Patents

Literature

95 results about "Process synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process synthesis is the step in design where the chemical engineer selects the component parts and how to interconnect them to create his flowsheet.

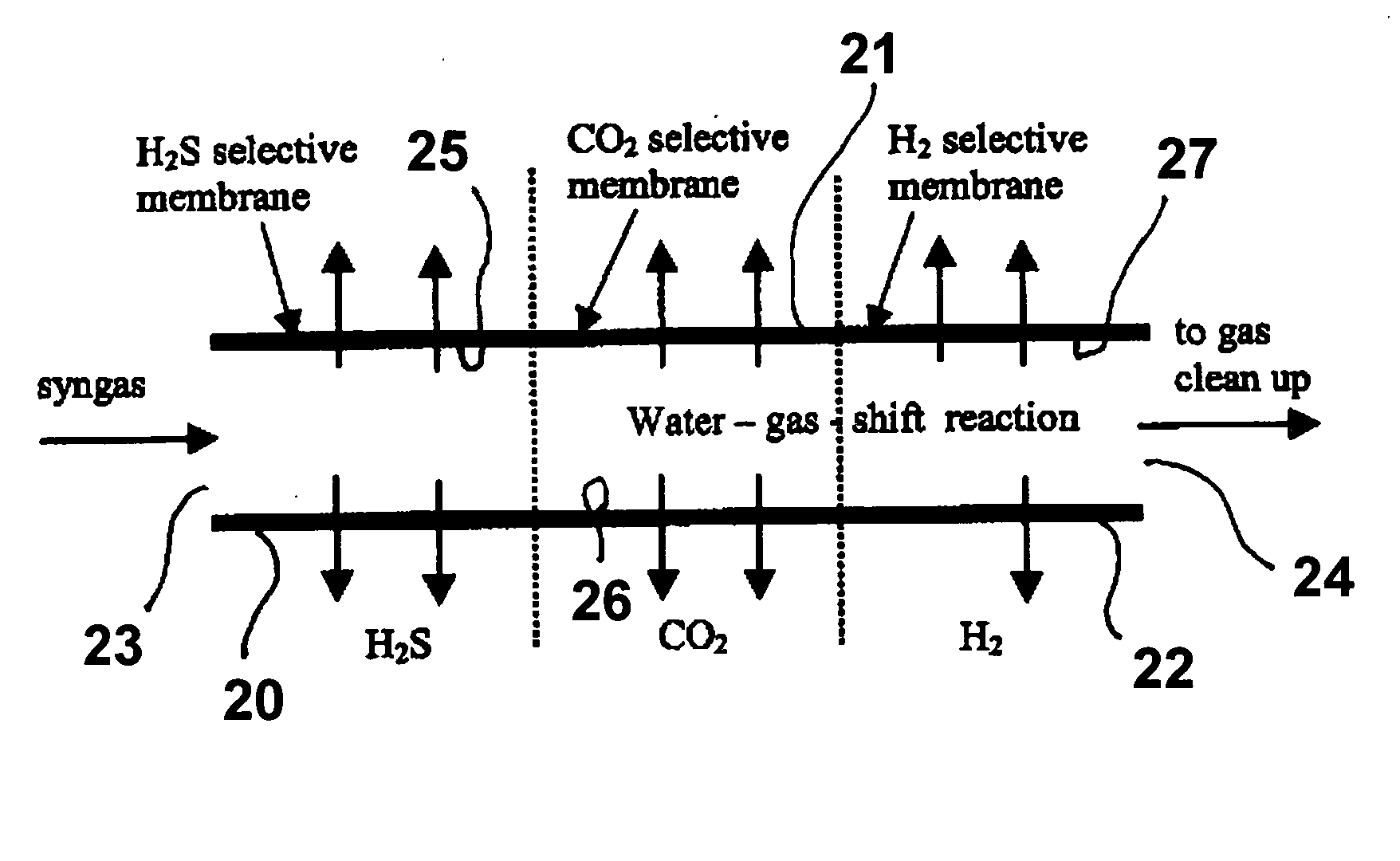

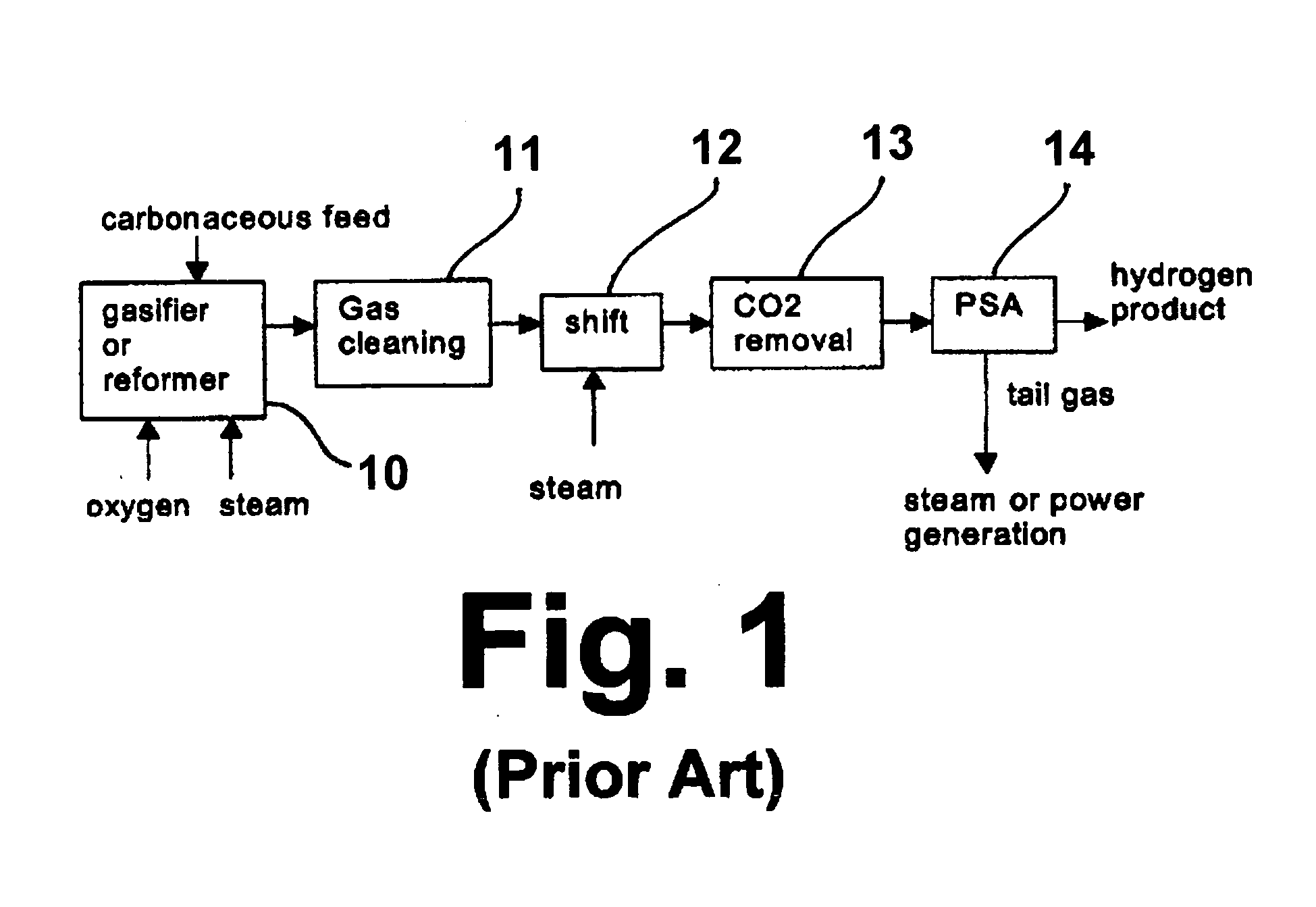

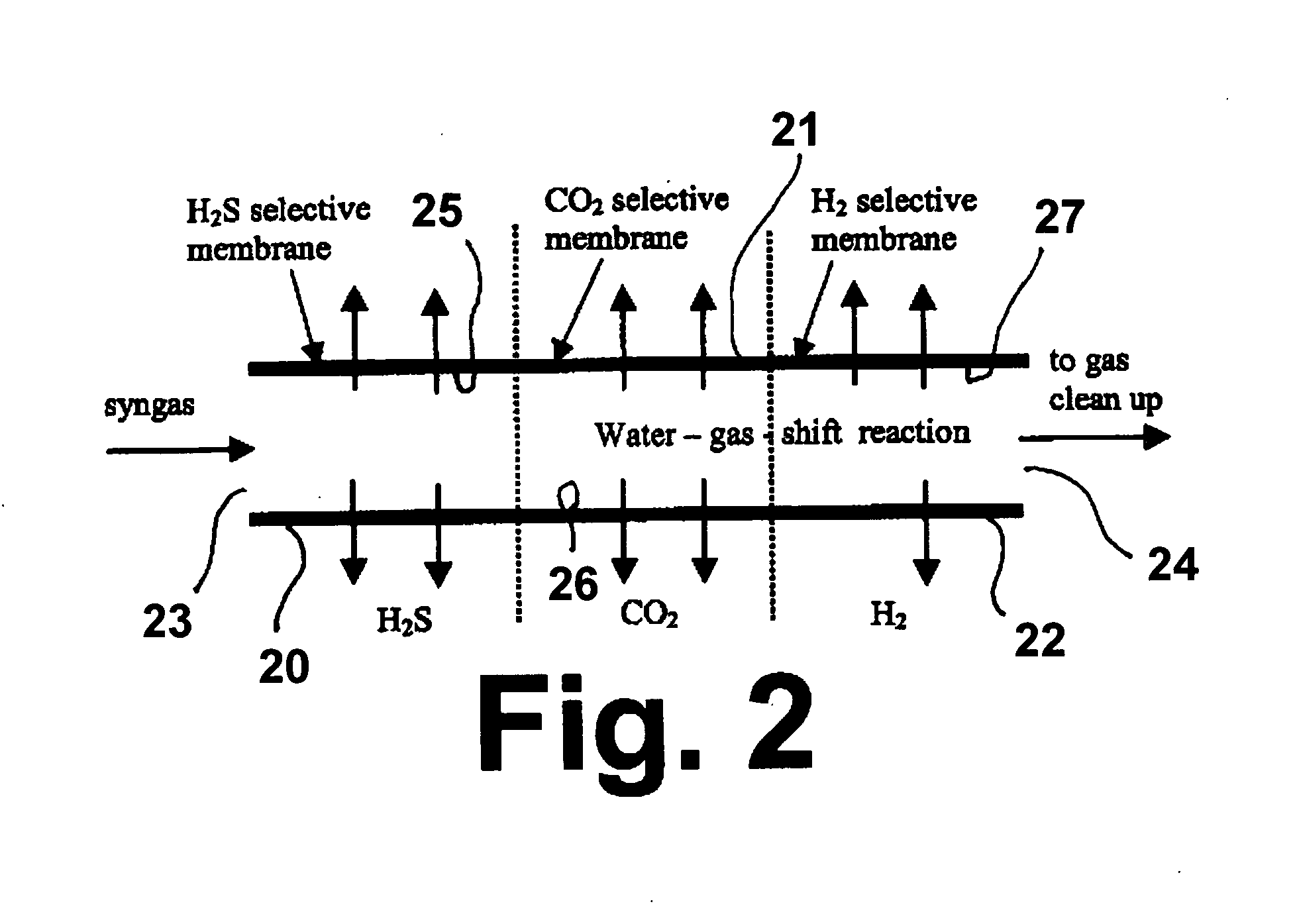

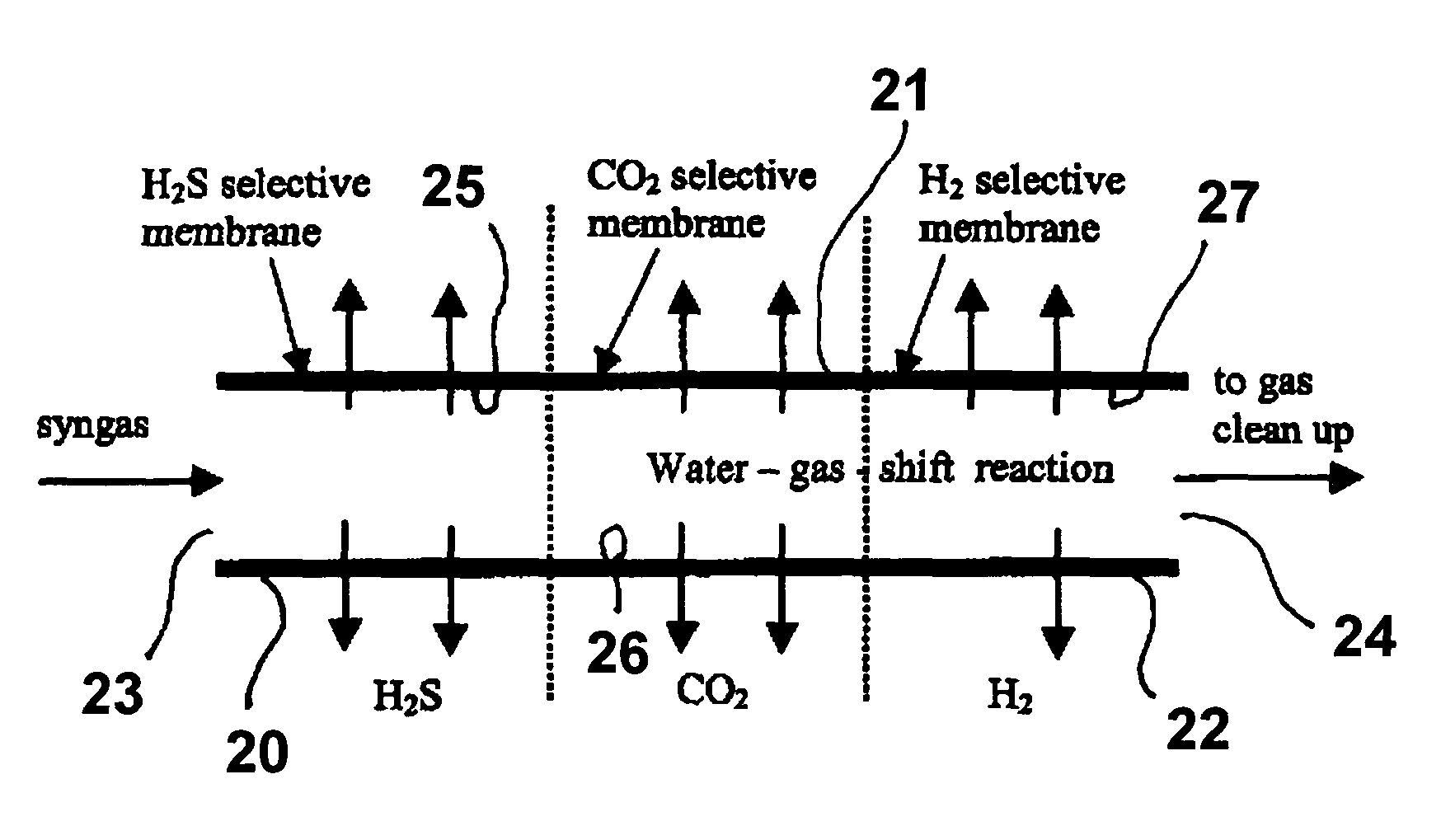

Membrane reactor for H2S, CO2 and H2 separation

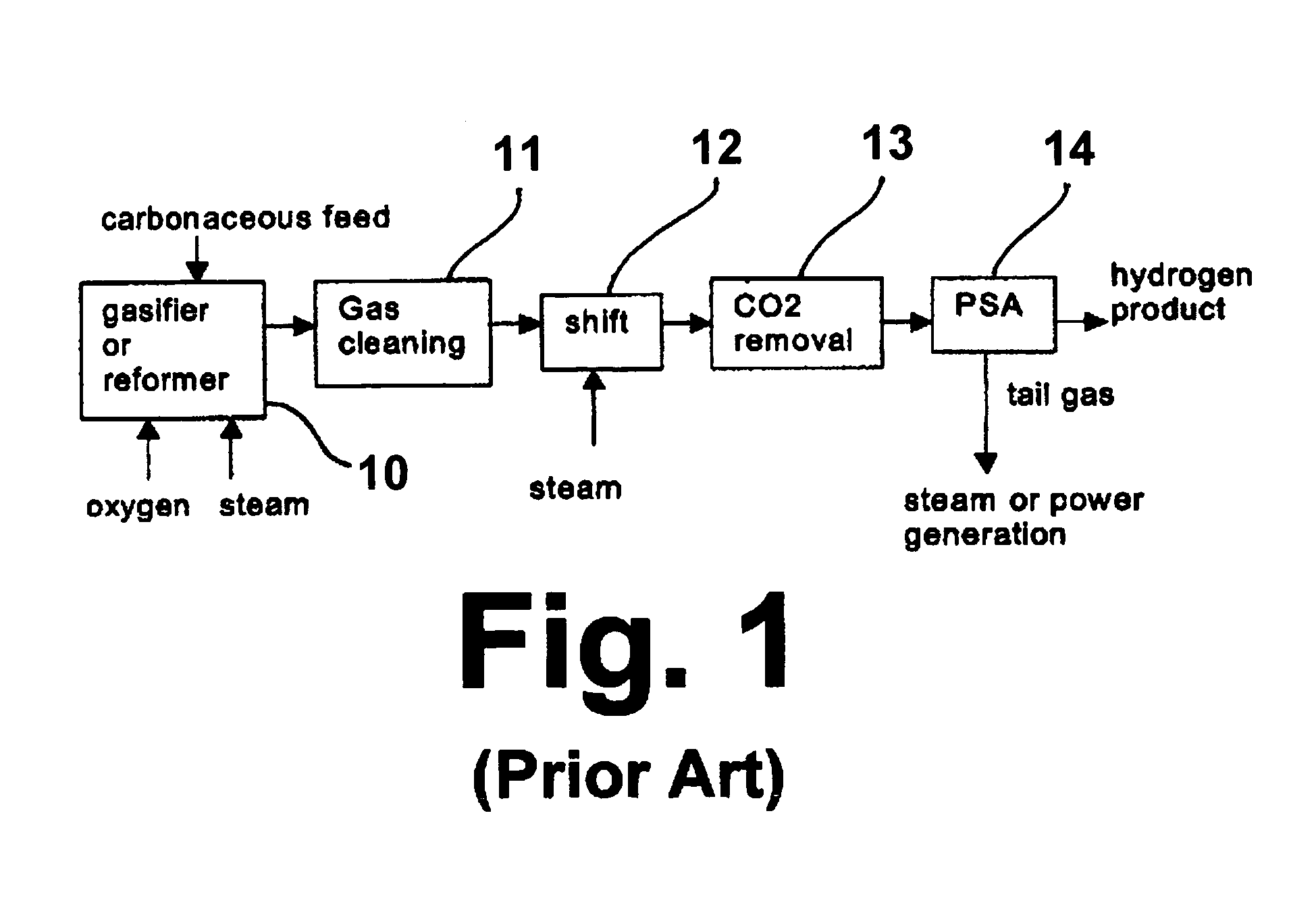

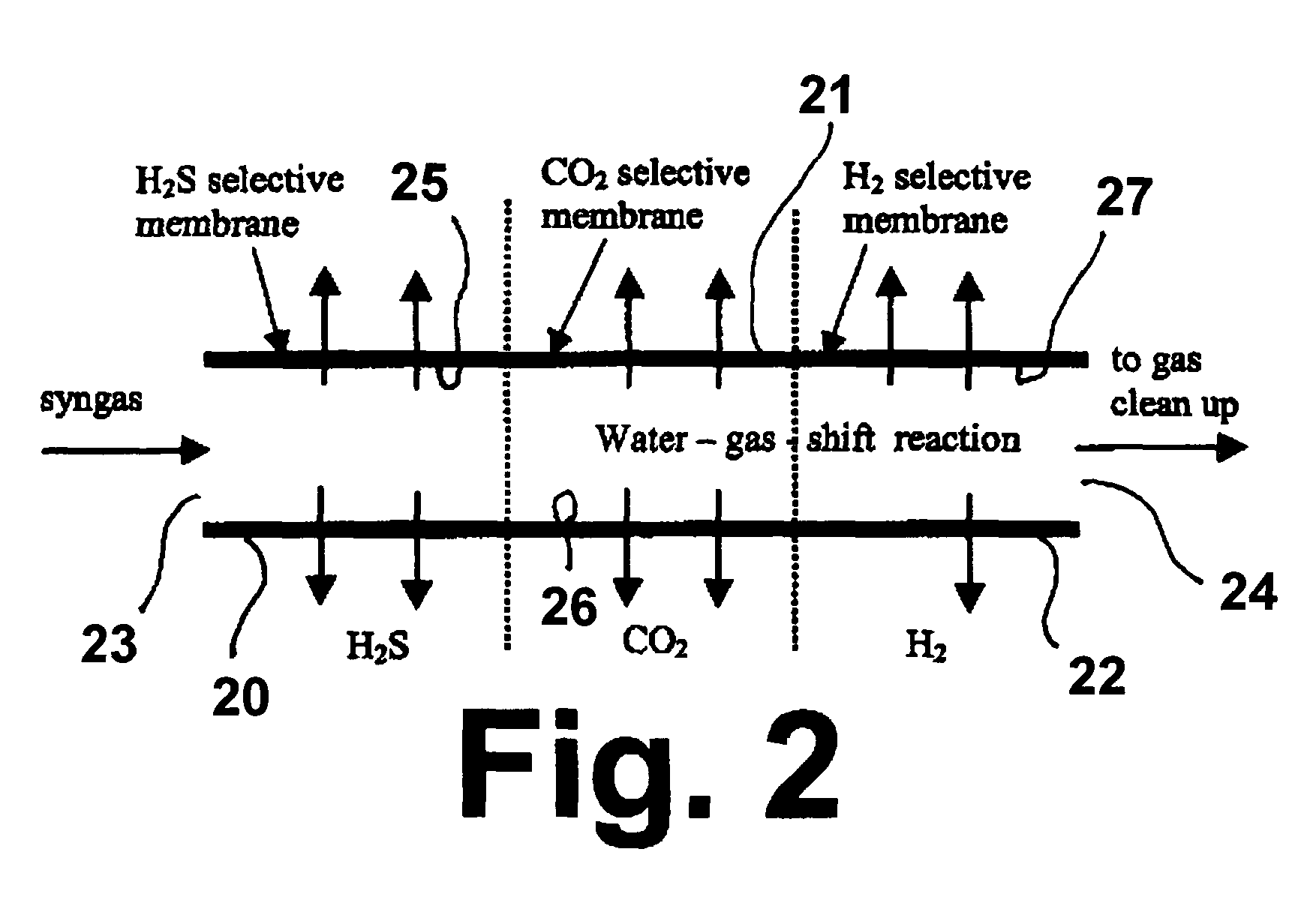

ActiveUS20070240565A1Speed up the conversion processCombination devicesCombustible gas catalytic treatmentMembrane reactorProcess synthesis

A system for the selective removal of CO2, H2S, and H2 from a gaseous fluid mixture comprising said CO2, H2S, and H2, which system includes a first membrane section having a nonporous metal oxide membrane, a second membrane section having a CO2-selective membrane, and a third membrane section having an H2-selective membrane. Each membrane section has a feed side and a permeate side and the membrane sections are arranged in series whereby the gaseous fluid mixture contacts the feed side, in sequence, of the first membrane section, the second membrane section and the third membrane section, resulting first in the separation or removal of H2S, second in the separation or removal of CO2, and third in the separation or removal of H2. The process can be used to process synthesis gas generated from the gasification or reforming of carbonaceous materials for hydrogen production and carbon dioxide capture.

Owner:GAS TECH INST

Membrane reactor for H2S, CO2 and H2 separation

ActiveUS7938893B2Speed up the conversion processCombination devicesCombustible gas catalytic treatmentMembrane reactorProcess synthesis

A system for the selective removal of CO2, H2S, and H2 from a gaseous fluid mixture comprising CO2, H2S, and H2, which system includes a first membrane section having a nonporous metal oxide membrane, a second membrane section having a CO2-selective membrane, and a third membrane section having an H2-selective membrane. Each membrane section has a feed side and a permeate side and the membrane sections are arranged in series whereby the gaseous fluid mixture contacts the feed side, in sequence, of the first membrane section, the second membrane section and the third membrane section, resulting first in the separation or removal of H2S, second in the separation or removal of CO2, and third in the separation or removal of H2. The process can be used to process synthesis gas generated from the gasification or reforming of carbonaceous materials for hydrogen production and carbon dioxide capture.

