Patents

Literature

398results about How to "Increase conversion rate per pass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

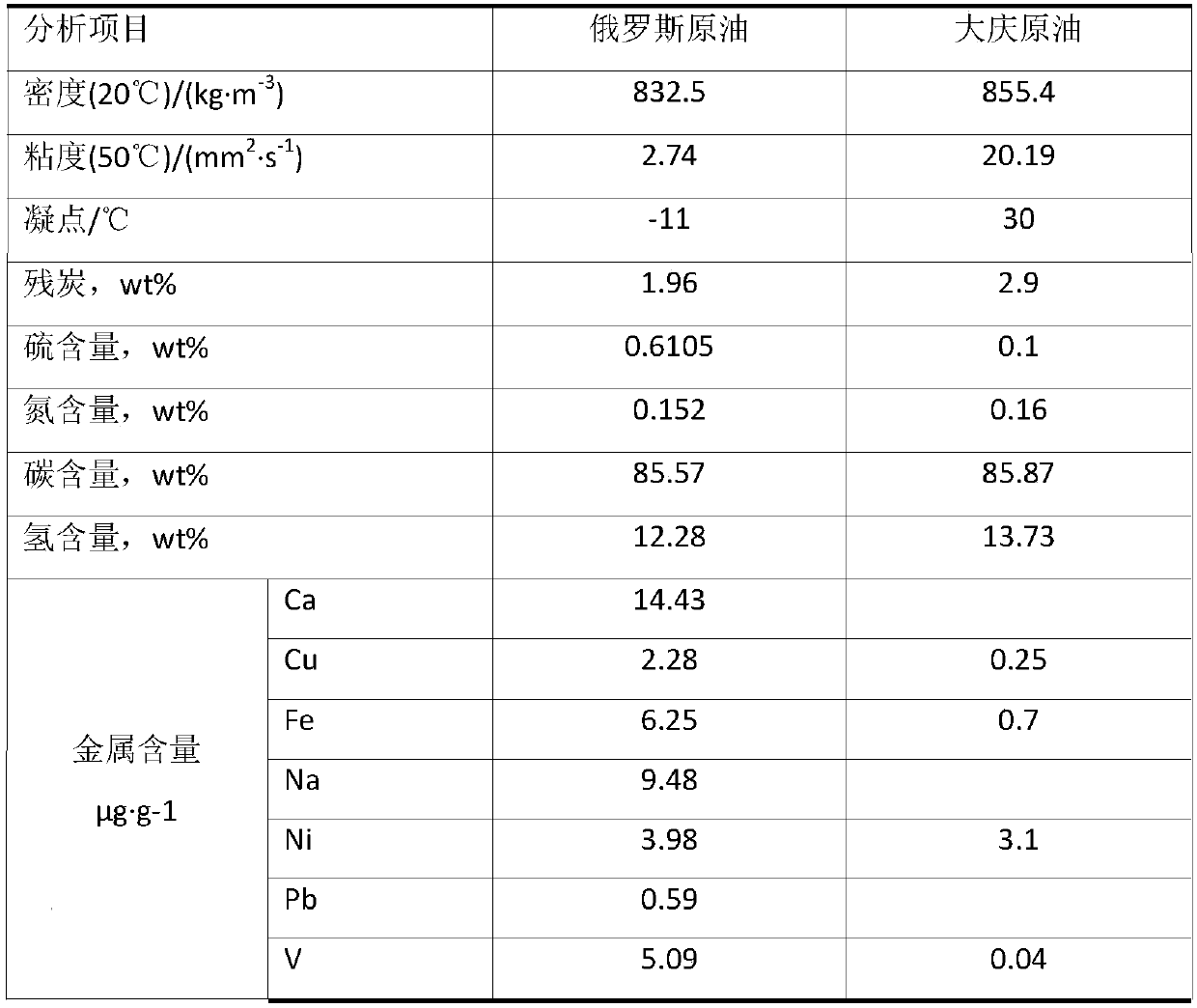

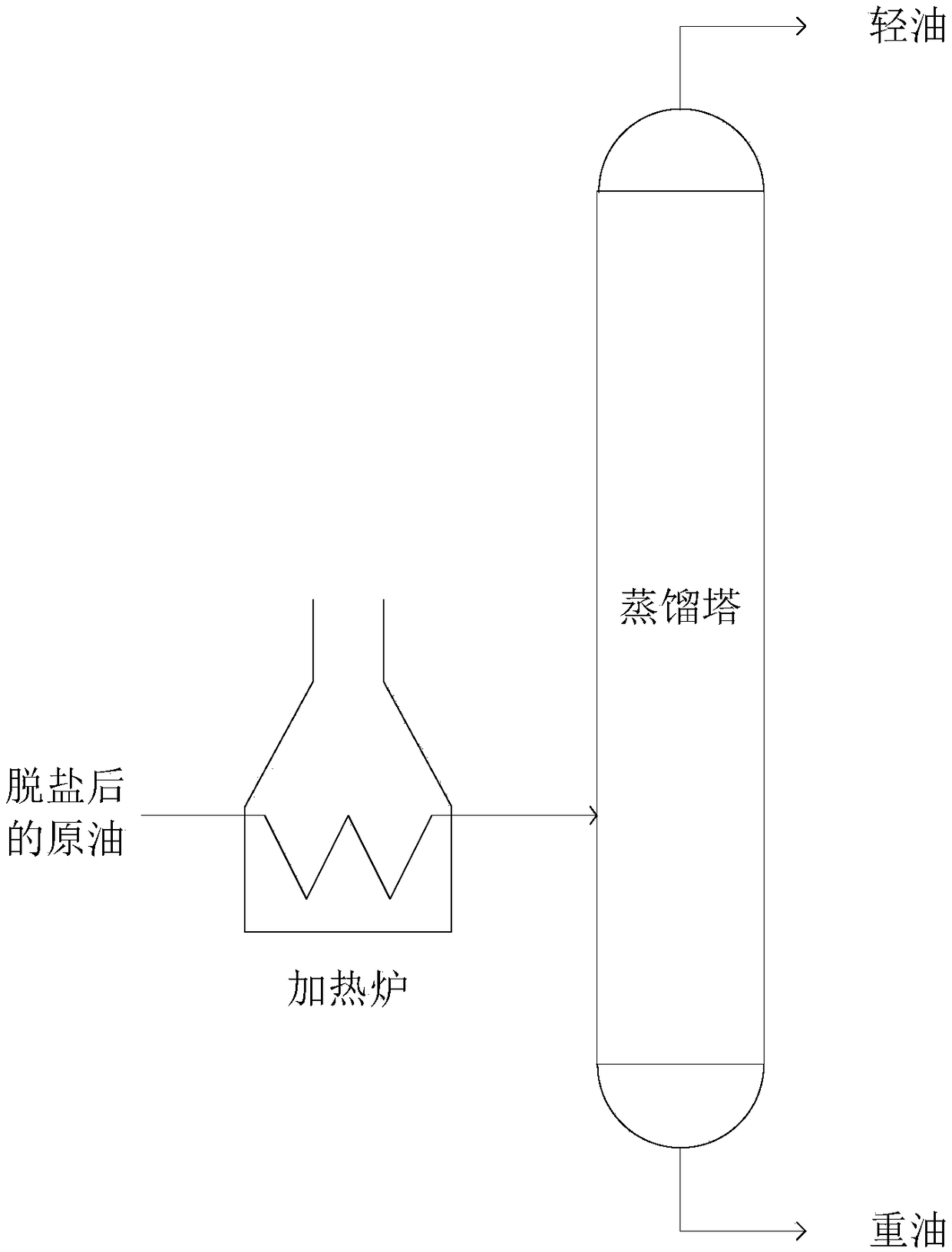

Crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparing method

PendingCN109575982AStrong raw material adaptabilityStrong resistance to metal pollutionCatalytic crackingCatalystsChemistryMetal contamination

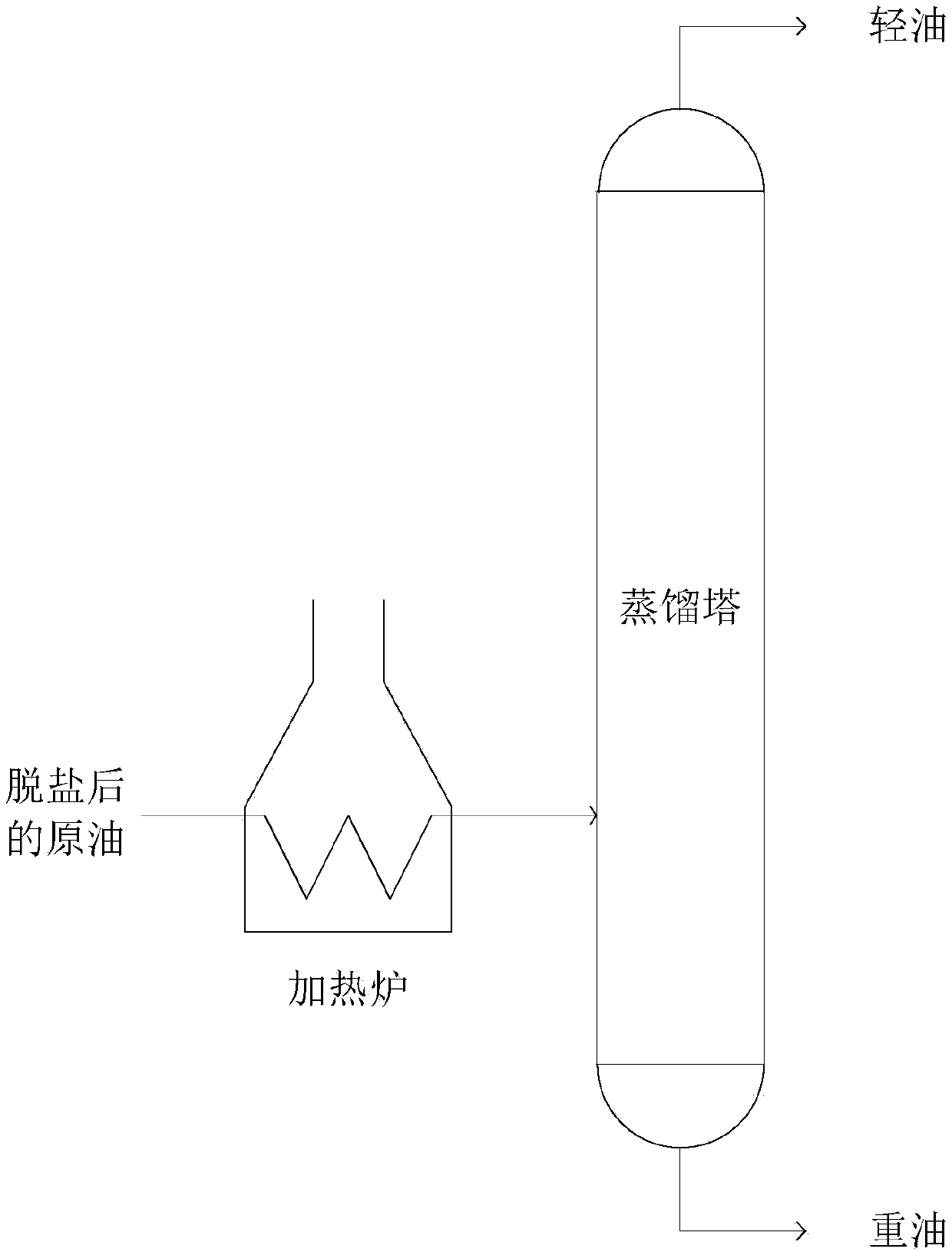

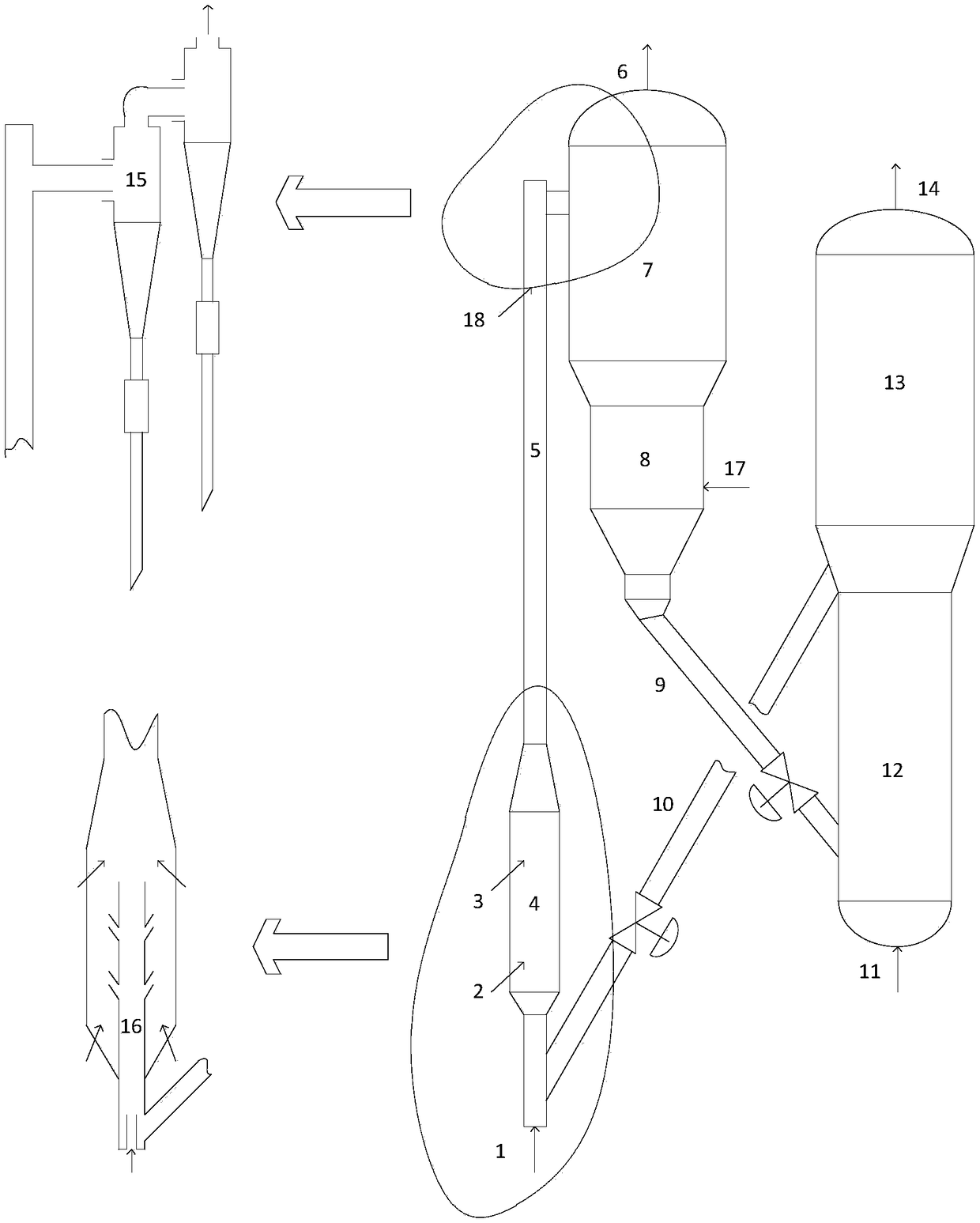

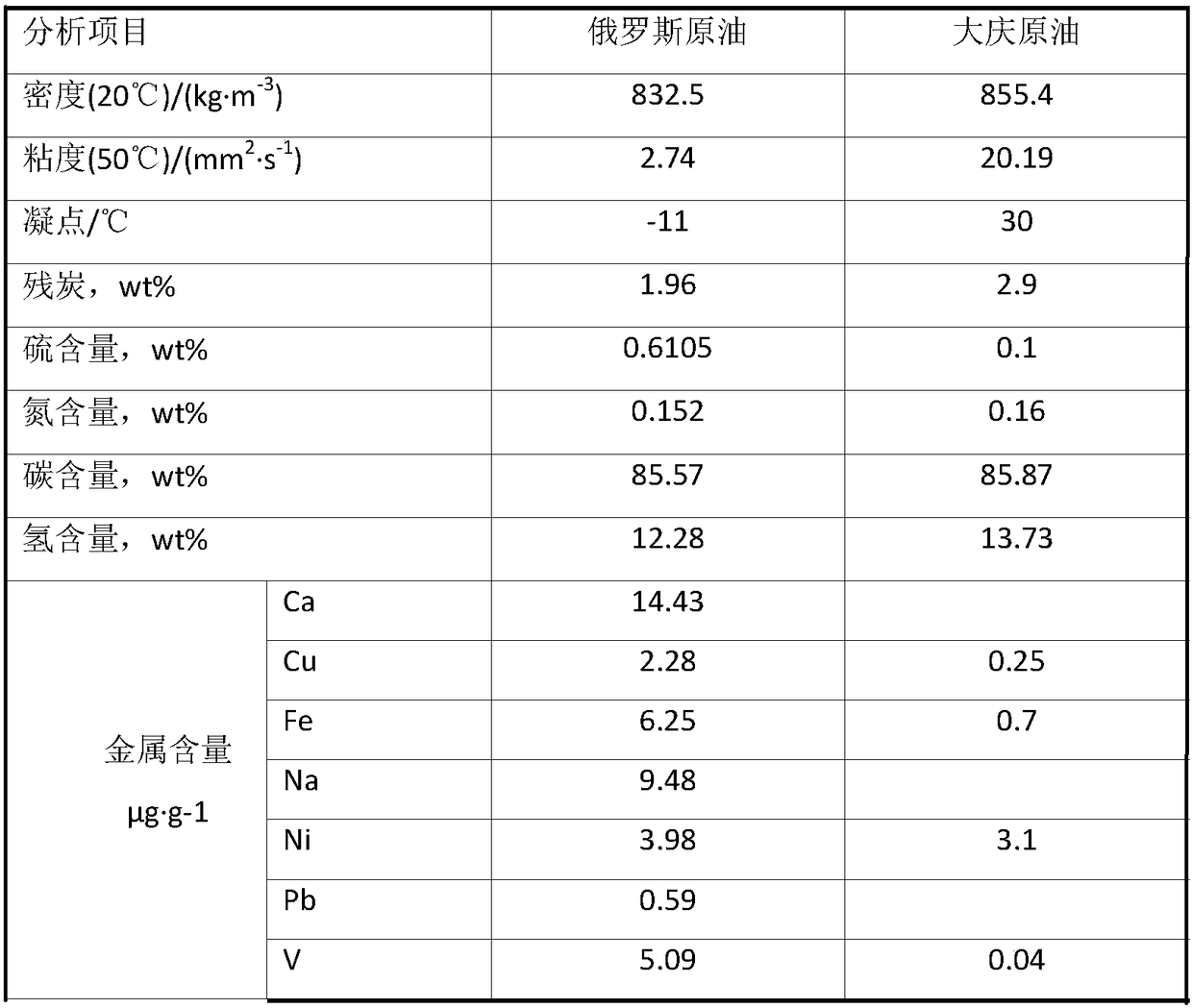

The invention provides a crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparing method. The crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparingmethod is characterized by comprising the following steps of 1), desalinating and dewatering crude oil, then heating the crude oil in a heating furnace, and then dividing the heated crude oil into heavy components and light components in a distillation tower at a cut point of 150-300 DEG C; 2) subjecting the light components discharged from the top of the distillation tower, namely a fed light material, and the heavy components discharged from the bottom of the distillation tower, namely a fed heavy material, to contact reaction with high-temperature catalysts under a vapor atmosphere in tworeactors separately. Compared with the prior art, the crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparing method has the advantages of 1) high raw material adaptability,2) high metal contamination resistance of the catalysts, no hydrothermal deactivation and low reagent consumption, 3) lower energy consumption compared with steam cracking, and 4) high per-pass conversion rate and high olefin selectivity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

