Continuous synthesizing method of vinyl isobutyl ether

A technology of vinyl isobutyl ether and synthesis method, which is applied in the direction of organic chemistry, can solve the problems of poor safety and reliability, and achieve the effects of stable reaction, clean production environment and low unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

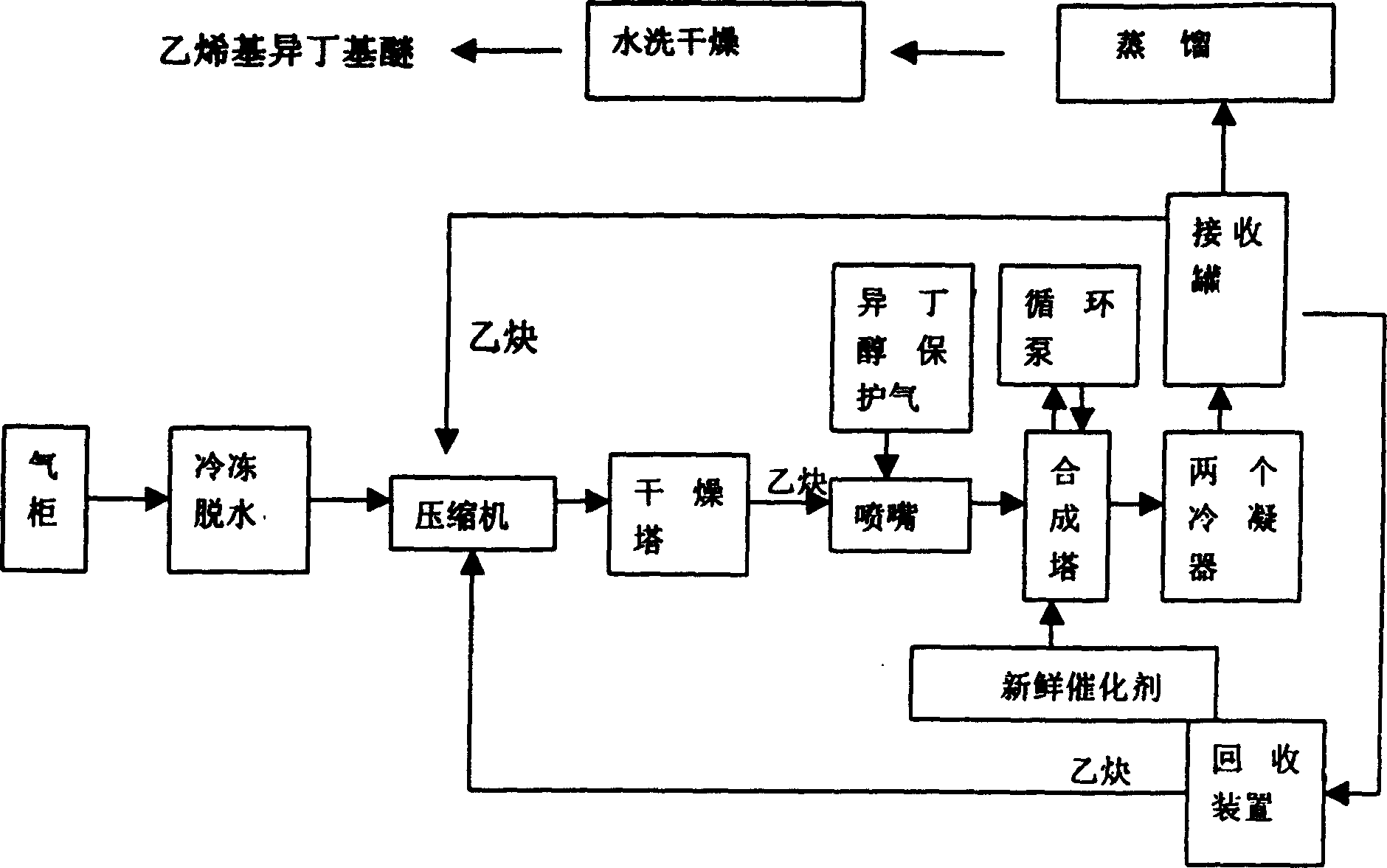

[0009] Continuous Synthesis of Vinyl Isobutyl Ether:

[0010] The synthesis tower is filled with 50-80% of the liquid level catalyst containing isobutanol solution containing KOH, and the KOH content in the solution is 12-20%.

[0011] The acetylene gas from the acetylene gas tank enters the primary inlet of the acetylene compressor after being refrigerated and dehydrated. After being compressed, the gas enters the drying tower to remove impurities. Then, the protective gas of acetylene and isobutanol enters after being mixed evenly through the nozzle from the bottom of the synthesis tower. Synthesis tower, the synthesis reaction is carried out in the synthesis tower, the catalyst solution is continuously pumped to the upper part of the synthesis tower through the circulating pump at the bottom of the tower, and circulated, and the small acetylene bubbles formed are fully contacted with isobutanol in the synthesis tower to carry out synthesis etherification reaction. The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com