Patents

Literature

53 results about "Ethyl(hydroxyethyl)cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

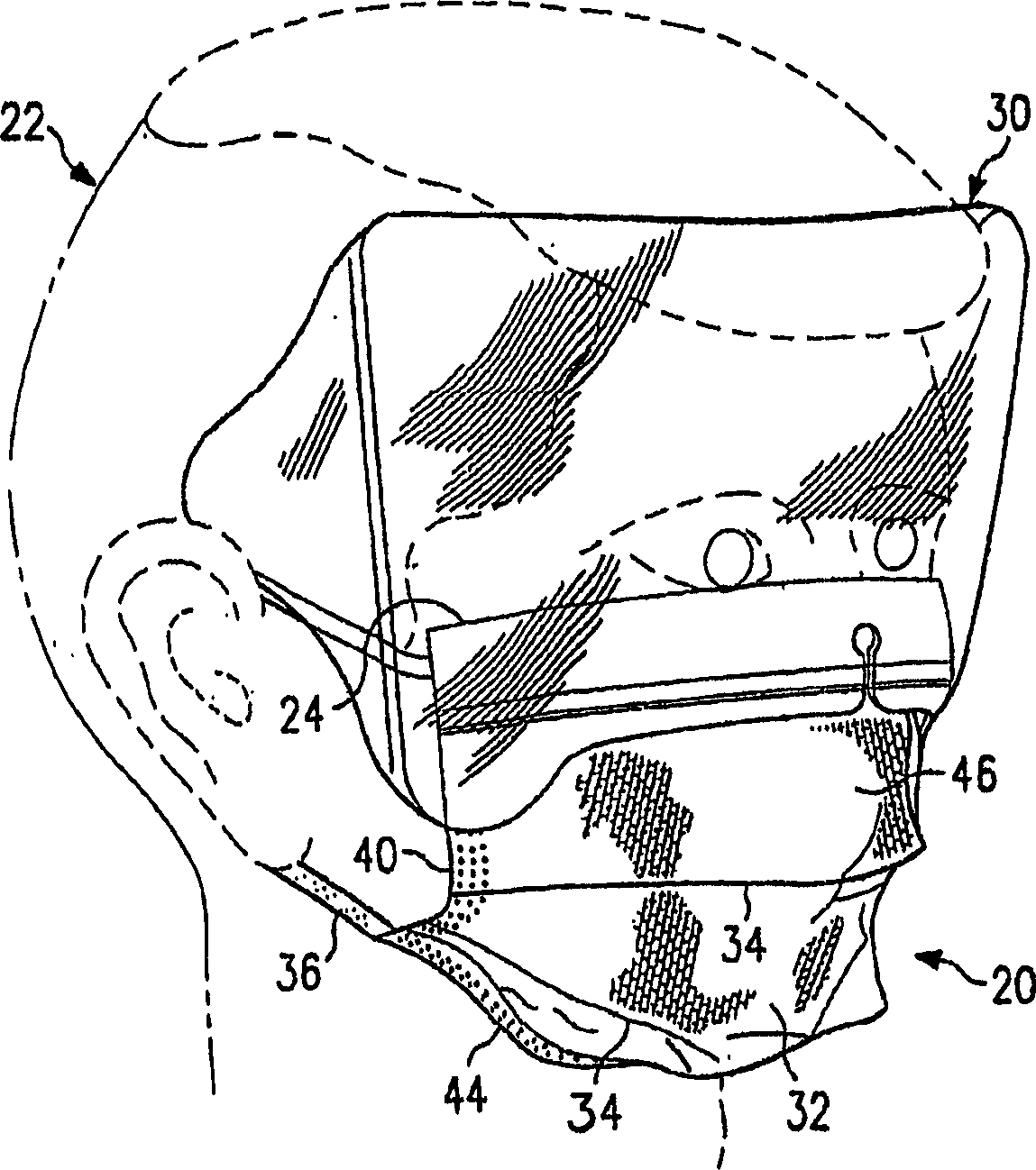

Facemasks containing an anti-fog / anti-glare composition

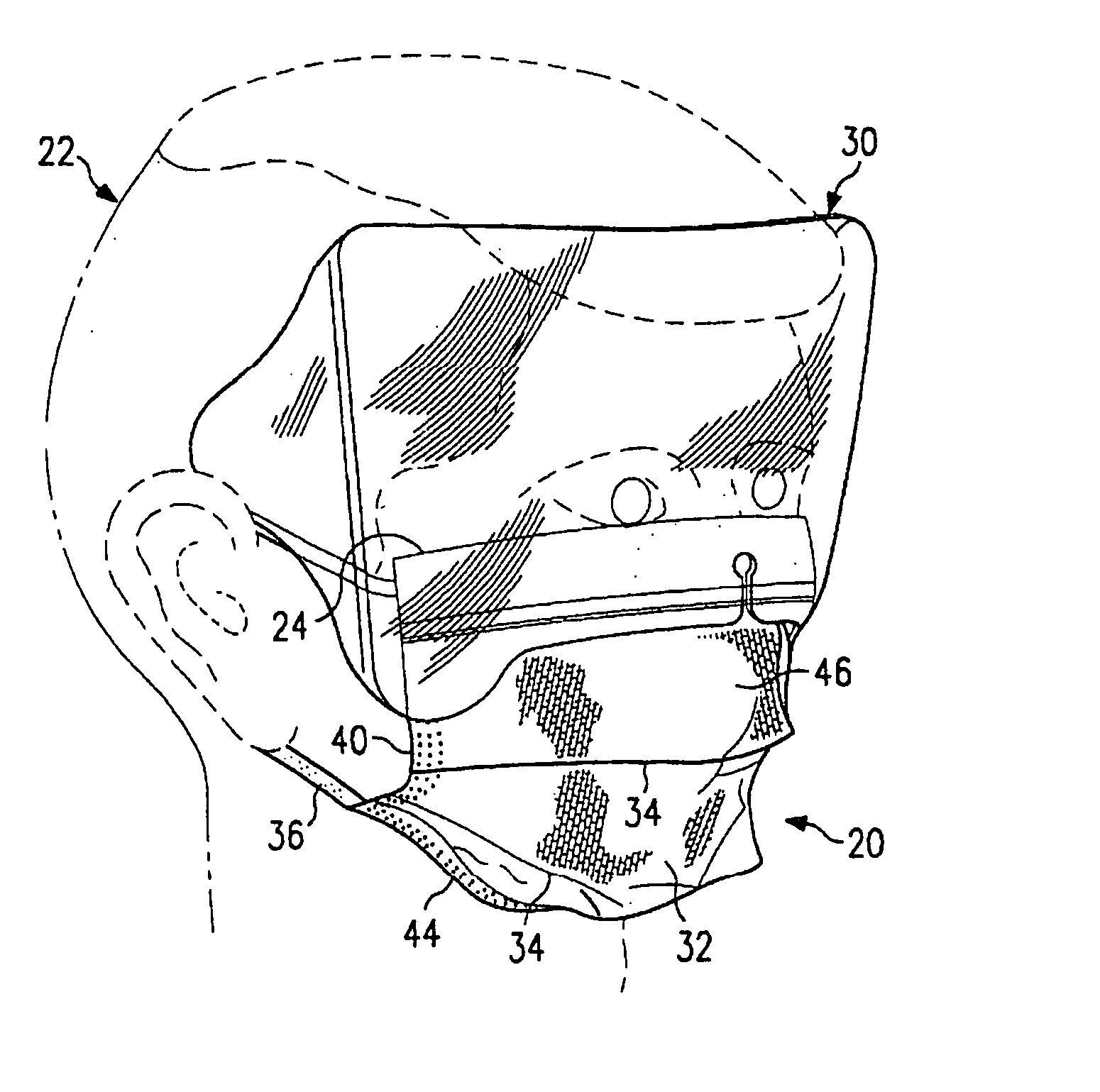

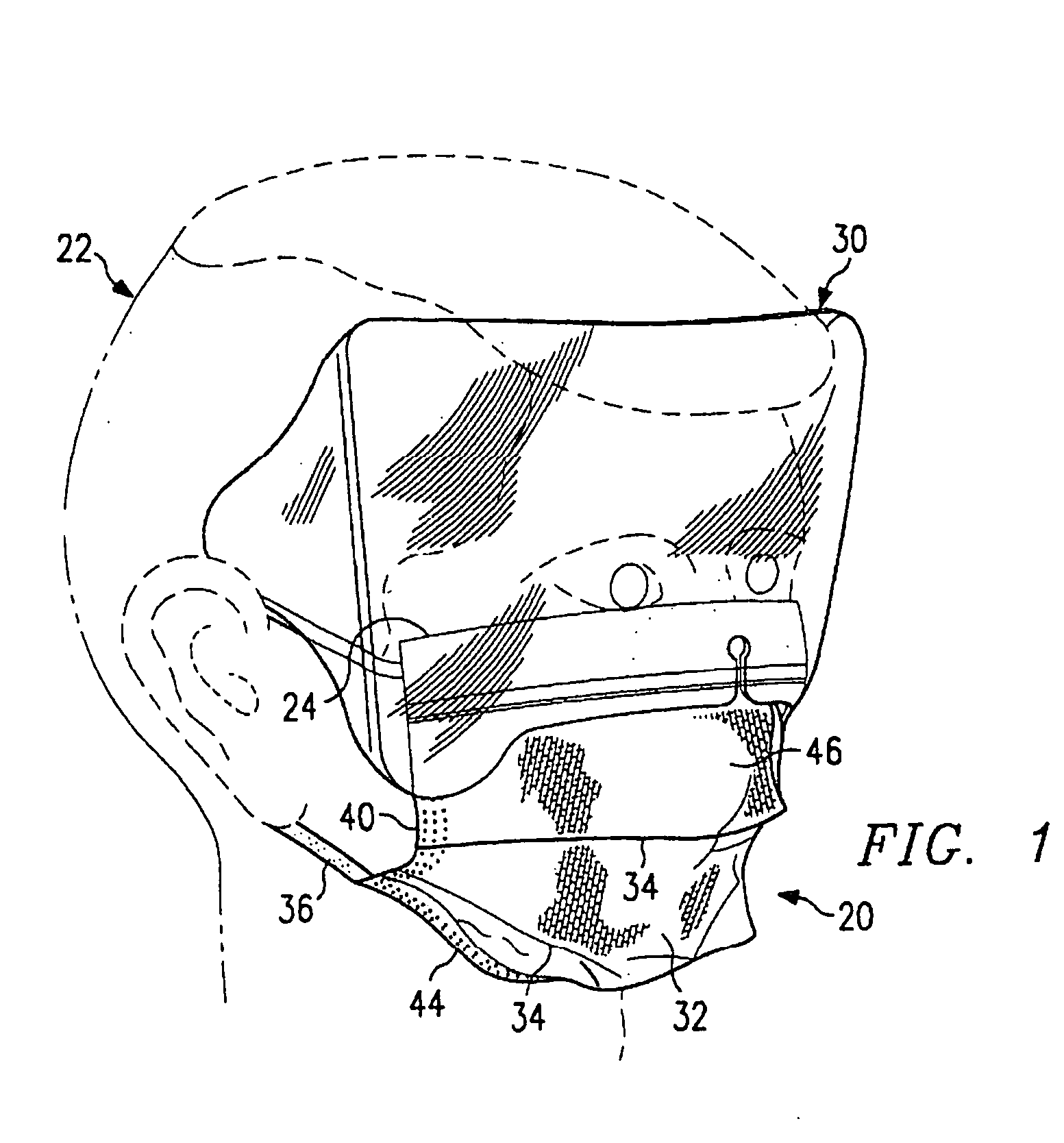

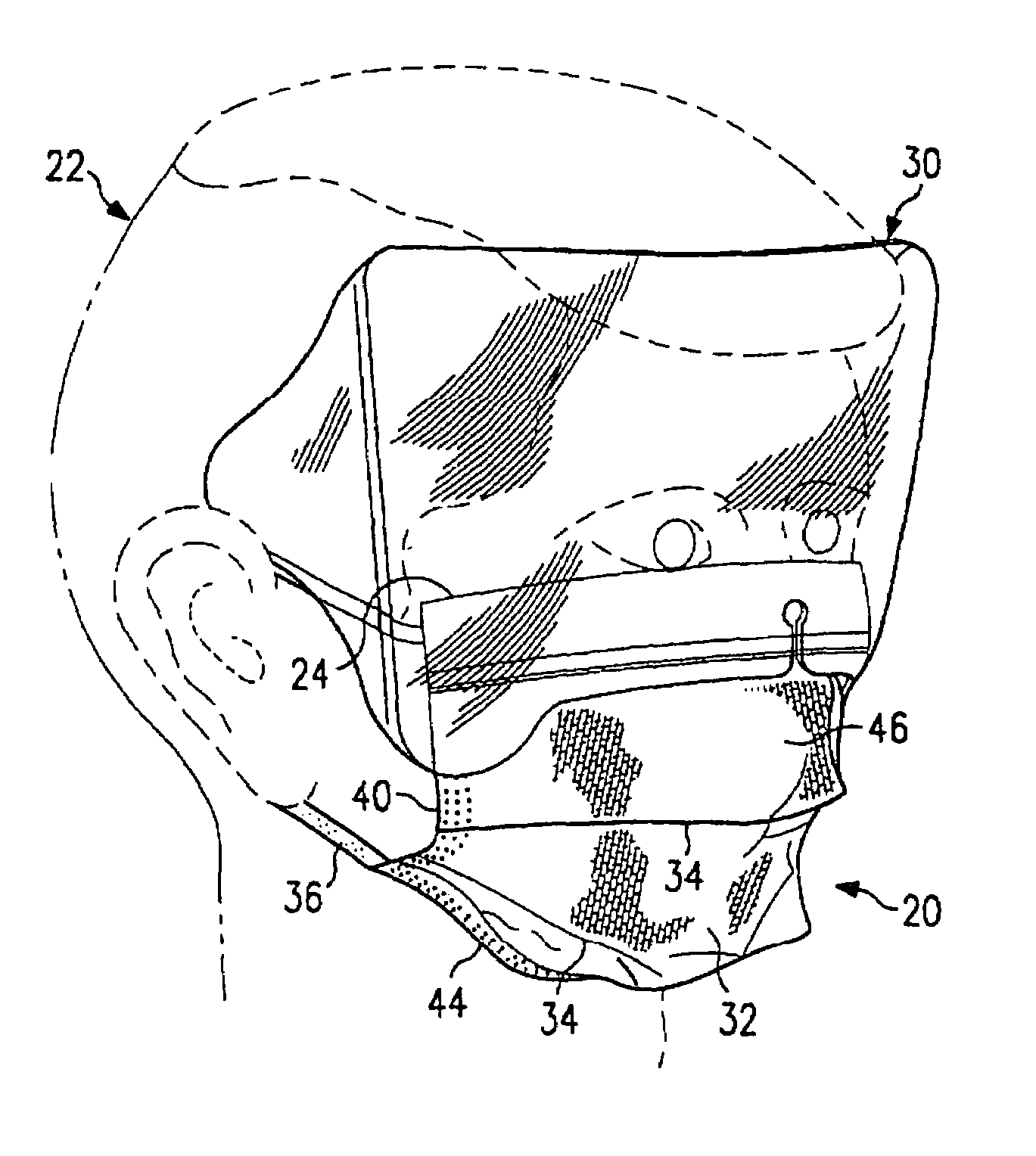

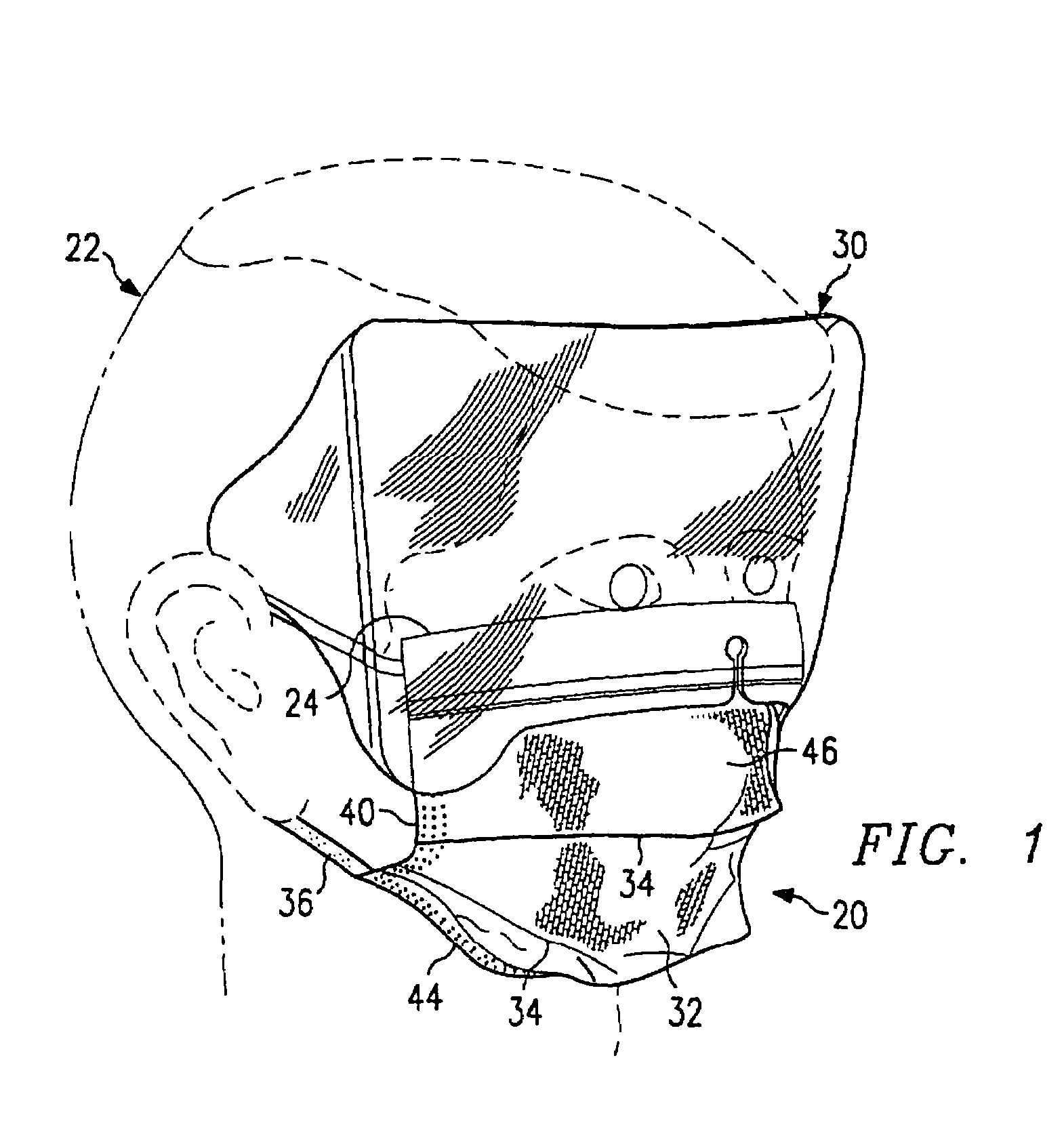

A coating composition that is incorporated into a facemask to reduce fogging and glare is provided. For example, in one embodiment, the facemask contains a shield or visor formed from a transparent substrate having at least one surface applied with the coating composition of the present invention. The present inventors have unexpectedly discovered that one or more water-soluble organic polymers, such as ethyl hydroxyethylcellulose, may be utilized as a principal component of the coating composition to reduce fogging and glare in a simple, yet effective manner.

Owner:O&M HALYARD INC

Facemasks containing an anti-fog / anti-glare composition

A coating composition that is incorporated into a facemask to reduce fogging and glare is provided. For example, in one embodiment, the facemask contains a shield or visor formed from a transparent substrate having at least one surface applied with the coating composition of the present invention. The present inventors have unexpectedly discovered that one or more water-soluble organic polymers, such as ethyl hydroxyethylcellulose, may be utilized as a principal component of the coating composition to reduce fogging and glare in a simple, yet effective manner.

Owner:O&M HALYARD INC

Controlled release composition

InactiveUS20080254124A1Easy for to follow prescribed regimenConstant of releasePowder deliverySolution deliveryEthyl(hydroxyethyl)celluloseCellulose acetate

A composition for controlled delivery of at least one active substance into an aqueous medium by erosion at a preprogrammed rate of at least one surface of the composition, comprising a matrix comprising the active substance, the matrix being erodible in the aqueous medium in which the composition is to be used, and a coating having at least one opening exposing at least one surface of said matrix, the coating comprising a first cellulose derivative which has thermoplastic properties and which is substantially insoluble in the aqueous medium in which the composition is to be used, and at least one of a second cellulose derivative which is soluble or dispersible in water, a plasticizer, and a filler. The coating is a coating which crumbles and / or erodes upon exposure to the aqueous medium such as a body fluid. The first cellulose derivative may be, e.g., ethylcellulose, cellulose acetate, cellulose propionate or cellulose nitrate, and the second cellulose derivative may be, e.g. methylcellulose, carboxymethylcellulose or salts thereof, cellulose acetate phthalate, microcrystalline cellulose, ethylhydroxyethylcellulose, ethylmethylcellulose, hydroxyethylcellulose, hydroxyethylmethylcellulose, hydroxypropylcellulose, hydroxypropylmethylcellulose, hydroxymethylcellulose or hydroxymethylpropylcellulose.