Owner:GAS TECH INST

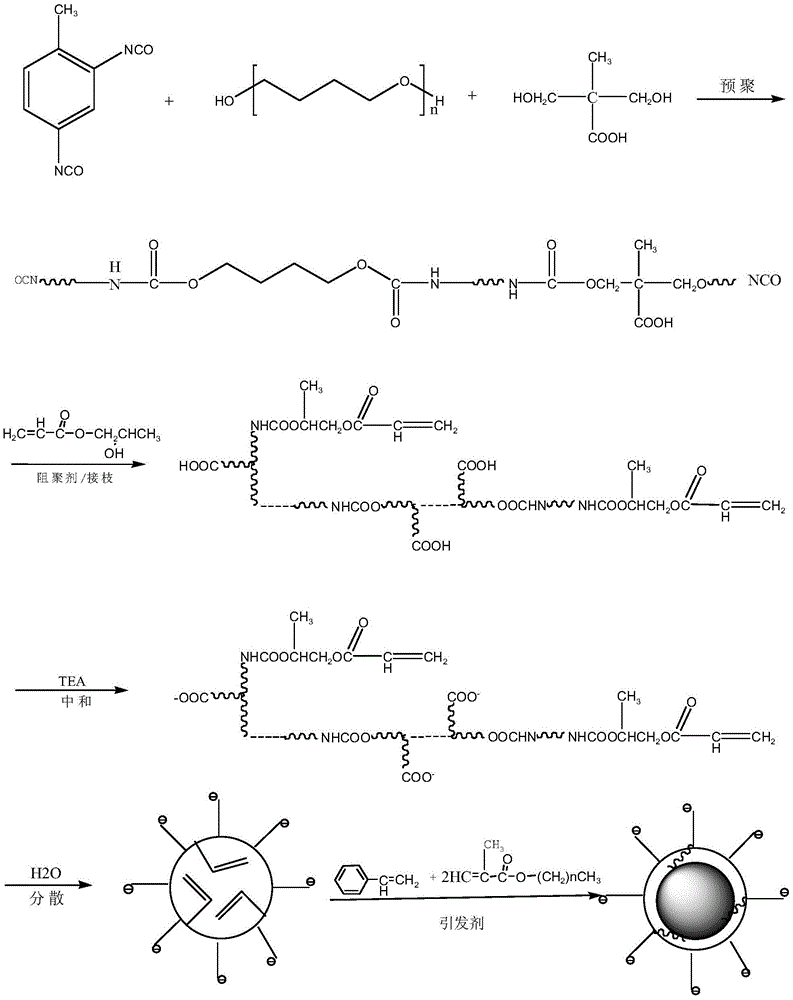

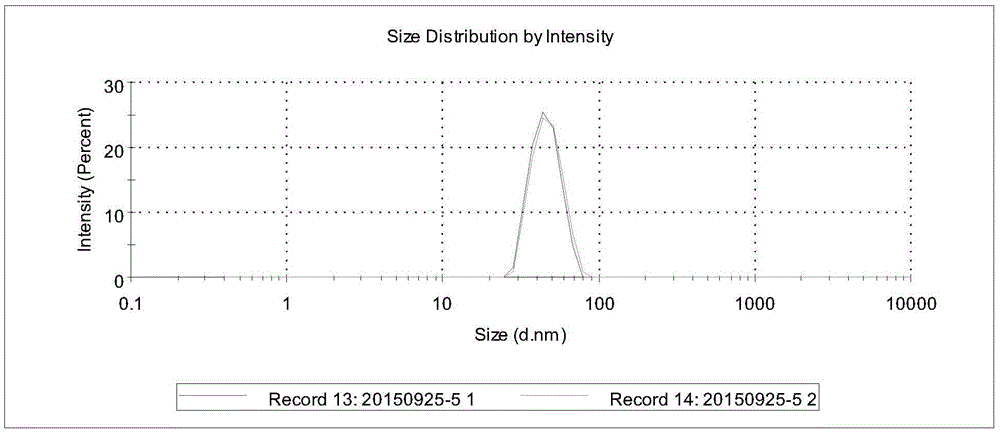

Preparation method of interpenetrating-network-structure water-based polyurethane nano composite material

The invention provides a preparation method of an interpenetrating-network-structure water-based polyurethane nano composite material. The preparation method comprises the following steps: 1) carrying out vacuum dehydration treatment on polymer polylol and hydrophilic functional monomer; 2) adding a catalyst and diisocyanate, reacting at room temperature for 0.5-2 hours, heating to 60-80 DEG C, and carrying out the reaction for 1-5 hours while keeping the temperature; 3) cooling to 40-50 DEG C, adding a chain extender, and carrying out the reaction for 2-4 hours while keeping the temperature; 4) heating to 60-70 DEG C, and adding a reactive monomer for termination; 5) cooling to 30-50 DEG C, and adding a neutralizer to regulate the pH value; 6) heating to 60 DEG C, dropwise adding deionized water, and dispersing by stirring; and 7) heating to 60-65 DEG C, dropwise adding an initiator water solution and a nucleation monomer, carrying out programmed heating, and carrying out the reaction while keeping the temperature, thereby obtaining the interpenetrating-network-structure water-based polyurethane nano composite material. The method effectively solves the problem of VOC (volatile organic compound) discharge. The nano composite material has the characteristics in both the core-shell structure and the interpenetrating network structure, and thus, has favorable mechanical properties. The adopted continuous-process synthesis technique is beneficial to enhancing the production efficiency.

Owner:武汉弘毅共聚新材料科技有限公司

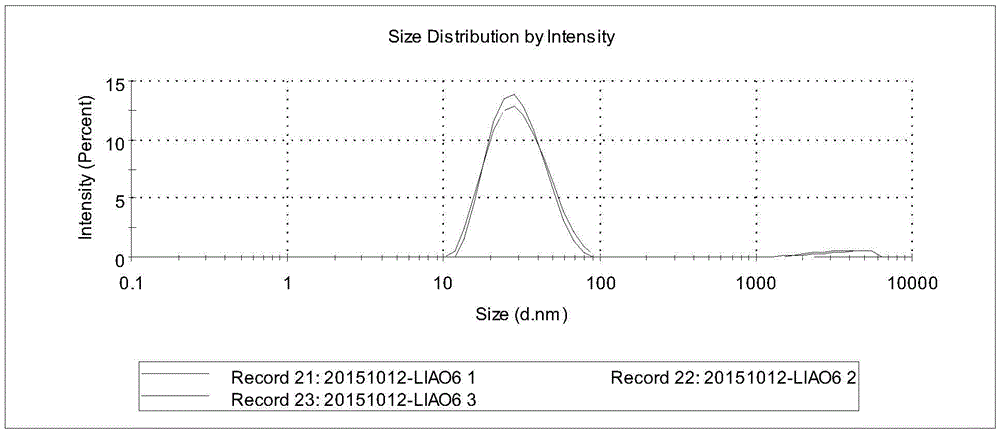

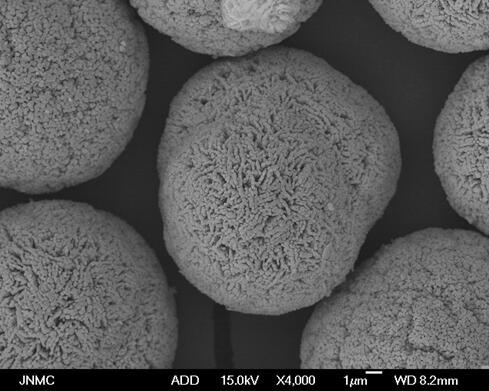

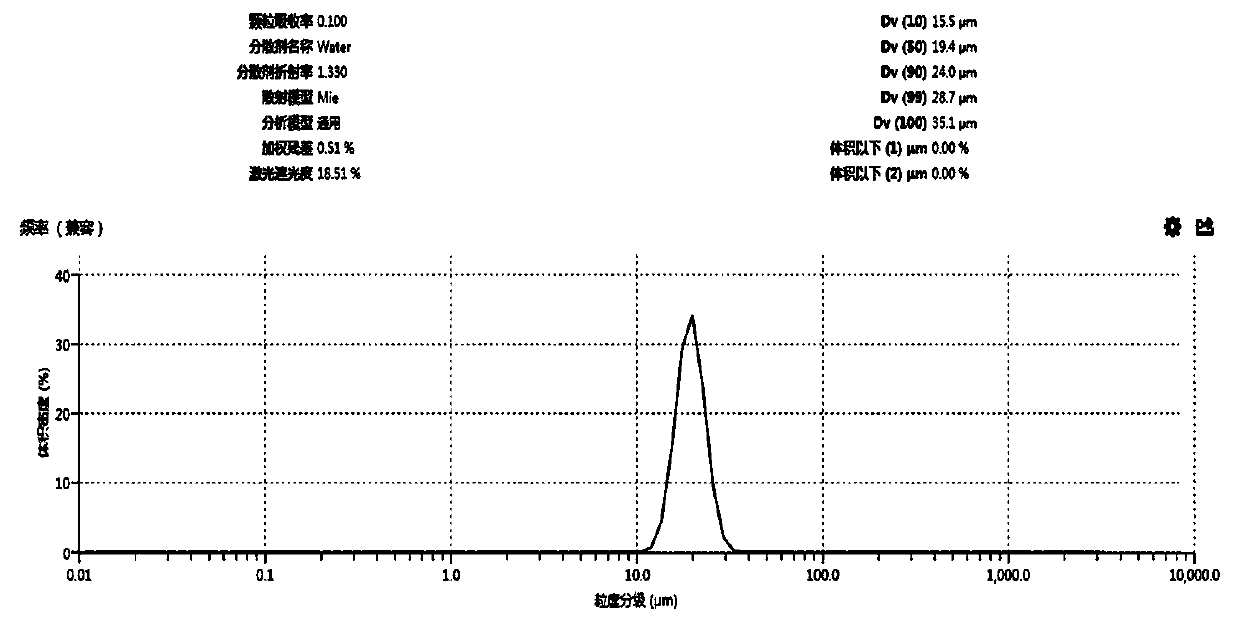

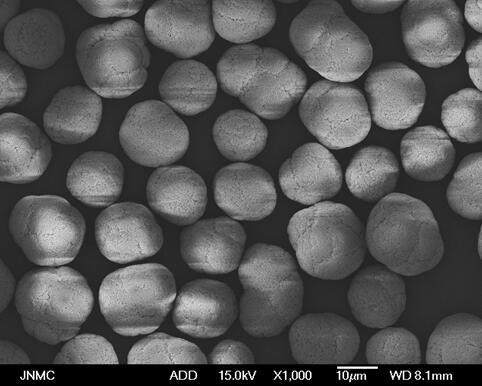

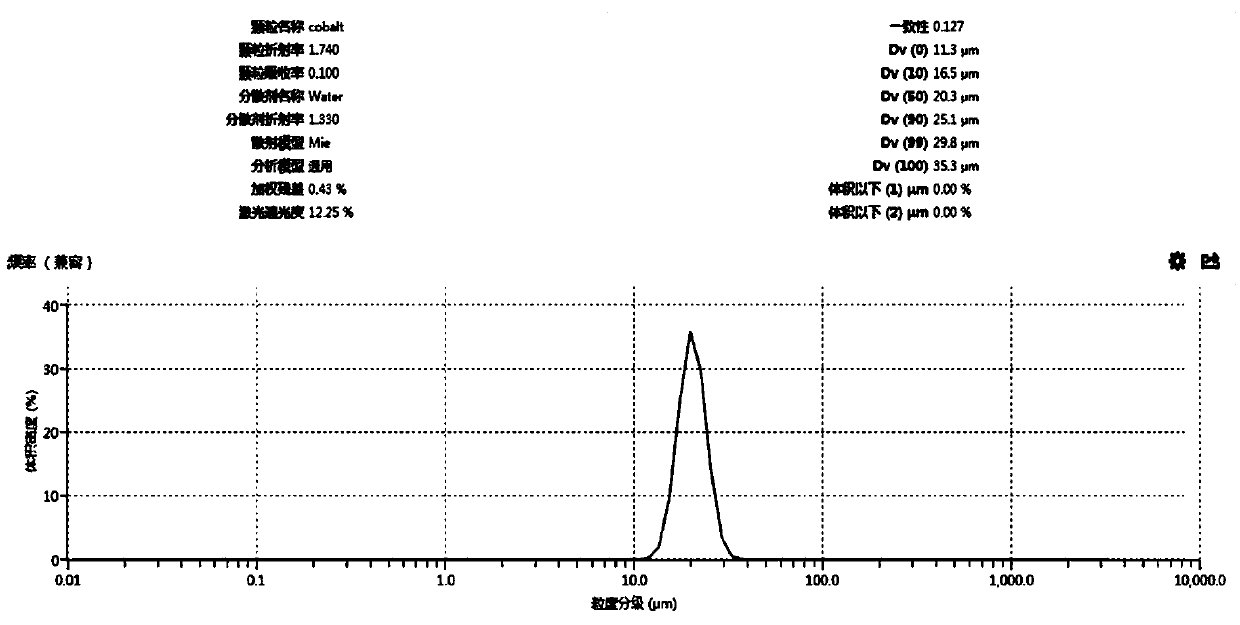

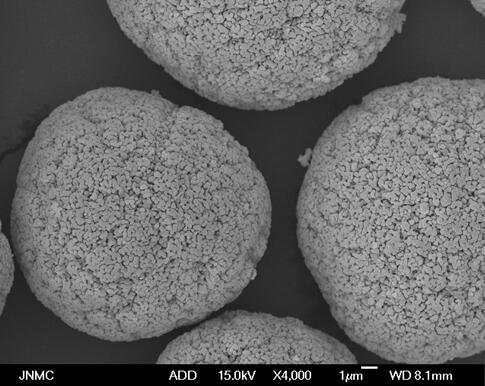

Preparation method of large-particle narrow-distribution aluminum doped tricobalt tetroxide

ActiveCN110217832AEvenly distributedHigh solid contentCell electrodesCobalt oxides/hydroxidesSynthesis methodsSynthesis Phase

The invention relates to the technical field of lithium ion batteries, in particular to a preparation method of large-particle narrow-distribution aluminum doped tricobalt tetroxide. The method includes a stage of continuously synthesizing large-particle narrow-distribution aluminum doped cobalt carbonate, and a stage of calcining the large-particle narrow-distribution aluminum doped cobalt carbonate. A large-particle cobalt carbonate precursor prepared by continuous centrifugation to improve the solid content, the continuous synthesis method and a special aluminum salt method in the cobalt carbonate wet-process synthesis stage is dense, narrow in particle size distribution, good in sphericity and uniform in aluminum element distribution. Through a three-step calcination method, the temperature in the first step is 180-250 DEG C and the cobalt carbonate is partially decomposed to form a micropore channel; the cobalt carbonate is completely decomposed in the second step in which the temperature is 300-500 DEG C; in the third step, the temperature is 650-800 DEG C, particle surfaces are densified, the content of the cobaltous phase is lower, the crystal form is more complete, and thelarge-particle narrow-distribution aluminum doped tricobalt tetroxide is formed. .

Owner:JINCHUAN GROUP LIMITED +1

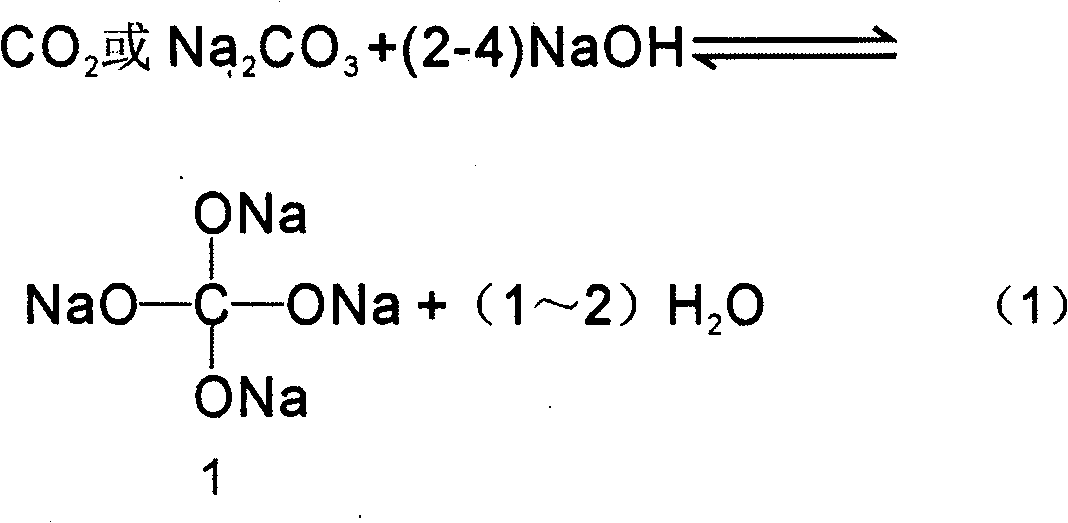

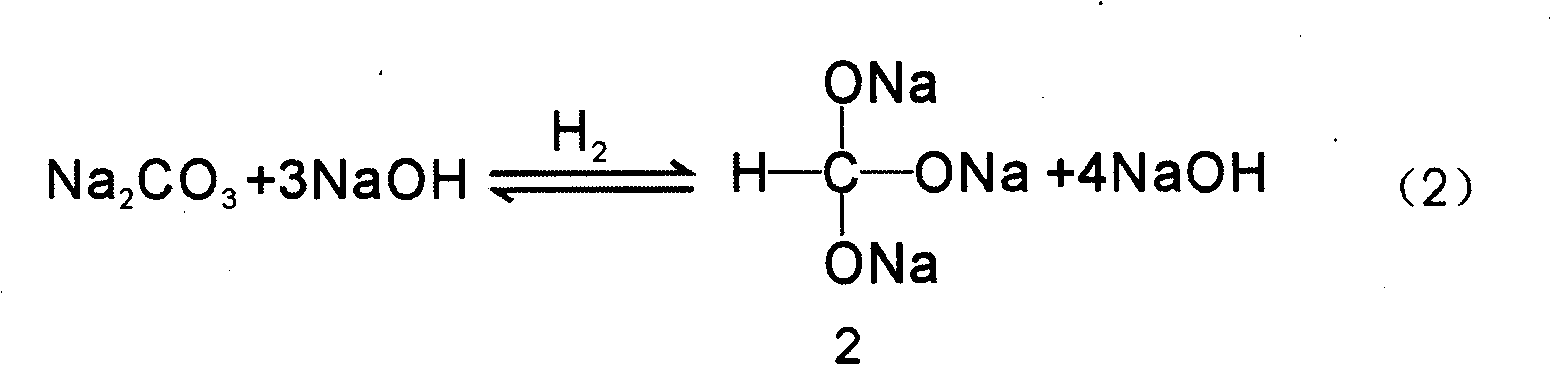

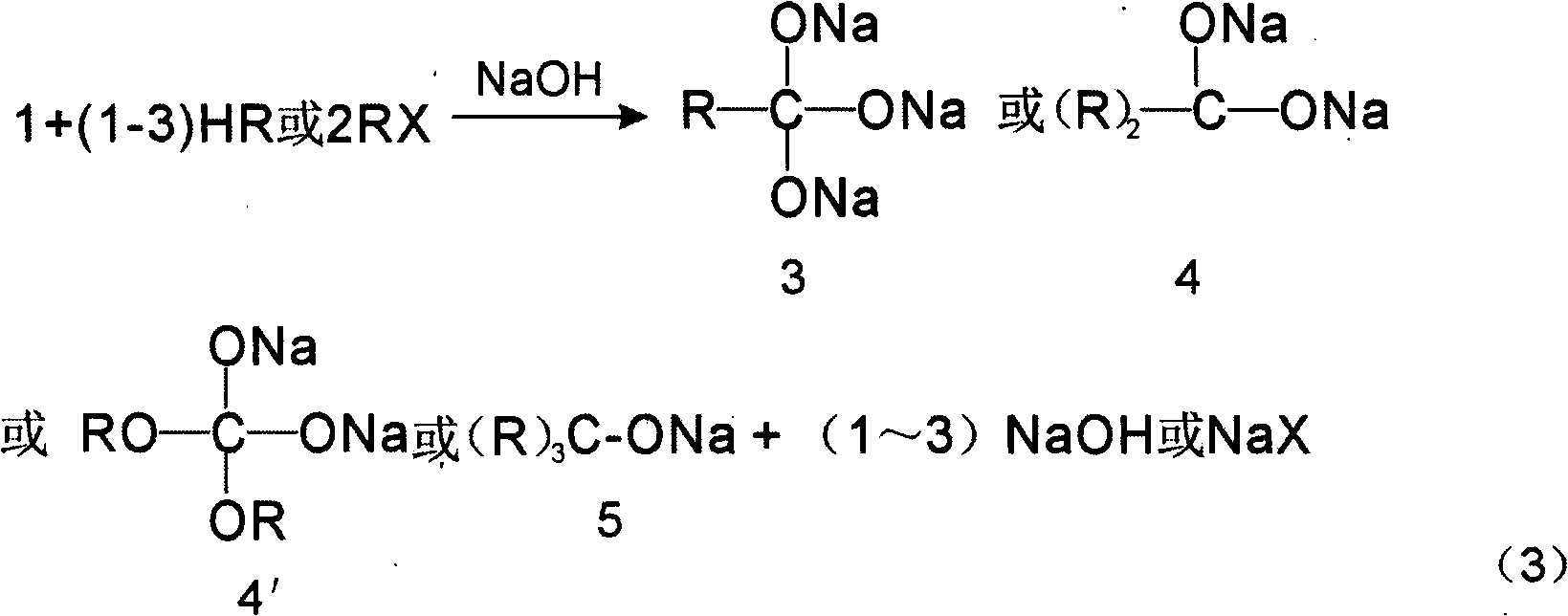

Method for preparing DMC, DPC, ortho-carbonate, ortho-formate, dimethyl ether, and the like by using Na2CO3 or sodium formate or CO2 or CO

InactiveCN103254084AOrganic compound preparationPreparation from ortho-estersSynthesis methodsProcess synthesis

The invention relates to a recently discovered universal synthesis method of tandem-substitution-rearrangement-elimination reaction (TSRE reaction) of elemental organic chemistry, production process synthesis routes of two products of dimethyl carbonate (DMC) and diphenyl carbonate (DPC) and traditional products of ortho-carbonate, ortho-formate, dimethyl ether, and the like through CO2 and CO direct synthesis method are redesigned. Compared with prior arts for producing the products, with the preparation method provided by the invention, energy can be greatly saved, emission can be greatly reduced, and cost can be greatly reduced.