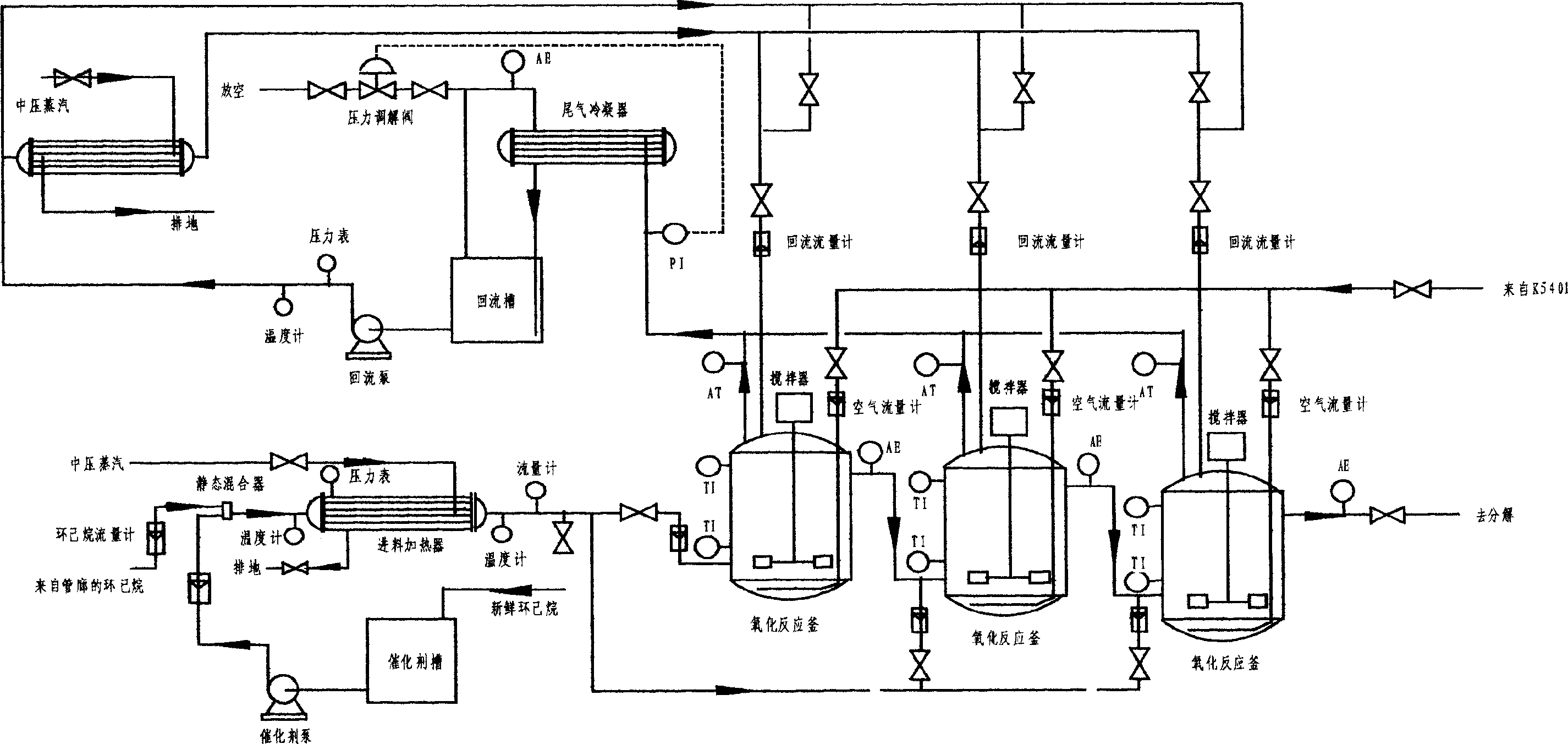

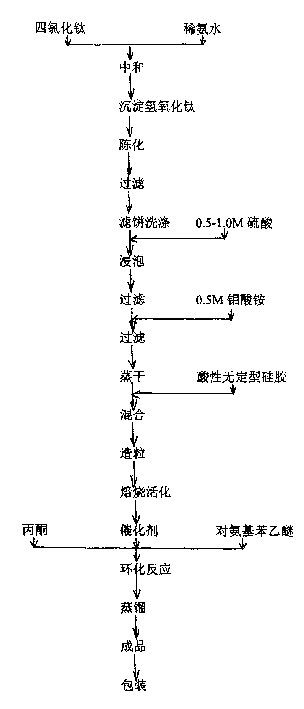

Catalyst oxdie cyclohexane process

ActiveCN1530358AIncrease conversion rate per passImprove one-way yieldOxygen compounds preparation by hydrocarbon oxidationCyclohexanonePorphyrin

A process for preparing cyclohexanol, cyclohexanone and adipic acid by catalytic oxidization of cyclohexane under existance of metallic porphyrin catalyst and a certain temp and pressure through combination of different reactors is disclosed. Its advantages are high single-pass conversion rate of cyclohexane and total output rate, low energy consumption and cost, and no need of cyclohexanol or acetone solvent and cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP

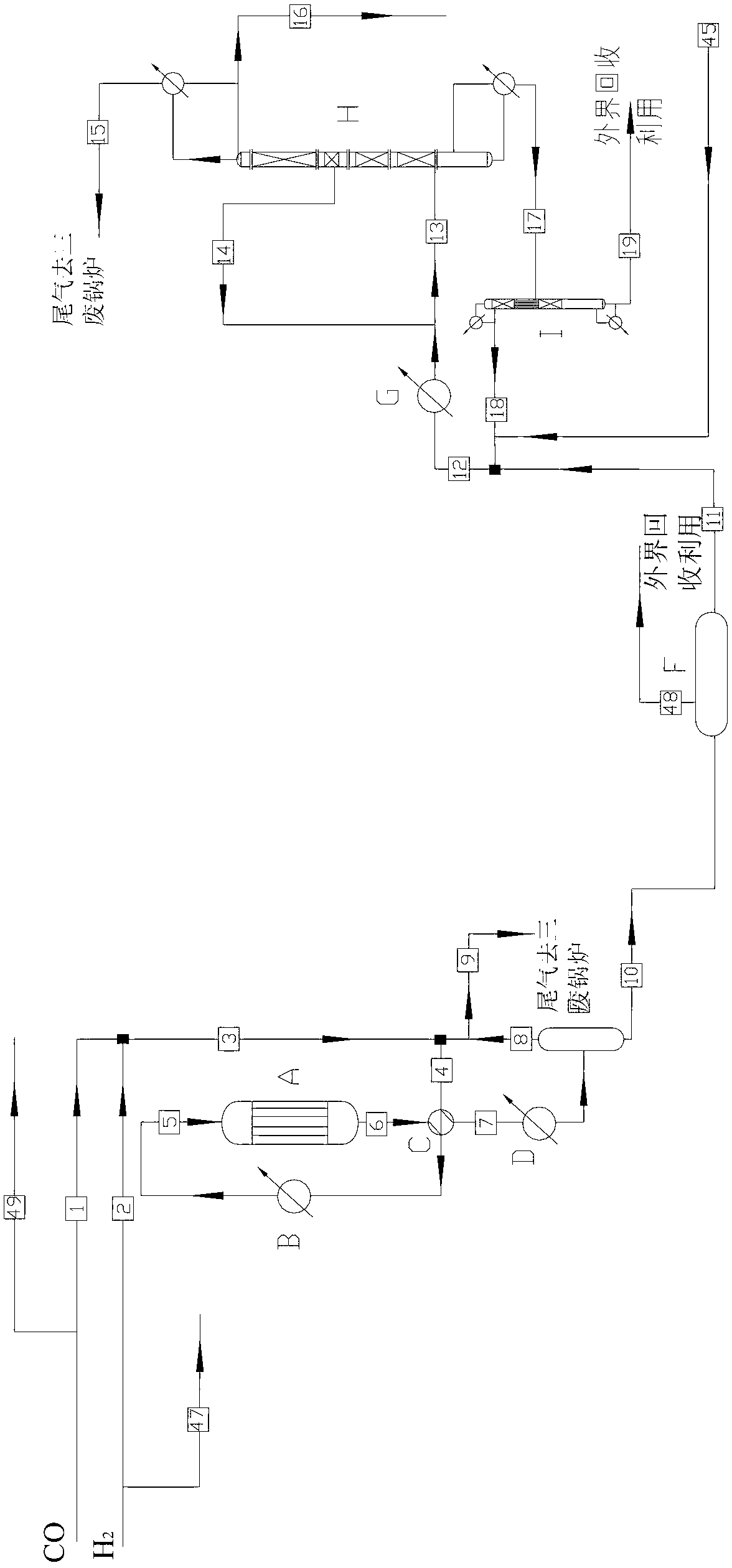

Process for indirectly producing alcohol with synthetic gas and application of process

ActiveCN103012062AReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention relates to a process for indirectly producing alcohol with synthetic gas. The process comprises the steps that the synthetic gas formed by mixing industrial carbon monoxide with hydrogen is taken as a raw material to synthesize methanol; methanol is dehydrated to prepare dimethyl ether; dimethyl ether, carbon monoxide and hydrogen are mixed for carbonylation reaction to prepare methyl acetate; methyl acetate is purified and hydrogenated; a hydrogenated product is purified; and an alcohol product is obtained. An adopted catalyst, the process and a device have the characteristics of high conversion per pass and high effective utilization rate of reaction heat; the load of separating a crude product is reduced greatly; the production flow is shortened; and the production energy consumption is reduced greatly.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Catalyst for preparing 1, 2-trimethylene glycol by glycerol hydrogenoiysis and preparation thereof

InactiveCN101214440AIncrease conversion rate per passHigh activityPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementGlycerol

The invention relates to a catalyst of a 1, 2-propanediol prepared by hydrogenolysis of glycerine. The catalyst is a compound oxide, and contains cuprocide (weight fraction) 25 percent to 60 percent, zinc oxide 35 percent to 70 percent, aluminum oxide (weight fraction) 0 percent to 10 percent and at least one or a plurality of rare-earth oxides 0.5 percent to 10 percent of rare earth elements, such as Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, etc. The catalyst is used in continuous hydrogenolysis reaction of glycerine, in which the conversion rate of the glycerine is high, the selectivity of the 1, 2-propanediol is high and the activity of the catalyst is very stable. The invention also provides the preparation method of the catalyst and application of the catalyst in preparation of 1, 2-propanediol by hydrogenolysis reaction of glycerine.

Owner:NANJING UNIV OF TECH

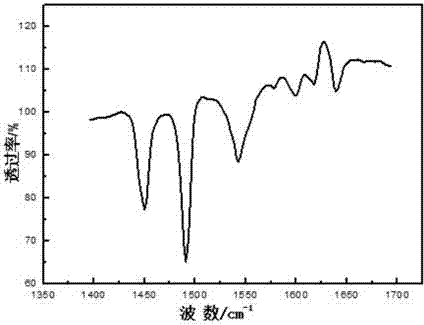

Method for preparing oxalate by coupling reaction of CO in gaseous phase

ActiveCN101475472AImprove conversion rateHigh selectivityPreparation by carbon monoxide or formate reactionContact timeSingle pass

The invention relates to a method for producing oxalic ester by CO gaseous phase coupling, which mainly solves the problems of low selectivity of target products and low single-pass conversion in the prior art. The method adopts a technical proposal that raw materials of nitrous acid ester-containing gas and CO are introduced into a reacting-separating tower and are contacted with palladium-containing catalysts under the condition that the temperature is between 60 and 160 DEG C, the reaction contact time is between 0.5 and 6 seconds, and the reaction pressure is between 0.05 and 1.5 MPa, a gas-liquid mixture containing oxalic ester is generated after the reaction; meanwhile, gas-liquid separation is performed in the reacting-separating tower, an oxalic ester product is obtained at the bottom of the tower, and gaseous phase effluenst containing unreacted nitrous acid ester and CO are obtained at the top of the tower. The method solves the problems well and can be used in industrial production for increasing the yield of the oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used for direct preparation of light olefin from synthetic gas, preparation method and application thereof

InactiveCN103157489ALow priceLow costHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasAlkane

The invention relates to a catalyst used for direct preparation of light olefin from synthetic gas, a preparation method and an application thereof. According to the invention, a parallel flow precipitation method is used to highly disperse Fe and auxiliary agents on surfaces of self-made alkaline carriers, and thus a catalyst load is low, a preparing technology is simple and a cost is lower than that of product with a same type. When the catalyst is used for direct preparation of the light olefin from the synthetic gas, a CO conversion rate can reach 75-85 % under a one-way catalytic condition of the synthetic gas, an alkene-alkane ratio can reach 4.5-6.0 in organic gas products, an alkene weight is 50-60 % and more than 98% of the liquid product is water. The catalyst is good in abrasion resistance and pressure resistance, and can be used for slurry beds and fixed beds. A reaction technology of the catalyst is that the temperature is 200-500 DEG C, a pressure is 0-5 MPa, and an air speed of the synthetic gas is 600-2400 <-1>.

