Process for separate production or joint production of ethanol and acetic ether through acetic acid indirect hydrogenation

A technology of ethyl acetate and hydrogenation method, which is applied in the direction of carboxylate preparation, sustainable manufacturing/processing, chemical industry, etc. It can solve the problems of difficult amplification, affecting product quality, and difficult separation and purification, so as to achieve good product quality, The effect of reducing equipment requirements and simple separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

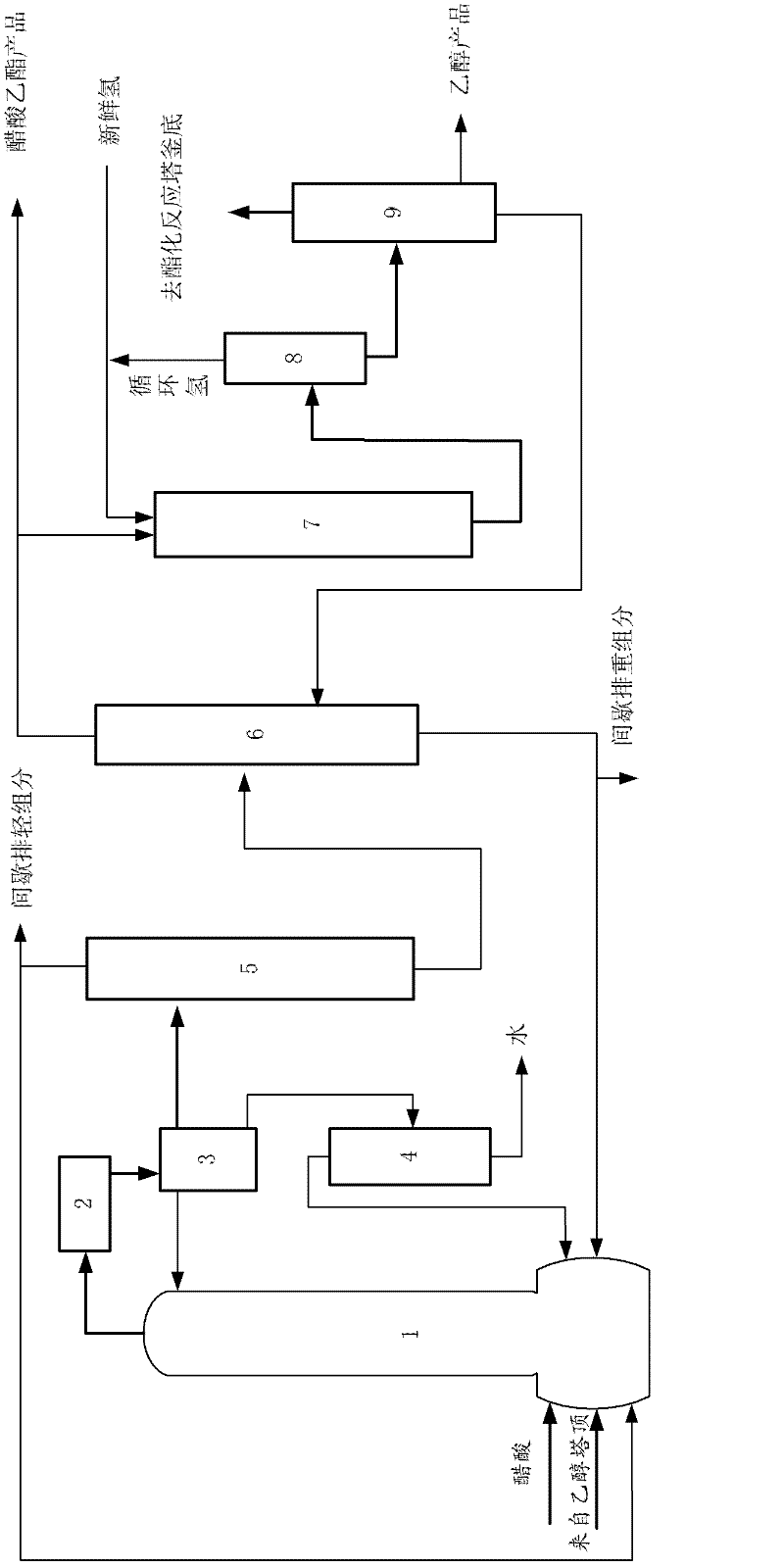

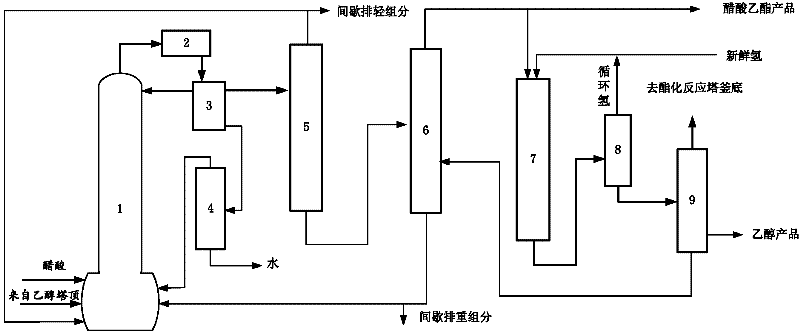

[0036] The process for single-unit or co-production of ethanol and ethyl acetate by indirect hydrogenation of acetic acid, the flow chart is as follows:

[0037] Acetic acid and the mixture of ethanol and ethyl acetate from the top of the ethanol rectification tower enter the tower still of the esterification reaction tower 1, and carry out the esterification reaction under the action of the acid catalyst. The content of the acid catalyst in the tower kettle is between 1wt.% and 5wt.%, which is regularly discharged and replenished. The molar ratio of acetic acid to ethanol in the feed is between 0.5 and 2.0, preferably 0.8 to 1.2. Generated ethyl acetate and water are distilled out from the top of the esterification reaction tower 1, condensed by the condenser 2, and then enter the water separator 3 to obtain crude ethyl acetate and water containing a small amount of ethyl acetate. The water containing a small amount of ethyl ester in the lower floor enters the recovery tower...

Embodiment 2

[0044] Annual production of 100,000 tons of ethanol

[0045] If the production target is 100,000 tons of ethanol, the three sets of devices, namely: esterification, hydrogenolysis and hydrogen production plants, need to operate at full capacity. Every year, 130,300 tons of acetic acid raw materials are consumed, 8,680 tons of hydrogen are consumed, and 39,100 tons of water are removed. The liquid product of the hydrogenolysis unit is separated and purified through the ethanol tower; the unreacted ethyl acetate and part of the ethanol are separated from the top of the tower, and the deesterification tower is used as the raw material for the esterification reaction.

Embodiment 3

[0047] Annual output of 100,000 tons of ethyl acetate

[0048] If 100,000 tons of ethyl acetate is the production target, the esterification unit will run at full capacity, and the hydrogenolysis and hydrogen production plants will both operate at about half the load, that is, the processing capacity of the hydrogenolysis unit will be about 100,000 tons, and the hydrogen production capacity will be 4540. Ton can be. When ethyl acetate is used as the target product, the liquid product from the hydrogenolysis unit can directly go to the esterification tower without separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com