Owner:李坚

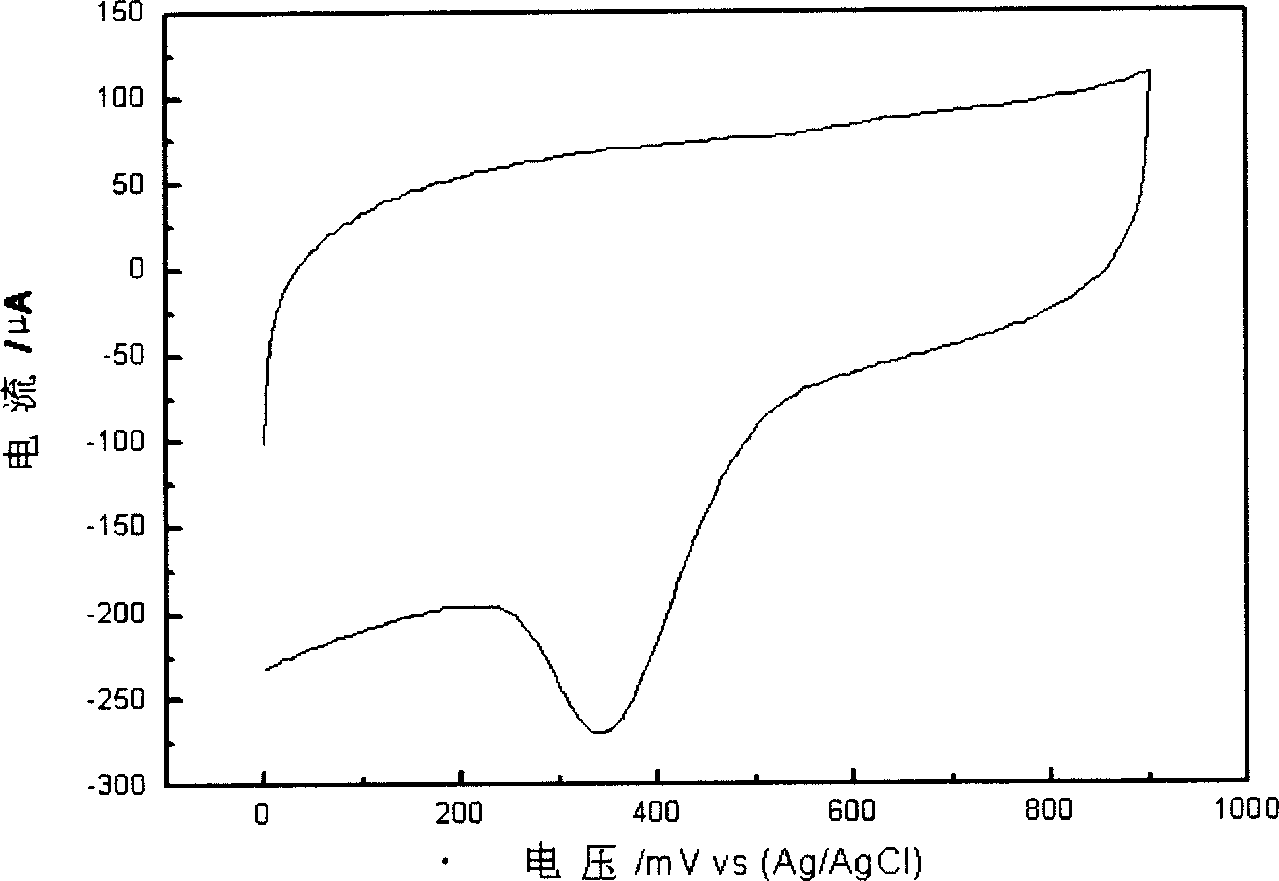

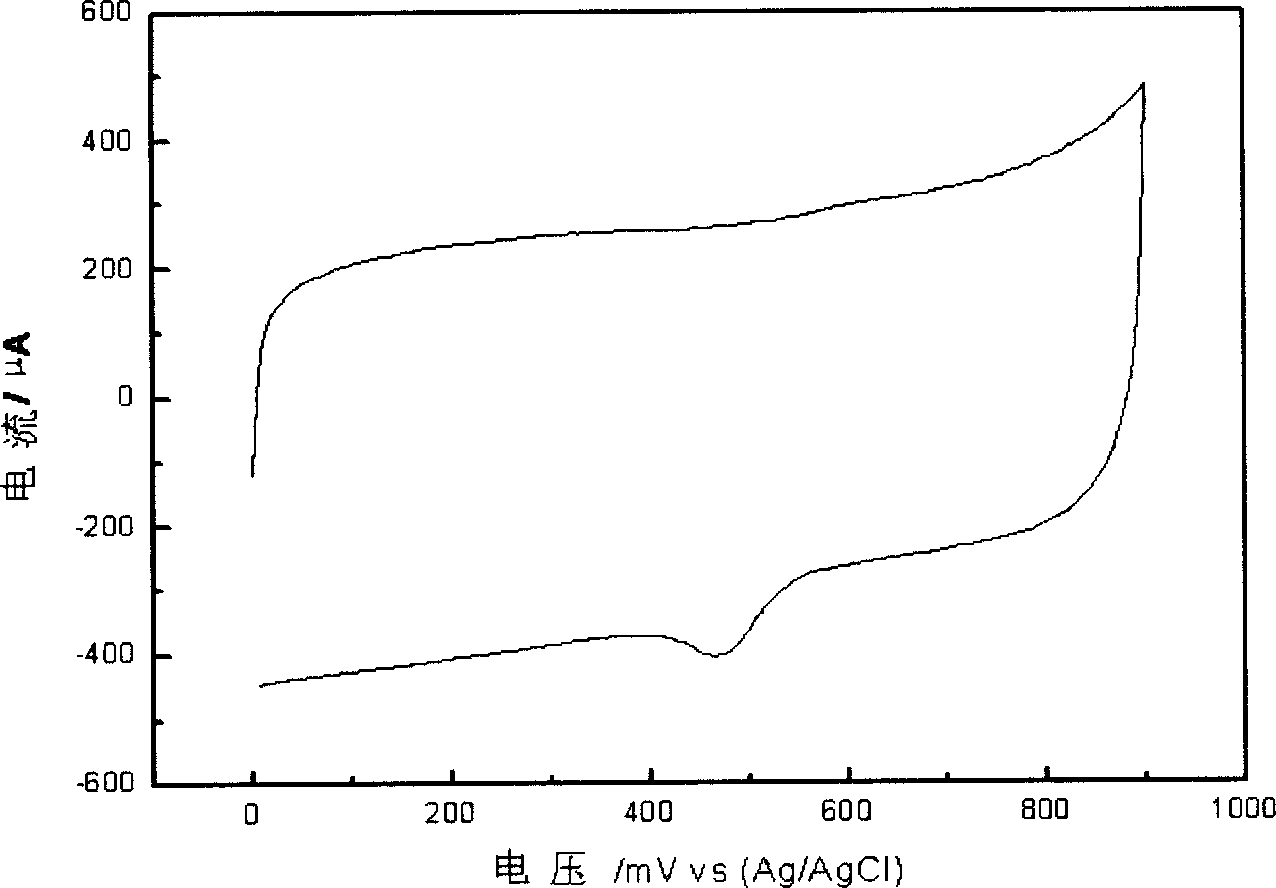

Preparation method of carbon carrying cobalt prophyrin oxygen reduction catalyst

InactiveCN1824385ASave human effortSave moneyCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsHigh energyPorphyrin structure

The present invention discloses a preparation method of cobalt porphyrin on carbon oxidation-reduction catalyst. Said method includes the following several steps: firstly, fully drying carbon black, high-energy ball grinding, then using 30 wt% of H2O2 or 6M HNO3 to make pretreatment; adding porphyrin monomer, cobalt acetate and pretreated carbon black into glacial acetic acid, uniformly mixing them, then placing them into a microwave reactor with reflux condensing device, heating to make reaction to obtain catalyst precursor body, then under the protection of argon heat-treating said catalyst precursor body for 2-4hr at 500-1000deg.C so as to obtain the invented cobalt porphyrin on carbon oxidation-reduction agent.

Owner:SHANGHAI JIAO TONG UNIV

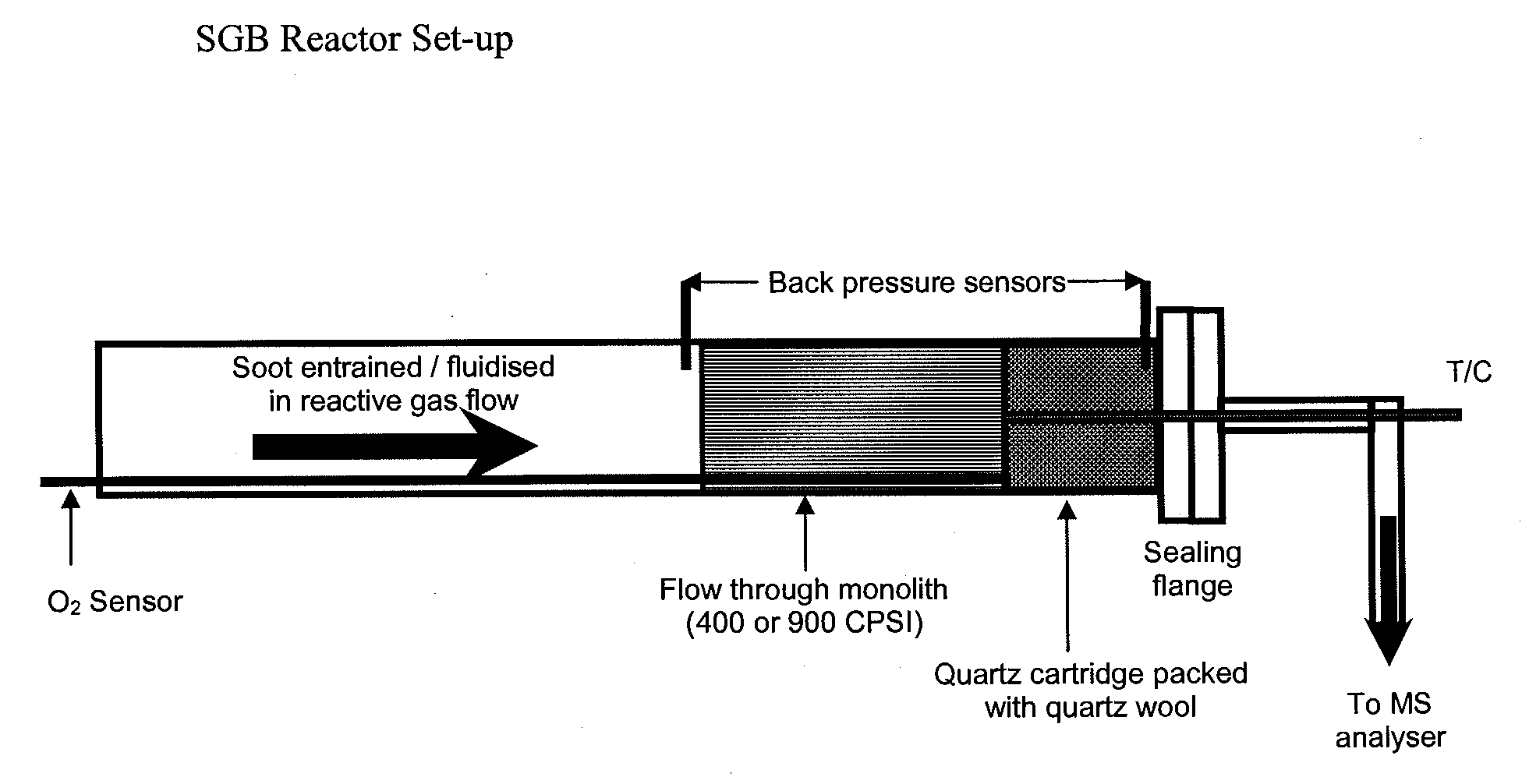

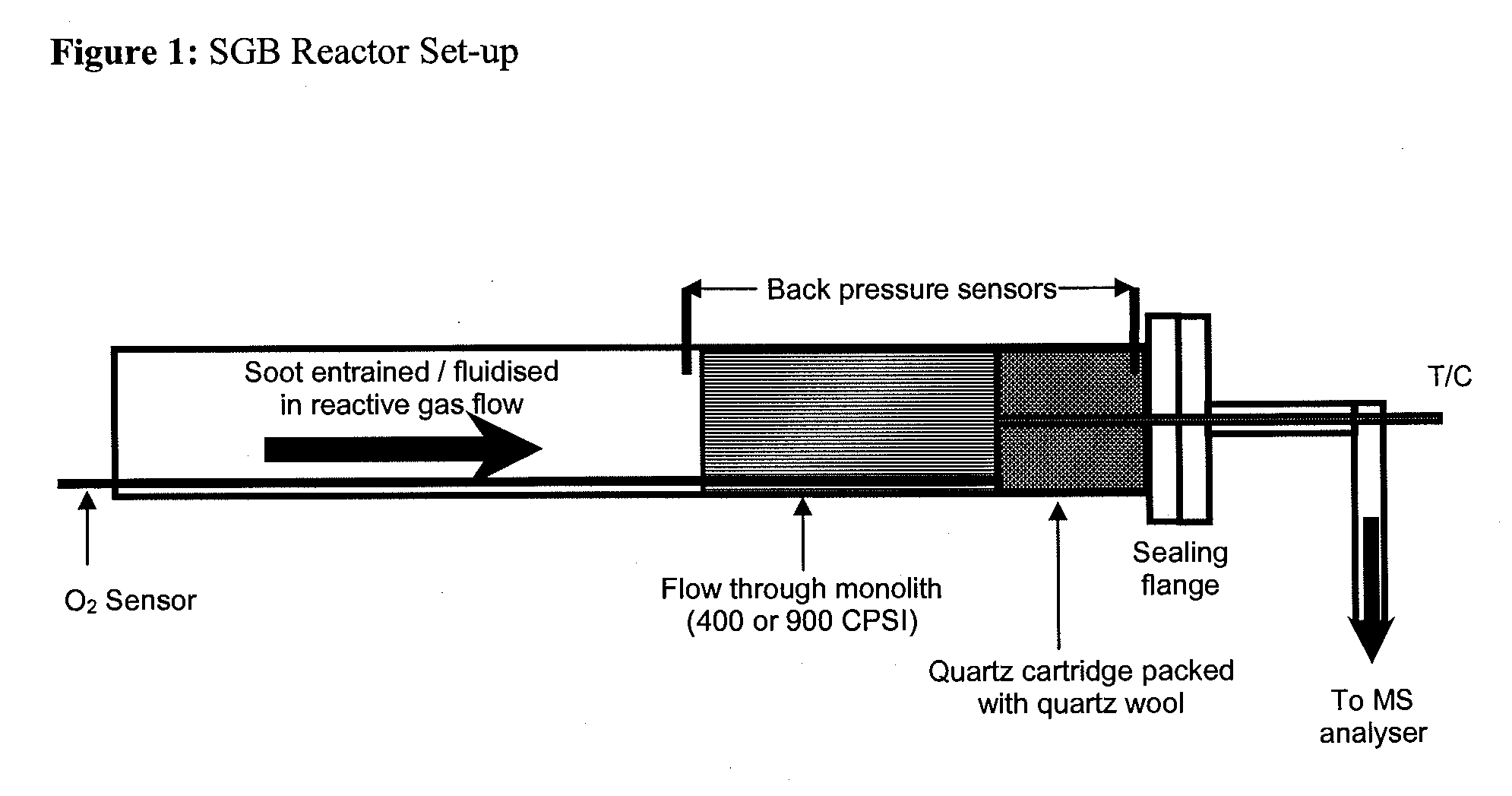

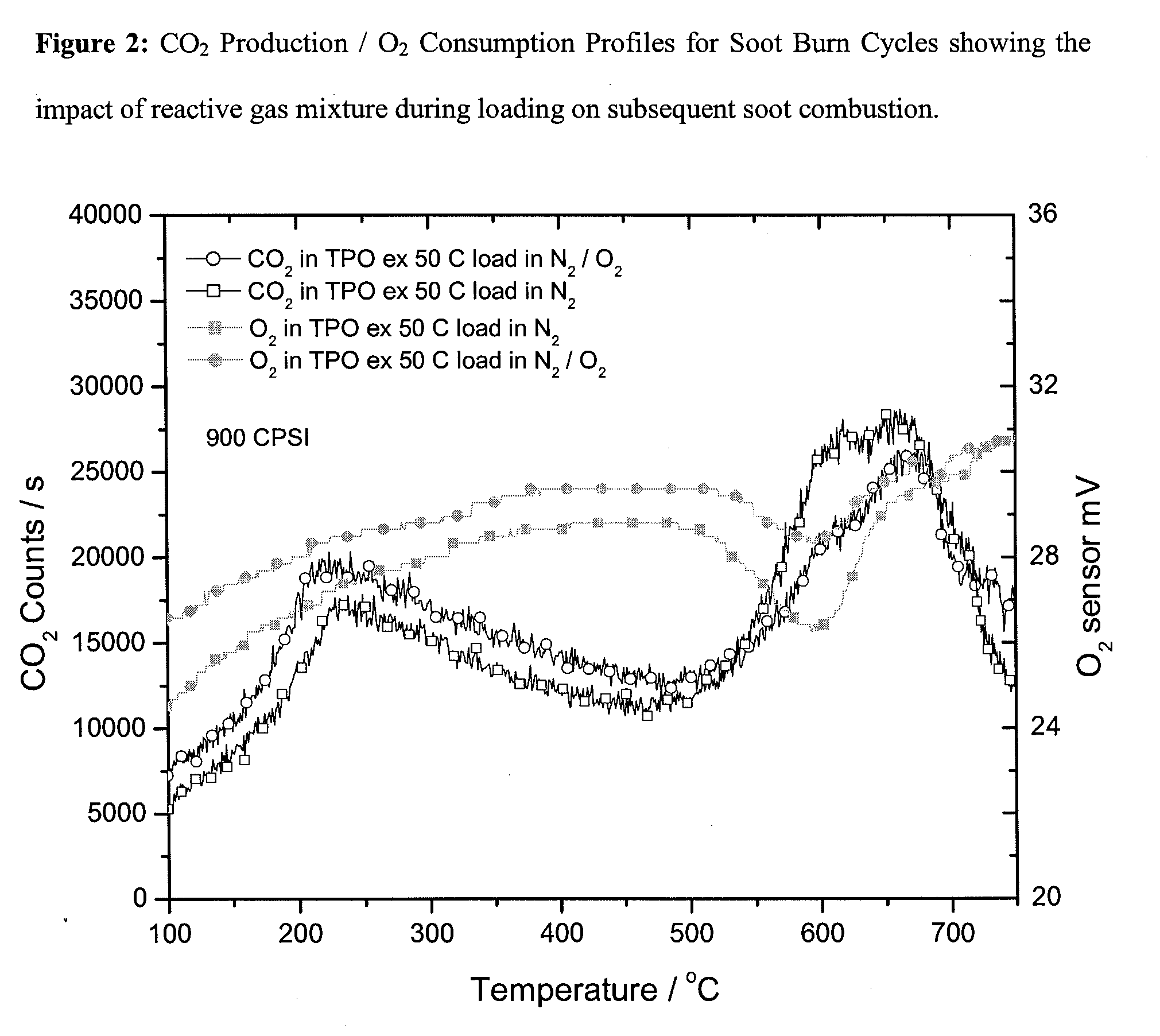

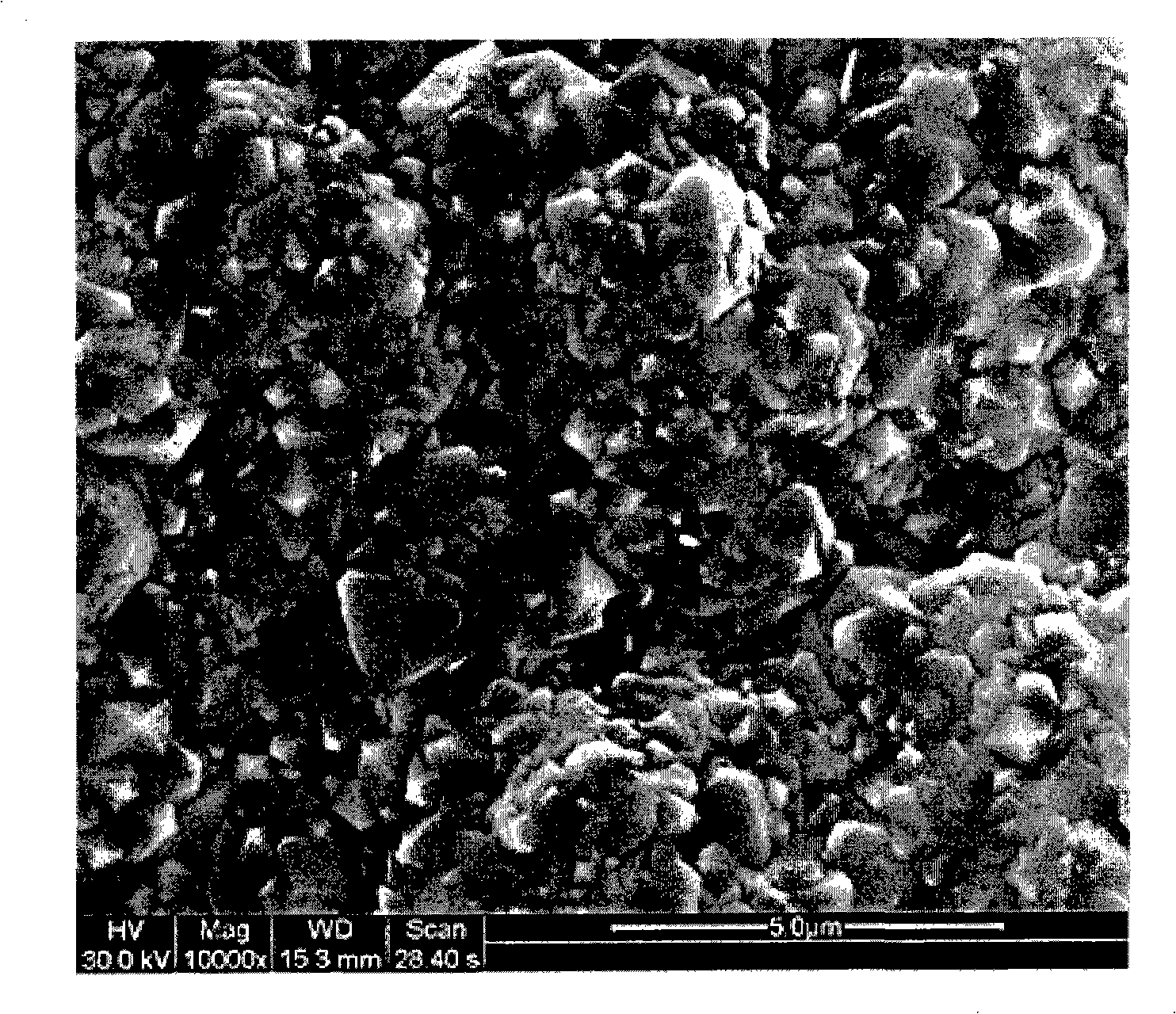

Continuous diesel soot control with minimal back pressure penatly using conventional flow substrates and active direct soot oxidation catalyst disposed thereon

InactiveUS20100077727A1Without large backpressure penaltyIncreased durabilityExhaust apparatusHeterogenous catalyst chemical elementsParticulatesHigh cell

There is disclosed high cell density or tortuous / turbulent flow through monolithic catalyst devices for the direct catalytic, and (semi) continuous oxidation of diesel particulate matter. The catalysts relate to OIC / OS materials having a stable cubic crystal structure, and most especially to promoted OIC / OS wherein the promotion is achieved by the post-synthetic introduction of non-precious metals via a basic (alkaline) exchange process. The catalyst may additionally be promoted by the introduction of Precious Group Metals.

