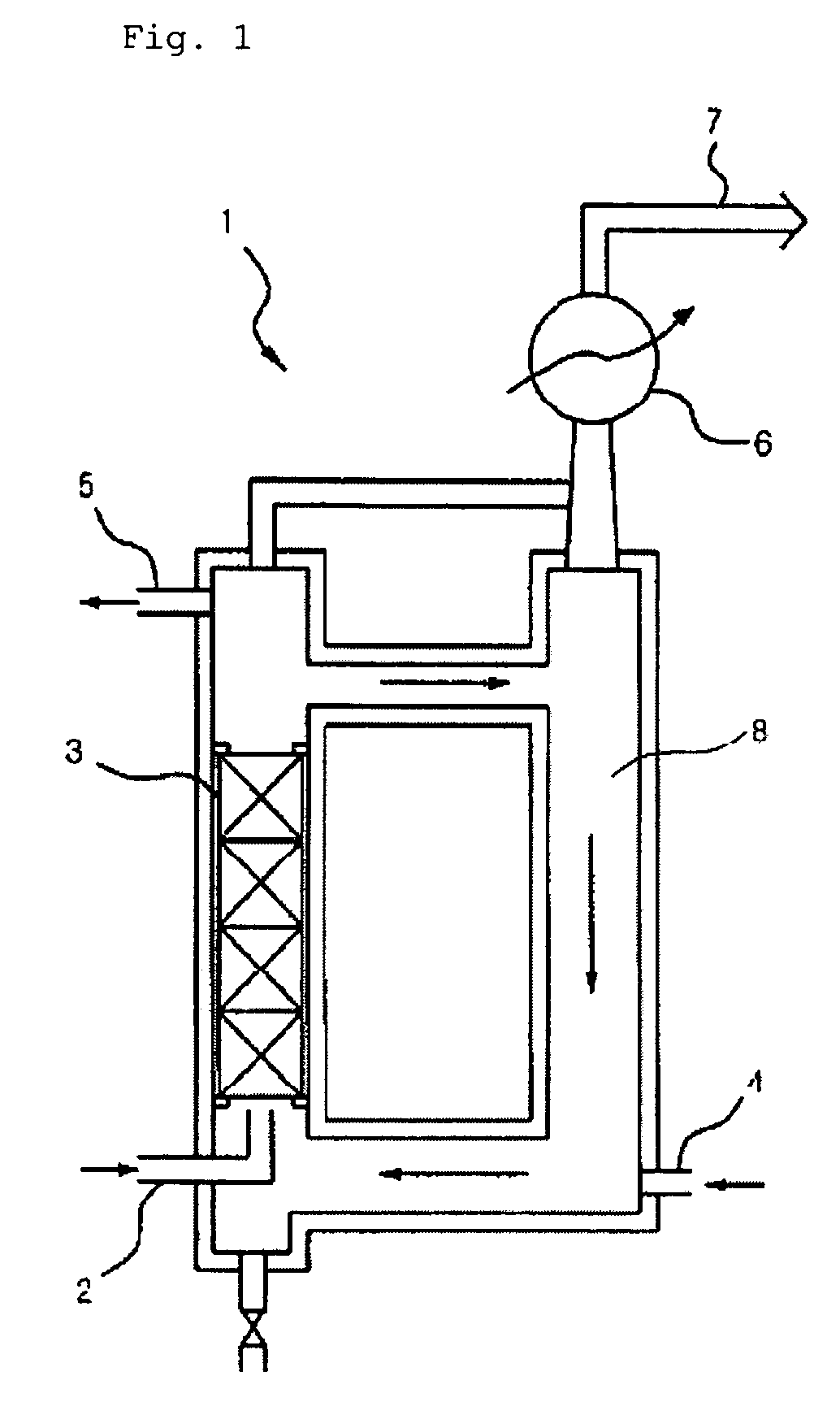

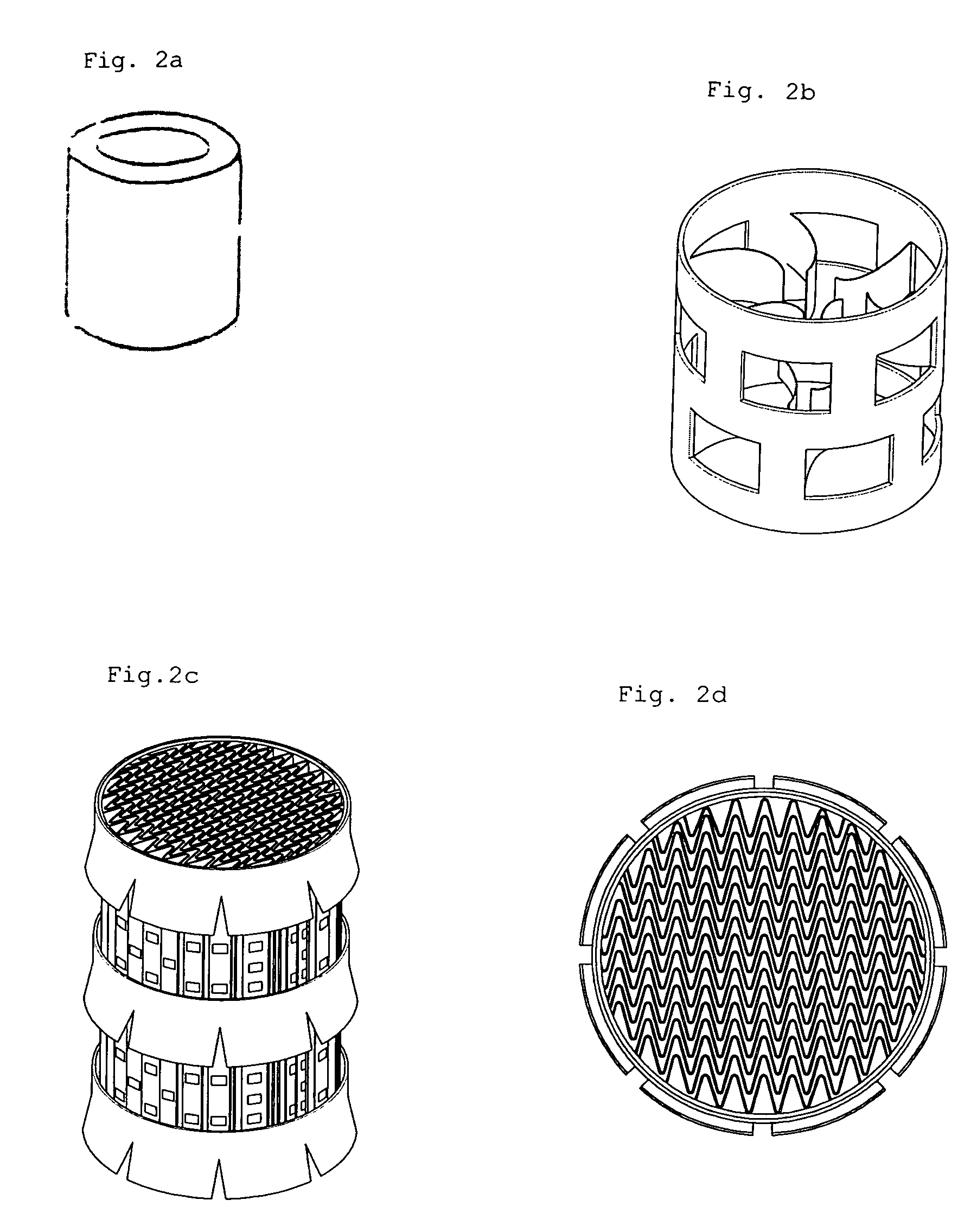

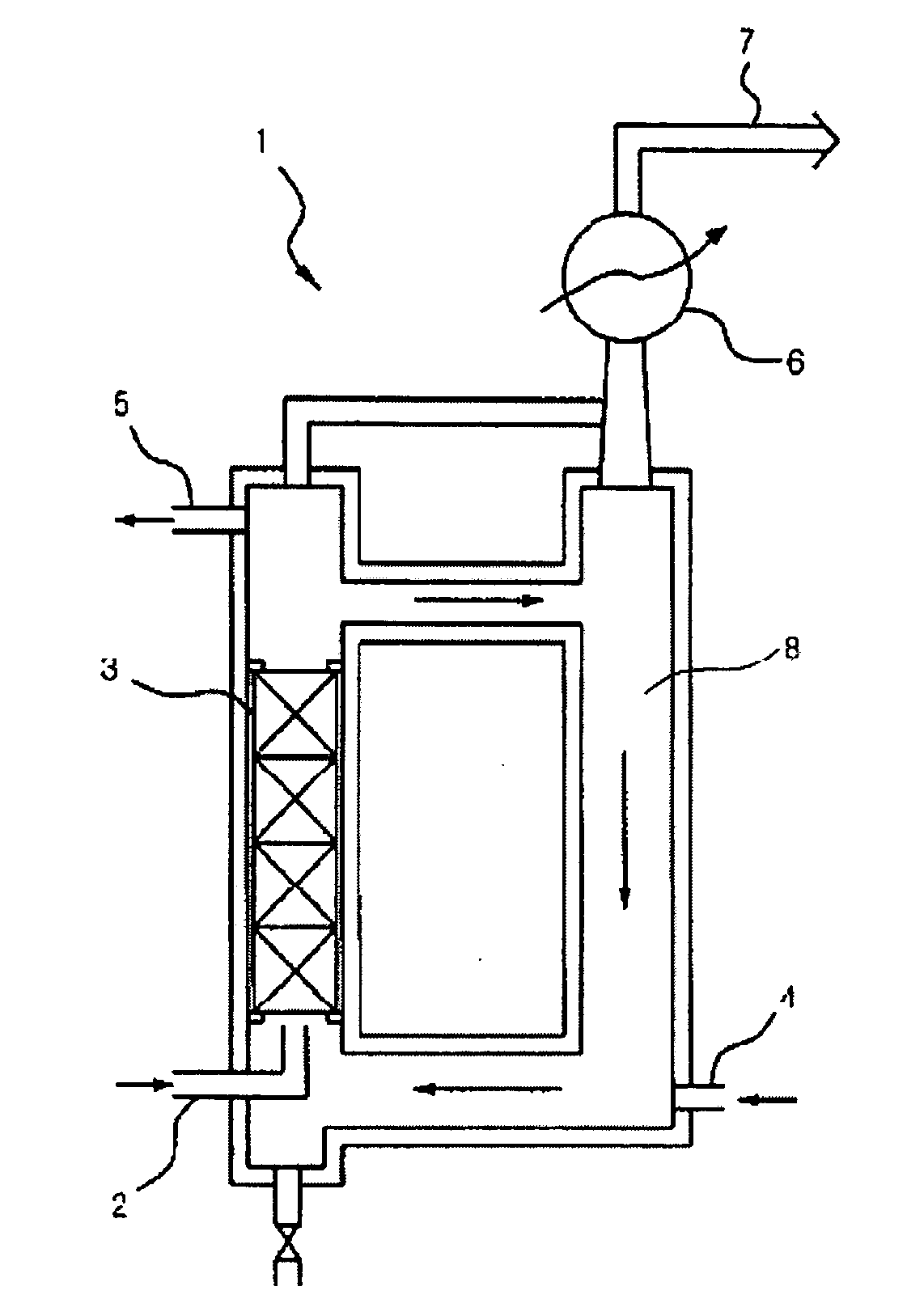

Manufacturing method and apparatus of 4-fluoroethylene carbonate

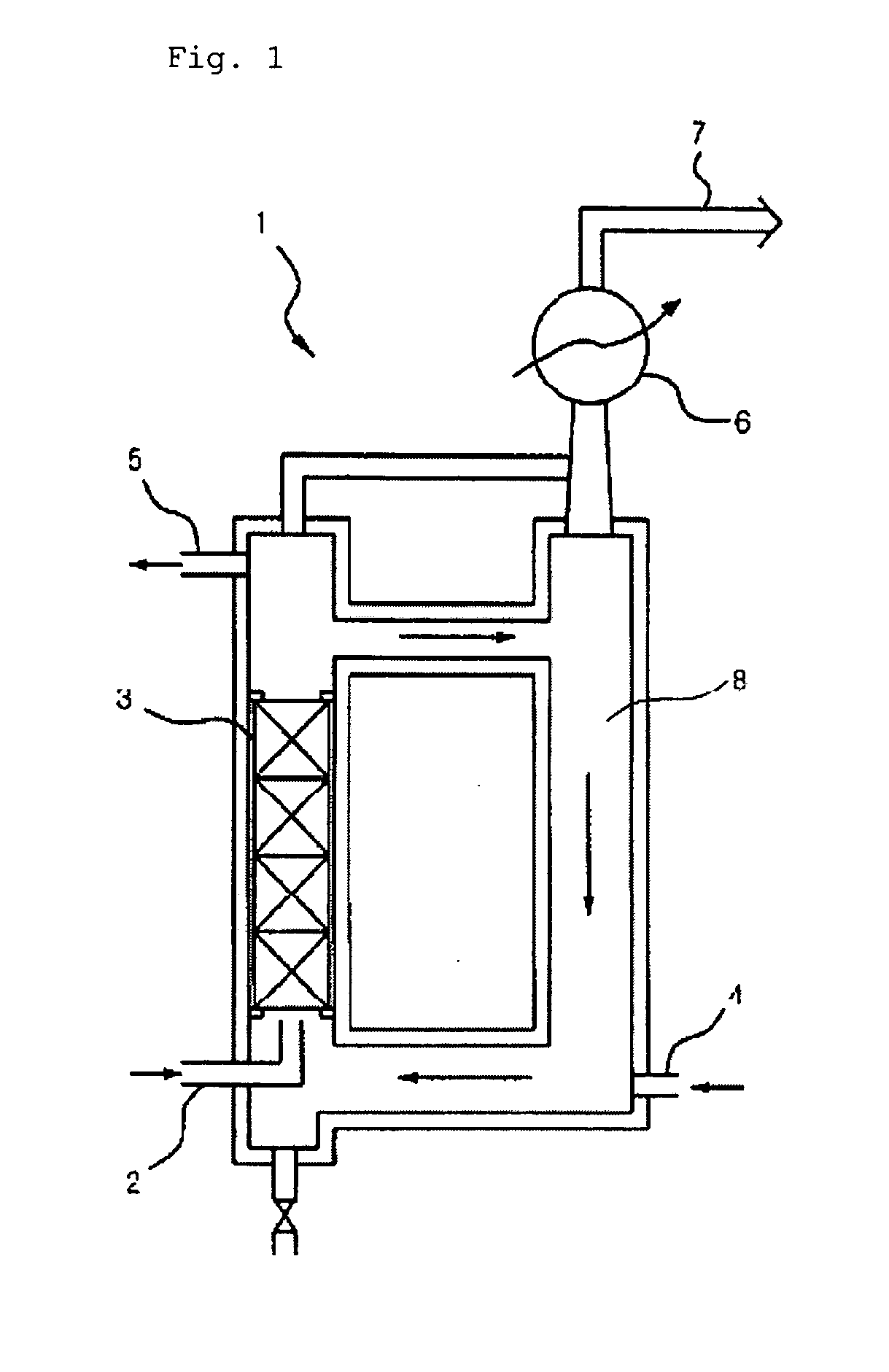

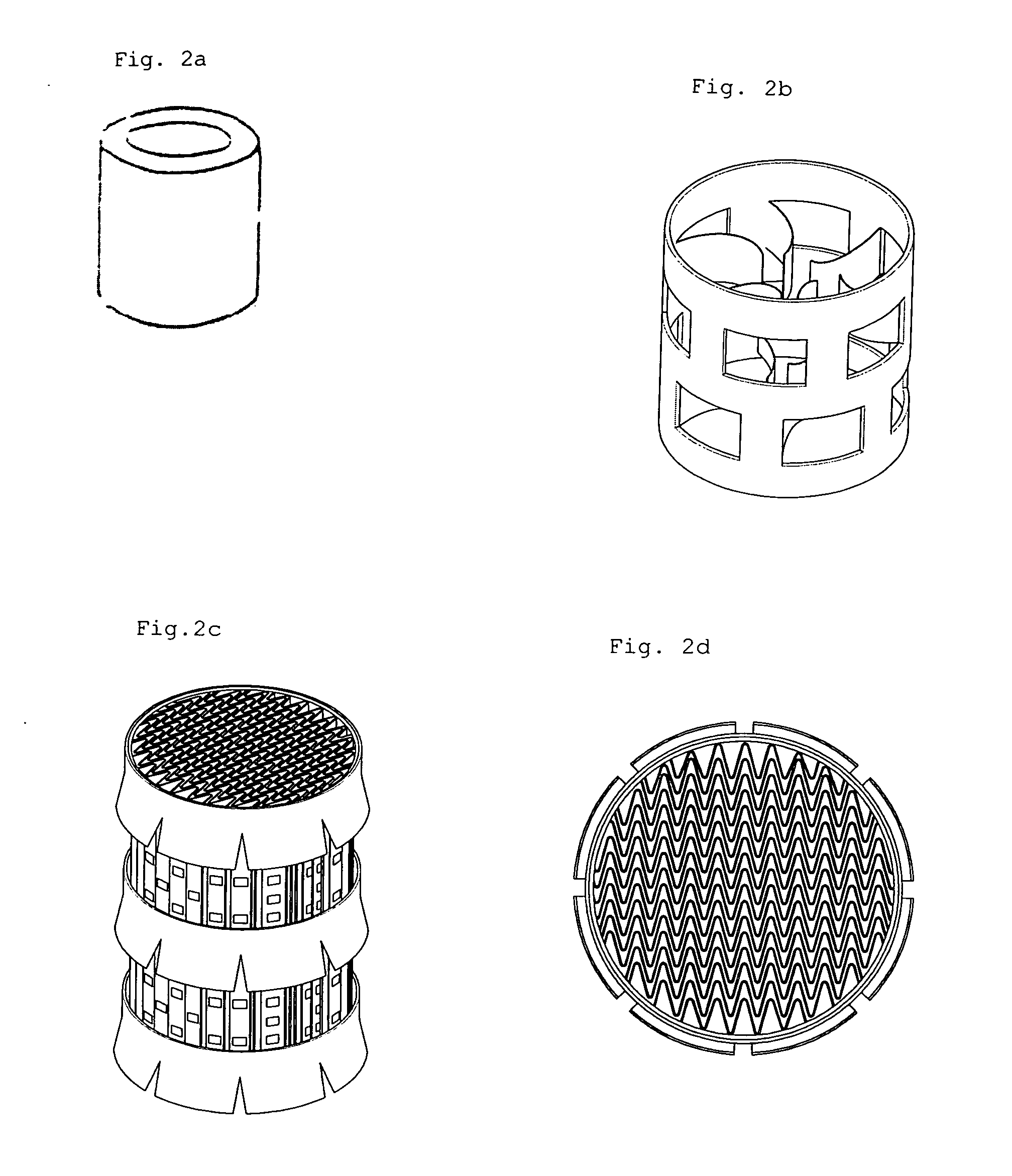

The method of producing 4-fluoroethylene carbonate (FEC), in which ethylene carbonate (EC) reacts with a mixture of fluorine and nitrogen gases, includes feeding a mixture gas of fluorine gas and nitrogen gas into a reactor having ethylene carbonate charged therein, so as to react the ethylene carbonate with the mixture gas of the fluorine gas and the nitrogen gas. The mixture gas fed in the reactor is regulated to have a desired bubble size while passing through a gas bubble regulating column, in which a packing for a packed column is packed. In the method, EC directly reacts with F2 / N2 mixture gas to produce FEC, thus a purification process is simple and it is possible to produce FEC at high conversion efficiency and selectivity.

