Patents

Literature

604 results about "Aceric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetic acid, also known as ethanoic acid, CH3COOH, is the simplest carboxylic acid. It is a pungent, colorless, corrosive liquid. It is the acid found in vinegar and is often used as a reagent in making acetates and in biosynthesis.

Controlled release composition

InactiveUS20080254124A1Easy for to follow prescribed regimenConstant of releasePowder deliverySolution deliveryEthyl(hydroxyethyl)celluloseCellulose acetate

A composition for controlled delivery of at least one active substance into an aqueous medium by erosion at a preprogrammed rate of at least one surface of the composition, comprising a matrix comprising the active substance, the matrix being erodible in the aqueous medium in which the composition is to be used, and a coating having at least one opening exposing at least one surface of said matrix, the coating comprising a first cellulose derivative which has thermoplastic properties and which is substantially insoluble in the aqueous medium in which the composition is to be used, and at least one of a second cellulose derivative which is soluble or dispersible in water, a plasticizer, and a filler. The coating is a coating which crumbles and / or erodes upon exposure to the aqueous medium such as a body fluid. The first cellulose derivative may be, e.g., ethylcellulose, cellulose acetate, cellulose propionate or cellulose nitrate, and the second cellulose derivative may be, e.g. methylcellulose, carboxymethylcellulose or salts thereof, cellulose acetate phthalate, microcrystalline cellulose, ethylhydroxyethylcellulose, ethylmethylcellulose, hydroxyethylcellulose, hydroxyethylmethylcellulose, hydroxypropylcellulose, hydroxypropylmethylcellulose, hydroxymethylcellulose or hydroxymethylpropylcellulose.

Owner:EGALET LTD

Catalyst for synthesizing acrylic acid (ester) by taking formaldehyde and acetic acid as raw materials and preparation method thereof

ActiveCN103611522AReduce typesReduce contentMolecular sieve catalystsOrganic compound preparationPositive pressureReaction temperature

The invention provides a catalyst for synthesizing acrylic acid (ester) by taking formaldehyde and acetic acid as raw materials and a preparation method thereof. The method is characterized by comprising the following steps: 1, selecting one or more than one oxide of cesium (Cs), barium (Ba), strontium (Sr), magnesium (Mg), antimony (Sb) and bismuth (Bi) according to the fact that the selected oxide accounts for 2% to 30% of total mass of a carrier, and selecting one or more than one oxide of vanadium (V), phosphorus (P) and molybdenum (Mo) as an auxiliary agent according to the fact that the selected oxide accounts for 0.1% to 20% of total mass of the carrier; 2, selecting gamma-Al2O3, SiO2 or a molecular sieve as the carrier of the catalyst; and 3, depolymerizing paraformaldehyde in methanol, ethanol, isopropyl alcohol and the like by using sodium hydroxide or potassium hydroxide, adding the depolymerization solution of the paraformaldehyde into the acetic acid according to the acid-aldehyde molar ratio being 2-6, evenly mixing the mixture and then directly pumping the mixture into a reaction kettle through a sample injection pump; and performing catalytic synthesis at a reaction temperature within 200 DEG C to 400 DEG C and under the micro-positive pressure by using a fixed bed reaction device for synthesizing the acrylic acid (ester). The two target products, namely, the acrylic acid and the corresponding ester, are contained in the synthesized catalyst under a proper condition, wherein the total yield of the acrylic acid (ester) can reach more than 35%; and the by-product is less in variety and low in content. The catalyst is low in cost and environment-friendly by taking the formaldehyde and the acetic acid as the raw materials. The catalyst applied to an acrylic acid (ester) synthesis technology is simple in process and easy to industrialize.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

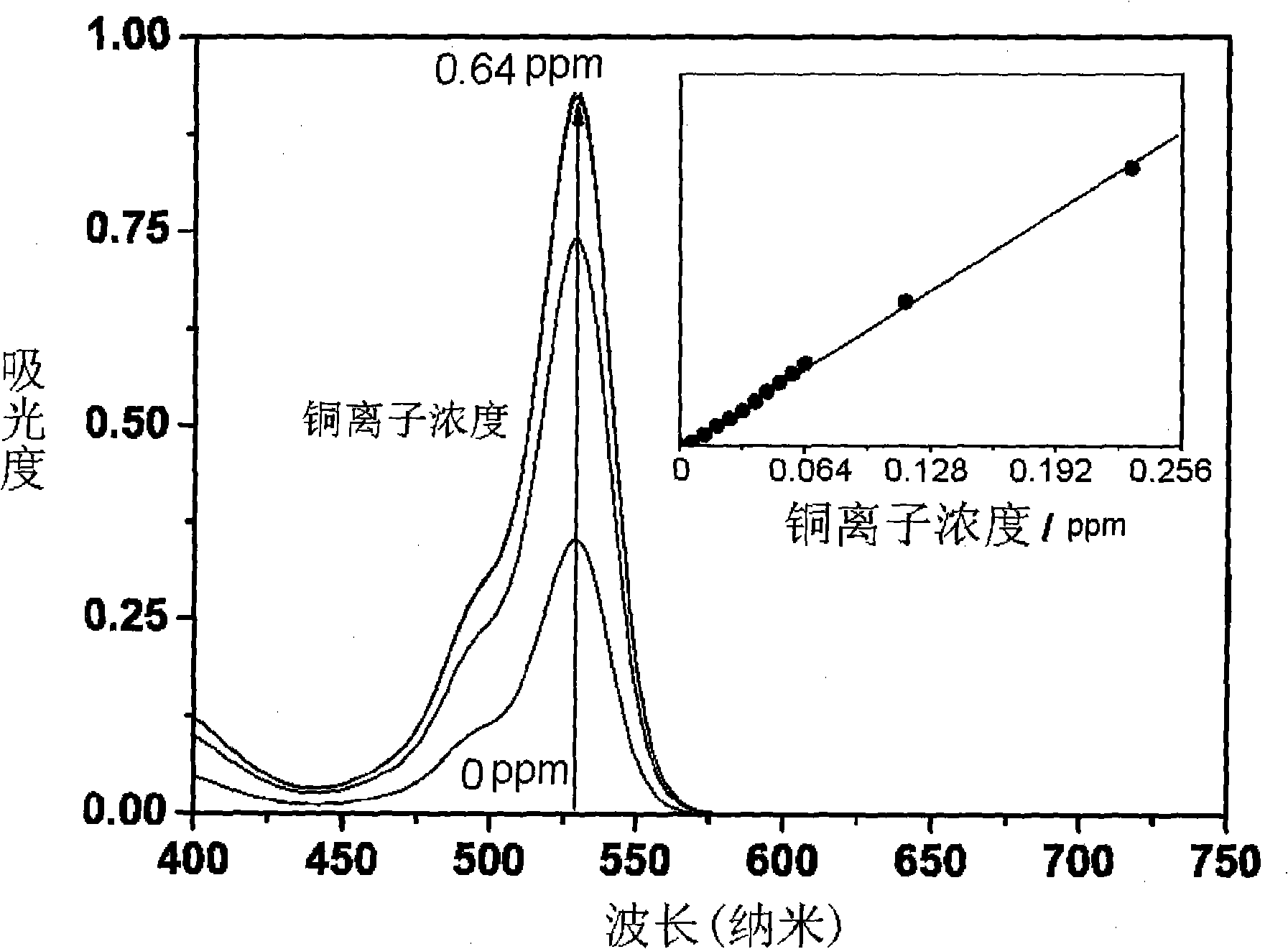

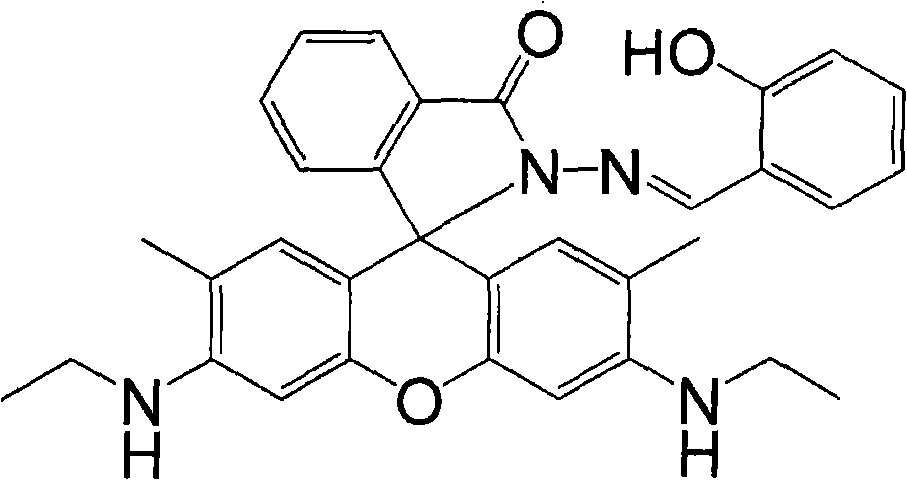

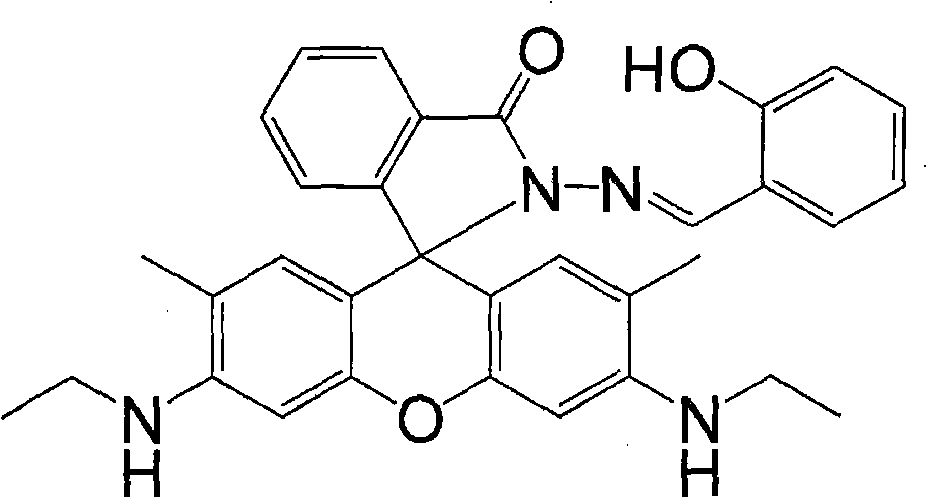

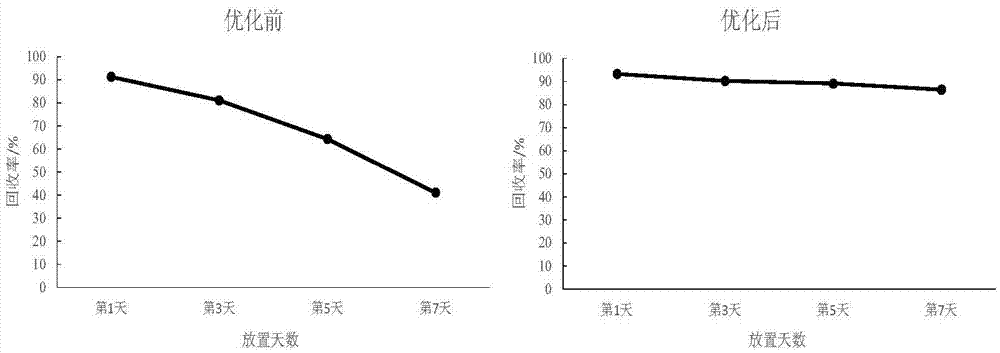

Rhodamine 6G hydrazide salicylaldehyde azomethine, synthesizing process and application in measuring content of copper ion

InactiveCN101270121AAccurate quantitative analysisHigh sensitivityAnalysis using chemical indicatorsOrganic chemistrySodium acetateSodium acetrizoate

The present invention relates to rhodamine 6G hydrazide salicylal azomethine, a synthesization method and an application in the content determination of cupric ions, which belong to the field of the analysis and determination of cupric ions in water sample. The molecular structural formula of the rhodamine 6G hydrazide salicylal azomethine is shown on the right, and the present invention discloses the synthesization method of the rhodamine 6G hydrazide salicylal azomethine and rhodamine 6G hydrazide salicylal azomethine solution used for the content determination of a small amount of cupric ions in water sample: 0 percent to 98.99 percent of ethanol, 99.99 percent to 1 percent of acetic acid / sodium acetate buffer solution with the pH value of 5 to 9, in which the total concentration of acetic acid is 1 to 100 millimoles per litre, 0.01 percent of N, N-dimethylformamide and 1ppm to 100ppm of rhodamine 6G hydrazide salicylal azomethine, all measured in mass percentage. By a spectrophotometer, the solution can be used for the accurate quantitative determination of 0.005ppm to 0.256ppm of cupric ions in water sample as well as the semiquantitative determination of no less than 0.075ppm of cupric ions in water sample by direct naked-eye observation on the change of colors.