Owner:EGALET LTD

Modified cellulose products

A modified cellulose product comprising cellulose ether, such as carboxymethyl cellulose, hydroxyethyl cellullose, carboxymethyl hydroxyethyl cellulose, methyl cellulose, hydroxyethyl methyl cellulose or ethyl hydroxyethyl cellulose, or xanthan gum product, characterized in that it further comprises salts of aluminium-, ferro-, ferri-, zinc-, nickel-, tin(2)- or tin(4)-cations, and nitrilo-tri-acetic acid, 1,2-cyclo-hexan-di-amin-N,N,N',N'-tetra-acetic acid, di-ethylen-tri-amine-penta-acetic acid, ethylen-di-oxy-bis(ethylen-nitrilo)-tetra-acetic acid, (N-(2-hydroxy-ethyl)-ethylen-diamin-N, N',N',tri-acetic acid, tri-ethylen-tetra-amine-hexa-acetic acid or N-(hydroxyethyl) ethylene-di-amine-tri-acetic acid as a ligand. The product can be used especially as a drilling mud additive.

Owner:METSA SPECIALTY CHEM

Nano titanium dioxide composite water-based building paint having high weathering-resistance

InactiveCN1557890AImprove anti-aging propertiesGood chemical stabilityEmulsion paintsWater basedEthyl(hydroxyethyl)cellulose

The building paint consists of water, hydroxyethyl cellulose, diisobutylsulfo sodium succinate, epoxyvinyl alkylphenol ether, methyl silicon oil, propylene glycol, nano titania assistant and other nine kinds of components. The nano composite weather-resisting titania building paint for outer wall can absorb and scatter ultraviolet ray, and has powerful antiageing performance and wide application.

Owner:大庆油田创业集团

Controlled release composition

InactiveUS20050019405A1Easy for to follow prescribed regimenConstant of releasePharmaceutical non-active ingredientsCoatingsEthyl(hydroxyethyl)celluloseCellulose acetate

A composition for controlled delivery of at least one active substance into an aqueous medium by erosion at a preprogrammed rate of at least one surface of the composition, comprising a matrix comprising the active substance, the matrix being erodible in the aqueous medium in which the composition is to be used, and a coating having at least one opening exposing at least one surface of said matrix, the coating comprising a first cellulose derivative which has thermoplastic properties and which is substantially insoluble in the aqueous medium in which the composition is to be used, and at least one of a second cellulose derivative which is soluble or dispersible in water, a plasticizer, and a filler. The coating is a coating which crumbles and / or erodes upon exposure to the aqueous medium such as a body fluid. The first cellulose derivative may be, e.g., ethylcellulose, cellulose acetate, cellulose propionate or cellulose nitrate, and the second cellulose derivative may be, e.g., methylcellulose, carboxymethylcellulose or salts thereof, cellulose acetate phthalate, microcrystalline cellulose, ethylhydroxyethylcellulose, ethylmethylcellulose, hydroxyethylcellulose, hydroxyethylmethylcellulose, hydroxypropylcellulose, hydroxypropylmethylcellulose, hydroxymethylcellulose or hydroxymethylpropylcellulose.