Owner:FOOSUNG CO LTD

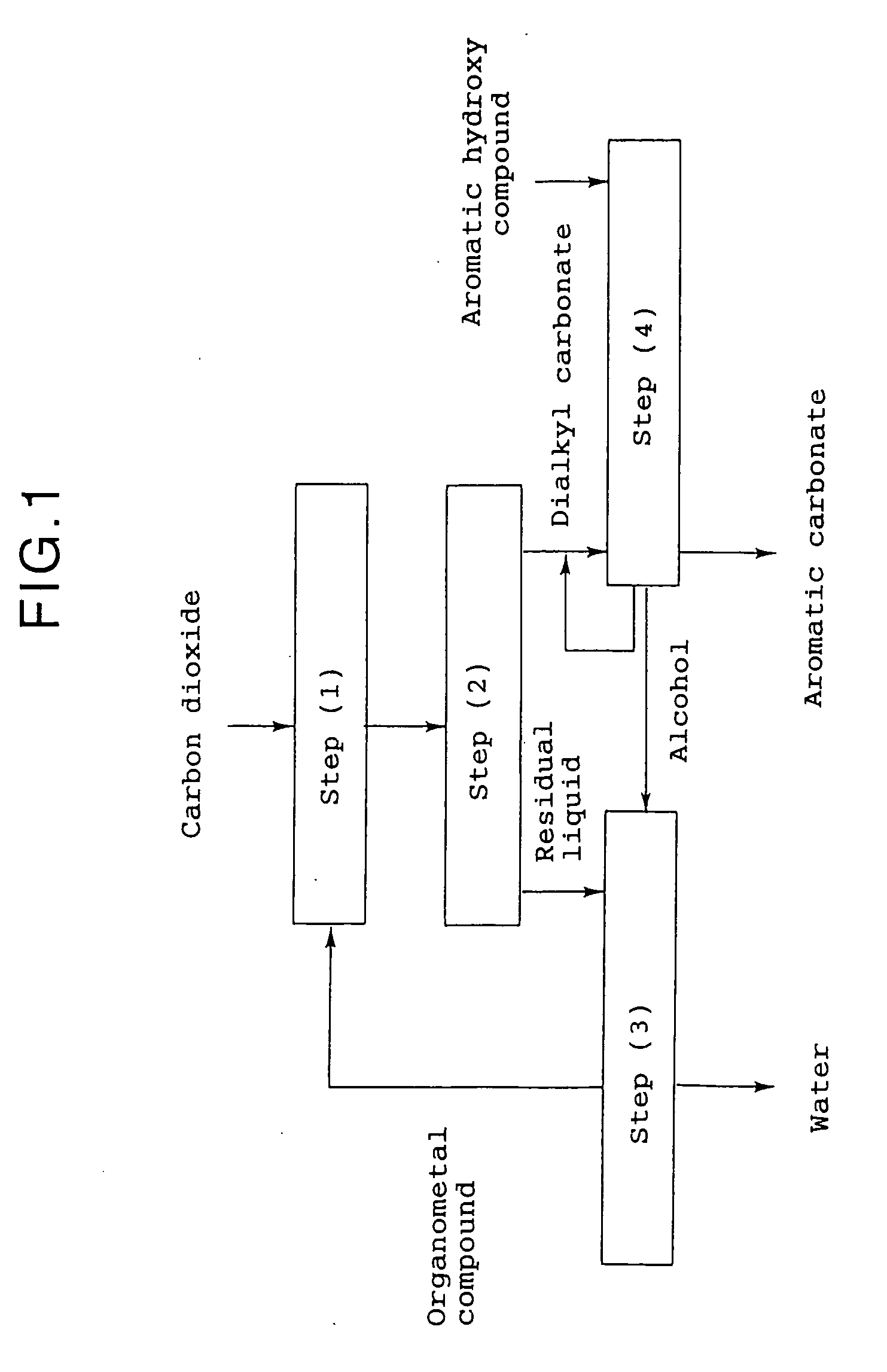

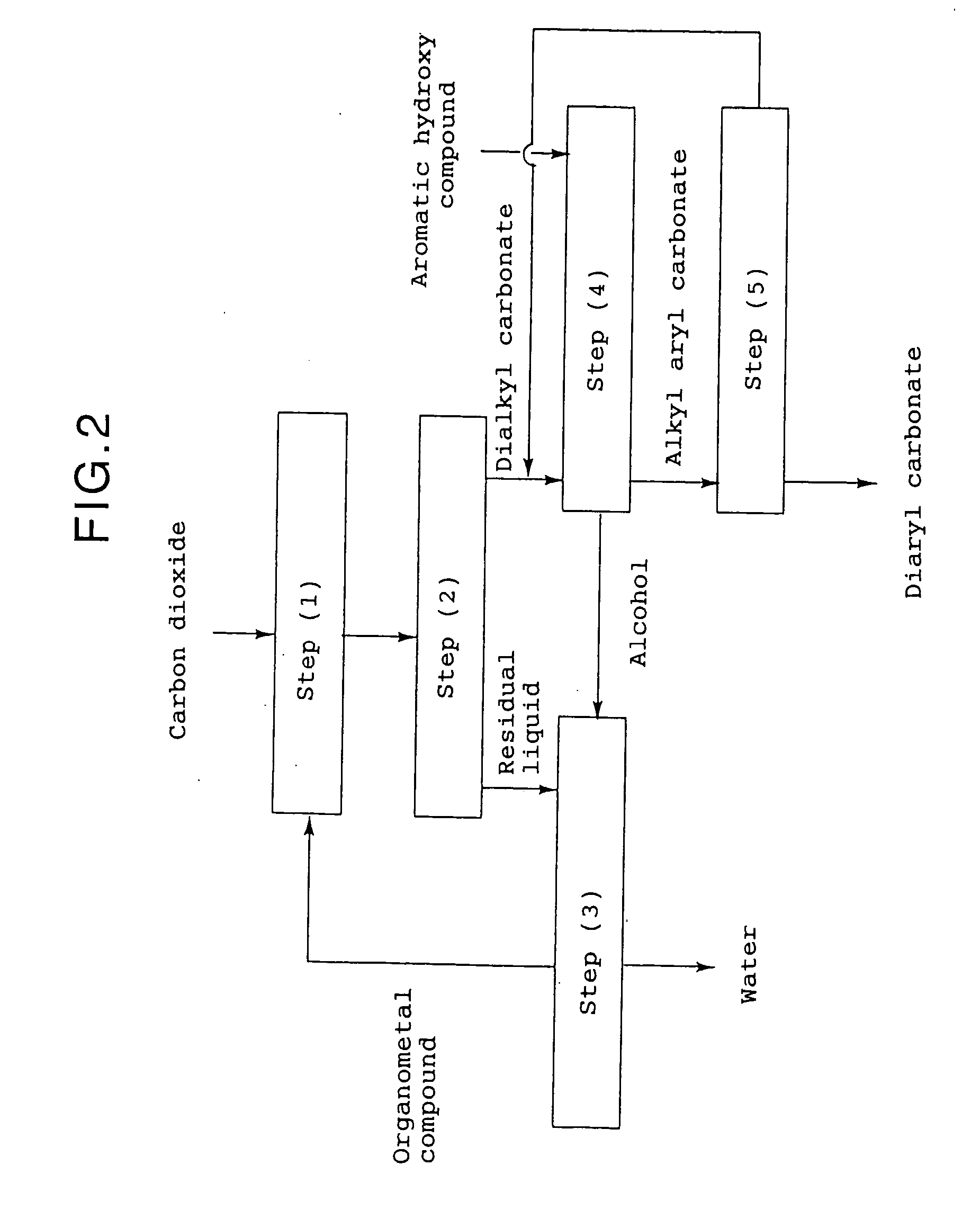

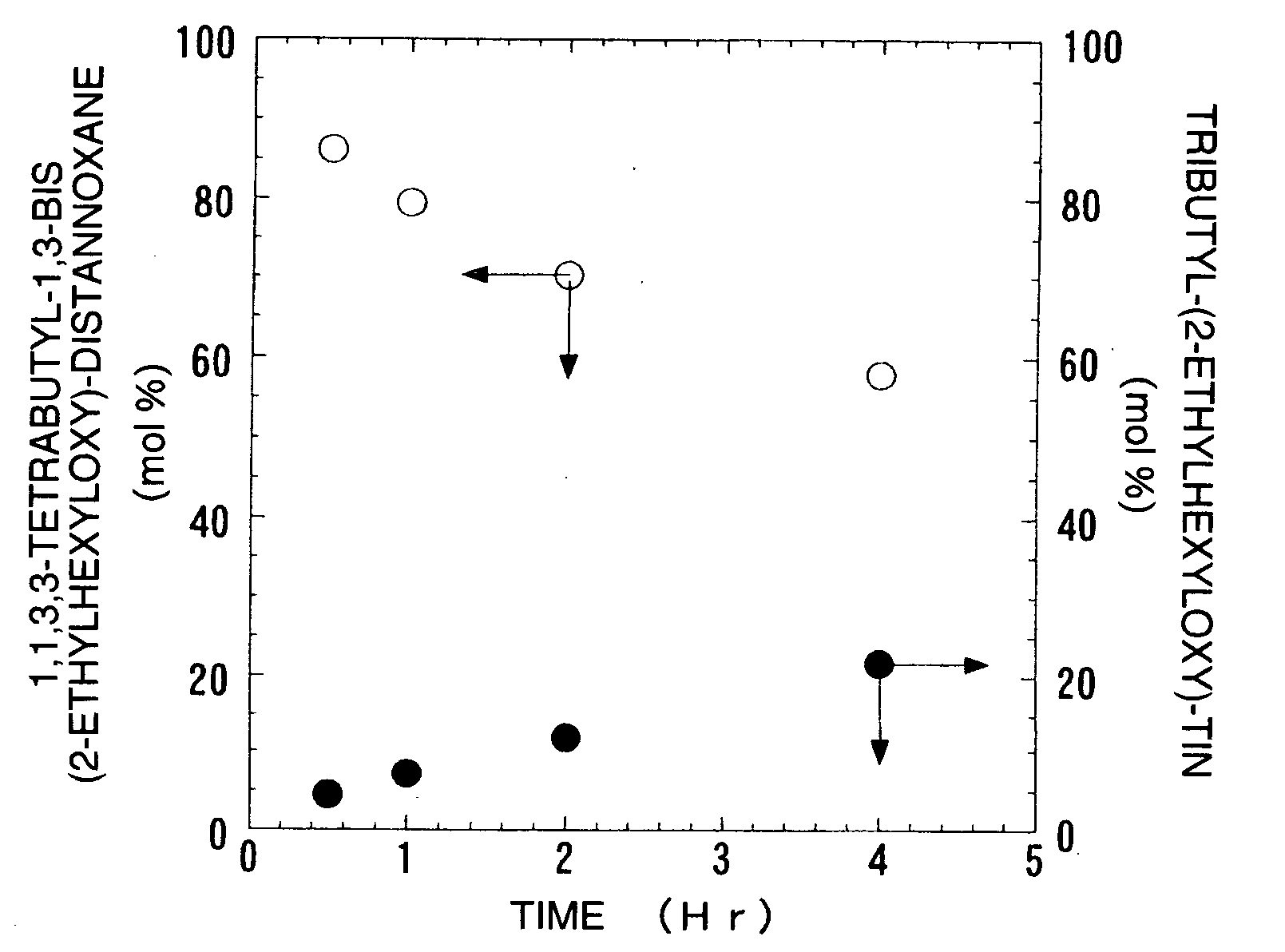

Method for producing an aromatic carbonate

ActiveUS20070055042A1Simple and efficient productionHigh purityPreparation from organic carbonatesPreparation from carbon dioxide or inorganic carbonatesAlcoholAromatic agent