Owner:TSINGHUA UNIV

Method for preparing glycyrrhetinic acid

The invention provides a method for preparing glycyrrhetinic acid, which comprises the followings steps of: dissolving glycyrrihizic acid powder with an organic solvent, and extracting and purifying to obtain an extract; in acetic acid, performing catalytic hydrolysis of mineral acid and acetylation to obtain acetyl glycyrrhetinic acid; adding water or alcohol into the acetyl glycyrrhetinic acid,and hydrolyzing under the catalysis of alkali to obtain crude glycyrrhetinic acid; dissolving with an organic solvent, adding active carbon for refluxing and decoloring, and crystallizing to obtain the glycyrrhetinic acid of which the purity is over 97 percent (by a neutralization process); and further crystallizing for multiple times with the organic solvent to obtain the glycyrrhetinic acid with the purity over 98 percent (HPLC). In the method, the glycyrrihizic acid powder is used as a raw material, so the raw material range is widened; the production is carried out under normal pressure, pressure containers are not needed, and the requirement on equipment is low; and the process is easily controlled, the process technology is simplified, and the production cost is low.

Owner:甘肃泛植制药有限公司

Long-acting sustained-release medicaments for treating and renovating bone disease and preparation thereof

InactiveCN101244275AExtended release timeImprove adhesionInorganic non-active ingredientsSkeletal disorderMicrosphereBiocompatibility Testing

The invention discloses a long acting slow-release drug carrier material for therapy and repair of bone disease and preparation method; wherein, the components of the drug carrier material are 4-8 weight account of strontium-doped calcium polyphosphate, 1-3 weight account of chitosan drug-loaded microspheres and 1-3 weight account of chitosan; the preparation method of the compound drug carrier material for therapy of osteomyelitis and other bone diseases is that (1) the chitosan-acetic acid solution is prepared, (2) the strontium-doped calcium polyphosphate powder is put into the chitosan-acetic acid solution and dispersed evenly, (3) the prepared chitosan drug-loaded microspheres is added, (4) the cross-linking agent is added for cross-linking, (5) freezing at temperature of 2-6 DEG C is processed for 12-48 hours, and (6) heating and drying are processed at temperature of 40-100 DEG C. The drug carrier material has the advantages of being applicable to therapy and repair of osteomyelitis and other bone diseases, releasing antibiotic for a long period, bone repair function, good biocompatibility and degradability, and ideal double function of therapy and repair of osteomyelitis and other bone diseases.

Owner:SICHUAN UNIV

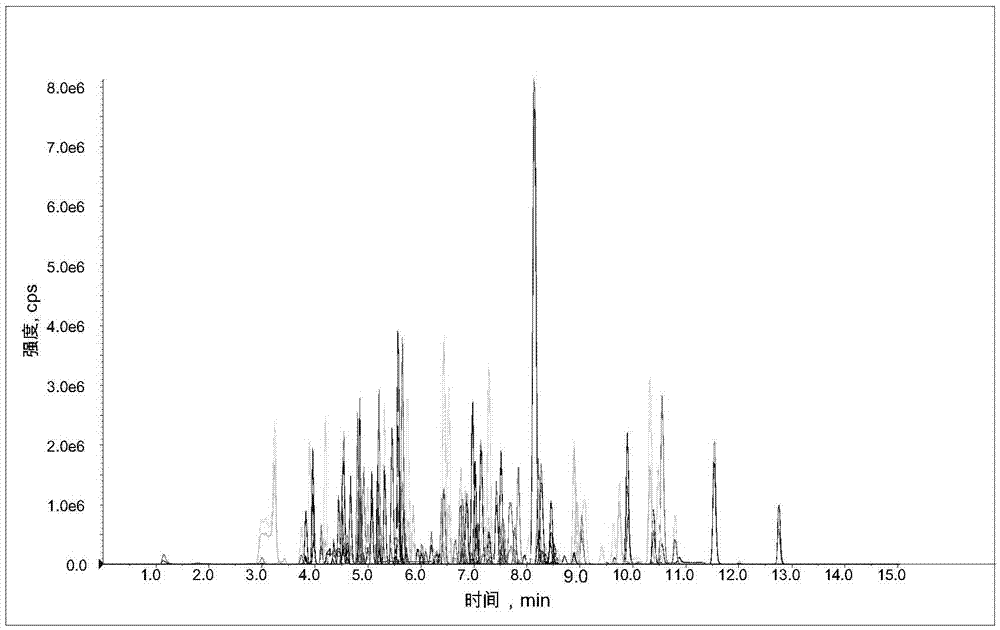

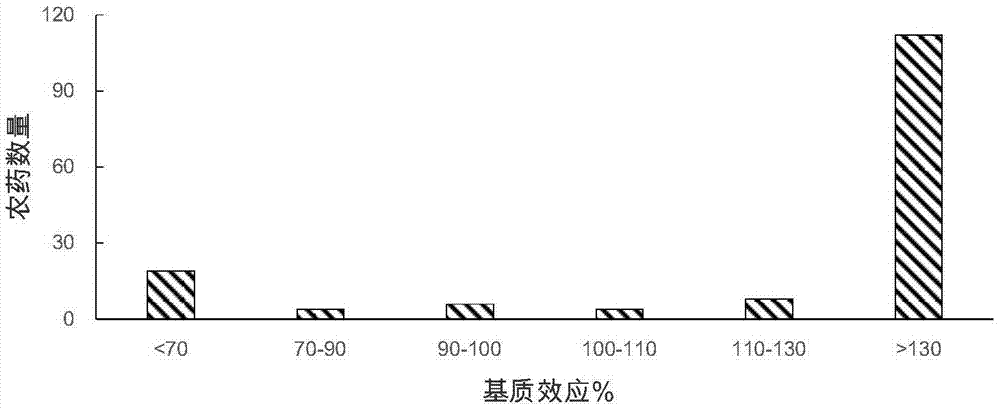

Method for detecting 153 pesticide residues in heart benefiting and pulse restoring particle

InactiveCN106918656AThe result is accurateReliable resultsComponent separationSodium acetatePesticide residue

The invention relates to a method for detecting 153 pesticide residues in a heart benefiting and pulse restoring particle. The method is a liquid chromatography-mass spectrometry method. The method comprises the following steps: preparing a sample solution, preparing a matrix mixed reference substance working solution, and detecting the solutions through using the high performance liquid chromatography-mass spectrometry, wherein the sample solution is prepared through the following steps: crushing the heart benefiting and pulse restoring particle, weighing 1.8-2.2 g of the heart benefiting and pulse restoring particle, adding 80-120 [mu]L of an internal standard solution with the concentration of 5 [mu]g / mL, adding 8-12 mL of water, infiltrating the particle for 28-32 min, adding 8-12 mL of an acetonitrile solution containing 0.08-0.12% of acetic acid, oscillating the obtained solution in a swirl mixing oscillator at a rate of 4000-6000 r / min for 1.8-2.2 min, adding 3-5 g of anhydrous magnesium sulfate and 0.08-1.2 g of sodium acetate, carrying out swirl shaking for 4-6 min, centrifuging the obtained solution at a speed of 4000-6000 r / min for 4-6 min, taking 0.8-1.2 mL of the obtained supernatant, adding the supernatant to a centrifuging tube which is filled with 140-460 mg of anhydrous sodium sulfate, 23-27 mg of PSA, 48-52 mg of C18 and 2.3-2.7 mg of GCB in advance, carrying out swirl shaking for 2-4 min, centrifuging the obtained solution at a rate of 4000-6000 r / min for 4-6 min, taking the obtained supernatant, and filtering the supernatant by a 0.2-0.24 [mu]m filter membrane.

Owner:TIANJIN TASLY PHARMA CO LTD

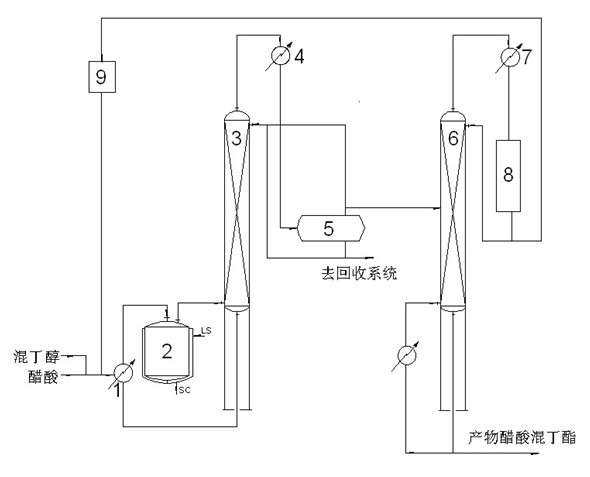

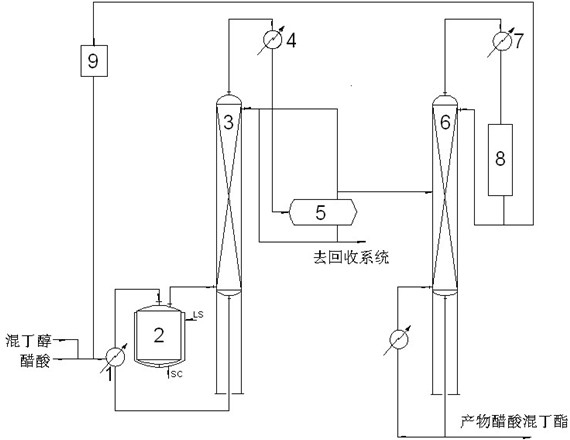

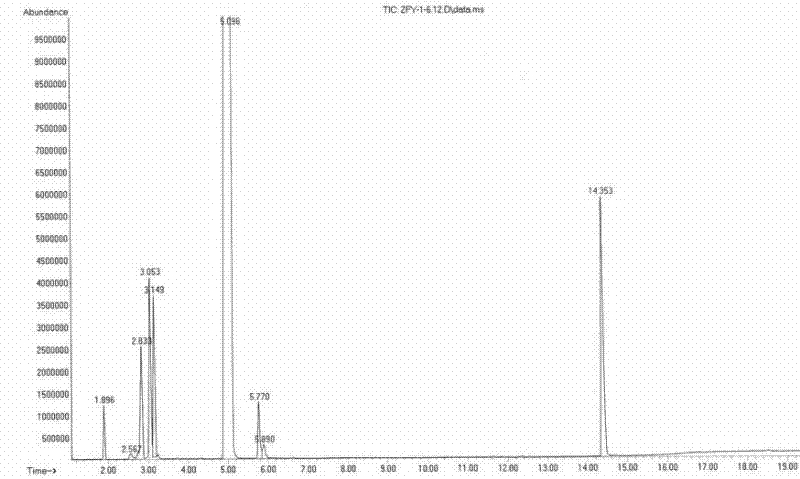

Method for preparing acetic acid mixed butyl ester by continuous reaction and rectification

InactiveCN102690197AEliminate dehydration processLow investment costOrganic compound preparationCarboxylic acid esters preparationAcetic acidPtru catalyst

The invention relates to a method for preparing acetic acid mixed butyl ester by continuous reaction and rectification. The method includes: acetic acid and mixed butanol are mixed and preheated according to molar ratio of 1:1, and temperatures of the mixed and preheated acetic acid and mixed butanol are increased after entering an esterification reactor and are reacted under catalysis of acid catalyst, a reaction product is performed initial gross separation in an esterification column in azeotrope form after being heated, a part of aqueous phase is performed reflux to the esterification column after a distillate at the top of the esterification column is performed condensation and phase separation, another part of the aqueous phase is discharged to a recovery column, a part of oil phase is performed reflux, and another part of the oil phase enters a rectification column as rough product to be further refined; and the rough product enters the rectification column from the middle of the same after being heated, a part of water and light components are removed by a membrane separator after a distillate at the top of the rectification column is condensed, a large part of the material reflows to the rectification column, a small part of the material is extracted to be reacted in the esterification reactor, and high-purity acetic acid mixed butyl ester is obtained at the bottom of the rectification column. Continuous production is achieved, and processes of neutralization, sedimentation and dehydration are omitted.