Owner:EGALET LTD

Water-in-water colorful art coating for brush coating and roller coating and preparation method thereof

InactiveCN106957578ARich construction methodsAppropriate areaAntifouling/underwater paintsPaints with biocidesEthyl(hydroxyethyl)celluloseFoaming agent

The invention discloses a water-in-water colorful art coating for brush coating and roller coating and a preparation method thereof. The weight ratio of protecting glue solution to basic paint to continuous phase is at 3:3:4; the protecting glue solution comprises the following components by weight percent: 96-97% of water and 3-4% of protecting glue powder; the basic paint comprises the following components: 22-25% of water, 0.3-0.4% of hydrophobic modified ethyl hydroxyethyl cellulose, 0.5-0.8% of modified bentonite, 0.15-0.25% of de-foaming agent, 0.1-0.15% of pH regulator, 0-0.1% of a wetting agent, 0-0.4% of a dispersing agent, 1-1.5% of an anti-freezing agent, 0-2% of titanium dioxide, 5-10% of a hardening agent, 2-2.3% of a coalescing agent, 60-65% of pure acrylic emulsion, 0.1-0.2% of bactericide and 2-3% of a protecting glue solution; the continuous phase comprises the following components: 80-85% of emulsion, 8.5-14% of water, 1-1.3% of an anti-freezing agent, 0.1-0.2% of bactericide, 4.3-5.1% of a coalescing agent and 0.15-0.2% of a de-foaming agent. The coating is suitable for brush coating and roller coating and the construction is various.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Preparation method of black iron oxide particles with corrosion inhibition performance

InactiveCN103289442AGood corrosion inhibition effectLiquidPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsViscous liquidEthyl(hydroxyethyl)cellulose

The invention discloses a preparation method of black iron oxide particles with corrosion inhibition performance. The method comprises the following steps of: dissolving urotropin, ethyl hydroxy ethylcellulose and lauryl sodium sulfate in deionized water according to the definite weight ratio, thereby obtaining a viscous liquid; putting black iron oxide into a granulating machine for granulating while evenly spraying the viscous liquid onto the black iron oxide powder at the same time, thereby forming small black iron oxide particles; and drying and screening the small black iron oxide particles, thereby obtaining a finished product. According to the method, the black iron oxide is modified by the urotropin and other components, so that the corrosion inhibition performance of the black iron oxide is enhanced; and the liquidity and the dispersibility of a black iron oxide pigment are realized. The produced black iron oxide has the characteristics of being excellent in temperature resistance, good in acid and alkali resistance, strong in light absorption, high in tinting strength, good in compatibility and dispersibility and the like, thereby being wide in market prospect.

Owner:TONGLING RELY TECH

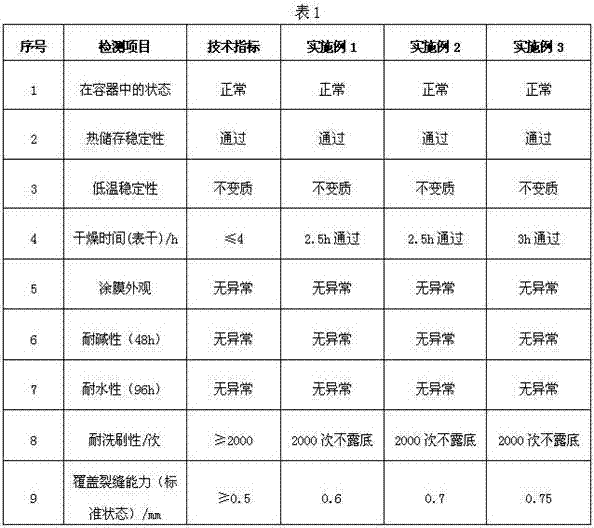

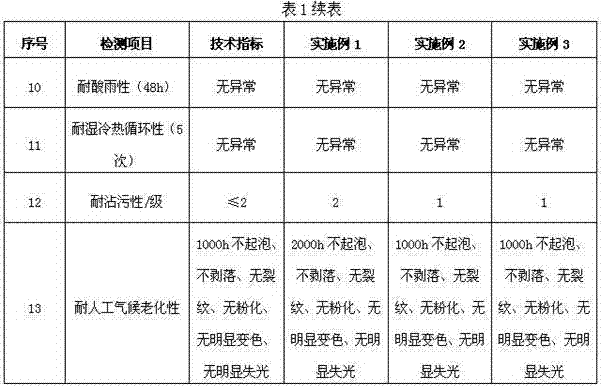

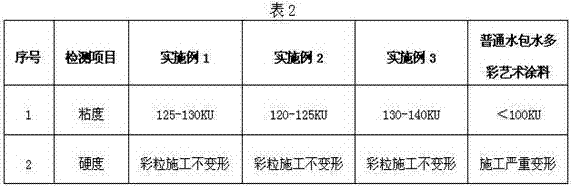

Basic paint of spotted colored stone-like coating, preparation method and spotted colored stone-like coating

ActiveCN113429849AImprove water whitening resistanceImprove toughnessCoatingsPolymer scienceEthyl(hydroxyethyl)cellulose

The invention relates to the field of stone-like coatings, and particularly discloses a basic paint of a spotted colored stone-like coating, a preparation method and the spotted colored stone-like coating. The basic paint improves the content of emulsion, cellulose is compounded by hydrophobic modified ethyl hydroxyethyl cellulose and high-molecular-weight hydroxyethyl cellulose, the toughness of the basic paint is remarkably improved, the prepared paint film is continuous and compact, the surface is smooth, and the stain resistance is excellent; the preparation method of the basic paint comprises the following steps: firstly, adding auxiliaries, a powder, the hydrophobic modified ethyl hydroxyethyl cellulose and the high-molecular-weight hydroxyethyl cellulose into the deionized water, and stirring at a low speed; then adding a pH regulator, and carrying out high-speed stirring at a rotating speed of 1500r / min; reducing the rotating speed to 1000 r / min or below, and adding the emulsion to prepare basic paint of the spotted colored stone-like coating; the spotted colored stone-like coating can be prepared by matching the basic paint with a granulation liquid and a continuous phase, the spotted colored stone-like coating has the stone imitation effect of real stone paint, the surface of a paint film is smooth, and has excellent stain resistance.

Owner:河北莱恩斯新材料科技有限公司

Method for preparing inverse suspension polymerization polymethacrylic acid moisture-absorption resin

The invention discloses an inverse suspension polymerization preparation method for polymethacrylic acid highly absorbent resin, which belongs to the hygroscopic material field; the preparation method is characterized of using cyclohexane as solvent, using methacrylic acid as monomer, using potassium persulfate as initiator, using N, N'- methylene diacrylamide as cross-bonding agent, using octadecanol phosphatide as dispersing agent, and using ethylhydroxyethylcellulose as thickening agent. The polymethacrylic acid highly absorbent resin is prepared by the inverse suspension polymerization method, with a moisture absorption rate greater than or equal to 7g / g.min, under the conditions of air temperature being at 30 DEG C and relative humidity at 90%.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