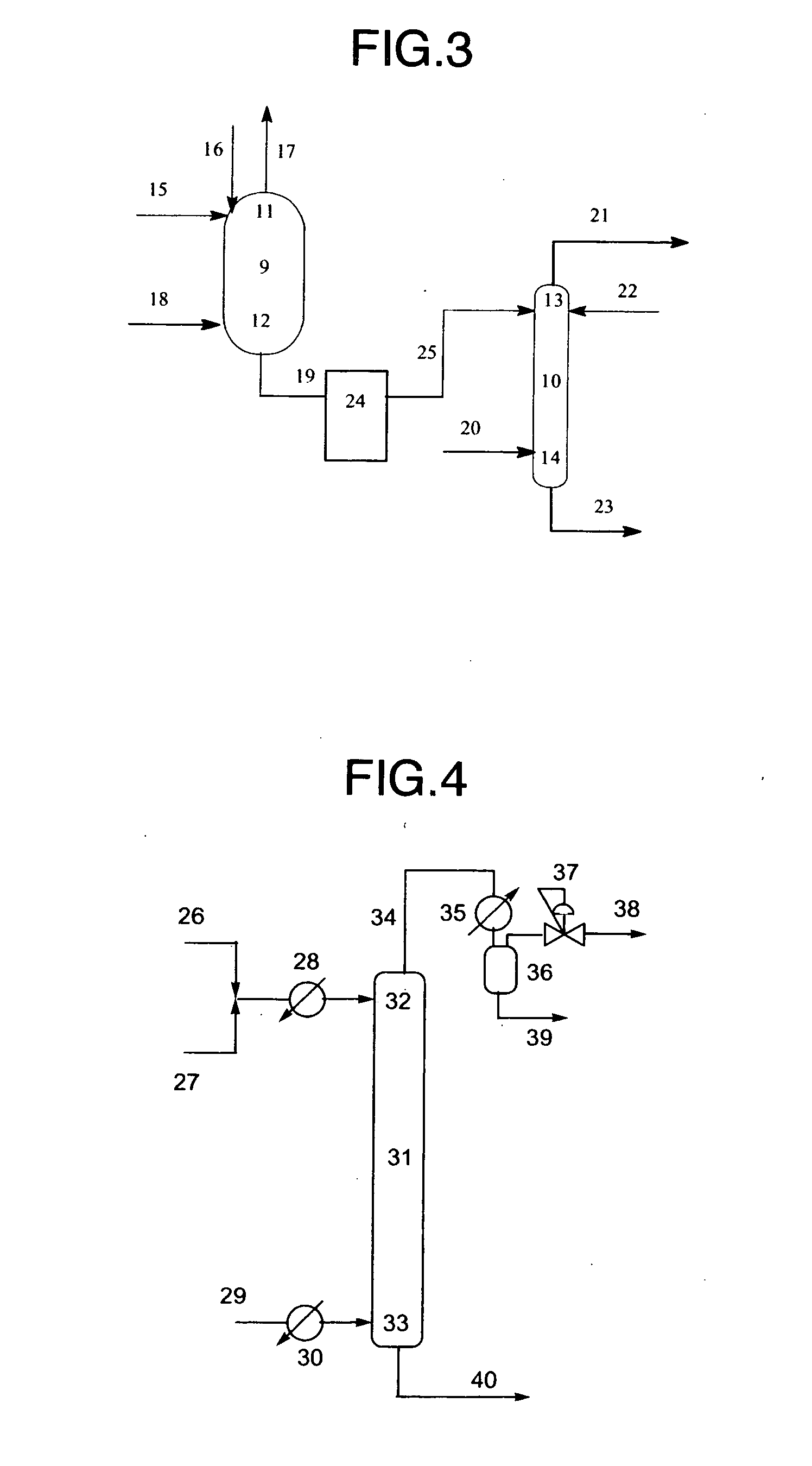

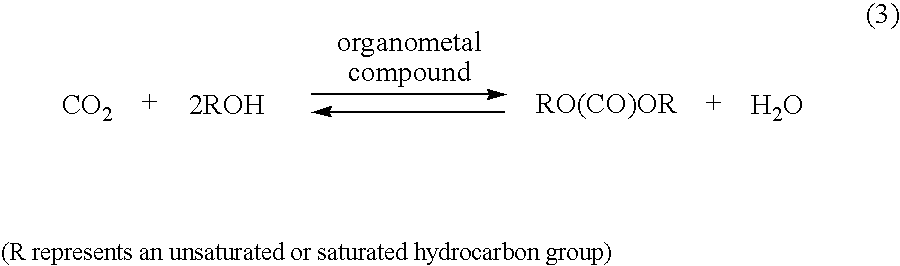

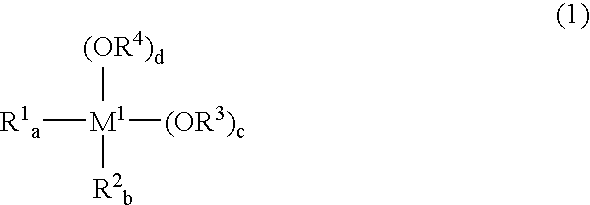

A method for producing an aromatic carbonate, comprising: (1) performing a reaction between an organometal compound and carbon dioxide to obtain a reaction mixture containing a dialkyl carbonate formed by the reaction, (2) separating the dialkyl carbonate from the reaction mixture to obtain a residual liquid, (3) reacting the residual liquid with an alcohol to form at least one organometal compound and form water and removing the water from the organometal compound, and (4) reacting the dialkyl carbonate separated in step (2) with an aromatic hydroxy compound to obtain an aromatic carbonate.

Owner:ASAHI KASEI KK

Catalyst used for catalytic synthesizing dimethyl carbonate directly from methanol and carbon dioxide and preparation and using method thereof

The invention discloses a direct catalytic synthesis catalyst to prepare dimethyl carbonate from methanol and carbon dioxide and the preparation and application methods of the catalyst. The catalyst of the invention consists of transitional metal soluble salt, promoter and carrier, with the weight ration from 0.01to 0.5: 0.01to 0.1:1. The preparation method is that: (1) the carrier is impregnated into the transition metal soluble salt solution; (2) the promoter is added into the solution, which is stirred in room temperature, ultrasonically dispersed and stored stationarily in room temperature; (3) the solution is dried, sintered, reduced and activated to produce catalyst. The application method is that: the catalyst is put in high pressure reactor or micro reaction device with the temperature of the catalyst bed controlled between 90 degrees centigrade to 140 degrees centigrade and the reaction pressure between 0.6 to 3.0MPa. The catalyst is applicable in direct catalytic synthesis to prepare dimethyl carbonate from methanol and carbon dioxide. The raw material sources are rich, the cost is low, the preparation method is simple and the operation is easy. The catalyst is easily separated from the products, the reaction conditions are mild and the catalyst can be used repeatedly. The catalyst has high activity and selectivity.

Owner:SUN YAT SEN UNIV

Manufacturing method and apparatus of 4-fluoroethylene carbonate control system of autonomous intelligent distributed control modules

Disclosed herein is a method of producing 4-fluoroethylene carbonate, in which ethylene carbonate reacts with a mixture of fluorine and nitrogen gases. The method comprises feeding a mixture gas of fluorine gas and nitrogen gas into a reactor having ethylene carbonate charged therein, so as to react the ethylene carbonate with the mixture gas of the fluorine gas and the nitrogen gas. The mixture gas fed in the reactor is regulated to have a desired bubble size while passing through a gas bubble regulating column, in which a packing for a packed column is packed. In the method, EC directly reacts with F2 / N2 mixture gas to produce FEC, thus a purification process is simple and it is possible to produce FEC at high conversion efficiency and selectivity.

Owner:FOOSUNG

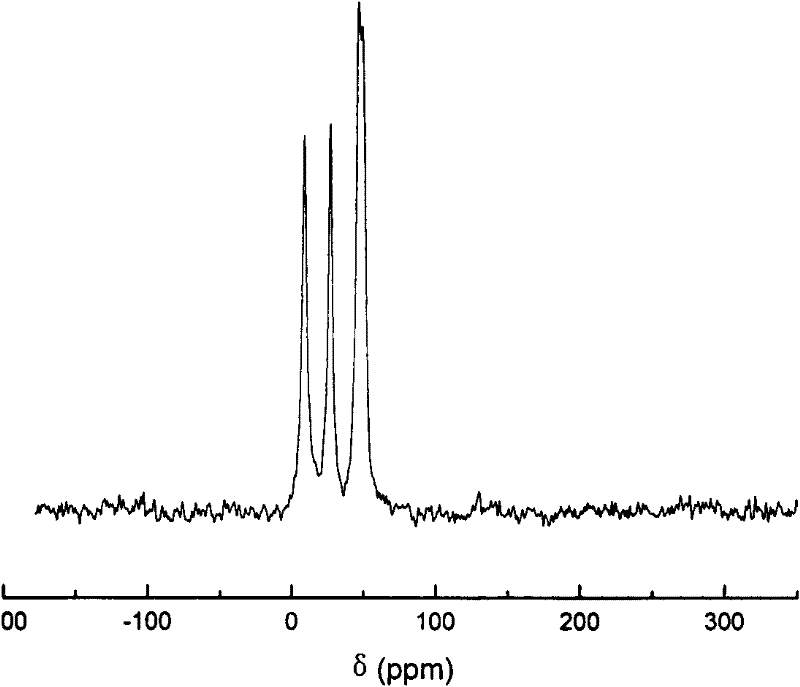

Catalyst for synthesizing propylene carbonate and its preparing method and use

InactiveCN1775356AEasy to prepareEasy to operateCatalyst carriersProductsPtru catalystPropylene carbonate

The present invention relates to a catalyst for synthesizing propylene carbonate. Said invention uses single active center organic quaternary ammonium hydroxide as active component, uses MCM-41 as carrier, uses chloropropyl trimethoxysilane as coupling agent and uses cyclohexane as solvent, and adopts ultrasonic technique to make the quaternary ammonium hydroxide be simply and moderately be grafted on the carrier MCM-41, its grafting quantity is 0.5-1.5 mmol / g, so as to obtain the invented catalyst.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Dimethyl carbonate supported catalyst directly synthesized by methanol and carbon dioxide

The invention discloses a dimethyl carbonate supported catalyst directly synthesized by methanol and carbon dioxide and a preparation method and a use method. The catalyst adopts diatomite as carrier, transition metal copper and nickel as main components of active components and zinc, iron, cobalt and the like as additives, wherein, the weight percent of diatomite in the catalyst is 60-95%, the weight percent of the transition metals is 5-30% and the weight percent of the additives is 0-15%. The preparation method comprises the following steps: soaking the carrier in a mixed solution of soluble transition metal salt and the additives, dispersing with ultrasound, evaporating and drying, calcining and reducting with hydrogen to obtain the supported catalyst. The use method comprises the following steps: placing the catalyst in a reaction device, adjusting the molar ratio of gas phase methanol to carbon dioxide to 2:1-3:1, and performing a reaction at 110-140 DEG C under the pressure of 0.6-3.0 MPa. The catalyst has the advantage of simple preparation steps, good stability and high catalytic efficiency and overcomes the defect that the carrier used by the existing catalyst needs be processed through complicated steps for pretreatment and has high price and instable catalytic performance.

Owner:SUN YAT SEN UNIV

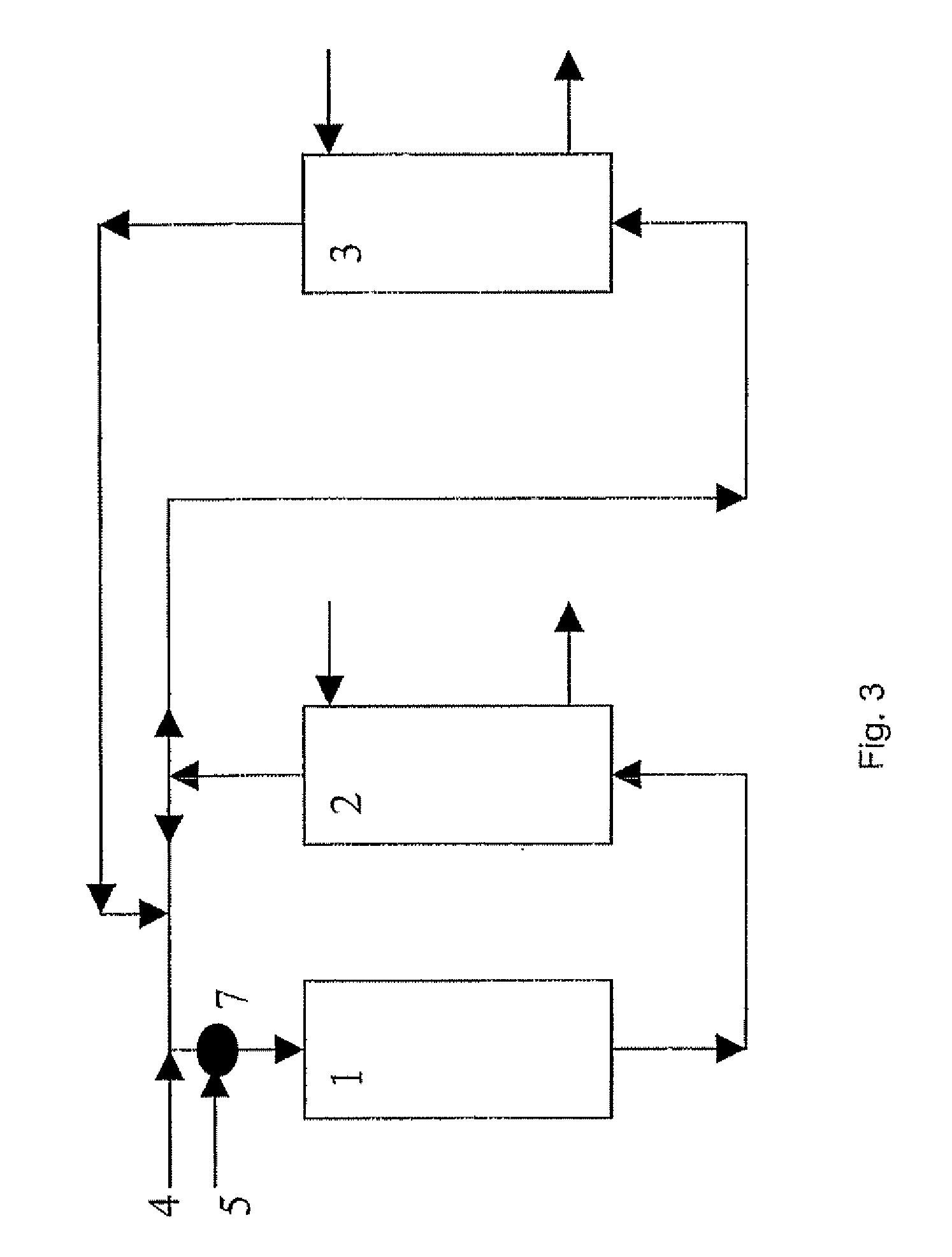

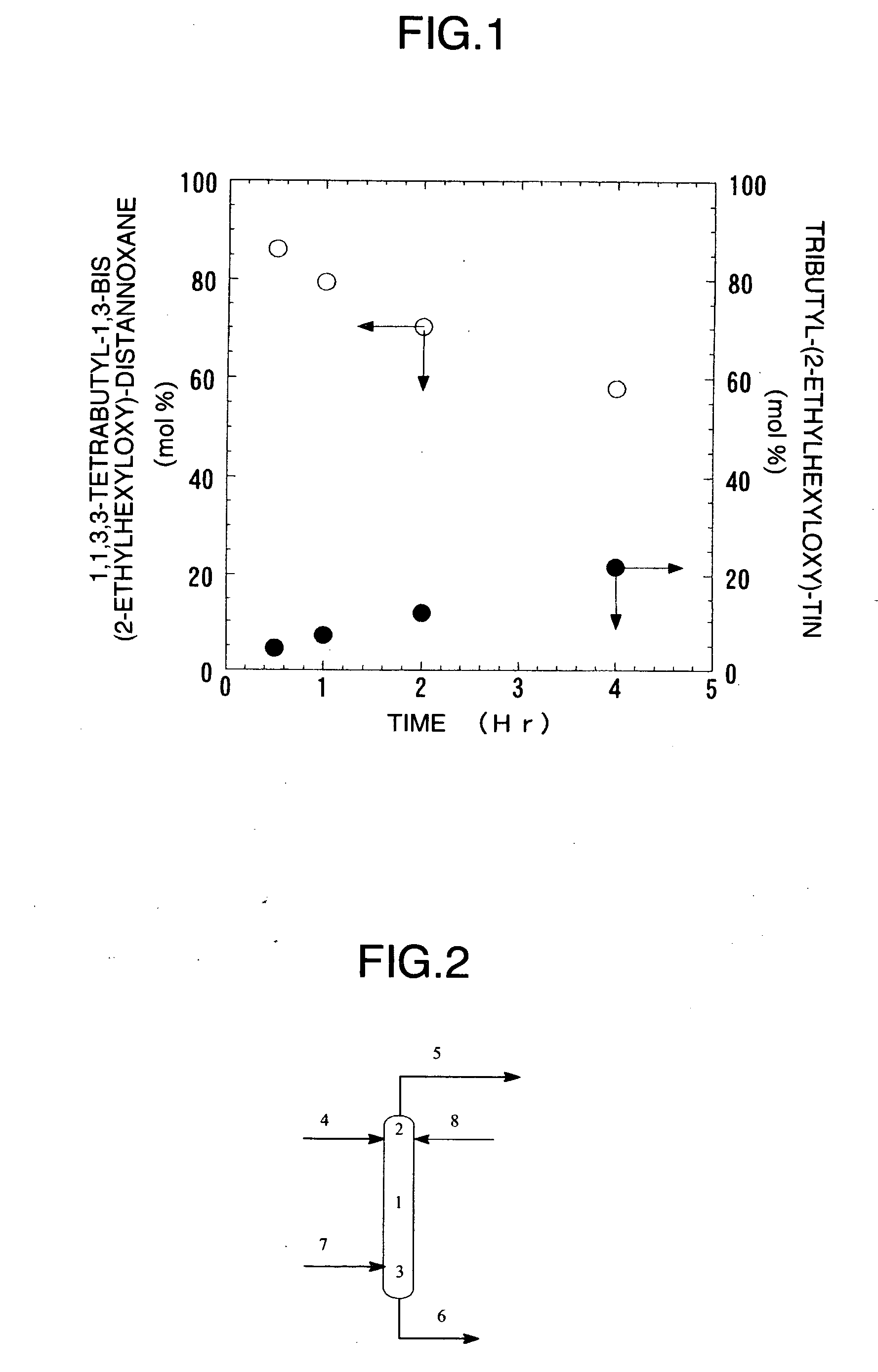

Process for producing carbonic ester

ActiveUS20050080274A1High yieldEasy to separateCarbonic/haloformic acid esters purification/separationPreparation from carbon dioxide or inorganic carbonatesAlcoholCarbonate ester

A method for producing a carbonic ester, comprising (1) performing a reaction between an organometal compound having a metal-oxygen-carbon linkage and carbon dioxide to obtain a reaction mixture containing a carbonic ester formed by the reaction, (2) separating the carbonic ester from the reaction mixture to obtain a residual liquid, and (3) reacting the residual liquid with an alcohol to form an organometal compound having a metal-oxygen-carbon linkage and form water and removing the water from the organometal compound, wherein the organometal compound obtained in step (3) is recovered for recycle thereof to step (1).