Owner:UMICORE AG & CO KG

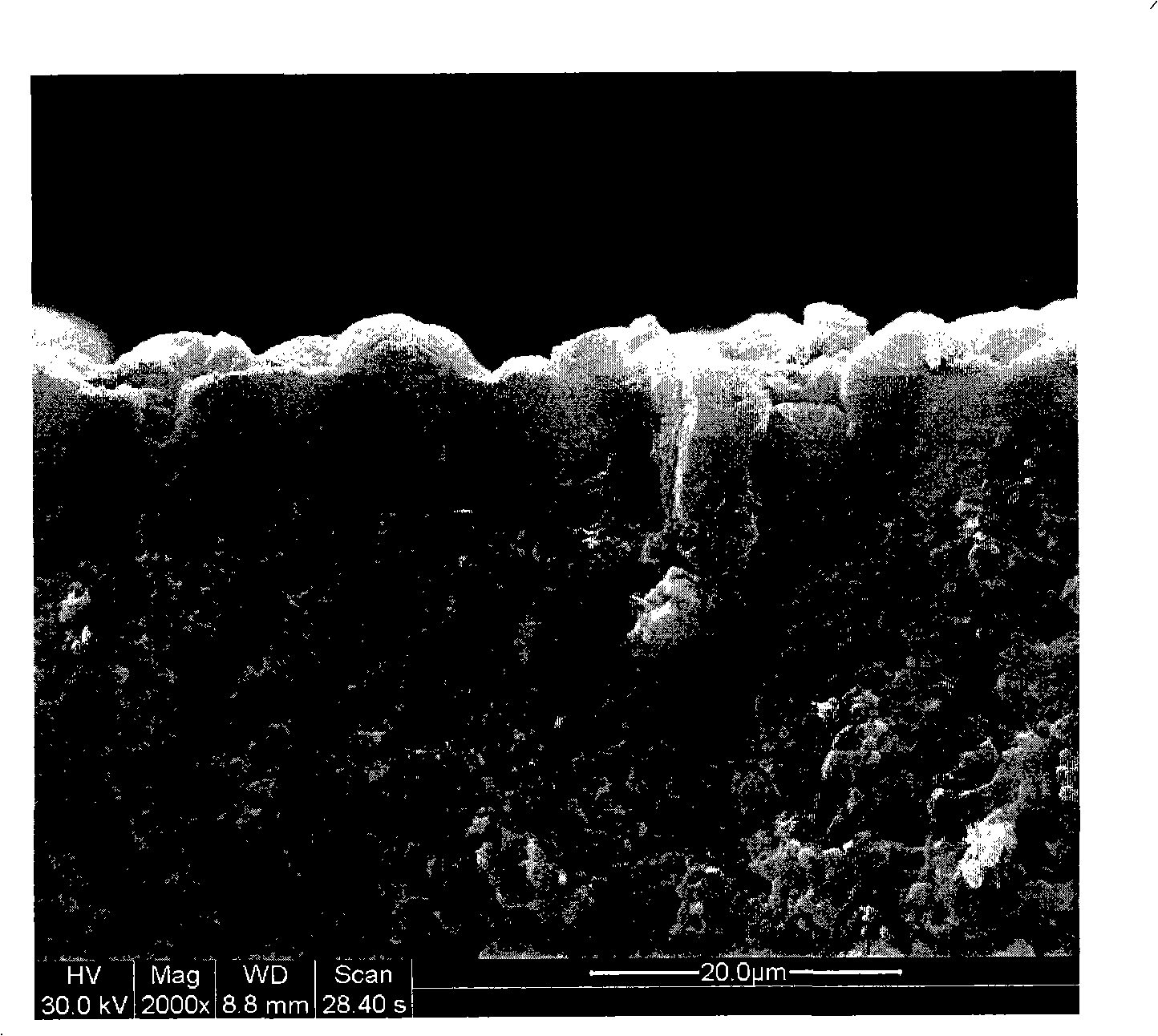

Method for preparing high-performance Y type molecular sieve film and application of the same in organic mixture separation

InactiveCN101318665AHigh purityShort synthesis timeFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteSeparation factorMolecular sieve

The invention provides a method for preparing a high-performance Y-type molecular sieve membrane and an application to the separation of organic mixture. The method is characterized in that a new high-temperature closed hydro-thermal synthesis reaction method is adopted, a layer of dense NaY-type molecular sieve membrane forms on the surfaces of three porous tubular support body. The synthetic time of preparation process is short, and the process of the membrane forming is simple. The membrane prepared by the method has fewer defects, the synthesized NaY-type molecular sieve membrane is used in the separation of organic mixtures by adopting a self-control permeating and vaporizing device, the process of the separation is simple and is easy to be operated and controlled, the separating property is good, the Y-type molecular sieve membrane has high permeation flux and high separation factor while the Y-type molecular sieve membrane is applied to methanol / methyl tert-butyl ether, ethanol / ethyl tertiary butyl ether and benzene / cyclohexane, the NaY-type molecular sieve membrane particularly synthesized by stainless steel support body has extremely high permeation flux.

Owner:JIANGXI NORMAL UNIV

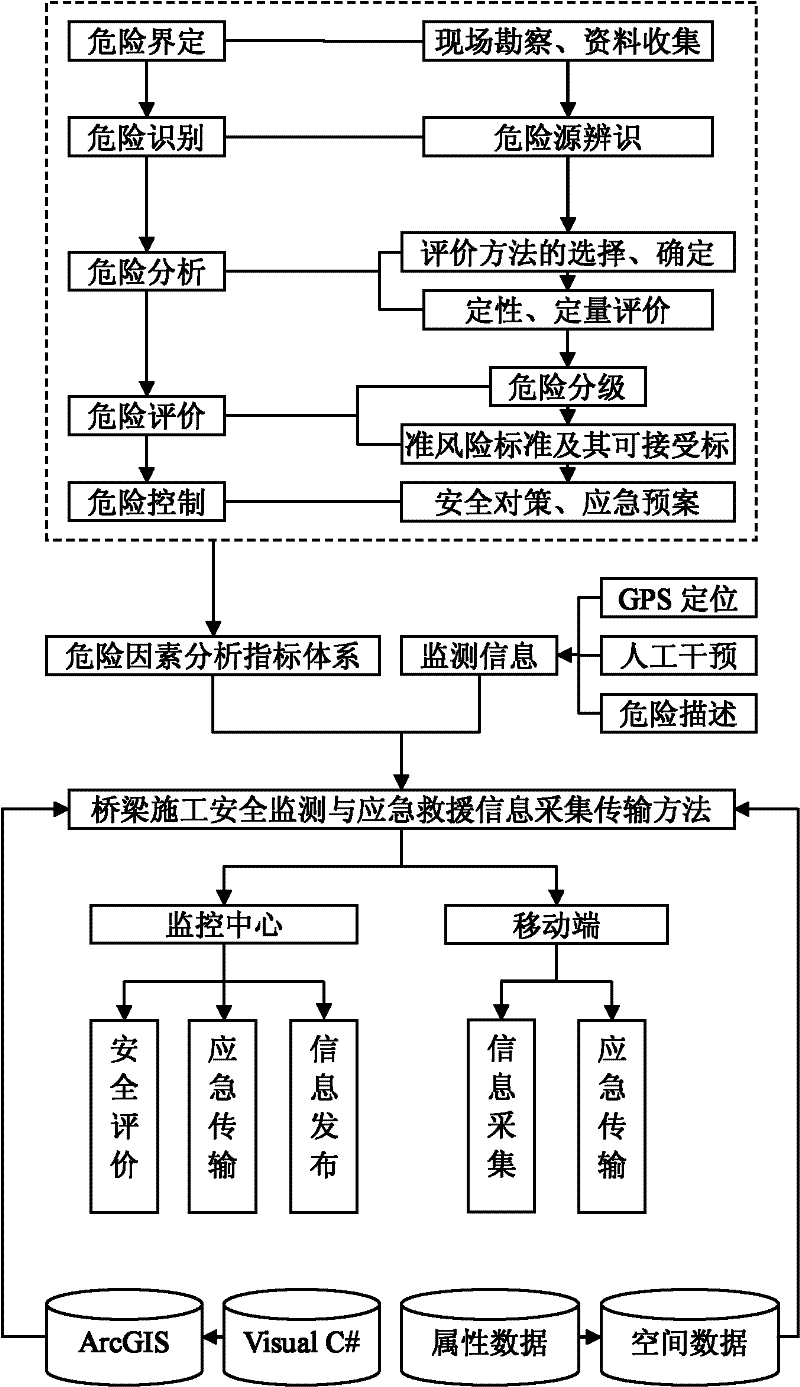

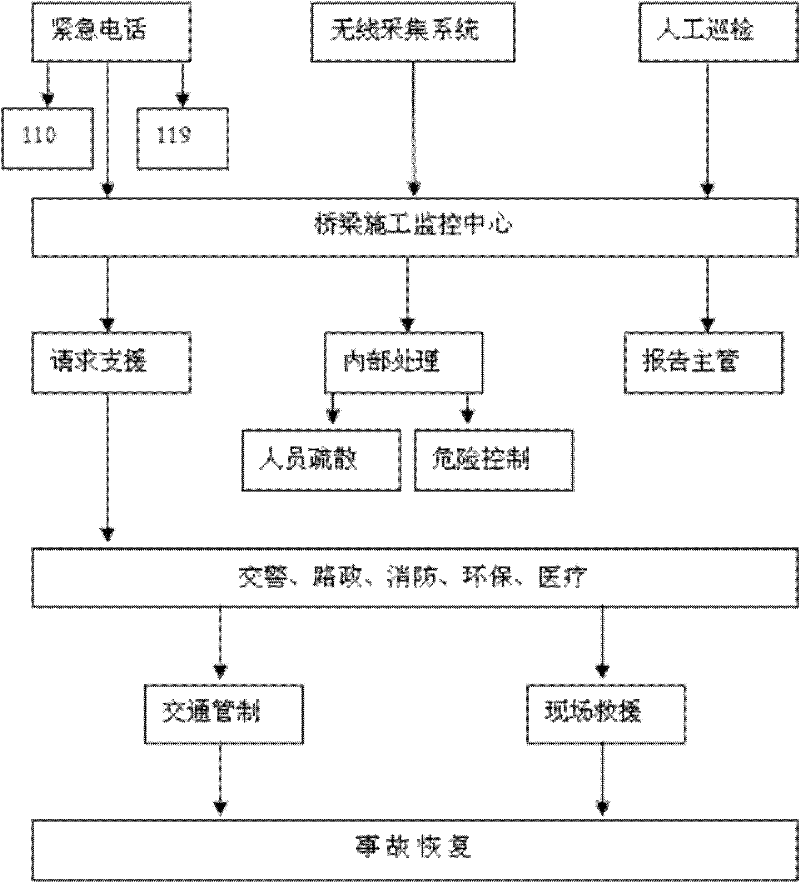

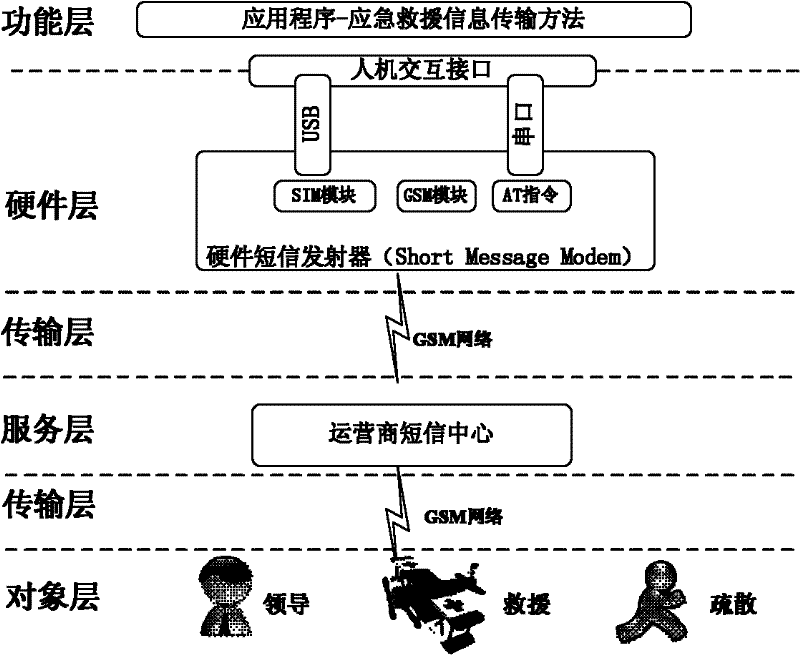

Safety monitoring and emergency rescue information collection and transmission method during bridge construction period

InactiveCN102271307ARealize acquisitionRealize sendingMessaging/mailboxes/announcementsLocation information based serviceProcess synthesisText messaging

The invention provides a method for collecting and transmitting safety monitoring and emergency rescue information during the bridge construction period. This method integrates the unsafe factors and hazard information existing in the process of bridge construction, divides all safety accidents into a unified level, conducts risk assessment, and uses mobile handheld PDA terminals and GPS acquisition modules to provide necessary data collection and transmission functions. And on the Visual Studio 2008 platform and Java Android ADT, the processing and display of bridge construction safety monitoring data, as well as the algorithm of emergency rescue route search, are used to obtain problems in bridge construction, and the information is transmitted in real time to the Lead the management level, realize process control, increase rescue speed, reduce and reduce losses caused by safety accidents. The method has the characteristics of real-time and high degree of automation, and the precision meets the engineering requirements.

Owner:WUHAN UNIV OF TECH

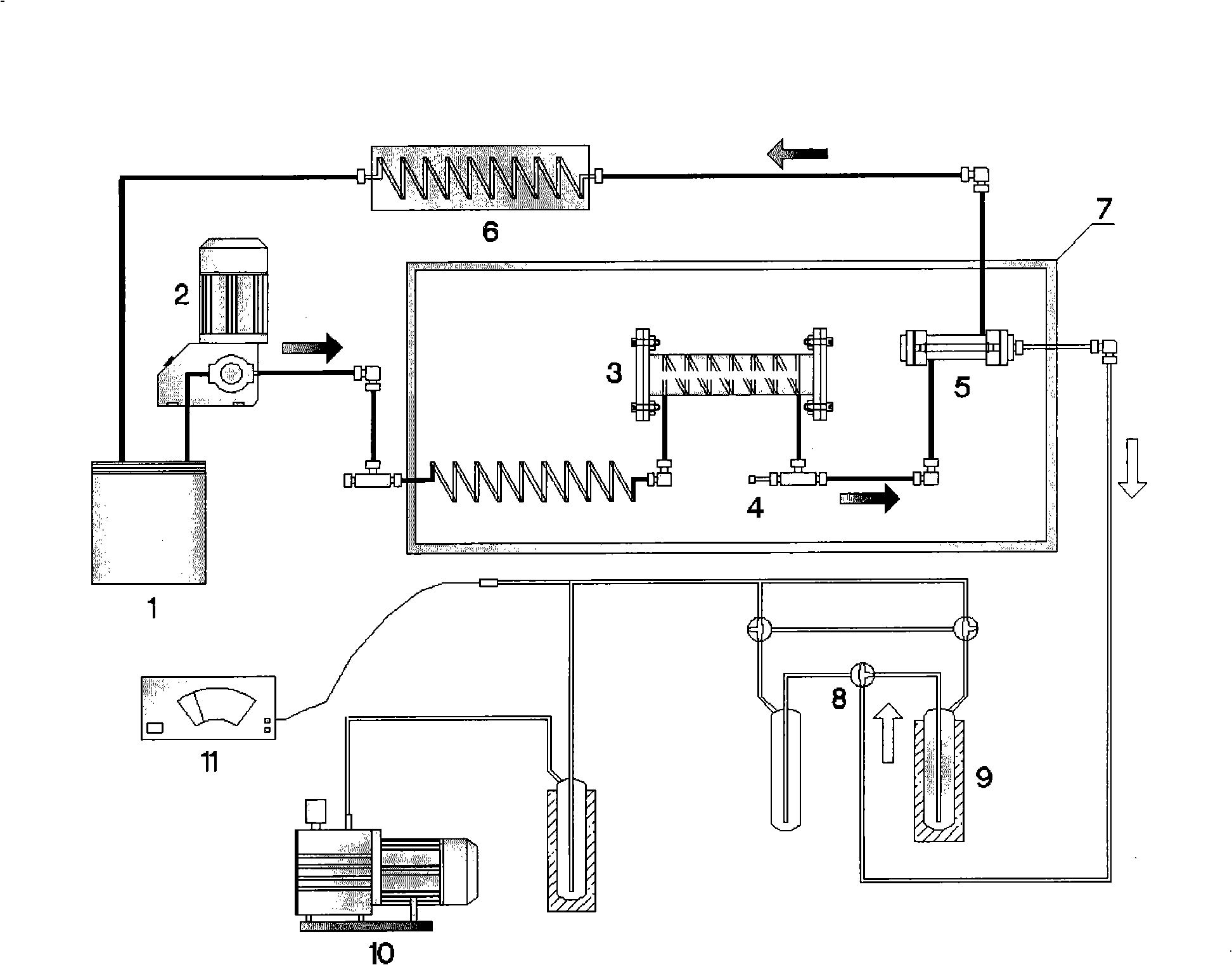

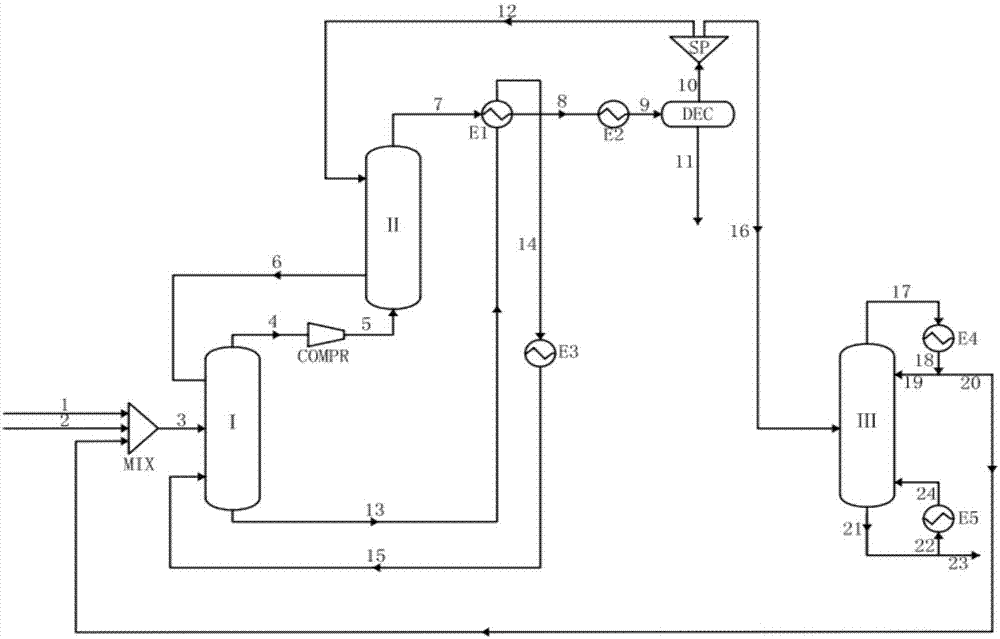

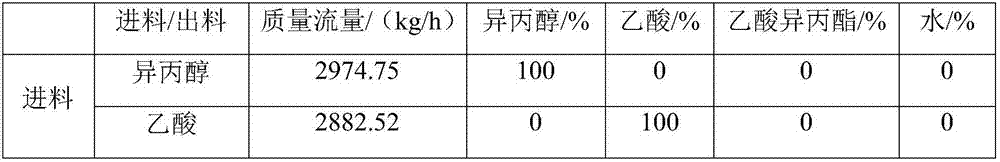

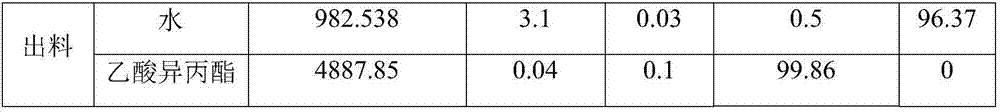

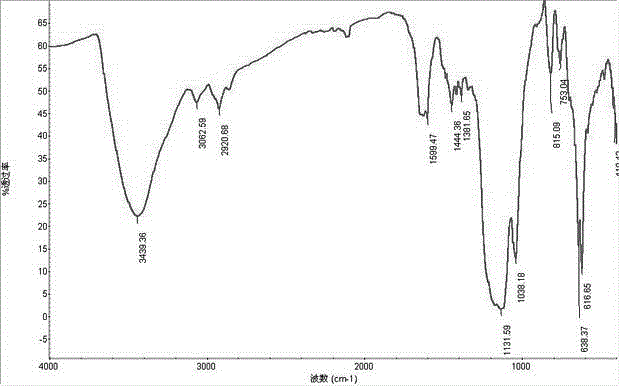

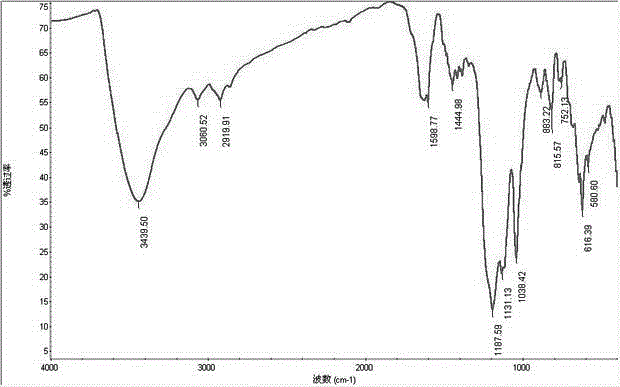

Method and apparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation

PendingCN107954866AAchieve integrationImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationReboilerPhase splitter

The invention relates to a method and apparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation. The apparatus comprises: a feeding mixer, a low-pressure reaction column, a high-pressure distillation column, a product refining column, a phase splitter, a separator, a compressor, a thermal coupling heat exchanger, a condenser and an auxiliary reboiler. Theapparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation allows synthesis of high-purity isopropyl acetate during distillation process; a traditional reactive distillation column is split into the high-pressure distillation column and the low-pressure reaction column, high-temperature steam at the top of the high-pressure distillation column is used to heat the reboiler of the low-pressure reaction column, the two columns share one heat exchanger, heat of the top steam of the high-pressure distillation column is made full use, and heat efficiency of the process is improved. By synthesizing isopropyl acetate via the differential thermal coupling reactive distillation process, esterification, distillation separation and thermal coupling are integrated; material that is not fully reacted flows back for reuse, so that total conversion rate of a reactant is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

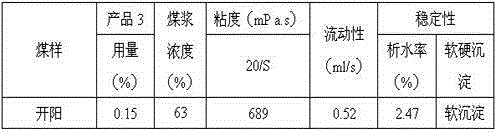

Tar-type coal water slurry additive prepared from composite raw materials and production technology of tar-type coal water slurry additive

InactiveCN105695001ADeployment ratio wideWide variety of sourcesLiquid carbonaceous fuelsFuel additivesAnthraceneCoal water

The invention discloses a tar-type coal water slurry additive prepared from composite raw materials and a production technology of the tar-type coal water slurry additive.The tar-type coal water slurry additive is synthesized by mixing the main materials such as scrubbing oil, naphthalene oil, anthracene oil and papermaking wastewater in different mass ratios, subjecting a mixture to processes such as sulfonation and condensation, and adding a pore blocking agent carbonate into a synthesized product.The tar-type coal water slurry additive has the advantages that the tar-type coal water slurry additive has the characteristic of general dispersants, namely improvement in coal surface hydrophility; electrostatic repulsion among particles is enhanced, so that improvement in coal slurry fluidity is benefited; since strong stereo-hindrance effect is generated, slurry rheologic stability is achieved; the tar-type coal water slurry additive has specific cooperative synergism characteristic, and accordingly mutually complementary cooperative synergism is achieved; the tar-type coal water slurry additive is good for slurry forming ability of coal types different in coalification degree, is particularly applicable to low-rank coal, and is high in slurry forming concentration and excellent in coal slurry fluidity and stability under the condition that additive coal-based consumption is not more than 1.0%.

Owner:兖矿水煤浆气化及煤化工国家工程研究中心有限公司

Method of coating MOF to improve photostability of gold nanocluster and application thereof

ActiveCN108213414AAvoid reunionGood dispersionMaterial nanotechnologyTransportation and packagingThin layerControllability

The invention discloses a method of coating a MOF to improve photostability of a gold nanocluster and application thereof. The method includes following steps: coating the surface of the gold nano cluster with a thin-layer metal organic frame in situ in a liquid-phase manner to serve as a coating layer, wherein the metal organic frame is made of a zeolite imidazate skeleton structure amterial, andthickness of the coating layer is 0.5-10nm. The invention further discloses a metal organic frame coated gold nanocluster composite material prepared by the method and application thereof in photocatalytic reduction CO2 reaction. The method has the advantages that an in-situ growing method is adopted to coat the thin-layer MOF, and the gold nanocluster is directly coated with the MOF without through surface modifying, so that photostability of the gold nanocluster is improved. The method is a low-temperature liquid-phase wet-process synthesis method, so that performance of the gold nanocluster is unaffected. The method is simple in process, mild in reaction condition, high in controllability, low in energy consumption and easy in large-scale popularization and application.