Owner:谦信化工集团有限公司

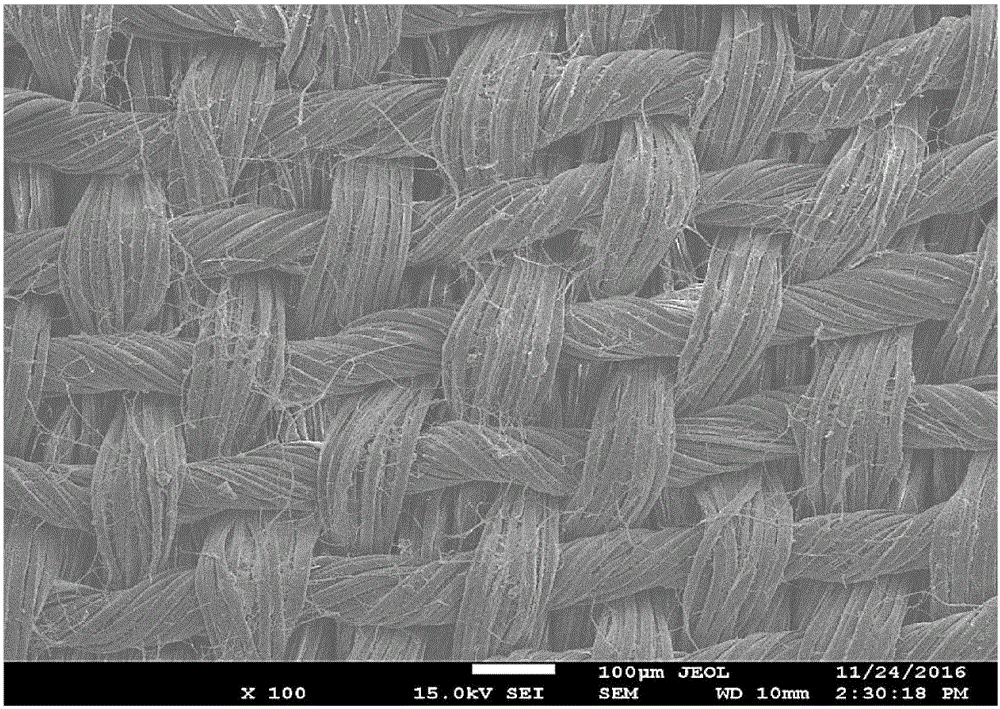

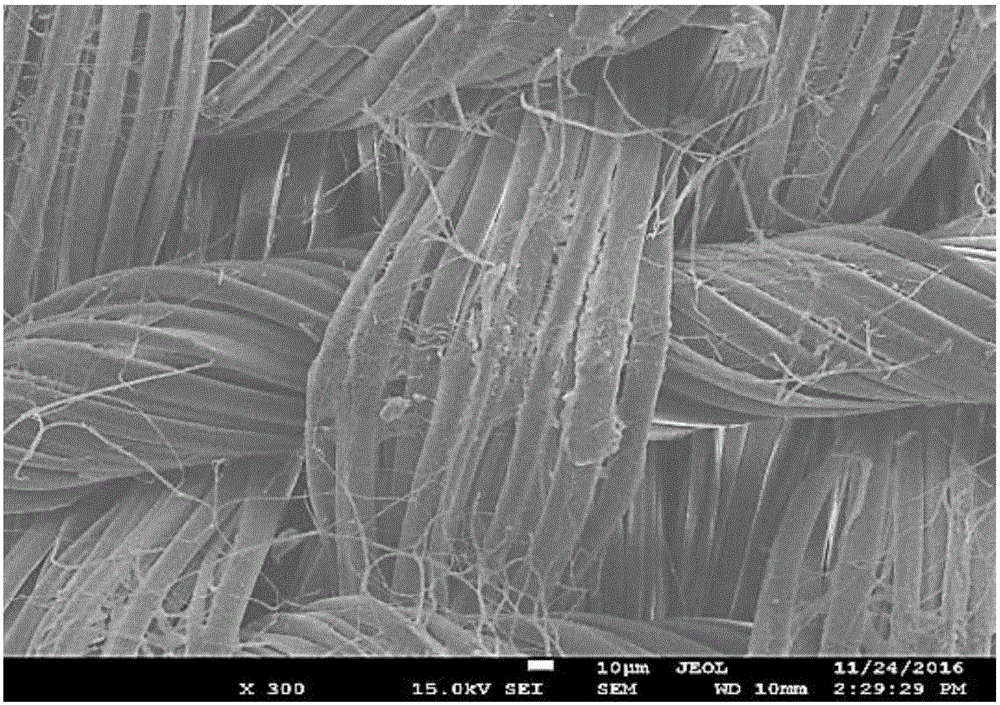

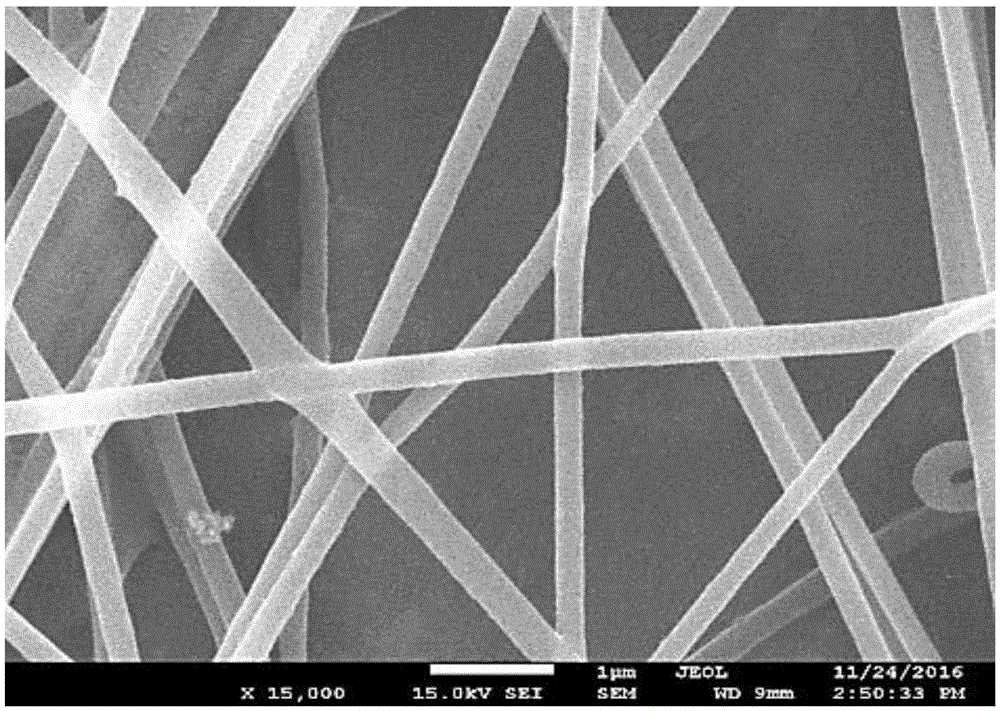

Temperature-sensitive antibacterial nanofiber and preparation method thereof

ActiveCN106757520AImprove breathabilityImprove thermal performanceConjugated synthetic polymer artificial filamentsAnimal fibresPolyethylene oxidePoly(N-isopropylacrylamide)

The invention provides temperature-sensitive antibacterial nanofiber. The temperature-sensitive antibacterial nanofiber is prepared by the following steps: adding N-isopropylacrylamide, chitosan, N,N-methylene bisacrylamide, an initiator and N,N,N,N-tetramethylethylenediamine into an acetic acid solution and performing free radical polymerization reaction to obtain chitosan / poly-N-isopropylacrylamide interpenetrating network hydrogel; mixing the chitosan / poly-N-isopropylacrylamide interpenetrating network hydrogen and an aqueous solution of polyethylene oxide to obtain electrostatic spinning liquid; performing electrostatic spinning on the electrostatic spinning liquid to obtain the temperature-sensitive antibacterial nanofiber. The temperature-sensitive antibacterial nanofiber provided by the invention has excellent antibacterial property and heat sensitivity.

Owner:EASTERN LIAONING UNIV

Preparation of bacteria cellulose food fresh keeping membrane

The invention discloses a method for preparing a bacteria cellulose food preservative film, which comprises the steps as follows: acetic acid bacteria cellulose which is prepared by bacteria cellulose, acetic anhydride, acetic acid and 98% concentrated sulfuric acid catalyst is treated to obtain modified bacteria cellulose, wherein, the mass ratio of the bacteria cellulose to the acetic anhydride is 1:6-1:8, the mass ratio of the acetic anhydride to the acetic acid is 1:3-1:4, and the amount of the 98% concentrated sulfuric acid catalyst is 0.6-0.8% of that of the bacteria cellulose. The following components are provided according to mass ratio: 40-60 portions of the modified bacteria cellulose, 10-20 portions of glycerol and 20-40 parts of stearic acid-palmiric acid with the mass ratio of the stearic acid to the palmiric acid being 1:1, 5-10 portions of 50-60 DEG C hot absolute ethyl alcohol; the three raw materials are respectively dissolved in a small amount of the hot absolute ethyl alcohol to obtain even solutions, and the three solutions are respectively stored in a container, evenly mixed with the residual absolute ethyl alcohol added, degassed in vacuum, repeatedly coated with film for 3 times and dried to obtain the bacteria cellulose food preservative film through film stripping.

Owner:NORTHEAST DIANLI UNIVERSITY

Method for separating straw acetylized component and preparing straw cellulose acetate

The present invention relates to the separation of straw acetyl cellulose and a preparation method for acetate: cold acetic acid and acetic acid which are of the same volume are added into the steamed straw; the steamed straw is acetylated with under a sulfuric acid condition to generate acetic acid fibrin, acetylation half-fibrin and acetylation lignin liquid; the liquid is placed in a centrifuge for centrifugal treatment; sypernatant and deposit are obtained; the deposit is disposed and the sypernatant is reserved; after that the sypernatant is cleaned by water to produce deposit which is then filtered; The deposit is washed to neutral and is boiled and dried; acetylation products of acetic acid fibrin, acetylation lignin and acetylation half-fibrin are generated; the acetylation products are extracted by solvent; twain-acetic acid fibrin, acetylated half-fibrin and lignin dissolve in the solvent and the remained that does not dissolve in the solvent is tri-acetic acid fibrin. The present invention overcomes the shortcoming of the traditional separation method in terms of environmental pollution. The acetic acid fibrin obtained through the method can be used in industry. The acetylated lignin is improved and becomes more stable. The group separation of straw can be realized through the method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composite clarifying agent, and preparation method and application thereof

InactiveCN102559466AFor the purpose of clarificationLow application costAlcoholic beverage preparationFood preparationCelluloseFruit juice

The invention relates to a composite clarifying agent, and a preparation method and application thereof. The composite clarifying agent comprises K solution and S solution, wherein the K solution is aqueous solution comprising 0.8 to 1.2 percent (w / v) of chitosan and 0.8 to 1.2 percent (v / v) of acetic acid; and the S solution is aqueous solution comprising 0.8 to 1.2 percent (w / v) of carboxymethylcellulose. The composite clarifying agent has low application cost and a good clarifying effect and is applicable to clarification of wine, vegetable and fruit juice, tea or health-care products. During clarification, flocs are combined tightly, so the composite clarifying agent is easy to separate, low in application cost, good in clarifying effect and high in speed, does not influence the liquid flavor, can effectively remove macromolecular substances such as excessive protein, pectin, tannin and the like and suspended matters from the liquid, and is convenient to use and simple to operate.