Owner:ASAHI KASEI KK

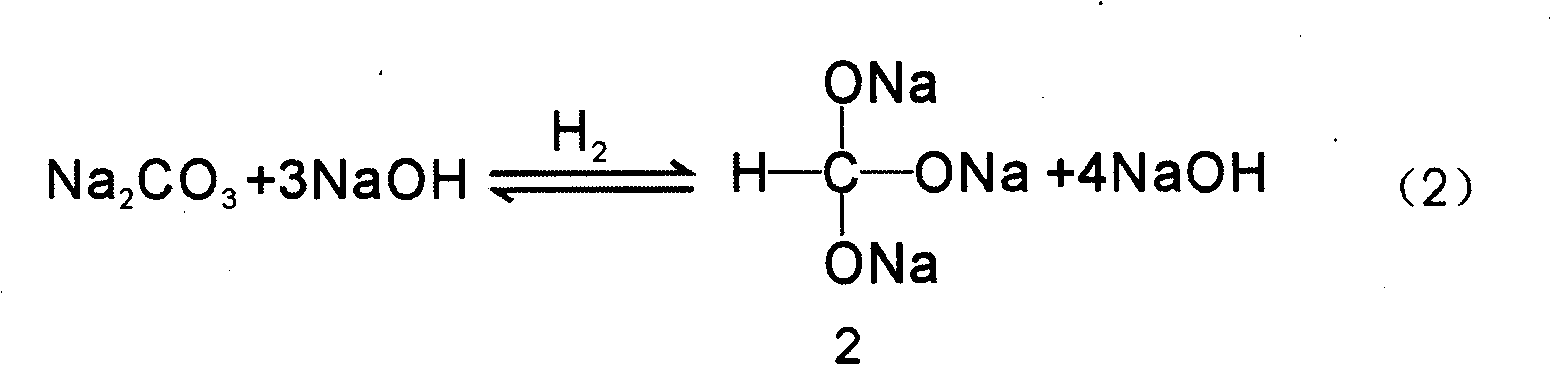

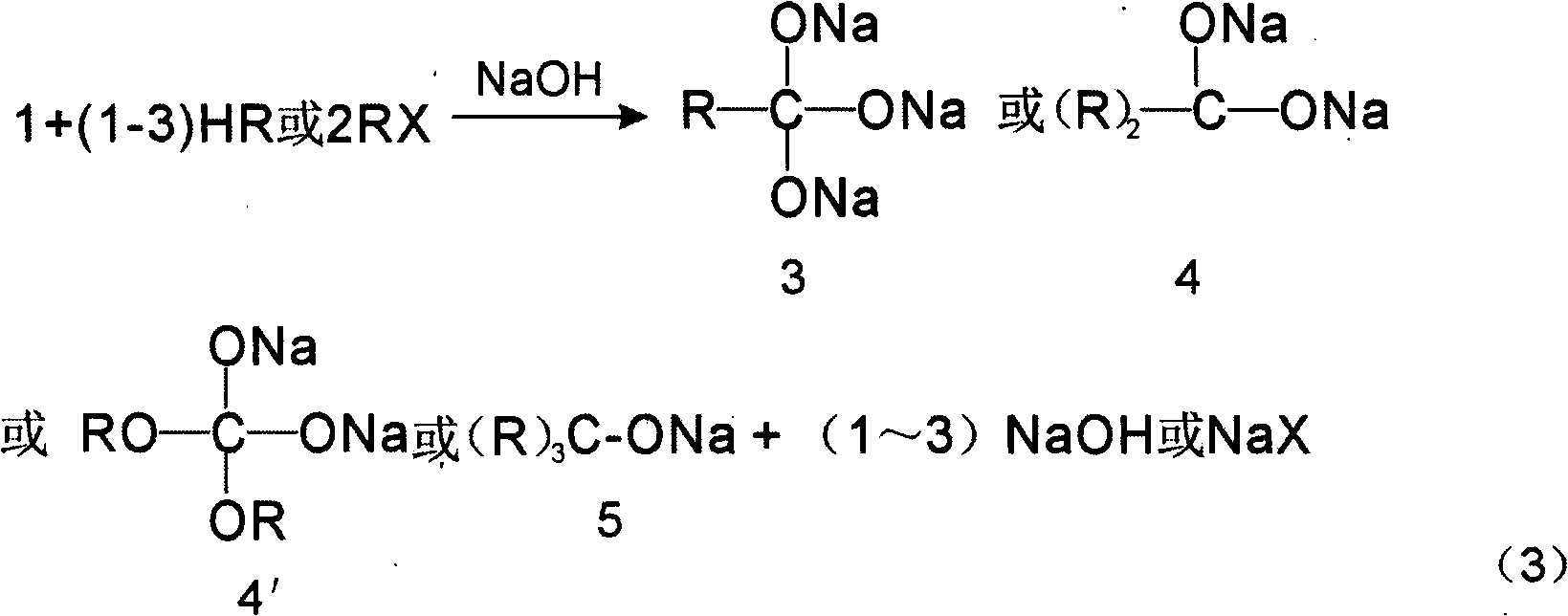

Method for preparing DMC, DPC, ortho-carbonate, ortho-formate, dimethyl ether, and the like by using Na2CO3 or sodium formate or CO2 or CO

InactiveCN103254084AOrganic compound preparationPreparation from ortho-estersSynthesis methodsProcess synthesis

The invention relates to a recently discovered universal synthesis method of tandem-substitution-rearrangement-elimination reaction (TSRE reaction) of elemental organic chemistry, production process synthesis routes of two products of dimethyl carbonate (DMC) and diphenyl carbonate (DPC) and traditional products of ortho-carbonate, ortho-formate, dimethyl ether, and the like through CO2 and CO direct synthesis method are redesigned. Compared with prior arts for producing the products, with the preparation method provided by the invention, energy can be greatly saved, emission can be greatly reduced, and cost can be greatly reduced.

Owner:李坚

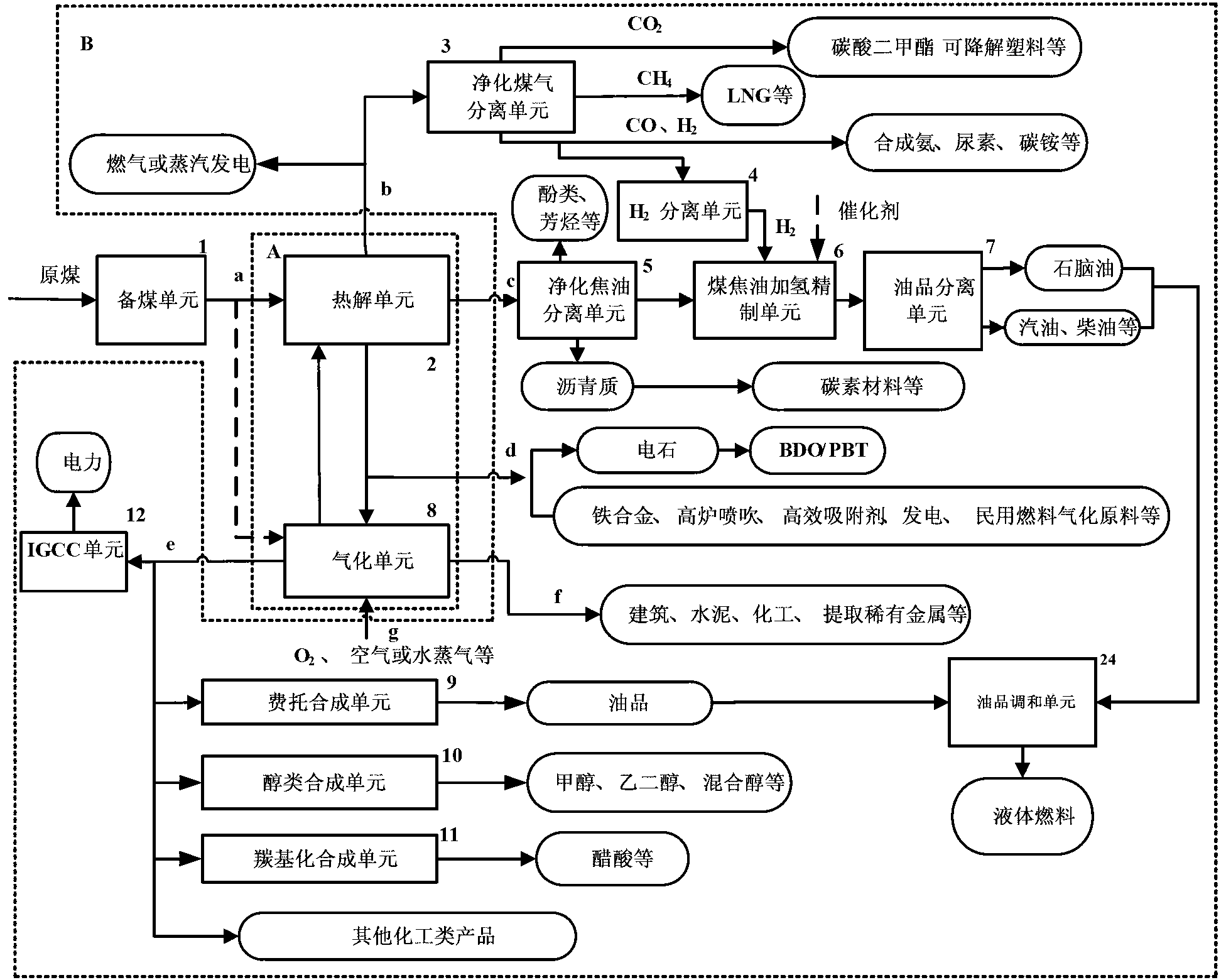

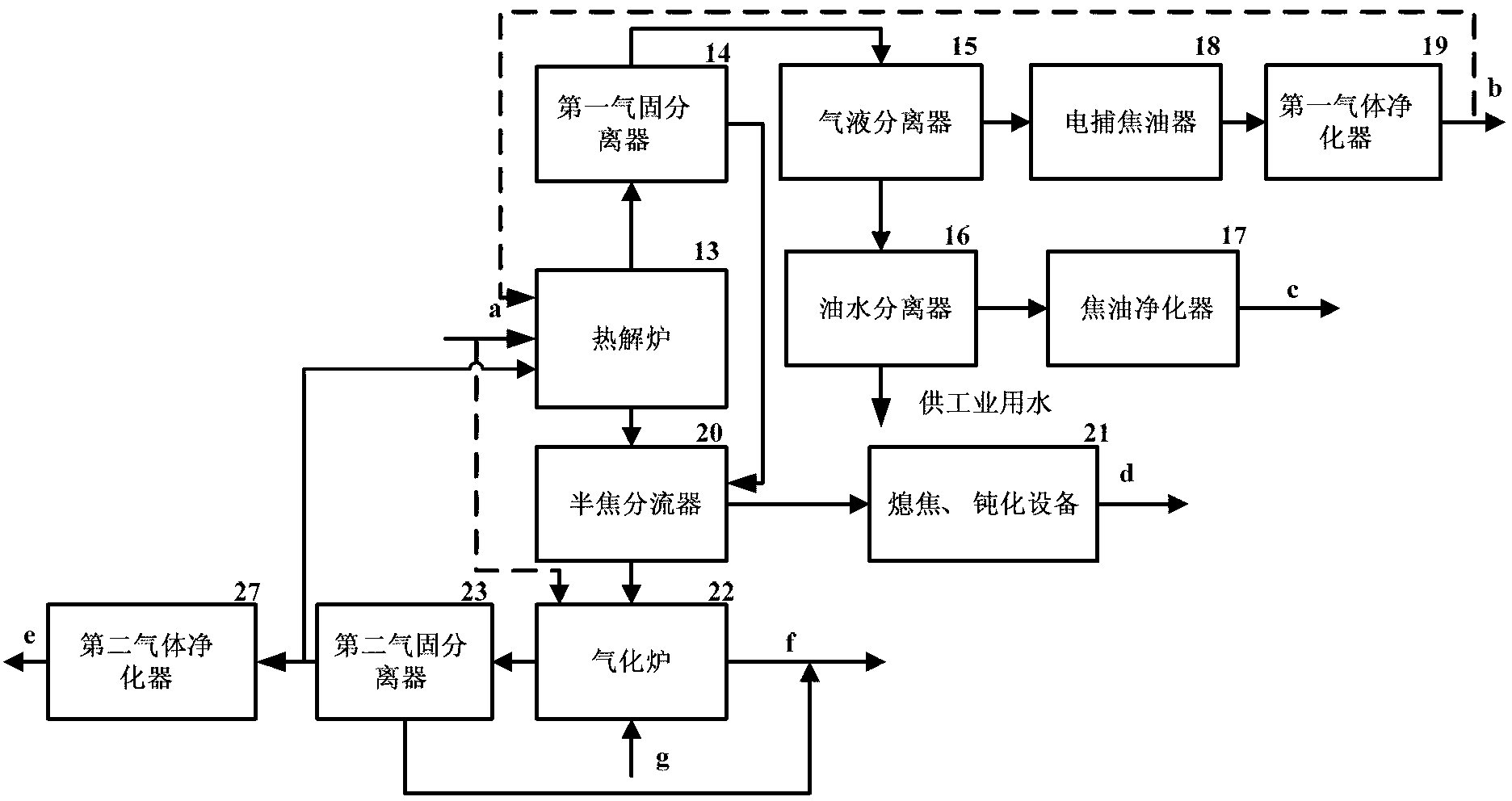

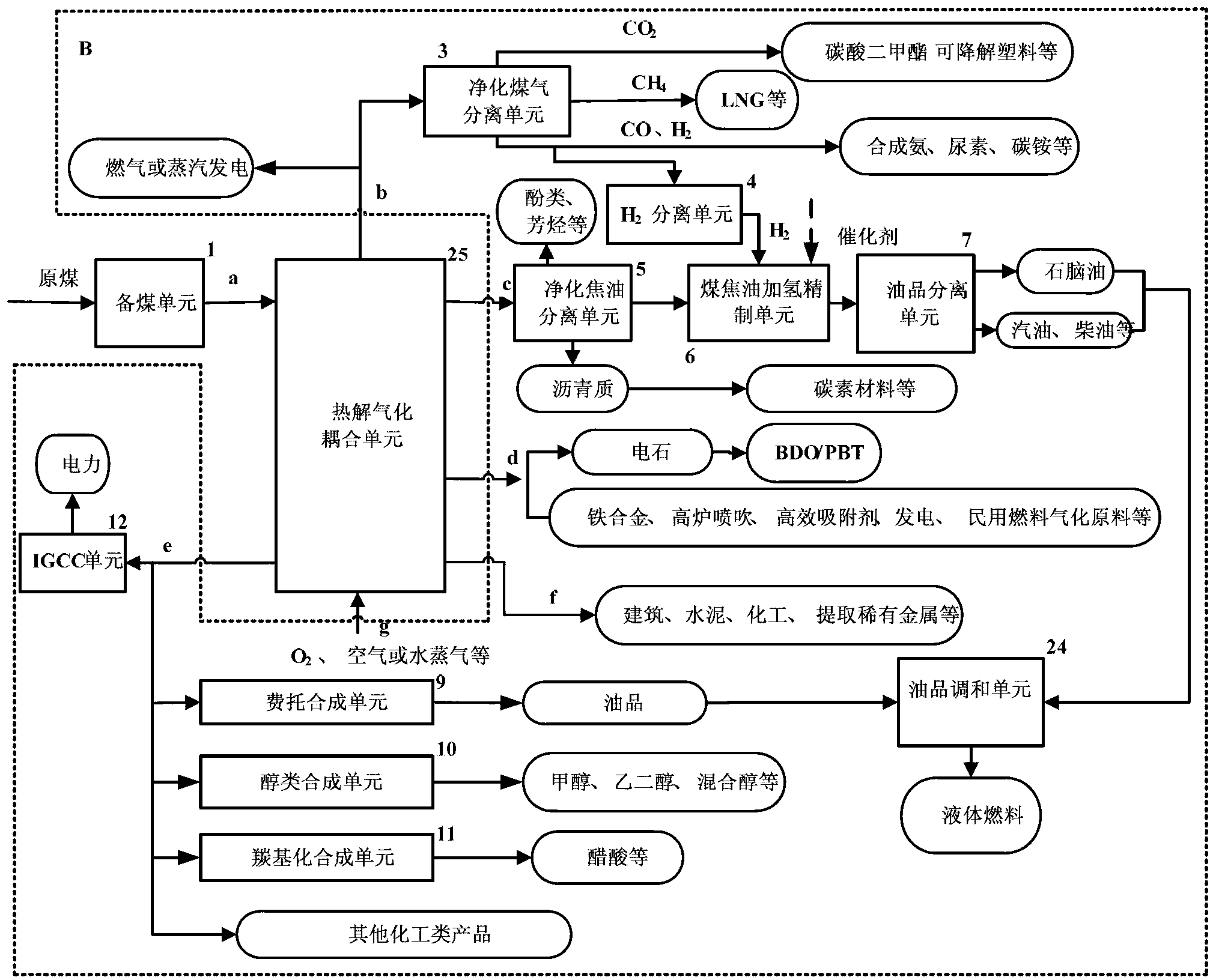

Pyrolysis gasification coupling integrated poly-generation system and process for coal chemical industry

ActiveCN103160296AImprove utilization efficiencyMaximize Utilization EfficiencyUrea derivatives preparationCarbon compoundsElectricityEngineering

The invention provides a pyrolysis gasification coupling integrated poly-generation system and process for the coal chemical industry. The system comprises a coal preparation unit, a pyrolysis-gasification coupling system A and a poly-generation system B, wherein the poly-generation system B comprises a purified gas separation unit connected with the purified gas outlet of the pyrolysis unit, a purified tar separation unit connected with the purified tar outlet of the pyrolysis unit, and a chemical product synthesis unit and an IGCC (Integrated Gasification Combined Cycle) unit which are respectively connected with purified gasification gas outlet of the gasification unit; and the purified tar separation unit is sequentially connected with a coal tar hydrofining unit and an oil product separation unit. The pyrolysis gasification coupling integrated poly-generation system and process can be used for organically combining coal pyrolysis gasification and the production process of oil, gas, chemicals, electricity and heat to realize integration of material conversion and energy conversion, maximize classified utilization, value promotion, utilization efficiency and economical benefit of coal resources, and improve the energy utilization efficiency.