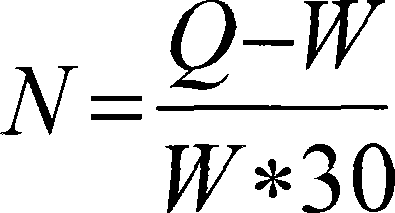

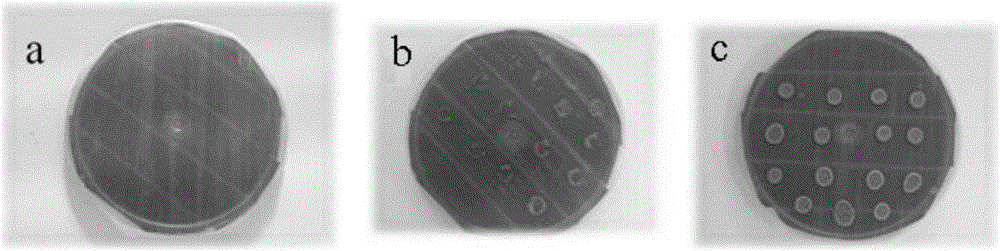

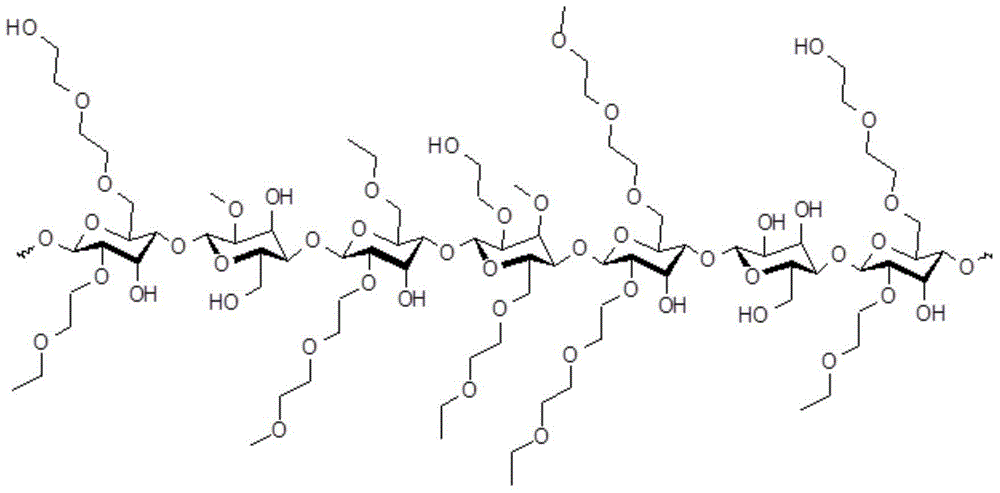

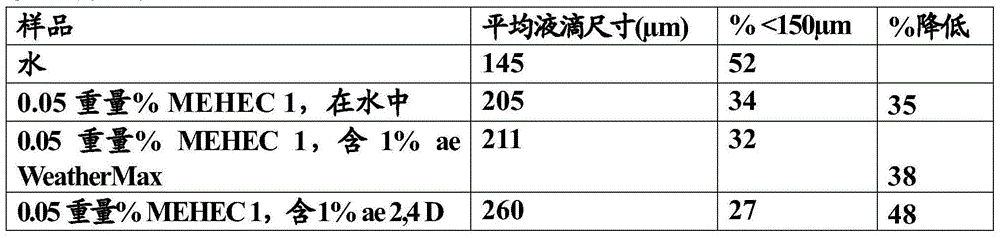

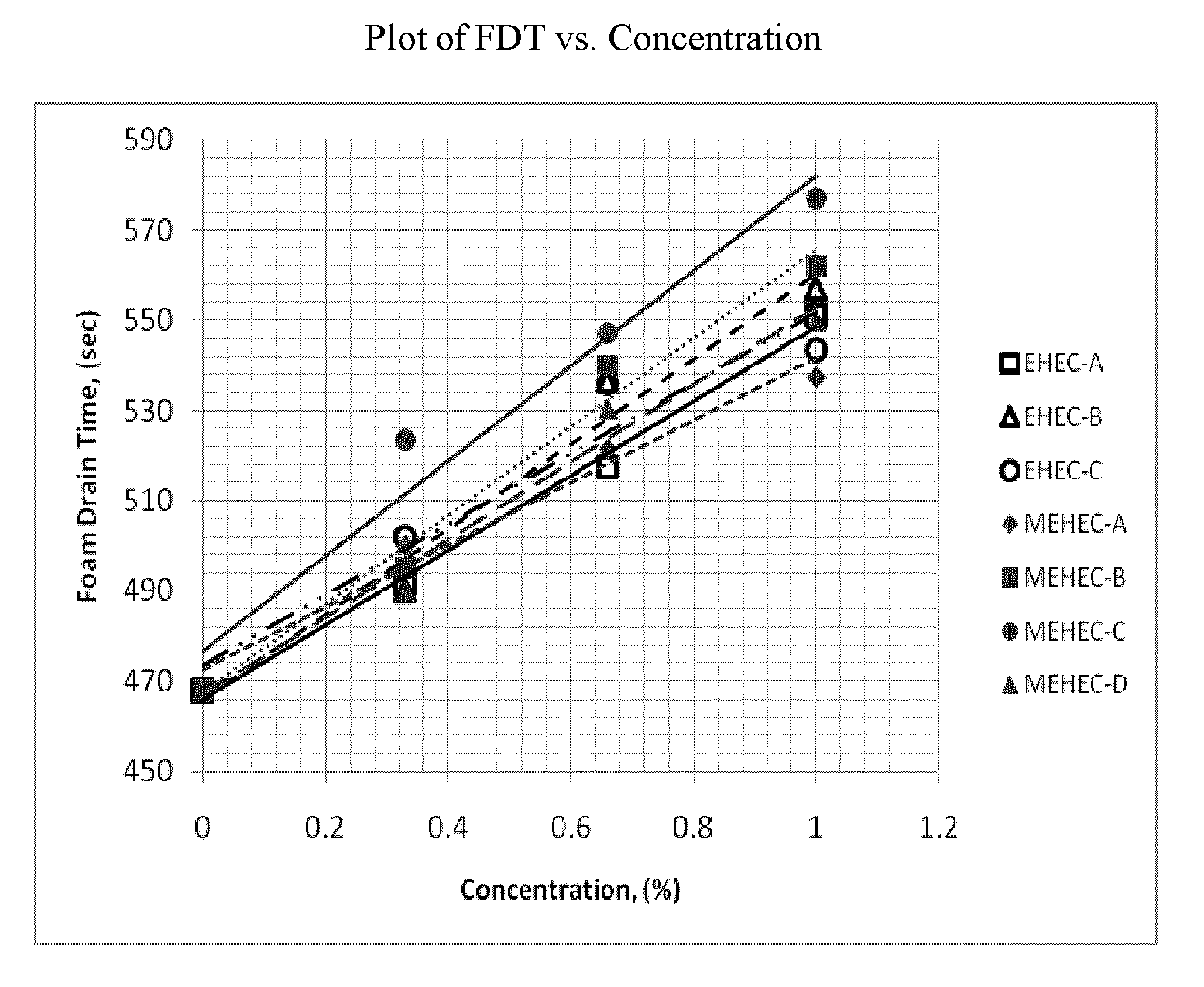

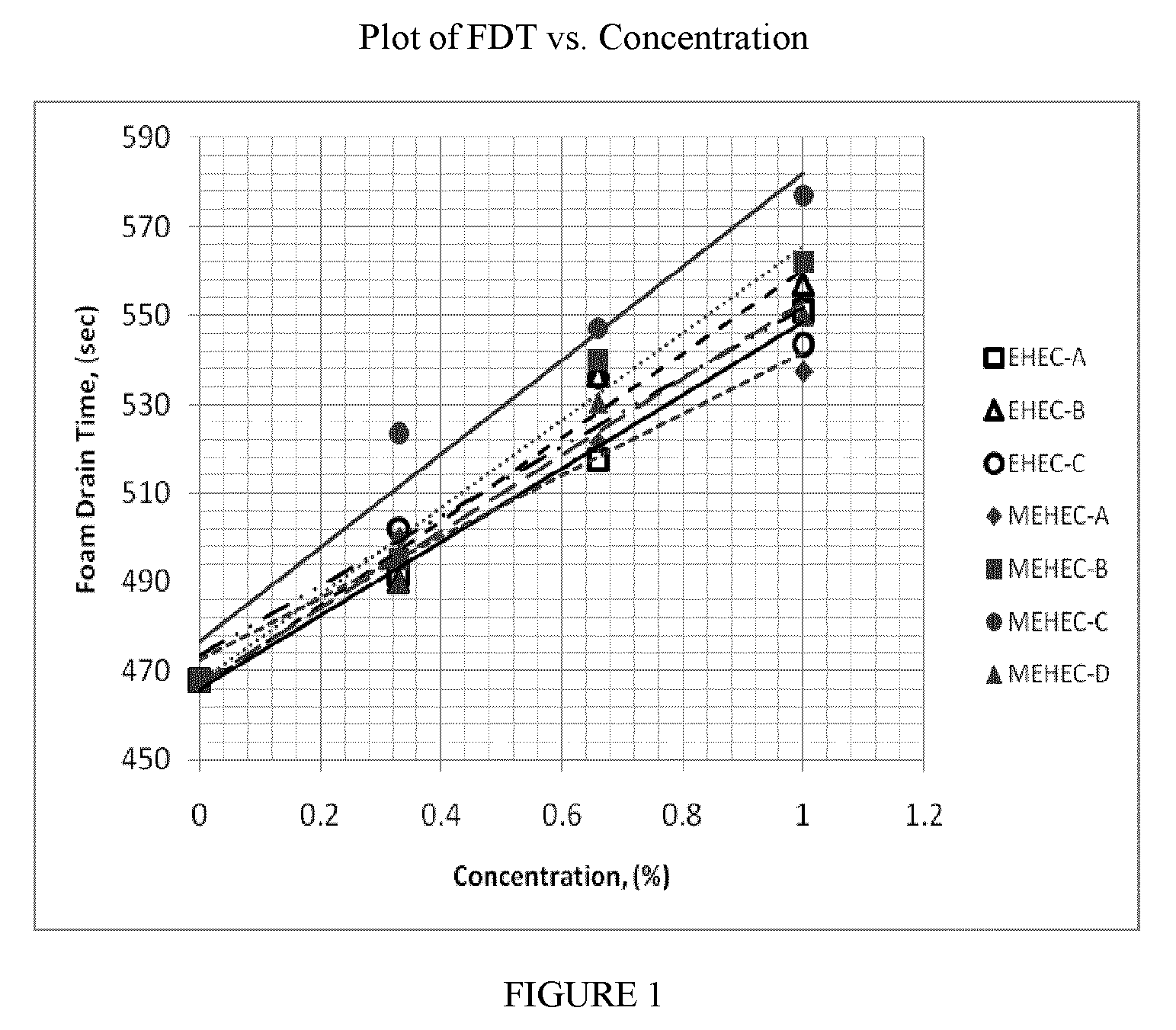

Cellulose ether as a drift control agent and rainfastness agent

The present invention is directed to an agricultural composition comprising at least one agricultural chemical and at least one cellulose ether, wherein the cellulose ether is a nonionic methylethylhydroxyethyl cellulose (MEHEC) polymer. The present invention is also directed to a method for reducing spray drift during the spraying of an aqueous solution. The method comprises: providing a nonionic MEHEC polymer; combining the MEHEC polymer with at least one agricultural chemical to obtain the aqueous solution; and spraying the aqueous solution. Further, the present invention is also directed to a method for increasing resistance to rain wash off of an aqueous solution sprayed onto a surface. The method comprises: providing a nonionic MEHEC polymer; combining the MEHEC polymer with at least one agricultural chemical to obtain the aqueous solution; and spraying the aqueous solution onto the surface.