Owner:ANQING NORMAL UNIV

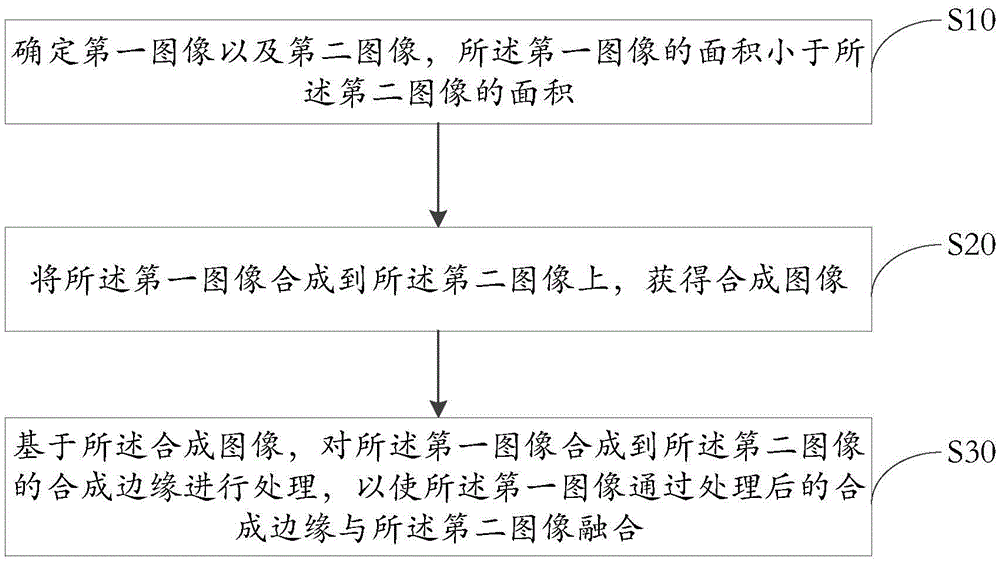

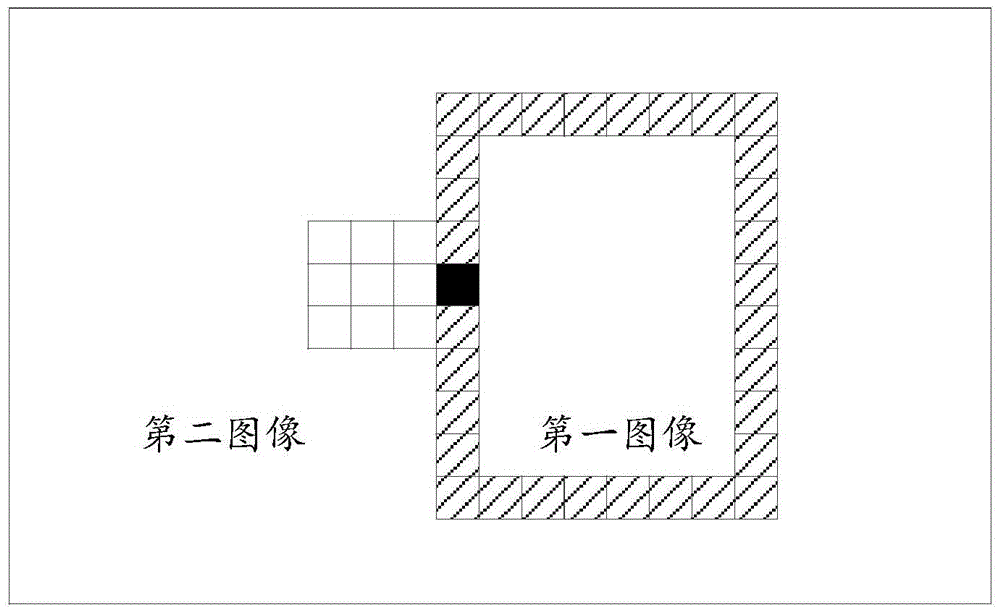

Information processing method and electronic equipment

ActiveCN105608716ASolve the technical problem of relatively blunt composite edgesComposite images look natural2D-image generationInformation processingComputer vision

The invention discloses an information processing method and electronic equipment. The method comprises the following steps: determining a first image and a second image, wherein the area of the first image is smaller than the area of the second image; synthesizing the first image onto the second image to obtain a synthesis image; and on the basis of the synthesis image, processing a synthesis edge for the first image to be synthesized to the second image to cause the first image to be fused with the second image through the processed synthesis edge. The invention provides the method for solving the technical problem that the synthesis edge is blunt when the image is synthesized in the prior art, and realizes a technical effect that the effect of the synthesized image is more nature.

Owner:LENOVO (BEIJING) CO LTD

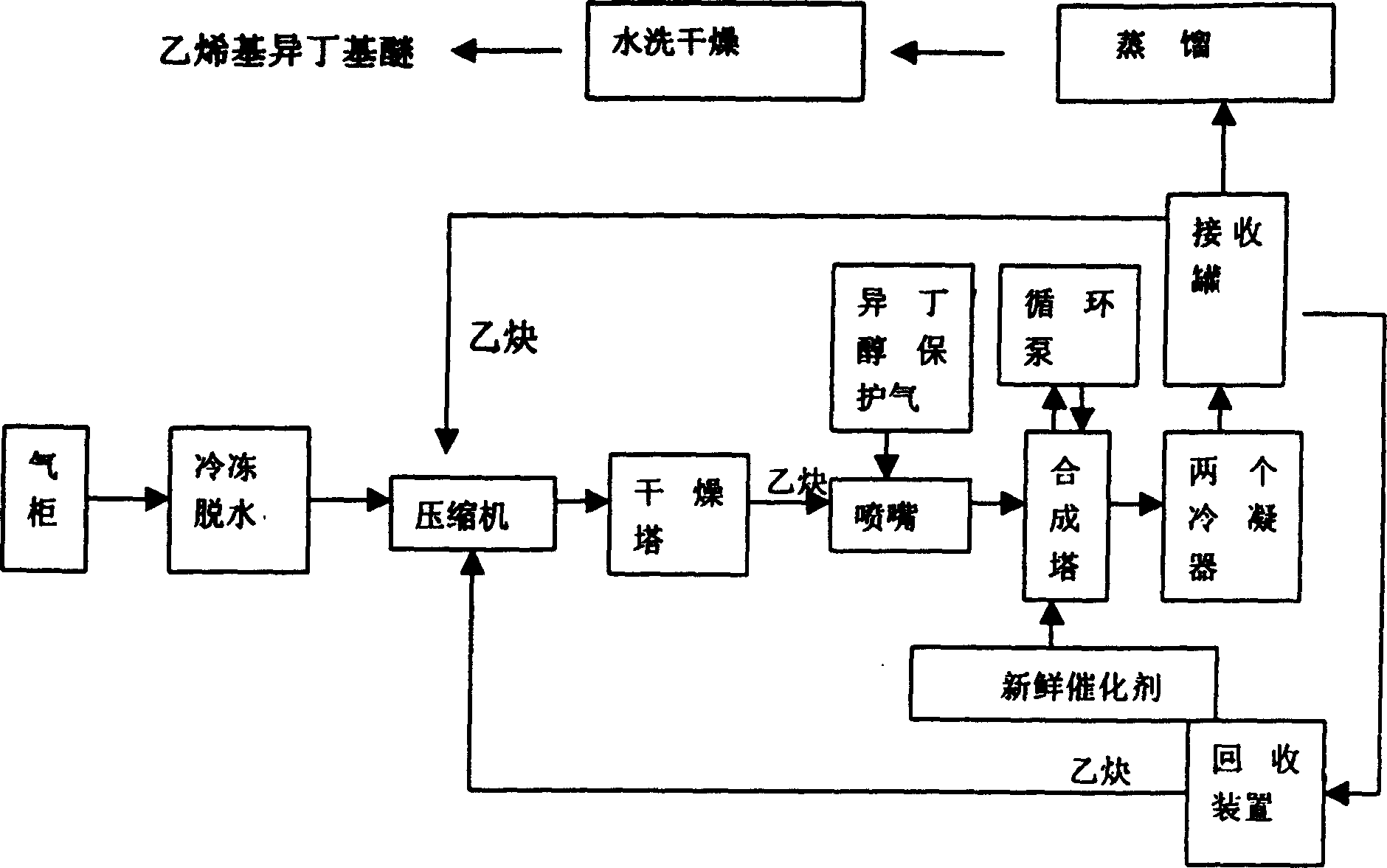

Continuous synthesizing method of vinyl isobutyl ether

This invention has disclosed a kind of continuous sythesizing method for vinyl-isobutyl ether. It regards acetylene and isobutyl alcohol as reaction raw materials, process synthesis reaction in converter, within which fills the catalyst solution with liquid location 50-80 percent. Acetylene and isobutyl alcohol gas get into the tower from converter bottom muzzle after mixed evenly, catalyst solution in the bottom get to top of the tower successively through circulation pump, carrying on circulation, after the small acetylene air bubble meet the isobutyl alcohol, they take etherification in converter, the etherification temperature is 125-150Deg. C, the converter pressure is 0.3-0.6Mpa; the catalyst is isobutyl alcohol solution including KOH, vinyl-isobutyl ether produced in reaction and acetylene and isobutyl alcohol not reacting, export from the top of the converter, through condenser it enter receive pot, then can make the vinyl-isobutyl ether of the finished product by the after-treatment. This reaction is safe and its reliability is good, the one way conversion ratio of acetylene and synthesis reaction harvest rate are high, the content of acetylene is low in the tail gas.

Owner:孟永华

Process for producing KMg3(AlSi3O10)F2 crystal powder with wet-process synthesis

The invention discloses a method for preparing synthesized KMg3(AlSi3O10)F2 crystal powder through a wet process. The method comprises the following steps: (1) crushing synthesized fluorophlogopite with the particle diameter of more than 0.85 millimeters, and using an ore washer for scrubbing and sieving so as to remove impurities, wherein the scrubbing hydraulic pressure is between 0.15 and 0.2 MPa; (2) making the scrubbed materials enter a pulper for pulping, wherein the pulping hydraulic pressure is between 5 and 7 MPa; (3) performing sieve classification on the obtained materials by pulping into three materials with three kinds of particle diameter, namely the materials with the particle diameter of more than 0.25 millimeter, the materials with the particle diameter of between 0.25 and 0.125 millimeter and the materials with the particle diameter of less than 0.125 millimeter, and performing pressure filtration on the three materials respectively, wherein the water content of the materials after pressure filtration is between 31 and 40 weight percent; (4) using a wheel mill to perform fine grinding and sizing on the three materials respectively, wherein the rolling gap is between 10 and 40 millimeters, the sizing is performed in a group of sizing pools, the materials with the particle diameter of more than 0.25 millimeter are subjected to rolling and sizing to generate powder products with the particle diameter of less than 100 mu m, the materials with the particle diameter of between 0.25 and 0.125 millimeter are subjected to rolling and sizing to generate powder products with the particle diameter of less than 250 mu m, and the materials with the particle diameter of less than 0.125 millimeter are subjected to rolling and sizing to generate powder products with the particle diameter of less than 160 mu m; and (5) using a plate-and-frame filter press to perform pressure filtration on the products after sizing, making the water content of the products be less.

Owner:鹿寨七色珠光云母材料有限公司

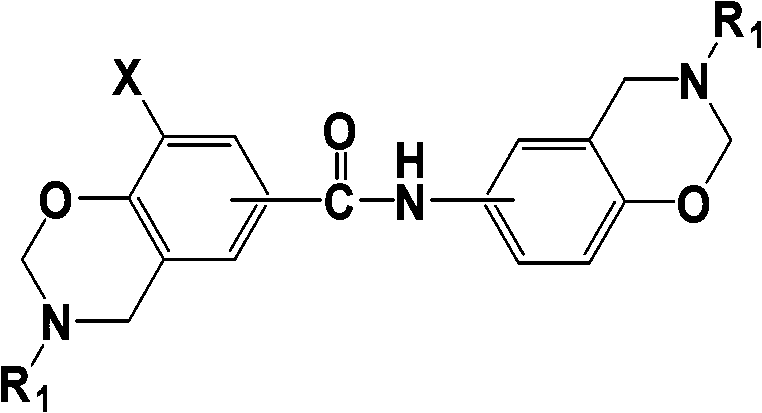

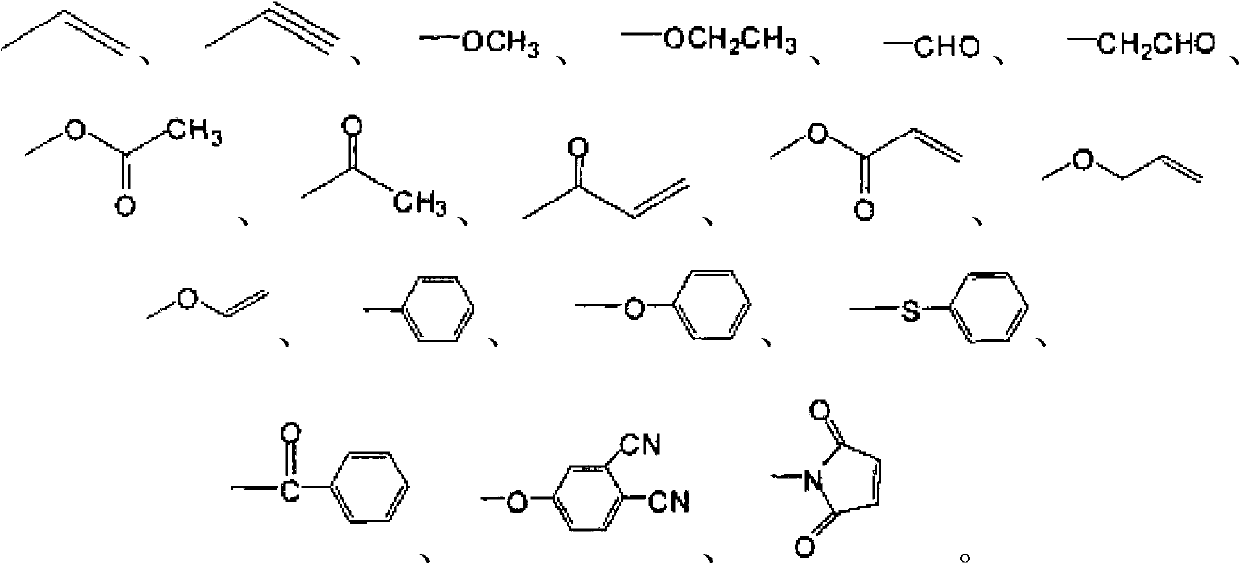

Benzoxazine resin mid-body containing arylamine and preparation method thereof

InactiveCN102827095AFew reaction stepsLess by-productsOrganic chemistryOrtho positionEngineering plastic

The invention discloses a benzoxazine resin mid-body containing arylamine; according to a structural formula shown in the description, X represents -H or methyl; R2 is represented or included; a R2 group substitution position is an ortho-position or a meta-position or a para-position; a R2 group is any one group of 26 groups; the benzoxazine resin mid-body containing arylamine can be used for a plurality of high technology fields in form of composite material, binding agent and engineering plastics; and a preparation method for benzoxazine resin mid-body containing arylamine is also disclosed by the invention; the preparation method makes diphenol compound containing arylamine and triazine compound which are in simple structures as raw material and processes synthesis to acquire benzoxazine; arylamine catalyst related by the preparation method is characterized by simple structure; in addition, the benzoxazine resin mid-body is characterized by few reaction steps and few by-products; the production cost of the benzoxazine resin mid-body is reduced; and the benzoxazine resin mid-body containing arylamine is preferably suitable for industrial production.

Owner:成都金桨高新材料有限公司

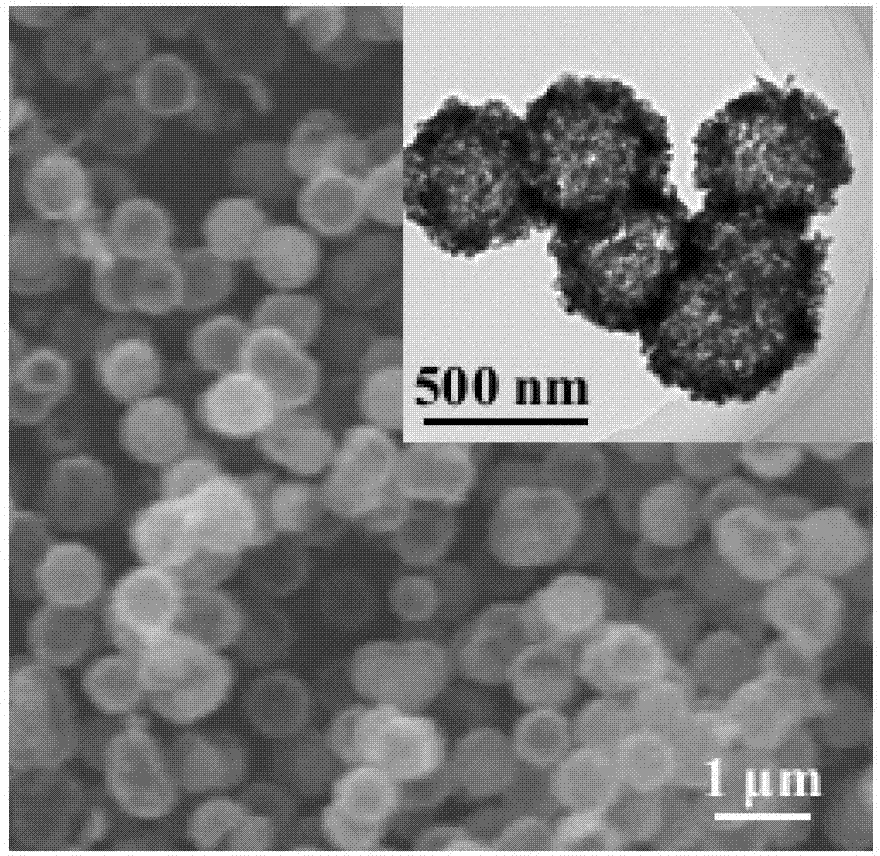

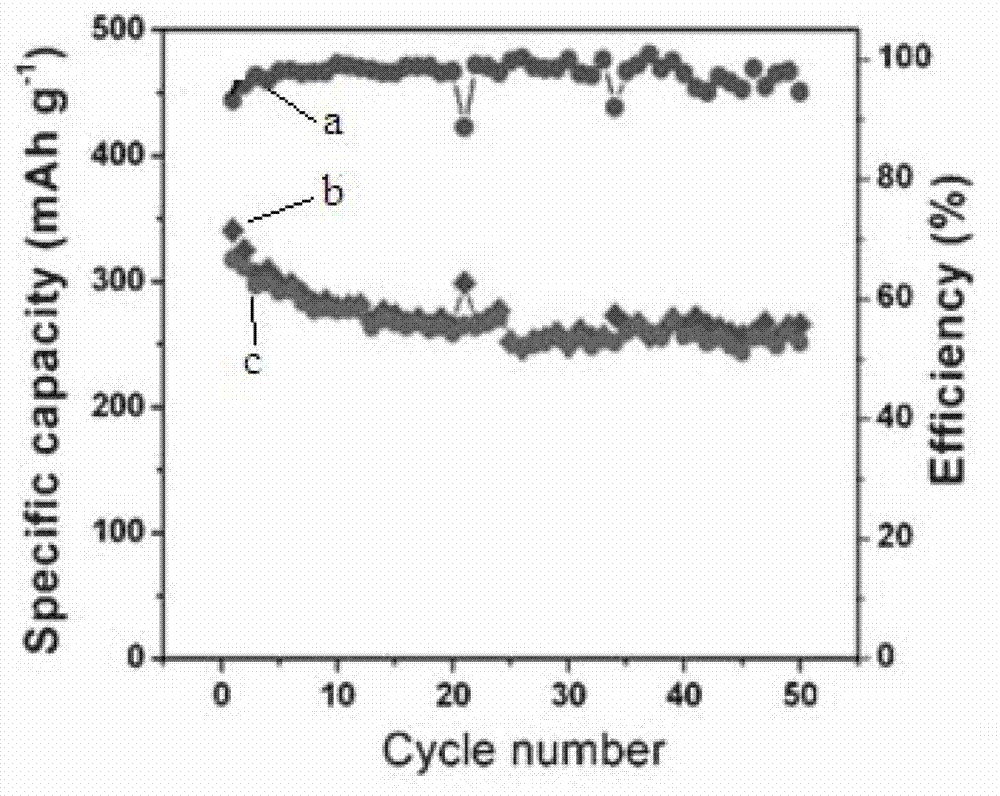

Lithium vanadate anode material and preparation method thereof

The invention discloses a lithium vanadate anode material which consists of nanosphere-shaped lithium vanadate particles with hollow core-shell structures, wherein nano holes are distributed in the core-shell layer. The preparation method comprises the following steps: dissolving a compound containing tetravalent vanadium in a reducing solvent, stirring until the solution is clarified, transferring the obtained clarified liquor into a sealed reaction kettle for carrying out a reduction reaction, cooling the liquor to room temperature after the reduction reaction is finished so as to obtain a nano V2O3 precipitate with a hollow structure; dissolving the obtained nano V2O3 precipitate and a lithium source compound in an organic solvent for sharply stirring, drying the products obtained in the reaction, and sintering the products to obtain the particles. The positive active material of the prepared lithium vanadium oxide has a hollow structure, is small in particle size, high in dispersing property, high in electric capacity and high in stability and has high cycle performance and high rate performance; and moreover, in the whole process, the synthesis temperature is low, the energy loss is low, the operation is easy and large-scale production can be performed.

Owner:XIANGTAN UNIV

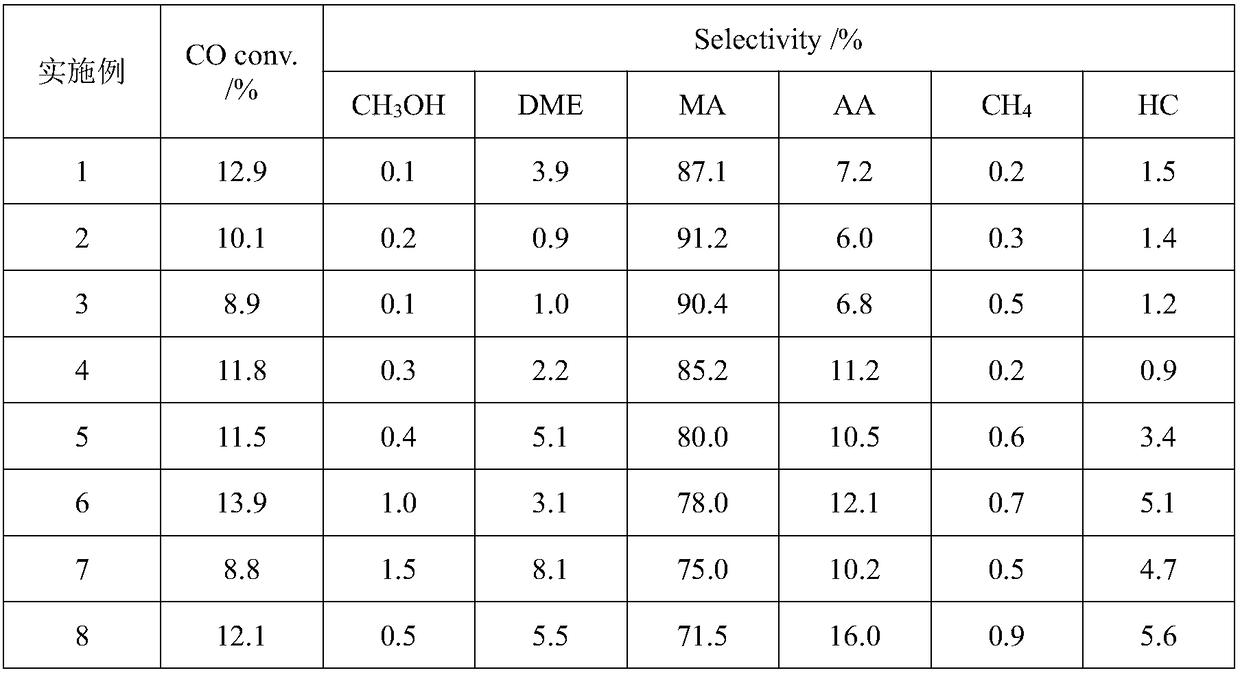

Method for producing methyl acetate from synthesis gas by one-step method

ActiveCN108774130AFew reaction stepsHigh catalytic efficiencyPreparation by carbon monoxide or formate reactionReaction stepProtein carbonyl

A method for producing methyl acetate from synthesis gas by one-step method relates to a method for synthesizing the methyl acetate. The synthesis gas or the synthesis gas containing CO2 is used as areaction raw material, and the continuous relay reaction is carried out on a multifunctional catalyst to realize the preparation of methyl acetate by one-step method with high selectivity. In the process, the synthesis gas or the synthesis gas containing CO2 is first converted into methanol, then the methanol is dehydrated to form dimethyl ether, and further the dimethyl ether is carbonylated to obtain the methyl acetate. The one-step route significantly simplifies the reaction steps, improves catalytic efficiency, and significantly reduces costs. The used catalyst is a multifunctional composite catalyst, and the synthesis gas is converted into the methyl acetate in one step with high efficiency by designing and functionally coupling components. The target product has high selectivity, themethyl acetate selectivity is up to 90% or more, and the stability is high. By introducing a dehydration catalyst, the dehydration step and the dimethyl ether carbonylation step are separated to eliminate the interference of water to a reaction system. The preparation process is simple and controllable.