Owner:SHAANXI COAL & CHEM TECH INST

Double-function catalyst for synthesizing cyclic carbonate and methyl carbonate

The double-function catalyst for synthesizing cyclic carbonate and methyl carbonate includes main catalyst quadridentate Schiff base aluminum complex (R1)(R2)SalenAlX, where R1 and R2 is H, Cl-C6 alkyl, alkoxy Cl, Br, NO2 and other group; and X is C1, Br, I, OR NO3, CH3COO, ClO4 BF4 and other one valent negative ion, and cocatalyst being organic compound YR3, where Y is group V element and R3 is C2-C12 alkyl or aryl, with the molar ratio between the main catalyst quadridentate schiff base aluminum complex and the cocatalyst being 0.05-1. The catalyst can catalyze the reaction of epoxy compound with Co2 to synthesize cyclic carbonate and catalyze the exchange reaction of cyclic carbonate with methoxide to synthesize methyl carbonate in high efficiency.

Owner:DALIAN UNIV OF TECH

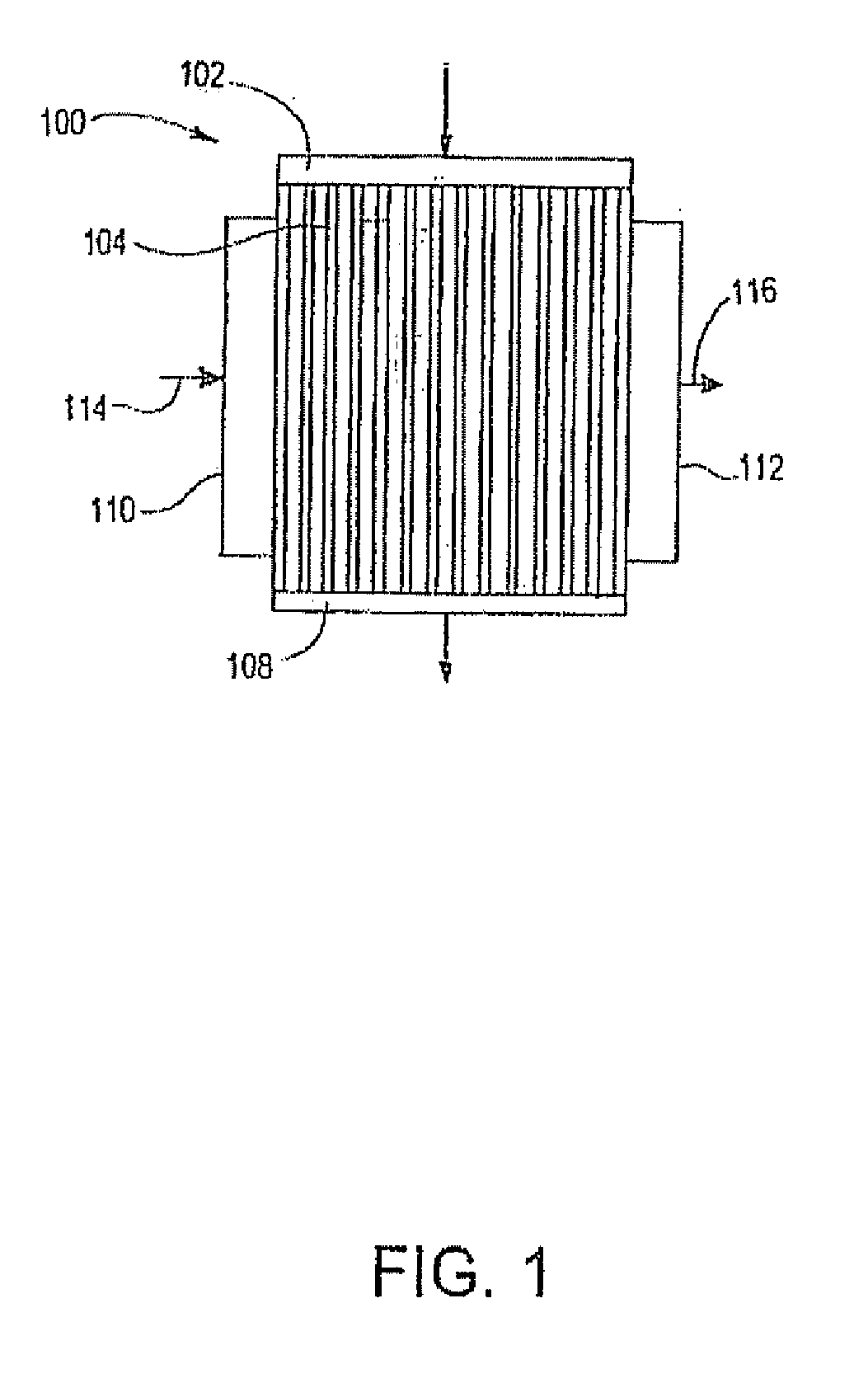

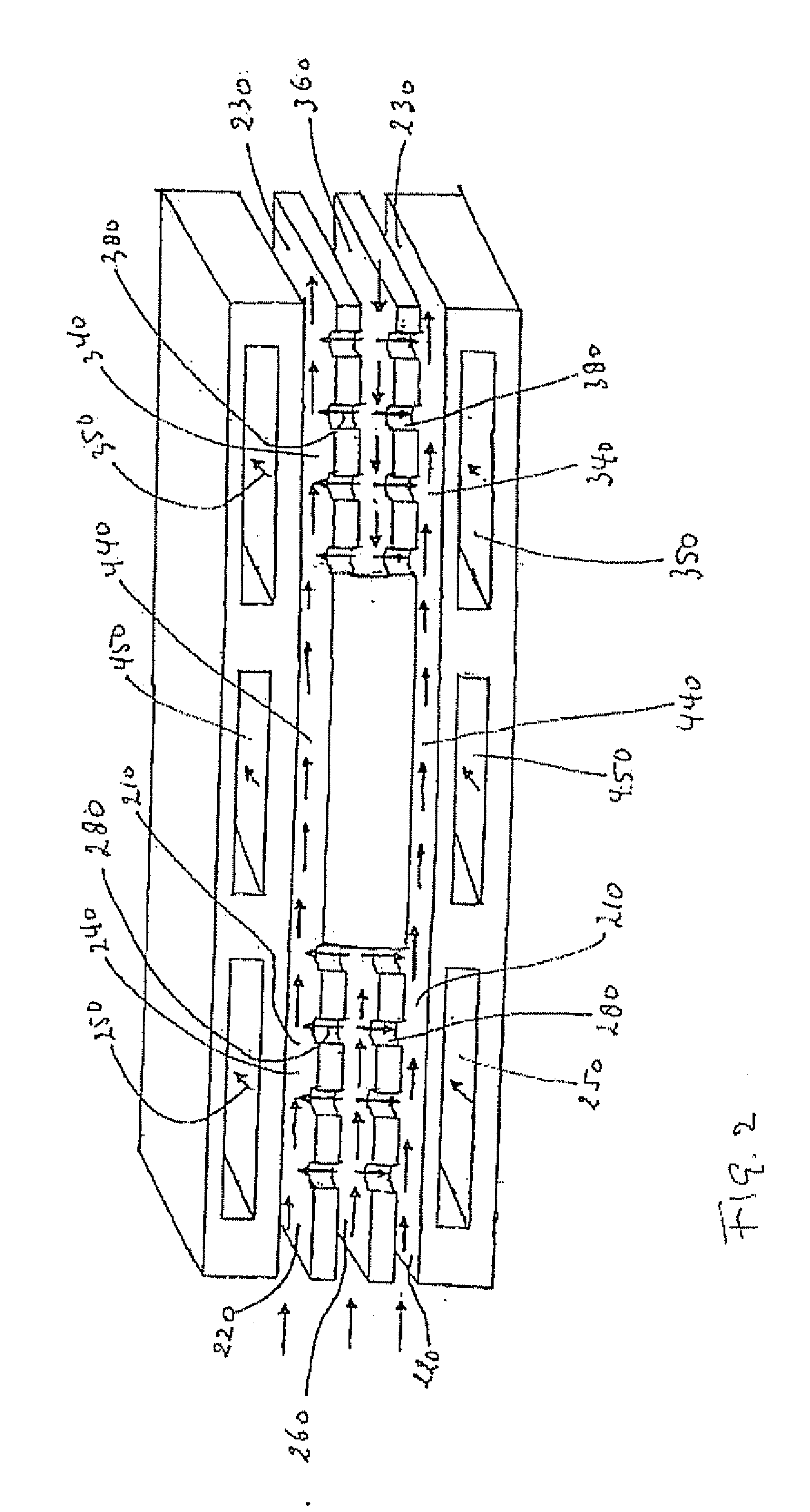

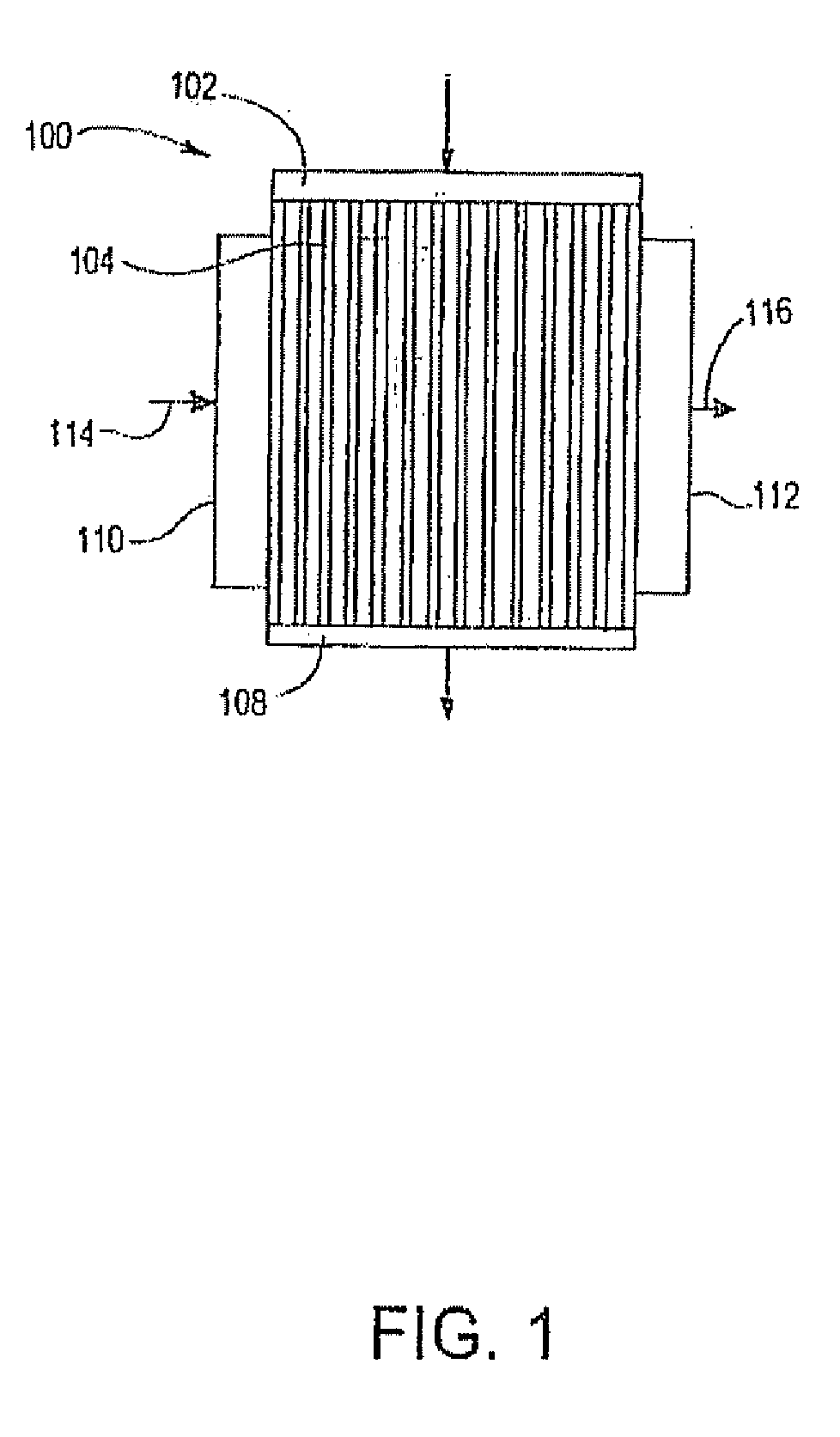

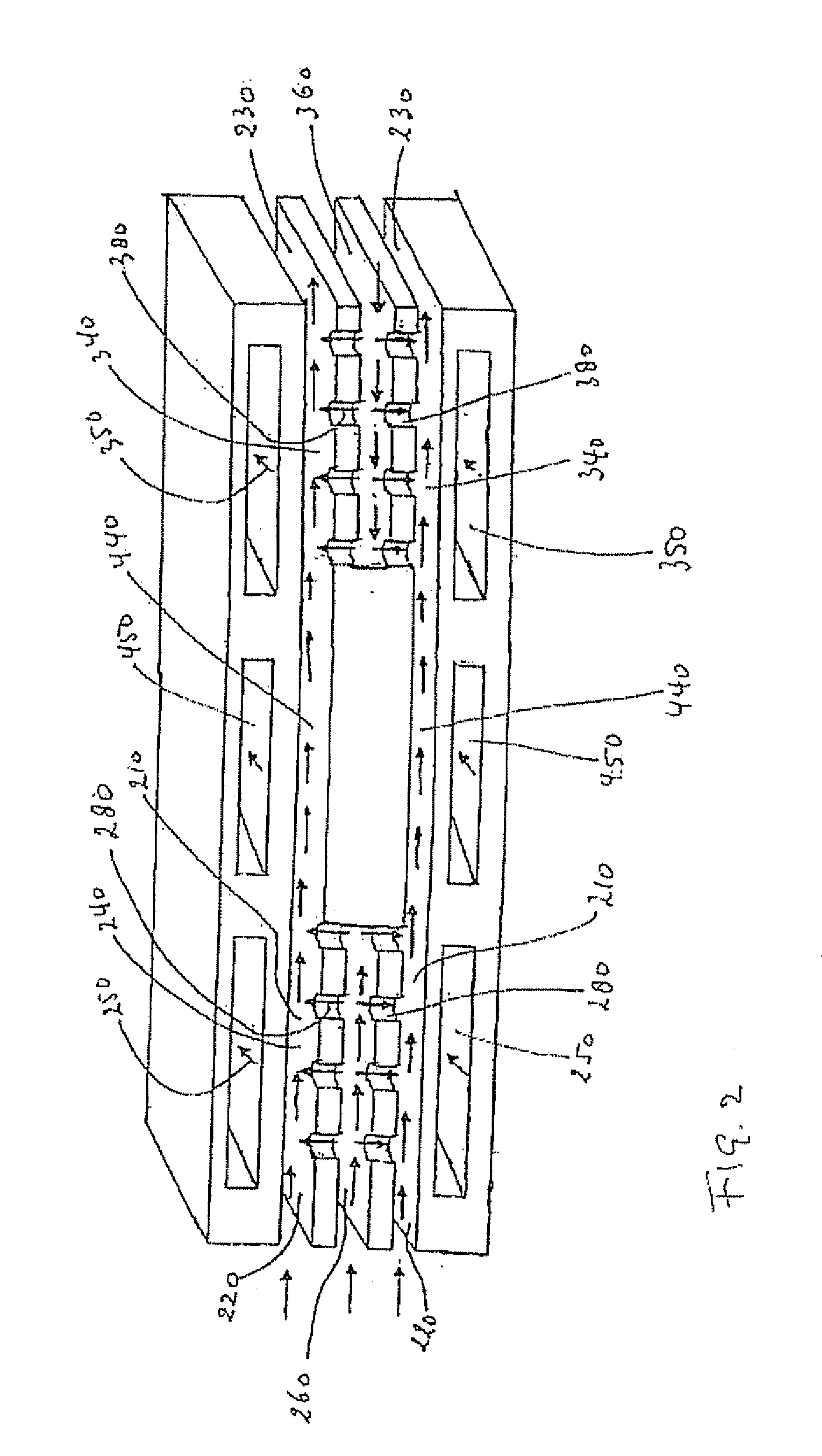

Method Of Installing An Epoxidation Catalyst In A Reactor, A Method Of Preparing An Epoxidation Catalyst, An Epoxidation Catalyst, A Process For The Preparation Of An Olefin Oxide Or A Chemical Derivable From An Olefin Oxide, And A Reactor Suitable For Such A Process

InactiveUS20070203349A1Speed up the processOrganic compound preparationChemical/physical/physico-chemical microreactorsCompound (substance)Alkene

The present invention relates to an improved epoxidation process and an improved epoxidation reactor. The present invention makes use of a reactor which comprises a plurality of microchannels. Such process microchannels may be adapted such that the epoxidation and optionally other processes can take place in the microchannels and that they are in a heat exchange relation with channels adapted to contain a heat exchange fluid. A reactor comprising such process microchannels is referred to as a “microchannel reactor”. The invention also provides a method of installing an epoxidation catalyst in a microchannel reactor. The invention also provides a method of preparing an epoxidation catalyst. The invention also provides an epoxidation catalyst. The invention also provides a certain process for the epoxidation of an olefin and a process for the preparation of a chemical derivable from an olefin oxide. The invention also provides a microchannel reactor.