Owner:SHANXI LUAN MINING GRP +1

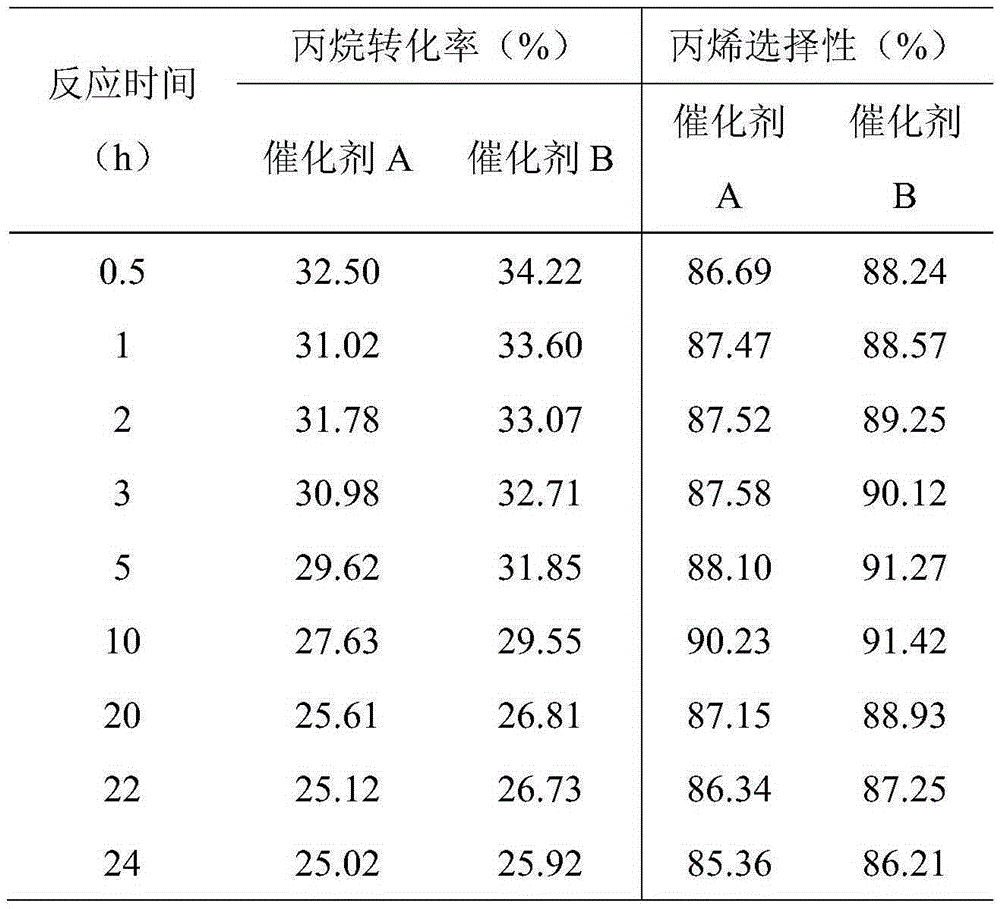

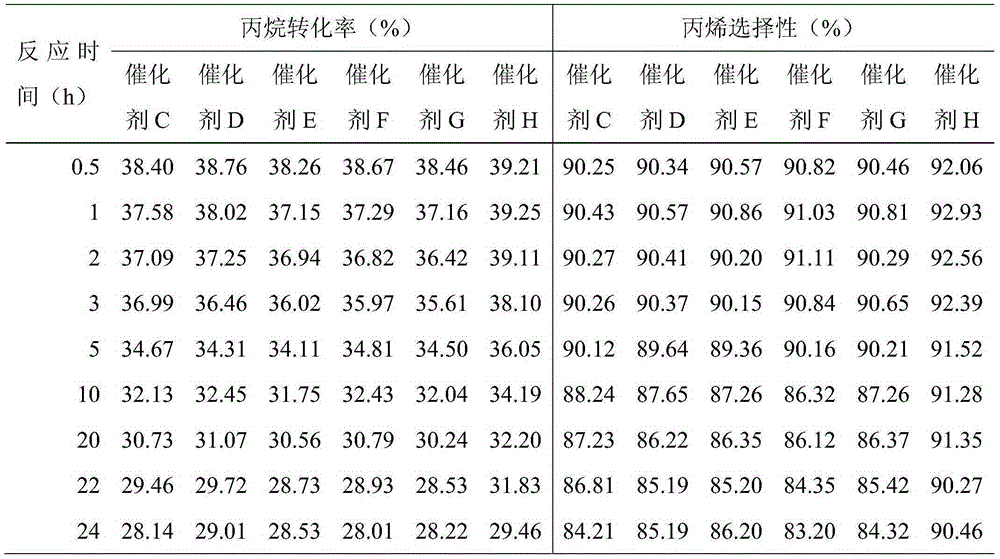

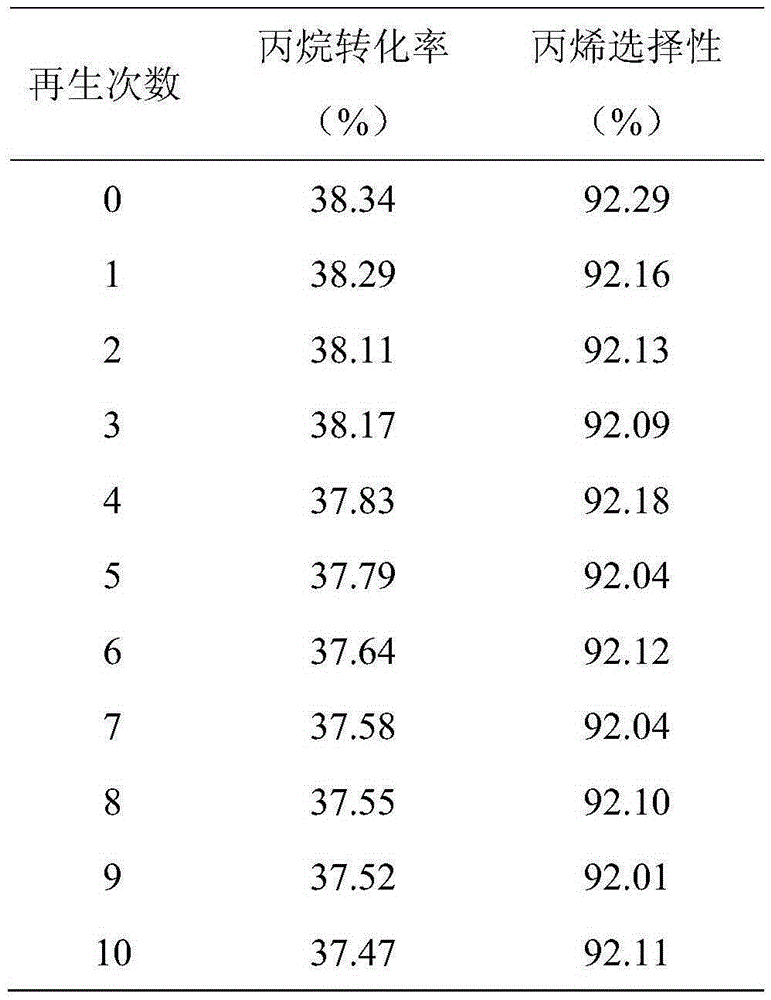

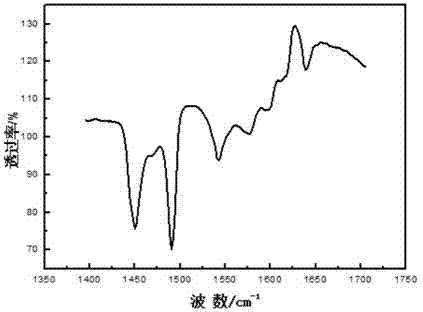

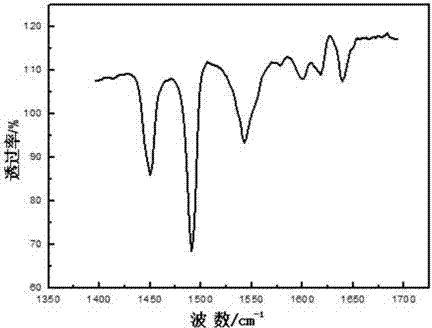

Quaternary platinum-based light-alkane dehydrogenation catalyst and preparation method thereof

ActiveCN105396586AHigh dehydrogenation activityGood dispersionCatalystsHydrocarbon preparation catalystsPlatinumAlkane

The invention discloses a quaternary platinum-based light-alkane dehydrogenation catalyst and a preparation method thereof. The catalyst comprises four components: Pt, Sn, Zr, and Ce, wherein Zr and Ce are added in the preparation of a carrier small aluminium oxide ball, and Sn and the active component Pt are uniformly loaded on the carrier by adopting an impregnation method; based on the weight of the catalyst, the content of Al2O3 is 95.0%-98.0%, the content of Pt is 0.1%-1.0%, the content of Sn is 0.1%-2%, the content of Zr is 0.5%-3.0%, and the content of Ce is 0.5%-2%. The catalyst prepared by the invention has the good catalytic activity when being used in propane dehydrogenation reaction, the catalyst has no obvious activity reduction after multiple-time regeneration, the average conversion per pass of propane is 37% and more, the propylene selection is more than 90%, and the good regeneration stability can be shown.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Normal-paraffin isomerization catalyst, preparation method and application thereof

ActiveCN104117369ALow reaction temperatureReaction conditions are easy to controlHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneLow activity

The invention provides a normal-paraffin isomerization catalyst, a preparation method and application of the normal-paraffin isomerization catalyst, and relates to the technical field of the paraffin-isomerization catalyst, and is used for solving the problems of low activity, poor stability and low conversion rate in the existing isomerization catalyst. The normal-paraffin isomerization catalyst comprises the following components in percentage by mass: 0.1-1.0% of metal component Pt and 2.0-5.0% of halogen Cl and the balance of carrier gamma-Al2O3. The normal-paraffin isomerization catalyst provided by the invention is prepared by dipping, reduction, inorganic chlorination and organic chlorination; the metal elementary substance Pt is loaded on the multi-porous carrier gamma-Al2O3, and after chlorination treatment, the Pt-Al2O3-Cl normal-paraffin low-temperature isomerization catalyst is formed; and the normal-paraffin isomerization catalyst has the advantages of high liquid absorption, high isomerization rate, high reaction activity and good stability.