Owner:XIAMEN UNIV

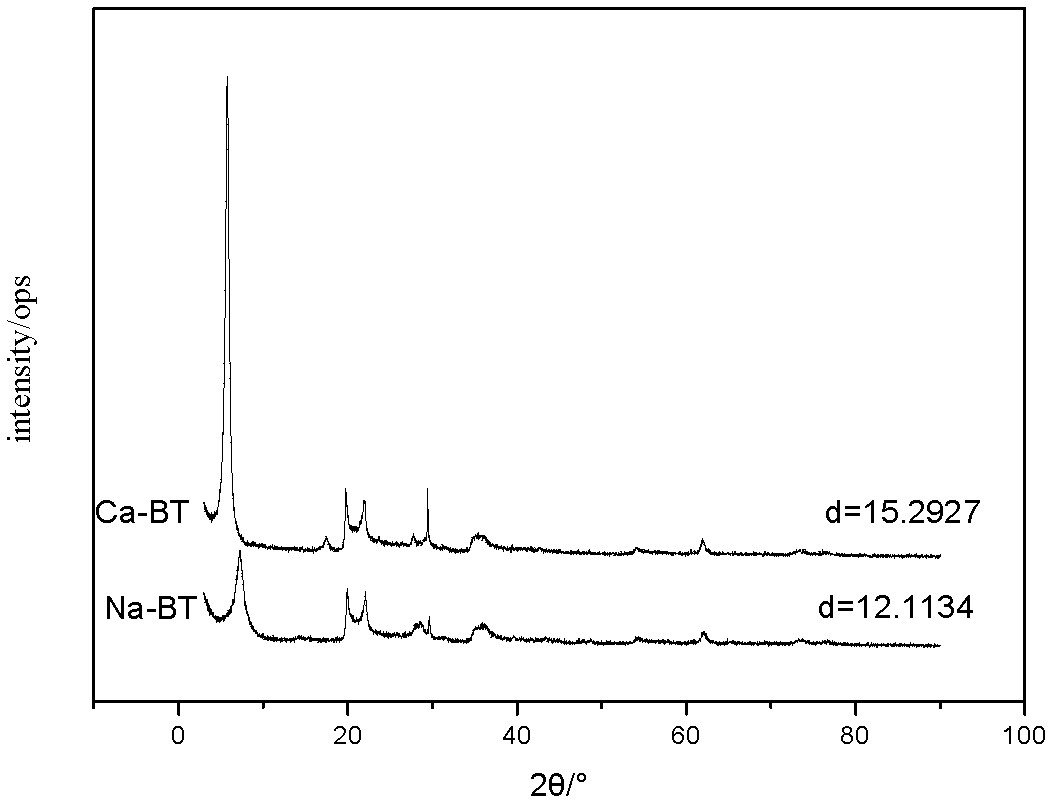

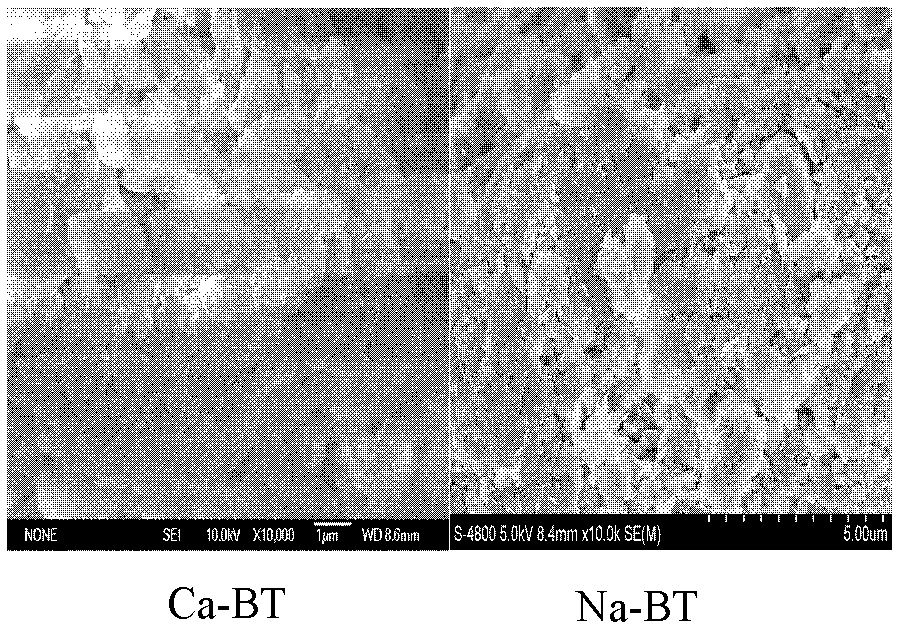

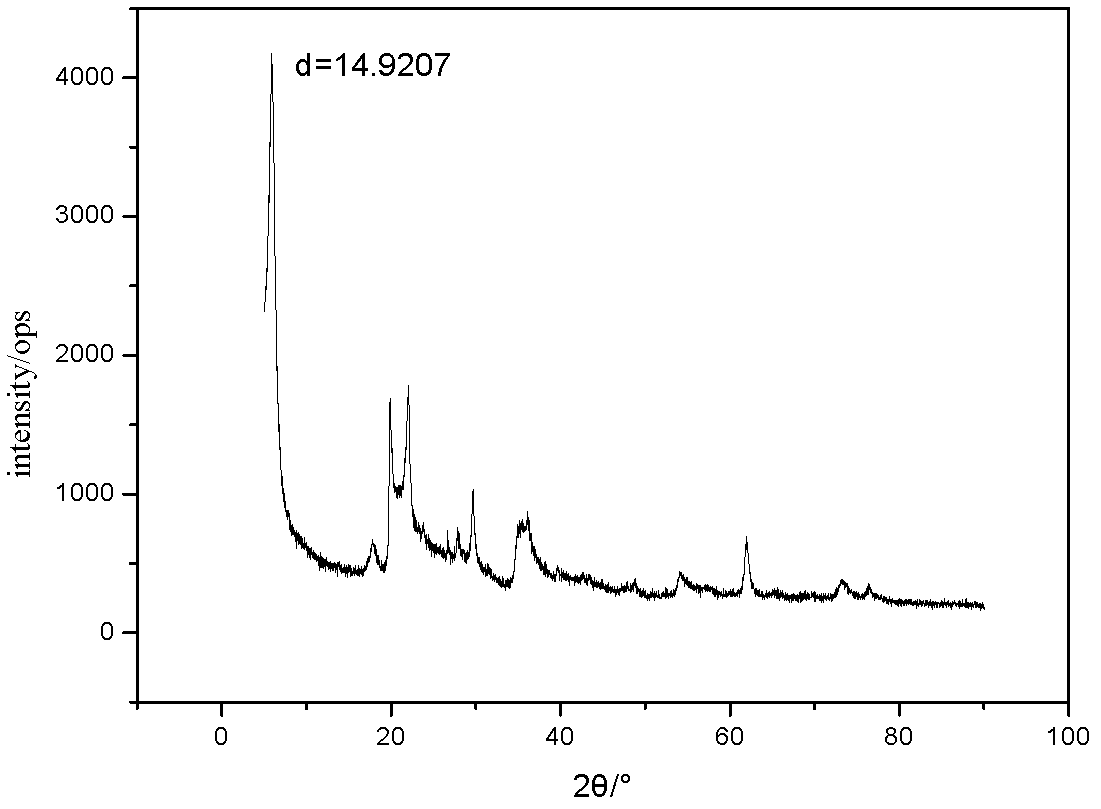

Novel sodium bentonite-AM-AA composite lead ion absorbing agent

InactiveCN102580697AIncrease contentUniform and stable structureOther chemical processesWater/sewage treatment by sorptionSodium BentoniteSorbent

The invention relates to a novel sodium bentonite-AM-AA composite lead ion absorbing agent which belongs to the technical field of water treatment. The novel sodium bentonite-AM-AA composite lead ion absorbing agent comprises sodium bentonite obtained subjecting sodium treatment to calcium bentonite and a material A polymerized on the sodium bentonite, wherein the material A accounts for 11-17 percent by mass of the total mass, the sodium bentonite accounts for 83-89 percent by mass of the total mass, the material A is generated by monomer acrylamide and crylic acid and a crosslinking agent for solution polymerization under the action of an initiator. The invention overcomes the problems of large swelling property, difficulty in solid-liquid separation and the like of the bentonite, and realizes final synthesis continuous operation of the sodium treatment of the calcium bentonite to the novel sodium bentonite-AM-AA composite lead ion absorbing agent; and the novel sodium bentonite-AM-AA composite lead ion absorbing agent has less synthesis steps in the whole preparation process, is safe in operation, has lower cost and lead absorbing performance of reaching 157.5mg / g.

Owner:HEBEI UNIV OF TECH

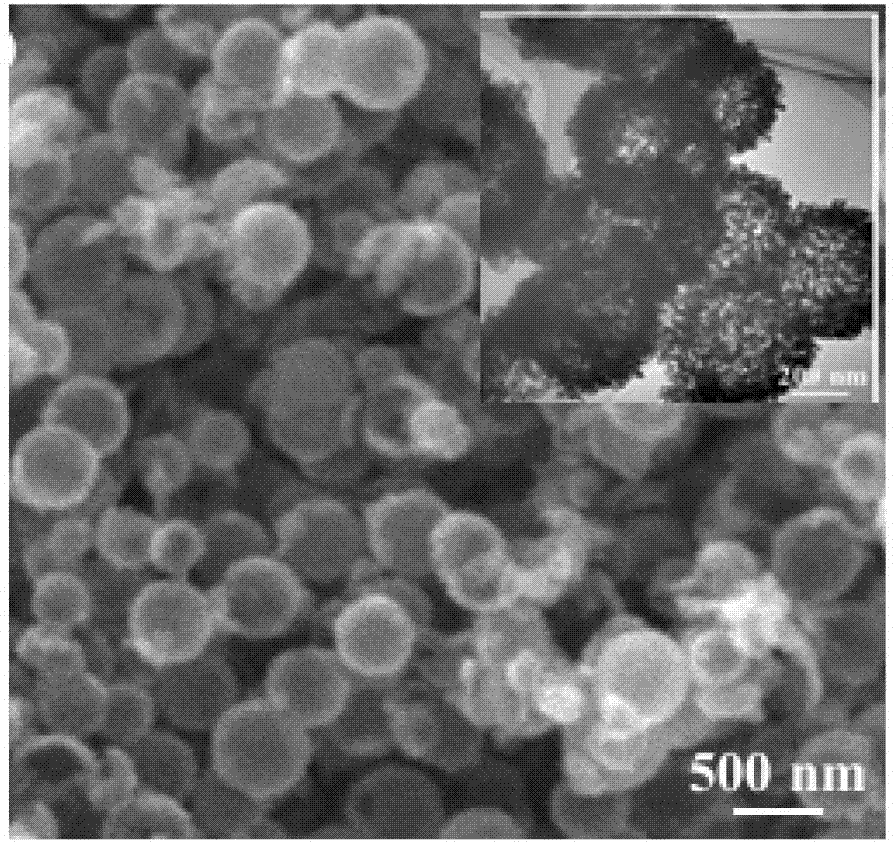

Method for preparing large-particle spherical narrow-distribution tricobalt tetroxide used for high-voltage lithium cobaltate

ActiveCN110217831ANarrow particle size distributionGood sphericityCobalt oxides/hydroxidesCobalt carbonatesSynthesis methodsSpherical shaped

The invention relates to the technical field of lithium ion batteries, in particular to a method for preparing large-particle spherical narrow-distribution tricobalt tetroxide used for high-voltage lithium cobaltate. The method includes a stage of continuously producing large-particle spherical narrow-distribution cobalt carbonate, and a stage of calcining the large-particle spherical narrow-distribution cobalt carbonate. A large-particle cobalt carbonate precursor prepared by continuous centrifugation to improve the solid content and the continuous synthesis method in is the cobalt carbonatewet-process synthesis stage is dense, narrow in particle size distribution and good in sphericity.

Owner:JINCHUAN GROUP LIMITED +1

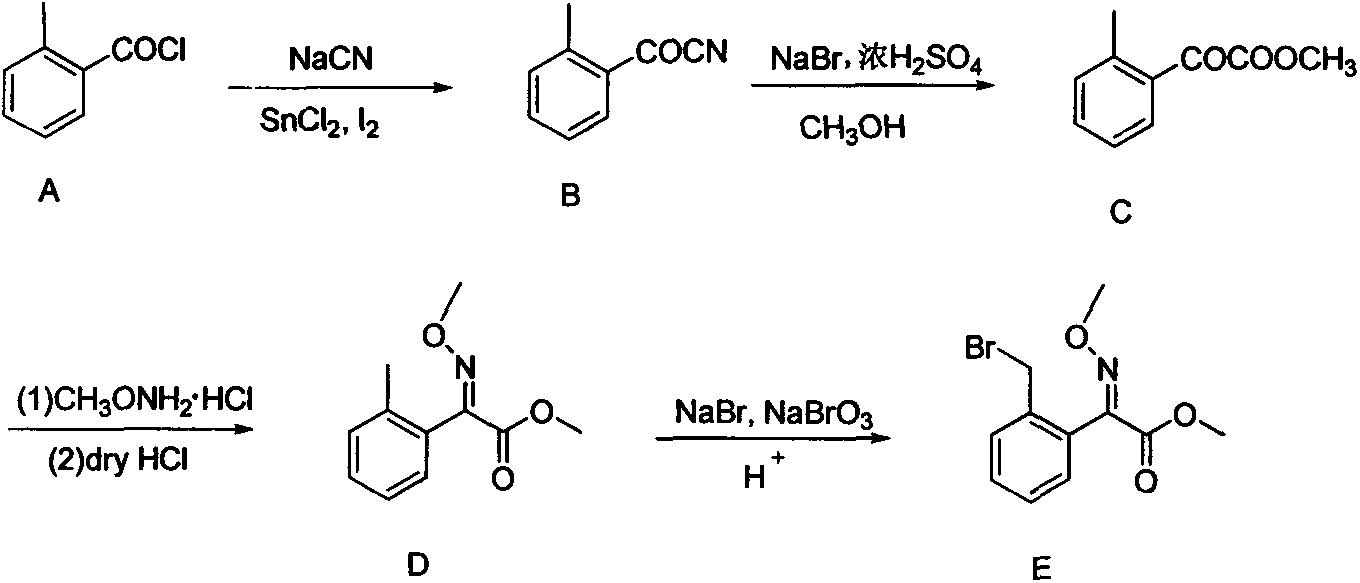

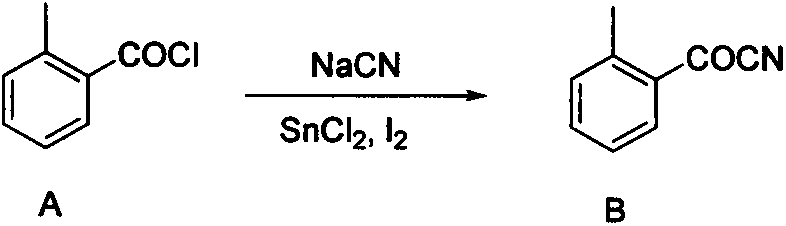

Preparation method of improved 2-(2'-bromomethylphenyl)-2-carbonyl methyl acetate

InactiveCN103450021AThe reaction method is simpleHigh yieldOrganic compound preparationCarboxylic acid esters preparationCyanideBenzoyl chloride

The invention relates to a process synthesis method of an improved trifloxystrobin intermediate 2-(2'-bromomethylphenyl)-2-carbonyl methyl acetate. The innovation of the process is reflected in the following two reaction steps: (1) 2-methyl benzoyl chloride reacts with cyanide to generate 2-methyl benzoyl cyanide, and (2) 2-(2'-methylphenyl)-2-carbonyl methyl acetate is brominated to generate 2-(2'- bromomethylphenyl)-2-carbonyl methyl acetate. The method provided by the invention is used for solving the following problems that the hydrolysis of the 2-methyl benzoyl chloride causes low synthesis yield of the 2-methyl benzoyl cyanide, light is needed in the bromination process to waste energy source, a solvent with large toxicity is used, the numerous generated dibromides are difficult to separate and purify, the yield is low and the like in the previous synthesis. According to the method provided by the invention, the operation is simpler and the reaction conditions are milder. Especially, the yield is greatly increased and the production cost is reduced, so that the method is suitable for industrial production.

Owner:NANKAI UNIV

Synthesis method of fine-grained alpha-AlH3

ActiveCN106335877ASmall particle sizeNarrow distributionMetal hydridesSynthesis methodsUltrasonic oscillation

A synthesis method of fine-grained alpha-AlH3 is characterized in that ultrasonic catalytic crystallization is introduced in the crystallization stage on the basis of an ether process synthesis technology, and the energy, the strength, the frequency and other parameters of ultrasonic oscillation are controlled on the basis of guaranteeing the crystal phase purity of alpha-AlH3 to control the crystallization granularity of the alpha-AlH3 to be 10-80 [mu]m and realize controllable granularity. Ultrasonic assisted alpha-AlH3 crystallization is carried out to synthesize the fine-grained alpha-AlH3 with the purity being greater than 99%, and the frequency, the amplitude and the working mode of ultrasonic waves are adjusted to adjust the granularity in a range of 10-80 [mu]m. The method has the advantages of simple required device, easiness in realization of amplification, and realization of repeated and stable generation of granularity-controllable fine-grained high quality alpha-AlH3, and allows the total yield to be greater than 70%, the purity to be greater than 99% and the chlorine content to be lower than 0.2%.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

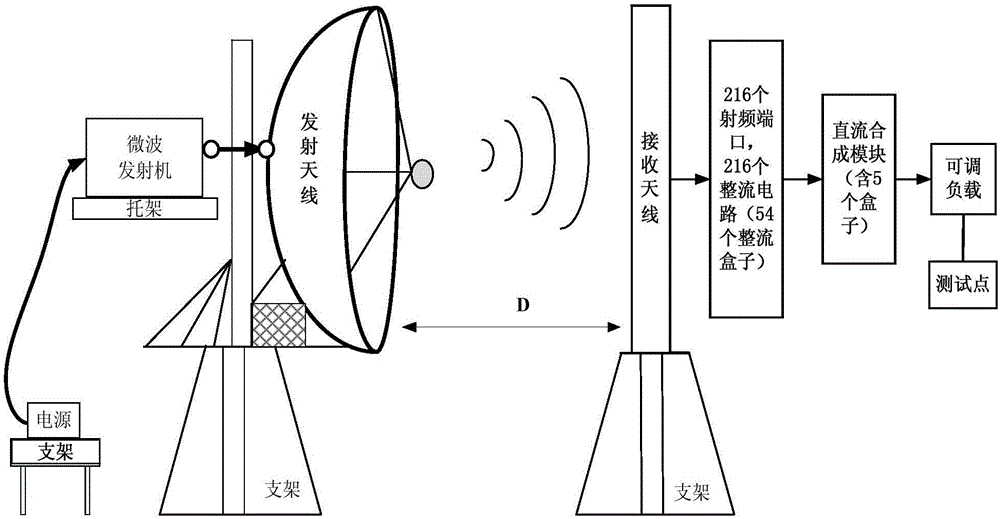

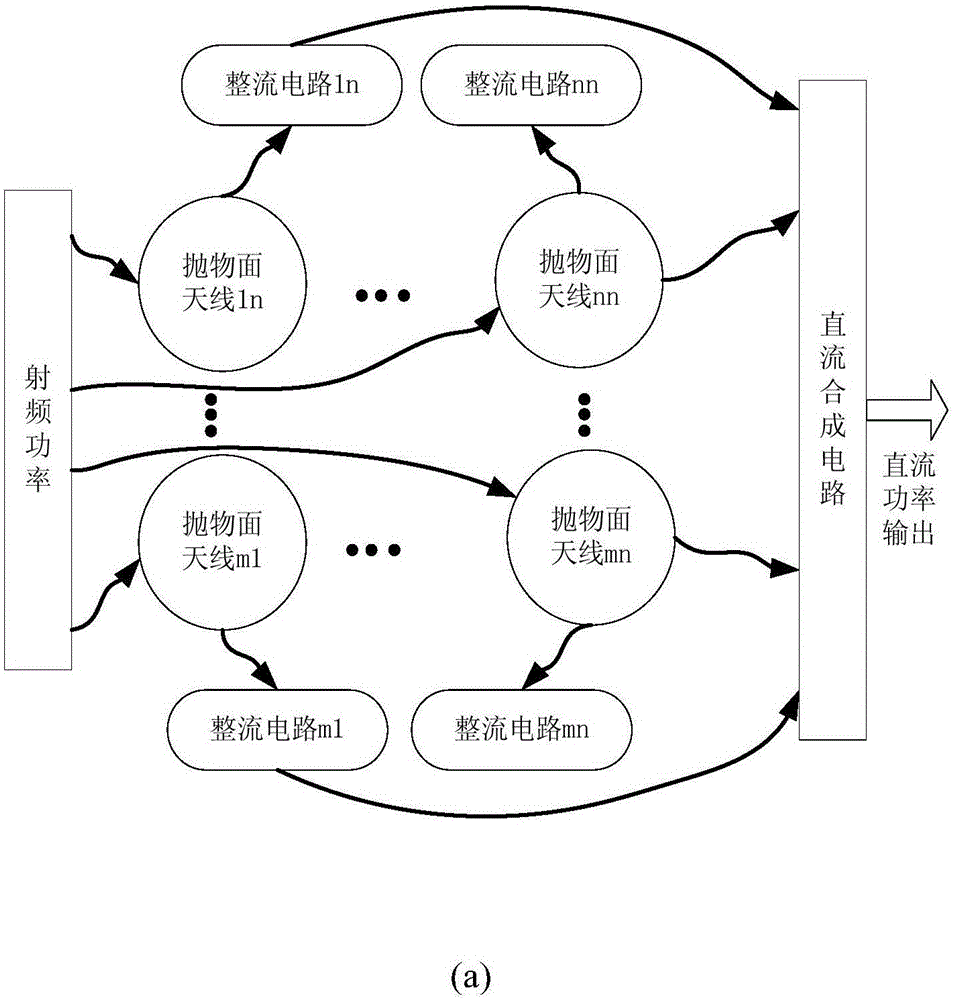

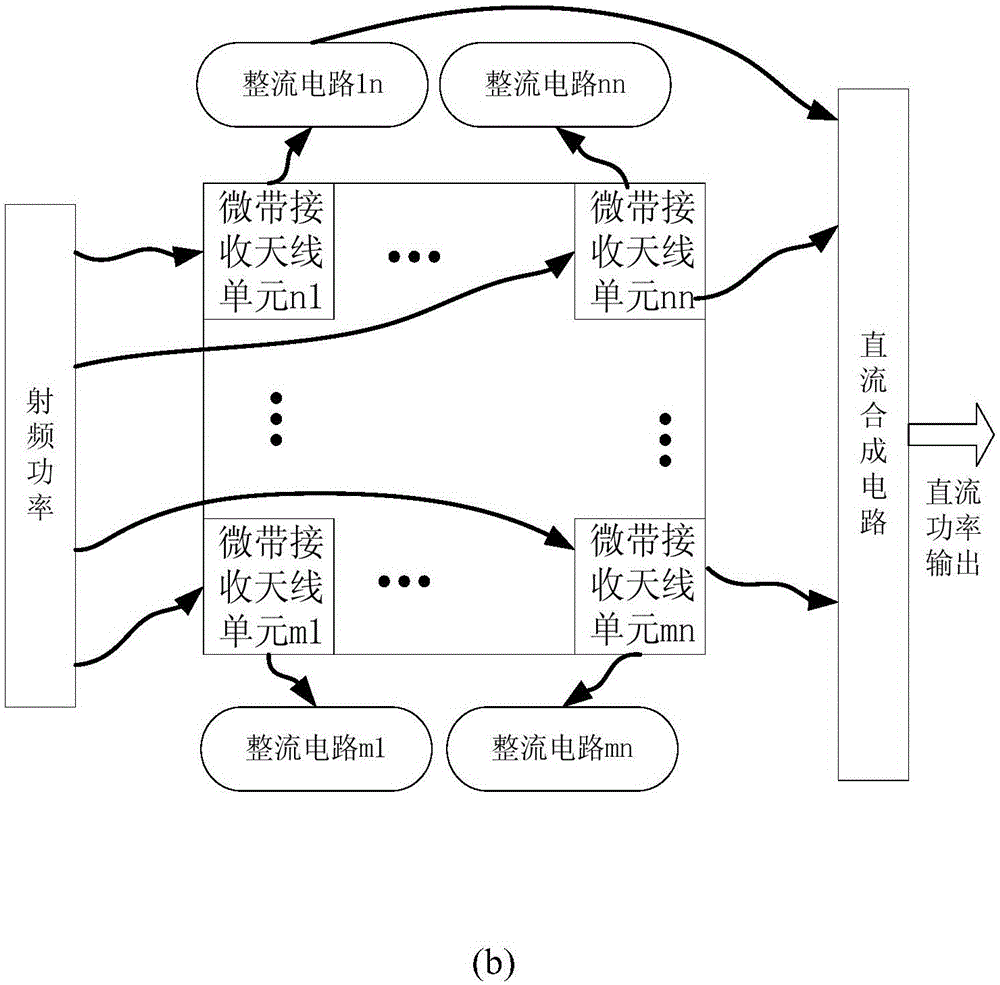

System and method for improving energy transmission efficiency based on energy distribution characteristic