Owner:SHELL OIL CO

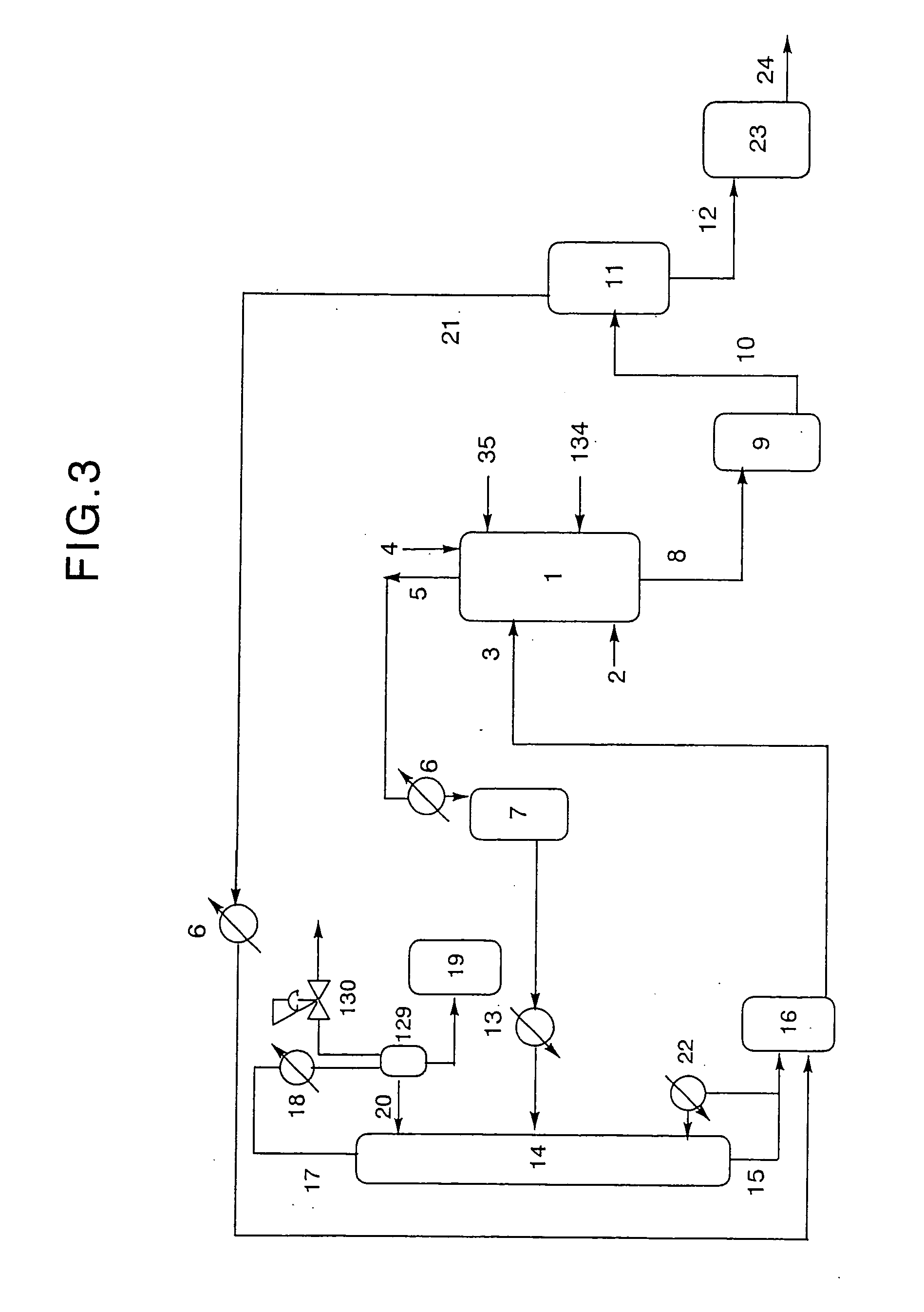

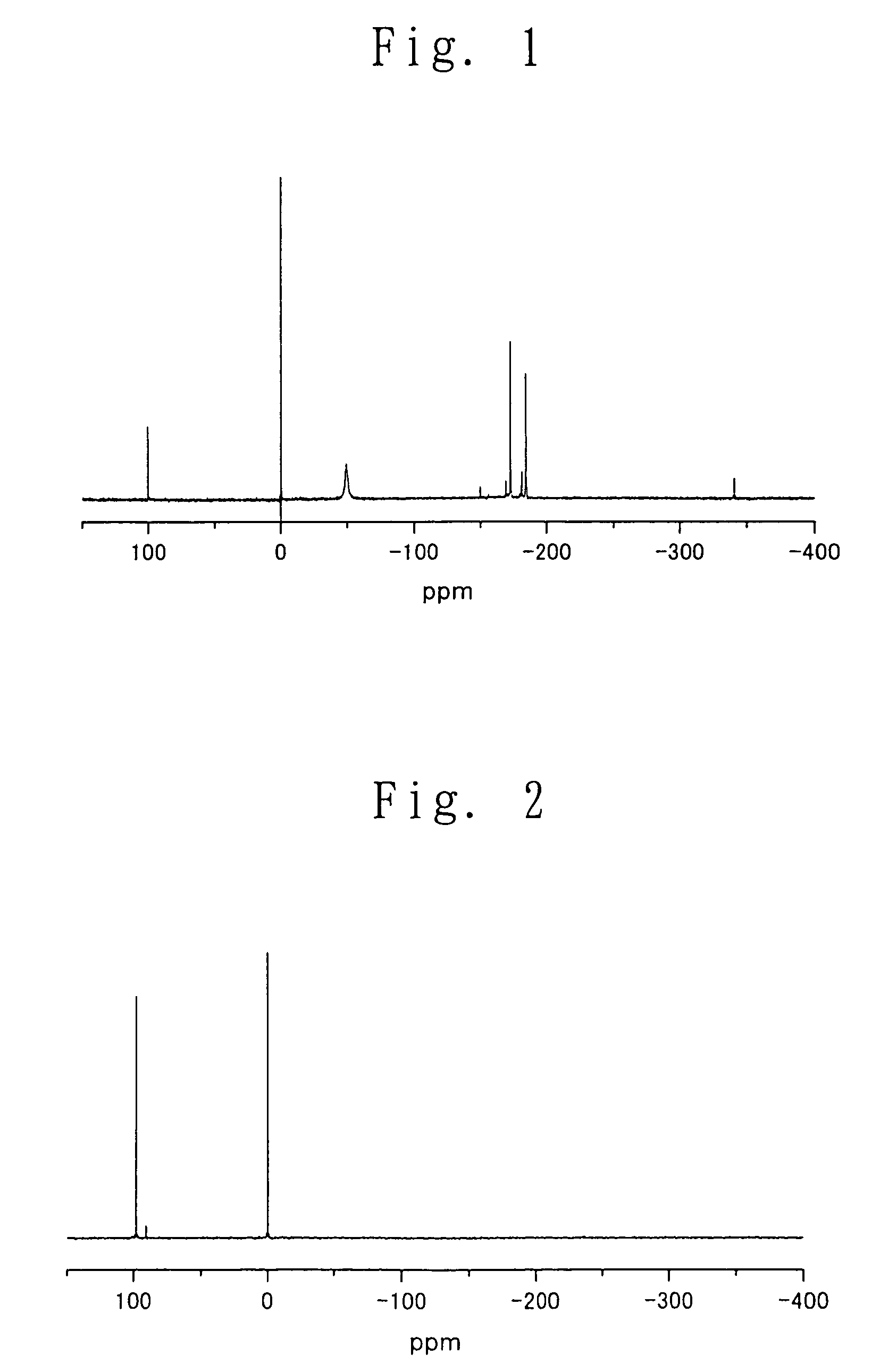

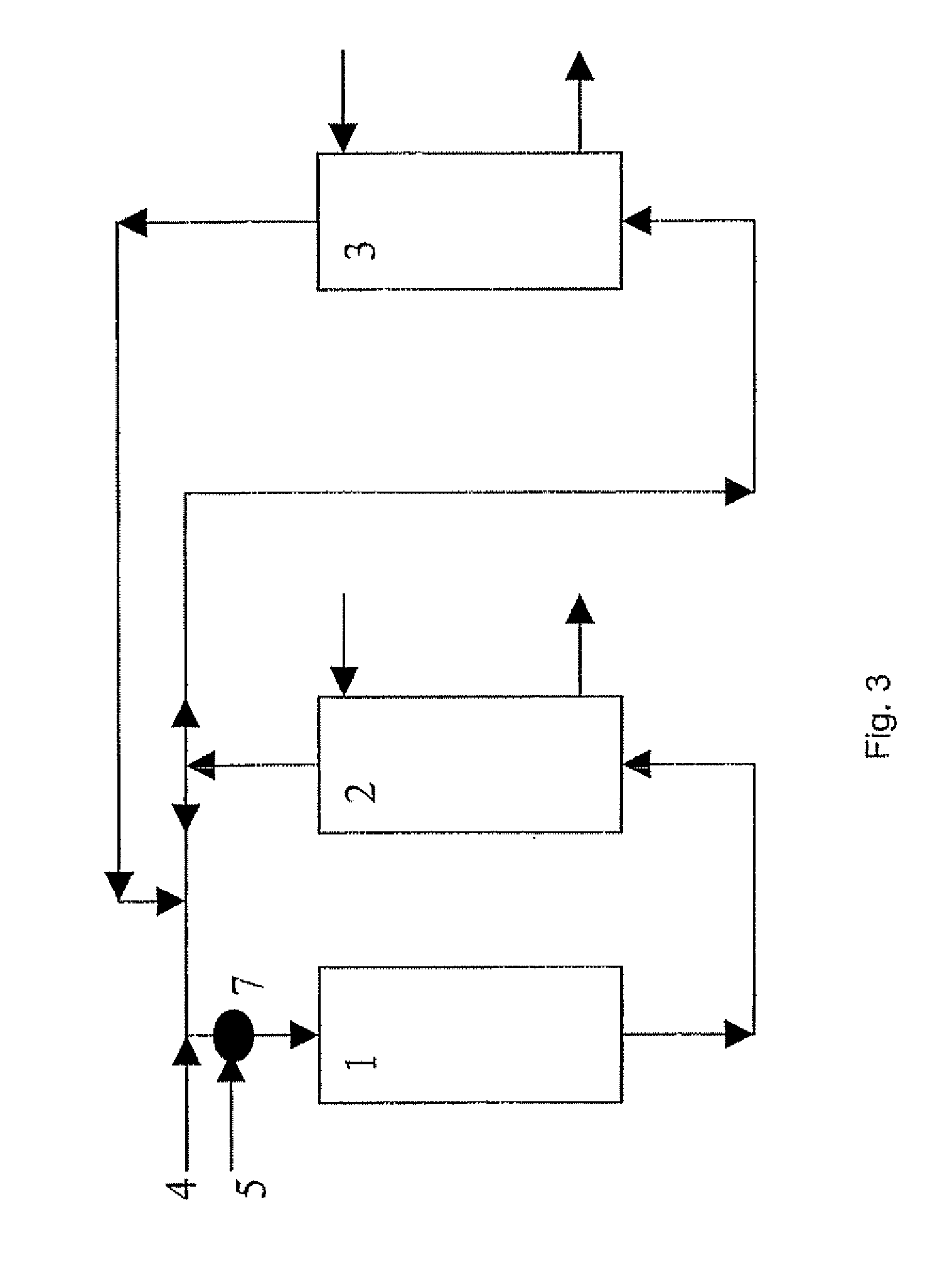

Process for Production of Alkyltin Alkoxides

ActiveUS20080275262A1Improve productivityTin organic compoundsOrganic compound preparationBoiling pointOxygen

A process for the production of alkyltin alkoxides which comprises subjecting at least one alkyltin compound selected from among organotin compounds having tin-oxygen-tin linkages as the starting compound and a hydroxyl compound as the reactant to dehydration to obtain an alkyltin alkoxide corresponding to the starting compound and the reactant, characterized by continuously feeding the starting compound and the reactant into a reactor, discharging a water-containing low boiling point component from the reactor, and continuously withdrawing a reaction fluid containing an alkyltin alkoxide as the bottom from the reactor.

Owner:ASAHI KASEI KK

Process for producing carbonic ester

ActiveUS7446218B2Improve isolationGuaranteed continuous performanceCarbonic/haloformic acid esters purification/separationPreparation from carbon dioxide or inorganic carbonatesAlcoholMetal

A method for producing a carbonic ester, comprising: (1) performing a reaction between an organometal compound mixture and carbon dioxide, the organometal compound mixture comprising a reactive organometal compound and an unregenerable unreactive compound derived from the reactive organometal compound, to thereby obtain a reaction mixture containing a carbonic ester, the unregenerable unreactive compound, and a regenerable metamorphic organometal compound derived from the reactive organometal compound, (2) separating the reaction mixture into a first portion containing the carbonic ester and the unregenerable unreactive compound, and a second portion containing the regenerable metamorphic organometal compound, and (3) reacting the second portion of the reaction mixture with an alcohol to form an organometal compound mixture and water and removing the water from the organometal compound mixture, the organometal compound mixture comprising a reactive organometal compound and an unregenerable unreactive compound derived from the reactive organometal compound.