Owner:NOURYON CHEM INT BV

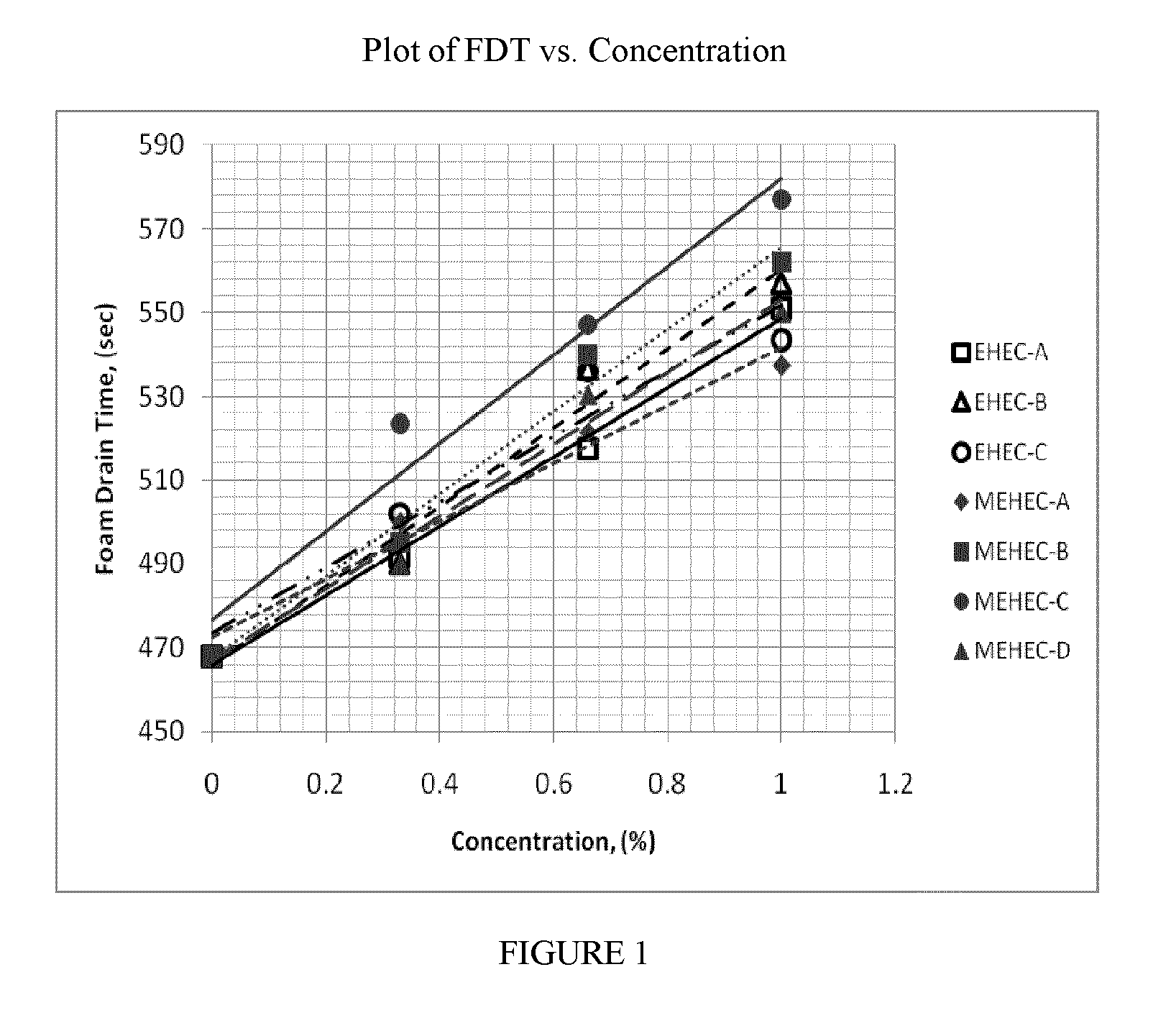

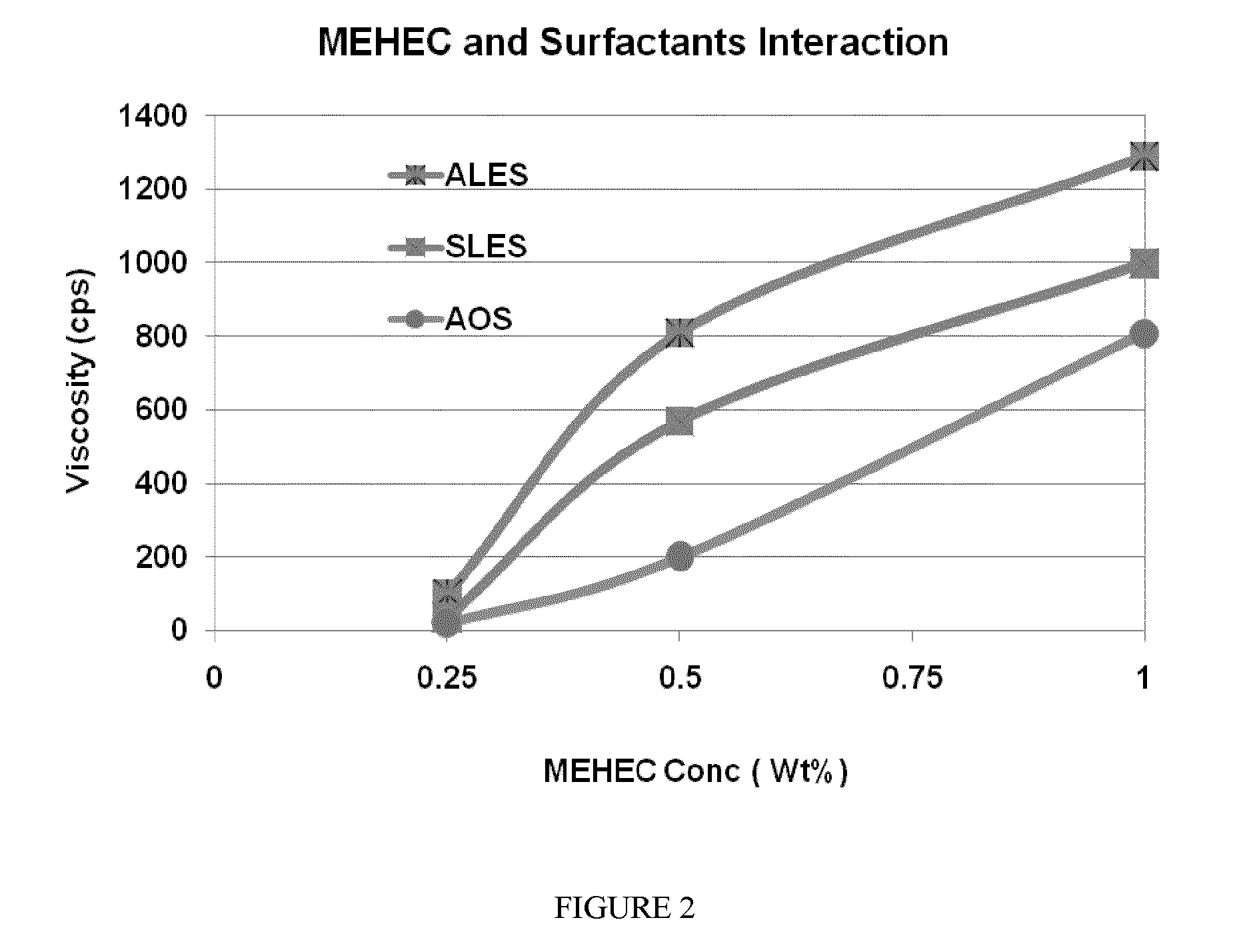

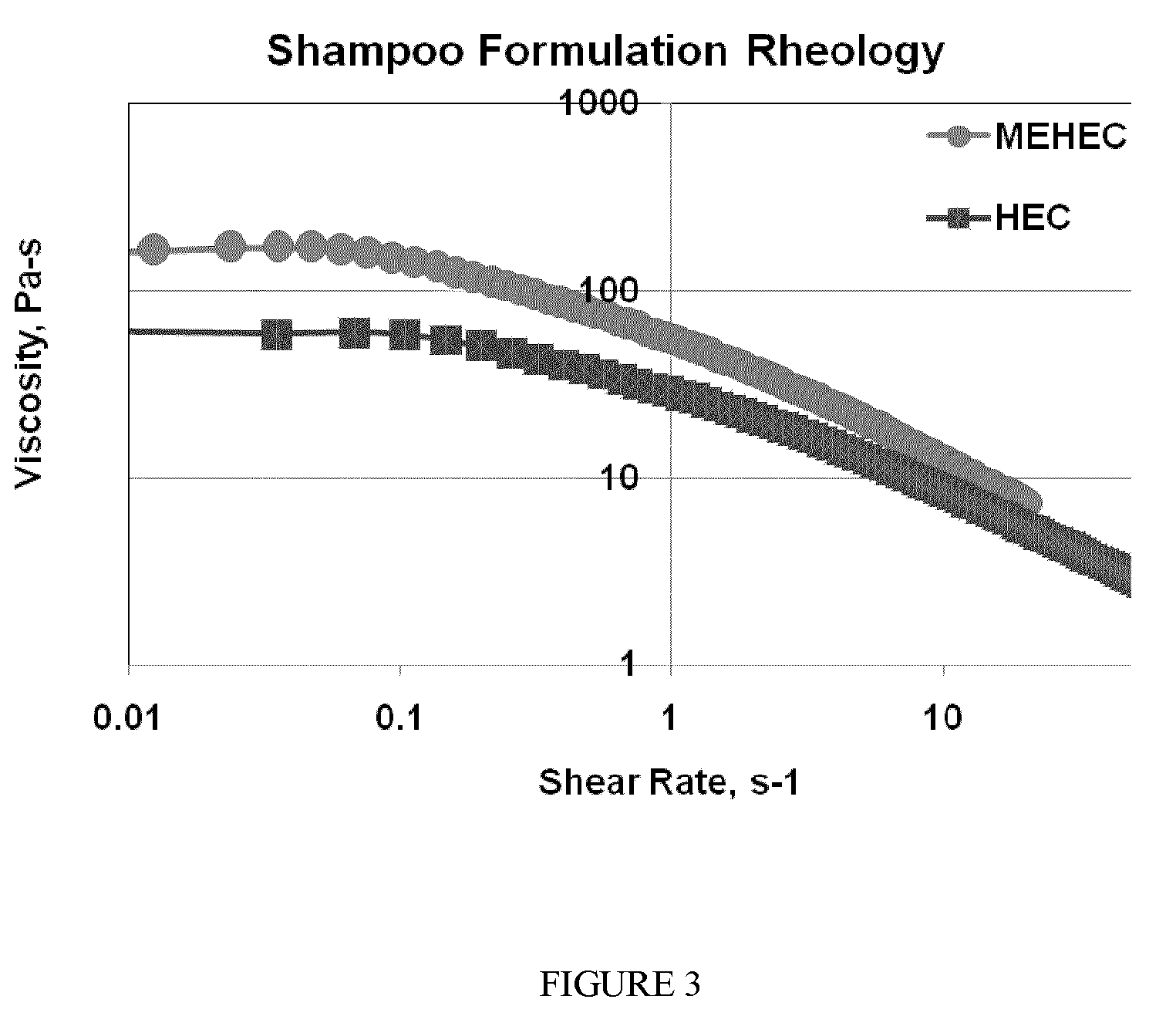

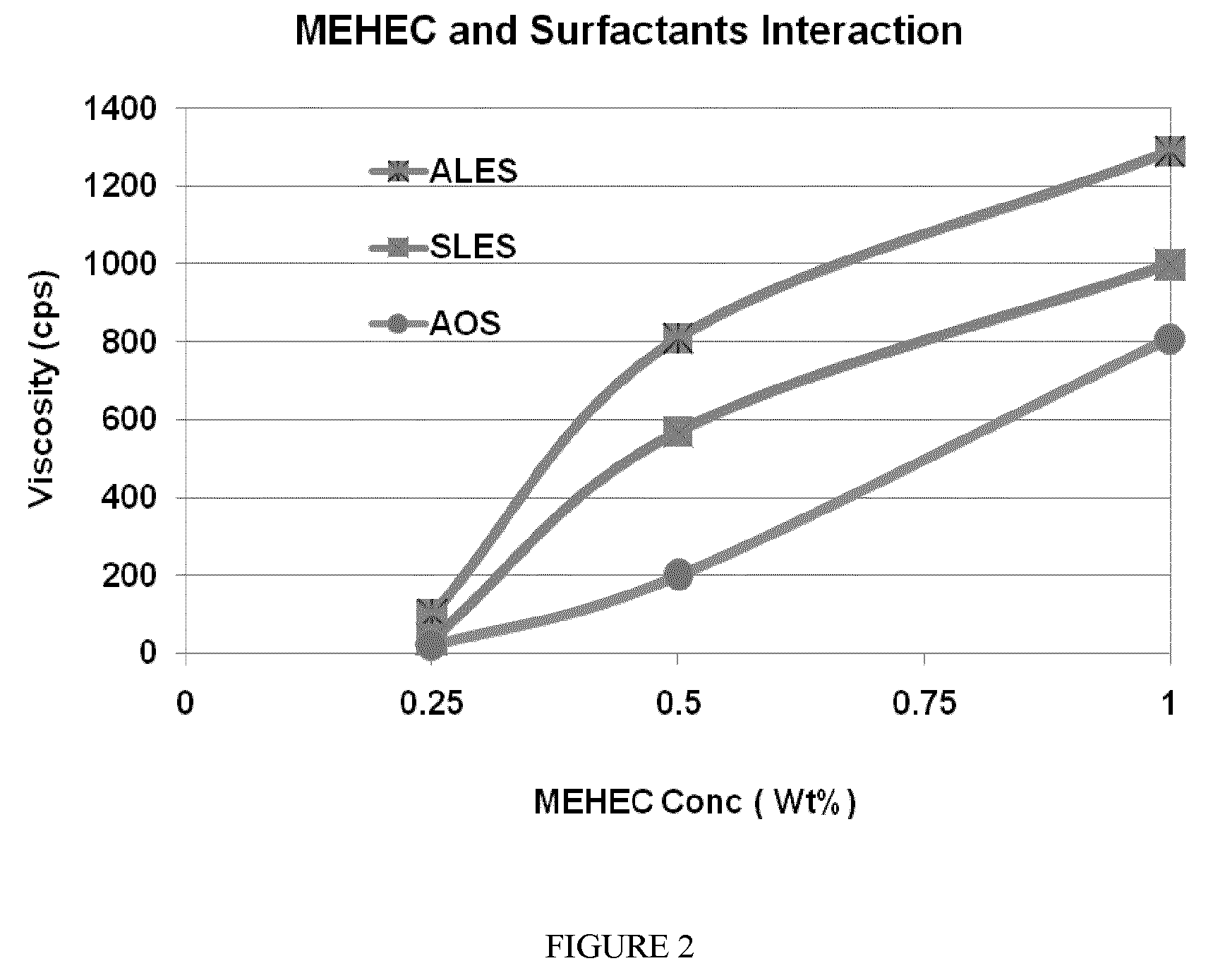

Methyl ethyl hydroxyethyl cellulose for personal care applications

A thickening system for personal care formulations including methyl ethyl hydroxyethyl cellulose provides efficient thickening power in applications areas such as shampoo and styling gels. In addition to providing thickening, the methyl ethyl hydroxyethyl cellulose derived polymers also provide foam stability to shampoos and improved high humidity curl retention to hair gel compositions.

Owner:AKZO NOBEL CHEM INT BV

Hot stamping image-text anti-oxidization type alumite hot stamping foil

ActiveCN109849546AWith exquisiteOxidation and corrosion resistanceRosin coatingsAnti-corrosive paintsWater basedNitrocellulose

Hot stamping image-text anti-oxidization type alumite hot stamping foil can solve the problem that after existing alumite hot stamping foil conducts hot stamping on the surface of thin paper, the phenomenon of oxidability corrosion is likely happen to the hot stamping image-text. According to the technical scheme, the hot stamping image-text anti-oxidization type alumite hot stamping foil is characterized in that water-based thermoplasticity maleated rosin resin, montan wax, thermoset acrylic resin, phenol, ethanol and water serve as raw materials and are compounded into a stripping material;phenolic aldehyde modified acrylic ester, polyamide resin, modified vinyl resin, EHEC, dye, zinc naphthenate soap and a mixed solvent serve as raw materials and are compounded into pigment; styrene-maleic anhydride copolymer, modified PU, isocyanate and a mixed solvent serve as raw materials and are compounded into an isolation layer coating; polyacrylate, rosin modified alkyl phenolic resin, nitrocellulose, catechol, a film forming addition agent and a mixed solvent are compounded into a sizing material; and the hot stamping image-text anti-oxidization type alumite hot stamping foil is produced and prepared sequentially through stripping material coating, pigment coating, vacuum aluminum plating, isolation layer coating applying and sizing material coating. The product has the characteristics that the hot stamping image-text are exquisite, and the hot stamping image-text are resistant to oxidation and corrosion.

Owner:ZHEJIANG HENGFENG PACKING

High-strength foam concrete material for floor heating and preparation method thereof

ActiveCN105884295AHigh compressive strengthLow thermal conductivitySolid waste managementCeramicwareEpoxyFoam concrete

The invention discloses a high-strength foam concrete material for floor heating and a preparation method thereof. The foam concrete material is prepared from, by weight, aluminum silicate cement, chlorinated butyl rubber, polyurethane, phosphogypsum, pulverized fuel ash, fine sand, stainless steel fiber, nano silicon-aluminum powder, calcium sulphate whiskers, sodium aluminate, opal powder, potassium citrate, fumed silica, 2-(3,4-epoxy cyclohexane) ethyl trimethoxy silane, ethyl hydroxyethyl cellulose, a water reducing agent, a foaming agent and water. The foam concrete material has high compressive strength, low water absorption and thermal coefficients, and various performance indicators meet the requirements of the field of floor heating application.

Owner:舟山市大昌预拌混凝土有限公司

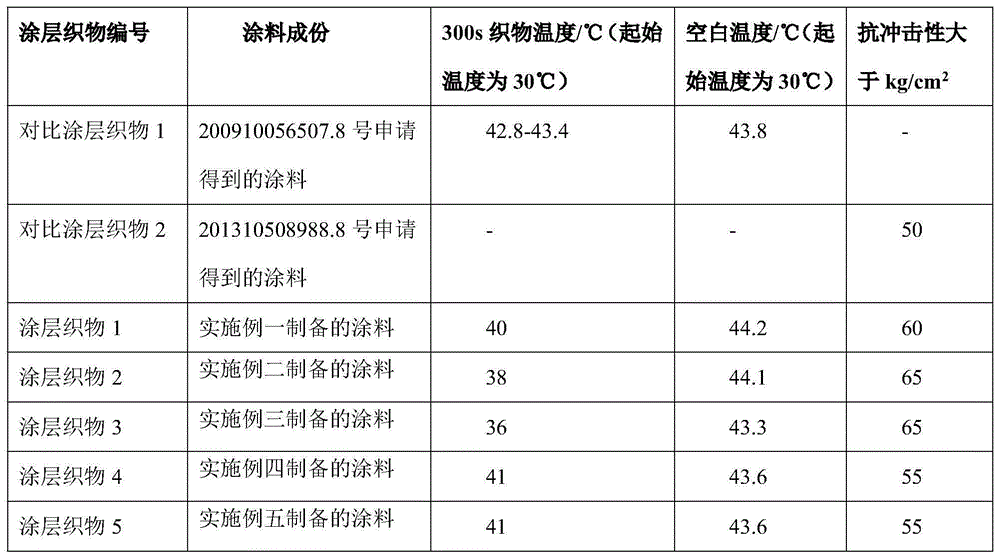

High-impact-resistance environment-friendly thermal-insulation textile coating and preparation method and application

ActiveCN104861849AGood heat insulationReflect heat wellPolyurea/polyurethane coatingsVegetal fibresEthyl(hydroxyethyl)cellulosePolyvinyl alcohol

The invention provides a high-impact-resistance environment-friendly thermal-insulation textile coating and a preparation method and an application. The textile coating is good in impact resistance and high in environment friendliness. The coating comprises ingredients of, by weight, 1% to 2% of polyvinyl alcohol, 1% to 2% of montmorillonite, 0.5% to 1% of polydimethylsiloxane, 0.2% to 0.4% of potassium chloride complex, 0.5% to 1% of ethyl hydroxyethyl cellulose, 25% to 30% of slag complex powder, 5% to 9% of water and the rest of composite water-dilutable resin.