Owner:HUBEI UNIV OF TECH

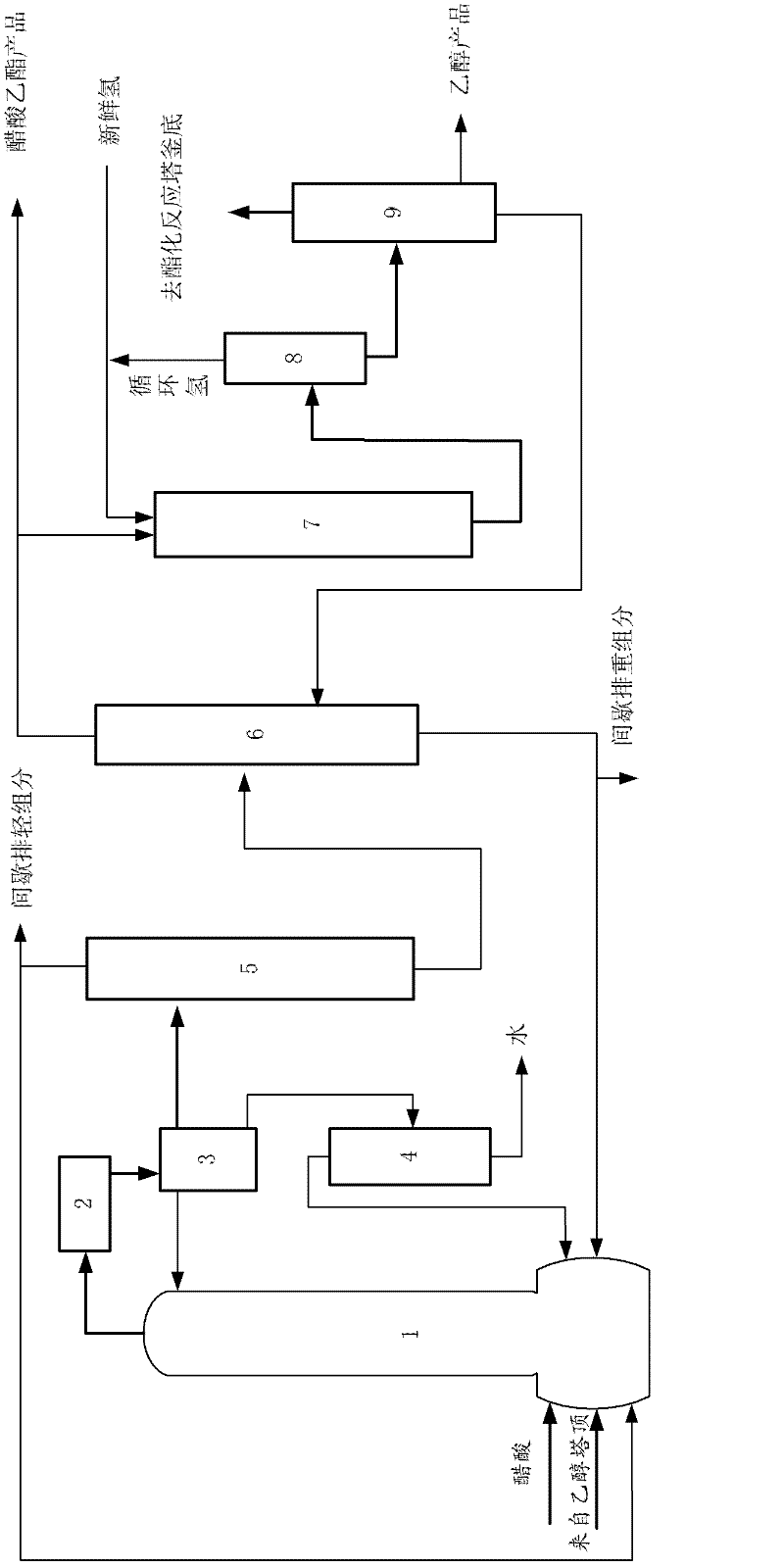

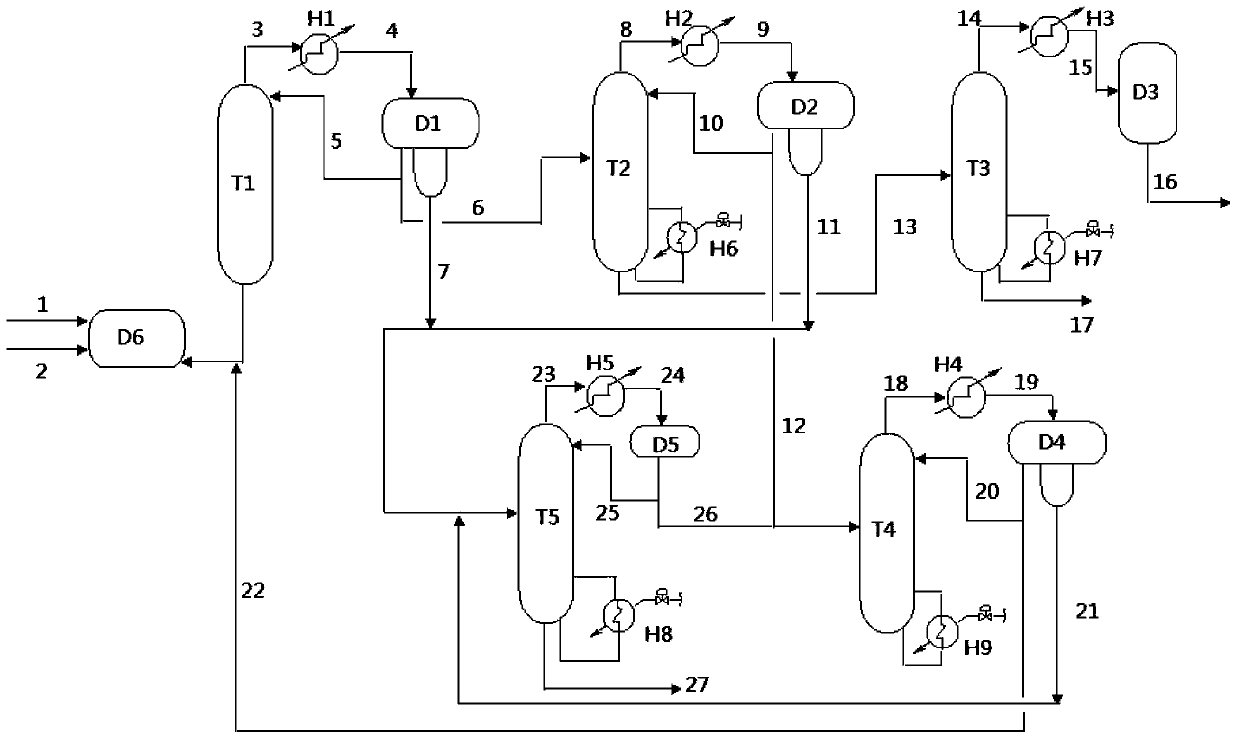

Process for separate production or joint production of ethanol and acetic ether through acetic acid indirect hydrogenation

ActiveCN102557931AReduce consumptionIncrease conversion rate per passOrganic compound preparationCarboxylic acid esters preparationAcetic acidReactive distillation

The invention relates to a process for separate production or joint production of ethanol and acetic ether through acetic acid indirect hydrogenation. Acetic acid and ethanol are placed in an esterification tower, the acetic acid and the ethanol are subjected to reactive distillation in the presence of acid catalysts, the acetic ether and water are obtained, the mixture is distilled off from the top of the tower and enters a water segregator, a rectification light removal tower and a rectification heavy removal tower after being condensed, so that impurities are removed and conforming products of the acetic ether are obtained. Part of the products are sold, and others are regarded as raw materials for producing the ethanol in a hydrogenolysis reaction, led to a hydrogenolysis tower and subjected to catalytic hydrogenolysis so as to selectively obtain the ethanol. Part of or all the ethanol obtained by hydrogenolysis of the acetic ether is regarded as a raw material for an esterification reaction and reacts with the acetic acid in the esterification tower. Compared with the existing technologies, the process is simple in flow and low in production cost; and either the ethanol or the acetic ether can be produced selectively, or both the ethanol and the acetic ether can be produced in a certain proportion through adjustment of the production capacity of a hydrogenolysis and hydrogen production device.

Owner:ZHONGRONG TECH CORP LTD +1

Slimming enzyme and preparation method thereof

ActiveCN105559088ARich and balanced nutritionWide variety of sourcesFood ingredient functionsAcetic acid bacteriaSweet taste

The invention provides a slimming enzyme and a preparation method thereof. The preparation method comprises the following steps: (1), preparing and pretreating materials in proportion; (2), aerobically fermenting the treated materials via high-sugar Angel yeast; (3), after fermentation with the yeast, aerobically fermenting with acetic acid bacteria; (4), after fermentation with the acetic acid bacteria, anaerobically fermenting with probiotics; (5), after fermentation with the probiotics, fermenting at low temperature and filtering to obtain the finished enzyme. The product produced by the above method has slight vinegar aroma and sour and sweet taste, is not less than 1046 U / ml in lipase activity and not less than 6.8*108 in the count of live Lactobacillus johnsonii and has significant slimming effect.

Owner:JIANGSU SHENHUA PHARMA

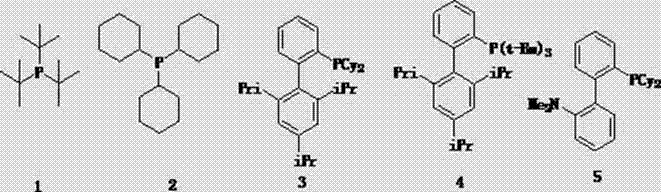

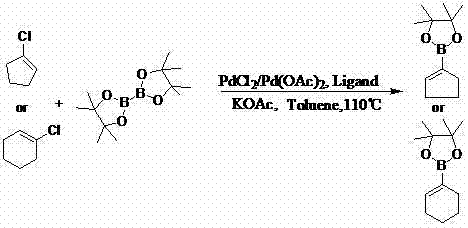

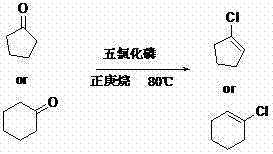

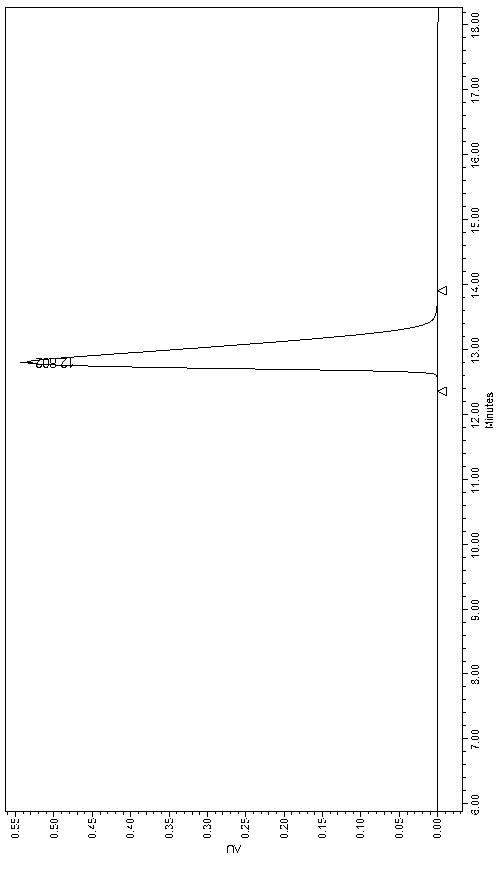

Method for preparing cyclopentene/cyclohexene-1-boronic acid pinacol ester

InactiveCN103044469AReduce dosageLow costGroup 3/13 element organic compoundsCyclopentenePtru catalyst

The invention discloses a method for preparing cyclopentene / cyclohexene-1-boronic acid pinacol ester. The method comprises the step of carrying out coupling reaction on 1-chlorine-cyclopentene / cyclohexene serving as a raw material in an organic solvent A in the presence of monophosphate ligand and a palladium catalyst based on potassium acetate as alkali so as to prepare the cyclopentene / cyclohexene-1-boronic acid pinacol ester. The method is characterized in that the physicochemical reaction at the n-butyllithium and ultralow temperature condition in the literature is avoided, and the palladium catalyst is adopted for catalyzing, so that the amount of the used catalyst is reduced, and the cyclopentene / cyclohexene-1-boronic acid pinacol ester can be prepared in relatively high yield at the acceptable temperature; the boronizing agent n-butyllithium / isopropoxy boronic acid pinacol ester system is replaced by the boronizing agent palladium catalyst / bis(pinacolato)diboron system, and therefore, the cost of the raw materials is greatly reduced, the reaction condition is relatively easy to realize, amplification is easy, and the technical operation is simpler and more convenient.

Owner:DALIAN NETCHEM CHIRAL TECH

Method for preparing acetic acid esterified modified dextrin and crosslinking acetic acid esterified composite modified dextrin

InactiveCN102206288AImprove polarity characteristicsReduce the number of hydrogen bondsFermentationAcetic acidFreezing thawing

The invention relates to a method for preparing acetic acid esterified modified dextrin and crosslinking acetic acid esterified composite modified dextrin, which comprises two methods, i.e., a direct method and an indirect method. The direct method comprises the steps of directly taking malto dextrin or pyrolyzed dextrin as the raw material and carrying out chemical modification, i.e., acetic acid esterification or crosslinking acetic acid esterification; and the indirect method comprises the steps of taking starch as the raw material, carrying out the chemical modification, i.e., the acetic acid esterification or the crosslinking acetic acid esterification, to obtain corresponding starch derivatives firstly, and then dextrinizing after enzymolysis or pyrolysis to obtain a final product. The method for preparing the crosslinking acetic acid esterified composite modified dextrin further comprises two modification sequences, i.e., crosslinking is carried out before esterification, or the esterification is carried out before the crosslinking. The acetic ester or crosslinking acetic ester dextrin derivatives have the characteristics of good stability, high transparence, strong thickening performance, low hygroscopicity, low retrogradation, freeze-thaw stability, excellent emulsibility and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for purifying teriparatide acetate

ActiveCN102993293AOperableHigh yieldPeptide preparation methodsParathyroid hormonesGradient elutionSilica gel

The invention provides a method for purifying teriparatide acetate, comprising the following steps: dissolving crude peptide by using the aqueous solution of 10-30% of acetic acid and 5-20% of acetonitrile in volume ratio; carrying out gradient elution and purification on a crude peptide solution; adjusting the pH value of the aqueous solution of 0.1-0.4% of sulfuric acid and 0.1-0.4% of acetic acid in volume ratio by using ammonia water to be 5.0-6.0; obtaining the solution as phase A and acetonitrile as phase B; eluting when the gradient of the phase B is 20-40%; salting out; washing by using an ammonium acetate solution containing 3-10% of acetonitrile; converting acetate by using the high performance liquid chromatography of the octadecylsilane chemically bonded silica gel; and eluting an acetic acid aqueous solution acetonitrile system. The invention aims to provide a method for purifying the teriparatide acetate, which is simple in operation, high in yield and purity, and favorably realizes industrialization.