Owner:ASAHI KASEI KK

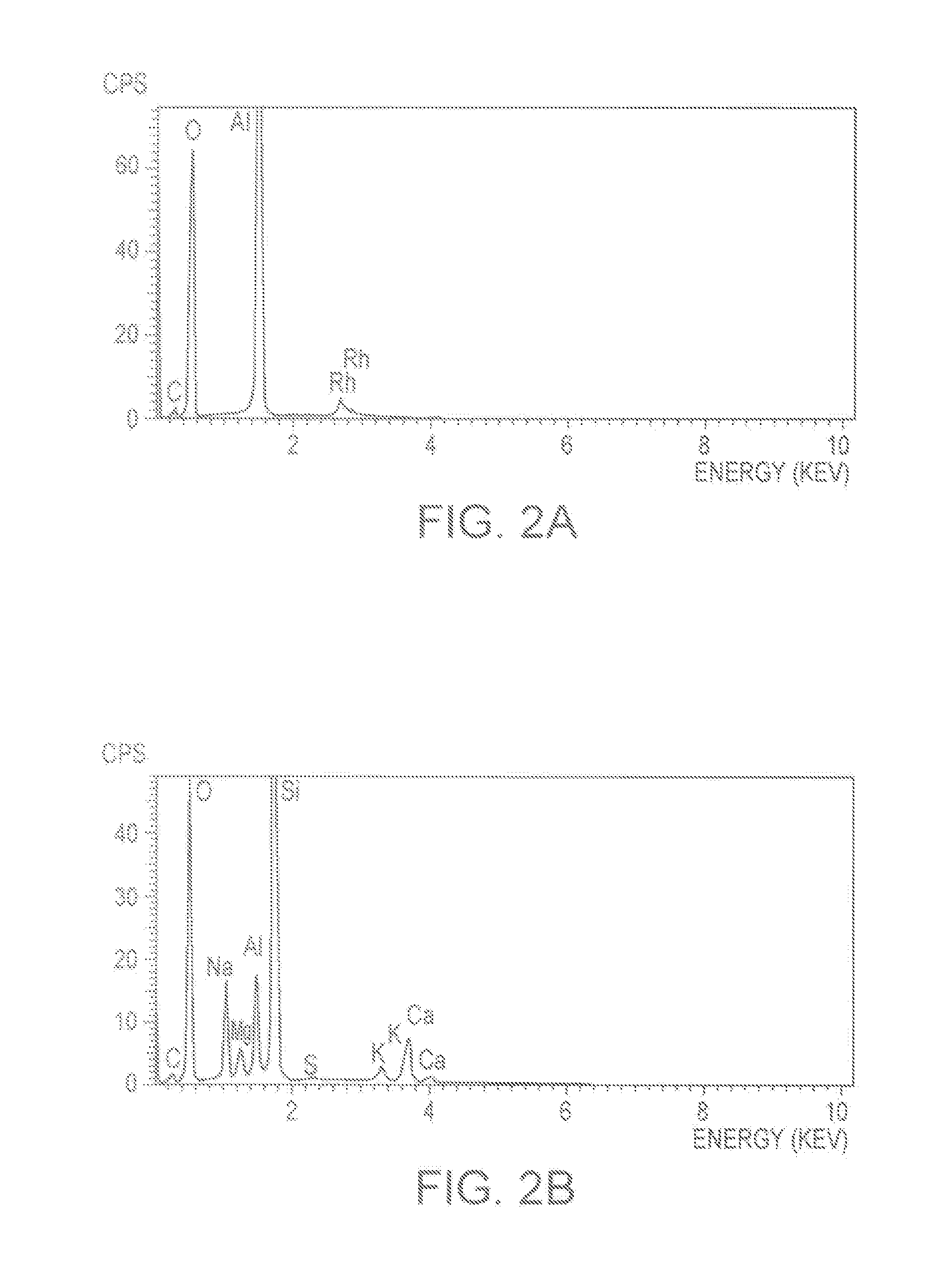

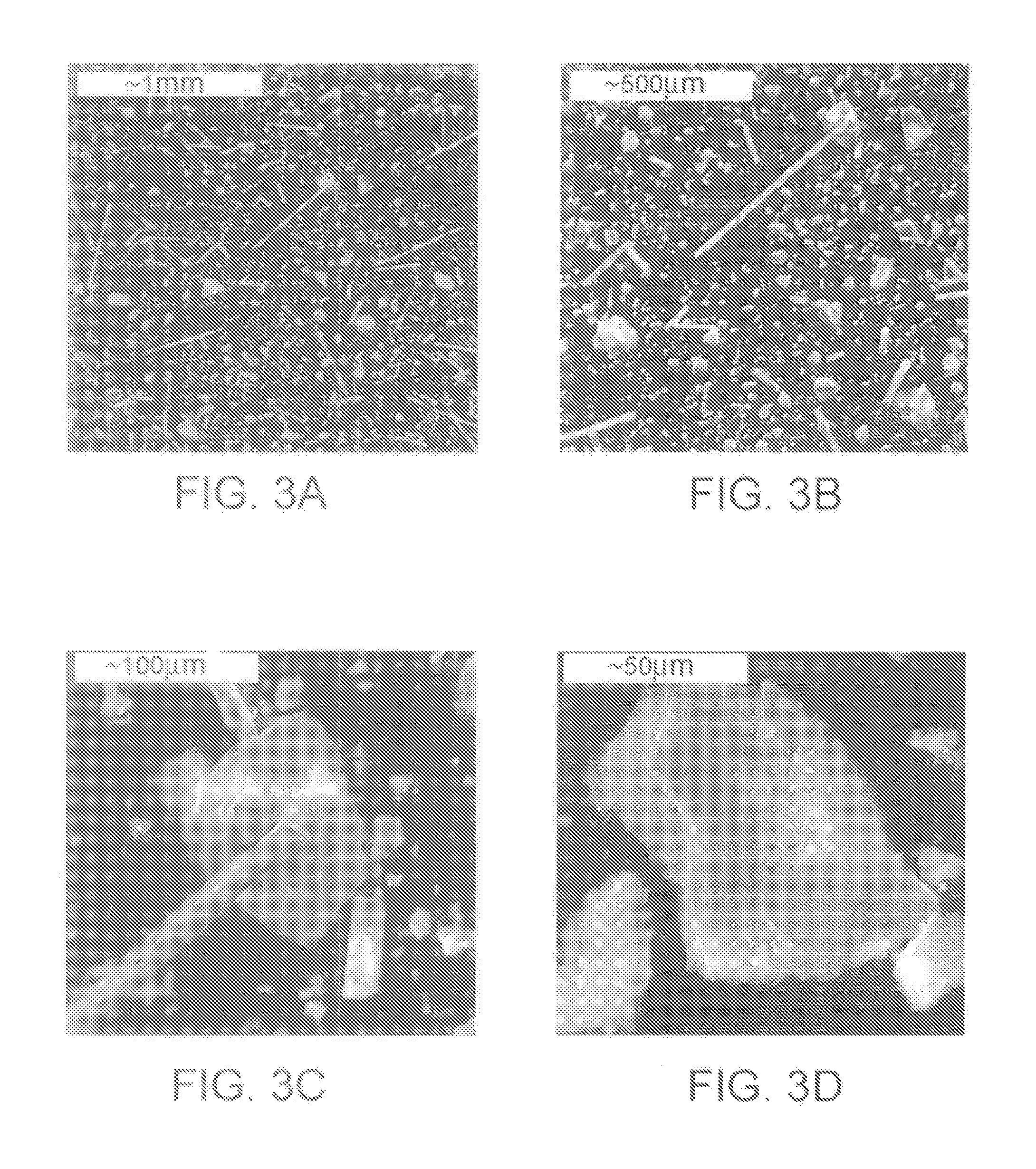

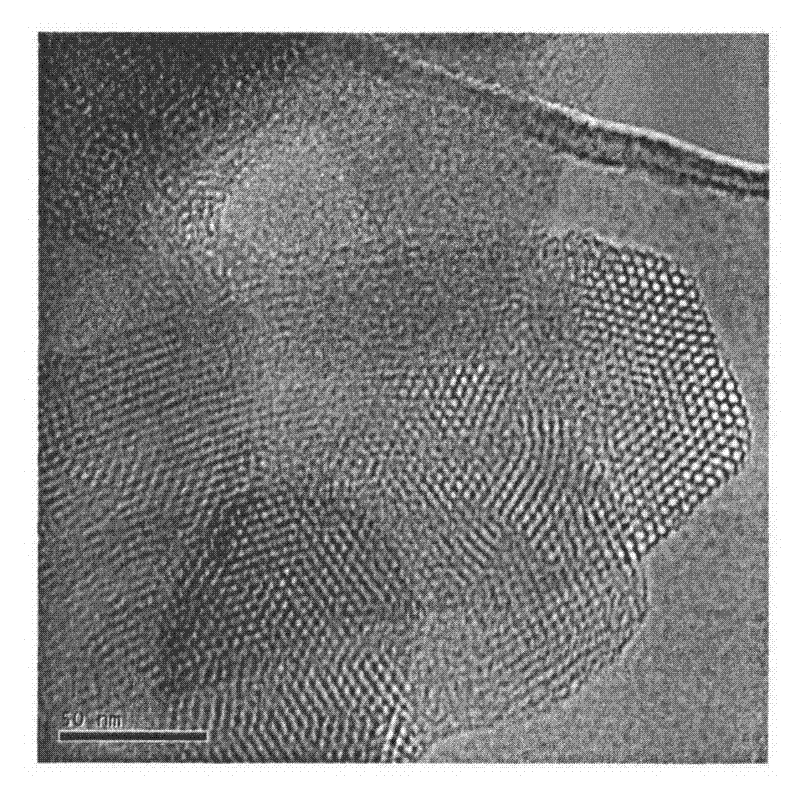

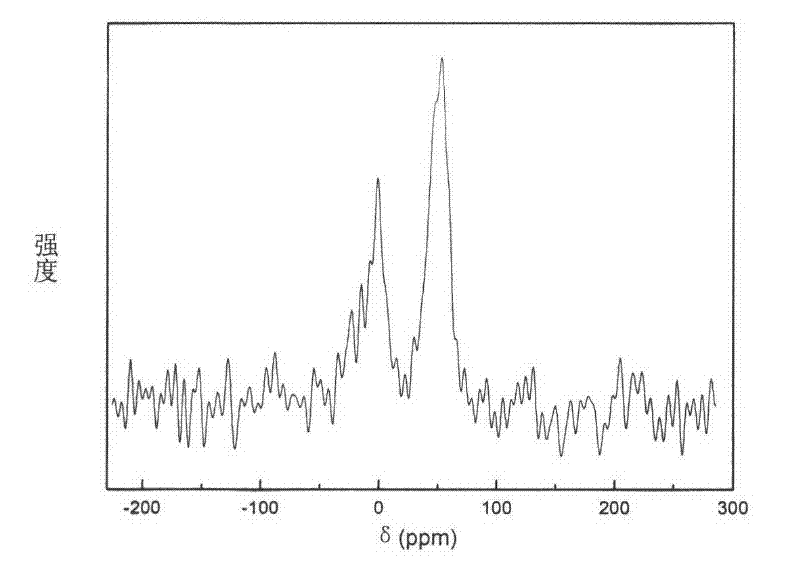

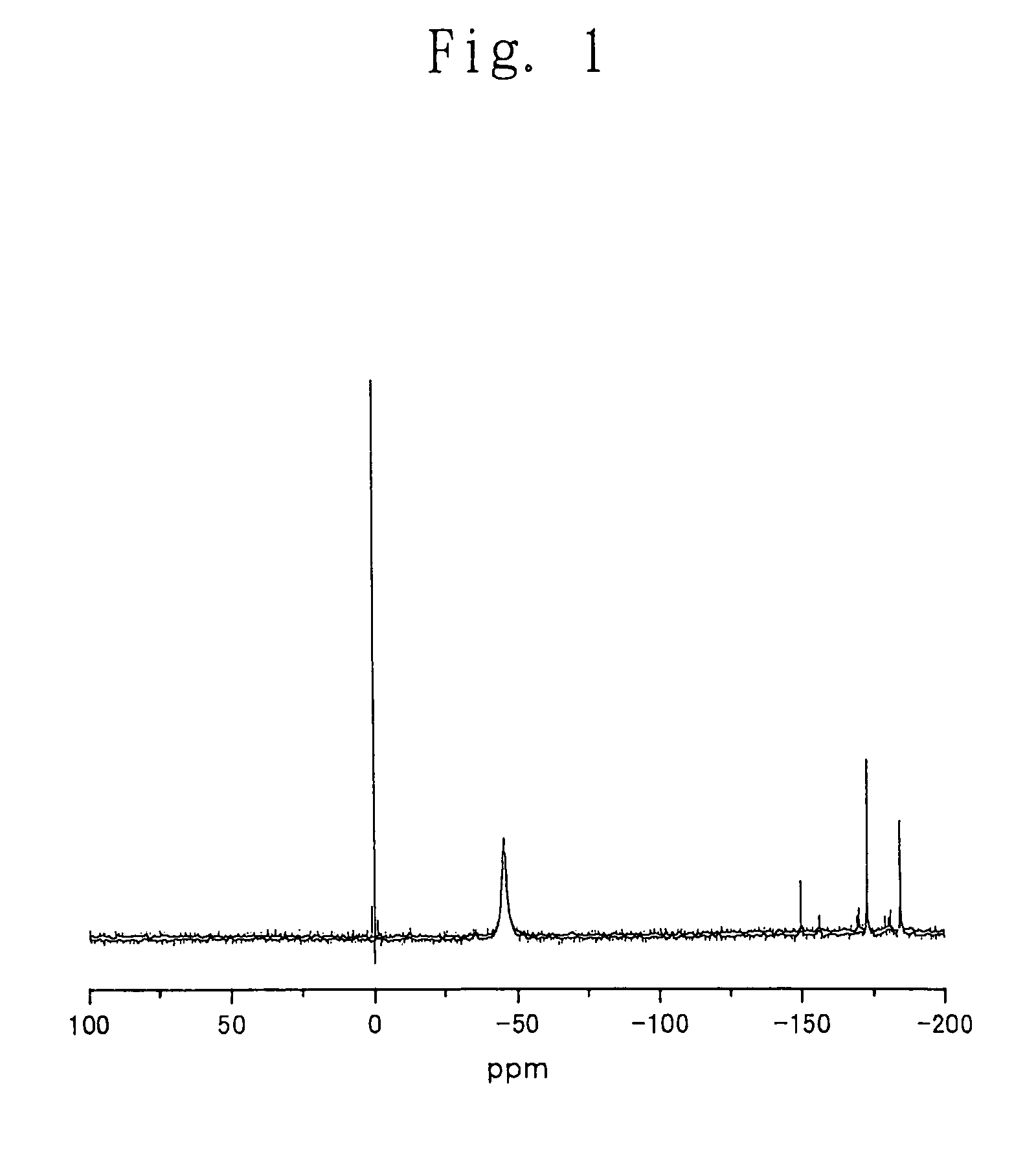

Preparation method and application of ionic liquid functionalized Al-MCM-41 mesoporous material

InactiveCN102188999AEasy to makeWell-ordered pore structureProductsReagentsMesoporous materialIonic liquid

The invention relates to a preparation method and application of an ionic liquid functionalized Al-MCM-41 mesoporous material. The preparation method comprises the following steps of: preparing a solution by taking CTAB (Cetyltrimethyl Ammonium Bromide) as a template agent, TEOS (Tetraethyl Orthosilicate) as a silicone source and aluminum nitrate or sodium metaaluminate as a precursor according to a molar ratio, and crystallizing, filtering, washing, drying and roasting the solution to obtain Al-MCM-41; obtaining Al-MCM-41-Cl through coupling; reacting the Al-MCM-41-Cl with N-methylimidazole,and carrying out cooling, suction filtering, washing and drying to obtain the ionic liquid functionalized mesoporous material Al-MCM-41-Im. The invention has the advantages that the method has simpleprocess, and the ionic liquid functionalized Al-MCM-41 mesoporous material has ordered and uniformly distributed pore structure and acid-situ surface and can be used as a catalyst for a reaction between epoxypropane and carbon dioxide to produce propylene carbonate.

Owner:TIANJIN UNIV

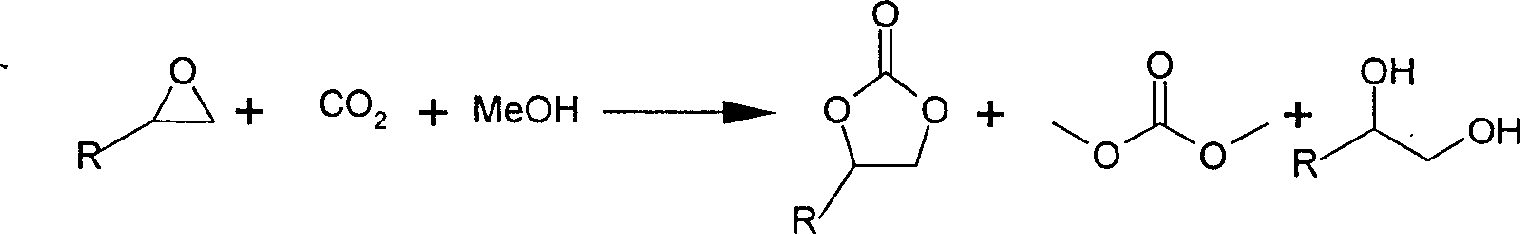

Method for synthesizing diethyl carbonate and coproducing diol by using carbon dioxide

ActiveCN104418701ARapid responseEasy to optimizeProductsOxygen-containing compound preparationEpoxyReaction temperature

The invention discloses a method for synthesizing diethyl carbonate and coproducing diol by using carbon dioxide, belonging to the field of synthesis of organic chemicals. An epoxy compound, the carbon dioxide and ethanol are used as raw materials and directly esterified in the presence of a catalyst to prepare the diethyl carbonate, and the diol is also coproduced; and the catalyst is characterized by consisting of an alkali metal halide and an alkali catalyst which are used as active ingredients, wherein the weight ratio of the epoxy compound to the catalyst is 100: (1-5), the reaction temperature is 80-230 DEG C, the reaction pressure is 0.5-15MPa, and the reaction time is 0.01-5h. The diethyl carbonate is synthesized by directly using the CO2, the epoxy compound and the ethanol, so the yield and selectivity of the target product are relatively high, the production cost of the diethyl carbonate can be reduced, and the diethyl carbonate has good industrial application value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method Of Installing An Epoxidation Catalyst In A Reactor, A Method Of Preparing An Epoxidation Catalyst, An Epoxidation Catalyst, A Process For The Preparation Of An Olefin Oxide Or A Chemical Derivable From An Olefin Oxide, And A Reactor Suitable For Such A Process

InactiveUS20070203350A1Speed up the processOrganic compound preparationChemical/physical/physico-chemical microreactorsCompound (substance)Alkene

The present invention relates to an improved epoxidation process and an improved epoxidation reactor. The present invention makes use of a reactor which comprises a plurality of microchannels. Such process microchannels may be adapted such that the epoxidation and optionally other processes can take place in the microchannels and that they are in a heat exchange relation with channels adapted to contain a heat exchange fluid. A reactor comprising such process microchannels is referred to as a “microchannel reactor”. The invention also provides a method of installing an epoxidation catalyst in a microchannel reactor. The invention also provides a method of preparing an epoxidation catalyst. The invention also provides an epoxidation catalyst. The invention also provides a certain process for the epoxidation of an olefin and a process for the preparation of a chemical derivable from an olefin oxide. The invention also provides a microchannel reactor.