Owner:NANTONG ABLE OUTDOOR PROD COMPANY

Methyl ethyl hydroxyethyl cellulose for personal care applications

A thickening system for personal care formulations including methyl ethyl hydroxyethyl cellulose provides efficient thickening power in applications areas such as shampoo and styling gels. In addition to providing thickening, the methyl ethyl hydroxyethyl cellulose derived polymers also provide foam stability to shampoos and improved high humidity curl retention to hair gel compositions.

Owner:NOURYON CHEM INT BV

Water-based multicolor stone like coating and preparation method thereof

InactiveCN106366742AImprove stabilityGood hardnessAntifouling/underwater paintsPaints with biocidesEmulsionWeather resistance

The invention discloses a water-based multicolor stone like coating. The coating is prepared from 7% parts of pre-binding buffer, color master batch, and silicone acrylic emulsion. The color master batch is prepared from deionized water, preservative, dry film antiseptic, methyl hydroxyethyl cellulose, diethanol amine, dispersant, surfactant, titanium dioxide, elastic silicone acrylic emulsion, coalescing agent, antifoaming agent, 10% lithium magnesium silicate solution, and color paste; the preparation of the water-based multicolor stone like coating is a process of mixing 7% parts of pre-binding buffer, color master batch, and silicone acrylic emulsion then filtering the mixture. The present invention provides water-based multicolor stone like coating and preparation method thereof. The stability of the stone like coating is high; the hardness, the anti-cracking and anti-graffiti abilities of the coating are good. The durability of the product, especially the water resistance, water white resistance, weather resistance, and acid and alkali resistance are better than the qualities of other products of the same type. The product achieves the effect of being almost naturally stone like.

Owner:HANGZHOU FERKASI CHEM PAINT

Facemasks containing an anti-fog/anti-glare composition

Owner:O&M HALYARD INT UNLTD

Hot stamping foil for irregular surface hot stamping

InactiveCN109835079AHot stamping fullHot stamping clearNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyThermoplastic

The invention provides a hot stamping foil for irregular surface hot stamping. The hot stamping foil for the irregular surface hot stamping mainly solves the technical problems that hot stamping graphic cracking, graphic defects and poor hot stamping adhesion are prone to occurring during hot stamping of an existing hot stamping foil on all kinds of irregular surfaces. According to the technical scheme, a stripping layer coating is prepared by mixing raw materials including thermoplastic modified polyurethane, high edge-cutting acrylate, polyethylene wax and a mixed solvent; a transparent protective coating is prepared by mixing raw materials including a modified polyamide resin, ethyl hydroxyethyl cellulose and ethyl acetate; a coloring material is prepared by mixing rosin-modified acrylate, a short oily alkyd resin, cellulose acetate, a dye and a mixed solvent; an aluminum-layer protective layer coating is prepared by mixing a urea-formaldehyde resin, a novolac epoxy resin and butylacetate; a hot melt adhesive material is prepared by mixing low softening point thermoplastic acrylate, a coumarone-indene resin, an EVA resin of Tg50 DEG C, a rosin-modified alkyl phenolic resin, nano silica powder and a mixed solvent; and the hot stamping foil for the irregular surface hot stamping is obtained after sequential coating of the stripping layer coating, coating of the transparent protective coating, coating of the coloring material, vacuum aluminum plating, coating of the aluminum-layer protective layer coating and coating of the hot melt adhesive material. The hot stamping foilfor the irregular surface hot stamping has the characteristics that the irregular surface hot stamping is full, clear and has good adhesion.

Owner:ZHEJIANG HENGFENG PACKING

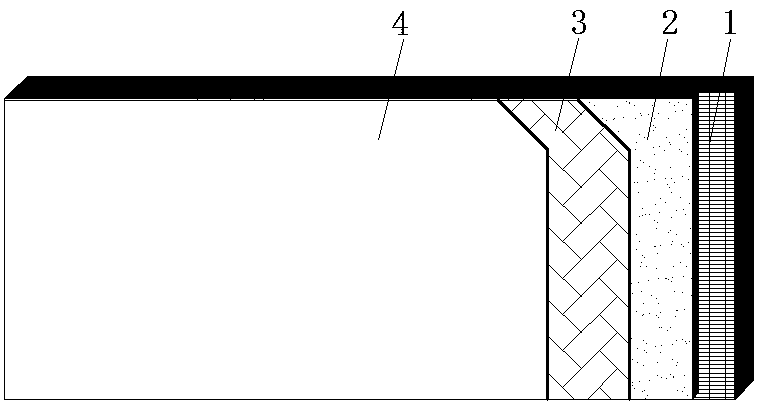

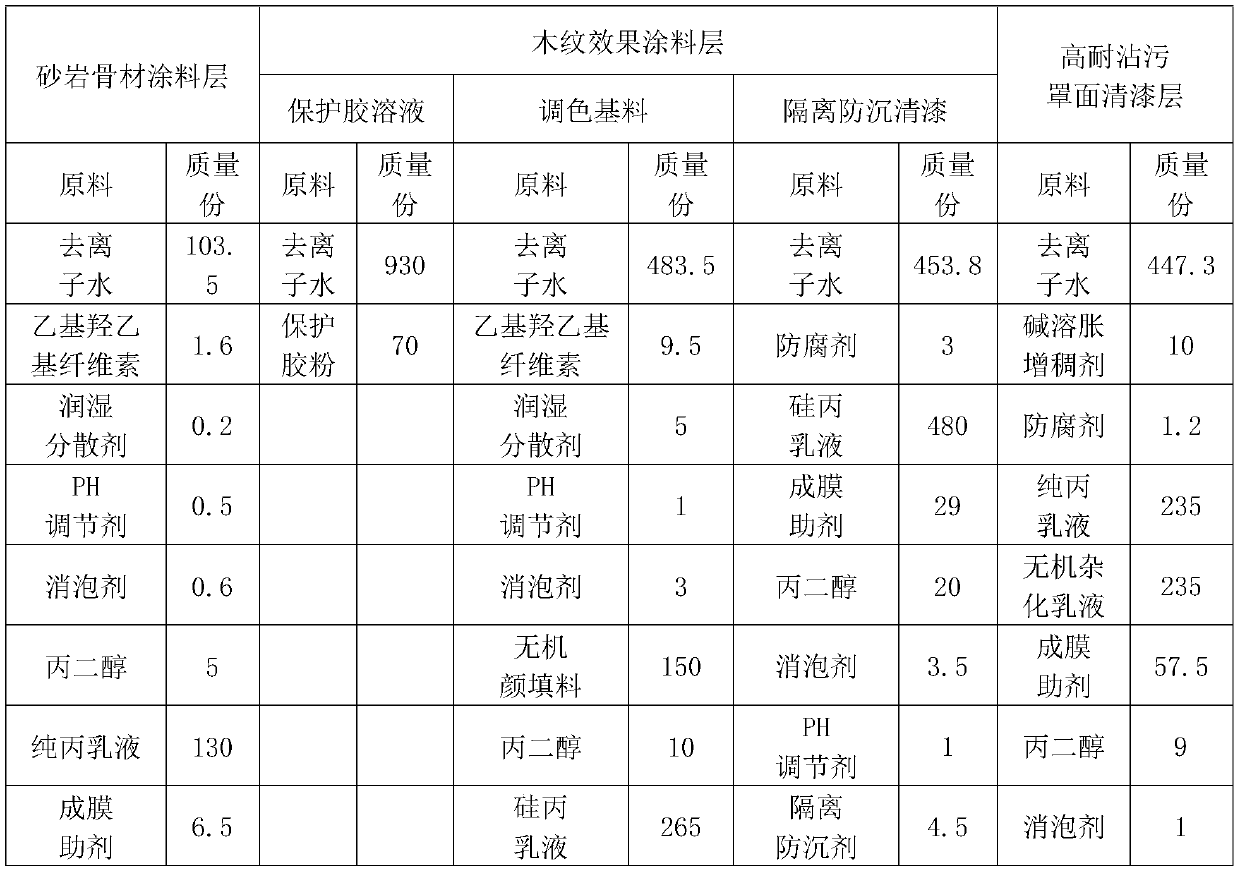

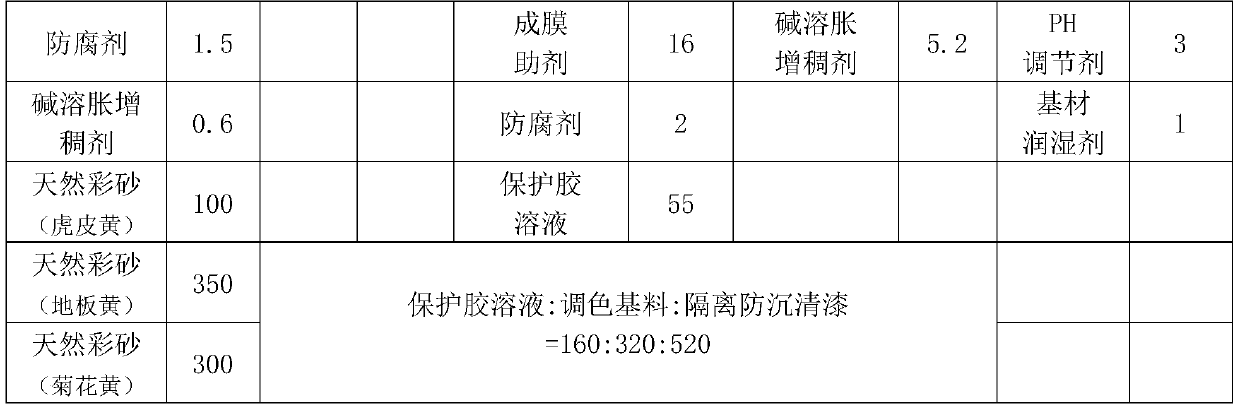

High-contamination-resistant wood-grain-like and sandstone-like coating system and construction method thereof

InactiveCN110317504AExtend your lifeDustproof and anti-contaminationCovering/liningsAntifouling/underwater paintsEthyl(hydroxyethyl)celluloseEmulsion

The invention discloses a high-contamination-resistant wood-grain-like and sandstone-like coating system. The high-contamination-resistant wood-grain-like and sandstone-like coating system comprises asandstone aggregate paint layer, a wood-grain-like paint layer and a high-contamination-resistant finish varnish layer which are sequentially arranged from inside to outside. The sandstone aggregatepaint layer comprises, by mass, 103-135 parts of deionized water, 1.6-2.0 parts of ethyl hydroxyethyl cellulose, 0.1-0.2 part of wetting dispersant, 0.4-0.6 part of pH regulator, 0.6-0.8 part of antifoaming agent, 4-6 parts of propylene glycol, 110-130 parts of pure acrylic emulsions, 5.5-6.5 parts of film forming aids, 1.3-1.5 parts of preservatives, 0.5-0.9 part of alkali-swelling thickener and700-750 parts of natural colored sand. The coating system has high degree of simulation, and the texture like natural wood grains and sandstone, can meet indicator requirements of the 'internal / external wall type-III composite type' in the standard 'GB / T 9779-2015 Multi-layer Coatings for Architecture', has reliable quality, and can be widely applied to buildings of individualized and differentiated architectural styles, such as villas, high-end office buildings and resorts, or applied to indoor background wall decorations.

Owner:固克节能科技股份有限公司

Silk screen ink for paper

InactiveCN103436077AFast dryingImprove adhesion fastnessInksPolymer scienceEthyl(hydroxyethyl)cellulose

The invention relates to silk screen ink for paper, which comprises the following components in parts by mass: 5-10 parts of benzidine yellow, 30-40 parts of light calcium carbonate, 15-30 parts of precipitated barium sulphate, 5-10 parts of methoxyl dipropanol, 2-6 parts of ethylhydroxyethylcellulose, 1-4 parts of butanone, 0.1-0.4 parts of cobalt naphthenate, 10-20 parts of pentalyn, 0.5-0.7 parts of manganese naphthenate, 1-5 parts of dioctyl phthalate and 1-2 parts of polyethylene wax. The silk screen ink for the paper is wear-resistant, high in drying speed, high in adhesion fastness, non-toxic, pollution-free, low in cost, heat-resistant, acid / alkali-resistant and solvent-oil-resistant, and does not adhere to dirt.