ActiveCN105119387AUniform amplitude distributionImprove interception efficiencyElectromagnetic wave systemMicrowaveRadio frequency energy

The invention discloses a system and a method for improving energy transmission efficiency based on energy distribution characteristics. Due to the non-uniformity of the energy distribution on the reception antenna end and the optimal matching state between the optimal efficiency and the input power of a rectification circuit , and on the basis of the energy distribution characteristics, various quantities of reception microstrip antenna units are adopted in various energy distribution areas to receive radio frequency signals and let the radio frequency signals to go into the rectification circuit directly or to go into the rectification circuit after power synthesis; the rectification circuit converts the radio frequency energy to DC energy after performing rectification processing on the radio frequency signal and lets the DC energy to go into a DC synthesis module; and the DC synthesis module obtains final output power after processing synthesis on the DC energy. The invention reduces connection loss between various members, realizes maximization reception of the radio frequency energy, finishes the maximization design of the rectification efficiency, and effectively improves the microwave wireless energy transmission efficiency of the system link.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

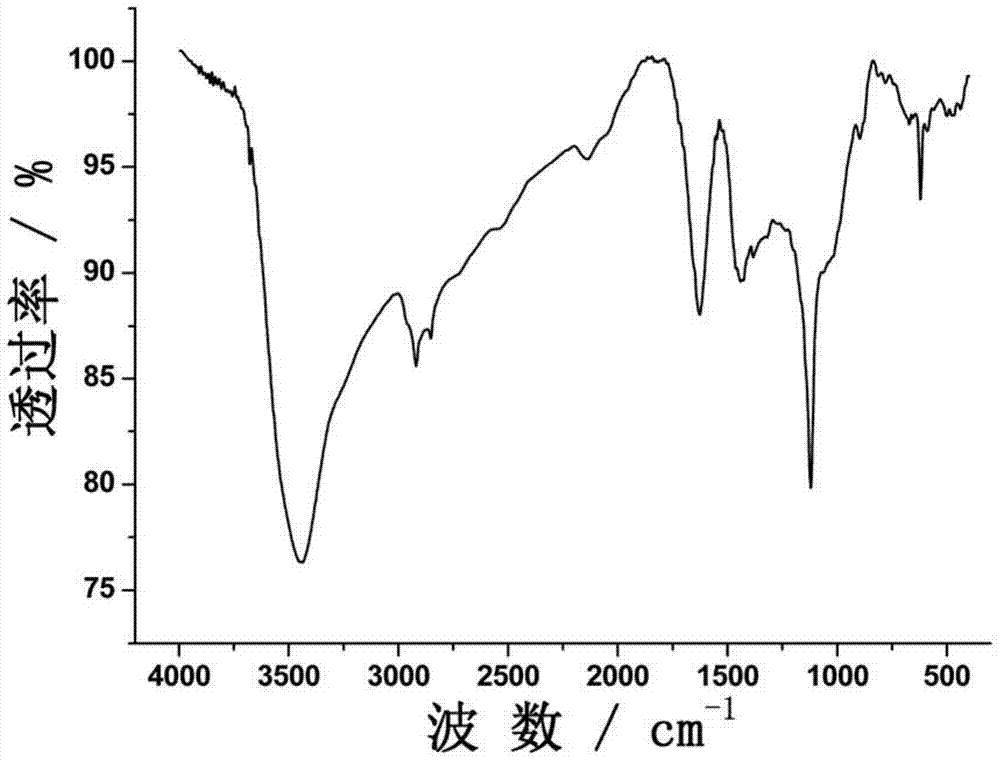

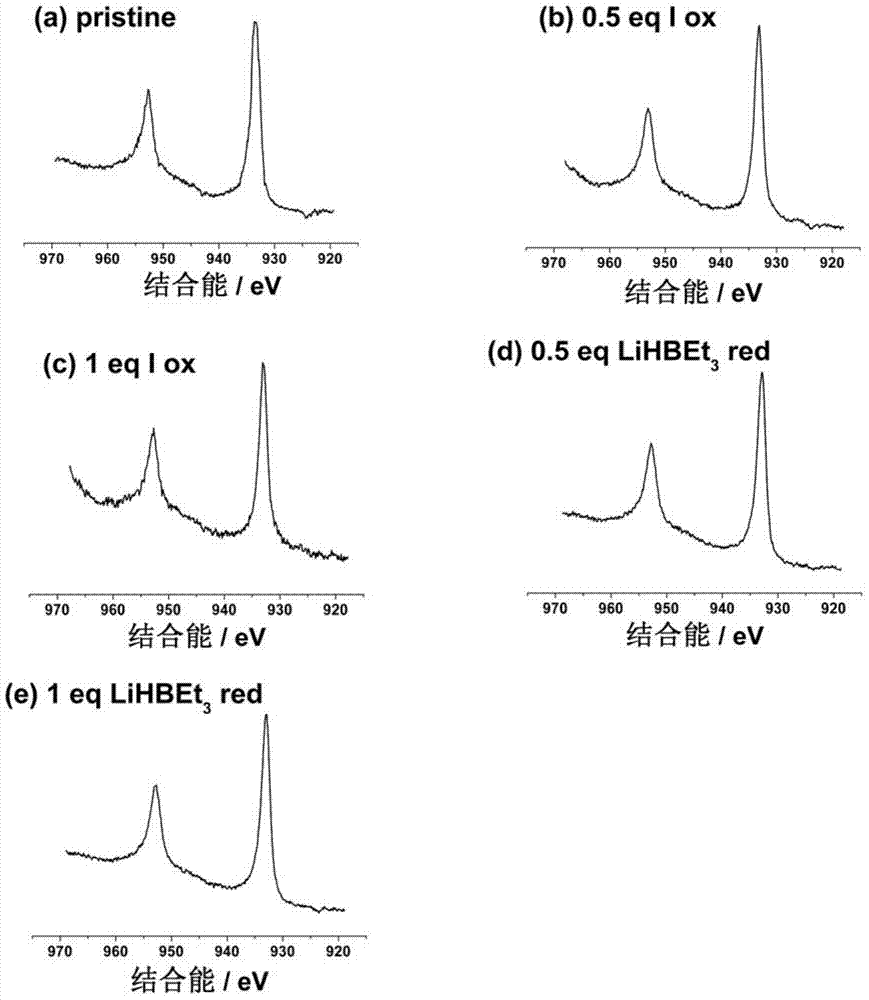

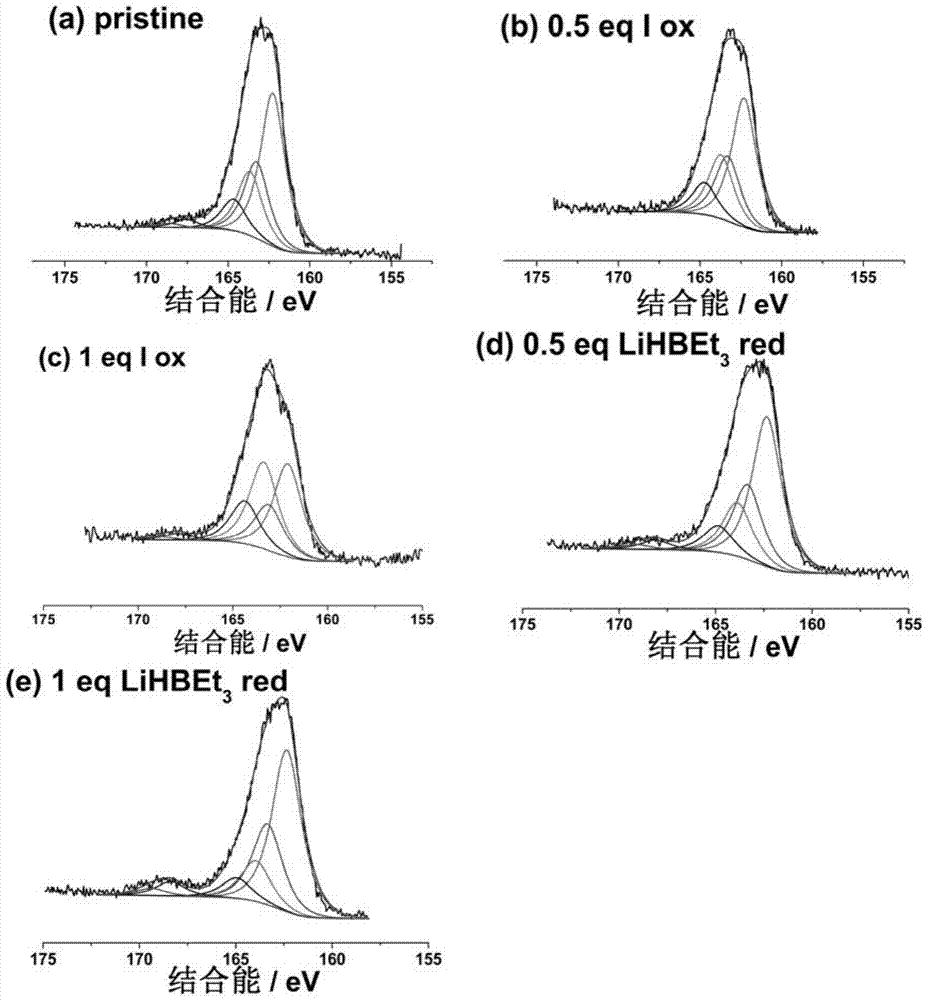

Organic thermoelectric material based on cuprous vinyl tetramercaptan and preparation method thereof

ActiveCN103755606AExcellent thermoelectric performanceShort processThiol preparationThermoelectric device junction materialsDiketoneOrganic solvent

The invention discloses an organic thermoelectric material based on cuprous vinyl tetramercaptan and a preparation method thereof. The organic thermoelectric material provided by the invention is cuprous vinyl tetramercaptan as shown in formula I. The preparation method of the cuprous vinyl tetramercaptan as shown in the formula I comprises the following steps: (1) under an inert atmosphere, letting sodium methylate have reaction with 1,3,4,6-tetrasulfide pencyclopentene-2,5-diketone under reflux in an organic solvent; (2) after the reaction is ended, adding cuprous iodide into the system after reaction, and performing reaction under reflux to obtain the organic thermoelectric material based on cuprous vinyl tetramercaptan. Cuprous vinyl tetramercaptan provided by the invention has an excellent thermoelectric performance after being treated by LiHBEt3 or I2, for instance at 400K, the electric conductivity is 314S cm<-1>, the Seebeck coefficient is 61.3 muV K<-1>, the thermal conductivity is 0.79 Wm<-1>K<-1>, and the thermoelectric figure of merit is as high as 0.060. Meanwhile, the preparation method of cuprous vinyl tetramercaptan disclosed by the invention is particularly a wet-process synthesis method, which is short in process and low in cost.

Owner:INST OF CHEM CHINESE ACAD OF SCI

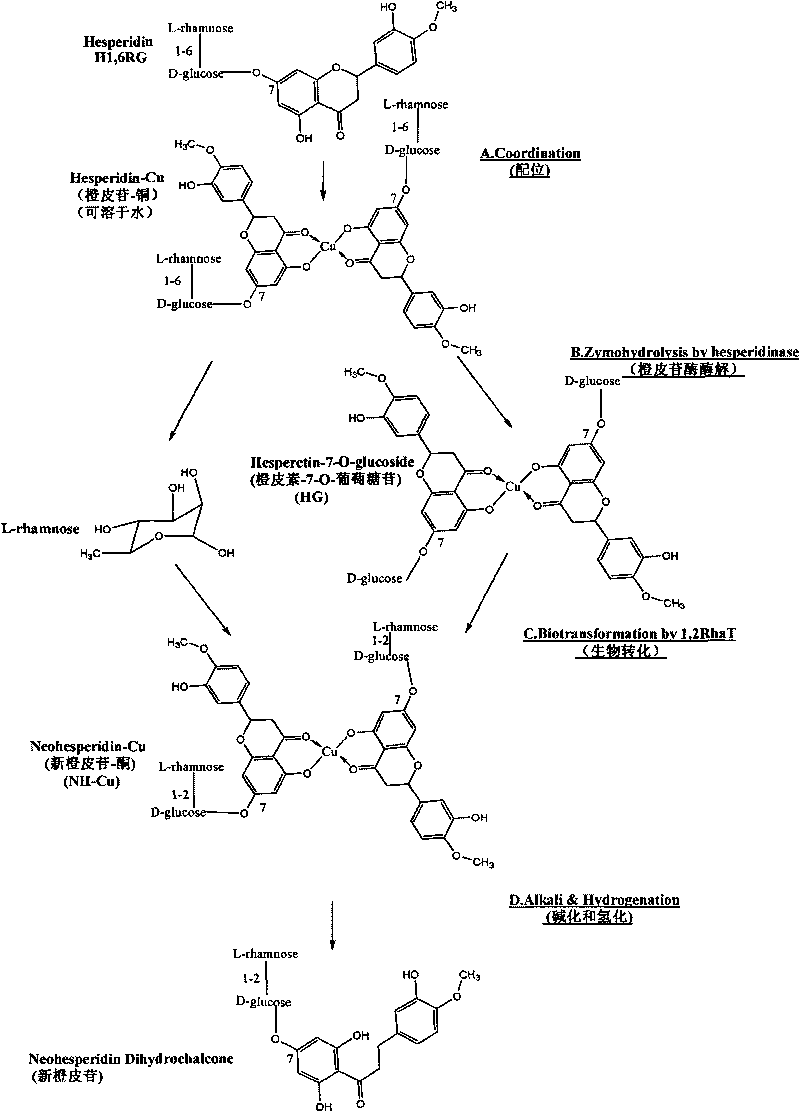

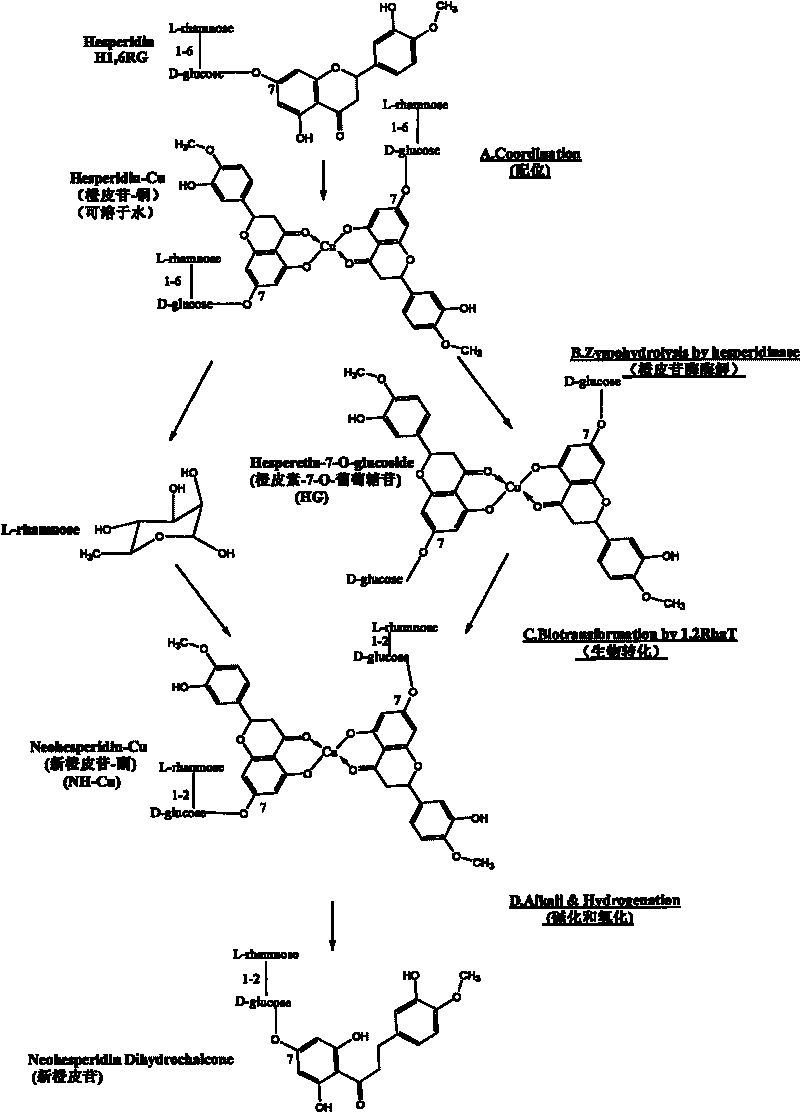

Method for synthesizing new hesperidin through high-flux enzyme process

The invention discloses a method for synthesizing new hesperidin through a high-flux enzyme process, which comprises the steps of performing metal coordination on hesperidin, biologically transforming a hesperidin metal complex into the new hesperidin by using hesperidinase and rhamnosyltransferase 1,2-RhaT, and de-coordinating a new hesperidin metal complex. The method is suitable for the industrial production of a low heat value sweetening agent NHDC, overcomes the technical bottleneck that the hesperidin water-solubility is poor during the biotransformation of the new hesperidin, achieves the high-flux enzyme process synthesis of the new hesperidin by using an NHDC synthesis precursor, solves the problem that an NH source is limited, and simultaneously opens up a new way for the resource utilization of industrial waste orange peels and the high added value of the hesperidin.

Owner:SHANDONG BENYUE BIOTECH

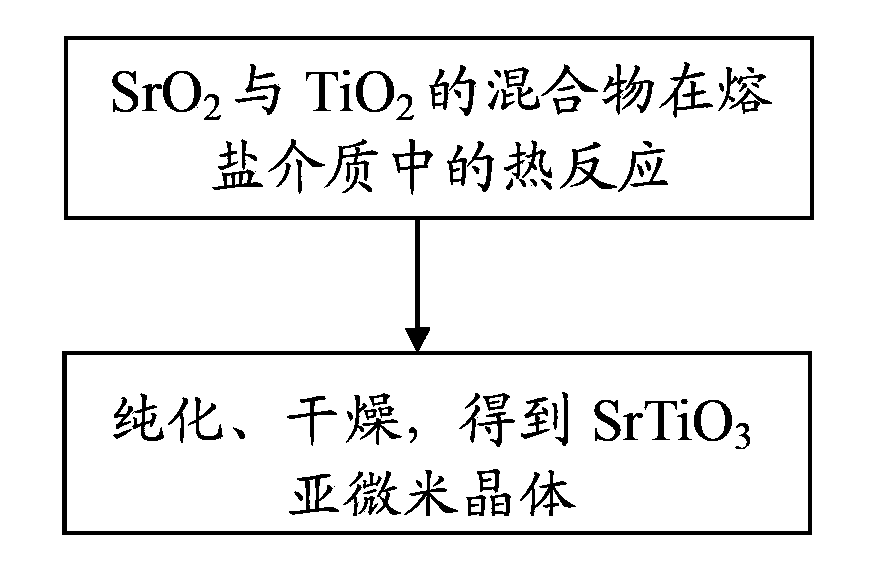

Strontium titanate submicron crystal and preparation method thereof

InactiveCN103449511AImprove solubilityReduce dependenceTitanium compoundsStrontium titanateMolten salt

The invention is suitable for the material chemical field, and provides a strontium titanate submicron crystal and a preparation method thereof. The strontium titanate submicron crystal is characterized in that the shape of the strontium titanate submicron crystal is a cubic-phase crystal, and the dimension is within 100nm-350nm, and reaches submicron level. The preparation method of the strontium titanate submicron crystal mainly comprises the following steps: (1), carrying out thermal reaction on a mixture of SrO2 and TiO2 for 9-10.5 hours in a molten salt medium at 650 DEGC-750 DEG C; (2), purifying and drying the thermal reaction product to obtain the SrTiO3 submicron crystal. Compared with the prior art, the preparation method is low in reaction system temperature, complete in reaction, simple in process operation and short in period; and the strontium titanate submicron crystal obtained by process synthesis is high in purity, fine and uniform in grain size which reaches the submicron level.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