Owner:SHELL OIL CO

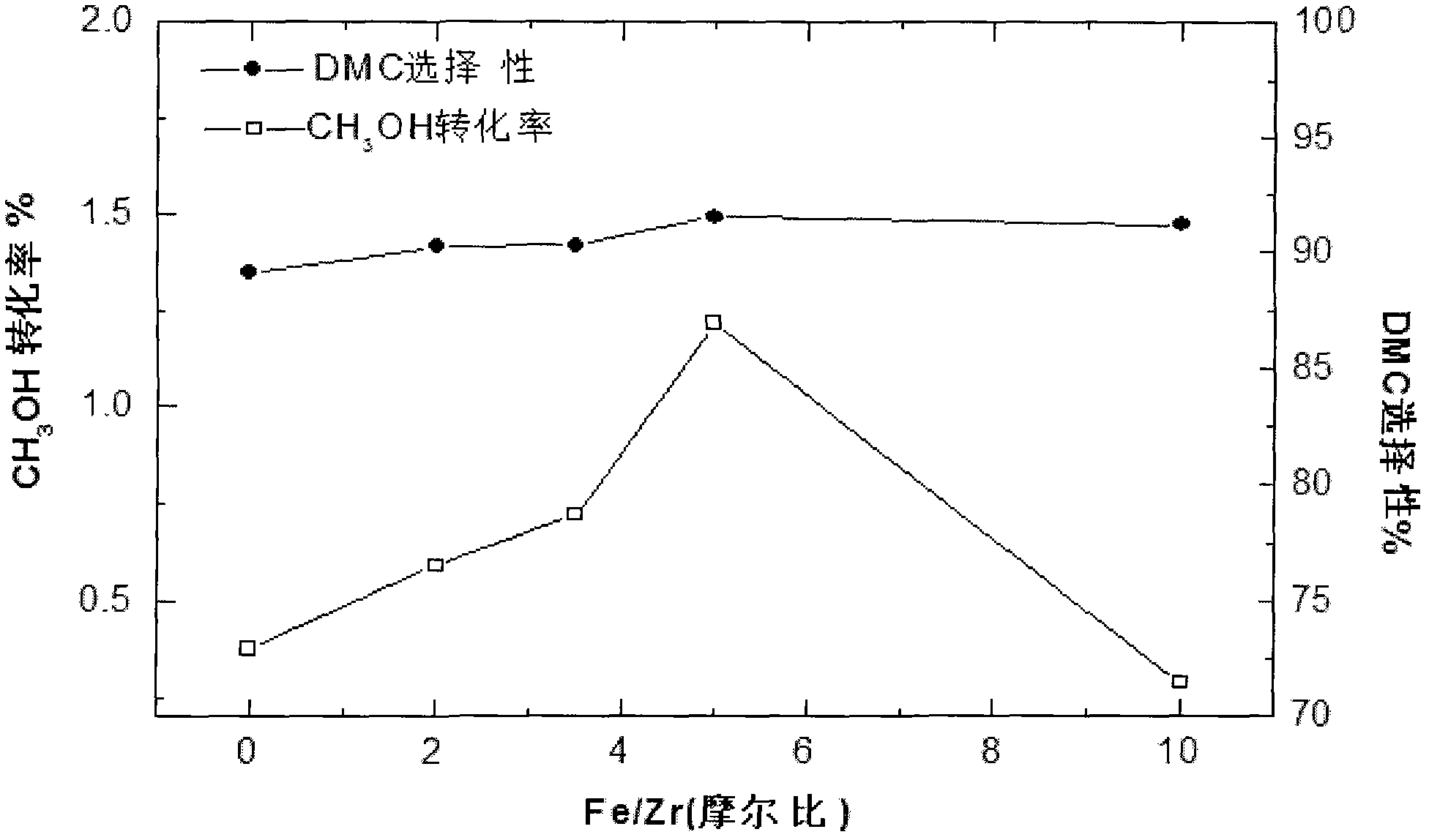

Preparation method and application method of iron-zirconium composite oxide catalyst

InactiveCN102423707ANo pollution in the processHigh catalytic activityProductsReagentsChemical industryMethyl carbonate

The invention belongs to the technical field of chemical industry, relates to a preparation method and application method of an iron-zirconium composite oxide catalyst, and is used for solving the problems that at present, the catalyst has low activity and is difficult for separation, recovery and reutilization in a catalytic process for direct synthesis of dimethyl carbonate from carbon dioxide and methanol. The catalyst provided by the invention is composed of iron and zirconium oxides, wherein the molar ratio of iron to zirconium is (10:1)-(0.5:1); the catalyst is prepared by adopting a sol-gel method, is used for reaction between CO2 and CH3OH for direct synthesis of dimethyl carbonate at the reaction temperature of 80-180 DEG C and CO2 pressure of 3-7MPa ( room temperature); and compared with the existing ZrO2 catalyst and H3PO4-treated ZrO2 catalyst, both the activity and selectivity of the catalyst are greatly improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for preparing dimethyl carbonate by reacting methanol, carbon monoxide and oxygen

InactiveCN1962602AImprove conversion rateHigh yieldProductsReagentsMethyl carbonateReaction temperature

The invention discloses a synthesizing method of dimethyl carbonate through oxidizing and oxonating liquid phase of carbinol in the chemical technological domain, which comprises the following steps: adopting ion liquid as solvent and metal copper salt as catalyst; setting the weight rate of carbinol and ion liquid at 1: 4-10: 1 and the rate of catalyst and carbinol at 1: 100-1: 10; reacting under 80-180 Deg C; setting the initial total pressure of CO and O2 at 0.5-6.0Mpa with the molar rate of CO and O2 at 100: 1-2: 1 for 1-6h; realizing the synthesizing reaction to form dimethyl carbonate with single-course transmission rate at 10-20% and object product selectivity not less than 95%.

Owner:SHAANXI NORMAL UNIV

Catalyst for synthesizing diethyl carbonate by ethanol vapor-phase carbonyl

InactiveCN101181688AStable structureHigh activityProductsPhysical/chemical process catalystsSucroseGas phase

The invention discloses a catalyst used in synthesizing diethyl carbonate by ethanol carbonylation and a preparation method thereof. Active component of the catalyst is CuCl or CuCl2, a carrier is mesoporous carbon, and charge number accounts for 5 to 20 percent of the carrier. The preparation process comprises that: acid solvent which contains screened SBA-15 molecular in sucrose is processed by two-step carbonization treatment, high-temperature roasting process is adopted to carbonize finally, HF solvent is adopted to dispel molecular and the mesoporous carbon carrier is screened and prepared, the mesoporous carbon carrier is then soaked in copper solution, and the catalyst is prepared after evaporation drying. The invention has the advantages that the preparation process is simple and preparation cost is low; the catalyst is used in the ethanol carbonylation reaction to synthesize the diethyl carbonate, which has the advantages of high selectivity and stable catalytic activity of the production of the diethyl carbonate, etc.

Owner:TIANJIN UNIV

Process for producing carbonic ester

ActiveUS7435842B2High yieldEasy to separateCarbonic/haloformic acid esters purification/separationPreparation from carbon dioxide or inorganic carbonatesAlcoholCarbonate ester

A method for producing a carbonic ester, comprising (1) performing a reaction between an organometal compound having a metal-oxygen-carbon linkage and carbon dioxide to obtain a reaction mixture containing a carbonic ester formed by the reaction, (2) separating the carbonic ester from the reaction mixture to obtain a residual liquid, and (3) reacting the residual liquid with an alcohol to form an organometal compound having a metal-oxygen-carbon linkage and form water and removing the water from the organometal compound, wherein the organometal compound obtained in step (3) is recovered for recycle thereof to step (1).

Owner:ASAHI KASEI KK

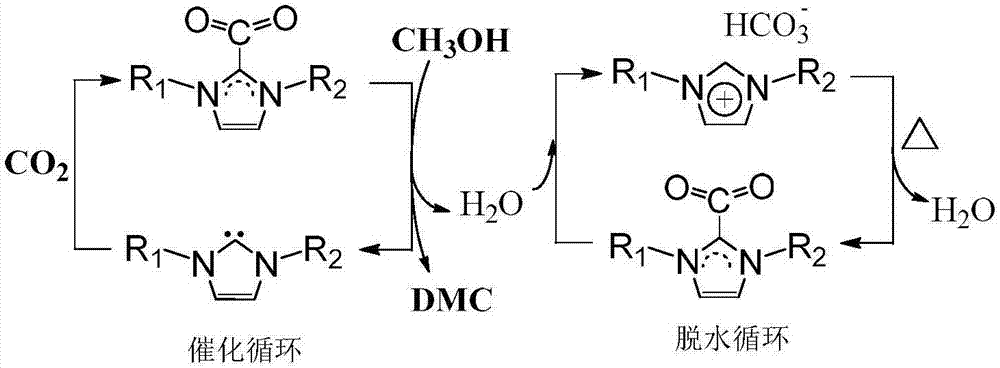

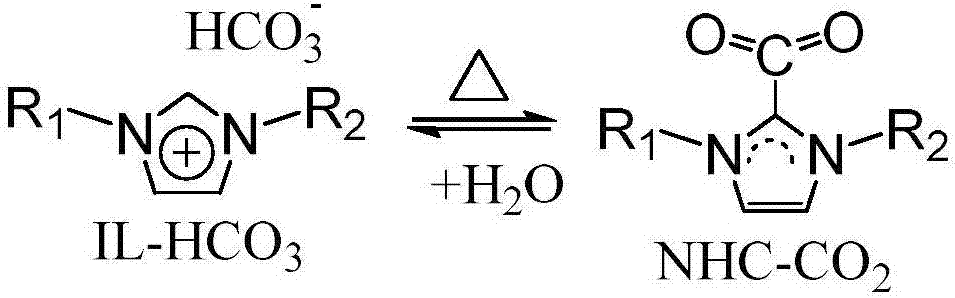

Method used for preparing dimethyl carbonate via direct reaction of carbon dioxide with methanol

The invention relates to a method used for preparing dimethyl carbonate via direct reaction of carbon dioxide with methanol. According to the method, a midazole bicarbonate ionic liquid is taken as a catalyst and a dehydrating agent, direct reaction of carbon dioxide with methanol at mild conditions is carried out so as to obtain dimethyl carbonate. Compared with the prior art, the method possesses following advantages: the midazole bicarbonate ionic liquid is taken as both as the catalyst and the dehydrating agent, so that the production process of dimethyl carbonate is simplified; the method is green and economical; the conversion rate of methanol is as high as 54%; and the selectivity of dimethyl carbonate production is as high as 99%.

Owner:NANJING UNIV

Technical method for associated producing carbonic allyl ester, methyl carbonate, and propylene glycol

InactiveCN101092365AReduce cakingEliminate the safety hazard of overpressureProductsReagentsMethyl carbonatePropanediol

This invention discloses a process for combined production of propylene carbonate, dimethyl carbonate and propylene glycol. The method utilizes propylene oxide, CO2 and methanol as the raw materials, and adopts two-step reaction to produce propylene carbonate, dimethyl carbonate and propylene glycol. The method avoids propylene carbonate refinery process; catalyst recovery process and propylene carbonate storage apparatus. The method utilizes a novel thin film evaporator to separate and refine crude propylene carbonate and catalyst, and thus increase the separation precision and productivity. The method utilizes a set of platform framework and a DCS control chamber to realze continuous operation of the whole process, and is stable and reliable. The produced propylene carbonate, dimethyl carbonate and propylene glycol can reach pharmaceutical grade purity.

Owner:SHANDONG SHIDA SHENGHUA CHEM GROUP

Monolithic catalyst for synthesizing dimethyl carbonate as well as preparation method and application method of the catalyst

InactiveCN110479287AImprove catalytic performanceImprove stabilityProductsReagentsNanoparticleActive component

The invention discloses a monolithic catalyst for synthesizing dimethyl carbonate. The catalyst is composed of active components Cu and Ni nanoparticles, a carrier that is a triphenylphosphine porouspolymer and a honeycomb ceramic matrix. The Cu and Ni nanoparticles are loaded on the triphenylphosphine porous polymer POP-PPh3, and the honeycomb ceramic matrix is coated with the triphenylphosphineporous polymer POP-PPh3 loaded with the CuNi nanoparticles to form the CuNi / POP-PPh3 monolithic catalyst. The application method comprises the following steps: putting the CuNi / POP-PPh3 monolithic catalyst into a steel pipe of a fixed bed reactor, and introducing CO2 for 5 minutes to remove other gases in a reaction system; heating to 120-180 DEG C, transporting the liquid methanol to a preheaterthrough a high-pressure constant-flow pump for gasification treatment, and reacting the mixture for 2-6 hours with the molar ratio of CH3OH to CO2 in the reaction gas being 1-3 to obtain the dimethylcarbonate. The monolithic catalyst provided by the invention is used for one-step synthesis of DMC from CO2 and methanol, and the yield of DMC exceeds 8%.

Owner:SOUTHWEST PETROLEUM UNIV

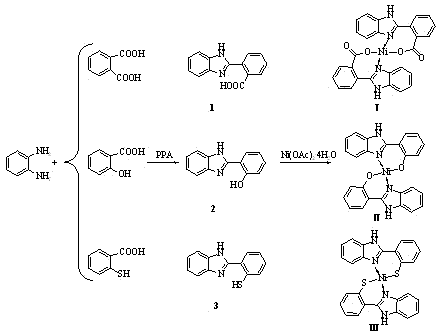

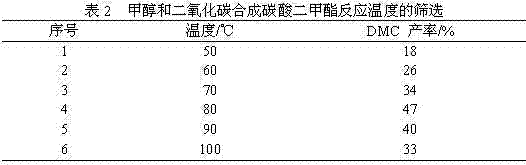

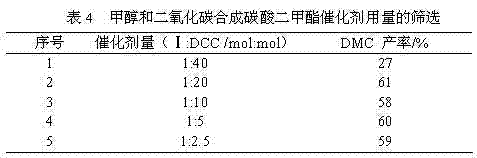

Dimethyl carbonate synthesis method by using methanol and carbon dioxide

The invention discloses a chemical compound as shown in a structural formula (1) and an application thereof in dimethyl carbonate synthesis. According to the invention, methanol and carbon dioxide serve as raw materials, DCC serves as a coupling agent, and dimethyl carbonate with satisfactory production rate is obtained under the condition of the existence of Ni coordination compound catalyst and relatively mild condition. The condition of the dimethyl carbonate synthesis in the catalyst system of the invention is relatively mild, and the requirement of equipment strength of high pressure is avoid; the catalyst is easy to prepare and the cost is low; and the usage amount of catalyst is small, the reaction time is short, the recycling after separation is easy, and the industrialized production is facilitated.

Owner:陕西高安绿能生物化工有限公司 +1

Process for the preparation of propylene carbonate

ActiveUS7728164B2Easy to operateChemical recyclingPreparation by hydrolysisTrimethylene carbonatePropylene carbonate

Owner:SHELL USA INC

Direct synthesis process of methyl carbonate

InactiveCN1526693AHigh yieldGood choiceBulk chemical productionPreparation from carbon dioxide or inorganic carbonatesEpoxyAlkane

The direct synthesis process of methyl carbonate includes adding epoxy alkane, methanol and CO2 in the molar ratio of 1 to 2-10 to 10-20 and catalyst in the amount of 2-8 wt% of reactant mixture into reactor; stirring and heating to 150-170 deg.c for reaction of 2-6 hr and lowering the temperature to 110-140 deg.c for reaction of another 2-6 hr; cooling, filtering to eliminate catalyst or supercritical extraction to obtain reactant solution containing methyl carbonate. The catalyst is one kind of composite including active component potassium iodide in 5-60 wt%; assistant K2CO3, KOH, Na2CO3 or NaOH in 0-20 wt% and carrier metal oxide or zeolite molecular sieve in 40-90 wt%. The direct synthesis process of the present invention has high yield and high selectivity.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Composite cerium-iron-zirconium oxide catalyst, and preparation method and application thereof

The invention provides a composite cerium-iron-zirconium oxide catalyst. The composite cerium-iron-zirconium oxide catalyst is a solid solution catalyst composed of cerium oxide, iron oxide and zirconium oxide, wherein the molar ratio of Ce to Fe to Zr is (1-30): (30-70): (30-70)%. The composite cerium-iron-zirconium oxide catalyst provided by the invention has the advantages of high catalytic activity, high selectivity, low cost and no pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Process for synthesizing carbonic ethenyl (allyl) ester from carbon dioxide and epoxy ethane (propane)

InactiveCN1569805AThe preparation method is simple and economicalThe reaction process is simpleMolecular sieve catalystsPreparation from carbon dioxide or inorganic carbonatesEpoxyAlkaline earth metal

The invention provides a process for synthesizing carbonic ethenyl (allyl) ester from carbon dioxide and epoxy ethane (propane), the reaction pressure being 3.0-7.0 MPa, the reaction temperature is 100-200 deg. C, wherein load type solid catalyst is employed, and beta-type molecular sieve is used as the carrier. the active component being alkali metal or halides of the alkaline earth metal or their mixture.

Owner:PETROCHINA CO LTD

Popular searches

Organic-compounds/hydrides/coordination-complexes catalysts Educts Carbonyl group formation/introduction Metal/metal-oxides/metal-hydroxide catalysts Catalyst activation/preparation Halogenated hydrocarbon preparation Hydroxy compound preparation Waste based fuel Liquid hydrocarbon mixture production Treatment with hydrotreatment processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com