Owner:苏州凹凸彩印厂

Natural herbicidal bacteriostatic agent and preparation method thereof

InactiveCN109090132AMaintain shoot activityIncreased versatilityBiocideFungicidesEthyl(hydroxyethyl)celluloseSecondary metabolite

The invention provides a natural herbicidal bacteriostatic agent and a preparation method thereof. The herbicidal bacteriostatic agent is prepared from glufosinate, alginic acid, glossy privet fruit extract, orange peel extract, xanthium sibiricum extracting solution, ferulic acid, D-alanine, D-serine, water, neutralized bamboo vinegar, organic silicon latex and ethylhydroxyethylcellulose. The growth of the natural herbicidal bacteriostatic agent is inhibited by utilizing weed photosynthesis and cell growth inhibited by allelochemicals in glossy privet fruit and the orange peel extract, weeding substances are plant secondary metabolites, there is a suitable way to enter the environment, the plant secondary metabolites are not accumulated in plant bodies, and the absorption by animals and humans is not affected. The prepared herbicidal bacteriostatic agent is green and environmentally friendly, has effects of broad spectrum bacteriostasis and avoidance of pests, and has good economic benefits.

Owner:覃静欣

Multi-effect cleaning agent

InactiveCN108034529AHelp removeEasy to clean and decontaminateInorganic/elemental detergent compounding agentsCationic surface-active compoundsAlkaline earth metalEthyl(hydroxyethyl)cellulose

The invention discloses a multi-effect cleaning agent. The multi-effect cleaning agent comprises the following components in parts by weight: 15 to 25 parts of cholinesterase, 0.5 to 1 part of filler,5 to 8 parts of nonylphenol polyoxyethylene ether, 15 to 20 parts of hexadecyl dimethyl benzyl ammonium bromide, 10 to 15 parts of dodecyl propyl betaine, 10 to 15 parts of alkaline earth metal salt,10 to 15 parts of salicylic acid and 5 to 7 parts of ethyl hydroxyethyl cellulose ether. The product provided by the invention is scientific in formula, contributes to removal of pesticide residue and bacteria on the surfaces of fruit and vegetables, can clean tableware and remove dirt easily, and can realize rapid washing and avoid residue.

Owner:广州馨香日用化工有限公司

Barium-titanium organic composite emulsion and application thereof for preparing external thermal insulation finishing mortar

ActiveCN101514085AImprove crack resistanceImprove water resistanceSolid waste managementEthyl(hydroxyethyl)celluloseCrack resistance

The invention provides a barium-titanium organic composite emulsion and application thereof for preparing external thermal insulation finishing mortar. The preparation method comprises the following steps: (1) mixing nanometer titanium powder, water and grafted gelatin with a barium nitrate solution and an ammonium sulphate solution, adding the ammonium sulphate solution into the mixed solution, preserving the heat, adjusting pH, washing precipitate, and adjusting the pH value once again, and collecting barium-titanium mixed crystal; (2) mixing (methyl) acrylic ester, (methyl) styrene and a molecular weight regulator, and mixing the mixture with a reactive emulsifying agent, an evocating agent and water to obtain a mixed solution; (3) mixing the barium-titanium mixed crystal with water, and adding ethyl hydroxyethyl cellulose, polyvinylpyrrolidone and methacryloxymethyl dimethylethoxysilane into the mixture; and (4) making the mixed solution, the reactive emulsifying agent and the evocating agent react with the product of the step (3), adding the mixed solution into the mixture to obtain the barium-titanium organic composite emulsion. The composite emulsion can be used for preparing the ornamental model finishing mortar composition, and the composition has excellent cracking resistance and water resistance after the mortar composition is formed.

Owner:苏州盛泽科技创业园发展有限公司

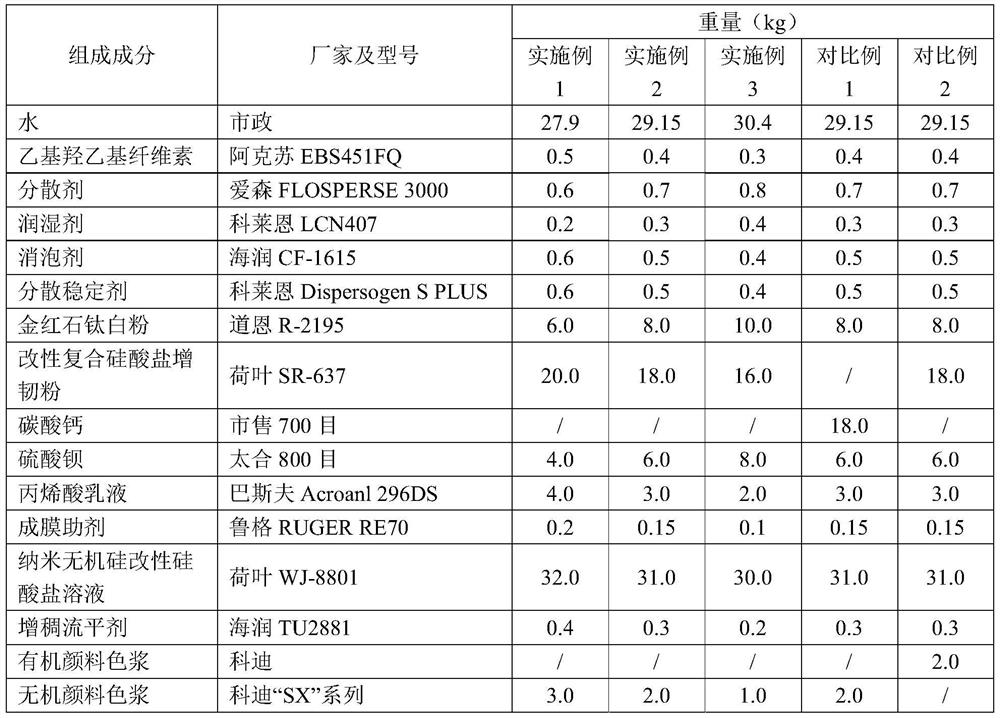

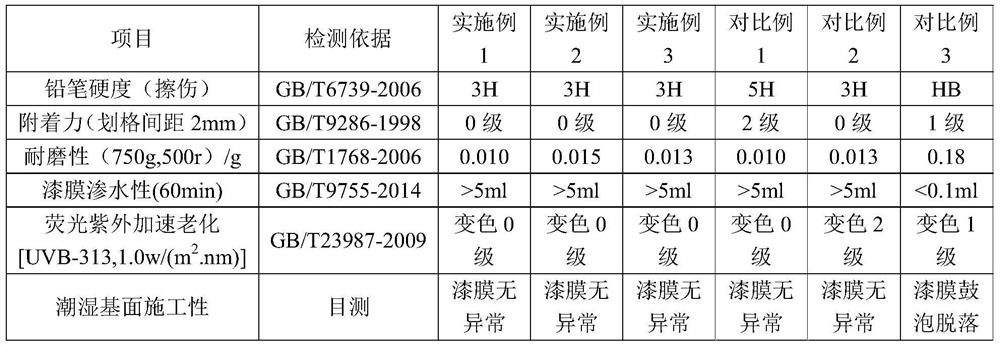

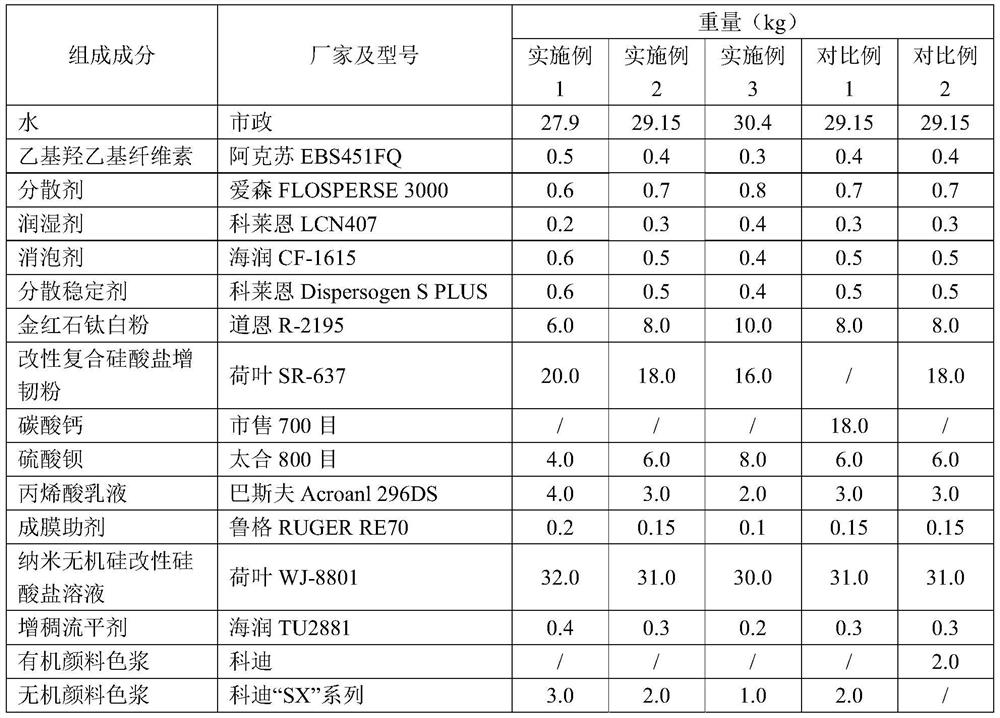

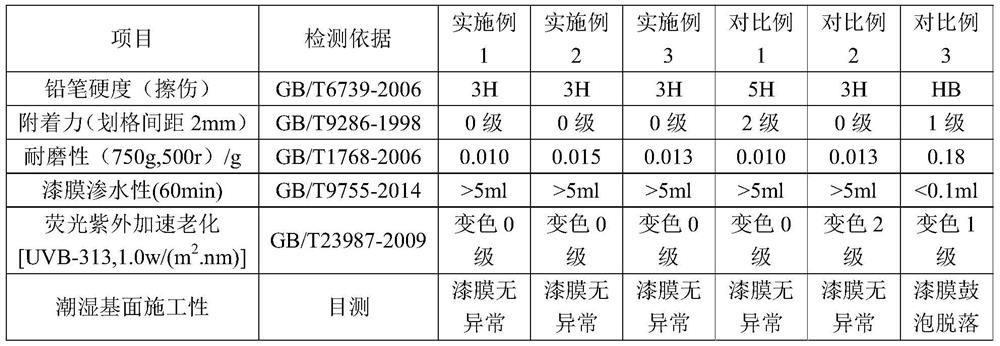

Urban greenway inorganic silicate coating and preparation method thereof

ActiveCN112251058AHigh strengthImprove wear resistanceAlkali metal silicate coatingsEthyl(hydroxyethyl)cellulosePhysical chemistry

The invention provides an urban greenway inorganic silicate coating which is prepared by mixing the following components in parts by weight: 27.9-30.4 parts of water, 0.3-0.5 part of ethyl hydroxyethyl cellulose, 0.6-0.8 part of a dispersing agent, 0.2-0.4 part of a wetting agent, 0.4-0.6 part of a defoaming agent, 0.4-0.6 part of a dispersion stabilizer, 6-10 parts of rutile titanium dioxide, 16-20 parts of modified composite silicate toughening powder and 4-8 parts of barium sulfate, wherein the modified composite silicate toughening powder can be subjected to bonding reaction with hydroxylfunctional groups of the nano inorganic silicon modified silicate solution, 2-4 parts of acrylic emulsion, 0.1-0.2 part of a coalescing agent, 30-32 parts of a nano inorganic silicon modified silicatesolution, 0.2-0.4 part of a thickening leveling agent and 1-3 parts of inorganic pigment color paste. The coating solves the problems of poor wear resistance, easy fading, poor water and air permeability and long construction period of the traditional organic coating in the field of urban greenway coating.

Owner:深圳广田高科新材料有限公司

Food appliance cleaning agent

InactiveCN106635464AEasy to cleanNon-ionic surface-active compoundsDetergent compounding agentsEthyl(hydroxyethyl)celluloseAlpha hydroxy acid

The invention relates to a food appliance cleaning agent and belongs to the field of cleaning agents. The food appliance cleaning agent comprises the following components in percentage by mass: 5-8% of primary alcobol ethoxylate, 4-7% of benzyl phenol polyoxyethylene ether, 10-15% of tartaric acid, 5-7% of alpha hydroxy acid, 6-8% of ethyl hydroxyethyl cellulose, 5-7% of sodium dodecyl benzene sulfonate, 5-7% of ethanol and deionized water, the cleaning agent can be used for cleaning various utensils for containing foods.