Owner:HYBIO PHARMA

Method for producing ethanol through acetic acid esterification-hydrogenation

InactiveCN103387481AReduce consumptionFlexible specification selectionOrganic compound preparationHydroxy compound preparationAnhydrous ethanolAcetic acid

The invention relates to a method for producing ethanol through acetic acid esterification-hydrogenation, which mainly solves the problems in the prior art that the whole flow of acetic acid esterification, ethyl ester hydrogenation and ethanol refining is not involved and ethyl ester hydrogenation only can be performed under the condition of high hydrogen ester content. The method for producing the ethanol through acetic acid esterification-hydrogenation comprises the following steps: (1) reacting ethanol with acetic acid to obtain a mixture containing ethyl acetate and water, performing azeotropic treatment to reach a condenser on the top of an esterification tower, then entering a separator for separating out water, and separating impurities out of coarse ester to obtain ethyl acetate; (2) enabling hydrogen and vaporized ethyl acetate to come into contact with a copper-containing catalyst in a reactor so as to perform hydrogenation reaction to obtain ethanol-containing fluid, and performing high-pressure gas liquid separation and low-pressure gas liquid separation to obtain coarse ethanol; and (3) separating the ethanol by using a light component removing tower and a heavy component removing tower to obtain an industrial ethanol or absolute ethanol product. According to the technical scheme, the problems in the prior art are solved well, and the method can be applied to production of the ethanol through acetic acid esterification-hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

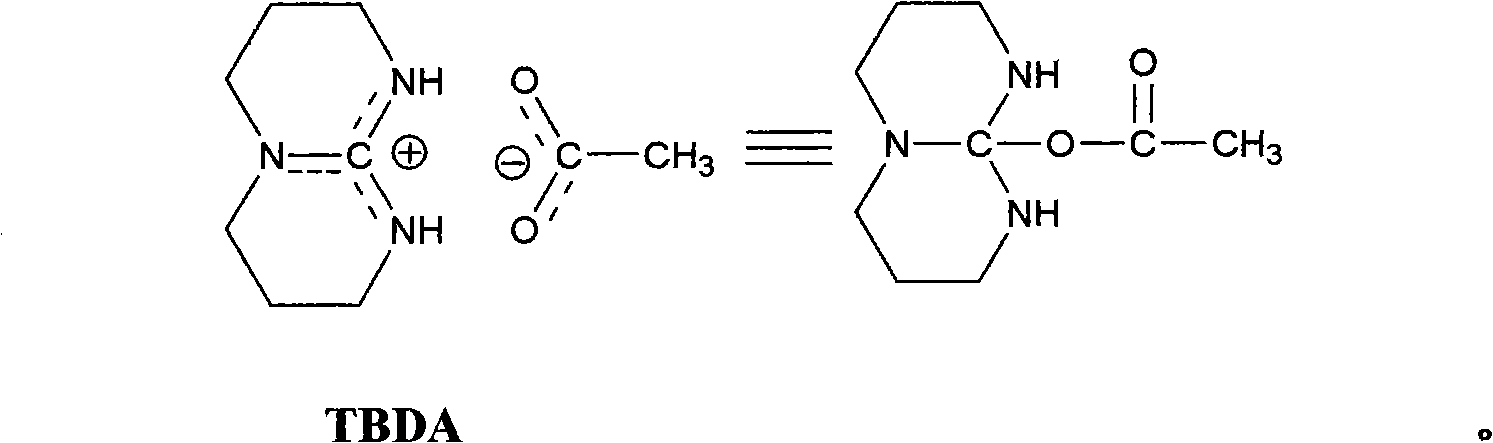

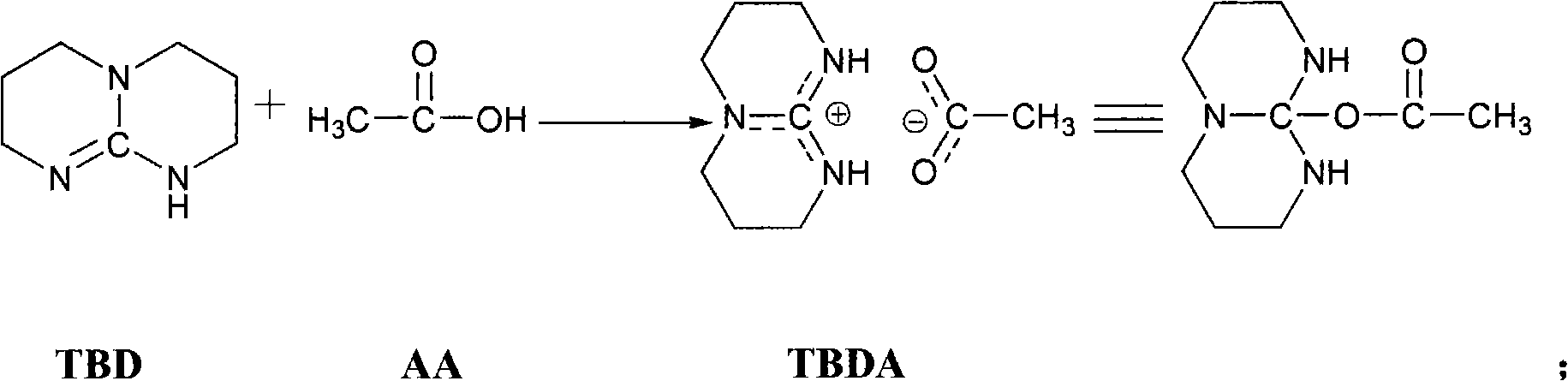

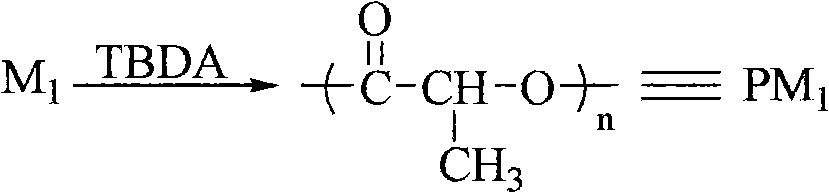

Process for synthesizing acetate bicyclo guanidine and catalysis synthesis for poly-lactide and poly-serine morpholine diketone

ActiveCN101318960AReduce manufacturing costNo pollution in the processOrganic chemistryMorpholinePoly(lactide)

The invention relates to an acetate bicyclic guanidine, a synthesizing method thereof and a synthesis of a polylactide and a polyserine morpholine dione by catalysis. The acetate bicyclic guanidine has the above structure and is synthesized by a direct reaction of bicyclic guanidine and acetic acid in a catalyst-free aqueous solution. In the invention, the acetate bicyclic guanidine is adopted as a catalyst to catalyze a bulk activity of L-lactide (LLA), D,L-lactide (DLLA) or (3S)-3- benzyloxymethyl-6-methyl-morpholine dione (BMMD) to perform ring opening polymerization reaction , thereby synthesizing a poly L-lactide (PLLA) and a poly D,L-lactide (PDLLA) with a number average degree of polymerization of between 120 and 280 and narrow molecular weight distribution and polyserine morpholine dione with a number average degree of polymerization of between 120 and 150. PBMMD can be used for preparing a lactic acid-serine copolymer. The acetate bicyclic guanidine as the catalyst is a nonmetallic and nontoxic organic compound; the method has low production cost, simple process operation, no pollution, a high product yield of more than or equal to 95 percent and a high product purity of more than or equal to 98 percent; and a synthesized biodegradable polymer has high biological safety.

