Urban greenway inorganic silicate coating and preparation method thereof

An inorganic silicate, greenway technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of poor water permeability, poor wear resistance, easy fading, etc., and achieve good water permeability High efficiency, excellent weather resistance, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

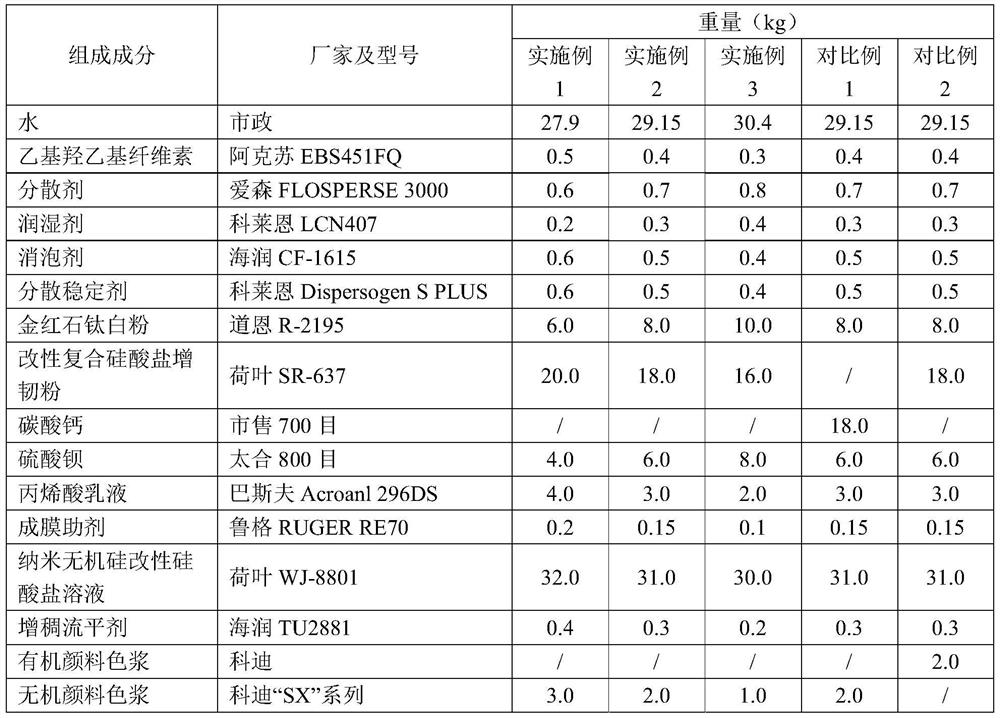

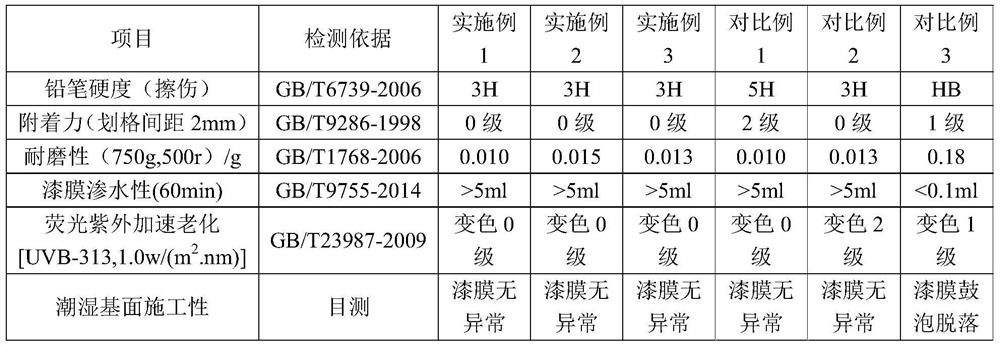

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of urban greenway inorganic silicate paint, and the steps are as follows:

[0028]Step 1: Add 27.9kg of water into the production tank, then add 0.5kg of ethyl hydroxyethyl cellulose under stirring, disperse at 400 rpm for 30 minutes, then add 0.6kg of dispersant and wetting agent in turn under stirring 0.2kg, defoamer 0.6kg, dispersion stabilizer 0.6kg, rutile titanium dioxide 6.0kg, modified composite silicate toughening powder 20.0kg, 800 mesh barium sulfate 4.0kg, increase the stirring speed to 1500 rpm after adding Disperse at high speed for 30 minutes.

[0029] Step 2. After the dispersion is completed, reduce the rotation speed to 800 rpm, add 4.0kg of acrylic emulsion, 0.2kg of film-forming aid, 32.0kg of nano-inorganic silicon modified silicate solution, and 0.4kg of thickening and leveling agent in sequence. After finishing, stir and mix at 800 rpm for 10-15 minutes. After mixing evenly, add 3.0kg ...

Embodiment 2

[0031] The present embodiment provides a kind of preparation method of urban greenway inorganic silicate paint, and the steps are as follows:

[0032] Step 1. Add 29.15kg of water into the production tank, then add 0.4kg of ethyl hydroxyethyl cellulose under stirring, disperse at 400 rpm for 30 minutes, then add 0.7kg of dispersant and wetting agent in turn under stirring 0.3kg, defoamer 0.5kg, dispersion stabilizer 0.5kg, rutile titanium dioxide 8.0kg, modified composite silicate toughening powder 18.0kg, 800 mesh barium sulfate 6.0kg, increase the stirring speed to 1500 rpm after adding Disperse at high speed for 30 minutes.

[0033] Step 2. After the dispersion is completed, reduce the speed to 800 rpm, add 3.0kg of acrylic emulsion, 0.15kg of film-forming aid, 31.0kg of nano-inorganic silicon modified silicate solution, and 0.3kg of thickening and leveling agent in sequence. After finishing, stir and mix at 800 rpm for 10-15 minutes. After mixing evenly, add 2.0 kg of in...

Embodiment 3

[0035] The present embodiment provides a kind of preparation method of urban greenway inorganic silicate paint, and the steps are as follows:

[0036] Step 1. Add 30.4kg of water into the production tank, then add 0.3kg of ethyl hydroxyethyl cellulose under stirring, disperse at 400 rpm for 30 minutes, then add 0.8kg of dispersant and wetting agent in turn under stirring 0.4kg, defoamer 0.4kg, dispersion stabilizer 0.4kg, rutile titanium dioxide 10.0kg, modified composite silicate toughening powder 16.0kg, 800 mesh barium sulfate 8.0kg, increase the stirring speed to 1500 rpm after adding Disperse at high speed for 30 minutes.

[0037] Step 2. After the dispersion is completed, reduce the rotation speed to 800 rpm, add 2.0kg of acrylic emulsion, 0.1kg of film-forming aid, 30.0kg of nano-inorganic silicon modified silicate solution, and 0.2kg of thickening and leveling agent in sequence. After finishing, stir and mix at 800 rpm for 10-15 minutes. After mixing evenly, add 1.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com