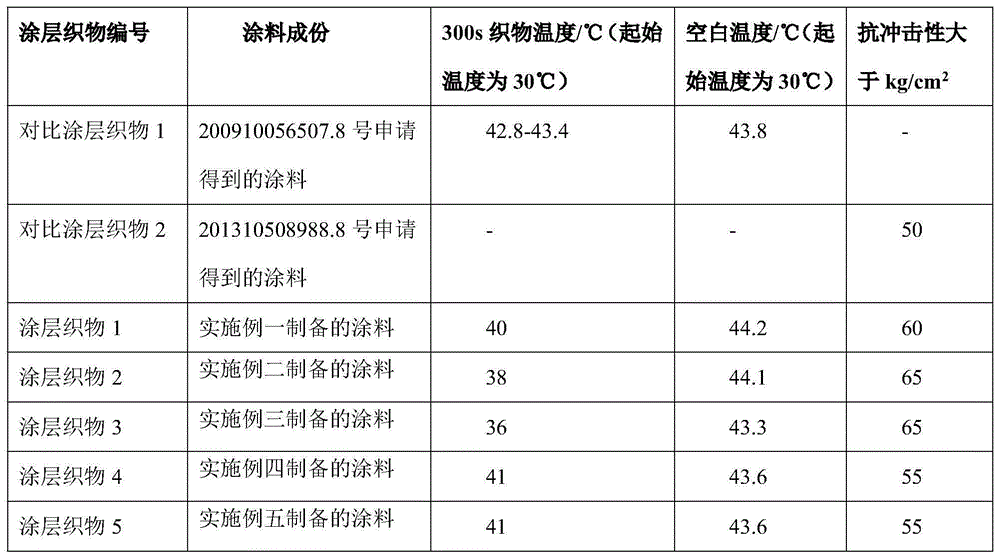

High-impact-resistance environment-friendly thermal-insulation textile coating and preparation method and application

A high-impact, coating technology, used in textiles and papermaking, reflective/signal coatings, polyurea/polyurethane coatings, etc., can solve the problems of harmful components, thermal insulation effects need to be improved, impact resistance needs to be further improved, etc. Achieve the effects of good stability and practicability, low production cost and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the high impact resistance environment-friendly heat-insulating fabric coating of the present invention, the method comprises the following steps:

[0047] Step 1, the preparation of potassium chloride complex:

[0048] Raw materials by weight percentage: 8% of 2-methylsiloxane oil, 9% of sodium tripolyphosphate, 5% of mannitol, 2% of silicon dioxide, and the remaining potassium chloride is used for batching, and 2-methylsiloxane is mixed at room temperature Mix silicone oil and silicon dioxide to form a mixture; mix sodium tripolyphosphate (crushed to 10-30 microns), mannitol, and potassium chloride to form a mixture; then fully stir the two mixtures, that is White powdery potassium chloride complex can be obtained;

[0049] Step 2, preparation of slag composite powder:

[0050] 1) Firstly, Cd(NO 3 ) 2 4H 2 O, Co(NO 3 ) 2 ·6H 2 O and tetraethyl orthosilicate Si(OC 2 h 5 ) 4 The three are dissolved in absolute ethanol respectively to...

Embodiment 2

[0060] The preparation method of the high impact resistance environment-friendly heat-insulating fabric coating of the present invention, the method comprises the following steps:

[0061] Step 1, the preparation of potassium chloride complex:

[0062] Raw materials by weight percentage: 10% of 2-methylsiloxane oil, 11% of sodium tripolyphosphate, 6% of mannitol, 3% of silicon dioxide, and the remaining potassium chloride is used for batching, and 2-methylsiloxane is mixed at room temperature Mix silicone oil and silicon dioxide to form a mixture; mix sodium tripolyphosphate (crushed to 10-30 microns), mannitol, and potassium chloride to form a mixture; then fully stir the two mixtures, that is White powdery potassium chloride complex can be obtained;

[0063] Step 2, preparation of slag composite powder:

[0064] 1) Firstly, Cd(NO 3 ) 2 4H 2 O, Co(NO 3 ) 2 ·6H 2 O and tetraethyl orthosilicate Si(OC 2 h 5 ) 4 Dissolve in absolute ethanol respectively to form three k...

Embodiment 3

[0074] In the coating preparation in this example, each composition is proportioned according to the following weight percentages: polyvinyl alcohol 1.5%, montmorillonite 1.52%, polydimethylsiloxane 0.8%, potassium chloride complex 0.3%, ethyl hydroxyethyl Base cellulose is 0.7%, slag composite powder is 28%, water is 7%, and the rest is composite water-based resin. All the other preparation processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com