Owner:白跃兵

A kind of urban greenway inorganic silicate coating and preparation method thereof

ActiveCN112251058BHigh strengthImprove wear resistanceAlkali metal silicate coatingsEthyl(hydroxyethyl)celluloseEmulsion

Owner:深圳广田高科新材料有限公司

Barium-titanium organic composite emulsion and application thereof for preparing external thermal insulation finishing mortar

ActiveCN101514085BImprove crack resistanceImprove water resistanceSolid waste managementEthyl(hydroxyethyl)celluloseCrack resistance

The invention provides a barium-titanium organic composite emulsion and application thereof for preparing external thermal insulation finishing mortar. The preparation method comprises the following steps: (1) mixing nanometer titanium powder, water and grafted gelatin with a barium nitrate solution and an ammonium sulphate solution, adding the ammonium sulphate solution into the mixed solution, preserving the heat, adjusting pH, washing precipitate, and adjusting the pH value once again, and collecting barium-titanium mixed crystal; (2) mixing (methyl) acrylic ester, (methyl) styrene and a molecular weight regulator, and mixing the mixture with a reactive emulsifying agent, an evocating agent and water to obtain a mixed solution; (3) mixing the barium-titanium mixed crystal with water, and adding ethyl hydroxyethyl cellulose, polyvinylpyrrolidone and methacryloxymethyl dimethylethoxysilane into the mixture; and (4) making the mixed solution, the reactive emulsifying agent and the evocating agent react with the product of the step (3), adding the mixed solution into the mixture to obtain the barium-titanium organic composite emulsion. The composite emulsion can be used for preparing the ornamental model finishing mortar composition, and the composition has excellent cracking resistance and water resistance after the mortar composition is formed.

Owner:苏州盛泽科技创业园发展有限公司

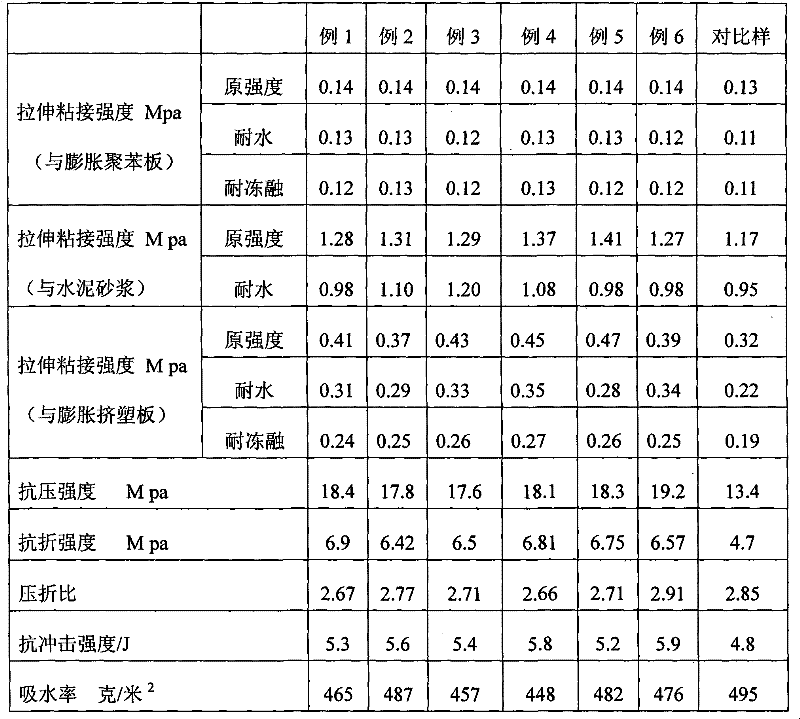

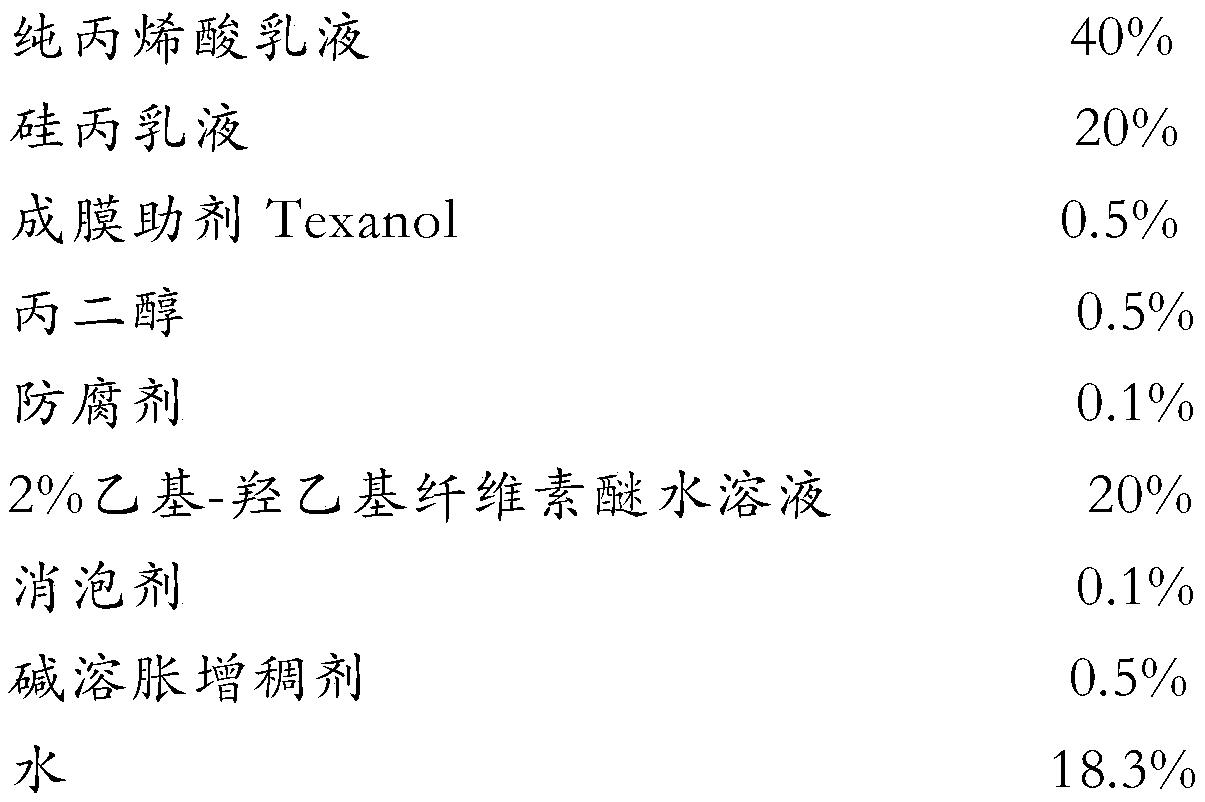

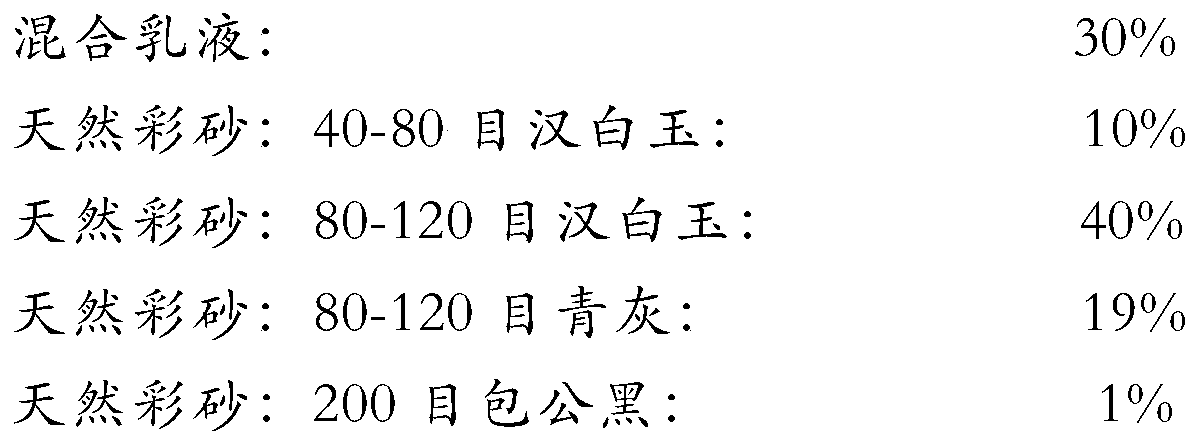

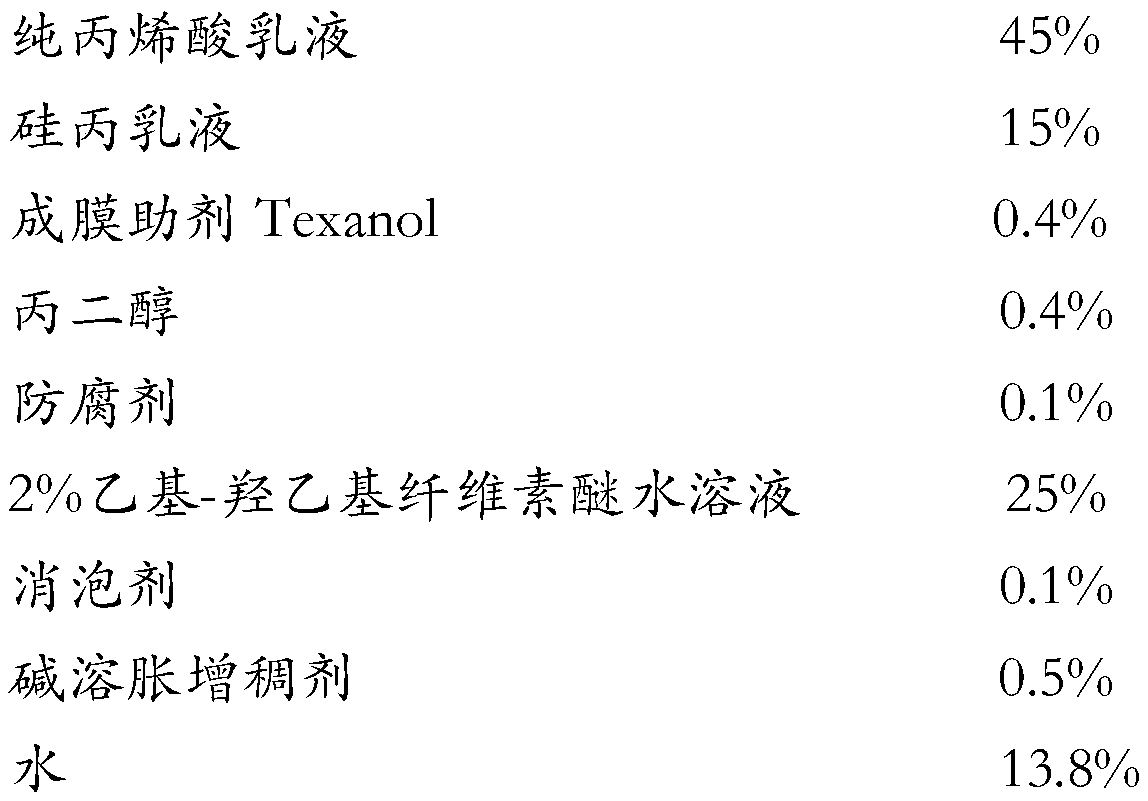

Special jointing agent for flexible sheet and preparation and construction method thereof

ActiveCN110550888AImprove outdoor durabilityLow priceBuilding constructionsCrack resistanceEthyl(hydroxyethyl)cellulose

The invention provides a special jointing agent for a flexible sheet and a preparation and construction method thereof.Thespecial jointing agent for the flexible sheetis prepared from the components in percentage by weight: 30%to 32% of amixing emulsion and 68%to 70% of natural color sand and / or sintering color sand, the mixing emulsion is prepared from 40%to 45% ofa pure acrylic emulsion, 15%to 20% of a silicone-acrylate emulsion, 0.4%to 0.5% of a coalescing agent, 0.4%to 0.5%of propylene glycol, 0.1%to 0.2% of a preservative, 20% to 25% of 2%ethyl-hydroxyethyl cellulose ether aqueous solution, 0.1%to 0.2%ofdefoamer, 0.4%to 0.6 of thickener,and 12% to 20% of water; the natural color sand has different particle sizes and different colors, and the sintering color sand is artificial sintering color sand with various colors formed through melting in high temperature, stirring, and evenly coating of pigment on the surface of the wear-resistant white sandat 600 to 1000 DEG C by using high-temperature resisting pigment and the wear-resistant white sand; and the special jointing agent for the flexible sheet has the characteristics of being cracking-resistance, whiskering-resistance, simple in jointing, and low in cost, and the defects of the prior art are overcome.

Owner:亚士创能新材料(滁州)有限公司 +1

Food tool cleaning agent

InactiveCN107641566AEasy to cleanNon-ionic surface-active compoundsDetergent compounding agentsEthyl(hydroxyethyl)celluloseCleansing Agents

The invention relates to a food tool cleaning agent, and belongs to the field of cleaning agents. The food tool cleaning agent is prepared from, by mass, 5-8% of fatty alcohol-polyoxyethylene ether, 4-7% of benzyl phenol polyoxyethylene ether, 10-15% of tartaric acid, 5-7% of tartaric acid, 6-8% of ethylhydroxyethylcellulose, 5-7% of sodium dodecyl benzene sulfonate, 5-7% of ethyl alcohol and deionized water. The cleaning agent can be used for cleaning various tools containing food.

Owner:白跃兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com