Owner:无锡南大绿色环境友好材料技术研究院有限公司

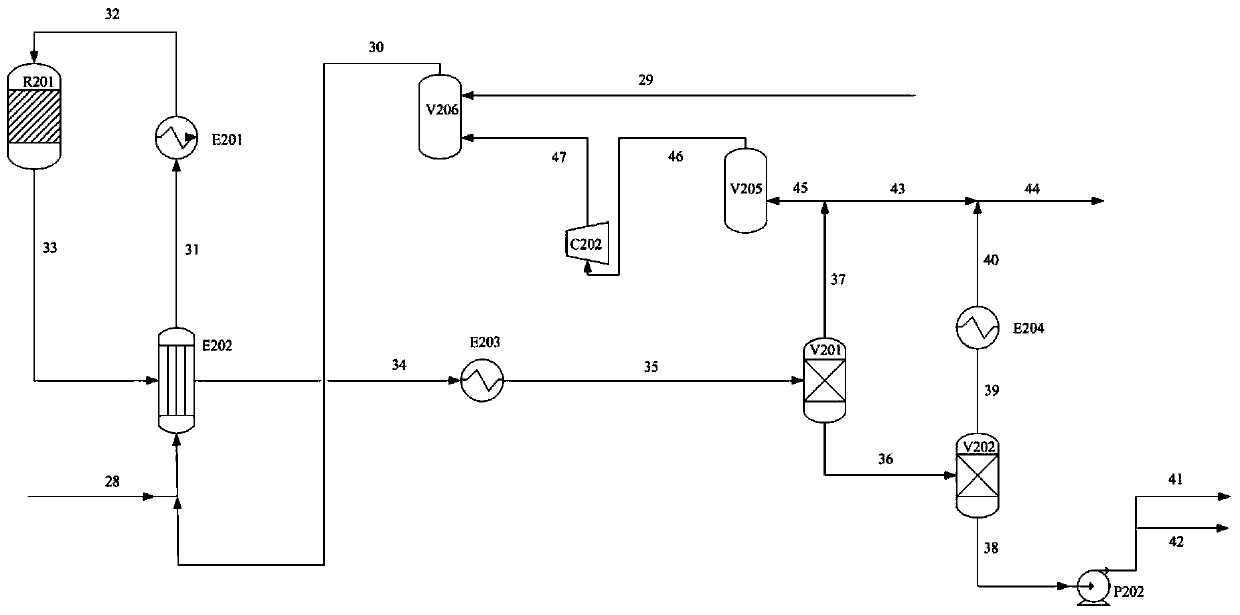

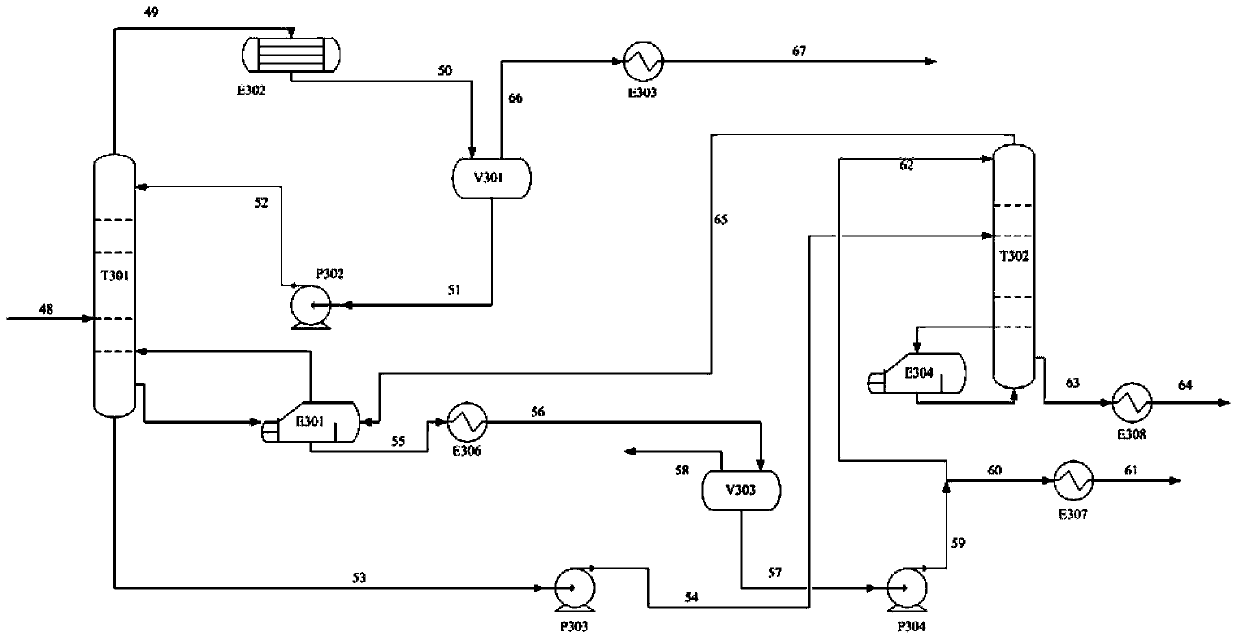

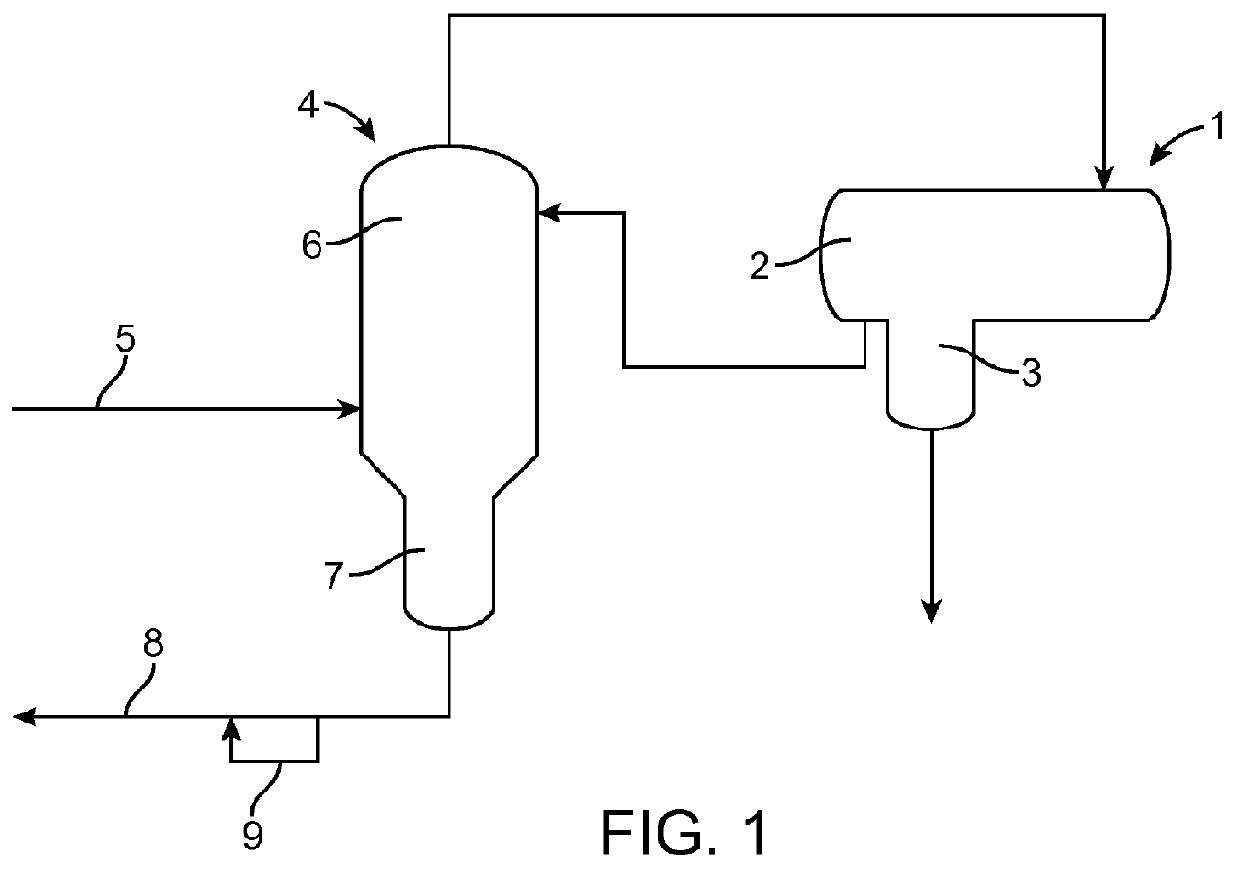

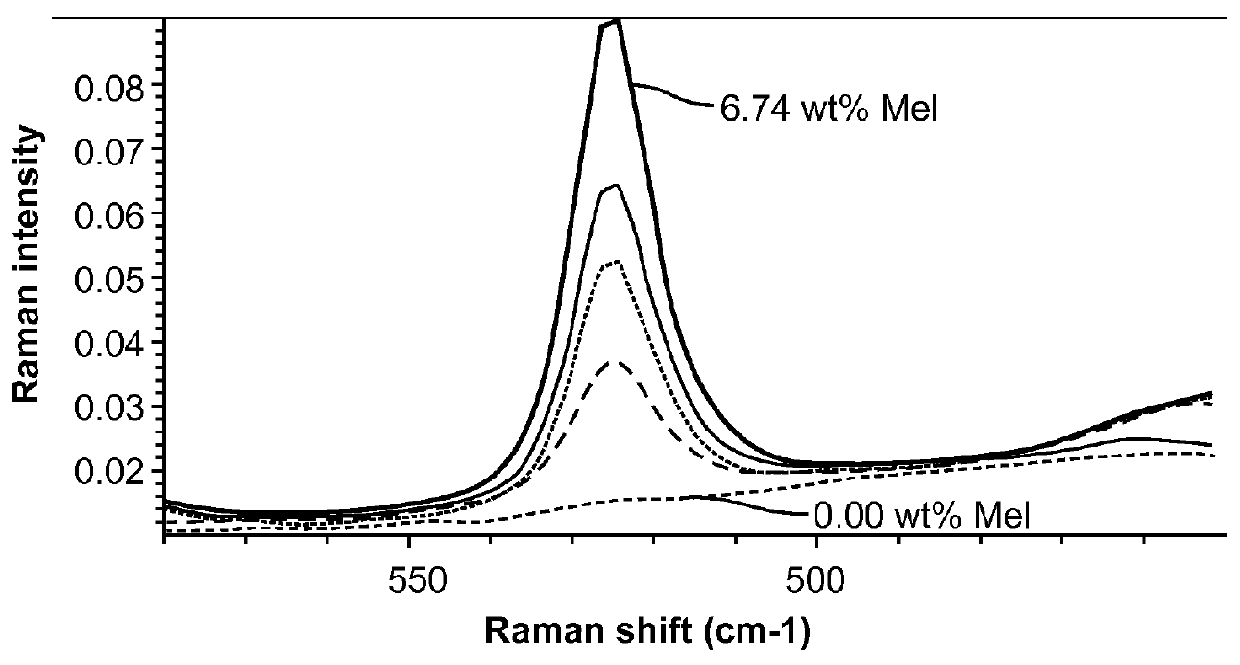

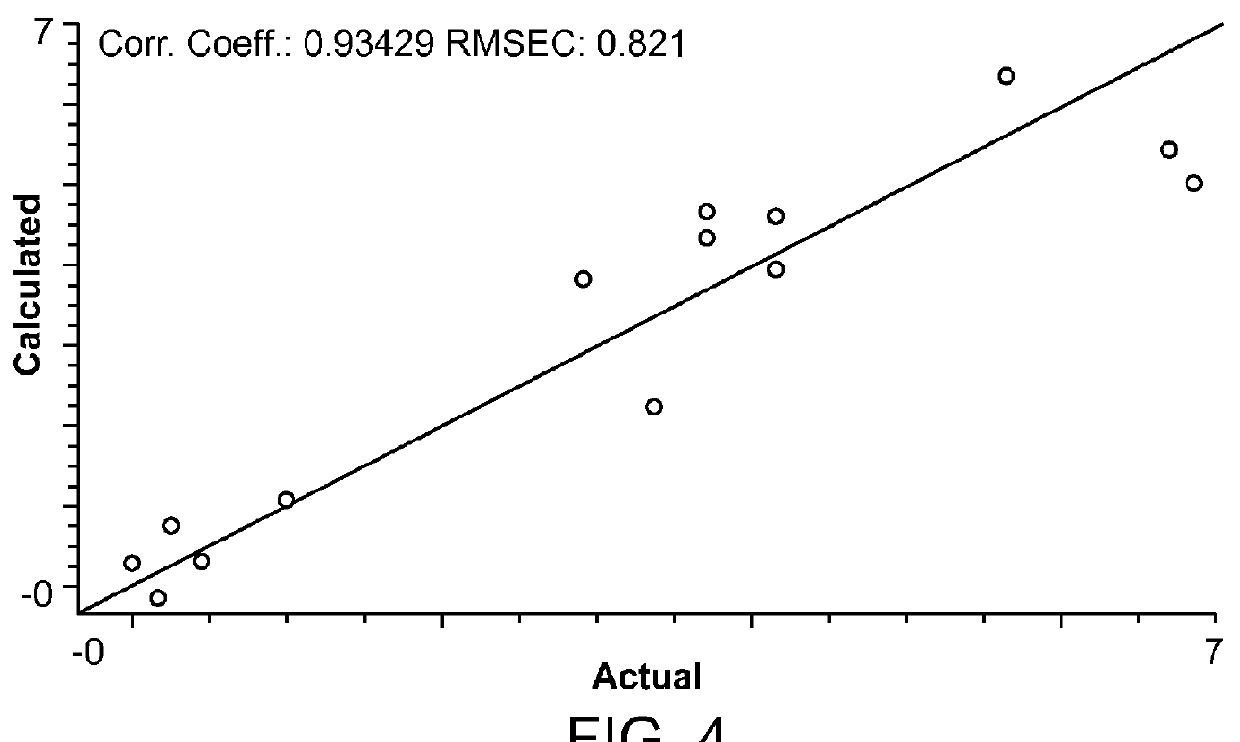

Acetic acid production process

ActiveUS20120220801A1Radiation pyrometryOrganic compound preparationAcetic acidRaman Optical Activity Spectroscopy

A method for determining the characteristic of one or more components in a step of an acetic acid production process using Raman spectroscopy. The process includes providing a feed stream comprising multiple components to a separations unit, one of the components being acetic acid, the separations unit separating the feed stream into two or more exit streams having a different composition from one another, and measuring a characteristic of one or more of the components by Raman spectroscopic analysis.

Owner:LYONDELLBASELL ACETYLS

DNA (Deoxyribonucleic Acid) electrochemical biosensor and preparation method thereof

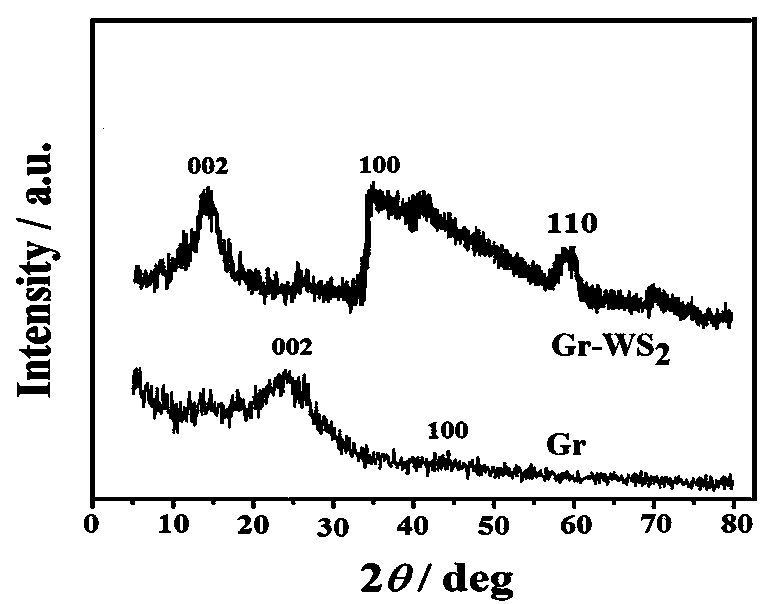

InactiveCN103616418AHigh sensitivityImprove stabilityMaterial electrochemical variablesElectrochemical biosensorA-DNA

The invention relates to a DNA (Deoxyribonucleic Acid) electrochemical biosensor and a preparation method thereof. The preparation method comprises the following steps: (1) adding 1mg / mL Gr-WS2 composite material aqueous dispersion liquid into 1mg / mL chitosan acetic acid solution; carrying out ultrasonic dispersion for 1 hour; and taking 8 microliters of a mixed solution, dripping the solution on a pre-treated glassy carbon substrate and airing; and (2) immersing an electrode into a gold size for 12 hours; washing and airing; reacting the electrode with 1.0*10<-6>mol / L of a DNA probe at 25 DEG C for 10 hours; and washing and sealing by using 1.0*10<-3>mol / L of mercaptoethanol for 2 hours and then reacting with a target DNA at 30 DEG C for 50 minutes to prepare the DNA electrochemical biosensor. According to the DNA electrochemical biosensor provided by the invention, a Gr-WS2 nano composite material and gold nanoparticles are combined so as to be good for simultaneously expressing the advantages of the Gr-WS2 nano composite material and the gold nanoparticles; the DNA electrochemical biosensor has the advantages of good stability, high sensitivity, good selectivity, good repeatability, convenience for carrying, low cost and the like.