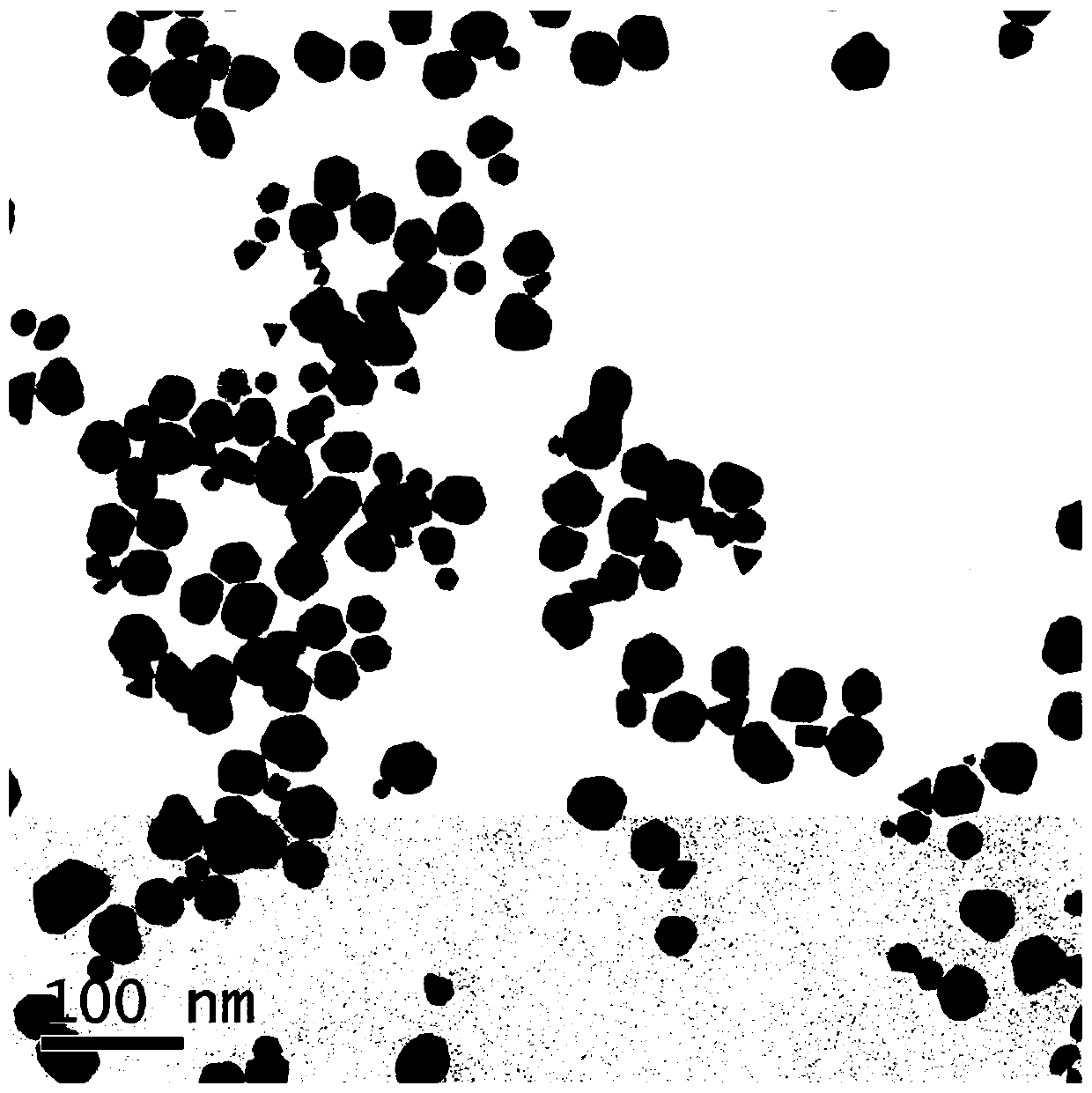

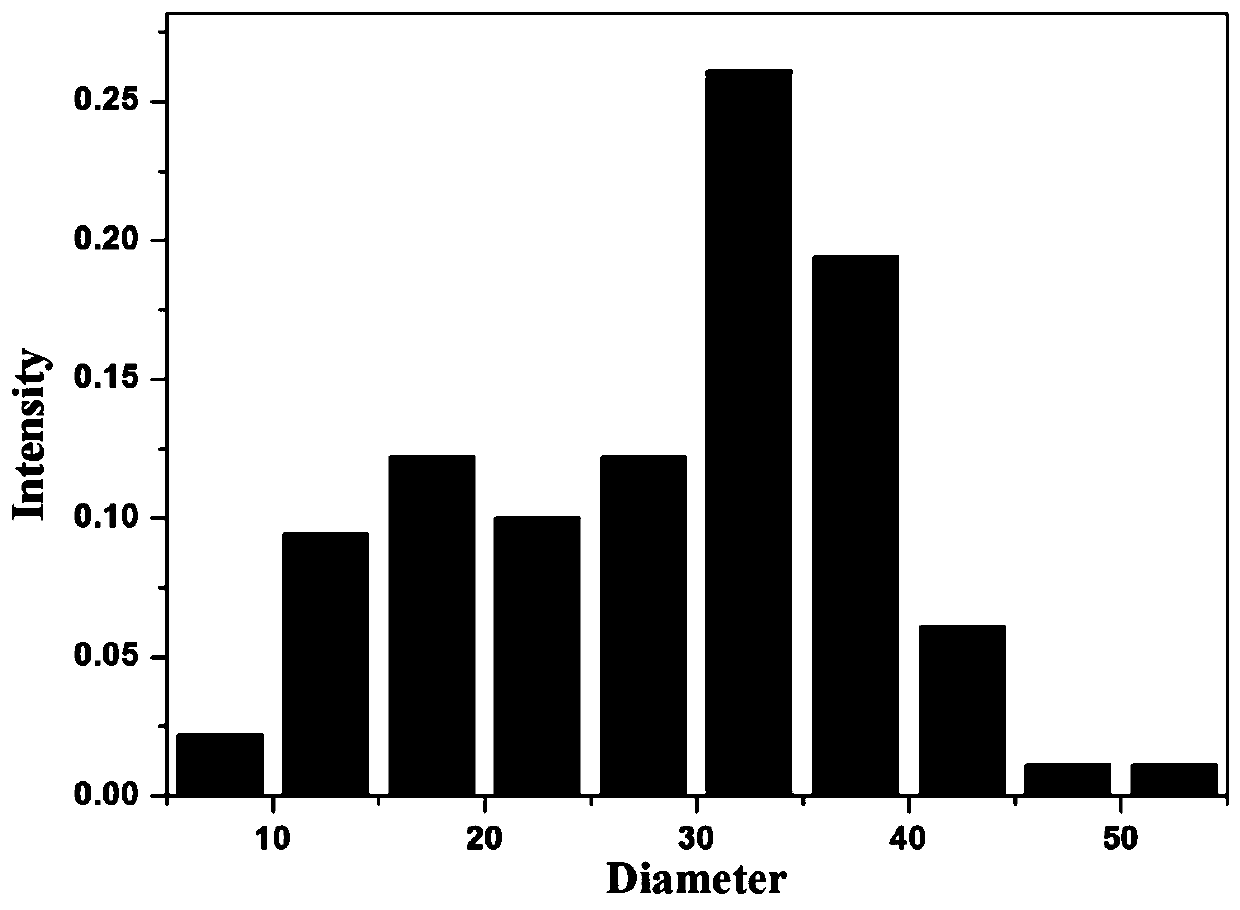

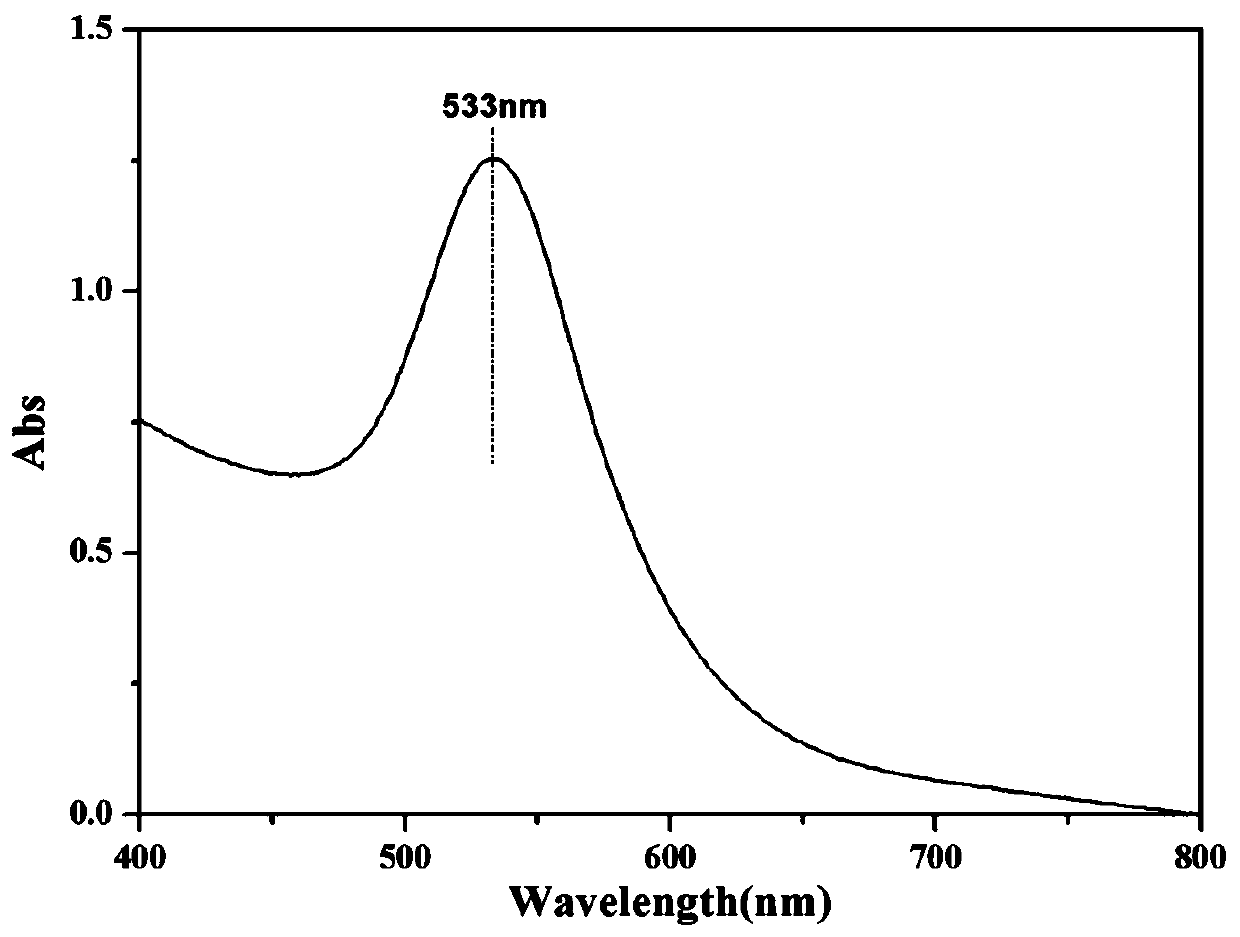

Preparation method and application of graphene quantum dot stable gold nanoparticles

InactiveCN109701527AWater/sewage treatment by irradiationWater contaminantsNano catalystParticle-size distribution

The invention provides a preparation method of a novel gold nanoparticle catalyst. The synthetic method only uses graphene quantum dots and chloroauric acid as raw materials without adding any other reducing agent and stabilizing agent, a mixing reaction is performed in deionized water, and therefore the graphene quantum dot-supported gold nanoparticles can be obtained. According to the preparation method provided by the invention, the gold nanoparticles prepared by the method have good water dispersibility and stability, uniform particle size distribution and good catalytic activity, and canrapidly degrade p-nitrophenol in industrial wastewater; the process synthesis method adopted in the invention is simple, green, and high-efficiency; and discovery and research of the preparation method of the catalyst facilitate further broadening a research field of metal nanoparticle materials, and provide some novel ideas for design and synthesis of a novel metal nano catalyst.

Owner:CHINA THREE GORGES UNIV

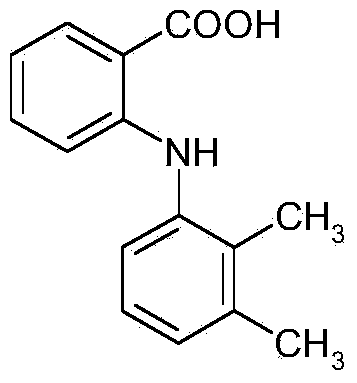

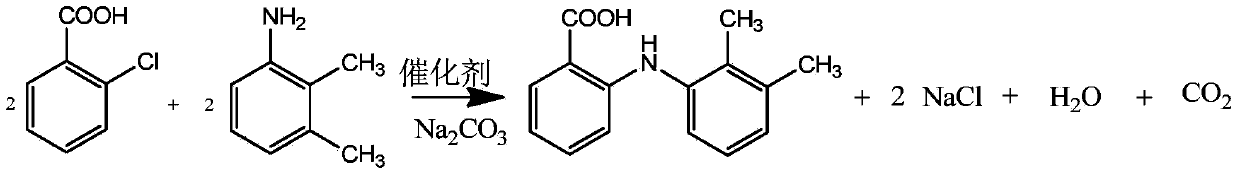

Mefenamic acid short-process synthesis preparation and refining method

InactiveCN103420863AHigh yieldHigh purityOrganic compound preparationAmino-carboxyl compound preparationDimethylaniline N-oxideOrganic solvent

A mefenamic acid synthesis preparation and refining method comprises the following steps: 1, adding o-chlorobenzoic acid and acid-binding agent at appropriate ratio in DMF for stirring; 2, adding a certain amount of 2,3-dimethyl aniline, and performing condensation reaction with a catalyst of suitable ratio at a certain temperature to obtain a mefenamic acid crude product; 3-6, allowing the mefenamic acid crude product to be subjected to refining including bleaching and crystallization in an organic solvent to obtain the mefenamic acid finished product, wherein the acid-binding agent adopts o-chlorobenzoic acid and sodium carbonate, the molar ratio of the o-chlorobenzoic acid to 2,3-dimethyl aniline to sodium carbonate to DMF to catalyst is 1:(2-3):(0.5-1):(5-6):0.05:0.15, and the temperature is 120-130 DEG C. Compared with the traditional process, the method has the advantages of high target product productivity, simple process procedures, mild reaction conditions, simple purifying process, high product purity and suitability for industrialized production; and the primary solvent N-dimethyl formamide can be recycled, so that the production cost is further reduced.

Owner:JIANGSU BEIHEDE CHEM

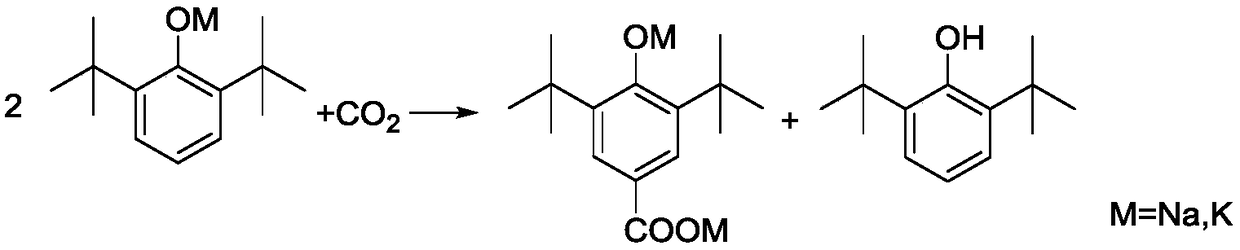

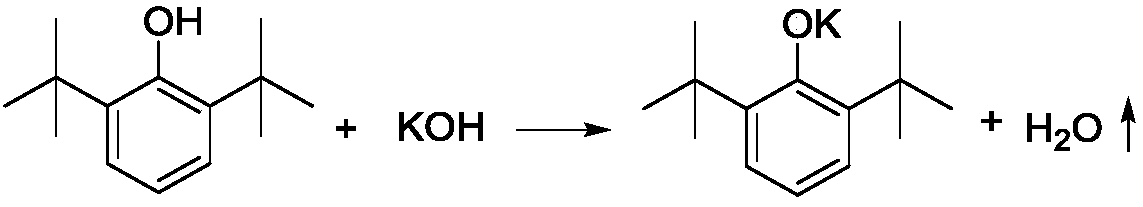

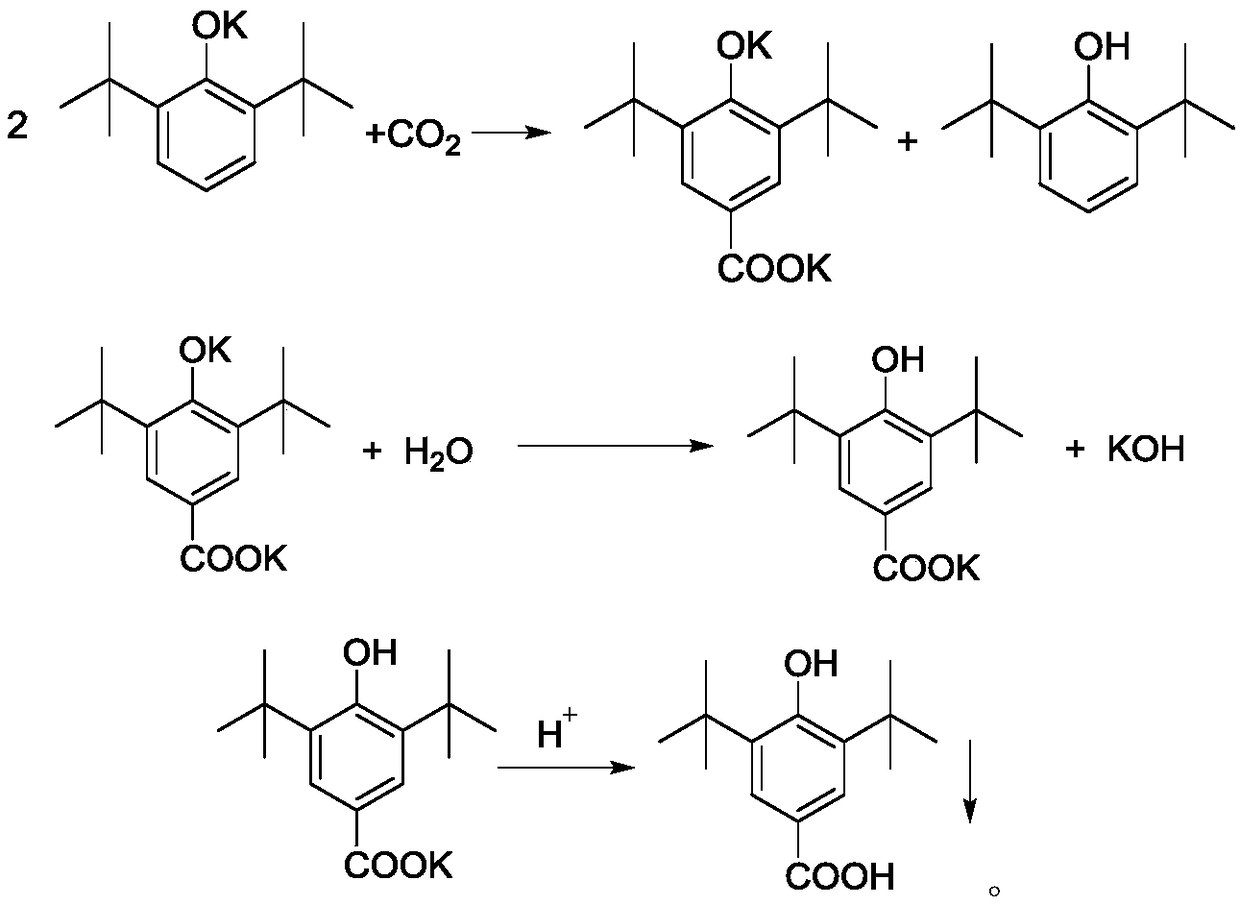

Production method of 3,5-di-tert-butyl-4-hydroxybenzoic acid

ActiveCN109096099APrevent spontaneous combustionAvoid problemsPreparation from carboxylic acid saltsOrganic compound preparationKolbe–Schmitt reactionSchmidt reaction

The invention discloses a production method of 3,5-di-tert-butyl-4-hydroxybenzoic acid. The production method sequentially comprises the steps as follows: 2,6-di-tert-butylphenol, a potassium hydroxide aqueous solution and toluene are added to a reactor under protection of nitrogen to be subjected to a reflux reaction under a water distribution condition; CO2 is introduced into the reactor until the pressure is 0.1-3.0 MPa, a Kolbe-Schmitt reaction is conducted under a pressure holding condition, after the reaction, corresponding aftertreatment is carried out, and a crude product of 3,5-di-tert-butyl-4-hydroxybenzoic acid is obtained. The method has short reaction time and high conversion rate, has obvious advantages as compared with traditional gas-solid processes and existing solvent-process synthesis processes and is suitable for further industrialization.

Owner:安徽新秀化学股份有限公司 +1

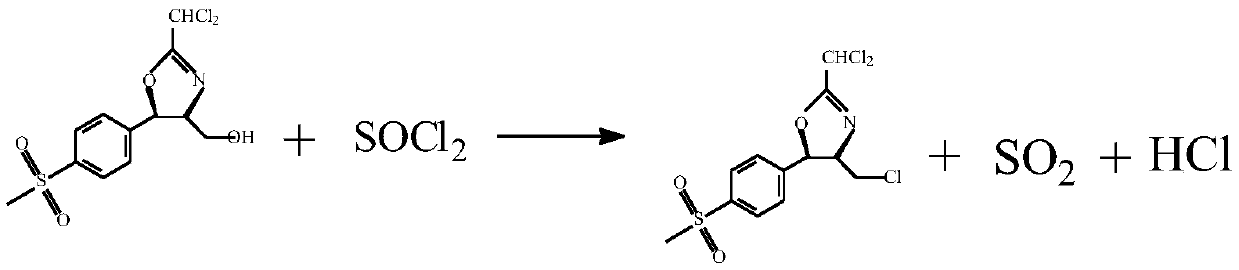

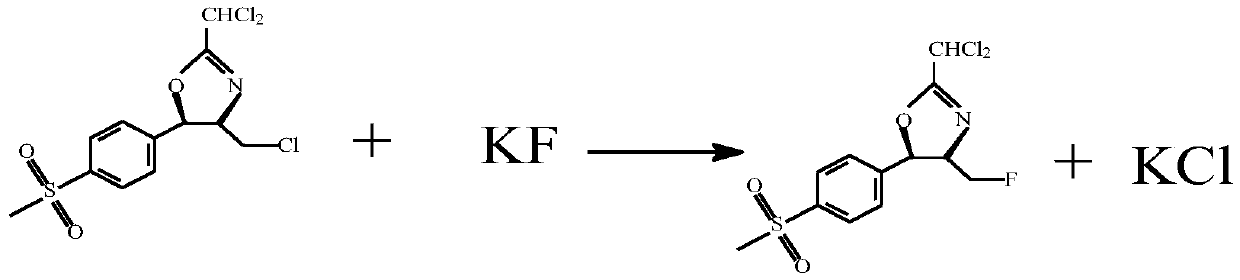

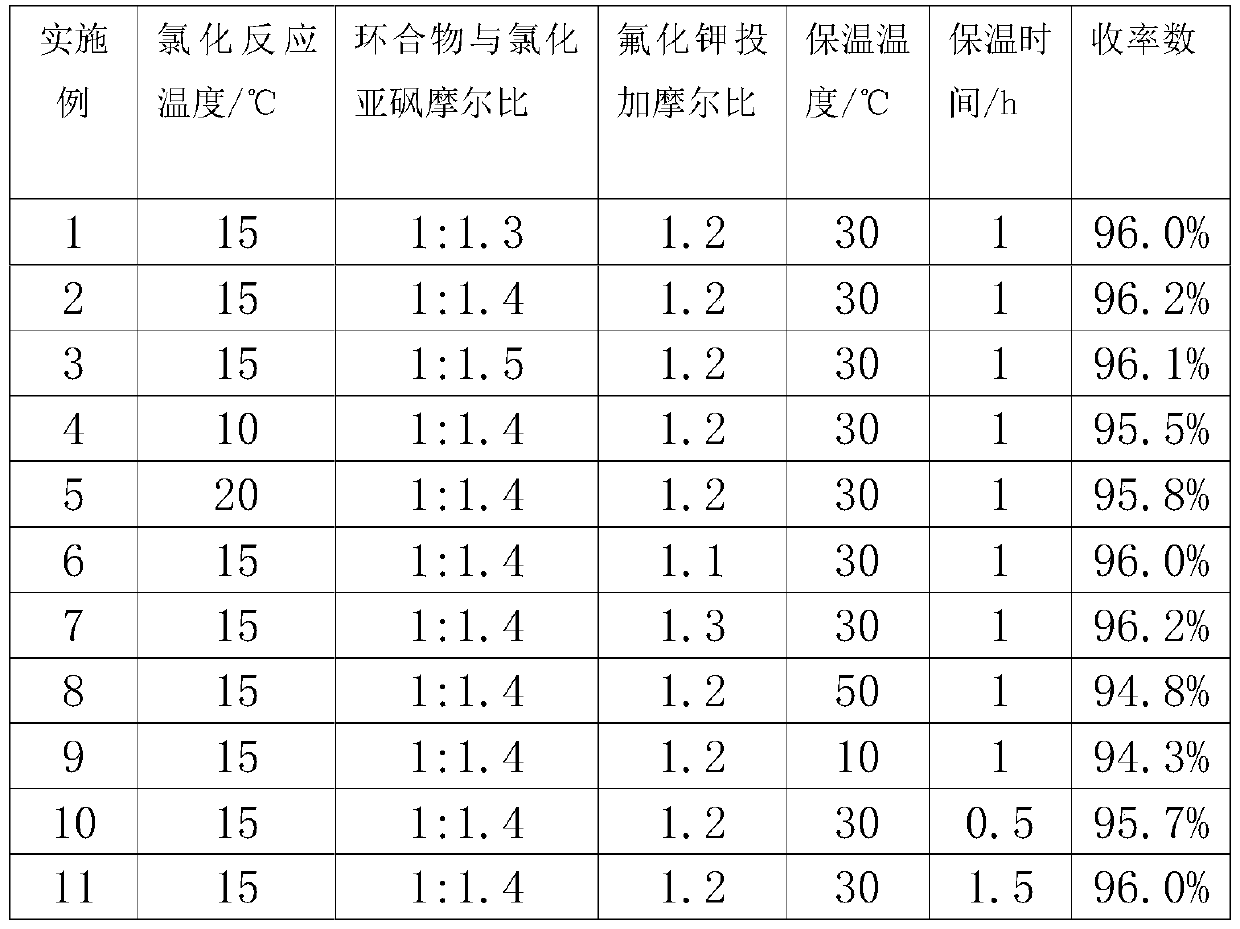

Preparation method of florfenicol intermediate

ActiveCN110330463ARealize comprehensive utilizationEasy to handleOrganic chemistryPotassium fluorideCyclic compound

The invention discloses a preparation method of a florfenicol intermediate. A cyclic compound oxazoline used as a starting material is chlorinated by thionyl chloride, and then is fluorinated by potassium fluoride to successfully introduce a fluorine atom, so a novel process synthesis method for preparing the florfenicol intermediate fluorinated oxazoline is developed. The preparation method has the advantages of simple process, low raw material investment, high product yield and strong market competitiveness.

Owner:SHANDONG GUOBANG PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com