Owner:JIANGSU YANGZI CATALYST CO LTD +1

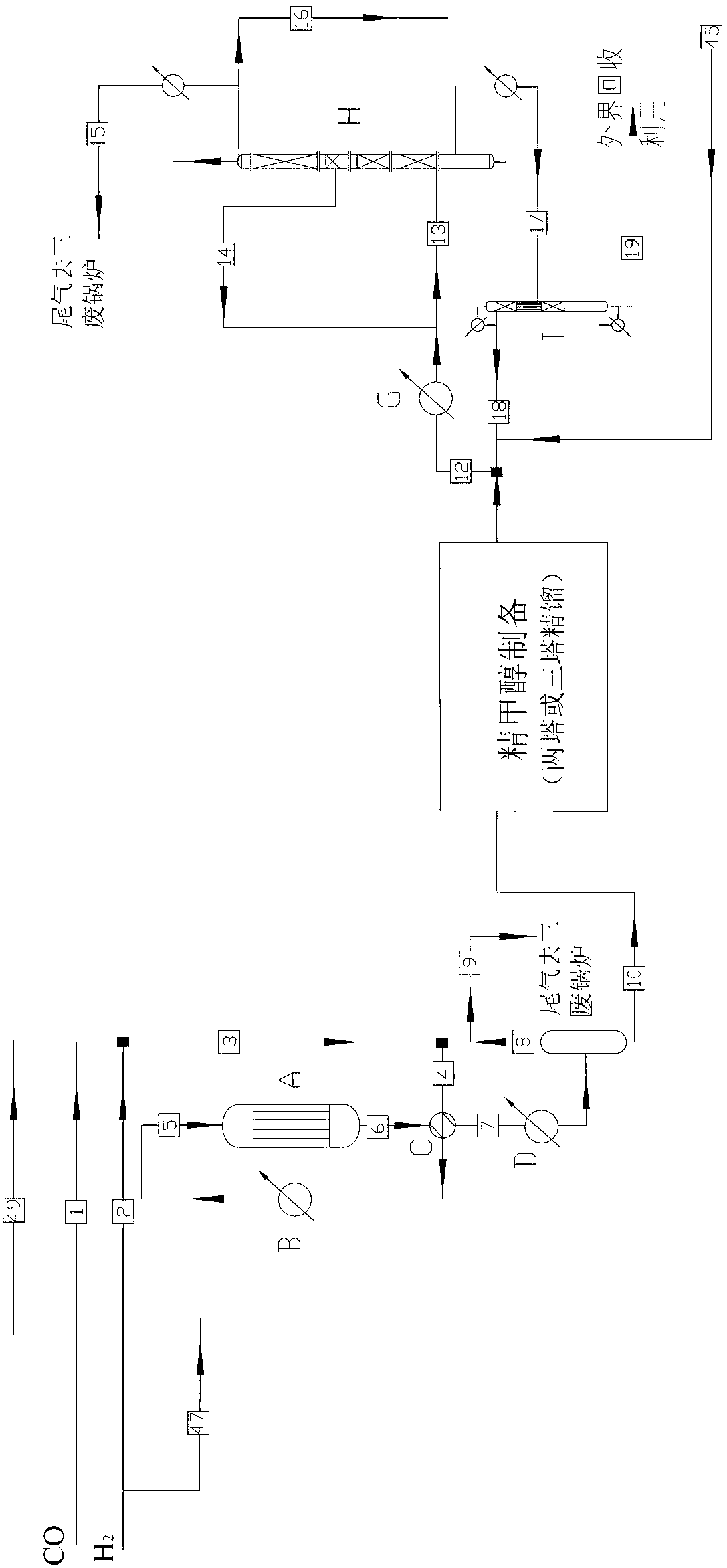

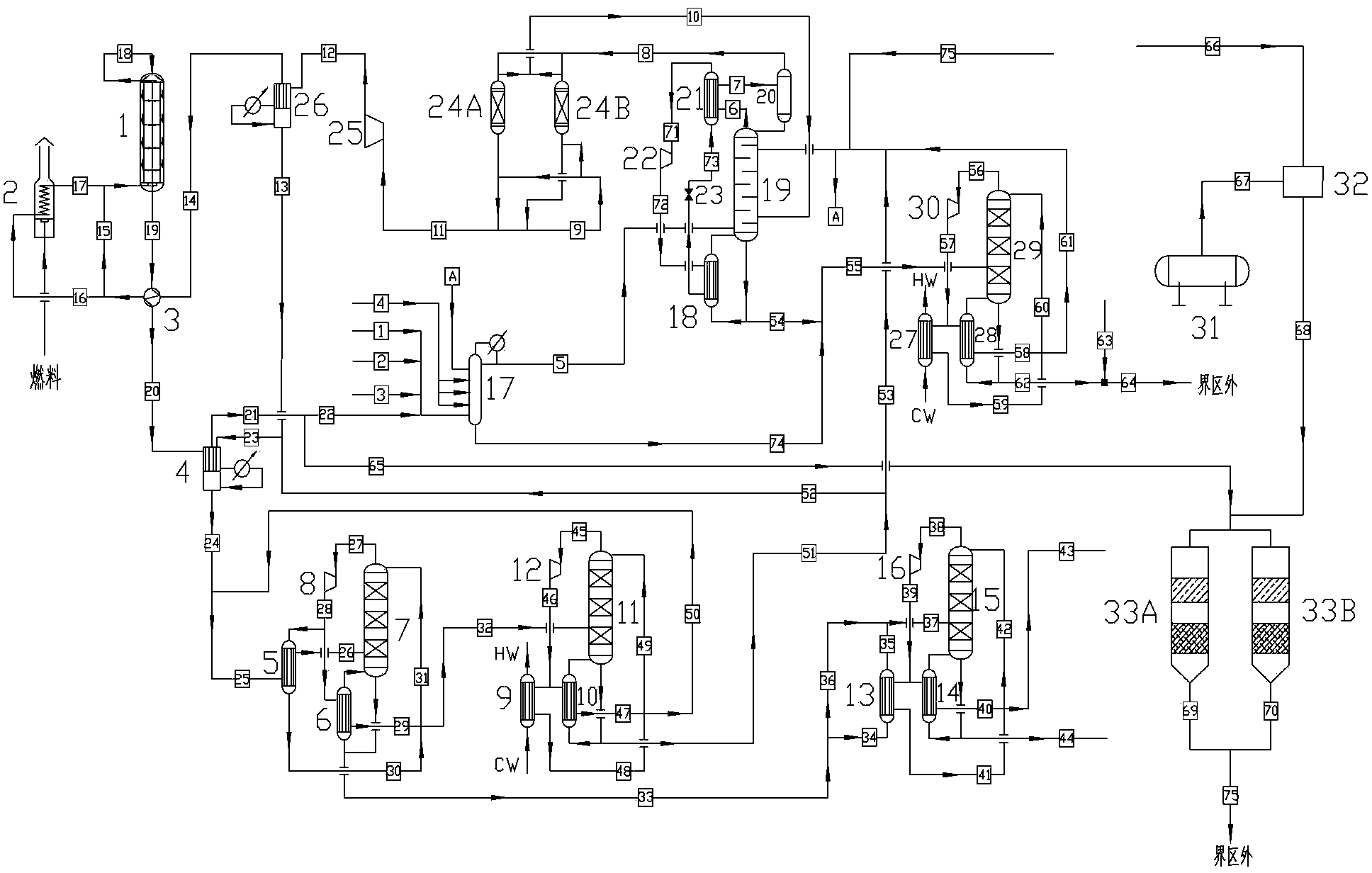

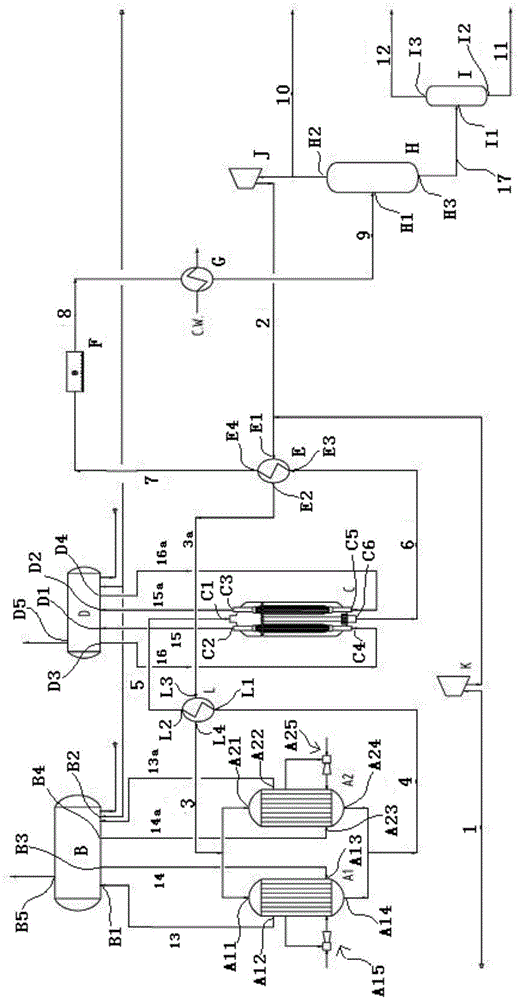

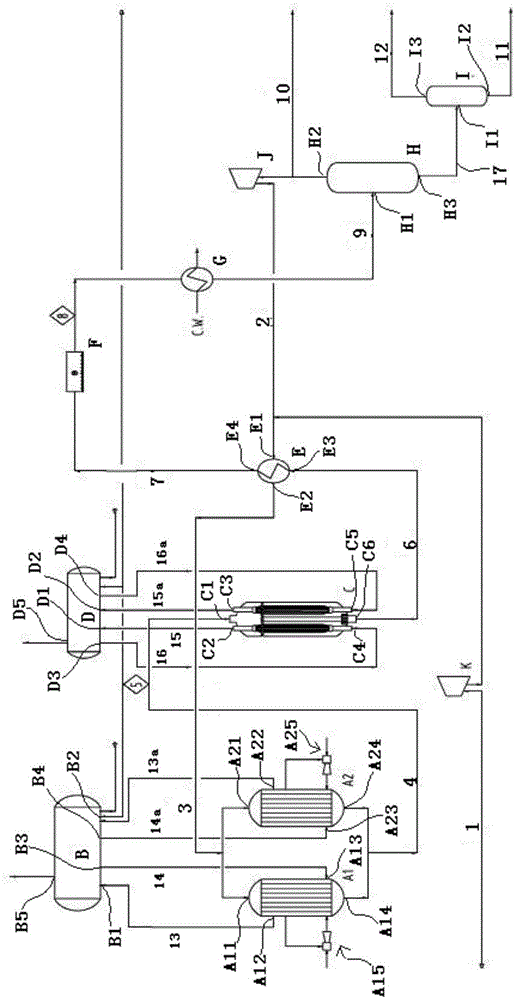

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

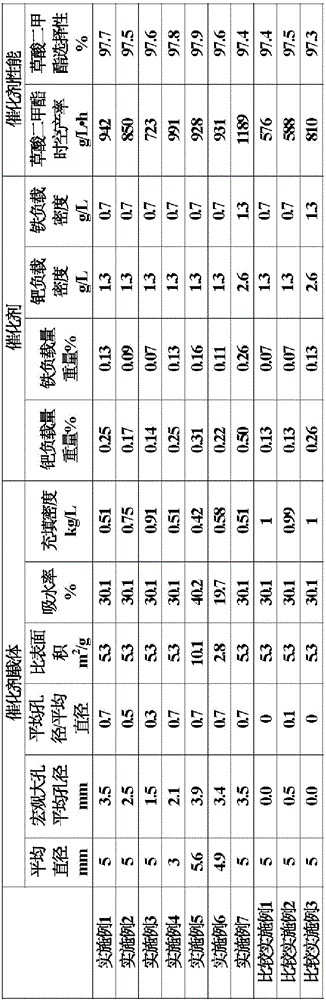

Catalyst carrier and catalyst comprising the same

ActiveCN106457227AEasy to fillEvenly stackedCatalyst carriersCatalyst activation/preparationOxalateGas phase

The invention relates to a catalyst carrier used in a process of coupling and synthesizing dialkyl oxalates through gas phase catalysis of carbon monoxide, the catalyst carrier comprises micro pores and one or more macro pores which can pass through the catalyst carrier, wherein the ratio of the average pore size of the macro pores and the average diameter of the catalyst carrier is more than 0.2. The invention also relates to the catalyst carrier and a catalyst which comprises activated components and an optional additive and is loaded on the catalyst carrier. The catalyst can effectively perform gas phase catalysis on carbon monoxide to couple and generate the dialkyl oxalates, the heat dissipation is improved, the pressure drop is reduced, the usage amount of precious metal such as palladium is reduced, the usage cost of the catalyst and the production cost of the dialkyl oxalates are reduced, so that the industrial mass production of the dialkyl oxalates can be contributed to realize.

Owner:HIGHCHEM

Autothermal catalytic marsh gas reforming process of preparing synthetic gas

InactiveCN1468800ASelf-heating reactionHigh activityHydrogenWaste based fuelSyngasCatalytic reforming

The present invention relates to the efficient clean utilization of marsh gas and is especially one new kind of catalyst for reforming methane-CO2 to produce synthetic gas. The present invention is one green process to utilize marsh gas with methane and CO2 as main components to produce synthetic gas via reformation. The present invention is significant for sustained supply of power source and environment protection.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

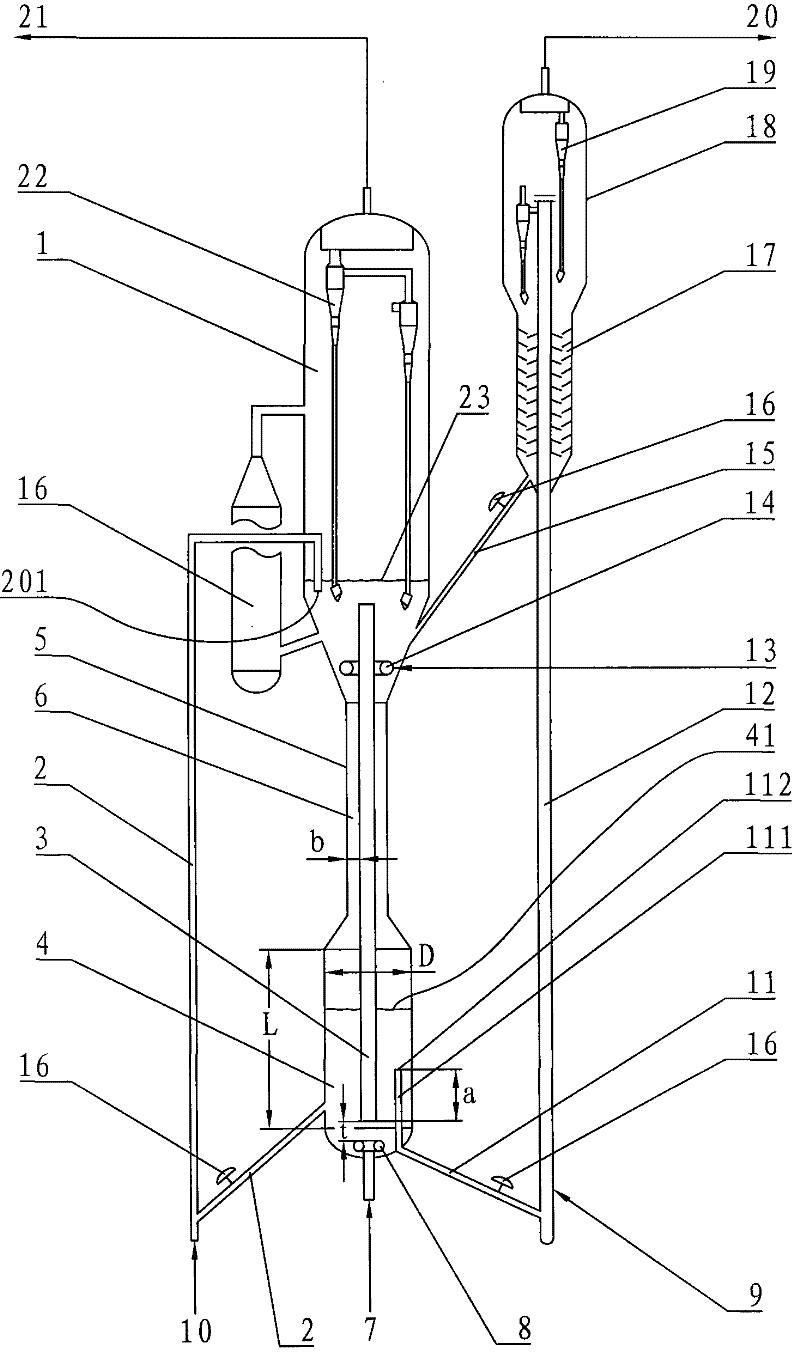

Device and method for reducing the temperature of catalytic cracking regenerated catalyst