Owner:XINYANG NORMAL UNIVERSITY

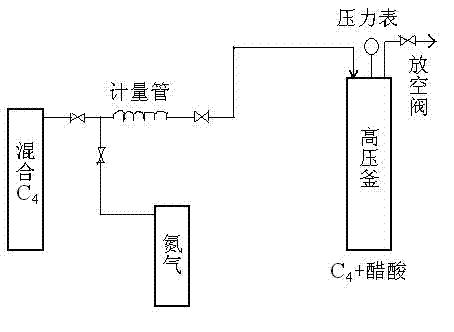

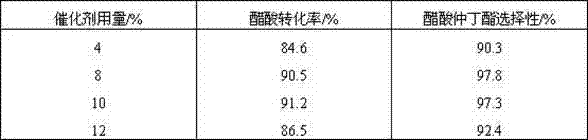

Method for producing sec-butyl acetate by synthesizing acetic acid and mixed C4

InactiveCN102344364AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationPtru catalystReaction temperature

The invention relates to a method for producing sec-butyl acetate by synthesizing acetic acid and mixed C4, which belongs to the chemical field. The invention aims to provide the method for producing the sec-butyl acetate by synthesizing the acetic acid and the mixed C4, which is used for fully and reasonably utilizing byproduct mixed C4 resources of petrochemical enterprises, broadening the way to comprehensively utilize C4 hydrocarbon, and producing fine chemical products with high added value. According to the invention, a kettle type batch reactor is adopted, strong-acid cation exchange resin is adopted as solid catalyst, the acetic acid and the mixed C4 are used as the raw materials to synthesize the sec-butyl acetate, the reaction pressure is 2.0-6.0MPa, the reaction temperature is 80-160 DEG C, the reaction time is 5-15h, the molar ratio of olefine acid is 0.2-1.5, and the catalyst amount is 4-12 percent of the acetic acid. According to the synthetic process of the sec-butyl acetate, the acetic acid and butane (refinery byproduct mixed C4 contains 1-butane and 2-butane) are adopted as the raw materials to be directly synthesized through addition reaction under the action of acid catalysts, an olefin resource is directly utilized, and ethanol is unnecessary to be an intermediate, so that the production cost of the sec-butyl acetate is reduced, the obvious economic advantage is achieved, the refinery mixed C4 resource is effectively utilized, and the method is an effective way to improve chemical utilization of C4 hydrocarbon.

Owner:CHANGCHUN UNIV OF TECH

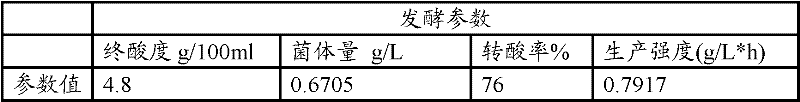

Acetic acid bacterium fermentation nutritive salt and use method thereof

InactiveCN102443549AQuality improvementIncrease productionBacteriaMicroorganism based processesYeastAcetic acid

The invention relates to acetic acid bacterium fermentation nutritive salt, which comprises the following ingredients in percentage by weight: 26 percent to 27 percent of hydrolyzed yeast powder, 15 percent to 16 percent of ammonium citrate, 44 percent to 45 percent of glucose, 4 percent to 5 percent of dipotassium phosphate, 3 percent to 4 percent of disodium hydrogen phosphate and 5 percent to 6 percent of magnesium sulfate, perfectly, the hydrolyzed yeast powder accounts for 26.5 percent, the ammonium citrate accounts for 15.5 percent, the glucose accounts for 44.8 percent, the dipotassium phosphate accounts for 4.2 percent, the disodium hydrogen phosphate accounts for 3.7 percent, and the magnesium sulfate accounts for 5.3 percent. The invention also relates to a use method of the acetic acid bacterium fermentation nutritive salt. The acetic acid bacterium fermentation nutritive salt has the advantages that the design is unique, the nutritive requirement of the acetic acid bacterium fermentation process is completely met, the fermentation period can be shortened, the acetic acid quality can be improved, the acetic acid yield can be improved, the production cost can be reduced, and the acetic acid bacterium fermentation nutritive salt is suitable for large-scale popularization and application.

Owner:JIANGNAN UNIV

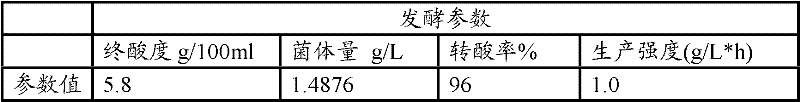

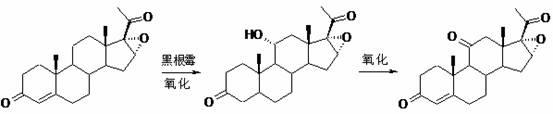

Preparation method of hydrocortisone

ActiveCN102367262AAvoid it happening againRaw materials are easy to getSteroidsDisplacement reactionsHydrocortisone acetate

The invention, relating to the field of pharmaceutical synthesis, particularly relates to a preparation method of hydrocortisone, comprising the following steps: using an intermediate 17 alfa-hydroxy-4-pregnene-3,11,20- triketone (II) in a Rhizopus nigricans method as raw material, successively carrying out ketal reaction, reduction reaction, hydrolysis reaction, iodine adding reaction, and displacement reaction to obtain hydrocortisone acetate (VII), and finally carrying out sodium hydroxide hydrolysis reaction to obtain the hydrocortisone (I). The invention has the advantages of easy obtainment of raw material, common auxiliary materials, and no need of using toxic, highly toxic, and carcinogenic reagents. The method is more efficient than the process in the prior art, and the products has good quality and yield.