Owner:CHINA PETROCHEMICAL CORP +1

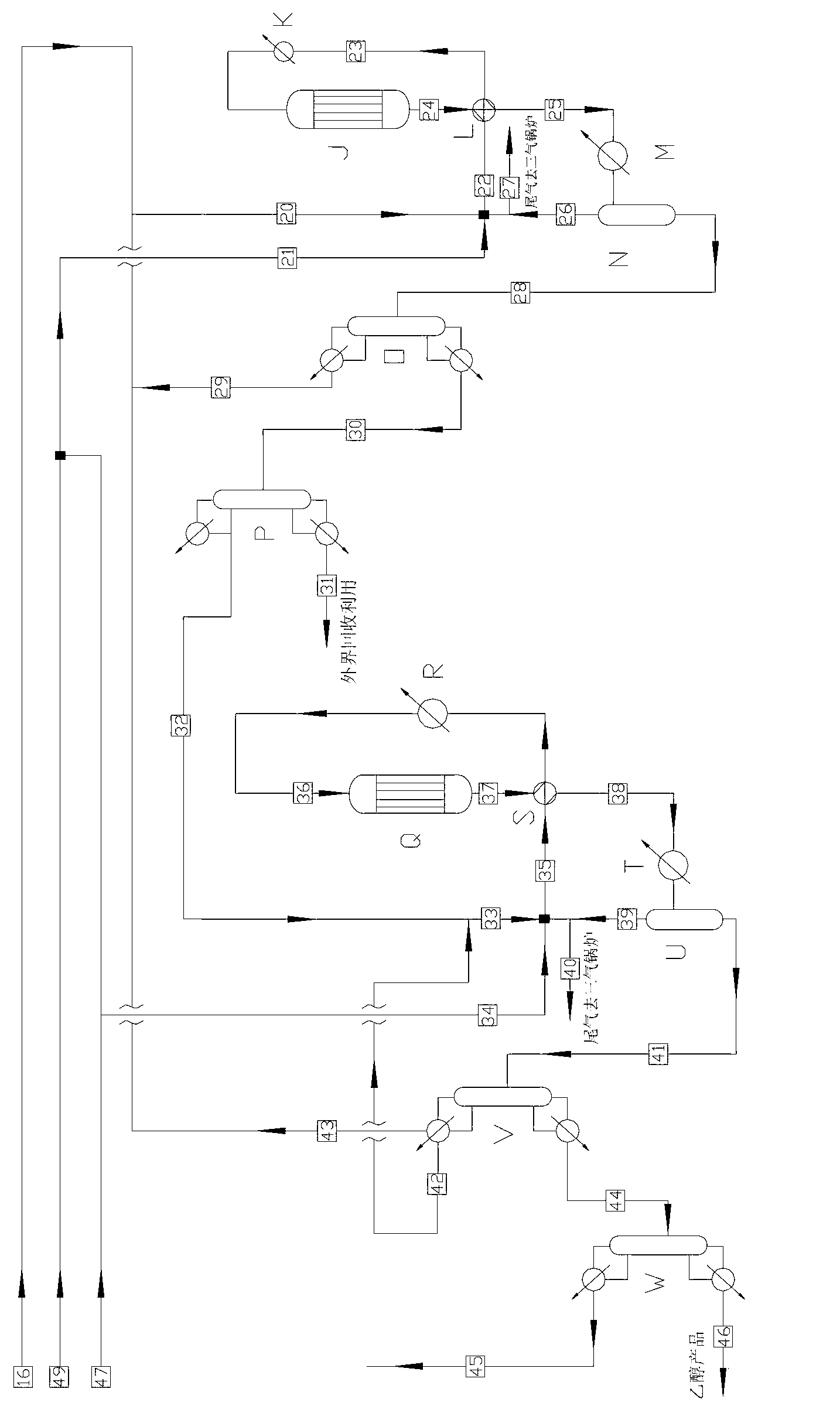

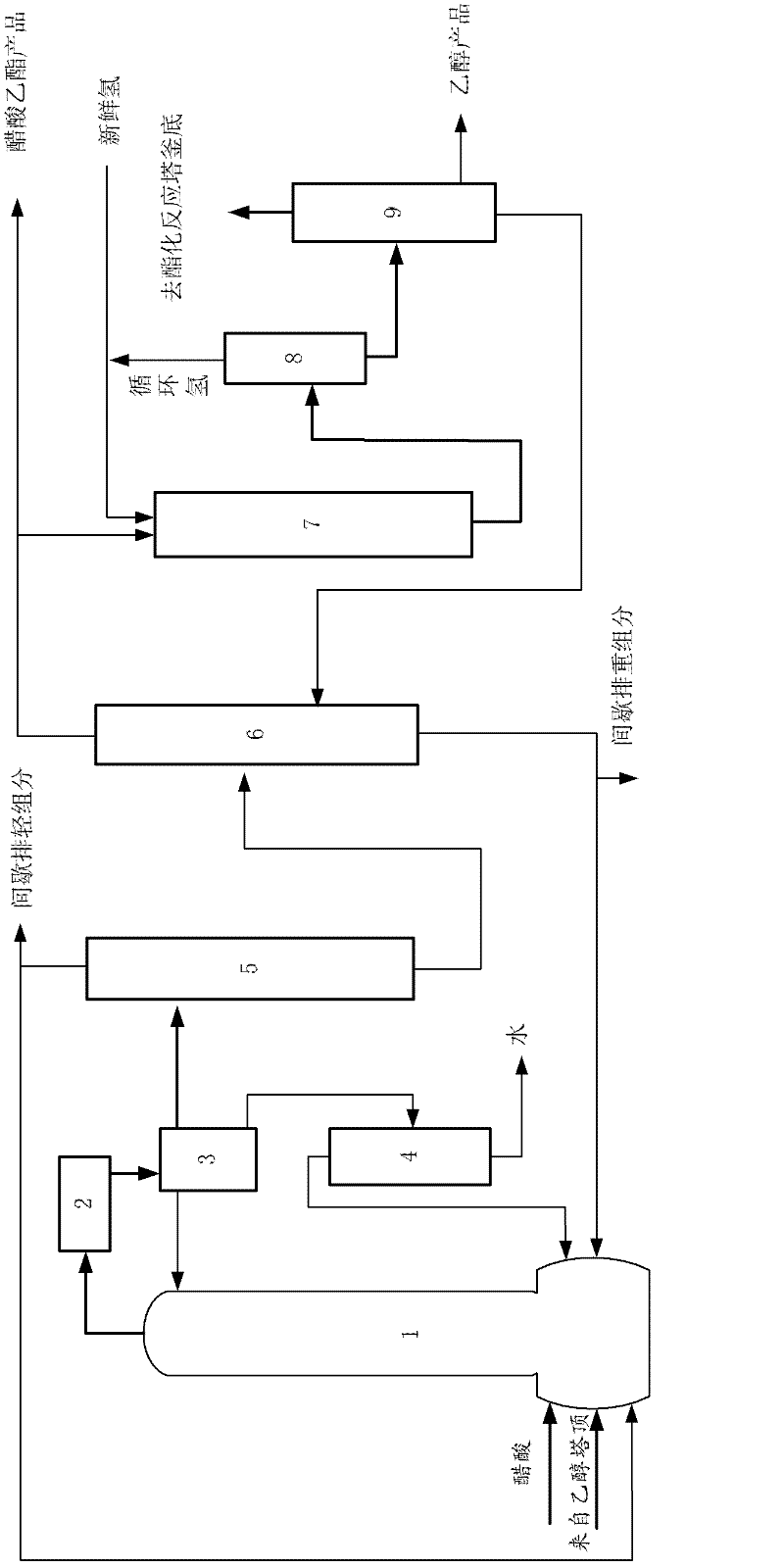

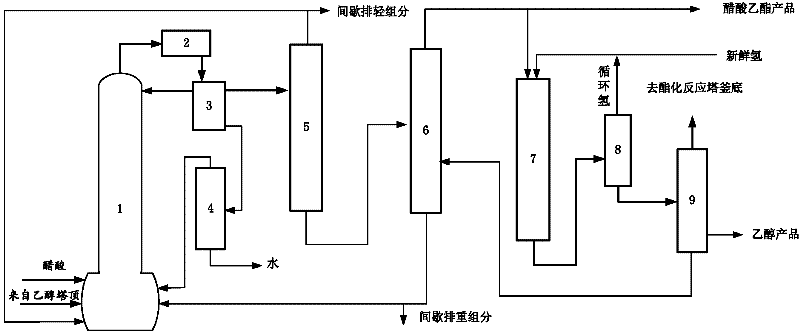

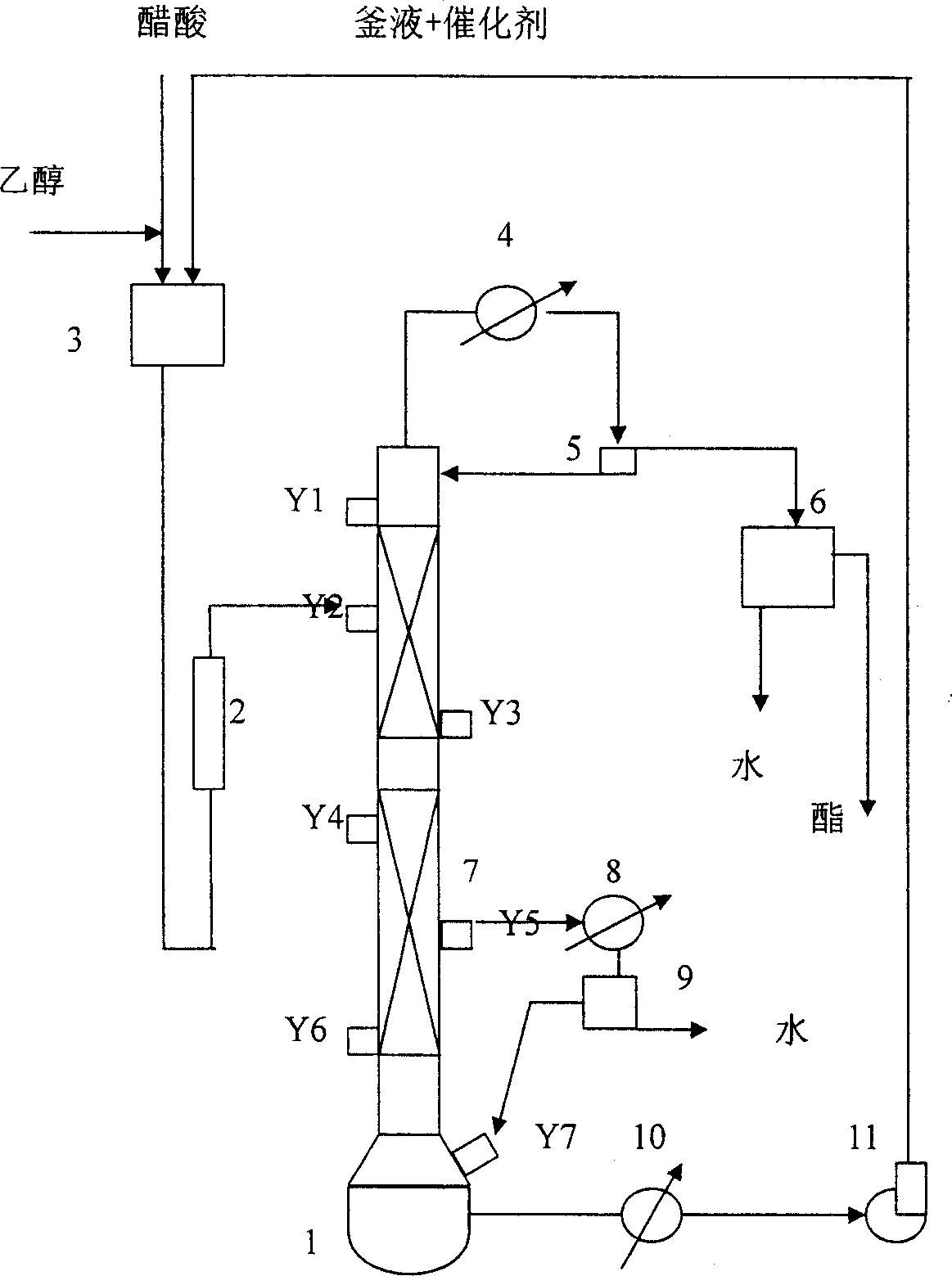

Process for separate production or joint production of ethanol and acetic ether through acetic acid indirect hydrogenation

ActiveCN102557931AReduce consumptionIncrease conversion rate per passOrganic compound preparationCarboxylic acid esters preparationAcetic acidReactive distillation

The invention relates to a process for separate production or joint production of ethanol and acetic ether through acetic acid indirect hydrogenation. Acetic acid and ethanol are placed in an esterification tower, the acetic acid and the ethanol are subjected to reactive distillation in the presence of acid catalysts, the acetic ether and water are obtained, the mixture is distilled off from the top of the tower and enters a water segregator, a rectification light removal tower and a rectification heavy removal tower after being condensed, so that impurities are removed and conforming products of the acetic ether are obtained. Part of the products are sold, and others are regarded as raw materials for producing the ethanol in a hydrogenolysis reaction, led to a hydrogenolysis tower and subjected to catalytic hydrogenolysis so as to selectively obtain the ethanol. Part of or all the ethanol obtained by hydrogenolysis of the acetic ether is regarded as a raw material for an esterification reaction and reacts with the acetic acid in the esterification tower. Compared with the existing technologies, the process is simple in flow and low in production cost; and either the ethanol or the acetic ether can be produced selectively, or both the ethanol and the acetic ether can be produced in a certain proportion through adjustment of the production capacity of a hydrogenolysis and hydrogen production device.

Owner:ZHONGRONG TECH CORP LTD +1

Catalyst for preparing isopropanol by hydrogenating acetone as well as preparation method and application thereof

ActiveCN104226354AEasy to prepareLow costMolecular sieve catalystsOrganic compound preparationAdditive ingredientCarbide

The invention relates to a catalyst for preparing isopropanol by hydrogenating acetone. The catalyst comprises the following ingredients by weight percent: 10 to 30 percent of metal oxide, 0.5 to 2 percent of metal carbonate, and 68 to 89.5 percent of carrier. The catalyst has advantages of simple production method, low price, high activity and selectivity and simplicity in operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

Environment-friendly preparation method of tert-butylamine

InactiveCN102633647AExtended service lifeLow reaction temperatureMolecular sieve catalystsAmino compound preparation by condensation/addition reactionsPtru catalystArgon atmosphere

The invention discloses an environment-friendly preparation method of tert-butylamine. Isobutylene and liquid ammonia are directly subjected to amination under the action of a catalyst to prepare the tert-butylamine. The catalyst uses a Y-type zeolite molecular sieve as the matrix, and the active component elements and modifying elements account for 10-30%. The Y-type zeolite molecular sieve is modified by the following steps: exchanging the Y-type zeolite molecular sieves with an NH4Cl aqueous solution, washing, drying in a nitrogen or argon atmosphere, and carrying out heat treatment by roasting to obtain an H-type zeolite molecular sieve; and carrying out dipping treatment on the H-type molecular sieve with metal salt, drying in a nitrogen or argon atmosphere, roasting to obtain the modified Y-type zeolite molecular sieve. The modified Y-type zeolite molecular sieve catalyst must be activated before use. The invention has the advantages of mild reaction conditions, high selectivity, high yield, environment friendliness and low catalyst modifying cost, and is suitable for industrial production.

Owner:ZHEJIANG HUANGMA TECH

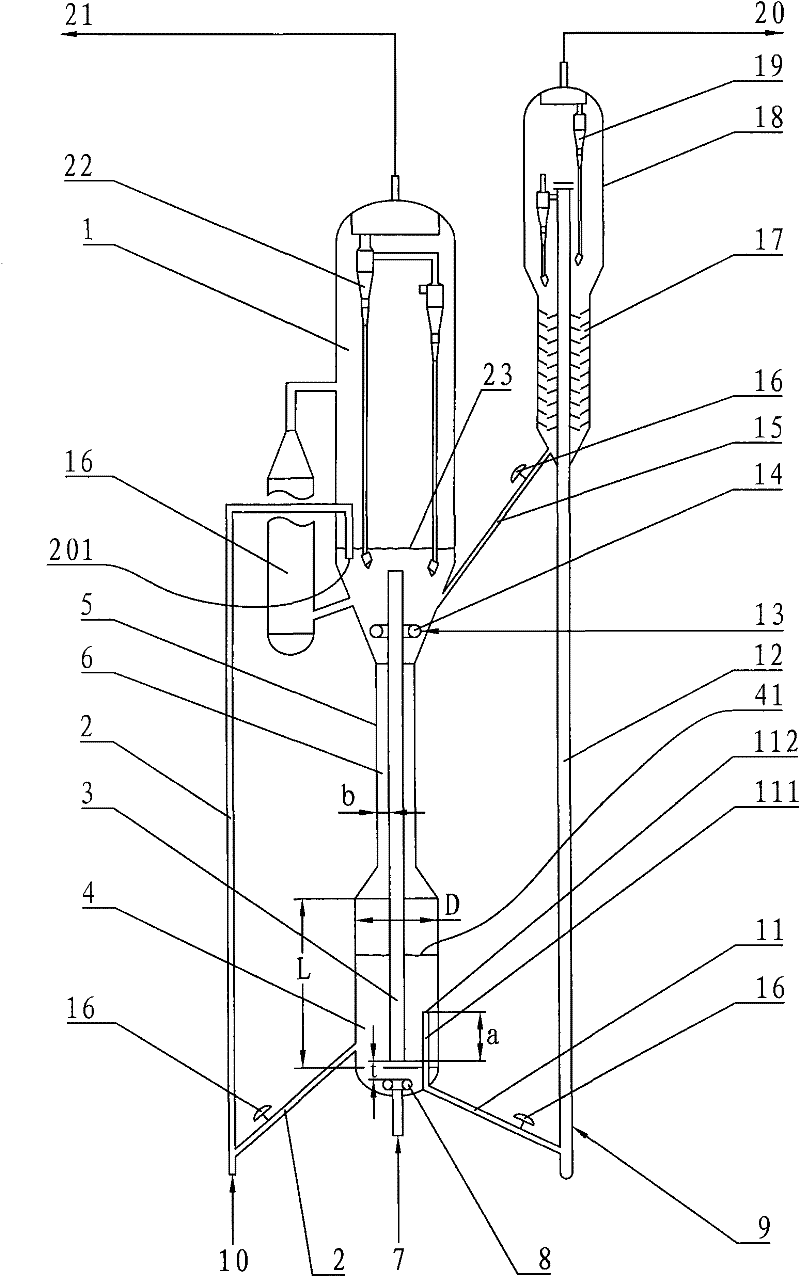

Method for preparing low-carbon olefin and arene by catalytic cracking of raw oil

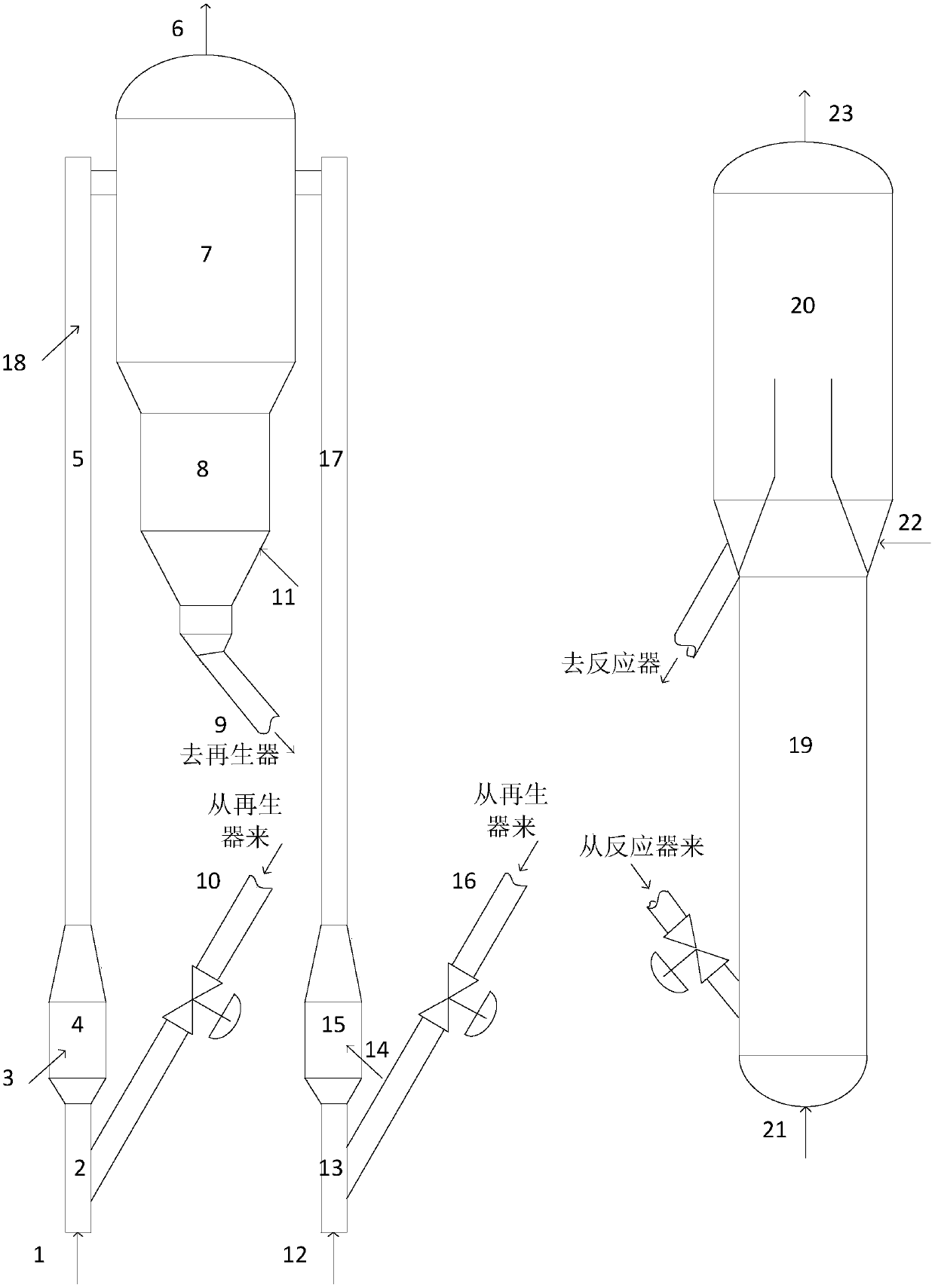

InactiveCN109370644AAdaptablePollution abilityTreatment with plural serial stages onlyHydrocarbon oils treatment productsReaction zoneTower

The invention provides a method for preparing low-carbon olefin and arene by catalytic cracking of raw oil. The method is characterized by comprising the following steps: 1) after desalting and dewatering, the raw oil enters a heating furnace for heating, then enters a distilling tower to be divided into light components and heavy components, and the cutting point is between 150 DEG C and 300 DEGC; 2) the light components coming from the tower top and the heavy components coming from the tower bottom carry out reaction at different reaction zones of a same reactor; the light components, namely lightweight fed materials, are firstly contacted and react with a high-temperature regeneration catalyst, and then the heavy components, namely heavyweight fed materials are contacted and react withthe catalyst. Compared with the prior art, the method for preparing the low-carbon olefin and arene by catalytic cracking of the raw oil, provided by the invention, has the following advantages: 1) the adaptability of the raw materials is strong; 2) the metal-pollution resistance of the catalyst is strong, and hydrothermal deactivation can not occur, so that the preparation consumption is low; 3)compared with steam cracking, the energy consumption is low; 4) the single-pass conversion ratio is high and the olefin selectivity is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

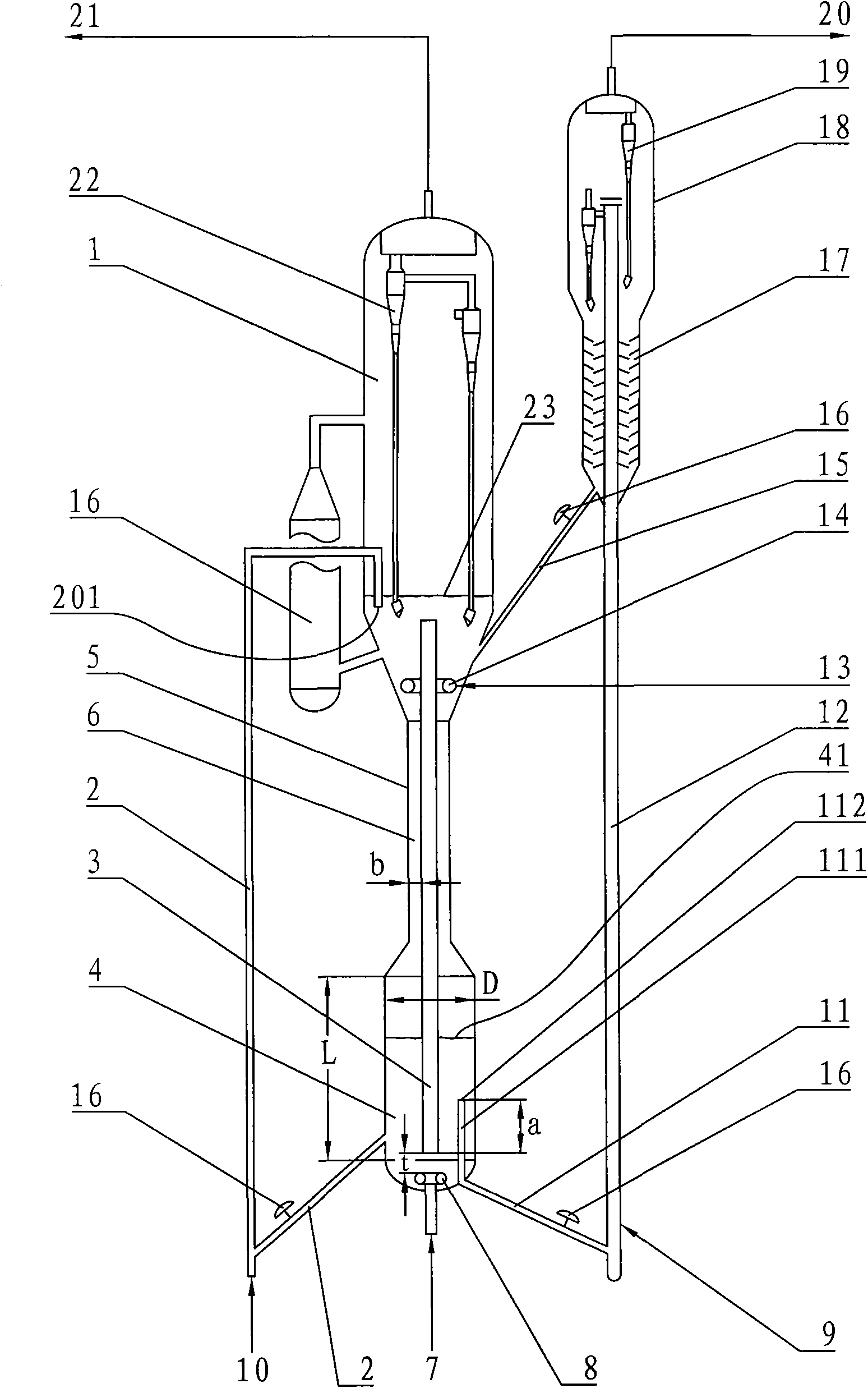

Device and method for reducing the temperature of catalytic cracking regenerated catalyst

ActiveCN101575534AWide range of applicationsReduce carbon contentCatalytic crackingPetrochemicalPetroleum

The invention discloses a device and a method for reducing the temperature of catalytic cracking regenerated catalyst in the field of petrochemical industry catalytic cracking and aims to solve the problems that the method for reducing the temperature of catalytic cracking regenerated catalyst has a small application range in the prior art, and the like. The device comprises a regenerated catalyst cooler (4) arranged below a regenerator (1) and the bottom head of the cooler is internally provided with a cooling main air distributor (8). A sleeve (5) is arranged between the top of a taper section of the regenerated catalyst cooler and the bottom of the regenerator and provided with a regenerated catalyst conveying pipe (3) internally, and an annular space (6) is formed between the sleeve and the conveying pipe. A regenerated inclined pipe (11) is arranged between the regenerated catalyst cooler and a heavy oil riser reactor (12) of a catalytic cracking device. The invention also discloses a method for reducing the temperature of catalytic cracking regenerated catalyst by adopting the device. The device and the method can be used for setting a catalytic cracking device of a single heavy oil riser reactor and a plurality of riser reactors.

Owner:CHINA PETROCHEMICAL CORP +1

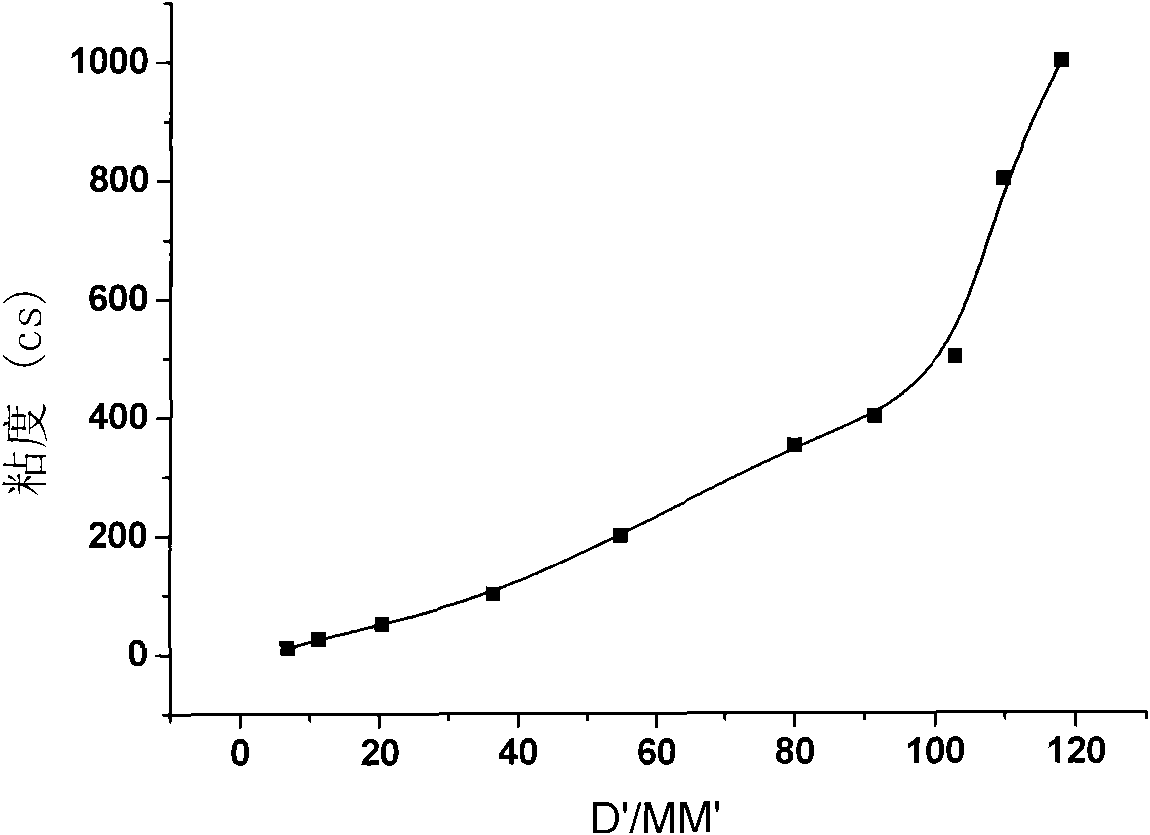

Method for preparation of silicon oil by silicon oil byproduct

The invention relates to a method for the preparation of silicon oil by silicon oil byproduct, in which dimethyl silicon oil byproduct in acid method production is used as raw material to prepare low-viscosity dimethyl silicone coil under the catalysis of solid acid catalyst. The method comprises the steps: calculating the constitution of raw materials in the silicon oil byproduct and drawing a proportion-viscosity relationship curve of the raw materials to set a feeding ratio, controlling reaction temperature between 50 and 110 DEG C under the catalyst of 3%-15% of solid catalyst, and implementing telomerization for 2 to 6 hours. By reutilizing the silicon oil byproduct, the method solves the problem of warehouse occupation of the silicon oil byproduct and lowers production cost. Using the solid acid catalyst can directly prepare neutral equilibration reaction product without neutralization and water washing procedures, the reaction process is simple, the viscosity of the product is easy to control and the regenerated byproduct can still be used repeatedly.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

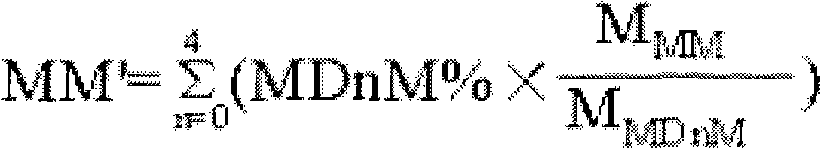

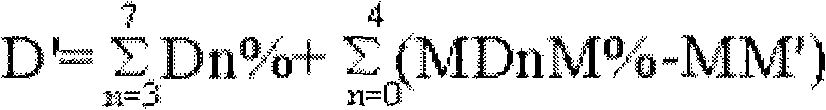

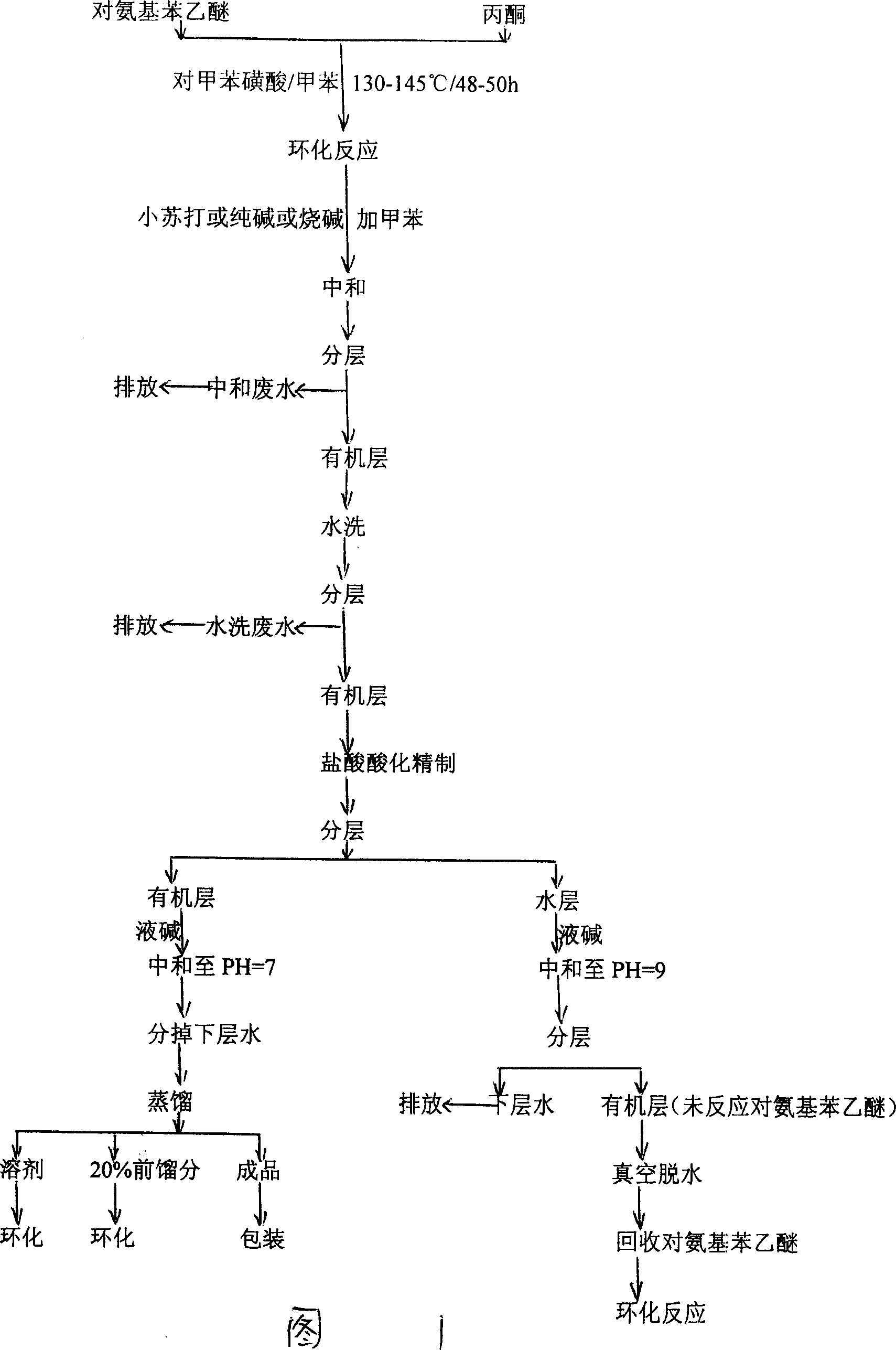

Method for composing ethoxy quinoline

InactiveCN1519232AAdvantages of Synthetic ReactionQuick responseOrganic chemistrySolid acidQuinoline

A process for synthesizing ethoxy quinoline from p-aminobenzoether and acetone features that in the synthesizing reaction, the super-strong solid acid H2SO4-MoO3-TiO2 is used as its catalyst for high reaction speed and high transform rate.

Owner:宜兴市天石饲料有限公司

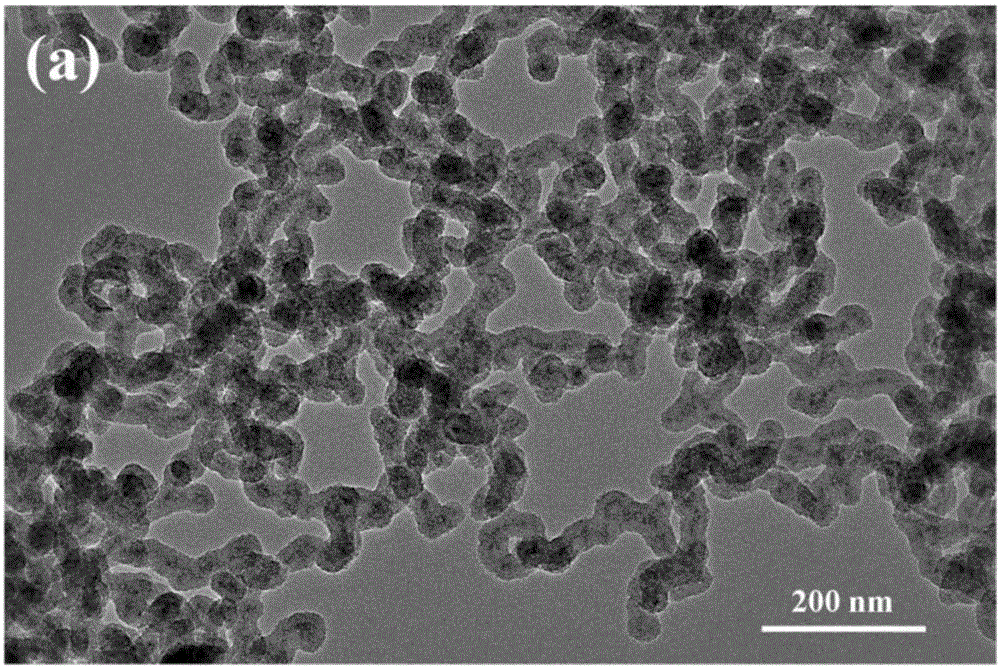

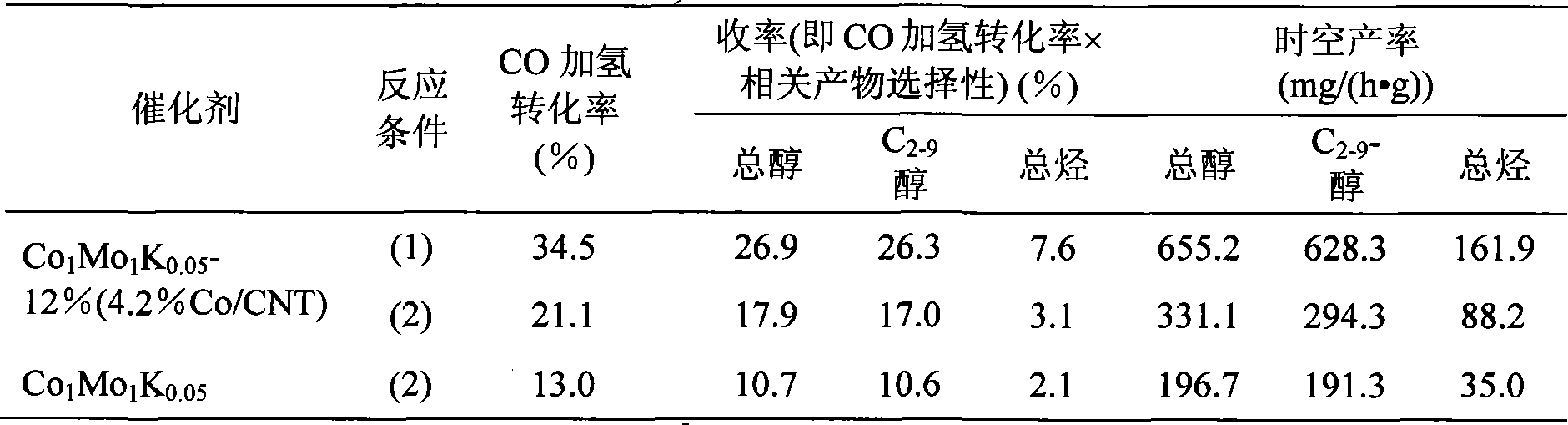

Promoting cobalt-copper base catalyst for preparation of low carbon mixed alcohol-carbon nano tube from synthetic gas and preparing method thereof

InactiveCN1669649AIncrease conversion rate per passHigh selectivityOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention relates to a method for preparing a catalyst, which is used in making low-carbon mixed alcohol carbon nanometer tube promoting Co-Cu group. The catalyst comprises Co, Cu and carbon nanometer tube, wherein the mass percent is: Co:40-75wt%,Cu:15-50wt%,CNTs:5-25wt%, the CNTs is a multi-wall carbon nanometer tube. The catalyst is prepared through coprecipitation, which has high activity and stability, and the C2+ alcohol has high selective, besides, both the conversion rate of CO and space time productivity of the low-carbon mixed alcohol are higher than the present catalyst.