Owner:ZHEJIANG XIANJU PHARMA

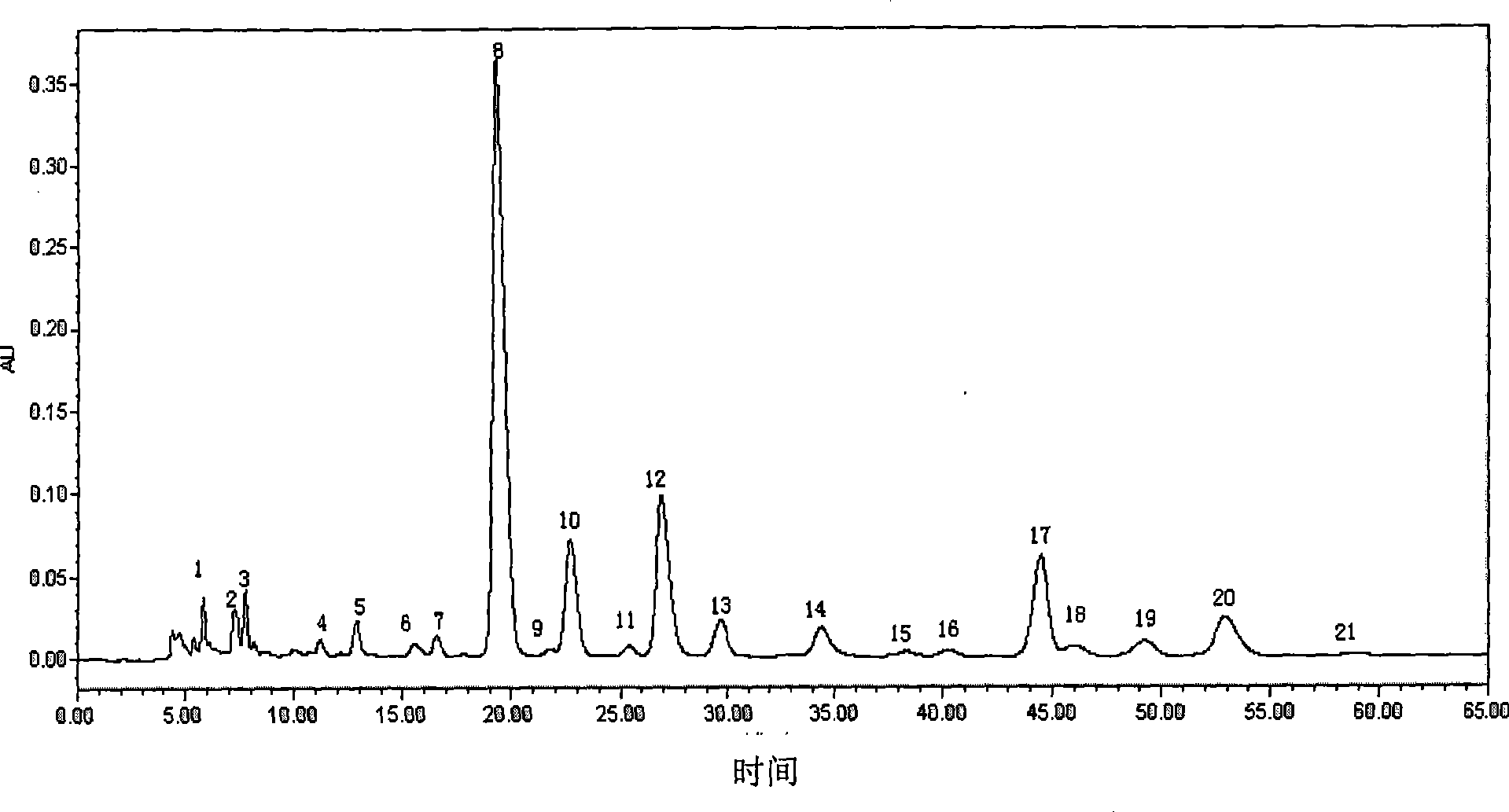

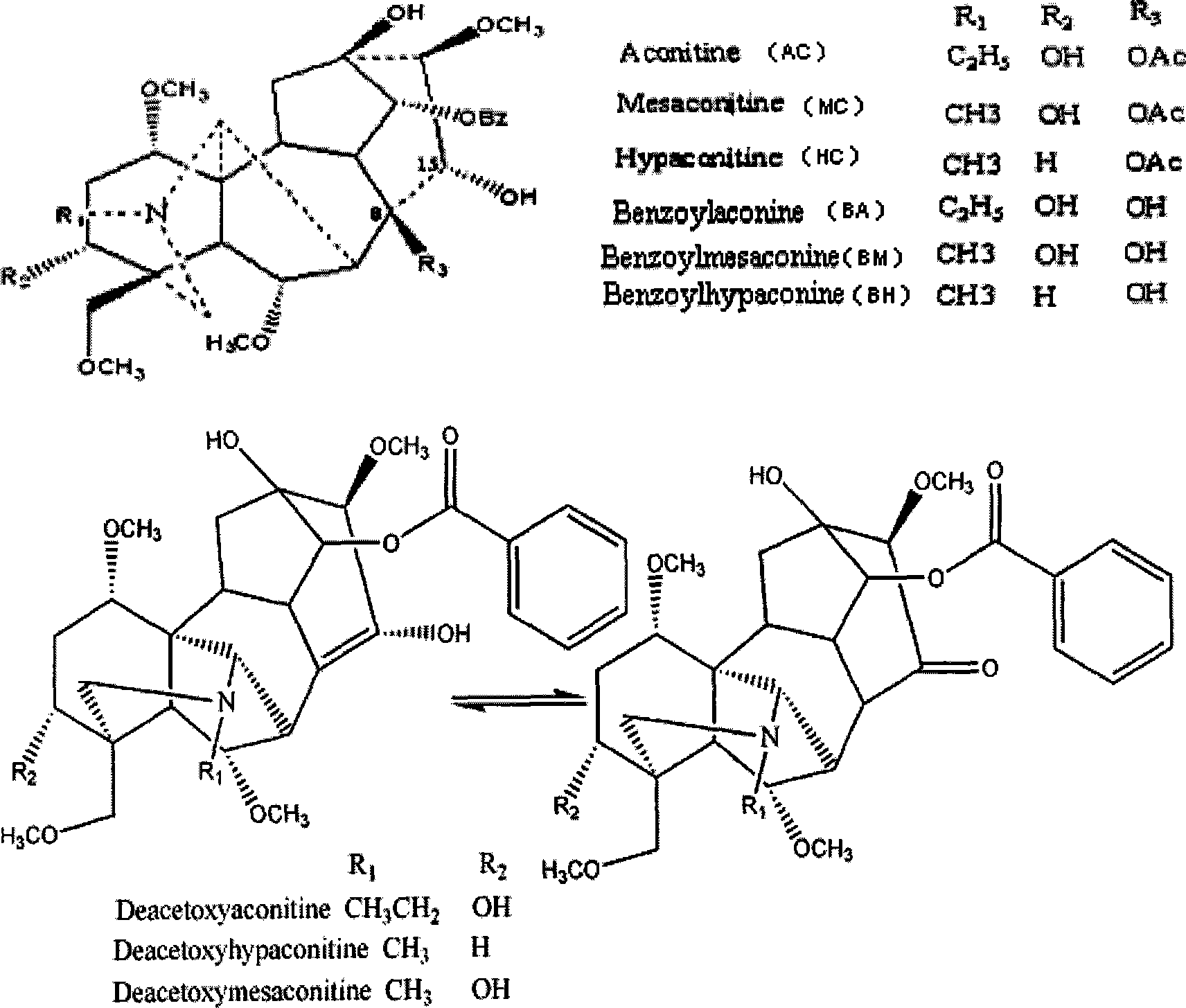

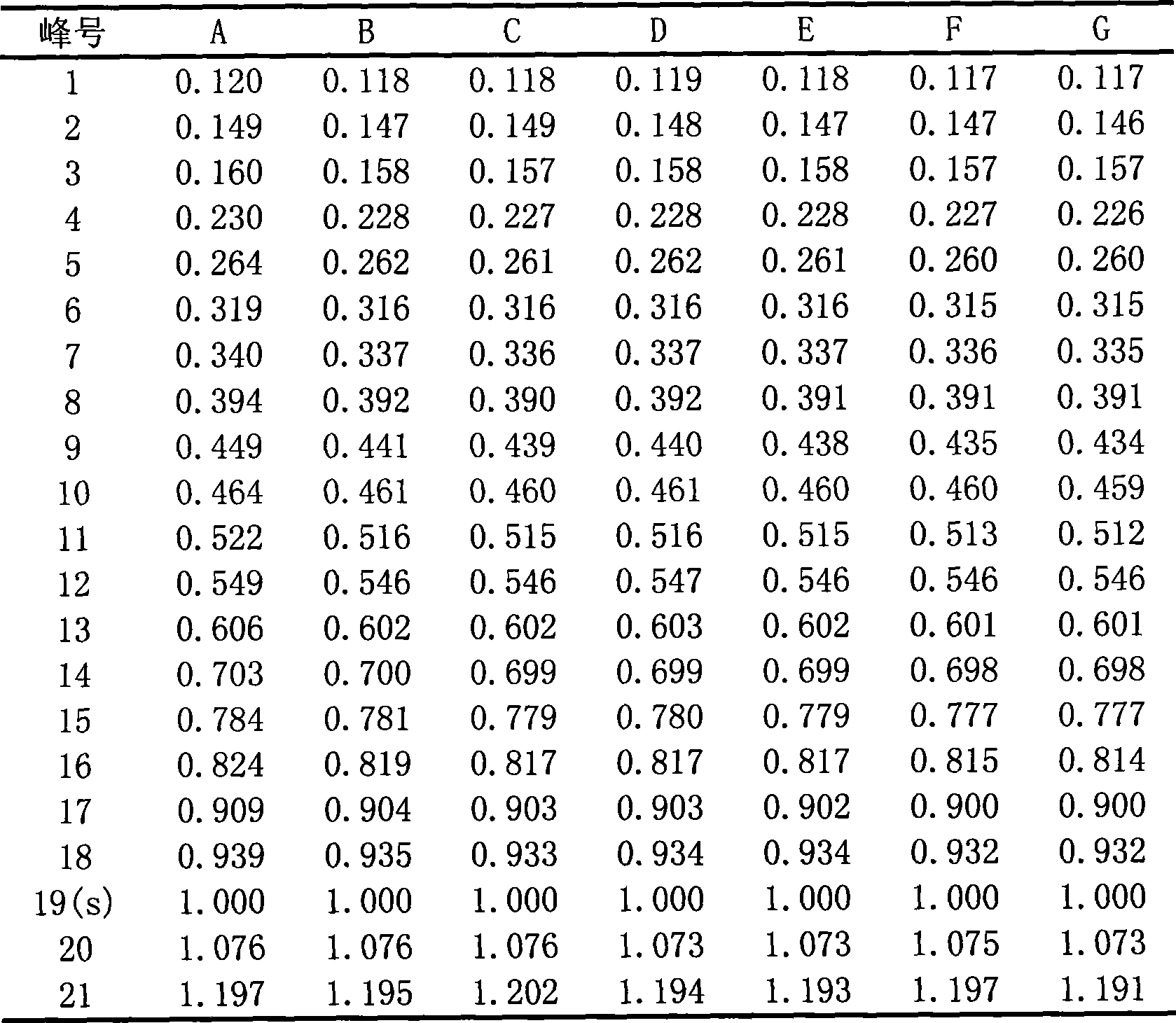

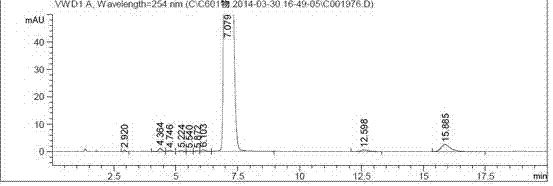

Chinese medicine prepared aconite root and method for establishing fingerprint of alkaloid in extract thereof

InactiveCN101433604AEasy to separateFully reflect the qualityComponent separationPlant ingredientsFiller ExcipientWavelength

The invention relates to a method for establishing fingerprint of alkaloid in traditional Chinese medicine aconite or extract thereof. The method adopts an opposite phase high performance liquid chromatography, uses octadecylsilane chemically bonded silica or octadsilane chemically bonded silica as a filling agent, and uses an organic phase-buffer solution as a mobile phase, wherein pH value of the organic phase-buffer solution is 3.0 to 8.0, detection wavelength is 230 to 240 nanometers, the organic phase accounts for 20 to 70 percent of volume percentage of the mobile phase, and the organic phase is acetonitrile or methanol; the buffer solution is one of ammonium acetate-acetic acid buffer solution, triethylamine-acetic acid buffer solution, triethylamine-ammonium acetate-acetic acid buffer solution and triethylamine-acetic acid ammonium-acetic acid buffer solution; and the method comprises the following steps: using proper amount of aconitine, mesaconine or hypaconitine to prepare reference substance solution, preparing test solution, and pouring the reference substance solution and the test solution into a high performance liquid chromatograph respectively by accurately sucking to establish the fingerprint of the alkaloid in the traditional Chinese medicine aconite or the extract thereof.

Owner:JIANGSU WANBANG BIOPHARMLS +1

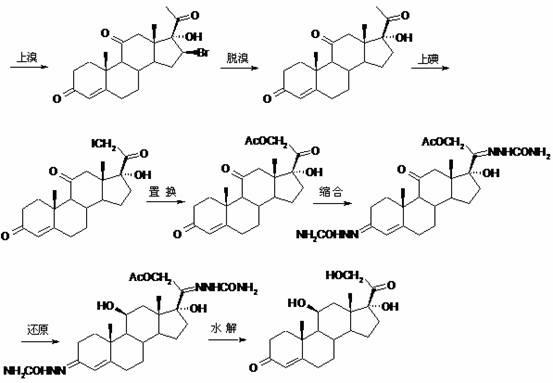

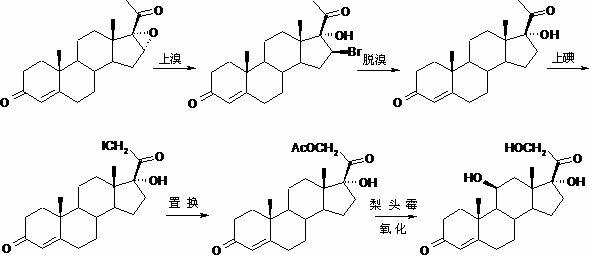

Preparation method of important intermediate of cortisone acetate

Owner:JIANGSU YUANDA XIANLE PHARMA

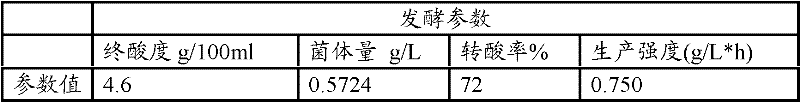

Method for composite acetic acid bacterium culture and solid-state acetic acid fermentation

InactiveCN101875908AMild tasteIncrease productionBacteriaMicroorganism based processesMetaboliteFruit juice

The invention relates to the table vinegar production field, in particular to a method for composite acetic acid bacterium culture and solid-state acetic acid fermentation, which solves the problems that the acetic acid bacterium is simplex in strain, the acetic acid conversion rate is low, the traditional acetic acid bacterium culture method causes instability of table vinegar quality and the like in the prior art. The method comprises the following steps: utilizing Huniang 1.01, As1.41, bacterium gluconicum, acetobacter separated from a Shanxi mature vinegar grains and high-yield acetaldehyde dehydrogenase acetobacter to form the composite acetic acid bacteria, and then carrying out continuous culture in a composite culture medium comprising grape fruit juice, multi-strain nutrition-enhancing yeast, yeast extract, ethanol and distilled water to obtain a composite acetic acid bacteria culture solution; and finally carrying out solid-state acetic acid fermentation, wherein the inoculation process adopts operating techniques of mixing the grains at a pan bottom, drawing fire, burying in fire and rubbing the grains. The invention uses the advantages of multiple strains, raises the yield of gluconic acid in metabolite, produces a final product which is moderately sour and has unique flavor, improves the conversion rate of acetic acid, and shortens the fermentation period, thereby having profound significance in the progress of the table vinegar brewage technology.

Owner:山西三盟实业发展有限公司

Process for preparing hydrocortisone acetate

This invention refers to a chemical synthesis preparation technique of acetic acid hydrocortisone. C3~C5 fat ketone is used as solvent and certain acetate is added. It is got by synthesizing hydrocortisone, acetic acid and acetic anhydride. Pyridine is replaced by low toxicity solvent, then pollution is reduced and yield is raised, the yield of acetic acid hydrocortisone can reach above 95%. The product quality is stabilized and cost is reduced, it is more acceptable for industrial production.

Owner:SHANDONG XINHUA PHARMA CO LTD

Method for synthesizing 1,2-cyclohexanediol by cyclohexene under selenium catalysis

InactiveCN102503774AImproved Catalytic Oxidative Hydrolysis ReactionReduce dosagePreparation by oxidation reactionsChemical recyclingPtru catalystDistillation

The invention provides a method for synthesizing 1,2-cyclohexanediol by cyclohexene under selenium catalysis. The method comprises the following steps of: taking cyclohexene as a raw material, taking a selenium compound as a catalyst, and taking hydrogen peroxide as an oxidant; carrying out reaction at a temperature of 15-80 DEG C in the presence of a solvent, wherein a mole ratio of the hydrogen peroxide to the cyclohexene is (0.5-1.5): 1, the mole fraction of the selenium compound and the cyclohexene is 0.1-1 percent, and the concentration of the reaction solution based on a solvent calculation is 1-20 mol / L. Furthermore, the production can be continuously carried out by adding the raw materials for the next turn into reaction residues. After the reaction, the solvent and non-reacted raw materials are respectively recycled by distillation and a product is refined. The selenium compound is selected from diselenide, selenious acid, and phenyl, fluoro-phenyl, tolyl substitutes and the like of the diselenide amd the selenious acid. The solvent is selected from acetonitrile, water, ethanol and acetic acid. The method disclosed by the invention has the advantages of simple process flow, temper reaction conditions, and high yield (the highest yield can be up to 92 percent). The method is efficient, clean and environment-friendly and further has the characteristics of simple components in a reaction system, easiness of product purification, and easiness of recycling the solvent and the catalyst.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Synthesis method of benzotriazole

The invention relates to a synthesis method of benzotriazole. The benzotriazole is synthesized in one step through an o-phenylenediamine pressurization method. The synthesis method particularly comprises the following steps that 1, material feeding is conducted, wherein o-phenylenediamine, sodium nitrite and water are added into a stainless steel reaction kettle according to the proportion of 1 to 1.1-1.2 to 10-15; 2, heating and pressurization are conducted, wherein stirring is started, the temperature is increased to range from 240 DEG C to 260 DEG C, the pressure is controlled to range from 3.0 MPa to 4.0 MPa, and heat preservation reaction is conducted for 3-3.5 h; 3, the reacted mixture is transferred to an acidification kettle, wherein the temperature is decreased to range from 120 DEG C to 130 DEG C, and a reaction product is transferred to the acidification kettle; 4, pH adjustment and delamination are conducted, the PH value is adjusted from 11.7 to 5.0 through concentrated sulfuric acid, and delamination is conducted; 5, purification and collection are conducted, wherein the delaminated oil layer enters a rectifying kettle for decompression purification, and distillate products at 202-204 DEG C / 15 mmHg are collected. The synthesis method of the benzotriazole has the advantages that acetic acid is not needed, side reactions are few, pollution is less, the yield is high, the reaction time is short, and continuous production can be achieved.

Owner:NANTONG BOTAO CHEM

Microbe-proof cloth and production thereof

An antimicrobial fabric is prepared through preparing the antimi crobial chemical from p-hydroxy benzoate, dimethyl fumarate, chitin protamine, and the antimicrobial component chosen from nisin, benzoic acid, sorbic acid and dehydrogenated acetic acid, and spraying it on the surface of fabric.

Owner:姚华珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com