Owner:XIAMEN UNIV

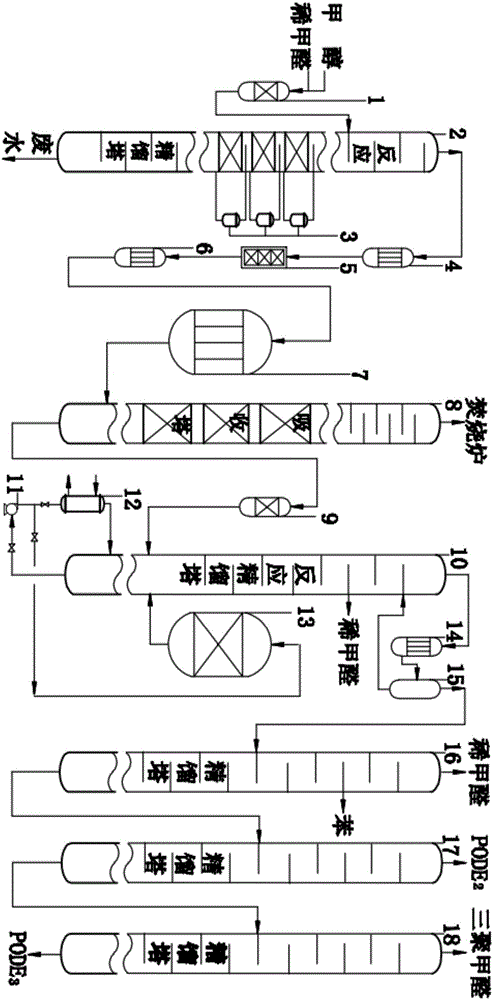

Method for synthesizing trioxymethylene by methanol through condensation, oxidation and polycondensation

InactiveCN106256822AEasy to separateReduce separation energy consumptionOrganic chemistryChemical industryHigh concentrationHigh energy

The invention relates to a method for synthesizing trioxymethylene by methanol through condensation, oxidation and polycondensation. According to the invention, methanol and dilute formaldehyde with concentration of 5-30% separated from a trioxymethylene apparatus are taken as raw materials to synthesize methylal with concentration of 85-99.9%; methylal and air are subjected to catalyst oxidation to generate formaldehyde through an iron molybdenum method, through refining water and methylal unit tower waste water absorption, a formaldehyde aqueous solution with concentration of 70% is generated; high-concentration formaldehyde is introduced into a trioxymethylene synthetic tower, and the trioxymethylene is synthesized under existence of a strong-acid cation exchange resin catalyst, and trioxymethylene with content of 99.9% can be obtained through steps of rectification and concentration, extraction, rectification, and purifying. The method solves the problems of low conversion rate, selectivity and low yield during a trioxymethylene production process, solves the problems of low catalyst reaction efficiency and corrosivity, and solves the problems of complex technology and high energy consumption. The method provides good raw materials for producing PODE, and realization of industrialization of PODE can solve the problem of excess production capacity of methanol in our country.

Owner:XIAN SHANGHUA TECH DEV CO LTD

Energy-efficient super-large scale methanol-synthesizing method with production of steam of different grades and apparatus thereof

ActiveCN105399604AIncrease concentrationIncrease conversion rate per passOrganic compound preparationHydroxy compound preparationSyngasProduct gas

The invention discloses an energy-efficient super-large scale methanol-synthesizing method with production of steam of different grades. Virgin gas is compressed and mixed with circulation gas for forming a gas mixture, the gas mixture is heated and simultaneously enters two parallelly arranged first methanol reactors for carrying out methanol synthesis reactions, and incompletely reacted synthetic gas and a methanol steam mixture are formed; the incompletely reacted synthetic gas and the methanol steam mixture are cooled and enter a second methanol reactor for carrying out a methanol synthesis reaction to obtain a final product; the final product is cooled and separated, and parts of the separated gas is used as circulation gas; and liquid crude methanol enters a downstream rectification unit. The invention also discloses an apparatus for realizing the method. A reasonably configured heat exchanger network is used for improving conversion per pass and concentration of methanol at the outlet of the reactor maximally, and reducing recycle ratio and energy consumption, and producing steam of different grades; the low pressure steam can meet low pressure steam demands of the downstream methanol rectification unit.

Owner:SHANGHAI INT ENG CONSULTING

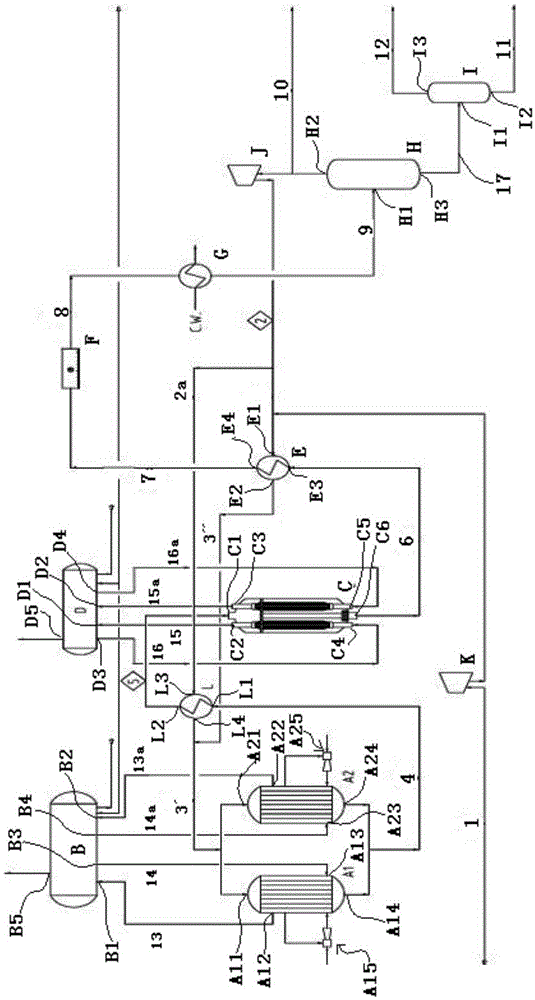

Method and apparatus for continuously preparing ethyl acetate by single tower

InactiveCN1616399ASimplify the production processIncrease conversion rate per passOrganic compound preparationCarboxylic acid esters preparationEthyl esterChemistry

The single tower ethyl acetate preparing process includes boiling the mixed liquid in certain acid / alcohol ratio and with strong acid catalyst and water carrying agent inside tower; opening condensating water for full reflux operation and stable top temperature after the vapor reaches to tower top; regulating acid / alcohol ratio to 1 and feeding strong acid catalyst from the top; regulating certain reflux ratio with the reflux ratio regulator, taking coarse ester product from the top and maintaining the top temperature unchanged; discharging gas material from the bottom, condensating in condensator, separating water in phase separator and refluxing organic phase with rich water carrying agent to the tower. The present invention has ester content in coarse ester product over 94 %, high conversion rate, low power consumption and low production cost.

Owner:GUANGXI UNIV FOR NATITIES

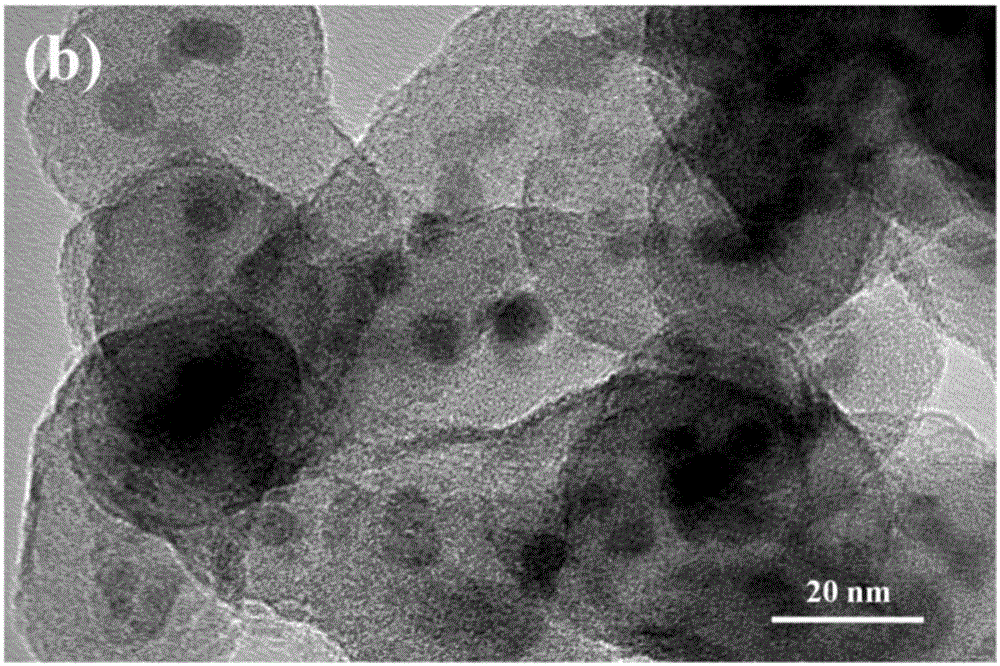

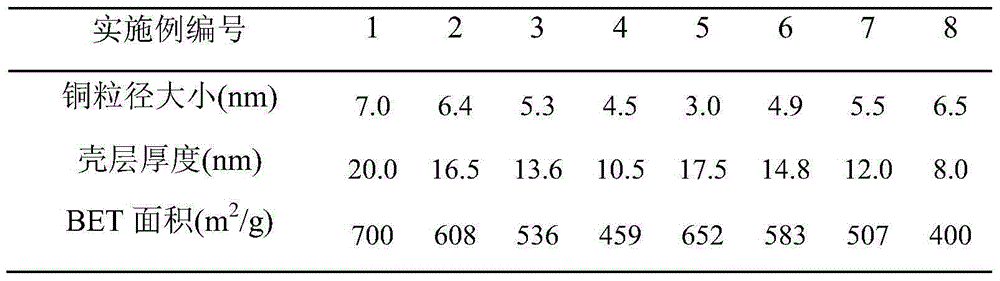

Core-shell structure type copper-based catalyst as well as preparation method and application thereof

ActiveCN105170151AUniform particle size distributionGood dispersionOrganic compound preparationHydroxy compound preparationHydrogenation reactionCopper

The invention provides a core-shell structure type copper-based catalyst as well as a preparation method and application thereof. The catalyst takes Cu as a core and takes mesoporous SiO2 as a shell layer material, the weight percentage of Cu is 8-25%, and the weight percentage of SiO2 is 75-92%. The core-shell structure type nano-composite catalyst material is uniform in grain distribution, adjustable in size, good in dispersibility, small in inner core copper grain, large in specific surface area, good in stability performance, and long in service life; in CO2 hydrogenation reaction operation, the catalyst is stable in performance, and high in activity, and can be operated at a high temperature (240-300 DEG C); the high CO2 conversion per pass can be still kept after long period evaluation, and the core-shell structure type copper-based catalyst has the advantages of being low in cost, easy to operate, easy to enlarge in industry and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

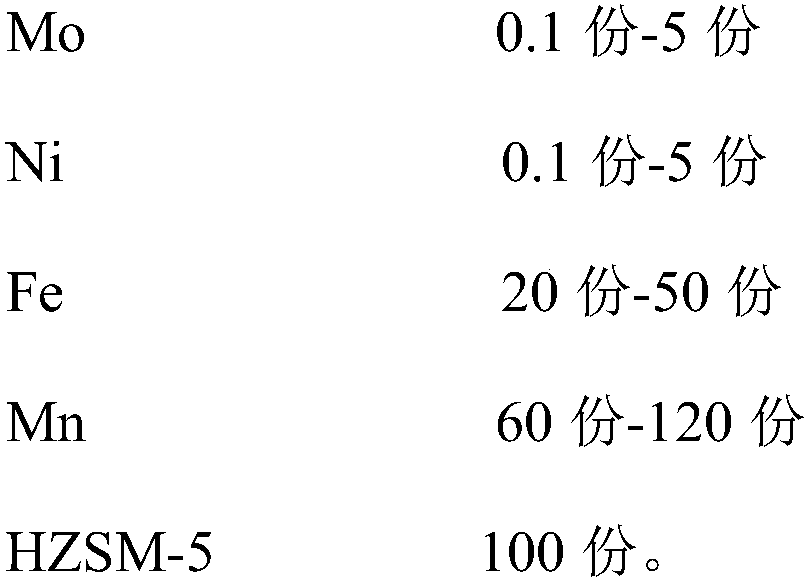

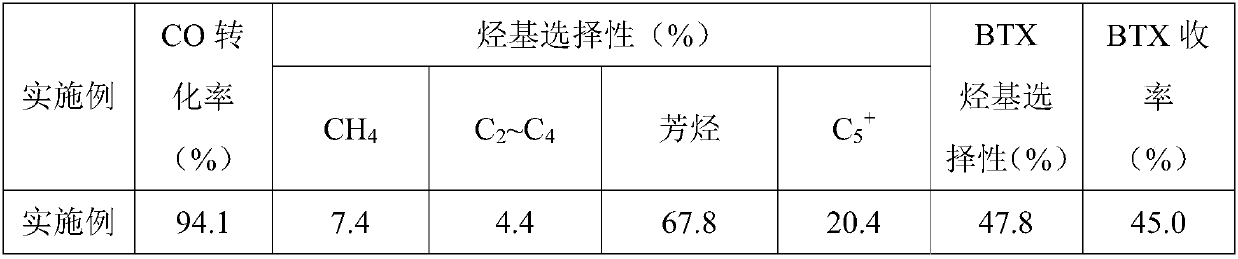

Catalyst for preparing light aromatic hydrocarbon by synthetic gas one-step process, and preparation method and application thereof

InactiveCN107626343AHigh selectivityTroubleshoot Temperature MismatchesMolecular sieve catalystsLiquid hydrocarbon mixture productionBimetalInorganic chemistry

The invention discloses a catalyst for preparing light aromatic hydrocarbon by synthetic gas one-step process, and a preparation method and an application thereof. The catalyst comprises a Fischer-Tropsch synthesis catalyst and an aromatization catalyst, wherein the Fischer-Tropsch synthesis catalyst includes an oxide of Fe and an oxide of Mn, and a composite metal oxide can fully improve the high-temperature Fischer-Tropsch synthesis activity; the aromatization catalyst is a modified molecular sieve with HZSM-5 as a carrier and with Mo and Ni double metals as active components, and the aromatization performance can be significantly improved. Through the combination of the two catalysts, series coupling of a Fischer-Tropsch synthesis reaction and an aromatization reaction is achieved, a one-way conversion rate of CO is increased obviously, and at the same time, a technology route for preparing light aromatic hydrocarbon-benzene, toluene and xylene (BTX) by synthetic gas one-step process is exploited. Experiments verify that the conversion rate of CO reaches up to 98% or more, the selectivity of hydrocarbonyl of aromatic hydrocarbon reaches 73% or more, and the selectivity of hydrocarbyl of BTX reaches 53%. The catalyst for preparing aromatic hydrocarbon by the synthetic gas one-step process has the advantages of relatively good catalytic activity, good stability and simple preparation, and has relatively good industrial application prospects.

Owner:EAST CHINA UNIV OF SCI & TECH

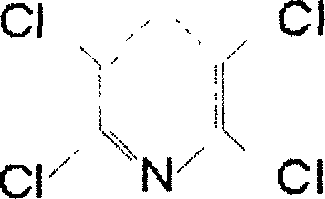

Process for preparing symmetric tetrachloro pyridine

InactiveCN1944408AIncrease conversion rate per passSimple processOrganic chemistryIron powderPyridine

The process of preparing symmetric tetrachloro pyridine includes the chlorination reaction of chloro pyridine containing 1-3 chlorine atoms and chlorine at 170-250 deg.c in the presence of iron powder or Lewis acid as catalyst for 8-48 hr. The preparation process uses chlorine in the liquid phase chlorination reaction to chlorinate chloropyridine, dichloropyridine, trichloropyridine, etc, and has single pass conversion rate up to 97 %, simple technological process, low production cost and excellent industrial application value.

Owner:盐城恒盛化工有限公司

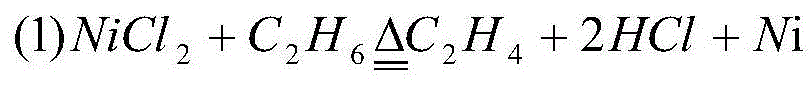

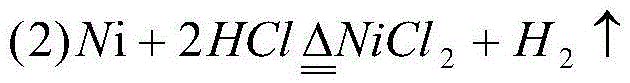

Method for continuously preparing ethylene by using ethane

ActiveCN104529688AIncrease conversion rate per passHigh selectivityHydrocarbonsHydrocarbon preparationMixed gasEthylene

The invention relates to a method for continuously preparing ethylene by using ethane. The method comprises the following steps: firstly, enabling ethane to react with NiCl2 to obtain C2H4 and HCl mixed gas; reducing solid NiCl2 into Ni; absorbing HCl from the C2H4 and HCl mixed gas by using a circulating NiCl2 solution; precipitating, crystalizing and separating the NiCl2 solution in which HCl is absorbed to obtain solid NiCl2 and a hydrochloric acid solution; drying the obtained solid NiCl2 and recycling; absorbing C2H4 gas from which HCl gas is removed, and performing rectification separation to obtain a C2H4 product; enabling the hydrochloric acid solution to react with Ni generated in the previous reaction to obtain H2 and a NiCl2 solution; recycling the obtained NiCl2 solution. During the process of the method, Ni is taken as an intermediate medium for circular reaction, and the method has the characteristics of low energy consumption, high yield, and use of recyclable medium nickel and capability of producing a byproduct H2 energy.

Owner:ZHONGKE YIGONG SHANGHAI CHEM TECH CO LTD

Synthesis gas preparing low carbon mixed alcohol catalyst and method of preparing the same

InactiveCN101249441AHigh selectivityIncreased space-time yieldOrganic compound preparationHydroxy compound preparationAlcoholCobalt

A catalyst for preparing low-carbon mixed alcohol from synthetic gas and preparation method thereof are provided. The invention relates to a Co-Mo-L oxide catalyst promoted by carbon nanotube-based nanomaterial, particularly a catalyst promoted by carbon nanotube-based nanomaterial capable of effectively improving single-pass conversion and selectivity and space-time yield of C2+ alcohol, and used for preparing low carbon mixed alcohol from synthetic gas. The catalyst contains Co-Mo-L oxides and carbon nanotube-based nanomaterial promoter, and is represented by a chemical formulation of CoiMojKk-x per cent(y per cent Co / CNT), and contains Co 20-50%, Mo 35-70%, K 0-3% and the promoter 8-16%. The carbon nanotube-based nanomaterial promoter is multi-wall carbon nanotube or metal Co-modified multi-wall carbon nanotube with a Co content of 1-8%.

Owner:XIAMEN UNIV

Method for preparing methyldiphenylchlorosilane and reactor thereof

ActiveCN101628917ASimple structural designEasy to cleanGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsChlorobenzeneHazardous substance

The invention relates to the field of organic silicon, in particular to a method for preparing methyldiphenylchlorosilane. The method is characterized in that chlorobenzene and methyl dichlorosilane are vaporized and then led into the reactor, and are thermally condensed with the participation of catalyst under the pressure of 0.2-0.8 MPa pressure and the temperature of 350-600 DEG C to obtain the methyldiphenylchlorosilane, wherein the catalyst is selected from chloroform, dichloromethane or carbon tetrachloride. The invention further relates to the reactor used for the preparation method. The selected catalyst is low in price and easy to obtain. The resultant produced by adopting the method is simple, and products and by-products are easily separated; with the invention, industrial continuous production is easily realized without generating other toxic and harmful substances or environment pollution; and the catalyst further can be recovered for reutilization.

Owner:ZHENJIANG JIANGNAN CHEM

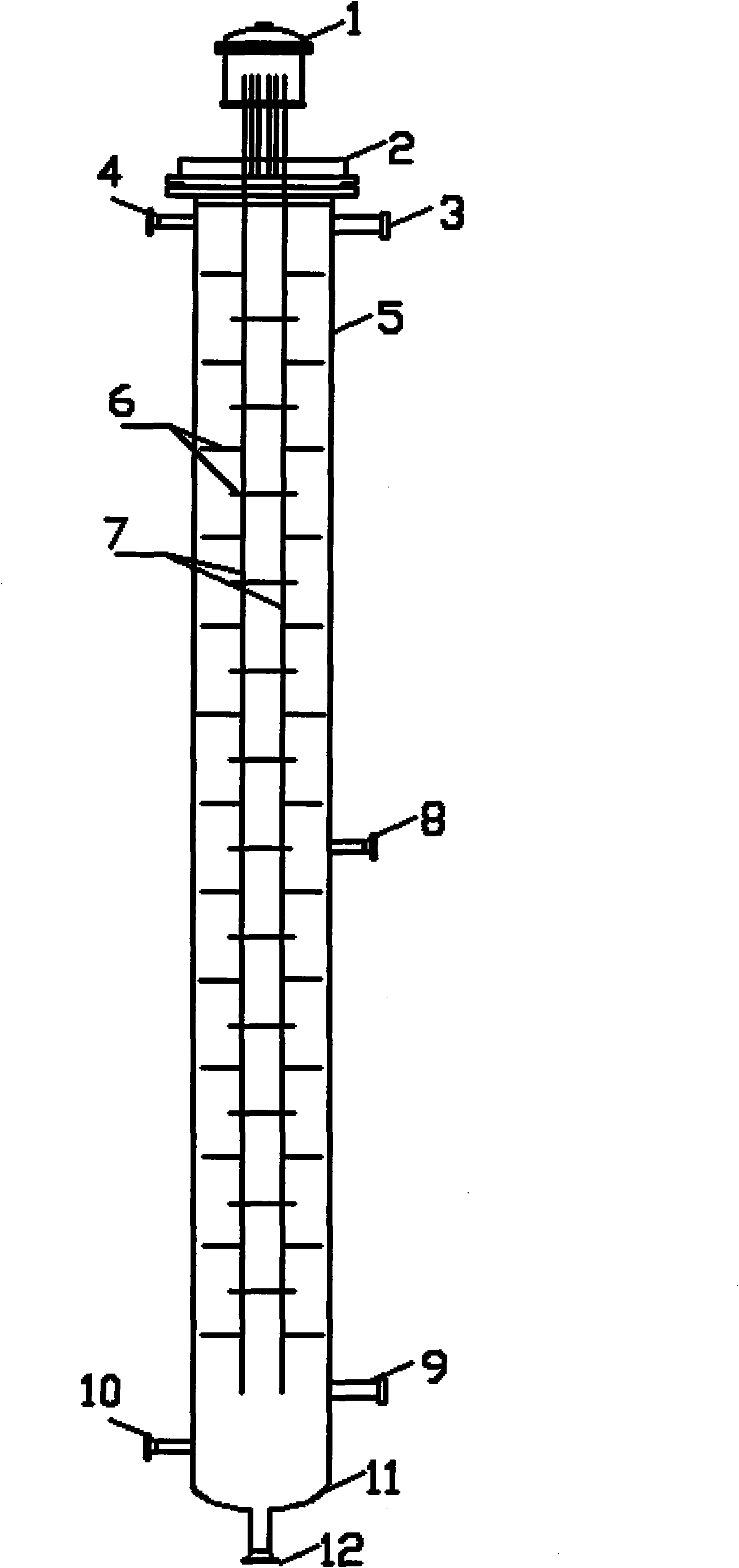

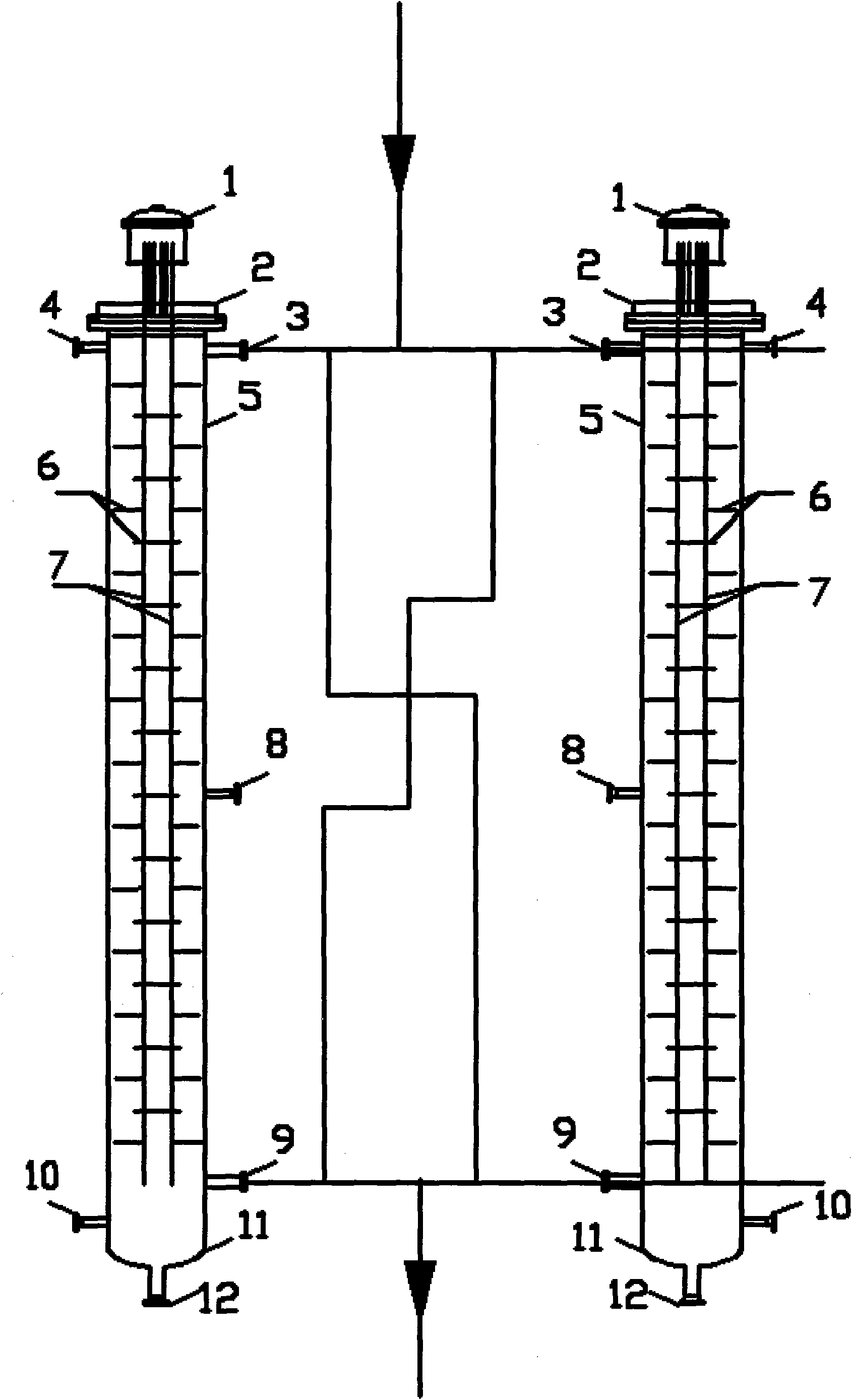

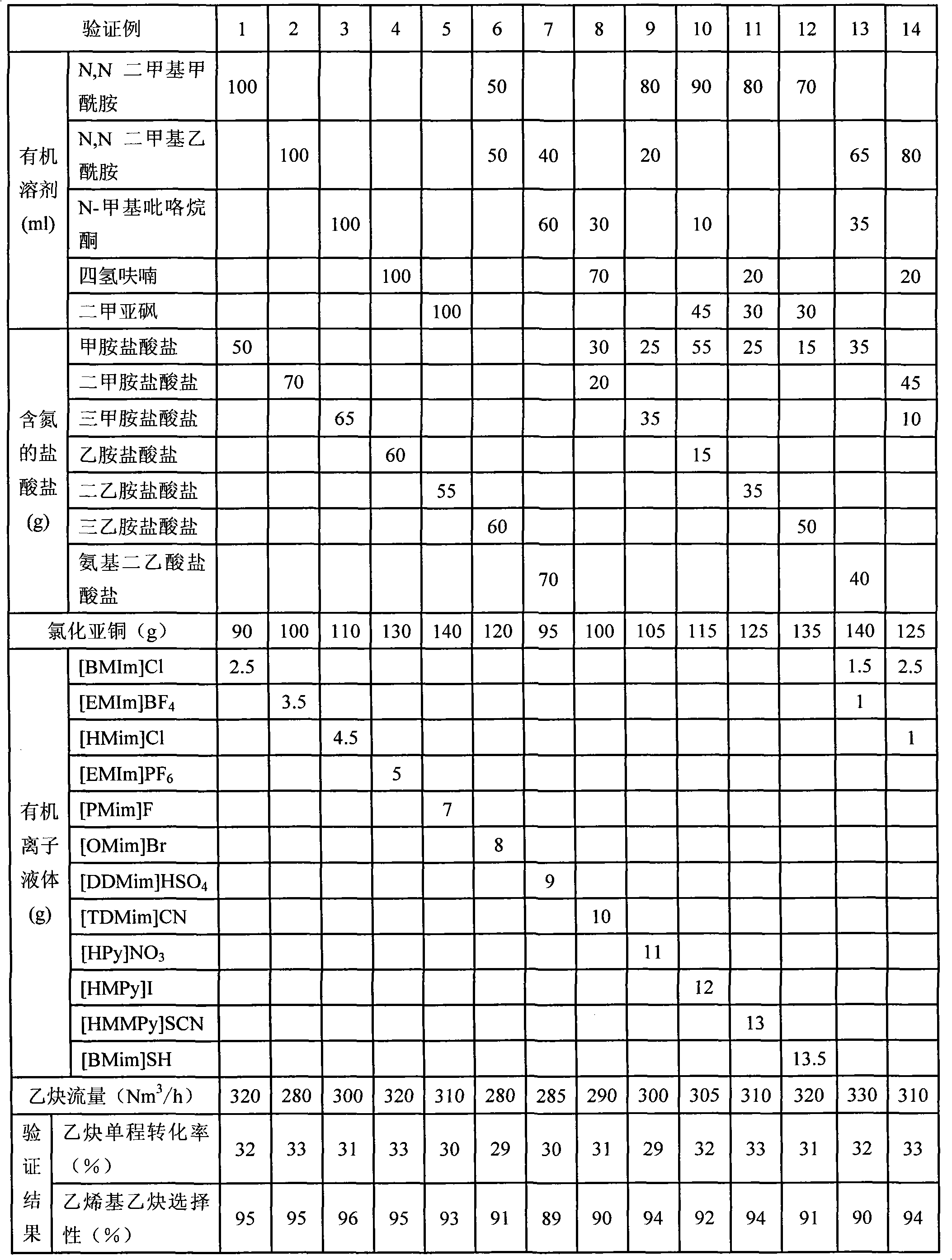

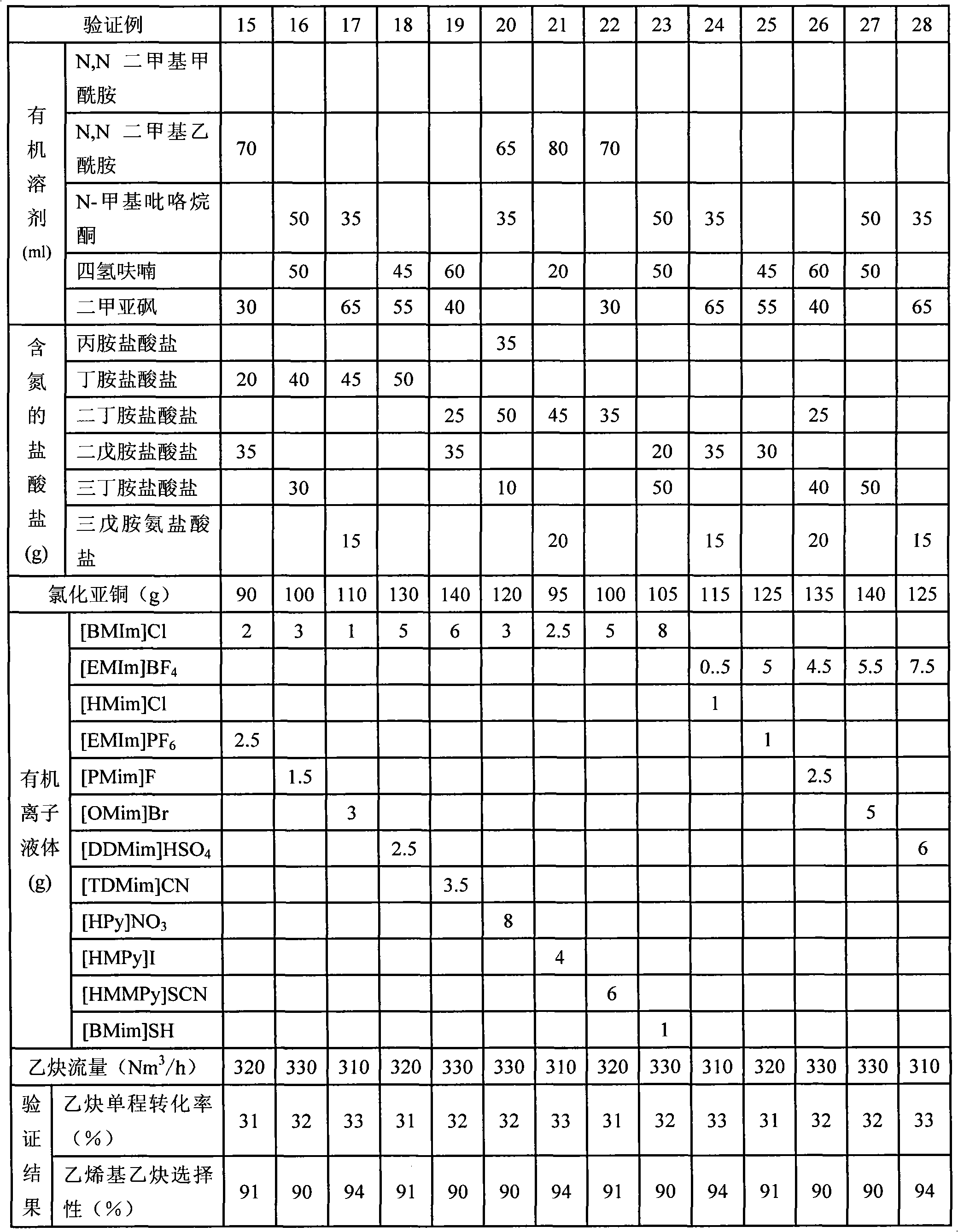

Catalyst for preparing vinyl acetylene and application method thereof

InactiveCN101786022AIncrease conversion rate per passImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsVinylacetyleneOrganic solvent

The invention discloses a catalyst for preparing vinyl acetylene and an application method thereof; the components of the catalyst include cuprous chloride, water, organic solvent, organic amine salt and organic ionic liquid. The application method includes steps that: under deoxygenation condition, the organic amine salt is dissolved in the solution of the organic solvent; and then cuprous chloride and organic ionic liquid are added to the solution; acetylene gas is introduced while the temperature is maintained constantly to produce vinyl acetylene. The invention improves the performance of an acetylene dimerization catalytic system, also increases the conversion per pass of acetylene and vinyl acetylene selectivity, produces less byproduct during reaction, greatly reduces the content of acetylene high polymer and accordingly reduces the separation difficulty and the production cost.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com